Light-emitting structure capable of improving light-emitting efficiency and controlling emergent angle and manufacture method thereof

A technology of light emitting angle and luminous efficiency, applied in the field of light emitting structure and its production, can solve the problems of increased cost and lack of elasticity of the white frame, and achieve the effect of increasing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

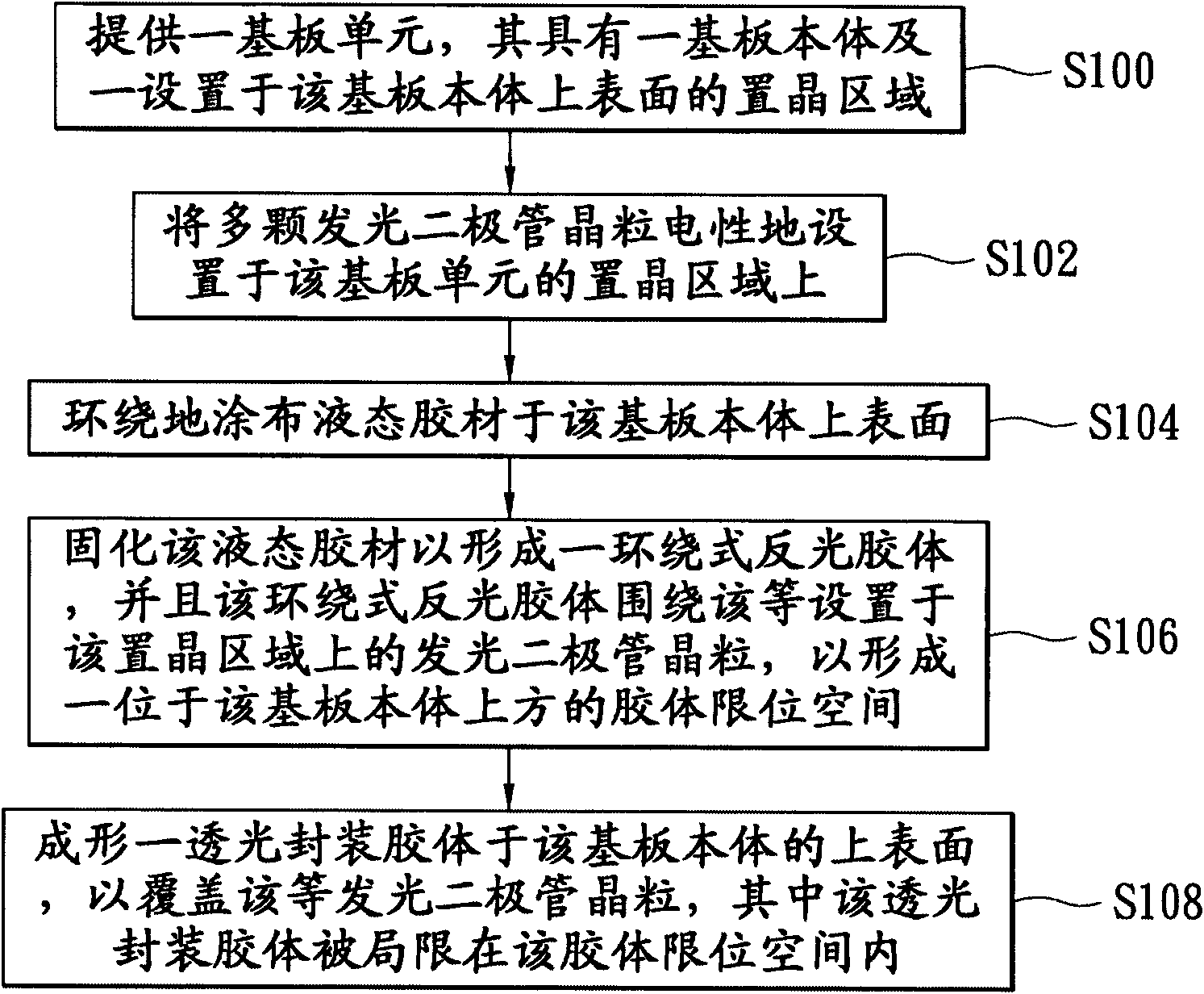

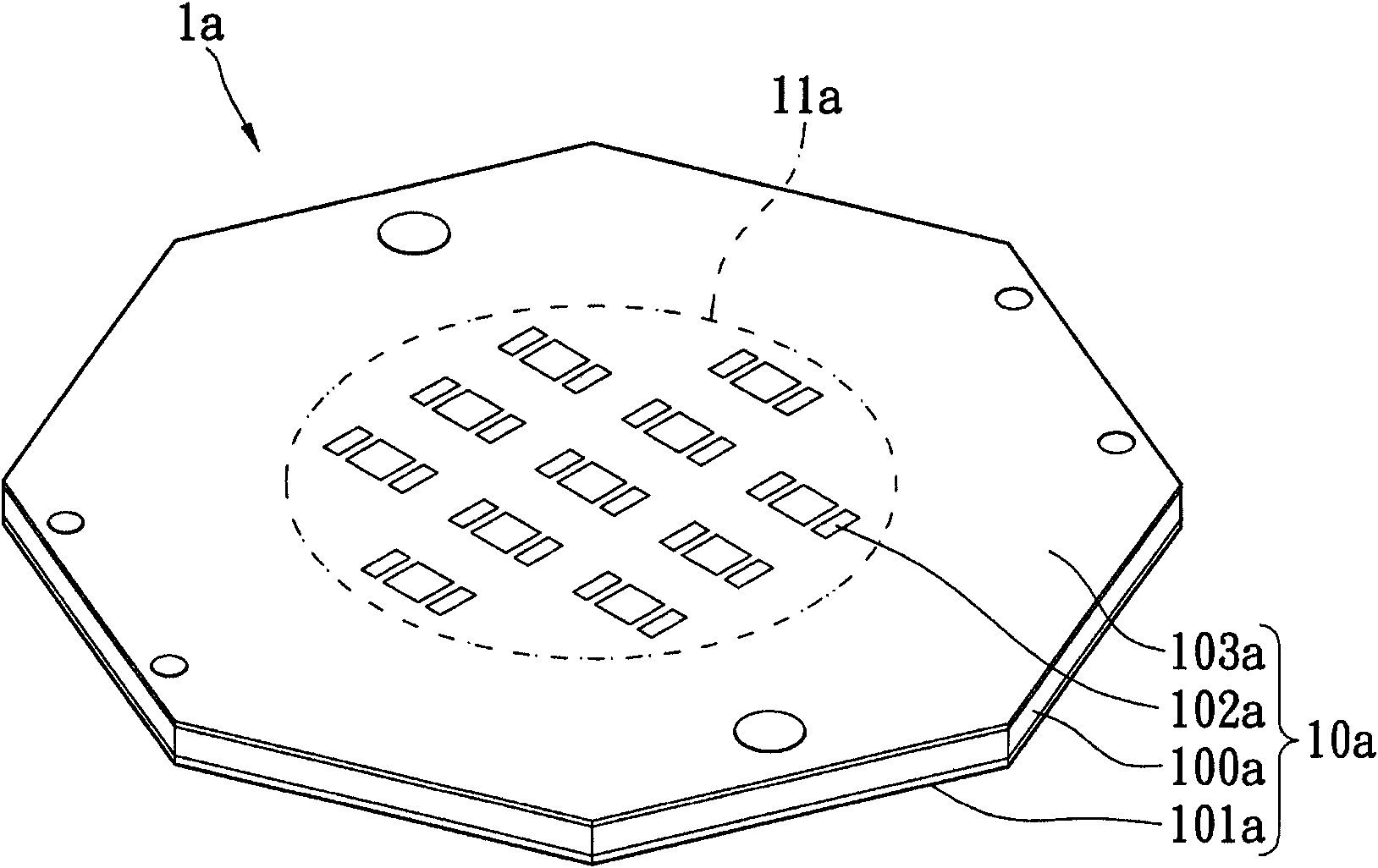

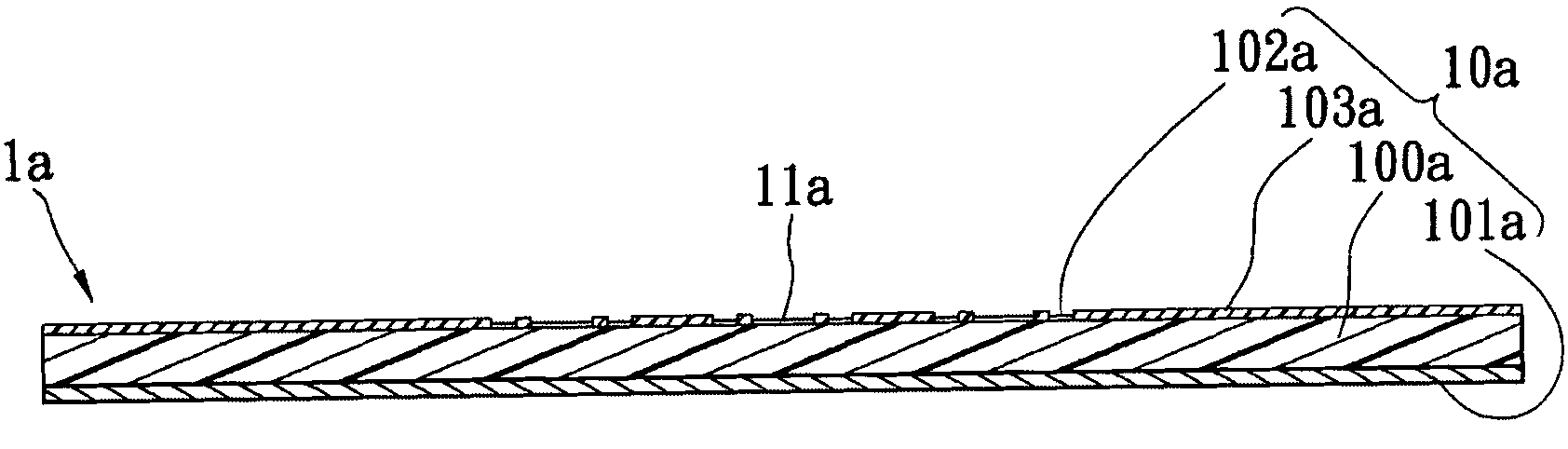

[0064] see figure 1 As shown, the first embodiment of the present invention provides a method for manufacturing a light-emitting structure that can improve luminous efficiency and control the light-emitting angle, which includes: firstly, providing a substrate unit, which has a substrate body and an The crystal placement area on the surface; then, firstly, a plurality of light-emitting diode crystal grains are electrically arranged on the crystal placement area of the substrate unit; then, the liquid adhesive material is coated on the upper surface of the substrate body in a surrounding manner; and then solidified. liquid adhesive material to form a wrap-around reflective colloid, and the wrap-around reflective colloid surrounds the light-emitting diode crystal grains arranged on the crystal placement area to form a colloid-limited space above the substrate body; finally, forming A light-transmissive encapsulant is placed on the upper surface of the substrate body to cover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com