Patents

Literature

182results about How to "Controllable distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

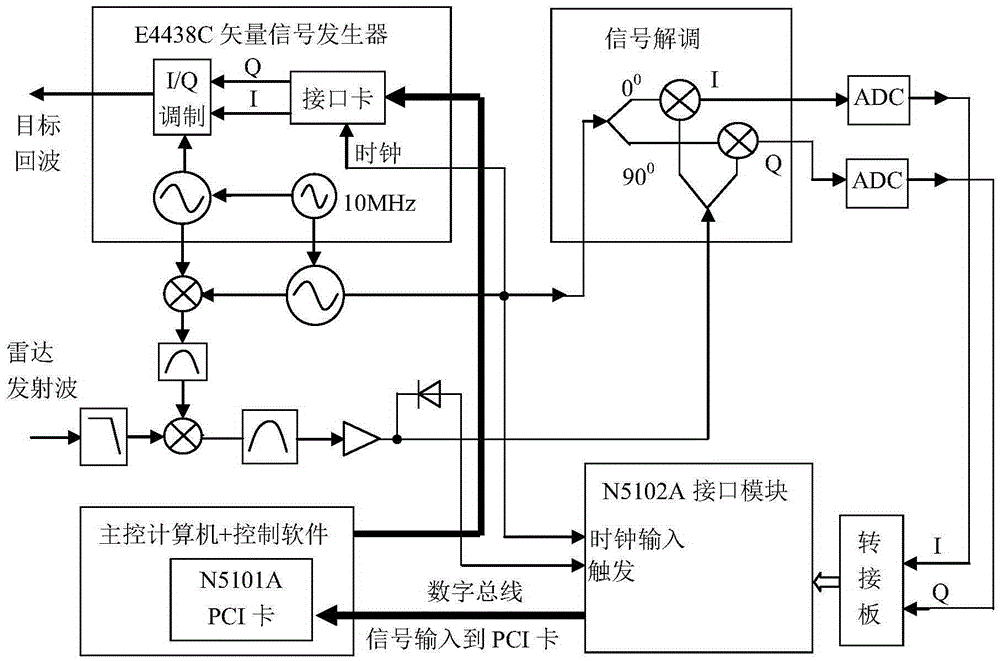

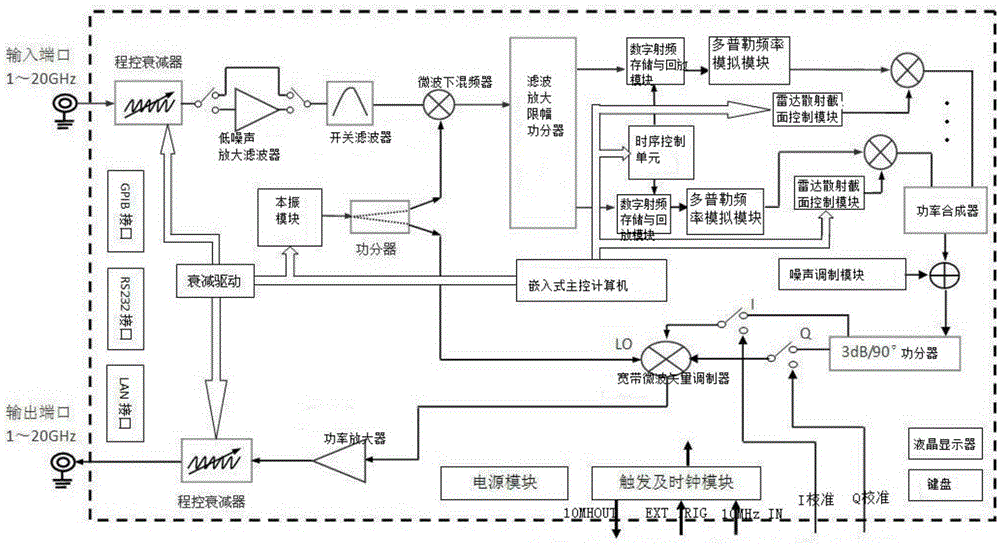

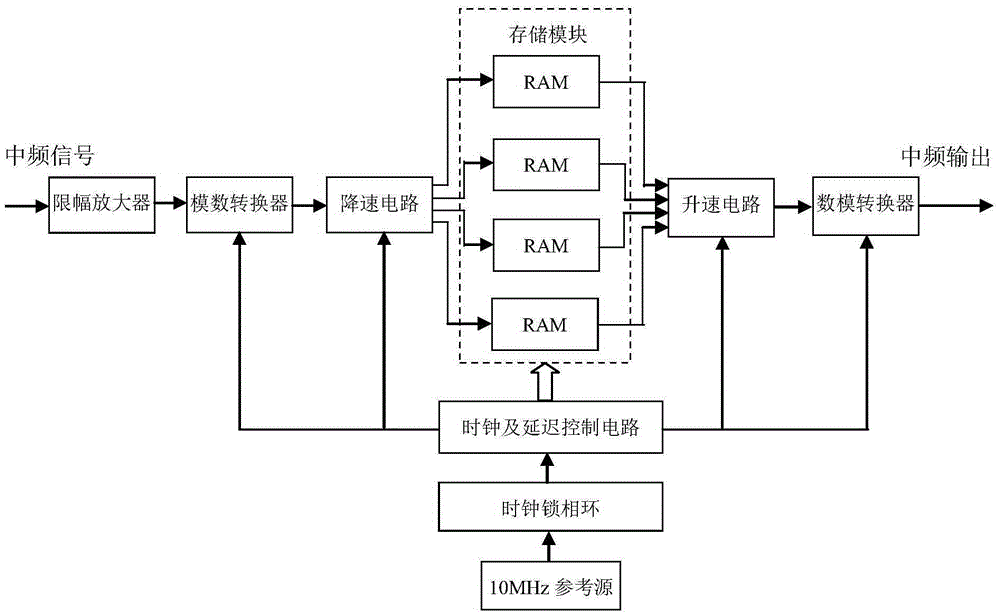

General signal generator for radar target simulation

InactiveCN105403870AControllable distanceEasy to control speedWave based measurement systemsSequence controlRadar systems

The invention, which relates to the technical field of the radar target simulation, discloses a general signal generator for radar target simulation. With the signal generator, a defect that the existing radar target signal generator is based on a special-purpose signal generator and only serve a radar system with a specific type in terms of frequency band coverage and function setting and thus the application range is limited can be solved. The signal generator comprises an embedded main control computer, a timing sequence control unit, an attenuation drive, a local oscillation module, a filtering, amplifying and limiting amplitude power divider, a plurality of digital radio frequency storage and playback modules, a plurality of Doppler frequency simulation modules, a radar cross section control module, a noise modulation module, a microwave down mixer, and IQ up mixing unit and the like. The output terminal of the microwave down mixer is connected with the filtering, amplifying and limiting amplitude power divider; the multiple digital radio frequency storage and playback modules are connected to the filtering, amplifying and limiting amplitude power divider; and the output terminal of each digital radio frequency storage and playback module is connected with one Doppler frequency simulation module.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

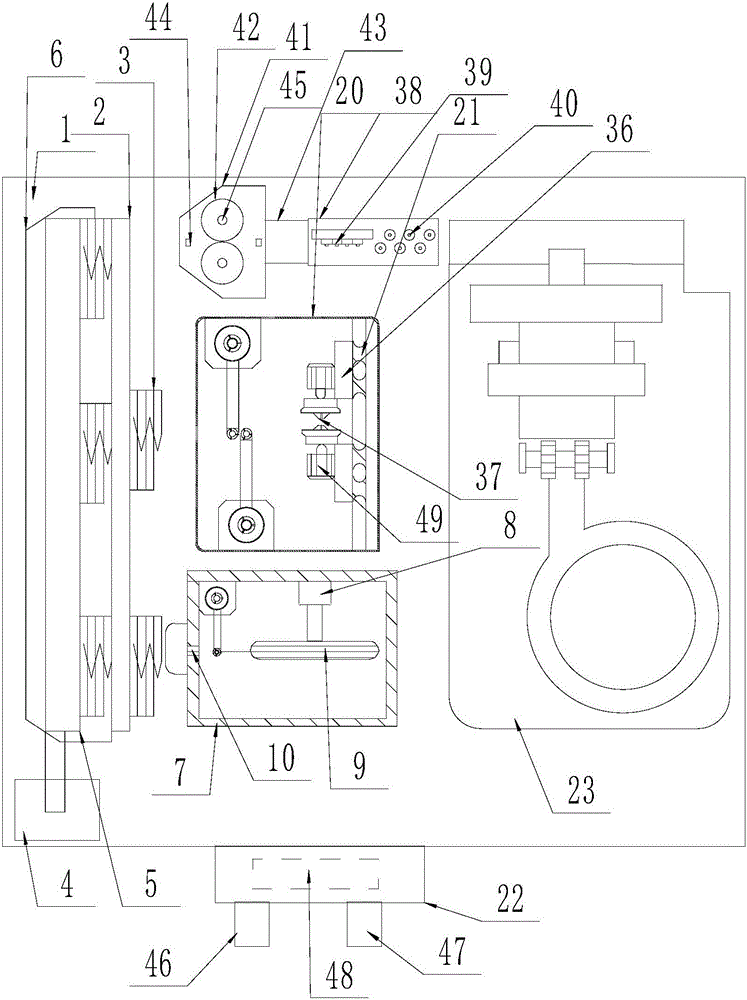

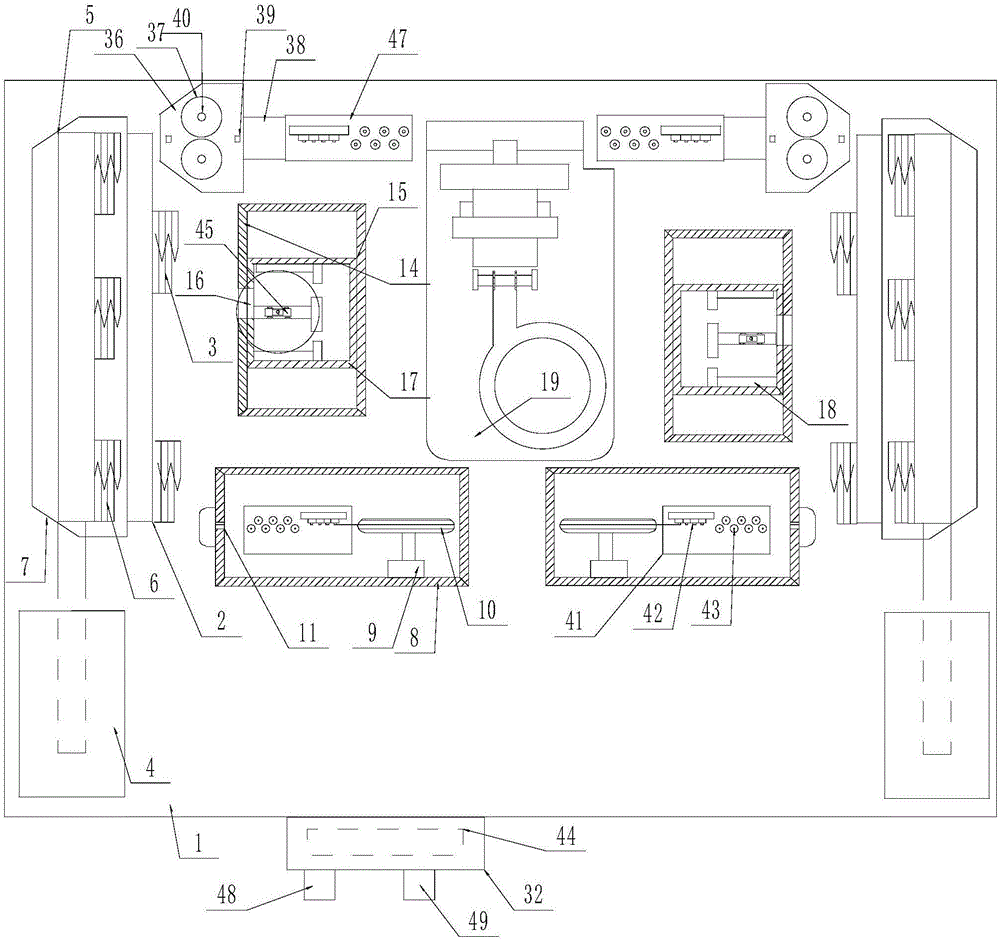

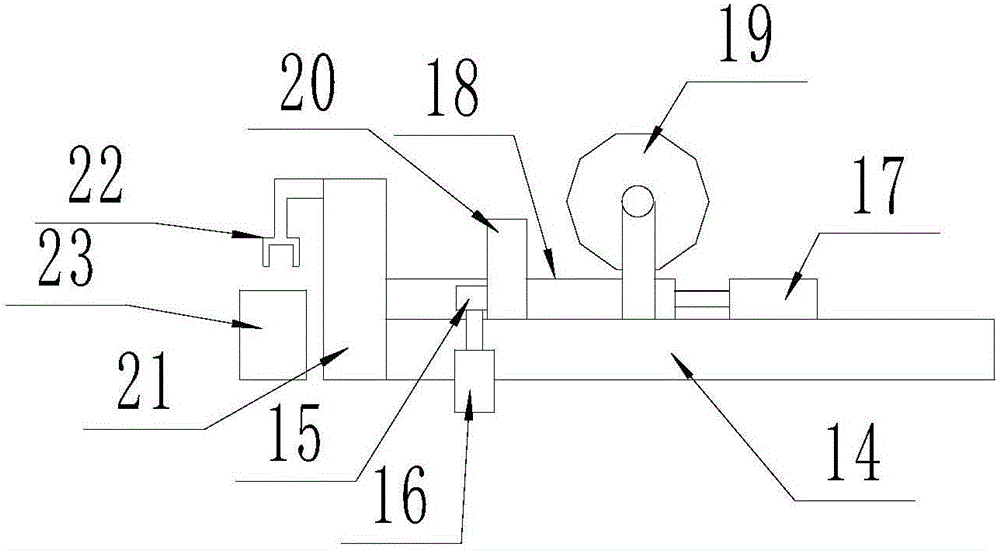

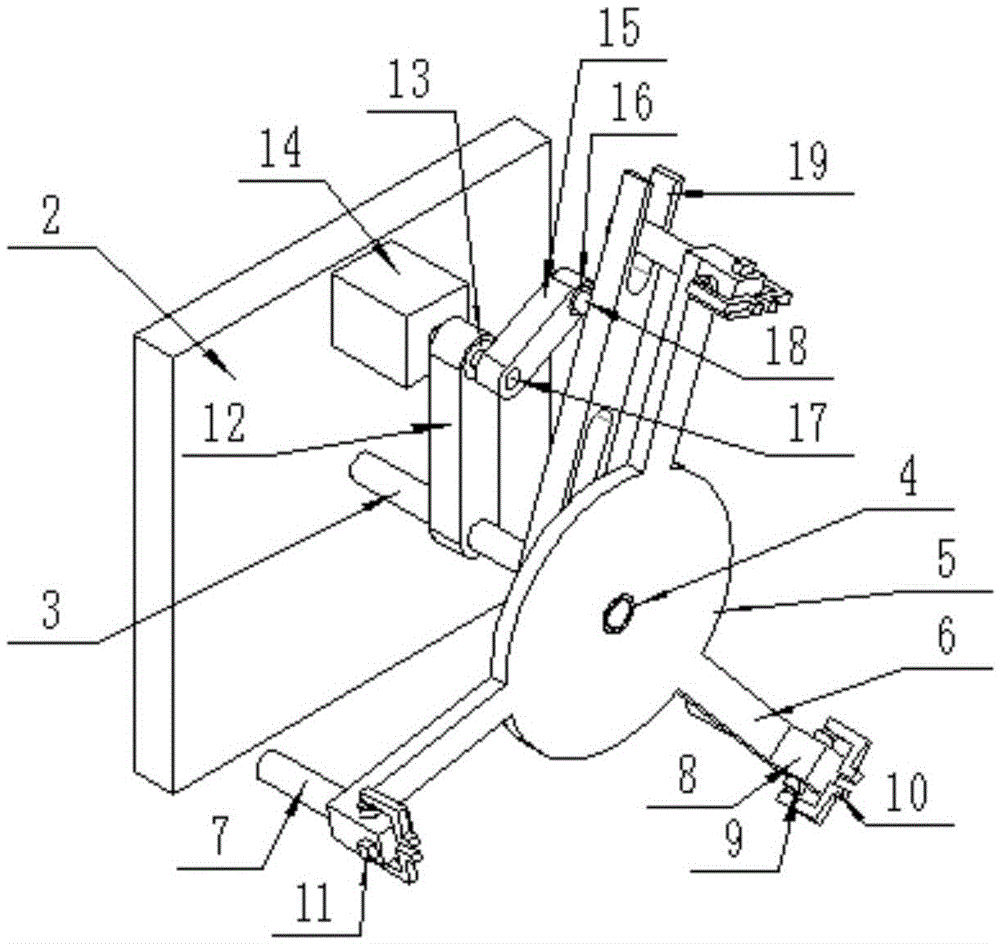

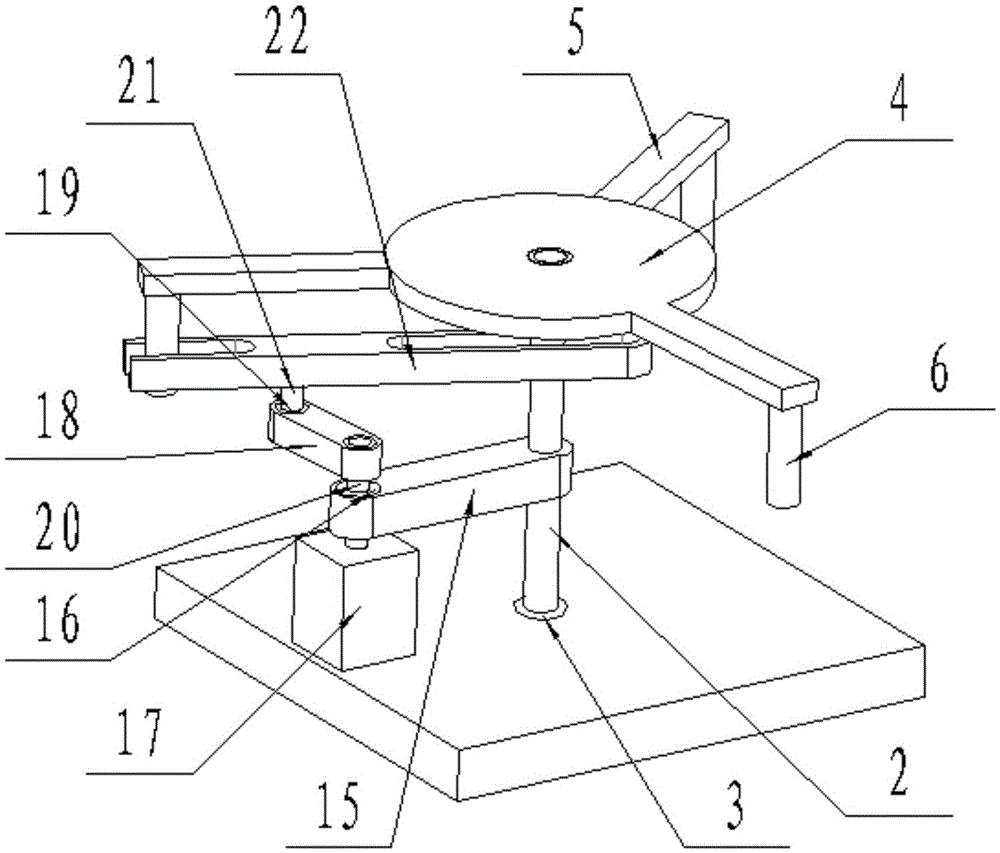

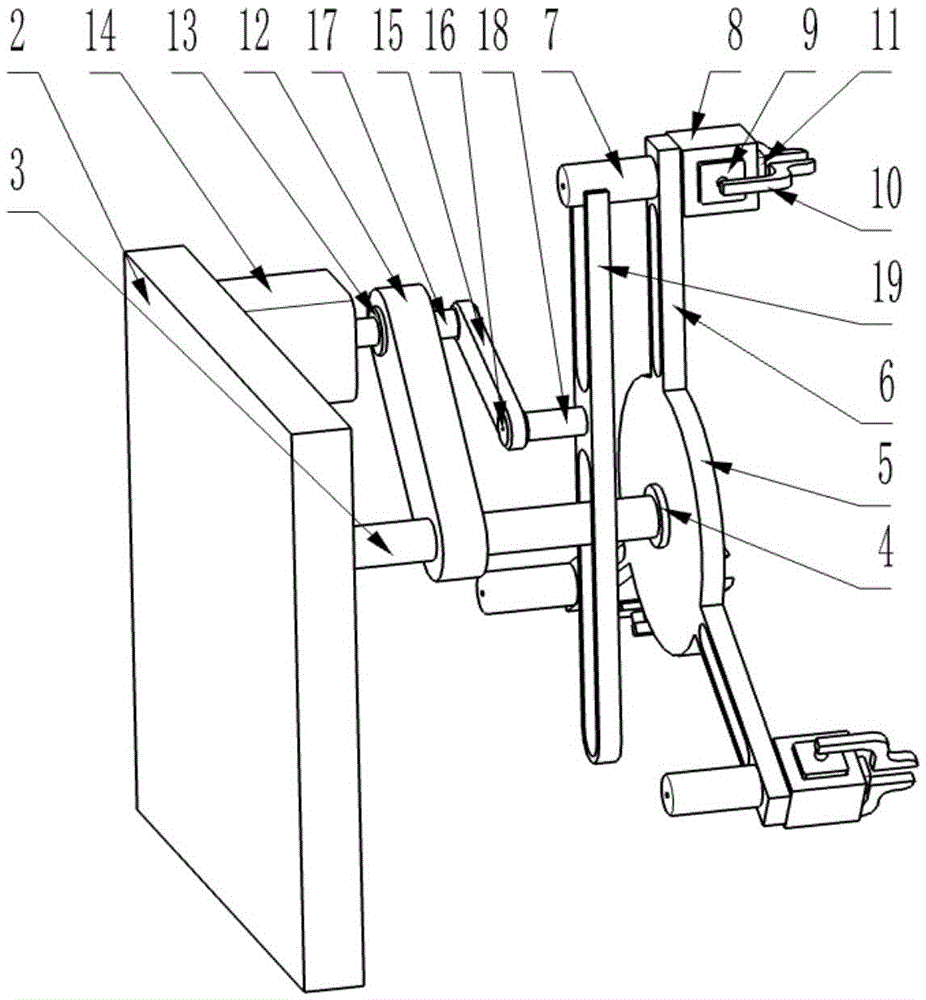

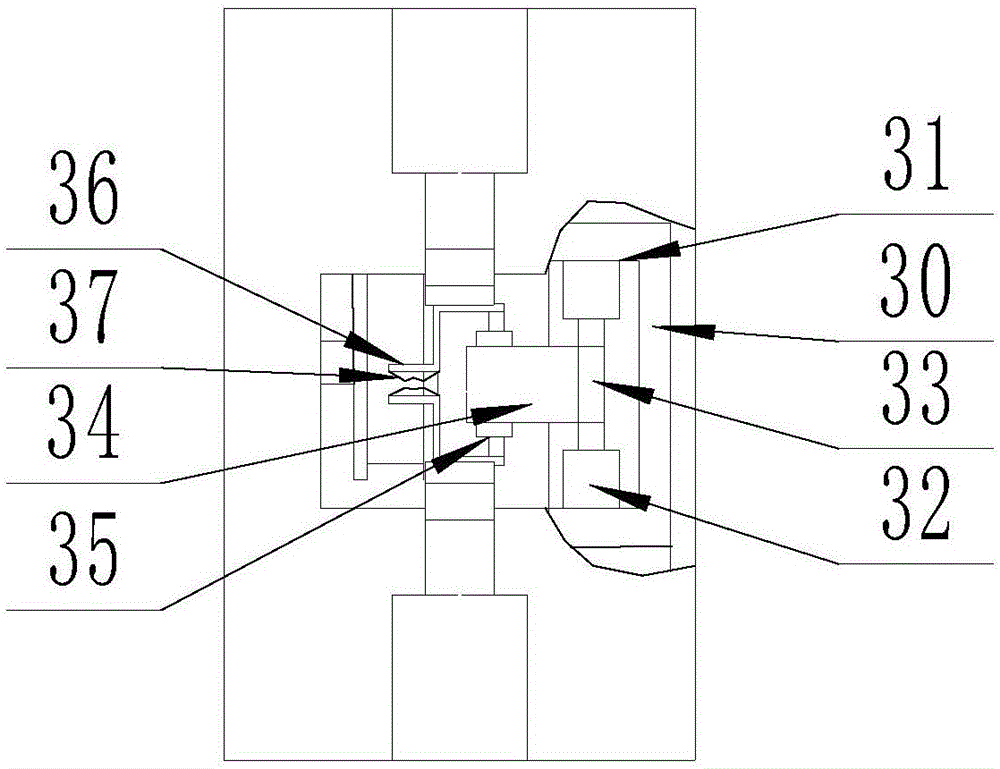

Swinging sliding rail type linear welding device for fuses conveyed through vibrating disk

ActiveCN105665978AReduce manufacturing costControllable distanceWelding/cutting auxillary devicesAuxillary welding devicesPunchingEngineering

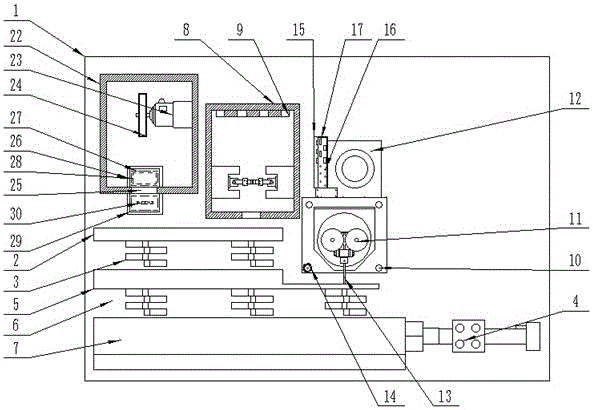

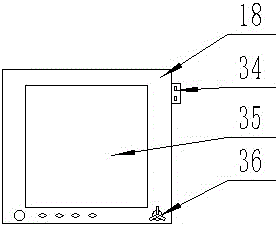

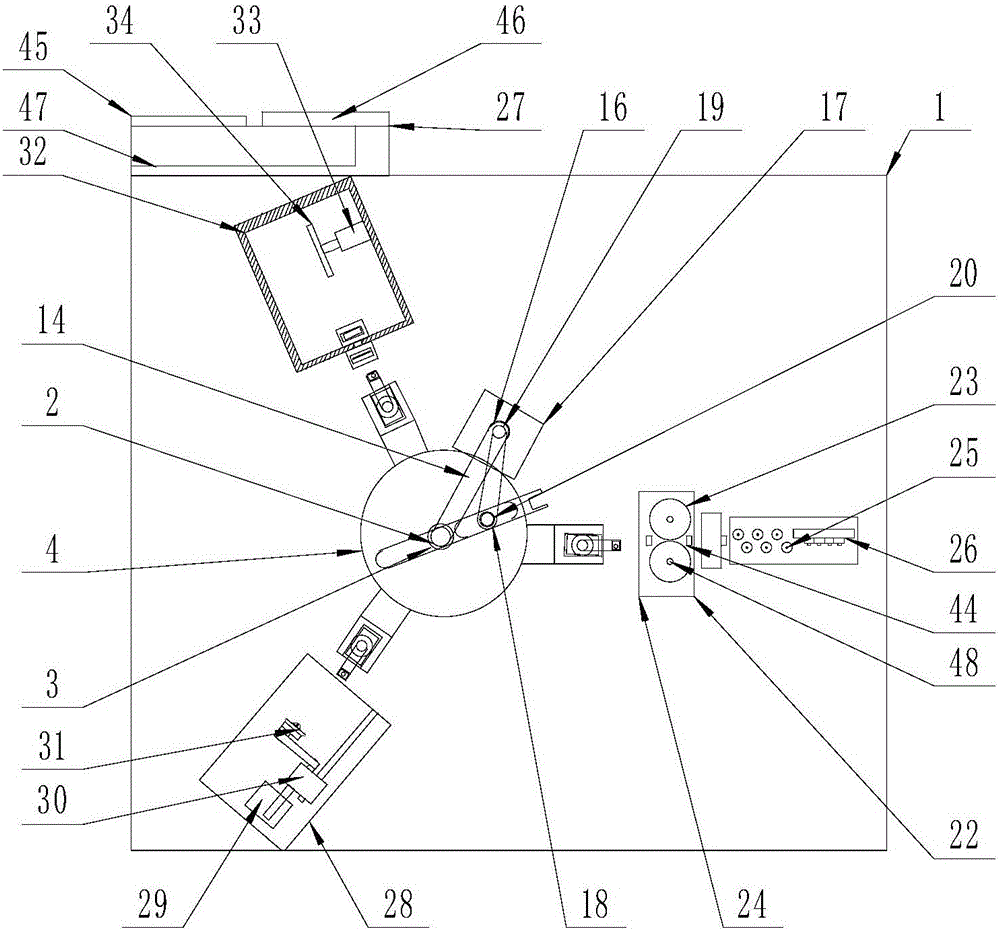

The invention discloses a swinging sliding rail type linear welding device for fuses conveyed through a vibrating disk.The linear welding device comprises a cuboid movable base, the upper surface of the movable base is provided with a swinging clamping and feeding mechanism, a sliding rail wire twisting mechanism, a terminal punching mechanism, an X-axis two-layer shifting wire clamping mechanism, a welding mechanism and a mechanism for conveying the fuses through the vibrating disk; the sliding rail wire twisting mechanism is located between the swinging clamping and feeding mechanism and the terminal punching mechanism, the X-axis two-layer shifting wire clamping mechanism is arranged opposite to the swinging clamping and feeding mechanism, the sliding rail wire twisting mechanism and the terminal punching mechanism, the welding mechanism is located on the back of the terminal punching mechanism, and a controller is electrically connected with the swinging clamping and feeding mechanism, the sliding rail wire twisting mechanism, the terminal punching mechanism, the X-axis two-layer shifting wire clamping mechanism, the welding mechanism and the mechanism for conveying the fuses through the vibrating disk respectively.The swinging sliding rail type linear welding device for the fuses conveyed through the vibrating disk has the advantages of being simple in structure and high in practicability.

Owner:泾县吉祥纸业有限公司

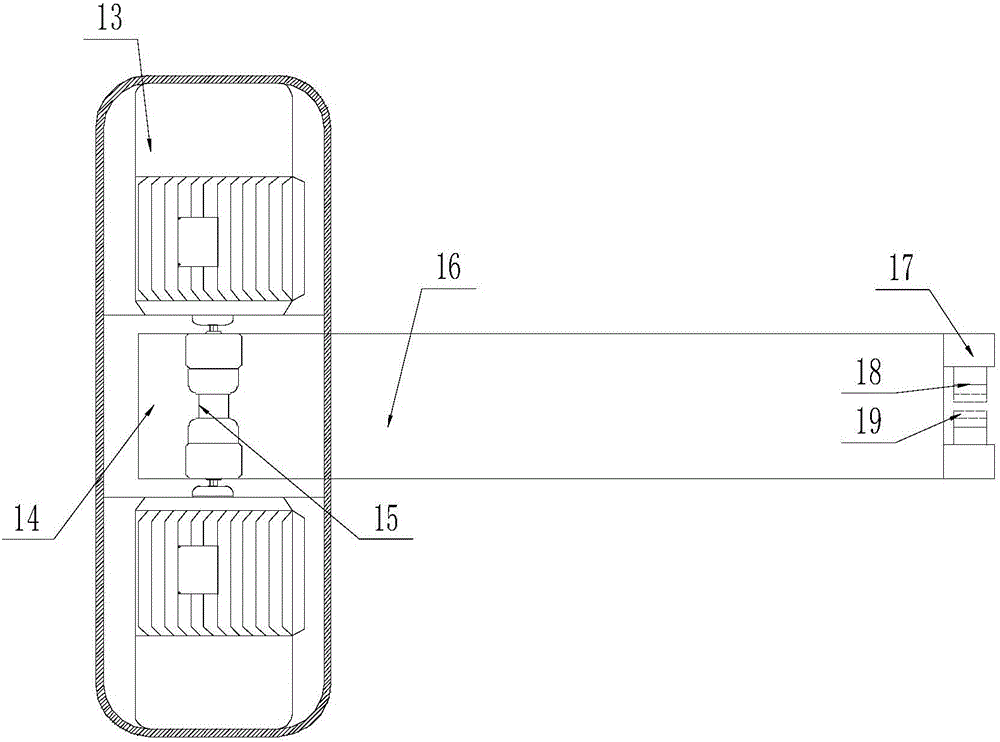

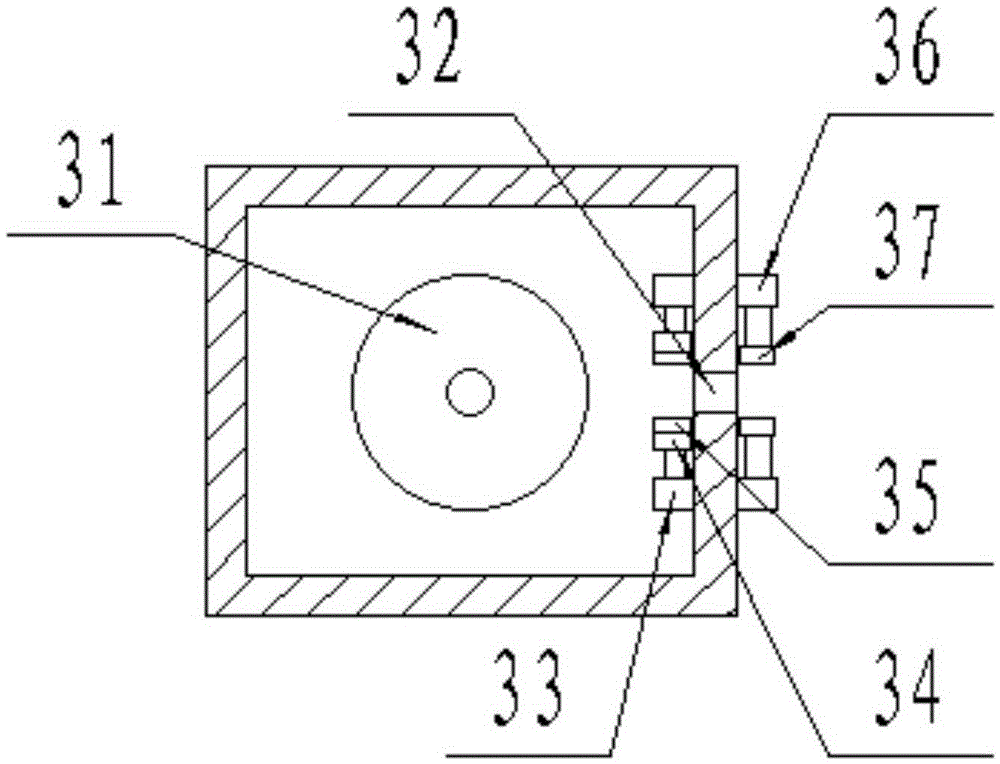

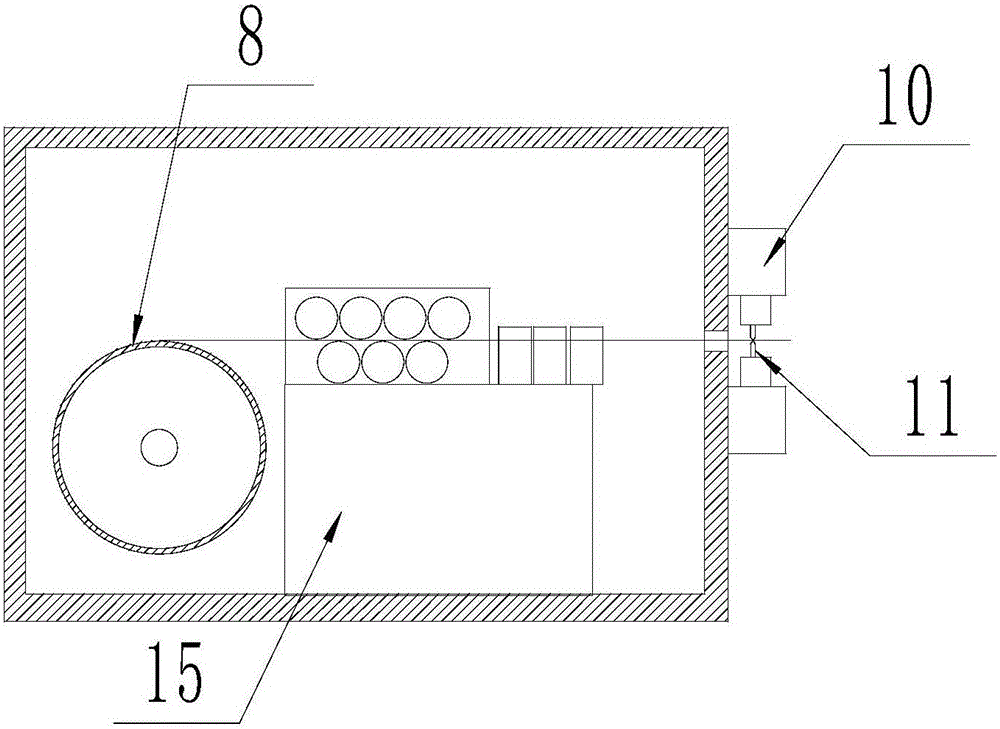

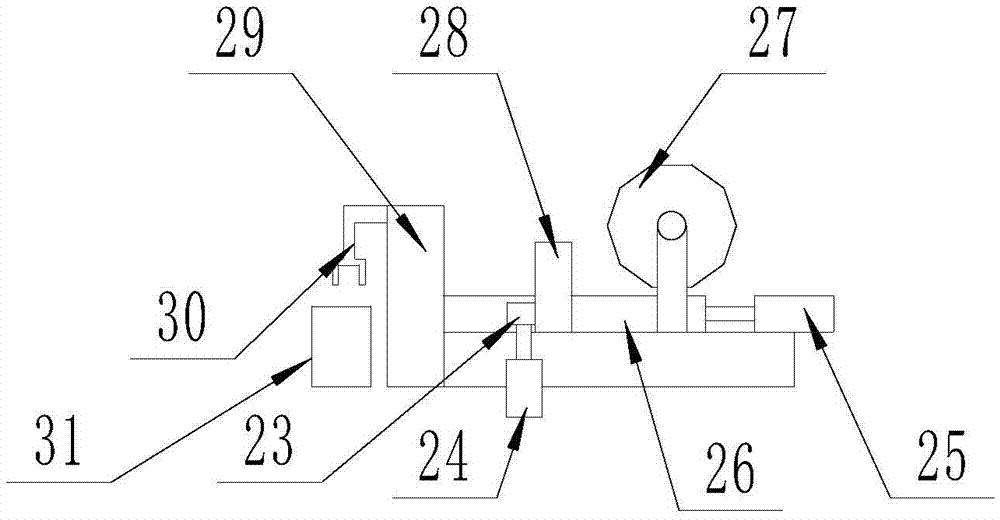

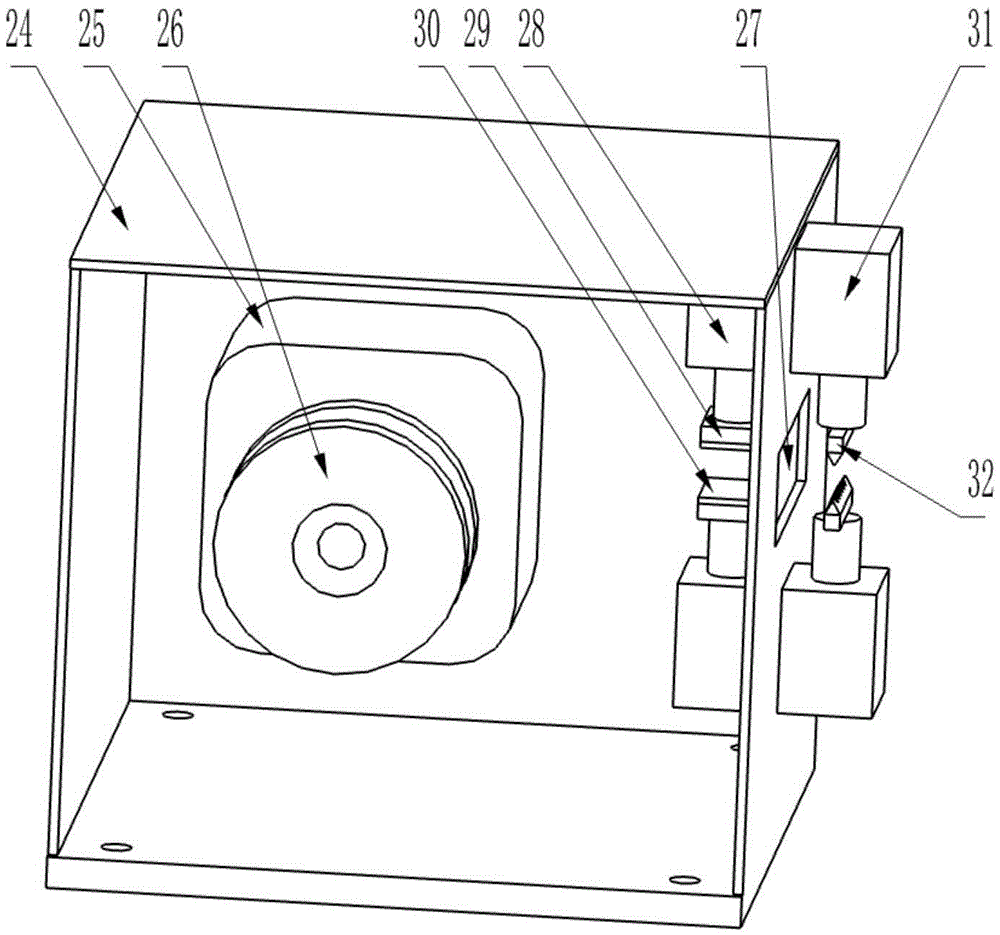

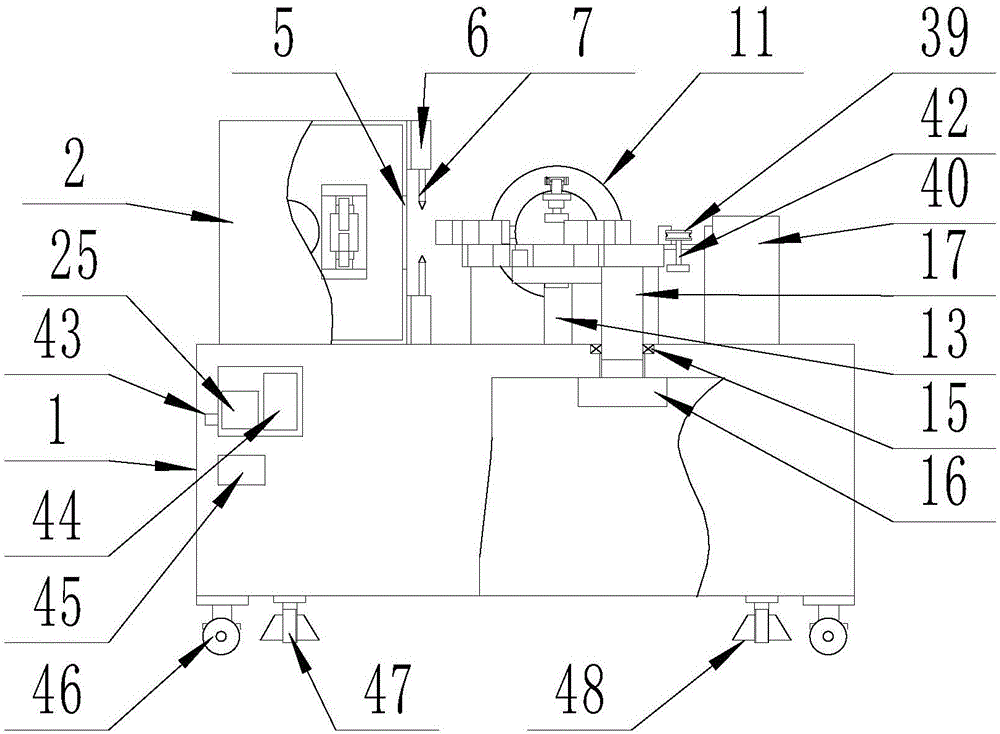

Protective-tube-conveying multi-pulley rail type linear welding machine

InactiveCN105703199AControllable distanceIncrease productivityLine/current collector detailsEngineeringPulley

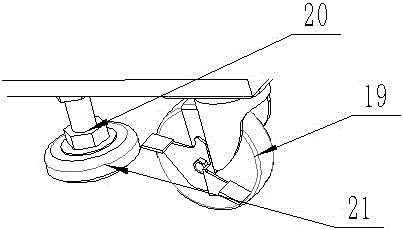

The invention discloses a protective-tube-conveying multi-pulley rail type linear welding machine. The protective-tube-conveying multi-pulley rail type linear welding machine comprises a cuboid-shaped movable base. Moving mechanisms are arranged at the four corners of the external lower surface of the movable base; the upper surface of the movable base is provided with a multi-pulley feeding mechanism, a pulley rail type wire twisting mechanism, a terminal striking mechanism, an X-axis double-layer movable wire clamping mechanism, a welding mechanism and a protective tube vibrating disk conveying mechanism; the pulley rail type wire twisting mechanism is located between the multi-pulley feeding mechanism and the terminal striking mechanism; the protective tube vibrating disk conveying mechanism is located behind the welding mechanism; a controller is arranged on the outer surface of the movable base; the controller is respectively electrically connected with the multi-pulley feeding mechanism, the pulley rail type wire twisting mechanism, the terminal striking mechanism, the X-axis double-layer movable wire clamping mechanism, the welding mechanism and the protective tube vibrating disk conveying mechanism. The protective-tube-conveying multi-pulley rail type linear welding machine has the beneficial effects of being simple in structure and strong in practicability.

Owner:黄斌

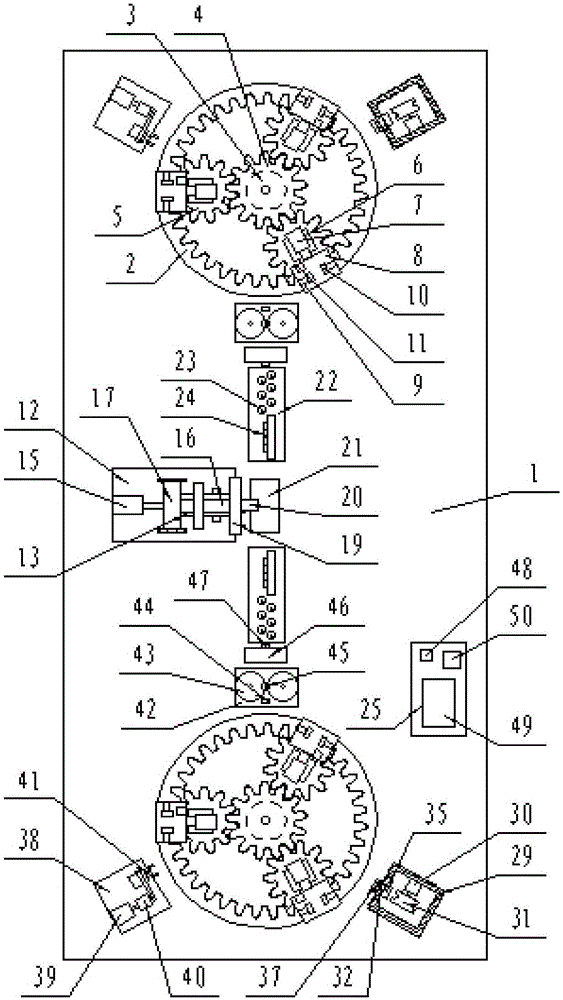

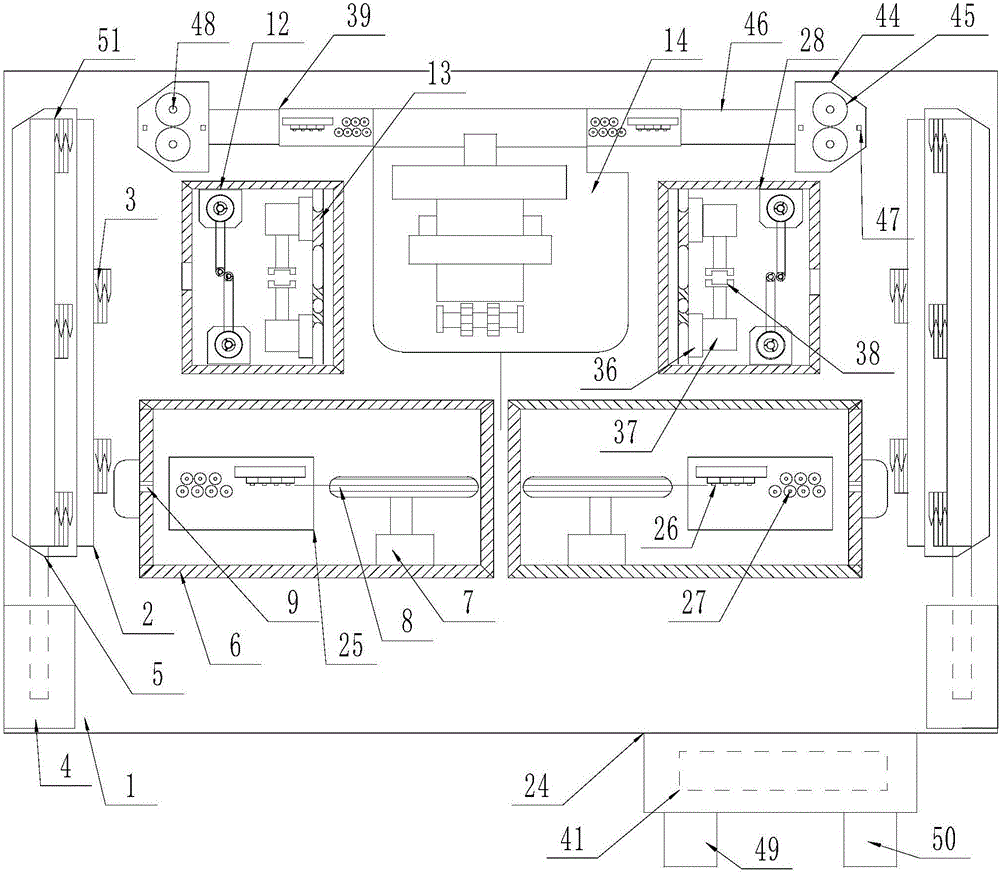

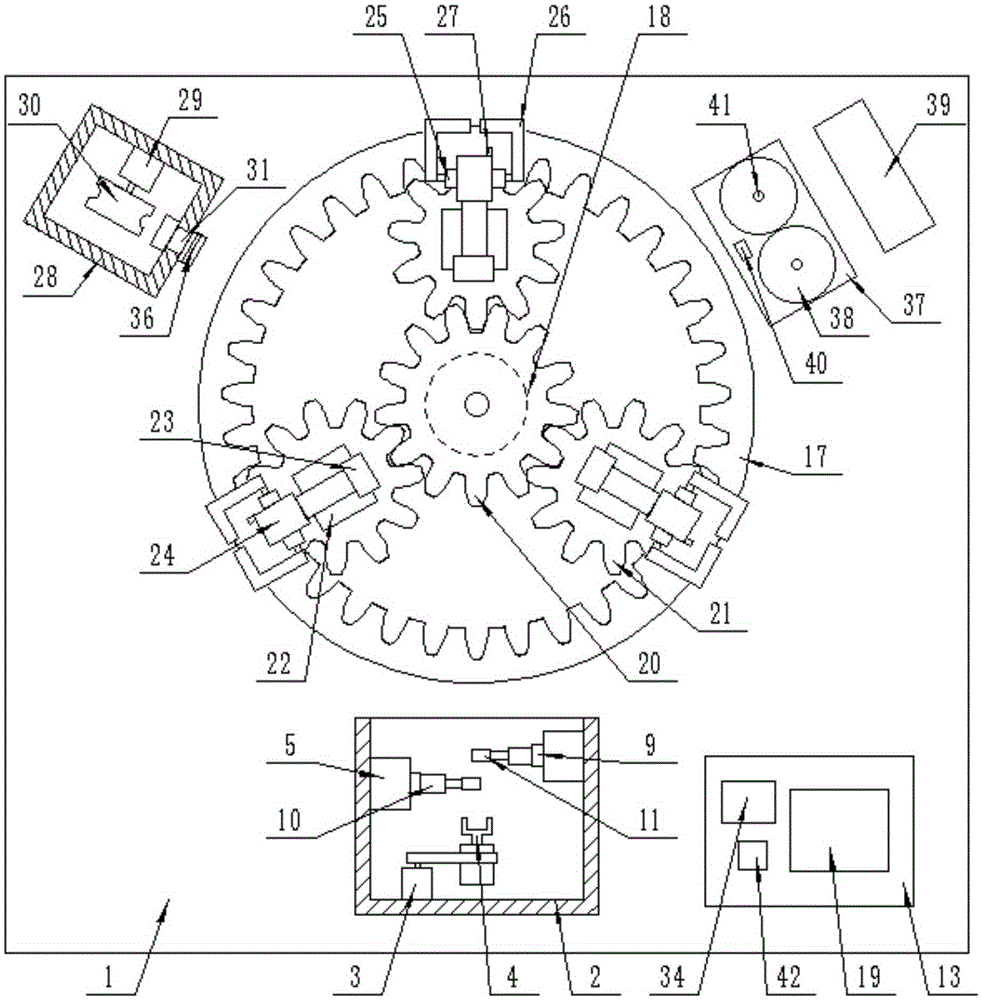

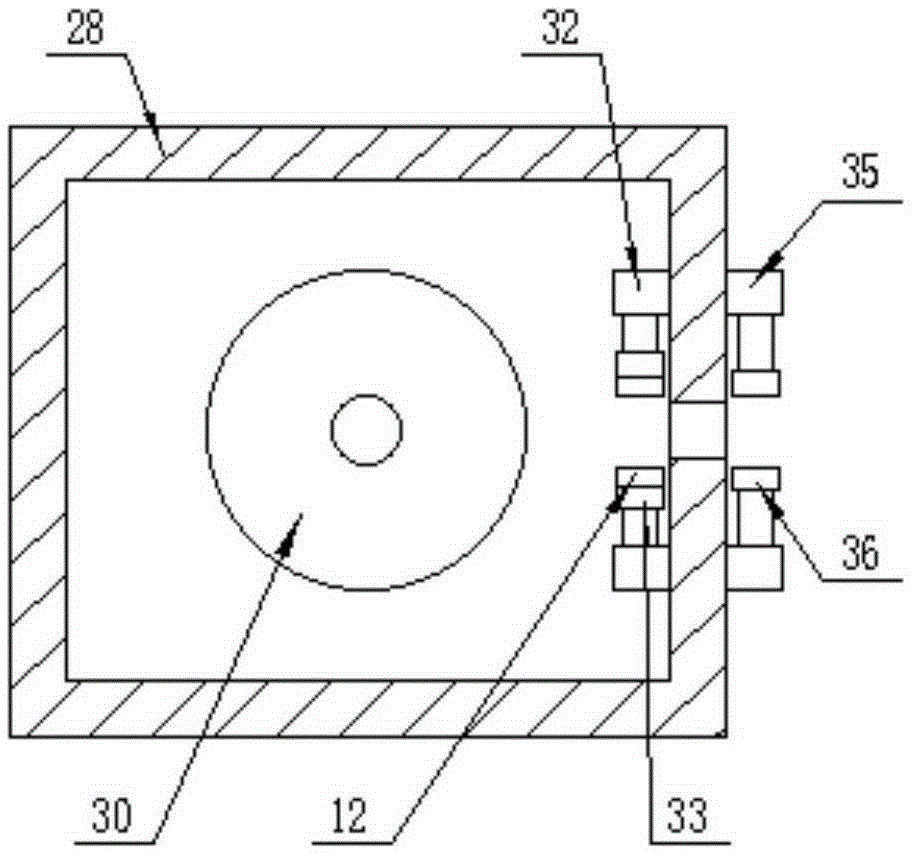

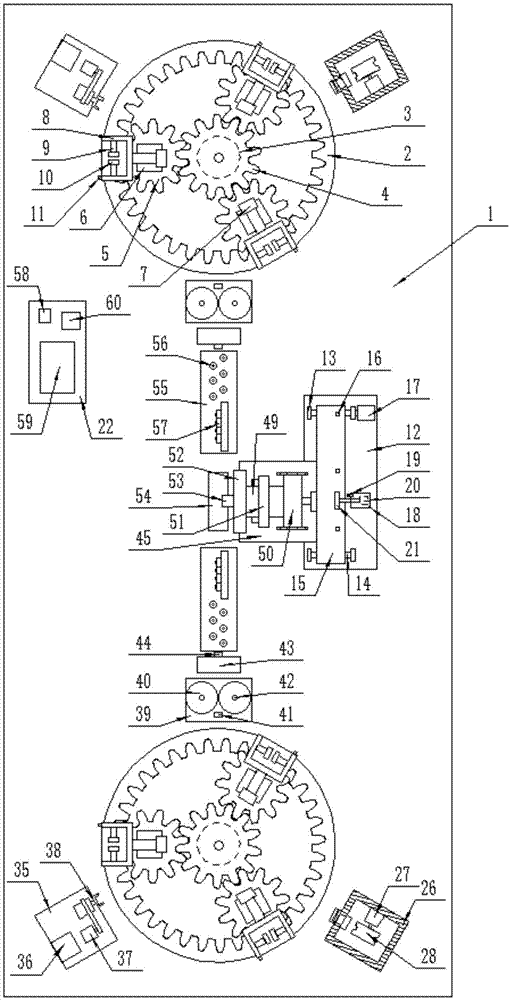

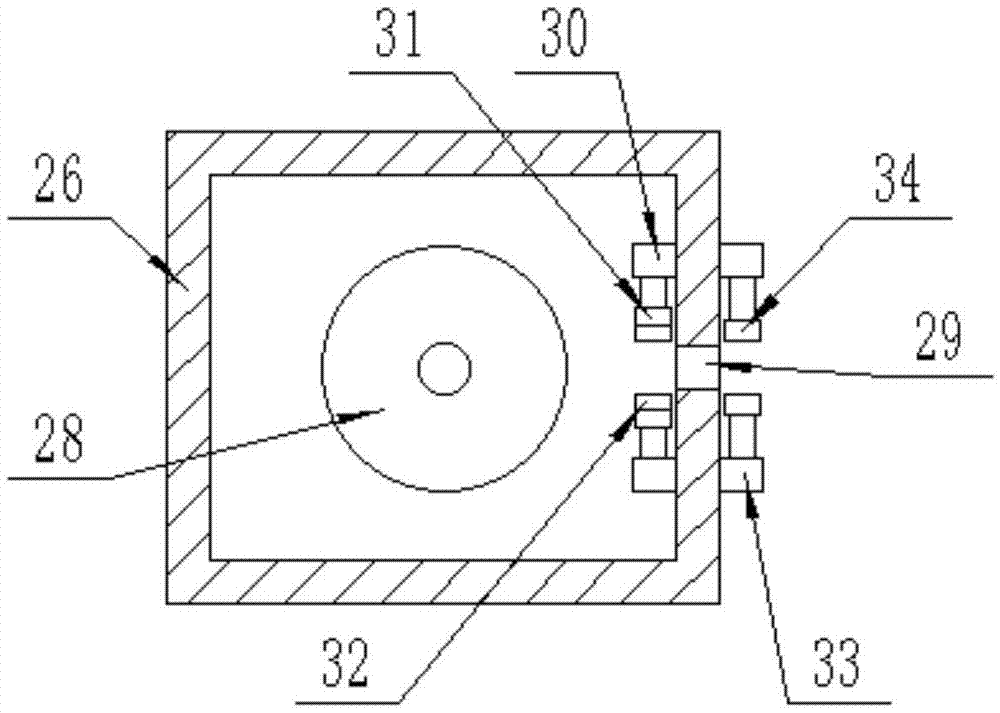

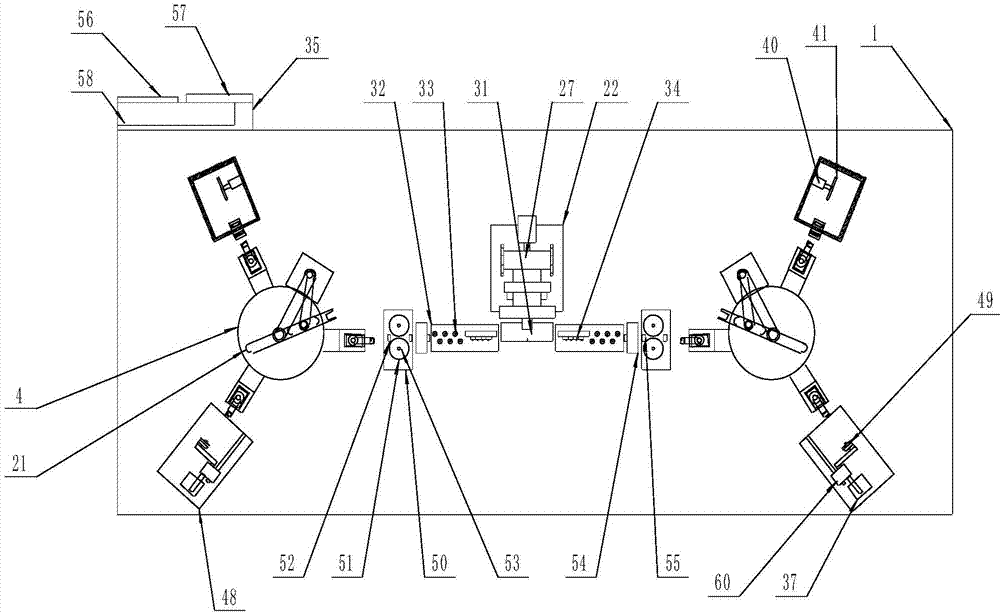

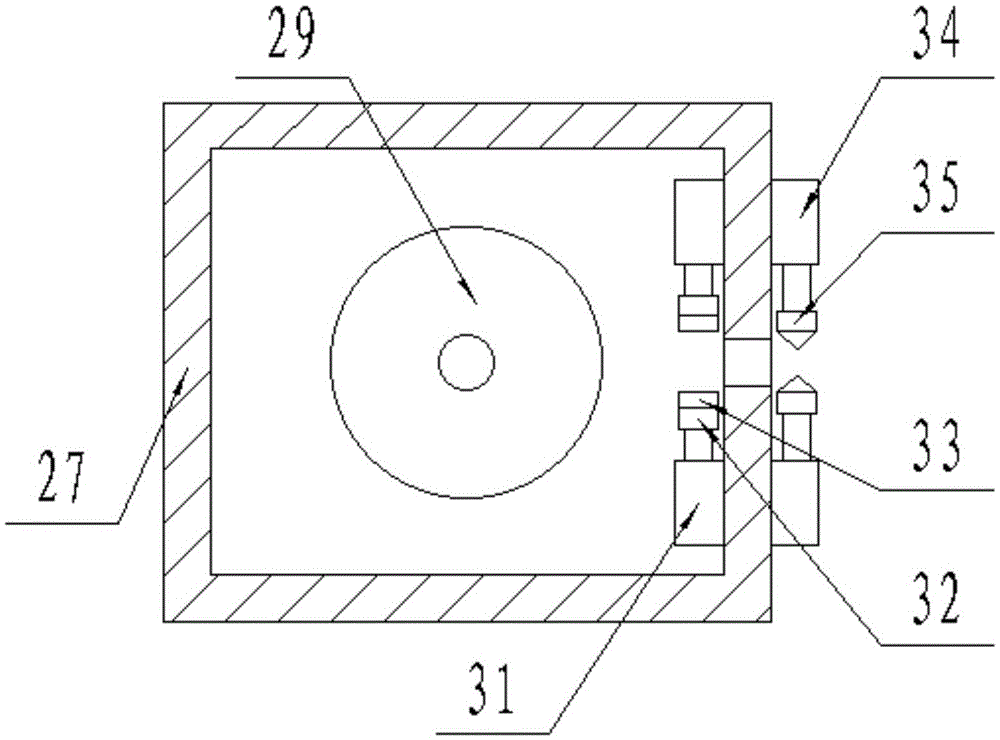

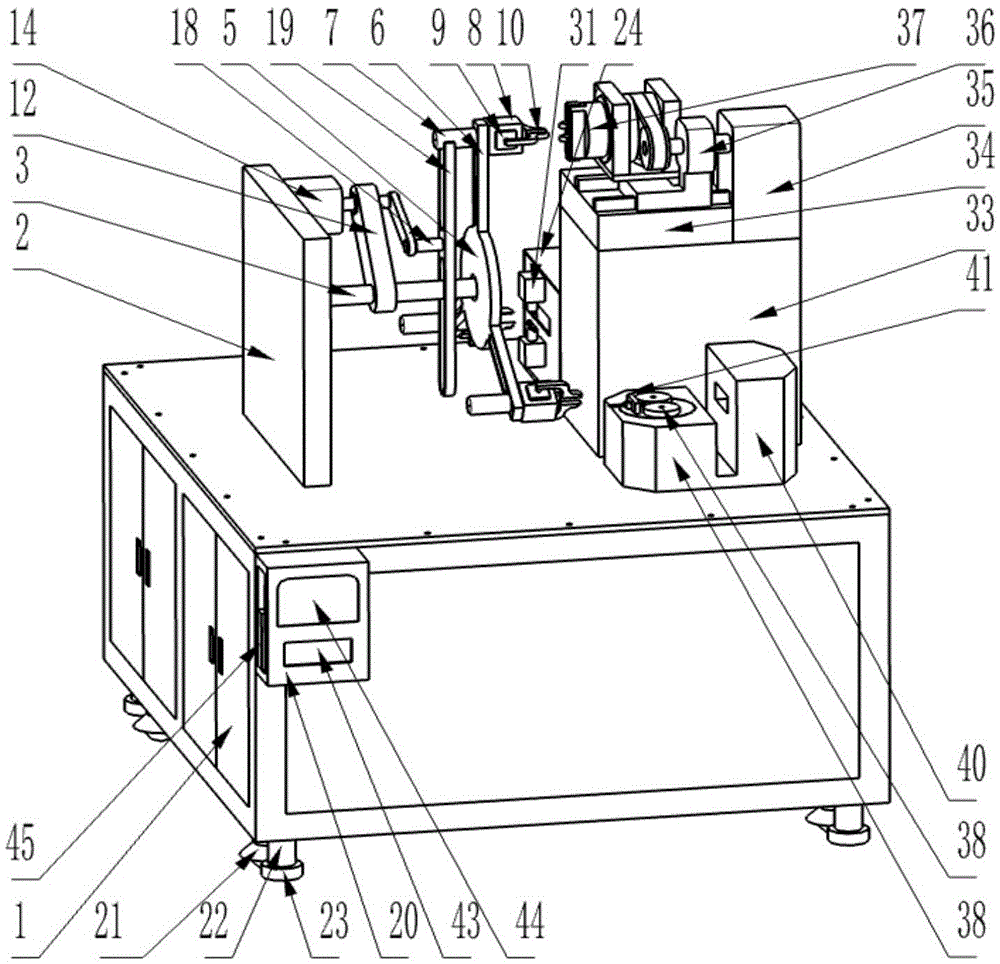

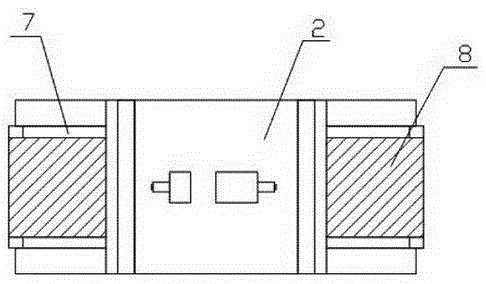

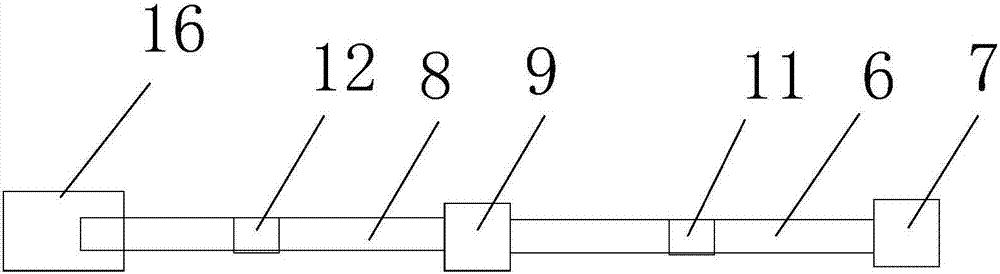

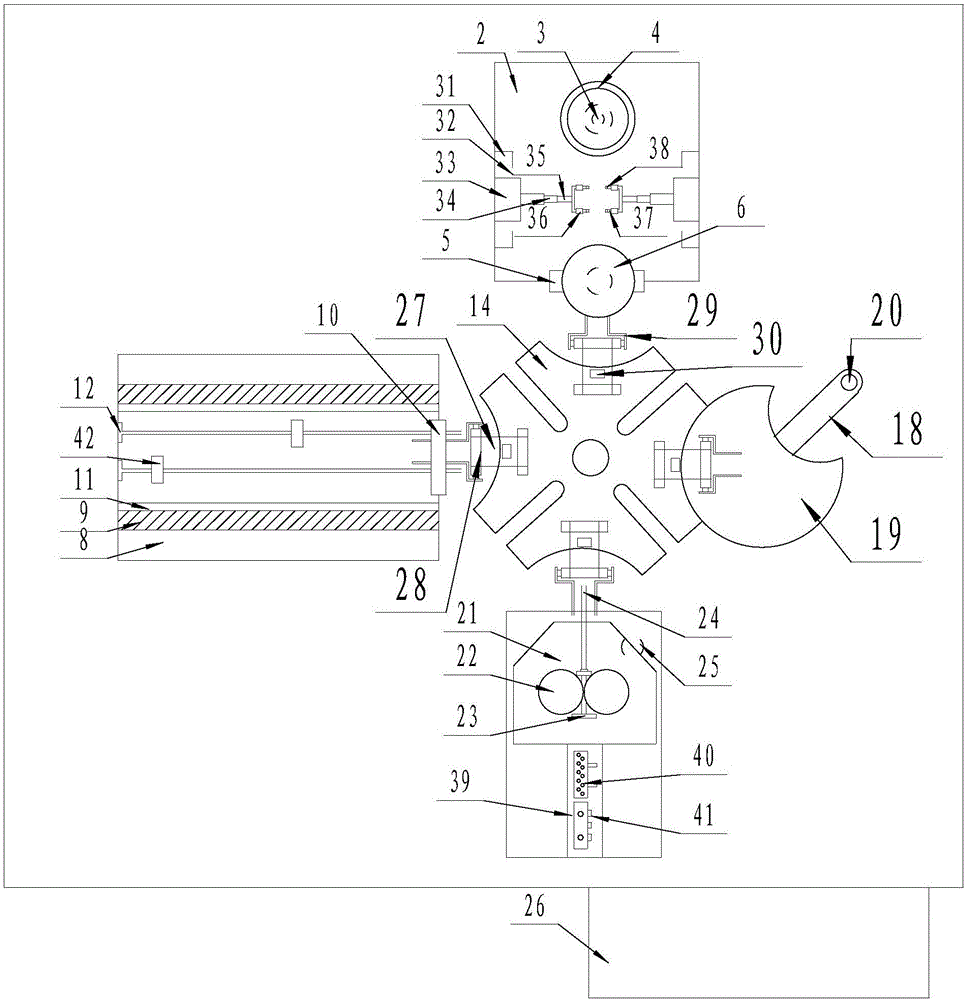

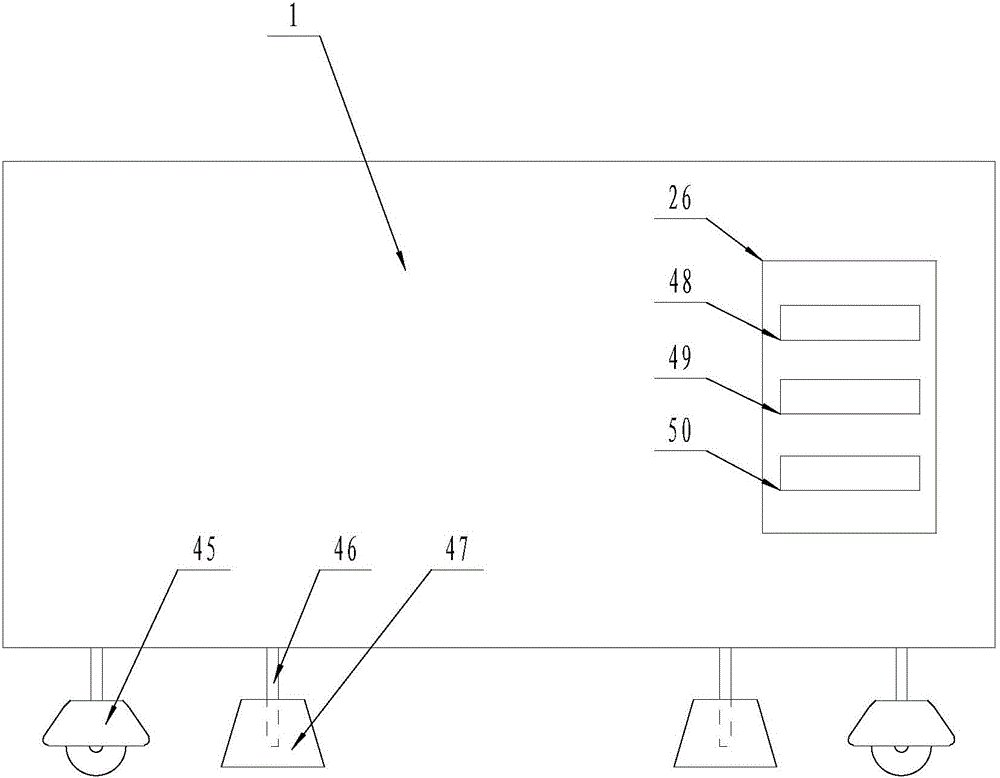

Bidirectional fuse-link wire welding production line

ActiveCN105406320AReduce manufacturing costControllable distanceLine/current collector detailsProduction lineElectric wire

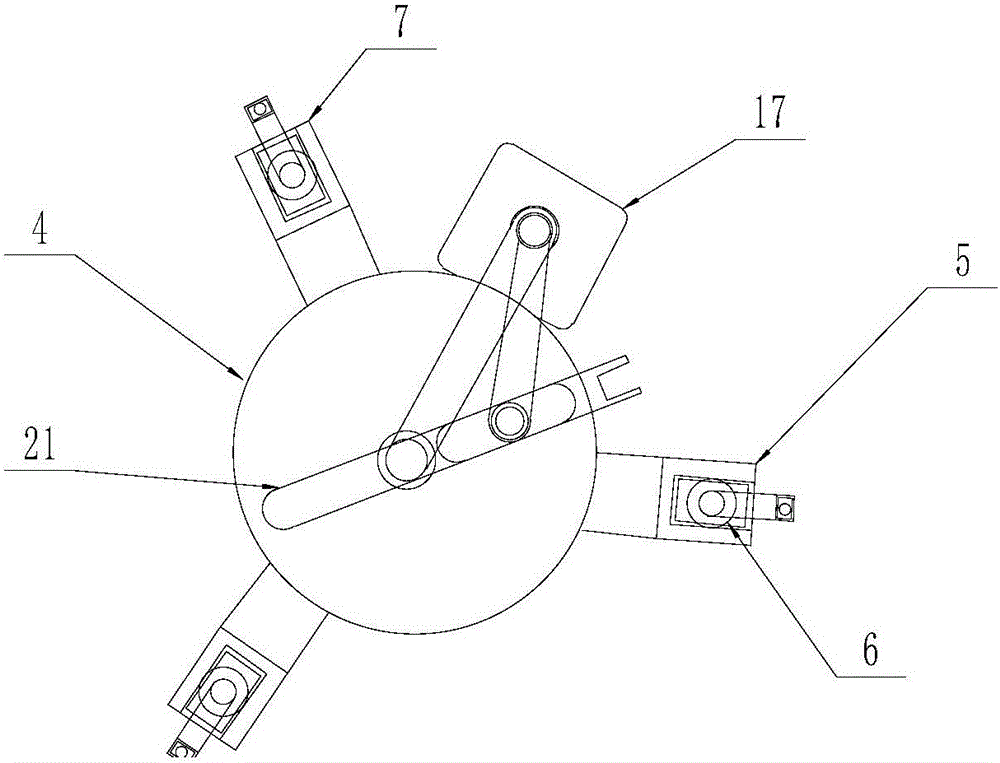

The invention discloses a bidirectional fuse-link wire welding production line. The bidirectional fuse-link wire welding production line comprises a cuboid mobile base; moving mechanisms are arranged at four corners of the lower surface of the mobile base; the mobile base is provided with two sets of wire terminal crimping devices and a welding mechanism; the welding mechanism is arranged between the two sets of wire terminal crimping devices; each wire terminal crimping device comprises a feeding mechanism, a wire twisting device, a terminal crimping device and a rotating grabbing mechanism, wherein the feeding mechanism, the wire twisting device and the terminal crimping mechanism are distributed on the surface of the mobile base and are separated from each other by the same angle, and the rotating grabbing mechanism is arranged at the center of the feeding mechanism, the wire twisting mechanism and the terminal crimping mechanism; the outer surface of the mobile base is provided with a controller; and the controller is electrically connected with the two sets of wire terminal crimping devices and the welding mechanism. The bidirectional fuse-link wire welding production line of the invention has the advantages of simple structure and high practicability.

Owner:广范企业发展(连云港)有限公司

Unidirectional multi-pulley sliding rail type linear welding production line

InactiveCN105728998AReduce manufacturing costControllable distanceWelding/cutting auxillary devicesAuxillary welding devicesProduction linePulley

The invention discloses a unidirectional multi-pulley sliding rail type linear welding production line. The unidirectional multi-pulley sliding rail type linear welding production line comprises a cuboid movable base. Movement mechanisms are arranged at the four corners of the lower surface of the movable base. A multi-pulley feeding mechanism, a sliding rail torsion wire mechanism, a terminal hitting mechanism, an X-axis double-layer displacement wire clamping mechanism and a welding mechanism are arranged on the upper surface of the movable base. The sliding rail torsion wire mechanism is located between the multi-pulley feeding mechanism and the terminal hitting mechanism. The X-axis double-layer displacement wire clamping mechanism is opposite to the multi-pulley feeding mechanism, the torsion wire mechanism and the terminal hitting mechanism. The welding mechanism is located behind the terminal hitting mechanism. A controller is arranged on the outer surface of the movable base. The controller is electrically connected with the multi-pulley feeding mechanism, the sliding rail torsion wire mechanism, the terminal hitting mechanism, the X-axis double-layer displacement wire clamping mechanism and the welding mechanism. The unidirectional multi-pulley sliding rail type linear welding production line has the beneficial effects of being simple in structure and high in practicability.

Owner:黄斌

Novel electric wire trimming machine provided with sliding shifting fork

InactiveCN105633762AReduce manufacturing costControllable distanceLine/current collector detailsEngineeringElectric wire

The invention discloses a novel electric wire trimming machine provided with a sliding shifting fork. The trimming machine comprises a cuboid moving base, wherein moving mechanisms are arranged on four corners of the lower surface of the moving base; a feeding mechanism, a sliding rail wire twisting mechanism, a terminal crimping mechanism and a sliding shifting fork rotary capturing mechanism are arranged on the upper surface of the moving base; the sliding rail wire twisting mechanism is positioned between the feeding mechanism and the terminal crimping mechanism; the height of the sliding rail wire twisting mechanism is higher than that of the feeding mechanism and the terminal crimping mechanism; the sliding shifting fork rotary capturing mechanism is arranged opposite to the feeding mechanism, the wire twisting mechanism and the terminal crimping mechanism; a controller is arranged on the outer surface of the moving base; and the controller is electrically connected with the feeding mechanism, the sliding rail wire twisting mechanism, the terminal crimping mechanism and the sliding shifting fork rotary capturing mechanism separately. The novel sliding shifting fork electric wire trimming machine has the beneficial effects of simple structure and high practicability.

Owner:吴建华

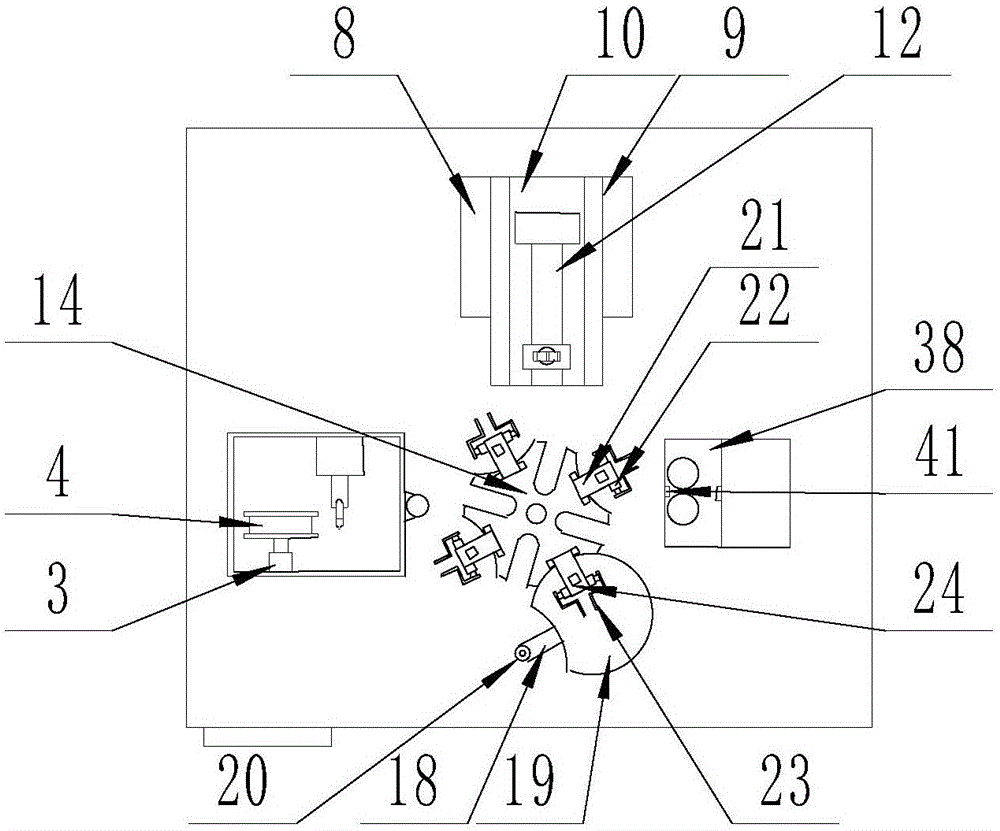

Novel wire terminal-crimping trimming machine

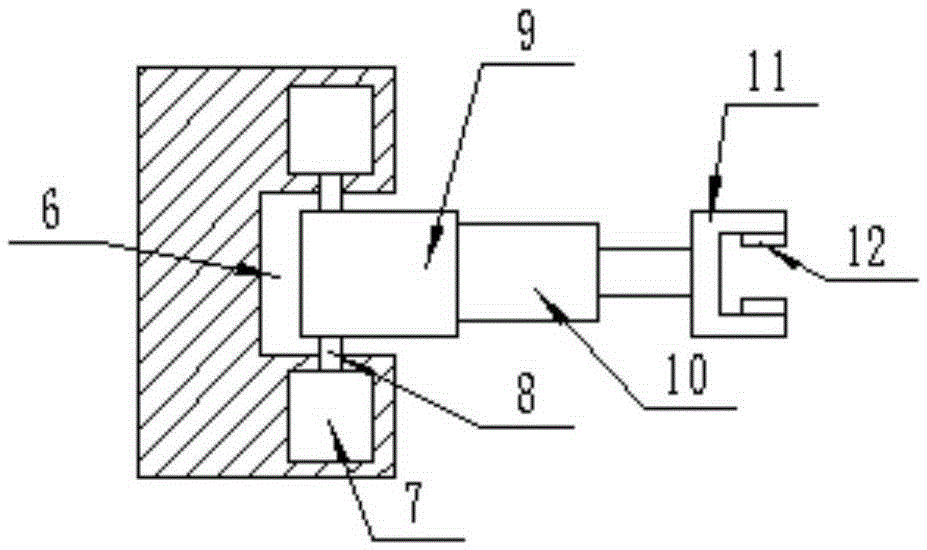

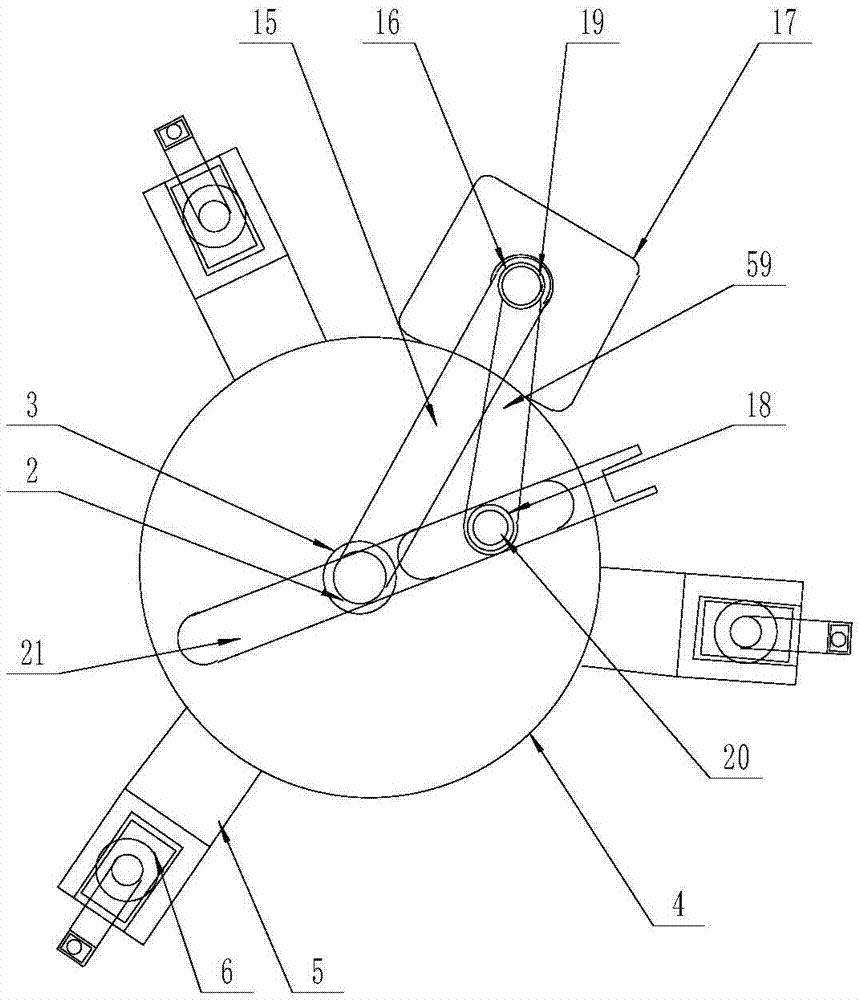

InactiveCN105428956AControllable distanceIncrease productivityLine/current collector detailsEngineeringManipulator

The invention discloses a novel wire terminal-crimping trimming machine. The novel wire terminal-crimping trimming machine comprises a cuboid mobile pedestal, a mobile mechanism is arranged at the four corners at the lower surface of the mobile pedestal, the upper surface of the mobile pedestal is provided with a feeding mechanism, a swing wire twisting mechanism, a terminal crimping mechanism and a rotation grabbing mechanism, the feeding mechanism, the swing wire twisting mechanism and the terminal scrimping mechanism are distributed at the surface of the mobile pedestal at equal angles, the rotation grabbing mechanism is disposed at the centers of the feeding mechanism, the swing wire twisting mechanism and the terminal crimping mechanism, and the swing wire twisting mechanism is composed of a wire twisting box body fixedly installed on the mobile pedestal, a first swing clamping mechanism and a second swing clamping mechanism respectively fixedly installed at the opposite side surfaces of the wire twisting box body, a rotation motor fixedly installed at the rear surface in the wire twisting box body and a rotation manipulator disposed at the side edge of the rotation motor and connected with the rotation end of the rotation motor through a belt. The novel wire terminal-crimping trimming machine has the advantages of simple structure and high practicality.

Owner:吴建华

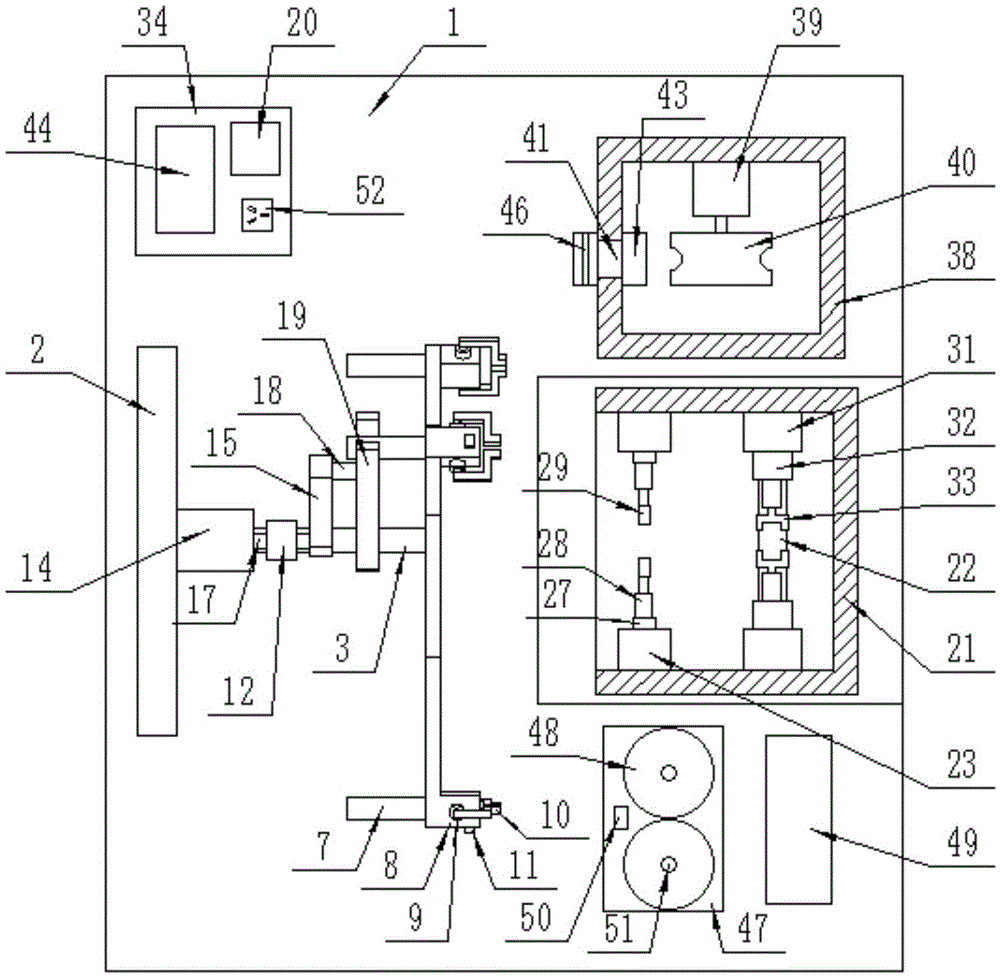

Protective tube feeding electric wire welding device

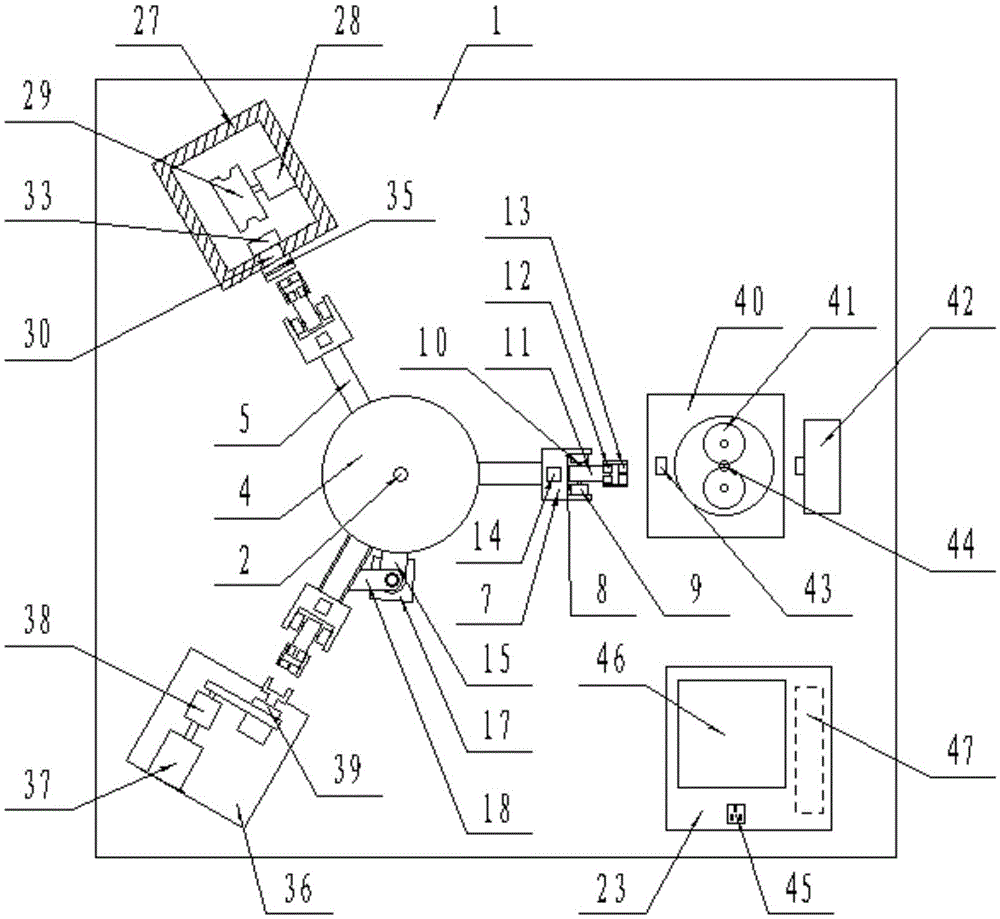

ActiveCN105449487AControllable distanceIncrease productivityLine/current collector detailsTransfer mechanismEngineering

The invention discloses a protective tube feeding electric wire welding device. The protective tube feeding electric wire welding device comprises a cuboid-shaped mobile base, moving mechanisms are arranged at four corners of the lower surface of the mobile base, two groups of electric wire terminal crimping devices, a welding mechanism and a protective tube transferring mechanism are arranged on the mobile base, the welding mechanism is located between the two groups of the electric wire terminal crimping devices, the protective tube transferring mechanism is located at the back of the welding mechanism, each electric wire terminal crimping device comprises a feeding mechanism, a wire twisting mechanism, a terminal crimping mechanism and a rotary grapping mechanism, the feeding mechanism, the wire twisting mechanism and the terminal crimping mechanism are distributed on the surface of the mobile base in equal angles, the rotary grapping mechanism is located at the centers of an area surrounded by the feeding mechanism, the wire twisting mechanism and the terminal crimping mechanism, and a controller is arranged on the outer surface of the mobile base. The protective tube feeding electric wire welding device has the beneficial effects of simple structure and strong practicability.

Owner:平邑仁安中医药产业发展有限公司

Two-way periodical shifting fork safety pipe welding device

InactiveCN105436763AControllable distanceIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingEngineering

The invention discloses a two-way periodical shifting fork safety pipe welding device. The two-way periodical shifting fork safety pipe welding device comprises a cuboid-shaped movable base; moving mechanisms are arranged at four corners of the outer lower surface of the movable base; the movable base is provided with two sets of electric wire terminal beating devices and a welding mechanism; the welding mechanism is positioned between the two sets of electric wire terminal beating devices; the electric wire terminal beating devices include feeding mechanisms, wire twisting mechanisms, terminal beating mechanisms and periodical shifting fork rotary grabbing mechanisms; the feeding mechanisms, the wire twisting mechanisms and the terminal beating mechanisms are distributed on the surface of the movable base by equal angles; the periodical shifting fork rotary grabbing mechanisms are positioned in centers of the feeding mechanisms, the wire twisting mechanisms and the terminal beating mechanisms; and a controller is arranged on the outer surface of the movable base, and is electrically connected with the two sets of electric wire terminal beating devices and the welding mechanism. The two-way periodical shifting fork safety pipe welding device has the beneficial effects of simple structure and strong practicability.

Owner:佛山市南海区粤骏达五金装饰有限公司

Periodic shift fork cable trimming machine

ActiveCN105490127AControllable distanceIncrease productivityLine/current collector detailsPunchingEngineering

The invention discloses a periodic shift fork cable trimming machine. The periodic shift fork cable trimming machine comprises a cuboid-shaped mobile base, wherein moving mechanisms are arranged at four corners of the lower surface outside the mobile base, a feeding mechanism, a torsion wire mechanism, a terminal punching mechanism and a periodic shift fork rotary grabbing mechanism are arranged on the upper surface of the mobile base, the feeding mechanism, the torsion wire mechanism and the terminal punching mechanism are arranged on the surface of the mobile base at equal angles, the periodic shift fork rotary grabbing mechanism is arranged at the centers of the feeding mechanism, the torsion wire mechanism and the terminal punching mechanism, a controller is arranged on the outer surface of the mobile base and electrically connected with the feeding mechanism, the torsion wire mechanism, the terminal punching mechanism and the periodic shift fork rotary grabbing mechanism respectively.

Owner:铜陵市力博中小企业服务有限公司

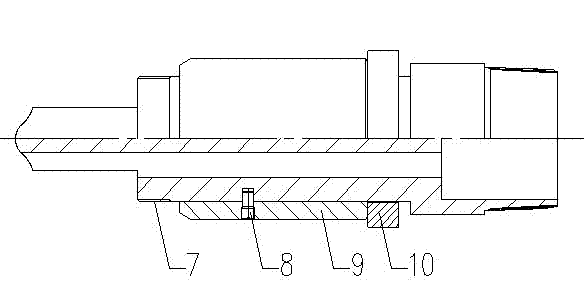

Pressurized coring tool

The invention discloses a pressurized coring tool comprising a pressure bearing device, a rotating assembly and a core catcher assembly, wherein the pressure bearing device comprises a pressure bearing assembly and a pin component, the pressure bearing assembly comprises a pressure bearing piston and a pressure bearing sleeve sheathed on the pressure bearing piston, the pin component comprises a shearing pin; the rotating assembly comprises a core shaft, one end of the core shaft is provided with a rotating device, the other end of the core shaft is provided with an automatic pressure relieving assembly; and the core catcher assembly comprises a connecting sleeve, a clamp seat, a clamp, a pressurized core catcher and a self-locking core catcher, one end of the clamp seat is connected with the lower end of the connecting sleeve, the other end of the clamp seat is connected with the pressurized core catcher, the upper end of the connecting sleeve is connected with an internal cylinder assembly, the clamp is arranged in the clamp seat, and the self-locking core catcher is arranged in the pressurized core catcher. When the pressurized coring tool disclosed by the invention is used for coring, the internal cylinder of a pressurizing tool can rotate along with the rotation of a drilling tool, and the problem that a core entering into the internal cylinder breaks easily is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

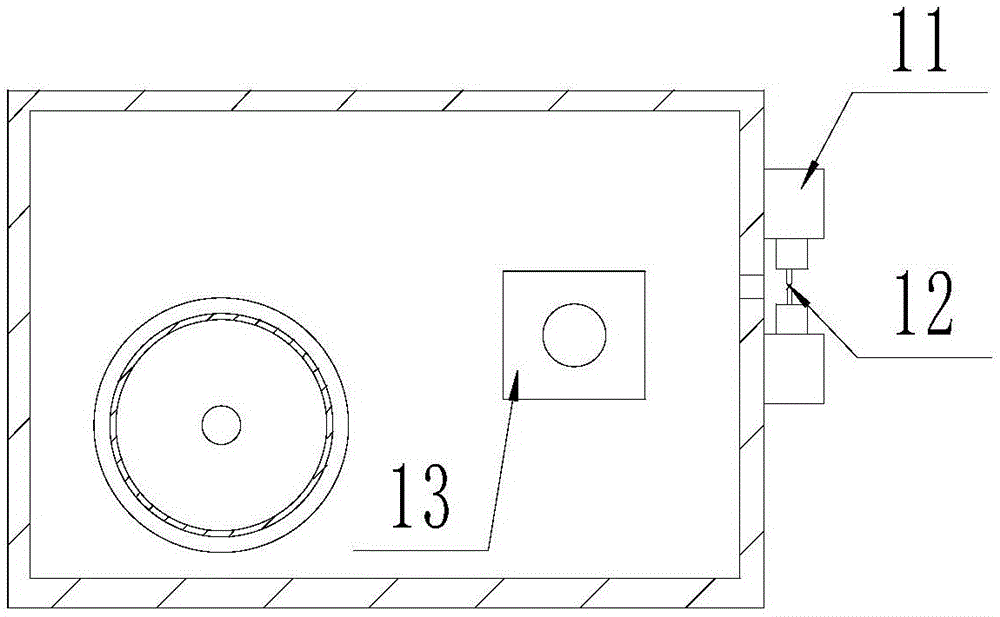

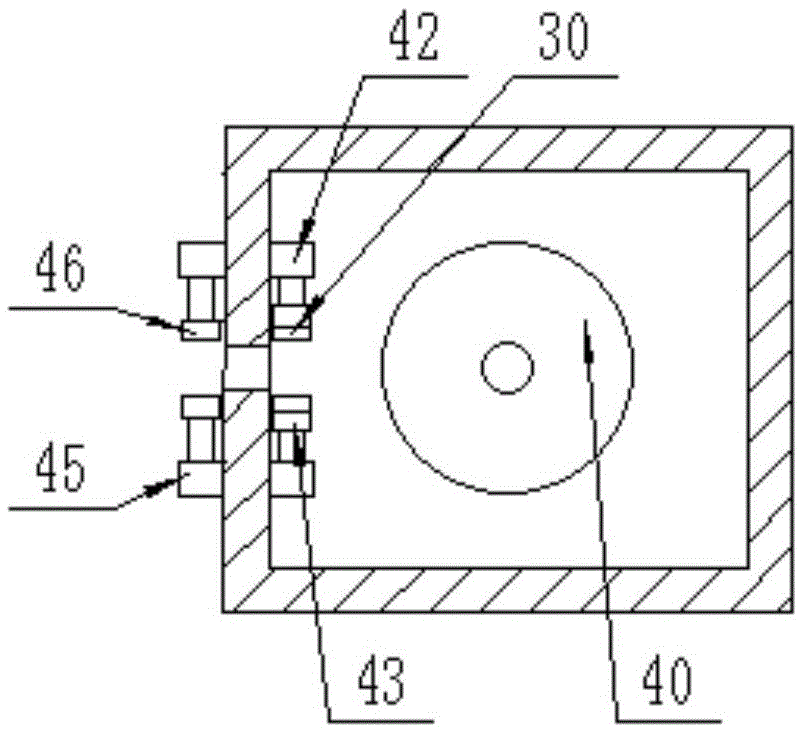

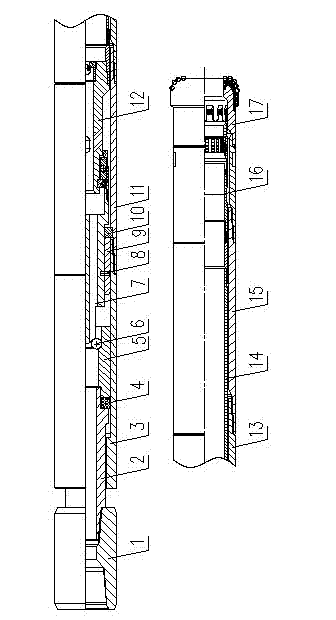

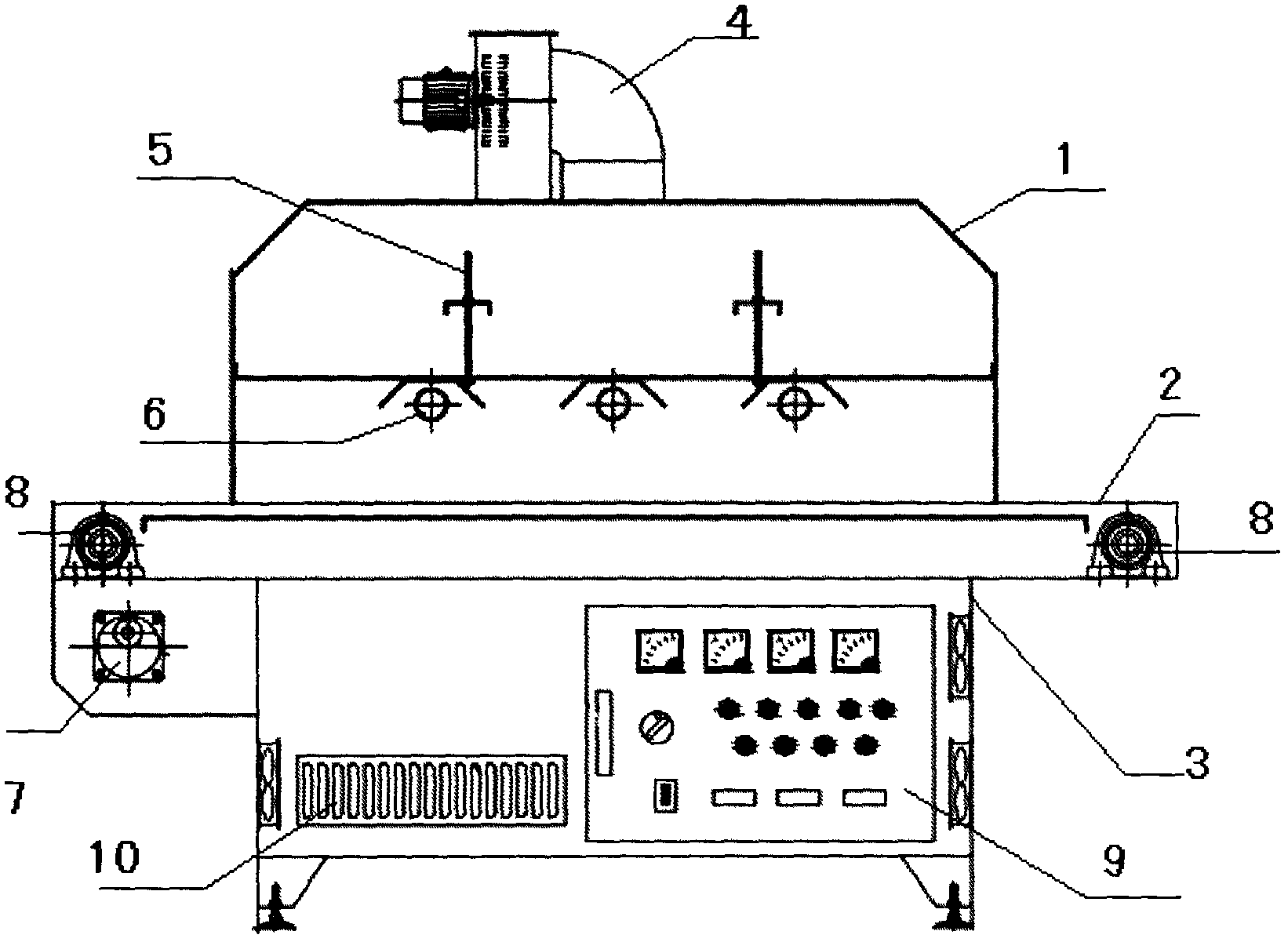

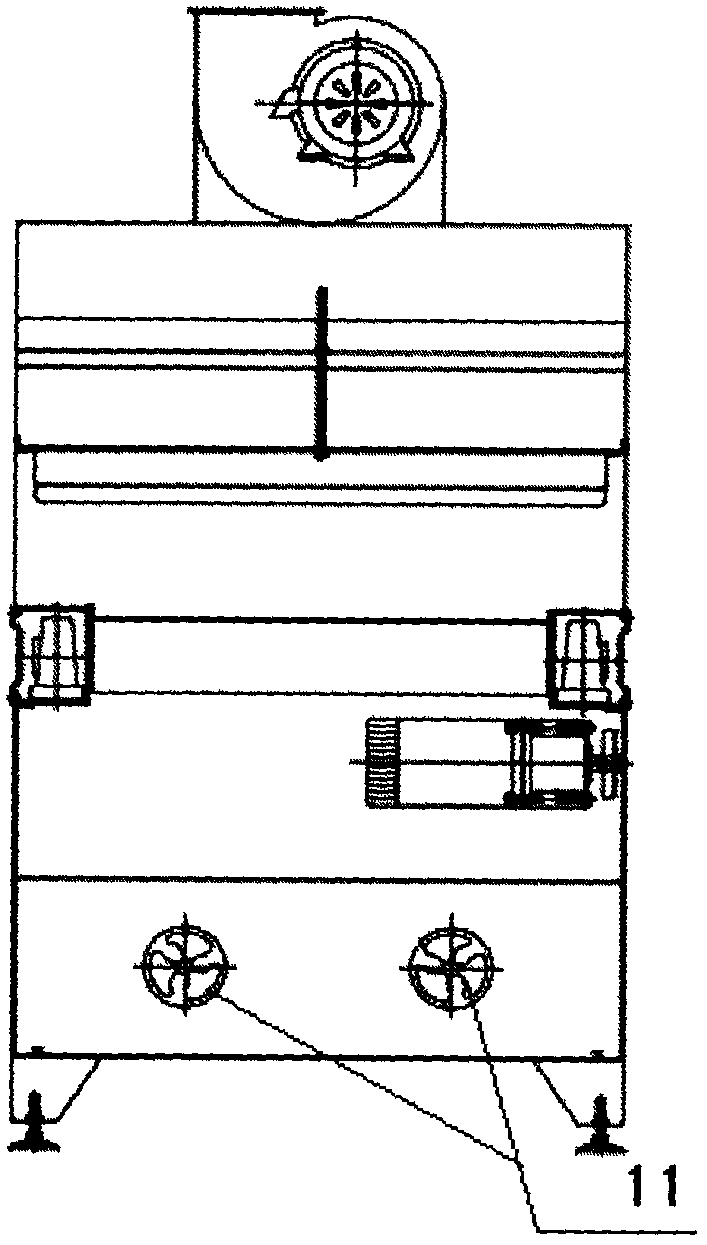

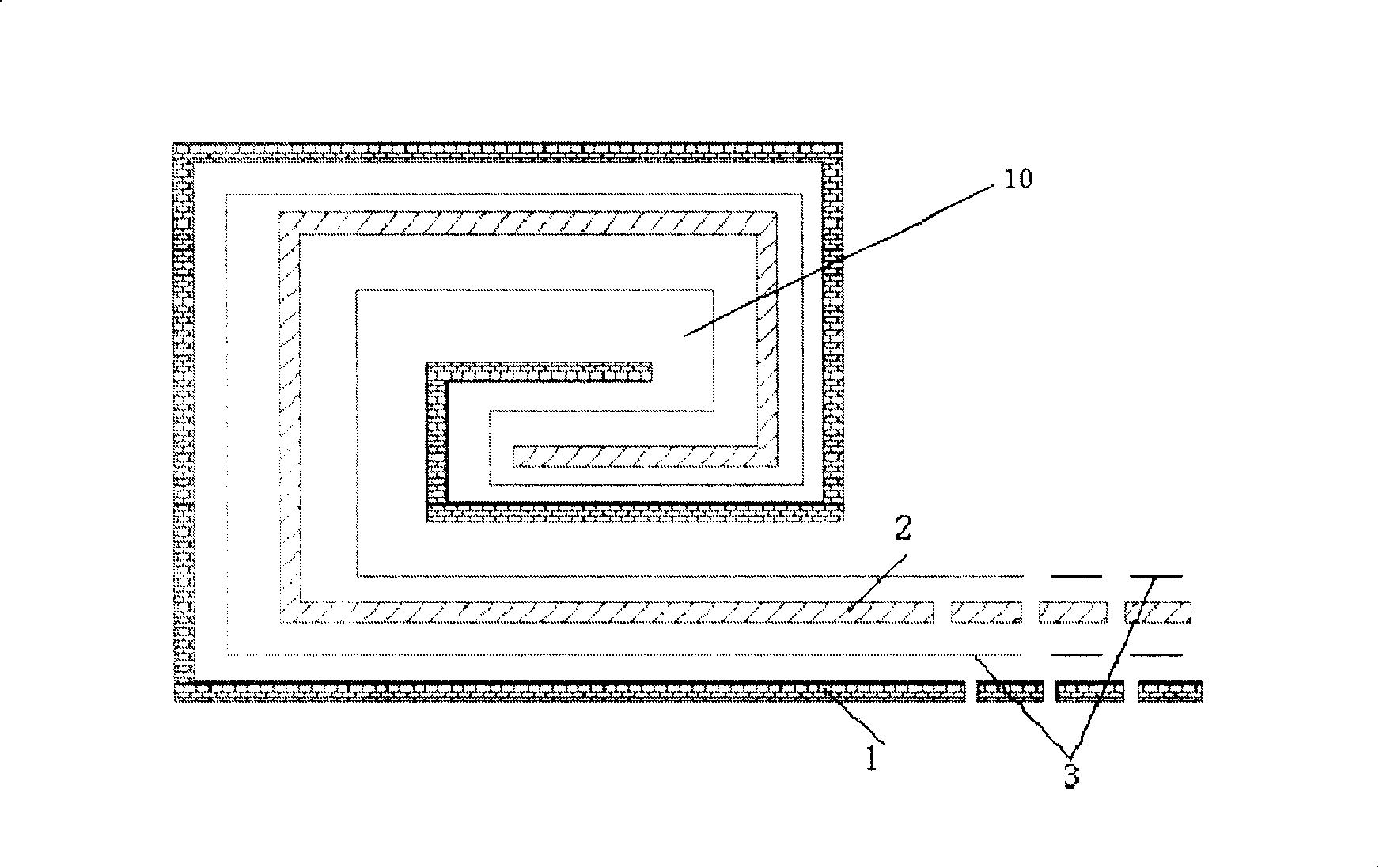

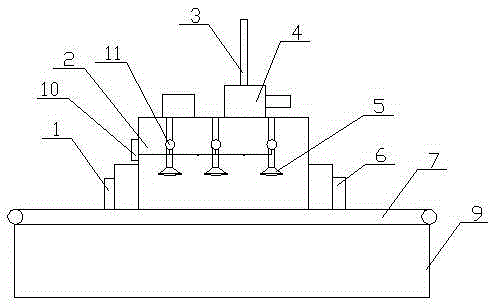

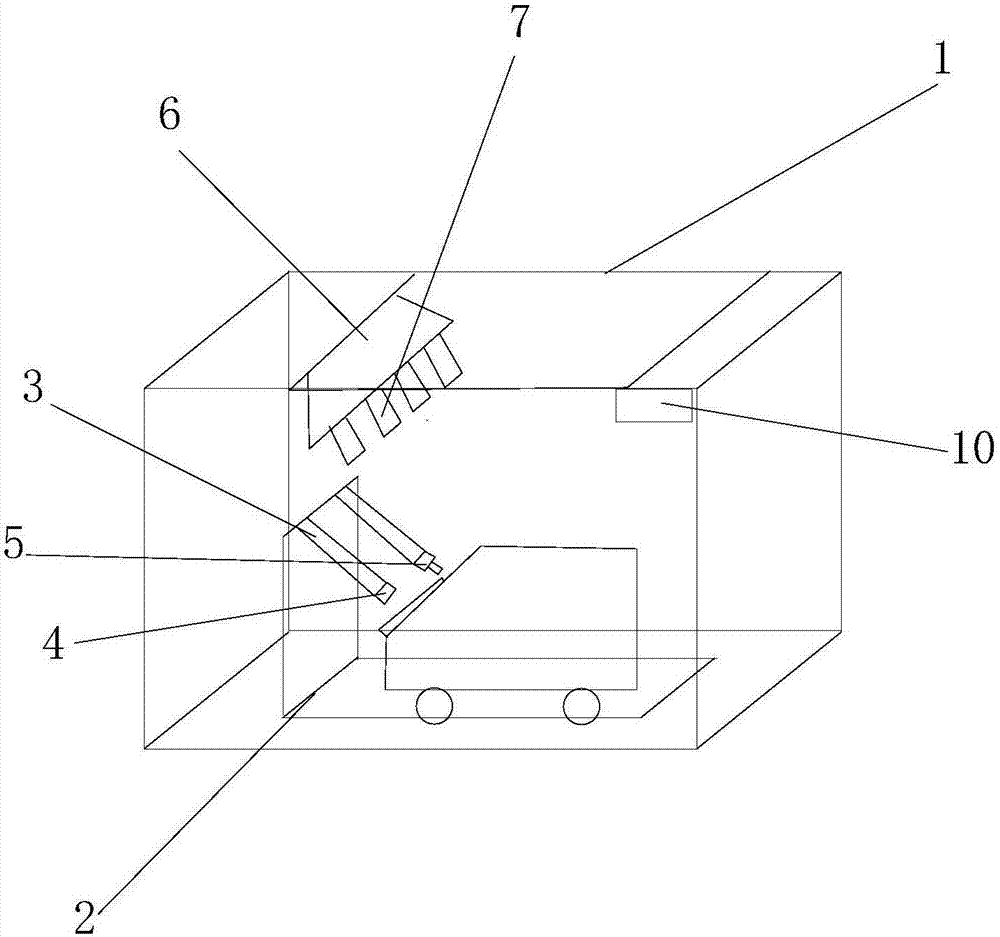

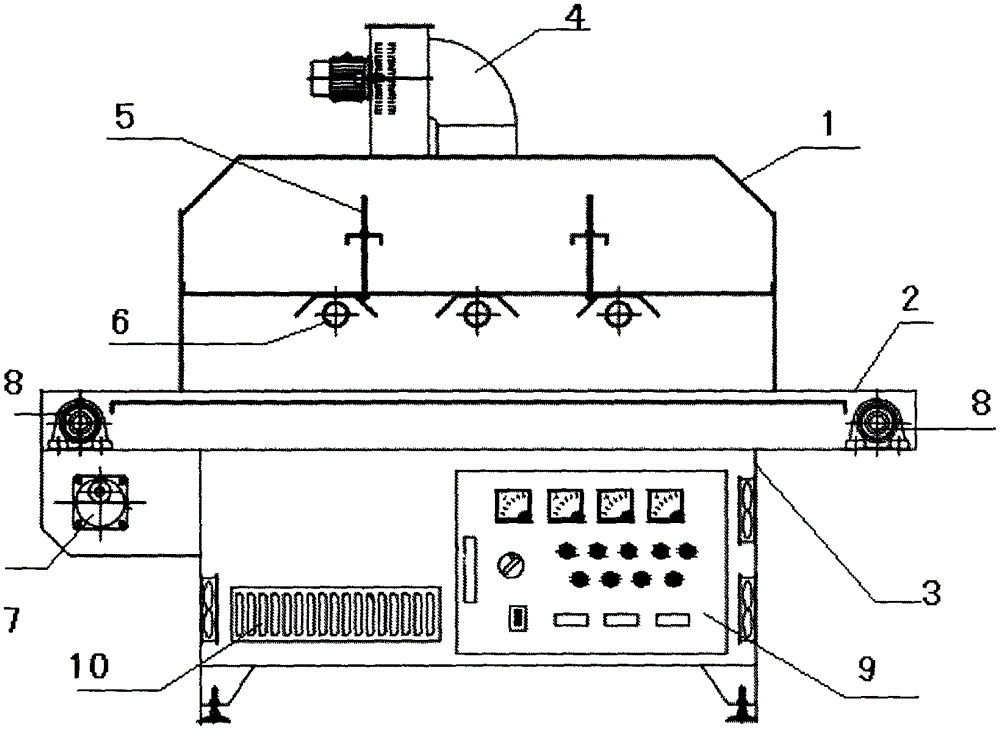

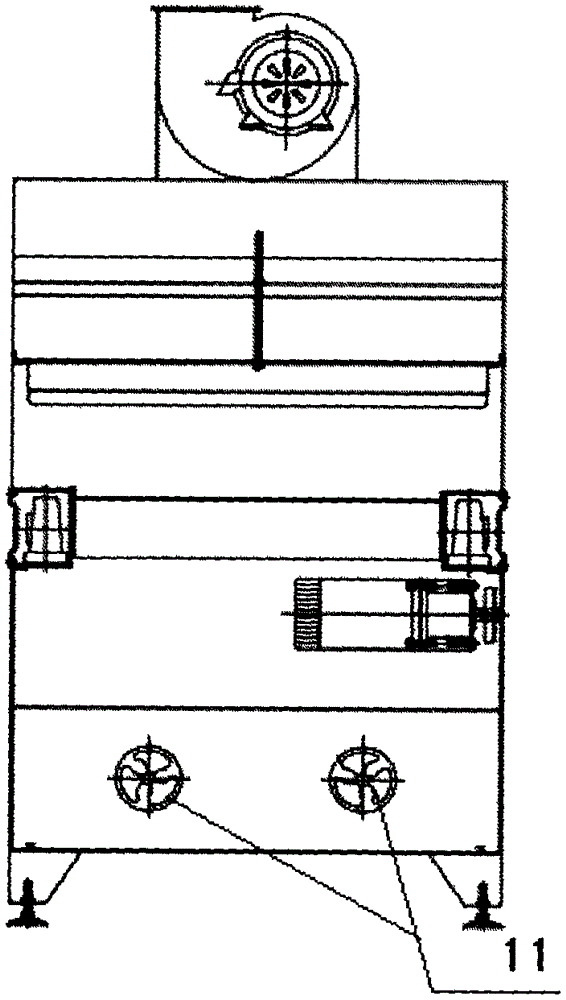

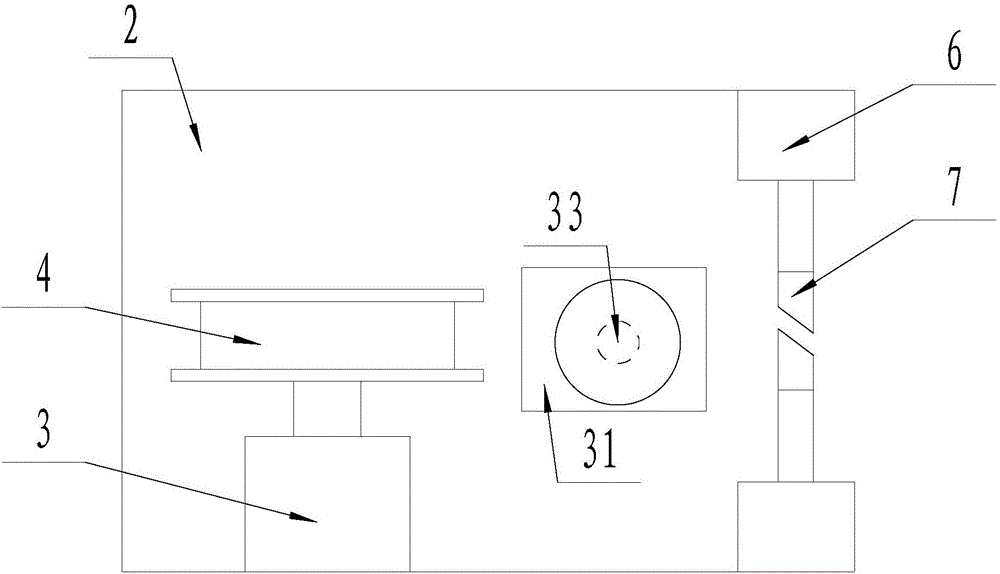

UV curing machine

InactiveCN104353597AControllable distanceReduce the temperaturePretreated surfacesCoatingsUV curingEngineering

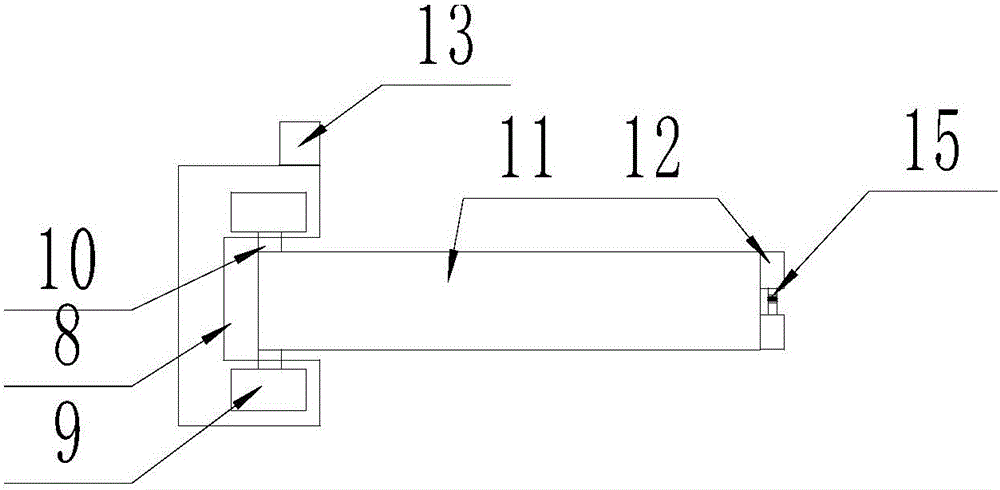

The invention discloses a UV (ultraviolet) curing machine which comprises a shell (1), a conveying table (2) and a control console (3), wherein the shell (1) is of a hollow box body structure, wherein a material inlet and a material outlet are respectively formed in the bottoms of two ends of the shell; an exhaust fan (4) is arranged at the top of the shell; UV lamps (6) fixed on a lamp support are suspended in the middle of the interior of the shell; the lamp support is fixed on a bracket above the lamp support through adjustment screw rods (5); the conveying table (2) is positioned below the UV lamp; one end of a conveying belt is connected with the material inlet, and the other end of the conveying belt is connected with the material outlet; a rotary drum (8) is arranged on the conveying table at each of the material inlet and the material outlet; the control console (3) is positioned below the conveying table and is of a topless square hollow steel structure; peripheral steel plates are welded with the conveying table (2); a control panel (9) is fixed on the steel plate on one side of the control console; heat dissipation holes (10) are formed close to the bottom of the control console; a speed reduction motor (7) is arranged close to the material inlet and is connected with the rotary drum (8) at the material inlet through the conveying belt.

Owner:SUZHOU AISITE IND EQUIP

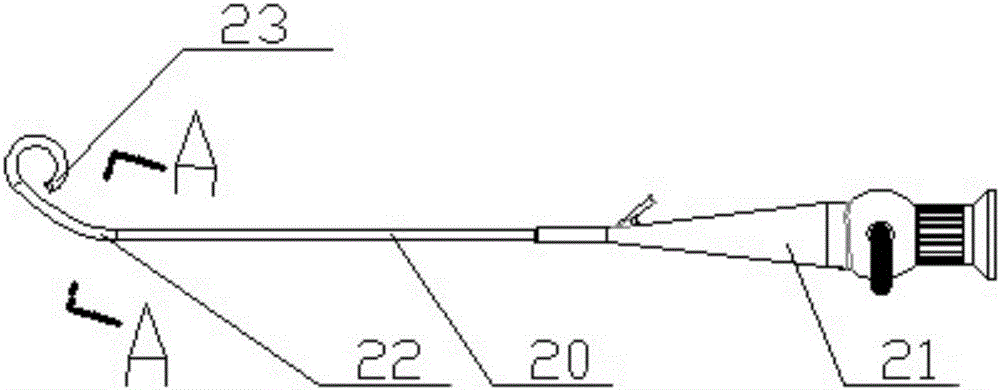

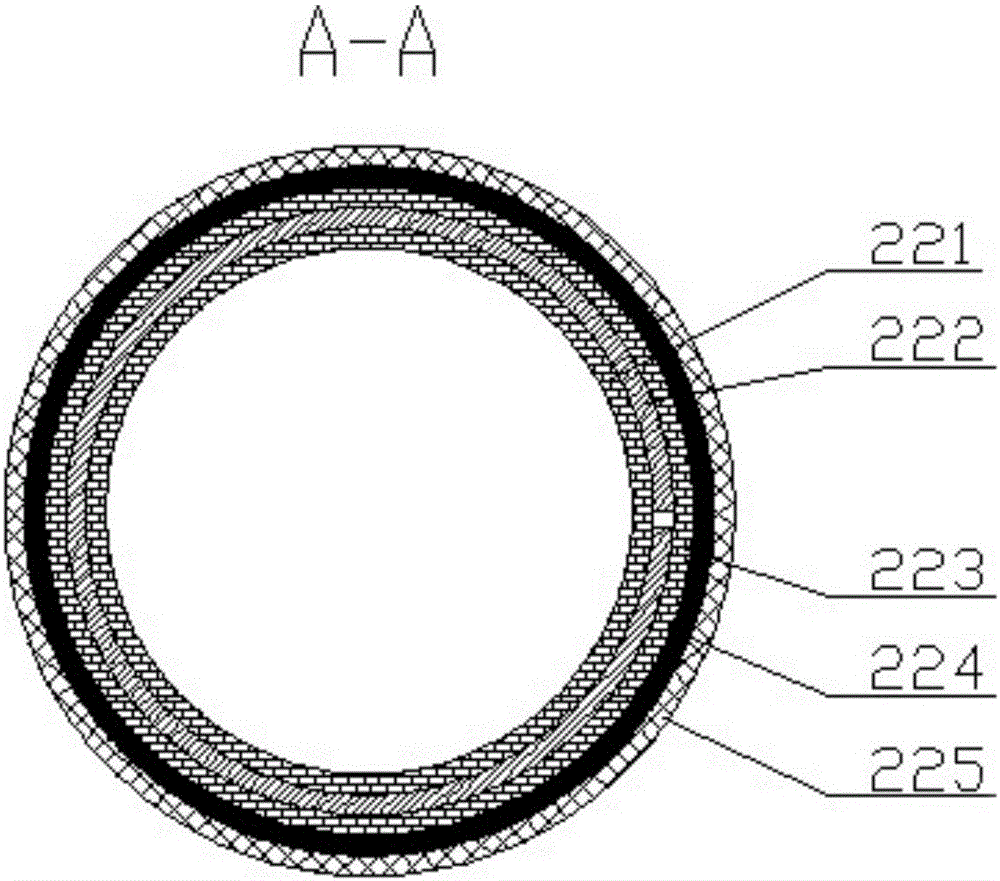

Bendable endoscope provided with tail end passively connected in a bent mode

The invention relates to a bendable endoscope provided with a tail end passively connected in a bent mode. The bendable endoscope comprises an endoscope body, a rigid section, a controllable bent section and a lens, wherein the rigid section, the controllable bent section and the lens are sequentially connected with the endoscope body, the rigid section and the controllable bent section are connected through a passive bent section, and the passive bent section is of a tubular structure and comprises at least five layers of structures which are respectively a first metal mesh belt braided layer, a metal piece shaped spring layer, a second metal mesh belt braided layer, a reinforced protection layer and an appearance protection layer from inside to outside. By adding the passive bent section between the rigid section and the controllable bent section connected with the endoscope, a bending angle of the endoscope in operation is increased.

Owner:SHANGHAI CHANGHAI HOSPITAL

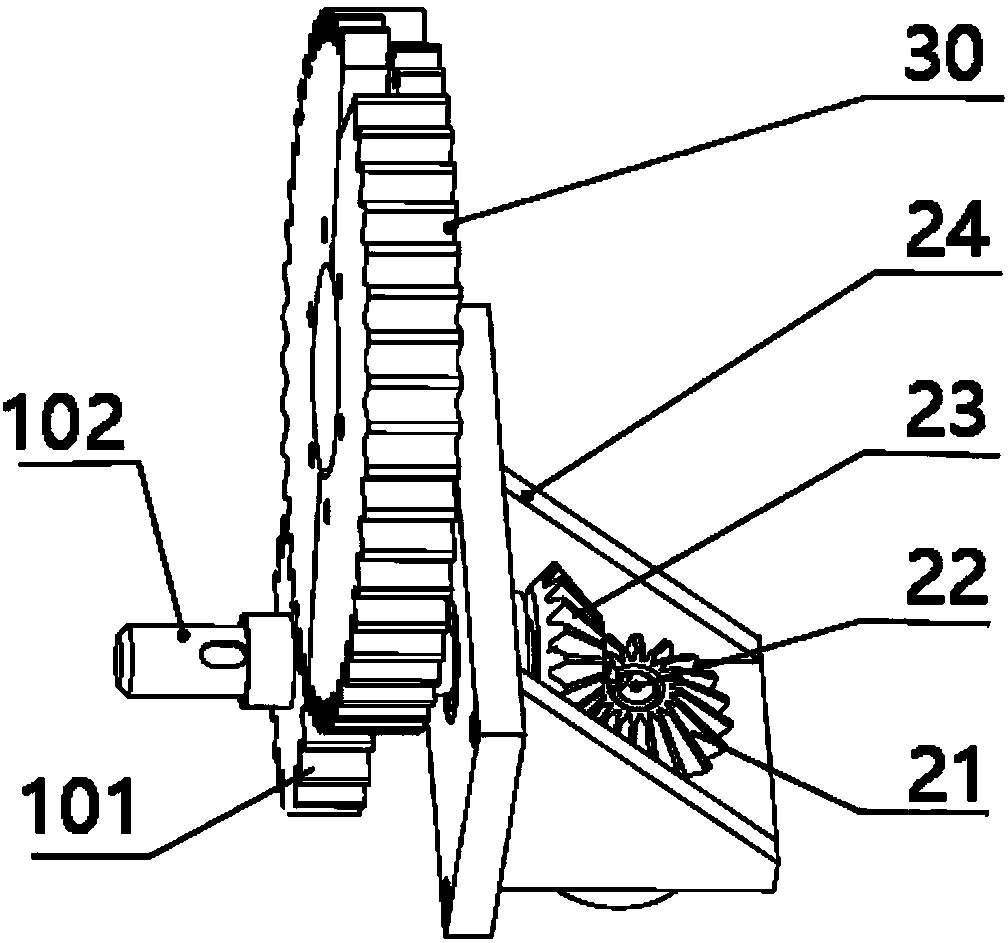

Intermediate high-voltage wire stripping device based on dual driving of electric driving and hand-operated driving

ActiveCN108539668AReduce labor intensityImprove work efficiencyApparatus for removing/armouring cablesSemi openCoupling

The invention discloses an intermediate high-voltage wire stripping device based on dual driving of electric driving and hand-operated driving. The device is composed of an electric transmission mechanism, a hand-operated transmission mechanism, an open stripping mechanism and a coupling mechanism. The hand-operated transmission mechanism consists of one pair of bevel gears and a hand-operated transmission shaft. The coupling mechanism includes a coupling shaft connected with a vertical bevel gear of the hand-operated transmission mechanism and a coupling pinion. A motor of the electric transmission mechanism is fixedly installed at a rack; and the motor is connected with the coupling shaft by one pair of straight gears. A half-opening gear is arranged at the outer side of the open peelingmechanism and is engaged with the coupling pinion; the inside of the open peeling mechanism is formed by hinging of two semi-open hollow shafts; tools are installed inside the semi-open hollow shafts; and drag hooks are fixedly installed at the outer sides of the semi-open hollow shafts and cooperate with bending hooks. According to the invention, the device is operated conveniently; the efficiency is high. The device is suitable for stripping outer insulating skins of cables with different types.

Owner:STATE GRID CORP OF CHINA +2

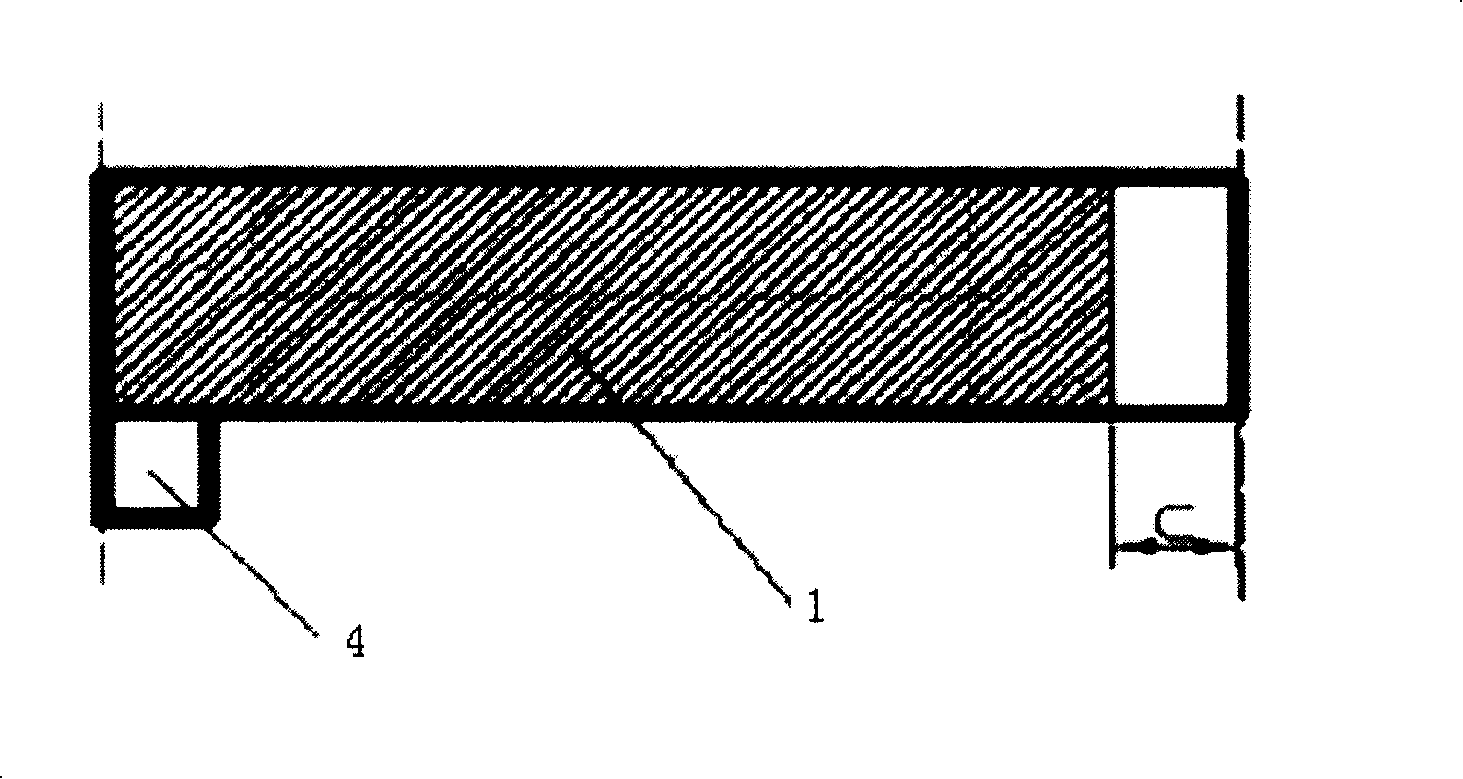

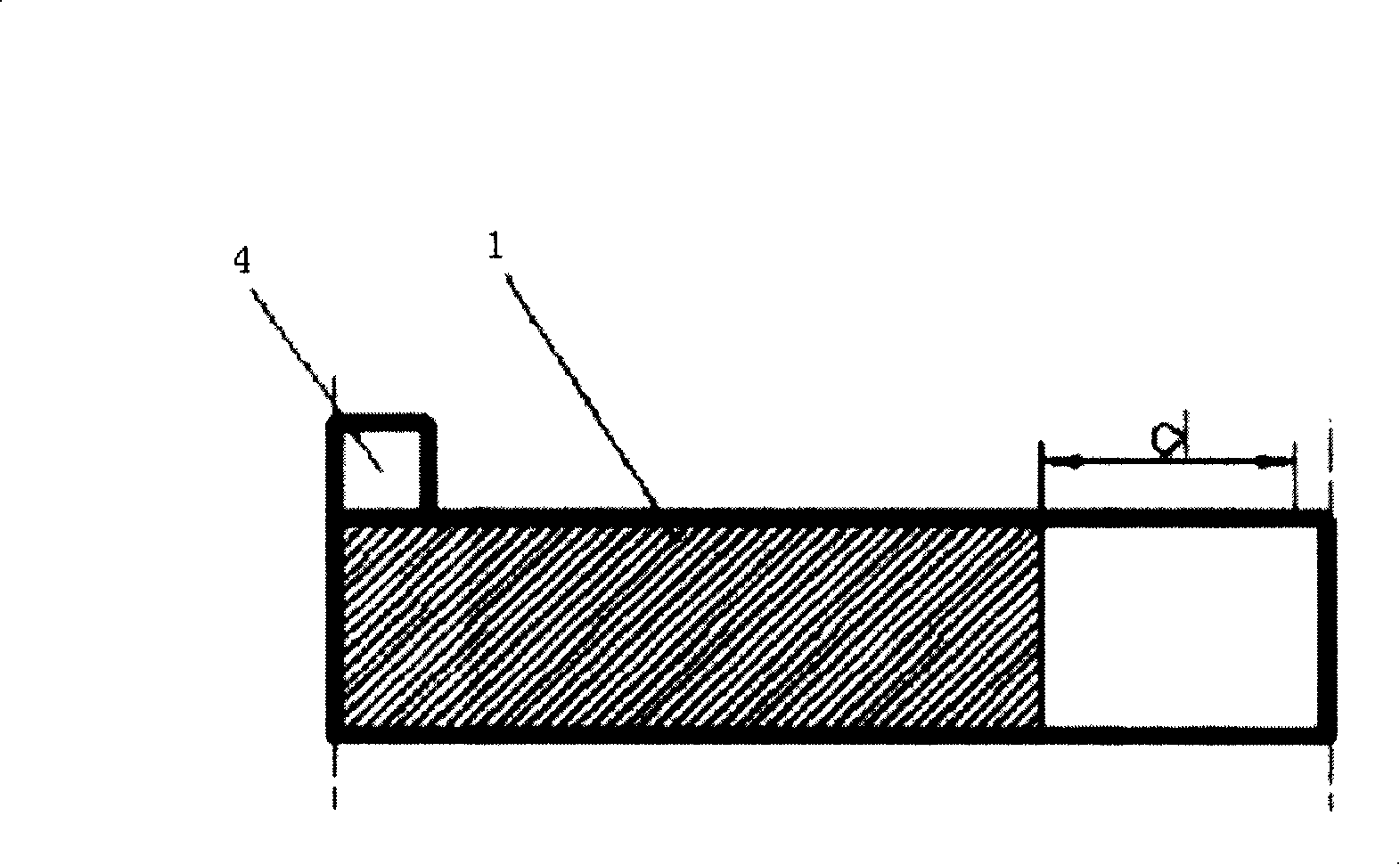

Battery pole plate, method for producing the pole plate, and Li-ion battery

ActiveCN101212040AFirmly connectedControllable distanceSecondary cellsActive material electrodesEngineeringLithium-ion battery

The invention relates to a battery polar core which comprising an anode slice, a diaphragm, a cathode slice and ears of the anode and cathode. The ears of the anode and cathode are respectively connected with the anode slice and the cathode slice. The anode slice, the diaphragm and the cathode slice are folded together and then circled into the battery polar core. A bulge is provided with in the width direction of an end part on the end of the anode slice and the cathode slice. The ears of the anode and cathode are respectively connected with the bulges of the anode slice and the cathode slice. The invention also provides a method for manufacturing the battery polar core and a lithium iron battery made of the battery polar core. The polar core manufactured according to the method for manufacturing the battery polar core provided by the invention is a polar core which can improve the battery capacity and meet the tolerance requirement for the distance between the ears of the anode and cathode. The capacity of the lithium ion battery made by using the battery polar core provided by the invention is high.

Owner:BYD CO LTD

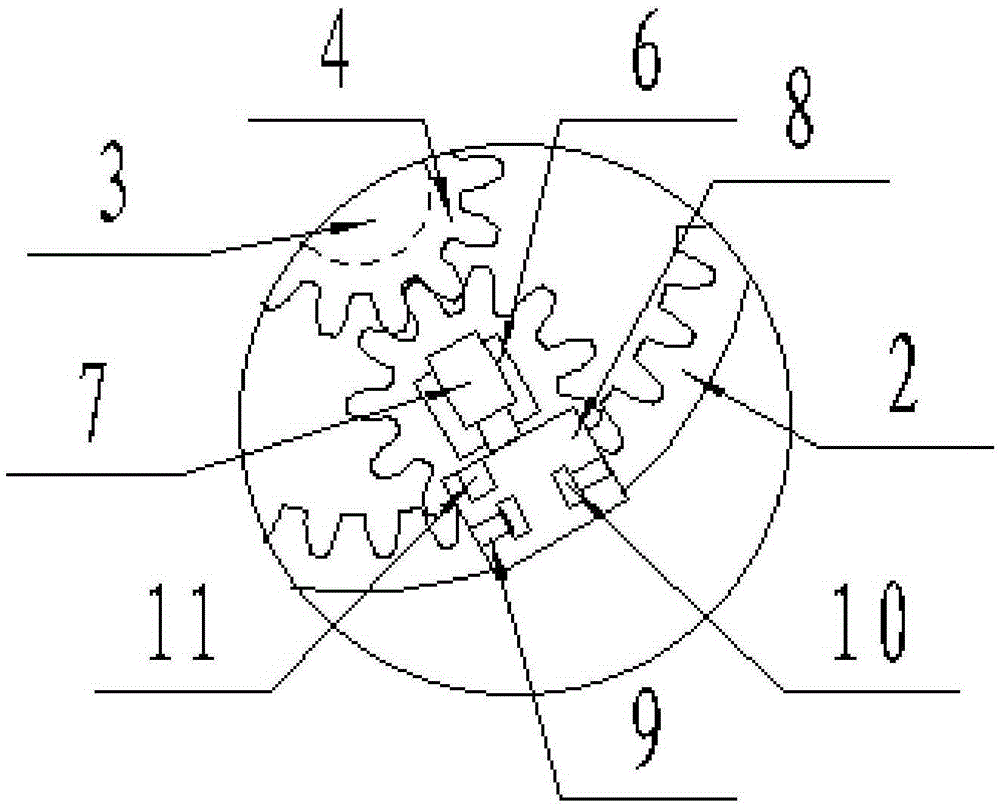

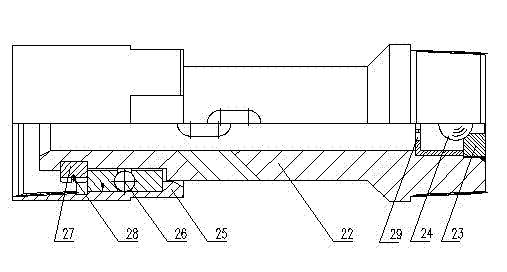

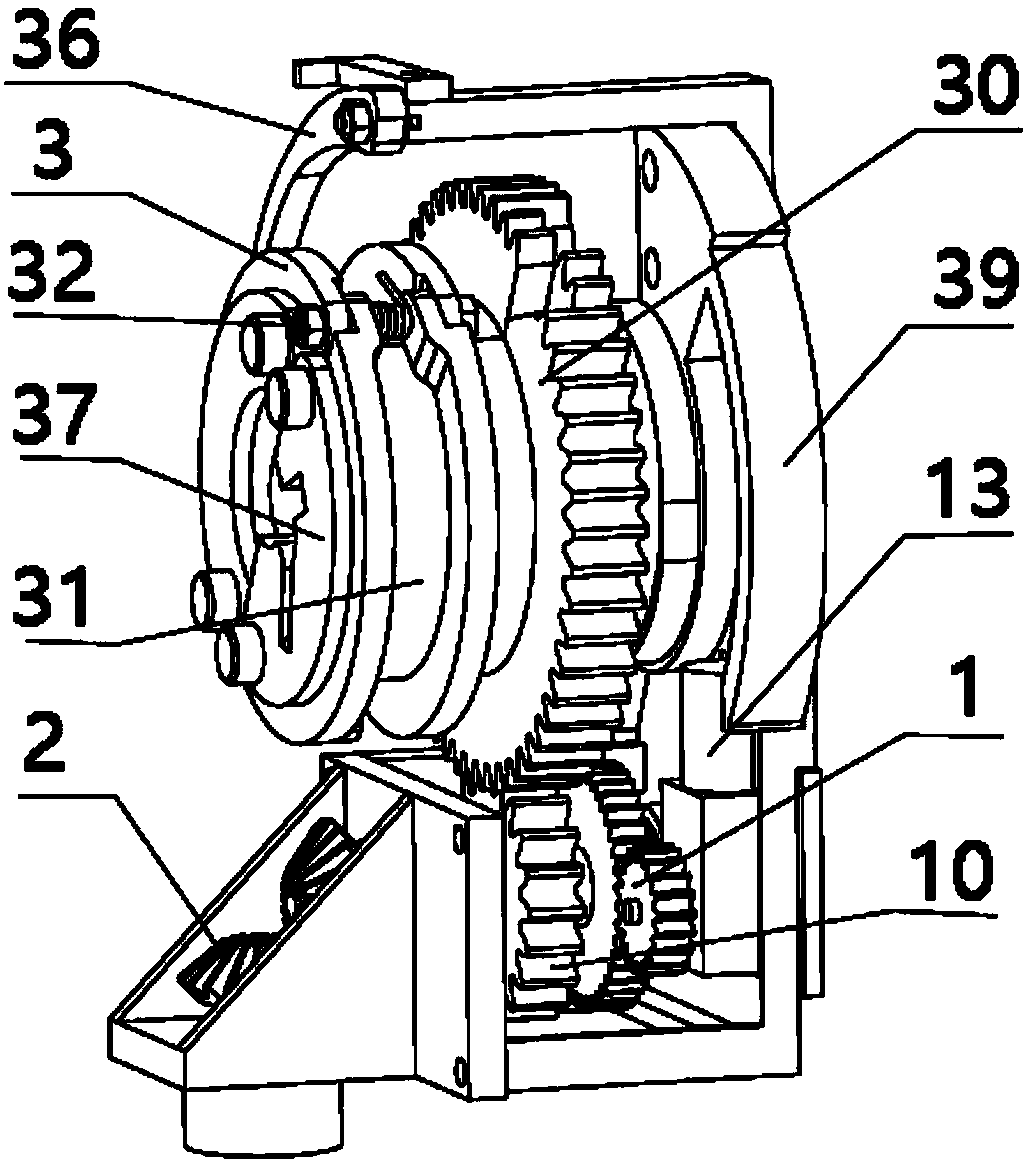

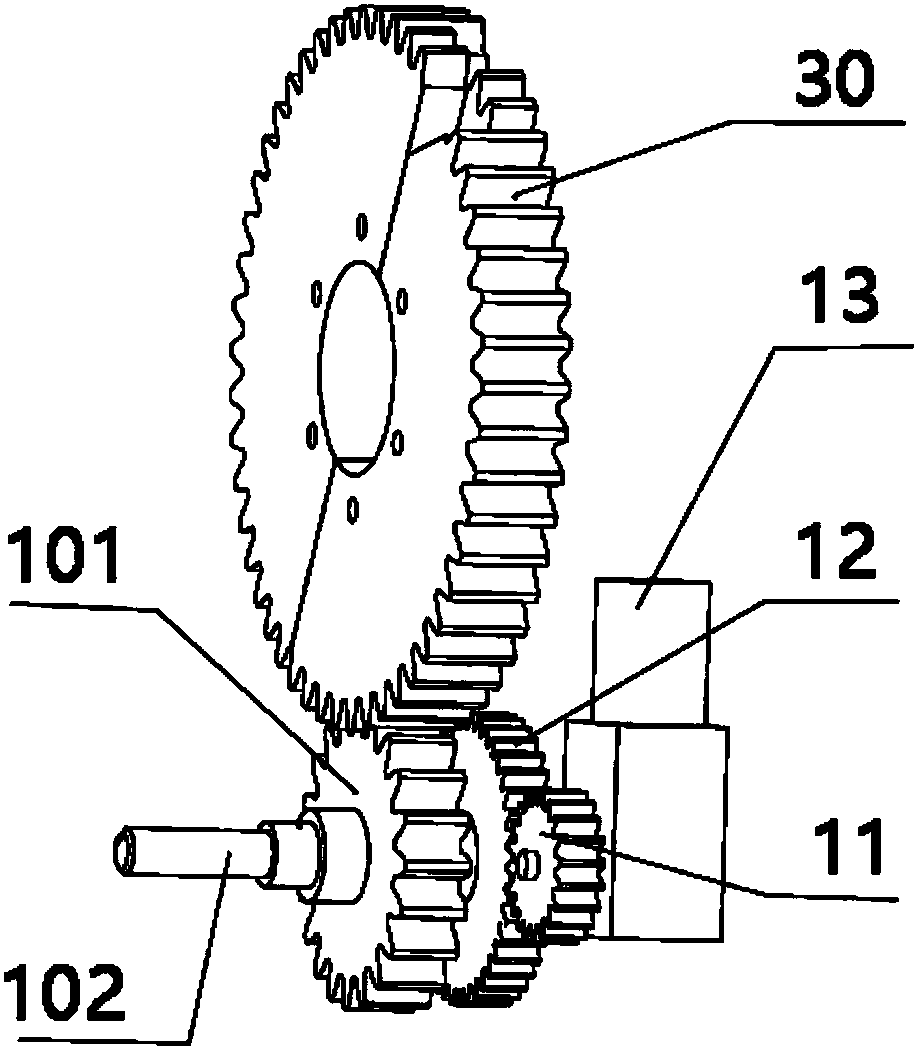

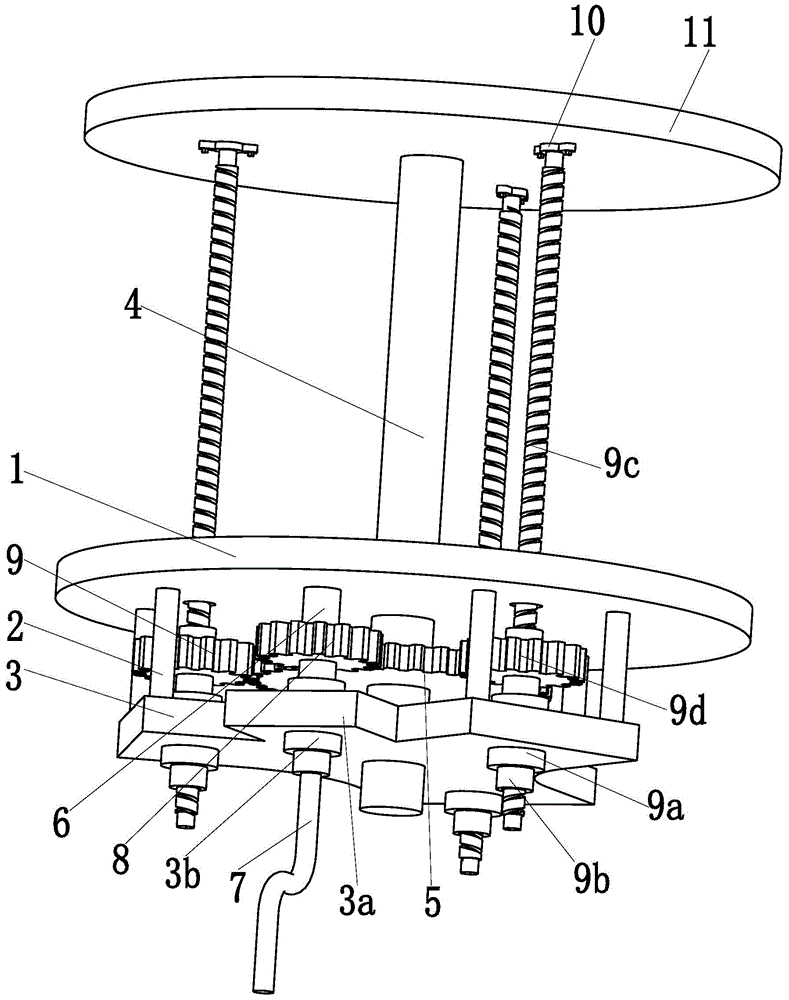

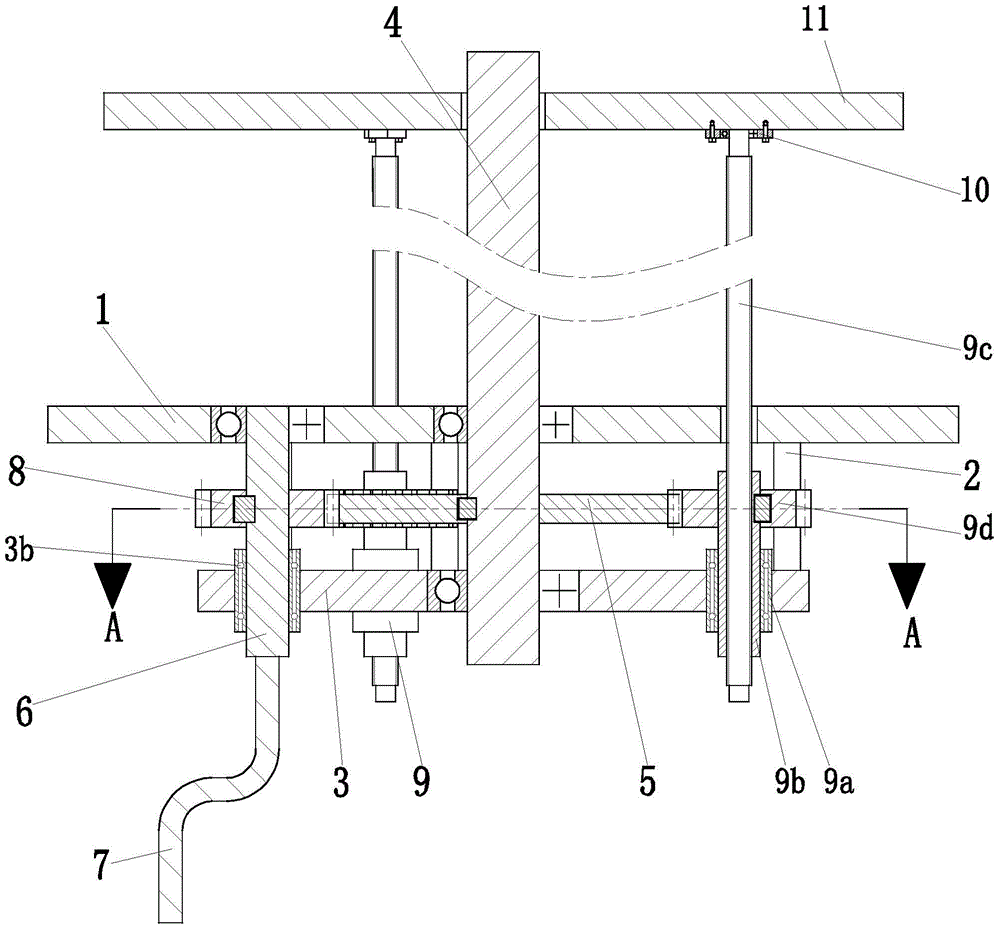

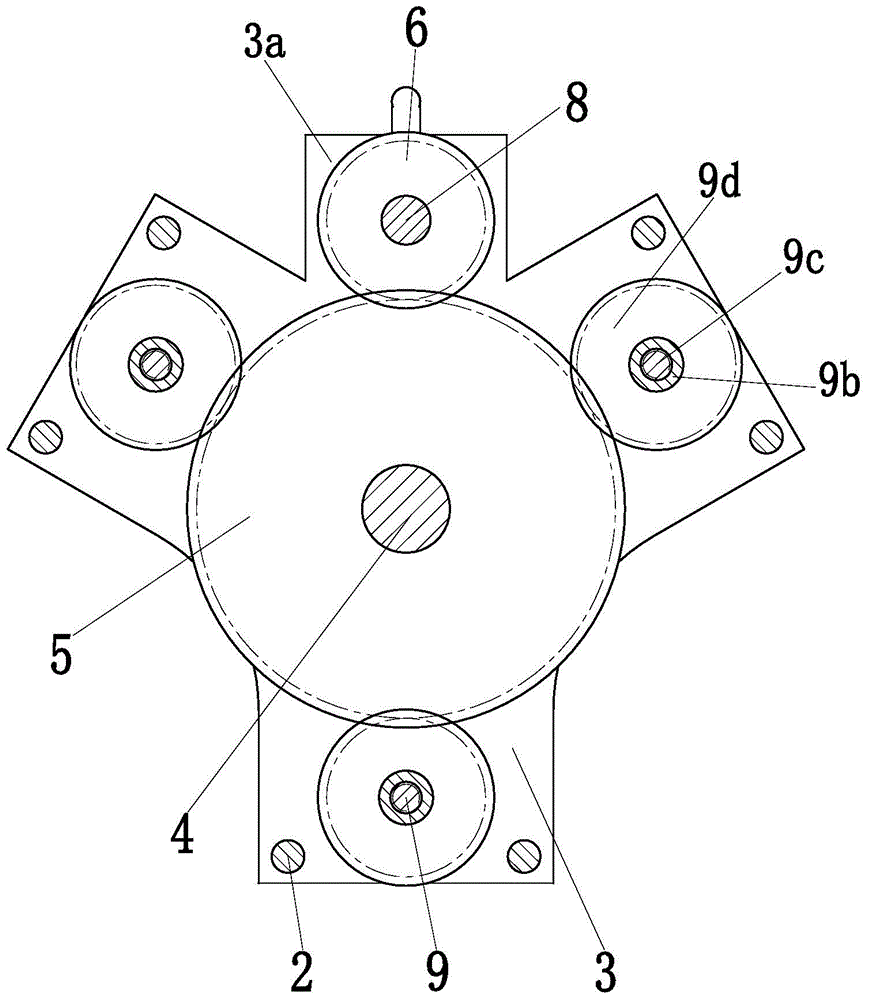

Three-linkage lifting locating device for lifting and locating tea table

ActiveCN104939506AControllable distanceGood balanceServing tablesVariable height tablesEngineeringCircular disc

The invention relates to a three-linkage lifting locating device for lifting and locating a tea table. The three-linkage lifting locating device comprises a fixed disc; the lower end of the fixed disc is provided with three pairs of connection columns; a Y-shaped fixing sheet is welded to the lower ends of the three pairs of connection columns; the middle of the Y-shaped fixing sheet is connected with a central shaft; the central shaft is connected with the fixed disc through a bearing; a central gear is arranged on the central shaft through a key; a firs ball bearing is arranged in the middle of the Y-shaped fixing sheet; a driving shaft is arranged on the first ball bearing; the top end of the driving shaft is connected with the fixed disc through a bearing; a driving gear is arranged in the middle of the driving shaft through a key; the Y-shaped fixing sheet is evenly provided with three locating mechanisms; the top ends of the three locating mechanisms are connected with a movably disc; the middle of the movable disc is connected with the central shaft in a clearance fit mode. The three-linkage lifting locating device for lifting and locating the tea table can achieve lifting and locating functions with high precision, and has the advantages of being simple in structure, easy and convenient to operate, good in balance performance and height locating performance in the movement process, high in working efficiency and the like.

Owner:海太欧林集团华南有限公司

Sliding shift fork wire feeding and terminal crimping machine

ActiveCN105552684AControllable distanceIncrease productivityLine/current collector detailsEngineeringMechanical engineering

The invention discloses a sliding shift fork wire feeding and terminal crimping machine, comprising a rectangular moving base, wherein moving mechanisms are arranged at four corners of an external lower surface of the moving base, a feeding mechanism, a wire twisting mechanism, a terminal crimping mechanism and a rotary sliding shift fork grabbing mechanism are arranged on an upper surface of the moving base, a controller is arranged on an outer surface of the moving base, and the controller is electrically connected with the feeding mechanism, the wire twisting mechanism, the terminal crimping mechanism and the rotary sliding shift fork grabbing mechanism respectively. The sliding shift fork wire feeding and terminal crimping machine disclosed by the invention has the beneficial effects of being simple in structure and strong in practicability.

Owner:刘婷婷

UV curing machine provided with 360-degree rotary light source

InactiveCN105268615ADissipate heat in timeReduce the temperaturePretreated surfacesCoatingsUV curingEngineering

The invention discloses a UV curing machine provided with a 360-degree rotary light source. The UV curing machine comprises a UV curing machine body, the UV curing machine body is provided with a feed inlet, a discharge port, an exhaust fan and a transmission table, and an electronic control device is further arranged in the machine. The electronic control device is installed above the feed inlet of the UV curing machine body. A UV lamp is rotationally installed in the UV curing machine body through a rotary bearing. The rotary bearing is connected with the electronic device through a wire and is controlled by the electronic control device to rotate. By means of the design, the illumination range and stability of the light source are guaranteed, and product quality is improved.

Owner:WUHU CHUNYUAN PHOTOELECTRIC EQUIP TECH CO LTD

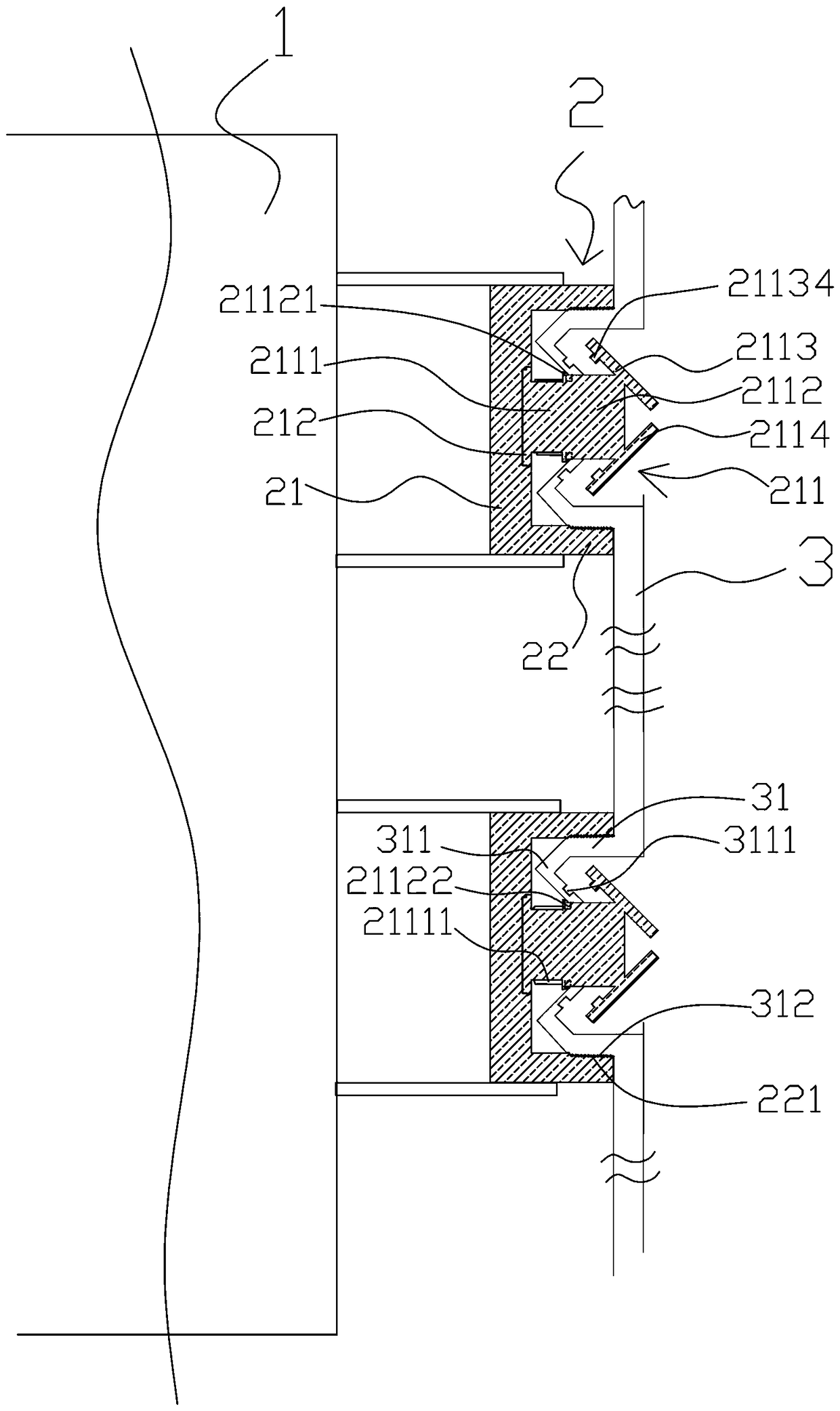

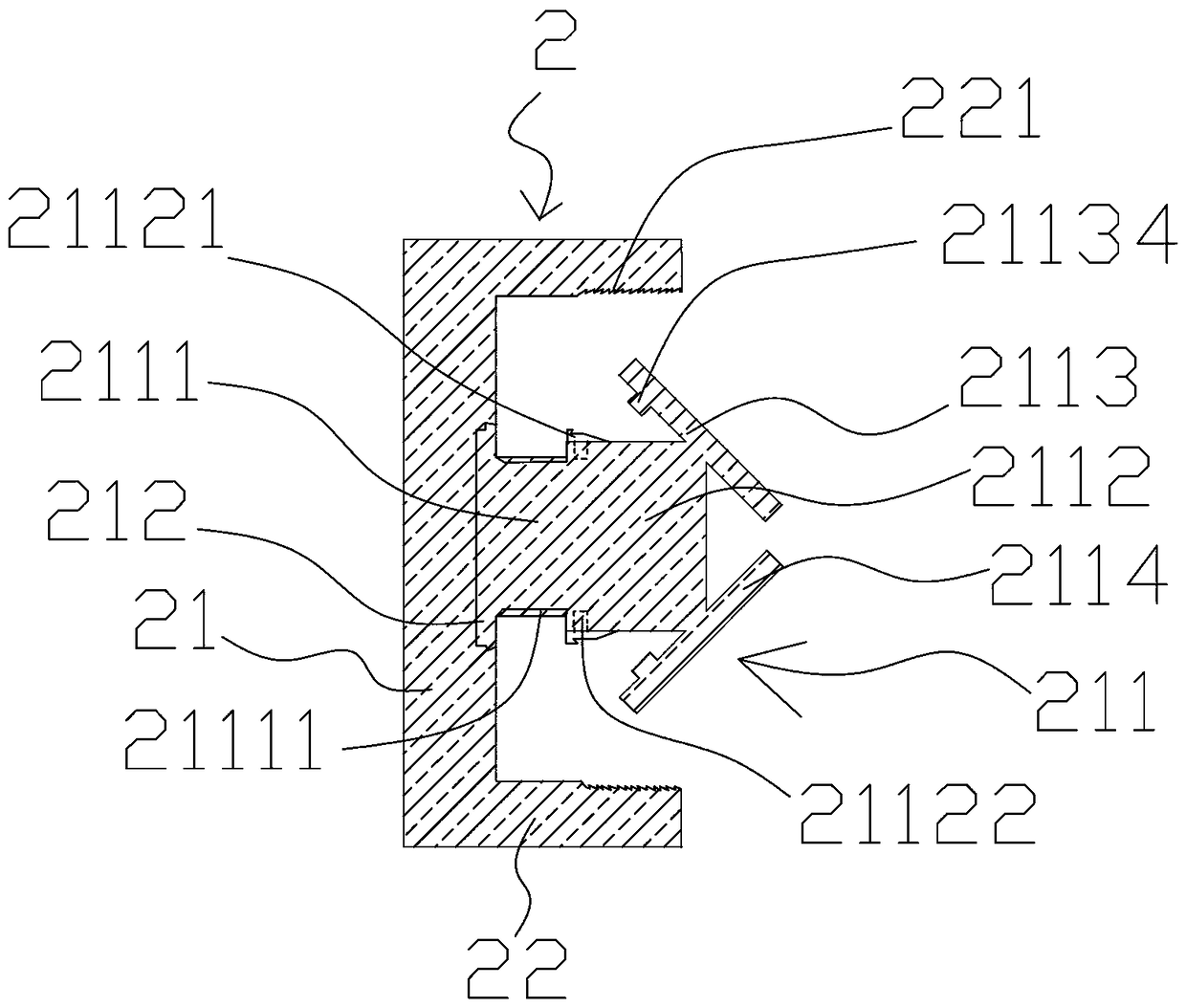

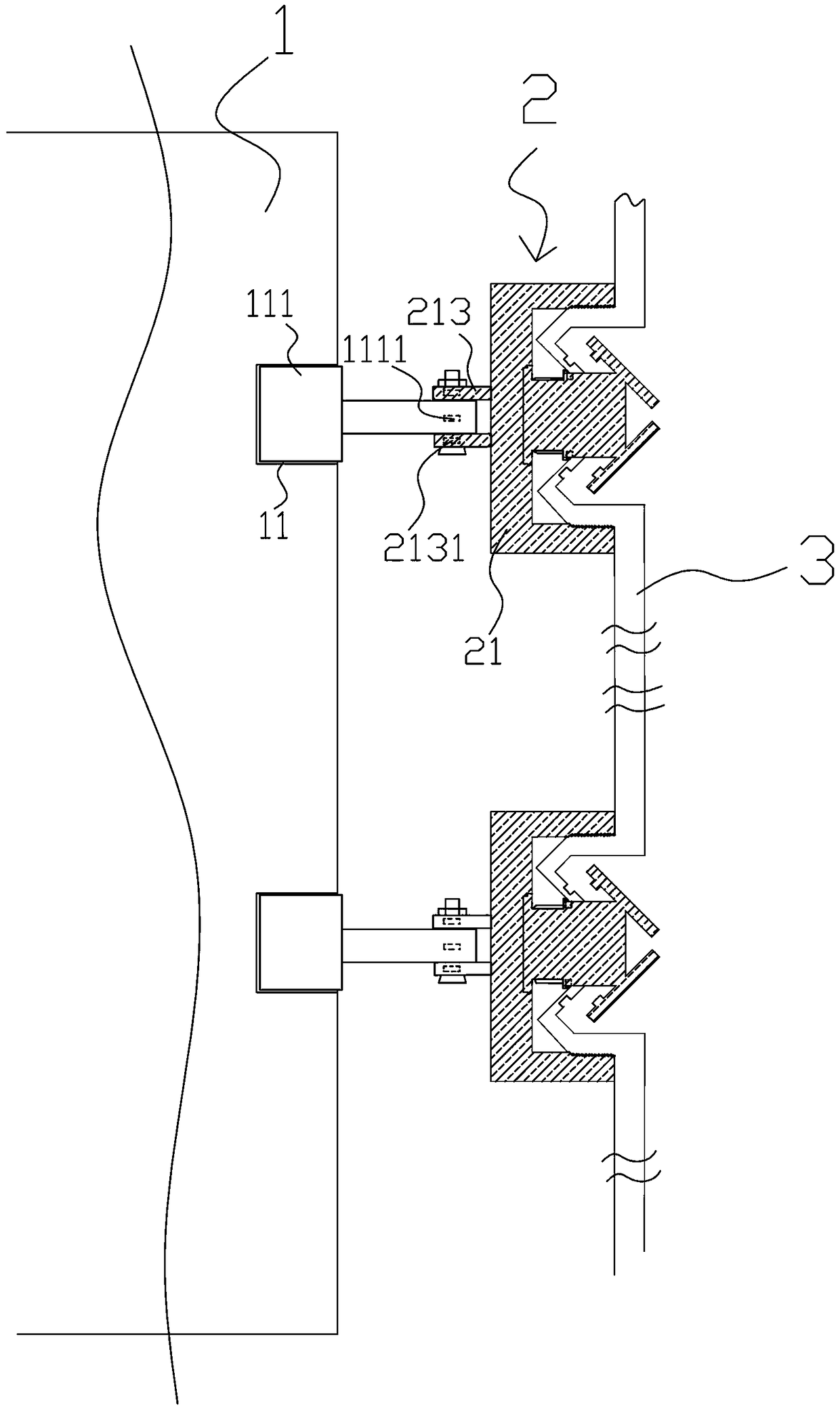

Curtain wall connecting structure

The invention discloses a curtain wall connecting structure comprising a wall body, a keel and an aluminum veneer. The keel comprises a bottom plate and side plates arranged on the two sides of the bottom plate, a locking device is arranged on the bottom plate, and the aluminum veneer and the locking device are connected in a clamped mode. The locking device comprises a fixed base and a telescopichead connected with the fixed base in a sleeving mode and further comprises an upper locking piece and a lower locking piece which are mutually obliquely and symmetrically arranged on the telescopichead. A flanging is arranged on the aluminum veneer, a barb is arranged on the flanging, the flanging is placed in a gap formed by the side plates and the locking device, so that the barb abuts against the upper locking piece or the lower locking piece, and thus clamped connection of the aluminum veneer and the locking device is achieved. According to the curtain wall connecting structure, weldingis not needed, mounting and dismounting are convenient, damage to the structure in mounting and dismounting is small, operation is flexible, easy and convenient, the mounting structure is compact, the firmness is high, and the stability is high.

Owner:浙江德清森朗装饰材料有限公司

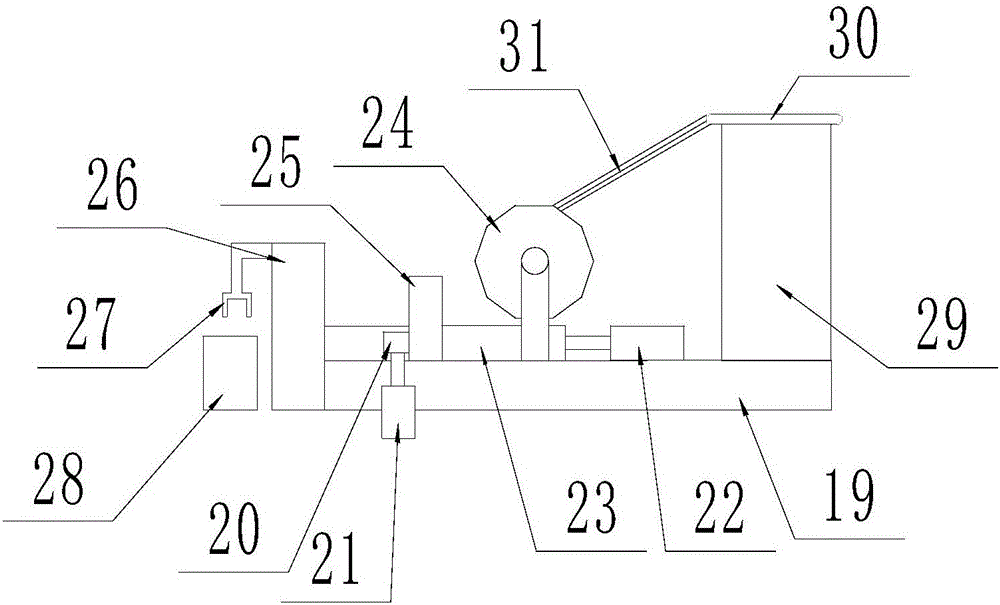

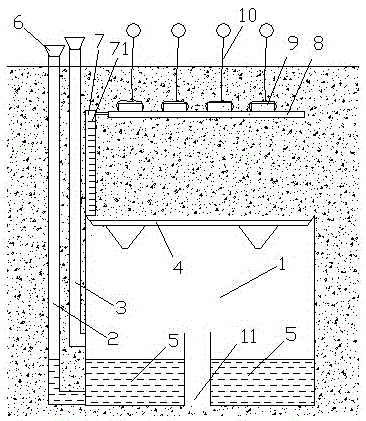

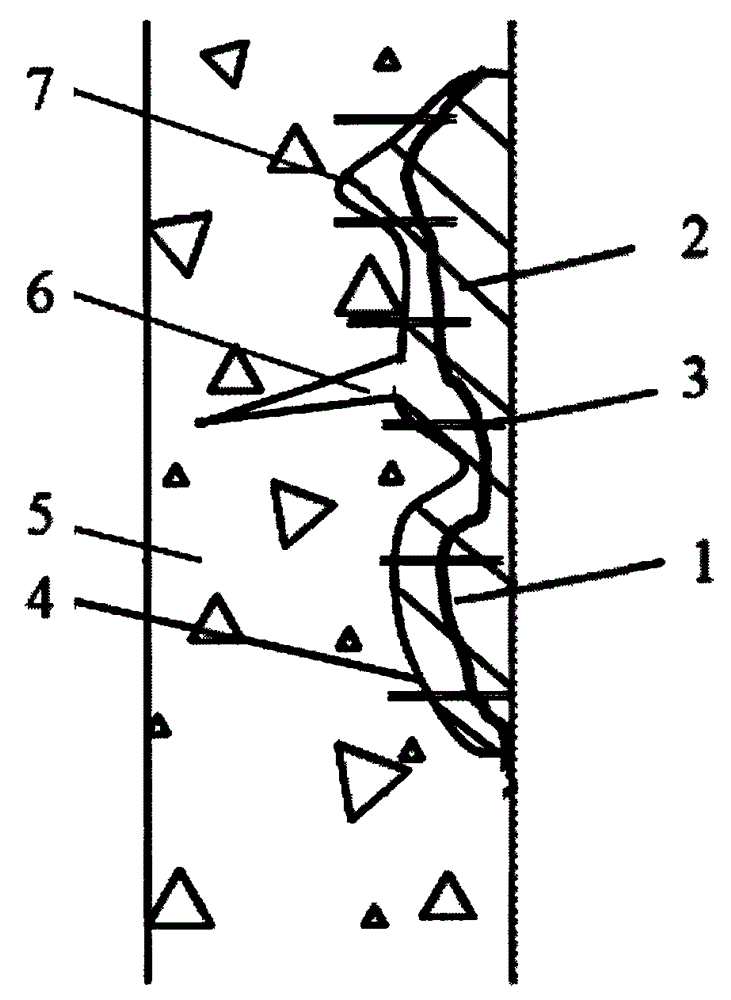

Experiment device for carbonate rock corrosion speed under karst-region soil environment

ActiveCN105572024AEasy to controlConvenient burial depth of flakesWeather/light/corrosion resistanceCarbonate rockKarst

The invention provides an experiment device for carbonate rock corrosion speed under a karst-region soil environment, aims to solve the problems that current corrosion experiments under the soil environment can only measure the corrosion test piece weight loss, detection data is single, and sufficient data support cannot be provided for corrosion researches, and belongs to the field of corrosion researches. The experiment device comprises a tank with an upper-end opening, a water guide pipeline and an air guide pipeline, wherein a draining hole is formed in the bottom of the tank, fiber cloth or a multilayer screen is laid at the upper-end opening of the tank, a water receiving tank is arranged at the bottom of the tank, one end of the water guide pipeline is communicated with the bottom of the water receiving tank, and one end of the air guide pipeline is communicated with the tank lateral wall above the water receiving tank.

Owner:GUIZHOU NORMAL UNIVERSITY

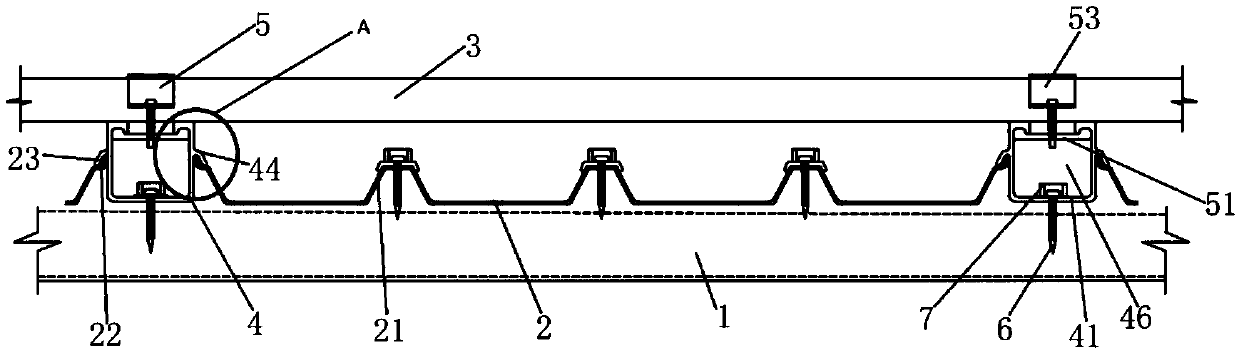

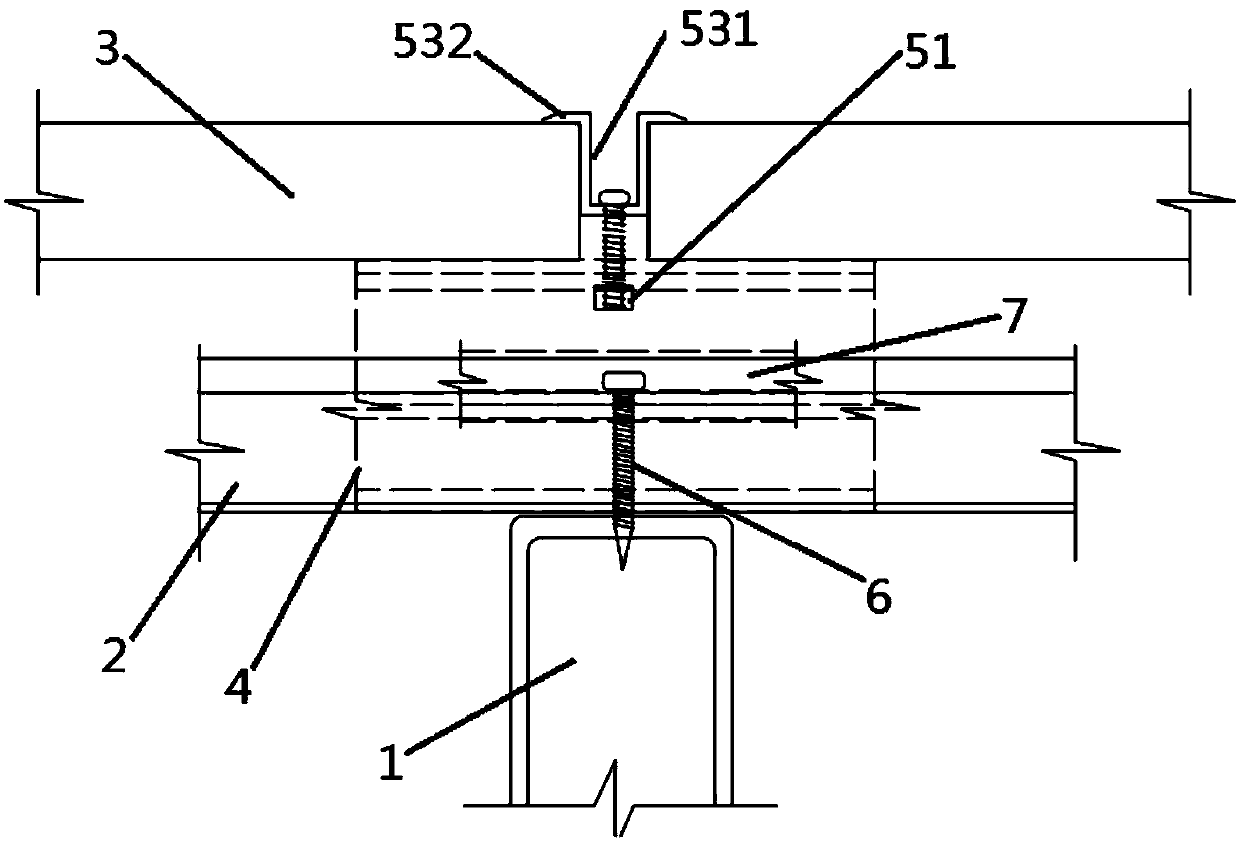

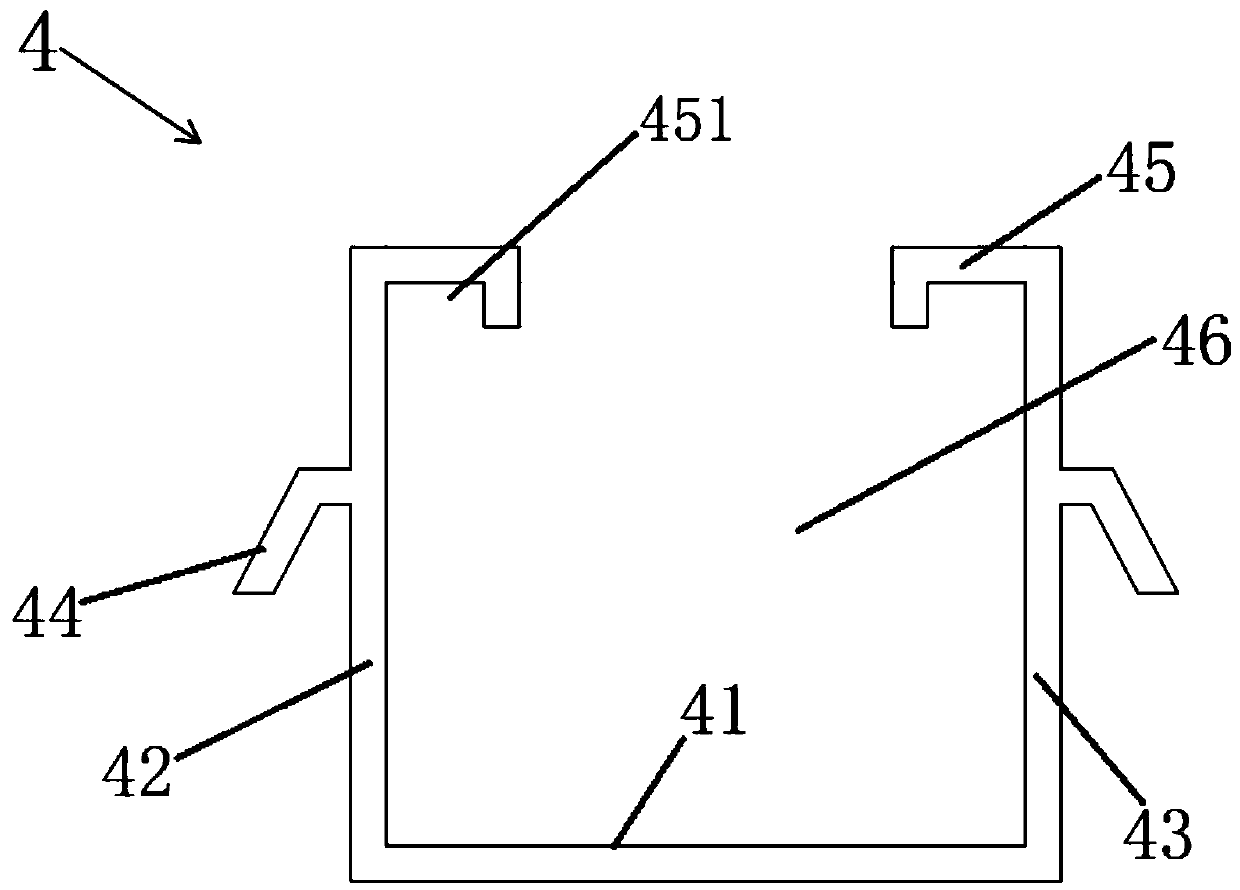

Roof photovoltaic power generation station structure and lap joint method thereof

PendingCN109537818ALighten the loadExtended service lifePhotovoltaic supportsRoof covering using slabs/sheetsLocking mechanismThermal insulation

The embodiment of the invention discloses a roof photovoltaic power generation station structure and a lap joint method thereof. The structure comprises a purline, a roof plate, a photovoltaic plate,a positioning mechanism and a locking mechanism. The positioning mechanism comprises a bottom plate, a left side plate, a right side plate, a wing and a flange. The locking mechanism comprises a clamping part, a fastener and a fixing part. The positioning mechanism and the locking mechanism have the effect of fixing the roof plate and the photovoltaic plate respectively. The positioning mechanismhas the fixing effect and meanwhile serves as a main load-bearing carrier of the roof photovoltaic power generation station structure. Thus, the roof photovoltaic power generation station structure has the good sealing performance, waterproof performance, corrosion resistance and thermal insulation performance and is long in service life and low in maintenance cost; the lap joint method is simplein process, safe in operation and suitable for wide use and popularization, local maintenance can be realized, and maintenance is convenient.

Owner:湖北中复能新型材料有限公司

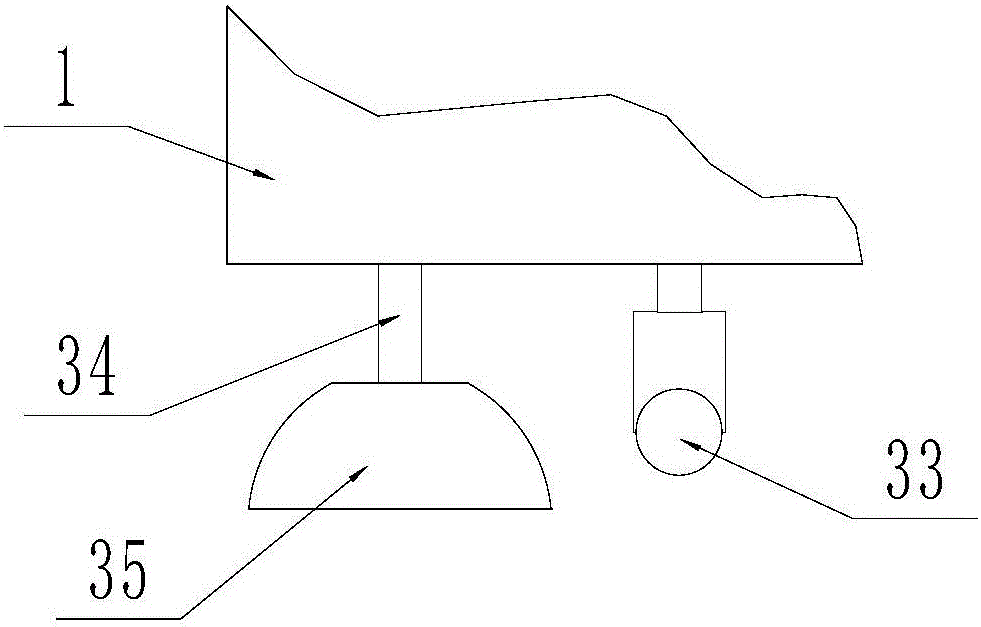

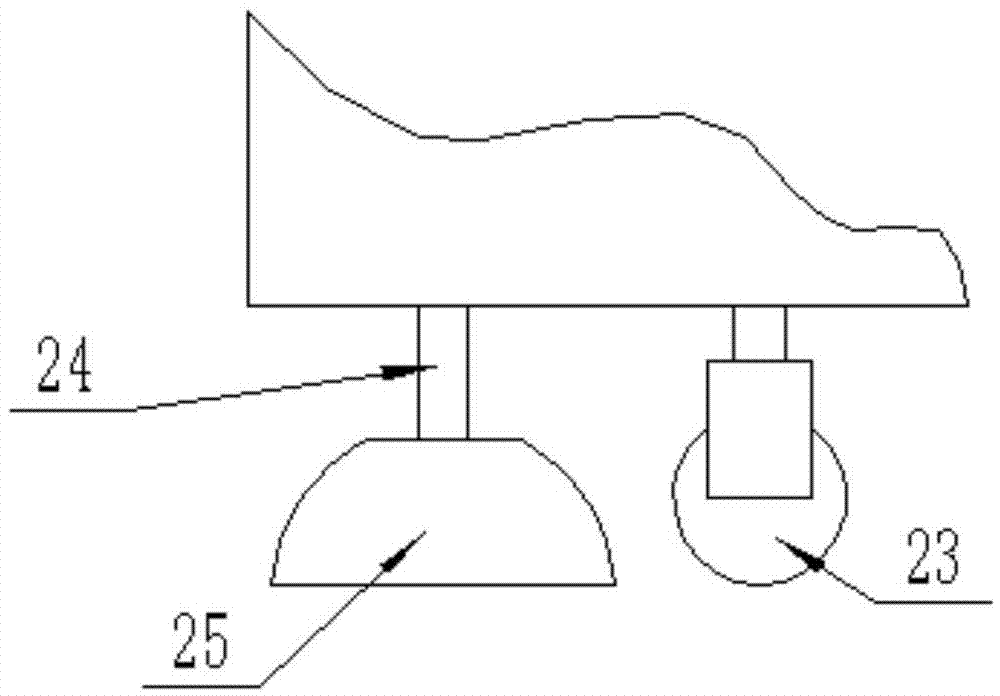

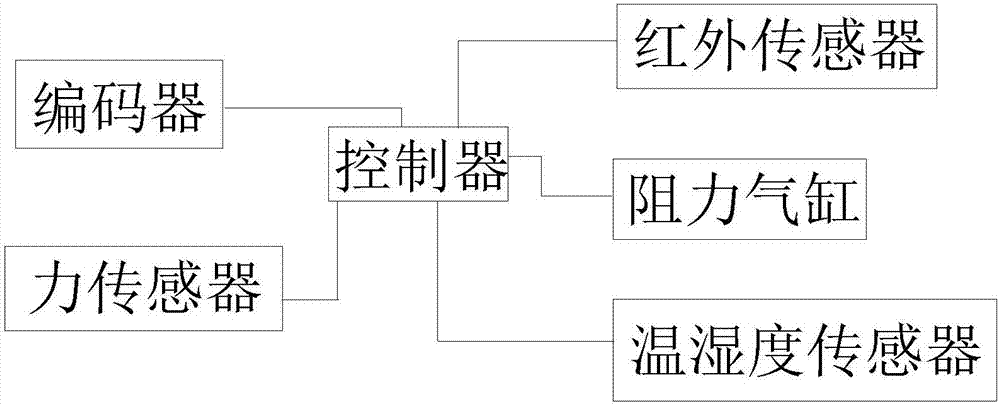

Motor vehicle real vehicle wiper test system and test method

PendingCN107132057AComplete measurement performanceHigh measurement accuracyVehicle testingAutomotive engineeringPilot system

The invention discloses a motor vehicle real vehicle wiper test system and a test method. The system comprises a spraying room. The spraying room is provided with a transportation frame for placing a motor vehicle; the bottom of the transportation frame is provided with a conveying mechanism for driving the transportation frame to transport to the inside of the spraying room; a bracket is fixed on the transportation frame; the bracket is fixed to an infrared sensor and a first resistance cylinder, wherein the infrared sensor and the first resistance cylinder face towards a windshield glass of the motor vehicle; a wiper floating rule on the windshield glass passes the infrared sensor and the first resistance cylinder in the process of movement sequentially. The motor vehicle wiper test system and the test method can measure the scraping frequency, automatic return, resistance braking, durability and other aspects of the wiper on the real vehicle, thus the measurement performance is integrated, and the measurement accuracy is high; the nozzle in the spraying room is controllable in water amount and distance, can simulate heavy rain, light rain and other environments so that the wiper can be tested in different environments, and the test accuracy is improved.

Owner:SUZHOU UNIV OF SCI & TECH

Swing clamp track type periodic grooved pulley wire trimming machine

InactiveCN106384927AControllable distanceIncrease productivityContact member manufacturingPulleyEngineering

The invention discloses a swing clamp track type periodic grooved pulley wire trimming machine comprising a cuboid mobile base. The four corners of the lower surface outside the mobile base are provided with mobile mechanisms. The upper surface of the mobile base is provided with a swing clamp material feeding mechanism, a pulley track type wire twisting mechanism, a hitting terminal mechanism and a periodic grooved pulley grabbing mechanism. The swing clamp material feeding mechanism, the pulley track type wire twisting mechanism and the hitting terminal mechanism are angularly distributed on the surface of the mobile base. The periodic grooved pulley grabbing mechanism is arranged at the center of the swing clamp material feeding mechanism, the pulley track type wire twisting mechanism and the hitting terminal mechanism. The external surface of the mobile base is provided with a controller. The controller is electrically connected with the swing clamp material feeding mechanism, the pulley track type wire twisting mechanism, the hitting terminal mechanism and the periodic grooved pulley grabbing mechanism. The beneficial effects of the swing clamp track type periodic grooved pulley wire trimming machine are that the swing clamp track type periodic grooved pulley wire trimming machine is simple in structure and high in practicality.

Owner:周末

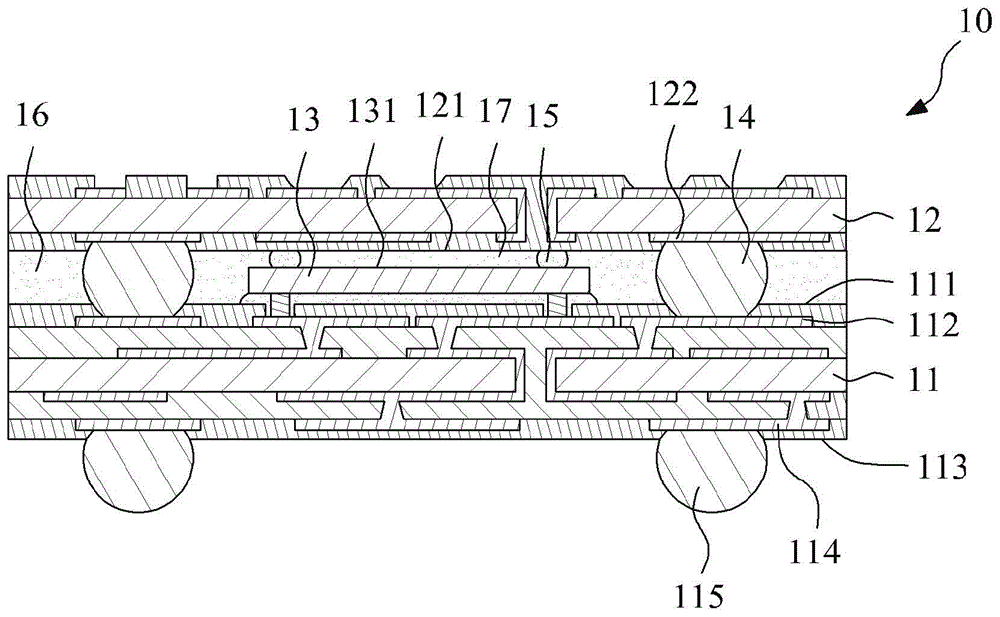

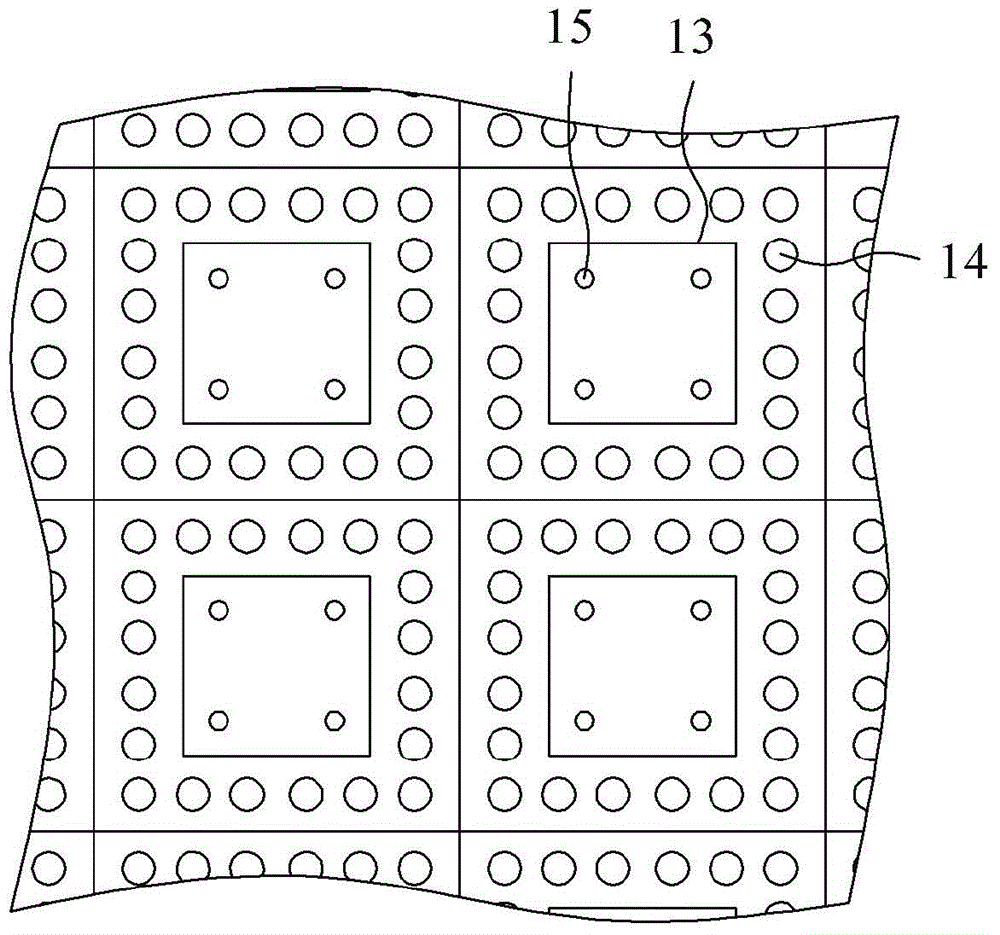

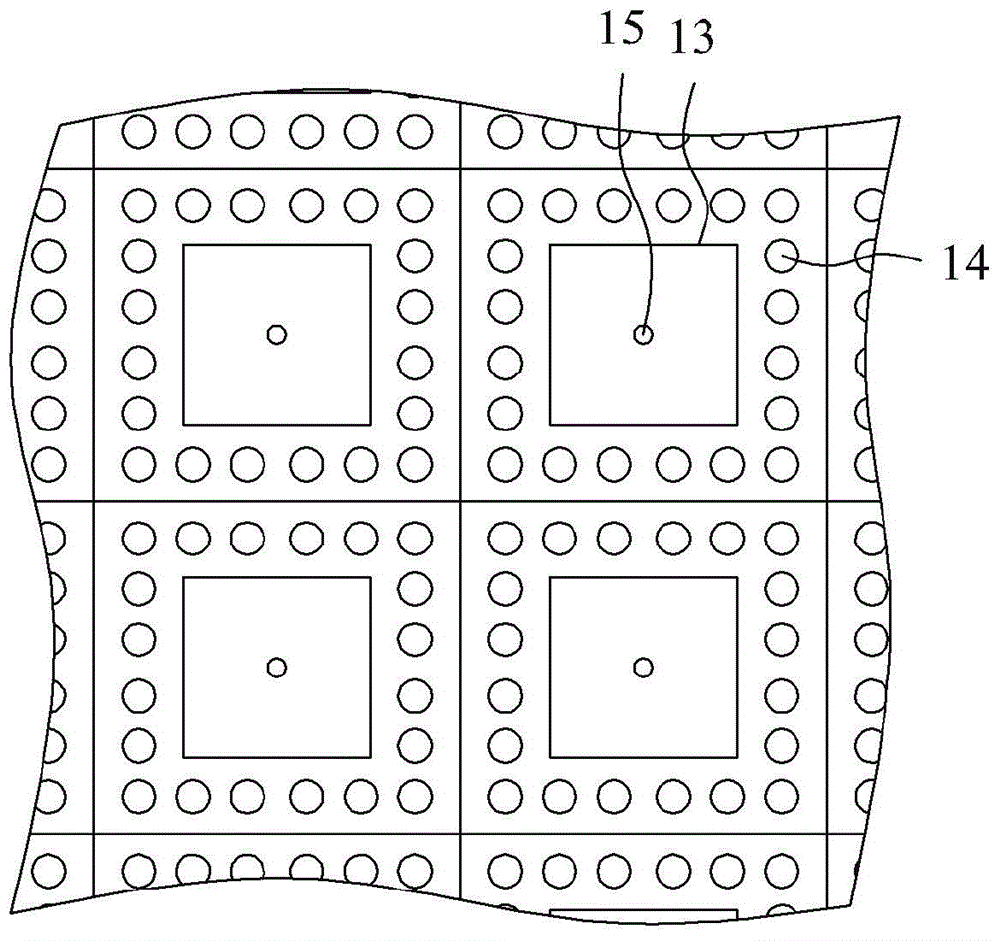

Packaging structure and semiconductor process

ActiveCN104465427ALow costControllable distanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectrical connection

The invention relates to a packaging structure and a semiconductor process. The packaging structure comprises a first substrate, a second substrate, a grain, a plurality of electrical connection elements, at least one spacer element and a sealing compound. The grain is located between the first substrate and the second substrate; the at least one spacer element is arranged between the grain and the second substrate and is in contract with the grain and the second substrate. The electrical connection elements are electrically connected to the first substrate and the second substrate. The at least one spacer element is employed to support the second substrate, allowing a setting distance between the first substrate and the second substrate. The electrical connection elements do not require high intensity materials so as to reduce material cost. The at least one spacer element can control a distance and a space between the grain and the second substrate, allowing the sealing compound to smoothly flow into the space, avoiding generating air or gap in the space and increasing a product yield rate.

Owner:ADVANCED SEMICON ENG INC

Linear multi-pulley transmission wire trimmer

InactiveCN105932514AReduce manufacturing costControllable distanceConnection formation by deformationEngineeringPulley

The invention discloses a linear multi-pulley transmission wire trimmer, which comprises a rectangular mobile base, wherein mobile mechanisms are arranged at four corners of the lower surface outside the mobile base; a feeding mechanism, a sliding rail twisting mechanism, a multi-pulley terminal crimping mechanism and an X-axis double-layer displacement clamping mechanism are arranged on the upper surface of the mobile base; the sliding rail twisting mechanism is located between the feeding mechanism and the multi-pulley terminal crimping mechanism; the X-axis double-layer displacement clamping mechanism is arranged oppositely to the feeding mechanism, the twisting mechanism and the multi-pulley terminal crimping mechanism; and the controller is electrically connected between the feeding mechanism, the twisting mechanism, the multi-pulley terminal crimping mechanism and the X-axis double-layer displacement clamping mechanism respectively. The linear multi-pulley transmission wire trimmer has the beneficial effects of being simple in structure and high in practicability.

Owner:孙宁

A uv curing machine

InactiveCN104353597BControllable distanceReduce the temperaturePretreated surfacesCoatingsUV curingEngineering

The invention discloses a UV (ultraviolet) curing machine which comprises a shell (1), a conveying table (2) and a control console (3), wherein the shell (1) is of a hollow box body structure, wherein a material inlet and a material outlet are respectively formed in the bottoms of two ends of the shell; an exhaust fan (4) is arranged at the top of the shell; UV lamps (6) fixed on a lamp support are suspended in the middle of the interior of the shell; the lamp support is fixed on a bracket above the lamp support through adjustment screw rods (5); the conveying table (2) is positioned below the UV lamp; one end of a conveying belt is connected with the material inlet, and the other end of the conveying belt is connected with the material outlet; a rotary drum (8) is arranged on the conveying table at each of the material inlet and the material outlet; the control console (3) is positioned below the conveying table and is of a topless square hollow steel structure; peripheral steel plates are welded with the conveying table (2); a control panel (9) is fixed on the steel plate on one side of the control console; heat dissipation holes (10) are formed close to the bottom of the control console; a speed reduction motor (7) is arranged close to the material inlet and is connected with the rotary drum (8) at the material inlet through the conveying belt.

Owner:SUZHOU AISITE IND EQUIP

Multi-roller swing picking track type electric wire terminal riveting machine

InactiveCN106299965AControllable distanceIncrease productivityLine/current collector detailsElectrical connectionEngineering

The invention discloses a multi-roller swing picking track type electric wire terminal riveting machine which comprises a cuboid movable base, wherein moving mechanisms are arranged at four corners of the outer lower surface of movable base; a swing picking feeding mechanism, a roller track type wire twisting mechanism, a multi-roller terminal riveting mechanism and a periodic sheave gripping mechanism are arranged on the upper surface of the movable base; the swing picking feeding mechanism, the roller track type wire twisting mechanism, the multi-roller terminal riveting mechanism and the like are distributed on the surface of the movable base at equal angles; the periodic sheave gripping mechanism is positioned in the center of the part formed by the swing picking feeding mechanism, the roller track type wire twisting mechanism and the multi-roller terminal riveting mechanism; a controller is arranged on the outer surface of the movable base; the controller is in electrical connection with the swing picking feeding mechanism, the roller track type wire twisting mechanism, the multi-roller terminal riveting mechanism and the periodic sheave gripping mechanism respectively. The multi-roller swing picking track type electric wire terminal riveting machine has the benefits of being simple in structure and strong in practicability.

Owner:王杨

Shift-fork multi-pulley conveying wire and terminal riveting assembly line

ActiveCN105932515AReduce manufacturing costControllable distanceLine/current collector detailsAssembly linePulley

The invention discloses a shift-fork multi-pulley conveying wire and terminal riveting assembly line, and the assembly line comprises a rectangular substrate. The upper surface of the substrate is provided with a feeding mechanism, a wire twisting mechanism, a multi-pulley wire and terminal riveting mechanism, and a rotating grabbing mechanism. The feeding mechanism, the wire twisting mechanism and the multi-pulley wire and terminal riveting mechanism are distributed on the surface of the substrate in an equal-angle manner. The rotating grabbing mechanism is located at the center of the feeding mechanism, the wire twisting mechanism and the multi-pulley wire and terminal riveting mechanism. The external surface of the substrate is provided with a controller, and the controller is electrically connected with the feeding mechanism, the wire twisting mechanism, the multi-pulley wire and terminal riveting mechanism and the rotating grabbing mechanism. The beneficial effects of the invention are that the assembly line is simple in structure, and is high in practicality.

Owner:HAIMEN THE YUECAI TEXTILE TECH CO LTD

Reinforcing structure and method for concrete construction with local damage

InactiveCN104100101AGood tensile propertiesReduce tensile stressBarrages/weirsBuilding repairsSurface finishingComposite structure

The invention discloses a reinforcing structure and method for concrete construction with local damage. The reinforcing method includes the following steps of 1), subjecting a to-be-repaired part to surface treatment; 2), filling holes with mortar and plugging cracks; 3), fixing a fiber-woven net on a damaged area with a fixing and connecting piece; 4), spraying the polymer concrete mortar to the design thickness; 5), forming a fiber-woven net and mortar composited structure. Therefore, the advantages of two materials can be given to full play by utilizing the fiber-woven net and the polymer concrete mortar in combination, and bearing capacity and durability of the damaged concrete construction can be remarkably enhanced.

Owner:浙江固邦新材料有限公司 +1

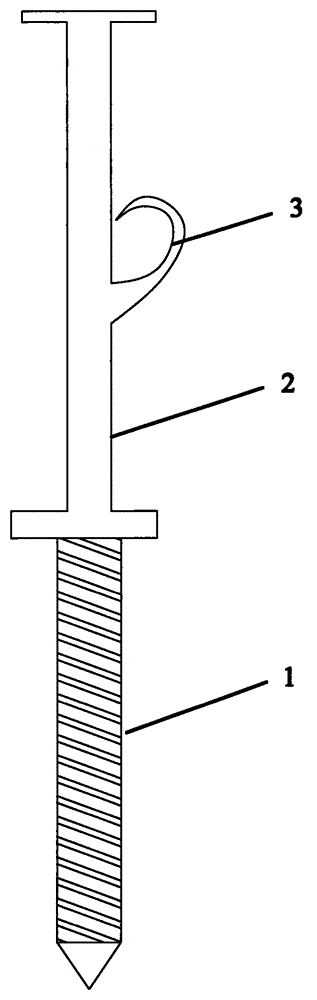

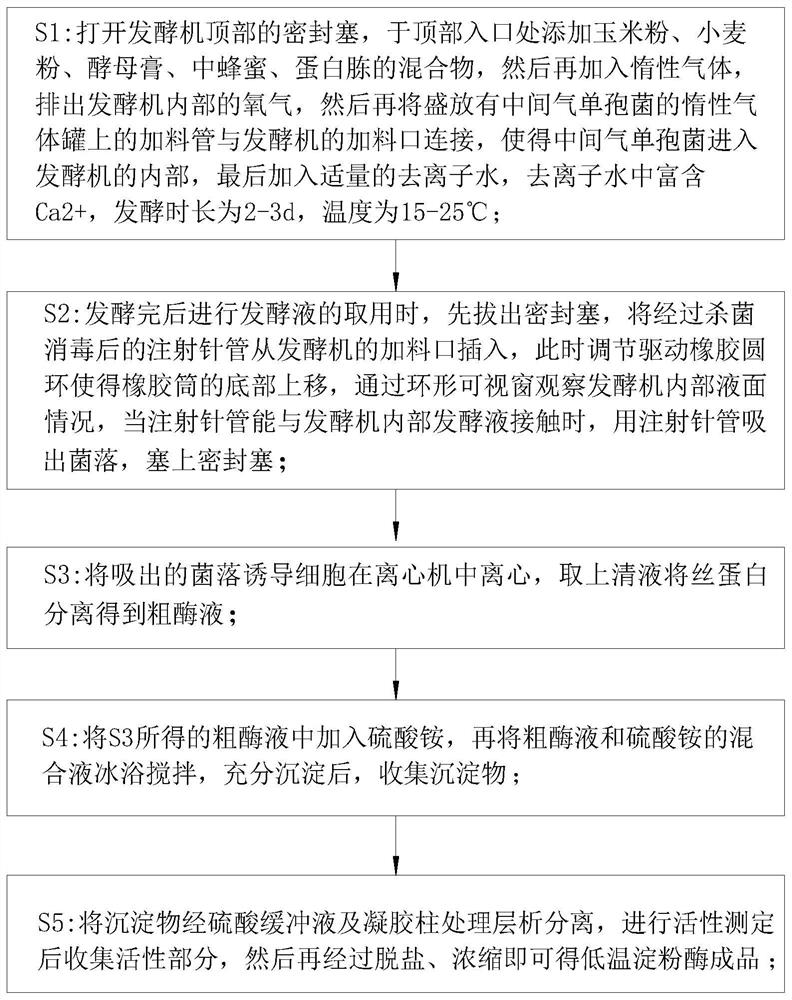

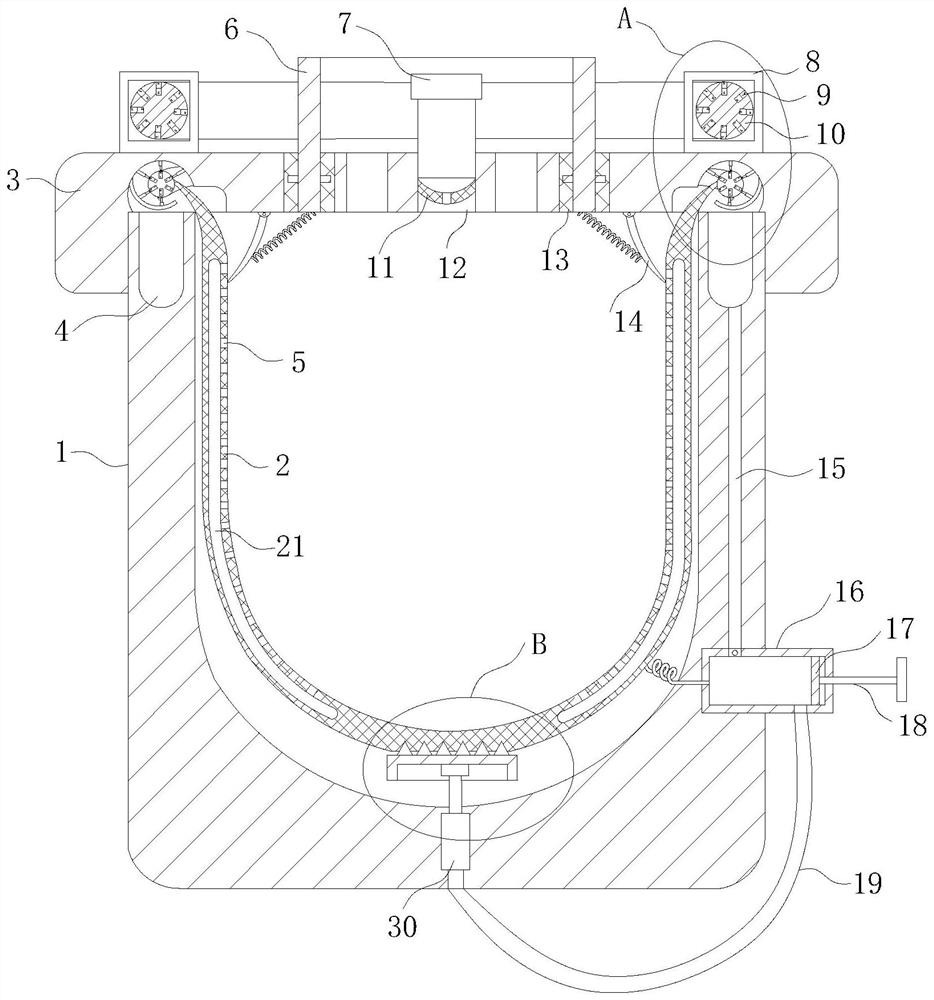

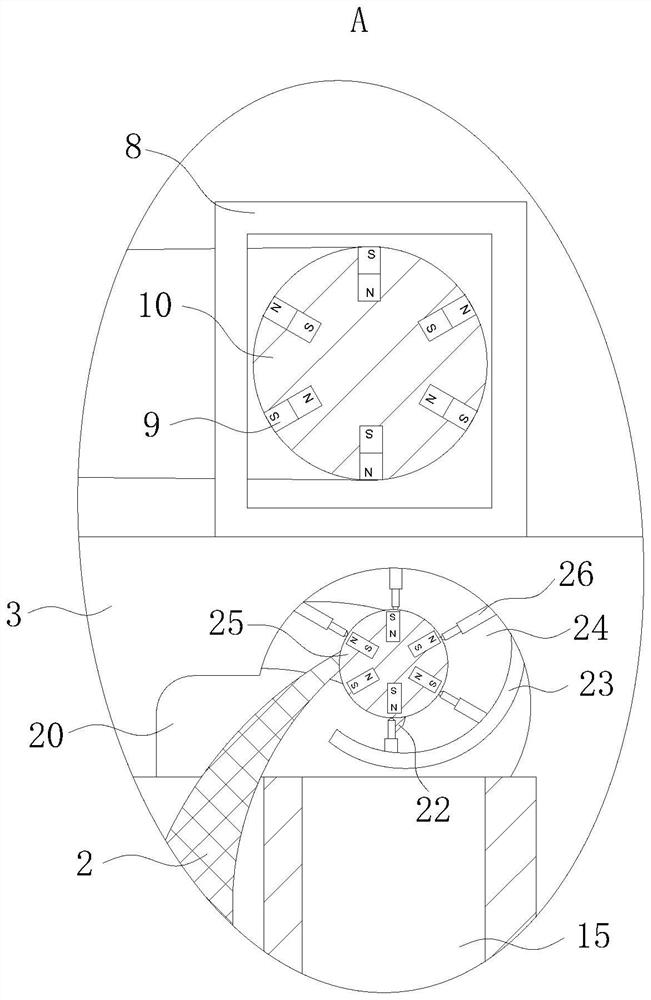

Low-temperature amylase strain and production method of low-temperature amylase

InactiveCN111647580AControllable volumeSmall volumeBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyAmylase

The invention relates to the technical field of low-temperature amylase production methods, in particular to a low-temperature amylase strain and a production method of low-temperature amylase. The method comprise the following steps of S1, adding a mixture of corn flour, wheat flour, yeast extract, medium honey and peptone at a top inlet, then connecting a feeding pipe on an inert gas tank containing aeromonas media with a feeding port of a fermentation machine, enabling the aeromonas media to enter the fermentation machine, finally adding a proper amount of deionized water, and performing fermentation for 2-3 days at the temperature of 15-25 DEG C; and S2, when fermentation liquor is taken after fermentation, inserting an injection needle tube from the feeding port of the fermentation machine, at the moment, adjusting and driving a rubber circular ring to enable the bottom of a rubber cylinder to move upwards, and sucking out bacterial colonies by using the injection needle tube. According to the method, the contact opportunity of a solution in the rubber cylinder and air is greatly reduced, so that the fermentation liquor can be prevented from being polluted; and when the next batch of bacterial colonies are cultured, raw materials can be directly injected from the feeding port, so that continuous production can be realized.

Owner:合肥汇酷谷生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com