Novel electric wire trimming machine provided with sliding shifting fork

A technology for trimming machines and wires, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of increasing production costs, unstable production quality, and large labor costs, and save labor costs. , The effect of stable product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

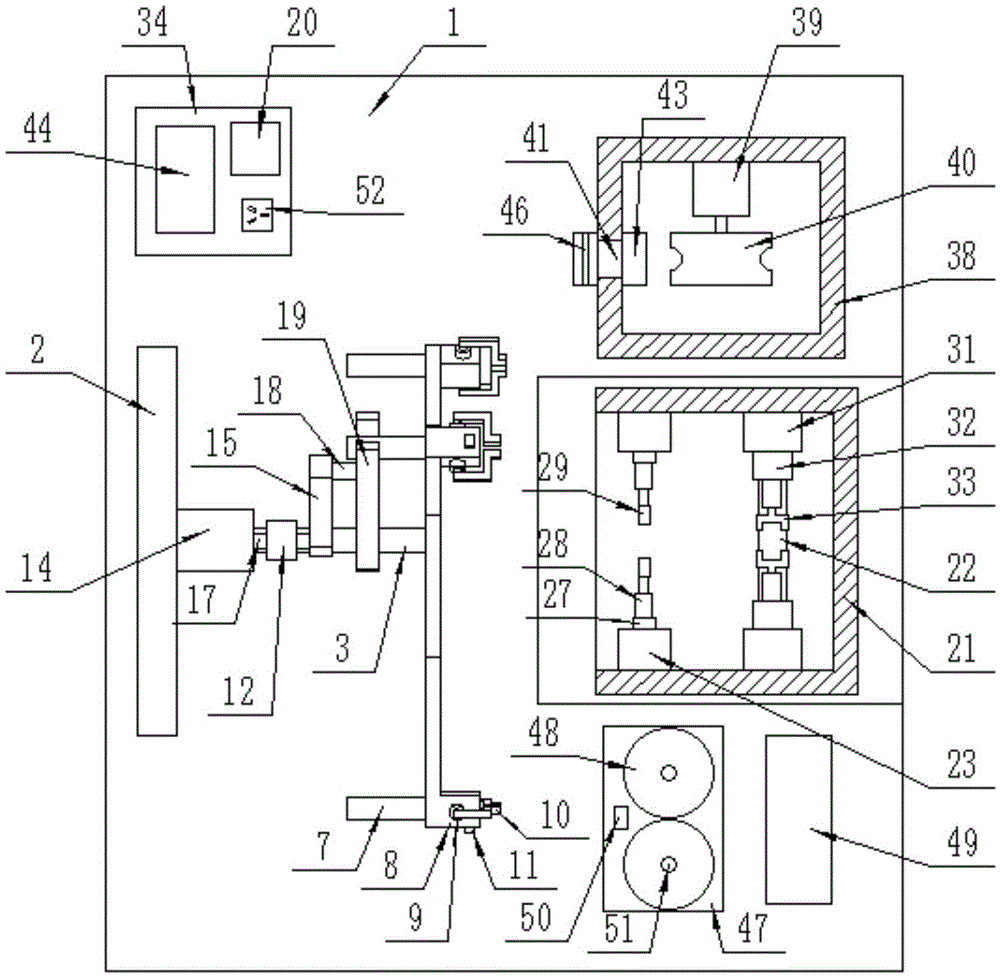

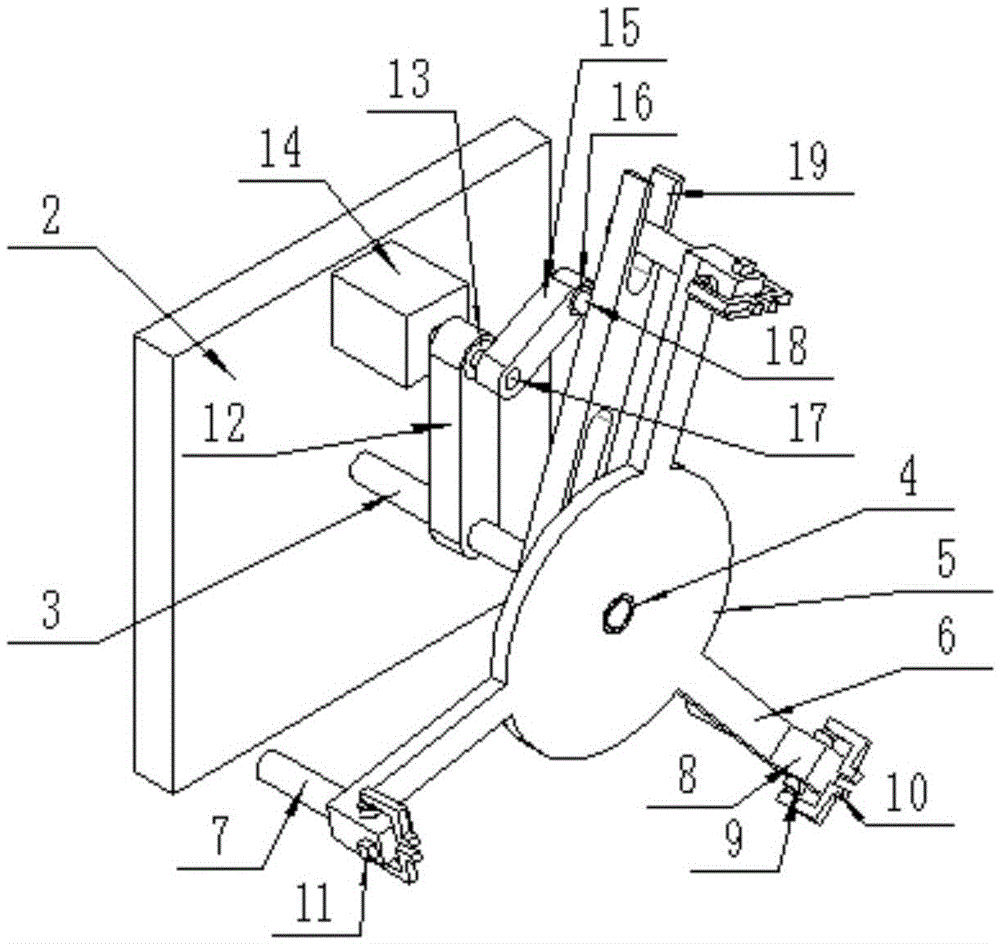

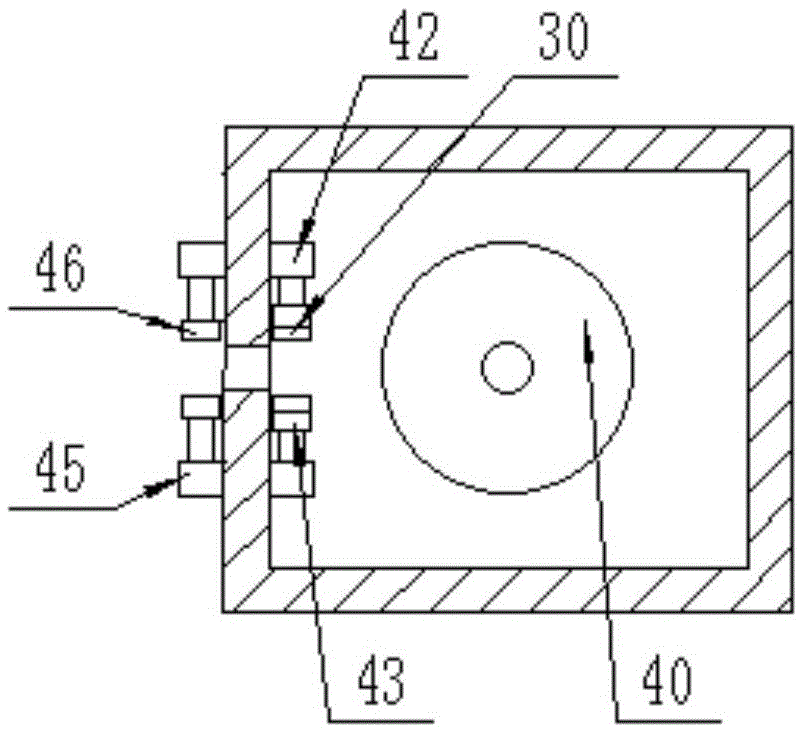

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a novel sliding fork wire trimming machine includes a cuboid mobile base (1), the four corners of the outer lower surface of the mobile base (1) are provided with a mobile mechanism, and the mobile base (1) The upper surface of the upper surface is provided with a feeding mechanism, a slide rail twisting mechanism, a terminal mechanism and a sliding fork rotation grabbing mechanism. The slide rail twisting mechanism is located between the feeding mechanism and the terminal mechanism, and the slide rail twisting mechanism The height of the mechanism is higher than that of the feeding mechanism and the terminal punching mechanism. The sliding fork rotating grabbing mechanism is placed opposite to the feeding mechanism, twisting wire mechanism, and terminal punching mechanism. The sliding shifting fork rotating grabbing mechanism is fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com