Patents

Literature

74results about How to "Improve pressure measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

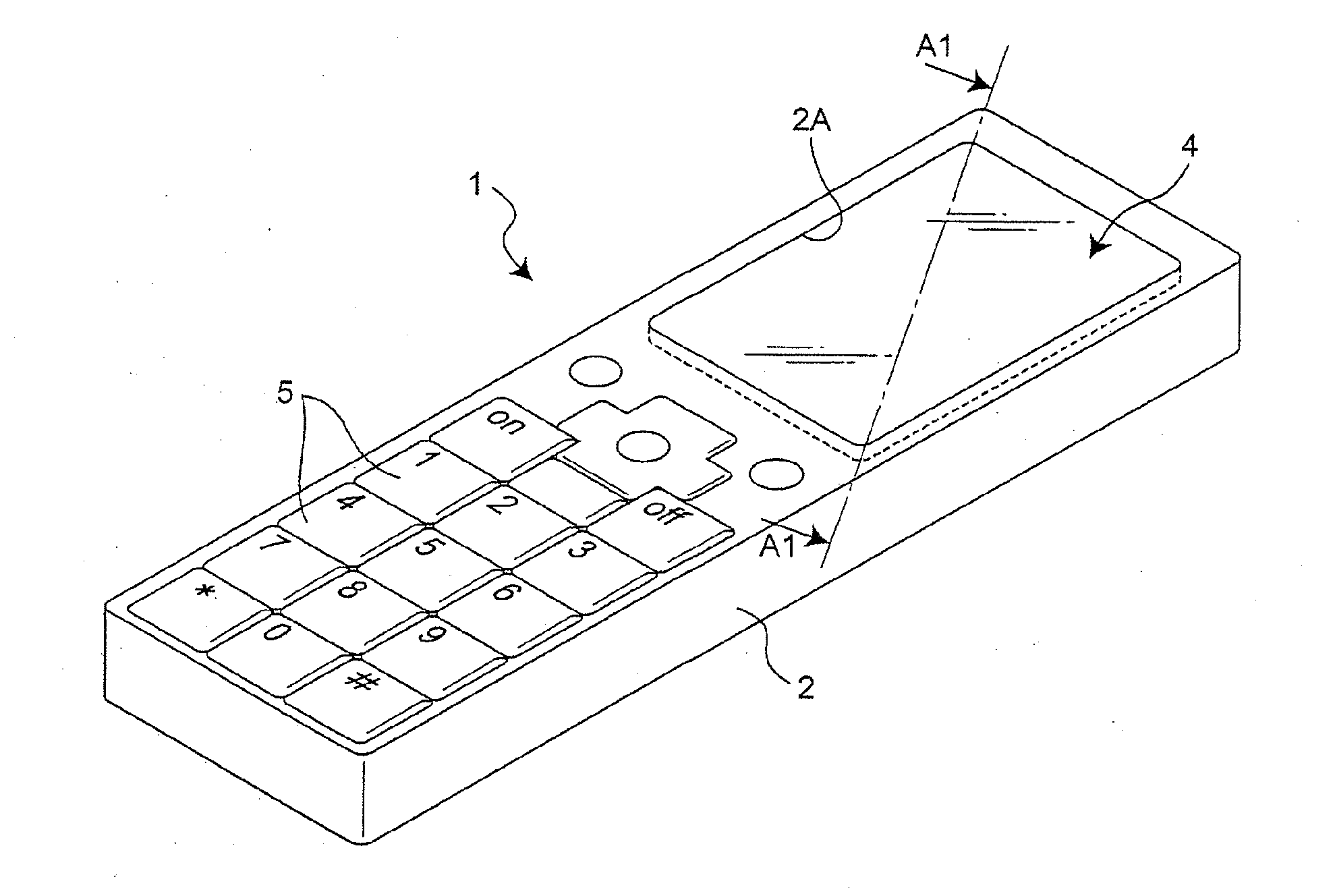

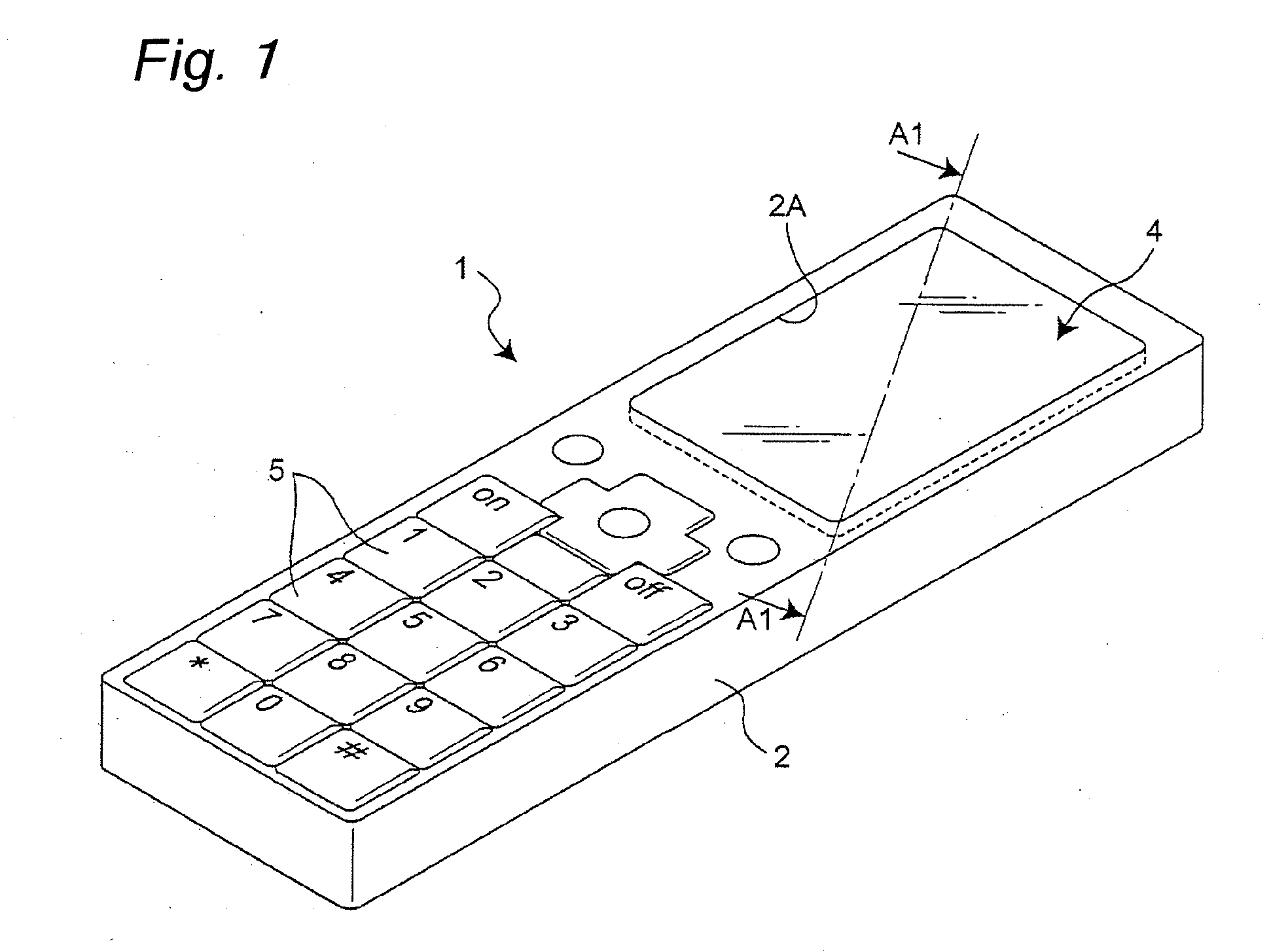

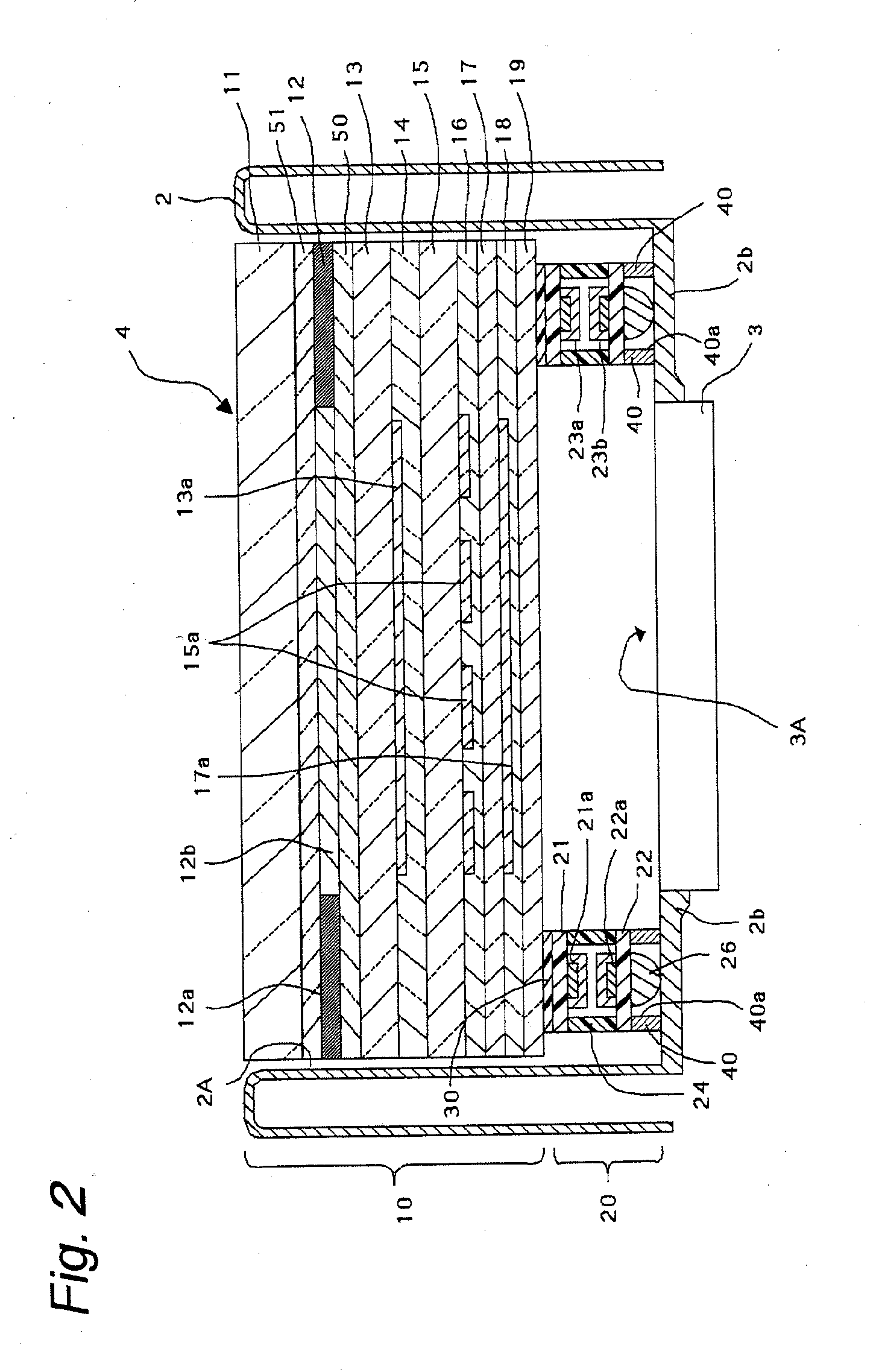

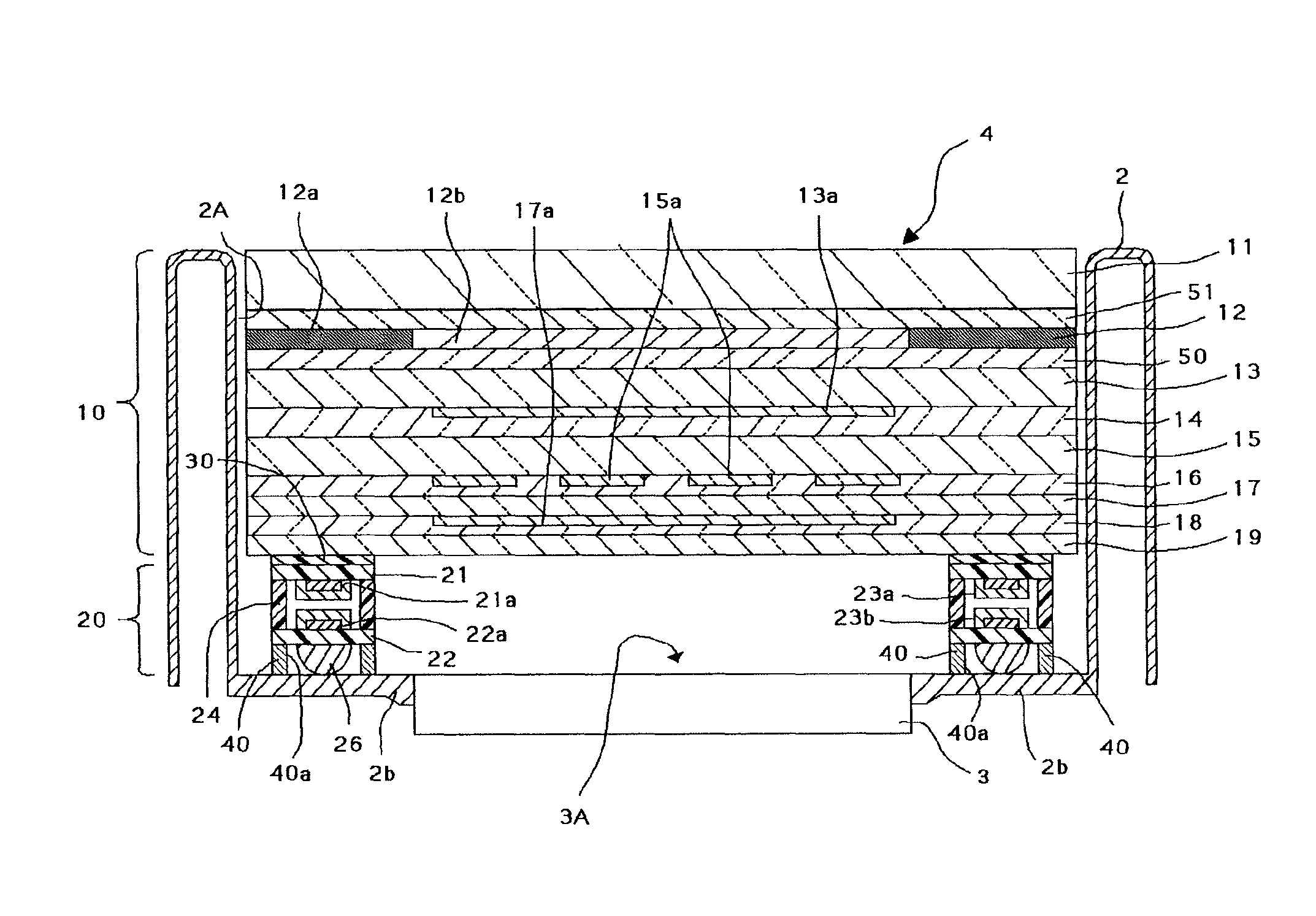

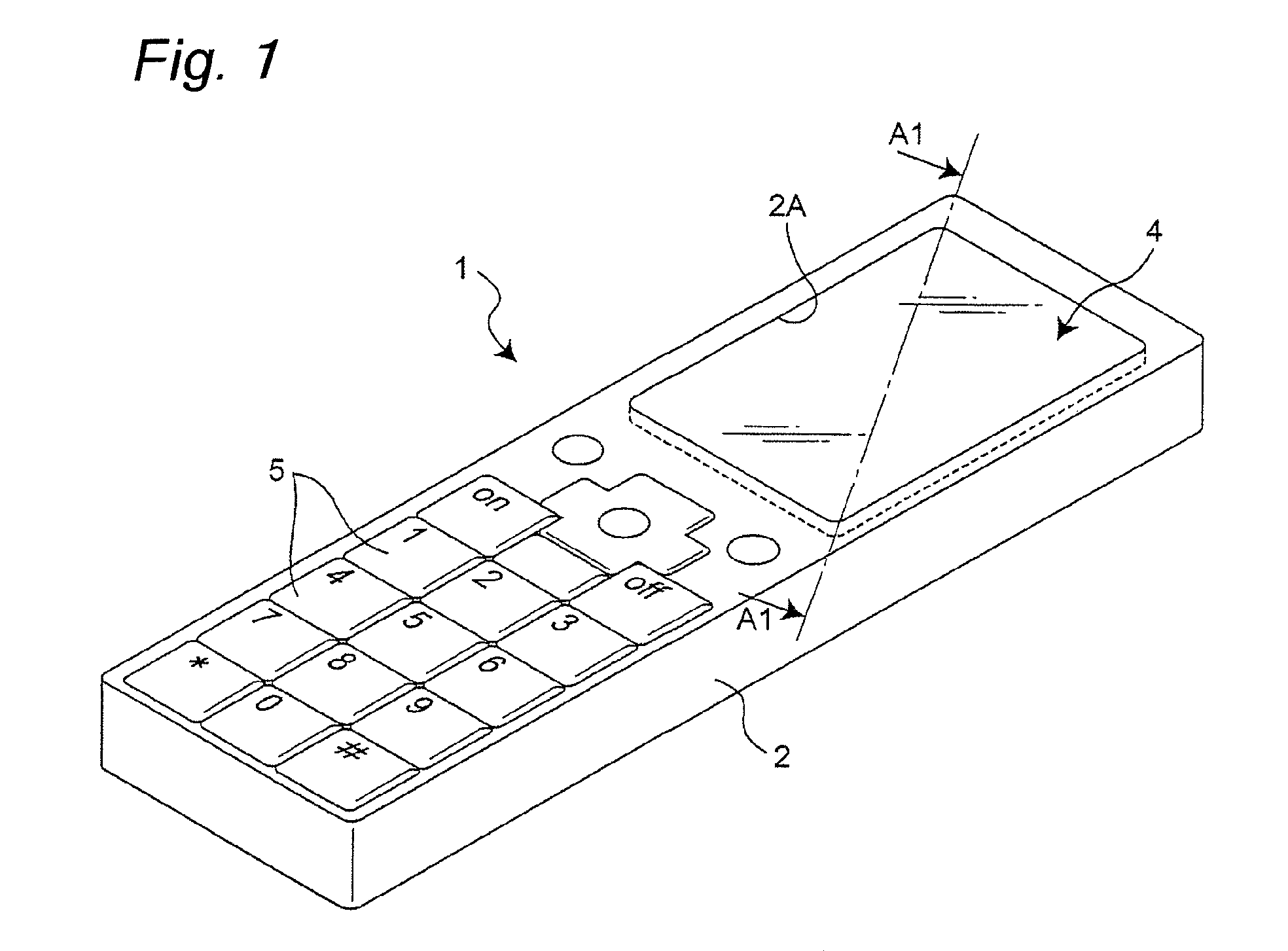

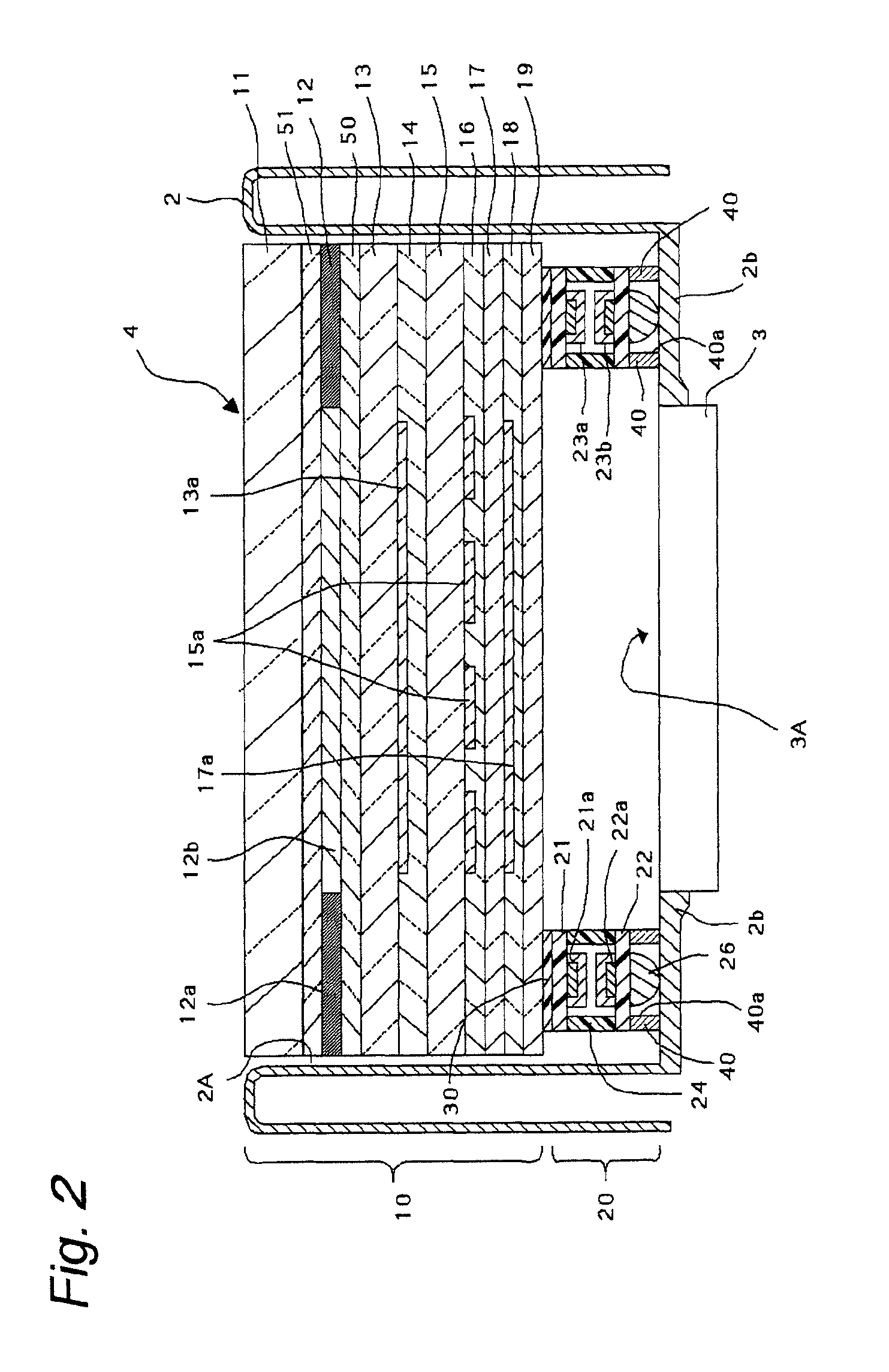

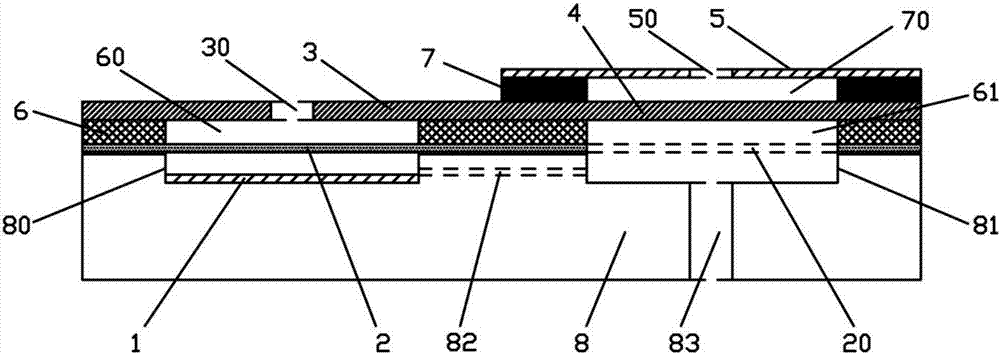

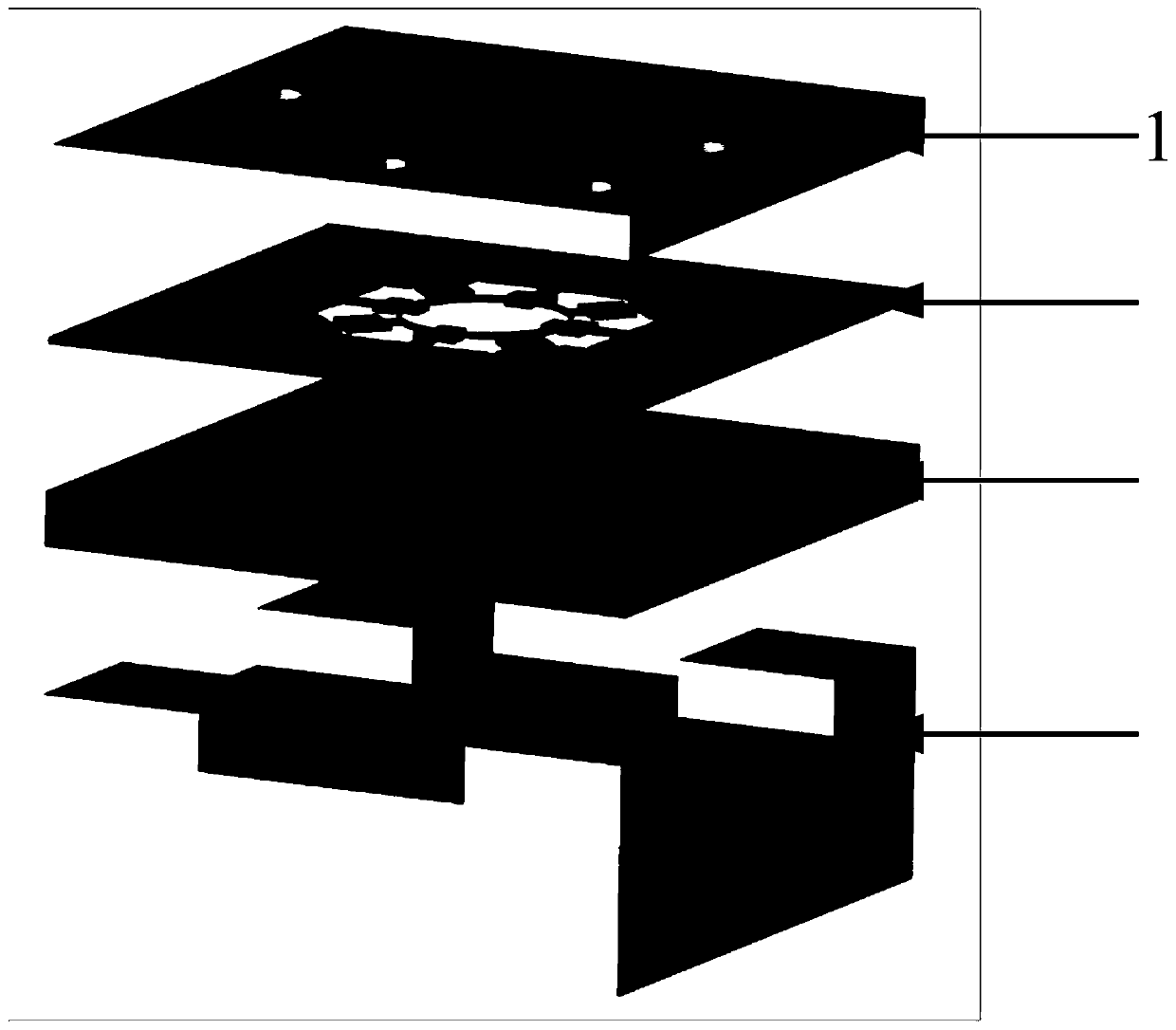

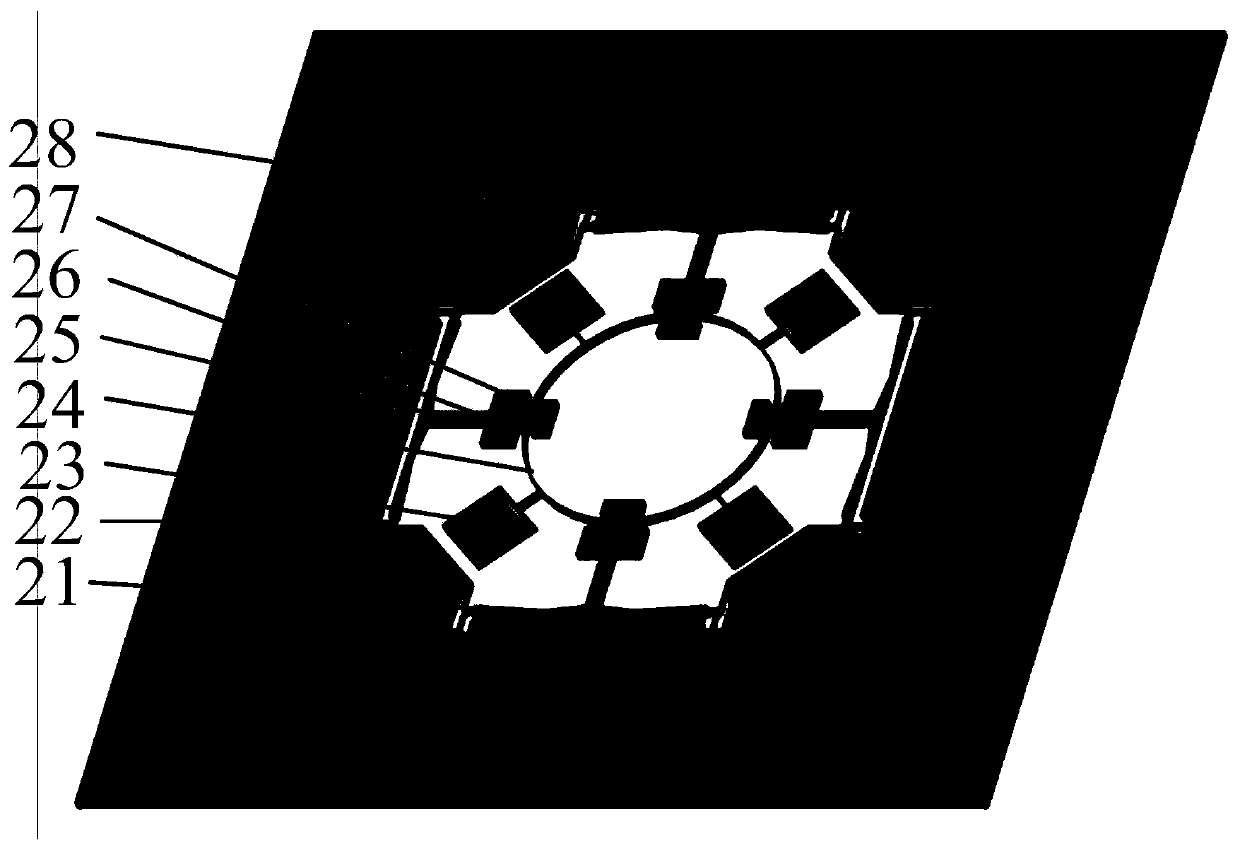

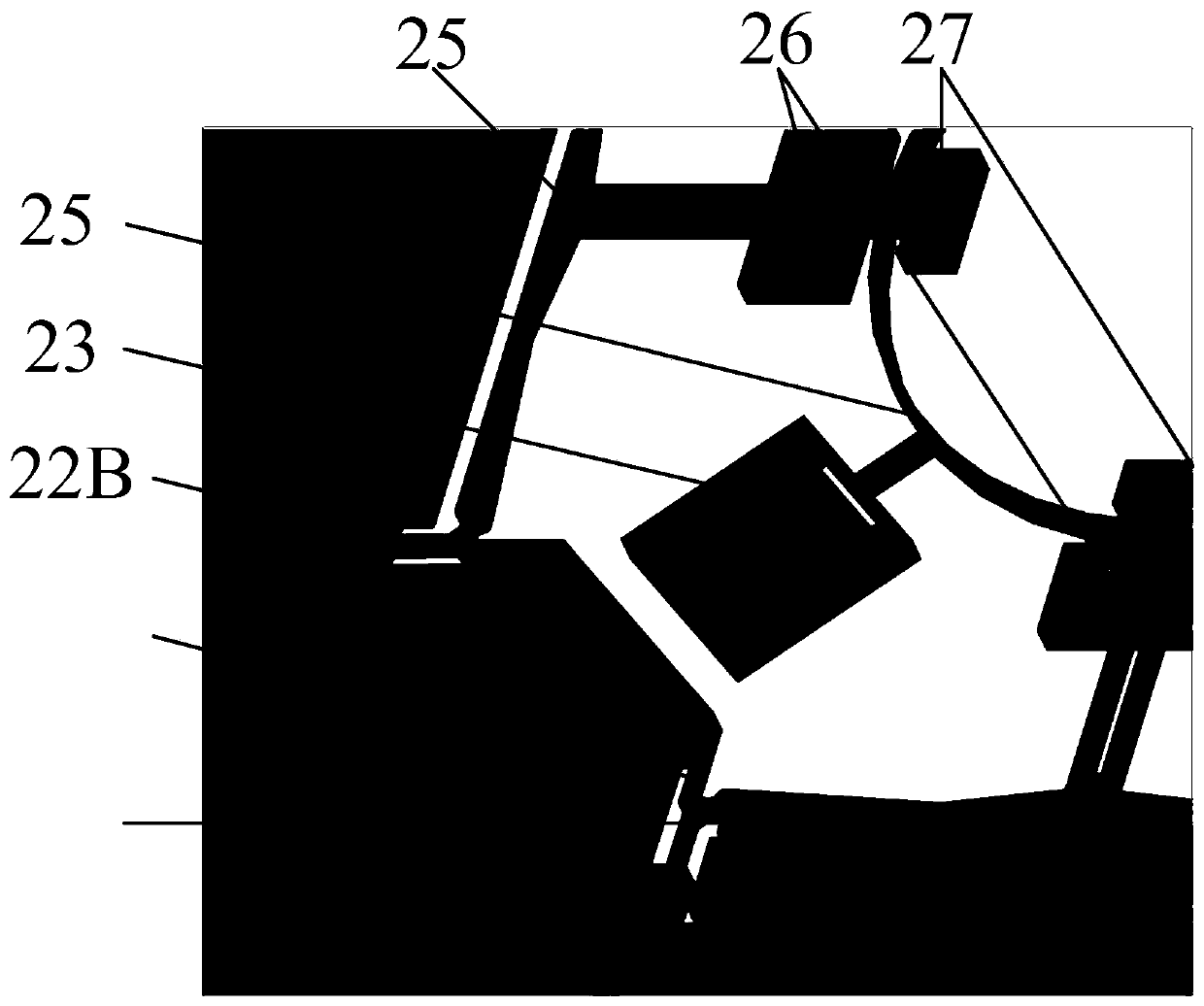

Mount structure of touch input device having pressure sensitive sensor

InactiveUS20120182249A1Improve visibilityImprove transmittanceForce measurementInput/output processes for data processingVisibilityDisplay device

[Subject] To provide a mount structure of a touch input device having a pressure sensitive sensor in which visibility can be prevented from being lowered even when the pressure sensitive sensor is mounted, water-proofness and dust-proofness are excellent, and a pressure can be easily detected with high measurement accuracy.[Solution] According to a mount structure of a touch input device which includes a touch input device having at least a touch panel, and a pressure sensitive sensor attached to a lower surface thereof, and a casing dented to allow the device to be externally fitted in, and having a concave part or an opening part for a display device, and a frame-shaped support part to support a back surface peripheral part of the touch input device, in its bottom surface, the pressure sensitive sensor includes a pressure concentration member laminated and arranged in a dot shape so as to support the pressure sensitive ink member on a back surface, and a frame-shaped gasket is attached between the pressure sensitive sensor and the support part of the casing, in which the gasket does not overlap with the pressure concentration member.

Owner:NISSHA PRINTING COMPANY

Mount structure of touch input device having pressure sensitive sensor

InactiveUS8698777B2Improve visibilityImprove transmittanceForce measurementCathode-ray tube indicatorsVisibilityDisplay device

[Subject] To provide a mount structure of a touch input device having a pressure sensitive sensor in which visibility can be prevented from being lowered even when the pressure sensitive sensor is mounted, water-proofness and dust-proofness are excellent, and a pressure can be easily detected with high measurement accuracy.[Solution] According to a mount structure of a touch input device which includes a touch input device having at least a touch panel, and a pressure sensitive sensor attached to a lower surface thereof, and a casing dented to allow the device to be externally fitted in, and having a concave part or an opening part for a display device, and a frame-shaped support part to support a back surface peripheral part of the touch input device, in its bottom surface, the pressure sensitive sensor includes a pressure concentration member laminated and arranged in a dot shape so as to support the pressure sensitive ink member on a back surface, and a frame-shaped gasket is attached between the pressure sensitive sensor and the support part of the casing, in which the gasket does not overlap with the pressure concentration member.

Owner:NISSHA PRINTING COMPANY

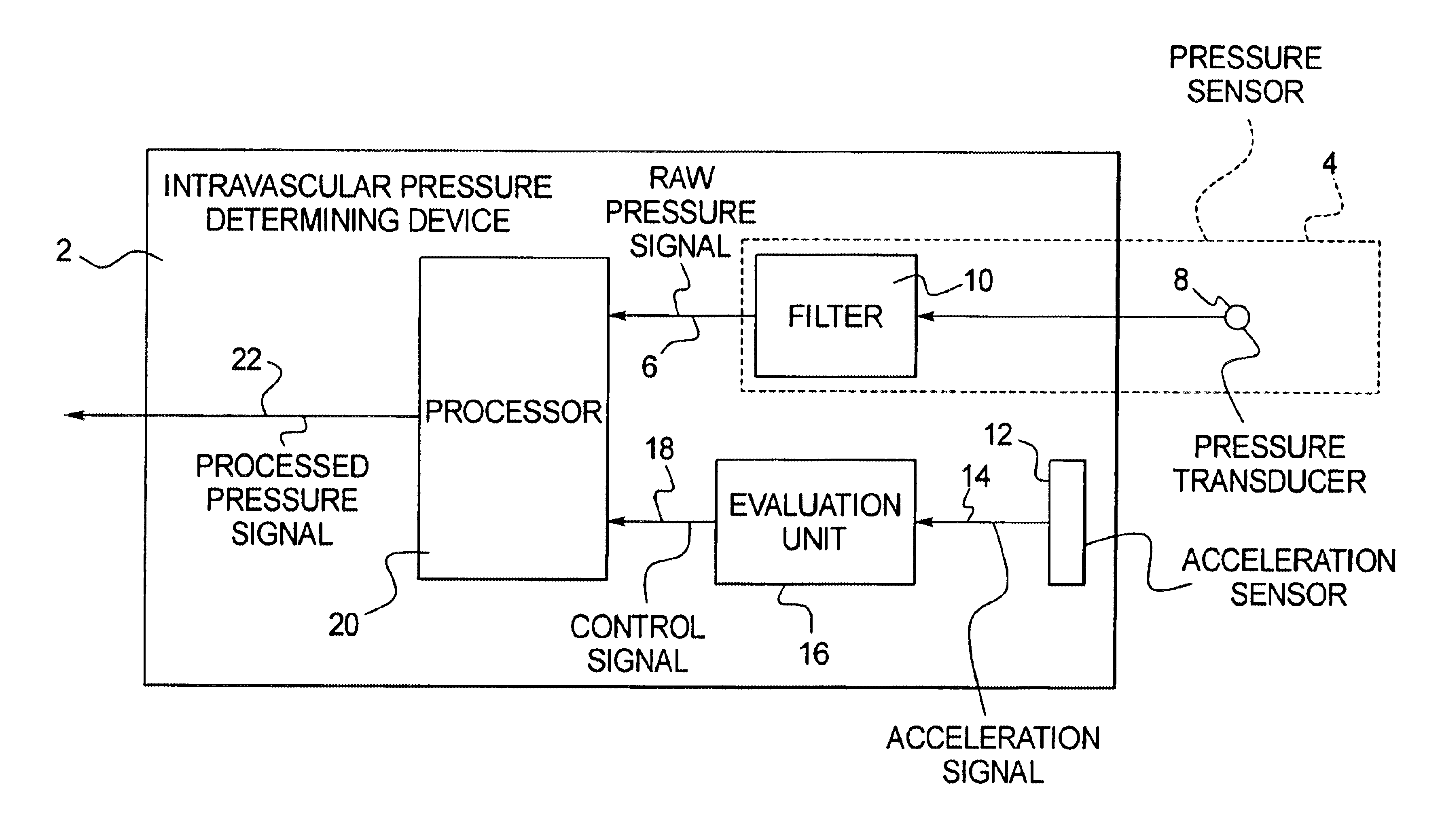

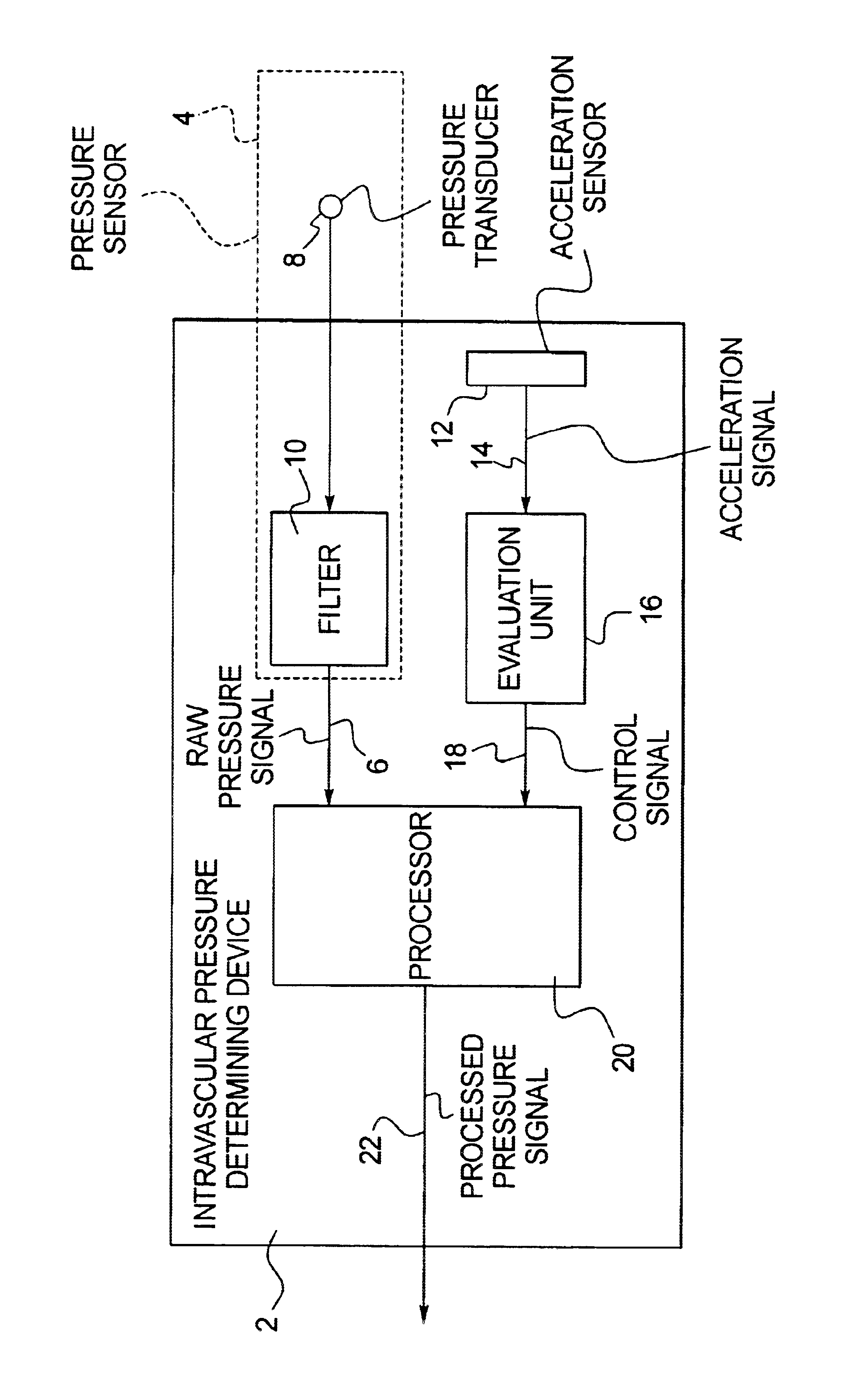

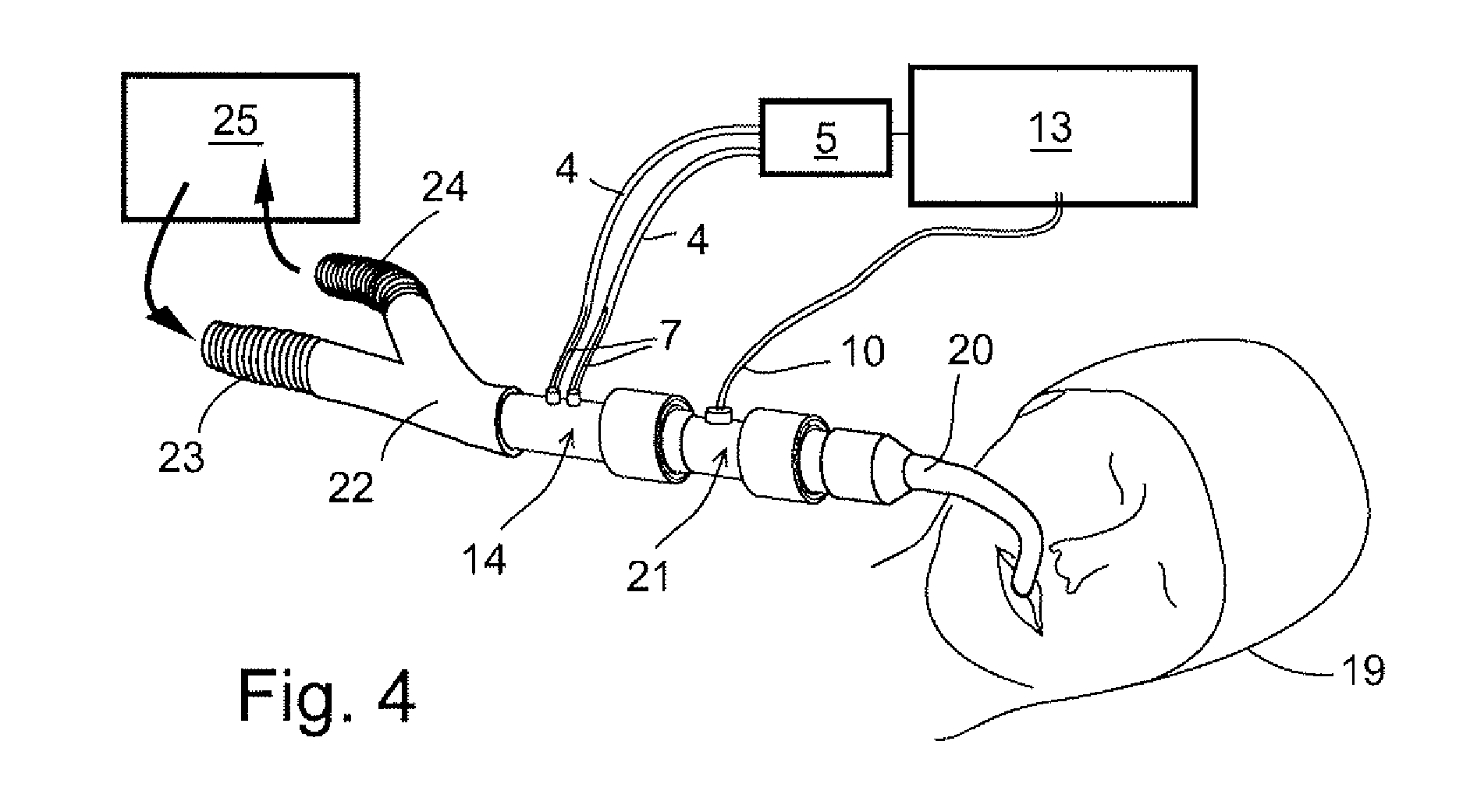

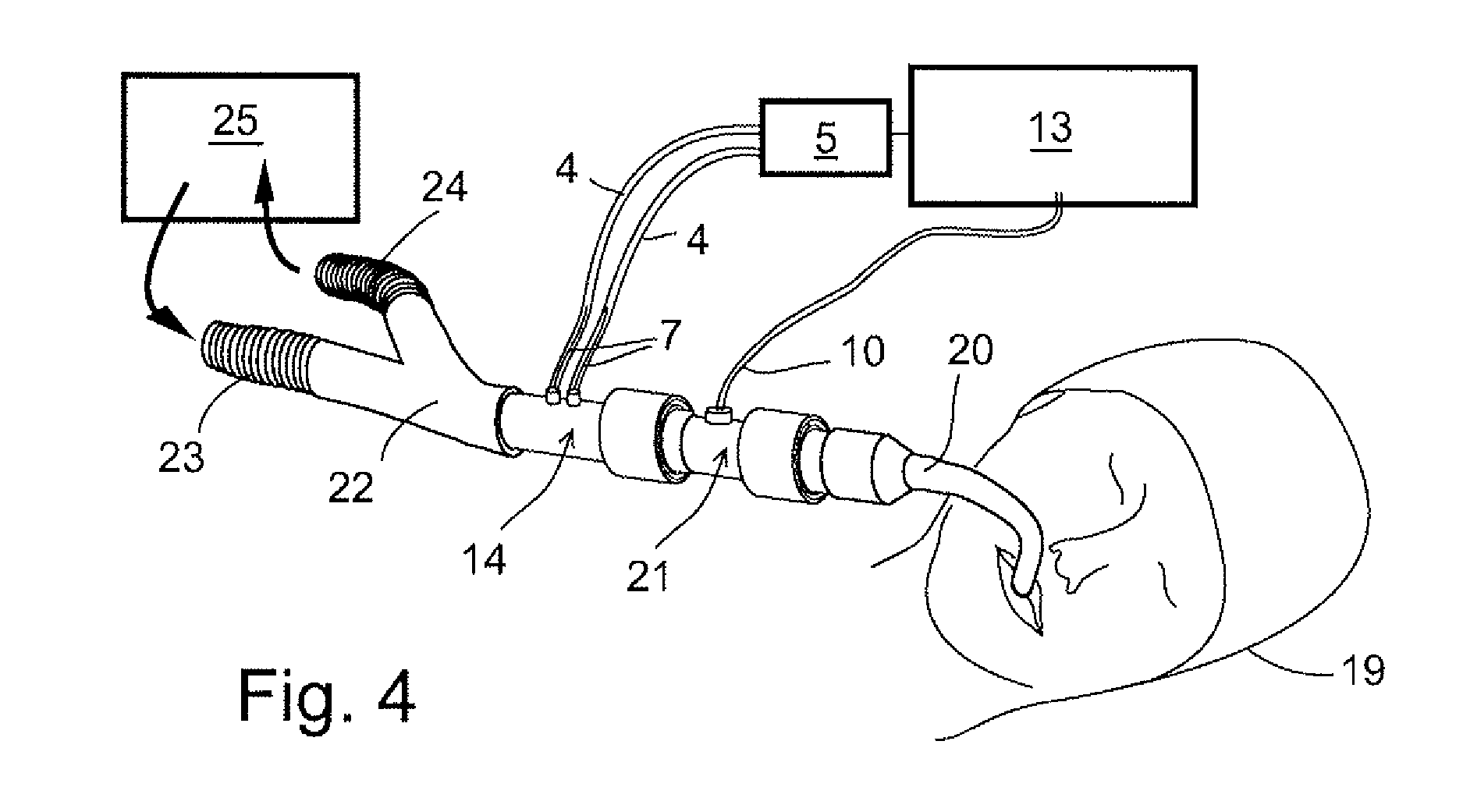

Implantable intravascular pressure determining device and method

InactiveUS6860857B2Improve pressure measurement accuracyImprove accuracyCatheterRespiratory organ evaluationBlood vesselPressure sensor

In an implantable intravascular pressure determining device and method, a pressure sensor generates a raw pressure signal and an acceleration sensor measures acceleration in a patient. Time intervals are identified wherein the raw pressure signal accurately represents the intravascular pressure, these intervals being identified as the time intervals wherein the measured acceleration is below a predetermined threshold. The raw pressure signal is processed, to generate a processed signal which is used as an intravascular pressure signal, only in the aforementioned time intervals.

Owner:ST JUDE MEDICAL

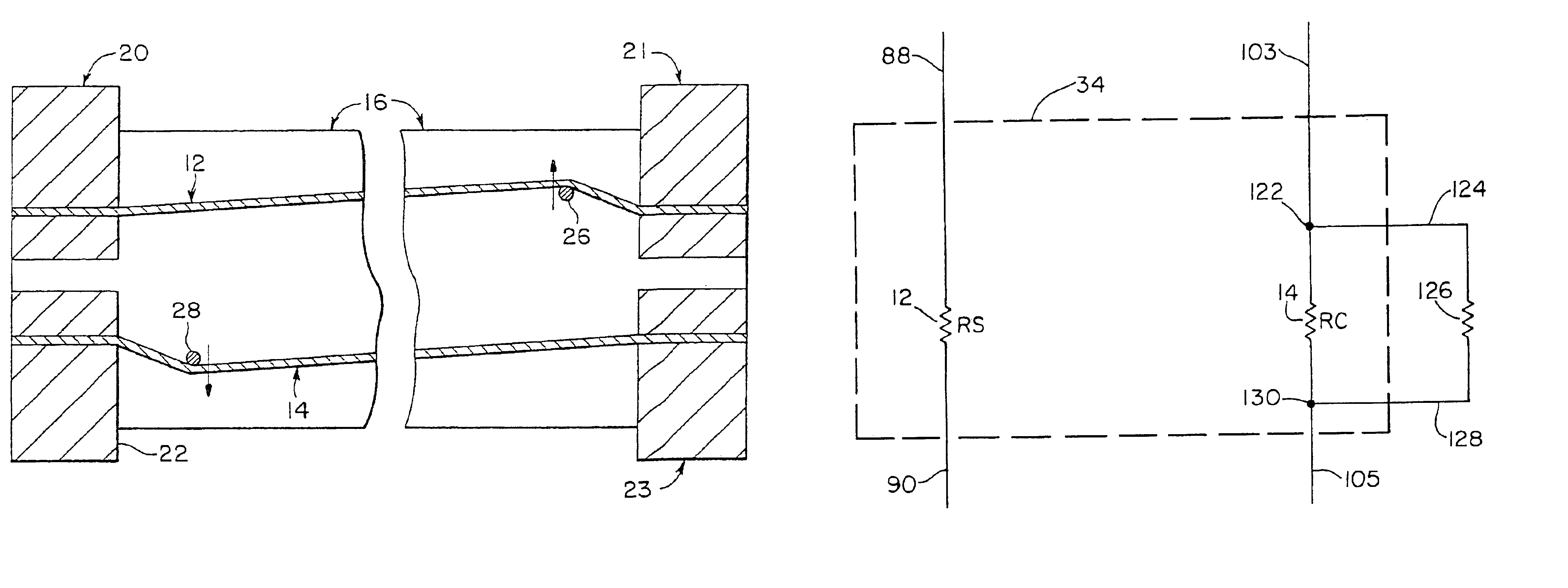

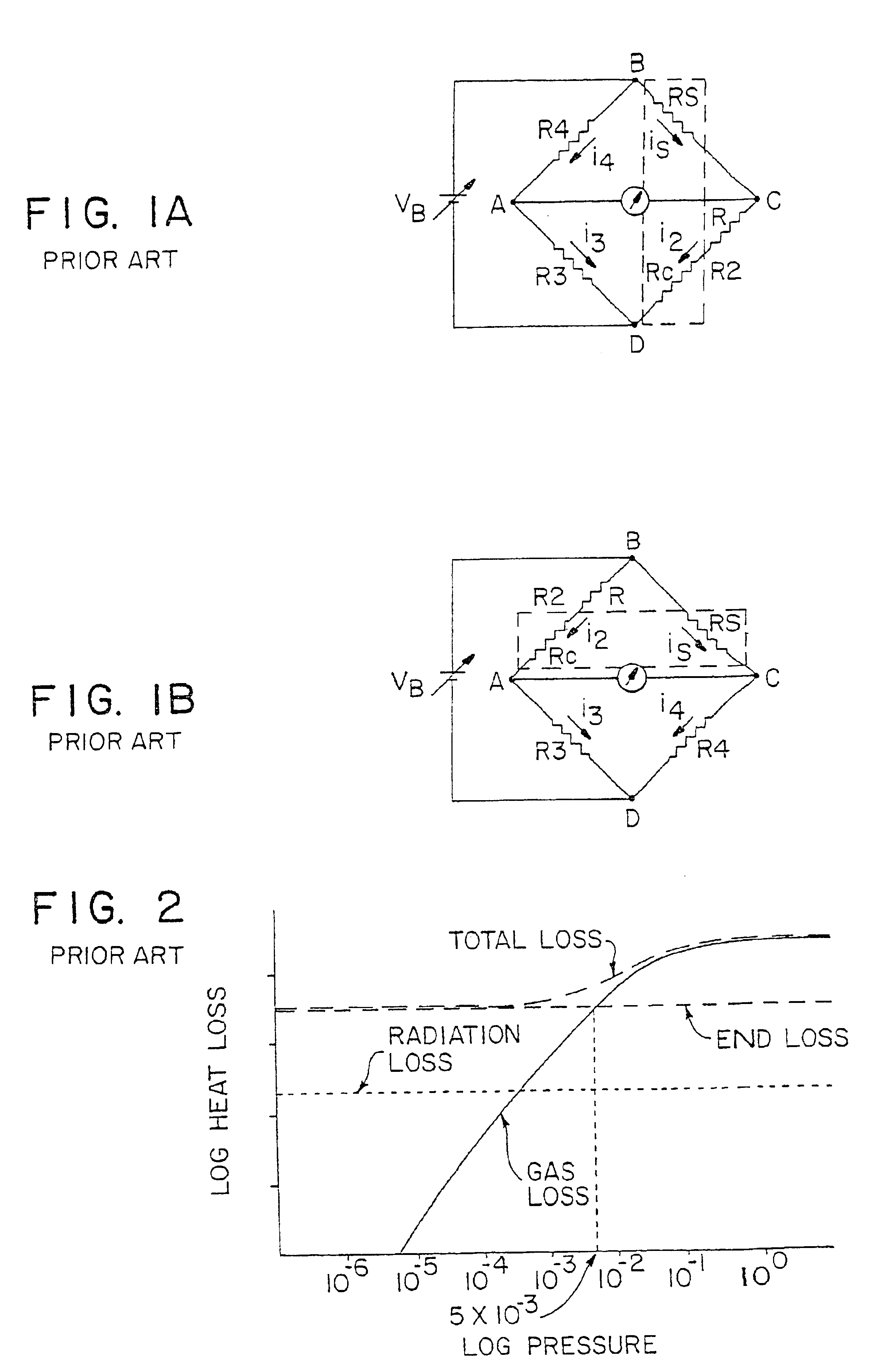

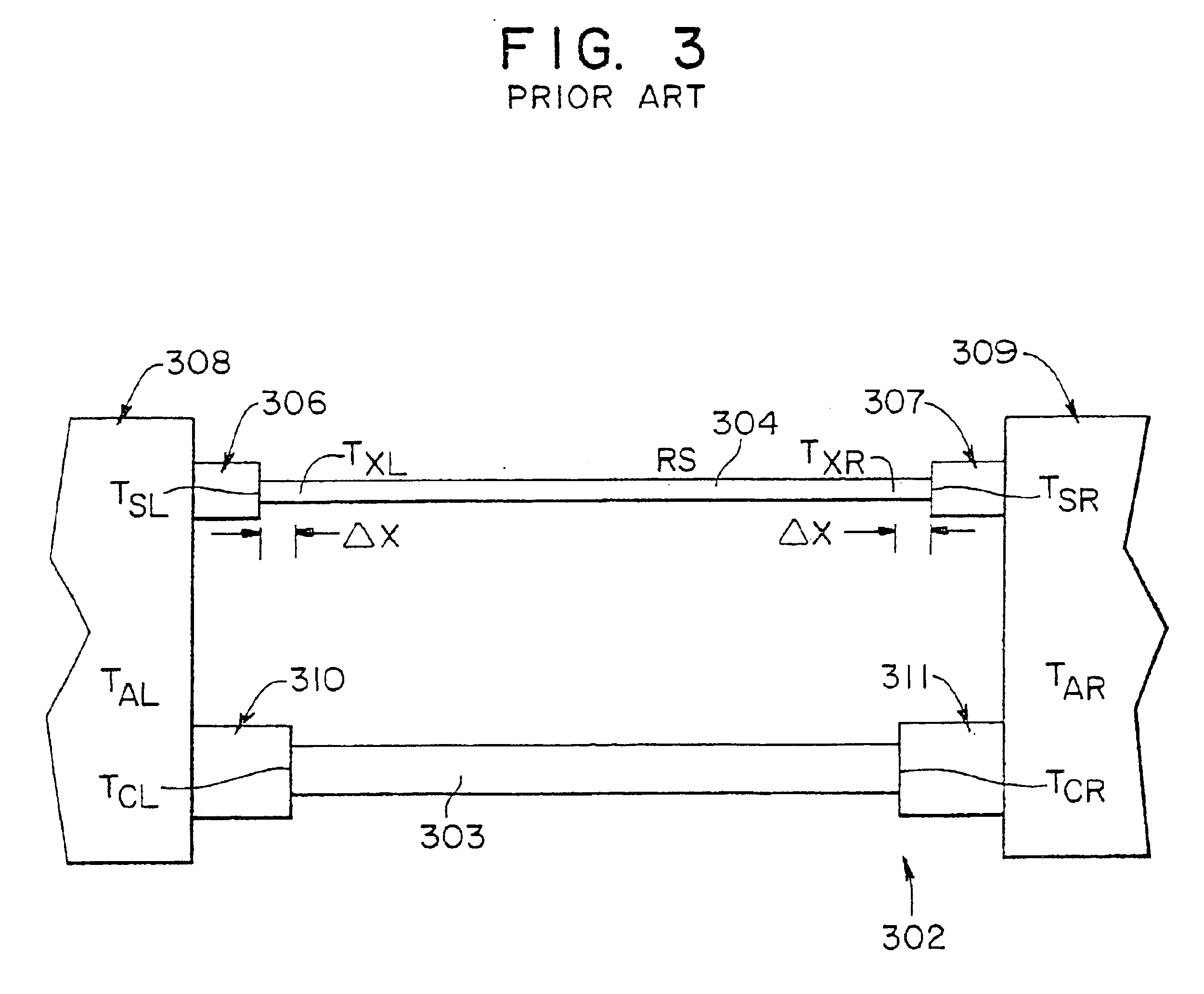

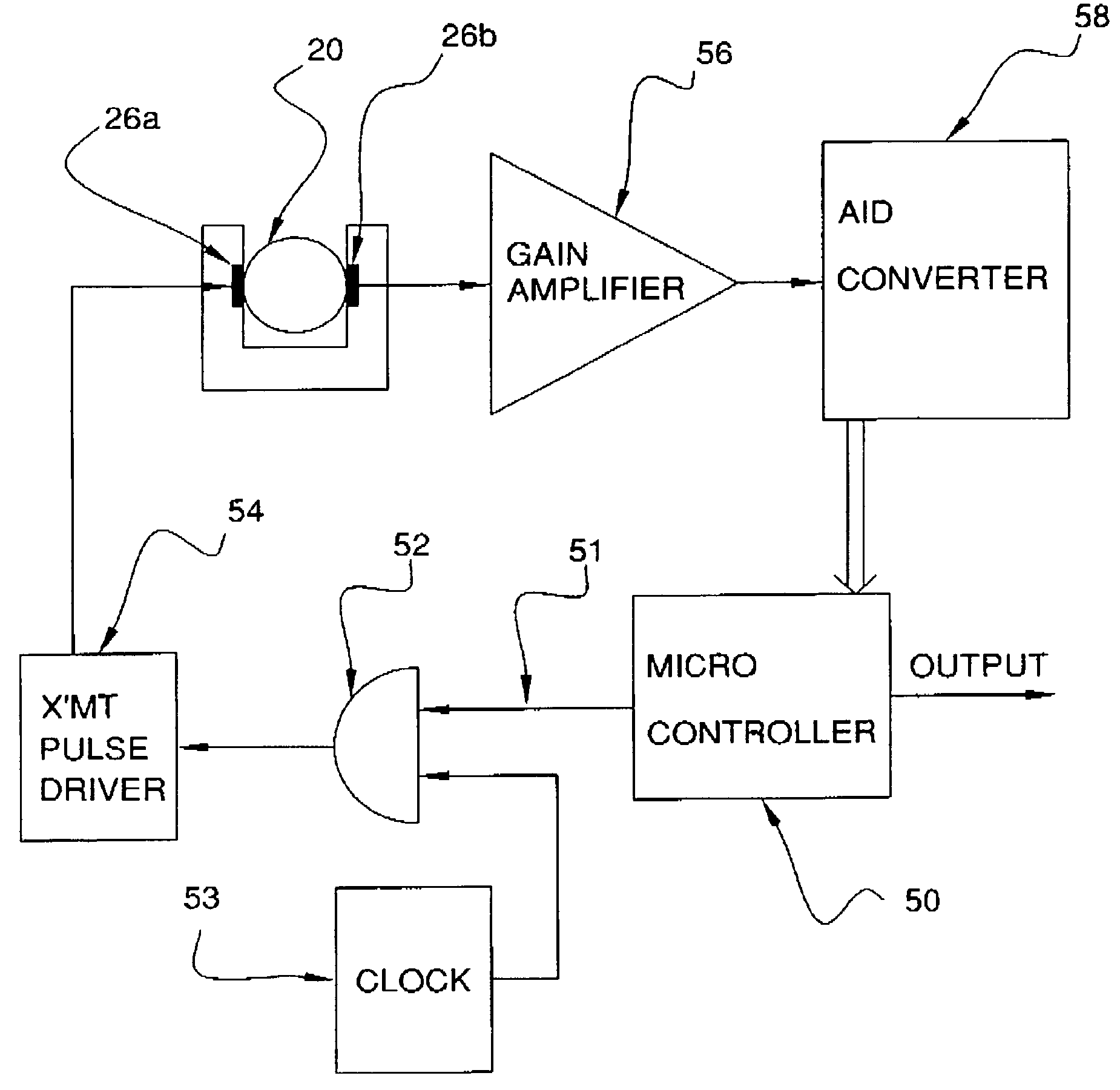

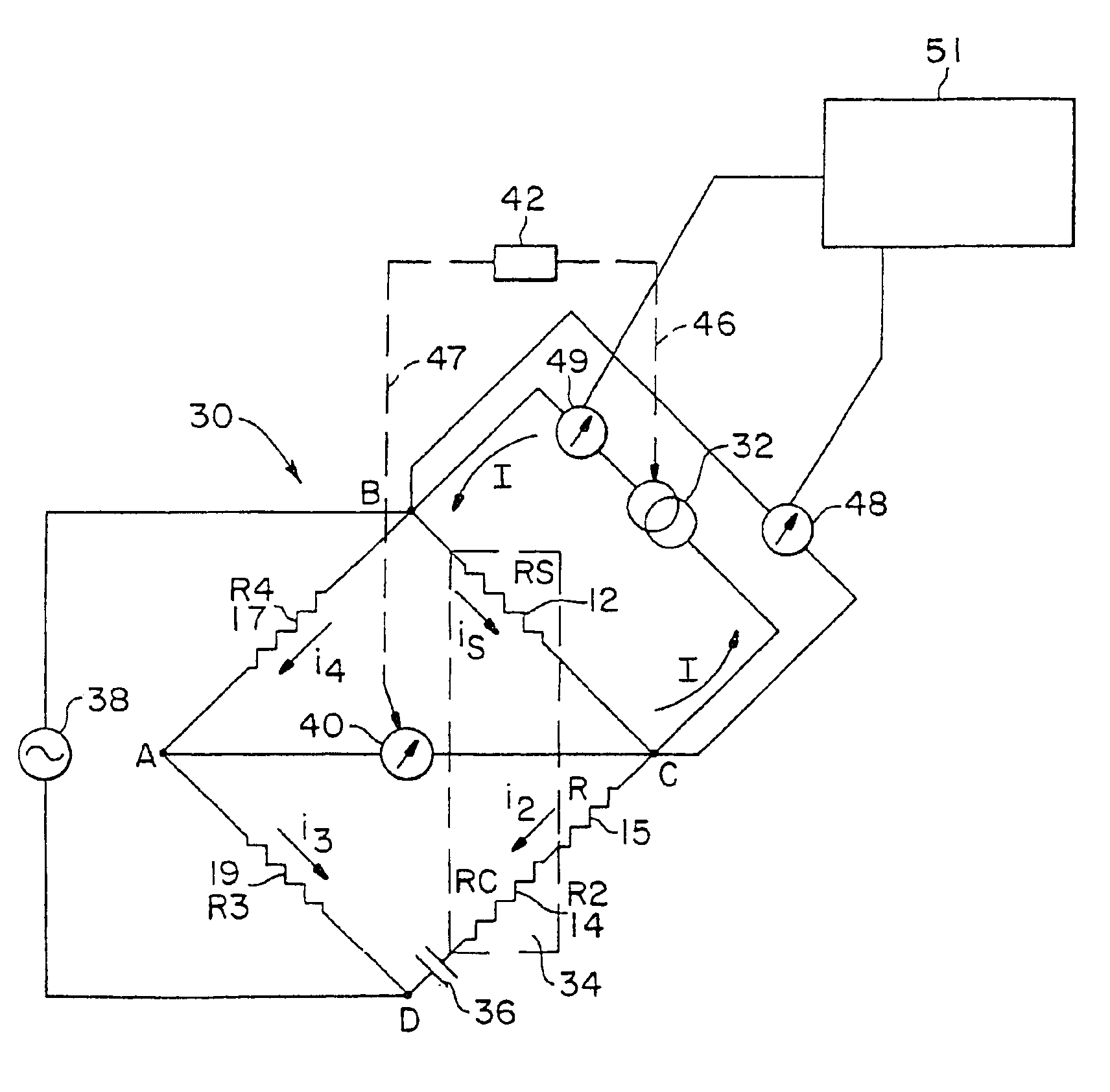

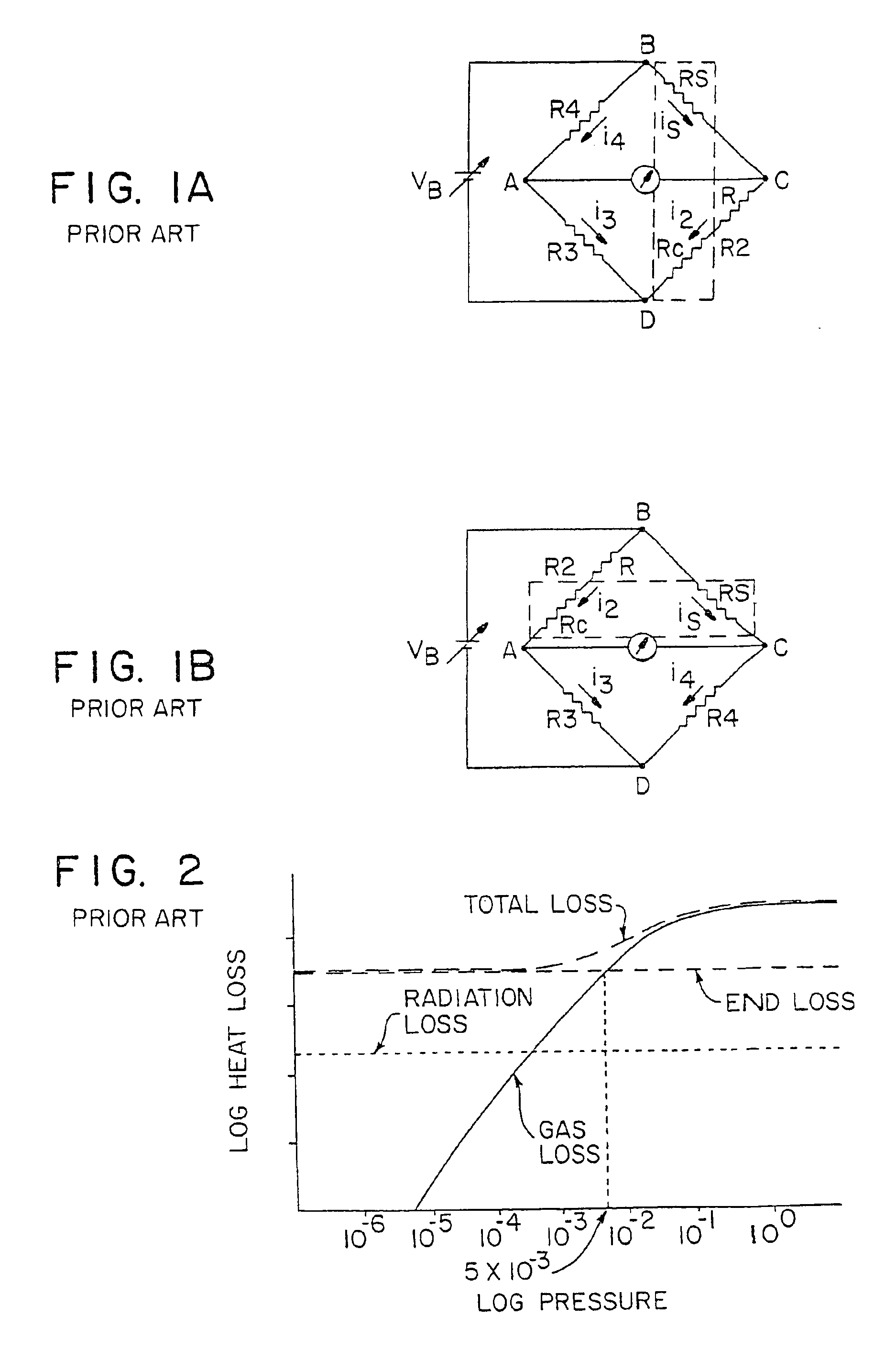

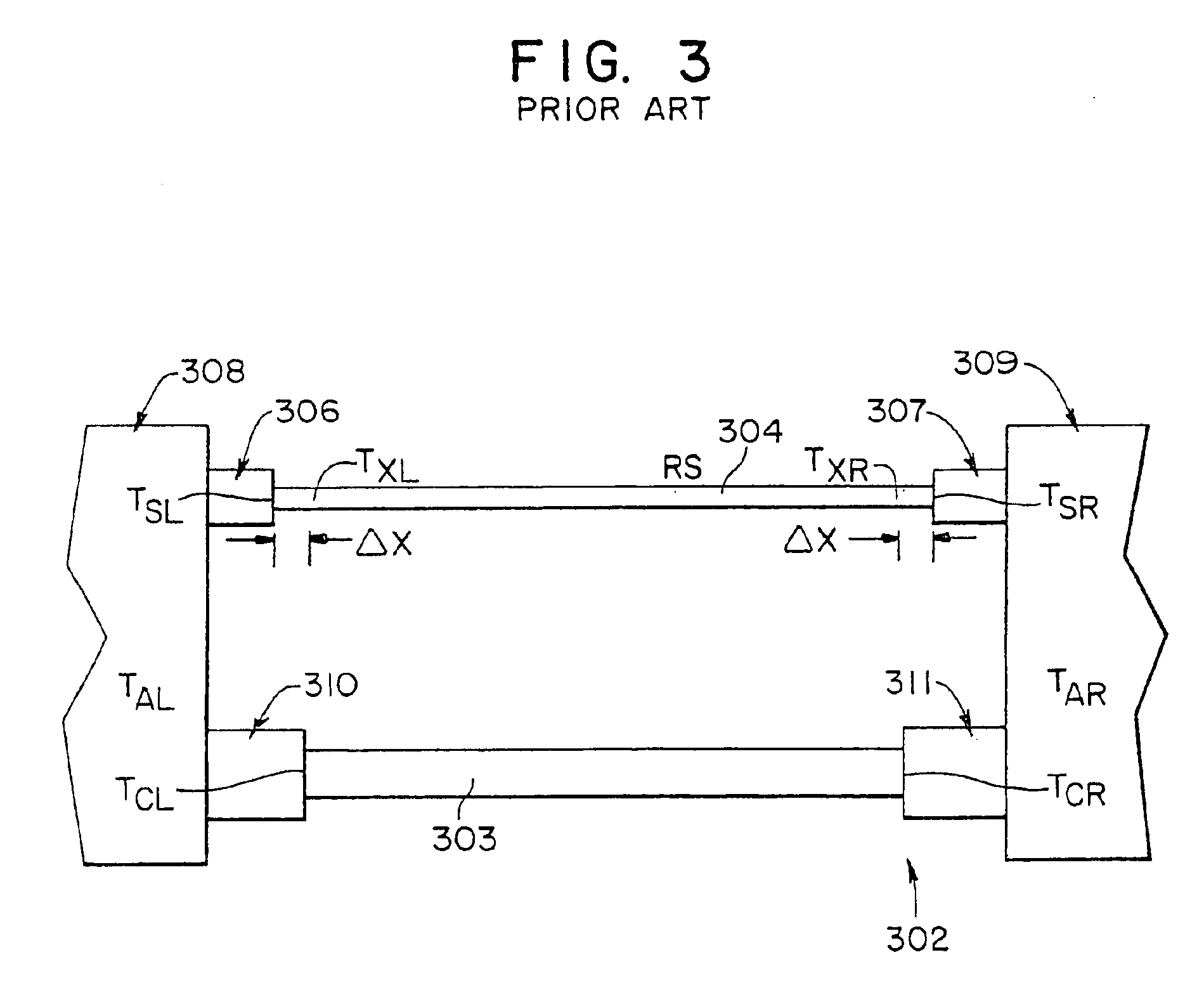

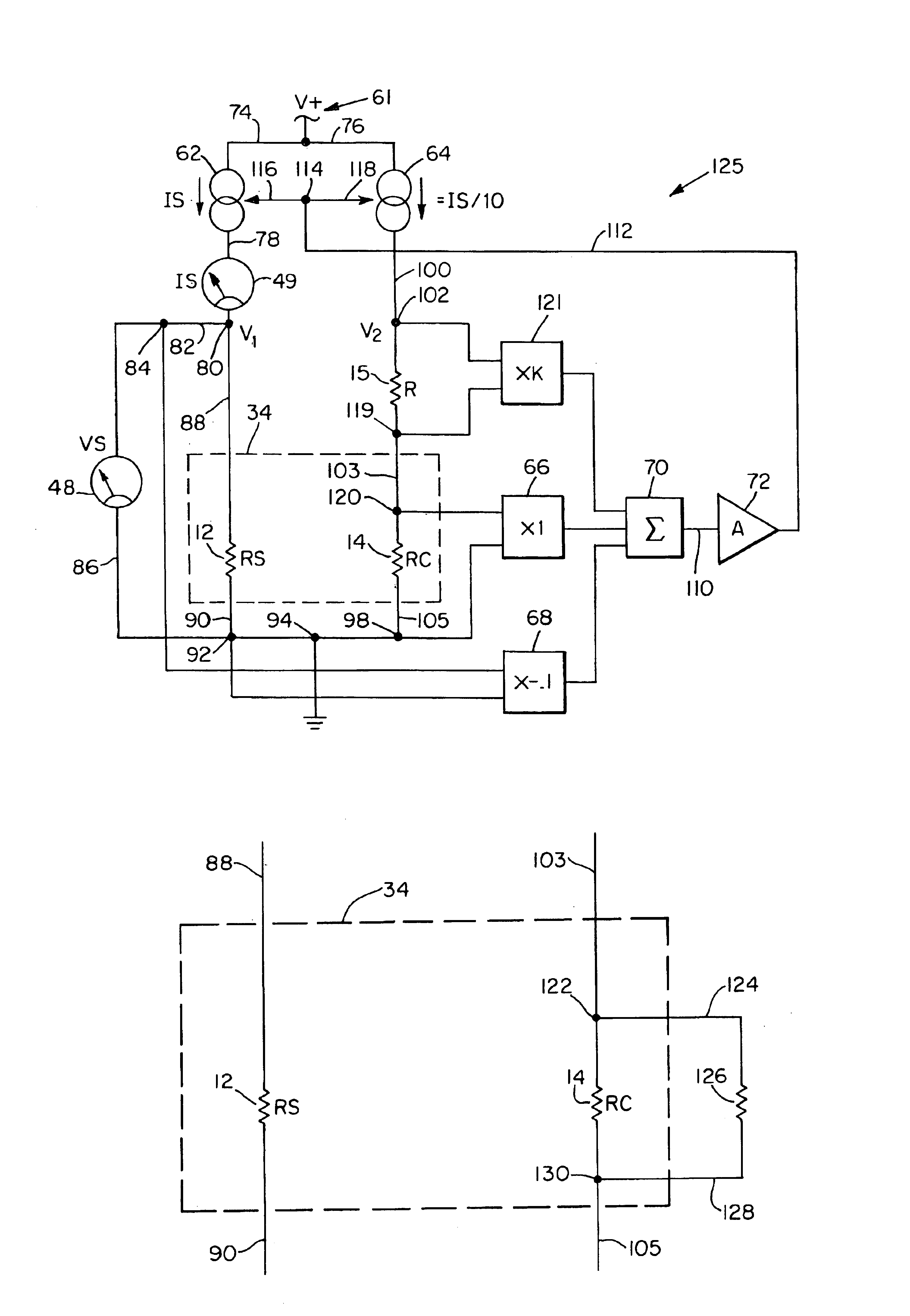

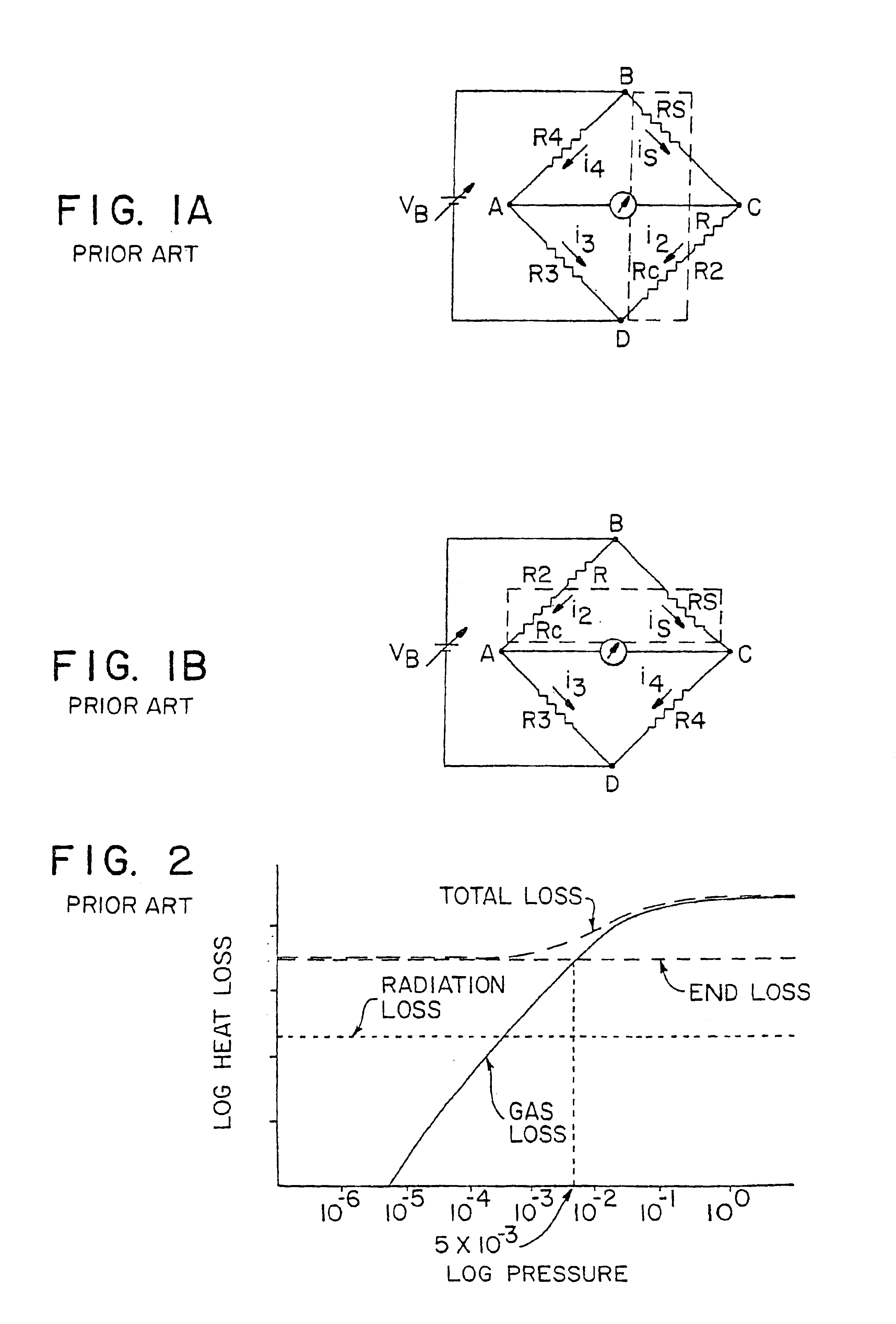

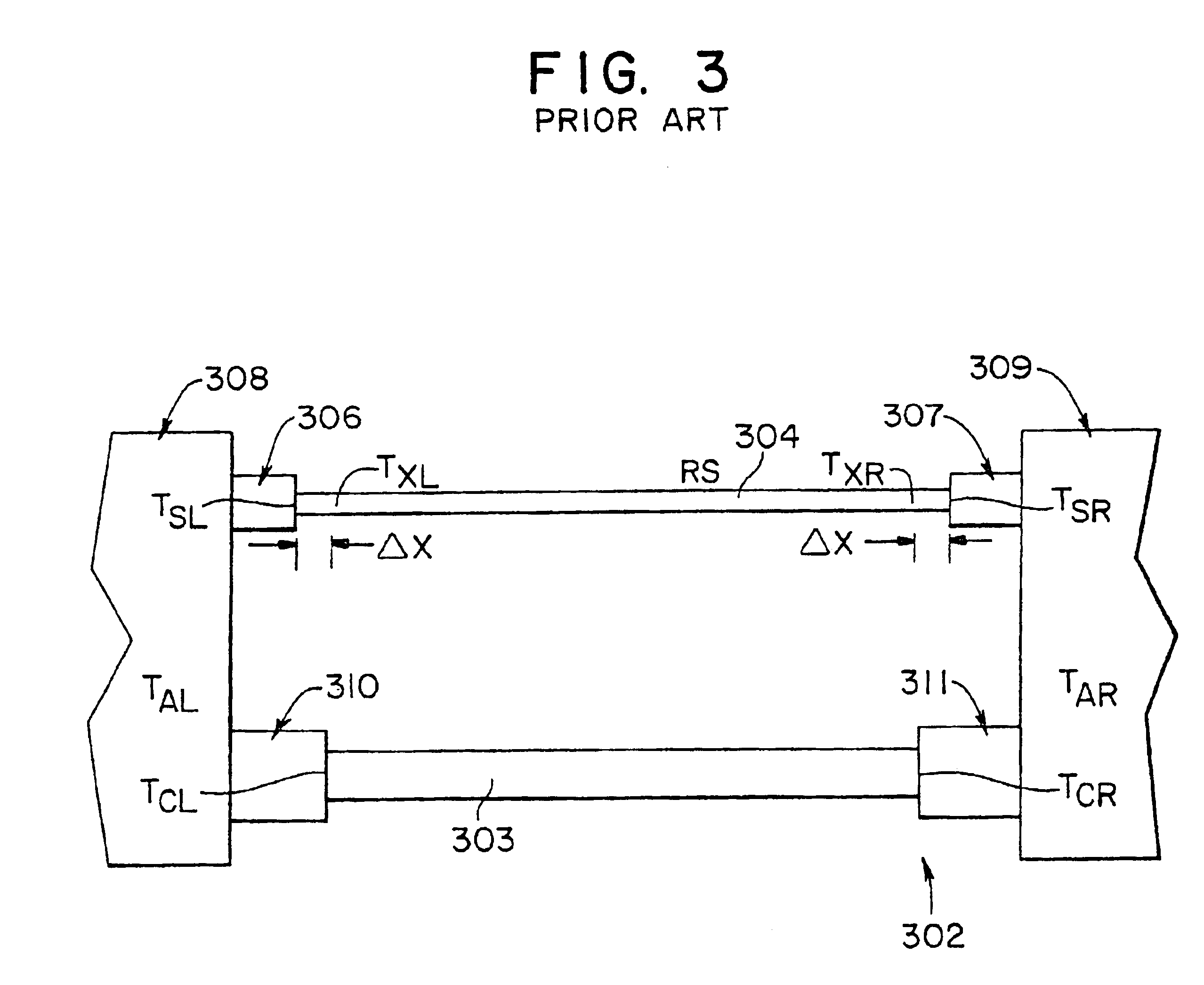

Apparatus and methods for heat loss pressure measurement

InactiveUS6865952B2Improve pressure measurement accuracyIncrease rangeFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElectricityElectrical resistance and conductance

A heat loss gauge for measuring gas pressure in an environment includes a resistive sensing element and a resistive compensating element. The resistive compensating element is in circuit with the sensing element and is exposed to a substantially matching environment. An electrical source is connected to the sensing element and the compensating element for applying current through the elements. The current through the sensing element is substantially greater than the current through the compensating element. Measuring circuitry is connected to the sensing element and the compensating element for determining gas pressure in the environment to which the sensing element and compensating element are exposed based on electrical response of the sensing element and the compensating element.

Owner:MKS INSTR INC

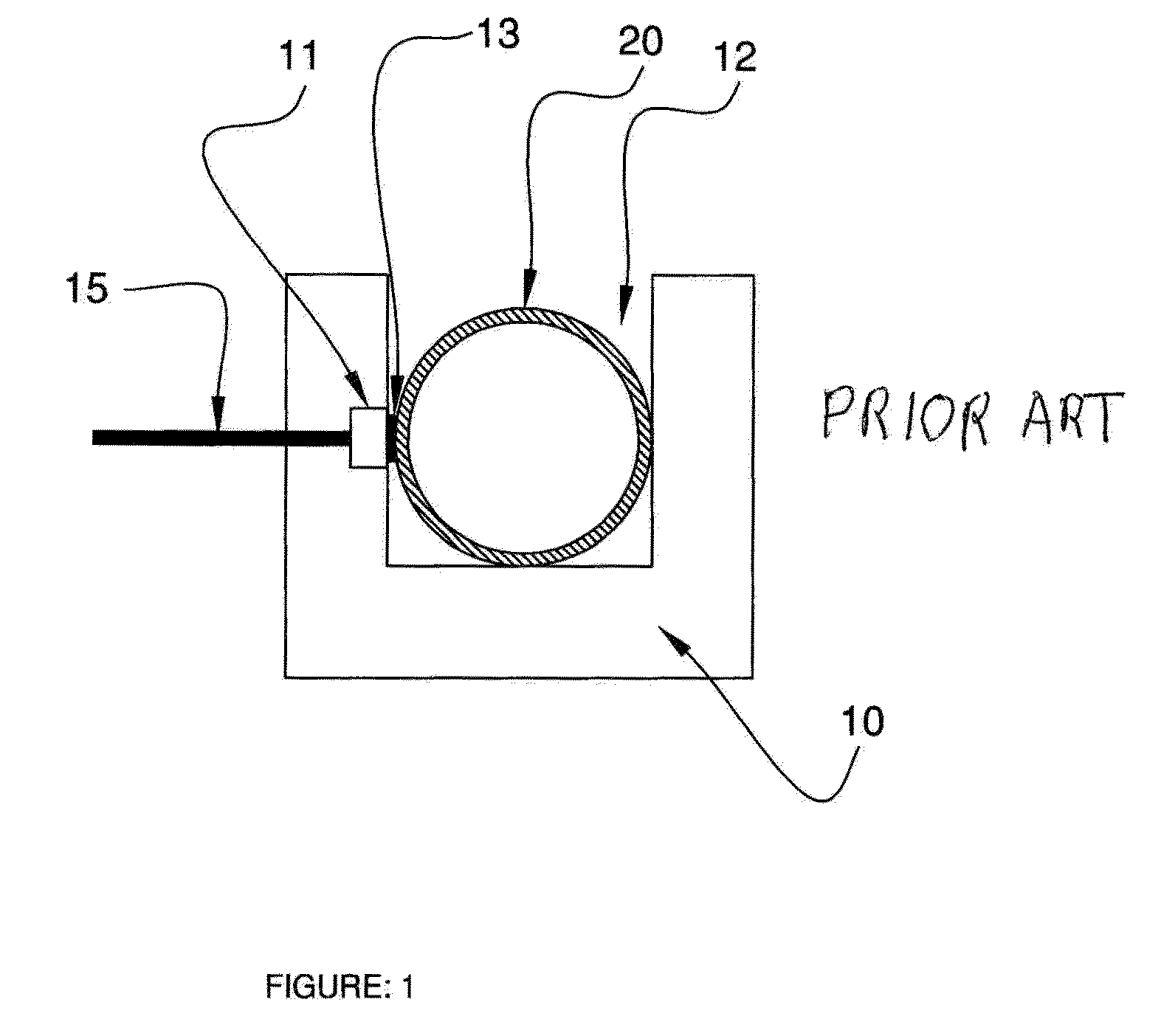

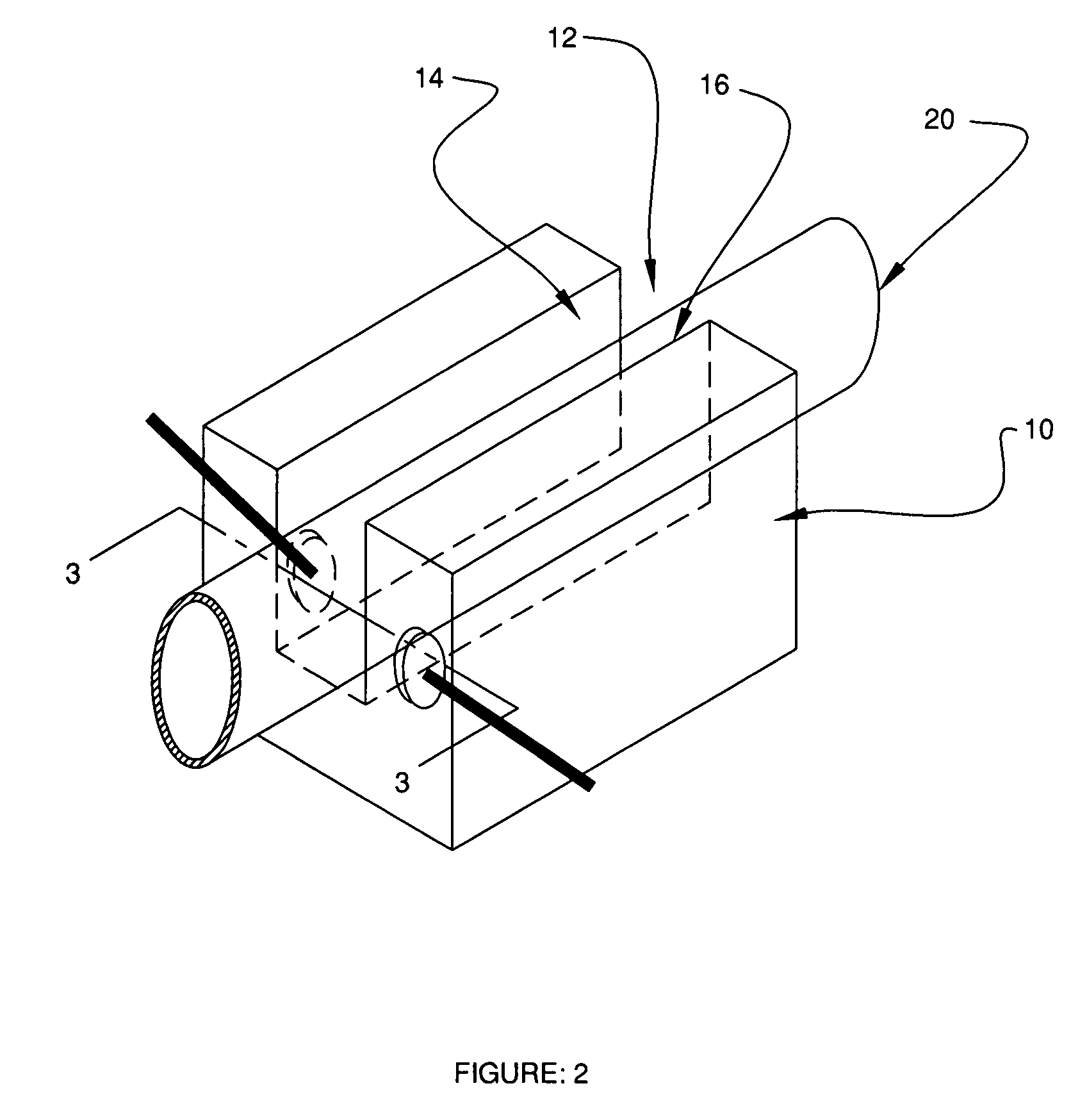

Non-invasive ultrasonic system to determine internal pressure in flexible tubing

InactiveUS7617739B1Improve pressure measurement accuracyImprove accuracyVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectricityInternal pressure

A system for determining pressure change in a liquid flowing in a tube of an elastic material has a sensor head having a slot and a pair of piezoelectric elements mounted in opposing walls of said slot between which the tube is placed in contact with the opposing elements. An electronic circuit generates periodic bursts of electro-mechanical energy from one of the elements that is transmitted through the tube to be received by the other element to be converted to an electrical signal from which is measured the travel time value of the energy through the tube and liquid therein and the amplitude value of the received signal which values are compared to at least one of base line travel time and amplitude values to determine a change of pressure of the liquid flowing in the tube.

Owner:MEASUREMENT SPEC

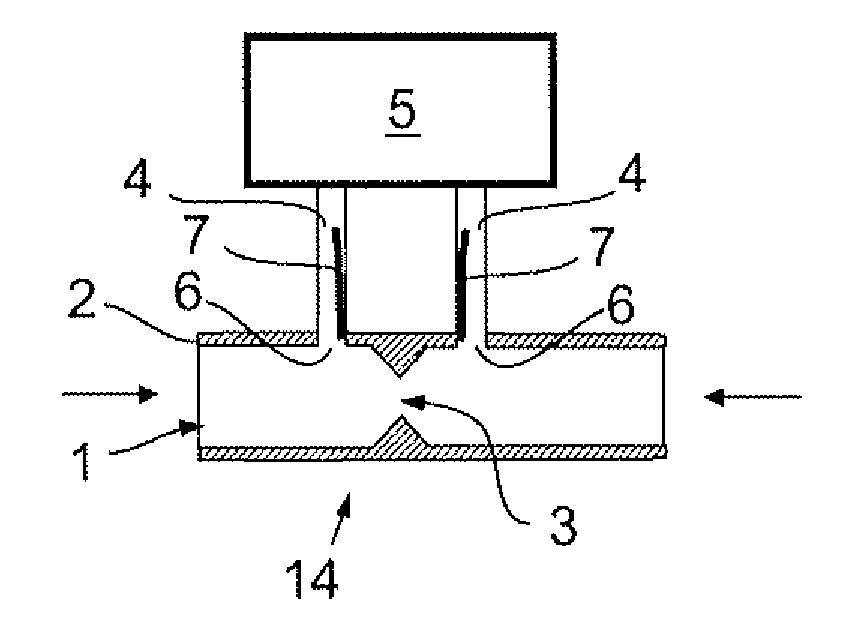

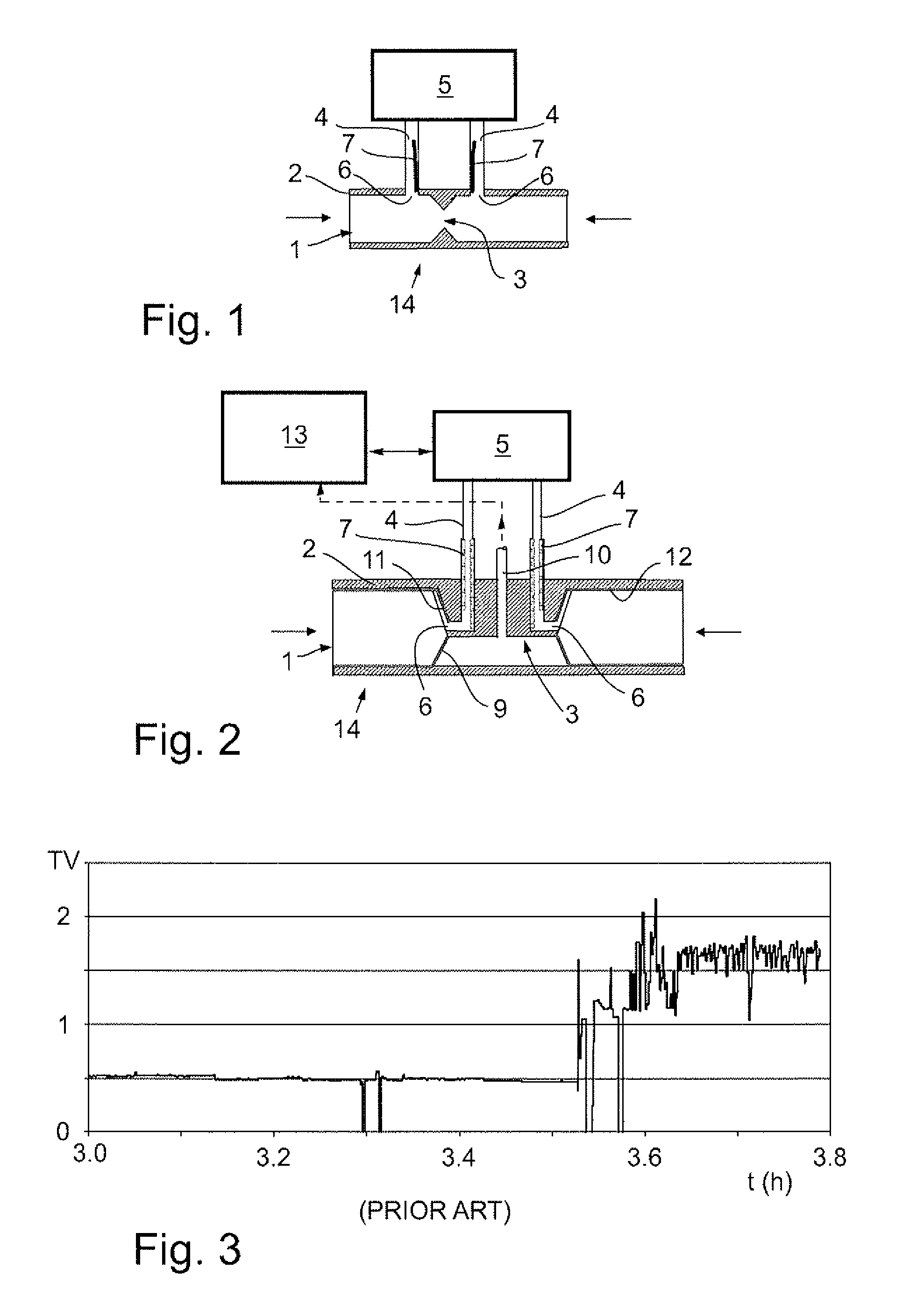

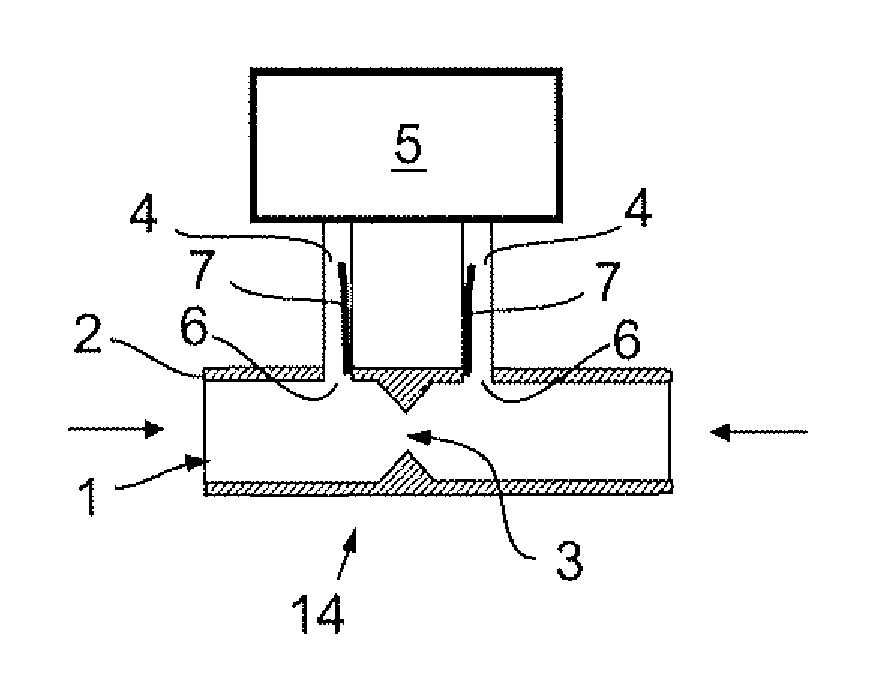

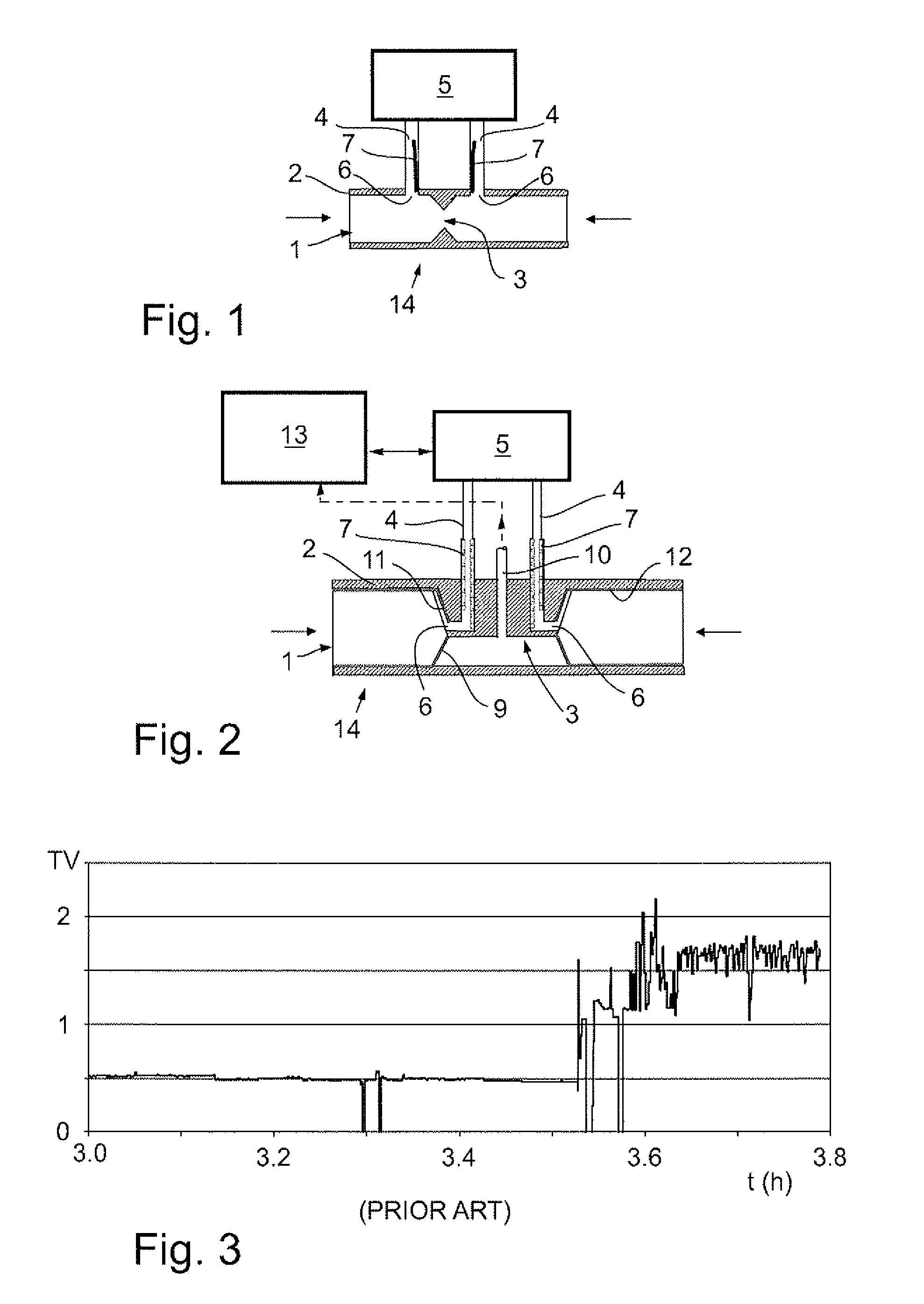

Arrangement for improving accuracy of pressure measurement and flow sensor

ActiveUS20100242622A1Improve pressure measurement accuracyImprove accuracyRespiratorsMedical devicesMeasurement deviceBreathing gas

An arrangement for improving an accuracy of a pressure measurement made of a breathing gas including drops of water or humidity flowing along a flow channel is disclosed herein. The arrangement includes at least one pressure measuring channel to transmit a pressure of the breathing gas flowing along the flow channel to a measuring device to make the pressure measurement. The pressure measuring channel is equipped with a capillary material enabling capillary suctioning of water. Also a flow sensor for a flow rate measurement of a breathing gas including drops of water or humidity is provided.

Owner:GENERAL ELECTRIC CO

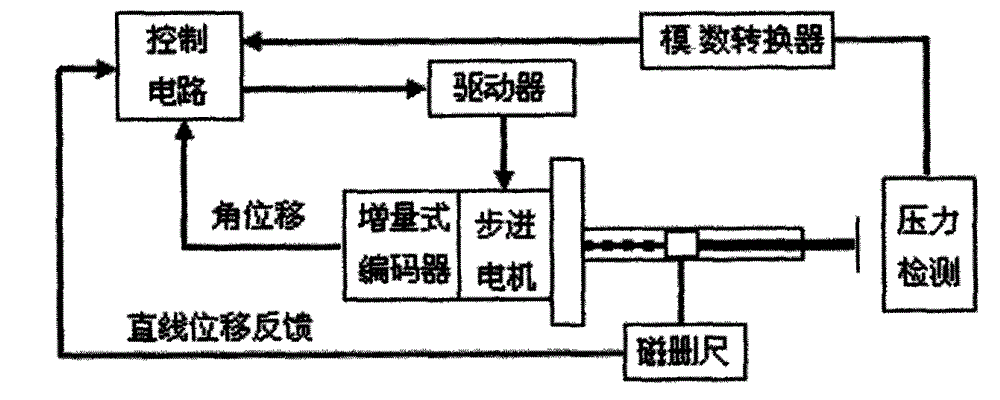

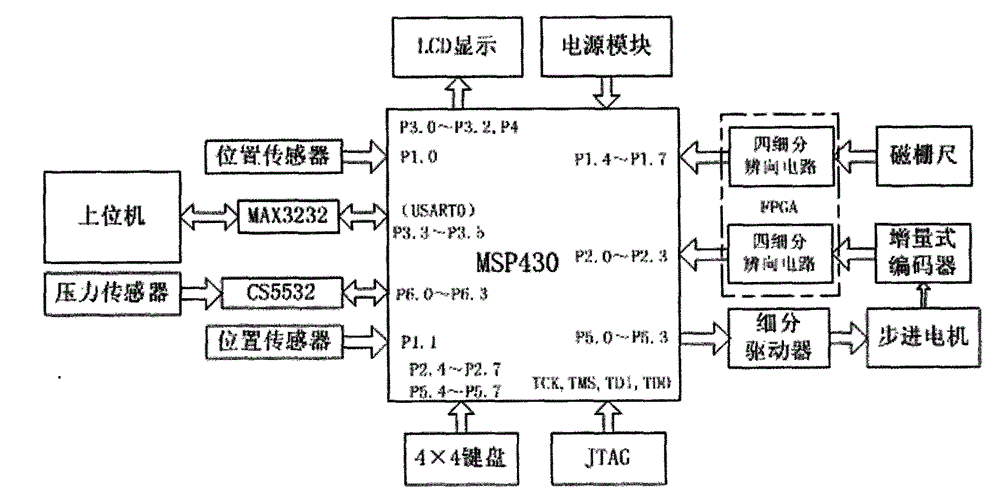

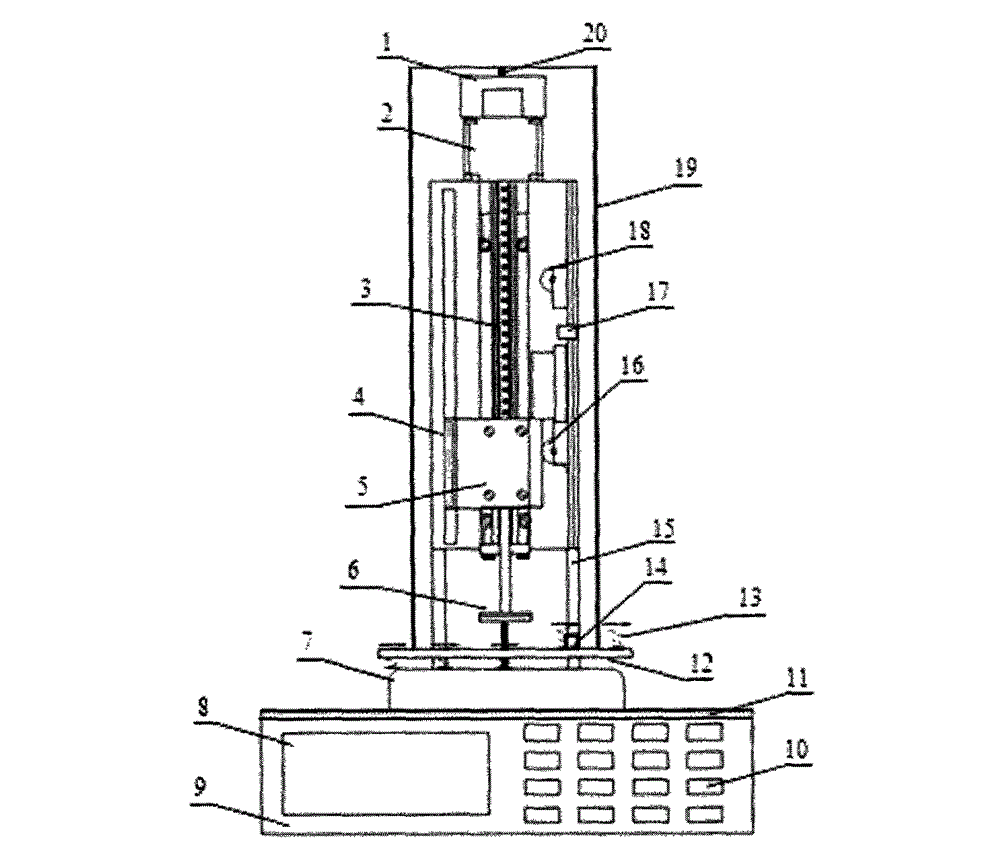

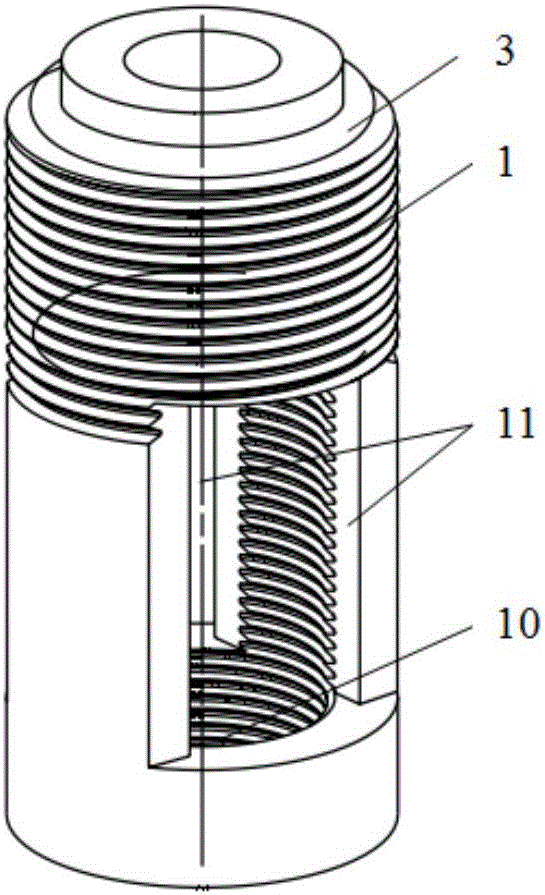

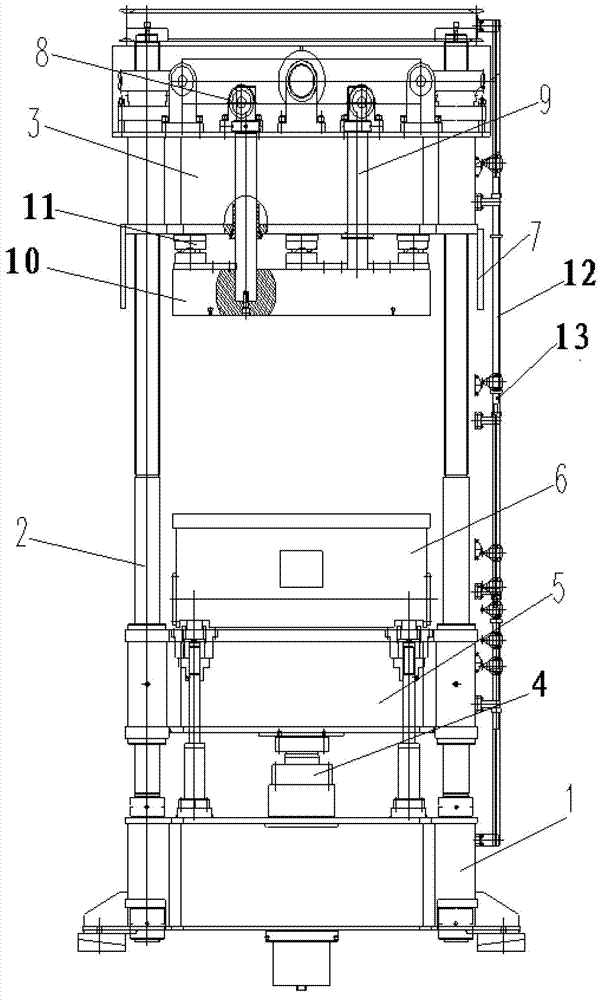

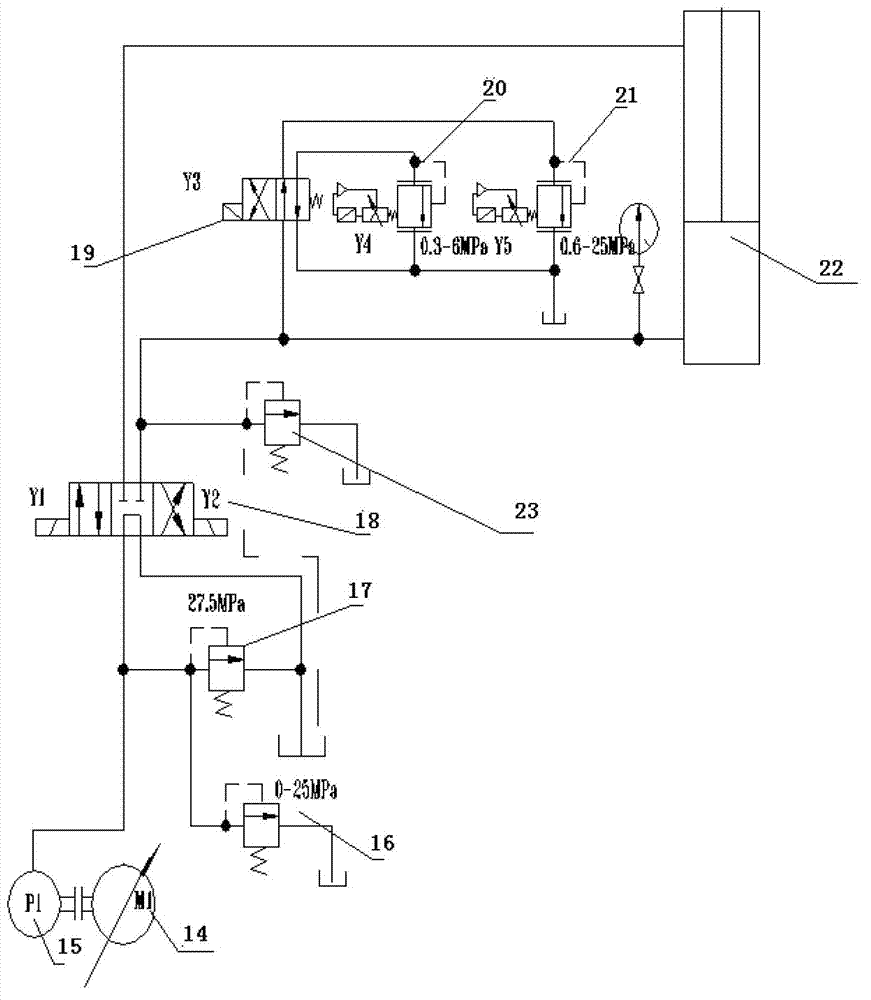

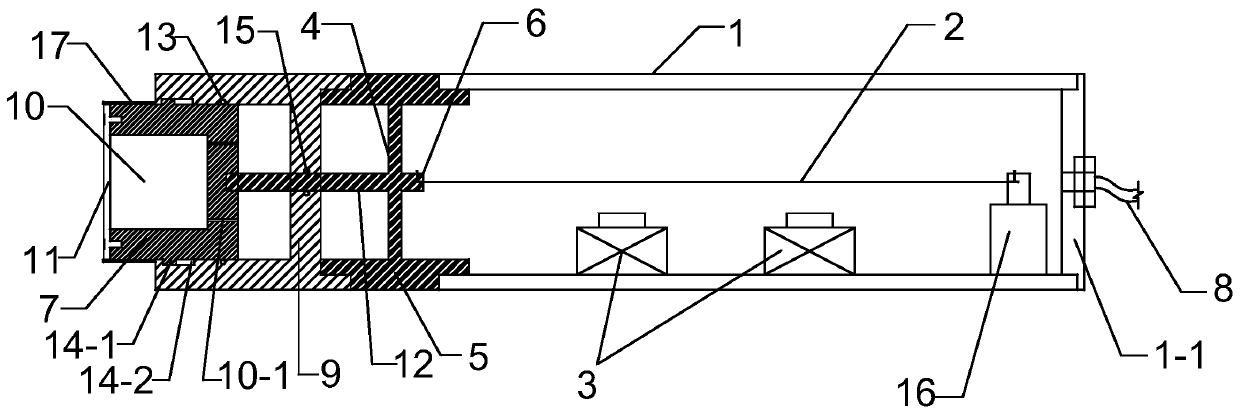

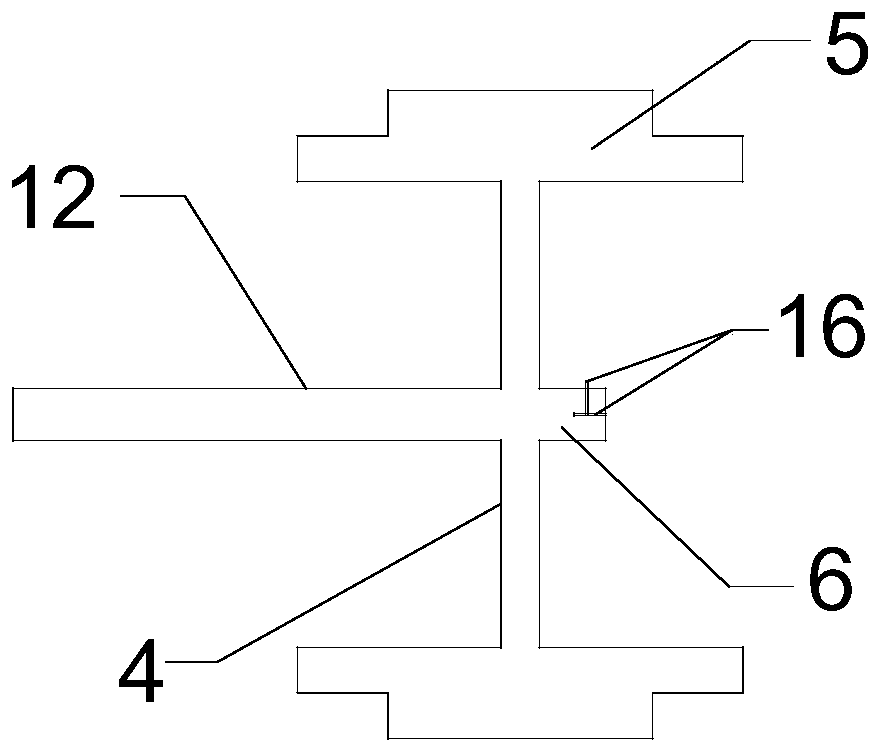

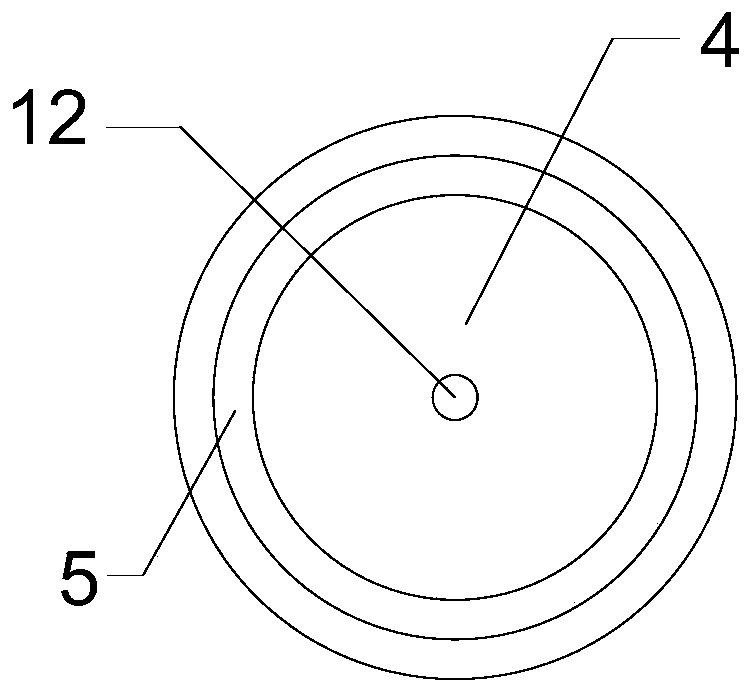

Spring performance automatic testing device

InactiveCN103063417AImprove control stabilityImprove anti-interference abilityMachine part testingStrength propertiesGeophoneClosed loop

The invention discloses a spring performance automatic testing device and a method of improving testing accuracy. A tested spring is micro pressure spring which is used in a geophone. The automatic testing device is composed of three parts, namely a mechanism structure, a transmission structure and a testing and controlling circuit. A stepping motor and a linear guide rail are vertically installed, and a pressure measurement module is horizontally installed. When a slider on the linear guide rail is driven by the stepping motor to vertically reciprocate, the slider drives a circular rotating disc to achieve automatic placement of the batch of the springs to be tested and automatic testing of the performance of the springs to be tested. The spring is compressed to the preset position by using a pressure plate which is connected with a dual closed-loop controlling driving slider, current elastic values are tested in real time by the pressure measurement module, and thereby the elastic value and stiffness factor of the spring which is at the random position within the elastic range can be accurately measured. The spring performance automatic testing device has the advantages of being high in accuracy, good in repeatability and capable of obviously improving measurement accuracy of the geophone.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Transparent nozzle self-circulation device for internal cavity flowing visualization research

ActiveCN103487232AEasy to operateRealize self-circulationHydrodynamic testingGas cylinderNitrogen gas

The invention discloses a transparent nozzle self-circulation device for internal cavity flowing visualization research. The transparent nozzle self-circulation device comprises a back pressure system, a gas circulation system, a temperature control system and a fuel injection system. The back pressure system comprises high-pressure nitrogen, a back pressure cavity, a gas flow control valve assembly and a first pressure transmitter. The gas circulation system comprises a filter, a gas circulation compressor, a pressure resistance gas cylinder, a gas control valve, a second pressure transmitter and an electronic control pressure stabilizer. The temperature control system comprises a temperature control unit and a heat exchanger and is used for ensuring that temperature in the back pressure cavity is constant. The fuel injection system comprises a proportion amplifying fuel injector and a proportion amplifying fuel spray nozzle. The problem that in the prior art, atomized diesel fuel blurs a sight window of the back pressure reception cavity is solved, so that further development of the experiment is facilitated. By the adoption of the proportion amplifying fuel spray nozzle, a visible experiment for internal flowing of the fuel proportion amplifying fuel spray nozzle of a diesel engine under the condition of certain back pressure is made to be possible.

Owner:泰州市海创新能源研究院有限公司

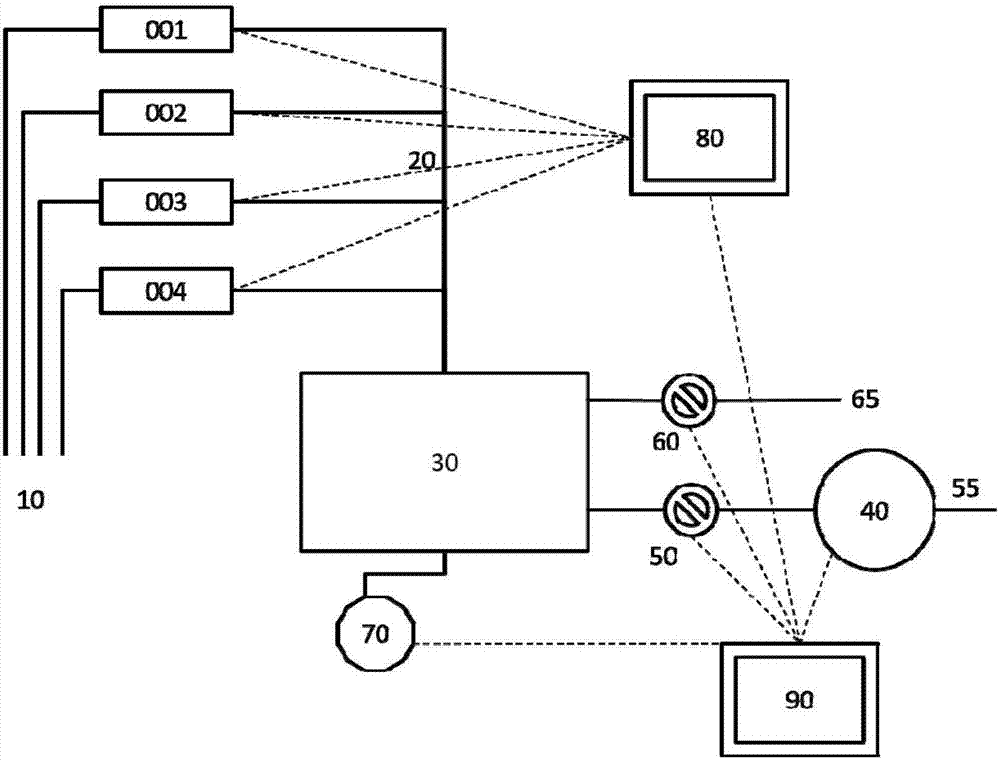

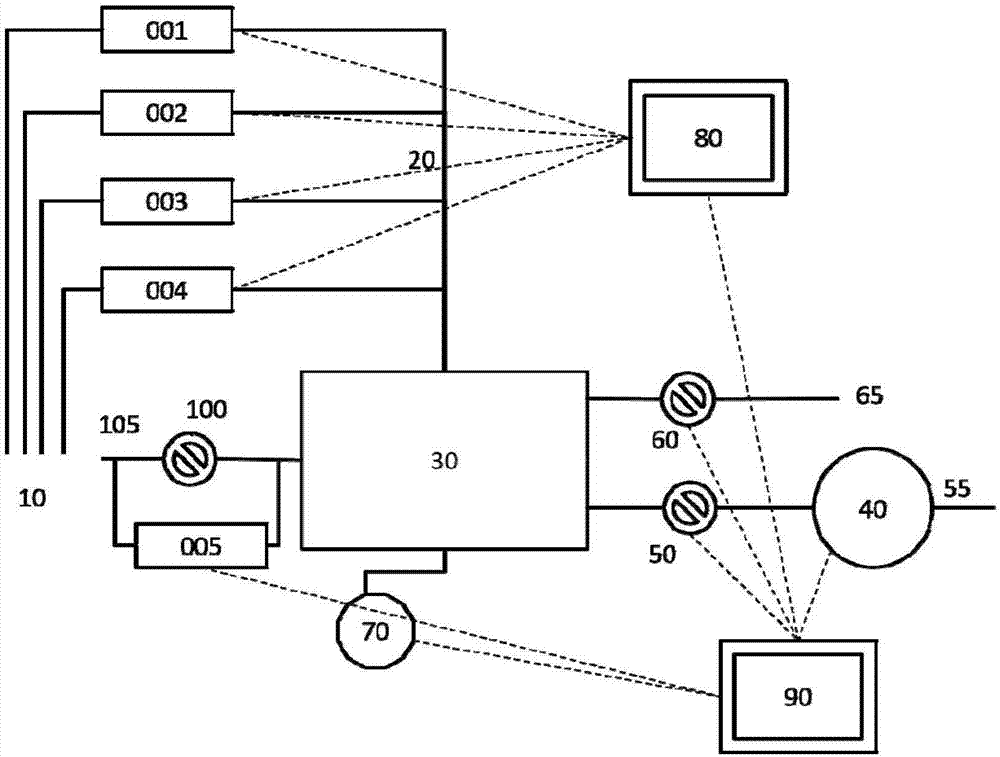

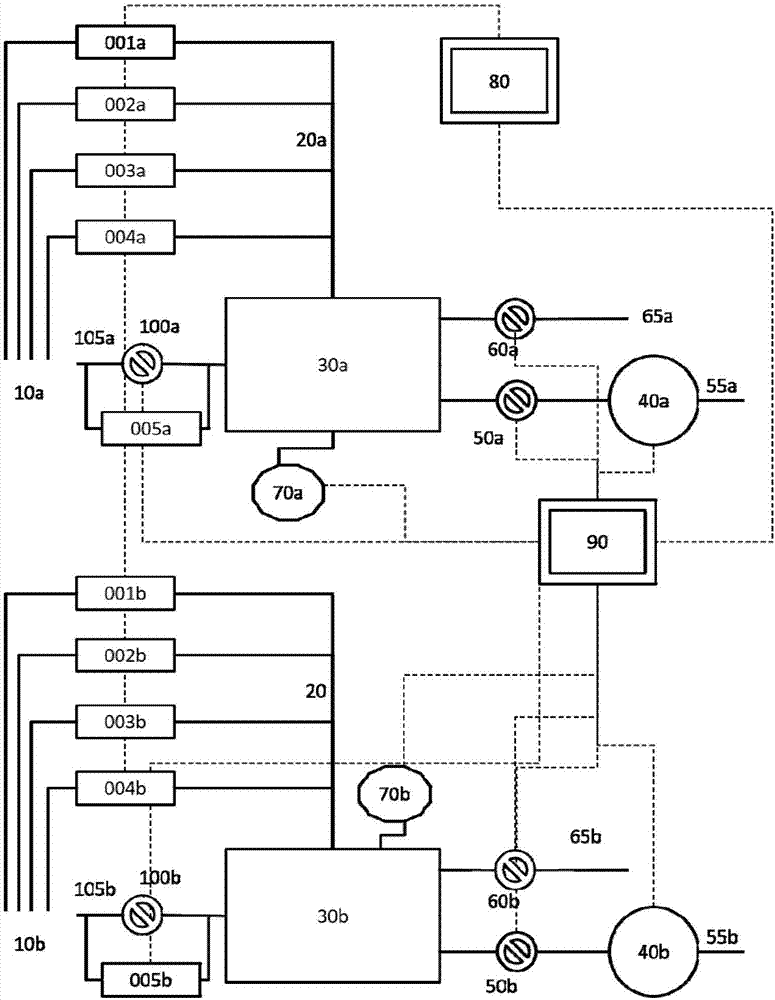

High-precision pressure measuring system with variable reference pressure

ActiveCN107966235AHigh measurement accuracySolve the low measurement accuracyAerodynamic testingPressure difference measurement between multiple valvesResponse FrequencyAccuracy and precision

The invention discloses a high-precision pressure measuring system with variable reference pressure. The high-precision pressure measuring system is mainly used for wind tunnel experiment measurement,and belongs to the technical field of gas pressure measurement. The high-precision pressure measuring system provides reference pressure Pref which is close to measured pressure P through a referencepressure cavity, the reference pressure Pref is measured by means of a high-precision steady-state pressure meter, and a difference value dP between P and Pref is measured by using a small-measuring-range dynamic differential pressure sensor, namely, the measured pressure is decomposed into stable reference pressure and dynamic pressure with a small absolute value, and the stable reference pressure and the dynamic pressure are measured by means of appropriate sensors and then are re-synthesized. The high-precision pressure measuring system can satisfy requirements for response frequency of dynamic pressure measurement, has high measuring precision, solves the problem of low measurement precision of a high-frequency dynamic pressure sensor, and can adjust the reference pressure to adapt toa wide measuring range scope, so as to reduce the quantity demand of the sensors.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Apparatus and methods for heat loss pressure measurement

InactiveUS6945119B2Improve pressure measurement accuracyIncrease rangeAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid pressure measurement using ohmic-resistance variationElectricityElectrical resistance and conductance

A heat loss gauge for measuring gas pressure in an environment includes a resistive sensing element and a resistive compensating element. The resistive compensating element is in circuit with the sensing element and is exposed to a substantially matching environment. An electrical source is connected to the sensing element and the compensating element for applying current through the elements. The current through the sensing element is substantially greater than the current through the compensating element. Measuring circuitry is connected to the sensing element and the compensating element for determining gas pressure in the environment to which the sensing element and compensating element are exposed based on electrical response of the sensing element and the compensating element.

Owner:MKS INSTR INC

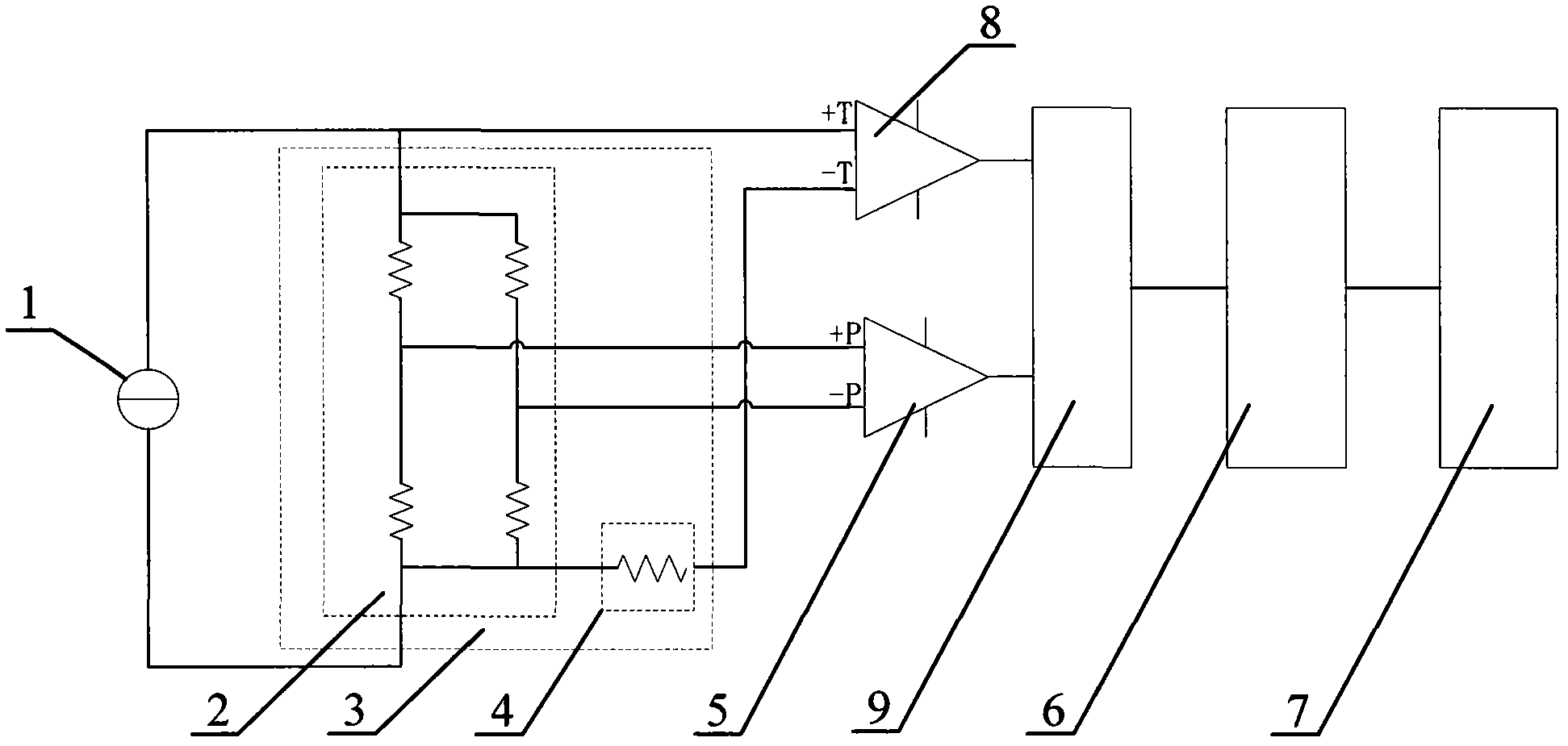

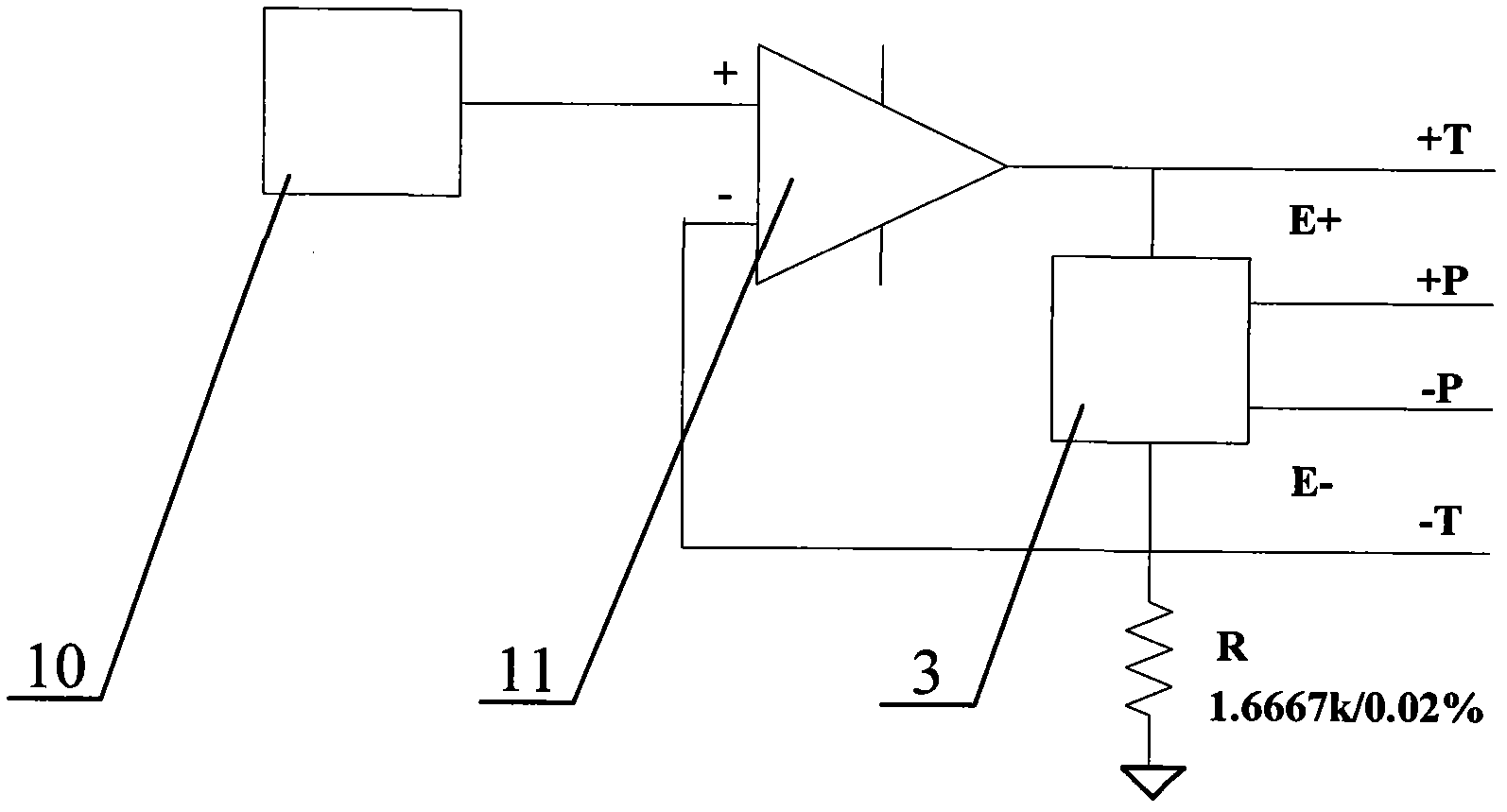

Digital temperature compensation system and method

ActiveCN102519666AAmplified temperature characteristicsRealize automatic temperature compensationFluid pressure measurementElectrical resistance and conductanceMultiplexing

The invention belongs to the field of pressure measurement, particularly to a digital temperature compensation system and a method. The temperature compensation system includes a constant-current source (1), a pressure sensing module (3), a pressure signal amplifier (5), a temperature signal amplifier (8), a multiplexing switch (9), an A / D conversion module (6) and a processor (7). The method includes steps including system calibration, storage of system temperature calibration results, and the measurement temperature compensation. According to the invention, in the digital temperature compensation system, a temperature compensation resistor is additionally arranged at a pressure sensor through the design of the pressure sensing module to amplify the temperature characteristic of the pressure sensor and realize the automatic temperature compensation, so that the installation and maintenance are convenient, and the function of serving as the pressure sensor and the temperature sensor at the same time are realized. The digital temperature compensation method provided by the invention realizes the automatic temperature compensation at any temperature and any pressure, has higher measuring accuracy, improves the pressure measuring accuracy, and has the full range error smaller than 0.02% or lager than minus 0.02%.

Owner:四川天利科技有限责任公司

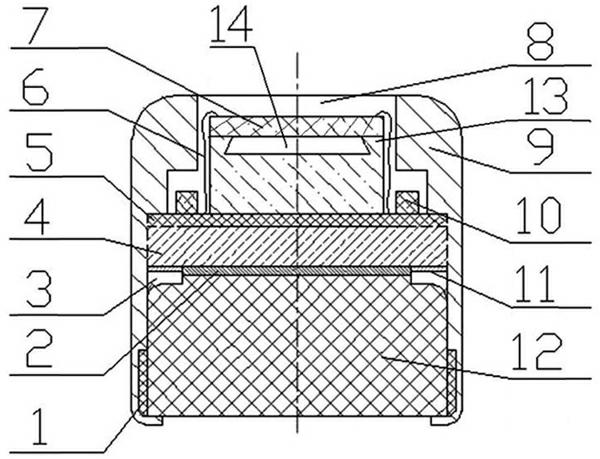

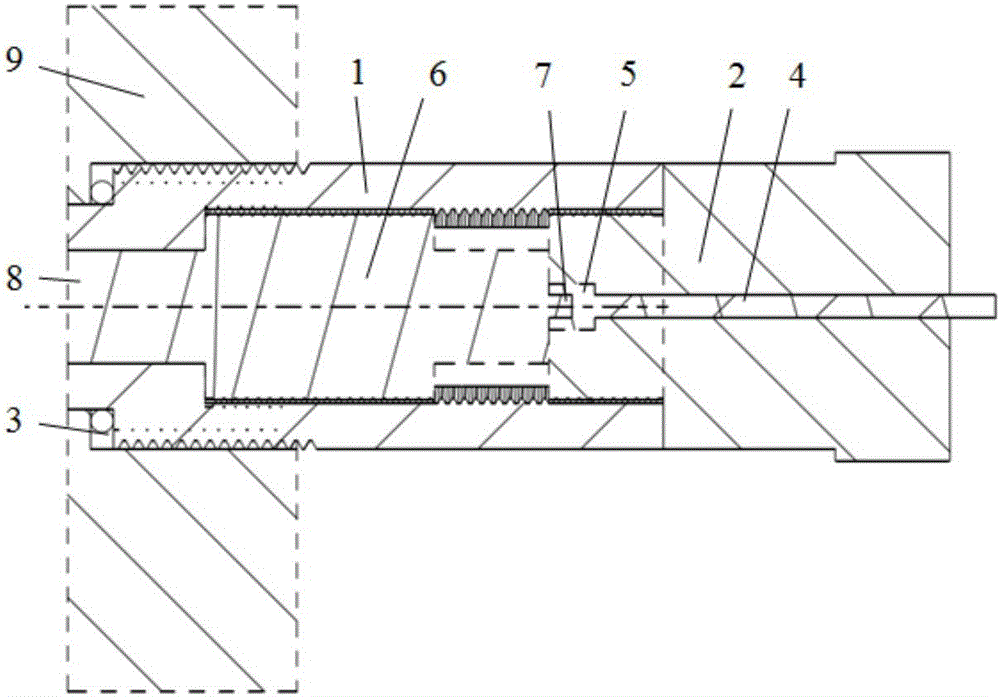

Miniature mud floating electronic pressure gauge, its working method, and pressure measuring device

The invention discloses a micro mud floating electronic pressure gauge, a working method thereof, and a pressure measurement device, relates to the field of oil and gas extraction, and aims to provide a device for measuring underground pressure and temperature in the mud drilling process in real time, and a working method thereof. The technical key point is that: a button cell, a singlechip with acquisition software, a circuit board, a connection block, and a pressure chip are stacked in a shell sequentially from bottom to top; the shell is a cylindrical shell of which the upper and lower ends are provided with openings, and the interior and the exterior of the shell are isolated by isolation protective adhesive; the pressure gauge acquires temperature and pressure information intermittently under a well; and the pressure measurement device comprises the pressure gauge, a data loading system, and a pressure and temperature calibrating device. The pressure gauge is as small as drill cuttings, so the pressure gauge can float in mud and move along with mud, measure pressure timely and recover data, and does not influence the drill construction.

Owner:CHENGDU HAOHAN WELL COMPLETION & LOGGING SCI & TECH

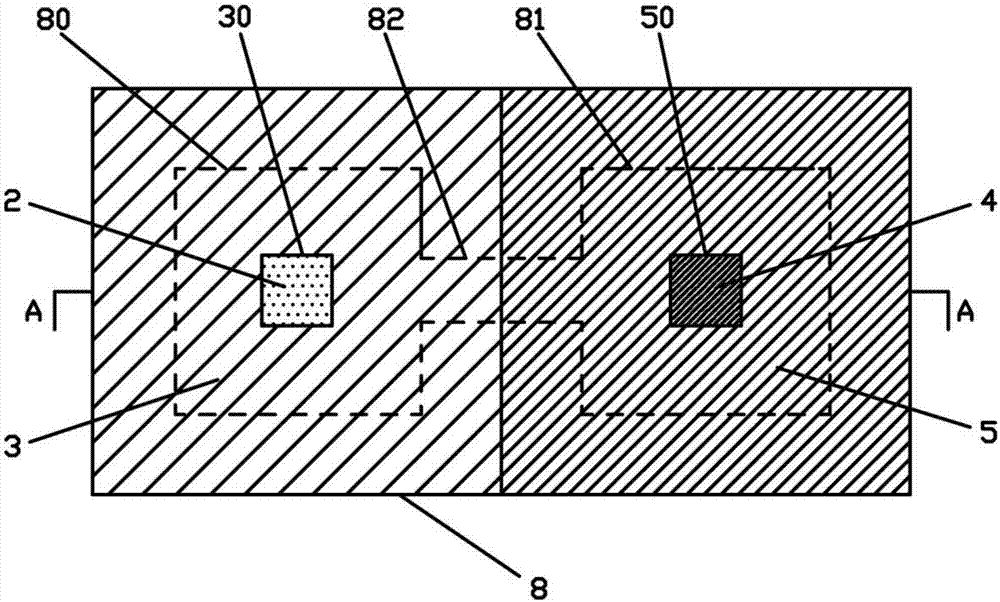

Wide-range high-precision double film-integrated capacitive pressure sensor and manufacturing method

InactiveCN107389230ARealize high-precision measurementExpand the measurement rangeForce measurementCapacitive pressure sensorElectricity

The invention relates to the technical field of pressure sensors and particularly relates to a wide-range high-precision double film-integrated capacitive pressure sensor and a manufacturing method. The wide-range high-precision double film-integrated capacitive pressure sensor comprises a glass substrate; a first shallow groove and a second shallow groove are arranged in the glass substrate; the first shallow groove and the second shallow groove are communicated through a thin groove; the center position of the second shallow groove is provided with a shallow groove through hole; the shallow groove through hole extends to the bottom surface of the glass substrate from the bottom surface of the second shallow groove; the first shallow groove is provided with a capacitor C1 capable of measuring a low pressure difference; the second shallow groove is provided with a capacitor C2 capable of measuring a high pressure difference; the capacitor C1 capable of measuring the low pressure difference comprises a bottom electrode plate and a thin pressure sensitive film; the capacitor C2 capable of measuring the high pressure difference comprises a thick pressure sensitive film and a top electrode plate; the shallow groove through hole and the capacitor C1 capable of measuring the low pressure difference are arranged correspondingly; and the shallow groove through hole and the capacitor C2 capable of measuring the high pressure difference are arranged correspondingly. Through the capacitor C1 capable of measuring the low pressure difference and the capacitor C2 capable of measuring the high pressure difference, high-precision pressure measurement in a low pressure section and a high pressure section can be realized respectively.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

Apparatus and methods for heat loss pressure measurement

InactiveUS6938493B2Improve pressure measurement accuracyIncrease rangeFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElectricityElectrical resistance and conductance

A heat loss gauge for measuring gas pressure in an environment includes a resistive sensing element and a resistive compensating element. The resistive compensating element is in circuit with the sensing element and is exposed to a substantially matching environment. An electrical source is connected to the sensing element and the compensating element for applying current through the elements. The current through the sensing element is substantially greater than the current through the compensating element. Measuring circuitry is connected to the sensing element and the compensating element for determining gas pressure in the environment to which the sensing element and compensating element are exposed based on electrical response of the sensing element and the compensating element.

Owner:MKS INSTR INC

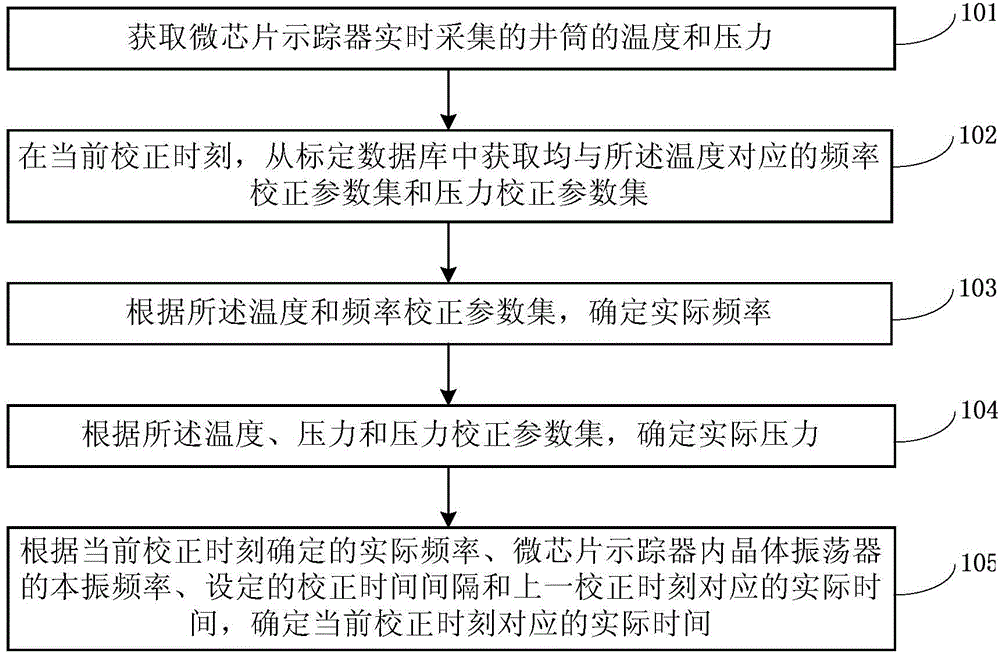

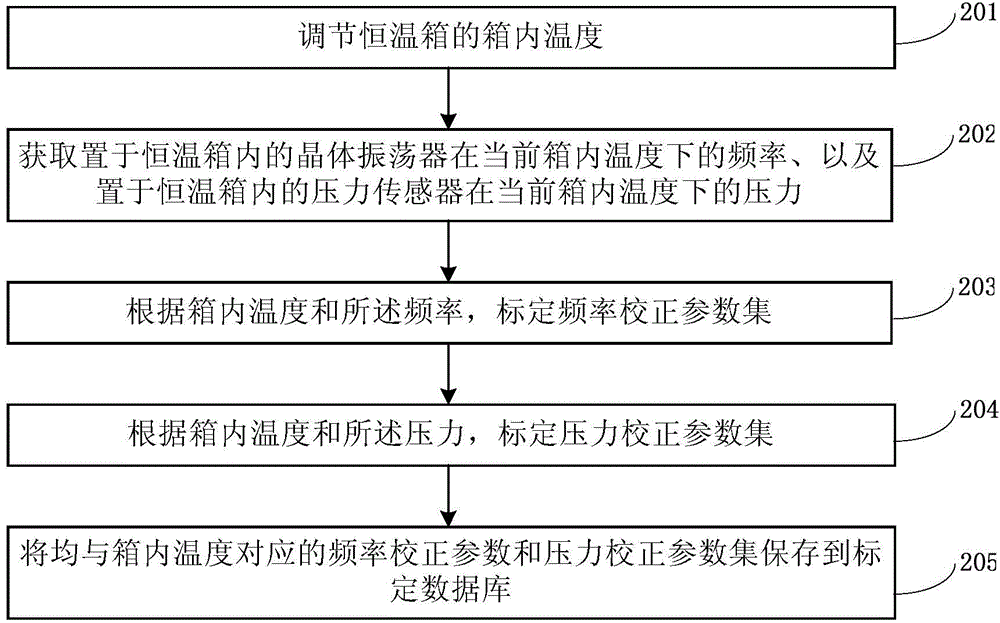

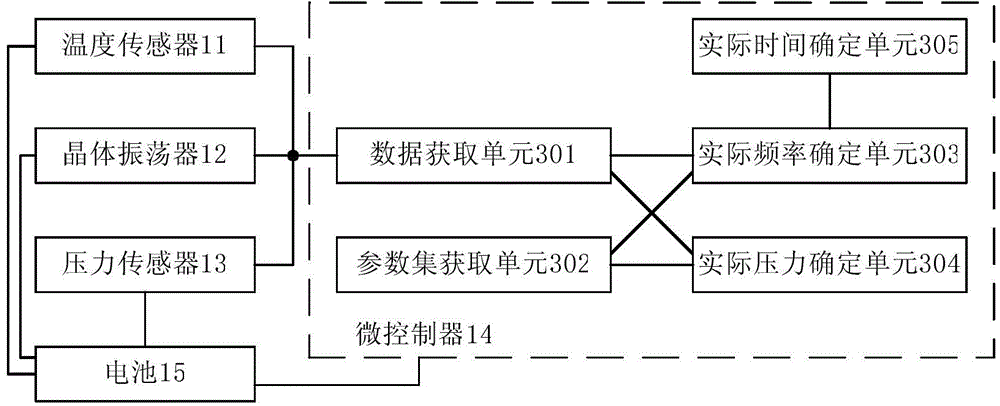

Temperature compensation method and system of microchip tracer

ActiveCN105484734AImprove pressure measurement accuracyDoes not increase hardware resourcesSurveyConstructionsEngineeringCrystal oscillator

The present invention discloses a temperature compensation method and system of a microchip tracer. The method comprises the steps of: obtaining shaft temperature and pressure which are acquired by the microchip tracer in real time; at the current correction time, obtaining a frequency correction parameter set and a pressure correction parameter set which are both corresponding to the temperature from a calibration database; determining actual frequency according to the temperature and the frequency correction parameter set; determining actual pressure according to the temperature, the pressure and the pressure correction parameter set; and determining actual time corresponding to the current correction time according to the actual frequency determined at the current correction time, local frequency of a crystal oscillator in the microchip tracer, a set correction time interval and actual time corresponding to the last correction time. The purpose of performing temperature compensation for pressure acquired by the microchip tracer and time recorded by the microchip tracer without increasing hardware resources is achieved, and the temperature compensation method and system has the characteristics of high reliability and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

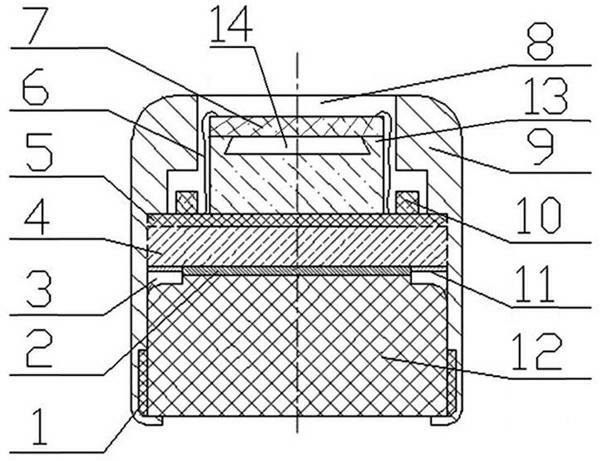

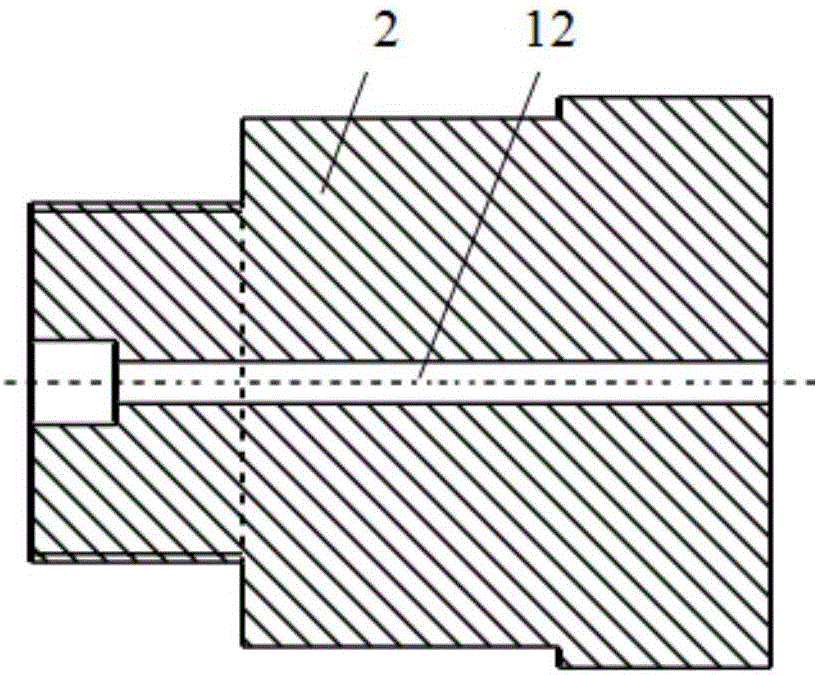

Stabilizing device used for fixing detonation pressure sensor and installation method thereof

ActiveCN106813820AImprove test efficiencyImproving the Measurement Accuracy of Detonation Wave PressureMeasurement of explosion forceCoaxial cableDetonation

The present invention discloses a stabilizing device used for fixing a detonation pressure sensor. The stabilizing device comprises a detonation pressure sensor stabilizer and a coaxial cable stabilizer, and the detonation pressure sensor stabilizer is a cylinder equipped with the large and small diameter stepped center holes matching an outer circle of a detonation pressure sensor body. The outer cylindrical surface of a circle body is equipped with the outer screw threads, and the end head is equipped with a concave edge bench. The large diameter center hole is equipped with the inner screw threads, and the outer cylindrical surface corresponding to the middle part of the large diameter center hole is symmetrically equipped with the installing holes communicated with the large diameter center hole. The coaxial cable stabilizer is a stepped cylinder equipped with an internal center hole and the external small, medium and large diameters, wherein the outer cylindrical surface of a small diameter cylinder is equipped with the outer screw threads, the end face is equipped with a counter bore communicated with the center hole. According to the present invention, the measurement data deviation caused by the instability of the sensor and a measurement error caused by the swinging or loosening of a coaxial cable are avoided effectively, thereby guaranteeing the accurate measurement of the detonation pressure sensor to a detonation wave.

Owner:镇江特瑞机电有限公司

Arrangement for improving accuracy of pressure measurement and flow sensor

ActiveUS8286504B2Improve pressure measurement accuracyImprove accuracyRespiratorsMedical devicesFlow transducerMeasurement device

An arrangement for improving an accuracy of a pressure measurement made of a breathing gas including drops of water or humidity flowing along a flow channel is disclosed herein. The arrangement includes at least one pressure measuring channel to transmit a pressure of the breathing gas flowing along the flow channel to a measuring device to make the pressure measurement. The pressure measuring channel is equipped with a capillary material enabling capillary suctioning of water. Also a flow sensor for a flow rate measurement of a breathing gas including drops of water or humidity is provided.

Owner:GENERAL ELECTRIC CO

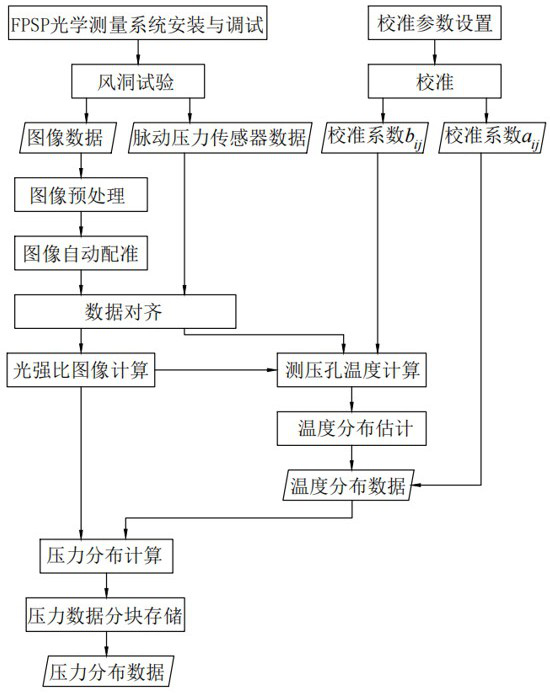

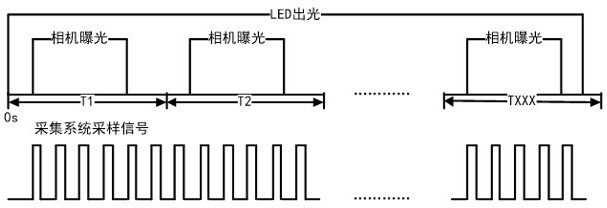

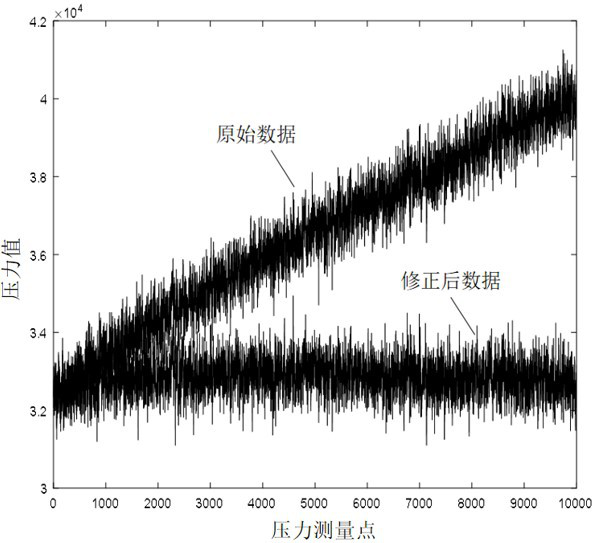

Quick response pressure-sensitive paint temperature effect correction method

ActiveCN114441090AReduce the effect of temperatureImprove pressure measurement accuracyAerodynamic testingFluid pressure measurementBackground imagePressure data

The invention discloses a quick response pressure-sensitive paint temperature effect correction method, and belongs to the technical field of aerospace aerodynamics wind tunnel tests and image data processing, and the method comprises the steps: calibrating a pressure-sensitive paint, and calculating a calibration coefficient of a relation among three variables of a light intensity ratio, pressure and temperature according to calibration data; test preparation; performing a wind tunnel test, collecting a background image and a windless image, and obtaining a windy image and pulsating pressure sensor data; preprocessing the image data; automatically registering the image; the image data and the pulsating pressure data are aligned; calculating the position temperature of the pulsating pressure sensor according to the pressure measurement value of the pulsating pressure sensor and the light intensity ratio; according to the position of the pulsating pressure sensor and the corresponding temperature, interpolating to obtain the temperature distribution of the whole measurement area; correcting the temperature effect; and storing the pressure data in blocks. The method is suitable for a quick response pressure-sensitive paint test, temperature effect correction is carried out on test data, and the pressure measurement precision of the quick response pressure-sensitive paint is remarkably improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Capillary pressure measuring device

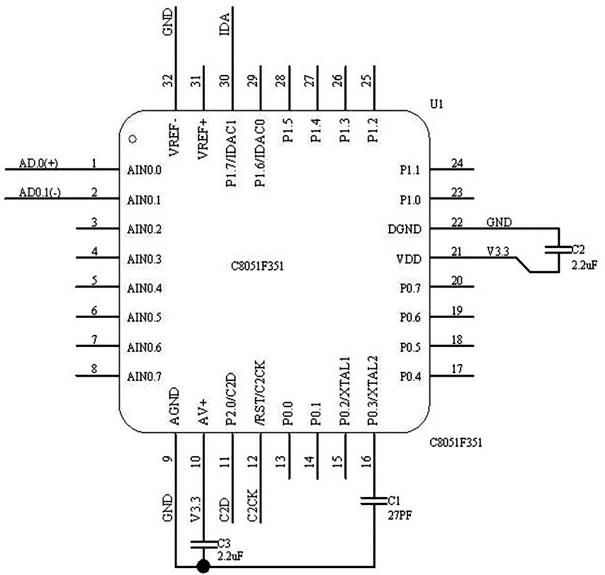

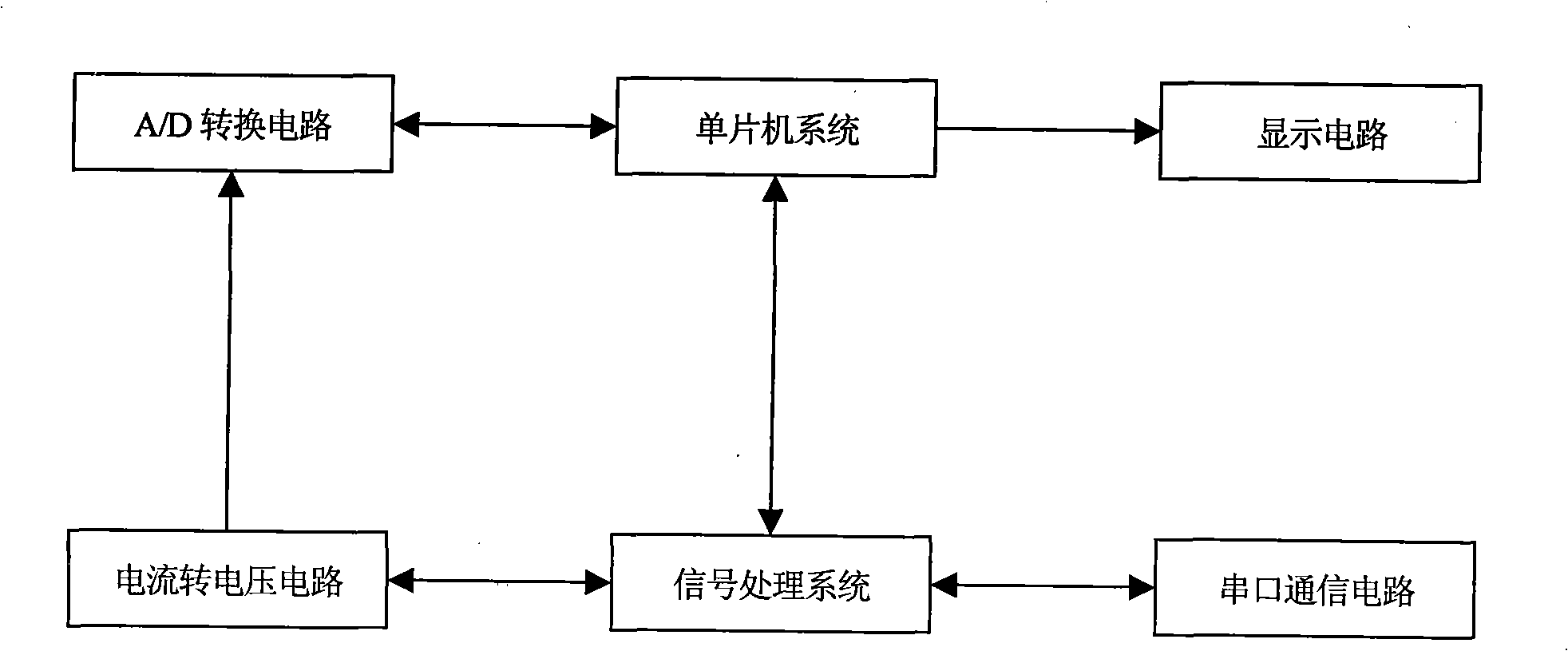

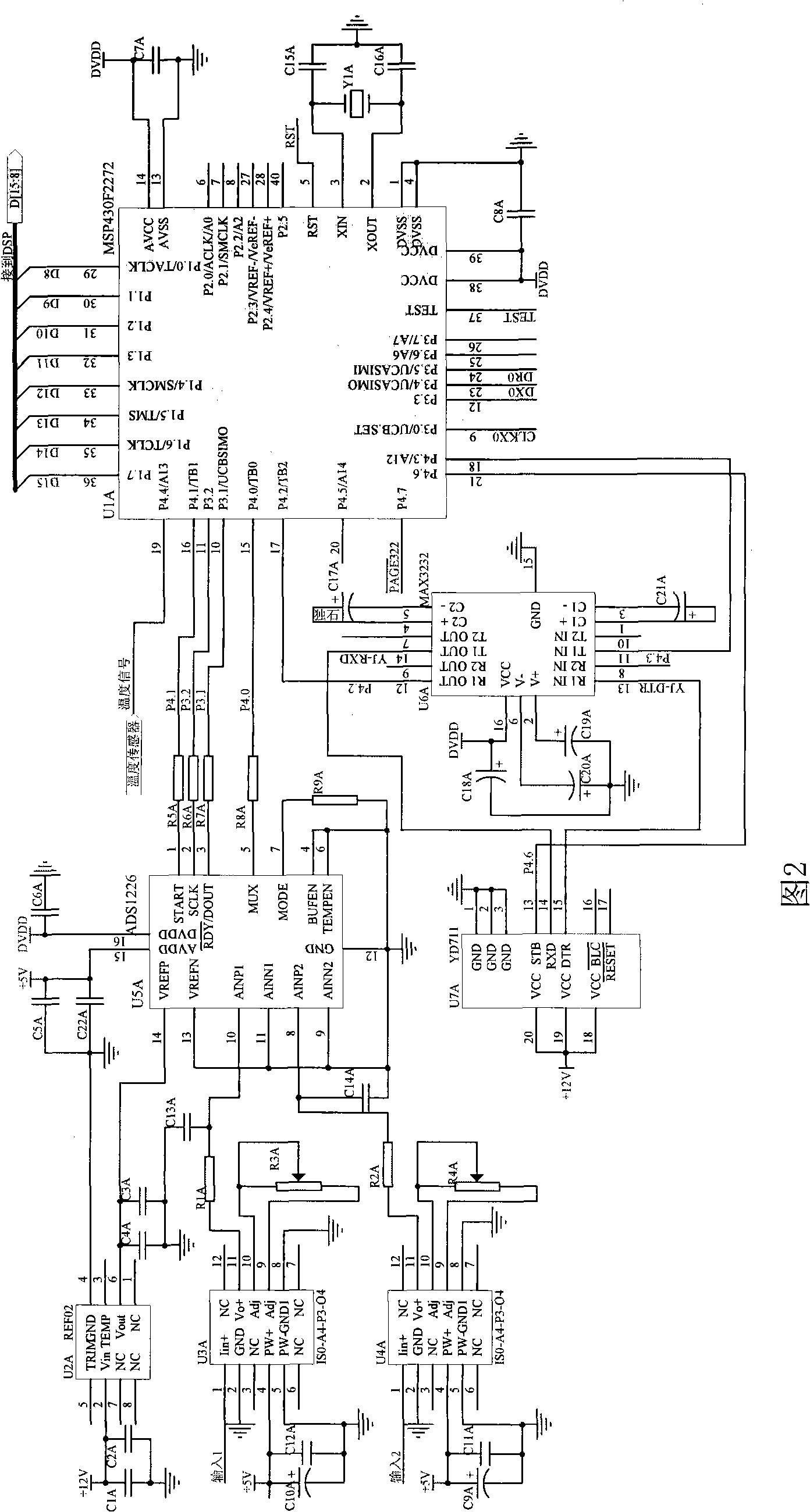

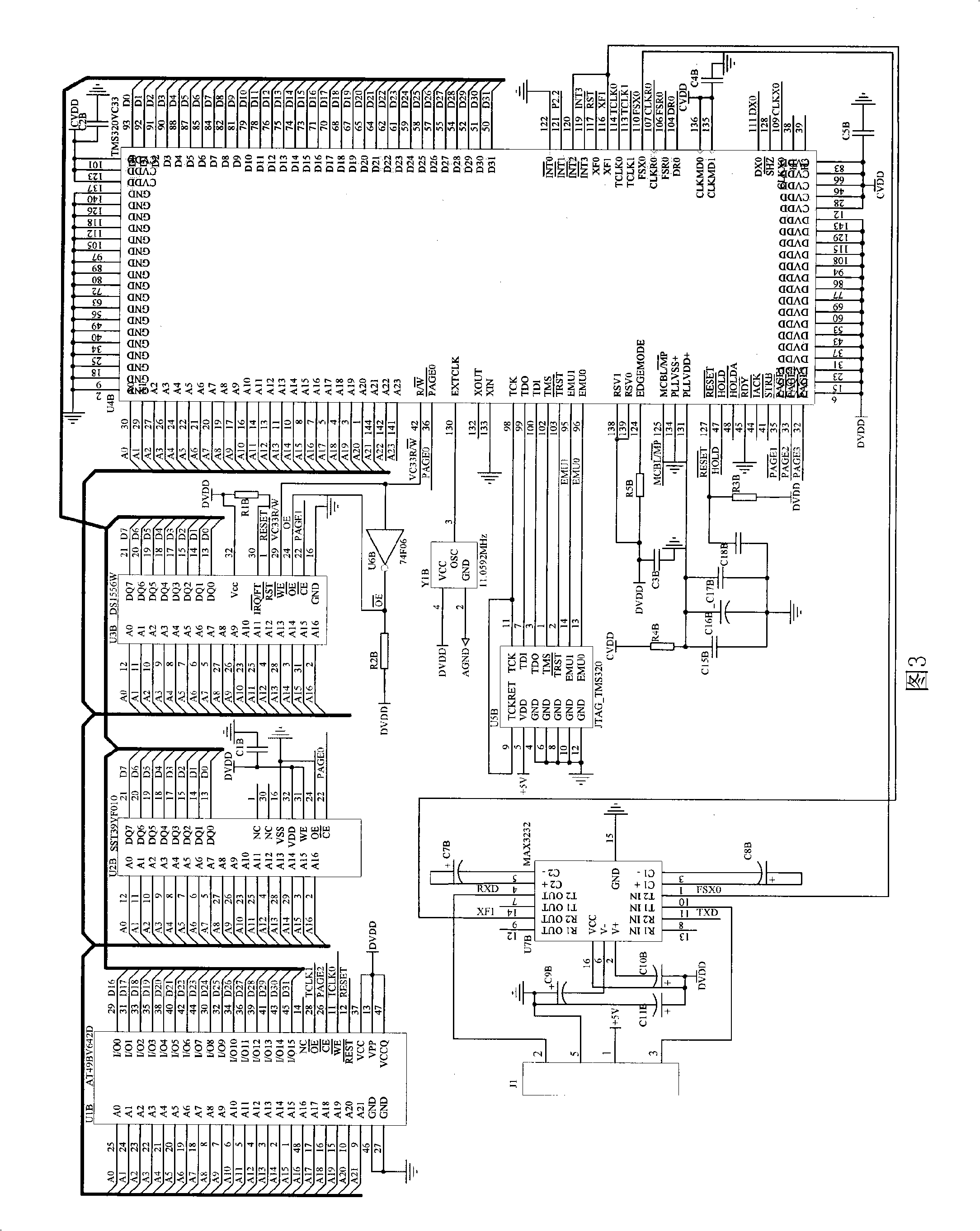

InactiveCN101328802AEasy to monitor real-time performanceImprove the display effectSurveyMicrocontrollerCapillary pressure

The invention provides a capillary tube pressure measuring device, comprising a singlechip system, a current-to-voltage circuit, an A / D conversion circuit, a signal processing system, a display circuit and a serial communication circuit, wherein the singlechip system controls the whole machine; the current-to-voltage circuit converts input pressure current signals into voltage signals; an input end of the A / D conversion circuit is connected with the current-to-voltage circuit and the singlechip system; a circuit of the signal processing system is connected with the singlechip system; an input end of the display circuit is connected with the singlechip system; and the serial communication circuit is connected with the singlechip system. The pressure measuring device adopts the singlechip system to accomplish the data acquisition of pressure and temperature; the signal processing system realizes complicated iterative algorithm, thereby improving the precision and execution efficiency of the system; a communication interface not only has the serial communication between the signal processing system and an external computer, but also has the data transmission between a singlechip and the display circuit. The pressure measuring device has the advantages of small volume, convenience for carrying, high pressure measuring precision, accurate and rapid measured data, real-time monitoring and display, etc., which can be used for monitoring the pressure in oil-gas wells.

Owner:XI'AN PETROLEUM UNIVERSITY

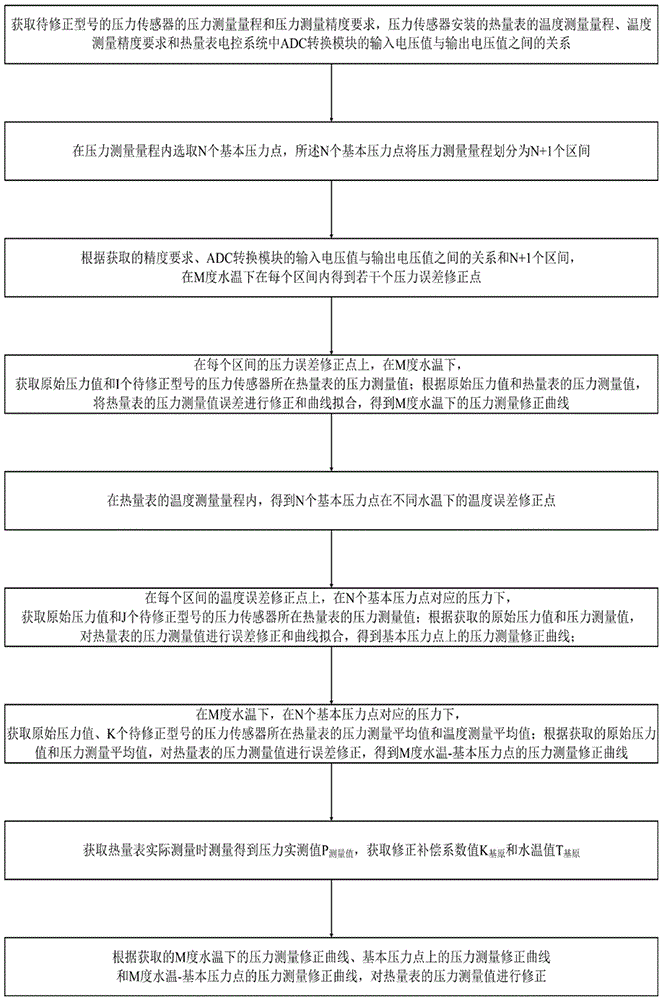

Error correction method for pressure sensor and calorimeter for measuring pressure by using the same

ActiveCN106248297AImprove pressure measurement accuracyImprove correction efficiencyFluid pressure measurementCalorimeterMeasurement precisionCorrection method

The invention discloses an error correction method for a pressure sensor. The method comprises: basic data are obtained; a basic pressure point is set; a pressure measuring correction curve under an M-degree water temperature is obtained; a pressure measuring correction curve on a basic pressure point is obtained; a pressure measuring correction curve of an M-degree water temperature-basic pressure point unit is obtained; and a pressure measuring value of a calorimeter is corrected. According to the invention, for each pressure sensor, correction is carried on a selected basic pressure point once to complete error correction work of the pressure sensor. With the method, the pressure measuring precision of the pressure sensor is improved and the production efficiency and the calibration and correction efficiencies of the calorimeter can be improved substantially. The provided method is used for pressure measurement with high accuracy; the application becomes reliable; the method is simple and the efficiency is high. In addition, when the error correction method is applied to the calorimeter, the calorimeter has advantages of high measuring precision and reliability.

Owner:HUNAN WEIMING ENERGY TECH CO LTD

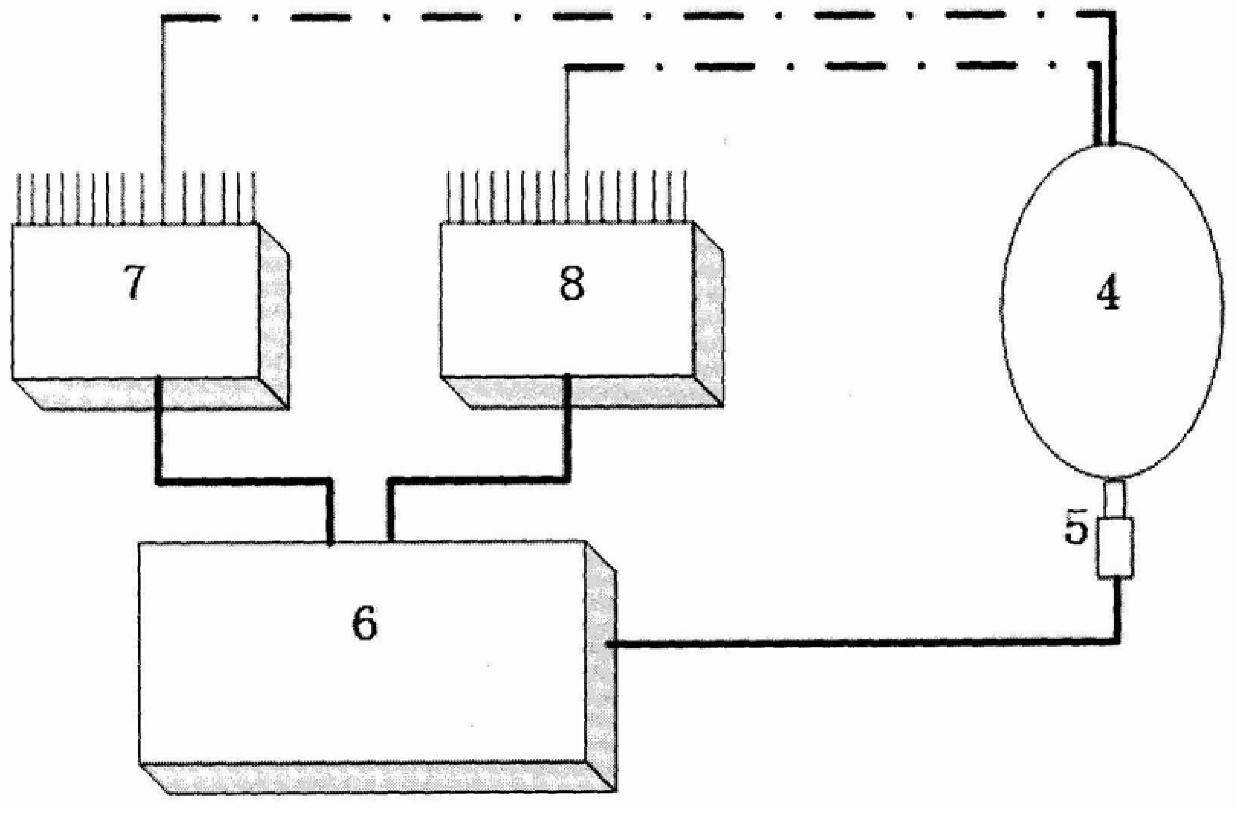

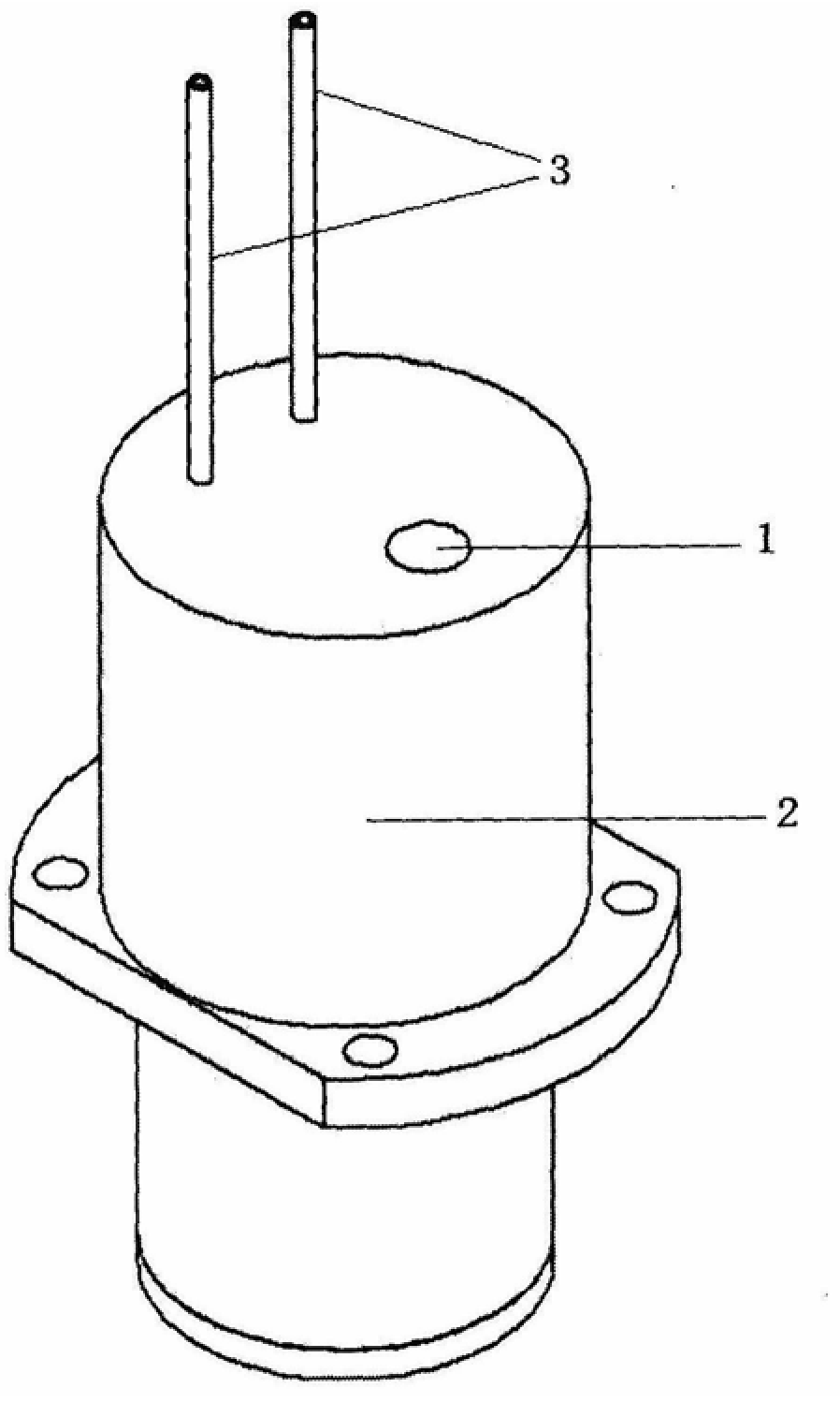

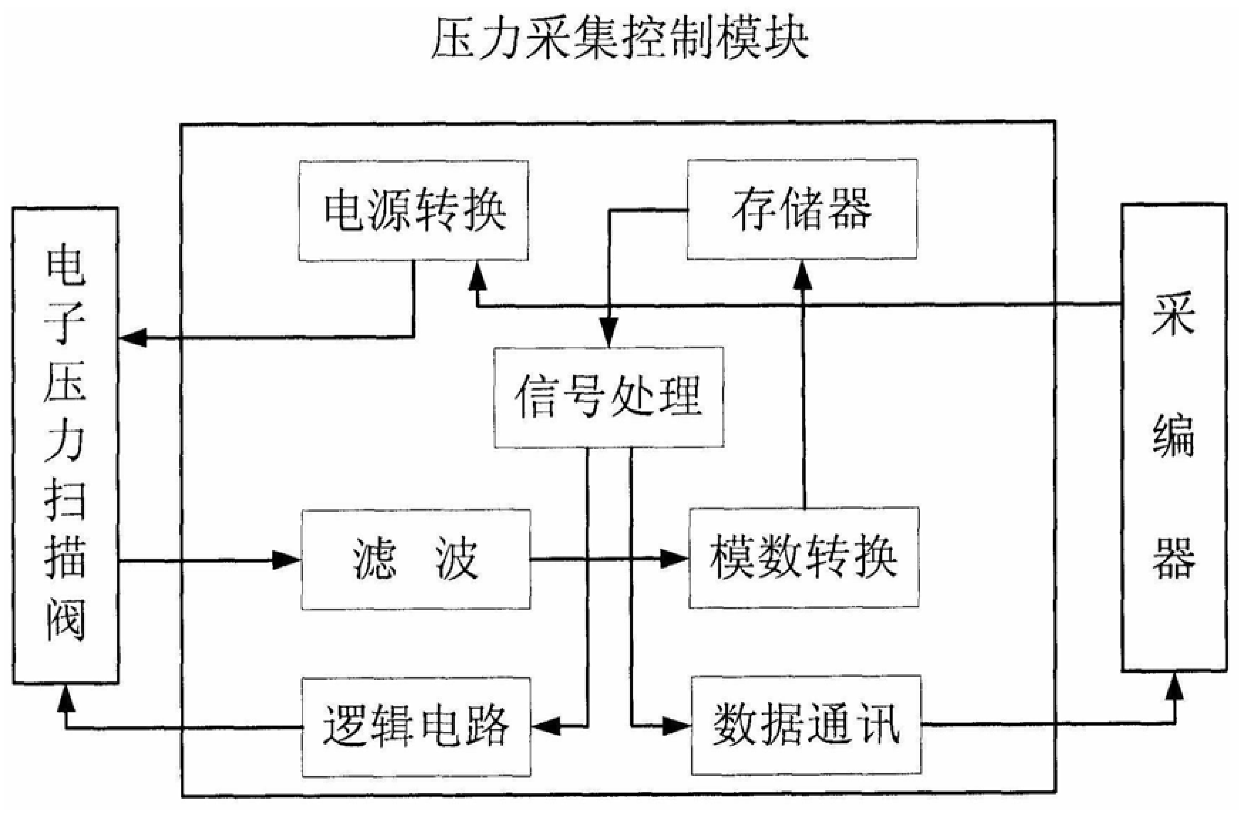

An Airborne Scramjet Pressure Measurement System

ActiveCN106507935BIncrease the proportionReduce volumeEngine testingRocket engine plantsRamjetEngineering

The invention provides an airborne scramjet pressure measurement system, which mainly includes an electronic pressure scanning valve, a pressure acquisition control module, a back pressure device and an absolute pressure sensor; the back pressure device provides reference pressure for the electronic pressure scanning valves 7 and 8 The absolute pressure sensor collects the pressure of the back pressure device, and the output signal of the electronic pressure scanning valve is sent to the pressure acquisition control module; the back pressure device is composed of an absolute pressure sensor interface, a back pressure device barrel and an impermeable steel pipe; the back pressure device barrel The inside is sealed with a local atmospheric pressure or evacuated; one end of the absolute pressure sensor interface is connected to the back pressure device cylinder, and the other end is connected to the absolute pressure sensor; one end of the stainless steel tube is connected to the back pressure device cylinder, and the other end is connected to the electronic pressure scanner through the pressure measuring pipeline valve. The invention is small in volume, light in weight and high in precision, helps to increase the proportion of payload in the aircraft structure, and provides an effective means of pressure measurement for hypersonic autonomous flight.

Owner:NAT UNIV OF DEFENSE TECH

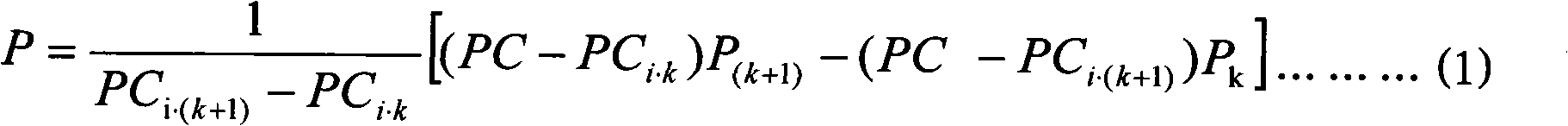

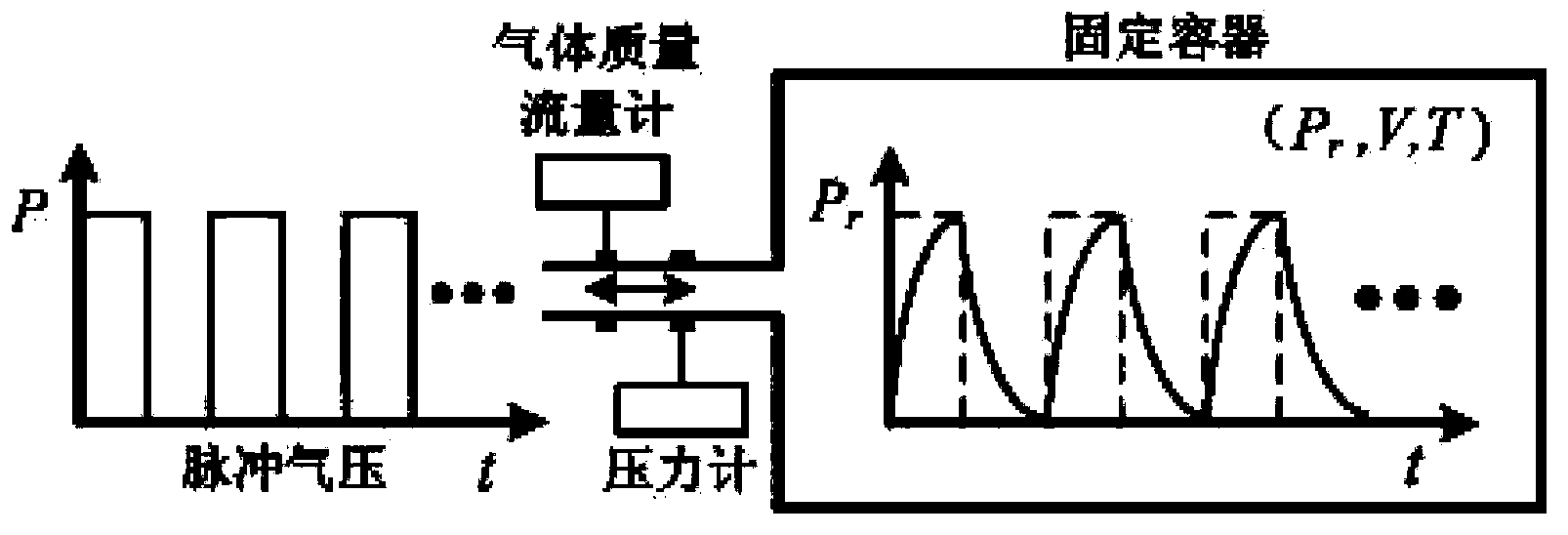

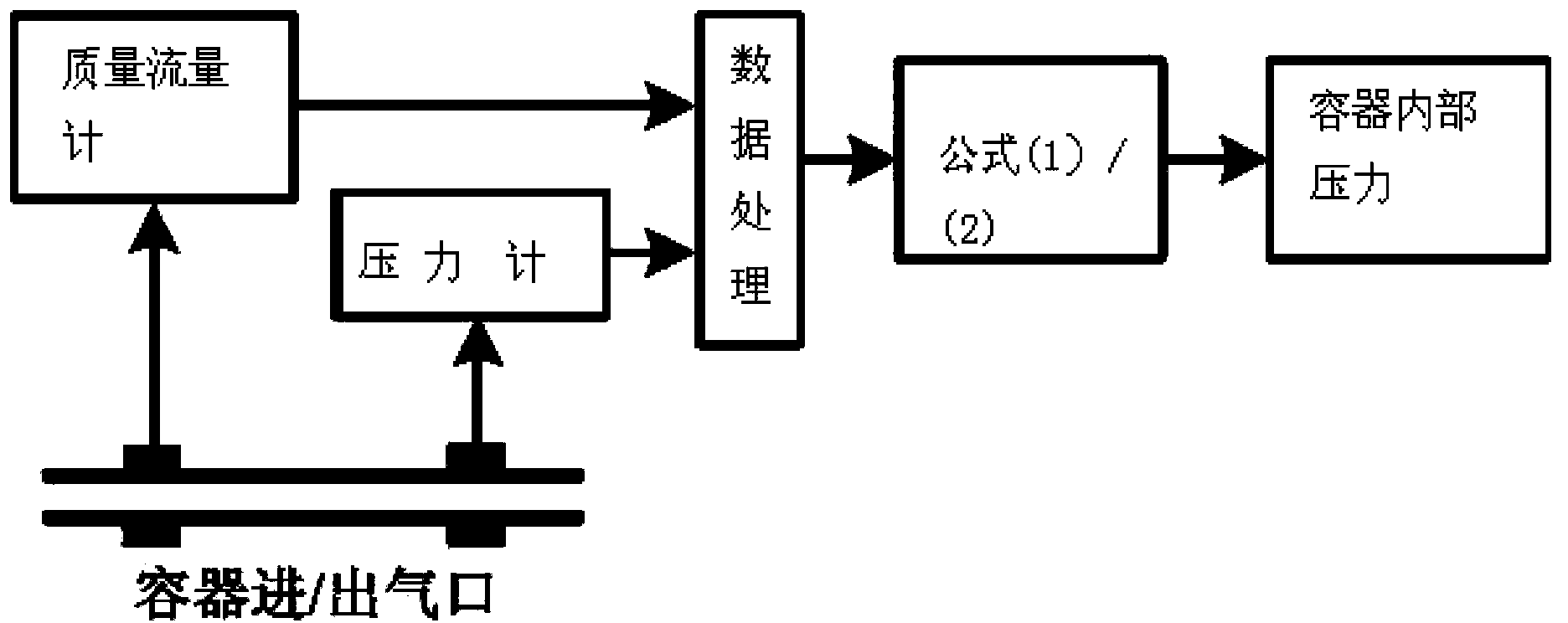

Method for measuring pressure of constant-volume quick inflation/deflation air cavity

ActiveCN103411724AHigh accuracy of test resultsImprove pressure measurement accuracyFluid pressure measurementInternal pressureEngineering

Provided is a method for measuring the pressure of a constant-volume quick inflation / deflation air cavity. In the constant-volume quick inflation / deflation process, gas mass flow and pressure data of an entrance of a container are detected in real time, the obtained data through detection is subjected to the averaging processing, and the pressure value of the inside of the container is obtained in the mode that the obtained data is substituted to the calculation formula of the pressure in the container in the inflation or deflation process. The method is good in realizability, and can be applied to occasions where pressure in the container needs to be accurately measured online in the constant-volume quick inflation / deflation process.

Owner:平邑仁安中医药产业发展有限公司

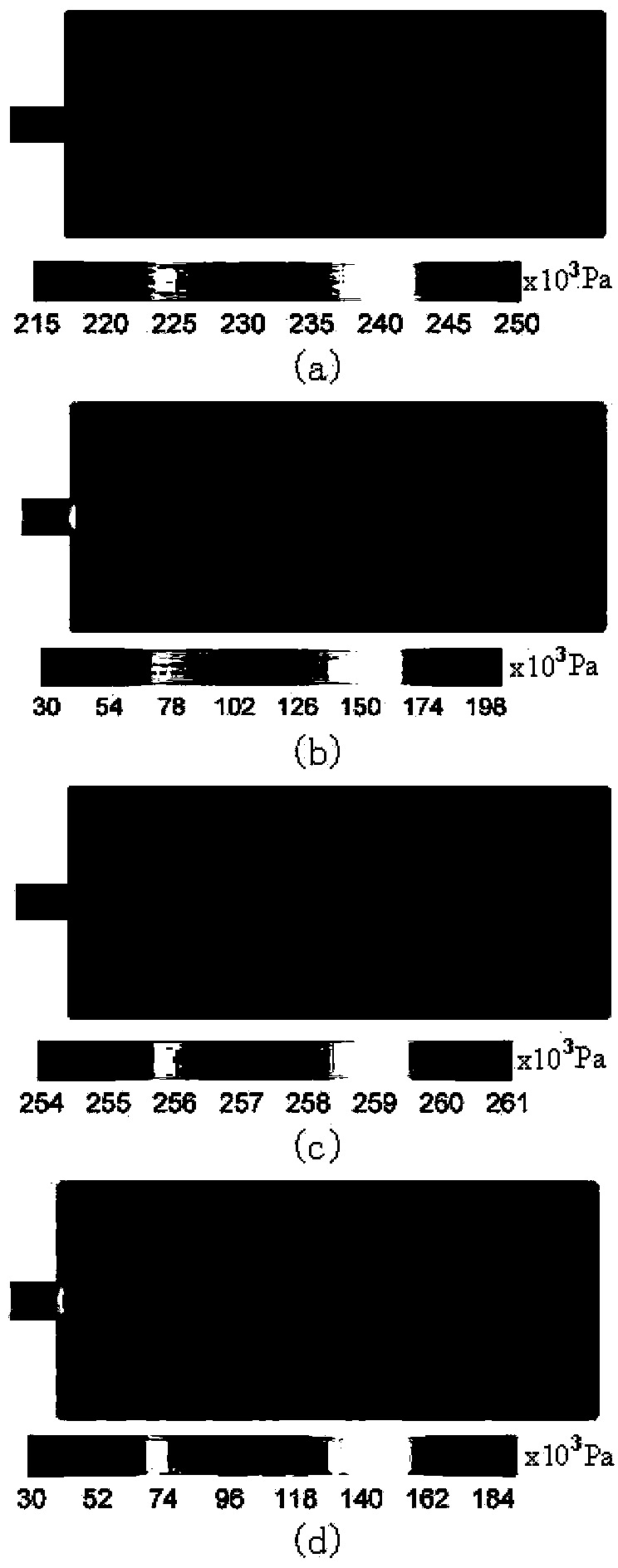

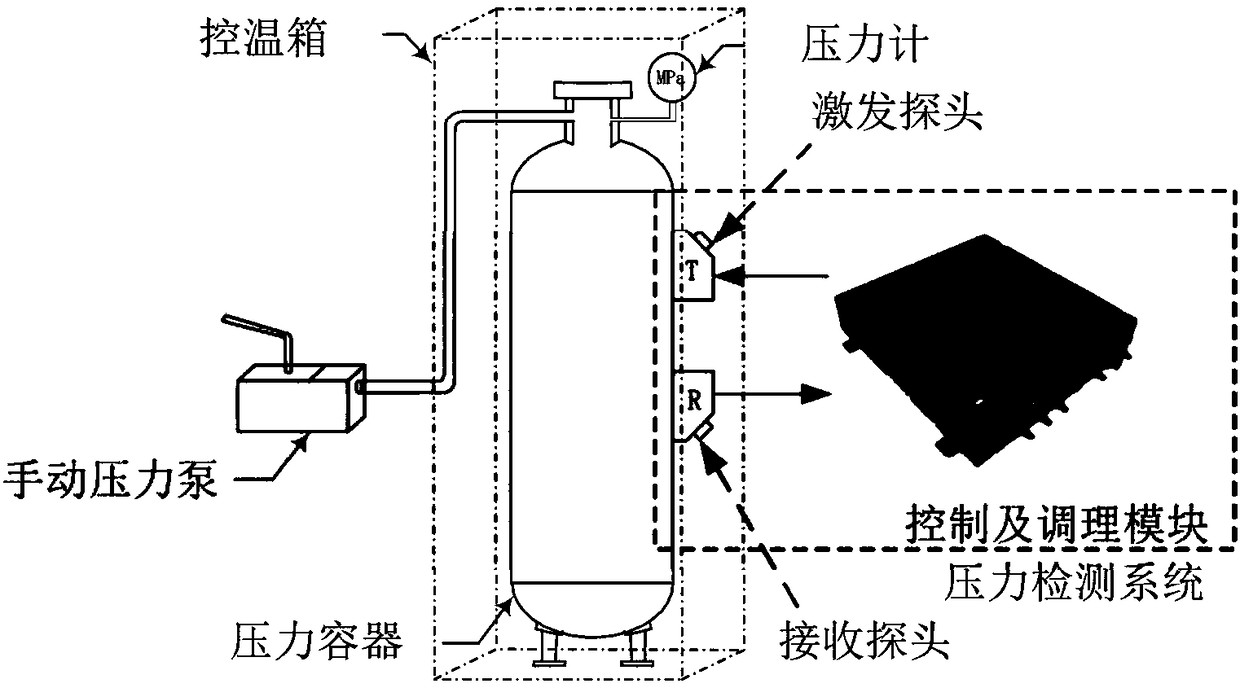

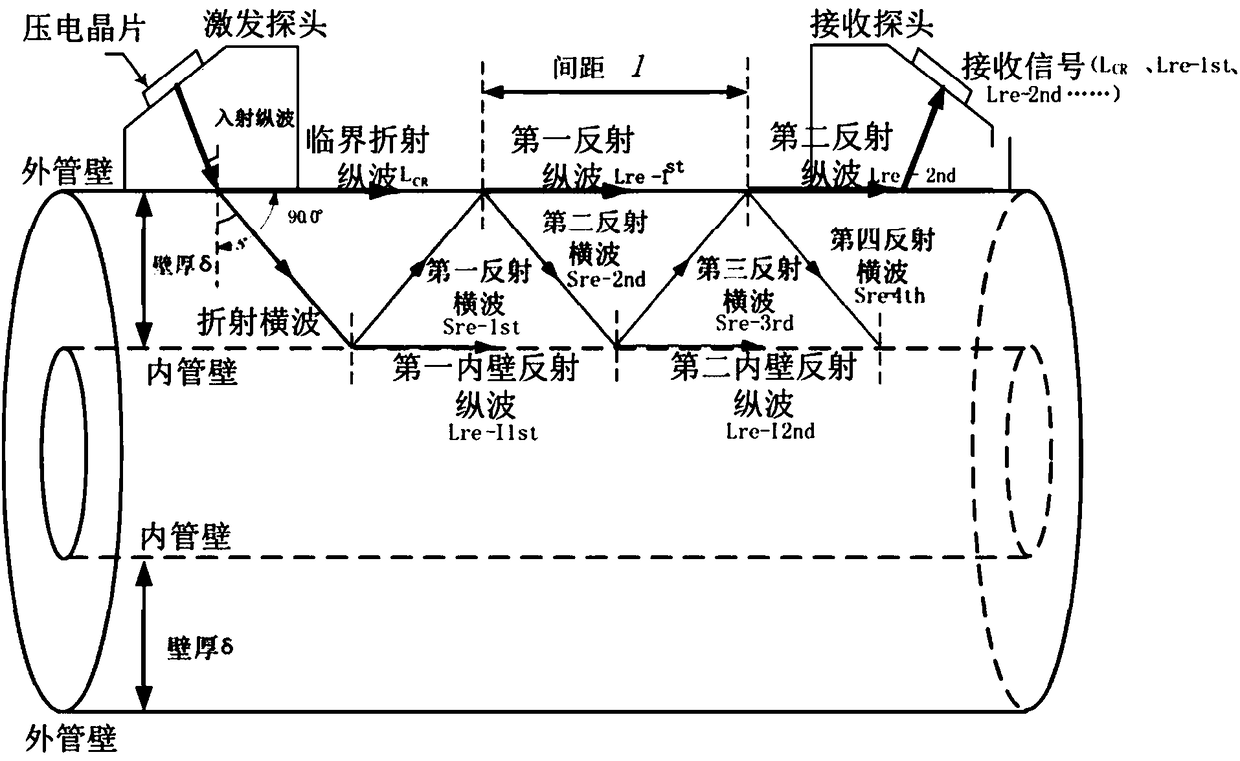

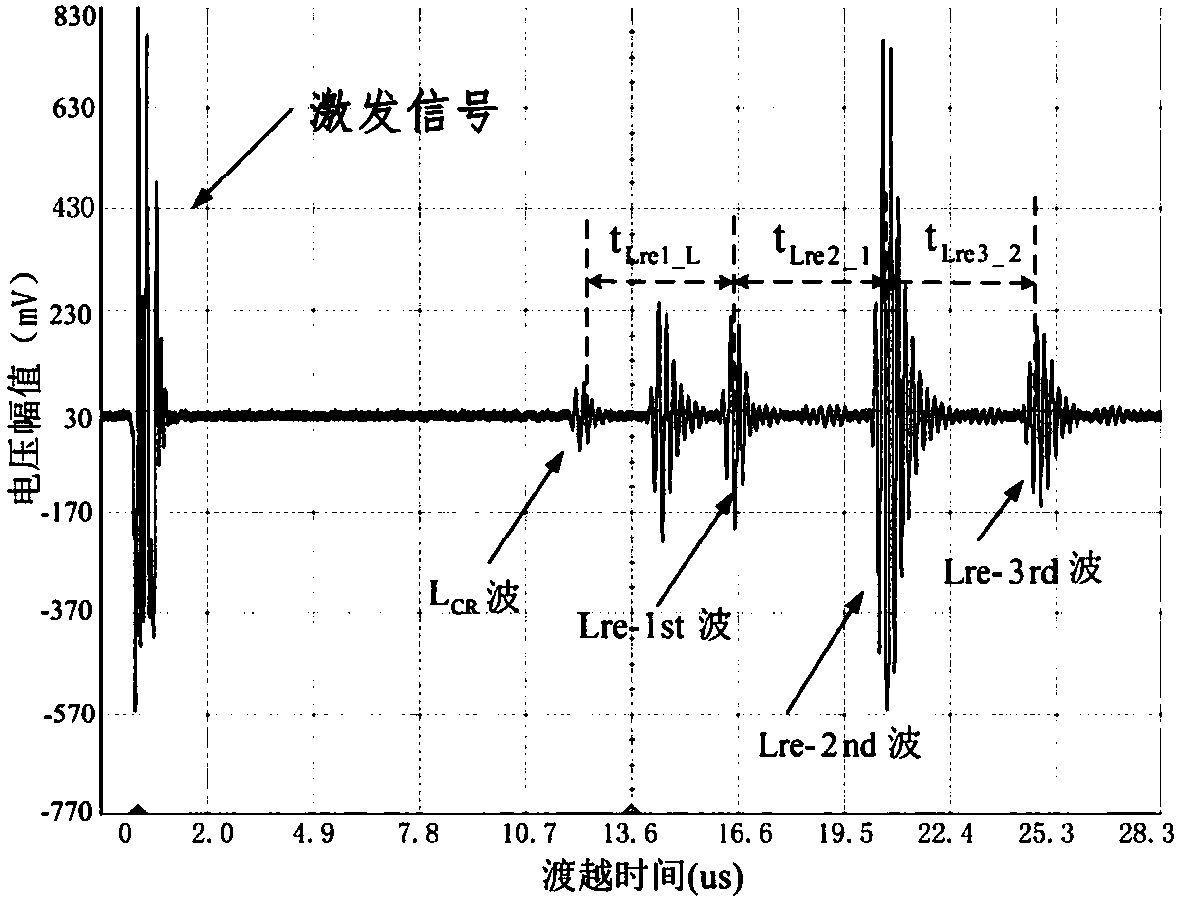

Non-intrusive pressure detection method and measurement system based on time delay intervals of adjacent longitudinal waves

InactiveCN108362431AGood effectAvoid measurement errorsFluid pressure measurement by acoustic meansStart timeTime delays

The invention discloses a non-intrusive pressure detection method and measurement system based on time delay intervals of adjacent longitudinal waves. According to the invention, the time delay intervals (including those between critical reflection longitudinal waves and first reflection longitudinal waves and those between adjacent reflection longitudinal waves) between adjacent longitudinal waves are selected as measurement parameters; a pressure measurement model of relation between pressure in a container and the time delay intervals between the adjacent longitudinal waves is established by utilizing ultrasonic wave acoustic elastic effect; and estimation of container pressure can be realized through measurement of the time delay intervals. Transit time of a critical refraction longitudinal wave and transit time of the reflection longitudinal waves generated under one excitation pulse are measured at the same time by adopting programmable shielding window technology and a TDC and the time delay intervals of the adjacent longitudinal waves can be obtained through calculation. The method provided by the invention can eliminate influence due to inconsistency of ultrasonic wave probe oscillation starting time and inconsistency of fixed characteristics of a coupling agent, an ultrasonic wave excitation and receiving circuit and a probe and pressure measurement precision can be improved.

Owner:ZHEJIANG UNIV

Device and method for measuring pressure intensity of gas inside microspheres

InactiveCN107870056ATransparency not requiredNo special restrictive requirementsFluid pressure measurementMeasurement deviceMicrosphere

The invention discloses a device and a method for measuring pressure intensity of gas inside microspheres. The method includes: adopting a corrugated-pipe-type crushing mechanism to crush a to-be-measured microsphere and a calibration sphere in a vacuum shell; through air pressure change of the vacuum shell before and after crushing, calibrating volume of the vacuum shell, and accurately measuringpressure intensity of gas inside the microspheres. The device and the method are suitable for precision measuring of pressure intensity of gas inside large-diameter-range microspheres having no requirement on transparency and composition of microsphere shell layers and microspheres with adsorptive gas.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

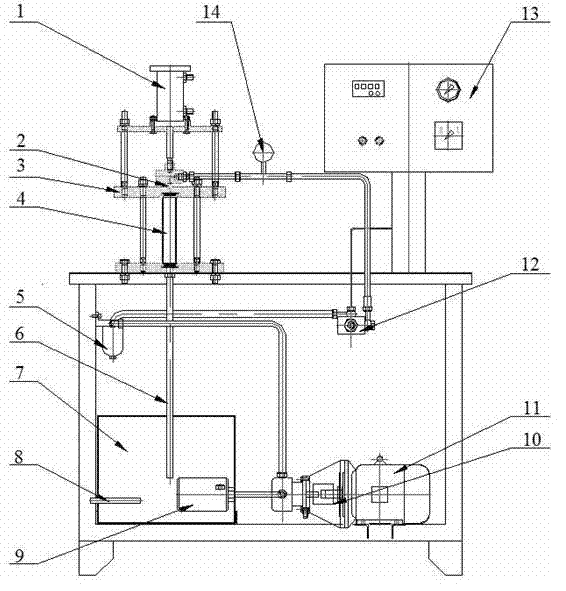

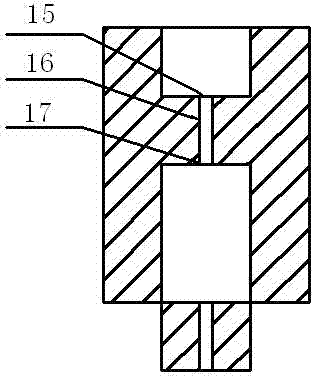

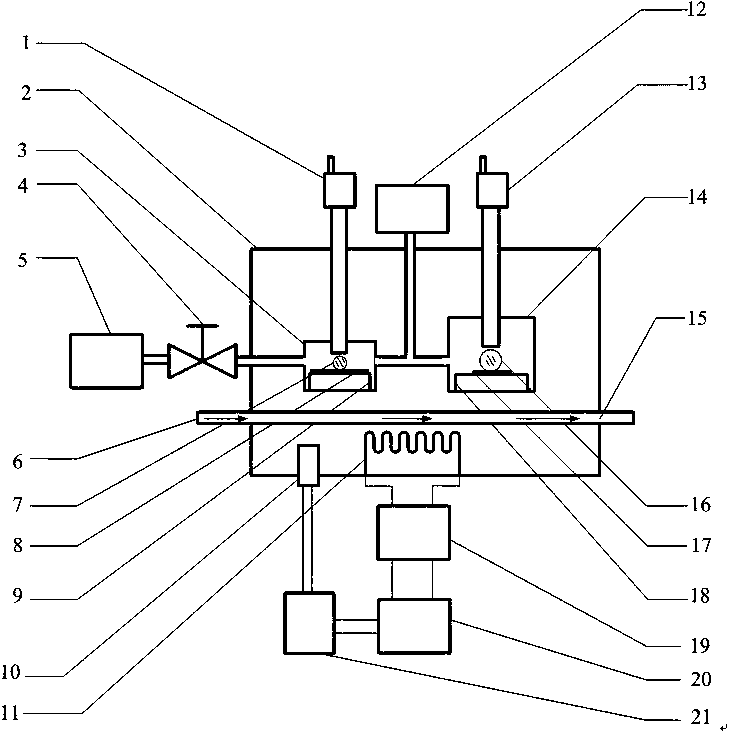

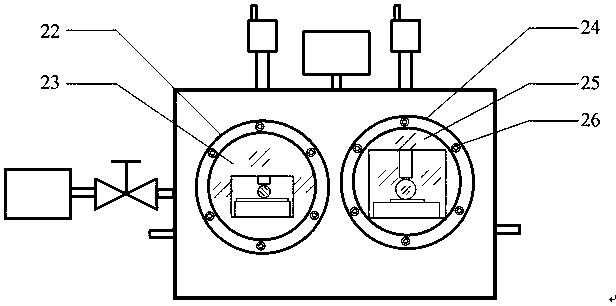

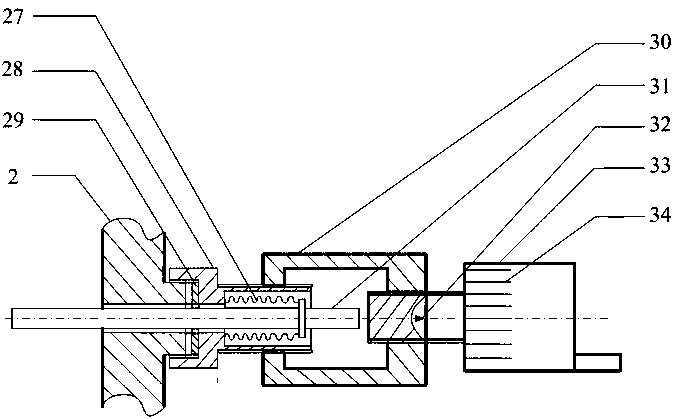

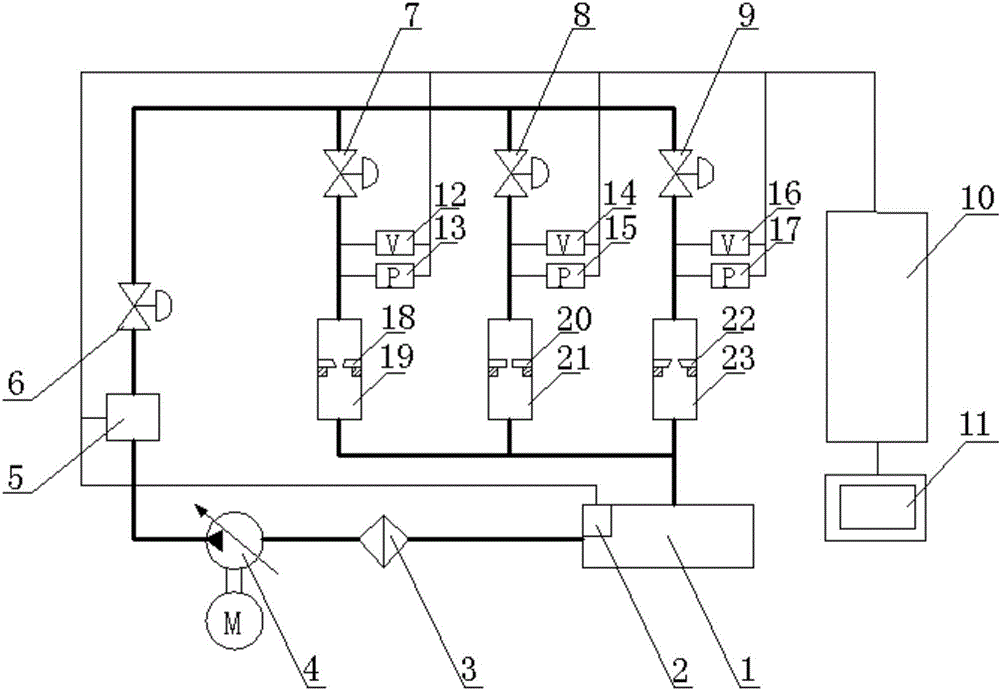

Experimental platform capable of synchronously measuring phenomena such as cavitation and cavitation erosion in different spraying nozzle structures

InactiveCN106596311ARealize automatic cycleFlow can be adjusted arbitrarilyInvestigating abrasion/wear resistanceSpray nozzleFuel tank

The present invention provides an experimental platform capable of synchronously measuring phenomena such as cavitation and cavitation erosion in different spraying nozzle structures. The experimental platform comprises a fuel oil supply system, a reaction system and a measurement system, wherein the fuel oil supply system comprises a fuel tank, a diesel oil cleaner, a pump station and an oil pressure regulation valve, the reaction system comprises a plurality of cavitators, spraying nozzles having different structures are respectively placed in the cavitators, and the measurement system comprises a pressure sensor, a flow sensor, a signal control terminal and a computer. According to the present invention, with the experimental platform, the spraying nozzles having a variety of structures can be synchronously measured under the same working condition; the experimental platform has characteristics of simple structure, stable operating, and continuous cavitation strength; and the spraying nozzles having different structures can be conveniently installed, and the production area and the dynamic characteristics of the vacuolar clusters near the cavitators are easily observed.

Owner:JIANGSU UNIV

Resonator based on electrostatic driving and differential piezoresistance detection and pressure sensor thereof

InactiveCN110672236AHigh Q valueIncrease output signal strengthForce measurement by measuring frquency variationsForce measurement using piezo-electric devicesEngineeringMechanical engineering

The invention belongs to the technical field of sensors, in particular to a resonator based on electrostatic driving and differential piezoresistance detection and a pressure sensor thereof. The pressure sensor comprises a cover cap, a resonator, a pressure sensing structure and a base, the cover cap, the resonator and the pressure sensing structure are rigidly connected through bonding to form avacuum cavity, and an electrostatic driving electrode, a first mass block, a second mass block, a resonance beam, a piezoresistive strip and a first connecting block are located in the vacuum cavity;and the base is in rigid connection with the pressure sensing structure through bonding and is not in contact with the pressure sensing film. An in-plane dynamic balance resonance mode of the annularresonance beam is adopted, the Q value of the sensor is increased, and the thermal elastic loss is reduced; and the working mode of electrostatic driving / differential piezoresistance detection is adopted, the output signal strength of the sensor is improved, the temperature of the resonator can be represented in situ, and the pressure measurement precision is improved through temperature compensation of the sensor.

Owner:CETC CHIPS TECH GRP CO LTD

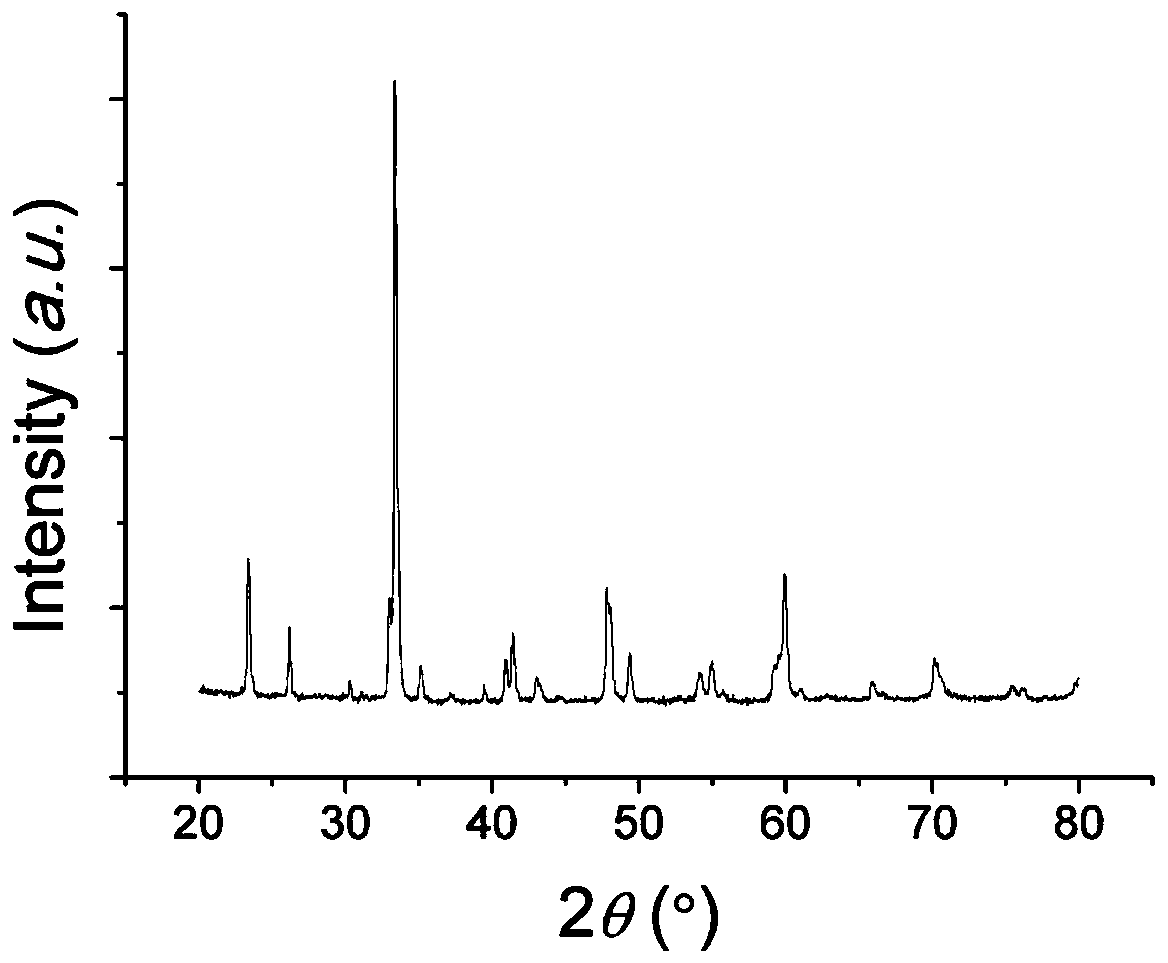

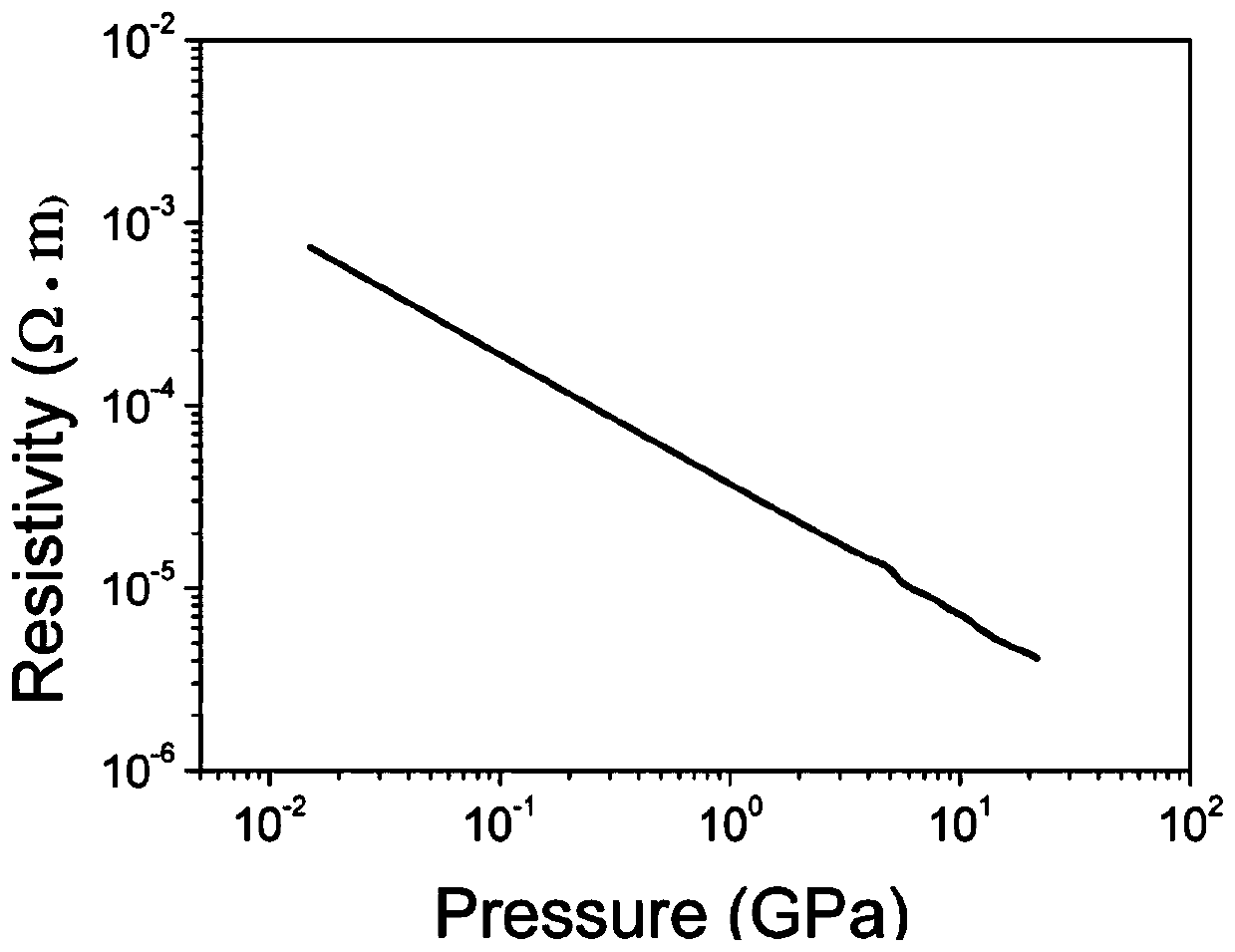

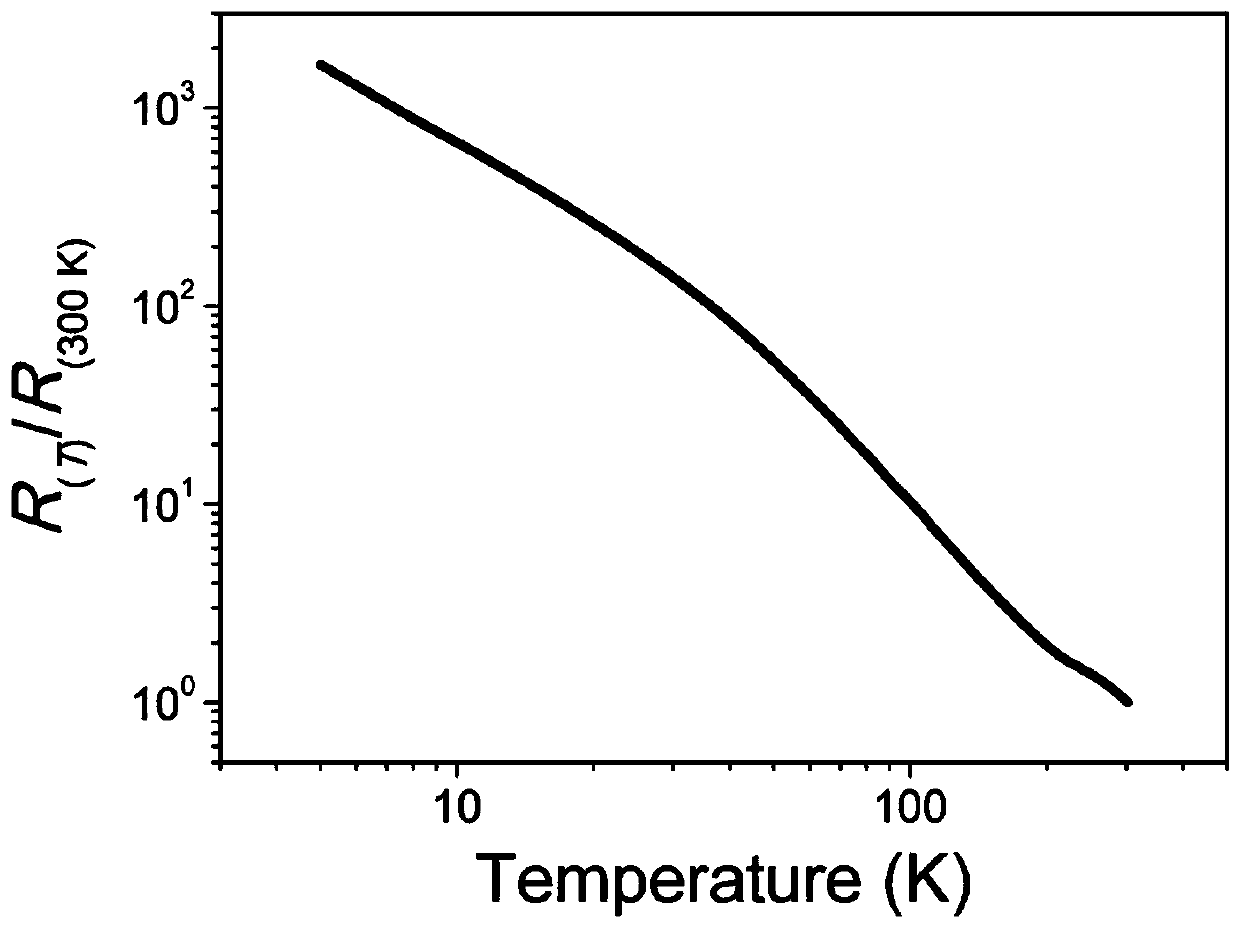

Pressure detection method based on metastable phase rare-earth nickel-based oxide

ActiveCN110146199AImprove pressure measurement accuracyFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsElectrical resistance and conductanceRare earth

The invention belongs to the field of ultrahigh pressure detection and relates to a pressure detection method based on a metastable phase rare-earth nickel-based oxide. According to the pressure detection method, a rare-earth nickel-based oxide with a thermodynamic metastable phase structure is used as a pressure sensitive material in a pressure detector; and pressure measurement in a high-pressure and ultrahigh-pressure spectral range is realized by utilizing a characteristic that the rare-earth nickel-based oxide changes sensitively along with pressure in the high-pressure and ultrahigh-pressure range and the relation of the change of resistivity and a resistance temperature coefficient along with pressure. Compared with previous pressure measuring methods, the method can realize pressure measurement in the spectral range, and realize the cross validation of pressure measurement in the high-pressure and ultrahigh-pressure range through the comprehensive characterization of the resistivity and a resistance temperature change rate, thereby greatly improving pressure measurement precision in the high-pressure range. The method of the invention can be further applied to the aspects of high-pressure detection, deep sea pressure measurement, geological pressure measurement and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

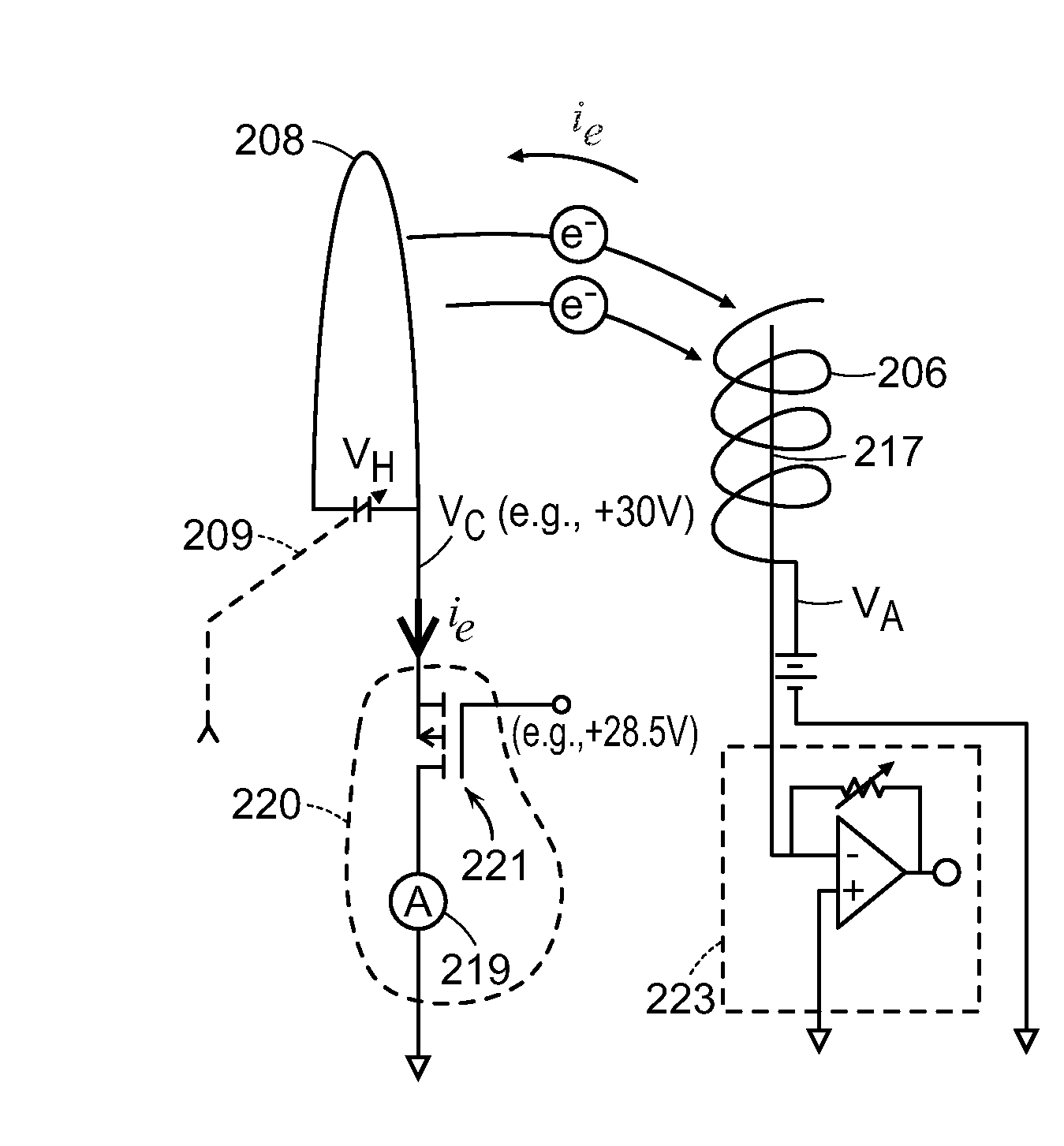

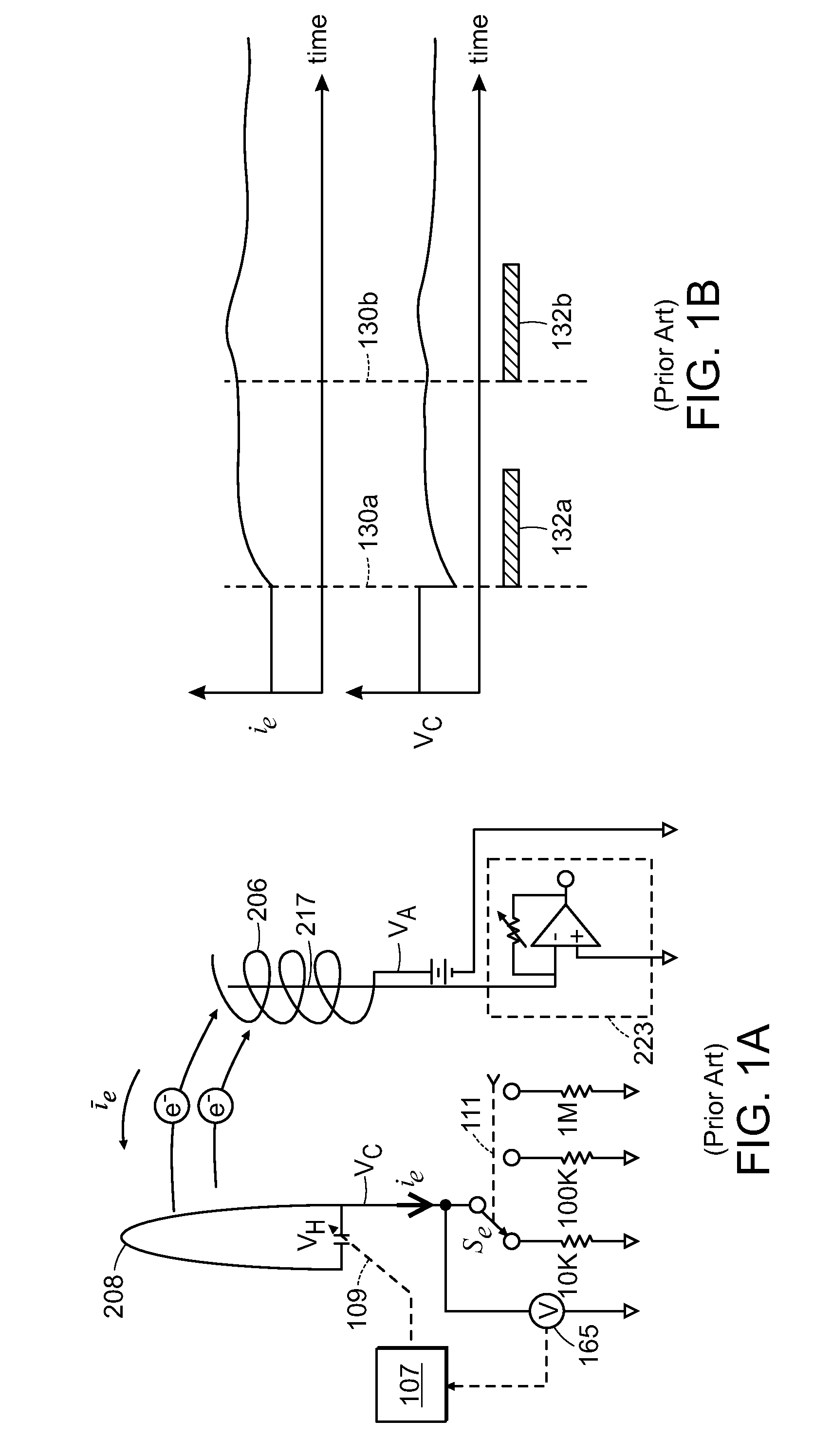

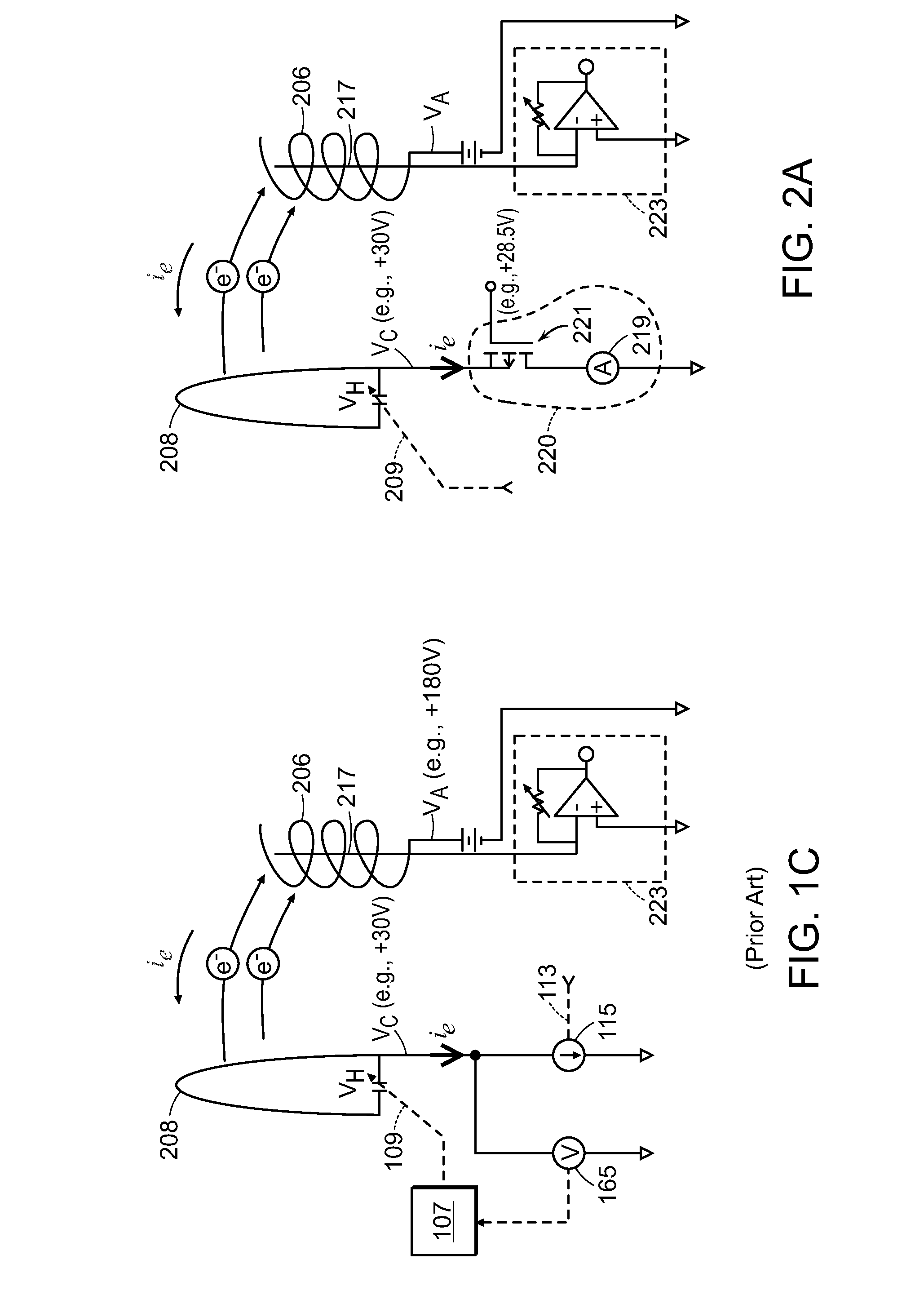

Ionization Pressure Gauge With Bias Voltage And Emission Current Control And Measurement

ActiveUS20170010172A1Easy to measureEliminate dead timeVacuum gauge using ionisation effectsForce measurementMeasurement deviceTransistor circuits

Devices and corresponding methods are provided to operate a hot cathode ionization pressure gauge (HCIG). A transistor circuit can be configured to pass the electron emission current with low input impedance and to control cathode bias voltage. Emission current and cathode bias voltage can be controlled independently of each other, without a servo settling time. HCIGs can be calibrated with respect to leakage current.

Owner:MKS INSTR INC

Digital wide-range ultra-high precision coil shaper

InactiveCN103117164ALarge pressure control rangeHigh precision of pressure controlCoils manufactureControl systemEngineering

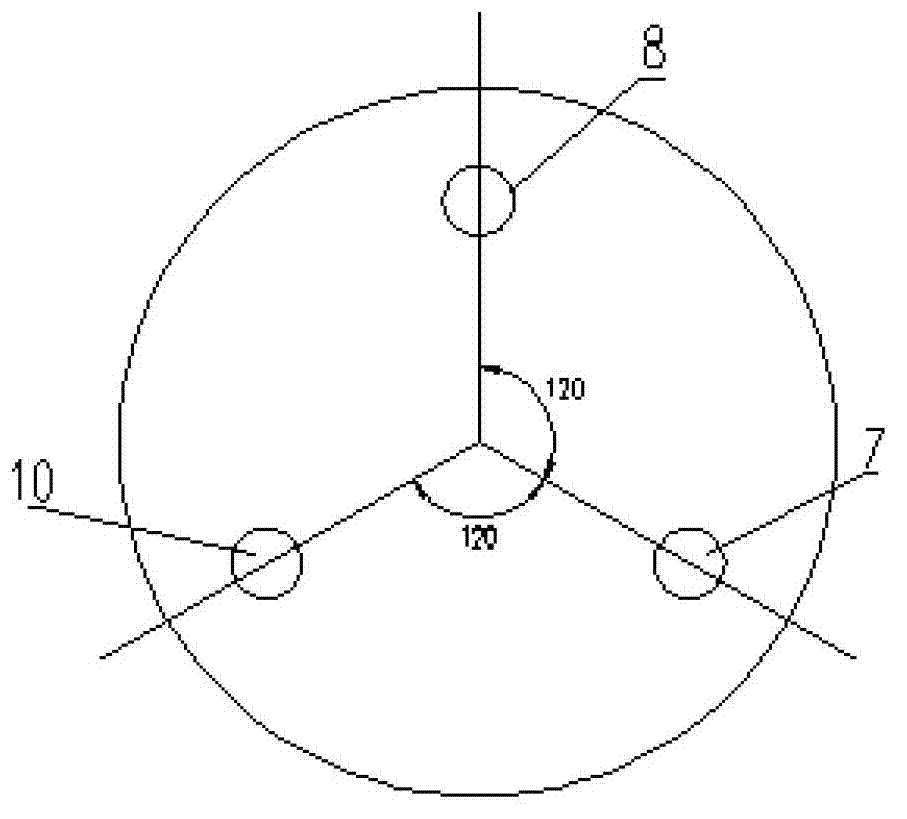

The invention discloses a digital wide-range ultra-high precision coil shaper. The digital wide-range ultra-high precision coil shaper comprises a mechanical part and a hydraulic control system for controlling the mechanical part. The digital wide-range ultra-high precision coil shaper has the advantages of being wide in pressure control range and high in pressure control precision. Through a position detecting device which is matched with a photoelectric protector, the position measurement of a sliding block can be conducted by redundancy control, working safety of the device is improved, and pressure measurement accuracy can be improved by using a plurality of force sensors arranged in a triangle.

Owner:HEFEI HAIDE HYDRAULIC PRESS

Vibrating wire type pressure sensor

PendingCN110579306AOvercome the adverse effects of deformationImprove pressure measurement accuracyForce measurement by measuring frquency variationsFluid pressure measurement using elastically-deformable gaugesContact pressureVibrating wire

The invention provides a vibrating wire type pressure sensor comprising a shell, a stress membrane, a force transmission piston, a piston cylinder body, a vibrating wire, a vibrating wire clamping device, a magnetic coil and a force transmission piston. The stress membrane is a circular membrane; a dowel bar is arranged in the center of one side of the stress membrane and a convex block is arranged in the center of the other side of the stress membrane; and a stress membrane shell with the same shape as the shell is arranged outside the stress membrane. The two ends of the stress membrane shell are connected with the shell and the piston cylinder body respectively. A hydraulic cavity communicated with the piston cylinder body is formed in the force transmission piston at one side of the dowel bar of the stress membrane; a free end of the dowel bar is directly connected with the force transmission piston through the bottom of the piston cylinder and the piston cavity. The cavity openingof the hydraulic cavity is formed in the outer end face of the force transmission piston; and a flexible contact film making contact with a measured object is arranged at the cavity opening of the hydraulic cavity in a sealed mode. The vibrating wire is fixed on the convex block. Therefore, the pressure measurement precision is improved; the performance is stable and reliable; and the vibrating wire type pressure sensor is suitable for measurement of liquid pressure, internal forces of concrete and rock-soil bodies, and an interface contact pressure.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com