Low-temperature amylase strain and production method of low-temperature amylase

A technology of low-temperature amylase and production method, which is applied in the production field of low-temperature amylase strains and low-temperature amylase, can solve the problems of large contact area between raw materials and air, inability to continuously culture colonies in a fermentation box, and easy contamination of raw materials, etc. The effect of saving culture time, realizing continuous production and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

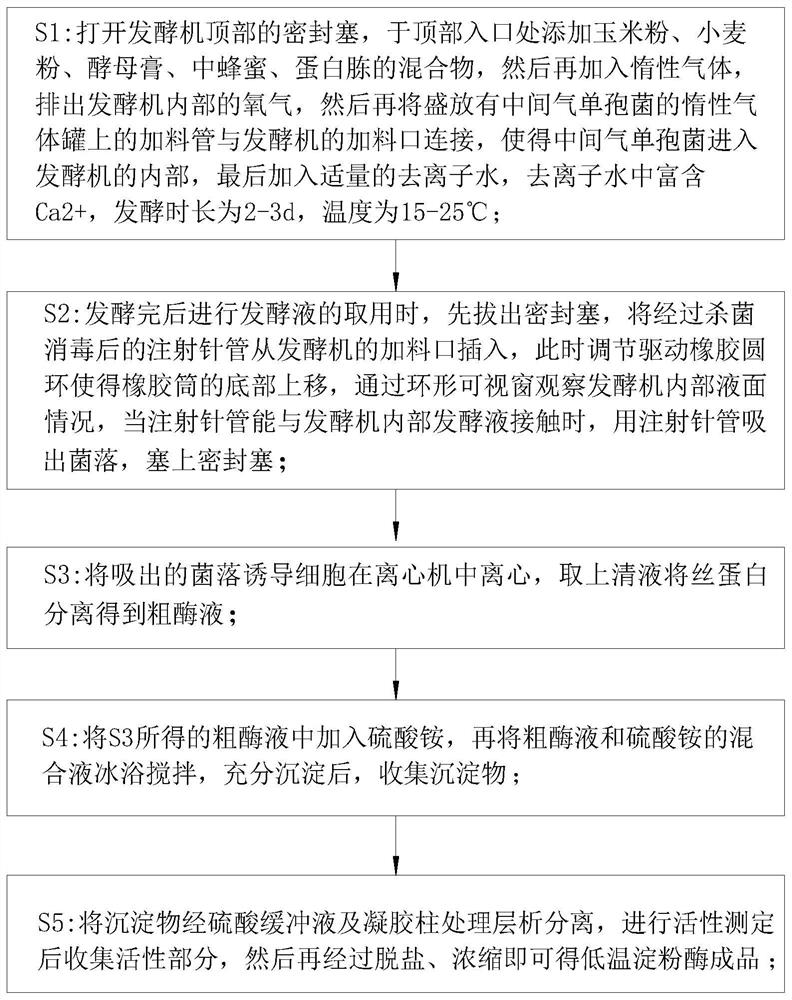

Method used

Image

Examples

Embodiment approach

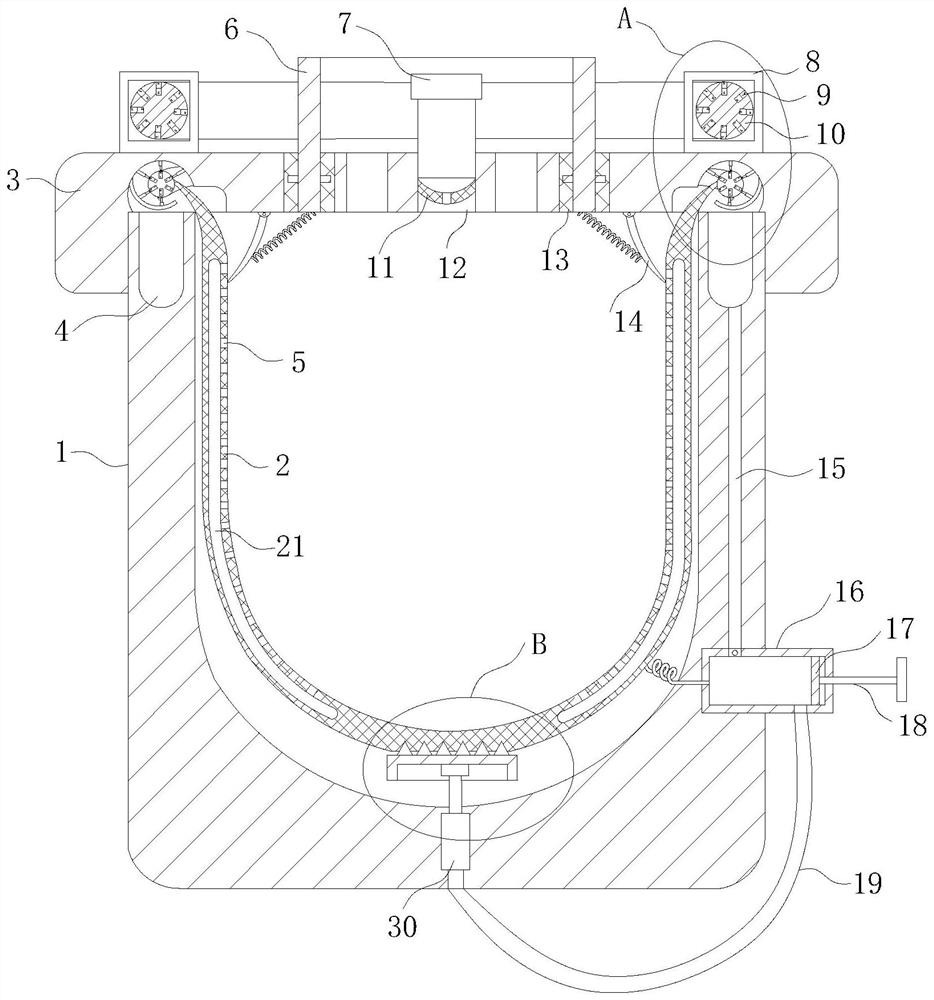

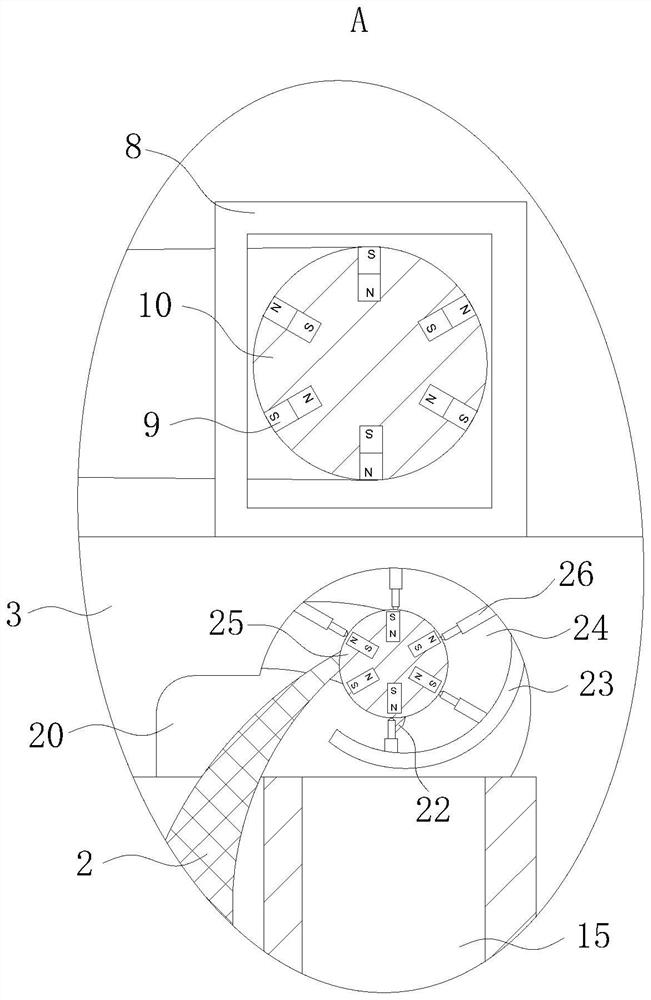

[0038] As an embodiment of the present invention, an annular through groove 13 is provided on the sealing cover 3 between the annular visible window and the second annular groove 20; an annular plate 6 is inserted inside the annular through groove 13; The inner wall of the annular channel 13 is bonded with an annular rubber pad; the annular protrusion provided on the annular plate 6 is located in the annular slide rail on the inner wall of the annular rubber pad; the top end of the annular plate 6 stretches out of the annular channel 13; the bottom end of the annular plate 6 is fixedly connected with the inner side wall of the sector scraper 14 through a compression spring; the compression spring presses the sector scraper 14 against the inner wall of the rubber cylinder 2; the sector scraper 14 is provided with several groups, and several groups of fan-shaped scrapers 14 are fixedly connected by rubber scrapers 33; the top of the fan-shaped scrapers 14 is hinged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com