Downhole Quartz Resonant Pressure Sensor

A pressure sensor and resonator technology, which is applied in elastic deformation meter-type fluid pressure measurement, fluid pressure measurement using piezoelectric devices, etc. The effect of reducing vibration damping, easy vibration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

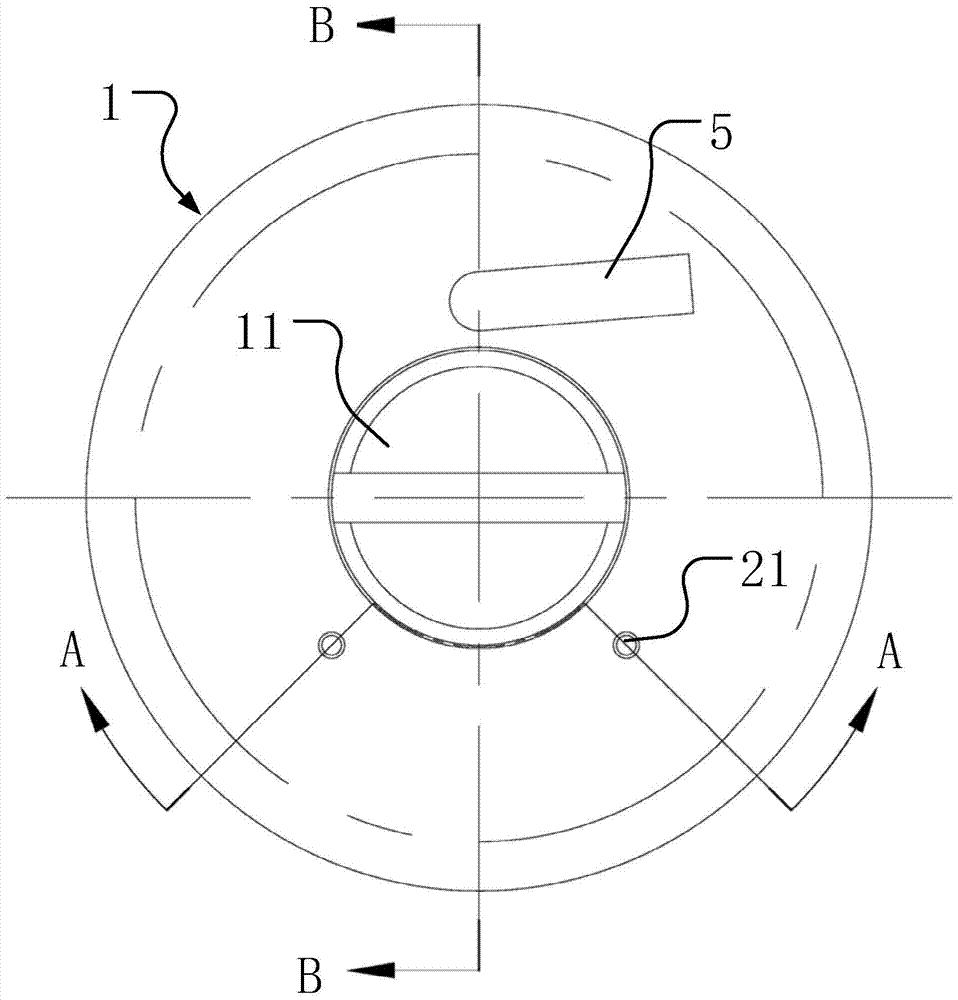

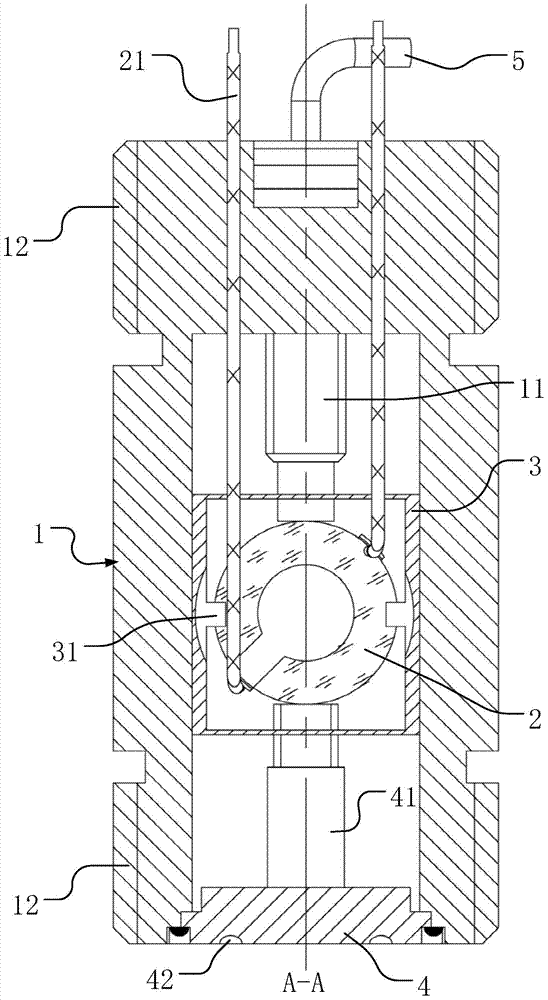

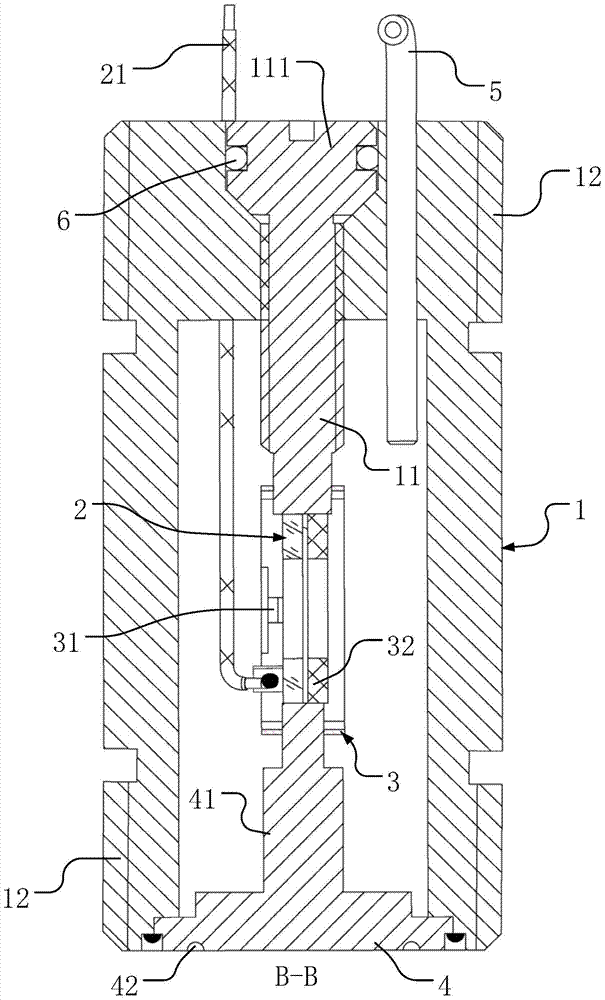

[0026] The present invention provides a downhole quartz resonant pressure sensor, which includes a cylindrical shell 1, a quartz crystal resonator 2 and a bracket 3 arranged in the shell 1, the quartz crystal resonator 2 is embedded in the In the bracket 3, the bracket 3 is fixedly installed in the housing 1; the center of one end of the housing 1 is preset with a screw hole, and a threaded connection is inserted in the screw hole for adjusting the preload. The fine-tuning screw 11 of force, the fine-tuning screw 11 is tightly connected with the screw hole, the other end of the housing 1 is provided with a pressure detection window, and the elastic metal diaphragm 4 is installed in the pressure detection window , the elastic metal diaphragm 4 is provided with a boss 41 corresponding to the center of one side of the housing 1; the quartz crystal resonator 2 is an open ring with a fifth-order harmonic thickness shear vibration mode Chip 4.992MHz quartz crystal resonator, the cut...

Embodiment 2

[0028] Embodiment 2: As mentioned above, a vacuum conduit 5 is sealed and inserted in the side wall of the end of the screw hole on the casing 1, and the vacuum conduit 5 is sealed at the end corresponding to the outside of the casing 1. The degree of vacuum in the housing 1 is 6×10 -1 Pa, when this embodiment is actually implemented, after the present invention is assembled, one end of the vacuum conduit 5 corresponding to the outside is connected to an external vacuuming device, and the vacuum degree in the housing 1 reaches 6×10-1Pa Finally, clamp the vacuum conduit 5 flat, and cut off the vacuum conduit 5 at the outer end at a distance of 3 to 5 mm from the clamp flat, and use high-temperature solder to completely seal the section. This structure is convenient for vacuuming, simple in structure, and easy to assemble Finishing is relatively easy.

Embodiment 3

[0029] Embodiment 3: Further, two locking keys 31 are protruded from one end of the support 3 corresponding to the axial end of the quartz crystal resonator 2 in the shape of an open ring, and the two locking keys 31 are respectively stuck on the The quartz crystal resonator 2 in the shape of an open ring is on both sides of the end face of the axial end, and the two keys 31 correspond to the radial direction of the housing 1 respectively. This arrangement structure is beneficial to all The position of the quartz crystal resonator 2 is fine-tuned and aligned during the assembly process. An annular gasket 32 is arranged at the other end of the bracket 1 corresponding to the axial direction of the quartz crystal resonator 2 in the shape of an open ring. The quartz crystal resonator 2 is embedded between the two snap keys 31 and the ring spacer 32, and the structure of the bracket 3 can effectively suspend the quartz crystal resonator 2 on the housing 1 , to prevent the quartz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com