Light-emitting diode packing structure of forming filling type convex lens and manufacturing method thereof

A technology for light-emitting diodes and packaging structures, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

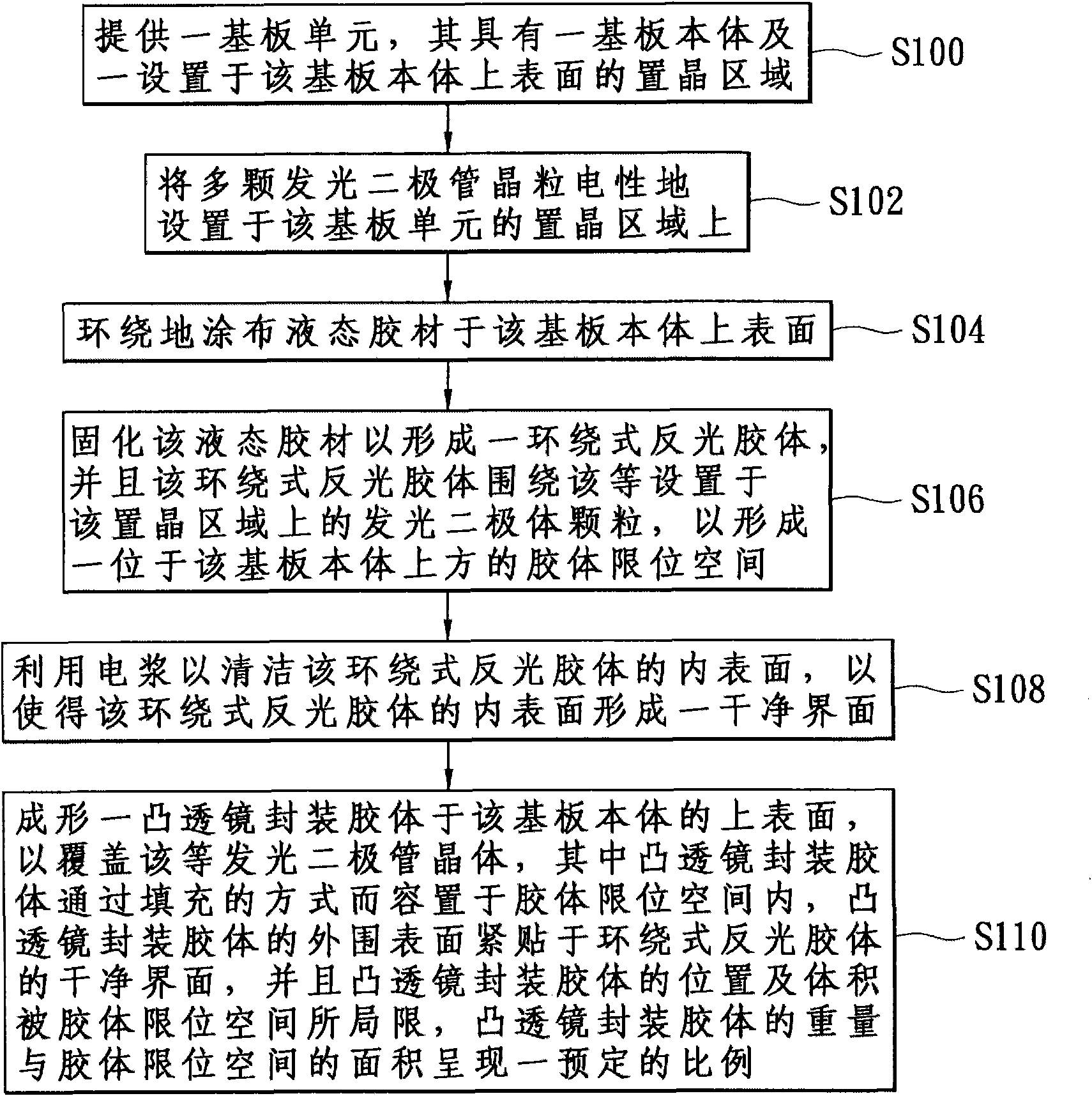

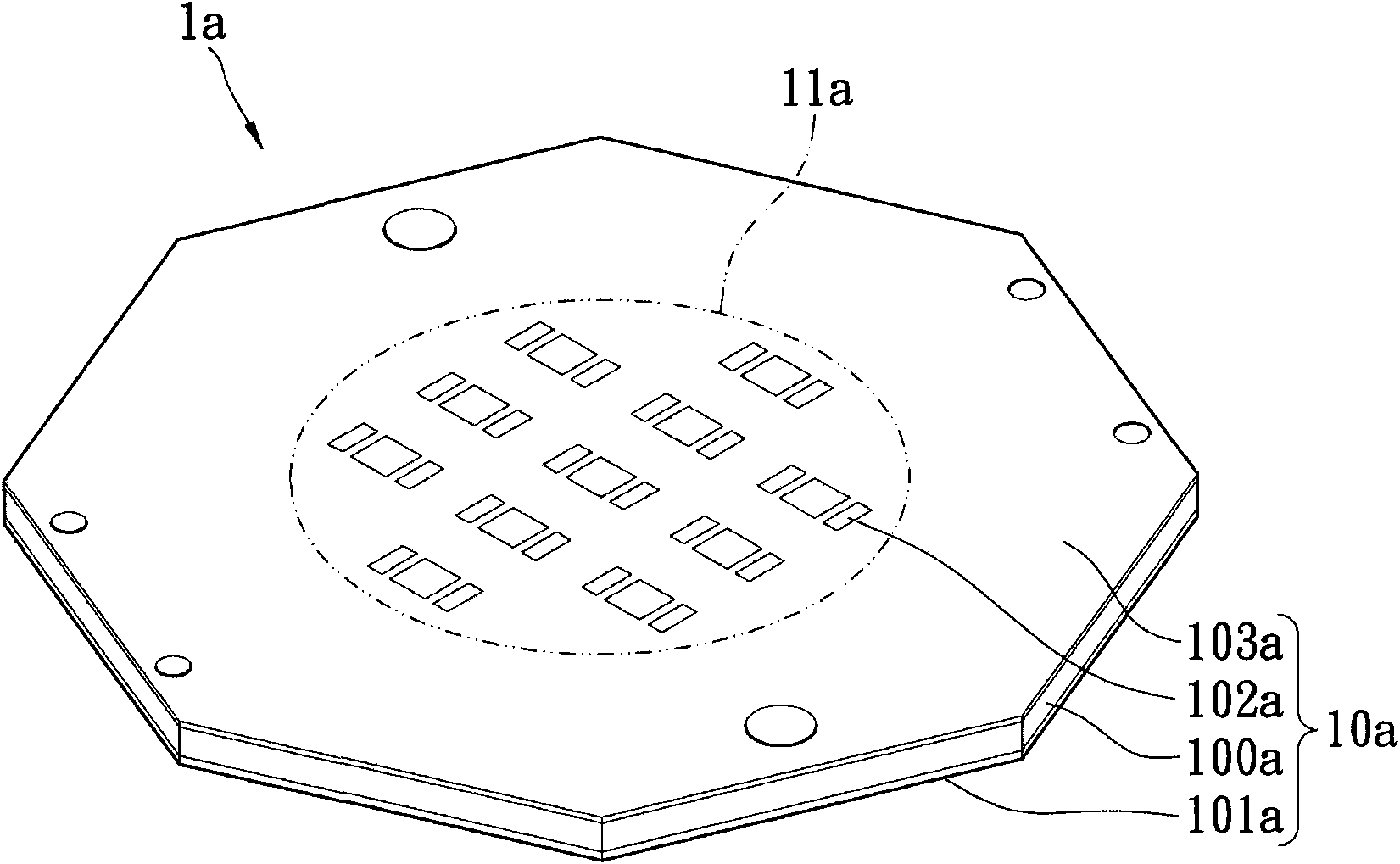

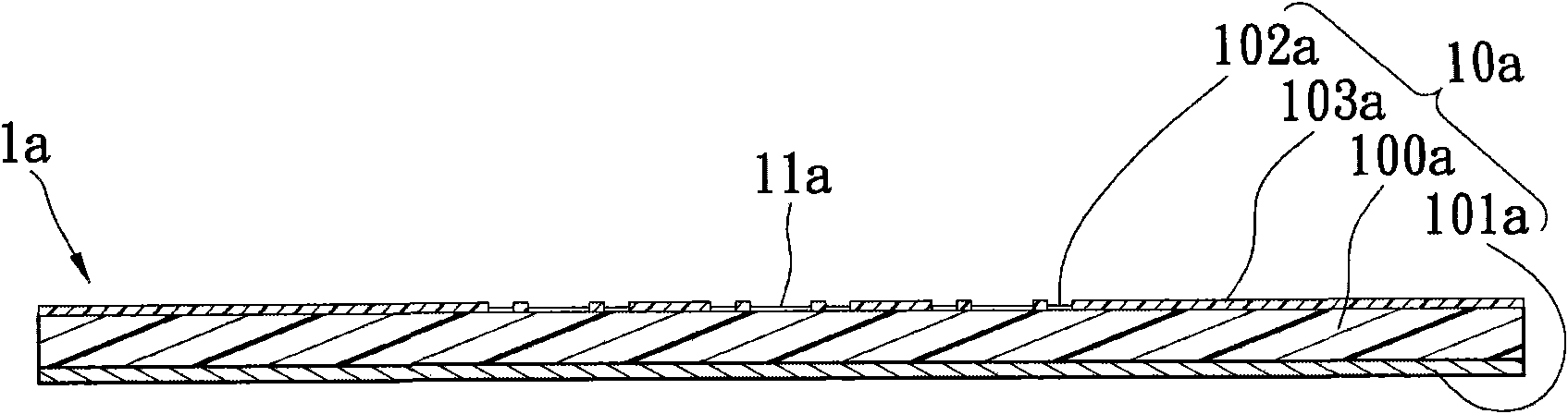

[0066] see figure 1 As shown, the first embodiment of the present invention provides a method for manufacturing a light-emitting diode packaging structure with a molded and filled convex lens, which includes: first, providing a substrate unit, which has a substrate body and a substrate disposed on the upper surface of the substrate body The crystal placement area; then, firstly, a plurality of light-emitting diode crystal grains are electrically arranged on the crystal placement area of the substrate unit; then, the liquid glue is coated on the upper surface of the substrate body; and then the liquid glue is cured material to form a wrap-around reflective colloid, and the wrap-around reflective colloid surrounds the light-emitting diode dies disposed on the crystal placement area to form a colloid-limited space above the substrate body; slurry to clean the inner surface of the surrounding reflective colloid, so that the inner surface of the surrounding reflective colloid for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com