Patents

Literature

136results about How to "Realize automatic cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

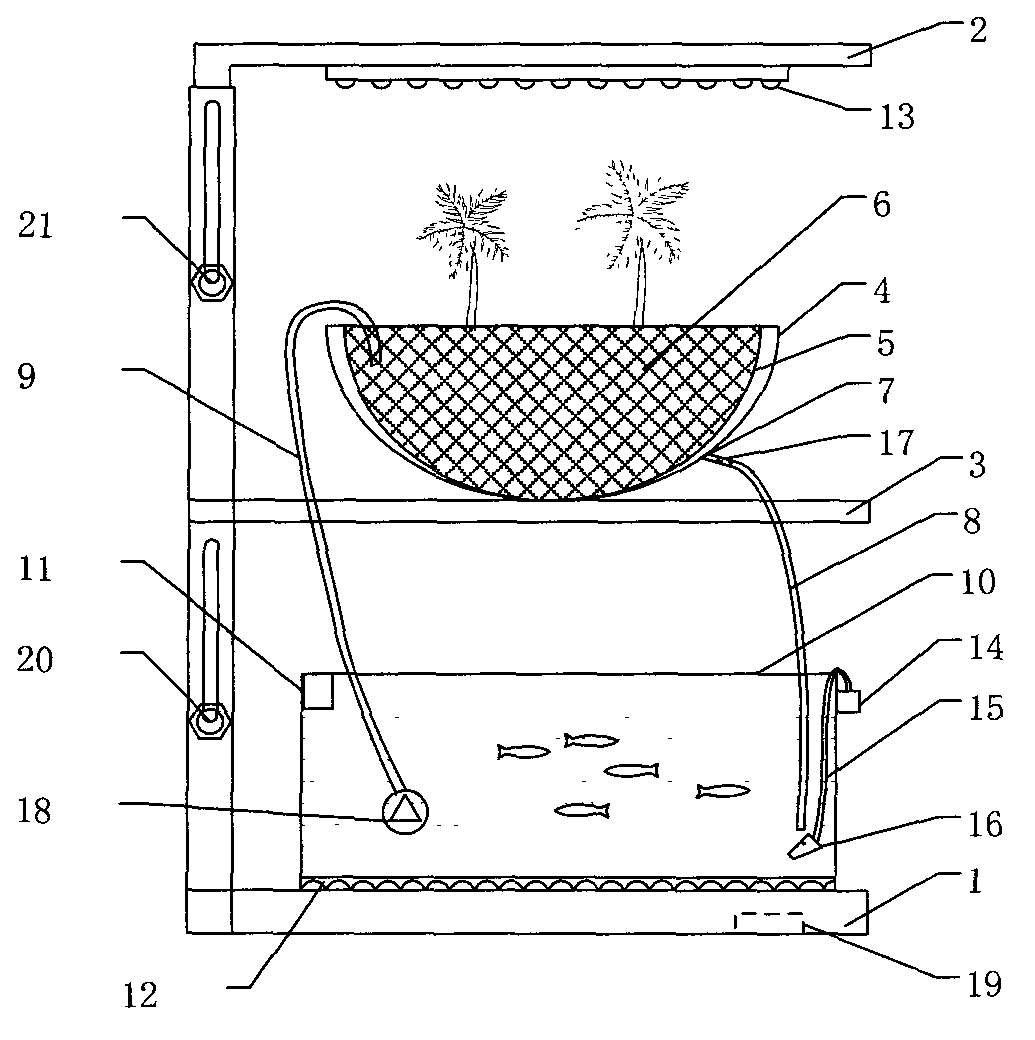

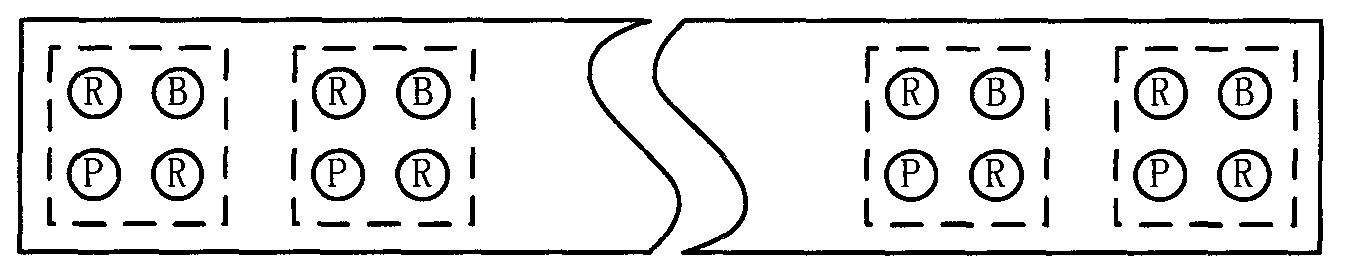

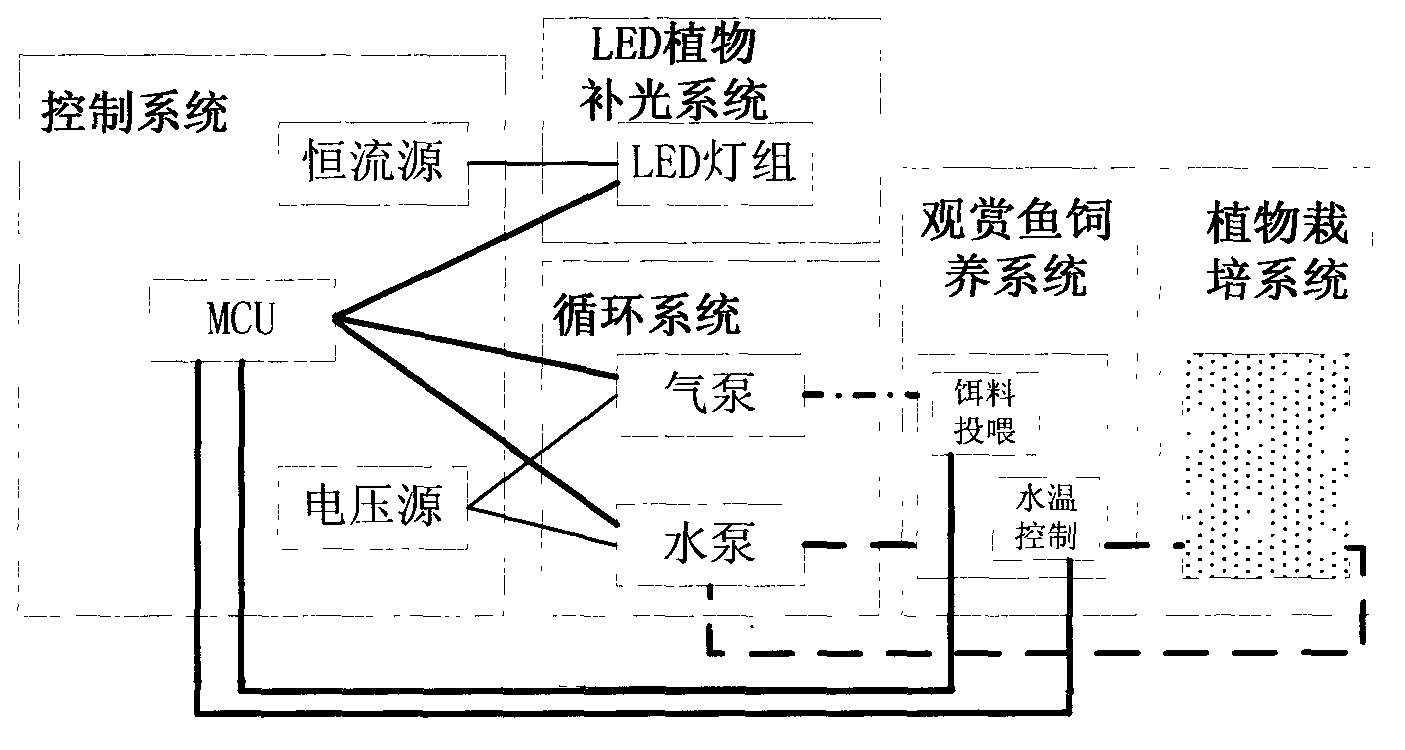

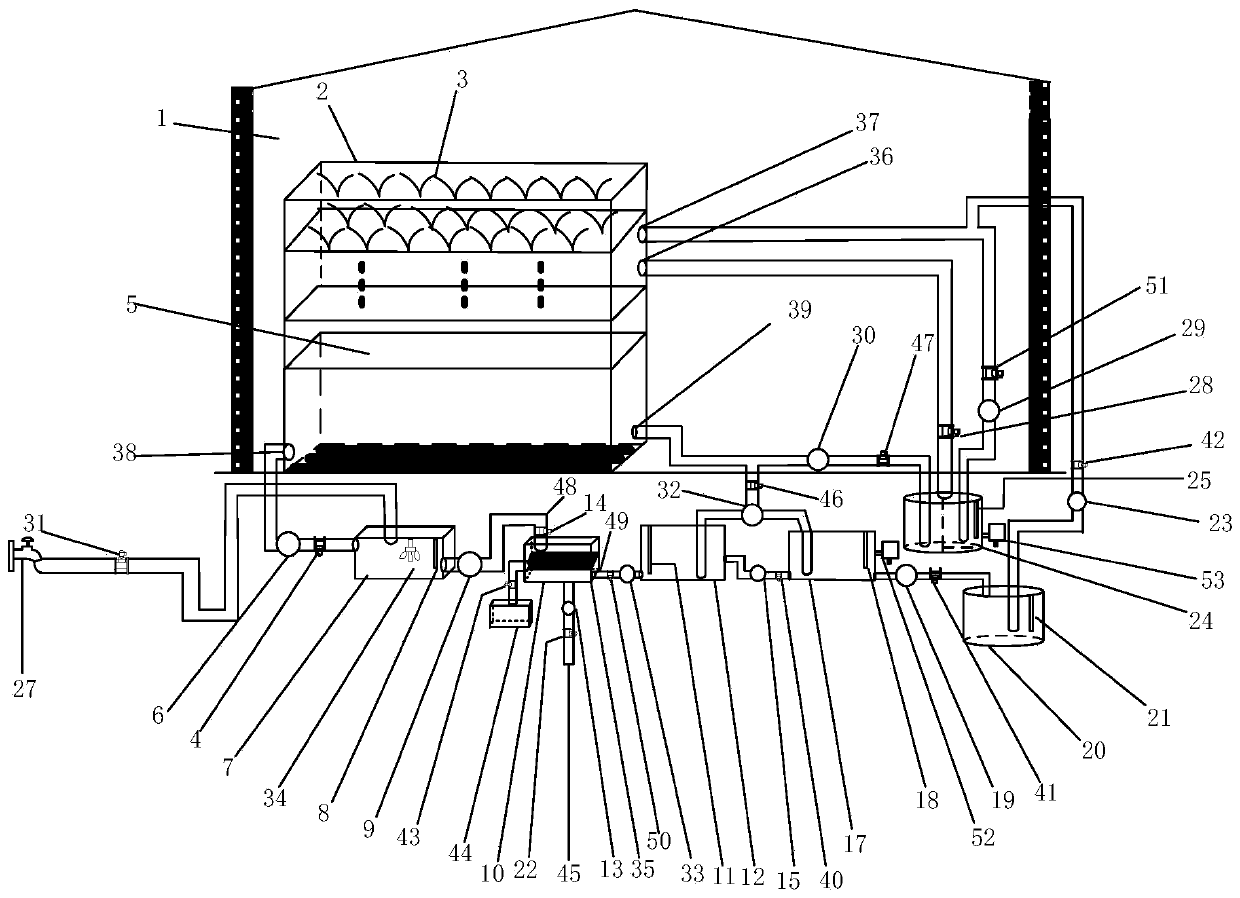

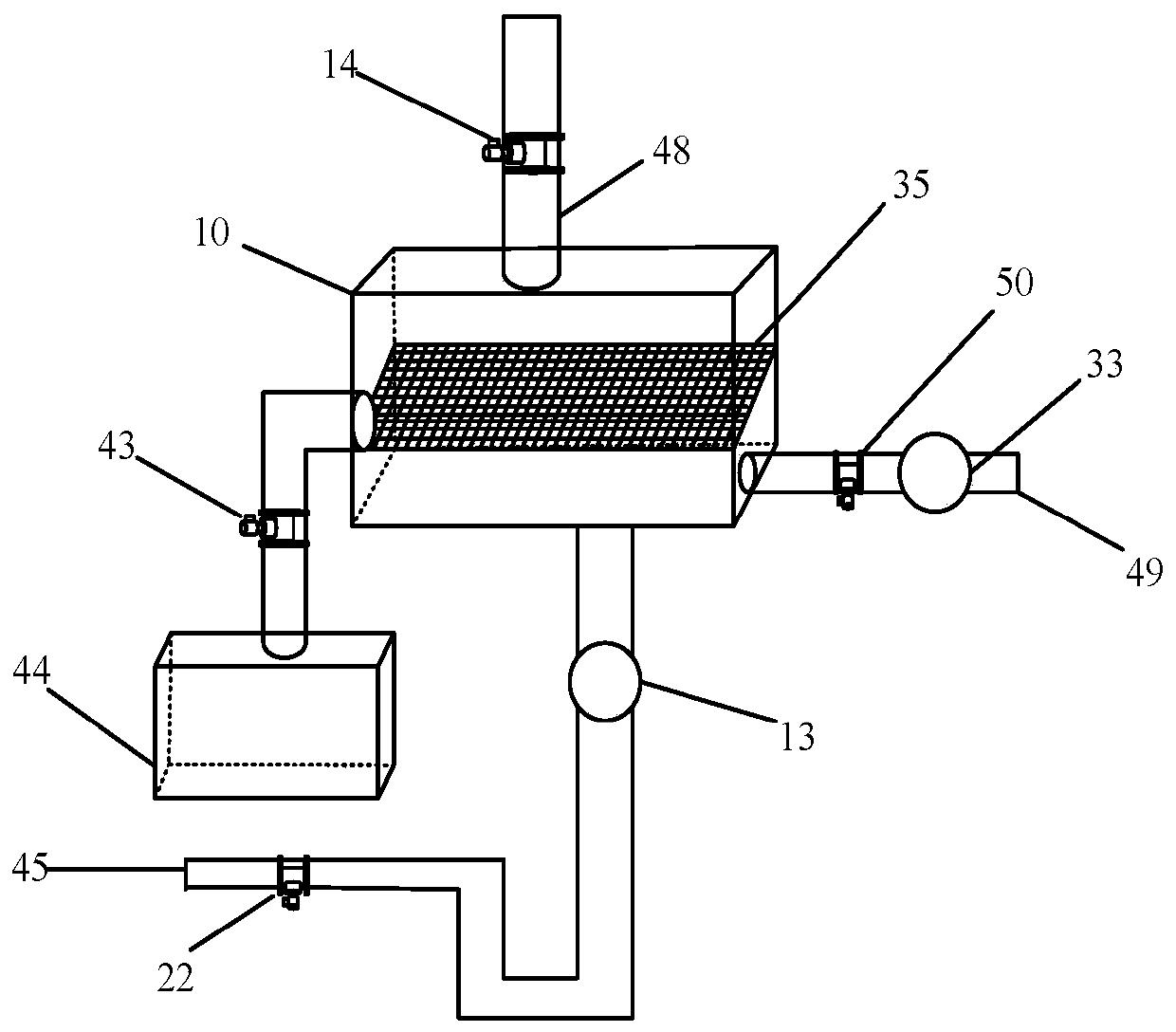

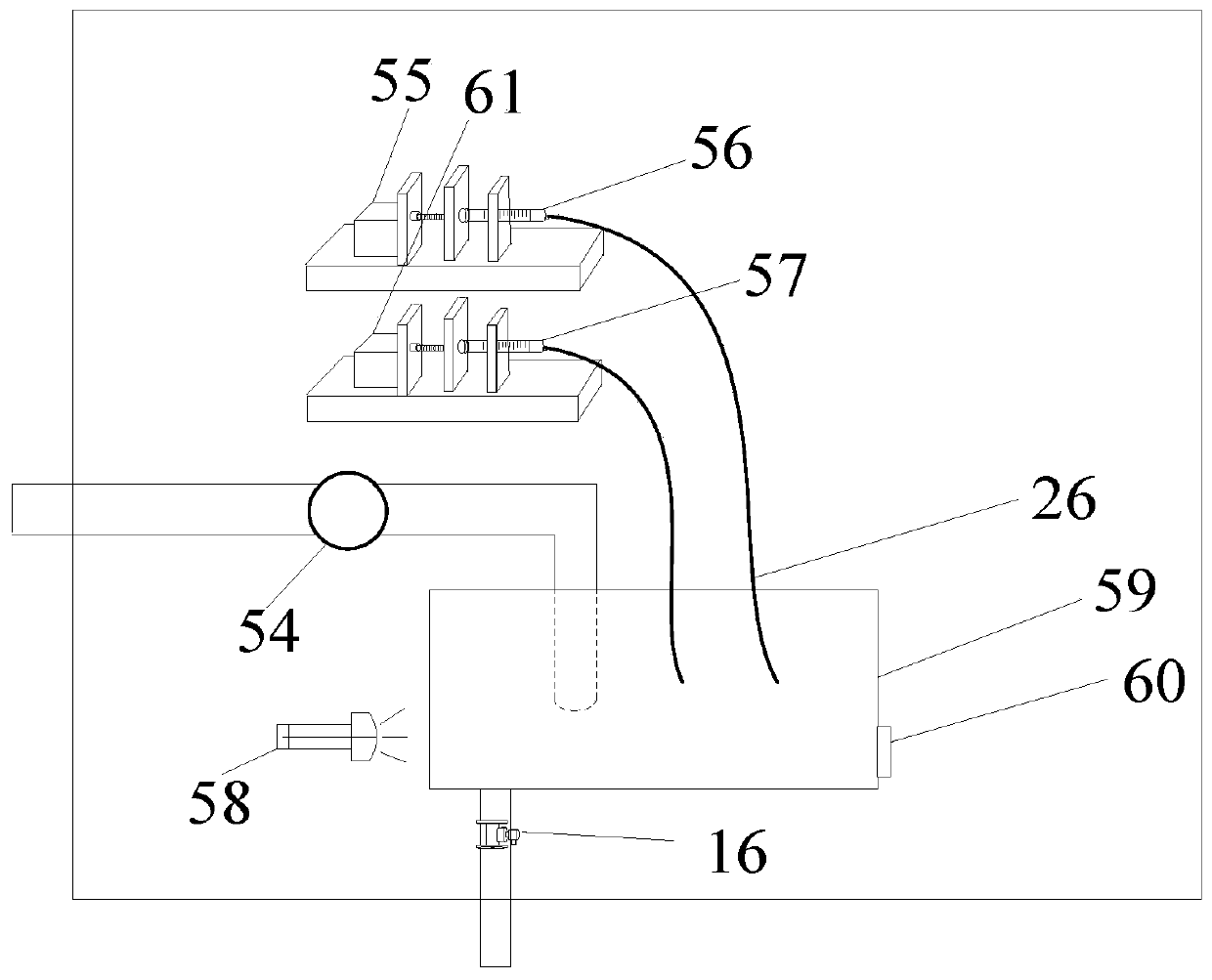

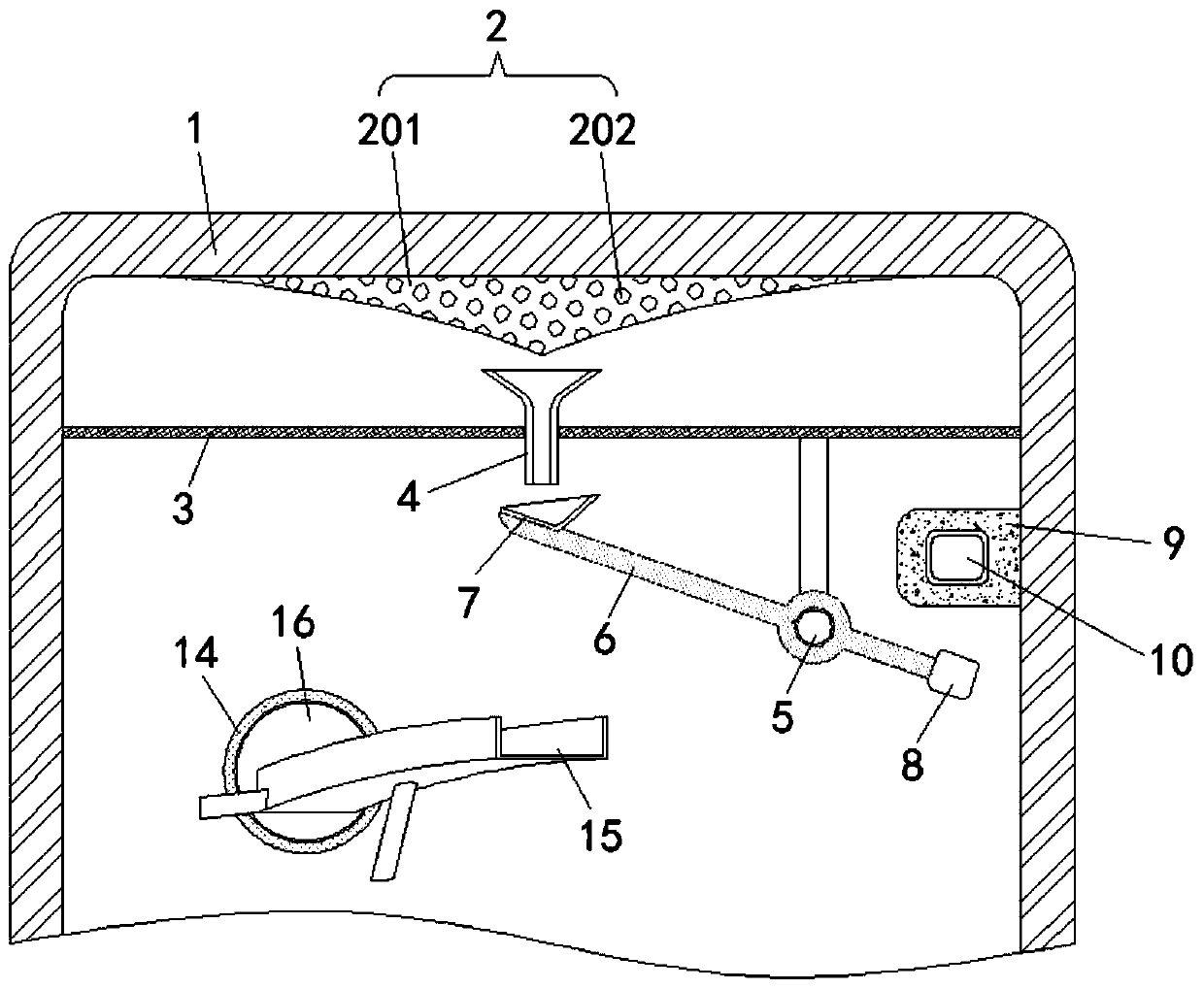

Intelligent LED (Light-Emitting Diode) light supplementing indoor circulating economical planting and breeding system

InactiveCN103070062AAchieve recyclingRegulate humidityPisciculture and aquariaAgriculture gas emission reductionAir cycleControl system

The invention discloses an intelligent LED (Light-Emitting Diode) light supplementing indoor circulating economical planting and breeding system, which is characterized by comprising a plant culturing system, an aquarium fish breeding system, an LED plant light supplementing system, an air circulating system, a water circulating system and a control system, wherein the plant culturing system is connected with the aquarium fish breeding system through the water circulating system; plants are irrigated by using fish breeding water, and excrements of fishes are purified by using the plants, so that circular utilization of water and nutrients is realized; the LED plant light supplementing system is connected with the plant culturing system, so that illumination adjustment and supplement are performed on the plants, and healthy growth of the plants is facilitated; and the aquarium fish breeding system is connected with the air circulating system, so that air with a certain flow amount is pumped into a fish tank periodically, and the oxygen content in water is ensured. According to the economical planting and breeding system, a complete indoor economical planting and breeding system is constructed, and the entire system is simple in structure and low in cost; and meanwhile, the economical planting and breeding system has the effects of purifying indoor air, adjusting indoor air humidity and beautifying indoor environment.

Owner:CHINA JILIANG UNIV

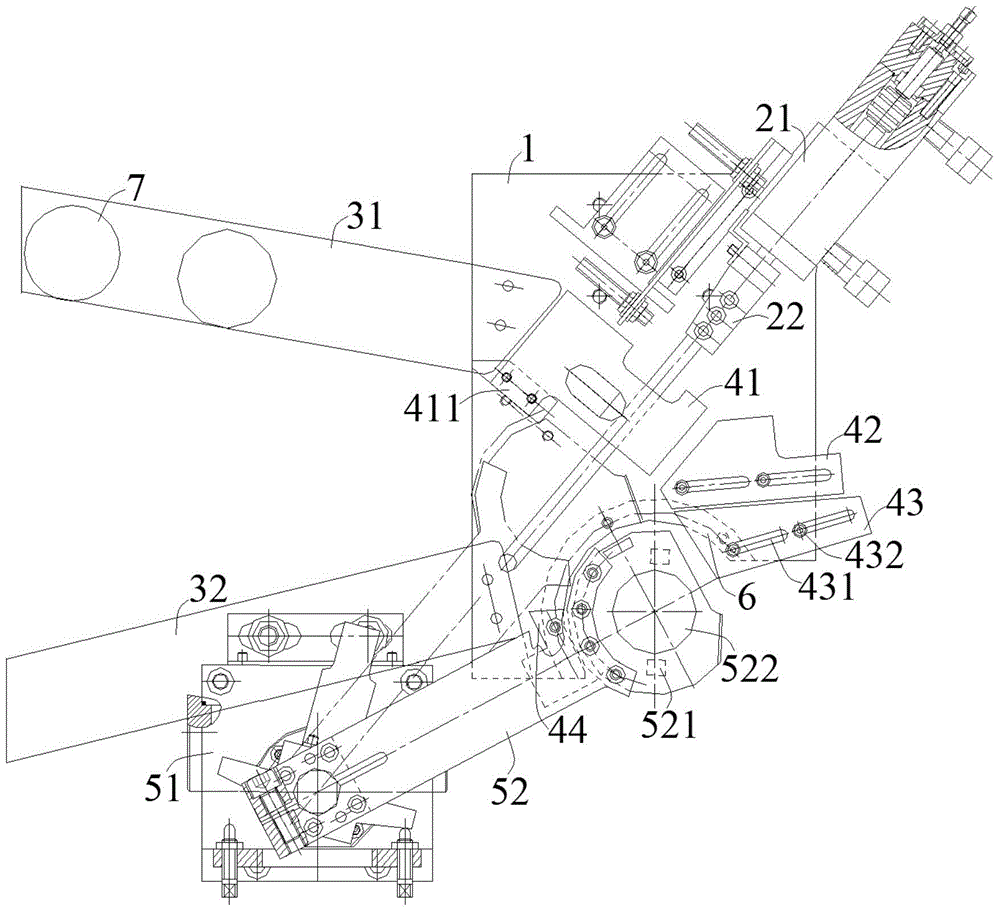

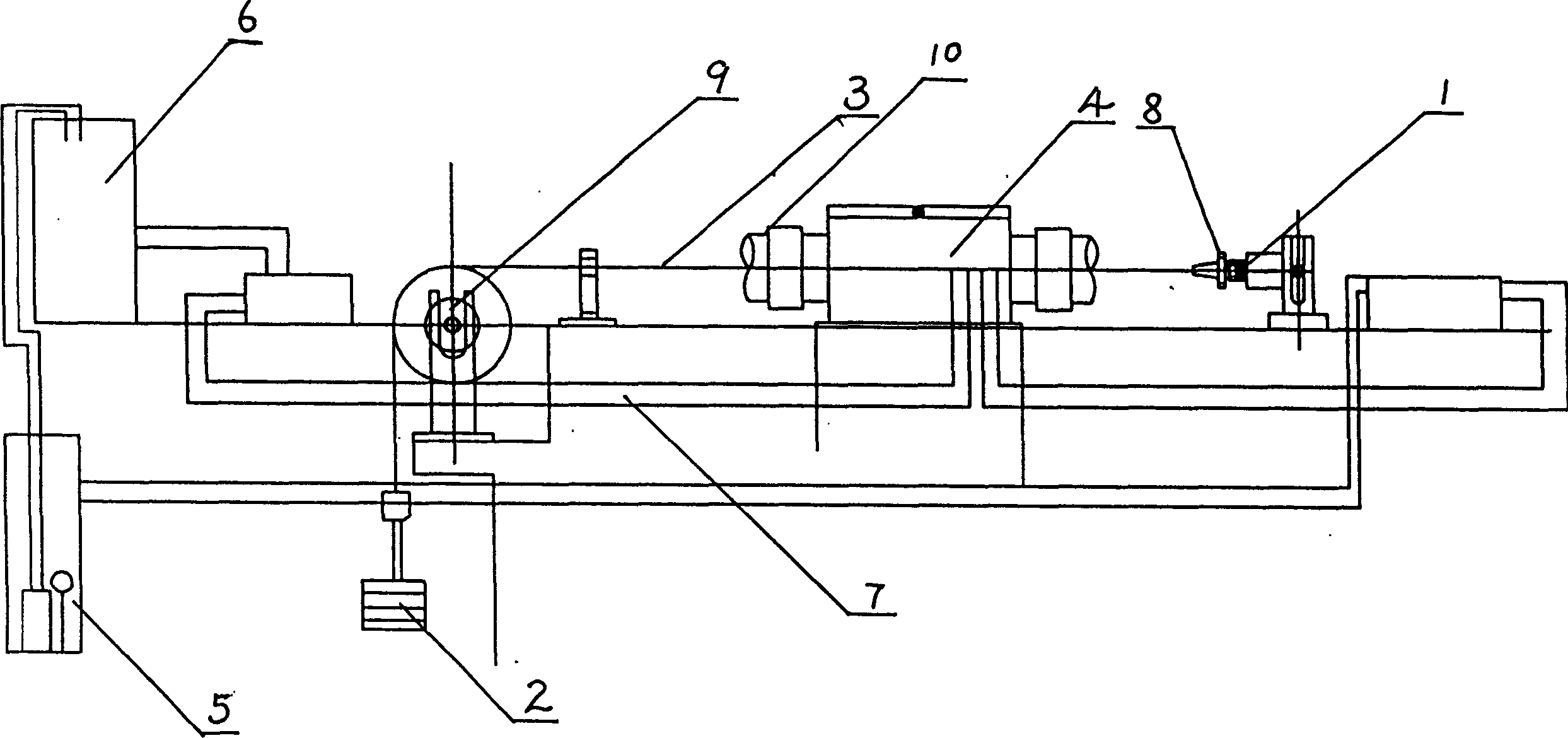

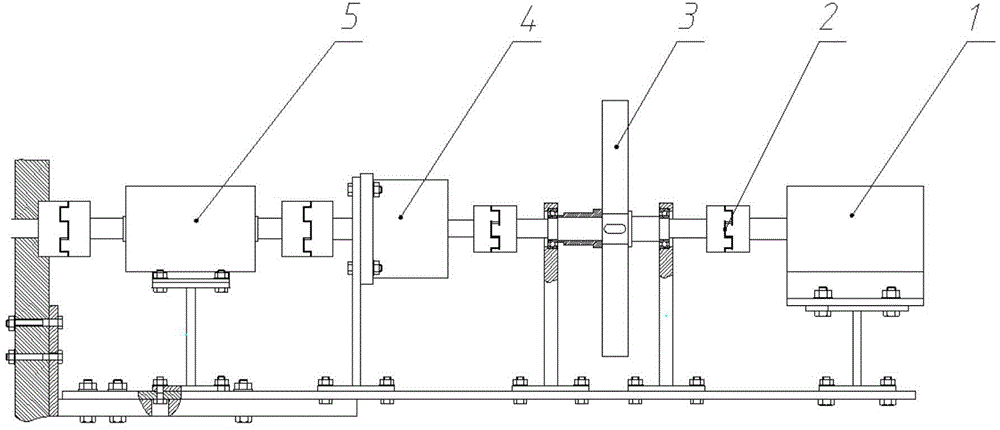

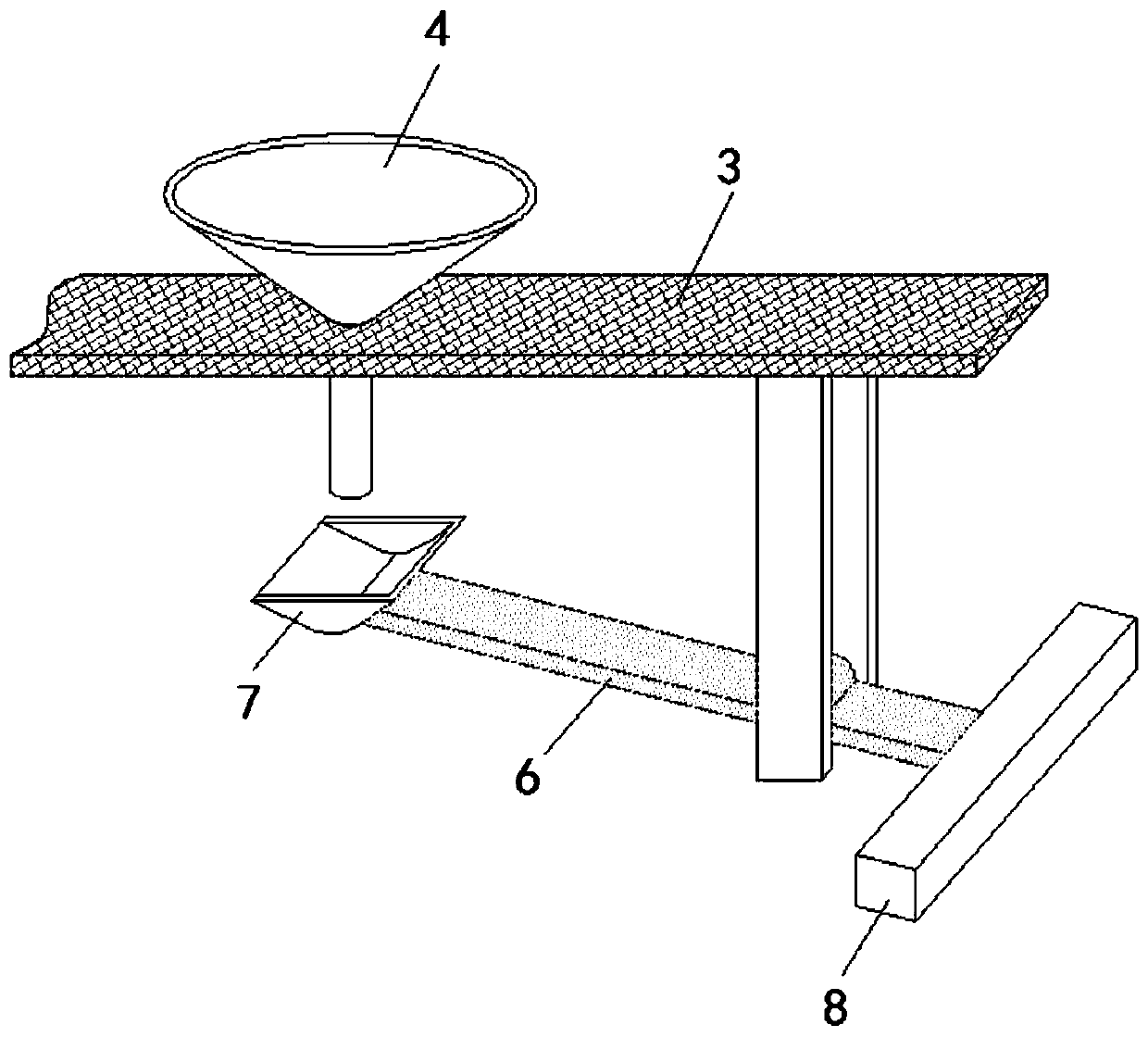

Automatic inner bore grinding device and automatic inner bore grinding method

ActiveCN104476340AImprove processing efficiencyEfficient cooperationRevolution surface grinding machinesEngineeringUltimate tensile strength

The invention discloses an automatic inner bore grinding device and an automatic inner bore grinding method and belongs to the technical field of processing of inner holes. The automatic inner bore grinding device comprises a feeding passage, a material saving mechanism, a pushing mechanism, a material blocking mechanism and a discharging passage, wherein the material saving mechanism is used for conveying to-be-ground pieces rolling in the feeding passage to the pushing mechanism, limiting the next to-be-ground piece when the previous to-be-ground piece is subjected to inner hole grinding until the previous to-be-ground piece is discharged through the discharging passage, and then conveying the next to-be-ground piece to the pushing mechanism; the pushing mechanism is used for rotating and pushing the to-be-ground pieces to processing stations for inner hole grinding; the material blocking mechanism is matched with the material saving mechanism and the pushing mechanism and used for limiting the to-be-ground pieces to move according to specified path. The feeding and discharging rhythm is controlled by virtue of up-and-down movement of a material saving rod; a manipulator is rotated to push the to-be-ground pieces to the processing stations, so that automatic feeding-processing-discharging circulation is realized, the whole processing process is free of manual intervention, the labor strength of working personnel is low and the inner hole processing efficiency is high.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

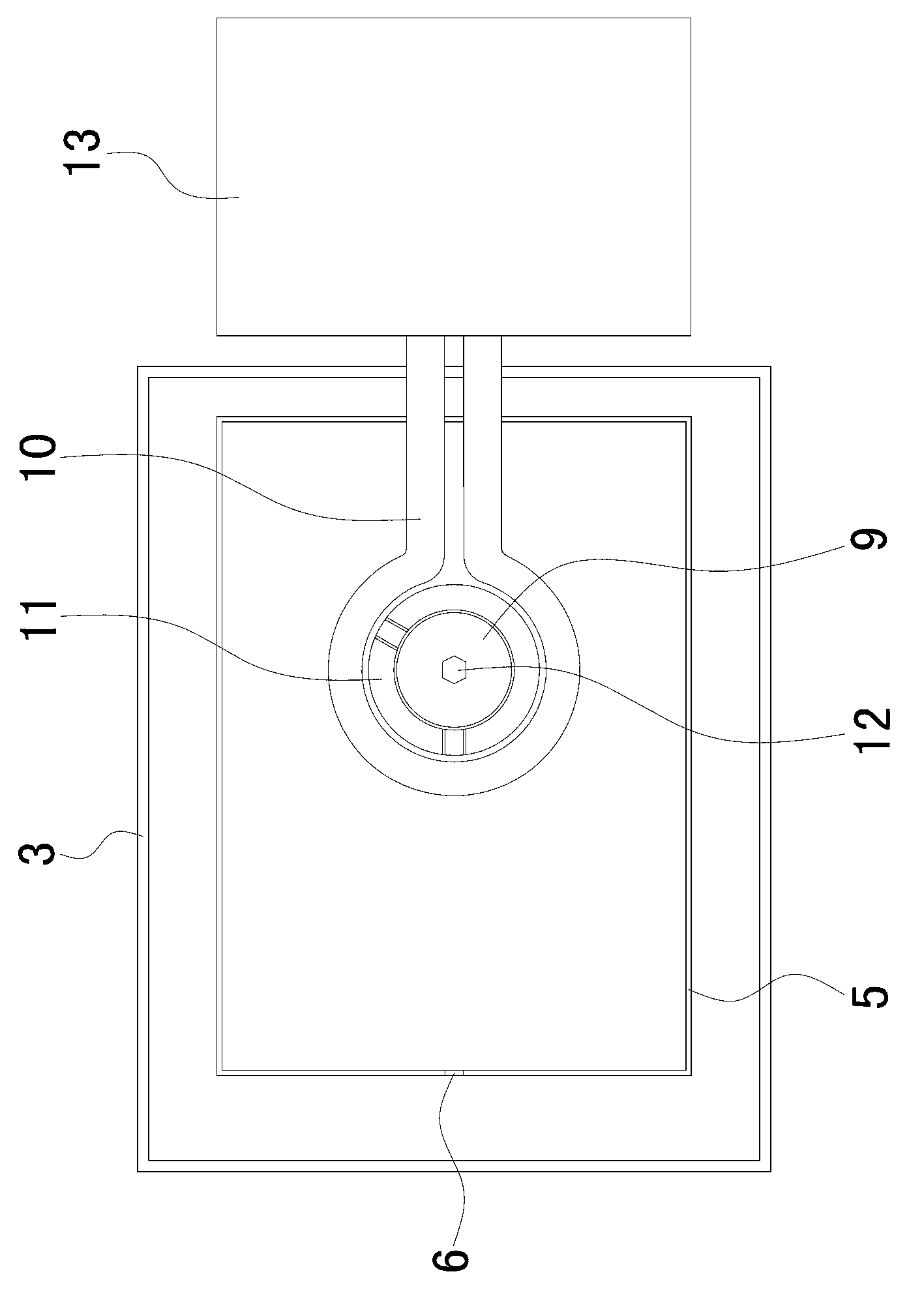

Gas generator component cleaning device

InactiveCN108405451AAvoid manual dryingShorten the timeDrying gas arrangementsCleaning using liquidsPipe fittingSprayer

The invention discloses a gas generator component cleaning device, and relates to the technical field of gas generator manufacturing. The gas generator component cleaning device comprises a box. The inner wall of the box is fixedly connected with a cleaning box through a supporting plate. The bottom of the inner wall of the box is fixedly connected with a cleaning pump, and the water inlet end ofthe cleaning pump communicates with a water inlet pipe. The water outlet end of the cleaning pump communicates with a tee-joint pipe fitting through a communication pipe. The two ends of the tee-jointpipe fitting communicate with a first cleaning pipe and a second cleaning pipe correspondingly. One end of the second cleaning pipe communicates with a fixing base, and the top of the fixing base isfixedly connected with a sprayer fixing base through an electric telescopic rod. The top of the fixing base communicates with one side of the sprayer fixing base through a hose. One side of the sprayer fixing base communicates with a universal bamboo joint sprayer. According to the gas generator component cleaning device, ultrasonic cleaning is adopted, so that the cleaning effect is improved; andmeanwhile, the universal bamboo joint sprayer is utilized for further cleaning a component obtained after ultrasonic cleaning, and the dirt is prevented from being left on the surface of the component.

Owner:江西元康新能源有限公司

Two-way lead wire device

InactiveCN1560558AAutomatic cycleResolve Level VariationsHydrostatic levellingMechanical measuring arrangementsMetallic LeadStatic force

The invention discloses a two-way bracing wire device, which belongs to a measuring device in water conservation, communication and rock and soil field. It includes a fixing end, suspending end, bracing wire body, two-way measuring box, automatic water filling device, liquid storage barrel and connecting pipe, the two-way measuring box has a water box, floating bracket, manual measuring meter and two-way bracing wire device; the water box, liquid storage barrel and the automatic liquid filling device are connected together through the connecting pipe, the bracing wire is leaded in through the fixed end to the suspending end through each measuring bracket, and the wire are winded on the heavy wheel. The invention changes the single measuring aim of the single way bracing wire device and static force level device, realizes two functions with one wire.

Owner:NANJING AUTOMATION INST OF WATER CONSERVANCY & HYDROLOGY MINIST OF WATER RESOURCES

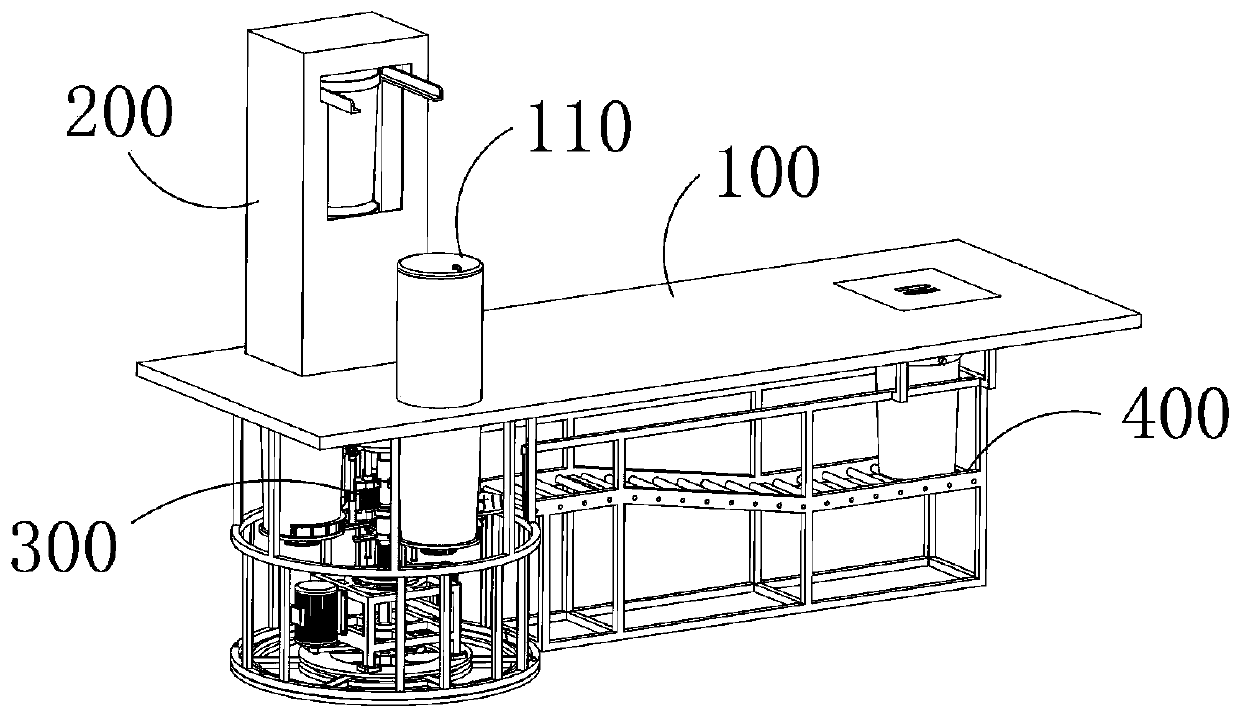

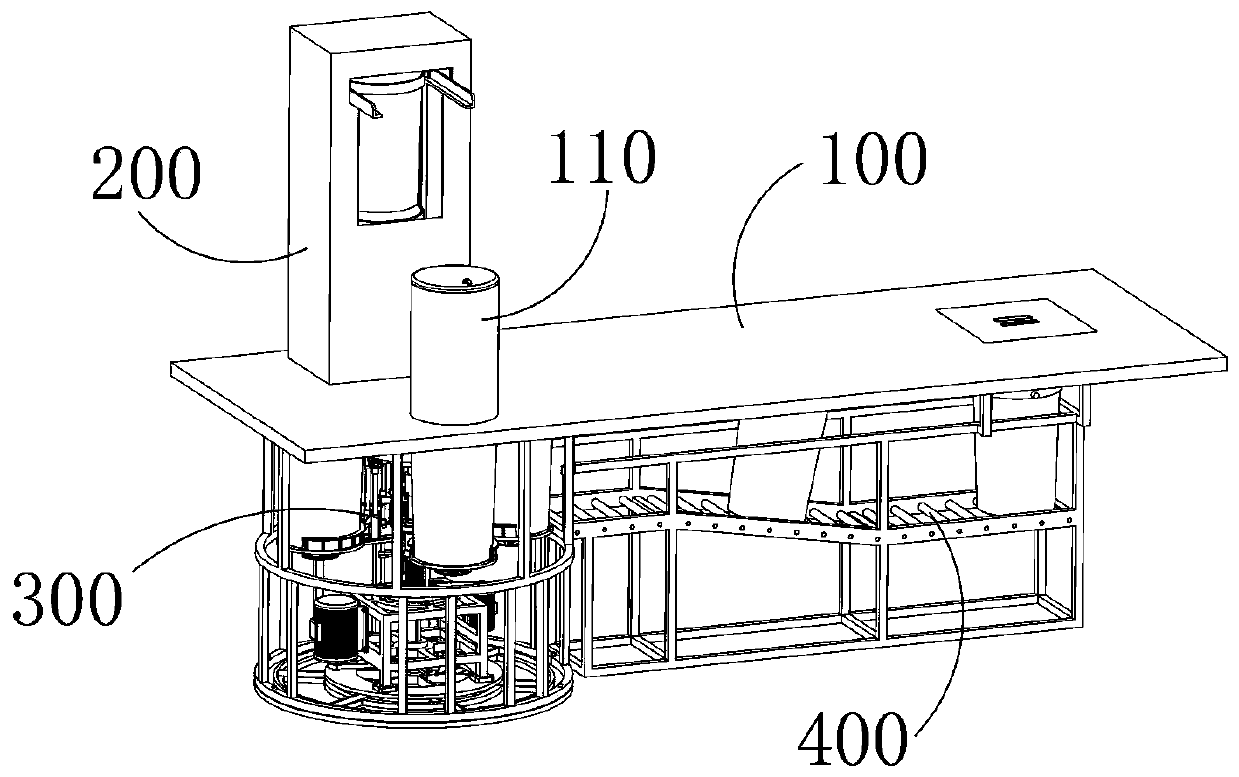

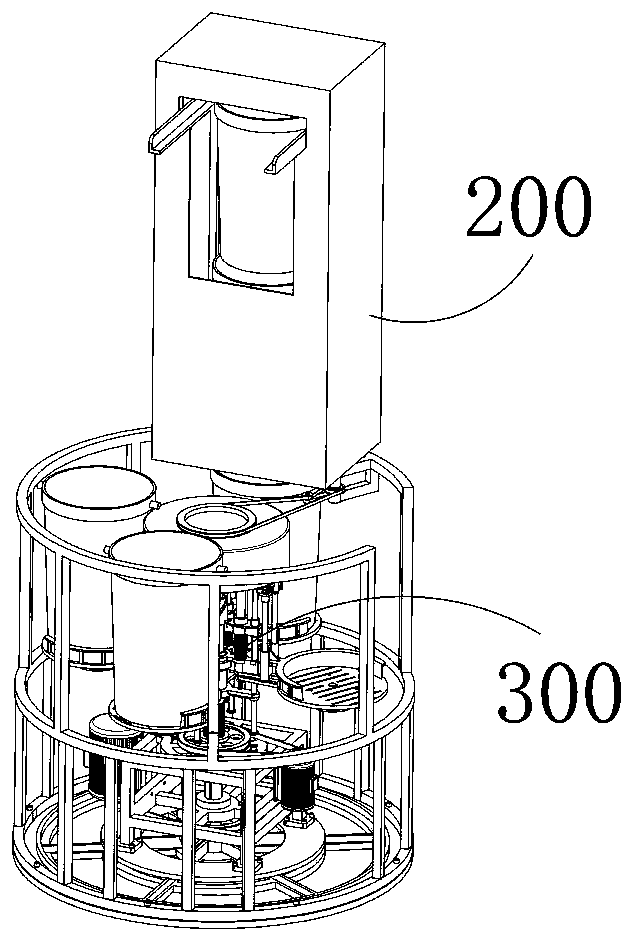

Wet garbage centralized collecting and disposing system

The invention provides a wet garbage centralized collecting and disposing system which comprises a mounting plate, an automatic drum adding device, an induction triggered drum changing device and a collecting and storing device. The mounting plate is horizontally mounted on the ground and is provided with a drum adding hole, an input hole and a collecting hole. The automatic drum adding device ismounted on the upper end surface of the mounting plate and communicates to the drum adding hole, the induction triggered drum changing device / the collecting and storing device are arranged underground, the automatic drum adding device is used for adding a new empty garbage can to the induction triggered drum changing device through the drum adding hole, the induction triggered drum changing deviceis used for inducing whether the garbage can is filled with wet garbage or not fully by way of gravity induction and replacing the full load garbage can by a next empty garbage can and driving the full load garbage can to move to the collecting and storing device, and the collecting and storing device is used for collecting and storing the full load garbage can temporarily and guiding the full load garbage can right below the collecting hole.

Owner:上海玖钬环保(集团)有限公司

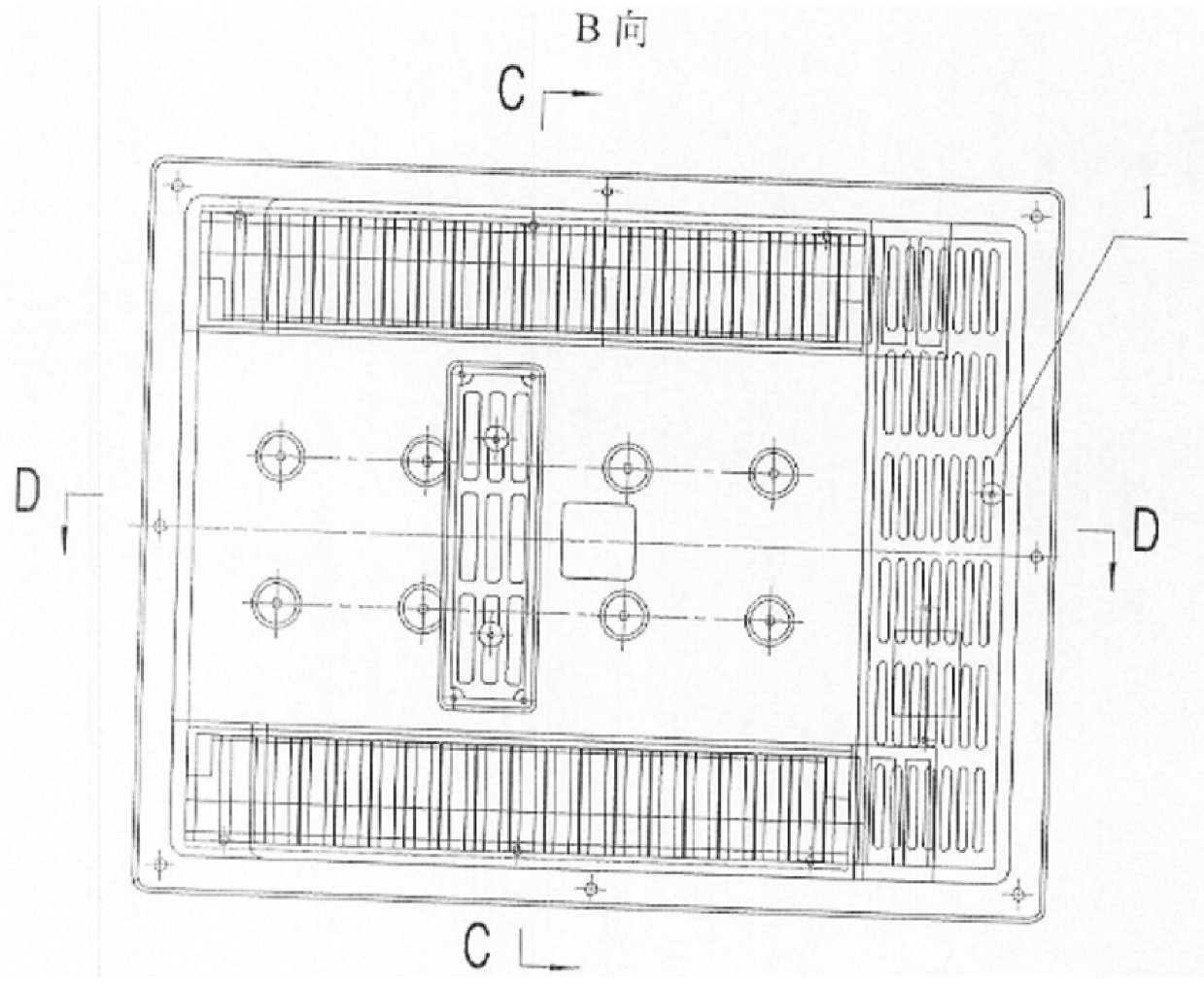

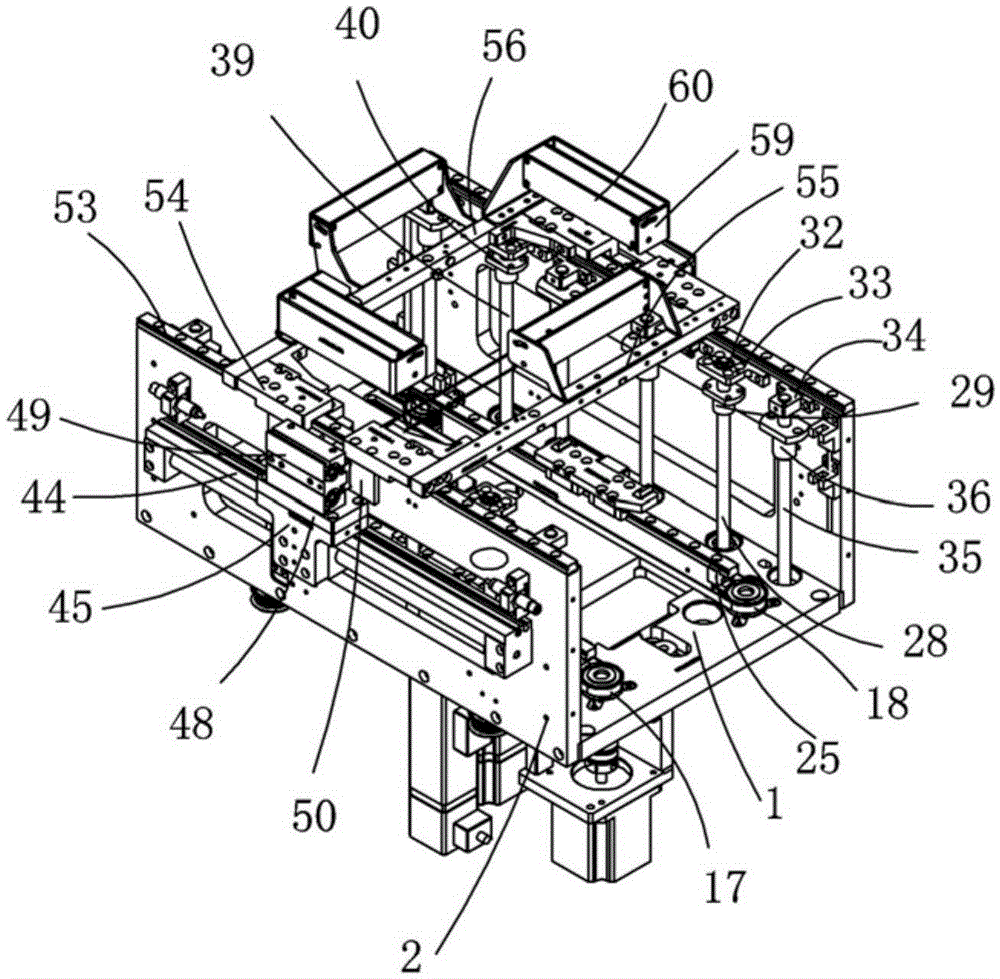

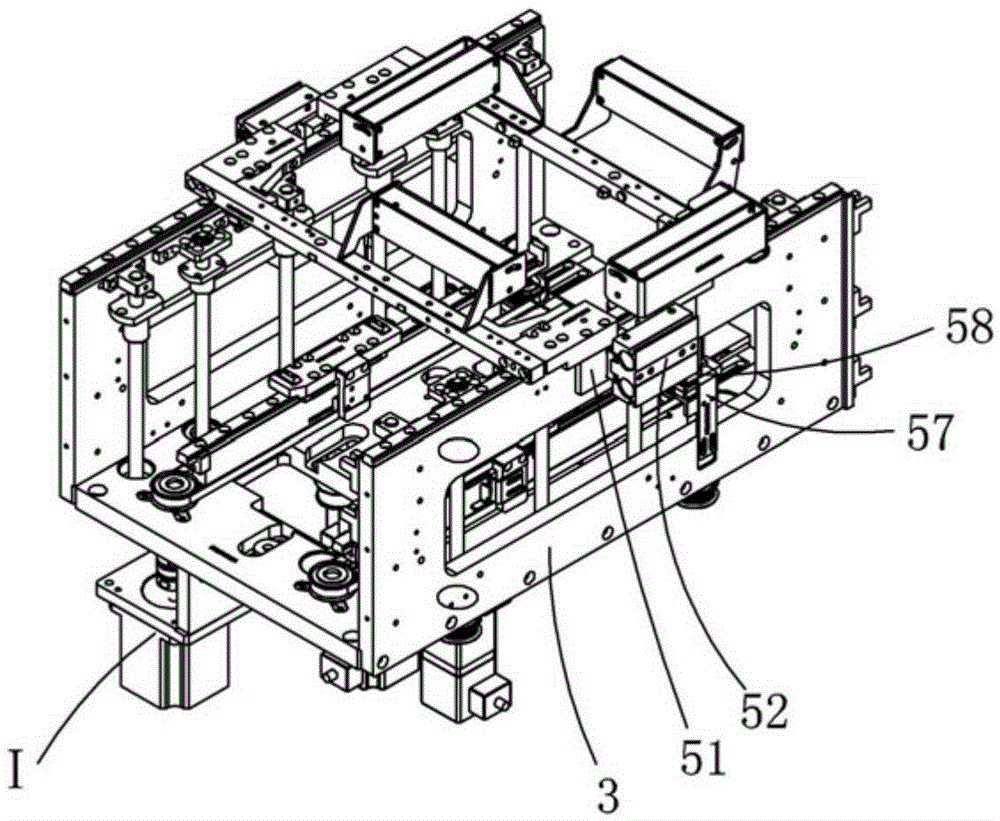

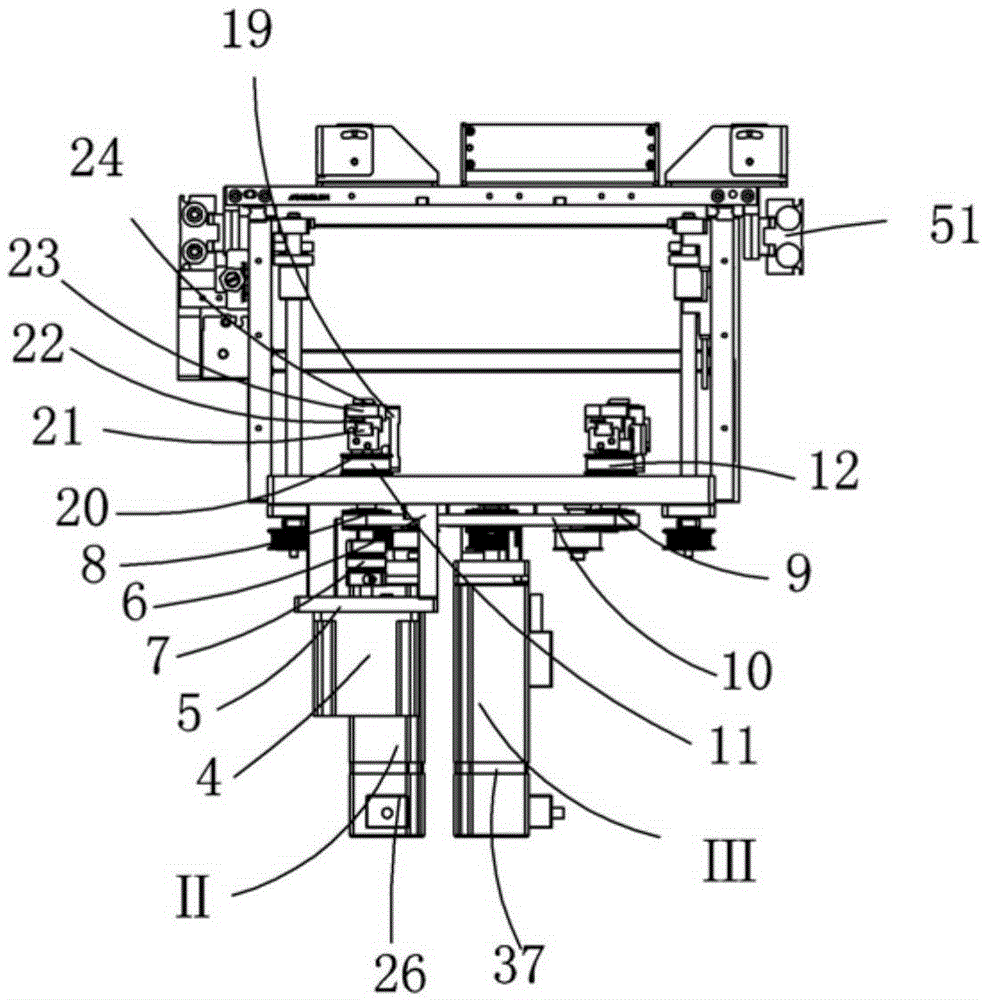

Feeding mechanism

The invention relates to a feeding mechanism. The left side and the right side of a bottom plate are provided with a left fixing plate and a right fixing plate respectively. The bottom plate is provided with a horizontal-moving drive assembly. A lifting drive assembly a and a lifting drive assembly b are arranged between the bottom plate and the left fixing plate and between the bottom plate and the right fixing plate respectively. A discharging disc assembly is arranged on the front side of the upper portion of the bottom plate. A feeding disc assembly is arranged on the lifting drive assembly a. A rotary feeding assembly is arranged on the lifting drive assembly b. A transferring assembly is arranged on the outer side of the left fixing plate. The transferring assembly and the left fixing plate are provided with a left carrying tool clamping device. A right carrying tool clamping device is arranged on the outer side of the right fixing plate. The upper portions of the left fixing plate and the right fixing plate are each provided with a sliding rail set. Two sliding blocks are arranged on each sliding rail set. A front clamp strip is connected between the two sliding blocks in the front side. A rear clamp strip is connected between the two sliding blocks on the rear side. By the adoption of the feeding mechanism, product carrying tools can be circulated automatically, product carrying tools are put on the lower layer, and empty product carrying tools on the upper layer are taken out, so that the product carrying tools can be taken out or put conveniently.

Owner:BOZHON PRECISION IND TECH CO LTD

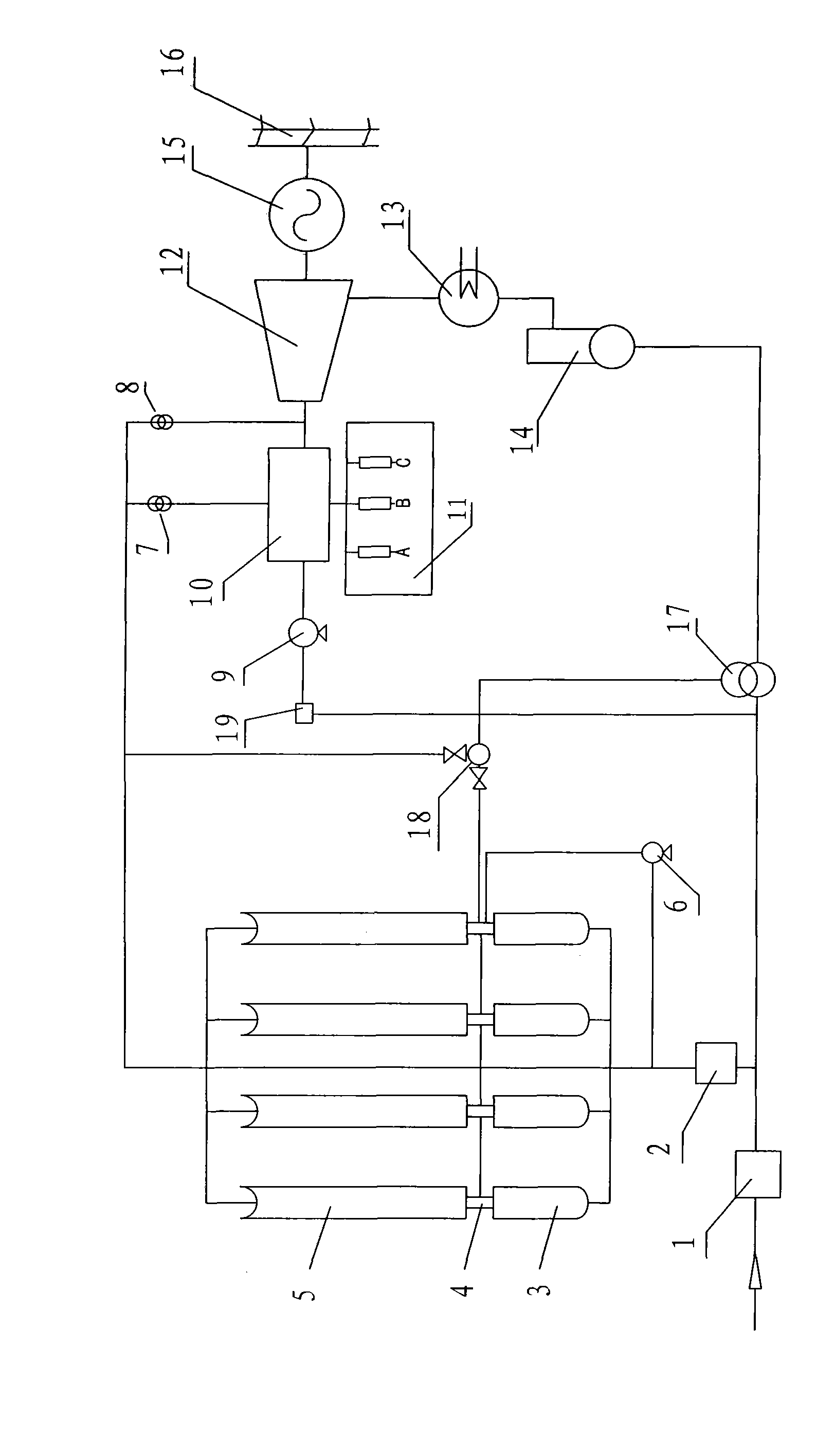

Sunlight thermoelectricity groove type power station system

InactiveCN103161700ARealize automatic cycleSignificant progressFrom solar energyMachines/enginesElectricityPower station

The invention relates to a sunlight thermoelectricity groove type power station system. The sunlight thermoelectricity groove type power station system makes full use of the principle of sunlight reflected ray focusing, and saturated vapor having rated working media is produced to push a turbine to act to generate power through an array composed of groove type reflected ray focus lenses. A flash boiler system which can combust various types of fuel is adopted for complementation, so that the sunlight thermoelectricity groove type power station system can generate the electricity not only when sunlight exists, but also when the sunlight is weak or the sunlight does not exist. Meanwhile, according to the sunlight thermoelectricity groove type power station system, vapour and water are not layered in a heating power pipeline, continuous automatic cycle can be achieved, and mutual supplementation can be achieved.

Owner:LUOYANG WEIQI SOLAR ENERGY TECH

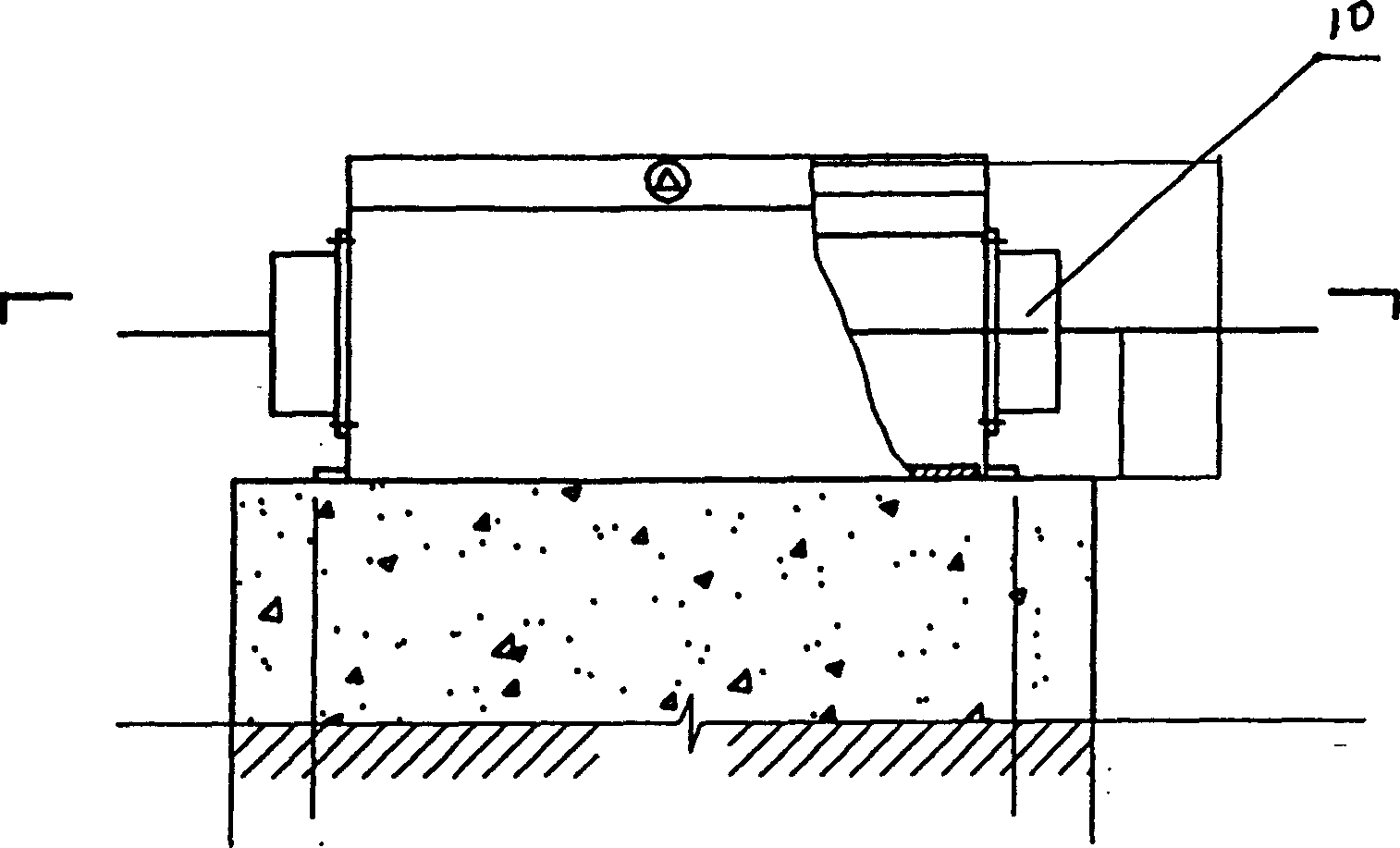

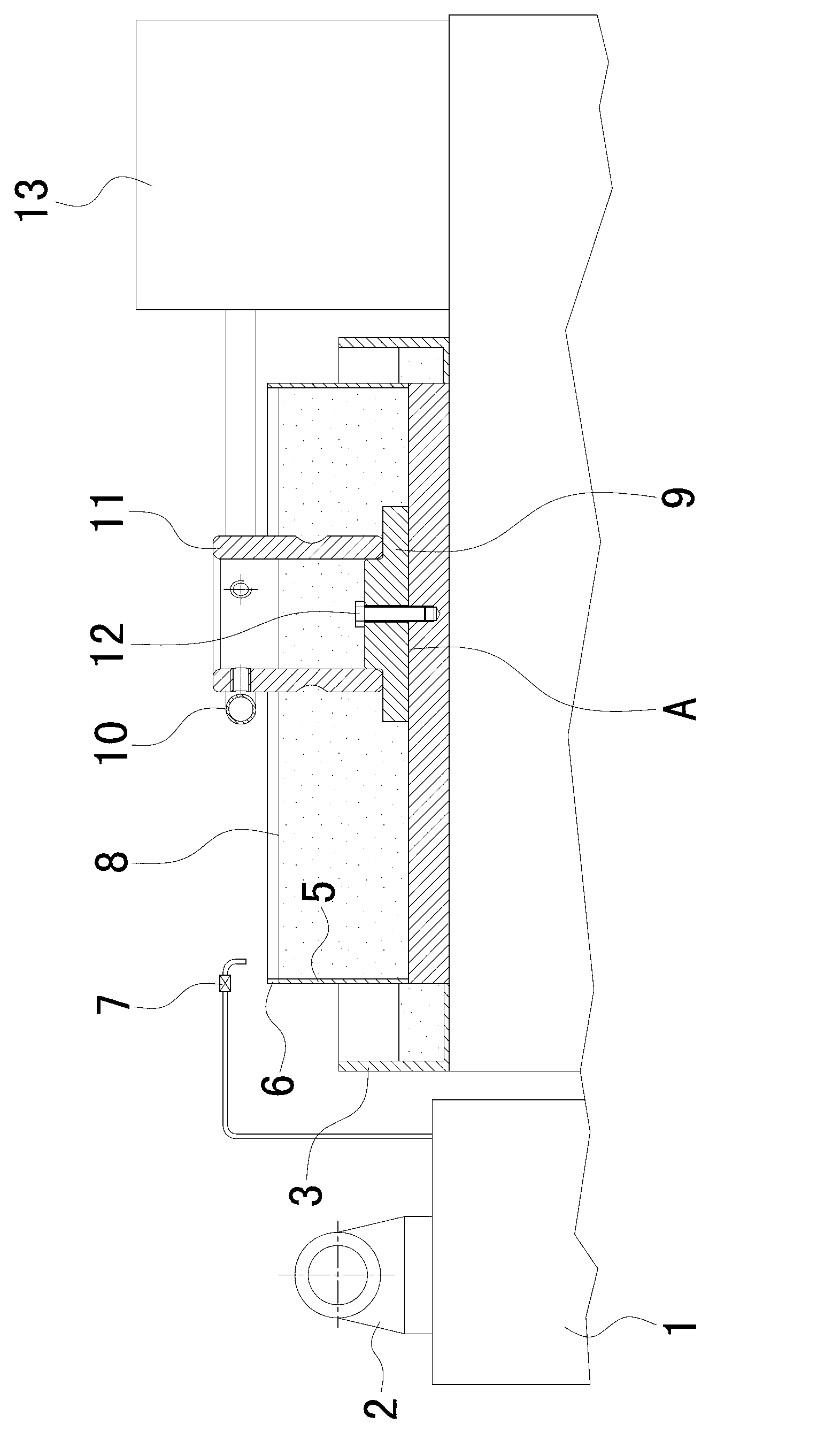

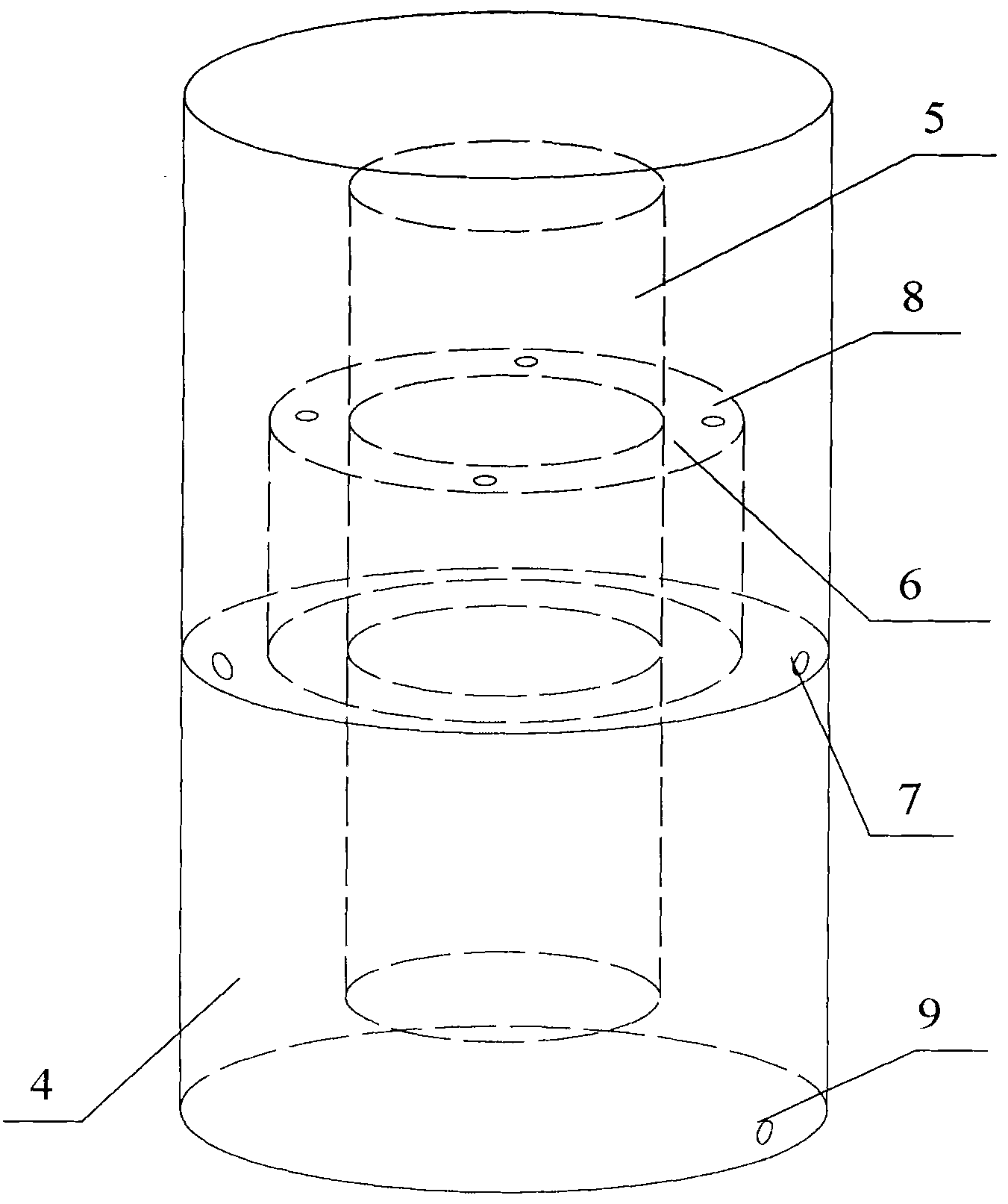

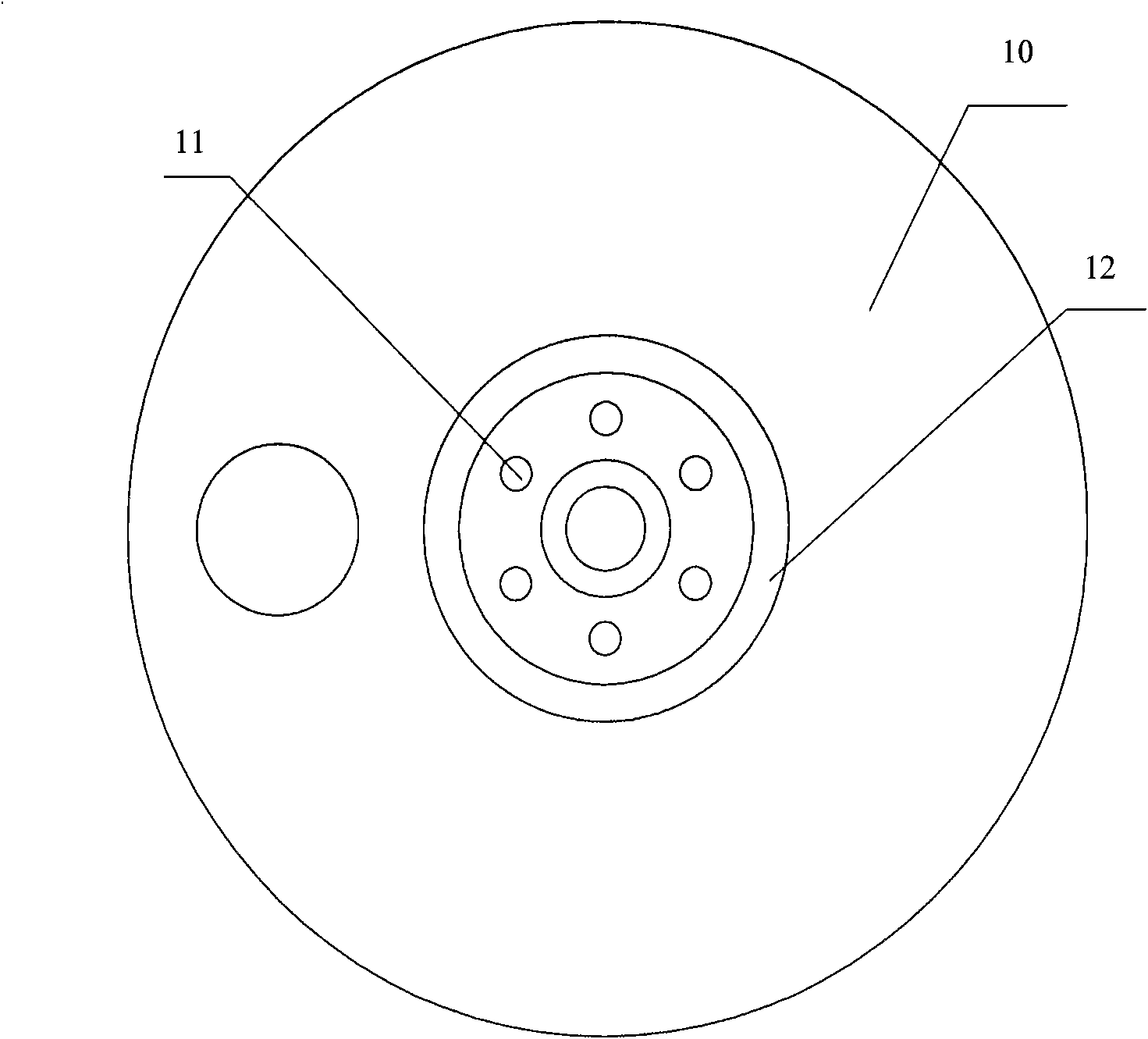

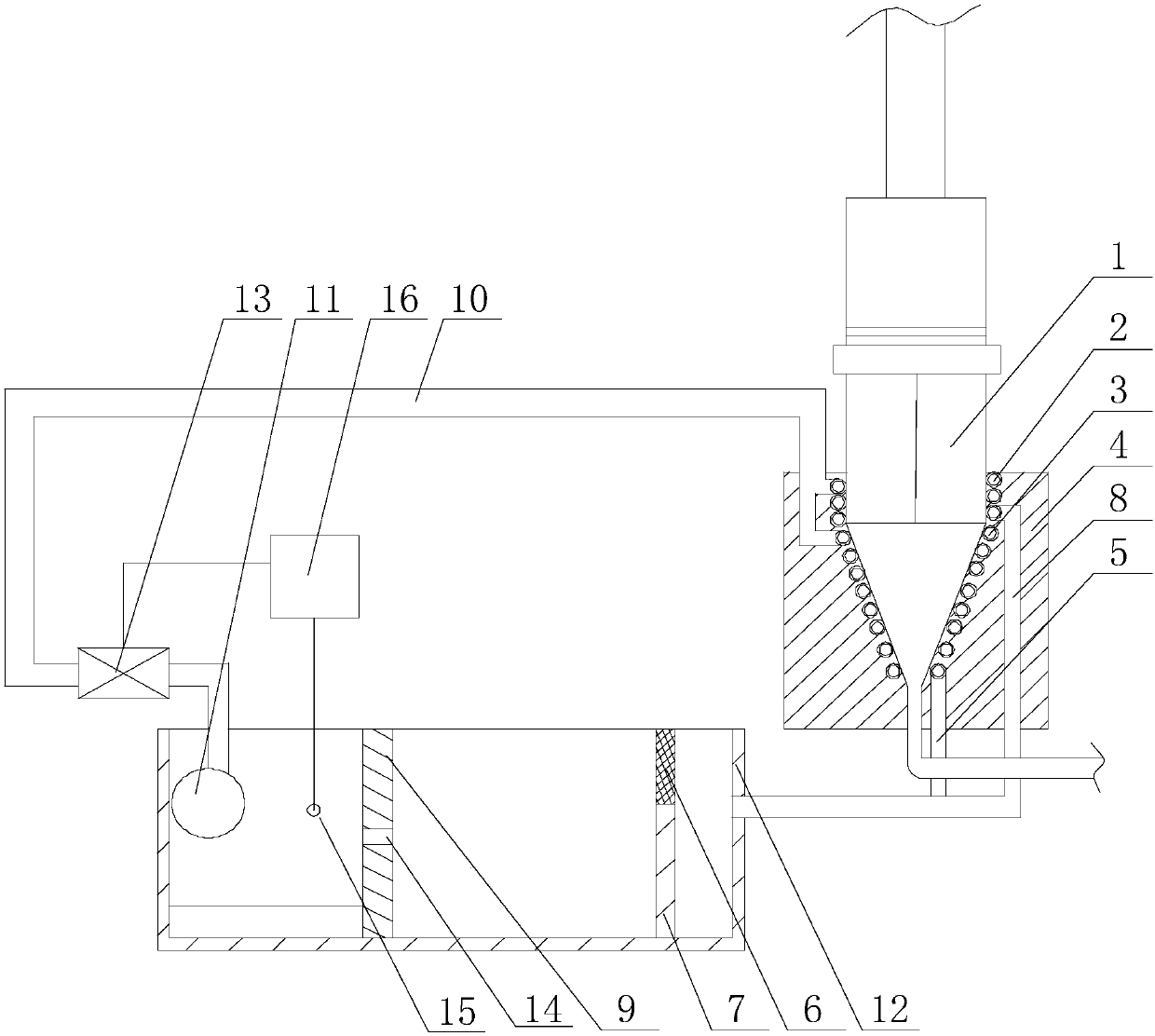

Partial annealing device and annealing method of bearing sleeve ring

InactiveCN103014302AHeating evenlyReduce heat transfer rateFurnace typesHeat treatment furnacesInduction heaterEngineering

The invention relates to machining equipment and a machining method of a bearing sleeve ring. The machining equipment comprises a high-frequency induction heater, wherein the high-frequency induction heater is provided with an annular heating pipe; the machining equipment further comprises a cooling water tank, a reflowing groove and a cooling water tank with a water pump; the cooling water tank is provided with a water feeding pipe; an overflowing opening is arranged on the tank wall of the cooling water tank; a water returning pipe is arranged between the reflowing groove and the cooling water tank; the cooling water tank is provided with a station for clamping the bearing sleeve ring; and a circular arc part of the annular heating pipe is located right above the station. The invention provides a rolling path protection device in a partial softening process of a screw hole; the circulating cooling water tank is arranged so that the rolling path and two proper parts of the two sides of the rolling path are immersed into cooling water when a sleeve ring screw hole and the periphery are heated and softened at a required high temperature; and a liquid surface of the cooling water tank is used for separating the bearing sleeve ring into a heating region containing the screw hole and a cooling region containing the rolling path, so as to effectively relieve the heat conduction speed of a heated part to the rolling path, and guarantee that the hardness of the rolling path is not influenced in a whole partial softening process.

Owner:中山市盈科轴承制造有限公司

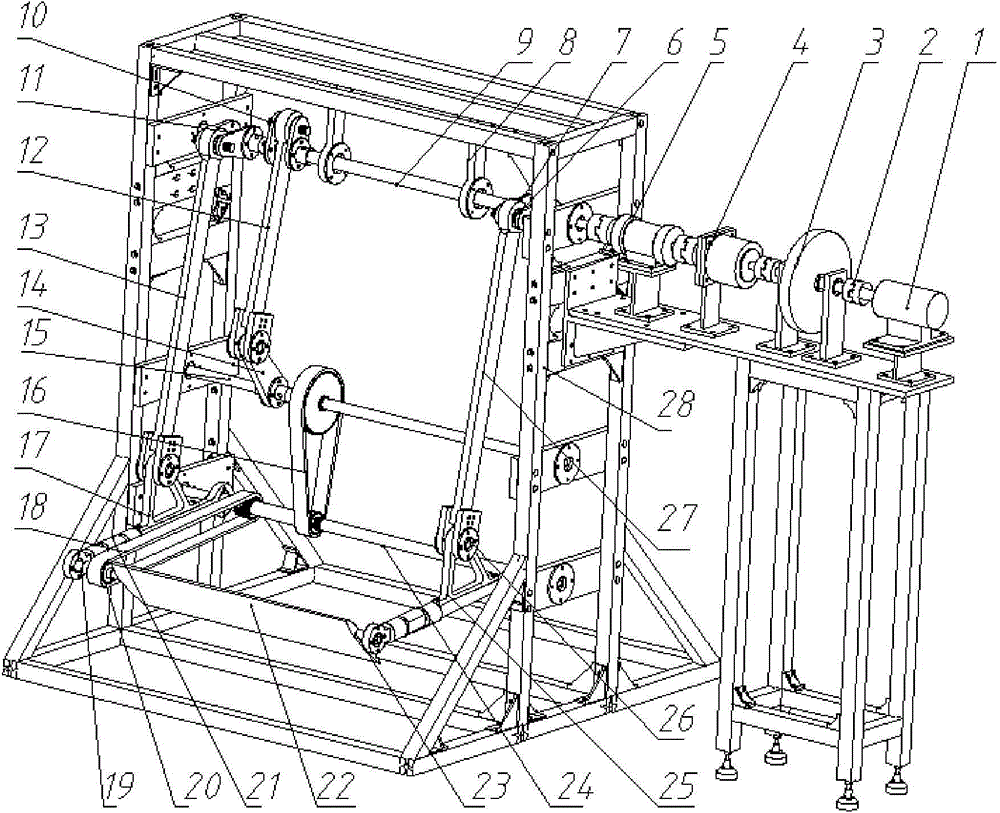

Swing type hydrofoil tidal current energy-powered electricity generating set

ActiveCN104481785ASimple structureEasy to installMachines/enginesEngine componentsEnergy lossFlywheel

The invention aims to provide a swing type hydrofoil tidal current energy-powered electricity generating set. The electricity generating set comprises three sets of crank-rocker mechanisms, wing panels, synchronous belts, belt wheels, a rotating shaft, a torque meter, a gearbox, a flywheel and a generator. By a luffing four-rod mechanism, transformation from up-and-down oscillation of a hydrofoil to unidirectional rotation of the rotating shaft can be effectively realized in order to drive another set of swinging four-rod mechanism; the rotation of a crank is transformed into up-and-down oscillation of a swinging rod so as to effectively control the law of motion of oscillating angles of the wing panels; the rotating speed of the rotating shaft is accelerated by the gearbox, and finally energy is transmitted to the generate to realize energy utilization. By ingeniously utilizing the own mechanical properties of the four-rod mechanism, the electricity generating set disclosed by the invention realizes an automatic energy collection process of the device, prevents energy loss caused by complex structure of an energy collecting device, control by a motor and the like, and has a quite large development range in future tide current energy collection.

Owner:HARBIN ENG UNIV

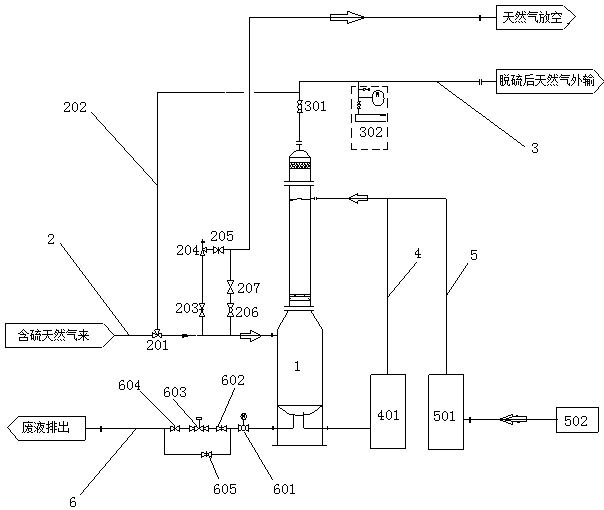

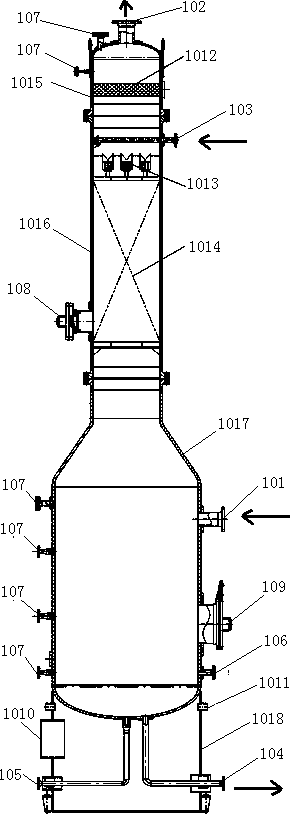

Integration device based on desulfurization of triazine solution and application method of integration device

PendingCN107930372AImprove work efficiencyDesulfurization achievedGaseous fuelsDispersed particle separationElectricityFluid infusion

The invention provides an integration device based on desulfurization of a triazine solution and an application method of the integration device. The integration device comprises an absorption tower,wherein an air inlet of the absorption tower is connected with an air inlet pipeline; an air outlet of the absorption tower is connected with an exhaust pipeline; a ball valve 1 and an on-line hydrogen sulfide detector are connected in series with the exhaust pipeline; a desulfurizer inlet and a desulfurizer outlet are connected through a circulating pipeline on which a circulating pump is mounted; the desulfurizer inlet is further connected with a fluid infusion pipeline; the fluid infusion pipeline is connected with an inlet of a fluid infusion pump; an outlet of the fluid infusion pump is connected with a desulfurizer storage tank; a drain outlet is connected with a blowdown pipeline; and the on-line hydrogen sulfide detector is electrically connected with the fluid infusion pump for interconnected control. The integration device based on desulfurization of the triazine solution and the application method of the integration device simultaneously realize desulfurization, automatic circulation and fluid infusion, and the whole process is fully automatic and does not need manual intervention.

Owner:XIAN CHANGQING TECH ENG

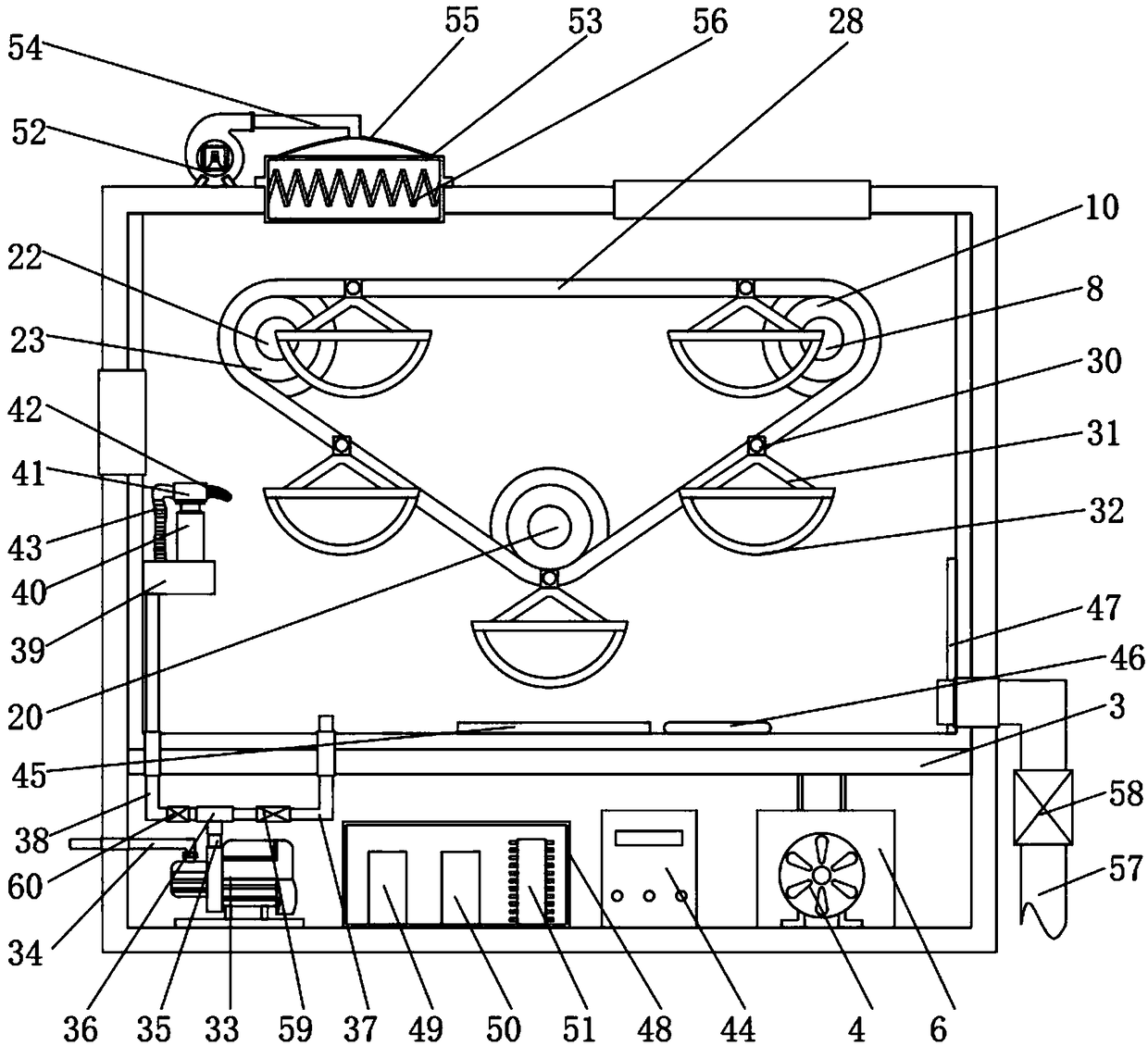

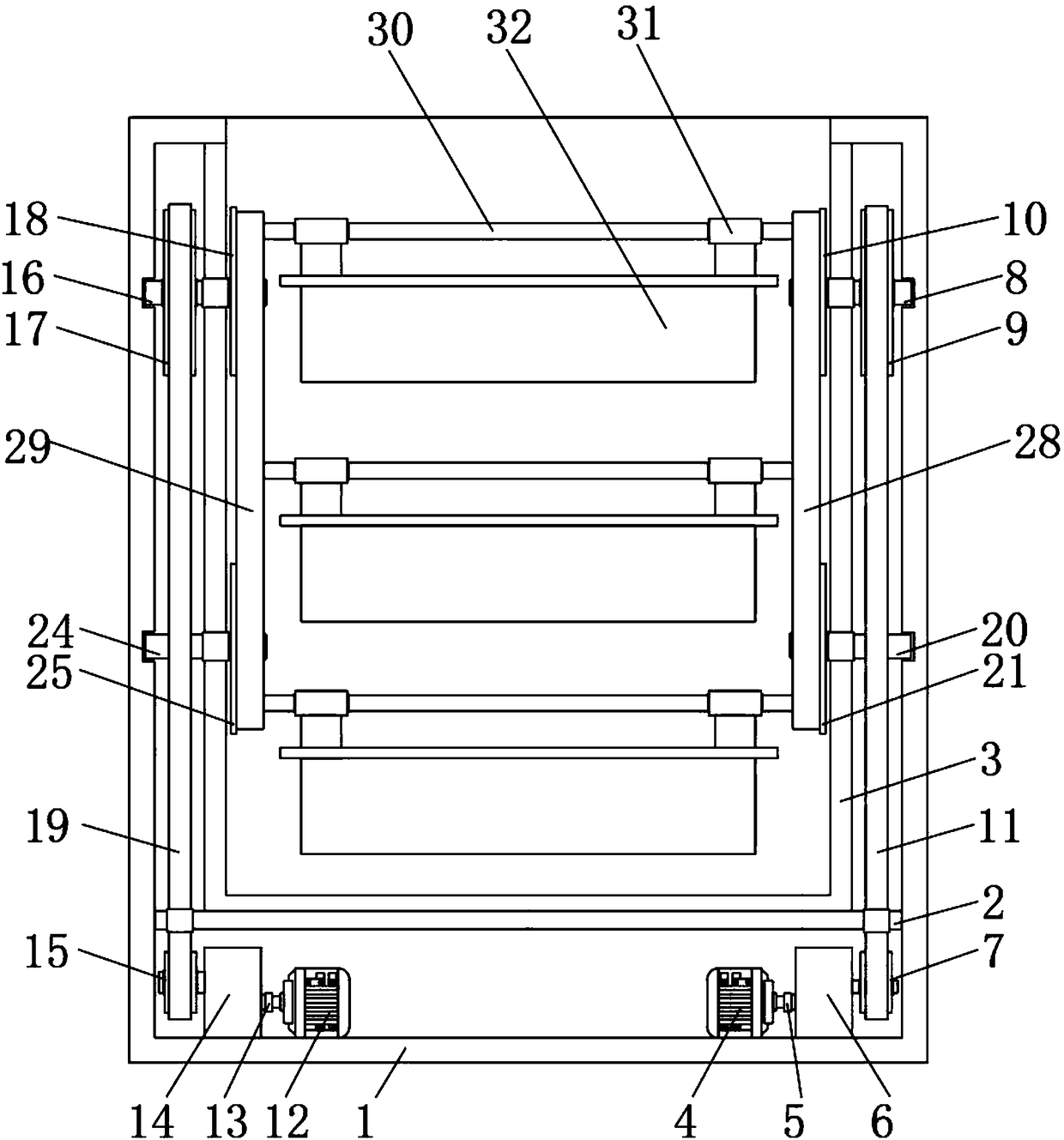

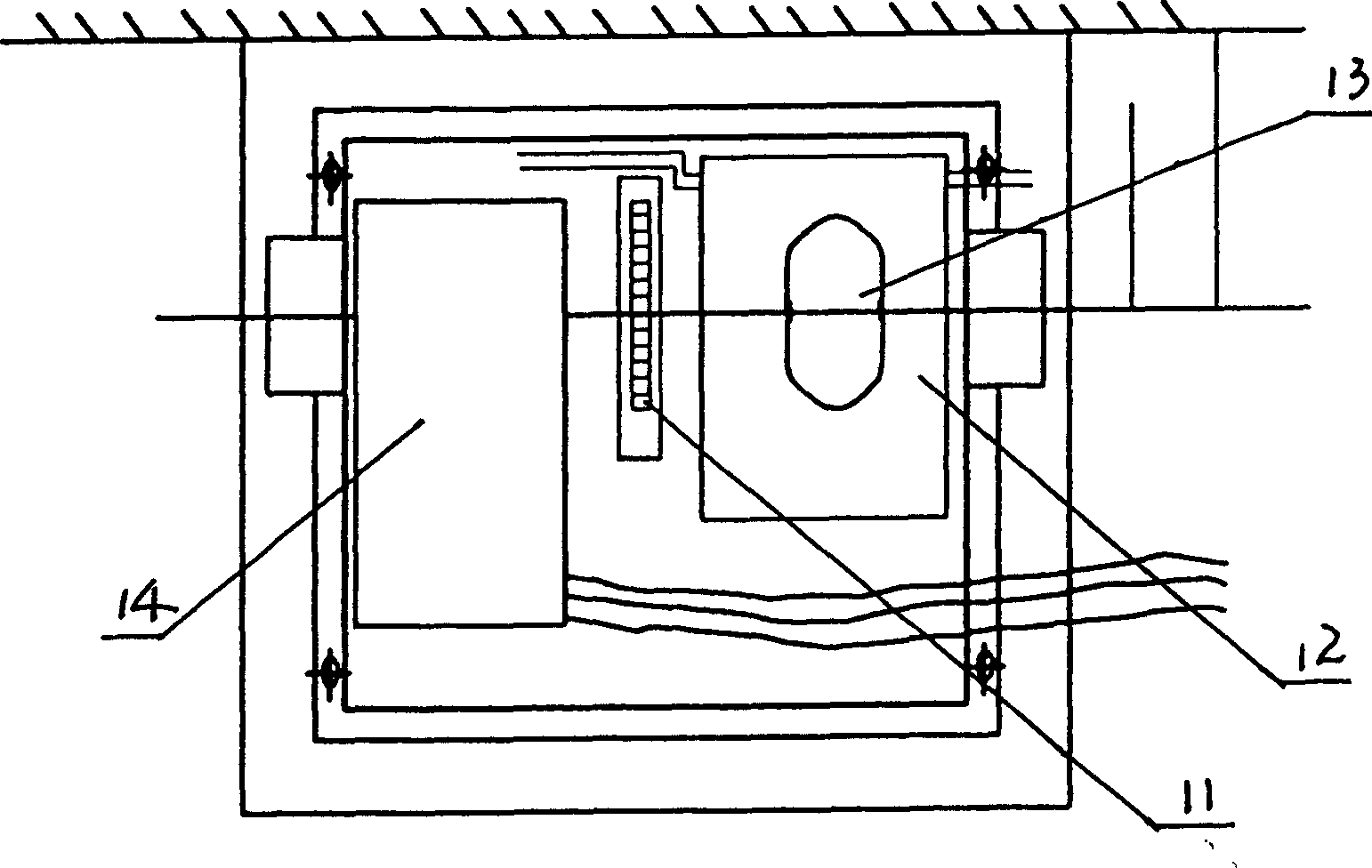

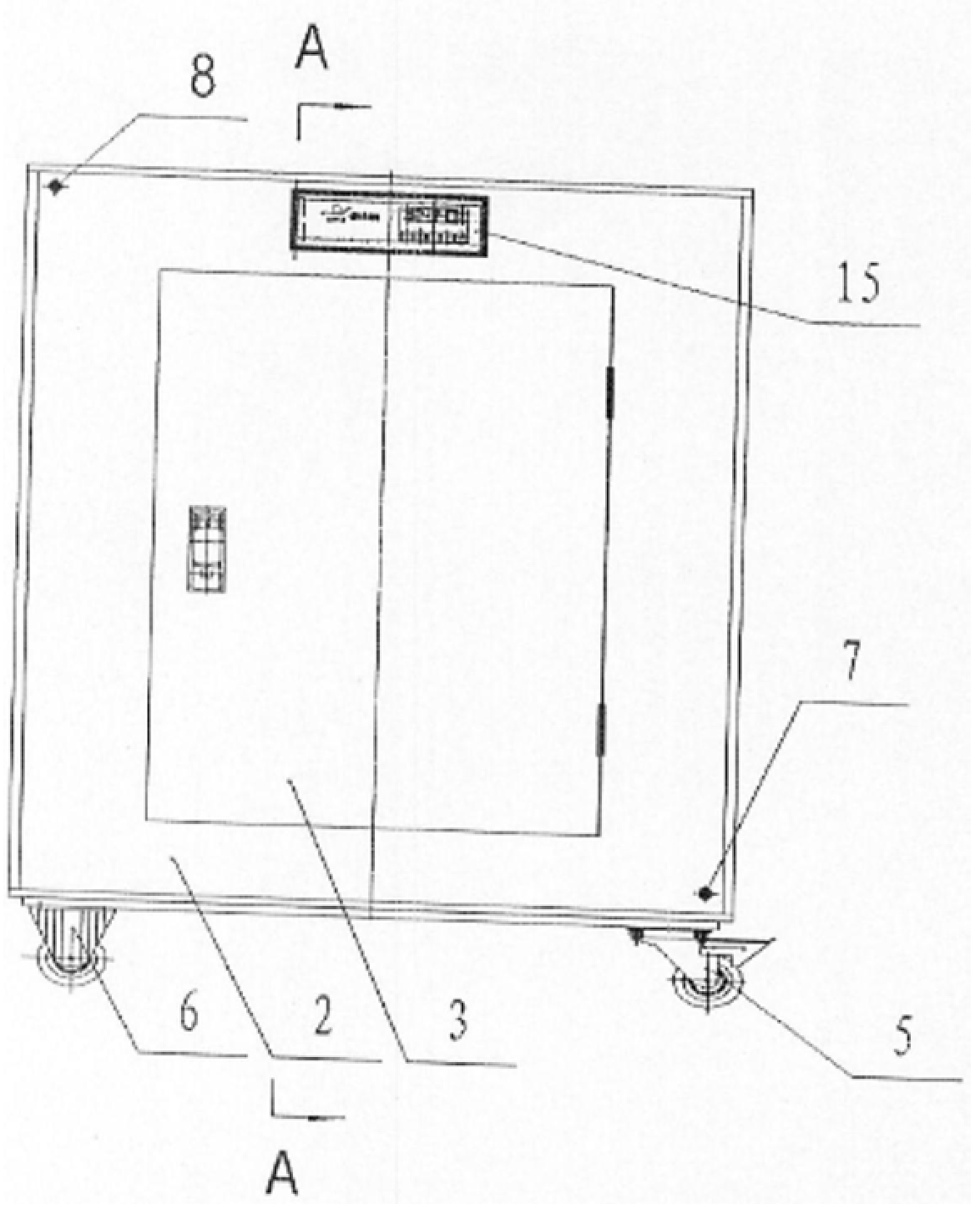

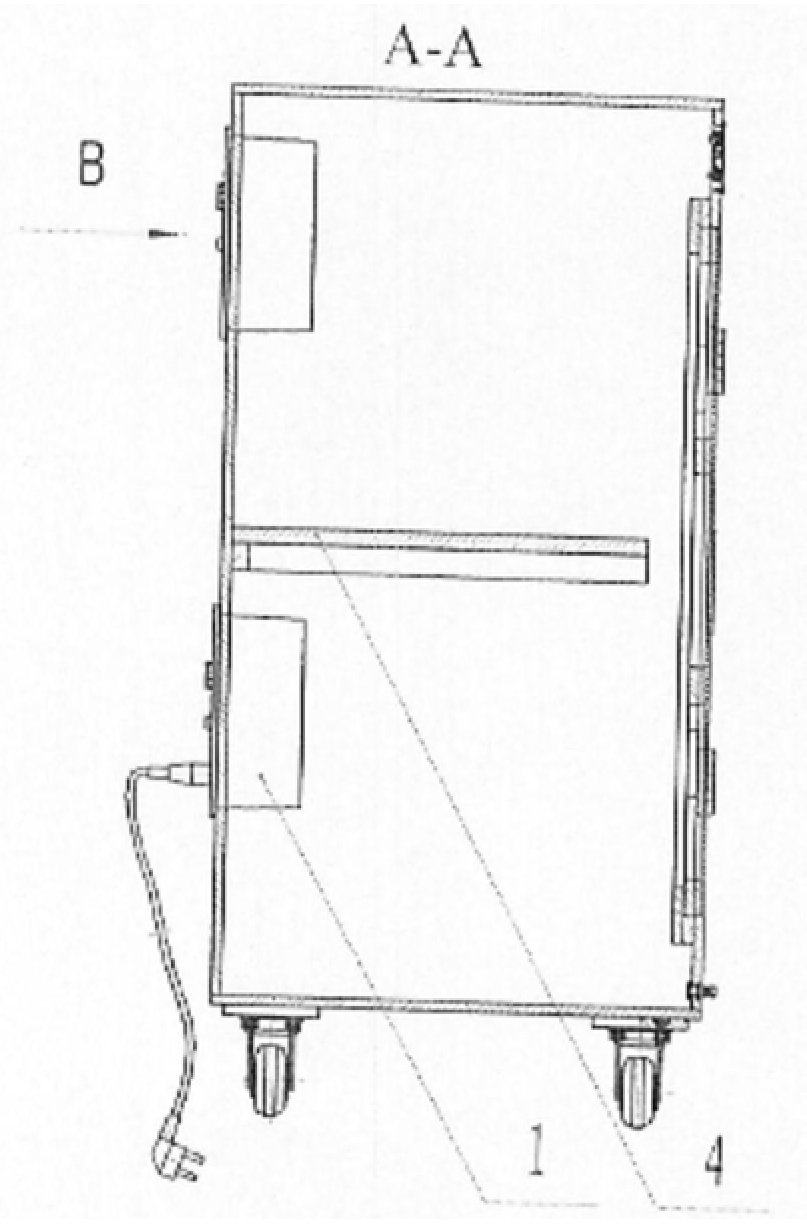

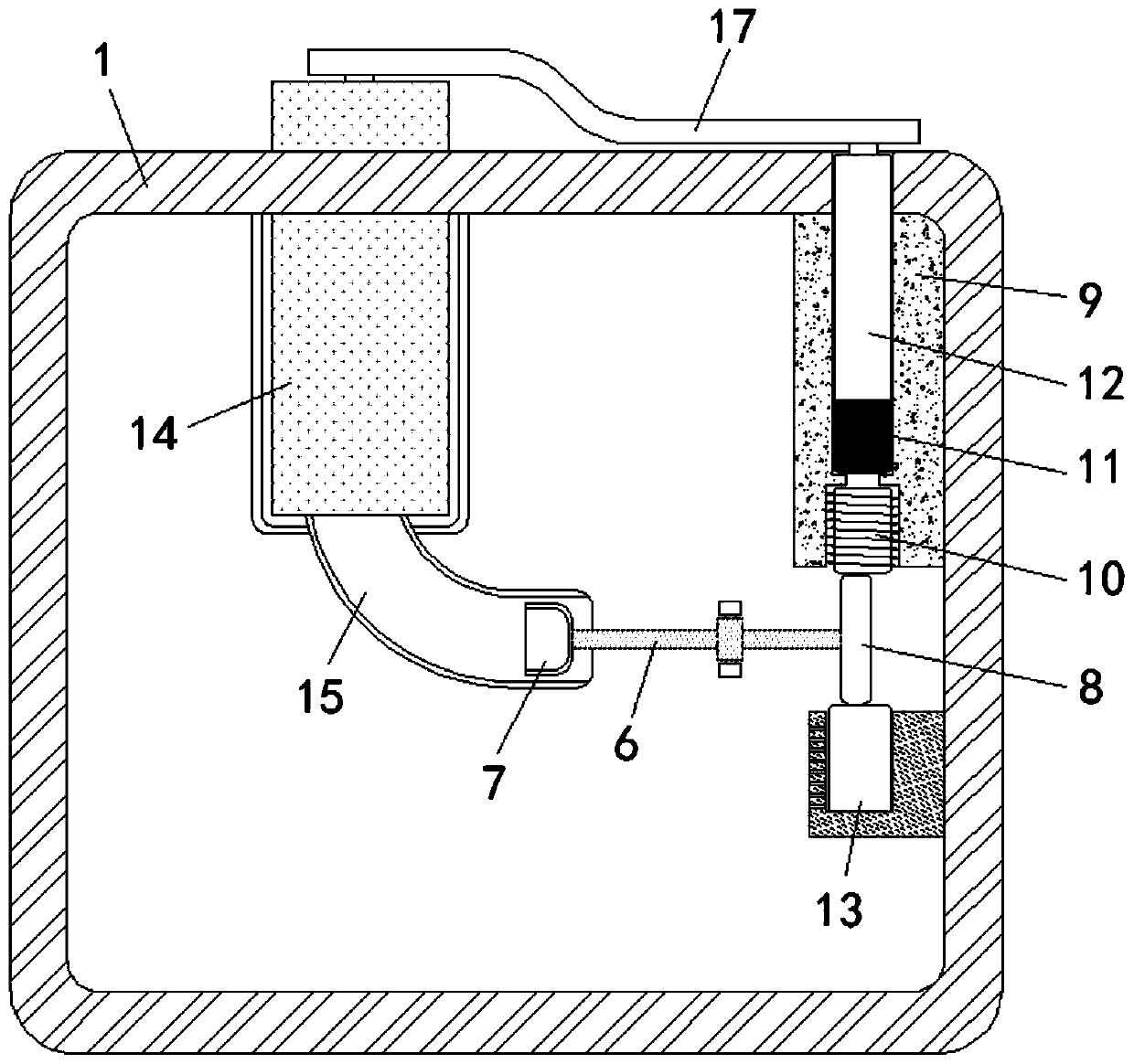

A storage cabinet for optoelectronic instruments

InactiveCN106508114BRealize automatic cycleIncrease humidityDispersed particle separationElectrical apparatus casings/cabinets/drawersAutomatic controlExhaust valve

The invention relates to a photoelectric instrument storage cabinet, comprising a cabinet body, a humidity controller (1), and an electrical control system, and the cabinet body includes an air charging interface (7) and an exhaust interface for filling high-purity nitrogen into the storage cabinet (8), the cabinet body is divided into upper and lower parts by the partition (4); the humidity controller (1) includes the humidity controller box body (9), molecular sieve box (10), and is contained in the molecular sieve box Molecular sieve in (10), heater (11), memory alloy spring (12), return spring (13) and dehumidification valve (14); Described electrical control system comprises display panel (15), microcomputer chip and temperature Humidity sensor, humidity controller (1) has two, is respectively installed on the square hole that has on the back board of upper and lower two parts cabinet body separated by clapboard (4). The invention adopts temperature control shape memory alloy material and microcomputer chip control, and realizes automatic cycle of dehumidification and dehumidification and automatic control of temperature and humidity.

Owner:WEIFANG WEISHIXIN GAS EQUIP CO LTD

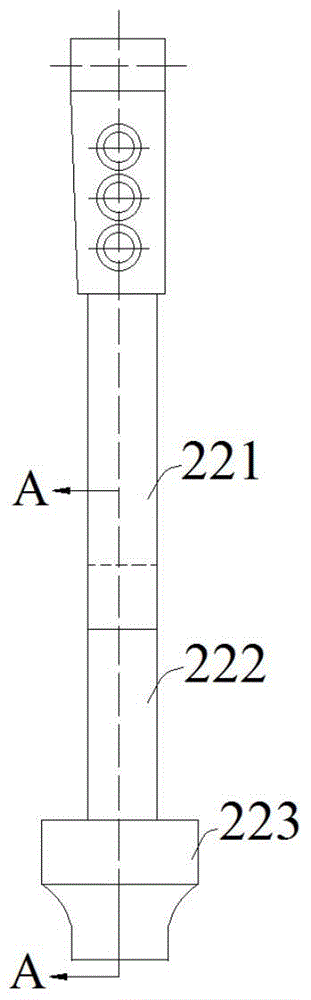

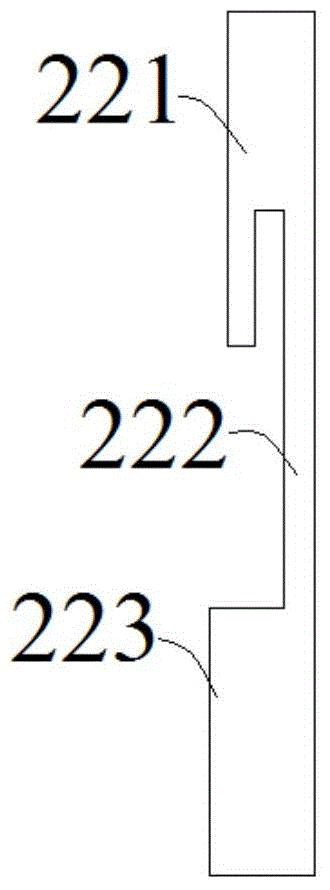

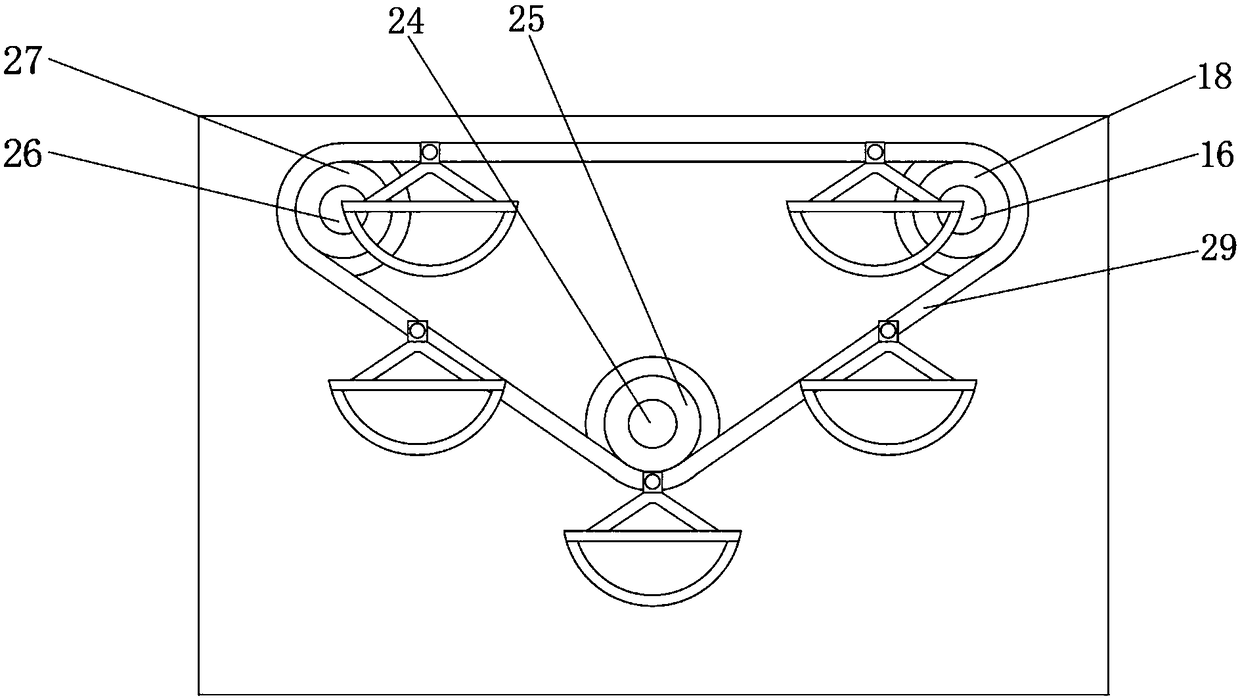

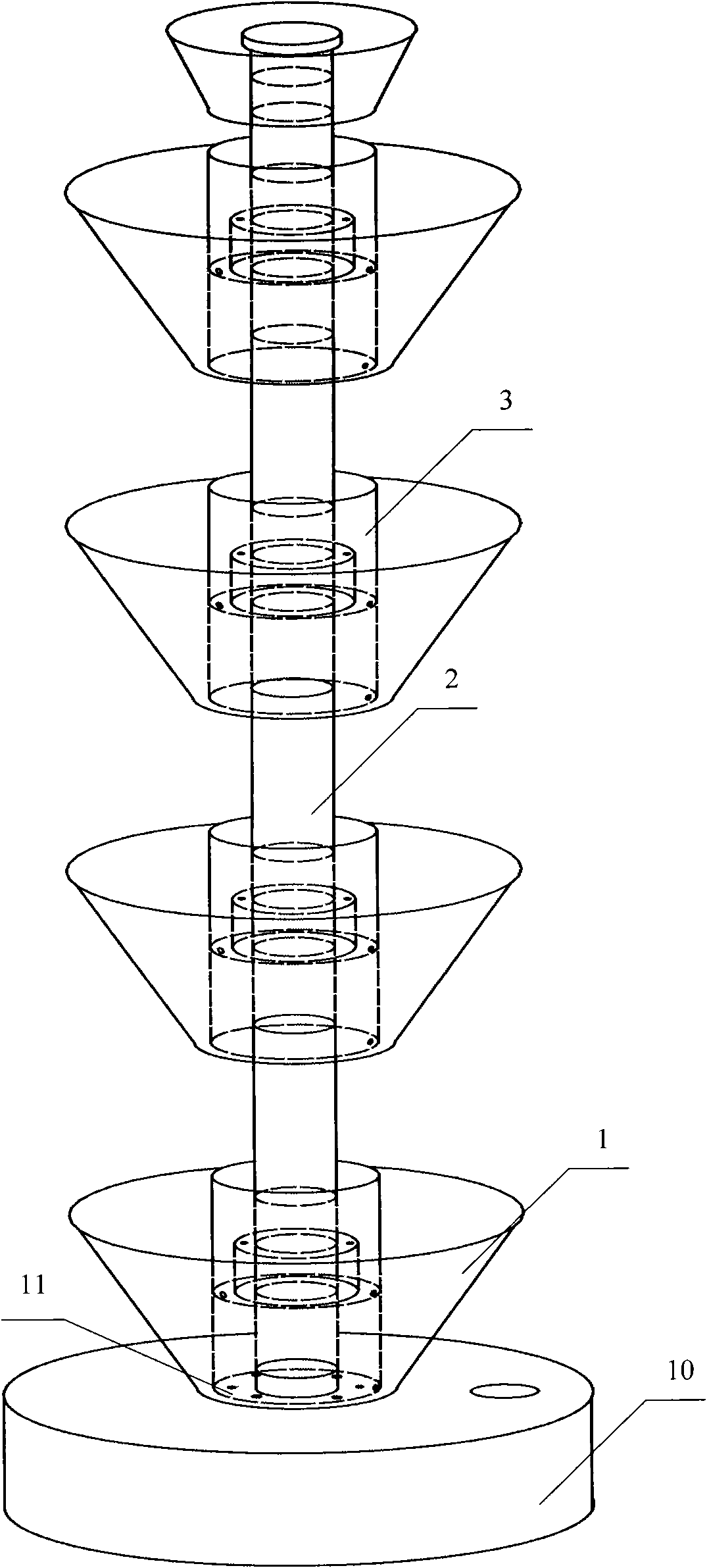

Vertical matrix culture device

InactiveCN102138504ASmall footprintSpeed up the cycleAgriculture gas emission reductionCultivating equipmentsNutrient solutionEngineering

The invention relates to the field of planters, and discloses a vertical matrix culture device. The device comprises a vertical column, a plurality of overflow devices, a plurality of basin-shaped containers, a liquid accumulator and a pump, wherein each overflow device penetrates through and is fixed on the upright column to ensure that the plurality of overflow devices are fixed on the upright column in stacks; each basin-shaped container is filled with a matrix and corresponds to one overflow device, and the bottom of each basin-shaped container is connected with the bottom of the corresponding overflow device; the liquid accumulator is arranged at the bottom of the upright column and is filled with a nutrient solution; and the pump is arranged in the liquid accumulator. By adopting the upright column-type design, the floor area is greatly saved; by adopting the overflow devices, the residual nutrient solution in the matrix of each layer can flow away in time, so that the nutrient solution is saved, and the circulating speed is accelerated; and by using the pump and a timer, automatic circulation of the whole device is realized.

Owner:BEIJING AGRI TECH PROMOTION STATION +1

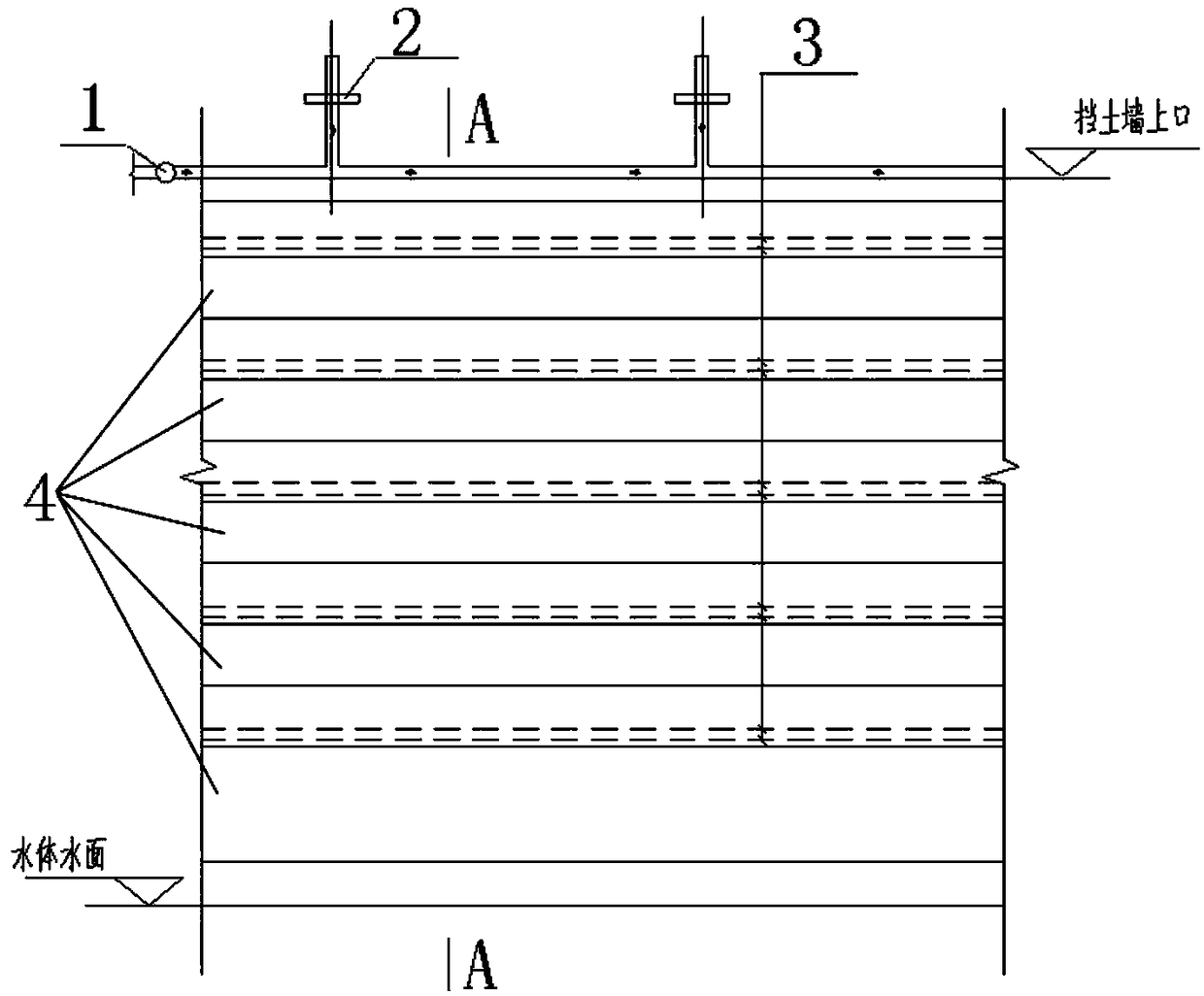

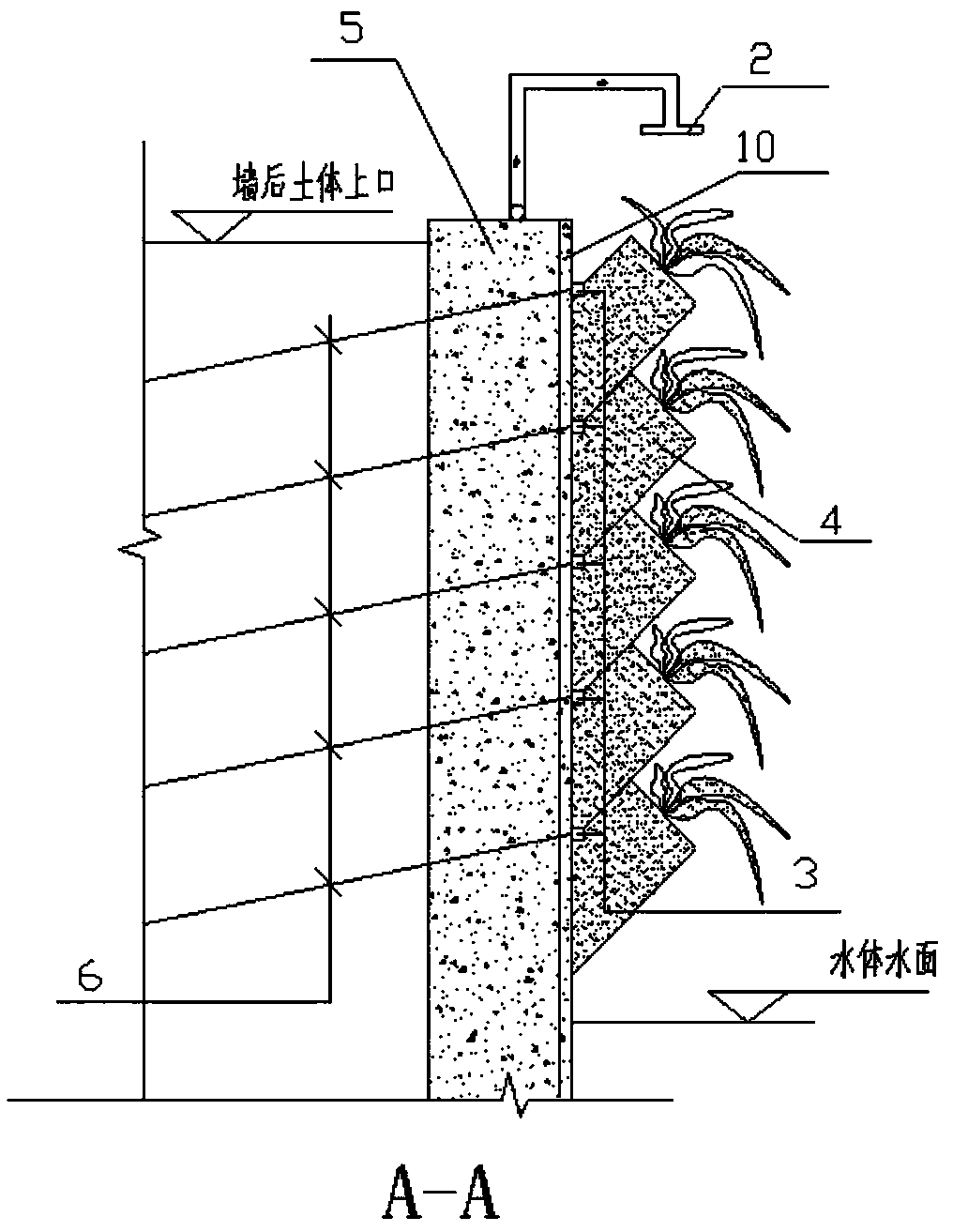

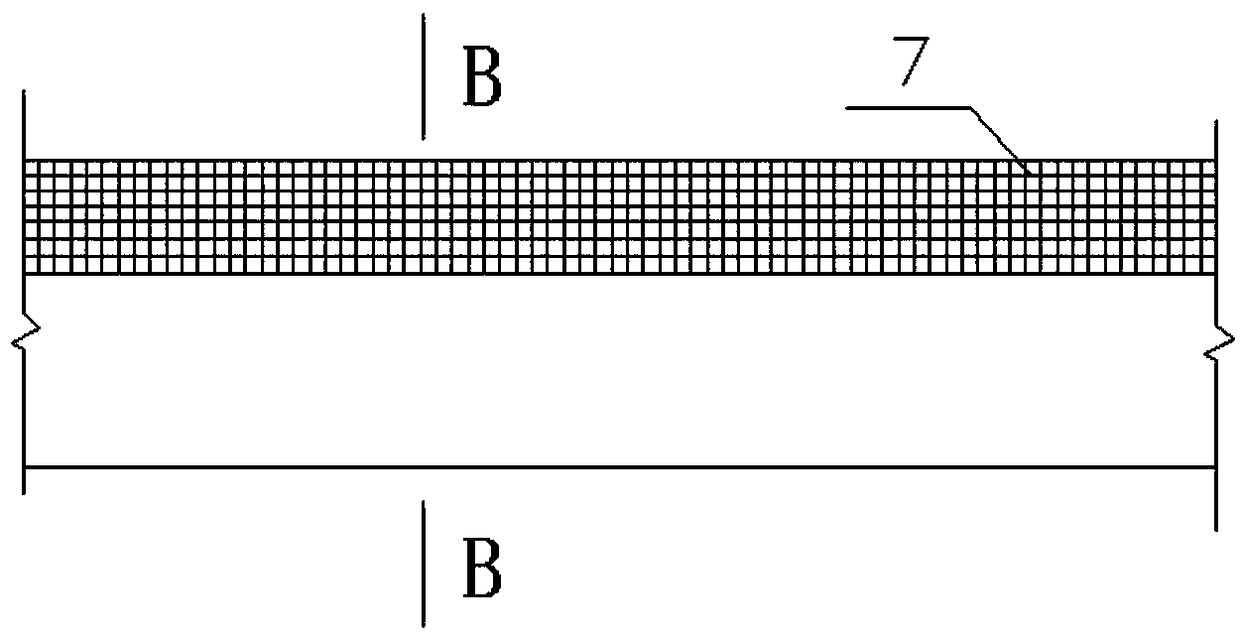

Vertical revetment three-dimensional greening system and manufacturing method thereof

InactiveCN108633545ABeautify the ecological environmentKeep a Steady Landscape WallSelf-acting watering devicesCoastlines protectionKeelWater source

The invention discloses a vertical revetment three-dimensional greening system, which comprises a retaining wall, an outer waterproof layer is arranged on the side of the retaining wall, a fixed keelsteel wire rope anchor cable is embedded in the outer waterproof layer, the outer side of the outer waterproof layer is fixed with a keel through an embedded fixed keel steel wire rope anchor cable, and a long-strip planting groove is arranged on the outer side of the outer waterproof layer; the strip-shaped planting groove is connected with the keel through a hook; a spraying system is arranged above the retaining wall. And the invention also discloses a manufacturing method of the vertical revetment three-dimensional greening system. In the method, the installation of the keel in the vertical revetment planting wall is convenient, the fixed strip planting groove is fixedly provided with fixed strip planting groove hooks, the front and rear space is large, and the plant is easy to survive; the plant does not need manual irrigation, which saves water source, and is economical and practical.

Owner:CHINA FIRST METALLURGICAL GROUP

Carrying drive assembly

The invention relates to a carrying drive assembly. A bottom plate is provided with a left fixing plate and a right fixing plate and provided with a horizontal-moving drive assembly. Lifting drive assemblies are arranged between the bottom plate and the left fixing plate and between the bottom plate and the right fixing plate respectively. A transferring assembly is arranged on the outer side of the left fixing plate and provided with a left carrying tool clamping drive device. The upper portions of the left fixing plate and the right fixing plate are each provided with a sliding rail set. Two sliding block sets are arranged on each sliding rail set. All the sliding block sets on the left fixing plate and the right fixing plate are correspondingly connected with left clamping blocks of the left carrying tool clamping drive device and right clamping blocks of a right carrying tool clamping drive device respectively. Front clamp strips are connected between the sliding blocks in front of the left fixing plate and the right fixing plate. Rear clamp strips are connected between sliding blocks on the rear portions of the left fixing plate and the right fixing plate. By the adoption of the carrying drive assembly, product carrying tools can be moved horizontally and can be driven to ascend and descend, and the front clamp strip and the rear clamp strip can clamp the product carrying tools to convey the product carrying tools to the standard positions.

Owner:BOZHON PRECISION IND TECH CO LTD

Cooling liquid recovering structure for blow-molding of chemical experimental containers

InactiveCN107696460ARealize automatic cycleMake up for the lossDomestic articlesElectricityBlow molding

The invention discloses a cooling liquid recovery structure for blow molding of chemical experiment containers, including a pool body and a water pump, a baffle plate is arranged at the bottom of the pool body, a first branch pipe and a second branch pipe are arranged in the heat insulation block, the first The branch pipe is spirally wound at the beginning of the discharge section of the blow molding machine, and the second branch pipe is spirally wound at the end of the discharge section of the blow molding machine. A liquid outlet pipe is connected to the outlet end of the water pump, and the liquid outlet pipe is connected to the inlet of the first branch pipe. end connection, on the outer wall of the pool body, a liquid inlet pipe communicating with the sedimentation chamber is provided, the inlet end of the liquid inlet pipe communicates with the outlet end of the second branch pipe, and a solenoid valve is provided on the liquid outlet pipe; A baffle is arranged in the middle of the liquid storage chamber, and a through hole is opened in the upper part of the baffle, the temperature sensor is electrically connected with the PLC control box, and the PLC control box is electrically connected with the electromagnetic valve. In the technical solution, the cooling water used for the first time is recovered and subjected to a series of treatments, and then used in the cooling process again, thereby achieving the purpose of reducing production costs.

Owner:成都市森德教学设备有限公司

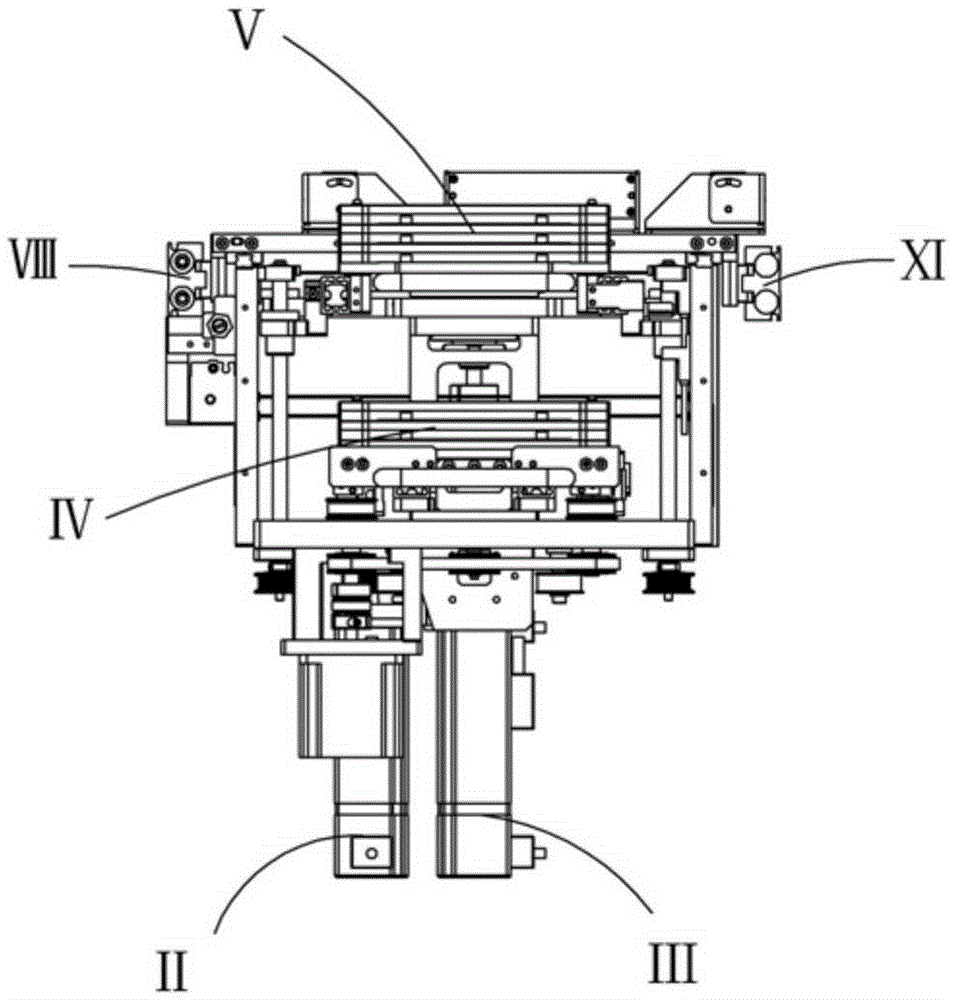

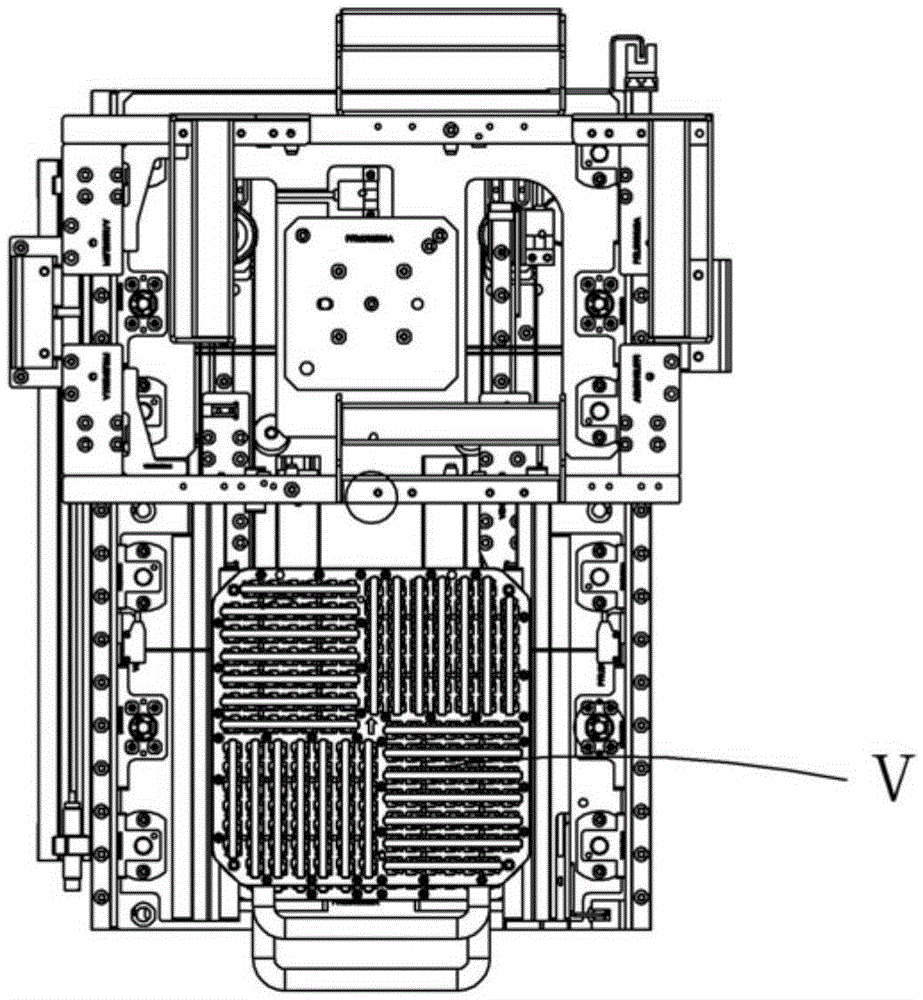

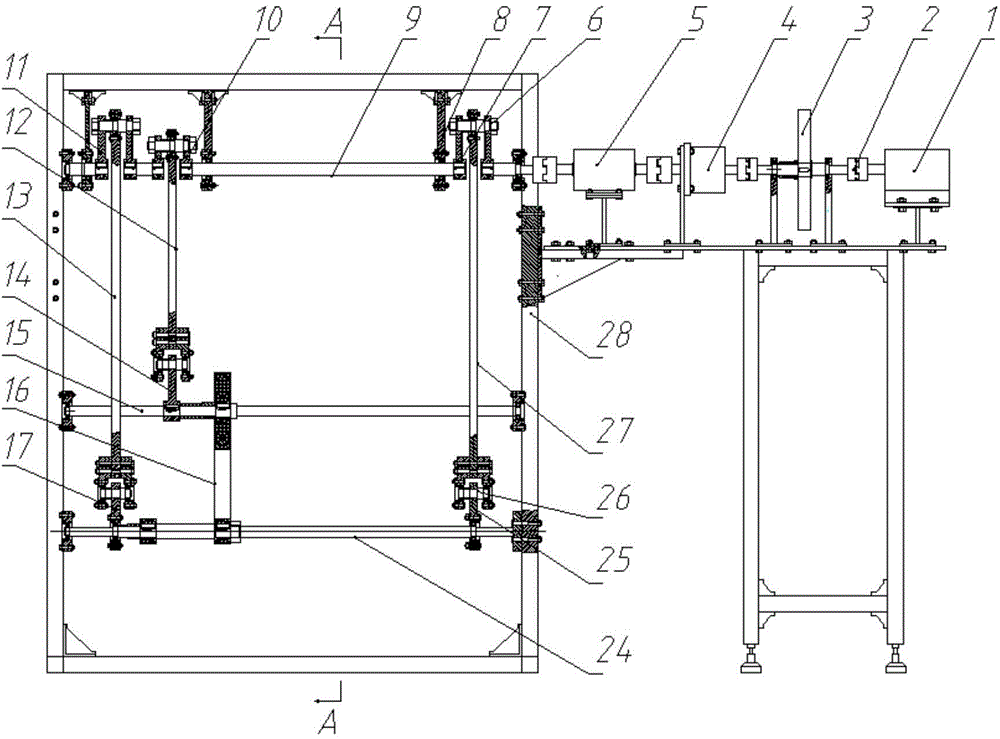

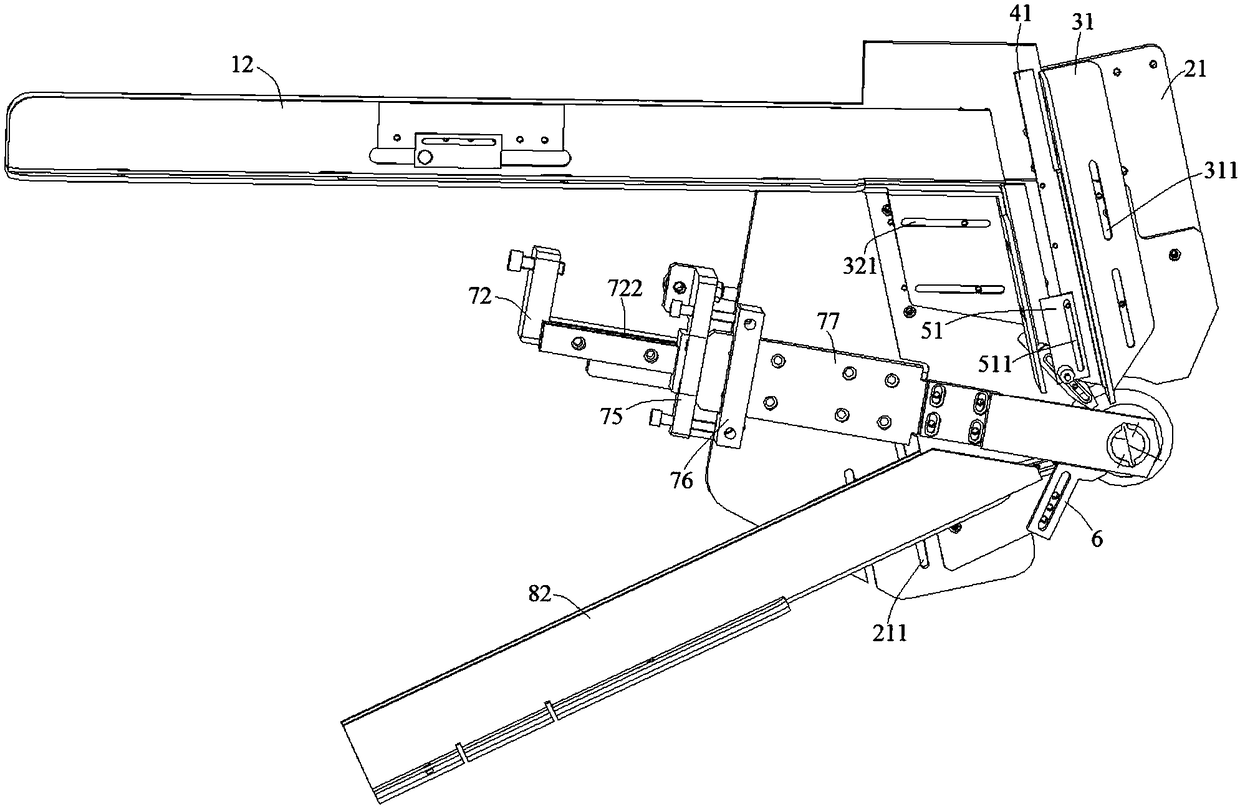

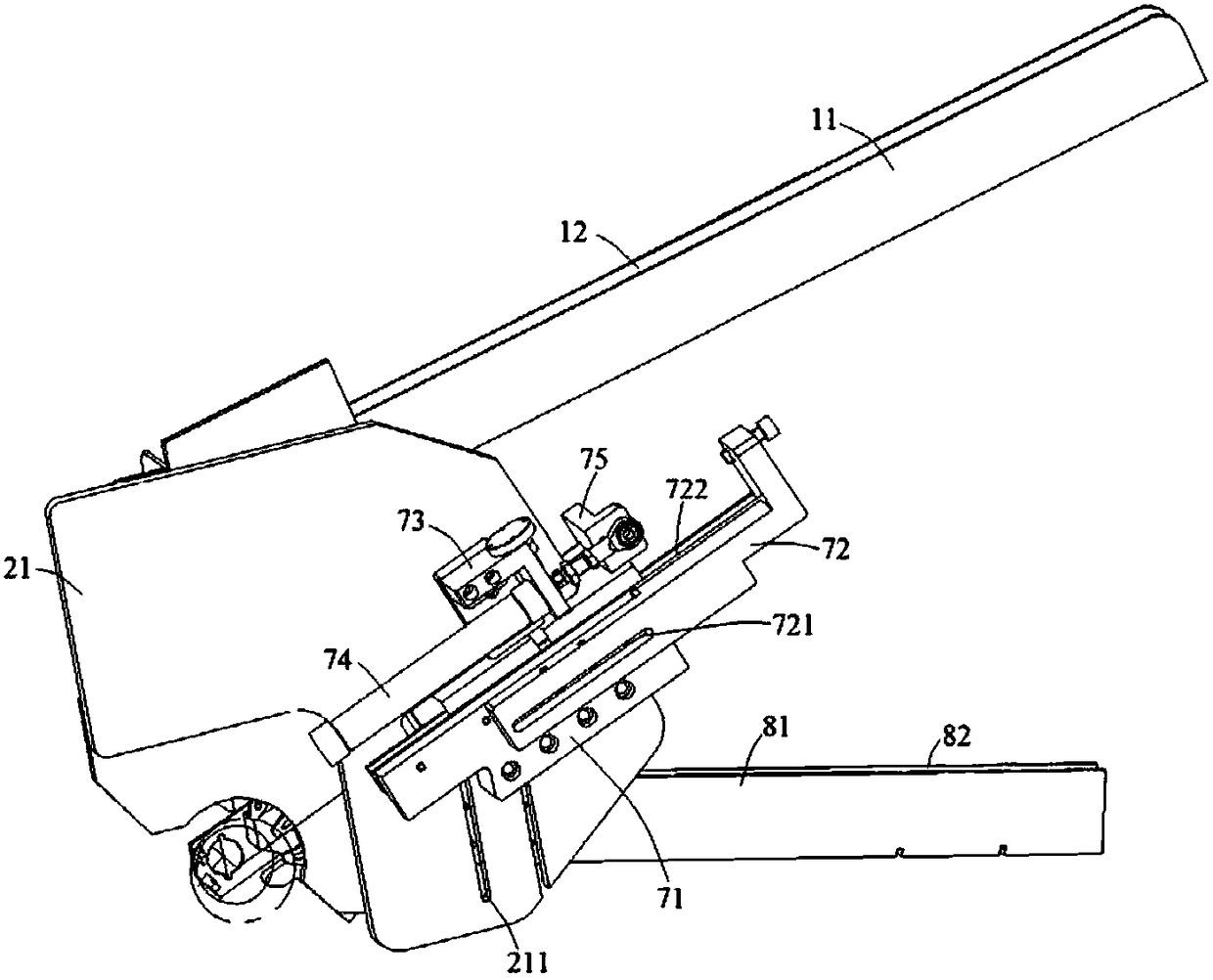

Fully-automatic numerical control composite inner surface grinding machine

PendingCN108340243AIngenious structural designSimple structureGrinding drivesGrinding machinesSurface grindingMotor drive

The invention discloses a fully-automatic numerical control composite inner surface grinding machine, and belongs to the technical field of composite grinding machines. The fully-automatic numerical control composite inner surface grinding machine comprises a machine body, a servo driving mechanism and a workpiece conveying mechanism, and the workpiece conveying mechanism comprises a feeding channel, a material stopping channel, a workpiece pushing assembly and a discharging channel; workpieces pass through the feeding channel and the material stopping channel and reach a grabbing station of the workpiece pushing assembly, the workpiece pushing assembly pushes the workpieces to a machining station for being ground; the ground workpieces are output through the discharging channel, and the feeding channel, the material stopping channel and the discharging channel are formed by enclosing of baffles, and the positions of the baffles can be adjusted; and the servo driving mechanism comprises a workpiece feed motor, a drag plate, a magnetic chuck and a grinding wheel, the magnetic chuck is arranged on the drag plate, the workpiece feed motor drives the drag plate to move in the horizontal direction, the magnetic chuck moves to the workpiece machining station, and the workpieces are adsorbed and fixed. The fully-automatic numerical control composite inner surface grinding machine canrealize automatic circulation of the whole process of feeding, machining and discharging, the material channels can be conveniently adjusted to adapt to the conveying requirement of the workpieces with the different sizes, and the good adaptability is achieved.

Owner:马鞍山市恒永利机械科技有限公司

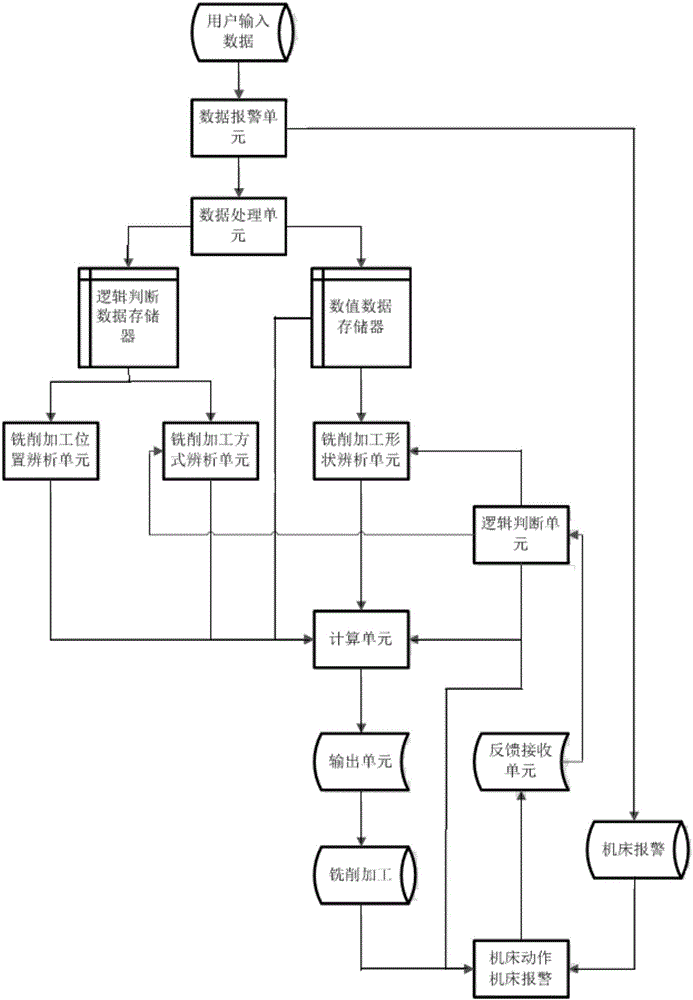

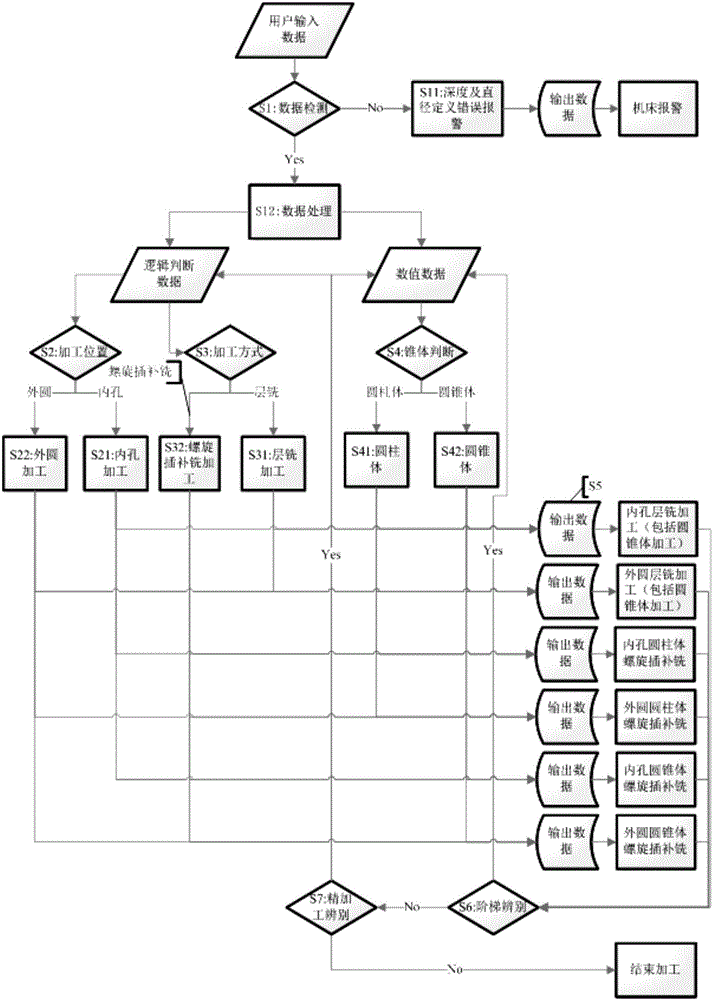

Numerical control machine tool for milling inner bores and outer circles and machining method

ActiveCN106735398AReduced programming ability requirementsEasy programmingBoring/drilling machinesMachining processManufacturing engineering

The invention provides a numerical control machine tool for milling inner bores and outer circles and a machining method. A milling module used for controlling operation is additionally mounted on the numerical control machine tool. The milling module comprises a milling position discrimination unit, a milling mode discrimination unit, a milling shape discrimination unit, a computing unit, a logical judgment unit, an output unit and a feedback receiving unit, wherein the computing unit receives output data coming from the milling position discrimination unit, the milling mode discrimination unit, the milling shape discrimination unit and the logical judgment unit and feedback data coming from the feedback receiving unit to compute machining depths, machining diameters and machining movement tracks of holes and outer circles and is in output connection with the output unit; the output unit outputs given machining commands and computational data output by the computing unit to the numerical control machine tool to conduct milling on the holes and the outer circles. The efficiency of the numerical control machine tool in the hole milling and outer circle machining process is improved. Programming errors and time are reduced. The product quality and machining flexibility are effectively improved.

Owner:HUDONG HEAVY MACHINERY

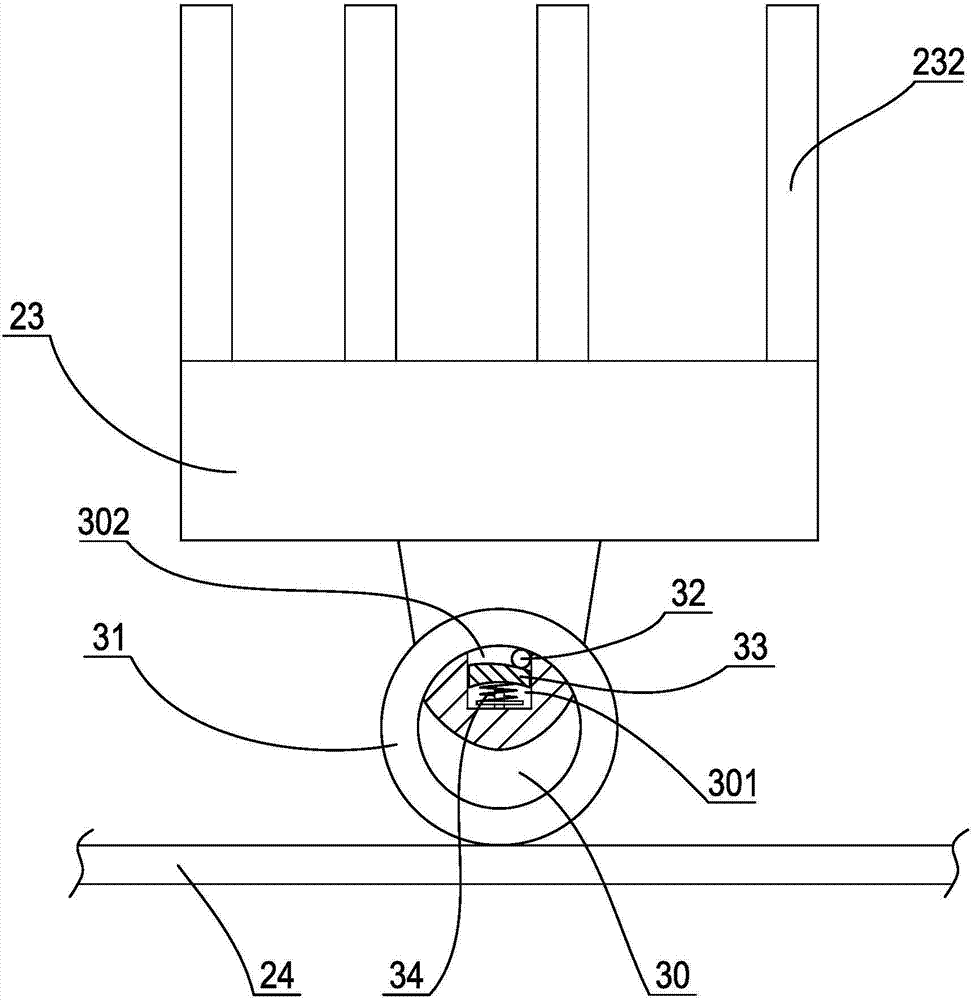

Greenhouse ecological circulation three-dimensional planting system and method thereof

InactiveCN111328757ARealize automatic cycleIncrease profitLiquid fertiliser distributionClimate change adaptationAmmoniacal nitrogenFiltration

The invention discloses a greenhouse ecological circulation three-dimensional planting system and a method thereof in pond culture technology. An organic vegetable cultivation device is directly abovea fish farming pond. Sludge water at the bottom of the fish farming pond is pumped into a mixing tank. Sludge water is pumped in a filter device for filtration. The ammonia nitrogen concentration ina nitrogen water pool is read by a first ammonia nitrogen concentration detection device. The nitrogen water in the nitrogen water pool and the water in the mixing tank are pumped into the fish farming pond. The water in the nitrogen water pool is pumped into a first nitrogen water reserve pool. The water in the first nitrogen water reserve pool is pumped into the organic vegetable cultivation device for being absorbed by vegetable. The ammonia nitrogen concentration in a second nitrogen water reserve pool is read by a second ammonia nitrogen concentration detection device. The nitrogen waterin the second nitrogen water reserve pool is pumped in the fish farming pond. The nitrogen water is recycled into the fish farming pond. The invention carries out secondary circulation absorption andutilization of the sludge water in the fish farming pond, and realizes the automatic circulation of water resources and nitrogen resources. The utilization ratio of water resources and nitrogen resources is high, and the automatic integration of the ecological circulation system can be realized.

Owner:JIANGSU UNIV

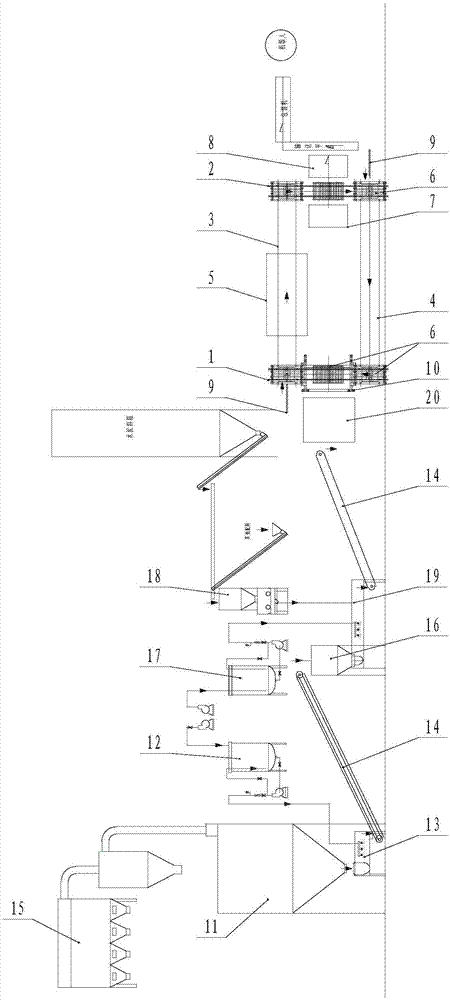

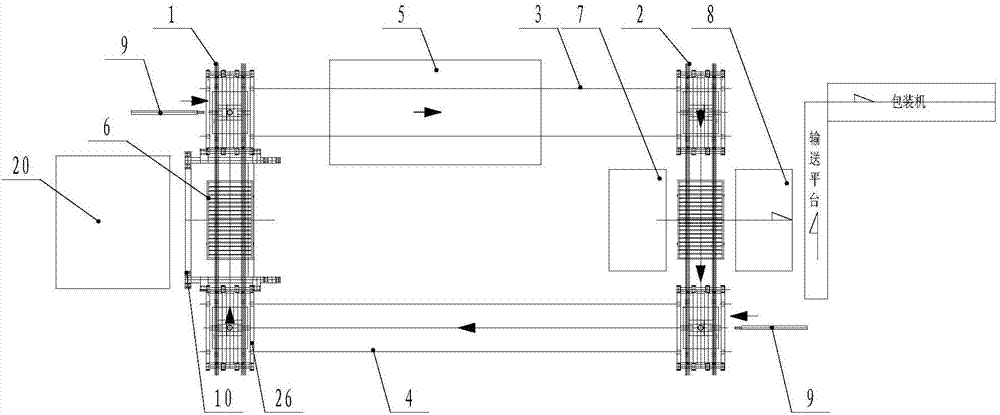

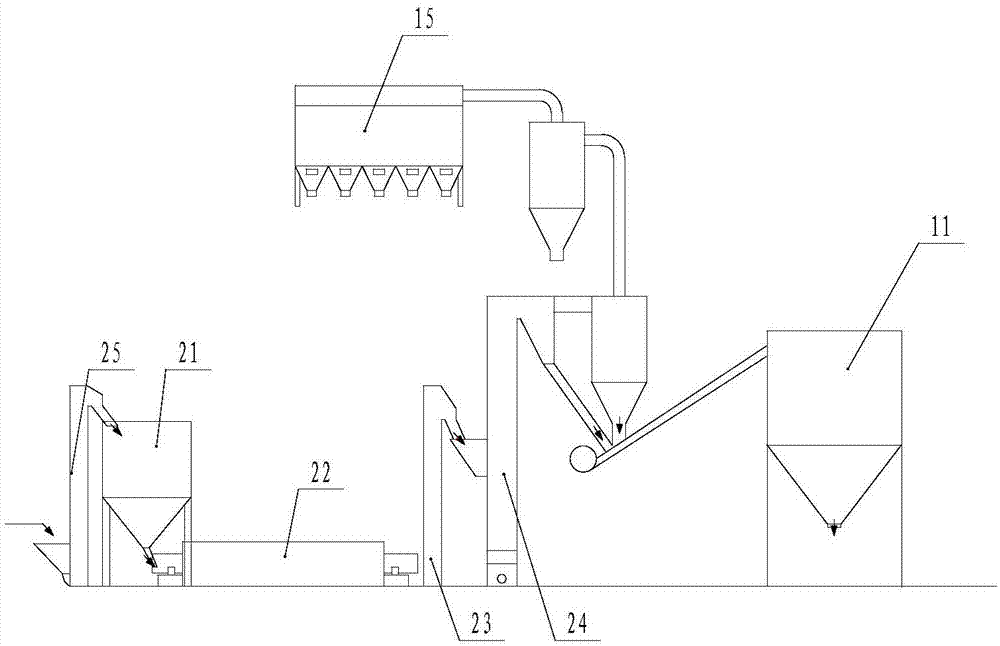

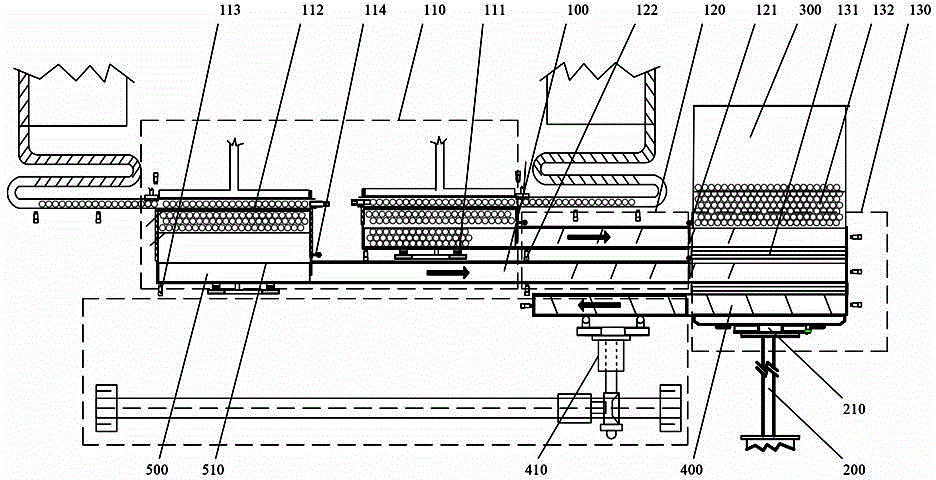

Full-automatic production device for expanded perlite heat preserving board

ActiveCN107571388ASave manpower and investmentStable transmissionCeramic shaping plantsAuxillary shaping apparatusPerliteProcess engineering

The invention discloses a full-automatic production device for an expanded perlite heat preserving board and relates to the field of heat preserving board production devices. The full-automatic production device for the expanded perlite heat preserving board is used for overcoming the defects that in the process of producing the expanded perlite heat preserving board, cost is high, efficiency is low, consumed time is long and assembly line production cannot be achieved. The full-automatic production device for the expanded perlite heat preserving board comprises a material mixing device, a board pressing device, a drying device and a packaging platform; the material mixing device is used for conveying materials to the board pressing device after the materials are mixed uniformly; the boardpressing device is used for pressing the mixed materials into the heat preserving board; the drying device is used for drying the heat preserving board; and then the dried heat preserving board enters the packaging platform to be packaged. The full-automatic production device for the expanded perlite heat preserving board is used for assembly line production of the expanded perlite heat preserving board.

Owner:华亿建材科技有限公司

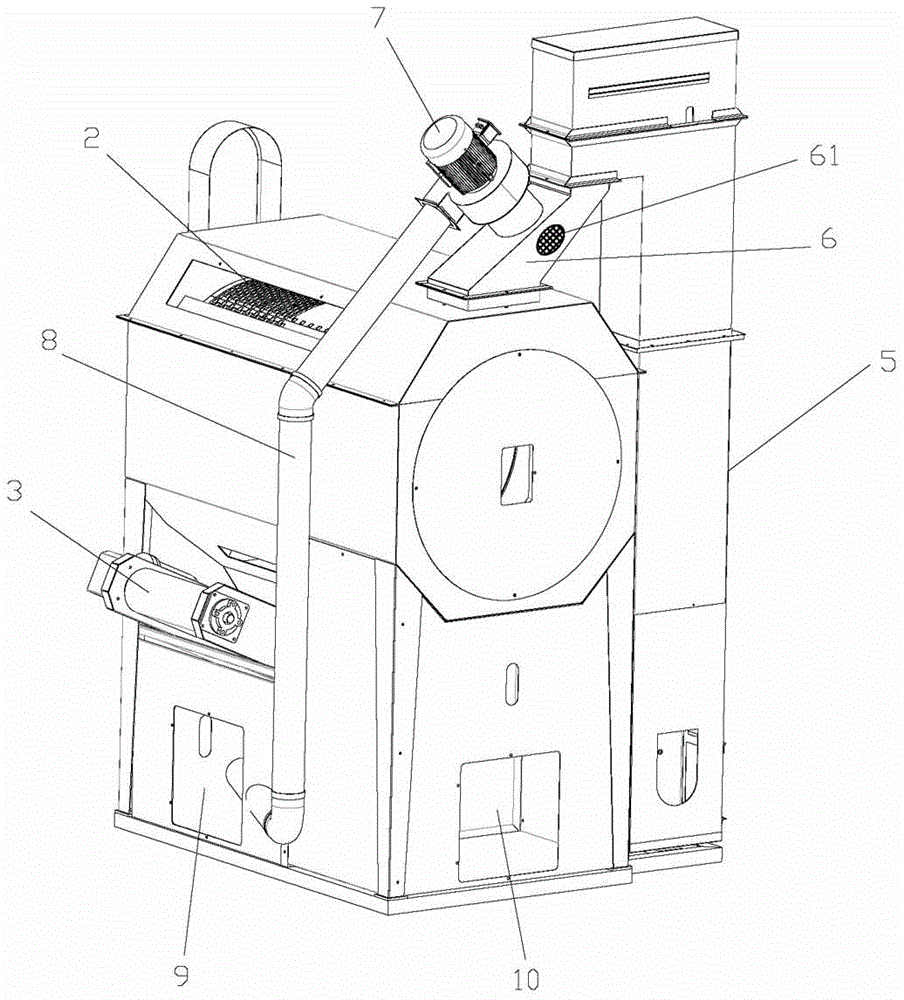

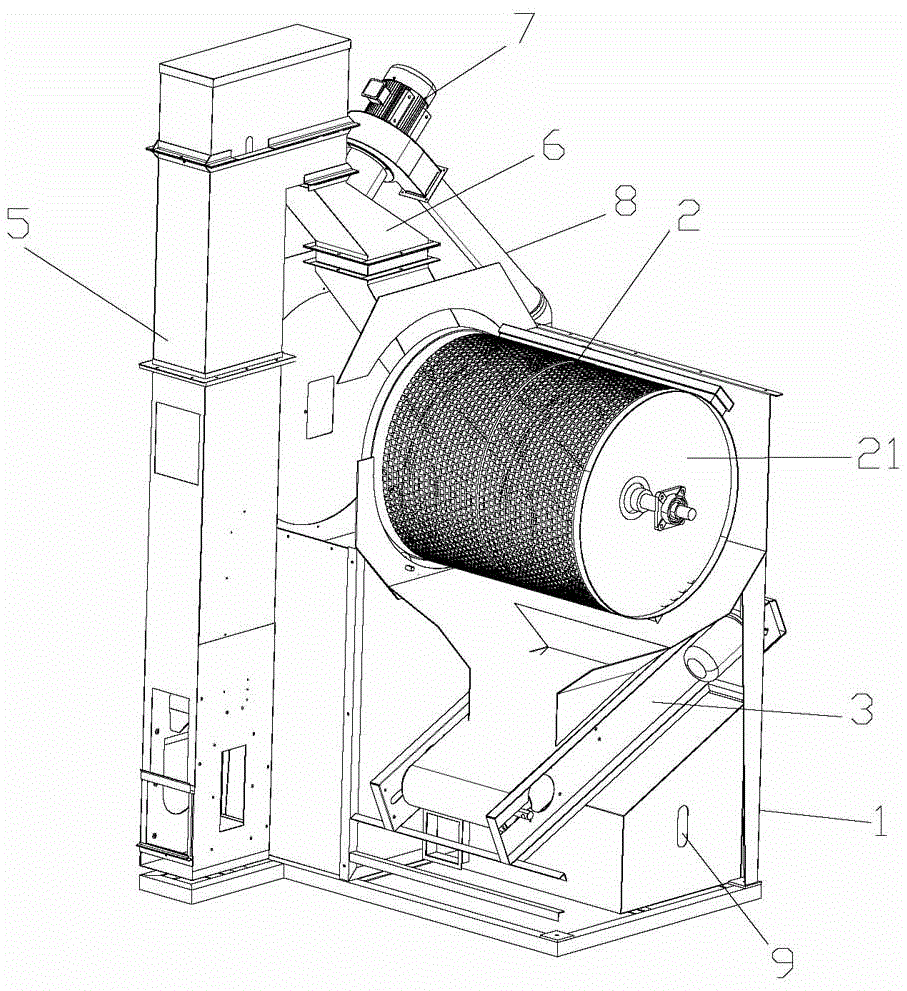

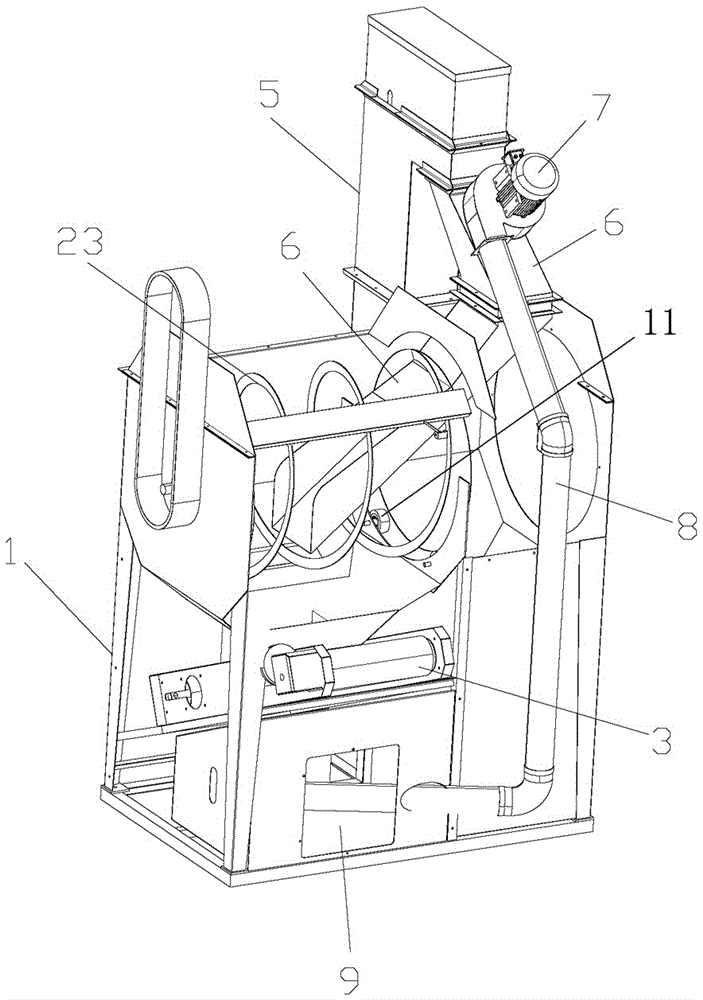

Rice roughing impurity remover and impurity removing method thereof

InactiveCN106000876AImprove work efficiencyRealize automatic cycleSievingGas current separationEngineeringCost performance

The invention relates to a rice roughing impurity remover. Rice is hoisted to the top of a machine through a hoisting mechanism, slides to the innermost end of a roughing roller through an inclined slide way, and is roughed in the roughing roller; meanwhile, dust, unripe rice and impurities in the rice are directly sucked away through a suction fan in the slide way; finally, the impurity-removed rice falling on a conveying belt below the roughing roller is conveyed to a rice dryer for circular drying by the conveying belt; and if the rice after one-time roughing and impurity removal cannot reach the requirements, multiple times of dust and impurity removal can be performed in the rice roughing impurity remover after drying. The rice roughing impurity remover finishes roughing and impurity removal at one time, greatly improves the working efficiency, and improves the product cost performance.

Owner:余继琅

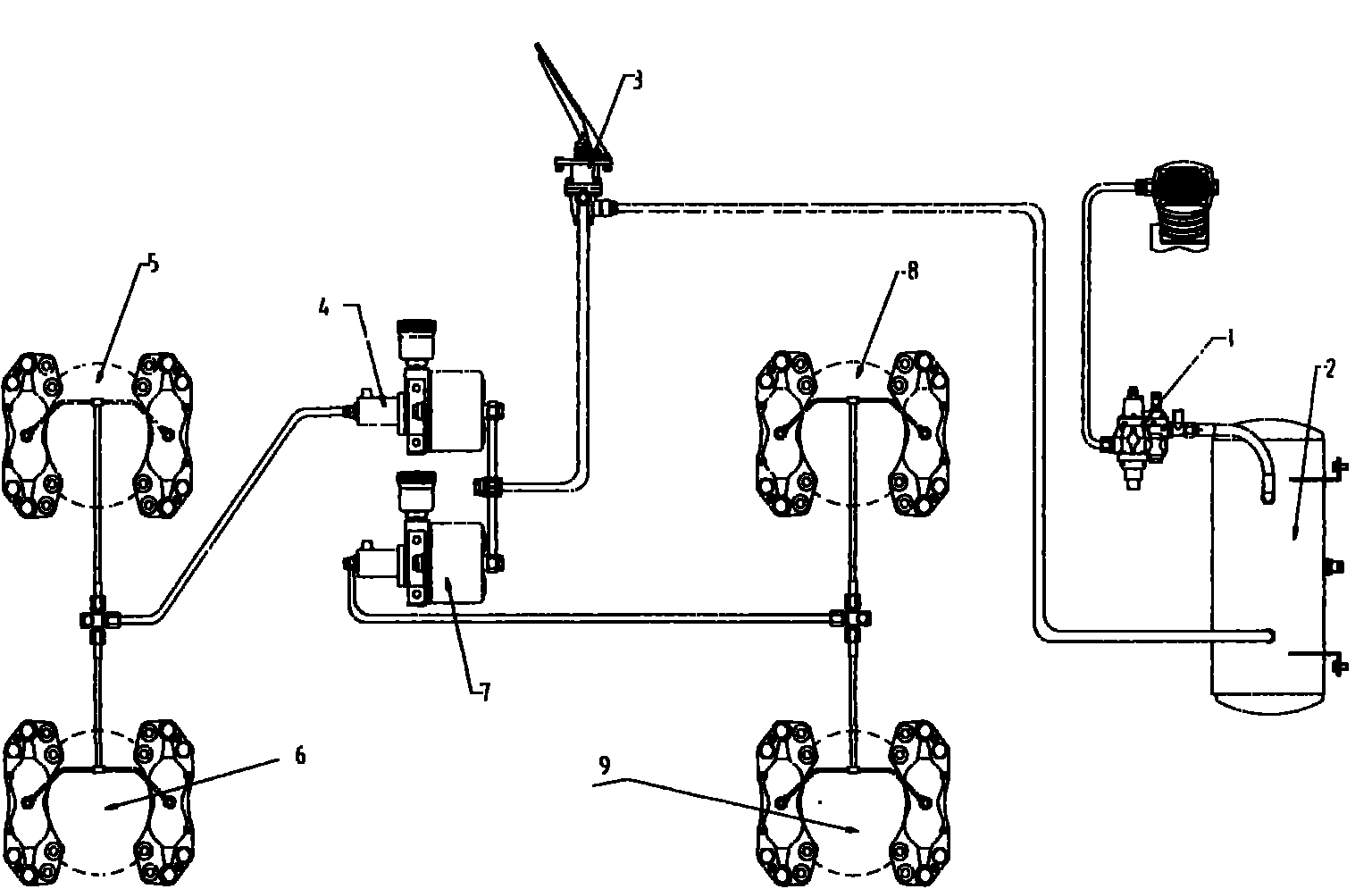

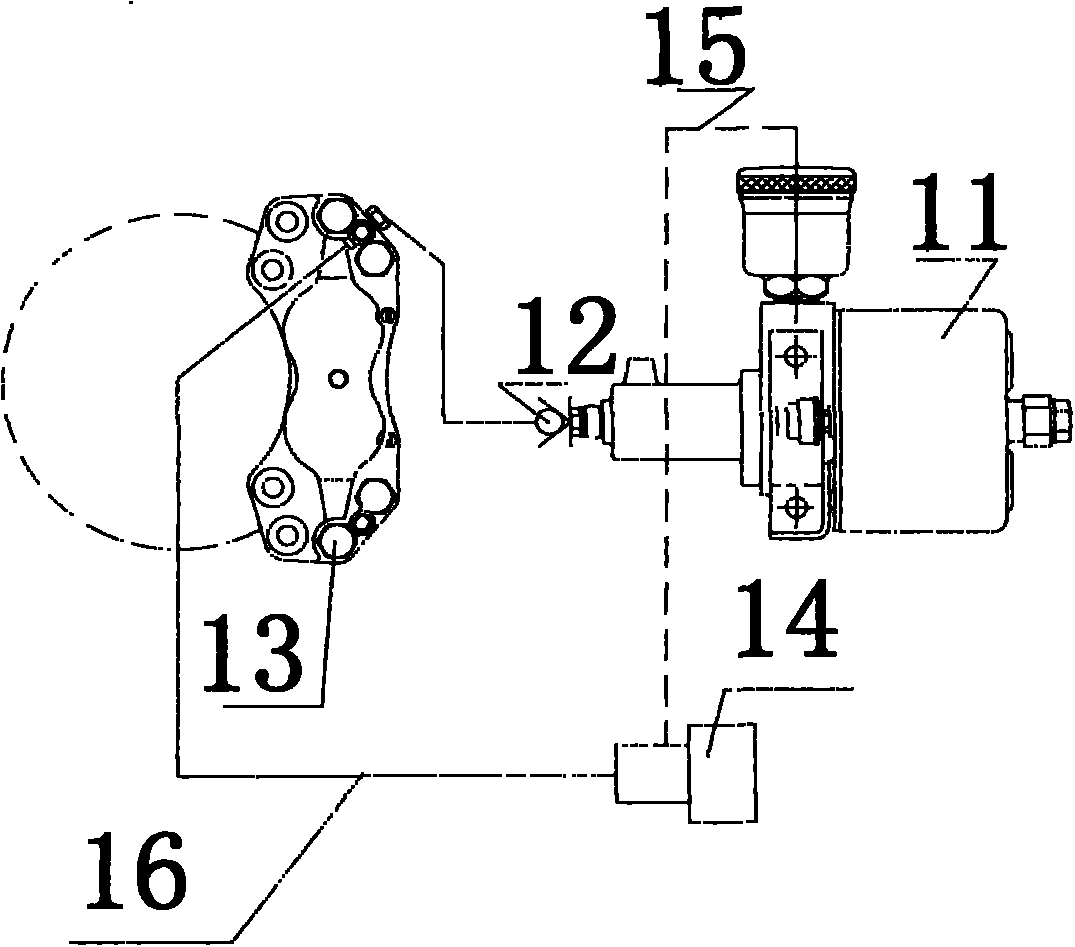

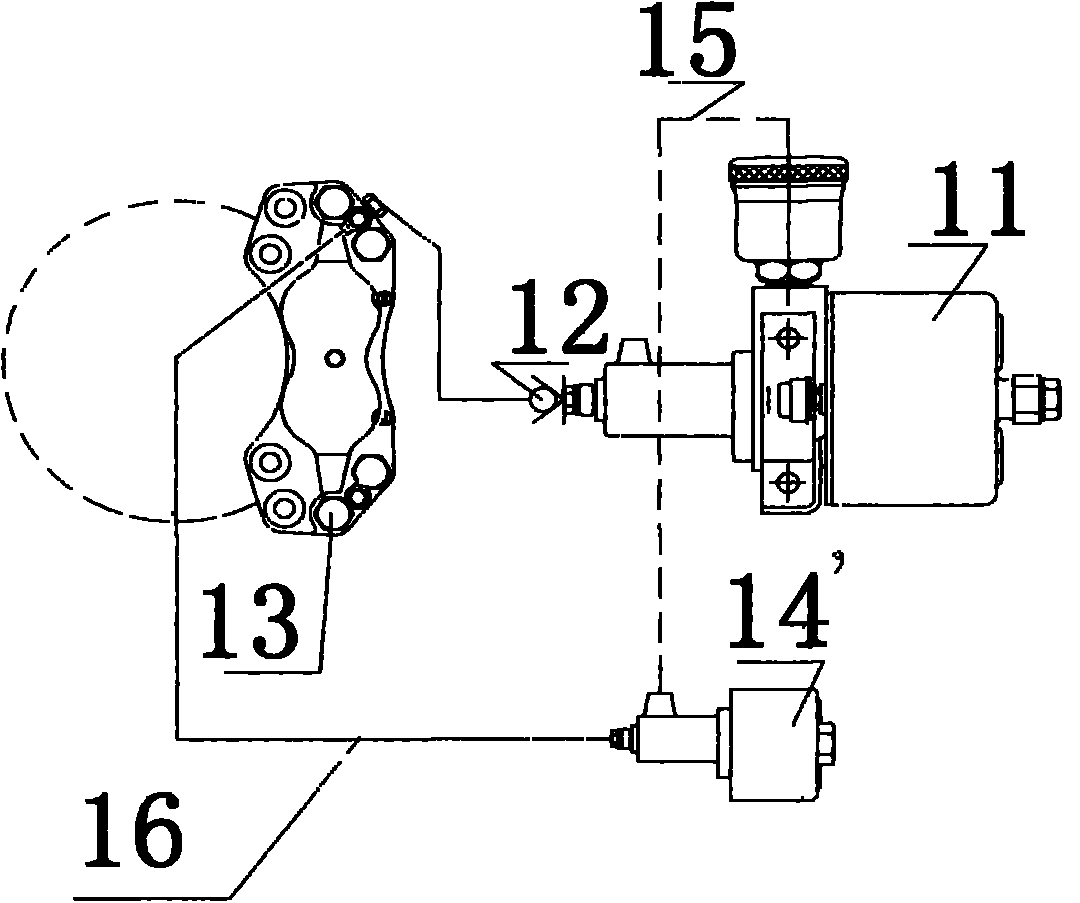

Automatic circulation system and automatic circulation braking system established by same

ActiveCN103802811AAchieving boost brakingRealize automatic cycleBraking action transmissionBraking componentsCalipersCheck valve

The invention relates to braking systems, in particular to an automatic circulation system and an automatic circulation braking system established by the same. The automatic circulation system and the automatic circulation braking system established by the same are suitable to loading machines and other vehicles and can achieve full effect braking through automatic circulation of brake fluid. The automatic circulation system comprises a booster pump, a check valve, an on-off control piece, an oil return pipe, oil line pipes and a brake caliper. The air inlet of the booster pump is externally connected to an air source, the oil outlet of the booster pump is connected to the inlet of the check valve, the outlet of the check valve is connected to the oil inlet of the brake caliper through the oil line pipes, the oil outlet of the brake caliper is connected to the oil inlet of the on-off control piece through the oil line pipes, the oil outlet of the on-off control piece is connected to one end of the oil return pipe, the other end of the oil return pipe is connected to an oil cup of the booster pump, and the air inlet of the on-off control piece is externally connected to the air source. The automatic circulation braking system comprises a pressure regulating valve, an air storage cylinder, a pneumatic brake assembly, a front axle automatic circulation system and a rear axle automatic circulation system.

Owner:厦门金利业科技有限公司

Intelligent electrical equipment for automatic protection in basin area in winter

ActiveCN110943374AImprove securityEffectively go outSubstation/switching arrangement casingsElectric switchesMeteorologyElectrically conductive

The invention relates to the technical field of electrical equipment protection. The invention further discloses intelligent electrical equipment for automatic protection in the basin area in winter.which comprises a shell, a water collecting plate is fixedly connected to the inner top wall of the shell; the left side and the right side of the lever plate are fixedly connected with a collection box and a conductive strip correspondingly, an electromagnet is fixedly installed in the support, a magnetic block is movably inserted into the support, an electric heating part is fixedly installed inthe shell, a piston rod is movably inserted into the air suction cylinder, and a drainage hole is formed in the bottom of the air suction cylinder. The invention discloses intelligent electrical equipment capable of automatically protecting a basin region in winter. A water collecting plate is arranged to collect moisture in air; the piston rod and the air extracting cylinder extract moisture andwater liquid, the electric heating part emits heat for drying, the dehumidifying and drying effects are effectively achieved, the dehumidifying and drying process is automatically conducted along with collection of moisture in air, the problem that the dehumidifying and drying frequency cannot be adjusted along with air humidity is solved, and electrical equipment is better protected.

Owner:华松电力集团股份有限公司

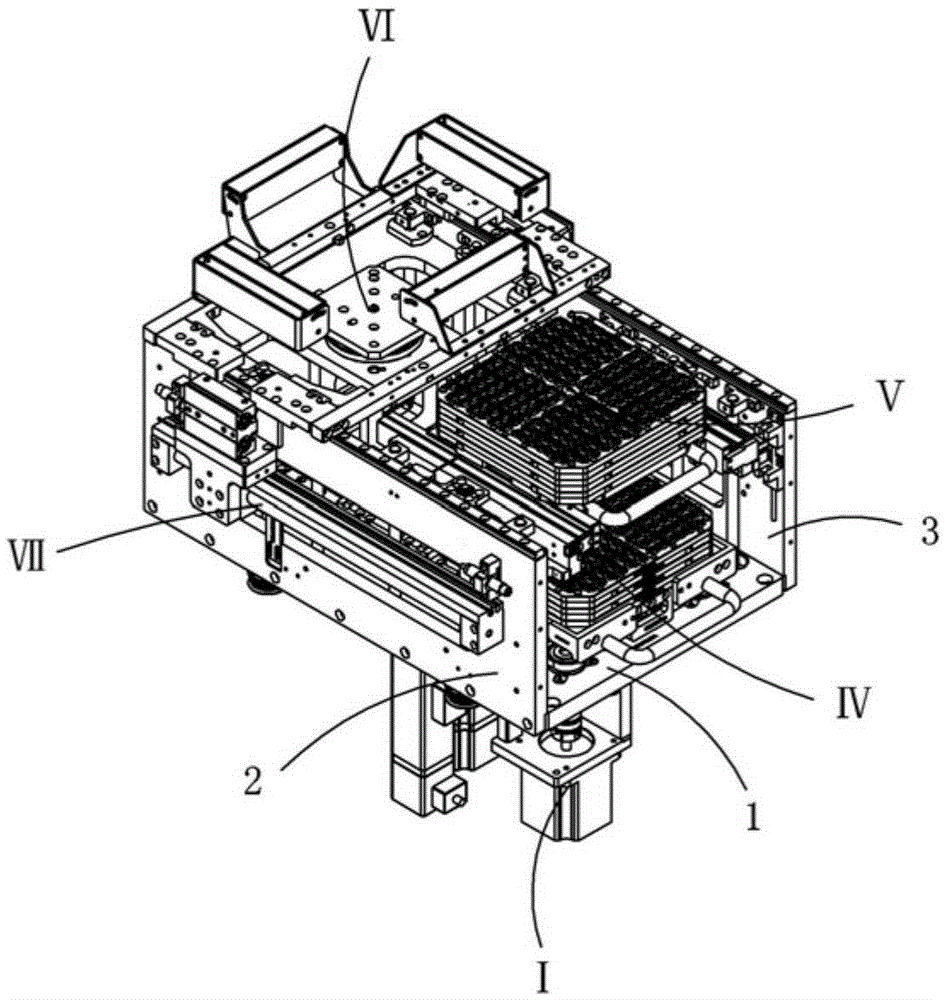

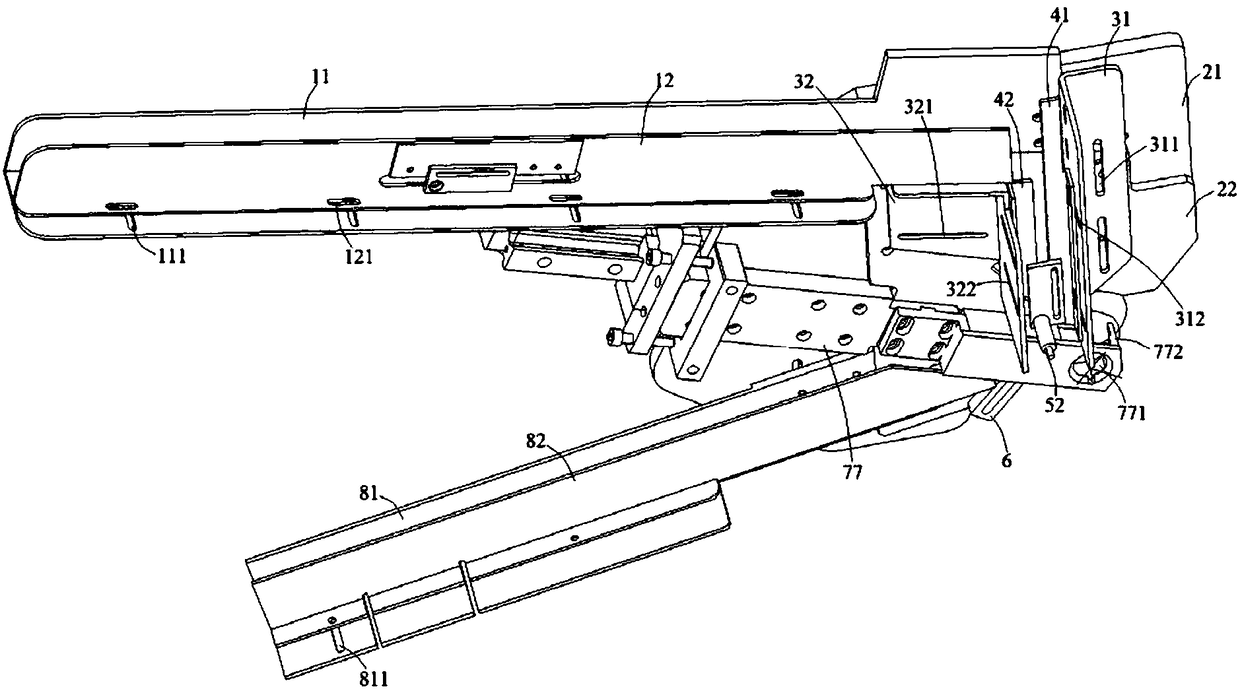

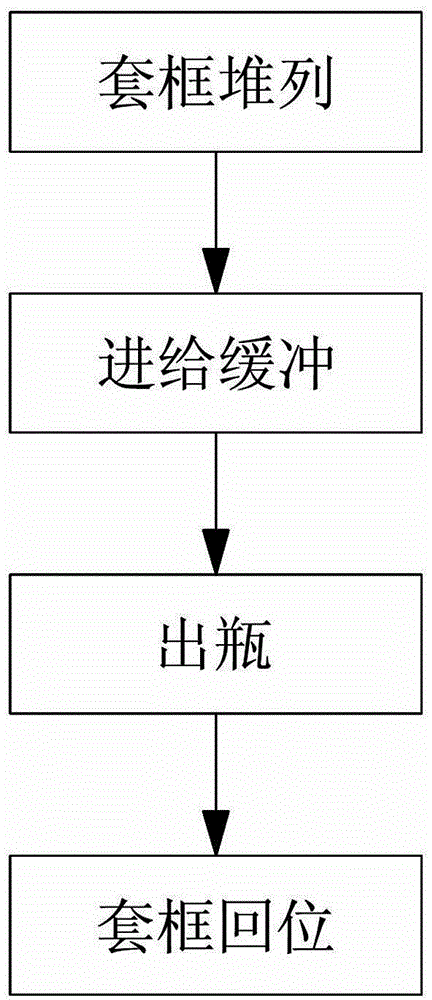

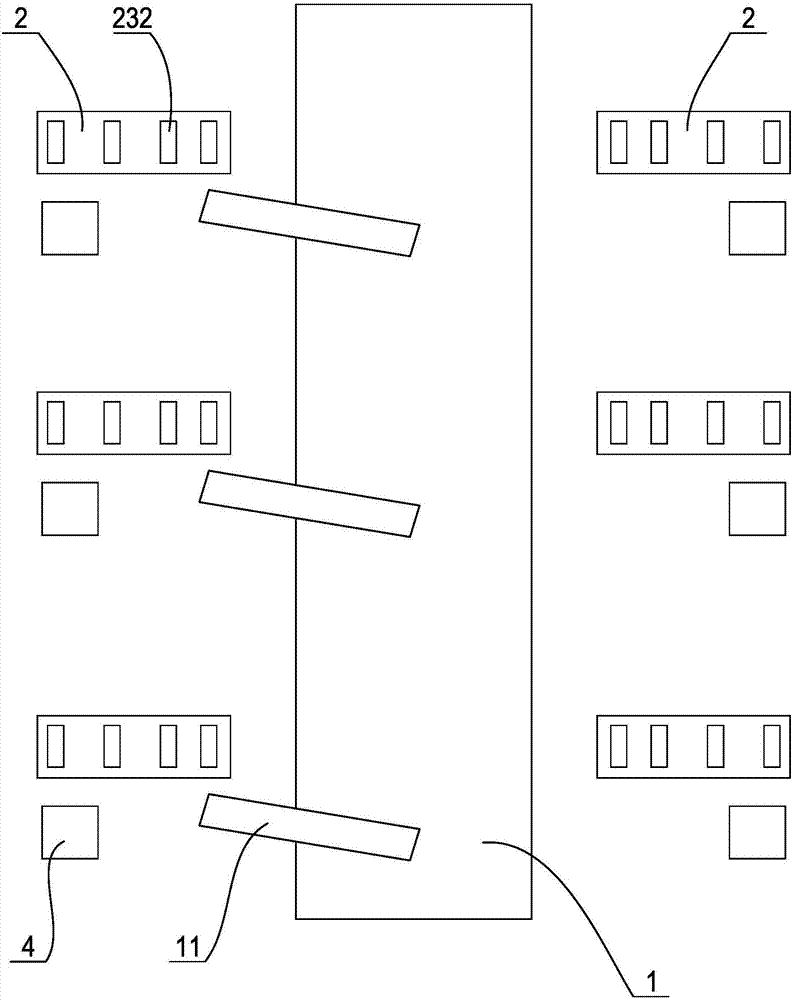

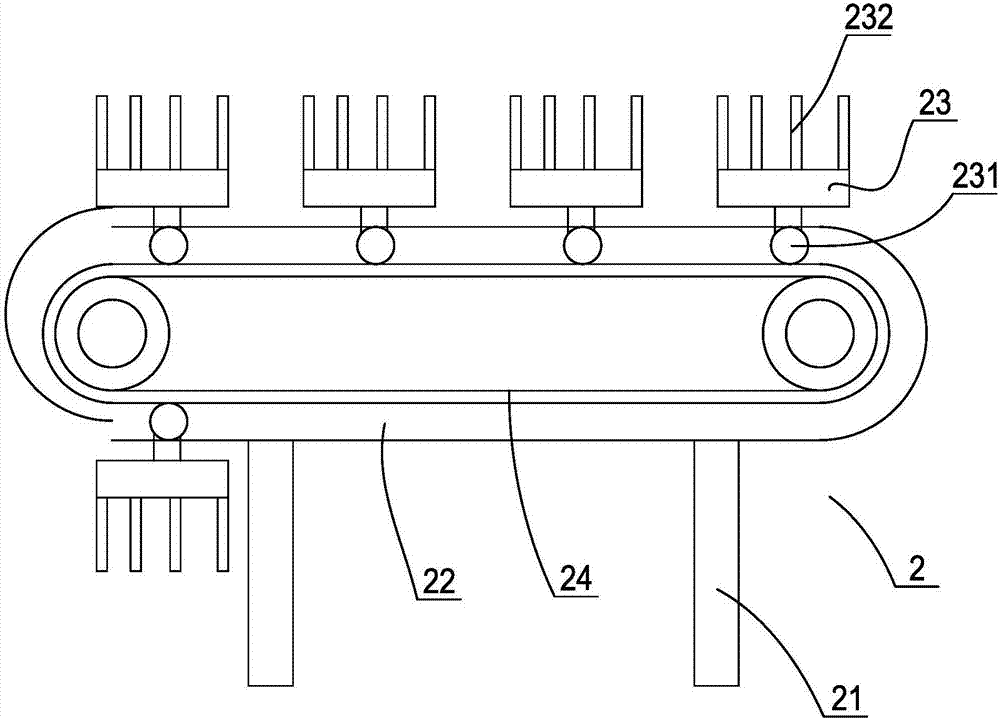

Freeze-drying preparation stacking and transfer system and control method

The invention discloses a freeze-drying preparation stacking and transfer system and a control method. The system comprises a bottle inlet push rod and a bottle inlet net belt; the bottle inlet net belt is provided with a stacking sleeve frame section, a buffer section and a bottle outlet section; a sleeve frame conveying belt is arranged along the bottle inlet net belt; a sleeve frame loading device is arranged beside the sleeve frame conveying belt; and the bottle inlet push rod is provided with a sleeve frame unloading device for automatically grabbing a sleeve frame and feeding the sleeve frame onto the sleeve frame conveying belt after releasing sleeve frame bottle queues. The method comprises the following steps: (S1) input bottles are stacked; and the bottle queues are input in the sleeve frame; (S2) the sleeve frame bottle queues are fed into the buffer section to wait bottle discharge; (S3) one set of sleeve frame bottle queues is fed to the bottle outlet section; the sleeve frame unloading device is in butt joint with the sleeve frame; the sleeve frame bottle queues are pushed to the freeze dryer plate layer; and the bottle inlet push rod is retracted to enable the sleeve frame to release the bottle queues; and (S4) the sleeve frame is fed to the sleeve frame conveying belt; the bottle inlet push rod is returned or prepared to push the sleeve frame bottle queues, waiting bottle discharge, on the next bottle inlet net belt; and the sleeve frame conveying belt transfers the sleeve frame to the bottle inlet end of the bottle inlet net belt to wait loading.

Owner:TRUKING TECH LTD

Vehicle assembly method

The invention discloses a vehicle assembly method. Annular conveying lines are respectively arranged on the side of a main production line corresponding to all procedure positions; assembly parts needing to be assembled can be put on positioning devices capable of moving on the annular conveying lines; the positioning devices circularly move on the annular conveying lines until the positioning device on the foremost side reaches a grabbing position; positioning mechanisms on the annular conveying lines are acted to lock and fix the positioning devices to accurately position in the grabbing position; a manipulator of the main production line can automatically grab the assembly parts positioned on the positioning devices in the grabbing position; and the assembly parts are shifted and positioned on assembled parts on the main production line; and an automatic assembly mechanism on the main production line is acted to automatically assemble the assembly parts on the assembled parts to finish automatic assembly. The vehicle assembly method can greatly reduce assembly workers of the production line, improves the working efficiency of the assembly workers, eliminates personal injury accidents of the assembly workers, and meanwhile, facilitates realization of mixed line assembly of multiple vehicle types.

Owner:ZHEJIANG LAND ROVER AUTOMOBILE +1

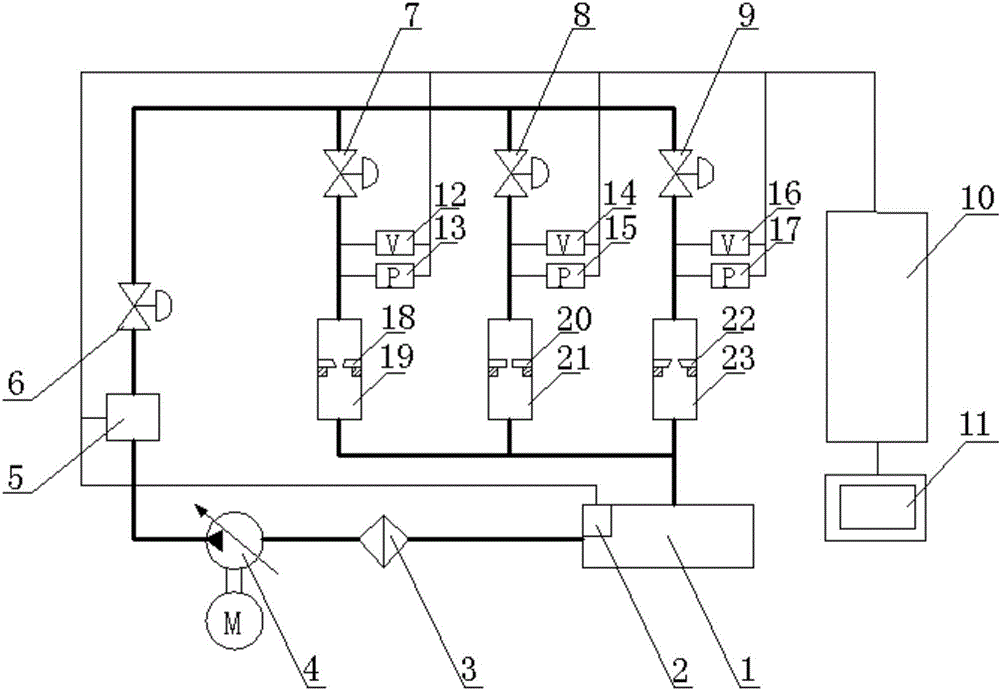

Experimental platform capable of synchronously measuring phenomena such as cavitation and cavitation erosion in different spraying nozzle structures

InactiveCN106596311ARealize automatic cycleFlow can be adjusted arbitrarilyInvestigating abrasion/wear resistanceSpray nozzleFuel tank

The present invention provides an experimental platform capable of synchronously measuring phenomena such as cavitation and cavitation erosion in different spraying nozzle structures. The experimental platform comprises a fuel oil supply system, a reaction system and a measurement system, wherein the fuel oil supply system comprises a fuel tank, a diesel oil cleaner, a pump station and an oil pressure regulation valve, the reaction system comprises a plurality of cavitators, spraying nozzles having different structures are respectively placed in the cavitators, and the measurement system comprises a pressure sensor, a flow sensor, a signal control terminal and a computer. According to the present invention, with the experimental platform, the spraying nozzles having a variety of structures can be synchronously measured under the same working condition; the experimental platform has characteristics of simple structure, stable operating, and continuous cavitation strength; and the spraying nozzles having different structures can be conveniently installed, and the production area and the dynamic characteristics of the vacuolar clusters near the cavitators are easily observed.

Owner:JIANGSU UNIV

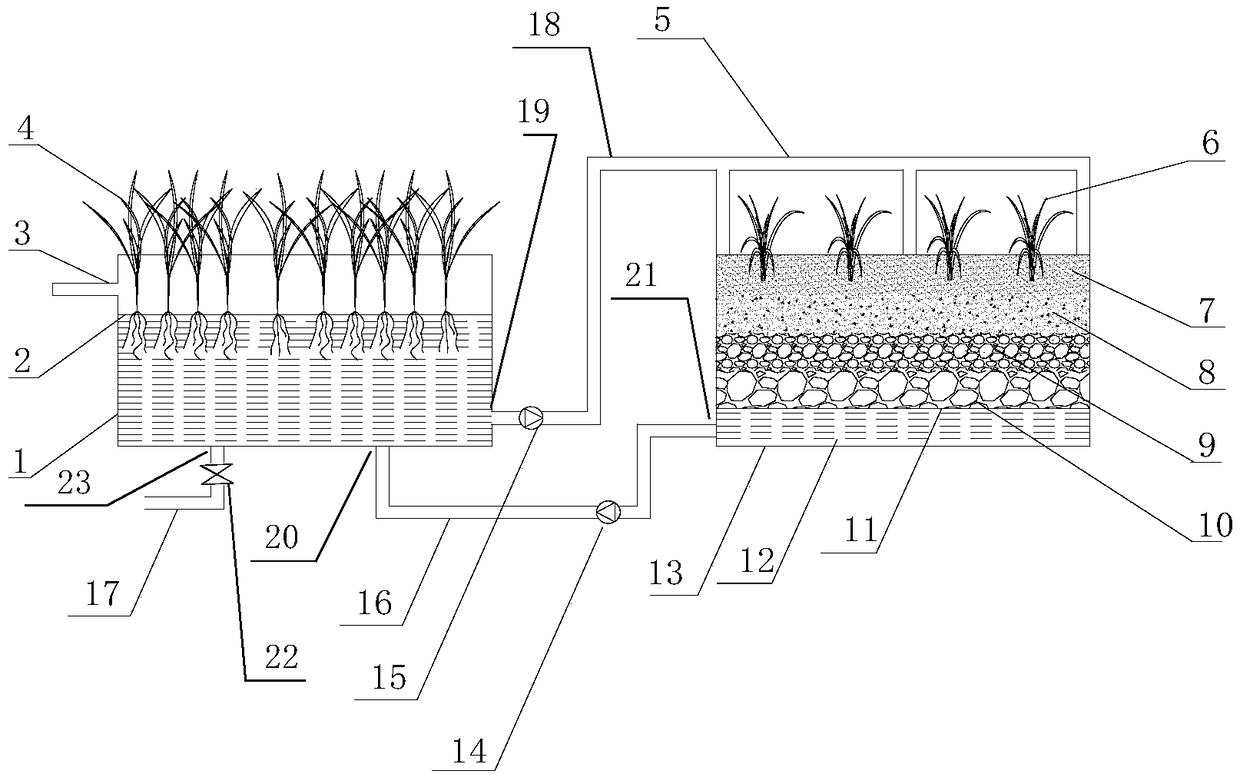

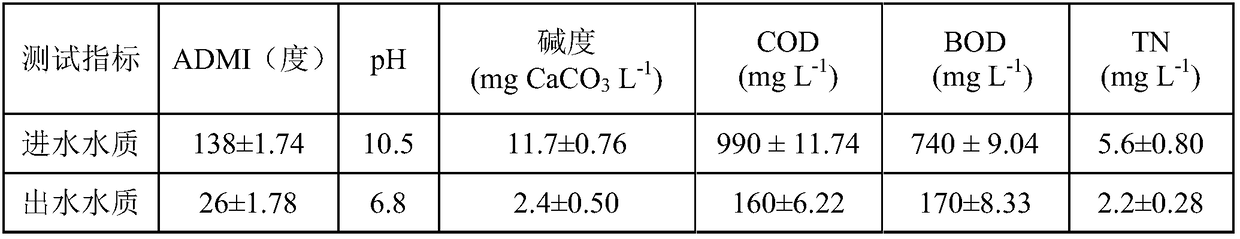

Printing and dyeing wastewater treatment device and treatment method

PendingCN109020099AImprove purification abilityLow costWater contaminantsBiological treatment apparatusPollutantBiological repair

The invention discloses a printing and dyeing wastewater treatment device and treatment method, and belongs to the field of wastewater treatment. The printing and dyeing wastewater treatment device comprises an aquatic plant reactor and a soil plant reactor. The biological repair and purification functions of aquatic plants and seedling nursery plants on a water body are organically combined; themicroflora and metabolic function level in a system can be improved; the combined action of plants, plant rhizospheric microorganisms and filter materials is synthesized; the synergistic effects of plants, microorganisms and environment are fully exerted; in the operation process, denitrification flora and electrogenesis flora simultaneously exist; the dye and other contaminants in the printing and dyeing wastewater are synergistically degraded; on the basis, the indexes such as printing and dyeing wastewater chroma are reduced; the goal of purifying the water body is realized. The treatment device and the treatment method have the advantages that the structure is simple; the design is reasonable; the operation is easy; the purification effect is good.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

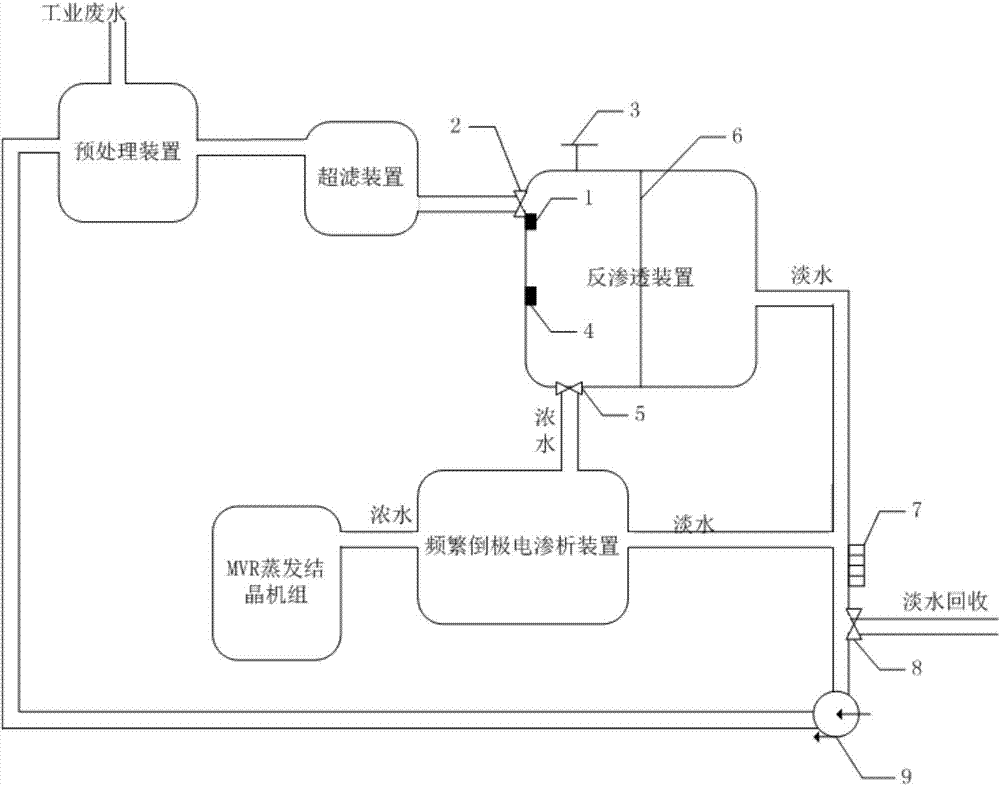

Industrial wastewater treatment equipment and method

InactiveCN106977037AReduce evaporationReduce consumptionTreatment involving filtrationMultistage water/sewage treatmentHigh energyUltrafiltration

The invention relates to the field of industrial wastewater treatment, in particular to an industrial wastewater treatment equipment and method, aiming to solve the problems of large-scale wastewater treatment with high equipment investment, high energy consumption, low equipment efficiency and low fresh water recovery rate at present. The industrial wastewater treatment equipment comprises a pretreatment device, an ultrafiltration device, a reverse osmosis device, a first liquid-level sensor, a first valve, a pressure charging valve, a second liquid-level sensor, a second valve, a semipermeable membrane based frequently electrode polarity changing electrodialysis device, an MVR evaporative crystallization unit and a water pump. The wastewater is subjected to pretreatment, ultrafiltration, reverse osmosis, frequently electrode polarity changing electrodialysis, the primarily treated wastewater is then returned to the equipment through the water pump for realizing circular process; thus, wastewater treatment efficiency and fresh water recovery rate are both increased. The industrial wastewater treatment equipment and method is applicable to wastewater treatment systems for large factories.

Owner:HARBIN BOILER

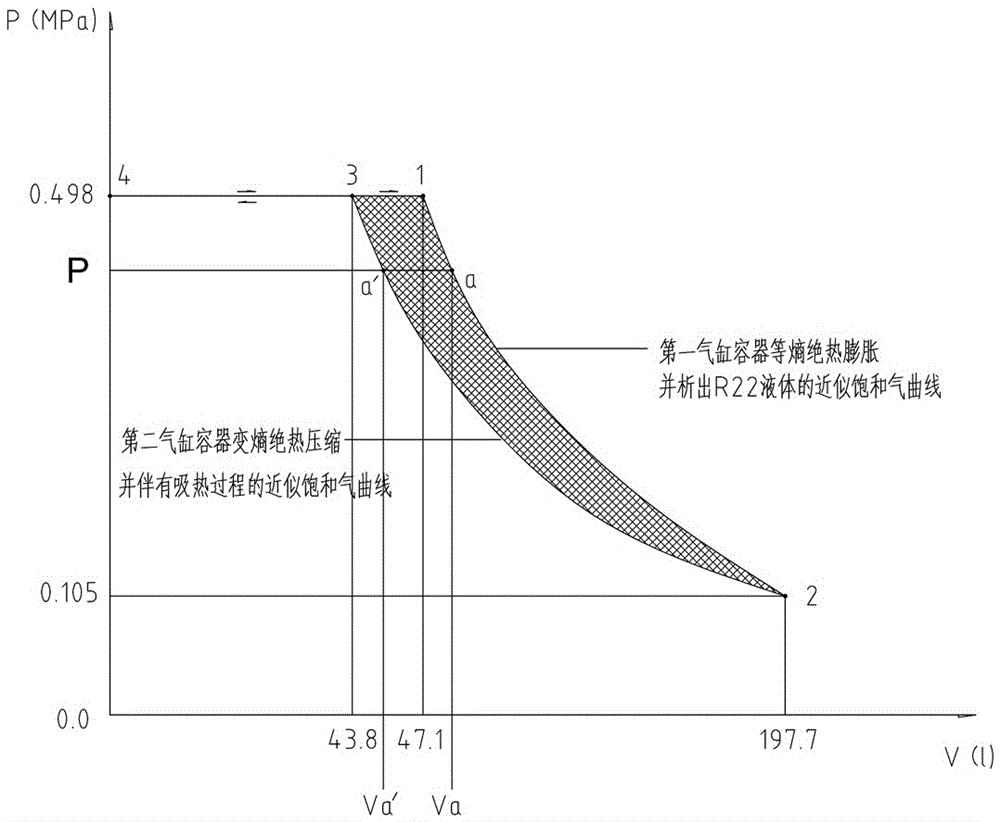

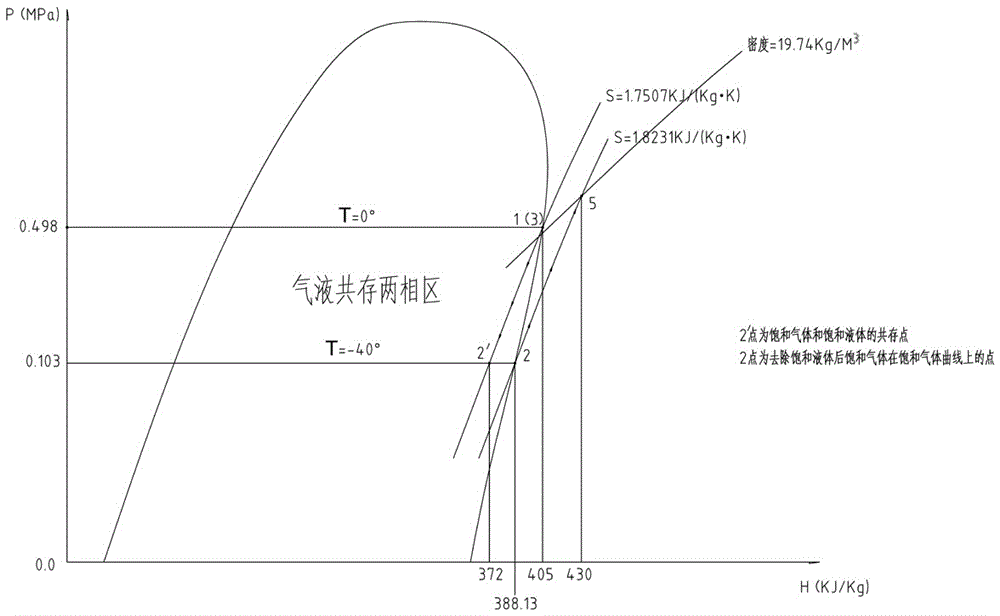

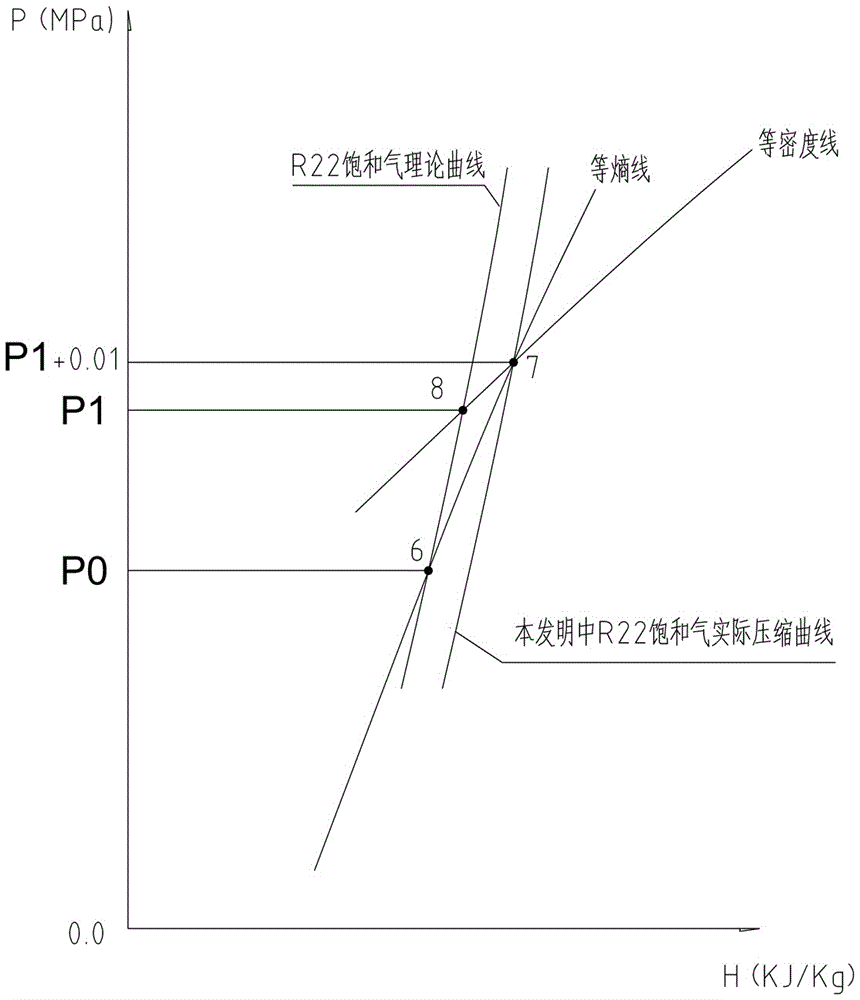

Power cycle output method and system for absorbing heat energy from air

InactiveCN106286173AMeet the protection requirementsThe need to realize unlimited use of clean energySteam engine plantsMechanical power devicesThermal energyPower cycle

The invention discloses a power cycle output method and system for absorbing heat energy from air. An A gas saturation and storage device, a condensation nucleus generation device, a positive work output device, a gas-liquid separation device, an A liquid heat exchange device, an air heat exchange device, an A gas and B liquid mixing device, a negative work input device and an A gas and B liquid separation device are respectively arranged, so that three cycles are performed in normal operation and include an A saturated gas cycle, an A liquid cycle and a B liquid cycle respectively, and the working process is a three-cycle working process. By a heat exchange mode, the air can be cooled, the heat energy of air molecules is absorbed, inexhaustible air internal energy is directly used as an energy source, and the sun ceaselessly supplements the air internal energy every day, the possibility of exhaustion of energy sources is avoided, so that the requirement of humans for unrestricted use of clean energy is met while environmental protection requirements are met.

Owner:符海龙

Device and method for cooling high-heat-flux device by using magnetic field

PendingCN111726973ARealize automatic cycleSimple structureCooling/ventilation/heating modificationsThermodynamicsHeat flow

The invention relates to the technical field of the cooling of high-heat-flux devices. The invention further discloses a device and a method for cooling a high-heat-flux device by using the magnetic field. The problems that the device and the method for cooling a high-heat-flux device by a magnetic field in the current market need an electromagnetic pump for active driving, an electromagnetic pumpoccupies a certain space and is restrained by space, the heat dissipation area is small, extra electric energy is consumed for driving the electromagnetic pump, the device does not have the capacityof being automatically adjusted along with the thermal power of a high-heat-flux device, and the single-loop heat exchange area is limited are solved. According to the invention, the device comprisesa heating device, the automatic driving under the seebeck effect and the magnetic field effect can be realized by using the temperature difference; an electromagnetic pump is not needed, the space constraint does not exist, the heat dissipation area is large, extra electric energy is not consumed, the automatic adjustment is conducted according to the thermal power of a high-current-density device, the automatic adaptation to cooling of electronic devices within a certain power range is achieved, and the flowing and heat exchange area of conductive fluid is increased through double annular loops.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

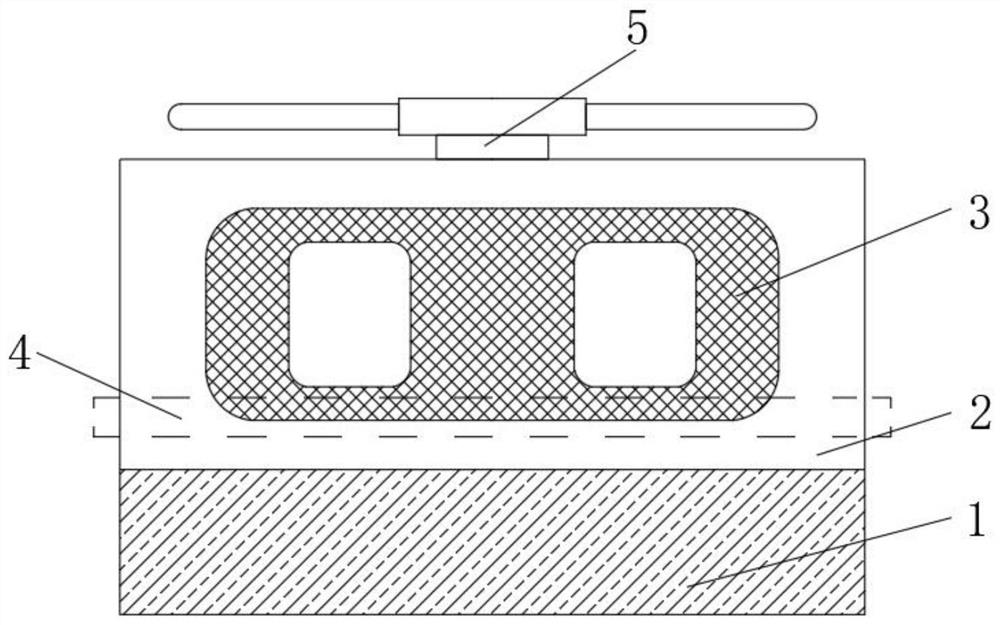

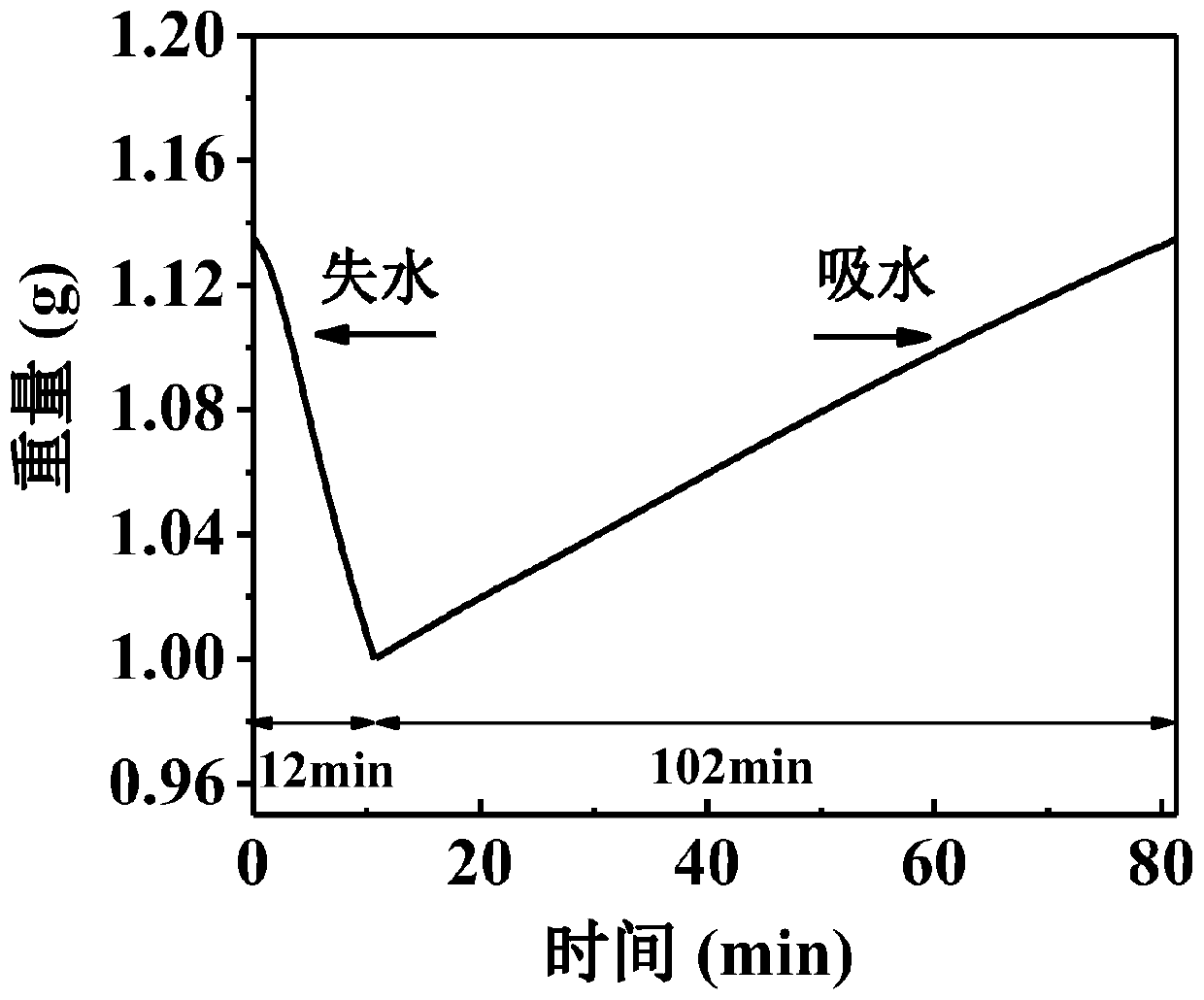

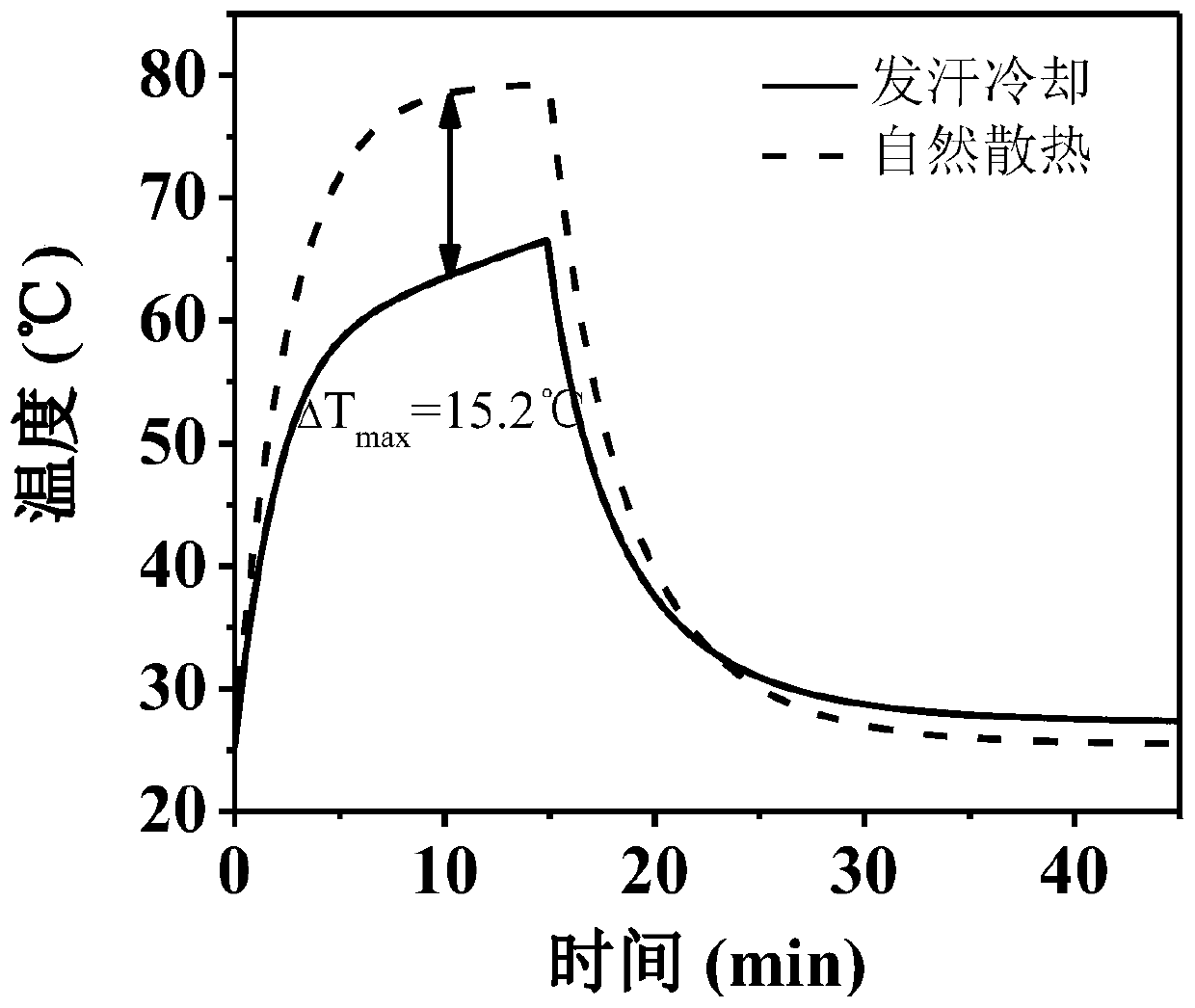

A self-absorbing hydrogel, preparation method and thermal management method based thereon

ActiveCN109943002BSimple structureImprove cooling effectHeat-exchange elementsEngineeringMoisture absorption

The invention discloses a self-absorbing hydrogel, a preparation method and a heat management method based on the self-absorbing hydrogel. The self-absorbing hydrogel is a hygroscopic hydrogel composed of a salt water-resistant gel and a certain concentration of hygroscopic salt solution. In the preparation process, the hydrogel is first prepared; then the hydrogel is heated and dried, and then the dried hydrogel is soaked in high-concentration hygroscopic salt until the hydrogel is completely swollen, and it is self-hygroscopic when taken out Hydrogels. The self-hygroscopic hydrogel can absorb moisture in the air for automatic water replenishment at low temperature, and can take away a large amount of heat when water evaporates at high temperature, and can realize the automatic cycle of moisture absorption and heat dissipation. The invention has the characteristics of simple structure and excellent heat dissipation ability, and can intelligently manage heat for various objects that need heat dissipation by imitating biological sweating and heat dissipation. It can automatically dissipate heat for the heating element without external power, and has the characteristics of no noise, small size, low cost, convenience and intelligence.

Owner:纾酷科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com