Continuous drying equipment for glucose and continuous drying technology for glucose

A drying equipment and drying process technology, applied in the production of glucose, sugar production, drying of solid materials, etc., can solve the problems of unsatisfactory drying effect, short drying time, low drying energy consumption, etc., and achieve improved drying effect and uniform particle size. , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

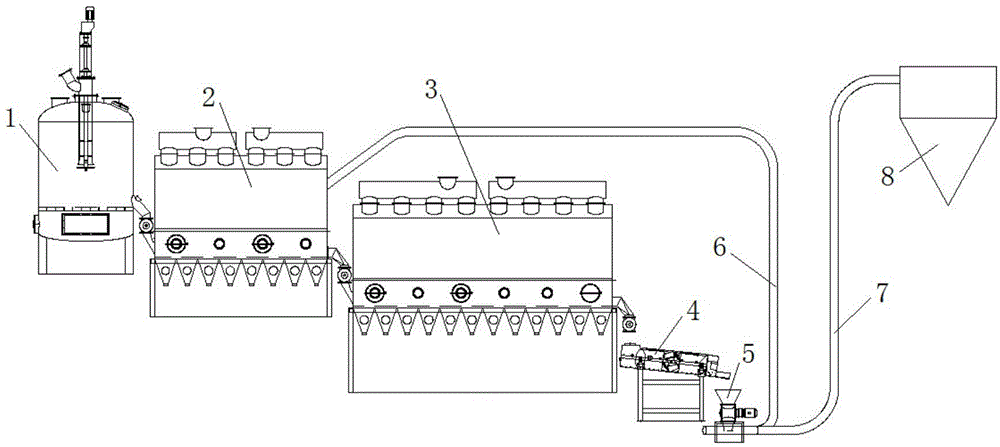

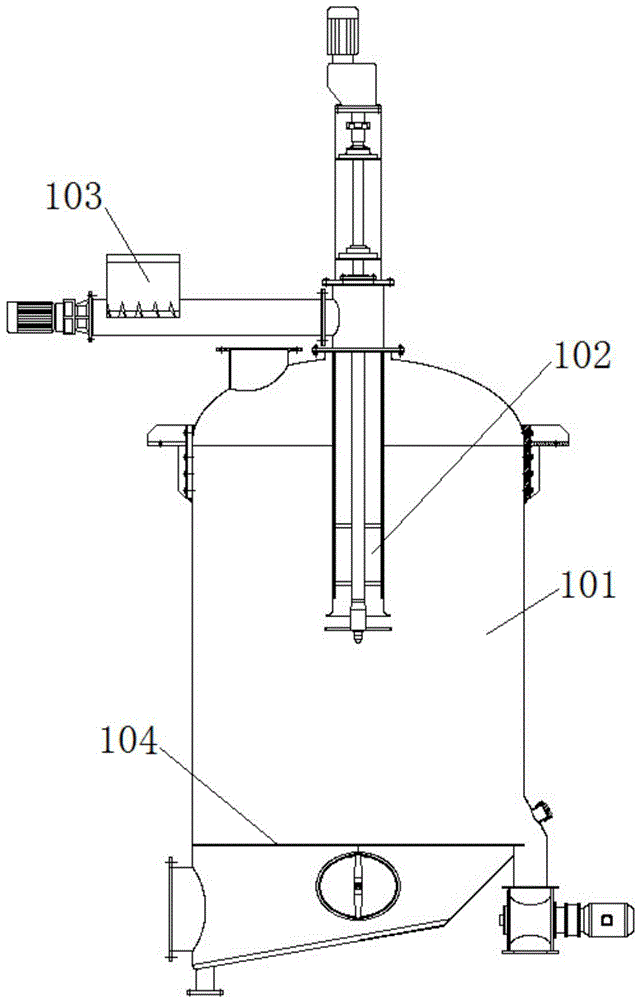

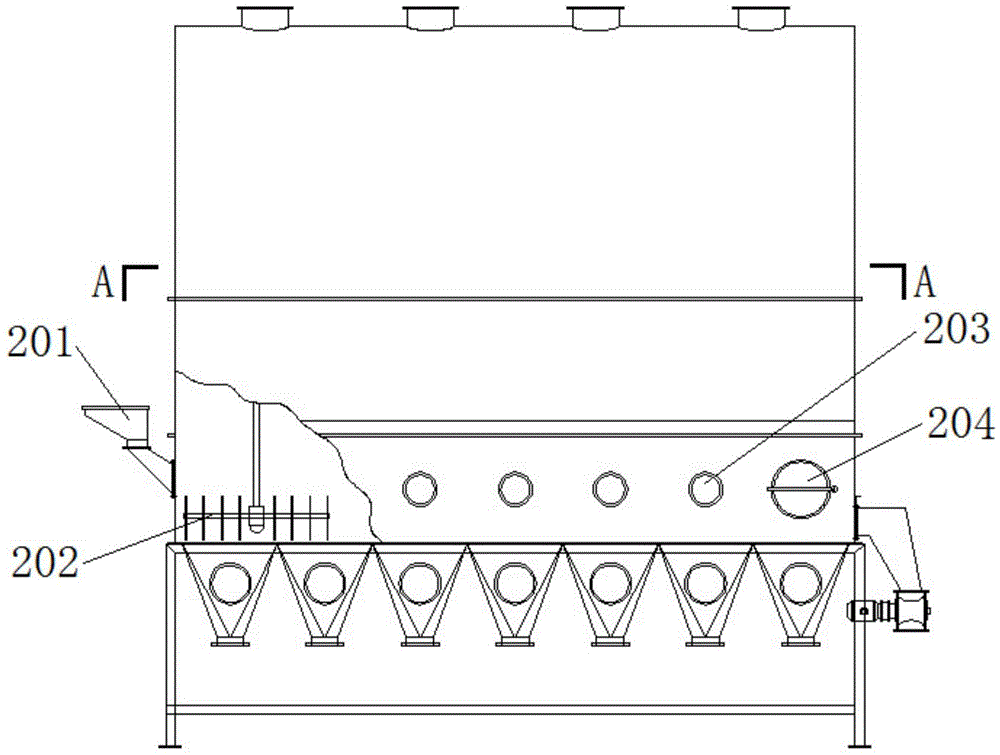

[0043] combine figure 1 , the continuous drying equipment of a kind of glucose of present embodiment, comprises vertical fluidized bed dryer 1, horizontal fluidized bed dryer 2, horizontal fluidized bed cooler 3, vibrating screen 4, pulverizer 5. The first pneumatic conveying pipe 6 , the second pneumatic conveying pipe 7 and the recovery tank 8 . The discharge port of the vertical fluidized bed dryer 1 is connected to the feed port of the horizontal fluidized bed dryer 2 through the shut-off fan, and the discharge port of the horizontal fluidized bed dryer 2 is connected to the horizontal fluidized bed dryer 2 through the closed fan. The feeding port of the vertical fluidized bed cooler 3 is connected, and the outlet port of the horizontal fluidized bed cooler 3 is connected with the vibrating screen 4 through the fan shut-off, wherein the vertical fluidized bed dryer 1 is used for The wet glucose material is pre-dried; the horizontal fluidized bed dryer 2 is used for second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com