Patents

Literature

498 results about "Metabolic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metabolic Functions of the Liver. The liver is a large, chemically reactant pool of cells that have a high rate of metabolism, sharing substrates and energy from one metabolic system to another, processing and synthesizing multiple substances that are transported to other areas of the body, and performing myriad other metabolic functions.

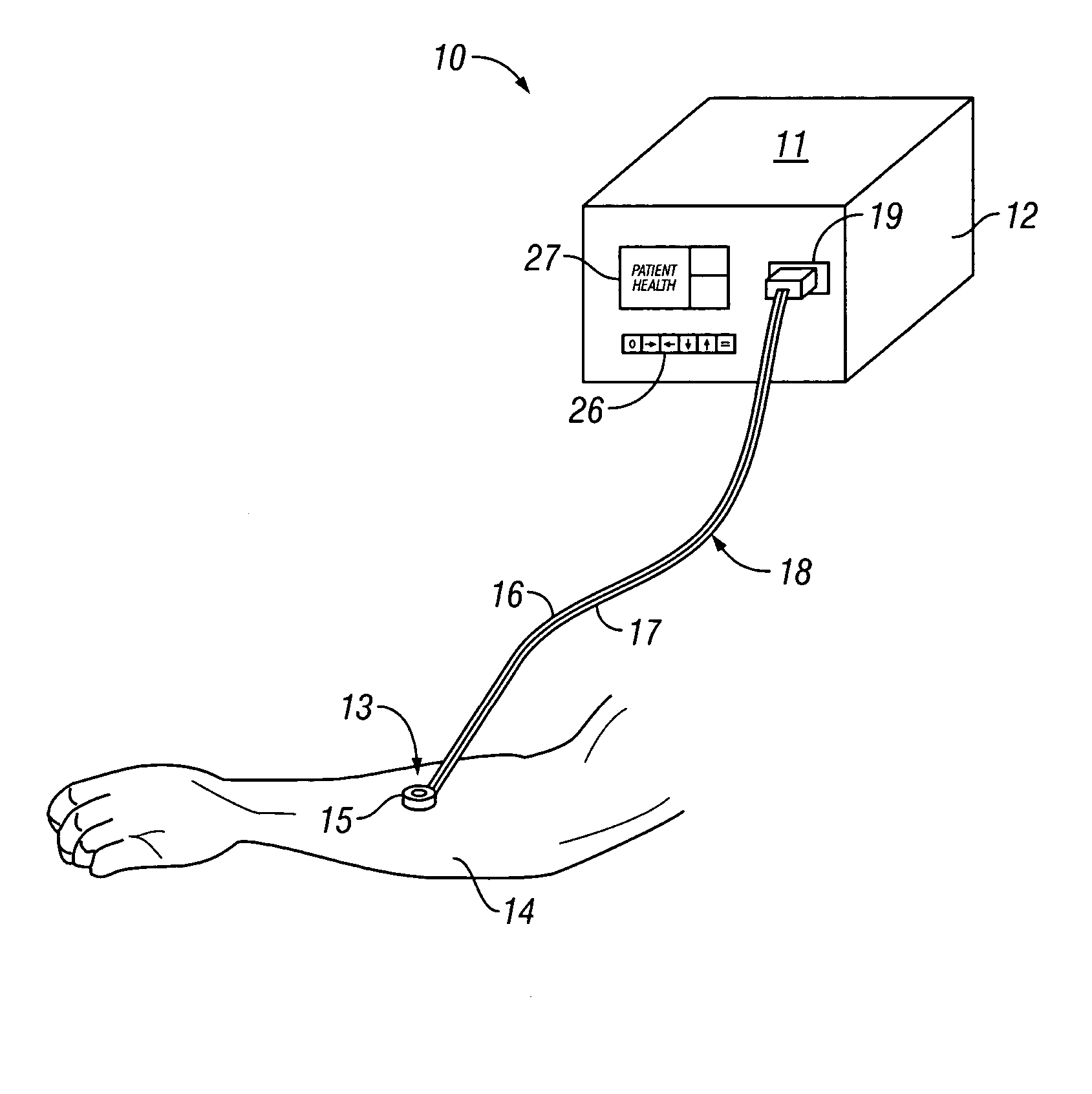

Apparatus and method for measuring biologic parameters

ActiveUS7187960B2Optimal signal acquisitionPreventing temperature disturbanceDiagnostic signal processingDiagnostics using lightInfraredWireless transmission

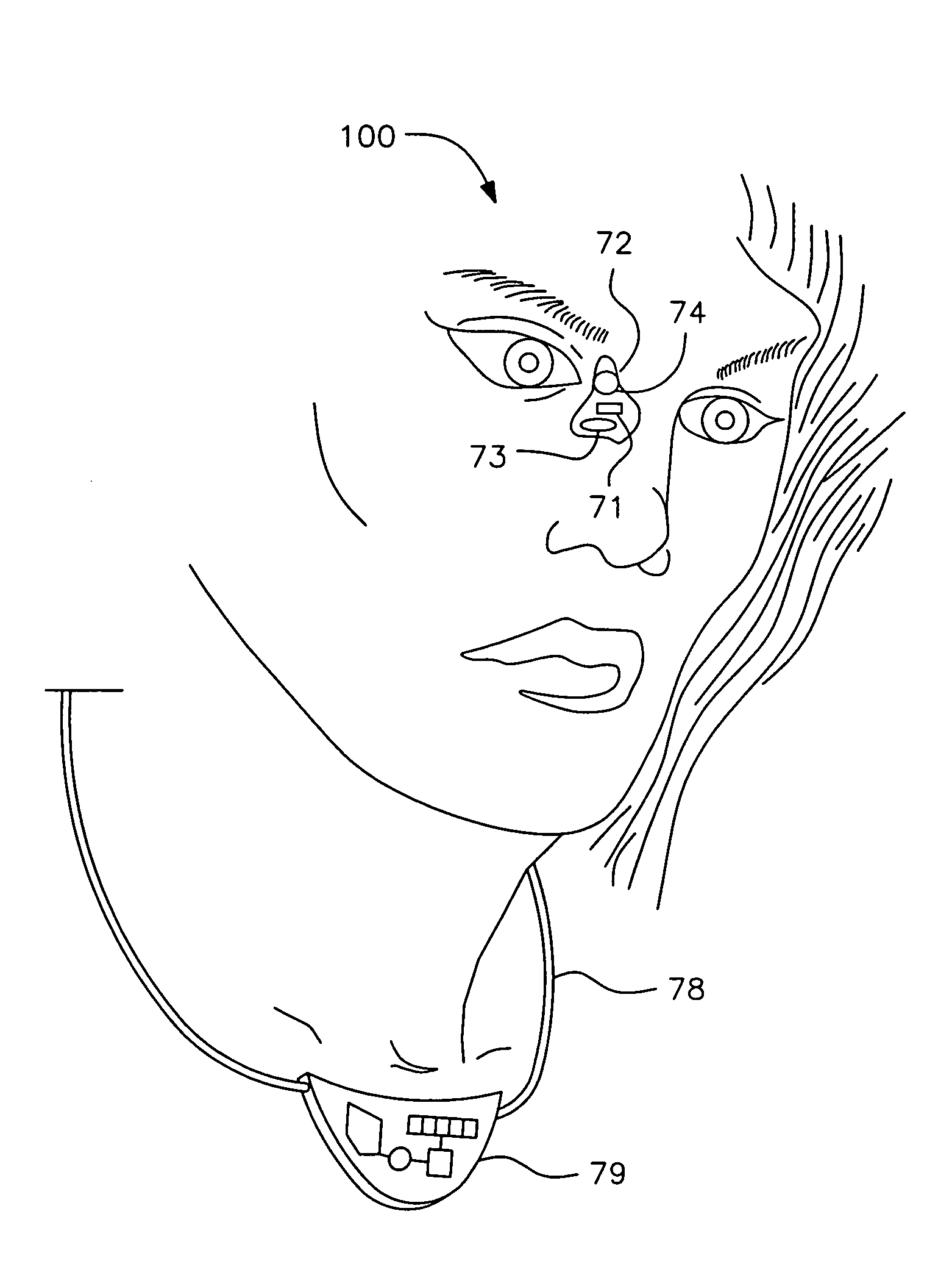

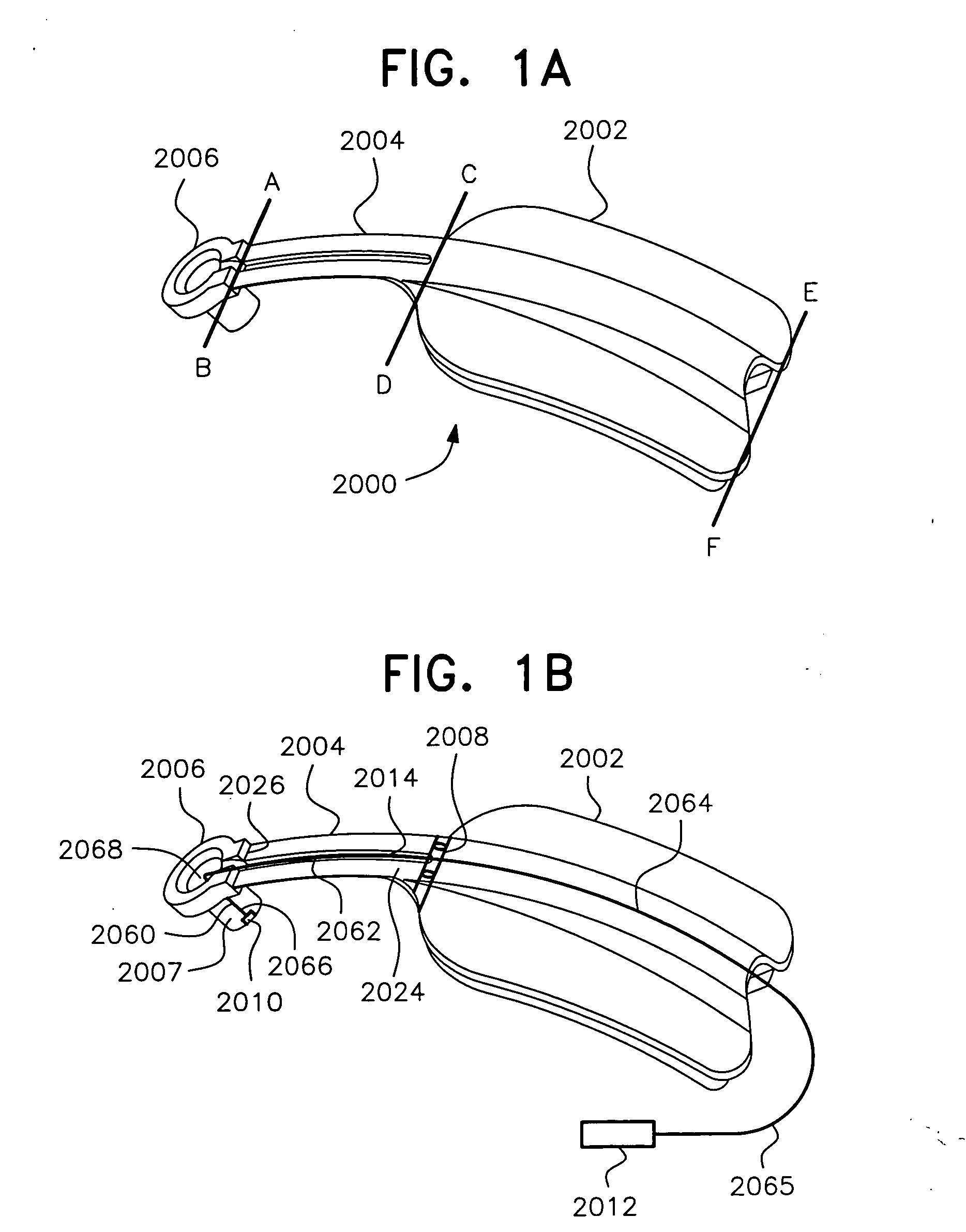

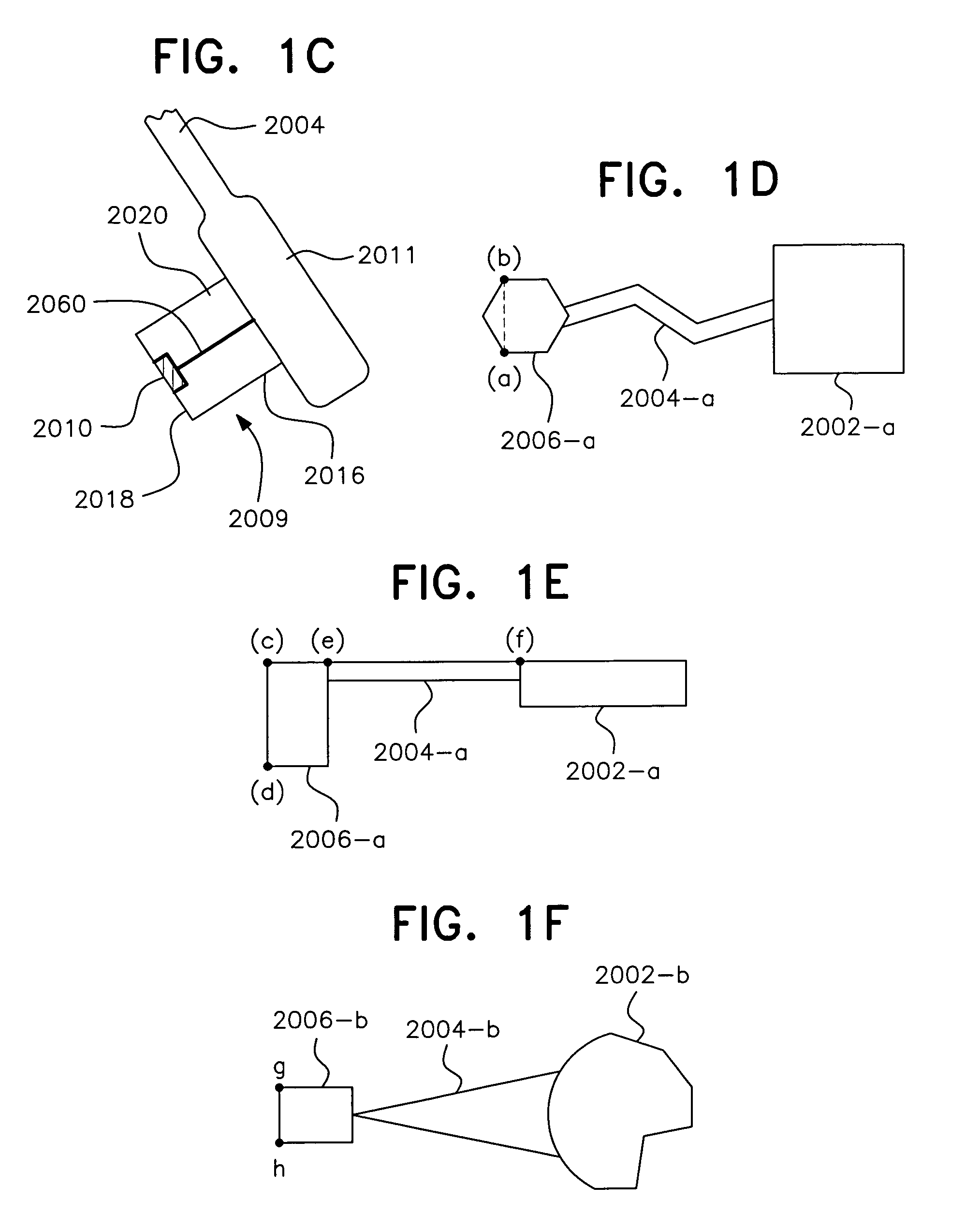

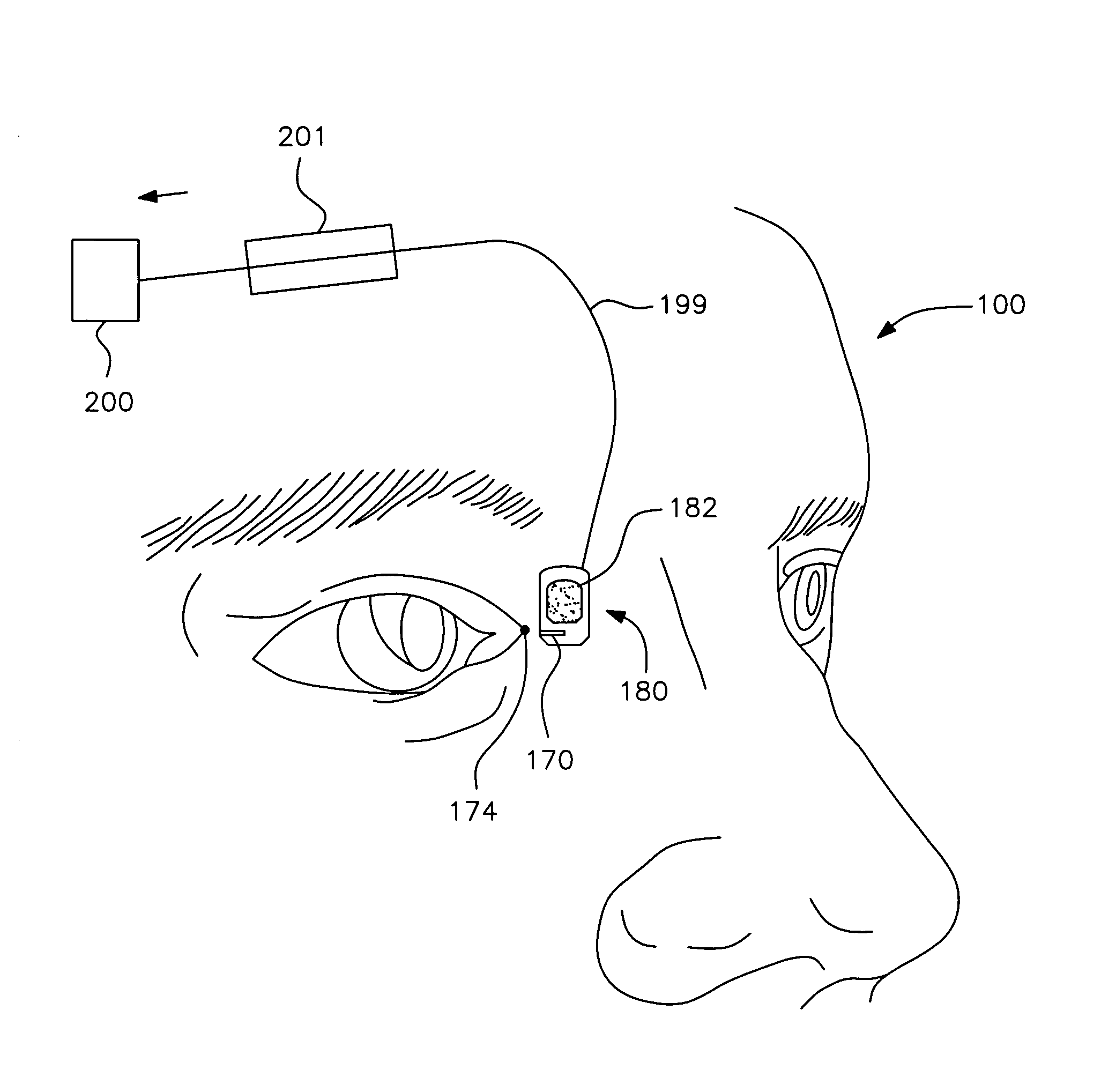

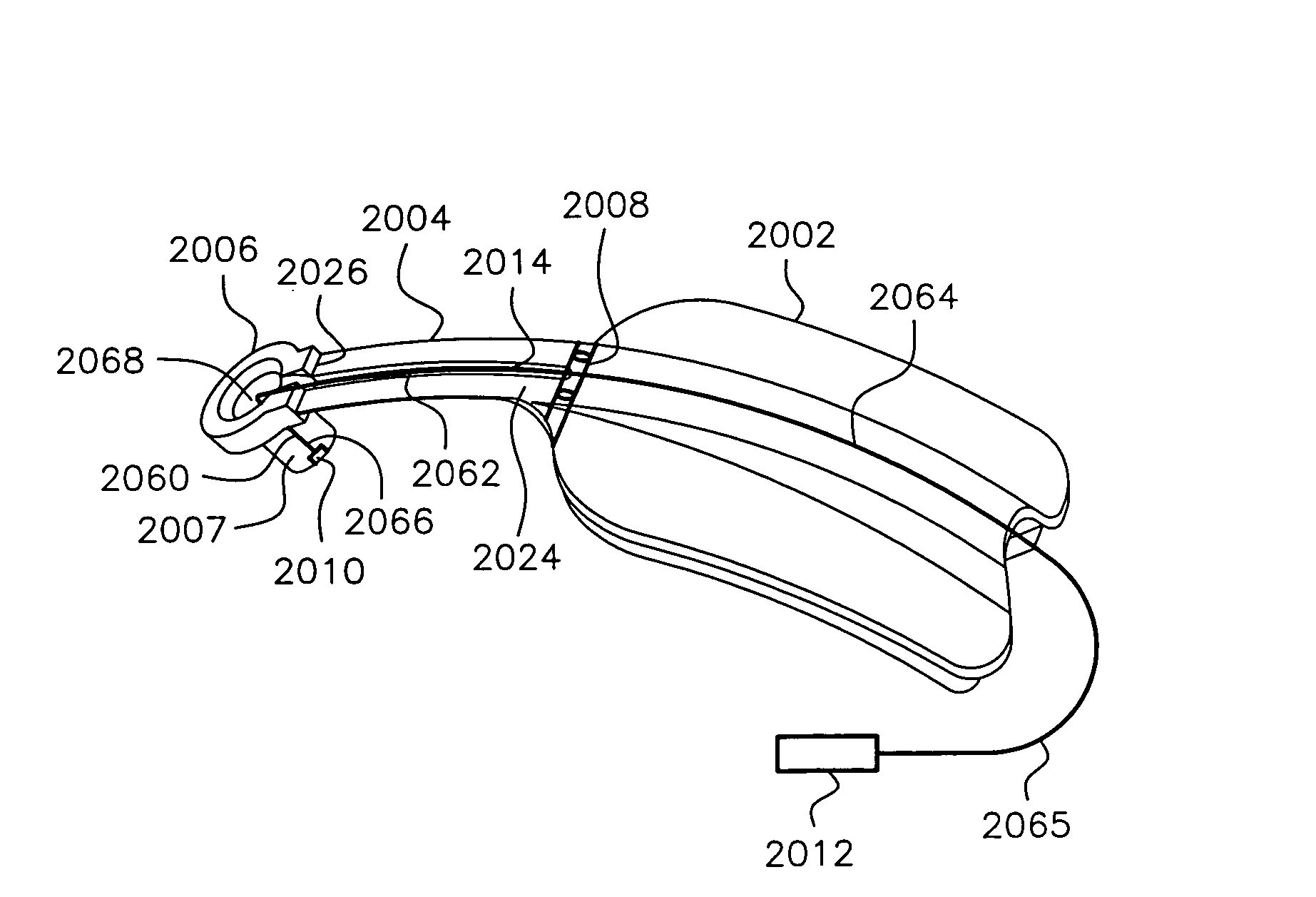

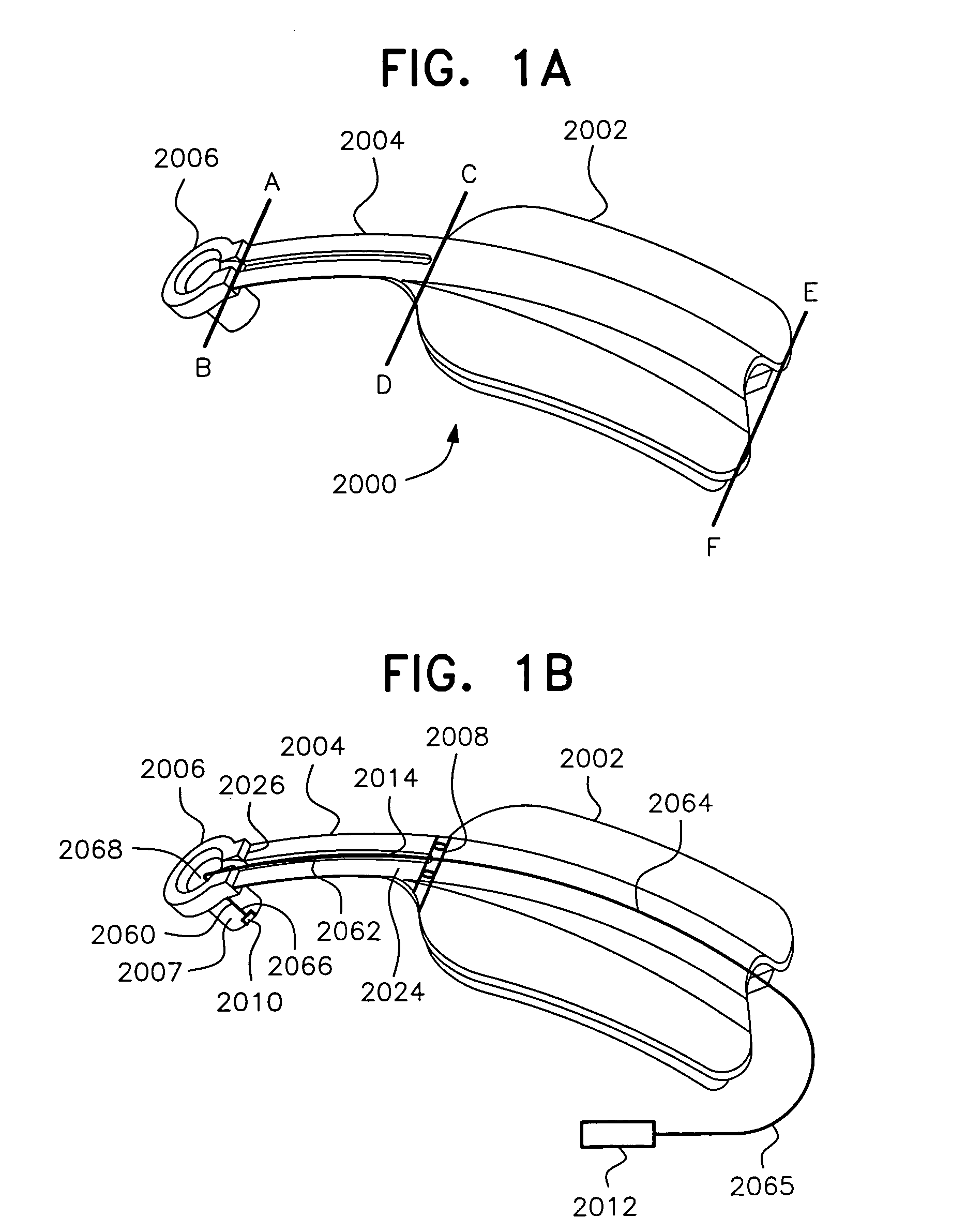

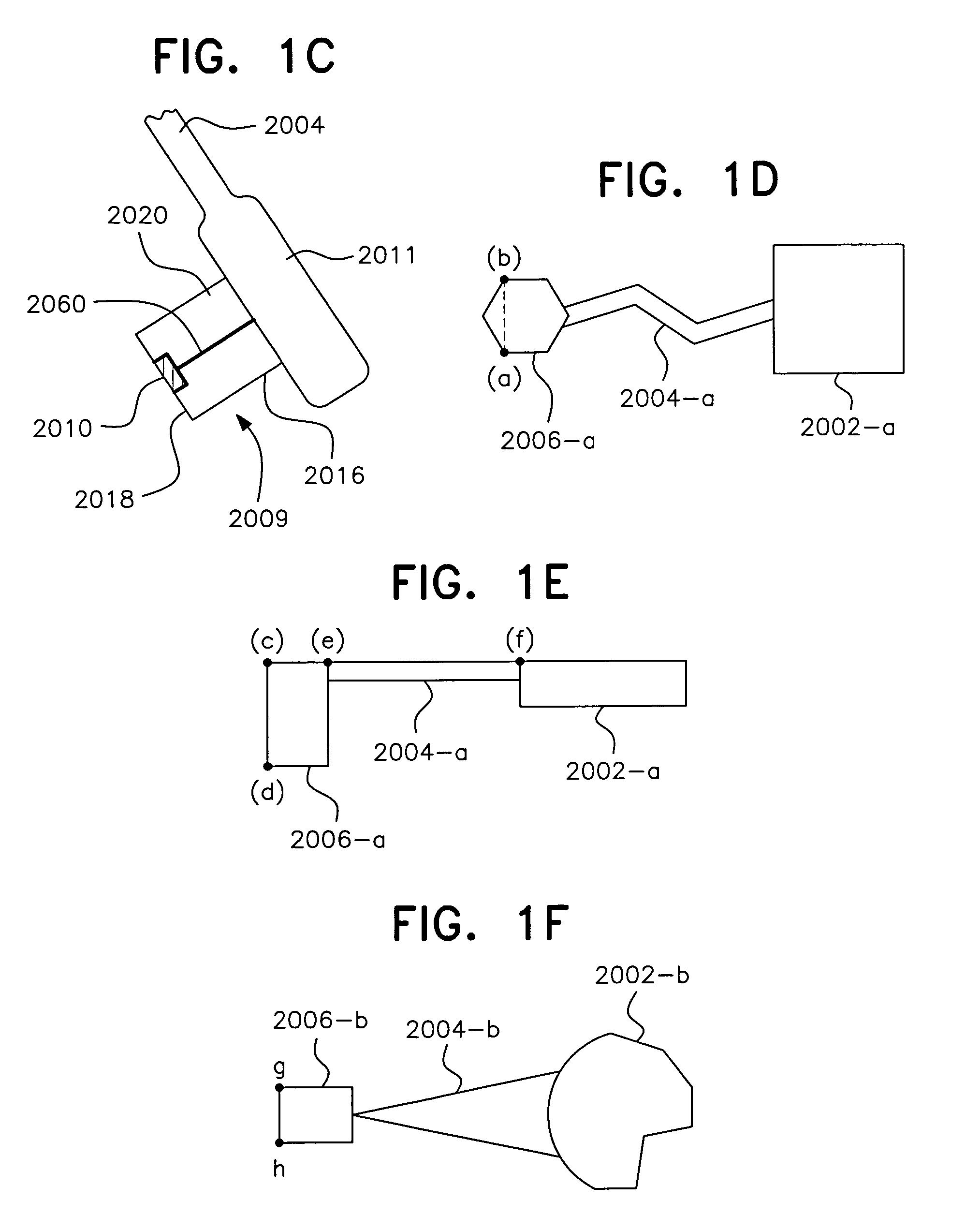

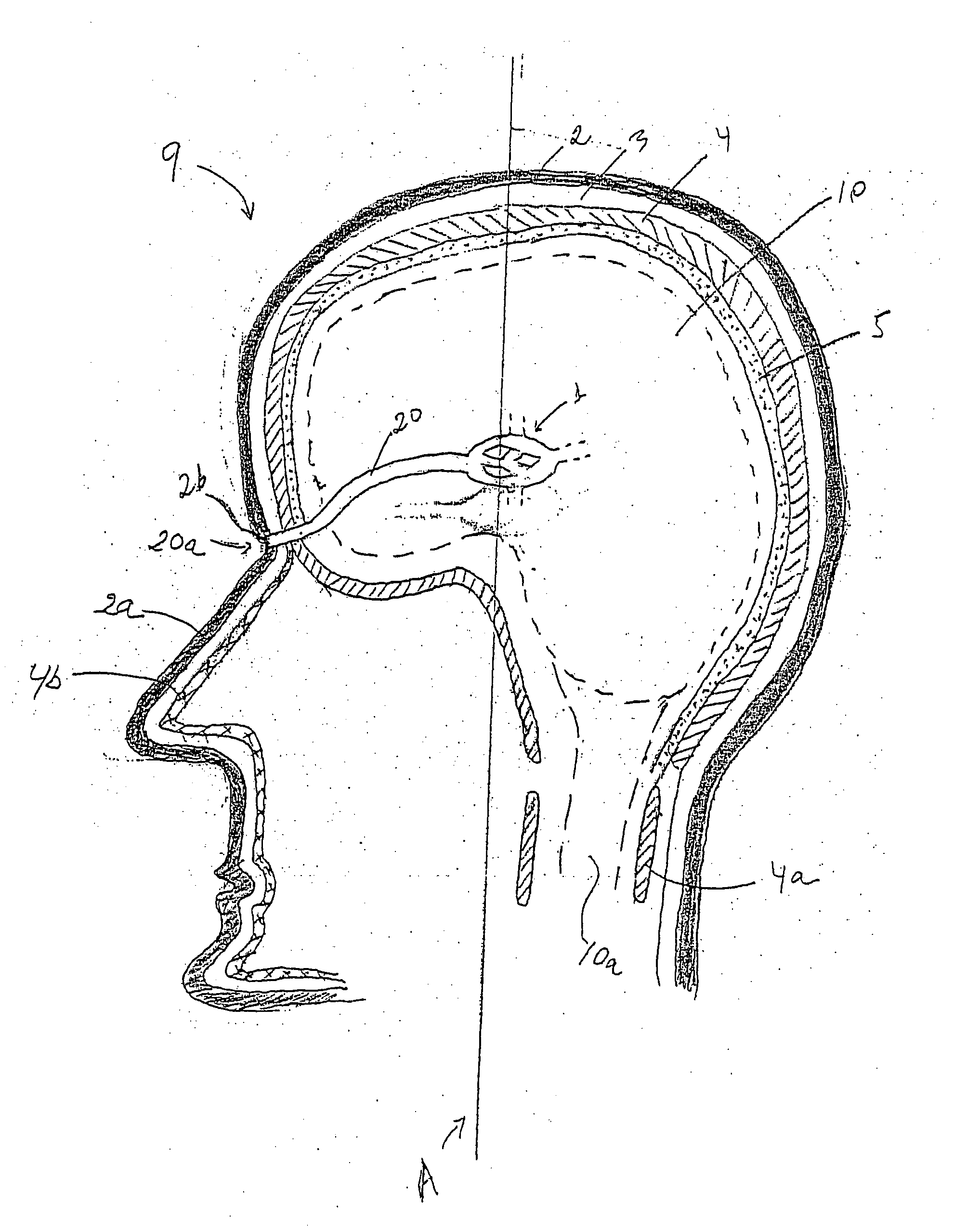

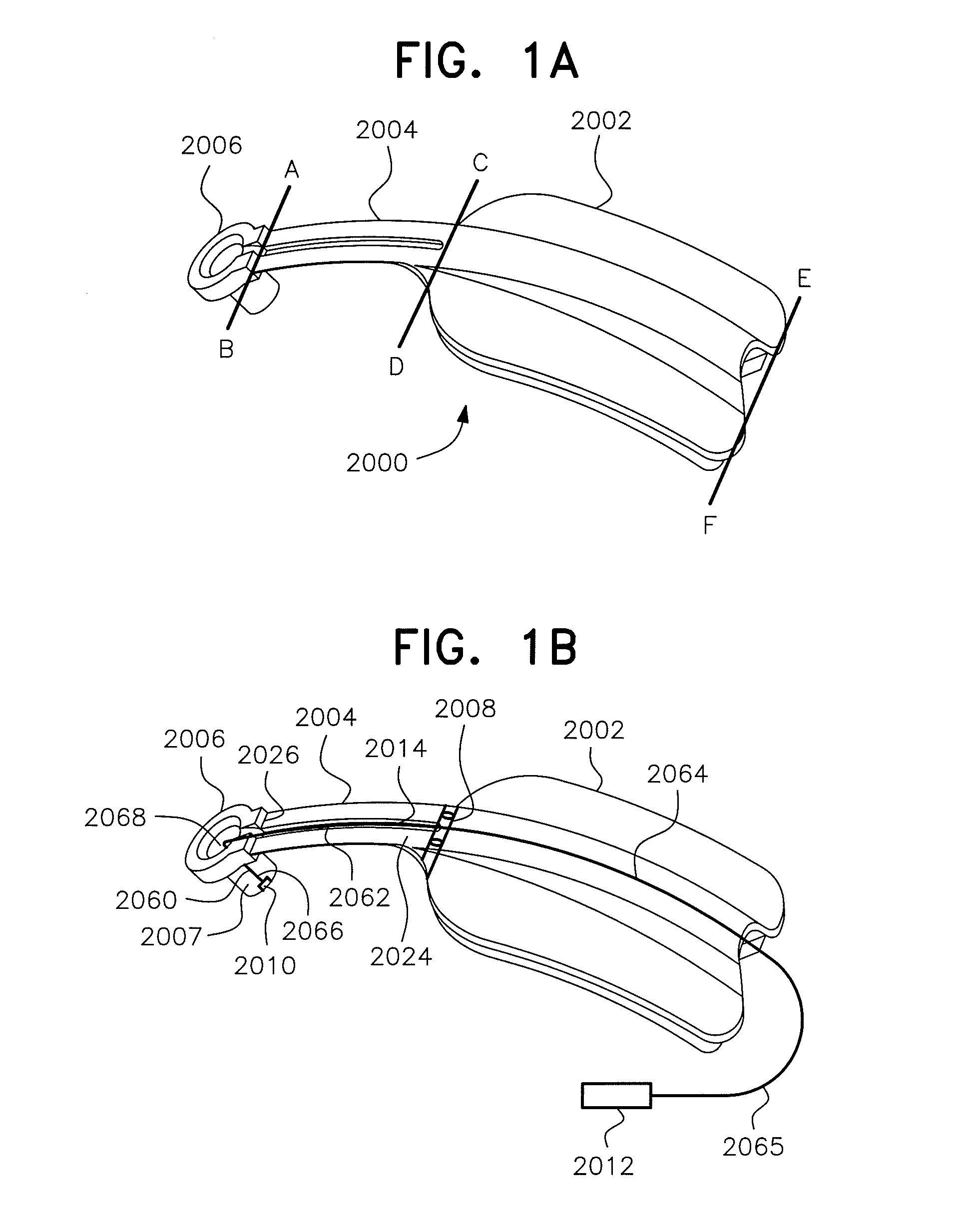

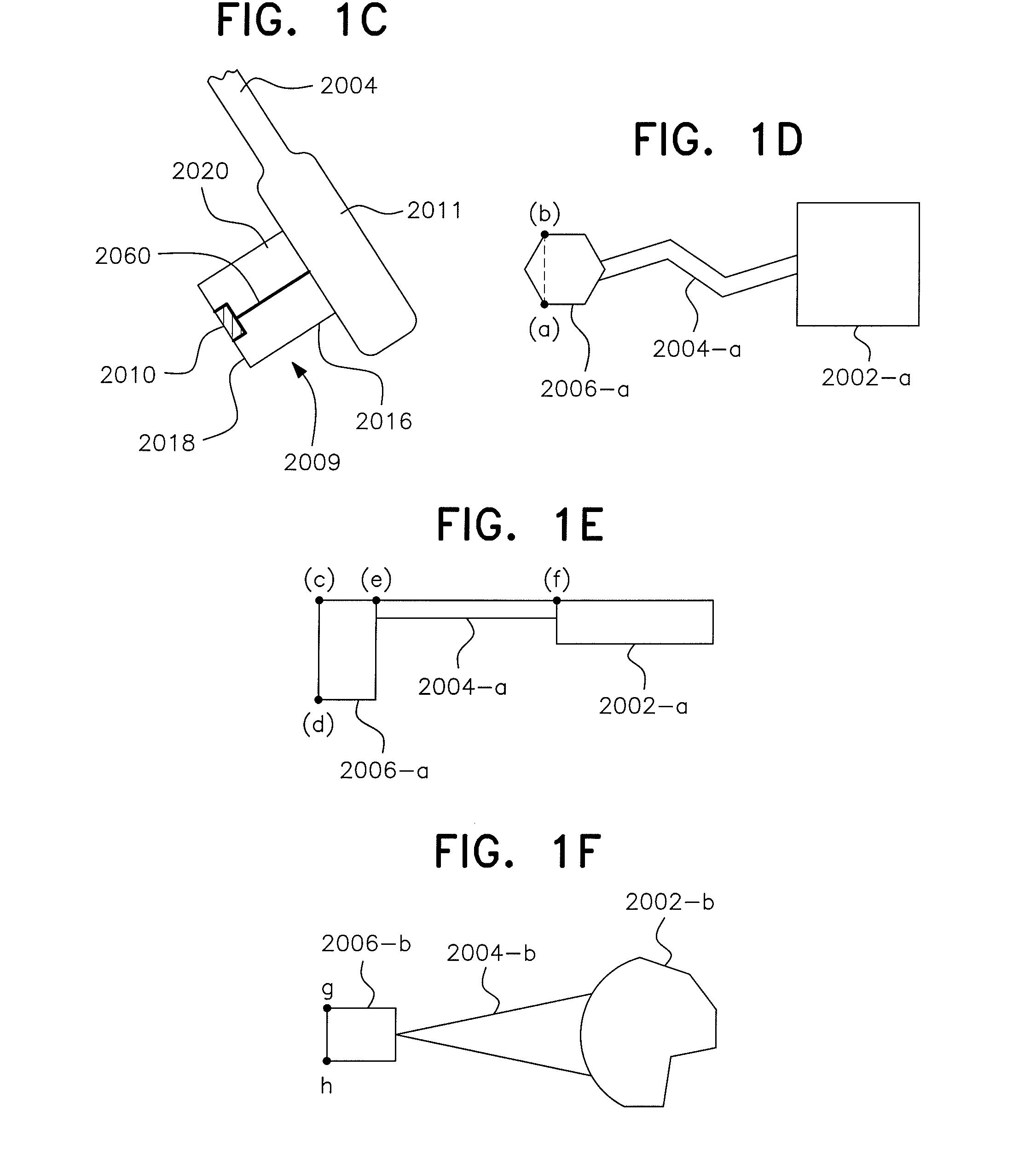

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

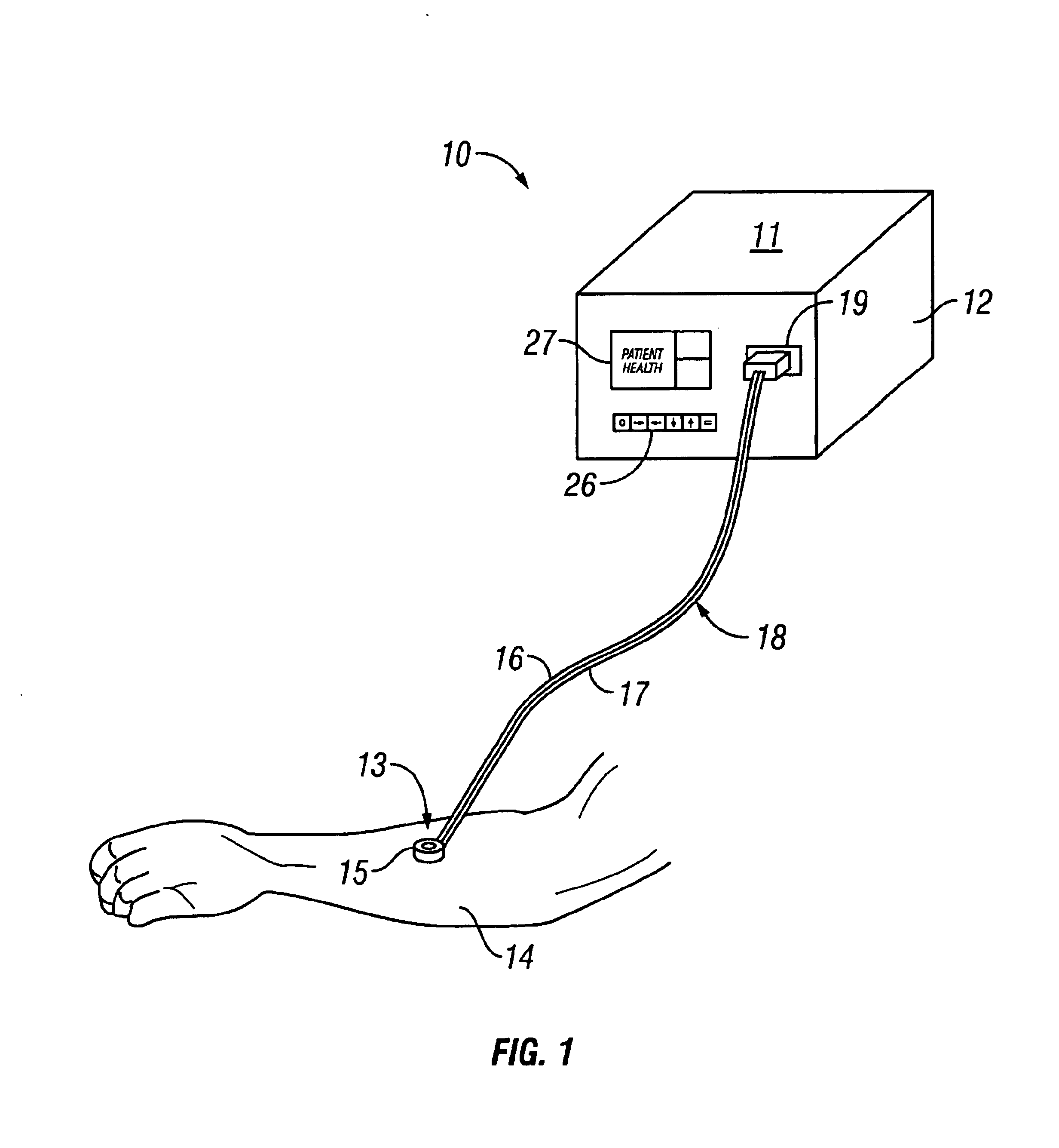

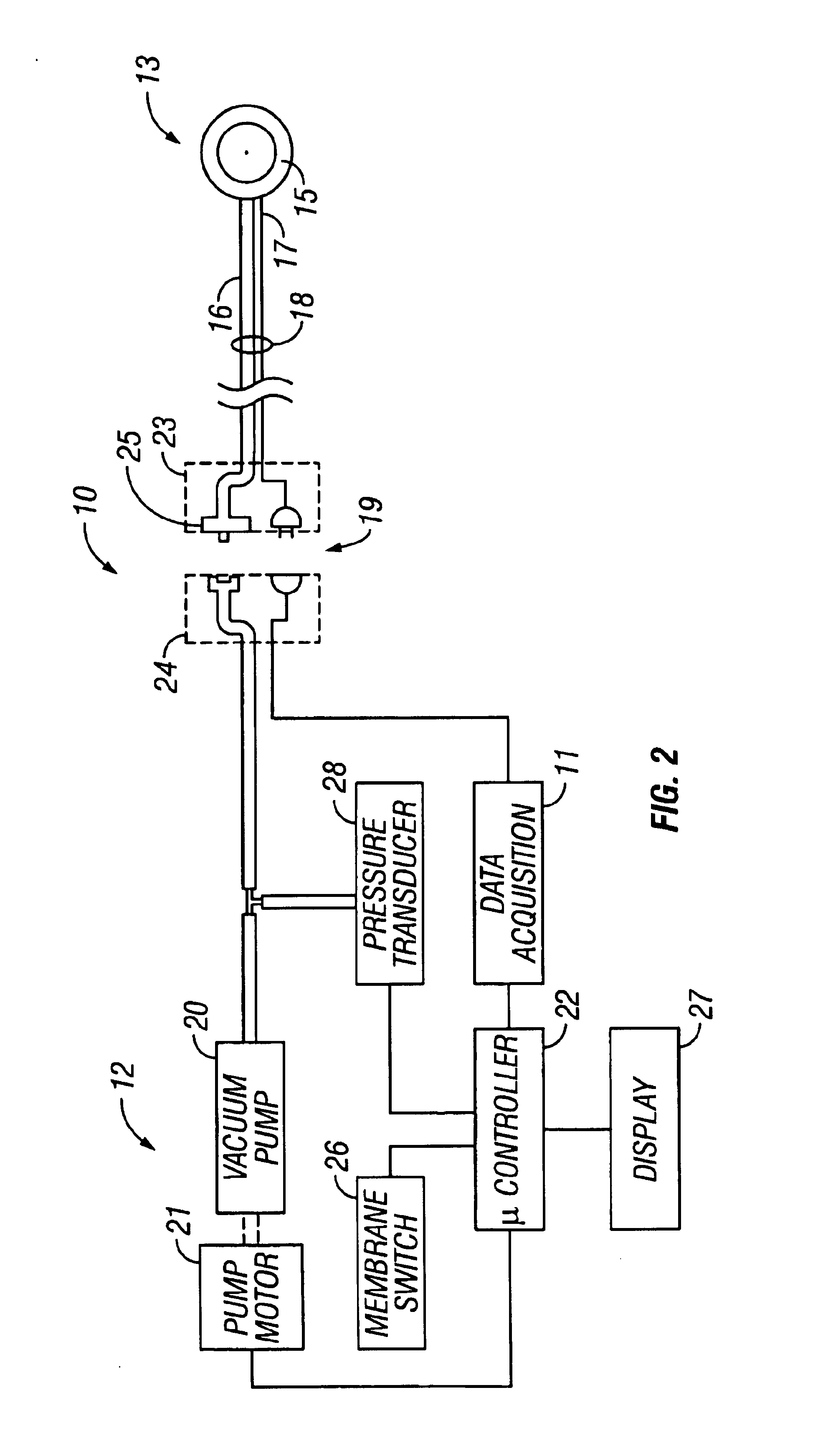

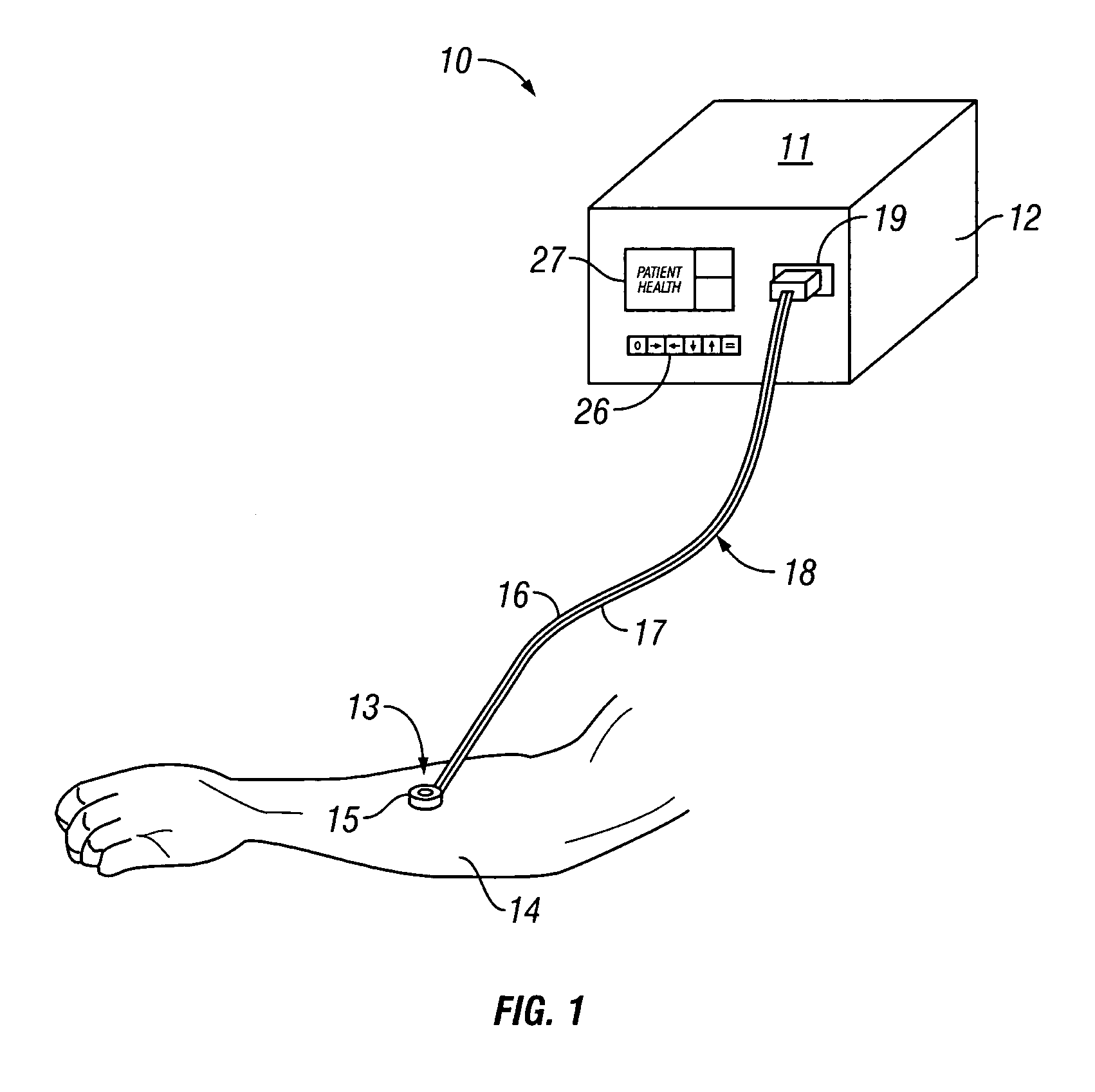

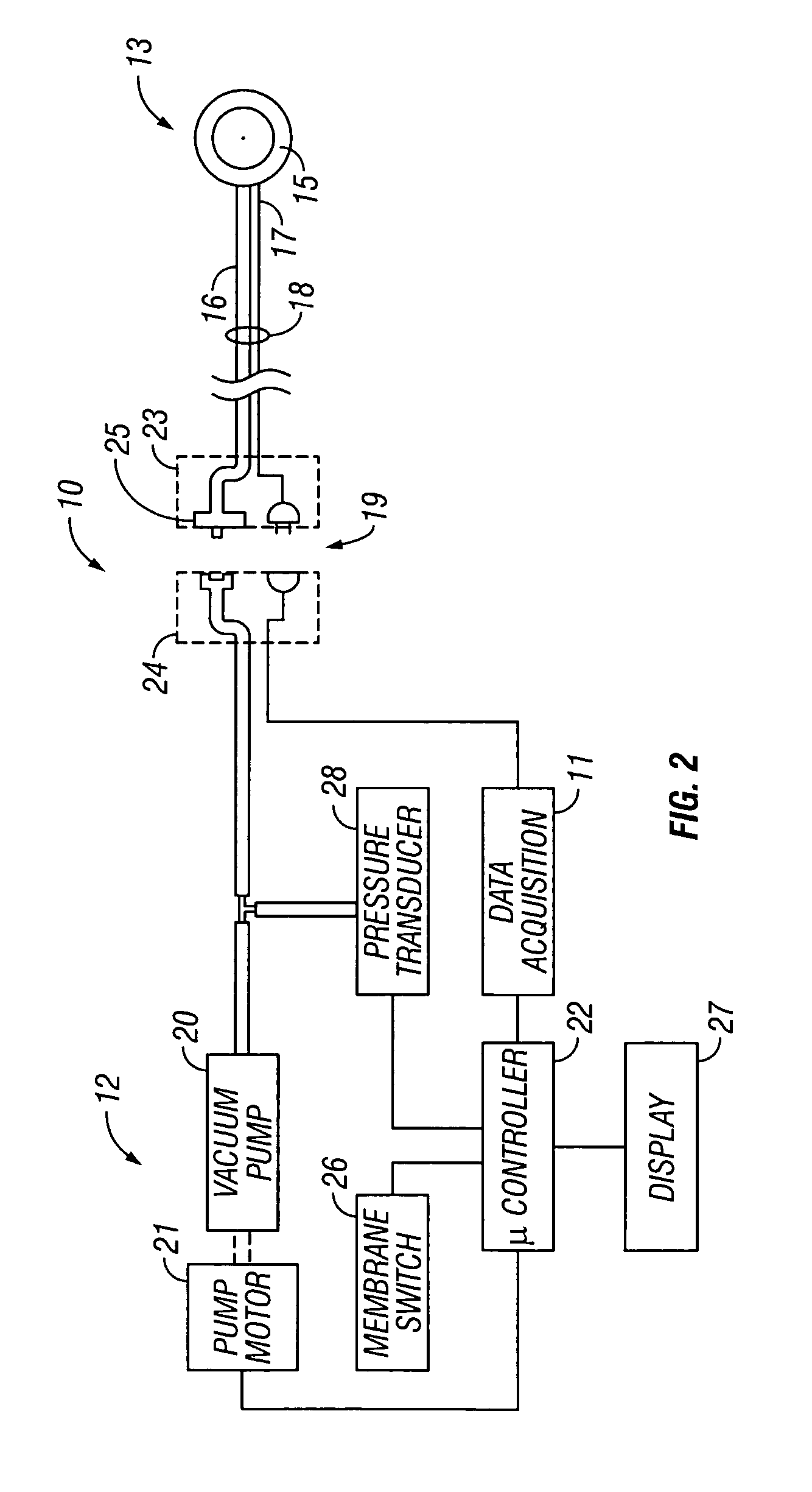

System for combined transcutaneous blood gas monitoring and vacuum assisted wound closure

InactiveUS6856821B2Eliminate opportunitySubstantial riskIntravenous devicesDiagnostic recording/measuringMicrocontrollerVacuum assisted

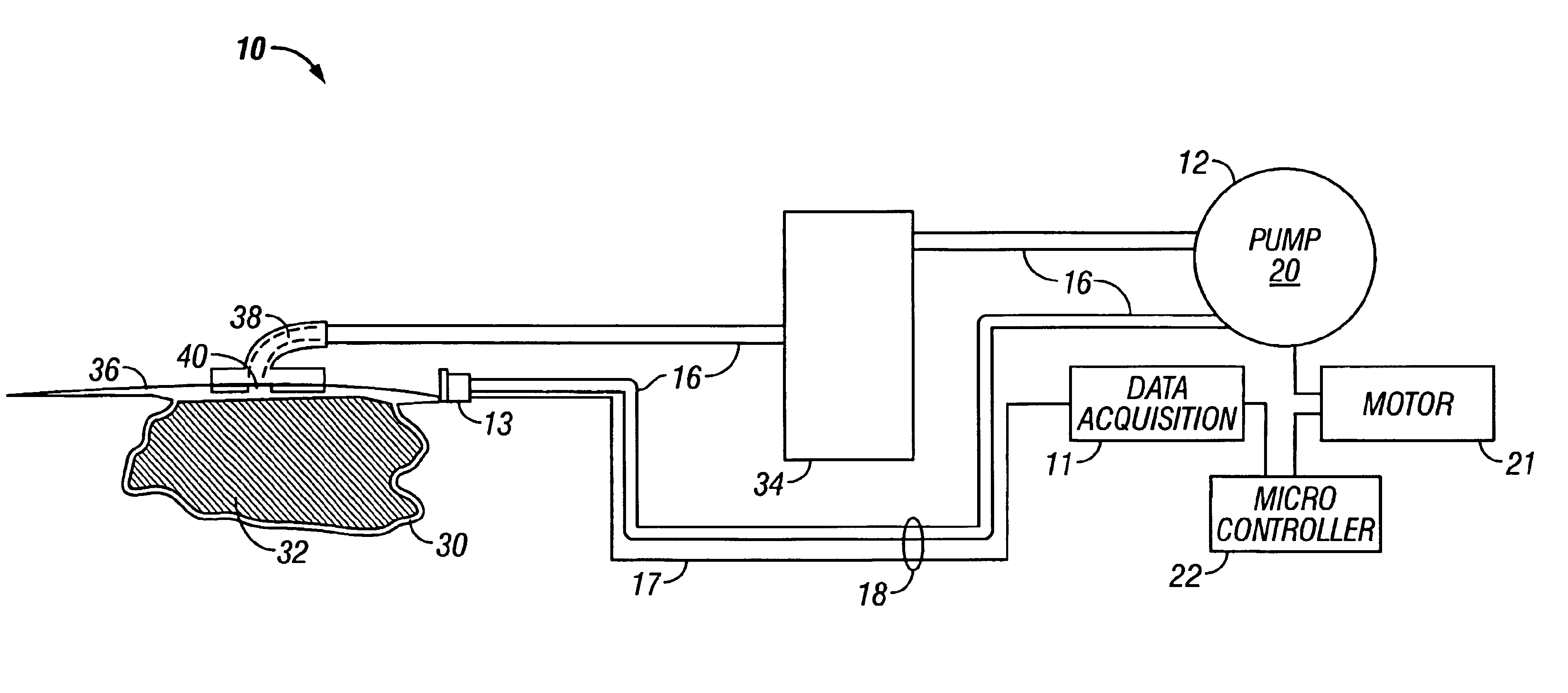

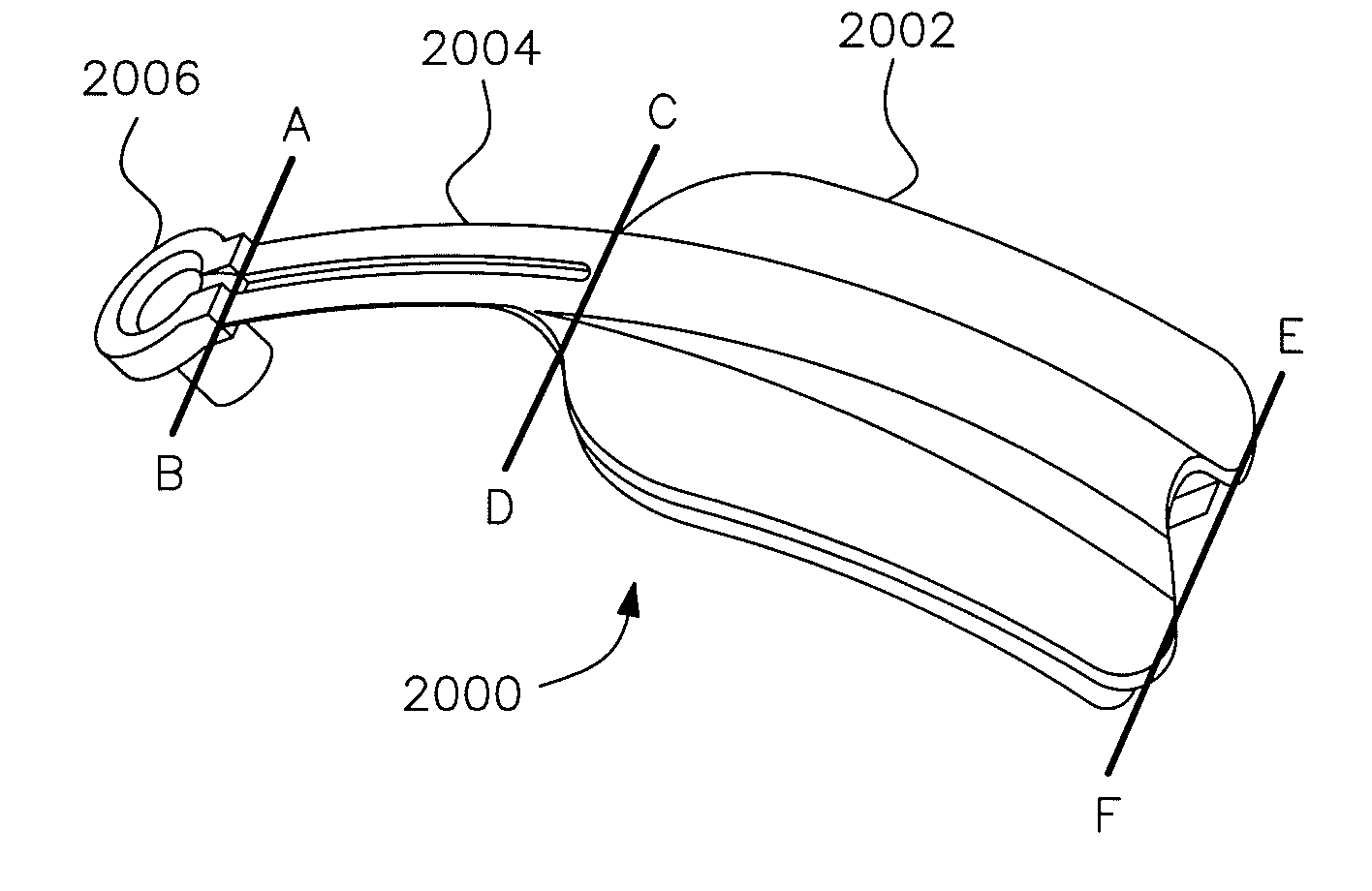

A method and apparatus for the transcutaneous monitoring of blood gases generally comprises a blood gas data acquisition device, a vacuum source and a blood gas transducer unit. The blood gas transducer unit is adapted for application to a patient's skin and administration of a local vacuum at the area of patient application. It further comprises an electrochemical blood gas transducer, well known to those of ordinary skill in the art, which is disposed entirely within the local vacuum at the area of patient application. The vacuum source is placed in fluid communication with the blood gas transducer unit, through a hydrophobic membrane filter for safety purposes, in order to induce a condition of hyperperfusion in the locality of the electrochemical blood gas transducer. Under the control of a microcontroller, or equivalent means, the blood gas acquisition device is then utilized to capture a measure of skin surface oxygen or carbon dioxide pressure. The microcontroller can then utilize this measure to arrive at an estimate of arterial partial pressure of oxygen or carbon dioxide, accordingly. Because vacuum induced perfusion produces the requisite condition of hyperperfusion without local heating and, therefore, without acceleration of the local metabolic function, the present invention results in more accurate than previously available estimates of partial pressure blood gas pressures and does so while eliminating a significant risk for injury to the patient.

Owner:KCI LICENSING INC

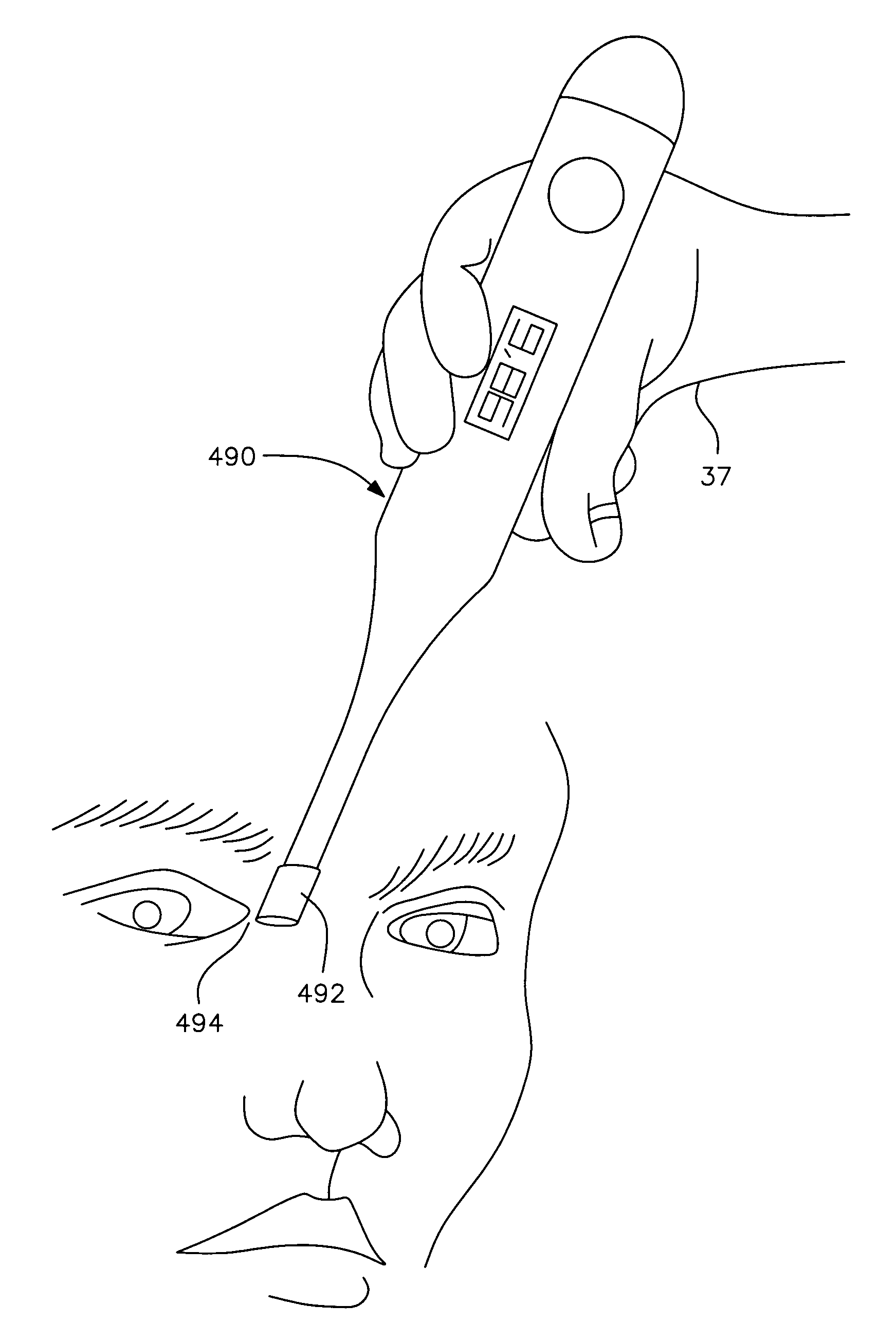

Apparatus and method for measuring biologic parameters

ActiveUS20090105605A1Prevent dehydrationAvoid overhydrationThermometer detailsTelevision system detailsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

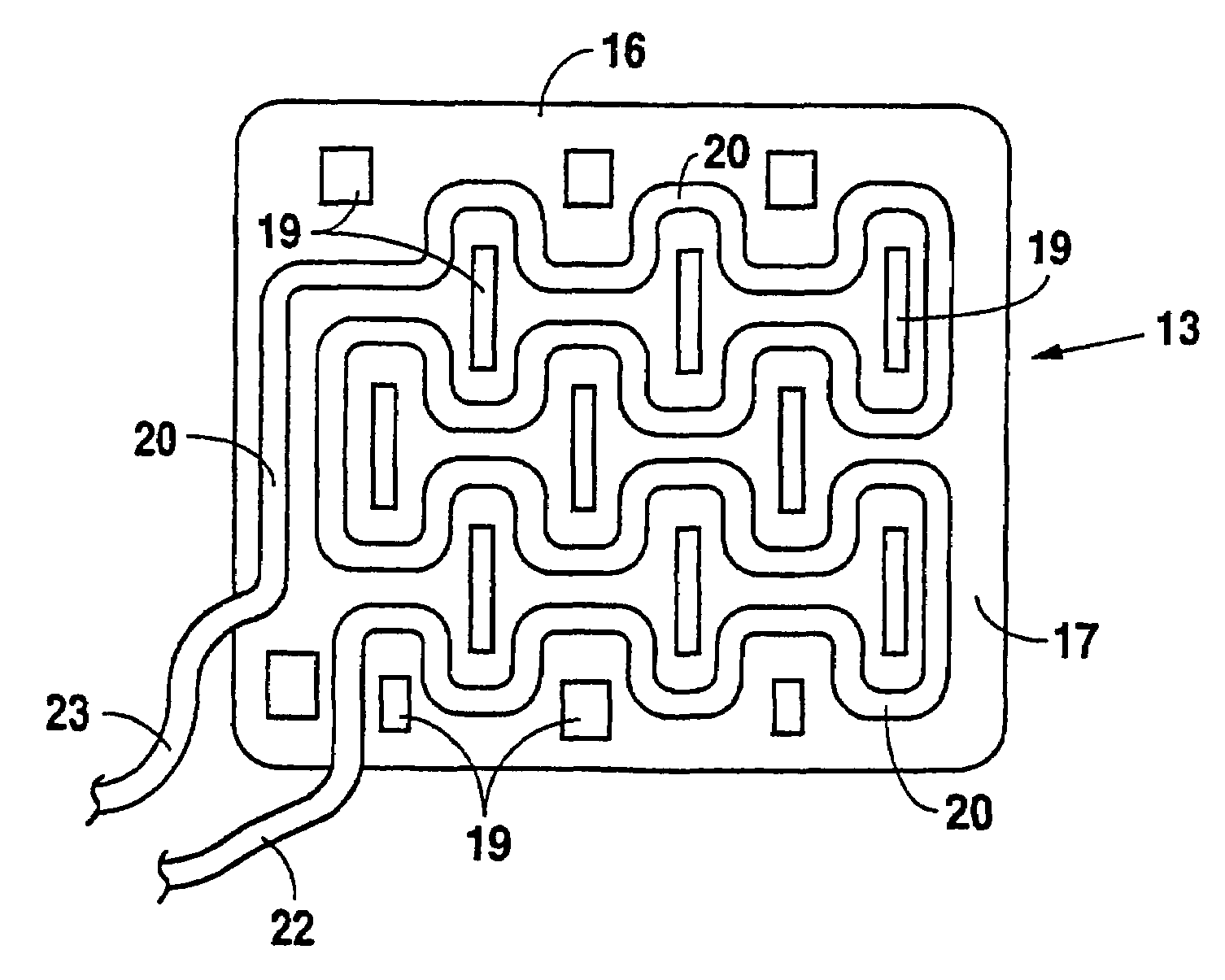

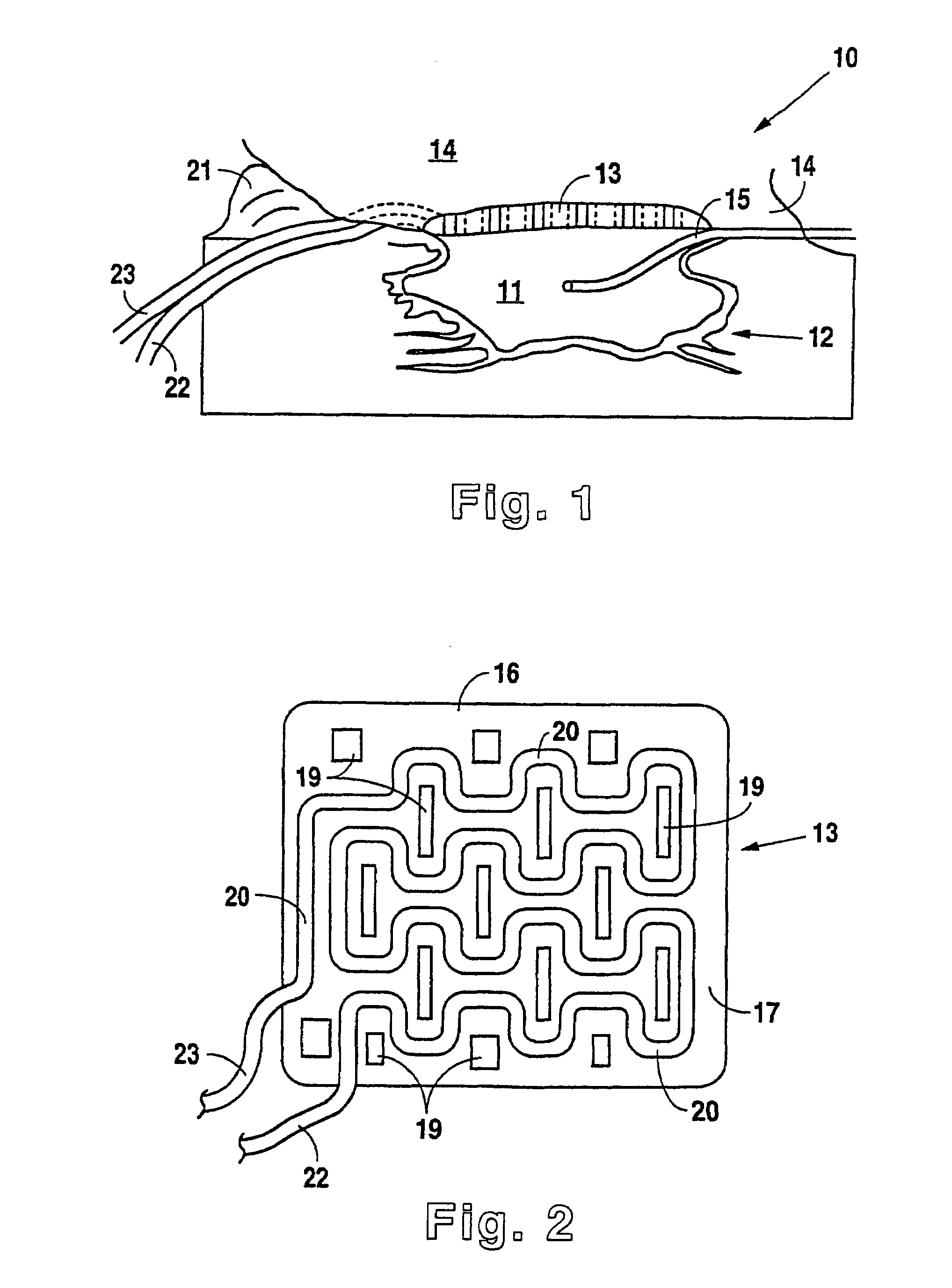

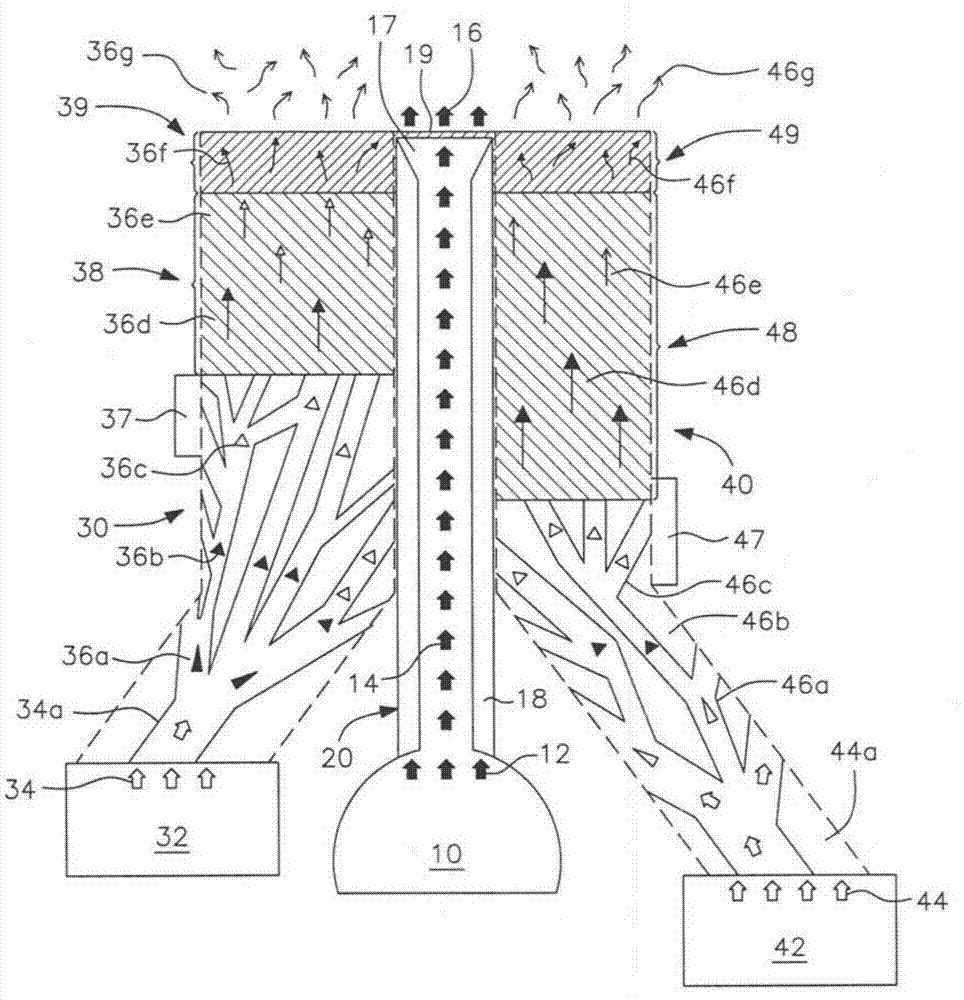

Negative pressure treatment system with heating and cooling provision

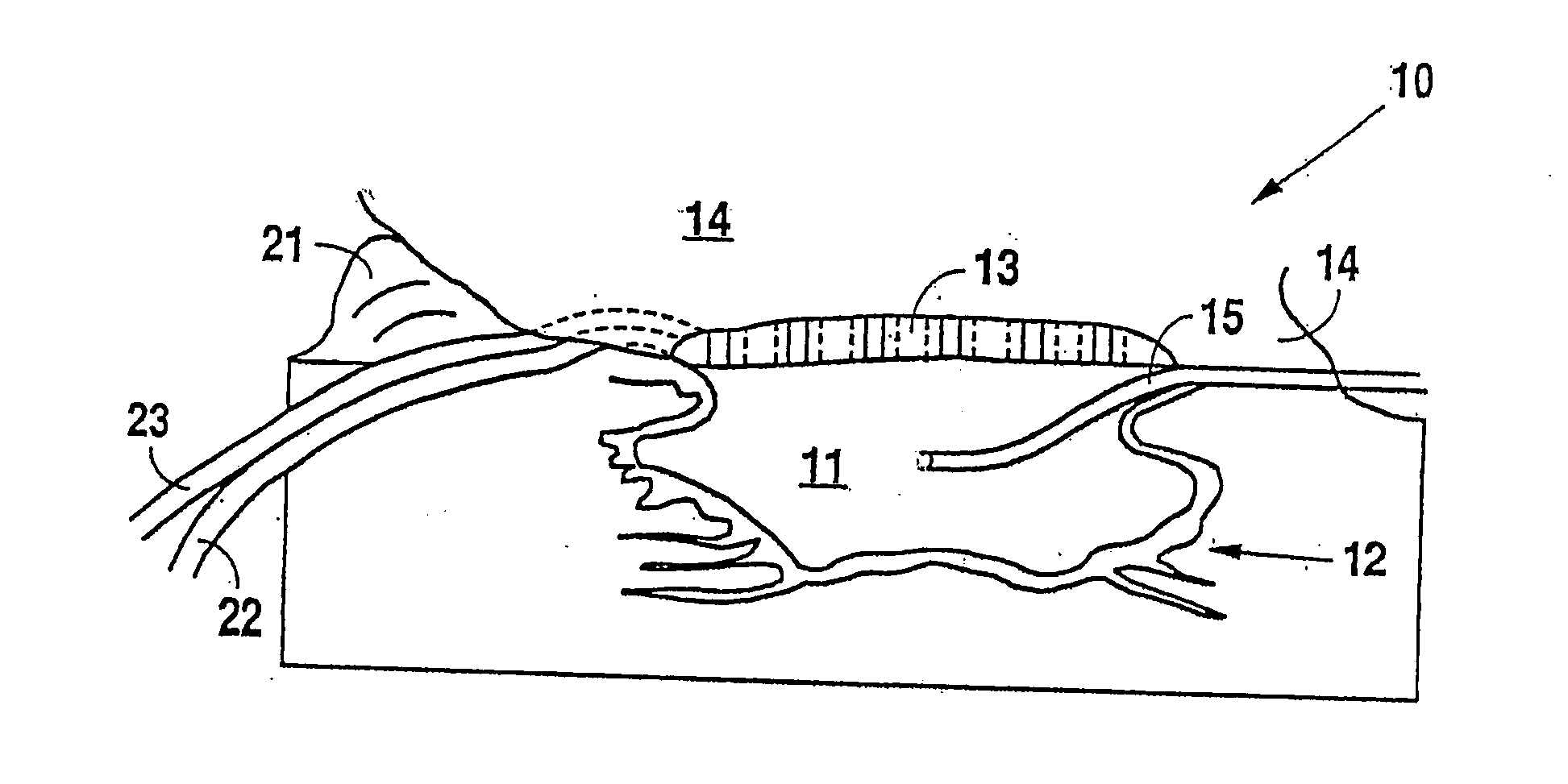

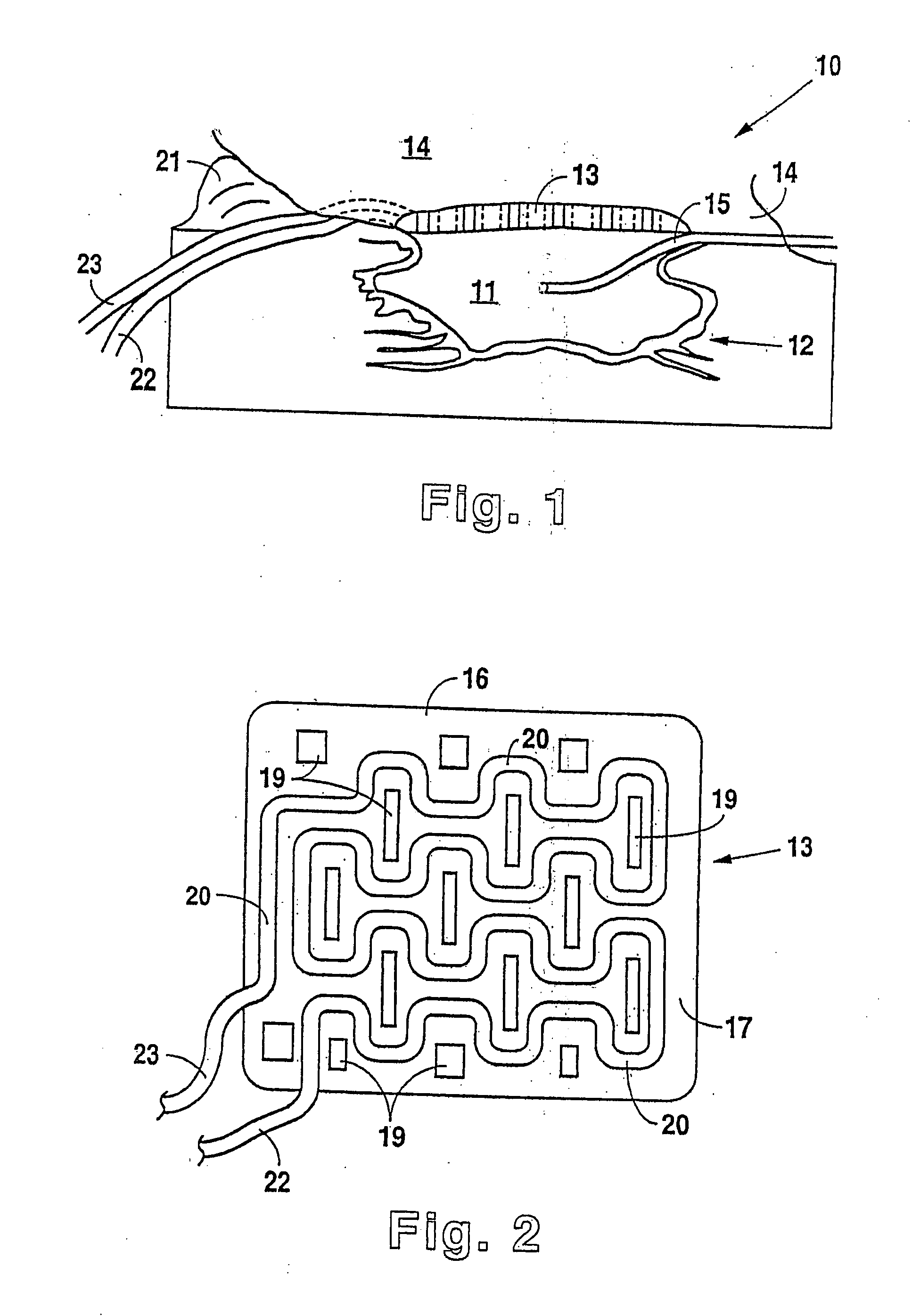

InactiveUS7144390B1Prevent vacuum leakageReduce inflammationSurgical needlesPlastersWound siteSurgery

A method, and apparatus (10) for the controlled acceleration, and / or retardation of the body's inflammatory response generally comprises a foam pad (11) for insertion substantially into a wound site, a heating, a cooling pad (13) for application over the wound site (12), a wound drape (14) or sealing enclosure of the foam pad (11), the heating, and cooling pad (13) at wound site (12). The foam pad (11) is placed in fluid communication with a vacuum source for promotion of the controlled acceleration or retardation of the body's inflammatory response. The heating, and cooling provision controls the local metabolic function as part of the inflammatory response.

Owner:KCI LICENSING INC

Apparatus and method for measuring biologic parameters

ActiveUS20070106172A1Precise positioningGood visual impactThermometer detailsUltrasonic/sonic/infrasonic diagnosticsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS8328420B2Increase blood flowReduce in quantityThermometer detailsTelevision system detailsInfraredWireless transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. A sensor fitted on the support structures uses a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS8172459B2Increase blood flowReduce in quantityThermometer detailsUltrasonic/sonic/infrasonic diagnosticsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

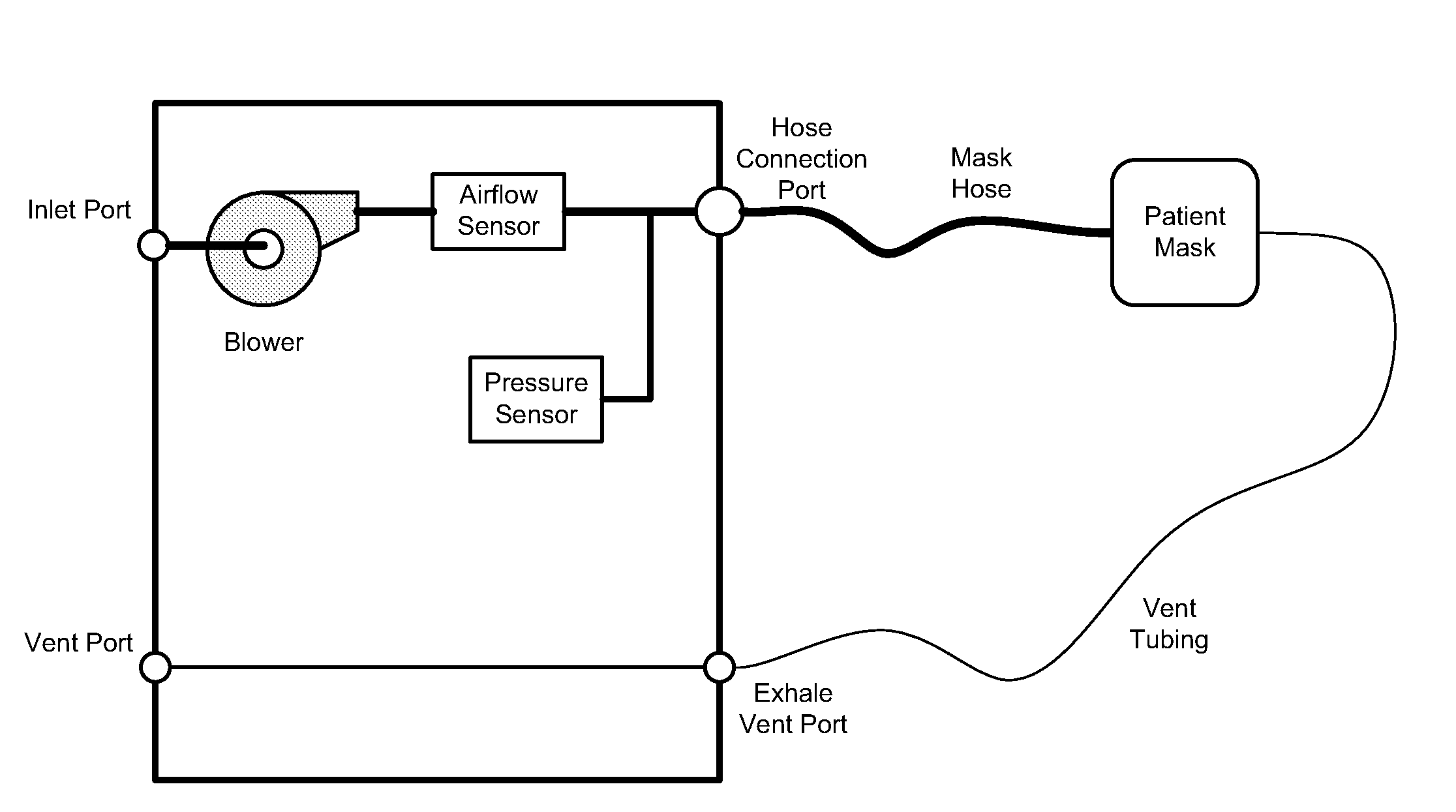

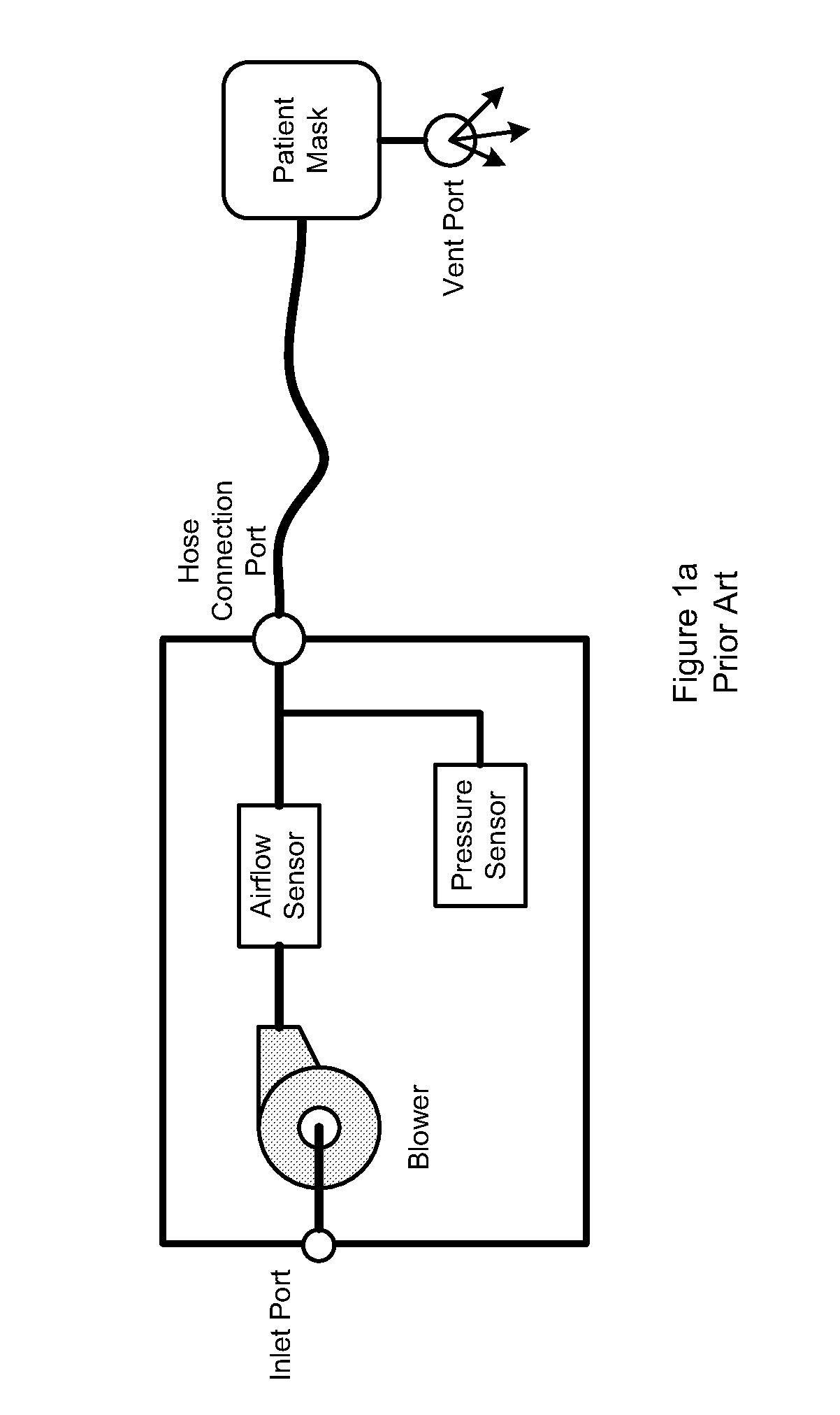

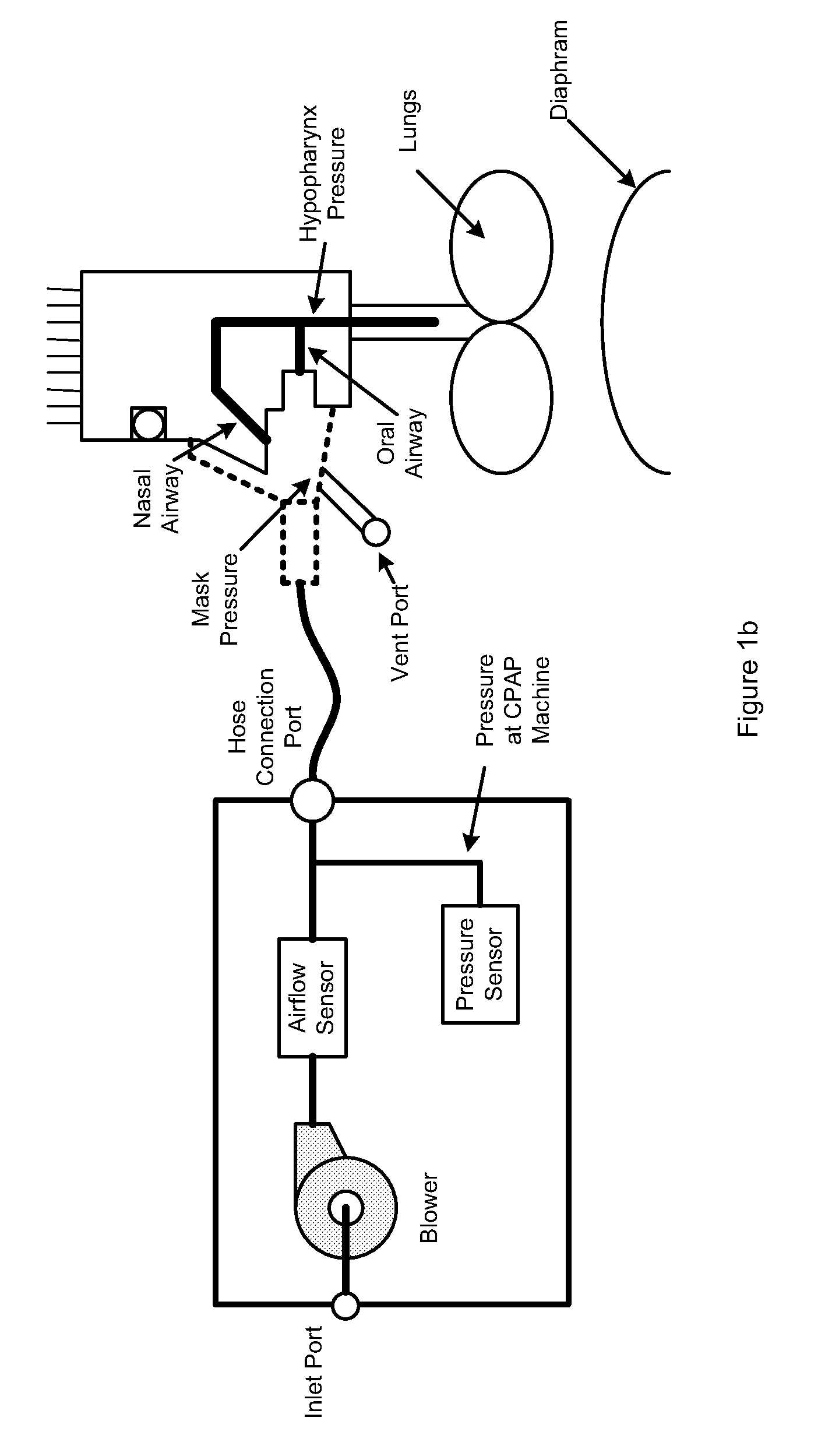

Positive Airway Pressure System and Method

InactiveUS20120065533A1Operating means/releasing devices for valvesRespiratory masksPositive airway pressurePositive pressure

A CPAP system and method which allows the control of released gases from the patient circuit. Coordination of blower speeds and the amount of released gases to improve patient therapy are disclosed. Methods and systems to control patient CO2 retention within the patient mask and to measure patient metabolic function are disclosed.

Owner:CARRILLO JR OSCAR +1

System for combined transcutaneous blood gas monitoring and negative pressure wound treatment

InactiveUS7524286B2Substantial riskAccurate estimateIntravenous devicesDiagnostic recording/measuringMicrocontrollerSignificant risk

Owner:KCI LICENSING INC

APJ ligand polypeptides

InactiveUS6492324B1Lower Level RequirementsImprove the level ofBiocidePeptide/protein ingredientsAcquired immunodeficiencyReproductive function

Owner:TAKEDA PHARMA CO LTD

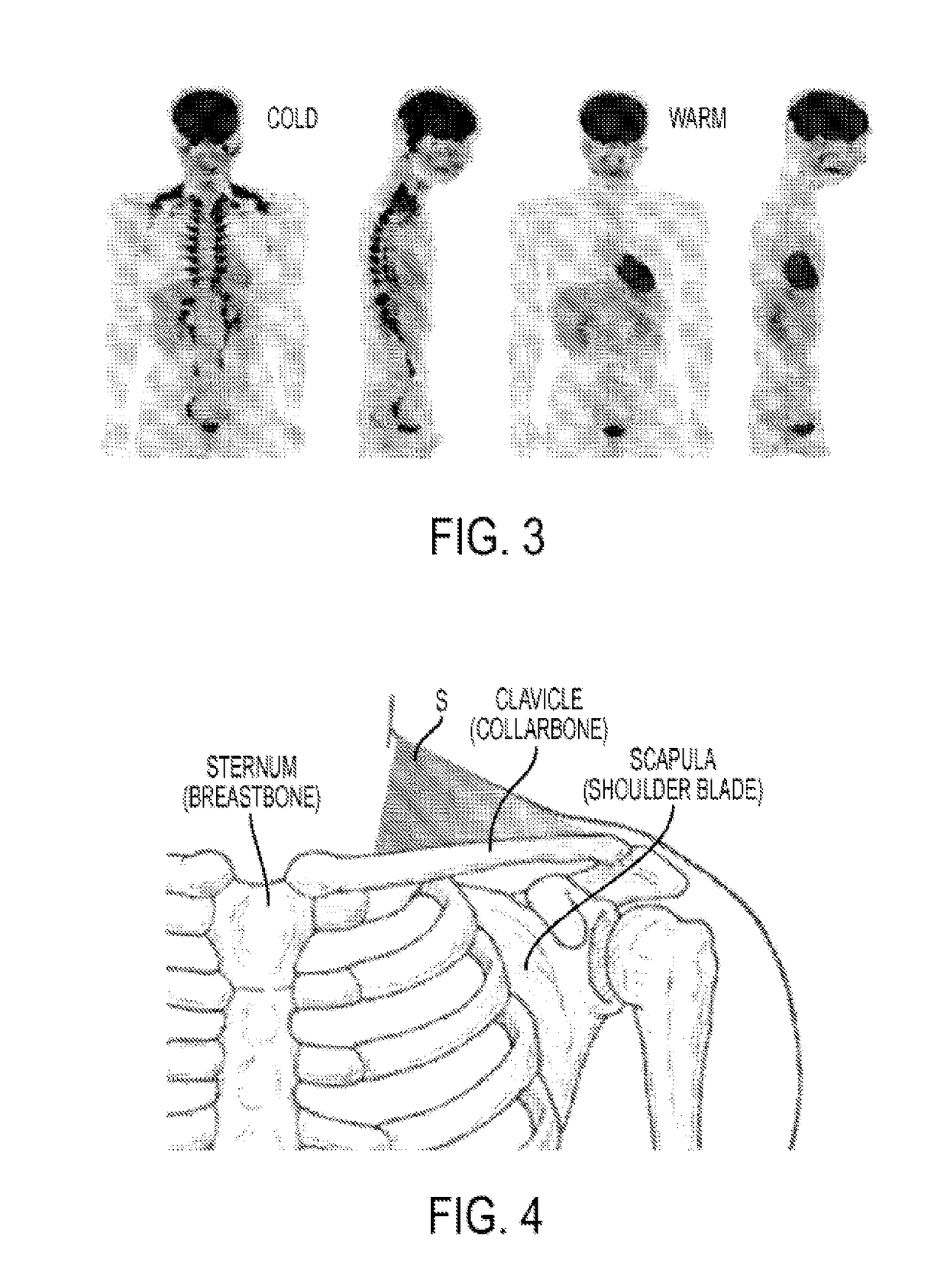

Thermal Imaging System

InactiveUS20130124039A1Increase blood flowReduce in quantityTelevision system detailsAir-treating devicesInfraredVideo transmission

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS20070219434A1Optimal signal acquisitionPreventing temperature disturbanceDiagnostic signal processingDiagnostics using lightWireless transmissionEyewear

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Peptides having ligand activities on APJ that is an orphan G protein-coupled receptor, and use thereof

Owner:TAKEDA PHARMA CO LTD

Tree nutrient solution

The invention relates to a plant nutrient solution, in particular to a tree nutrient solution. The nutrient solution is formed by mixing a plant macroelement, a plant microelement, a physiologically active substance, an external source hormone and water. After the tree nutrient solution is applied to a tree, a survival rate of the large tree after transplantation can be increased as soon as possible, and the tree nutrient solution particularly has an important and positive effect on improving a metabolic function of the old tree and recovering the tree vigor.

Owner:四川韵然景观园林工程有限公司

Apparatus and method for measuring biologic parameters

ActiveUS20120316459A1Increase blood flowReduce in quantityUltrasonic/sonic/infrasonic diagnosticsBody temperature measurementInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Negative pressure treatment system with heating and cooling provision

InactiveUS20070073200A1Reduce inflammationImprove inflammatory responseSurgical needlesPlastersWound sitePartial heating

A method, and apparatus for the controlled acceleration, and / or retardation of the body's inflammatory response generally comprises a foam pad for insertion substantially into a wound site, a heating, a cooling pad for application over the wound site, a wound drape or sealing enclosure of the foam pad, the heating, and cooling pad at wound site. The foam pad is placed in fluid communication with a vacuum source for promotion of the controlled acceleration or retardation of the body's inflammatory response. The heating, and cooling provision controls the local metabolic function as part of the inflammatory response.

Owner:KCI LICENSING INC

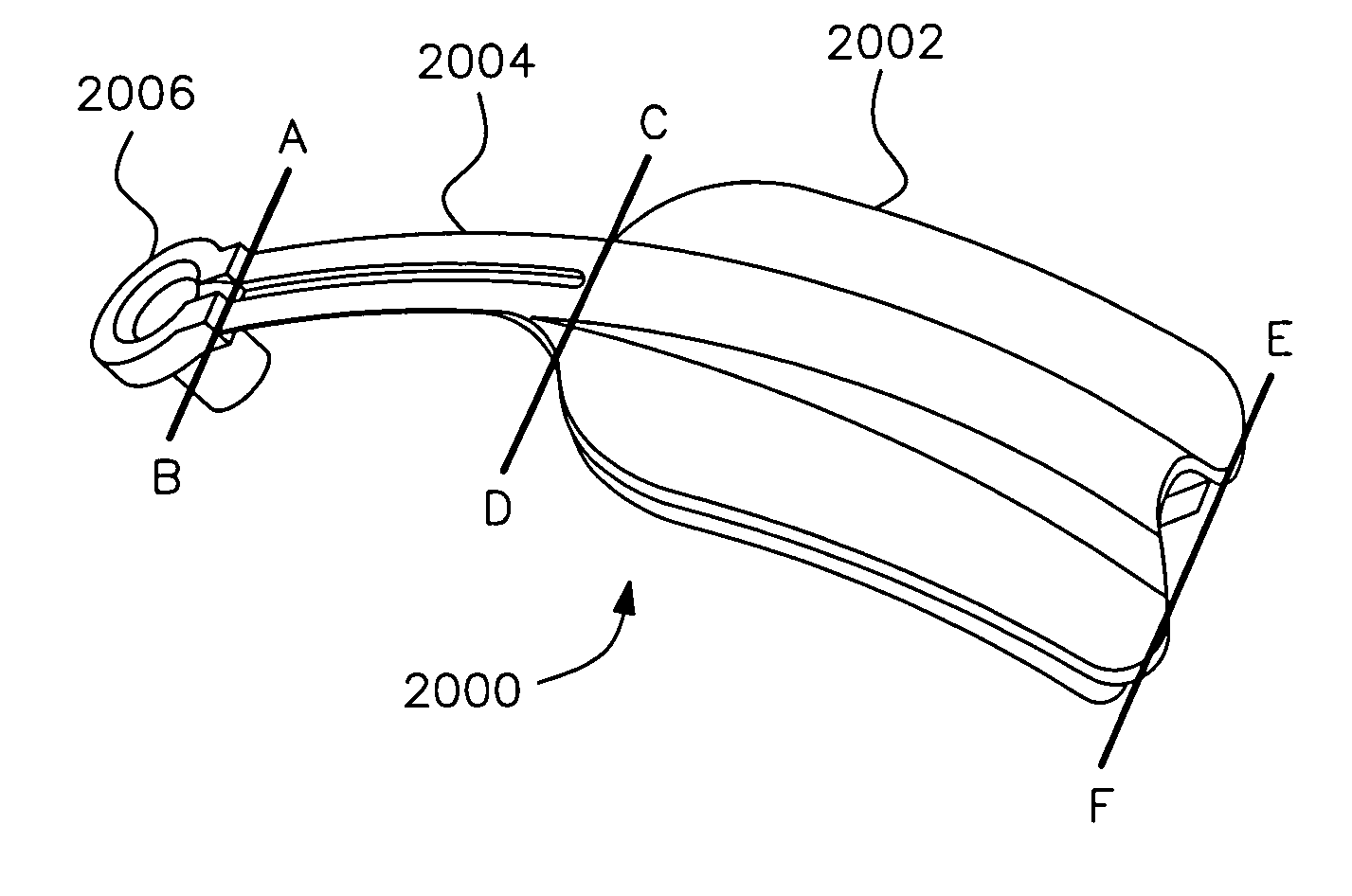

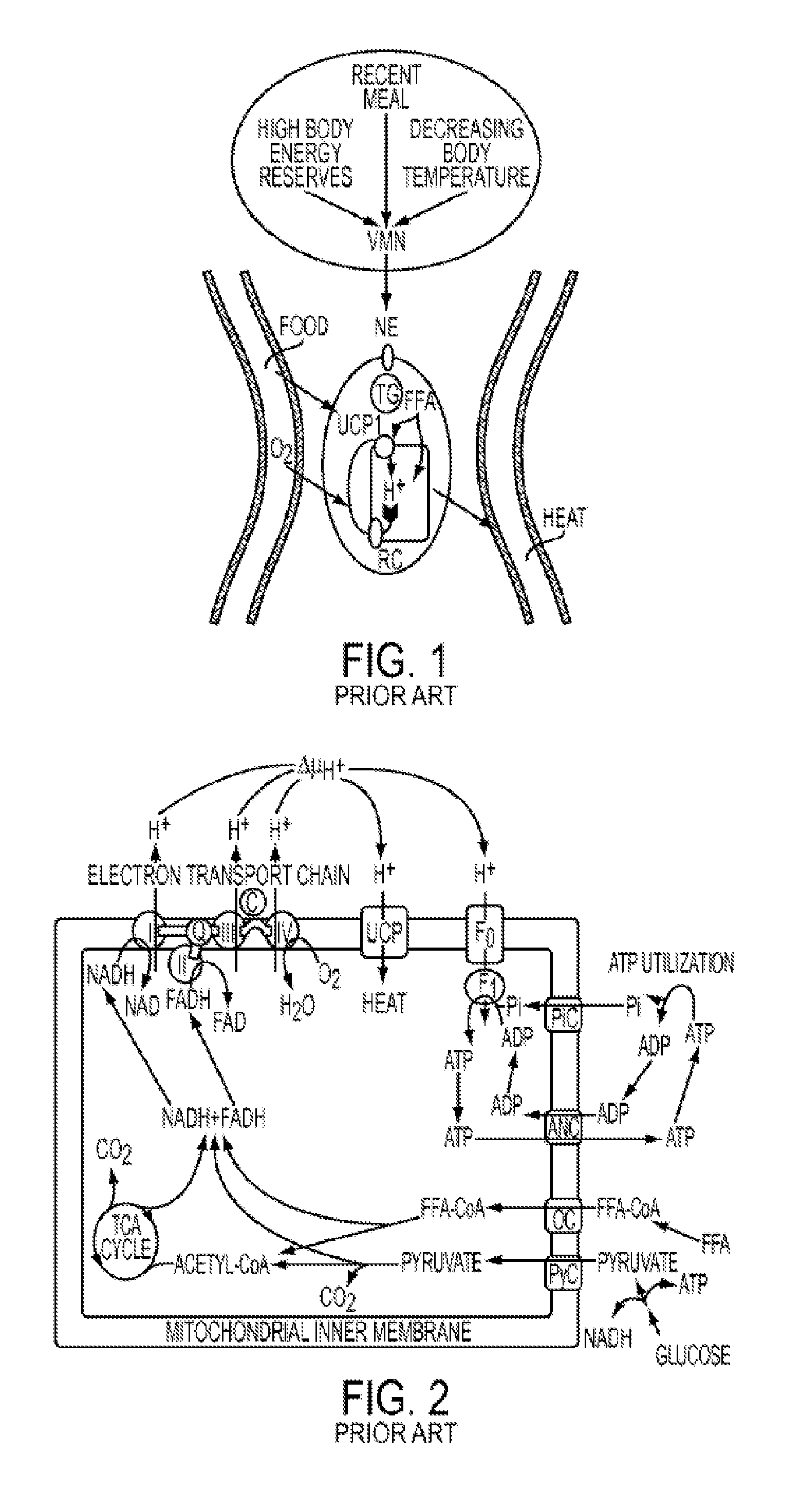

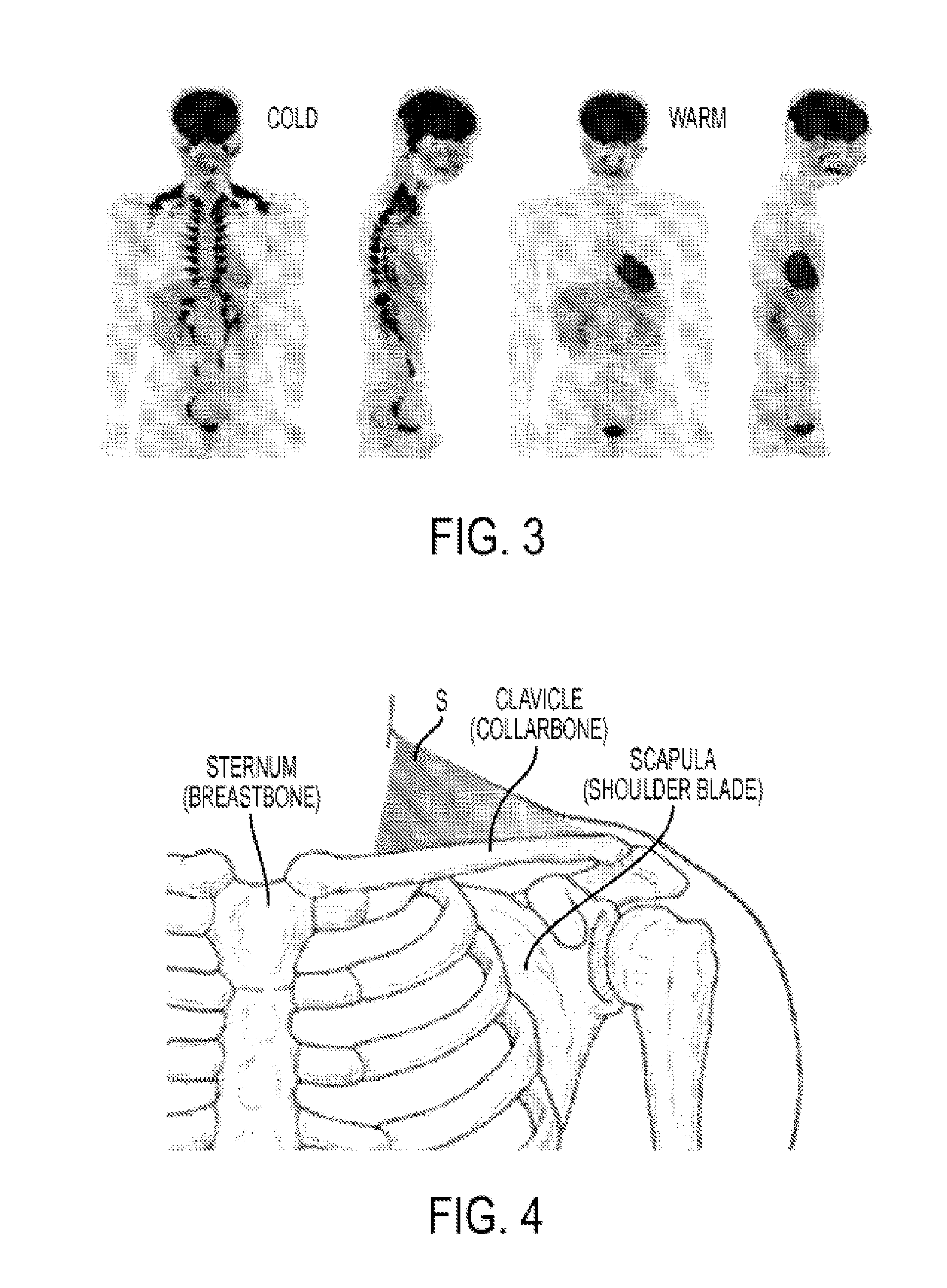

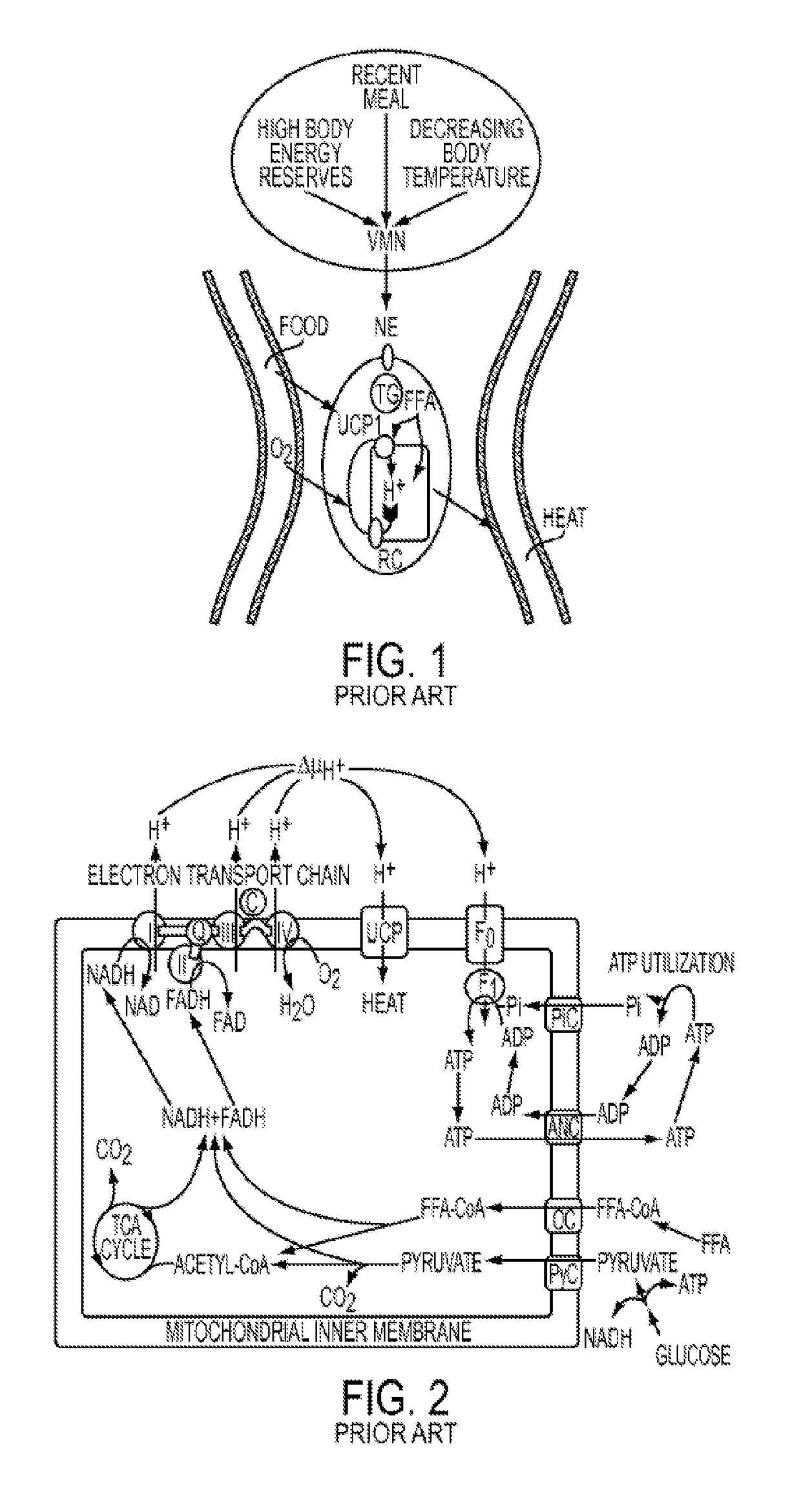

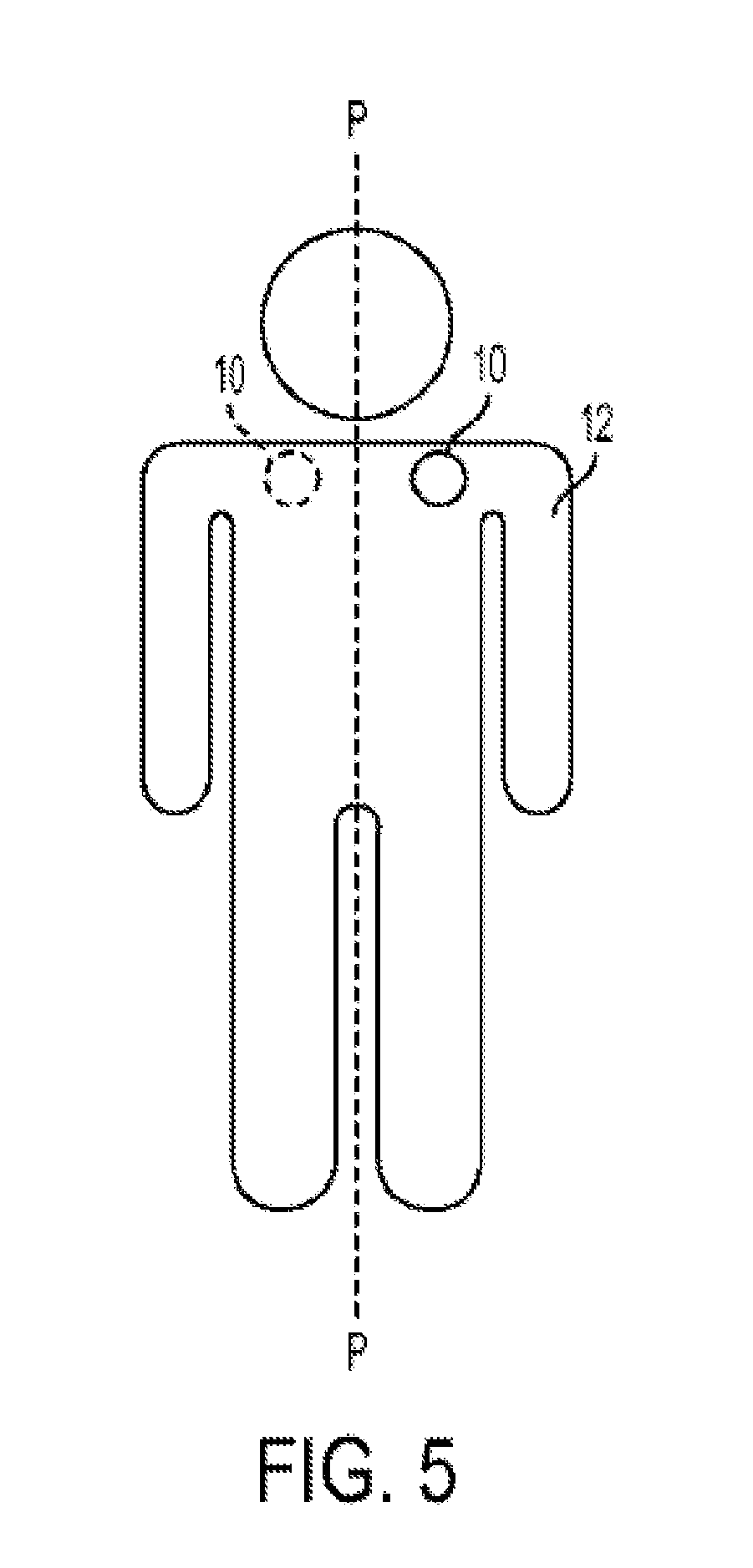

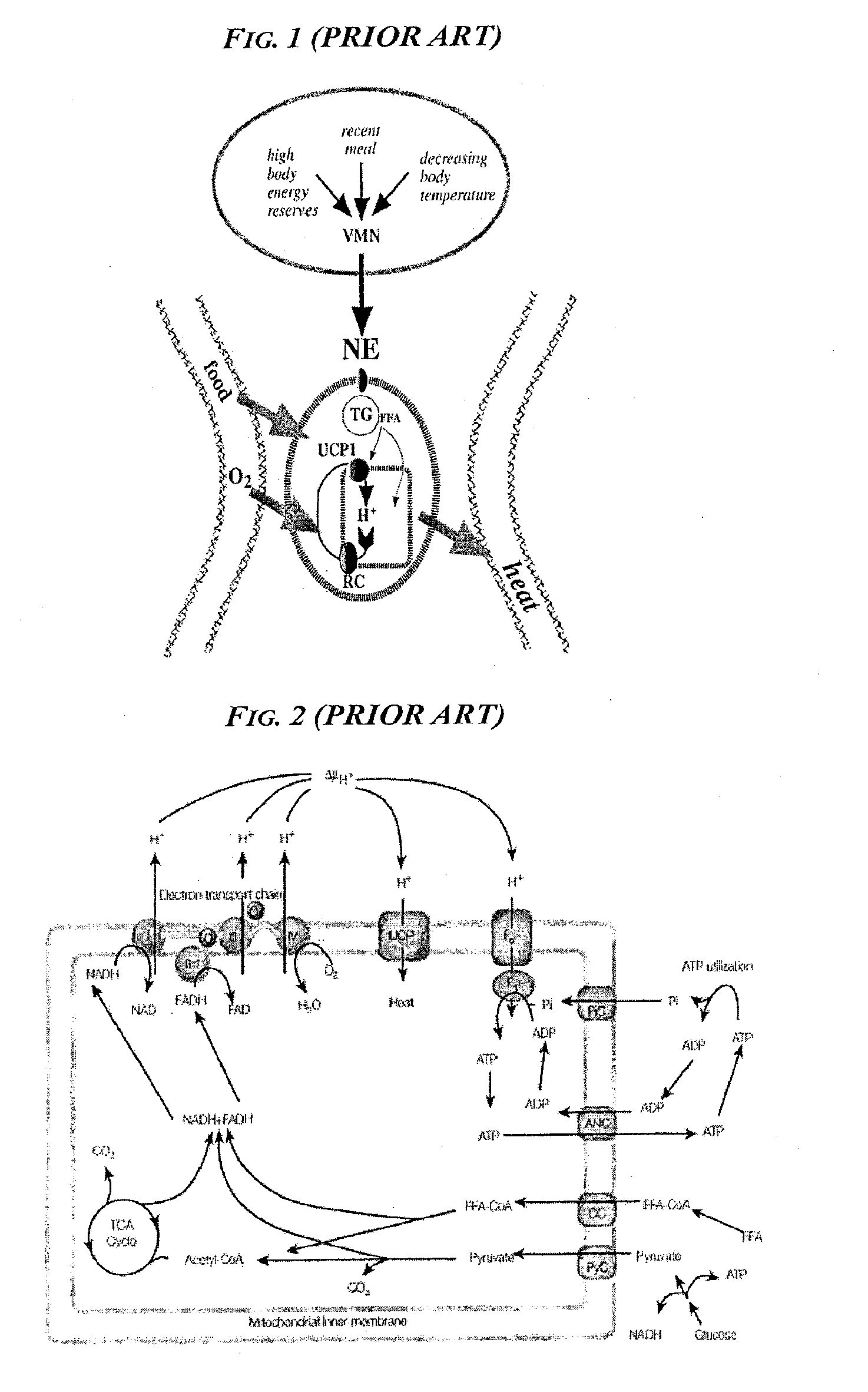

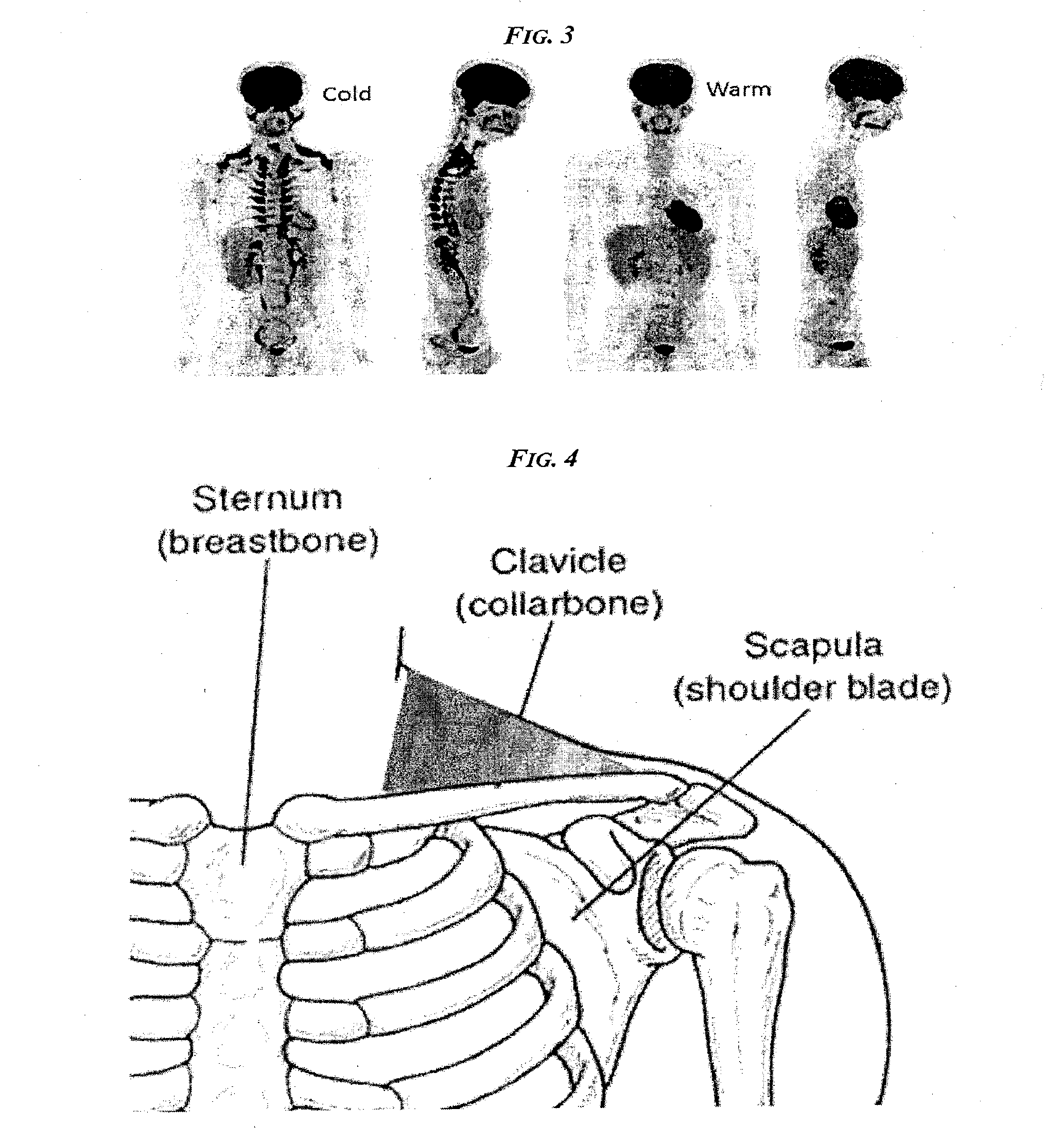

Methods and devices for activating brown adipose tissue with targeted substance delivery

ActiveUS20140018767A1Increased energy expenditureElectrocardiographyMedical devicesBrown adipose cellWhole body

Methods and devices are provided for activating brown adipose tissue with targeted substance delivery. Generally, the methods and devices can activate BAT to increase thermogenesis, e.g., increase heat production in the patient, which over time can lead to weight loss and / or improved metabolic function. In one embodiment, a chemical configured to stimulate nerves that activate the BAT and / or to stimulate brown adipocytes directly can be delivered to a patient, thereby increasing thermogenesis in the BAT and inducing weight loss and / or improved metabolic function through energy expenditure. The chemical can be delivered to the patient locally and / or systemically to stimulate the nerves and / or the brown adipocytes.

Owner:THE GENERAL HOSPITAL CORP +1

Methods and devices for activating brown adipose tissue with targeted substance delivery

ActiveUS9610429B2Increased energy expenditureElectrocardiographyMedical devicesBrown adipose cellMicrochiroptera

Methods and devices are provided for activating brown adipose tissue with targeted substance delivery. Generally, the methods and devices can activate BAT to increase thermogenesis, e.g., increase heat production in the patient, which over time can lead to weight loss and / or improved metabolic function. In one embodiment, a chemical configured to stimulate nerves that activate the BAT and / or to stimulate brown adipocytes directly can be delivered to a patient, thereby increasing thermogenesis in the BAT and inducing weight loss and / or improved metabolic function through energy expenditure. The chemical can be delivered to the patient locally and / or systemically to stimulate the nerves and / or the brown adipocytes.

Owner:THE GENERAL HOSPITAL CORP +1

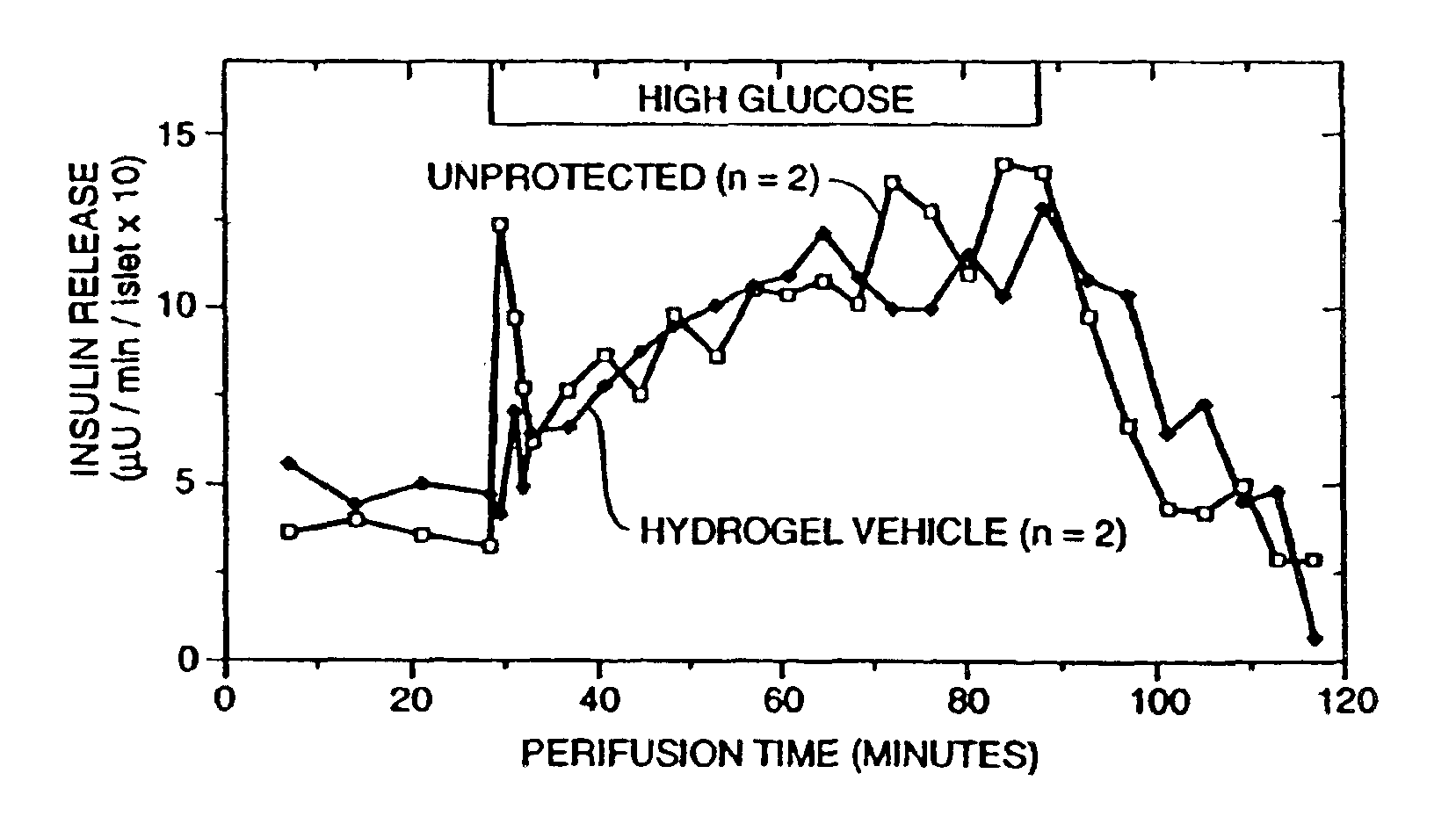

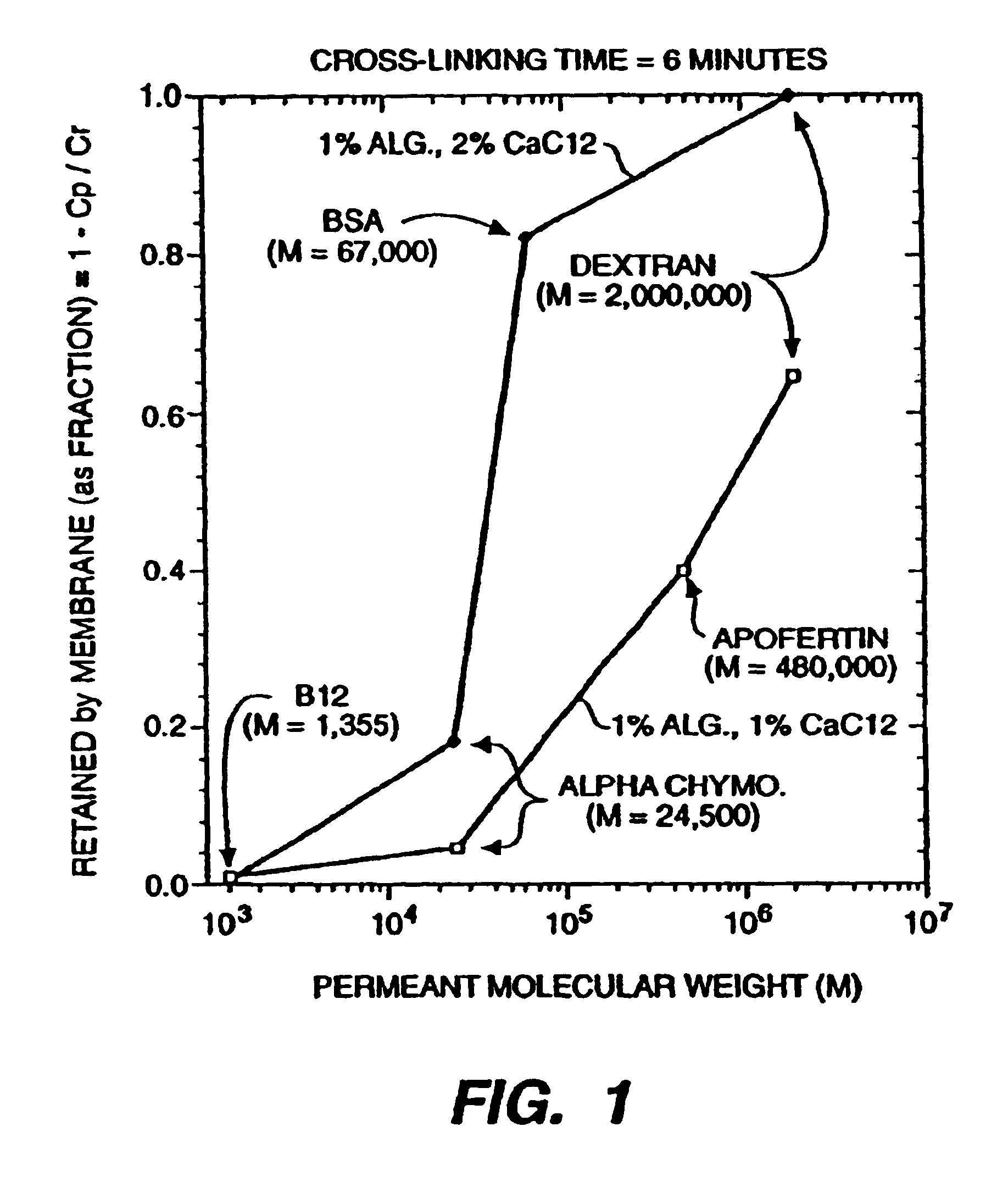

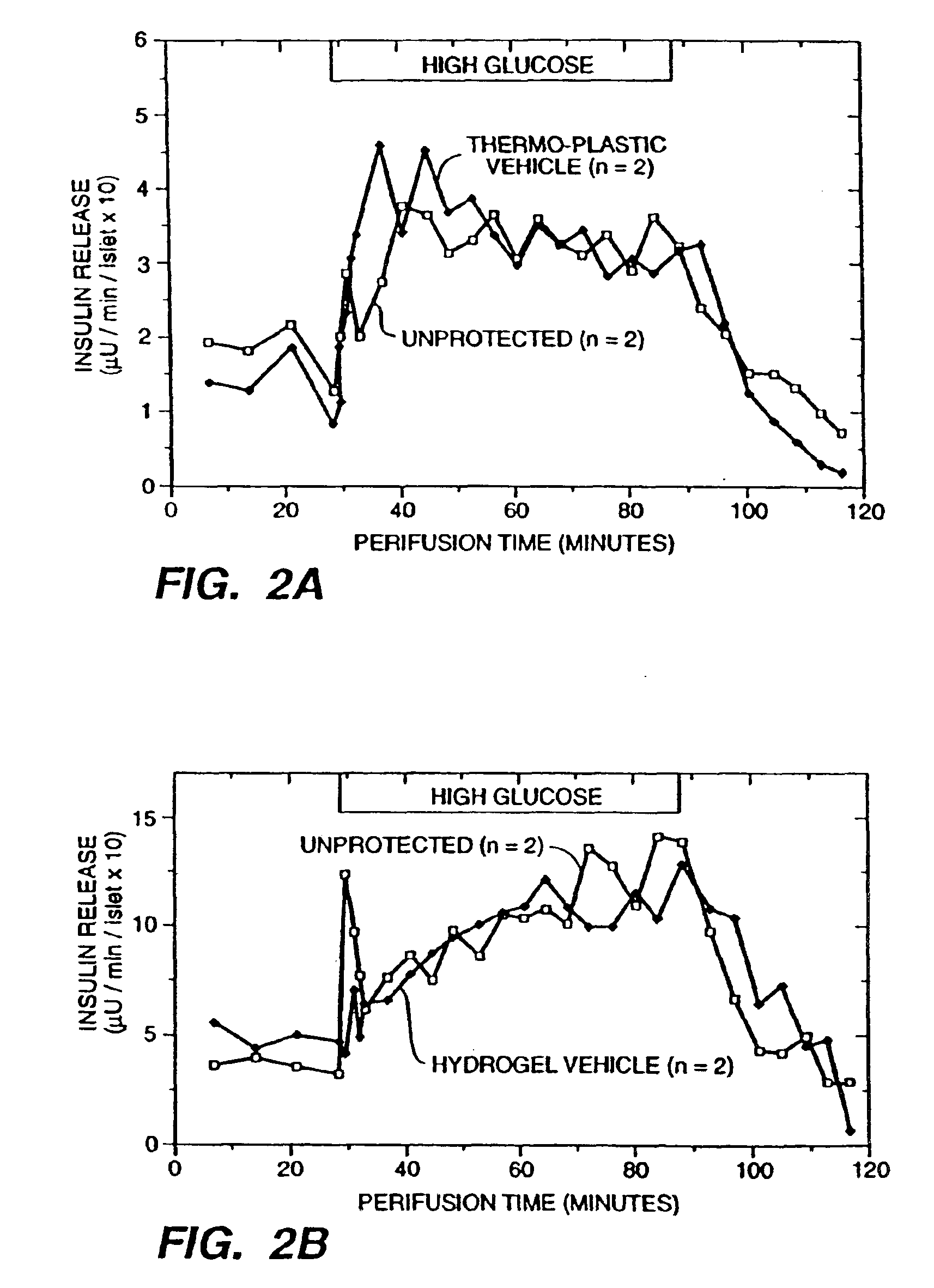

Implantable biocompatible immunoisolatory vehicle for delivery of selected therapeutic products

InactiveUS6960351B2Sufficient protectionProtection attackNervous disorderPancreatic cellsBiologyBiological product

An immunoisolatory vehicle for the implantation into an individual of cells which produce a needed product or provide a needed metabolic function. The vehicle is comprised of a core region containing isolated cells and materials sufficient to maintain the cells, and a permselective, biocompatible, peripheral region free of the isolated cells, which immunoisolates the core yet provides for the delivery of the secreted product or metabolic function to the individual. The vehicle is particularly well-suited to delivery of insulin from immunoisolated islets of Langerhans, and can also be used advantageously for delivery of high molecular weight products, such as products larger than IgG. A method of making a biocompatible, immunoisolatory implantable vehicle, consisting in a first embodiment of a coextrusion process, and in a second embodiment of a stepwise process. A method for isolating cells within a biocompatible, immunoisolatory implantable vehicle, which protects the isolated cells from attack by the immune system of an individual in whom the vehicle is implanted. A method of providing a needed biological product or metabolic function to an individual, comprising implanting into the individual an immunoisolatory vehicle containing isolated cells which produce the product or provide the metabolic function.

Owner:BROWN UNIV RES FOUND INC

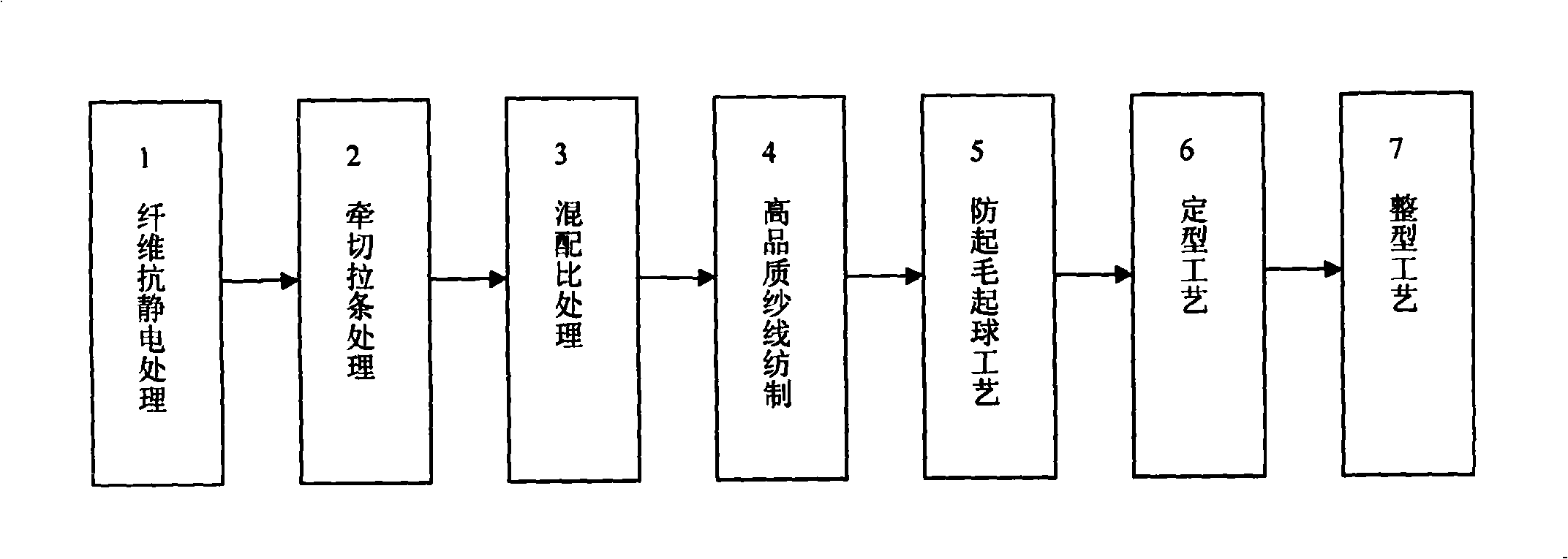

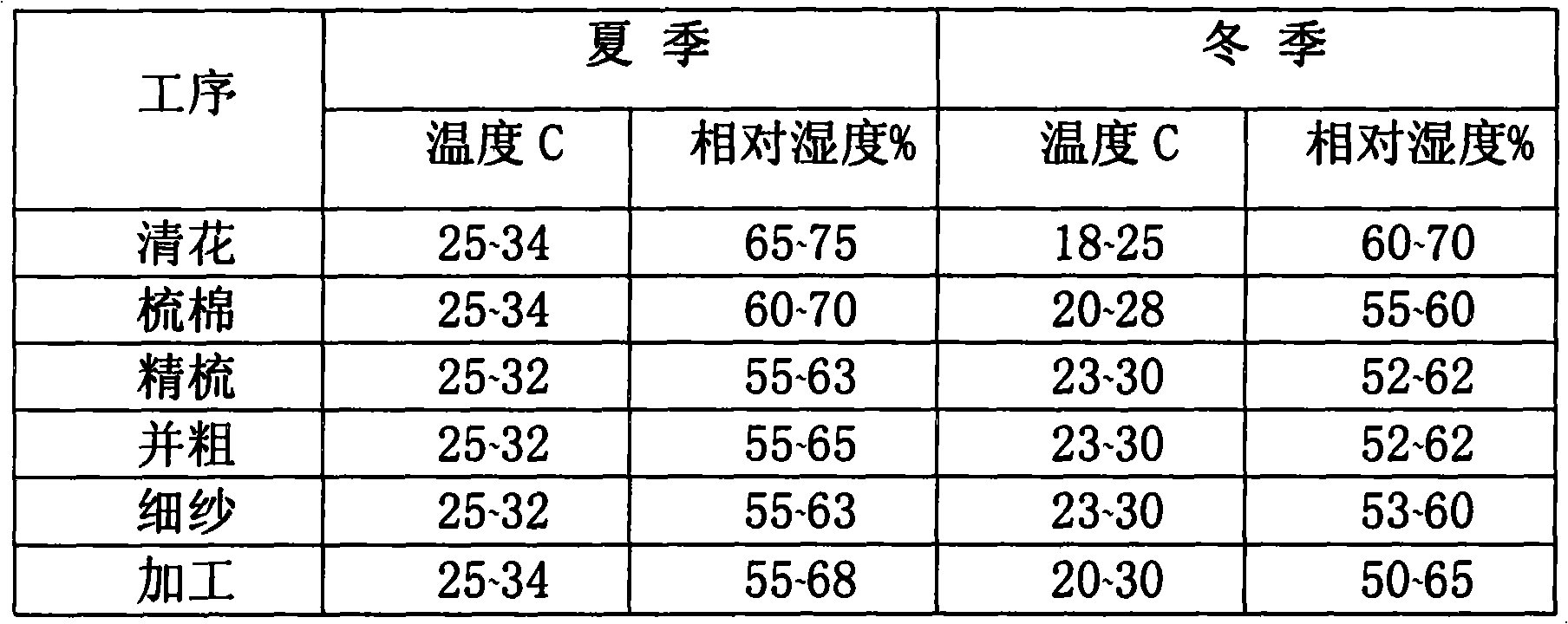

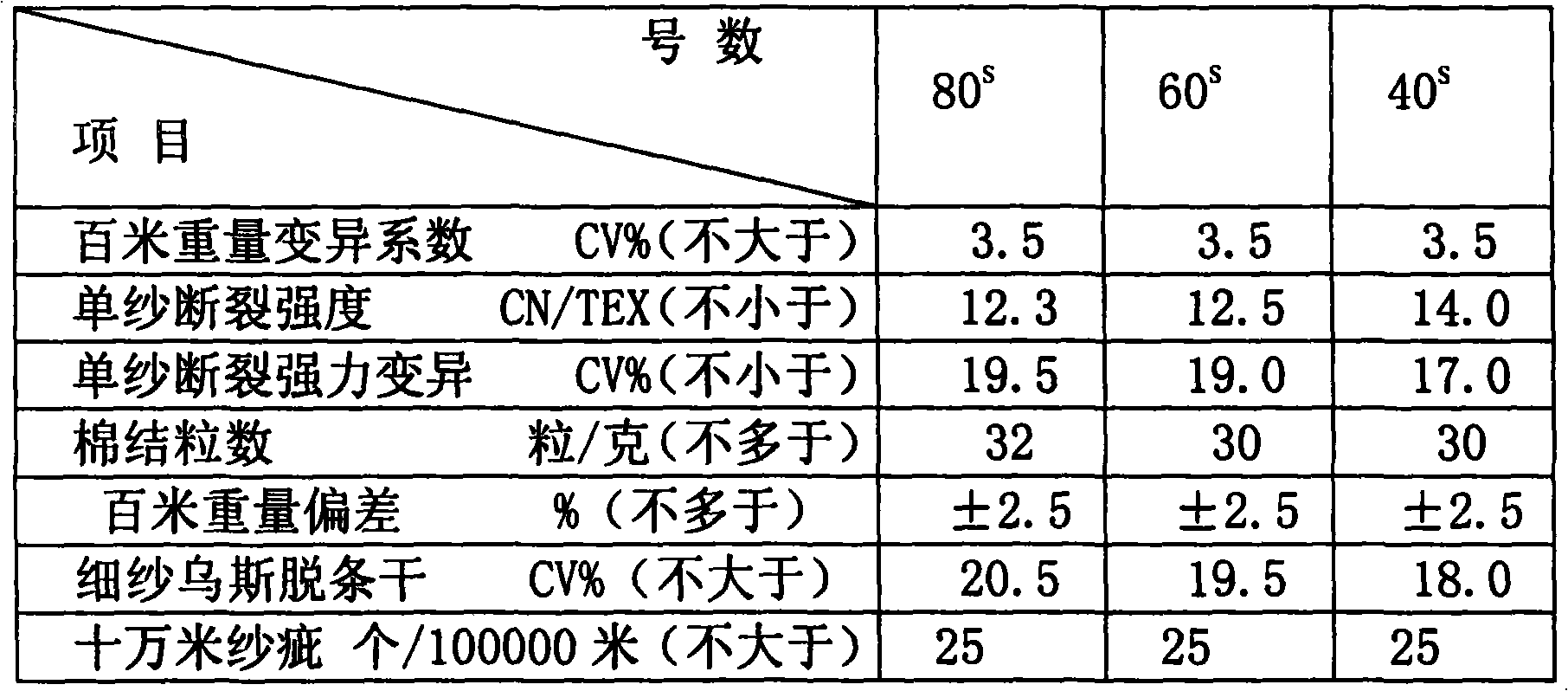

Clear and smooth blended yarn and production process thereof

The invention relates to a cotton textile-engineering field in the textile industry, in particular to a pure nylon blended yarn composed of the blended fabric of natural and chemical fibers and the production process of the pure nylon blended yarn, which has the technical scheme that through the changes of process parameters in the yarn spinning process and the special production processes of anti-static fiber blending treatment, yarn spinning twisting, double-twisting, modeling, integrating and other process steps in sequence, a special yarn with crepe twisting is produced in which the twisting coefficient range is 600 to 760 and the range of yarn count is 20s to 80s (yarns) is produced. The utility model is mainly to resolve the relevant technology issue that how to increase the twisting coefficient of spinning yarn substantially. The invention has the advantages that the twisting coefficient range of pure nylon blended yarn can reach 600 to 760 and the production yarn range thereof can reach the single and double yarns of 20s to 80s, which can be widely applied in circular knitting machines, flat knitting machines, tatting and other woven fabric series to fill in a gap in this domestic product category.. Therefore, the invention has the advantages the evaporation and permeability are increased with strong emotional cold feeling, unique luster, bright color and strong wear resistance. The moisture absorption and perspiration can be increased to facilitate the metabolic functions.

Owner:SHANGHAI HEYE TEXTILE

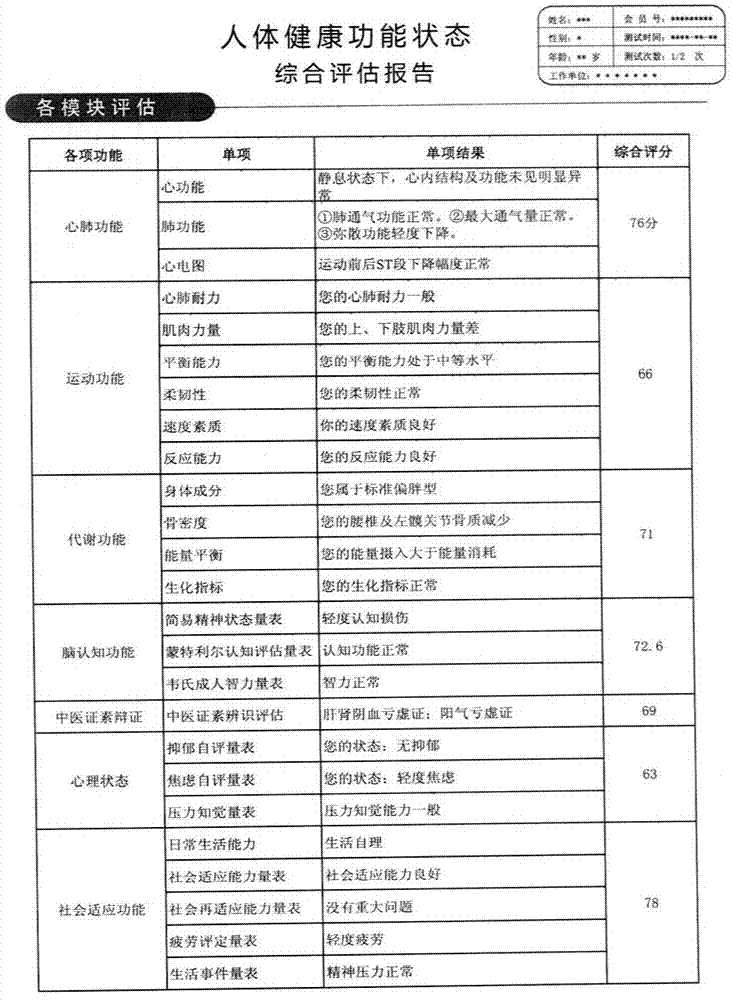

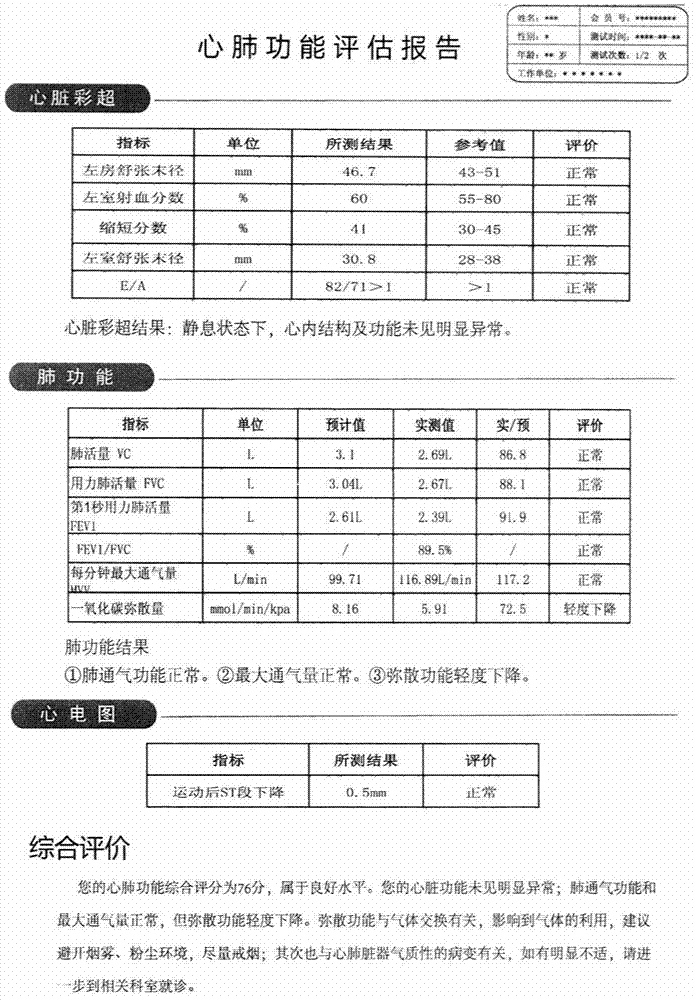

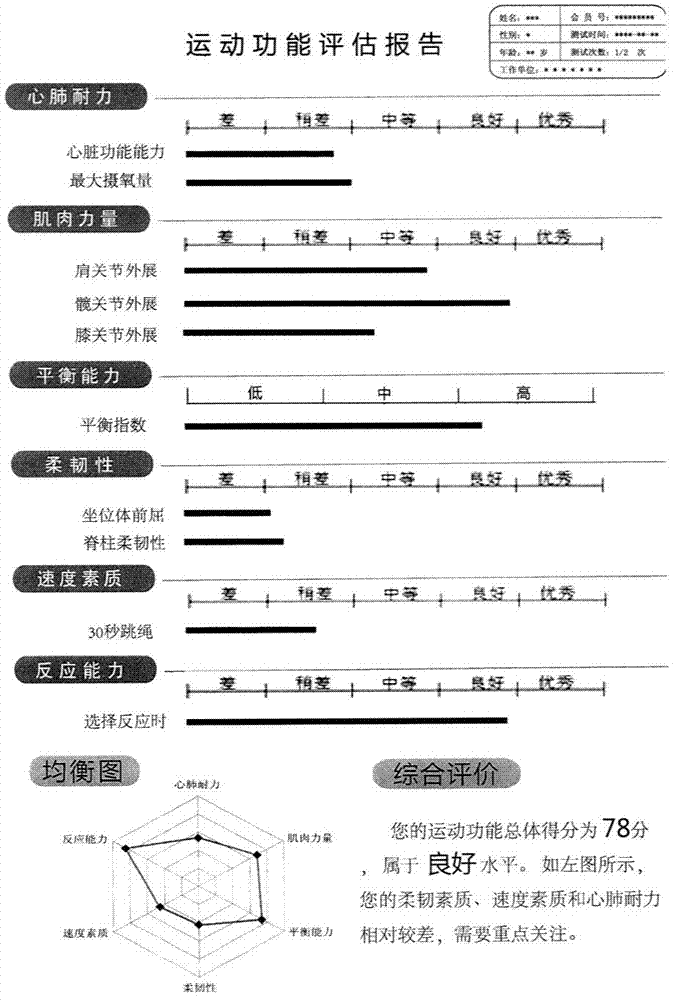

Human-body health function-status evaluating model

The invention relates to a human-body health function-status evaluating model, relates to an evaluating method for comprehensively evaluating the functional level of a human body and belongs to the category of health evaluation. The construction of the evaluating model comprises the establishment of seven modules, i.e. a brain-cognizing function module, a metabolic function module, a traditional-Chinese-medicine symptom-identifying module, a psychological function module, a social-adapting function module, a cardio-pulmonary function module and a movement function module and the establishment of a specific testing project, an index system and a specific index under each module and a testing-project evaluating standard. The score evaluation of the whole module is finally obtained through each-step index evaluation, weight determination and calculation step by step. The integral comprehensive evaluation and the evaluating result of each module are all shown by corresponding evaluation reports. Functional-status levels in the aspects of physiology, psychology and social adaptation of the human body can be obtained through the health function-status evaluation of the human body, so that potential health hazards are found in advance, and intervention treatment is carried out as early as possible, so as to guarantee the physical and psychological function-status health of the human body.

Owner:陈立典

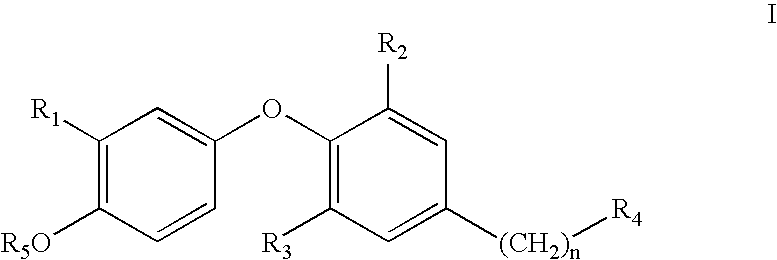

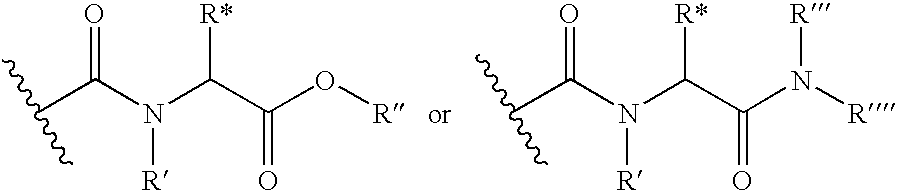

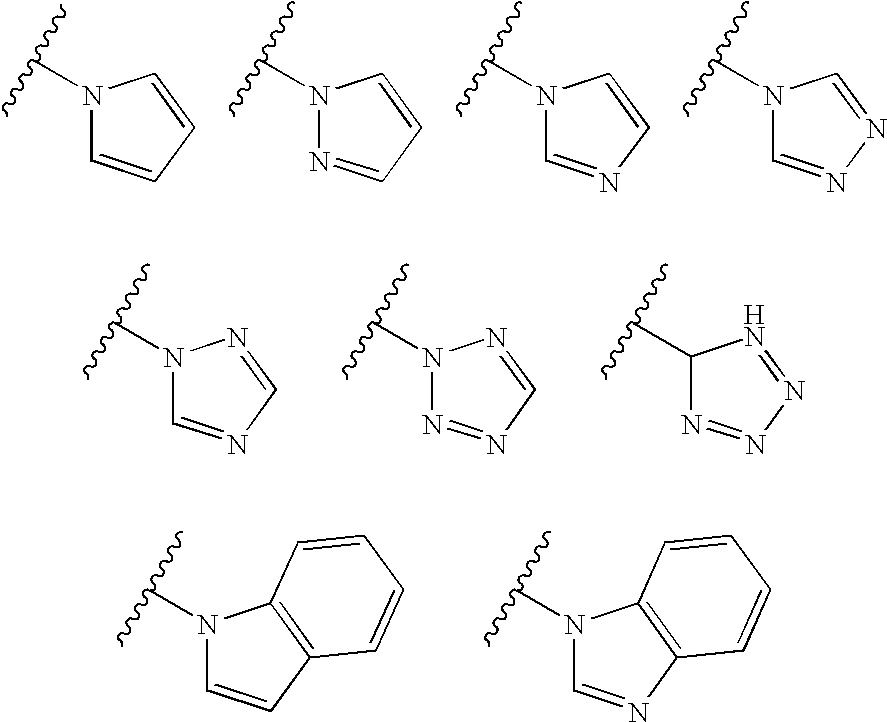

Thyroid receptor ligands and method II

New thyroid receptor ligands are provided which have general formula (I) in which: n is an integer from 0 to 4; R1 is halogen, trifluoromethyl, or alkyl of 1 to 6 carbons or cycloalkyl of 3 to 7 carbons; R2 and R3 are the same or different and are hydrogen, halogen, alkyl of 1 to 4 carbons or cycloalkyl of 3 to 5 carbons, at least one of R2 and R3 being other than hydrogen; R4 is a carboxylic acid amide (CONR′R″) or an acylsulphonamide (CONHSO2R′) derivative, or a pharmaceutically acceptable salt thereof, and all stereoisomers thereof; or when n is equal to or greater than one, R4 may be a heteroaromatic moiety which may be substituted or unsubstituted, or an amine (NR′R″). R5 is hydrogen or an acyl (such as acetyl or benzoyl) or other group capable of bioconversion to generate the free phenol structure (wherein R5=H). In addition, a method is provided for preventing, inhibiting or treating a disease associated with metabolism dysfunction or which is dependent upon the expression of a T3 regulated gene, wherein a compound as described above is administered in a therapeutically effective amount. Examples of such diseases associated with metabolism dysfunction or are dependent upon the expression of a T3 regulated gene include obesity, hypercholesterolemia, atherosclerosis, cardiac arrhythmias, depression, osteoporosis, hypothyroidism, goiter, thyroid cancer as well as glaucoma, congestive heart failure and skin disorders.

Owner:KARO BIO AB

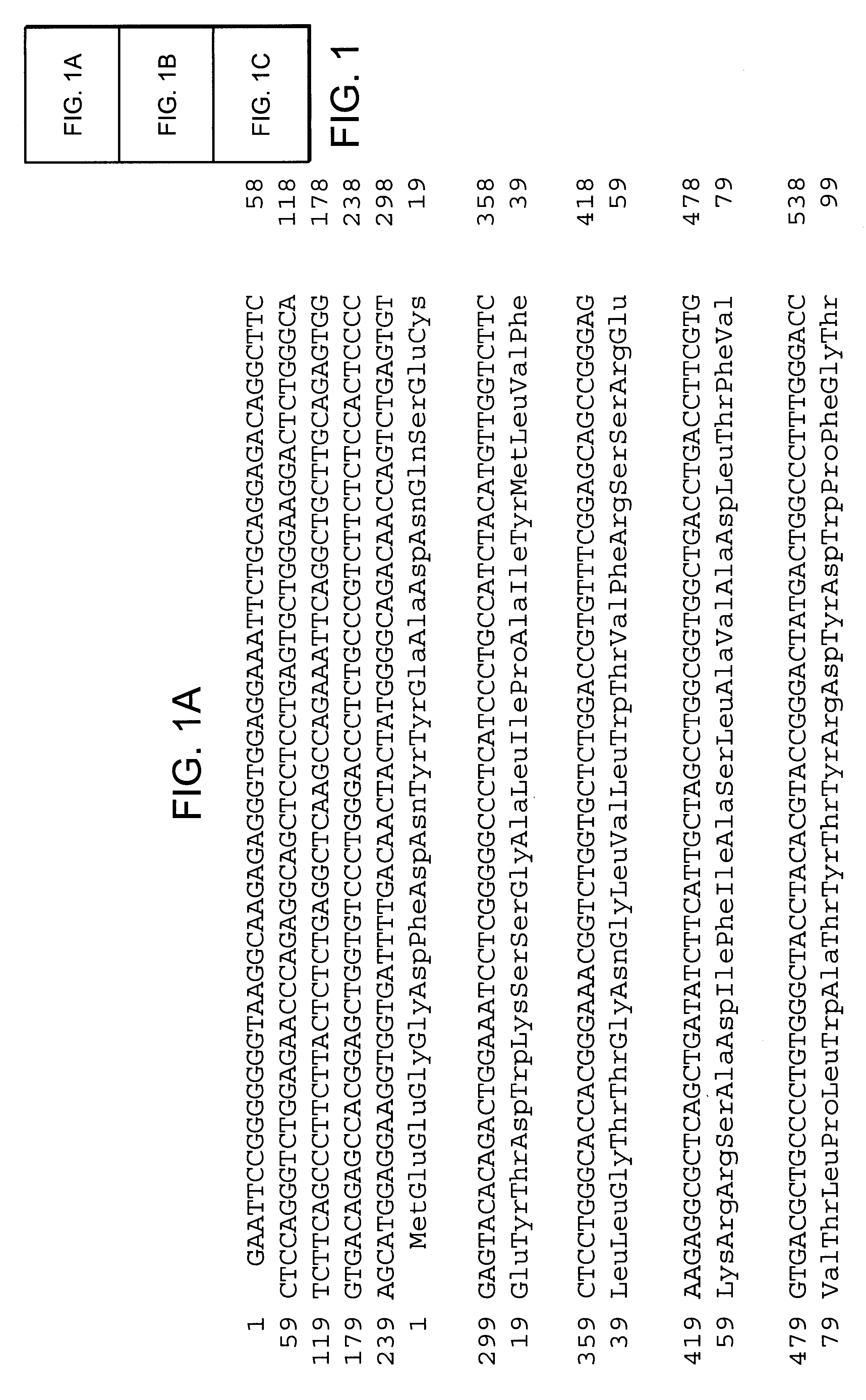

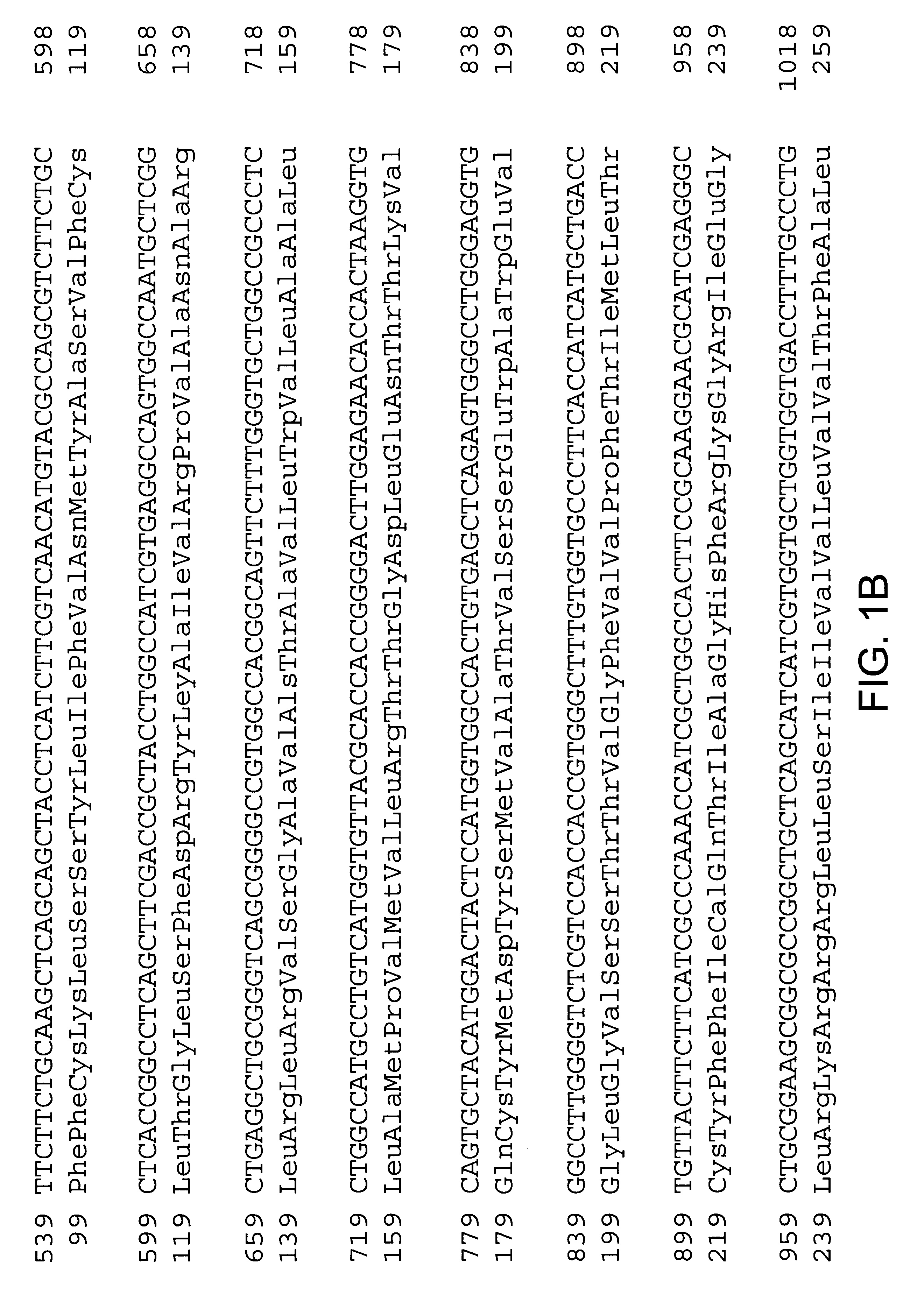

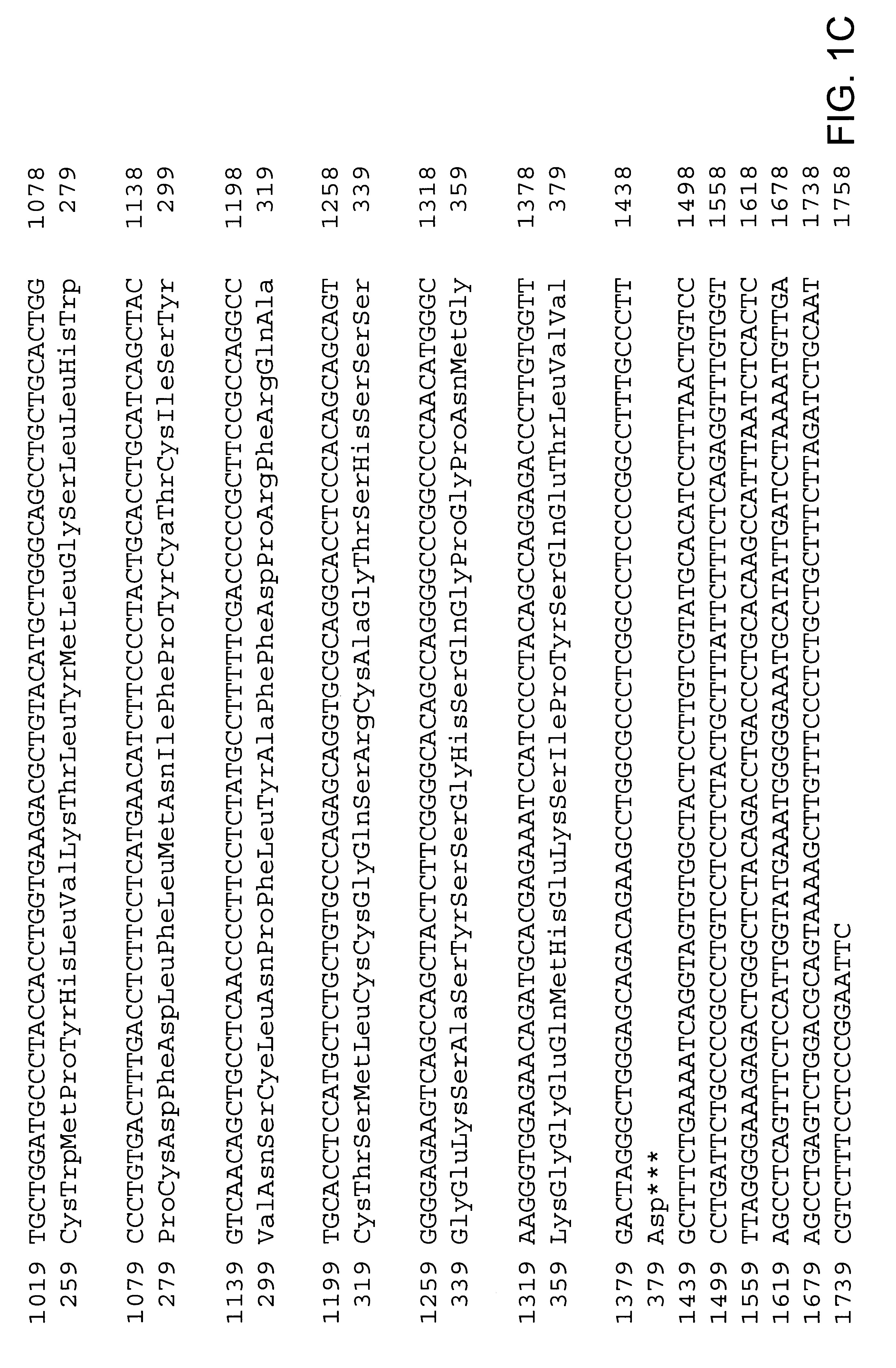

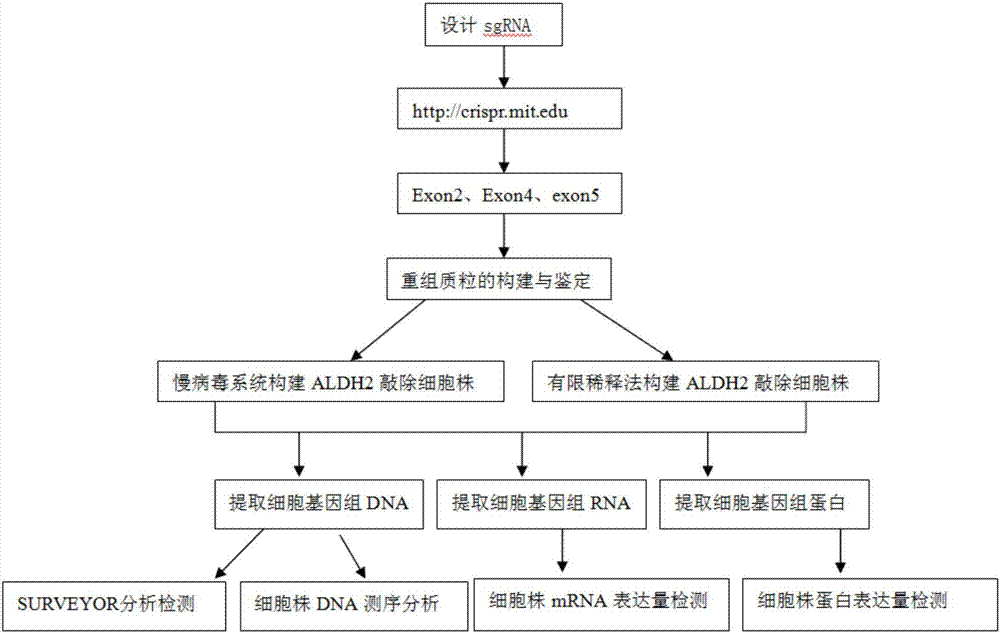

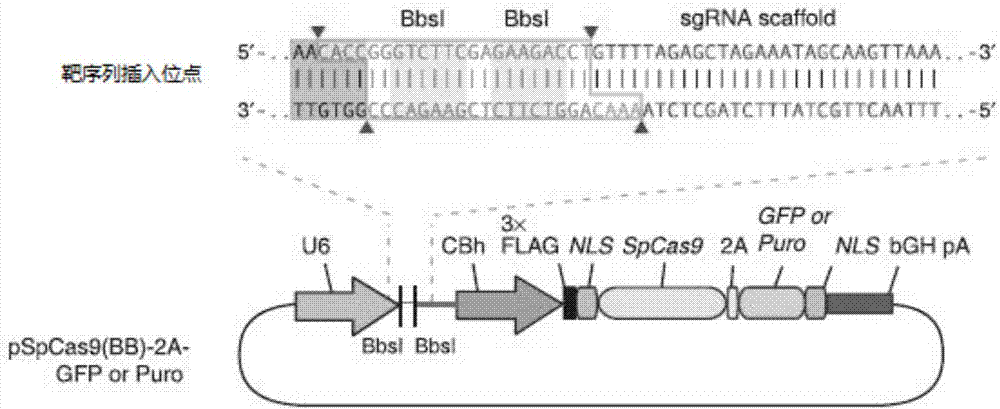

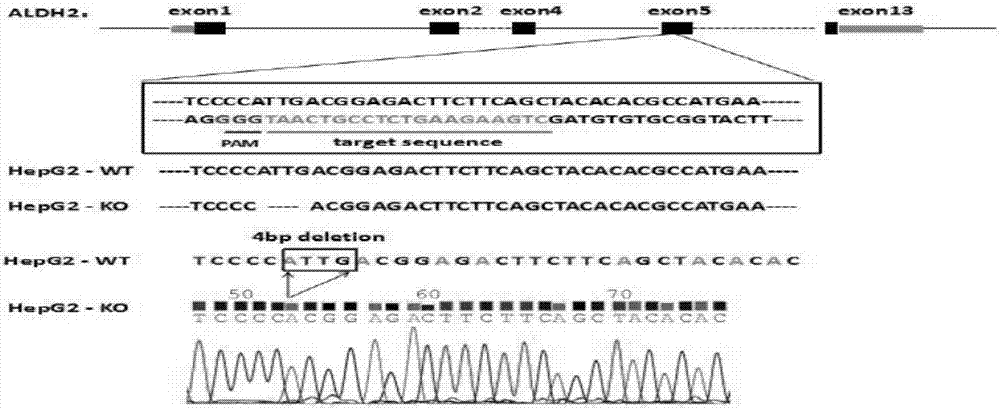

Construction method and application of sg RNA and ALDH2 gene deletion cell strains used for knocking out human ALDH2 gene

ActiveCN107502608AAchieve silencingImproved silence is not completeHydrolasesStable introduction of DNAIn vivoWilms' tumor

The invention provides an sg RNA sequence used for knocking out a human ALDH2 gene;,a target DNA sequence of the sg RNA is at least one of sequences as shown in SEQ ID NO:1, SEQ ID NO:2 and SEQ ID NO:3. The invention further provides a method for knocking out a human hepatoma carcinoma cell ALDH2 gene; the method utilizes a CRISPR / Cas system to modify the ALDH2 gene in a human hepatoma carcinoma cell. The invention further provides two ALDH2 gene deletion cell strains; ALDH2 participates in an important metabolic function of a body. The ALDH2 gene deletion cell strains provided by the invention provide an effective platform for metabolism study, in vivo, of exogenous chemicals or exogenous poisons, so that powerful means are provided for researching chronic diseases (such as alcoholic liver diseases and diabetes) as well as tumor-associated diseases.

Owner:SUN YAT SEN UNIV

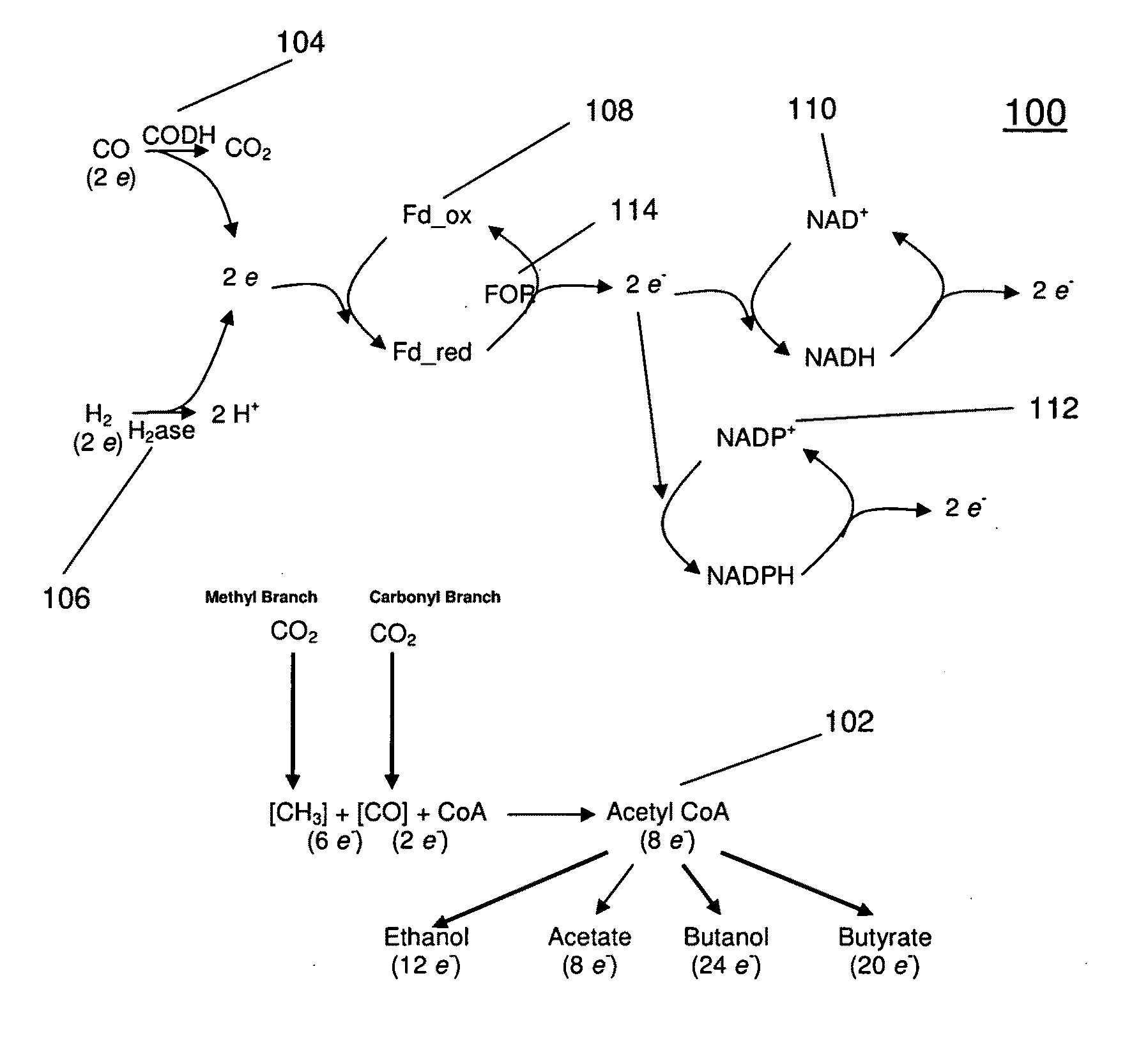

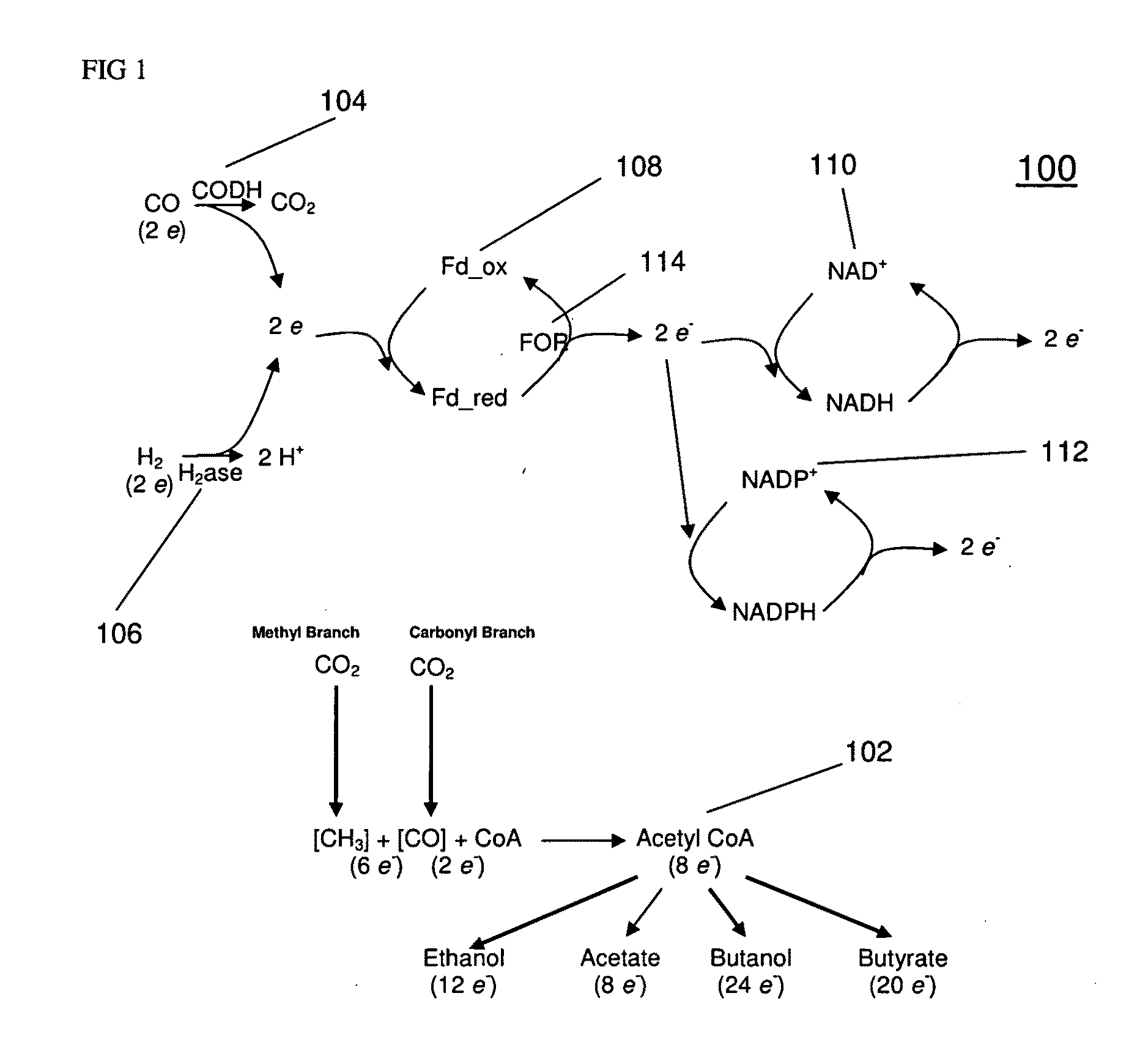

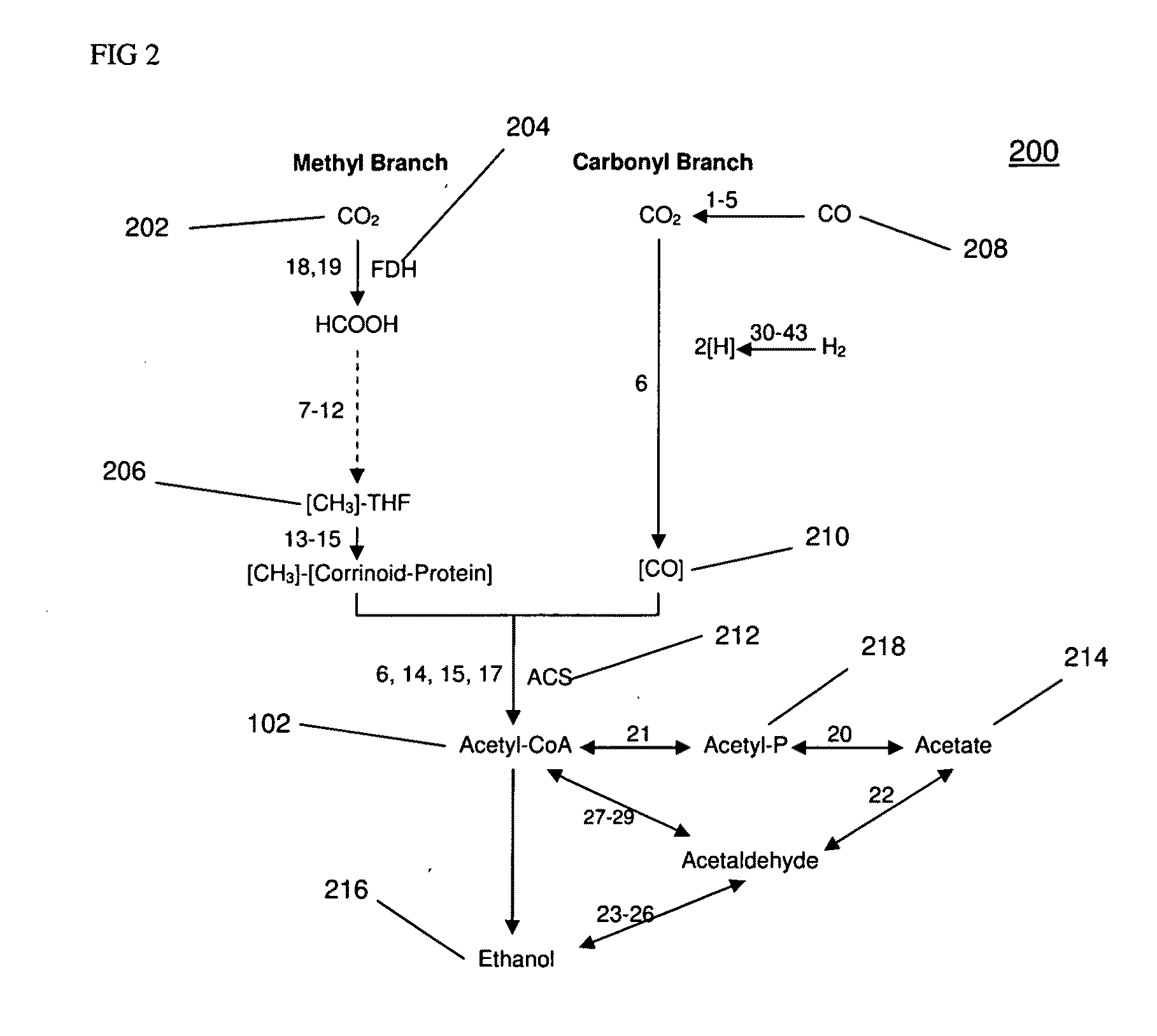

Essential genes encoding conserved metabolic pathway function in autotrophic solventogenic clostridial species

Essential genes coding for the metabolic pathway of solventogenic autotrophic Clostridia were sequenced, and functionality was confirmed. The present invention utilizes a comparative inter-species approach to develop the minimum set of essential genes for metabolic function and estimate productivity in species of suspected solventogenic capability.

Owner:SYNATA BIO INC

Silica gel healthy material and making method, healthy shoes, healthy insoles and healthy soles

The invention relates to a silica gel healthy material and an application technology of the silica gel healthy material, and in particular relates to a silica gel healthy material and a making method, a pair of healthy shoes, a pair of healthy insoles and a pair of healthy soles. The silica gel healthy material comprises a silica gel main material, negative ion powder, far infrared ray powder, a wear-resisting agent, titanium powder, a vulcanizing agent and a pigment, and can be molded or injected into a required shape. The silica gel healthy material can be applied to shoes and insoles, and has the advantages of simple manufacture process, flexibility and comfort in wearing, capabilities of balancing electrolyte in a human body, promoting blood circulation, enhancing metabolic function of the human body and purifying air, health care, wear resistance, good environmental friendliness, electrical insulation property and the like.

Owner:杨红光

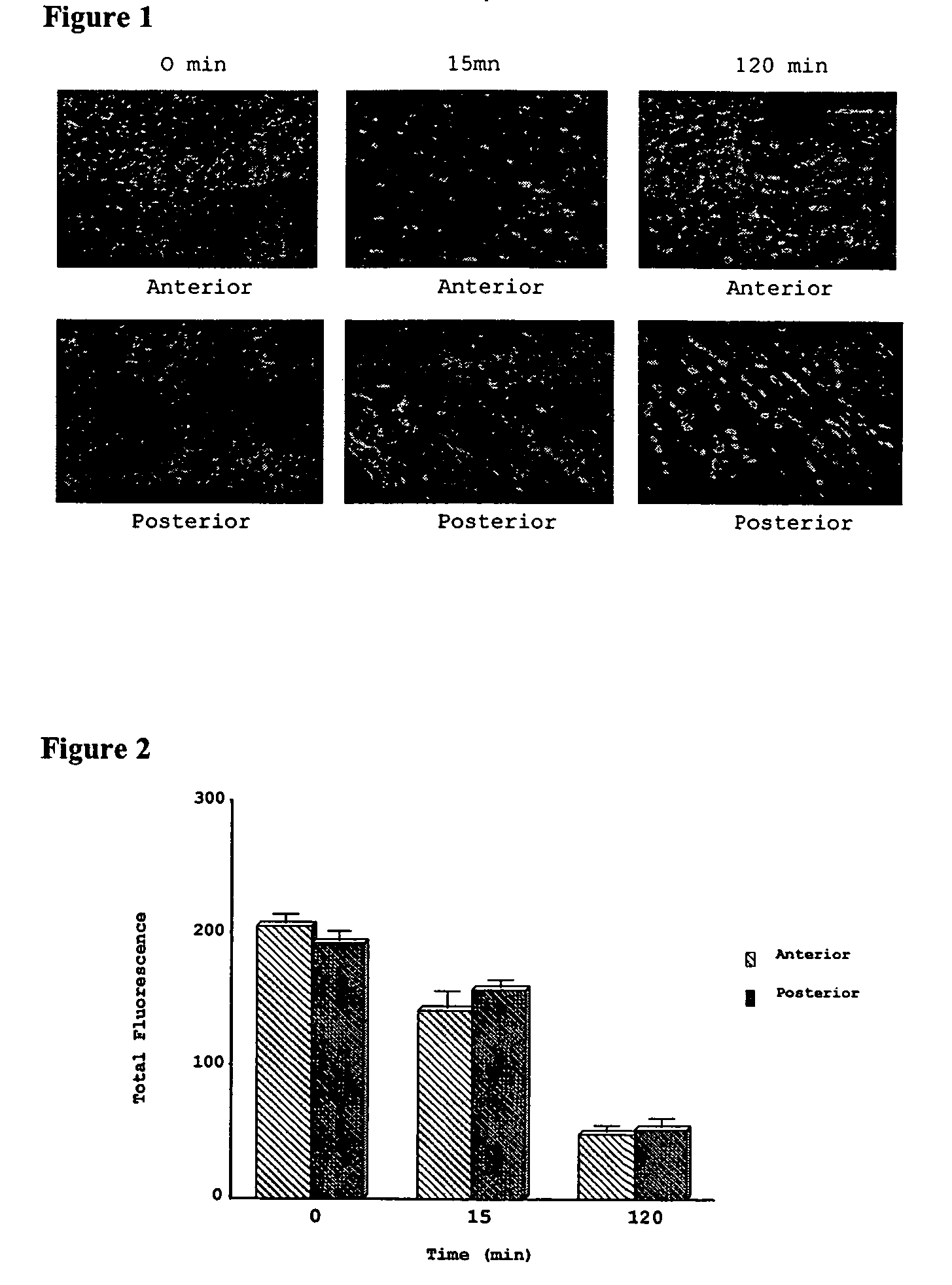

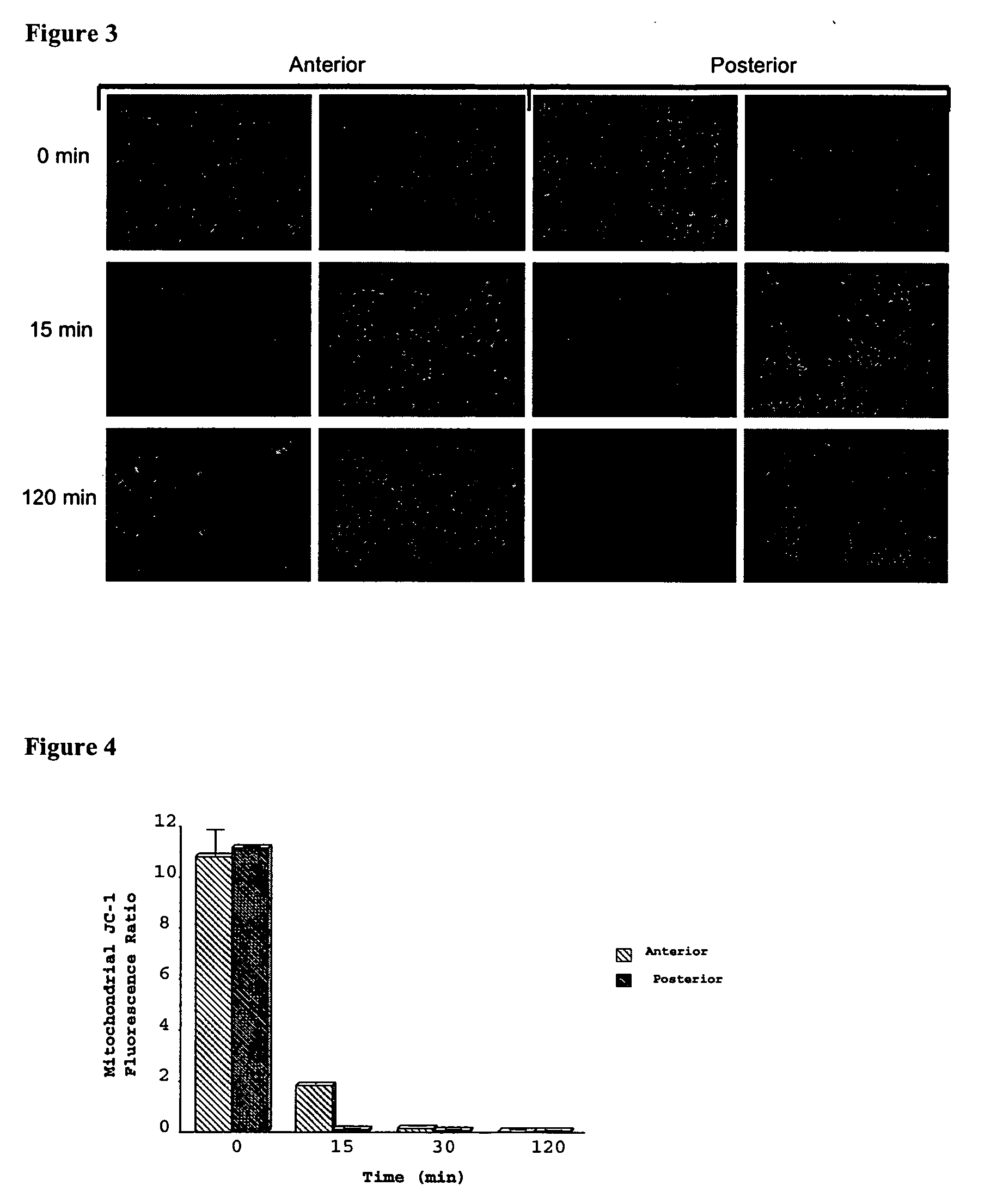

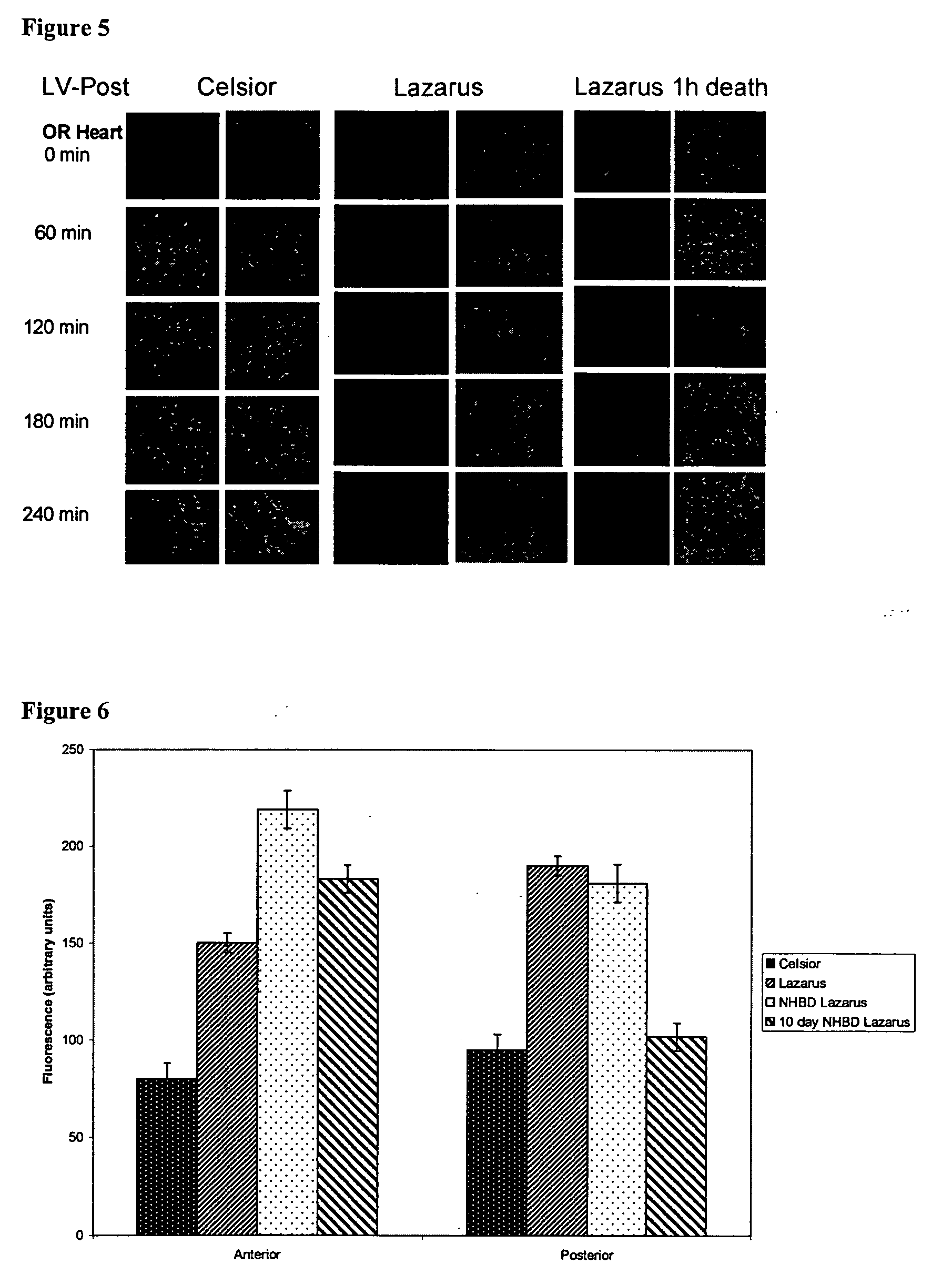

Compositions and methods for tissue preservation

ActiveUS20100151435A1Maintain functional integrityRecovery functionMicrobiological testing/measurementDead animal preservationPotassiumApoptosis

Methods and compositions for resuscitating, storing, and preserving functional integrity of organs and tissues. Metabolic function is maintained by sustaining ATP levels, mitochondrial function, cardiomyocyte contractility, prevention of acidosis, inhibition of induction of apoptosis, maintaining ionontrophy and lusiotrophy by regulating calcium, sodium, potassium and chloride ions.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

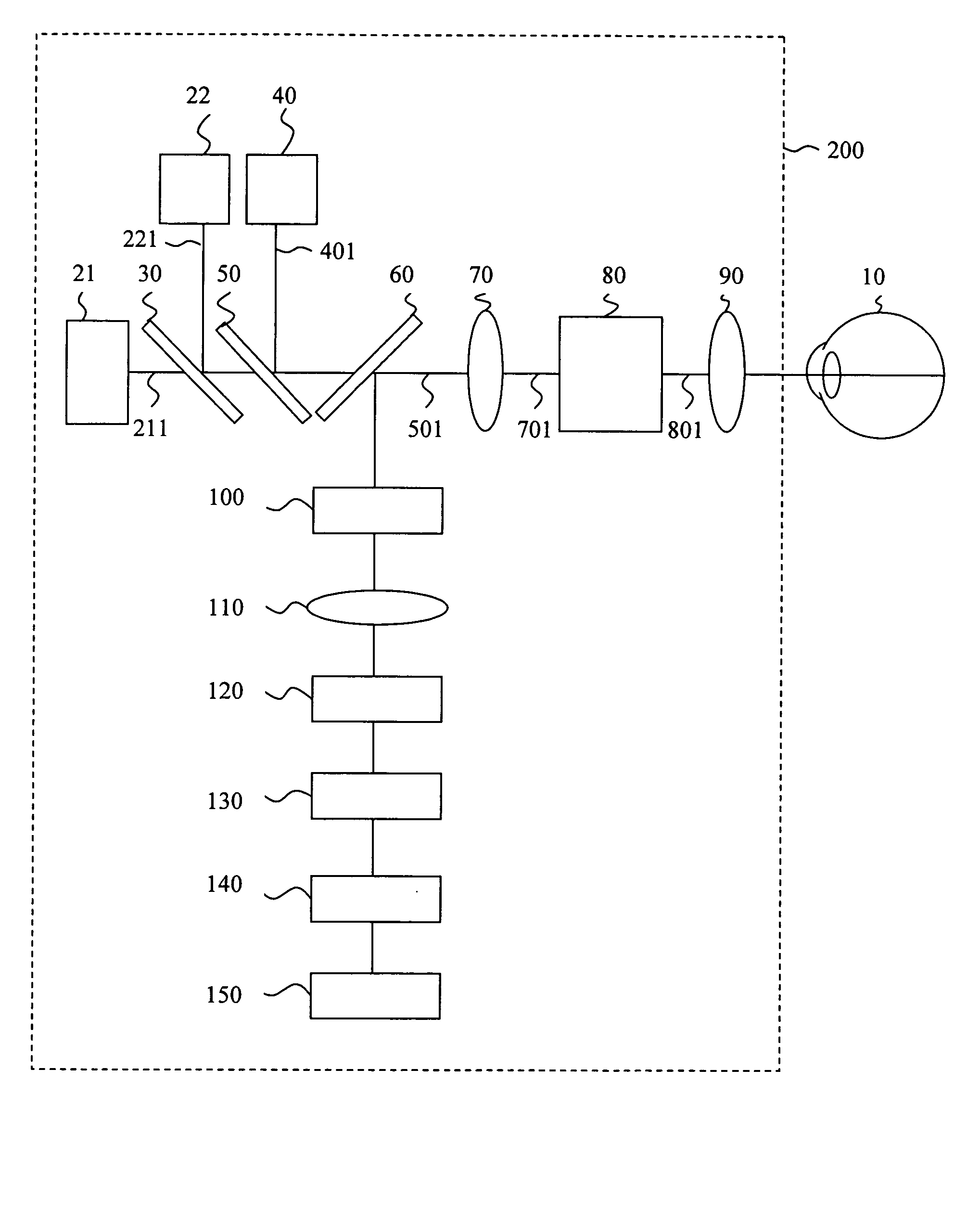

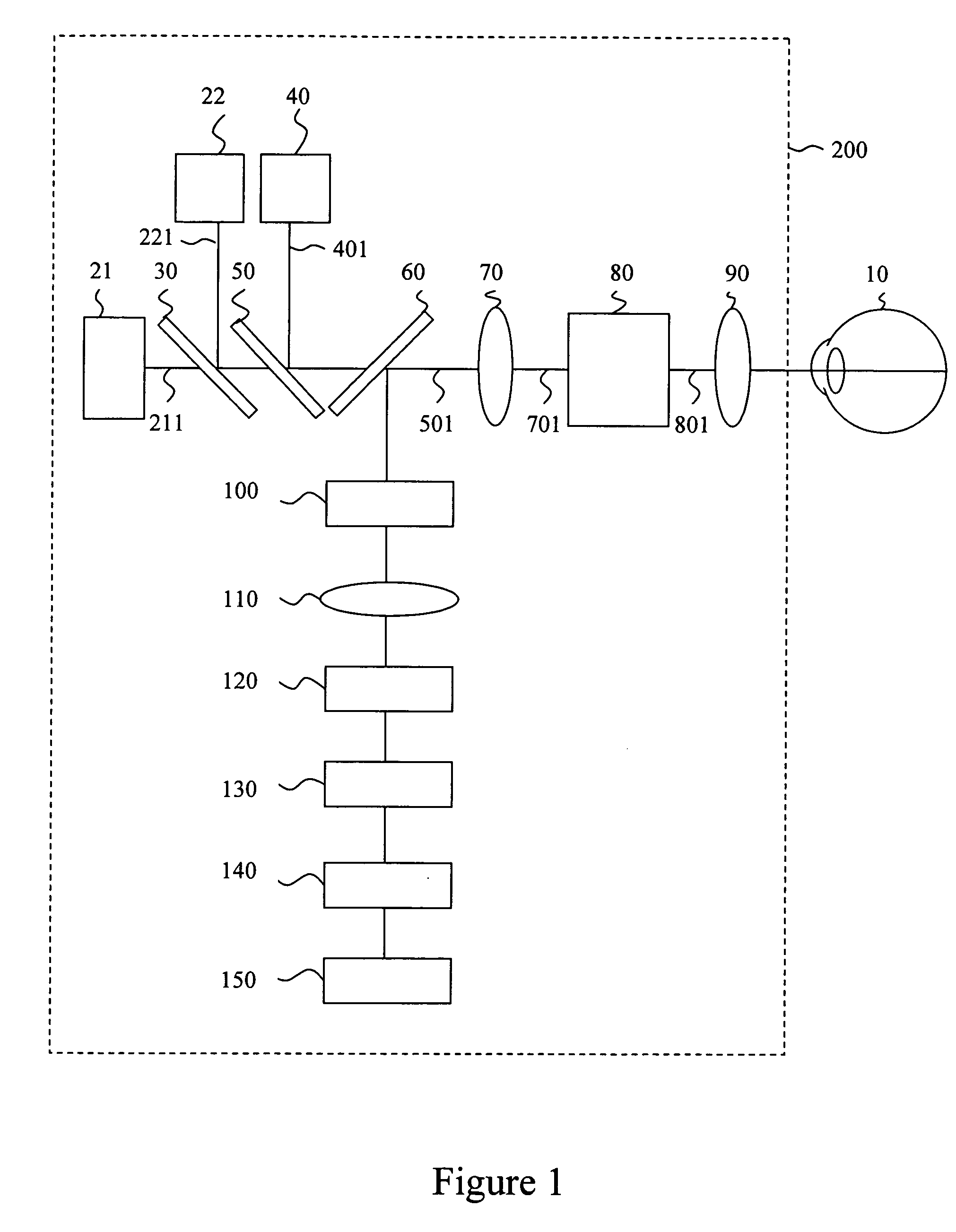

Analysis of retinal metabolism over at least a portion of a cardiac cycle

Retinal metabolism is analysed with a retinal function camera over at least a portion of a cardiac cycle by first illuminating a portion of a retina of an eye 10 with light of a first wavelength and producing a first image. The portion of the retina is subsequently illuminated with light of a second wavelength, the first and second wavelengths being selected such that absorptivity of light of the first wavelength by oxygenated blood is greater than absorptivity of light of the second wavelength and the absorptivity of light of the first wavelength by deoxygenated blood is less than absorptivity of light of the second wavelength, to produce a second image. The first and second images are processed to map relative oxygenation of the portion of the retina as an indication of retinal metabolic function of the portion of the retina. The procedure is repeated over at least a portion of a cardiac cycle to analyse metabolic function changes of the portion of the retina within the at least a portion of a cardiac cycle. In some embodiments at least a portion of the retina is subjected to optical stimulation and effects of the optical stimulation on retinal metabolic function analysed.

Owner:KERR PATRICK

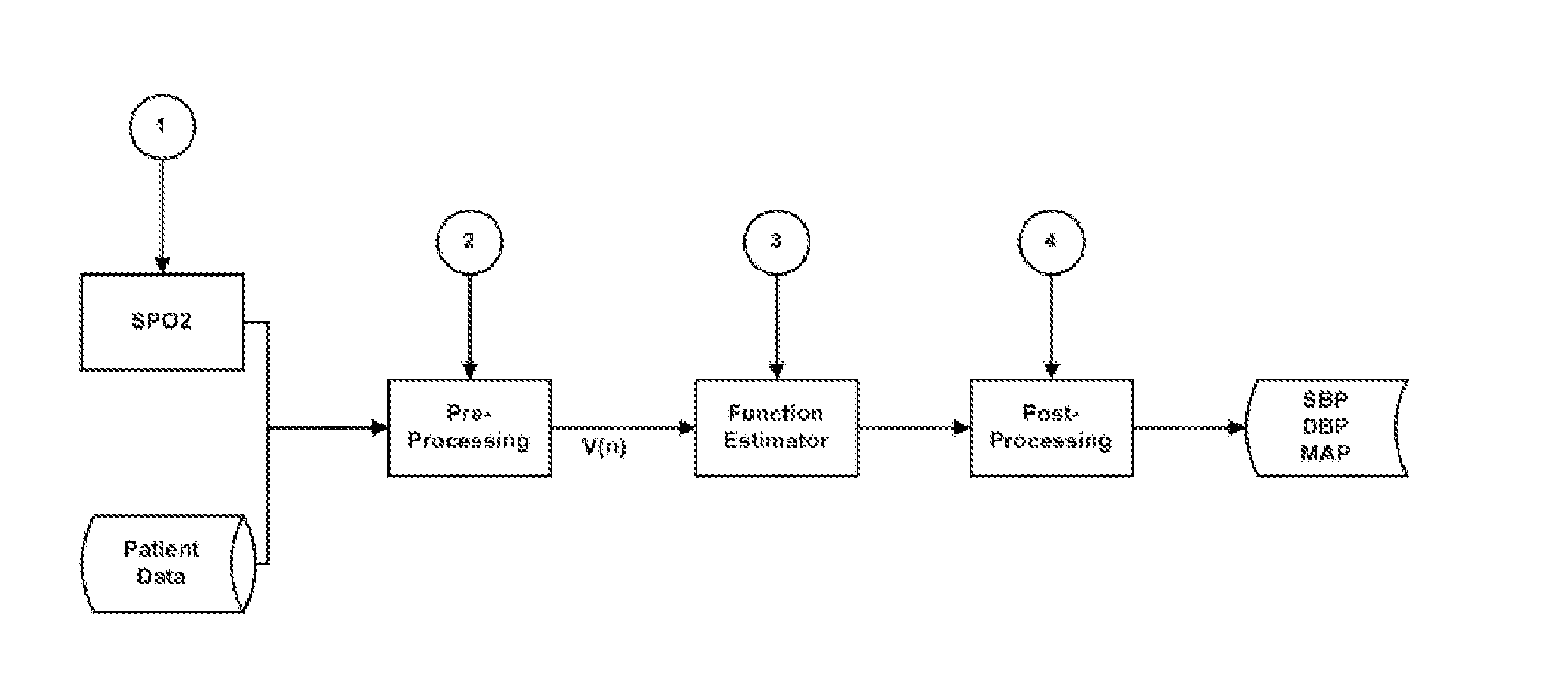

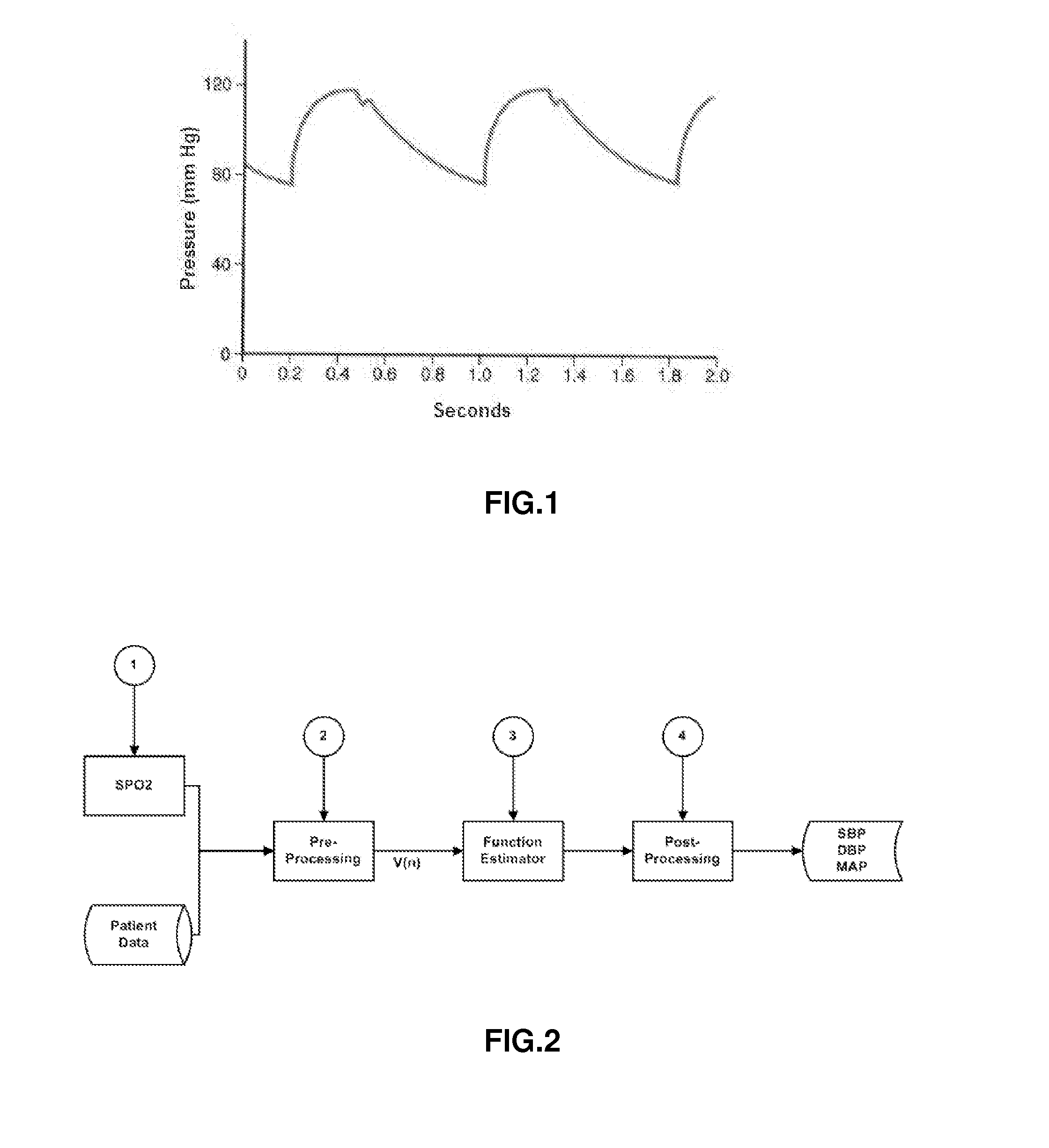

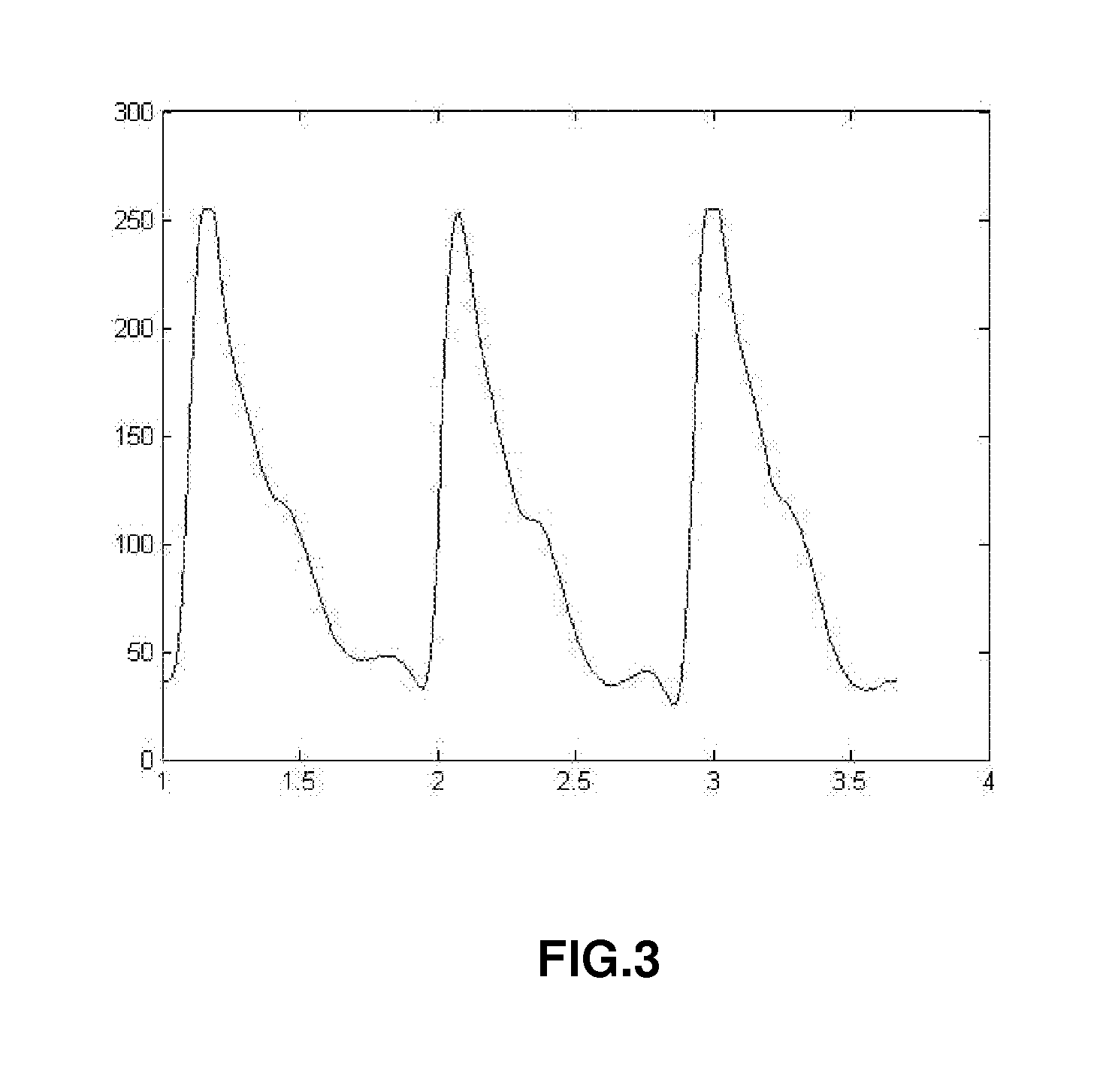

System and apparatus for the non-invasive measurement of glucose levels in blood

A system for estimating the glucose levels in blood is developed in the present invention. Said system establishes a physiological model of the pulse wave and its energy, which are also correlated with the glucose metabolic function, for generating a fixed length vector containing the values of the previous model combined with other variables related to the user such as, for example, age, sex, height, weight, etc. . . . This fixed length vector is used as an excitation of a function estimation system based on “random forests” for the calculation of the interest variable. The main advantage of this parameter estimation system lays in the fact that it does not apply any restriction a priori on the function to be estimated, and that it is robust in front of heterogeneous data, such as in the case of the present invention.

Owner:SABIRMEDICAL

Methods and devices for activating brown adipose tissue with light

ActiveUS20140088487A1Increased energy expenditureIncrease light energyElectrotherapyElectrocardiographyBrown adipose cellBrown Adipocytes

Methods and devices are provided for activating brown adipose tissue (BAT) with light. Generally, the methods and devices can activate BAT to increase thermogenesis, e.g., increase heat production in the patient, which over time can lead to weight loss and / or improved metabolic function. In one embodiment, a medical device is provided that activates BAT by using light to stimulate nerves that activate the BAT and / or to stimulate brown adipocytes directly, thereby increasing thermogenesis in the BAT and inducing weight loss and / or improved metabolic function through energy expenditure. The light can be configured to directly or indirectly stimulate the nerves and / or the brown adipocytes. The light can be configured to indirectly stimulate the nerves and / or the brown adipocytes by activating a light activatable medium administered to a patient and configured to respond to the light to cause activation of the brown adipose tissue.

Owner:ETHICON ENDO SURGERY INC +1

Appartus and method for measuring biologic parameters

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:ABRUE MARCIO MARC AURELIO MARTINS (I) (US)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com