Patents

Literature

41results about How to "Lower burst pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building method for artificial dry-hot-rock geothermal reservoir

ActiveCN105696996ALower burst pressureObvious lithofacies structureOther heat production devicesGeothermal energy generationStructure of the EarthHydraulic fracturing

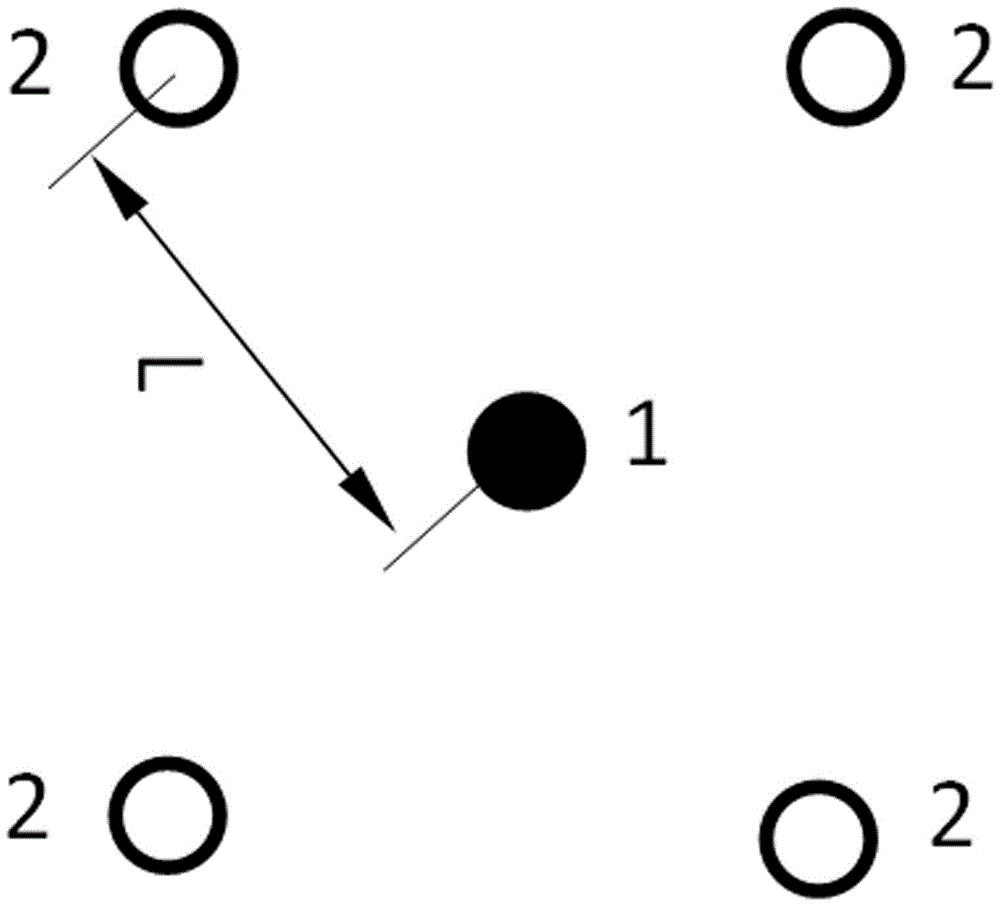

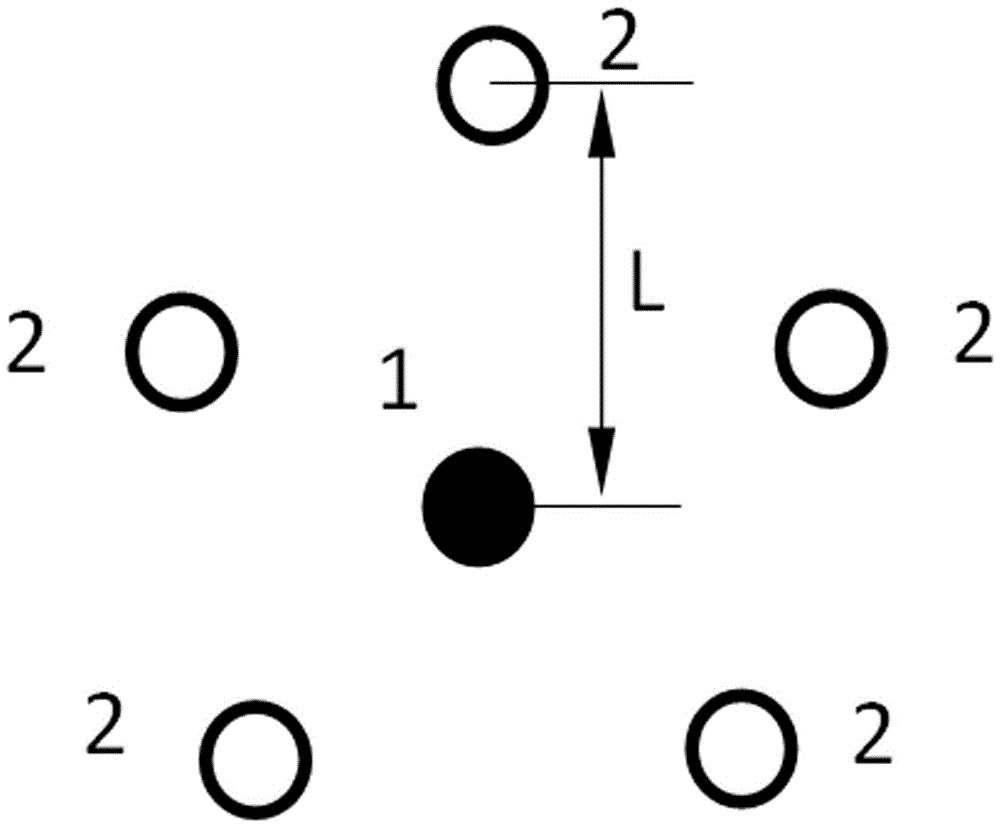

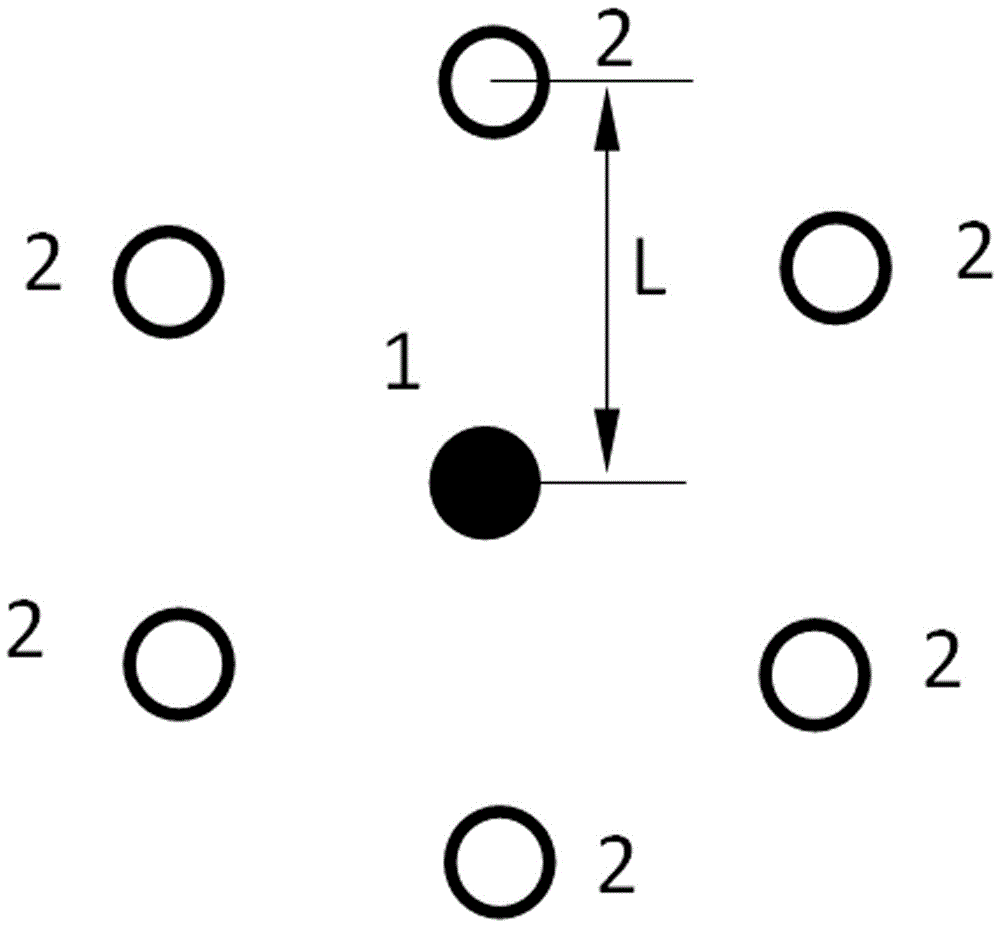

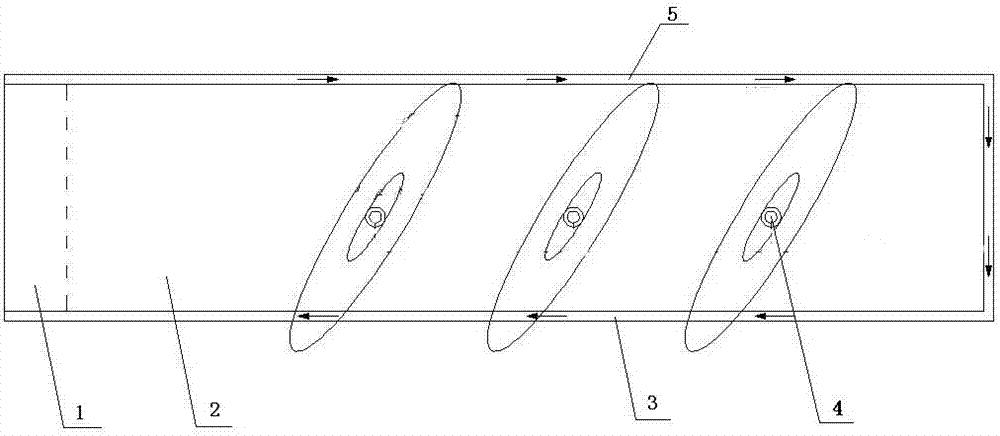

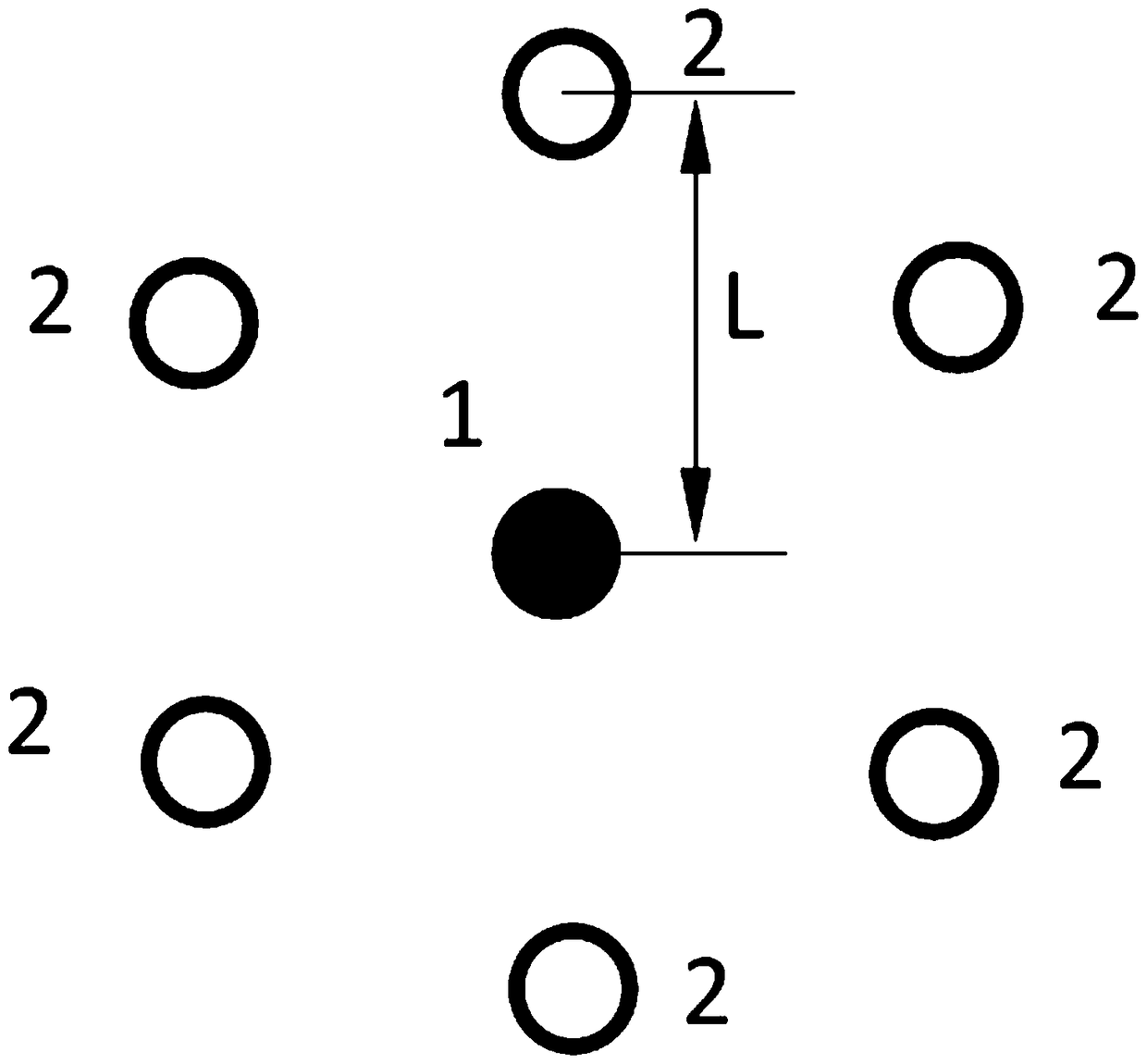

The invention provides a building method for an artificial dry-hot-rock geothermal reservoir and belongs to the field of artificial dry-hot-rock geothermal reservoir building. According to the technical scheme, the method includes the steps that supercritical carbon dioxide fracturing is conducted on the soft weak face or an interlayer formed along the igneous rock phase to generate a major crack, then large displacement of hydrofracturing is conducted on the interior of the major crack to generate secondary fracturing, bulk fracturing or cluster type fracturing of a dry hot rock body is generated under cyclic fracturing, and the artificial geothermal reservoir is built. The building method has the beneficial effects that the characteristics of low viscosity and easy diffusion of the supercritical carbon dioxide and the characteristic that the crack is easy to form due to the fact that the fracturing pressure of igneous rock under supercritical carbon dioxide fracturing is low are fully utilized; and in combination with the characteristics that the igneous rock is of the obvious rock phase structure and thermal fracturing is easy to generate, the problems that current hydrofracturing cannot be implemented to building of the artificial geothermal reservoir in a deep rock mass, the fracturing pressure is large, the crack group or the crack band of an ideal structure is difficult to form, and an artificial geothermal reservoir stratum is particularly difficult to build are solved.

Owner:TAIYUAN UNIV OF TECH

Shale gas reservoir pre-fracture composite acid solution, preparation method and application thereof

InactiveCN105086989APrevent collapseCore dissolution rate maintenanceDrilling compositionAcetic acidHydrofluoric acid

The invention belongs to the field of petroleum engineering and relates to a shale gas reservoir pre-fracture composite acid solution and its preparation method and application. The composite acid solution comprises the following components: Component a) at least one component of hydrochloric acid, hydrofluoric acid, fluorboric acid, phosphoric acid, formic acid and acetic acid; and Component b) a corrosion inhibitor, a discharge aiding agent, a ferric iron stabilizer and a clay stabilizer. The composite acid solution containing different acids is selected for different reservoirs. Rock core corrosion ratio is 25-30%. A certain rock core corrosion ratio is maintained, and borehole wall collapse caused by too high corrosion ratio is also prevented. The corrosion inhibitor, the discharge aiding agent, the ferric iron stabilizer and the clay stabilizer which are used as additives have good compatibility with acid. The composite acid solution provided by the invention has advantages of fast dissolving speed, uniform mixing, high corrosion inhibition efficiency, high surface activity, good clay stabilizing effect and wide range. Applicable temperature of the composite acid solution is 20-180 DEG C. by the use of the composite acid solution, normal construction of large-scale fracturing of long horizontal-section shale gas wells can be guaranteed under the condition of existing equipment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for weakening coal seam hard top plate

InactiveCN107387082AGive full play to the softening effectGive full play to the role of cutting and sewingUnderground miningSurface miningCoalEngineering

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

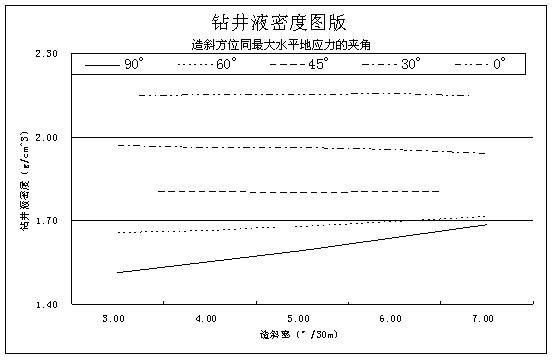

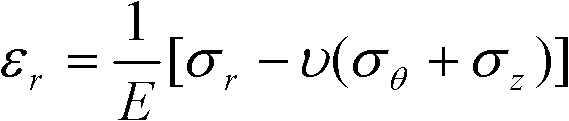

Method for determining drilling fluid density in salt-gypsum layer deflection

ActiveCN102128025APrevent wellbore shrinkagePrevent downhole complicationsSurveyFlushingBurst pressureGypsum

The invention relates to a drilling technology in the field of petroleum exploration and development, in particular to a method for determining drilling fluid density in salt-gypsum layer deflection. The method for determining drilling fluid density in salt-gypsum layer deflection comprises the following steps of: (1) establishing a salt-gypsum layer creep model under the variable-curvature and variable-azimuth conditions; (2) according to the salt-gypsum layer creep model, establishing a salt-gypsum layer borehole wall deformation model under the conditions of drilling fluid density, borehole curvature and borehole azimuth; (3) establishing a relationship chart of the drilling fluid density, borehole curvature and borehole azimuth; and (4) according to the relationship chart established in the step (3), determining the reasonable drilling fluid density. By using the method provided by the invention, the appropriate drilling fluid density, deflection azimuth and deflection curvature can be preferably selected, thereby reducing the drilling fluid density to satisfy the minimum burst pressure of the stratum, effectively preventing borehole undergauge and avoiding complex downhole circumstances.

Owner:PETROCHINA CO LTD

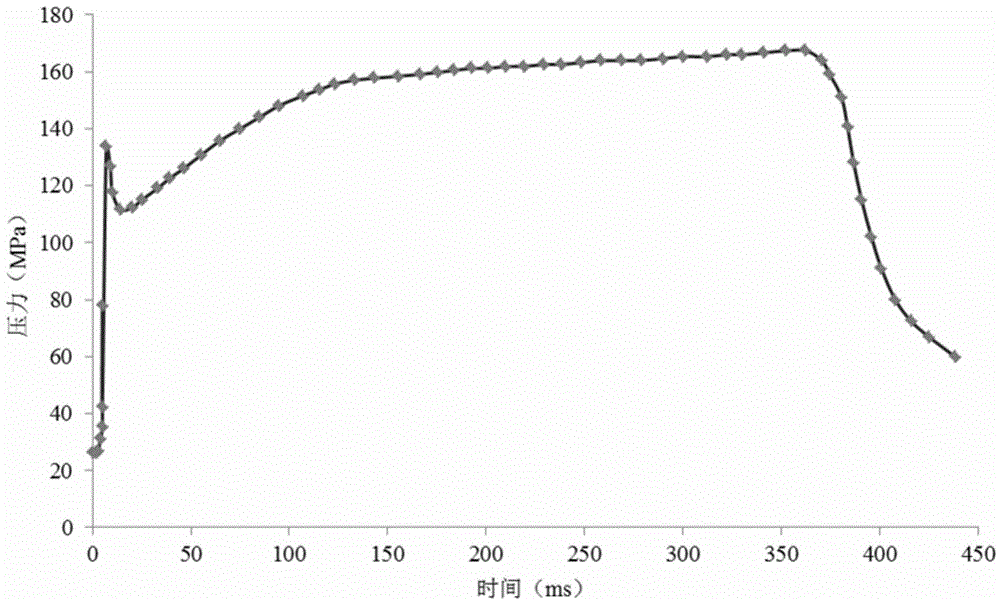

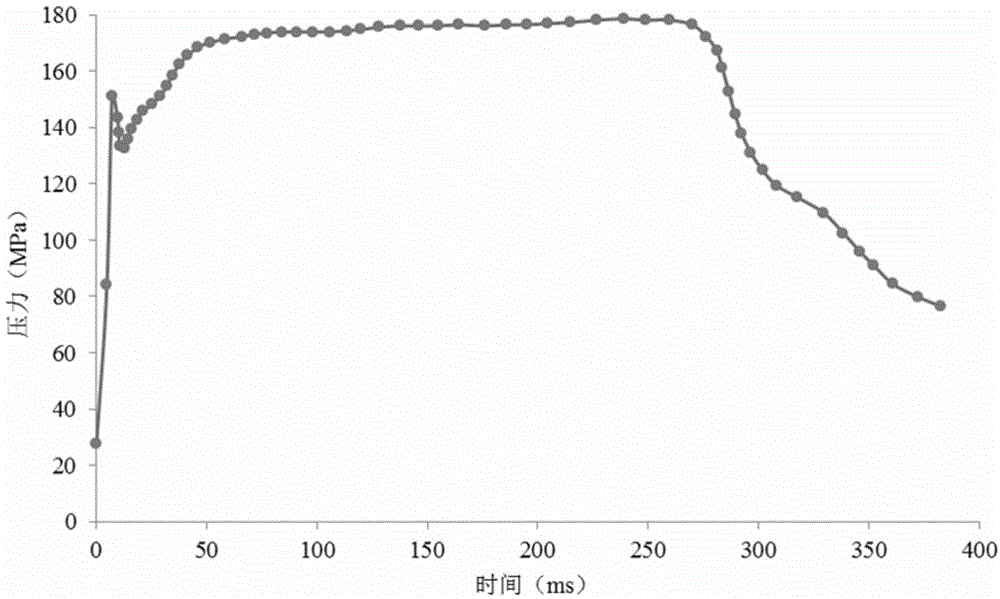

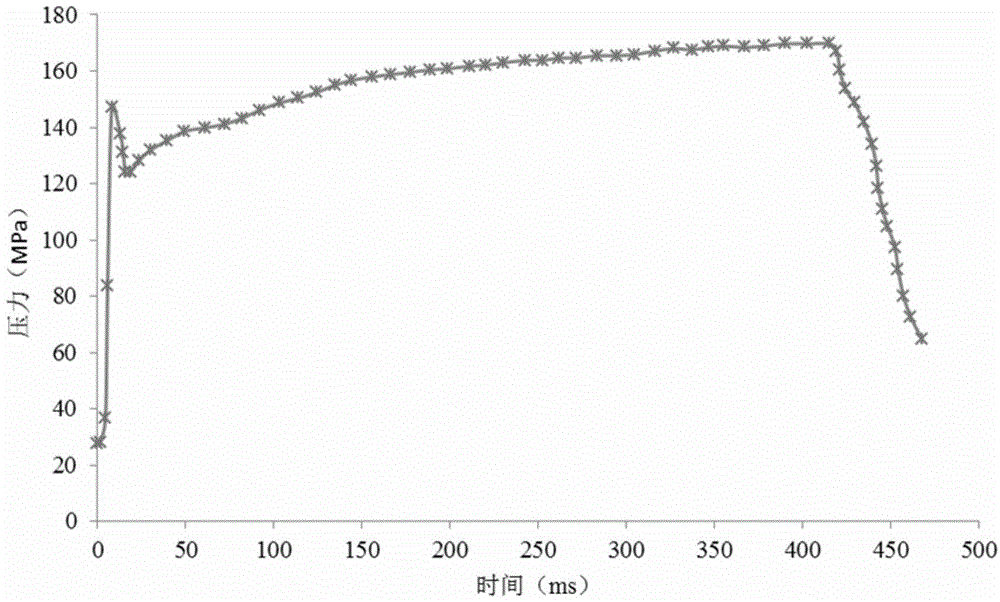

Gunpowder for realizing deep well deep bumming and fracturing

InactiveCN104402659AStable burning rateReduce burning rateExplosivesPtru catalystUltra high pressure

The invention discloses gunpowder for realizing deep well deep bumming and fracturing, the gunpowder includes solid powder and liquid powder; the solid powder comprises a binder, a plasticizer, an oxidizing agent, a metal combustion agent, a high-energy additive, a stabilizer and a catalyst; and the liquid powder comprises an oxidizing agent, a combustion agent, a performance modifier and water. The solid powder of the gunpowder can overcome the restriction of large stress difference coefficient and high fracturing pressure of deep-layer and ultra high pressure formation, a plurality of radial cracks and branched cracks are formed in a broken rock layer, main crack is preliminarily extended, the fracture pressure is reduced to help the liquid powder to continue to fracture the formation, at the same time, the role of ignition of the liquid powder is played, after the solid powder is burn out, the liquid powder continues to maintain a high pressure environment in a wellhole, and effects on the formation for longer time, the main crack length is further extended, the branched cracks are developed, natural cracks are communicated, and a complex fracture network structure is formed in a larger-range purpose layer near the wellbore.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

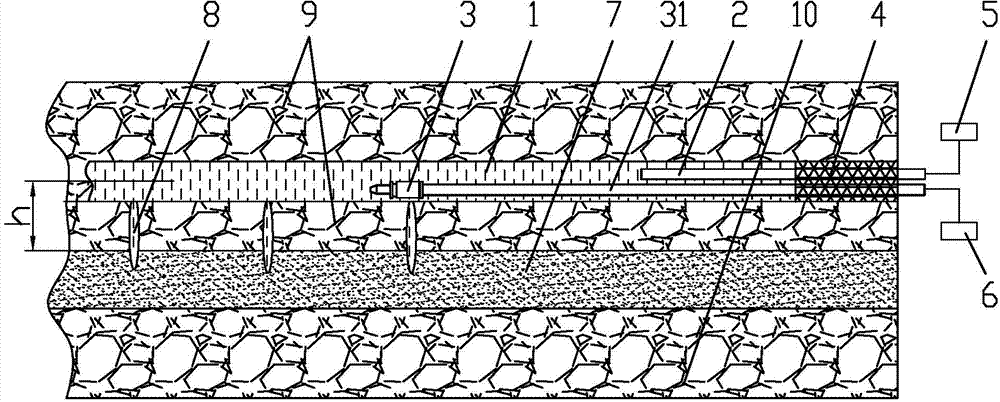

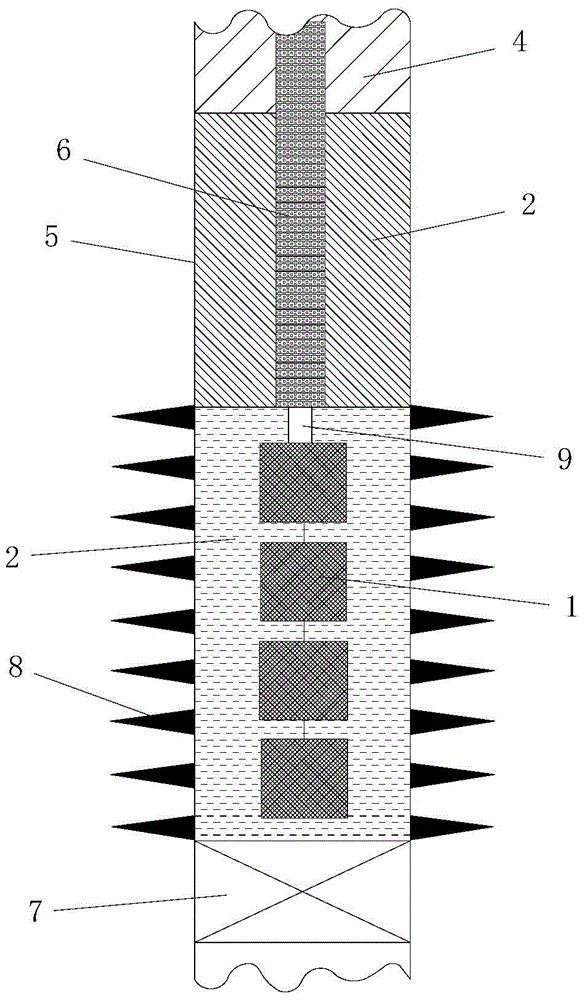

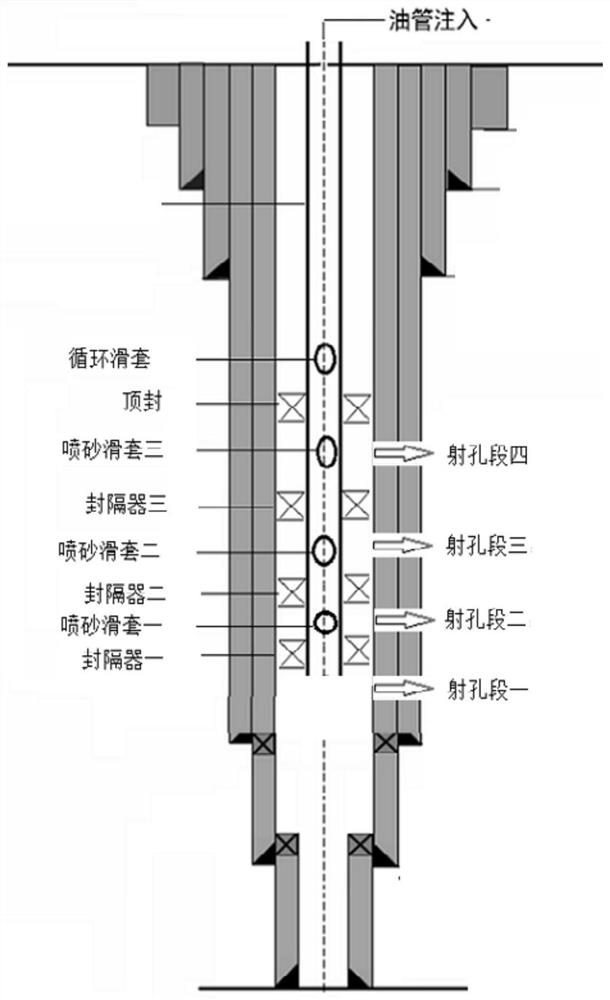

Orientation jetting and fracturing exploitation method for coal bed gas under coal mine

InactiveCN103883303AGuaranteed stabilityLower burst pressureFluid removalSocial benefitsCoal mine methane

The invention discloses an orientation jetting and fracturing exploitation method for coal bed gas under a coal mine. The method includes the steps that a drilled hole along a coal bed is formed in a top plate or a bottom plate; a fracturing pipe set and a radial perforator are placed in a first perforation position; the hole is sealed; the fracturing pump set and the perforator are connected with corresponding pump sets respectively, and a jet flow channel is formed by the perforator and used for communicating the coal bed and the drilled hole; annular fracturing liquid is injected into the drilled hole in a pressure mode, and meanwhile annular pressure is kept; the coal bed is continuously jetted for preset time so that cracks can be formed on coal bodies and extend in the bottom direction of jetting holes of the coal bed; jetting and fracturing are stopped at the same time, the perforator is moved to a next jetting position to form the jet flow channel, and then fracturing liquid is pressurize and jetted continuously; the steps of independently jetting a rock stratum and pressurizing and jetting the coal bed are repeatedly executed until jetting and fracturing at all positions in the drilled hole is finished, and then the coal bed gas is extracted. The orientation jetting and fracturing exploitation method has the advantages that the trend and the quantity of the cracks are controllable, exploitation efficiency of the coal bed is high, the gas disaster of the mine can be effectively prevented and treated, and economic and social benefits can be improved.

Owner:重庆市能源投资集团科技有限责任公司

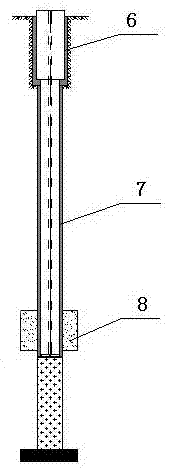

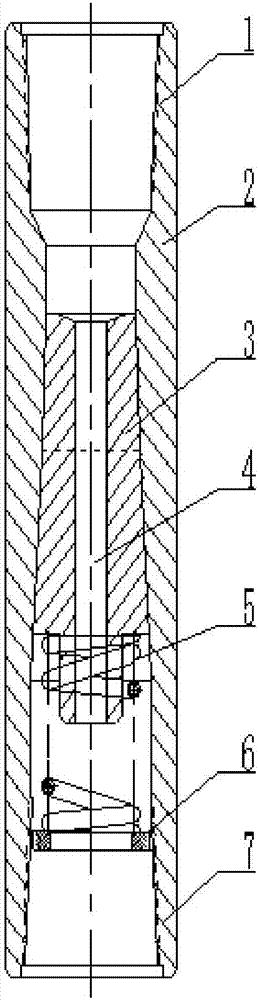

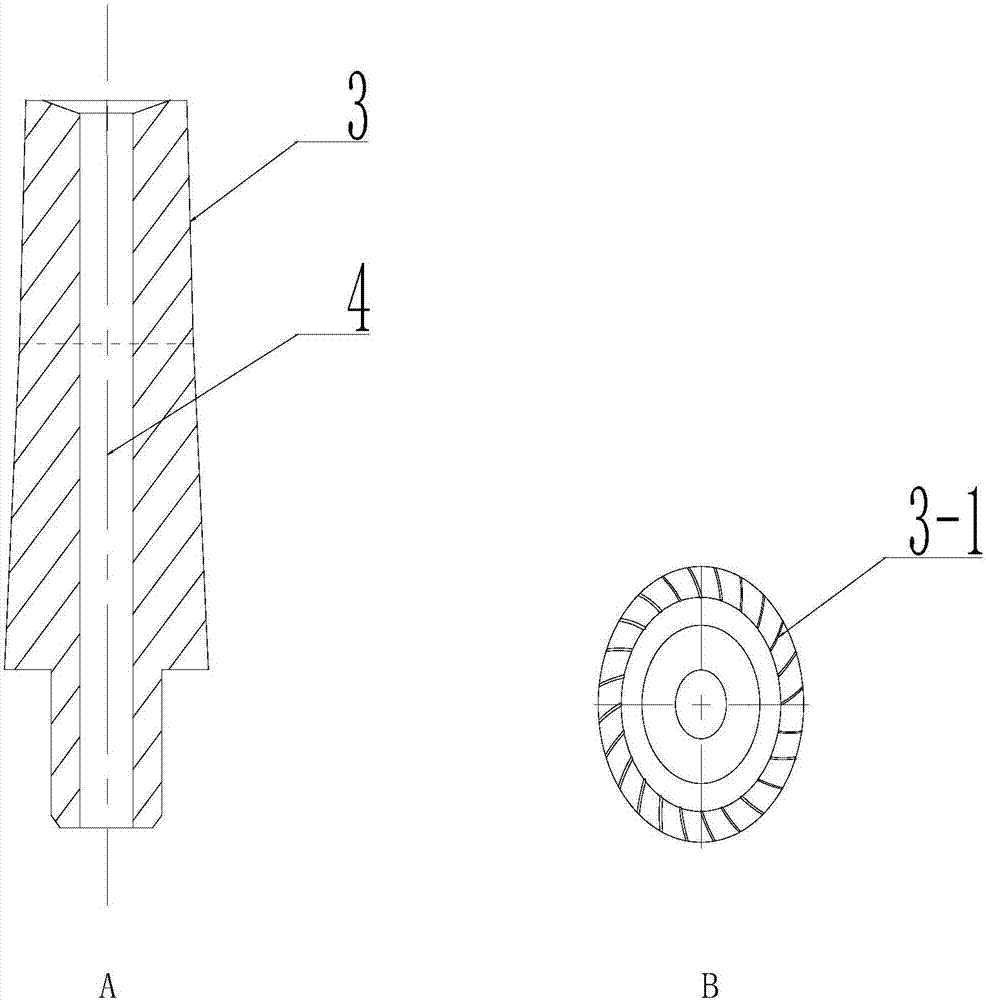

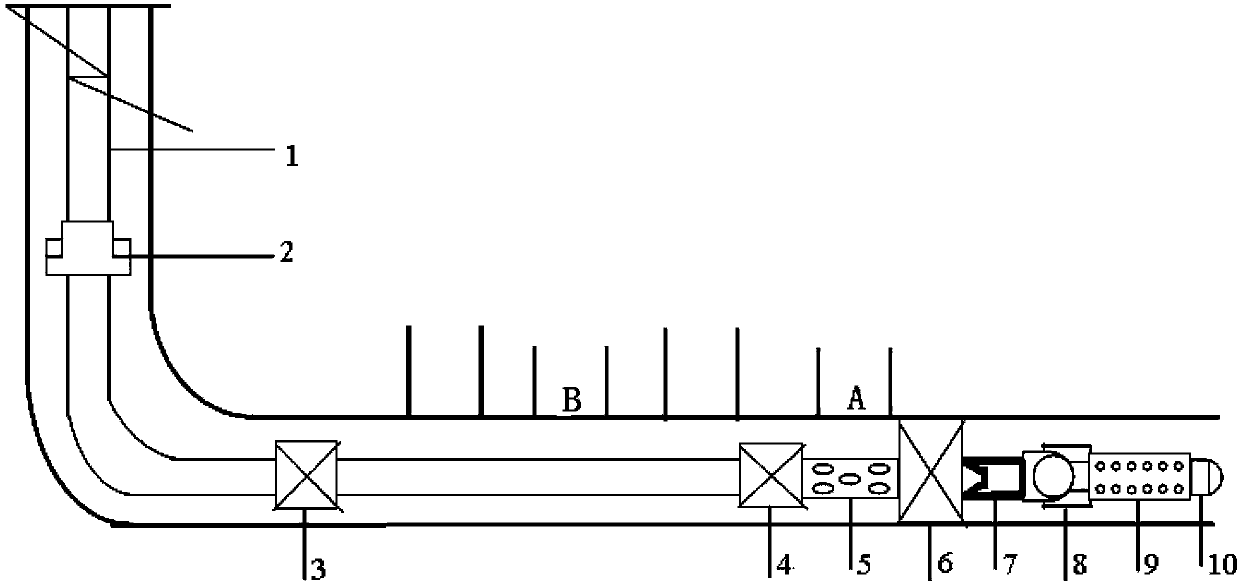

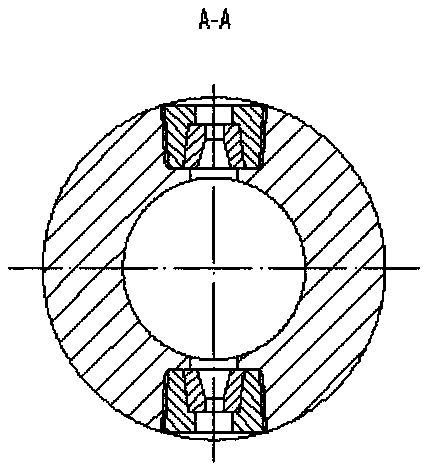

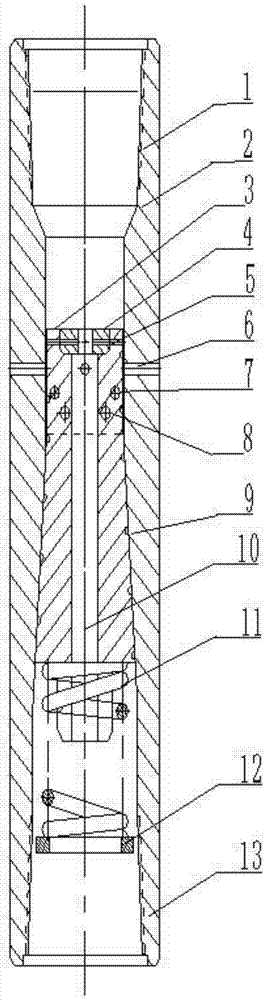

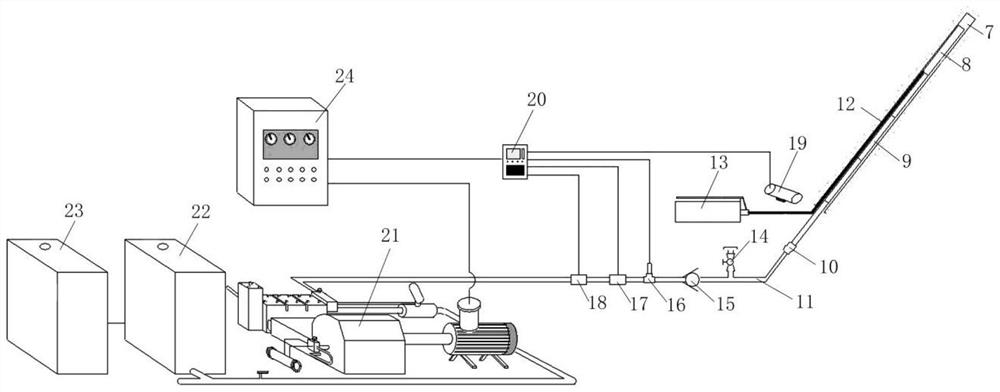

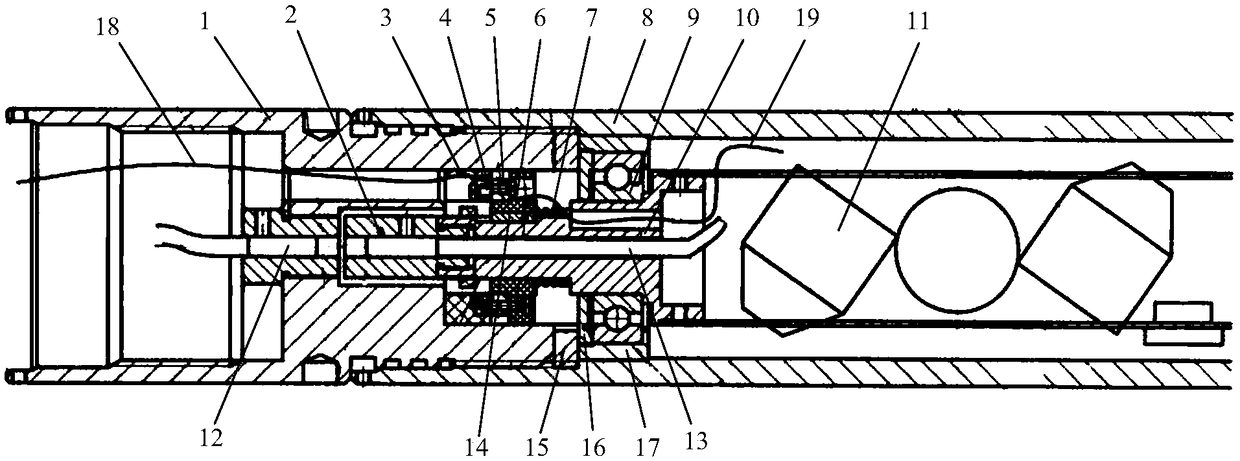

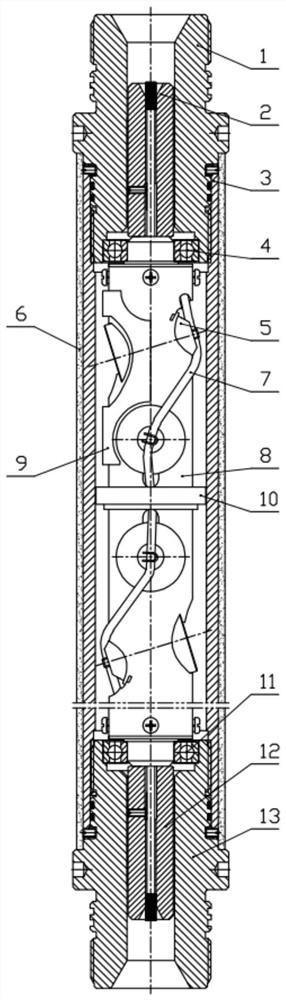

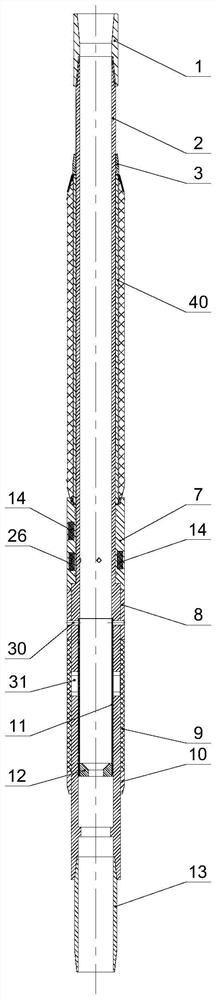

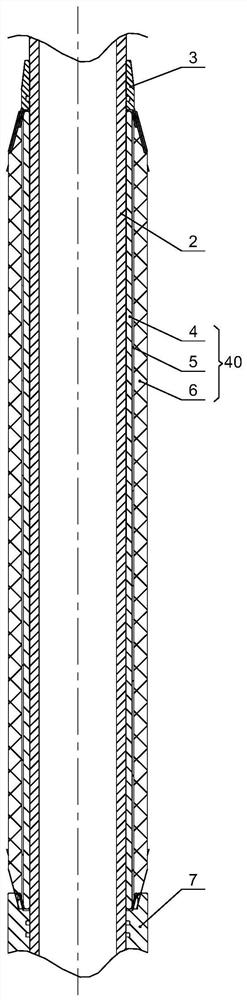

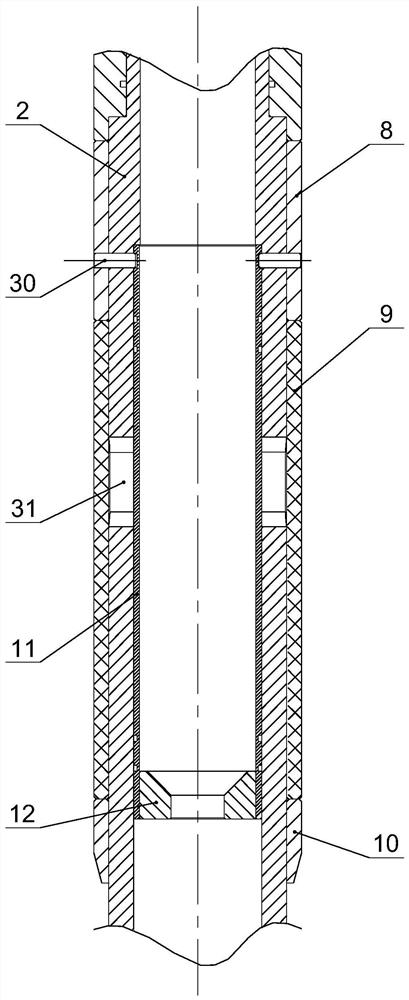

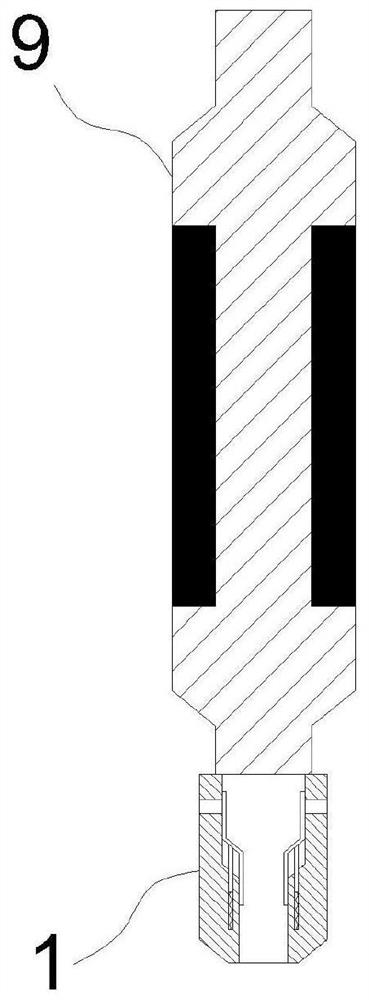

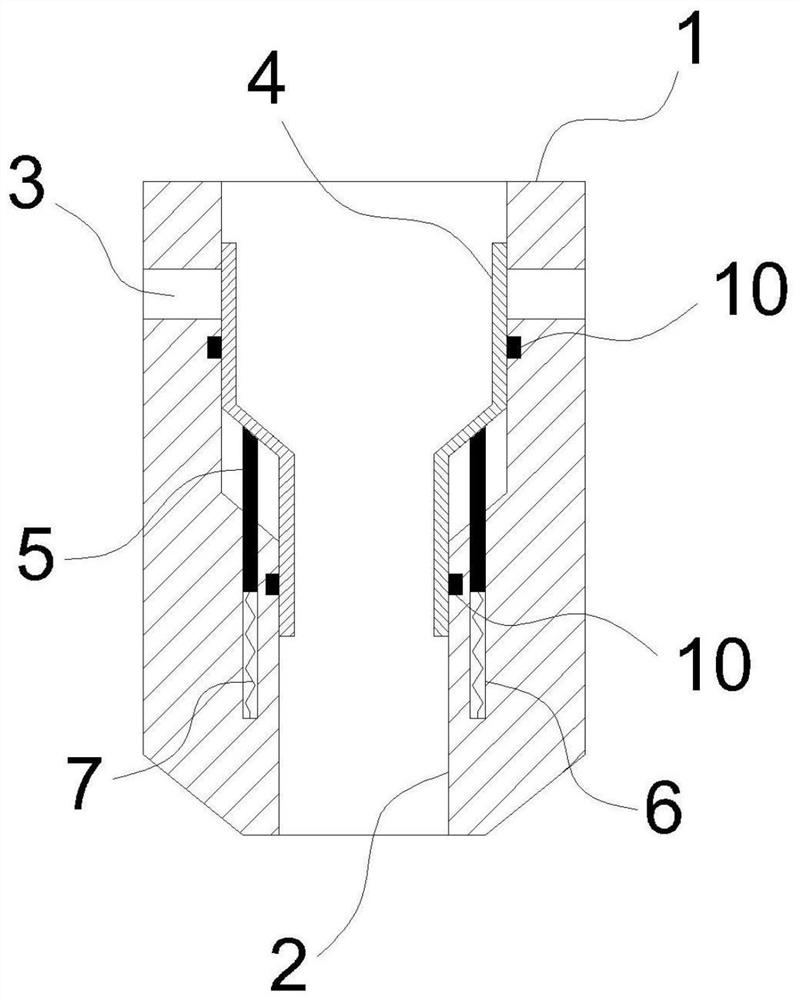

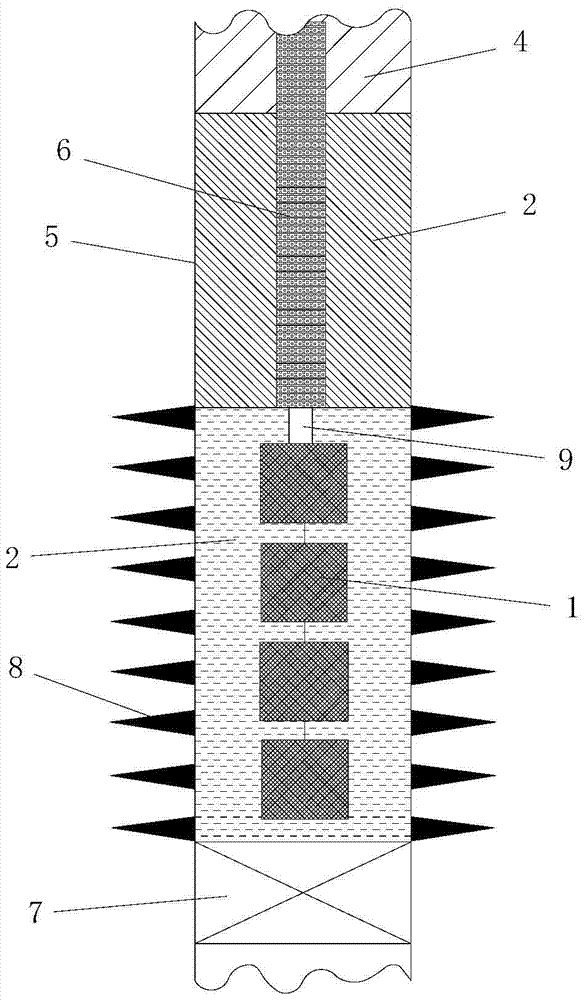

Oil-gas-well hydraulic-fracturing down-hole low-frequency hydraulic-pulse generating device

ActiveCN107083944AImprove diversion capacityReduce settlementFluid removalDifferential pressureFracturing fluid

An oil-gas-well hydraulic-fracturing down-hole low-frequency hydraulic-pulse generating device comprises a composite frustum cylinder body assembly, an upper connector and a lower connector, wherein the upper connector is arranged at the upper end of the composite frustum cylinder body assembly, and the lower connector is arranged at the lower end of the composite frustum cylinder body assembly. A composite frustum plunger matched with the composite frustum cylinder body assembly is arranged in the composite frustum cylinder body assembly, a through-hole is formed in the composite frustum plunger, and semi-circular grooves used for preventing sand blocking are evenly distributed on the periphery of the composite frustum plunger; and a reset spring is arranged on the lower portion of the composite frustum plunger, and a bearing seat is arranged at the lower end of the reset spring. After the up-down differential pressure of the composite frustum plunger reaches a certain value, operating liquid descends to compress the reset spring, when the composite frustum plunger descends, the flow area on the periphery of the composite frustum plunger gradually increases, the up-down differential pressure of the composite frustum plunger decreases, and the reset spring pushes the composite frustum plunger to ascend; and thus, reciprocating type vibration is generated, and low-frequency hydraulic pulse is generated in output fracturing fluid. According to the oil-gas-well hydraulic-fracturing down-hole low-frequency hydraulic-pulse generating device, based on the working displacement range of the hydraulic-fracturing operation, low-frequency hydraulic-pulse output of a hydraulic driving mode is achieved, and the hydraulic-fracturing effect can be improved on the whole.

Owner:XI'AN PETROLEUM UNIVERSITY

Selective re-fracturing technology for old well of oil field

ActiveCN104213894ASimple structureFlexible construction methodFluid removalOil fieldMaterial Perforation

The invention discloses a selective re-fracturing technology for an old well of an oil field. The selective re-fracturing technology for the old well of the oil field is designed to achieve re-transformation of the old well of the oil field effectively. According to the selective re-fracturing technology for the old well of the oil field, perforation of an interval needing to be transformed is achieved by assembling a pipe column, placing the pipe column in the well and dragging the pipe column, fracturing of a lowest new interval is achieved by packing an upper packer and an intermediate packer, unpacking is conducted, and the pipe column is dragged to a second new transformed interval. According to the selective re-fracturing technology for the old well of the oil field, a duct with the large diameter and the deep penetration is formed through hydraulic jet perforation, and thus fracturing pressure can be effectively reduced; the requirements for supporting facilities of a well mouth and the steel grade of a sleeve are lowered by means of the advantage of the dual-packing and single-clamping fracturing technology. The selective re-fracturing technology for the old well of the oil field has the advantages that the pipe column is simple in structure, the construction method is flexible, operation is convenient, the efficiency is high, re-transformation of the old well of the oil field can be achieved effectively, re-fracturing of the transformed interval can be achieved, and perforating and fracturing of the new interval can also be achieved integrally.

Owner:PETROCHINA CO LTD

Vertical well orientated hydraulic jet multi-stage fracturing method for oil and gas well

InactiveCN108952664APrecise location of perforationEasy alignmentFluid removalWell killSand blasting

The invention discloses a vertical well orientated hydraulic jet multi-stage fracturing method for an oil and gas well. The method includes the following steps of well flushing, well killing and drifting scrapping. A guiding head, a rotatable casing collar locator, a repeatable-setting packer, an oriented hydraulic jet gun, a safety joint, an oriented pup joint and an oil tube oriented hydraulic jet multi-stage fracturing string are sequentially connected to the tail end of an oil tube; after the string enters the well, the position of the jetting tool is localized accurately through the rotatable casing collar locator; the string is rotated at the mouth of the well to determine the orientation corresponding to a spray nozzle of the oriented hydraulic jet gun; after orientation is determined, setting of the repeatable-setting packer is performed, perforating fluid enters from an oil tube pump to perform sand blasting perforation, and oil jacket annular space sand fracturing is performed; after fracturing construction is ended, the oil tube is lifted to unpack the repeatable-setting packer. With the method, the operation period is short, the demand that during fracturing, crack initiation is performed in the minimum main stress direction can be met, construction pressure is decreased, and the recovery efficiency of the oil and gas well is substantially improved.

Owner:CNPC BOHAI DRILLING ENG

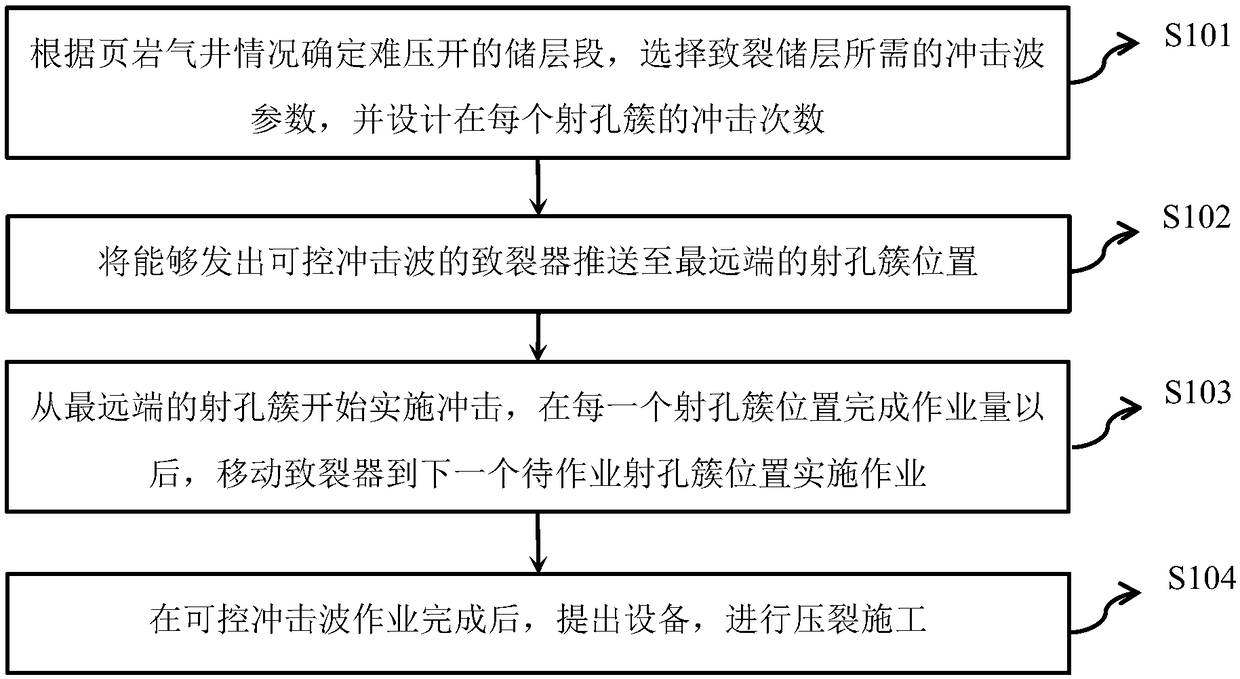

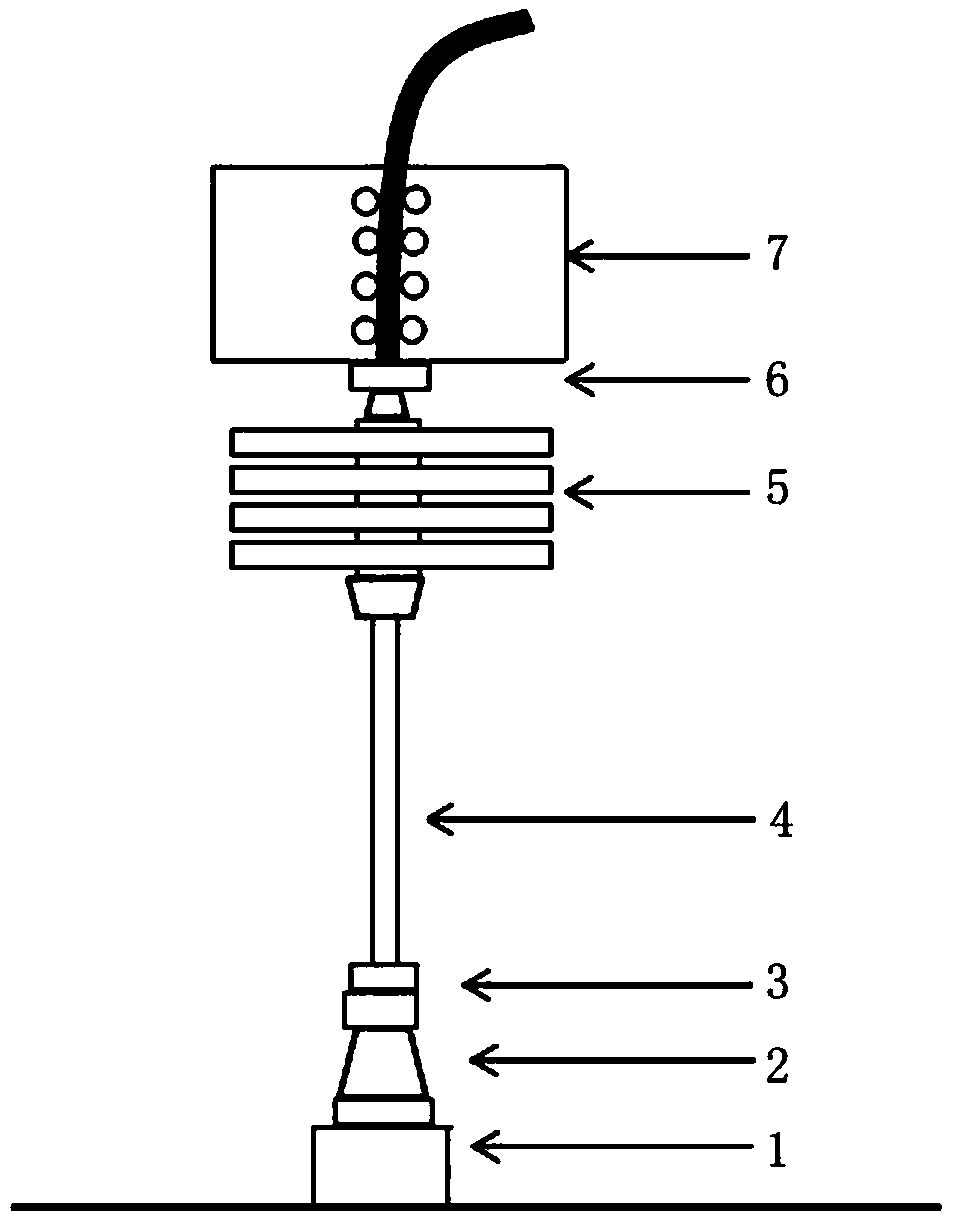

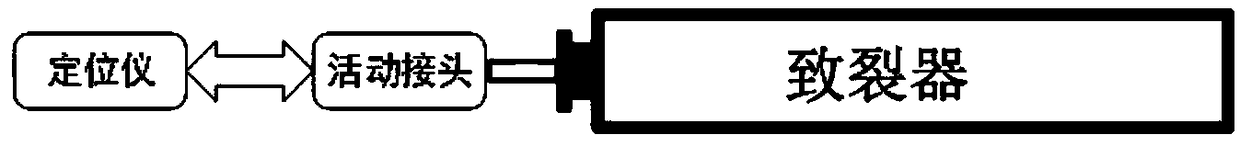

Controllable impact-wave shale reservoir pre-fracturing method

The invention discloses a controllable impact-wave shale reservoir pre-fracturing method. The controllable impact-wave shale reservoir pre-fracturing method comprises the following steps that 1, a reservoir section difficult to split is determined according to shale gas data, impact-wave parameters required by fracturing a reservoir are selected, and the impact times of each perforation cluster are designed; 2, a fracturing device capable of producing controllable impact waves is pushed to the perforation cluster position at the farthest end; 3, impact is carried out beginning from the perforation cluster at the farthest end, and after operation amount is completed at each perforation cluster position, the fracturing device is moved to a next perforation cluster position to be operated foroperation; 4, after controllable impact-wave operation is completed, a device is lifted out, and fracturing construction is performed. By adopting the controllable impact-wave shale reservoir pre-fracturing method, cracks can further extend under multiple times of impact effect, a crack net is formed around a well shaft, and fracturing pressure of a reservoir can be reduced or a reservoir difficult to fracture can be fractured open.

Owner:西安闪光能源科技有限公司

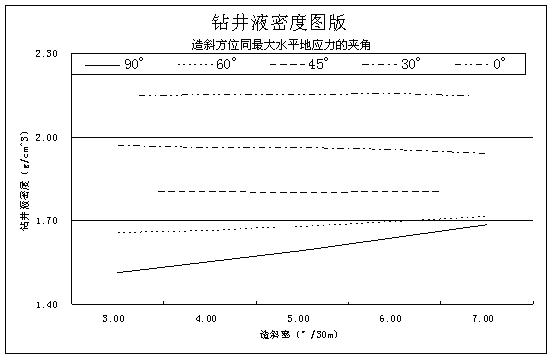

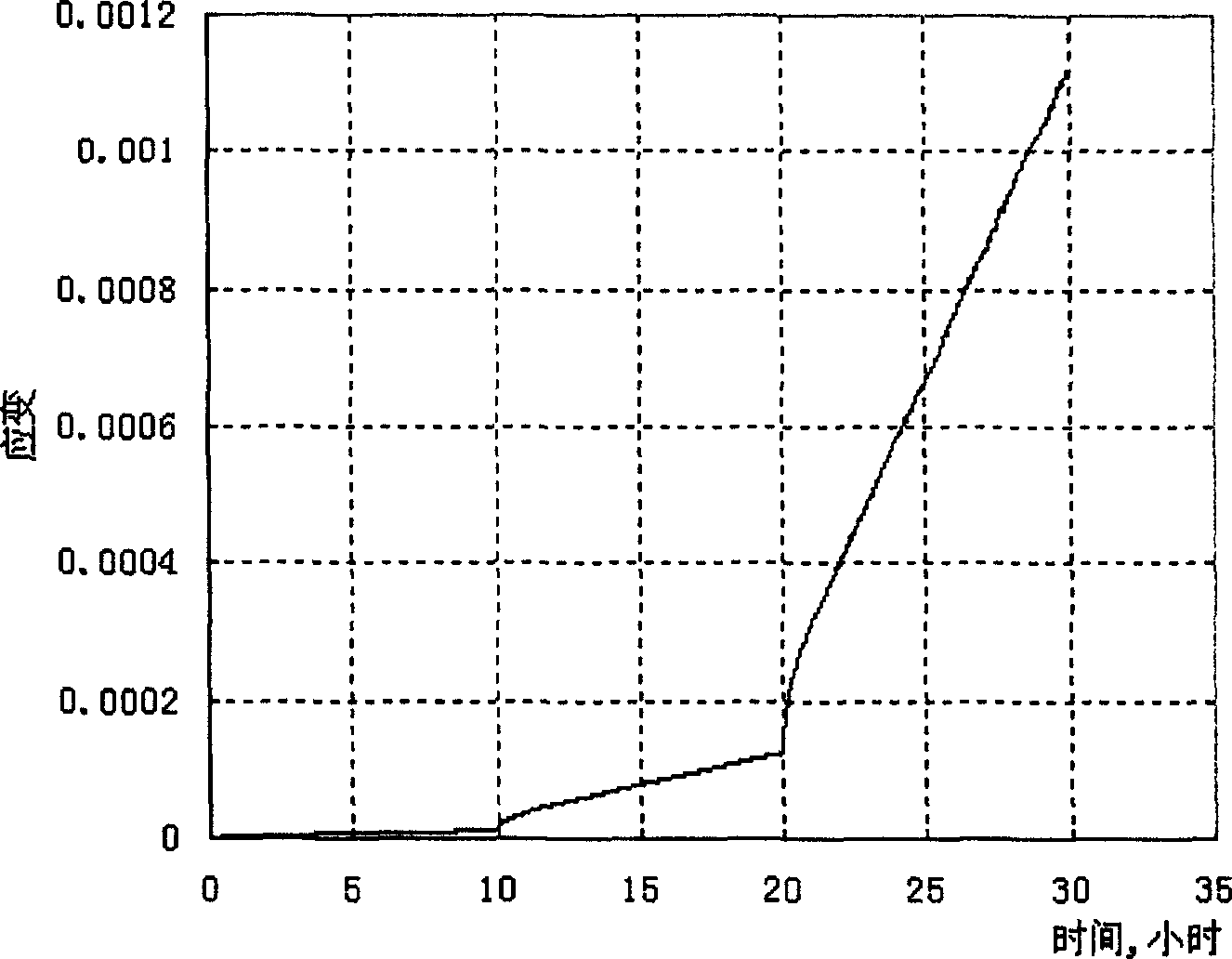

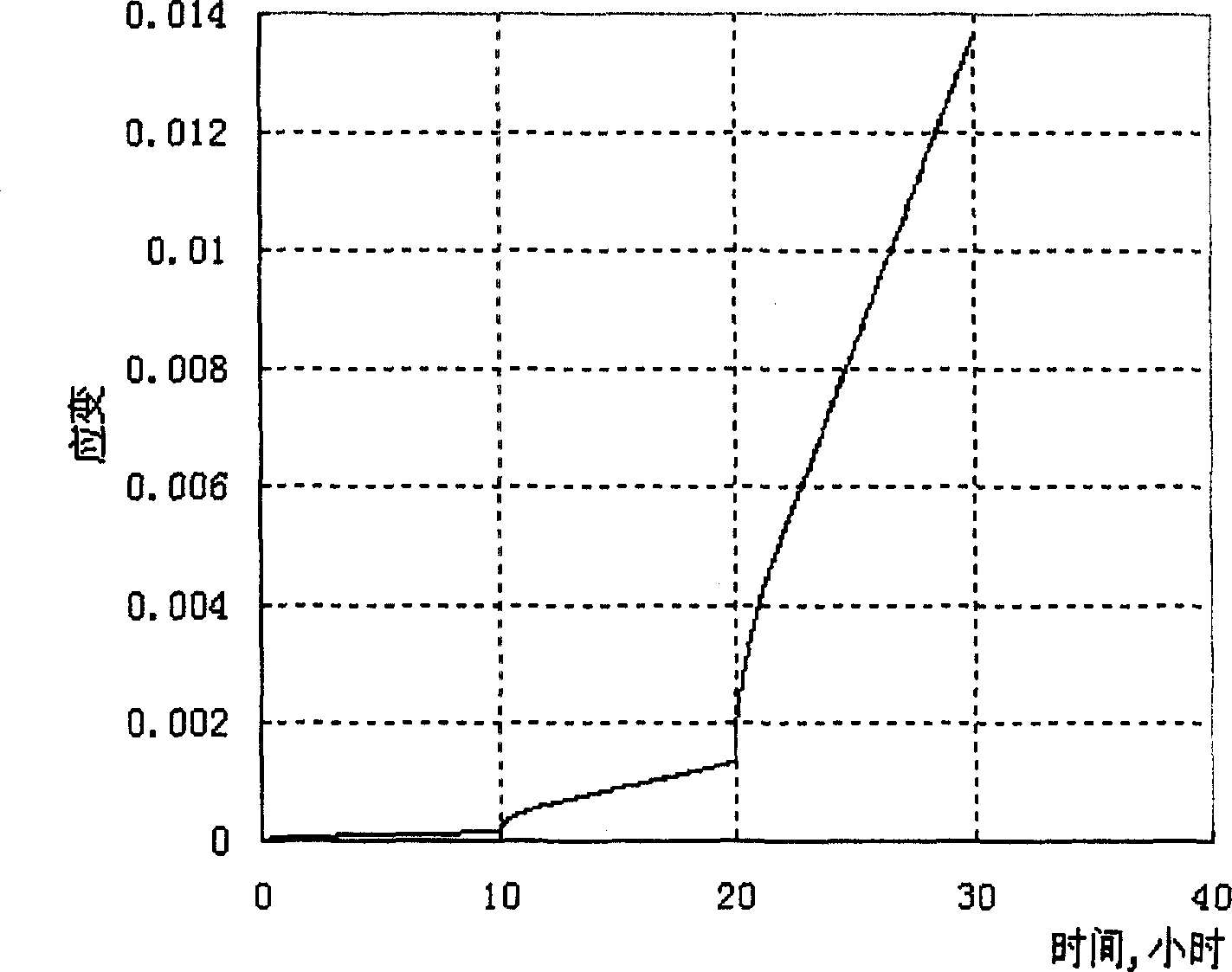

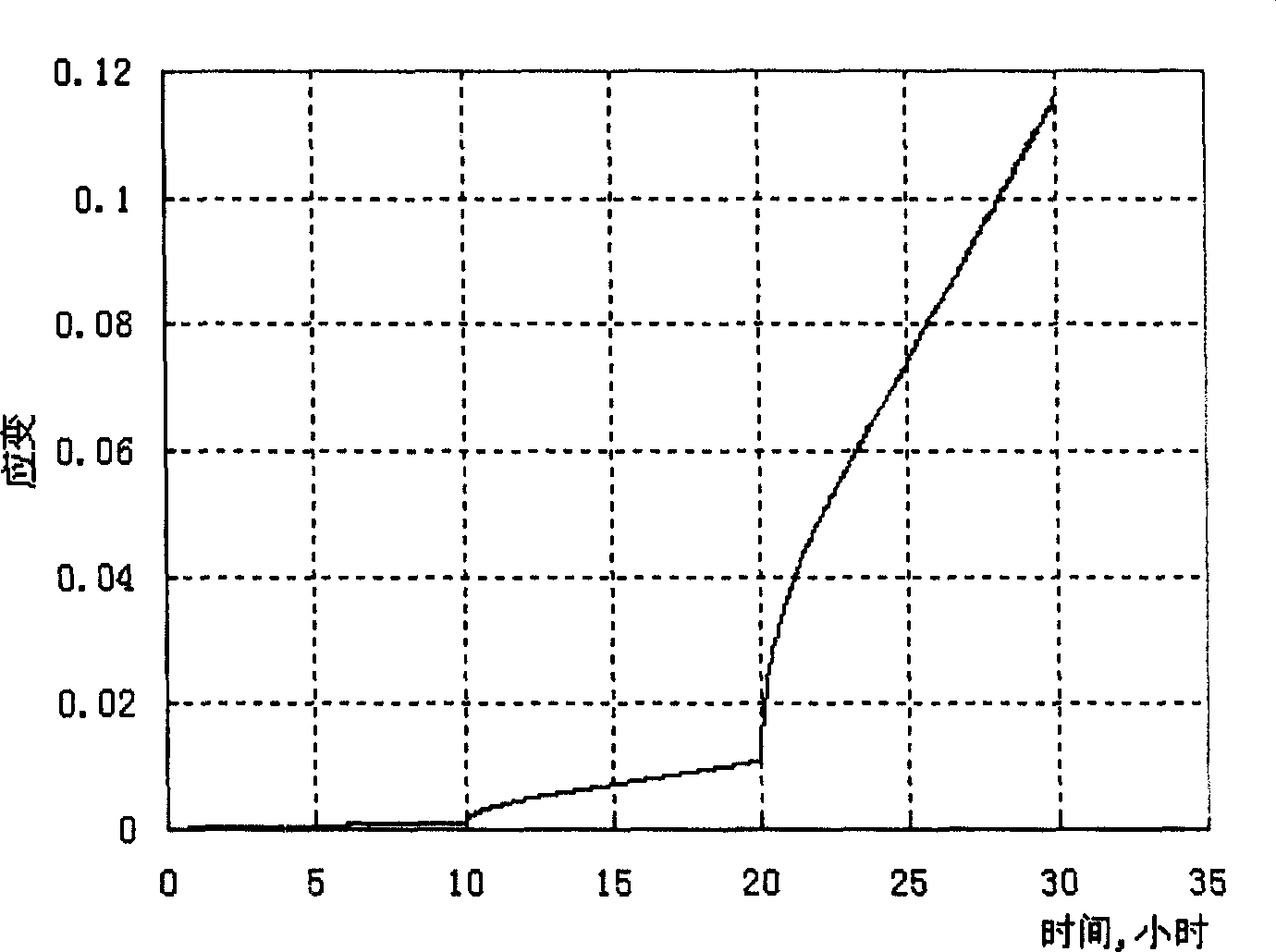

Method for overcomming creep of salt-rock layer by using ralation of drilling fluid density and chloride concentration

InactiveCN1814986ALower minimum burst pressureLower burst pressureFlushingDrilling compositionRelational modelCurve matching

Present invention refers to a method for overcoming salt rock layer creepage utilizing drilling fluid density and chlorides concentration relationship concentration relationship. It contains 1, to make hole boring with sampling and test sample processing, 2, taking four experiment test samples, to proceed creep test to each test sample, taking multiple level temperature and multiple level loading compound experiment mode to obtain creep test straining and timetable, 3, establishing salt rock creepage constitutive relation equation i.e. creep stress-rate of strain relation equation through curve matching method, 4, establishing well bore necked-in rate and drilling fluid density relation equation,5, taking the rest of four test samples, to proceed salting in experiment, corresponded salting in dissolution rate and chlorides pH indicator relation curve, establishing salting in rate and chlorides pH indicator relational model through nonlinear regression, 6, establishing drilling fluid density, temperature and chlorides pH indicator graph of relation edition, determining rational drilling fluid density and chlorides concentration to overcame salt bed creepage according to steps 6 graph of relation edition to salt bed well drilling in same zone block with experiment well core.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

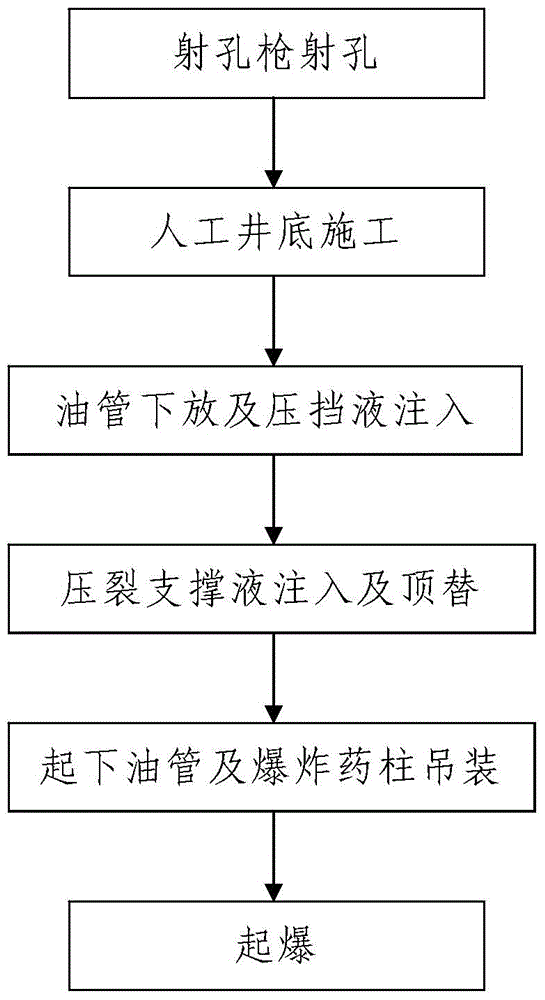

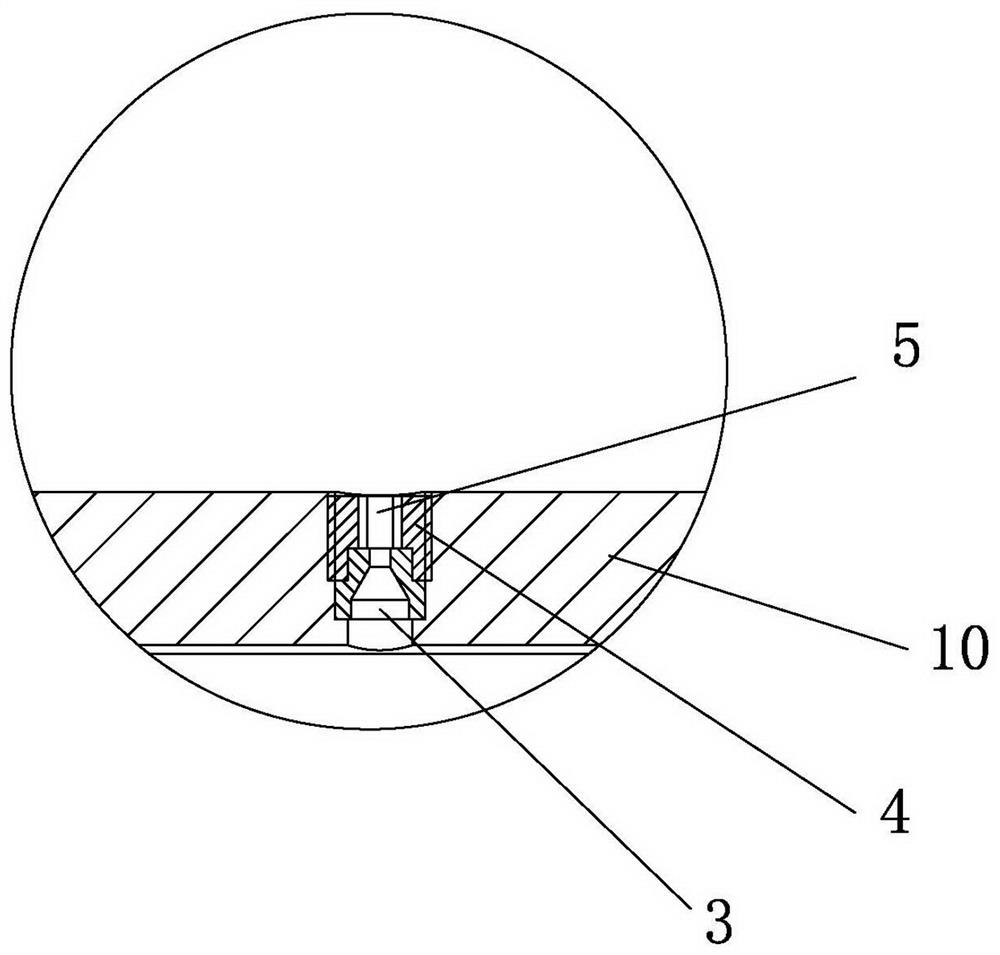

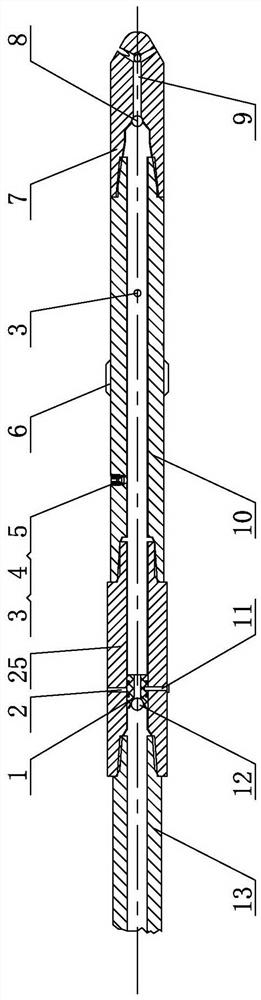

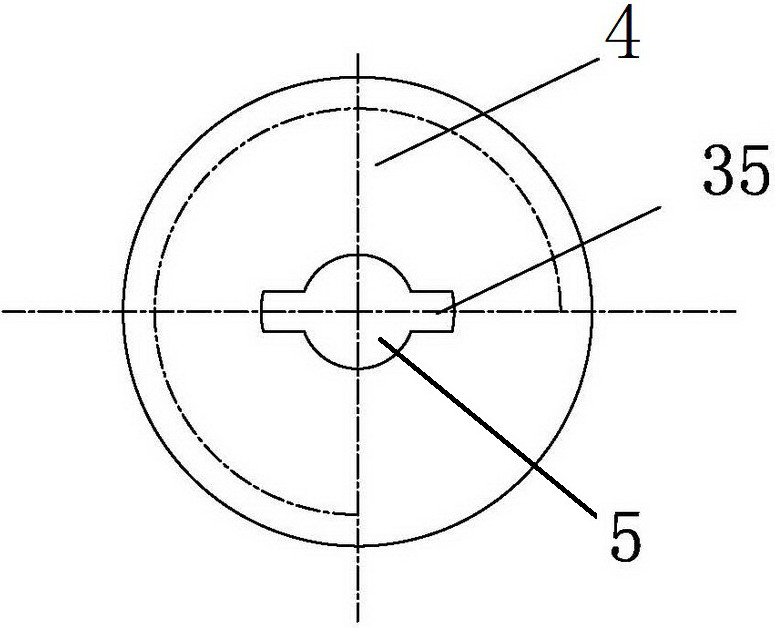

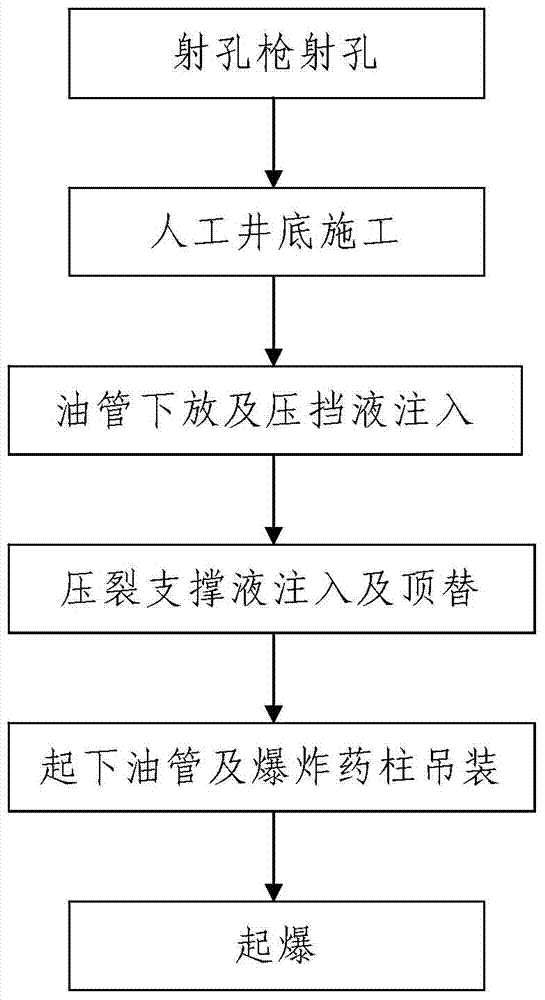

Method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture

The invention discloses a method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture. The method comprises following steps: 1, perforation by a perforating gun: adopting the perforating gun put lower into a well bore of an oil-gas well for perforation and forming multiple perforation tunnels in a target interval; 2, construction of an artificial bottom of the well: constructing the artificial bottom of the well at the bottom of the well bore of the oil-gas well; 3, downward placement of an oil pipe and injection of pressure baffle liquid: downwardly placing the oil pipe to the position where the target interval is located, injecting pressure baffle liquid into wellbores of the oil-gas well by means of the oil pipe till a sleeve pipe and the oil pipe are poured with pressure baffle liquid; 4, injection and displacement of fracturing propping liquid with the process as follows: primary injection of separation liquid, injection of fracturing propping liquid, secondary injection of separation liquid and displacement of fracturing propping liquid till the fracturing propping liquid is displaced to the target interval; 5, tripping of the oil pipe, hoisting and displacement of explosive columns; 6, initiation of explosion. The method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture has following beneficial effects: the method has simple steps and a reasonable design and is conveniently realized and has fine usage effect; and a crack closure problem during the process of high-energy gas fracture is effectively solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

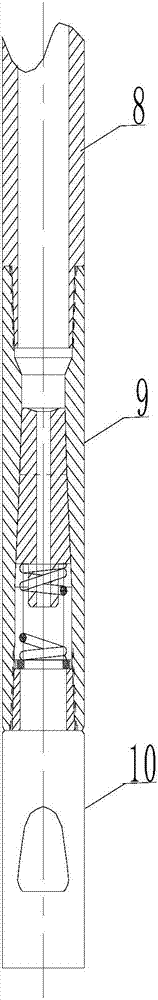

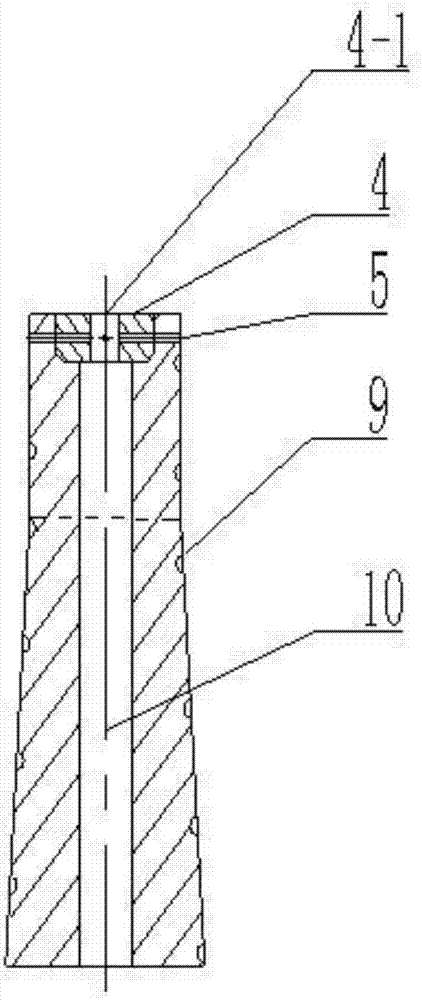

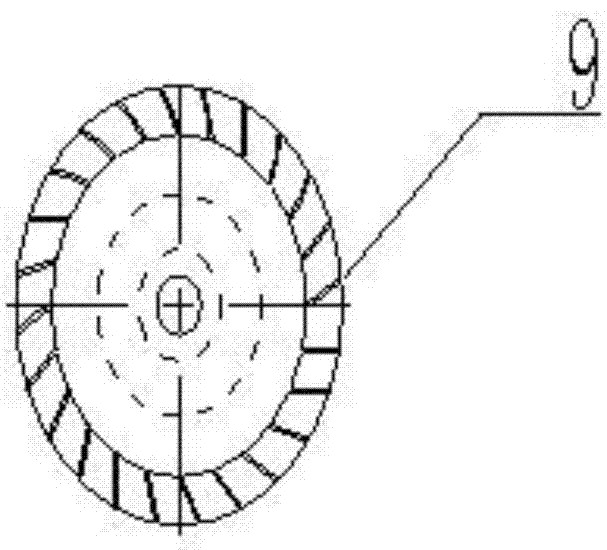

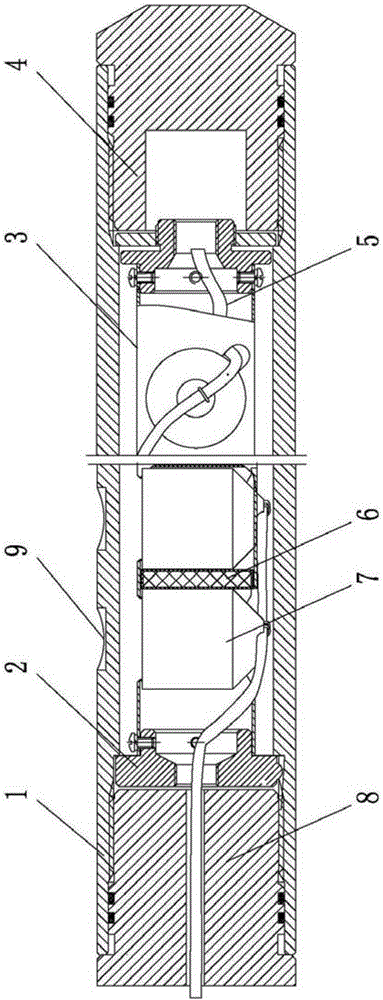

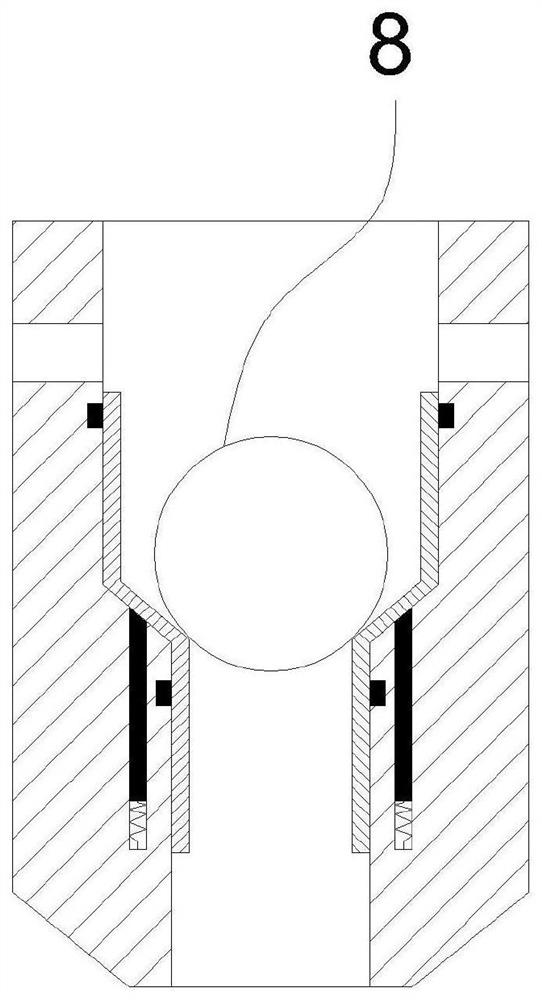

Low-frequency hydraulic pulse generating device and method for reservoir temporary-plugging diversion fracturing

ActiveCN107288576ASpread sand evenlyEffective Sand CarryingFluid removalHydro energy generationHydraulic fracturingEngineering

The invention discloses a low-frequency hydraulic pulse generating device and method for reservoir temporary-plugging diversion fracturing. The low-frequency hydraulic pulse generating device comprises a cylinder body, an upper connector and a lower connector, wherein the upper connector and the lower connector are connected to the upper end and the lower end of the cylinder body correspondingly; a piston matched with the cylinder body is arranged in the cylinder body; the upper portion of the cylinder body is of a cylinder structure, and the lower portion of the cylinder body is of a cone structure; a throttling device is arranged at the upper end of the piston; a flow guiding through hole is formed inside the piston; a throttling through hole is formed in the center of the throttling device and vertically communicate with the flow guiding through hole, and the diameter of the throttling through hole can become larger under erosion of fracturing liquid; a reset spring is arranged at the bottom of the piston; and a first pressure relief hole , a second pressure relief hole and a third pressure relief hole are further circumferentially formed in the side wall, corresponding to the piston, of the cylinder body. According to the low-frequency hydraulic pulse generating device and method, based on the working displacement ranges of the injection stages of a temporary-plugging diversion repeated hydraulic fracturing operation plugging agent, a prepad fluid, a sand-carrying fluid and a displacing fluid, low-frequency hydraulic pulse output in a hydraulic driving mode is achieved, and the temporary-plugging diversion repeated hydraulic fracturing effect can be improved overall.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

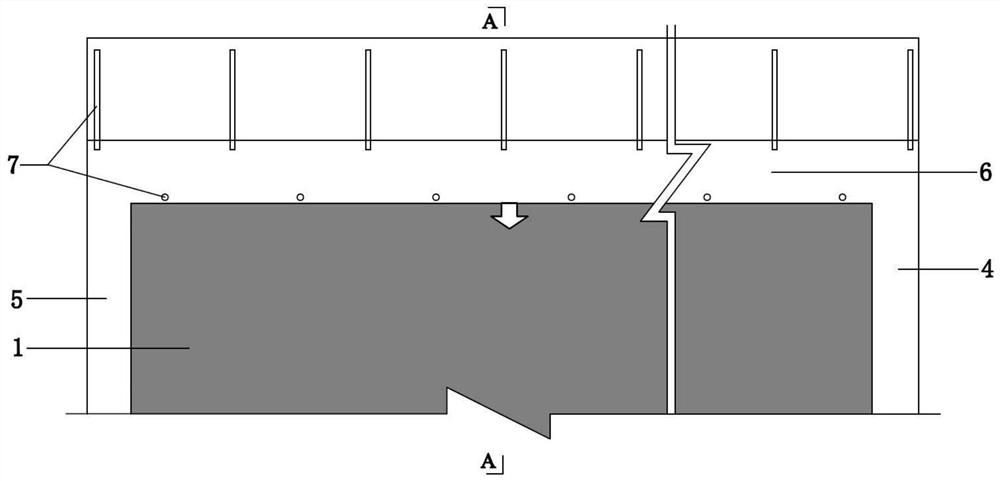

Equipment and method for controlling industrial and mining limestone roof of well through acid fracturing

ActiveCN112647944AImprove overhang caving effectReduce limestone strengthUnderground miningSurface miningDrill holeCoal

The invention discloses equipment and method for controlling an industrial and mining limestone roof of a well through acid fracturing, and relates to the technical field of mining. The method comprises the following steps of constructing a group of parallel drill holes between working face frames close to a coal wall side and a goaf side; sealing the drill holes, starting a high-pressure pump to inject acid liquor into the drill holes, stopping injecting when the pressure of the pipeline reaches 10 MPa, and maintaining the pressure for 5-10 min; after pressure maintaining is finished, starting the high-pressure pump again to conduct limestone roof acid fracturing for 30 min; after fracturing is finished, turning off the high-pressure pump, and carrying out pressure maintaining for 5-10 min; after pressure maintaining is finished, relieving the pipeline pressure, and taking a hole packer; and repeating the steps until fracturing of all the drilled holes is completed. According to the method, the acid fracturing mode is adopted for treating the industrial and mining hard limestone roof of the well, through dissolution of acid liquor to limestone, on one hand, the construction pressure in the fracturing process can be reduced, on the other hand, the opening degree of a fracturing crack can be increased, the meshing effect of rock blocks on the two sides of the fractured crack is reduced, and sufficient caving of the limestone roof is facilitated.

Owner:CHINA UNIV OF MINING & TECH

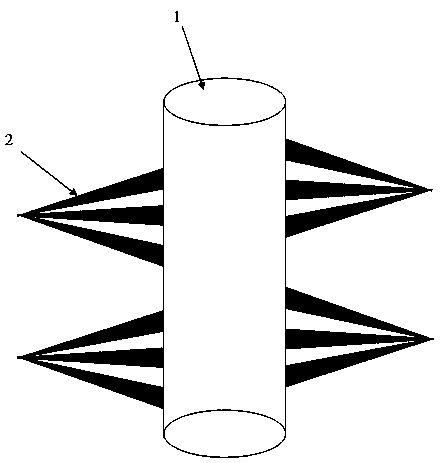

Special perforating gun for fracturing, special FracGun composite perforating device and method for fracturing

Owner:XIAN TONGYUAN PETROTECH

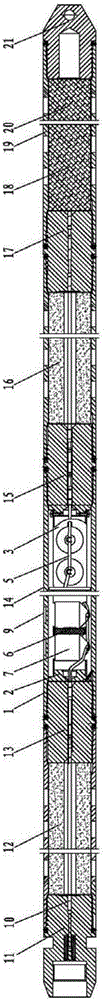

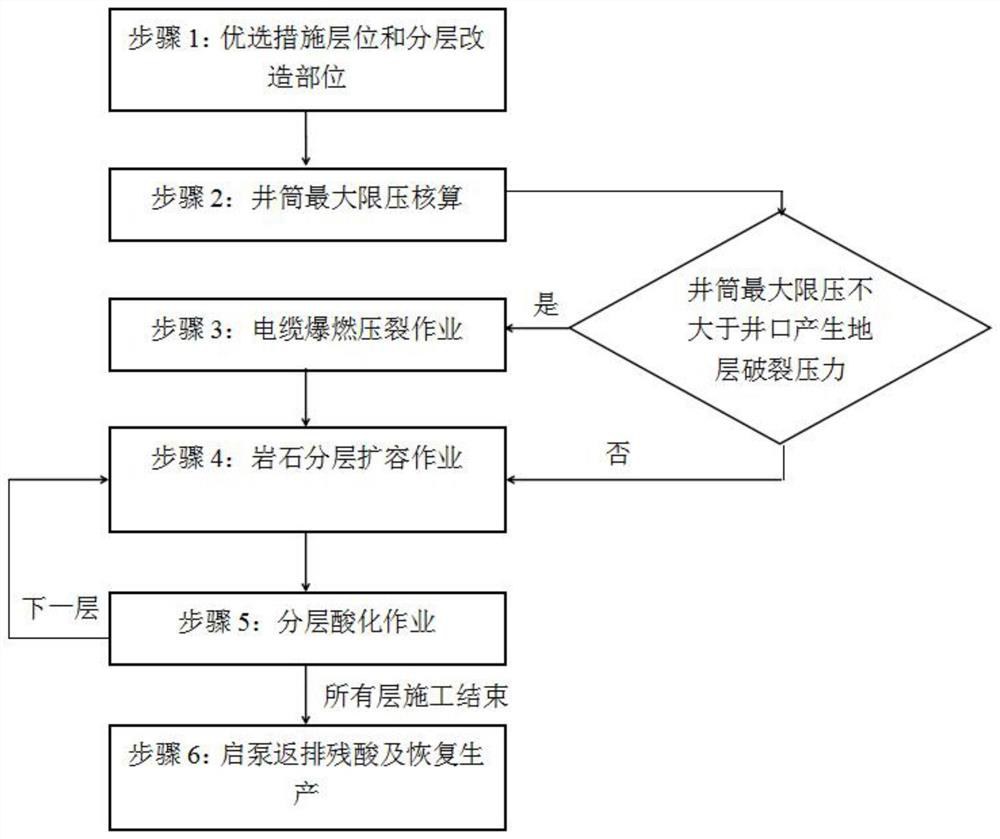

Low-cost and high-efficiency transformation process method for low-permeability reservoir of offshore oilfield

PendingCN114135265AOptimizing deflagration fracturing operationsEnsure safetyFluid removalWater sourceOil field

The invention discloses a low-cost and high-efficiency transformation process method for a low-permeability reservoir of an offshore oilfield, and belongs to the technical field of oilfield reservoir transformation. The method mainly comprises the following steps: step 1, preferably selecting a measure horizon and a layered transformation part; 2, the maximum limited pressure of the shaft is calculated; 3, cable deflagration fracturing operation is carried out; 4, rock layering expansion operation is carried out; step 5, layered acidification operation; and 6, starting the pump to flow back the residual acid and recovering production. According to the method, the modification effect of the low-permeability reservoir of the offshore oilfield can be effectively improved through selective combination of several low-cost modification processes, and the problem of conventional hydraulic fracturing caused by limitation of platform space and water sources of the offshore oilfield, large span of the low-permeability reservoir, high operation cost and long period is solved; and a new thought is provided for low-cost and high-efficiency transformation of the low-permeability reservoir of the offshore oilfield.

Owner:CNOOC ENERGY TECH & SERVICES

A construction method of hot dry rock geothermal artificial heat storage

ActiveCN105696996BLower burst pressureObvious lithofacies structureGeothermal energy generationFluid removalHydraulic fracturingIgneous rock

The invention provides a building method for an artificial dry-hot-rock geothermal reservoir and belongs to the field of artificial dry-hot-rock geothermal reservoir building. According to the technical scheme, the method includes the steps that supercritical carbon dioxide fracturing is conducted on the soft weak face or an interlayer formed along the igneous rock phase to generate a major crack, then large displacement of hydrofracturing is conducted on the interior of the major crack to generate secondary fracturing, bulk fracturing or cluster type fracturing of a dry hot rock body is generated under cyclic fracturing, and the artificial geothermal reservoir is built. The building method has the beneficial effects that the characteristics of low viscosity and easy diffusion of the supercritical carbon dioxide and the characteristic that the crack is easy to form due to the fact that the fracturing pressure of igneous rock under supercritical carbon dioxide fracturing is low are fully utilized; and in combination with the characteristics that the igneous rock is of the obvious rock phase structure and thermal fracturing is easy to generate, the problems that current hydrofracturing cannot be implemented to building of the artificial geothermal reservoir in a deep rock mass, the fracturing pressure is large, the crack group or the crack band of an ideal structure is difficult to form, and an artificial geothermal reservoir stratum is particularly difficult to build are solved.

Owner:TAIYUAN UNIV OF TECH

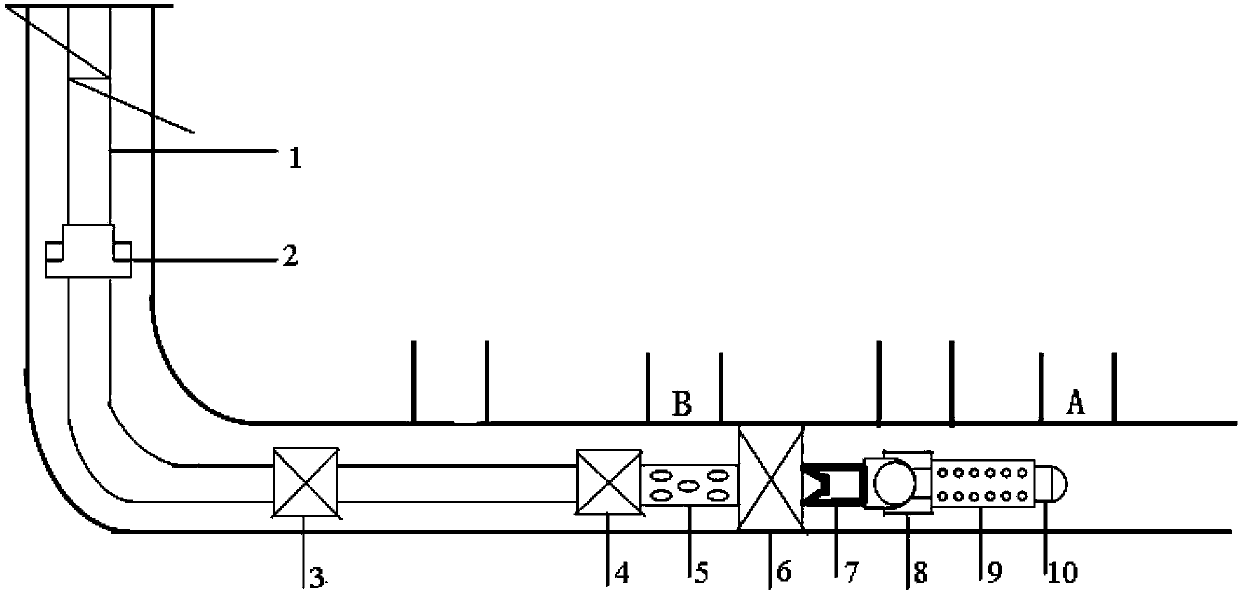

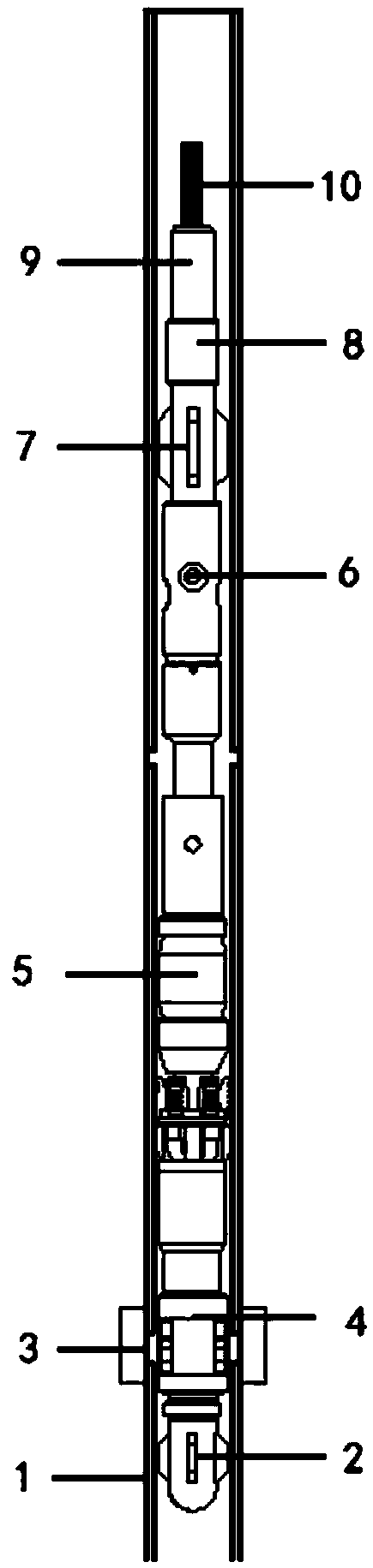

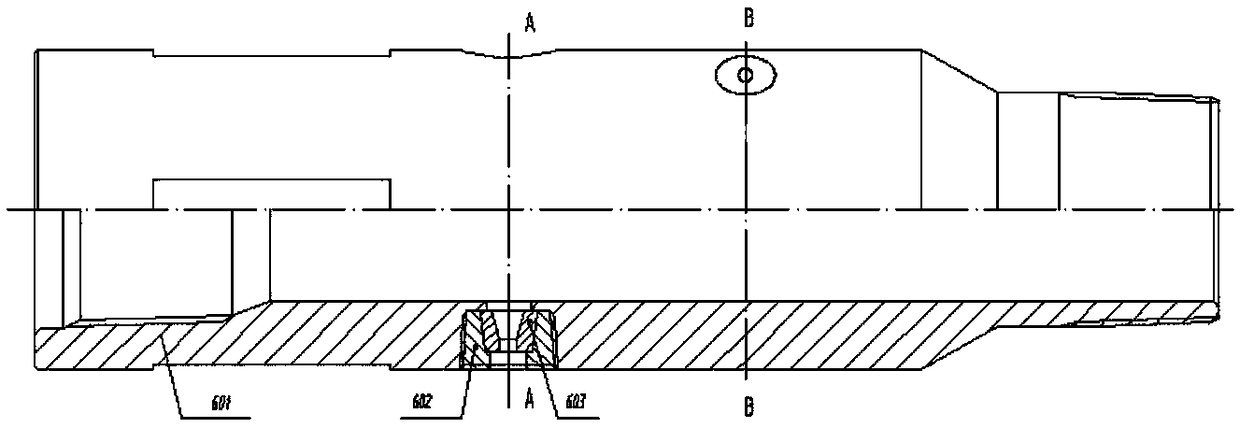

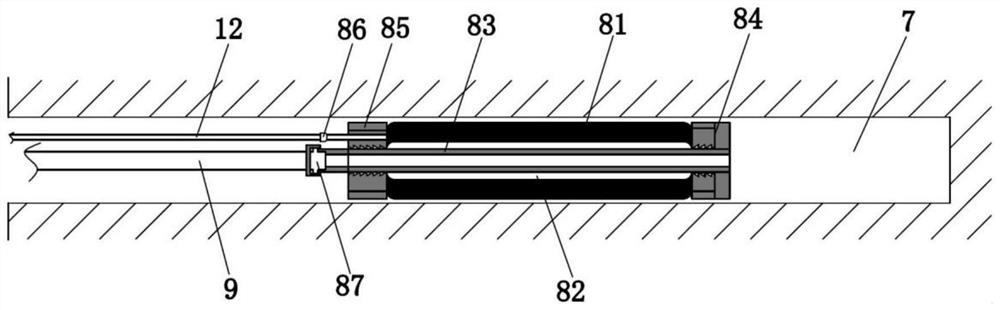

Horizontal well pumping perforating surface-fixed orientation-point clustering perforator detonation transfer conversion device

InactiveCN108518206ALower burst pressureImprove oil recovery efficiencyFluid removalElectricityElectric signal

The invention discloses a horizontal well pumping perforating surface-fixed orientation-point clustering perforator detonation transfer conversion device. The device comprises a detonation transfer conversion joint, a fixing cap for fixing a detonation transfer tube, a first conductive sheet and a second conductive sheet for electric conduction, a spring for pressing the second conductive sheet, insulating sleeves, insulating pads, a gun body, a bearing, a positioning ring, perforating bullet clusters, the detonation transfer tube, a detonating cord, a control key, locking pieces, a bearing cap, a bearing sleeve, an upper through wire and a lower through wire. According to the device, in order to achieve detonation transfer between gun strings and transmission of electric signals under anyangle rotation state of gun carriers, wires for transmitting the electric signals and detonating cords installed on the gun carriers in the perforating gun strings rotate along with the gun carriers,an intermediate detonation transfer conversion device is installed between the two gun strings, moving wires respectively fixed on the gun carriers in the two gun strings can be rotated freely in guns along with the gun carriers, the electrical signals can be reliably transmitted, the detonation transfer tube is used for docking, and the detonation transfer can be effectively implemented.

Owner:吉林市双林射孔器材有限责任公司

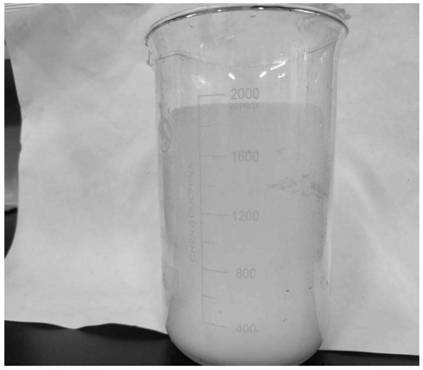

Fracturing preposed authigenic acid system and fracture reduction method thereof

PendingCN113214818AEasy to transportEasy to storeFluid removalDrilling compositionSolution polymerizationAqueous solution

The invention provides a fracturing preposed authigenic acid system and a fracture reduction method thereof. The fracturing preposed authigenic acid system comprises authigenic acid mother liquor A, authigenic acid mother liquor B and authigenic acid mother liquor C, wherein the authigenic acid mother liquor A is a paraformaldehyde aqueous solution, and the polymerization degree n is 10-100; the authigenic acid mother liquor B is an ammonium chloride aqueous solution; and the authigenic acid mother liquor C is an ammonium fluoride aqueous solution. According to the fracturing preposed authigenic acid system, the authigenic acid mother liquor A, the authigenic acid mother liquor B and the authigenic acid mother liquor C can be mixed at the bottom of a well on the basis of efficient transportation and no corrosion of a tubular column, and acid liquor is spontaneously and continuously generated, so that the purpose of no corrosion of the tubular column is achieved. Meanwhile, the generated acid liquor reacts with rock minerals, so that drilling and completion fluid pollution in a near shaft zone can be efficiently relieved, the porosity and permeability of a reservoir stratum are increased, the fluid absorption capacity of the reservoir stratum is improved, the fracture pressure of the reservoir stratum is reduced, the displacement of construction can be increased, and the effect of large-scale yield increase and transformation is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Selective refracturing technology for old oilfield wells

The invention discloses a selective repeated fracturing technology for old wells in oil fields, which is designed for effectively solving the problem of repeated reformation of old wells in oil fields. The technology of the present invention adopts assembling, lowering the pipe string, and dragging the pipe string to complete the perforation operation of the required reformed layer, set the upper and middle packers, carry out the fracturing construction of the lowest newly added layer, unseal and drag The construction is carried out in the technological steps from moving the pipe string to the second newly-increased reconstruction layer. The technology of the invention utilizes hydraulic sand blasting perforation to form large-diameter and deep-penetrating tunnels, which can effectively reduce the fracture pressure, and utilizes the advantages of double-seal and single-clamp fracturing technology to reduce requirements on wellhead matching and casing steel grades. The technical string structure of the invention is simple, the construction method is flexible, the operation is convenient and the efficiency is high, which can effectively solve the problem of repeated reconstruction of old wells in the oil field, and can not only complete the repeated fracturing of the reconstructed section, but also carry out the hole repair of the newly added section Integrated operation with fracturing.

Owner:PETROCHINA CO LTD

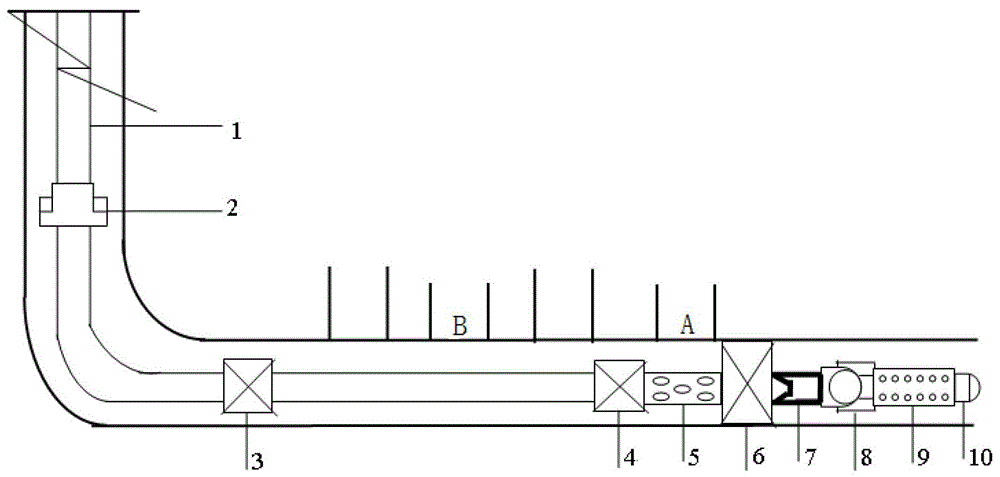

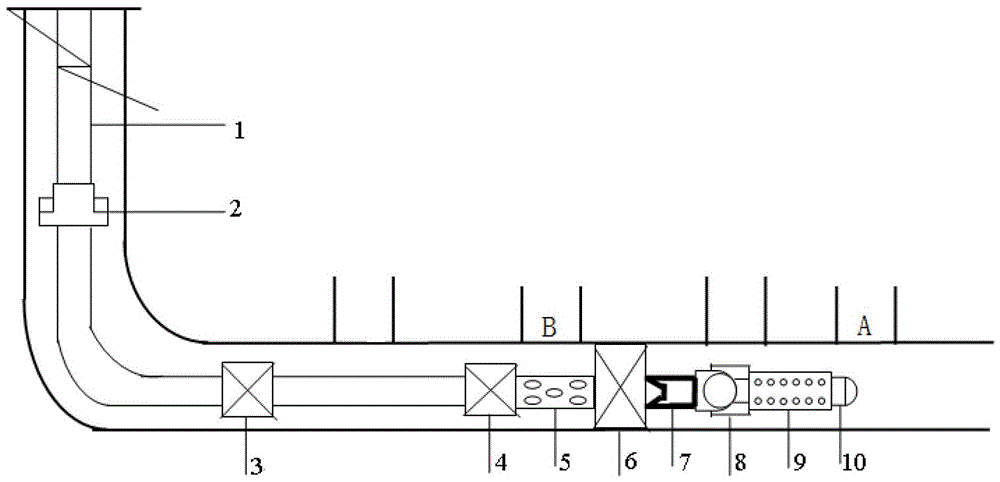

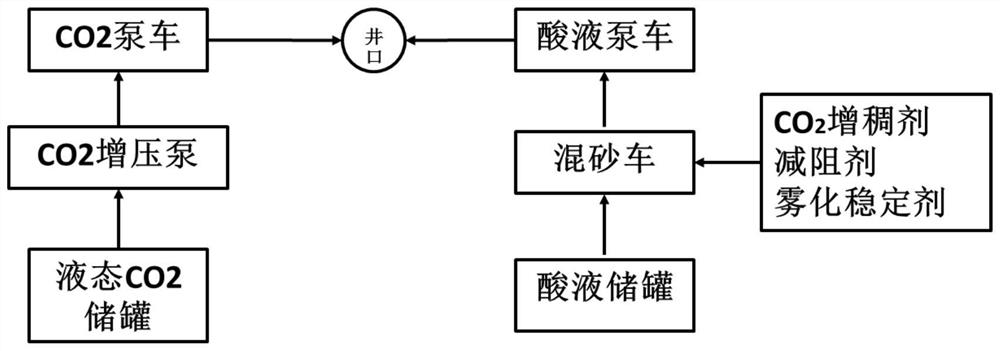

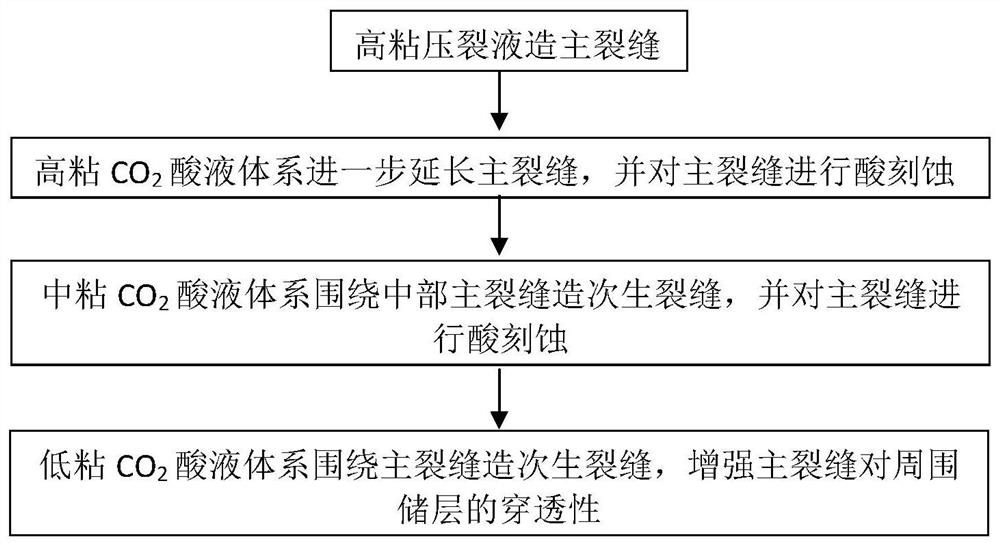

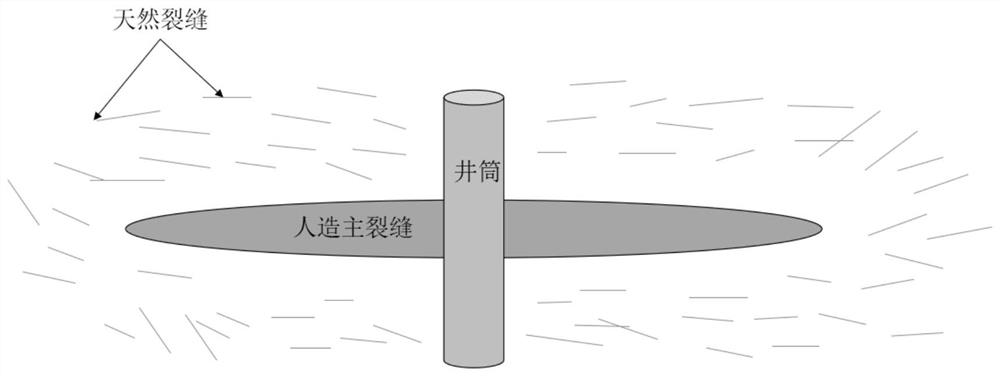

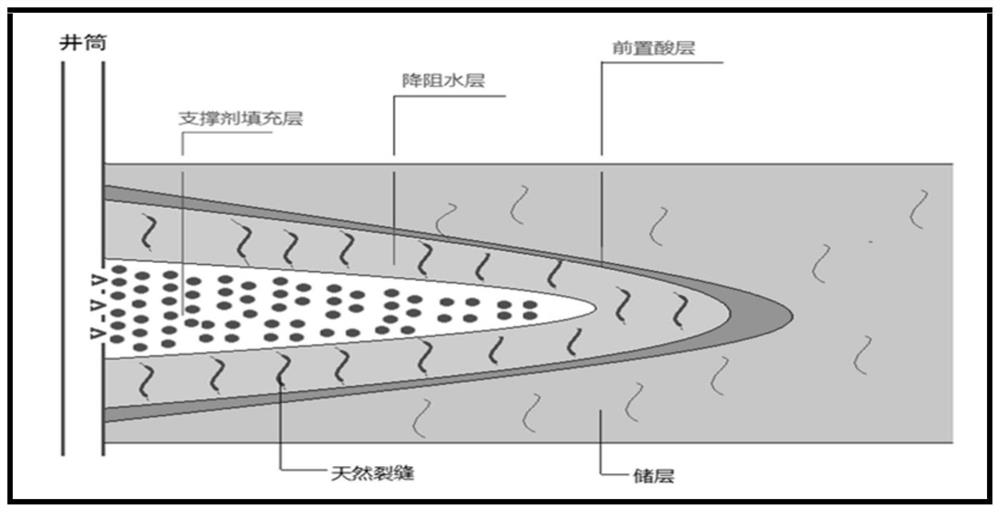

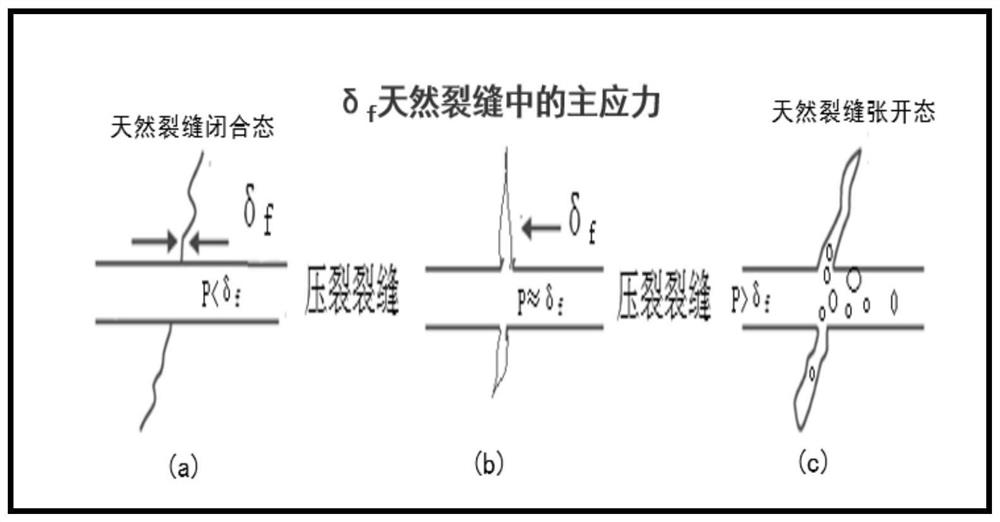

Carbon dioxide acid fracturing method for ultra-deep well carbonate reservoir transformation

ActiveCN113187459ALow viscosityReduce surface tensionOther gas emission reduction technologiesFluid removalAcid fracturingPhysical chemistry

The invention belongs to the technical field of carbon dioxide sequestration and oil and gas reservoir yield increase transformation, and particularly relates to a carbon dioxide acid fracturing method for ultra-deep well carbonate reservoir transformation. The carbon dioxide acid fracturing method for ultra-deep well carbonate reservoir transformation is characterized in that the fluidity of a system is controlled by adjusting the viscosity of a CO2 composite acid liquor system, acid liquor is composed of hydrochloric acid with the concentration of 20%, a CO2 thickening drag reducer and an atomization stabilizer, the acid liquor with different viscosities is obtained by adjusting the using amount of the CO2 thickening drag reducer, and the CO2 composite acid liquor system with the high viscosity is suitable for making complex fractures at the ends of main fractures; the CO2 composite acid liquid system with the medium viscosity is suitable for making the complex fractures in the middle of the ends of the main fractures; the CO2 composite acid liquid system with the low viscosity is suitable for making the complex fractures around the main fractures of a near-well section. According to the carbon dioxide acid fracturing method for ultra-deep well carbonate reservoir transformation, the complexity of the reservoir fractures can be effectively improved, the volume of the fractures can be increased to meet the exploitation requirement, meanwhile, the effective action range of the artificial fractures can be further increased, and the exploitation efficiency of carbonate reservoir oil and gas resources can be effectively improved.

Owner:新疆恒洲景业石油技术服务有限公司

Stratum transformation method

The invention provides a stratum transformation method, which comprises the following steps of: 1, performing refined segmentation on a reservoir according to reservoir conditions; 2, perforation operation is carried out to form perforations in all the divided sections; 3, fracturing operation is conducted through a fracturing pipe column, in the step 3, pre-acid is pumped into the fracturing pipe column to be used for corrosion of pollution of slurry and cement slurry to a fracture system in the drilling and completion process before main fractures are formed for the divided sections, according to the stratum transformation method, the reservoir is segmented firstly, the transformation layer position can be defined, and the stratum transformation efficiency can be improved; and in the subsequent fracturing operation process, the pre-acid is pumped to corrode the pollution of slurry and cement slurry to a crack system in the drilling and completion process, meanwhile, the fracturing pressure is reduced, the construction difficulty is reduced, the reservoir transformation effect is improved, and the yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sleeve type composite positioning and shooting angle-fixed perforating device

PendingCN112709554AImprove injection capacityImprove washing abilityFluid removalMechanical engineeringMaterials science

The invention relates to a sleeve type composite positioning and shooting angle-fixed perforating device. The sleeve type composite positioning and shooting angle-fixed perforating device comprises a perforating gun body, a shooting angle-fixed bullet rack, a first middle joint and a second middle joint, wherein the two ends of the perforating gun body are connected with the first middle joint and the second middle joint respectively, the shooting angle-fixed bullet rack is installed in the perforating gun body, perforating bullets are installed on the shooting angle-fixed bullet rack, and the perforating bullets communicate through detonating cords; the perforating gun body is sleeved with a sleeve type bullet barrel, and the two ends of the sleeve type bullet barrel are fixed through the first middle joint and the second middle joint. According to the sleeve type composite positioning and shooting angle-fixed perforating device, the perforating gun body is sleeved with the sleeve type bullet barrel, the explosive loading amount can be increased by nearly 10 times compared with that of conventional composite perforating explosive cake type gunpowder, the limitation of the space of the perforating gun body is eliminated, and the positioning and shooting angle-fixed perforating technology and the fracturing technology can be implemented at the same time.

Owner:大庆金祥寓科技有限公司

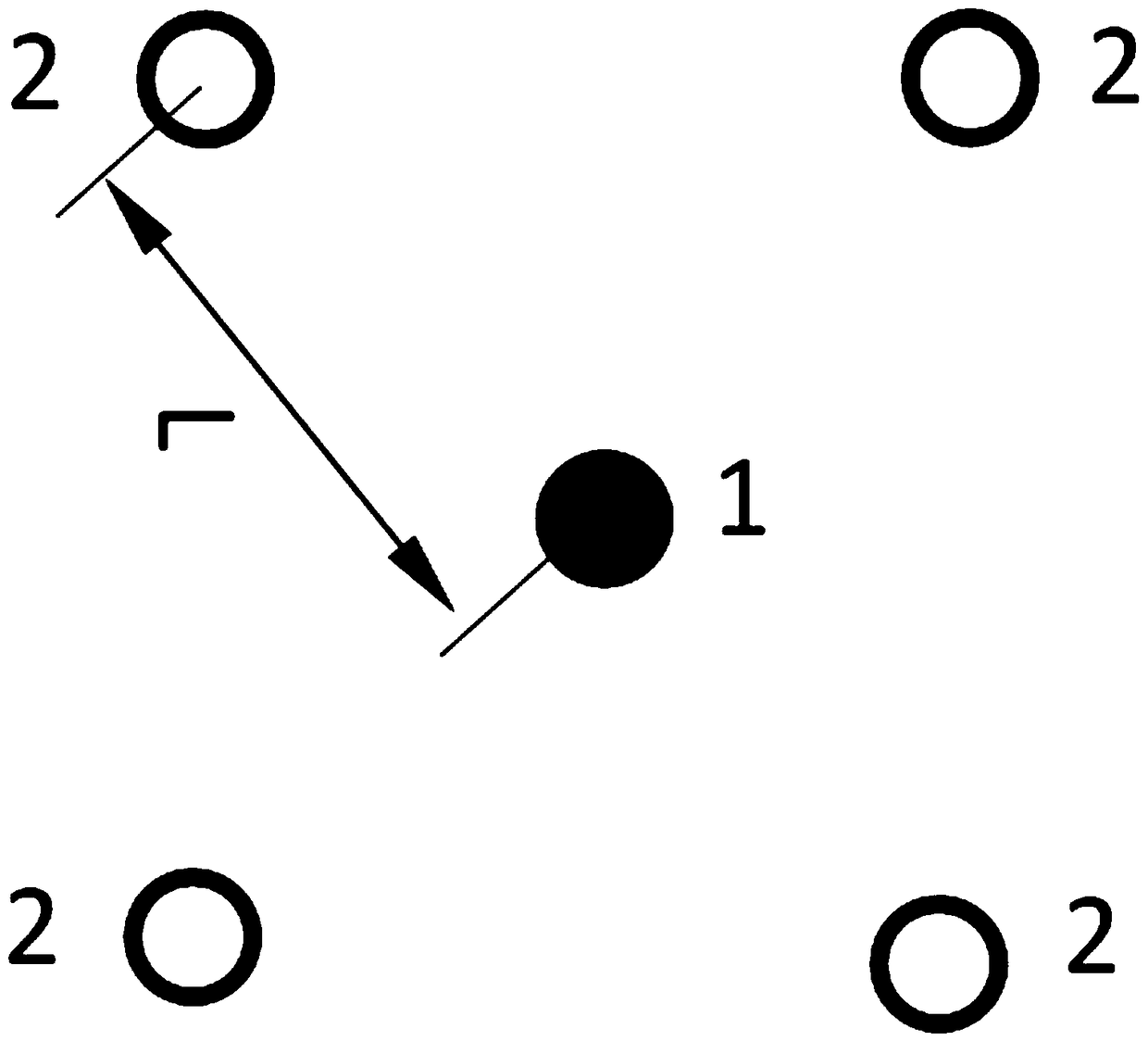

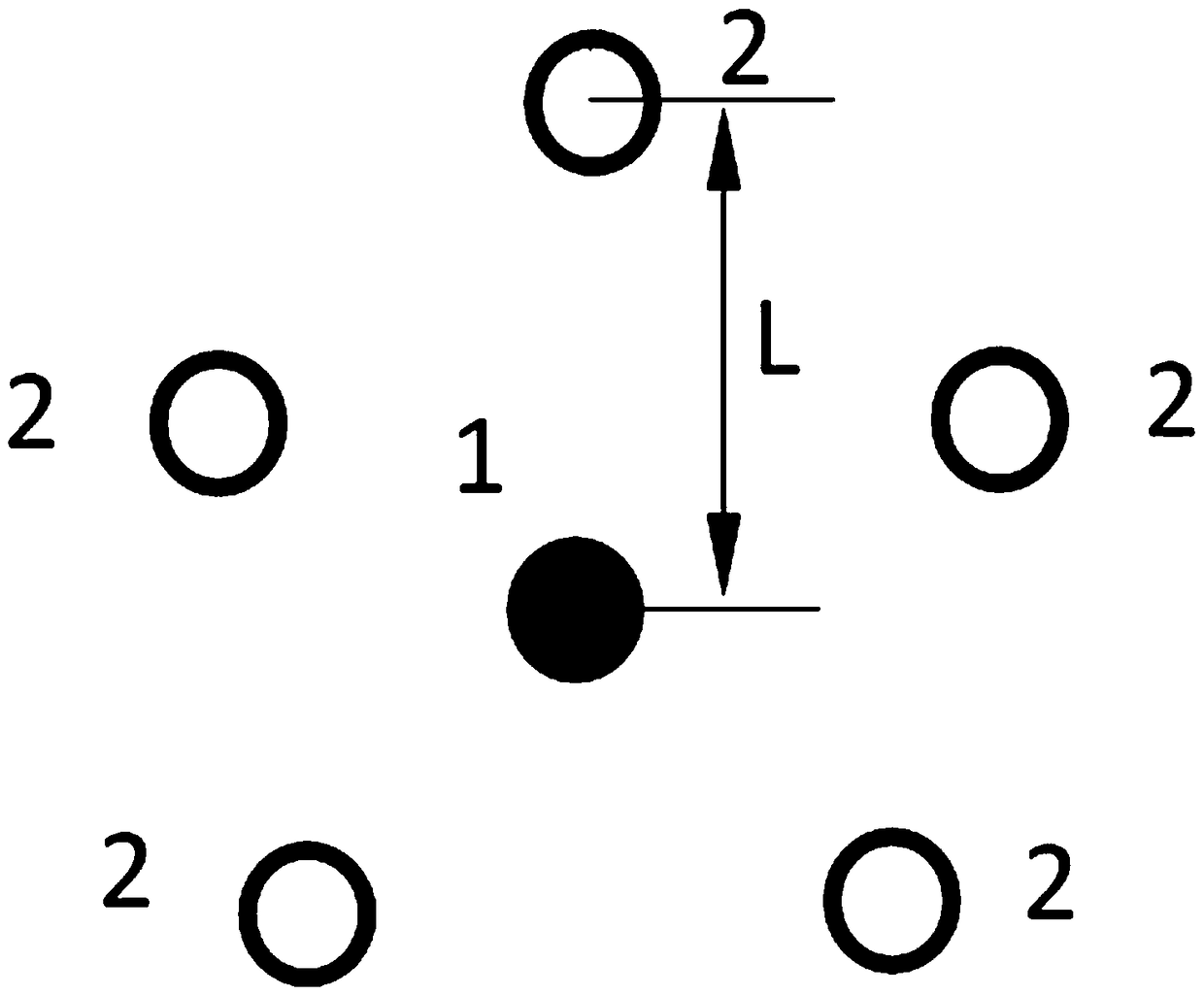

Hydraulic fracturing method for reducing cracking pressure through fixed-point perforation

InactiveCN111022018ALower burst pressureEasy to operateFluid removalDrilling compositionThermodynamicsHydraulic fracturing

The invention provides a hydraulic fracturing method for reducing cracking pressure through fixed-point perforation. The method comprises the following specific steps that a perforating gun performs multiple-group fixed-point perforation, each group of perforating bullets are concentrated at one point, each group of perforating bullets form a stress crushing area in a stratum, so that the crackingpressure of the stratum is reduced, and then hydraulic fracturing is performed on a reservoir stratum. The method is easy to operate, construction procedures are not increased, the operation cost isnot increased, the stratum cracking pressure can be effectively reduced, and the method is suitable for hydraulic fracturing operation of a high-hardness and high-cracking-pressure reservoir stratum.

Owner:PETROCHINA CO LTD

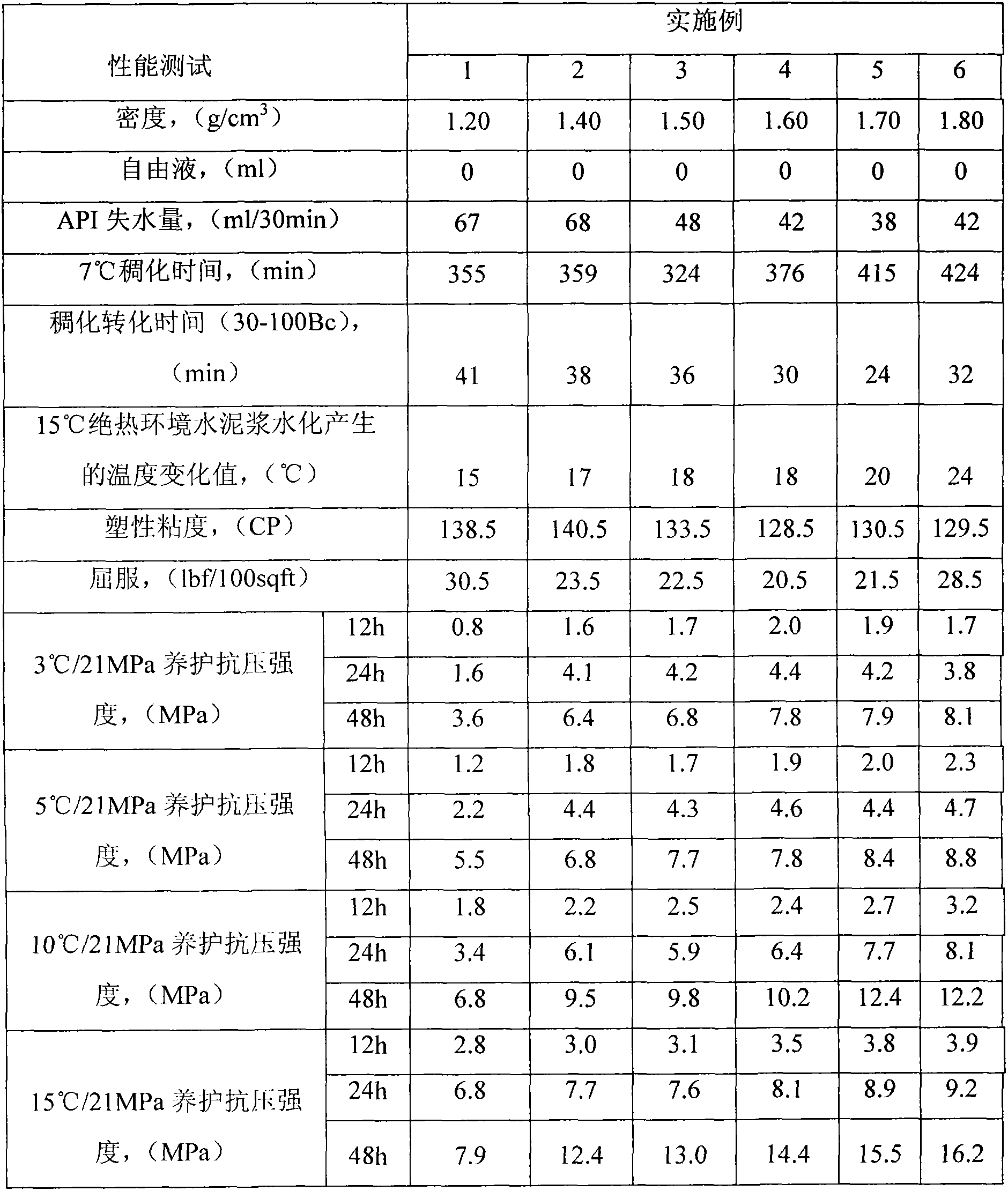

Silicate grout for deep water

ActiveCN102382633BLow costWide range of market sourcesDrilling compositionLow densityUltimate tensile strength

The invention discloses silicate grout for deep water, which consists of the following ingredients in parts by mass: 100 parts of cement, 2 to 40 parts of lightening agents, 3 to 7 parts of filtrate or reduction agents, 1 to 5 parts of dispersant, 10 to 50 parts of reinforcing agents, 0.1 to 1.5 parts of retarder and 50 to 100 parts of water. The silicate grout has excellent low-temperature early strength and low-temperature approximately right-angle thickening performance, the defects of slow gel strength development of the silicate grout at low temperature and low density and low early strength are overcome, and the surface casing and cementing operation can be ensured under the conditions of low temperature and low cracking pressure in deep water and complicated air flows in shallow water.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Casing well cementation sliding sleeve

ActiveCN114575779AAvoid pollutionEliminate distractionsWell/borehole valve arrangementsSealing/packingRubber materialWell cementing

The invention provides a casing pipe well cementation sliding sleeve which comprises an oil pipe body, a casing pipe body, a casing pipe body, a casing pipe body and a casing pipe body, and the oil pipe body is provided with a fracturing port; the center cylinder is installed on the oil pipe body through a shear pin and covers the fracturing port; the ball seat is fixedly connected to the central cylinder and is used for capturing the packing body; the protective rubber sleeve is mounted outside the oil pipe body, covers the fracturing port and is made of a decomposable rubber material; the expanding rubber sleeve is arranged outside the oil pipe body, and the expanding rubber sleeve and the protective rubber sleeve are distributed along the axial direction of the oil pipe body; and the hydraulic control valve device can enable the protection rubber sleeve to be communicated with the pipe cavity of the oil pipe body and enable the expansion rubber sleeve to be communicated with the pipe cavity of the oil pipe body under the condition that the pressure of the pipe cavity of the oil pipe body reaches an opening pressure value. By means of the sleeve well cementation sliding sleeve, the technical problem that it is difficult to give consideration to reduction of construction pressure and guarantee of the packing effect in a sleeve well cementation sliding sleeve is solved.

Owner:PETROCHINA CO LTD

Ball seat suitable for acidification of ultra-deep carbonate rock gas reservoir and use method of ball seat

ActiveCN114542011AImprove job stabilityQuick unblockConstructionsFluid removalAcid fracturingMining engineering

The invention discloses an acidizing ball seat suitable for an ultra-deep carbonate rock gas reservoir and a using method thereof.The acidizing ball seat comprises a ball seat body, an acidizing channel and a ball receiving shaft core, the ball seat body is arranged at the bottom of a packer, a main channel communicated with a center pipe of the packer is arranged in the ball seat body, a reducing part is arranged in the main channel, and the ball receiving shaft core is in a funnel shape; the fitting reducing part is arranged in the main channel and can coaxially move up and down along the main channel in the ball seat body, and the acidification channel is arranged on the inner wall of the ball seat body, communicates the main channel with a shaft annulus and is movably shielded by the ball seat body; when in use, the ball seat is mounted at the bottom of a K344 packer, the ball seat and the K344 packer are tripped into a fractured well together, the packer is allowed to carry out slurry reverse replacement when acid fracturing is not carried out, and a setting ball is put into the ball seat for pressurization when fracturing operation is carried out, so that an acidification channel is opened, acid fracturing is carried out smoothly, and smooth acidification construction is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

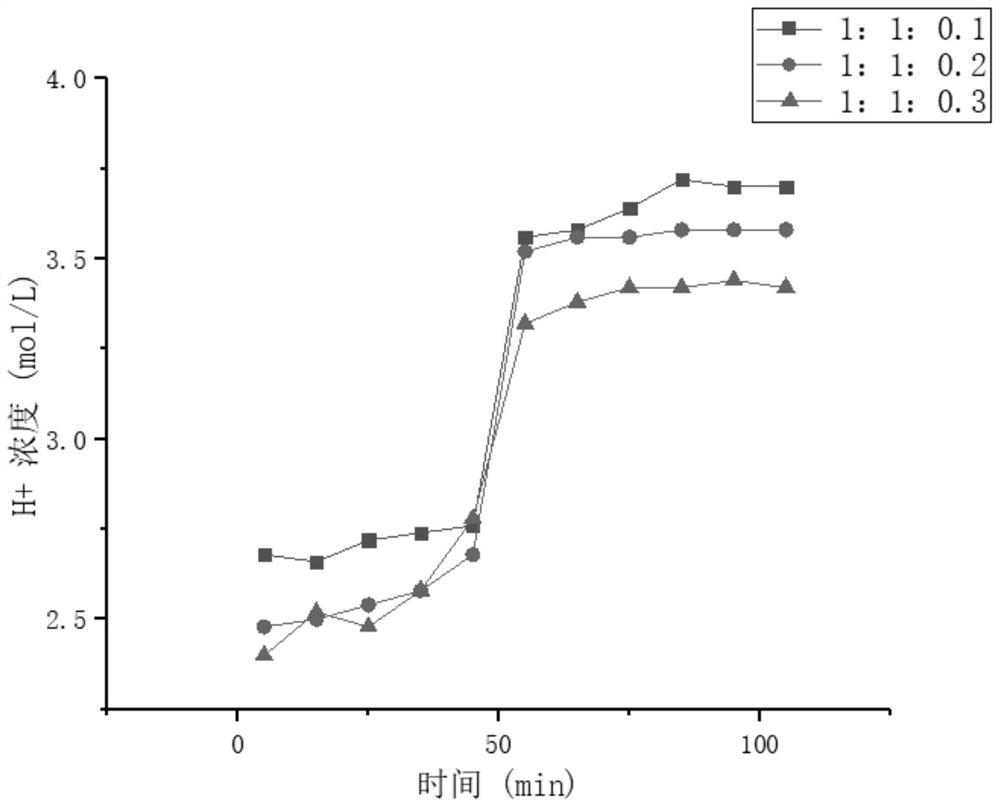

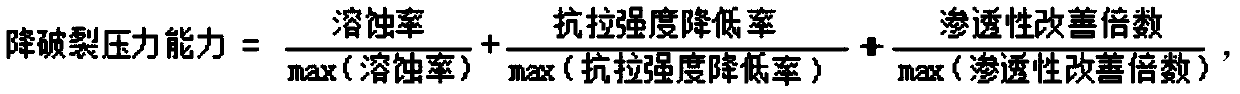

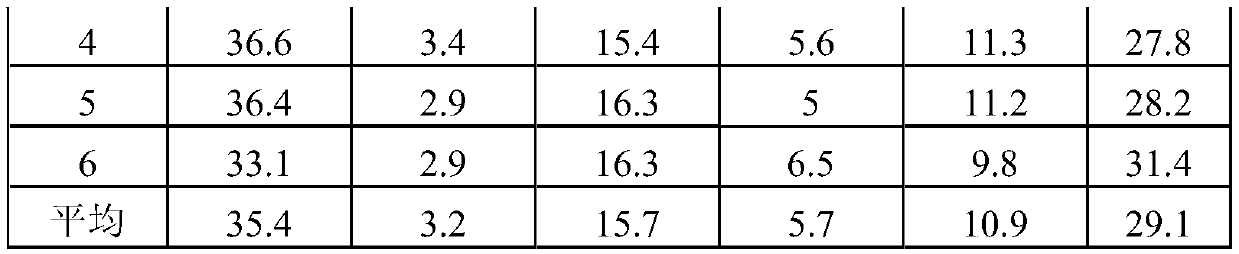

A method for optimizing shale reservoir fracturing pretreatment acid fluid

ActiveCN107842353BLower burst pressureLow tensile strengthFluid removalRock samplePressure reduction

The invention provides a method for optimizing shale reservoir fracturing pretreatment acid fluid. The method comprises the steps that a rock sample from a shale reservoir and a plurality of kinds ofacid fluid in different types and different concentrations are provided; corrosion rate data, acidification permeability improved multiple data and tensile strength reduction rate data of each kind ofacid fluid to the rock sample are tested; the fracturing pressure reduction capability of each kind of acid fluid to the shale reservoir is obtained according to the corrosion rate data, the acidification permeability improved multiple data and the tensile strength reduction rate data; and the appropriate acid fluid is selected to serve as the shale reservoir fracturing pretreatment acid fluid according to a fracturing pressure capability reduction result. According to the method, an acid fluid system with the fracturing pressure reduction capability being the highest aiming at the specific shale reservoir can be optimized through a corrosion rate test, an acidification permeability improvement test and a tensile strength reduction test, further the requirements for the power and the bearing capacity of fracturing construction equipment are lowered, and the construction risk is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reservoir reconstruction tool for electric-controlled hydraulic slotting and plugging removal

ActiveCN110230470BEffective unblockingTo achieve the goal of increasing production and increasing attentionCleaning apparatusLiquid/gas jet drillingSteel ballScrew joint

The invention discloses an electronically controlled hydraulic slottingblocking-removing reservoir modification tool capable of performing a slottingoperation on an oil well reservoir. Theelectronically controlled hydraulic slottingblocking-removing reservoir modification toolcomprises a reservoir modification valve connected to an oil pipe, the reservoir modification valve comprises a sleeve pipevalve seat and a sliding sleeve is fixedly arranged in a central hole of the sleeve pipe valve seat, and the outer side end surface, close to the oil pipe, of the sliding sleeve is recessed, and an electric wood ball is installed onthe outer side end surfaceof the sliding sleeve. The lower end of the sleeve pipevalve seat is coaxially connected with a spray gun nipple through a threaded joint,wiper blocksare evenly distributed on the axial outer peripheral wall of thespray gun nipple, and a central passage is arranged in thespray gun nipple. Nozzles are arranged on the spray gun nippleon thefrontsides and rear sides of the wiper blocks, and the two nozzles are arranged in a 90-degree-included-angle mode. The lower end of the spray gun nipple is connected to a well washing guide shoe by athreaded joint, and the lower end of the well washing guide shoe is closed, a backwashing passage is arranged at the center shaft position of the well washing guide shoe, a steel ball is arranged atthe liquid inlet end of the backwashing channel, and four liquid outlets are formed in thebackwashing passage.

Owner:XINJIANG YONGSHENG ENERGY CO LTD

A method to prevent the closure of pre-existing fractures in high-energy gas fracturing

ActiveCN104975838BThe method steps are simpleEasy to implementFluid removalHigh energyFracturing fluid

The invention discloses a method capable of preventing the closure of pre-existing fractures in high-energy gas fracturing, including the steps: 1. Perforating with a perforating gun: using a perforating gun that is lowered into the wellbore of an oil and gas well to perforate in the target interval Multiple perforation holes are formed; 2. Artificial bottom hole construction: construction of artificial well bottom at the bottom of the wellbore of oil and gas wells; Inject the barrier fluid into the wellbore of the oil and gas well until the casing and tubing are filled with the barrier fluid; 4. The injection and displacement of the fracturing propping fluid, the process is as follows: the initial injection of spacer fluid, the injection of fracturing propping fluid, the spacer fluid Secondary injection and replacement of fracturing propping fluid until the fracturing propping fluid is replaced to the target zone; 5. Hoisting and lowering of the tubing and explosive column; 6. Detonation. The method of the invention has simple steps, reasonable design, convenient implementation and good application effect, and can effectively solve the crack closure problem existing in the high-energy gas fracturing process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com