Patents

Literature

732results about "Tea drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

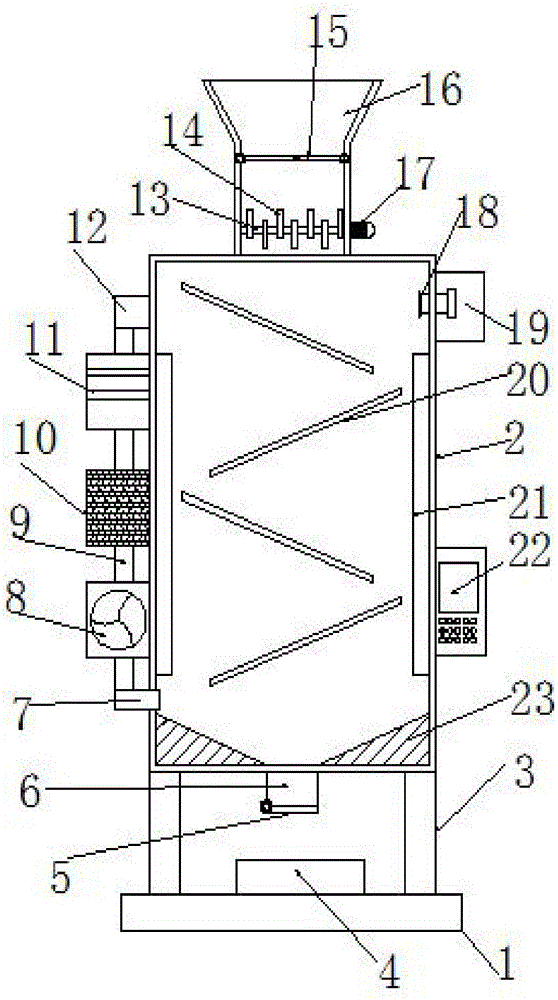

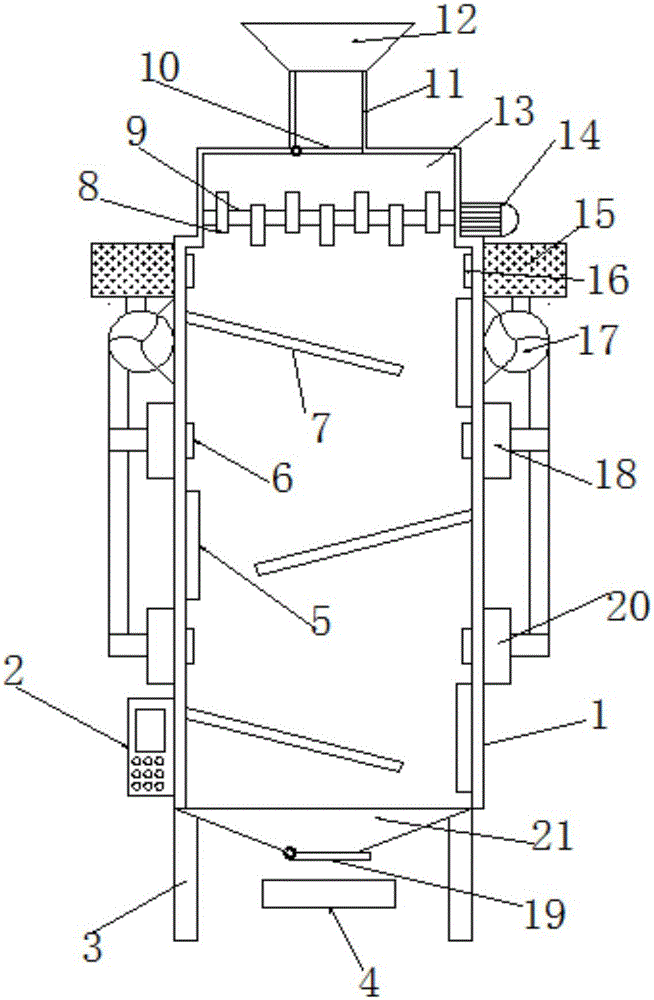

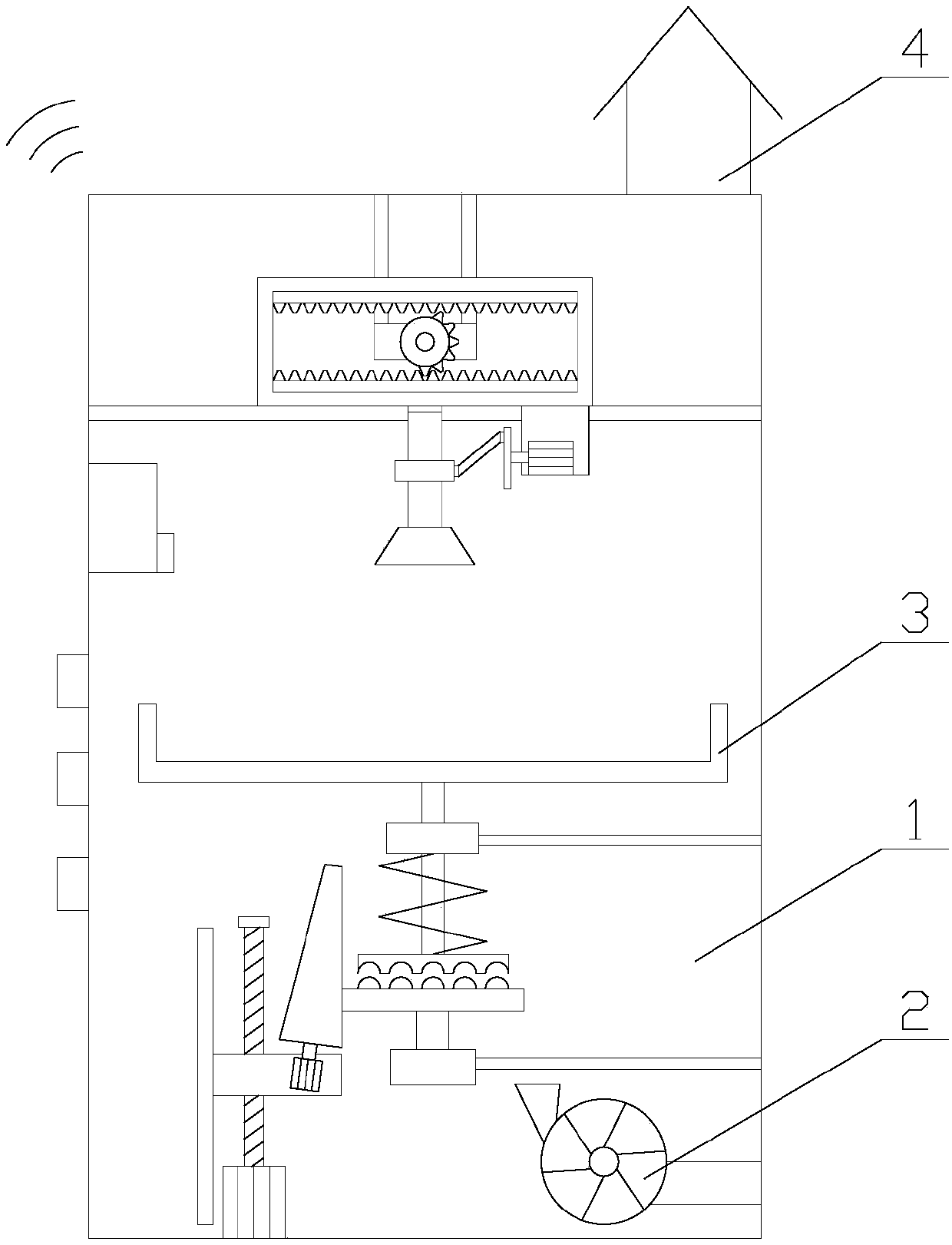

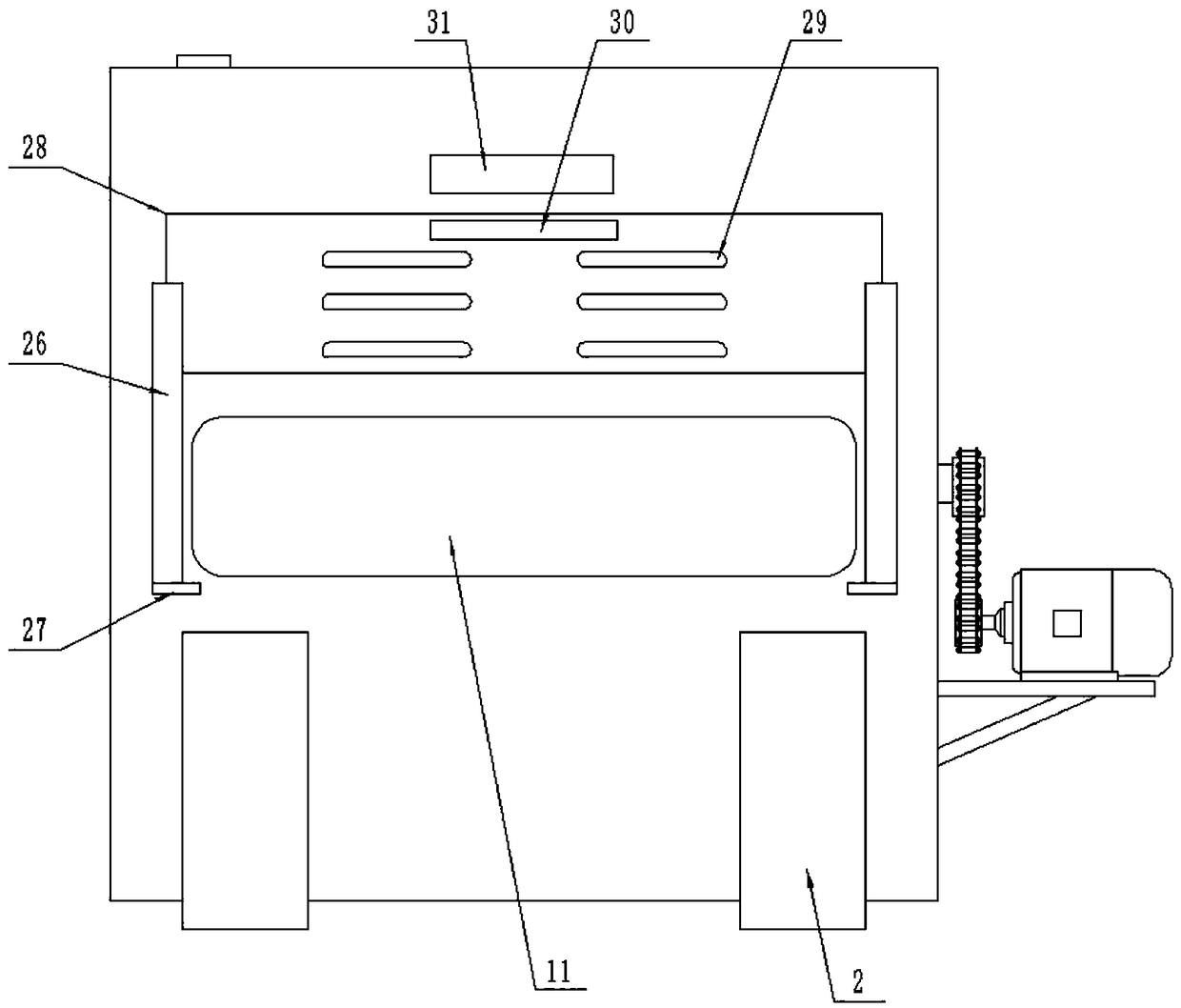

Environment-friendly anti-blocking tea leaf drying machine

InactiveCN106017040AAchieve recyclingRealize wastePre-extraction tea treatmentTea dryingDrive shaftAgricultural engineering

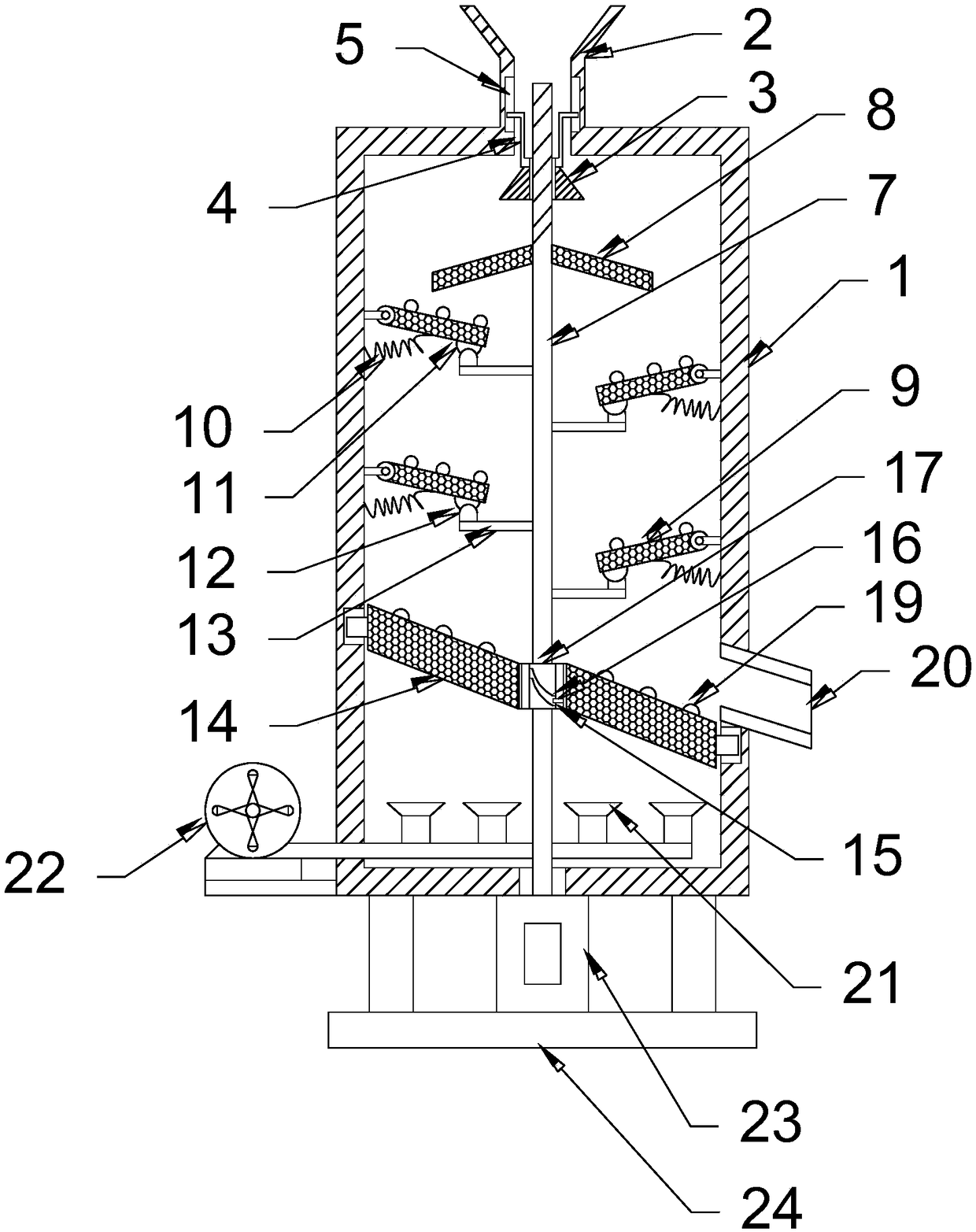

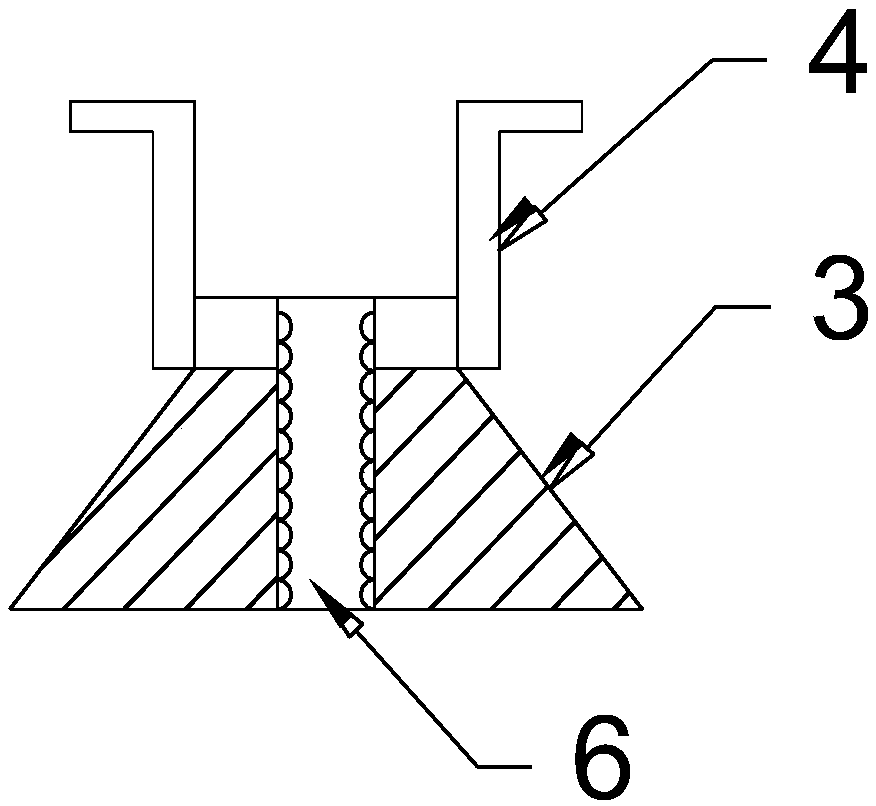

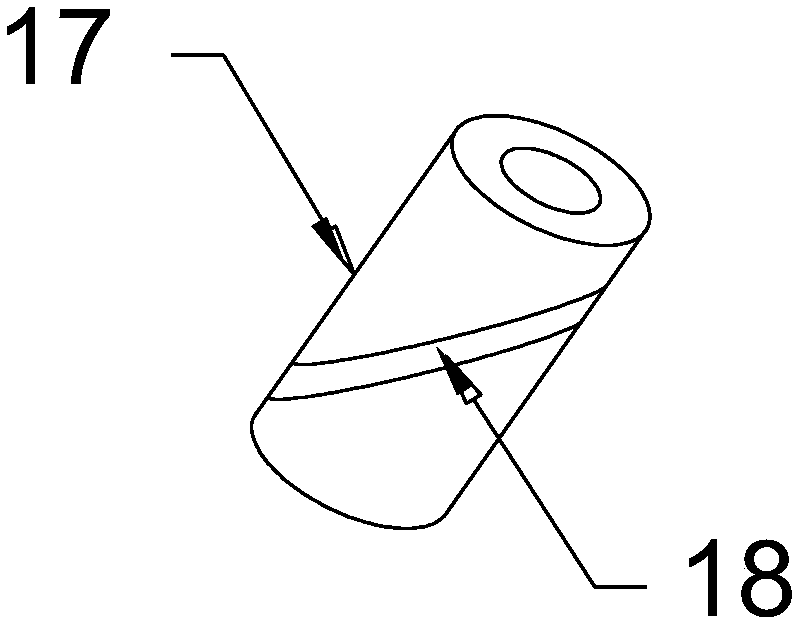

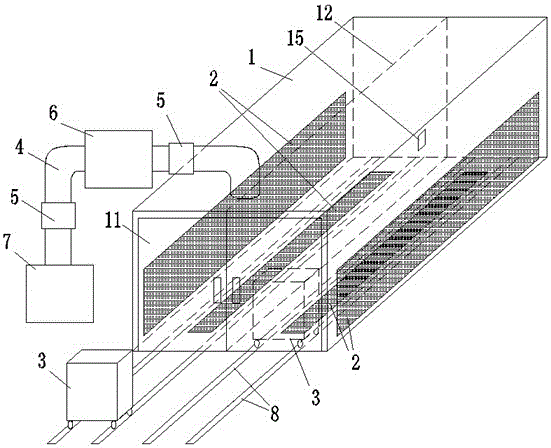

The invention discloses an environment-friendly anti-blocking tea dryer, which comprises a base and a drying box, a drying box is arranged above the base, a leg is arranged between the lower end of the drying box and the base, and a There is a discharge pipe, the upper end of the base below the discharge pipe is provided with a feeding conveyor belt, the upper end of the drying box is provided with a feeding hopper, and a feeding channel is provided between the feeding hopper and the drying box, and the right side is placed horizontally in the feeding channel. There are several eccentric wheels on the drive shaft. The right end of the drive shaft passes through the right side of the feeding channel and connects with the output end of the driving motor. There are several guide ramps in the drying box below the feeding channel. The left side of the drying box is provided with an air outlet and an air inlet respectively from top to bottom, and the air inlet and the air outlet are connected through a circulation conduit. The structure of the invention is simple and reasonable, and the heat in the waste gas is recovered and utilized. The device reduces the pollution to the environment, saves energy and protects the environment, and has strong practicability.

Owner:SUQIAN HUAIHAI TECH SERVICES

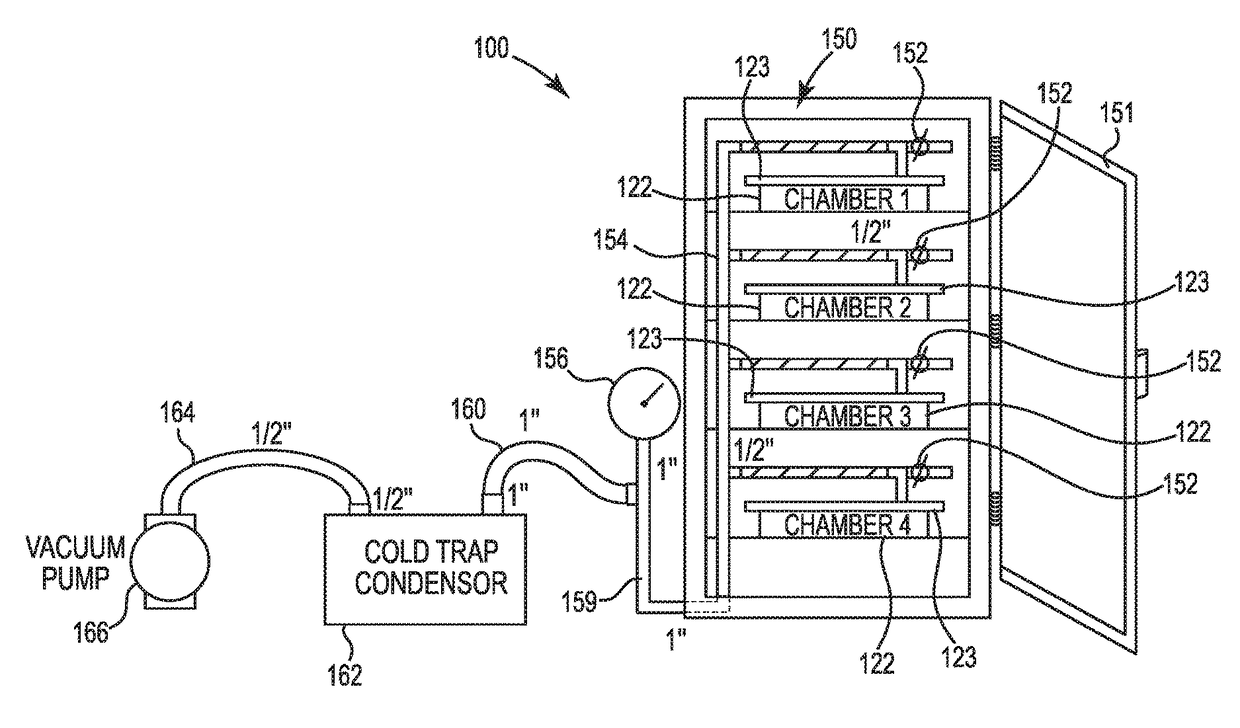

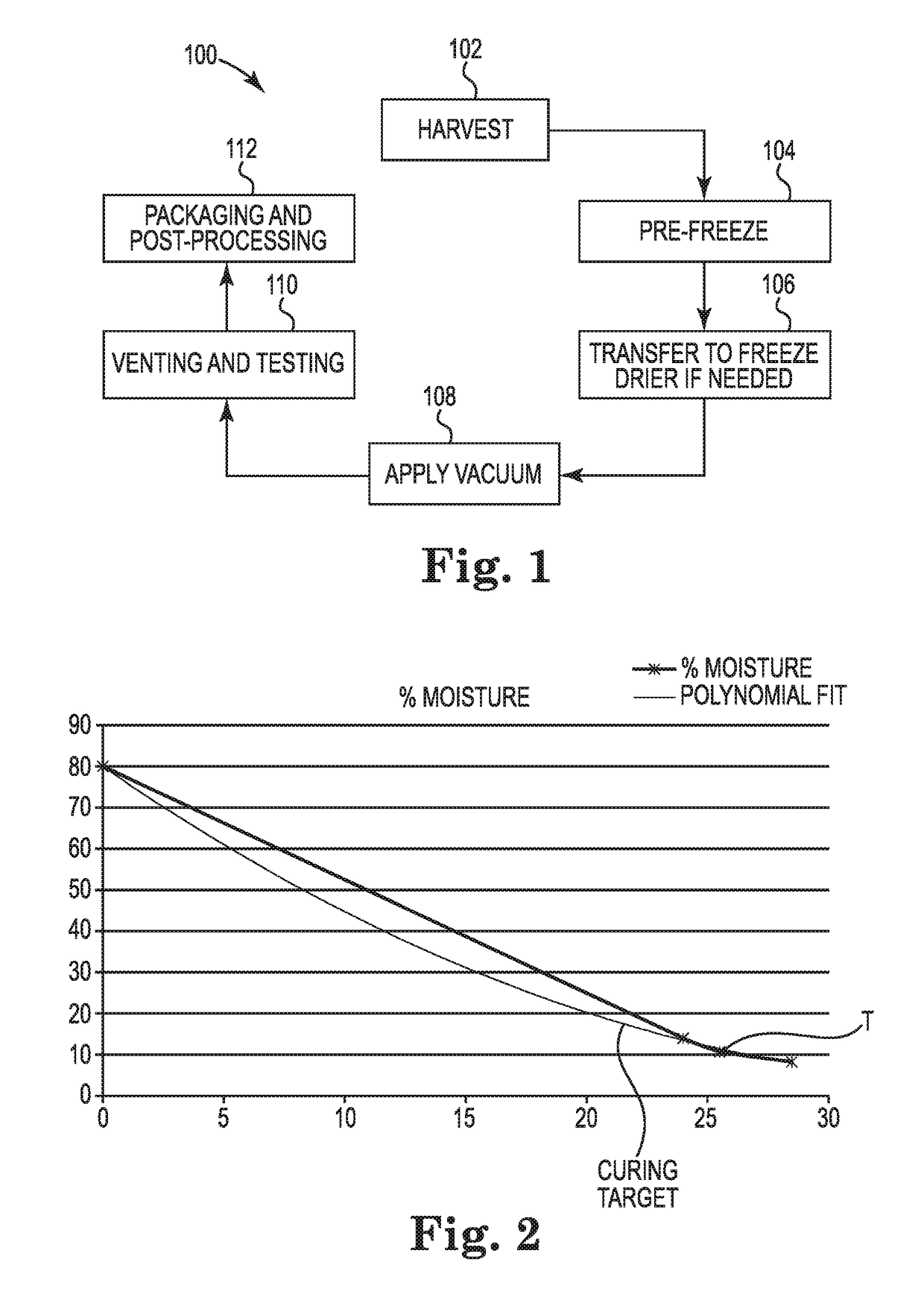

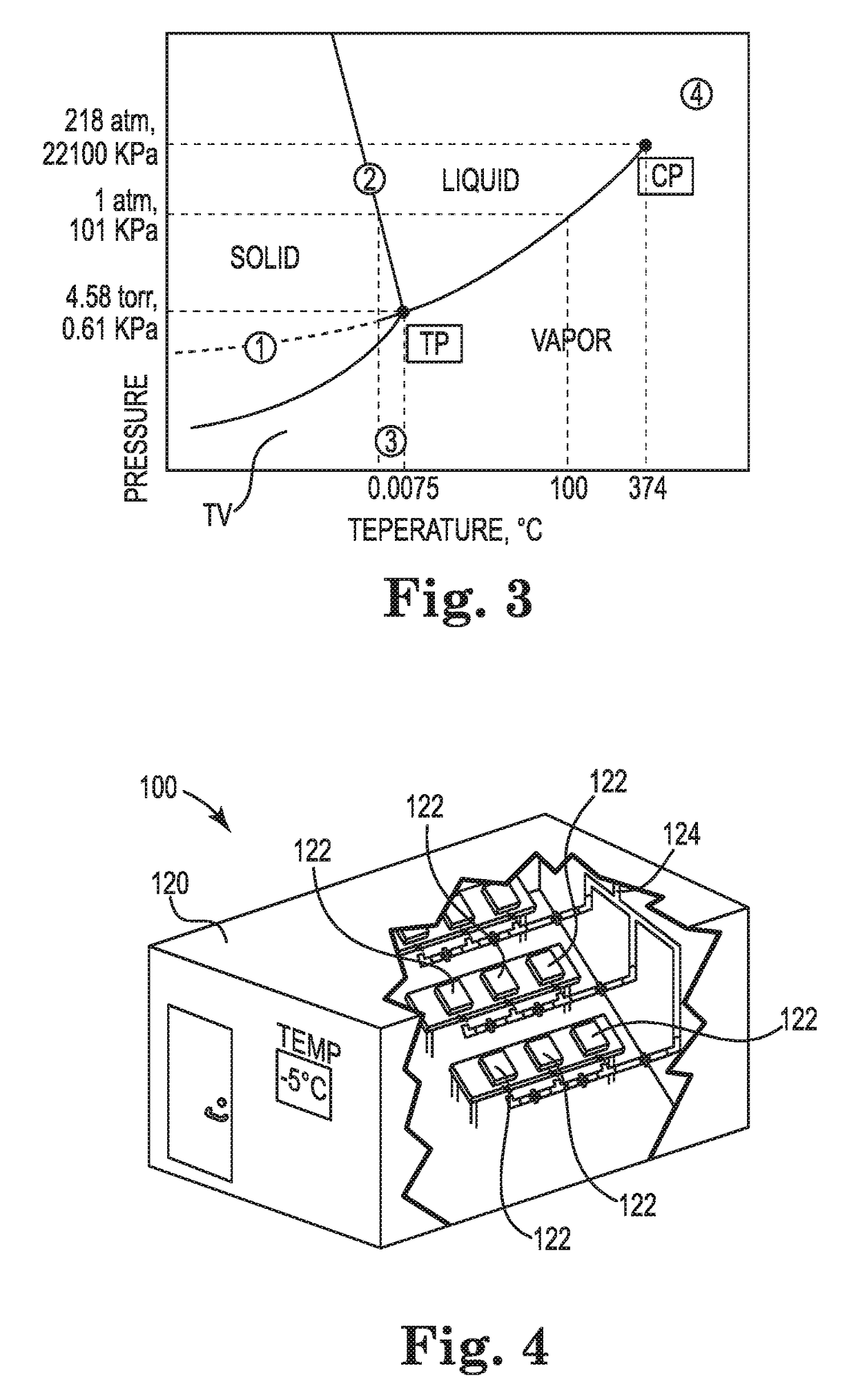

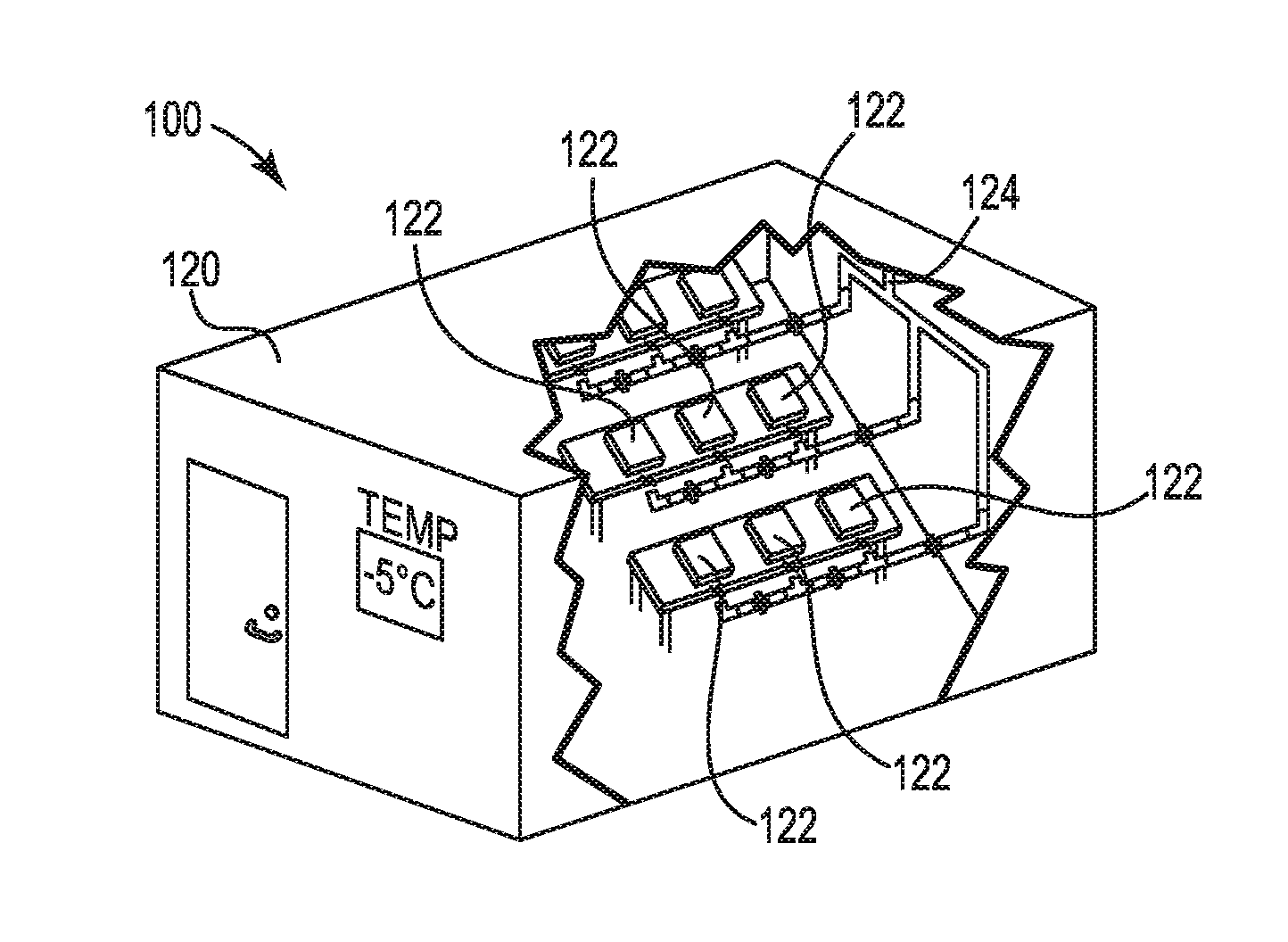

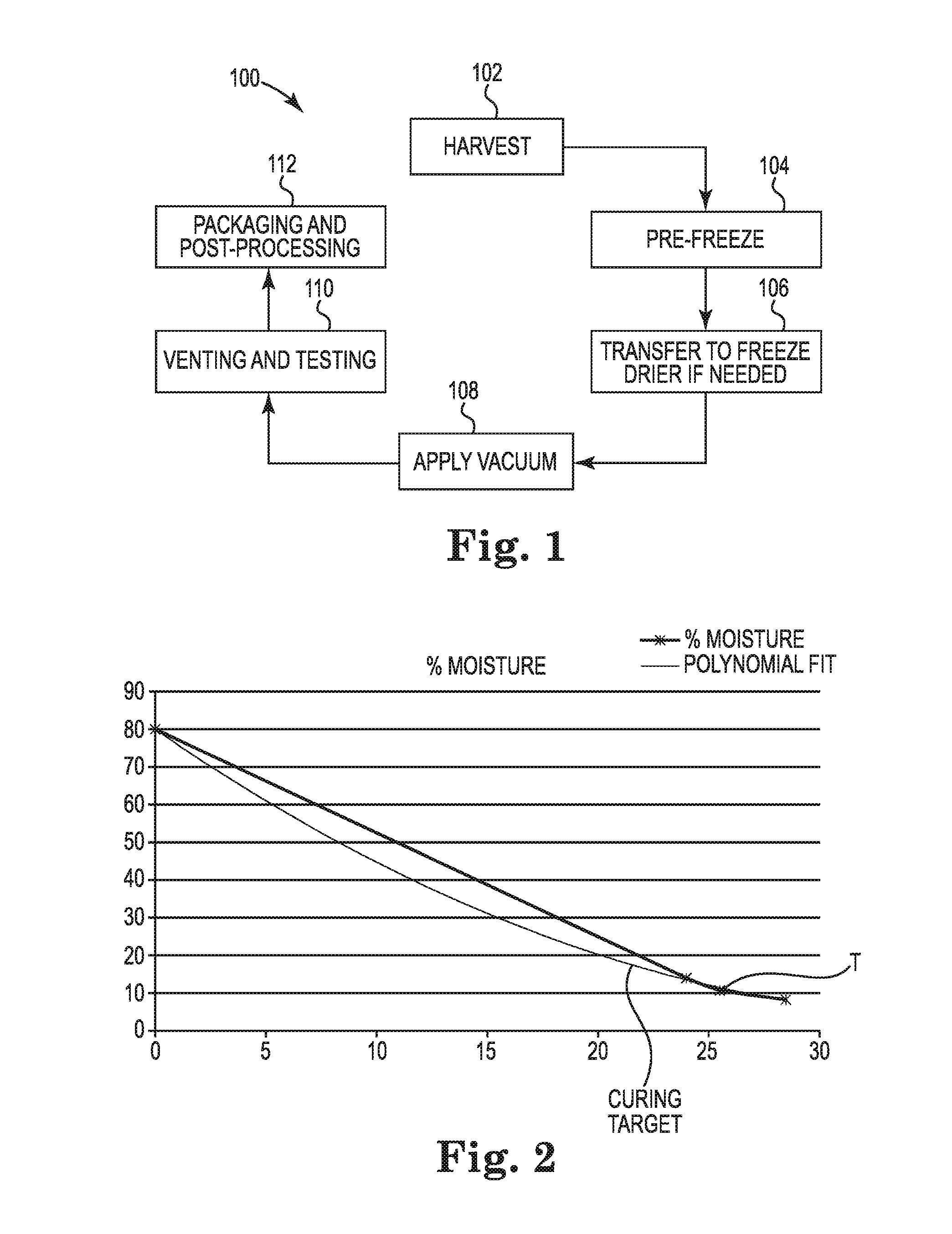

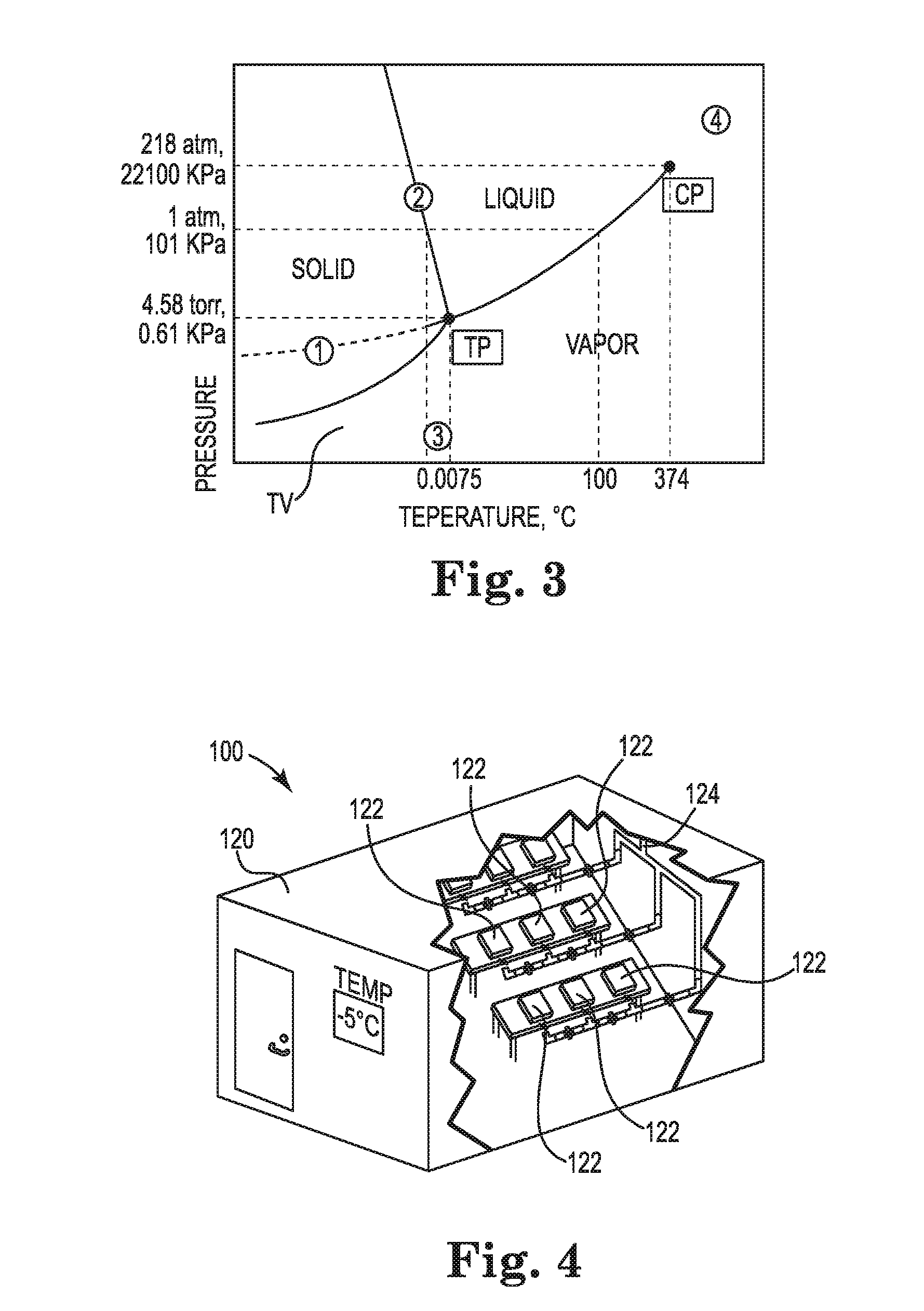

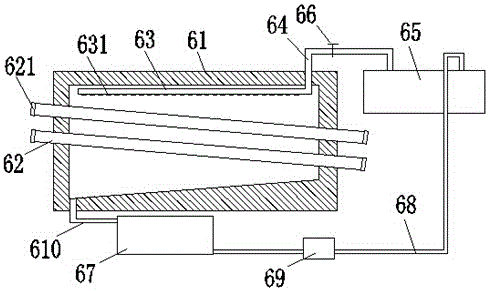

Botanical freeze drying system and method

ActiveUS9739532B2Reduce and prevent evaporative lossPromotes sublimationDrying solid materials without heatTea dryingFreeze-dryingPulp and paper industry

Systems and methods for freeze drying botanical or herb items or products using a modular vacuum chamber configuration are provided. Such configurations can reduce or prevent the evaporative loss of volatile compounds while reducing the temperature and removing air to prevent oxidation of the product. The freeze drying systems and methods of the present invention can improve organoleptic characteristics, shelf life, and extractions.

Owner:BAUGH STEVEN F +1

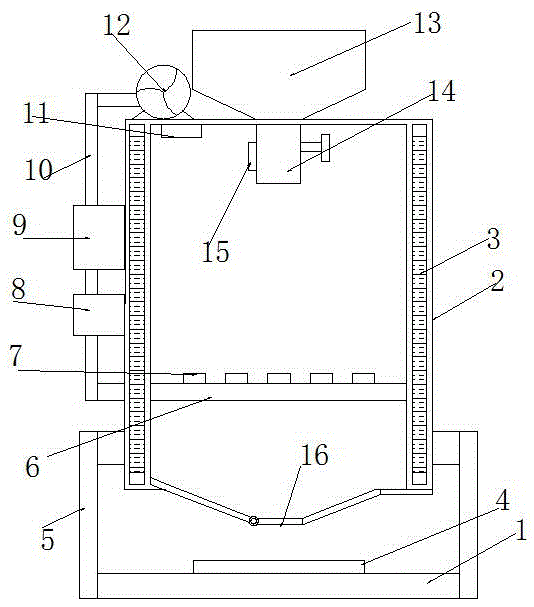

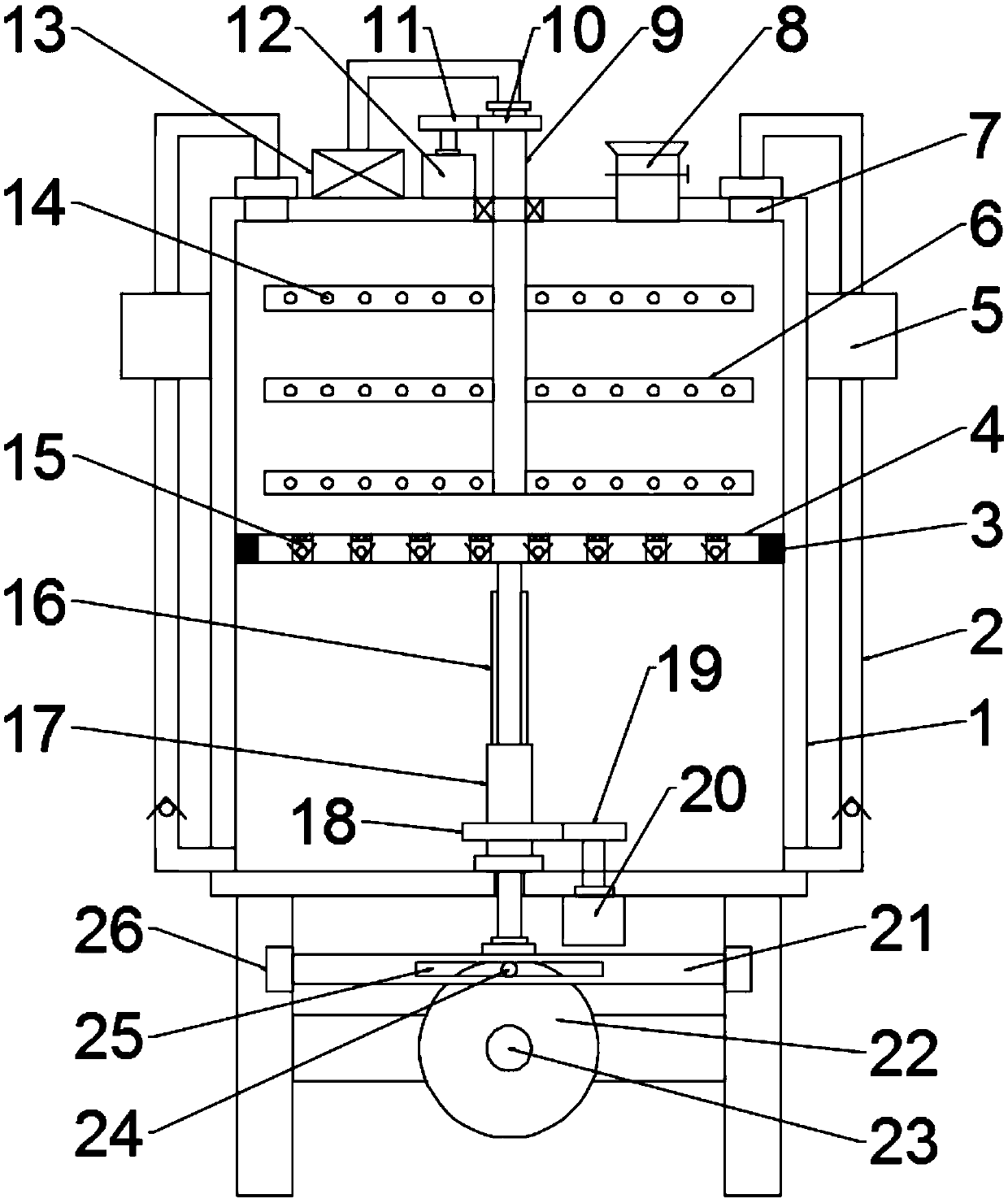

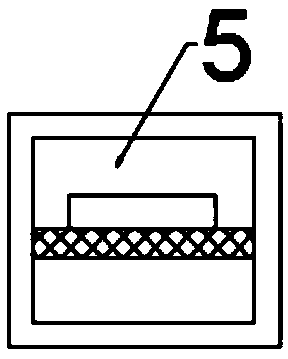

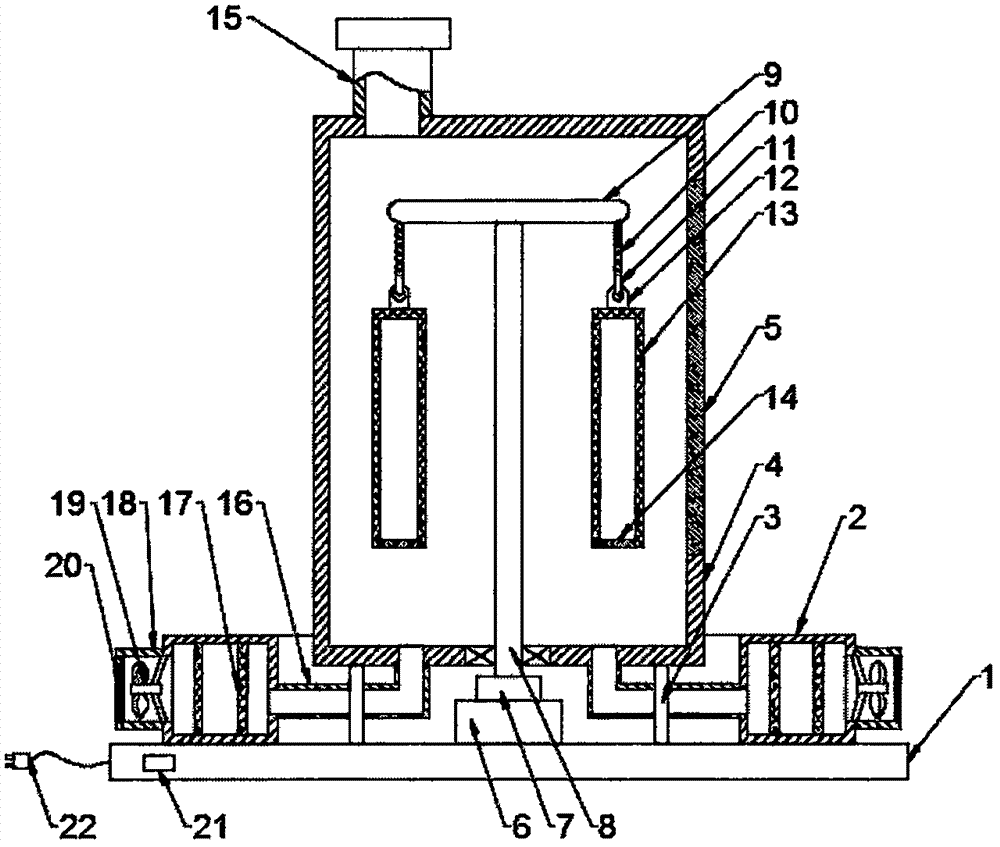

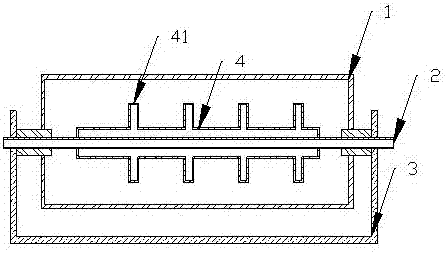

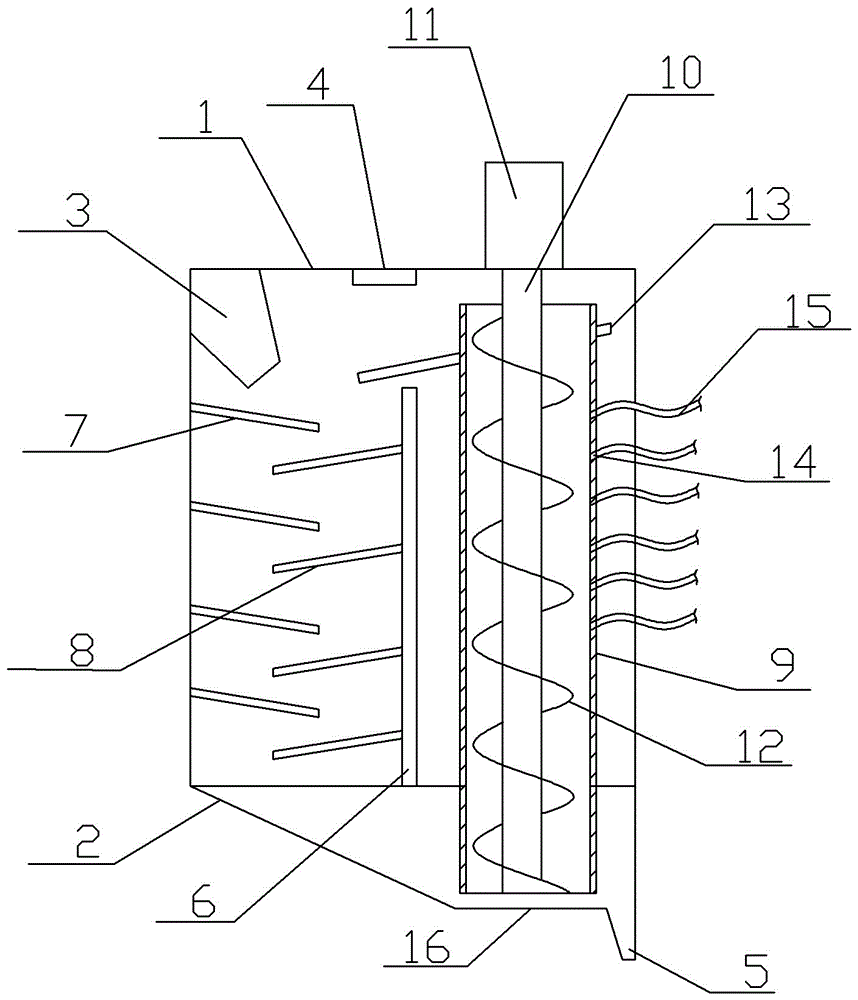

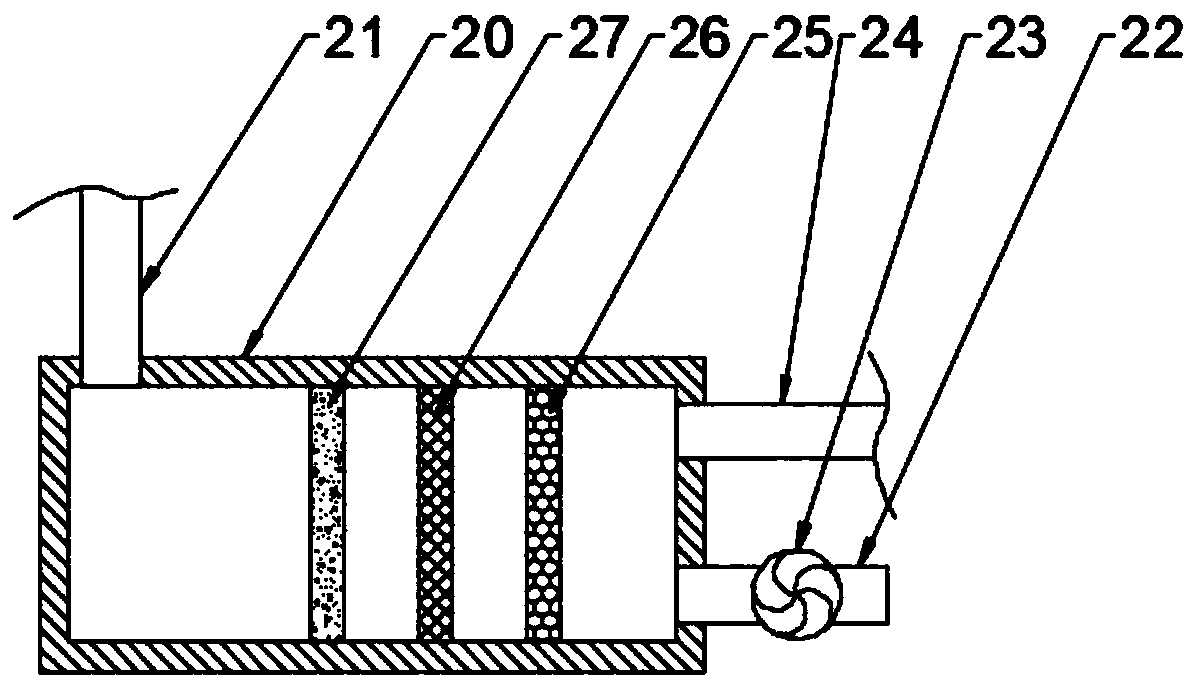

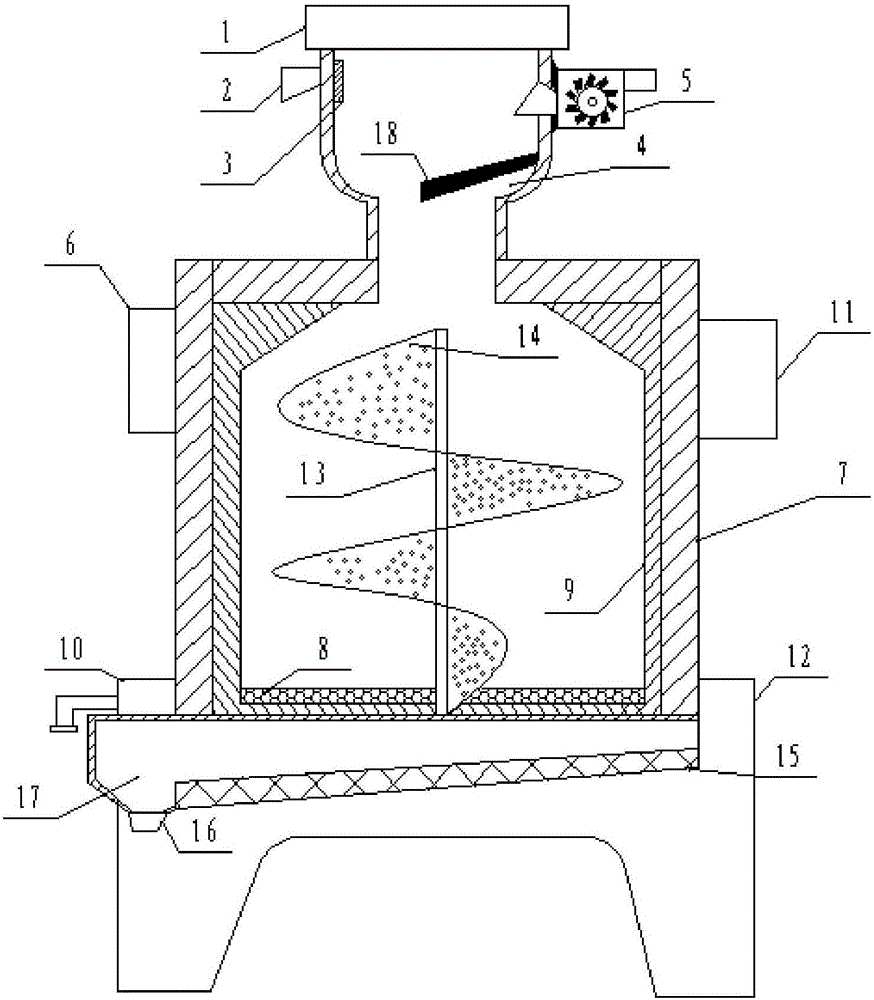

Tea leaf drying device

InactiveCN105605889AAvoid damageImprove filtering effectDrying solid materials with heatDrying solid materials without heatPulp and paper industryHeat losses

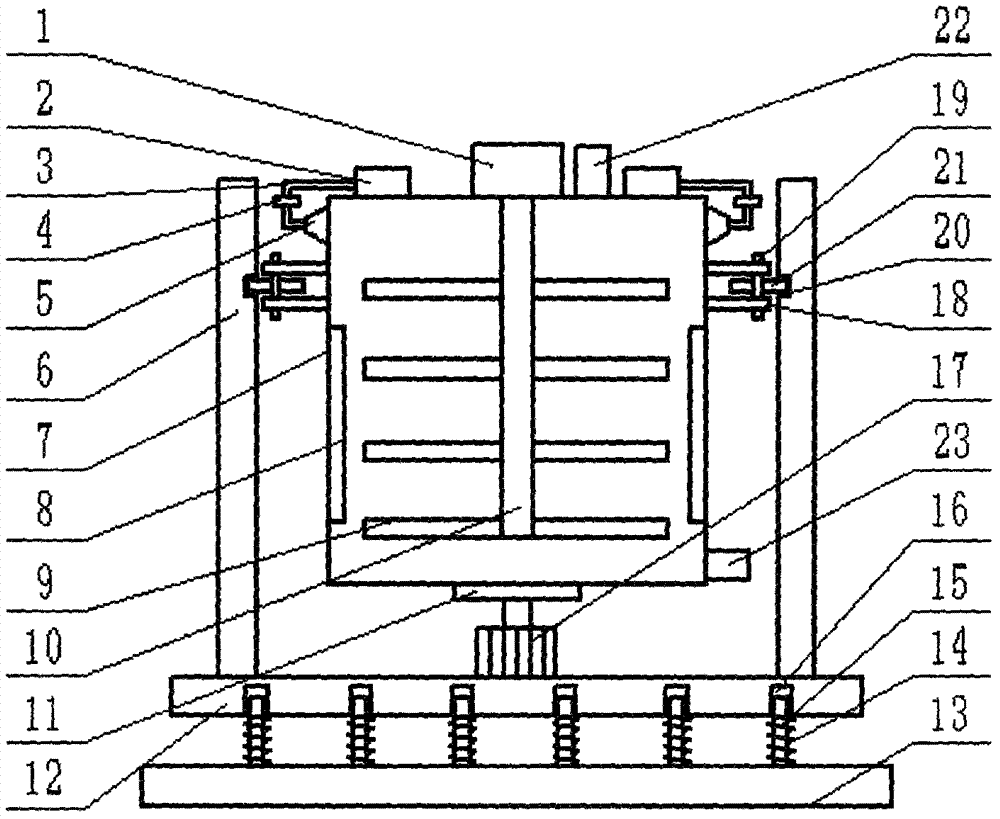

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a base and a drying box. The drying box is arranged above the base, supporting legs are arranged between the drying box and the base, an electromagnetic heating coil is embedded in the wall of the drying box, a feeding hopper is arranged at the upper end of the drying box, a discharging pipe is arranged at the lower end, located in the drying box, of the feeding hopper, an air jet pipe is arranged in the drying box, an air jet port is formed in the upper side of the wall of the air jet pipe, an exhaust port is formed in the upper left end of the drying box, the air outlet end of the exhaust port is connected with a circulating fan, an air outlet of the circulating fan is connected with the air inlet end of the air jet pipe through an air guide pipe, the air guide pipe penetrates through a filtering box and a dehumidifying box in sequence from top to bottom, a discharging door is further arranged at the bottom of the drying box, and a conveying belt is further arranged on a base at the lower end of the drying box. The tea leaf drying device is simple and reasonable in structure, high in heating efficiency and good in drying effect; heat loss is avoided while dryness of air in the drying box is maintained, and thus the effect of saving energy is achieved.

Owner:廖志标

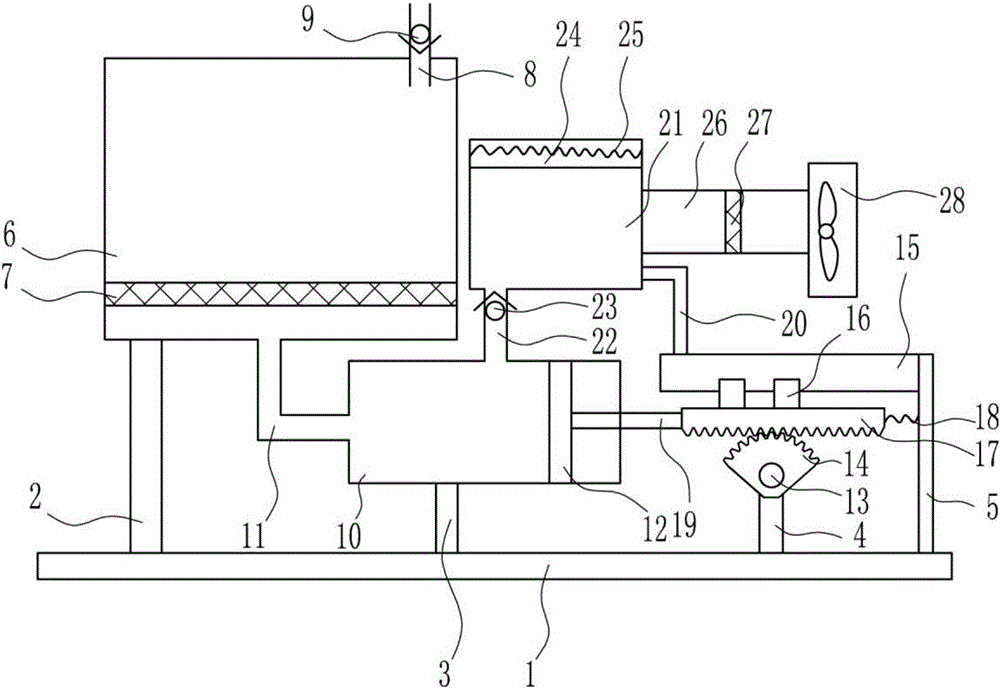

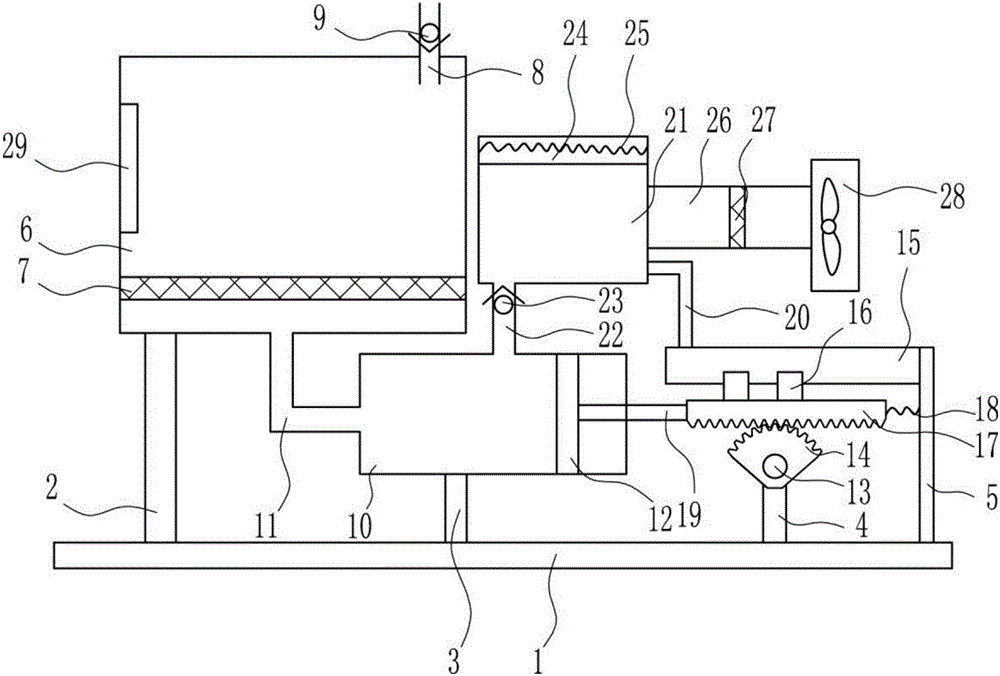

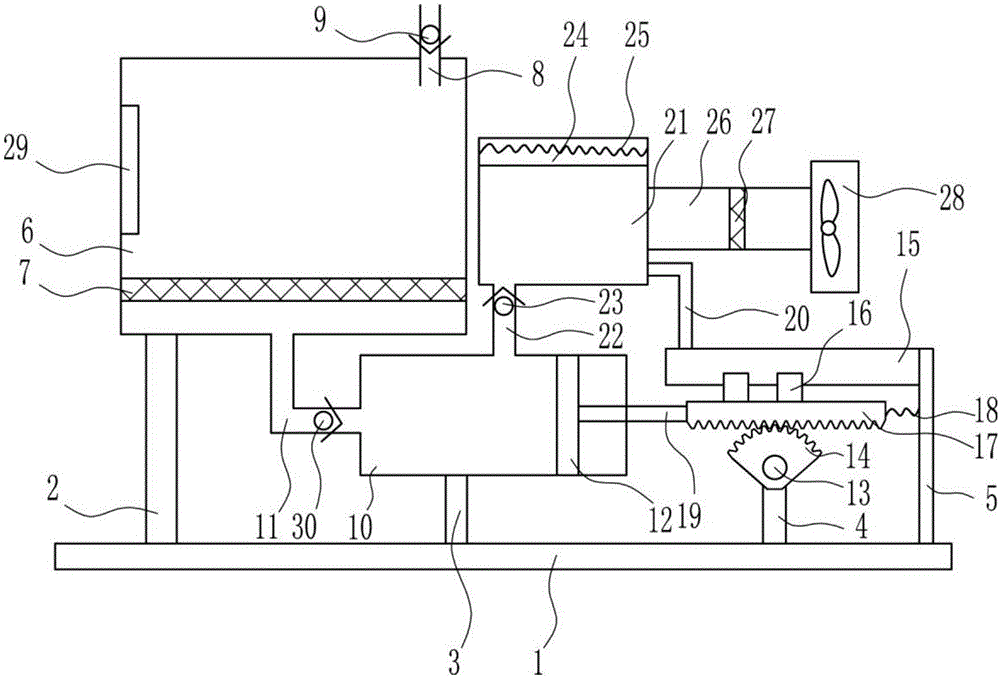

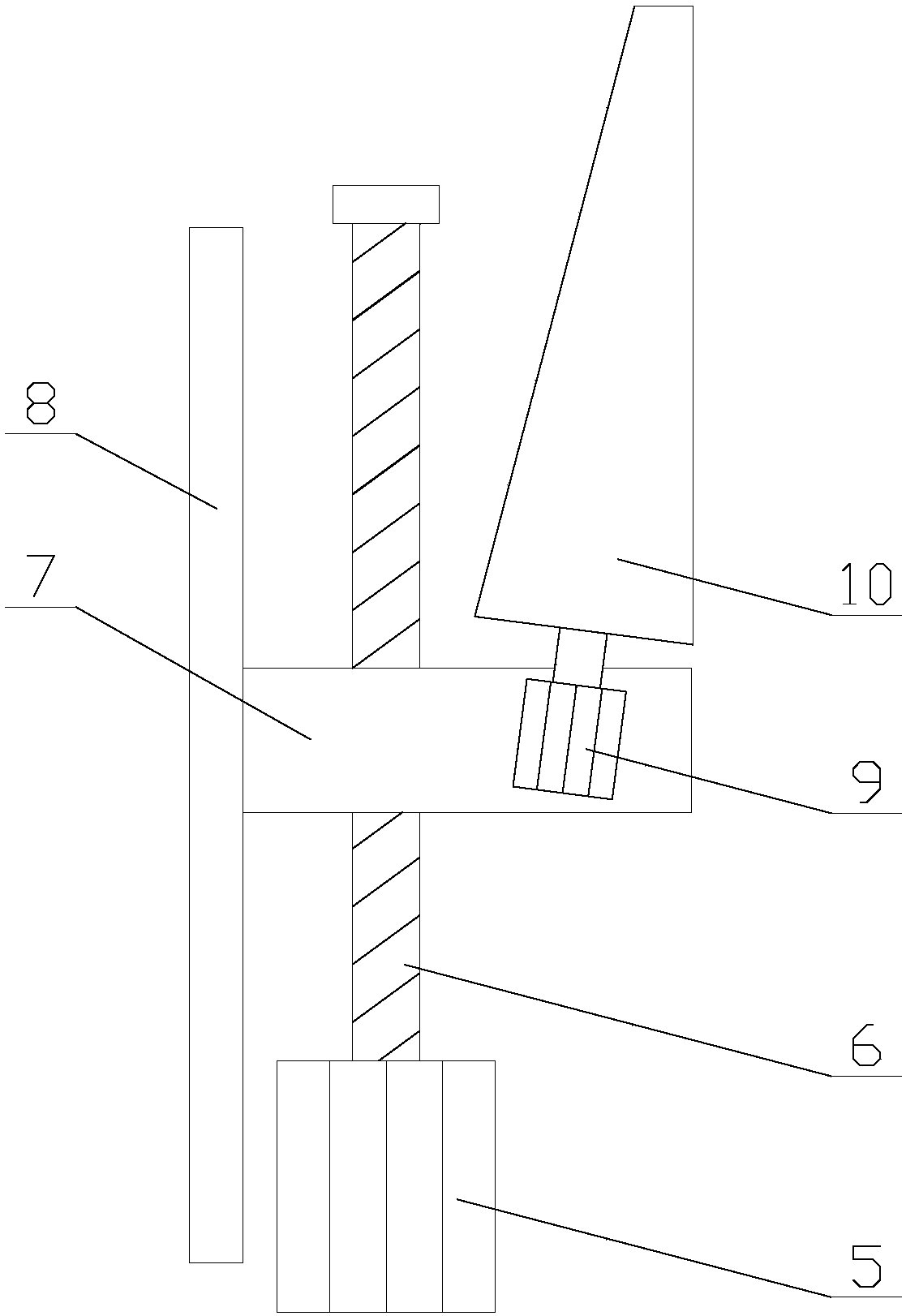

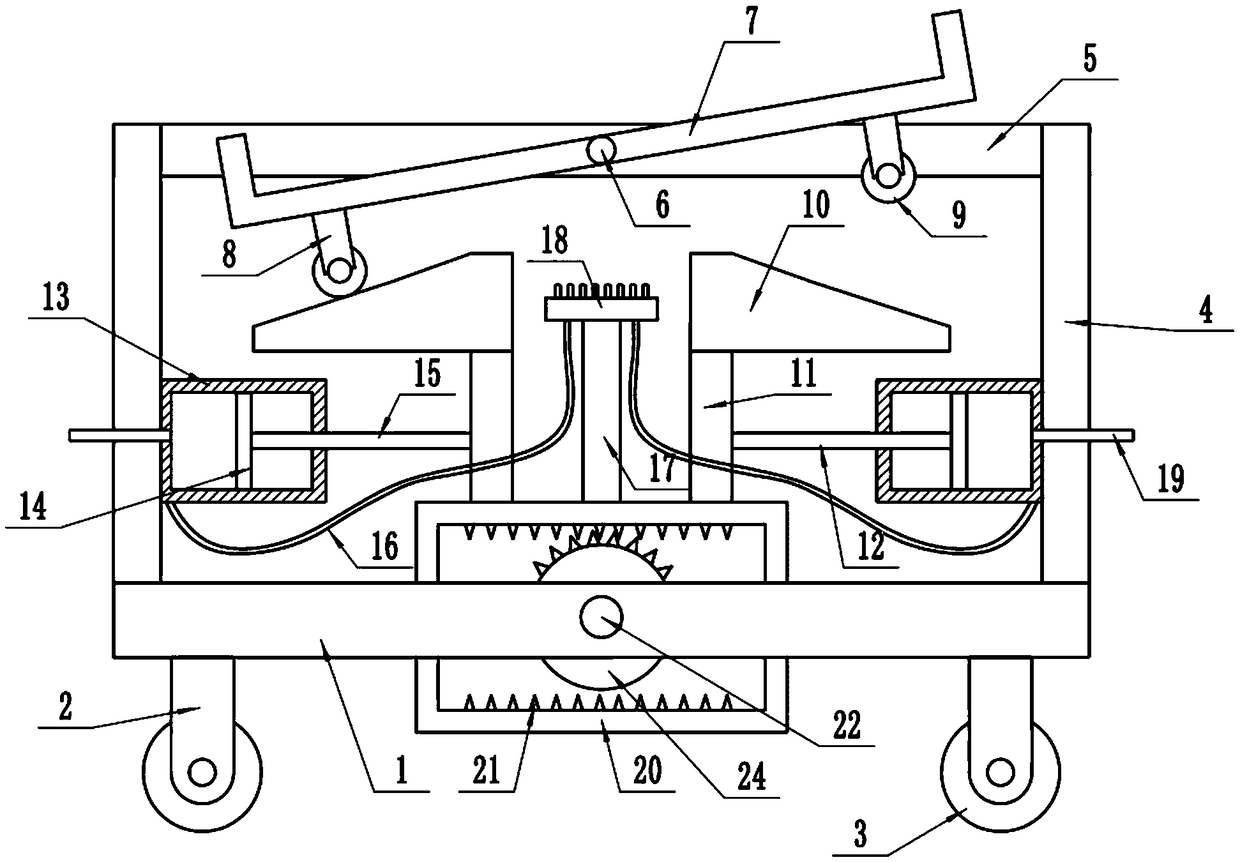

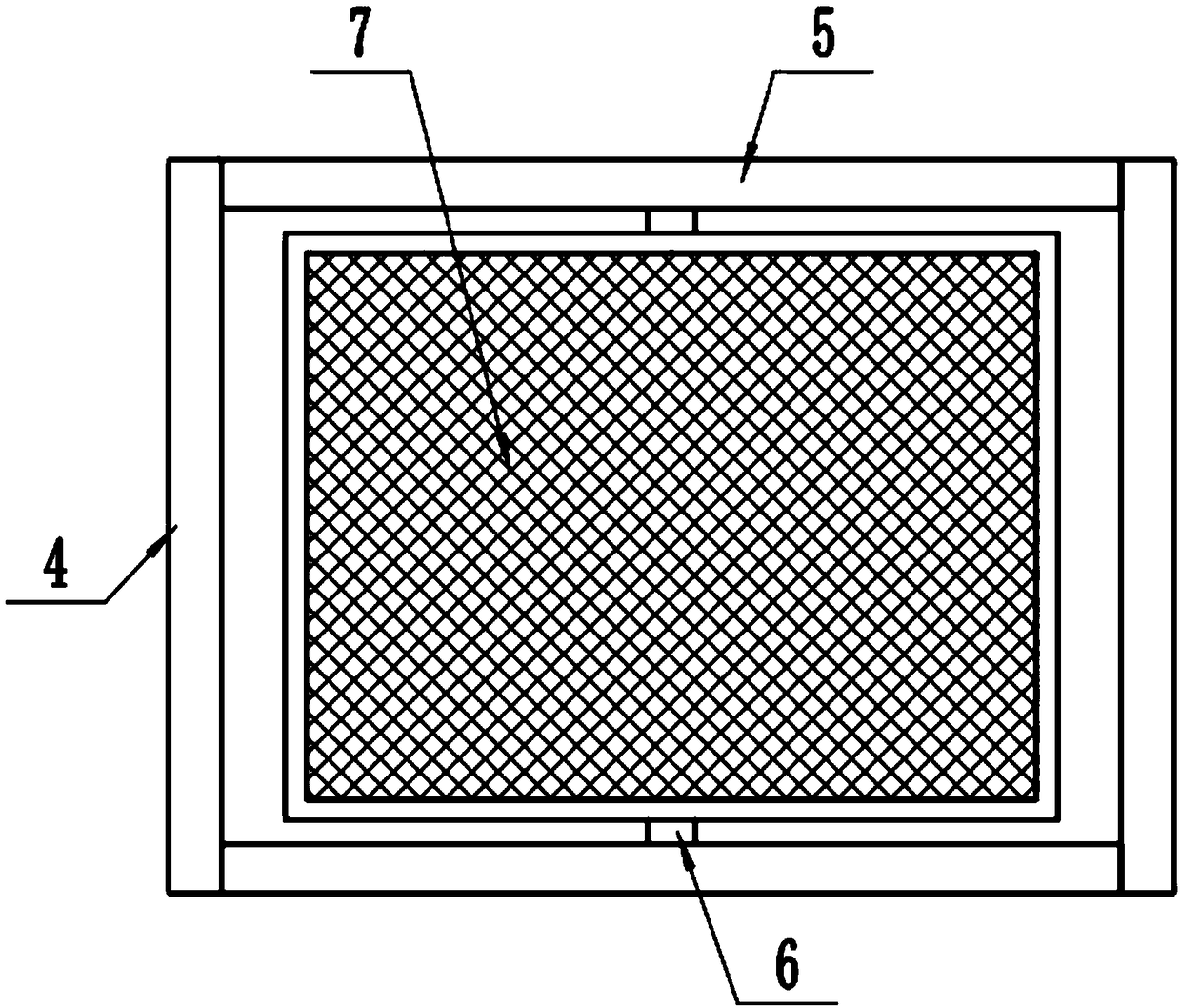

Efficient drying device for tea leaves

InactiveCN106643032AQuality assuranceEasy accessPre-extraction tea treatmentTea dryingEngineeringCheck valve

The invention relates to a drying device for tea leaves and especially relates to an efficient drying device for tea leaves. The technical problem to be solved by the invention is to provide the efficient drying device for the tea leaves, with the advantages of simple operation, dust prevention in the drying process of the tea leaves, capability of guaranteeing the quality of the tea leaves and high working efficiency. In order to solve the technical problem, the efficient drying device for the tea leaves provided by the invention comprises a base plate, a first support rod, a right bracket, a drying oven, a first filter screen, an exhaust pipe, a first check valve, a chamber, a first air inlet pipe, a piston, a motor, a fan-shaped gear, a slide rail, a slide block, a rack, a spring, a first connecting rod, an air collecting box, a shell, an electric heating wire, an air inlet pipe, a second filter screen and a fan, wherein the first support rod, a second support rod, a third support rod and the right bracket are successively arranged on the upper part of the base plate from left to right. The efficient drying device for the tea leaves can achieve the effects of simple operation, dust prevention in the drying process of the tea leaves, capability of guaranteeing the quality of the tea leaves and high working efficiency.

Owner:吴达君

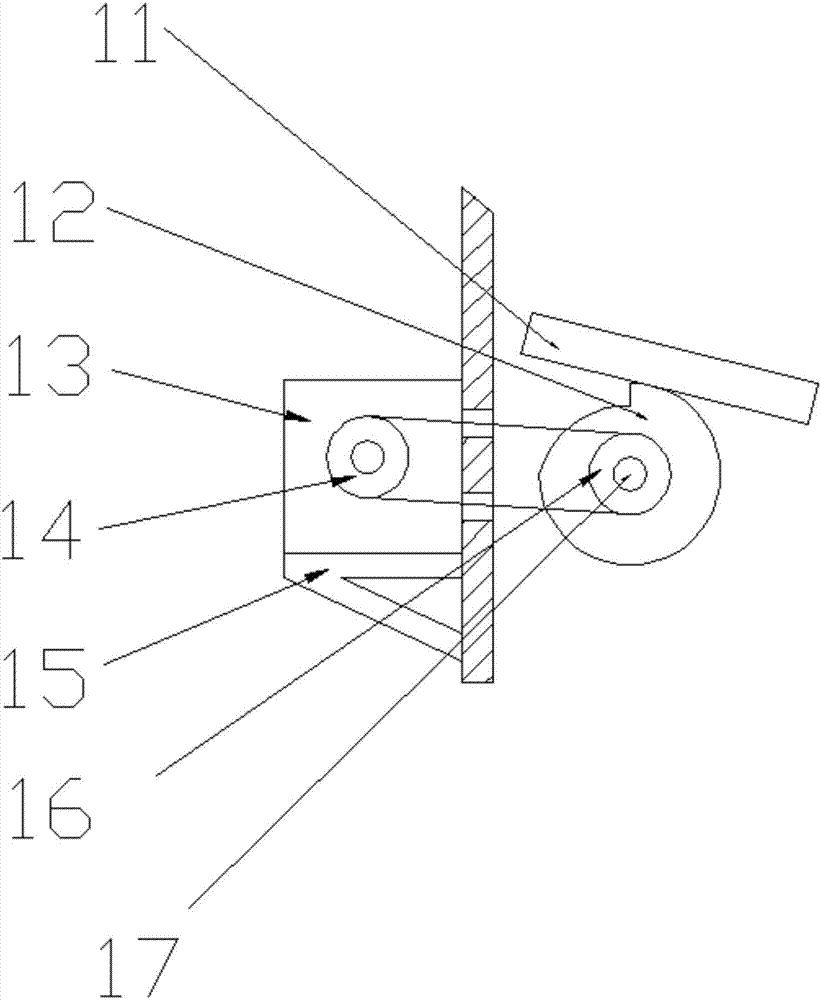

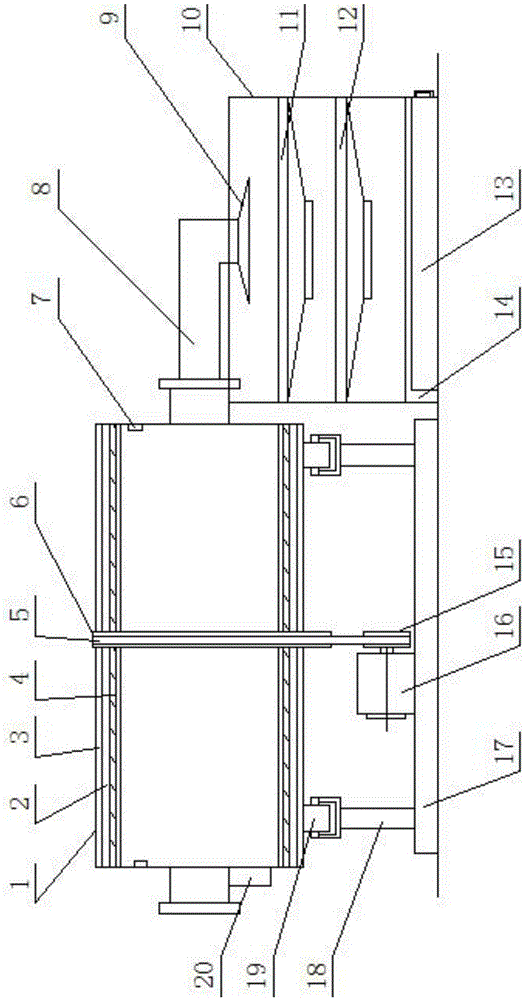

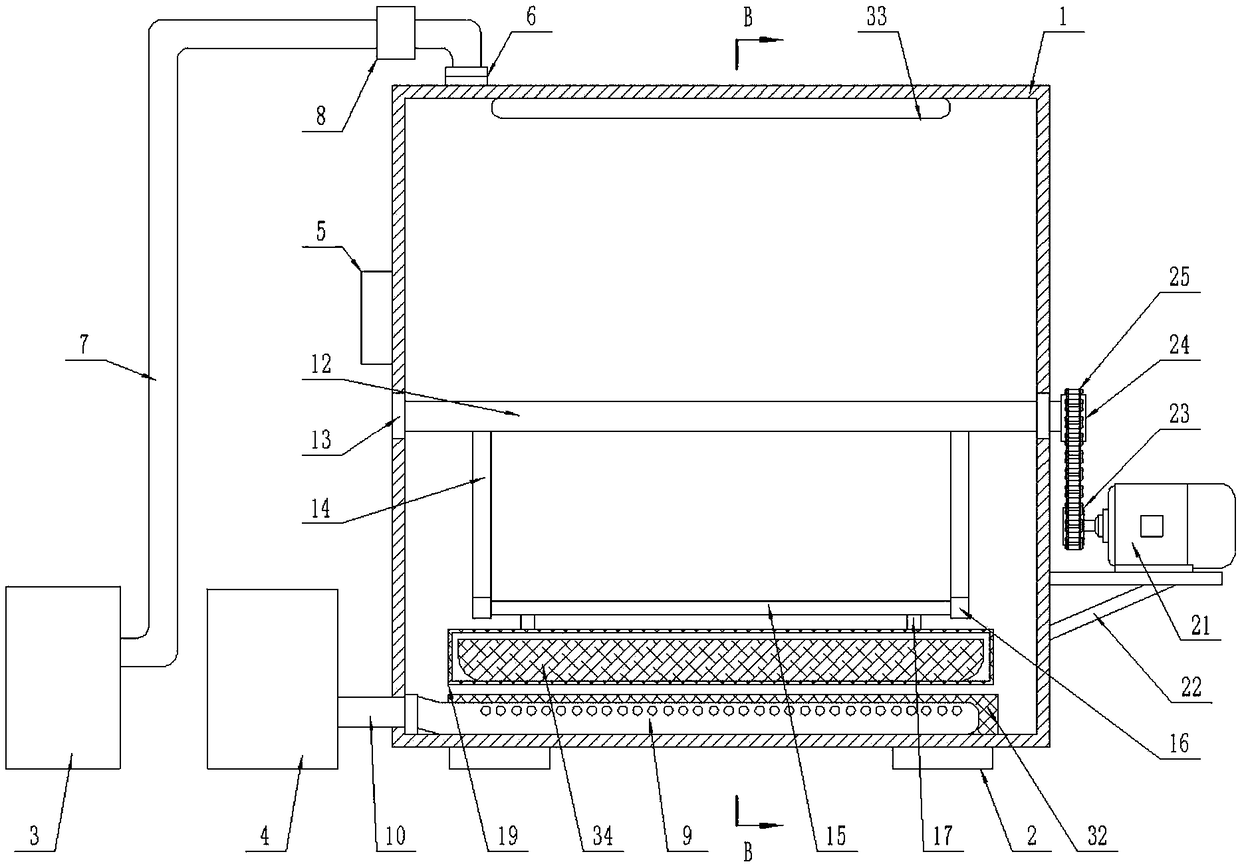

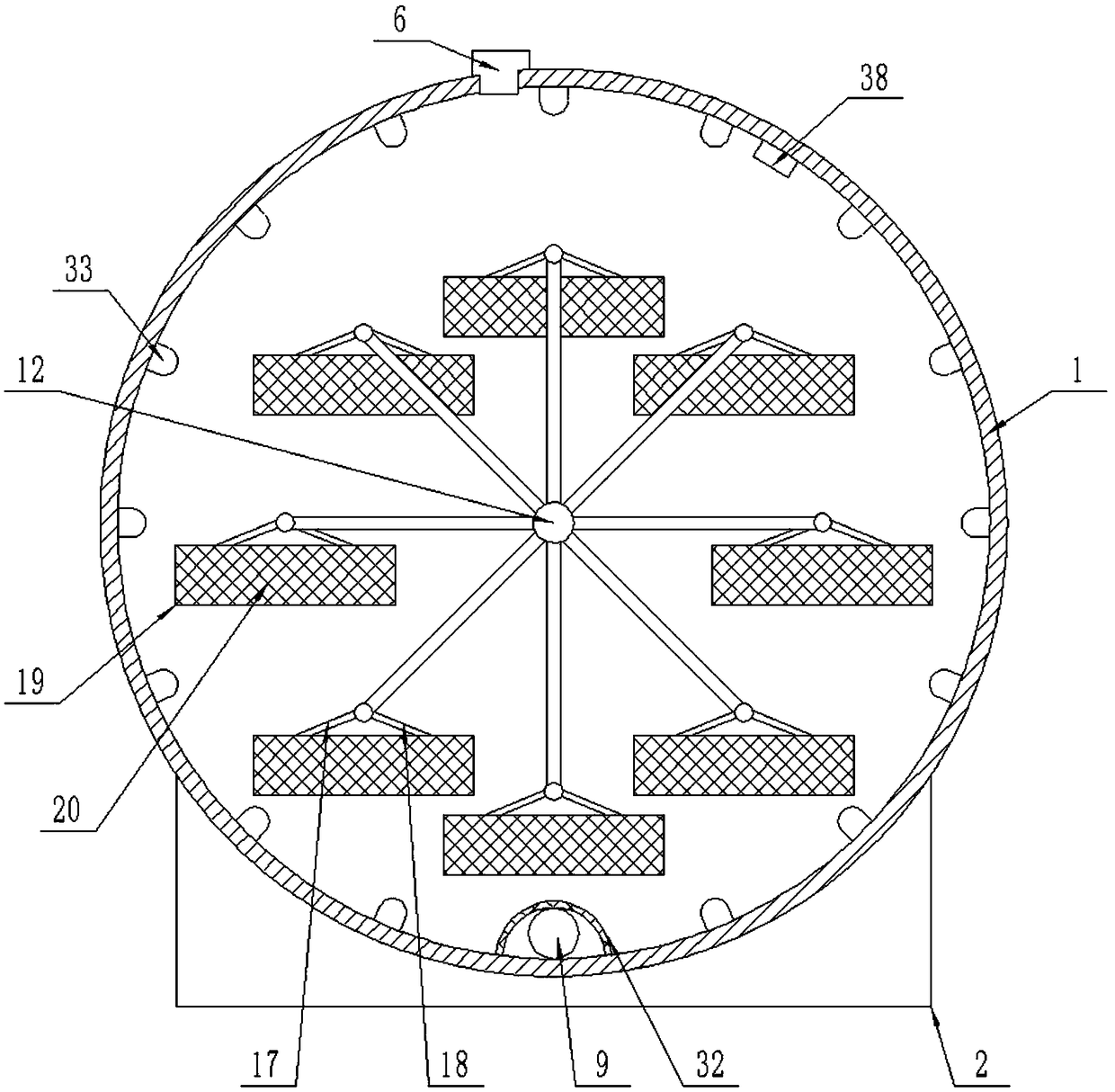

Improved anti-blocking tea dryer

InactiveCN105865171AReduce the effect of breaking upPlay a role in breaking upPre-extraction tea treatmentTea dryingDrive shaftDrive motor

The invention discloses an improved anti-blocking tea dryer, which comprises a drying box and a hopper. The feeding hopper, the lower port of the feeding pipe is provided with a No. 1 flip baffle through an elastic hinge, and the upper end of the drying box connected with the feeding pipe is provided with a breaking chamber, and a drive shaft is horizontally provided in the breaking chamber, and a drive shaft is provided on the driving shaft. Several eccentric wheels, the right end of the drive shaft passes through the right side wall of the dispersing chamber, and connects with the output end of the drive motor. Several sloping guide plates are arranged alternately in the drying box below the dispersing chamber. The outer side of the drying box between the slant plates is ringed with an upper air injection ring and a lower air injection ring from top to bottom in turn, and the left and right sides of the upper air injection ring and the lower air injection ring are connected with the air outlet of the circulating fan through the air guide pipe. The structure is simple and reasonable, the drying effect is good, energy saving and environmental protection, and strong practicability.

Owner:SUQIAN HUAIHAI TECH SERVICES

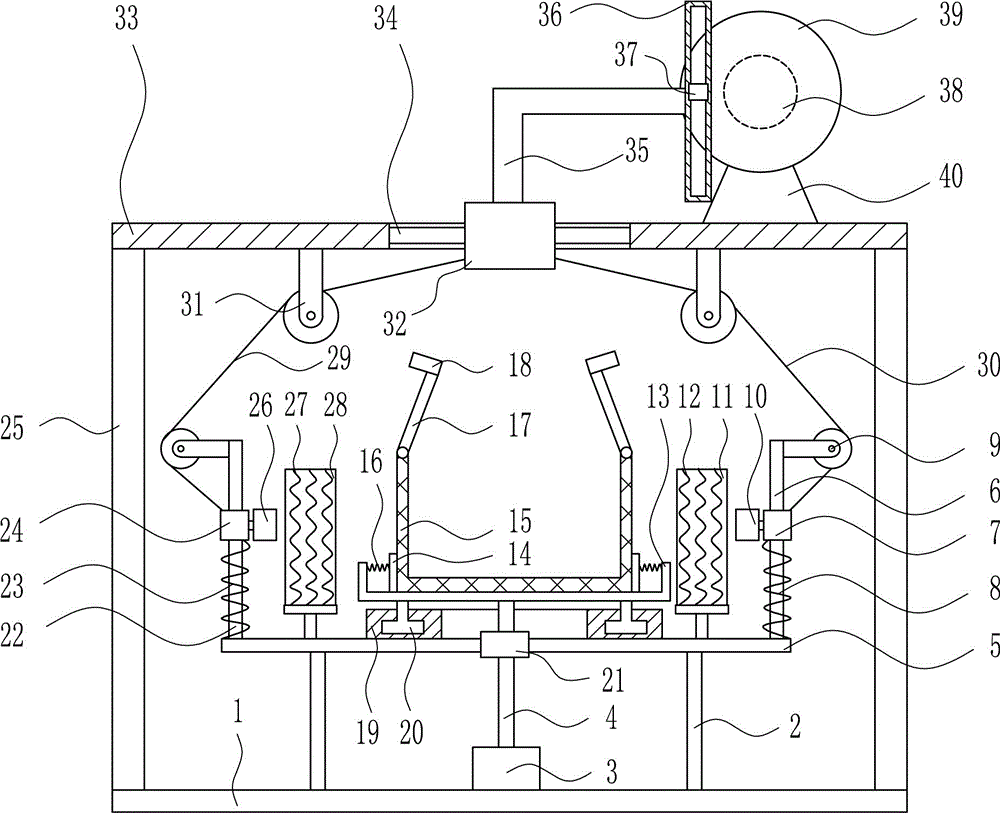

Drying device for stevia rebaudiana tea processing

The invention relates to a drying device, in particular to a drying device for stevia rebaudiana tea processing. The technical problem to be solved by the invention is to provide the drying device for stevia rebaudiana tea processing with complete drying and convenience for operation. In order to solve the technical problem, the invention provides the drying device for stevia rebaudiana tea processing; the drying device comprises a baseplate, a support rod, a motor I, a rotating shaft, a fixed plate I, a guide rod I, a slide block I, a spring I, a fixed pulley I, a fan I, a heating wire I, a heating device I, a placing disc, a clamping block, a net frame, a spring II, a box cover, an electromagnet I, an annular slide rail, a slide block II, a bearing base, a guide rod II, a spring III, a slide block III, a fixed plate II, a fan II, a heating wire II, a heating device II, a pull wire I, a pull wire II, a fixed pulley II, a slide block IV, a top plate, a guide rod III, an L-shaped connecting rod, a return slide rail, a slide block V, a motor II, a turntable and a mounting base. The drying device achieve the effects of complete drying and convenience for operation.

Owner:浙江巨力宝纺织科技有限公司

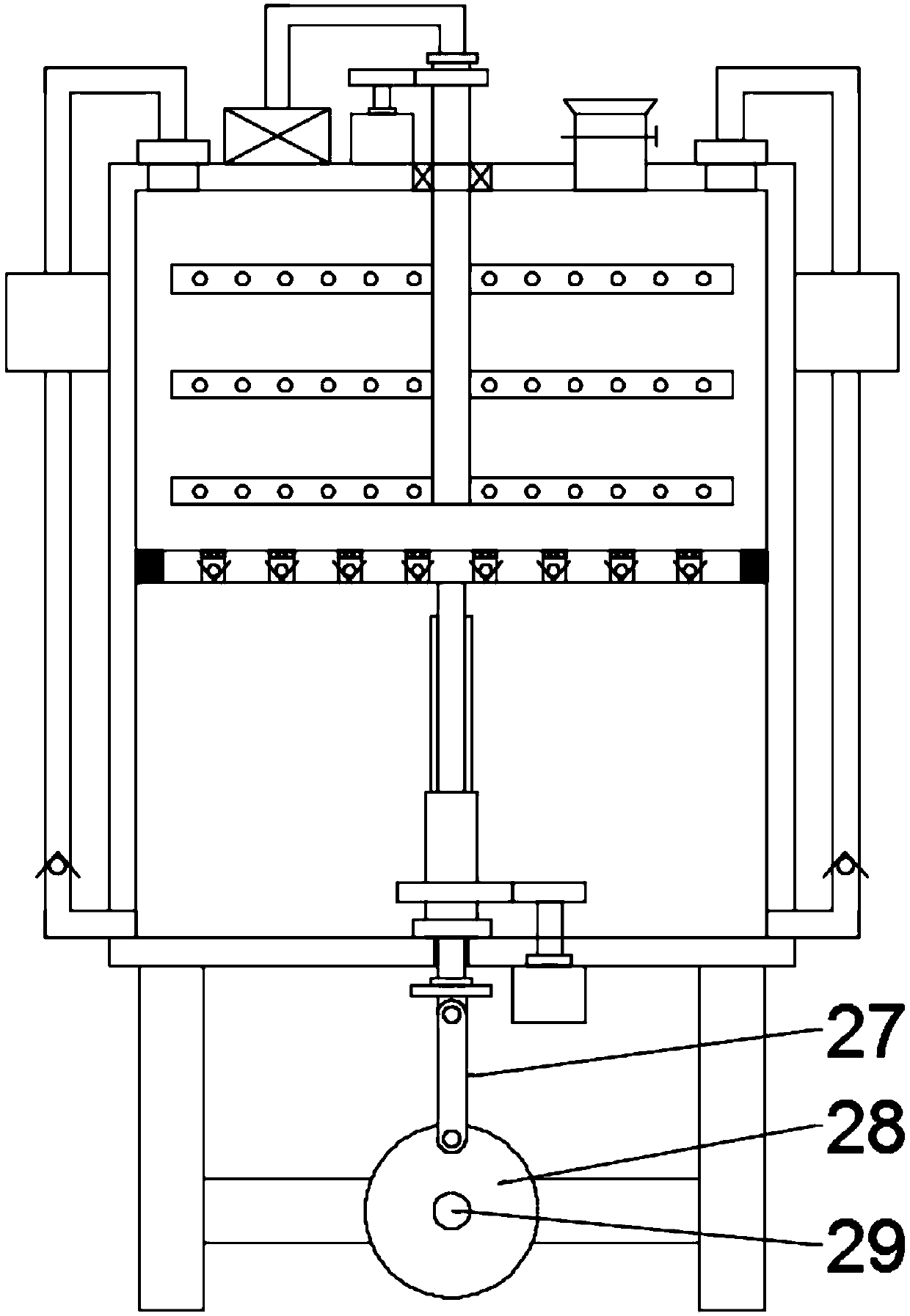

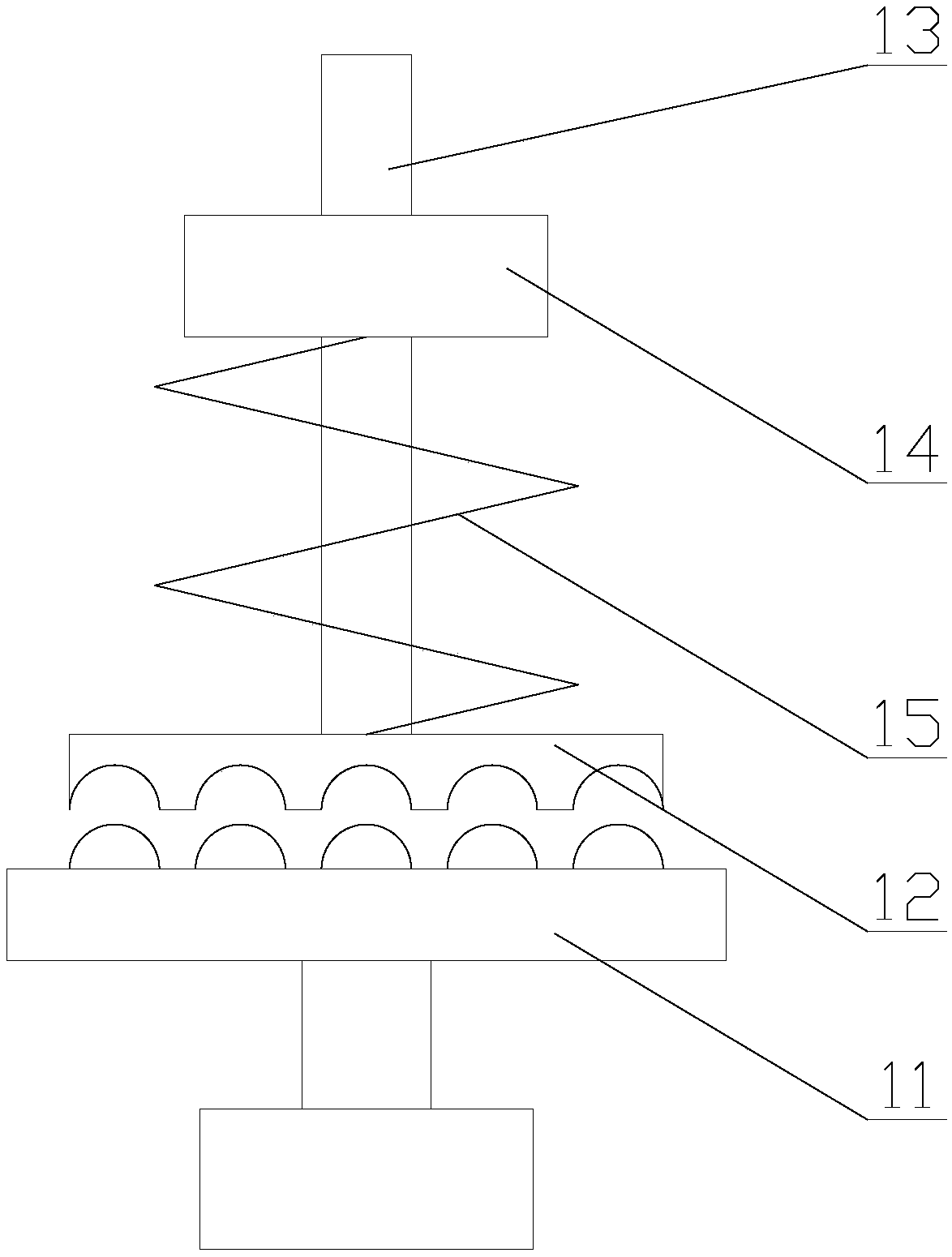

Efficient tea leaf drying device

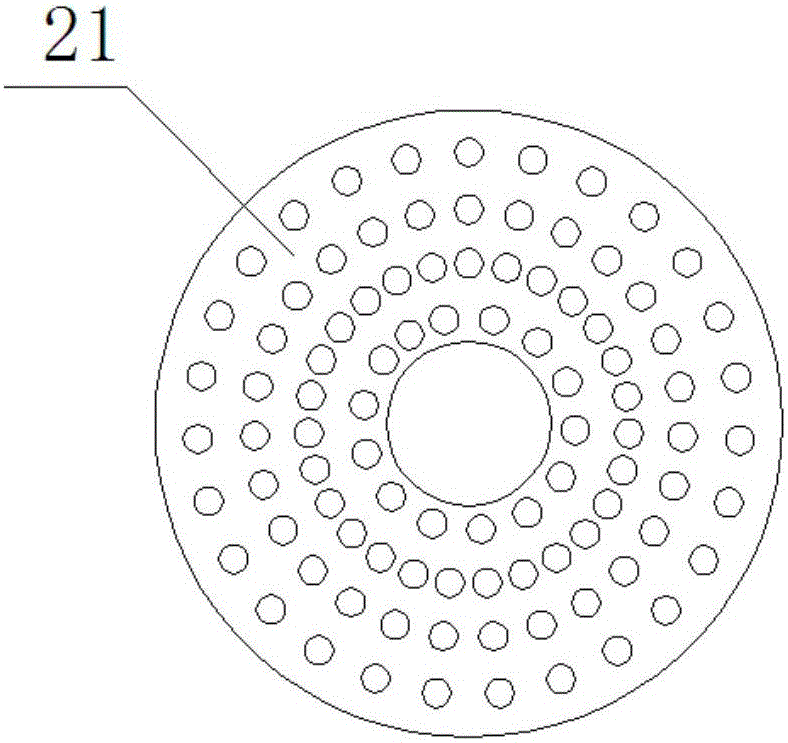

ActiveCN109612234AFully dryDry evenlyPre-extraction tea treatmentTea dryingWater vaporAgricultural engineering

The invention discloses an efficient tea leaf drying device and relates to the technical field of tea production. The efficient tea leaf drying device aims at solving the problems that an existing device causes tea leaf accumulation and is low in drying speed. The efficient tea leaf drying device comprises a barrel body, a hot air blower, a hollow stirring shaft and hollow stirring rods. A pistondisc is mounted at the position, located below the hollow stirring shaft, inside the barrel body. The bottom end of a spline shaft is provided with a first driving mechanism. The first driving mechanism comprises a third motor, a disc and a movable rod. An air suction pipe is connected to an exhaust opening. The other end of the air suction pipe communicates with the bottom of an inner chamber ofthe barrel body. The piston disc is uniformly provided with multiple air outlet through holes. A one-way valve is mounted in each air outlet through hole. The efficient tea leaf drying device is provided with the hollow stirring shaft, the hollow stirring rods, the hot air blower, the piston disc, the spline shaft, a sleeve and the first driving mechanism; tea leaves are dried while being stirred;drying is conducted more thoroughly and more uniformly; the drying efficiency is improved; drying vapor is continuously pumped out through the piston disc, and after drying, the tea leaves are driedfrom the bottom in a whirlwind manner; and the drying efficiency is further improved.

Owner:徐州青钱柳农业科技有限公司

Tea leaf drying and processing device

InactiveCN107348031AEasy to dryExtended service lifePre-extraction tea treatmentTea dryingAgricultural engineeringTea leaf

The invention discloses a tea drying and processing device, which comprises a drying box, a crushing cylinder and an extruding cylinder. A feeding hopper is connected to the top of the drying box, and a rotating shaft is connected to the feeding hopper for horizontal rotation. There are multiple eccentric wheels welded on the top, and there are air ducts on the left and right sides of the drying box. The air ducts are connected with fans and heating boxes in sequence from top to bottom. A vibrating screen is installed on the inside of the drying box. The height of the vibrating screen is The lower end is provided with a discharge port on the side wall of the drying box, and an oblique discharge plate is fixedly connected to the discharge port. A crushing cylinder is arranged under the lower end of the discharge plate, and the bottom of the crushing cylinder is connected There is an extruding barrel, and an extruding screw is arranged horizontally in the extruding barrel. The invention has a simple structure and a reasonable design, can greatly improve the drying efficiency of tea leaves, and can separate tea dregs at the same time, improving the quality of finished products.

Owner:赵桂华

Tea dryer with vibration and tea ash absorption functions

InactiveCN107747849AAffect qualityIncrease the gapPre-extraction tea treatmentTea dryingEngineeringImpurity

The present invention relates to a tea dryer with functions of vibrating and absorbing tea ash, which includes a main body, a hot air blower, a supporting plate and an air outlet, and also includes a vibrating mechanism and an absorbing mechanism. The vibrating mechanism includes a lifting component and a vibrating component. The absorbing mechanism includes Reciprocating and swinging components. In the tea dryer with the function of vibrating and absorbing tea ash, through the vibrating mechanism, the gap between the tea leaves increases during the vibration process, which is beneficial to the flow of hot air and speeds up drying, thus improving the drying efficiency. Effect, and by adjusting the vibration frequency, you can adjust the vibration of different levels of tea leaves, gradually changing the vibration frequency is beneficial to the drying of tea leaves, through the absorption mechanism, you can remove tea ash and tea leaves and other impurities produced inside the main body Absorption is carried out to prevent these impurities from being mixed in the tea and affecting the quality of the tea. Through these, the practicability of the tea dryer is greatly improved.

Owner:南安市瑞欣生物科技有限公司

Botanical Freeze Drying System and Method

ActiveUS20160245588A1Reduce and prevent evaporative lossReduce the temperatureDrying solid materials without heatTea dryingFreeze-dryingPulp and paper industry

Systems and methods for freeze drying botanical or herb items or products using a modular vacuum chamber configuration are provided. Such configurations can reduce or prevent the evaporative loss of volatile compounds while reducing the temperature and removing air to prevent oxidation of the product. The freeze drying systems and methods of the present invention can improve organoleptic characteristics, shelf life, and extractions.

Owner:BAUGH STEVEN F +1

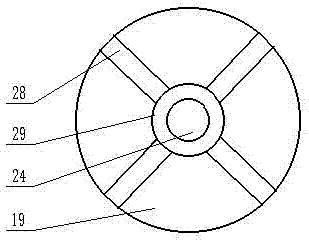

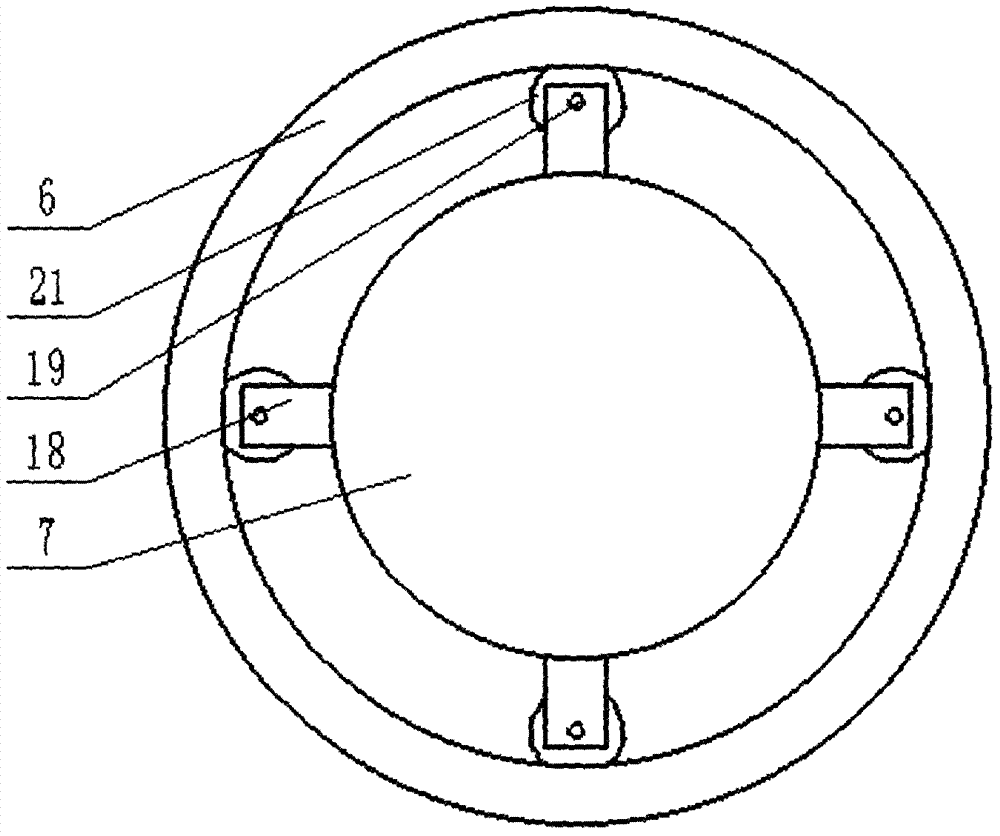

Suspension rotation type tea leaf drying device

InactiveCN107152850ADry evenlyAvoid harmPre-extraction tea treatmentTea dryingMotor speedAgricultural engineering

The invention discloses a hanging and rotating tea drying equipment, which comprises a base, a heating box, a drying box and a drying box cage. The top of the base is provided with a heating box. The top is fixedly connected to the drying box, the bottom of the base is provided with a motor, the motor shaft of the motor is connected to a reducer, the reducer is connected to a rotating shaft in rotation, the other end of the rotating shaft protrudes into the inner cavity of the drying box, and is fixedly connected to the support ring; The bottom end of the cage is hinged with a cage door, and there are several ring-shaped electric heating nets uniformly arranged in the heating box, and several air inlets are uniformly arranged on the outer side of the heating box in the circumferential direction, and the air inlets are provided with fans in turn from the inside to the outside. And the protective net, the invention utilizes the rising principle of the hot air flow to dry the tea leaves hanging in the drying box, and the tea leaves hanging in the drying box are doing slow circular motion, so that the hot air flow can evenly act on the tea leaves Make sure that the tea leaves are dried evenly and that the tea leaves are not damaged.

Owner:刘云海

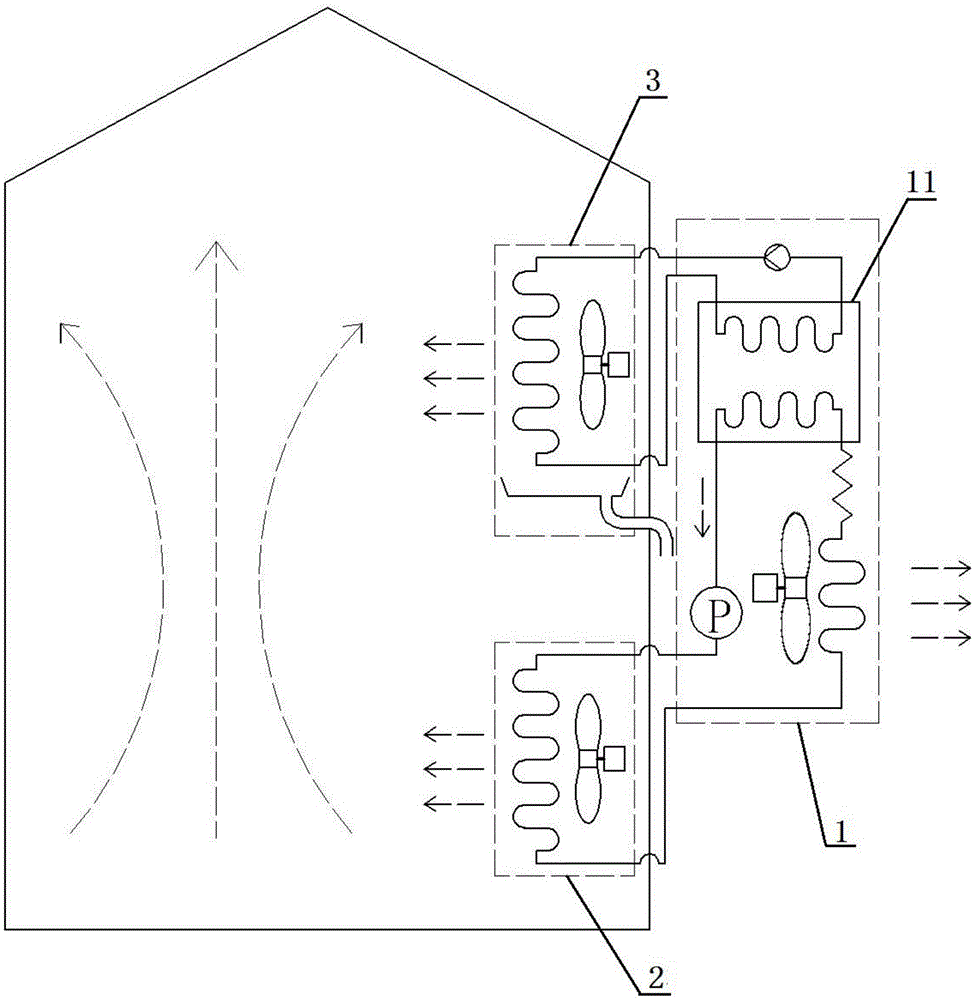

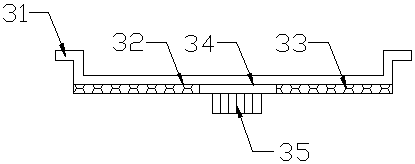

Dehumidifying house

ActiveCN105546940AAchieve dryingTea dryingCompression machines with several condensersCold airCoolant flow

The invention relates to a dehumidifying house. The dehumidifying house mainly comprises a house and a drier. A heating fan inhales air in the house, and the air is blown over a first condenser, so that water in articles enters the air to become hot humid air; a coolant flows back into a second condenser and a throttle in a main machine to be further cooled, and then the cooled coolant enters a third condenser in a cold storage box; the coolant in the third condenser flows back to a compressor to be squeezed into a high-temperature high-pressure coolant, and then the high-temperature high-pressure coolant flows back to a heating machine, so that cold storage fluid in the cold storage box is kept within a preset temperature range; a fourth condenser soaked in the cold storage fluid in the cold storage box is affected by the cold storage fluid to be cooled; the cooled coolant in the fourth condenser is conveyed to an evaporator through a high-pressure pump; a condensing fan inhales the indoor hot humid air which is blown to the evaporator, water in the hot humid air is separated out to downwards drop into a water pan under the evaporator, dry cold air is blown out from a condensing machine, and after the temperature of a cold drive of the evaporator rises, the dry cold air flows back to the fourth condenser, and then is cooled by the cold storage fluid to flow to the evaporator.

Owner:李耀强

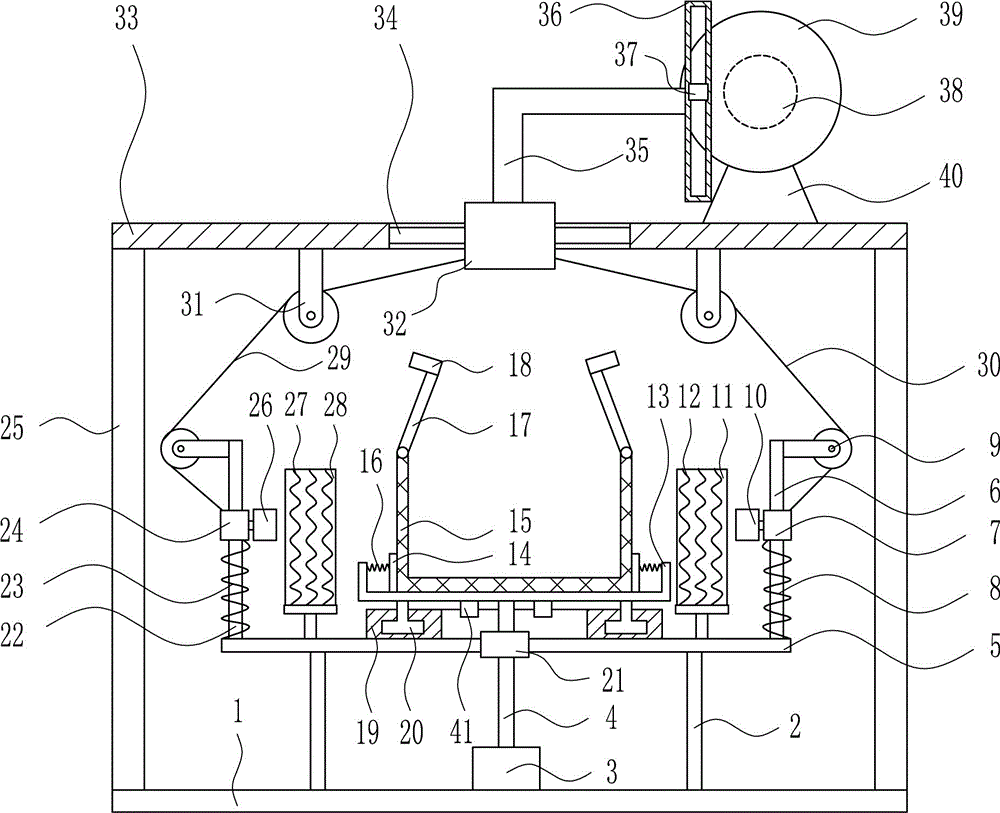

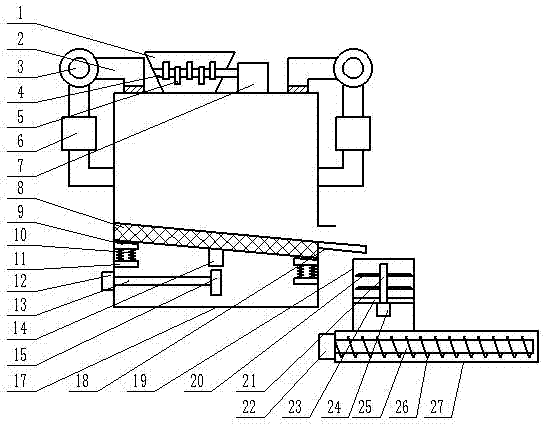

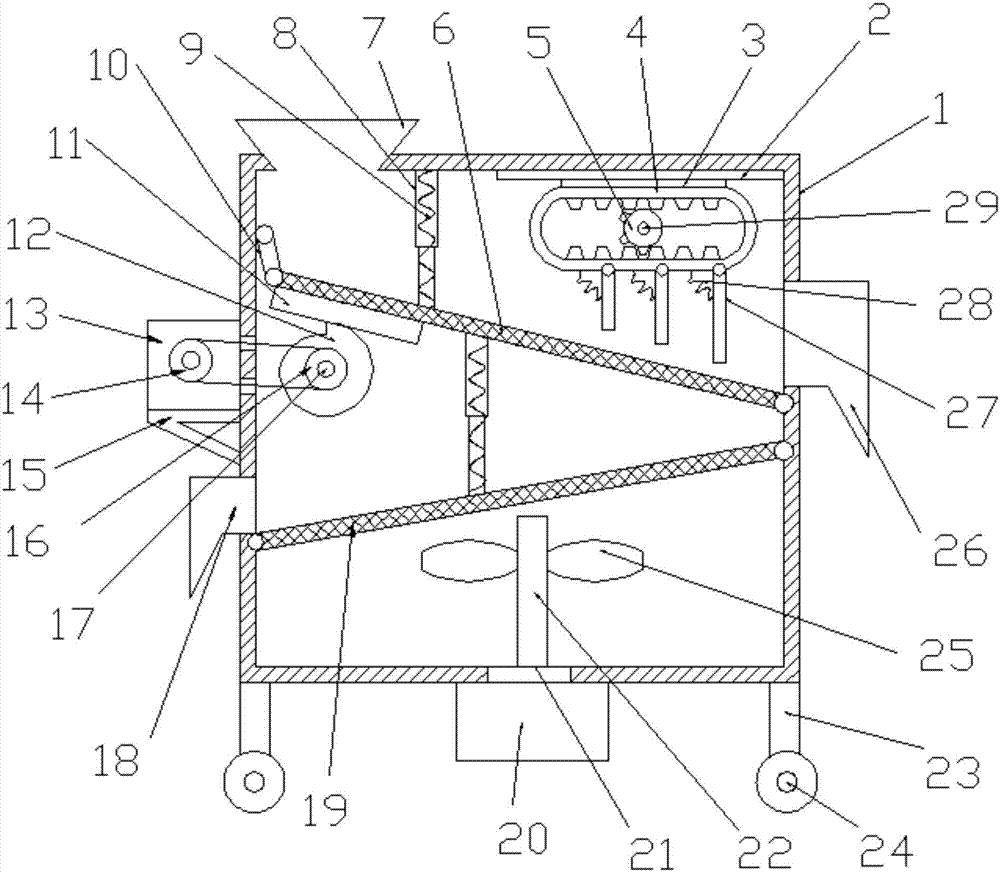

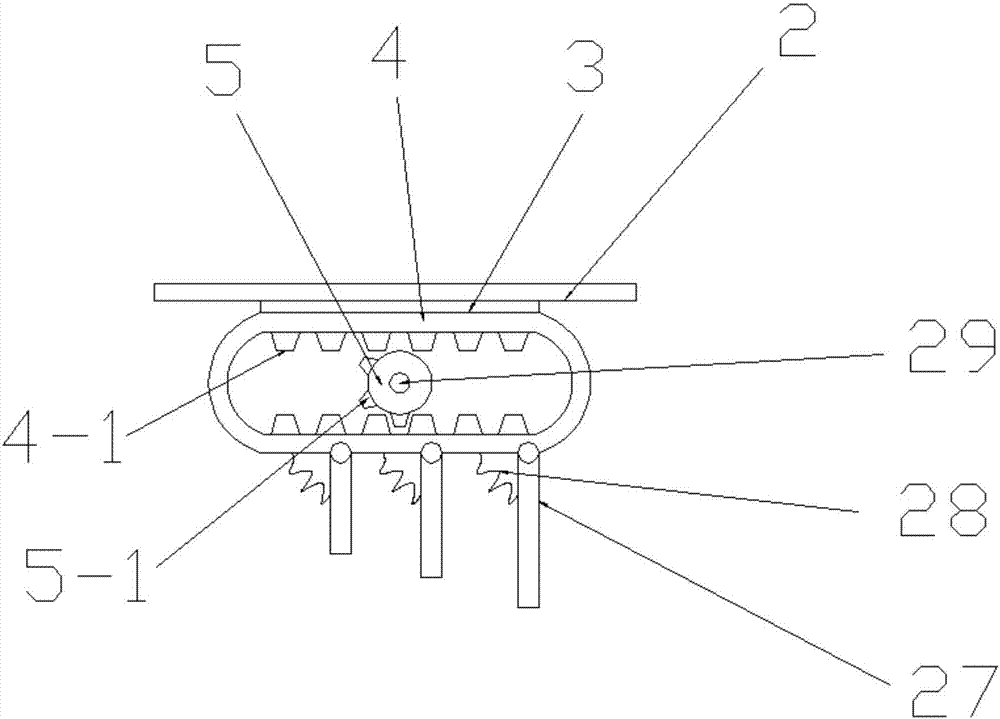

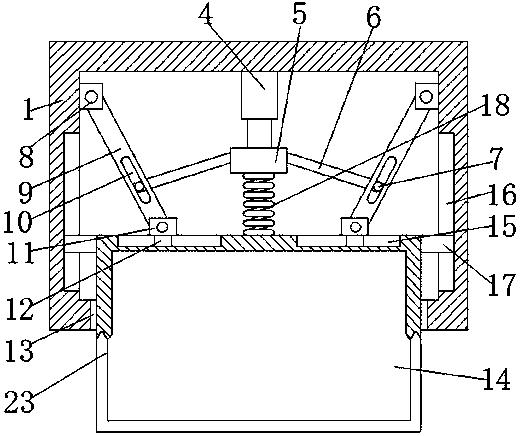

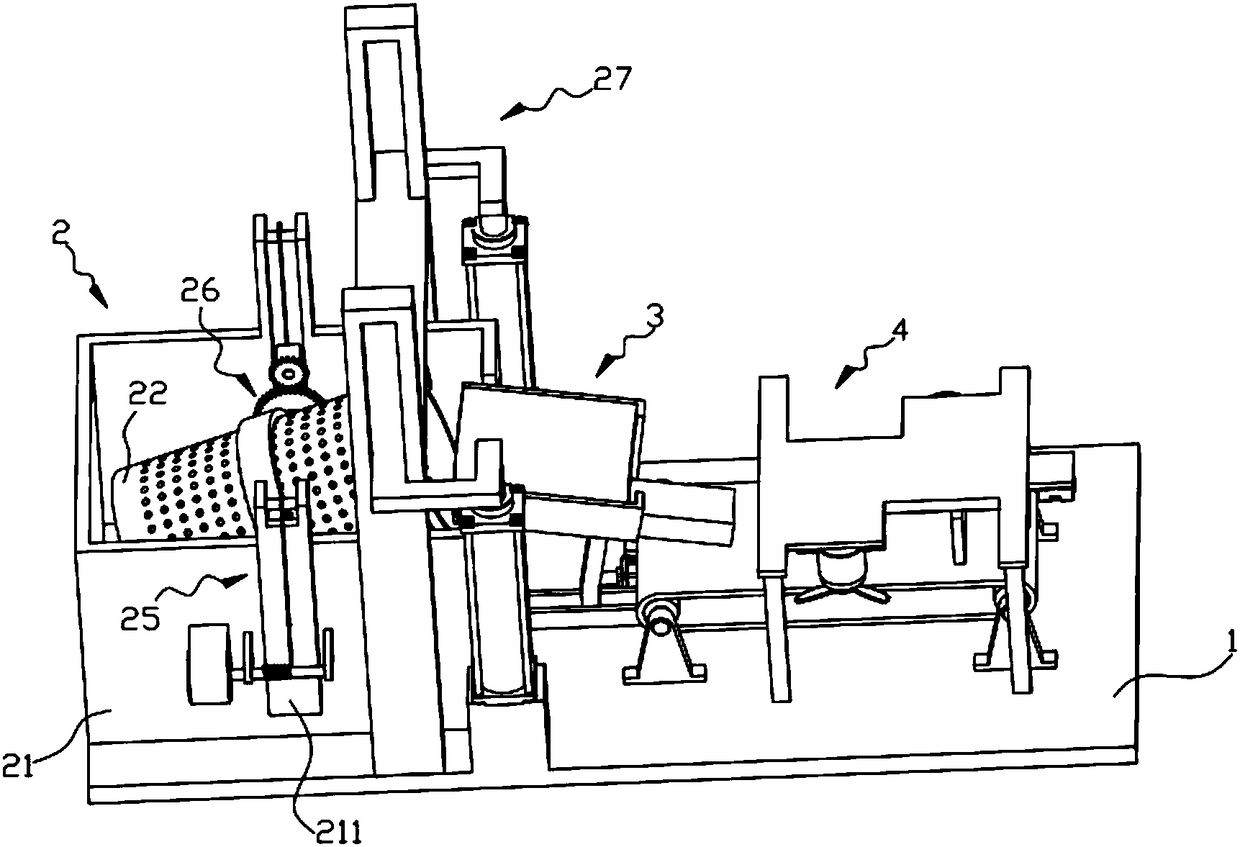

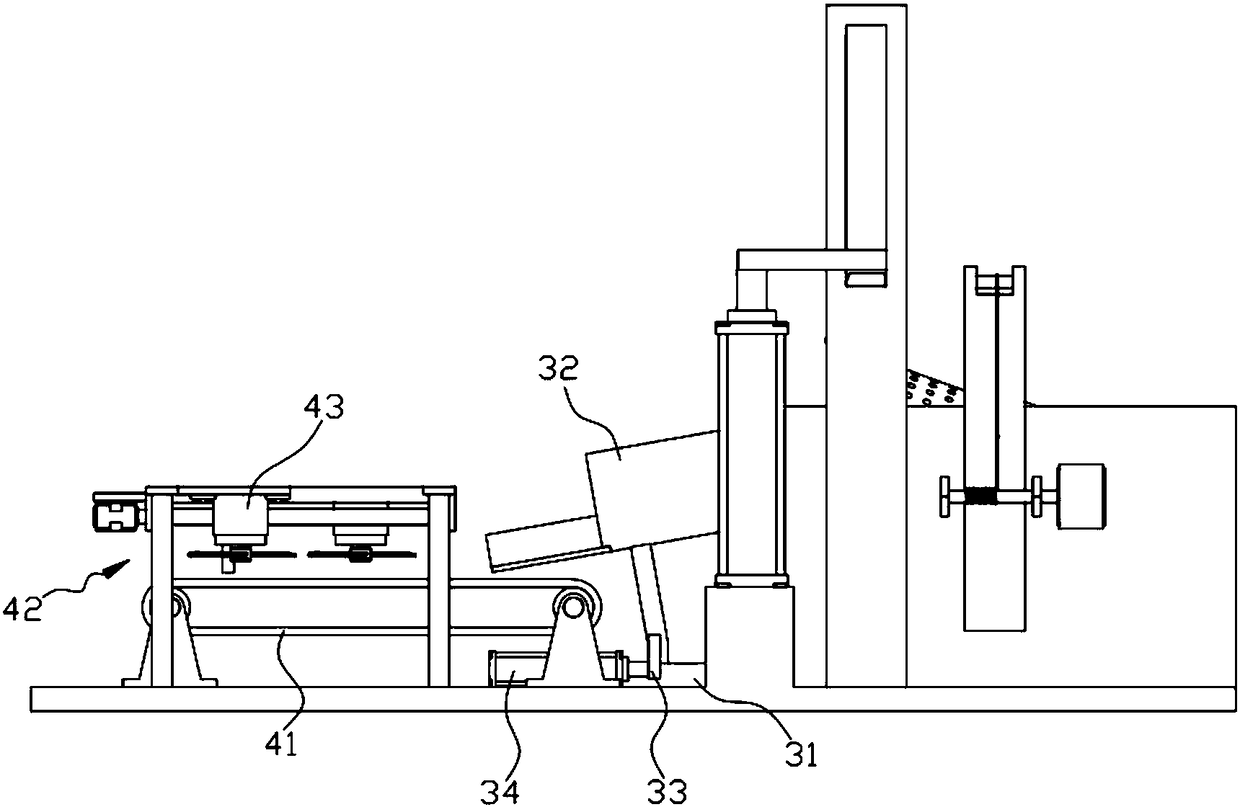

Efficient tea leaf rolling, screening and drying device

InactiveCN107449262ACleverly structuredEasy to filterSievingScreeningReciprocating motionEngineering

The invention discloses an efficient tea leaf rolling, screening and drying device. The efficient tea leaf rolling, screening and drying device comprises a shell, supporting feet are arranged at the bottom of the shell in a bilateral symmetry manner, trundles are arranged at the bottom ends of the supporting feet, a vibration screen is arranged in the shell, and is arranged in an inclined manner, a feeding opening is formed in the top of the left side of the shell, and a vibration drive mechanism driving the vibration screen to vibrate is arranged on the lower side of the top end of the left side of the vibration screen. The vibration screen and the vibration drive mechanism of the vibration screen are ingeniously arranged, a rolling mechanism is arranged above the vibration screen, the structure of the rolling mechanism is ingeniously arranged, through back-and-forth reciprocated motion, rolling is sufficient, a rolling plate in the rolling mechanism is elastically connected to effectively protect tea leaves in the rolling process, the damage of a rolling plate to the tea leaves is avoided, in addition, fine materials generated in the screening or rolling process are directly screened through the vibration screen, fan blades are arranged, and the fan blades rotate to generate the airflow so as to rapidly dry the tea leaves on the vibration screen from bottom to top.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

Processing device for tea leaves

InactiveCN107484850AReduce labor efficiencyReduce production energy consumptionConveyorsPre-extraction tea treatmentEngineeringFermentation

The invention discloses a processing device for tea leaves. The processing device comprises a fermentation tank, wherein the fermentation tank comprises an air pipe and a tank body which can be overturned up and down around the air pipe; the air pipe penetrates through the tank body; a feeding port and an air exhaust port are formed in the tank body; a cover is arranged on the feeding port; brackets are fixed at the two ends of the air pipe; a mesh screen is arranged on the air pipe located in the tank body; through holes are formed in the mesh screen; an air vent is formed in the air pipe in the mesh screen; an elastic sheet covers on the air vent; a gap is formed in the elastic sheet. According to the invention, the traditional fermentation device is used for replacing the fermentation tank and the processing device is clean, hygienic and capable of reducing labor efficiency and is beneficial to the reduction of production energy consumption and labor intensity, so that the production cost can be lowered. The unique fermentation tank, the conveying device and the drying device are designed, all the devices are used cooperatively and the quality of the tea leaves can be guaranteed in the manner of controlling the feeding volume, promoting the uniformity coefficient of fermentation and controlling the drying temperature.

Owner:GUIZHOU PROVINCE MEITAN COUNTY XINHUI TEA IND CO LTD

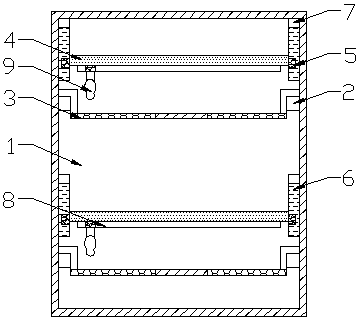

Tea drying box capable of conducting drying uniformly

The invention discloses a tea drying box capable of conducting drying uniformly. The tea drying box comprises a box body. A feeding pipe is connected to the top of the box body. A movable piston is arranged at the position, below the feeding pipe, inside the box body. Overturning plates are hinged to the positions, below a dispersing plate, of the inner walls of the left side and the right side ofthe box body, wherein the overturning plates are distributed in a staggered manner. A discharging plate is arranged below the overturning plates. According to the tea drying box, by means of the dispersing plate and the overturning plates with the surfaces being provided with protruding strips, tea is dispersed and then shaken to fall; the tea is uniformly dried by hot air through mesh holes in the overturning plates; meanwhile, the overturning plates ceaselessly shakes the tea, so that nonuniform heating is avoided; the tea drying box is provided with the movable plug, the movable plug movesup and down, so that intermittent discharging is achieved, and the drying effect is guaranteed; and the tea drying box is provided with the discharging plate which moves up and down, so that discharging is conducted uniformly.

Owner:南安市科联专利应用服务有限公司

Environment-friendly tea leaf dryer

InactiveCN107328195AImprove stabilityImprove drying efficiencyTea dryingDrying chambers/containersDamping functionEngineering

The invention discloses an environment-friendly tea dryer, which comprises a drying cylinder, a motor is fixedly installed in the middle of the upper end of the drying cylinder, the output shaft of the motor is connected with a rotating shaft, and stirring blades are welded on the rotating shaft for drying. The lower end of the cylinder is provided with a bottom plate, the middle part of the upper end of the bottom plate is fixedly installed with a driving motor, the output shaft of the driving motor is fixedly connected with a turntable, the lower end of the bottom plate is provided with a base, and the end of the bottom plate facing the base is provided with a plurality of sleeve holes, which slide A shock absorbing rod is provided, and a shock absorbing spring is set on the shock absorbing rod. The upper and lower ends of the shock absorbing spring are respectively fixedly connected with the lower surface of the bottom plate and the upper surface of the base. The rotation effectively improves the stirring efficiency of the tea leaves, thereby improving the drying efficiency of the tea leaves. At the same time, the device causes little pollution, and also has a shock absorption function to prolong the service life.

Owner:桐乡市大麻杰匠电子产品经营部

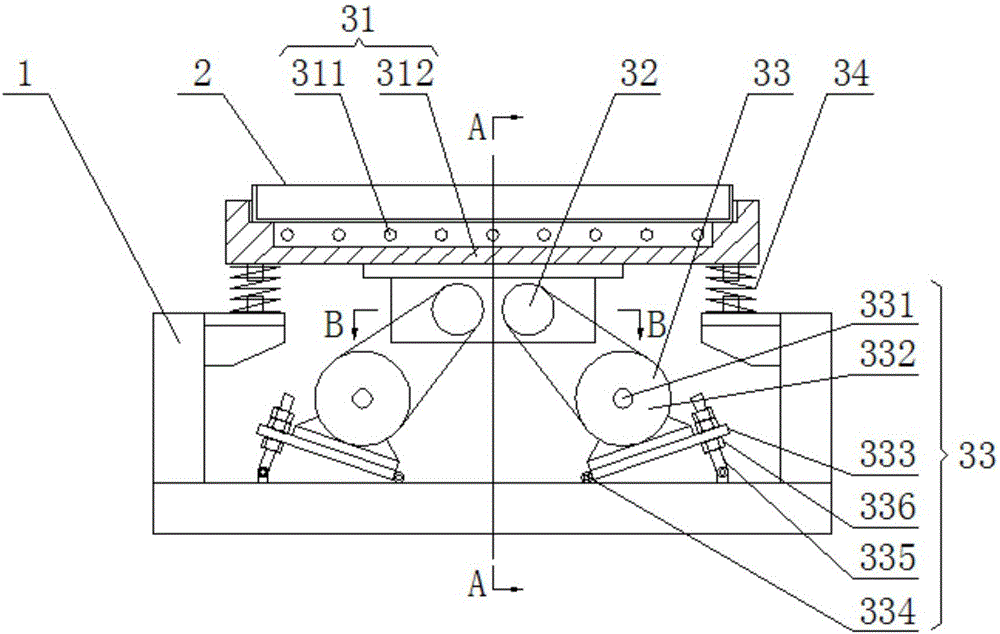

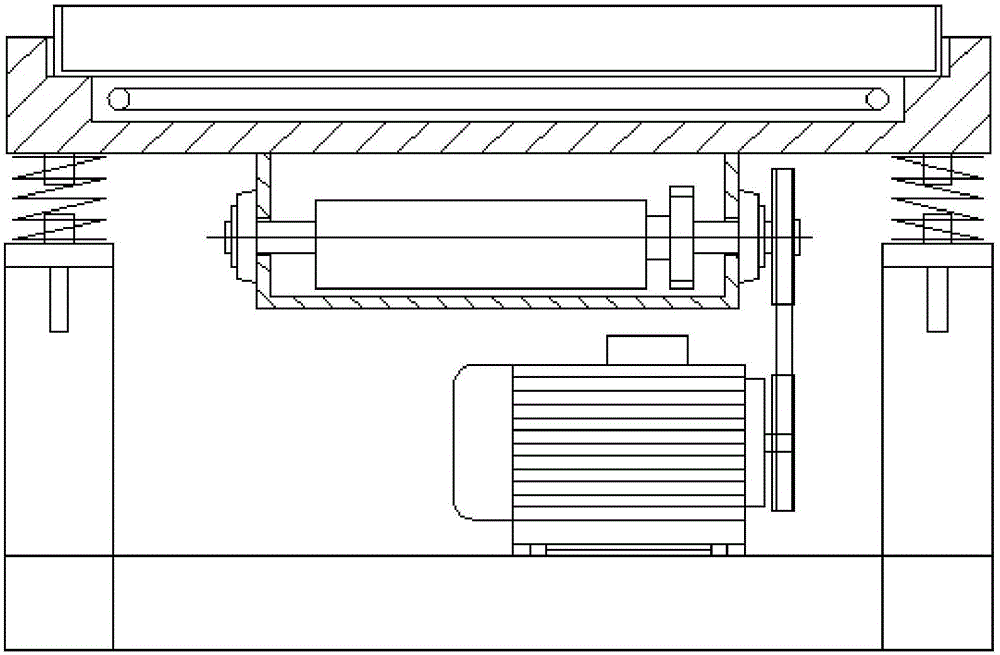

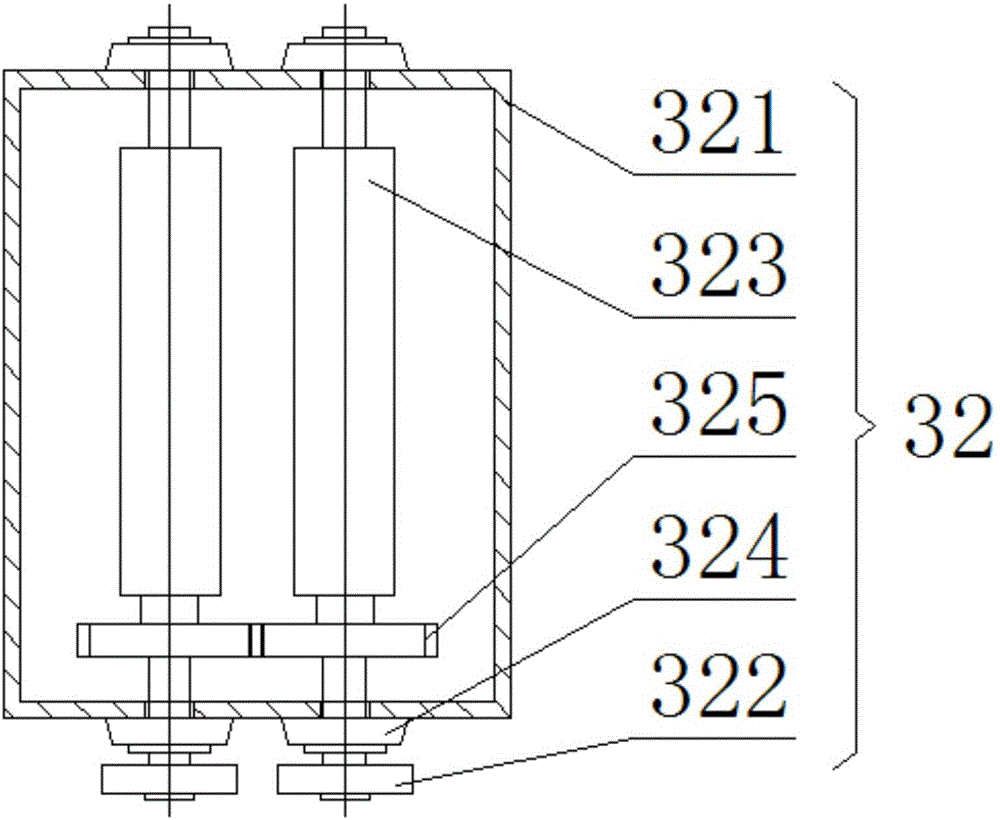

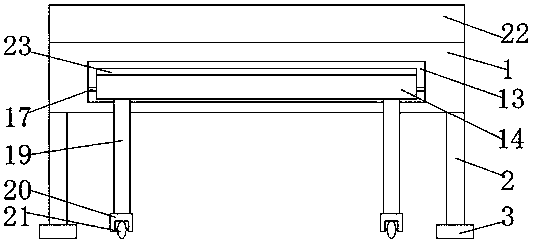

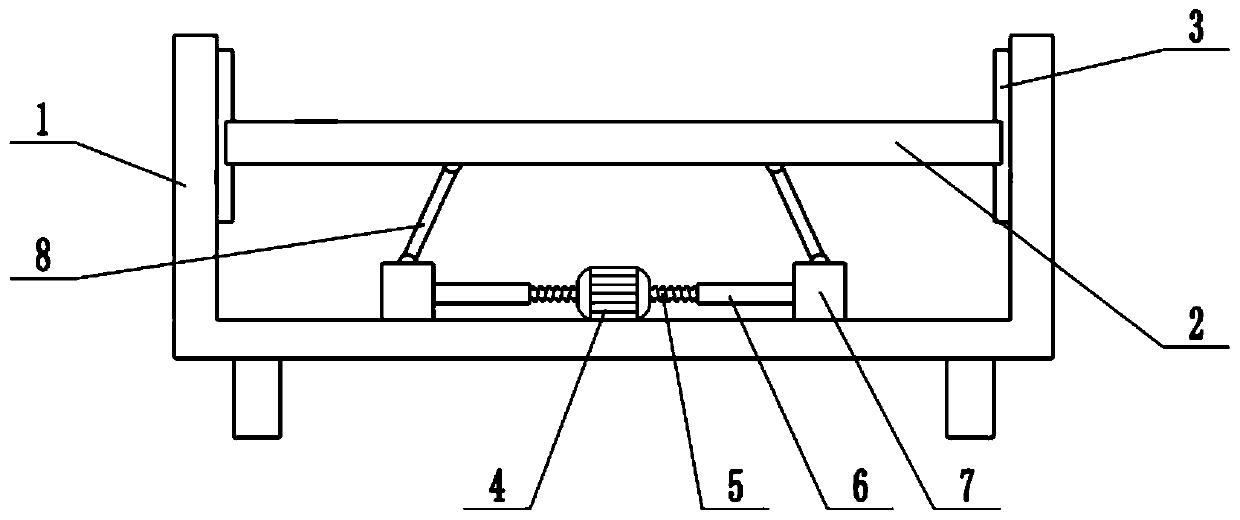

Tea vibration dryer

InactiveCN106524710AEvenly heatedEasy transferTea dryingDrying machines with non-progressive movementsFiberAluminum silicate

The invention discloses a tea vibration dryer. The tea vibration dryer comprises a rack, a tray and a vibration heating device which comprises a heating table, vibration assemblies, driving assemblies and supporting springs; the driving assemblies are fixedly arranged at the bottom of the rack and drive the vibration assemblies fixedly installed below the heating table through chains; the heating table and the rack are connected through the supporting springs; and the tray is placed on the heating table. After the above technical scheme is adopted, a vibration manner is adopted for the tea vibration dryer, tea can be automatically spread and turned over, and it is guaranteed that heating of the tea is more uniform; and a tray placement manner is adopted, and an individual tray is used for each pot of tea. The tea can be conveniently transferred, and spillage or damage caused by feeding and discharging of the tea is avoided; and the peripheries of electric heating pipes are filled with aluminum silicate fiber boards, losses of heat are reduced, and meanwhile, a shock isolating effect is achieved on the electric heating pipes.

Owner:陈飚

Full-automatic tea leaf drying device

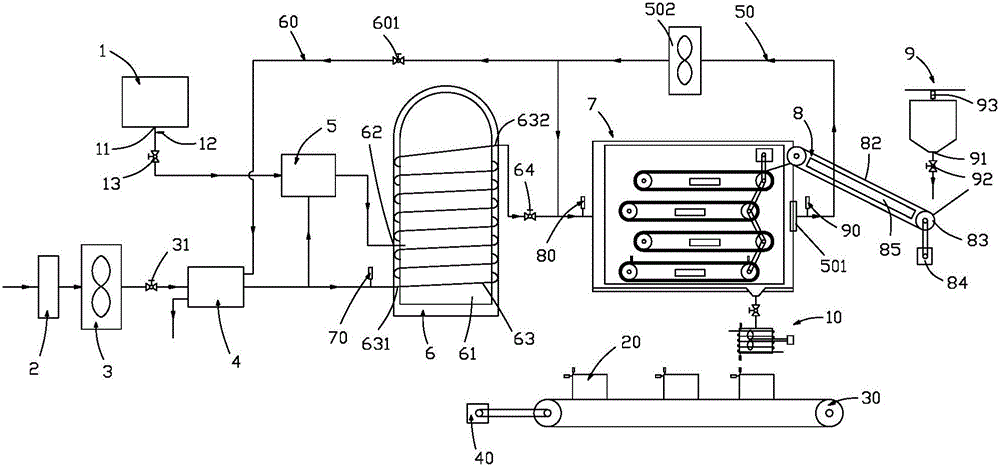

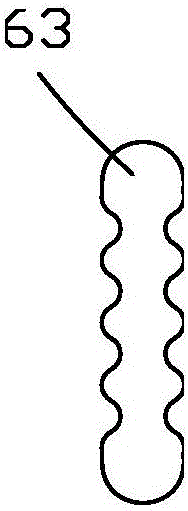

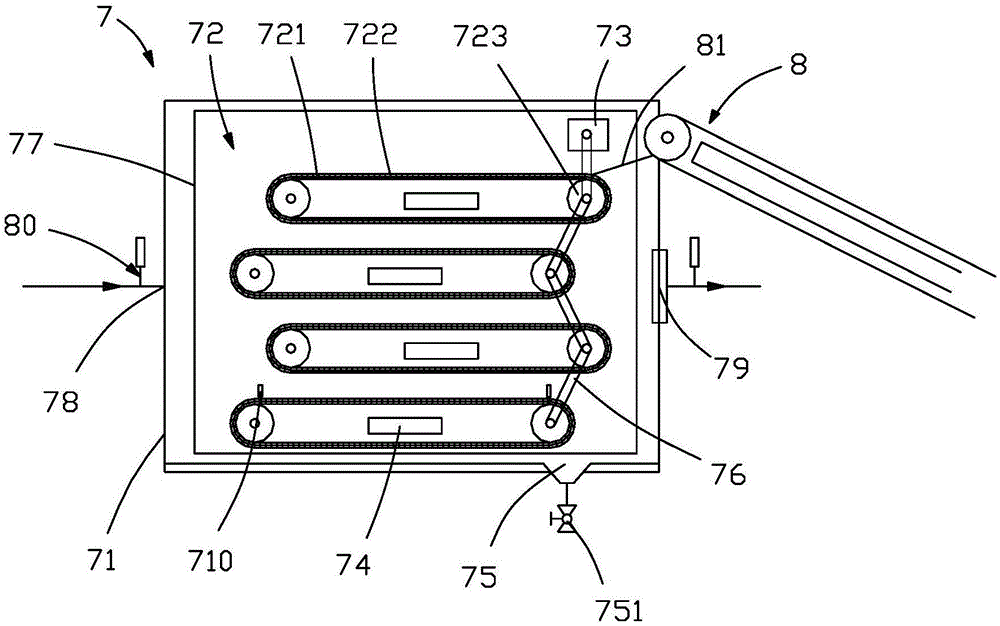

ActiveCN106288727ASolve pollutionAvoid moisture returnTea dryingDrying gas arrangementsMechanical equipmentEngineering

The invention provides a full-automatic tea leaf drying device, and belongs to the field of tea leaf processing mechanical equipment. The full-automatic tea leaf drying device comprises a fuel storage bin, a first draught fan, a boiler, a drying box, a feeding device and a leaf storage bin. The fuel storage bin and the first draught fan are connected with the boiler, and the boiler is then connected with the drying box. The leaf storage bin is sequentially connected with the feeding device and the drying box. A heat exchange pipe is arranged on the inner wall of the boiler and provided with a heat exchange pipe opening end and a heat exchange pipe outlet end which are connected with the first draught fan and the drying box correspondingly. The drying box is provided with a hot air inlet end and a hot air outlet end which are connected with each other through a hot air circulation pipe. The hot air circulation pipe is provided with a second draught fan and a hot air extension pipe which is provided with a first electromagnetic valve in a penetrating manner. The full-automatic tea leaf drying device can achieve automatic feeding, drying, discharging and cooling of the tea leaf drying process and can accurately control the drying degree of tea leaves and improve the tea leaf drying quality and drying efficiency, and the device is easy and convenient to operate.

Owner:江西浮梁贡茶叶有限公司

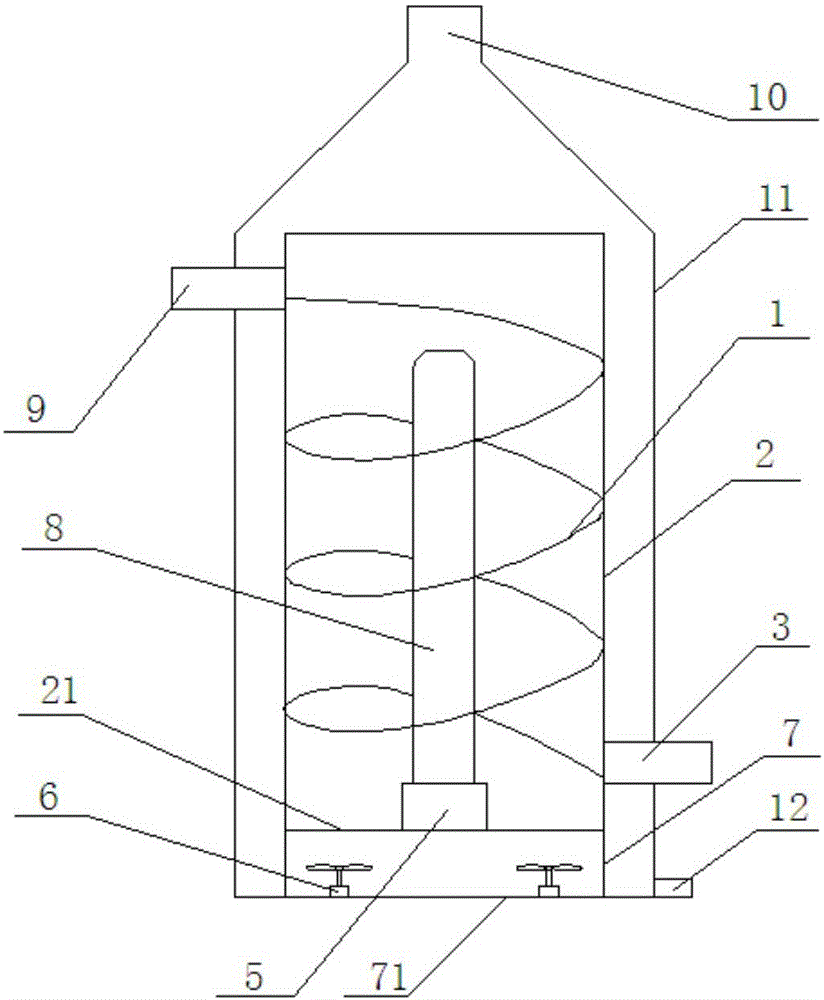

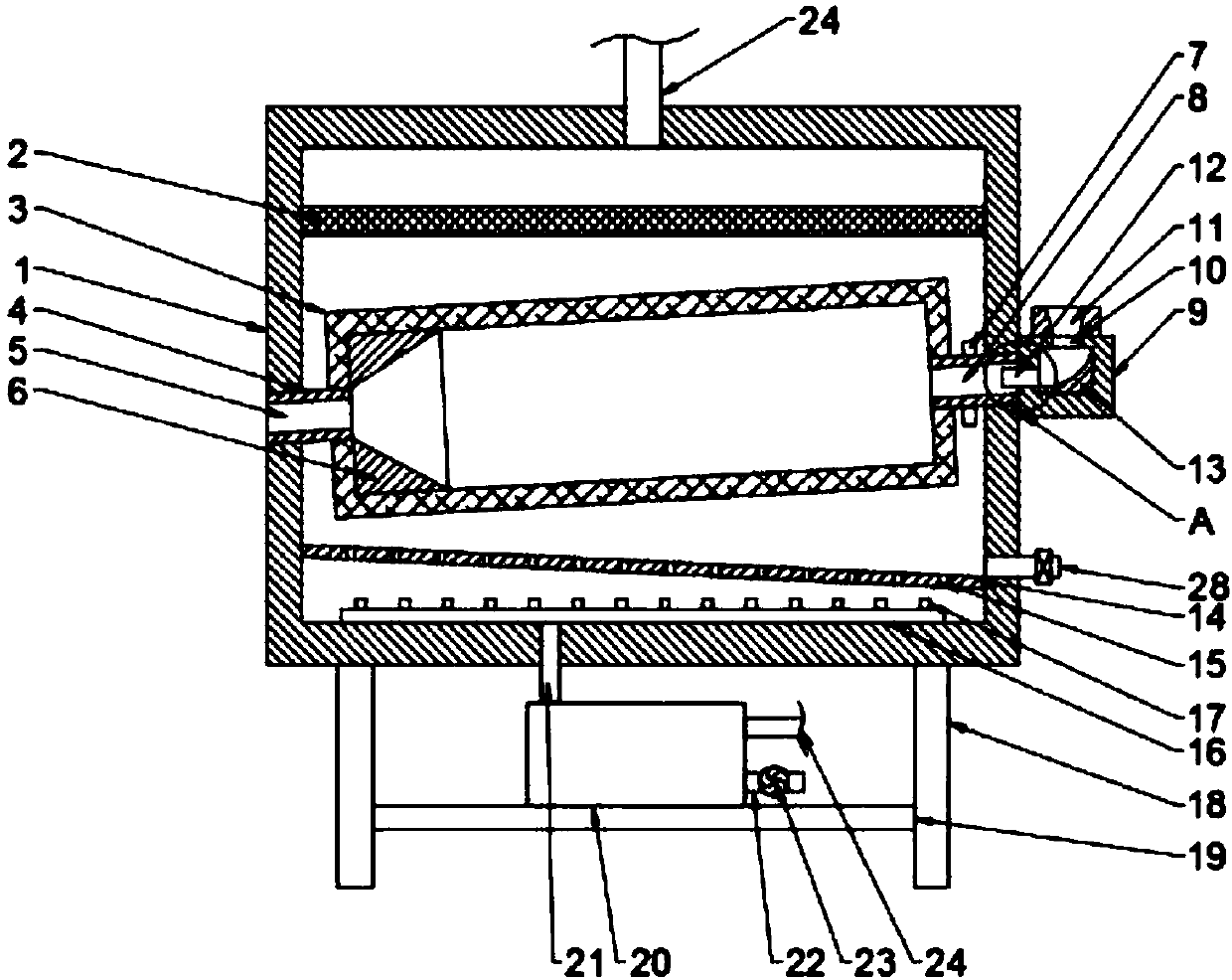

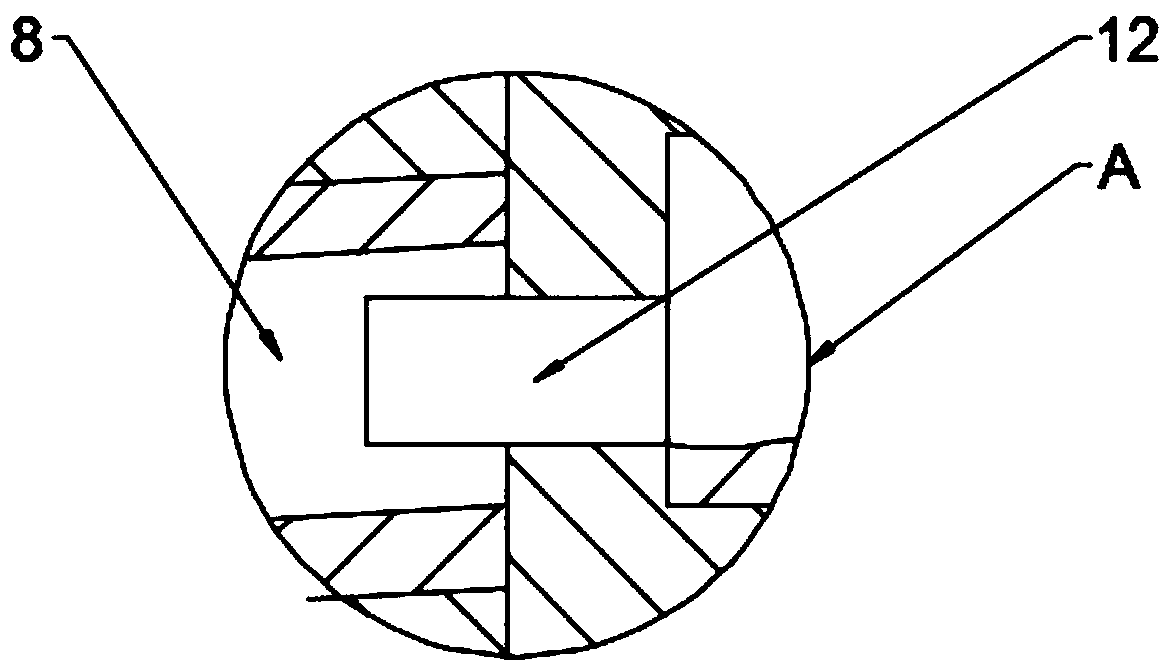

Drying device used for green tea processing

InactiveCN106123565AEvenly heatedSpeed up dryingTea dryingDrying machines with progressive movementsPulp and paper industryDrying time

The invention provides a drying equipment for green tea processing. The inner cylinder of the tower is fixedly installed on the base and placed inside the outer cylinder of the tower. The top of the outer cylinder of the tower is provided with an exhaust port; The upper part of the cylinder is provided with a feed port, and the lower part is provided with a discharge port, and both the feed port and the discharge port extend to the outside of the outer cylinder of the tower, and a spiral conveyor belt is fixedly installed on the inner wall of the inner cylinder of the tower. The upper end of the spiral conveyor belt is connected with the feed port, and the lower end is connected with the discharge port. The heating device installed in the tower body of the present invention ensures that the green tea on the spiral conveyor belt can be heated evenly during the conveying process, blows air through the fan at the bottom, and adds a plurality of ventilation holes on the side wall of the inner cylinder of the tower to speed up the cooling process of the tower. The discharge of steam in the inner cylinder speeds up the drying speed of green tea and reduces the drying time; the bottom plate A of the inner cylinder of the tower is set as a breathable plate for better drying effect.

Owner:贵州台江高原生态茶业有限公司

Dryer for broadleaf holly leaves

ActiveCN105910413AImprove drying effectReduce impact forcePre-extraction tea treatmentTea dryingSpiral bladeEngineering

The invention belongs to the technical field of broadleaf holly leaf processing, and particularly relates to a dryer for broadleaf holly leaves. The dryer comprises a casing and an air heater, wherein a casing cover is fixed at the top of the casing; a feeding hopper is arranged at the upper end of the casing; a main hot air inlet connected with the air heater is formed in the casing cover; the dryer also comprises a conical barrel which is fixedly connected with the lower end of the casing; a discharge opening is formed in the lower end of the conical barrel; a separating board is arranged inside the casing; an inner cavity of the casing is divided into a left chamber and a right chamber by the separating board; the feeding hopper is positioned above the left chamber; first folded plates and second folded plates which are mutually staggered are arranged in the left chamber; free ends of the first folded plates and the second folded plates are separately downwards inclined; a vertical cylinder is arranged in the right chamber; a rotating shaft extending into the cylinder is rotationally connected onto the top cover; the lower end of the rotating shaft extends into the conical barrel; and a spiral blade is welded on the rotating shaft. The dryer disclosed by the invention is simple in structure; and compared with a traditional dryer, the dryer disclosed by the invention has the advantages that tea can be sufficiently contacted with hot air, and the influence on final modeling of the tea is avoided.

Owner:桐城市建设投资发展有限责任公司

Tea dryer based on roller stir-frying technology

InactiveCN108050804AEvenly heatedReduce lossSievingPre-extraction tea treatmentPulp and paper industryInjection air

The invention discloses a tea dryer based on a roller stir-frying technology. The tea dryer comprises a box body and a drying roller; a dustproof net, a drying roller and a second flow guide plate aresequentially arranged in the inner cavity of the box body from top to bottom, wherein the top end of the box body communicates with an exhaust pipe, and the drying roller is rotationally connected tothe box body through a rotating shaft; a discharging port coordinated with a guide hopper is formed in the lowest end of the rotating shaft, a feeding port is formed in the other end of the rotatingshaft, and one end of the feeding port communicates with the drying roller in a penetrating mode; multiple through holes are uniformly formed in the second flow guide plate; multiple supporting legs are uniformly arranged at the bottom end of the box body, and a supporting pressing plate is arranged between every two supporting legs; and a purification box is arranged at the top ends of the supporting pressing plates. According to the tea dryer, high-temperature gas enters an air injection device through the purification box, then enters the box body through air nozzles, tea leaves in the drying roller are dried, and then are rolled continuously along with the rolling of the drying roller, so that the tea leaves are heated more uniformly, the loss of the tea leaves can be reduced, and occurrence of the broken tea leaves can be reduced.

Owner:储昭义

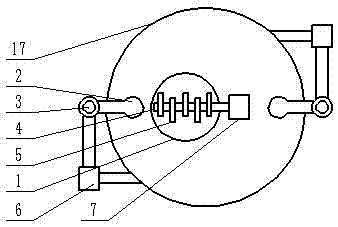

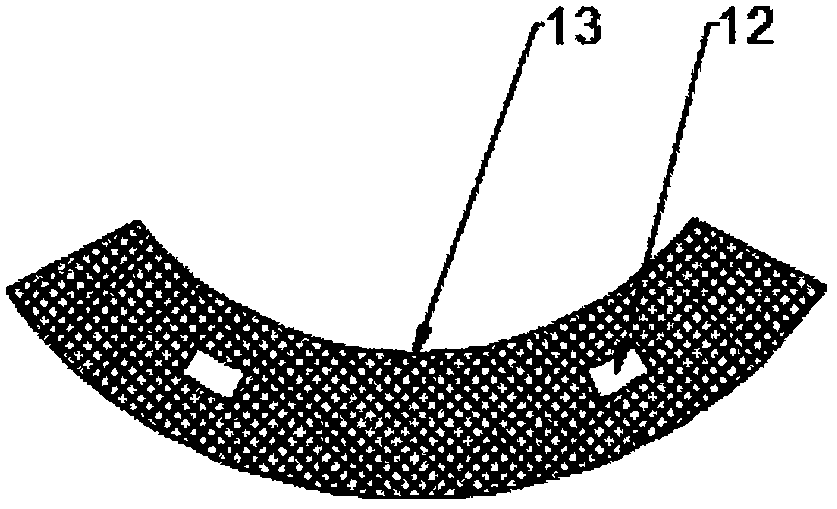

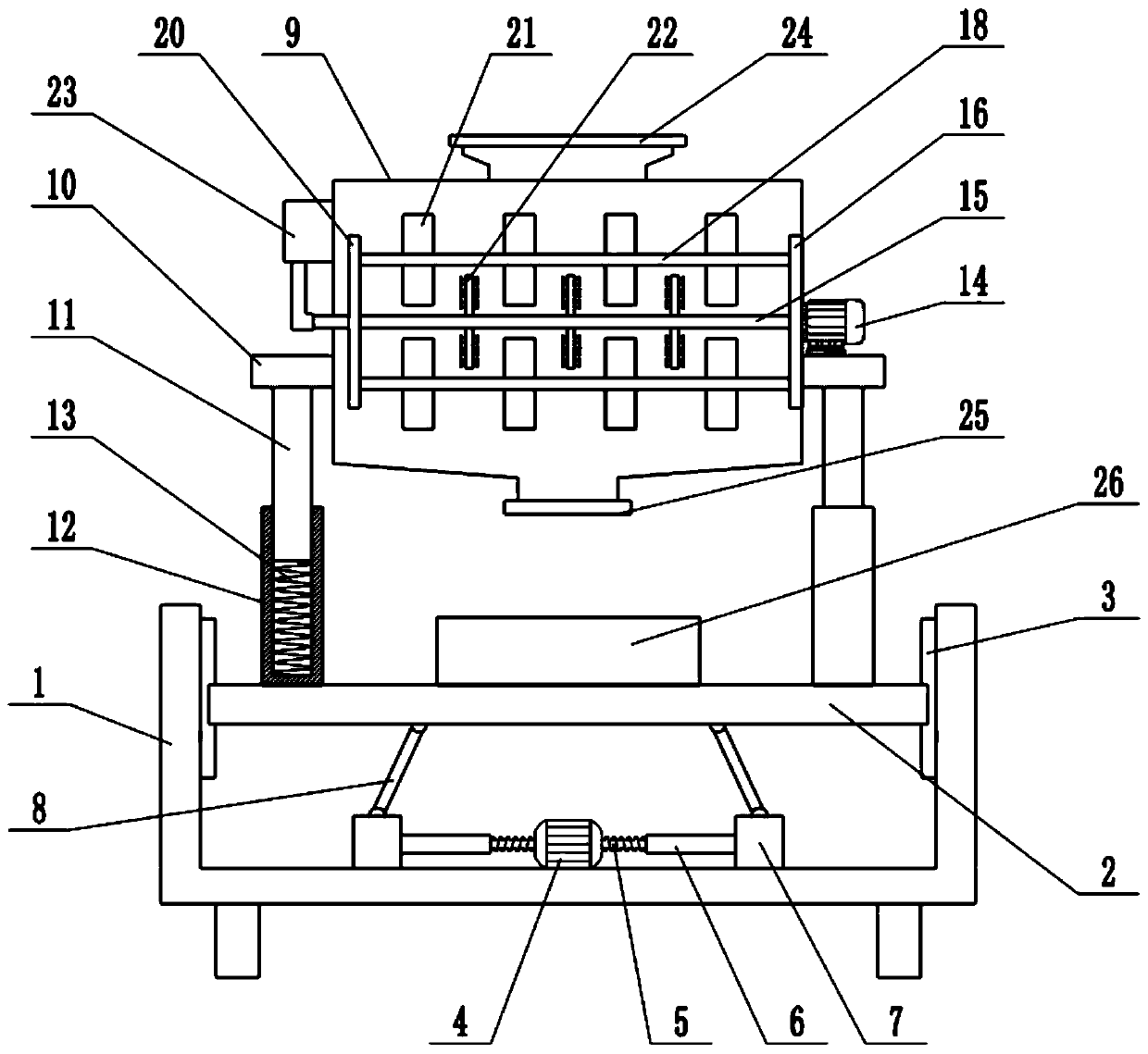

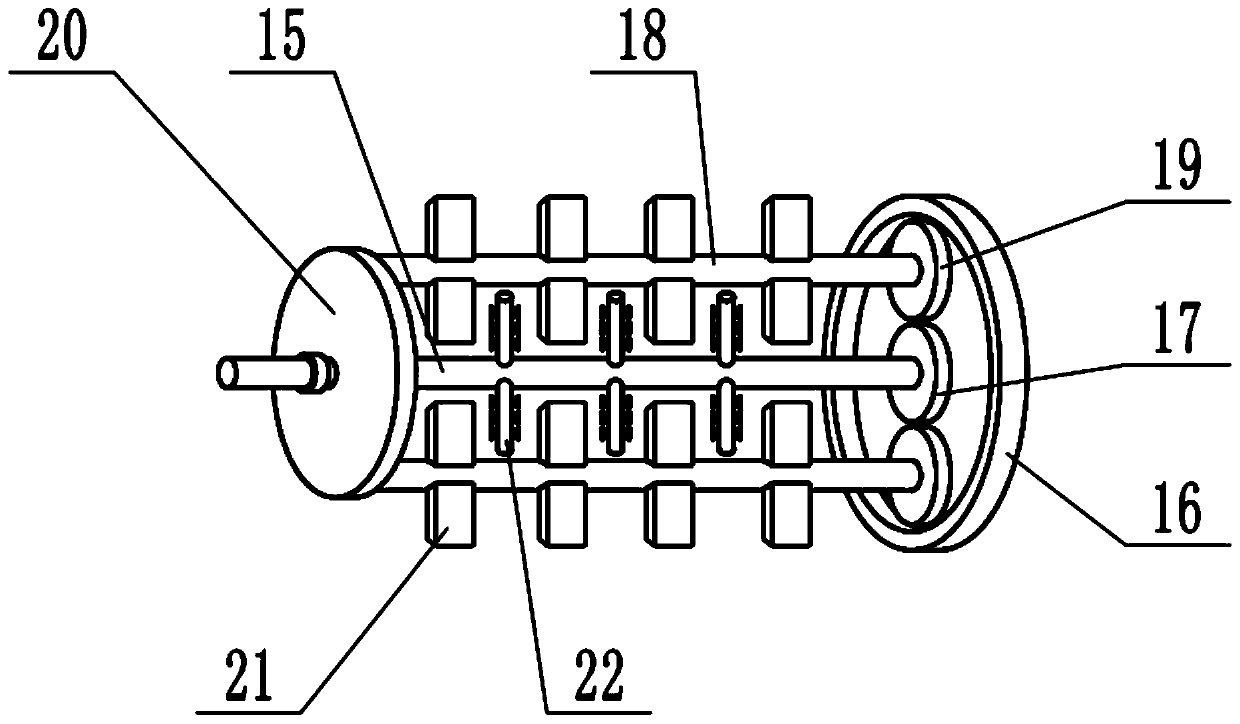

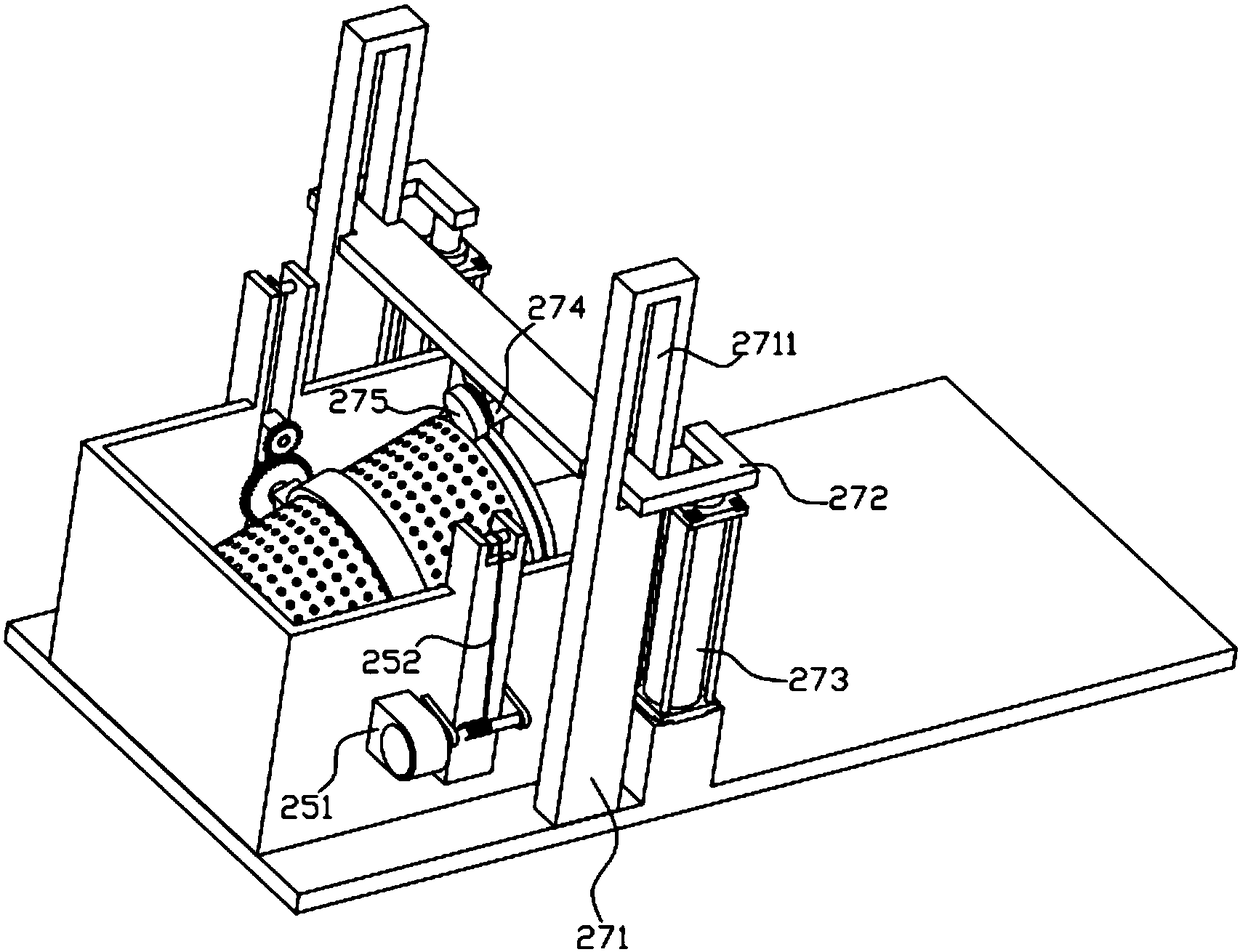

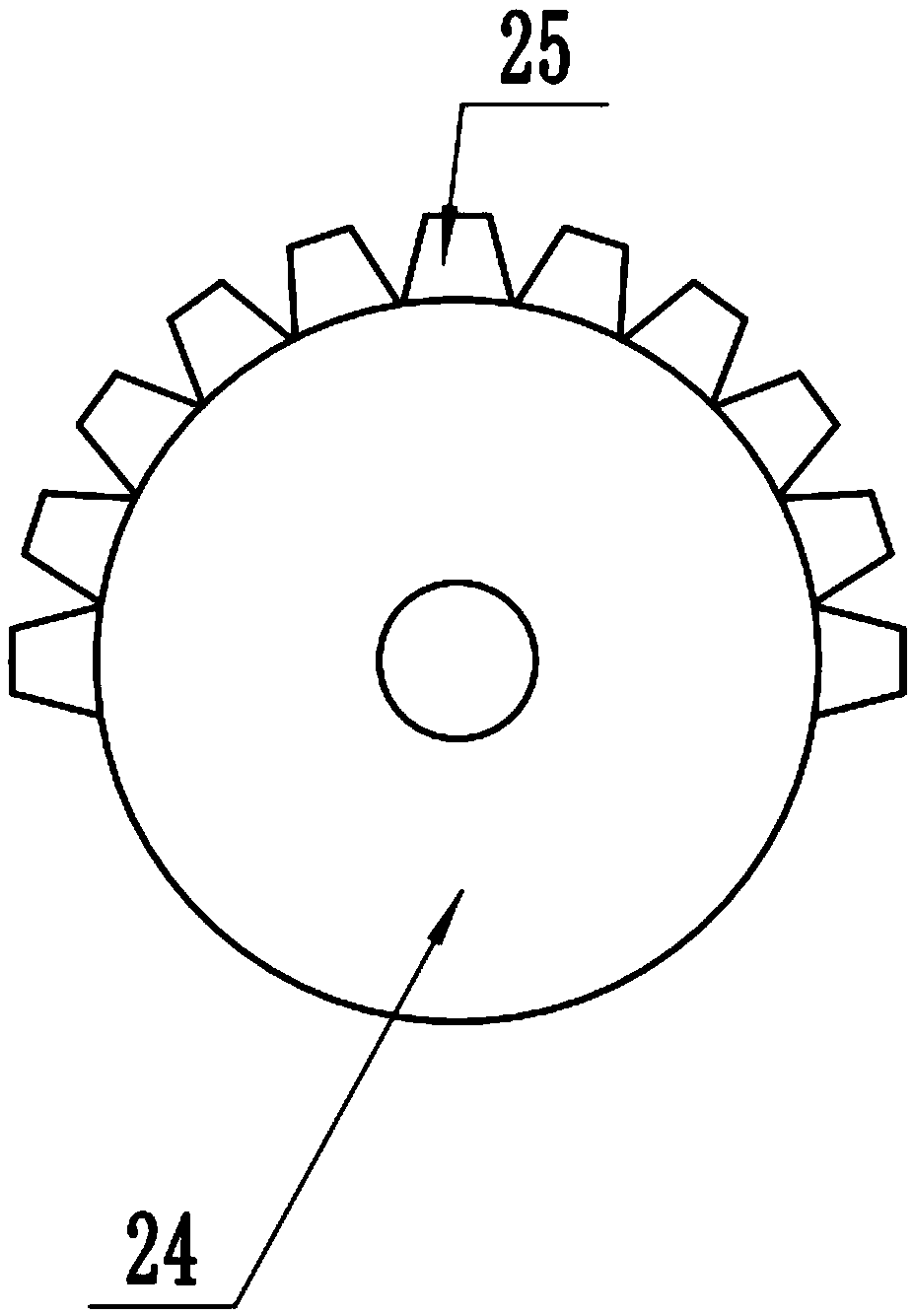

Vibration-type grading scrap removal device with drying function for tea machine

PendingCN105394228ADry evenlyImprove qualitySievingPre-extraction tea treatmentThermal insulationMultiple layer

The invention relates to the tea machine device technology field, and concretely relates to a vibration-type grading scrap removal device with a drying function for a tea machine. The vibration-type grading scrap removal device comprises a pedestal. Support frames are arranged on the left side and the right side of the upper surface of the pedestal correspondingly. U-shaped roll racks are arranged on the support frames respectively. A roller is arranged in each U-shaped roll rack. A baking cylinder is arranged on the two rollers. A cavity is arranged in the cylinder wall of the baking cylinder. A heating wire layer, a hollow layer and a thermal insulation layer are arranged in the cavity in order from inside to outside. A gear ring is arranged at the upper and middle part of the baking cylinder. A motor is arranged at the central part of the upper surface of the pedestal. The shaft end of the motor is connected with a driving gear. The driving gear is connected with the gear ring through a chain. A feed inlet is arranged at the central part of the left side surface of the baking cylinder. An inverted-L-shaped discharge opening is arranged at the central part of the right side surface of the baking cylinder. The structure is simple, operation is convenient, tea can be dried uniformly based on control of temperature and humidity, tea quality is raised, and the working efficiency is raised through multi-layer grading processing.

Owner:CHONGQING FURUICHENG AGRI CO LTD

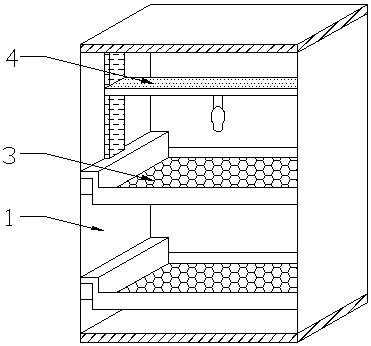

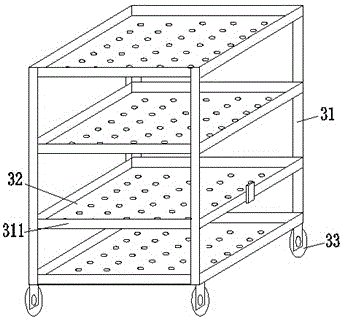

Air drying device for tea leaf processing

The invention discloses an air drying device for tea leaf processing. The air drying device for tea leaf processing comprises air drying chambers, tea leaf air drying trays and hot air blowers. A plurality of holding frames are installed on the two opposite sides inside the air drying chambers. The tea leaf air drying trays are installed on the holding frames. Each tea leaf air drying tray comprises a tray fixing frame and a tray bottom plate, wherein the tray fixing frame is installed on the corresponding holding frames. A transverse plate is installed inside each air drying chamber at the top of the corresponding tea leaf air drying tray. According to the air drying device for tea leaf processing, the hot air blowers move to achieve hot air drying of tea leaves on the tea leaf air dryingtrays, so that the tea leaves are heated uniformly, temperature balance and air flowing inside the air drying chambers can be facilitated, air drying efficiency is improved, and the air drying cost of the tea leaves is reduced; by vibrating the tray bottom plates, the gaps between the tea leaves on the tray bottom plates can be widened, the contact probability and contact area between hot air generated by the hot air blowers and the tea leaves at the bottoms of the tea air drying trays are increased, and thus the air drying uniformity and efficiency of the tea leaves are effectively improved,manual turning of the tea leaves is not needed, and the labor intensity of personnel is reduced.

Owner:龙岩市八仙岩茶业有限公司

Air-drying rack for tea processing

ActiveCN107726766ASolve the problem that the drying area cannot be adjustedIncrease contact areaPre-extraction tea treatmentClimate change adaptationEngineeringSunlight

The invention discloses an air-drying rack for tea processing. The air-drying rack comprises a first sun-drying plate, wherein support columns are fixedly connected with four corners of the bottom ofthe first sun-drying plate; anti-slip pads are fixedly connected with the bottoms of the support columns; a cylinder is fixedly connected with the rear side of an inner cavity of the first sun-dryingplate; a movable plate is fixedly connected with the front side of the cylinder; fixed rods are fixedly connected with two sides of the movable plate; movable blocks are movably connected with one ends, away from fixed blocks, of movable rods. According to the air-drying rack for tea processing, the problem that the air-drying area of an existing tea air-drying rack cannot be adjusted is solved under matching of the cylinder, the movable plate, the fixed rods, support rods, the fixed blocks, the movable rods, movable grooves, the movable blocks, first sliders and first sliding chutes, the air-drying rack for tea processing has the advantage that the air-drying area can be adjusted, the contact area of sunlight and tea is increased, the air-drying time of tea is shortened, the area occupiedby the air-drying rack is reduced, and the air-drying rack is conveniently used by a tea farmer and worthy of popularization and application.

Owner:湖南桑仁行农业科技股份有限公司

Drying device for tea processing

InactiveCN111595129AEvenly heatedFully contactedTea dryingDrying gas arrangementsAgricultural engineeringStructural engineering

The invention relates to the field of tea processing equipment, in particular to a drying device for tea processing. The drying device for tea processing comprising a base, a lifting plate, a drying cylinder and an hot air blower, the lifting plate is mounted inside the base, the drying cylinder is arranged above the lifting plate, fixing plates are fixedly connected to the left side and the rightside of the drying cylinder correspondingly, supporting rods are fixedly connected to the lower surfaces of the fixing plates, guide cylinders are arranged at the lower ends of the supporting rods ina sleeving mode, a hollow rotating shaft is installed inside the drying cylinder, the hot air blower is fixedly connected to the left side wall of the drying cylinder, a gear ring is installed on theinner wall of the right side of the drying cylinder, a driving gear is arranged at the right end of the hollow rotating shaft in a sleeving mode, and driven shafts are symmetrically arranged on the upper side and the lower side of the hollow rotating shaft. According to the drying device for tea processing, tea leaves in the drying cylinder are dried through the hot air blower, and the tea leavesare turned over through stirring plates, so that the tea leaves are heated more evenly, and the drying efficiency is improved; and the lifting plate is driven by a double-shaft motor to vibrate up and down, and therefore the tea leaves are turned over up and down in the drying cylinder, so that the tea leaves are in full contact with hot air.

Owner:高桂云

Drying equipment for tea production

InactiveCN106679368AEvenly heatedEasy temperature controlPre-extraction tea treatmentGas current separationPropellerEngineering

The invention discloses drying equipment for tea production. The equipment comprises a vibrating discharging bin and a stop piece; a feeding port is formed in the top end of a feeding bin; the stop piece is mounted on the bottom side of the inner cavity of the feeding bin; a dust outlet is formed in the left side of the feeding bin; a dust removal fan is mounted on the right side of the feeding bin; a drying bin is located on the bottom side of the feeding bin; an electrical cabinet and a temperature controller are mounted on outer walls of two sides of the drying bin; a drying electric heating wire is located on the inner wall of the drying bin; a propeller is mounted in the inner cavity of the drying bin; a discharging port is formed in the bottom end of the inclined vibrating discharging bin; a filter net is mounted on the inner wall of the left side of the feeding bin; and a base is located at the back end of the vibrating discharging bin. The equipment adopts the method for heating through the electric heating wire, the temperature is easy to control, tea is blown up through air outlet on the bottom side, is uniformly heated and is fully turned over through the spiral propeller, a vibrator is additionally arranged at the discharging port, and discharging is more convenient.

Owner:GUIZHOU KAIYANG NANGONGHE SE ENRICHED TEA

Tea leaf washing device

InactiveCN108543760ASo as not to damageQuick breakPre-extraction tea treatmentDrying solid materials without heatEngineeringMechanical engineering

The invention provides a tea leaf washing device which comprises a bottom plate, a washing mechanism, a discharging mechanism and a conveying mechanism. The washing mechanism comprises a water tank, awashing cylinder, an integral type rotating bearing, sliding blocks, jacking mechanisms, a corner adjusting mechanism and a drive mechanism. The water tank is fixedly installed on the bottom plate. The two sliding blocks are movably installed on the two sides of the water tank correspondingly. The washing cylinder is installed in the integral rotating bearing. The two ends of the integral rotating bearing are installed on the two sliding blocks through bearings correspondingly. The two jacking mechanisms are fixedly installed on the outer side of the water tank and are connected with the twosliding blocks in a power manner correspondingly. The corner adjusting mechanism is fixedly installed on the sliding blocks and is in power connection with the integral rotating bearing. The drive mechanism is installed on the bottom plate. According to the tea leaf washing device, the rotating washing cylinder washes tea leaves deeply, after washing is completed, the tea leaves are dehydrated inthe washing cylinder, and the tea leaves are washed and dehydrated integrally.

Owner:万新知识产权服务(安徽)有限公司

Swing type chrysanthemum natural drying and impurity removing device

InactiveCN109470038AReasonable structureInnovative designPre-extraction tea treatmentTea dryingDrive shaftPulp and paper industry

The invention discloses a swing type chrysanthemum natural drying and impurity removing device, which belongs to the technical field of chrysanthemum processing, and comprises a bottom plate, whereinsupport frames are arranged on two sides of the upper end of the bottom plate; a top frame is arranged between the top ends of the support frames; a swing shaft is arranged in the middle of the top frame; a screen is arranged in the middle of the swing shaft; guide posts are arranged on two sides of the lower end of the screen; guide wheels are arranged at the lower ends of the guide posts; a hollow groove is formed in the middle of the bottom plate; a drive shaft is arranged in the hollow groove; a drive wheel is arranged in the middle of the drive shaft; limiting grooves are arranged at twoends of the hollow groove; limiting springs are arranged in the limiting grooves; limiting rods are arranged at the other ends of the limiting springs; a swing frame is connected to the limiting rods;the upper end and the lower end of the swing frame are provided with swing teeth; the two sides of the upper end of the swing frame are provided with swing columns; and wedge blocks are arranged at the upper ends of the swing columns. The swing type chrysanthemum natural drying and impurity removing device realizes left-right swing of the swing frame, so that chrysanthemum is dried more uniformlywhen being dried naturally, and meanwhile, the effect of removing dust and impurities on the screen by an air injection cavity is also realized.

Owner:临泉县同鑫达农业有限公司

Efficient chrysanthemum flower drying device

InactiveCN109307413AImprove drying efficiencyTea substituesTea dryingChrysanthemum FlowerSolenoid valve

The invention discloses an efficient chrysanthemum flower drying device. The efficient chrysanthemum flower drying device comprises a drying barrel, saddles, a dehumidifier, an air heater and a controller. A rotary drying mechanism is arranged in the drying barrel, and a driving mechanism is arranged outside the drying barrel. The drying mechanism is connected with the rotary drying mechanism. Thenumber of the saddles is two, the drying barrel is fixed to the saddles, the dehumidifier and the air heater are located on one side of the drying barrel, and an air outlet is formed in the top end of the drying barrel. The dehumidifier and the air outlet are in sealed connection through a dehumidifying pipe, and the dehumidifying pipe is connected with a solenoid valve in series. An air distributing pipe is arranged at the bottom of an inner cavity of the drying barrel, the output end of the air heater is connected with a hot air pipe, and the hot air pipe stretches into the drying barrel and is connected with the air distributing pipe. A taking opening is formed in the drying barrel, a door blocking mechanism is arranged on the outer side of the taking opening, and the controller is mounted on the drying barrel. The efficient chrysanthemum flower drying device has the beneficial effects of being simple in structure and high in practicality.

Owner:ANHUI GERUI AGRI DEV

Chrysanthemum central heating negative-pressure drying killout system

ActiveCN105928332ADry fastImprove utilization efficiencyTea substituesTea dryingProcess engineeringHeat pipe

The invention provides a chrysanthemum central heating negative-pressure drying killout system. The system comprises a drying chamber; snake-shaped heating pipes are respectively arranged at the bottom and on side walls of two sides of the drying chamber, and are heat steam pipes; multiple drying brackets are arranged in the drying chamber side by side; steam pipes are led out from the drying chambers; and exhaust fans and condensation devices are arranged on the steam pipes. The system solves the problems of lower energy utilization rate, waste of a lot of energy, lower drying efficiency, long time and reduction of the utilization value and efficiency of chrysanthemums due to loss of part beneficial components of the chrysanthemums along with high-temperature steam in a traditional chrysanthemum drying method. The system belongs to the field of chrysanthemum processing.

Owner:贵州绿太阳制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com