Swinging sliding rail type linear welding device for fuses conveyed through vibrating disk

A linear welding and insurance tube technology, applied in the field of assembly line, can solve the problems of increasing the production cost of the enterprise, unstable production quality, a lot of labor costs, etc., and achieve the effect of saving labor costs, stable product quality, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

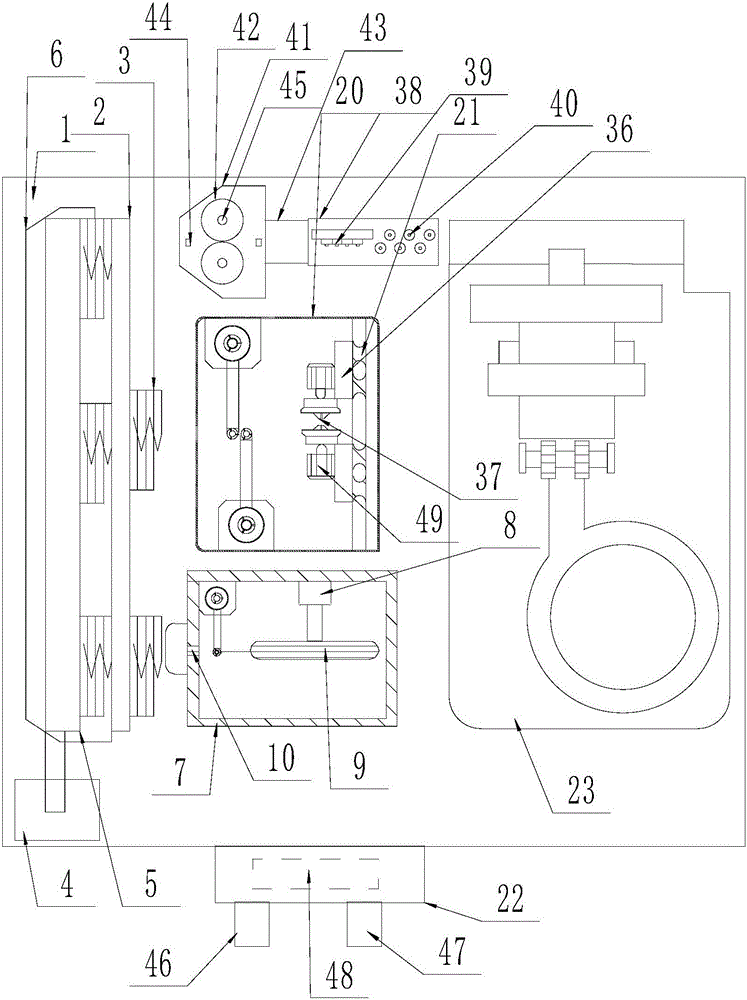

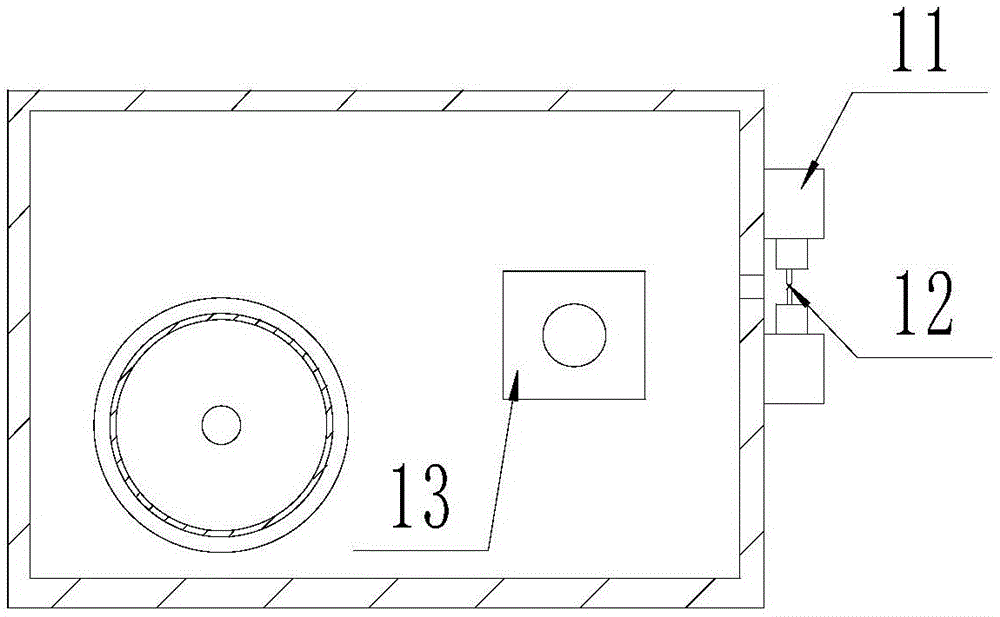

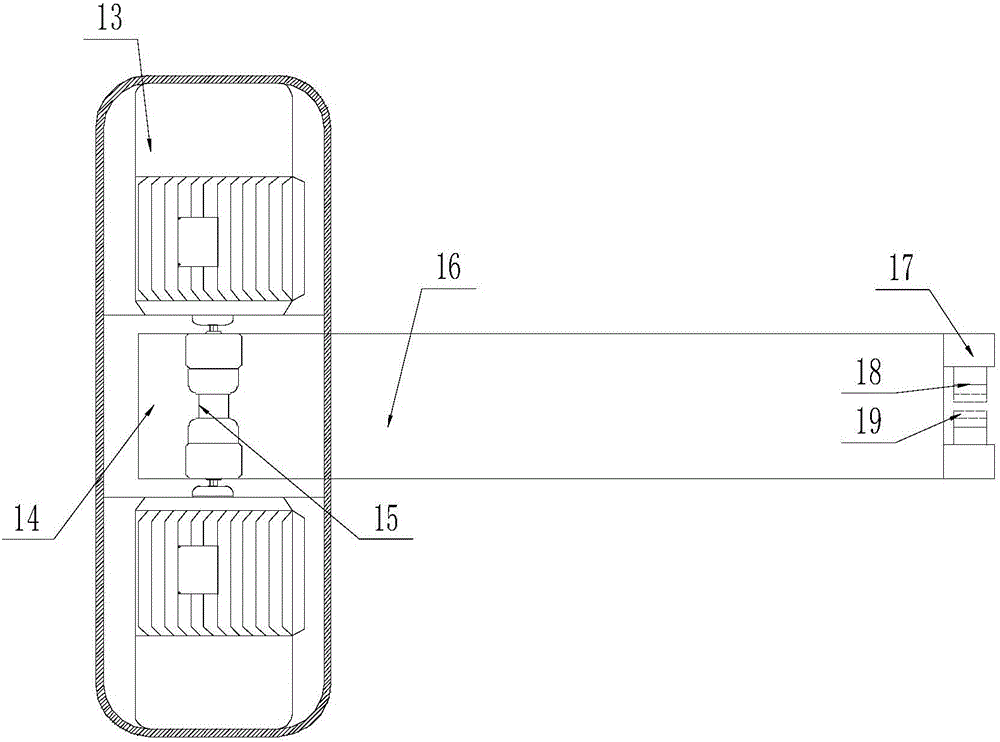

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4As shown, a vibrating plate feeds the safety tube swing slide rail type linear welding device, which includes a cuboid mobile base (1), and the upper surface of the mobile base (1) is provided with a swing clamping and feeding mechanism, a slide rail The wire twisting mechanism, the terminal punching mechanism, the X-axis double-layer displacement clamping mechanism, the welding mechanism and the vibrating plate feeding safety tube mechanism, the slide rail twisting mechanism is located between the swing clamping and feeding mechanism and the terminal punching mechanism. The X-axis double-layer displacement clamping mechanism is placed opposite to the swing clamping and feeding mechanism, the slide rail twisting mechanism, and the terminal striking mechanism. The welding mechanism is located behind the terminal striking mechanism. At the rear, the X-axis double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com