Roof photovoltaic power generation station structure and lap joint method thereof

A photovoltaic power station and roof panel technology, applied in photovoltaic power generation, photovoltaic module support structure, roof and other directions, can solve the problems of poor sealing, insufficient corrosion resistance and high maintenance cost of roof photovoltaic power station, so as to reduce the construction cost and The effect of maintenance cost, weight reduction and high roof strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

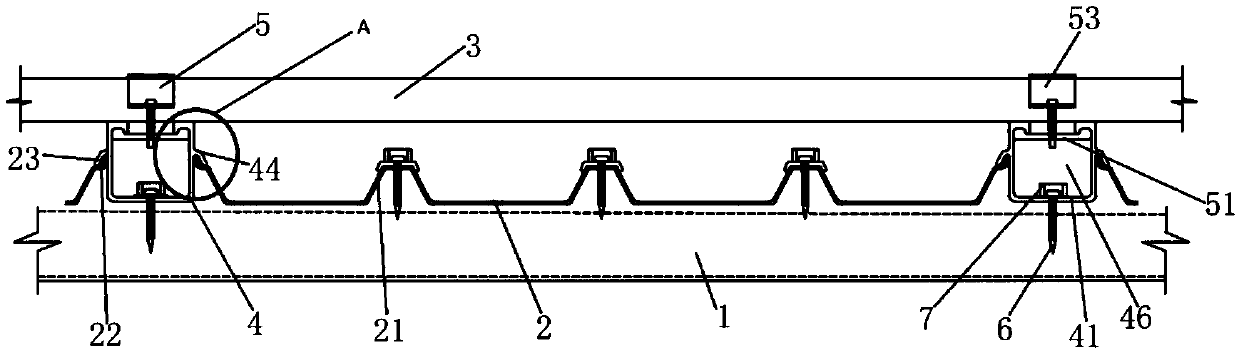

[0047] This embodiment provides a roof photovoltaic power station structure, such as figure 1 , figure 2 As shown, the roof photovoltaic power station structure includes a purlin 1 , a roof panel 2 , a photovoltaic panel 3 , a positioning mechanism 4 and a locking mechanism 5 .

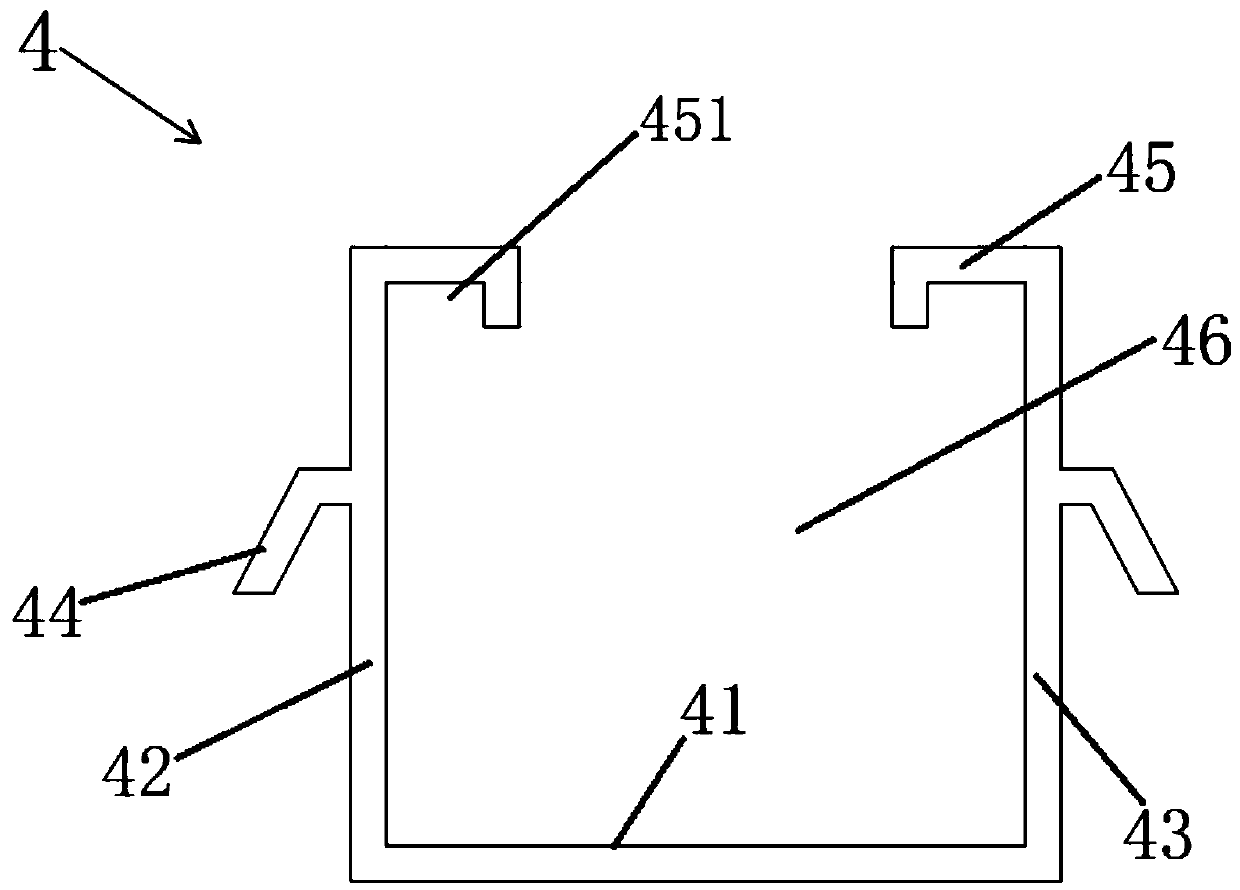

[0048] like image 3 As shown, the positioning mechanism 4 includes a bottom plate 41 , a left side plate 42 , a right side plate 43 , a flange 44 and a flange 45 . The left side plate 42 and the right side plate 43 are vertically arranged on the top surface of the bottom plate 41 to form a through groove 46, the flange 44 is arranged on the outer wall of the left side plate 42 and the right side plate 43, and the flange 45 is arranged on the left side plate 42 and the inner wall of the right side panel 43, the flange 44 is clamped and fixed with the edge of the roof panel 2, and the bottom panel 41 is fixed on the purlin 1.

[0049] In this embodiment, the flange 44 is arranged on the middle part...

Embodiment 2

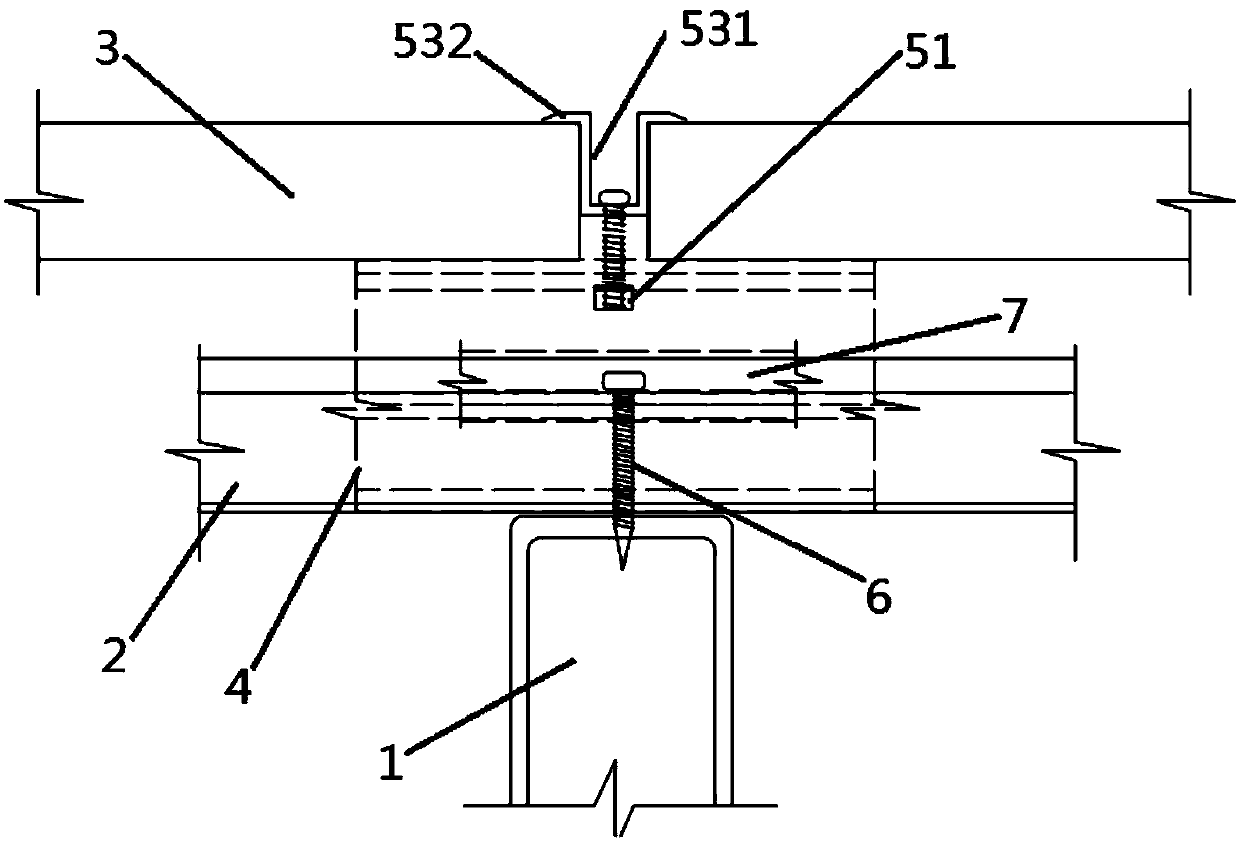

[0056] like figure 1 , figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. The structure of the roof photovoltaic power station provided by this embodiment also includes self-tapping screws 6 and waterproof fasteners 7, and a through hole is provided on the surface of the bottom plate 41 through its thickness. The tapping screw 6 passes through the through hole to fix the bottom plate 41 on the purlin 1, and the waterproof fastener 7 is covered on the nail cap of the self-tapping screw 6 to protect the self-tapping screw 6 and prevent rainwater from corroding the self-tapping screw 6. The fastening combination of the bottom plate 41 and the purlin 1 .

Embodiment 3

[0058] like figure 1 , figure 2 , Image 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. In the roof photovoltaic power station structure provided by this embodiment, the roof panel 2 includes corrugated 21, water-stop ribs 22 and sealing rubber strips 23, and the corrugated 21 is along the roof panel 2. The width direction is arranged at intervals, and the water-stop ribs 22 are arranged at the ends of the roof panel 2 in the length direction. The water-stop ribs 22 extend upwards and outwards. 23 is arranged on the upper surface of the water-stop rib 22 and is crimped and fixed by the flange 44 .

[0059] In this embodiment, the total width of the roof panel 2 is 835 mm, the thickness of the board is 2.5 mm, there are five corrugated 21, the height of the corrugated 21 is 35 mm, and the interval between each corrugated 21 is 195 mm.

[0060] In this embodiment, the rigidity of the roof panel 2 is enhanced by arranging the corru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com