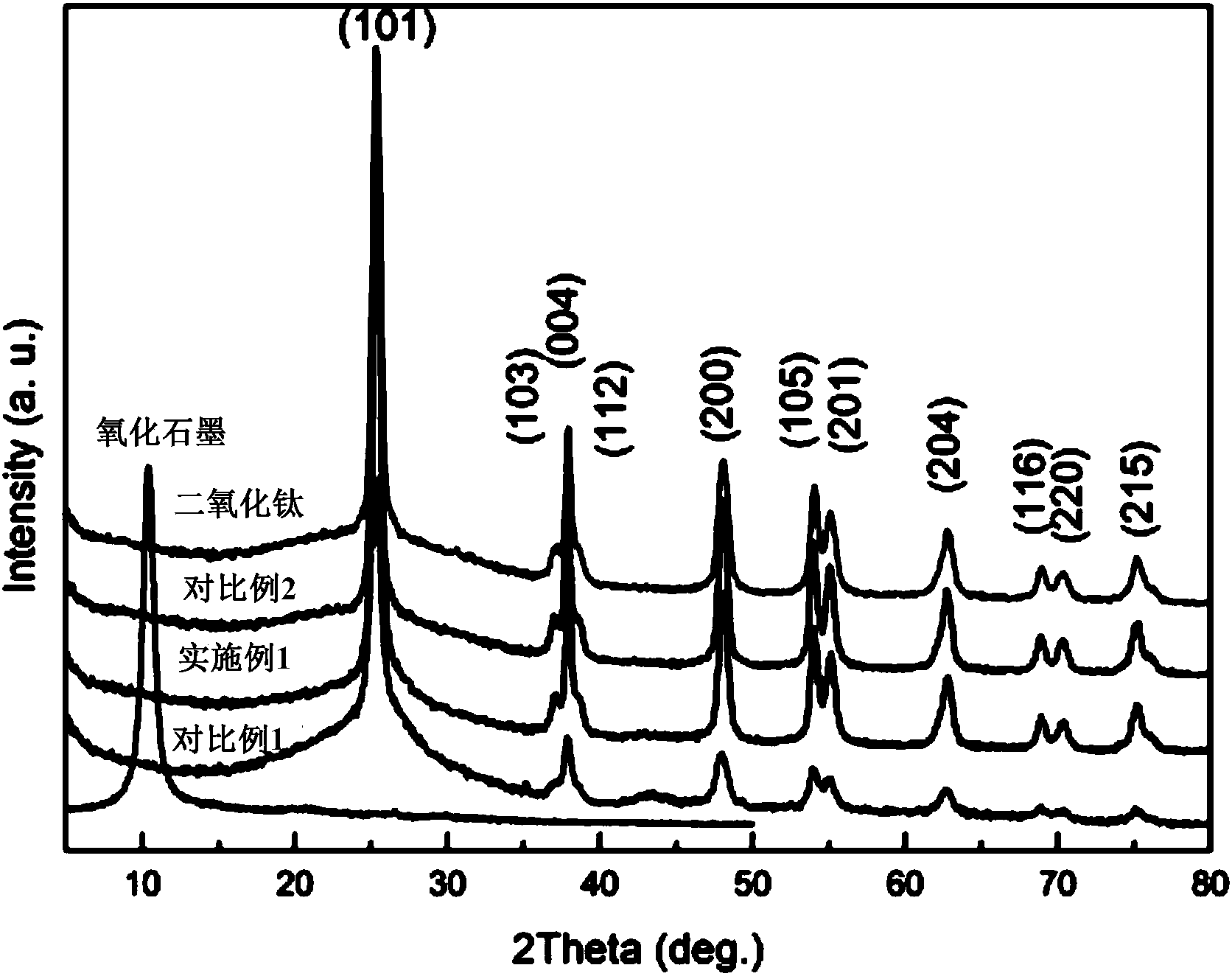

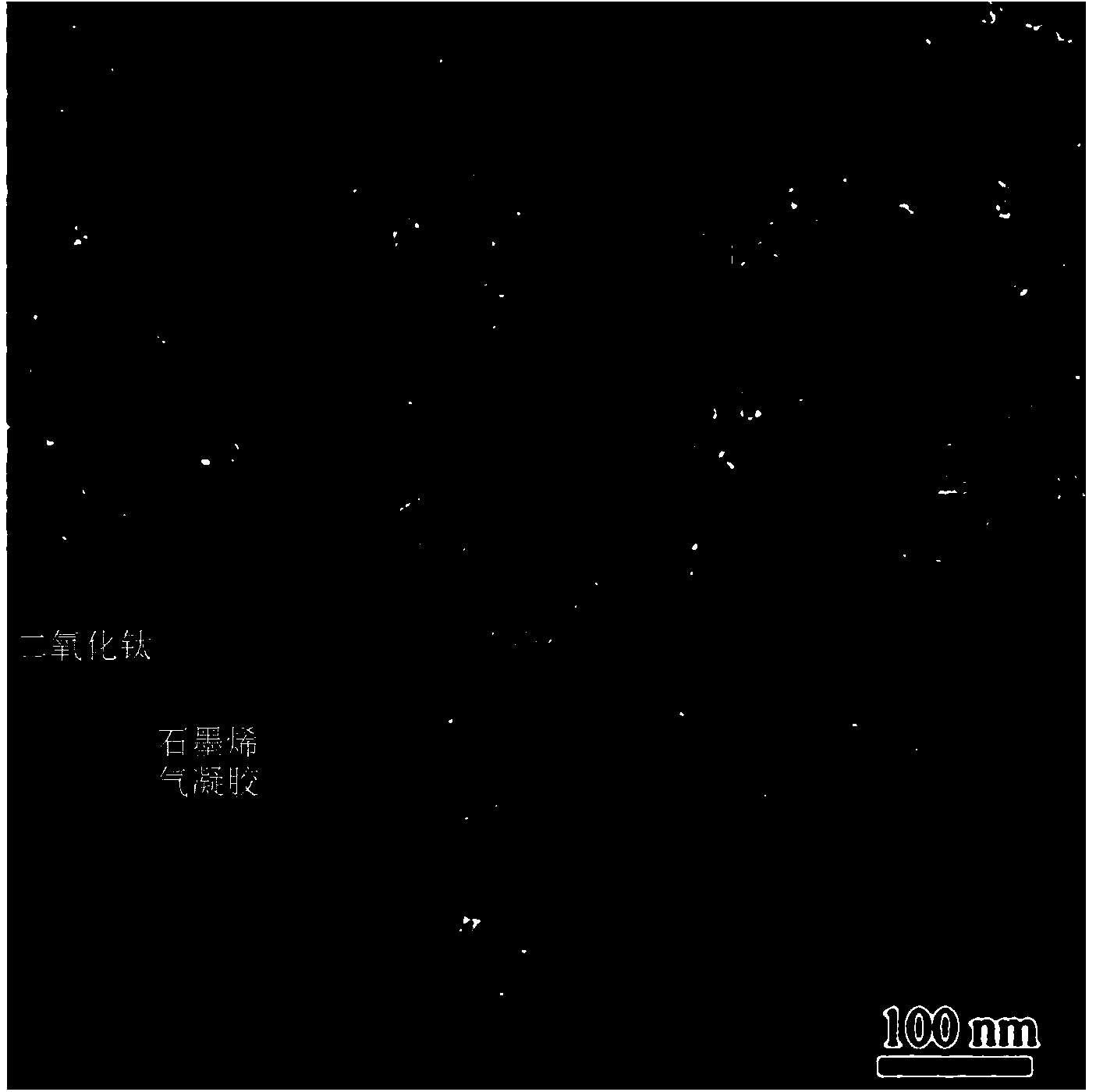

Grading three-dimensional porous graphene/titanium dioxide photocatalyst and preparation method thereof

A titanium dioxide, three-dimensional porous technology, applied in the fields of environment and energy, can solve problems such as affecting the performance of photocatalyst materials, and achieve the effect of enhancing effective contact area, adsorption performance and photocatalytic performance, and enhancing adsorption performance and photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of hierarchical three-dimensional porous graphene / titania photocatalyst, it comprises the following steps:

[0032] 1) Use the Hummers method to prepare graphite oxide, dissolve graphite oxide in deionized water, and ultrasonically obtain a graphene oxide aqueous solution with a concentration of 3 mg / ml for 2 hours;

[0033] 2) Add 7.95g of hexadecylamine to an aqueous solution of 800ml of absolute ethanol and 3.20ml of potassium chloride (0.1M), sonicate for 10 minutes, and slowly drop 18.10ml of isopropyl titanate into the mixed solution under vigorous stirring , reacted for 18 hours, filtered the reaction solution, then repeatedly washed 3 times with ethanol, and dried to obtain a titanium dioxide precursor;

[0034] 3) Dissolve 0.50g of titanium dioxide precursor in 10ml of ethanol, ultrasonically disperse for 10 minutes, then add 50ml of graphene oxide solution (3mg / ml) and 500μl of ammonia water in turn ...

Embodiment 2

[0041] The present embodiment is roughly the same as Example 1, except that the volume of the potassium chloride aqueous solution in step 2) is 5.49ml, i.e. H 2 When the molar ratio of O:Ti is 5:1: the particle size of titanium dioxide nanoparticles gradually decreases with the increase of water content. Due to the stretchability of the three-dimensional graphene skeleton, its coating structure still makes its photocatalytic efficiency higher than that of P25.

Embodiment 3

[0043] This embodiment is roughly the same as Example 1, except that the quality of hexadecylamine in step 2) is: 3.975g, that is, the molar ratio of hexadecylamine:titanium is reduced from 0.5:1 in Example 1 to 0.25 : 1, part of the titanium dioxide nanoparticles began to bond together, and three-dimensional graphene pore structure to form a coating, photocatalytic performance similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com