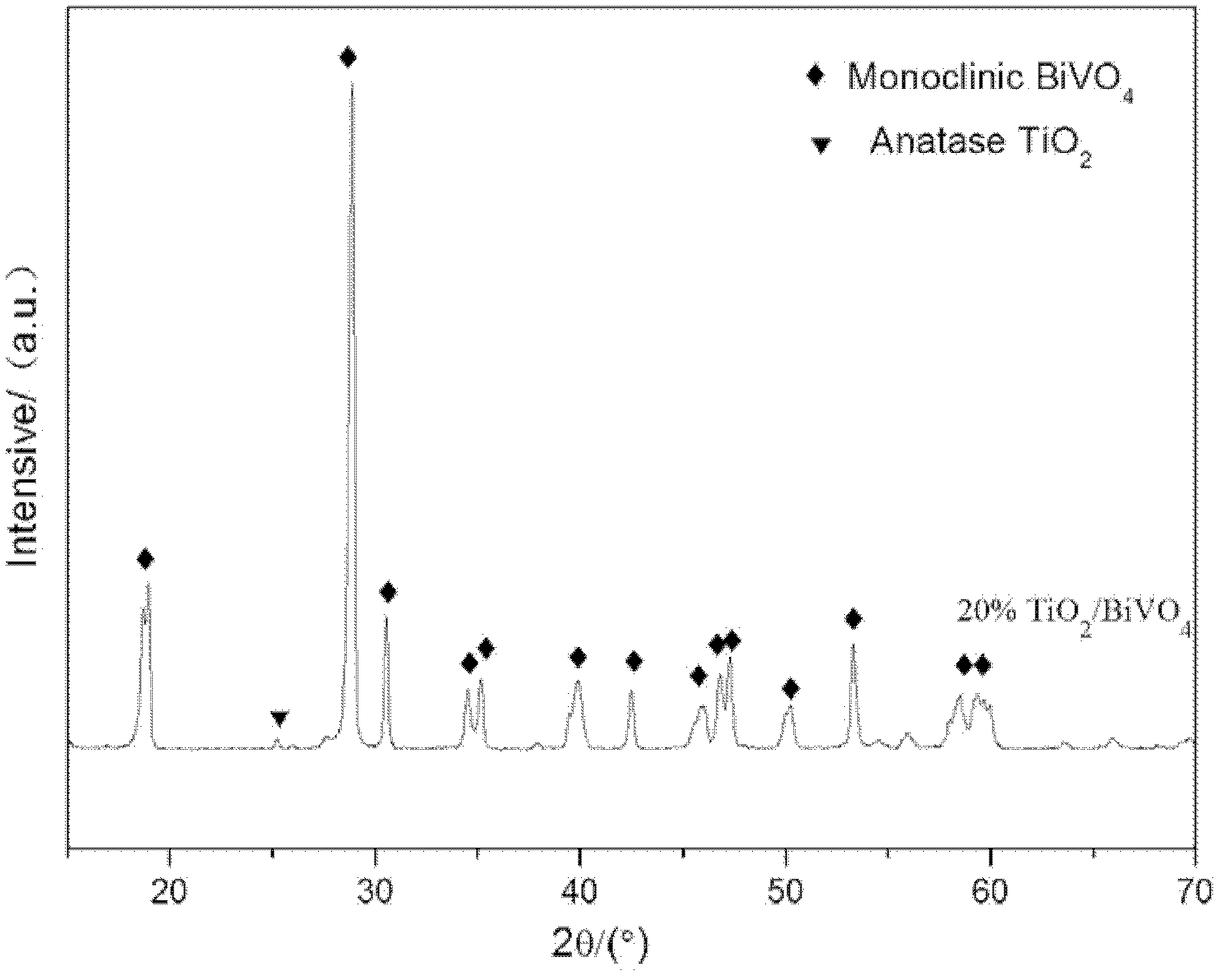

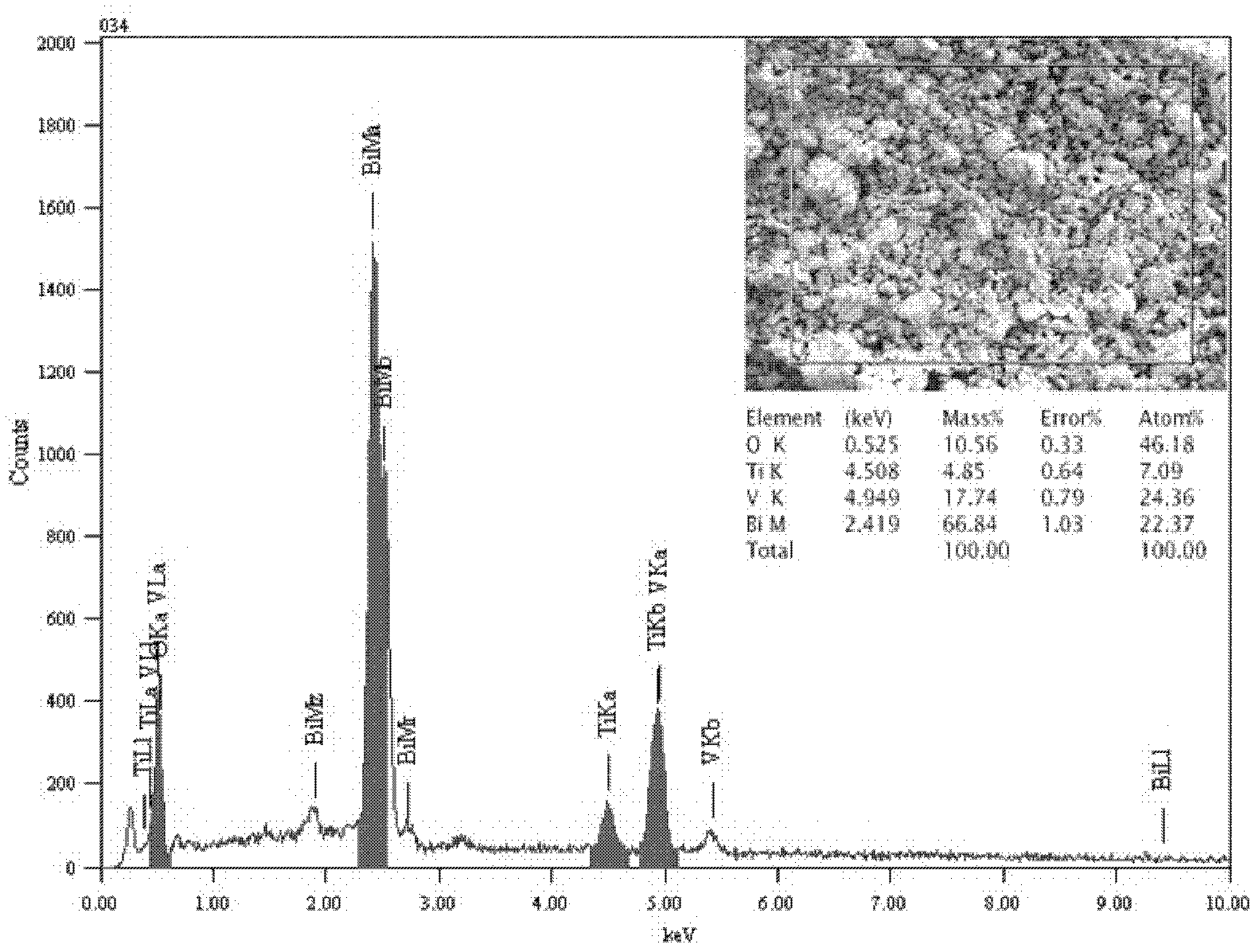

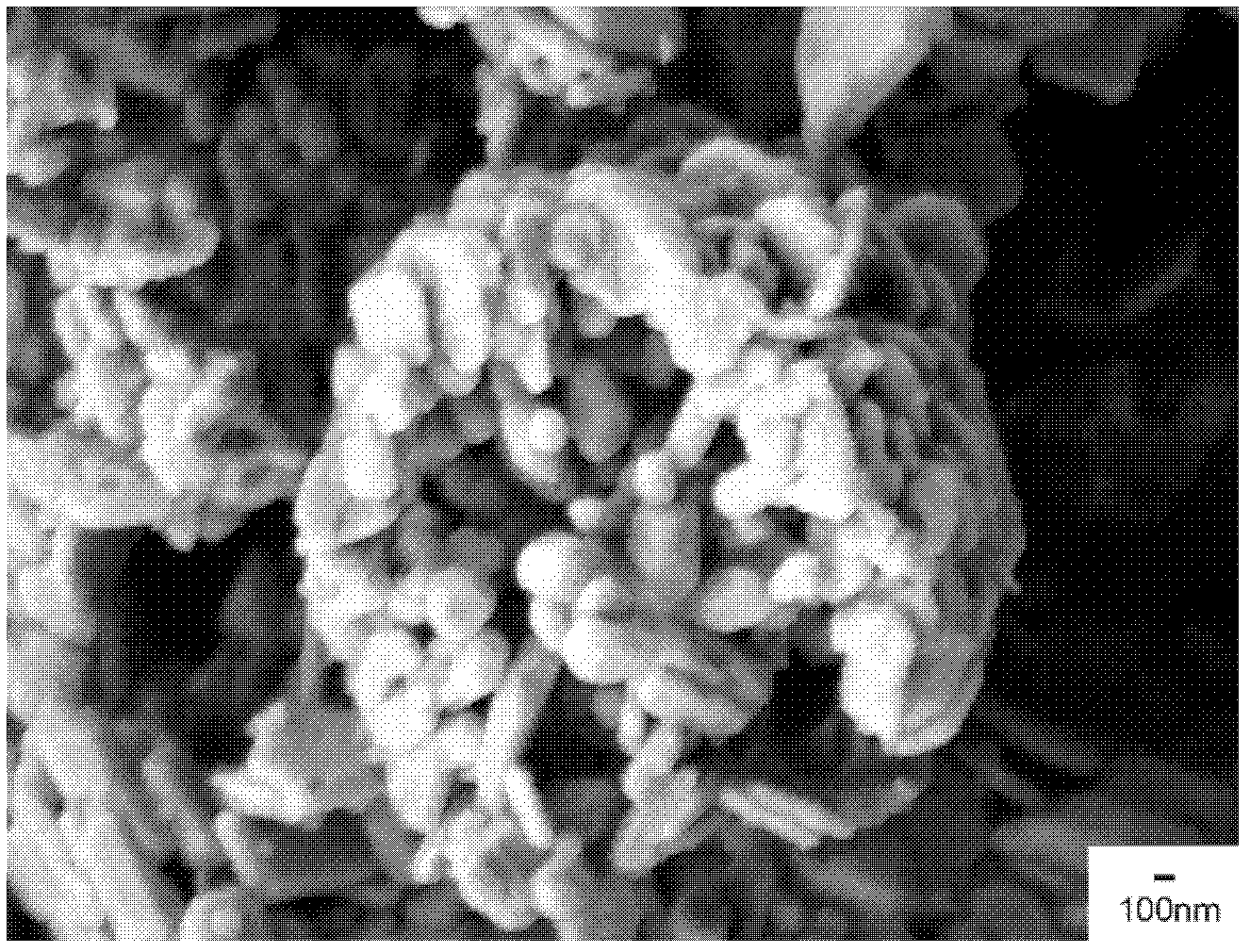

Method for preparing TiO2/BiVO4 composite photocatalyst by MH method

A microwave hydrothermal and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of short reaction time, inhibition of recombination, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Step 1: Bi(NO 3 ) 3 ·5H 2 O and (NH 4 ) 2 TiF 6 Dissolve in 20mL of HNO with a concentration of 2mol / L 3 solution, where n Bi : n Ti =1:0.2, stir on a magnetic stirrer for 10-20min, and prepare mother salt solution A;

[0017] Step 2: Add NH 4 VO 3 Dissolve in 20mL NaOH solution with a concentration of 4mol / L, where n Bi : n V = 1: 1 Stir on a magnetic stirrer for 10-20 minutes to prepare mother salt solution B;

[0018] Step 3: mix the mother salt solution A obtained in step 1 and the mother salt solution B obtained in step 2 evenly, stir on a magnetic stirrer for 10-30 minutes, and prepare a precursor solution;

[0019] Step 4: Add the precursor solution into the microwave hydrothermal reaction kettle with a filling ratio of 40-60%, then place the reaction kettle in a microwave-assisted hydrothermal synthesizer, set the reaction temperature at 180-220°C, and hold the time for 60~120min;

[0020] Step 5: After the reaction is completed, cool down, take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com