Patents

Literature

97results about How to "Dry completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

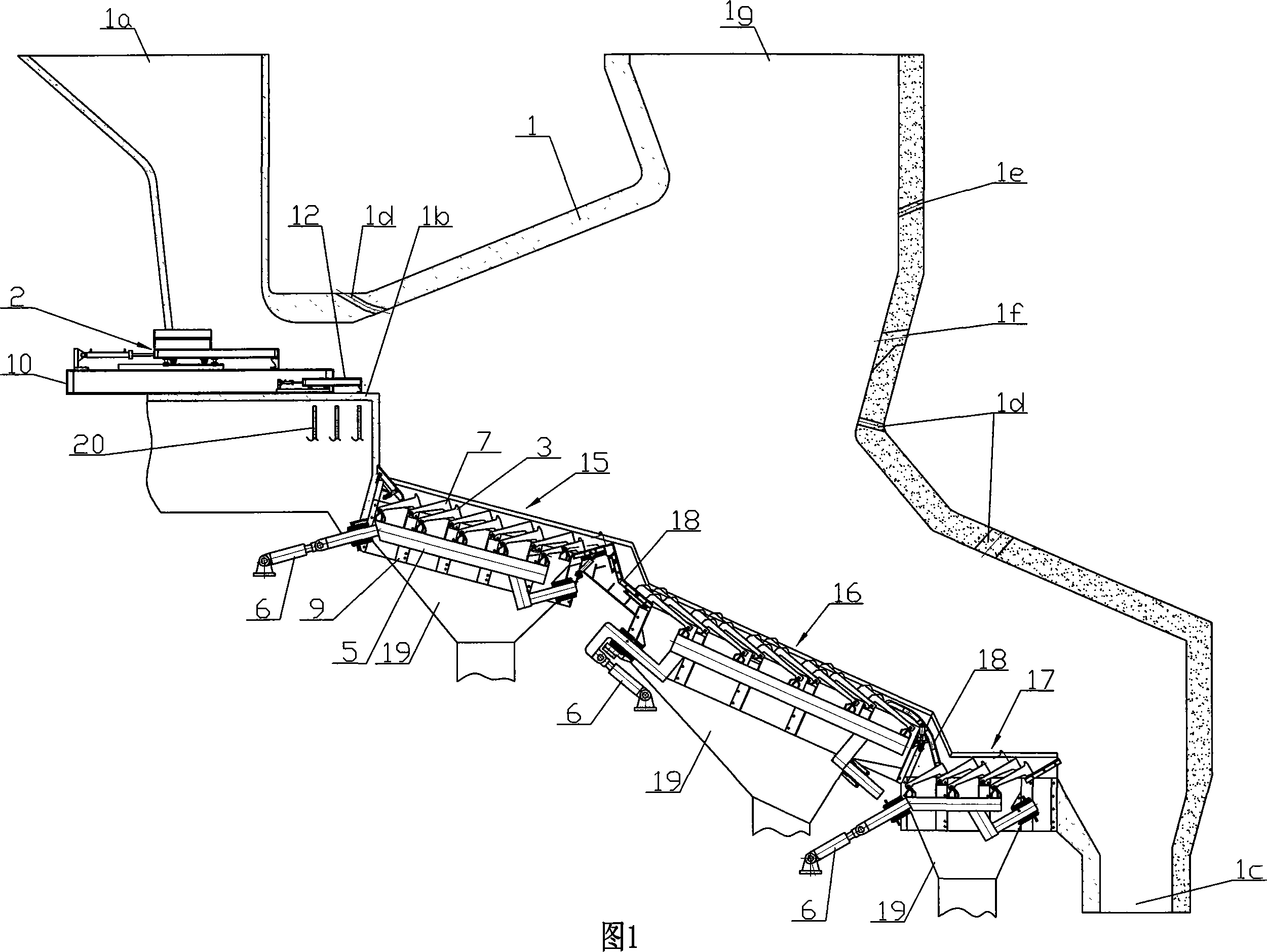

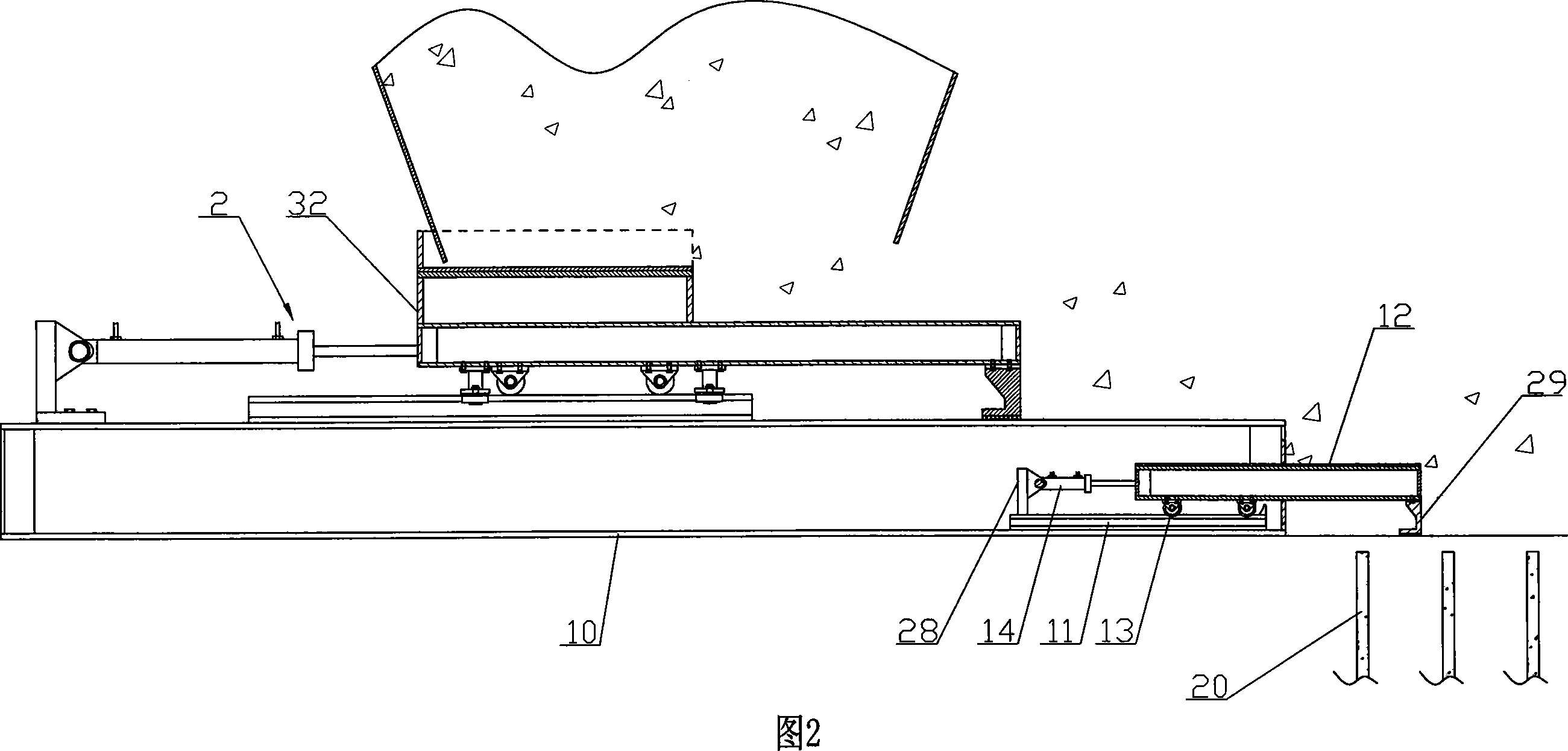

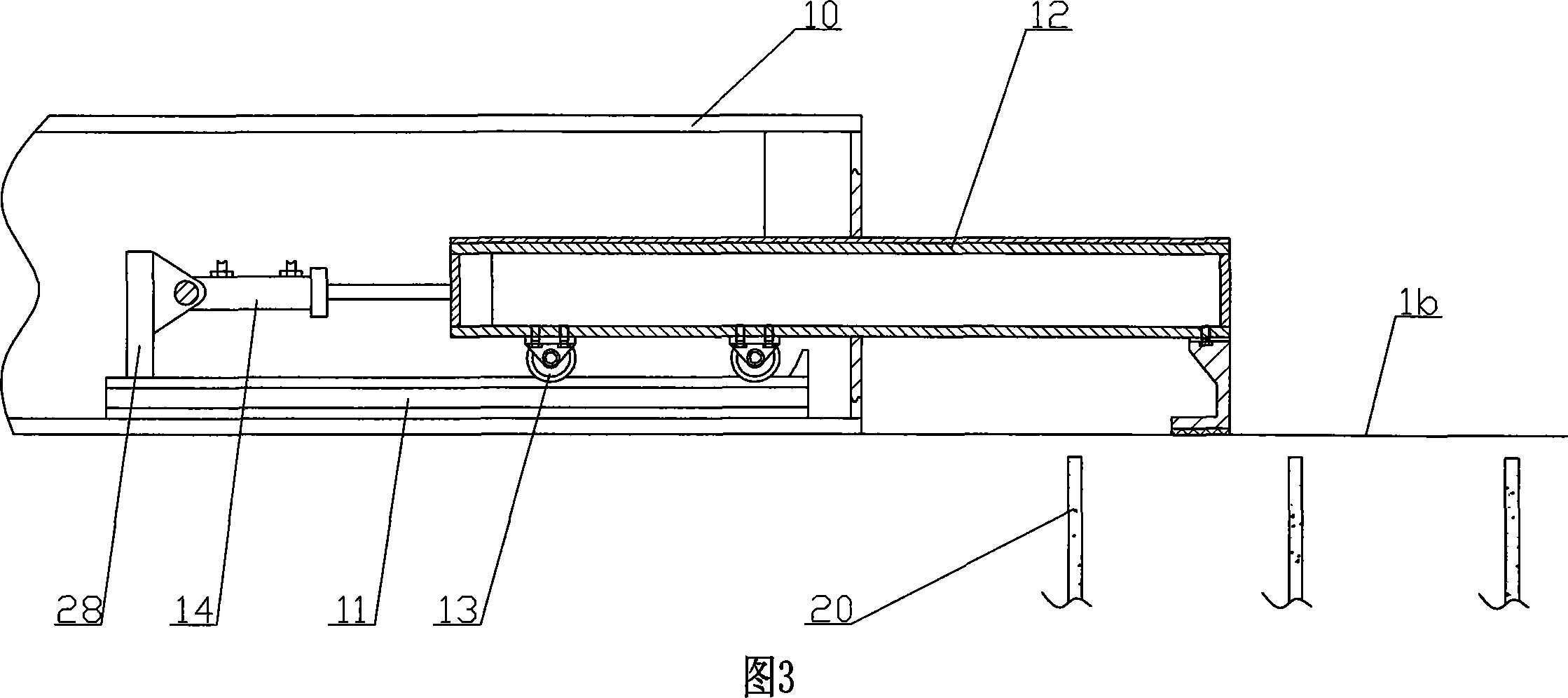

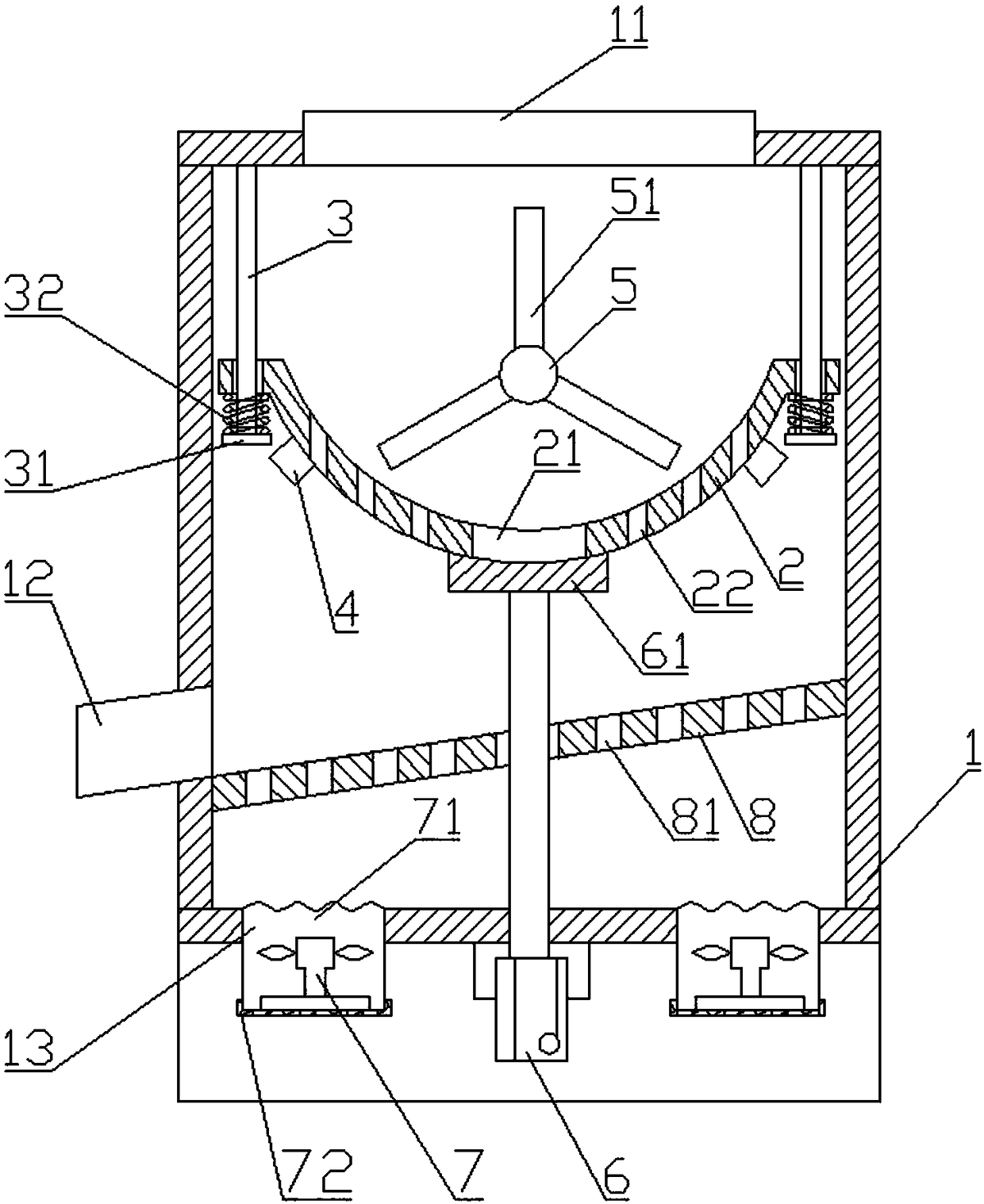

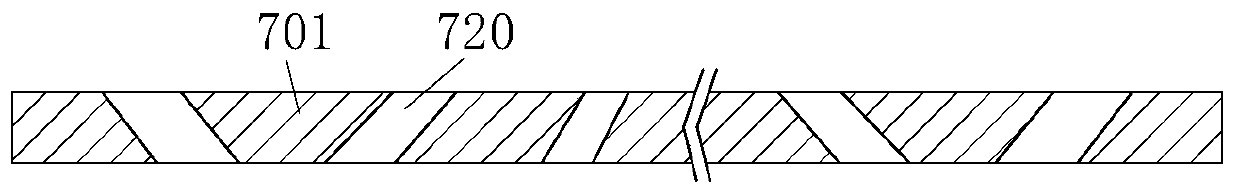

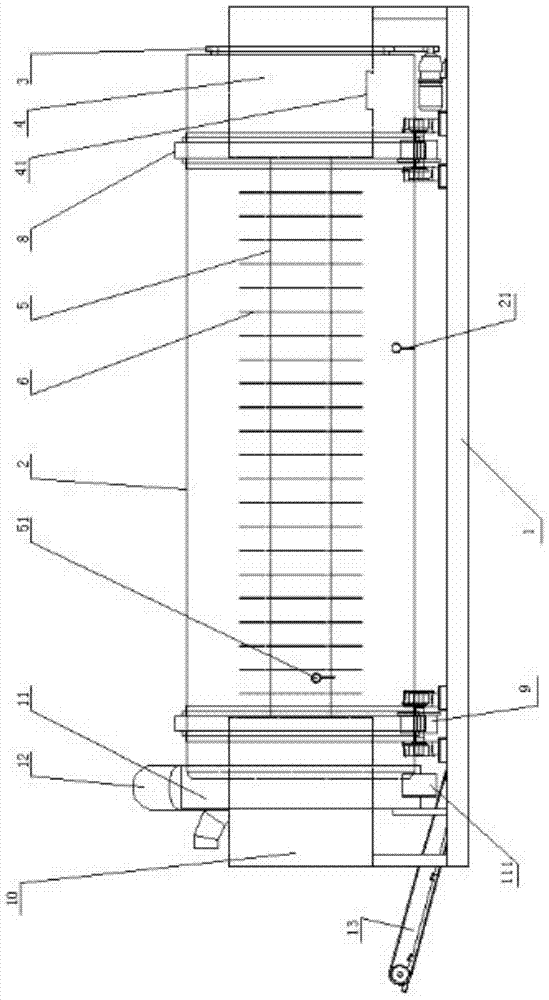

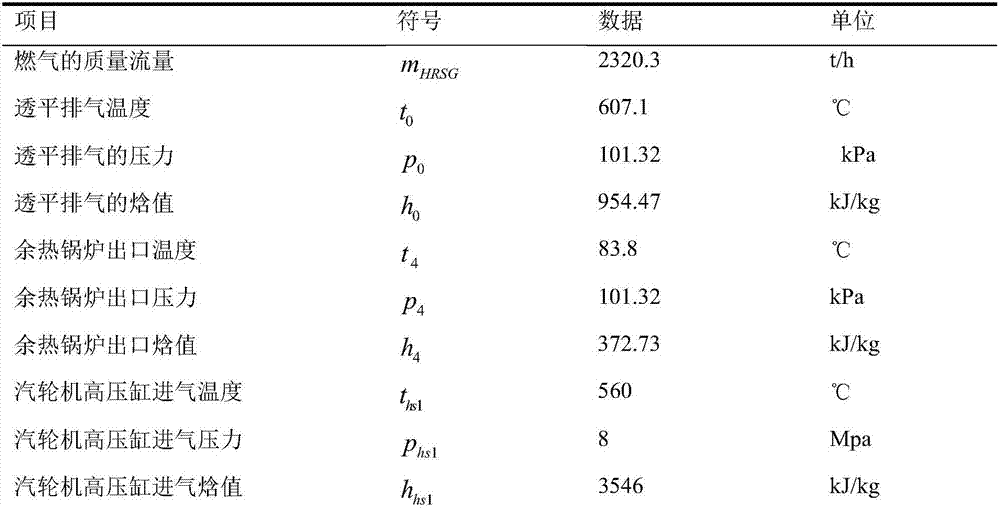

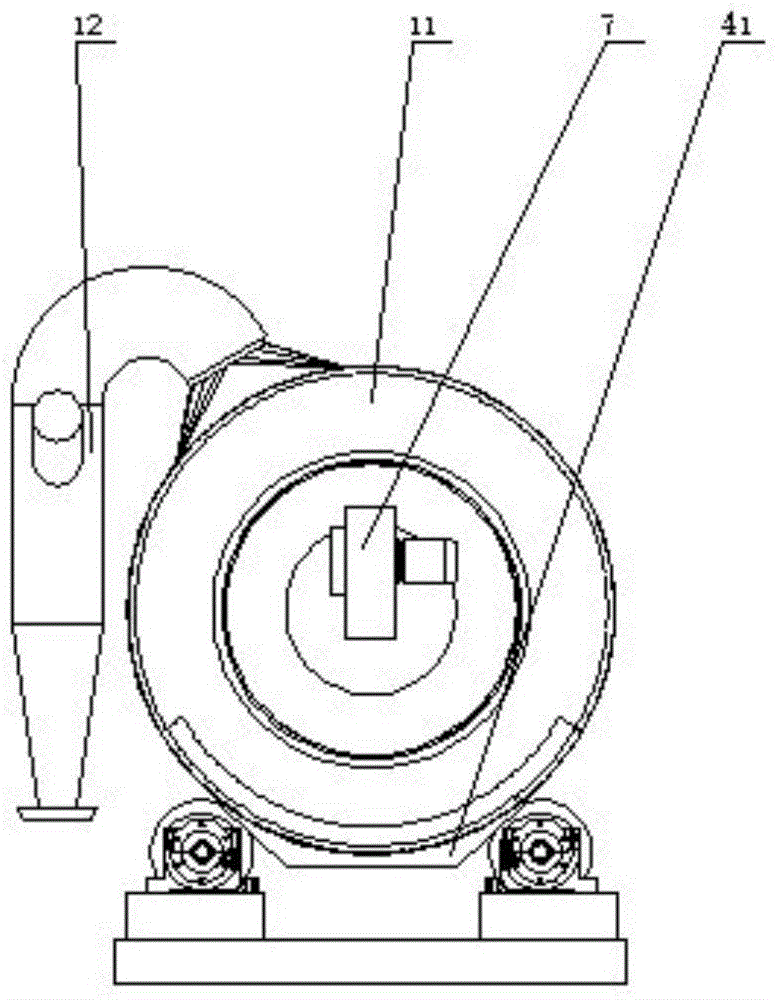

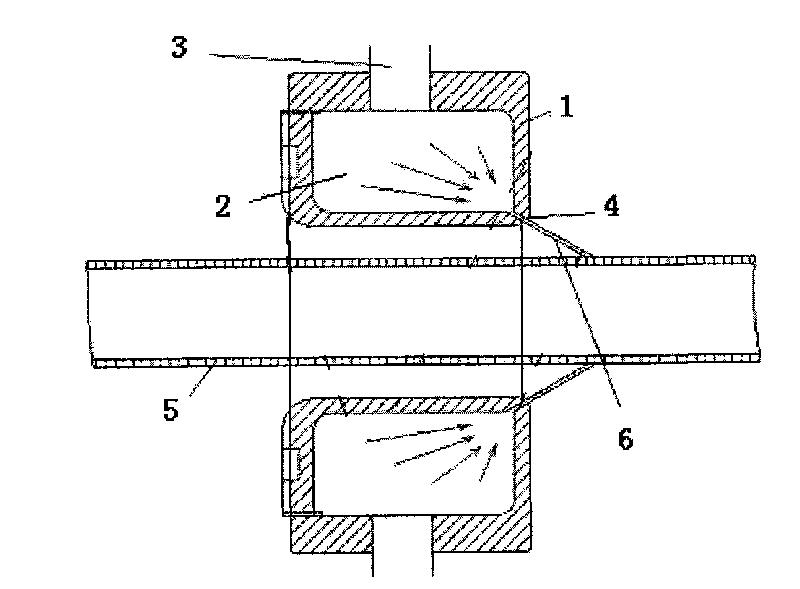

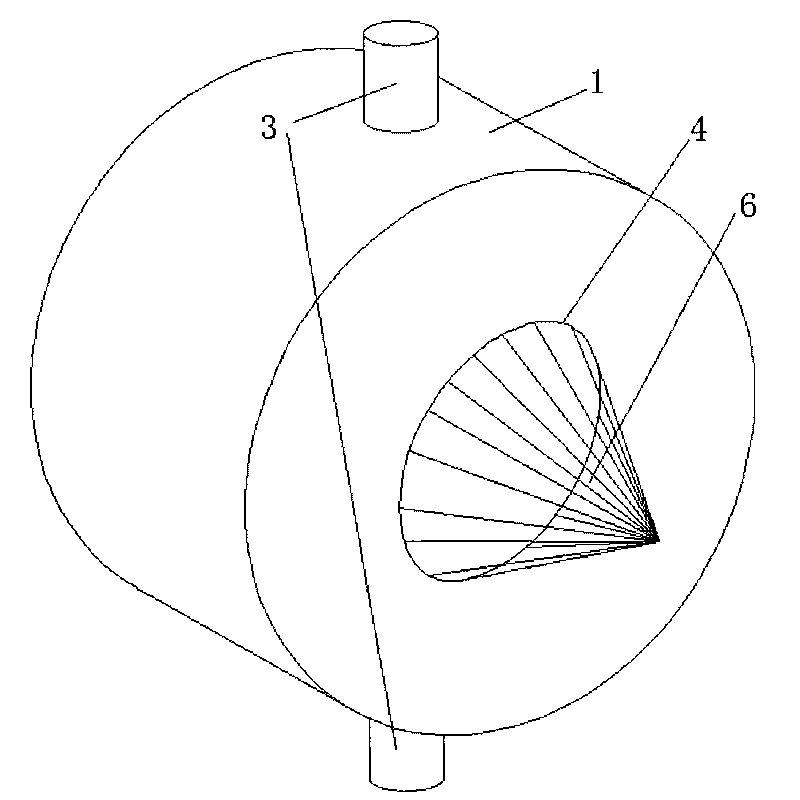

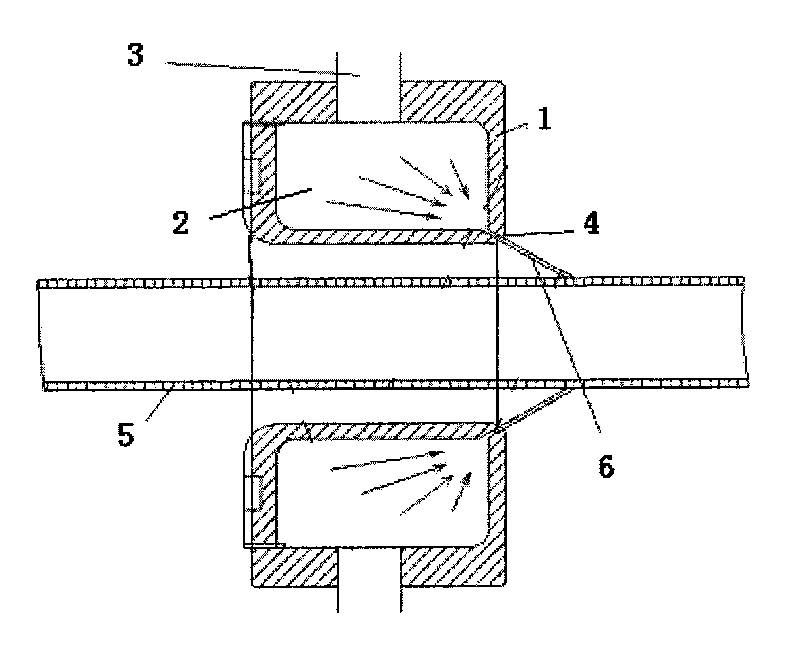

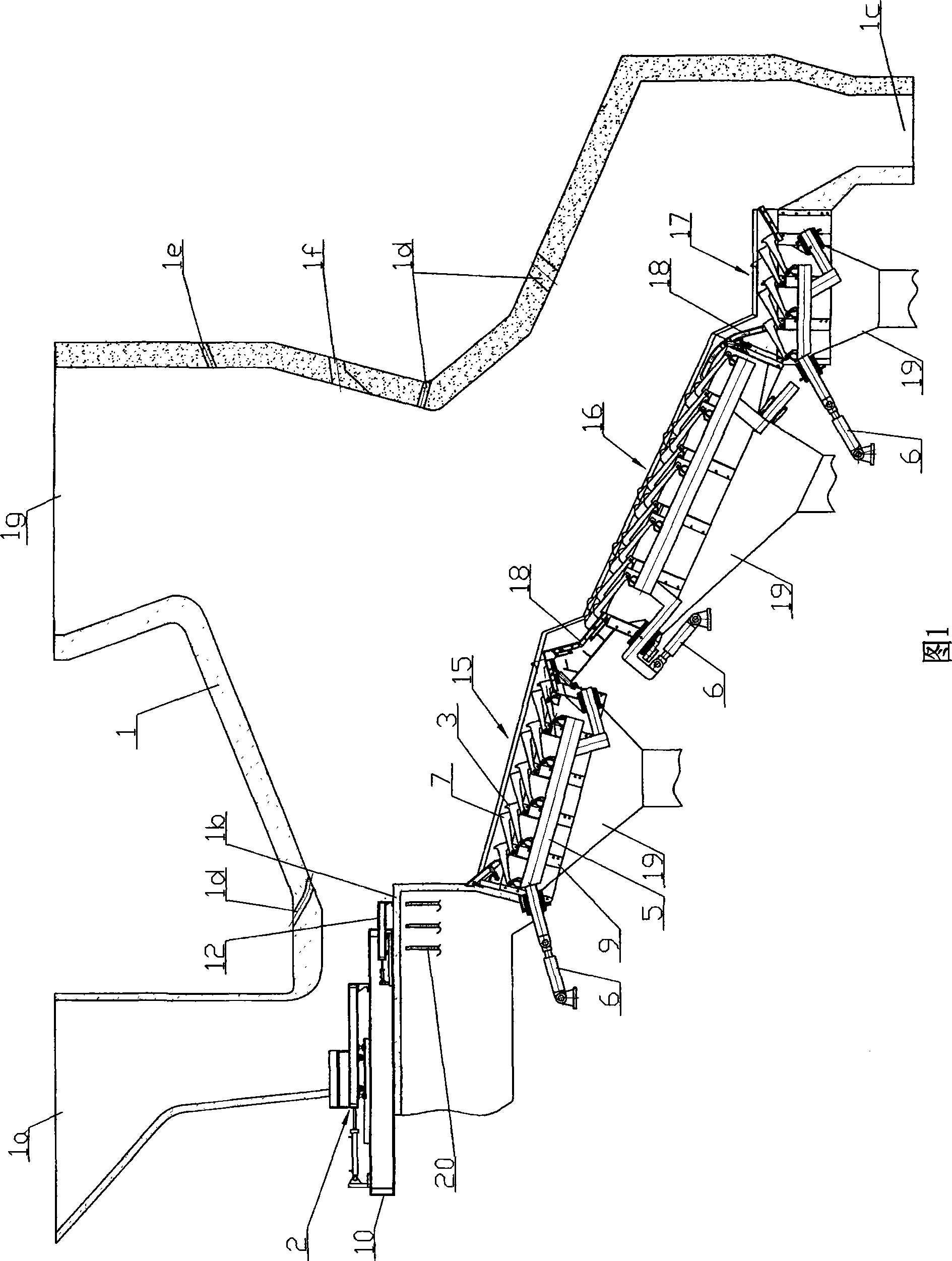

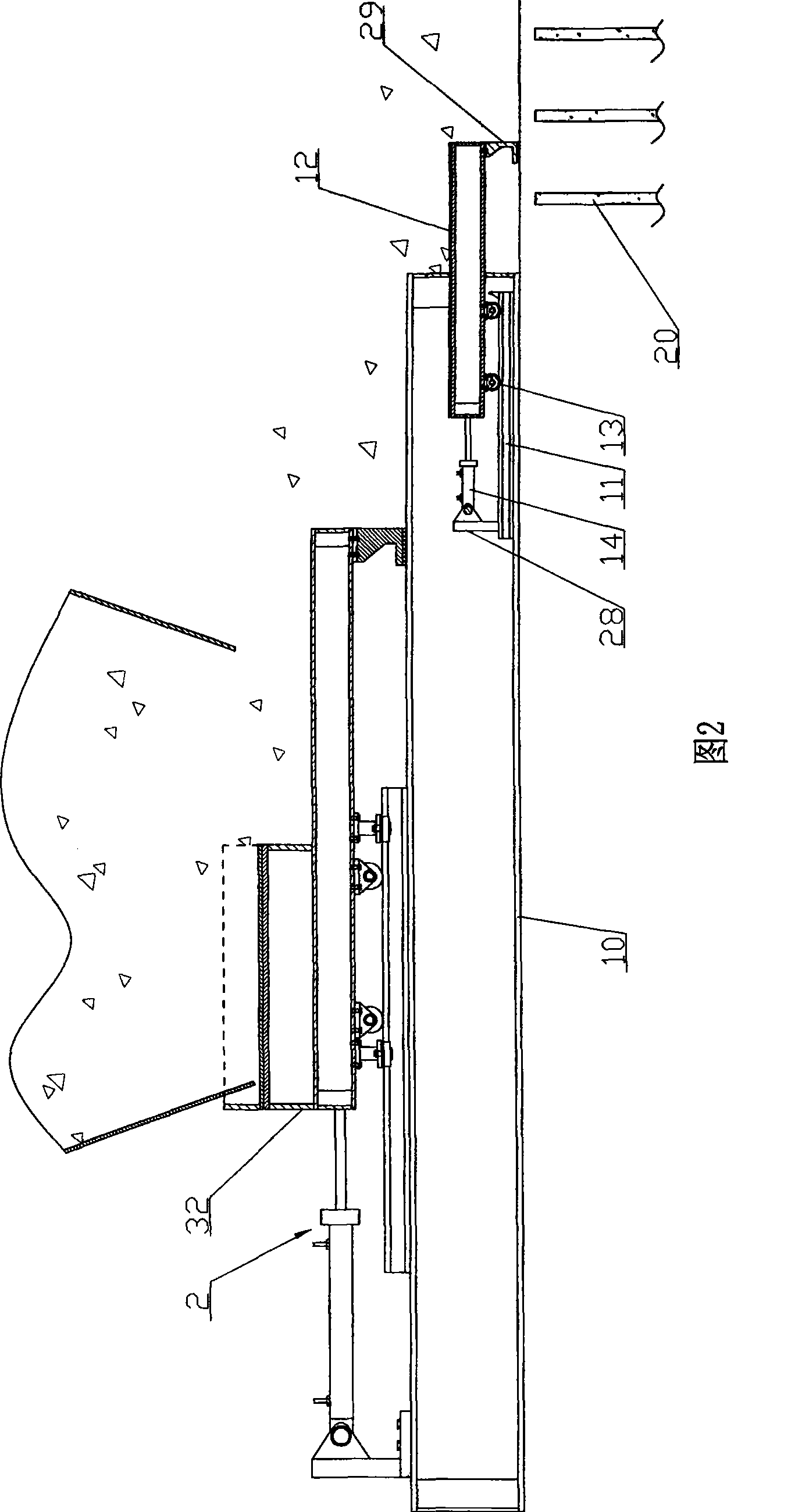

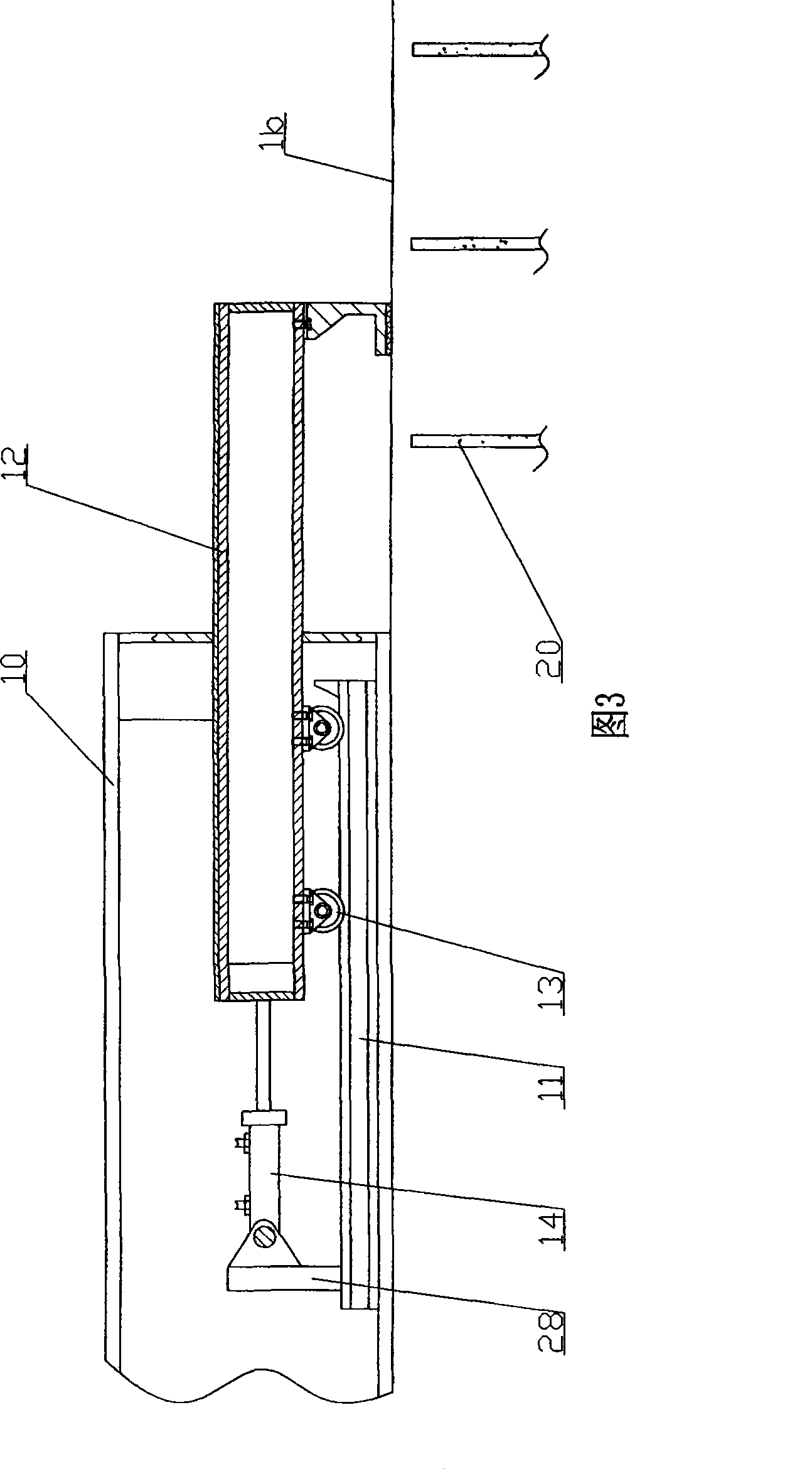

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

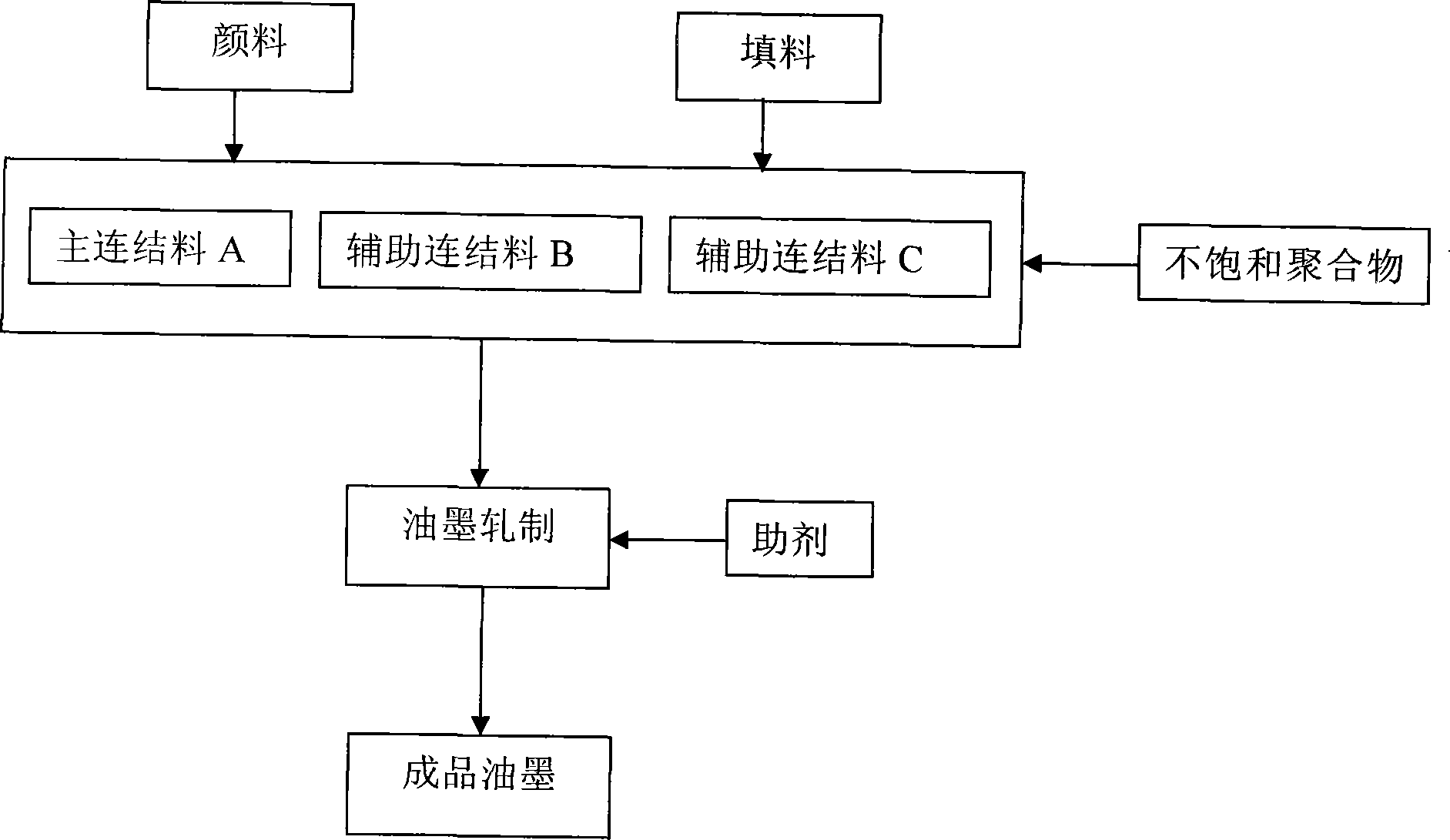

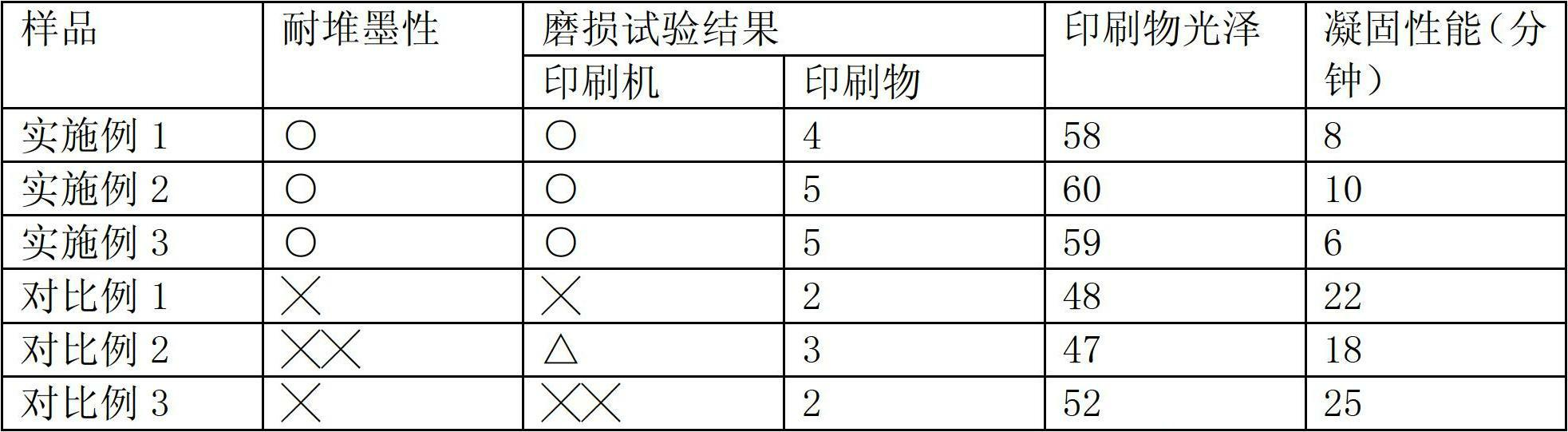

Soybean oil based protruding printing ink

ActiveCN101250350AImprove rheologyIncrease elasticityInksOther printing apparatusVegetable oilLetterpress printing

The invention relates to soybean oil base letterpress printing ink, which adopts modified phenolic with high viscosity and high dissolving ability, prepares resin oil through matching soybean oil with Chinese wood oil, regulates acid value with alkyd resin to improve appropriate hydrophilicity, uses gelatinizing agent to improve the rheological property of resin oil and increase elasticity, uses unsaturated polymer which can dissolve with vegetable oil to provide extra drying property as bonding material of printing ink. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, and has the advantages of small VOC content, low heavy metal content, excellent printability, set stability and processability after printed.

Owner:CHINA BANKNOTE PRINTING & MINTING

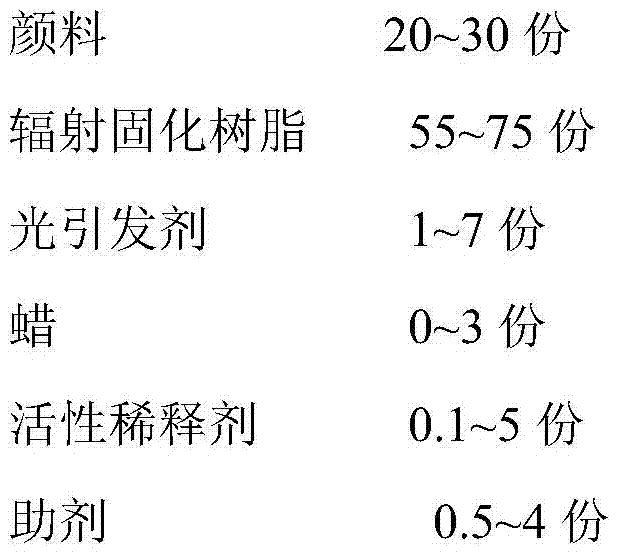

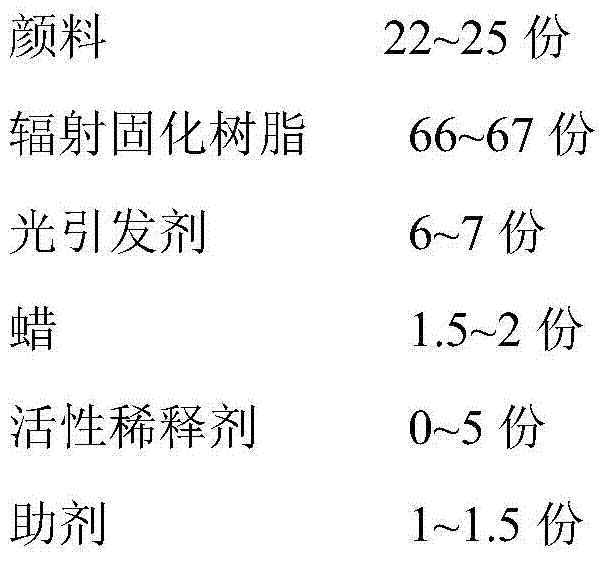

Ultraviolet light-cured offset printing ink with LED as light source

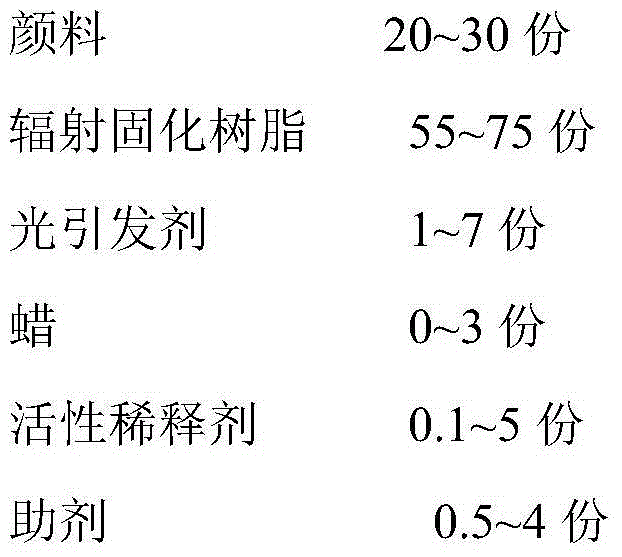

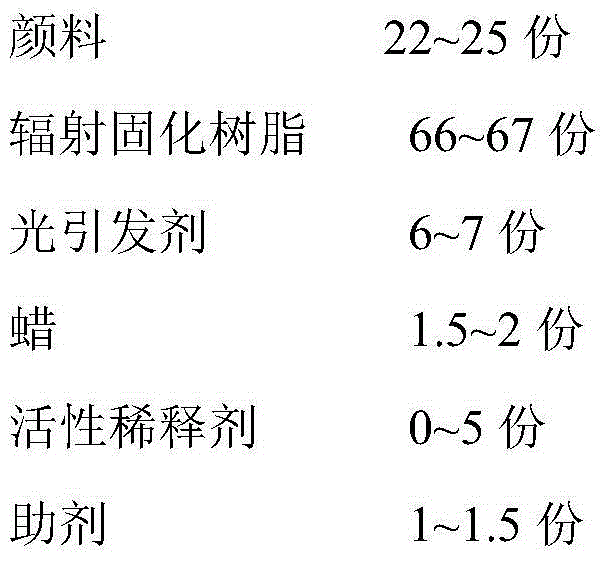

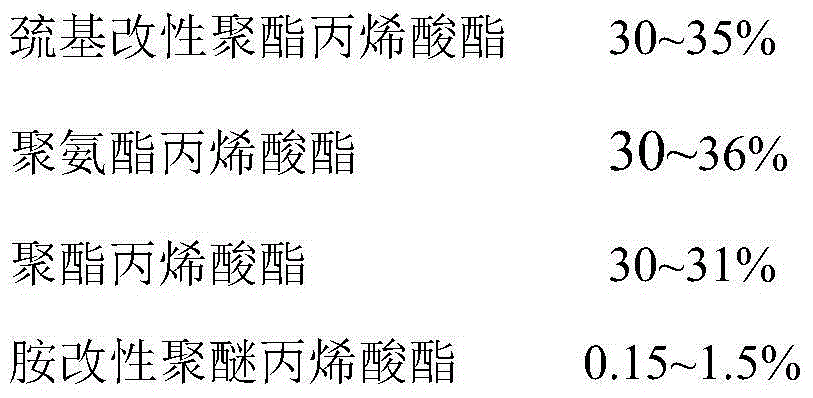

The invention discloses an ultraviolet light-cured offset printing ink with LED as a light source. The ultraviolet light-cured offset printing ink comprises, by weight, 20 to 30 parts of pigment, 55 to 75 parts of radiation-cured resin, 1 to 7 parts of a photoinitiator, 0 to 3 parts of wax, 0.1 to 5 parts of an active diluent and 0.5 to 4 parts of an auxiliary agent. The UV-LED light-cured printing ink has the following characteristics: the printing ink is applicable to offset printing; electric energy consumed in curing is about 1 / 4 of electric energy consumed by a common ultraviolet lamp; emission of CO2 is substantially reduced; ozone is not generated; etc. The printing ink is completely dried under the printing condition of a curing speed of 40 to 200 m / min and enables printed lines to be clear; and after curing, each performance index (adhesion, friction resistance, chemical resistance and the like) of the printing ink accords with requirements on printing of securities.

Owner:CHINA BANKNOTE INK +1

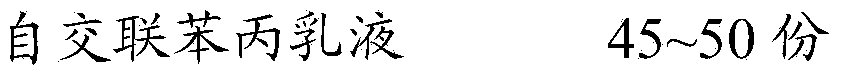

Waterborne ink and preparation method thereof as well as application of waterborne ink in PP (Polypropylene) decorative film

ActiveCN104371420ADry completelyGood reproducibilitySpecial ornamental structuresInksPolymer scienceSolvent based

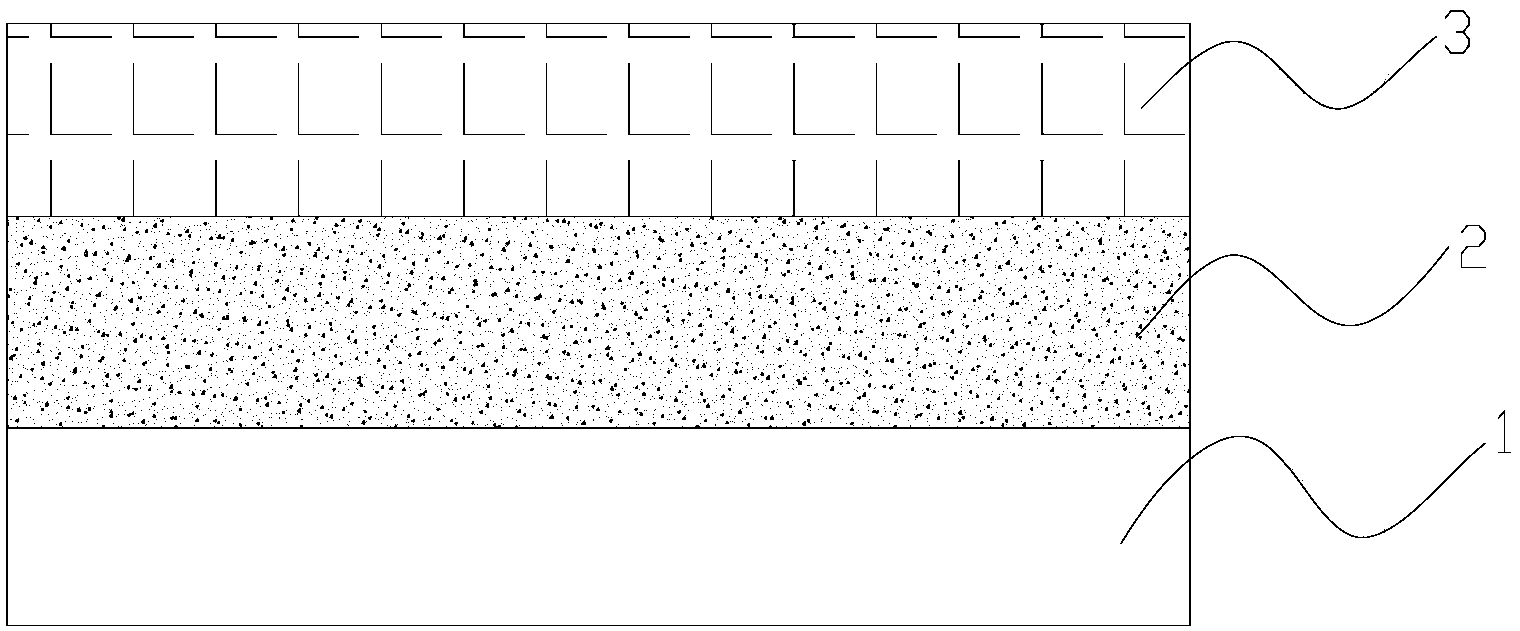

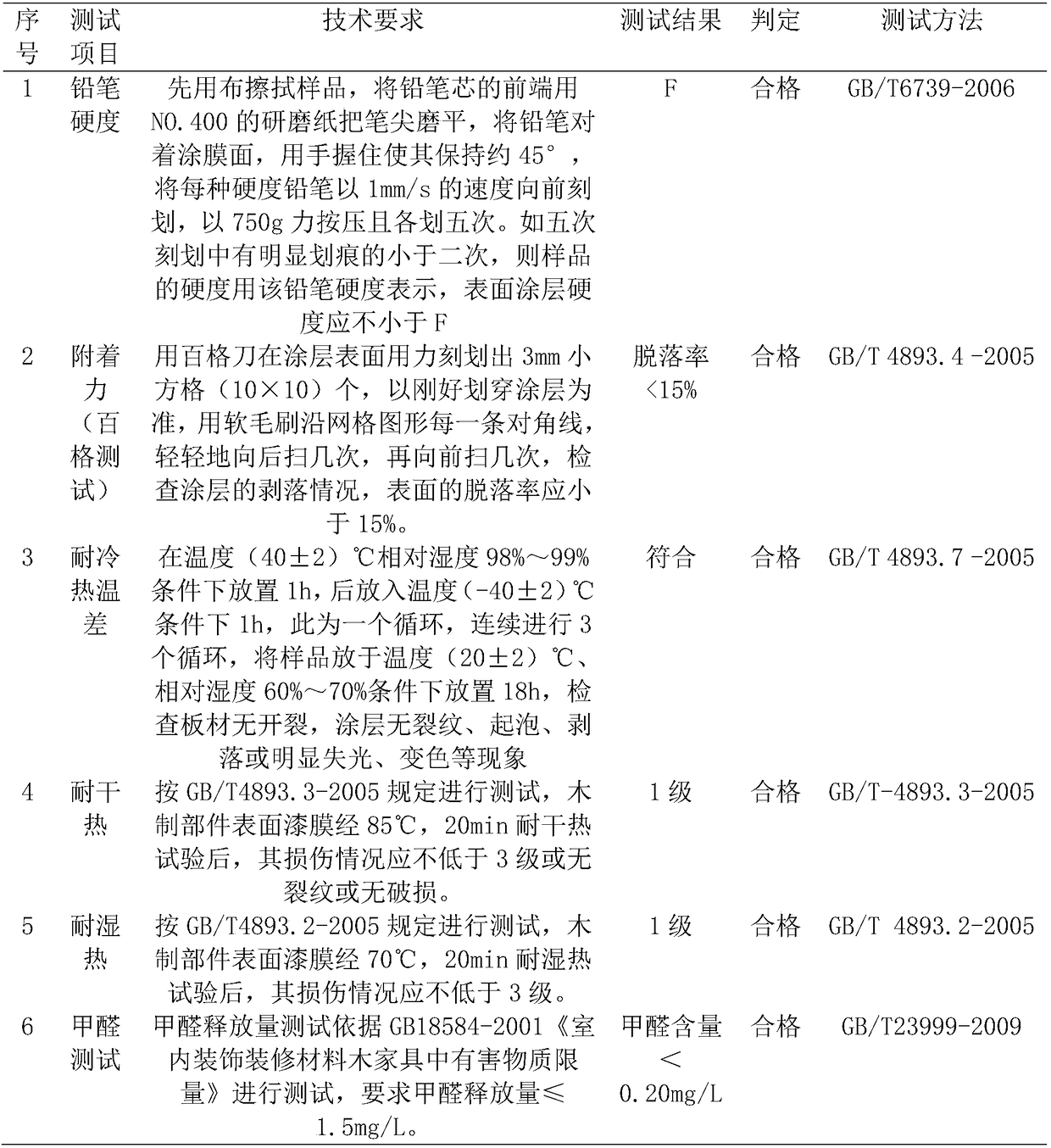

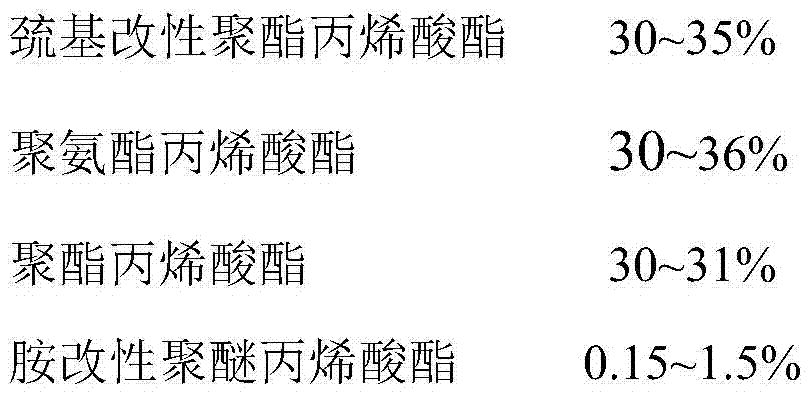

The invention discloses a waterborne ink and a preparation method thereof, application of the waterborne ink in a PP (Polypropylene) decorative film and a preparation method of the PP decorative film. The preparation method of the waterborne ink comprises the following process steps: a, preparing mill base; b, grinding; and c, blending ink. The PP decorative film sequentially comprises a PP substrate layer, a waterborne ink printing layer and a varnish coating layer from bottom to top. The preparation method of the PP decorative film comprises the following process steps: 1) carrying out polarity treatment on the surface of the PP film; 2) preparing the waterborne ink; 3) printing the waterborne ink; 4) glazing and coating; and 5) embossing. By integrating the selection of materials and optimization of the process, the PP decorative film reaches the printing effect of a solvent-based ink, the printed product has no water mark, the texture is shallow and clear, natural and realistic and the PP decorative film is non-toxic and odorless and has excellent performances such as light resistance, scratch resistance, wear resistance, disinfection and sterilization; the preparation method is convenient and feasible in production processes, simple to operate and low in production cost, and is prone to industrial production.

Owner:佛山市南海天元茂新新材料有限公司

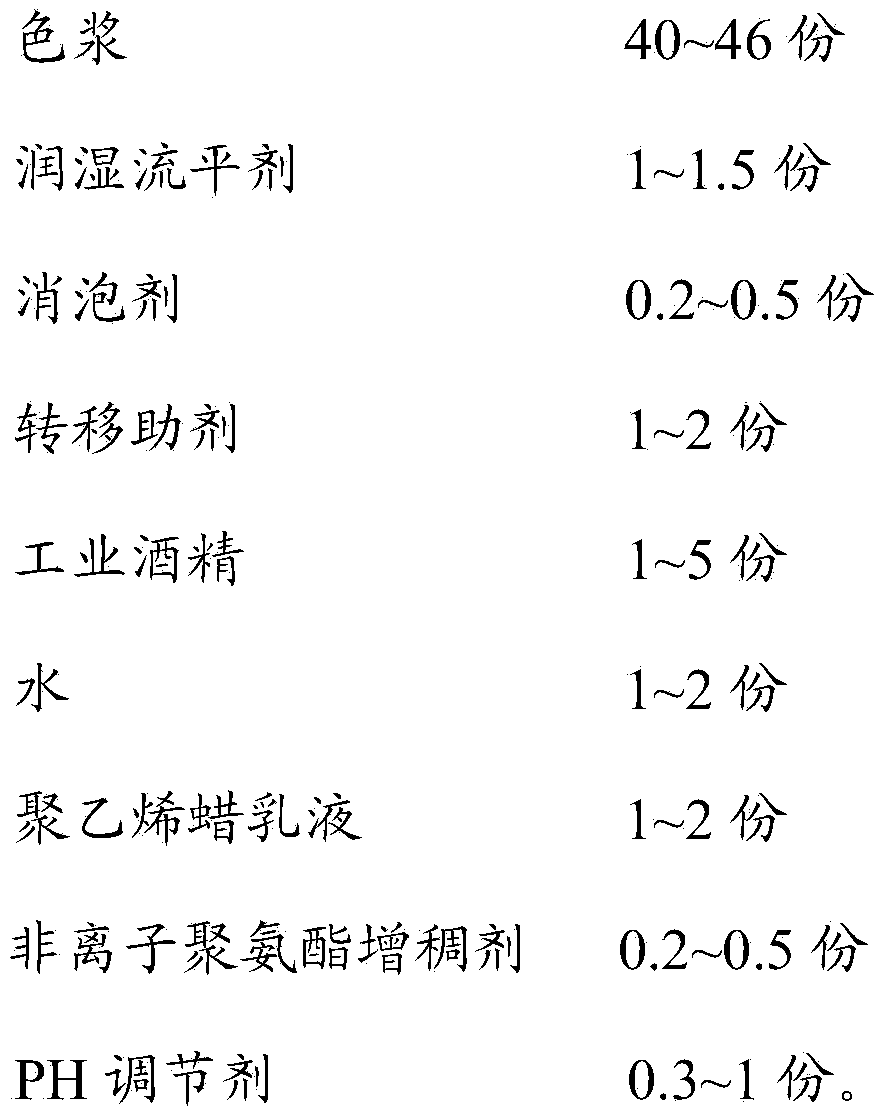

Soybean oil based silk-screen ink

ActiveCN101250351AEasy to identifyReduce harmful effectsInksOther printing apparatusScreen printingLetterpress printing

The invention relates to soybean oil base silk screen printing ink, which is formed by bonding material A, auxiliary bonding material B and auxiliary bonding material C, which have different effects. Printing ink proportion can be randomly regulated when in use, the auxiliary bonding material B and auxiliary bonding material C can be used to regulate ink property, and silk screen printing ink which meets the requirements can be produced through singly adding or adding by mixing in bonding material according to different printers. The printing ink replaces petroleum solvent with soybean oil, solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, and has the advantages of anti-counterfeiting, environment-friendly, excellent printability, extensive application range and prominent materialization index.

Owner:CHINA BANKNOTE PRINTING & MINTING

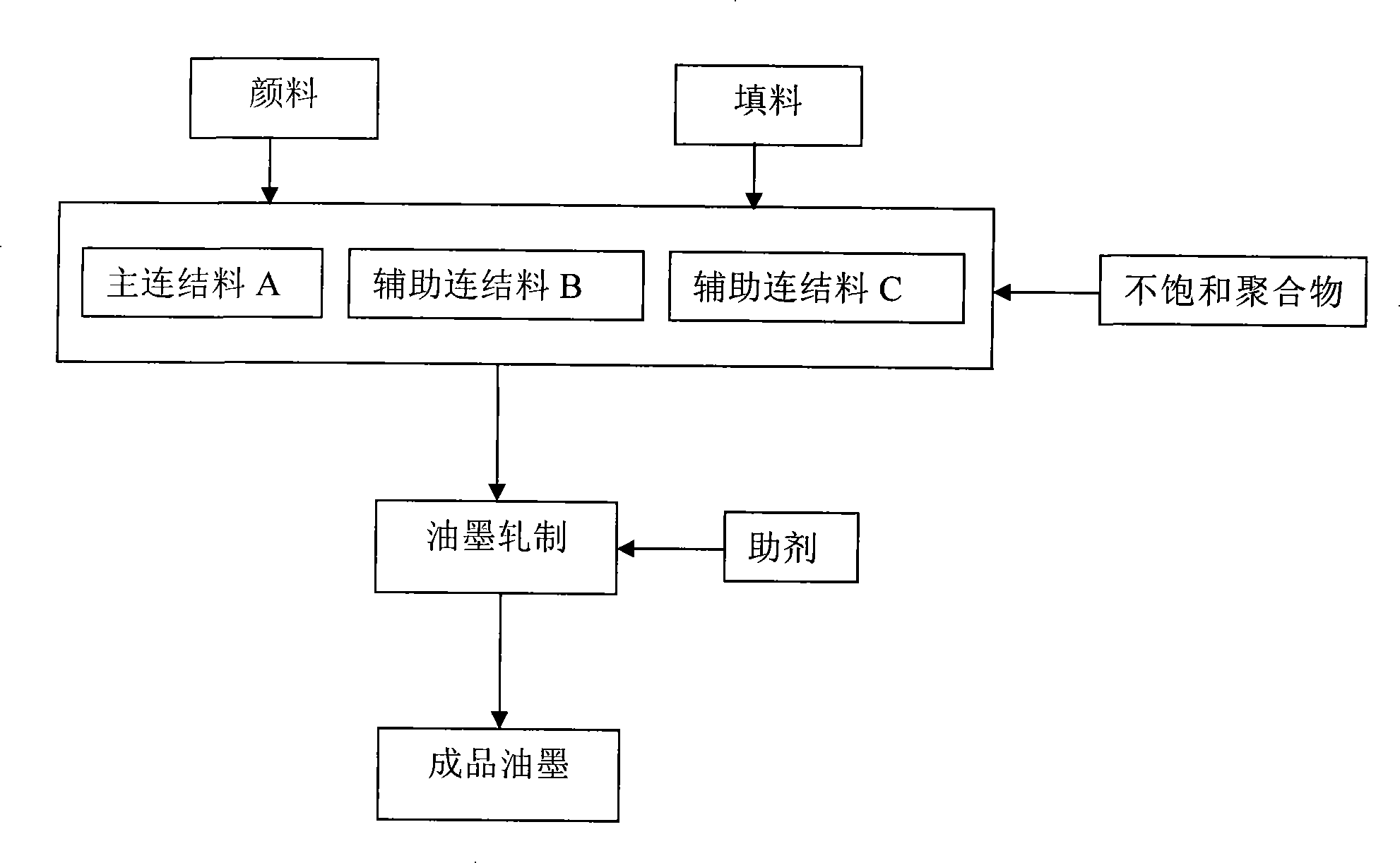

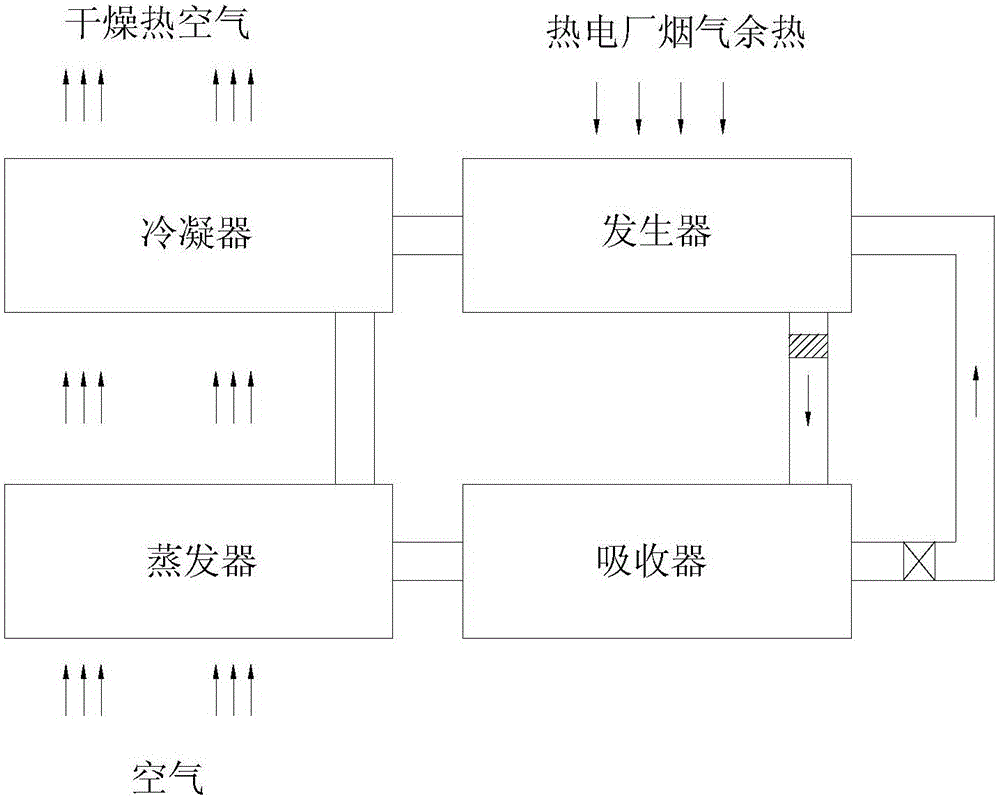

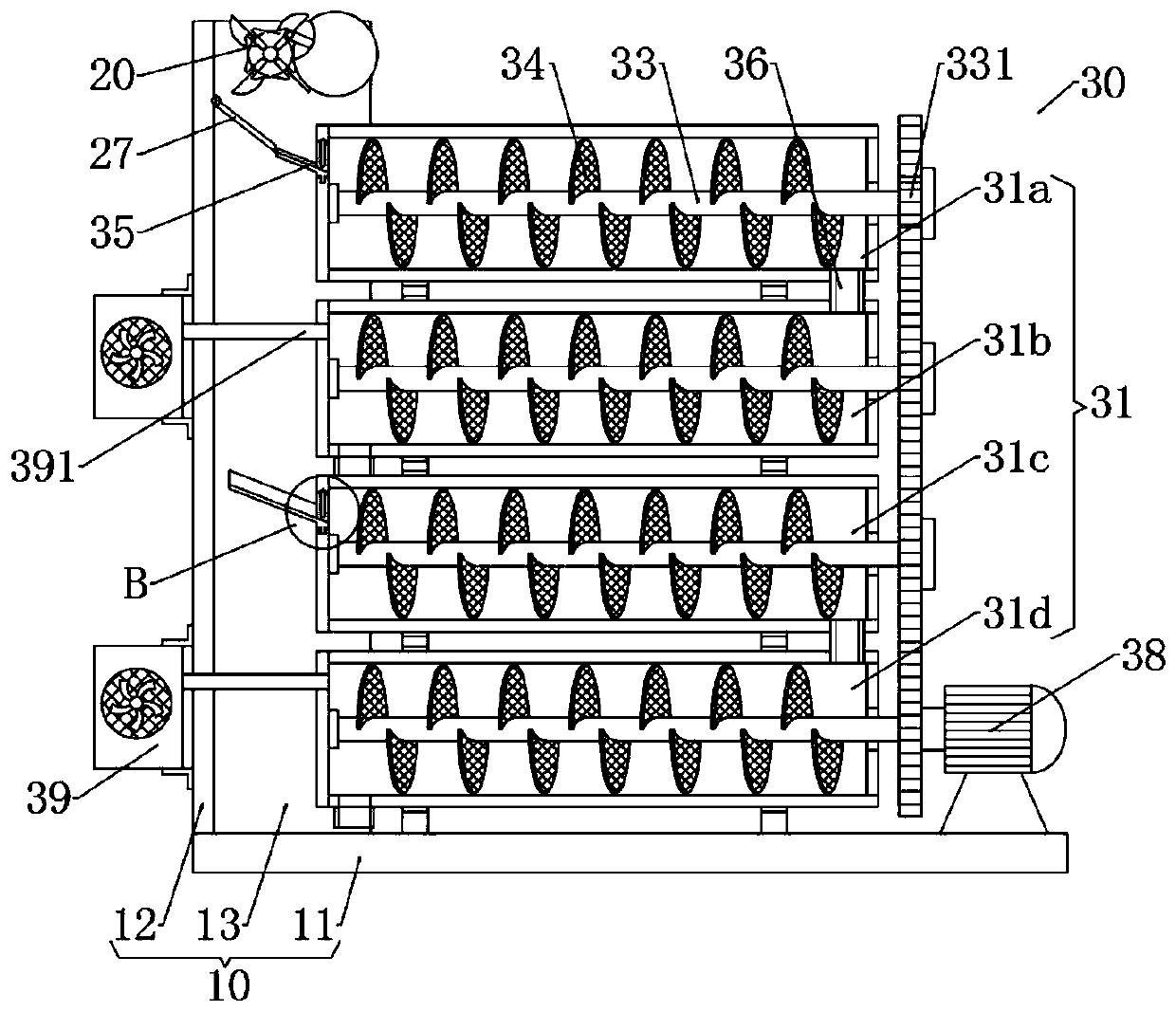

Method and device for drying sludge by utilizing thermal power plant waste heat

InactiveCN105859097ASuitable for dryingSimple technical meansSludge treatment by de-watering/drying/thickeningDispersed particle filtrationSludgeFlue gas

The invention discloses a sludge drying method combined with waste heat utilization in a thermal power plant and a device thereof, comprising a plate-type feeding conveyer belt and a plate-type discharge conveying belt in which a furnace is arranged in the furnace; From top to bottom, there are multiple layers of middle-layer plate conveyor belts; each layer of middle-layer plate conveyor belts divides the internal airflow channel of the furnace into an S-shaped airflow channel; the drying wind presents an S-shaped flow trajectory in the furnace under the action of their diversion. Circuitous flow; the sludge rolls down from the end of the plate feed conveyor belt to the plate type middle layer conveyor belt of the first layer, and then rolls down from the end of the first layer plate type middle layer conveyor belt to the plate type discharge conveyor belt in turn, so that the sludge It moves in the furnace in an S-shaped trajectory from top to bottom, and is finally sent out by the plate-type discharge conveyor belt. The device can save a large amount of high-grade electric energy, and realize drying with low-grade flue gas waste heat, high efficiency, energy saving, environmental protection, high space utilization rate, and easy large-scale scale.

Owner:SOUTH CHINA UNIV OF TECH

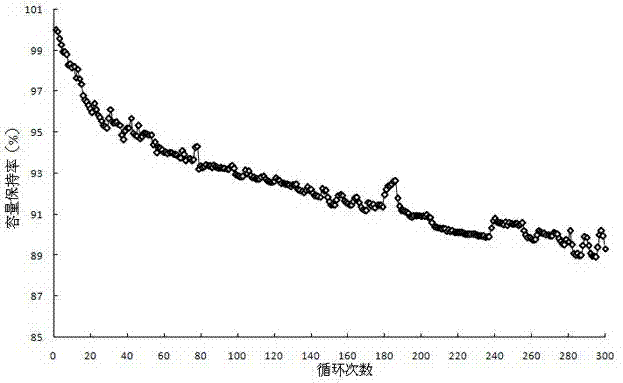

Preparation method for lithium iron phosphate positive electrode of lithium ion battery

ActiveCN104733689AImprove stabilityImprove consistencyElectrode manufacturing processesSolid componentLithium iron phosphate

The invention discloses a preparation method for a lithium iron phosphate positive electrode of a lithium ion battery. The preparation method overcomes the problems of uneasy dispersion of solid components and hard thorough drying of positive electrodes in preparation of lithium iron phosphate positive electrodes of lithium ion batteries in the prior art. The preparation method mainly comprises the following steps: (1) weighing materials; (2) preparation of a premix; (3) primary dispersion; (4) secondary dispersion; (5) slow stirring; (6) coating; and (7) drying in segments. The preparation method provided by the invention has the advantages of simple steps, uniform dispersion of each solid component in the process of preparation and thorough drying of pole pieces; and the battery prepared from the positive electrode has good electrochemical performance.

Owner:宁波维科新能源科技有限公司

Printing ink composition containing starch

The invention provides a printing ink composition containing starch. 2 to 2.5 weight parts of starch of which the fineness is 8 to 12 microns is added into 100 weight parts of printing ink; and the printing ink containing starch comprises the following components in percentage by weight: 9 to 15 percent of pigment, 40 to 45 percent of ester gum, 4 to 8 percent of acrylic resin, 18 to 20 percent of linseed oil or soybean oil, 20 to 25 percent of isopropanol and ethyl acetate mixture, and 3 to 8 percent of aid. Due to the adoption of the technical scheme, the obtained printing ink composition can effectively accelerate the drying speed of ink, solve the problems that printing matters are adhered to each other, and ensure that a printer has a normal printing speed; a product can be dried completely, and the phenomenon of set-off and the phenomenon that the products are adhered to be dimmed can be avoided; the product is high in glossiness; and the printing ink composition has the advantages of simple component, convenience in preparation and obvious effect.

Owner:TIANJIN QIAOYANG PRINTING

SapC-phosphatide nano vesicle freezed-drying preparation, and preparation method and application thereof

ActiveCN102614125ASimple processFreeze completelyNervous disorderPeptide/protein ingredientsChemistryIsopropyl alcohol

The invention, belonging to the field of biomedicine, relates to a SapC-phosphatide nano vesicle freezed-drying preparation and its preparation method and application. specifically, the preparation method of the SapC-phosphatide nano vesicle freezed-drying preparation comprises the following steps: 1)preparing a co-solution of SapC and phosphatide, wherein the co-solution comprises water and organic solvent, one or more organic solvents selected from 1-propyl alcohol, 2-propyl alcohol, methanol, tert-butyl alcohol, and acetonitrile; 2) carrying out vacuum freeze drying: carrying out vacuum freeze drying on the co-solution obtained by the step 1) to obtain the SapC-phosphatide nano vesicle freezed-drying preparation. The invention also relates to a SapC-phosphatide nano vesicle freezed-drying injection preparation. The SapC-phosphatide nano vesicle freezed-drying preparation disclosed herein has no need of high-temperature disinfection, and has uniform particle size and good stability.

Owner:CHANGZHOU CHANGJI BIOTECH DEV

Making method of dried pitaya peel fruit

InactiveCN107183296ALong storage timeGet the most out of your nutrientsConfectionerySweetmeatsFreeze-dryingDesorption

The invention relates to a making method of dried pitaya peel fruit. The method comprises the following steps of (1), pretreatment of a raw material: removing the peel of the pitaya, washing the peel by using distilled water, trimming, and slitting for later use; (2), sugar soaking: soaking the peel of the pitaya, which is subjected to the pretreatment, into a sugar alcohol solution, and treating by using an ultrasonic wave; (3), congealing: putting the peel of the pitaya, which is subjected to sugar soaking treatment, into a refrigerator for freezing until free water and bound water in the peel of the pitaya are both congealed; (4), sublimation drying: putting the peel of the pitaya, which is subjected to congealing treatment, into a vacuum freeze drier, and meanwhile, turning on a vacuum pump to extract air in the dryer; (5), desorption drying: putting the peel of the pitaya, which is subjected to the sublimation drying, into a freeze dryer, and meanwhile, turning on the vacuum pump, wherein the moisture of the freeze-dried peel is always maintained to be between 2 percent and 4 percent; further, the peel is subjected to collapse, coking and oxidation; (6), packaging: charging nitrogen for packaging the freeze-dried peel of the pitaya by using an aluminum foil-polyethylene material.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

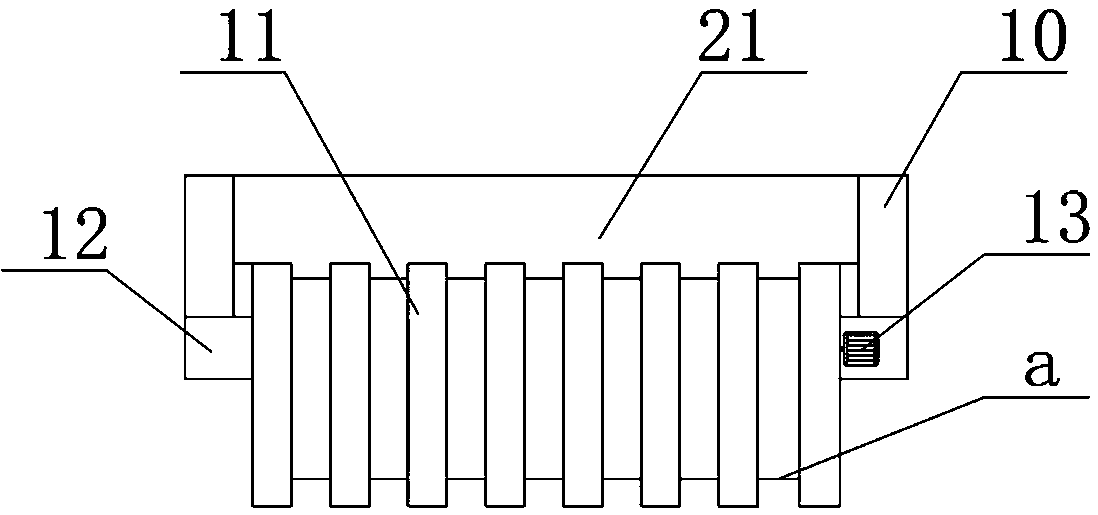

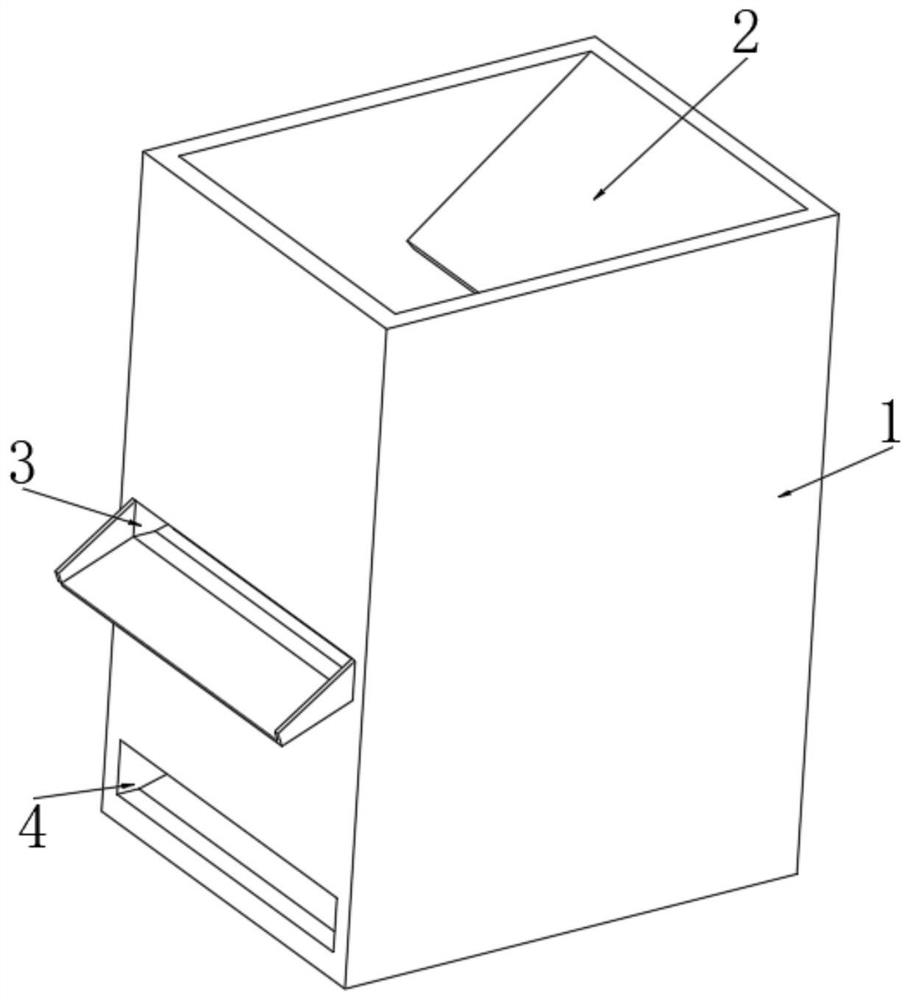

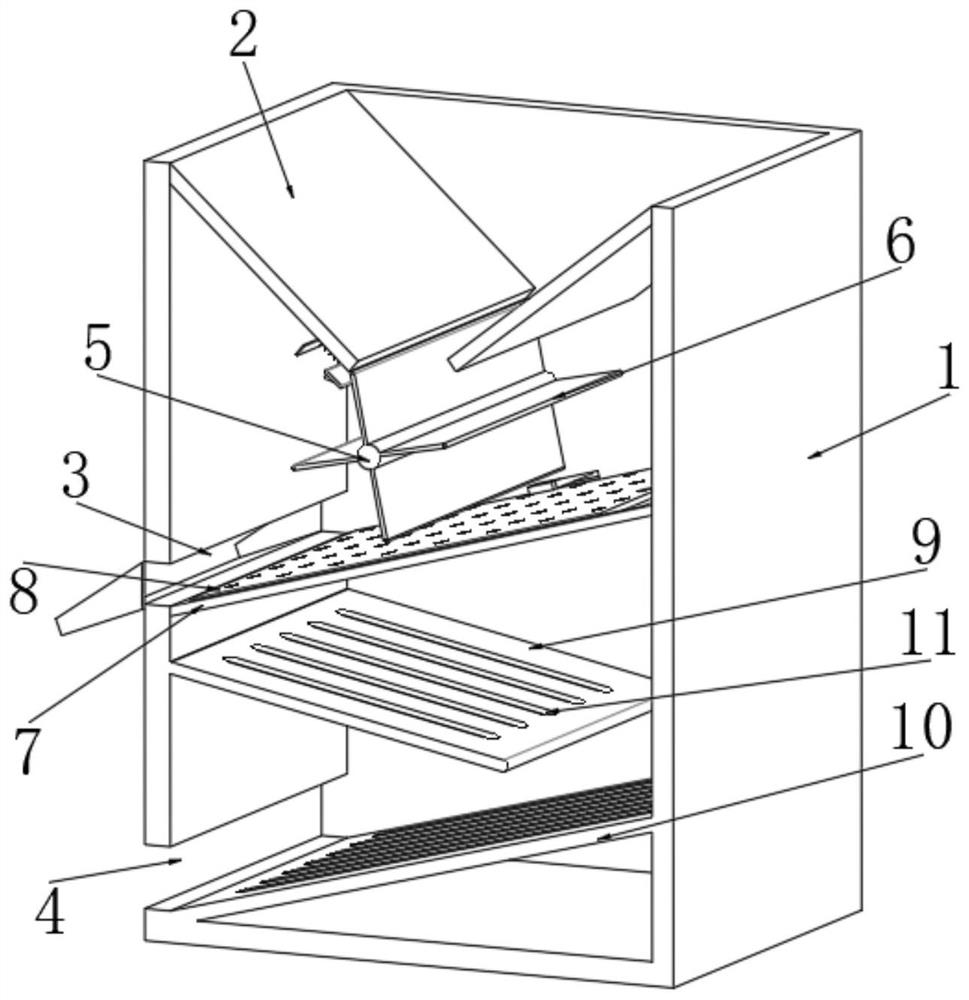

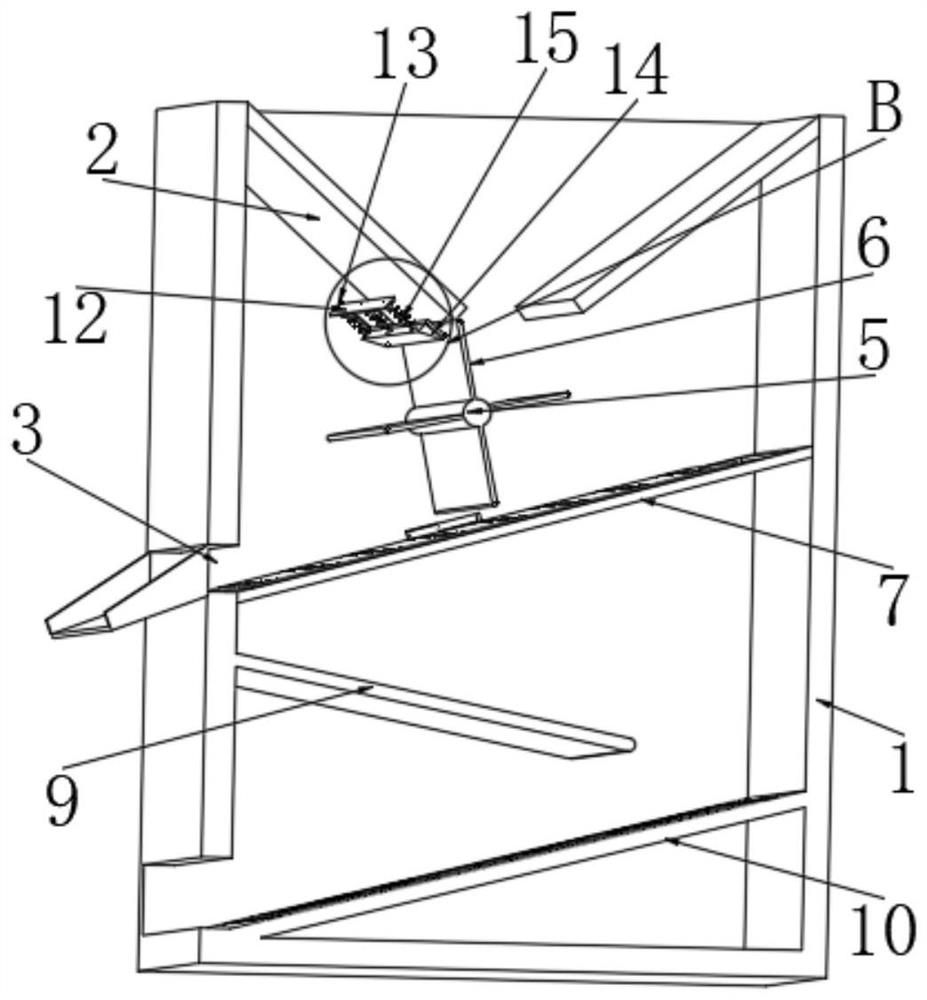

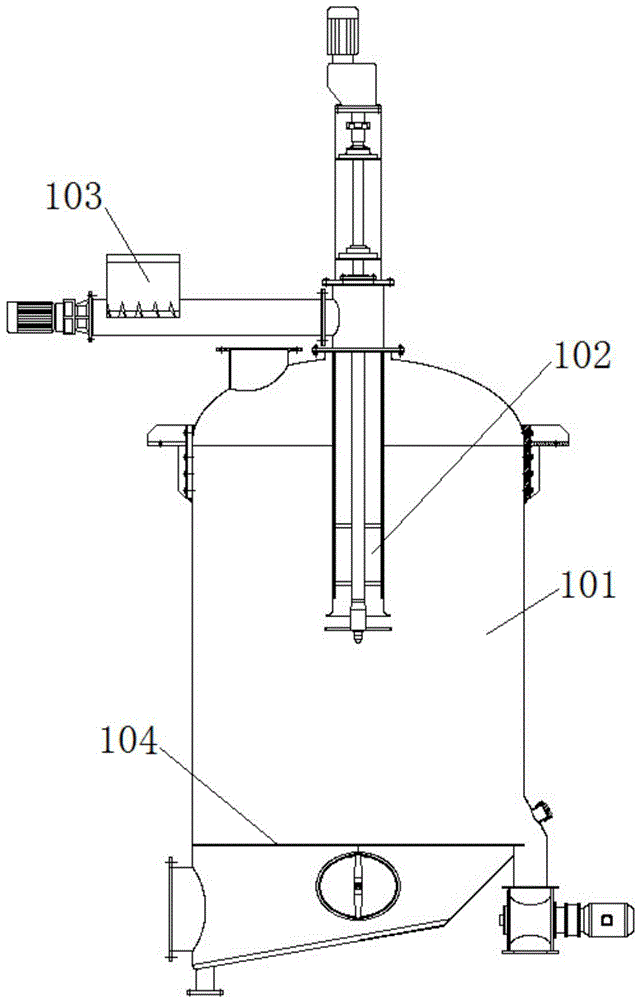

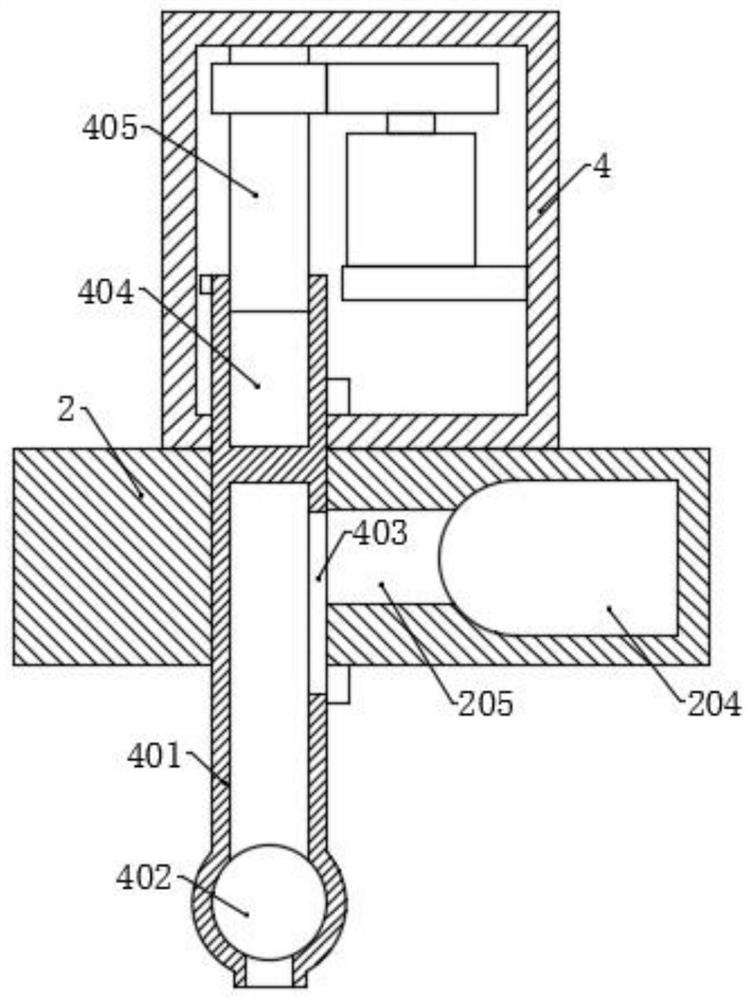

Drying device for plastic particles

InactiveCN108381811ADry evenlyDry completelyDrying gas arrangementsDrying solid materialsElectrical resistance and conductanceEngineering

The invention discloses a drying device for plastic particles. The drying device for the plastic particles comprises a box body; a material collecting groove is formed in the box body; discharging holes are formed in the bottom of the material collecting groove; first ventilation holes are formed in the side wall of the material collecting groove; a connection rod is fixedly arranged on the innersurface of the top of the box body; the edge of the material collecting groove is arranged on the connection rod in a sleeved manner; the lower end of the connection rod is provided with a stopping block; a compression spring is arranged between the stopping block and the material collecting groove; the compression spring is arranged on the connection rod in a sleeved manner, and one end of the compression spring is connected with the material collecting groove; the other end of the compression spring is connected with the stopping block; a vibration motor is arranged on the outer surface of the material collecting groove; a stirring mechanism is arranged in the material collecting groove; an unloading plate is arranged below the material collecting groove; the unloading plate is providedwith second ventilation holes; the bottom of the box body is provided with an air inlet; the air inlet is internally provided with an air blower and a heating resistance wire; and a switching mechanism capable of opening and closing the discharging holes is arranged below the material collecting groove. According to the drying device for the plastic particles, when hot air is blown out of the airblower, the stirring mechanism performs stirring on the plastic particles, uniform drying of the plastic particles is promoted, and automatic unloading can be achieved.

Owner:苏州市丽苏塑胶科技有限公司

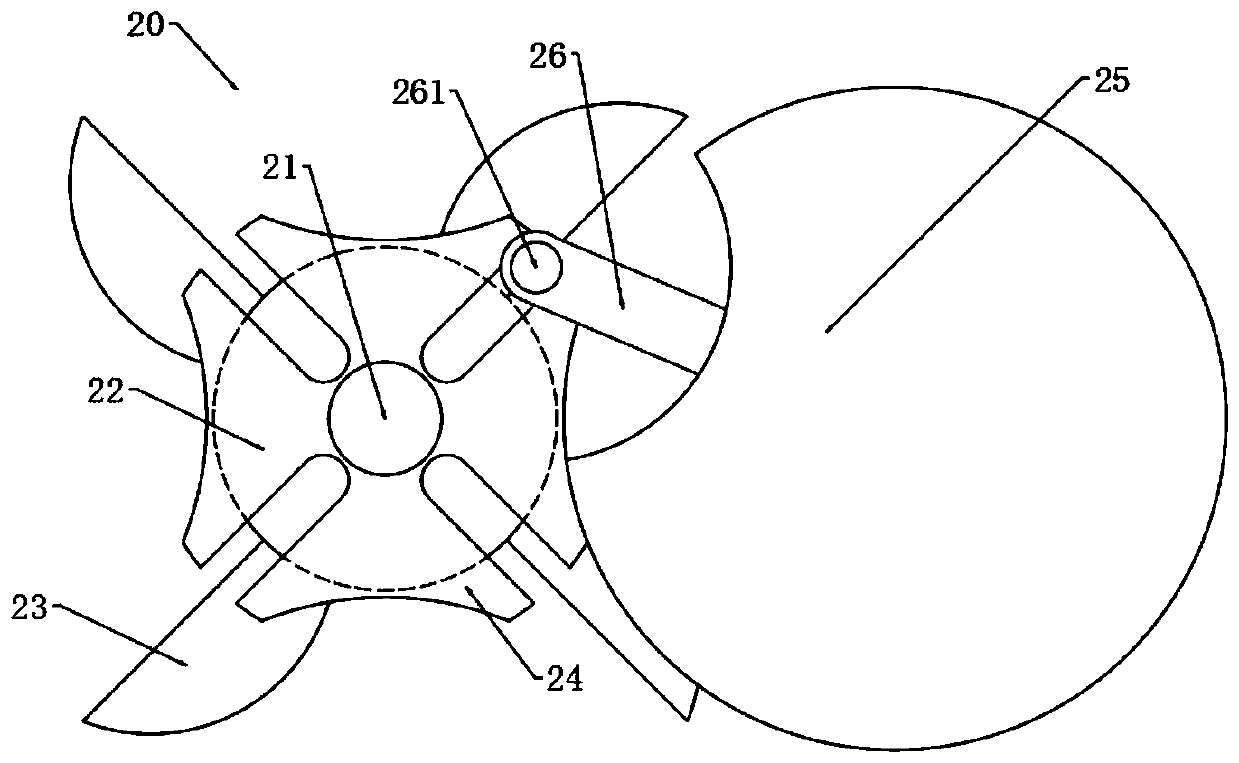

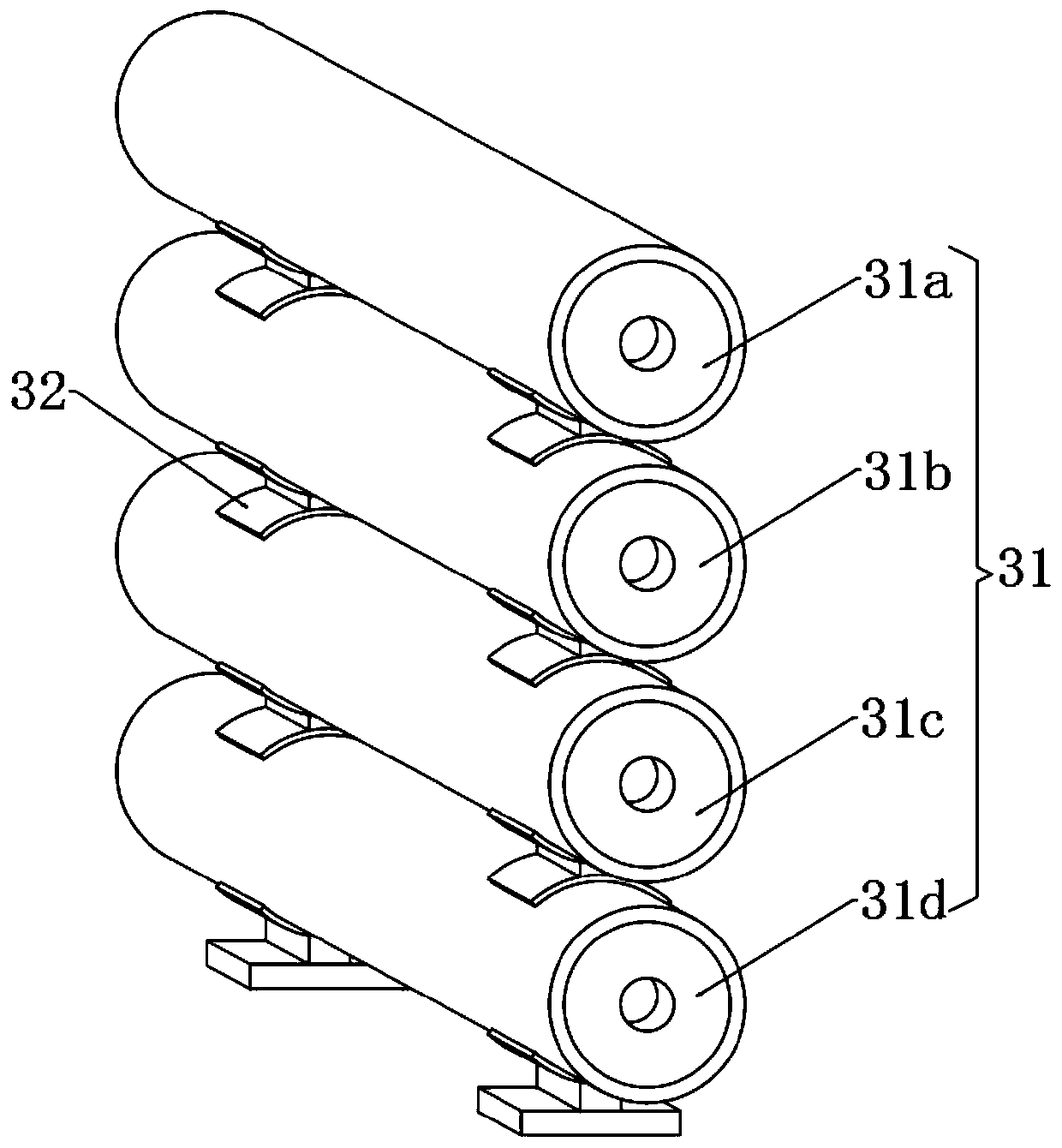

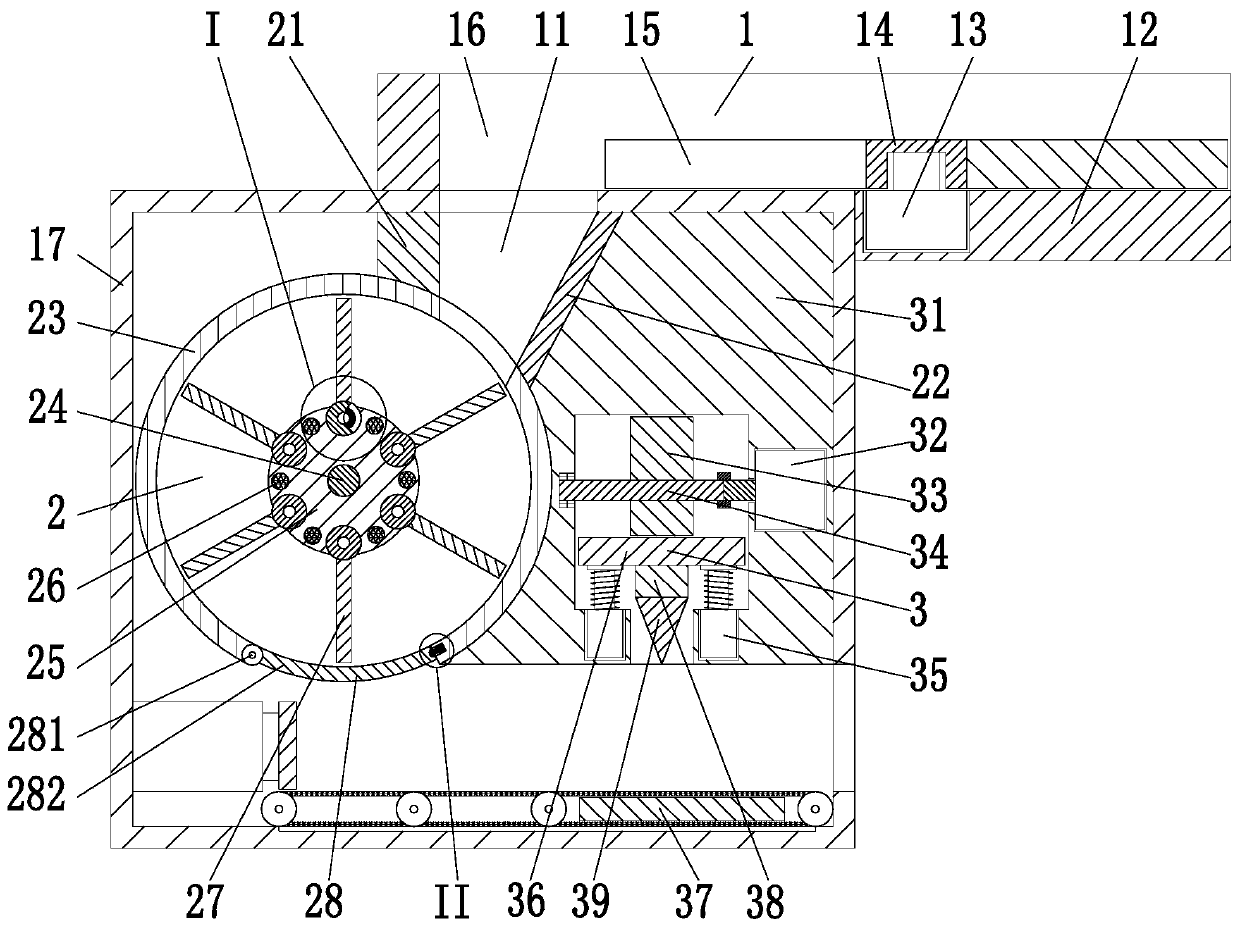

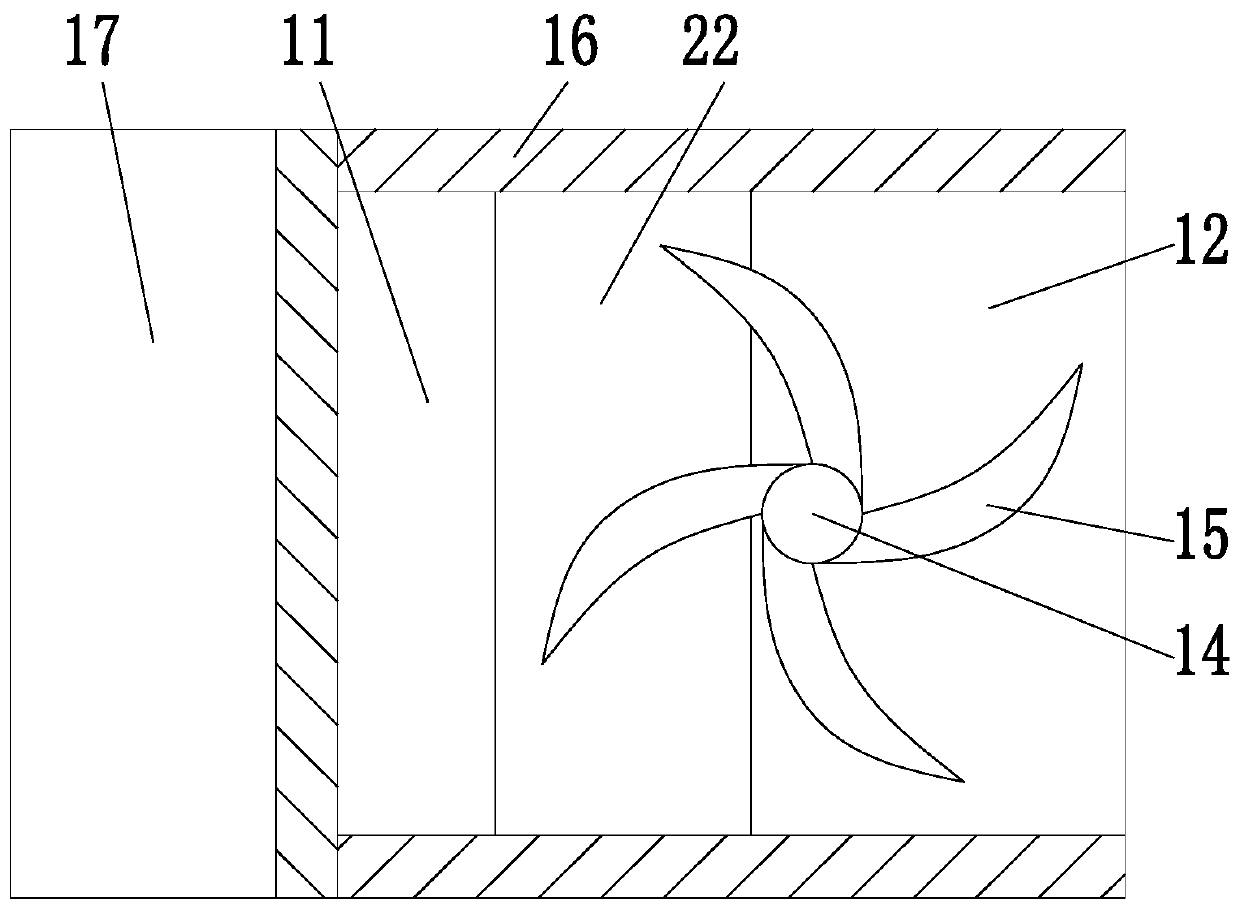

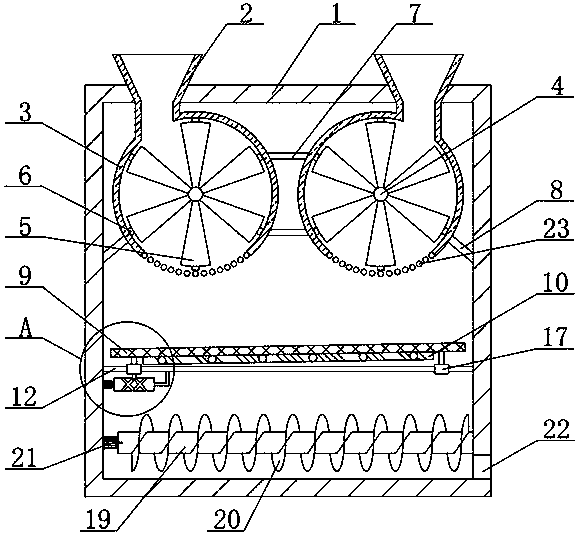

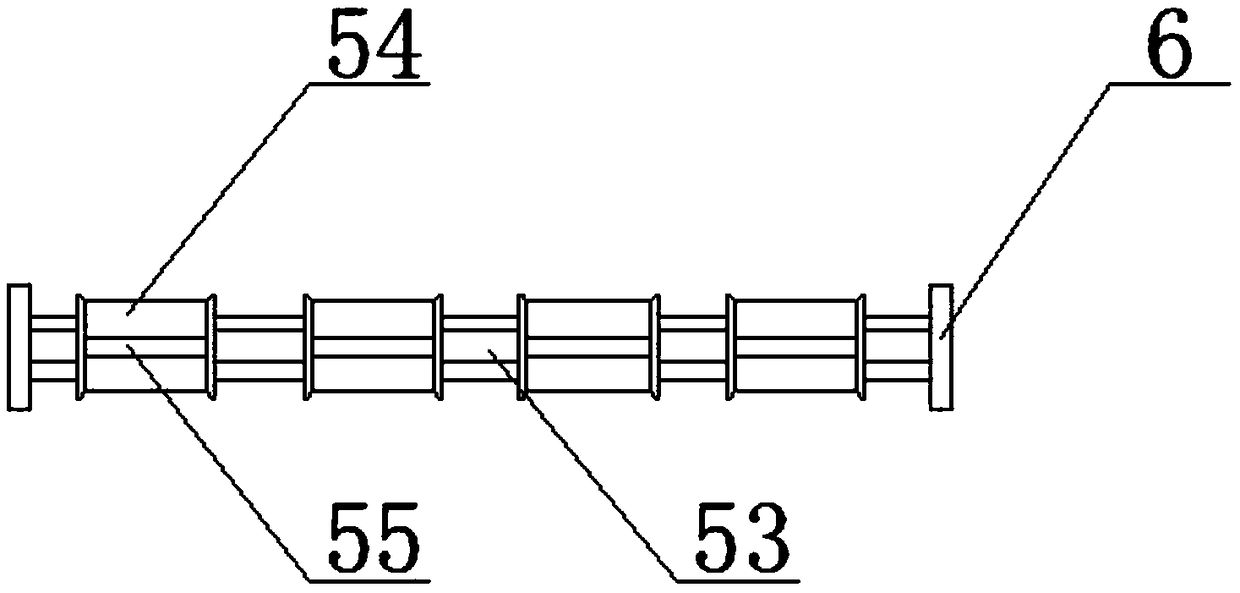

Automatic particle plastic dehumidification drying system and technology

ActiveCN111504042AReduce drying loadExtension of timeDrying solid materials without heatDrying gas arrangementsAir blowerMechanical engineering

The invention relates to an automatic particle plastic dehumidification drying system and technology. The automatic particle plastic dehumidification drying system comprises a pedestal, a material distributing device and a drying device, wherein the material distributing device and the drying device are installed on the pedestal. The drying device comprises drying cylinders which are horizontallyarranged. Rotating shafts extending in the length directions of the drying cylinders are formed in the corresponding drying cylinders. Screw blades which are distributed in the length directions of the rotating shafts are arranged on the outer walls of the rotating shafts. According to the automatic particle plastic dehumidification drying system and technology, a grooved wheel is used for drivinga material receiving groove to rotate intermittently, and plastic particles are sequentially guided into the different drying cylinders through a material guide plate; and meanwhile, the plastic particles are subjected to primary dehumidification with feeding mechanisms at feeding inlets of the drying cylinders, and drying loads of the drying device are lowered. By means of the automatic particleplastic dehumidification drying system and technology, the screw blades are used for conveying the plastic particles, the plastic particles enter the next set of the drying cylinders through a firstcommunicating pipe, the time for the plastic particles to stay in the drying cylinders is prolonged, a hot-air blower is used for blowing reverse hot air into the drying cylinders, the contact area ofthe hot air and the plastic particles is increased, the contact time of the hot air and the plastic particles is prolonged and hence drying is made more thorough.

Owner:山东华鹏高分子材料有限公司

Water-based paint drying method

The invention discloses a water-based paint drying method. The drying process of the water-based paint is as follows, firstly, microwave drying is carried out, then infrared and hot air mixed drying is carried out, wherein the microwave drying temperature is 25-80 DEG C, and the drying time is 5-120 minutes; and the temperature of the infrared and hot air mixed drying is 25-80 DEG C, and the drying time is 5-120 minutes. According to the method, the microwave drying is carried out firstly, then the infrared and hot air mixed drying is adopted, so that water in the paint film of the water-basedpaint is discharged from the inside to the outside, the water-based paint is dried from inside to outside, and then from the surface to the inside, so that the water-based paint can be rapidly dried,the drying period is shortened, plates are not easy to crack, and the drying is complete.

Owner:JOMOO KITCHEN & BATHROOM

Microwave assisted fluidized cold wind drying method

InactiveCN105767849AShorten cold air drying timeImprove cold air drying efficiencyFood preservationThird phaseCarbon dioxide

The present invention relates to a microwave assisted fluidized cold wind drying method. The cold wind drying method includes the following four steps: a cleaning pretreatment, a first phase fluidized cold wind drying, a second phase fluidized microwave and fluidized cold wind combined drying, and a third phase fluidized and cold wind drying. The advantages are as follows: the method enables the food materials to be more even in heat and mass transfers in the drying process, the microwave-assisted cold wind drying is used, and the method solves the problems that the traditional cold wind drying time is long and the efficiency is low. At the same time, carbon dioxide is used as a drying medium, the oxidative browning caused by contact of food and air during the drying processes is effectively avoided, and the drying quality of the food is improved.

Owner:SHANGHAI OCEAN UNIV

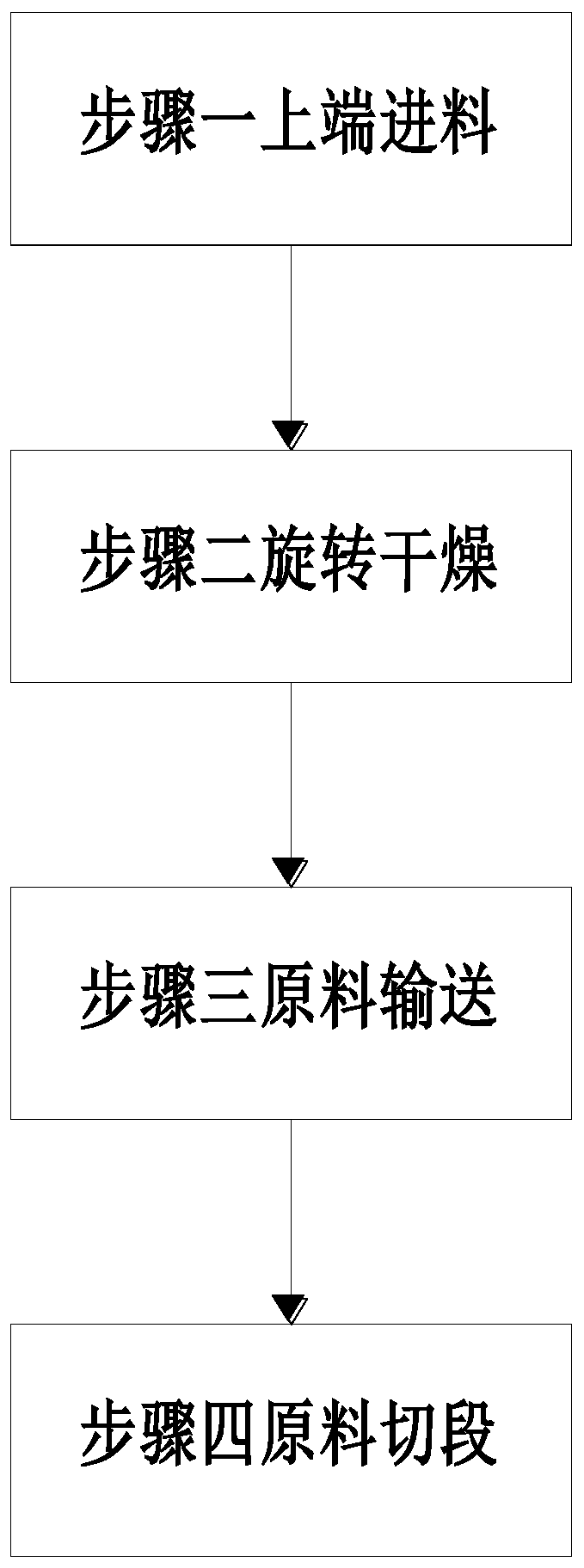

Drying dehydration treatment process for vegetable processing and making

InactiveCN111296553ADry completelyImprove drying rateMetal working apparatusFruits/vegetable preservation by dehydrationVegetable processingProcess engineering

The invention relates to a drying dehydration treatment process for vegetable processing and making. The drying dehydration treatment process for vegetable processing and making adopts the following processing, drying and dehydration treatment equipment. The processing, drying and dehydration treatment equipment comprises a conveying device, a drying and dehydration device and a sectioning device;and the drying and dehydration device is installed on the lower side of the conveying device, and the sectioning device is installed on the lower side of the drying and dehydration device. The invention can be solve the problems that existing drying dehydration treatment processes for vegetable processing and making generally adopt tiled air-drying treatment, the vegetable leaf processing and drying efficiency is low due to the fact that the air-drying treatment time in vegetable leaf stacking is long, existing drying dehydration treatment processes for vegetable processing and making directly store vegetable leaves after air-drying treatment is completed, consequently, the vegetable leaves are different in size, and the storage and follow-up sub-packaging difficulty is large.

Owner:罗嘉宇

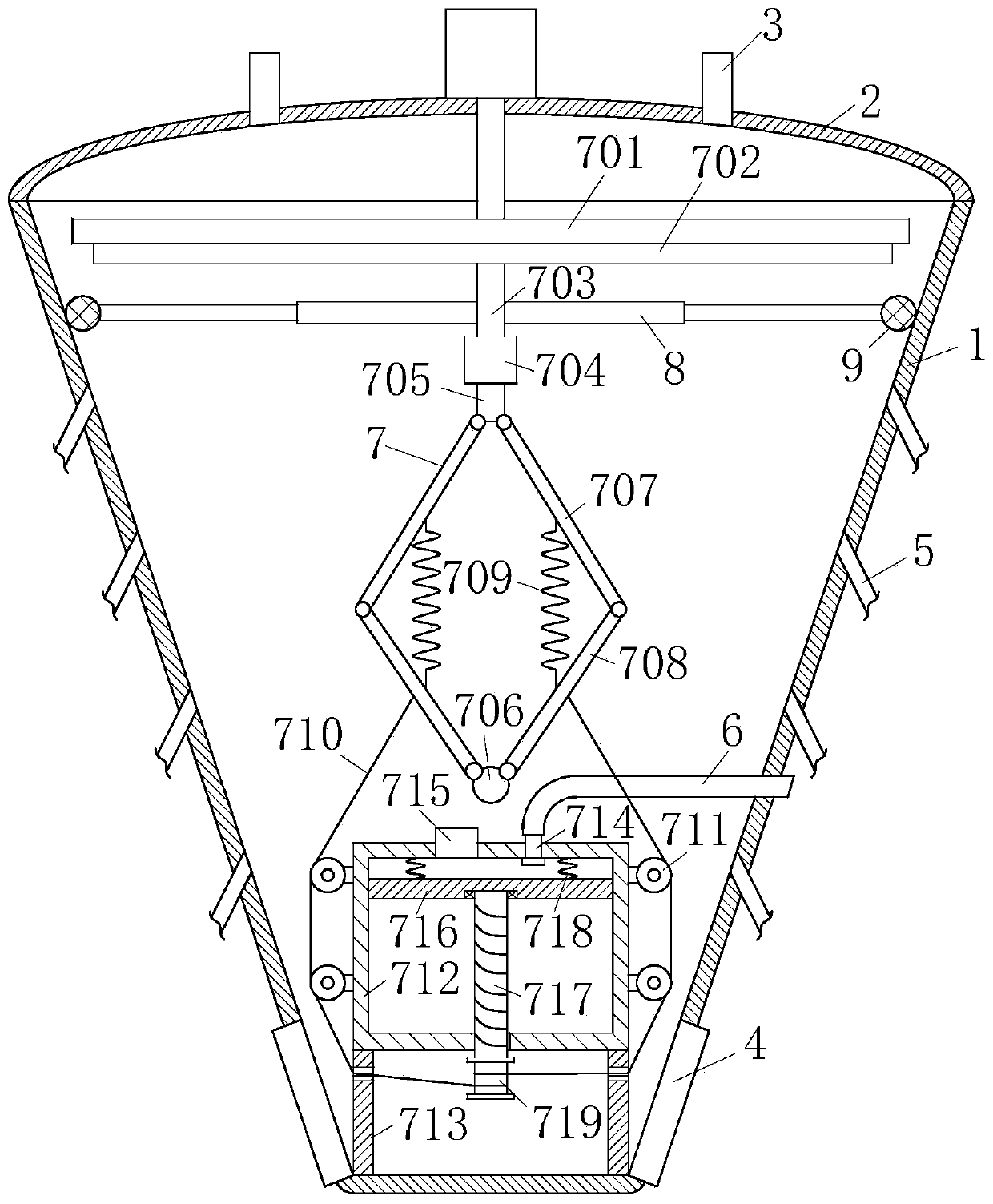

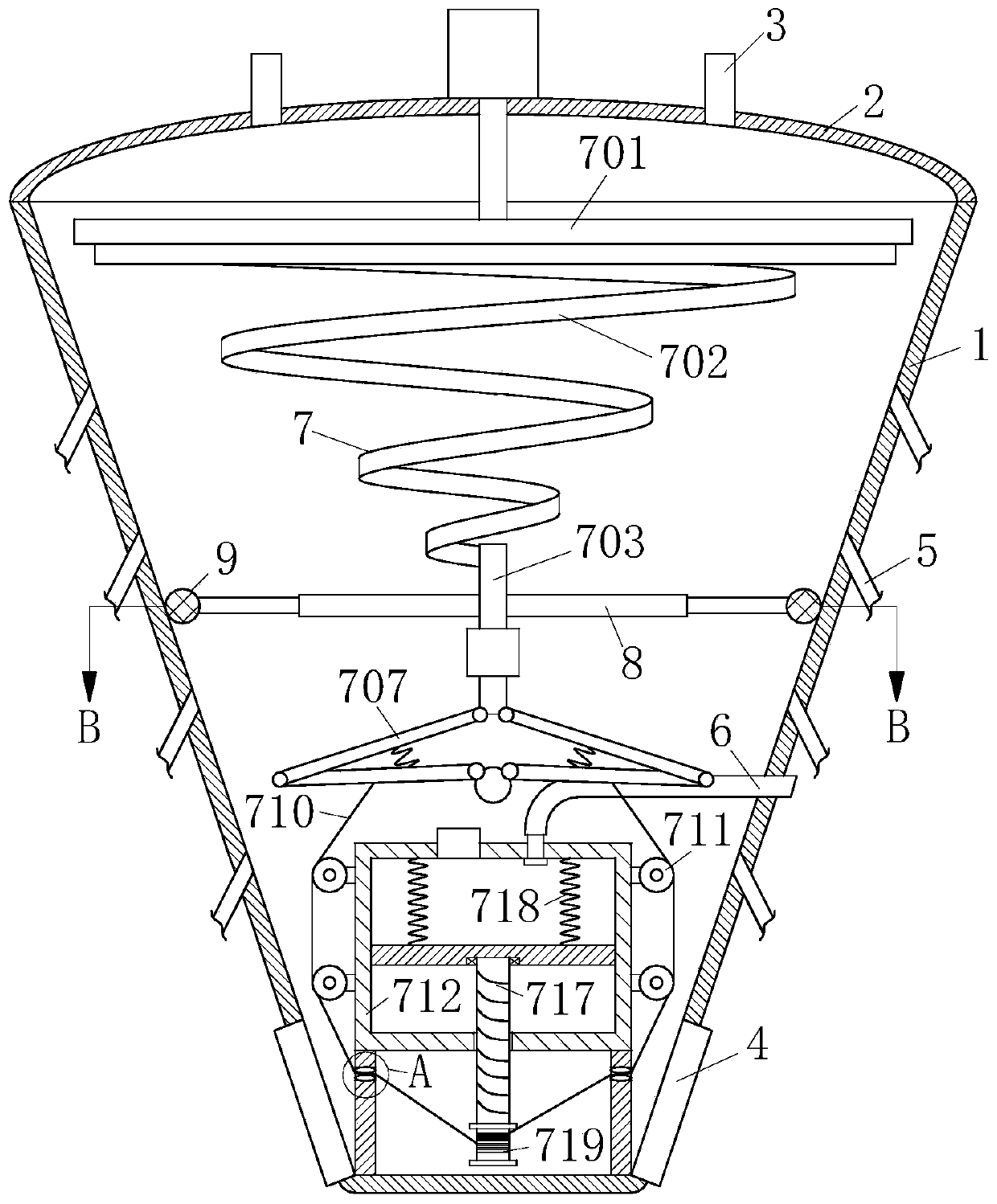

Chemical fiber drying device

InactiveCN109737707ADry completelyReduce falling speedDrying gas arrangementsDrying machines with non-progressive movementsFiberMainspring

The invention belongs to the technical field of chemical fiber production equipment, and particularly relates to a chemical fiber drying device. The chemical fiber drying device comprises a cone-shaped tower body and a tower cover, and further comprises feeding pipes, discharging holes, a plurality of layers of air inlet pipes, an air outlet pipe, an auxiliary unit, a motor and a controller; the controller is used for controlling the operation of the drying device; the tower cover is installed on the upper part of the cone-shape tower body, and the multiple layers of air inlet pipes are arranged on the side wall of the cone-shaped tower body in a penetrating mode; the air inlet pipes are evenly distributed in the circumferential direction of the cone-shaped tower body; by the coordinationamong a mainspring, an air cylinder, a rope and a rotating shaft, the stretched mainspring is driven to rotate by the motor; the rotating mainspring is mutually matched with the cone-shaped tower body, and thus an upward eddy formed by high-temperature air is generated; and the falling speed of chemical fibers is decreased greatly, so that the chemical fibers can stay in the air for longer time, and thus the chemical fibers can be dried by the high-temperature air more completely.

Owner:海安荣祥化纤有限公司

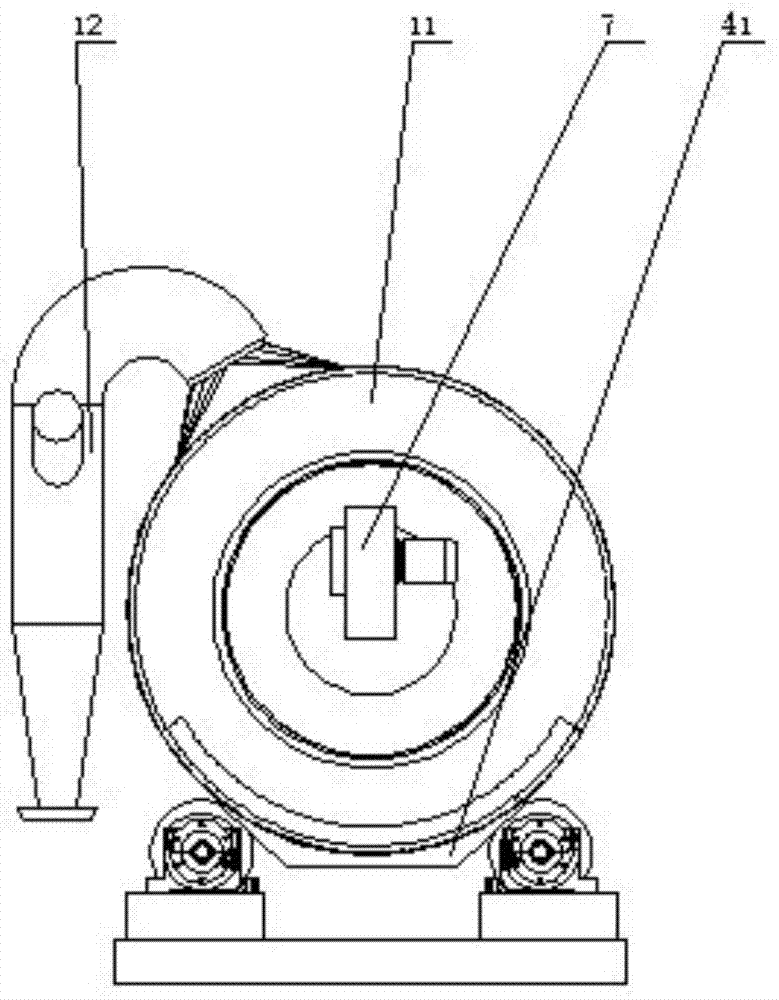

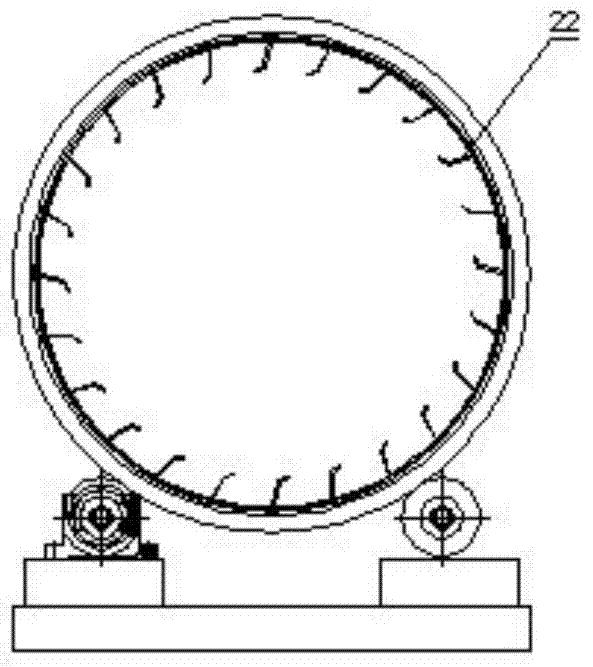

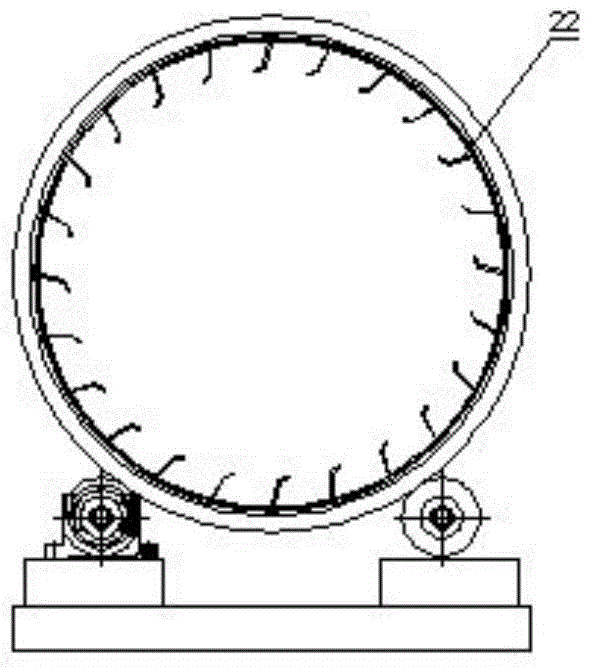

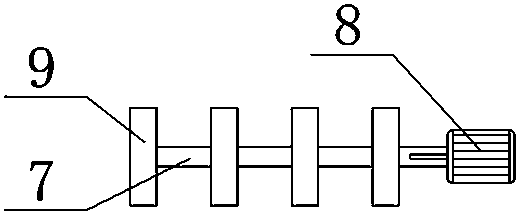

crop dryer

ActiveCN104938620BSave electricityReduce volumeSeed preservation by dryingDrying machines with non-progressive movementsThermal energyEngineering

The invention discloses a crop dryer, comprising: a frame; a drum, which is arranged on the frame and defines a storage space; a driving gear, coupled to the drum to rotate the drum along its axis; The feeding unit is provided with a feeding port at its lower part; and the drying device arranged in the storage space includes: a heating pipe, which is a hollow pipe body, arranged at the central axis of the drum; and several The radiant plate protrudes from the outer surface of the heating tube, and the bottom of the heating tube defines several through holes; the end of the heating tube away from the feed inlet is provided with a fan; the end of the roller away from the feed inlet is Openings for draining crops. In the present invention, the heat energy is utilized more fully, and the electric energy for using the crop dryer is greatly saved, and the volume of the crop dryer is reduced at the same time, thereby improving user satisfaction.

Owner:HUBEI YE WEI INTELLIGENT TECH

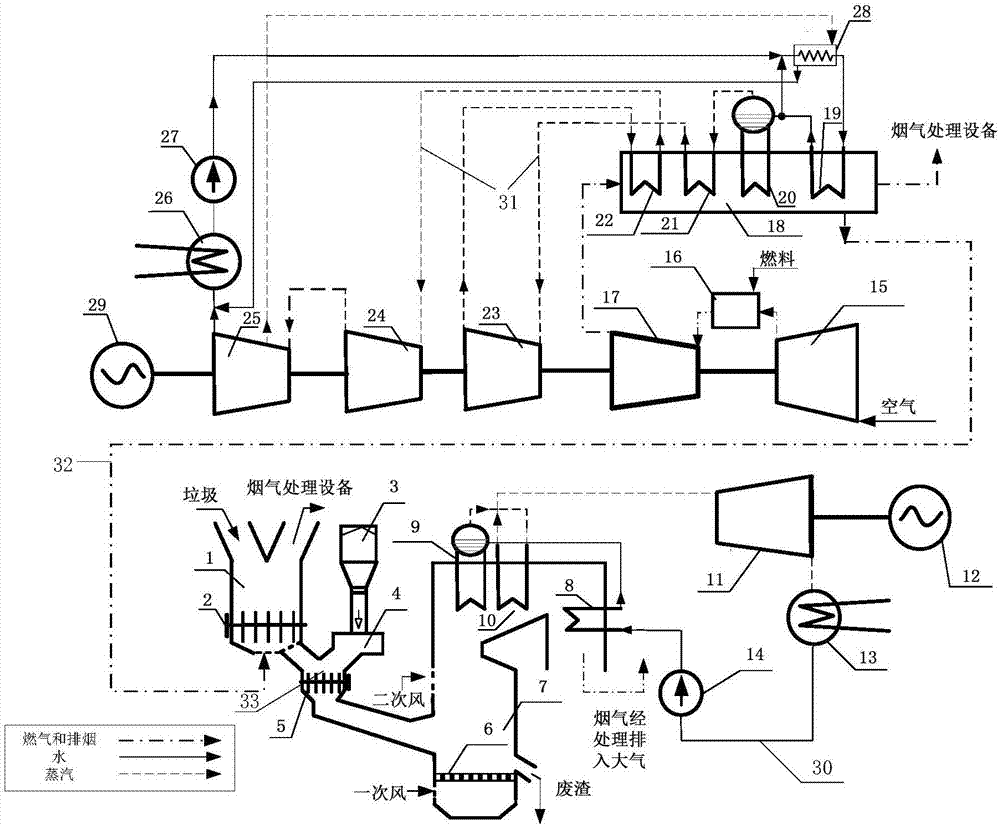

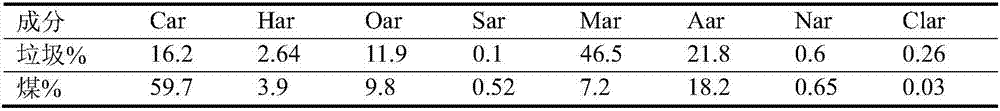

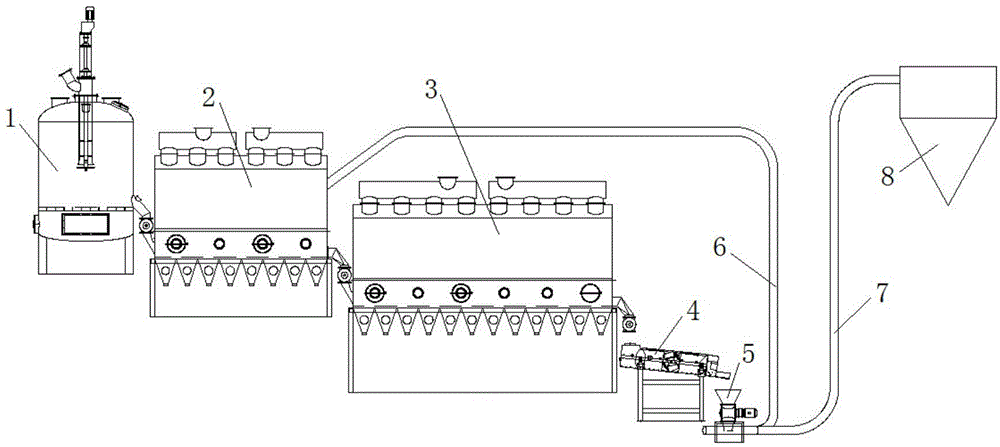

Garbage and gas-steam combined cycle power generation system adopting gas for drying garbage

ActiveCN107269335AShort construction periodLess investmentSteam engine plantsIncinerator apparatusCombustion chamberGas compressor

The invention discloses a garbage and gas-steam combined cycle power generation system adopting gas for drying garbage. The garbage and gas-steam combined cycle power generation system comprises a garbage incineration generator set and a gas-steam combined cycle generator set. The garbage incineration generator set comprises a garbage drier adopting gas for drying garbage, a garbage incinerator, a first turbine and a first generator. The gas-steam combined cycle generator set comprises a gas compressor, a combustion chamber, a turbine, a second turbine and a second generator, all of which are connected in sequence and further comprises a waste heat boiler connected with the turbine through a smoke discharging pipeline, and a second thermodynamic cycle pipeline connected between the waste heat boiler and the second turbine. A smoke pipeline is connected between the waste heat boiler and the garbage drier and is used for leading a small part of low-temperature gas in the waste heat boiler into the garbage drier to serve as a drying heat source for water-containing garbage, and the water-containing garbage can be dried. The garbage and gas-steam combined cycle power generation system has the beneficial effects that the service life of the incinerator is prolonged, the heat efficiency of the incinerator is improved, the combustion supporting coal amount is reduced, and the environment pollution is reduced.

Owner:ZHEJIANG UNIV

Crop dryer

ActiveCN104938620ASave electricityReduce volumeSeed preservation by dryingDrying machines with non-progressive movementsThermal energyEngineering

The invention discloses a crop dryer. The crop dryer comprises a rack, a roller, a driving gear, a feeding unit and a drying device; the roller is arranged on the rack, and a storage space is defined by the roller; the driving gear is connected to the roller so as to enable the roller to rotate along the axis; a feeding opening is formed in the lower portion of the feeding unit; the drying device is arranged in the storage space and comprises a heating plate and a plurality of radiation plates; the heating pipe is a hollow pipe body and is arranged at the position of the axle wire of the roller; the multiple radiation plates extend out from the outer surface of the heating pipe, and a plurality of through holes are defined in the bottom of the heating pipe; a draught fan is arranged at the end, far away from the feeding opening, of the heating pipe; an opening for discharging crops is formed in the end, far away from the feeding opening, of the roller. According to the crop dryer, the heat energy is used more sufficiently, and the electric energy used for the crop dryer is greatly saved; meanwhile, the size of the crop dryer is reduced, and the satisfaction of a user is improved.

Owner:HUBEI YE WEI INTELLIGENT TECH

Feed processing raw material crushing device

InactiveCN107736639ADry comprehensiveDry completelyFeeding-stuffGrain treatmentsEconomic benefitsEngineering

The invention relates to the technical field of feed processing, in particular to a raw material crushing device for feed processing, which includes a housing and a connecting rod. A feeding hopper is fixedly connected to the top of the housing, and a drying plate is arranged below the feeding hopper. The inner side of the drying plate is fixedly connected with a horizontally arranged heating wire, the top of the drying plate is fixedly connected with a gear lever, and the bottom of the drying plate is provided with a horizontally arranged support plate, and one end of the support plate is connected to the housing Fixedly connected, the outer top of the support plate is rotatably connected with an elliptical runner, the bottom end of the support plate is fixedly connected with a connecting rod, the bottom end of the connecting rod is fixedly connected with a second rotating shaft, and the second rotating shaft One end is fixedly connected with a second motor, and the inner side of the second motor is rotatably connected with a runner, which is conducive to improving the completion rate of products and increasing work efficiency, has huge economic benefits and broad market prospects, and is worthy of popularization and use.

Owner:邛崃驰阳农牧科技有限公司

Full-automatic poultry feed processing machine

The invention relates to the technical field of feed processing, in particular to a fully automatic poultry feed processing machine, comprising a housing and a crushing box, the bottom end of the feed hopper is fixedly connected to the crushing box, and the center of the crushing box rotates Connected with a central rotating shaft, the outer side of the central rotating shaft is fixedly connected with crushing leaves, there is a horizontal grid directly below the crushing leaves, a drying plate is provided directly below the crushing box, and the bottom of the drying plate A heating plate is fixedly connected, one side of the heating plate is fixedly connected with a heat dissipation wire, a slide bar is arranged horizontally under the drying plate, a first motor is provided directly below the left end surface of the slide bar, and the first motor A motor is fixedly connected to the casing, and the end of the main shaft of the first motor is rotatably connected to a multi-groove cam, which is convenient for crushing and mixing multiple raw materials at the same time, has huge economic benefits and broad market prospects, and is worthy of promotion and use.

Owner:邛崃驰阳农牧科技有限公司

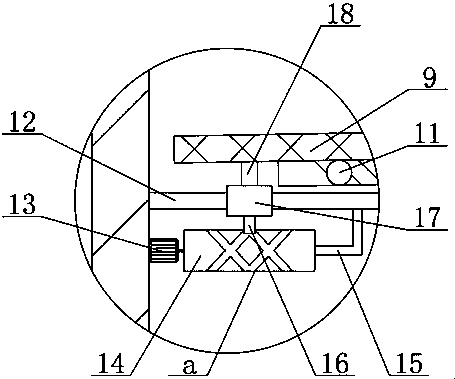

Blowing drying device after underwater pressure test of welded pipe

ActiveCN101749930AContinuous productionDry completelyDrying solid materials without heatDrying machines with progressive movementsCylindrical channelEngineering

The invention relates to a blowing drying device after underwater pressure test of a welded pipe, comprising a cylindrical channel (1) leading a stainless steel welded pipe (5) to penetrate through, at least more than one air inlet (3) is arranged at the outer side of the cylindrical channel (1), an annular air cavity (2) is arranged at the inner side of the cylindrical channel (1), the annular air cavity (2) is connected with the air inlet (3), and a blowing gap (4) is arranged at a corner of the annular air cavity (2) and close to the axis of the cylindrical channel (1). The blowing drying device has the benefits that the production of the stainless steel pipes is continuous, the drying is complete, fast and high efficient, the problems of water stain and scale and probable corrosion pits on the surface of the stainless steel pipe and water residue in product packaging are avoided, and a large number of manpower and material resources are saved as well.

Owner:上海华钢不锈钢有限公司

UV curable offset printing ink with LED as light source

The invention discloses an ultraviolet light-cured offset printing ink with LED as a light source. The ultraviolet light-cured offset printing ink comprises, by weight, 20 to 30 parts of pigment, 55 to 75 parts of radiation-cured resin, 1 to 7 parts of a photoinitiator, 0 to 3 parts of wax, 0.1 to 5 parts of an active diluent and 0.5 to 4 parts of an auxiliary agent. The UV-LED light-cured printing ink has the following characteristics: the printing ink is applicable to offset printing; electric energy consumed in curing is about 1 / 4 of electric energy consumed by a common ultraviolet lamp; emission of CO2 is substantially reduced; ozone is not generated; etc. The printing ink is completely dried under the printing condition of a curing speed of 40 to 200 m / min and enables printed lines to be clear; and after curing, each performance index (adhesion, friction resistance, chemical resistance and the like) of the printing ink accords with requirements on printing of securities.

Owner:CHINA BANKNOTE INK +1

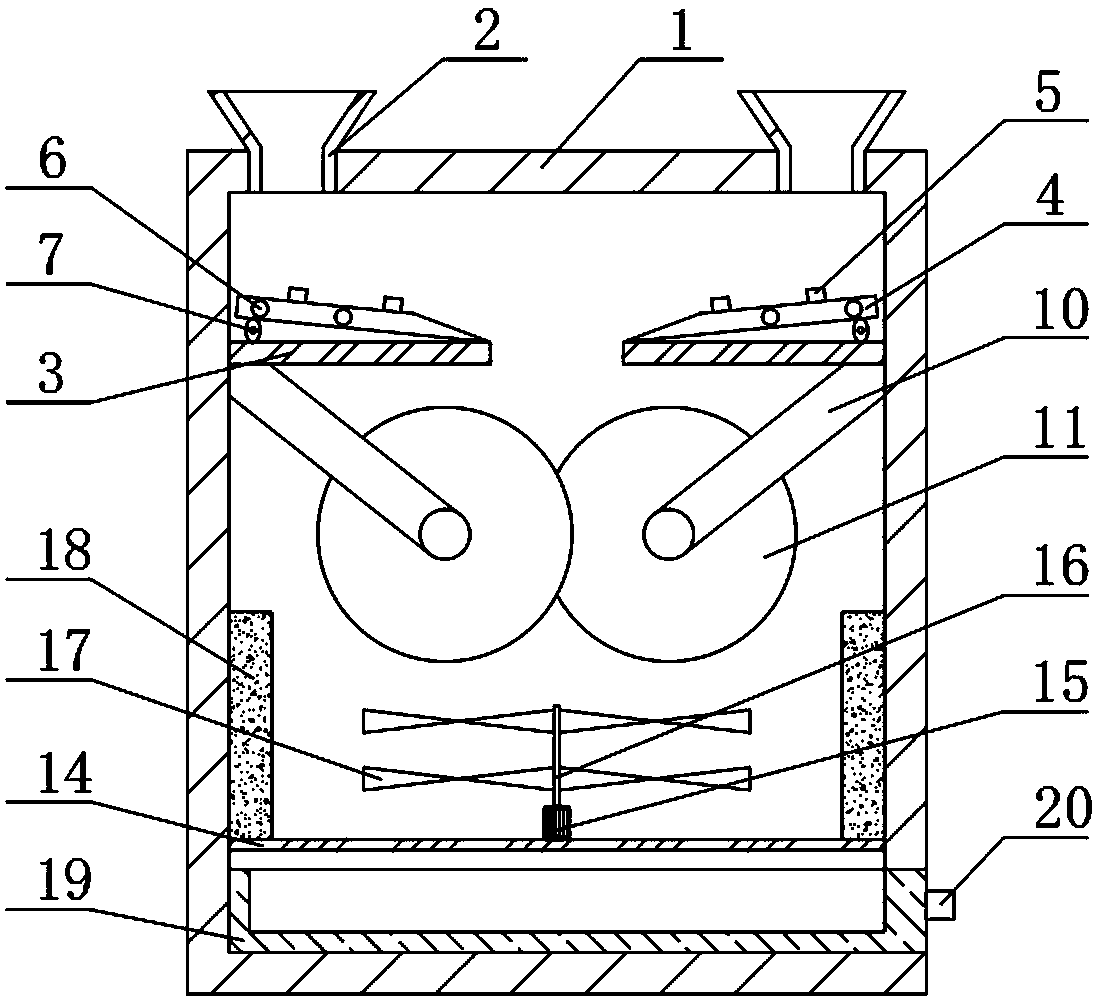

Filtering and drying device for calcium carbonate preparation

PendingCN112432493AFully dryExtend the motion pathCalcium/strontium/barium carbonatesSievingEngineeringMechanical engineering

The invention discloses a filtering and drying device for calcium carbonate preparation. The filtering and drying device comprises a machine body, wherein two baffles are symmetrically arranged on theinner side wall, close to the top, of the machine body, and the two baffles are obliquely arranged; a rotating shaft is rotationally connected to the inner side wall, close to the baffles, of the machine body, and a plurality of material blocking plates are uniformly and fixedly connected to the outer side wall of the rotating shaft; a supporting frame is obliquely and fixedly connected to the inner side wall, located below the material blocking plates, of the machine body, and a sieve plate is slidably connected to the upper side wall of the supporting frame; an L-shaped inclined block is fixedly connected to the side wall of one side of the sieve plate, and a rectangular opening is formed in the side wall of the side, close to the L-shaped inclined block, of the machine body; and the side wall of one end of the rotating shaft penetrates through the side wall of the machine body and is fixedly connected with a cam. The invention relates to the technical field of calcium carbonate production and processing. The rotating shaft is driven to rotate through the material blocking plates, so that the cam pushes a push plate to move, then the sieve plate can be driven to shake, and calcium carbonate particles can be conveniently screened.

Owner:耒阳市百汇粉体有限公司

Baking process of profile and sand core, made from resin sand, of natural gas power cylinder body

InactiveCN103537630ASolve styling poresSolve the problem of casting defects such as many pinholesFoundry mouldsFoundry coresCooking & bakingProcess engineering

The invention discloses a baking process of a profile and a sand core, made from resin sand, of a natural gas power cylinder body, aiming at overcoming the casting defects of pores, pin holes and the like of existing baking processes of a profile and a sand core, made from resin sand, of a natural gas power cylinder body. The baking process comprises the steps of putting the profile and the sand core, made from the resin sand, of the natural gas power cylinder body into a drying oven; heating up to 210-230 DEG C, and carrying out heat preservation for 3.5h-4.5h; and adjusting the temperature to 95-105 DEG C, and carrying out heat preservation until mould assembling. The baking process can reduce the water content and the gas displacement of the profile and the sand core, overcomes the casting defects of pores, pin holes and the like of existing resin sand profiles, and improves the casting quality. The baking process not only is suitable for baking of the profile and the sand core, made from the resin sand, of the natural gas power cylinder body, but also is suitable for baking of profiles and sand cores made from other resin.

Owner:CNPC JICHAI POWER EQUIP

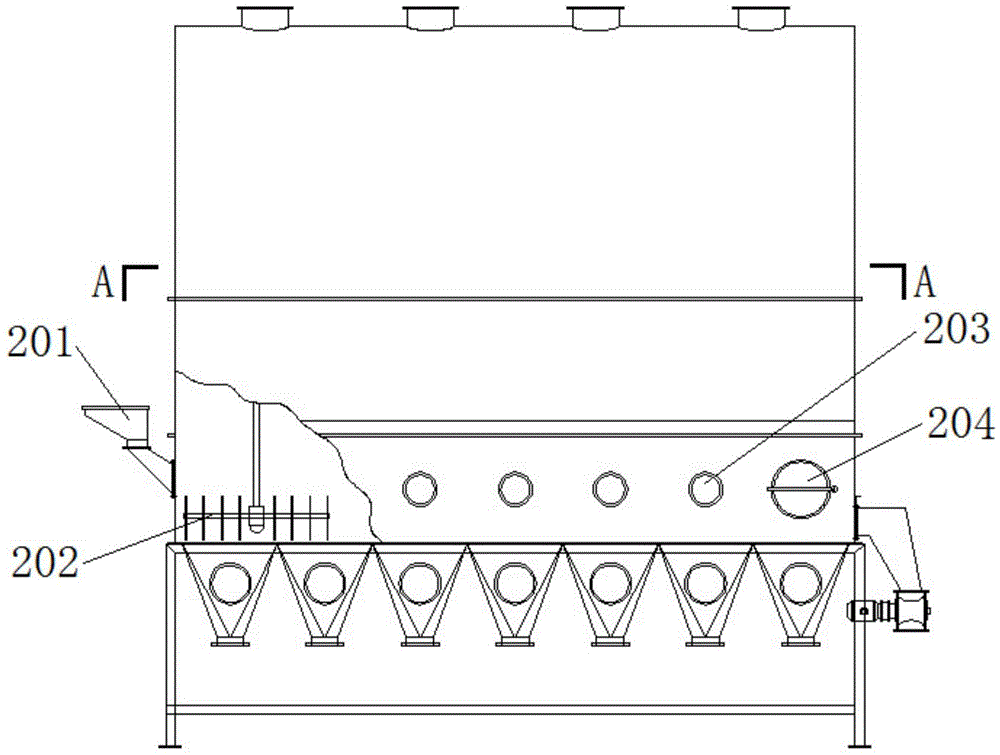

Continuous drying equipment for glucose and continuous drying technology for glucose

ActiveCN103591770BPrevent discolorationKeep dryDrying solid materials with heatHearth type furnacesD-GlucoseSmall footprint

The invention discloses a set of continuous drying equipment for glucose and a continuous drying technology for glucose and belongs to the technical field of drying. The drying equipment comprises a vertical boiling fluid bed dryer, a horizontal boiling fluid bed dryer, a horizontal boiling fluid bed cooler, a vibrating screen, a pulverizer, a first pneumatic delivery pipe, a second pneumatic delivery pipe and a recovery tank, wherein the vertical boiling fluid bed dryer, the horizontal boiling fluid bed dryer and the horizontal boiling fluid bed cooler are sequentially connected, the horizontal boiling fluid bed cooler is connected with the vibrating screen, a large particle outlet of the vibrating screen is connected with the pulverizer, the pulverizer is connected with the horizontal boiling fluid bed dryer through the first pneumatic delivery pipe, and a small particle outlet of the vibrating screen is connected with the recovery tank through the second pneumatic delivery pipe. The continuous drying equipment for glucose is not only low in drying energy consumption, high in heat exchange efficiency and short in drying time but also small in occupied area, large-particle materials can be screened, pulverized and redried with the equipment, and the drying effect is greatly improved.

Owner:FANQUN DRYING EQUIP FACTORY WUJIN CITY

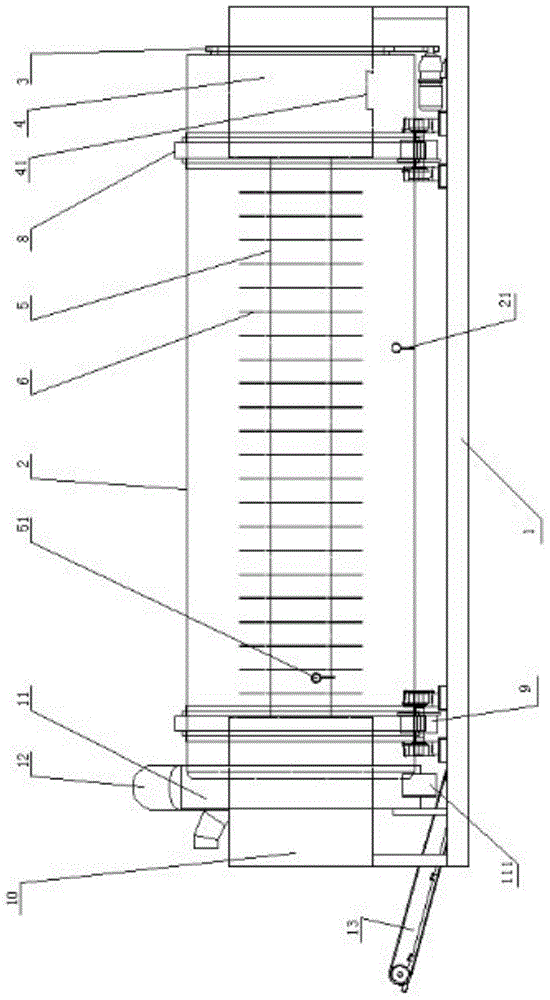

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

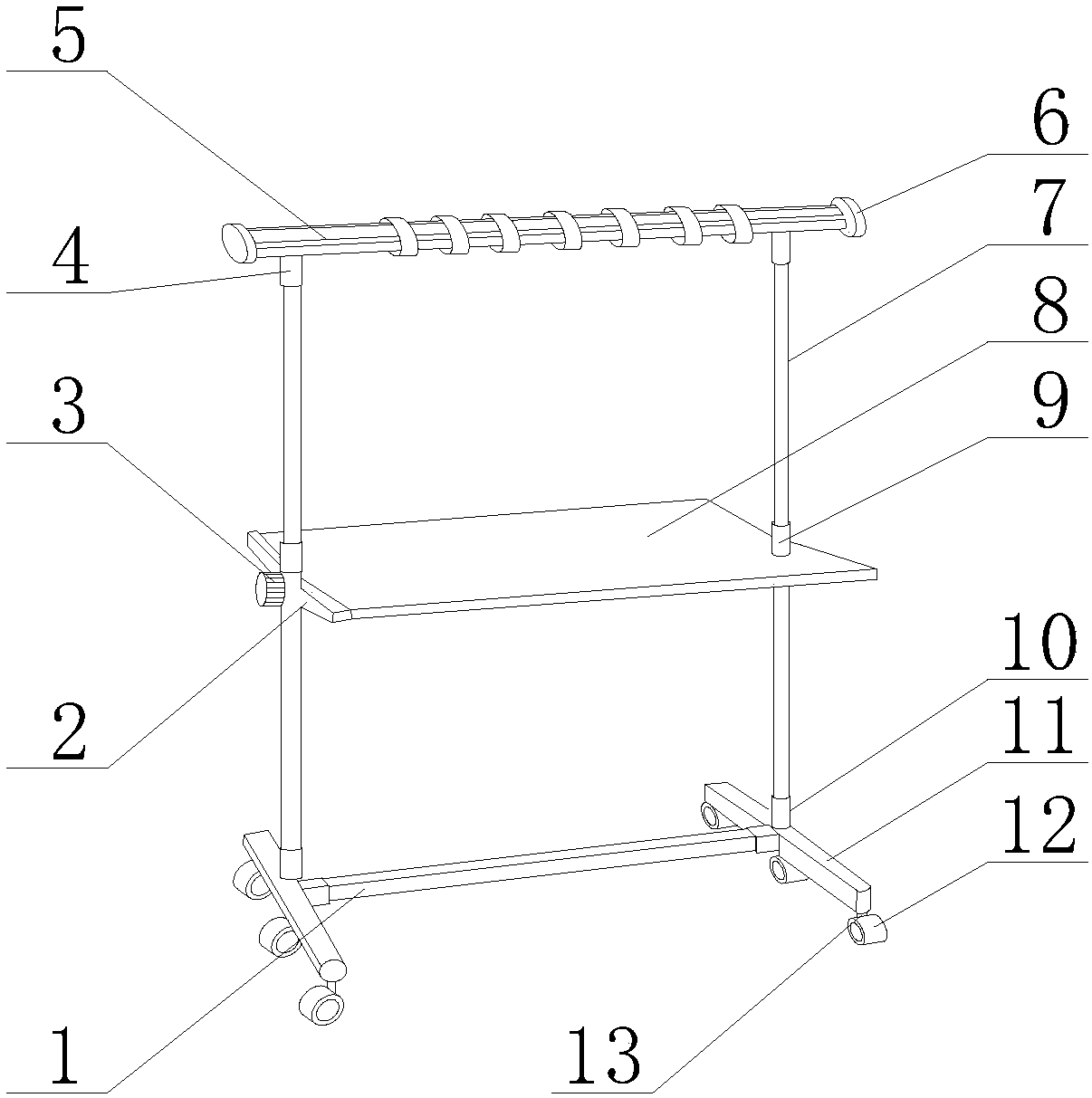

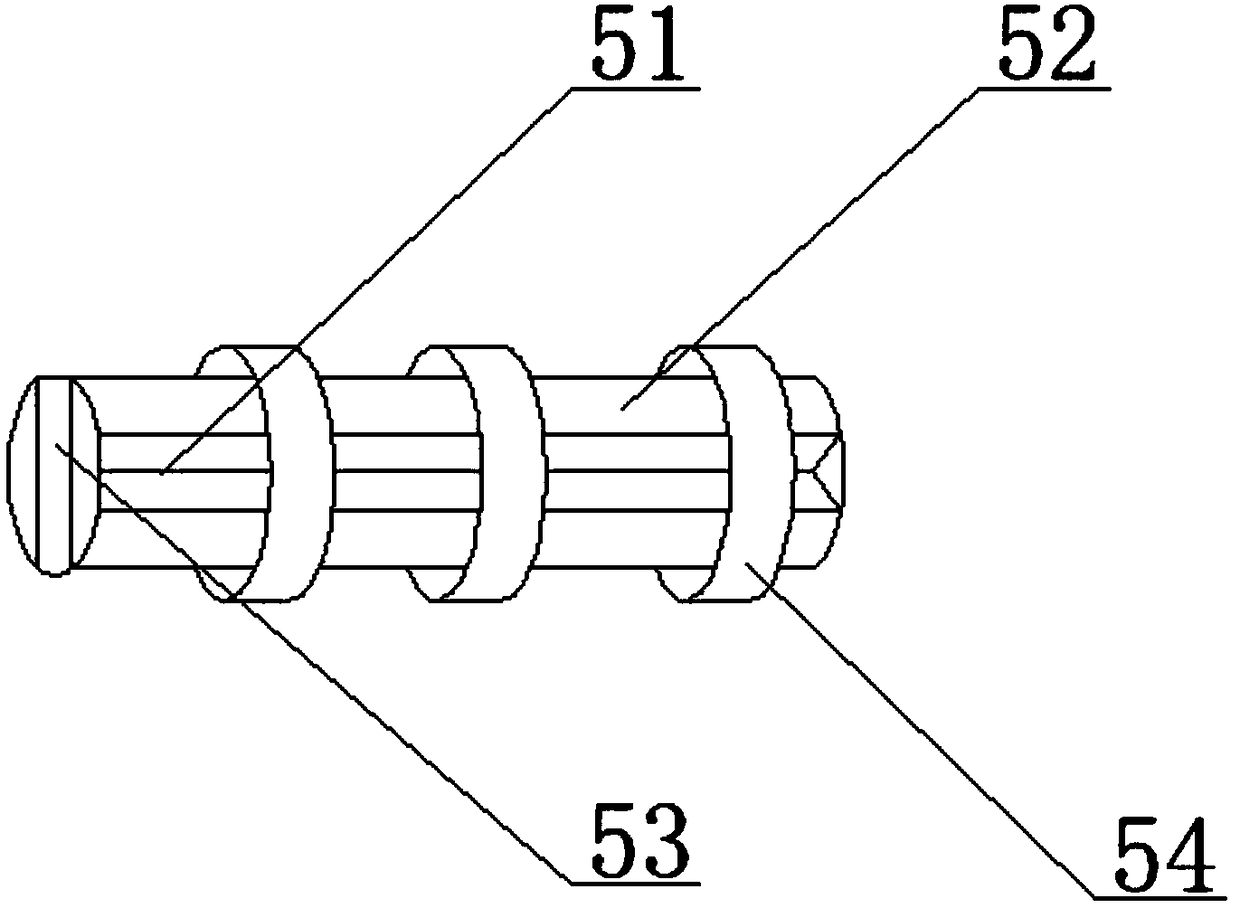

Multifunctional drying rack for daily life

ActiveCN108611822AChange distanceDry completelyOther drying apparatusTextiles and paperEngineeringClothes hanger

The invention discloses a multifunctional drying rack for daily life. The multifunctional drying rack comprises a shoe drying board, a clothes drying device is arranged above the shoe drying board, fall preventing buckles are connected to the left and right sides of the clothes drying device, a blanching support is arranged below the shoe drying board, base supports are connected to the left and right sides of the balancing support, and roller supports are connected to the front, middle and back of the lower side of each base support. Fixing joints are arranged in clothes drying rings, fixingclamping grooves are formed in the middle of the outer surface of a clothes drying rod, and therefore the clothes drying rings cannot rotate up and down; the clothes drying rings can be moved left andright to change the distance between clothes, and therefore the clothes can be dried more completely and a user can perform adjustment more conveniently. In windy weather, as the clothes drying ringshave weight and clothes drying ring grooves in the clothes drying rings are not communicated, clothes hangers can be well fixed in the clamping grooves instead of accumulating together, and thus clothes can be dried more completely.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

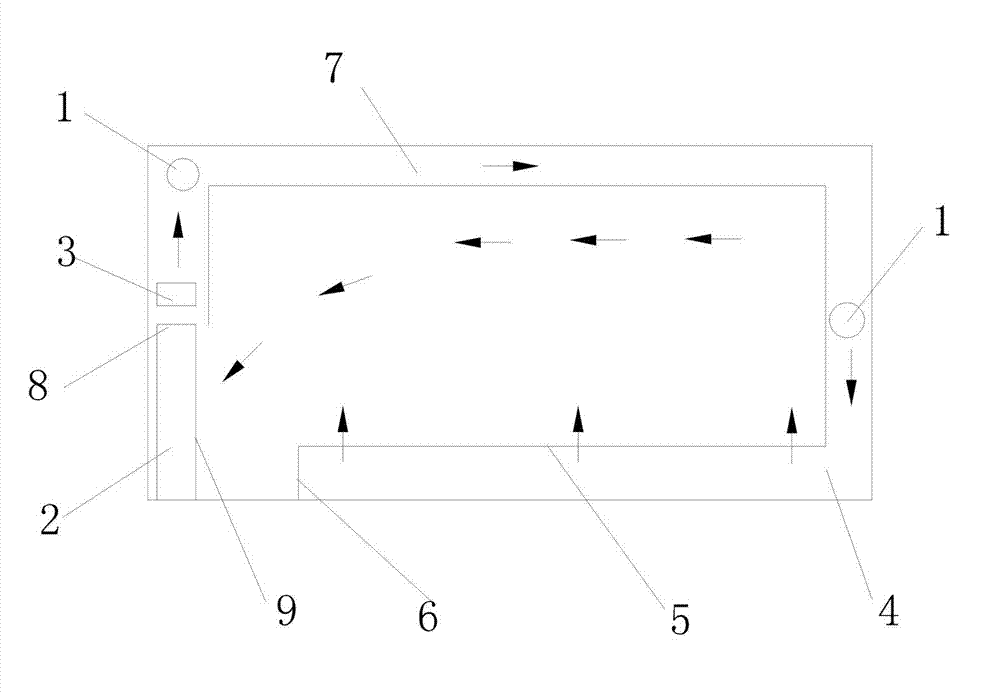

Dehumidifying room for drying glue impregnated bamboo curtain

ActiveCN102967123AImprove ventilationDry completelyDrying gas arrangementsDrying machines with local agitationProduction rateEngineering

The invention discloses a dehumidifying room for drying a glue impregnated bamboo curtain. The dehumidifying room is characterized in that a dehumidifying machine, an air tube and a material platform are arranged in a sealed dehumidifying room; the dehumidifying machine is arranged at one end of the dehumidifying room; a set distance is kept between the material platform and the dehumidifying machine; two sides of the material platform are close to the inner walls of the two sides of the dehumidifying room; a set distance is kept between the material platform and the bottom of the dehumidifying room and ventilating holes are intensively formed in the material platform and the bottom of the dehumidifying room; a wind shielding device is arranged at one end of the material platform close to the dehumidifying machine; an opening is formed at the other end of the material platform; one end of the air tube is arranged at the air outlet of the dehumidifying machine and the other end of the air tube is connected with the opening; and a driving fan is arranged in the air tube. The dehumidifying room for drying the glue impregnated bamboo curtain, disclosed by the invention, has the advantages as follows: (1) the dehumidifying room is suitable for vertically drying bamboo curtain materials so as to ensure that the materials are uniformly ventilated and completely dried; (2) as a low temperature dehumidifying method is adopted, the activity of thermosetting dehydration is completely kept, so that the bonding strength of bamboo plywoods can be guaranteed; and (3) the labor intensities of workers are reduced and the production rate is increased.

Owner:浙江凯森板业有限责任公司

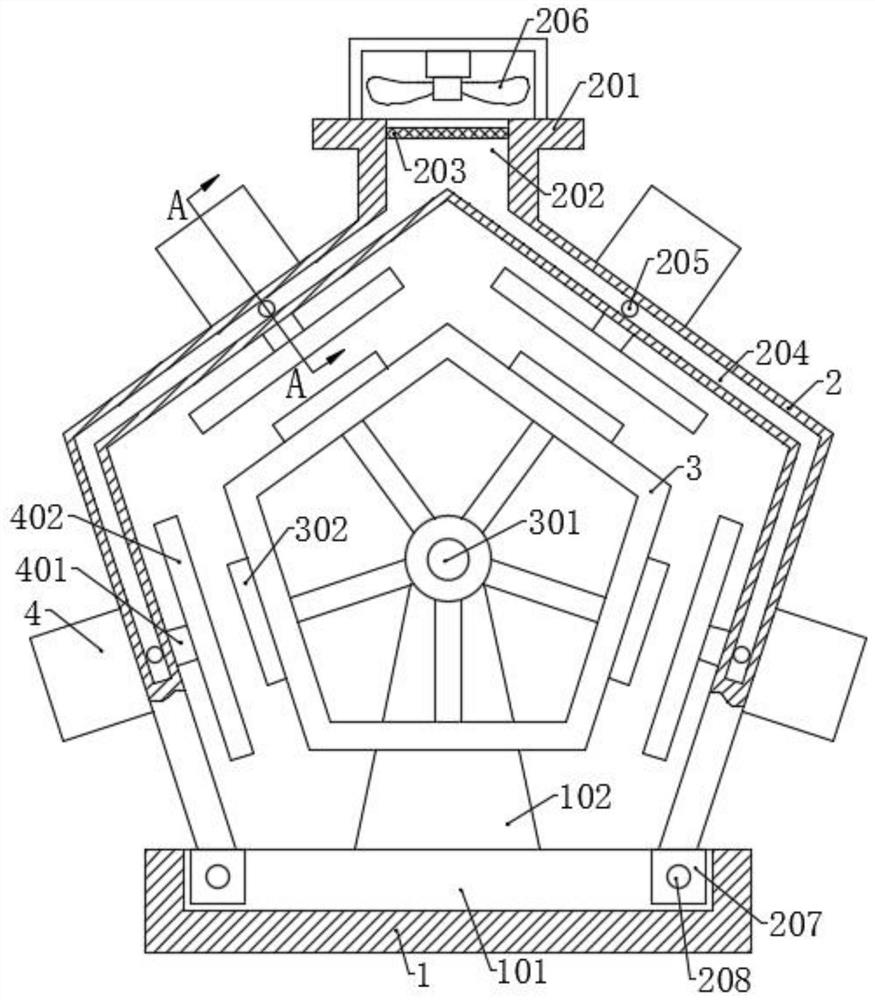

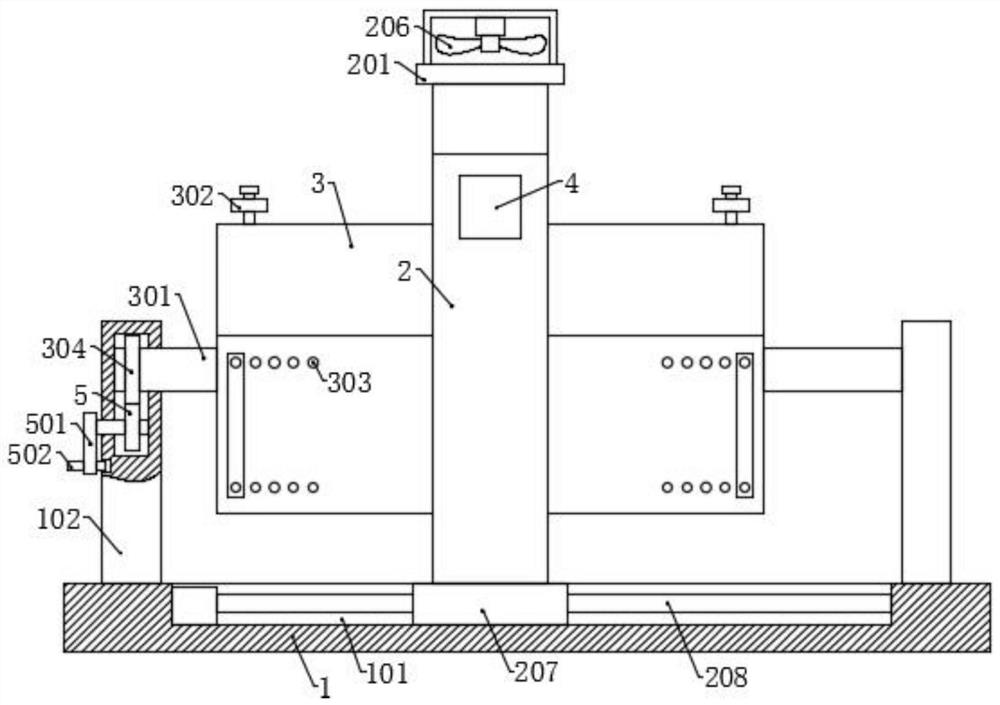

A water-based wood paint drying equipment

ActiveCN108704820BDrying is simple and convenientEasy to usePretreated surfacesCoatingsLacquerHot blast

The invention discloses a water-based wood paint drying equipment in the technical field of wood processing, which includes a base, a moving frame, a rotating frame and an adjustment box. The rotating frame includes a rotating shaft and five placement plates. The top of the moving frame is equipped with Fan, air inlet and heating net, the invention fixes the boards with water-based wood paint on the surface in turn by rotating the turret, and the boards are dried through the fan, heating net, hot air duct, drying pipe, etc., and the drying is simple It is convenient and can dry multiple boards at the same time to improve the drying efficiency; the moving tube drives the drying tube to move by turning the screw, and the distance between the drying tube and the board can be adjusted to dry boards of different thicknesses, and the drying effect is good; The moving frame presses the turret to reciprocate in the length direction through the screw rod and the moving block, so that the water-based wood paint on the wooden board is dried evenly and completely; the invention has a reasonable structure and is convenient to use.

Owner:安徽江锐新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com