Patents

Literature

133results about How to "Mature construction technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

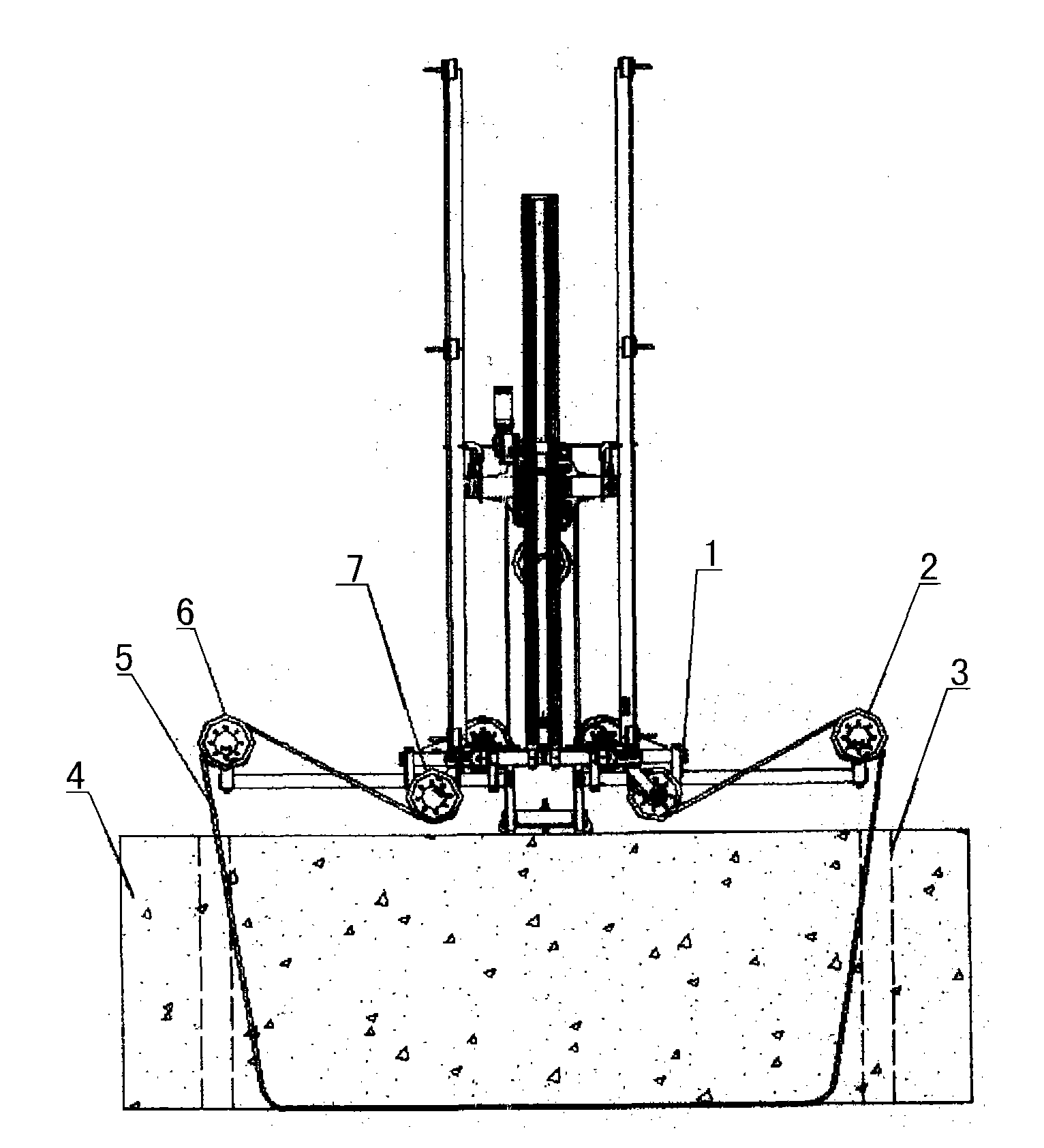

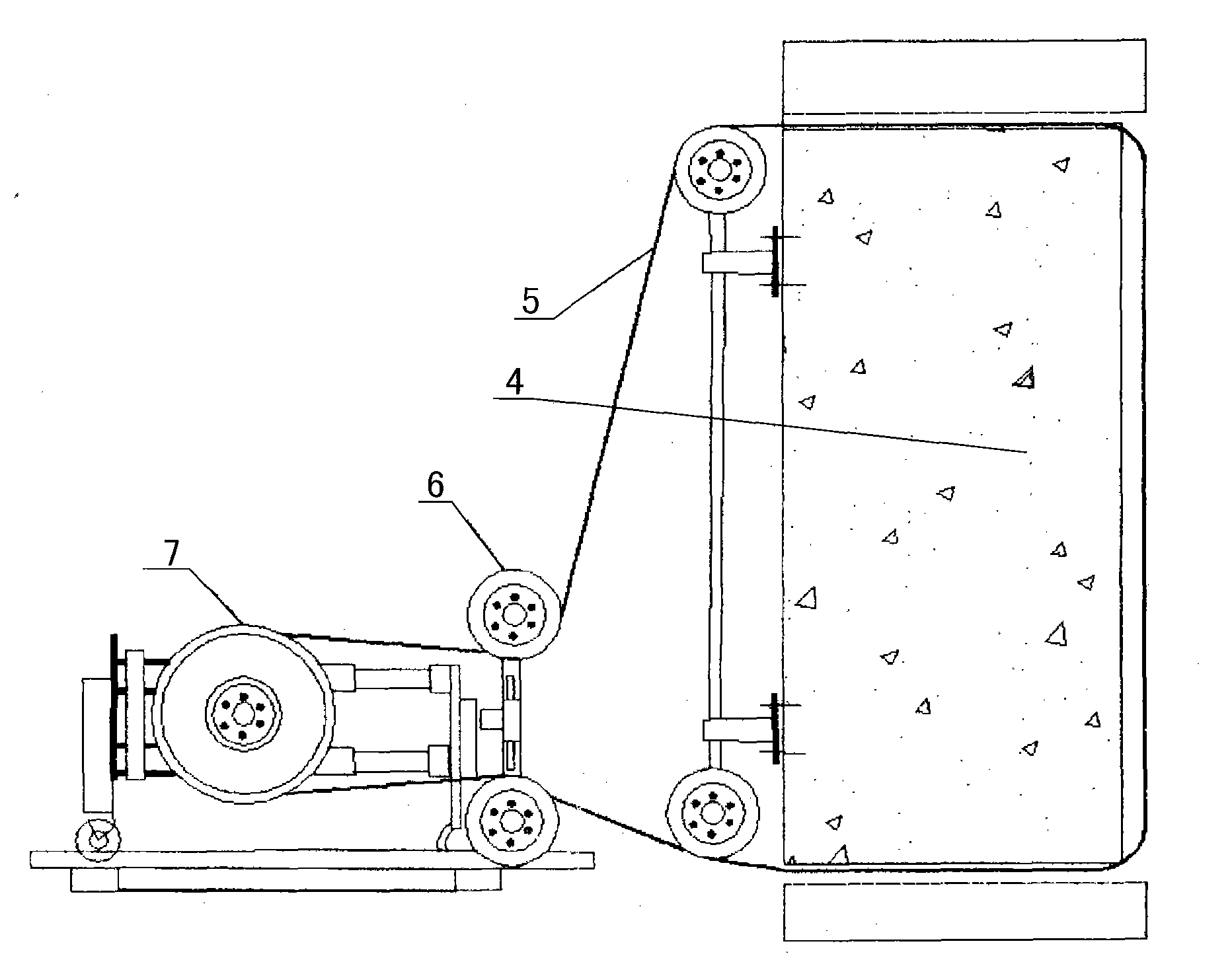

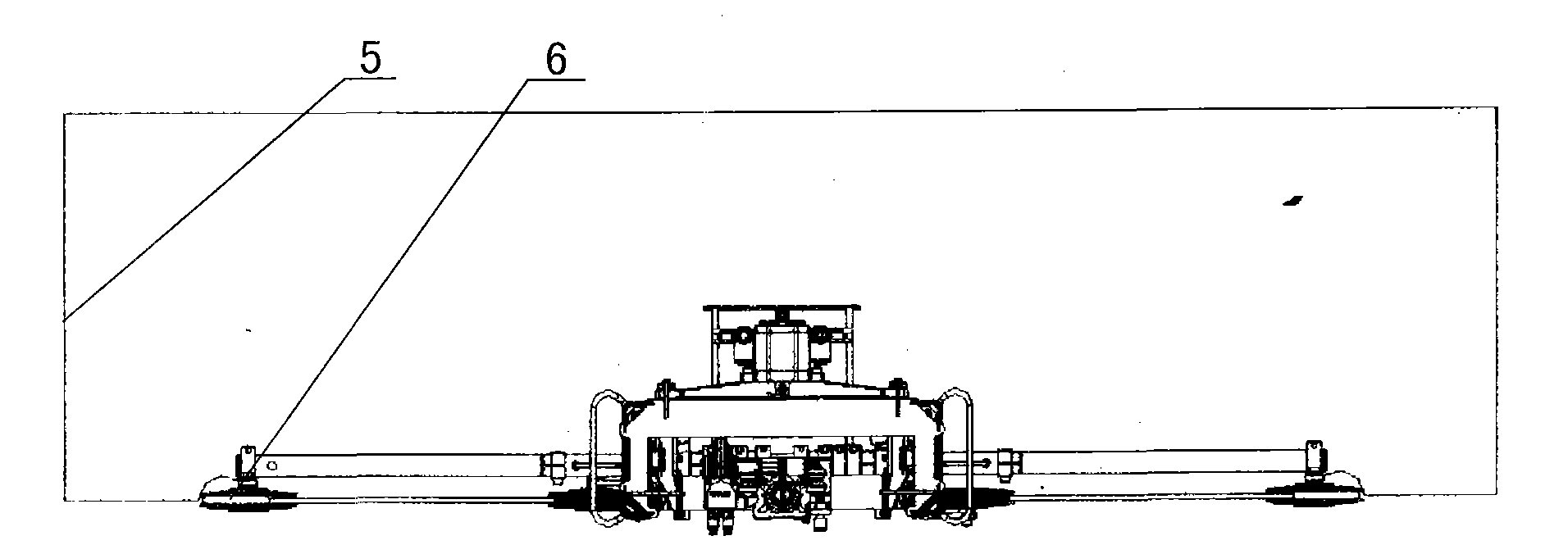

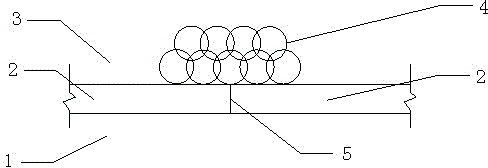

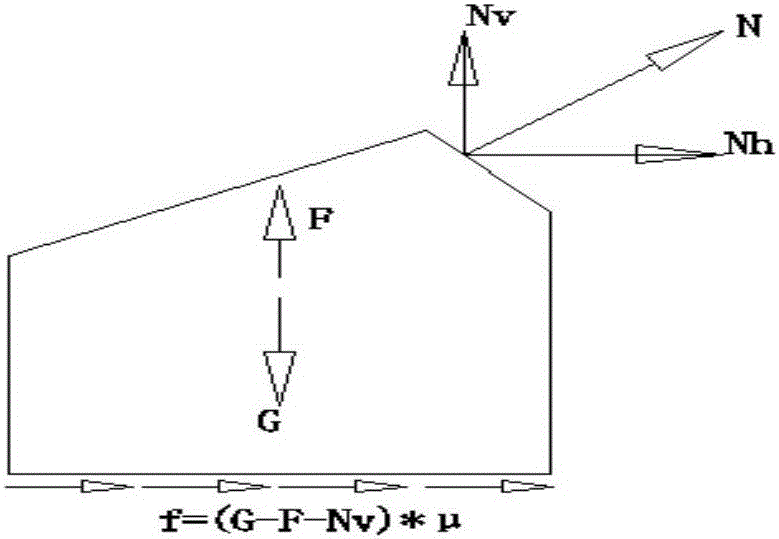

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

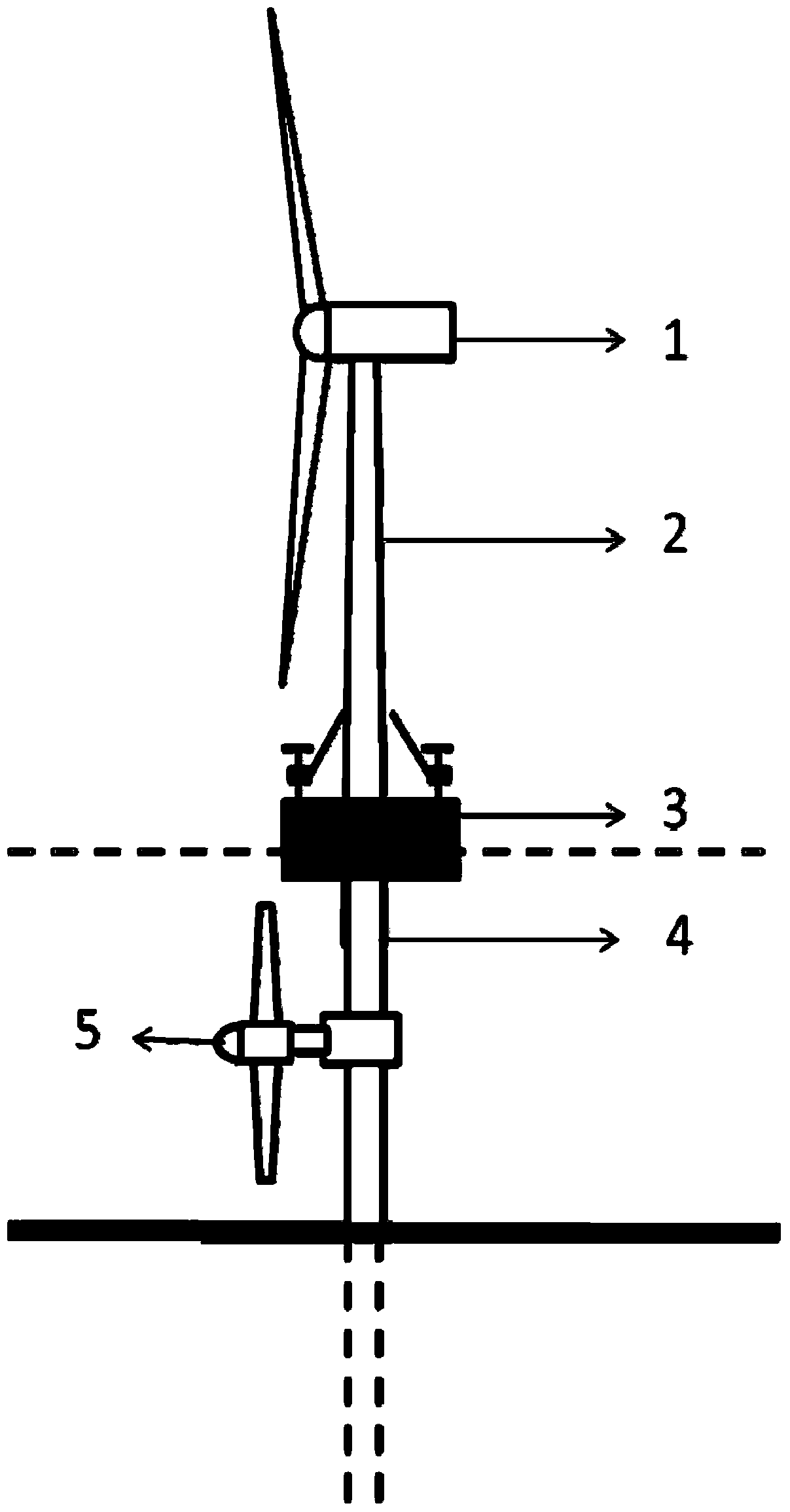

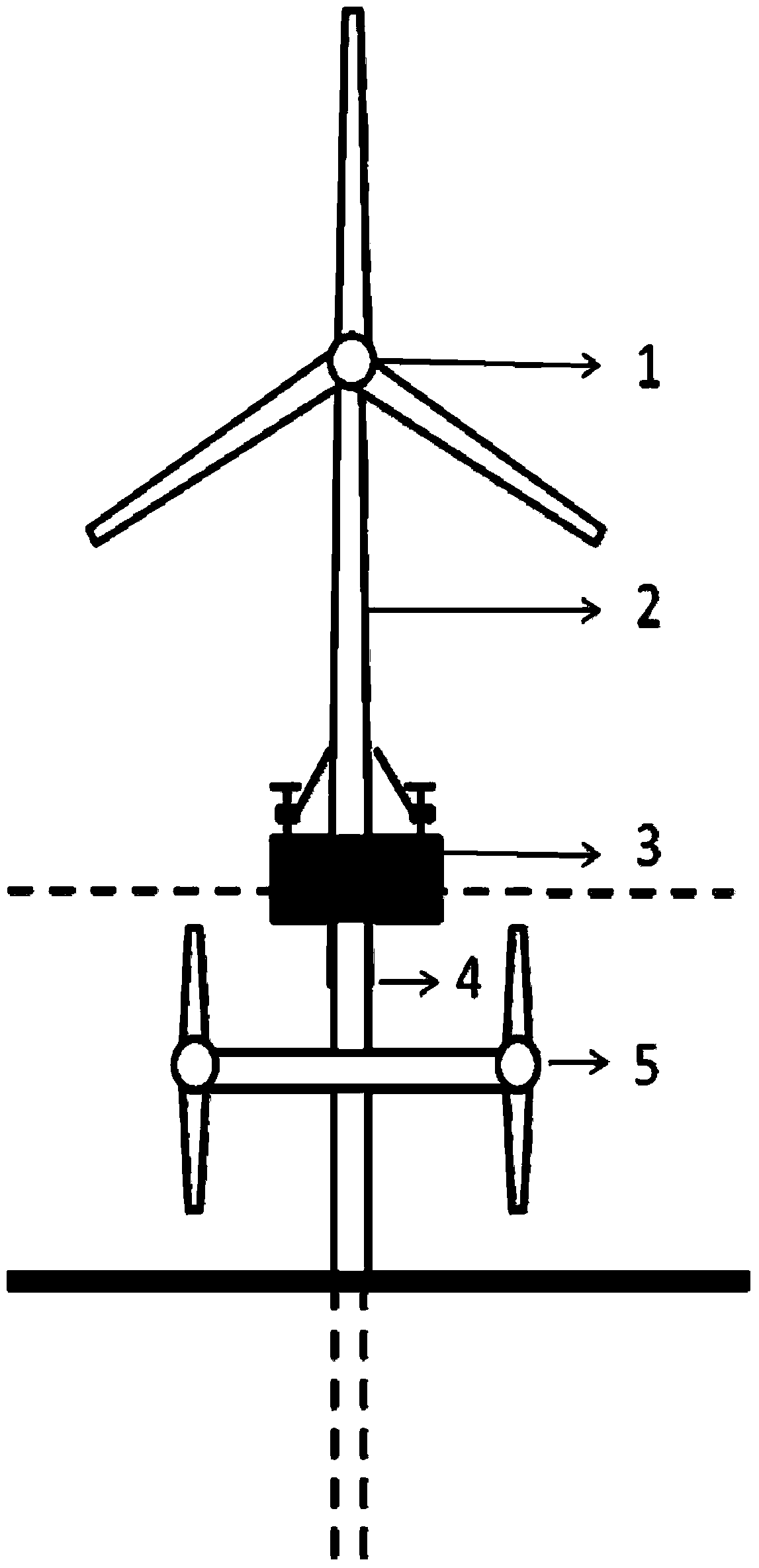

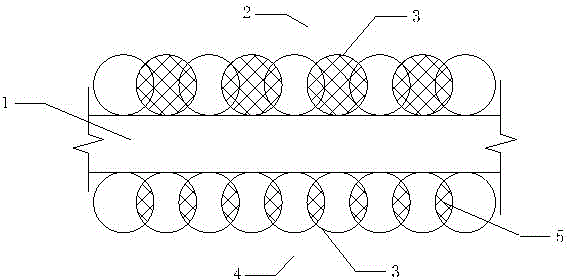

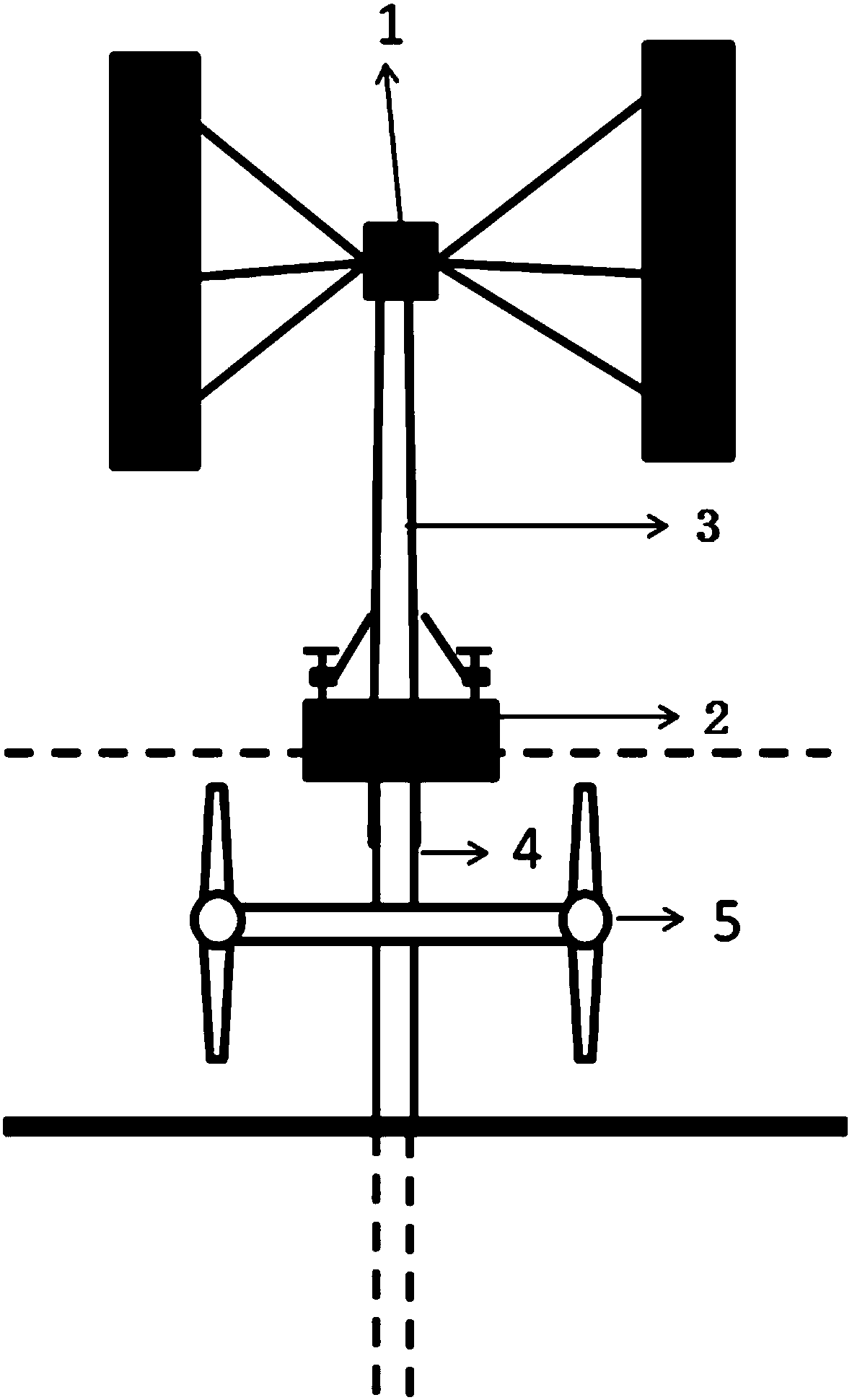

Wind energy-wave energy-tidal current energy integrated power generation structure based on single pile platform

InactiveCN103967714AEasy structure constructionReduce construction costsWind motor combinationsMachines/enginesElectric power transmissionWinding machine

A wind energy-wave energy-tidal current energy integrated power generation structure based on a single pile platform comprises a single pile platform wind power generation structure, a wave energy power generation device and a tidal current energy power generation device, the single pile platform wind power generation structure comprises a wind machine, a tower frame structure, a single pile supporting structure and a matched power transmission system, the wave energy power generation device is arranged on the water surface of the tower frame structure, and the tidal current energy power generation device is arranged on an underwater single pile supporting structure. The wind energy-wave energy-tidal current energy integrated power generation structure has the advantages that the single pile platform structure is convenient to construct, low in construction cost and wide in application range, the wind power generation structure, the wave energy power generation device and the tidal current energy power generation device share the single pile supporting structure and the power transmission system, the unit power generation cost can be effectively reduced, the structural design is reasonable and stable, the construction scheme is mature in technology, existing commercial products can be selected by a wind power generator and a tidal current power generator, modeling is simple and convenient to achieve, and performance optimizing design can be performed on a wave energy power generator by combining wave statistical features of a site selecting place.

Owner:DALIAN UNIV OF TECH

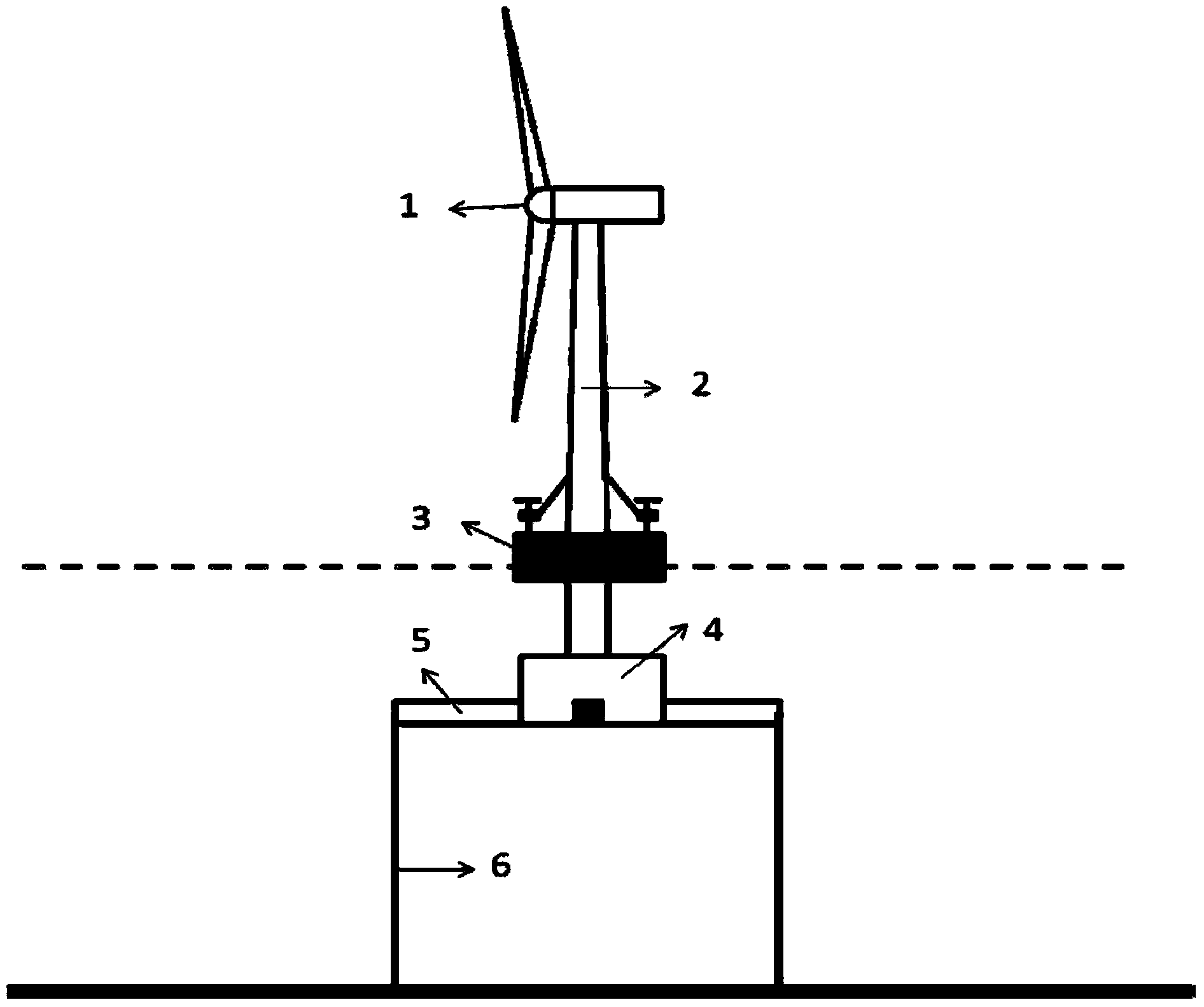

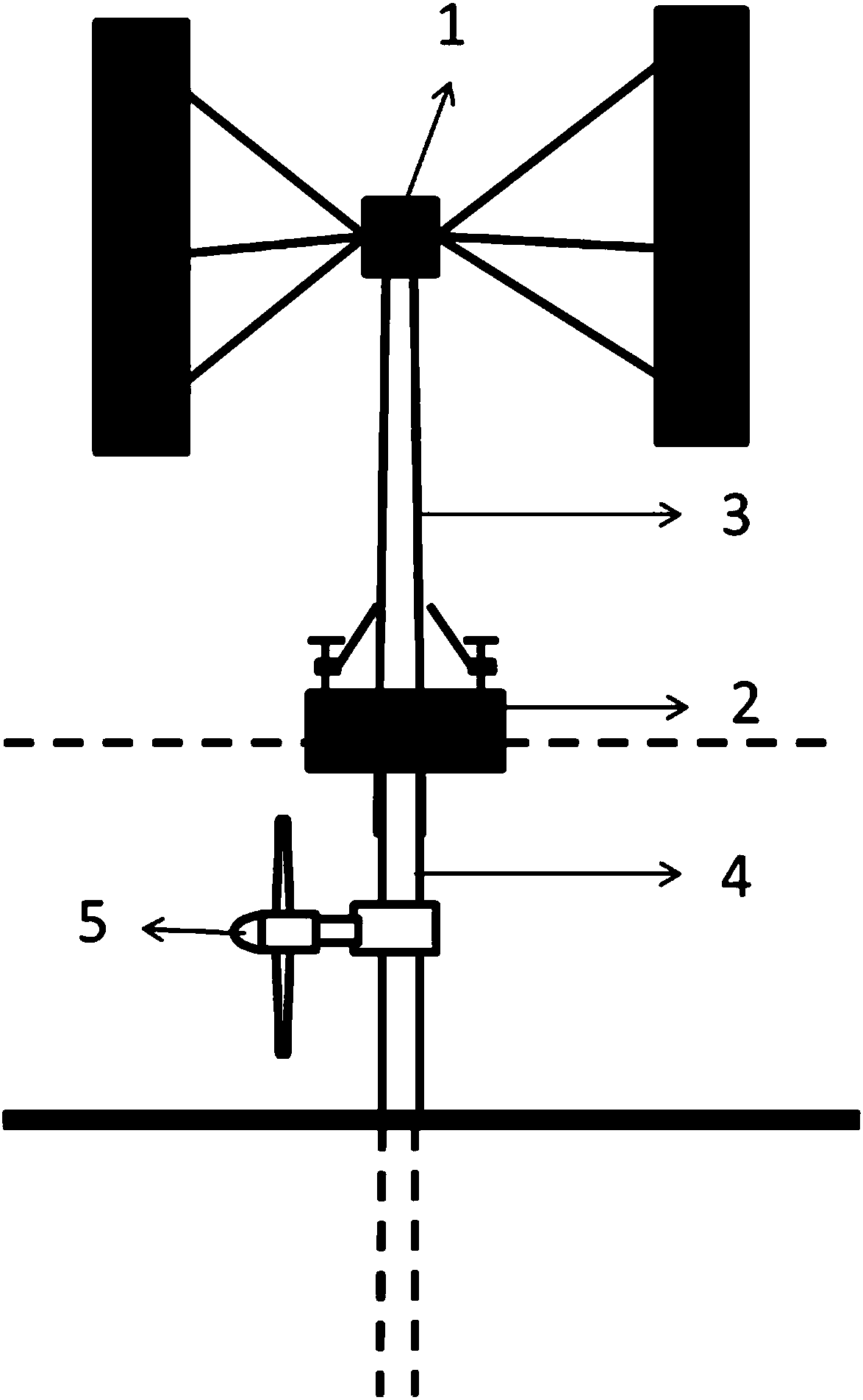

Wind energy-wave energy integration power generation structure based on floating type tension leg platform

InactiveCN103967713AReasonable structural designStable structural designWind motor combinationsMachines/enginesElectric power transmissionWave power generation

A wind energy-wave energy integration power generation structure based on a floating type tension leg platform comprises a floating type tension leg wind power generation structure and a wave power generation device. The floating type tension leg wind power generation structure comprises a wind turbine, a tower structure, a tension leg type supporting platform structure and a matching power transmission system. The wave power generation device is arranged on the water surface of the tower structure, and the wave power generation device is in coupling connection with the outer side face of the tower structure through a slide way type contact device. The wind energy-wave energy integration power generation structure has the advantages that the structure is reasonable and stable in structural design, the technology is mature in the construction scheme, the supporting platform structure and the power transmission system are shared, construction cost of independently using the wind turbine and the wave power generation device is reduced, the tension leg structure is favorable for optimal control of movement and improvement of utilization efficiency of wave energy. A system of the wind energy-wave energy integration power generation structure can be widely applied to development of deep water wind energy-wave energy resources.

Owner:DALIAN UNIV OF TECH

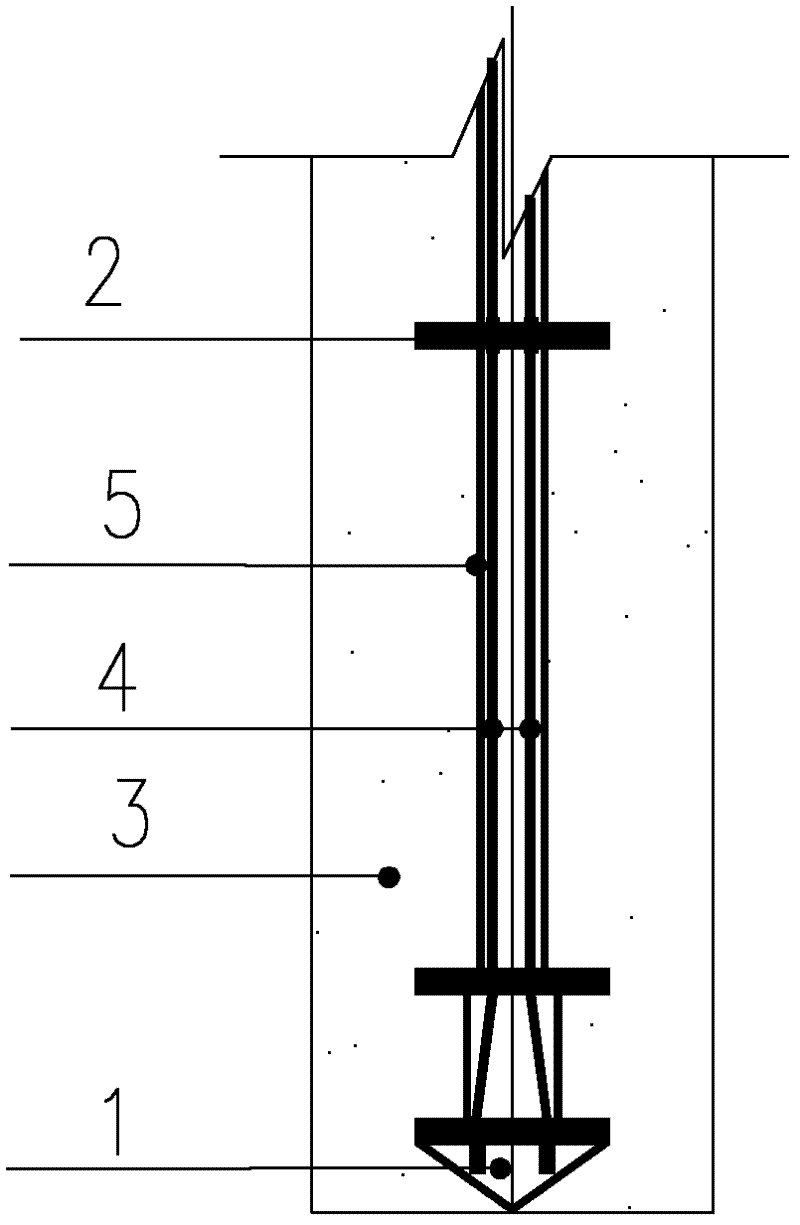

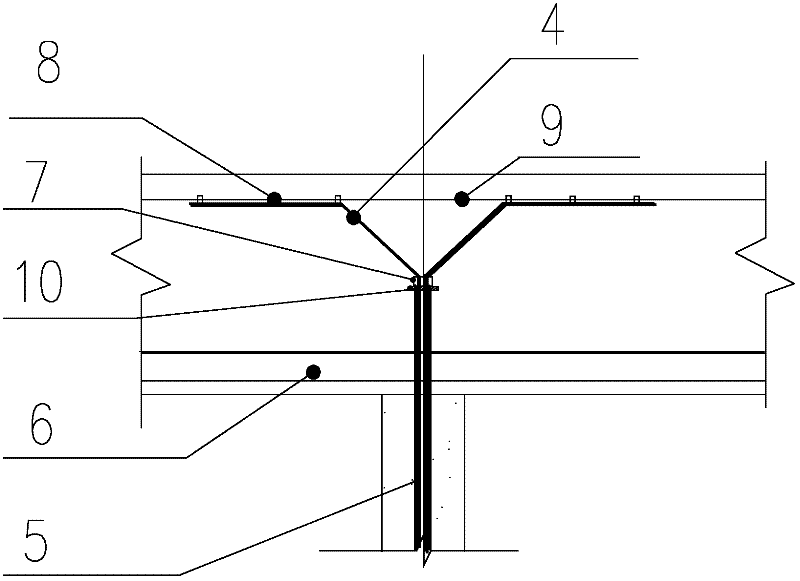

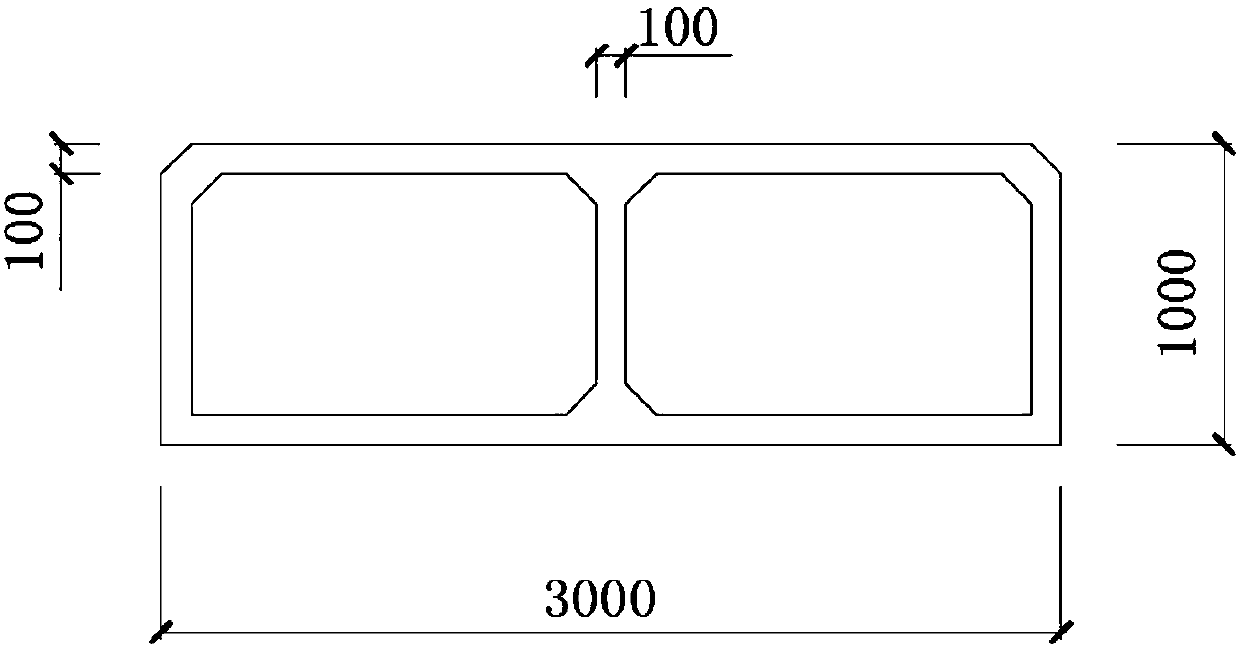

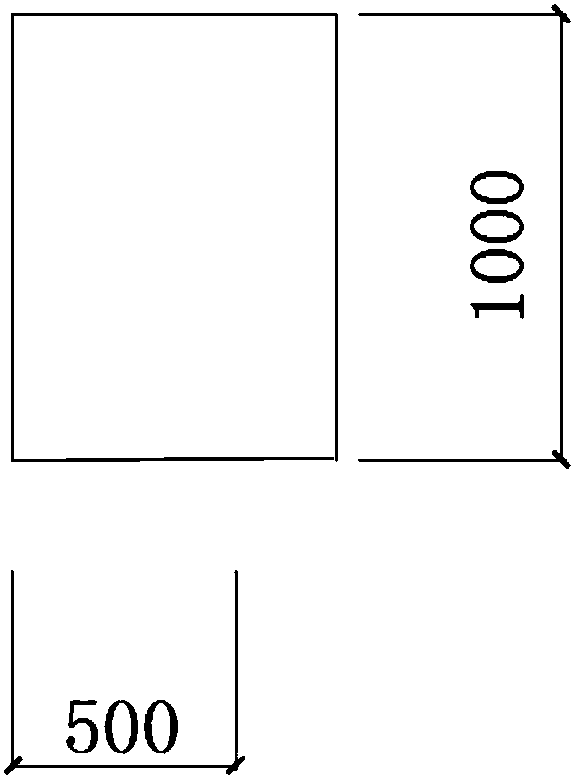

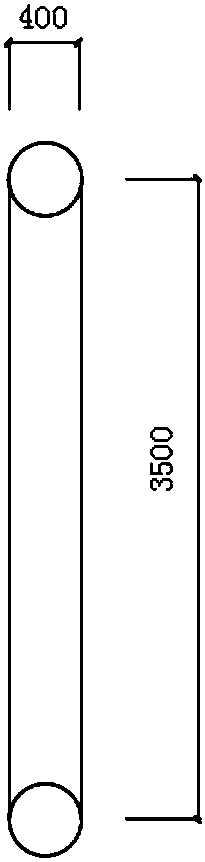

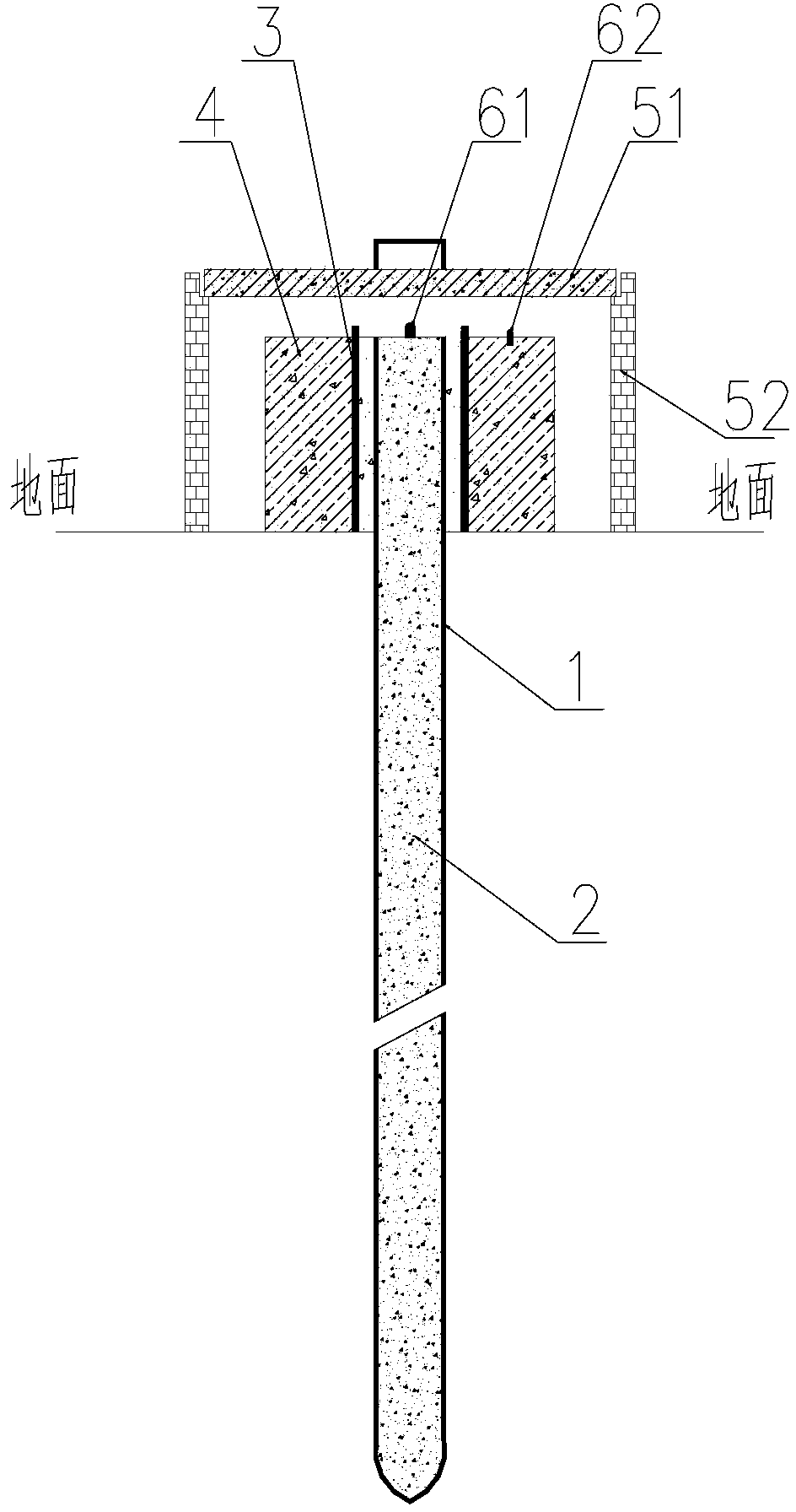

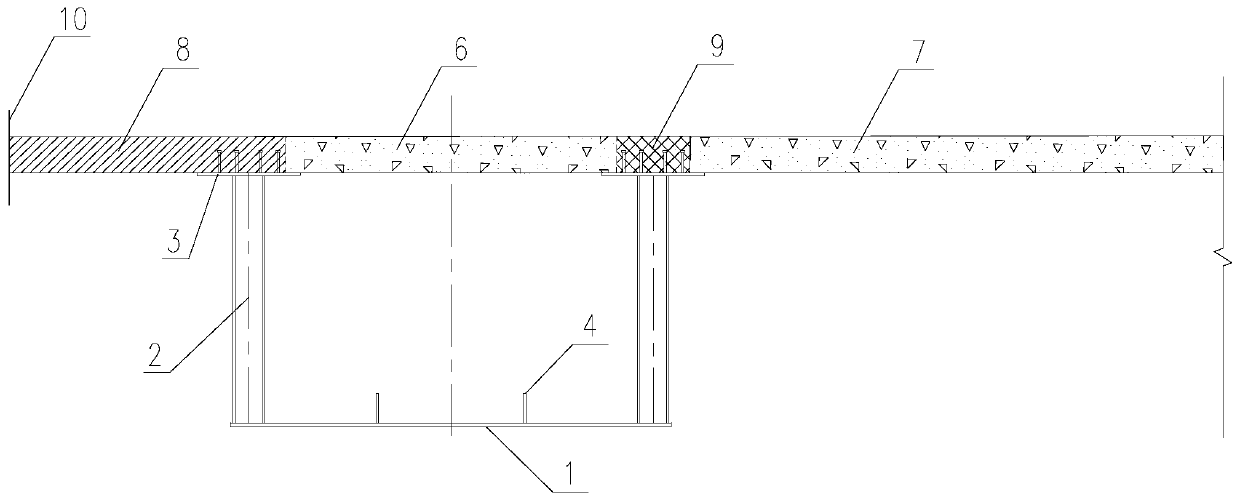

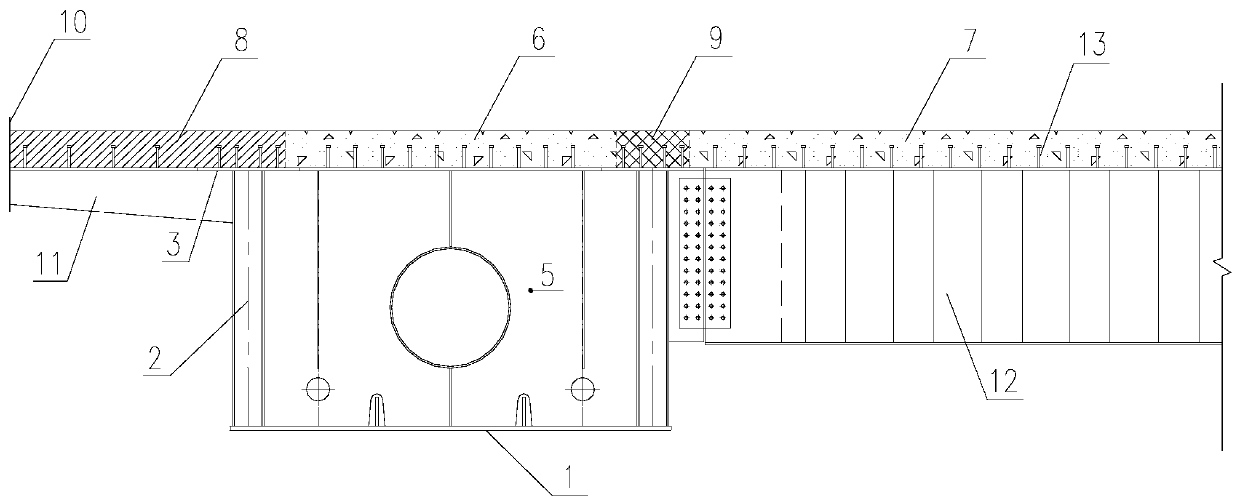

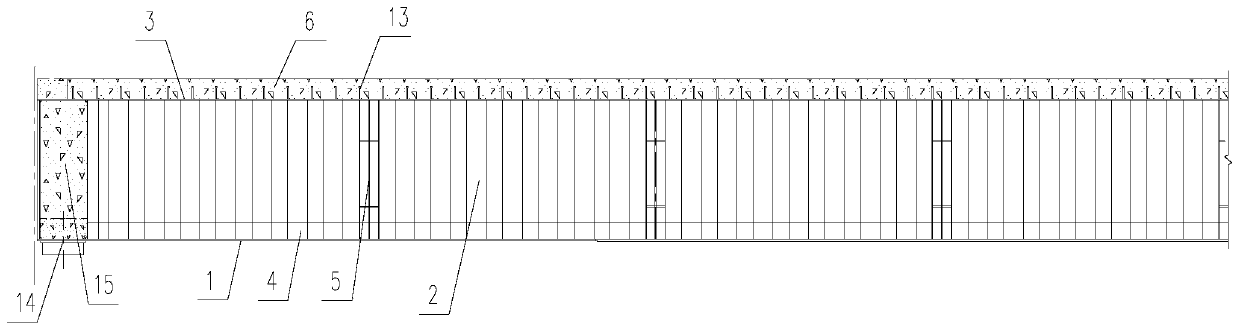

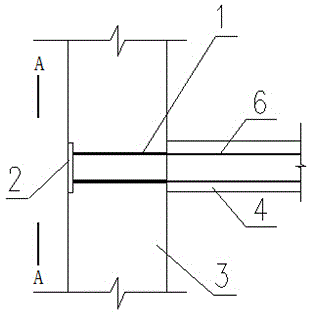

Post stress method stake body prestressed antislid stake and construction method

The present invention adopts construction on ground surface, and makes post-tensional pile-body prestressed anti-slide pile. Its structure is as follows: firstly-poured concrete interior has steel reinforcement cage, cage edge interior has corrugated pipe, in the corrugated pipe interior a stranded wire is placed, two ends of said stranded wire are extended from said corrugated pipe, lower end of said stranded wire is connected with anchorage device of anchored part in the pile bottom, its upper end is connected with anchorage device of pile top, and the upper portion of anchorage device of pile type has secondary poured concrete. Said invention also provides its construction method.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Synchronous excavation supporting system for deep and large asymmetric pit in soft soil area and implementation method of supporting system

ActiveCN104563128AControl pit deformationThe surrounding environment protection effect is goodExcavationsEnvironmental geologyStructure of the Earth

The invention discloses a synchronous excavation supporting system for a deep and large asymmetric pit in a soft soil area and an implementation method of the supporting system. The deep and large asymmetric pit consists of a deep area and a shallow area which are internally close to each other, the top elevation of an enclosure structure at the junction of the deep area and the shallow area is a substrate of the shallow area, the total pit is provided with a first horizontal support in a unified way, the deep area is additionally provided with a plurality of deep-area horizontal supports, a soil body platform used for balancing the horizontal transfer force of the deep-area horizontal supports is reserved at the junction of the interior of the shallow area and the deep area, and two sides of the soil body platform are sloped to the substrate of the shallow area, so that open excavation and bottom-up construction in the deep area and the shallow area can be synchronously carried out, the problem of imbalance of the internal force and the deformation of the pit caused by an asymmetric excavation mode due to function requirements is solved, and the asymmetric pit can be excavated in a safe, reliable, economic and environment-friendly mode; through the synchronous excavation of the deep area and the shallow area, the construction period can be effectively shortened, and the construction cost is reduced; moreover, the supporting system is definitely stressed, the horizontal force of each horizontal support additionally arranged in the deep area is reliably transferred, and the construction feasibility is high.

Owner:SHANGHAI CONSTRUCTION GROUP

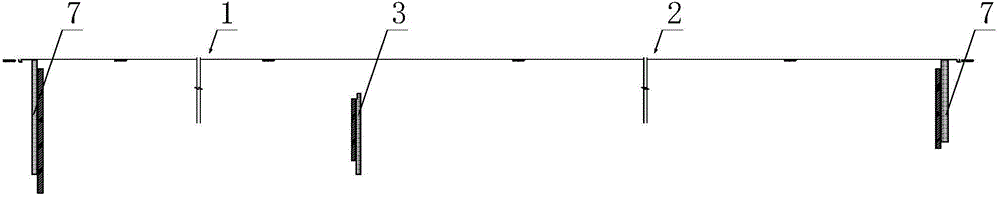

Safe and fast construction method of down-traversing river shallow depth bored tunnel

InactiveCN104631475AReduce vertical infiltrationReduce moisture contentUnderwater structuresTunnelsCofferdamFluvial

The invention discloses a safe and fast construction method of a down-traversing river shallow depth bored tunnel. The method includes the steps that on the two sides of the tunnel, the upstream and the downstream of a river are each provided with a clay cofferdam so that the river can be intercepted, and a dry river bed is formed in a tunnel construction area; the two constructed clay cofferdams are communicated through a flow guiding pipe, and therefore upstream river water and downstream river water can flow; the two sides of the tunnel are each provided with at least one row of Larsen steel plate piles, and the tunnel is excavated after the Larsen steel plate piles extend to a river bank in the axial direction of the tunnel. The clay cofferdams, the flow guiding pipe and the Larsen steel plate piles are matched coordinately and comprehensively utilized, and tunnel construction safety is guaranteed by the clay cofferdams, the flow guiding pipe and the Larsen steel plate piles jointly. The method is good in construction safety and high in construction efficiency, treatment measures are flexible, pertinent adjustment can be performed according to different geological conditions, and manufacturing cost of projects is saved as much as possible on the premise that safety is guaranteed.

Owner:中铁隧道局集团有限公司市政工程公司

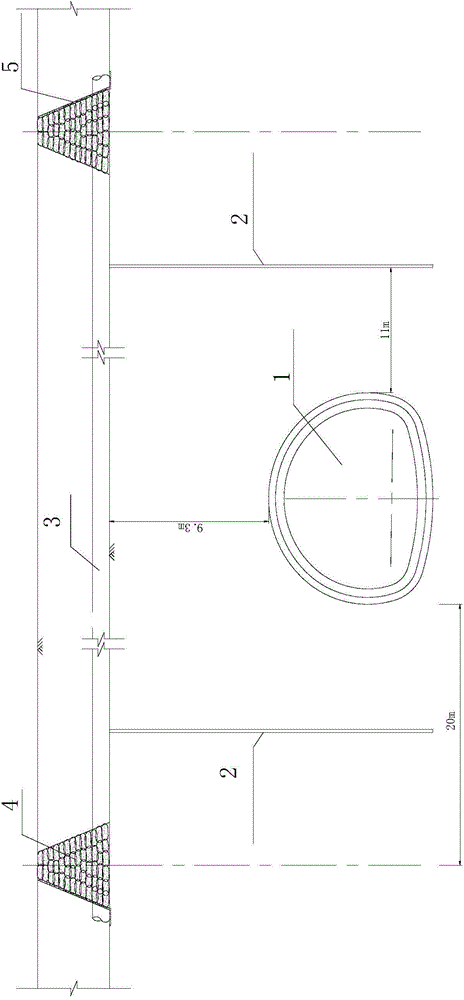

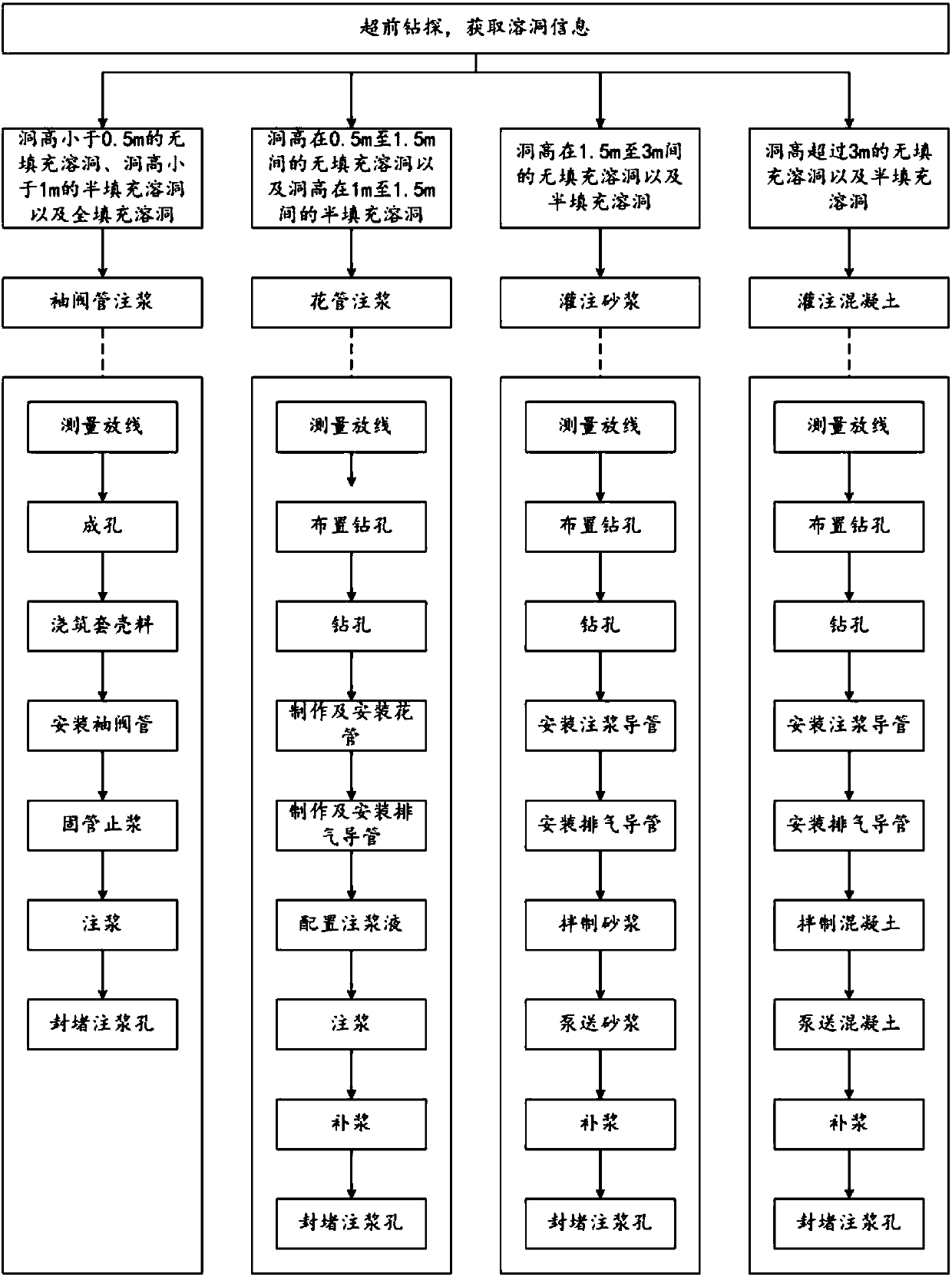

Karst cave treatment method applied to karst area cast-in-situ bored pile construction

The invention relates to a treatment method of karst caves with different sizes and types applied to karst area cast-in-situ bored pile construction. Firstly, the depths and the heights of the karst caves at pile positions are obtained by adopting an advance drilling technology; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being higher than 3 mby adopting a concrete pouring method; treatment is conducted on non-filled karst caves and semi-filled karst caves with the cave heights being between 1.5 m and 3 m by adopting a mortar pouring method; treatment is conducted on non-filled karst caves with the cave heights being between 0.5 m and 1.5 m and semi-filled karst caves with the cave heights being between 1 m and 1.5 m by adopting a screen pipe grouting method; and treatment is conducted on non-filled karst caves with the cave heights being lower than 0.5 m and semi-filled karst caves and full-filled karst caves with the cave heights being lower than 1 m by adopting a sleeve valve pipe grouting method. The karst cave treatment method can conduct treatment on the different types of karst caves well.

Owner:CHINA FIRST METALLURGICAL GROUP

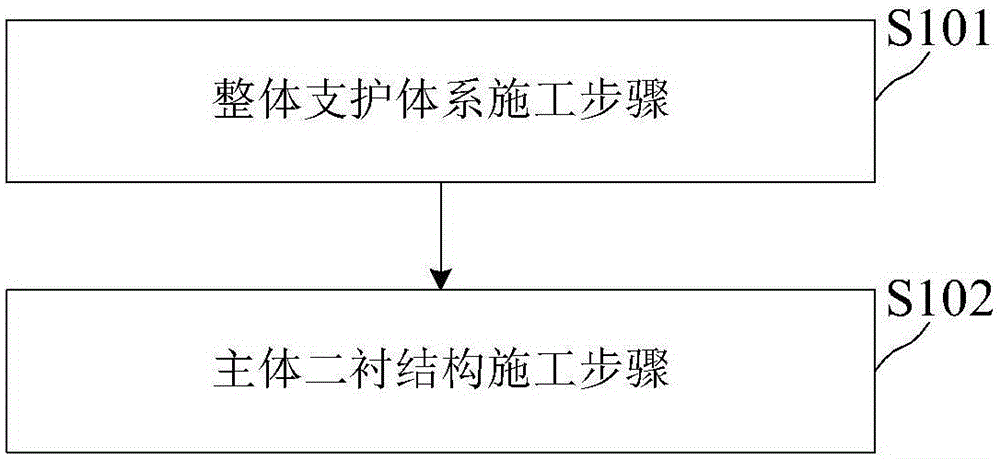

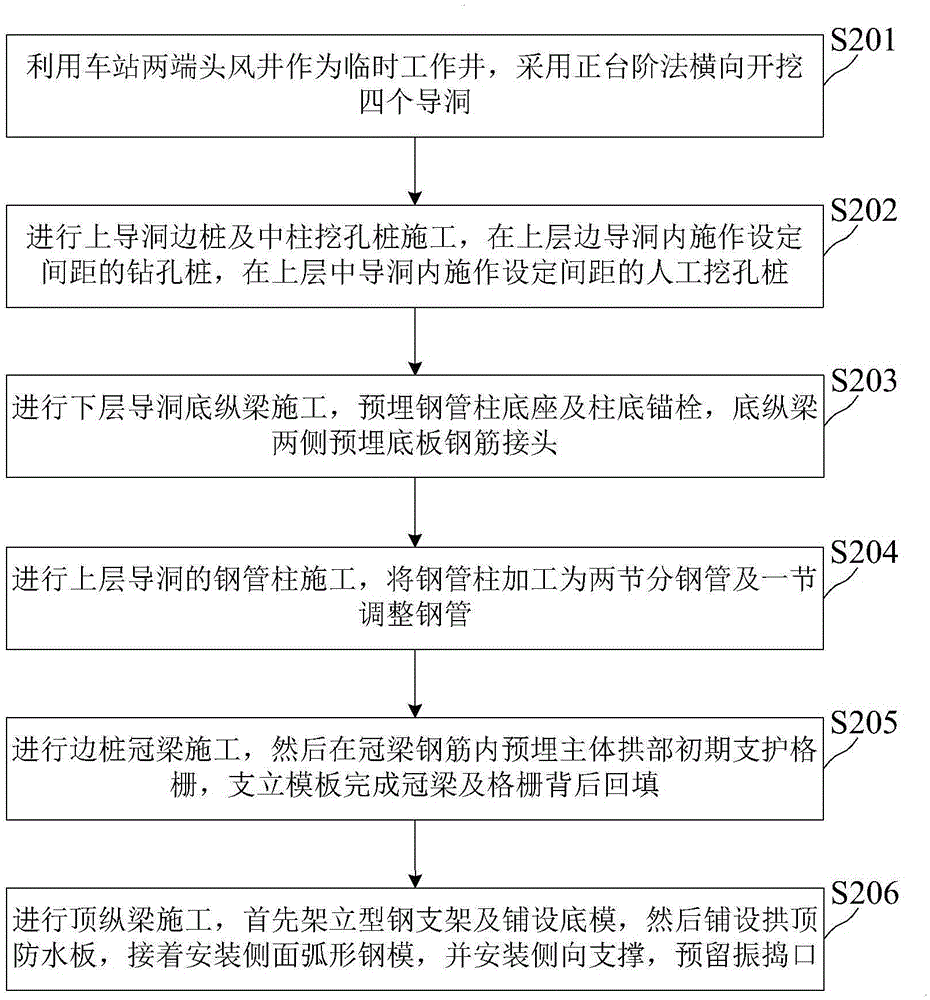

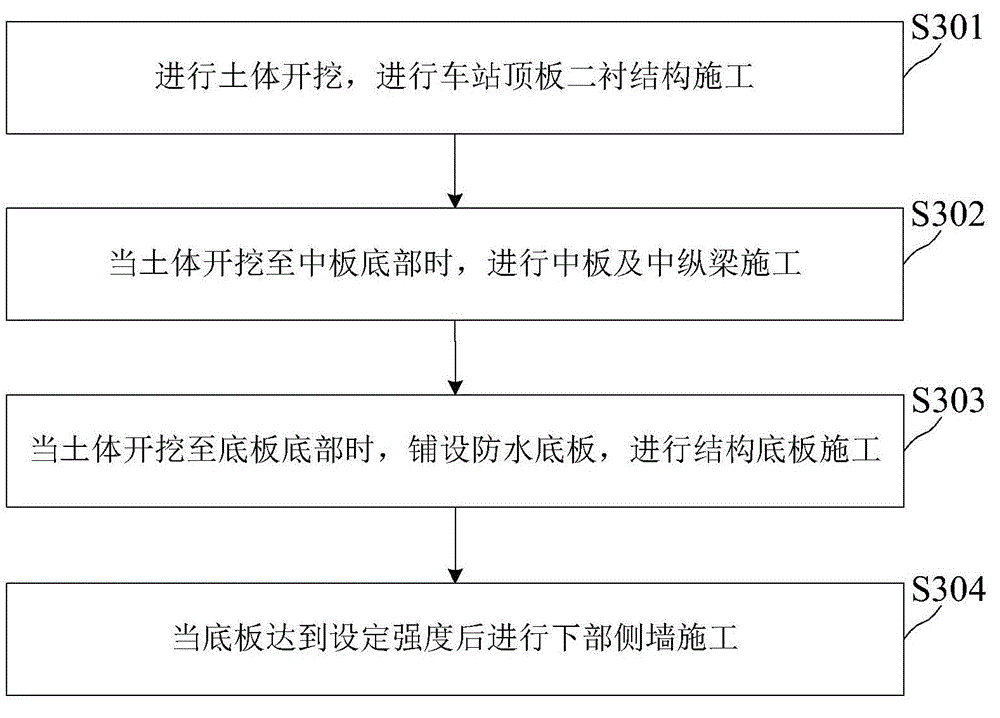

Mined metro station hole pile construction method

ActiveCN106703814AReduce the impact of settlementSave masonryUnderground chambersTunnel liningSupporting systemMetro station

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

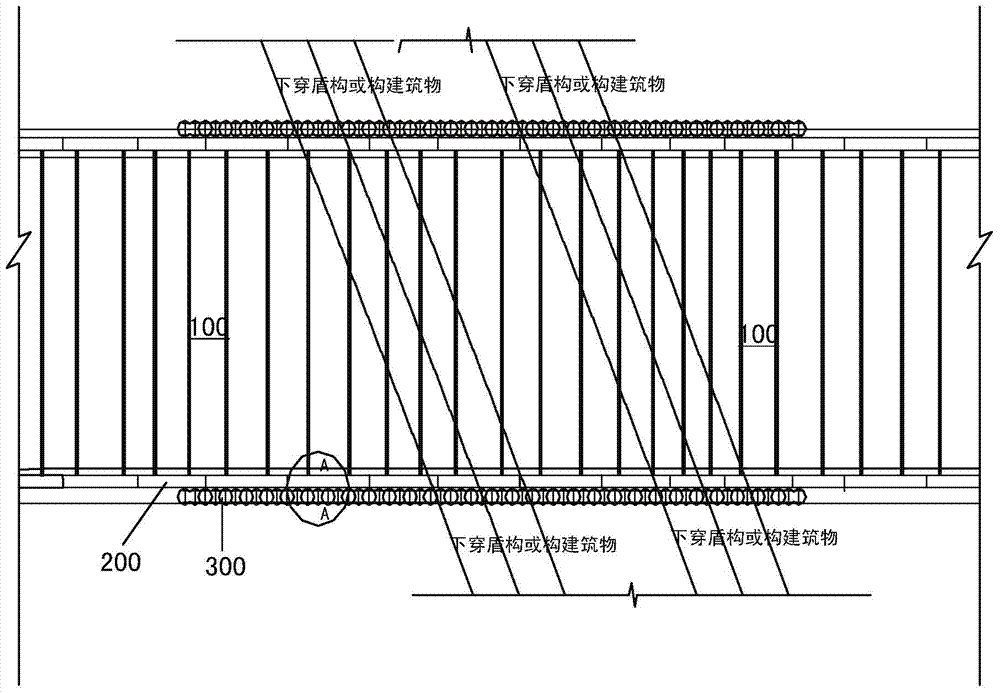

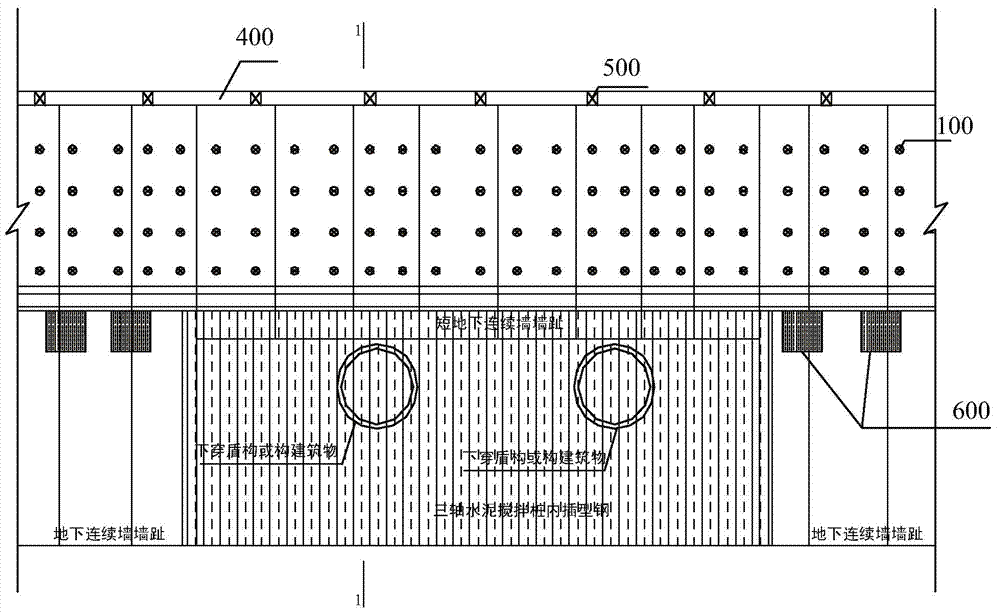

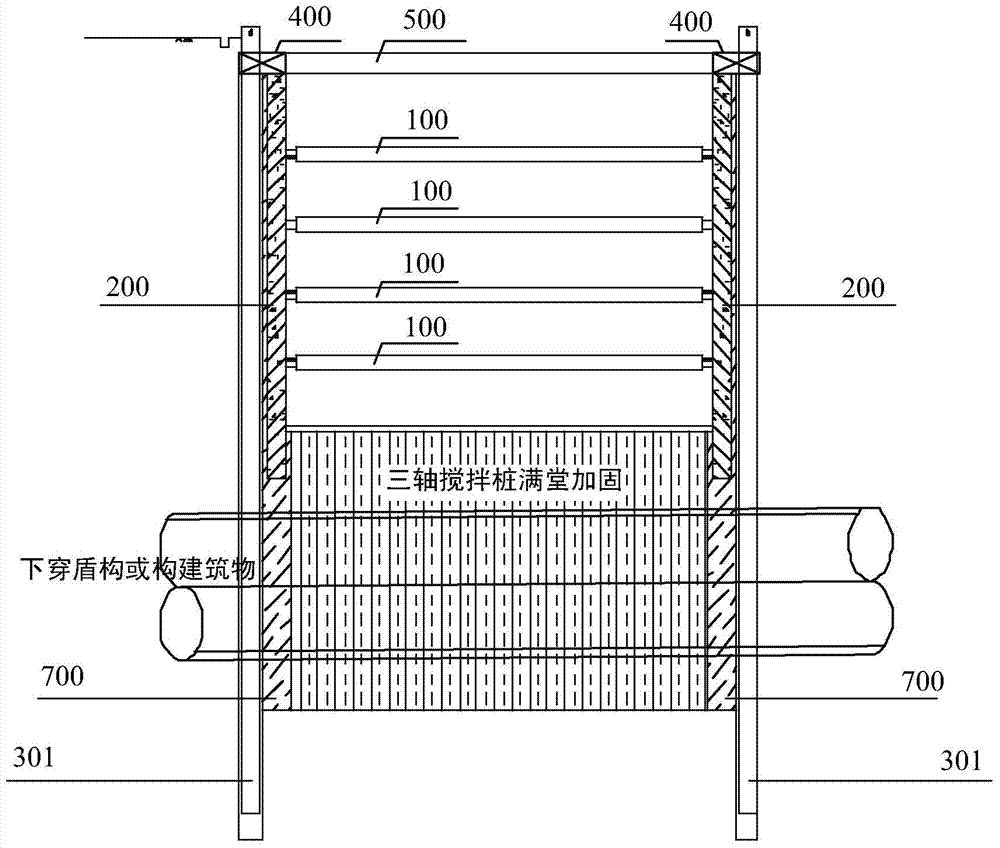

Shield-reserved penetration composite type foundation pit support wall and construction method thereof

ActiveCN104846829AMature construction technologyReduce the impactExcavationsBulkheads/pilesSupporting wallHigh pressure

The invention provides a shield-reserved penetration composite type foundation pit support wall and a construction method of the support wall. The support wall can effectively reduce the influence of construction of rail transit underground engineering in the front period on the later-period shield-reserved excavation construction. In order to solve the technical problem, the shield-reserved penetration composite type foundation pit support wall is characterized by comprising a short underground continuous wall and a stirring pile which is externally placed relative to the short underground continuous wall and used for reinforcing the continuous wall; structural steel is inserted in the stirring pile, and the short underground continuous wall is located above a shield-reserved penetration area; the position between the short underground continuous wall and the stirring pile is filled with a high-pressure rotary spraying pile, and the depth of the high-pressure rotary spraying pile exceeds that of the lower portion of the penetration area and meanwhile exceeds a shallow pressure bearing water layer, and the stirring pile is adopted by the support wall for internal reinforcing; and the position between an internal reinforced part and the short underground continuous wall is filled by a high-pressure rotary spraying pile.

Owner:宏润建设集团上海有限公司

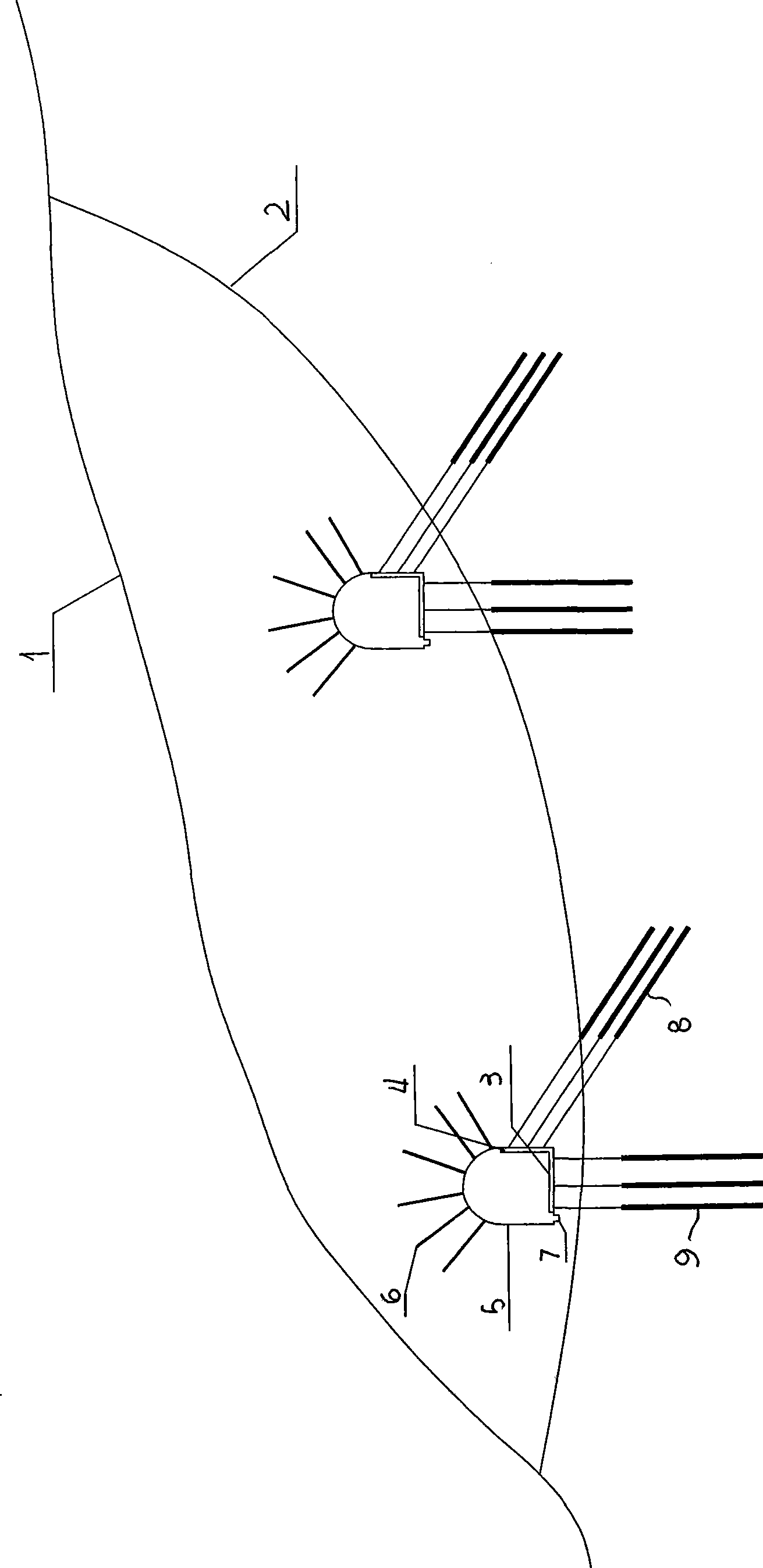

Giant heavy laver land slide pre-stress anchor cable antiskid tunnel construction method and novel prevention structure

InactiveCN101476466ARealize engineering prevention and controlThe prevention and control structure construction is feasibleUnderground chambersTunnel liningReinforced concretePre stress

The invention relates to a method for constructing a prestress anchor rope anti-skid tunnel on a thicker layer landslide. The method comprises the following steps: carrying out on-site investigation, examination and engineering geologic investigation of the thicker layer landslide; confirming corresponding situation like the slip surface position of the thicker layer landslide and the like; calculating through the landslide thrust; carrying out the prestress anchor rope anti-skid tunnel design prior to the space position laid out by the prestress anchor rope according to the landslide thrusting force under the most unfavorable load assembling conditions; constructing from both sides of the landslide body section by section, and minimizing the section length; casting a rib post and a ground beam of reinforced concrete in place on the mountain side of the tunnel and the ground, and casting linings of the reinforced concrete in place at other positions; laying out the prestress anchor rope on the rib post and the ground beam, and making the anchor rope pass through the mountain landslide surface. An anchor is fixed in the stable and hard terrane. The top arc of the tunnel is provided with a water draining hole, and the bottom is provided with a drainage ditch. The construction method can improve the stability of the thicker layer landslide and has the advantages of economy, expeditiousness, convenience and safety.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

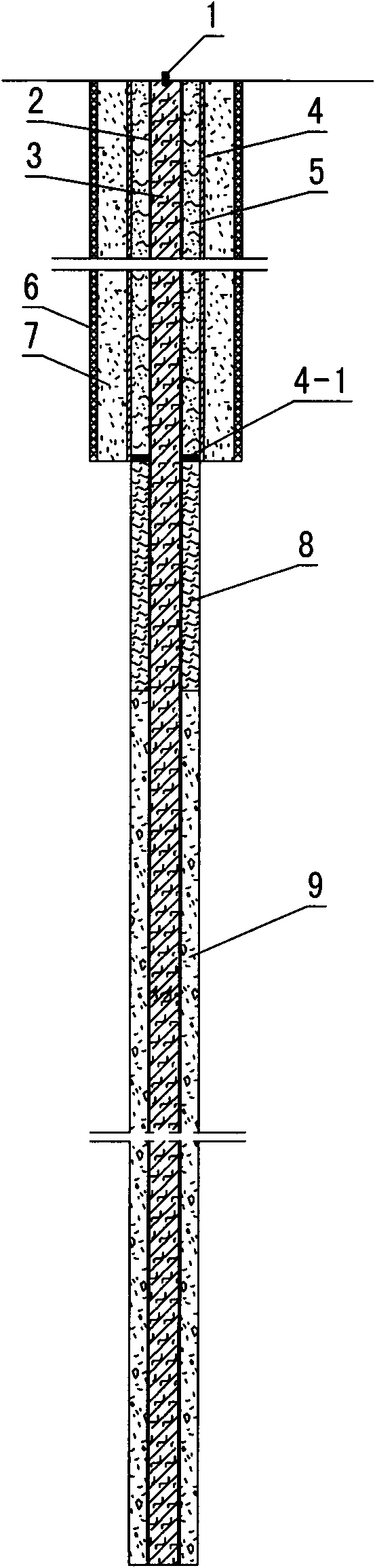

Deep-embedded pile for plane vertical control point at freeze-thaw area and embedding method of deep-embedded pile

ActiveCN102465525AGuaranteed target stabilityReduce tangential frost heaving forceMeasuring points markingBulkheads/pilesFreeze thawingSurface layer

The invention relates to a deep-embedded pile for plane vertical control point at a freeze-thaw area and an embedding method of the deep-embedded pile. A marker post consists of a steel protection tube and a cement protection tube at the upper part of the marker post, a fine-sand filled layer between the steel protection tube and the cement protection tube, a slide structure between the steel protection tube and the marker post, a cement-mortar protection layer of the marker post, a button stem and a slurry surface layer. The embedding method comprises the steps of upper pile hole excavation, cement protection tube embedding, drilling, marker post placement, cement mortar filling, slide structure arrangement, fixed base point mark measuring and the like. The tangential frozen-heave force can be reduced obviously by the slide structure of the deep-embedded pile, the cement-mortar protection layer of the marker post which is capable of removing bad holes, and the button stem of the marker post. The frozen-heave phenomenon is almost not generated in the fine-sand filled layer in the freezing process in the condition of fully water-saturation. The test proves that the thaw settlement amount can be controlled within the permissible range in both of the thaw area and the strong thaw area by using the deep-embedded pile, especially the embedding depth of the marker post can be adjusted to the gravel soil layer under the freezing depth according to the freezing depth, and the tangential frozen-heave force of the embedding depth of the marker post is nearly close to zero.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

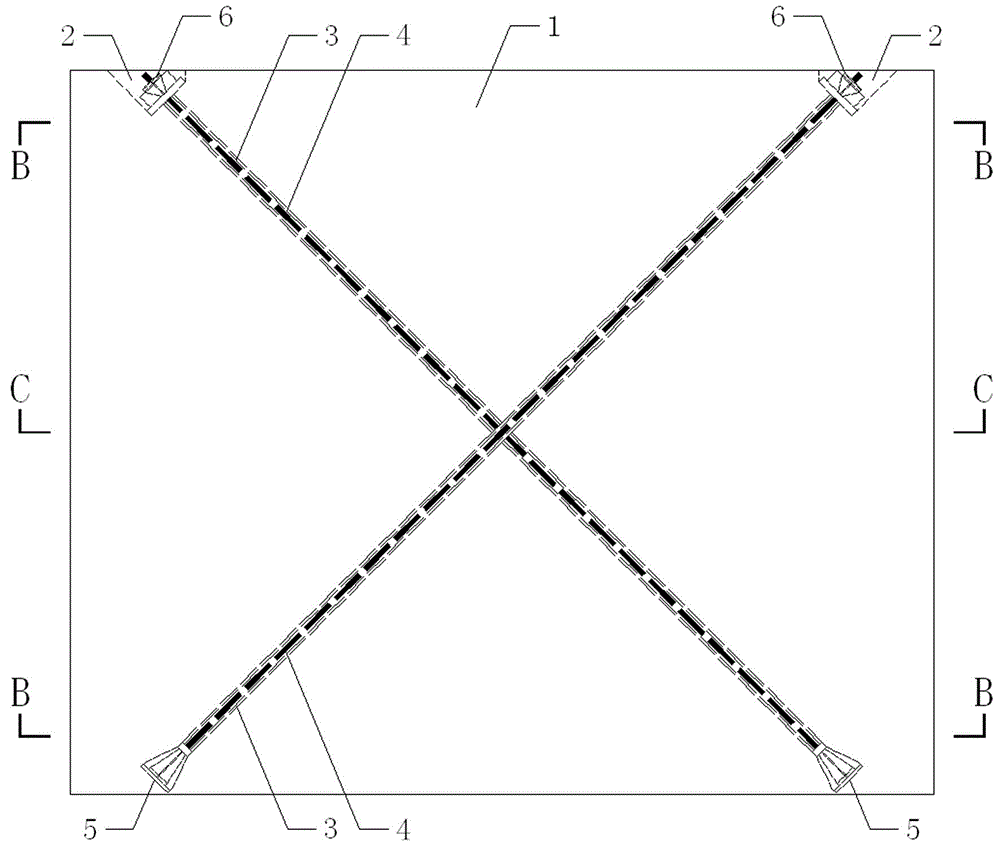

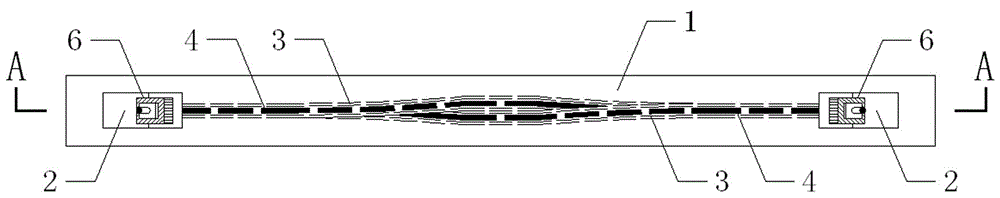

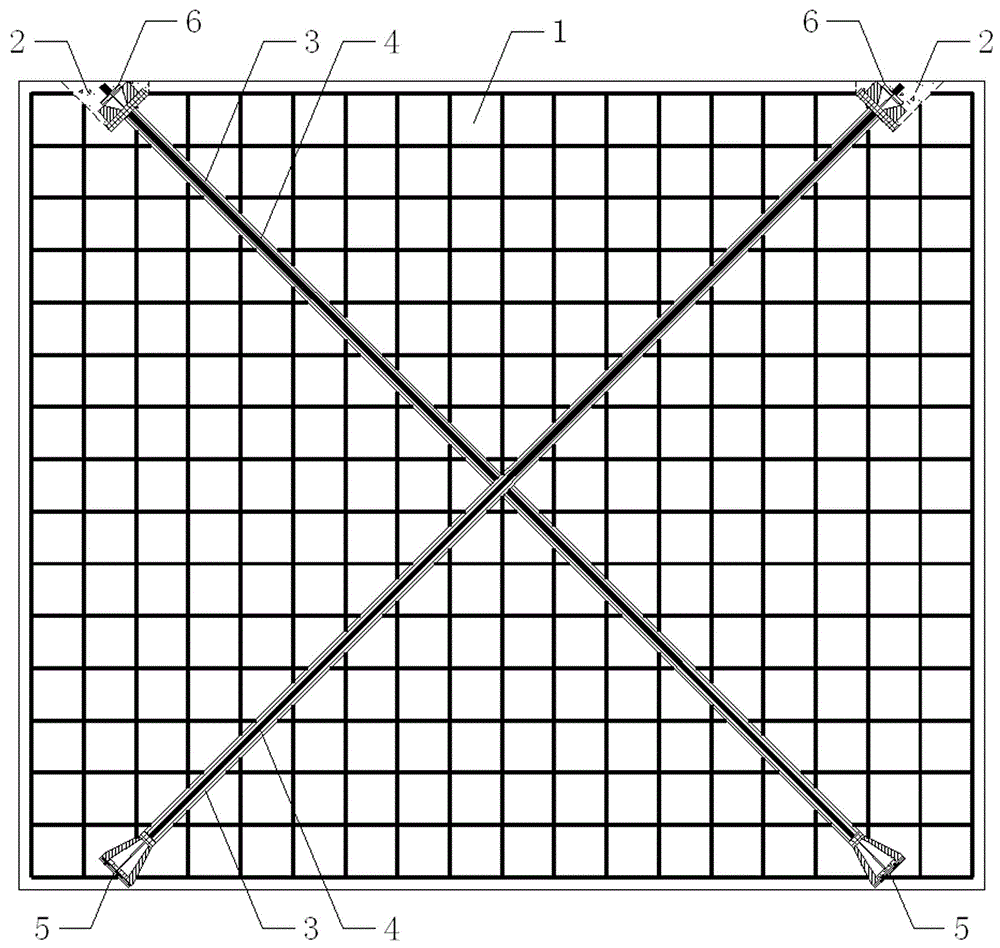

Shear wall structure configured with crossed slant internal prestress and construction method of shear wall structure

InactiveCN102979221ADirect forceReduces the likelihood of crossing oblique cracksWallsBuilding material handlingRebarPre stress

The invention relates to a shear wall structure configured with crossed slant internal prestress. The shear wall structure comprises a shear wall body, horizontal steel bars of the shear wall body and vertical steel bars of the shear wall body, wherein a shear wall tooth plate and a prestress tension end anchor tool are respectively arranged at the left upper corner and the right upper corner of the shear wall body, prestress anchoring end anchor tools are respectively arranged at the left lower corner and the right lower corner of the shear wall body, and a crossed slant prestress steel beam and a crossed slant prestress pipeline are arranged between the prestress anchoring end anchor tool and the prestress tension end anchor tool at the opposite corners. A construction method of the structure comprises steps of shear wall template erection and binding of ordinary steel beams of the wall body; crossed slant prestress pipeline arrangement and installation; prestress steel beam penetration and prestress anchor tool installation; shear wall concrete casting and maintenance; and prestress tension, pipeline grouting and end part anchor sealing. The shear wall structure greatly improves the anti-seismic performance of the shear wall.

Owner:ZHENGZHOU UNIV

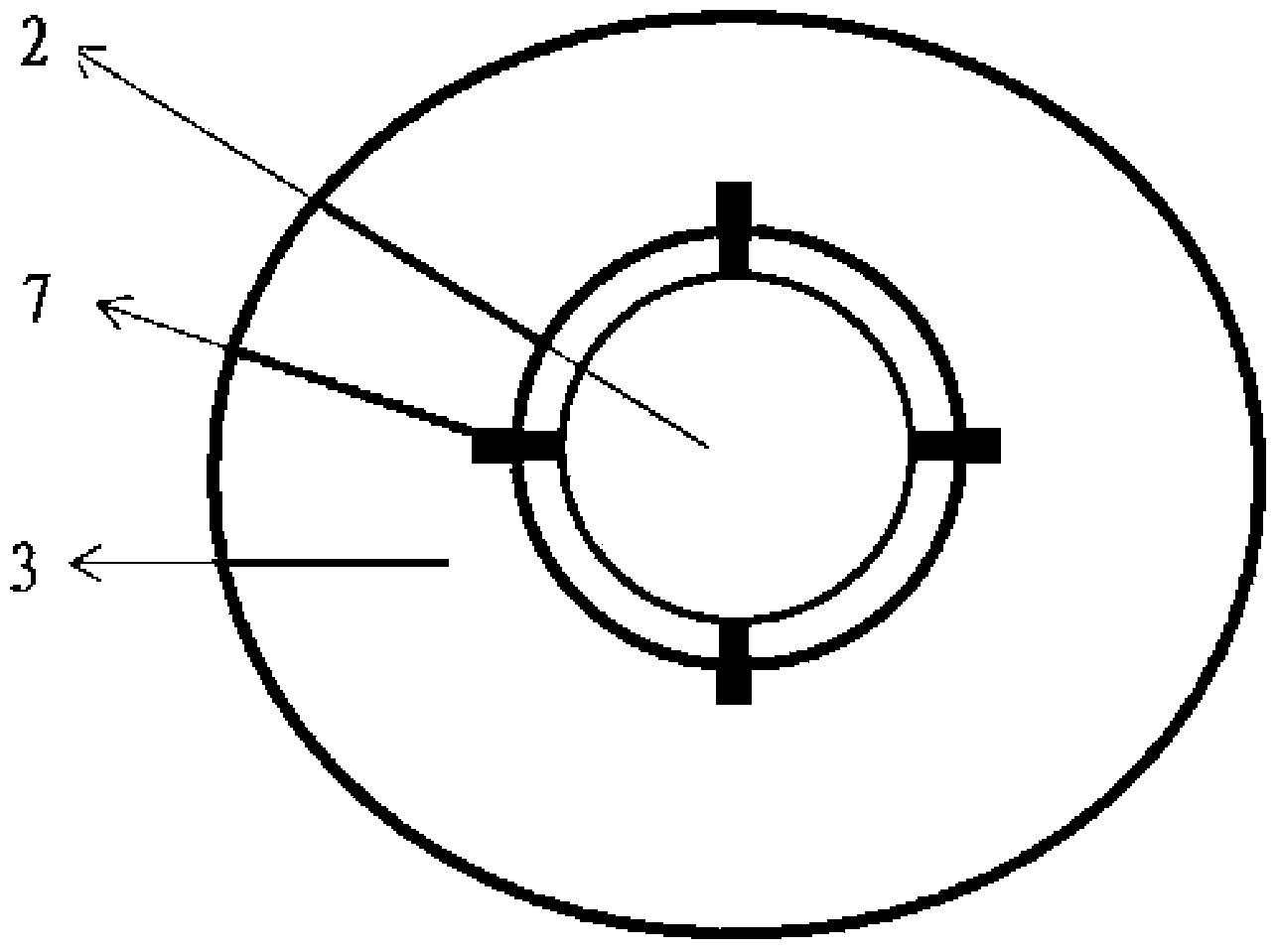

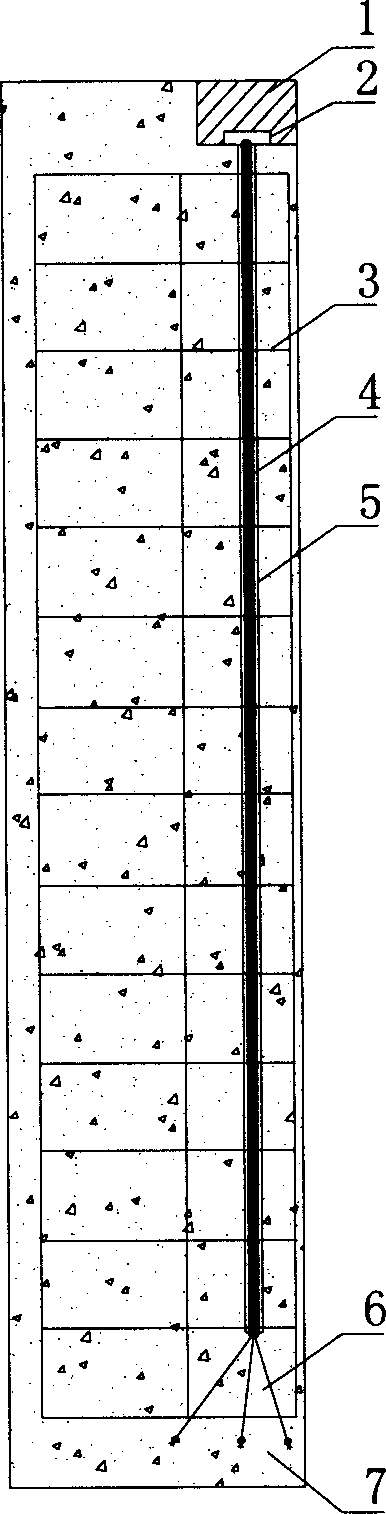

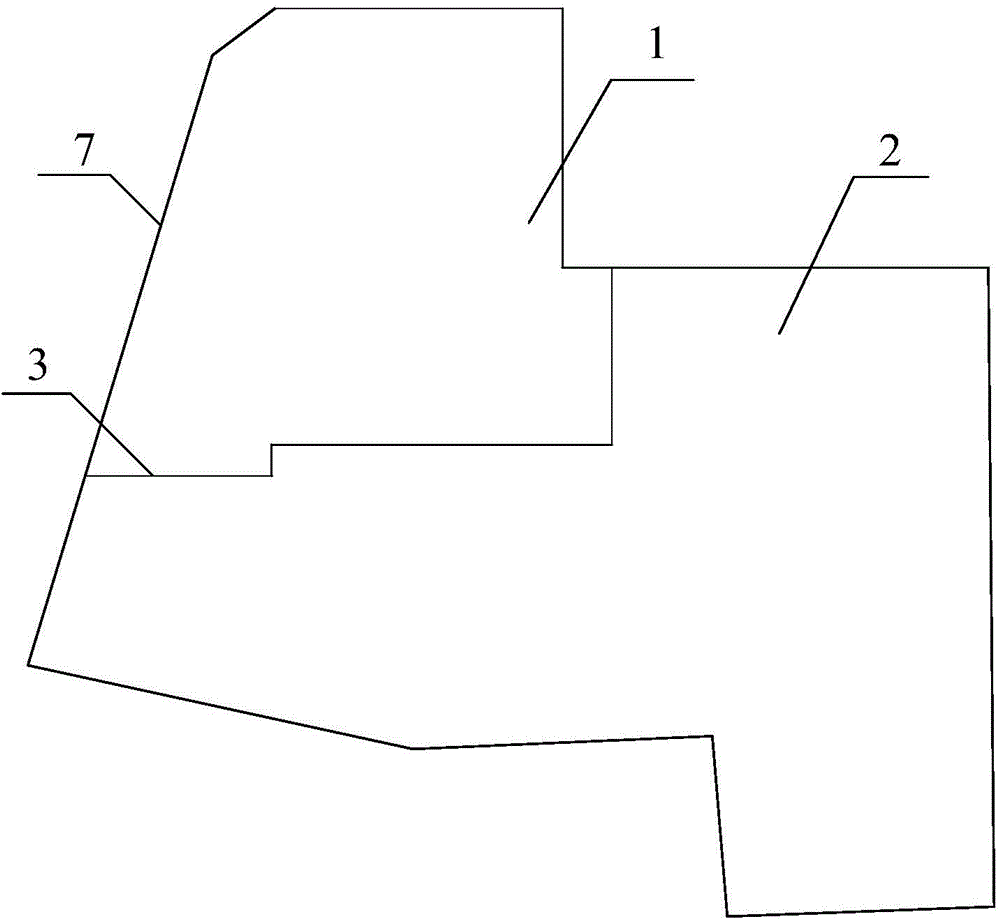

Novel energy-saving anti-floating pile

The invention provides a novel energy-saving anti-floating pile, which comprises a cement pile body. An anti-pulling rib body, a pile tip, anchoring plates and a protective tube are embedded in the pile body, and are connected together; the anti-pulling rib body is connected with a base plate of a structure, and transmits the anti-floating force provided by the anti-floating pile to the base plate of the structure to realize the anti-floating of an underground building. Large anti-floating force can be acquired through large friction force between a large-diameter rotary-jet mixing pile body and foundation soil. The protective tube is adopted to protect the anti-pulling rib body, and the durability of the anti-pulling rib body is greatly improved; and the anti-pulling rib body is made of a high-strength material, so steel can be saved. In addition, the anti-floating rib material is connected with a plurality of anchoring plates, and the binding power between the anti-floating rib material and the rotary-jet mixing pile body is greatly increased, so that several problems of the conventional anti-floating pile are effectively solved, the construction period is effectively shortened,and the engineering cost is reduced.

Owner:SHANGHAI STRONG FOUND ENG

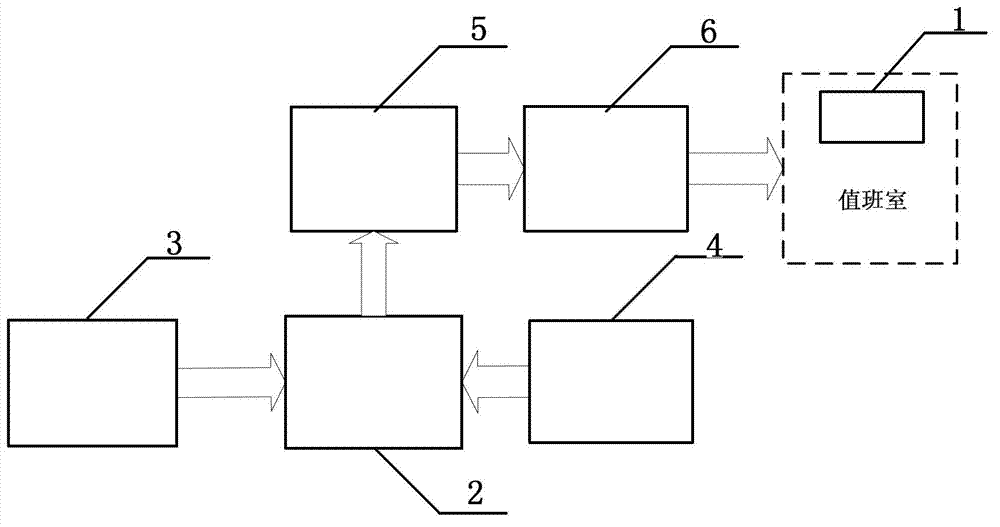

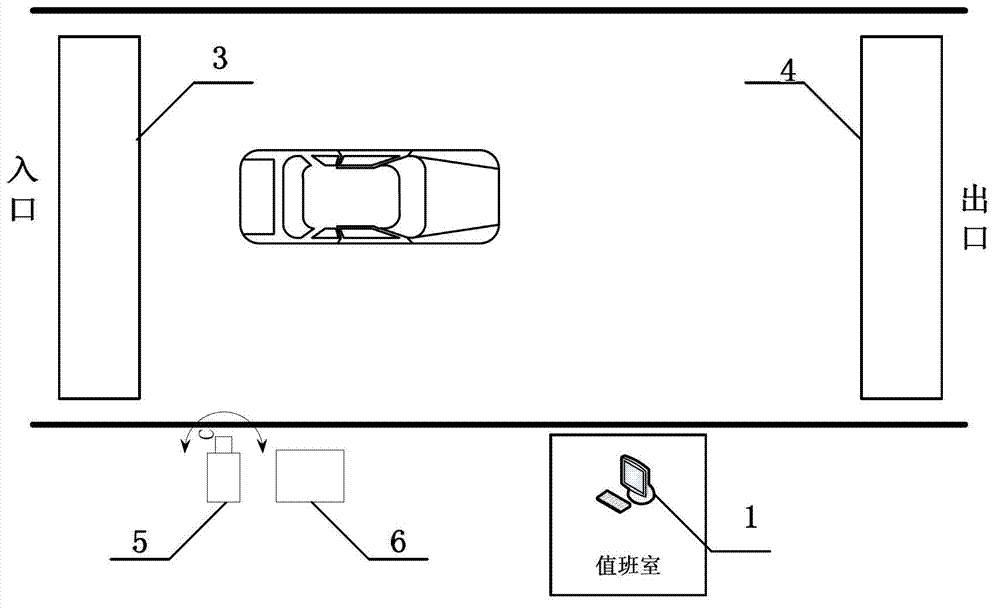

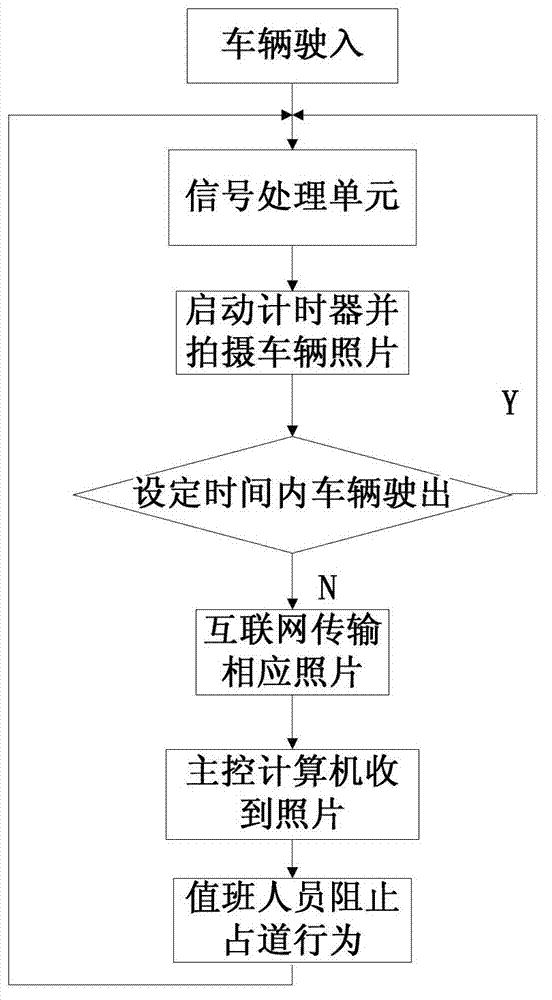

System and method for detecting road occupation of automotive vehicle on fire-fighting access

ActiveCN103077612AMature construction technologyImprove accuracyRoad vehicles traffic controlTime differenceSignal processing

The invention discloses a system for detecting road occupation of an automotive vehicle on a fire-fighting access. The system comprises an entrance ground induction coil arranged at an entrance of the fire-fighting access, an exit ground induction coil arranged at an exit of the fire-fighting access, a signal processing unit connected with the entrance ground induction coil and the exit ground induction coil, a vidicon connected with the signal processing unit, a local computer connected with the vidicon and the signal processing unit, and a remote main controlled computer interactively communicated with the local computer. The invention also provides a detection method based on the system. Compared with the prior art, with the adoption of the system and the method, whether a vehicle occupies a road or not through time difference that the automotive vehicle runs into the fire-fighting access, and runs out of the fire-fighting access, so that the accuracy is higher, meanwhile, the driving in and out accuracy of the automotive vehicle induced by the induction coil is high, the construction technique of an underground coil is mature, and the whole system is convenient to install and use.

Owner:嘉兴卓十生物科技有限公司

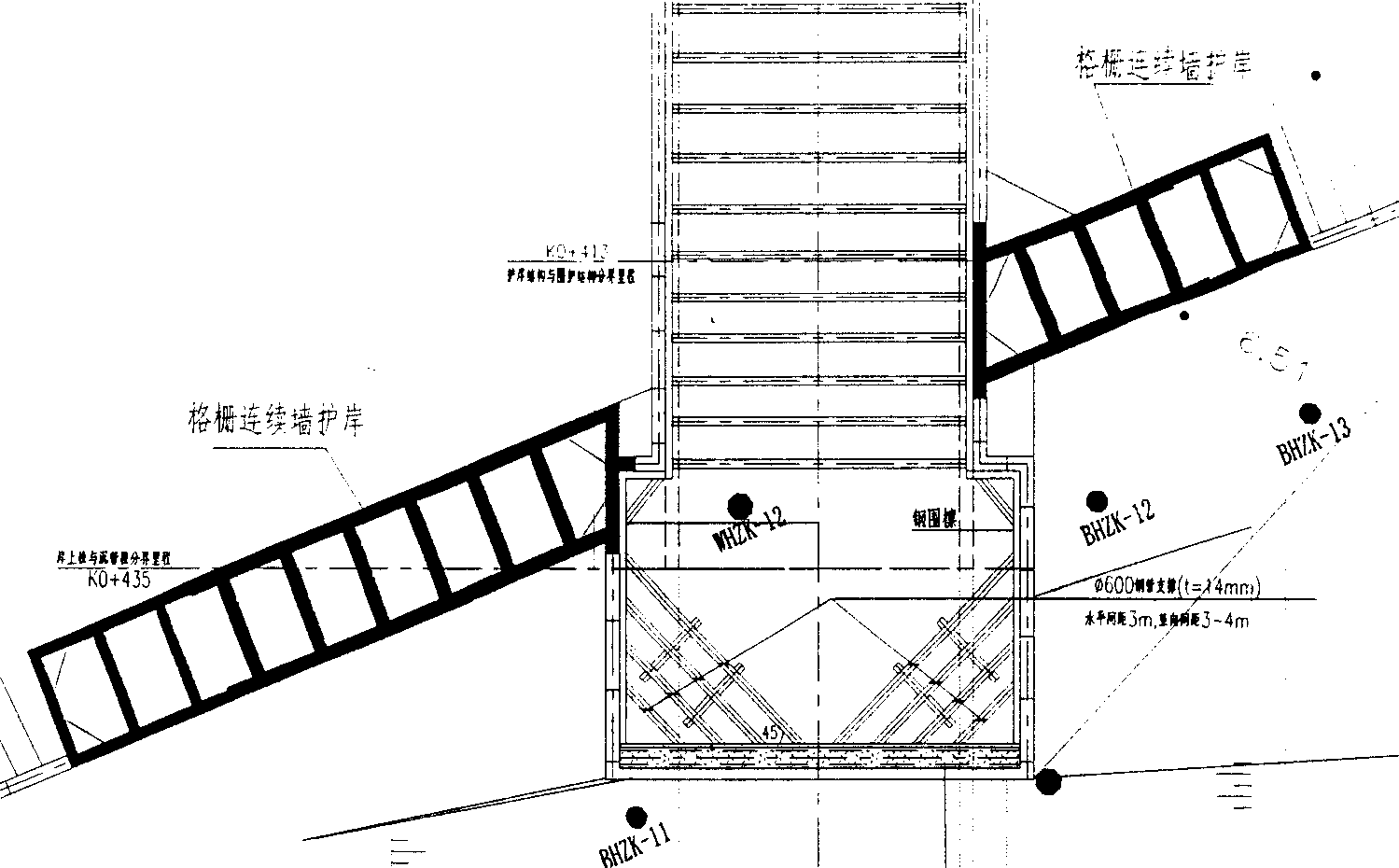

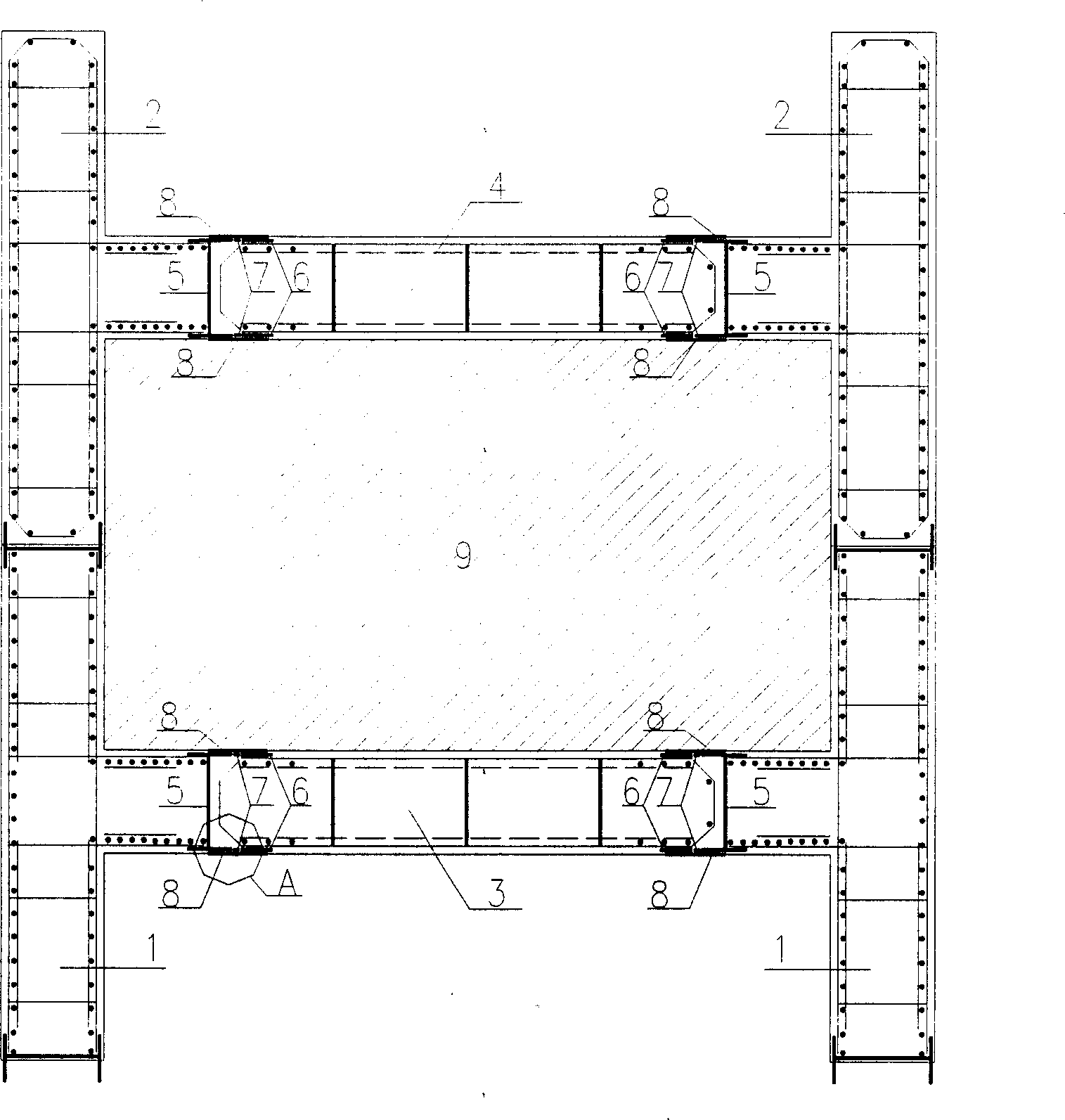

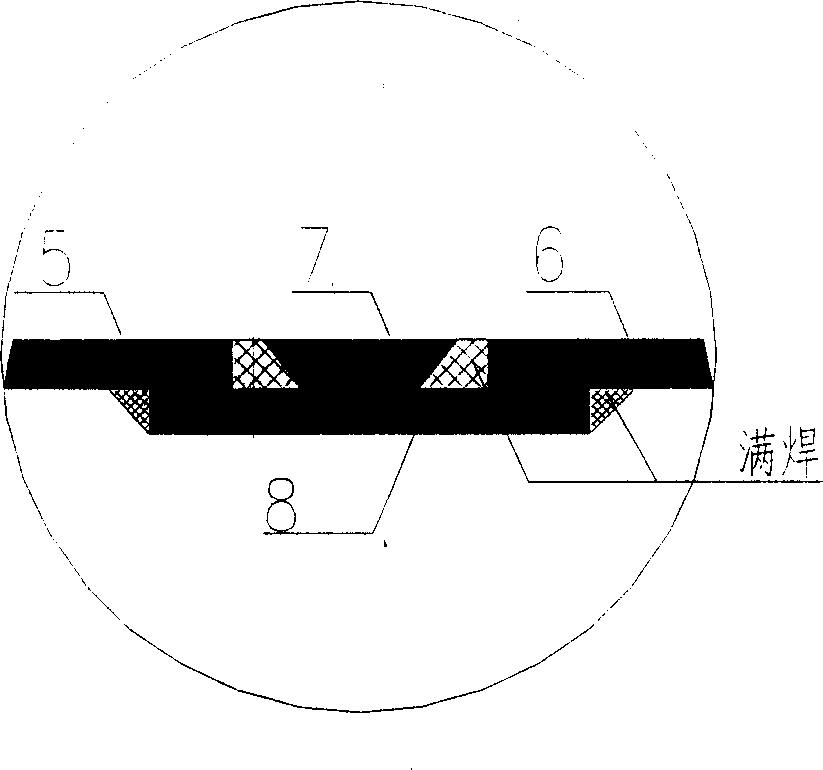

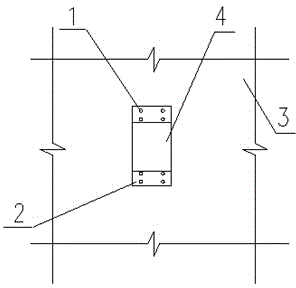

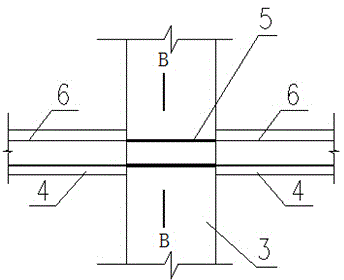

Grille type connection method of rigid joint for underground continuous wall

ActiveCN1884722ASimple construction processMature construction technologyArtificial islandsBreakwatersSlurry wallSteel bar

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

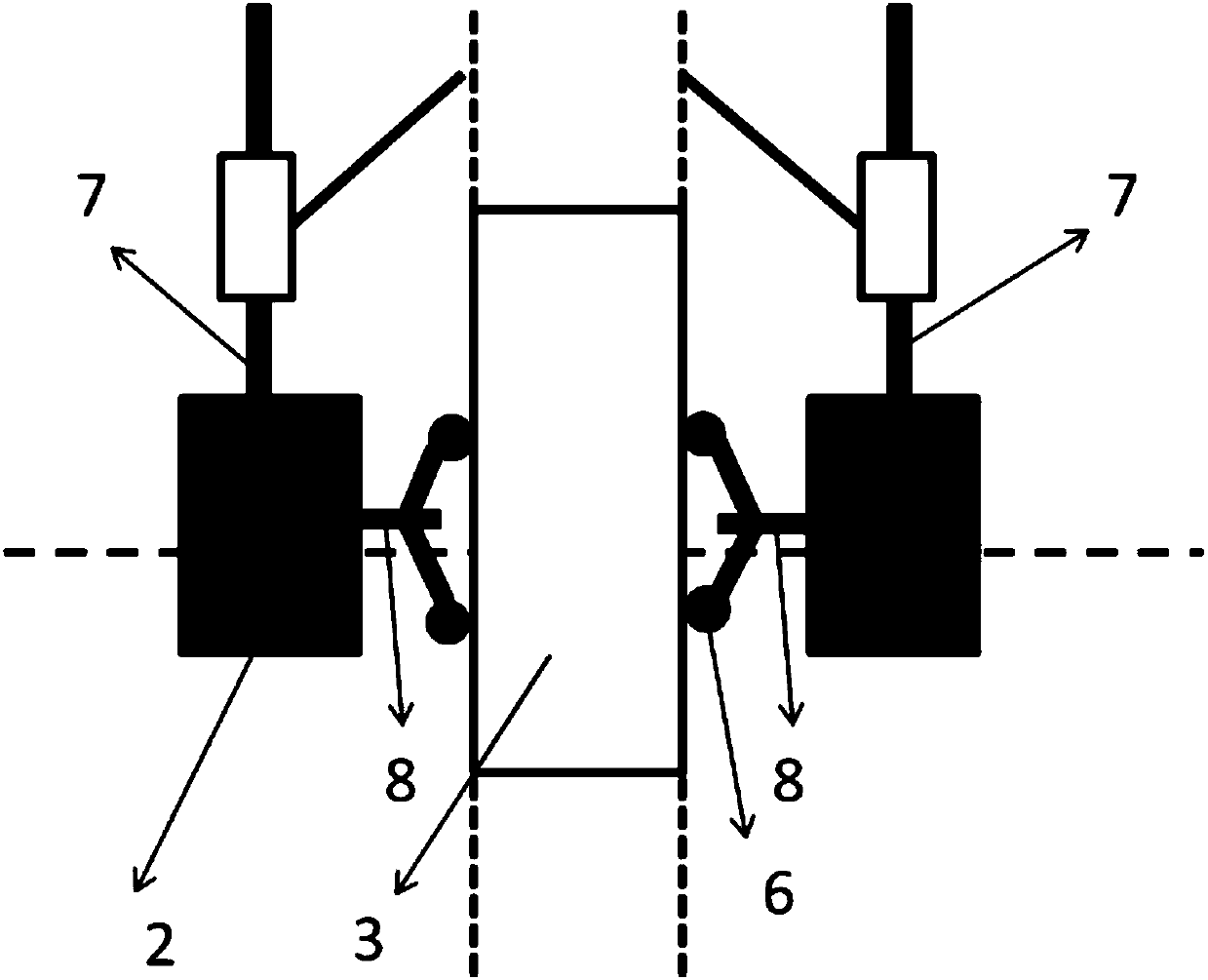

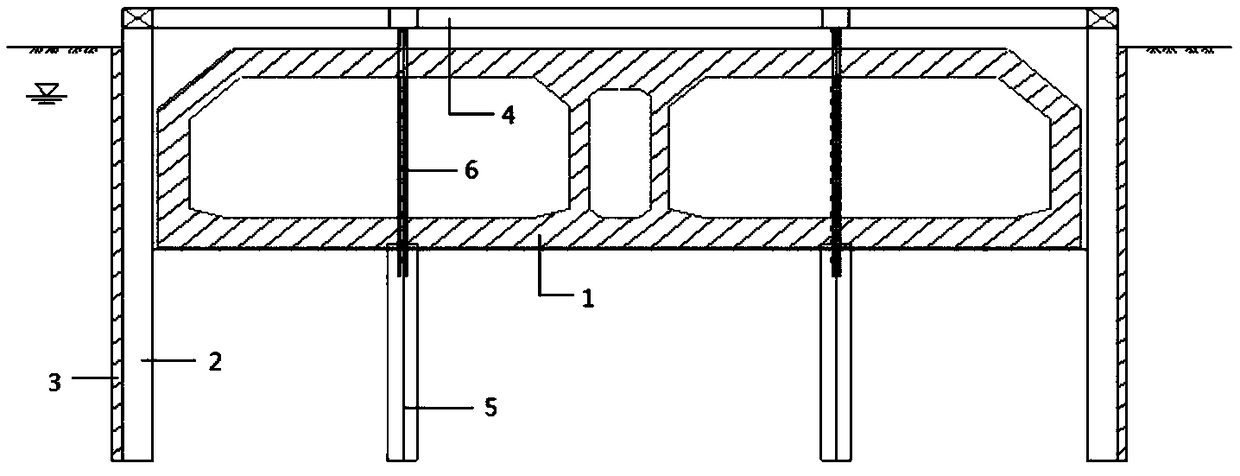

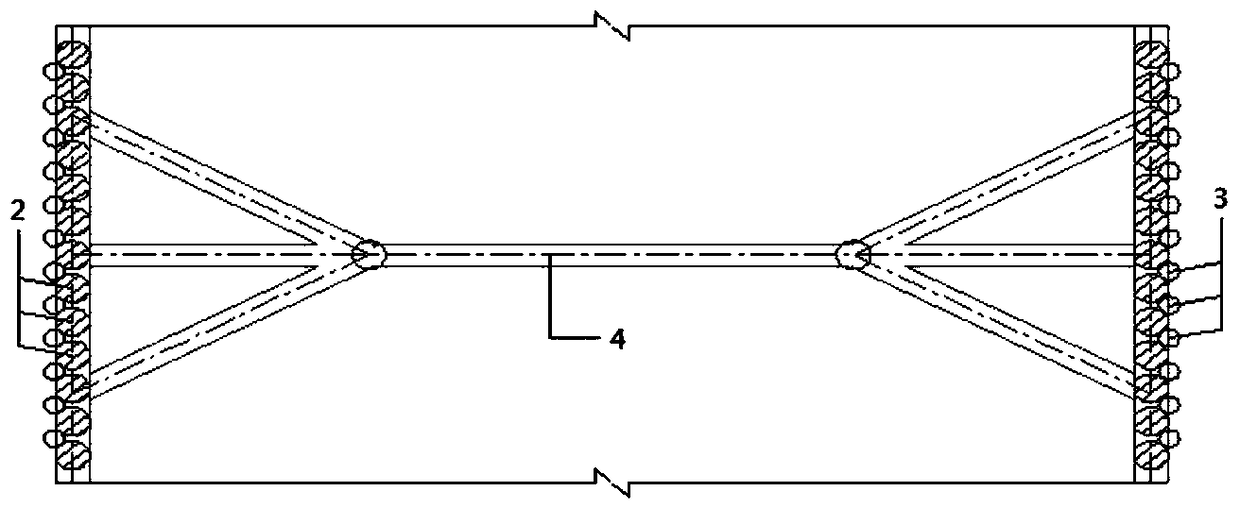

Cable-stayed immersed tunnel structure and method

PendingCN107663865AIncrease the scope of applicationReduce instability damageArtificial islandsUnderwater structuresTunnel constructionEngineering

The invention discloses a cable-stayed immersed tunnel structure and a method, and solves the problem in the prior art that a great quantity of manpower, equipment and financial resources need to be input for immersed tunnel structure construction. The cable-stayed immersed tunnel structure has the beneficial effects that the cable-stayed immersed tunnel structure can be effectively suitable for bad geological conditions including soft riverbeds, seabeds and the like and is adjustable. The cable-stayed immersed tunnel structure has the following scheme that the cable-stayed immersed tunnel structure comprises multiples sections of immersed tubes, wherein two sides of each section of immersed tube are respectively fixedly provided with a pile foundation vertical to the surface of the immersed tube; the pile foundation and the immersed tubes are connected through multiple stay cables; the stay cables are symmetrically arranged on two sides of the pile foundation and are aslant arranged.

Owner:SHANDONG UNIV

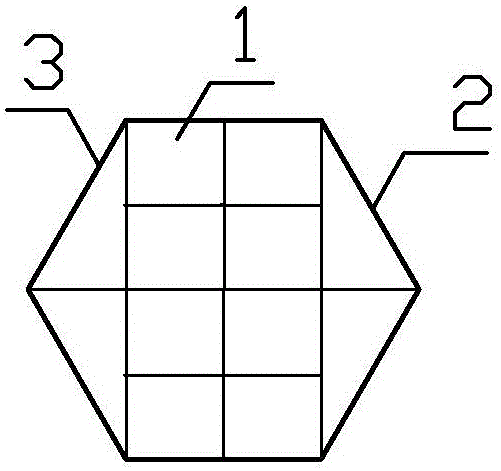

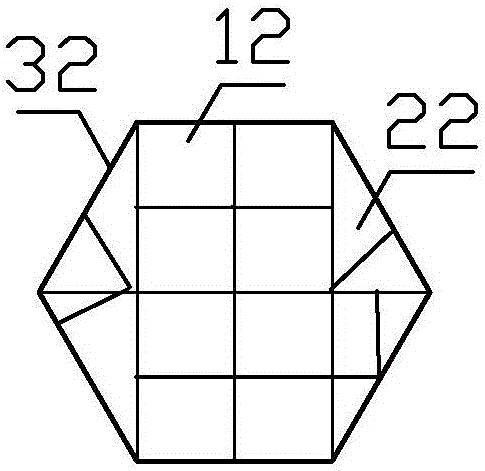

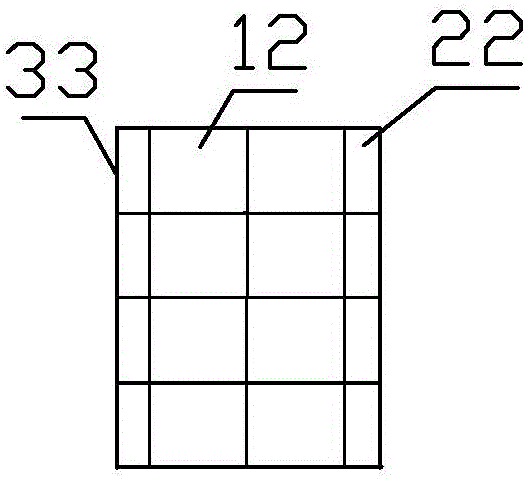

Construction method of honeycomb-shaped convex irregular curtain wall

The invention discloses a construction method of a honeycomb-shaped convex irregular curtain wall. The construction method is used for constructing a honeycomb-shaped convex irregular curtain wall integral structure. The honeycomb-shaped convex irregular curtain wall integral structure is formed by combining P glass curtain wall assemblies. The glass curtain wall assemblies include the orthohexagonal curtain wall assemblies and the triangular honeycomb-shaped glass curtain wall assemblies. During construction, every two planar triangular glass curtain walls with different sizes are connected equilaterally, so that the honeycomb-shaped convex irregular curtain wall integral structure is formed; and the value range of P is that P is an integer which is larger than three. The construction technological process comprises the steps of preparation before construction, embedding of iron pieces, installation of connecting pieces, positioning and setting-out of a vertical beam, installation of adaptor pieces, installation of the vertical beam, positioning of the storey height and a cross beam, positioning and installation of cross beam corner braces, namely adaptor pieces for the cross beam and the vertical beam, installation of the glass curtain wall assemblies, and construction of the grating curtain wall. According to the construction method, the technique is mature; and the construction method has the advantages that the construction difficulty can be lowered, the construction speed can be increased, and the construction cost can be reduced.

Owner:广西建工第五建筑工程集团有限公司

Three axes agitating pile construction method capable of assisting in grooving of reinforced underground diaphragm wall

ActiveCN105696550AMature construction technologyEasy constructionExcavationsBulkheads/pilesSlurry wallInjection pressure

The invention discloses a three axes agitating pile construction method capable of assisting in grooving of a reinforced underground diaphragm wall. The construction method is characterized by comprising the following technological steps that a, the range of a reinforced target of three axes agitating piles is determined; b, the reinforcing depth of the three axes agitating piles is determined; c, the distance between an inner reinforcing pile body and an outer reinforcing pile body of the three axes agitating piles is determined; d, guide wall construction is conducted according to a construction technique of an ordinary underground diaphragm wall; e, the slurry proportion is adjusted properly; f, main quality control points of reinforcement of the three axes agitating piles are determined; g, the stability of a pile machine is checked; h, the perpendicularity control over a pile frame of the three axes agitating piles is strengthened; i, the water cement ratio, the stirring time and the slurry quality are controlled strictly, and the slurry injection pressure and the slurry injection speed during slurry injection are controlled; and j, the drilling speed and lifting speed of a drill pipe are controlled strictly. The construction method has the advantages that the technique is mature, construction is easy and convenient, the project quality is safe and reliable, the horizontal displacement and settlement amount of important structures are quite small, the requirements for economic benefits are met, and smooth implementation of a project is guaranteed.

Owner:MCC5 GROUP CORP SHANGHAI

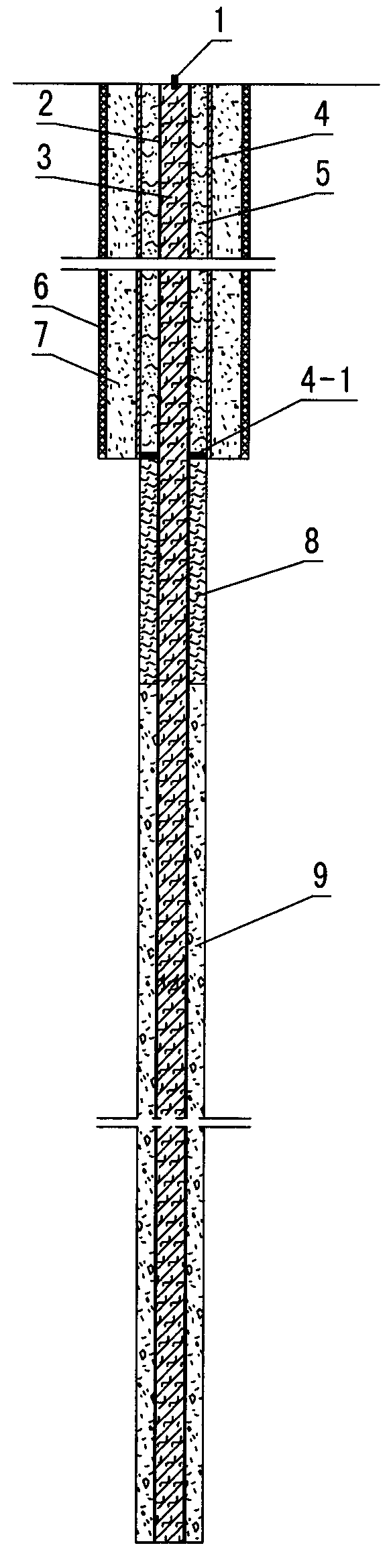

Soft soil area plane height measurement control point and embedding method thereof

InactiveCN104121895AGuaranteed stabilityGuaranteed target stabilitySurveyor's staffsMovable markersAbutmentCement mortar

The invention provides a soft soil area plane height measurement control point and an embedding method of the soft soil area plane height measurement control point. The soft soil area plane height measurement control point comprises a surveying rod, wherein a core column made of cement mortar is arranged in the surveying rod, the bottom of the surveying rod is embedded to a dense sand layer or a solid bearing layer, a steel protecting tube is sheathed on a part of the surveying rod, which is exposed above the ground, an upper opening of the steel protecting tube is flush with the top end of the surveying rod, and a concrete abutment is poured to the periphery of the steel protecting tube. The embedding method comprises the following steps: embedding the surveying rod into a drilling hole, injecting the cement mortar to form the core column, installing the steel protecting tube, pouring the concrete abutment, fixing a surveying marker and repairing and building safeguards. The soft soil area plane height measurement control point and the embedding method have the advantages of reasonable structure, mature construction process, long service life and the like and are especially suitable for embedding the soft soil area plane height deep embedded measurement control point, and the stability of the basic point surveying rod can be guaranteed.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

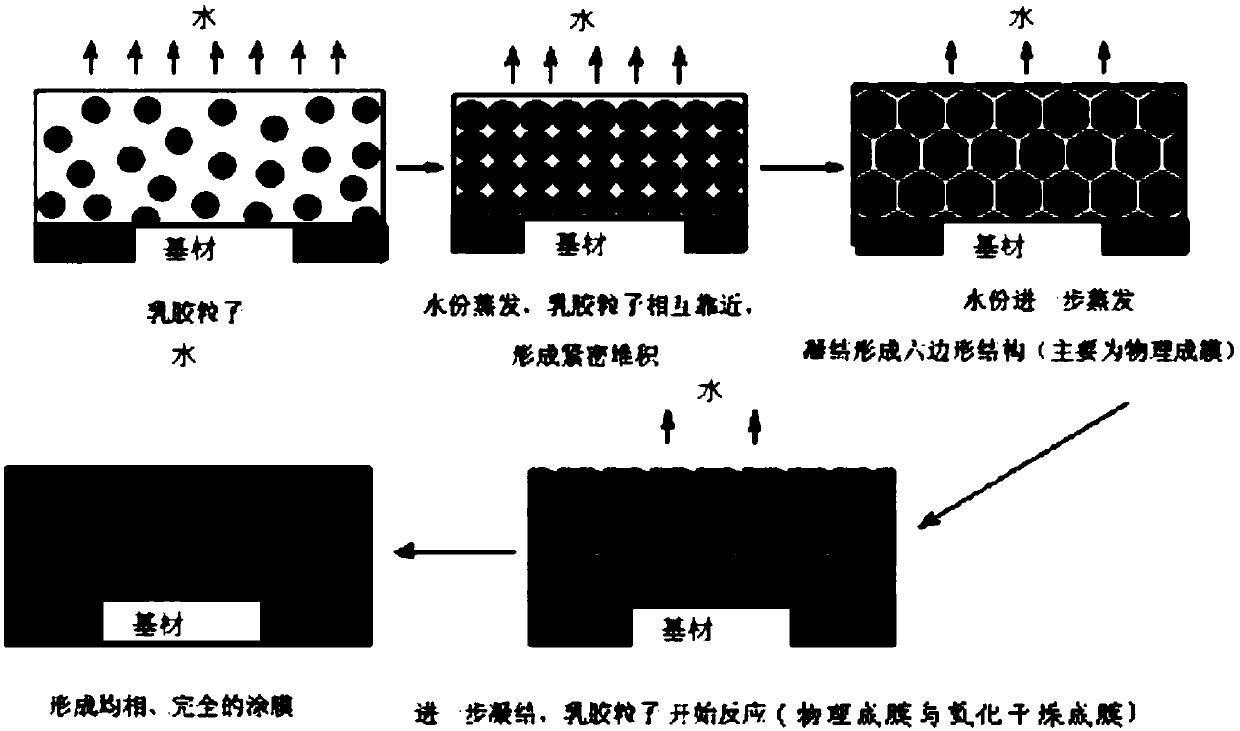

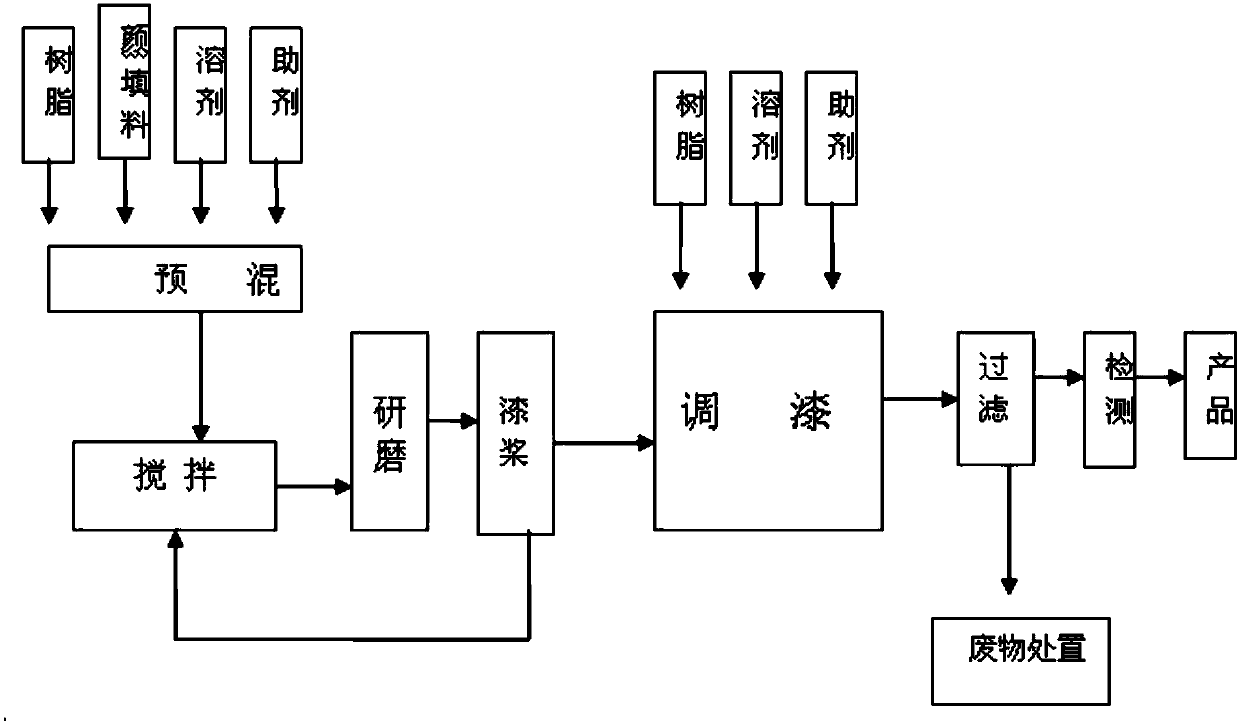

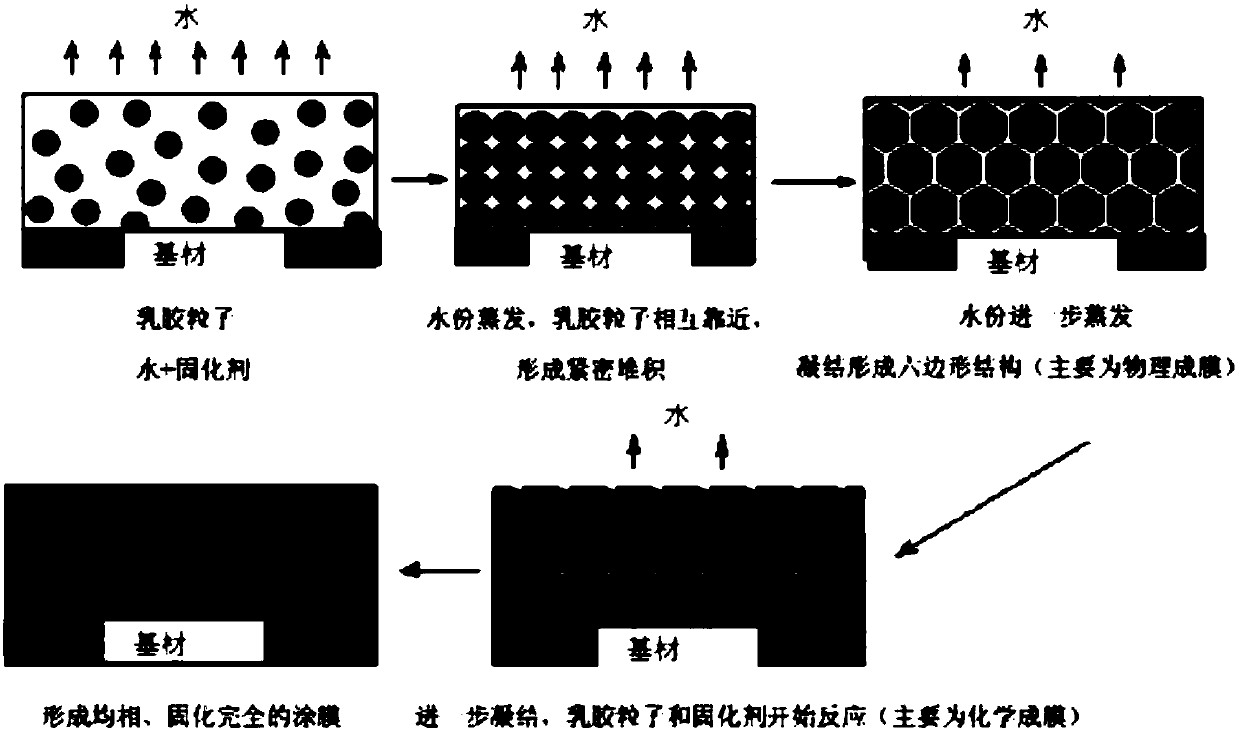

Coating composition for repairing rubber floor cloth and its application

ActiveCN107793903AGood flexibilityExcellent outer surface wear resistancePolyurea/polyurethane coatingsLacquerAcrylic resin

The application provides a coating composition for repairing a rubber floor cloth and its application. The coating comprises one-component polyurethane basecoat and dual-component polyurethane lacquer; the one-component polyurethane basecoat is prepared from, by weight percent, 20-40% of self-crosslinking polyurethane resin, 10-20% of hydroxy acrylic resin, 10-20% of titanium dioxide, 5-10% of functional filler, 10-15% of solvenet and 0-15% of assistant; the rest is tinting paste; the dual-component polyurethane lacquer comprises elastic polyurethane resin, hydroxyl acrylic dispersing body andisocyanate curing agent. The coating system has good integral flexibility, excellent outer surface wear resistance and anti-aging performance, good interlayer adhering force and good matching property with rubber floor cloth. The coating component can be applied to repair the rubber floor cloth and can achieve refreshed expression effect, and avoid the increased dismounting course of the overhaul, prolonged overhaul cycle, and waste by replacing the floor cloth.

Owner:CRRC QINGDAO SIFANG CO LTD

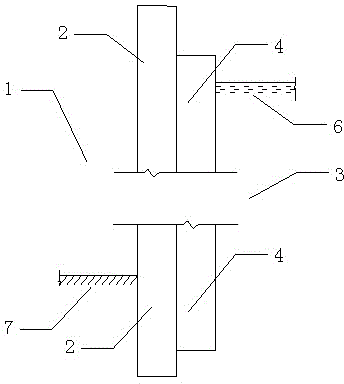

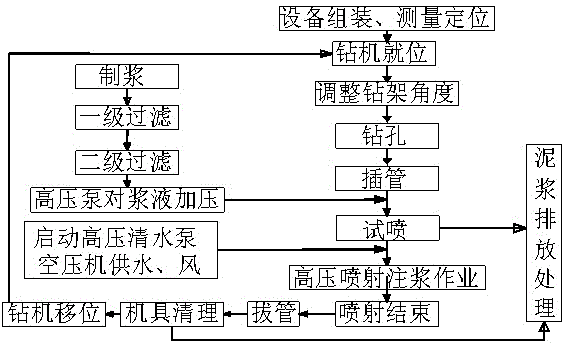

Construction method of high-pressure jet grouting pile used outside underground diaphragm wall joint for reinforcing seal waterstop

ActiveCN105986570AMature construction technologyEasy constructionBulkheads/pilesSlurry wallEconomic benefits

The invention relates to a construction method of a high-pressure jet grouting pile used outside an underground diaphragm wall joint for reinforcing a seal waterstop. The mature high-pressure jet grouting pile construction method is adopted, and the seal waterstop is strengthened and reinforced in the underground diaphragm wall joint weak link in a form of constructing the high-pressure jet grouting pile outside the underground diaphragm wall joint. The method is characterized by including the following technical steps of a, determination of construction parameters and selection of construction methods, b, jet material control, c, measurement and locating, d, pile test, e, technical control on jet process construction, f, grout return observation, g, recharge, h, observation of surroundings in the jet process, and i, abandoned slurry sewage discharge. The method has the advantages of the mature construction process of the high-pressure jet grouting pile, simpleness, convenience in construction, safety and reliability in construction quality, obvious effect on waterstop reinforcement of the underground diaphragm wall joint, capabilities of greatly lowering potential risk in foundation pit construction and meeting economic benefit of engineering construction.

Owner:MCC5 GROUP CORP SHANGHAI

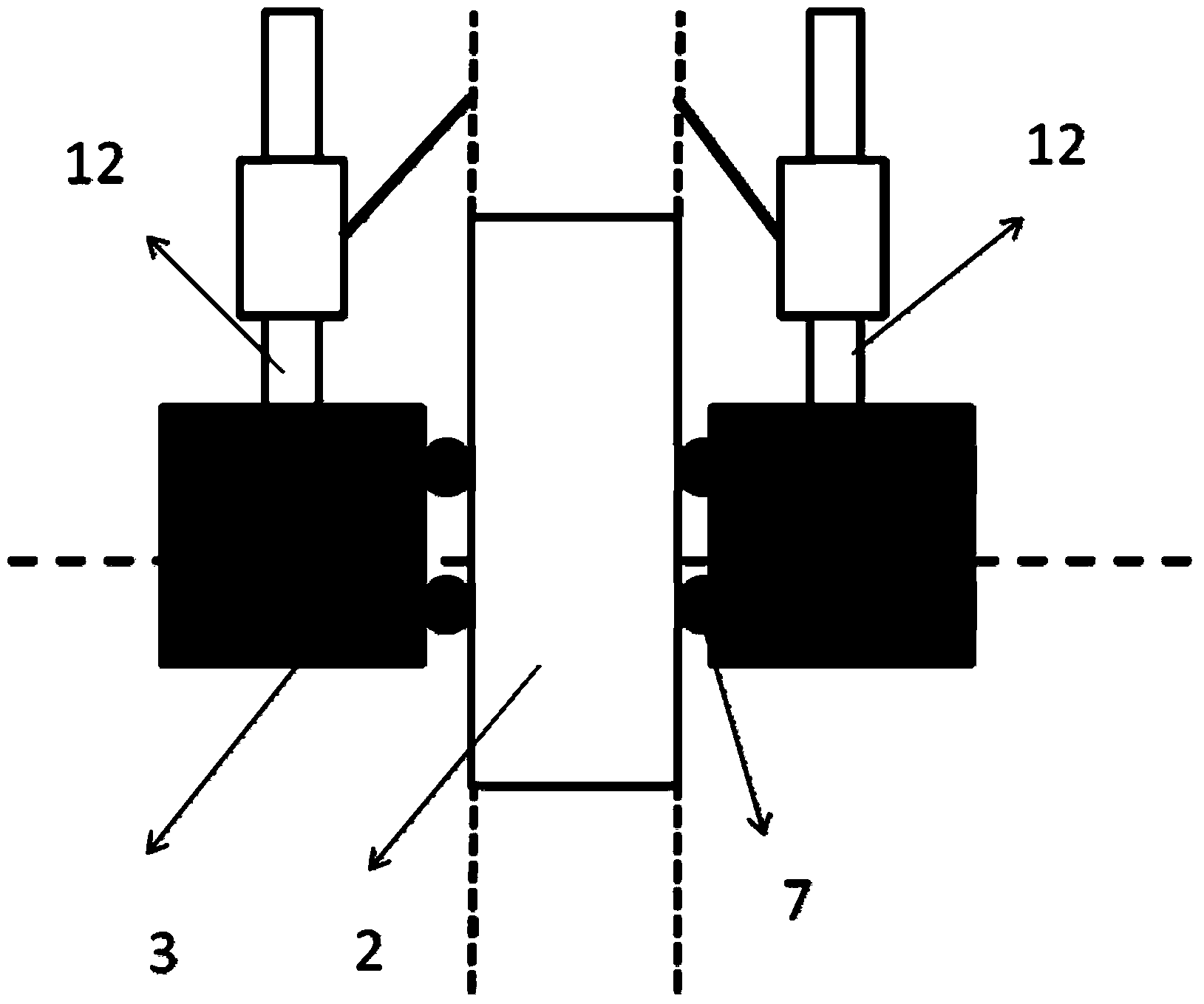

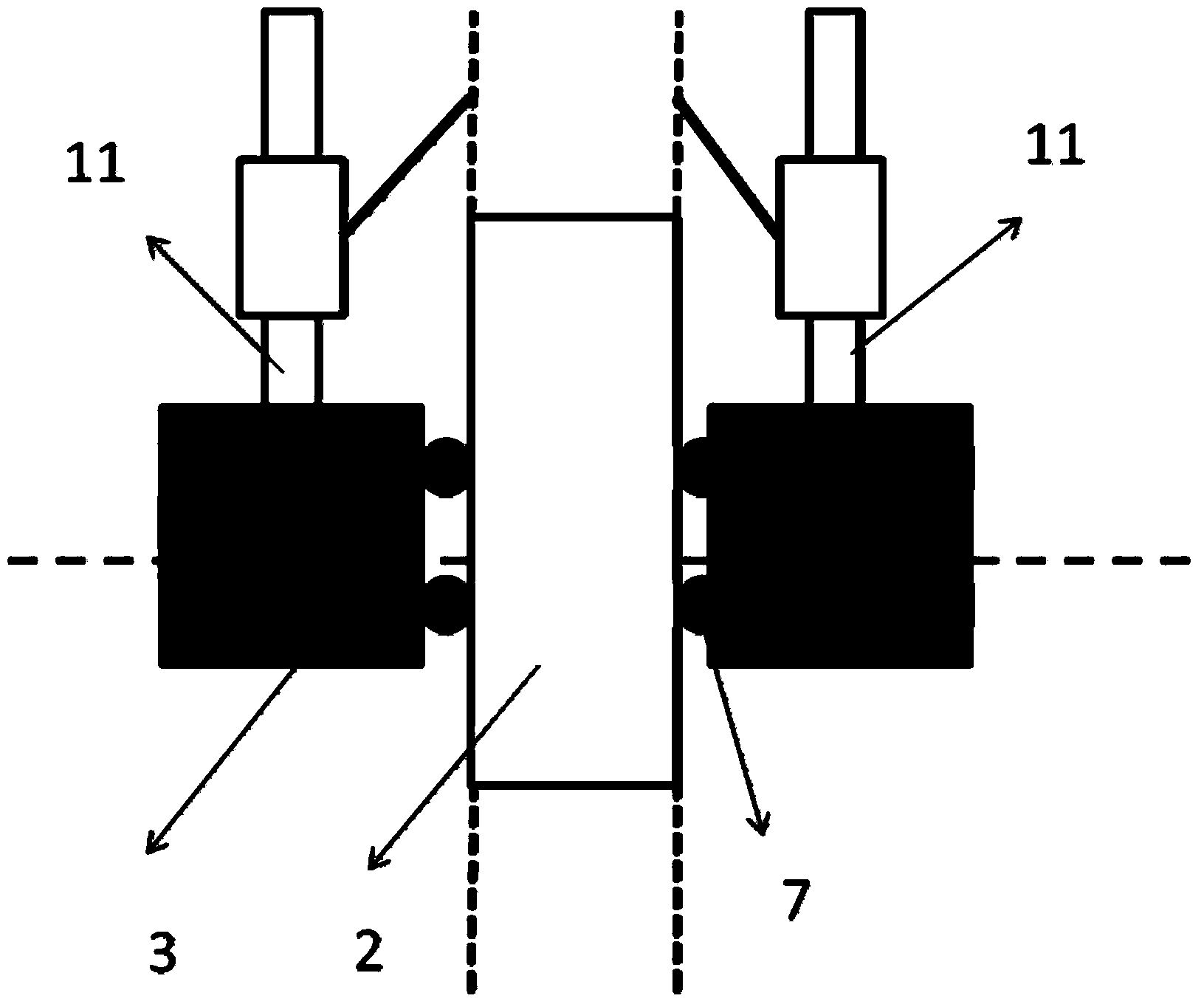

Single pile platform-based vertical axial wind turbine-bidirectional wave energy device-tidal current energy device integration structure

InactiveCN107795431AEasy structure constructionReduce construction costsWind energy with water energyEnergy industryElectric power transmissionVertical axis wind turbine

The invention discloses a single pile platform-based vertical axial wind turbine-bidirectional wave energy device-tidal current energy device integration structure, and belongs to the field of ocean energy utilization. The single pile platform-based vertical axial wind turbine-bidirectional wave energy device-tidal current energy device integration structure comprises a vertical axial wind turbine, a bidirectional wave energy power generation device, a bidirectional hydraulic power generation system located in the bidirectional wave energy power generation device, a tower structure, a single pile supporting platform structure, a tidal current energy power generation device and an assorted power transmission system. The integration structure obtains wind energy by using the vertical axial wind turbine at the upper part, obtains wave energy by using the vertical and horizontal bidirectional wave energy power generation devices arranged on the water level of the tower structure, and obtains tidal current energy by using the tidal current energy power generation device arranged on the underwater single pile supporting platform structure. The bidirectional wave energy device can simultaneously make use of motions relatively vertical and horizontal to the tower structure to drive a hydraulic transmission system to generate power, thus effectively improving the utilization efficiencyof wave energy.

Owner:DALIAN UNIV OF TECH

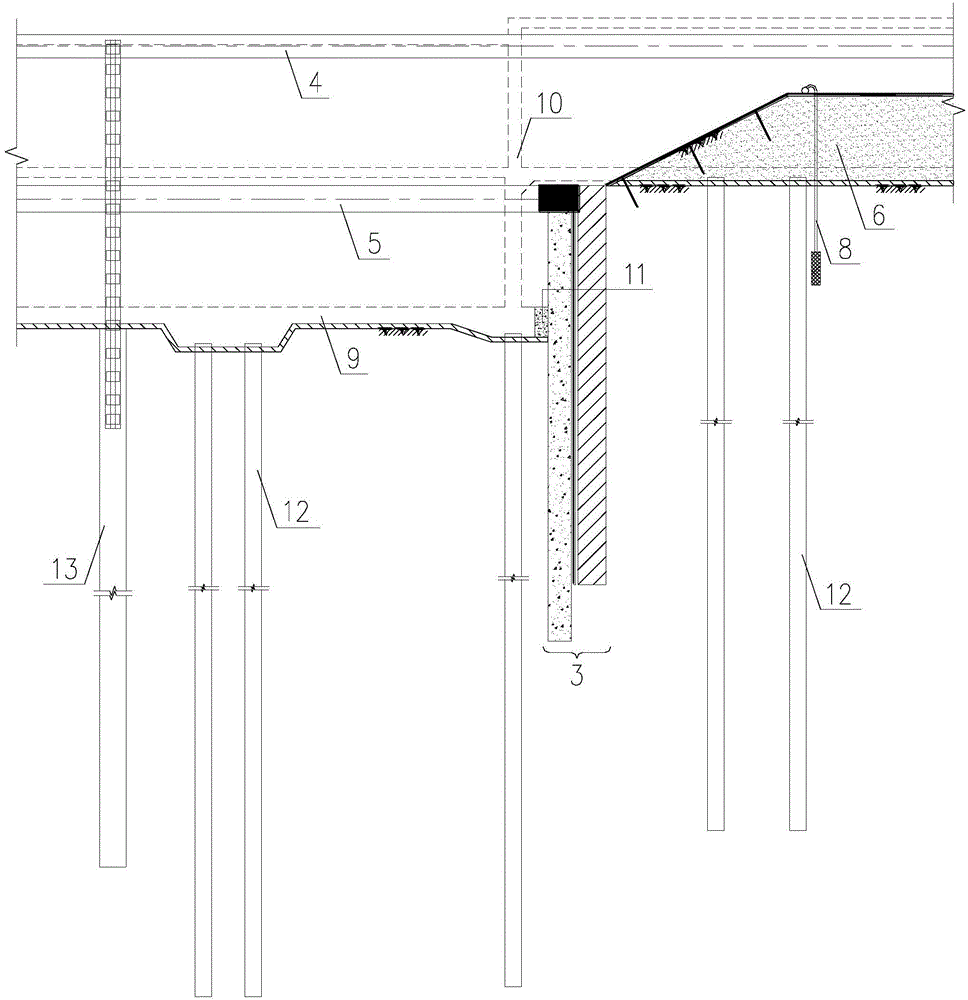

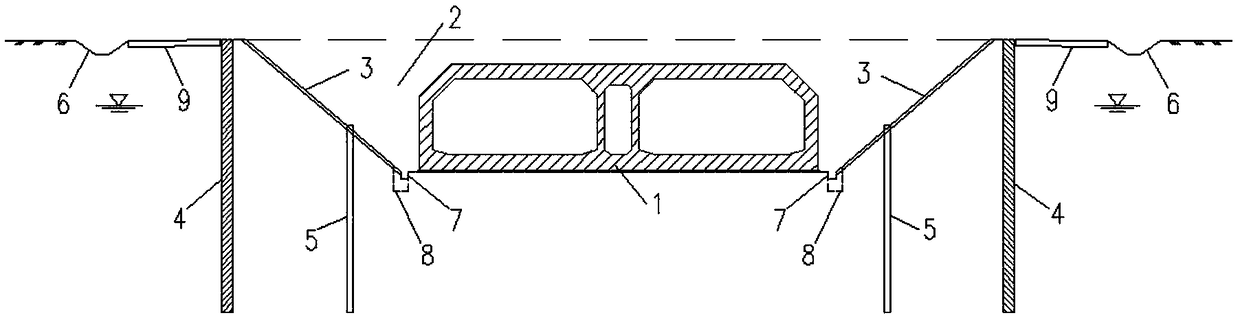

Close-to-river submerged tunnel foundation pit excavation support and water precipitation and blocking method and structure

PendingCN109113076ASmall supportThe amount of water-stop work is smallExcavationsBlock effectWater table

The invention discloses a close-to-river submerged tunnel foundation pit excavation support and water precipitation and blocking method and structure. The close-to-river submerged tunnel foundation pit excavation support and water precipitation and blocking method mainly comprises the steps that a tunnel foundation fit adopts stratified and symmetrical unprotected open cut excavation, and slope protection is carried out on a slope of the foundation pit to ensure the stability of the slope of the foundation pit; a water stop curtain is arranged around the foundation pit, and the water stop curtain is formed by the water stop piles interlocking with each other, the foundation pit is closed, the water stop piles enter an impervious layer, and the water seepage of adjacent rivers outside the foundation pit is intercepted; water precipitation wells are longitudinally arranged along both sides of the foundation pit in the water stop curtain to reduce the groundwater level in the foundation pit; penetrating ground intercepting ditches are arranged on the outer periphery of the water stop curtain of the foundation pit for closure to prevent the ground water from entering the foundation pit; and drainage side ditches are arranged on both sides of the bottom of the foundation pit, and water collecting wells are arranged at appropriate intervals to exclude the water accumulated in the bottom of the foundation pit. The close-to-river submerged tunnel foundation pit excavation support and water precipitation and blocking method and structure are simple in construction equipment, the process is mature, the engineering period is shortened, the engineering investment is reduced, the combination of the water stop curtain, the water precipitation wells and the intercepting drainage sideditches is adopted, and the foundation pit has a good water precipitation and blocking effect and high safety guarantee.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

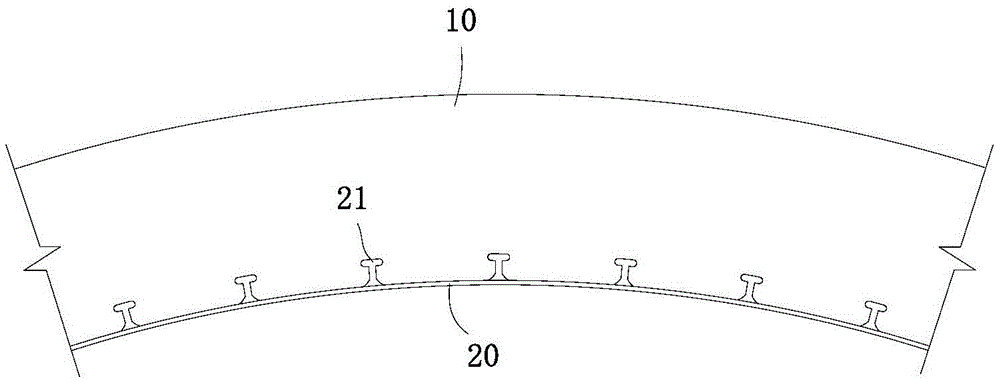

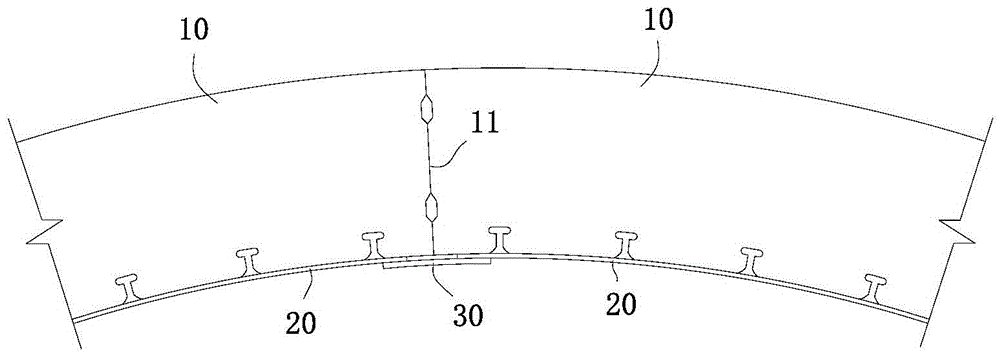

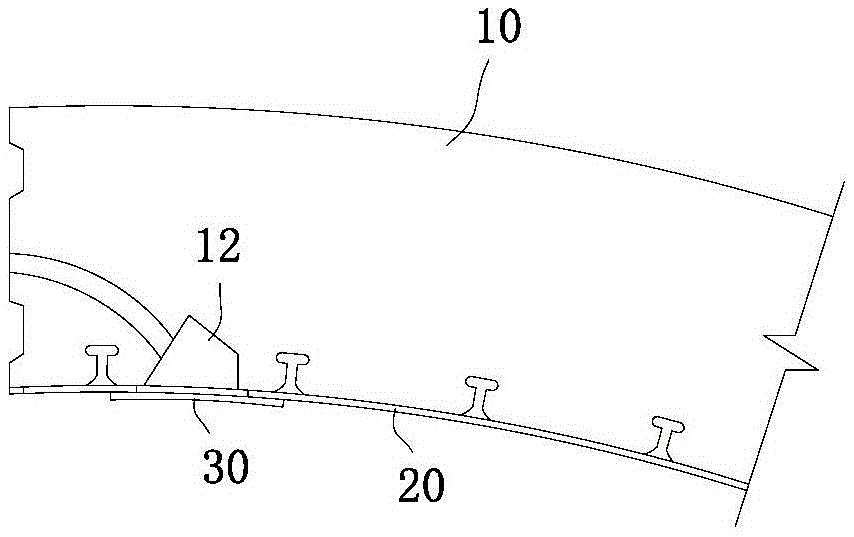

PVC sheet shield tunnel segment inner corrosion prevention system with linings

ActiveCN105649649AEasy to get materialsMature construction technologyUnderground chambersTunnel liningLap jointEngineering

The invention discloses a PVC sheet shield tunnel segment inner corrosion prevention system with linings. The system comprises a plurality of lining segments and the corrosion prevention linings embedded in the inner walls of the lining segments. The lining segments and the corrosion prevention linings are spliced together and constructed into the tubular shape in a lining mode. Joints are formed between the lining segments. The corrosion prevention linings are connected into a whole in a lap joint mode through hot melting and embedded in the inner walls of the lining segments. The corrosion resistance of the segment structure is greatly enhanced. After the lining segments are spliced, hot melting and lap joint processing is conducted on local parts without corrosion prevention linings such as the seams between the corrosion prevention linings and holes in the corrosion prevention linings, and it is ensured that the shield tunnel has the reliable overall leakproofness. Materials of the segment structure are convenient to take, the construction process is mature, and the construction cost is not high; for a water drainage pipeline formed by the lining segments under the sewage environment, corrosion of corrosive substances to the segment structure is isolated, the defect that the shield tunnel is prone to leakage at the seams of the segments is eliminated, and good application prospects are achieved.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

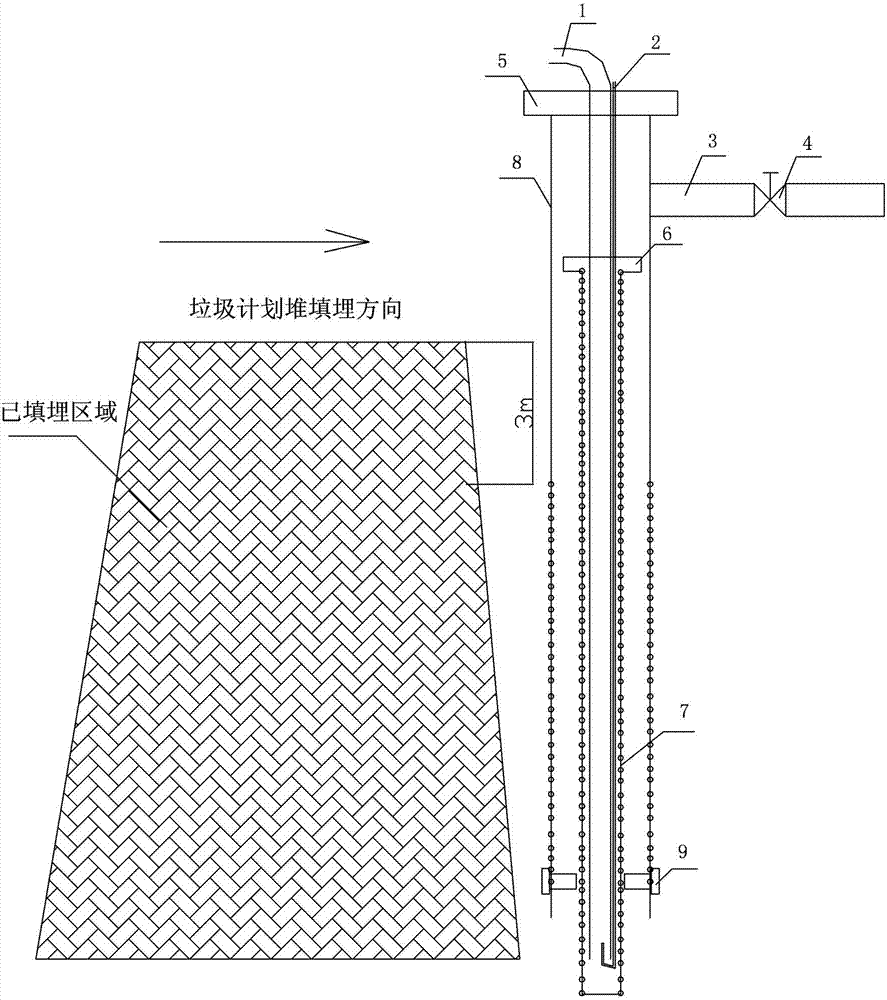

Pre-buried elevating landfill gas collecting well

InactiveCN102896131ASimple structureReasonable designLandfill technologiesSolid waste disposalEconomic benefitsEnvironmental engineering

The invention relates to a landfill gas collecting well which is used for collection of garbage landfill gas. A pre-buried elevating landfill gas collecting well provided by the invention comprises a gas collection pipe and an exhaust pipe, wherein the exhaust pipe is installed at the upper part of the gas collection pipe and is used for connecting a branch exhaust pipe to realize gas collection, a well mouth valve is arranged on the exhaust pipe and is used for controlling negative pressure and collection flow of the landfill gas collecting well, the gas collection pipe is composed of an outer gas collection pipe and an inner gas collection floral pipe, the outer gas collection pipe is composed of an outer gas collection solid pipe at an upper part and an outer gas collection floral pipe at a lower part, and the inner gas collection floral pipe is arranged in the outer gas collection pipe. According to the invention, the pre-buried elevating landfill gas collecting well has a simple structure and reasonable design, the characteristics of a simple process, convenient construction, a fast well forming speed, a mature construction process, strong environmental adaptability and a good gas collection effect are obtained, and low cost and economic benefits are achieved.

Owner:HENAN BCCY IND

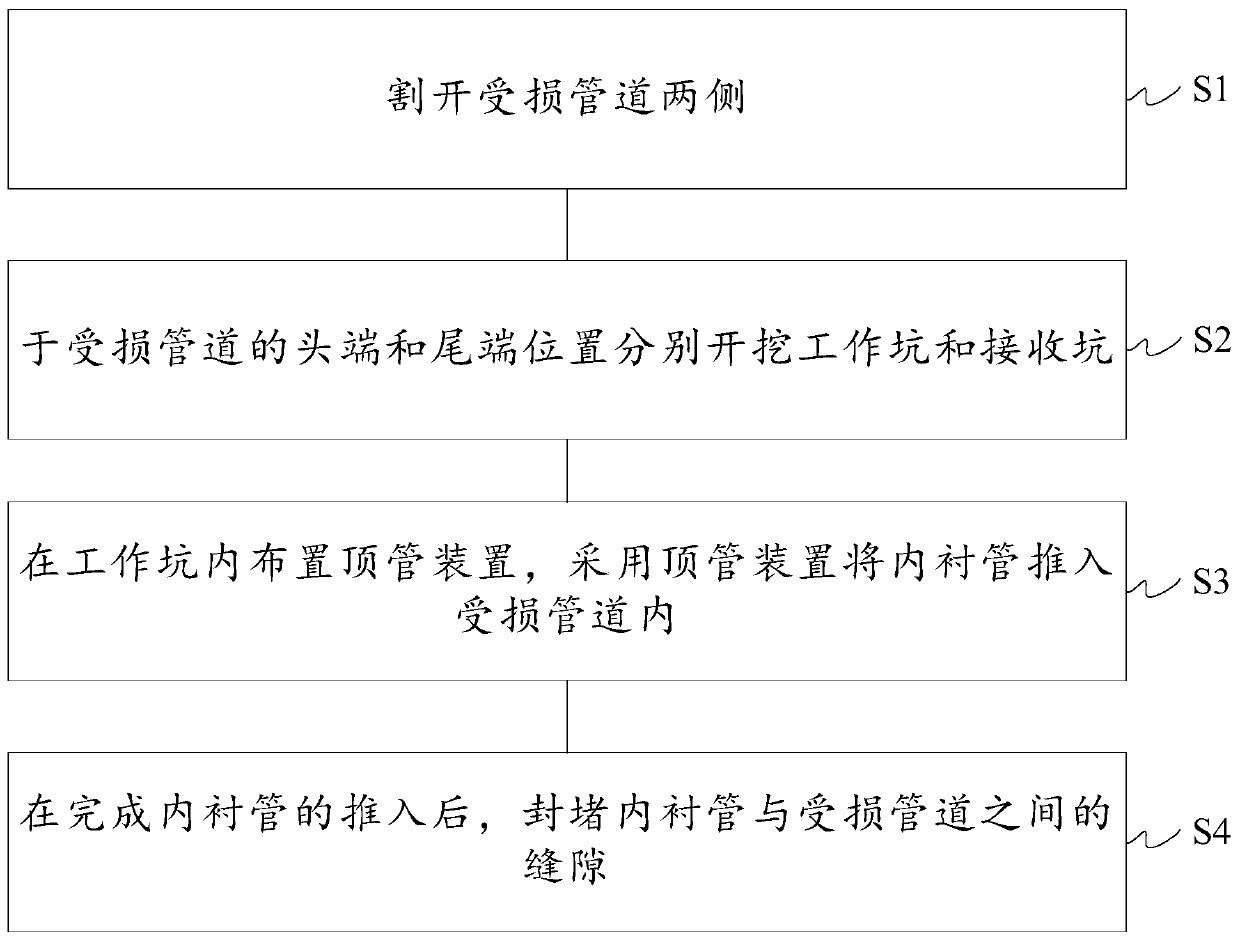

Trenchless large-caliber water supply pressure pipeline rehabilitation construction method

InactiveCN110925517AMature construction technologyReliable construction technologyPipe elementsArchitectural engineeringPipe

The invention discloses a trenchless large-caliber water supply pressure pipeline rehabilitation construction method. The trenchless large-caliber water supply pressure pipeline rehabilitation construction method comprises the steps that the two sides of a damaged pipeline are cut up; a working pit and a receiving pit are excavated in the head end and the tail end of the damaged pipeline correspondingly; a pipe jacking device is arranged in the working pit, lining pipes are pushed into the damaged pipeline through the pipe jacking device, glass reinforced plastic sand pipes and steel pipes arecombined to serve as the lining pipes, and sealing joints are arranged between the lining pipe sections, wherein the steel pipes are adopted as the lining pipes at the head end and the tail end of the damaged pipeline and pipe sections connected with branches, and after pushing in of the lining pipes is completed, clearances between the lining pipes and the damaged pipeline are blocked. The construction method is relatively simple, mature in process, economical and practical, and the rehabilitated pipeline has the advantages of being small liquid conveying resistance, good in corrosion resistance, long in service life and free of water quality pollution.

Owner:上海水务建设工程有限公司 +1

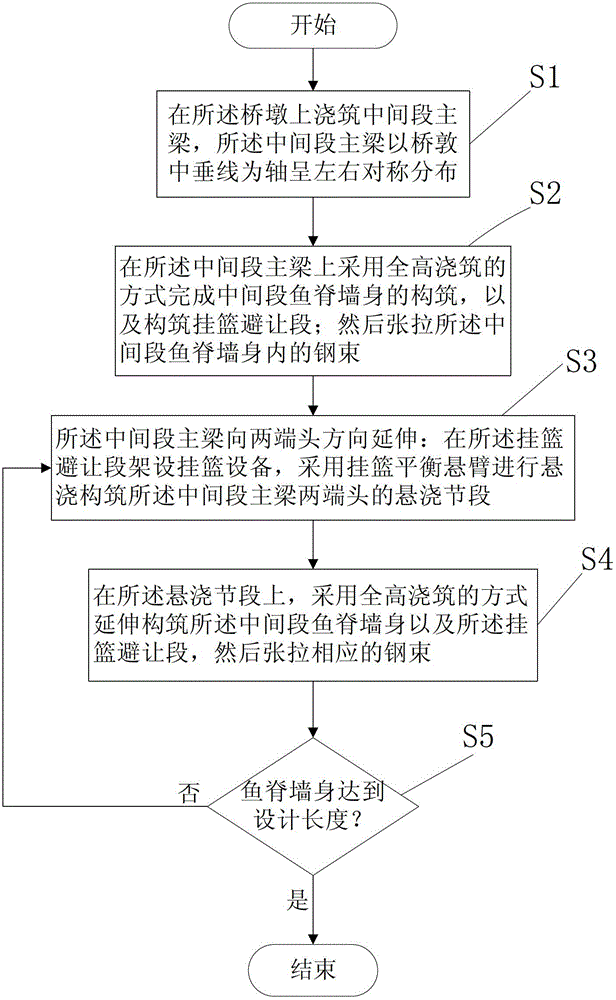

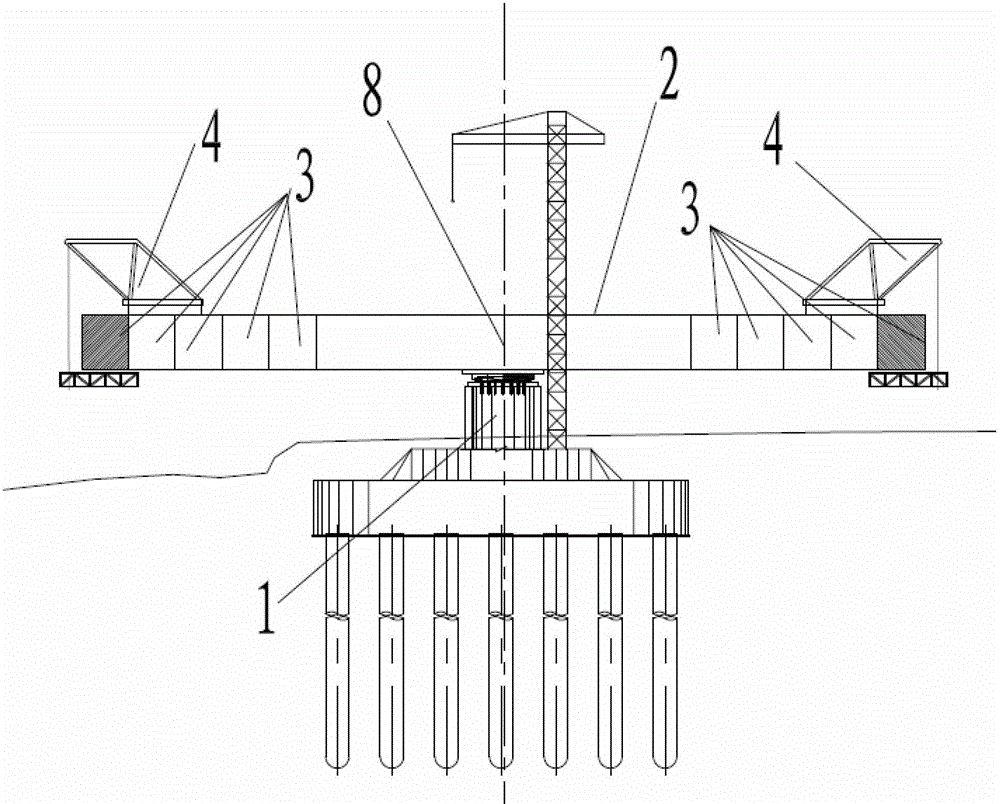

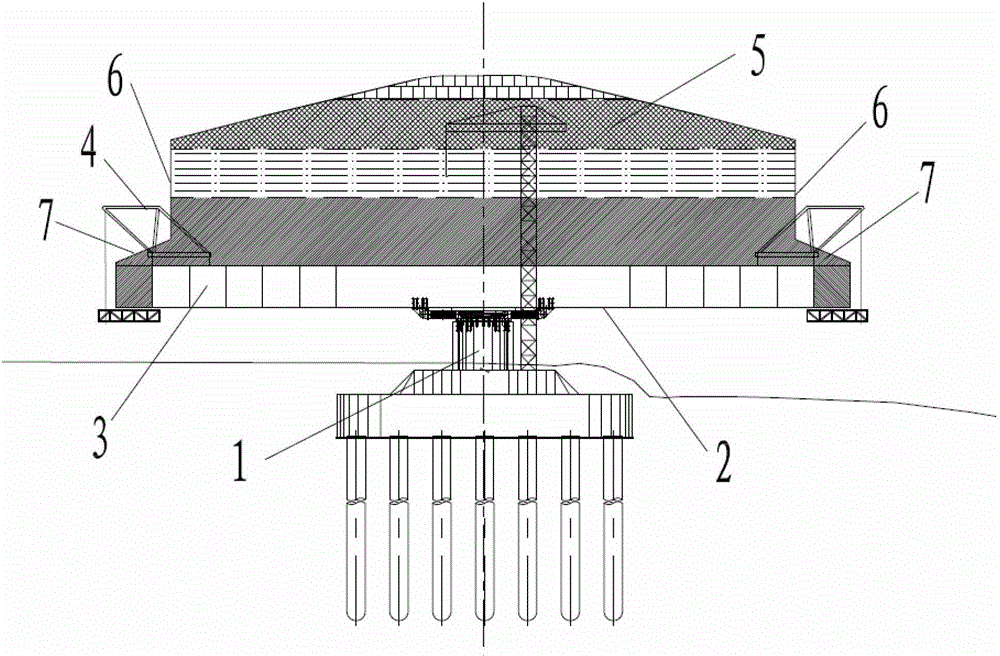

Herring-bone wall body construction method of large-span concrete herring-bone continuous girder bridge and structure thereof

ActiveCN102877416AClear forceReduce construction complexityBridge structural detailsBridge erection/assemblyGirder bridgeBuilding construction

The invention discloses a herring-bone wall body construction method of a large-span concrete herring-bone continuous girder bridge and a structure thereof. The middle symmetric sectional pouring construction method for a herring-bone wall body and a main beam comprises following steps that step 1, a middle section main beam is poured on a bridge pier; step 2, the construction of a middle section herring-bone continuous girder bridge and the cradle avoidance section are completed on the middle section main beam through a completely-high pouring way, and a steel bundle in the middle section herring-bone wall body is strained; step 3, the middle section main beam extends towards the direction of two ends; step 4, the middle section herring-bone wall body and the cradle avoidance section are constructed on a suspension pouring section in an extending mode, and then the corresponding steel bundle is strained; and step 5, the step 3 and the step 4 are sequentially circulated until the herring-bone wall body reaches the designed length, and the entire construction flow is completed. The construction method and the construction structure of the herring-bone wall body of the large-span concrete herring-bone continuous girdler bridge are convenient to construct and specific in stress.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Fabricated corrugated web steel box-UHPC composite beam bridge and construction method thereof

PendingCN111206489AMeet different design needsReduce welding workloadBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a fabricated corrugated web steel box-UHPC composite beam bridge and a construction method thereof, the fabricated corrugated web steel box-UHPC composite beam bridge is composed of corrugated web steel boxes and UHPC bridge deck slabs, each corrugated web steel box is of an open box-shaped structure composed of a flat steel bottom plate, corrugated steel webs and a flat steel top plate, and the adjacent corrugated web steel boxes are connected through cross beams between the boxes; the UHPC bridge deck slabs comprise in-box prefabricated UHPC bridge deck slabs, inter-box prefabricated UHPC bridge deck slabs and cantilever cast-in-place UHPC bridge deck slabs, and the adjacent prefabricated UHPC bridge deck slabs are connected through cast-in-place wet joint UHPC bridge deck slabs; and the multiple UHPC bridge decks are correspondingly installed on the multiple corrugated web steel boxes to form the assembly type corrugated web steel box-UHPC composite beam bridge. According to the fabricated corrugated web steel box-concrete composite beam bridge, the steel consumption configuration is optimized, the self-weight of the structure is further reduced, the prefabricated concrete bridge deck is adopted, the fabricated degree is further improved, the construction period is short, the standardization degree is high, remarkable economic and social benefits areachieved, and the fabricated corrugated web steel box-concrete composite beam bridge has important significance in promoting large-scale application of steel structure bridges.

Owner:甘肃省交通规划勘察设计院股份有限公司

Beam bar anchoring sleeve pre-embedded in thin wall and construction method thereof

ActiveCN104452978AMature construction technologyEasy to operateBuilding constructionsConcrete beamsRebar

The invention discloses a beam bar anchoring sleeve pre-embedded in a thin wall and a construction method of the beam bar anchoring sleeve pre-embedded in the thin wall. The beam bar anchoring sleeve comprises a unilateral thread sleeve body and a bilateral thread sleeve body. One side of the unilateral thread sleeve body is provided with an anchoring end plate. The sum of the length of the unilateral thread sleeve body and the thickness of the anchoring end plate is the same as the thickness of the concrete thin wall. The anchoring end plate is located on the side, opposite to the concrete thin wall, of a concrete beam. The bilateral thread sleeve body is located in the concrete thin wall. The length of the bilateral thread sleeve body is the same as the thickness of the concrete thin wall. The center position of the bilateral thread sleeve body is the same as the center position of concrete beam main bars on the two sides of the concrete thin wall. According to the beam bar anchoring sleeve, the anchoring end plate and the sleeve are welded into an anchoring whole, the defect that in a conventional construction process, when a beam bar is pre-embedded, two-end thread machining cannot be conducted due to an excessively short steel bar is overcome, the anchoring problem of a horizontal structural beam subsequently constructed in the thin wall is solved, and the beam bar anchoring sleeve can be widely applied to the process that nodes are pre-embedded in a beam bar when a shear wall is not synchronous with the concrete beam in the construction process.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

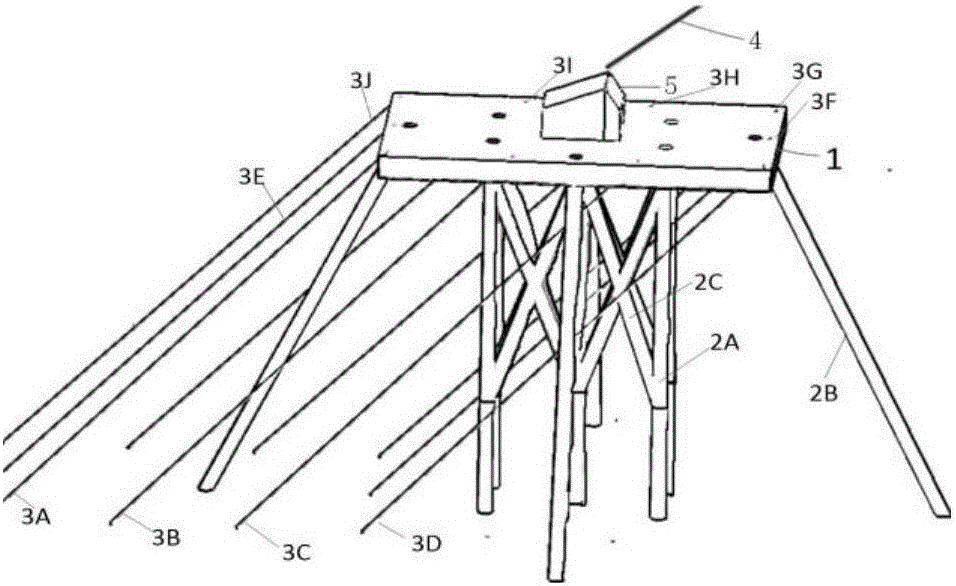

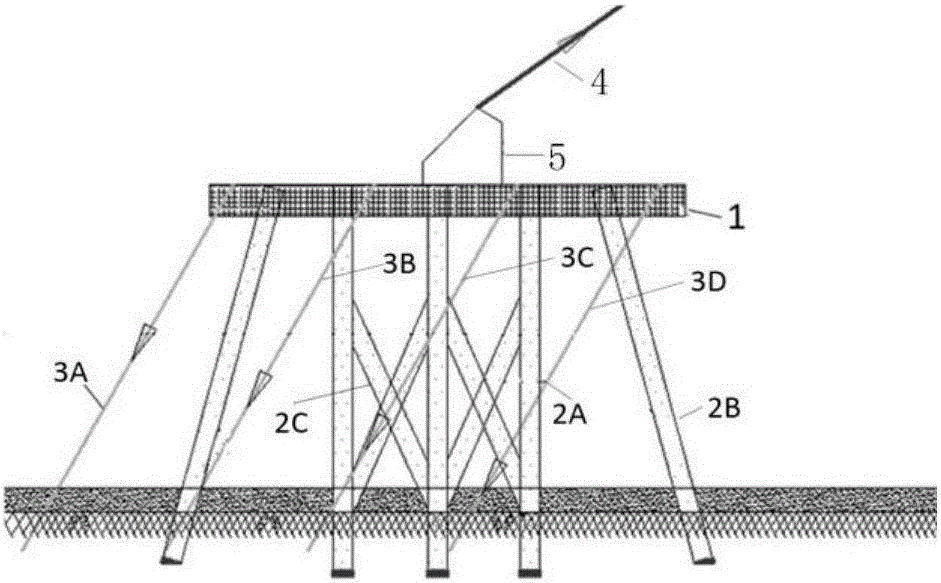

Suspension cable bridge pier abutment type pre-stress anchorage

InactiveCN106087742AIncrease the bearing rangeReduce dosageBridge structural detailsFoundation engineeringPull forcePre stress

The invention discloses a suspension cable bridge pier abutment type pre-stress anchorage. The suspension cable bridge pier abutment type pre-stress anchorage is composed of a steel-structure concrete bearing platform, a steel pipe pile group, a pre-stress anchor cable group, a main cable and a main cable anchoring system, and is characterized in that the steel pipe pile group is composed of a vertical pile and an inclined pile; one end of the vertical pile and one end of the inclined pile stretch into a base rock and the other ends of the vertical pile and the inclined pile are in rigid connection with the steel-structure concrete bearing platform; an inner anchor head end of the pre-stress anchor cable group is fixed on the base rock and an outer anchor head end of the pre-stress anchor cable group is fixedly connected with the steel-structure concrete bearing platform; an included angle between the direction of the pre-stress anchor cable group and the direction of the main cable is 0-5 degrees; an inclined angle of the pre-stress anchor cable group is greater than that of the main cable; and the main cable anchoring system is fixed at the top of the steel-structure concrete bearing platform. A huge pull force of the main cable is transmitted to the base rock through the pre-stress anchor cable group and a traditional stressing manner of an anchorage structure is changed; and a force bearing range of the anchorage structure is extremely improved and a brand new way is provided for construction of ultra-large suspension cable bridges.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com