Stone-clamping preventing tyre

A tire and anti-pinch technology, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. It can solve the problems of affecting tire drainage performance and increasing the difficulty of tire mold processing, so as to improve the anti-stone trapping performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

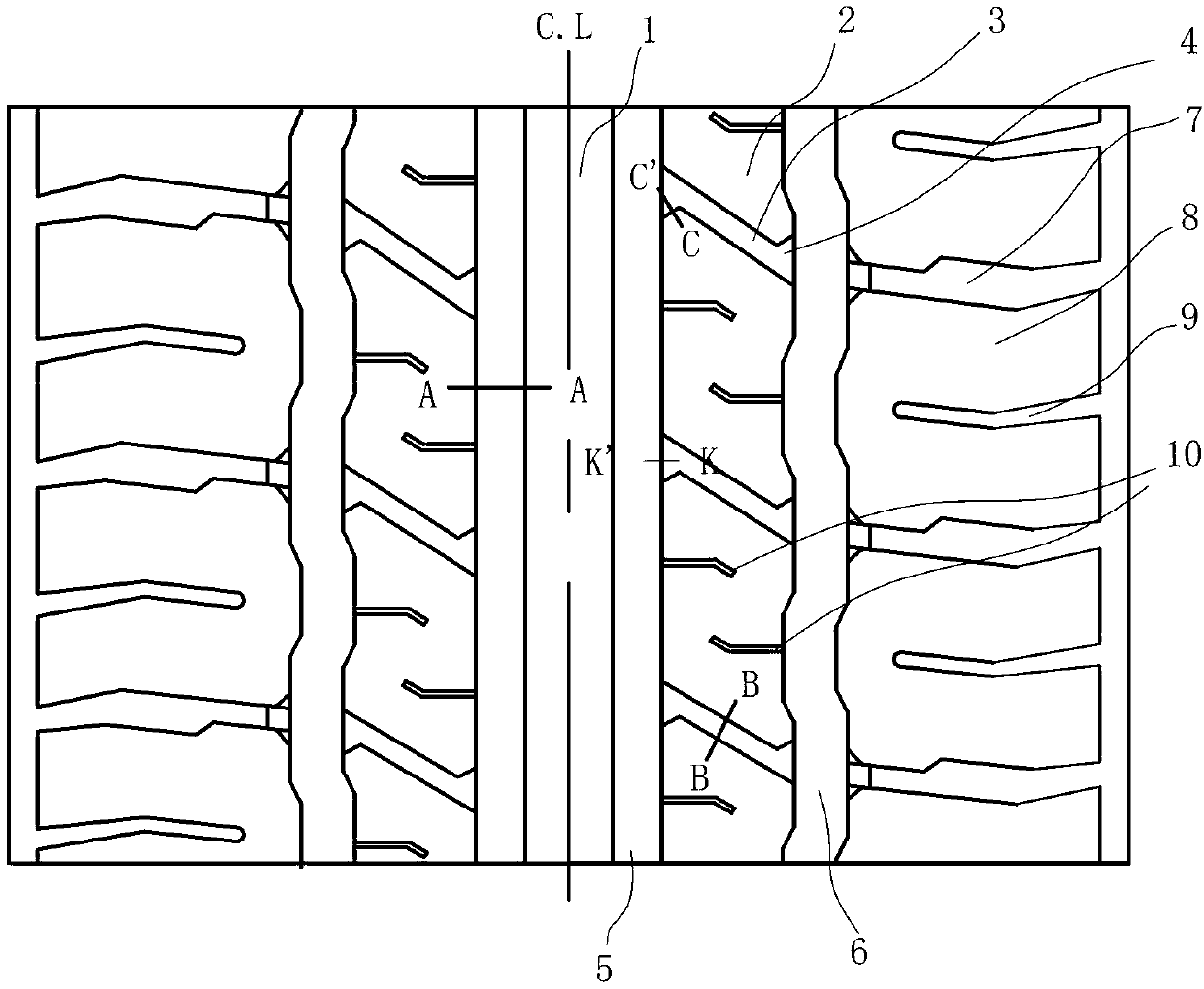

[0023] The anti-rock trap tire of the present invention has a carcass and a tread pattern. please see figure 1 and Figure 10 , the tread pattern is provided with an annular first main groove 5 and a zigzagging annular second main groove 6 outside the first main groove 5 along both sides of the center line C.L. Between the two first main grooves 5 is a central pattern block 1, between the first main groove 5 and the second main groove 6 on the same side are a plurality of side pattern blocks 2 evenly distributed along the tread, and the two second main grooves Outside the main groove 6 are a plurality of shoulder blocks 8 uniformly distributed along the tread.

[0024] The central pattern block 1 is located at the center of the tire tread and is a continuous and integral annular pattern block. Please see Figure 6 , The width G of the central block 1 is 5%-20% of the total width W of the tread pattern, preferably 7%-10%. Usually, when the tire is running, the central posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com