Patents

Literature

141results about How to "Scattered evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

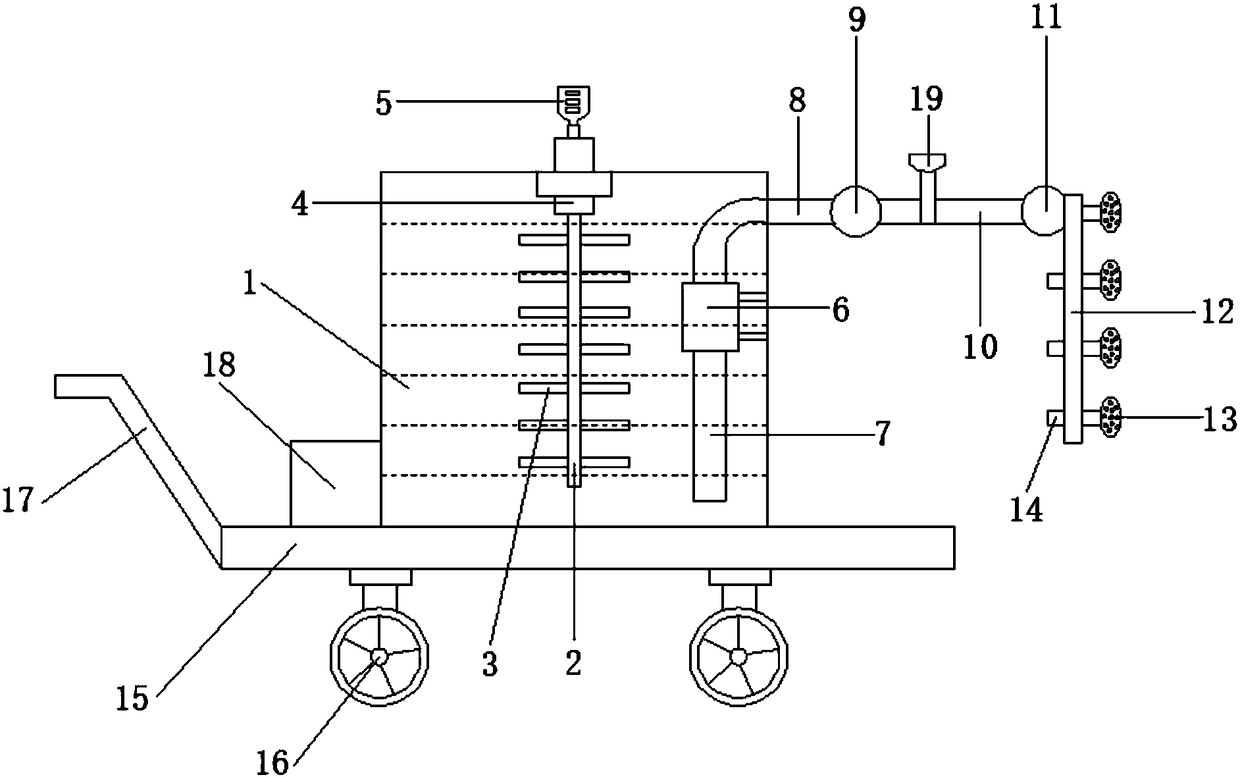

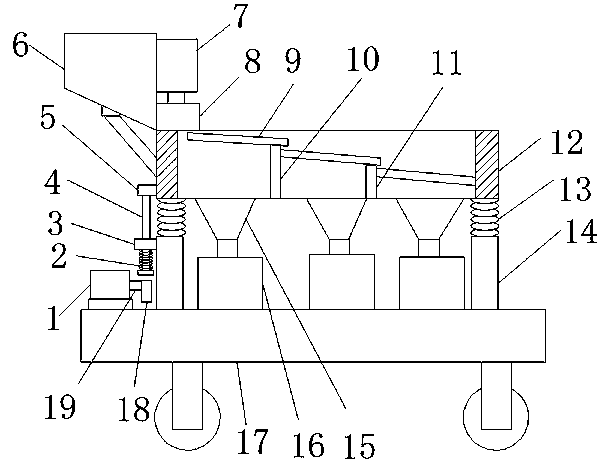

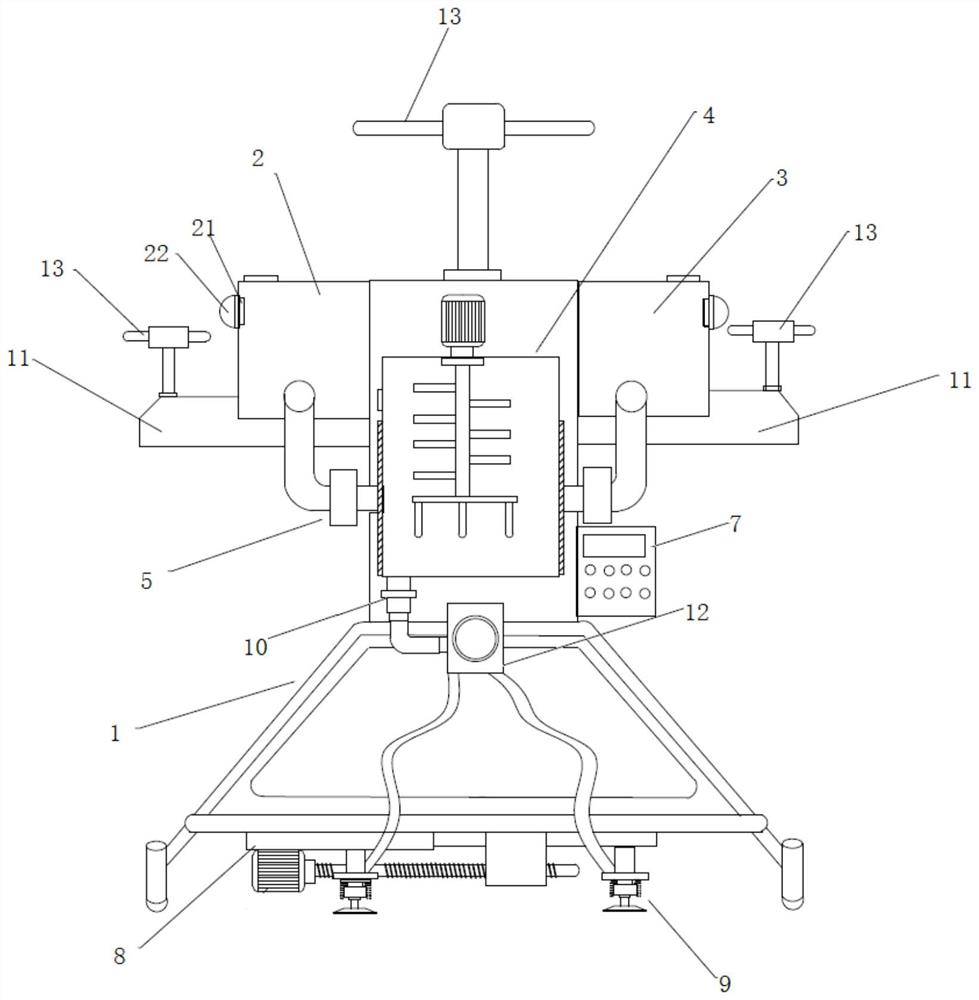

Portable cultivation and sterilization apparatus

InactiveCN108096615AScattered evenlyRich varietyAtomized substancesChemicalsDrive motorLiquid storage

The invention discloses a portable cultivation and sterilization apparatus. The portable cultivation and sterilization apparatus comprises a bottom plate, as well as a liquid storage box, a rotating shaft and a spraying mechanism which are arranged on the bottom plate; a stirring apparatus is arranged inside the liquid storage box, the stirring apparatus comprises a stirring shaft and stirring blades, the stirring shaft is connected with a driving motor arranged on the top of the liquid storage box by virtue of the rotating shaft, the spraying mechanism comprises a hydraulic stretchable rod, afirst universal rotating joint, a liquid outlet pipe, a second universal rotating joint, a spraying rod and atomizing spraying heads, the outer wall of the liquid storage box is provided with the hydraulic stretchable rod communicated with the liquid storage box, one end of the hydraulic stretchable rod is connected with a liquid suction pipe by virtue of a liquid suction pressurizing pump, the other end is connected with the liquid outlet pipe by virtue of the first universal rotating joint, the liquid outlet pipe is connected with the spraying rod by virtue of the second universal rotatingjoint, the spraying rod is provided with a plurality of atomizing spraying heads, the bottom of the bottom plate is provided with a movable wheel, and a pushing handle is welded on one side of the bottom plate. The portable cultivation and sterilization apparatus is applicable to various fields, convenient to carry, can realize the 360-degree rotation of the spraying rod by virtue of the second universal rotating joint, and is wide in spraying range and good in sterilization effect.

Owner:张守明 +7

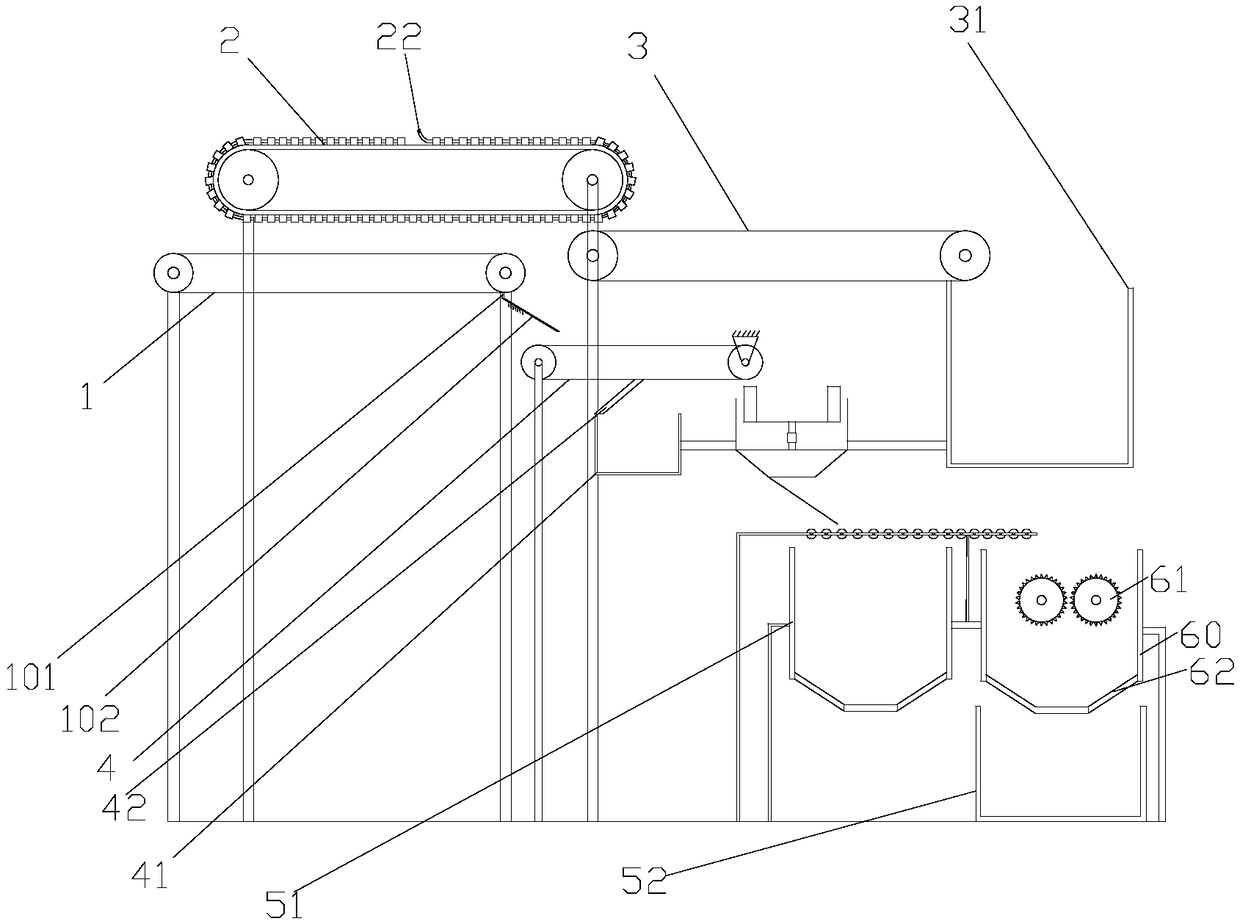

Garbage classification and recovery system

InactiveCN109095032AAvoid cloggingImprove processing and recycling efficiencyRefuse receptaclesEngineeringMechanical engineering

The invention discloses a garbage classification and recovery system. The garbage classification and recovery system comprises a first separation device, a second separation device, a third separationdevice and a crushing device, wherein the first separation device is used for separating plastic garbage; the second separation device is used for separating metal; the third separation device is used for separating liquid; the crushing device is used for treating garbage; the crushing device comprises a screening structure, a first recycling box, a crushing box arranged below the right of a screening assembly, and a second recycling box arranged below the crushing box; the screening structure comprises a first supporting frame, a plurality of rolling rods, transmission gears fixedly connected to the two ends of the rolling rods, a dredging part, transmission chains and a driving part, wherein the transmission chains are matched with the transmission gears, and the driving part drives thetransmission chains to rotate; the rolling rods can be driven to rotate by driving the transmission chains, and then the garbage on the rods is driven to move, so that the relatively small garbage which does not need to be crushed can fall into the first recycling box through the gap between the two rolling rods, and the relatively large garbage is transported to the crushing device for processing, so that unnecessary processing of the relatively small garbage which does not need to be crushed and is conveyed to the crushing device by a conveying belt is avoided, and the garbage treatment andrecycling efficiency is improved.

Owner:陈健

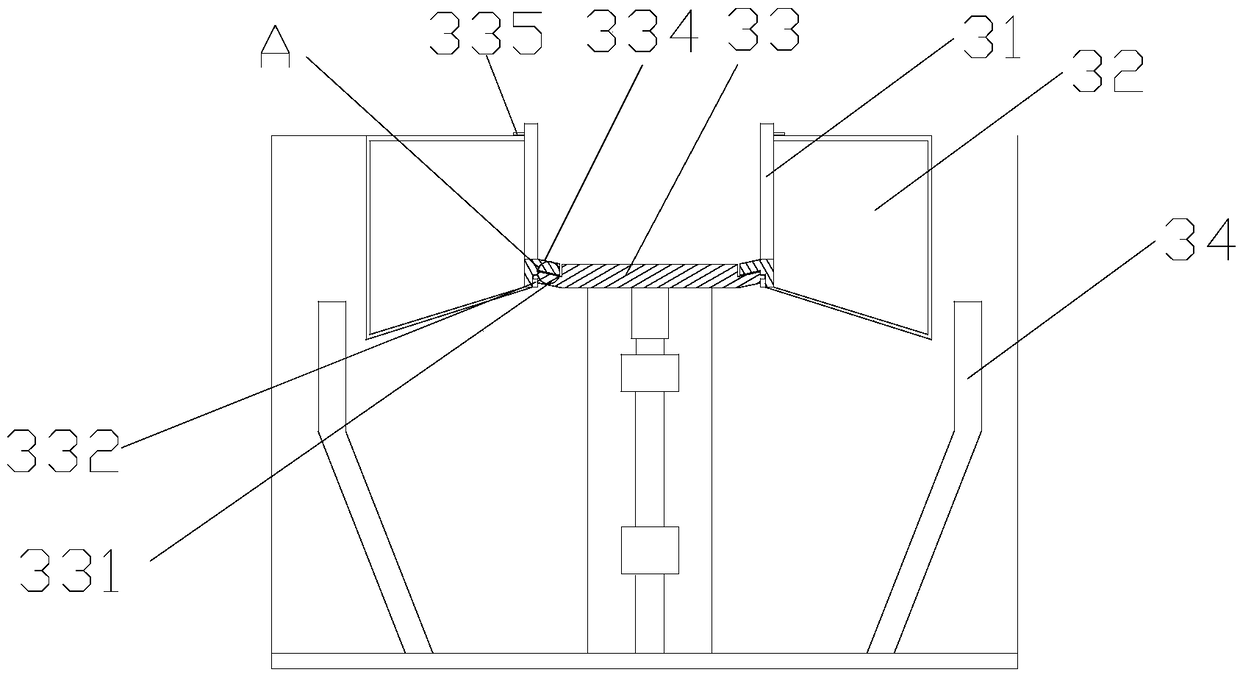

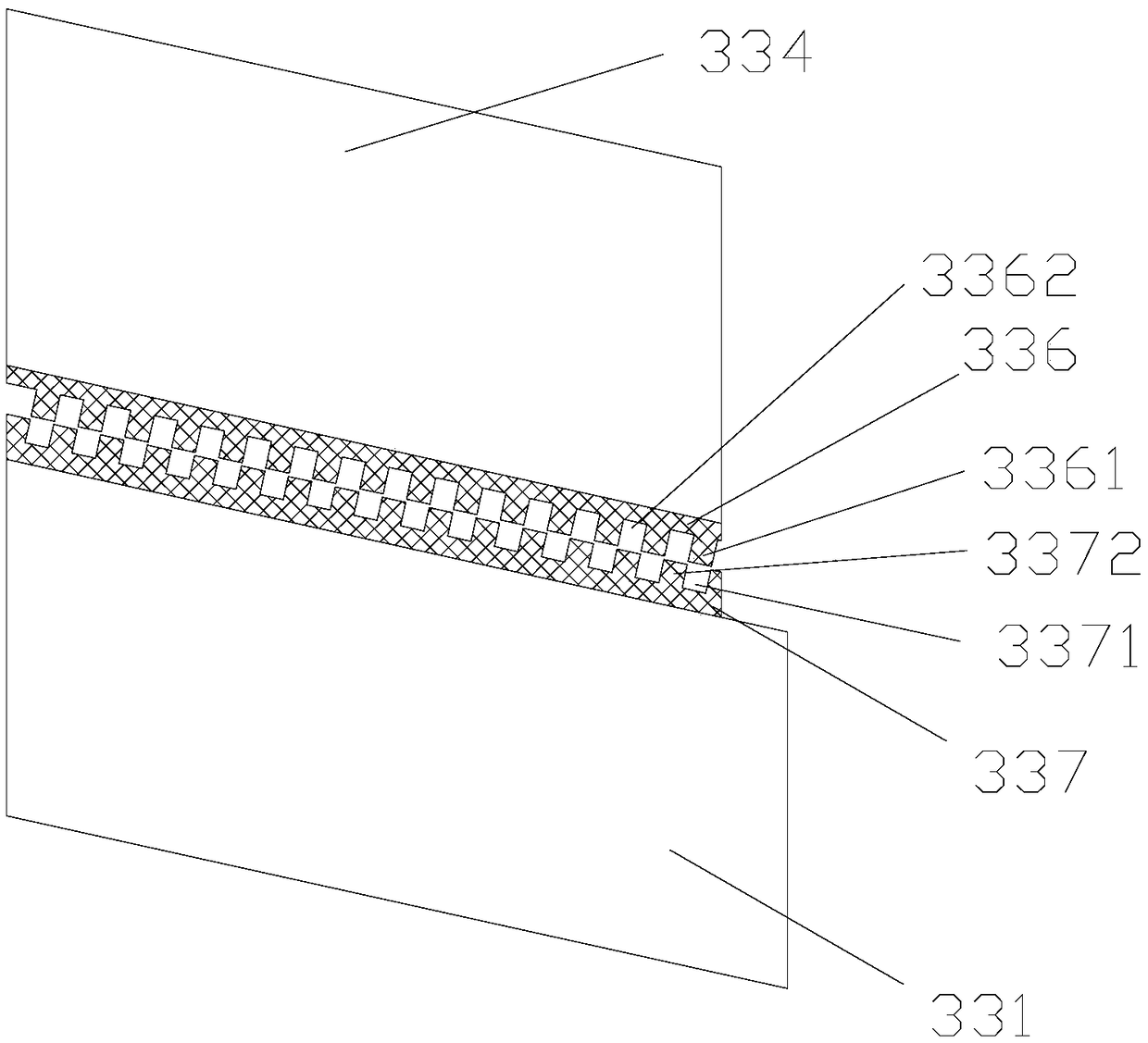

Pure natural botanical insecticide and preparation method thereof

ActiveCN113180067AEvenly distributedImprove grinding qualityBiocideAnimal repellantsStrychnos nux-vomicaToxicology

The invention belongs to the technical field of pesticides, and relates to a pure natural botanical insecticide and a preparation method thereof. The preparation method includes the steps that: S1, fructus cnidii, camphor, tobacco leaves, herba lysimachiae, radix sophorae flavescentis, liquorice and semen strychni are weighed according to the weight part ratio and sequentially put into a grinding machine to be ground into powder; S2, the mixed powder obtained in the step S1 is added into a leaching kettle, water, an emulsifying agent and a dispersing agent are added according to a ratio, heating, and uniform stirring are performed; and S3, after the mixture obtained in the step S2 is cooled, the mixture is put into a centrifugal machine to be subjected to high-speed centrifugal separation, a finished product is collected and put into a chemical agent tank, and the chemical agent tank is closed. When materials are put into a grinding box, the materials cannot be uniformly laid in a grinding seat, as a result, the grinding efficiency is reduced, and the grinding quality of grinding balls on the materials is influenced. With the pure natural botanical insecticide and the preparation method thereof adopted, the above problems can be solved.

Owner:HENAN DECI YANGNONG BIOTECH CO LTD

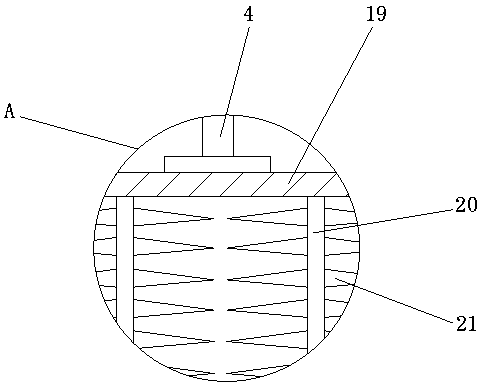

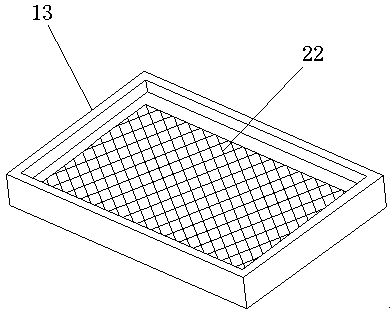

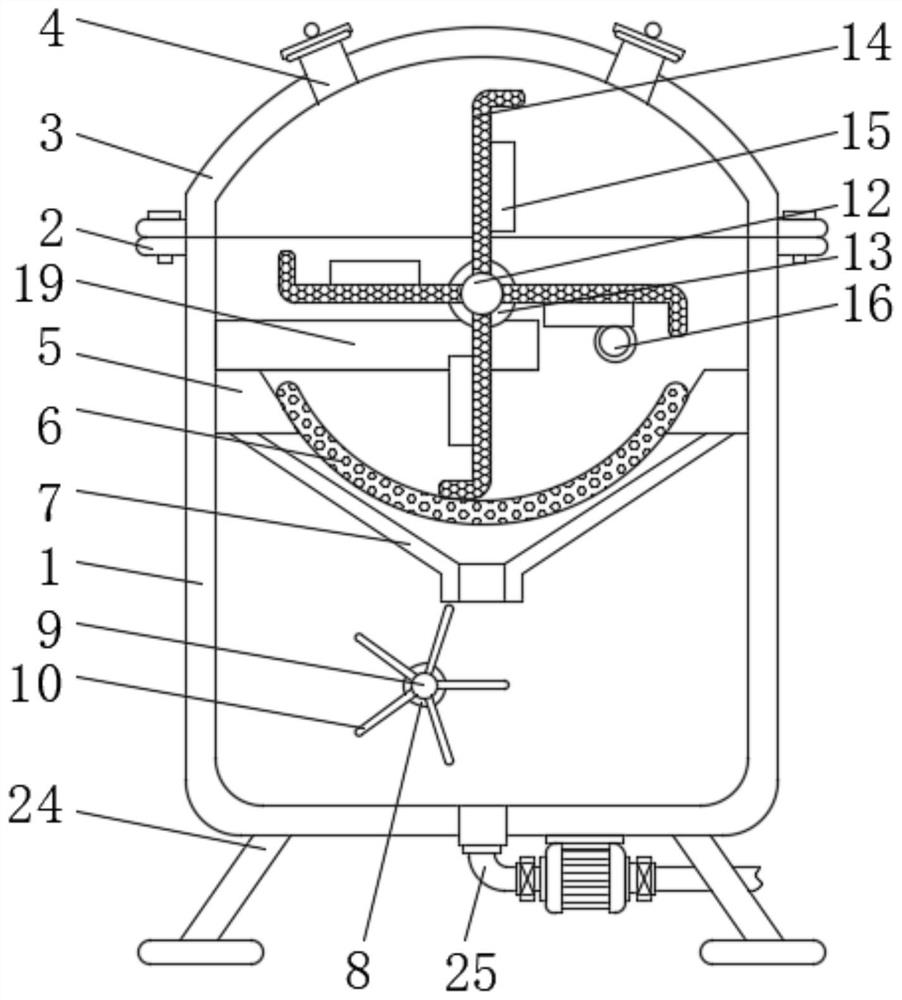

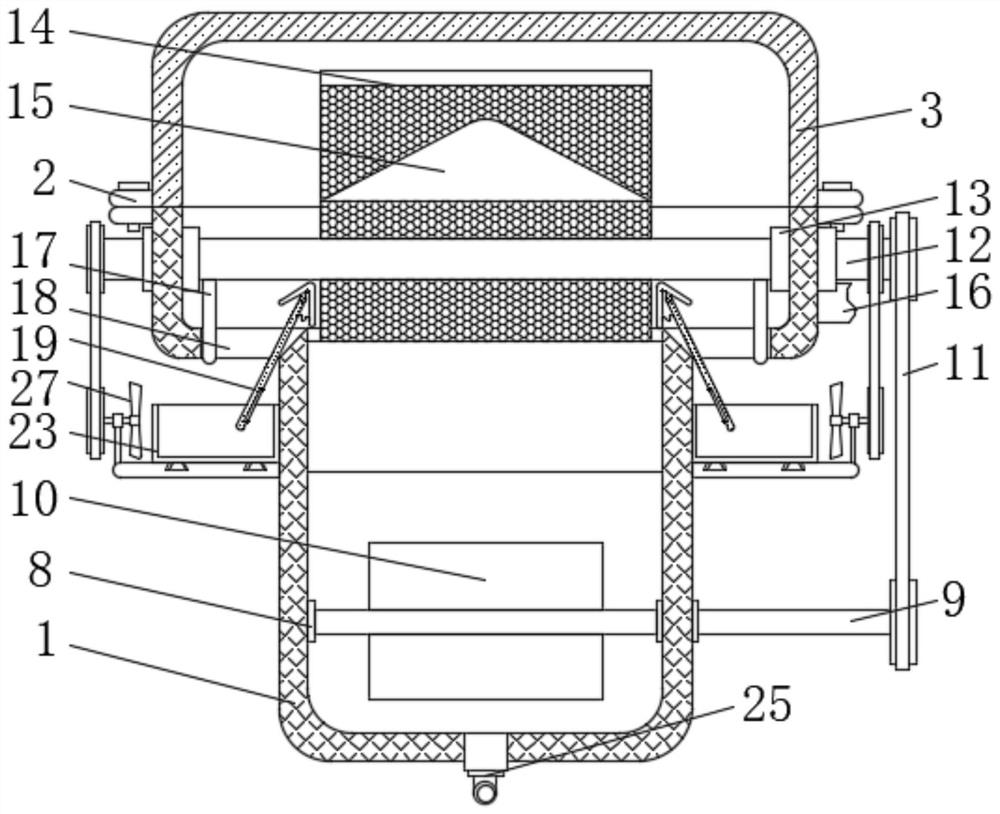

Chinese toon sauce decocting device

InactiveCN109452611AScattered evenlyImprove mixing efficiencyTransportation and packagingRotary stirring mixersEngineeringElectric heating

The invention discloses a Chinese toon sauce decocting device. The device comprises a decocting tank, an outer heat preservation seat sleeves the outer side of the decocting tank, an electric heatingblock is embedded at the joint of the decocting tank and the outer heat preservation seat, electric heating tubes are embedded in the electric heating block, an unloading pipe penetrating the outer heat preservation seat is connected to the center of the bottom of the decocting tank, a stirring motor is fixed at the center of the top of the decocting tank by bolts, and the top of the decocting tank is provided with an auxiliary material adding port and a main material bin which are symmetrically arranged at two sides of the stirring motor. According to the invention, an auxiliary material boxis welded on the stirring shaft, spray heads are connected to the bottom of the auxiliary material box, auxiliary materials can be added into the auxiliary material box through an auxiliary material adding bin and a feeding port in the using process, then the auxiliary material box is driven to rotate through the stirring shaft, the auxiliary materials in the auxiliary material box can be uniformly scattered on the main materials in the decocting tank, so that the mixing and stirring efficiency of the main materials and the auxiliary materials is improved.

Owner:十堰市天河缘农业科技有限公司

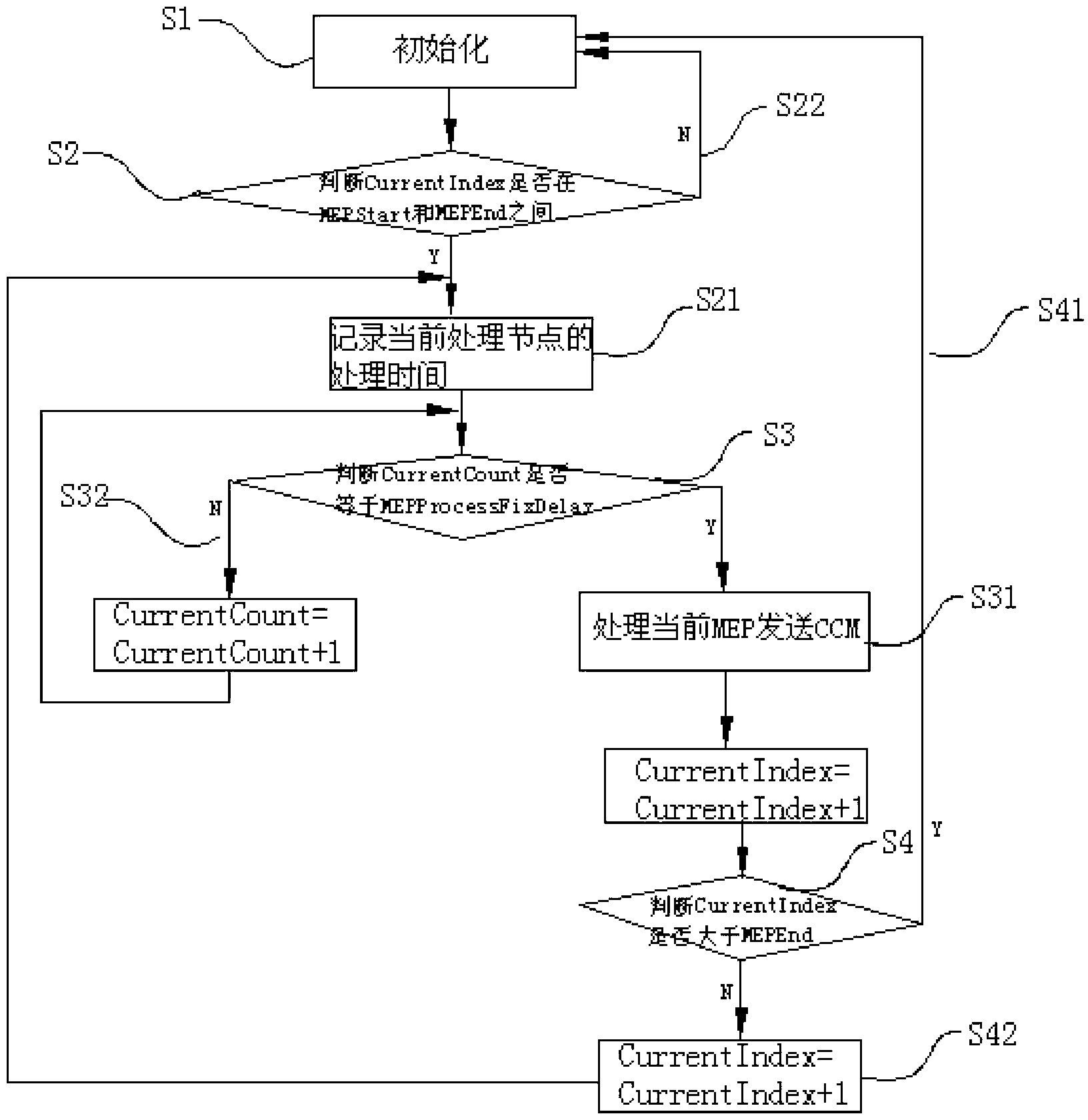

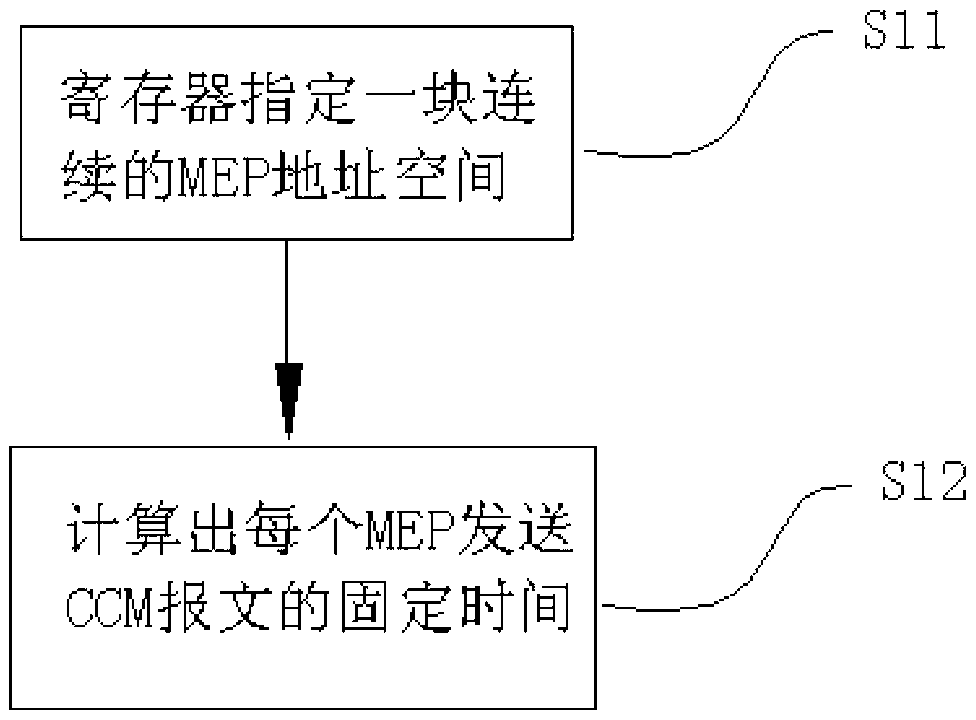

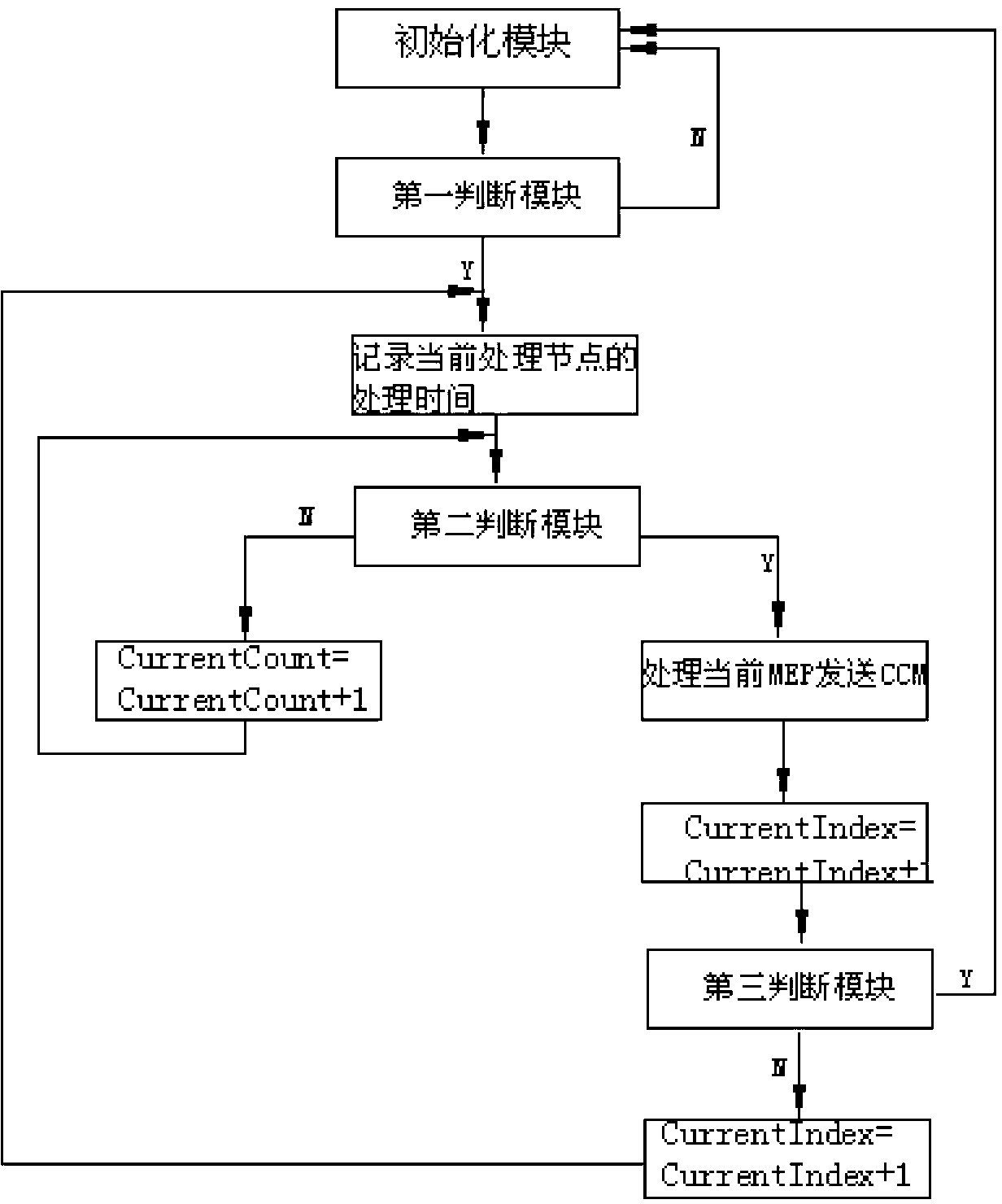

Method and device for enabling switch chip to generate OAM (Operation Administration and Management) messages at constant speed

ActiveCN103312633AGuaranteed productionEnsure that each MEP entry is correctly generatedData switching networksTraffic capacityProcessor register

The invention discloses a method and a device for enabling a switch chip to generate OAM (Operation Administration and Management) messages at a constant speed, which belong to the field of network communication. Different CCM (Continuity Check Messages) sending frequencies are supported by multiple timer intervals. A register is used for configuring the adjustable delay time of MEP (Maintenance Endpoint) tables and adjusting the regular CCM sending time of each MEP. All the MEPs on the current time shaft can be processed at just one Interval, and the processing time dots of all the MEPs are evenly scattered on the dots of the Interval / (MEP End-MEP Start+1), so that the CCM sending frequency is set as the Interval, and the processing time of all the MEPs is evenly scattered. The method and the device can ensure that CCMs are generated by each MEP at a correct frequency, messages needing to be transmitted by the network are transmitted at a constant speed to an utmost extent, and the impact on the flow of network equipment is reduced.

Owner:SUZHOU CENTEC COMM CO LTD

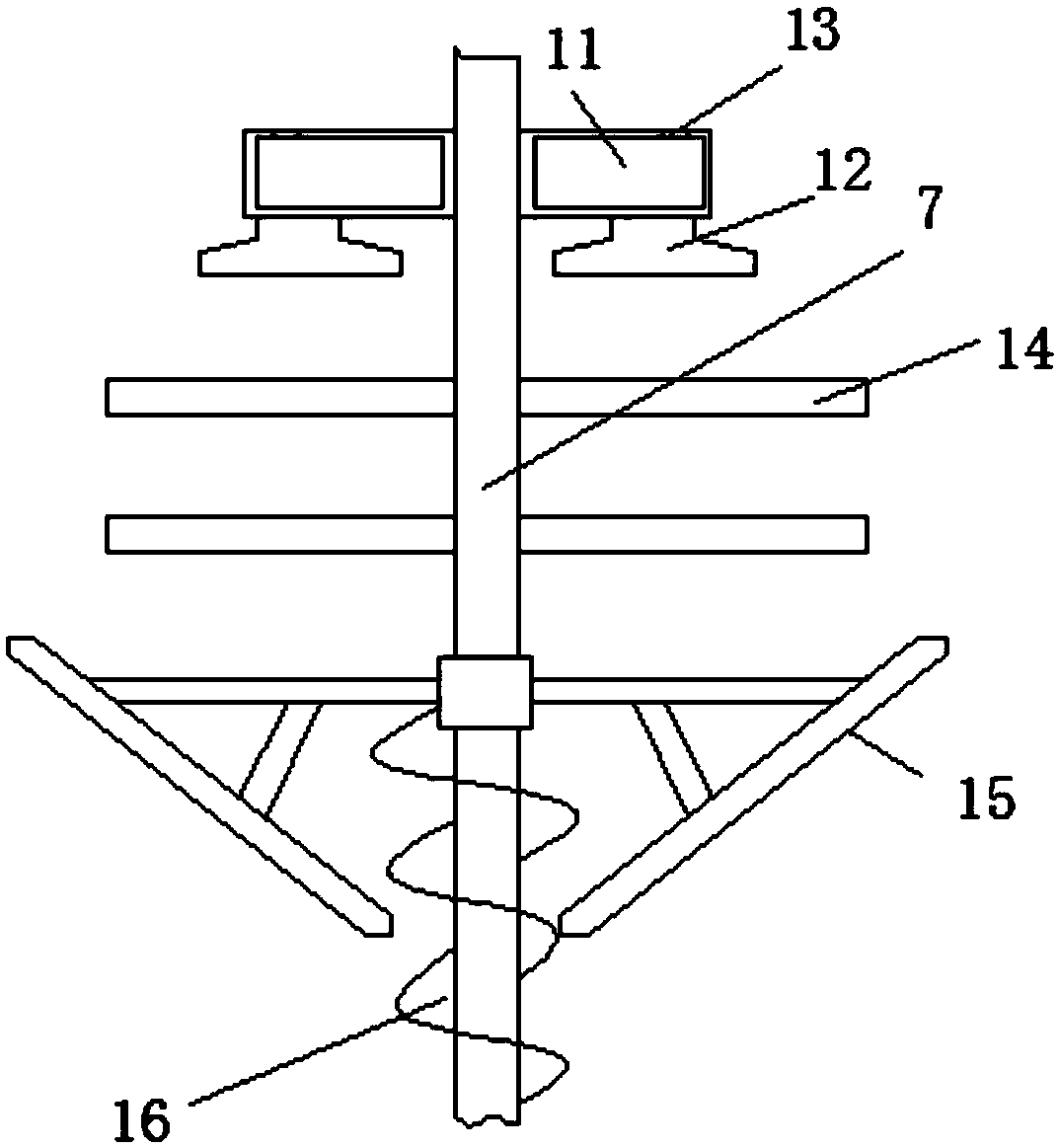

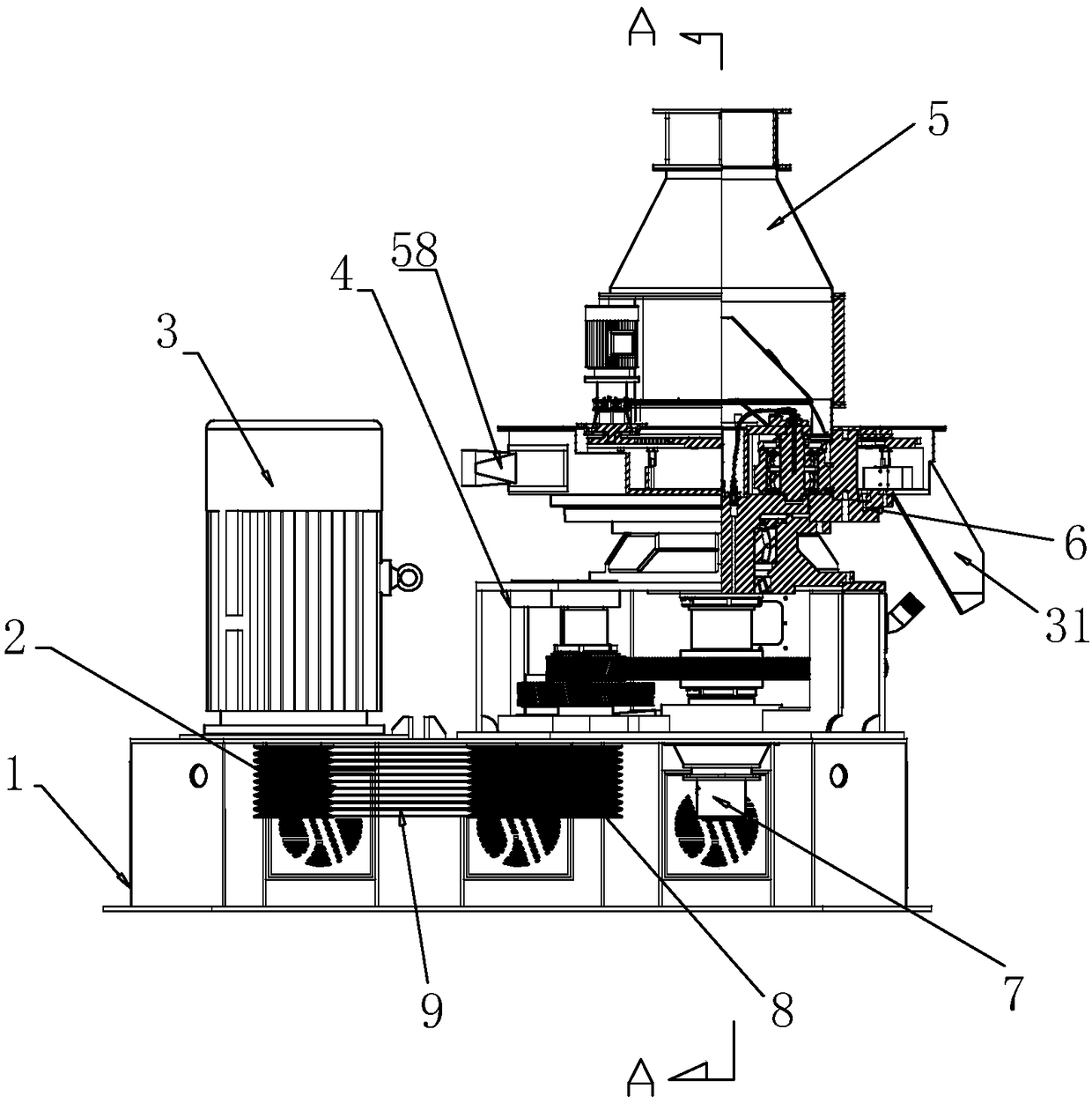

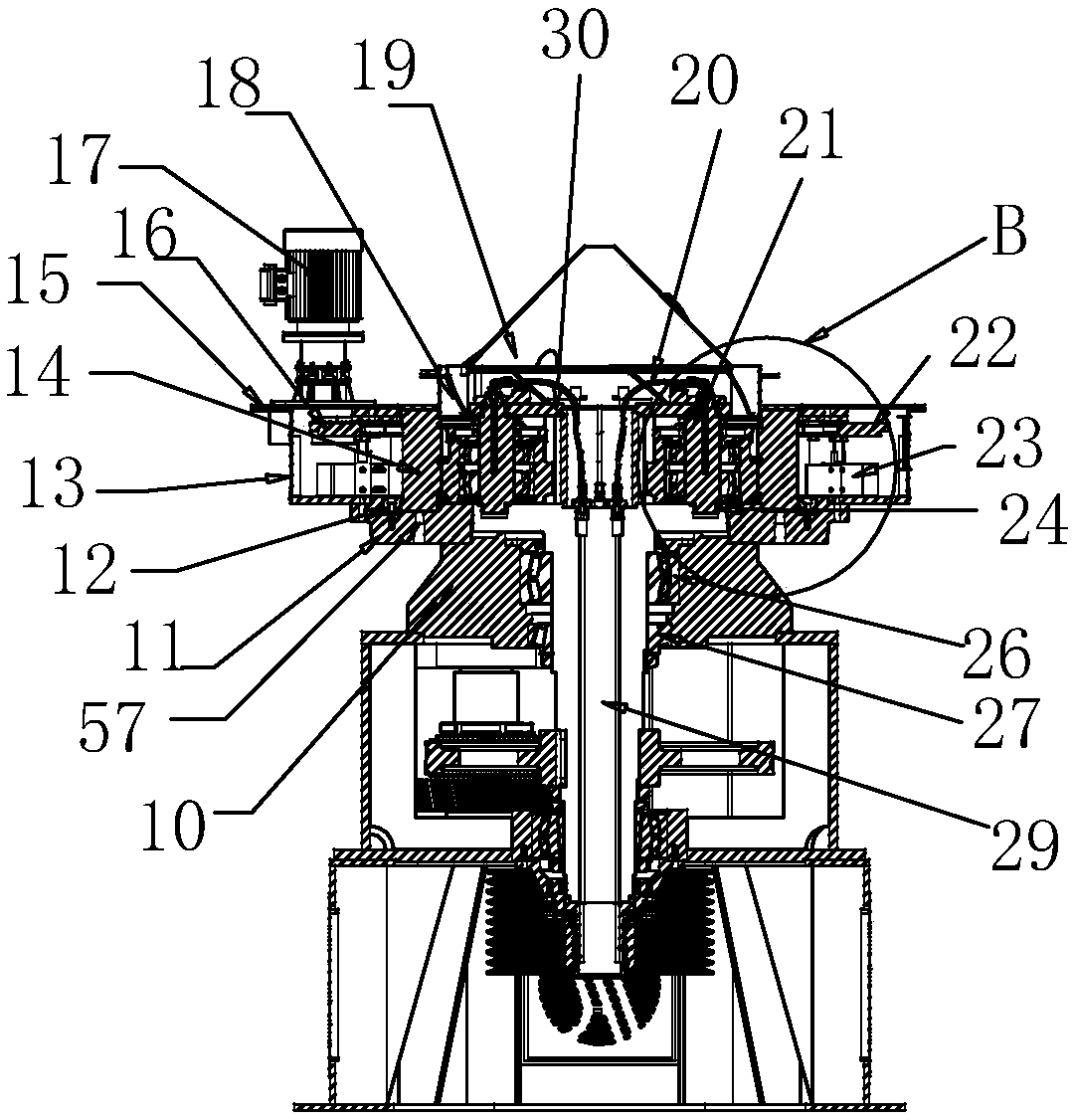

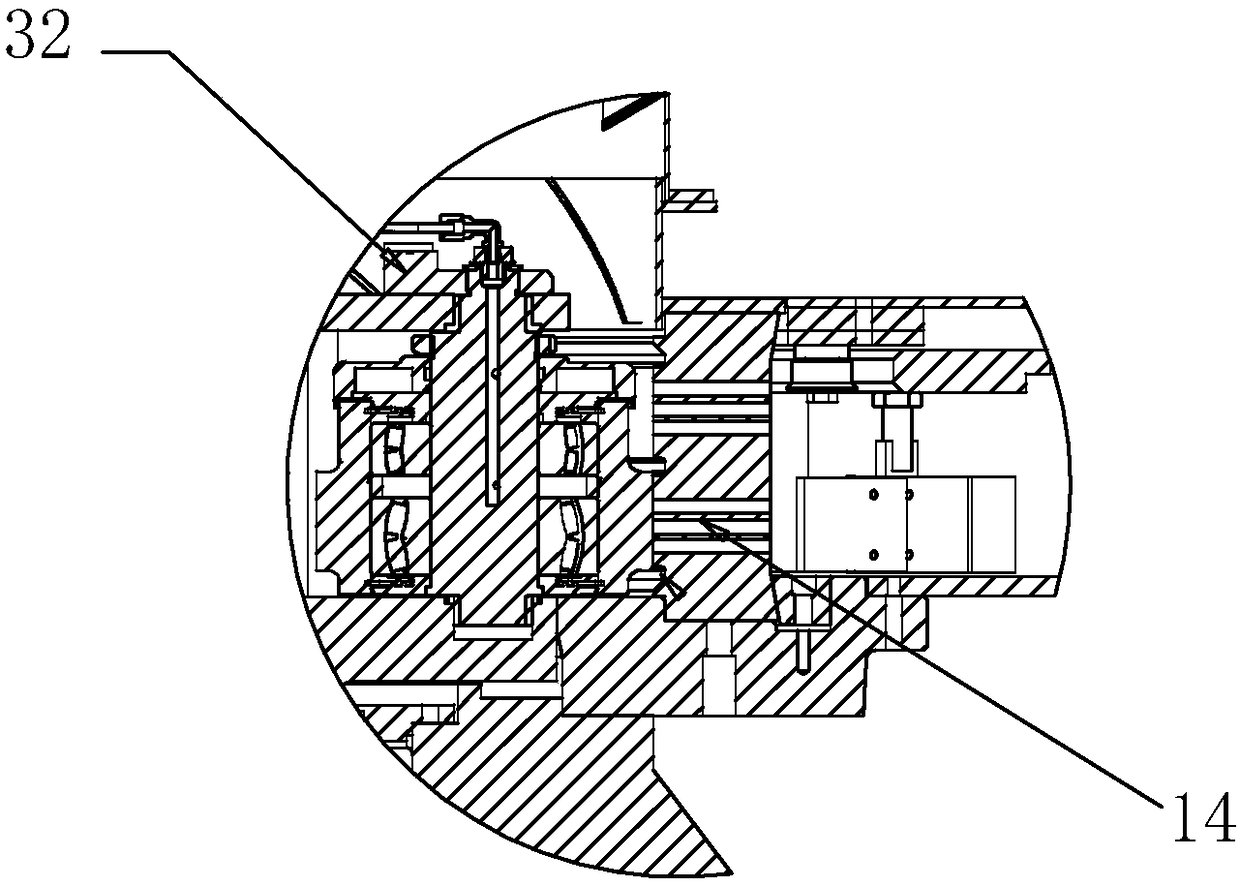

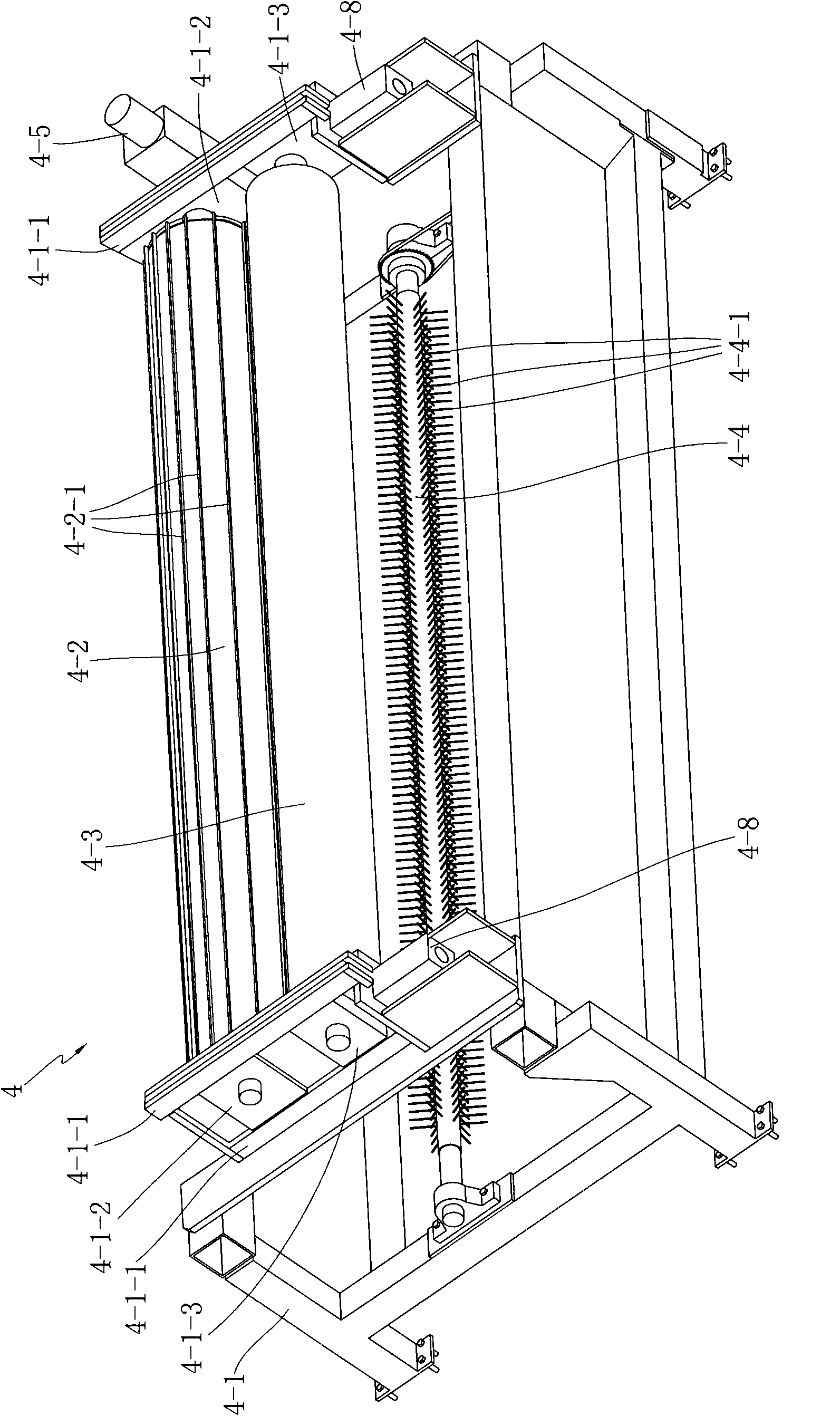

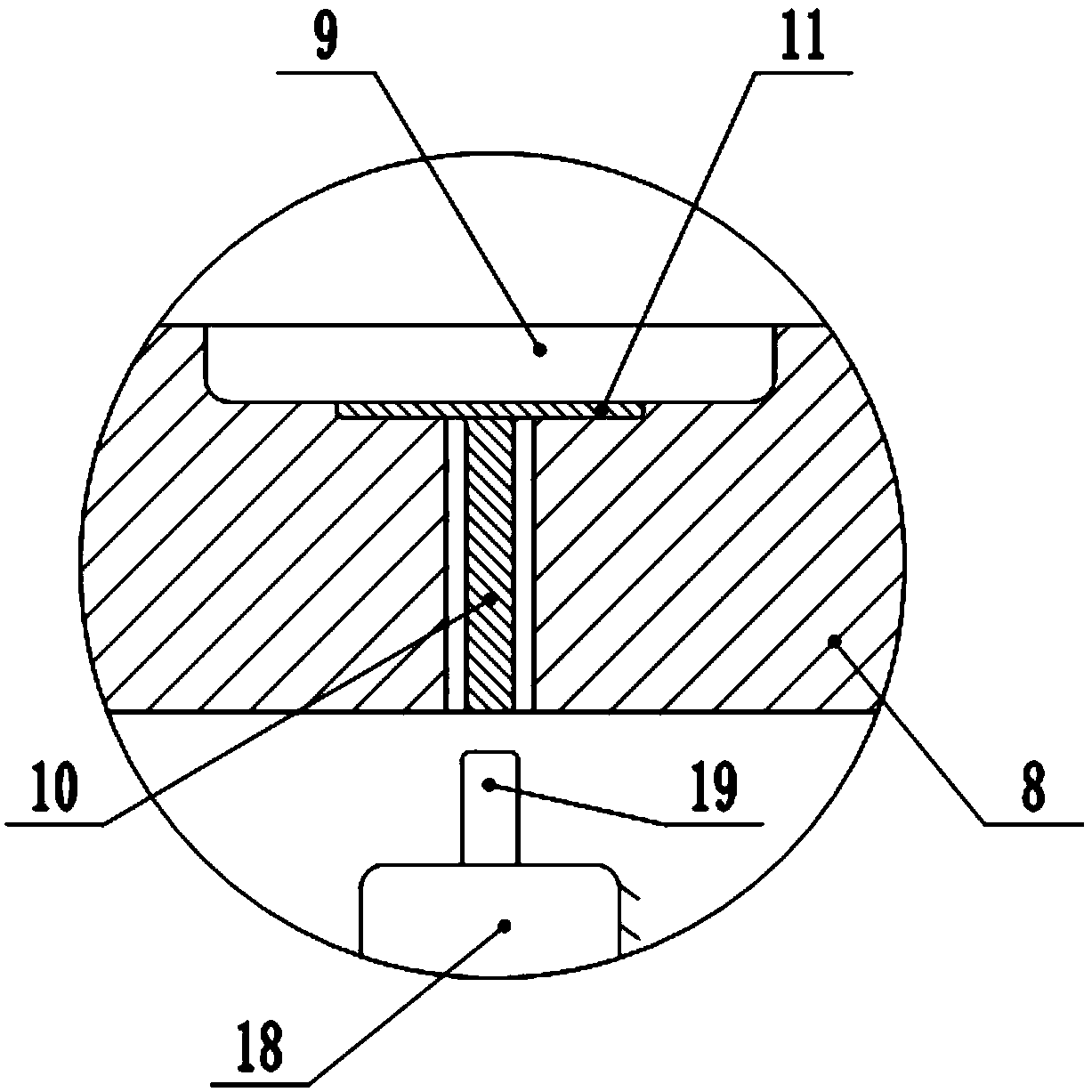

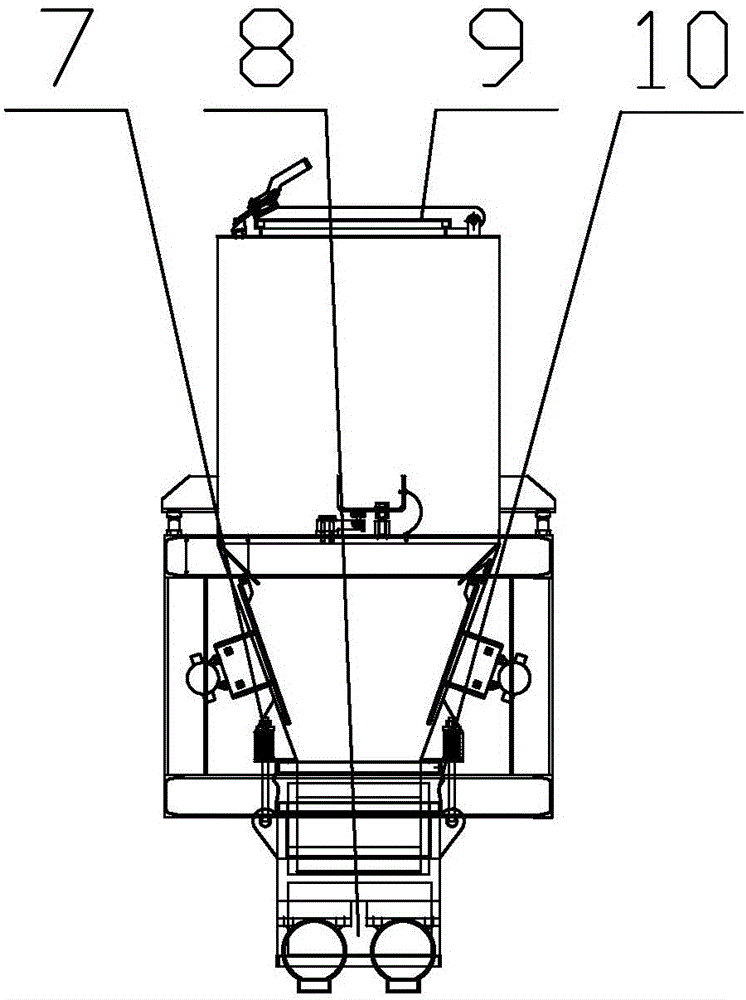

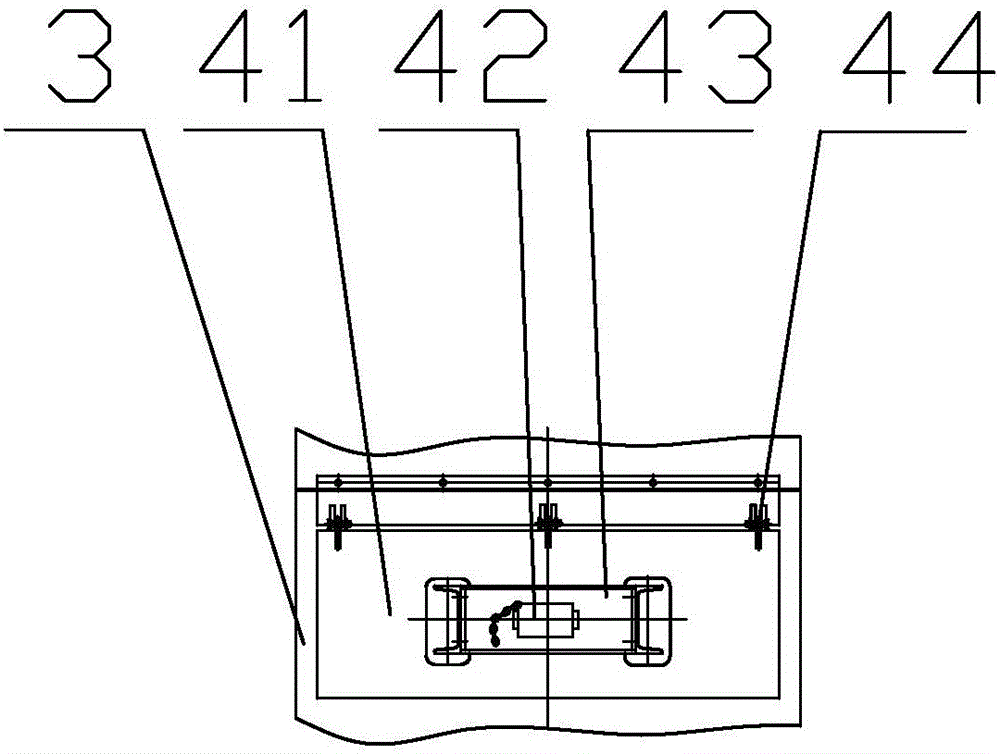

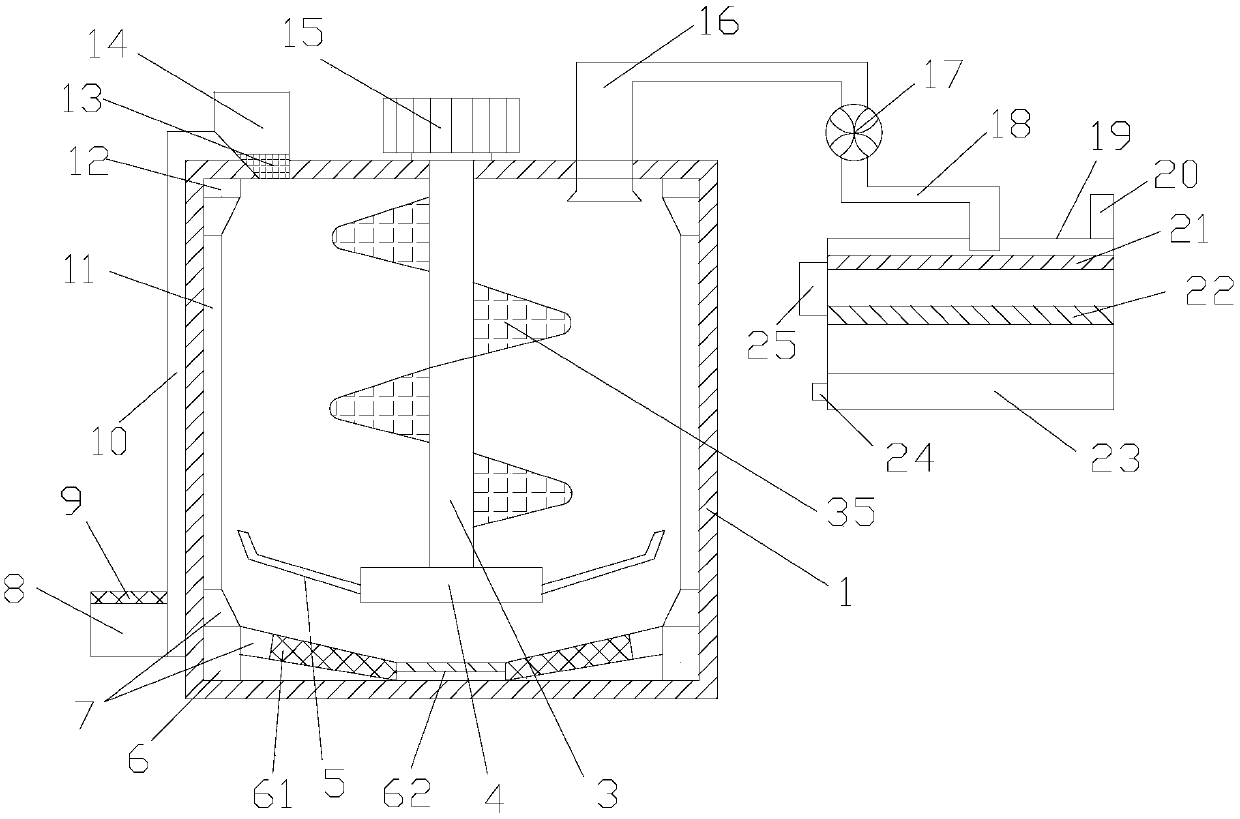

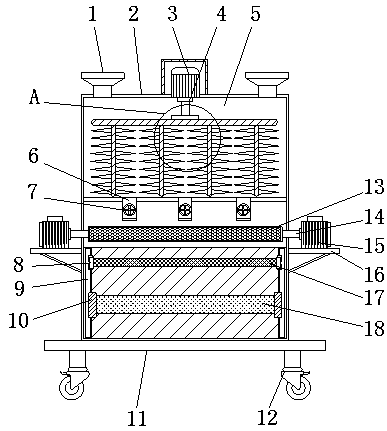

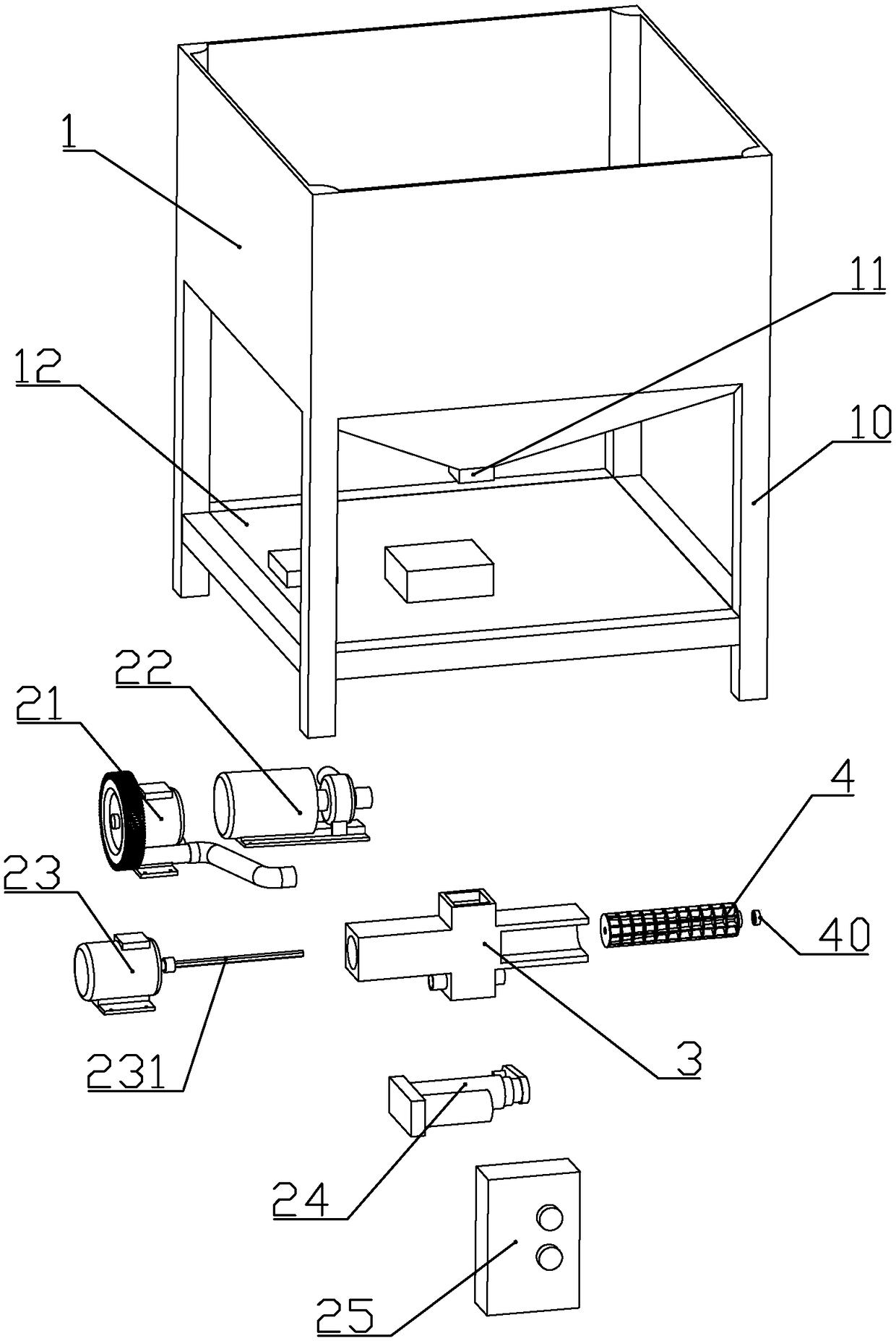

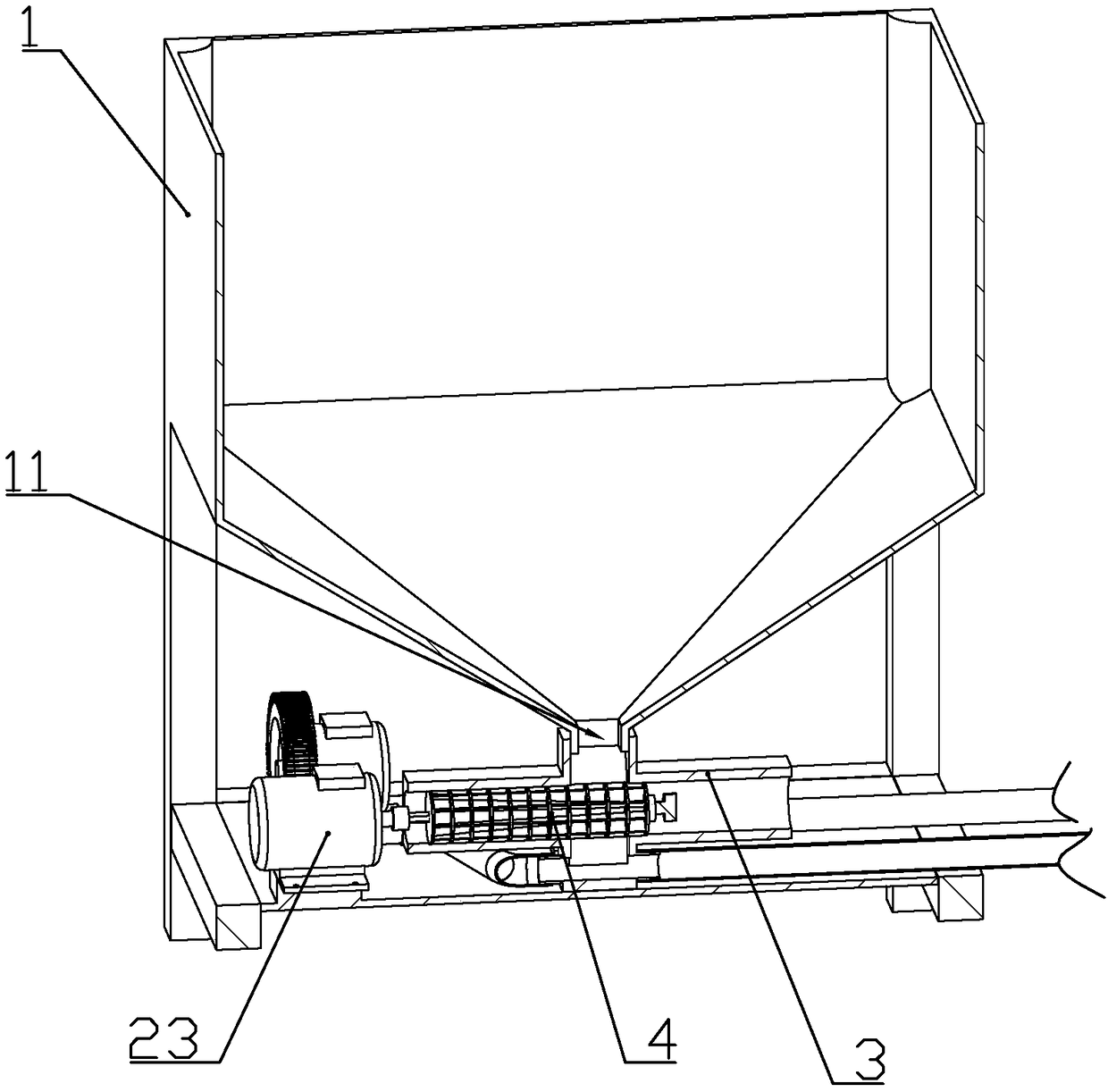

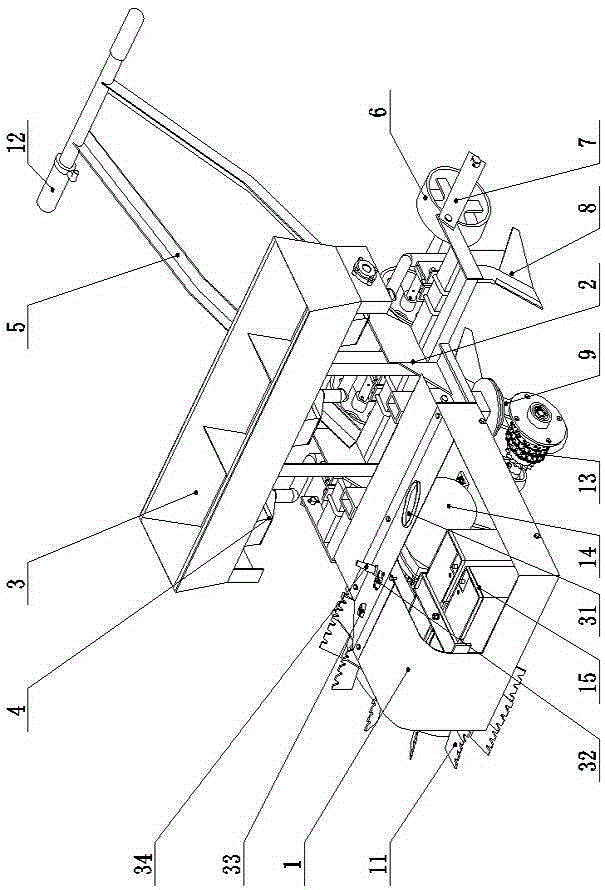

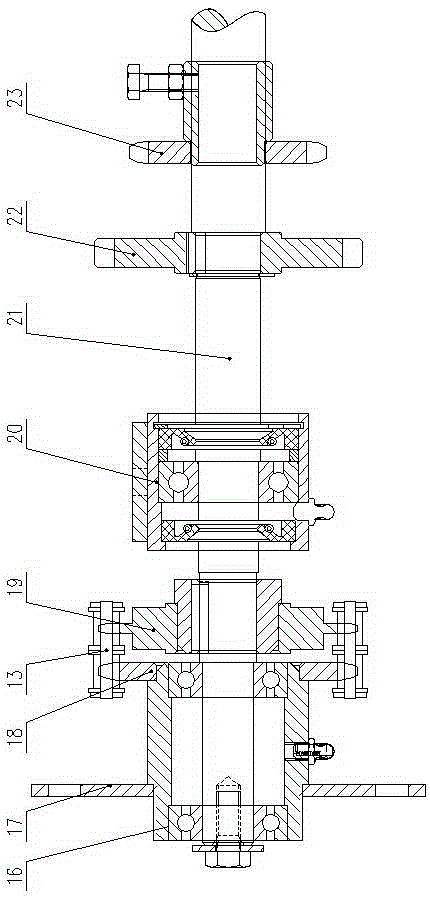

Vertical ring die pelleter

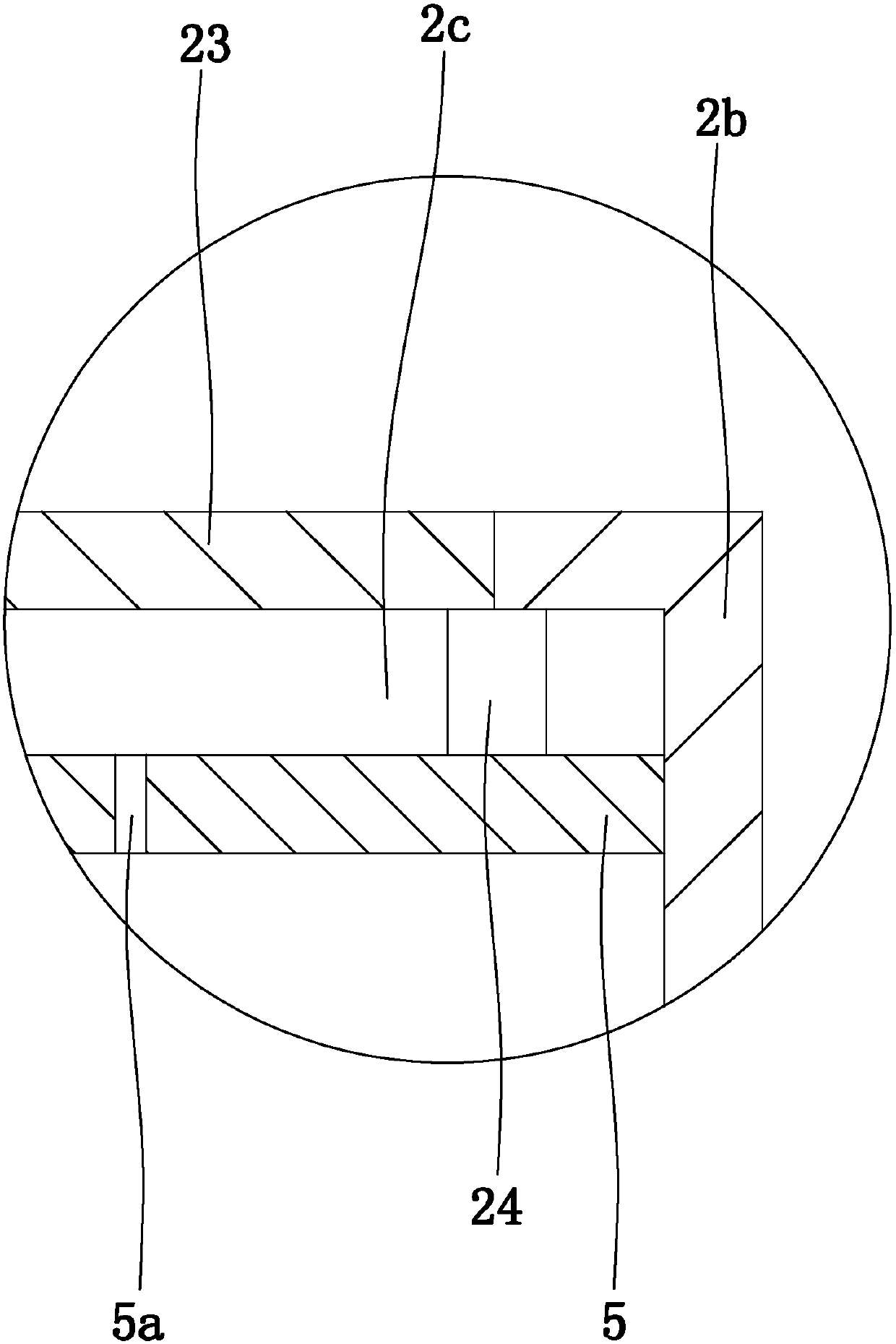

PendingCN108246203ADissipate heat in timeImprove efficiencyBiofuelsSolid fuelsMotor driveAgricultural engineering

The invention relates to a vertical ring die pelleter, which comprises a main machine (6), wherein the main machine comprises a bracket (10), a ring die seat (11), a connection seat (18), a main machine shell (13), an upper cover (15), a ring die (14), a pressure roller assembly (21) and a main shaft (29), the main shaft (29) and the power output shaft of a speed reduction box share a shaft, the pressure roller assembly (21) is fixed on the upper portion of the main shaft, the ring die and the pressure roller assembly (21) are matched, the outer side of the ring die is provided with the main machine shell (13), the upper cover (15) is fixed on the main machine shell (13), a speed reduction motor (17) is fixed on the upper cover (15), a material scraping plate and a cutter are fixedly connected on a tooth disc (22), and the speed reduction motor drives the tooth disc to move. With the technical scheme of the present invention, the vertical ring die pelleter is reliable and safe.

Owner:JIANGSU YONGLI MACHINERY

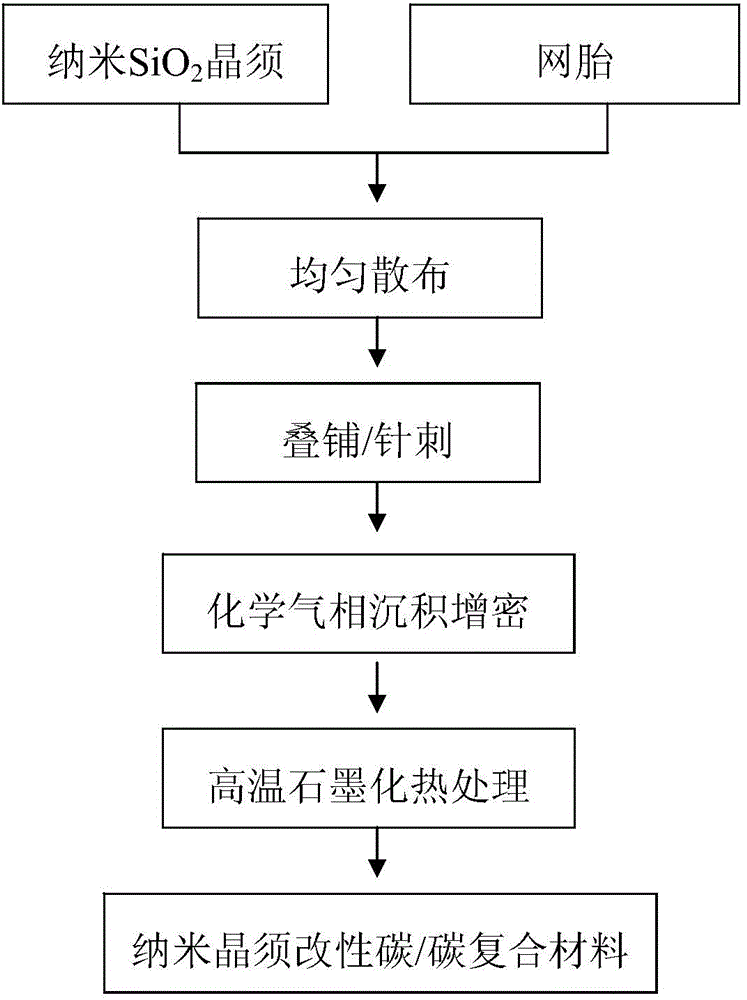

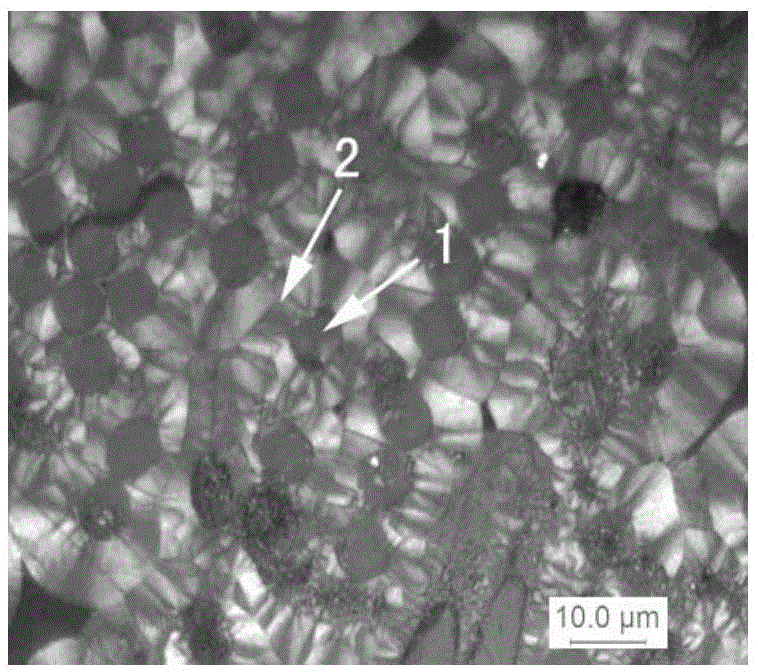

Preparation method of whisker modified carbon/carbon composite material

The invention relates to a carbon / carbon composite material and a preparation method thereof, in particular to a nano SiO2 whisker modified carbon / carbon composite material and a preparation method thereof. Nano SiO2 whiskers are uniformly dispersed on the surface of each layer of carbonfiber web, the carbonfiber webs are overlaid layer by layer and woven, and a carbon fiber preform is obtained; CVI (chemical vapor infiltration) treatment is performed; a carbon fibergreen body containing pyrolytic carbon is obtained; and finally, graphitization treatment is performed, and the whisker modified carbon / carbon composite material is obtained. The nano SiO2 whiskers are uniformly added to full-web carbon fiber felt, pyrolytic carbonnucleation and growth environment in the CVI process is changed, the pyrolytic carbon structure is improved, the performance of the carbon / carbon composite material is improved; and compared with an unmodified carbon / carbon composite material, the degree of graphitization is increased by 25%-30%, the thermal conductivity is improved by 24%-28%, and the resistivity is reduced by 12%-15%.

Owner:CENT SOUTH UNIV

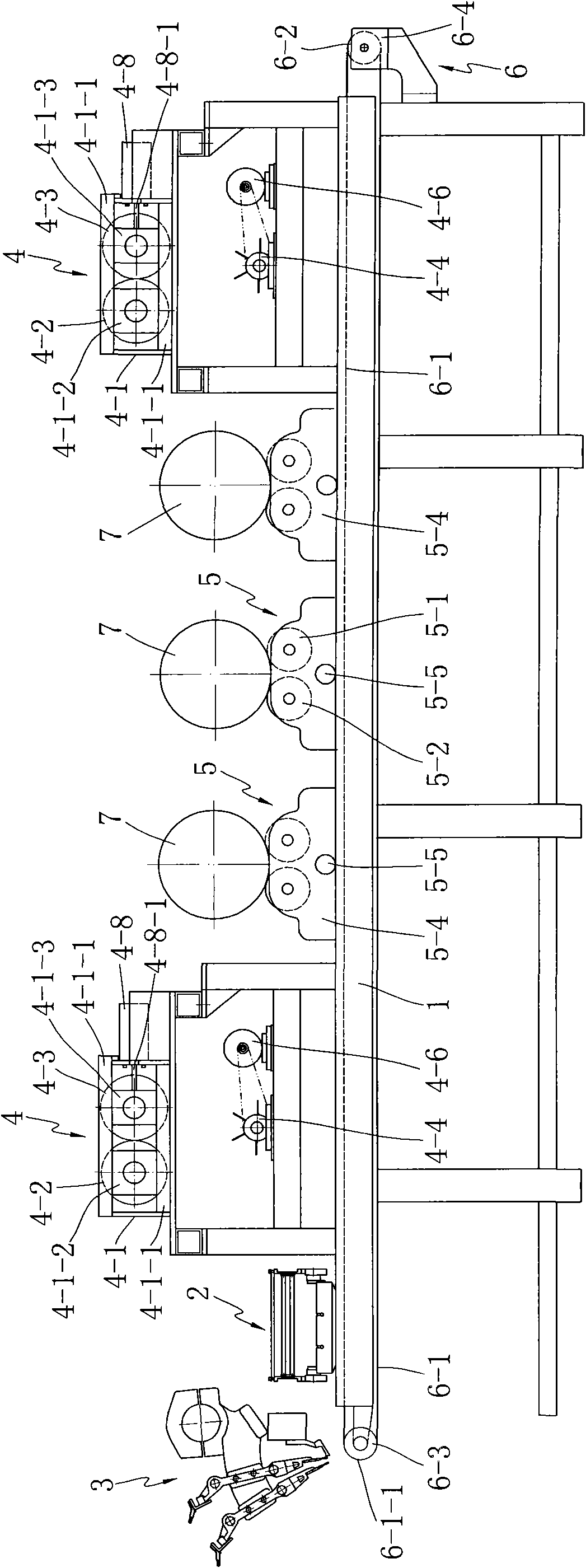

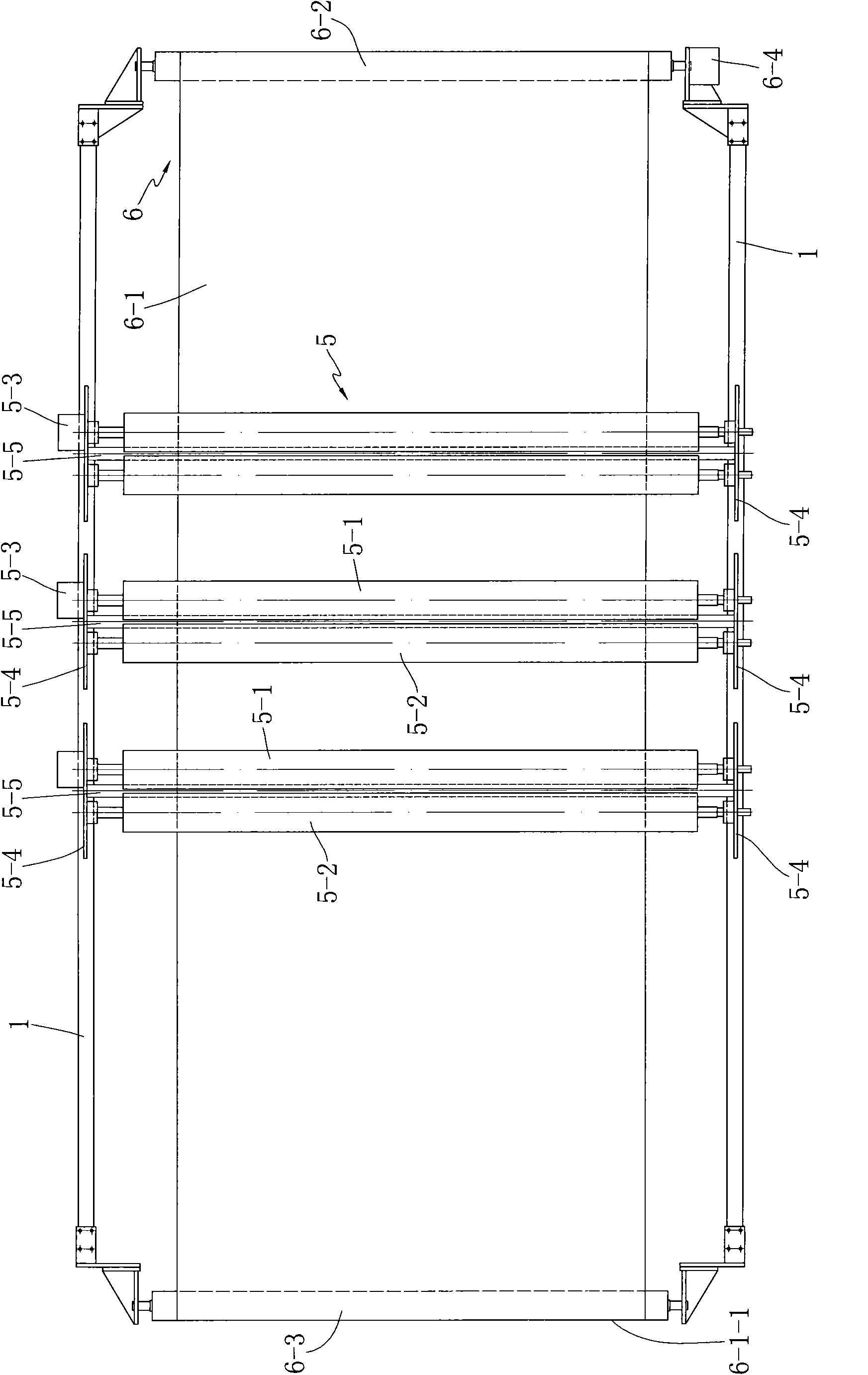

Double axial warp knitting machine

The invention discloses a double axial warp knitting machine, which comprises a warp inserting mechanism, a weft inserting mechanism, a knitting mechanism, a drawing and winding mechanism, at least two fiber chopping machines capable of cutting fibers by required length, at least one fabric conveying mechanism arranged between adjacent fiber chopping machines and a conveying mechanism arranged below the fiber chopping machines and the fabric conveying mechanism. Each fiber chopping machine comprises a machine frame, a knife roll, a rubber roll and a fiber throwing roll, wherein the knife roll is provided with a plurality of cutting blades which are distributed in a radial direction and have an axial vertical plate shape; the fiber throwing roll is provided with a plurality of short shafts which are distributed along a radial direction and are arranged along an axial direction at intervals; the cutting blades on the knife roll is matched with the rubber roll; and the fiber throwing roll is arranged below the knife roll and the rubber roll. The fabric conveying mechanism comprises a driving roll and a driven roll. The conveying mechanism comprises an annular closed conveying belt, a driving conveying roll and a driven conveying roll. The fabrics produced by the warp knitting machine of the invention have high service performance, can well meet actual service requirements and have wide application range.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

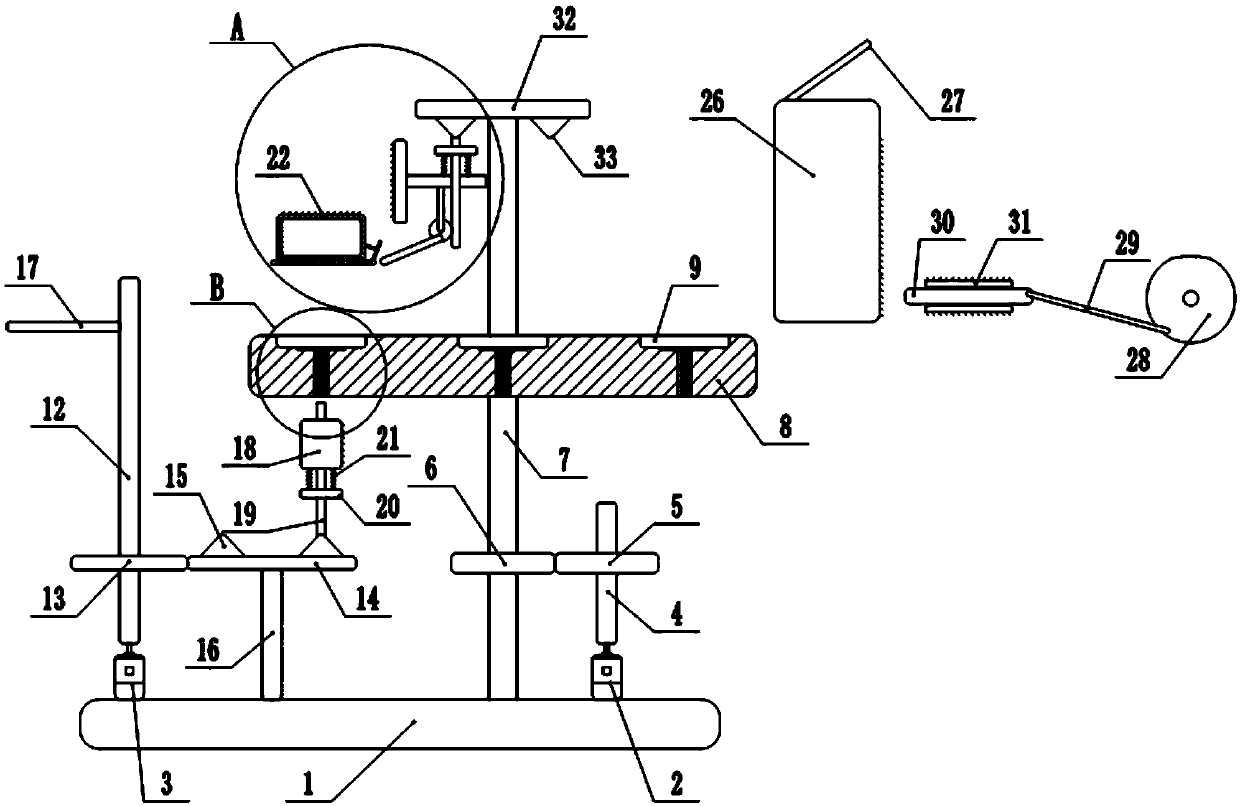

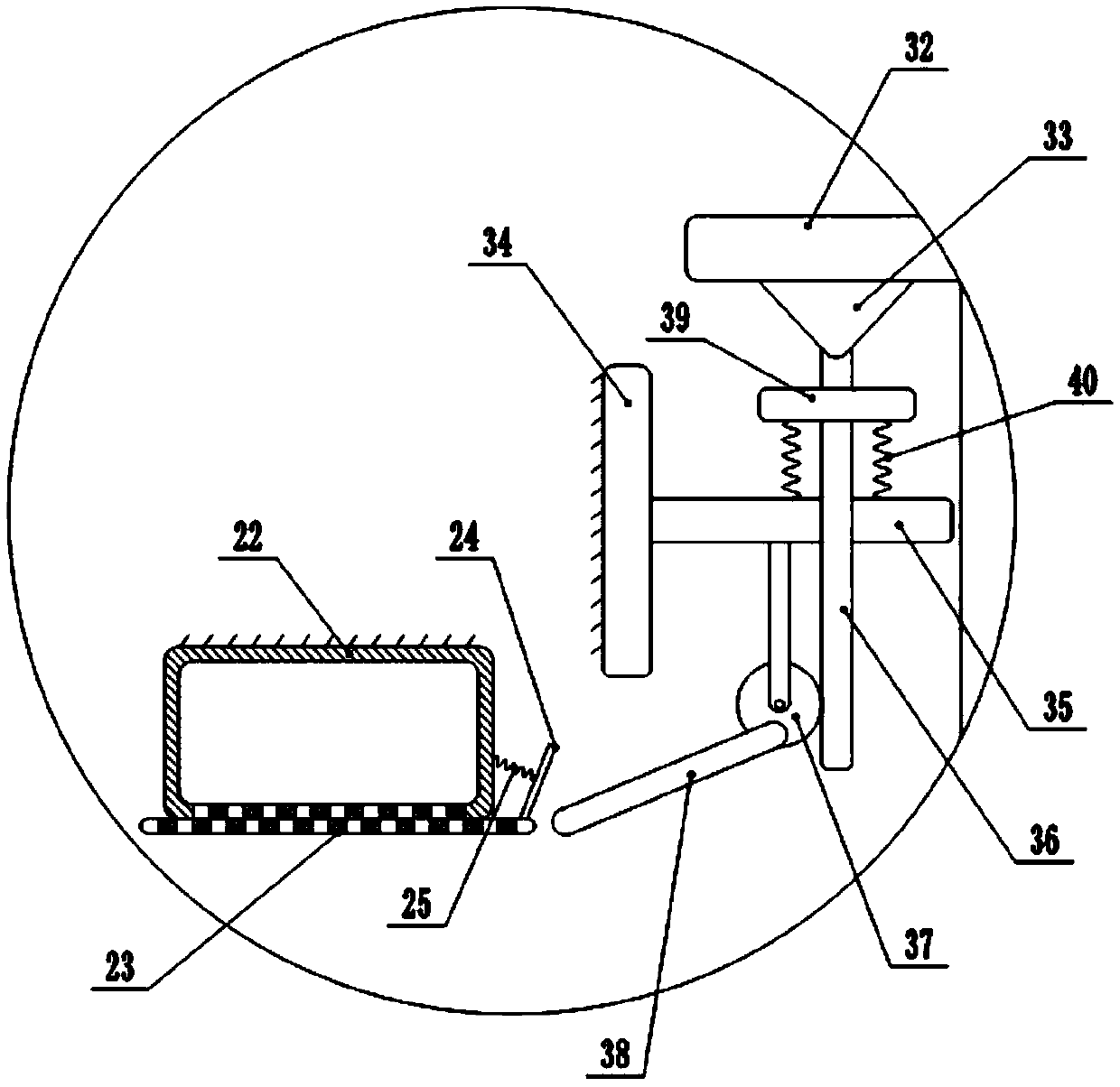

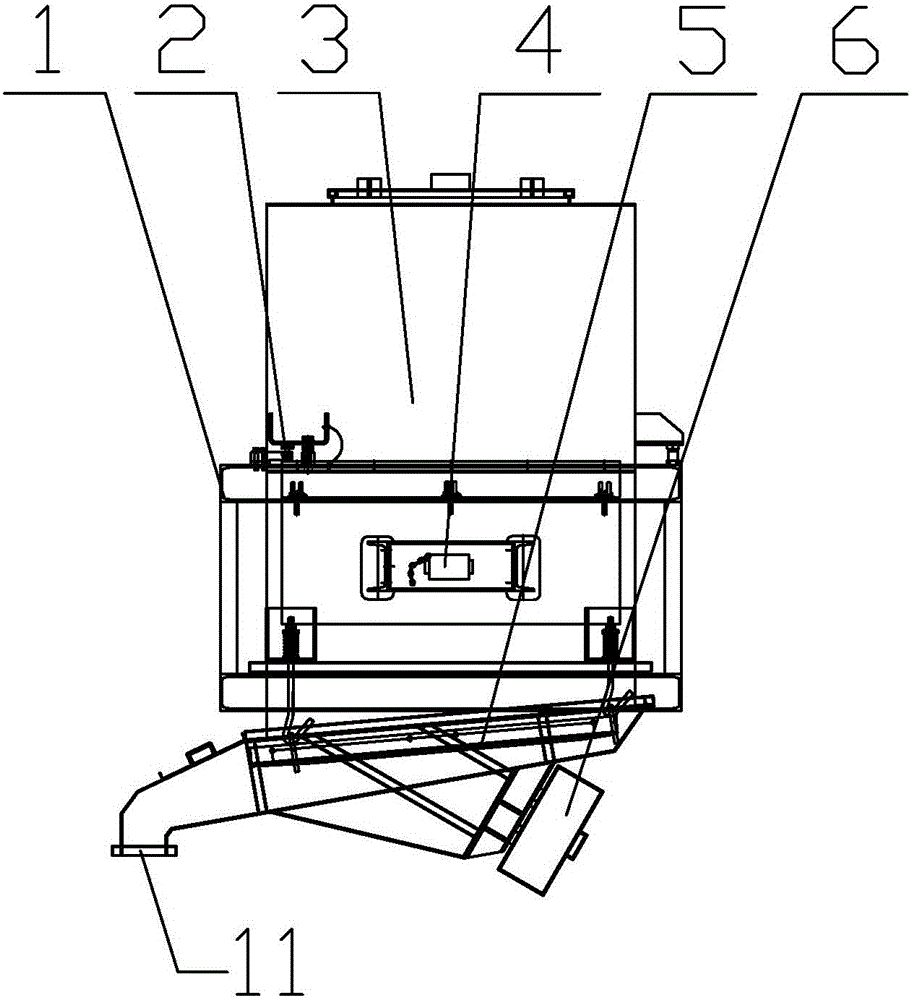

Food sesame sprinkling machine

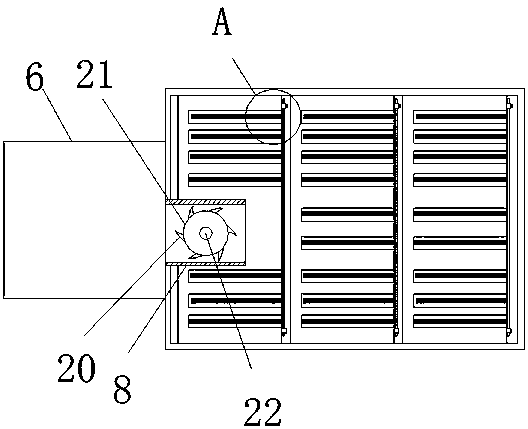

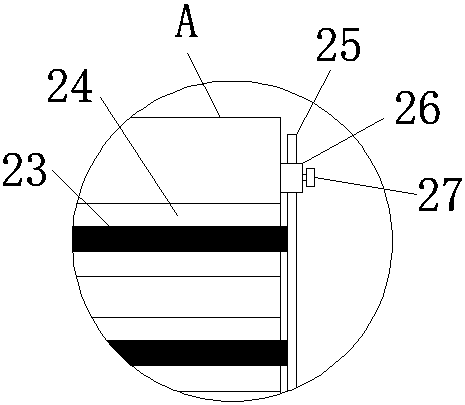

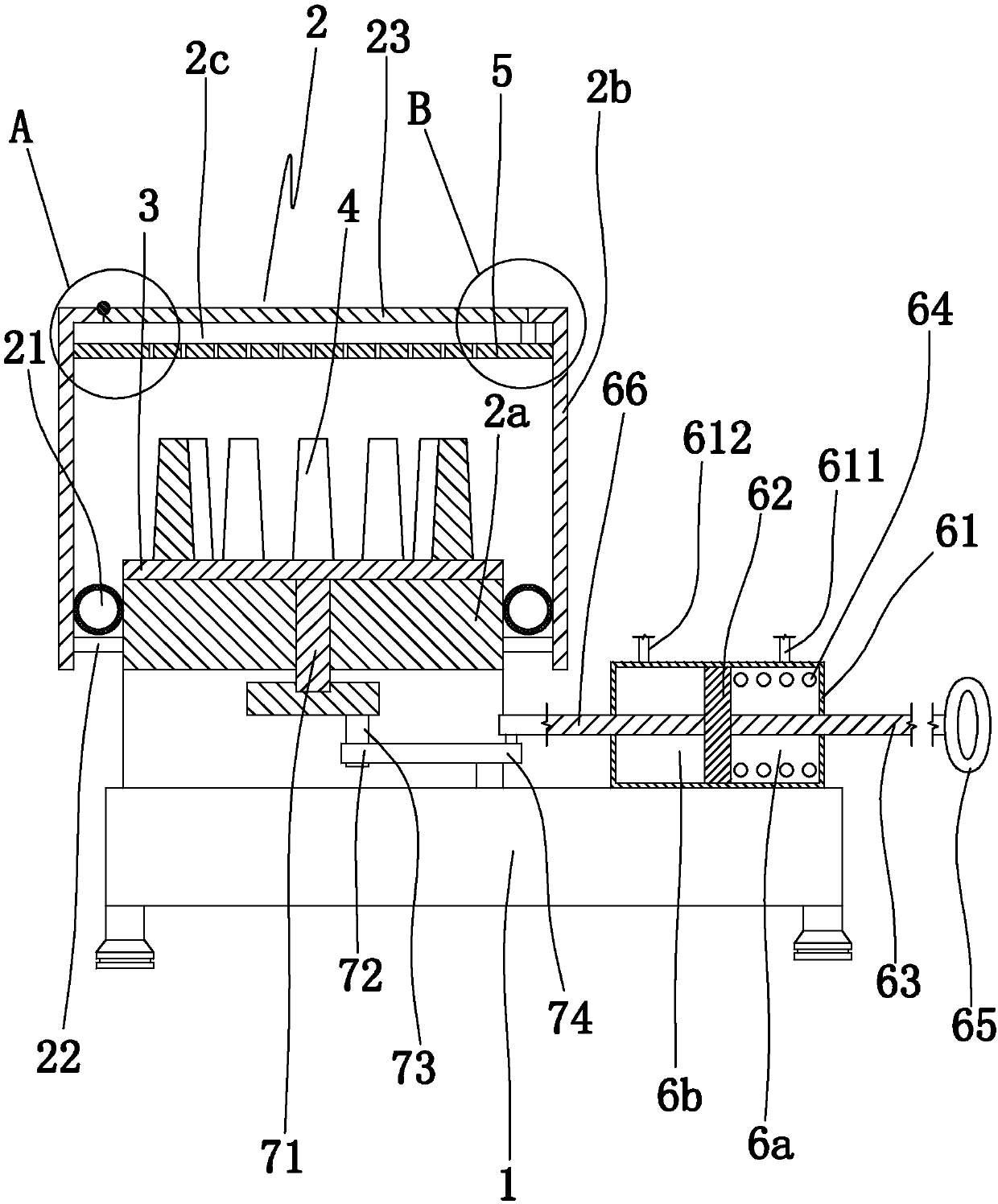

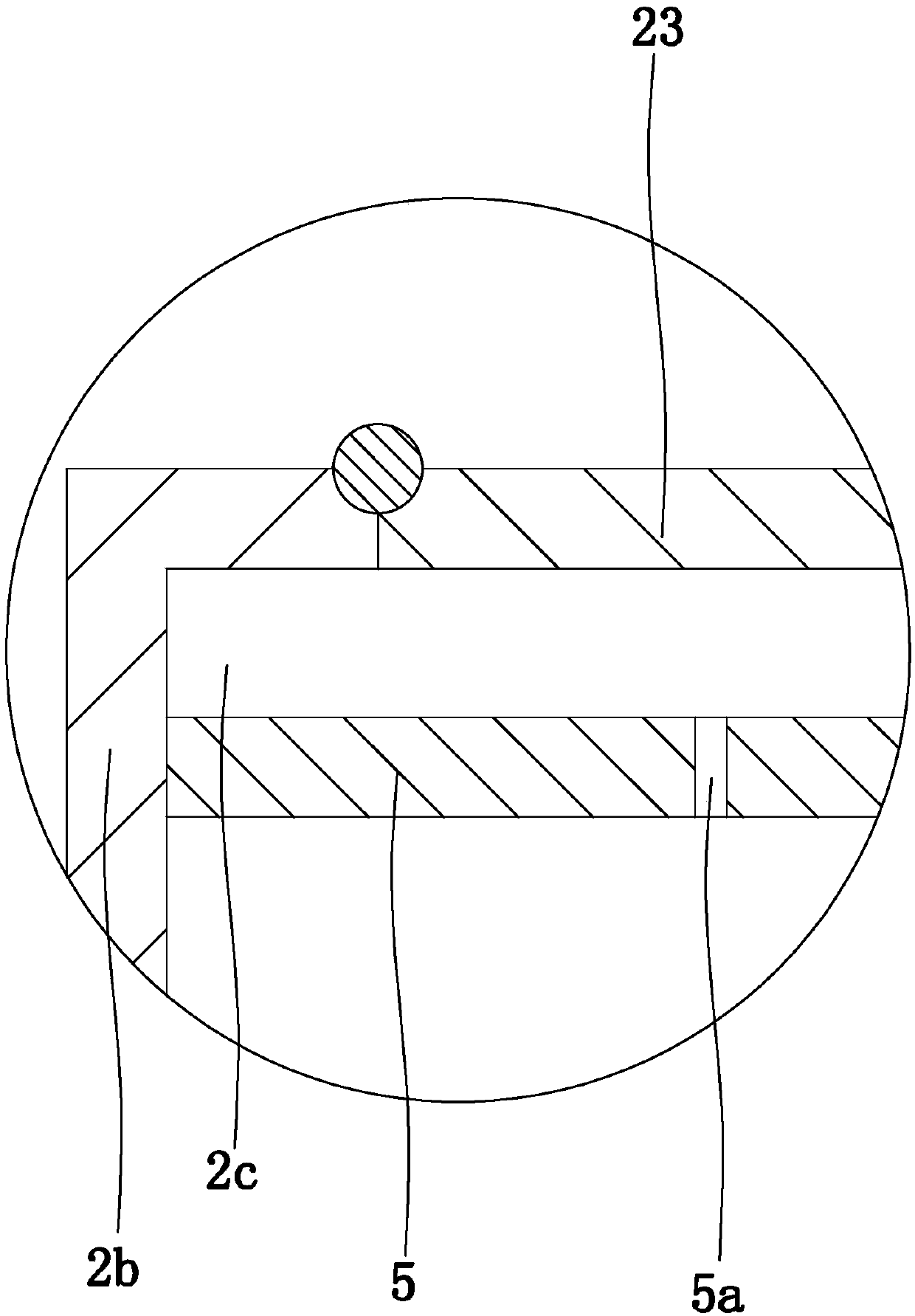

InactiveCN109662116AAchieve slipScattered evenlyFood coatingDough processingAgricultural engineeringFood processing

The invention relates to the technical field of food processing, and discloses a food sesame sprinkling machine. The machine comprises a rack, a base is fixedly connected to the rack, the base is fixedly connected with a first motor and a second motor, the first motor is connected with a first rotating shaft, the first rotating shaft is fixedly connected with an incomplete gear, the incomplete gear is meshed with a first gear intermittently, the first gear is fixedly connected with a second rotating shaft, and the second rotating shaft is fixedly connected with a feeding disc; four feeding grooves are formed in the upper end face of the feeding disc, a through hole is formed in the bottom of each feeding groove, a supporting rod is slidably connected with the interior of each through hole,and a tray is fixedly connected to the upper ends of the supporting rods; the second motor is connected with a third rotating shaft, the third rotating shaft is fixedly connected with a second gear,and the second gear is meshed with a third gear; four first arc-shaped protrusions are arranged on the upper end face of the third gear; the rack is fixedly connected with a limiting block, a storagebox and a cylinder body, the limiting block is slidably connected with a push rod, and a pushing component is arranged on the rack. The machine has the advantage that sesame is added to cake-shaped food quantitatively and uniformly.

Owner:象山锦绣升平食品有限公司

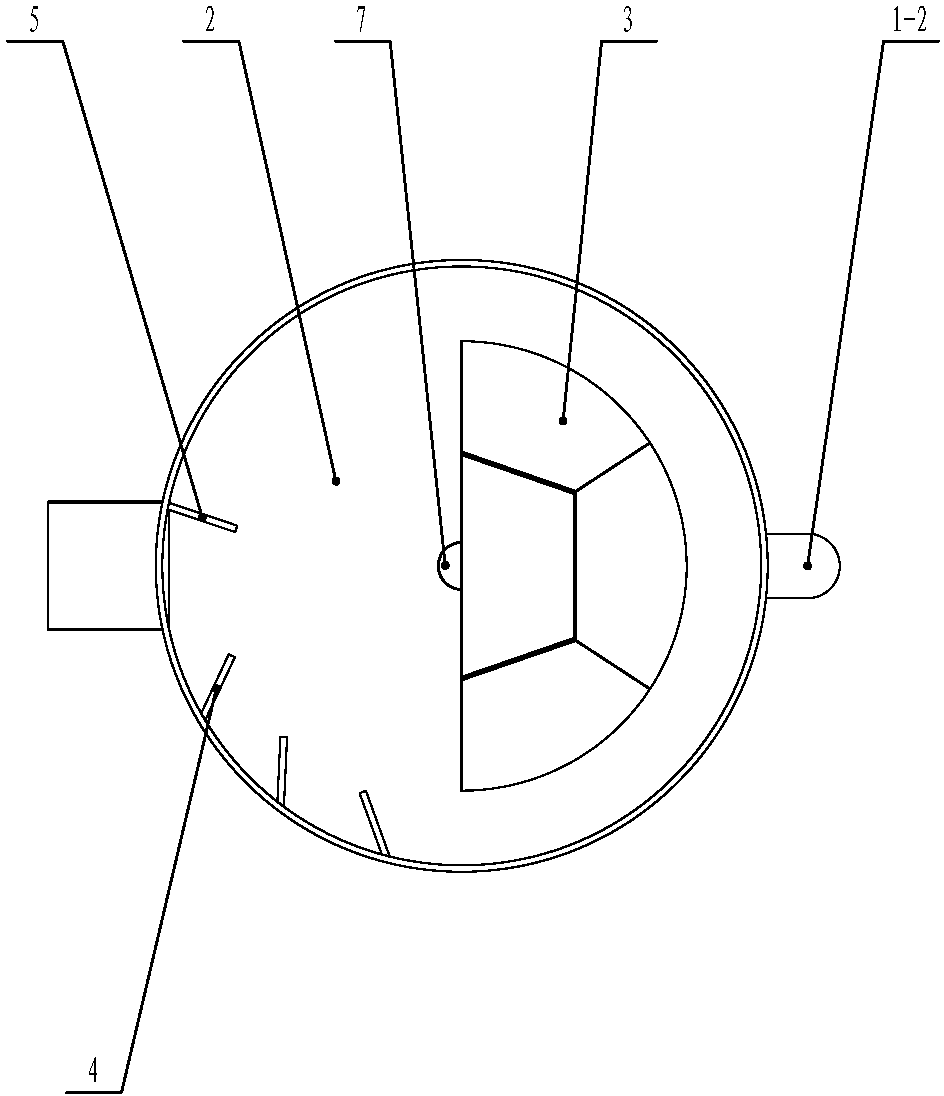

Screening device for efficient separation and slagging of mass-flow slurry

InactiveCN103230869AImprove support capacityImprove working conditionSievingScreeningSlurryEngineering

A screening device for efficient separation and slagging of mass-flow slurry comprises a screen stand, a screen mesh and a screen frame, wherein a slagging port is arranged on the screen frame. The screening device is characterized in that a support body is fixed on the screen stand, and the upper end of the support body is connected with the screen mesh; a material distributor is arranged above the screen mesh, and a gap is reserved between the material distributor and the screen mesh; a hopper and a material distribution plate are connected and arranged in the material distributor, a material discharge port is arranged at the lower end of the hopper, and a material distribution port is arranged on the material distribution plate; a baffle is arranged on the screen frame, one end of the baffle is fixed on the inner wall of the screen frame on the side of the slagging port, the bottom surface of the baffle contacts or is close to the upper surface of the screen mesh, and the other end of the baffle faces to the slagging port. The screening device has the advantages that the middle portion of the screen mesh is fixed through the support body so that the bearing capability of the screen mesh is improved and slurry impact is reduced; and simultaneously the middle portion of the screen mesh cannot fall so that slurry diffuses towards the periphery without gathering at the center, the vibration force is nearly stable, further the vibration effect is greatly improved, and the working state of the screen mesh is greatly improved.

Owner:淄博正邦知识产权企划有限公司

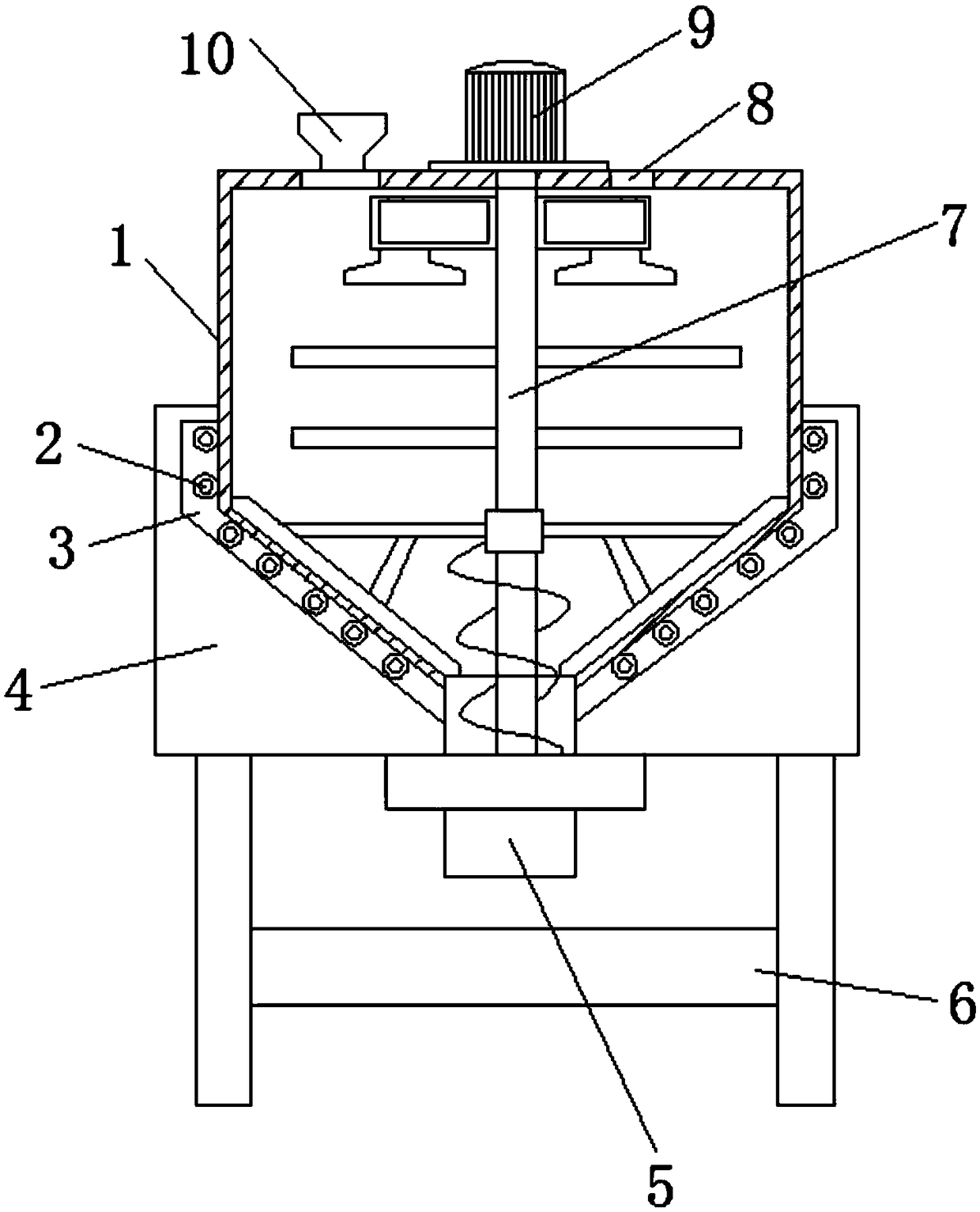

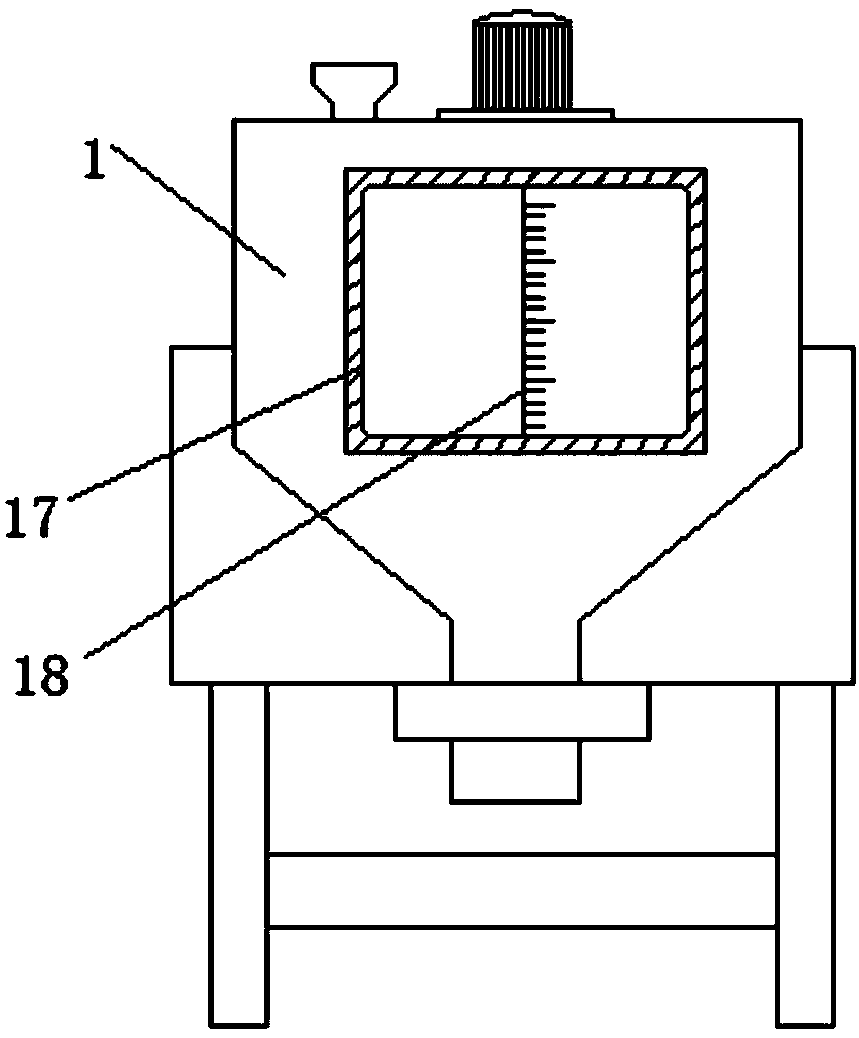

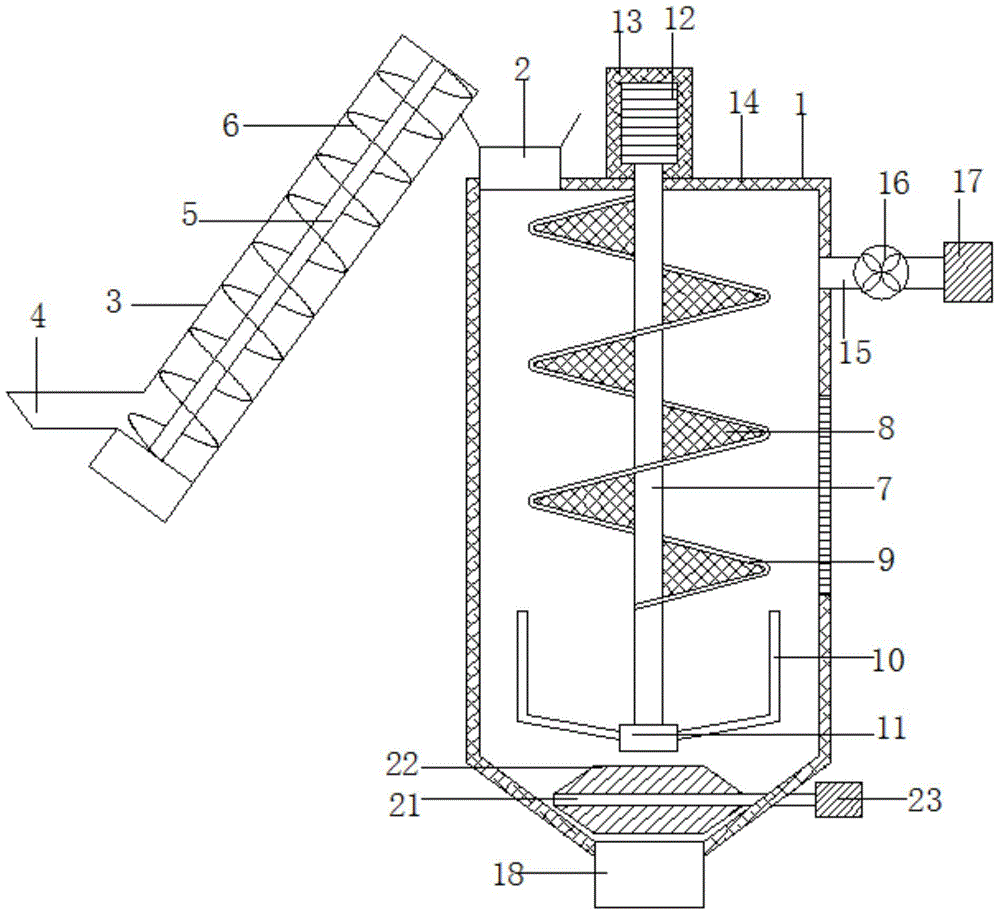

Vertical efficient mixer for ceramic production

InactiveCN104924456AImprove the mixing effectImprove the mixing effect and improve the working effect of the mixerClay mixing apparatusSold ingredients supply apparatusWorking environmentNoise reduction

The invention discloses a vertical efficient mixer for ceramic production. The vertical efficient mixer for ceramic production comprises a mixer body, a helical feeding barrel and a stirring plate, a charging hopper is connected to the left end of the upper side of the mixer body, the helical feeding barrel is arranged on the left side of the mixer body obliquely, and the bottom end of the helical feeding barrel is connected with a hopper. The vertical efficient mixer for ceramic production has the advantages that a stirrer and a screw blade are combined to stir and mix materials, mixing effect and efficiency are high, maintenance and detachment are facilitated, the stirring plate at the bottom of the mixer can raise the bottom materials to be stirred so as to avoid that the bottom materials cannot be stirred, mixing effect is guaranteed, the materials can be heated and dried in the mixing process, drying effect and efficiency are improved by inside humidity elimination, a noise reduction cover effectively lowers noise of motor operation, working environment of operators is improved, in addition, automatic charging is realized, manual feeding is not required, and working efficiency of the mixer is increased.

Owner:陆丽曼

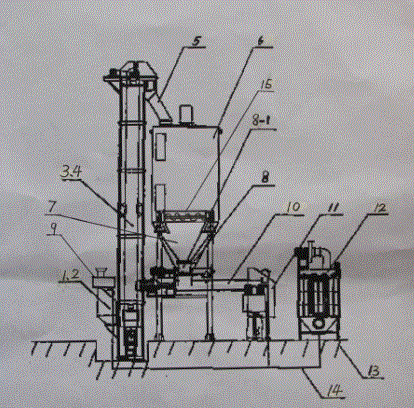

Thermal-insulating mortar proportioning and stirring equipment

The invention discloses thermal-insulating mortar proportioning and stirring equipment, belonging to the field of mixing and stirring production equipment for a construction thermal-insulating material. The thermal-insulating mortar proportioning and stirring equipment comprises two feeding hoppers, two lifting machines, an upper material cabin, a lower material cabin, two metering mixers and a packaging machine. The thermal-insulating mortar proportioning and stirring equipment is characterized in that the two feeding hoppers, the two lifting machines and the packaging machine are fixedly arranged on a foundation; the two material cabins and the two metering mixers are supported and fixed on the foundation through metal pillars; the two feeding hoppers are respectively mounted at the feeding openings of the bottoms of the two lifting machines; one metering mixer is connected with the front parts of the feeding hoppers; the two lifting machines are connected with the cylindrical upper material cabin through articulated chutes; a spiral mixer is mounted between the upper material chamber and a funnel-shaped lower material cabin; a discharging opening of the lower material cabin is connected with the other metering mixer through a hose; and discharging openings of the metering mixers are connected with the packaging machine. The thermal-insulating mortar proportioning and stirring equipment is used for sufficiently and uniformly mixing a light material with powder, and accurately weighting, so that the problem in the traditional thermal-insulating mortar assembly line that the light material is easy to crack, and the powder and the light material are separated can be solved.

Owner:HUNAN ZHONGZHENG CONSTR MATERIALS

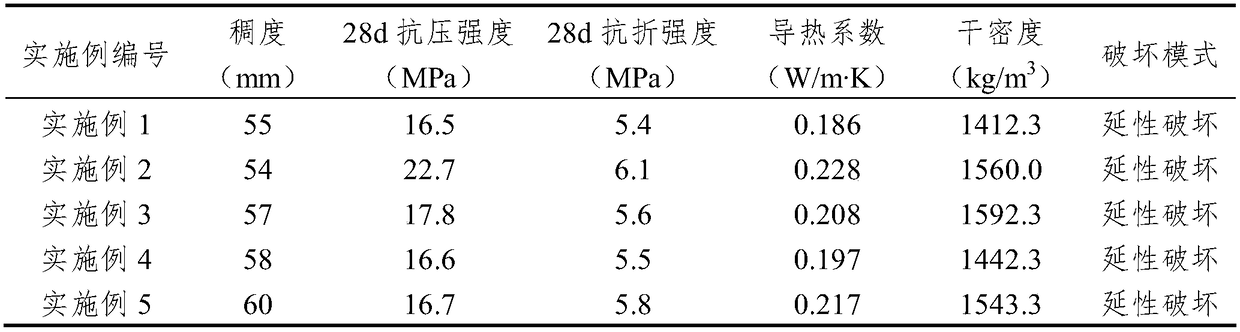

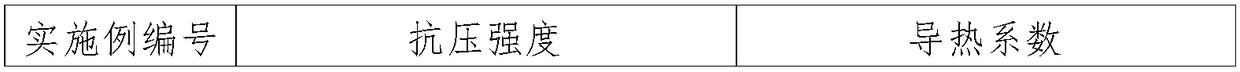

Hibiscus cannabinus straw light anti-crack insulating mortar and preparation method thereof

The invention belongs to the field of novel building materials and provides hibiscus cannabinus straw light anti-crack insulating mortar and a preparation method thereof. The mortar contains a gel material, sand, hibiscus cannabinus straw fibers, coal ash floating beads and hibiscus cannabinus straw cores, wherein the hibiscus cannabinus straw cores serve as a material for replacing glass beads inthe prior art, so that the heat resistance of the hibiscus cannabinus straw light anti-crack insulating mortar can be increased and the cost is lowered. The hibiscus cannabinus straw fibers replace polyvinyl alcohol fibers, so that the crack resistance and the toughness of the hibiscus cannabinus straw light anti-crack insulating mortar can be improved obviously. Compared with a treatment methodof directly adding straws into the mortar, the method of adding hibiscus cannabinus straw cores and the hibiscus cannabinus fibers into the mortar separately can make full use of the hibiscus cannabinus straws and improves the mechanical properties and the insulating property of the mortar. The hibiscus cannabinus straw light anti-crack insulating mortar is prominent in crack resistance, and can improve the wall heat resistance and reduce the heat conductivity coefficient obviously if being smeared to the wall, so that the hibiscus cannabinus straw light anti-crack insulating mortar is energy-saving, environment-friendly and waste-utilizing while a building is energy-saving. The hibiscus cannabinus straw light anti-crack insulating mortar has good environmental benefit, economical benefitand social benefit.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Powdered veterinary drug mixing device

InactiveCN106994312APrevent running outStir wellRotating receptacle mixersTransportation and packagingMixing tankLeft wall

The invention relates to a mixing device, in particular relates to a powdered veterinary drug mixing device and aims to provide the powdered veterinary drug mixing device which is uniform in mixing and can prevent a powdered veterinary drug from being easily adhered to a wall. In order to solve the technical problems above, the invention provides the powdered veterinary drug mixing device which comprises a rack and the like; the middle part of the left wall in the rack is connected with a rotary mechanism; the right side of the rotary mechanism is connected with a mixing tank; the mixing tank is arranged in the rack; a through hole is formed in the top of the mixing tank; the top of the mixing tank is connected with a switching mechanism; and the switching mechanism is arranged on the top of the through hole. According to the powdered veterinary drug mixing device, by arranging the rotation mechanism, the powdered veterinary drug can be mixed; and by arranging the switching mechanism, the powdered veterinary drug is facilitated to entering the mixing tank and being poured out from the mixing tank.

Owner:冯勇

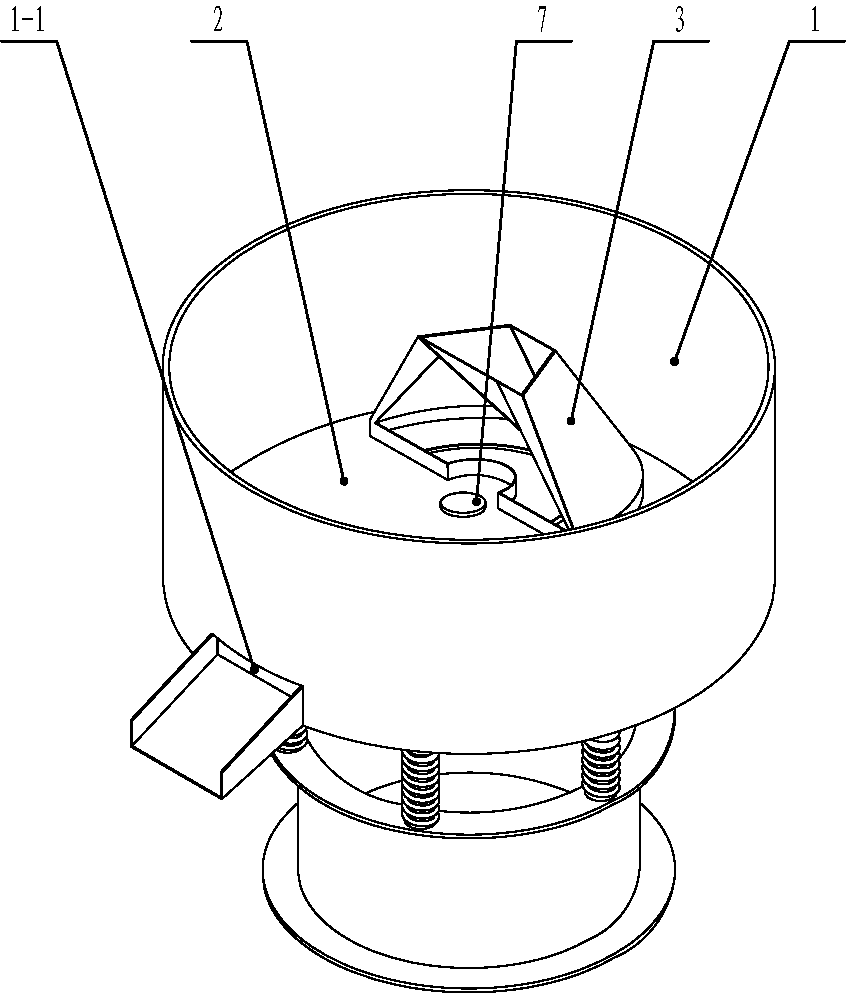

Seed removing and sorting machine

The invention discloses a seed removing and sorting machine. The machine comprises a base plate and a vibration mechanism arranged on the base plate, wherein a plurality of uniformly-distributed supporting columns are fixedly connected to the upper surface of the base plate, and first springs are fixedly connected to the upper ends of the plurality of supporting columns; the upper ends of the first springs are fixedly connected with a frame, and a plurality of obliquely-arranged screening plates are fixedly connected in the frame; a plurality of uniformly-distributed rectangular through grooves are formed in the side walls of the screening plates, two fixing blocks, corresponding to each other in position, are fixedly connected to the side wall of each screening plate, the two fixing blocks are provided with through holes correspondingly, and the fixing blocks are movably connected with a guide rod through the through holes in a sleeving mode; and a plurality of blocking rods are fixedly connected to the rod wall of each guide rod, the blocking rods are located in the rectangular through grooves, and the fixing blocks are in threaded connection with limiting bolts through threadedholes. According to the seed removing and sorting machine, the operation is convenient, seeds can be uniformly scattered on the screening plates, and the size of filtering holes can be conveniently adjusted; and meanwhile, the screening plates can be vibrated, so that the removing and sorting speed of the seeds is increased.

Owner:王则敏

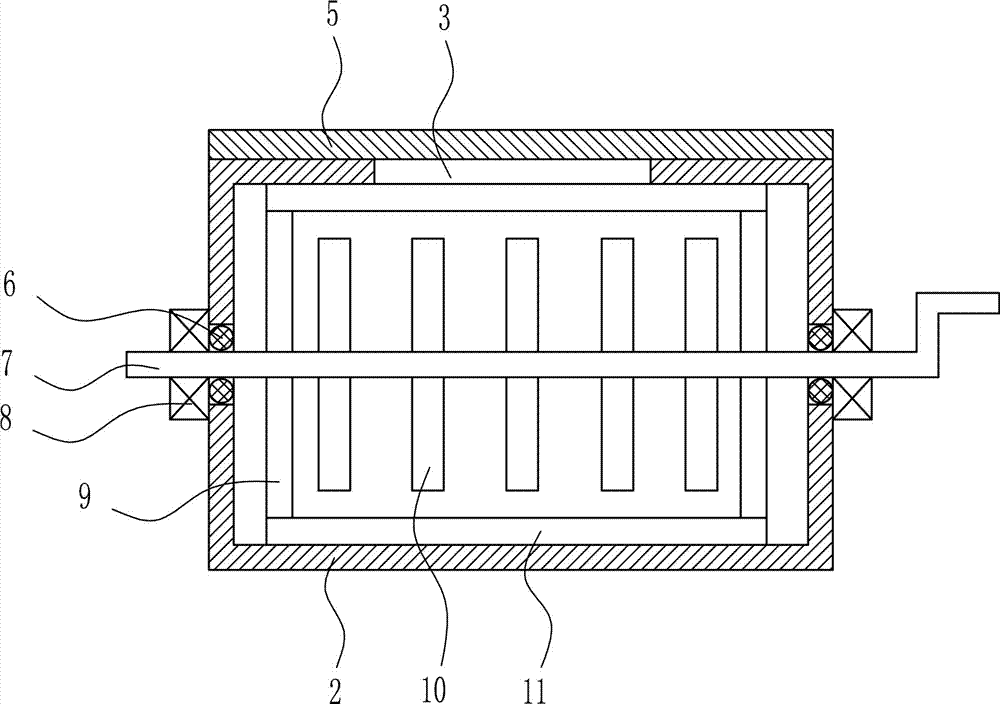

Sealing and protecting device for electrician gloves

ActiveCN107640420AEffective independent storageNot easy to be damaged by adhesionDirt cleaningSealingEngineeringStorage effect

The invention discloses a sealing and protecting device for electrician gloves. The device comprises a main machine base, a box and a chassis, wherein multiple storage columns are arranged on the chassis; the box comprises a box baseboard and a main box body, and inflatable sealed rings and a plurality of transverse connecting rods are arranged in an annular air channel; an upper partition board is arranged in the box, multiple spraying holes are formed in the upper partition board, a cylinder is arranged on the main machine base, and an air compressing piston is arranged in the cylinder; a first piston rod is arranged on the air compressing piston, an air inlet, an air outlet and an air adjusting opening are formed in the cylinder, the air outlet is communicated with a sealed air sprayingcavity through an air outlet pipe, the air adjusting opening is communicated with the inflatable sealed rings through an air adjusting pipe, and springs are arranged in an air supplying cavity. The device has the advantages that the structure is reasonable, individual storage can be effectively conducted on the various electrician gloves, so that it is guaranteed that the electrician gloves are not easily adhered or damaged; a powder scattering structure is provided, so that it is guaranteed that talcum powder evenly scatters on the electrician gloves, and waste is reduced; a cleaning function is provided, fast cleaning can be conducted on all the electrician gloves simultaneously, and the storage effect is guaranteed.

Owner:江苏瑞斯达安全防护用品有限公司

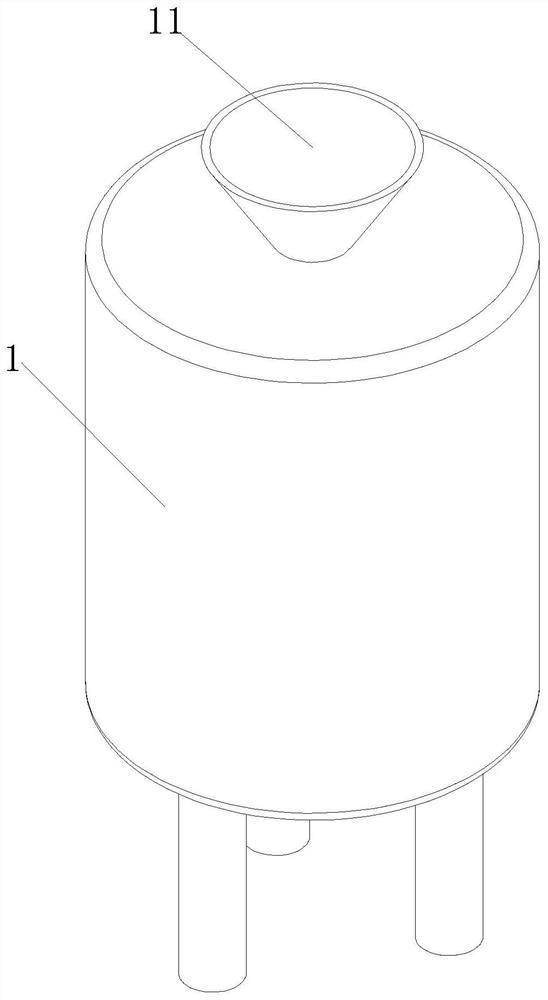

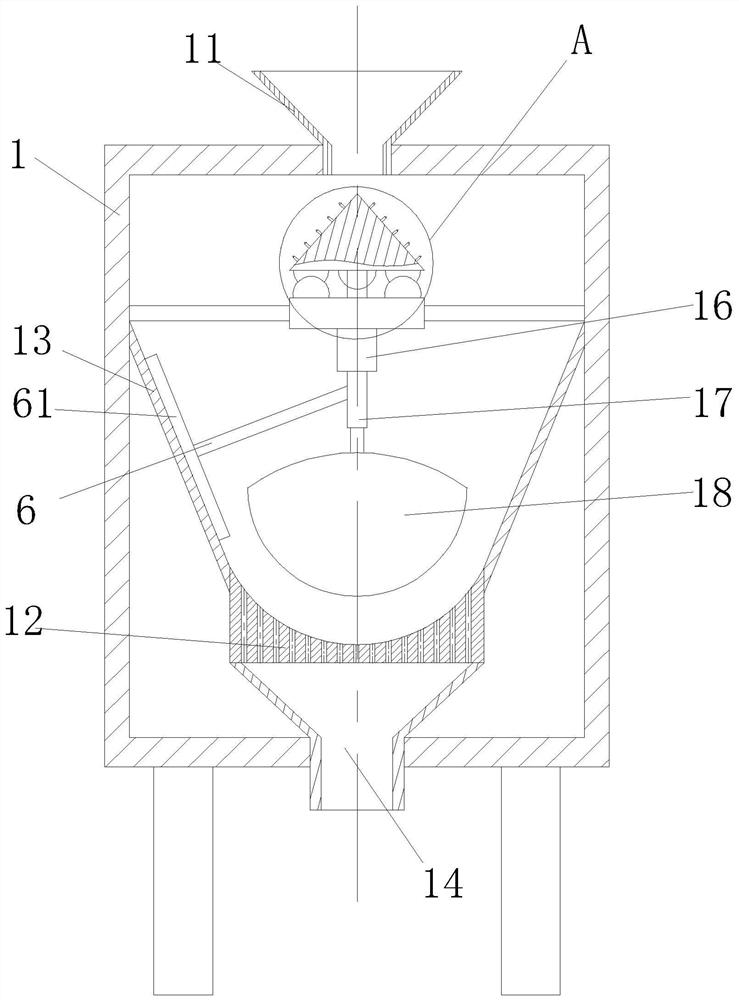

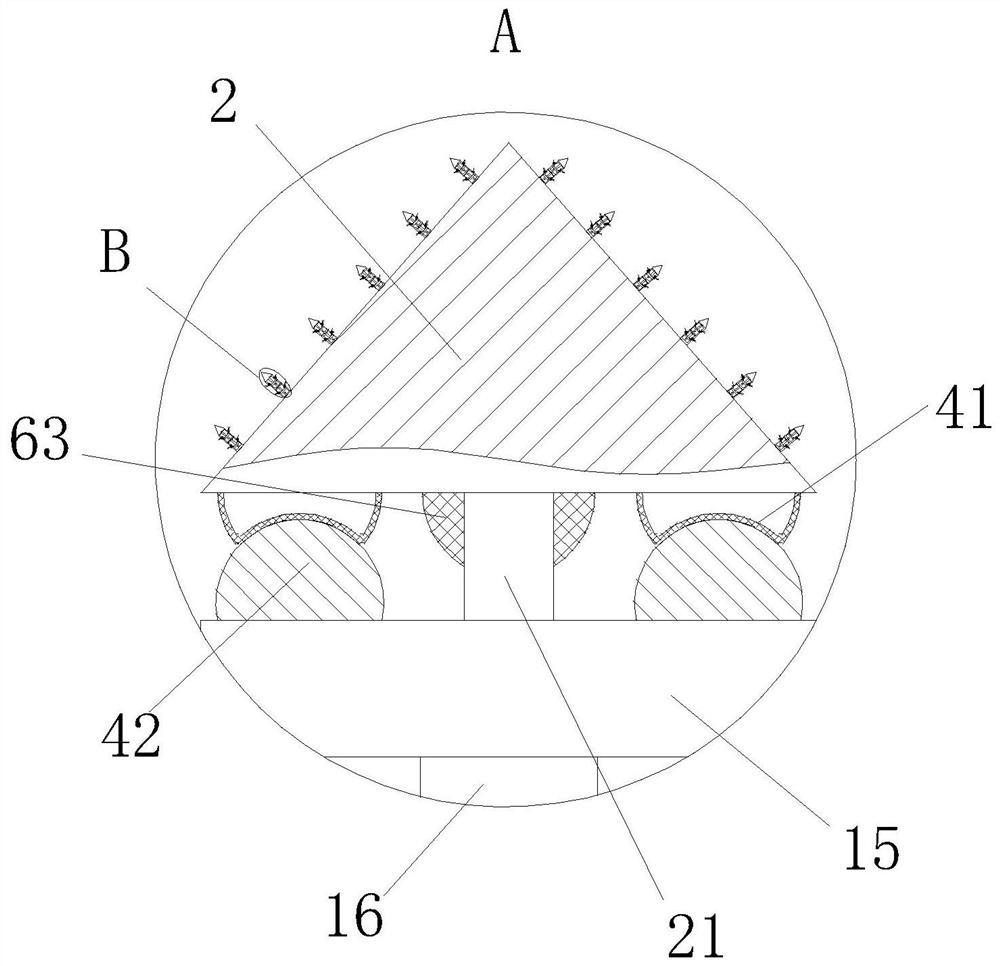

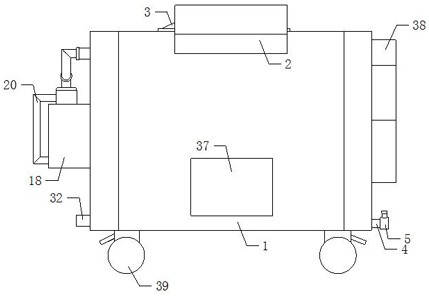

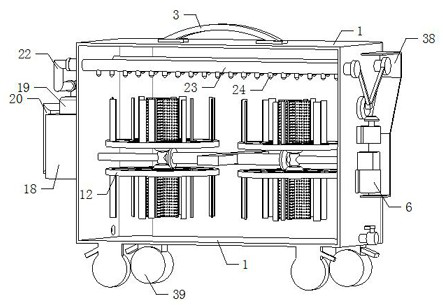

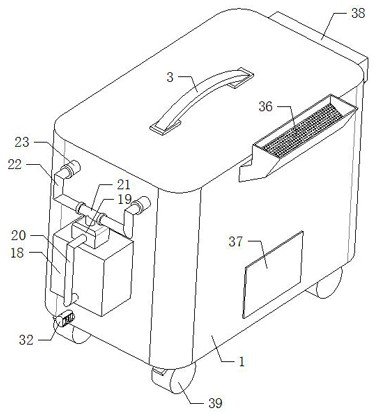

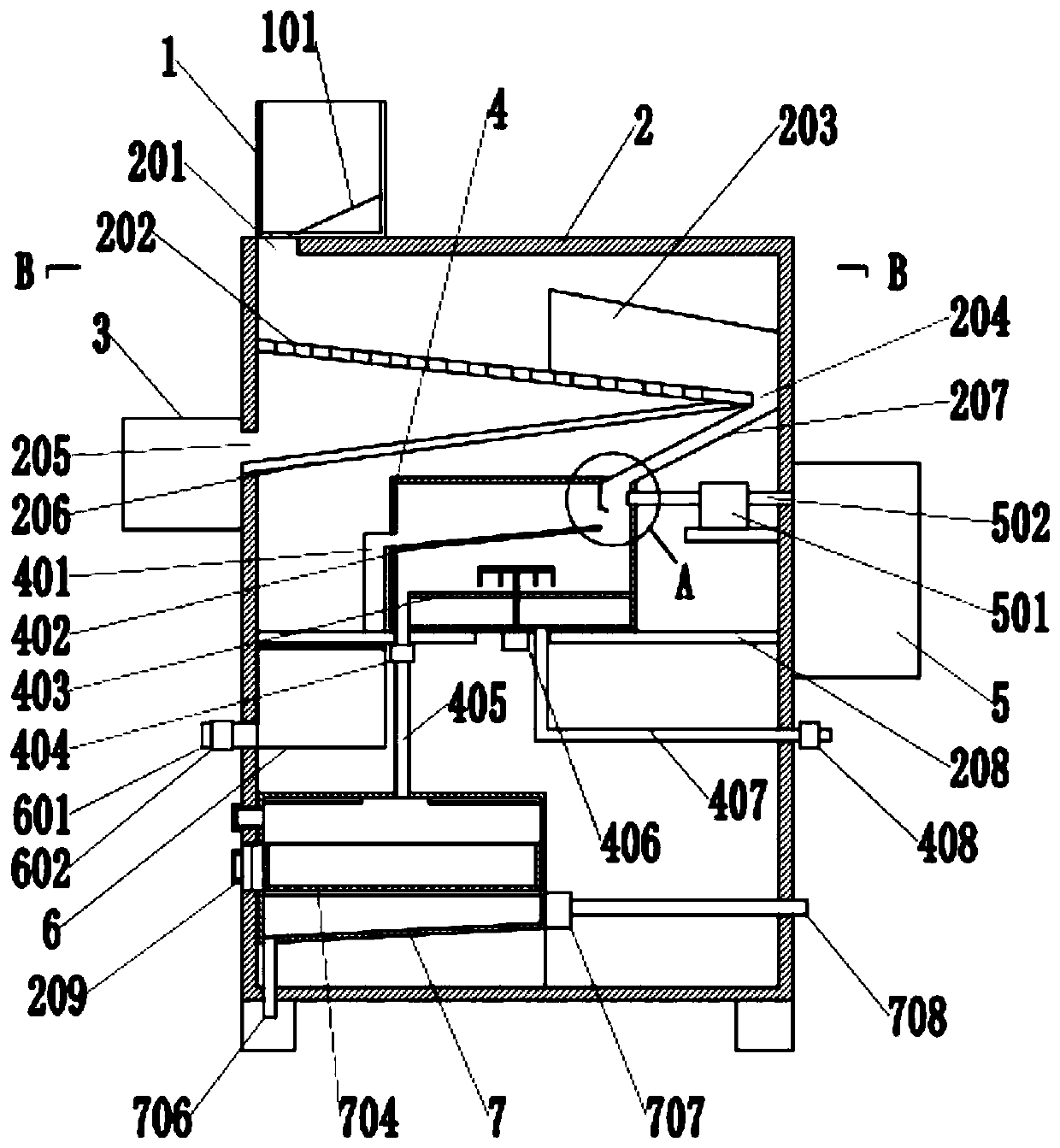

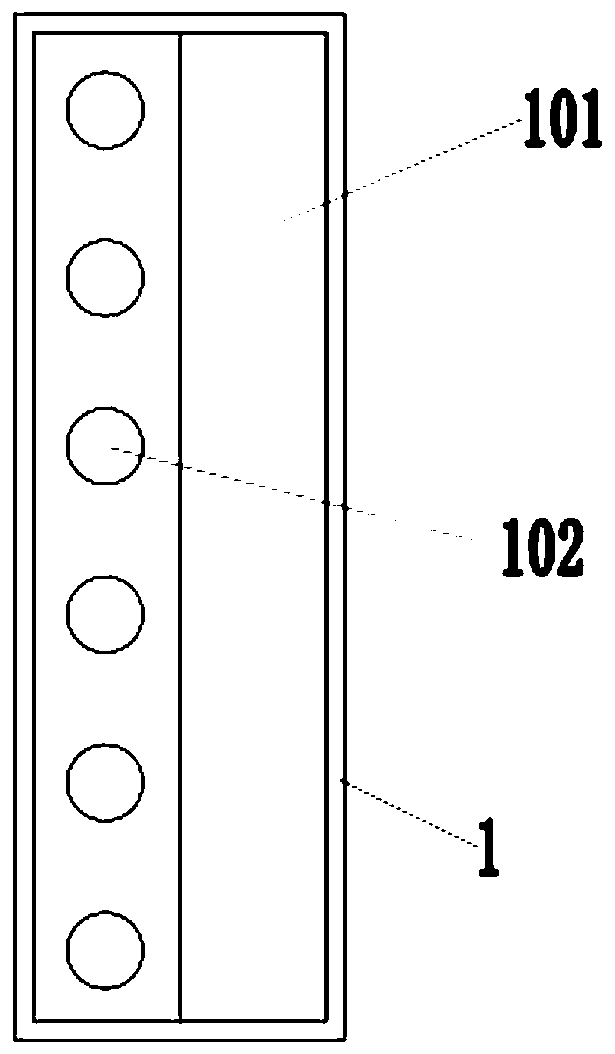

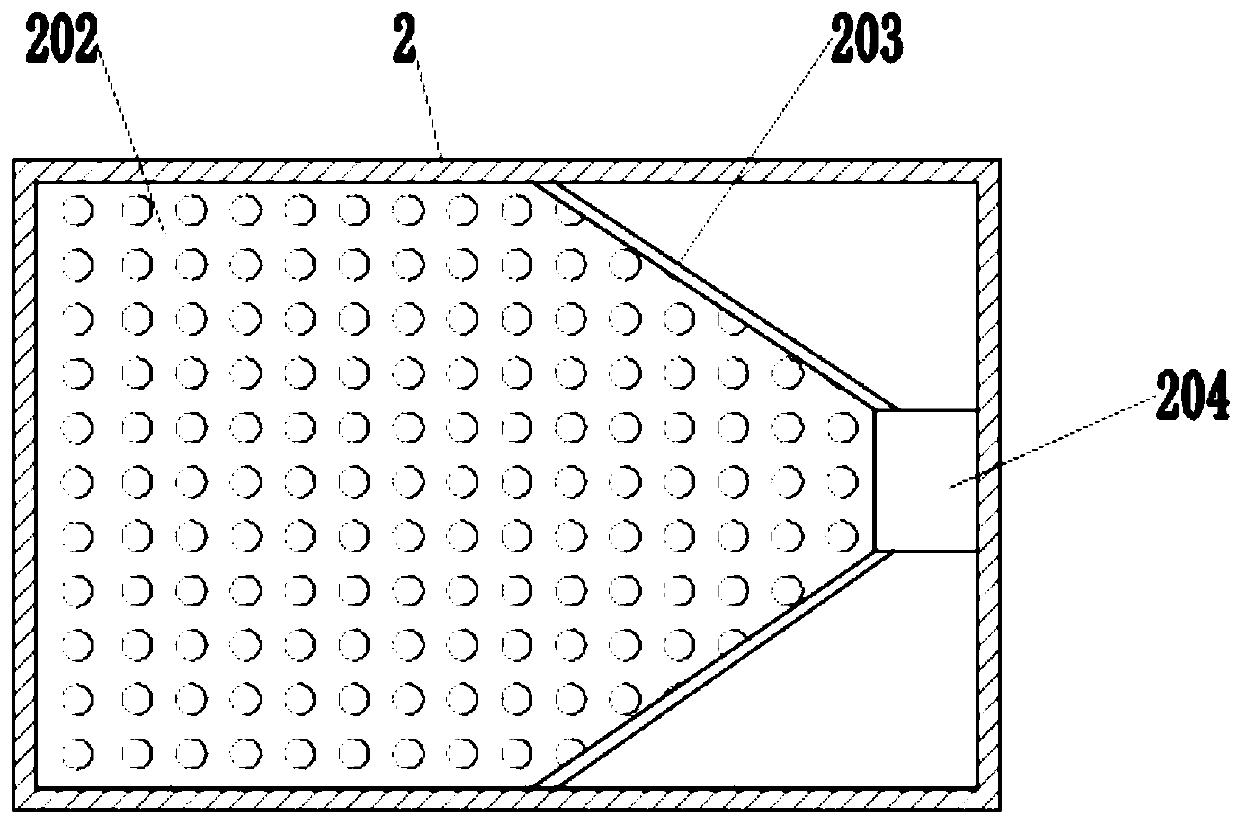

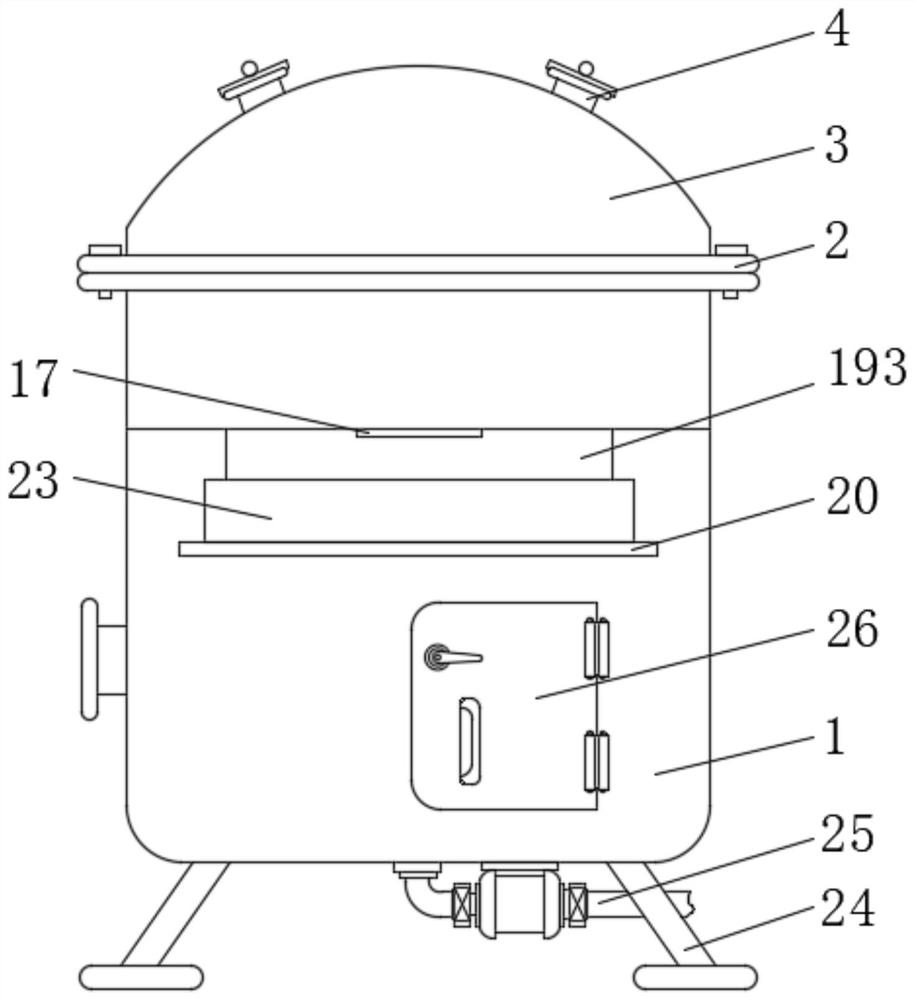

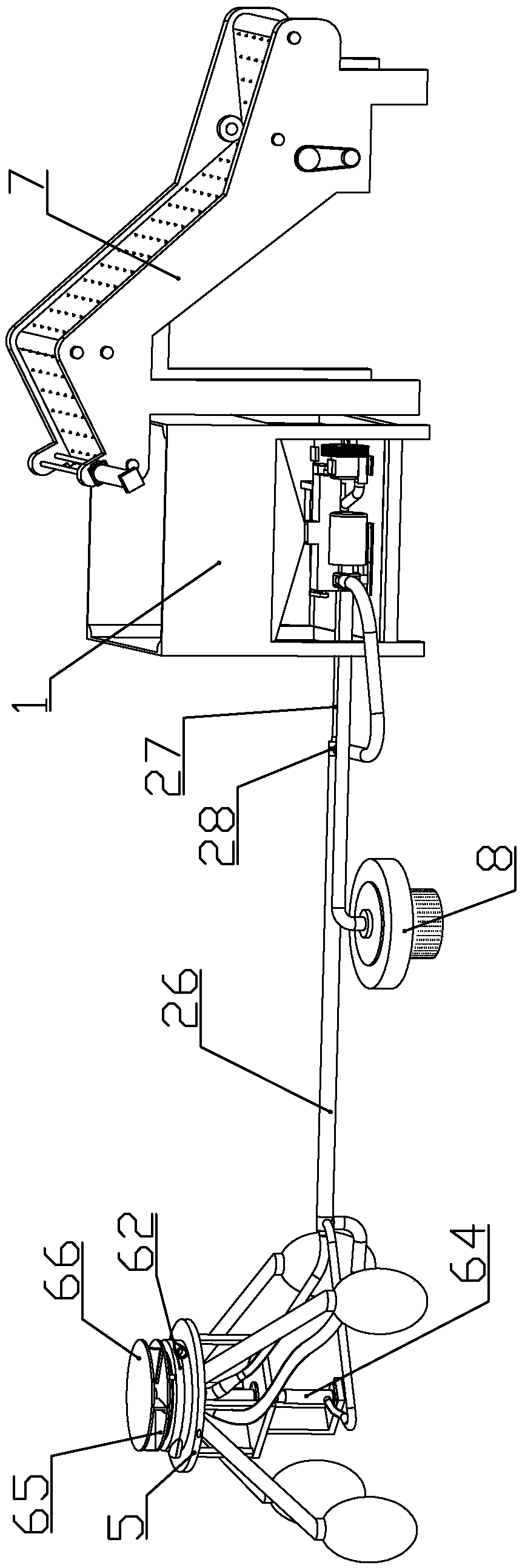

Portable waste liquid collecting and treating device

ActiveCN111675389AEasy to isolate and protectAvoid harmTreatment involving filtrationMultistage water/sewage treatmentElectric machineryEnvironmental engineering

The invention relates to the technical field of purification equipment, especially to a portable waste liquid collecting and treating device. According to the portable waste liquid collecting and treating device, waste liquid is collected and treated, so the waste liquid can be effectively prevented from being discharged to the outside and damaging the external environment, viruses in the waste liquid are prevented from damaging a human body, the viruses are prevented from being spread through the waste liquid, and practicability and reliability of the device are improved. The device comprisesa treatment bin, a liquid inlet hopper, a handle, a liquid discharging pipe, a liquid discharging valve and a first motor, wherein the liquid inlet hopper is installed on the upper side of the frontportion of the treatment bin, the handle is installed on the top of the treatment bin, the liquid discharging pipe is installed on the lower right side of the treatment bin and communicates with the interior of the treatment bin, and the liquid discharging valve is installed on the liquid discharging pipe.

Owner:诸城市人民医院 +1

Soybean screening and cleaning all-in-one machine

The invention discloses a soybean screening and cleaning all-in-one machine. The machine comprises a feeding box, a machine box and a cleaning box, a screening plate is arranged below a feeding hole,a collecting plate is arranged below the screening plate, collecting holes are formed in the screening plate, the collecting holes communicate with the upper end of the cleaning box through a first material conveying pipe, a partition plate is obliquely arranged in the cleaning box, a filter screen is arranged below the partition plate, a material falling gap is formed between one higher end of the partition plate and the inner wall of the cleaning tank, the side wall of the cleaning box is connected with a water inlet pipe and an impurity removal pipe, a discharge end of the first material conveying pipe, the water outlet end of the water inlet pipe are located above the material falling gap, a feeding end of the impurity removal pipe is positioned above the lower end of the separation plate, the bottom of the cleaning box is connected with a sewage discharge pipe, a second material conveying pipe is arranged at the bottom of the filter screen, wherein one end of the second material conveying pipe is connected with a drying box, a first valve is arranged on the second material conveying pipe, and a second valve is arranged on the sewage discharging pipe.

Owner:SHANDONG CROP GERMPLASM CENT

Plant protection unmanned aerial vehicle with automatic pesticide liquid proportioning device and working method thereof

InactiveCN113198383AAvoid wastingAvoid harmAircraft componentsRotary stirring mixersPesticideAgricultural engineering

The invention discloses a plant protection unmanned aerial vehicle with an automatic pesticide liquid proportioning device. Wings are arranged on the two sides of an unmanned aerial vehicle body, a pesticide liquid tank and a water tank are arranged below the wings, blades are rotationally installed on the top of the unmanned aerial vehicle body and above the wings, and a mixing and proportioning tank is arranged on the unmanned aerial vehicle body and located between the two wings; the pesticide liquid tank and the water tank are both connected with the mixing and proportioning tank through a liquid proportioning pipeline, an electromagnetic proportioner is arranged on the liquid proportioning pipeline, a liquid guide pipe is arranged at a liquid outlet in the mixing and proportioning tank, a liquid outlet control valve is arranged on the liquid guide pipe, the liquid guide pipe is connected with the high-voltage electrostatic spraying head through a hose, and a flow meter is arranged on the hose; a telescopic support is arranged between the unmanned aerial vehicle body and the high-voltage electrostatic spraying head, and mounting supports used for mounting the high-voltage electrostatic spraying head are arranged at the positions, located at the two ends of the high-voltage electrostatic spraying head, of the telescopic support. Automatic proportioning of pesticide liquid can be achieved, waste caused by excessive dosage is avoided, and meanwhile harm to operators caused by manual dosage is avoided to the maximum extent.

Owner:徐州网递智能科技有限公司

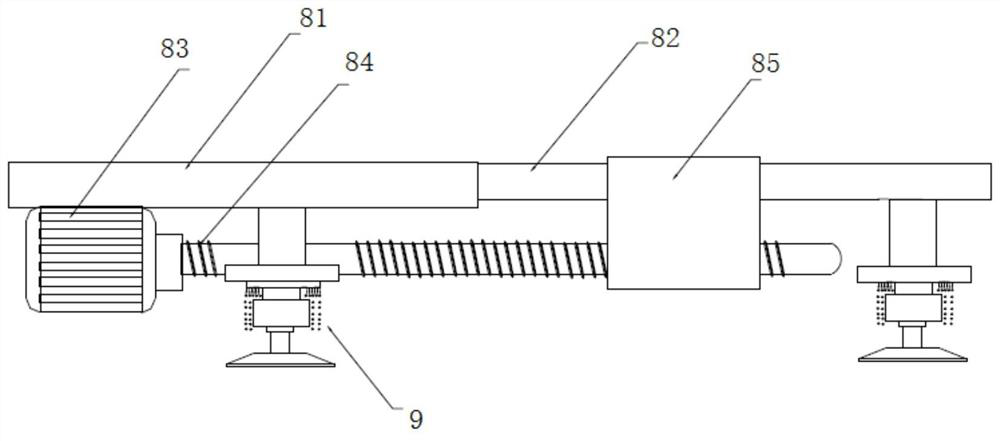

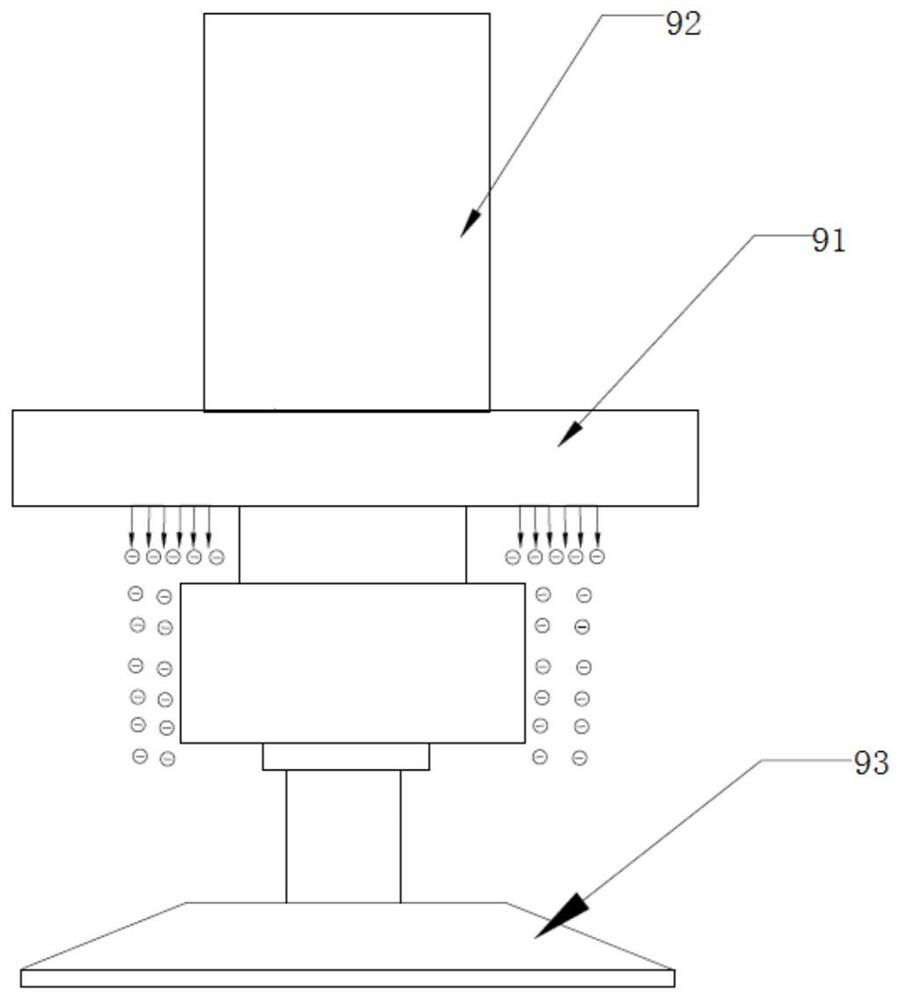

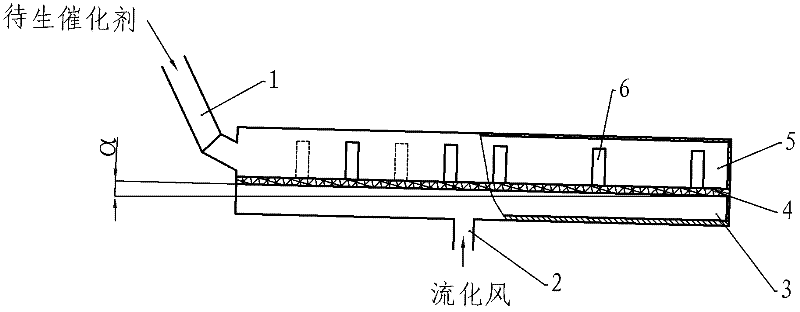

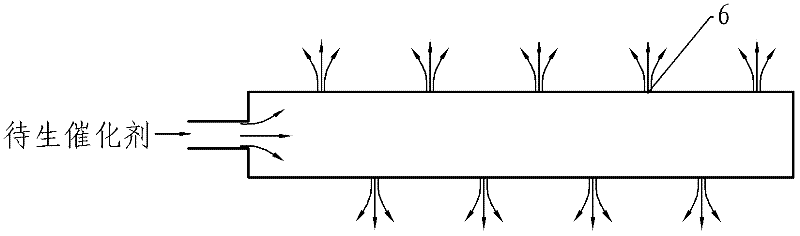

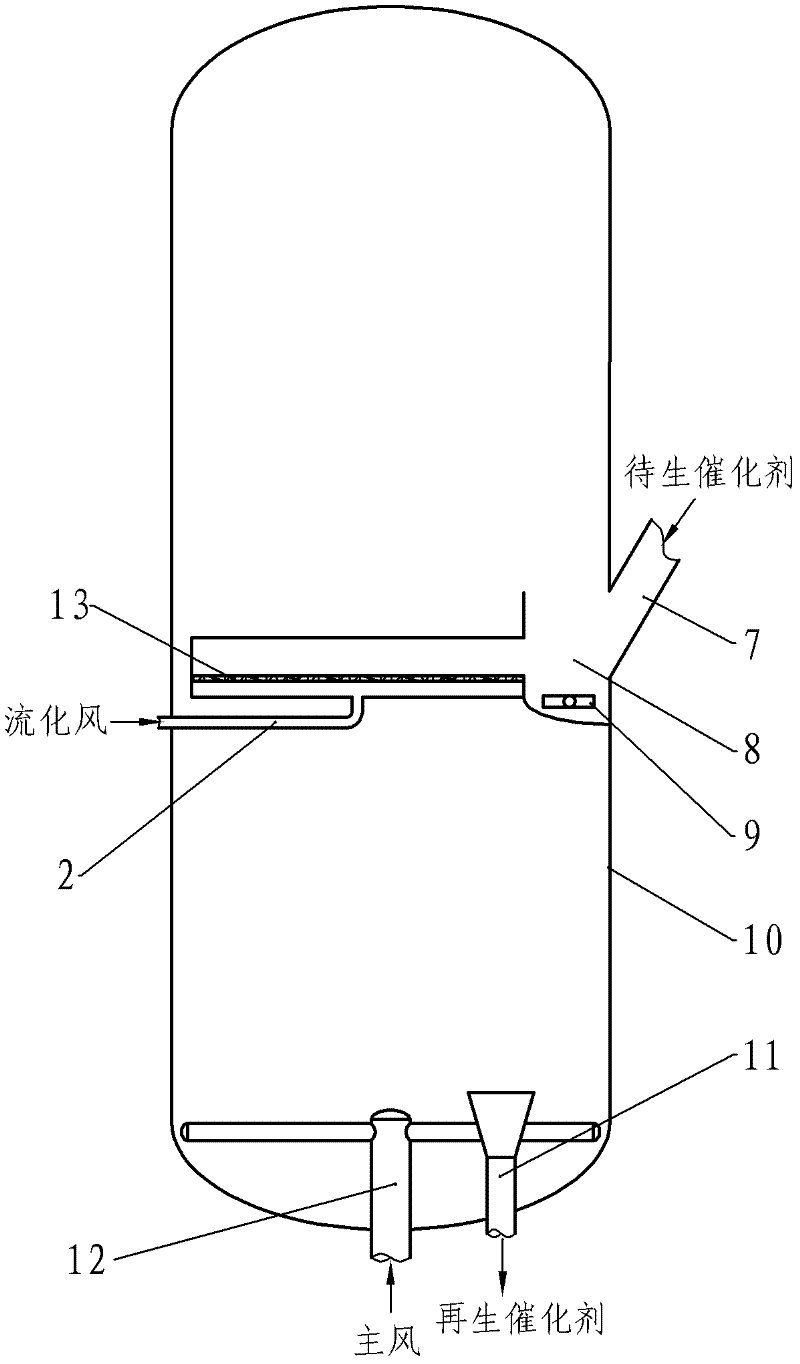

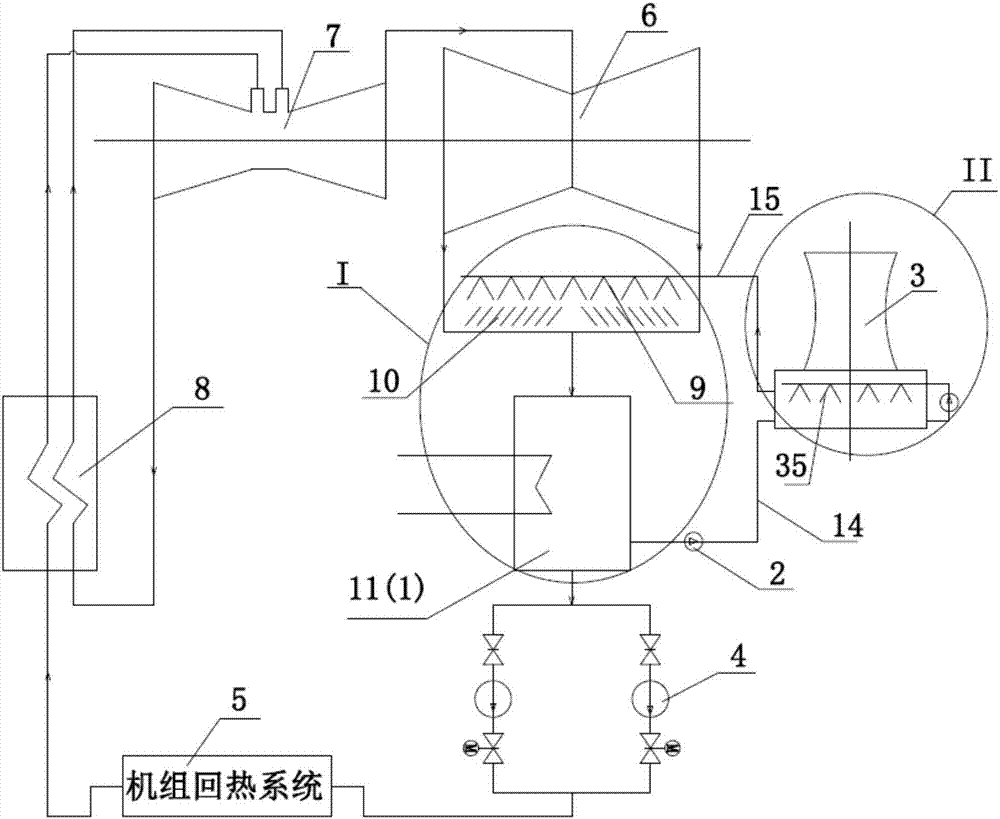

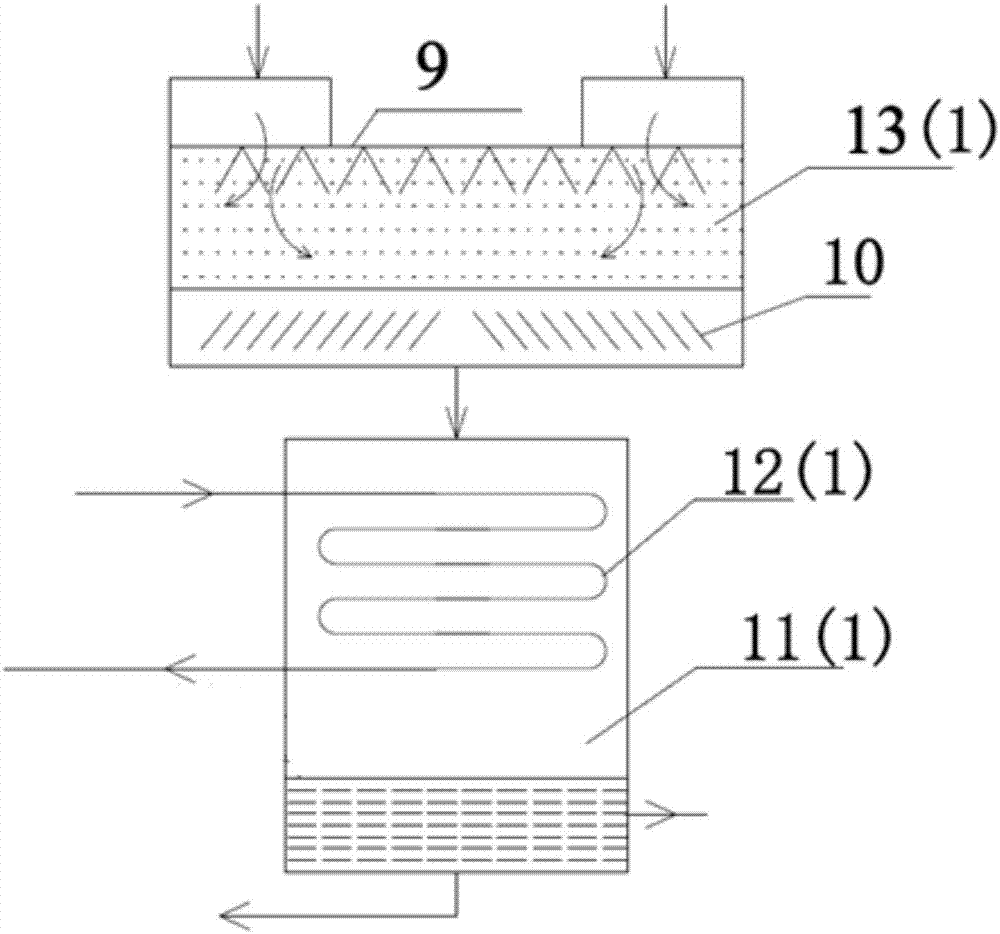

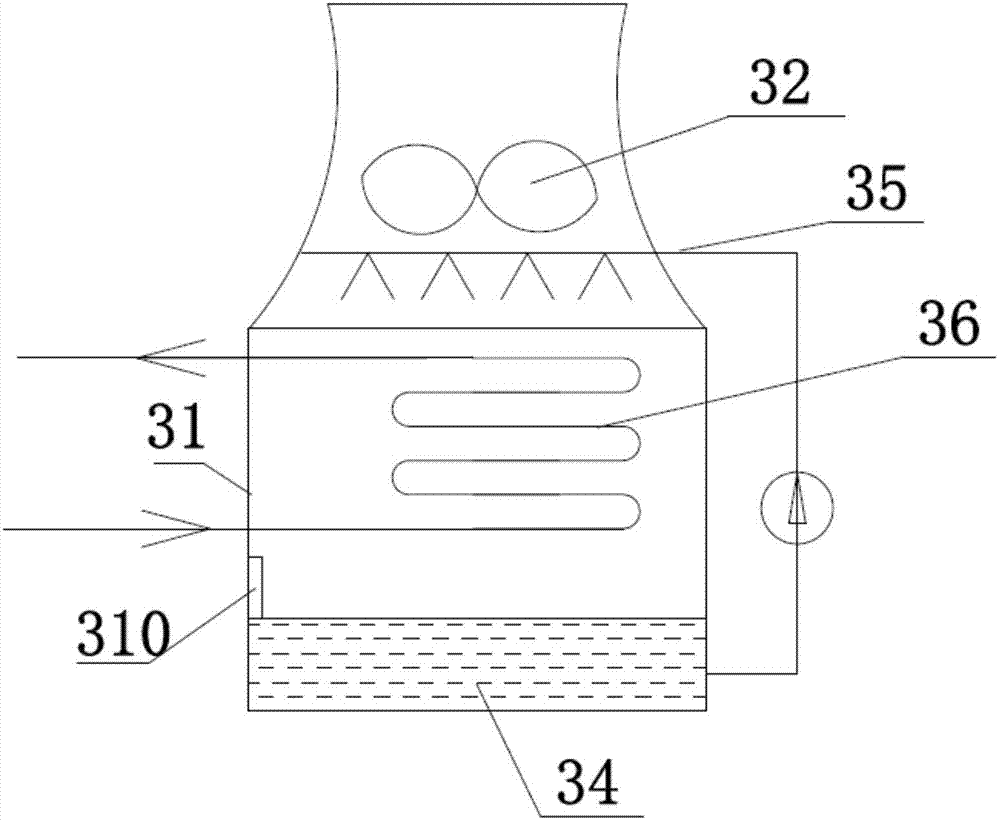

Spent catalyst distributor and spent catalyst distribution method for fluid catalytic cracking device

InactiveCN102504861AGood distribution uniformitySmall gas flowCatalytic crackingDistribution methodFluid catalytic cracking

The invention provides a spent catalyst distributor and a spent catalyst distribution method for a fluid catalytic cracking device. The spent catalyst distributor comprises at least one spent catalyst distribution trough provided with an upper structure and a lower structure parallel to each other, the upper trough body and the lower trough body are separated by a gas distribution plate, the upper trough body is a spent catalyst distribution cavity communicated with a spent catalyst delivery standpipe, two sides of the upper trough body are provided with a plurality of catalyst distribution holes, the lower trough body is a fluidizing air buffer cavity provided with a fluidizing air inlet, the gas distribution plate is provided with gas distribution holes by which the spent catalyst distribution cavity is communicated with the fluidizing air buffer cavity, gas flowing into the fluidizing air buffer cavity evenly flows into the spent catalyst distribution cavity through the gas distribution holes, and a layer of catalyst solid particles in the distribution cavity are fluidized and flow out of the distribution holes on two sides of the upper trough body. The spent catalyst distributor is uniform in catalyst distribution, required gas flow is low, wear of equipment and particles is low, and impact on resistance and stability of a spent catalyst particle delivery pipeline is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Steam condenser self-circulation spraying peak cooling system

InactiveCN106895713AIncrease cooling areaAchieve hybridSteam/vapor condensersEngineeringPhase change

The invention provides a condenser self-circulation spray peak cooling system, comprising: a condenser, a self-circulation output pipeline, a cooler, a self-circulation input pipeline and a self-circulation spray device; the steam inlet of the condenser It is connected with the steam exhaust outlet of the steam turbine, and the condenser is provided with a throat, a condensation pipe and a hot well in sequence from top to bottom; the water inlet of the self-circulation output pipeline is connected with the first condensate outlet of the hot well, and the water outlet is connected with the The heat medium inlet of the cooler is connected; the water inlet of the self-circulation input pipeline is connected with the heat medium outlet of the cooler, and the water delivery port is connected with the spray liquid inlet of the self-circulation spray device; The throat of the device; among them, the condensed water sprayed from the spray port of the self-circulating spray device mixes with the exhaust steam of the steam turbine in the throat, absorbs heat and evaporates, and undergoes a phase change. The condenser self-circulation spray peak cooling system provided by the invention can effectively control the vacuum of the unit.

Owner:北京质为科技有限公司

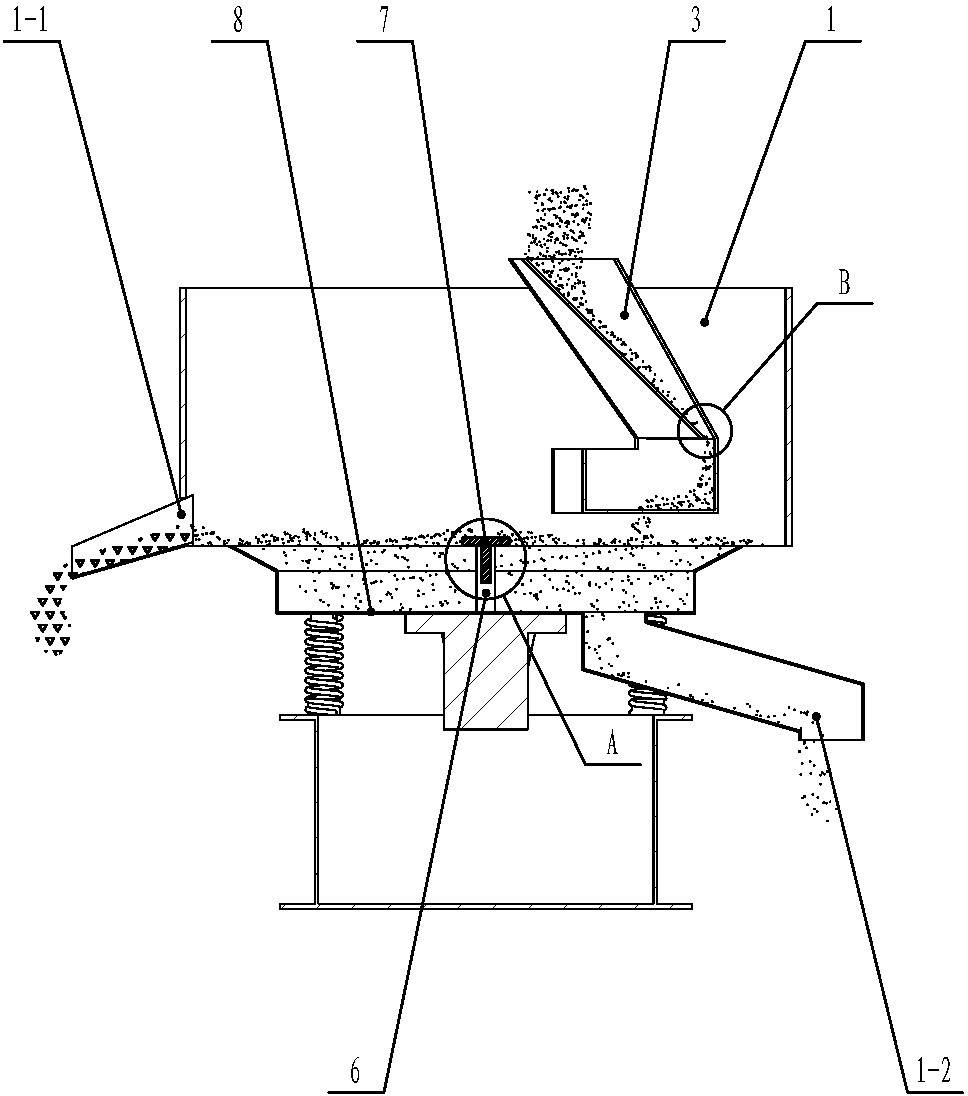

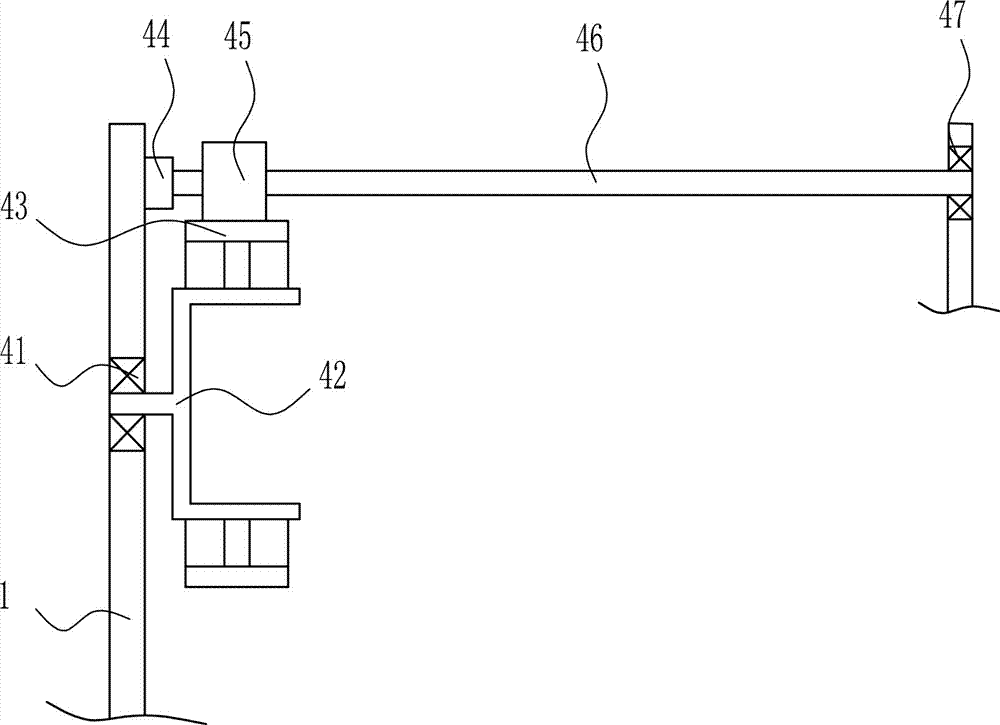

Fiber weighing and conveying device

ActiveCN104985700AScattered evenlyMeet environmental protection requirementsMixing operation control apparatusIngredients weighing apparatusFiberControl system

The invention discloses a fiber weighing and conveying device. The fiber weighing and conveying device structurally comprises a scale body, a fiber scale support, an arch breaking device and a vibrating conveying device. The arch breaking device is arranged on the side wall of an inner cavity of the scale body. The vibrating conveying device is arranged at an opening in the bottom of the scale body. The scale body is connected with the fiber scale support through a weighing assembly. The vibrating conveying device is connected with the scale body through a spring assembly and comprises a conveyor box, a conveyor vibration exciter and a screen net. One end of the conveyor box is connected with the scale body in a sealed mode through a flexible connector, and a discharging opening is formed in the other end of the conveyor box. A fiber scale door cover is arranged at an opening in the top face of the scale body. The weighing assembly, the vibrating conveying device and the arch breaking device are connected with a control system. According to the fiber weighing and conveying device, throwing of materials is achieved through a conveyor, and therefore the materials which are likely to become conglobated can be evenly scattered; smooth throwing of the materials can be well achieved through the arch breaking device on the scale body and the vibrating conveyor, and meanwhile the measuring precision of the materials can be well guaranteed.

Owner:SHANTUI JANEOO MACHINERY

Building raw material mixing equipment

InactiveCN109591186AImprove the mixing effectImprove work performanceShaking/oscillating/vibrating mixersNon-rotating vibration suppressionPropellerEngineering

The invention discloses building raw material mixing equipment. The equipment comprises a mixing barrel, supporting columns, a damping base and brake universal wheels. The mixing barrel is provided with a discharging hopper. The discharging hopper is connected with a lifting device. A loading hopper and an electromagnetic valve are mounted on the lifting device. A screw shaft is vertically arranged in the internal axis center of the mixing barrel. Screw blades are arranged on the outer wall of the screw shaft. A mixing propeller is arranged on the lower side of the screw shaft. A mounting baseis arranged on the mixing propeller and mounted at the bottom end of the screw shaft. The mixing barrel is connected with a recovery pipe and connected with a dust collecting box through a fan. An inclined panel and a discharging outlet are connected to the bottom of the mixing barrel. The supporting columns are arranged on the lower side of the mixing barrel and connected with the damping base.The brake universal wheels are connected with the damping base. By means of the building raw material mixing equipment provided by the invention, quantitative feeding can be achieved, the material mixing effect is good, the efficiency is high, the time is short, and maintenance and dismounting are convenient; dust produced during material mixing can be recovered; dust pollution is avoided, and rawmaterials are saved; through the additionally-arranged damping base, the vibration resistance is improved; and the service life of a mixing machine is prolonged.

Owner:广州市世博建筑工程有限公司

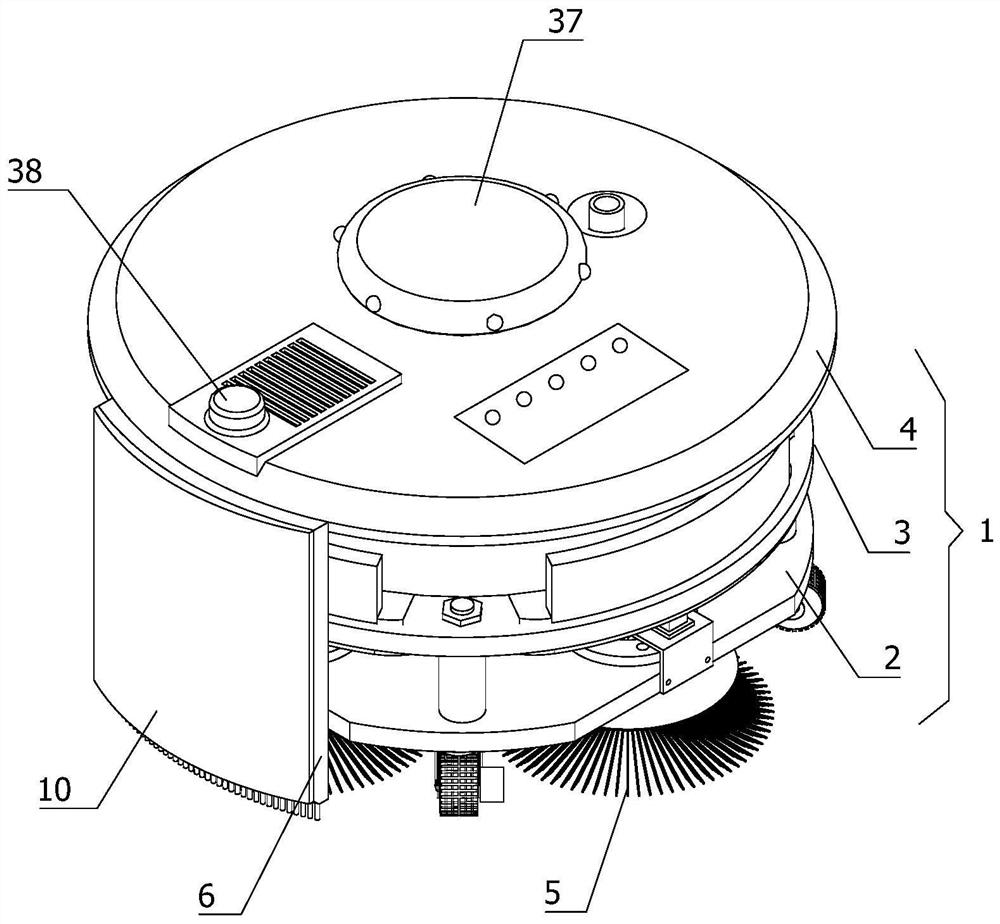

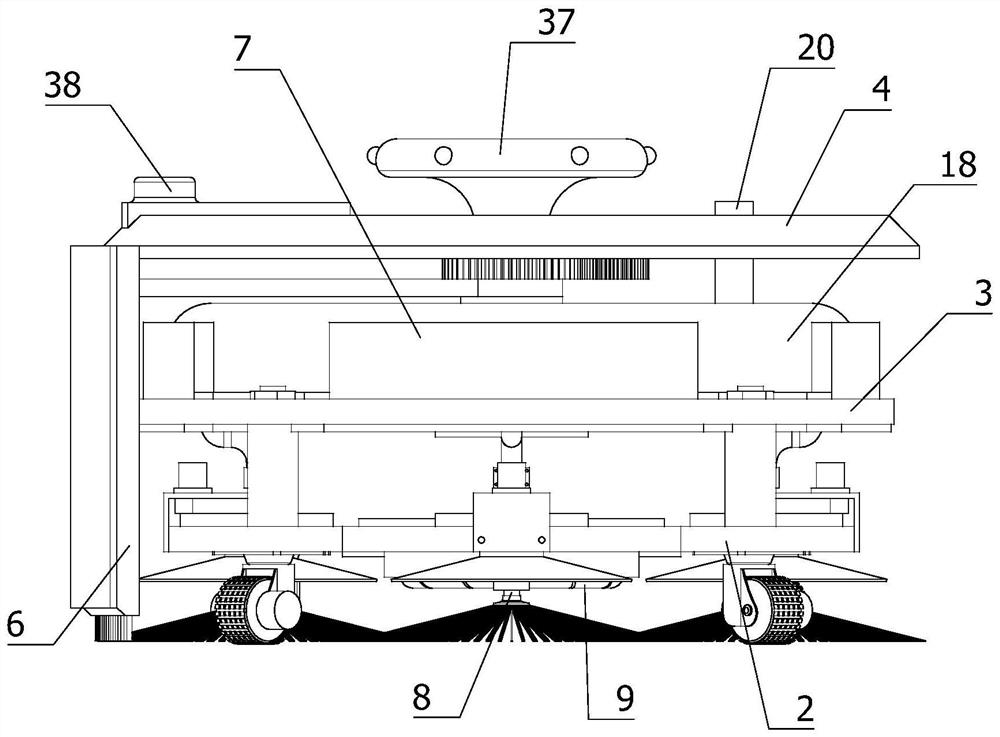

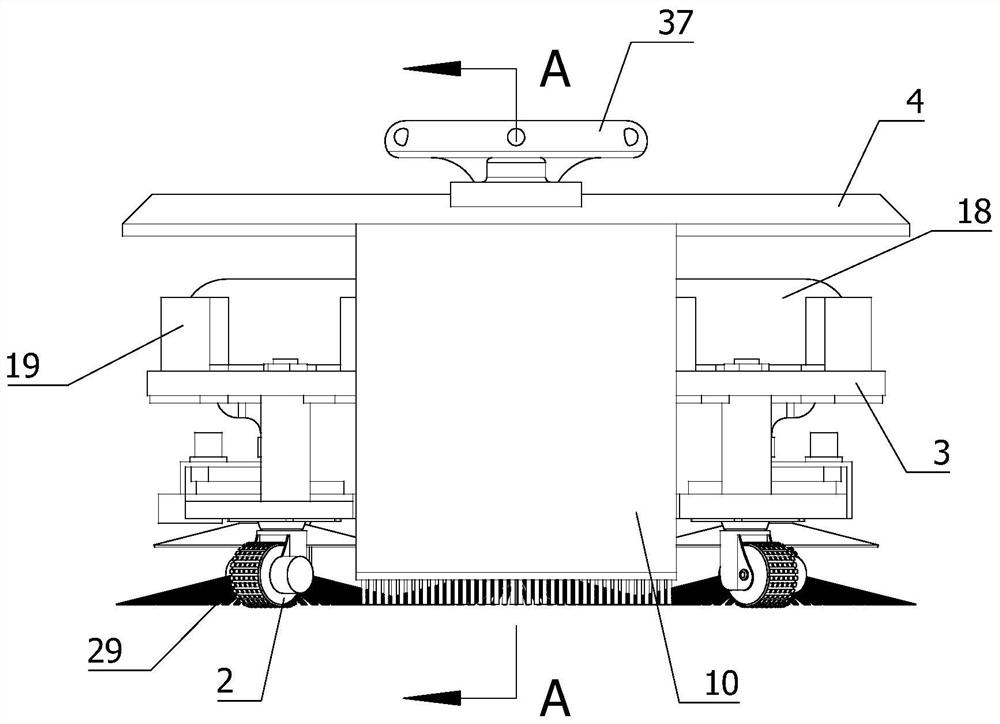

Automatic disinfection robot for ground of medical department

ActiveCN113842482AApply evenlyDo not polluteAutomatic obstacle detectionTravelling automatic controlMedical departmentEnvironmental engineering

The invention relates to the technical field of medical instruments, in particular to an automatic disinfection robot for ground of medical department. The automatic disinfection robot comprises a walking device, an alarm device and a disinfection device, the walking device is a disc-shaped robot, and the walking device is composed of a chassis walking vehicle, a middle end supporting disc and a top disc which are sequentially installed from bottom to top; the disinfection device comprises a uniform disinfection assembly and a baffle, the uniform disinfection assembly comprises a liquid supply mechanism, a liquid spraying mechanism and an air blowing fan. According to the automatic disinfection robot for the ground of the medical department, through cooperation between the walking device and the disinfection device, automatic and comprehensive disinfection of the ground of the medical department is achieved, and through blocking of the baffle on obstacle; the obstacles cannot be contaminated by disinfectant, the disinfectant only disinfects the floor, the disinfectant is evenly smeared through a liquid spraying mechanism and the air blowing fan, and even smearing of the disinfectant is guaranteed while the floor is comprehensively disinfected.

Owner:SOUTHWEST JIAOTONG UNIV +1

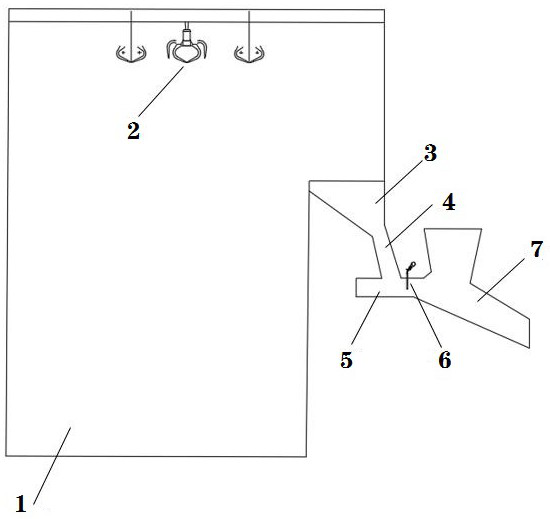

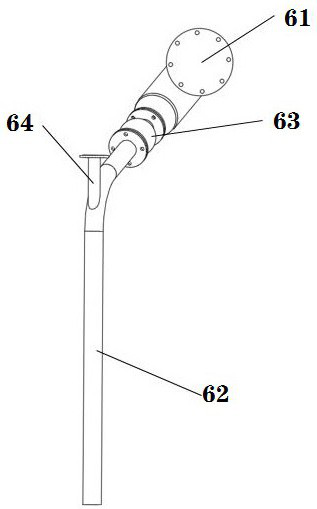

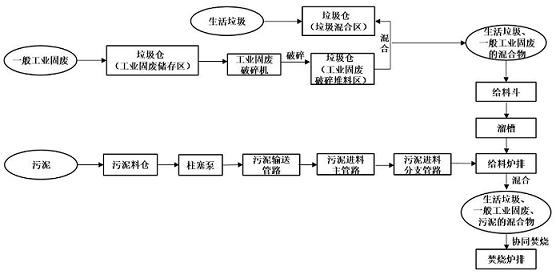

Feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge

PendingCN113339809AWell mixedAvoid uneven calorific valueIncinerator apparatusSludgeRefuse Disposals

The invention discloses a feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge, and belongs to the technical field of garbage treatment. The feeding system comprises a garbage bin, a garbage grab bucket, a feeding hopper, a chute, a feeding fire grate, a sludge feeding pipeline and an incinerator fire grate, wherein the garbage grab bucket is arranged at the top of the garbage bin; the top of the feeding hopper is communicated with the garbage bin; the bottom of the feeding hopper is communicated with the chute; the feeding fire grate is arranged at the bottom of the chute; the sludge feeding pipeline is arranged above the feeding fire grate; an inlet of the incinerator fire grate is communicated with an outlet of the feeding fire grate; an industrial solid waste storage area, an industrial solid waste crushing area, an industrial solid waste crushing and stacking area and a garbage mixing area are sequentially arranged in the garbage bin; an industrial solid waste crusher is arranged in the industrial solid waste crushing area; and a sliding way is arranged at the bottom of the industrial solid waste crusher and used for conveying crushed general industrial solid waste to the industrial solid waste crushing and stacking area. According to the feeding system, the three wastes can be uniformly mixed, and stable combustion is promoted.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +2

Metal powder granulating machine

InactiveCN108889410ARealize multi-angle cuttingThere will be no excessive block diameter after cuttingSievingScreeningMetallic materialsMetal particle

The invention discloses a metal powder granulating machine which comprises a body. A cutting bin is arranged in the body, a motor is mounted at the top end of the cutting bin, one end of the motor isconnected with a fixed beam through a stirring shaft, the bottom of the fixed beam is rotatably connected with cutting saw teeth through a shaft rod, a discharging pipe is mounted at the bottom of thecutting bin, two sides of the body are fixed with bearing plates through supports, one end of a vibration motor is connected with a vibrating screen plate through a fixed shaft, clamping grooves areformed in two inner ends of the body, first clamping connection blocks and second clamping connection blocks are mounted on the clamping grooves, a filter screen is arranged between the first clampingconnection blocks, and iron attracting magnets are arranged between the second clamping connection blocks. The granulating machine is provided with multi-group cutting devices, metal materials can besufficiently cut and grinded, the vibrating screen plate is matched with the filter screen, so that metal particles can be screened and filtered, and copper and iron can be separated by the iron attracting magnets.

Owner:NANJING HUANWU RESOURCES RECYCLING TECH

Sewage separation treatment equipment for biological pharmacy

ActiveCN112791479AStrong ability to continue workingGuaranteed efficiencyMembrane filtersStationary filtering element filtersEngineeringEnvironmental geology

The invention discloses sewage separation treatment equipment for biological pharmacy, and belongs to the technical field of sewage separation. The equipment comprises a separation frame, cushion blocks are arranged on the left side surface and the right side surface of the inner wall of the separation frame, a same filter plate is arranged on the opposite surfaces of the two cushion blocks, first bearings are arranged on the front surface and the back surface of the inner wall of the separation frame, and a same first rotating shaft is arranged in the two first bearings. According to the sewage separation treatment equipment for biological pharmacy, by arranging a scraping plate, a water wheel, a filter plate, a guide plate and a collecting frame, sundries fall into the collecting frame along a swinging plate at the moment, energy generated by water flow falling can be converted into power for rotation of the scraping plate, and the scraping plate can be guaranteed to continuously clean the filter plate; impurities can be directly taken out and automatically collected, so that the workload of people can be reduced while the filter plate is prevented from being blocked; and the continuous working capacity of the device is more ideal, and the sewage treatment efficiency can be ensured while energy conservation and environmental protection are achieved.

Owner:ZHEJIANG KECHAO ENVIRONMENTAL PROTECTION

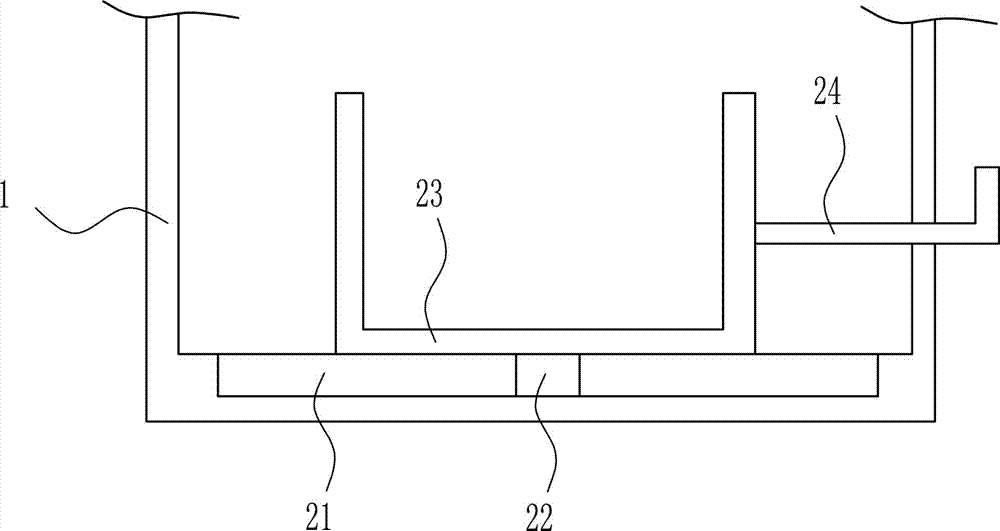

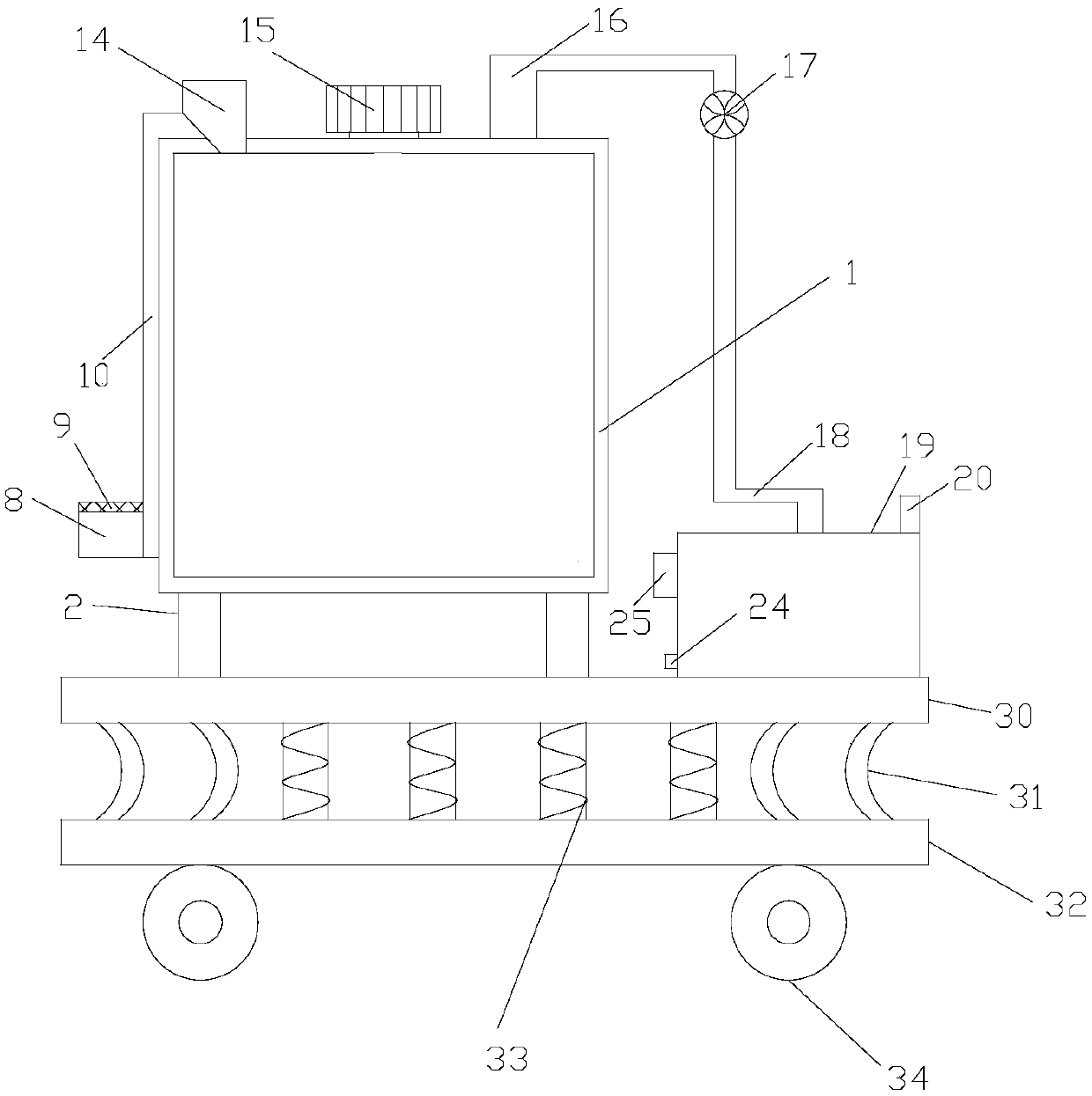

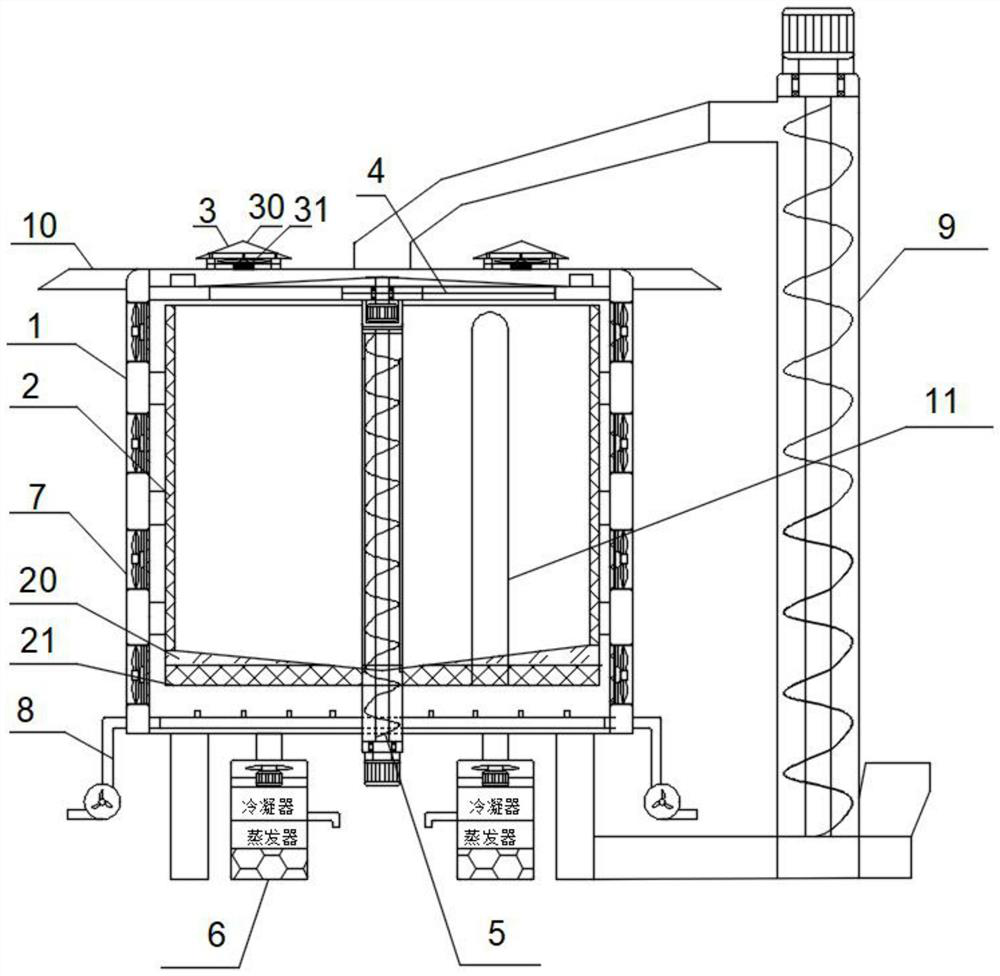

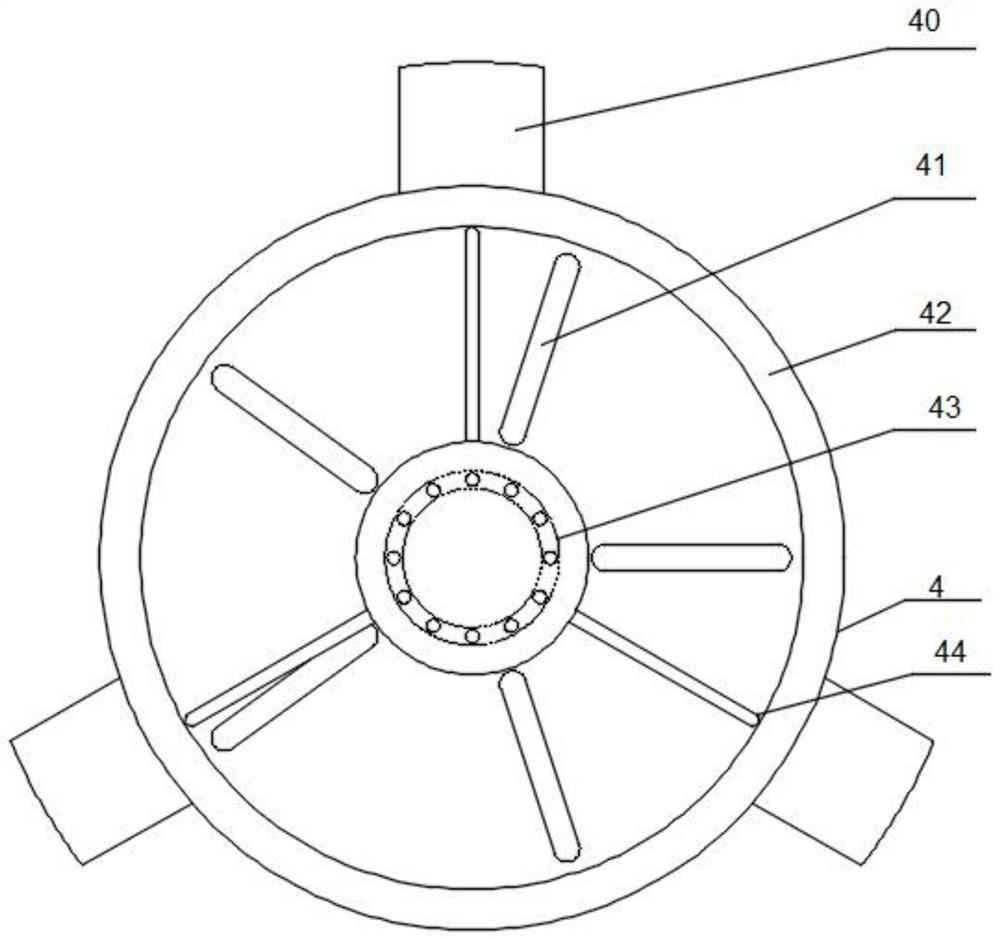

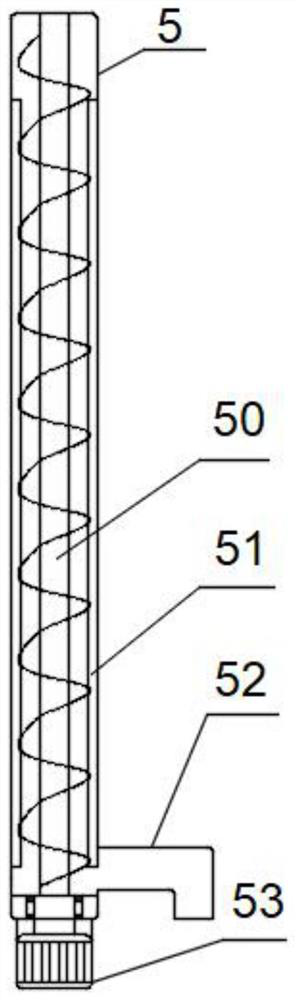

Batch type circulating grain drying granary with multi-stage moisture removal and heat dissipation structure

InactiveCN112567985AEffective coolingImprove cooling effectAgriculture tools and machinesSeed preservation by dryingThermodynamicsGrain storage

The invention discloses a batch type circulating grain drying granary with a multi-stage moisture removal and heat dissipation structure. The batch type circulating grain drying granary comprises a granary outer box body, a grain storage tank, two groups of heat dissipation assemblies, a grain throwing assembly, a grain outlet assembly, a dry air inlet assembly, a dehumidification fan, an air blower and a grain inlet assembly, wherein the granary outer box body is supported and fixed above the ground through a bracket; the grain storage tank is located in the granary outer box body and fixedlyconnected to the inner wall of the granary outer box body through a bracket, and the two groups of heat dissipation assemblies are located at the upper end of the granary outer box body, symmetrically arranged relative to a feeding port of the granary, fixedly connected to the top end of the granary outer box body and communicate with the interior of the box body; and the grain throwing assemblyis located at the top end of the grain storage tank and fixedly connected to the inner wall of the granary outer box body, the upper end of the grain outlet assembly is fixedly connected with the middles of the bottom ends of the heat dissipation assemblies, the bottom end of the grain outlet assembly extends out of the bottom of the granary outer box body, and the periphery of the bottom end of the grain outlet assembly is fixedly connected with the bottom wall of the granary outer box body.

Owner:湖北盛琪达工程科技有限公司

Fish pond feeding device

InactiveCN109156412AAvoid economic lossAvoid harmClimate change adaptationPisciculture and aquariaWater flowMaterial storage

The invention discloses a fish pond feeding device. The device comprises a material storage assembly and a material throwing assembly. The material storage assembly comprises a bracket and a trough. The material throwing assembly comprises a floating bracket, floaters, a lower bottom plate and a material throwing tray for throwing a feed into the fish pond. A bottom plate is fixedly connected to afirst blower for blowing feed falling from a discharge pipe into the material throwing disc. An upper end of the floating bracket is rotatingly connected to a hydrodynamic rotating wheel that is under the material throwing disc and drives the material throwing disc to rotate. A bottom plate is fixedly connected to a water pump which can drives the hydrodynamic rotating wheel to rotate. A materialdividing cone which can be inserted into a feeding pipe is formed at the center of the material throwing disc. The lower end of the lower bottom plate is equipped with a hydrodynamic pushing rod which is driven by water flow generated by the water pump to drive the material throwing disc to move axially. According to the fish pond feeding device, by setting a motor, the first blower and the waterpump on the bottom plate, electric components are not used in the material throwing assembly, and the damage to fishes and the economic losses of a user caused by electric leakage when the material throwing assembly is turned over and the electric components are immersed in the fish pond are avoided.

Owner:麻景峰

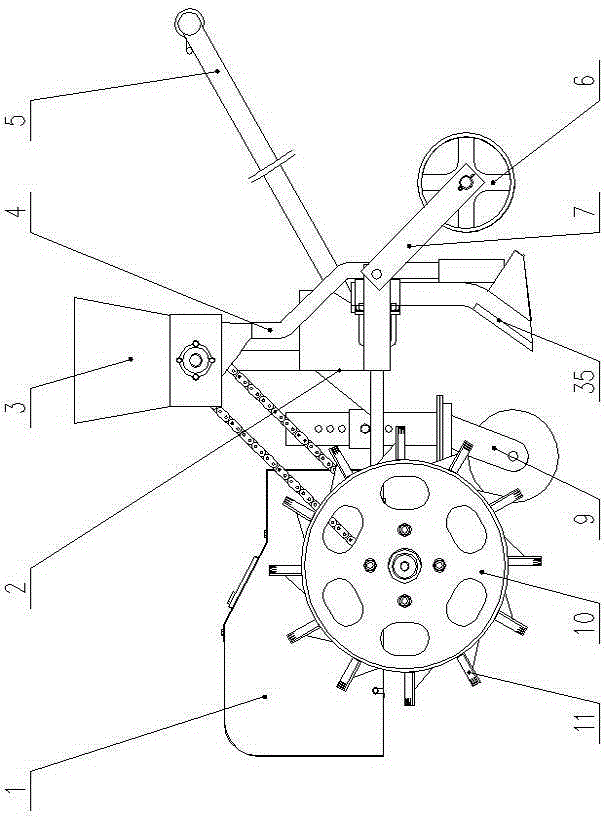

Self-propelled electric mountainous large-width precision seeder

ActiveCN105265074AReal-time power observationCreate pollutionSeed depositing seeder partsRegular seed deposition machinesElectricitySeeder

A self-propelled electric mountainous large-width precision seeder comprises a rack. A handrail is welded to the rear portion of the rack. A speed regulating rotary handle is mounted at one end of the handrail. A seed case is arranged above the middle of the rack. A seed discharge pipe is arranged on the lower portion of the seed case. A furrowing and seeding shovel is arranged on the rack and located below the seed case. The lower end of the seed discharge pipe is located at the back side of the furrowing and seeding shovel. Driving wheels are arranged on the two sides of the lower front portion of the rack. A driving shaft is arranged between the two driving wheels. A double-wheel mechanism is arranged at the two ends of the driving shaft. A driven gear and a driving sprocket are arranged in the middle of the driving shaft. The driving sprocket is connected with a seed discharge wheel of the seed case. The driven gear is connected with a brushless motor. The brushless motor is installed on the upper front portion of the rack and connected with a storage battery. The speed regulating rotary handle is connected with the brushless motor. The storage battery and the brushless motor are adopted as the main source of power, repeated use is achieved, and application of pure electricity to agricultural machinery creates a new prospect for development of agricultural machinery at present.

Owner:GANSU TAOHE TRACTOR MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com