Patents

Literature

33results about How to "Flexible construction method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

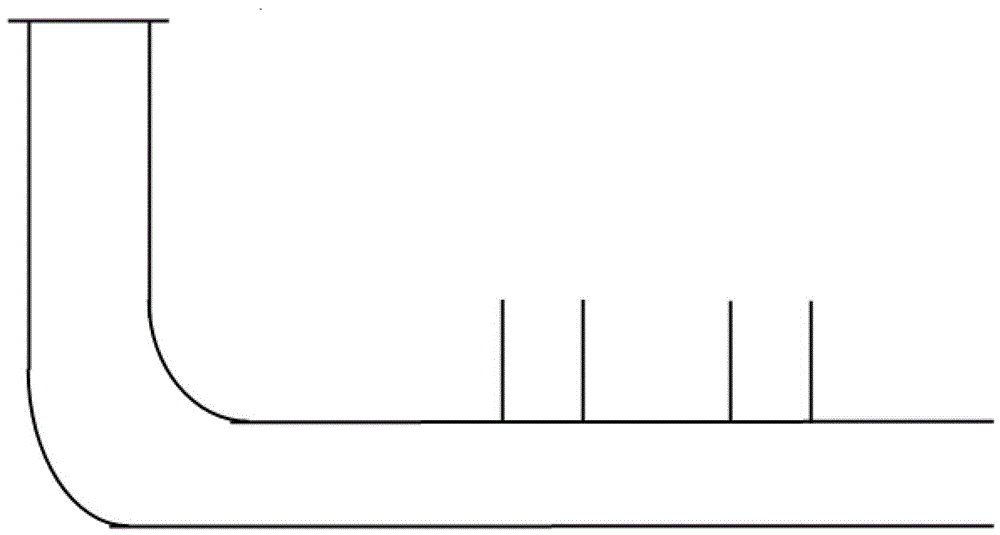

Shield receiving forward-shift construction method of boulder group open excavation and embedment mutation space

ActiveCN103032071AEliminate the risk of construction downtimeFast constructionExcavationsTunnelsShield machineEmbedment

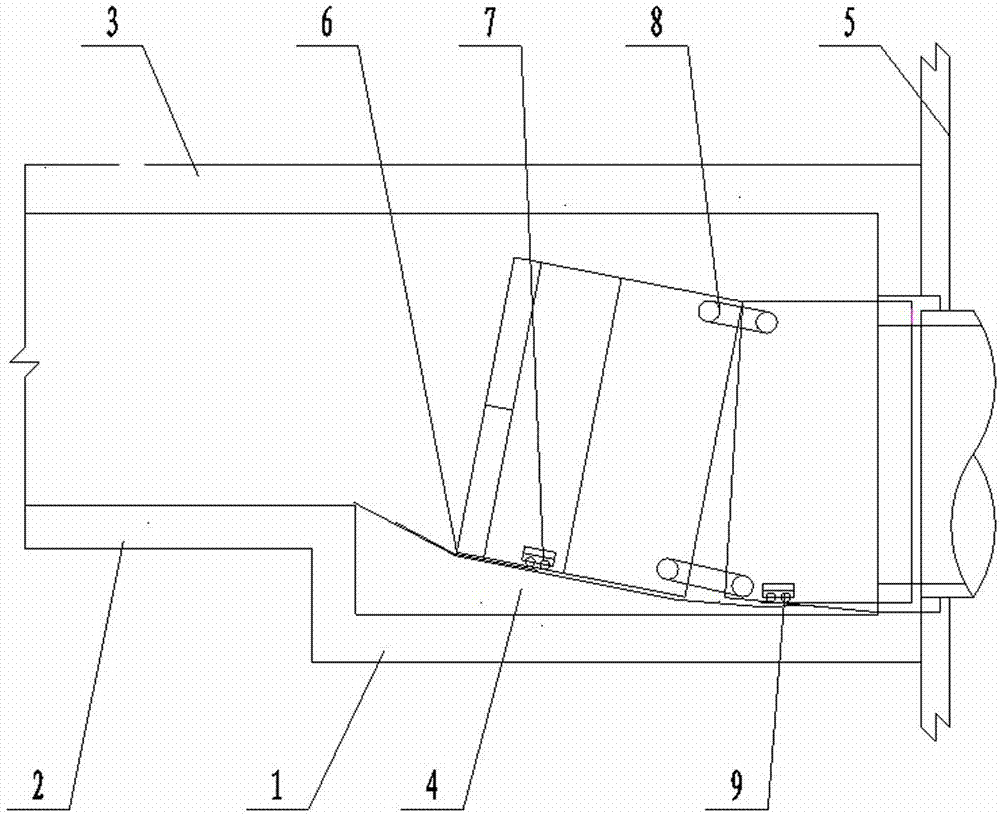

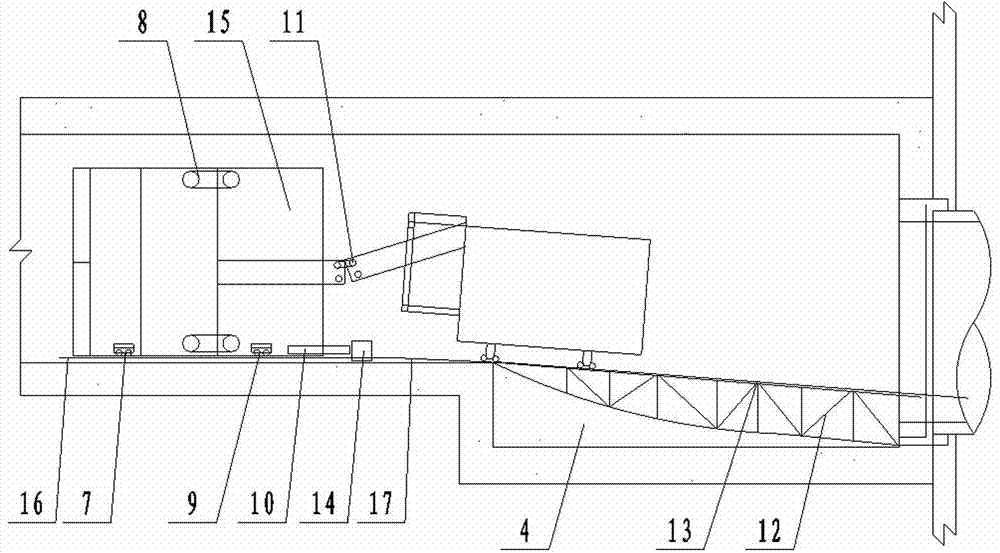

The invention relates to the technical field of tunnel shield construction and particularly provides a shield receiving forward-shift construction method of a boulder group open excavation and embedment mutation space. The problem that a shield cannot be normally received and hoisted out by shifting forward to a station by using the traditional method in conventional construction can be solved. The shield receiving forward-shift construction method comprises the following steps of: digging a boulder group open excavation and embedment section; forming a transition curve by a refilled receiving well as a large-slope curve with the open excavation and embedment section, and receiving and shifting forward the shield with the large-slope curve; and shifting forward the entire shield in the open excavation and embedment section, paving a back-up transition rail bar and a transition guide rail on the large-slope curve, shifting forward the entire shield by using a movable counter-force device and an oil cylinder of a shield machine, and shifting forward and respectively paving a forward-shift guide rail and a back-up forward-shift guide rail of a shield body on the open excavation and embedment section simultaneously. With the adoption of the shield receiving forward-shift construction method provided by the invention, the section tunneling mission is smoothly completed by the shield; a curve shield receiving process is started; and a technology of forward shifting the entire machine when the shield is backed up without the rail bar is innovated. The shield receiving forward-shift construction method has the advantages of simple process, low construction cost, flexible construction method and the like.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

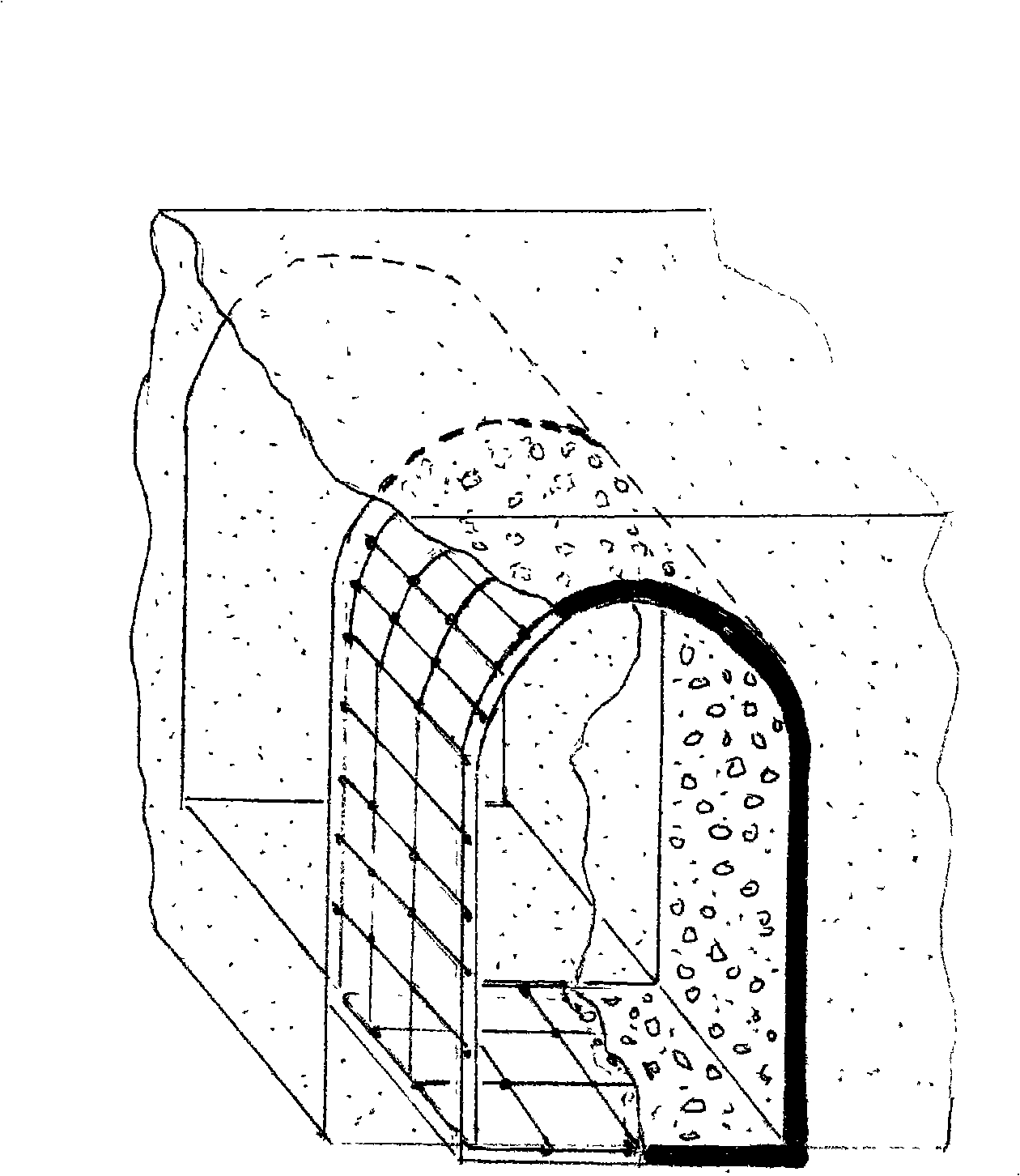

Mined metro station hole pile construction method

ActiveCN106703814AReduce the impact of settlementSave masonryUnderground chambersTunnel liningSupporting systemMetro station

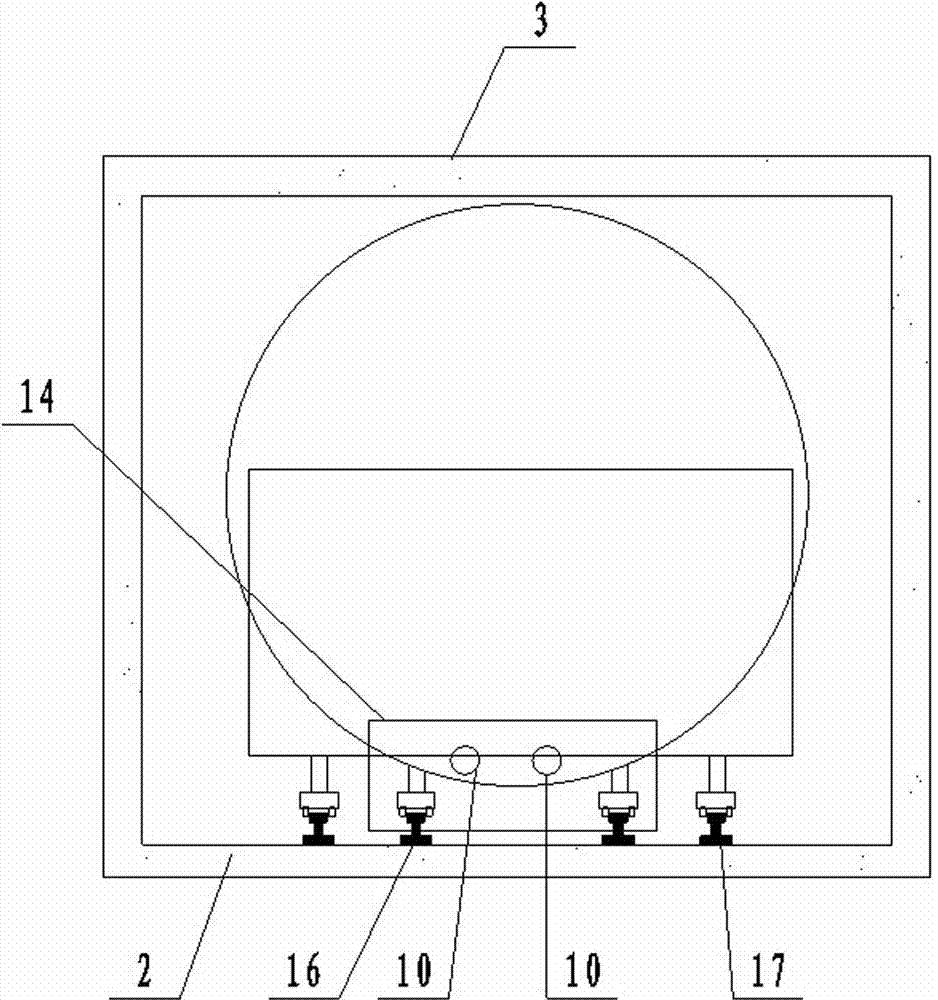

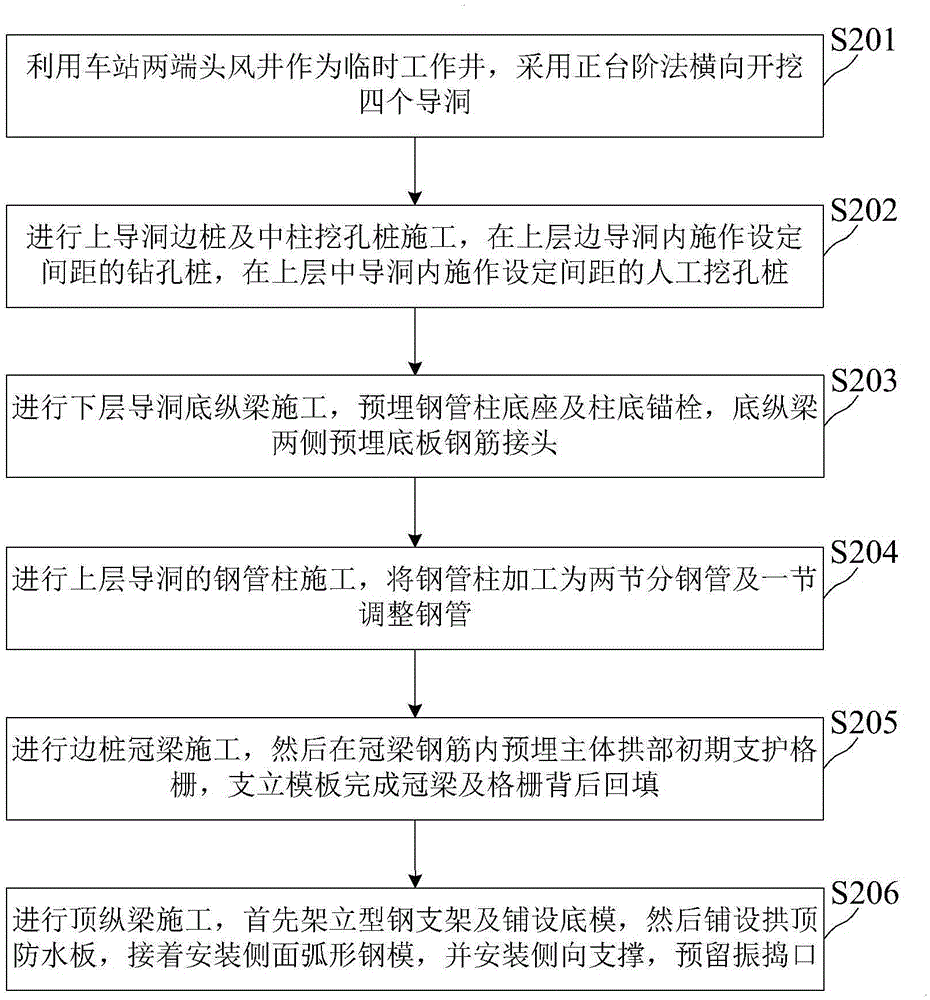

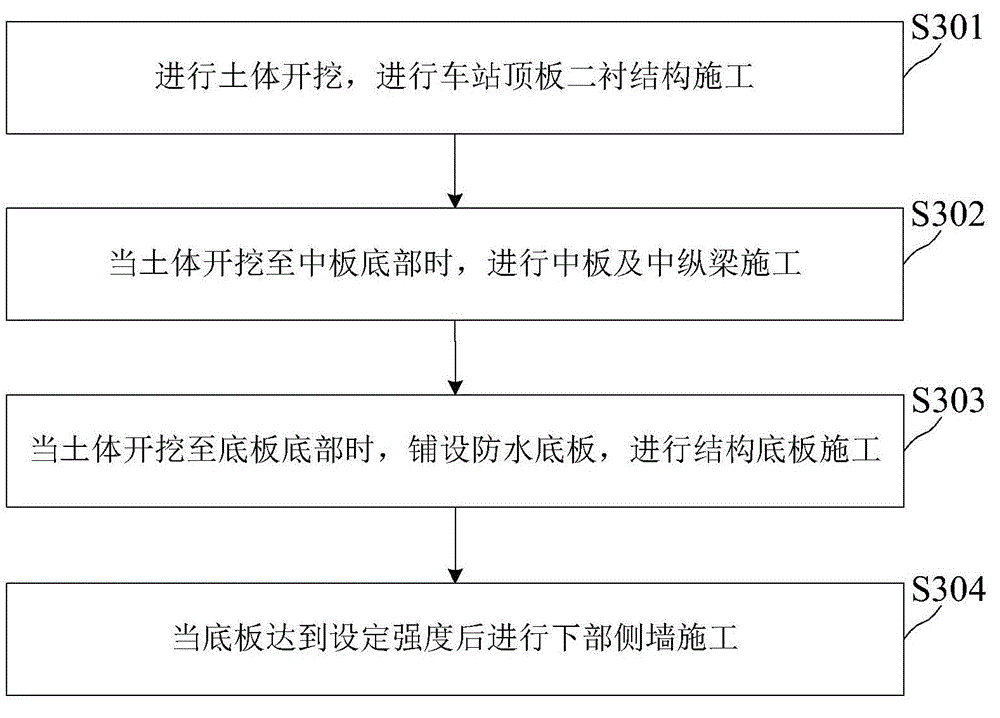

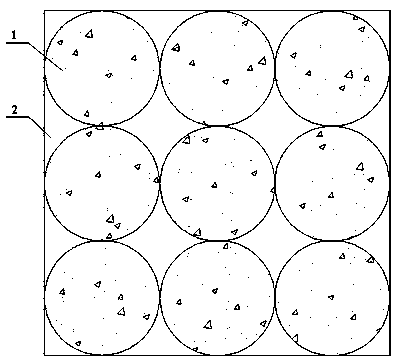

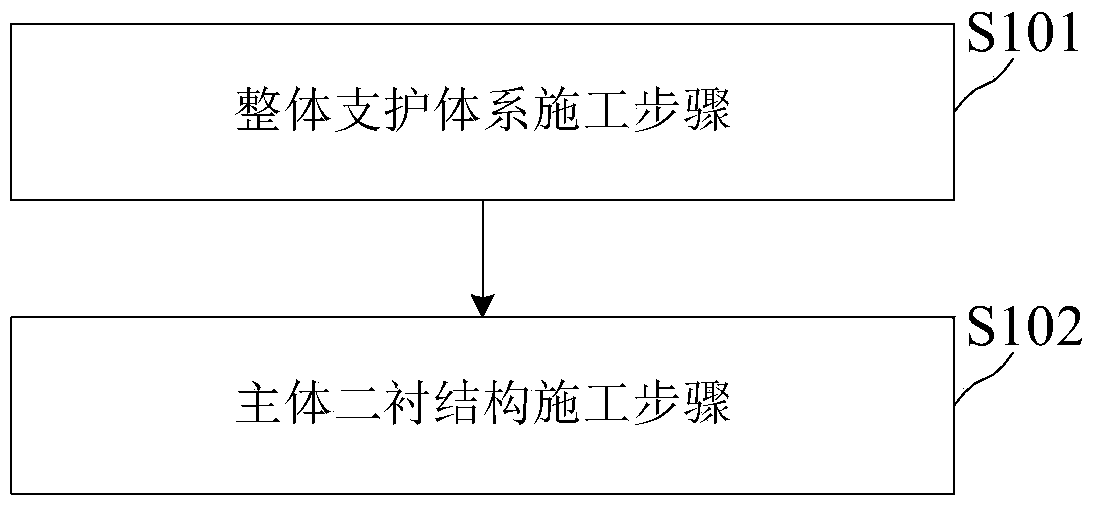

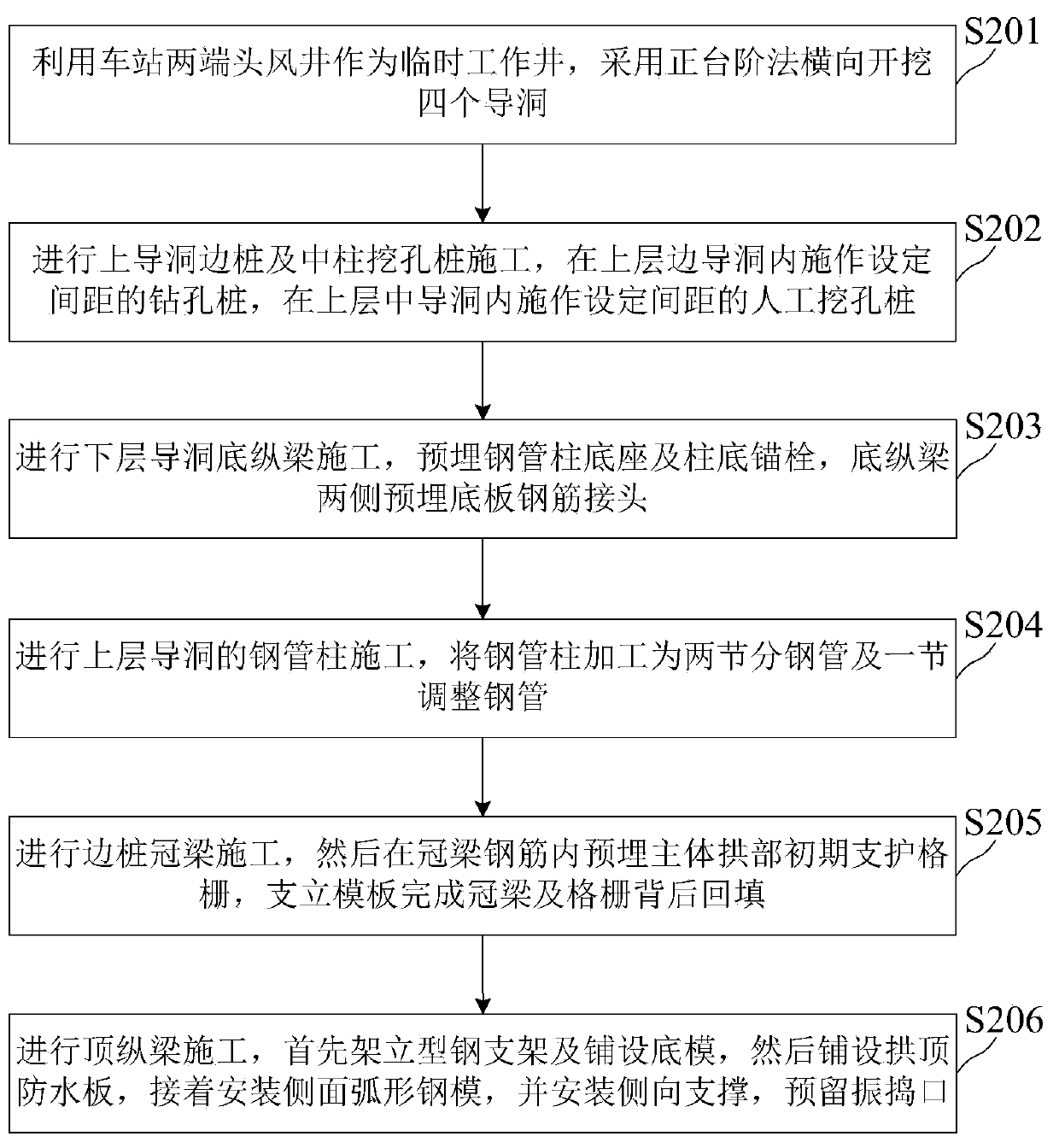

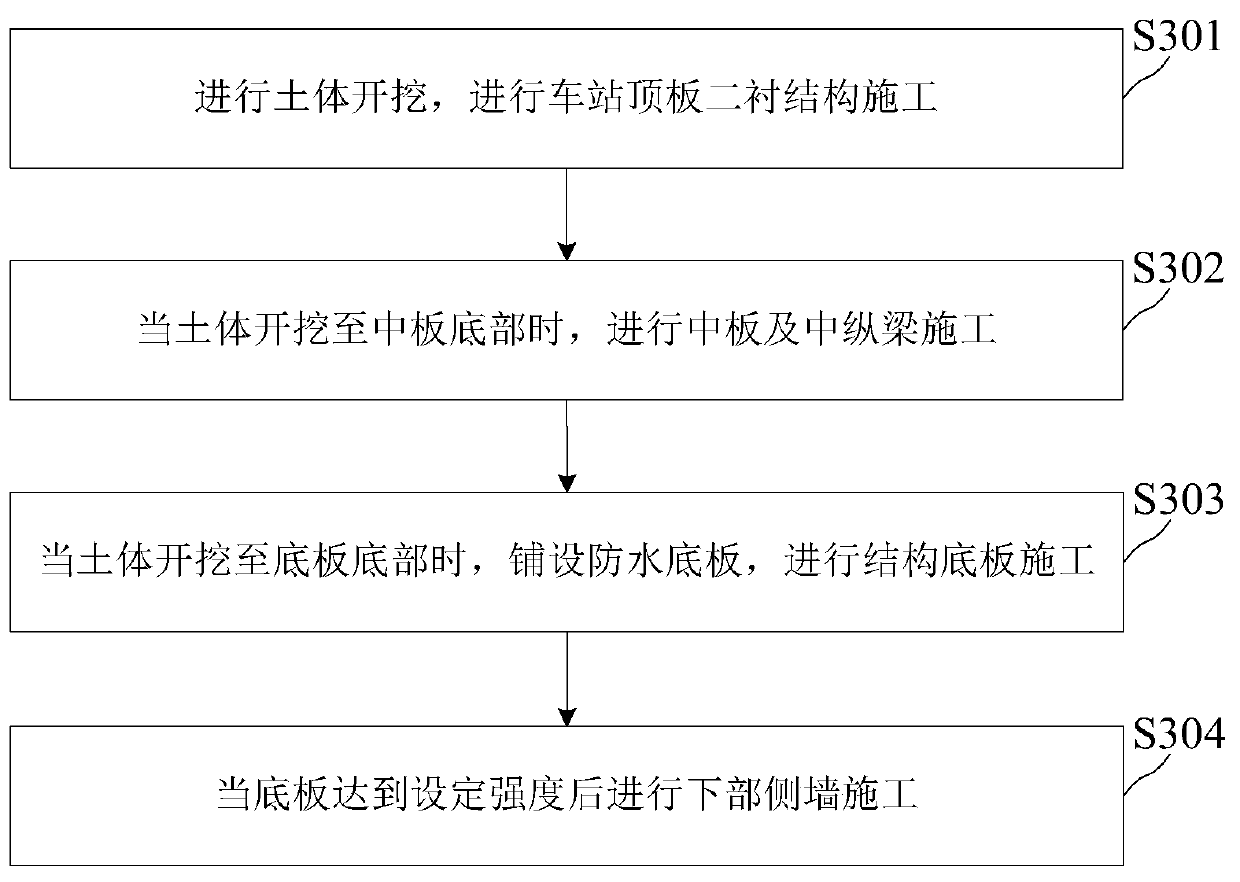

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

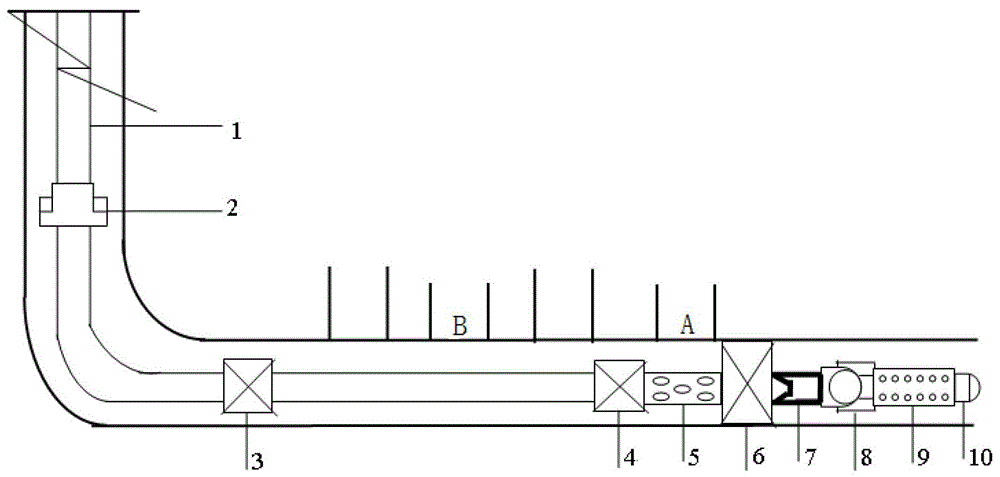

Application construction method of shield separate launching technology in urban drainage engineering

InactiveCN108952733ASmall sizeSave installation timeUnderground chambersTunnel liningSoil massUrban area

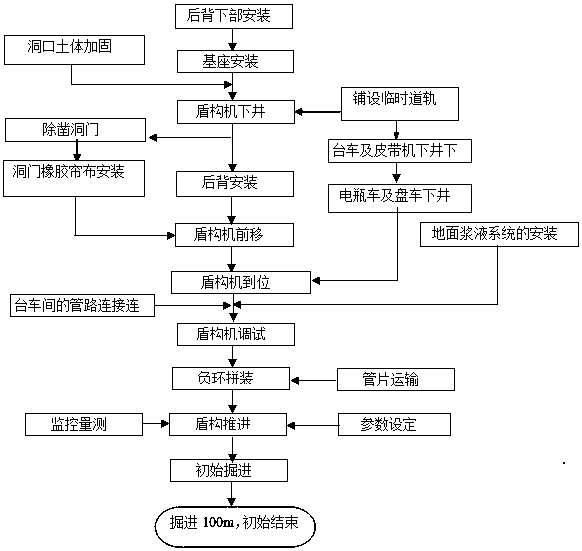

The invention relates to the technical field of civil engineering, in particular to an application construction method of a shield separate launching technology in urban drainage engineering. The application construction method of the shield separate launching technology in the urban drainage engineering is suitable for shield construction of drainage pipeline engineering in an urban area, especially for the engineering that a construction site is narrow and small, and all shield equipment cannot be mounted at a time. The application construction method of the shield separate launching technology in the urban drainage engineering comprises the steps of arranging of a launching shaft, arranging of facilities in the launching shaft, hoisting trying of a shield machine, hoisting-into-shaft ofthe shield machine, reinforcing of tunnel opening soil mass, mounting of a tunnel opening rubber cord fabric, chisel-off of a tunnel opening pouring pile, transport arrangement, shield launching preparation, initial tunneling construction, launching of a shield trolley. The application construction method of the shield separate launching technology in the urban drainage engineering adopts the shield machine separate launching technology, the size of the launching vertical shaft can be effectively decreased, the engineering cost is lowered, and meanwhile, the influence on the surrounding environment can also be reduced to the maximum limit.

Owner:SHENYANG MUNICIPAL GROUP +1

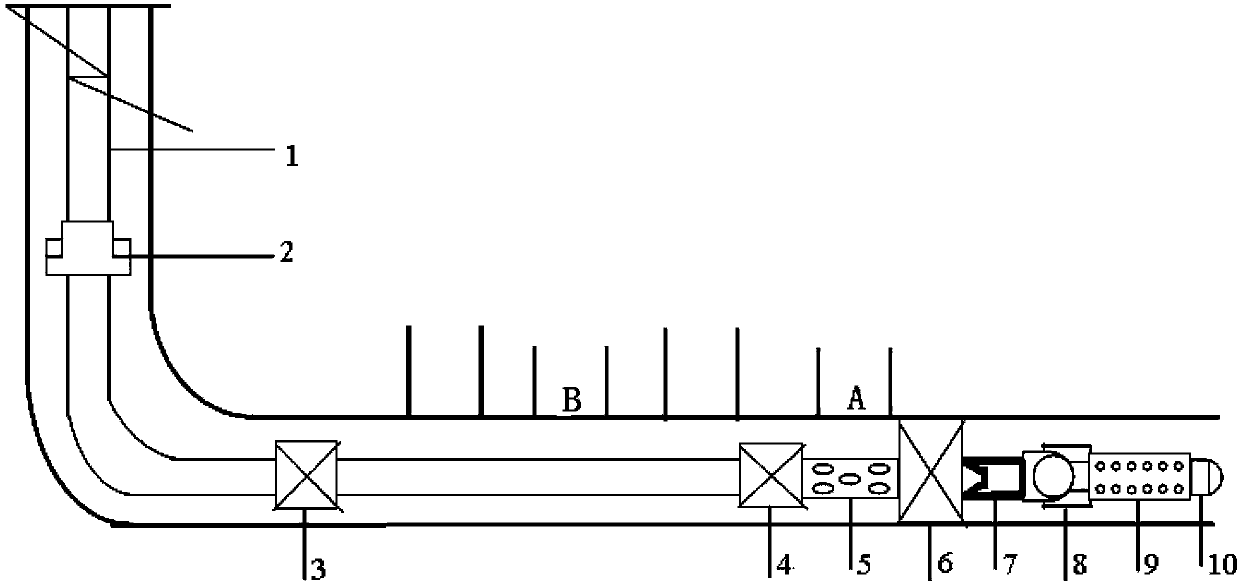

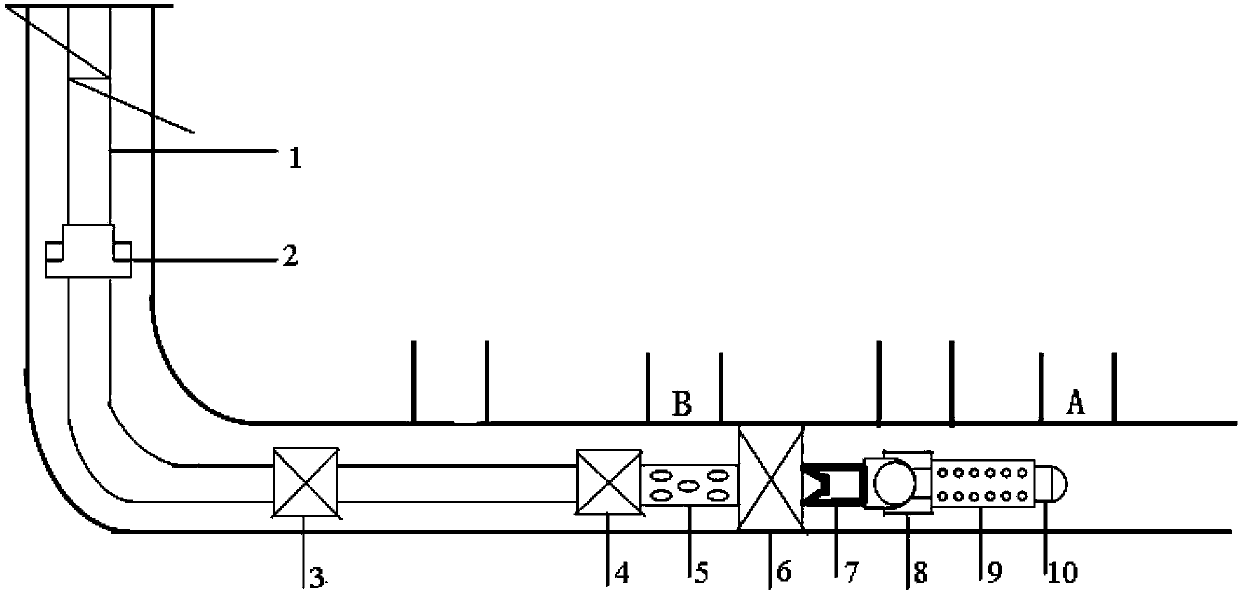

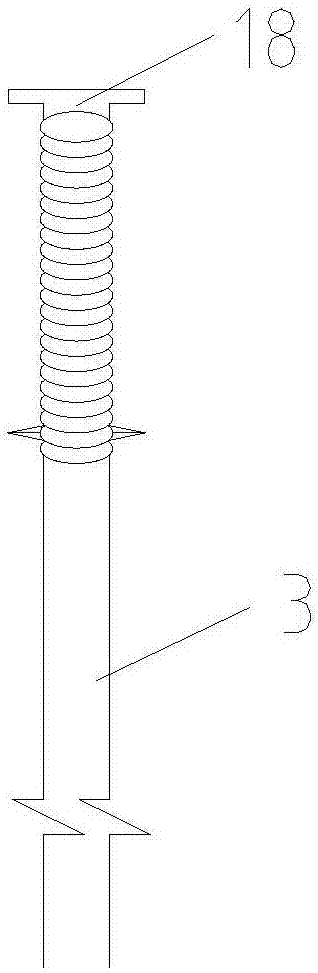

Selective re-fracturing technology for old well of oil field

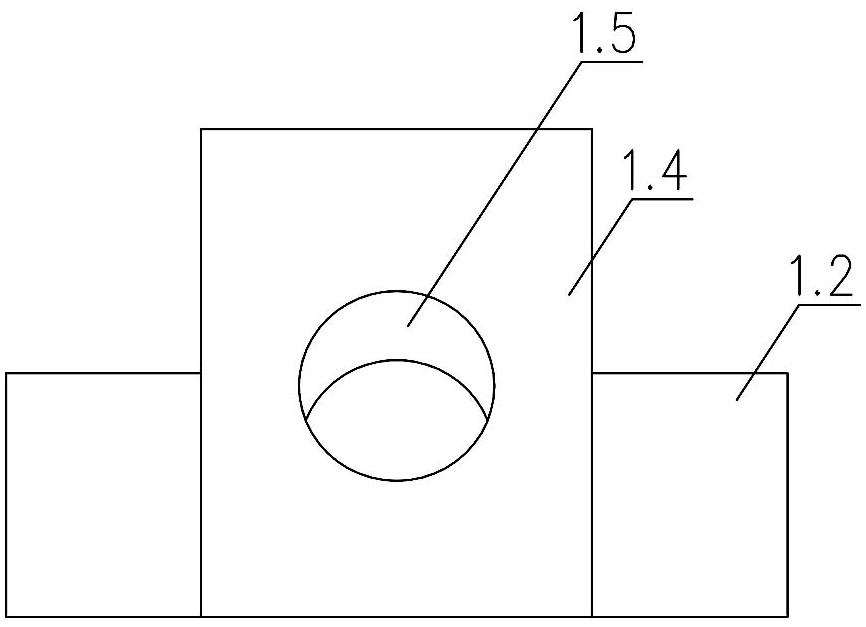

ActiveCN104213894ASimple structureFlexible construction methodFluid removalOil fieldMaterial Perforation

The invention discloses a selective re-fracturing technology for an old well of an oil field. The selective re-fracturing technology for the old well of the oil field is designed to achieve re-transformation of the old well of the oil field effectively. According to the selective re-fracturing technology for the old well of the oil field, perforation of an interval needing to be transformed is achieved by assembling a pipe column, placing the pipe column in the well and dragging the pipe column, fracturing of a lowest new interval is achieved by packing an upper packer and an intermediate packer, unpacking is conducted, and the pipe column is dragged to a second new transformed interval. According to the selective re-fracturing technology for the old well of the oil field, a duct with the large diameter and the deep penetration is formed through hydraulic jet perforation, and thus fracturing pressure can be effectively reduced; the requirements for supporting facilities of a well mouth and the steel grade of a sleeve are lowered by means of the advantage of the dual-packing and single-clamping fracturing technology. The selective re-fracturing technology for the old well of the oil field has the advantages that the pipe column is simple in structure, the construction method is flexible, operation is convenient, the efficiency is high, re-transformation of the old well of the oil field can be achieved effectively, re-fracturing of the transformed interval can be achieved, and perforating and fracturing of the new interval can also be achieved integrally.

Owner:PETROCHINA CO LTD

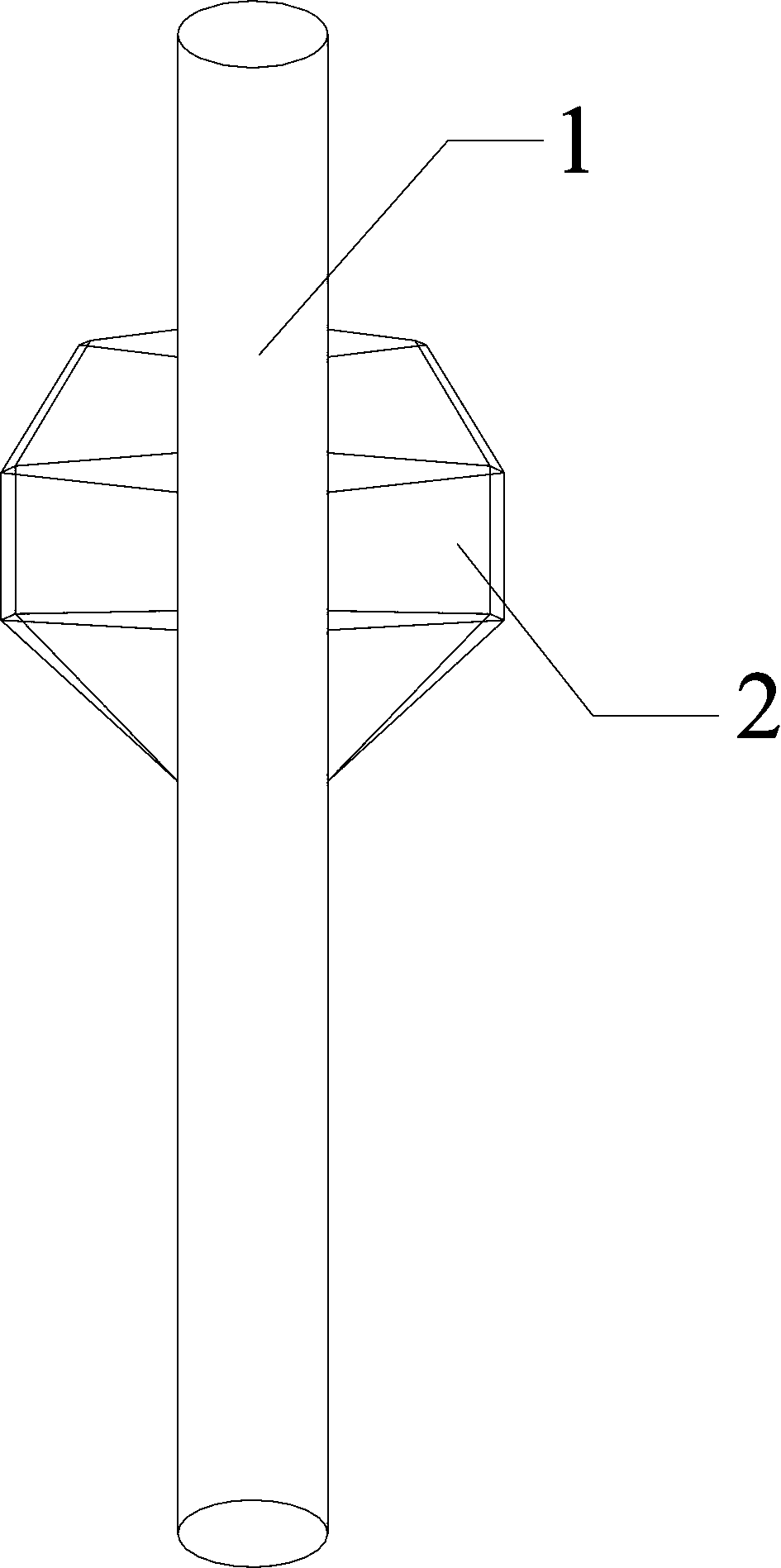

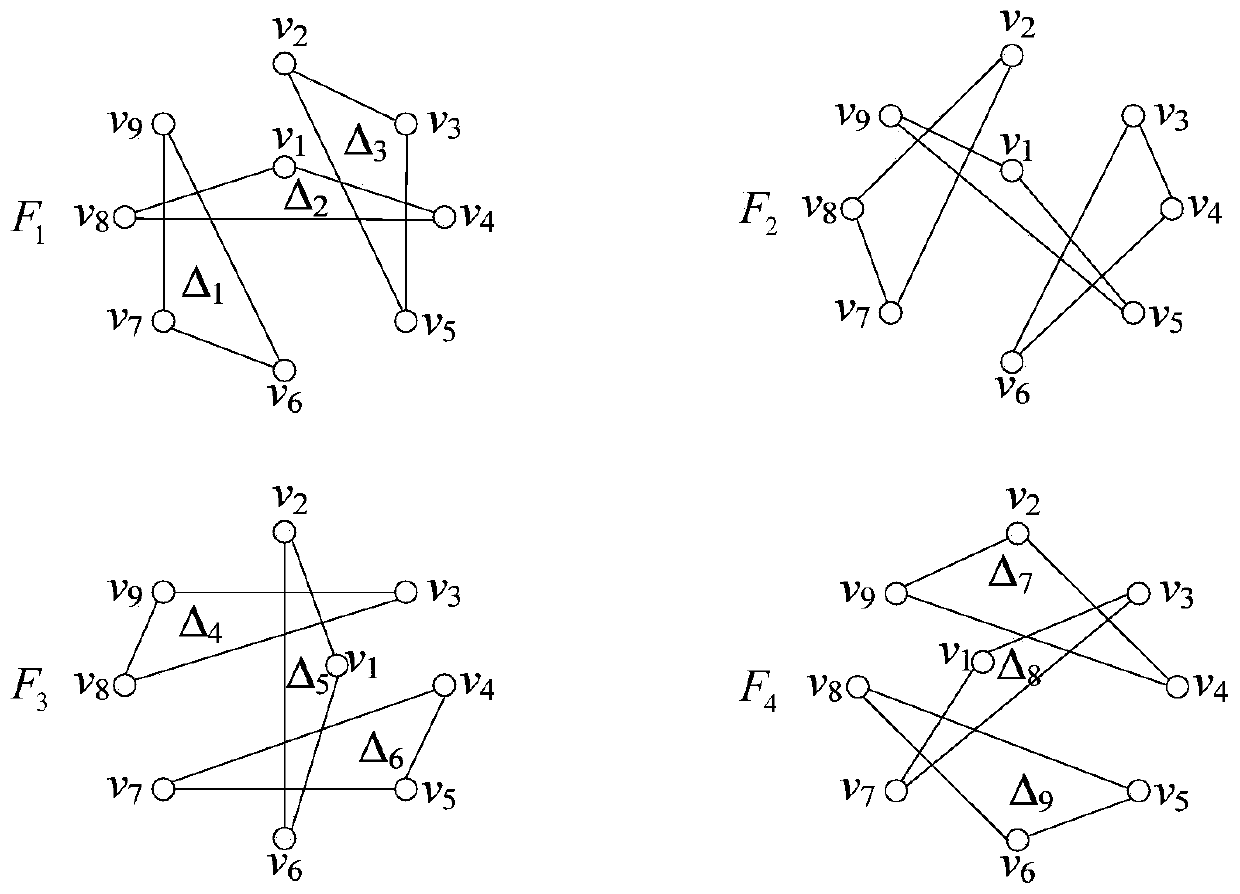

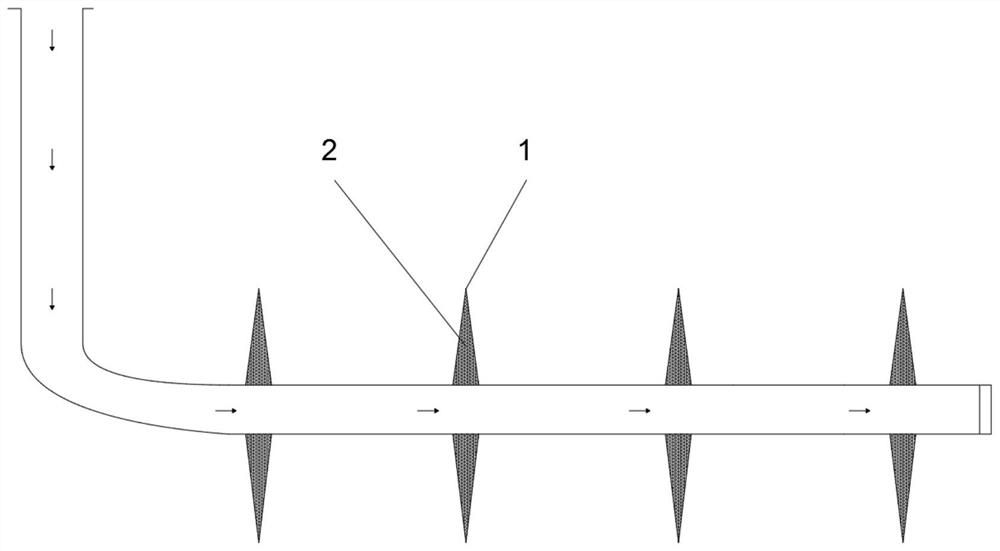

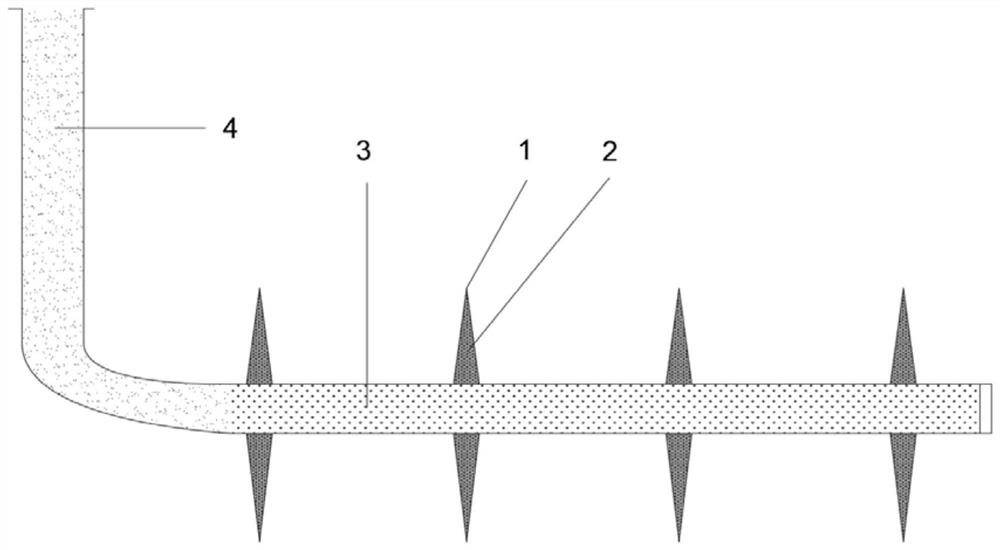

Offshore wind electricity single pile-wing plate-rockfill composite foundation and construction method thereof

PendingCN110984214AImprove carrying capacityFully mobilize resistanceFoundation engineeringRockfill materialStructural engineering

The invention discloses an offshore wind electricity single pile-wing plate-rockfill composite foundation and a construction method thereof. The foundation comprises a single pile, a wing plate and rockfill, the wing plate is of a conical structure, and is welded to the outer wall of a pile body, the rockfill is formed through dense stacking of the rockfill, the upper end of the wing plate is located in the rockfill, and the lower end of a pile wing is located on a seabed supporting layer. The construction method of the offshore wind electricity single pile-wing plate-rockfill composite foundation comprises the following steps of S1, determining the sizes of the single pile, the wing plate and the rockfill; S2, driving the single pile with the wing plate by the designed anchorage depth; and S3, stacking the rockfill on a seabed nearby the single pile. The problems of the low single pile bearing force, the large pile wing of the wing plate pile, serious foundation washing and the like can be solved, the single pile, wing plate and rockfill combination structure uses pile periphery soil resistance and rockfill friction force, the pile foundation bearing force can be improved, the pile foundation horizontal displacement can be reduced, the wing plate size is reduced, a wing plate stress mechanism is changed, washing of waves and ocean currents to seabed soil can be blocked, and safe and stable running of an offshore wind generation set can be ensured.

Owner:CHINA THREE GORGES CORPORATION

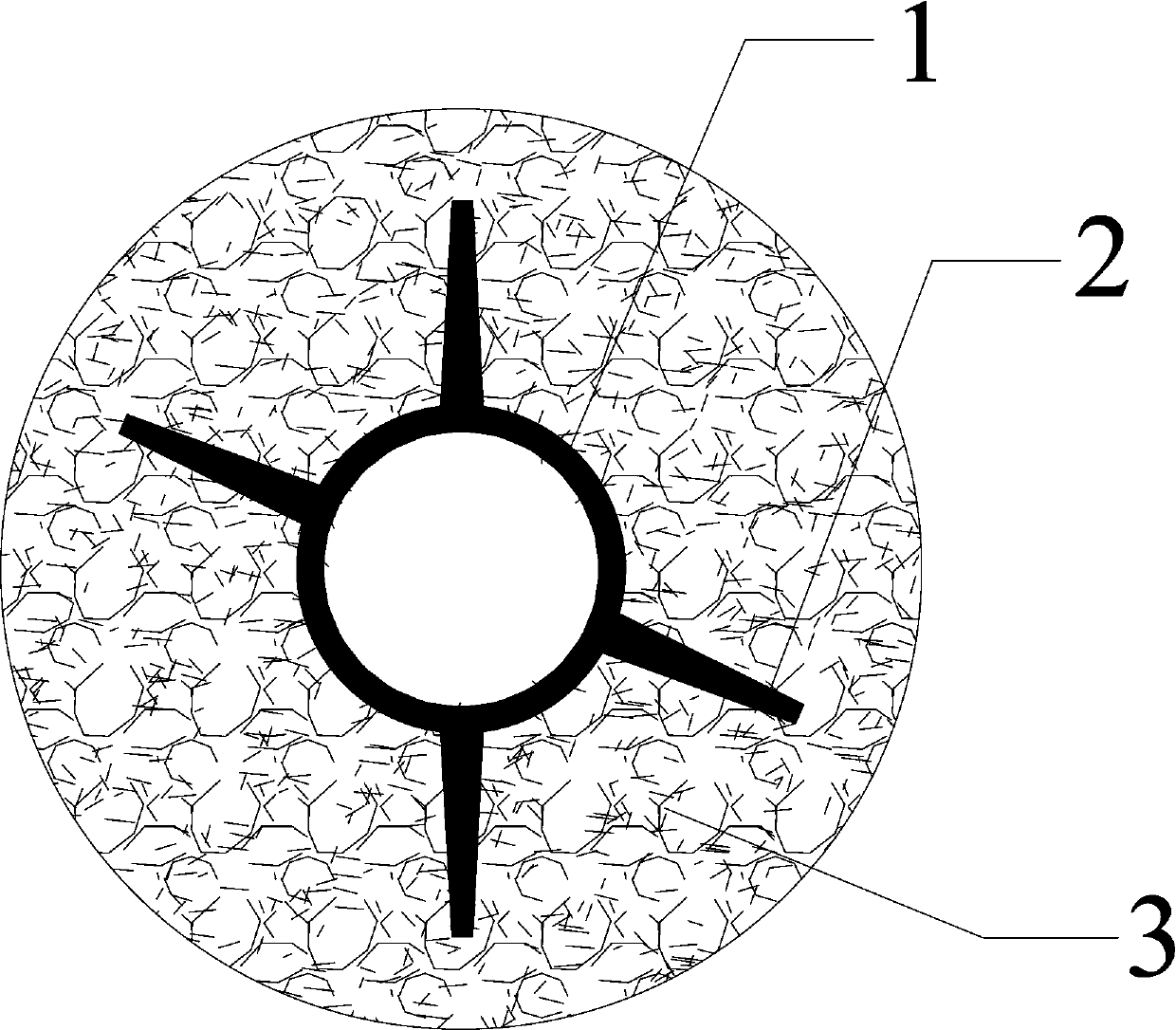

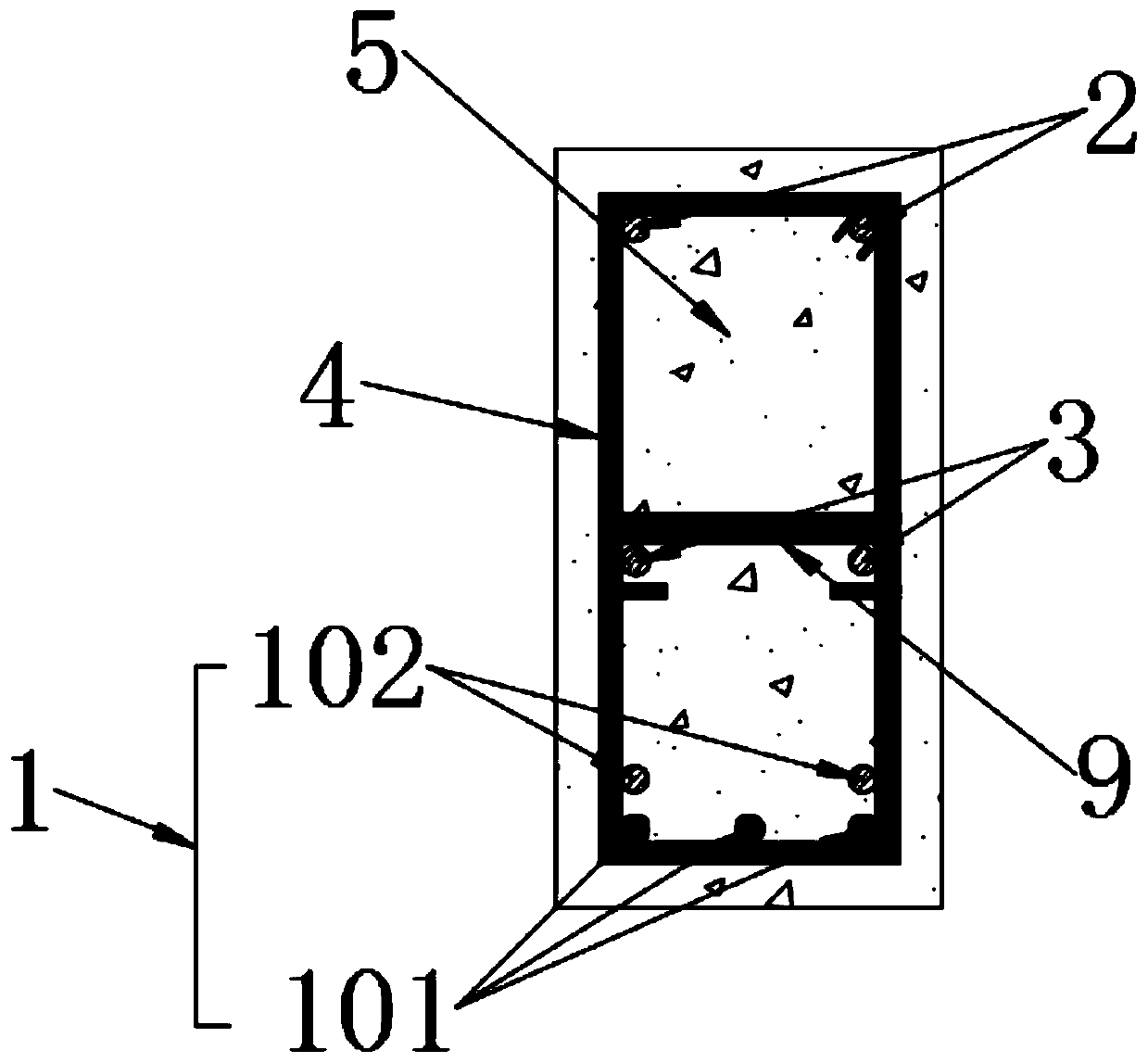

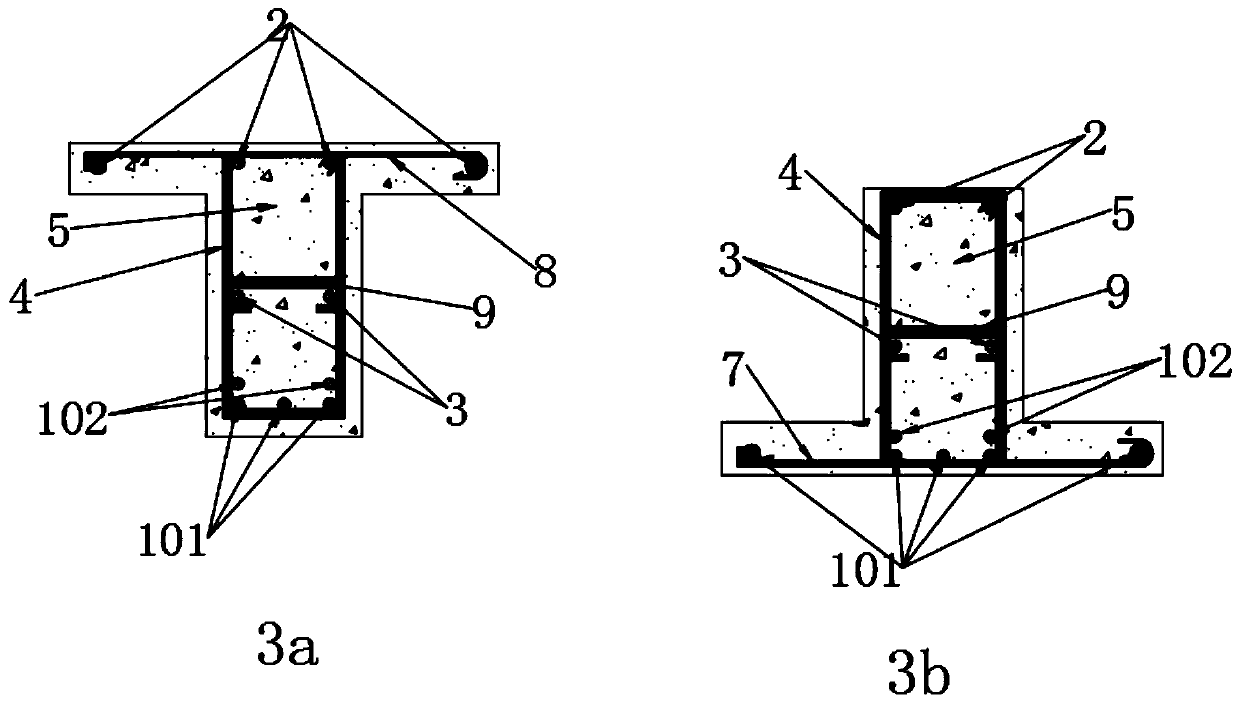

Enhanced ultra-high-performance concrete component made of mixed fiber reinforced plastic (FRP) bars

InactiveCN102936940AReduce consumptionEmission reductionBridge structural detailsGirdersFiberEngineering

The invention relates to an enhanced ultra-high-performance concrete component made of fiber reinforced plastic (FRP) bars and is suitable for the field of beam components of building and bridge structures and particularly suitable for the environment strong in corrosivity. The enhanced ultra-high-performance concrete component comprises ultra-high-performance concrete and a framework poured inside and composed of the mixed FRP bars. The enhanced ultra-high-performance concrete component gives full play to the advantages of the ultra-high-performance concrete and the mixed FRP bars, overcomes the shortcomings that a single FRP material is insufficient in ductility, effectively reduces a section, saves materials and energy and simultaneously enlarges the available space, the two materials are good in corrosion resistance and particularly suitable for the environment strong in corrosivity, and durability of the structure can be greatly improved. The enhanced ultra-high-performance concrete component made of FRP bars is simple in construction process, suitable for prefabricating production, can be constructed on site when the requirements on performance of the ultra-high-performance concrete are not high, and is flexible in construction method and favorable for popularization application in engineering of the two materials and research and development of novel materials.

Owner:BEIJING UNIV OF TECH

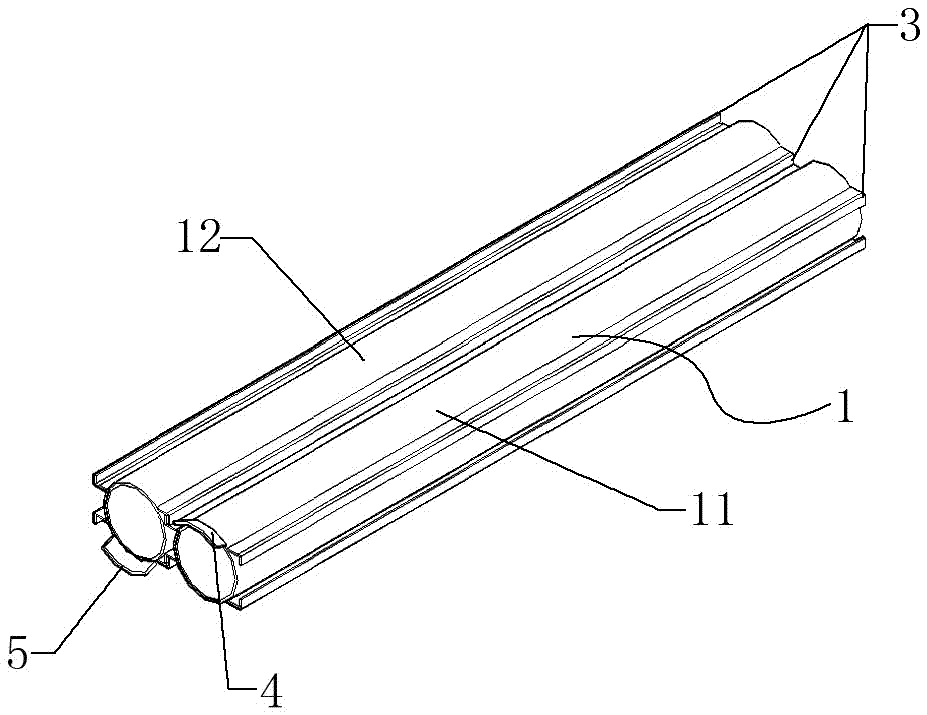

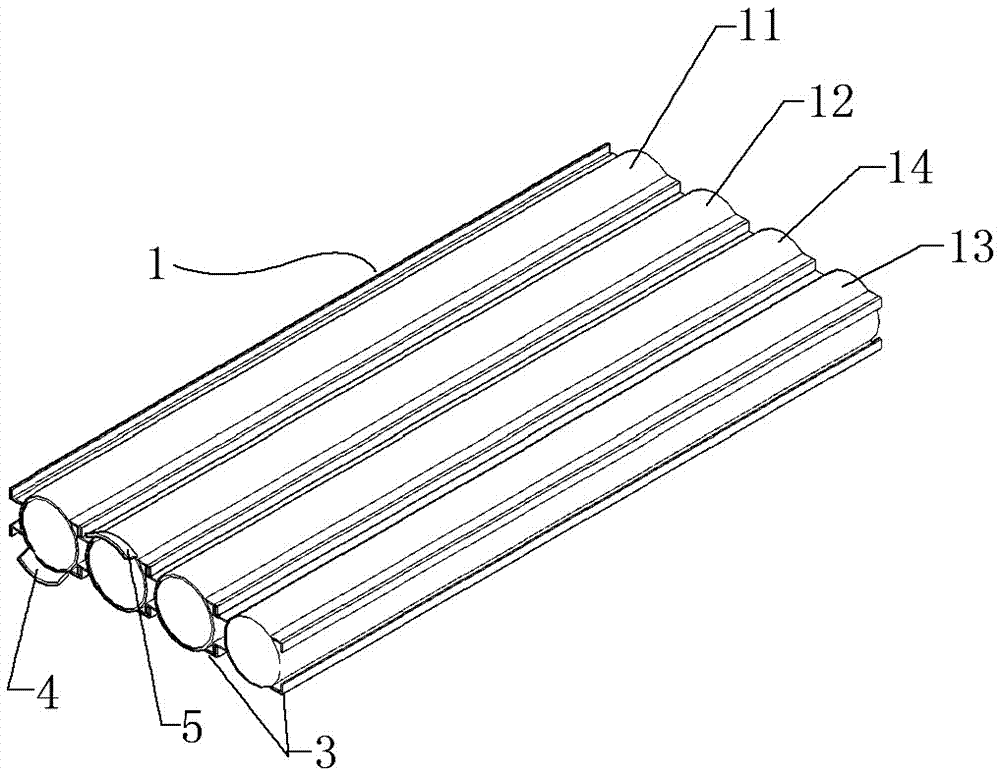

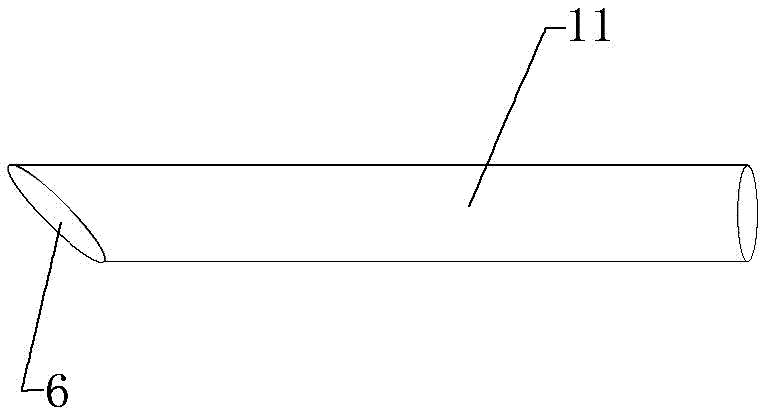

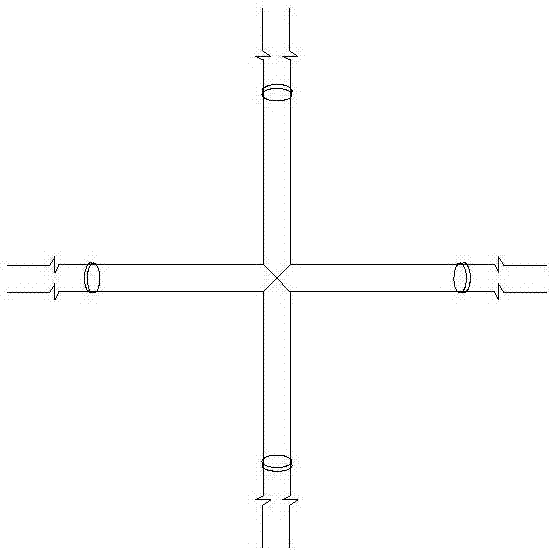

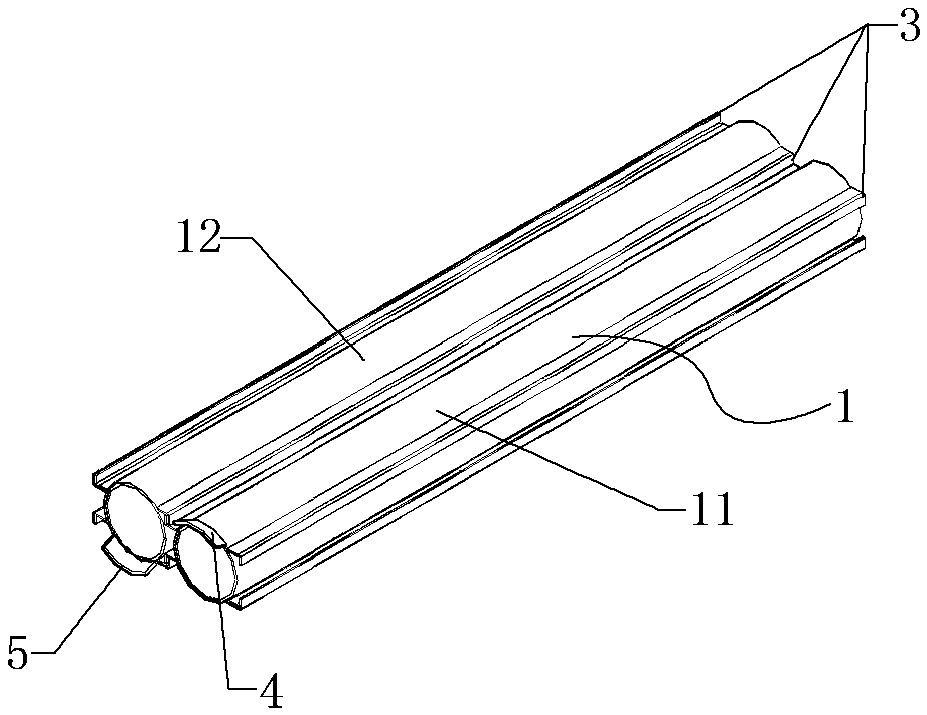

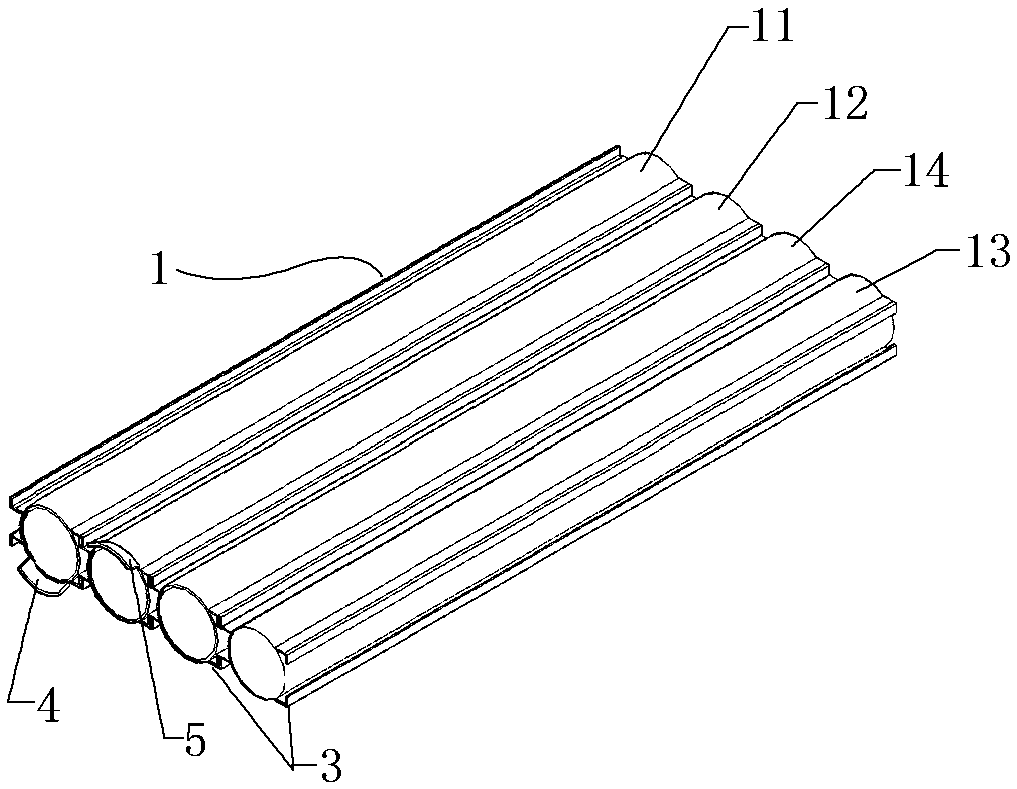

Pipe curtain construction method based on pipe banks

ActiveCN107190775ASimple construction methodFlexible construction methodArtificial islandsUnderwater structuresArchitectural engineeringUnderground space

The invention relates to the technical field of underground space construction, and discloses a pipe curtain construction method based on pipe banks. According to the pipe curtain construction method based on the pipe banks, the pipe banks are used as the construction unit and jacked at the same time for constructing a pipe curtain structure, each pipe bank is formed by arranging a set of steel pipes side by side, every two adjacent steel pipes are connected through a connecting component, and the number of the steel pipes in each set is not smaller than two. By adoption of the pipe curtain construction method based on the pipe banks, the construction efficiency is high, the jacking tendency can be controlled highly, jacking deviation can be rectified easily, and the construction precision is high.

Owner:BEIJING SHOUER ENG TECH

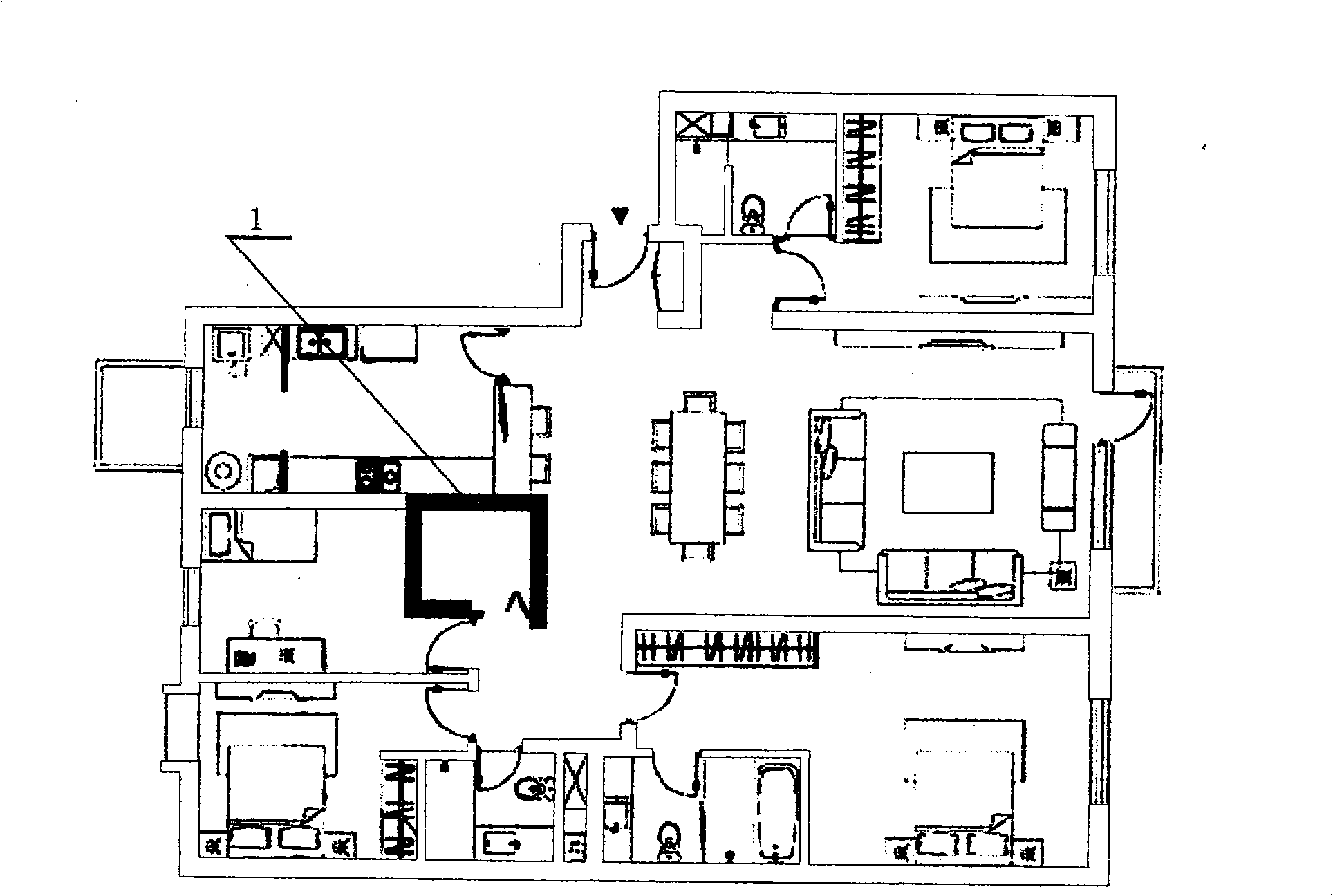

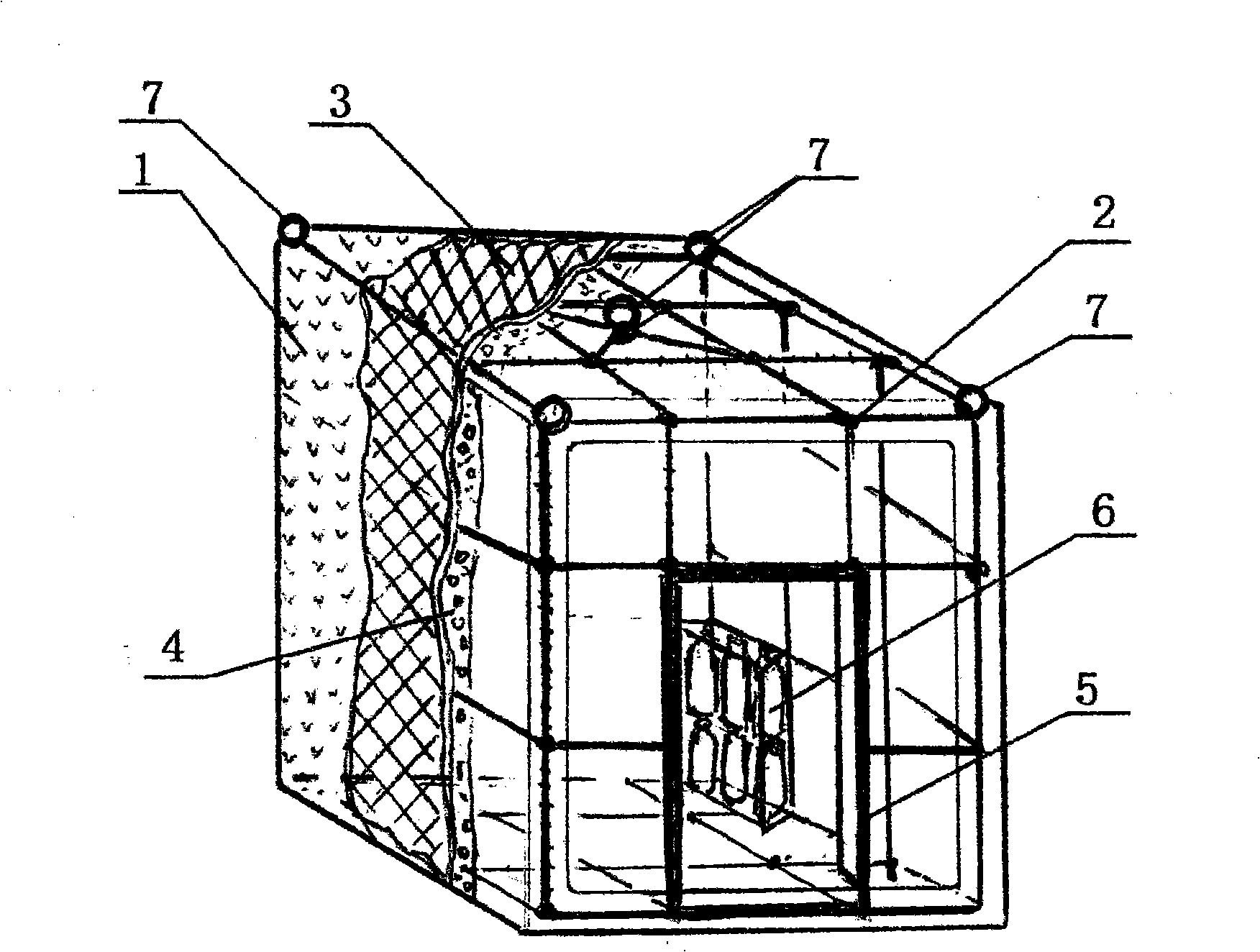

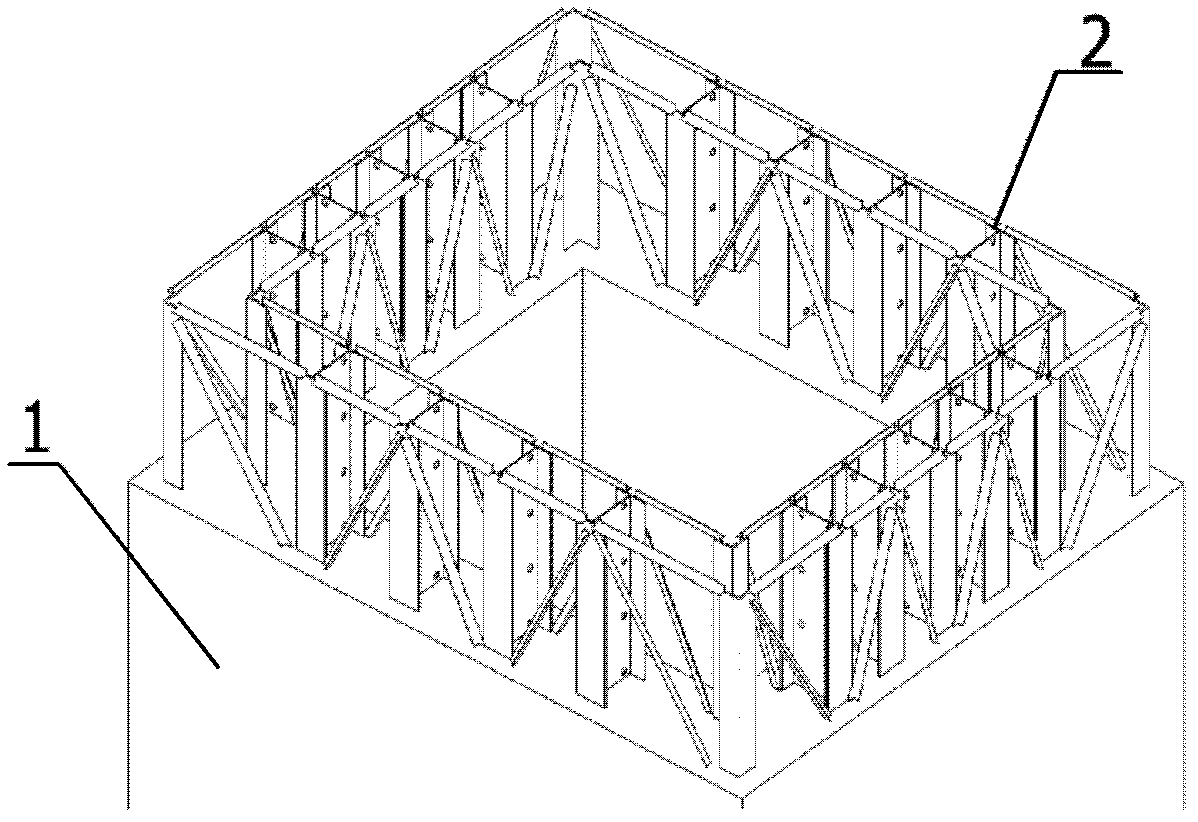

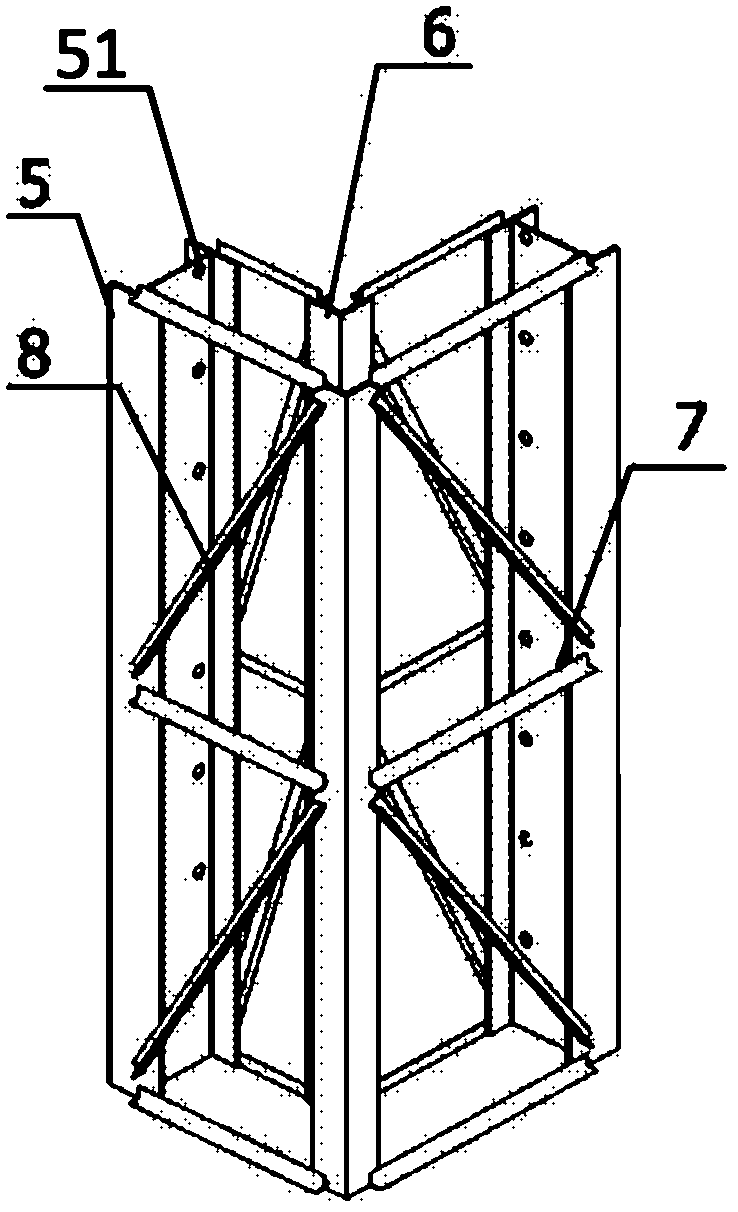

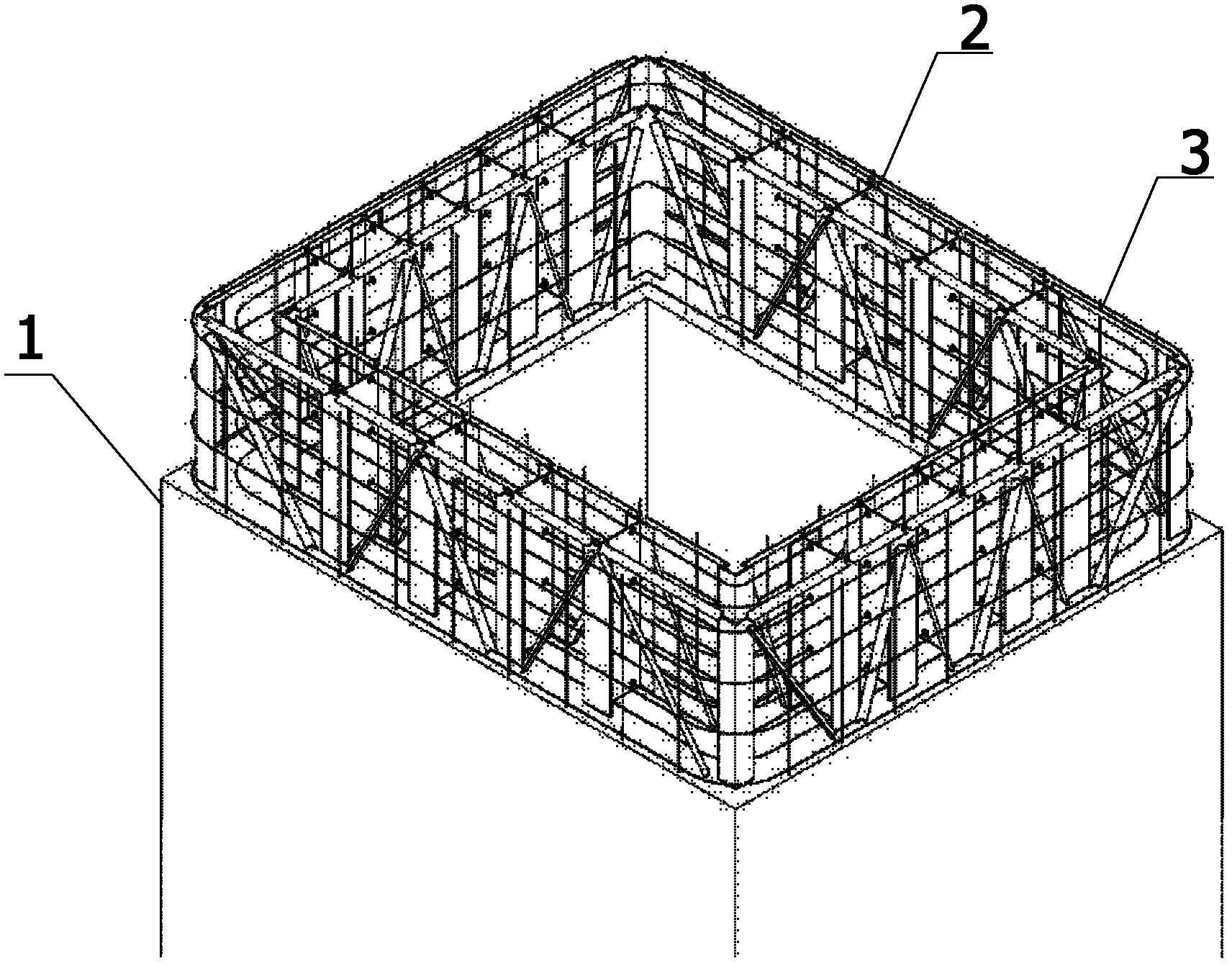

Building independent structural frame inner reinforcement nucleiform anti-vibration refuge compartment and molding method thereof

InactiveCN101324158ARealize local special reinforcementProtect or prolong lifeProtective buildings/sheltersEngineering

The invention relates to a method for reinforcing a kernel-shaped quake-proof refuge cabin in the independent frame of a building, and the molding method thereof. 1 the quake-proof refuge cabin of the invention determines the better principle of refuge and escape when an earthquake occurs, namely, (1) life priority: the protection of the life is a priority selection; (2) hedging nearby; (3) escaping by selecting chances. 2 different from generally known building reinforcing and pre-set reinforcing techniques, the invention is a new quake-proof additional system of the building, adopts the independent in-frame reinforcing technique, and carries out reinforcement from the interior of certain singletons or local units of the building so as to form the refuge cabin used for protecting the life; 3 the invention adopts dual structure, and the quake-proof refuge cabin is formed by taking existing buildings or newly-built buildings as a shell to co-act with internal hard kernel-shaped quake-proof refuge cabin structure with the independent frame. The invention is suitable for most existing buildings or new buildings, and constructs a system that hedging is carried out nearby and the protection of the life is prior together with other quake-proof measures of the buildings.

Owner:齐荣生

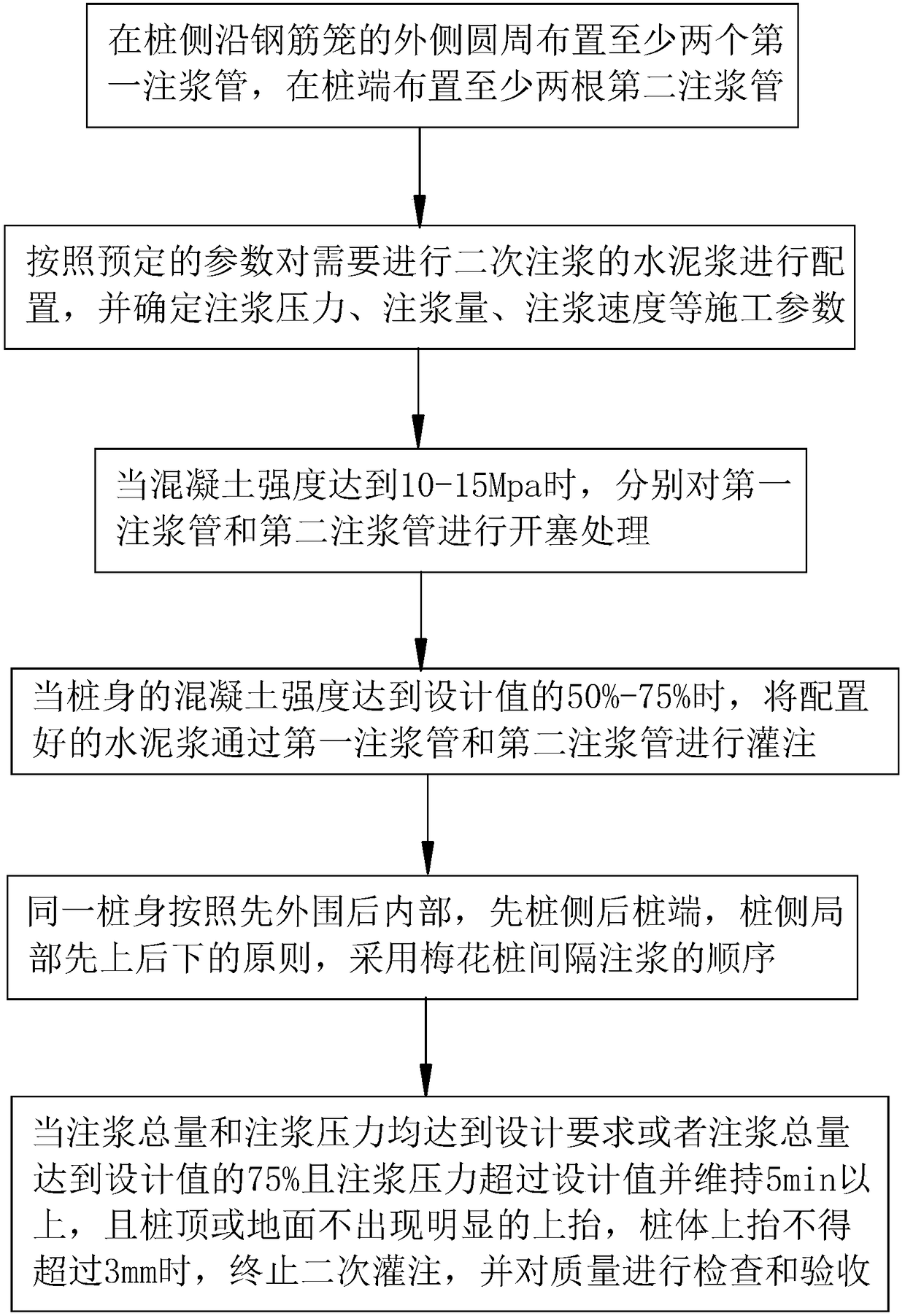

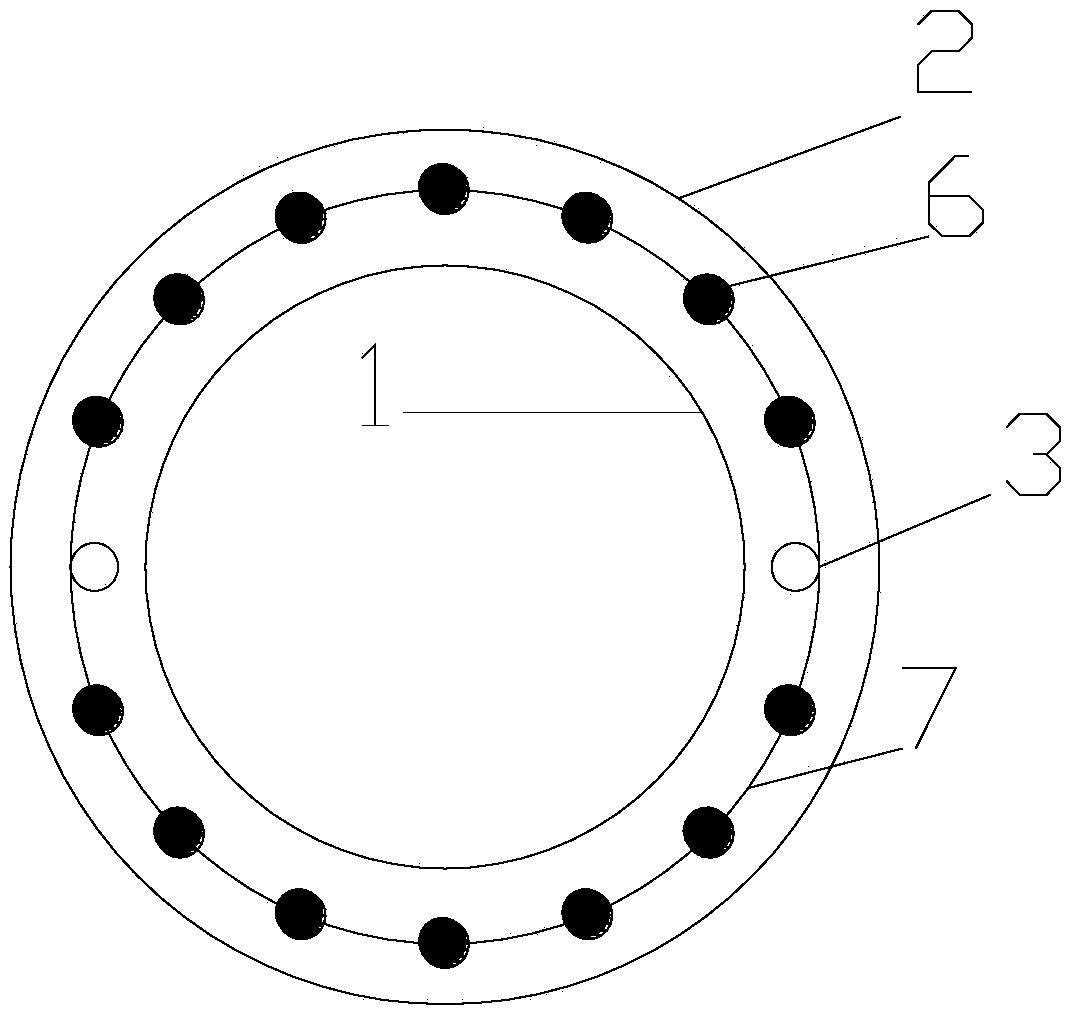

Cast-in-place pile post-grouting construction technology

InactiveCN108130903AImprove carrying capacityImprovement and surrounding pile conditionsBulkheads/pilesRebarCement slurry

The invention provides a cast-in-place pile post-grouting construction technology. The technology comprises the following steps that at least two first grouting pipes are circumferentially arranged onthe pile side along the outer side of a reinforcement cage, at least two second grouting pipes are arranged at a pile end, and the first grouting pipes and the second grouting pipes are connected with a grouting device separately; cement slurry needing to be grouted is prepared; when the concrete strength reaches 10-15 Mpa, a grout pump is adopted for opening the first grouting pipes and the second grouting pipe; when the concrete strength reaches 50%-75% of a design value, the prepared cement slurry is subjected to secondary grouting through the first grouting pipes and the second grouting pipes; the quality of secondary grouting is inspected and accepted. According to the post-grouting construction technology, the pile end supporting layer and the pile side condition can be effectivelyimproved, the pile end resistance and pile side frictional resistance are improved, the load transmitting property is improved, the single pile bearing capacity is greatly increased, the settling volume is reduced, it is guaranteed that the grouting process is performed smoothly, and the grouting quality is improved.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

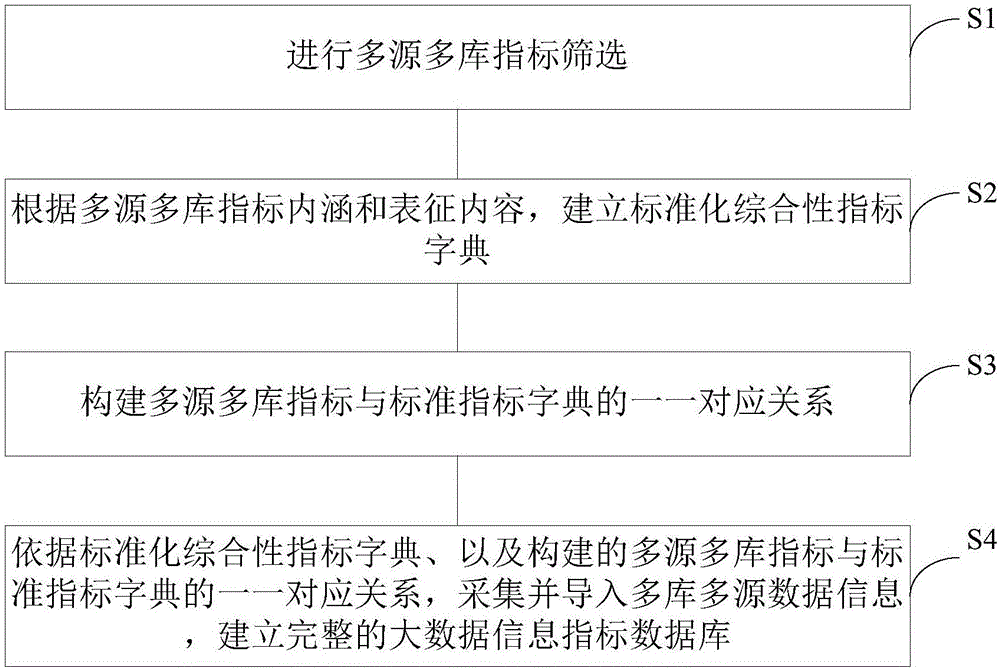

Multi-source multi-base enterprise innovation monitoring big-data standard database construction method

InactiveCN107526820AEasy to buildFlexible construction methodAutomatic library buildingSpecial data processing applicationsData informationInformation index

The invention provides a multi-source multi-base enterprise innovation monitoring big-data standard database construction method. The method includes the steps of: carrying out multi-source multi-base index screening; establishing a standardized comprehensive index dictionary according to multi-source multi-base index connotations and characterization contents to enable the standardized index dictionary to cover all multi-source multi-base indexes; constructing one-to-one correspondence relationships between the multi-source multi-base indexes and the standard index dictionary; and collecting and importing multi-source multi-base data information according to the standardized comprehensive index dictionary and the constructed one-to-one correspondence relationships between the multi-source multi-base indexes and the standard index dictionary, and establishing a complete big-data information index database. The construction method is simple and flexible, and is high in adaptability.

Owner:GUANGDONG R&D CENT FOR TECHNOLOGICAL ECONOMY

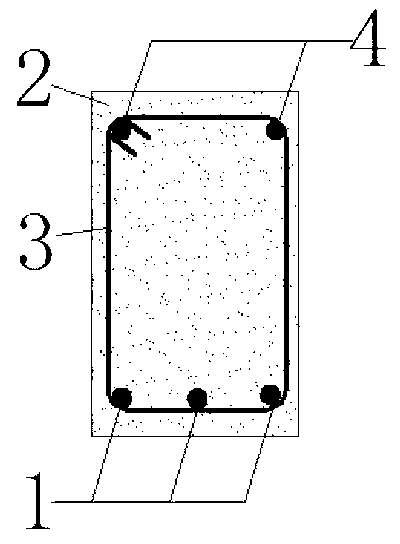

Steel structure-concrete combined bridge tower structure

InactiveCN102505633AImprove stabilityMake sure to work togetherBridge structural detailsReinforced concreteEngineering

The invention discloses a steel structure-concrete combined bridge tower structure, which comprises a steel structure and a concrete bridge tower, wherein the steel structure penetrating from top to bottom is arranged inside the concrete bridge tower, and connecting pieces are arranged between the steel structure and the concrete bridge tower; the steel structure is completely contained in the concrete pylon; preferably the section of the concrete bridge tower is of a hollow tank shape; hoop reinforcements are arranged in a partition manner in the reinforced concrete pylon along the cross section of the bridge tower structure; and longitudinal ribs are arranged in a partition manner in the reinforced concrete pylon along the vertical direction of the bridge tower structure on the circumference surrounding the cross section of the bridge tower structure. According to the invention, the use amount of temporary steel structures during bridge tower construction is reduced, the turnover amount of the templates is increased, the construction progress is accelerated, the construction convenience is provided and the construction cost is saved.

Owner:TONGJI UNIV

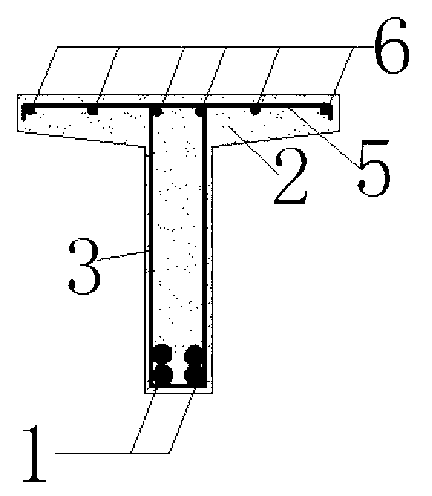

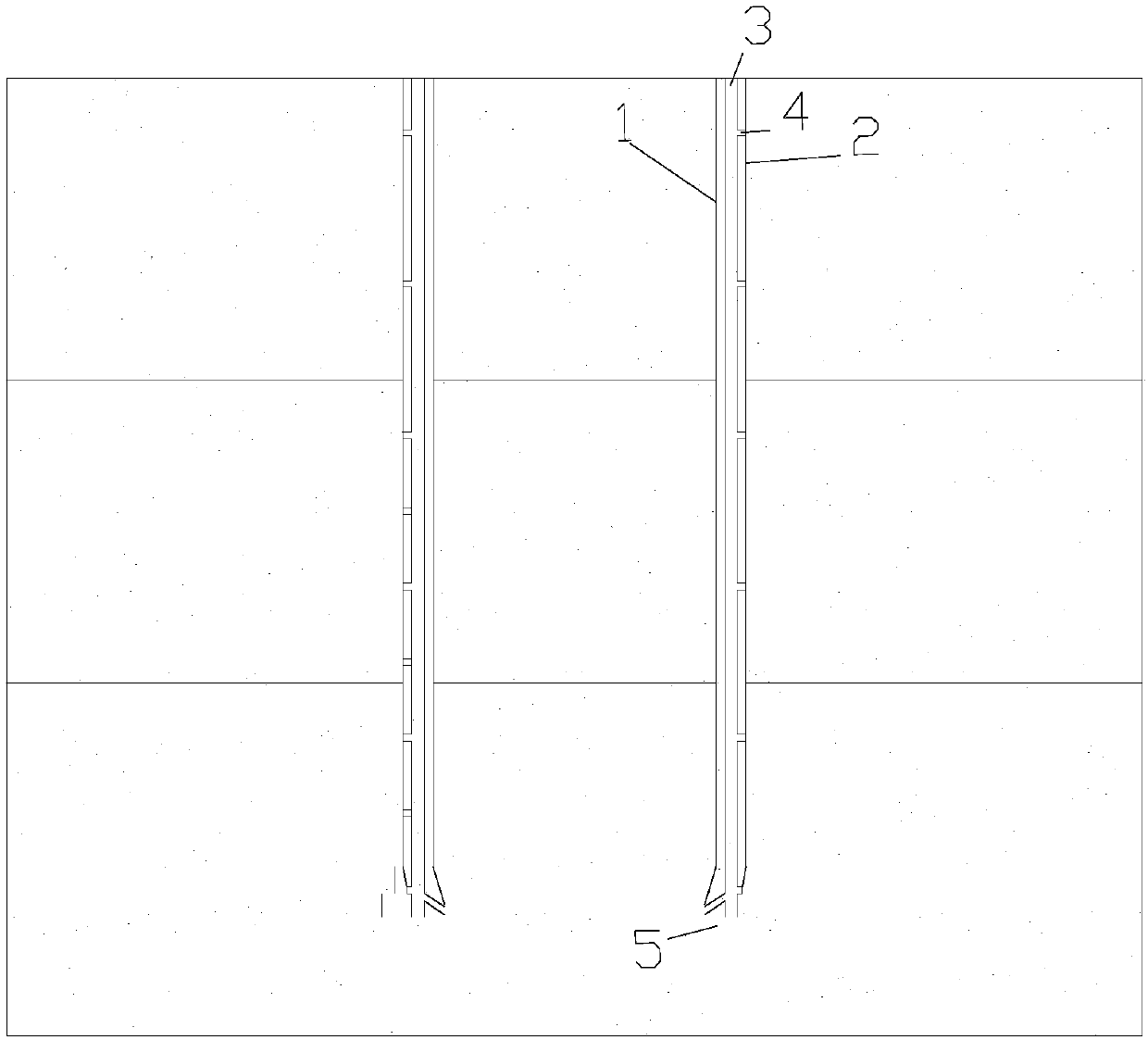

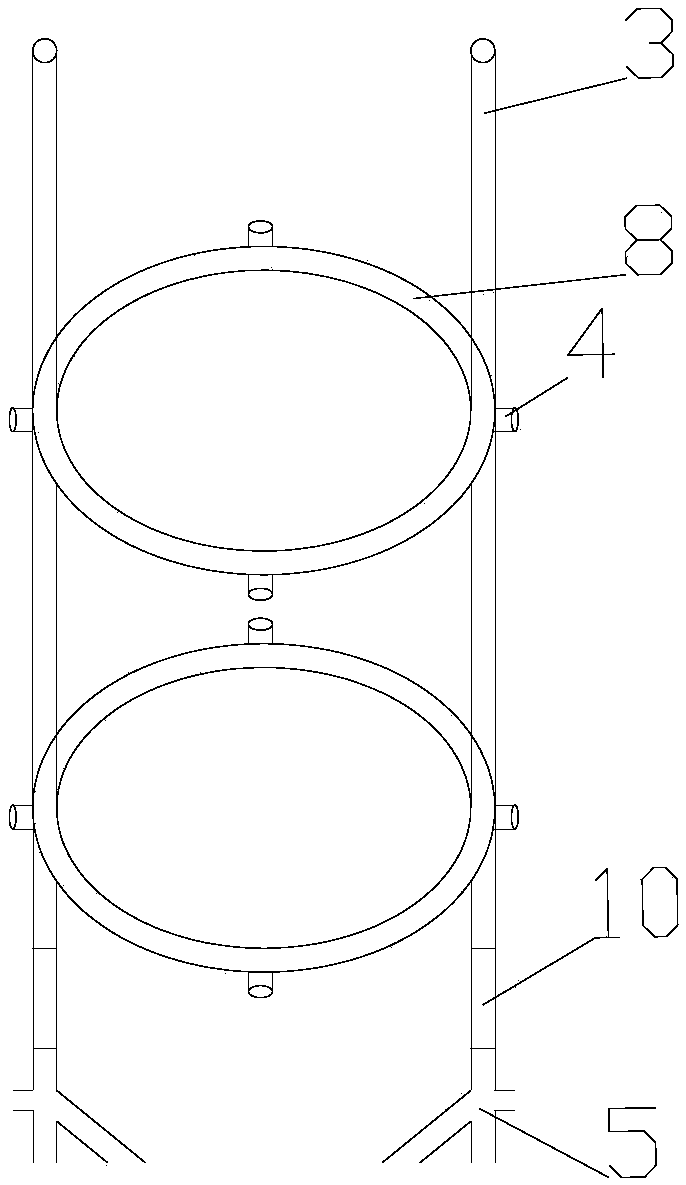

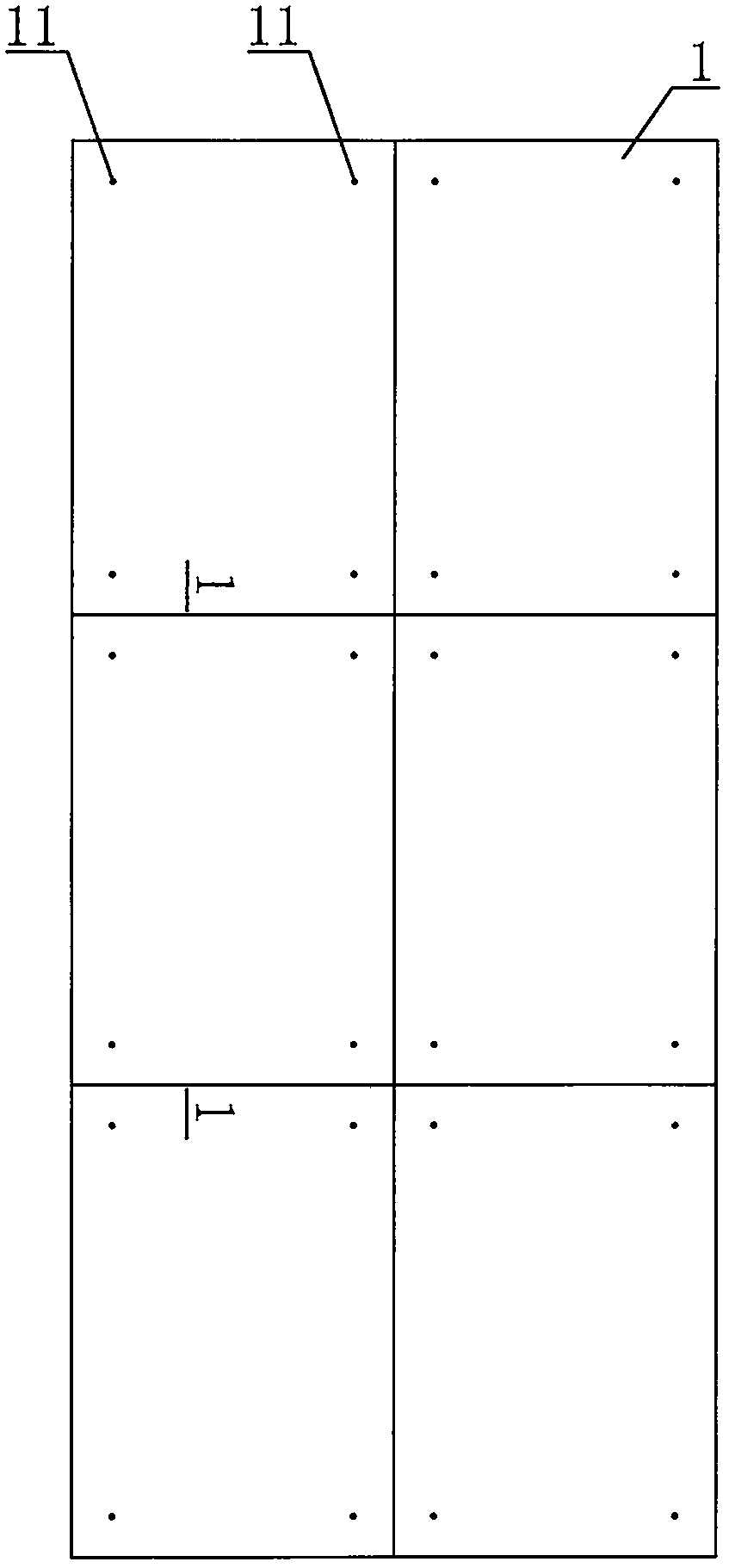

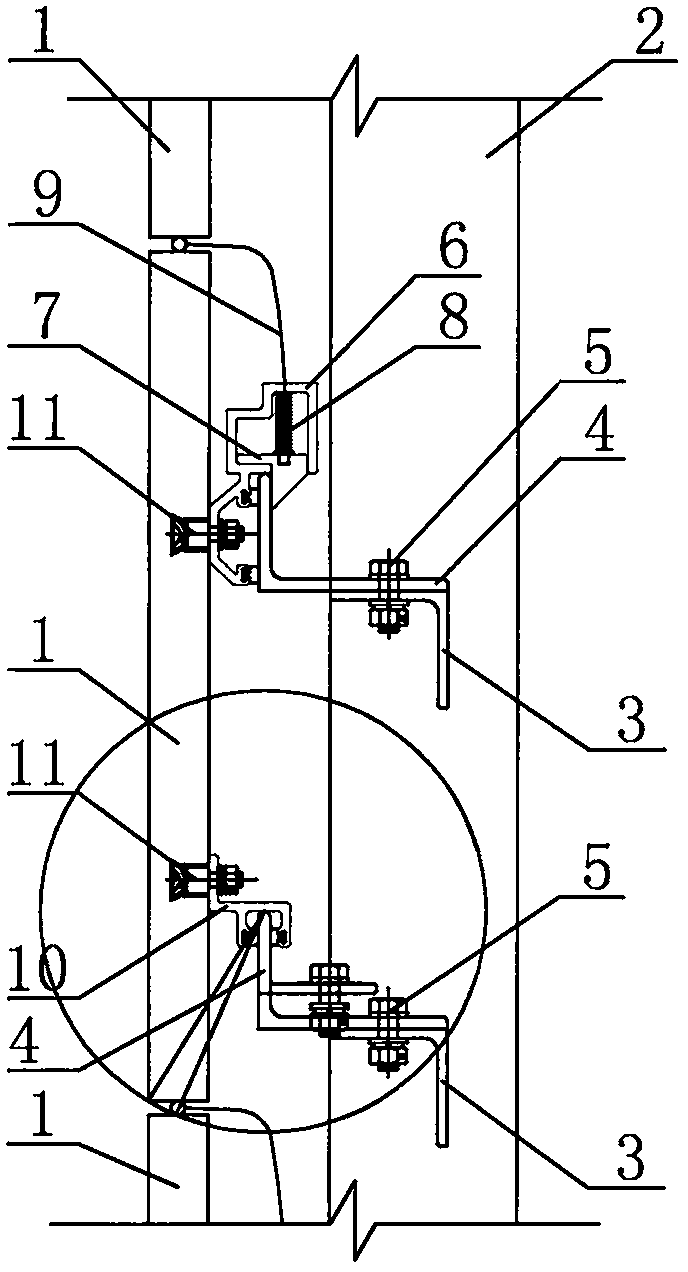

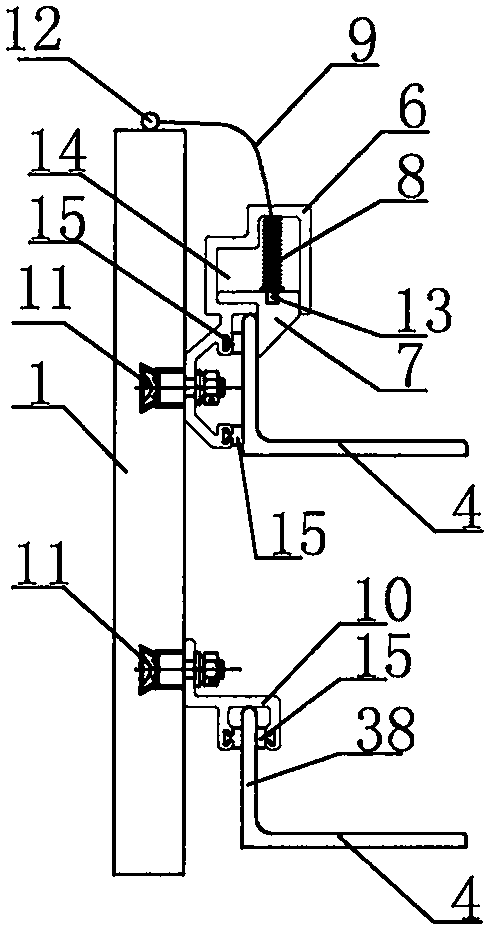

Post-grouting cast-in-place thin-wall pipe pile with grouting pipeline being reserved and construction method

The invention relates to a post-grouting cast-in-place thin-wall pipe pile with a grouting pipeline being reserved. The post-grouting cast-in-place thin-wall pipe pile comprises a reinforcement cage and a post-grouting device. The post-grouting device comprises grouting pipes, pile side one-way grout outlets, pile end one-way root-type grout outlets, pile side ring-type grouting pipes, grouting pipe pile side connectors and pile end grouting pipes. The grouting pipes are fixed to the two sides of the reinforcement cage. The pile side ring-type grouting pipes are fixed to the outer circle of the reinforcement cage. The pile side one-way grout outlets are distributed in the circle of each pile side ring-type grouting pipe at equal intervals. The two sides of each pile side ring-type groutingpipe are connected with the corresponding grouting pipe pile side connectors. The upper ends and the lower ends of the grouting pipe pile side connectors are connected with the grouting pipes. The pile end grouting pipes are arranged at the bottoms of the corresponding grouting pipes. The pile end one-way root-type grout outlets are formed in the lower ends of the pile end grouting pipes. The post-grouting cast-in-place thin-wall pipe pile has the beneficial effects that by adoption of the grouting technology, hole bottom dregs can be effectively removed, and the pile end resistance of the thin-wall pipe piles is increased.

Owner:ZHEJIANG UNIV CITY COLLEGE

Connecting system for back-bolt type stone curtain wall

InactiveCN109138233AIncreased installation difficultyIncrease installation costWallsStructural engineering

The invention provides a connecting system for a back-bolt type stone curtain wall. According to the connecting system for the back-bolt type stone curtain wall, by arranging a locking device on a back-bolt connecting member at the upper end of a stone plate, locking and opening of the back-bolt connecting member at the upper end of the stone plate and a metal supporting piece on a curtain wall frame cross beam are realized in situ; a back-bolt connecting member at the lower end of the curtain wall stone plate and an L-shaped metal supporting piece on the curtain wall frame cross beam rotate for a certain angle so that the stone plate can be changed and mounted at will. The connecting system for the back-bolt type stone curtain wall has the advantages that the construction method is flexible; without any effect on the mounting quality, the stone curtain wall can be mounted from any position of the stone curtain wall according to the actual situation of the site; the curtain wall stoneplate can be conveniently detached and changed; by using a locking device on the connecting system on the back of the curtain wall stone, the locking and opening between the connecting member and themetal supporting piece on a curtain wall frame can be realized in situ so as to detach and change the curtain wall stone plate in situ; the maintenance is convenient; by using the connecting system, the curtain wall stone plate is changed in an original position; the stone curtain wall is very convenient to maintain; and for the originally mounted stone curtain wall, the stone plate can also be conveniently maintained and changed by using the connecting system.

Owner:邱建平 +2

Water-based coating using shell powder and preparation method thereof

The invention relates to a water-based coating using shell powder and a preparation method thereof. The water-based coating is prepared by the following steps of using the shell powder as the main rawmaterial, adding diatomite, calcium powder, kaolin and other additives, and mixing, so as to form the water-based coating using the shell powder. The water-based coating using the shell powder has the beneficial effects that the air ventilating property is good, the mildew-proof effect is realized, the poisonous substances are decomposed and adsorbed, and the air humidity is regulated; the environment-friendly effect is better, all adopted raw materials are substances containing no grease or benzene ring, and the finished product is free from toxicity or odor; the abrasion-resistant propertyis high, and the flame-retardant function is realized; the construction property is good, the construction method is flexible, and the water-based coating can be sprayed or coated.

Owner:高卓彤

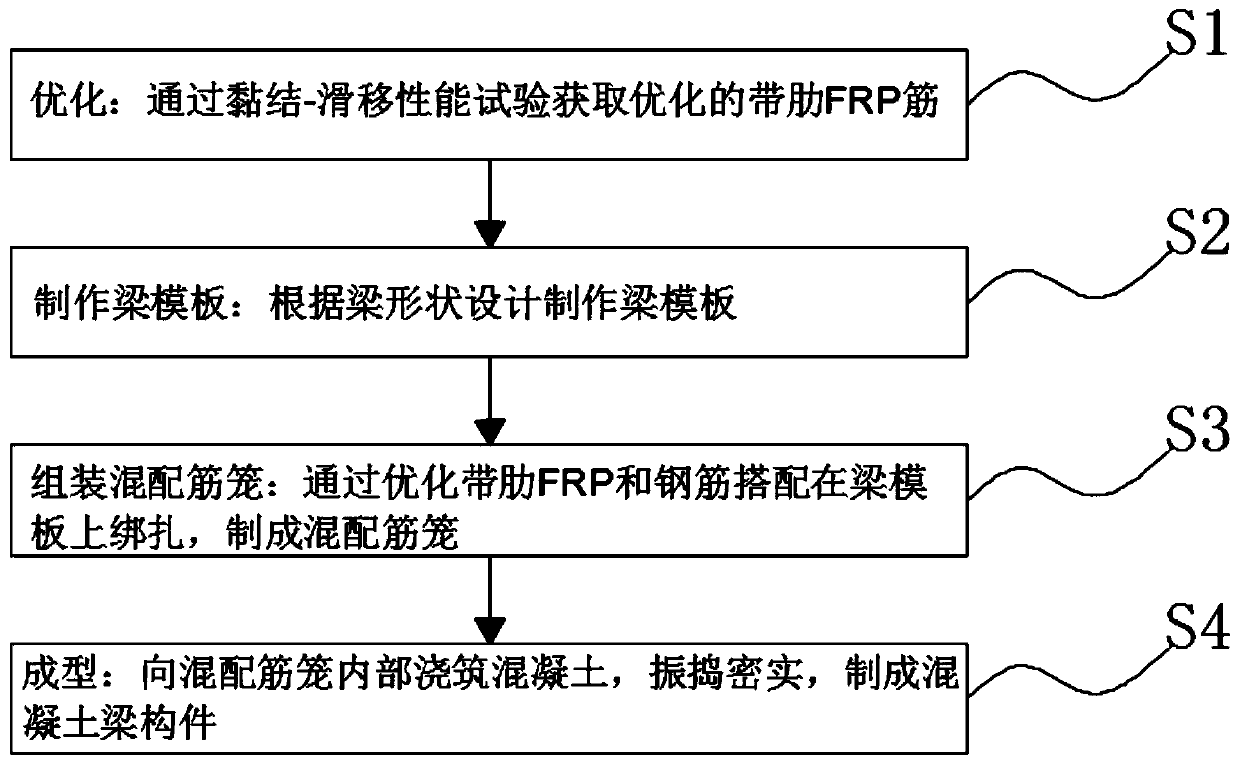

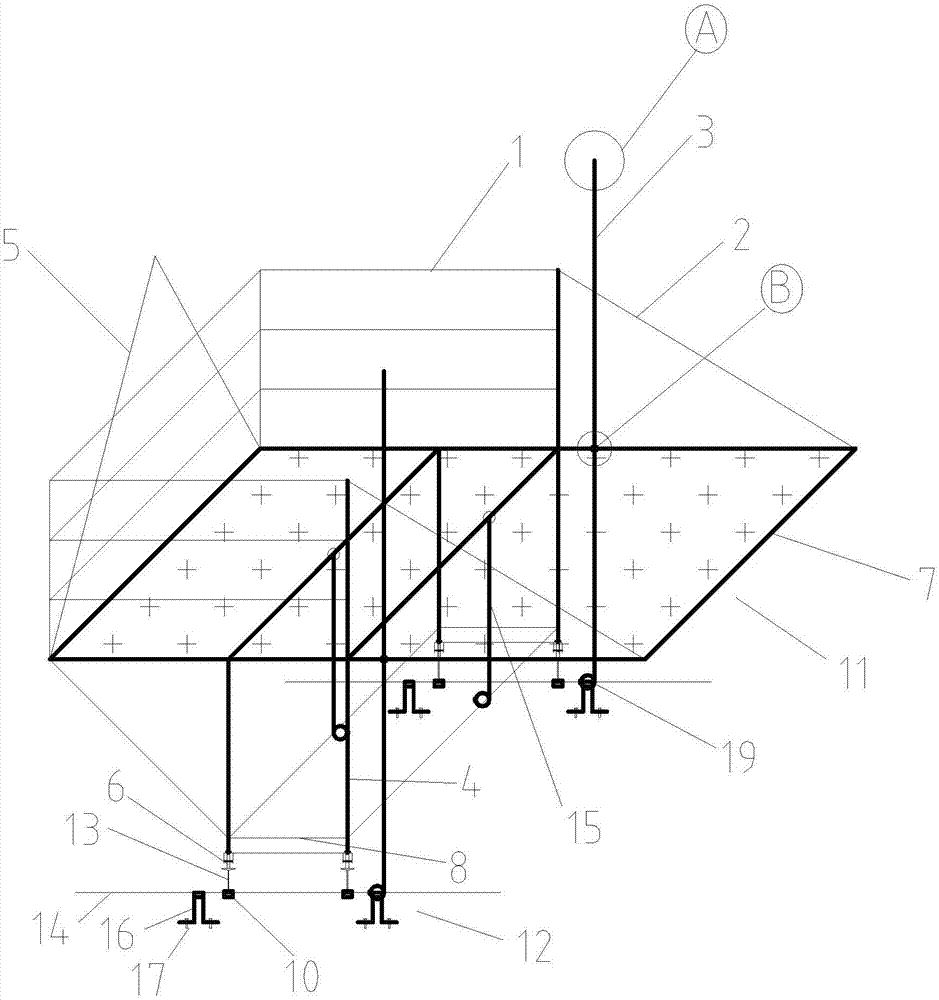

Method for realizing crack resistance of concrete beam member by optimizing ribbed FRP bars

InactiveCN111168809AScientific and reasonable structureSafe and convenient to useCeramic shaping apparatusBridge erection/assemblyRebar corrosionCrack resistance

The invention discloses a method for realizing crack resistance of a concrete beam member by optimizing ribbed FRP bars. The method comprises the steps of optimizing, manufacturing of a beam template,assembling of a mixed reinforcement cage and forming, the concrete beam member is reinforced by adopting the mixed reinforcement of the FRP bars and reinforcing bars, compared with single reinforcingbar reinforcement, the characteristics of high tensile strength and corrosion resistance of the FRP bars and good ductility of common reinforcing bars are sufficiently utilized, mutual complementation is realized, the defects of large deflection and crack width and insufficient ductility of the FRP reinforced concrete flexural member are overcome, the FRP bars are configured to the easy-to-corrode corner of the concrete beam member, the problem of steel bar corrosion of the reinforced concrete beam member and the defects of large deflection, wide cracks and brittle failure of the FRP reinforced concrete beam member are solved, the FRP bars are optimized, the problems that the bonding stress of the common ribbed FRP bars and concrete is small, bonding sliding performance is poor, the crackwidth cannot be effectively controlled are solved, and steel bars on the inner side are still likely to corrode are solved, the construction method is flexible, and both factory prefabrication and in-place casting can be realized.

Owner:江苏绿材谷新材料科技发展有限公司

Building special-shaped eave decoration curtain wall installing platform and construction method

InactiveCN107313586ASimple structureEasy to operateScaffold accessoriesBuilding support scaffoldsFalseworkEaves

The invention belongs to the field of building, and discloses a building special-shaped eave decoration curtain wall installing platform. The building special-shaped eave decoration curtain wall installing platform comprises a construction platform trolley and a platform rail. The invention also discloses a construction method of a building special-shaped eave decoration curtain wall. The construction method is implemented by using the installing platform. The installing platform is applicable to the curtain wall construction of various complicated special-shaped buildings, mainly including construction with scaffold-free or hanging-basket-free requirements such as upward layer-by-layer inward adduction inclination structures, building inter-storey eaves and complicated suspended ceilings. The building special-shaped eave decoration curtain wall installing platform provided by the invention has the advantages that the structure is simple; the operation is convenient; the use is safe; the manufacturing cost is low; the construction method using the installing platform is flexible and fast; the installing efficiency can be greatly improved; the construction period and the labor cost can be reduced; and the practicability is high.

Owner:CHINA MCC17 GRP

Selective refracturing technology for old oilfield wells

The invention discloses a selective repeated fracturing technology for old wells in oil fields, which is designed for effectively solving the problem of repeated reformation of old wells in oil fields. The technology of the present invention adopts assembling, lowering the pipe string, and dragging the pipe string to complete the perforation operation of the required reformed layer, set the upper and middle packers, carry out the fracturing construction of the lowest newly added layer, unseal and drag The construction is carried out in the technological steps from moving the pipe string to the second newly-increased reconstruction layer. The technology of the invention utilizes hydraulic sand blasting perforation to form large-diameter and deep-penetrating tunnels, which can effectively reduce the fracture pressure, and utilizes the advantages of double-seal and single-clamp fracturing technology to reduce requirements on wellhead matching and casing steel grades. The technical string structure of the invention is simple, the construction method is flexible, the operation is convenient and the efficiency is high, which can effectively solve the problem of repeated reconstruction of old wells in the oil field, and can not only complete the repeated fracturing of the reconstructed section, but also carry out the hole repair of the newly added section Integrated operation with fracturing.

Owner:PETROCHINA CO LTD

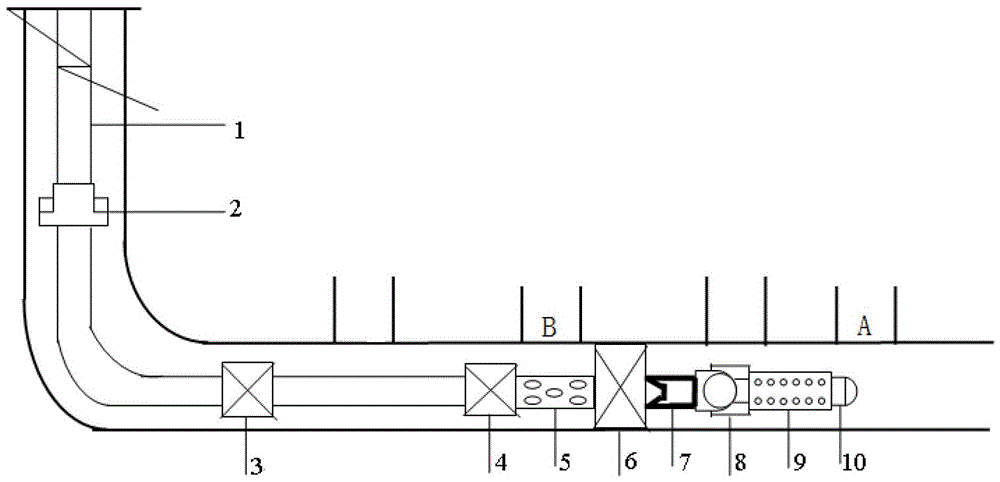

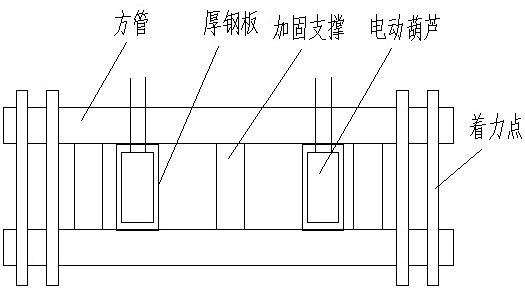

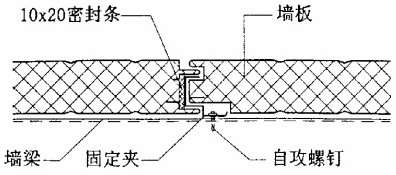

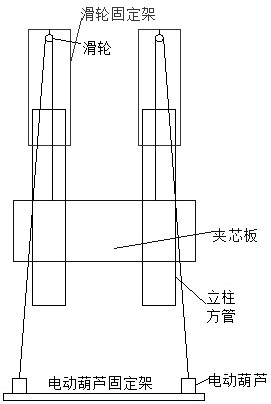

Installation and Construction Technology of Sandwich Panel Exterior Wall in Steel Structure Workshop

ActiveCN109098453BIncrease stiffnessThe fastening method is reasonableBuilding material handlingBrickArchitectural engineering

The invention discloses a mounting and construction process of the steel structure workshop sandwich plate outer wall surface. Two electric hoists are mounted on the ground, and a pulley is mounted ona roof for hoisting. Compared with a high-altitude mounting method, the construction method thereof is flexible, convenient to move, fast in construction speed and high in construction efficiency; and meanwhile, compared with a brick outer wall, the construction time is relatively short, the construction speed is fast, the number of construction personnel is less, and after the construction is completed, the outer wall surface has good sealing performance, beautiful appearance, good rigidity, reasonable fastening mode, firm fixing method and good overall image.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

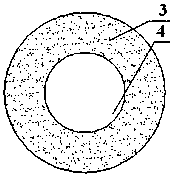

A Dispersion Layer Composite Damping Material Using Hollow Shell Foam Ceramic Balls as Aggregate

ActiveCN105330201BLarge attenuation coefficientGood value for moneyCeramicwareClaywaresCompression moldingPorosity

The invention belongs to the technical field of national defense engineering protection materials, and especially relates to a dispersion layer composite damping material with vacant-shell foam ceramic balls as aggregate and with a civil air defense command work layered structure. The purpose of the invention is to use a dispersion layer material with large attenuation coefficient, high cost performance and stable performances to substitute sandy soil and other local materials used at present in order to improve the comprehensive protection ability of the layered protection structure. The dispersion layer material is prepared through mixing the vacant-shell foam ceramic balls, highly adhesive and elastic asphalt base and polyphenyl particles according to a certain ratio, and through carrying out compression molding, wherein the vacant-shell foam ceramic balls are a hollow foam ceramic structure, and have the characteristics of high amount of porosity and small density. The cavity diffraction and foam compression destroy energy dissipation of the vacant-shell foam material and the intrinsic damping of the highly adhesive and elastic asphalt base are fully used in the invention, so the attenuation coefficient of the prepared dispersion layer material is 4.2, the density is 0.85g / cm<3>, the wave velocity is 120m / s, and the comprehensive protection ability of the civil air defense command engineering layered structure is greatly improved.

Owner:UNIT 61489 OF PLA

Construction method of excavating hole piles in subway stations

ActiveCN106703814BReduce the impact of settlementSave masonryUnderground chambersTunnel liningMetro stationSupporting system

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

Method for constructing self-assembly environment-friendly long-lasting easy-to-clean anticorrosion coating

ActiveCN111842070AReduce consumptionChannel shortCoatingsSpecial surfacesPolystyrenePhysical chemistry

The invention discloses a method for constructing a self-assembly environment-friendly long-lasting easy-to-clean anticorrosion coating, and belongs to the technical field of chemical engineering. Theconstructing method is flexible, the technology is simple, the efficiency is high, the period is short, environmental protection and pollution free are achieved, the coating binding force is high, through the electrostatic self assembly, based on the electrostatic adsorption action of polyacrylamide hydrochloride and sodium polystyrene sulfonate electrolytes, urushiol is combined through the existence of polyelectrolytes, and gradual deposition is carried out to form a urushiol coating; and then the mode of layer-by-layer assembly is adopted to deposit the two polyelectrolytes to uniformly cover the surface of the urushiol coating, the absorption process is more uniform, film formation is more compact, the anticorrosion effect is the most lasting, efficient and table, and thus the anticorrosion effects such as galvanized sheet iron and aluminized zinc iron sheet are obviously improved.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

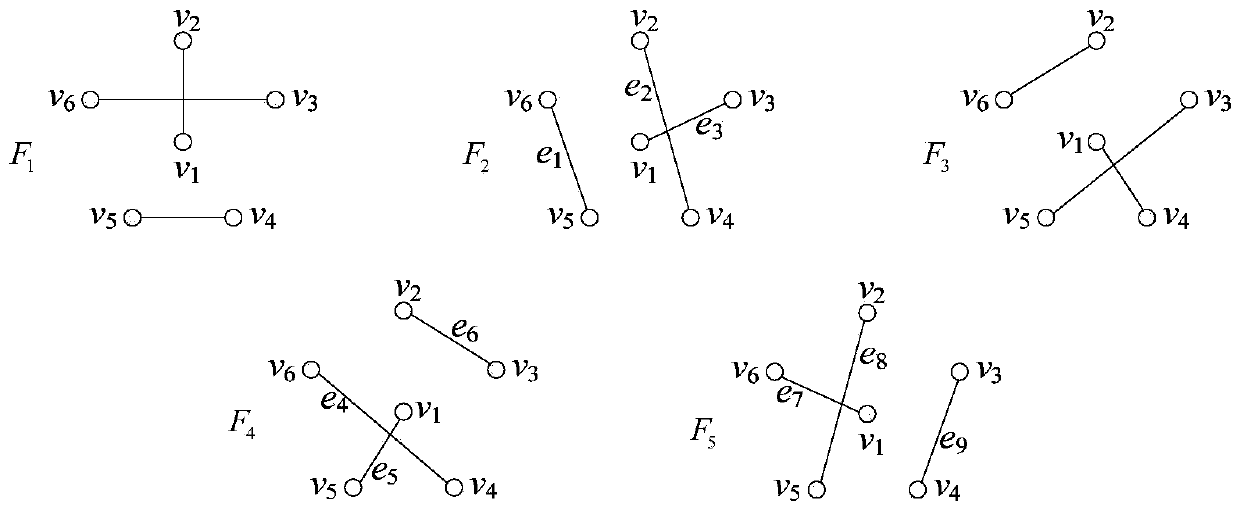

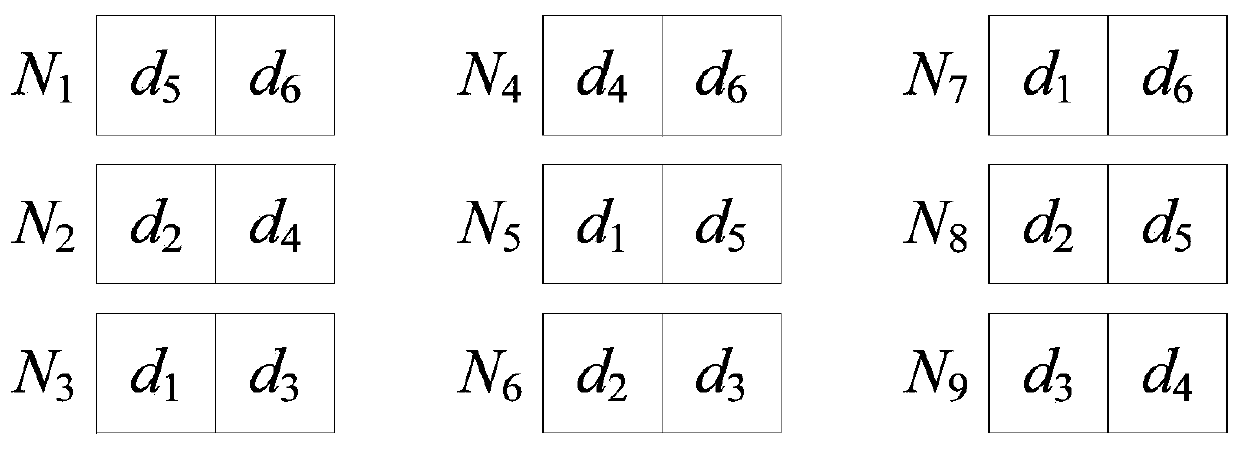

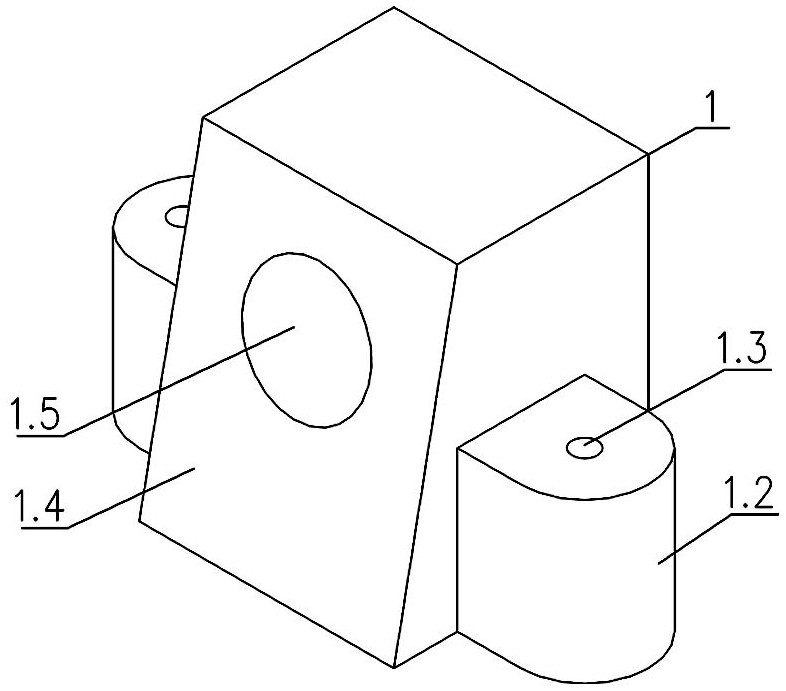

Partial repeat code construction method based on graph factorization

PendingCN110532125AFlexible construction methodRedundant data error correctionAlgorithmComplete graph

The invention discloses a partial repeat code construction method based on graph factorization, which mainly comprises the following steps: step 1, taking each vertex vi (i is more than or equal to 1and less than or equal to n) of an n-order complete graph G as a data block di (i is more than or equal to 1 and less than or equal to n) stored by a partial repeat code, and then carrying out graph factorization on the n-order complete graph G; 2, determining the repetition degree rho for constructing the FR code, numbering the edges or triangles of the selected factors in sequence according to the factorization of one factor or the factorization of two factors, and then taking each edge or triangle as each storage node of the FR code, wherein in the constructed FR code with the repetition degree of rho, each node stores a data block di (1 < = i < = n) on each edge or an adjacent vertex of each triangle. According to the method, the construction parameters and the repetition degree of thedata blocks can be selected in a large range, and the construction method has the characteristic of diversity.

Owner:CHANGAN UNIV

Construction method of chain-lock ecological block retaining wall

ActiveCN110965577BFlexible construction methodEnsure stabilityArtificial islandsExcavationsRetaining wallEcology

The invention discloses a construction method for a chain-lock type ecological block retaining wall. 1. Excavate on the side slope according to the designed excavation line, and stake out the hole positions of the anchor rods to be anchored on the excavation surface; 2. 3. Pouring the foundation of the retaining wall; 4. Place the first layer of chain blocks on the foundation of the retaining wall. The distance between adjacent chain blocks is equal to the width of a block. The holes on the slope of the chain block are aligned with the axis of the anchor rod. Place the first layer of blocks between the adjacent chain blocks to form the first layer of retaining wall; 5. Backfill the first layer of graded gravel behind the first layer of retaining wall, and then cover the channel of the first layer of blocks Fill the planting soil with grass seeds or flower seeds to form the first layer of chain-lock ecological retaining wall; 6. Repeat steps 4 and 5 on the first layer of chain-lock ecological retaining wall to form the second layer of chain lock 7. Repeat steps 4 to 6 until the construction of the entire chain-lock ecological retaining wall is completed. The invention is not limited by the excavation space and has strong adaptability to geological conditions.

Owner:YELLOW RIVER ENG CONSULTING

Novel aluminum alloy external window hole cleaning installation construction method

PendingCN114687643AFast installationReduce pollutionFrame fasteningJoints tightening/coveringEngineeringStructural engineering

The invention relates to the technical field of aluminum alloy external windows, and discloses a novel aluminum alloy external window clean hole mounting construction method which comprises the following steps: firstly, observing an external window hole, measuring the size of the hole, checking whether the height and the width of the hole are approximately the same as those of the external window, and if the height and the width of the hole are too large or too small, judging whether the hole is opened or not; and the hole is constructed, so that the height and the width of the hole are approximately the same as those of the outer window. According to the novel aluminum alloy external window hole cleaning installation construction method, through measurement, construction, cleaning and detection of the external window hole, the external window frame can be installed in place at a time after the external window hole is completely constructed, and pollution and deformation of the surface of an aluminum alloy profile caused by procedures such as embedding seams are greatly reduced; a gap between an original reserved hole and an outer window frame body is filled with a waterproof heat preservation agent, a neutral silicone sealant is used for sealing an installation gap, and the problem of water seepage and gushing caused by the fact that cement caulking is not compact in the traditional technology can be effectively solved.

Owner:湖南教建集团有限公司

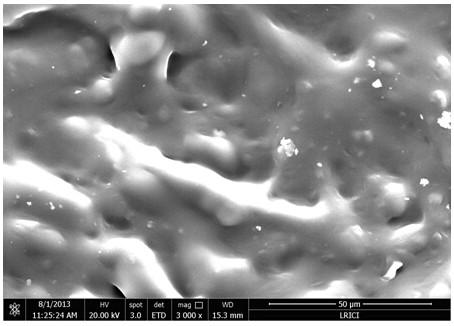

Normal-temperature solidification polyurethane elastomer waterproof material and preparation method thereof

The invention discloses a normal-temperature solidification polyurethane elastomer waterproof material and a preparation method thereof. The polyurethane waterproof material comprises a component A and a component B. Proportioning by weight percent, the component A is an isocyanate prepolymer with the content of 4-15% of isocyanic acid radical NCO; the component B comprises 0-65% of polyether glycol with the degree of functionality of 2-3 and the molecular weight of 1,000-5,000, 0.6-1.2% of organic bismuth catalyst, 20-27.5% of polybasic amine, 0-1.3% of antioxidant and 12.5-71.9% of plasticizer. The component A and the component B are mixed according to the weight ratio of 100(60-81); the material obtained by room-temperature solidification has the mechanical properties that the tensile strength is 15-35MPa, the tearing strength is 44-62N / mm, the breaking elongation rate is 405-840%, and the Shao' hardness is 75-90A.

Owner:LIMING RES INST OF CHEM IND

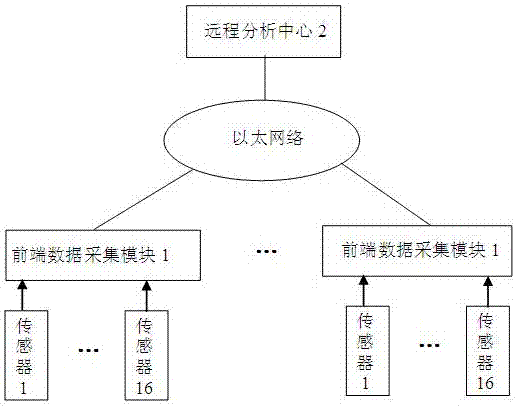

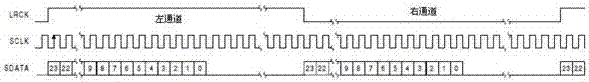

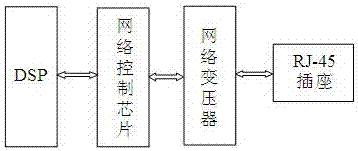

System and method for on-line detection and analysis of multi-channel vibration signals of rotating machinery

InactiveCN104483011BHighly integratedImprove work efficiencySubsonic/sonic/ultrasonic wave measurementUsing electrical meansAnalysis centerData acquisition

The invention discloses a system and method for on-line detection and analysis of multi-channel vibration signals of rotating machinery, comprising a front-end data acquisition module and a remote analysis center, the front-end data acquisition module is connected to the remote analysis center through an Ethernet network; the front-end data acquisition module includes an acceleration Sensor, channel switching module, constant current power supply circuit module, signal conditioning circuit module, A / D conversion module, interface logic circuit module, microprocessor module, network interface module, speed signal detection module and relay module, with 16-channel polling 2. The function of collecting vibration signals in parallel with 2 channels and the collection function of 2 speed signals. The collected data can be transmitted to the remote analysis center through the network interface module connected with the microprocessor module through Ethernet, and the relay connected with the microprocessor module The module is used to connect the controlled peripherals; the remote analysis center includes a parameter configuration module, a data communication module, a data analysis module and a database maintenance module.

Owner:南京理工大学紫金学院

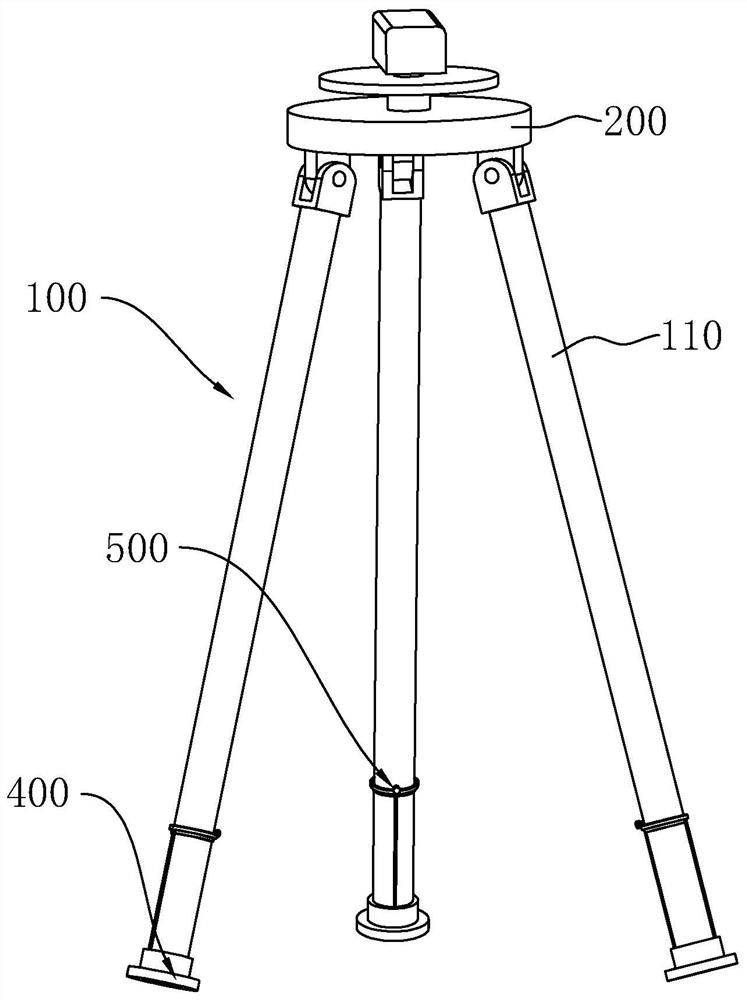

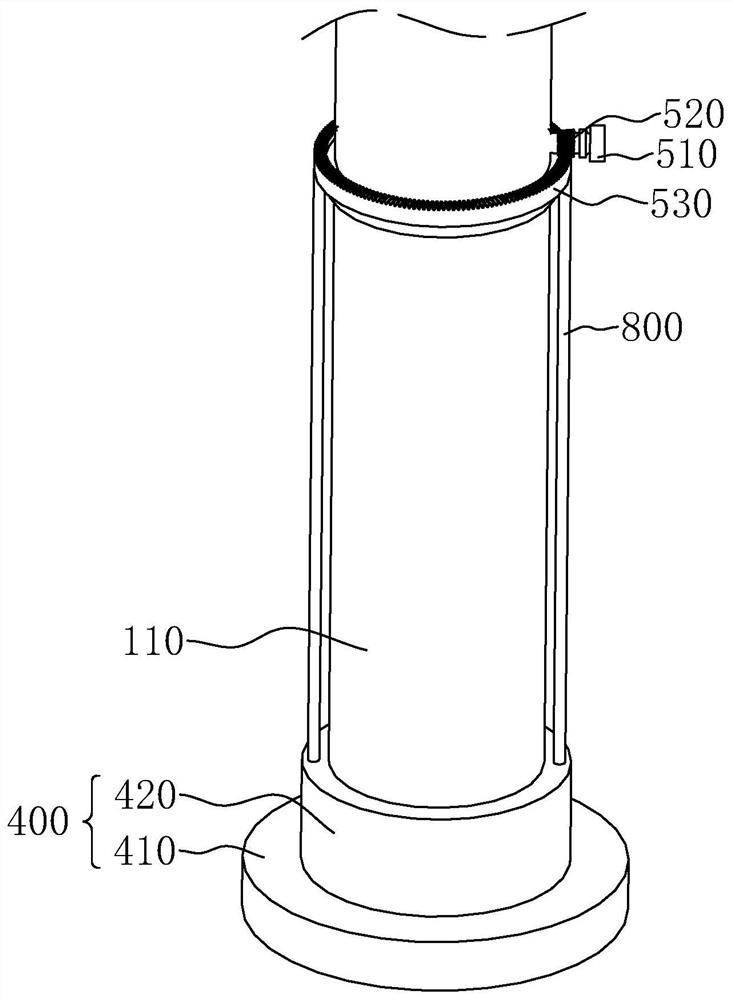

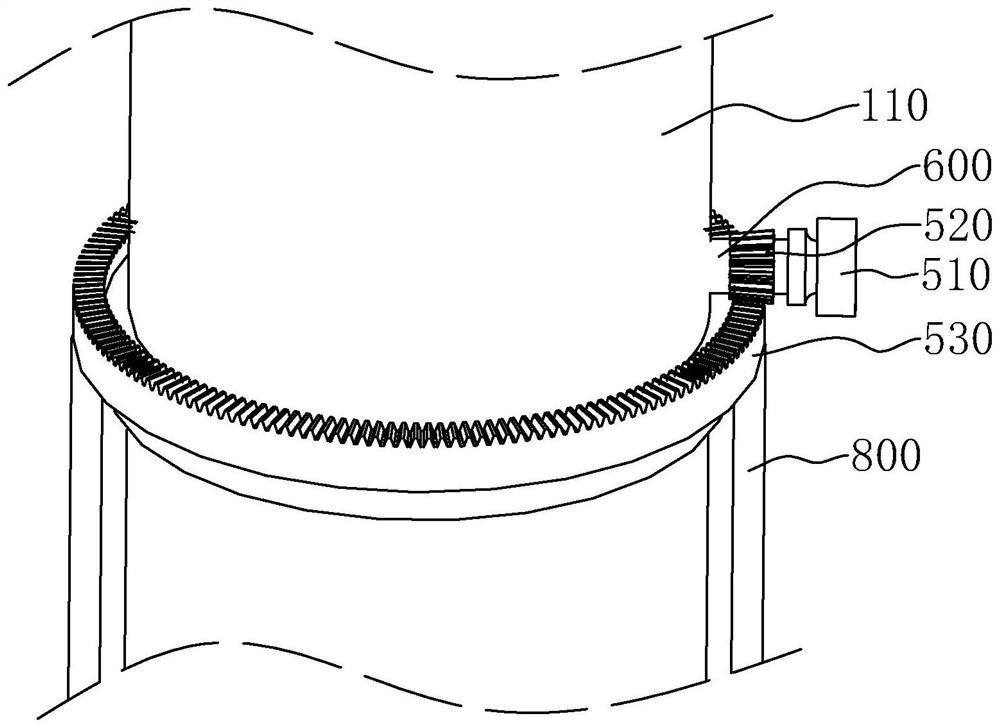

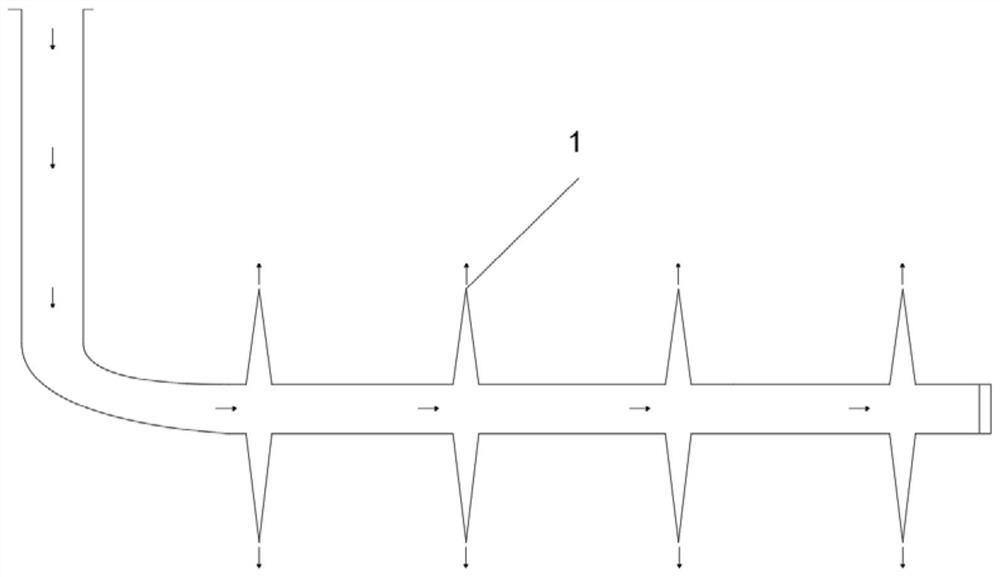

Steel floral tube soil nailing wall hole forming process and level gauge

ActiveCN113932125AEasy to installReduce distractionsFoundation testingStands/trestlesSoil nailingAgricultural engineering

The invention relates to a steel floral tube soil nailing wall hole forming process and a level gauge, and relates to the technical field of foundation pits. The steel floral tube soil nailing wall hole forming process comprises a tripod and a base; the tripod comprises three supporting rods; one ends of the three supporting rods are rotatably installed on the base, and the three supporting rods are located on the same side of the base; a stabilizing assembly used for stably installing the tripod and a leveling assembly used for making contact with the ground are installed at the end, away from the base, of each supporting rod; the supporting rods are further provided with driving assemblies; and the driving assemblies are connected with the stabilizing assemblies and the leveling assemblies, and the driving assemblies drive the leveling assemblies to rotate. According to the steel floral tube soil nailing wall hole forming process provided by the invention, when the level gauge needs to be installed on the uneven ground, the tripod can make the to-be-installed ground become smoother relatively, and installation is more stable.

Owner:HANGZHOU XIAOSHAN WATER CONSTR ENG CO LTD

Horizontal Well Fracture Sealing Wellbore Reengineering and Repeated Fracturing Method

ActiveCN109973067BEffective blockingPrevent sand burialFluid removalSealing/packingHorizontal wellsWell cementing

Horizontal well fracture plugging wellbore reconstruction and repeated fracturing method, injecting liquid into the formation until the wellhead injection pressure is greater than the formation closure pressure of the well; injecting fracture sealing particles into the original fracture; injecting cement into the formation; then injecting drillable plugging materials; After the particles and fracture plugging particles are stabilized, drill and grind the drillable plugging material and circulate it out of the ground through liquid; pump the first drillable bridge plug and perforating gun into the first new Control the perforating gun to perforate the fracture position. At the same time, the perforating gun is separated from the first drillable bridge plug, the first drillable bridge plug is set and sealed, and then the perforating gun is pulled out, and then the casing injection pressure cracks, drillable bridge plugs and perforating gun pumps were injected repeatedly to complete all intervals to be reconstructed. The present invention creates a brand-new wellbore by plugging old fractures and filling the unqualified layers with plugging agent and cement, which can effectively prevent tool sand burial caused by communication between the upper and lower layers outside the casing due to poor cementing quality. .

Owner:PETROCHINA CO LTD

Two-stair five-step excavation construction method for shallow-buried large-span soft plastic clay tunnel

ActiveCN102042019BLarge construction spaceImprove ergonomicsUnderground chambersTunnel liningShotcreteSteel frame

The invention discloses a two-stair five-step excavation construction method for a shallow-buried large-span soft plastic clay tunnel, relates to an excavation construction method for the shallow-buried large-span soft plastic clay tunnel and aims to solve the problems of a large number of working procedures, slow construction process, high cost, frequent disturbance of surrounding rock, large surrounding rock deformation and long inverted arch enclosing time existing in the conventional excavation technology for a soft ground tunnel. The method comprises the following steps of: excavating anupper bench and preserving core soil, namely preserving a soil body along a contour line while excavating by using an excavator, excavating and arranging an expanded arch springing at the position ofthe arch springing; supporting the upper bench, namely enclosing an excavation surface by primarily spraying concrete, arranging an arch springing support cushion, erecting a profile steel lagging jack, laying steel bar net slices, constructing a locking foot anchor pipe and ejecting concrete to designed thickness; excavating and supporting a lower bench in a staggered way, namely excavating leftand right parts in a staggered way, tightly connecting a section steel frame of a side wall with an arch steel frame, constructing a reinforcing mesh and a foot locking anchor pipe and ejecting concrete; excavating core soil; and excavating and supporting an inverted arch. The method is suitable for construction of the shallow-buried large-span soft plastic clay tunnel.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP NO 4 ENG

Construction method of pipe row and pipe curtain

ActiveCN107190775BSimple construction methodFlexible construction methodArtificial islandsUnderwater structuresArchitectural engineeringUnderground space

The invention relates to the technical field of underground space construction, and discloses a pipe curtain construction method based on pipe banks. According to the pipe curtain construction method based on the pipe banks, the pipe banks are used as the construction unit and jacked at the same time for constructing a pipe curtain structure, each pipe bank is formed by arranging a set of steel pipes side by side, every two adjacent steel pipes are connected through a connecting component, and the number of the steel pipes in each set is not smaller than two. By adoption of the pipe curtain construction method based on the pipe banks, the construction efficiency is high, the jacking tendency can be controlled highly, jacking deviation can be rectified easily, and the construction precision is high.

Owner:BEIJING SHOUER ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com