Patents

Literature

32results about How to "Isolation erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-silicon negative electrode material and preparation method thereof

PendingCN112054171AAlleviate volume expansionOvercome costsSecondary cellsNegative electrodesElectrolytic agentCarbon layer

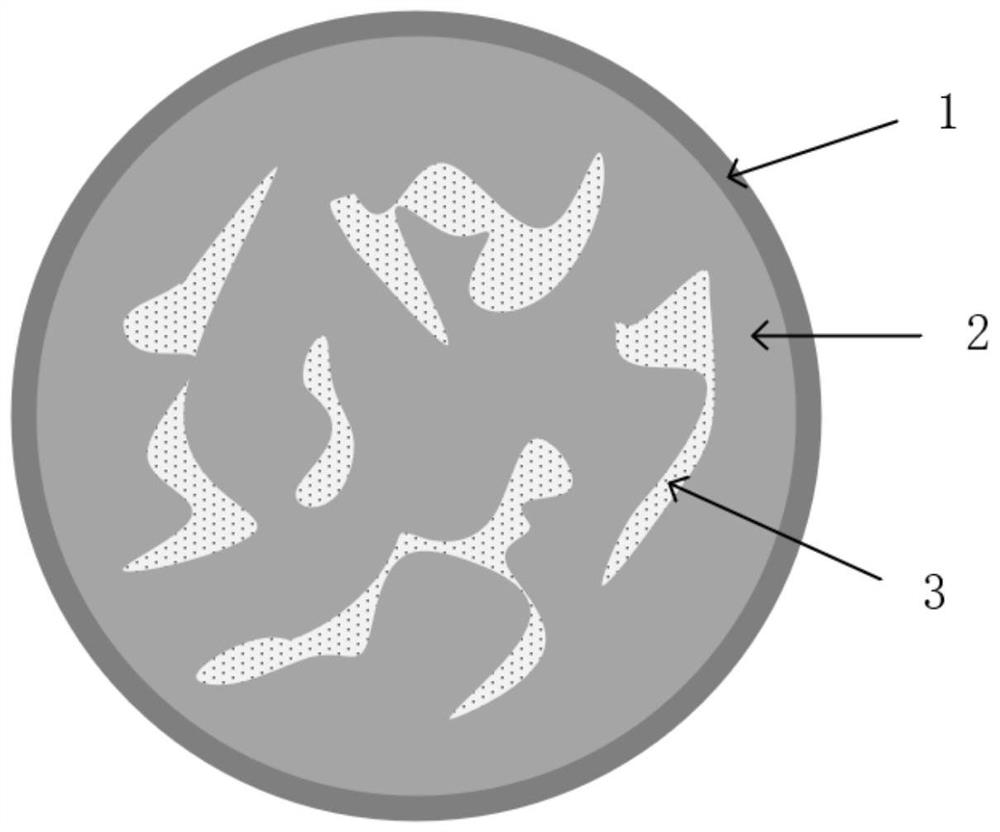

The invention discloses a carbon-silicon negative electrode material and a preparation method thereof.The carbon-silicon negative electrode material is of a core-shell structure with a core part and ashell part, the core part is a porous carbon material loaded with nano-silicon, and the shell part is a conductive carbon layer coating the core part; the conductive carbon layer contains a conductive agent and organic cracked carbon formed by cracking an organic cracking carbon source. According to the preparation method of the carbon-silicon negative electrode material, nano-silicon is loaded on pores and the surface of a porous carbon material, so that the problem of volume expansion of the nano-silicon is relieved; nano-silicon is generated by hydrolyzing an organic silicon source, so that the problems of high preparation cost, agglomeration and the like of the nano-silicon are solved; the organic cracked carbon and a conductive agent are used as a conductive carbon layer to coat theporous carbon material loaded with nano silicon, so that the corrosion of electrolyte is isolated, and the stability of the material structure is ensured. The carbon-silicon negative electrode material disclosed by the invention has excellent electrochemical performance.

Owner:利普同呈(江苏)新能源科技有限公司 +1

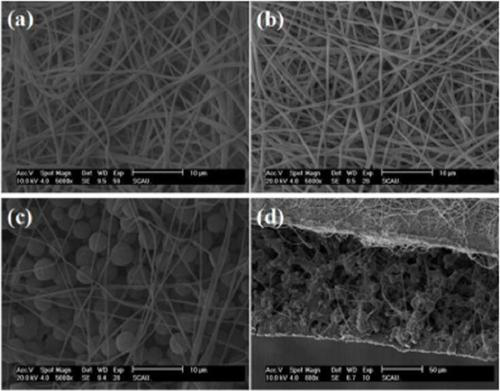

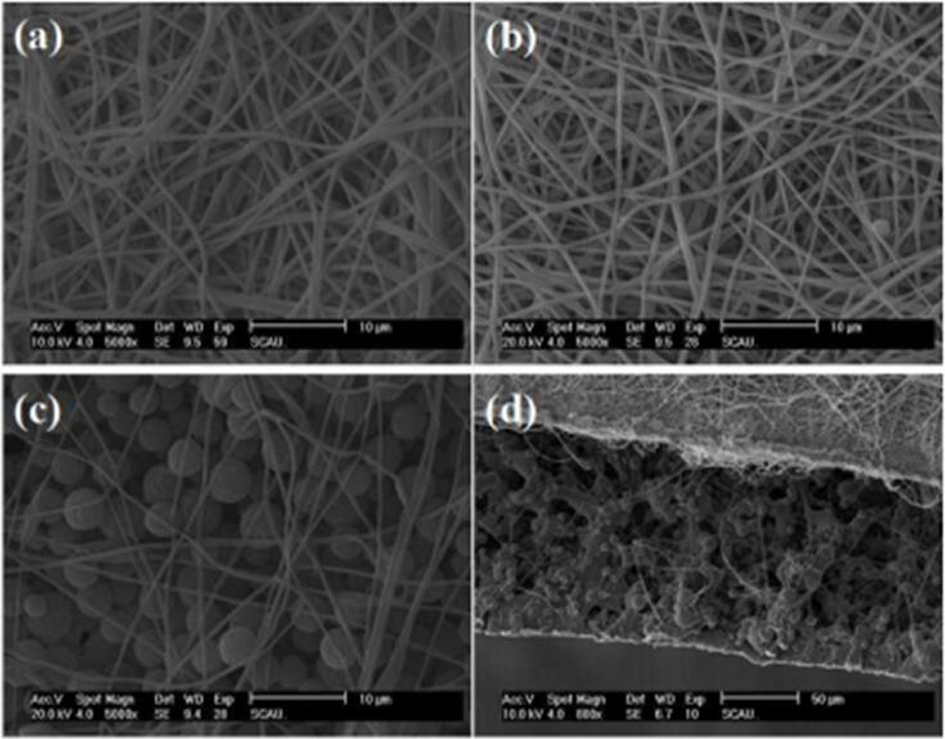

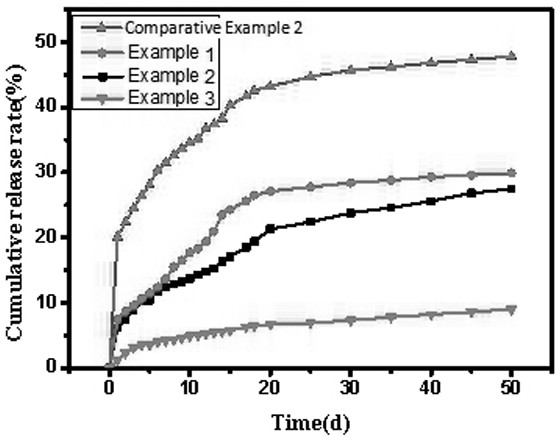

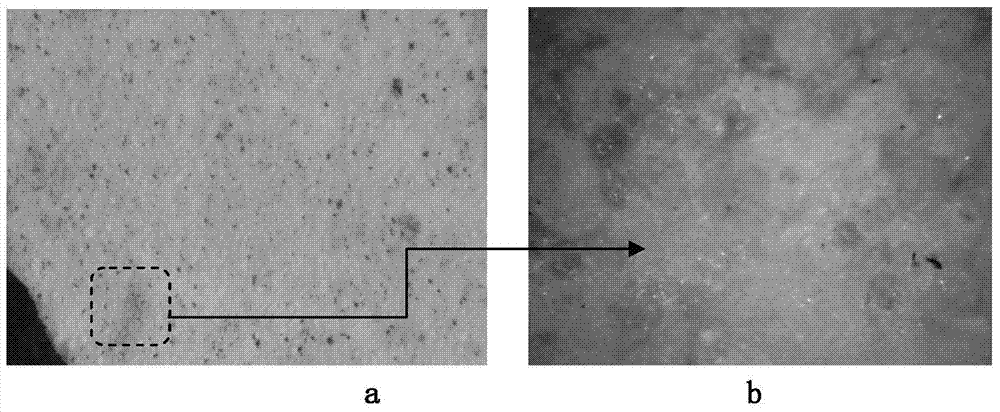

Novel dustproof, antibacterial and antiviral nano-fiber mask

ActiveCN111235756AEasy to stay dryIsolation erosionElectro-spinningNon-woven fabricsMicrosphereEngineering

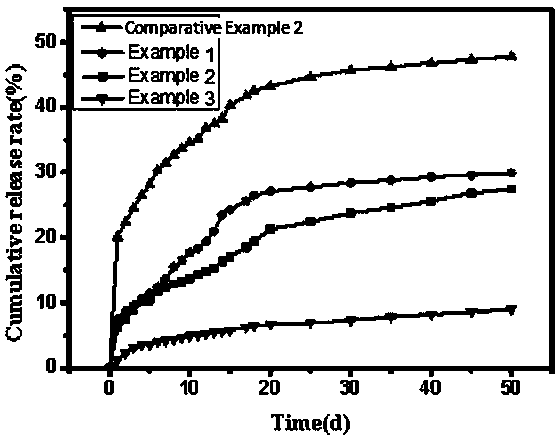

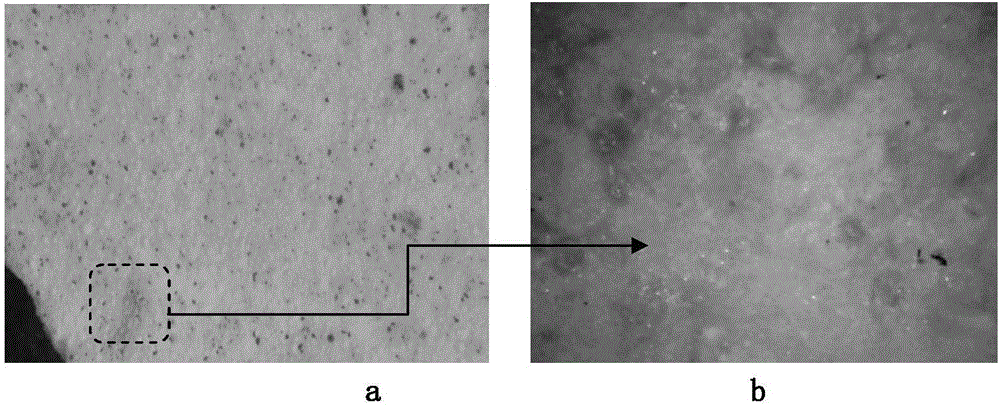

The invention belongs to the technical field of ultrafiltration materials and sanitary protection, and particularly relates to a novel dustproof, antibacterial and antiviral nano-fiber mask. The maskcomprises a mask main body, and is characterized in that the mask main body sequentially comprises a non-woven fabric layer, a multi-layer drug-carrying composite fiber membrane layer and a non-wovenfabric layer from inside to outside, wherein the multi-layer drug-carrying composite fiber membrane layer comprises at least three layers, the inner layer and the outer layer are melt blown layers orelectrostatic spun fiber membrane layers, and the middle layer is a loaded drug-carrying nano microsphere fiber membrane layer. The multi-layer drug-carrying composite fiber membrane layer used in themask can enhance the slow-release performance and the anti-virus and antibacterial properties of a drug through multiple mesoporous structures formed by drug-carrying nano microspheres and differentmaterials, the function of filtering particles and smell in air is enhanced, and the mask has relatively strong killing and inhibiting effects on public health safety, respiratory systems and infectious viruses.

Owner:广东云曌医疗科技有限公司

Alkali resistant ceramic coating material and preparation method thereof

The invention relates to an alkali resistant ceramic coating material and a preparation method thereof which are mainly applied in lithium battery production. The alkali resistant ceramic coating material is characterized by being formed by mixing the raw materials including composite powder, a binding agent and an additive, and the raw materials comprise, by mass, 50 parts of the composite powder, 10-40 parts of the binding agent and 15-40 parts of the additive. The alkali resistant ceramic coating material has the advantages that the coating is good in alkali resistance, capable of being fired in a wide temperature range and low in preparation cost.

Owner:WUHAN UNIV OF TECH

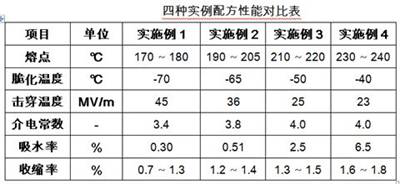

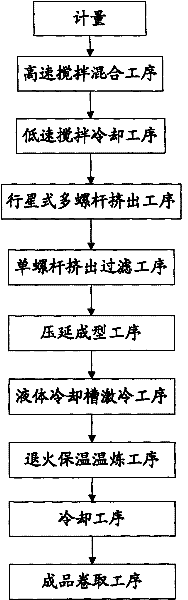

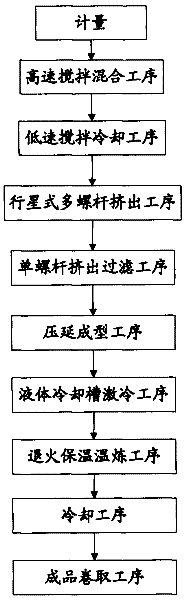

Hard polrvinyl chloride product and preparation method thereof

ActiveCN101792562AAvoid the phenomenon of surface sensitive water whiteningProtect the surfaceThiolPlasticizer

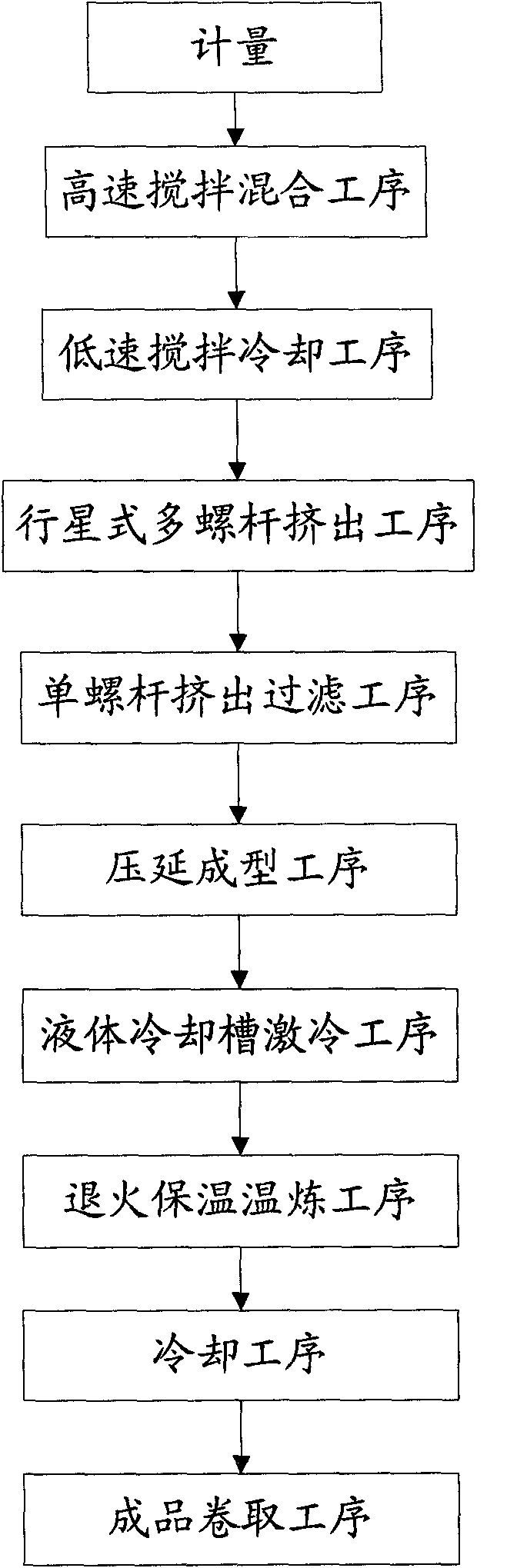

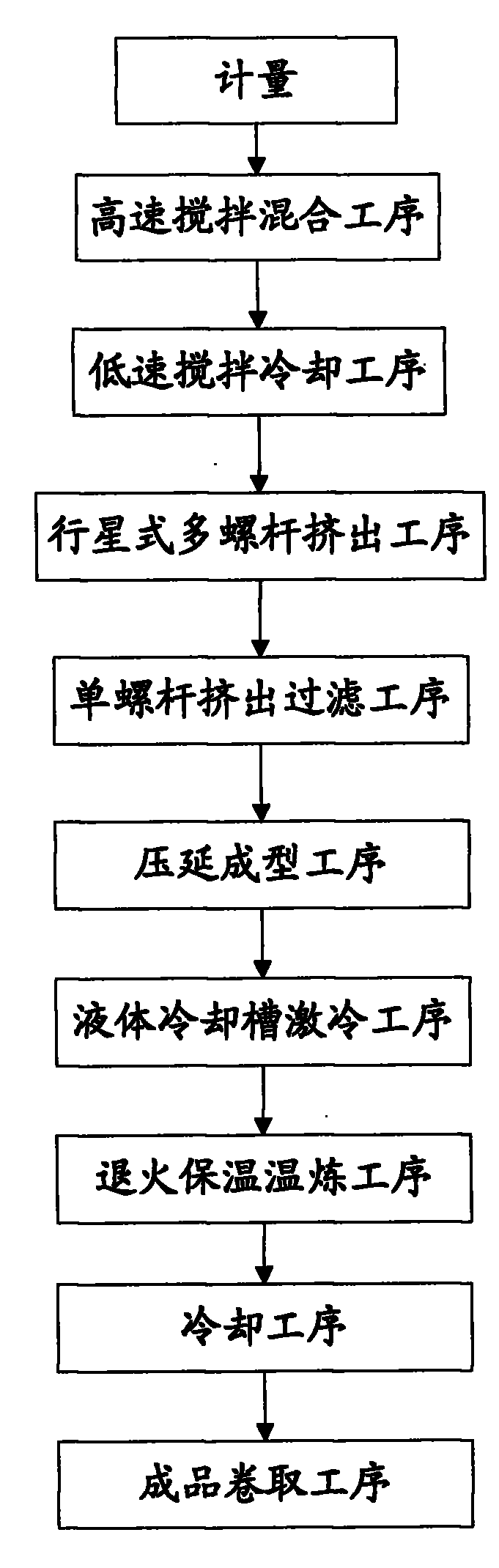

The invention discloses a hard polrvinyl chloride product, which contains the following components in parts by weight: 100 parts of polrvinyl chloride, 1.6-2.2 parts of organotin thiol, 0.6-1.0 part of internal lubricant, 0.2-0.5 part of external lubricant, 6-14 parts of impact-resistant modifier, 0.2-0.5 part of waterproof modifier, and proper amount of pigment is added. The invention also discloses a preparation method of the hard polrvinyl chloride product. The formula of the hard polrvinyl chloride product does not add any plasticizer, thus avoiding the phenomenon that the surface of the polrvinyl chloride product is water-sensitive and becomes white due to the influence of ester group of the plasticizer. In addition, the formula of the hard polrvinyl chloride product adds the waterproof modifier containing hydrophobic group, thus obviously improving the solvent resistance and the impermeability of the polrvinyl chloride product, effectively isolating the corrosion of external water or steam, protecting the surface of the polrvinyl chloride product, and leading the polrvinyl chloride product to have good appearance performance.

Owner:ANHUI TIANAN NEW MATERIAL CO LTD

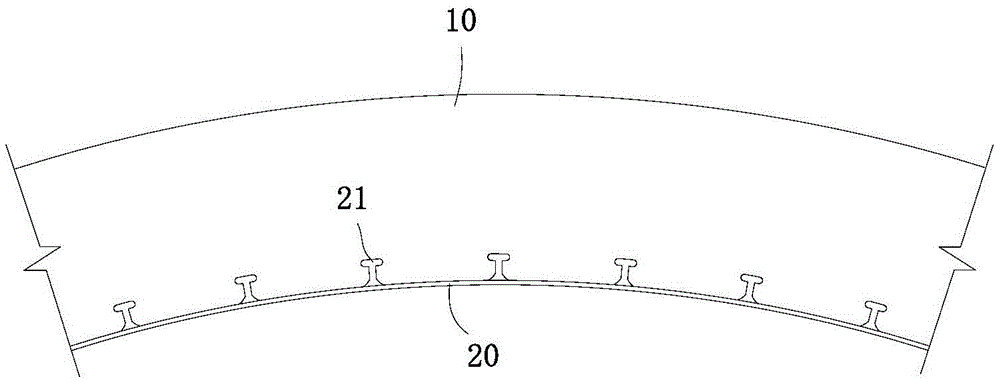

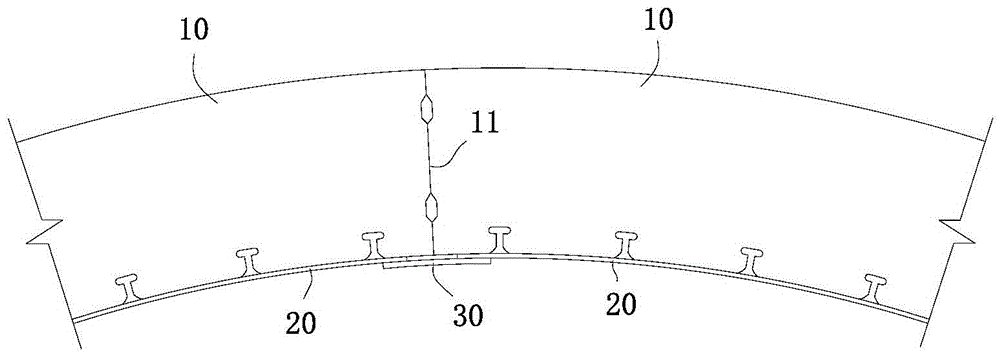

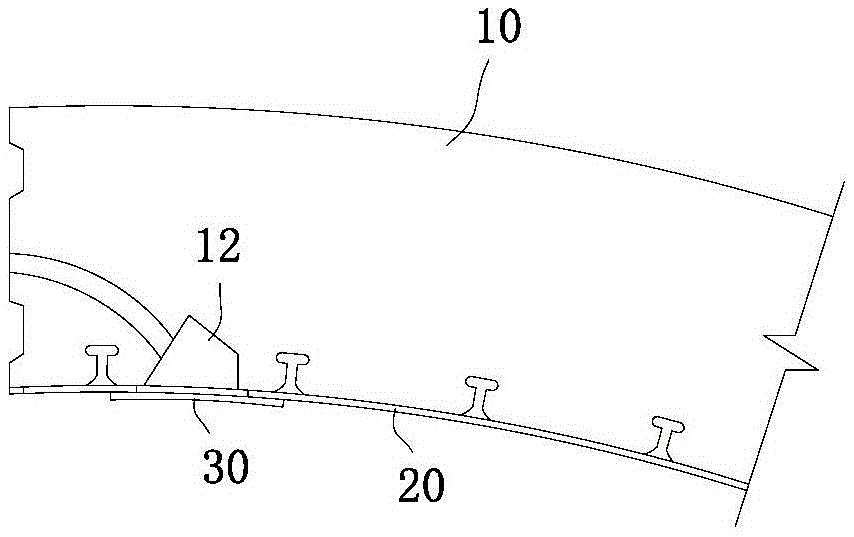

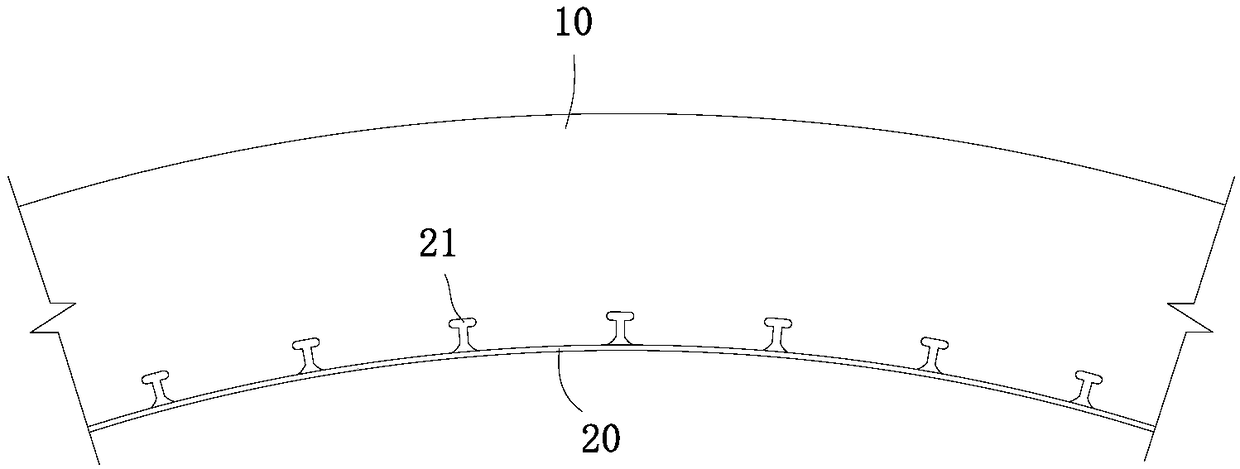

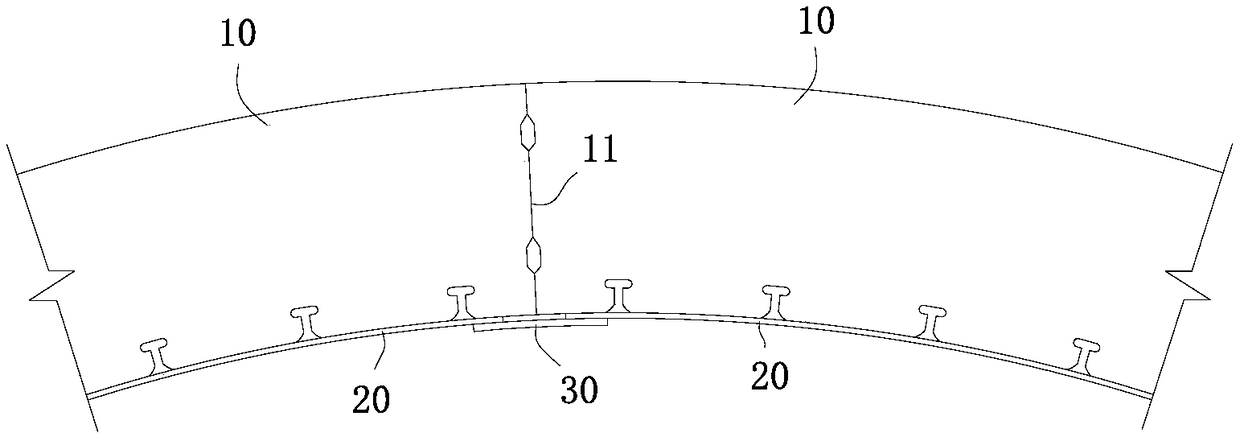

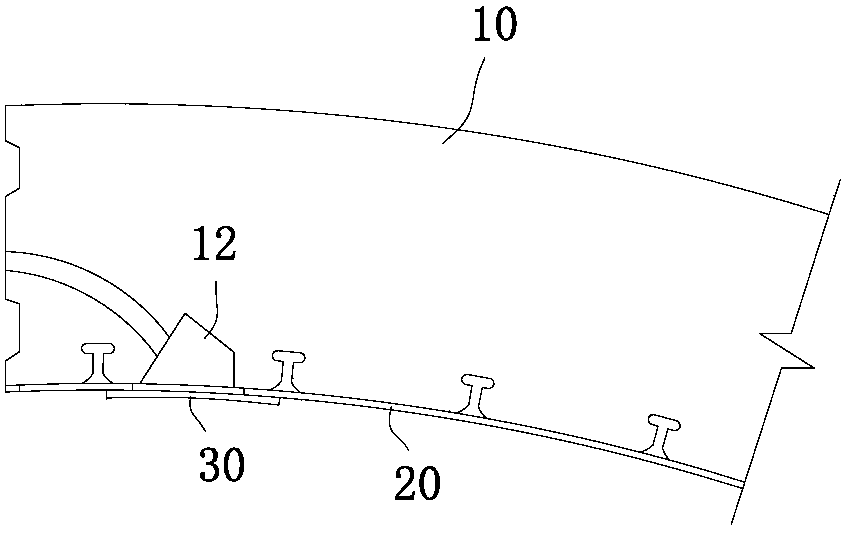

PVC sheet shield tunnel segment inner corrosion prevention system with linings

ActiveCN105649649AEasy to get materialsMature construction technologyUnderground chambersTunnel liningLap jointEngineering

The invention discloses a PVC sheet shield tunnel segment inner corrosion prevention system with linings. The system comprises a plurality of lining segments and the corrosion prevention linings embedded in the inner walls of the lining segments. The lining segments and the corrosion prevention linings are spliced together and constructed into the tubular shape in a lining mode. Joints are formed between the lining segments. The corrosion prevention linings are connected into a whole in a lap joint mode through hot melting and embedded in the inner walls of the lining segments. The corrosion resistance of the segment structure is greatly enhanced. After the lining segments are spliced, hot melting and lap joint processing is conducted on local parts without corrosion prevention linings such as the seams between the corrosion prevention linings and holes in the corrosion prevention linings, and it is ensured that the shield tunnel has the reliable overall leakproofness. Materials of the segment structure are convenient to take, the construction process is mature, and the construction cost is not high; for a water drainage pipeline formed by the lining segments under the sewage environment, corrosion of corrosive substances to the segment structure is isolated, the defect that the shield tunnel is prone to leakage at the seams of the segments is eliminated, and good application prospects are achieved.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

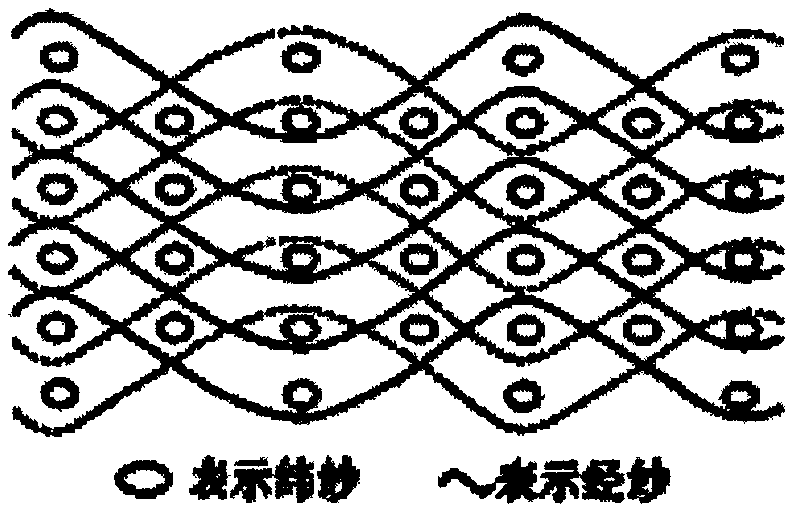

Preparation method of cover plate for polycrystalline ingot furnace thermal field

The invention provides a preparation method of a cover plate for a polycrystalline ingot furnace thermal field. The method includes the following steps of firstly, selecting carbon fiber, and weaving the carbon fiber to form a carbon fiber prefabricated body; secondly, putting the carbon fiber prefabricated body into a resin impregnation solution to be impregnated; thirdly, conducting thermal compression and carbonization treatment on the product; fourthly, conducting compaction treatment and high-temperature purification treatment on the product; fifthly, preparing a silicon carbide coating on the surface of the product; sixthly, conducting machining to obtain the final product. The method is easy and convenient to operate, high in integrity, free of layering and cracking in the use process and long in service life.

Owner:北京赛恩高科技有限公司

Vehicle cleaning wax and production method and using method thereof

InactiveCN101892130AAchieve a clean and bright effectIsolation erosionNon-ionic surface-active compoundsPolishing compositionsMicrocrystalline waxUltraviolet

The invention discloses vehicle cleaning wax, which comprises the following components in percentage by weight: 6 to 10 percent of anionic surfactant, 8 to 12 percent of nonionic surfactant, 15 to 25 percent of carnauba wax, 12 to 20 percent of microcrystalline wax, 12 to 18 percent of wetting thickening agent, and the balance of water. The surface of a vehicle can be cleaned and waxed by the vehicle cleaning wax without using the water and mechanical equipment, so that not only the water resource is saved effectively, but also the surface of the vehicle has the shiny and clean effect anytimeanywhere, conveniently and quickly; the vehicle cleaning wax is a nontoxic and innocuous aqueous product, the used additive is a biodegradable environmental-friendly material, is not added with an organic solvent and does not have pungent smell of the organic solvent, so that the vehicle cleaning wax does not pollute air without volatilizing the organic solvent, does not damage vehicle paint, does not irritate human skin, and does not pollute the environment; meanwhile, compound plant protection wax can be covered on the surface of the vehicle so as to isolate the erosion of sand wind and acid rain, resist ultraviolet rays and delay the aging of the vehicle paint.

Owner:郭阳明

Fireproof door core plate formed through rapid autoclaved curing and preparation method thereof

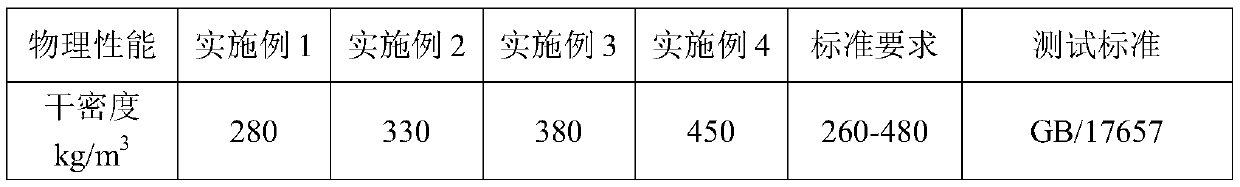

InactiveCN111099874APrevent fire and smokeImprove fire resistanceFireproof doorsCeramicwareFiberFoaming agent

The invention belongs to the technical field of fireproof door materials, and particularly relates to a fireproof door core veneer formed through rapid autoclaved curing and a preparation method thereof. The fireproof door core veneer is prepared from the following raw materials: water, a cement additive, nano silica sol, a waterproof agent, short fibers, fly ash, gypsum powder, active slag powder, ground calcium carbonate powder, Portland cement and a water-based composite foaming agent. Directional high-temperature and high-pressure curing of the fireproof door core plate is achieved throughthe autoclaved curing forming procedure. A product which has the advantages of the light weight, high strength, heat insulation, the stable volume, excellent water resistance, low water content, lowwater absorption, the low mass loss rate, high heat resistance, good heat stability, excellent carbonization resistance, metal protection function, safety, environmental protection and A-grade fireproof performance is formed; and the whole process flow time of the product from burdening production to terminal qualified products is less than 48 hours, the production efficiency is high, and the comprehensive cost is low.

Owner:广州科源新材料有限公司

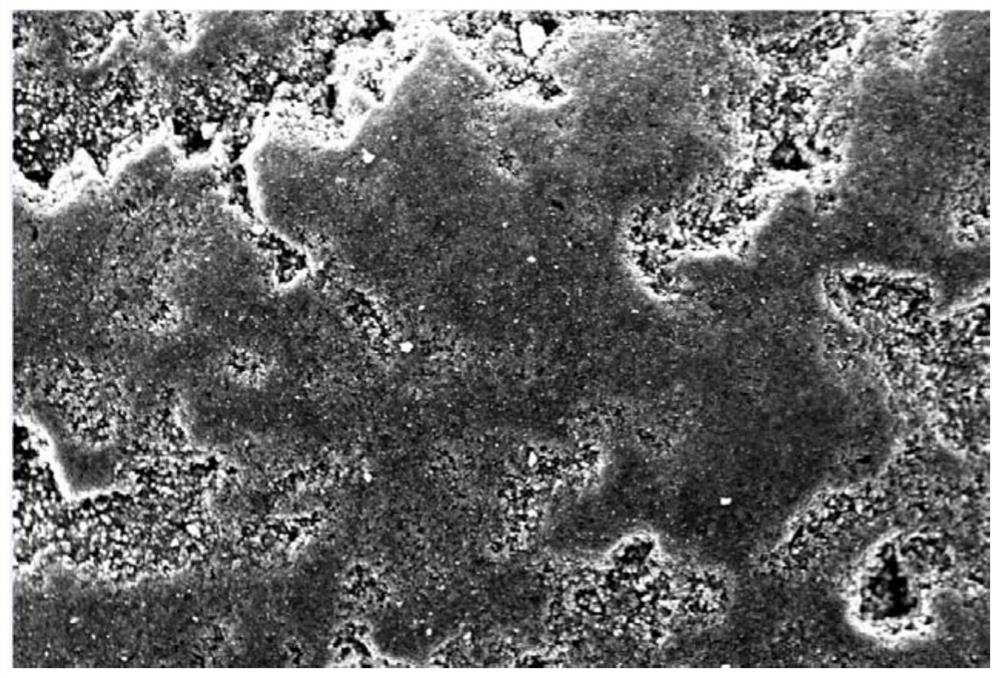

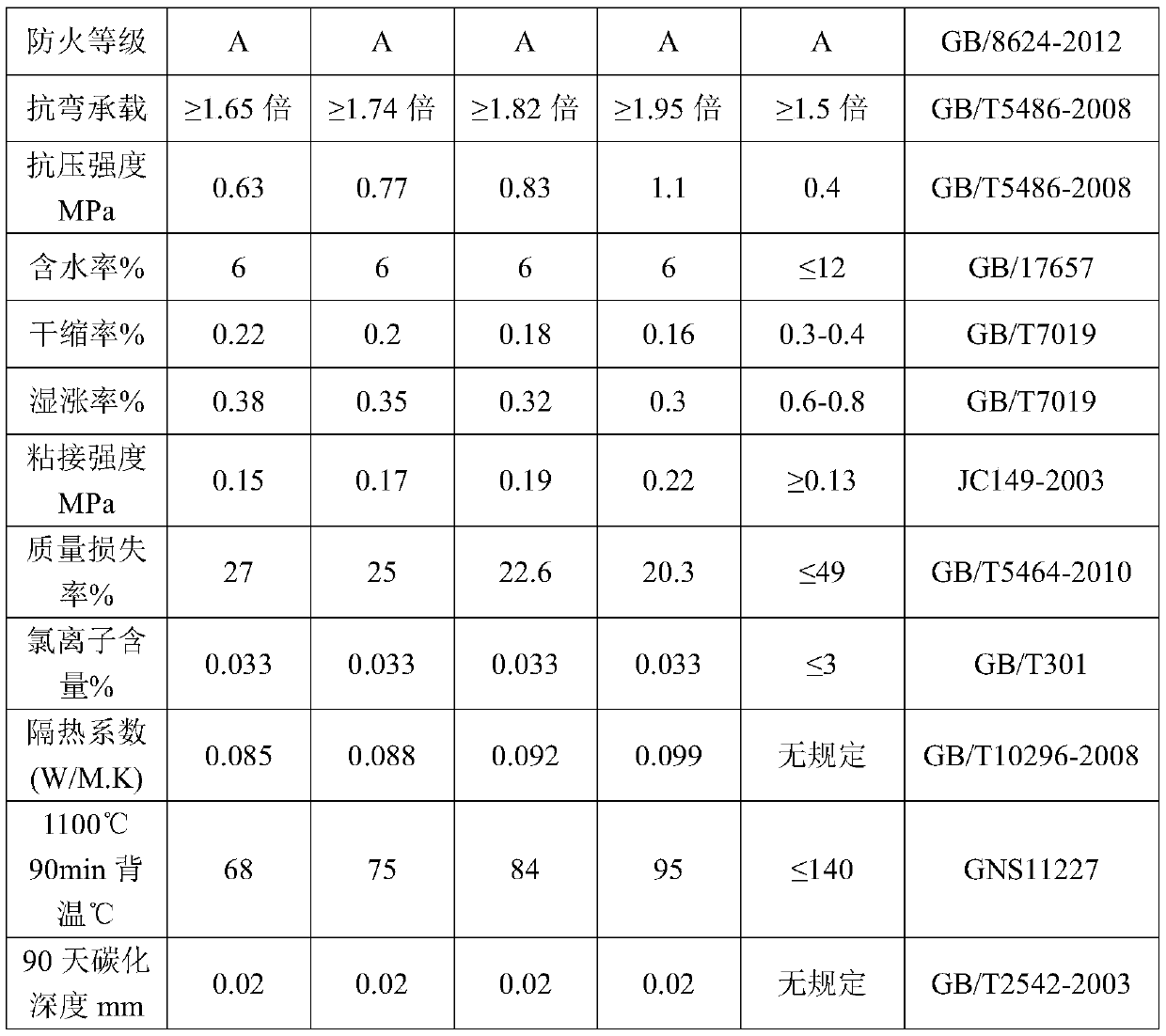

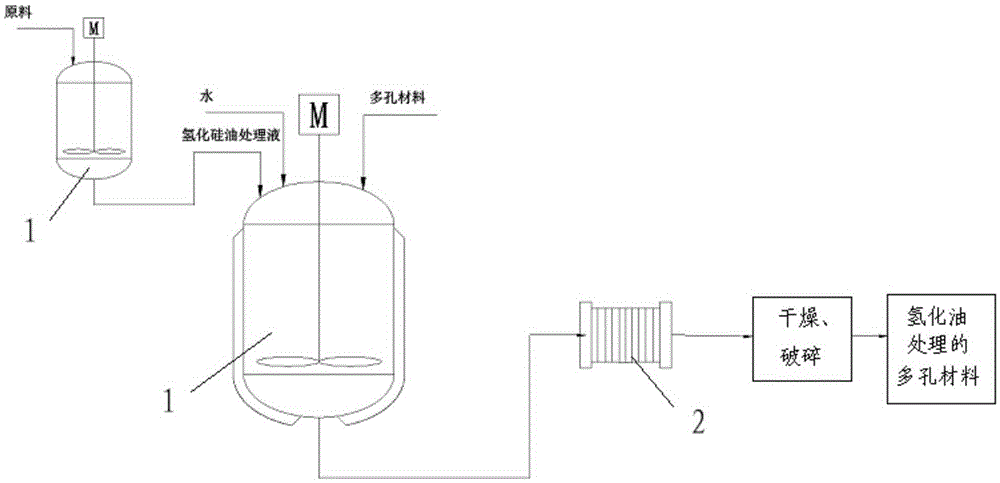

Method for processing porous material by hydrogenated silicon oil

ActiveCN103923493ASuperhydrophobicIsolation erosionPigment treatment with organosilicon compoundsPorosityFiltration

The invention relates to a method for processing a porous material by hydrogenated silicon oil, which comprises the following steps: taking 0.1-0.8% of hydrogen amount-containing hydrogenated silicon oil and cooperating with a silane coupling agent and an aqueous solvent to prepare a water-dilutable hydrogenated silicon oil processing agent, performing heat treatment, performing pumping filtration and drying on the surface of the porous material, and on internal porosity. The hole of the processed porous material is not sealed, the processed porous material has super-hydrophobicity, can effectively isolate the erosion of corrosion mediums such as aqueous vapor and pollutants on the material, can be used for surface treatment on the porous materials such as metals, inorganic silicate and an organic polymer, and can ensure the stabilization of the performances of porosity and machinery intensity in various environment. The processing method can be used for protecting porous materials such as heat insulation materials, sound-insulation sound-absorption materials and low-density structure materials.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

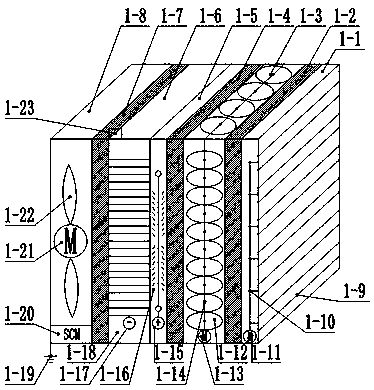

Industrial automation control cabinet dustproof and anti-corrosion ventilation system and method

PendingCN109951991AIncrease productivityIsolation erosionCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsMicrocontrollerEngineering

The present invention provides an industrial automation control cabinet dustproof and anti-corrosion ventilation system and method. The system comprises: air inlet units (an air inlet module, a dust filtering module, an internal and external circulation module, an electrostatic dust collection module, an activated carbon adsorption module, a fan module, a temperature collection module and a singlechip microcomputer control module), and an air inlet unit (an air outlet module). The temperature in a control cabinet is determined through temperature sensing, internal and external circulation ventilation modes are selected, more than 99.9% tiny dust or harmful particles are removed by the electrostatic dust collection module through the dust filtering module in the air required being ventilated or in a purification cabinet, and enter the activated carbon adsorption module to absorb chemical gases, and the fan is employed to drive the air with high cleanness to enter the control cabinet tocomplete ventilation and circulation. The ventilation problem of the automation control cabinet installed indoors and outdoors in a work environment with poor conditions, a large dust concentration or having few of chemical corrosive gases in the industries such as metallurgy, buildings, petro-chemical and cement is solved.

Owner:XIAN HUAJIANG ENVIRONMENTAL TECH

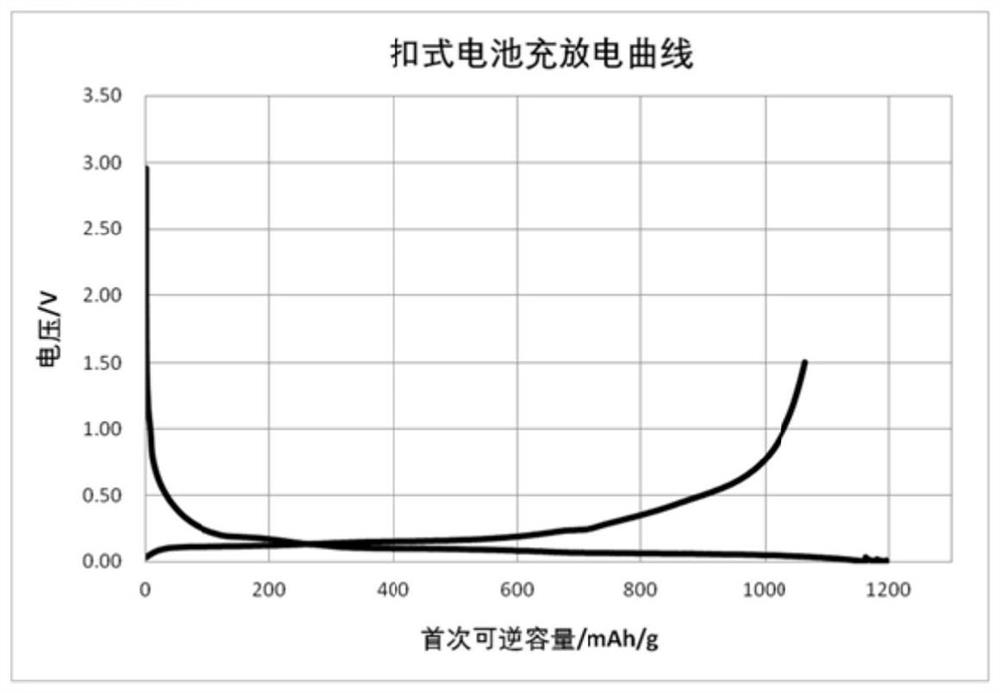

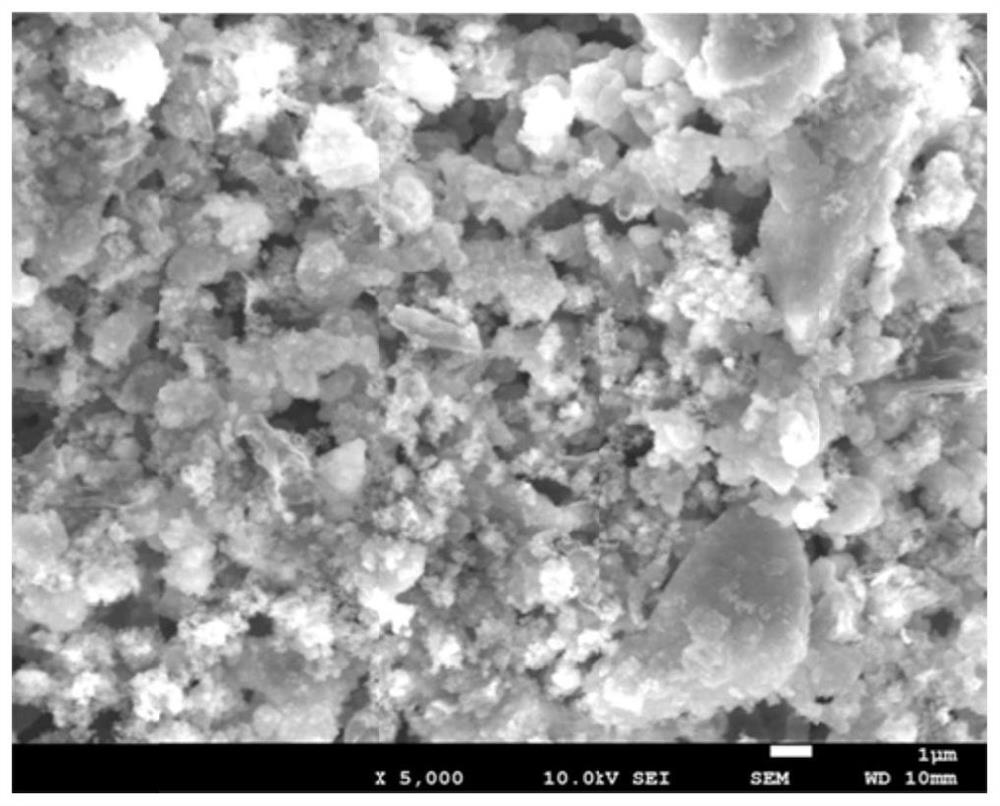

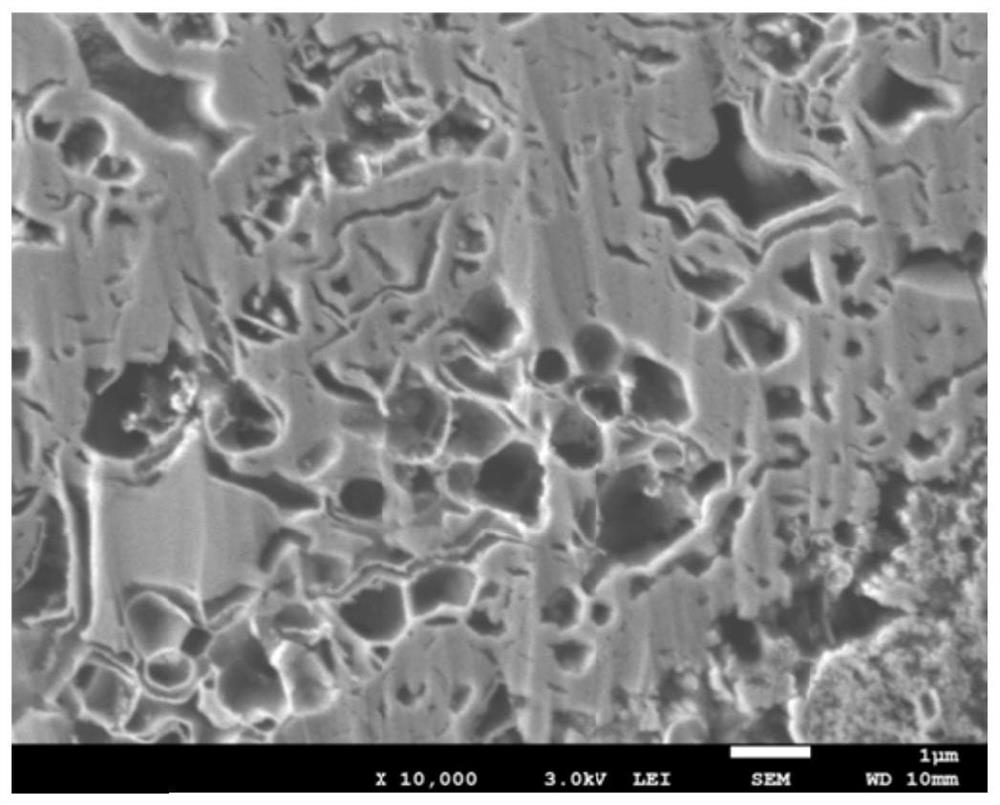

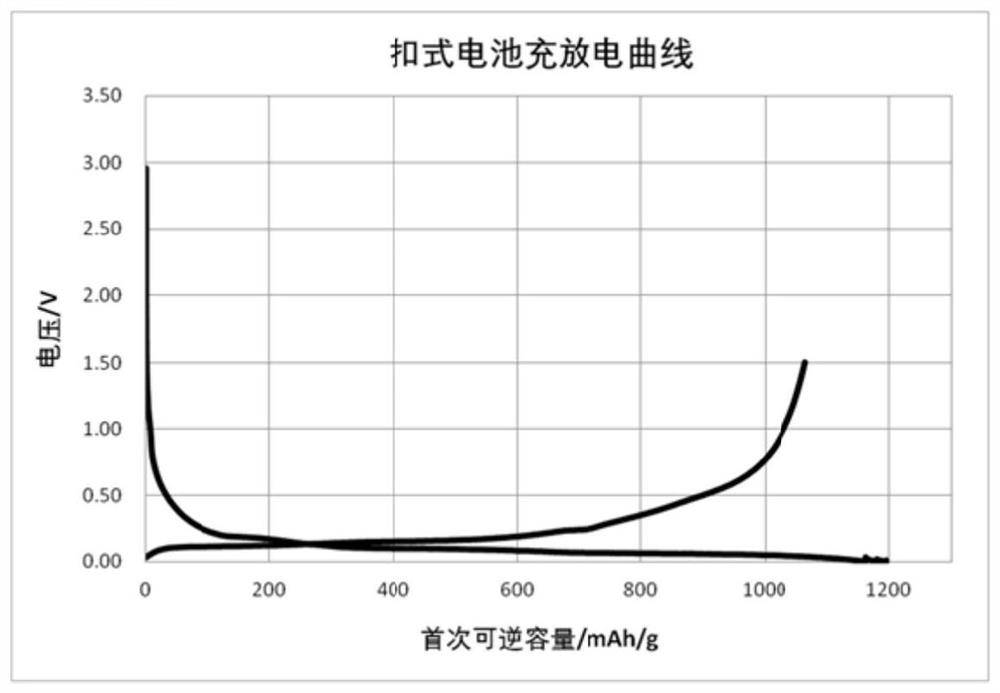

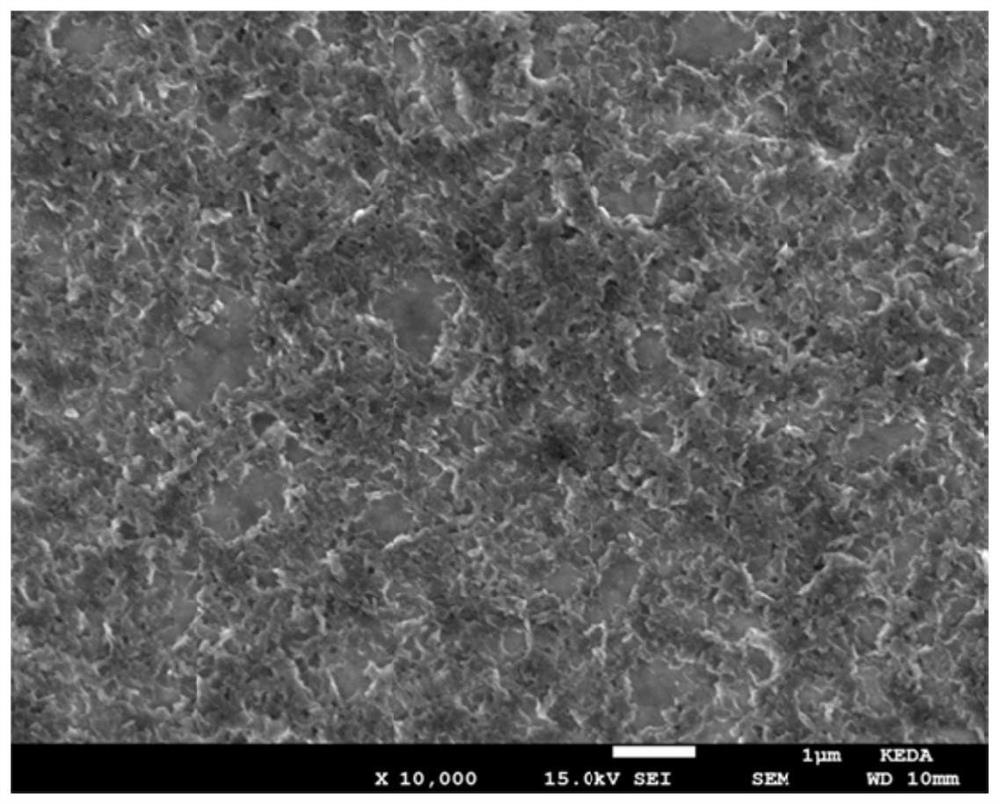

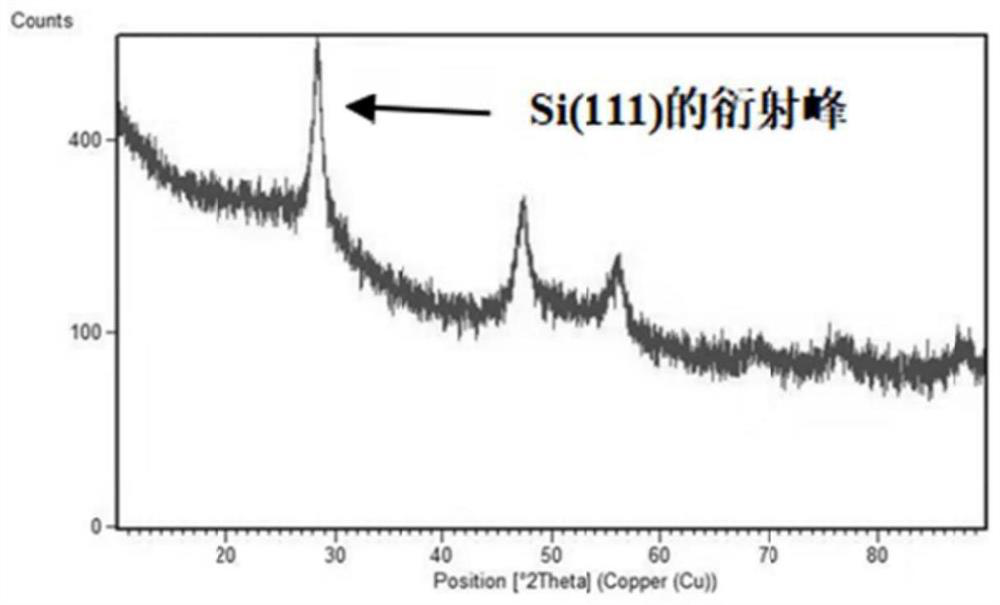

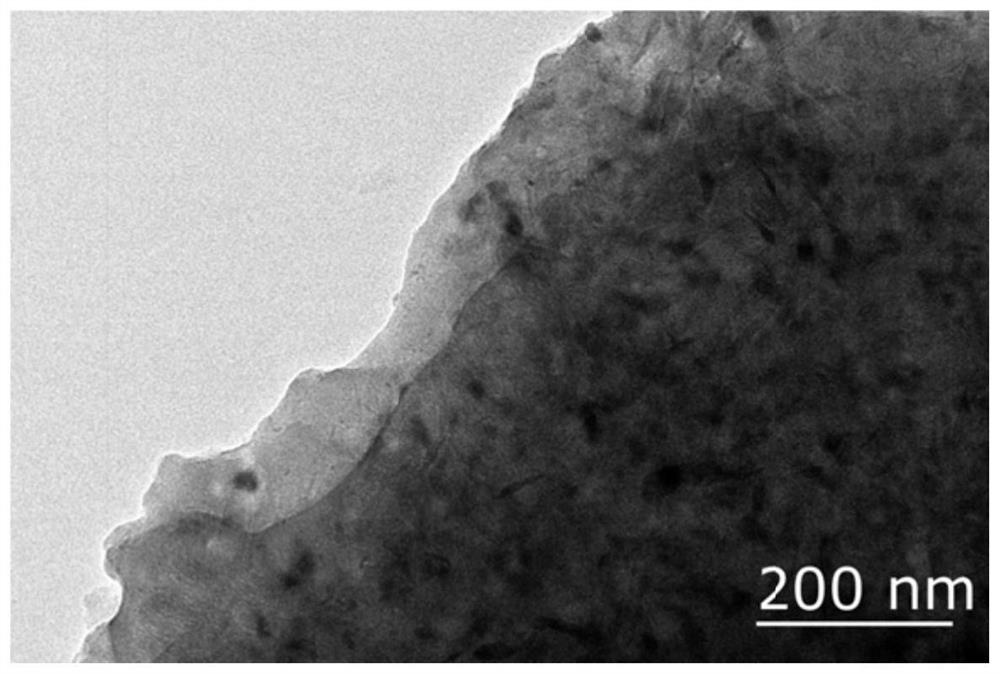

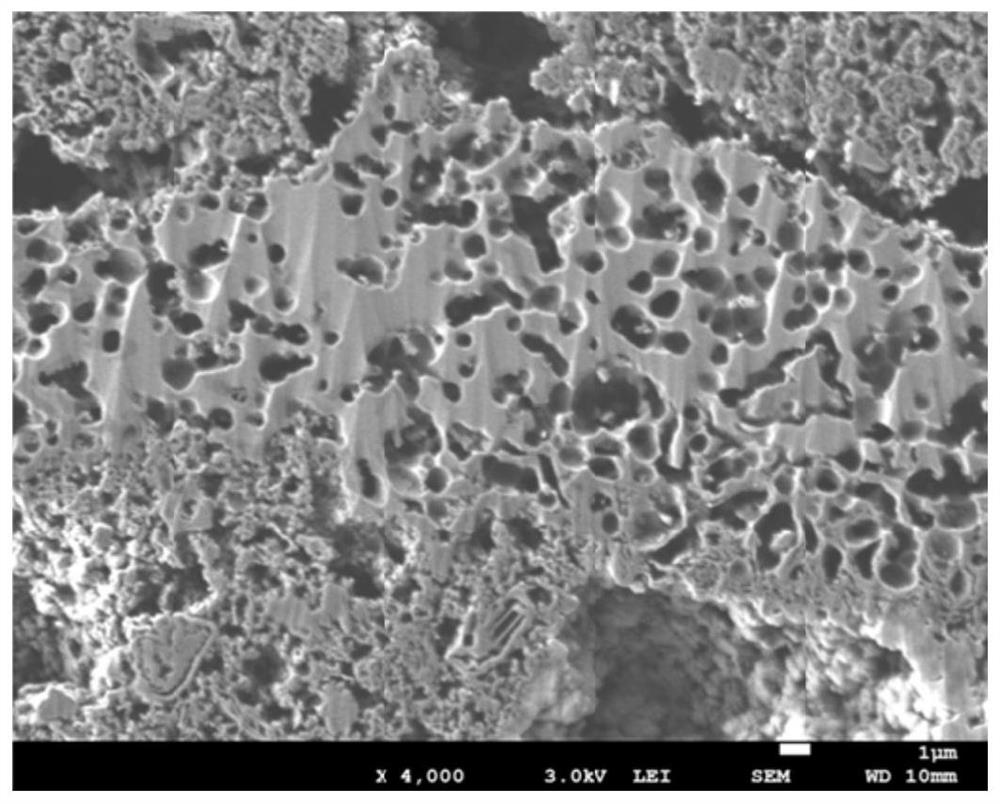

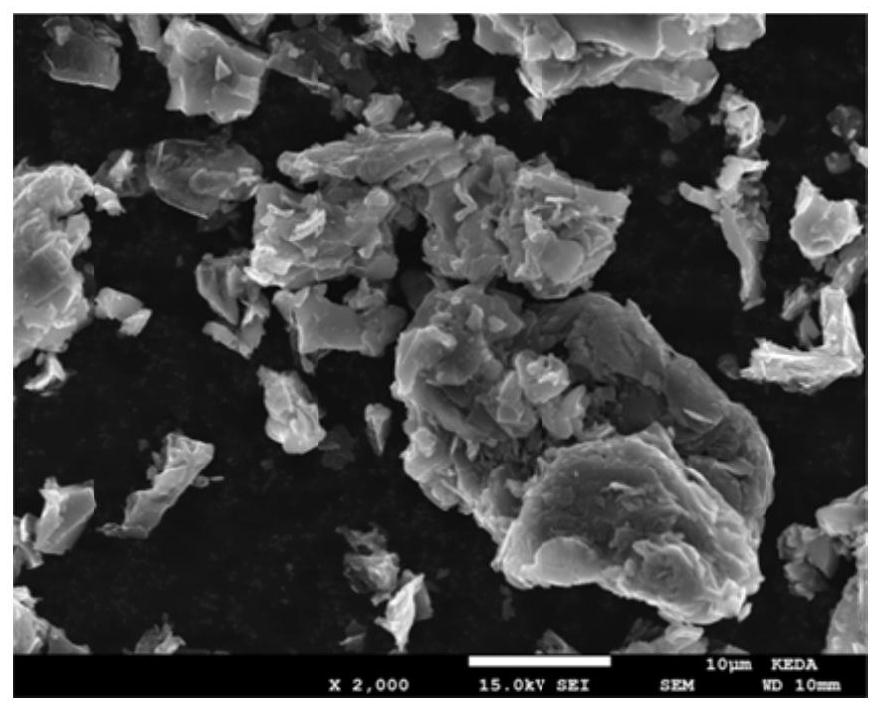

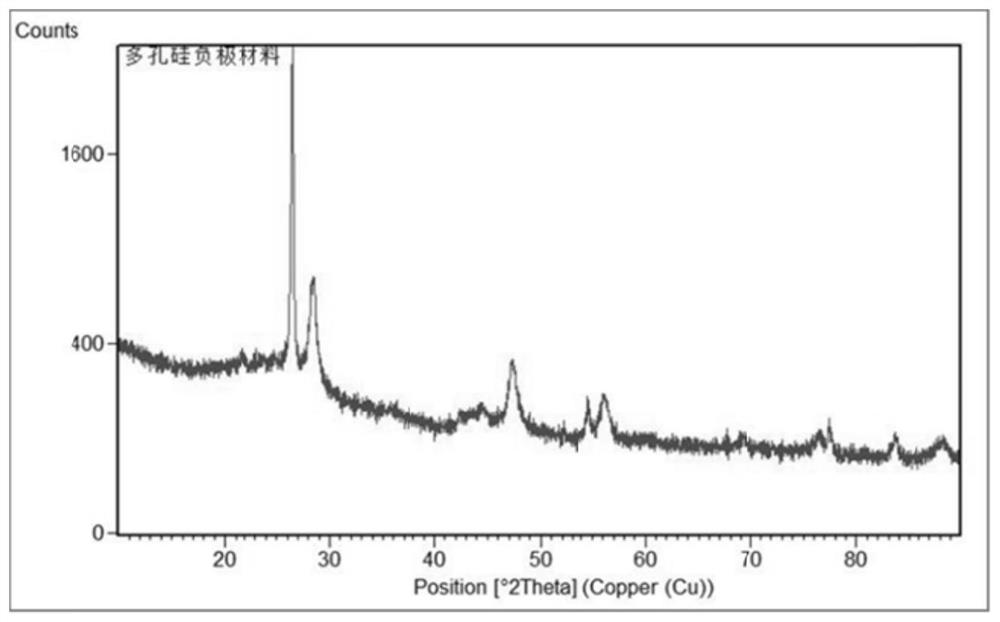

Porous silicon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111628162ASmall volume expansionLarge capacityMaterial nanotechnologyPigmenting treatmentLithium-ion batteryMaterials science

The invention belongs to the technical field of lithium ion batteries, and specifically relates to a porous silicon negative electrode material for a lithium ion battery and a preparation method thereof. The porous silicon negative electrode material comprises nano-porous silicon, conductive carbon and amorphous carbon. The nano-porous silicon contains oxygen, the oxygen content is 10-40wt%, and the nano-porous silicon in the negative electrode material accounts for 30-80wt%. The conductive carbon accounts for 5 to 30 weight percent. The ratio of the amorphous carbon is 10 to 40 weight percent. The median particle size D50 of the nano-porous silicon is 110 nm or below, the maximum particle size D100 of the nano-porous silicon is 260 nm or below, the nano-porous silicon is prepared througha wet grinding process, the raw material is porous silicon powder, and the porous silicon negative electrode material disclosed by the invention has excellent electrochemical performance, high specific capacity, excellent cycle performance and high initial efficiency.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Boric oxide fibre moisture-proof coating material and method of manufacturing the same

The invention relates to a boric oxide fiber damp-proof coating material and the production method thereof, and belongs to the technical field of special ceramic. The invention comprises the steps as follows: liquid paraffin and paradichlorobenzene are mixed in the ratio of 100ml: (5 to 30) g. The liquid paraffin is mixed with the paradichlorobenzene to be heated and mixed by a magnetism mixing device with the heating temperature of 40 to 80 DEG C till the paradichlorobenzene unfreezes completely and the solution is cooled to the room temperature, then the damp-proof coating material for the boric oxide fiber is obtained. The coating material of the invention has the functions of drawing lubrication, and preventing the boric oxide fiber from pulverization. The material is coated at the surface of the front boric oxide fiber and can form a layer of thick protective films at the boric oxide fiber surface, and separates the corrosion of water to the boric oxide fiber, improves the intensity of the boric oxide fiber obviously, thereby improving the integrative performance of the boric oxide fiber and having good basis for research of the fiber reinforcing ceramics composite material. The invention which has simple and reasonable production method is convenient and practical.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

A kind of porous silicon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111628162BSmall volume expansionLarge capacityMaterial nanotechnologyPigmenting treatmentPhysical chemistryNanoporous silicon

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Silicon-carbon negative electrode material for lithium ion battery and preparation method of silicon-carbon negative electrode material

PendingCN111755681AIncrease battery capacityExcellent cycle performanceMaterial nanotechnologyCell electrodesSilicon particleCarbon source

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a silicon-carbon negative electrode material for a lithium ion battery and a preparation method of the silicon-carbon negative electrode material. The silicon-carbon negative electrode material comprises the following components in percentage by weight: 30%-60% of silicon particles, 0.5%-8% of zirconium oxide, 10%-30% of an asphalt cracking carbon source and 30%-60% of graphite particles, the silicon-based particles can be represented by SiOX, and x is greater than 0 and less than 0.5. When the silicon-carbon negative electrode material provided by the invention is used as a negative electrode active substance of the lithium ion battery, the battery capacity can be obviously increased, excellent cycle performance is achieved, and the raw material micron pure silicon is wide in application, low in price and suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Prestressed carbon plate-ECC combined reinforced concrete structure and construction method

PendingCN113914652AImprove crack resistanceDelayed strippingClimate change adaptationBuilding repairsRebarInterfacial shear

The invention discloses a prestressed carbon plate-ECC combined reinforced concrete structure and a construction method. A cement-based composite material ECC layer, a prestressed plate and a cement-based composite material ECC layer outer protective layer are laminated at the bottom of a concrete beam; the plate is protected on the outer side of the plate reinforced by the prestressed plate by utilizing good durability such as crack resistance and impermeability of the cement-based composite material ECC, so that the erosion effect of the external severe environment on the plate is isolated, and meanwhile, the overall bearing capacity of the concrete beam and the crack resistance of the beam bottom can be improved; and the ECC layer is arranged between the prestressed plate and the concrete, so that the stripping of the plate can be delayed due to the characteristics of fine cracks, the interfacial shear stress is effectively transmitted, and the advantage of high tensile strength of the plate is better exerted.

Owner:河南郑大建筑材料有限公司

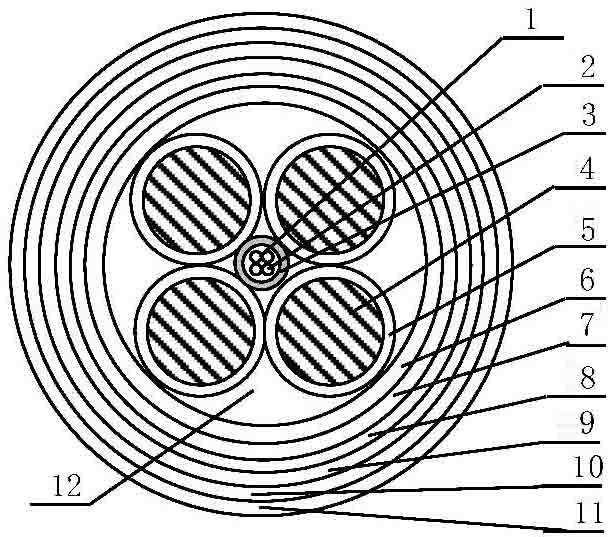

Intelligent mineral insulated cable

PendingCN113161067AGood fire retardantPromote environmental protectionInsulated cablesOrganic insulatorsCopper conductorPolyolefin

The invention provides an intelligent mineral insulated cable, which comprises a cable inner core structure and a cable sheath structure, wherein the cable inner core structure comprises a distributed optical fiber temperature sensing system, an optical fiber, a PBT sheath, a copper conductor and a mineral insulating layer, the cable sheath structure sequentially comprises a halogen-free low-smoke flame-retardant polyolefin inner sheath, a quartz net layer, a mica tape layer, a ceramic polyolefin sheath, a nylon sheath layer and a halogen-free low-smoke flame-retardant polyolefin sheath layer from inside to outside, and filling is arranged between the cable inner core structure and the cable sheath structure. The intelligent mineral insulated cable has the beneficial effects that the intelligent mineral insulated cable can transmit optical signals while transmitting power, can intelligently detect physical quantities such as stress, temperature, liquid flow rate, sound pressure, hydraulic pressure and magnetic field around the mineral insulated cable along with the change of working conditions, enables the mineral insulated cable to be in an optimal working state, and adopts the ceramic polyolefin sheath and the nylon sheath, so that the cable has the performance of being resistant to bite of rats and ants, fireproof, flame-retardant, green, environment-friendly and the like.

Owner:LUNENG TAISHAN QUFU CABLE CO LTD

A new dustproof, antibacterial and antiviral nanofiber mask

ActiveCN111235756BEasy to stay dryIsolation erosionElectro-spinningNon-woven fabricsMicrosphereNonwoven fabric

The invention belongs to the field of ultrafiltration materials and the field of health protection technology, and specifically relates to a novel dustproof, antibacterial and antiviral nanofiber mask, which includes a mask main body, and is characterized in that: the mask main body sequentially includes non-woven fabrics from inside to outside Layer, multi-layer drug-loaded composite fiber film layer and non-woven fabric layer, the multi-layer drug-loaded composite fiber film layer includes at least three layers, the inner and outer layers are meltblown layers or electrospun fiber film layers, and the middle layer It is a fiber membrane layer loaded with drug-loaded nano microspheres. The multi-layer drug-loaded composite fiber membrane layer used in the present invention can enhance the slow-release performance, anti-virus and anti-bacterial properties of drugs through drug-loaded nano-microspheres and various mesoporous structures formed by different materials, and enhance the filtration of particulate matter and odor in the air It has a strong killing and inhibiting effect on public health safety, respiratory system, and infectious viruses.

Owner:广东云曌医疗科技有限公司

Boric oxide fibre moisture-proof coating material and method of manufacturing the same

Owner:ZHONGCAI HIGH NEW MATERIAL +1

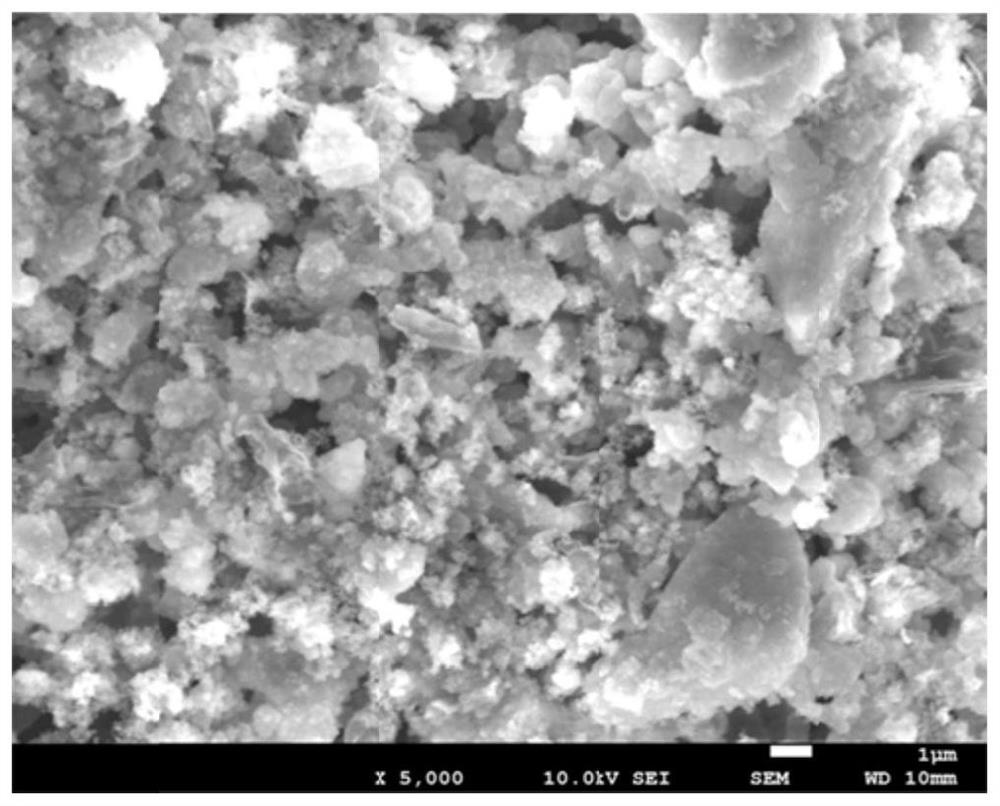

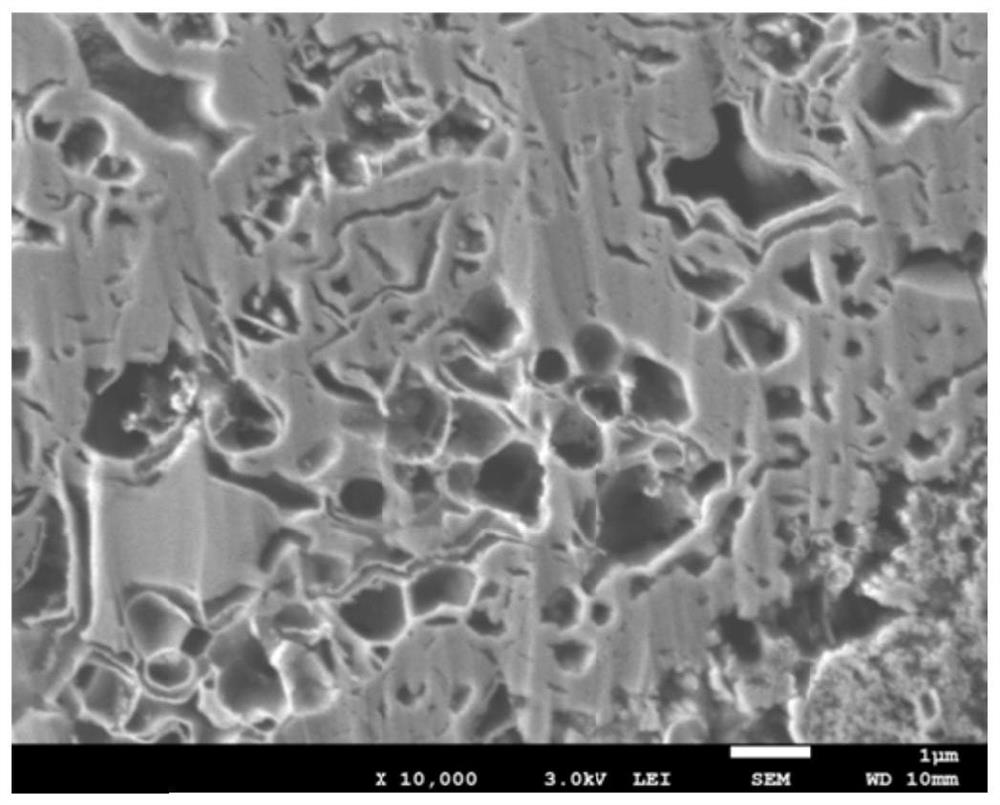

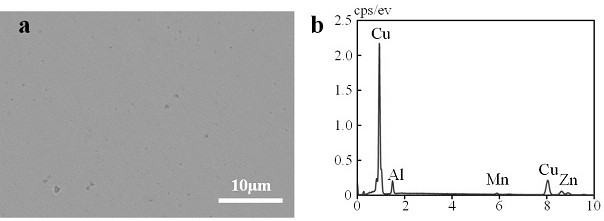

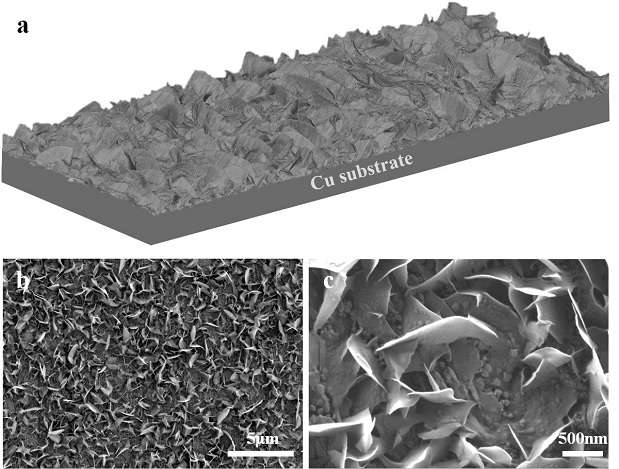

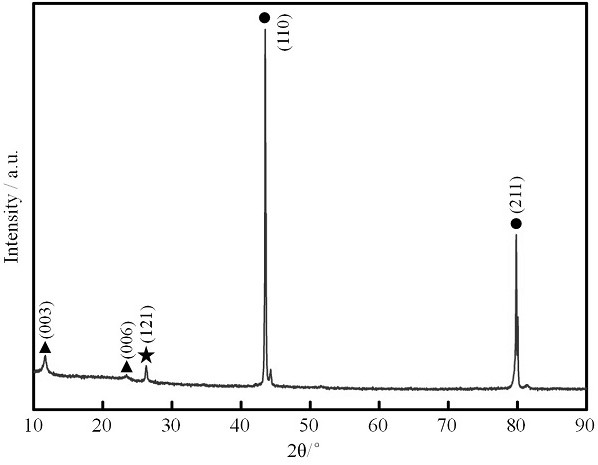

Method for in-situ construction of superhydrophobic coating on copper alloy surface

ActiveCN111005014BThe method is simple and fastEasy to operateMetallic material coating processesSuperhydrophobeSuperhydrophobic coating

In order to fill in the gaps in the prior art, the present invention discloses a method for in-situ construction of a superhydrophobic coating on the surface of a copper alloy for the first time: introduce divalent and trivalent elements (such as Zn, Al) into the copper alloy, and the copper alloy Immersed in sodium chloride solution, the layered double metal hydroxide / oxide multi-level structure film can be obtained in situ; determine the microscopic morphology and phase type of the synthesized multi-level structure, and adjust the temperature for preparing the coating. A multi-level structure with different densities was built; the static contact angle of the surface modified by perfluorooctyl triethoxysilane was determined; and the corrosion resistance of copper alloys with superhydrophobic coatings was characterized by electrochemical tests, thereby Demonstration of corrosion resistance of superhydrophobic coatings. The present invention is the first proposed method for constructing a superhydrophobic coating on the surface of copper alloy in situ, which is simple, convenient, energy-saving, environmentally friendly, low in cost, strong in controllability, strong in binding force with copper alloy substrate, stable in structure and relatively practical. Strong, can be widely used in industrial production.

Owner:SHANGHAI UNIV

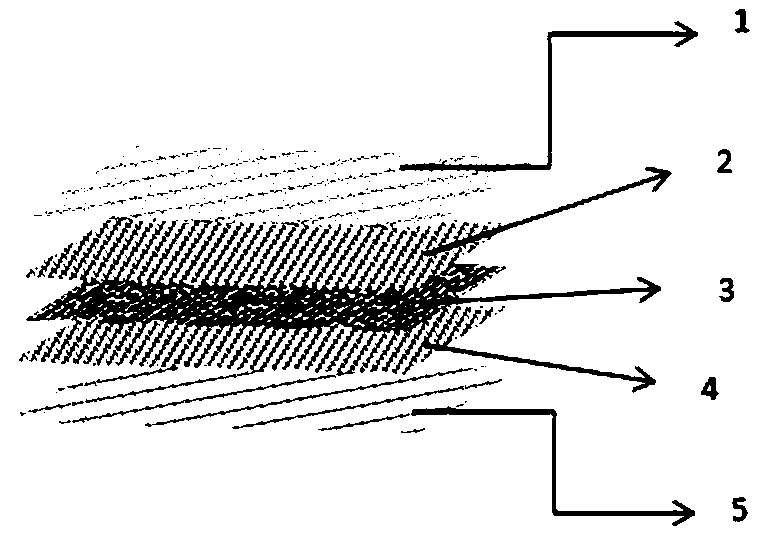

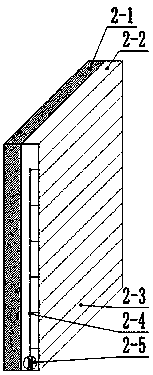

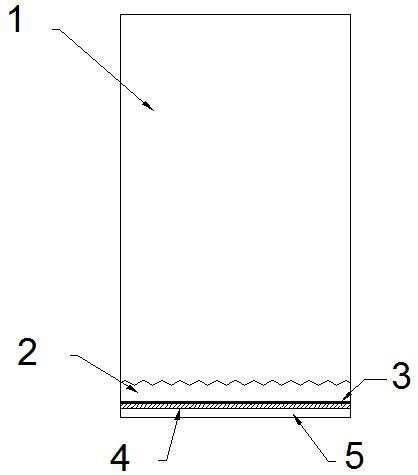

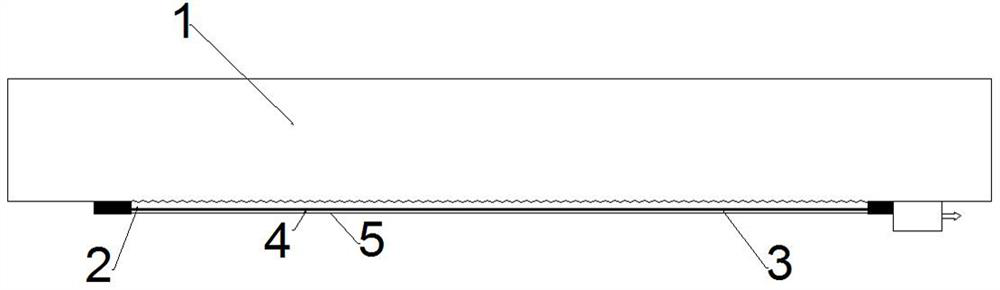

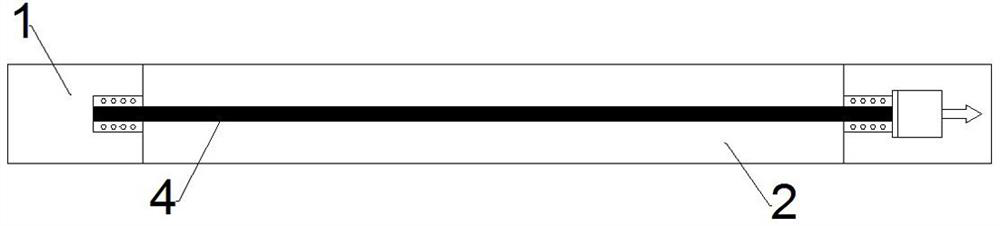

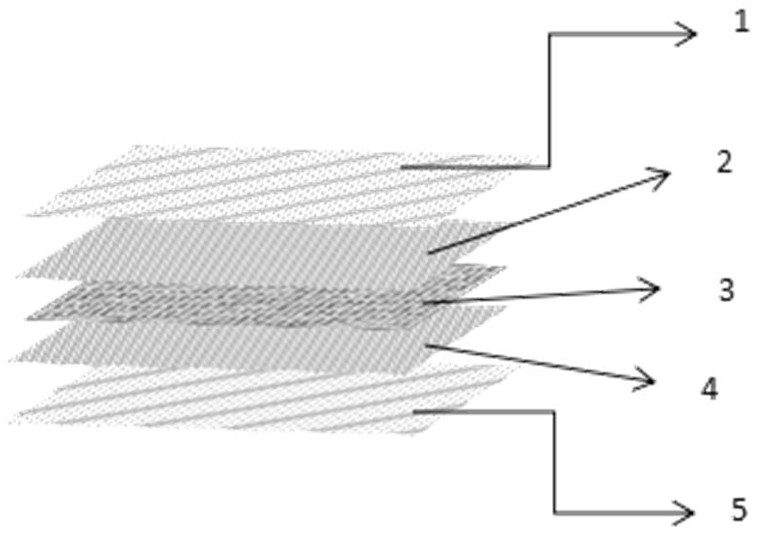

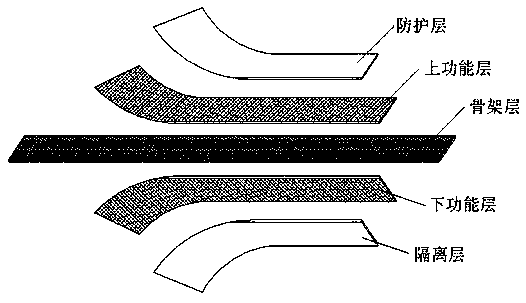

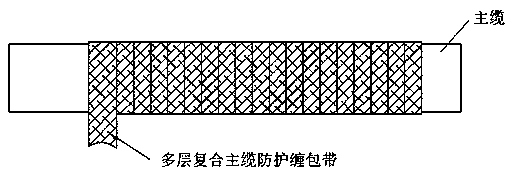

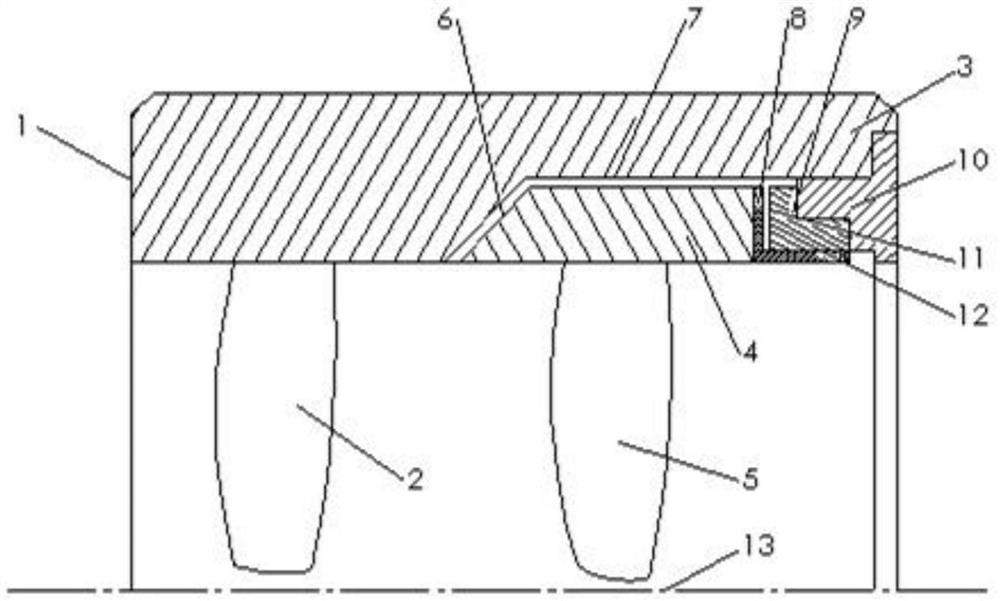

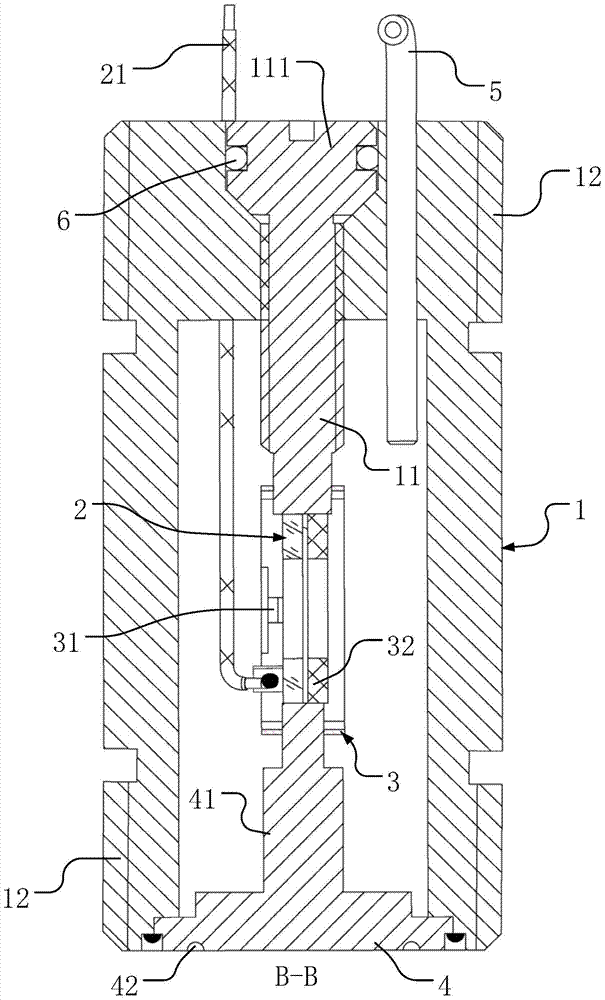

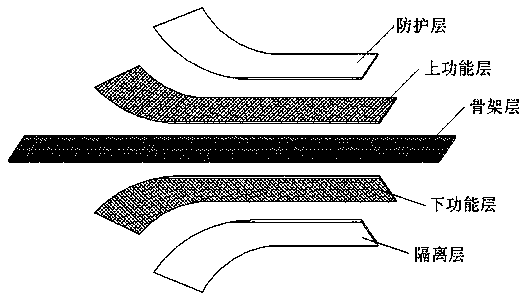

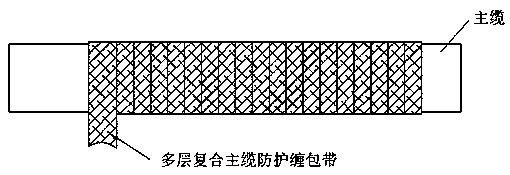

Multi-layer composite main cable protection tedlar tape

PendingCN111434599AIncrease elasticityEffective protectionBridge structural detailsFrostProtection layer

The invention discloses a multi-layer composite main cable protection tedlar tape. The multi-layer composite main cable protection tedlar tape mainly consists of a surface protection layer (1), an upper functional layer (2), a skeleton layer (3), a lower functional layer (4) and an isolating layer (5). According to the multi-layer composite main cable protection tedlar tape disclosed by the invention, in a spiral twining manner, the multi-layer composite main cable protection tedlar tape is twined onto the surface of a bridge main cable; and the tedlar tape can be cured onto the surface of themain cable in the manners of overlapping and hot pressing to protect the main cable steel rope;. The multi-layer composite main cable protection tedlar tape disclosed by the invention has excellent isolation protection effect, and can effectively isolate invasion of natural environments including wind, frost, rain, snow, salt fog, acidic atmosphere and the like to the bridge main cable; and the overlapping intensity and the adhering intensity are high, and long-term service life of the products is guaranteed.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND +1

A kind of anti-alkali ceramic coating material and preparation method thereof

The invention relates to an alkali resistant ceramic coating material and a preparation method thereof which are mainly applied in lithium battery production. The alkali resistant ceramic coating material is characterized by being formed by mixing the raw materials including composite powder, a binding agent and an additive, and the raw materials comprise, by mass, 50 parts of the composite powder, 10-40 parts of the binding agent and 15-40 parts of the additive. The alkali resistant ceramic coating material has the advantages that the coating is good in alkali resistance, capable of being fired in a wide temperature range and low in preparation cost.

Owner:WUHAN UNIV OF TECH

An internal anti-corrosion system for shield tunnel segments lined with pvc sheets

ActiveCN105649649BEasy to get materialsMature construction technologyUnderground chambersTunnel liningEngineeringHot melt

The invention discloses a PVC sheet shield tunnel segment inner corrosion prevention system with linings. The system comprises a plurality of lining segments and the corrosion prevention linings embedded in the inner walls of the lining segments. The lining segments and the corrosion prevention linings are spliced together and constructed into the tubular shape in a lining mode. Joints are formed between the lining segments. The corrosion prevention linings are connected into a whole in a lap joint mode through hot melting and embedded in the inner walls of the lining segments. The corrosion resistance of the segment structure is greatly enhanced. After the lining segments are spliced, hot melting and lap joint processing is conducted on local parts without corrosion prevention linings such as the seams between the corrosion prevention linings and holes in the corrosion prevention linings, and it is ensured that the shield tunnel has the reliable overall leakproofness. Materials of the segment structure are convenient to take, the construction process is mature, and the construction cost is not high; for a water drainage pipeline formed by the lining segments under the sewage environment, corrosion of corrosive substances to the segment structure is isolated, the defect that the shield tunnel is prone to leakage at the seams of the segments is eliminated, and good application prospects are achieved.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

A kind of method for treating porous material with hydrogenated silicone oil

ActiveCN103923493BSuperhydrophobicIsolation erosionPigment treatment with organosilicon compoundsPorosityFiltration

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

A core-shell structure porous silicon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111755677BReduce absolute volume expansionAlleviate the volume expansion effectMaterial nanotechnologyCell electrodesNanoporous siliconGraphite

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a core-shell structure porous silicon negative electrode material for lithium ion batteries and a preparation method thereof; the porous silicon negative electrode material has a core-shell structure, and the core contains nanoporous silicon, graphite and amorphous carbon, the shell is amorphous carbon; the proportion of nanoporous silicon in the negative electrode material is 30% to 70wt.%, the proportion of graphite is 20% to 45wt.%, and the proportion of amorphous carbon is 10% to 40wt. .%; the microporous silicon raw material contains 1 to 10wt.% of oxygen, and the oxygen content in the nanoporous silicon obtained by wet grinding is 12 to 35wt.%; the negative electrode material of the present invention is used as lithium ion When the negative active material of the battery is used, it can significantly increase the battery capacity, and has excellent cycle performance, and the raw material is cheap, and the preparation process and equipment are mature, which is suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

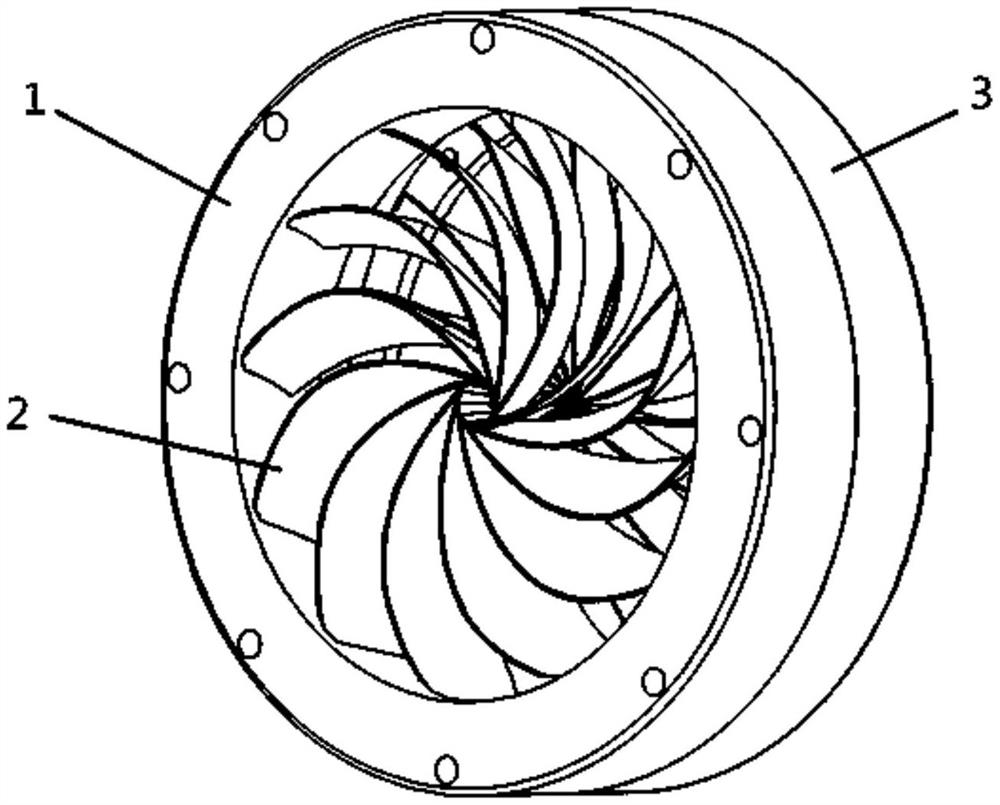

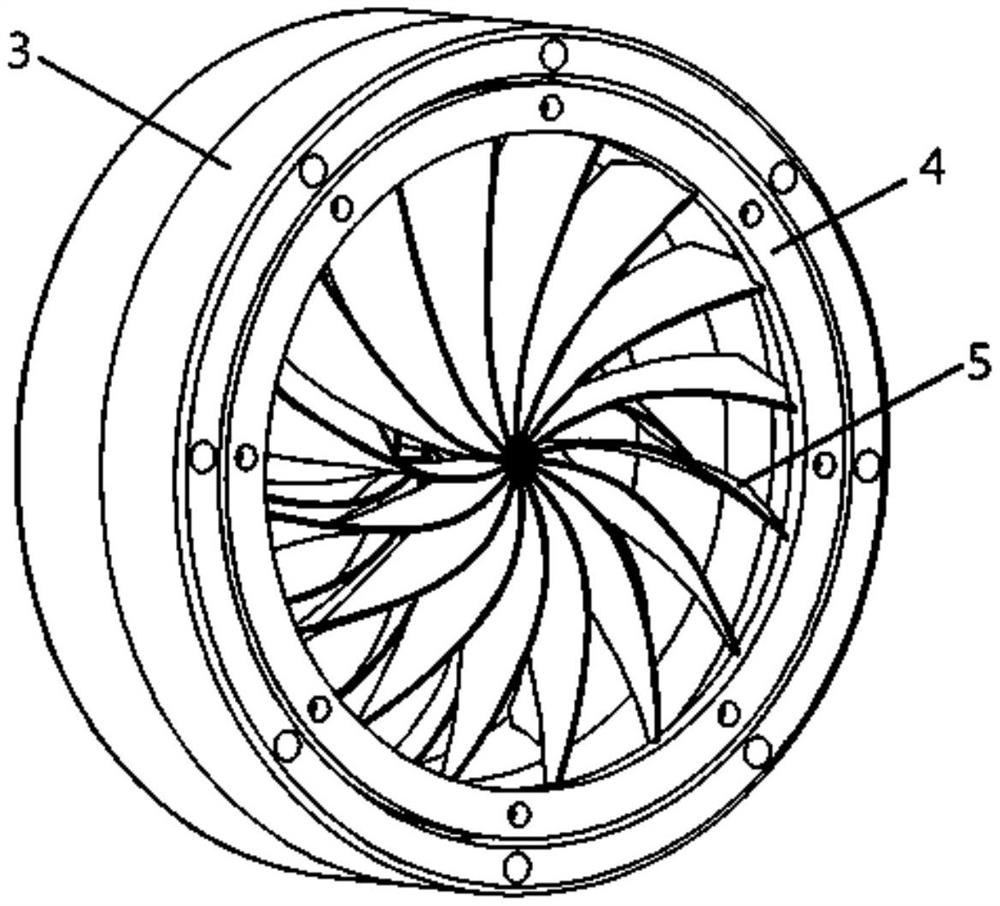

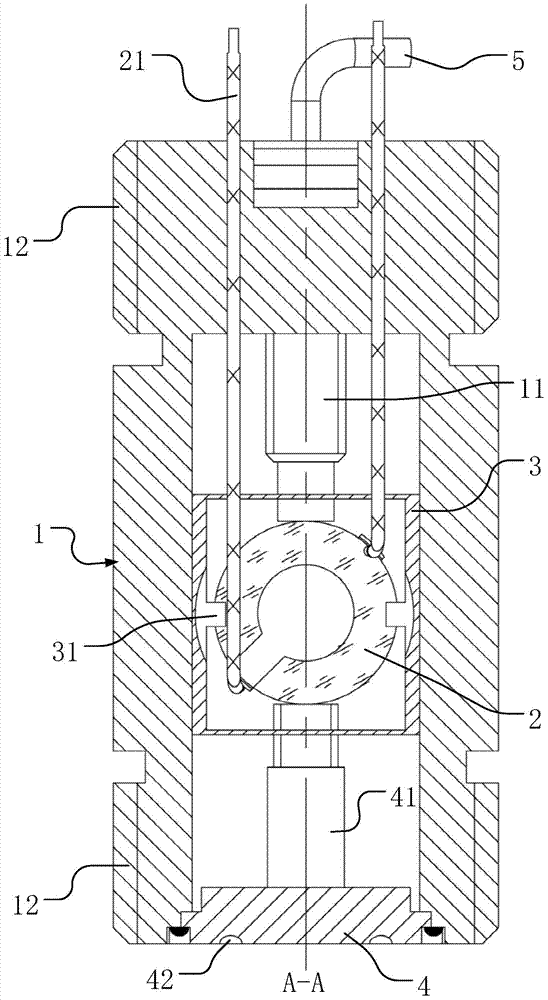

A shaftless gas turbine

ActiveCN110821570BCompact structureDo more workBlade accessoriesStatorsFlight vehicleEnergy conversion efficiency

The invention provides a gas turbine without a main shaft. The gas turbine is characterized by comprising a housing, a rotor assembly, a stator assembly and a bearing assembly, wherein the rotor assembly and the bearing assembly are mounted in the housing, the bearing assembly supports the rotor assembly, and the stator assembly is connected with the housing; the rotor assembly comprises a rotor ring and a plurality of rotor blades, the rotor blades are arranged on the rotor ring, and the rotor ring is arranged on the housing; and the stator assembly comprises a rim and a plurality of guide blades, the guide blades are arranged on the rim, and the rim is arranged on the housing. The gas turbine has the advantages of being small in occupied space, high in energy conversion efficiency, largein output mechanical power, small in vibration and the like, and is particularly suitable for being applied to the engine technology of a new generation of advanced aerospace vehicles and modern civil airliners.

Owner:BEIJING JIAERDE TECH

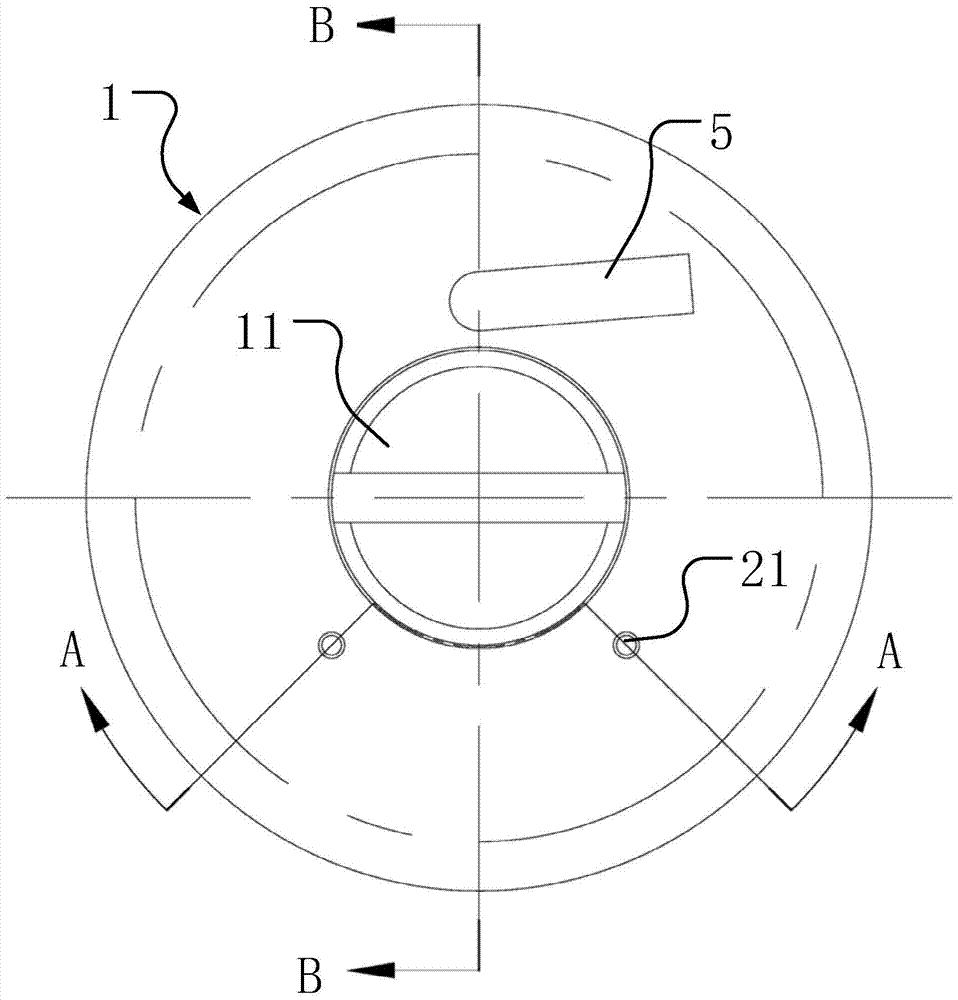

Downhole Quartz Resonant Pressure Sensor

InactiveCN105092136BSimple structureLow costFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesQuartz crystal resonatorMicrometer

A downhole quartz resonant pressure sensor, which includes a cylindrical housing, a quartz crystal resonator and a bracket arranged in the housing, the quartz crystal resonator is embedded in the bracket, and the bracket is fixedly installed in the housing; the housing There is a screw hole in the center of one end of the housing, and a fine-tuning screw is inserted into the screw hole. The other end of the housing is provided with a pressure detection window. The pressure detection window is sealed with an elastic metal diaphragm. Corresponding to the center of one side of the shell, there is a convex column; the quartz crystal resonator is an open ring sheet-shaped 4.992MHz quartz crystal resonator with a fifth-order overtone thickness shear vibration mode, and a quartz crystal resonator is welded on it. For the sealed lead-out ends of the electrodes passing through the shell; the corresponding ends of the fine-tuning screw and the protruding post are respectively inserted into the bracket, and the force-sensitive points of the quartz crystal resonator are in contact with the corresponding end faces of the fine-tuning screw and the protruding post respectively.

Owner:YICHUN UNIVERSITY

Flexible main cable protection material

The invention discloses a flexible main cable protective material which is mainly composed of a protective layer (1), a framework layer (2) and a rubber sheet layer (3) and is wound on the surface ofa bridge main cable in a spiral winding mode. Hot-pressing vulcanization is conducted on the protective material through corresponding equipment, and the protective material is solidified on the surface of the main cable, and protects a main cable steel cable. The flexible main cable protective material has excellent isolation and protection effects, can effectively isolate corrosion of natural environments such as wind, frost, rain, snow, salt mist and acid atmosphere to the bridge main cable, has good flexibility, can adapt to the extension change of the main cable, and has a good isolationand protection effect.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND +1

A kind of rigid polyvinyl chloride product and its preparation method

ActiveCN101792562BAvoid the phenomenon of surface sensitive water whiteningProtect the surfaceAmbient waterPolymer science

The invention discloses a rigid polyvinyl chloride product, which contains the following components in parts by mass: 100 parts of polyvinyl chloride, 1.6-2.2 parts of organic tin mercaptan, 0.6-1.0 parts of internal lubricant, and 0.2-2.2 parts of external lubricant. 0.5 parts, 6-14 parts of impact modifier, 0.2-0.5 parts of waterproof modifier, and add appropriate amount of pigment. The invention also discloses a preparation method of the rigid polyvinyl chloride product. In the hard polyvinyl chloride product formula of the present invention, do not add any plasticizer, have avoided the phenomenon that the surface of the polyvinyl chloride product is sensitive to water and become white due to the influence of the ester group of plasticizer; In addition, in the hard polyvinyl chloride product of the present invention The formula of high-quality polyvinyl chloride products contains a hydrophobic base waterproof modifier, which significantly improves the solvent resistance and permeability resistance of polyvinyl chloride products, effectively isolates the erosion of external water or water vapor, and protects the polyvinyl chloride products. The surface of vinyl products makes it have good appearance performance.

Owner:ANHUI TIANAN NEW MATERIAL CO LTD

A preparation method of ultra-high temperature oxidation-resistant graphite mold

ActiveCN108178663BImproves the effect of antioxidant treatmentPermeable sealCarbide siliconOxidation resistant

The invention discloses a preparation method of a super-high temperature antioxidation graphite die. The method comprises the following steps: 1) cleaning a processed graphite die blank sample, dryingthe processed graphite die blank sample, and performing calcinations; 2) employing a graphite die antioxidation pretreatment agent for dipping the graphite die blank sample; 3) performing high-temperature solidification on the graphite die blank sample, 4) coating the surface of the graphite die blank sample with a silicon carbide slurry, after air drying, performing heat treatment on the graphite die blank sample, and cooling the graphite die blank sample to room temperature to prepare the graphite die blank sample having a silicon carbide transition layer; and 5) coating the surface of thegraphite die blank sample having the silicon carbide transition layer with a high-temperature ceramic paint, after air drying, performing heat treatment on the graphite die blank sample, and cooling the graphite die blank sample to room temperature to obtain the super-high temperature antioxidation graphite die. The super-high temperature antioxidation graphite die has the advantages of good thermal shock stability, high temperature resistance and antioxidation performance, and after usage for 200 h at the temperature of 2000 DEG C, the graphite die sample is intact.

Owner:HENAN CHEM IND RES INST

Vehicle cleaning wax and production method and using method thereof

InactiveCN101892130BAchieve a clean and bright effectDelay agingNon-ionic surface-active compoundsPolishing compositionsMicrocrystalline waxUltraviolet

The invention discloses vehicle cleaning wax, which comprises the following components in percentage by weight: 6 to 10 percent of anionic surfactant, 8 to 12 percent of nonionic surfactant, 15 to 25 percent of carnauba wax, 12 to 20 percent of microcrystalline wax, 12 to 18 percent of wetting thickening agent, and the balance of water. The surface of a vehicle can be cleaned and waxed by the vehicle cleaning wax without using the water and mechanical equipment, so that not only the water resource is saved effectively, but also the surface of the vehicle has the shiny and clean effect anytimeanywhere, conveniently and quickly; the vehicle cleaning wax is a nontoxic and innocuous aqueous product, the used additive is a biodegradable environmental-friendly material, is not added with an organic solvent and does not have pungent smell of the organic solvent, so that the vehicle cleaning wax does not pollute air without volatilizing the organic solvent, does not damage vehicle paint, does not irritate human skin, and does not pollute the environment; meanwhile, compound plant protection wax can be covered on the surface of the vehicle so as to isolate the erosion of sand wind and acid rain, resist ultraviolet rays and delay the aging of the vehicle paint.

Owner:郭阳明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com