Noise-reducing axial flow fan

An axial flow fan and noise reduction technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of inability to cut and comb large eddy currents, cannot form ideal airflow, and cannot play the role of guiding, etc., to achieve reduction The effects of personal injury, timely heat dissipation, and uniform air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

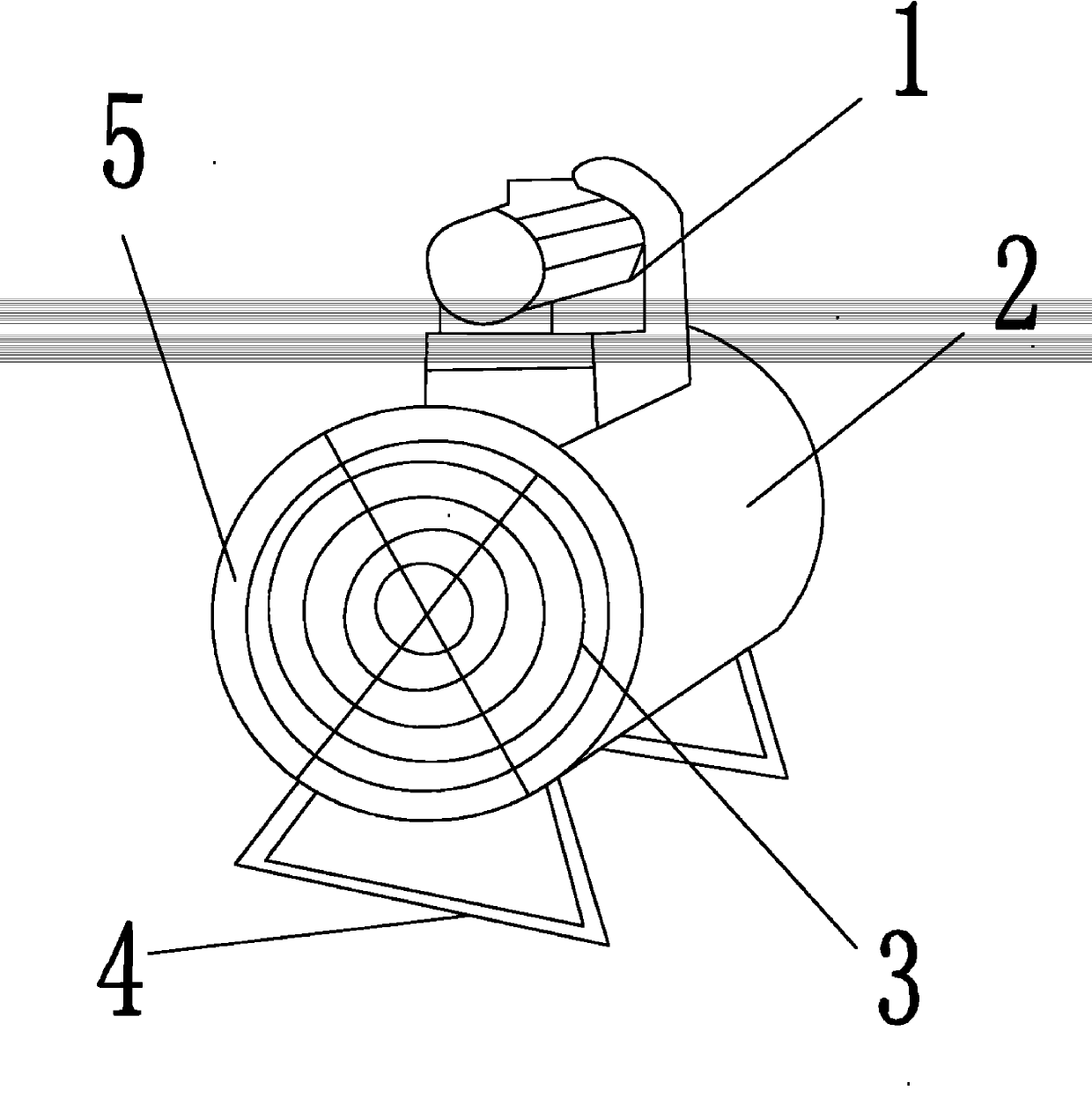

[0018] Such as figure 1 figure 2 As shown, a noise-reducing axial flow fan includes a housing, an impeller is installed in the housing, a protective cover is installed in the housing, a motor is arranged on the outer wall of the housing, and the two ends of the housing are A support seat is provided, the two sides of the support seat and the bottom edge are mutually inclined, and a rubber pad is provided at the lower end of the bottom edge of the support seat.

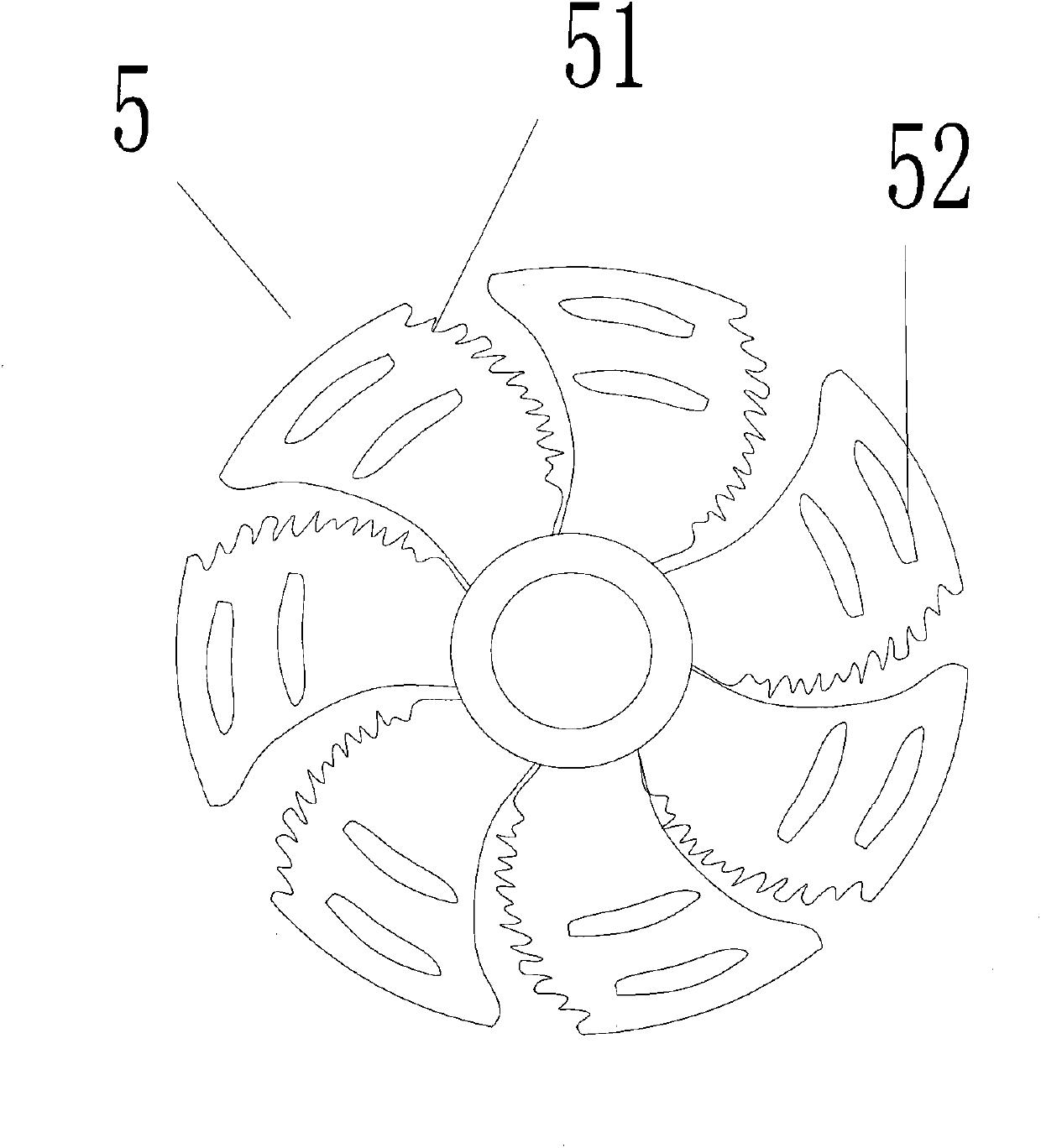

[0019] The tail of each fan blade of the impeller has a plurality of unequal sawtooth slots. The unequal-spaced sawtooth cuts and combs the large vortex generated at the outlet of the wind into countless small eddies, and controls the viscous airflow at the root of the fan blade. Effective separation and guidance, resulting in an ideal airflow.

[0020] The blade adopts a new type of high-efficiency forward-swept sickle blade with circular arc thin plate, which is designed according to the negative exponential flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com