Method for preparing radioactive waste solidified body

A technology of radioactive waste and solidified body, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problem of complicated preparation process, and achieve the effects of strong radioactivity, high toxicity and long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

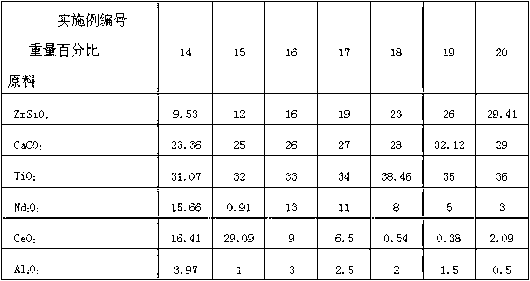

[0029] ZrSiO 4 , CaCO 3 、TiO 2 、Nd 2 o 3 、Al 2 o 3 As raw material, the formula is: ZrSiO 4 27.12wt.% (weight percent), CaCO 3 27.59 wt.%, TiO 2 35.46 wt.%, Nd 2 o 3 8.03wt.%, Al 2 o 3 1.80wt.%; Weigh various raw materials, select materials: balls: absolute ethanol as 1:2.0:1.3 (mass ratio), use planetary mill for 4 hours, dry, add 6% polyvinyl alcohol (PVA) sol (The concentration of PVA is 12%), mixing, sieving and granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 50MPa, and then use a pressure of 250MPa to cold isostatically press it; the molded green body is heat-treated at 1100°C for 30 minutes; the heat-treated green body is Sintering in a vacuum hot-pressing sintering furnace at 1130°C and 30MPa for 180 minutes to obtain a solid-dissolved neodymium perovskite zircon and sphene composite mineral solidified body.

Embodiment 2

[0031] ZrSiO 4 , CaCO 3 、TiO 2 、Nd 2 o 3 、Al 2 o 3 As raw material, the formula is: ZrSiO 4 26.73 wt.% (weight percent), CaCO 3 26.01 wt.%, TiO 2 34.31 wt.%, Nd 2 o 3 10.58 wt.%, Al 2 o 3 2.38 wt.%; Weigh various raw materials, select materials: balls: absolute ethanol as 1:1.8:1.4 (weight ratio), use planetary mill for 4 hours, dry, add 6% polyvinyl alcohol (PVA) sol (The concentration of PVA is 12%), mixing, sieving and granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 50MPa, and then use a pressure of 200MPa to cold isostatically press it; the molded green body is heat-treated at 1050°C for 60 minutes; the heat-treated green body is Sintering in a vacuum hot-pressing sintering furnace at 1160°C and 40MPa for 45 minutes to obtain a solid-dissolved neodymium perovskite zircon and sphene composite mineral solidified body.

Embodiment 3

[0033] ZrSiO 4 , CaCO 3 、TiO 2 、Nd 2 o 3 、Al 2 o 3 As a raw material, according to the formula design principle described in the manual, through formula calculation, the formula of the ingredient ratio is ZrSiO 4 27.85 wt.%, CaCO 3 27.18 wt.%, TiO 2 34.47 wt.%, Nd 2 o 3 8.06 wt.%, Al 2 o 3 2.44wt.%.; Weigh various raw materials, select material: ball: absolute ethanol as 1:1.5:1.2 (weight ratio), use planetary mill for 5h, dry, add 6% polyvinyl alcohol (PVA) Sol (the concentration of PVA is 12%), mixing, sieving and granulating. Put the granulated powder into a steel mold, press it on a hydraulic press with a pressure of 30MPa, and then use a pressure of 150MPa to cold isostatically press it; the molded green body is heat-treated at 1080°C for 45 minutes; the heat-treated green body is Sintering in a vacuum hot-pressing sintering furnace at 1190° C. and 30 MPa for 30 minutes to obtain a solid-dissolved neodymium perovskite zircon and sphene composite mineral s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com