Selective refracturing technology for old oilfield wells

A re-fracturing and selective technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problem of inability to meet the requirements of isolating the upper reformed interval, affecting oil well productivity, compaction damage, etc. problem, to achieve the effect of flexible construction method, simple structure and reduced rupture pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

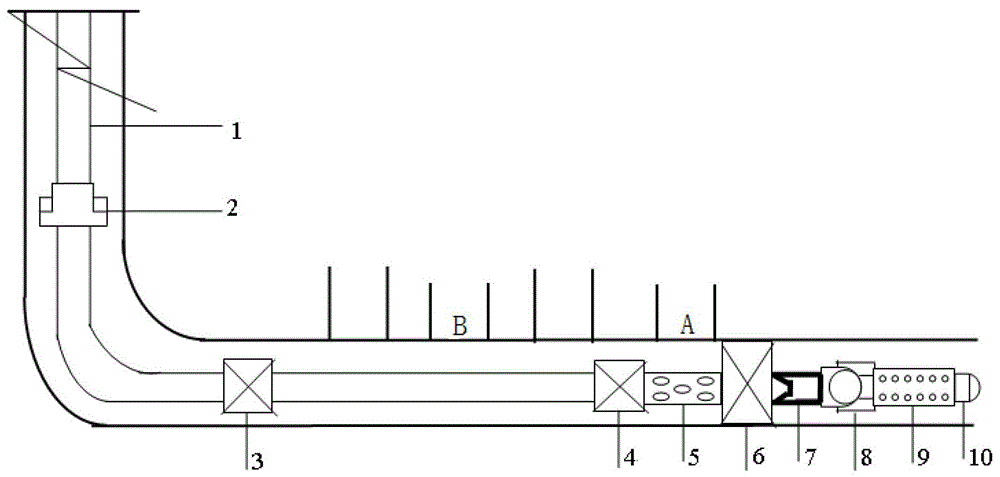

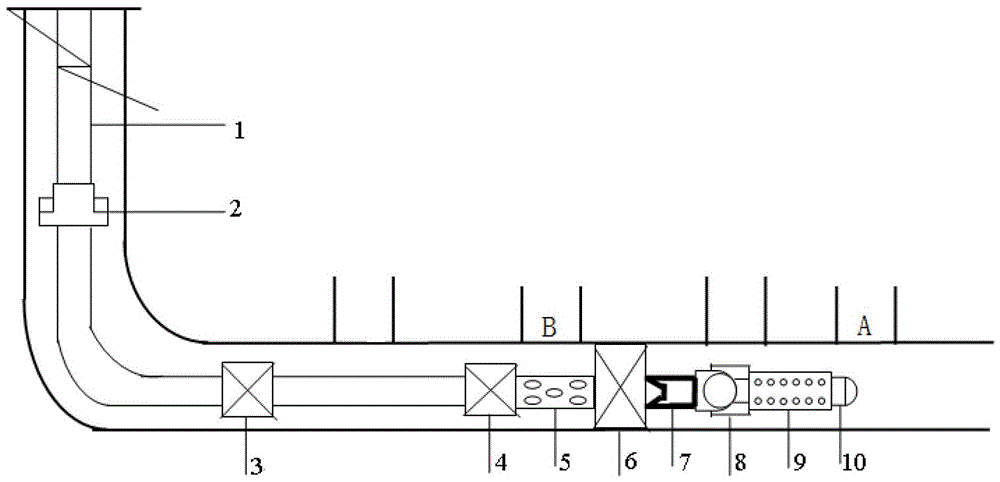

[0019] refer to Figures 1 to 5 The embodiment of the technology of the present invention is further described:

[0020] Taking an old horizontal well in an oil field as an example, there are two intervals that have been transformed, and now it is necessary to re-perforate and add two intervals to be transformed. The process string used in this construction consists of oil pipe 1, safety hand 2, upper packer 3, middle packer 4, hydraulic jet 5, lower packer 6, ball seat 7, check valve 8, eye pipe 9 and plug 10 form.

[0021] The concrete process steps of the technology of the present invention are as follows:

[0022] 1) According to the needs of repeated transformation and the designed interval, assemble and lower the pipe string (see figure 2 );

[0023] 2) Drag the pipe string several times to complete the perforation operation in the required reformed layer (see figure 2 , 3 );

[0024] 3) After the perforation of all intervals to be reformed is completed, the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com