Patents

Literature

396results about How to "Position is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

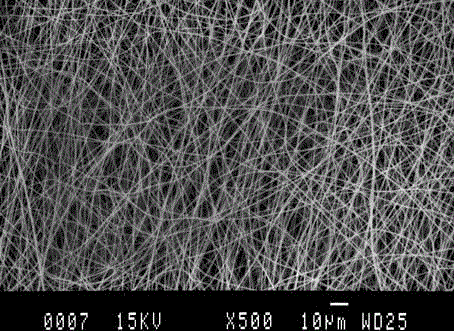

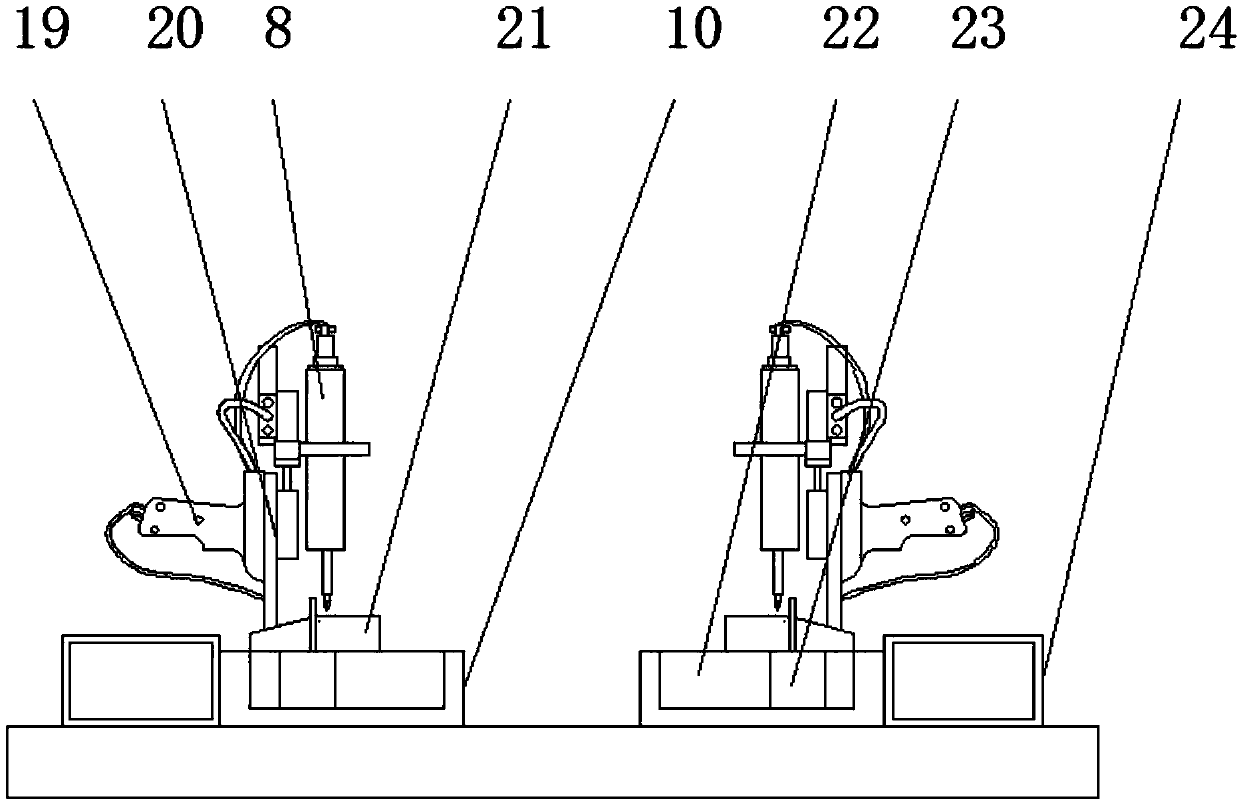

Cell-biological scaffold complex and 3D printing forming method thereof

ActiveCN104888277AAvoid immune rejectionContour controllableAdditive manufacturing apparatusProsthesisBiomedical engineeringNanofiber

The invention provides a cell-biological scaffold complex and a 3D printing forming method thereof. The cell biological scaffold complex comprises a biological scaffold with an actual deficit condition similar to the tissues and organs of patients, a nanometer fiber layer printed on the biological scaffold, capable of simulating natural extracellular matrixes, and beneficial for the adhesion, reproduction and growth of cells, and cell suspension printed on the nanometer fiber layer. According to the actual deficit condition of the tissues and organs of patients, the cell-biological scaffold complex needed by patients can be precisely printed by adopting the bioprinting forming method.

Owner:深圳尤尼智康医疗科技有限公司

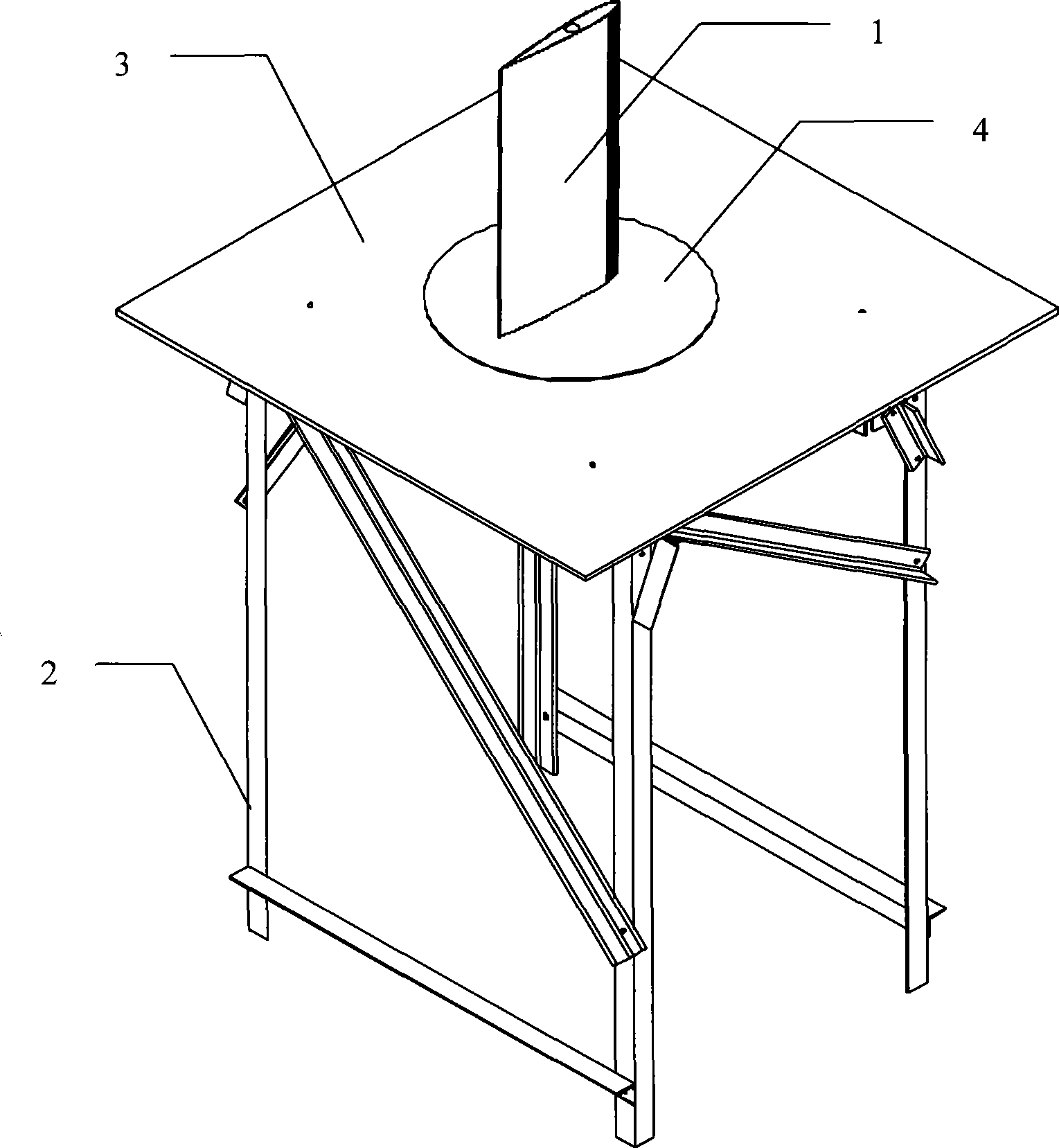

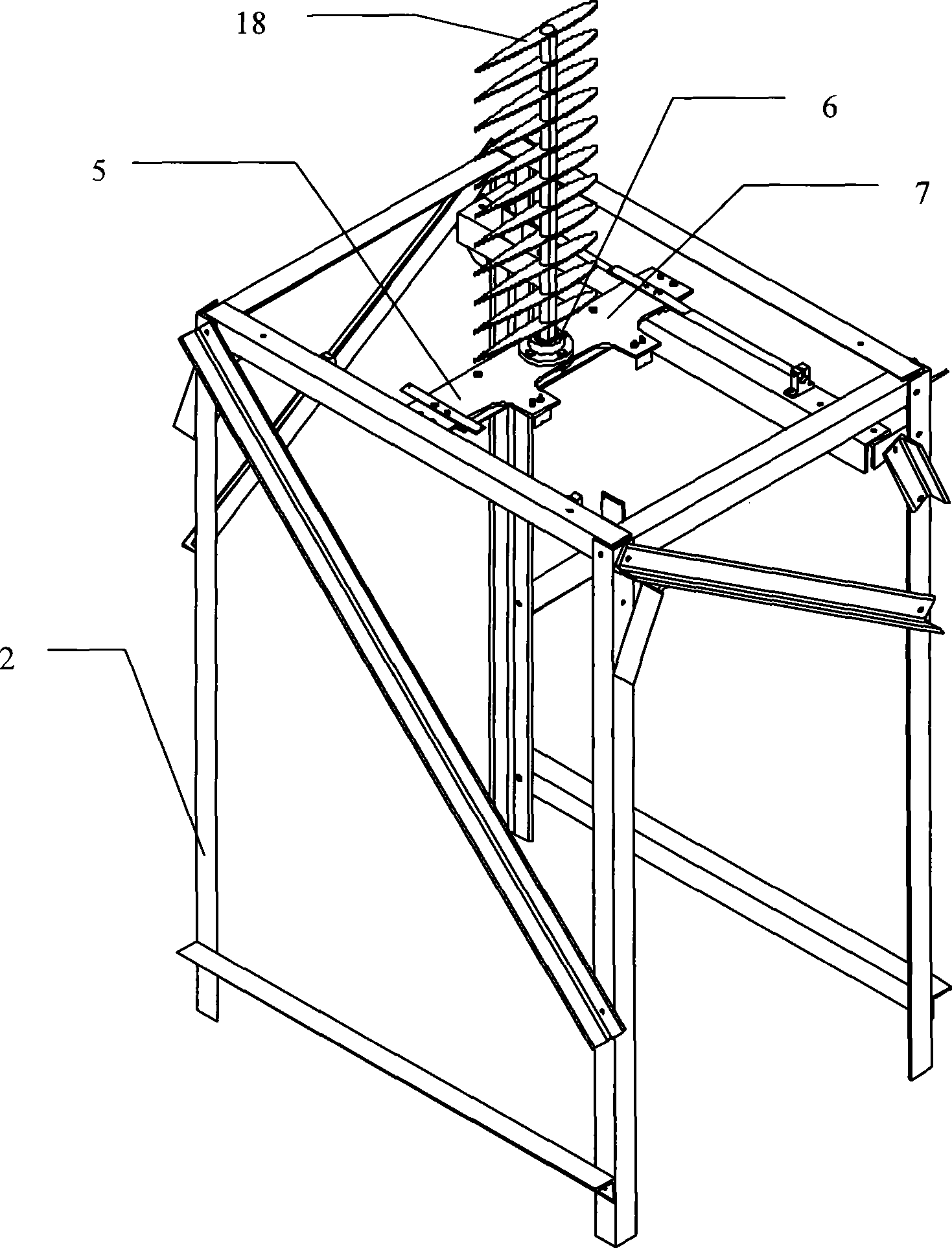

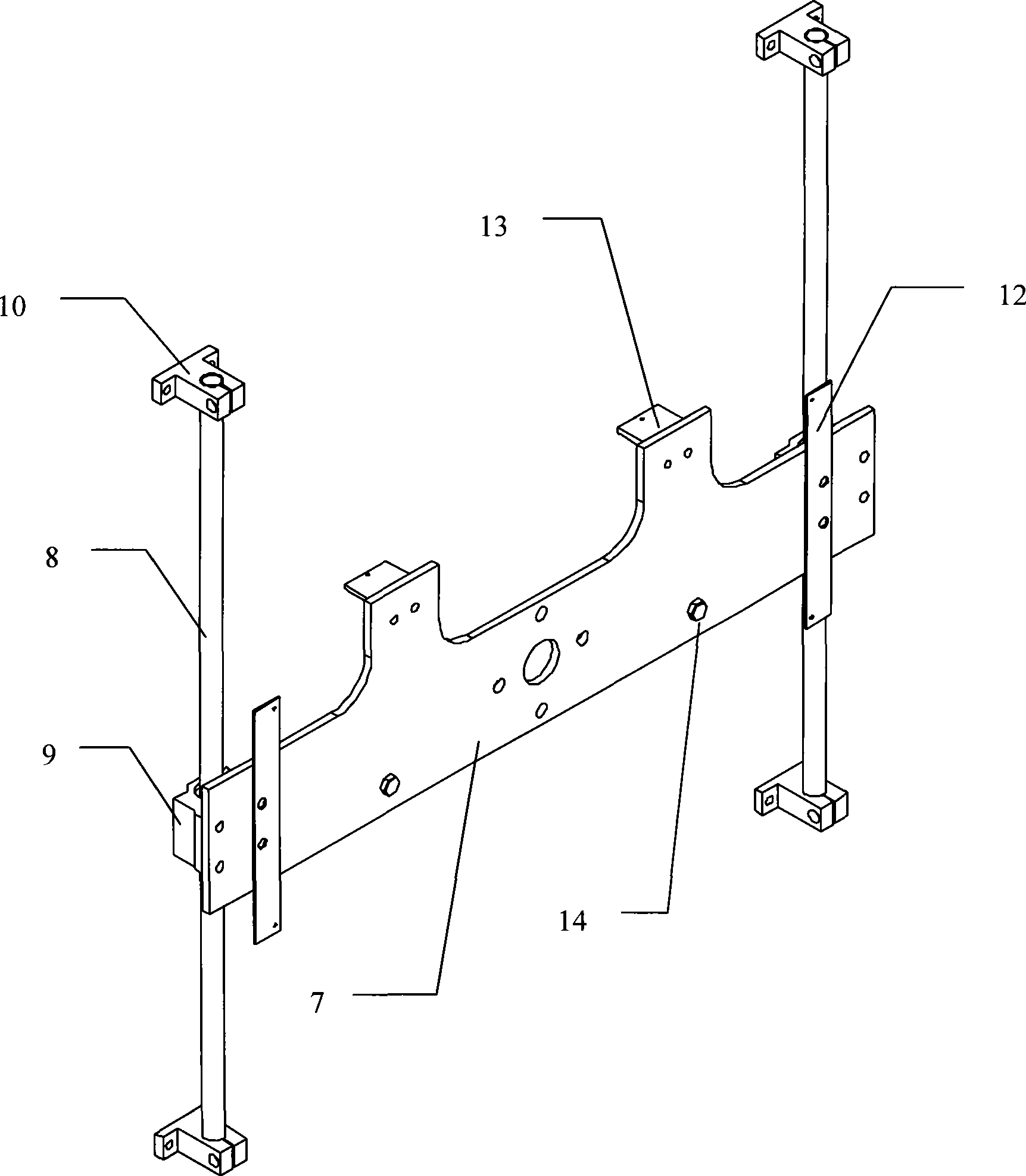

Aeroelastic flutter generating device

InactiveCN101419117ALow wind speed requirementClear presentationAerodynamic testingTorsional rigidityAerospace engineering

The invention provides an aeroelastic flutter generator, which comprises a wing panel, a platform, a translation return mechanism which is coupled between the platform and the wing panel, and a torsion return mechanism which is coupled between the platform and the wing panel. The aeroelastic flutter generator can make the aeroelastic phenomenon easy to be observed by naked eyes and make the sinkage rigidity and the torsional rigidity adjustable, and has limitation protection.

Owner:BEIHANG UNIV

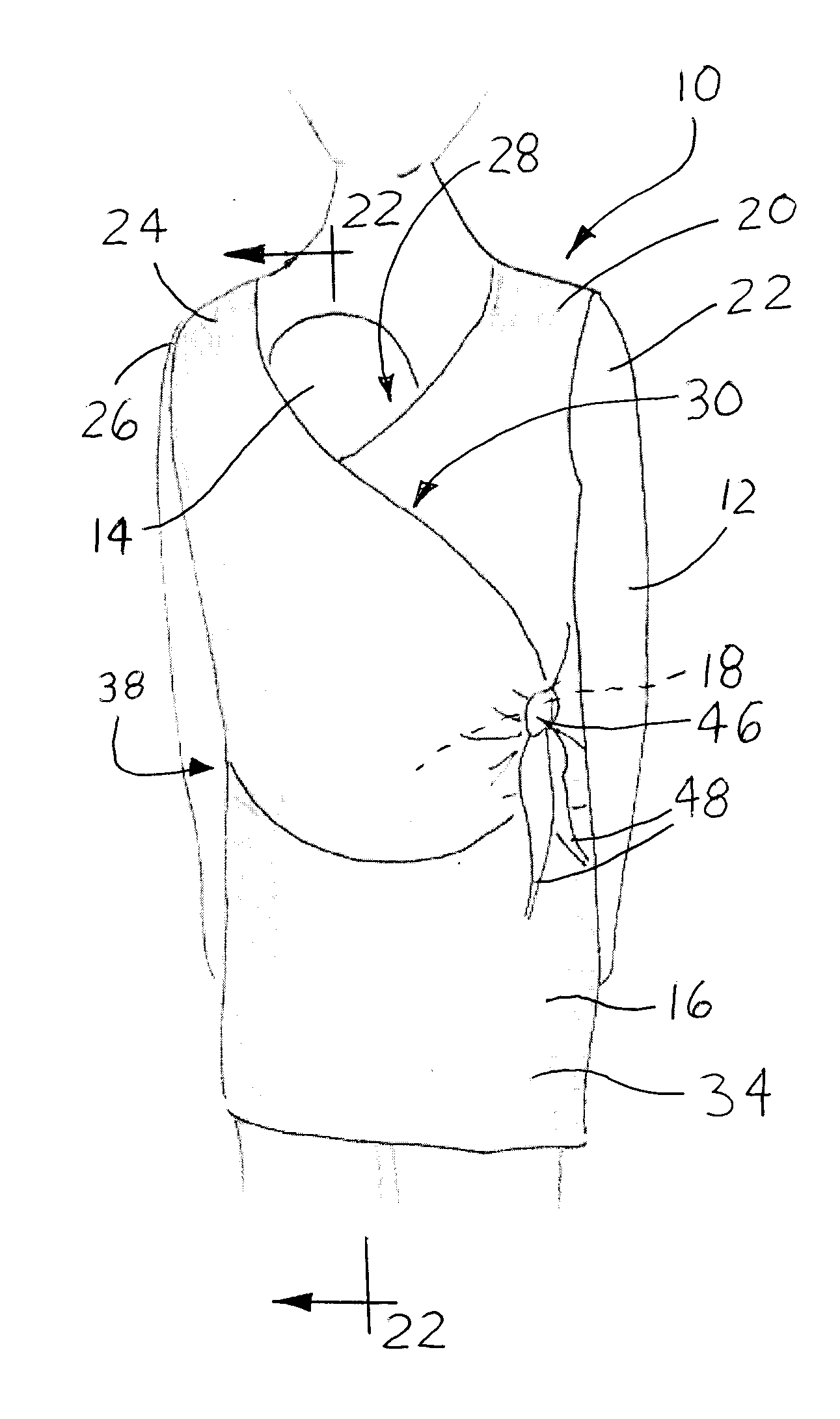

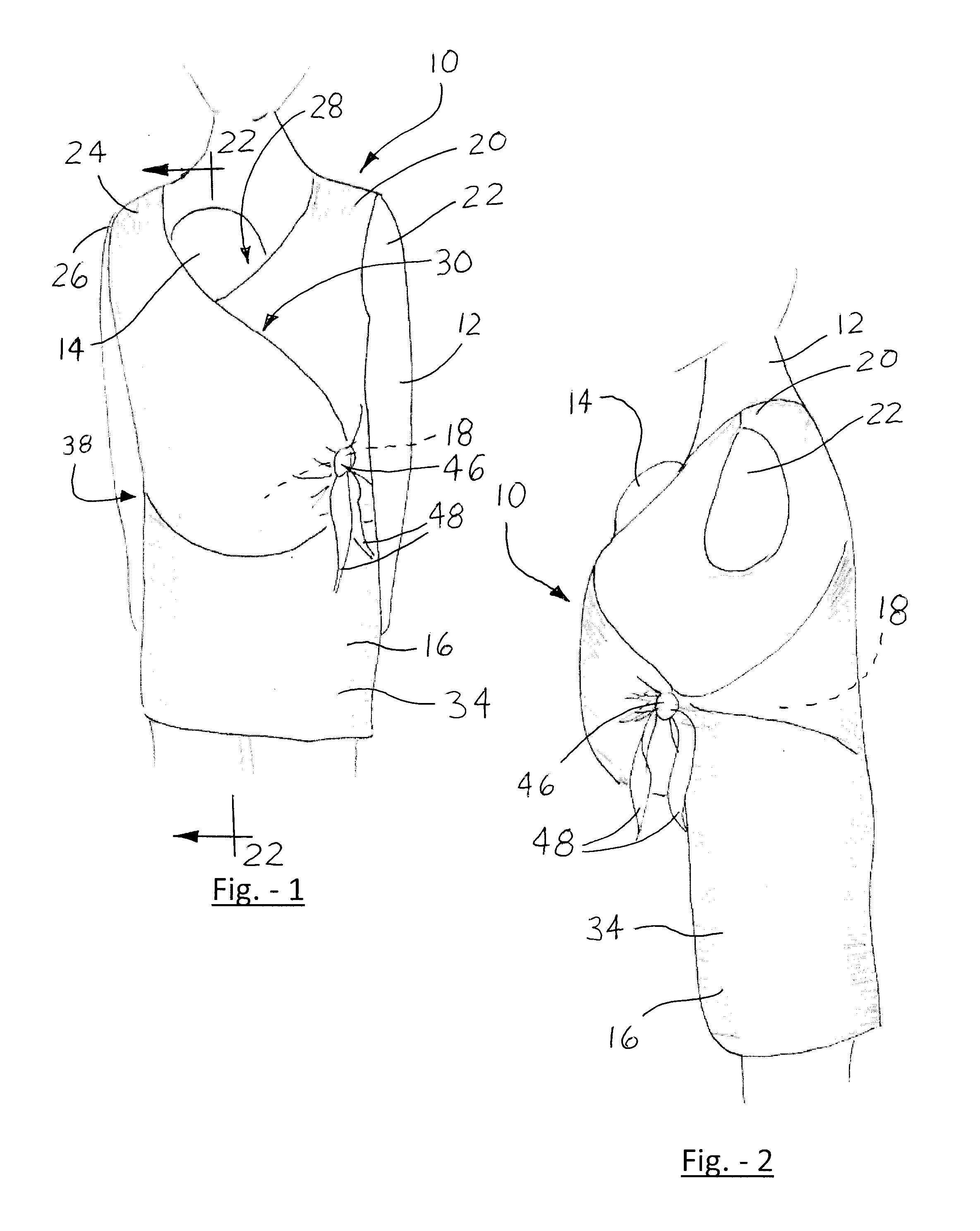

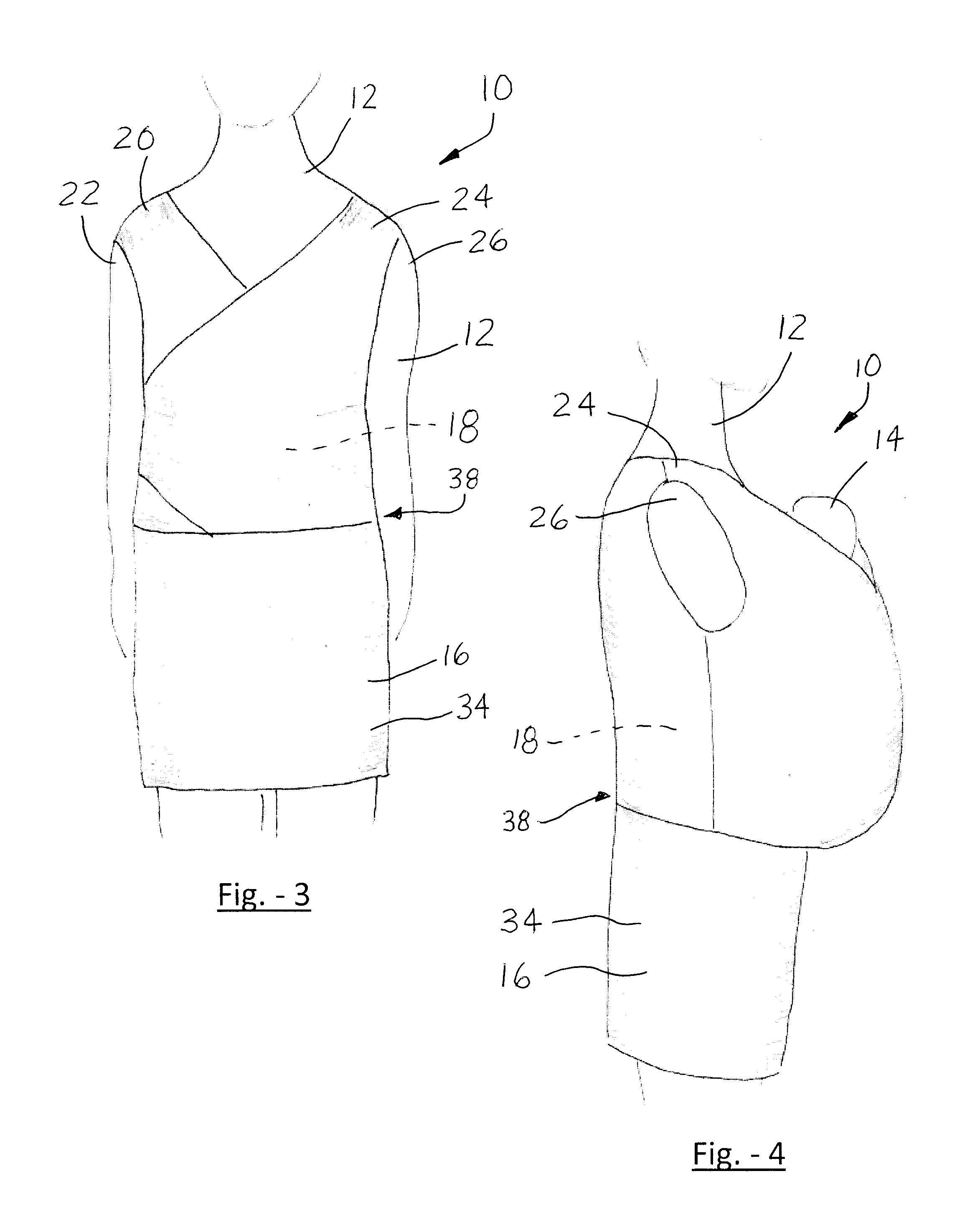

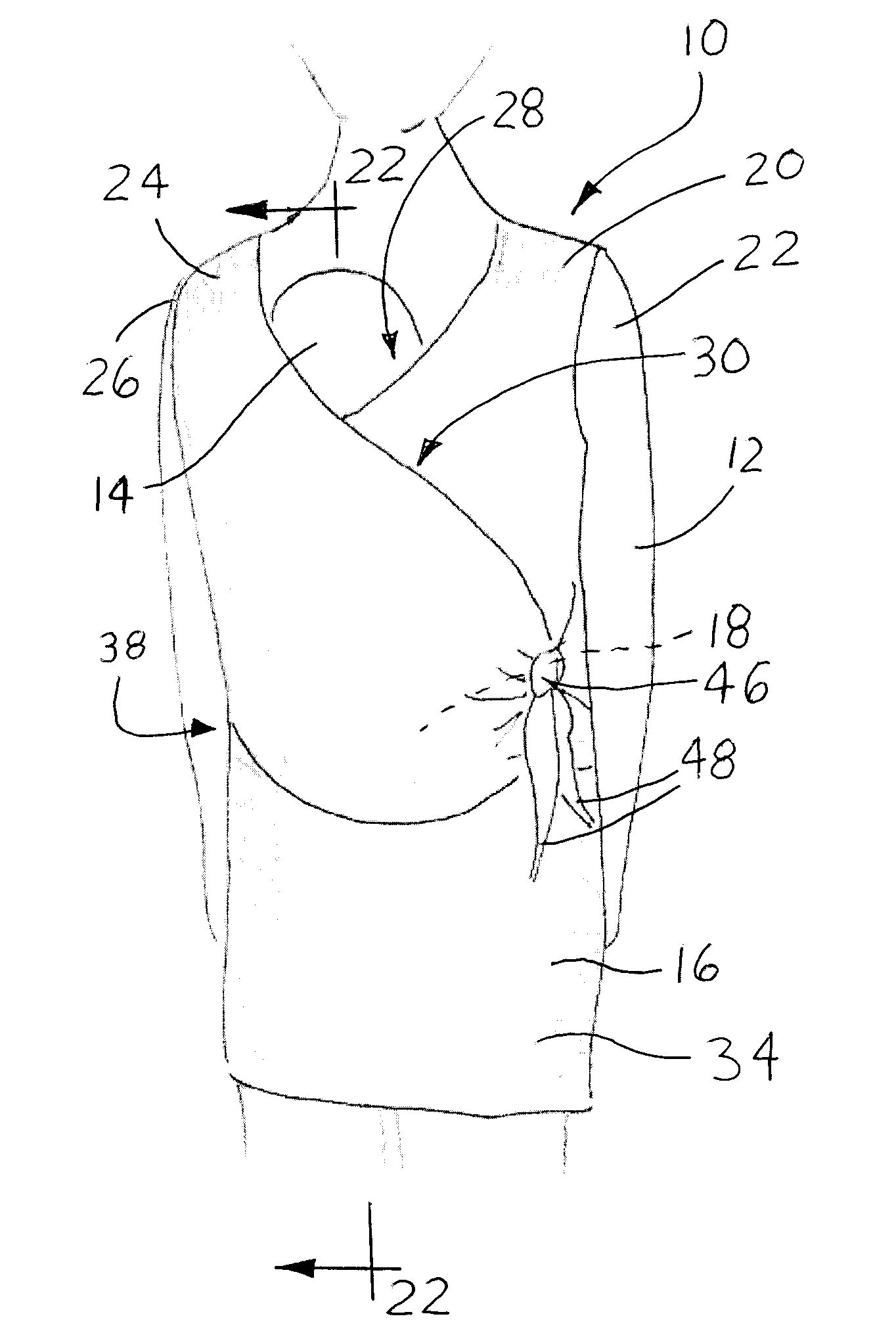

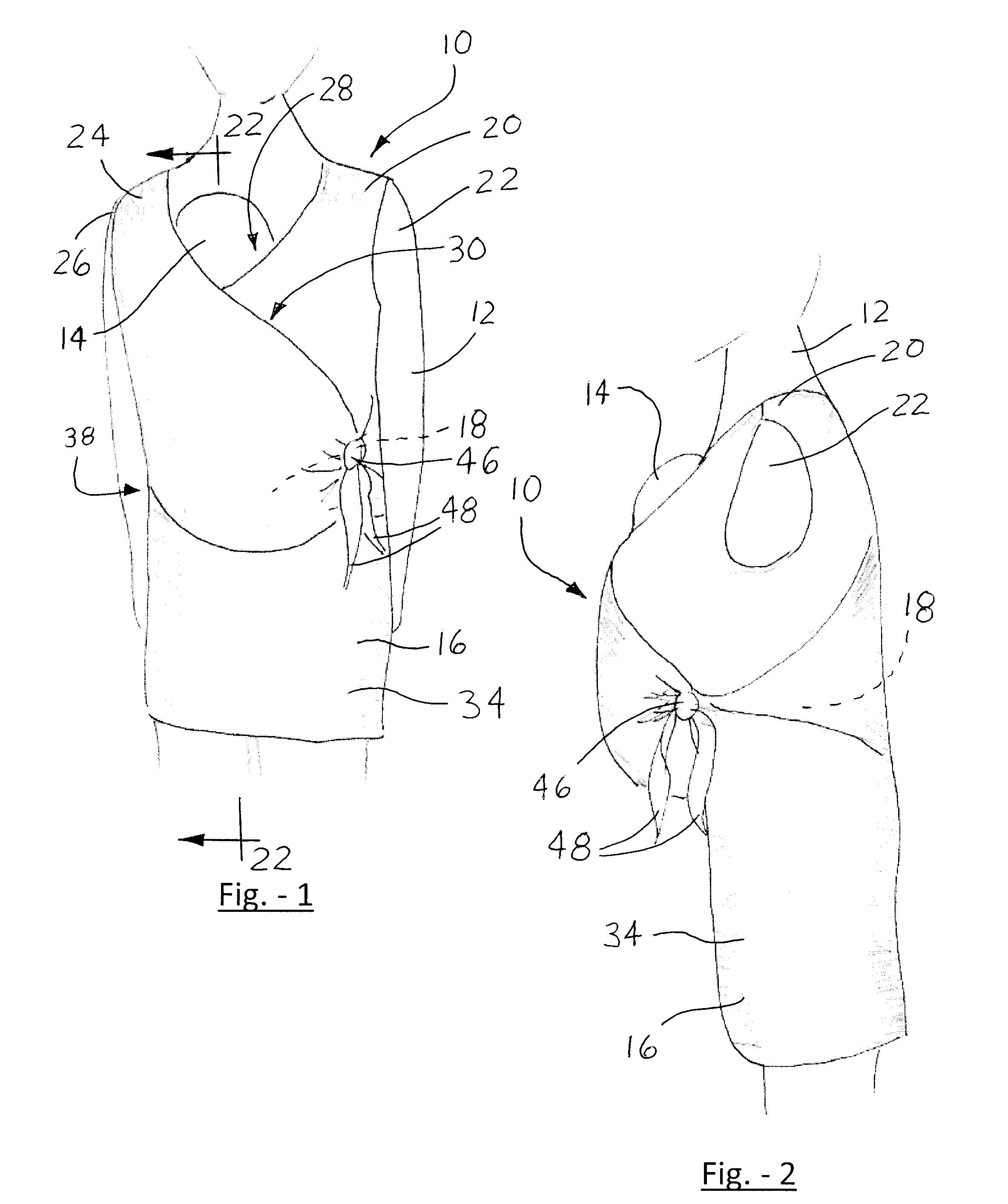

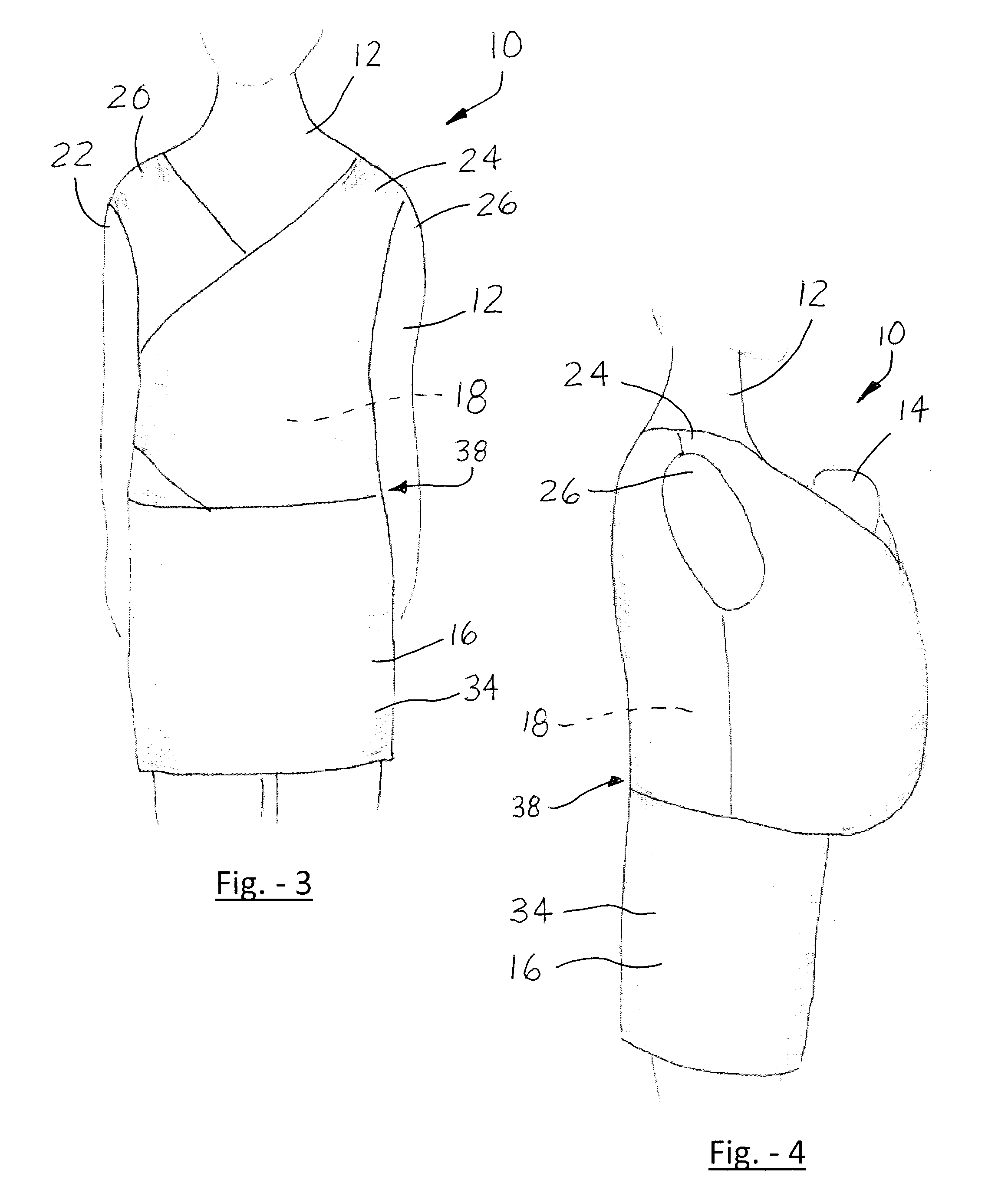

Infant Support Garment

InactiveUS20130200116A1Minimize stressPosition can be controlledStretcherWheelchairs/patient conveyanceEngineering

Owner:ARVAN JULIE

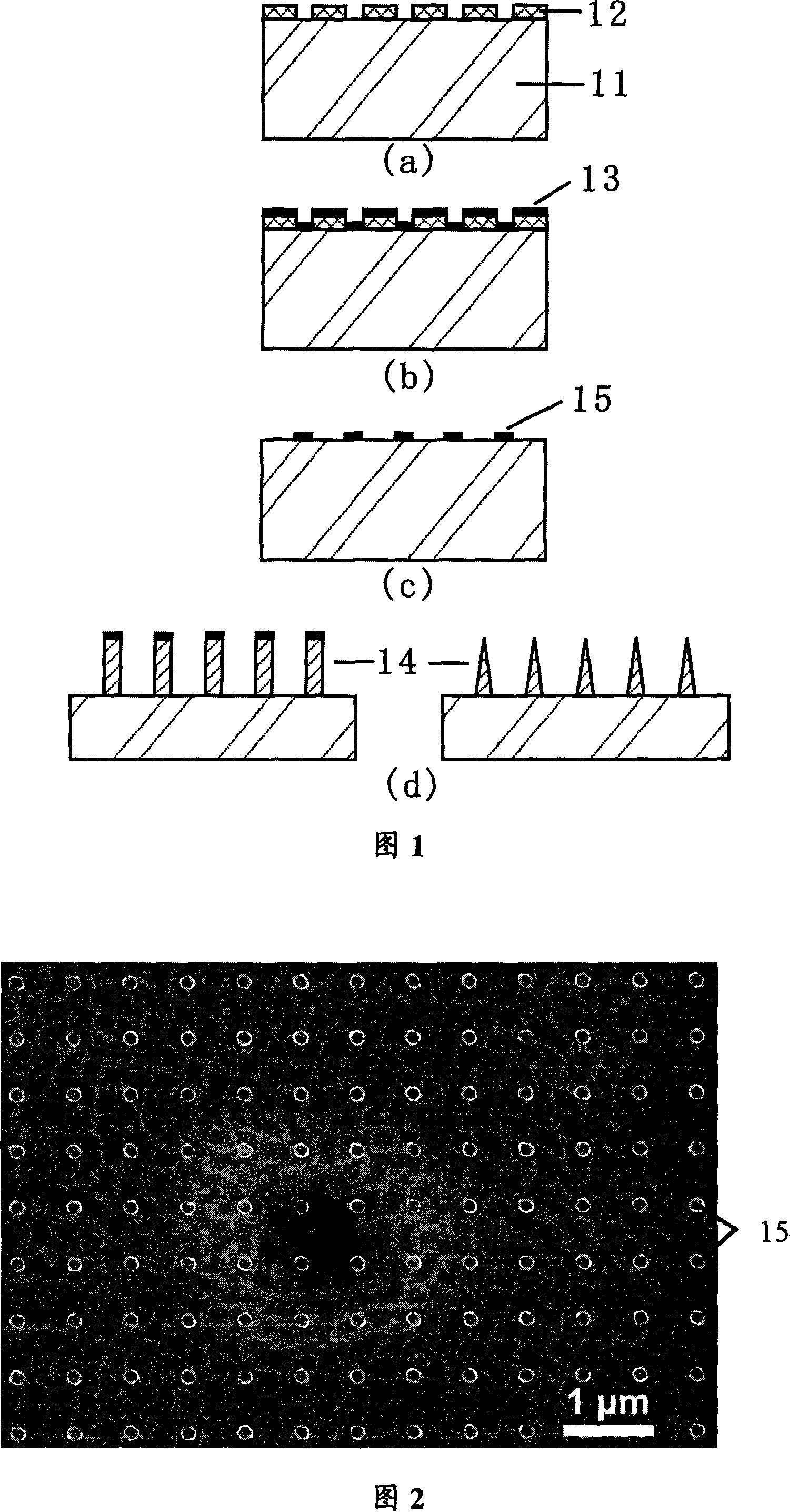

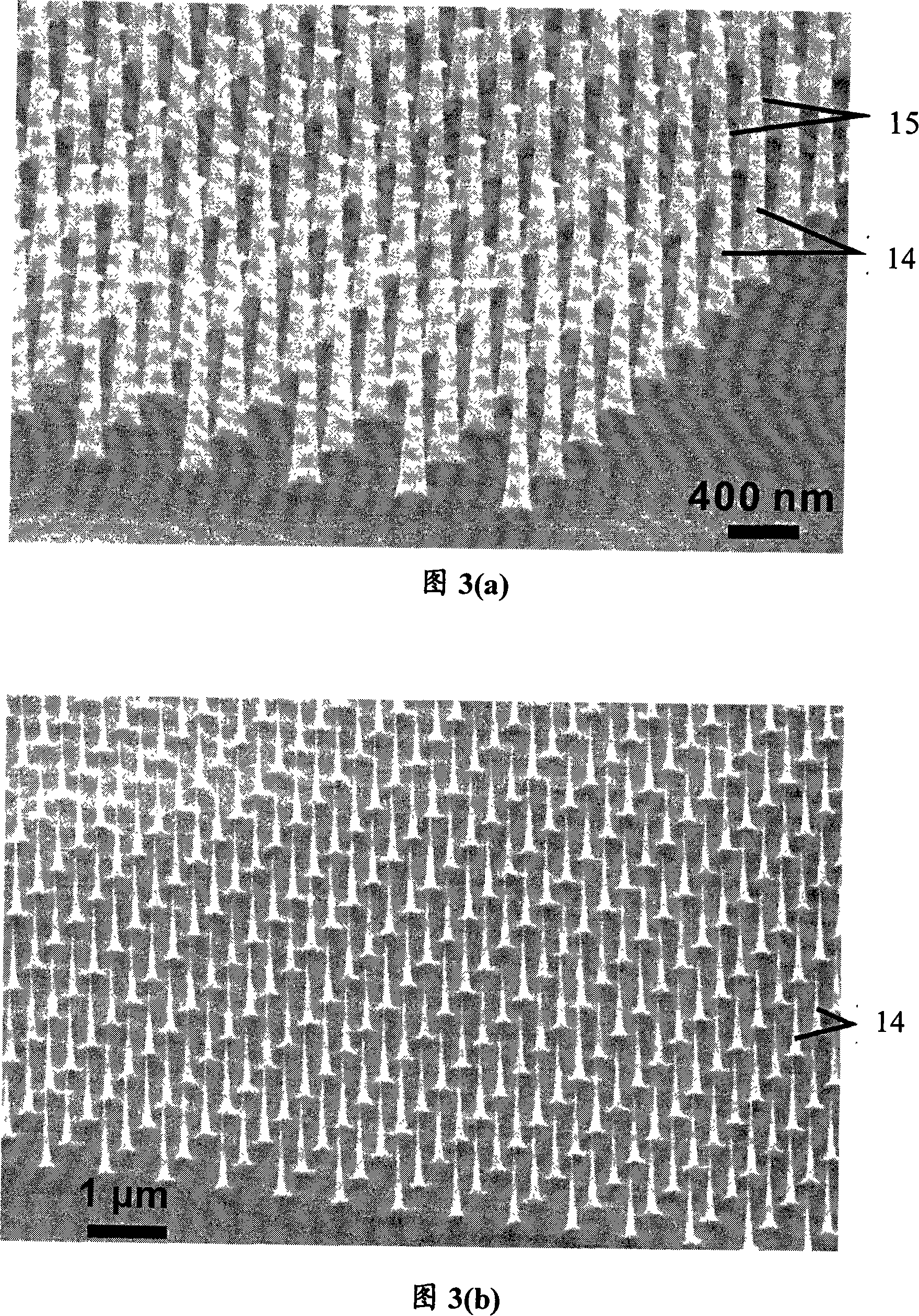

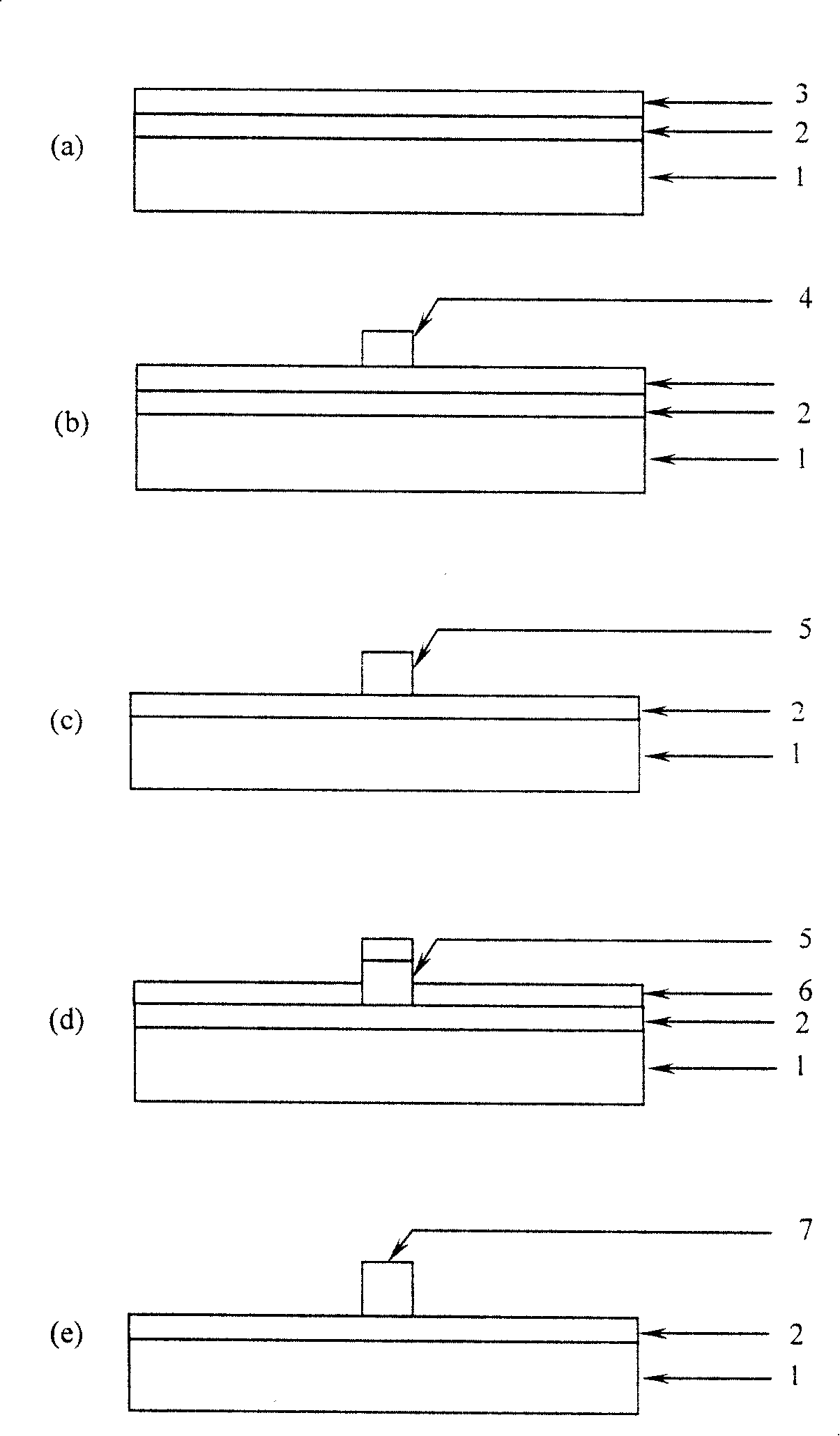

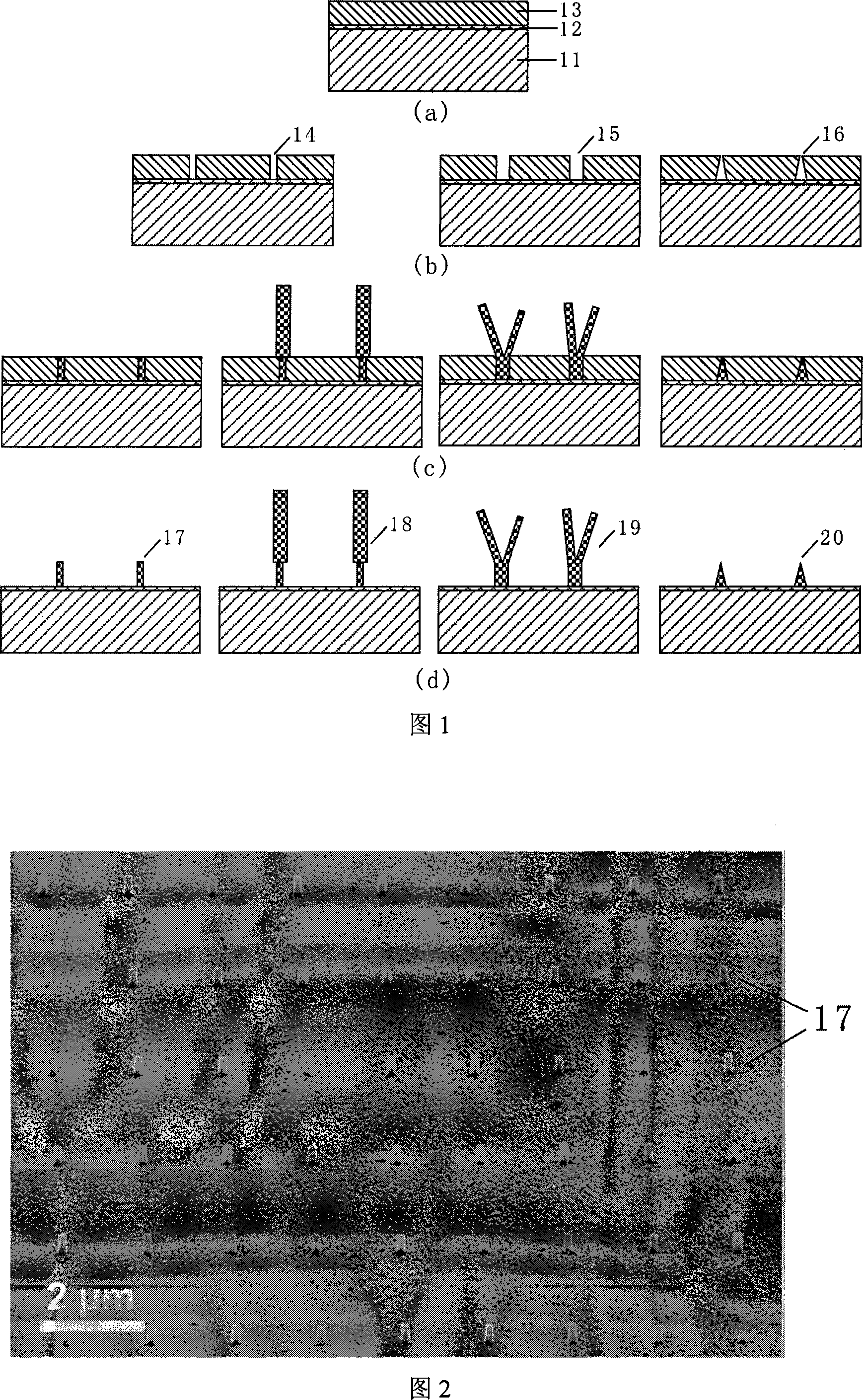

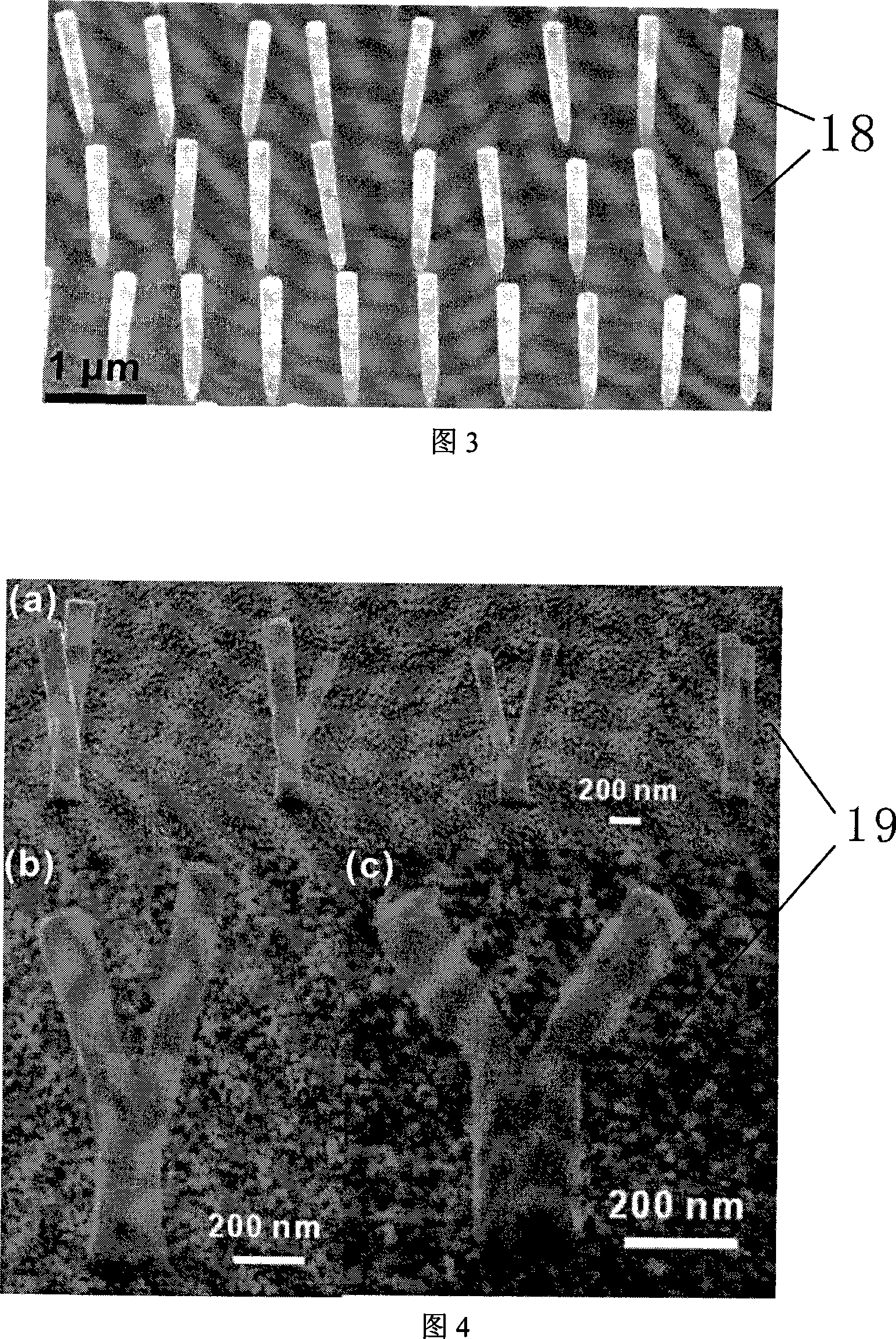

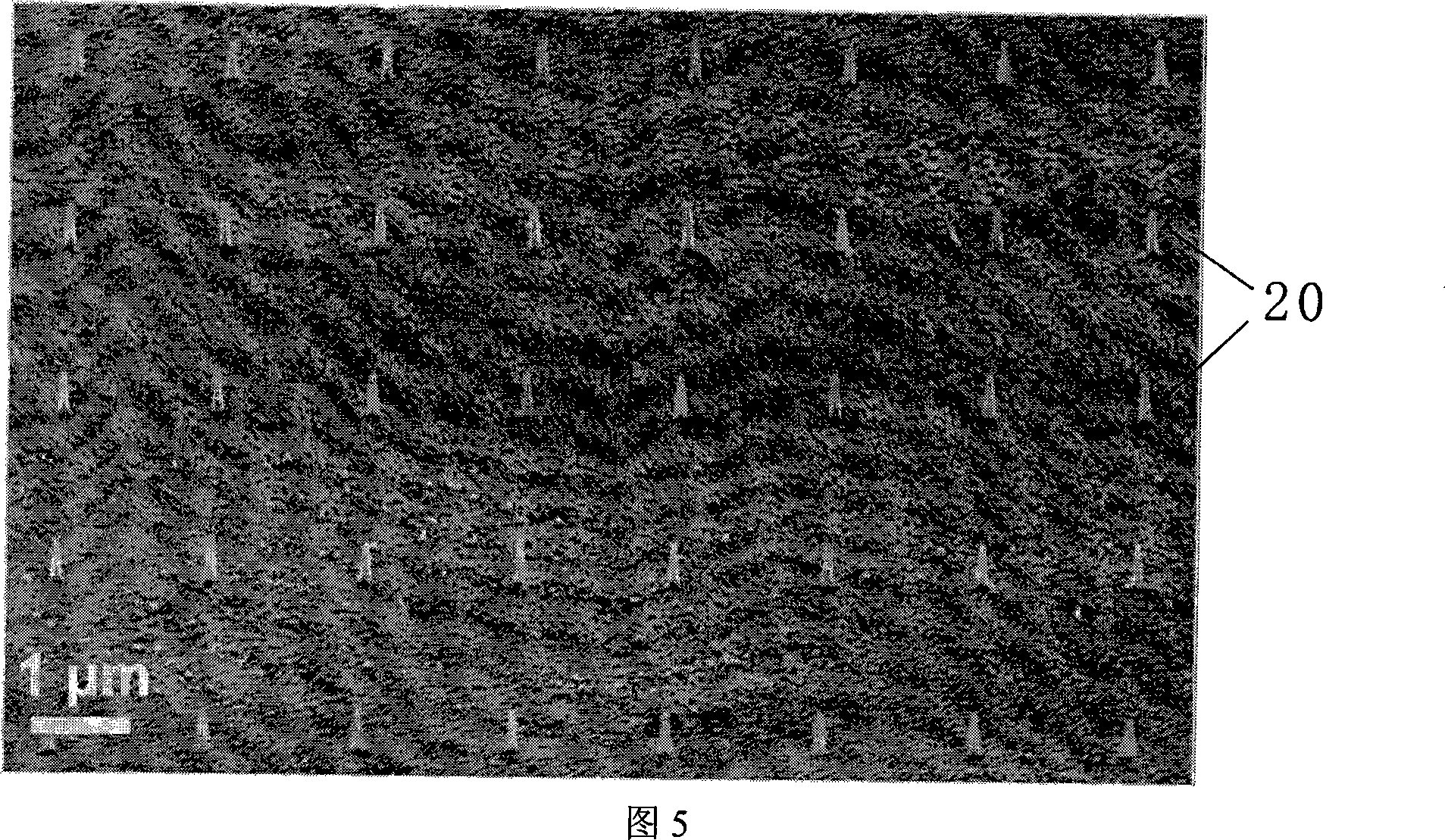

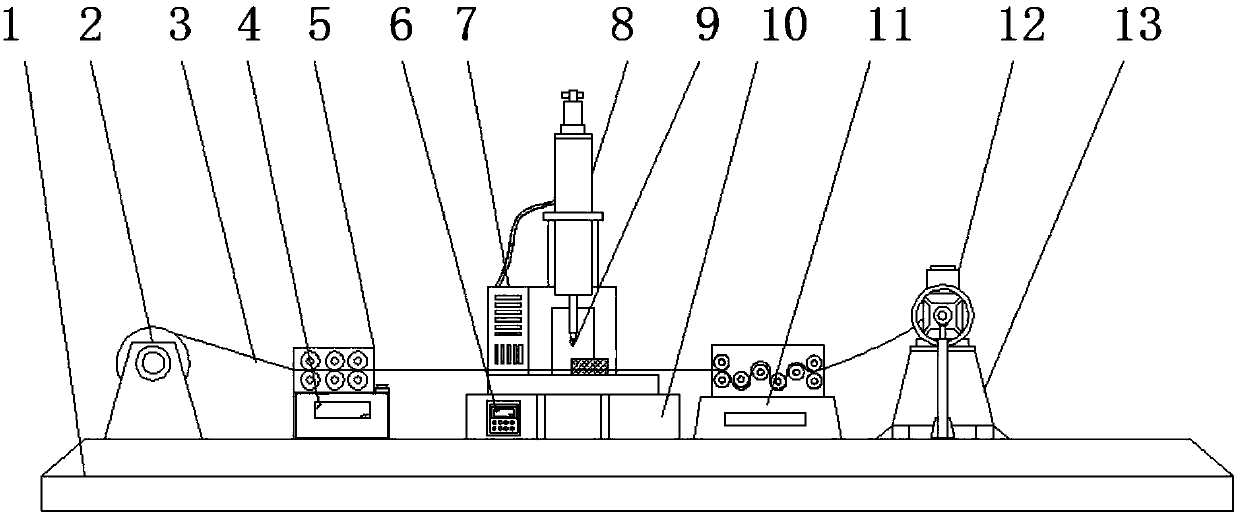

Method for preparation of one-dimensional silicon nanostructure

InactiveCN101117208APosition is easy to controlEasy to manufactureNanostructure manufactureNanoparticleSilicon nanowires

The invention discloses a method for preparing one-dimensional silicon nanostructure. The order of the processing steps adopted by the invention is as follows: (A) nanometer particle mould is prepared on the surface of backing material; (B) etching of the backing material is completed by use of plasma etching technology. The step (A) includes the following procedures: (i) the surface of backing material is coated with one layer of photoresist through spin coating at first, and then micropores are formed at the surface of backing material through adopting electronic photoetching technique; (ii) one layer of mask film is deposited on the surface of backing material; (iii) photoresist peeling-off of the surface of backing material deposited with the mask film is completed so as to form the nanometer particle mask at the micropores of procedure (i). In addition, step (A) can also be as follows: one layer of metallic film is firstly deposited on the surface of backing material and then heat treatment of the metallic film is completed to obtain metallic nanometer particle mask on the surface of backing material. The silicon nano wire / tip prepared by the invention is characterized in erection, order and controllable position and diameter etc., thereby being particularly favorable to manufacture and assembly of device.

Owner:SUN YAT SEN UNIV

Metal silicide nano-wire and its making method

InactiveCN1979828APosition is easy to controlControllable line widthSemiconductor/solid-state device detailsSolid-state devicesSalicideSputtering

The method for preparing metal silicides Nano wire with width being as 7 nm includes following steps: developing a layer of insulation film on substrate of monocrystalline silicon; etching grooves in use for producing metal silicides Nano wires through process technology in Nano scale; using method of metal sputtering and coating by vaporization to deposit layer of metal film on silicon substrate with Nano grooves being prepared; carrying out high temperature annealing to make reaction between metal and monocrystalline silicon exposed on bases of grooves so as to produce metal silicides; using chemical corrosion to eat off unreacted metal on surface; producing discrete metal silicides Nano wires in Nano grooves. The method can control position, shape, and width of wire of metal silicides Nano wire to be made. Thus, the invention is applicable to IC to prepare interconnection wires, source pole, drain pole and grid pole based on need.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

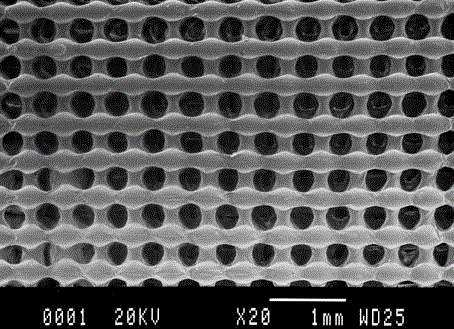

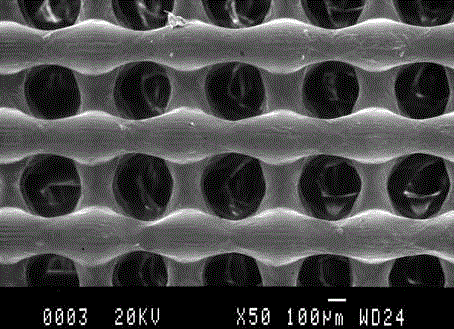

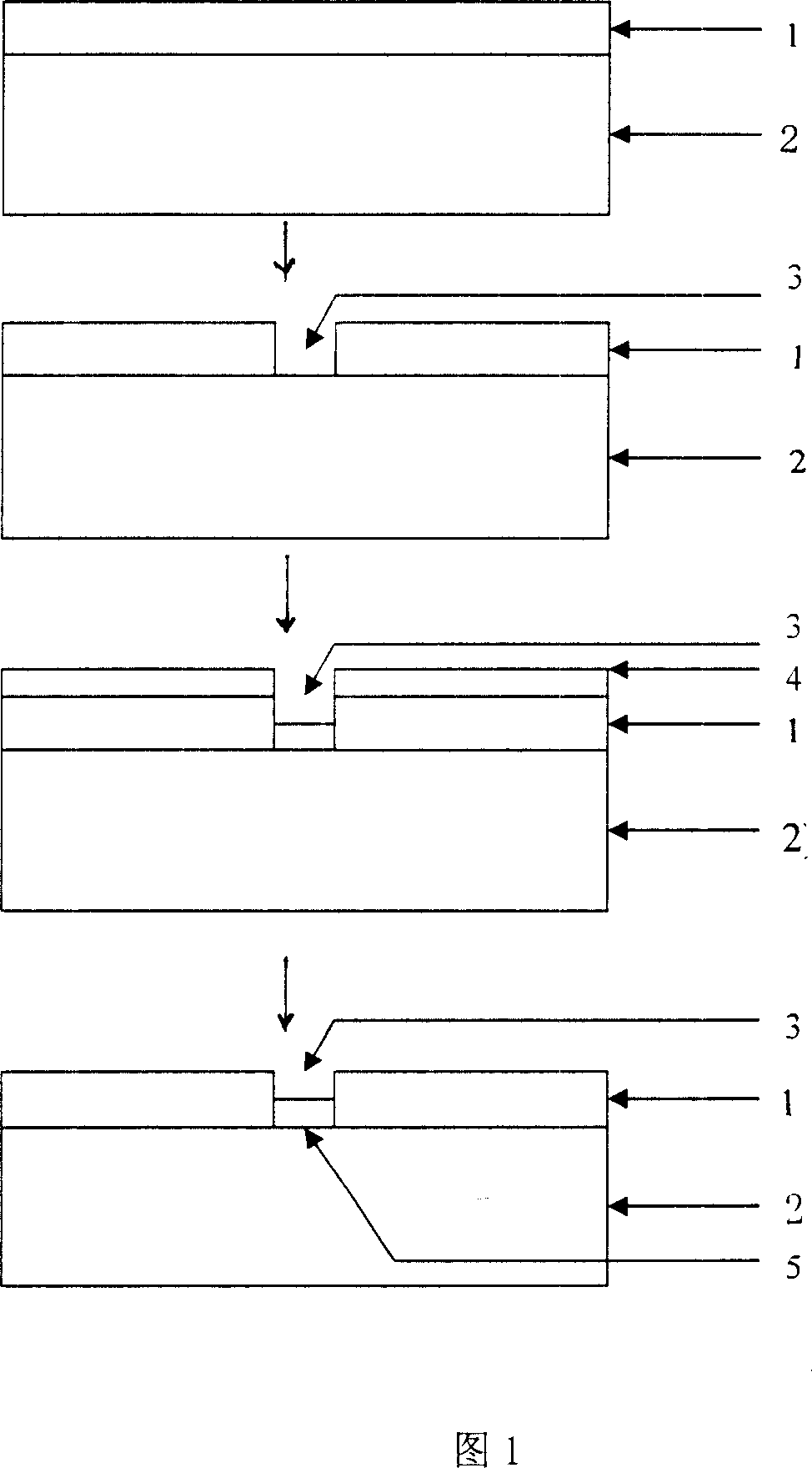

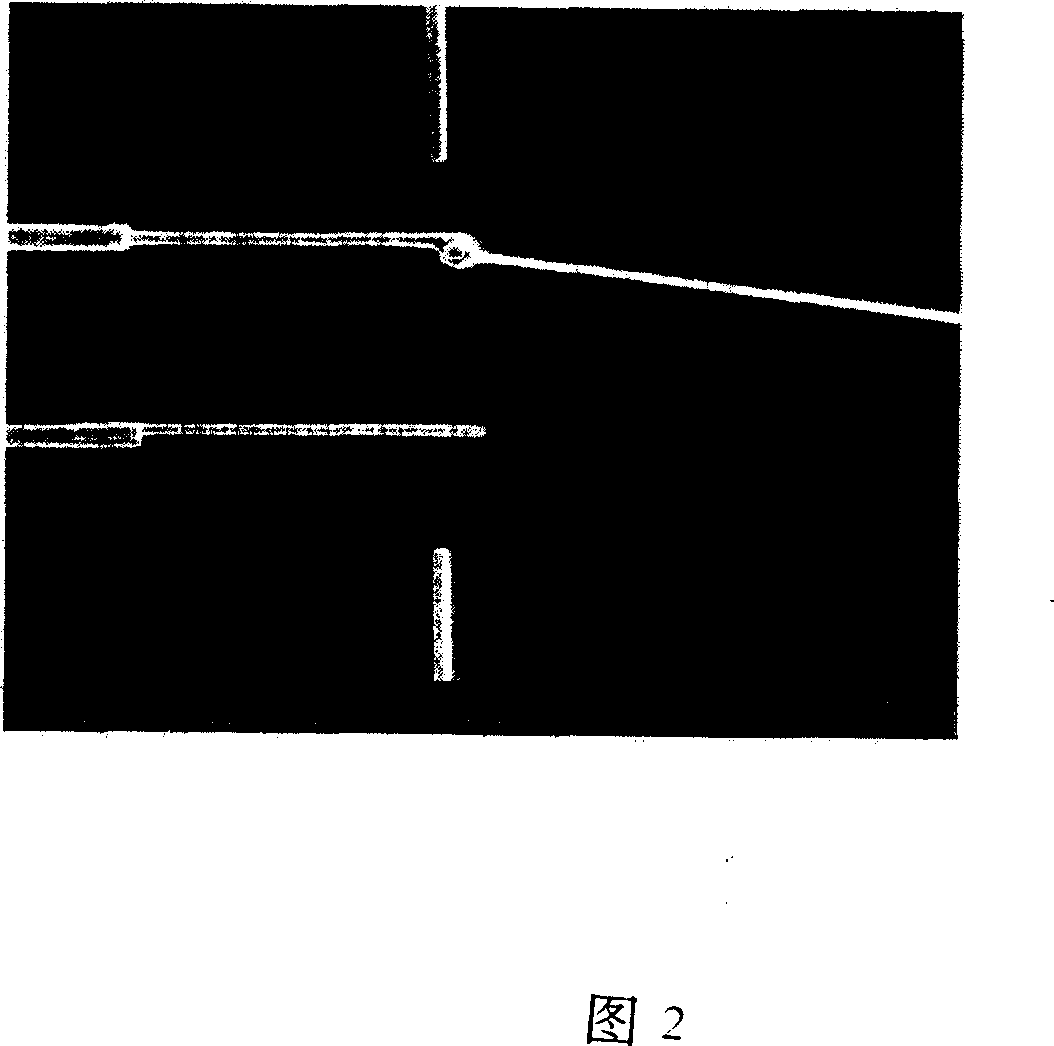

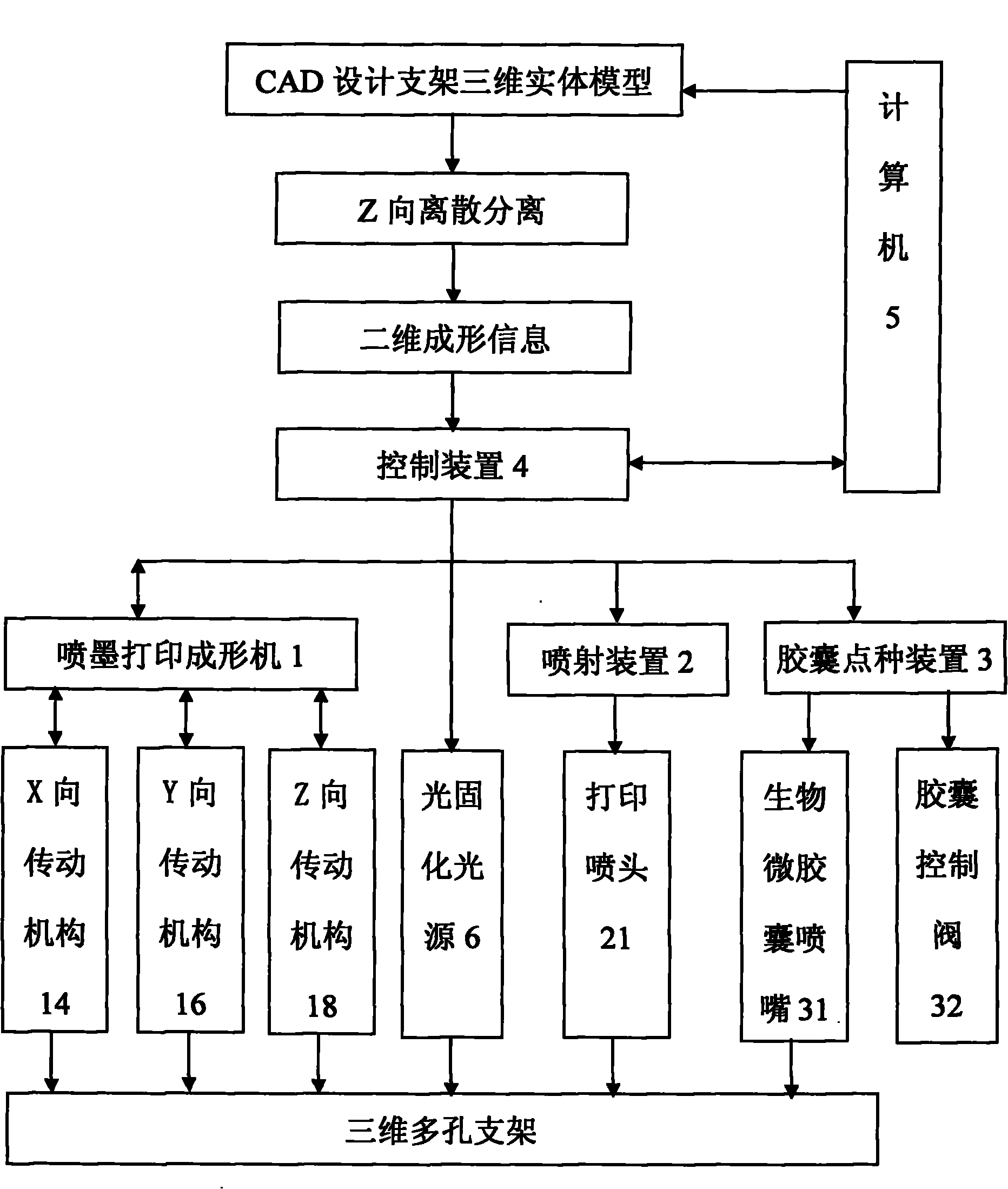

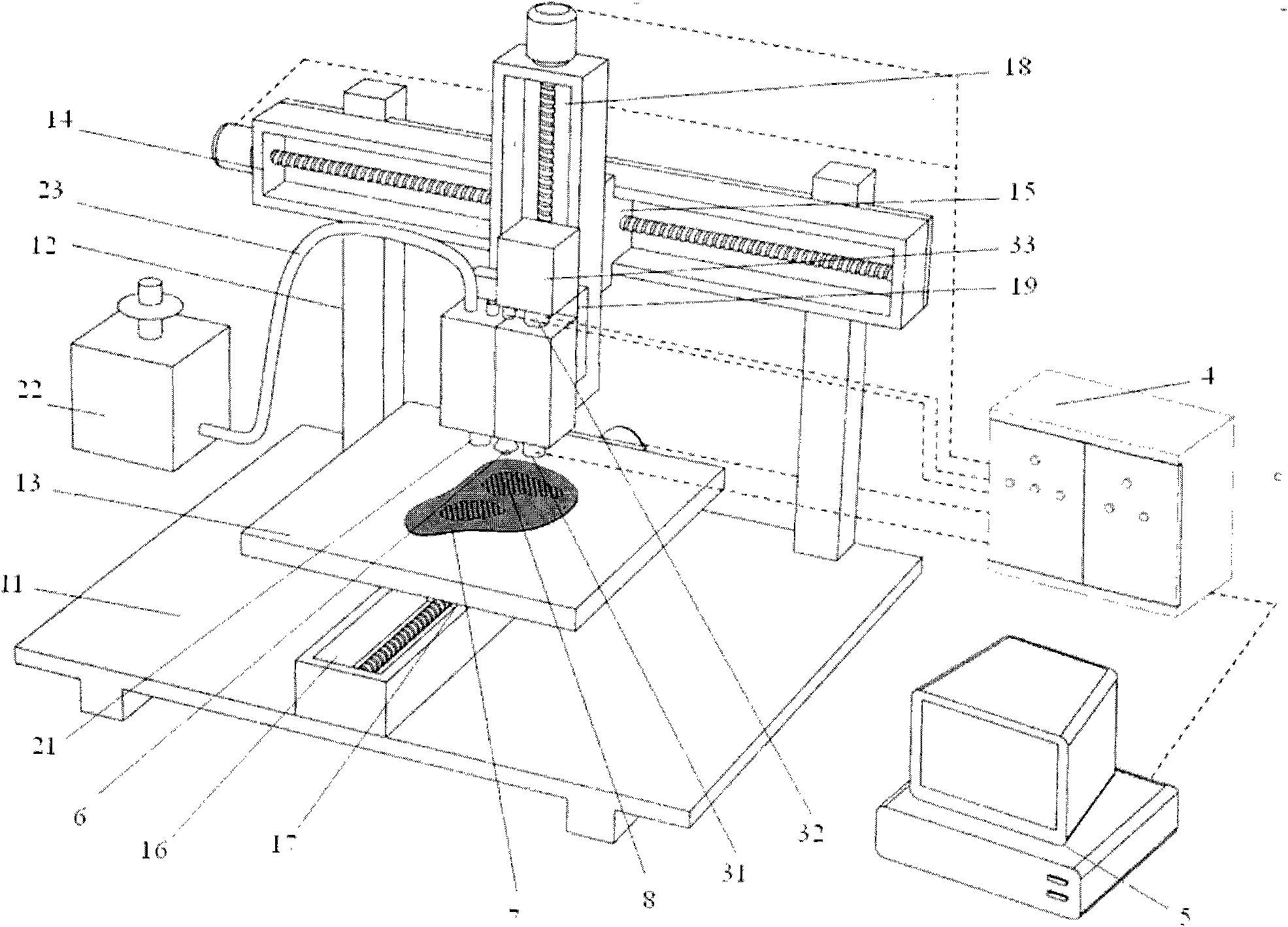

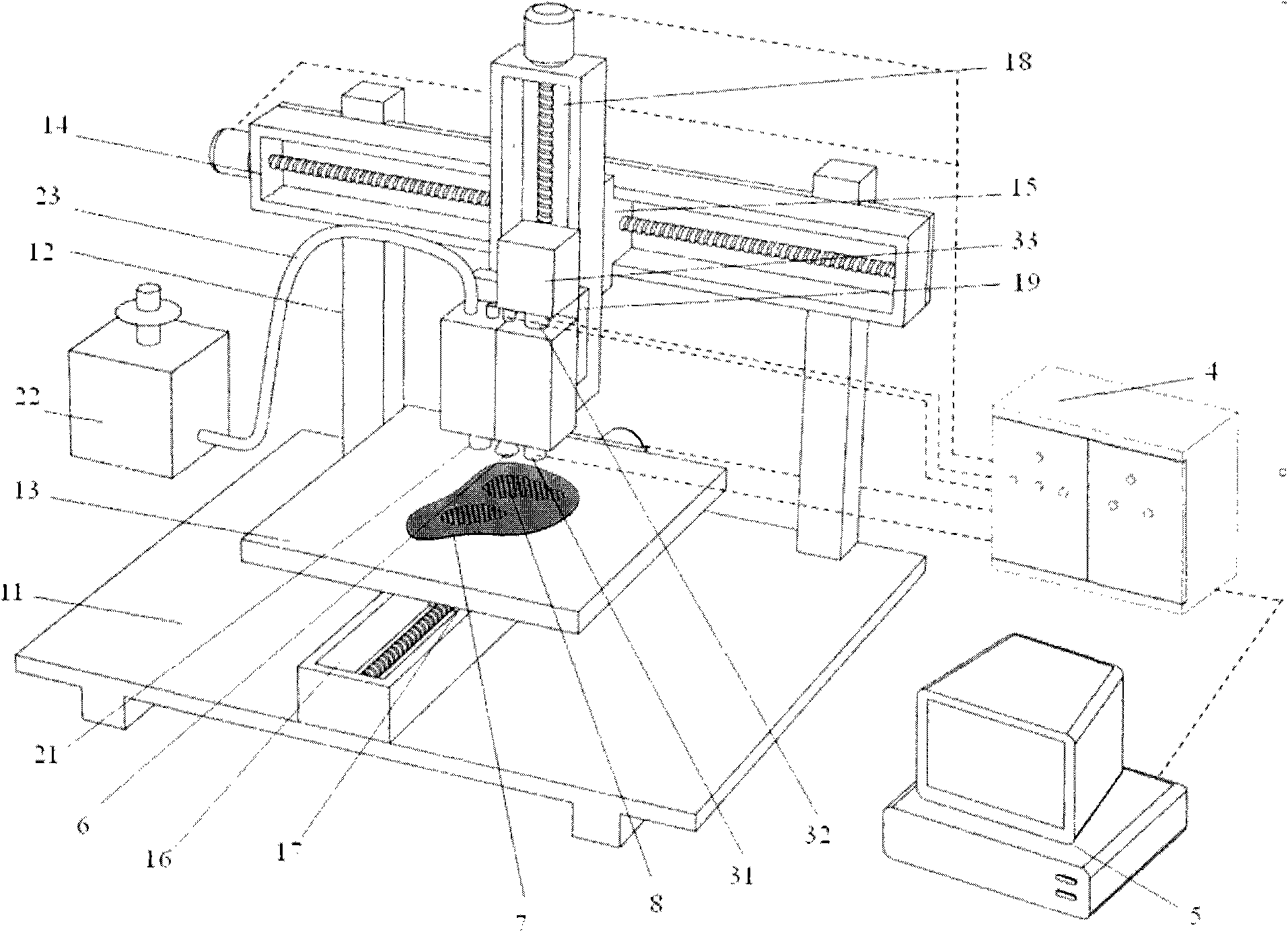

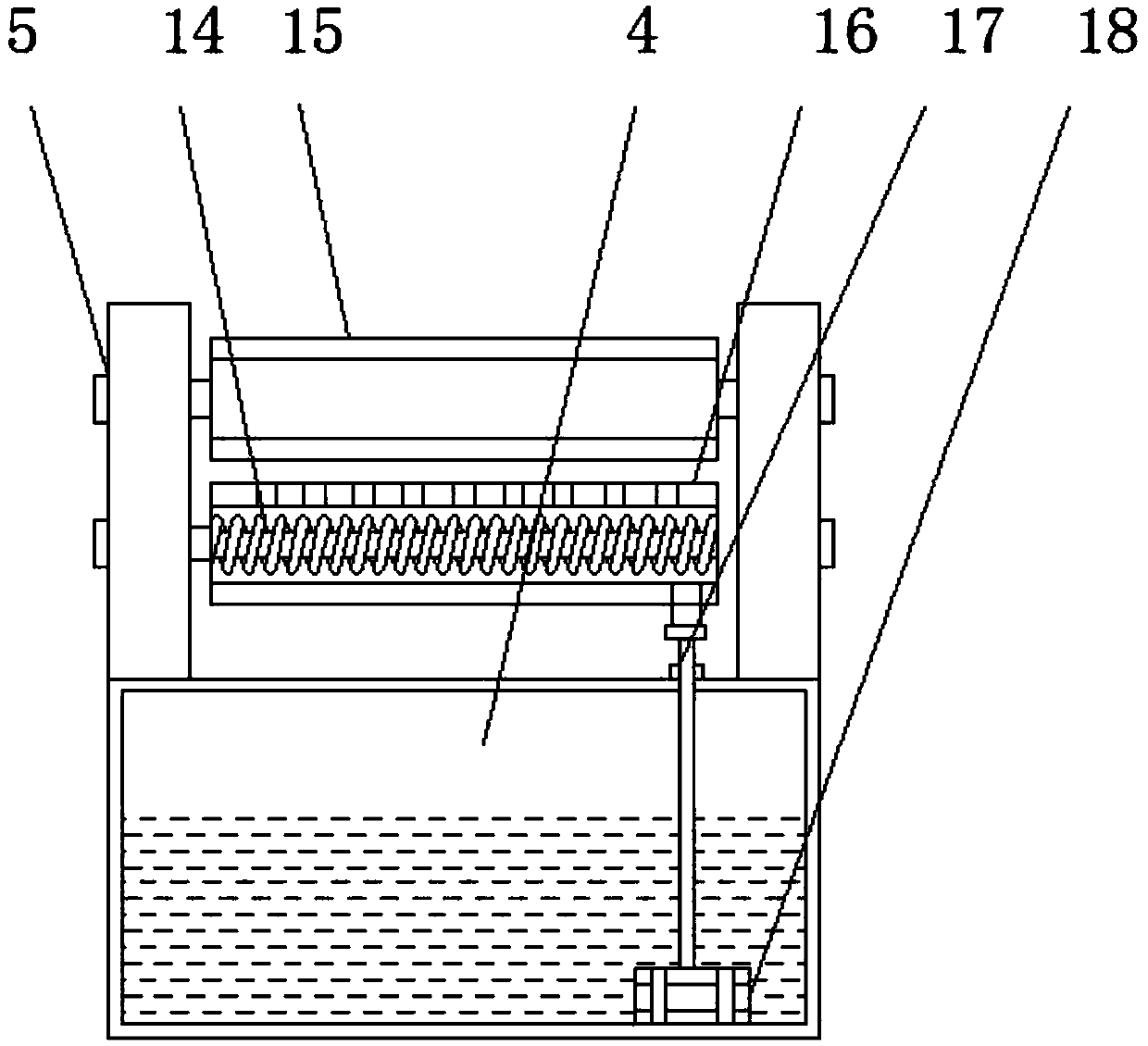

Method and device for preparing three-dimensional porous support for tissue engineering

InactiveCN101884574APosition is easy to controlControllable Aperture SizeStentsProsthesisControl systemLayer wise

The invention discloses a method and device for preparing a three-dimensional porous support for tissue engineering. The preparation method comprises the following steps of: 1, slicing and layering a support according to a certain thickness firstly to obtain two-dimensional cross section information of each layer of the support; 2, preparing a first layer slice of the support by using a three-dimensional inkjet printing spray head under the control of CAD software, dibbling microcapsule particles on the first layer slice of the support by using a bio-microcapsule preparation nozzle, and stacking the microcapsule particles to form gaps required by a support design; 3, moving the three-dimensional inkjet printing spray head and the bio-microcapsule preparation nozzle for the height of one layer slice of the support to finish the forming preparation of a second layer of the support; and 4, repeating the method layer by layer until the three-dimensional porous support is prepared. The device for preparing the three-dimensional porous support is suitable for the preparation method, and comprises a three-dimensional inkjet printing forming machine, a jetting device, a bio-microcapsule dibbling device and a control system.

Owner:HEBEI UNIV OF TECH

Infant support garment

ActiveUS8973793B2Stress minimizationPosition is easy to controlStretcherWheelchairs/patient conveyanceEngineering

Owner:ARVAN JULIE

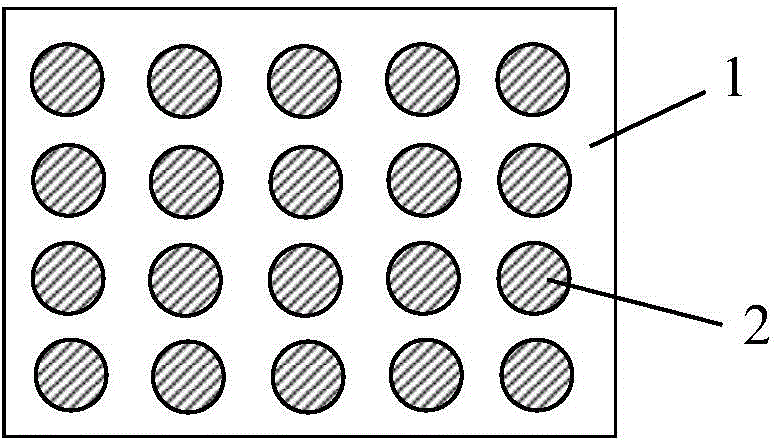

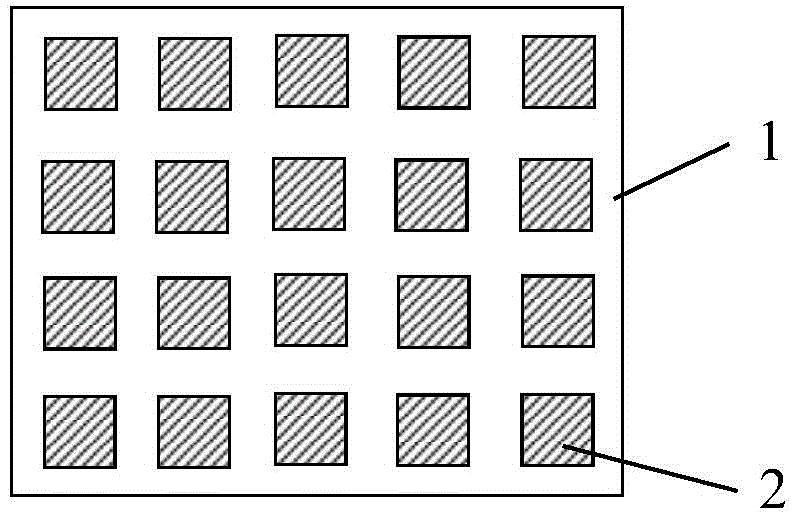

Method for preparing nanomaterial array system by porous alumina template nano mask method

InactiveCN1594068AUniform sizeControllable orientationNanostructure manufactureChemical reactionNanoparticle

Method for preparing nanomaterial array system by porous alumina template nano mask method is constituted by following steps: (1) adopting the porous pellumina as templet of the mask and covering it on the base material; (2) forming nano granule array system on the base material by coating technique; (3) removing porous pellumina template to get nano granule array system; (4) processing a chemical reaction conversion in situ by the nano granule array prepared from step (1)(2)(3), further obtaining nano granule array system of the other materials. The produced nano material has an good controllability in dimension, orientation and position and a wide adjustable property (5-200 nano) of the diameter of the nano material. The invention can produce multifunctional nano granule, nano wire, nano tube or nano column array system and assembles nano material on a plurality of nano materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

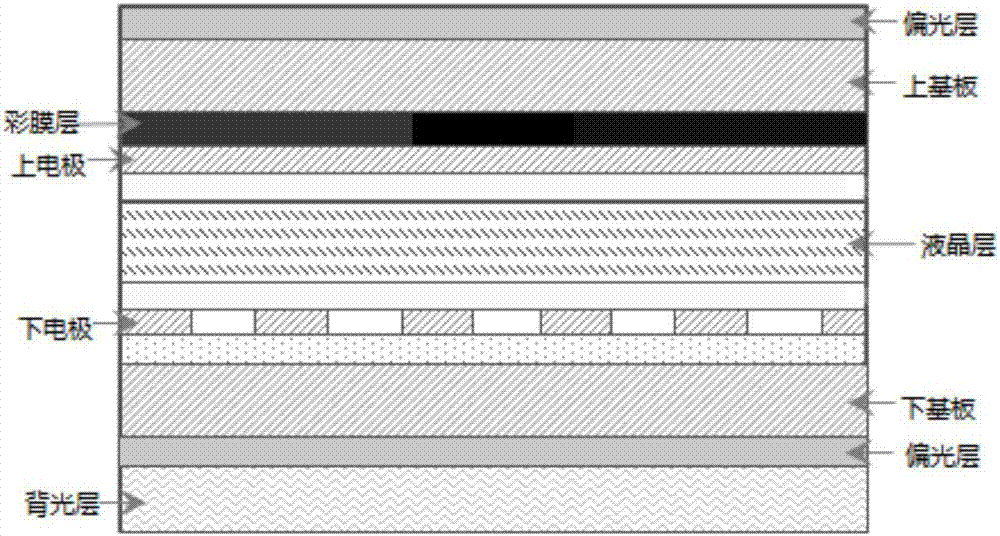

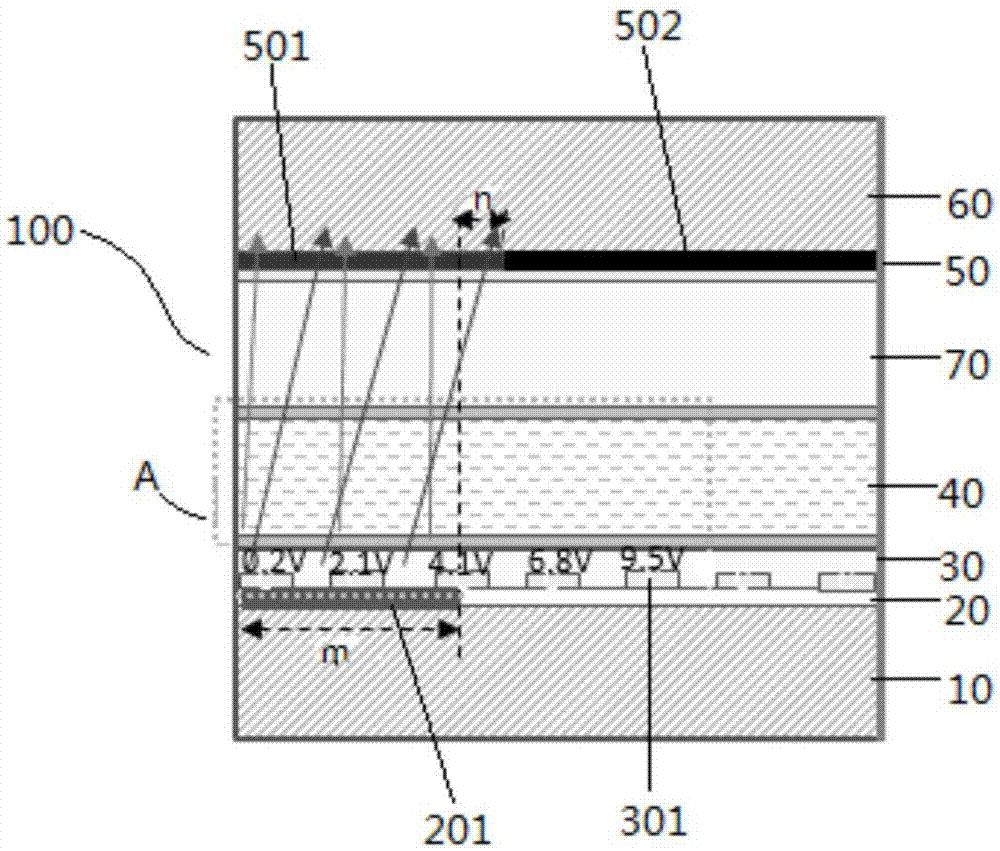

Gray scale control structure and method, liquid crystal display panel and display device

ActiveCN107450211ADifferent display effectsChange shapeStatic indicating devicesNon-linear opticsGratingLiquid-crystal display

The invention provides a gray scale control structure which comprises a first substrate, a light extraction layer, an electrode layer, a liquid crystal layer, a filter layer and a second substrate which are sequentially arranged in a laminating mode. A plurality of side-by-side strip electrodes are arranged in the electrode layer, so that a lens unit can be formed in the liquid crystal layer; the filter layer comprises a light emergence strip and a black matrix which are arranged side by side; the light emergence strip is opposite to the lens unit; a light extraction grating is arranged in the light extraction layer; the light extraction grating is opposite to the light emergence strip; the projection of the light emergence strip on the light extraction layer covers the light extraction grating. The gray scale controls the size of a gray scale by regulating and controlling a deflection direction of incident light, meanwhile, can improve light transmittance, and has a high contrast ratio.

Owner:BOE TECH GRP CO LTD

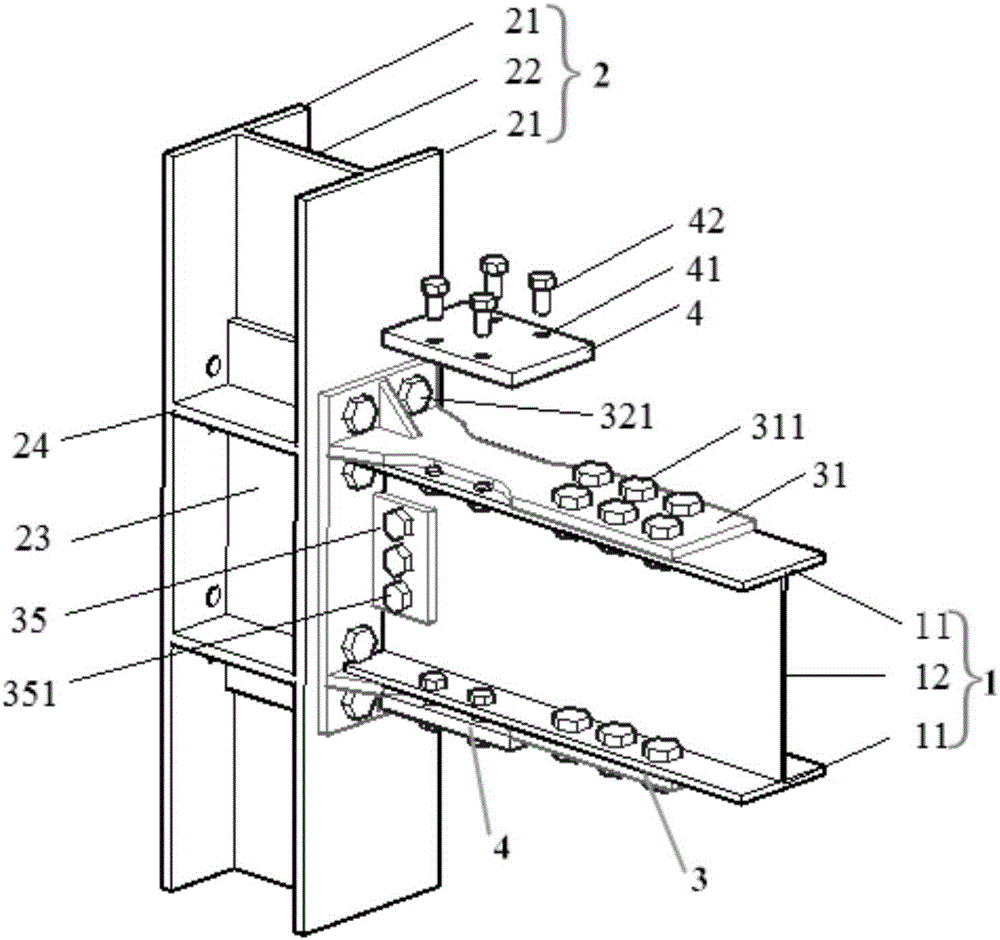

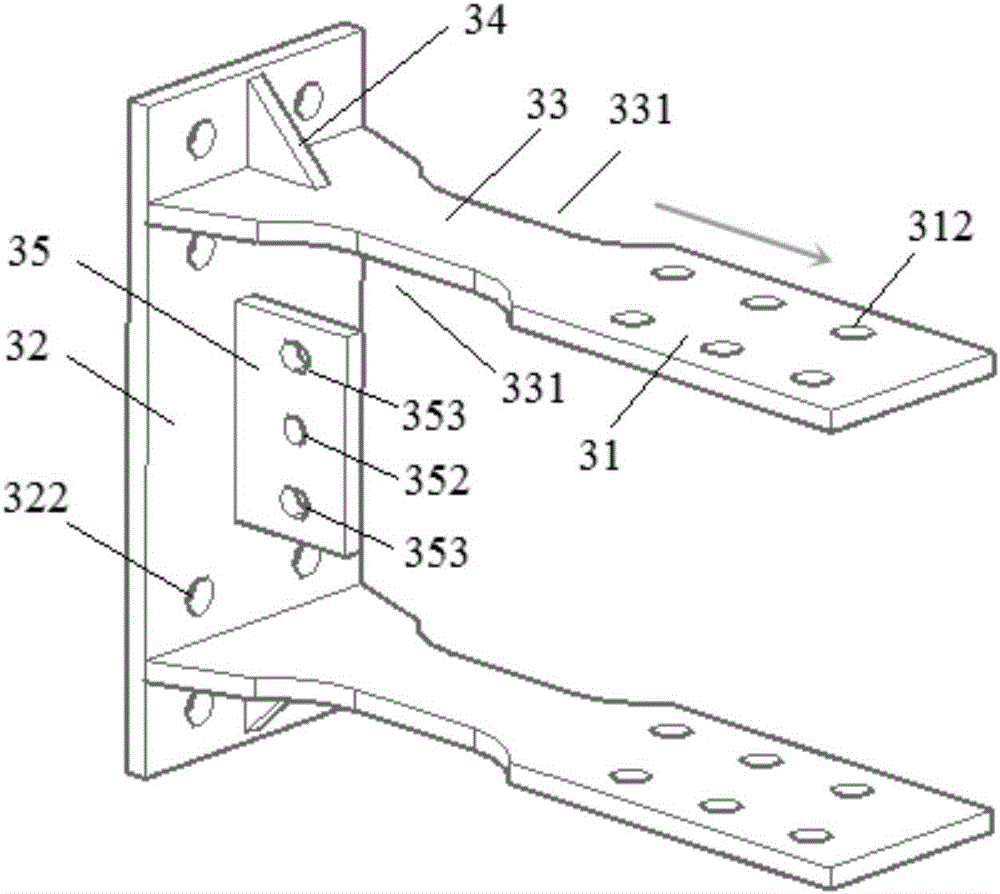

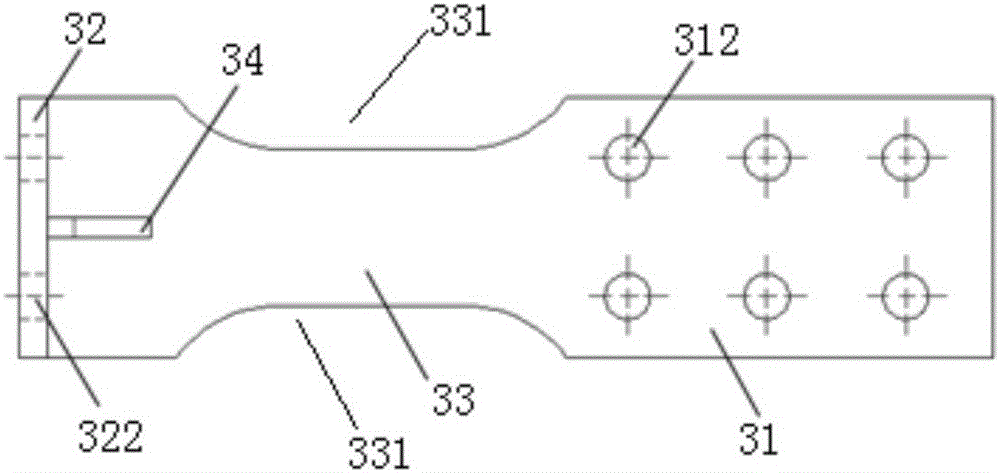

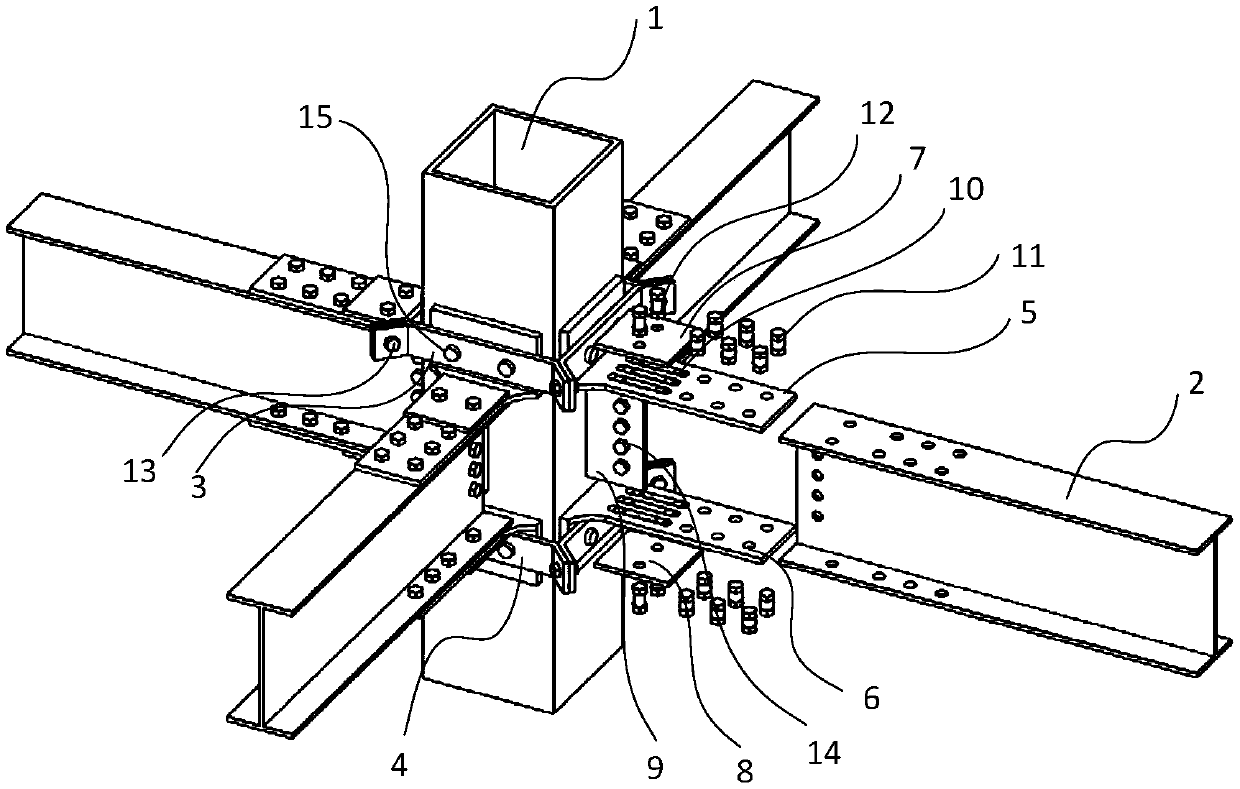

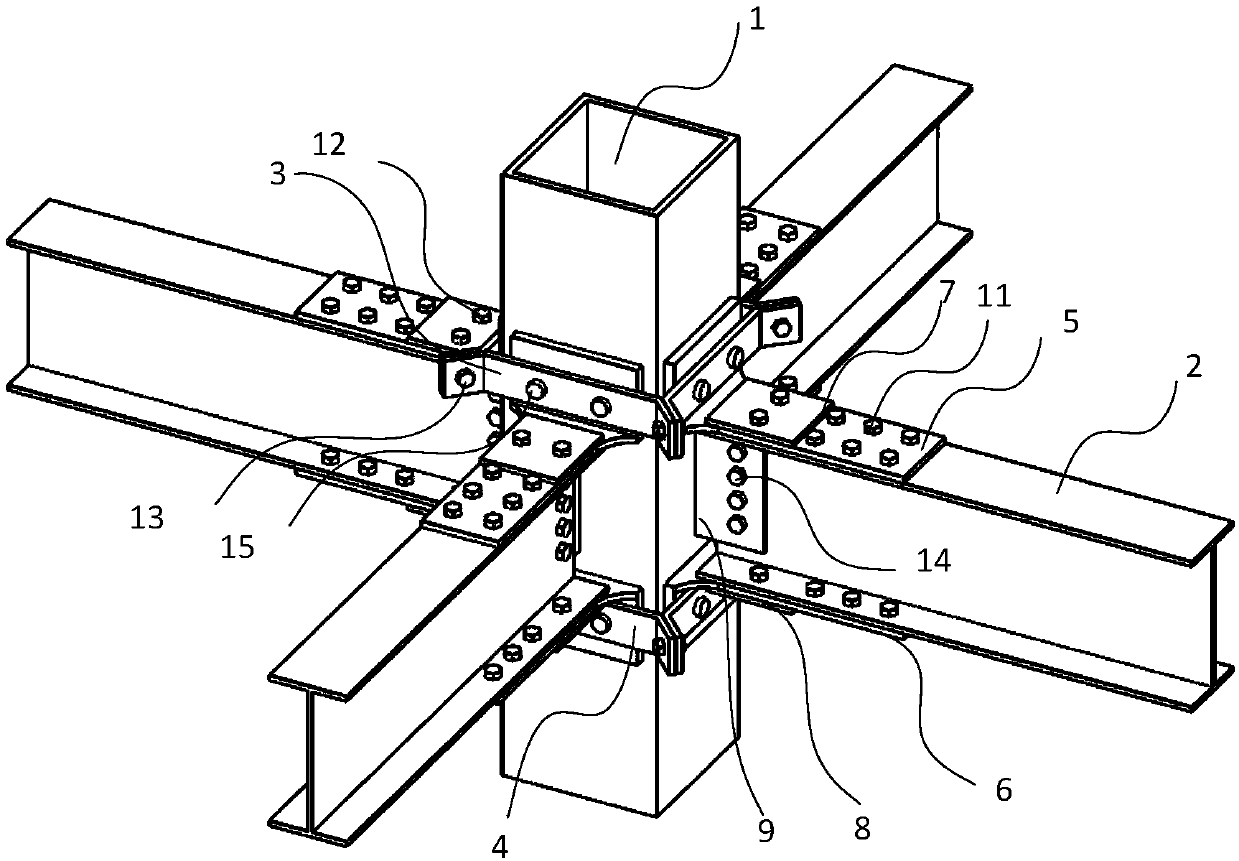

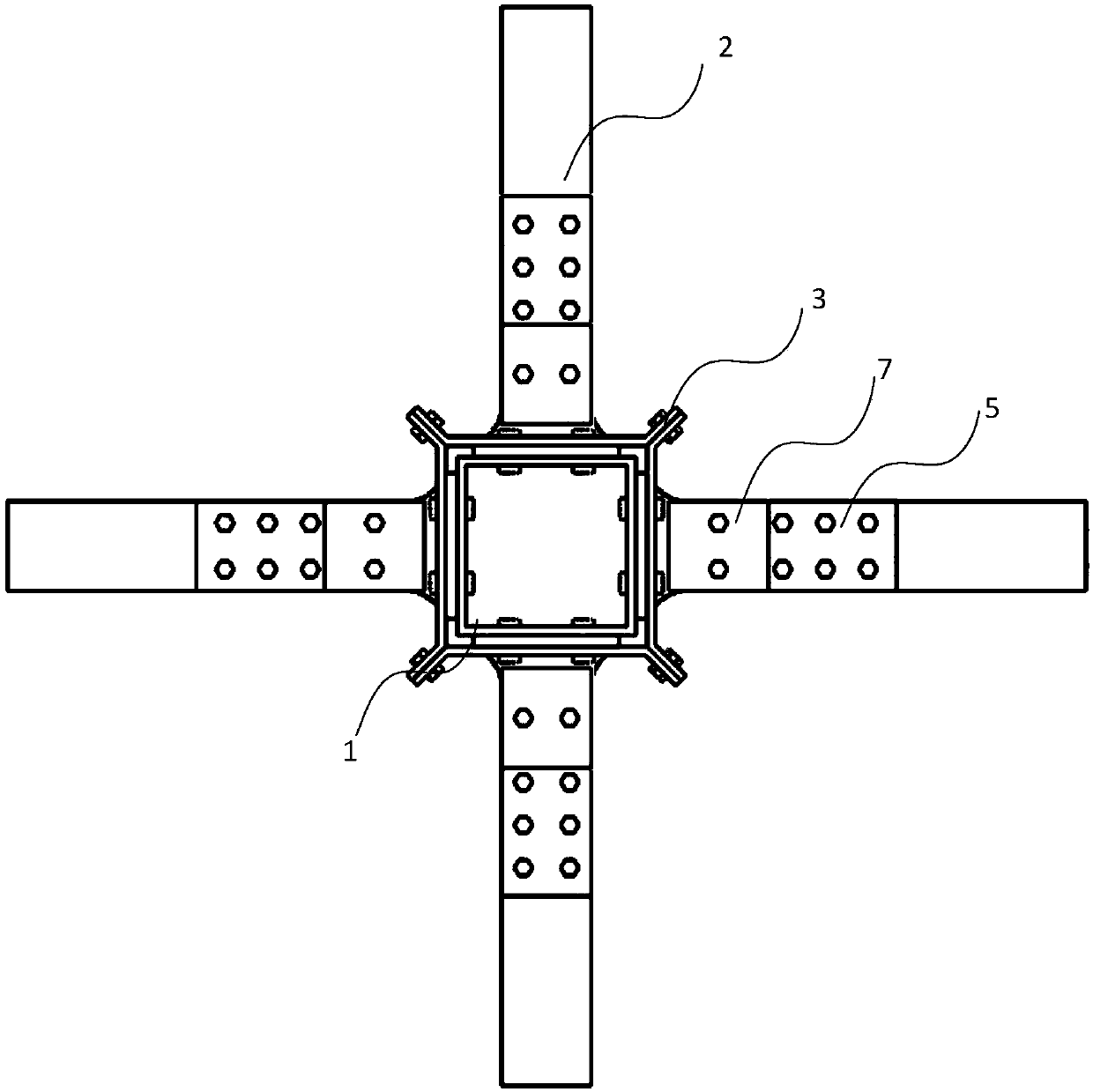

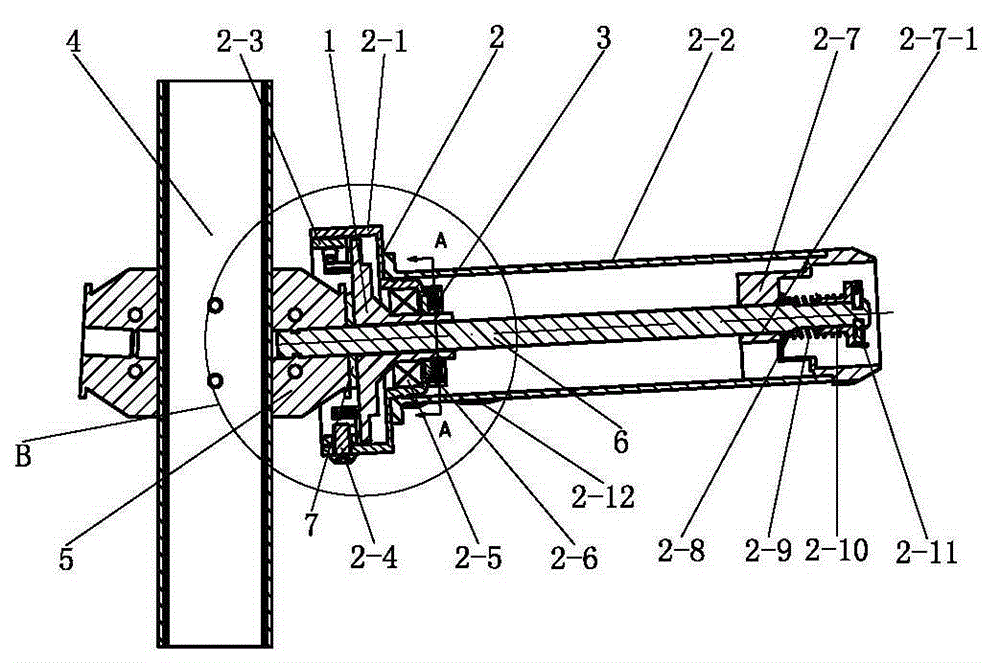

Buckling constraint type steel-beam-and-column end-plate connection joint and steel structure building

ActiveCN105839776APosition is easy to controlImprove ductilityProtective buildings/sheltersShock proofingSteel frameEngineering

The invention discloses a buckling constraint type steel-beam-and-column end-plate connection joint and a steel structure building, and belongs to the field of a building steel structure. The buckling constraint type steel-beam-and-column end-plate connection joint comprises a steel beam and a steel column; an end connecting piece is arranged at a joint of the steel beam and the steel column; the end connecting piece comprises a pair of horizontally arranged flange connecting plates and end plates arranged at the tail ends of the flange connecting plates; the free ends of the flange connecting plates are used for being connected with upper and lower flanges of the steel beam; both ends of the end plates are used for being connected with flanges of the steel column; the middle parts of the flange connecting plates are weakened regions. According to the buckling constraint type steel-beam-and-column end-plate connection joint and the steel structure building which are disclosed by the invention, seismic performance is superior, and ductility and the energy consumption ability of a steel frame structure can be obviously improved; plastic hinges are moved outside, so that appearance of the plastic hinges at the welded positions at the end parts of the steel beam is avoided; after an earthquake, the steel beam and the steel column are not damaged, and can be reused only by replacing or repairing the end connecting pieces; moreover, the buckling constraint type steel-beam-and-column end-plate connection joint is convenient to mount.

Owner:SHANDONG UNIV

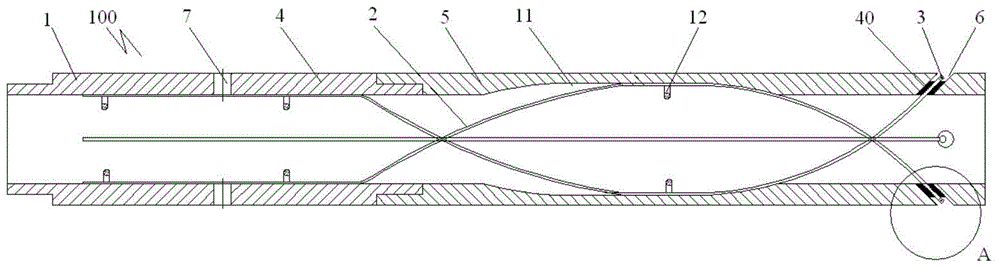

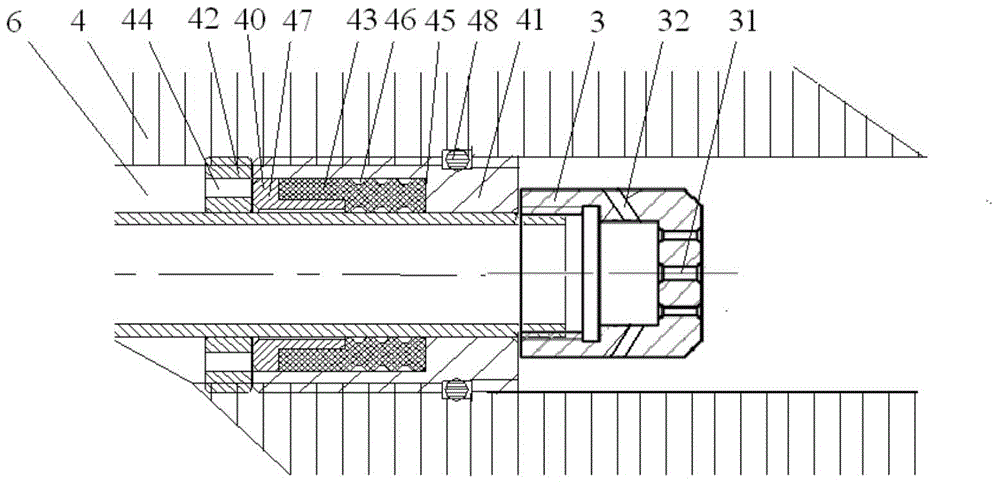

Oil gas exploitation apparatus and method

ActiveCN105443085AImprove effectivenessImprove controllabilityFluid removalHigh effectivenessPropelling nozzle

The invention relates to an oil gas exploitation apparatus and method. The apparatus includes at least an exploitation unit, a needle tubing, and a self-propelled nozzle arranged at a second end of the needle tubing. The exploitation unit includes a jet pipe nipple and an adjusting pipe nipple detachably connected to the jet pipe nipple, wherein penetrating installation holes are arranged on a sidewall of the jet pipe nipple, and the adjusting pipe nipple is provided with oil holes for the oil gas flowing from a stratum into an inner cavity of the exploitation unit. In the original state, a first end of the needle tubing is arranged in the inner cavity of the exploitation apparatus. The second end of the needle tubing is inserted in the installation holes. During a process for pumping the liquid to the exploitation apparatus, the needle tubing extends in a storage stratum so as to form an exploitation pore passage. In the oil gas exploitation process, the oil gas exploitation apparatus has high effectiveness for the reconstruction of the storage stratum and good oil gas output.

Owner:CHINA PETROLEUM & CHEM CORP +1

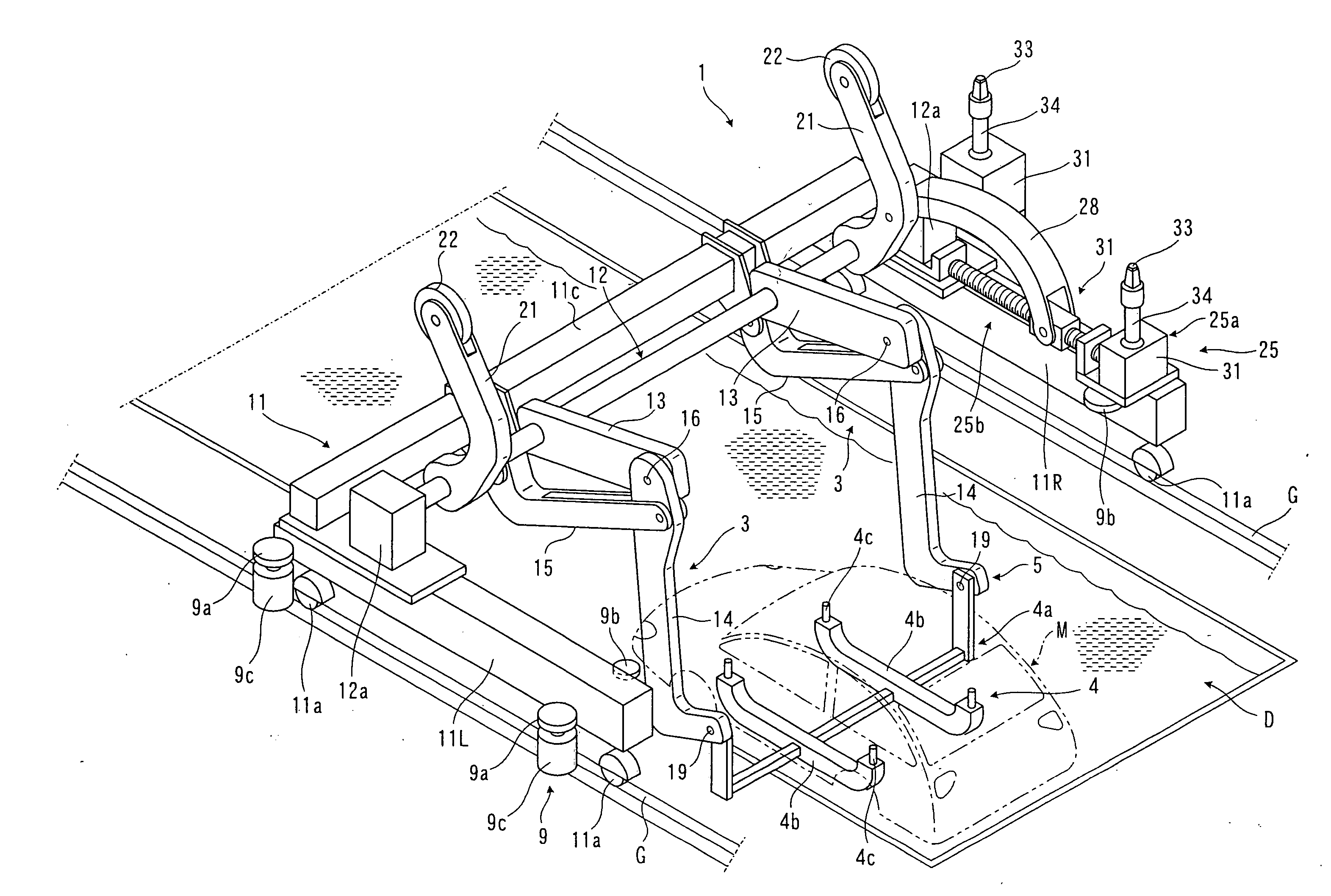

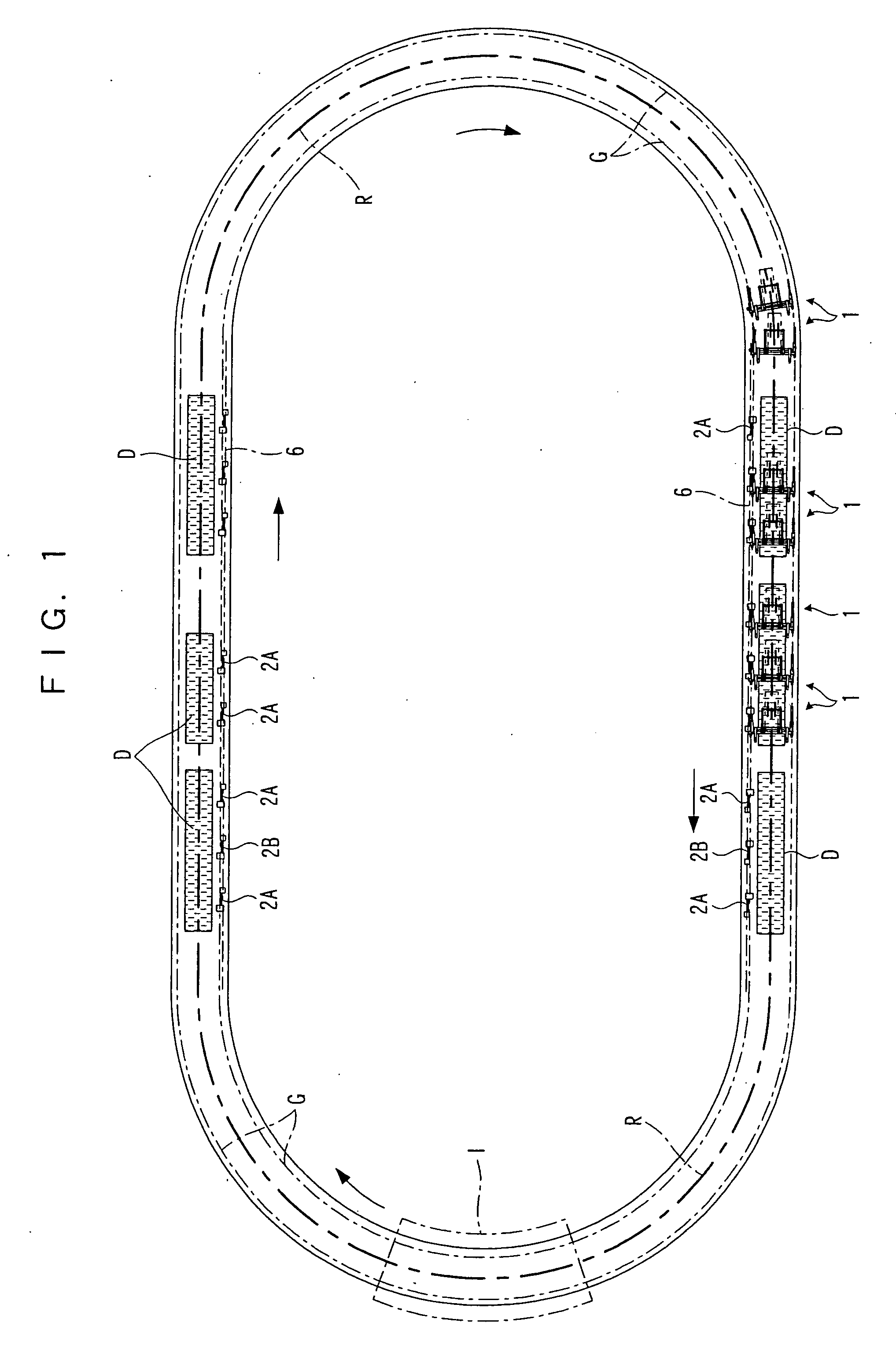

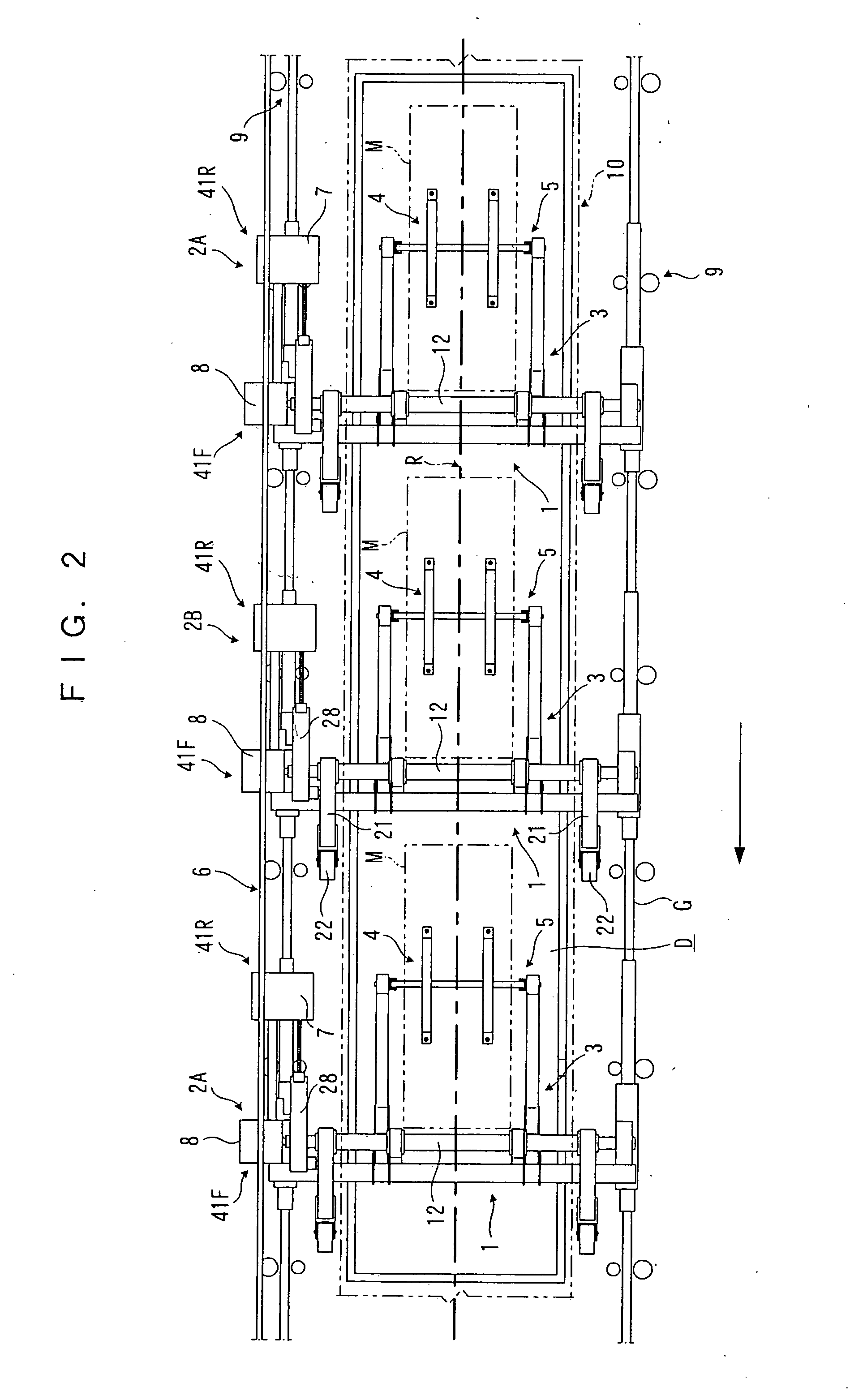

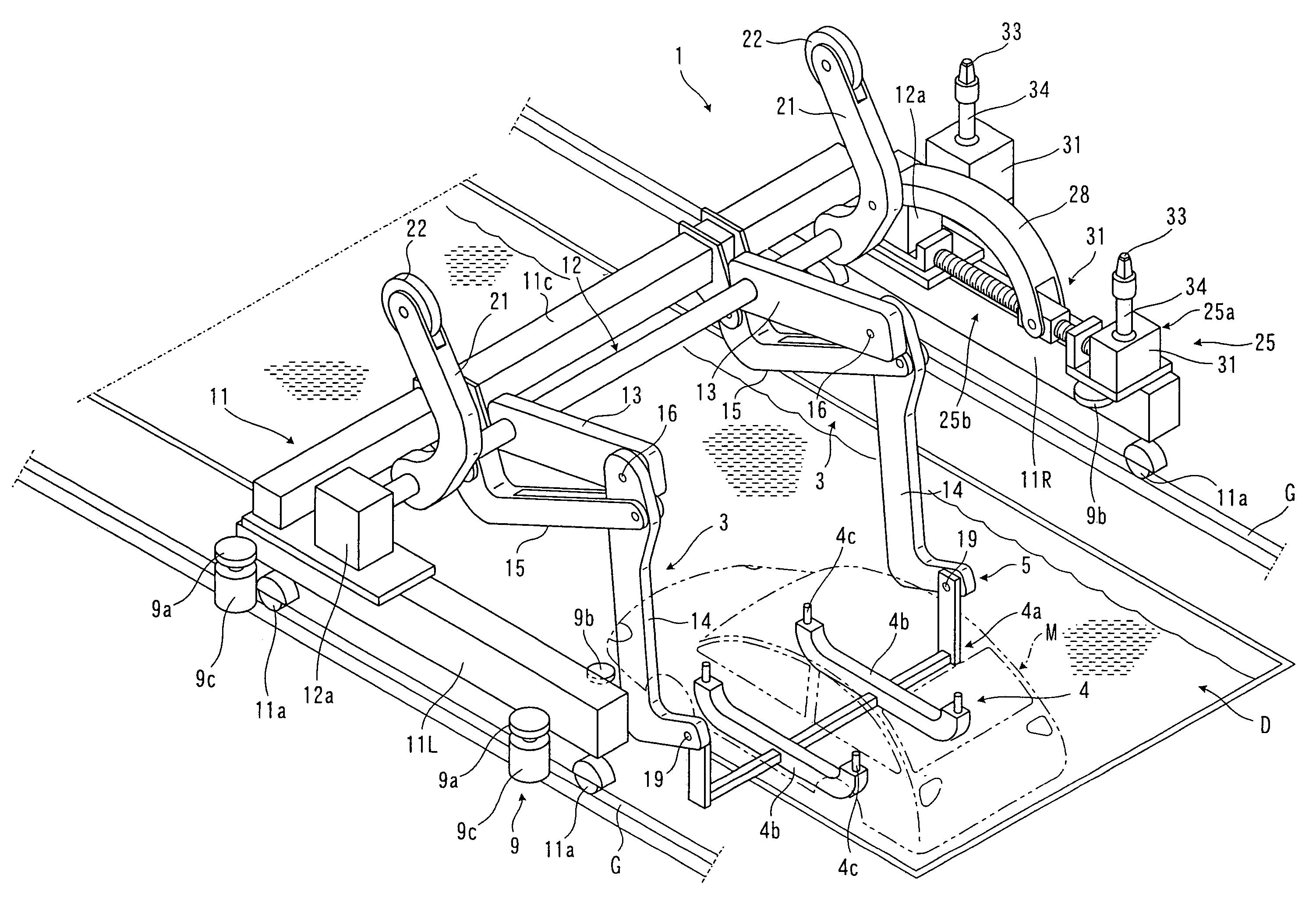

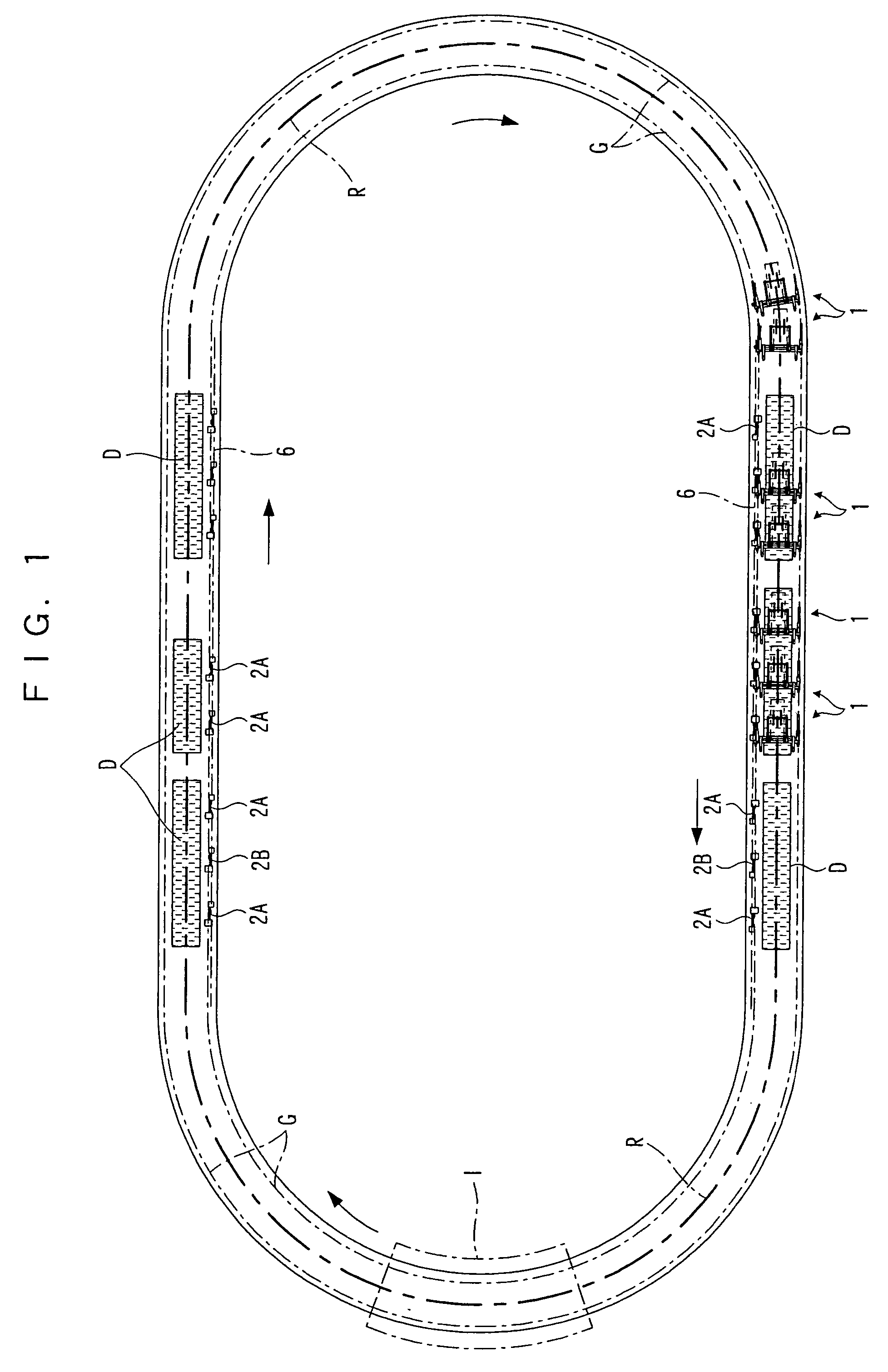

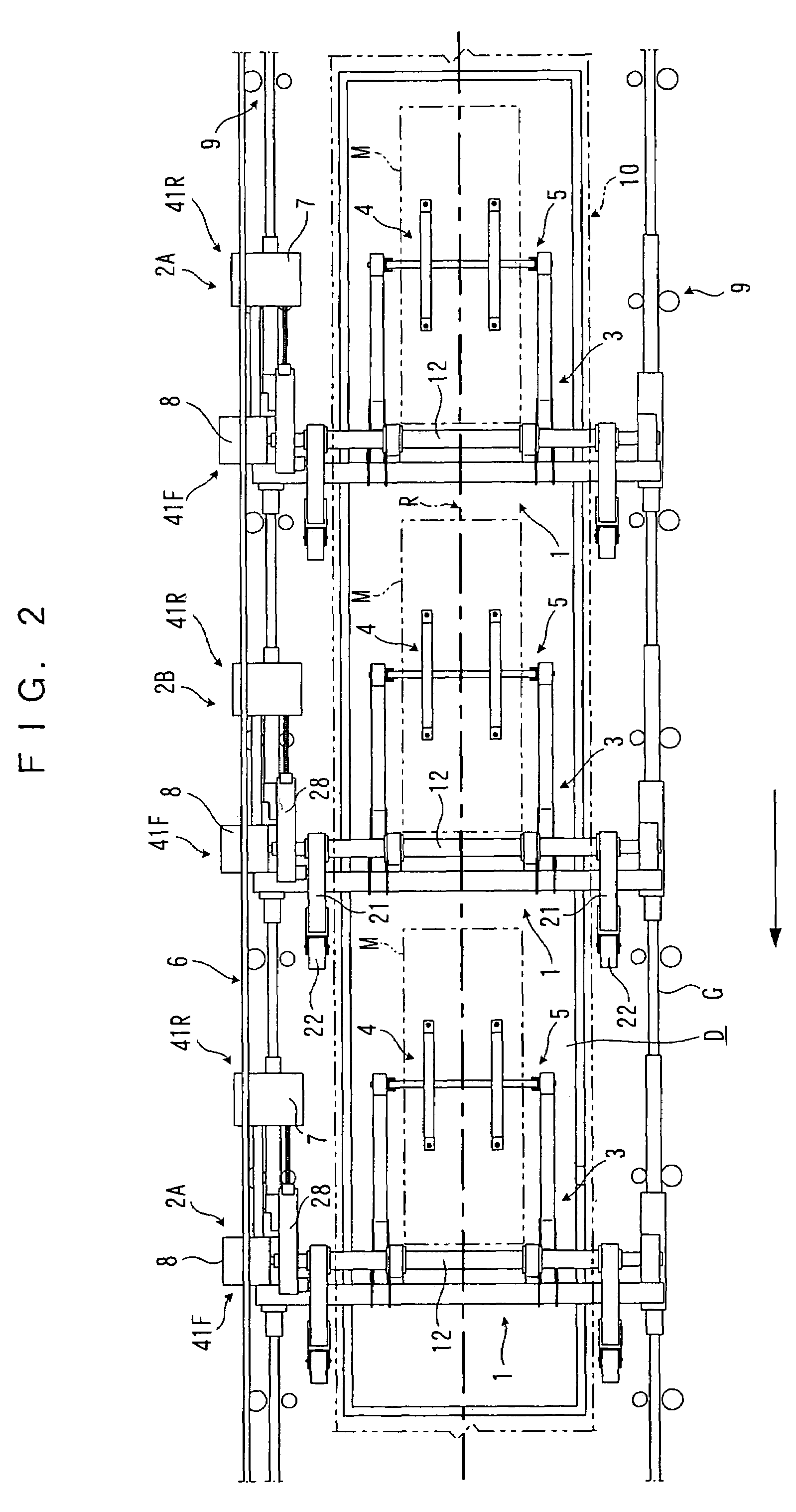

Conveyance method and apparatus for processing step

InactiveUS20050061239A1Reduce equipment costsReduce maintenance costsLiquid surface applicatorsRailway tracksEngineeringTruck

A swinging link mechanism, provided on a conveyance truck, for raising and lowering a vehicle body held on a supporting member includes a first arm having a fixed end section which is attached to the conveyance truck in a vertically rotatable manner by means of a horizontally oriented support axle, a second arm having a fixed end section supported rotatably on the free end section of the first arm and having a supporting member provided on the free end section thereof, and a third arm coupled rotatably between the conveyance truck and a prescribed position on the second arm. Third arm is caused to rotate the second arm in the opposite direction to the first arm in response to rotation of the first arm, thereby to make the lower movement path of the supporting member to extend substantially vertically. Hence, the vehicle body can be raised or lowered in a substantially vertical movement path, and the position and attitude of the vehicle body can be controlled readily, by adopting a link mechanism of a simple configuration.

Owner:TAIKISHA LTD +1

Material with metal silicide nanostructure and method for making the same

InactiveCN101207137AEliminates latch-upImprove integration densitySolid-state devicesSemiconductor/solid-state device manufacturingMetal silicideSilicon thin film

The invention relates to a material with metal silicide nanometer structure and the preparation method thereof. The material comprises a metal silicide nanometer structure which is produced on an SOI substrate; the thickness of an insulation medium layer of the SOI substrate is 100 to 1000 nanometers, and the thickness of silicon thin film is 50 to 500 nanometers. The preparation method comprises the following steps: a required mask feature structure of nanometer structure is produced on the silicon thin film surface of the SOI substrate after cleaning, drying, spin coating positive photoresist, exposing, developing, and fixing; the silicon thin film of the SOI substrate is etched to the required nanometer structure by adopting a reactive ion etching, the etching depth is equal to the thickness of the silicon thin film, a metal thin film which is required by the metal silicide is deposited on the isolation layer which contains the silicon nanometer structure, then high temperatures anneal is performed to ensure that soild phase reaction is reacted between the metal and the silicon, thus to generate the metal silicide, the unreacted metal is removed through chemical etch, and then the metal silicide nanometer structure is formed. The method is simple, and the position and the dimension of the nanometer structure can be controlled.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

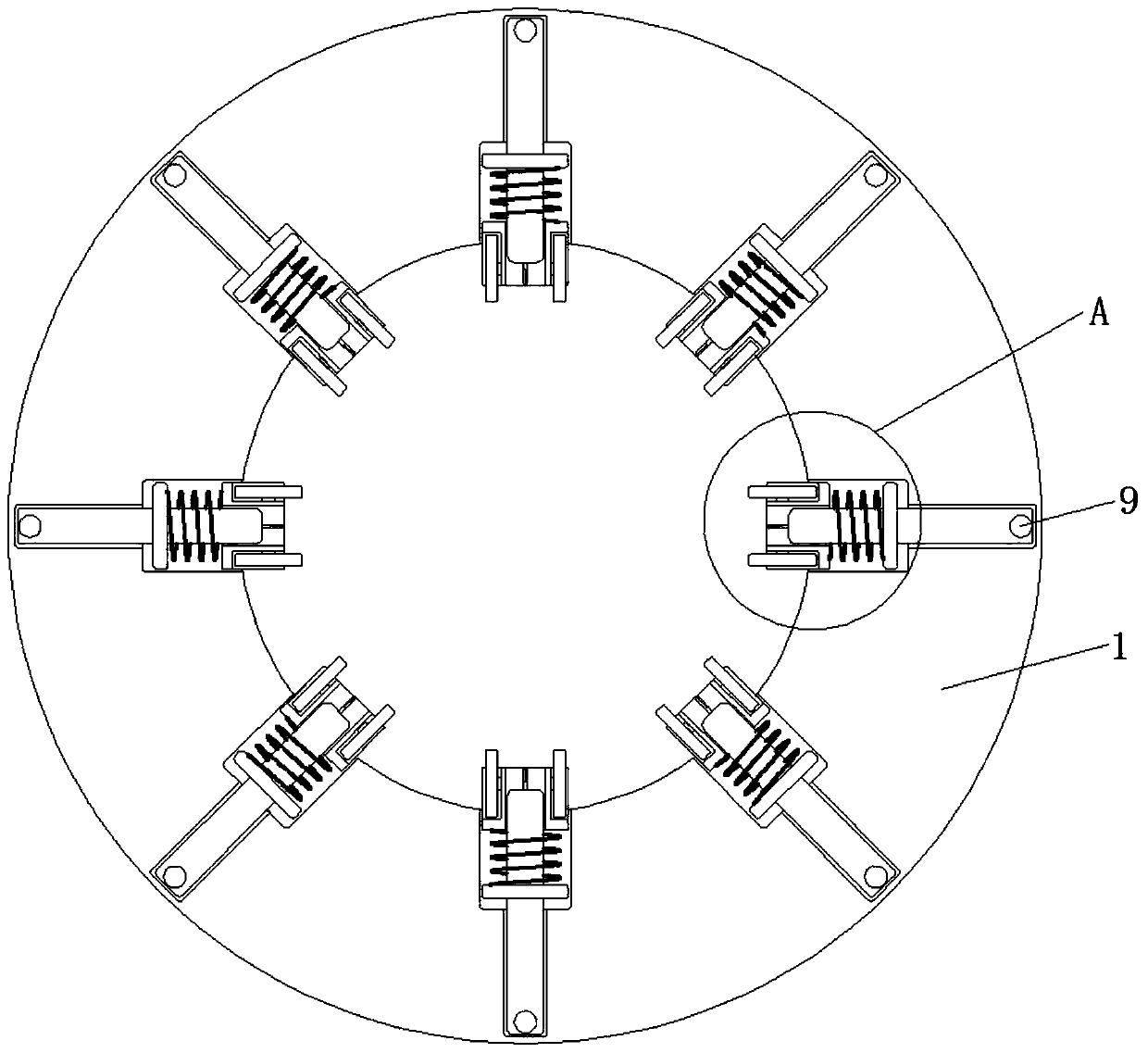

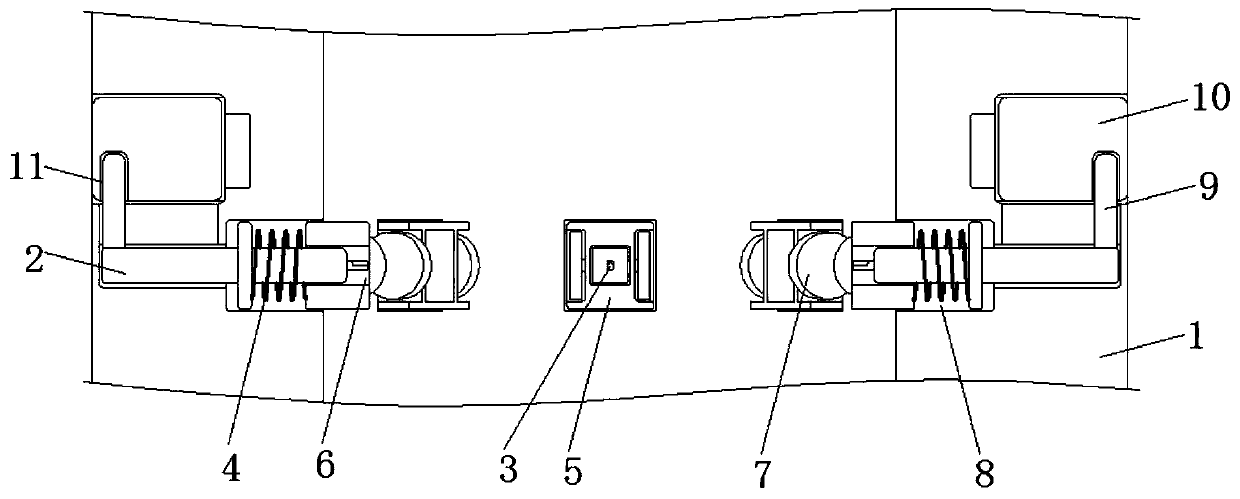

Replaceable energy consumption connecting node of assembly-type rectangular steel pipe column-H-type steel beam

PendingCN109537725AVarious formsImprove construction efficiencyProtective buildings/sheltersShock proofingArchitectural engineeringEngineering

The invention discloses a replaceable energy consumption connecting node of an assembly-type rectangular steel pipe column-H-type steel beam. A rectangular steel tubular column, an H-type steel beam and a replaceable energy consumption connecting force transmitting component are included, the replaceable energy consumption connecting force transmitting component comprises an unequal limb angle steel energy consumption connecting member, a rectangular sleeve tube, a buckling preventing constraint cover plate and a vertical web plate connecting plate; the unequal limb angle steel energy consumption connecting member is connected with the rectangular steel tubular column and a wing plate of the H-shaped steel beam; the buckling preventing constraint cover plate is connected with a weakening area of the unequal limb angle steel energy consumption connecting member; the rectangular sleeve tube sleeves the outer side of the short limb of the unequal limb angle steel energy consumption connecting member and is connected with the rectangular steel tubular column through a bolt; the vertical web plate connecting plate is connected with the rectangular tubular column and the web plate of theH-shaped steel beam. The replaceable energy consumption connecting node has the advantages that the node force transmission is reasonable and reliable, the advantages of building industrialization can be achieved, the replaceable energy consumption connecting force transmitting component is adopted by a node position, the expandability and energy consumption capability of the node are improved, the steel tubular column is not damaged after vibration, and the steel tubular column can be used again by replacing connecting components.

Owner:TIANJIN UNIV

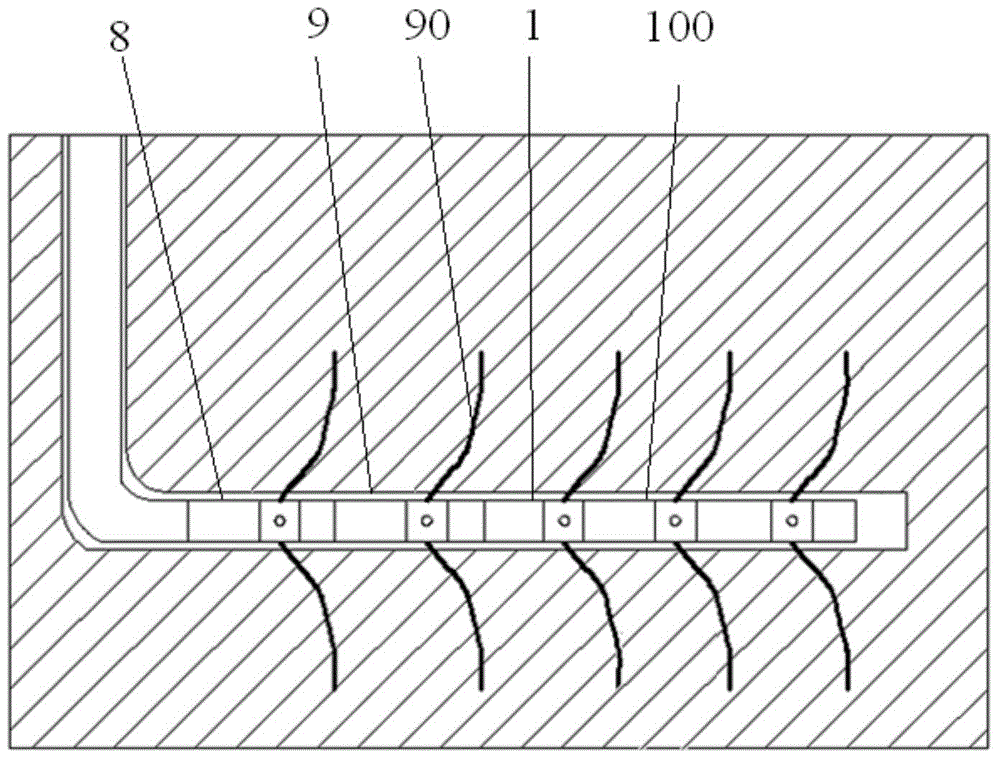

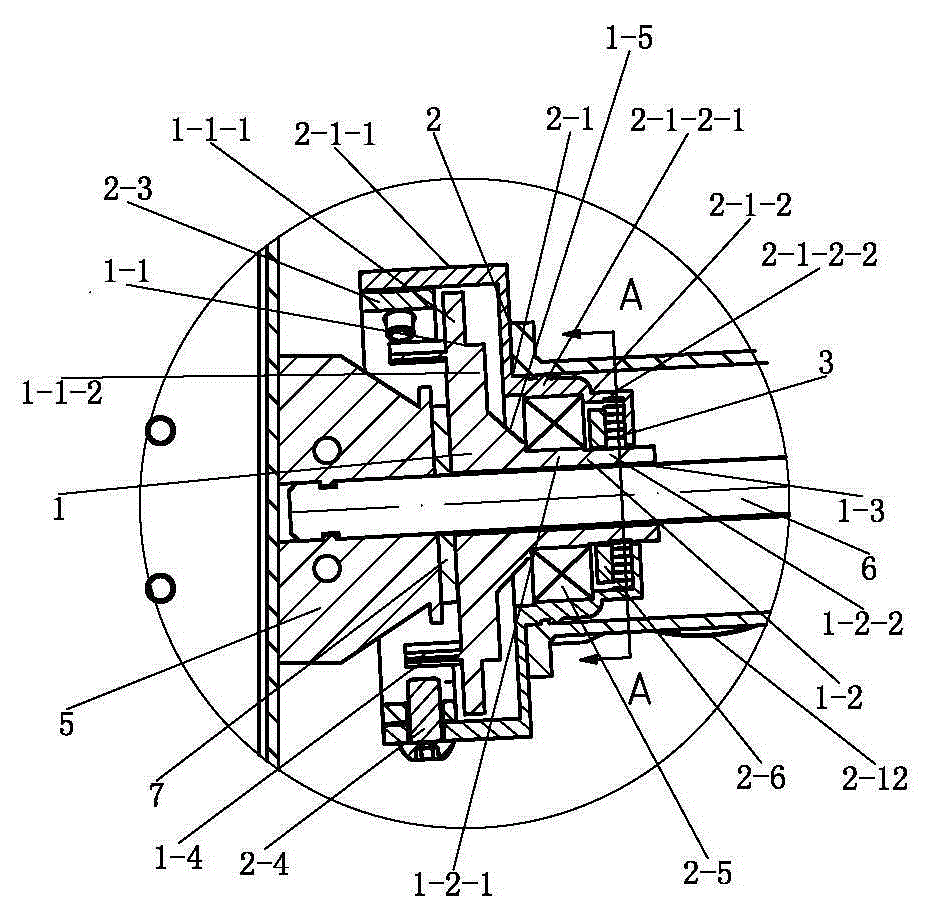

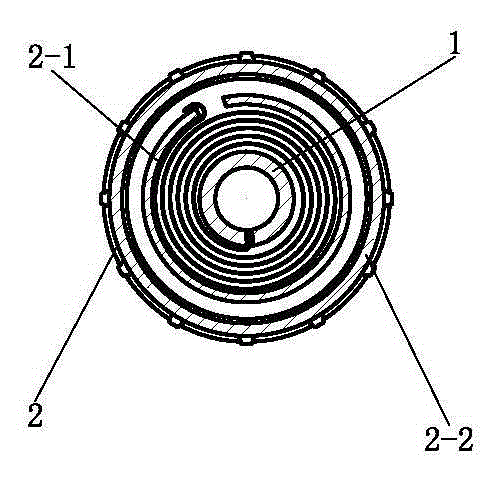

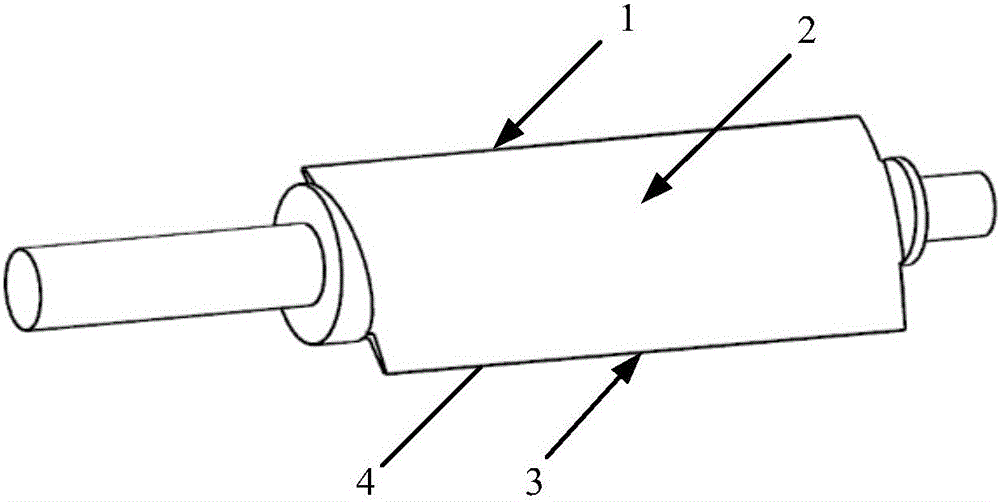

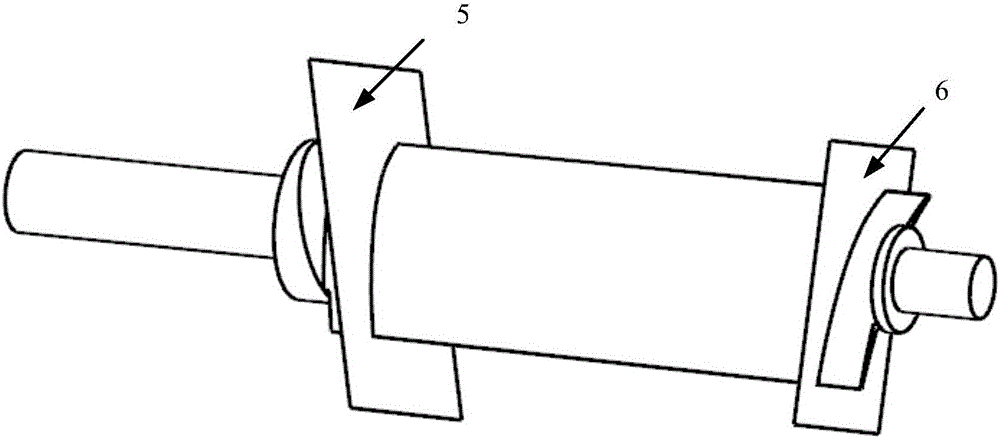

Bobbin assembly capable of realizing peripheral unwinding

The invention discloses a bobbin assembly capable of realizing peripheral unwinding. The bobbin assembly comprises a bobbin, wherein a rotating shaft is arranged in the bobbin; a rotary elastic component is arranged between the rotating shaft and the bobbin; one end of the rotary elastic component is connected with the rotating shaft; the other end of the rotary elastic component is connected with the bobbin. The rotary elastic component is a coil spring, a torsional spring, a corrugated telescopic spring or a rubber band. The rotating shaft and the bobbin are rotatably connected through a bearing. The bearing is adjacent to the rotary elastic component, and an isolation retainer ring is arranged between the bearing and the rotary elastic component. According to the bobbin assembly disclosed by the invention, cheese is fixedly arranged on the bobbin of the bobbin assembly in a sleeving manner and used as warp yarns for 3D weaving, the unwound warp yarns are always at a tensioned state, are not easily entwined per se and are further not easily twined with other yarns, and therefore normal proceeding of 3D weaving can be ensured and the quality of a 3D fabric is greatly improved.

Owner:CHANGZHOU RUISAI ELECTROMECHANICAL EQUIP CO LTD

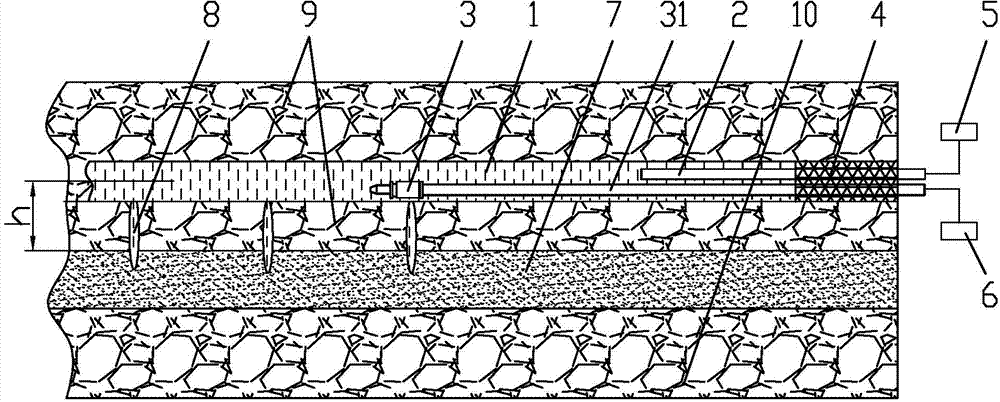

Orientation jetting and fracturing exploitation method for coal bed gas under coal mine

InactiveCN103883303AGuaranteed stabilityLower burst pressureFluid removalSocial benefitsCoal mine methane

The invention discloses an orientation jetting and fracturing exploitation method for coal bed gas under a coal mine. The method includes the steps that a drilled hole along a coal bed is formed in a top plate or a bottom plate; a fracturing pipe set and a radial perforator are placed in a first perforation position; the hole is sealed; the fracturing pump set and the perforator are connected with corresponding pump sets respectively, and a jet flow channel is formed by the perforator and used for communicating the coal bed and the drilled hole; annular fracturing liquid is injected into the drilled hole in a pressure mode, and meanwhile annular pressure is kept; the coal bed is continuously jetted for preset time so that cracks can be formed on coal bodies and extend in the bottom direction of jetting holes of the coal bed; jetting and fracturing are stopped at the same time, the perforator is moved to a next jetting position to form the jet flow channel, and then fracturing liquid is pressurize and jetted continuously; the steps of independently jetting a rock stratum and pressurizing and jetting the coal bed are repeatedly executed until jetting and fracturing at all positions in the drilled hole is finished, and then the coal bed gas is extracted. The orientation jetting and fracturing exploitation method has the advantages that the trend and the quantity of the cracks are controllable, exploitation efficiency of the coal bed is high, the gas disaster of the mine can be effectively prevented and treated, and economic and social benefits can be improved.

Owner:重庆市能源投资集团科技有限责任公司

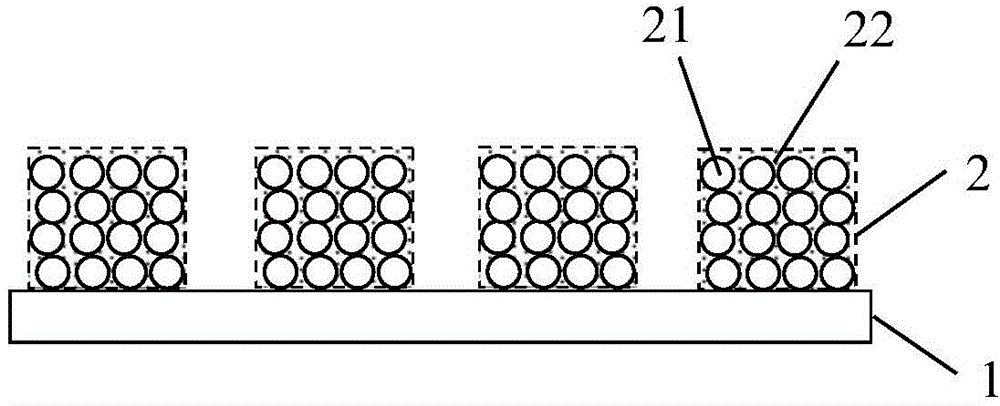

Surface enhanced Raman scattering substrate and manufacturing method thereof

The invention discloses a surface enhanced Raman scattering substrate. The surface enhanced Raman scattering substrate comprises a base and a metal nano unit array arranged on the base, wherein each metal nano unit is formed by fixedly adhering metal powder particles by an adhesive; the adhesive is an inorganic adhesive or an organic adhesive; and the height of each metal nano unit is 400nm-800nm and the distance between the two adjacent metal nano units is 1-2 microns. The invention further provides a manufacturing method of the substrate; the metal powder particles are adhered through 3D printing equipment by using the adhesive to form a metal nano unit array structure on the base; and the surface enhanced Raman scattering substrate is obtained by adopting sintering and annealing processes. The surface enhanced Raman scattering substrate disclosed by the invention has a stable structure and the high surface activity; the adhering method is simple and the manufacturing cost is reduced; and the shape and the position of the nano array structure are easy to control and the repetitive rate is high.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Stripping device for cable stripping machine capable of changing cutter extension length

ActiveCN111009858AWide range of applicationsReduce manufacturing costBasic electric elementsApparatus for removing/armouring cablesKnife cutsPulley

A stripping device for a cable stripping machine capable of changing a cutter extension length relates to the technical field of cables, and comprises a shell. A middle part of the shell is movably connected with uniformly distributed cutter bars, inner sides of the cutter bars are fixedly connected with stripping cutters, the inner sides of the cutter bars are fixedly connected with springs I, and the two sides of a movable block are rotatably connected with pulleys. By using the stripping device for the cable stripping machine capable of changing the cutter extension length, a rotation discis cooperated with a limiting rod for use; during usage, a cable extends into the middle part of the shell; according to a diameter of the cable, the rotation disc is rotated and adjusted, the rotation disc drives a limiting rod to move through a limiting hole so that the limiting rod drives the cutter bar to move, the extending length of the stripping cutter is changed, the cable sheath is cut bythe stripping cutter; and the length of the stripping cutter cutting into the cable sheath is equal to a thickness of an outer sheath of the cable so that an effect of changing the extending length of the cutter is achieved, an application of the stripping device is wider, production cost is saved, and production efficiency is improved.

Owner:广东电网有限责任公司肇庆封开供电局

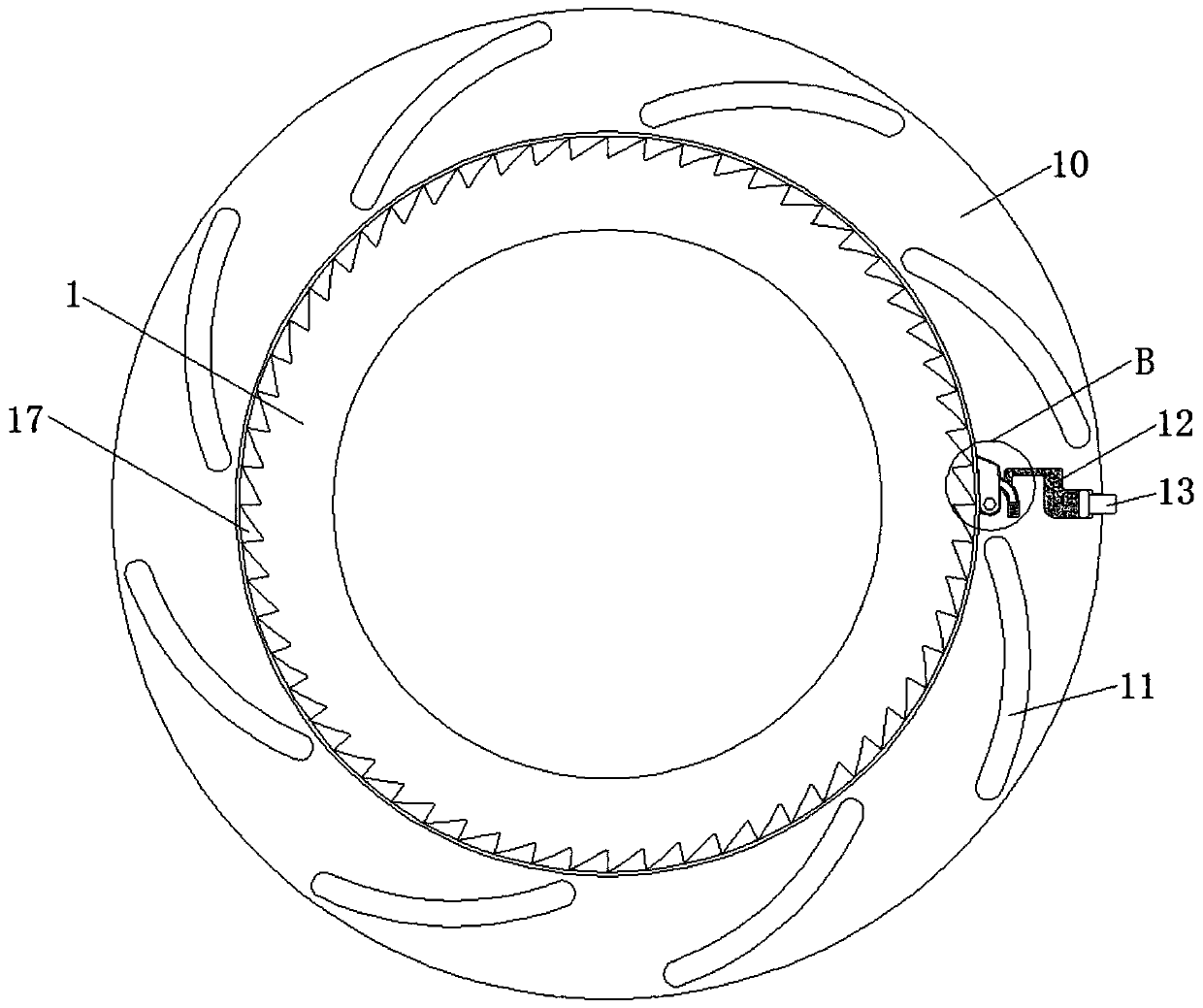

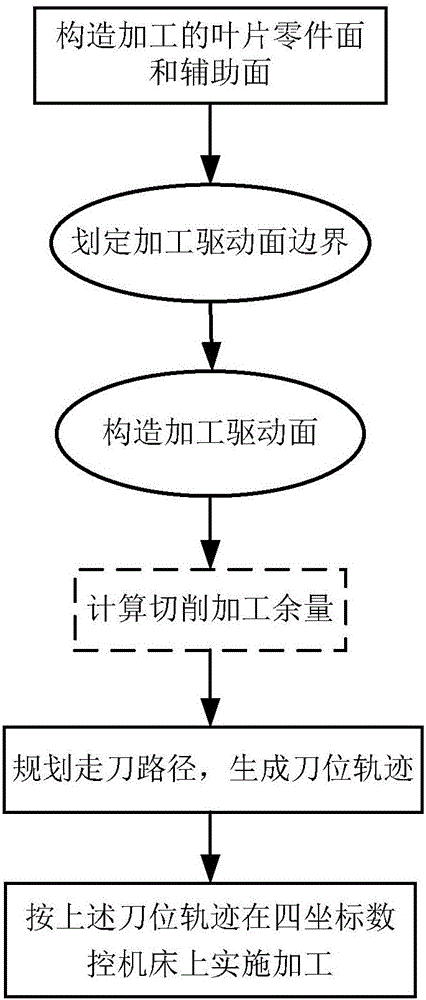

Thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation

ActiveCN106001720AReduce bending deformationReduce torsional deformationWorkpiecesMilling equipment detailsPosition toleranceTorsional deformation

The invention provides a thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation. Modeling is carried out by utilizing a three-dimensional modeling software, and an auxiliary surface and a boundary surface are formed, so that a driving surface is determined by utilizing a section line lofting process. Cutter machining paths are generated according to the driving surface, and the machining allowance of each cutter position point on each machining path is determined by adopting a Newton interpolation method. Finally, vanes are cyclically processed according to symmetrical milling rules. Compared with a traditional longitudinal fixed-allowance cutting and spiral milling method, the thin-walled vane nine-point control variable-allowance milling method has the advantages that technical problems, such as large torsional deformation, low contour precision, poor section position tolerance and difficult error control, in the machining process can be solved; and by adopting a Newton interpolation process allowance fine adjustment method, surface quality can be more comprehensively controlled, and problems, such as large bending deformation, poor section position tolerance and low surface contour precision, in the machining process can be effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

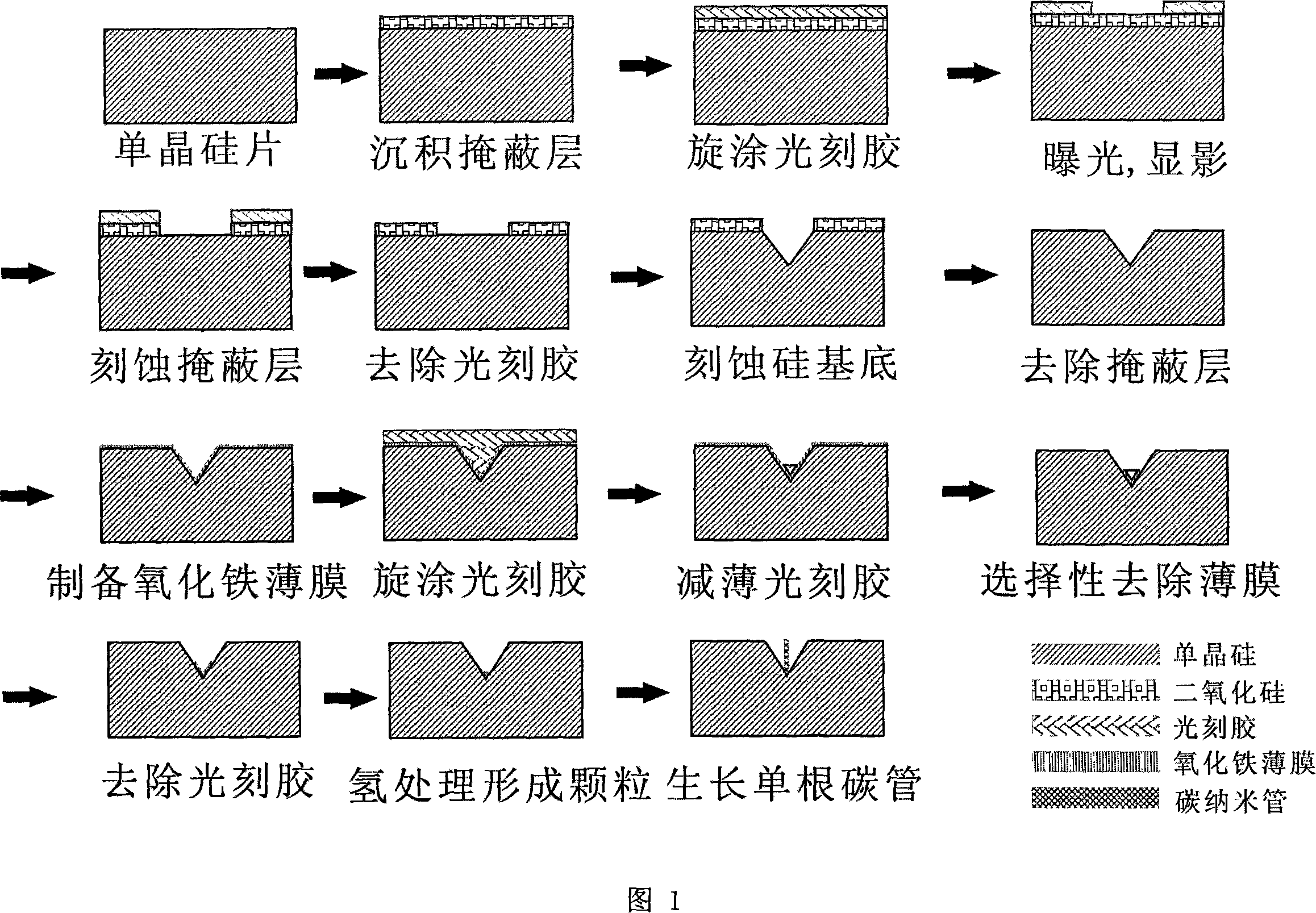

Method for preparing single nano material in pore space structure

The present invention relates to the preparation field of nanometer materials, disclosing a method for producing a single piece of nanometer material in a hole-shaped structure. First, a tiny hole is etched on a substrate, then metals or oxide films are positionally deposited on the bottom of the tiny hole, so that a single nanometer particle is formed in high-temperature annealing; or a single piece of one-dimensional nanometer material can be vegetated under the effects of metals or oxide films (such as catalytic action) through gas phase or liquid phase. The method has the advantages of simple technology and controllable location, which can realize the orientation growth of a single piece of nanometer material through controlling the position of the hole. The invention enables large-scale array type preparation with high efficiency.

Owner:SUN YAT SEN UNIV

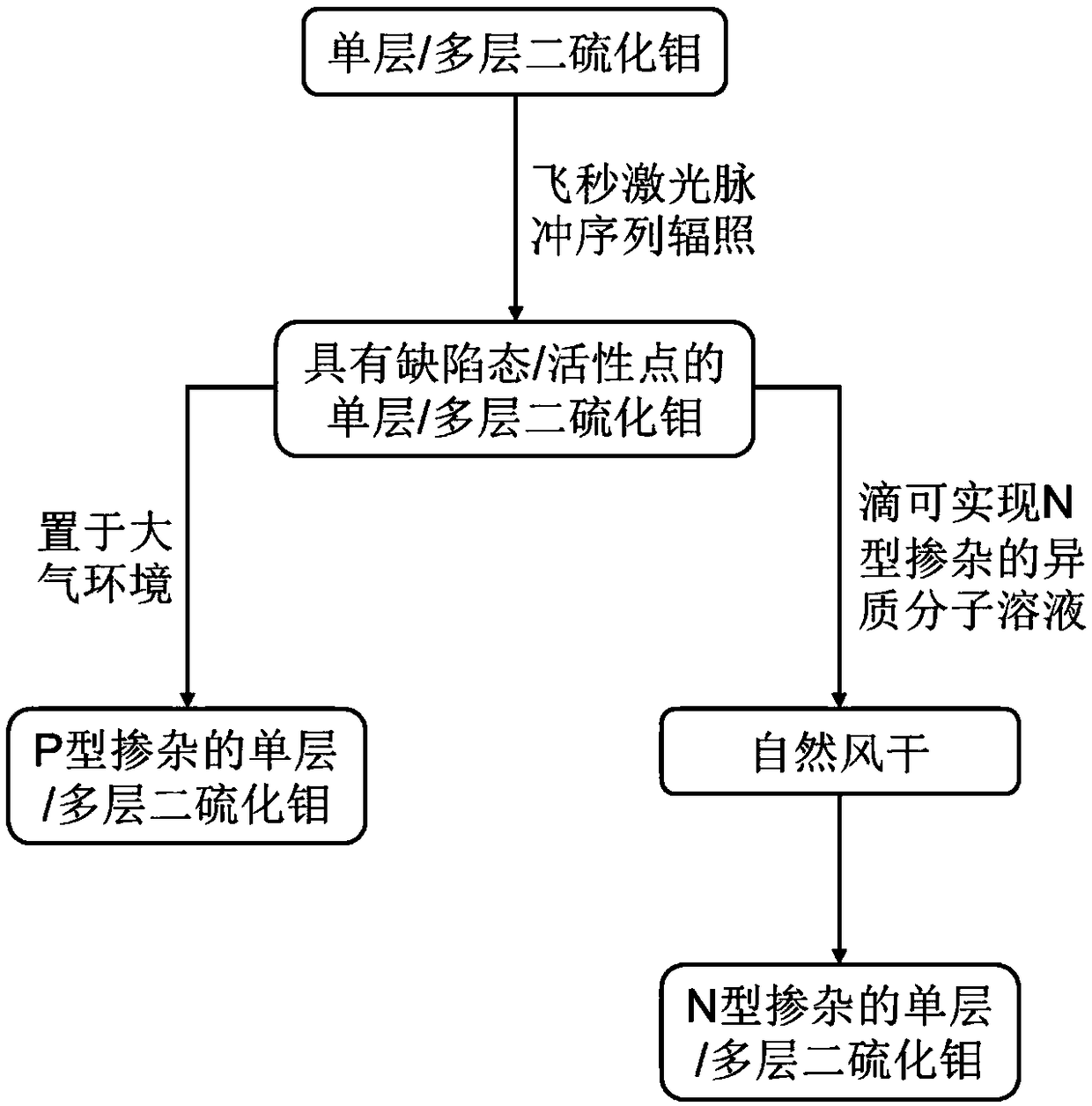

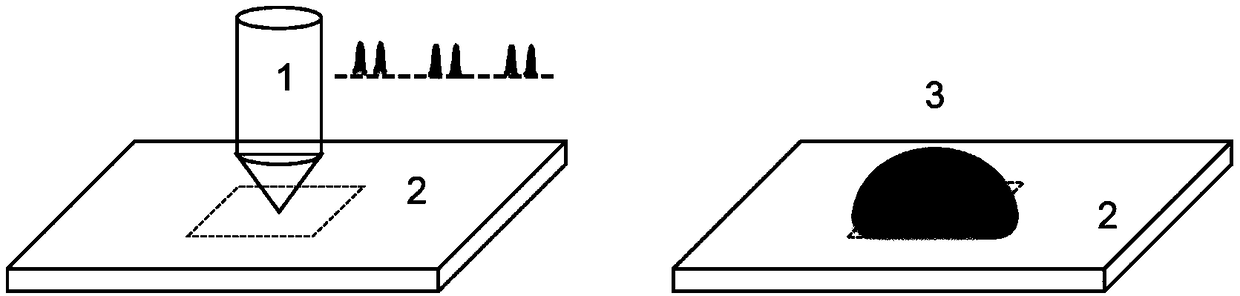

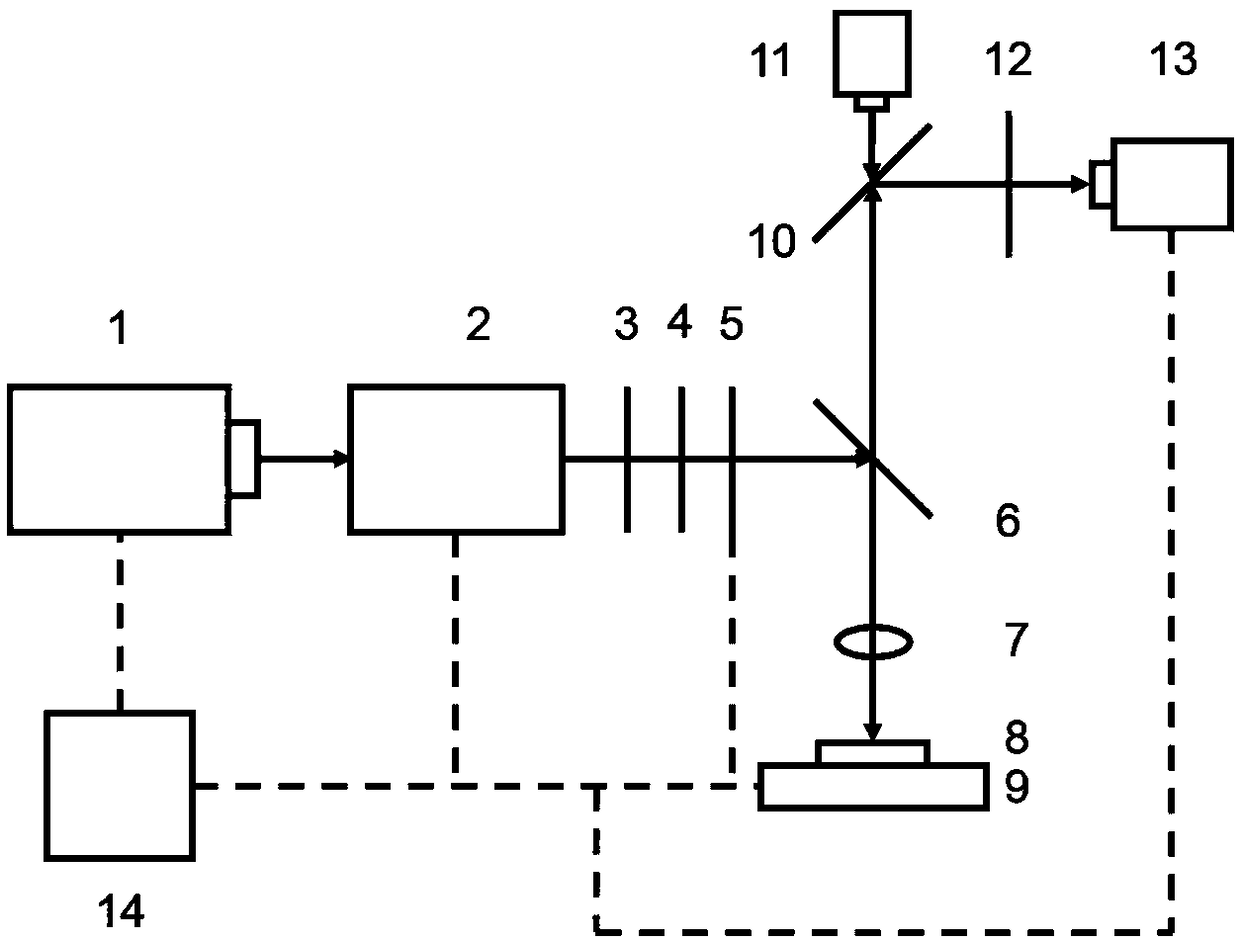

Method for enhancing heterogeneous molecule-doped molybdenum disulfide based on electronic dynamic regulation

ActiveCN108862388AThe degree and position of defect states are controllableEasy to operateMaterial nanotechnologyRaman scatteringPhysicsMicro nano

The invention discloses a method for enhancing heterogeneous molecule-doped molybdenum disulfide based on electronic dynamic regulation, and belongs to the field of micro-nano manufacturing. The method comprises the following steps of step 1, enabling a femtosecond laser pulse sequence to focus onto the single or multiple molybdenum disulfide layers at the surface of a substrate, controlling the processing parameters and processing location of the femtosecond laser pulse sequence, inducing the defect mode with controllable degree and location at the surface of the molybdenum disulfide meetingthe preset use requirements, and enabling the molybdenum disulfide with defect mode / active point to effectively adsorb oxygen in air under the air environment, so as to obtain the controllable oxygenmolecule P-doped single or multiple molybdenum disulfide layers; step 2, dripping an N-doped organic matter / inorganic matter / biological molecule solution onto the single molybdenum disulfide layer with defect mode / active point, and waiting for natural airing, so as to obtain the organic matter / inorganic matter / biological molecule N-doped single molybdenum disulfide layer. The method has the advantages that the degree and location of the defect mode are controllable, the operation is simple and flexible, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

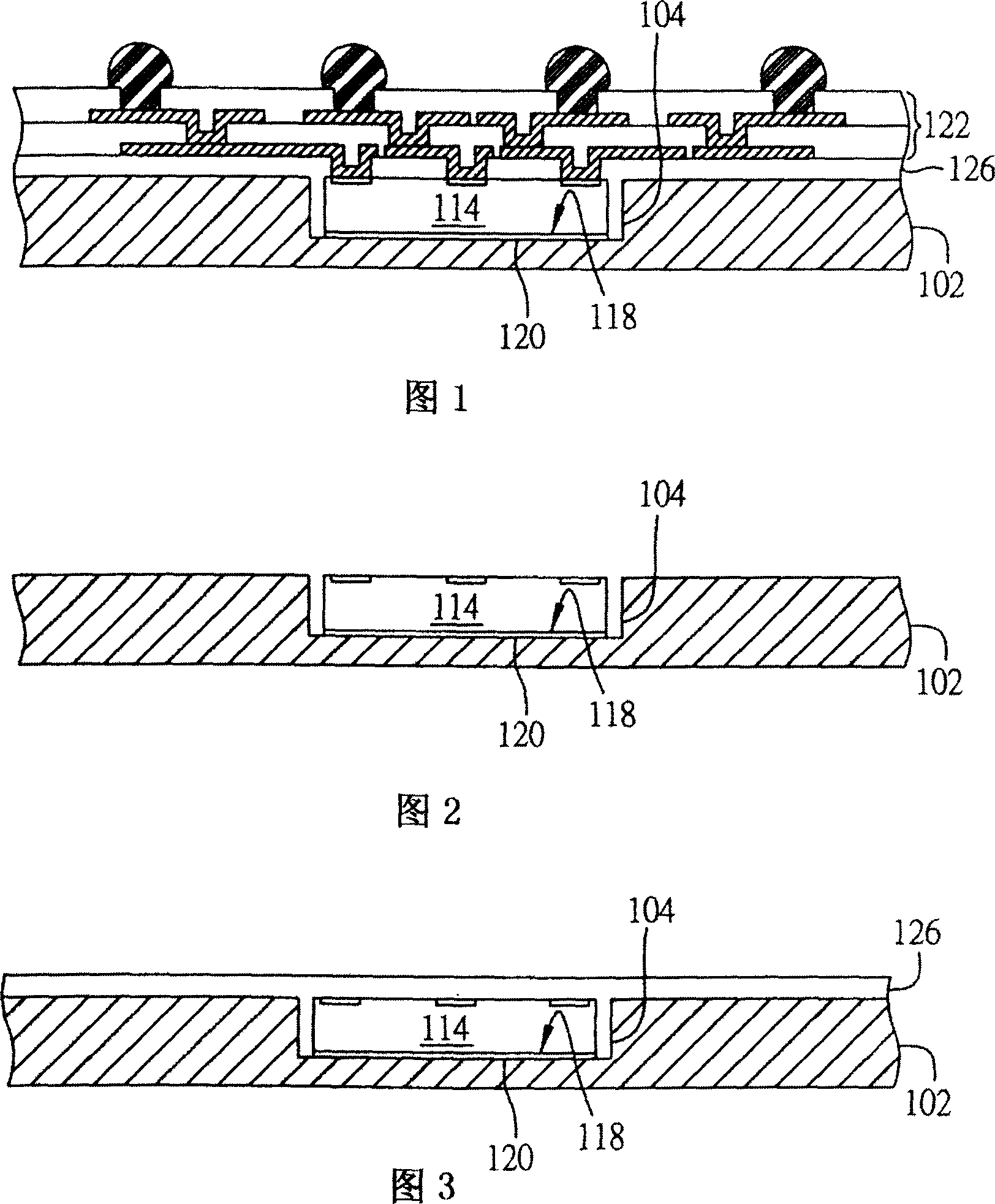

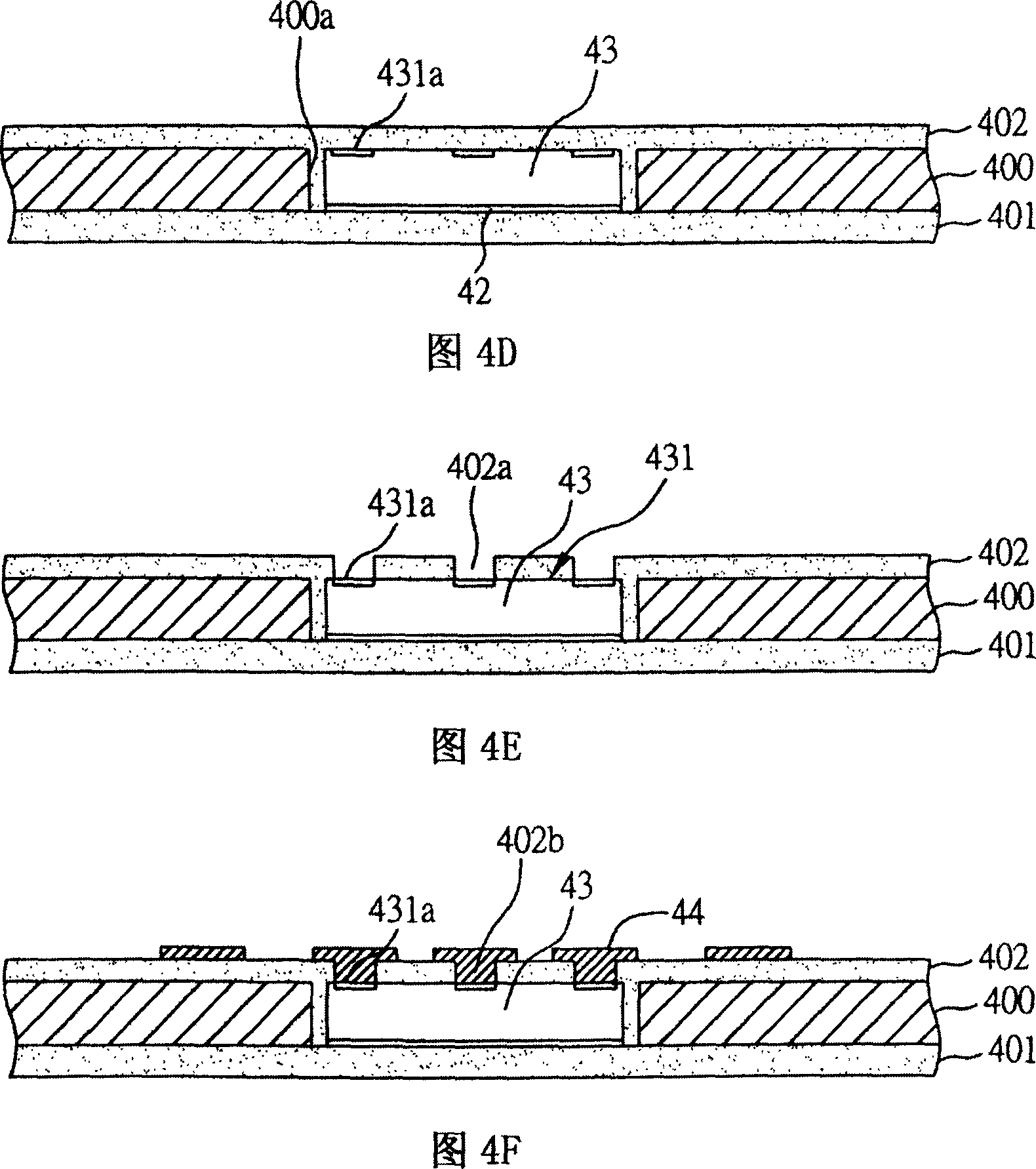

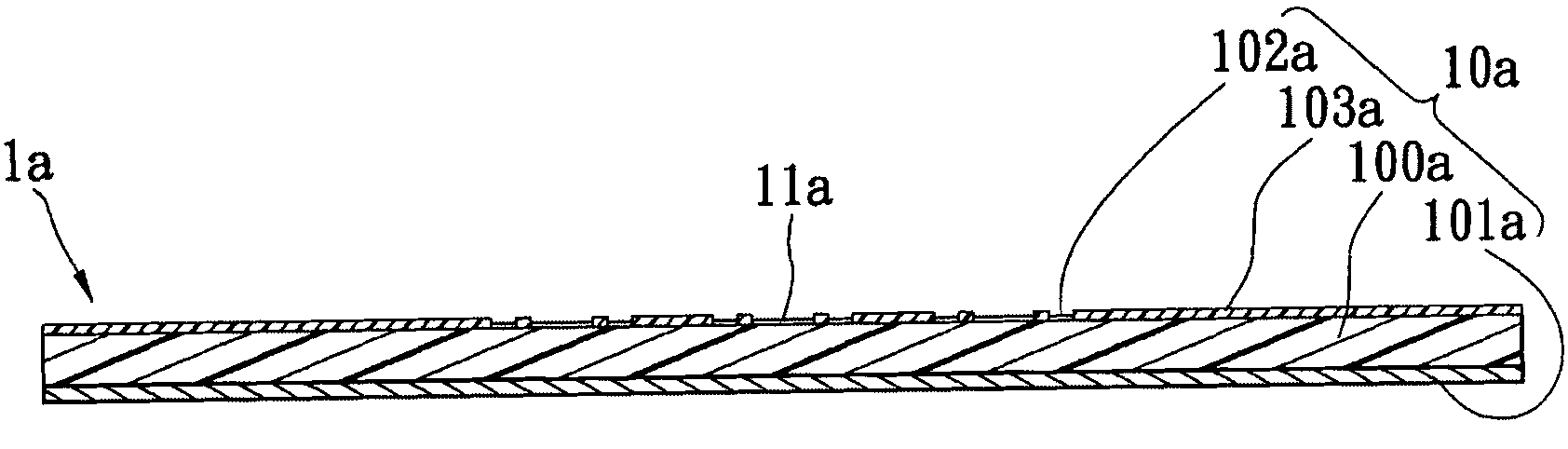

Semiconductor chip buried base plate 3D construction and its manufacturing method

ActiveCN1971863AGood quality and reliabilityImprove product reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

This invention relates to semiconductor chip imbed baseboard three dimensional seal structure and its process method, which comprises the following steps: connecting load parts with at least one hole to first insulation layer and at least one conductor chip onto first insulation contained in the load holes; then forming second insulation layer onto load part and chips for adhesion and filling insulation resin into gap between load board and chip to form electricity connection to chip circuit layer; forming chip dissipation blind hole on first insulation layer to aid semiconductor chip to dissipate heat outside.

Owner:PHOENIX PRECISION TECH CORP

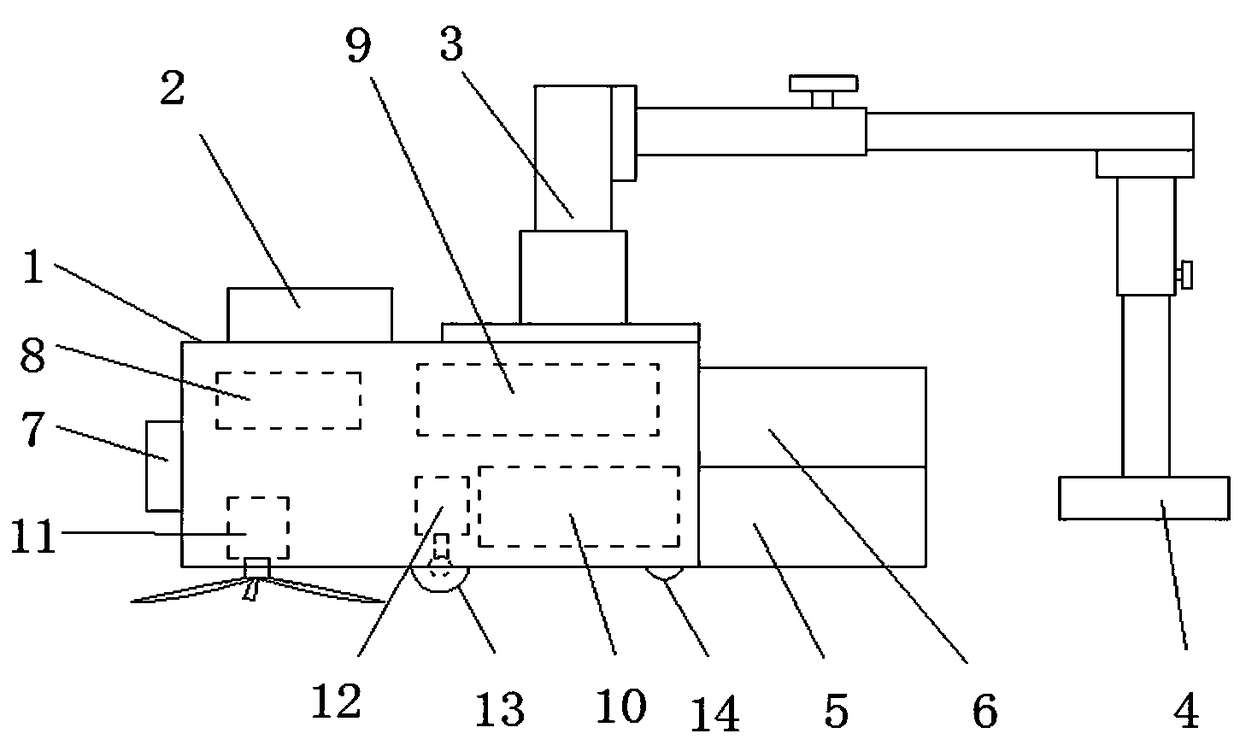

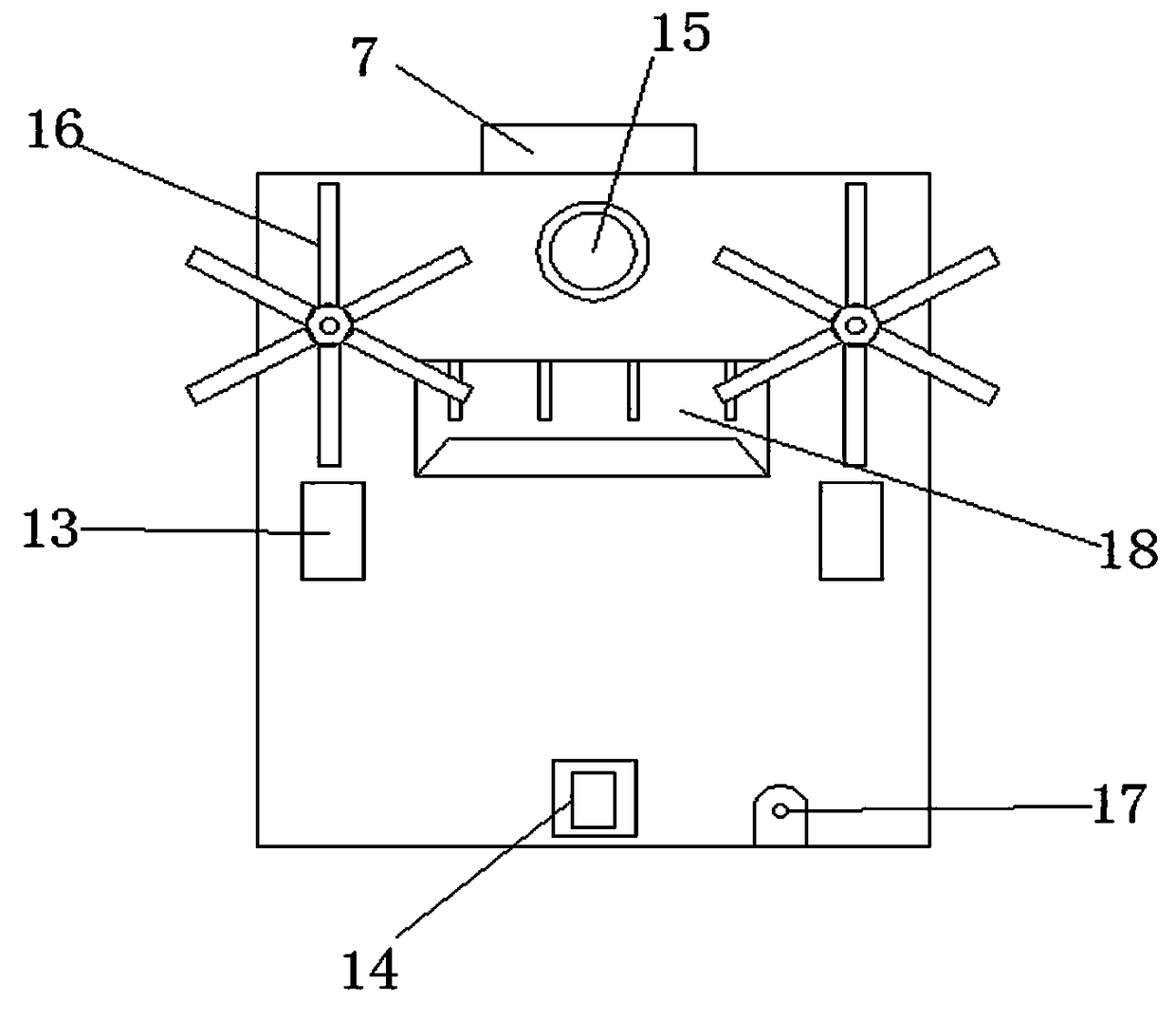

Novel scrap iron sweeping device used for machining

The invention discloses a novel scrap iron sweeping device used for machining. The novel scrap iron sweeping device structurally comprises a device body, a controller, a telescopic rod, an electromagnet, a dust collecting box and a scrap iron collecting box, the controller is arranged on the left side of the upper end of the device body, the telescopic rod is arranged on the right side of the upper end of the device body, the dust collecting box and the scrap iron collecting box are connected to the right side of the device body, the scrap iron collecting box is arranged at the upper end of the dust collecting box, a processor, a storage battery, a dust collector, a rotating motor and a driving motor are arranged separately inside the device body, driving wheels are symmetrically arrangedin the middle of the lower end of the device body and connected with the driving motor, a guiding wheel is arranged on the left side of the lower end of the device body, a supporting wheel is arrangedon the right side of the lower end of the device body, and a charging hole is formed in the right side of the supporting wheel. The novel scrap iron sweeping device is simple in structure, convenientto operate, more intelligent, more automatic, capable of effectively separating, adsorbing and collecting dust and scrap iron on the ground and good in clearing effect.

Owner:扬州天润传感技术有限公司

Conveyance method and apparatus for processing step

InactiveUS7238392B2Low costPosition is easy to controlLiquid surface applicatorsConveyorsEngineeringTruck

Owner:TAIKISHA LTD +1

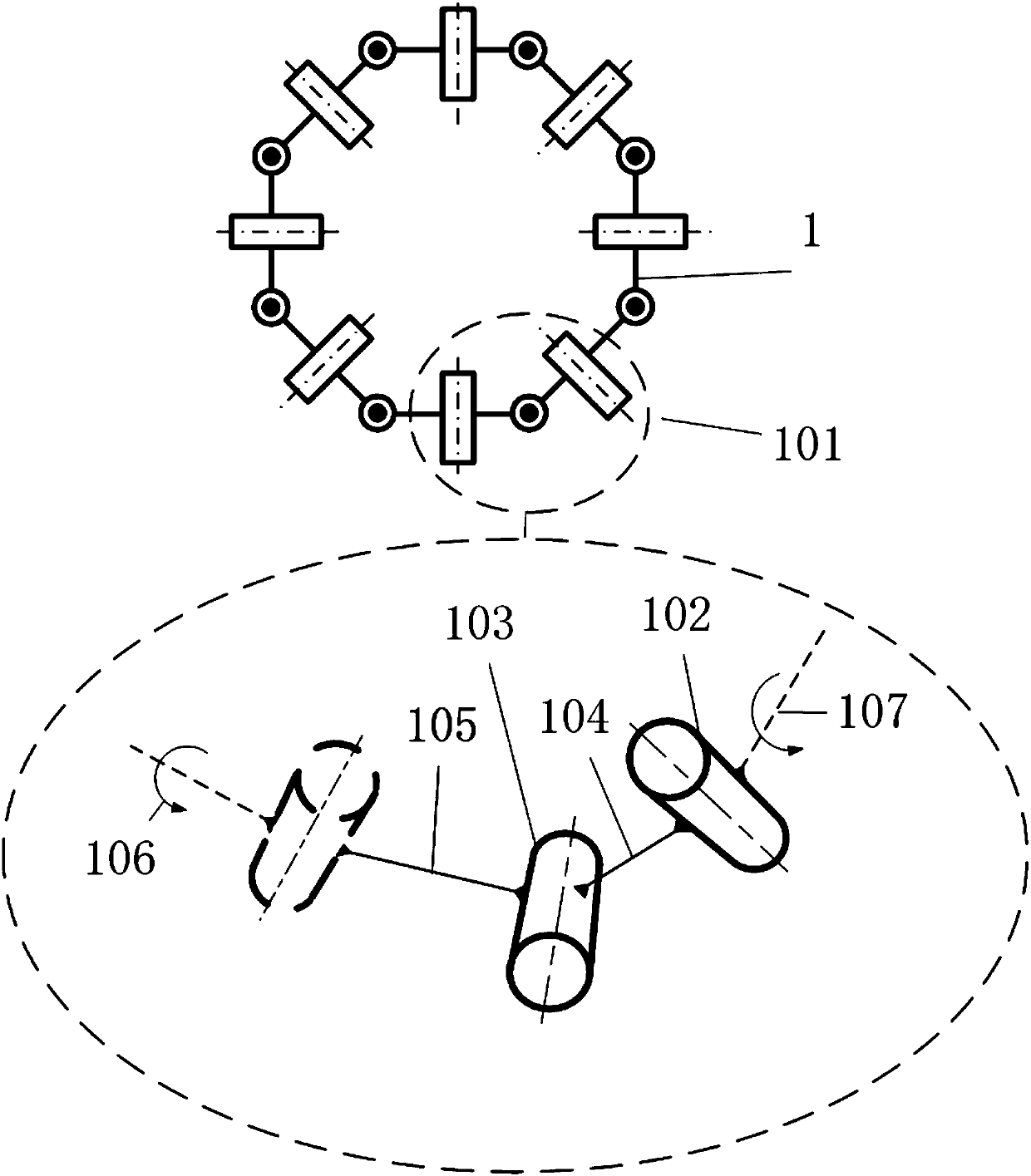

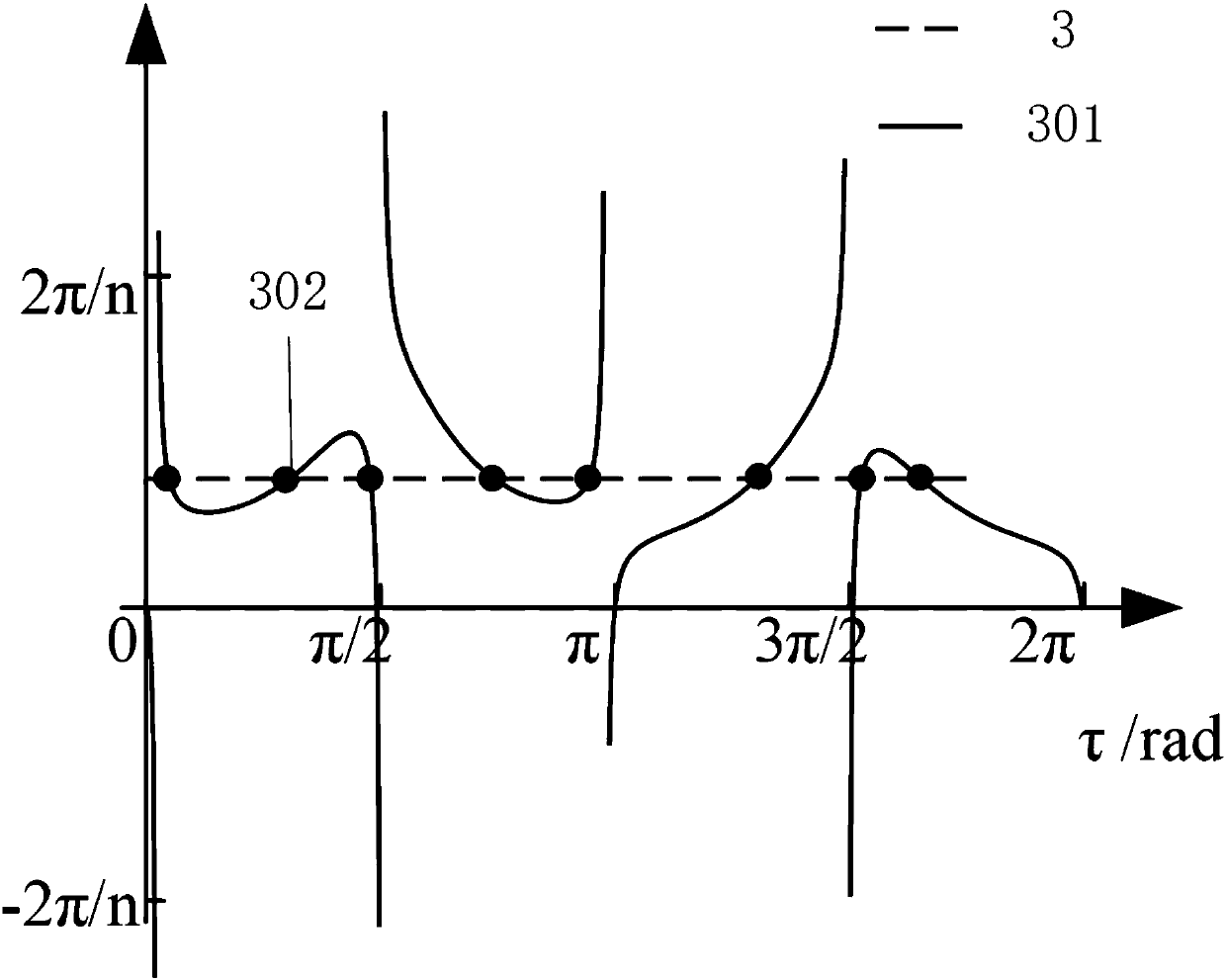

Multi-steady-state compliant Bricard mechanism and steady-state analysis method thereof

ActiveCN108515511AVariable topologyAdapt to actual working conditionsMachine part testingProgramme-controlled manipulatorAnalysis methodContinuous rotation

The invention discloses a multi-steady-state compliant Bricard mechanism and a steady-state analysis method thereof. The multi-steady-state compliant Bricard mechanism is formed by connecting a plurality of Bricard basic units in an end-to-end manner so as to form an annular closed structure; each Bricard basic unit comprises two flexible hinges and two rigid connecting parts, which the two flexible hinges are provided with different planes orthogonal to each other, and two rigid connecting parts are used for enabling the flexible hinges to be connected; every two flexible hinges are connectedthrough one rigid connecting part; one flexible hinge is connected to one flexible hinge of the adjacent Bricard basic unit through the other rigid connecting part; the two rigid connecting parts inthe same Bricard basic unit have to be equal in length; but the rigid connecting parts of different Bricard basic units do not have to be equal in length. The multi-steady-state compliant Bricard mechanism and the steady-state analysis method thereof have the advantages that the continuous rotation, multiple steady states and the like of a compliant triple Bricard mechanism can be achieved, meanwhile, the mechanism topology is changeable, the unit number is adjustable, and implementation and popularization are easy.

Owner:SOUTH CHINA UNIV OF TECH

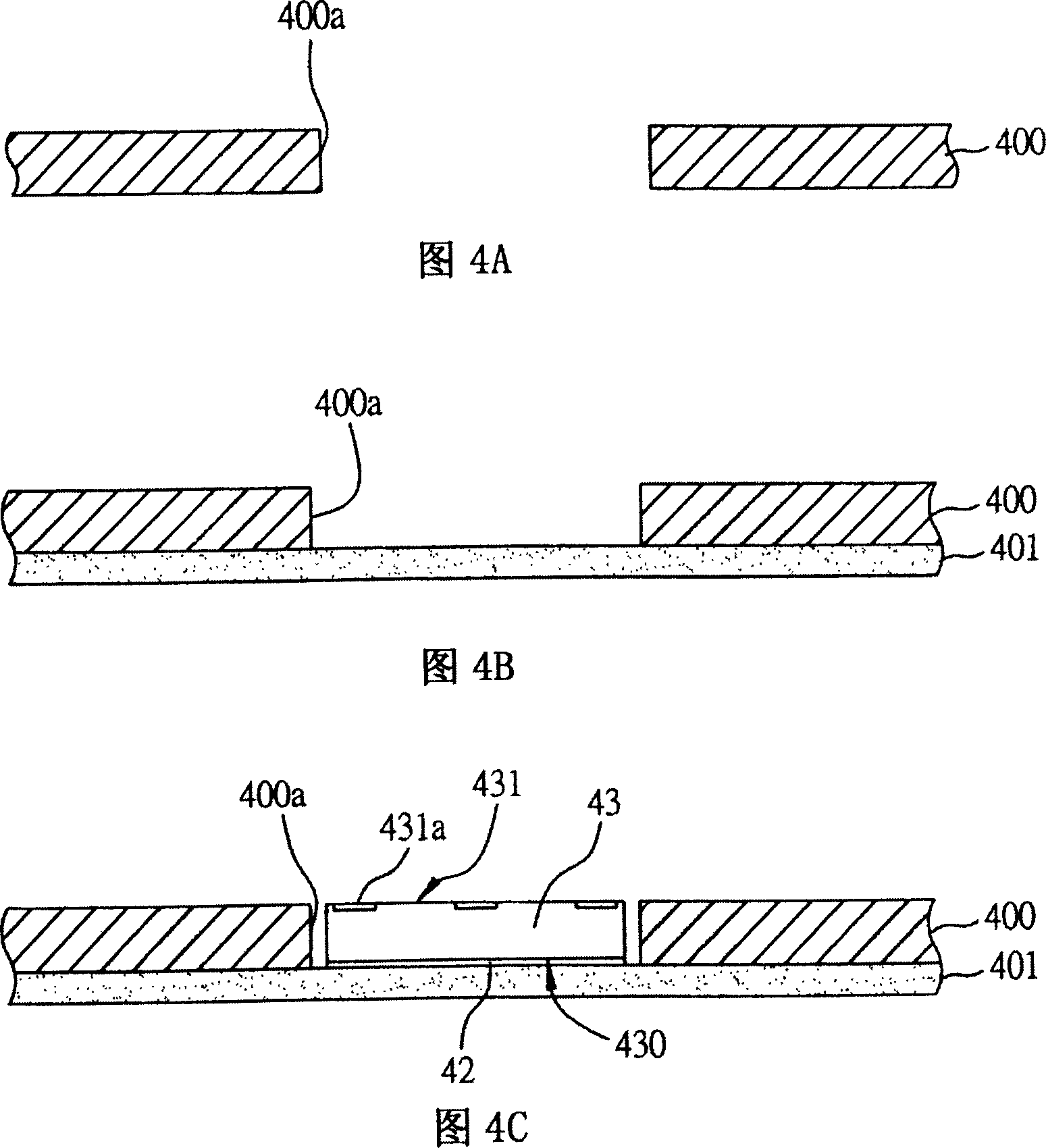

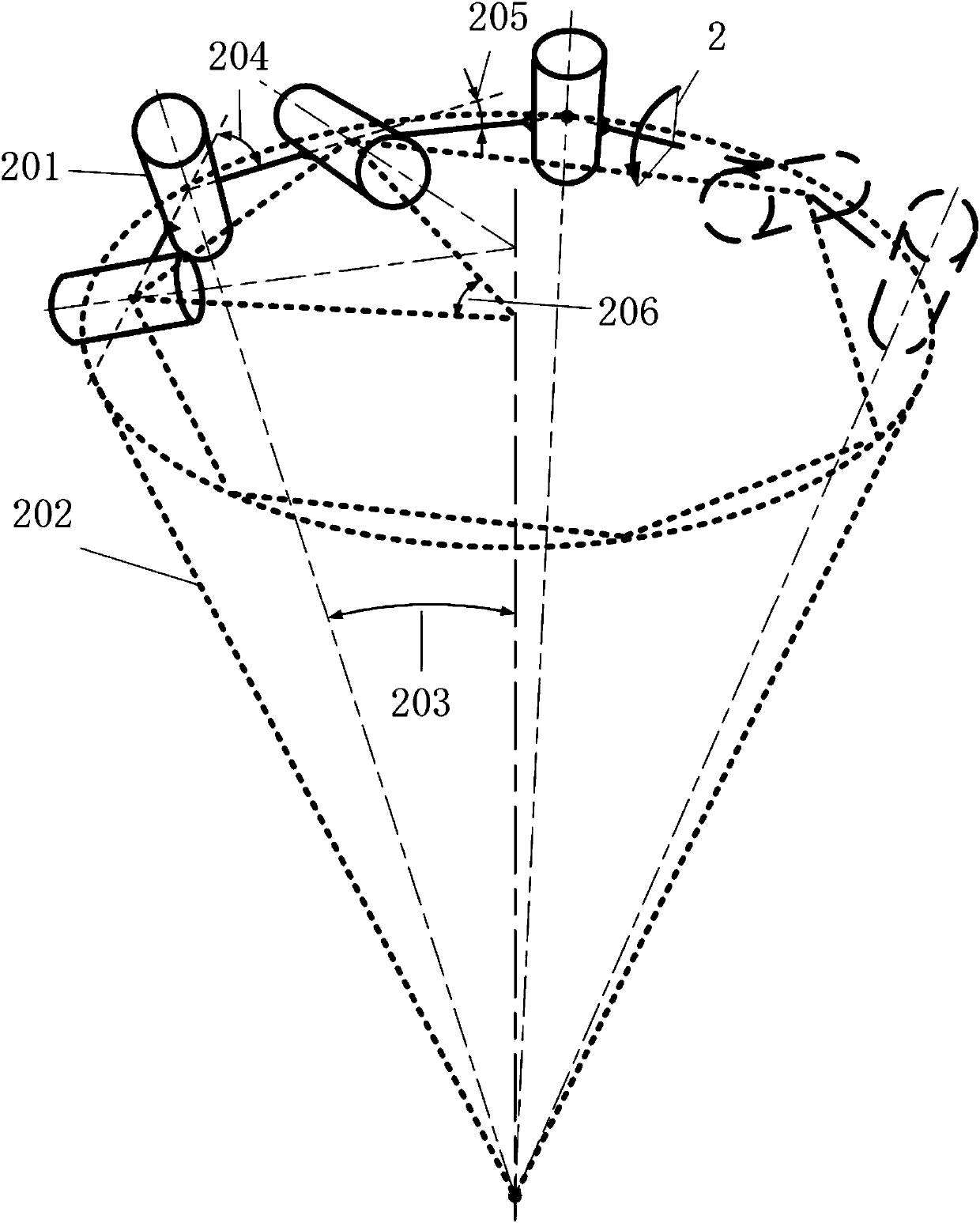

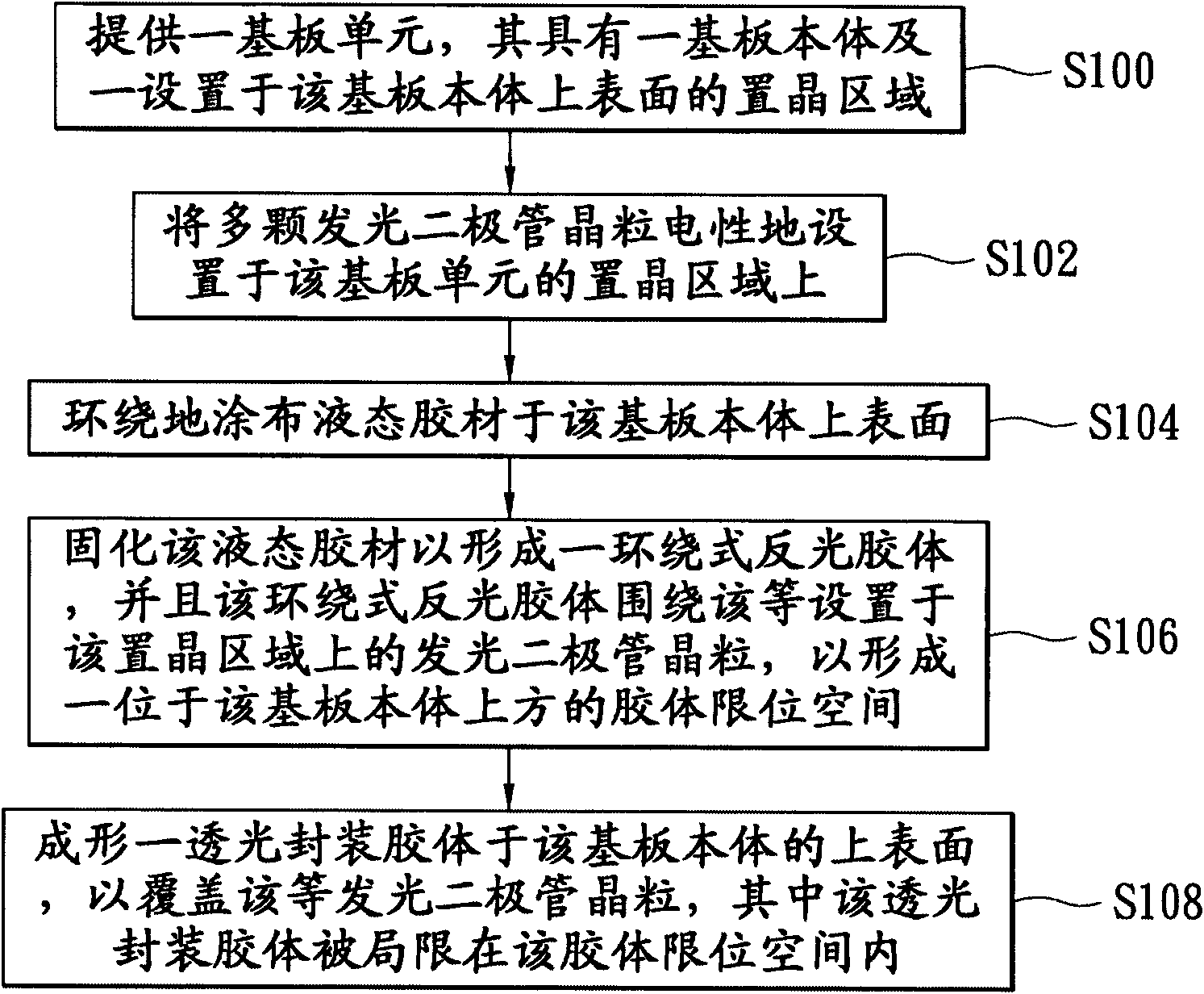

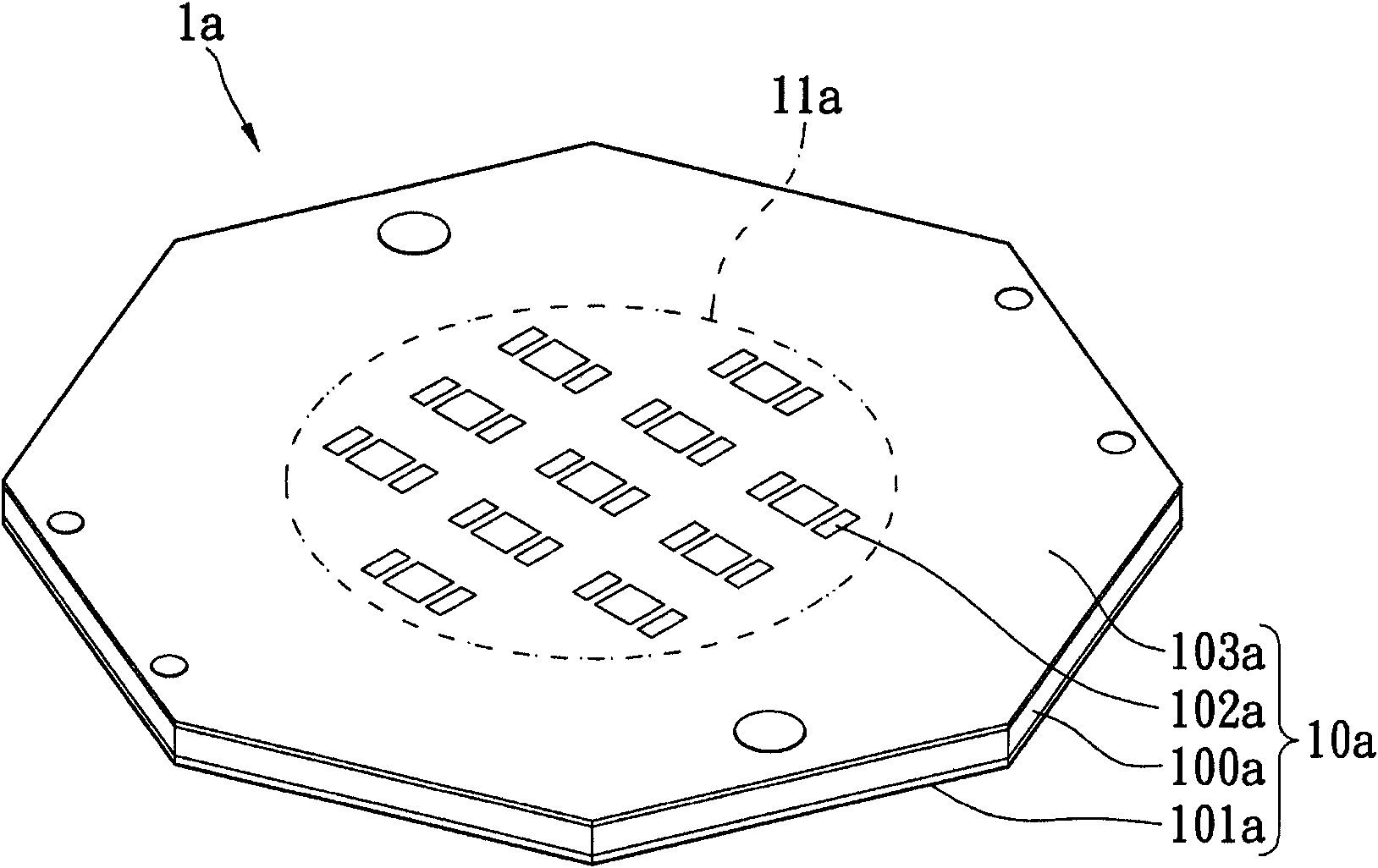

Light-emitting structure capable of improving light-emitting efficiency and controlling emergent angle and manufacture method thereof

InactiveCN101963288ACan control the light angleImprove luminous efficiencyPoint-like light sourceElectric circuit arrangementsEngineeringColloid

The invention relates to a light-emitting structure capable of improving light-emitting efficiency and controlling an emergent angle, which comprises a base plate unit, a light-emitting unit, a reflecting unit and a packaging unit, wherein the base plate unit is provided with a base plate body and a crystal placing area; the light-emitting unit is provided with a plurality of light-emitting diode (LED) grains which are electrically arranged on the crystal placing area; the reflecting unit is provided with a surrounding type reflecting colloid which is annularly formed on the upper surface of the base plate body in a coating way; the surrounding type reflecting colloid surrounds the LED grains which are arranged on the crystal placing area to form a colloid limiting space above the base plate body; the packaging unit is provided with a transmitted packaging colloid which is formed on the upper surface of the base plate body to cover the LED grains; and the transmitted packaging colloid is limited in the colloid limiting space, thereby improving the light-emitting efficiency of an LED packaging structure.

Owner:PARAGON SEMICON LIGHTING TECH

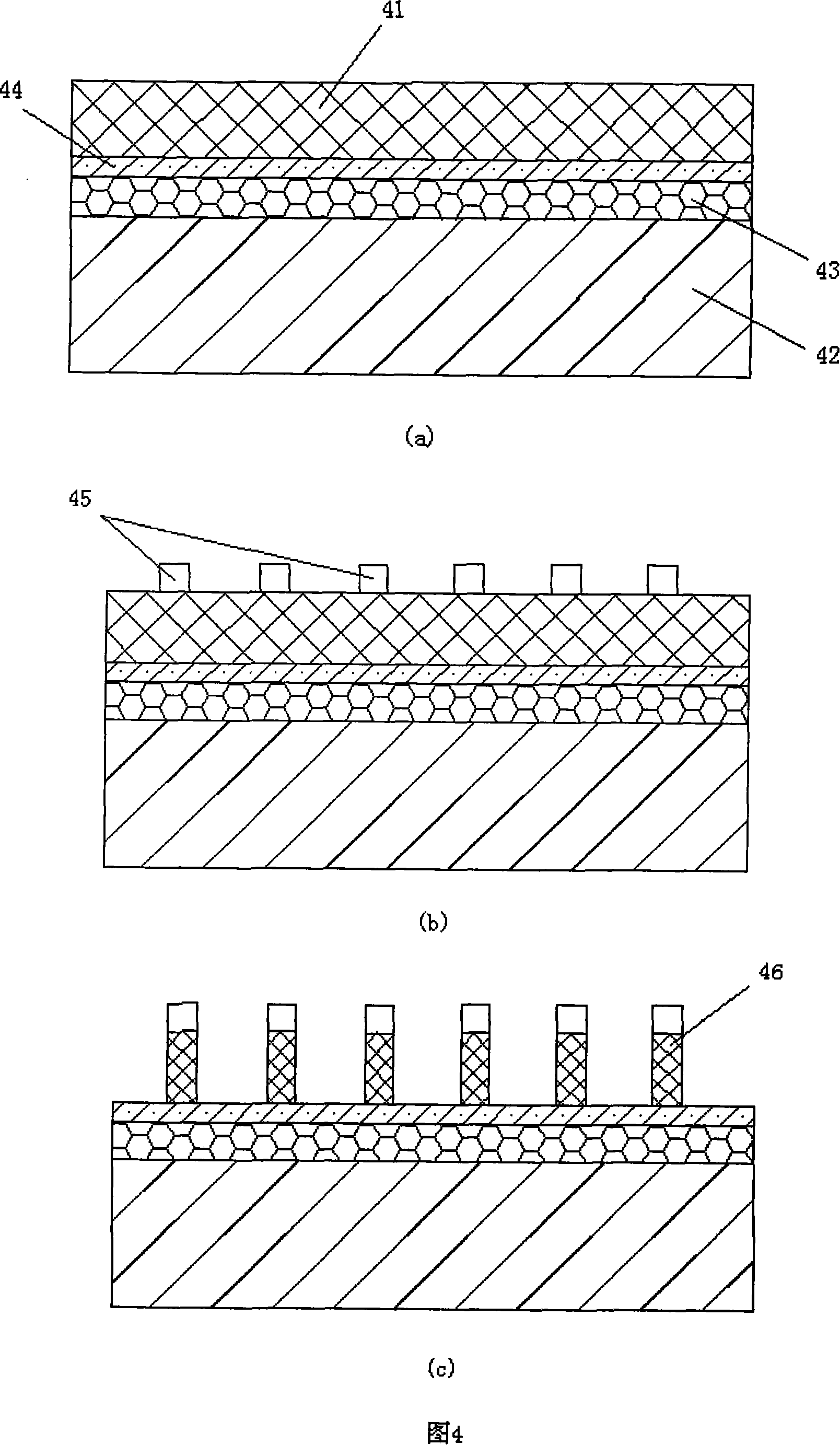

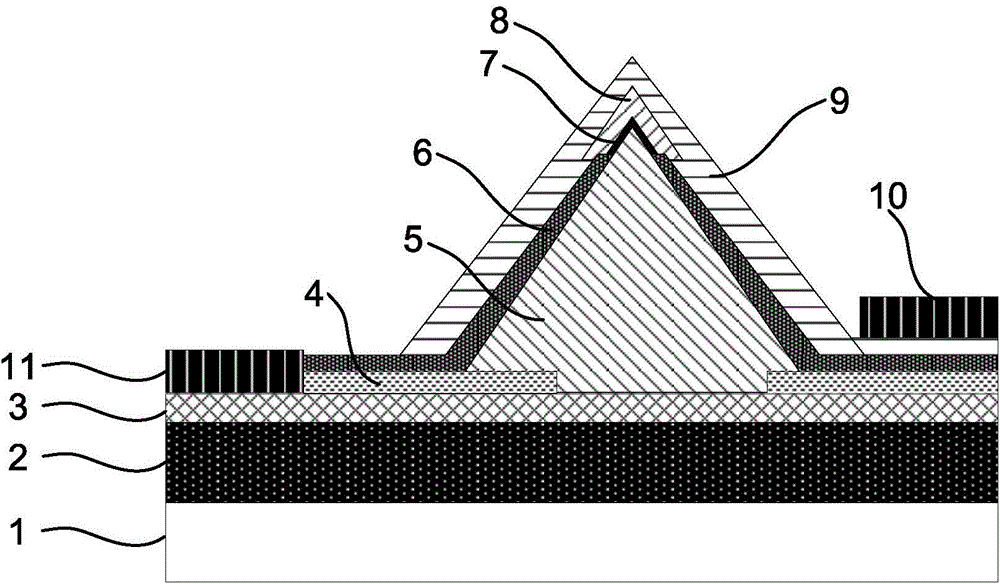

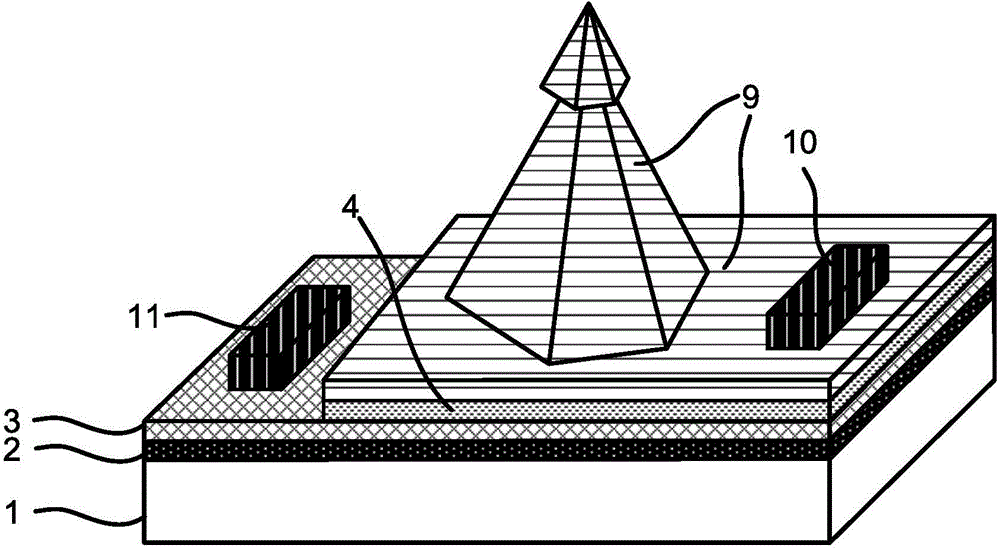

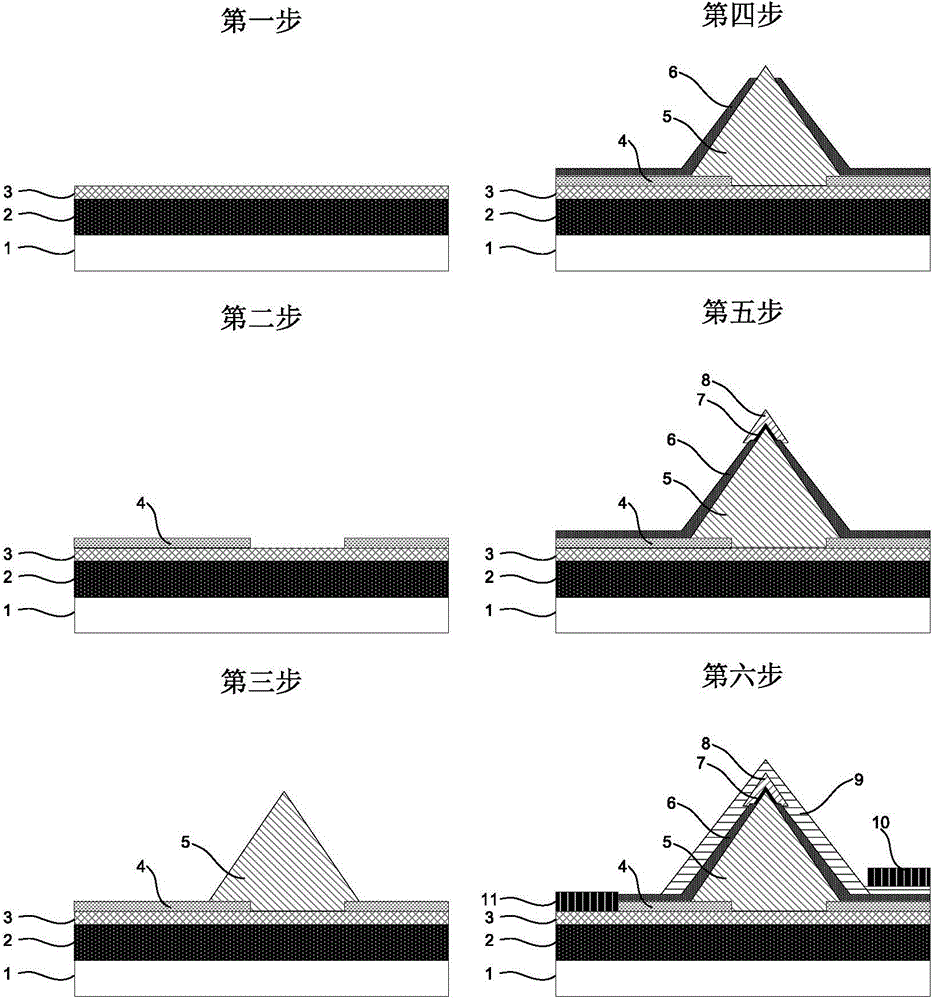

Three-group nitride micro-nano light-emitting device with embedded active layer and manufacturing method

ActiveCN104465929AImprove quantum efficiencyPosition is easy to controlSemiconductor devicesQuantum efficiencyMicro nano

The invention discloses a three-group nitride micro-nano light-emitting device with an embedded active layer and a manufacturing method. The light-emitting device comprises an initial light-emitting device, a transparent conducting layer, a p-type electrode and an n-type electrode; the initial light-emitting device is sequentially provided with a substrate, a three-group nitride nucleating layer, a buffering layer, an n-type three-group nitride layer, imaging 5 masking film, a selective epitaxial growth n-type three-group nitride structure, selective epitaxial growth exposed masking film at the top of the n-type three-group nitride structure, the three-group nitride active layer and a p-type three-group nitride coverage layer from bottom to top. The three-group nitride active layer is arranged between a part, which is not masked and covered, between the selective epitaxial growth n-type three-group nitride structure and the p-type three-group nitride coverage layer; the transparent conducting layer is deposited to the front face of the initial light-emitting device, the p-type electrode is arranged on the transparent conducting layer, and the n-type electrode is arranged on the n-type three-group nitride layer or the bottom of the substrate. The light-emitting device (10) has the advantages of being controllable in position and size, stable in performance and ultra high in quantum efficiency.

Owner:SUN YAT SEN UNIV

Process for preparing nano structure of zinc oxide

ActiveCN101214989APosition is easy to controlUniform shapeNanostructure manufactureZinc oxides/hydroxidesEmulsionNanostructure

The invention discloses a process for preparing zinc oxide nanometer structure, which is characterized in that the process steps are as follows: (A) coating a layer of light-sensitive emulsion on the underlay which is deposited with a layer of seed and then forming a microhole on the light-sensitive emulsion by photolithograpic technology, (B) placing the underlay which is obtained by step A in the growth solution and proceeding the growth of the nanometer structure. The employment of the process can successfully realize the preparation of various zinc oxide nanometer structures. Compared with the prior art, the technique method has the advantages that the process step is simple and controlled, the position of the prepared zinc oxide nanometer structure is controllable, the vertical occurrence is orderly and the appearance is uniform, which is much beneficial for preparing element.

Owner:SUN YAT SEN UNIV

Trimming device for textile fabrics

InactiveCN107815847AEasy to collectAvoid flashSevering textilesTextile shapingWaste materialUltrasonic generator

The invention discloses a trimming device for textile fabrics. The device comprises a base plate, an ultrasonic generator, a cutting head and a steam ironing wheel; a roller is installed at one side of a top part of the base plate; textile fabrics are winded on the roller; a roll pedestal is installed on the other side of the top part of the base plate and a motor is fixed on one end of a top partof the roll pedestal; a fixed roll is fixed to an output end of the motor through a rotating shaft; one end, away from the motor, of the rotating shaft is connected with the other end of the top partof the roll pedestal; waste material cases are fixed at two ends of the middle position in the top part of the base plate; pedestals are fixed at two ends of the top part of the base plate between the waste material cases; a control panel is installed on one end of the pedestal; slideways are installed at the middle position of the top end of the pedestal and slide blocks are fixed in the slideways. The invention has the steam ironing wheel and the pressing wheel installed so that the device can be used for ironing the textile fabrics before trimming to facilitate subsequent cutting operations.

Owner:丽水遂智科技咨询有限公司

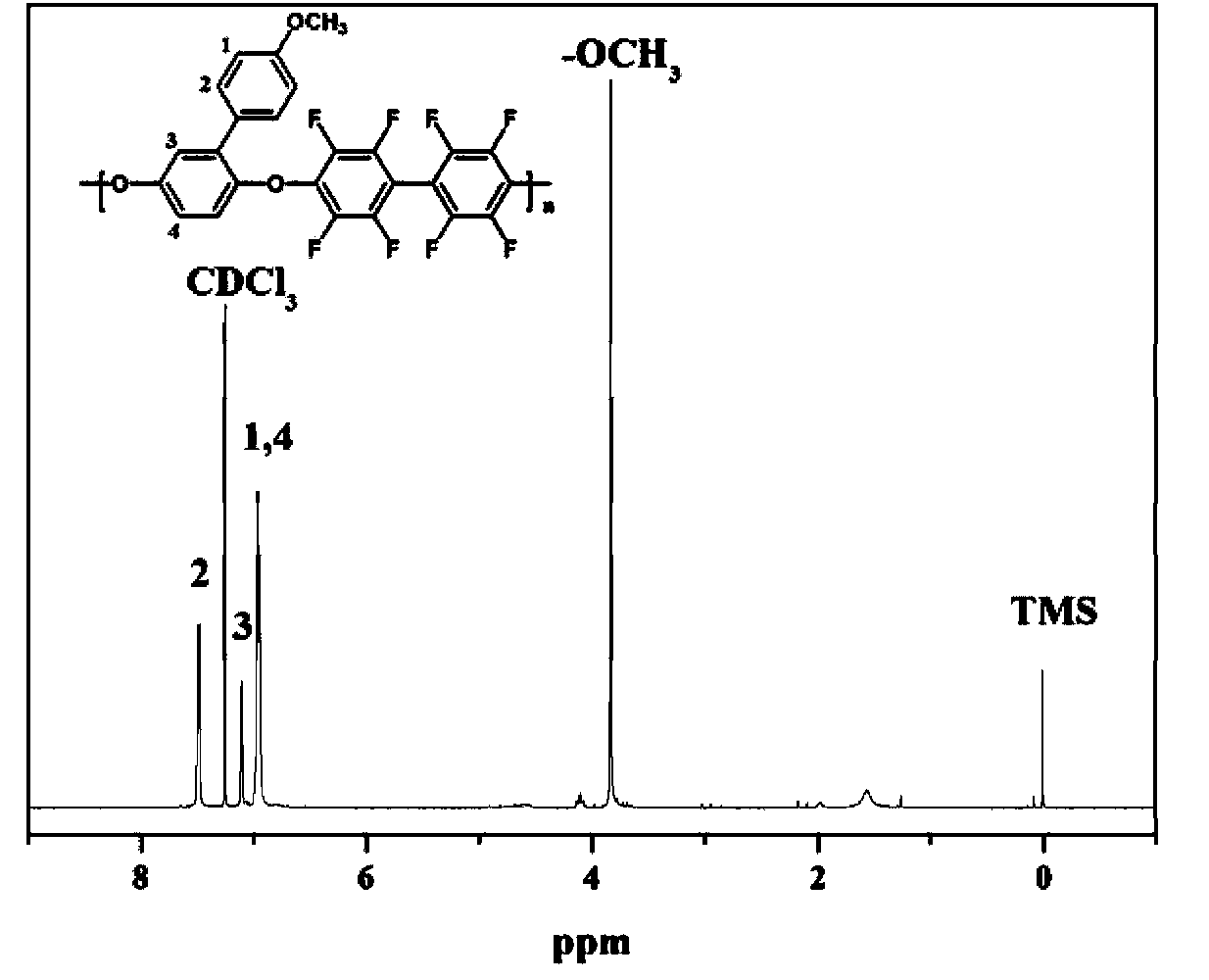

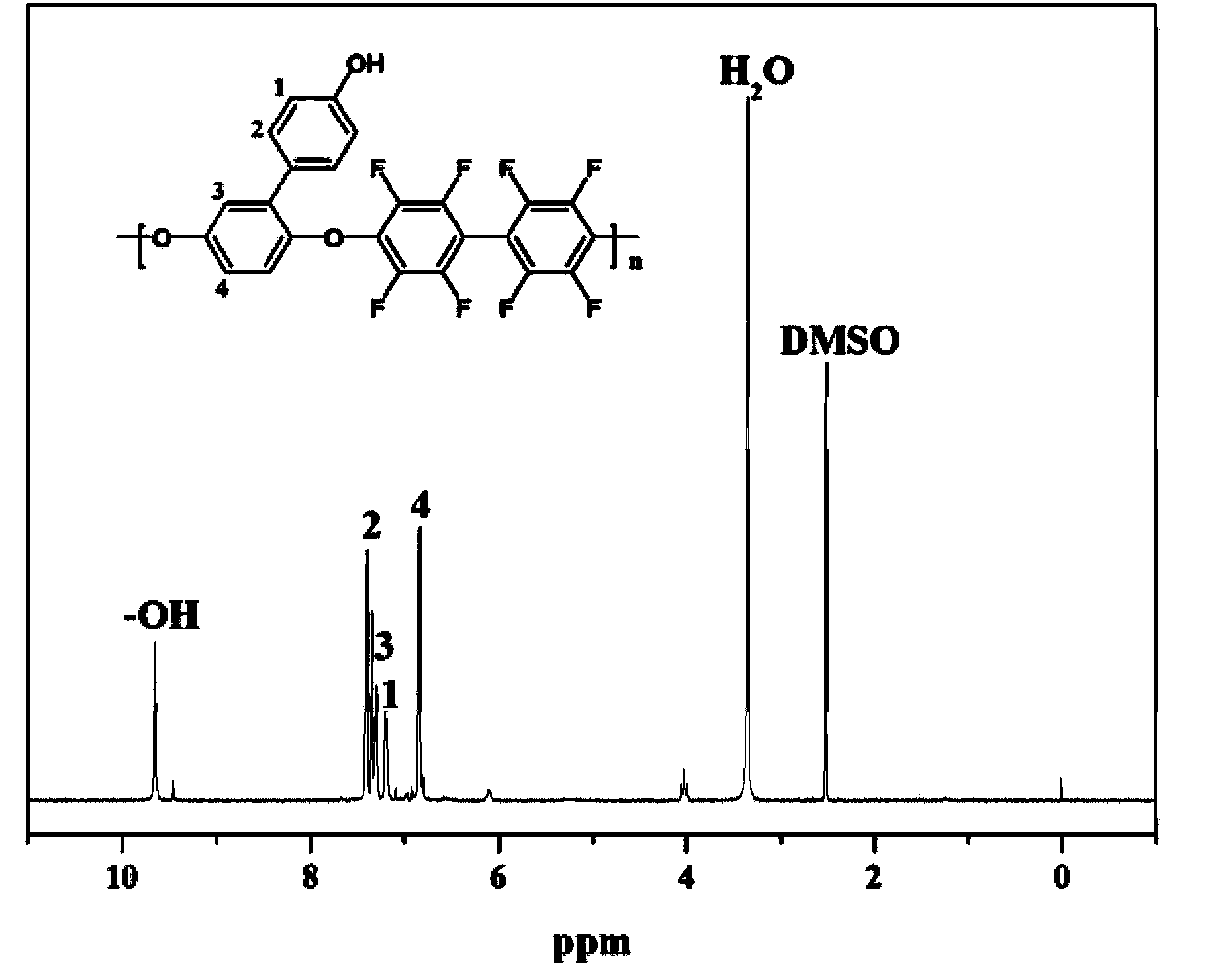

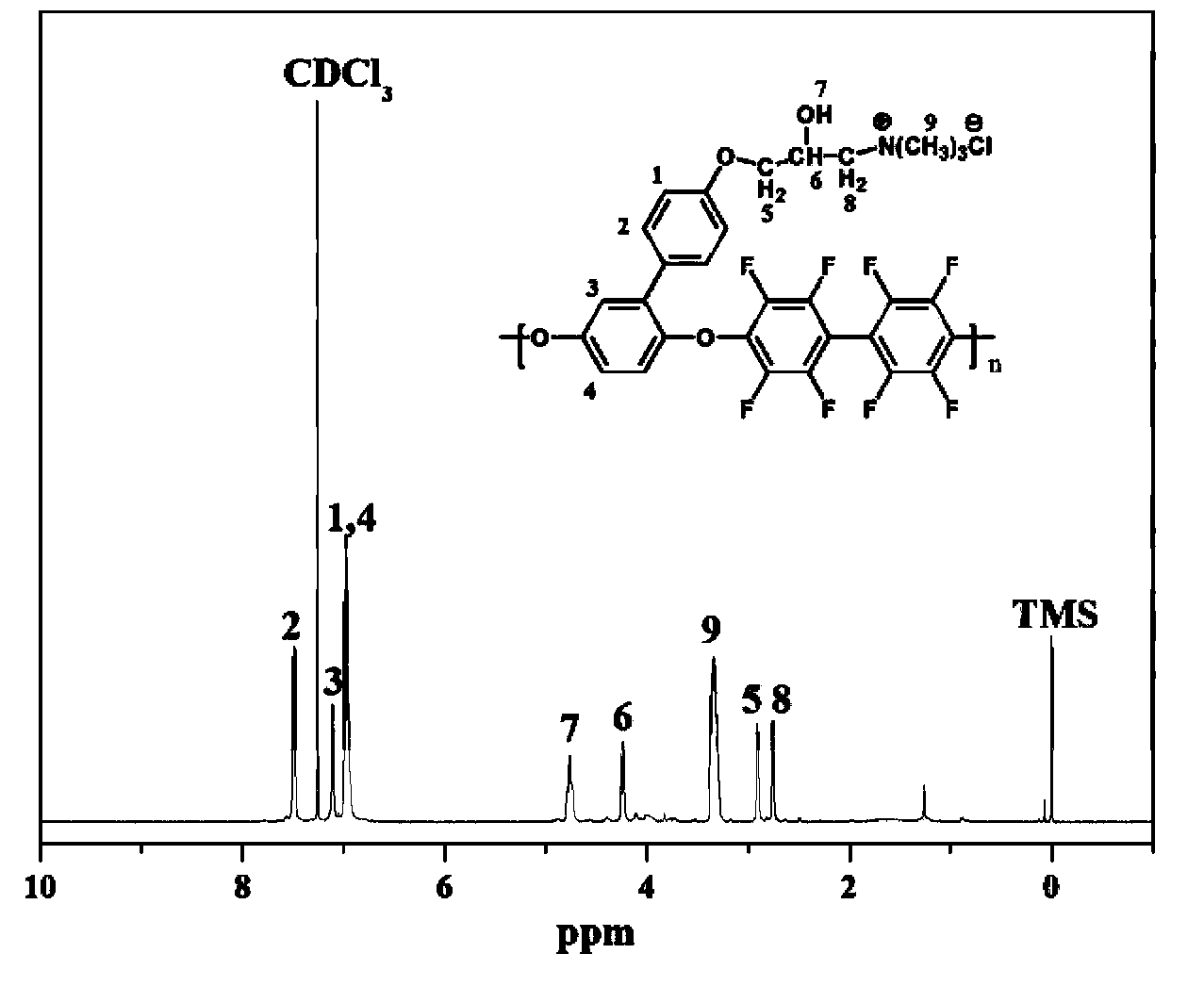

Polyarylether containing quaternary ammonium side group and its preparation method, and anion exchange membrane containing quaternary ammonium side group and its preparation method

ActiveCN103788365ALow water absorptionImprove ionic conductivitySolid electrolyte fuel cellsFuel cell detailsHalogenIon-exchange membranes

The invention provides a polyarylether containing a quaternary ammonium side group and its preparation method, an anion exchange membrane preparation method, and an anion exchange membrane prepared through the anion exchange membrane preparation method. The polyarylether has a structure represented by formula (1); and in the formula (1), R1 is a C2-C5 alkylidene group with a hydroxy group, R2-R4 are C1-C5 alkyl groups, X is halogen, n is not lower than 2, Ar1 has one or more of structures represented by formula (2)-formula (4) respectively, and R5-R28 are H, halogen or C1-C5 alkyl groups respectively. The anion exchange membrane has the advantages of high ion conductivity, low water absorption and inhibited swelling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com