Printing and dyeing wastewater treatment device and treatment method

A technology for printing and dyeing wastewater and treatment device, which is applied in biological treatment devices, textile industry wastewater treatment, multi-stage water treatment and other directions, can solve the problems of high chromaticity value, difficult treatment and high inorganic salt content, and achieves improved purification capacity and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

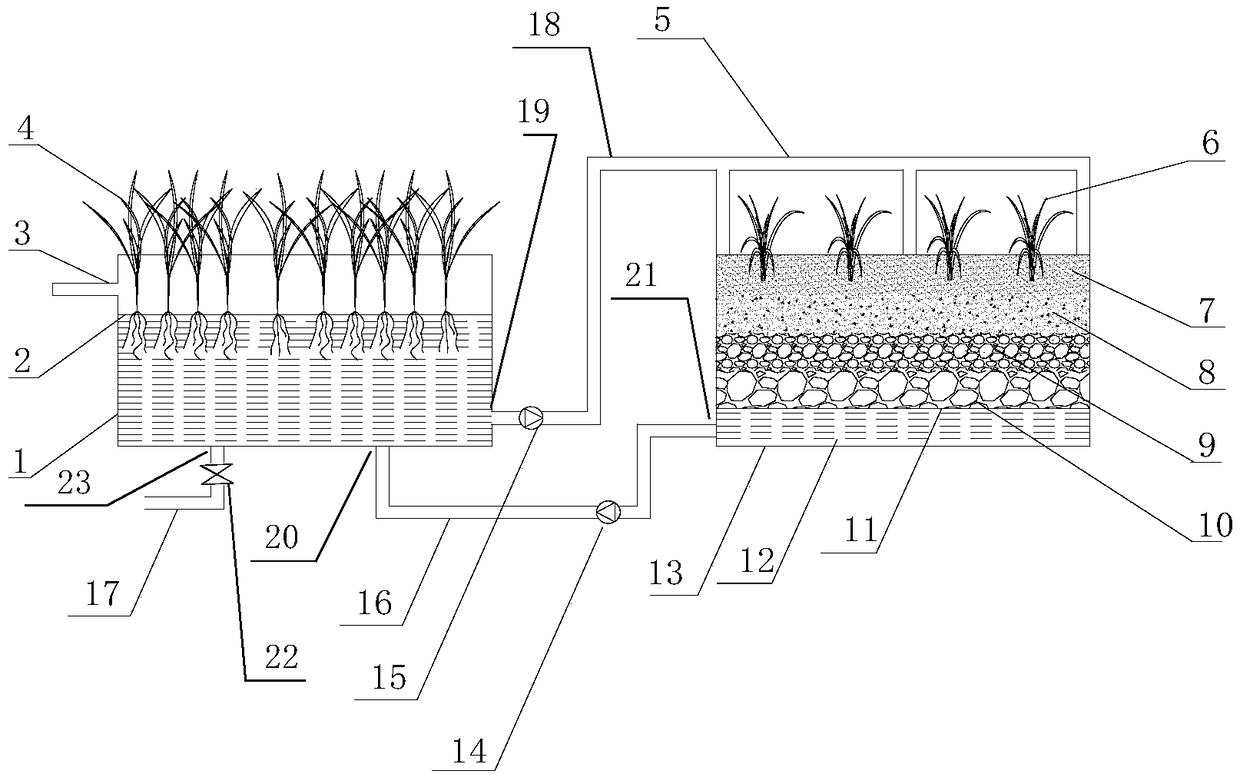

[0039] Such as figure 1 and figure 2 As shown, a printing and dyeing wastewater treatment device includes an aquatic plant reactor 1, a circulating water pipe, and a soil plant reactor 13; the lower part of the aquatic plant reactor 1 is provided with a primary water outlet 19 and a water return port 20; the soil The bottom of the plant reactor 13 is provided with a secondary water outlet 21; the circulating water pipe includes a water inlet pipe 18 and a water return pipe 16; the water inlet pipe 18 is connected with the primary water outlet 19 and the soil plant reactor 13; The water return pipe 16 is connected with the secondary water outlet 21 and the water return port 20; the water inlet pipe 18 is provided with a peristaltic pump 15; the return pipe 16 is provided with a return pump 14. The aquatic plant reactor 1 and the soil plant reactor 13 are the cores to realize water body purification, and the return pump 15 and the peristaltic pump 14 are the driving components...

Embodiment 2

[0051] The difference between this embodiment and Example 1 is that the aquatic plant reactor 1 is a plexiglass cuboid, and the aquatic plants in it are selected from water hyacinth, and its surface coverage area is 75%, which is used for hanging water hyacinth. The wire mesh is located at 4cm below the water inlet 3 of the aquatic plant reactor, and the mesh aperture is 0.1cm. The soil plant reactor 13 is a plexiglass cuboid, and the drip irrigation pipeline 5 provided on the soil plant reactor 13 is an inlaid drip irrigation with a pipe diameter of 12mm, and drip holes are set every 30cm on the drip irrigation; sweet potatoes, high-quality coconut palms are planted in the plant layer 6 The shell activated carbon layer 8 is filled with high-quality coconut shell activated carbon with a particle size of 4-12 mm, the gravel filler layer 9 is filled with small gravel with a particle size of 10-25 mm, and the gravel filler layer 2 10 is filled with small gravel with a particle siz...

Embodiment 3

[0062] This embodiment has been further optimized on the basis of Example 2. The aquatic plants in the aquatic plant reactor 1 are Elodea and reeds, and the surface coverage of the plants is 80%. The barbed wire for hanging plants is located in the aquatic plant reactor. 5cm below the device water inlet 3, the mesh aperture is 1cm. The drip irrigation pipeline 5 provided on the soil plant reactor 13 is an inlaid drip irrigation with a pipe diameter of 16 mm, drip holes are set every 70 cm on the drip irrigation, potatoes and sweet potatoes are planted in the plant layer 6, and grains are filled in the high-quality coconut shell activated carbon layer 8. High-quality coconut shell activated carbon with a diameter of 6-10mm, gravel filler layer 1 9 is filled with small gravels with a particle size of 15-20mm, gravel filler layer 2 10 is filled with large gravels with a particle size of 25-35mm; iron grid The bar spacing is 20mm.

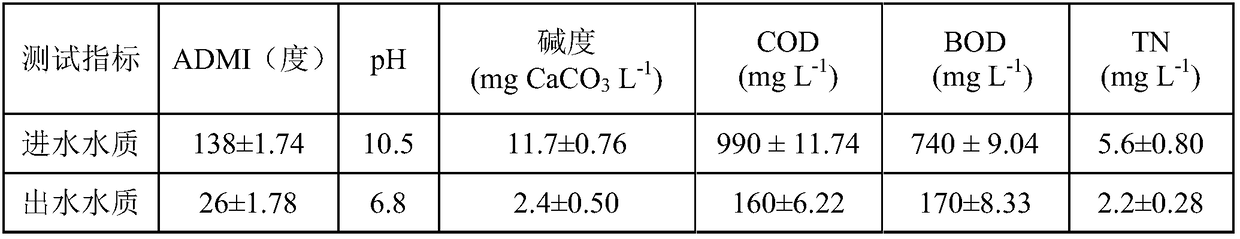

[0063] The purification method of printing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com