PVC sheet shield tunnel segment inner corrosion prevention system with linings

A shield tunnel segment and internal anti-corrosion technology, which is applied in the direction of tunnels, tunnel linings, shaft linings, etc., can solve the problems that cannot meet the long-term use needs of municipal drainage tunnels, expensive post-maintenance costs, and damage to concrete materials, etc., and achieve good results. Application prospects, prevent water vapor from penetrating into the wall of the segment, and the effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

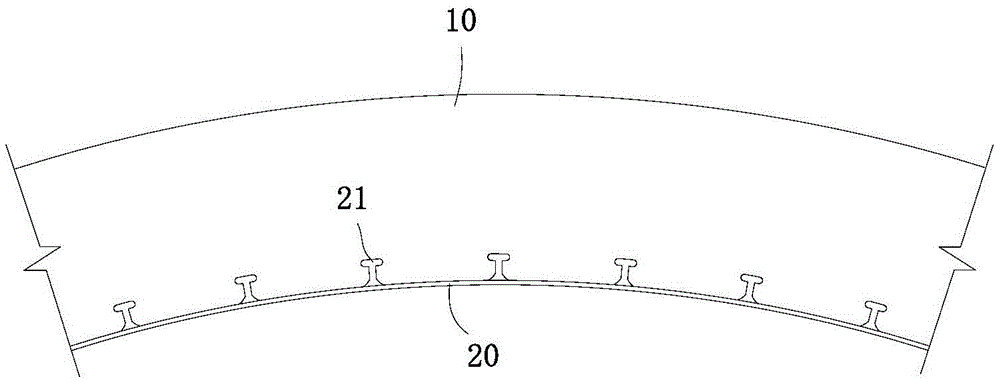

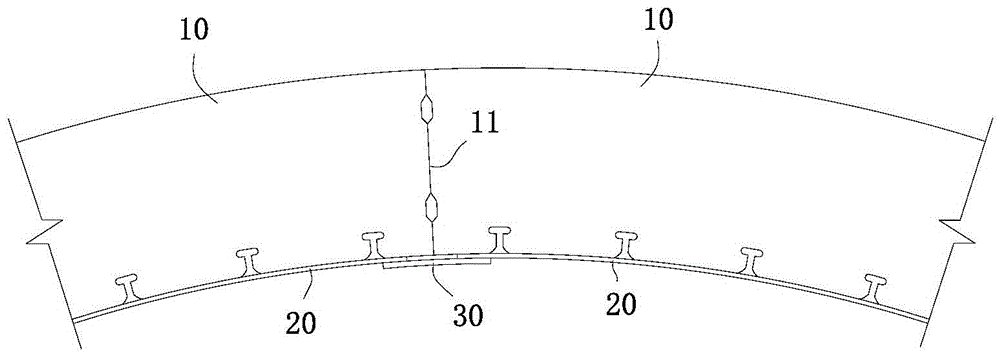

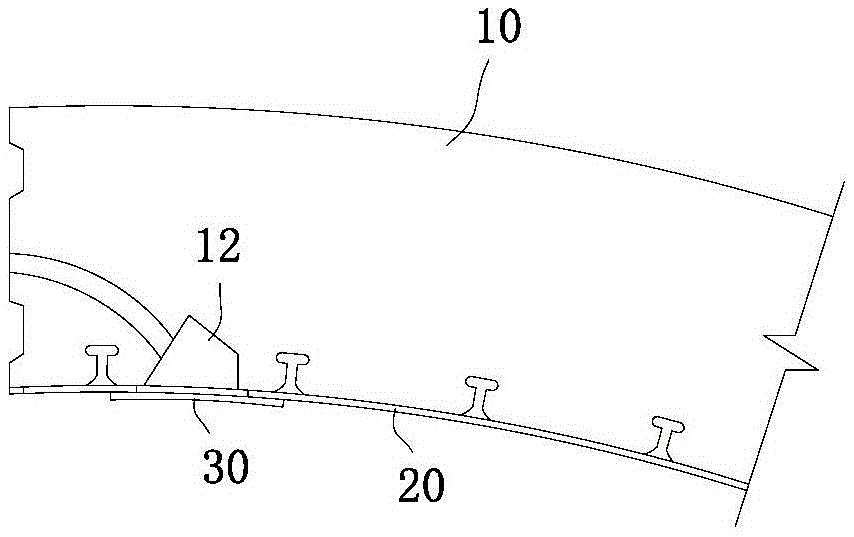

[0016] refer to Figure 1 to Figure 3 , the present invention is an anti-corrosion system for shield tunnel segments with lined PVC sheets, comprising a plurality of lining segments 10 and anti-corrosion inner linings 20 embedded on the inner walls of each lining segment 10, each lining segment 10 and The anti-corrosion inner linings 20 are assembled together to form a tubular shape, and there are seams 11 between the lining segments 10, and the anti-corrosion inner linings 20 are formed into one body by hot-melt lap joints.

[0017] In this embodiment, the lining segment 10 is formed by pouring reinforced concrete, and the anti-corrosion lining 20 is made of polyvinyl chloride (PVC) anti-corrosion sheet, and the lining segment 10 and the anti-corrosion lining 20 are formed by integral casting. The side of the vinyl chloride anti-corrosion sheet has a plurality of fixed keys 21 anchored on the inner wall of the reinforced concrete segment, so as to improve the bonding force be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com