Waterborne ink and preparation method thereof as well as application of waterborne ink in PP (Polypropylene) decorative film

A water-based ink and decorative film technology, applied in special decorative structures, applications, inks, etc., can solve the problems of limiting the application of environmentally friendly water-based inks, unstable light and heat, endangering health, etc., and achieves easy industrial production and low production costs. , texture natural and realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

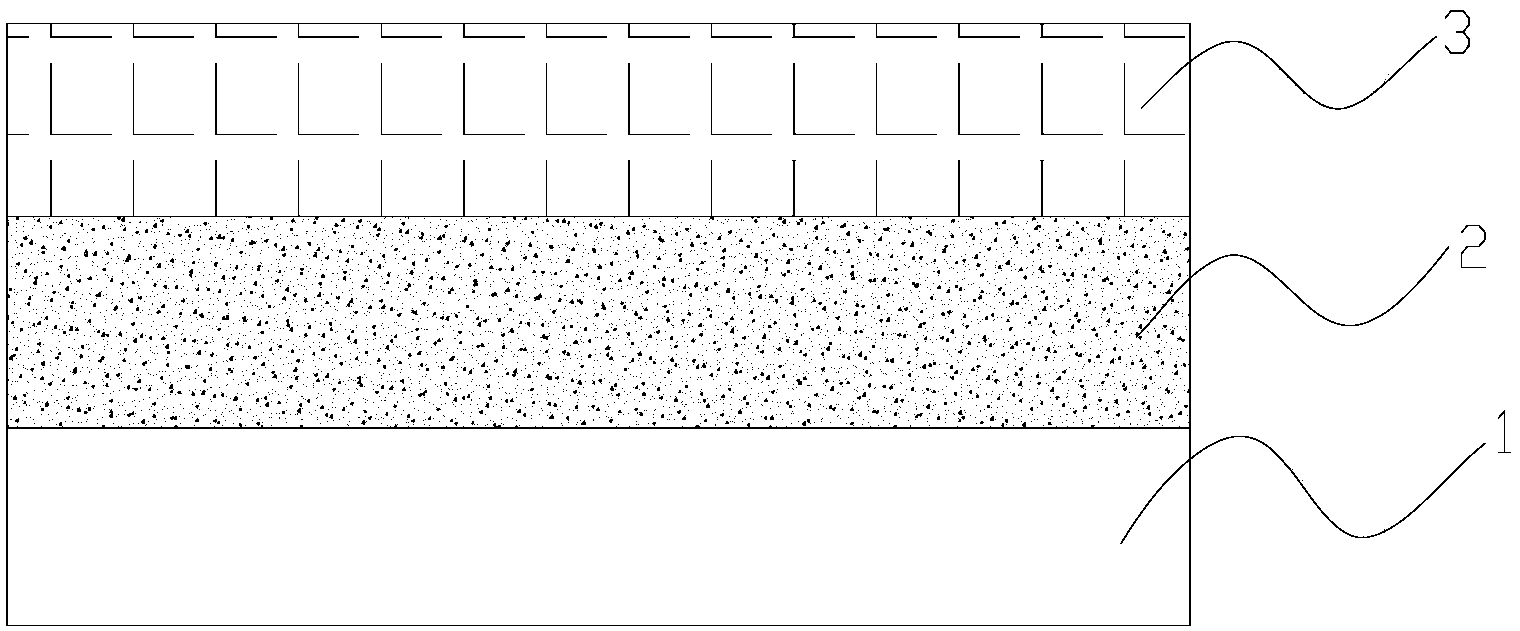

Image

Examples

specific Embodiment 1~3

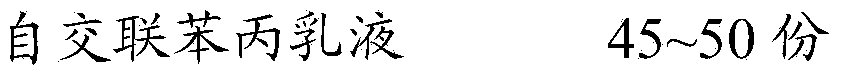

[0035] A water-based ink, which is prepared from the following raw materials in parts by weight:

[0036]

[0037]

[0038] The preparation method of the described water-based ink of embodiment 1~3, concrete process step is as follows:

[0039] a. Preparation of color paste: Weigh each component of the following formula, mix them evenly, and put them into a disperser for dispersion;

[0040]

[0041] B, grinding: the mixture obtained in step a is dropped into a sand mill filled with pure zirconia for grinding;

[0042] c. Ink adjustment: add self-crosslinking styrene-acrylic emulsion, wetting and leveling agent, defoamer, transfer aid to the mixture obtained in step b and disperse evenly after mixing, adjust the viscosity with non-ionic polyurethane thickener, Add a pH regulator to adjust the pH value.

[0043] In the above steps, the dispersion speed of step a is 1500r / min, and the dispersion time is 30-50min; in step b, grind twice at a grinding speed of 100kg / h u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com