Vertical ring die pelleter

A granulator and ring die technology, applied in the direction of mold extrusion granulation, solid fuel, biofuel, etc., can solve the problems of affecting output and compression efficiency, increasing manufacturing difficulty and cost, and not being able to dissipate heat in time in the granulating chamber. To achieve the effect of improving service life, improving efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

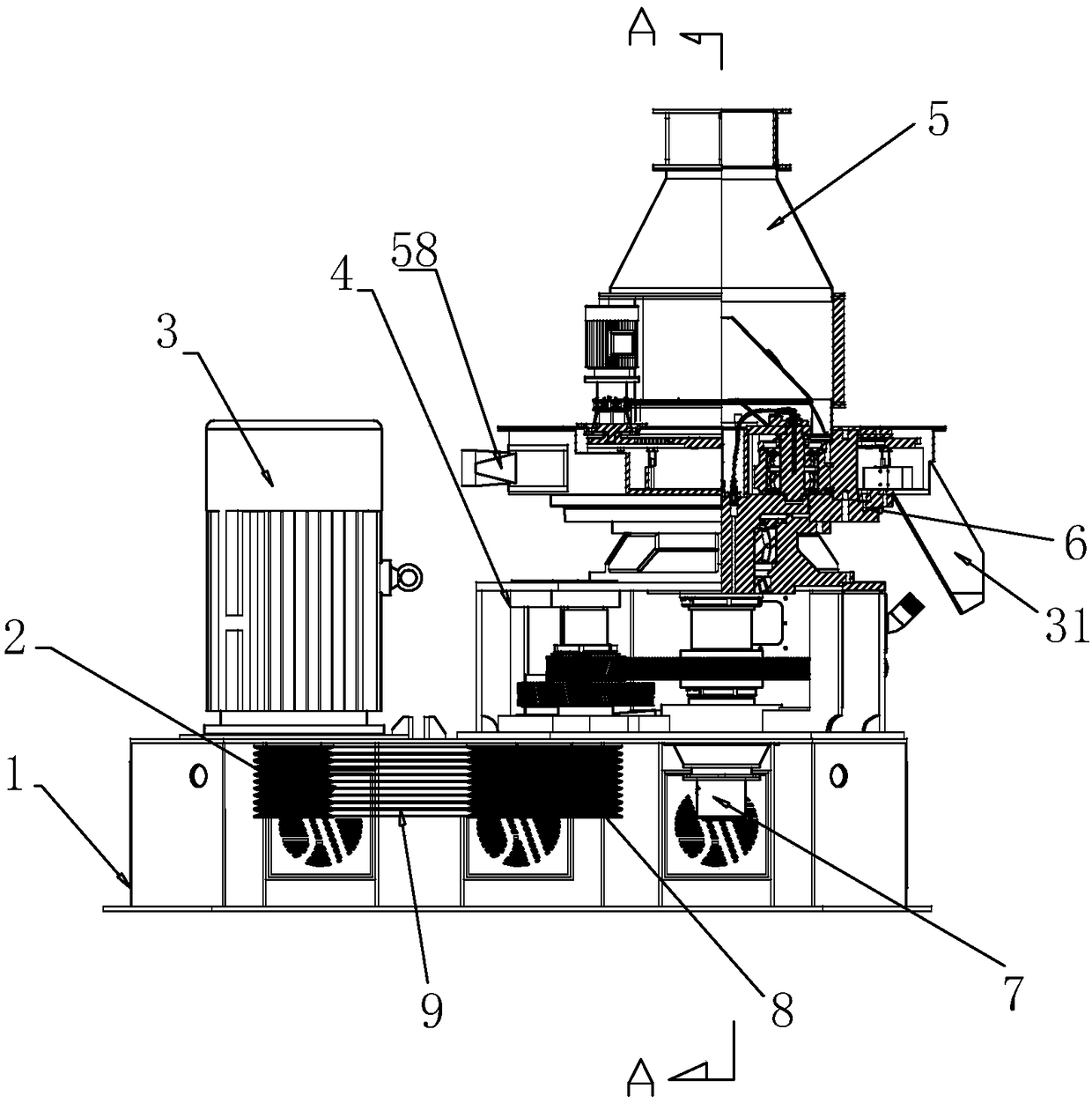

[0048] Embodiment one, such as Figure 1~4 , 6, 7, and 12,

[0049] The vertical ring die granulator includes an organic base 1, a main motor 3, a reduction box 4, a main machine 6, a feeding cover 5, a reduction motor 17, a gear plate 22, a scraper 23 and a cutter 22-5, wherein:

[0050] --Such as figure 1 As shown, the main motor 3 is installed on one side of the frame, and the reduction box 4 is installed on the other side of the frame. , a belt 9 is wound between 1# belt pulley 2 and 2# belt pulley 8;

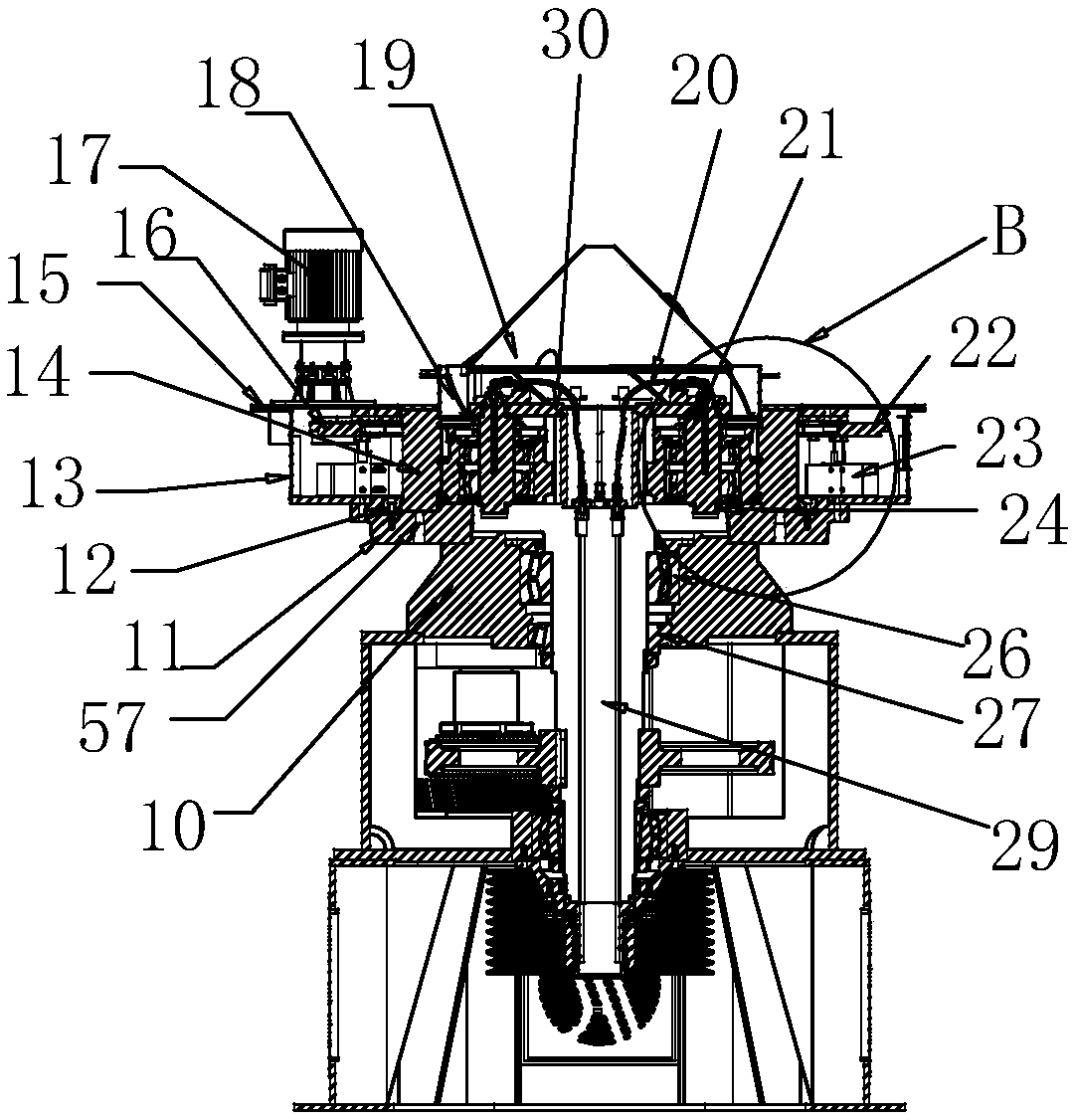

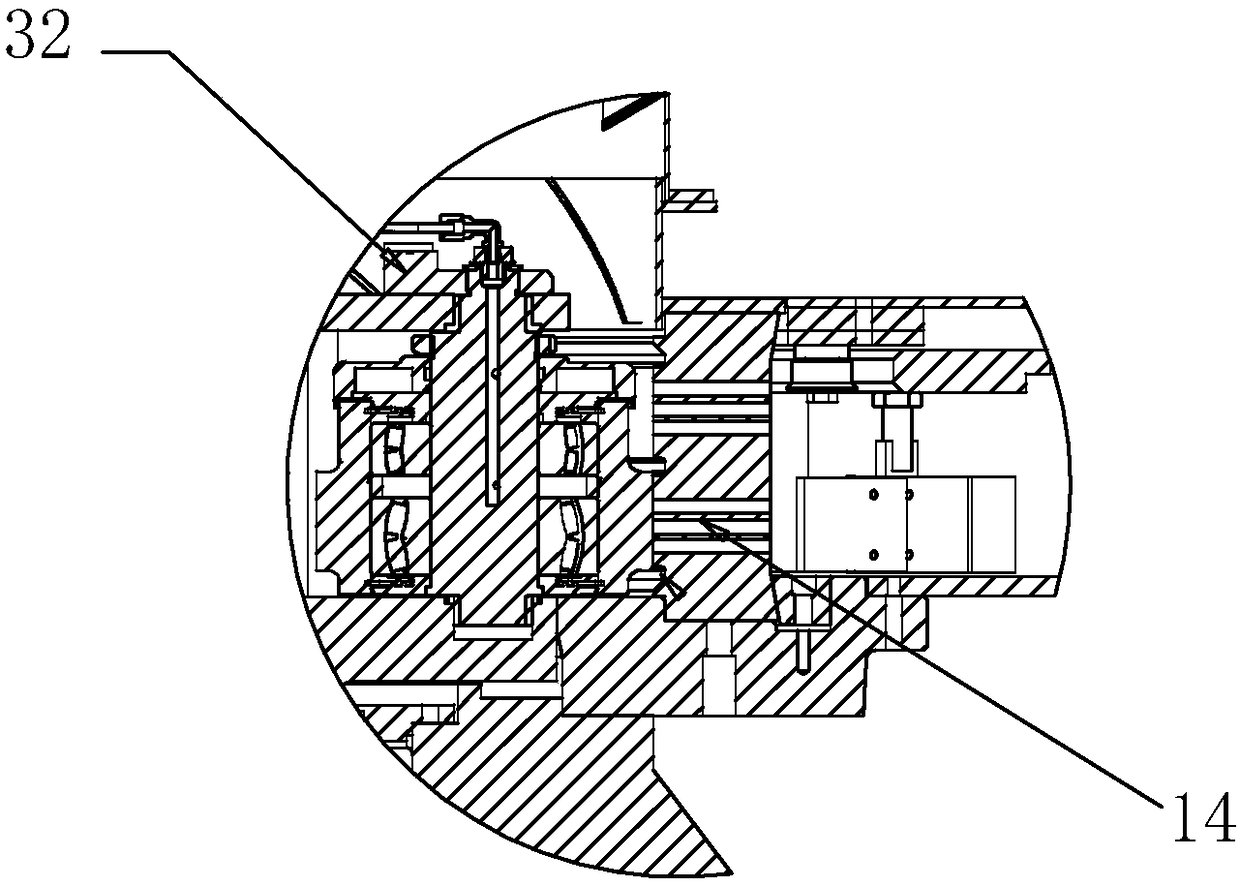

[0051] --Such as Figure 1~3 , 6, 7, and 12, the main engine includes a support 10, a ring mold base 11, a connecting base 18, a main engine shell 13, an upper cover 15, a ring mold 14, a pressure roller assembly 21 and a main shaft 29, and the support 10 is fixed On the reduction box 4, the ring die base 11 is fixed on the support 10, the ring die 14 is fixed on the ring die base 11, the connection base 18 is fixed on the ring die 14, and the feed cover 5 is fixed on t...

Embodiment 2

[0057] Such as figure 2 , 6 As shown, as an improvement of the present invention: the aforementioned main shaft and the reduction box are connected through 3# main shaft bearing 52; the main shaft and the support are connected through 1# main shaft bearing 26 and 2# main shaft bearing 27;

[0058] The aforementioned 1# main shaft bearing 26 and the 3 # main shaft bearing 52 are spherical roller bearings, and the aforementioned 2# main shaft bearing 27 is a tapered roller bearing.

Embodiment 3

[0059] Embodiment three, such as figure 1 , 2 , 6, 8, and 11,

[0060] As an improvement of the present invention:

[0061] There is a 1# lubricating grease pipeline in the middle of the aforementioned main shaft 29;

[0062] An oil separator 7 is also provided, and the oil separator 7 includes: an oil separator shaft 7-1, an oil separator bearing 7-2, a connecting flange 7-3, a seal 7-4, and an "O" ring 7-5, oil separator shell 7-6, oil separator end cap 7-8 and oil separator retaining ring 7-9; the aforementioned oil separator shaft 7-1 is installed on the oil separator through two oil separator bearings 7-2 Inside the oil separator shell 7-6; the fixed oil separator end cover 7-8 at one end of the aforementioned oil separator casing, the oil separator bearing 7-2 located on the side of the aforementioned oil separator end cover passes through the oil separator retaining ring 7 -9 limit; the other end of the aforementioned oil distribution pan shell is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com