Patents

Literature

60 results about "Special geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

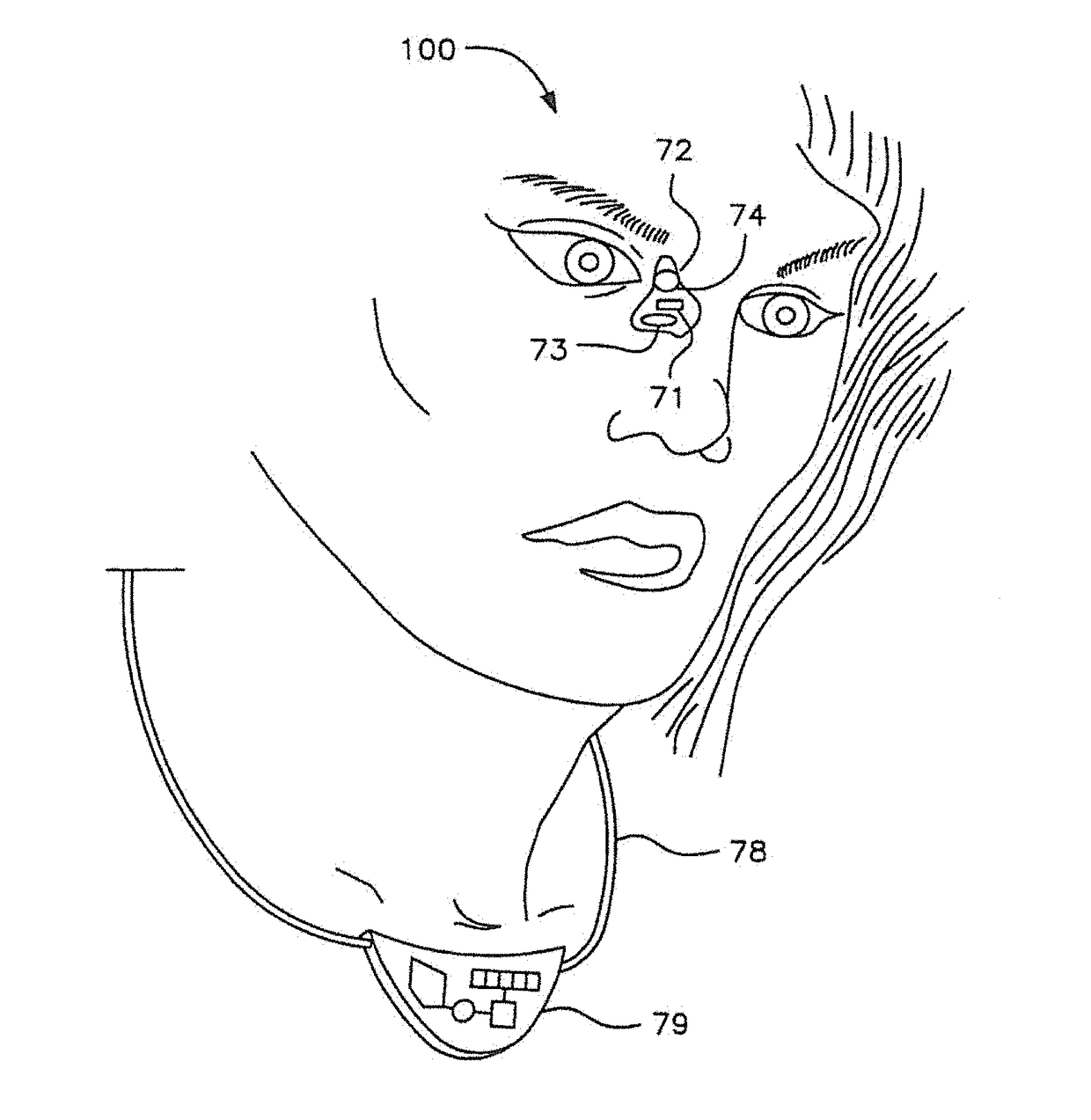

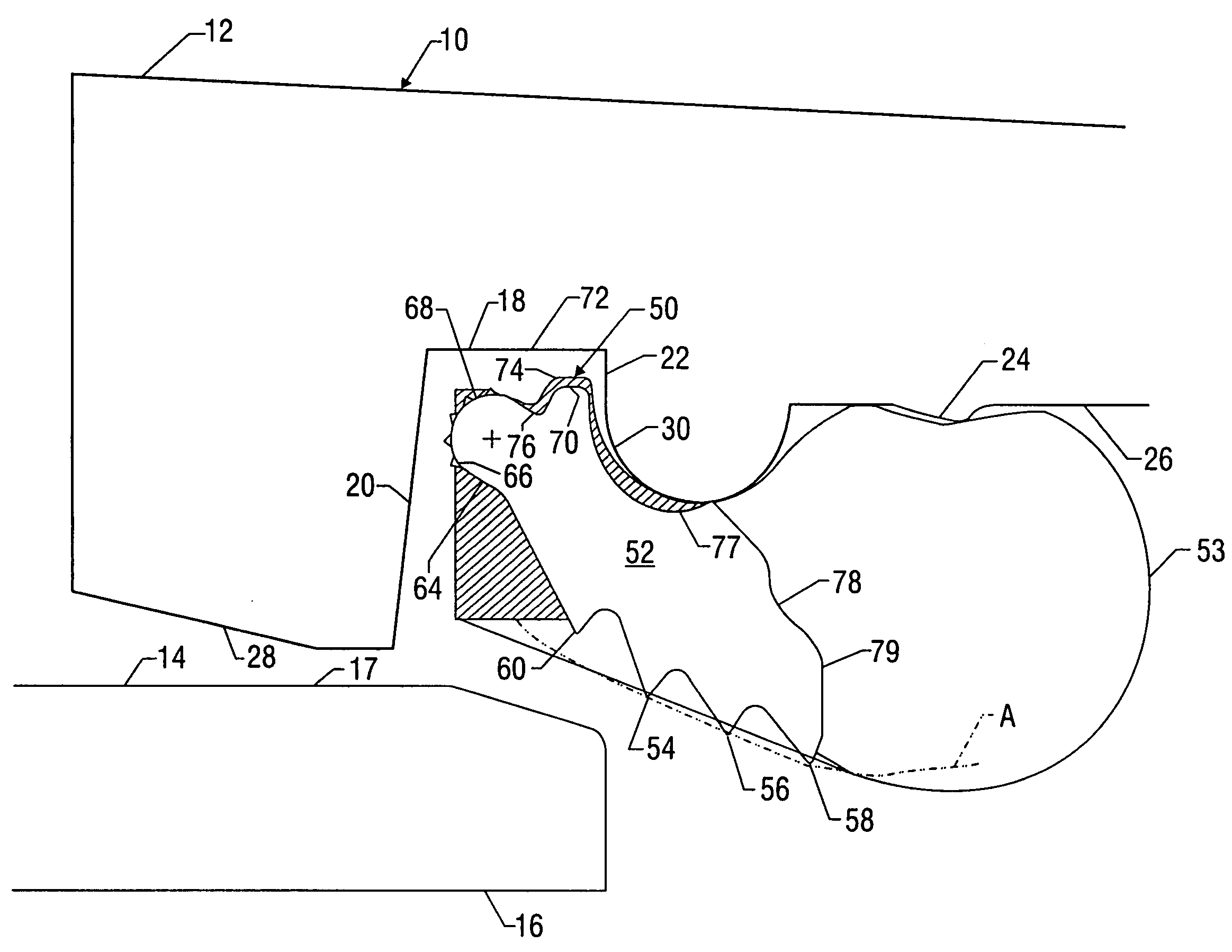

Apparatus and method for measuring biologic parameters

ActiveUS7187960B2Optimal signal acquisitionPreventing temperature disturbanceDiagnostic signal processingDiagnostics using lightInfraredWireless transmission

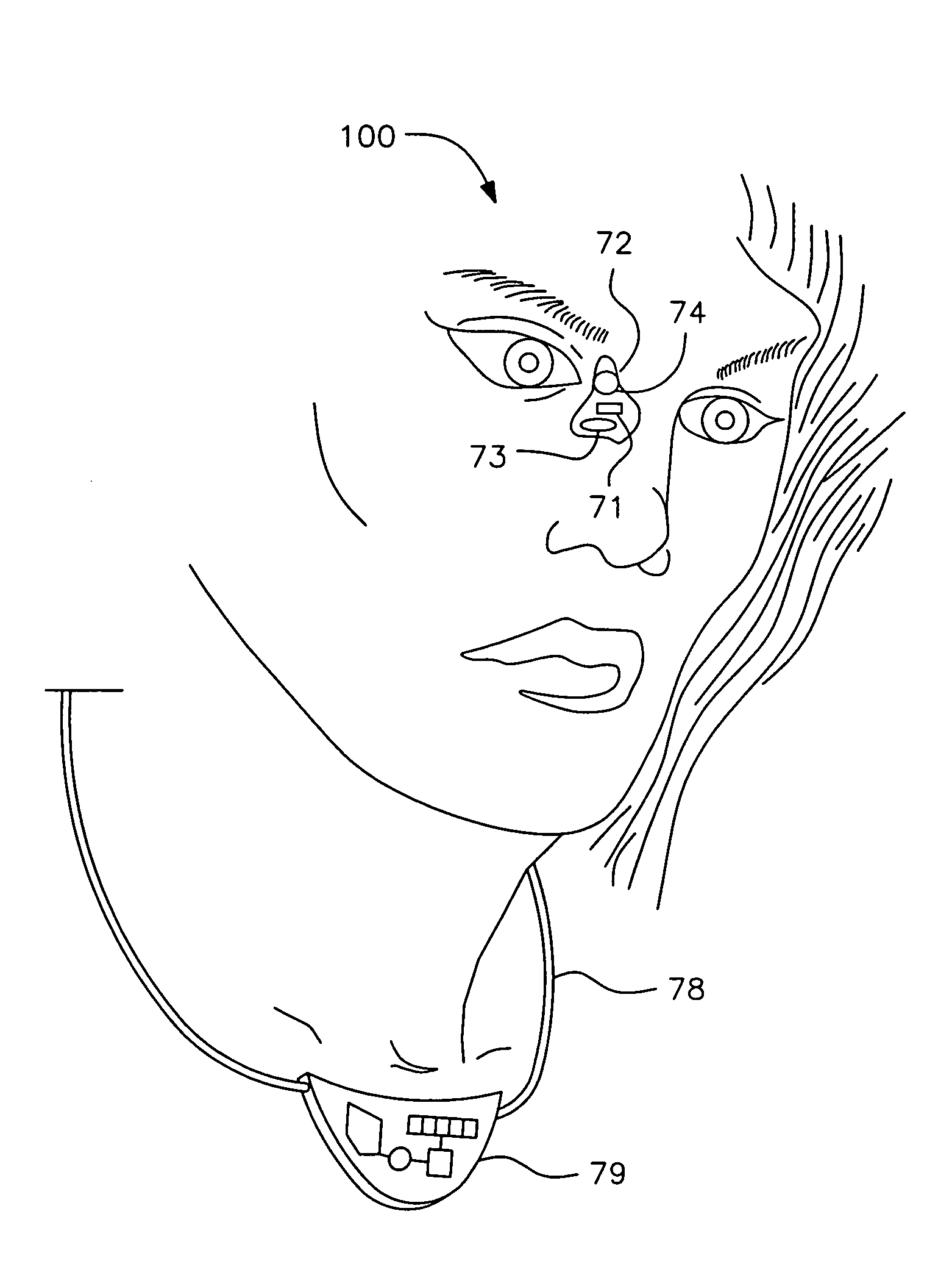

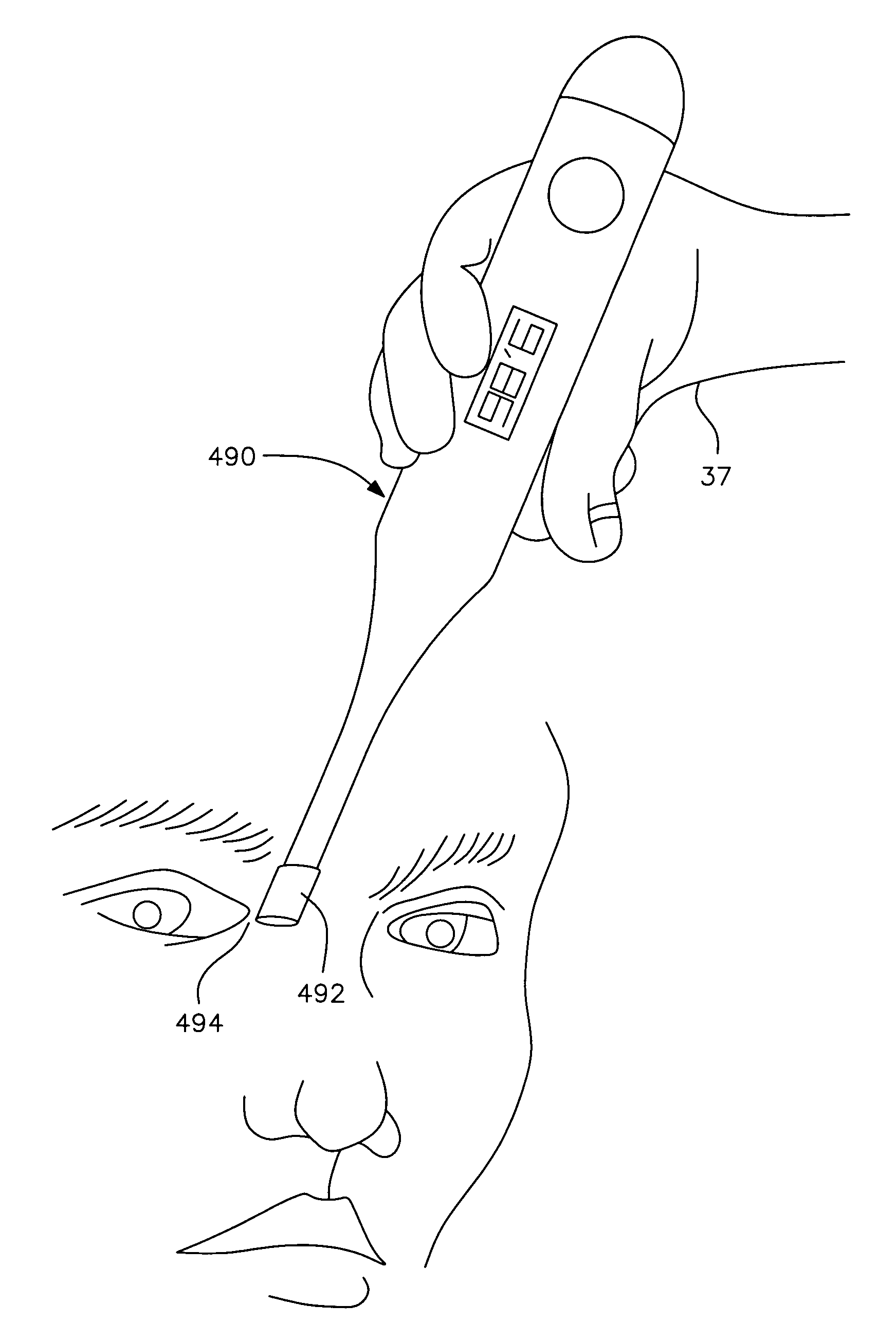

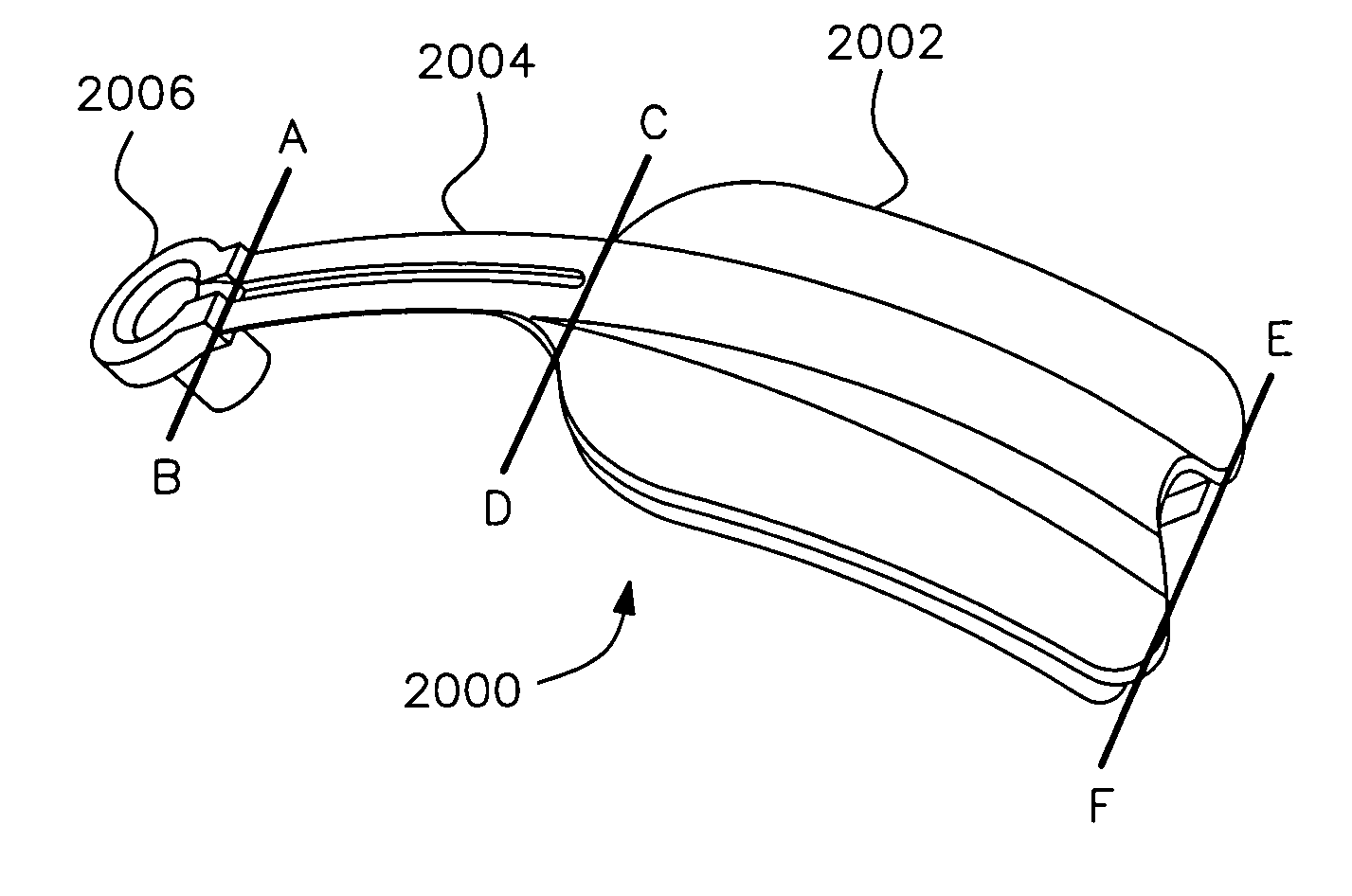

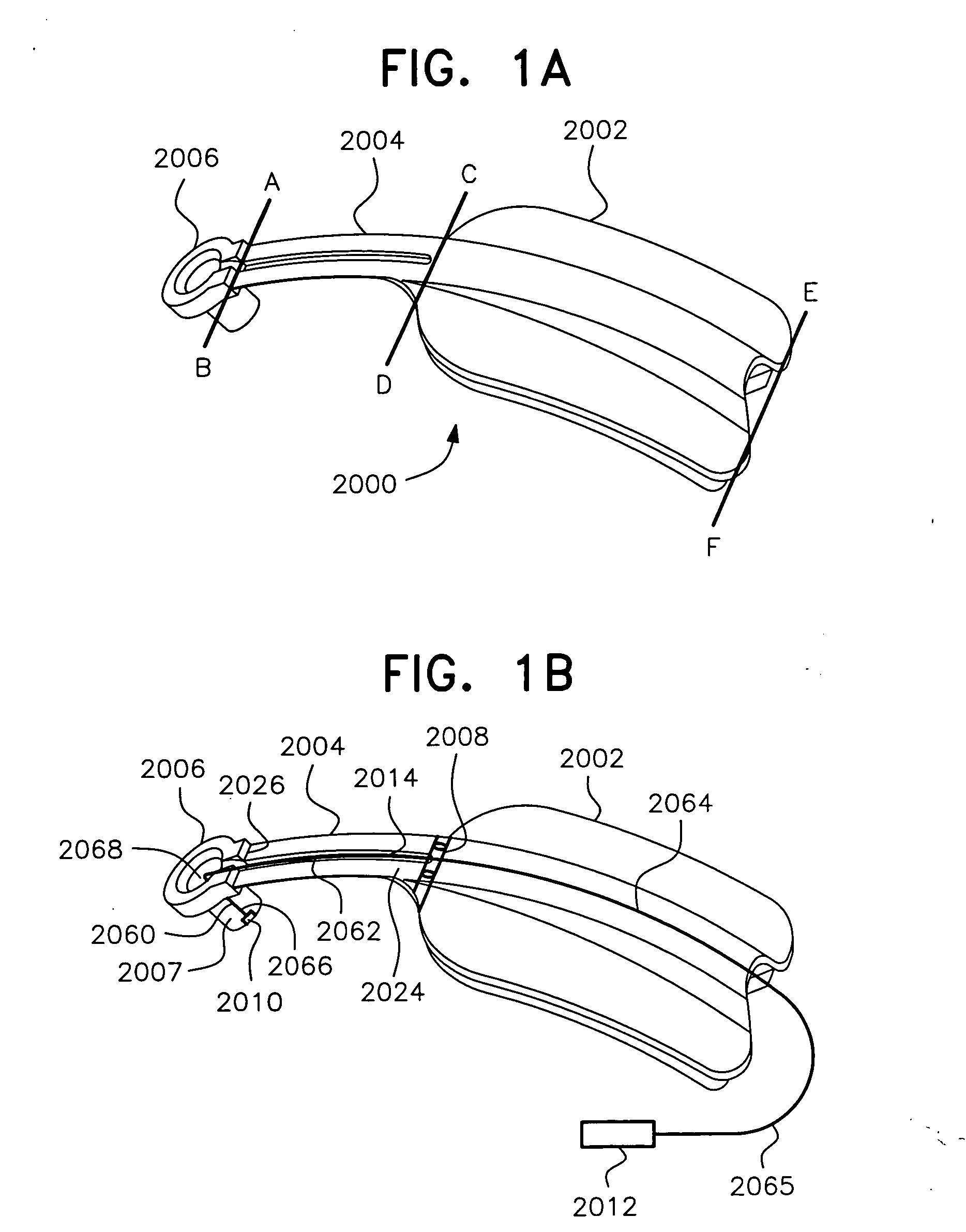

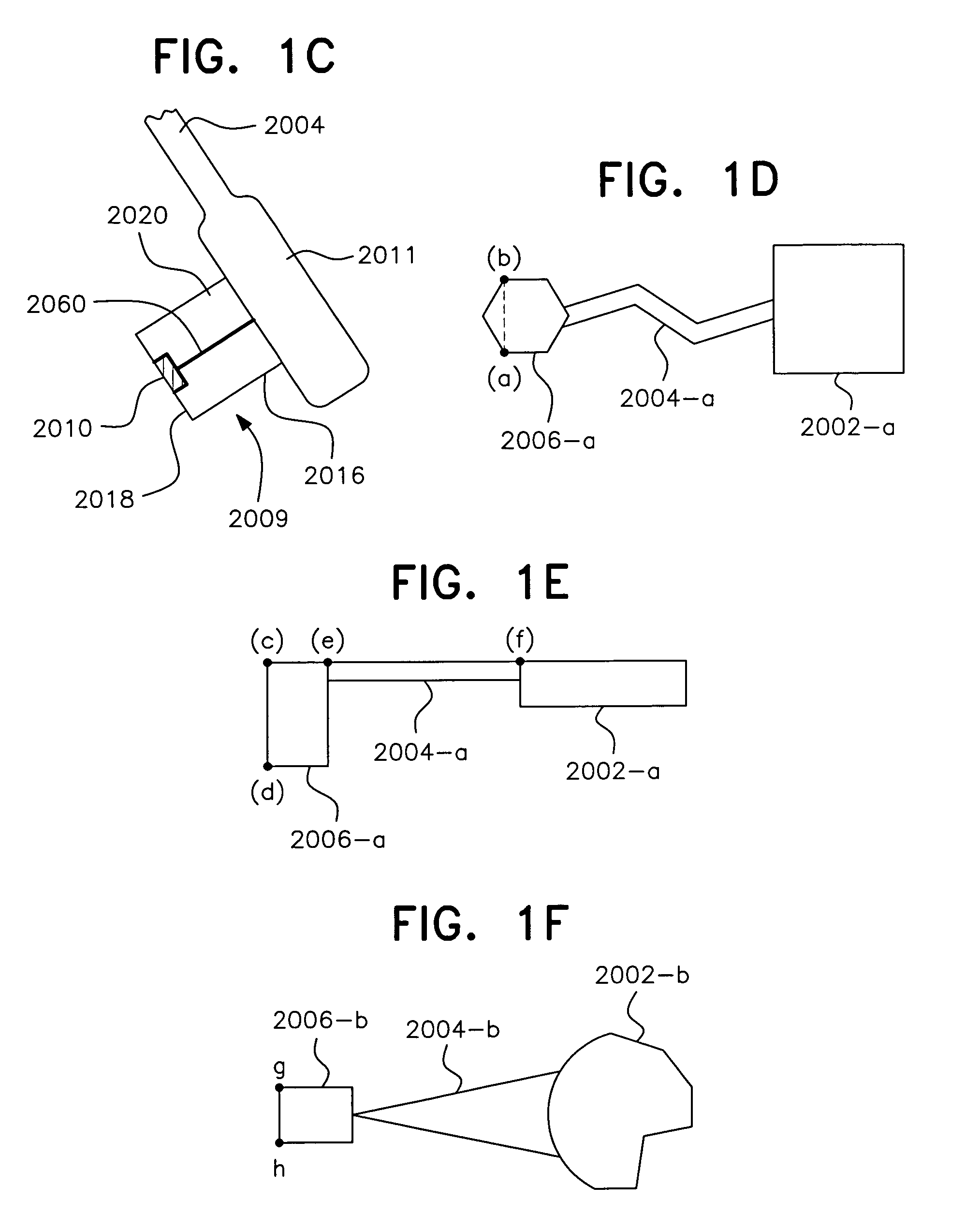

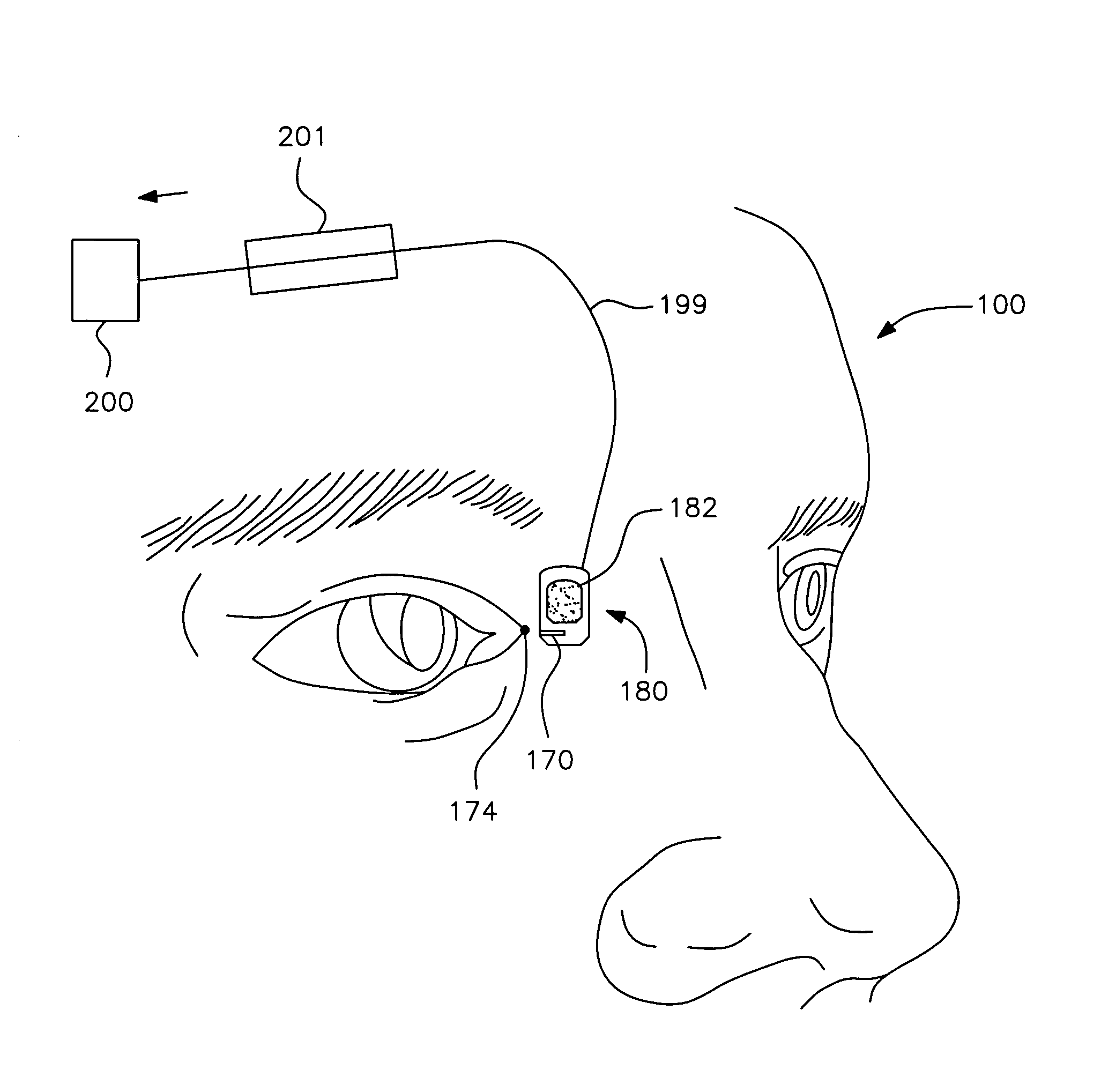

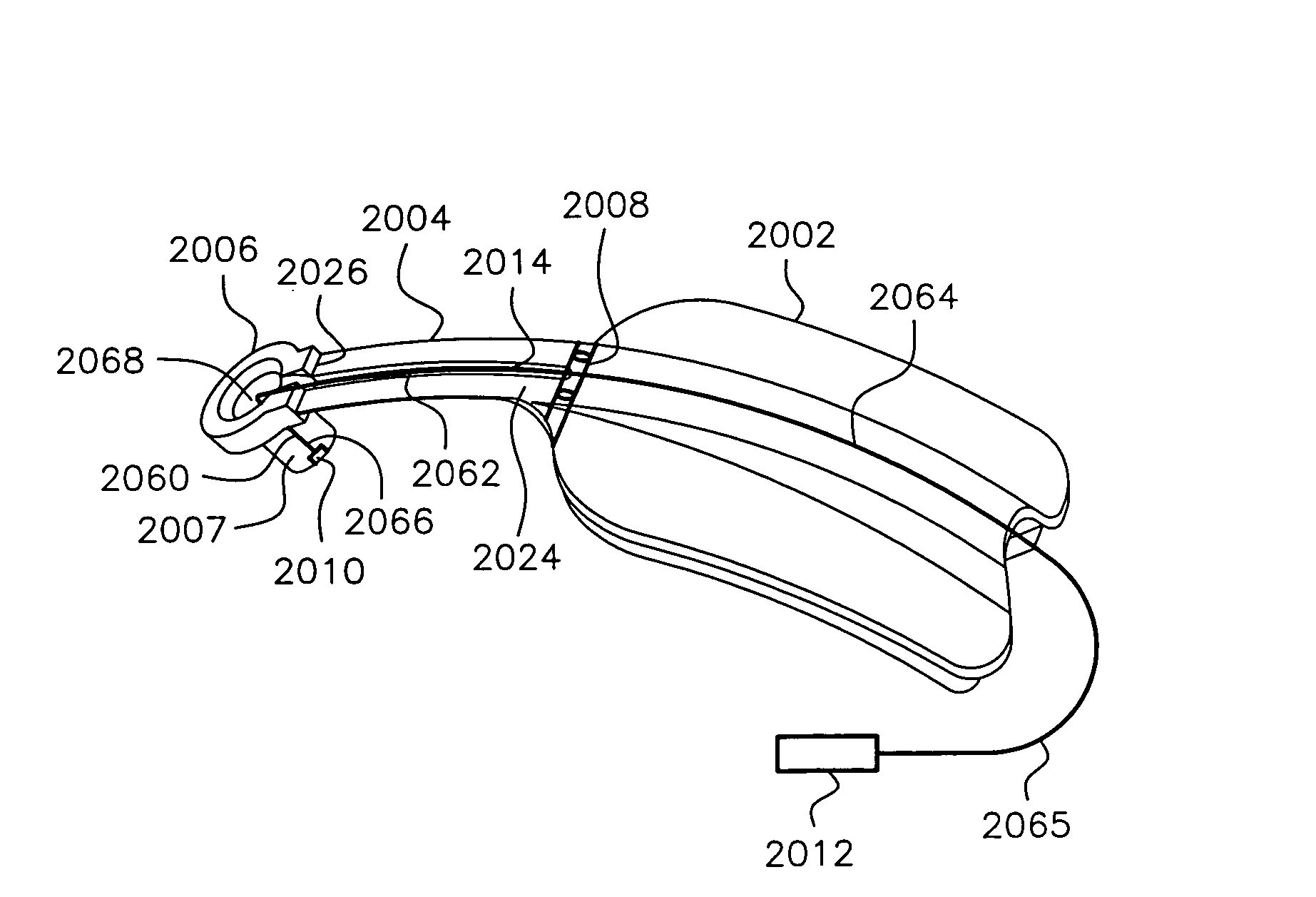

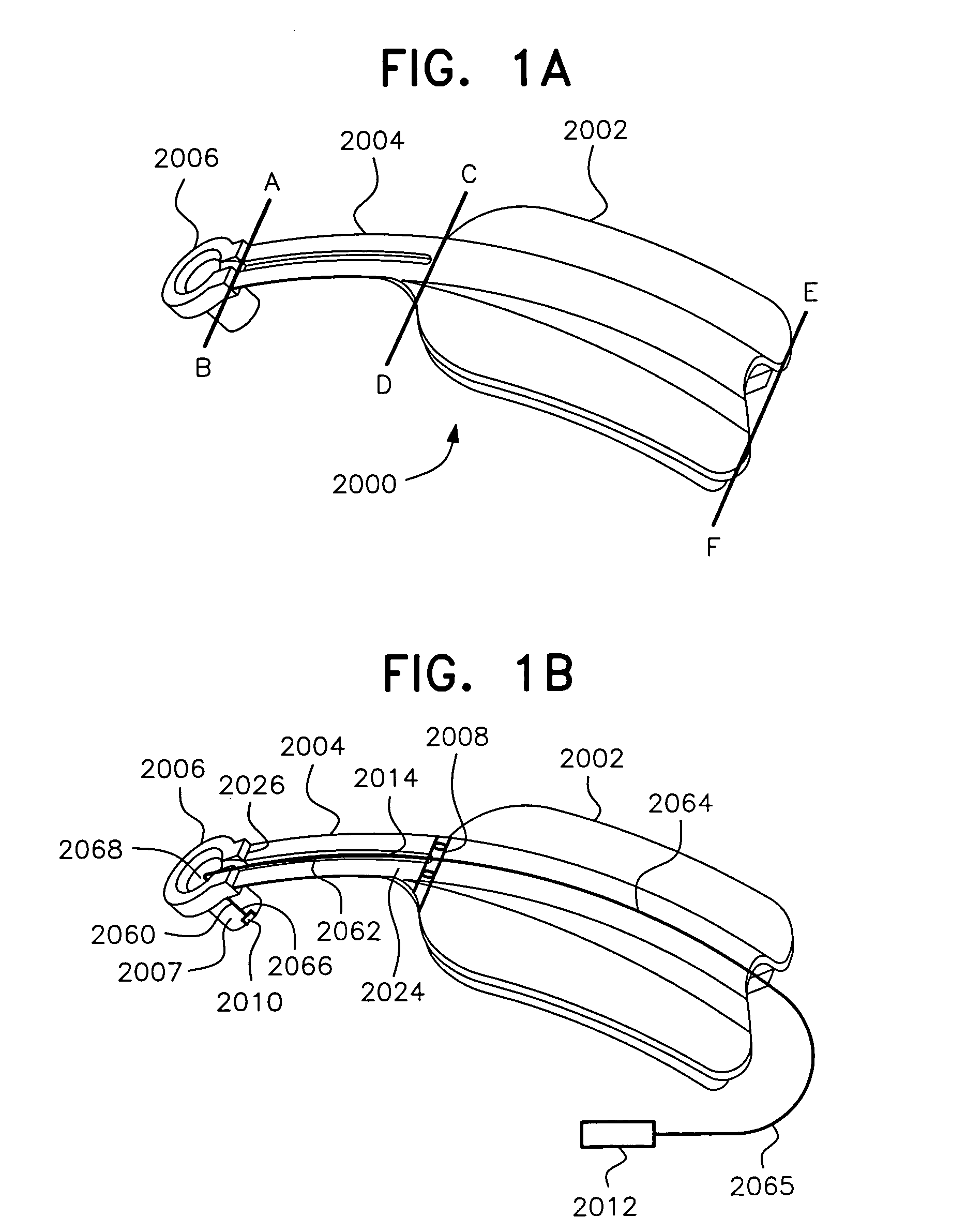

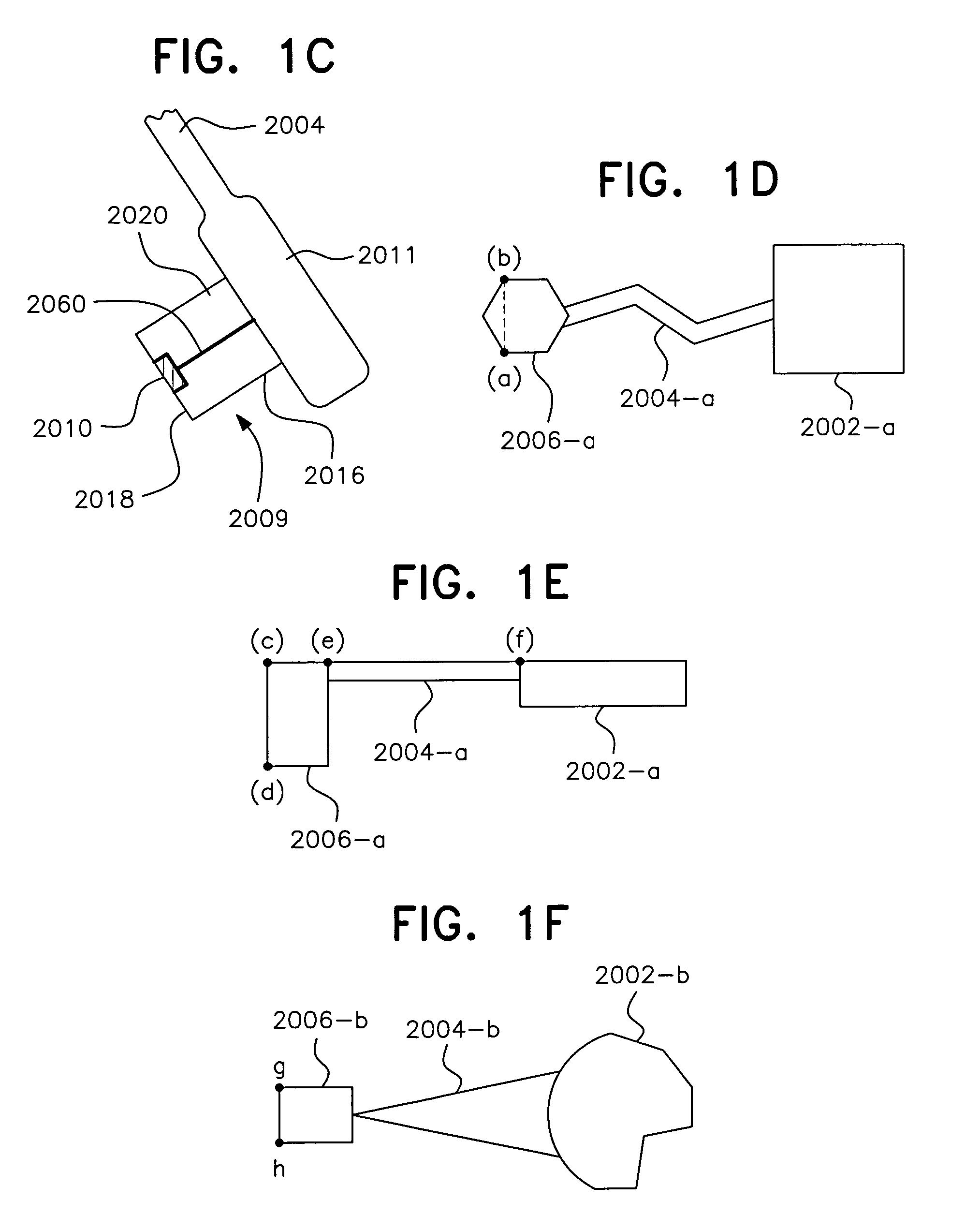

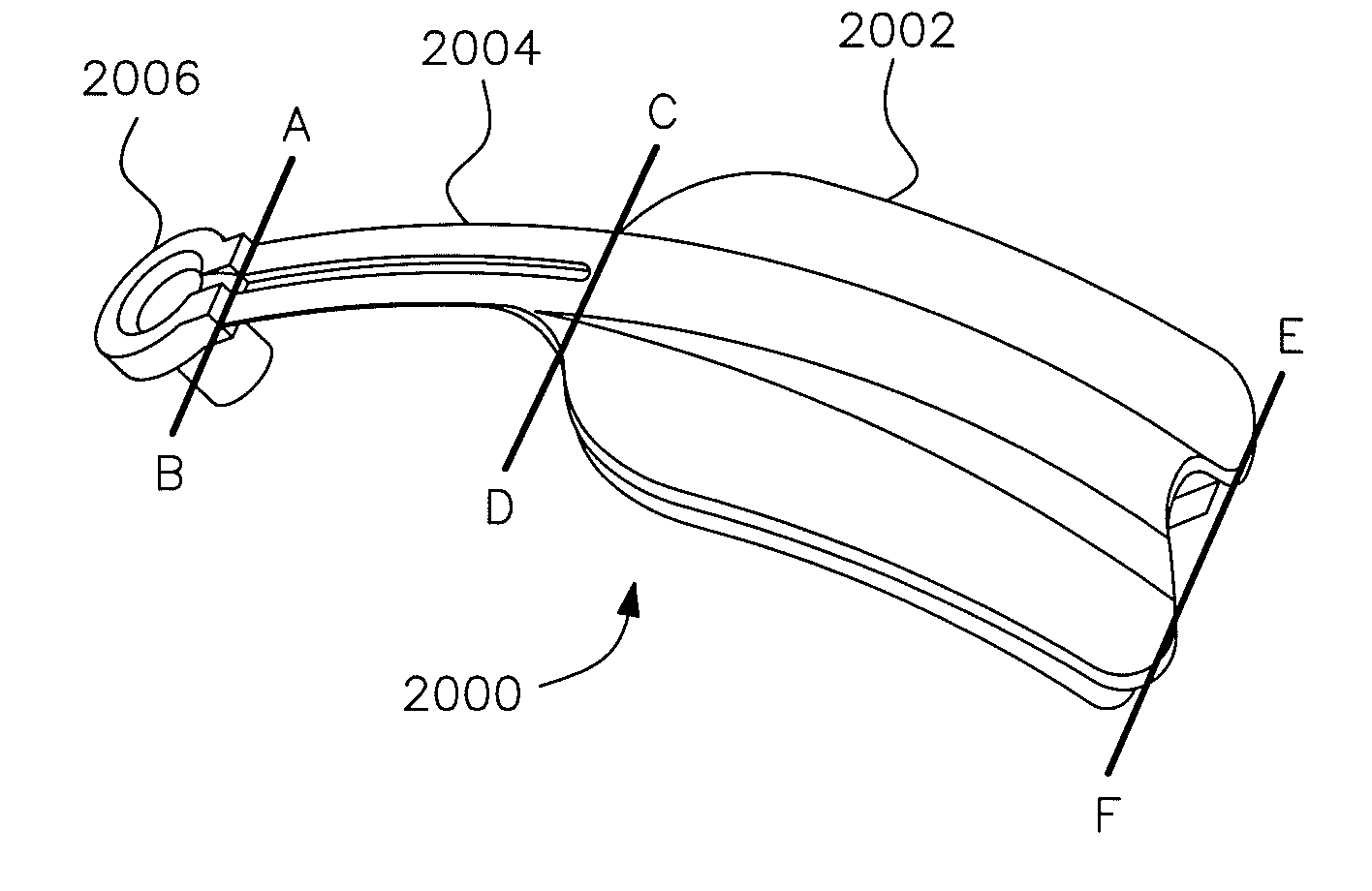

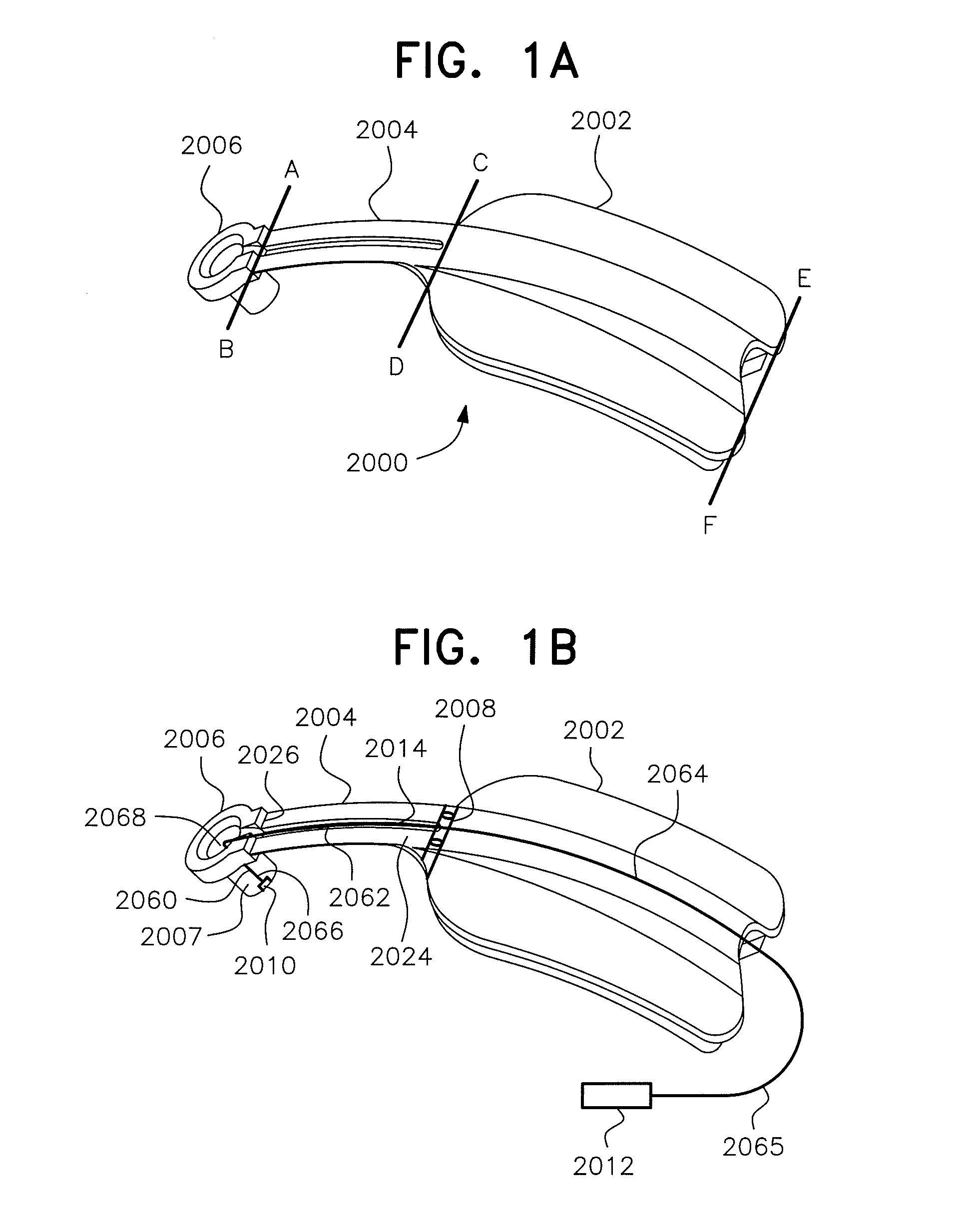

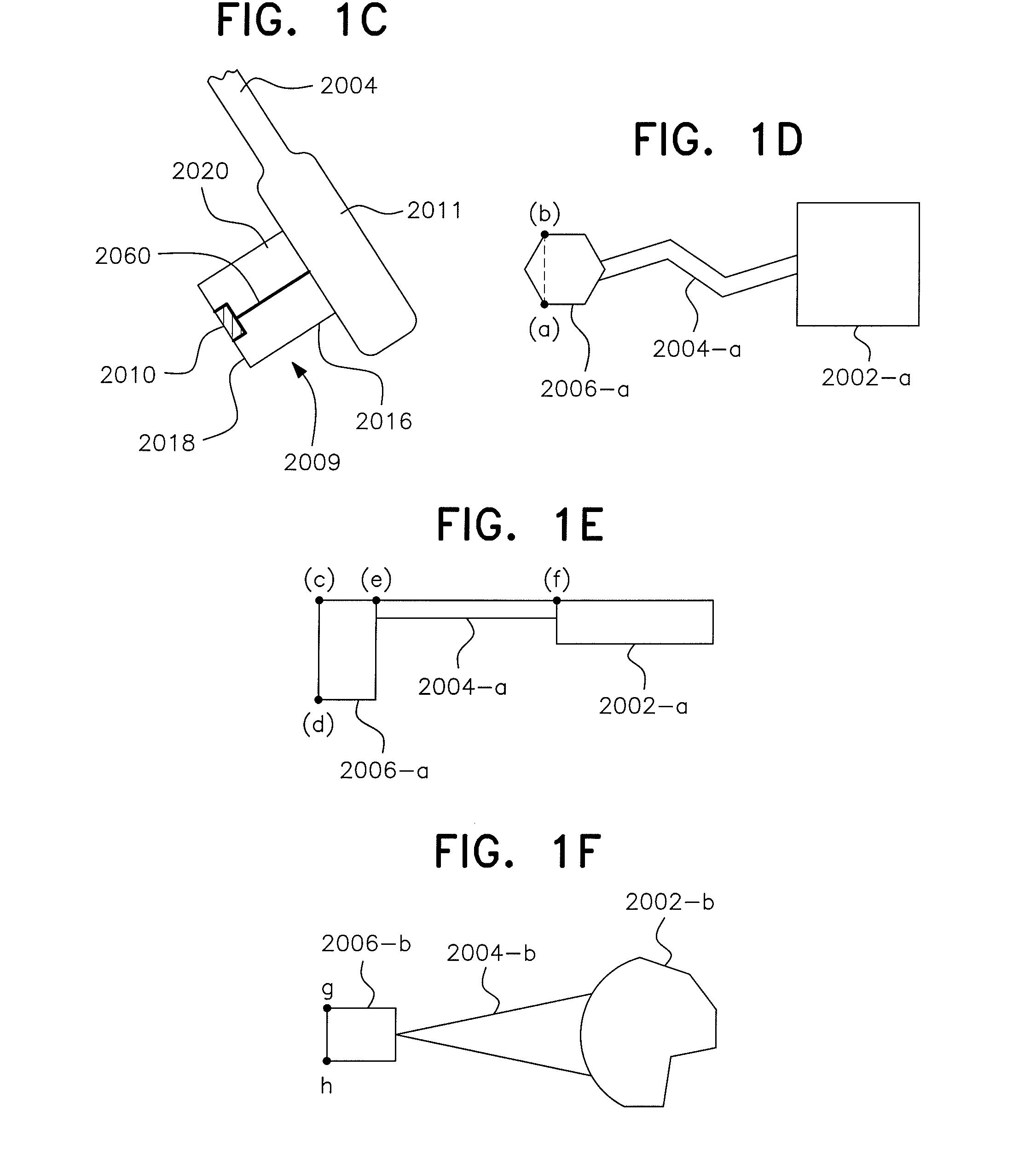

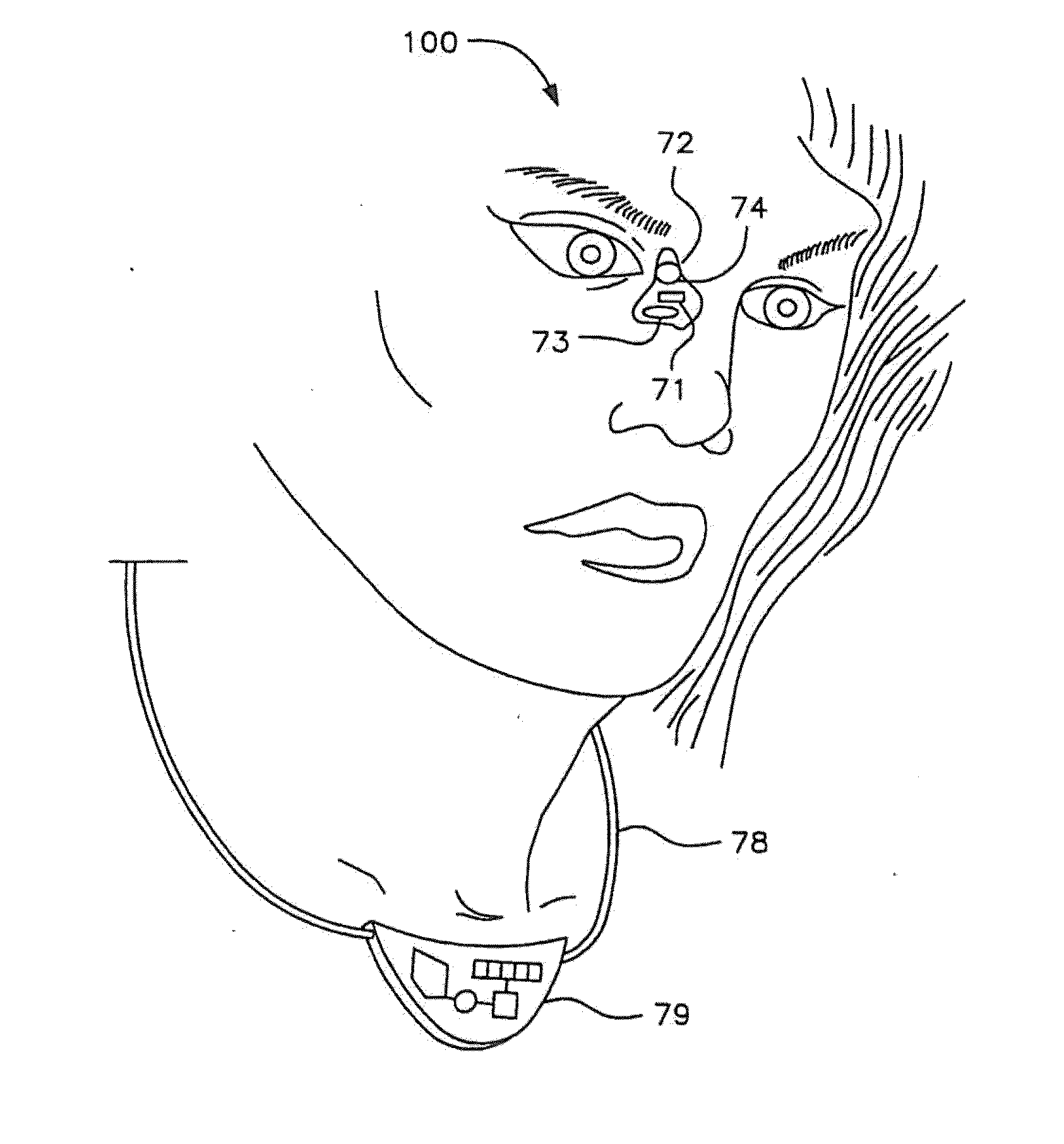

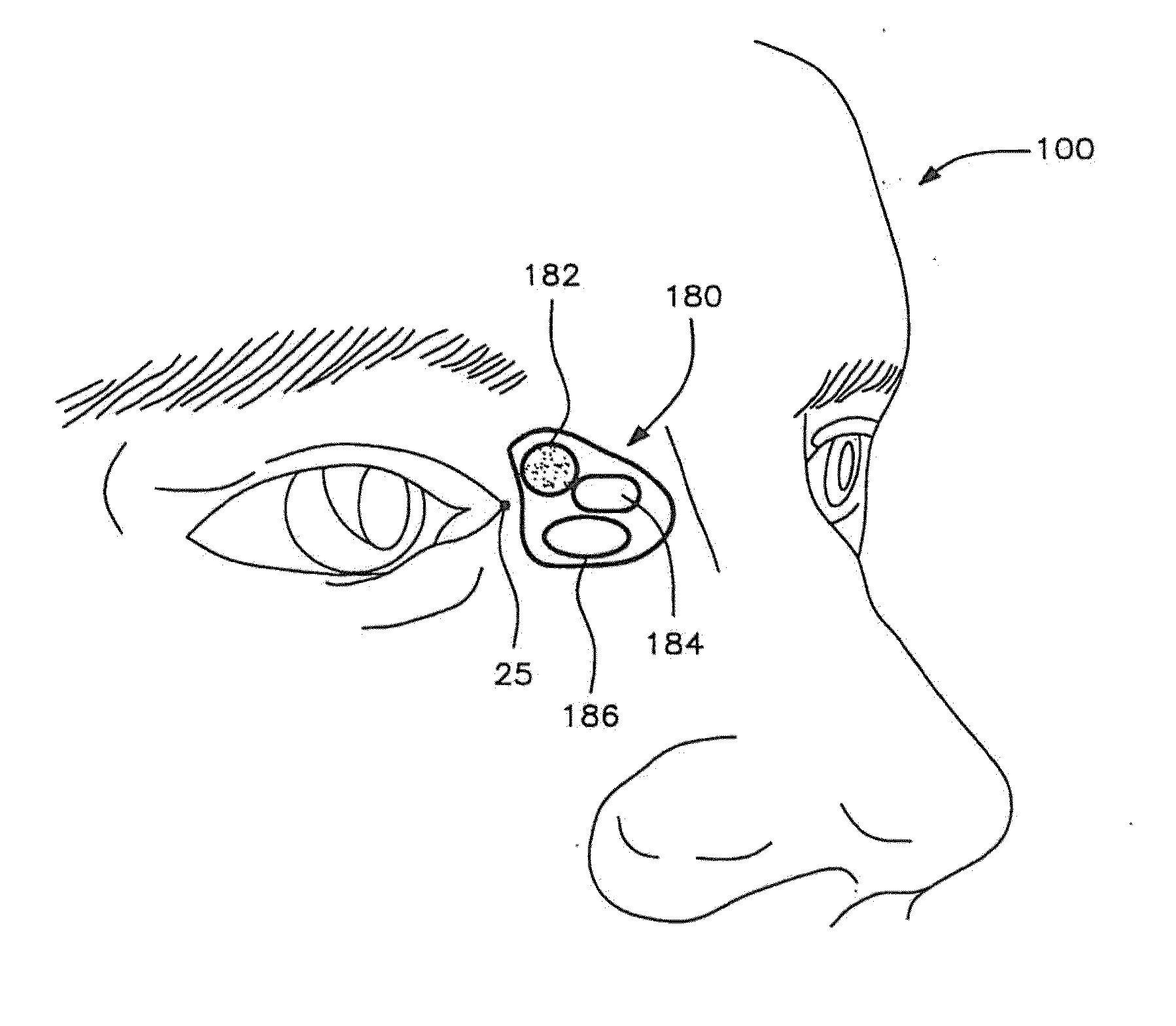

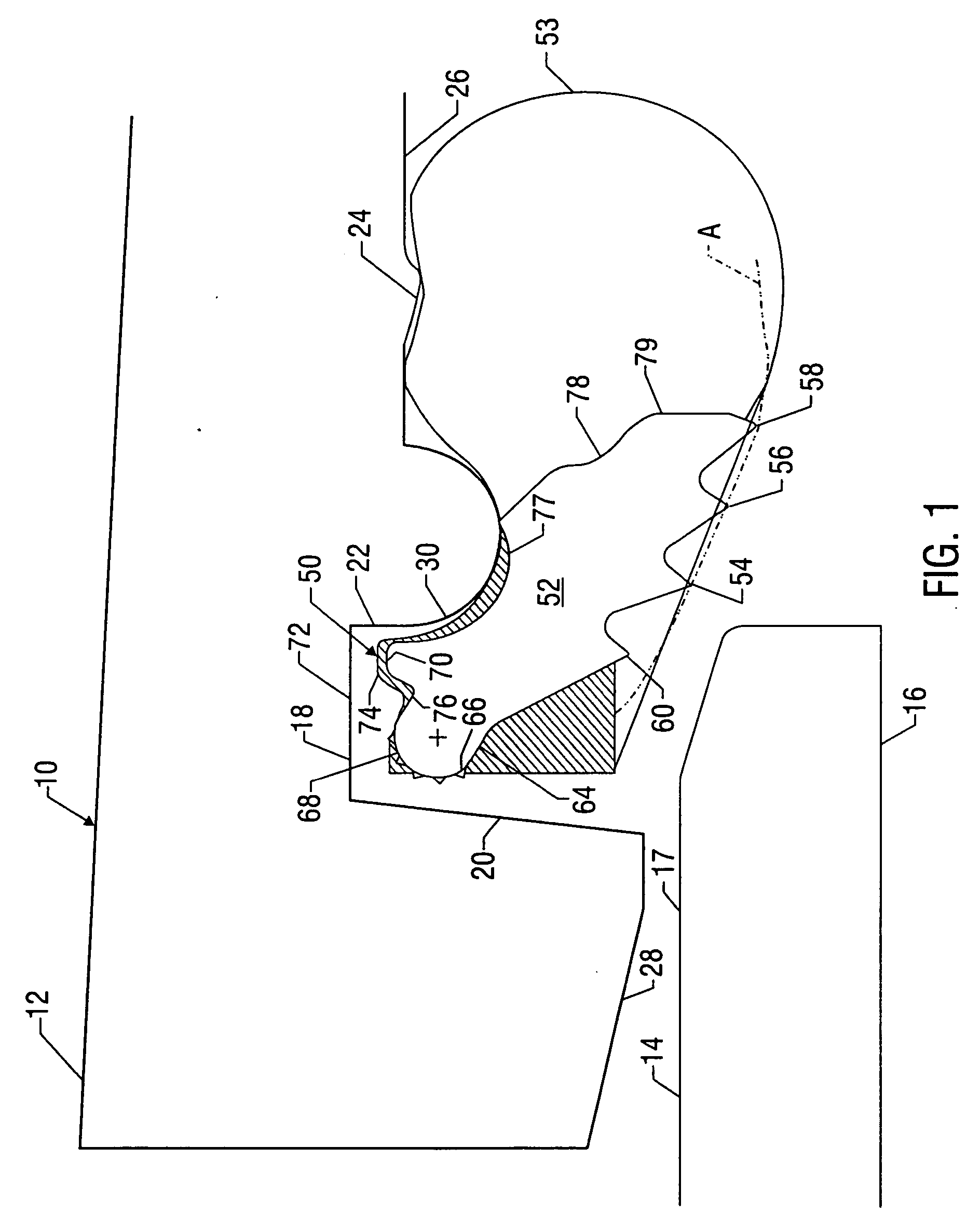

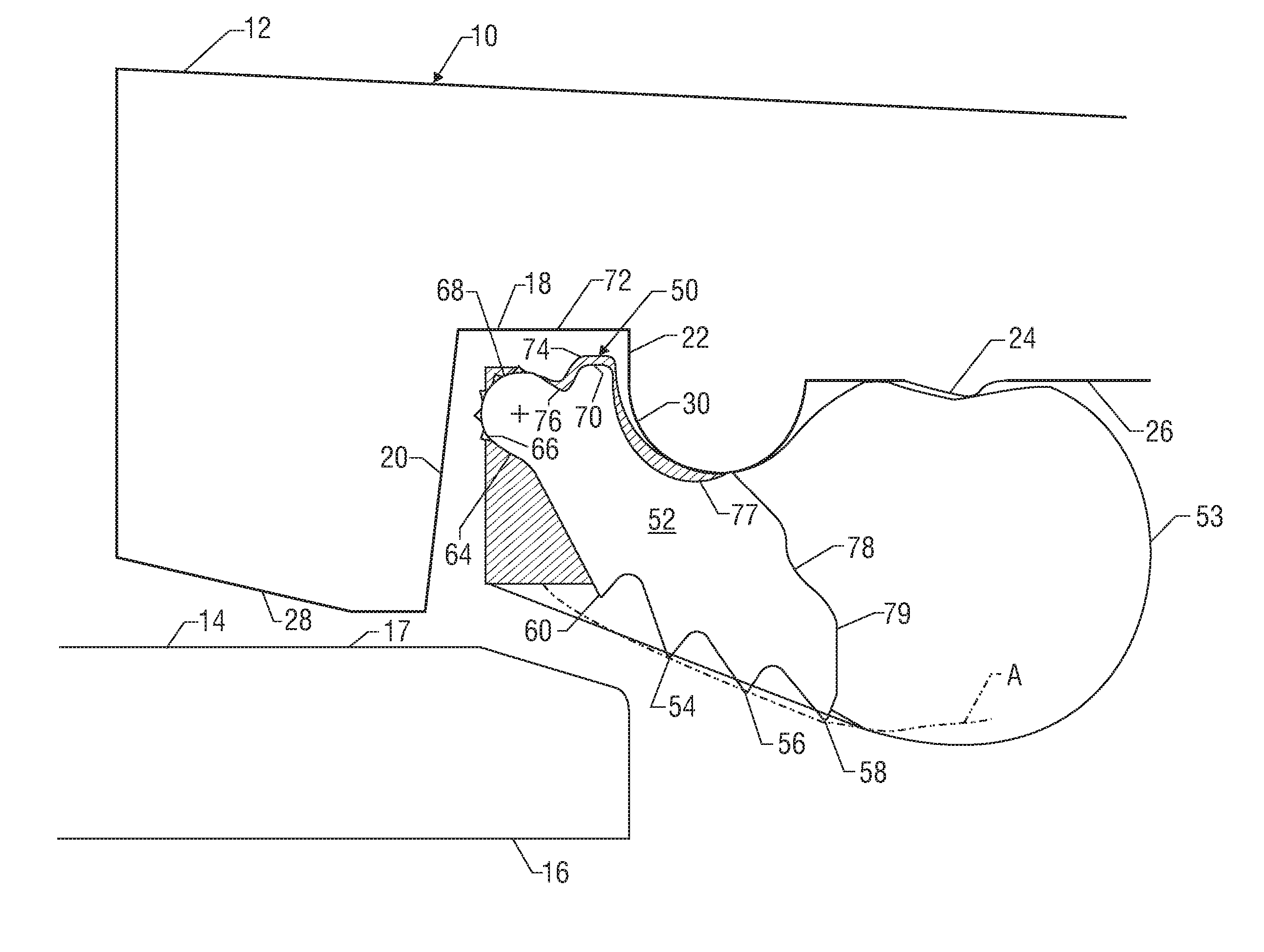

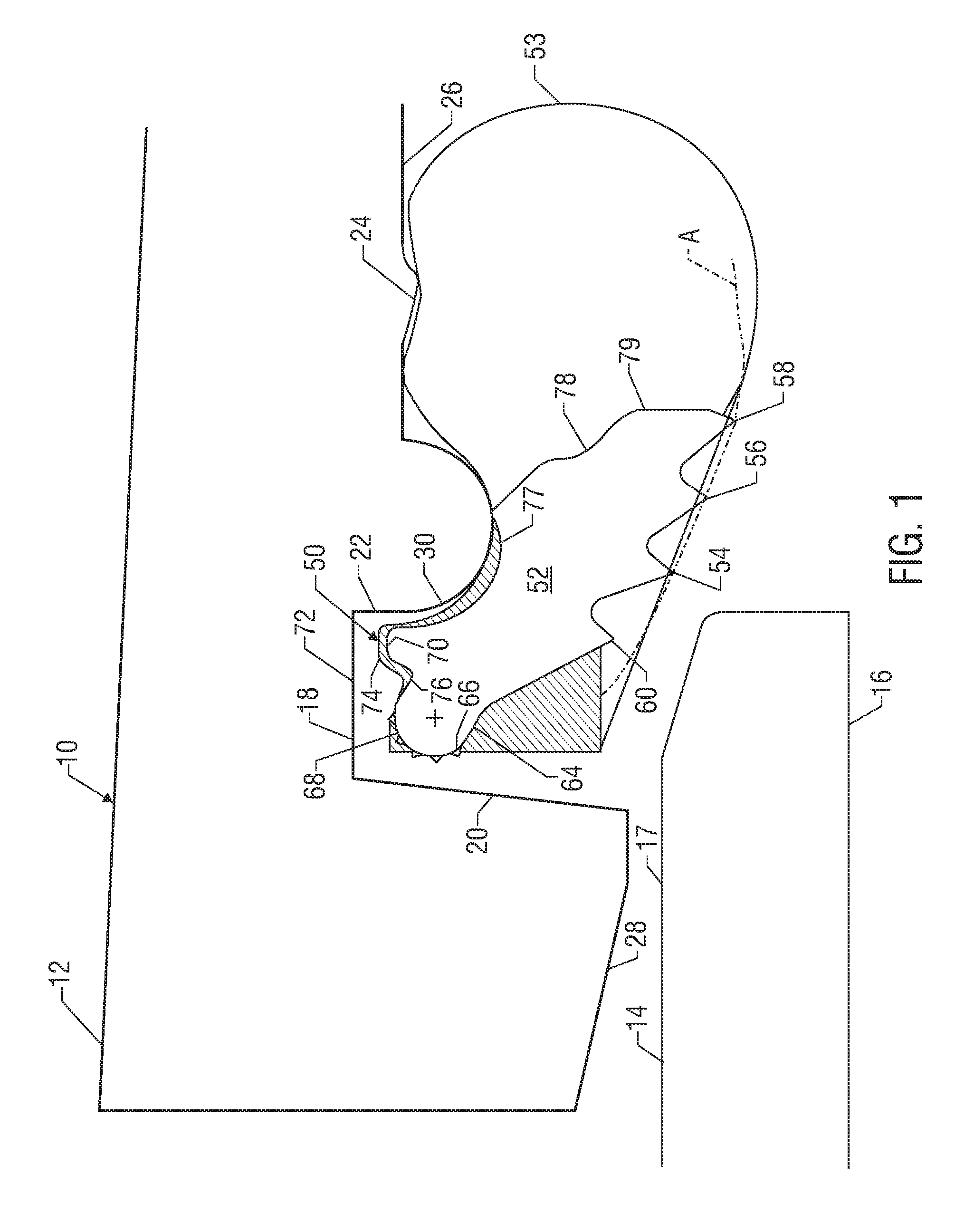

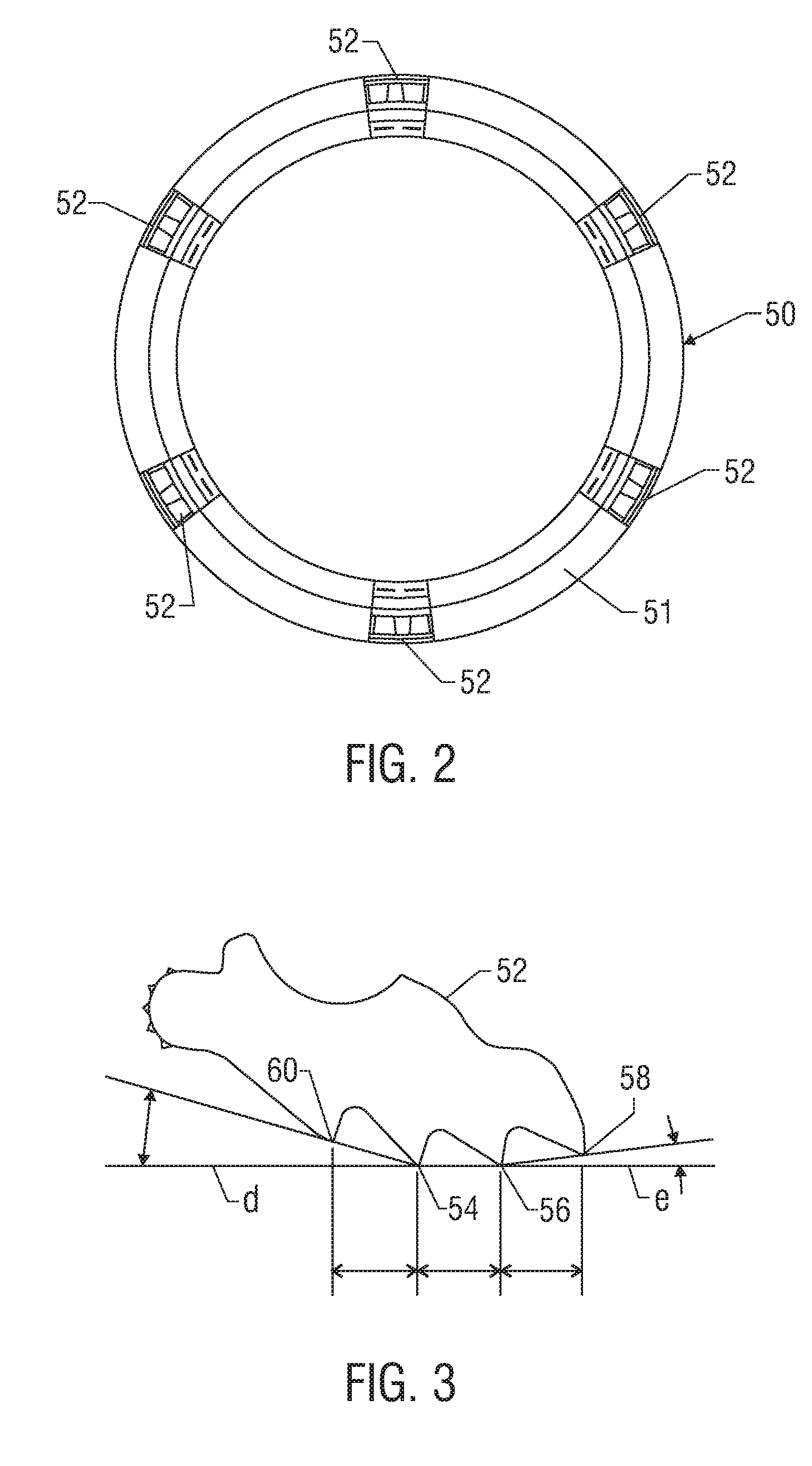

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS20090105605A1Prevent dehydrationAvoid overhydrationThermometer detailsTelevision system detailsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS20070106172A1Precise positioningGood visual impactThermometer detailsUltrasonic/sonic/infrasonic diagnosticsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS8328420B2Increase blood flowReduce in quantityThermometer detailsTelevision system detailsInfraredWireless transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. A sensor fitted on the support structures uses a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Apparatus and method for measuring biologic parameters

ActiveUS8172459B2Increase blood flowReduce in quantityThermometer detailsUltrasonic/sonic/infrasonic diagnosticsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

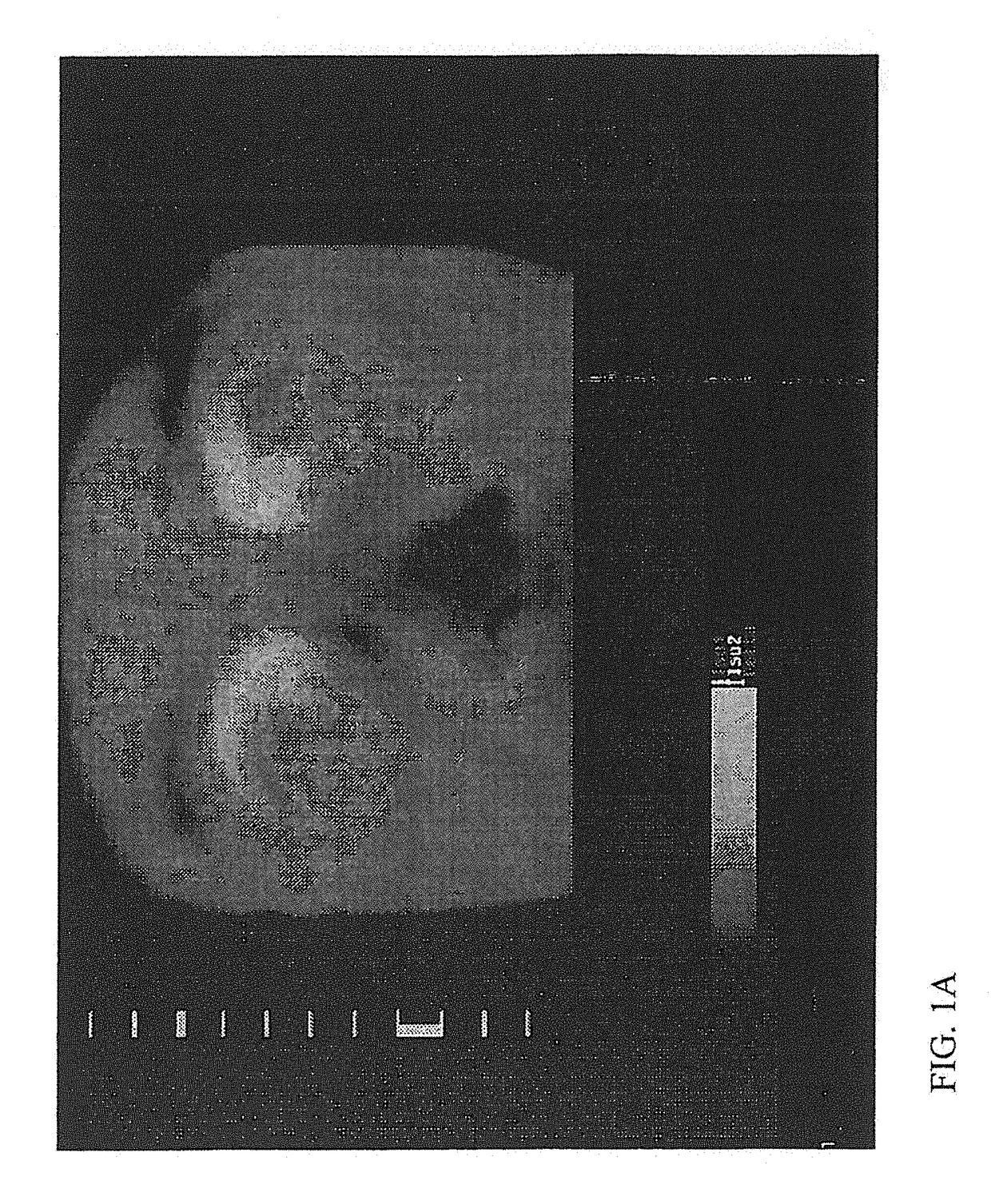

Thermal Imaging System

InactiveUS20130124039A1Increase blood flowReduce in quantityTelevision system detailsAir-treating devicesInfraredVideo transmission

Owner:BRAIN TUNNELGENIX TECH CORP

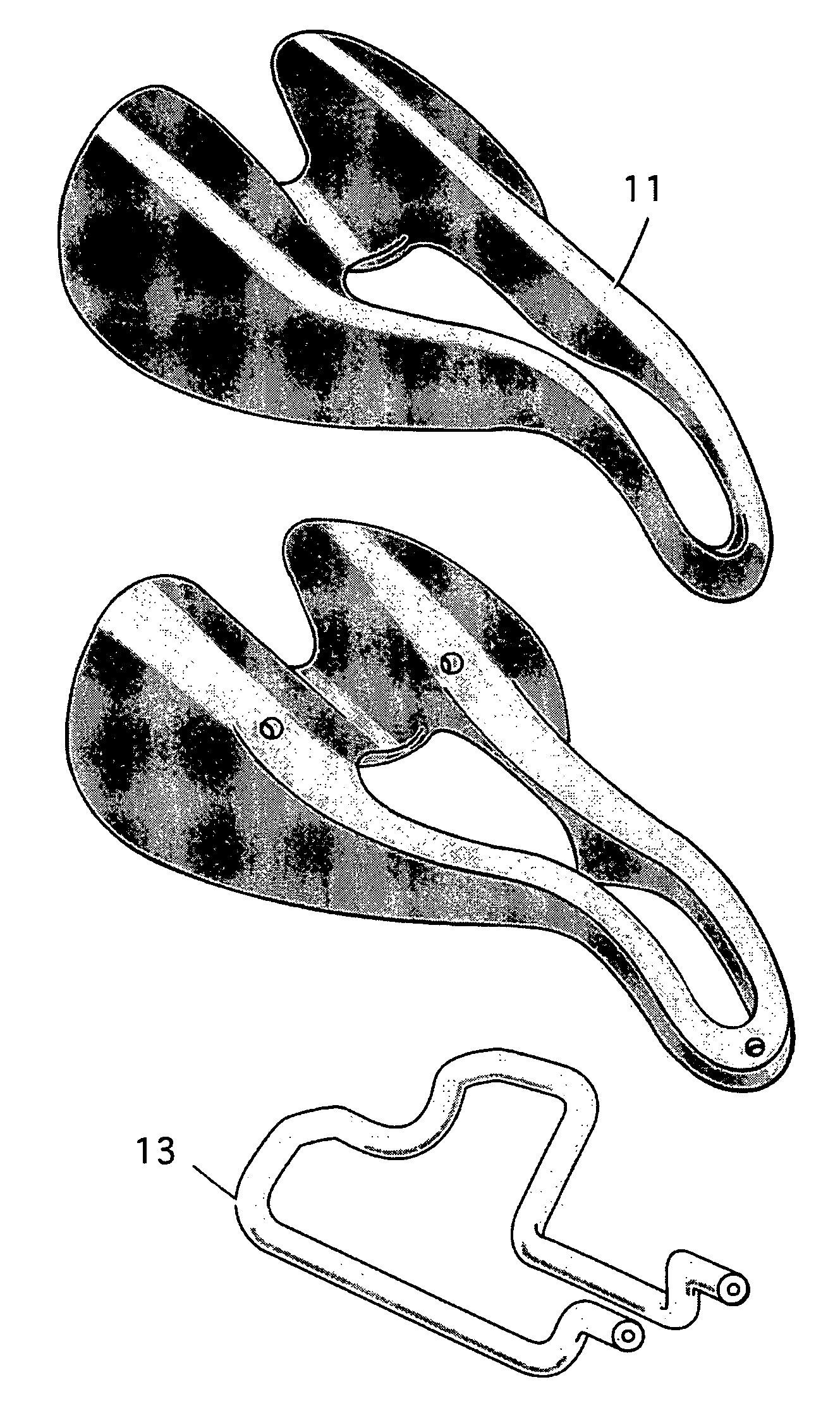

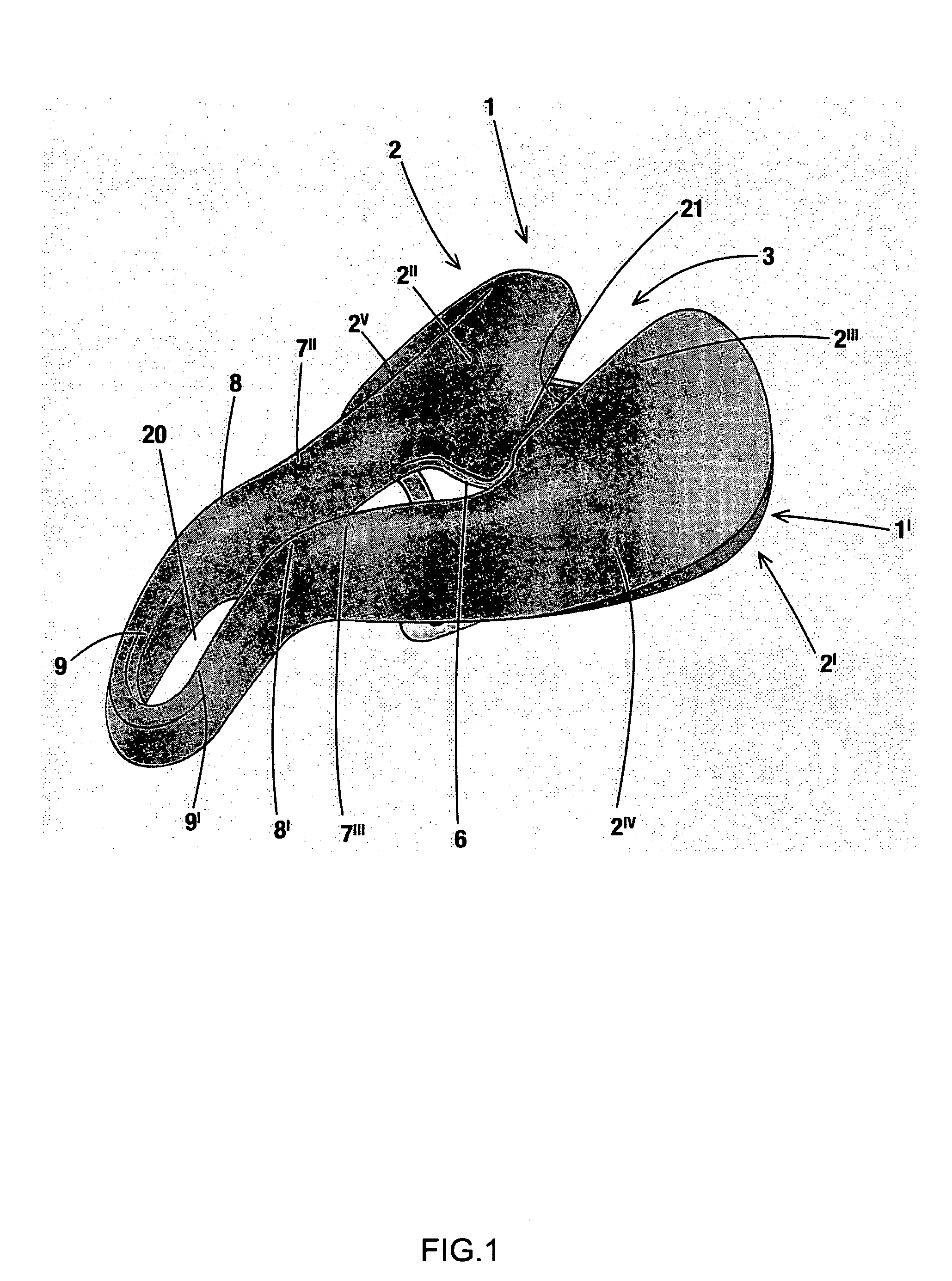

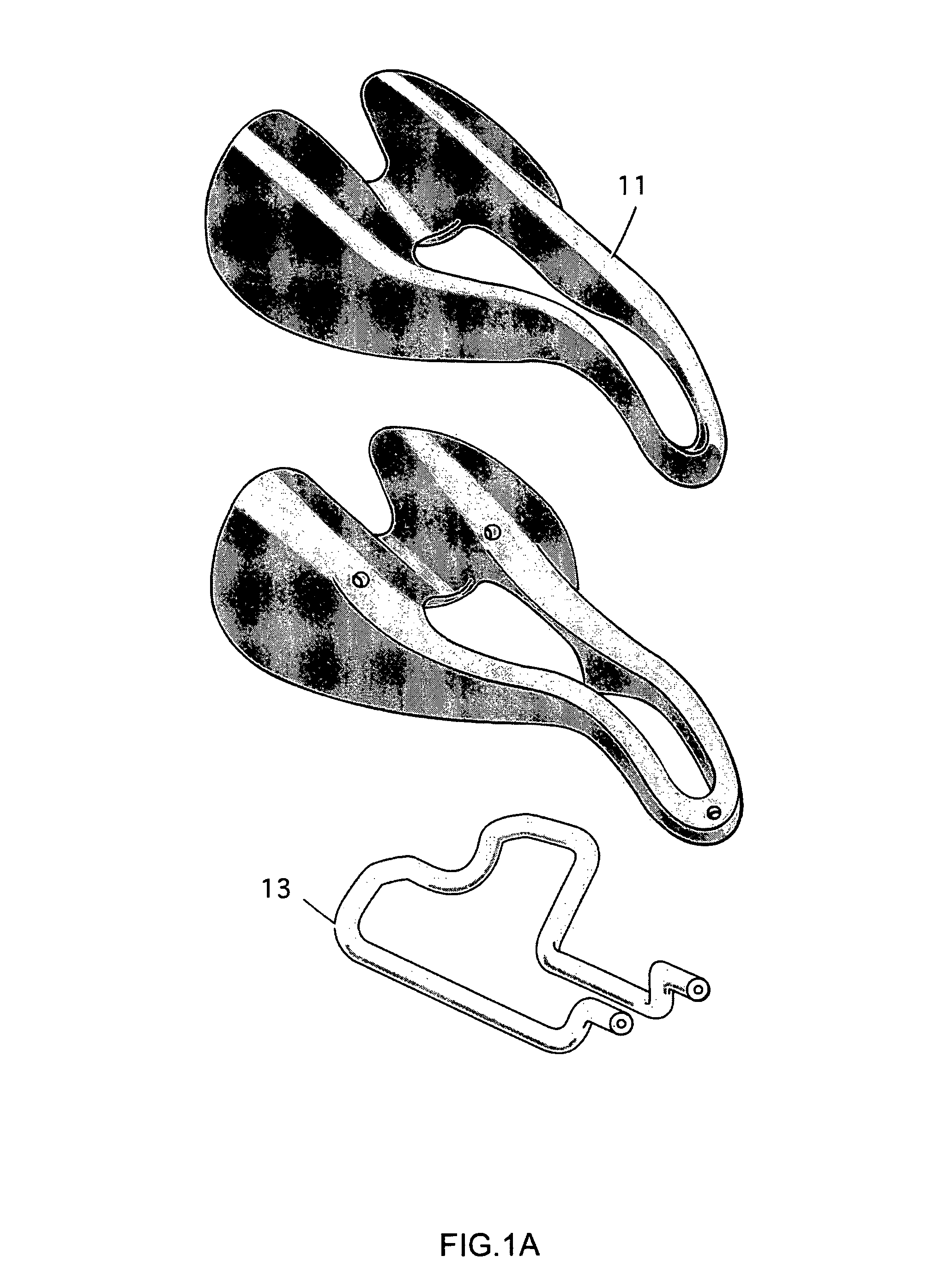

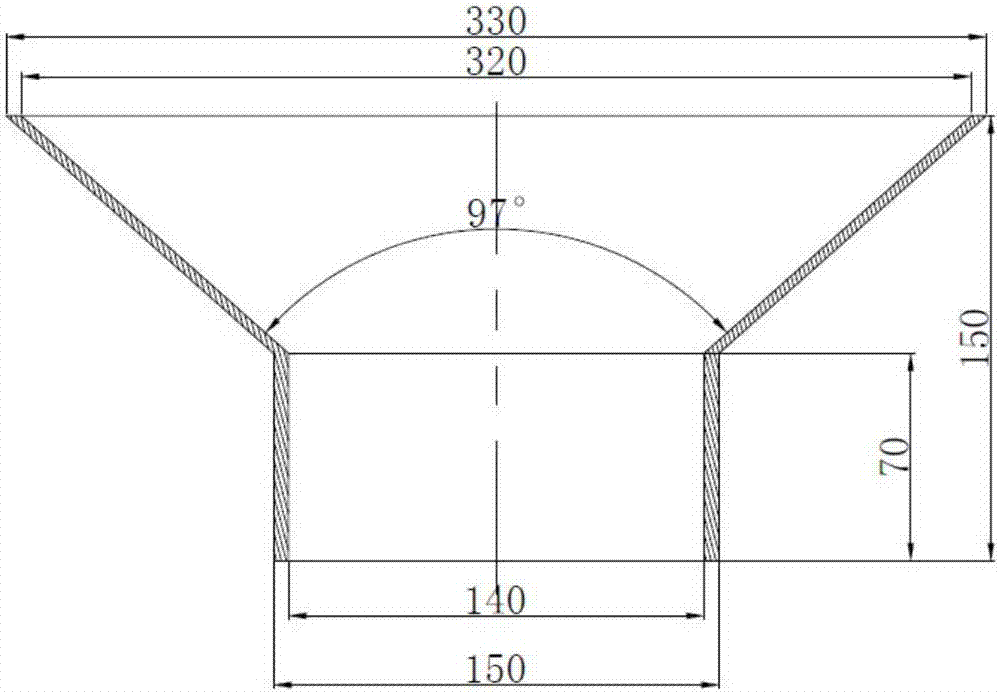

Bicycle saddle

This relates to a bicycle saddle of the type that presents two identical portions (1, 1′) longitudinally symmetrical. Thanks to its special conformation, said saddle permits the cyclist to avoid the occurrence of pathologies normally caused by the use of a racing saddle of commonly known types, eliminating the crushing of the vascular structure of the perineum, as well as the testicles of male cyclists and the clitoris of female cyclists. The special geometry permits a pedaling action without causing friction of the thigh muscles, in particular the delicate and adducent muscles.

Owner:SELLE SMP DI MAURIZIO SCHIAVON

Apparatus and method for measuring biologic parameters

ActiveUS20120316459A1Increase blood flowReduce in quantityUltrasonic/sonic/infrasonic diagnosticsBody temperature measurementInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

Specially configured and surface modified medical device with certain design features that utilize the intrinsic properties of tungsten, zirconium, tantalum and/or niobium

InactiveUS20100305682A1Good physical propertiesIncrease success rateStentsSurgeryNiobiumSpecial geometry

Owner:MICO INNOVATIONS

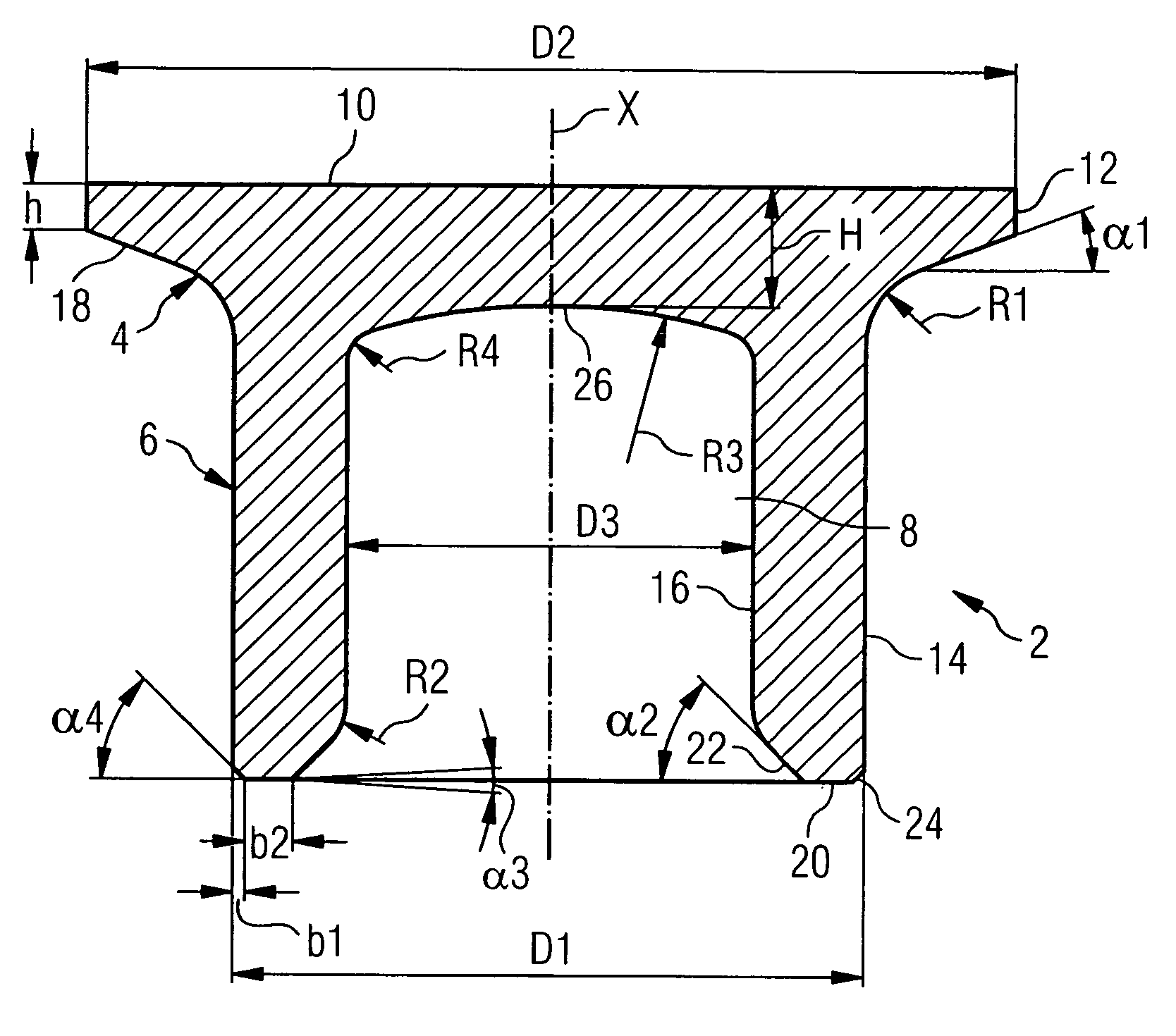

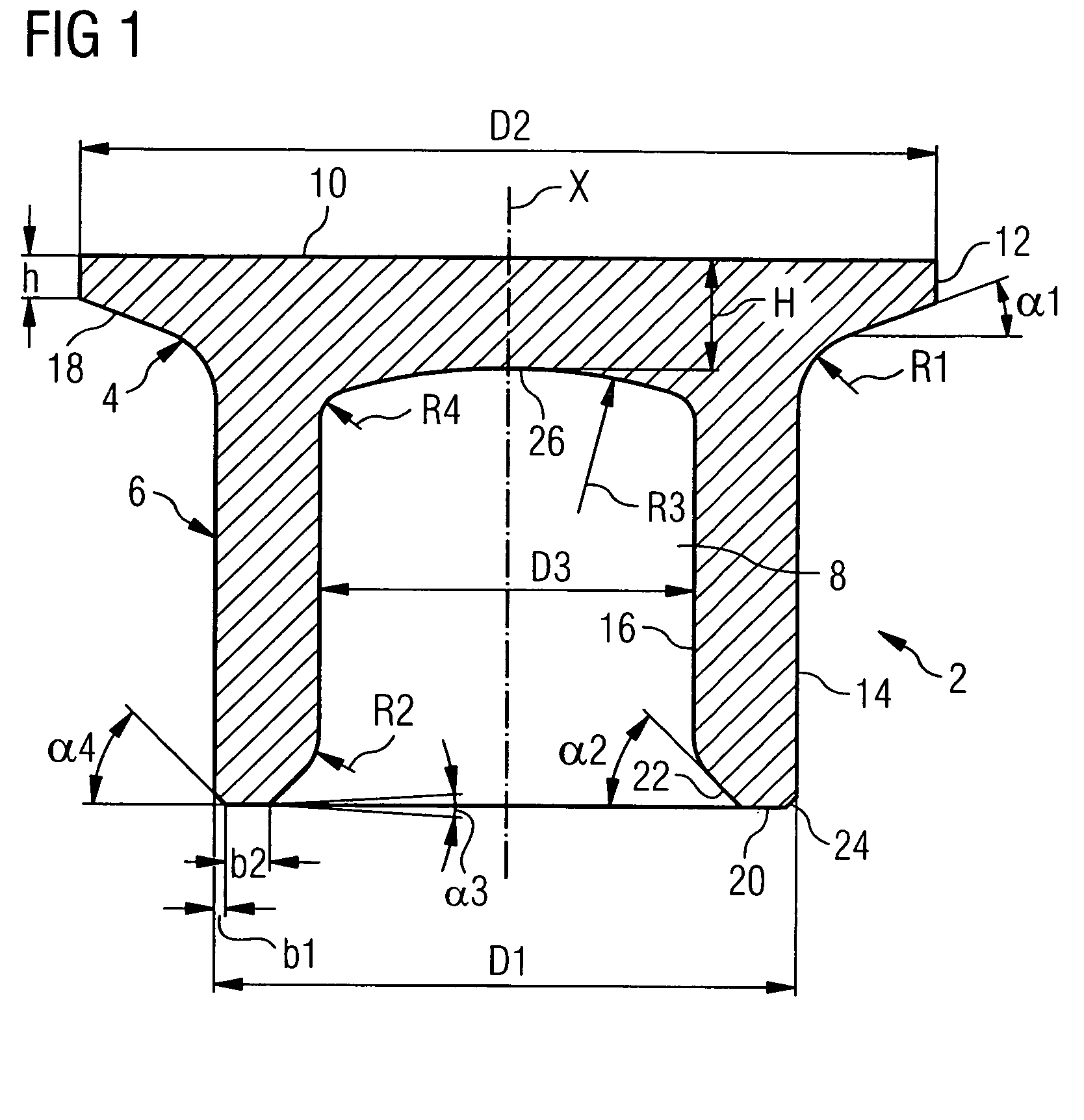

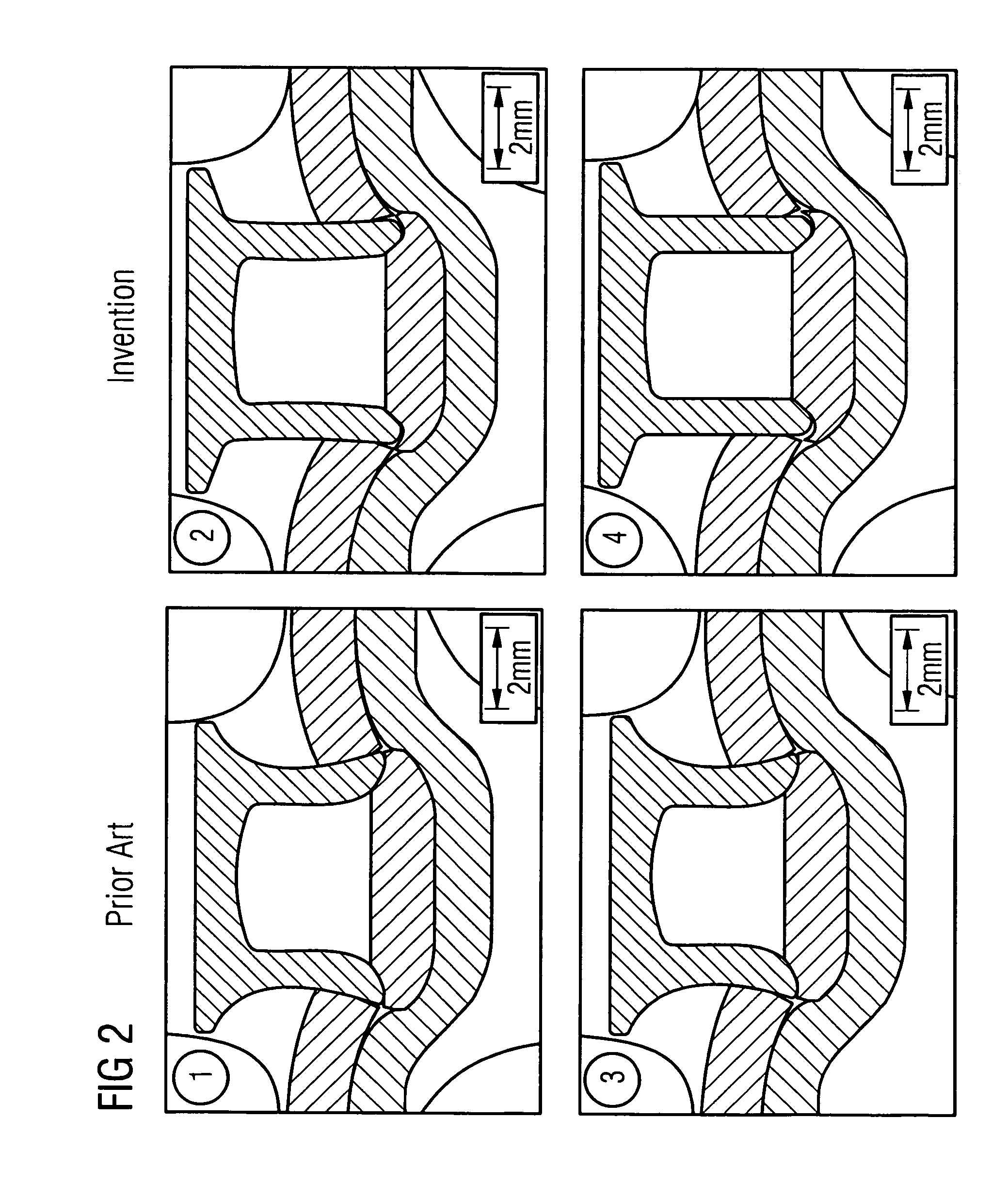

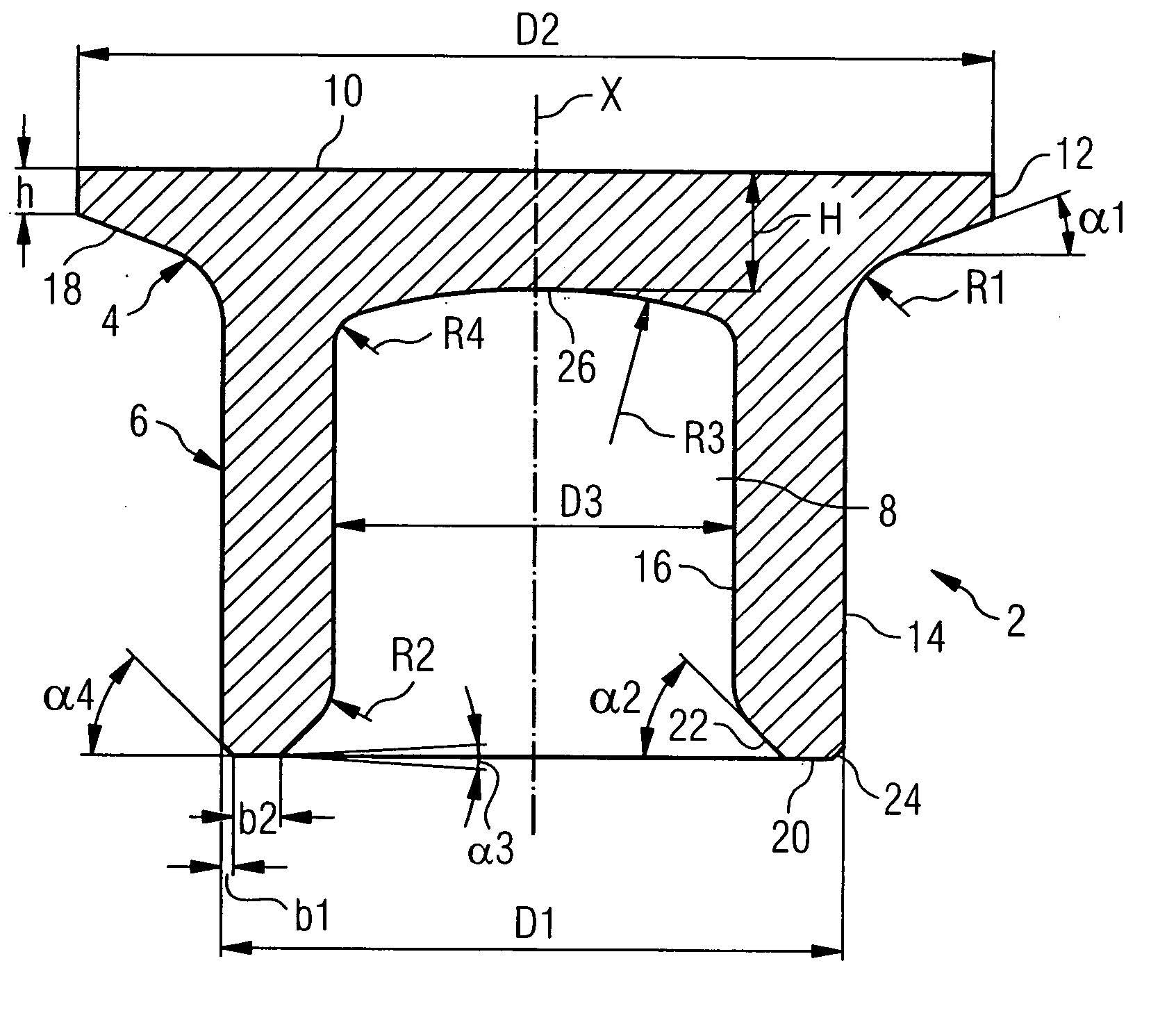

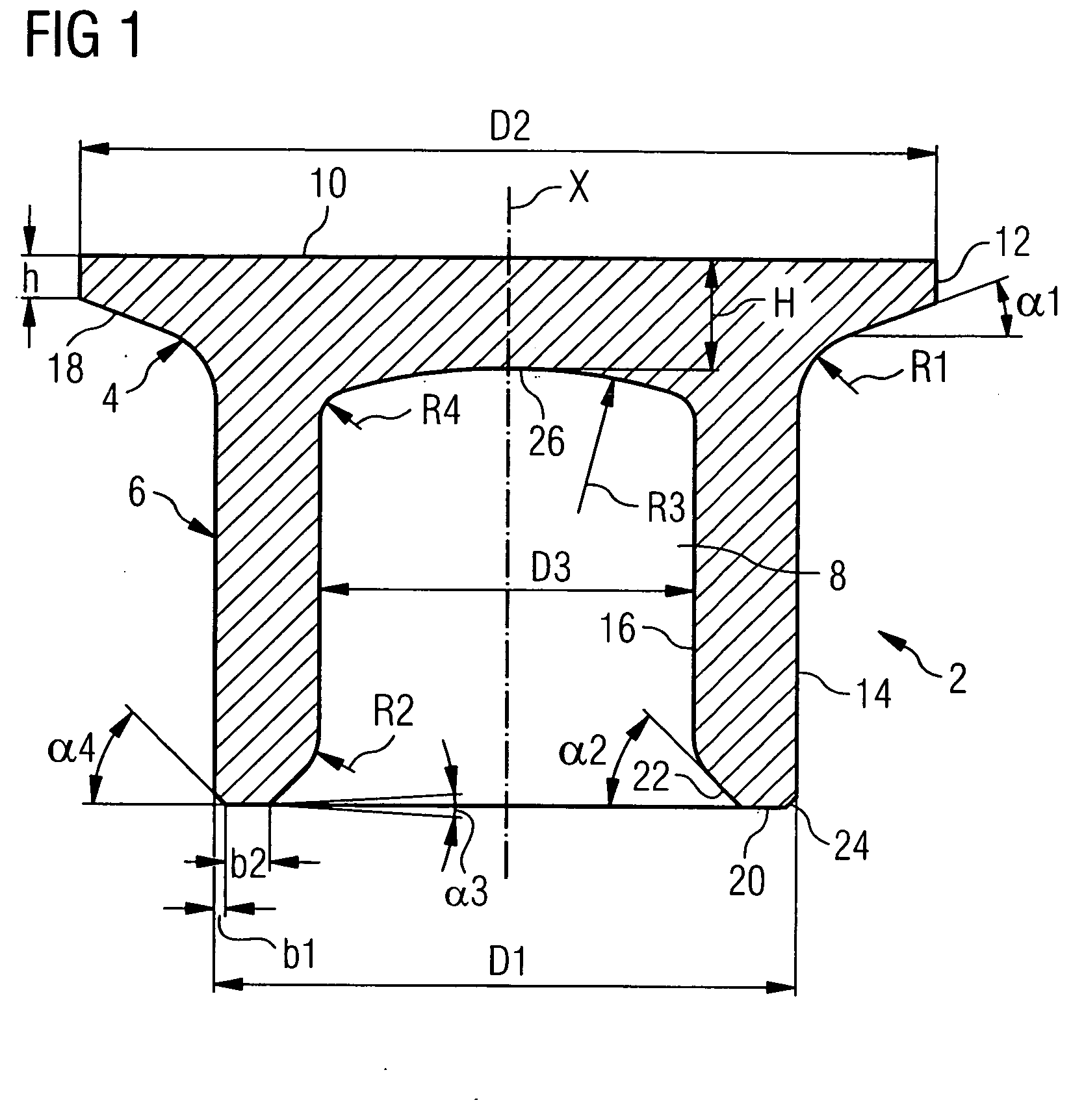

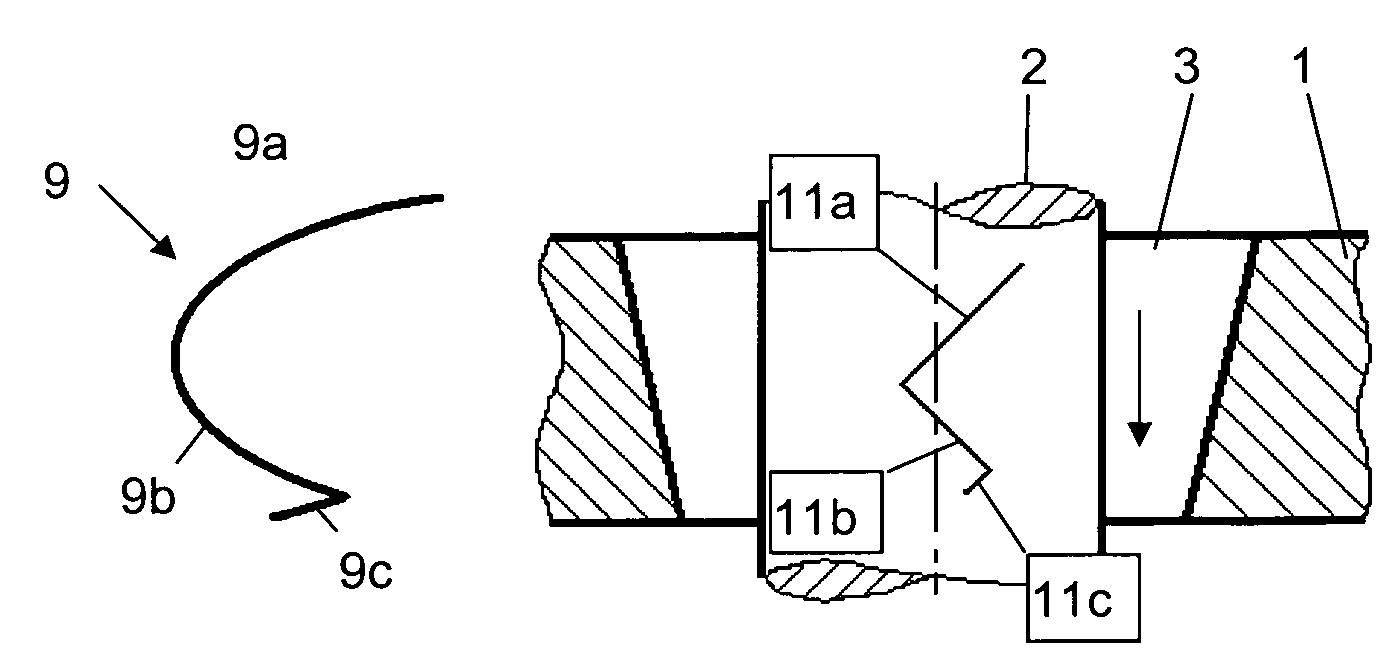

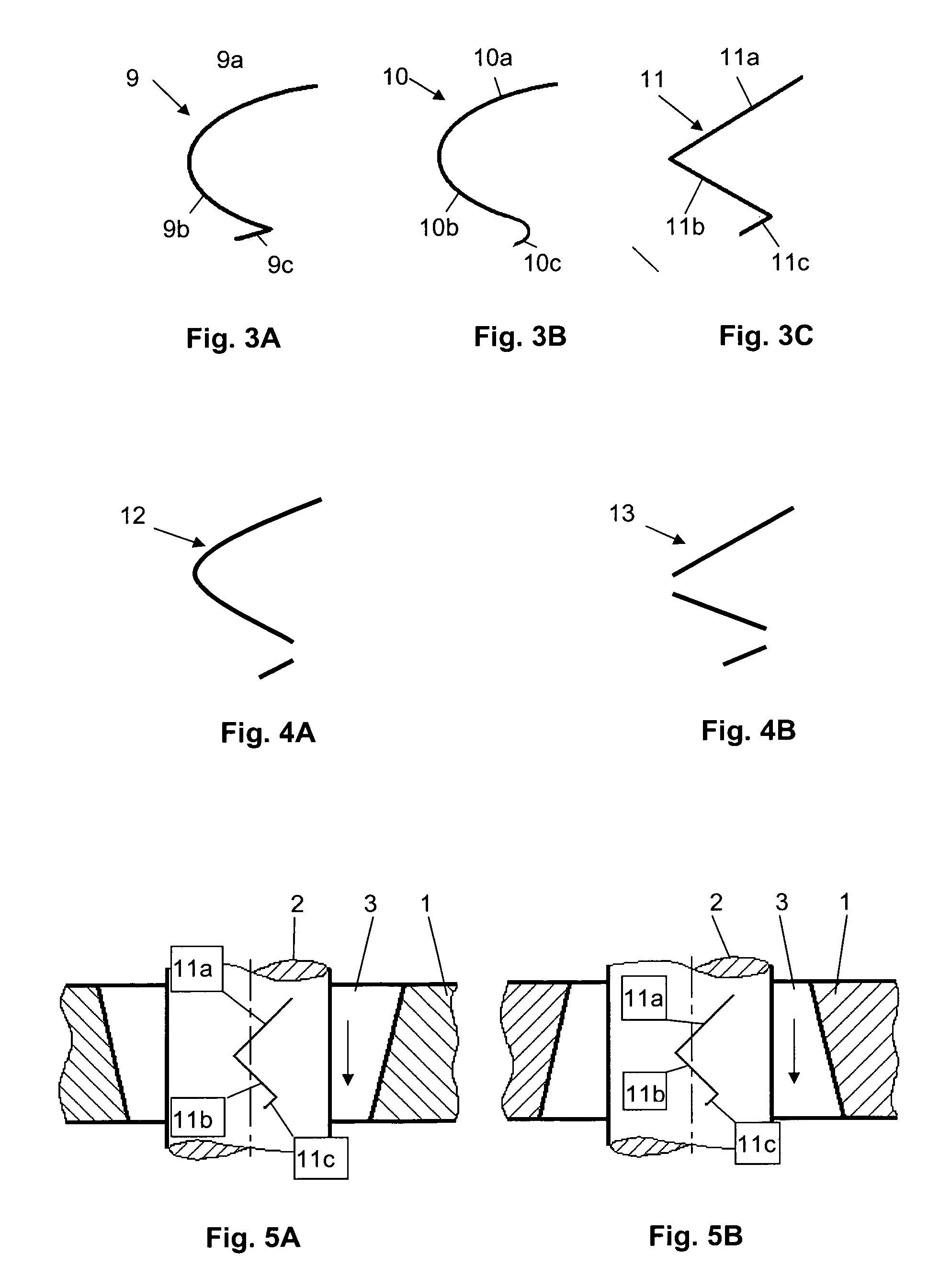

Self-piercing rivet

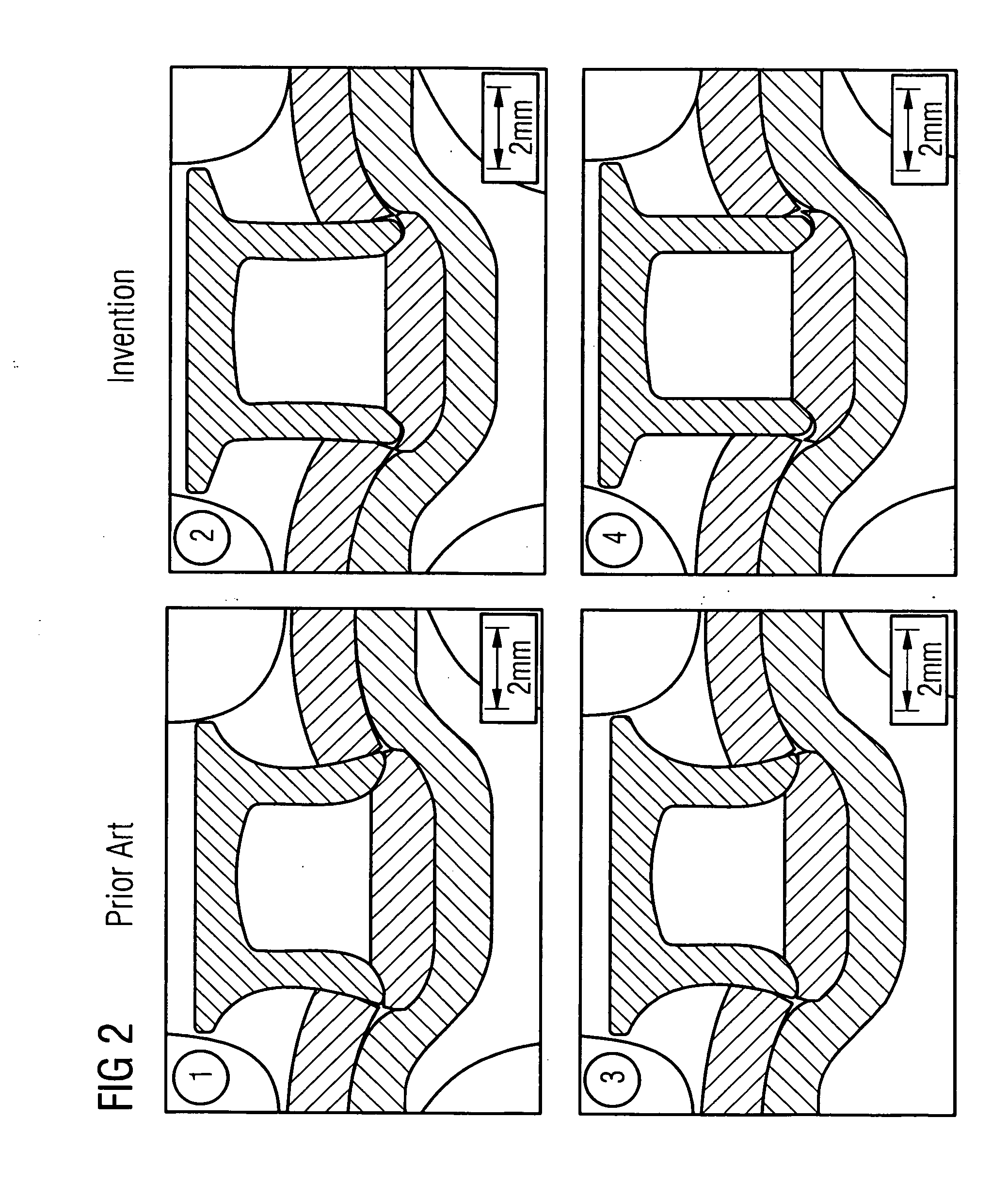

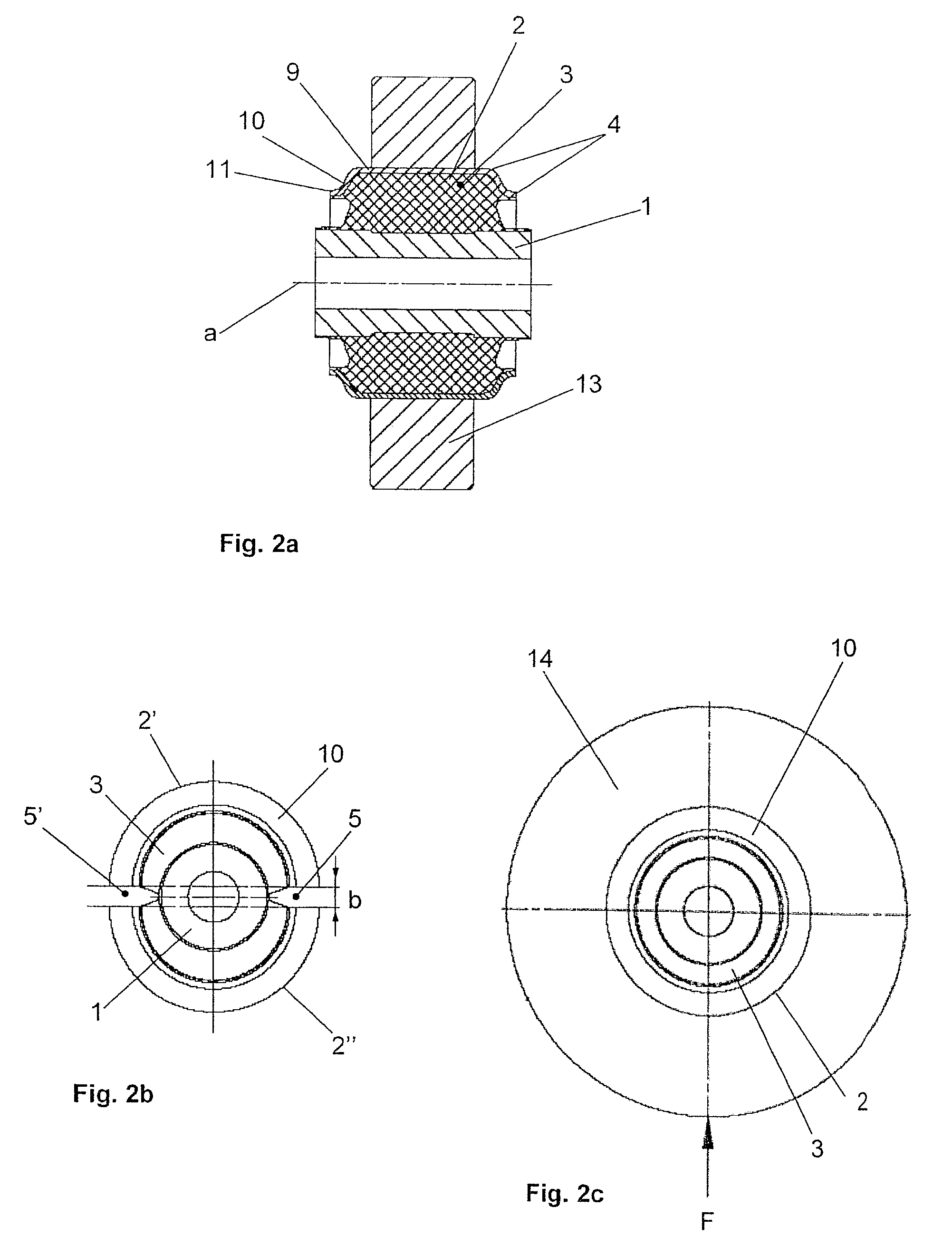

A self-piercing rivet of a special rivet geometry is described, which in particular is suitable for joining high strength steel sheets, but can also be used for other metal sheets. The self-piercing rivet is in particular characterized by a special underhead geometry as well as a special geometry of the rivet foot (cutting region). Thus the self-piercing rivet has an underhead chamfer which with a radial plane of the self-piercing rivet encloses an angle of 20°+5° / −5° and merges tangentially into the cylindrical outer surface of the rivet shank via a radius. In the region of the rivet foot the self-piercing rivet has a plane shank face, which extends essentially at a right angle to the rivet axis and which merges “smoothly” into the cylindrical inner surface via a shank inner surface and a radius. In comparison to conventional self-piercing rivets the special rivet geometry enables lower joining forces and tensile forces in the joining operation, an optimized load bearing performance and an optimum joint quality of the self-piercing rivet joint as well as minimum gap formation between the rivet and the metal sheet.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Self-piercing rivet

A self-piercing rivet of a special rivet geometry is described, which in particular is suitable for joining high strength steel sheets, but can also be used for other metal sheets. The self-piercing rivet is in particular characterized by a special underhead geometry as well as a special geometry of the rivet foot (cutting region). Thus the self-piercing rivet has an underhead chamfer which with a radial plane of the self-piercing rivet encloses an angle of 20°+5° / −5° and merges tangentially into the cylindrical outer surface of the rivet shank via a radius. In the region of the rivet foot the self-piercing rivet has a plane shank face, which extends essentially at a right angle to the rivet axis and which merges “smoothly” into the cylindrical inner surface via a shank inner surface and a radius. In comparison to conventional self-piercing rivets the special rivet geometry enables lower joining forces and tensile forces in the joining operation, an optimized load bearing performance and an optimum joint quality of the self-piercing rivet joint as well as minimum gap formation between the rivet and the metal sheet.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Appartus and method for measuring biologic parameters

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:ABRUE MARCIO MARC AURELIO MARTINS (I) (US)

Apparatus and method for measuring biologic parameters

InactiveUS20150148628A1Prevent dehydrationAvoid overhydrationDiagnostics using spectroscopyEvaluation of blood vesselsInfraredWireless transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

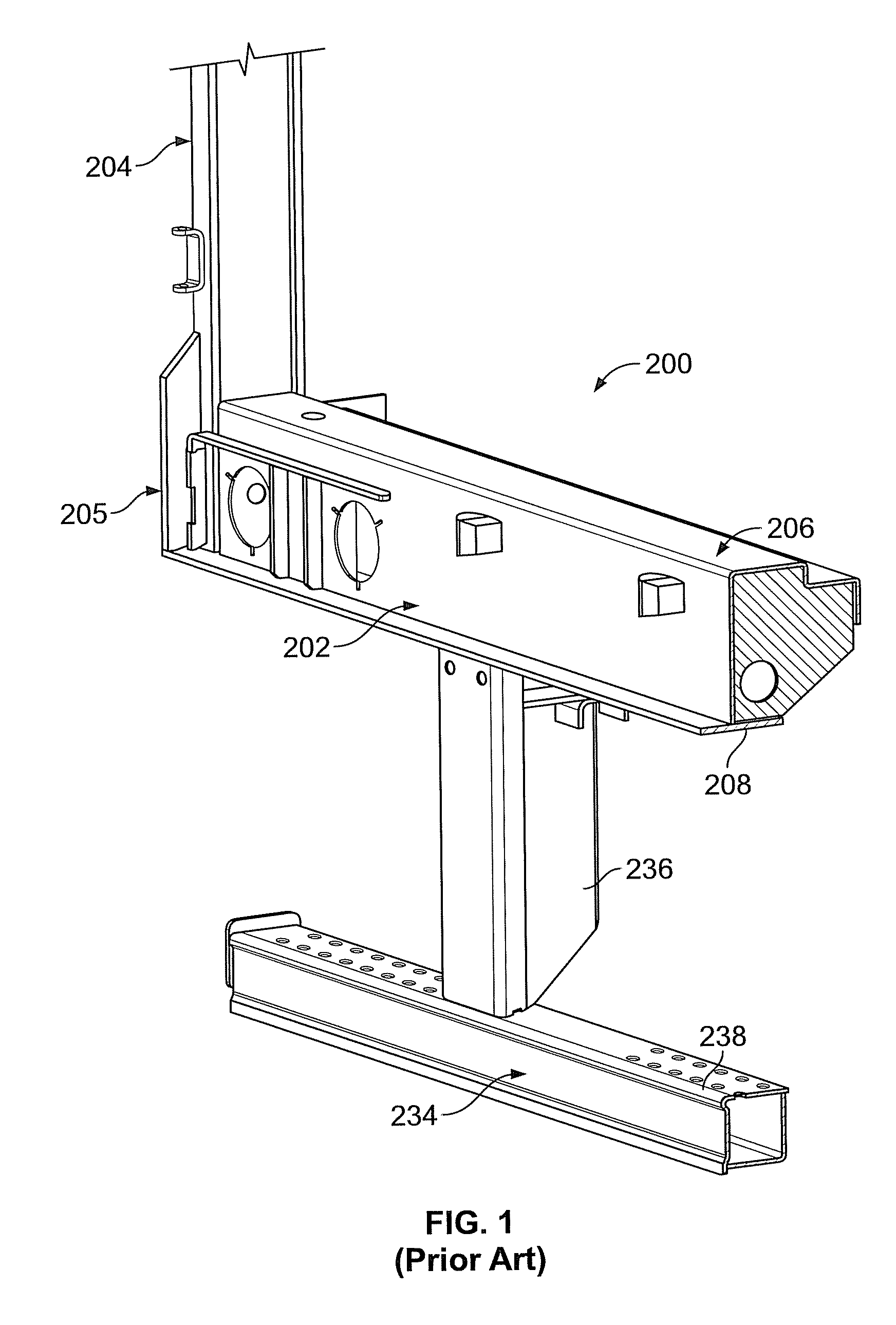

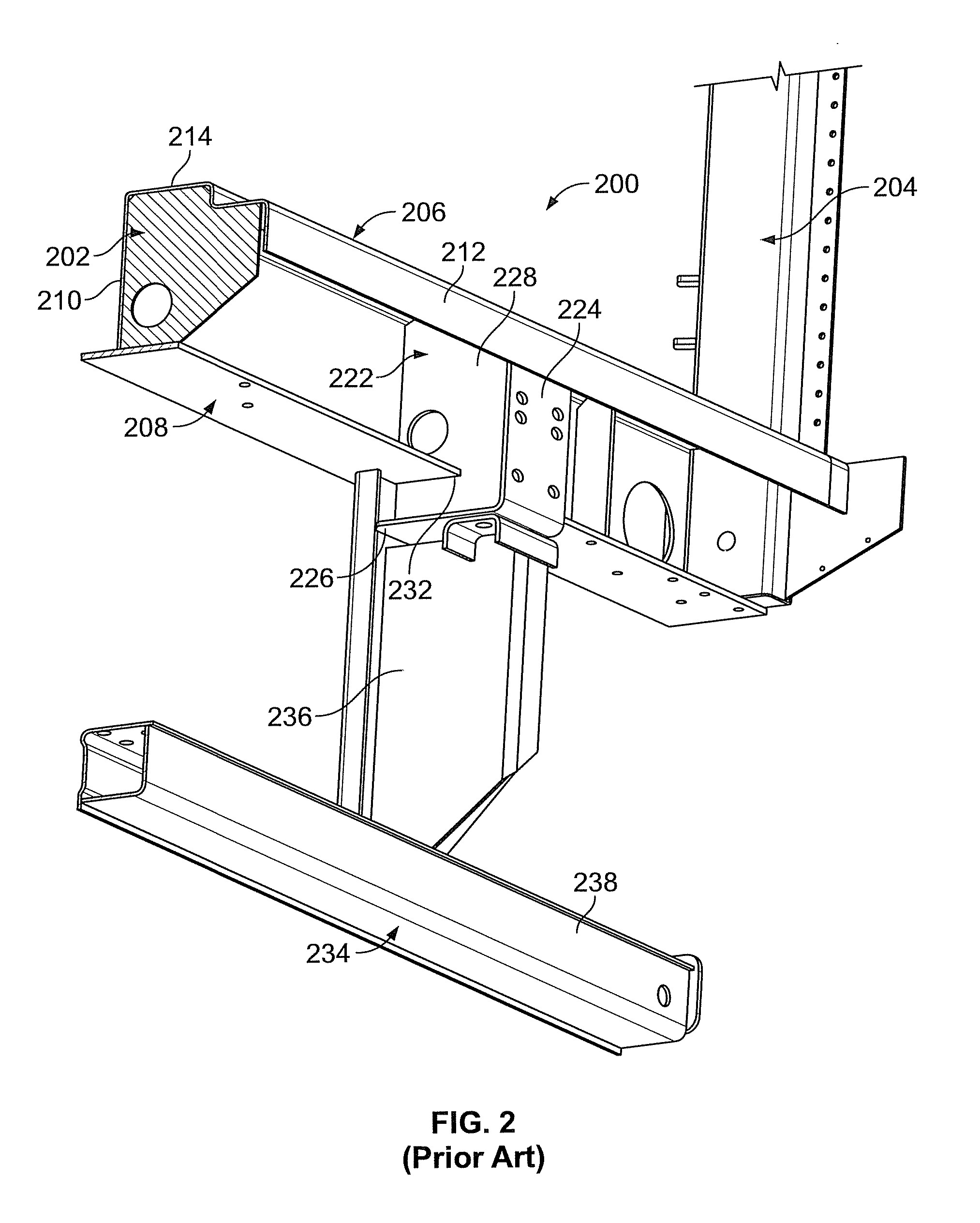

Trailer rear door frame with angled rear sill

ActiveUS20080073941A1Minimal vertical dimensionVehicle seatsLoading/unloading vehicle arrangmentVehicle frameEngineering

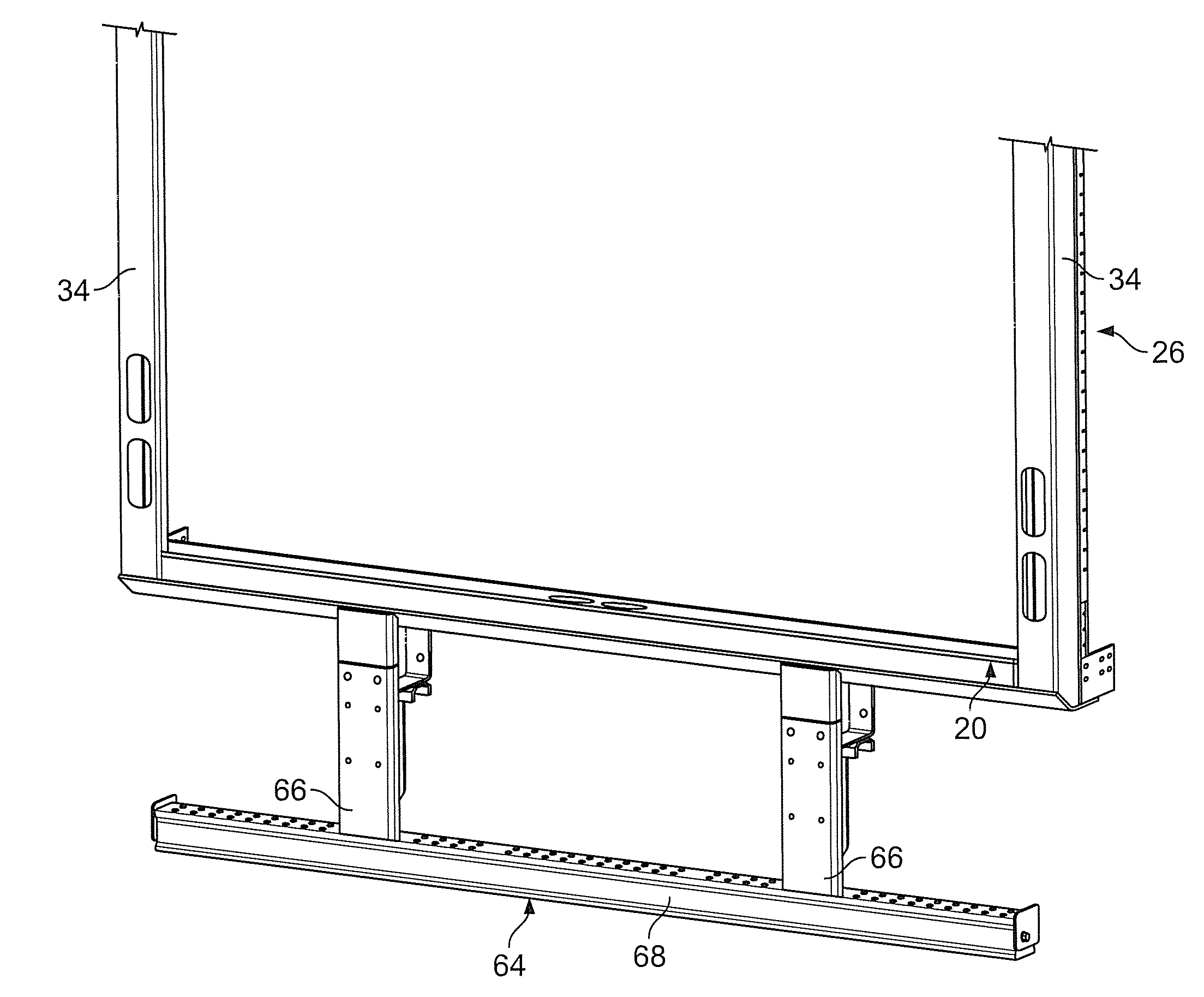

A rear frame of a trailer has an elongated horizontal sill having a closed cross-section which is rigid in bending and in torsion. The elongated horizontal sill is formed of a fantail and a base plate attached to an underside of the fantail. The base plate has front and rear sections that are not notched as notching of the sill can weaken it. The front section is horizontal and the rear section is angled upwardly relative to the horizontal front section at a predetermined angle of approximately 22 degrees. The angling of the base plate provides a specialized geometry for accommodating a tuck-under lift gate. The sill also has minimal vertical dimensions to aid in the non-interference with legs of the tuck-under lift gate.

Owner:WABASH NATIONAL

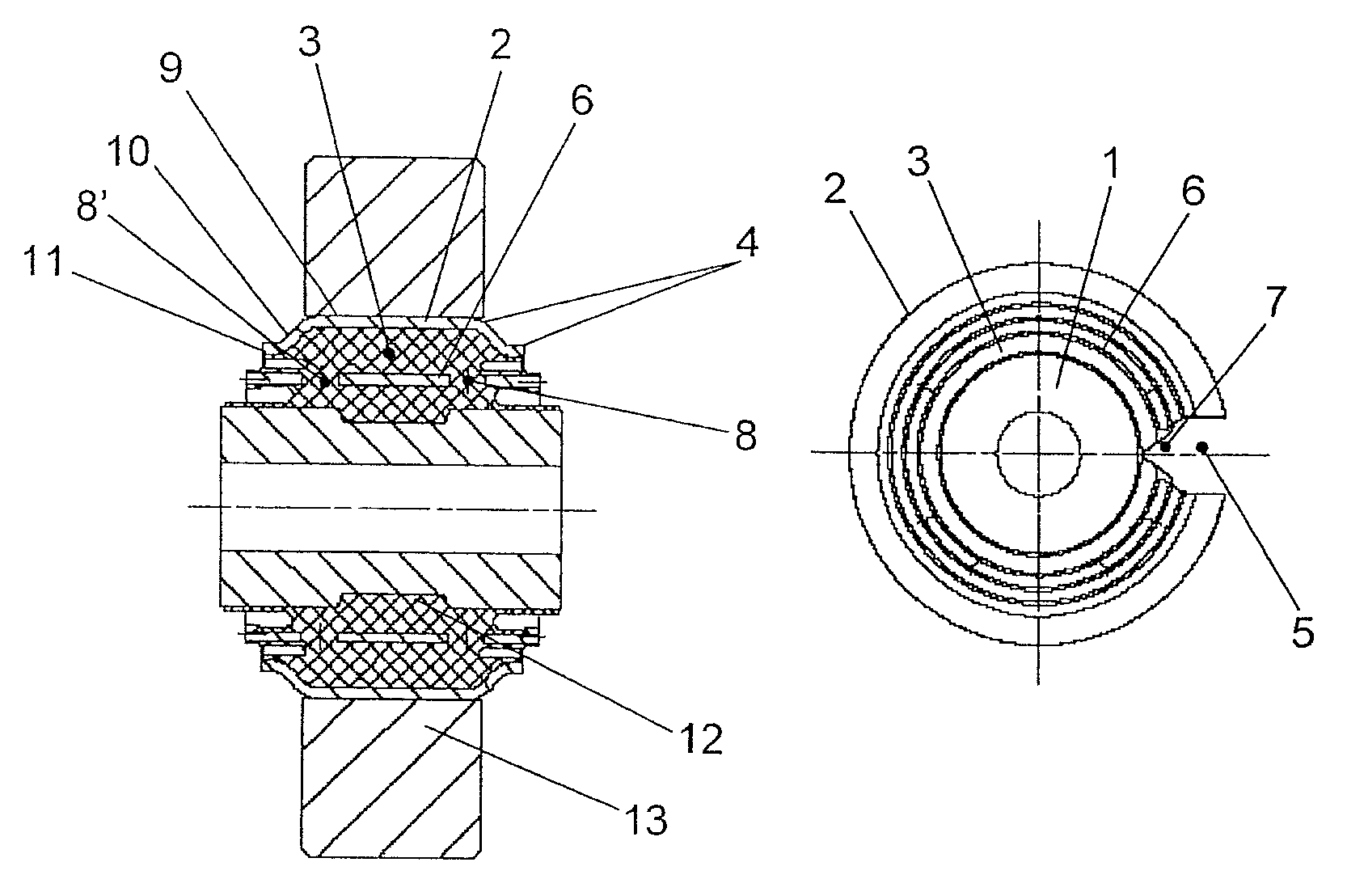

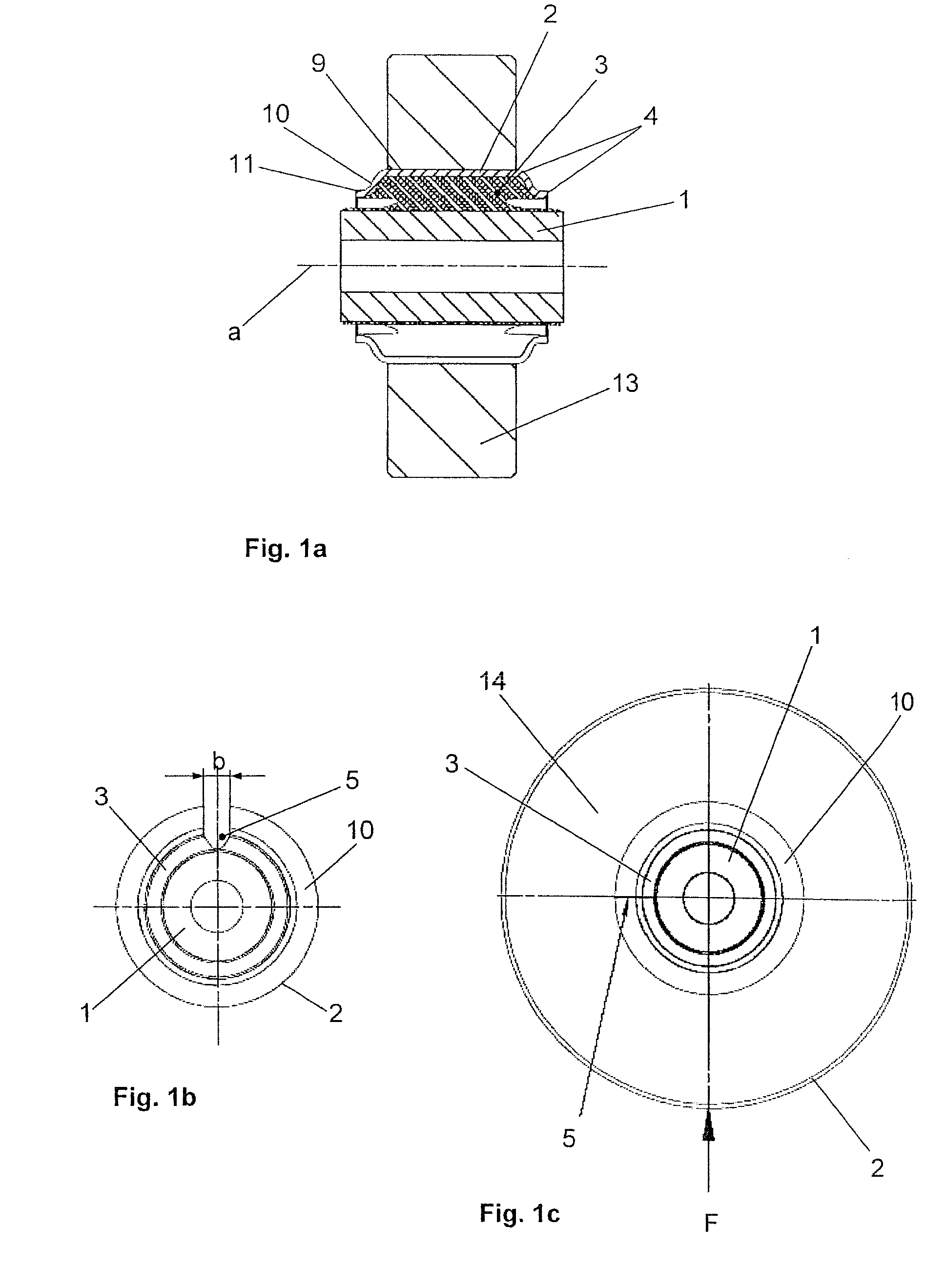

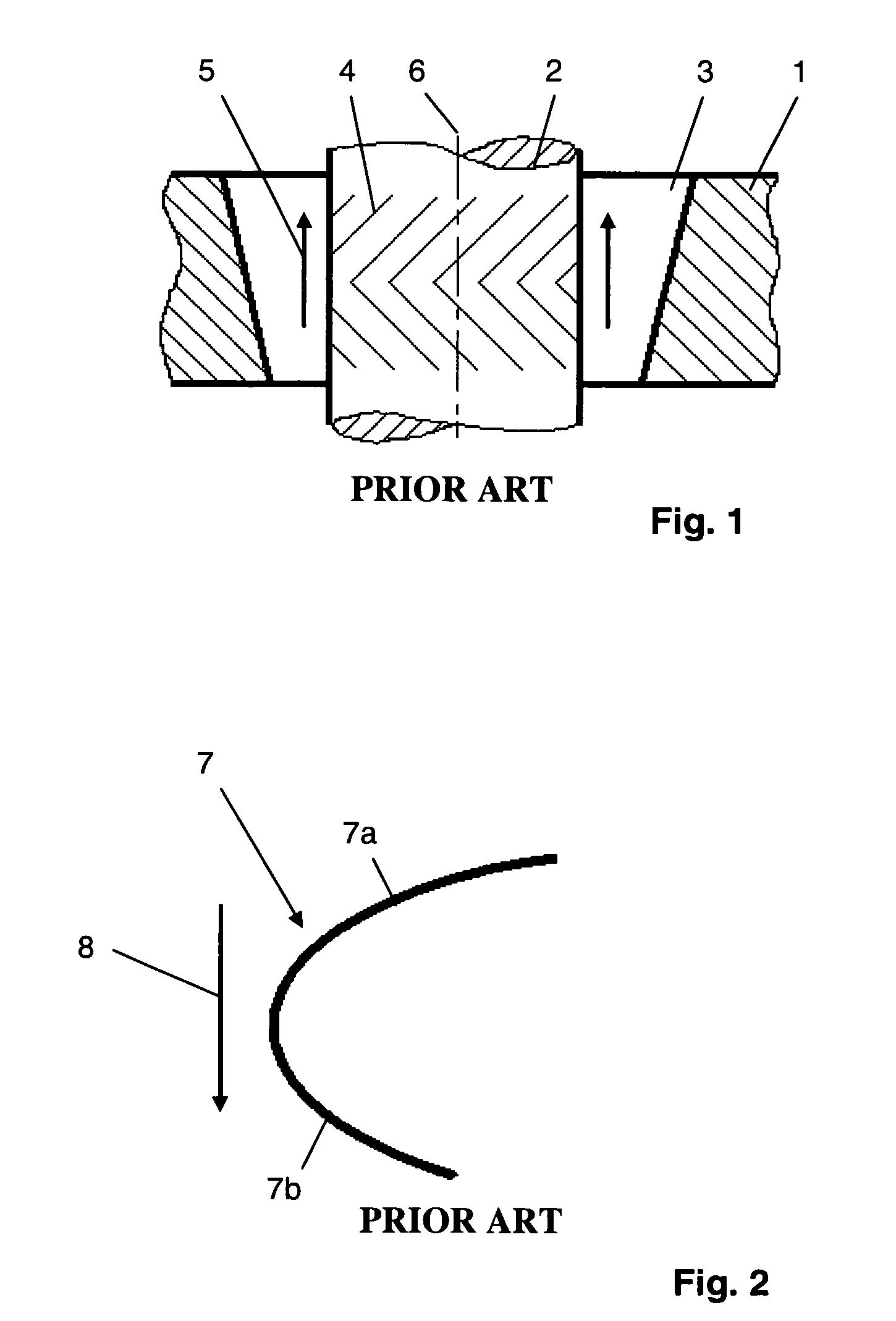

Elastomeric bush bearing and process for manufacturing same

InactiveUS7441759B2Improve radial stiffnessEvenly distributedSprings/dampers functional characteristicsResilient suspensionsElastomerGeometric design

An elastomeric bush bearing is designed as a slotted bush. To reach a high ratio of static radial stiffness to torsion spring rate along with a high axial stiffness at the same time, a beading is formed at least at one axial end but preferably at both axial ends of the slotted bush. In case of an especially advantageous embodiment, a slotted bush with additional intermediate parts inserted into the elastomeric bearing body, two encapsulated rubber packets are created by the simultaneous special geometric design of the inner part. The individual stiffnesses of the two rubber packets are thus compensated and thus there is a homogeneous increase in the overall stiffness of the bush. The beadings are prepared before the components of the bearing are assembled and vulcanized to the parts of the later outer sleeve.

Owner:ZF FRIEDRICHSHAFEN AG

Apparatus and method for measuring biologic parameters

ActiveUS20150148681A1Prevent dehydrationAvoid overhydrationDiagnostics using spectroscopyEvaluation of blood vesselsInfraredWireless transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

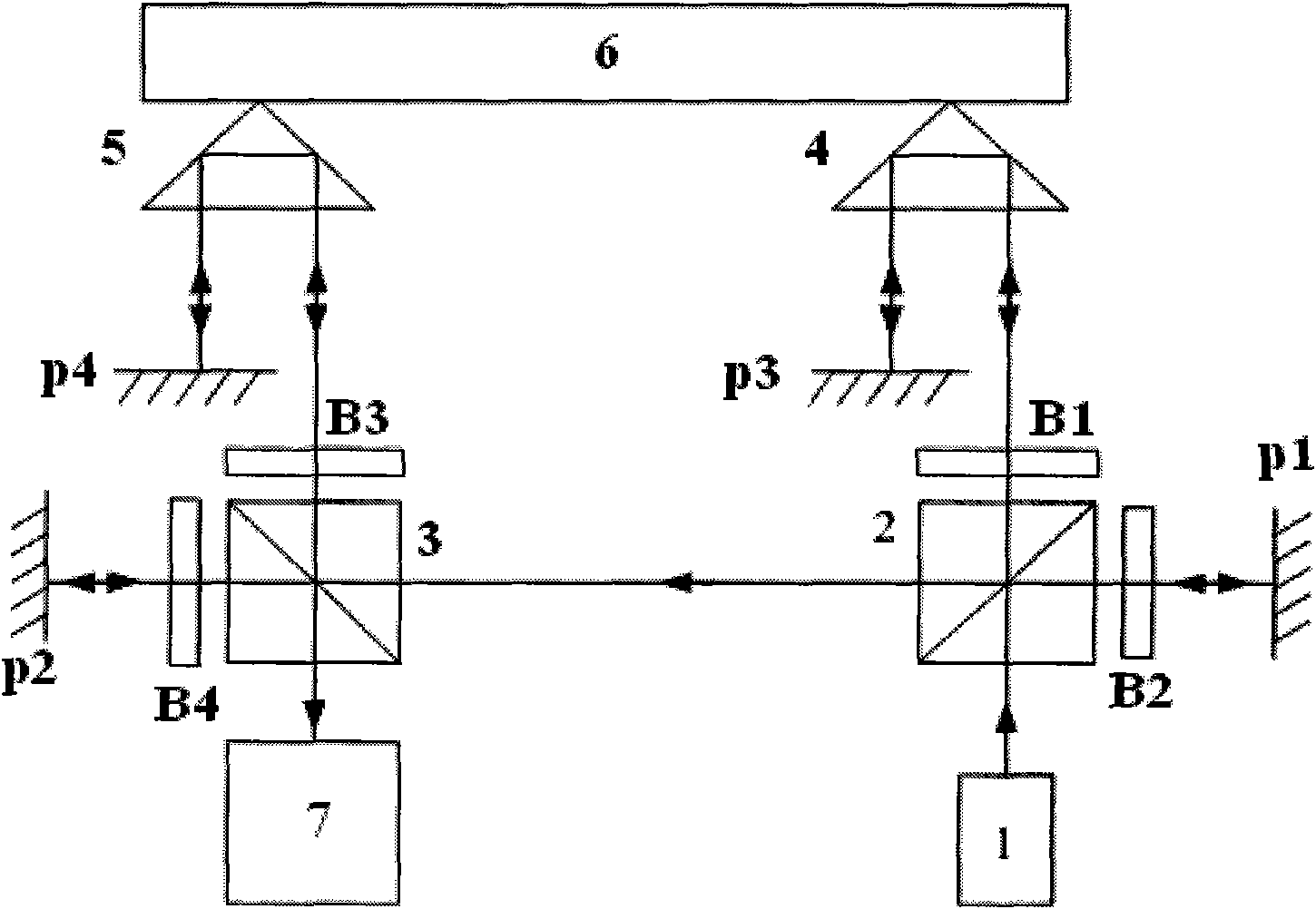

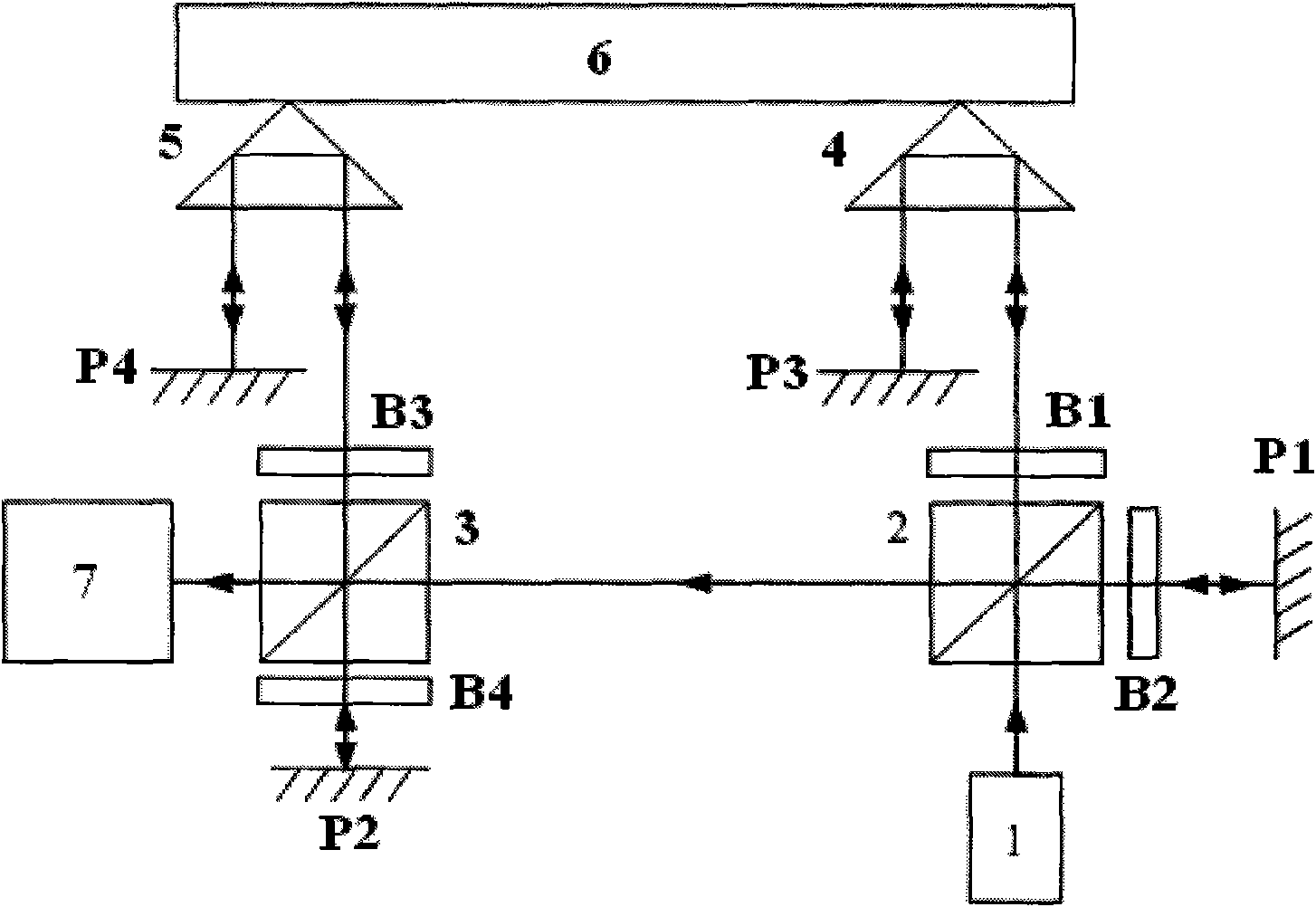

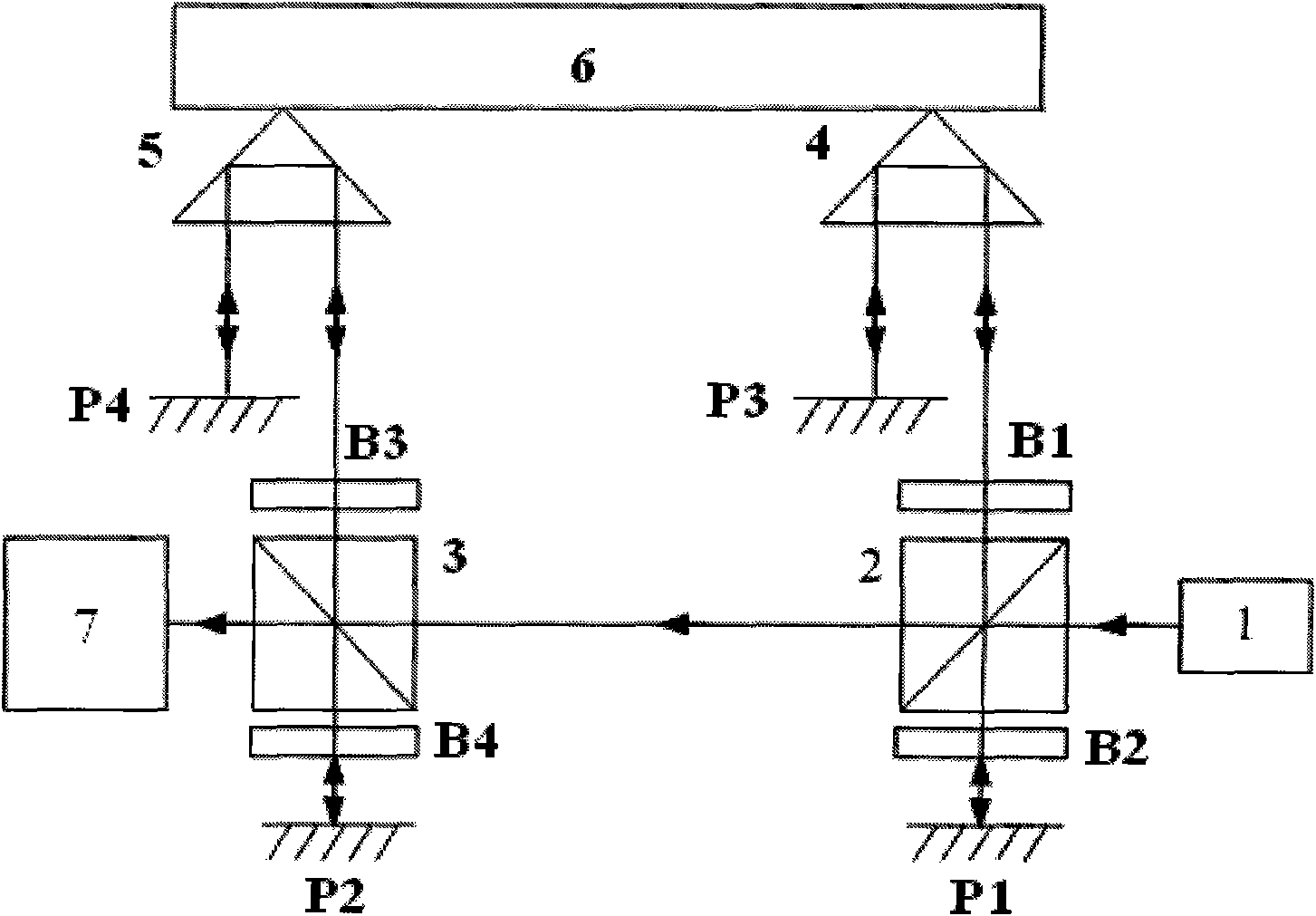

Optical doubling frequency laser interference measurement system and optical doubling frequency laser interference measurement method for displacement of special geometric point

The invention belongs to the field of optical measurement and relates to an optical doubling frequency laser interference measurement method for the displacement of a special geometric point. The method comprises the following steps: symmetrically placing two pyramid prisms on two sides of a special geometric point on a measured object; accurately obtaining the displacement of a central point by utilizing the displacement sum of two points; and dividing laser output light into measurement light and reference light by utilizing a polarization light splitter, wherein the measurement light respectively passes through the two pyramid prisms and returns twice in each pyramid prism and the measurement light moves for 8 Delta if a measured point moves for one Delta so that the optical octuple frequency of interference measurement is realized and the measurement accuracy is improved. Because the measurement light returns along the prior path in the pyramid prisms, even if the measured object moves in a plane vertical to a motion direction according to the characteristics of the pyramid prisms, the measurement accuracy of the motion direction is not influenced so that the method can be more widely applied. The invention can be applied to the measurement of non-guide rail movement and other complicated movements with more measured object freedom.

Owner:NAT INST OF METROLOGY CHINA

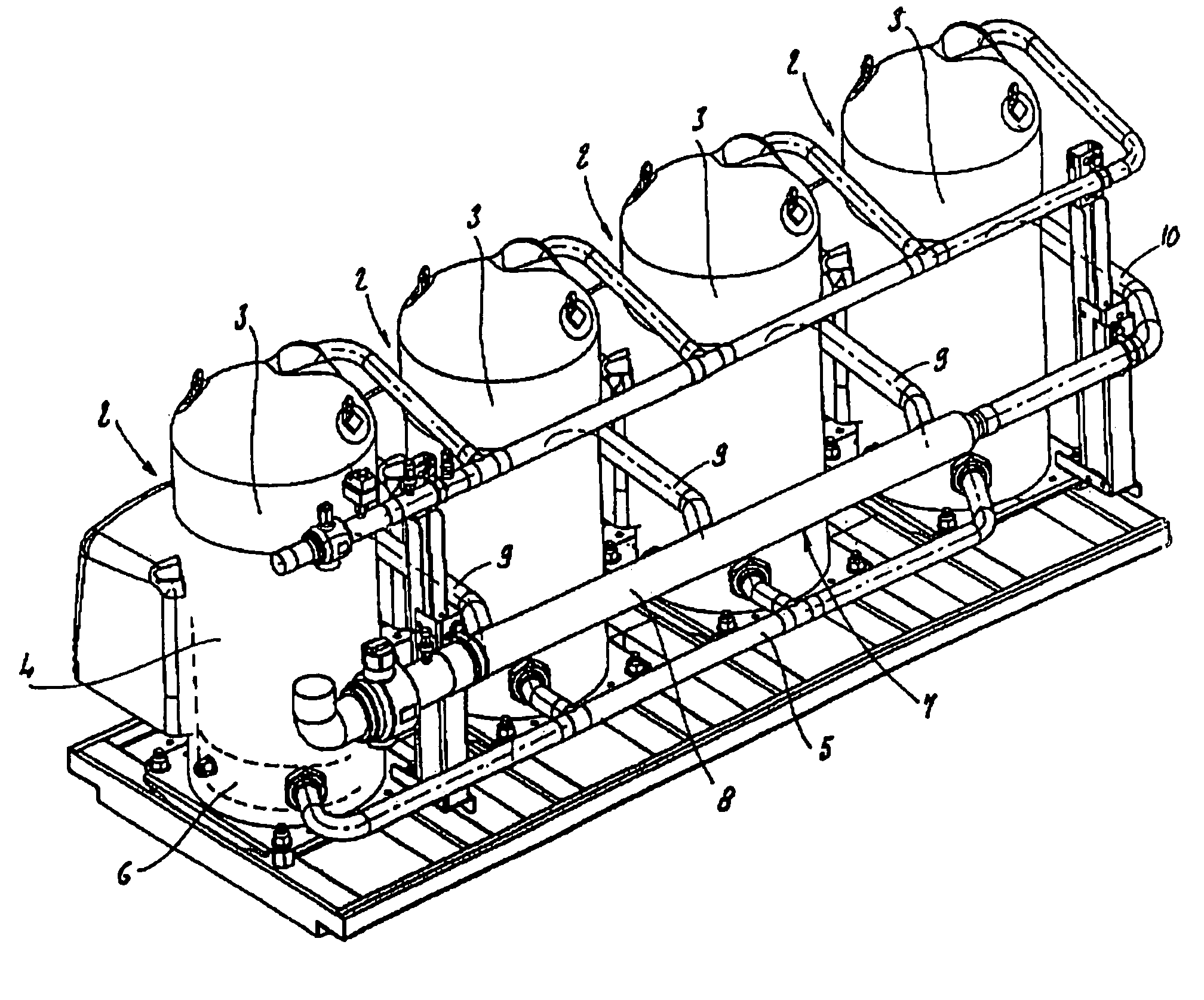

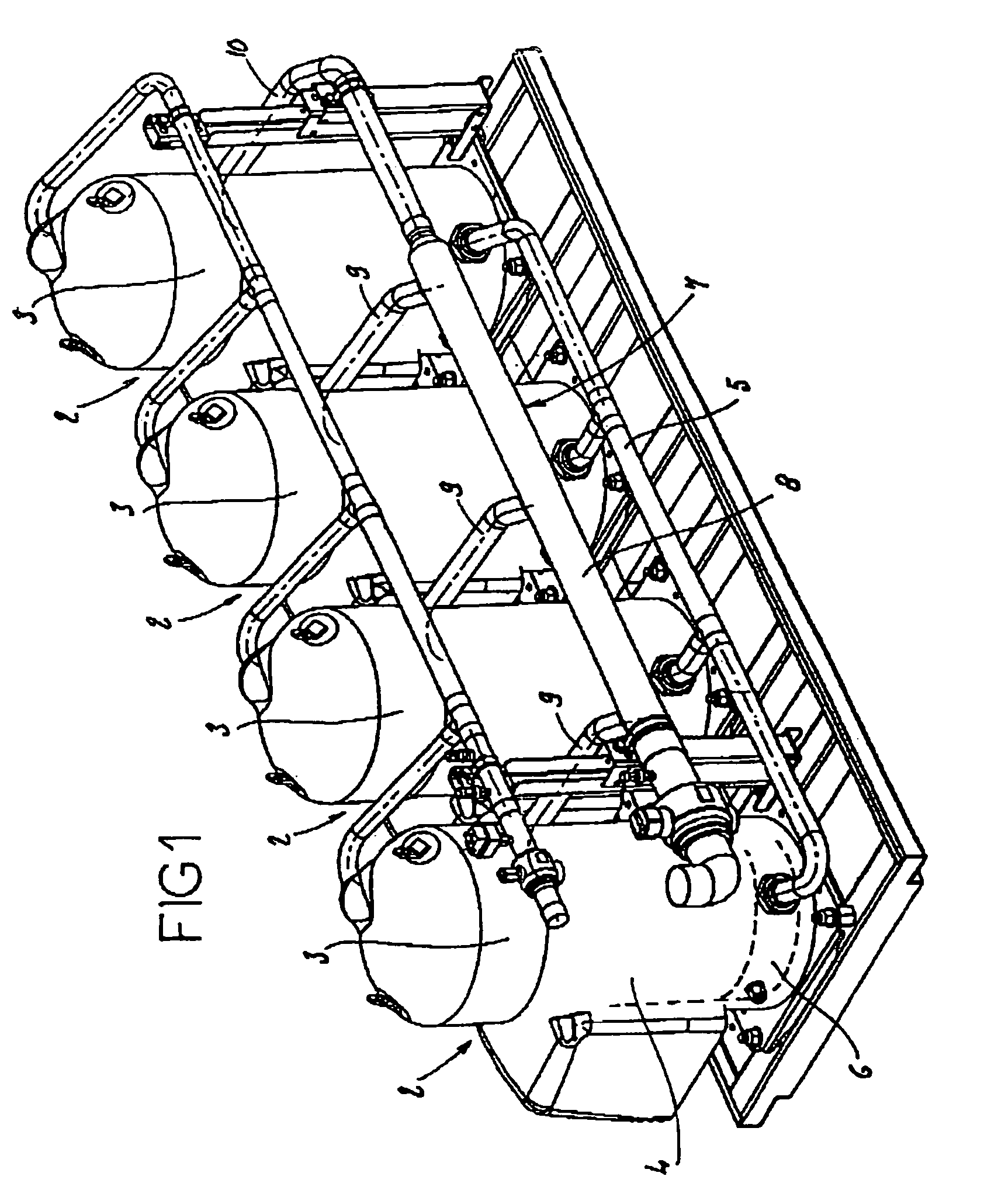

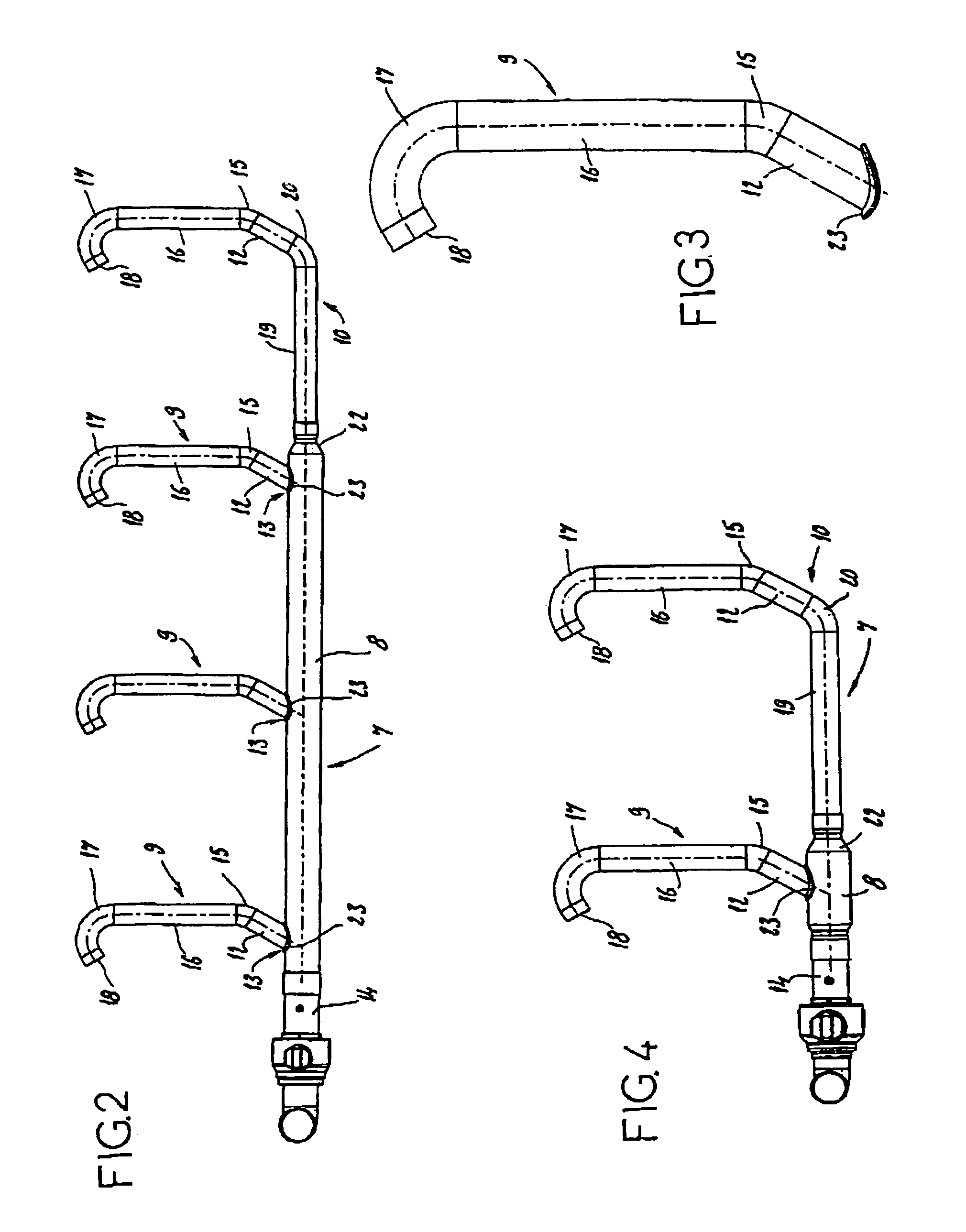

Gas distribution device

ActiveUS6983622B2Easy to balanceOvercome disadvantagesCompressorRotary/oscillating piston combinations for elastic fluidsRefrigeration compressorProduct gas

Device for distributing suction gas for a parallel compressor installation, said installation having at least two refrigeration compressors, at least one oil level equalization tube providing a communication between the oil pans provided in the bodies of the compressors, at least one suction gas distribution device comprising an essentially straight distribution tube, and branch tubes. The branch tubes have at least one portion forming an angle of between 55° and 65° with the axis of the distribution tube. The present invention uses a special geometry for equalizing the pressures in the oil pans of each compressor and thus using simple equalization channels.

Owner:DANFOSS COMML COMPRESSORS +1

Apparatus and method for measuring biologic parameters

InactiveUS9848815B2Optimal signal acquisitionPreventing temperature disturbanceDiagnostics using spectroscopyEvaluation of blood vesselsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

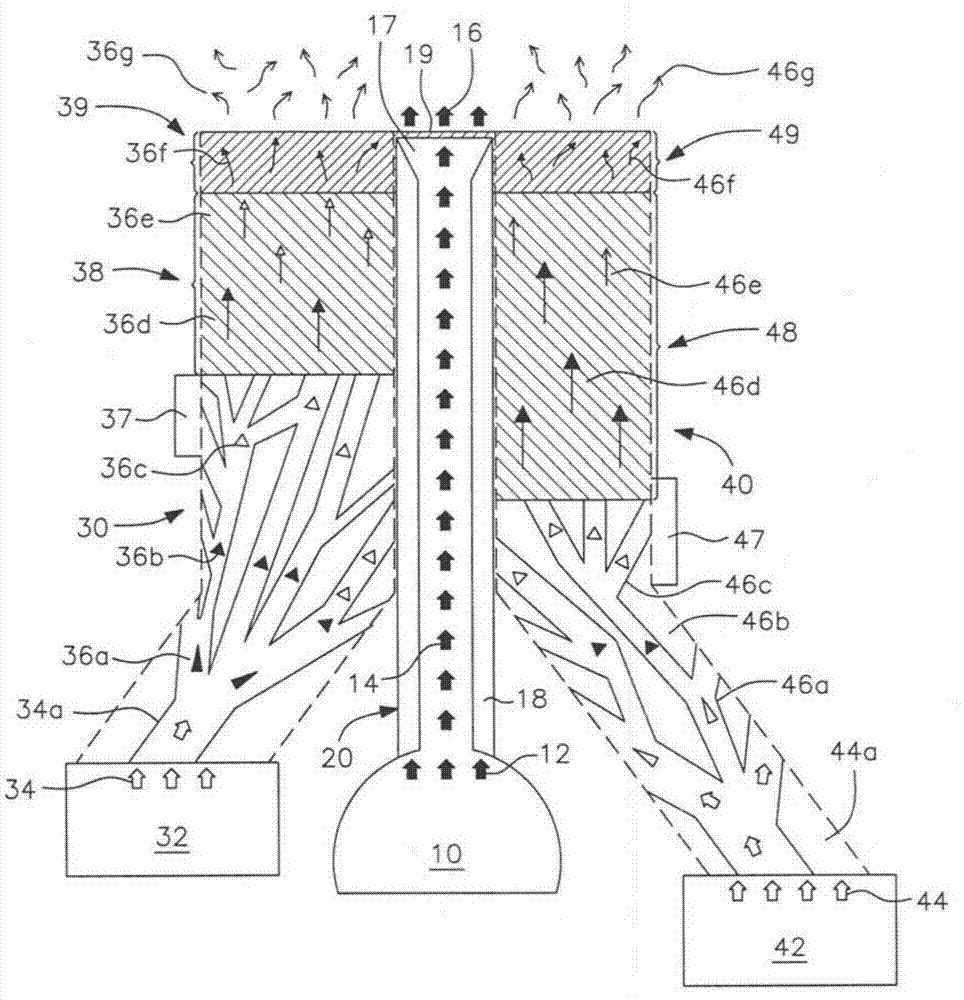

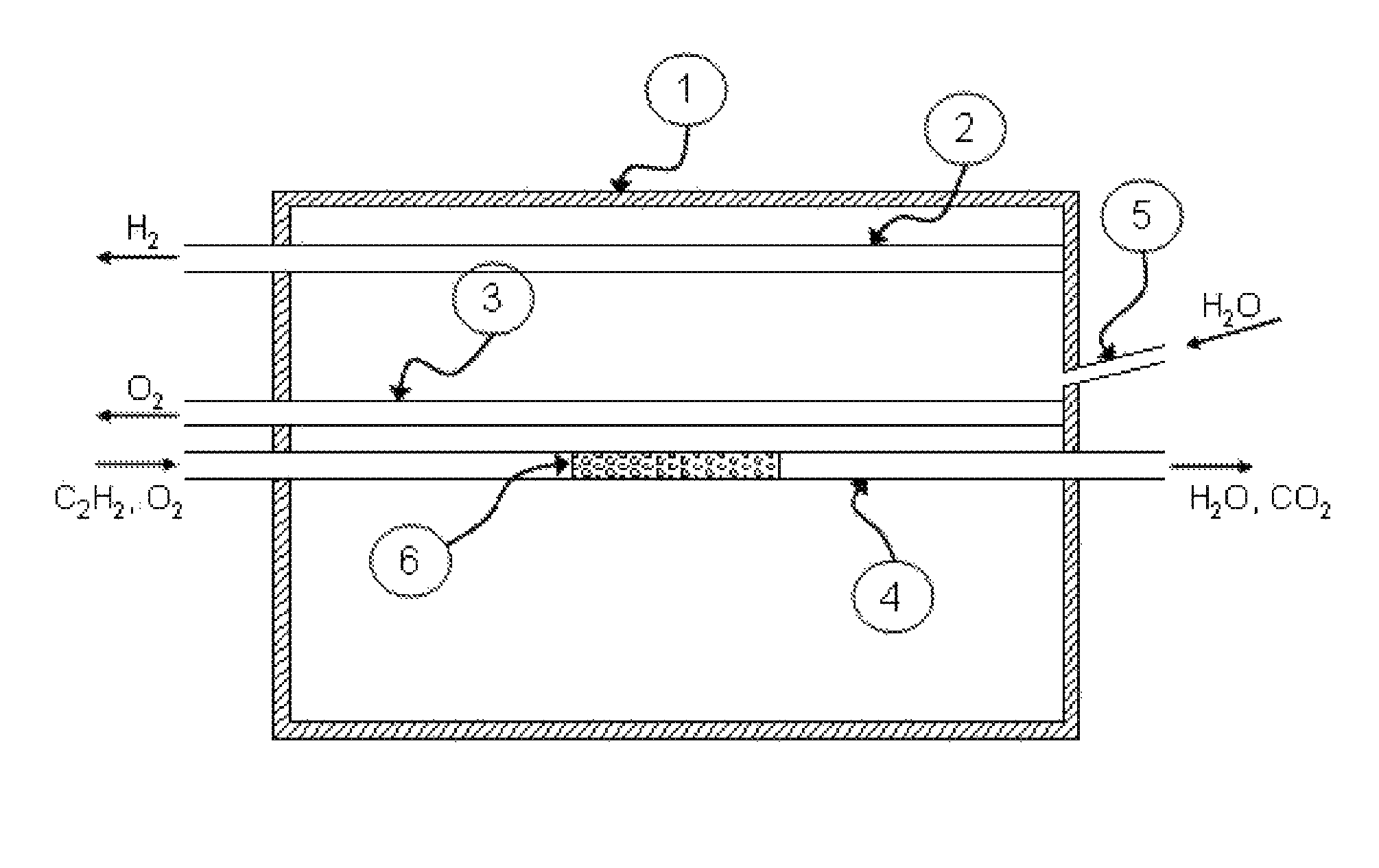

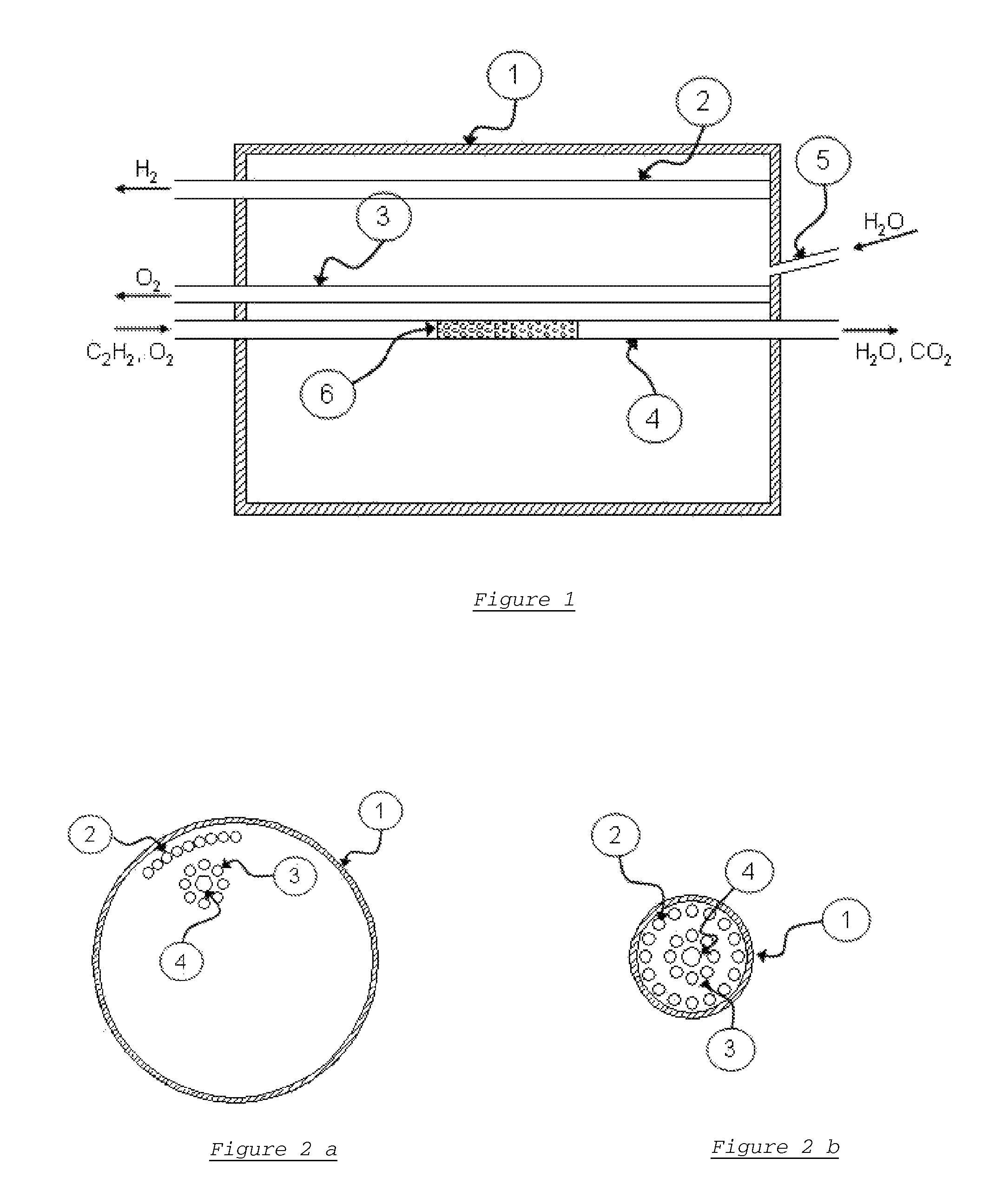

Reactor for simultaneous separation of hydrogen and oxygen from water

InactiveUS7935254B2Reduce needIncreasing introductionRegenerative fuel cellsIsotope separationWater useOxygen

We disclose a device for the production of hydrogen from water using heat. The device employs thermal water splitting and works essentially without electricity. It is based on the concept of a membrane reactor with two kinds of membranes allowing the separation of hydrogen and oxygen simultaneously in stoichiometric quantities from the reactor volume. The device has a special geometry resulting in a temperature distribution inside the reaction chamber to accommodate the use of hydrogen selective membranes. The device will help to reduce the need for hydrogen transport and storage as it will be rather compact for on-site use in households, small factories or gas stations. The use of the device in mobile applications is conceivable. The heat source of the device as described is combustion of a hydrocarbon using porous burner technology; however the device can be modified to exploit any other heat source, especially solar radiation.

Owner:H2 POWER SYST

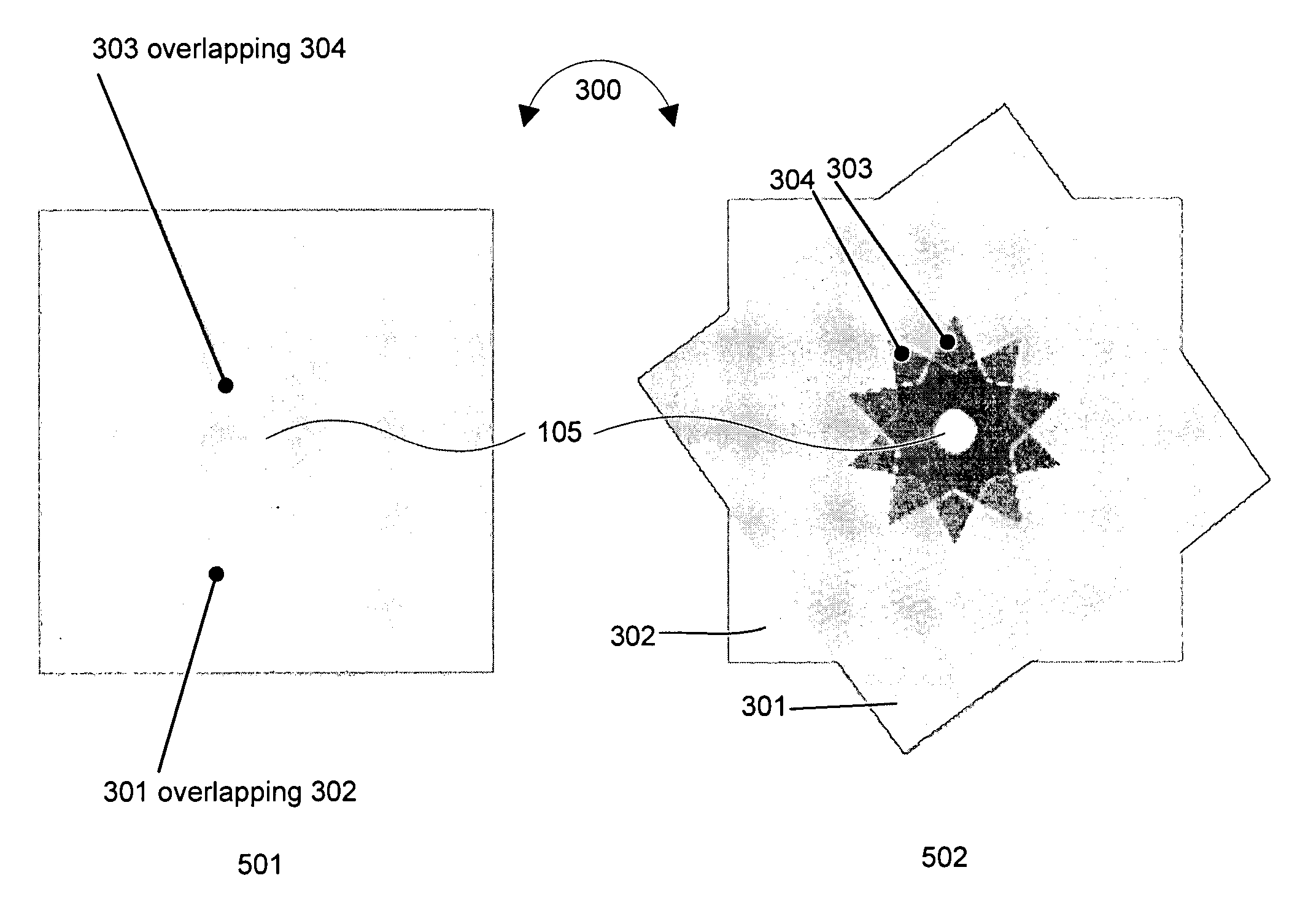

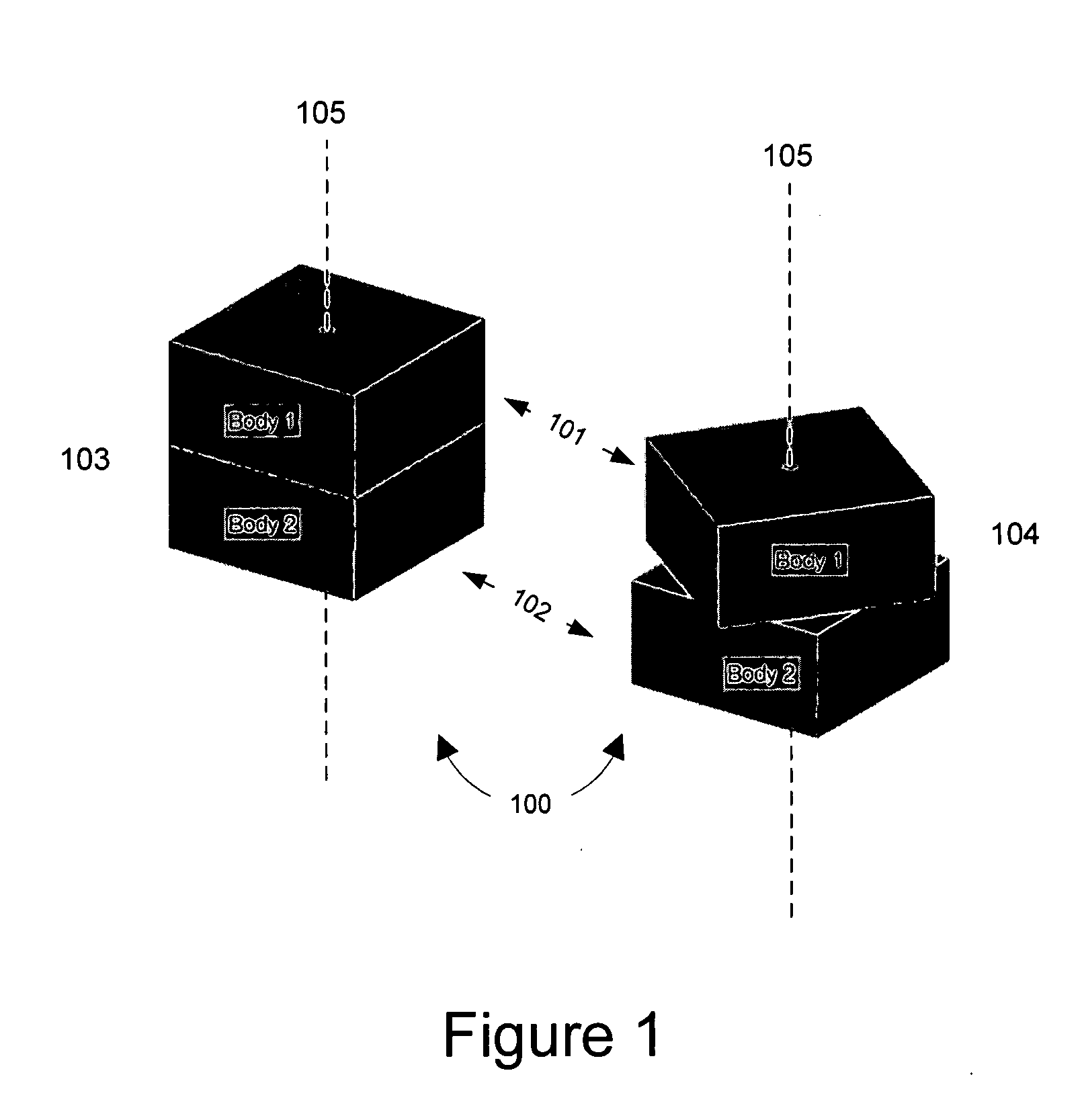

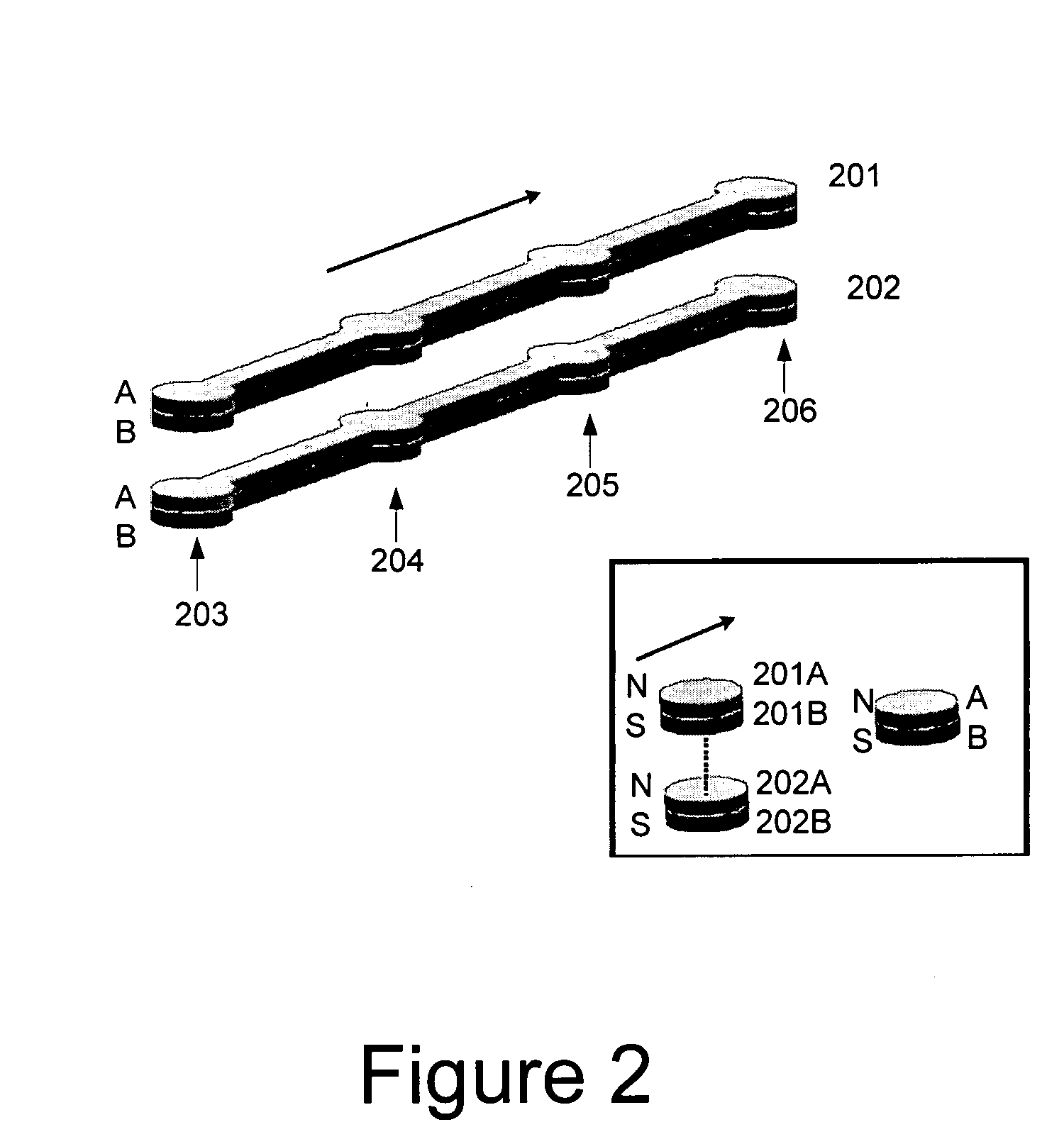

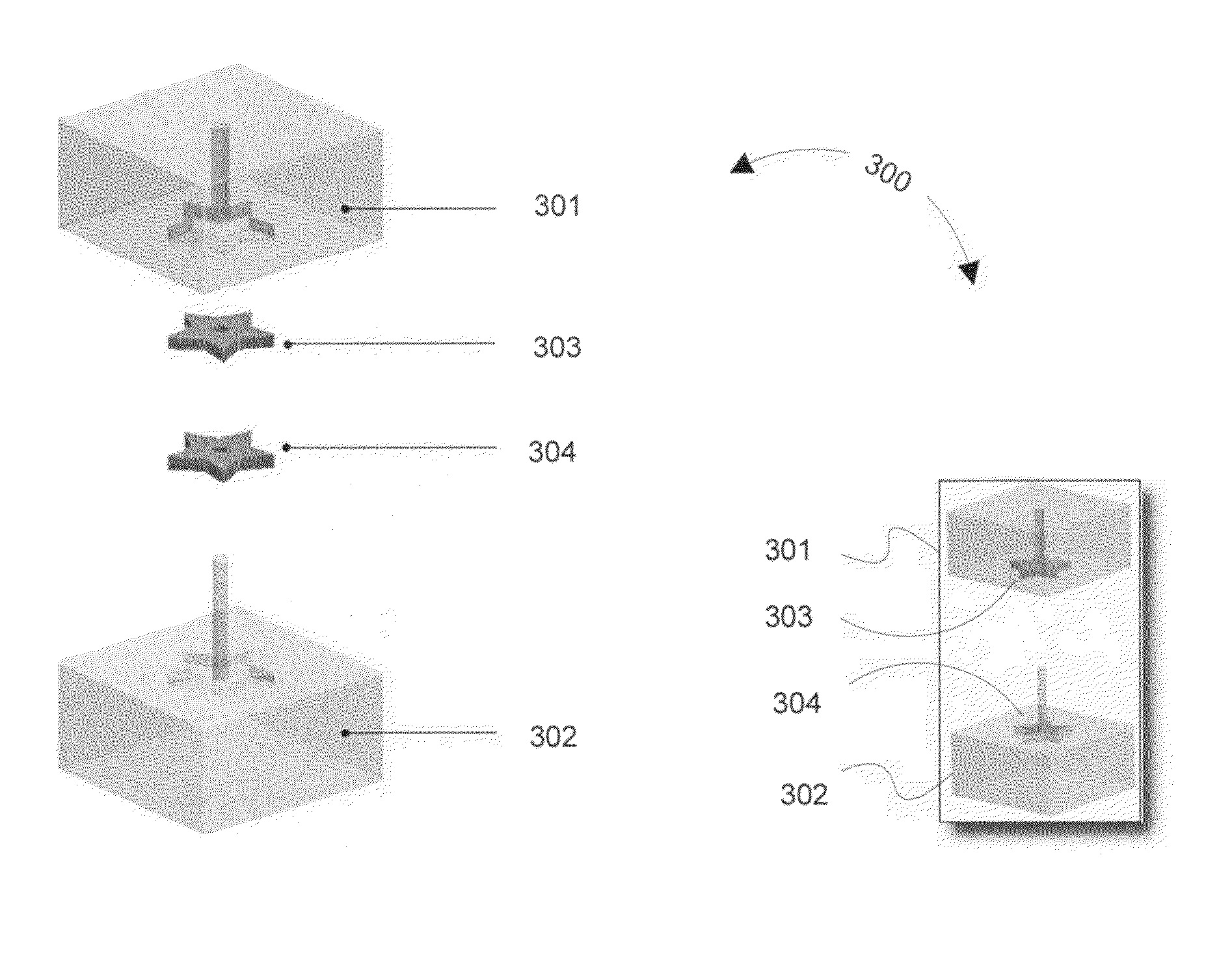

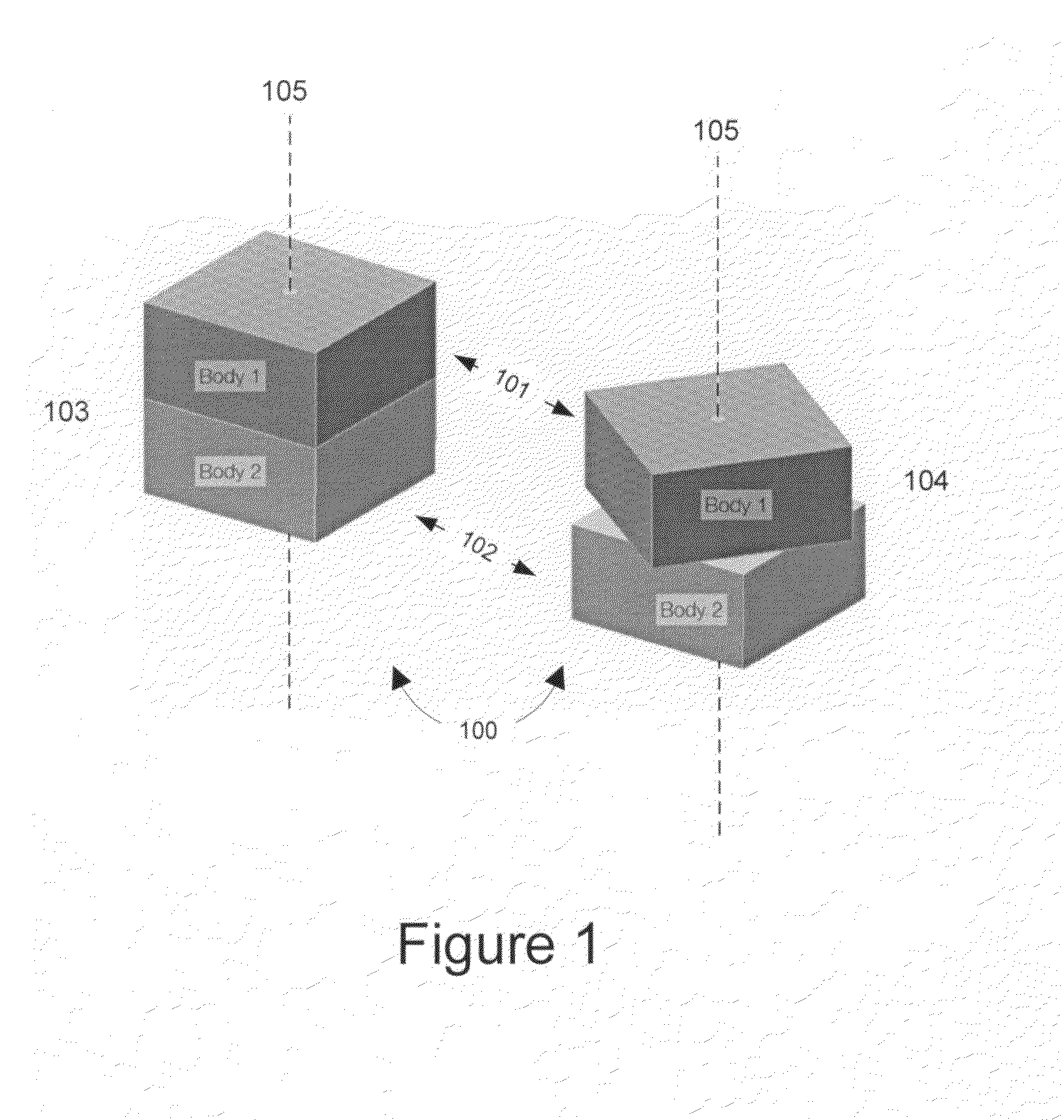

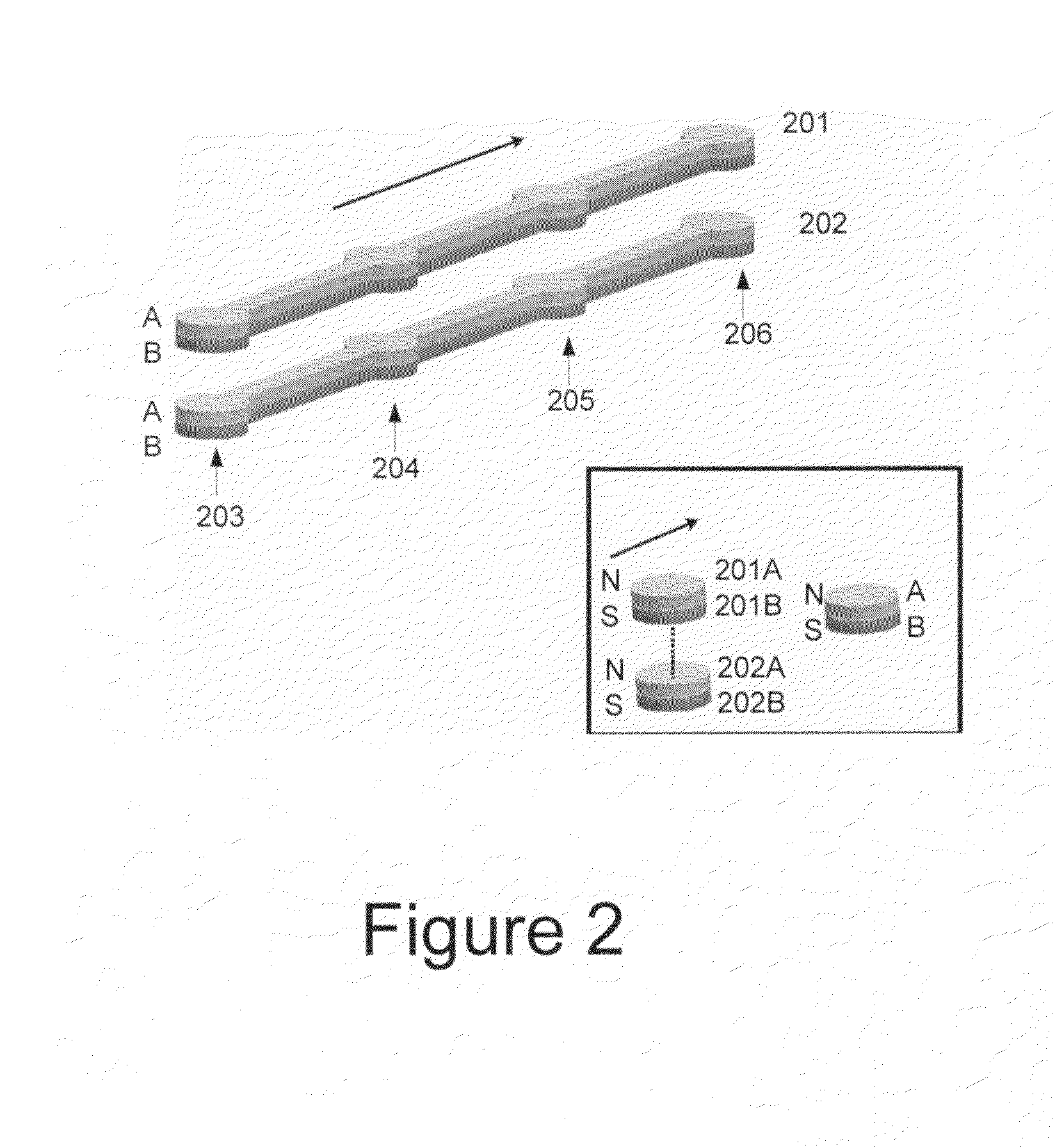

Multi-Position Magnetic Detents

InactiveUS20080303618A1Easy and cost-effective to manufactureEasy to manufactureElectromagnets without armaturesPermanent magnetsDocking stationDetent

Various embodiments for magnetic detent assemblies provide for detent devices with improved performance and manufacturability. In one embodiment, magnetic detent assemblies provide for custom detent positions and custom force profiles by including a pair of unitary magnetic components each having a special geometry. In an embodiment, the changing area of overlap (and hence magnetic flux) between the magnetic components can give rise to the custom detent positions and custom force profiles. In a specific embodiment, the magnetic components can comprise an N-point star shaped geometry, where the number and distribution of the start wings can be varied to define customized detent positions and the contour of the star wings can be varied to create customized force profiles. In other embodiments, devices such as laptop computers and docking stations for handheld electronic devices can implement multi-position detent hinges with the magnetic detent assemblies.

Owner:APPLE INC

Multi-position magnetic detents

InactiveUS7934291B2Easy and cost-effective to manufactureEasy to manufactureElectromagnets without armaturesPermanent magnetsDocking stationDetent

Various embodiments for magnetic detent assemblies provide for detent devices with improved performance and manufacturability. In one embodiment, magnetic detent assemblies provide for custom detent positions and custom force profiles by including a pair of unitary magnetic components each having a special geometry. In an embodiment, the changing area of overlap (and hence magnetic flux) between the magnetic components can give rise to the custom detent positions and custom force profiles. In a specific embodiment, the magnetic components can comprise an N-point star shaped geometry, where the number and distribution of the start wings can be varied to define customized detent positions and the contour of the star wings can be varied to create customized force profiles. In other embodiments, devices such as laptop computers and docking stations for handheld electronic devices can implement multi-position detent hinges with the magnetic detent assemblies.

Owner:APPLE INC

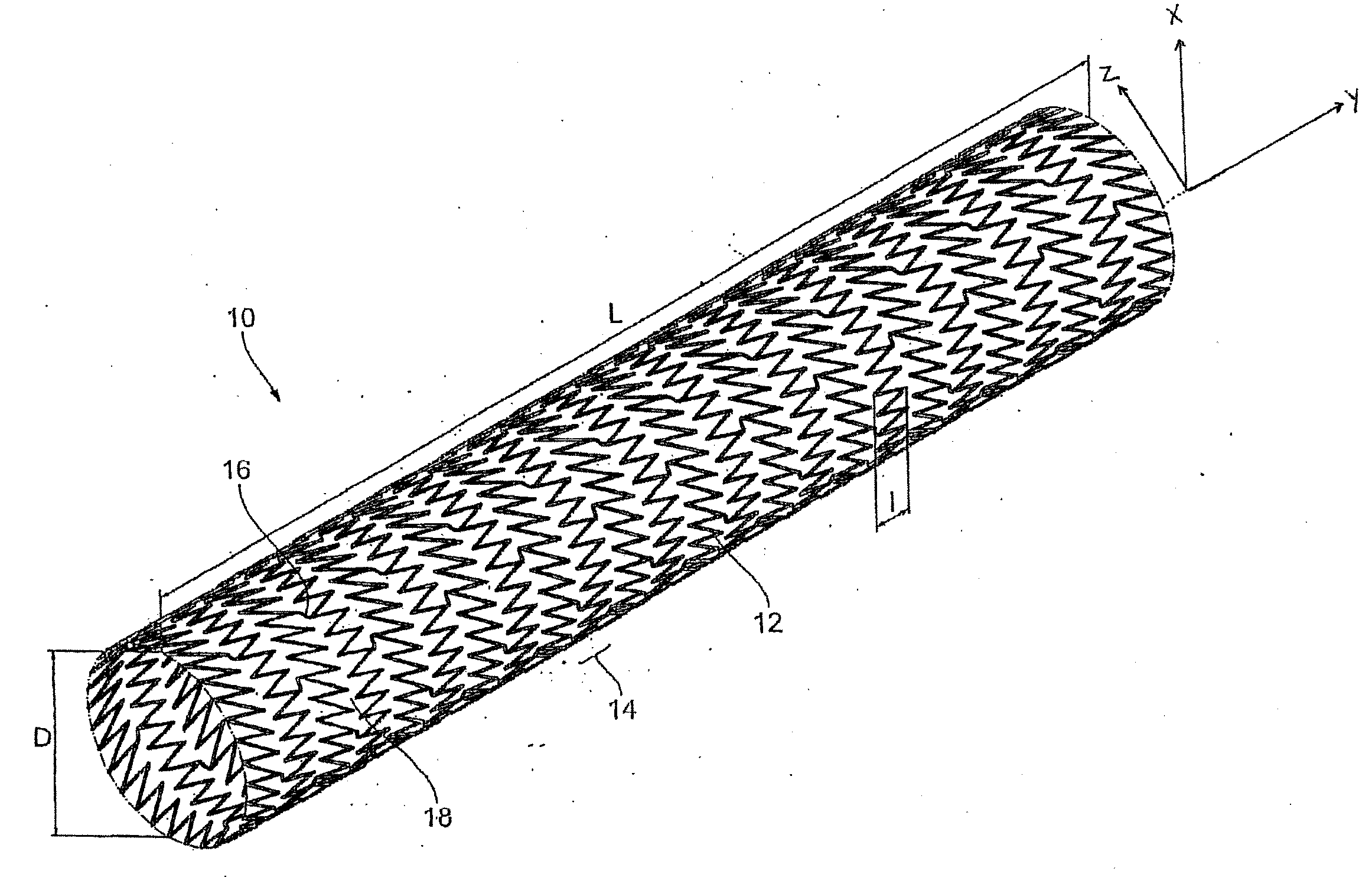

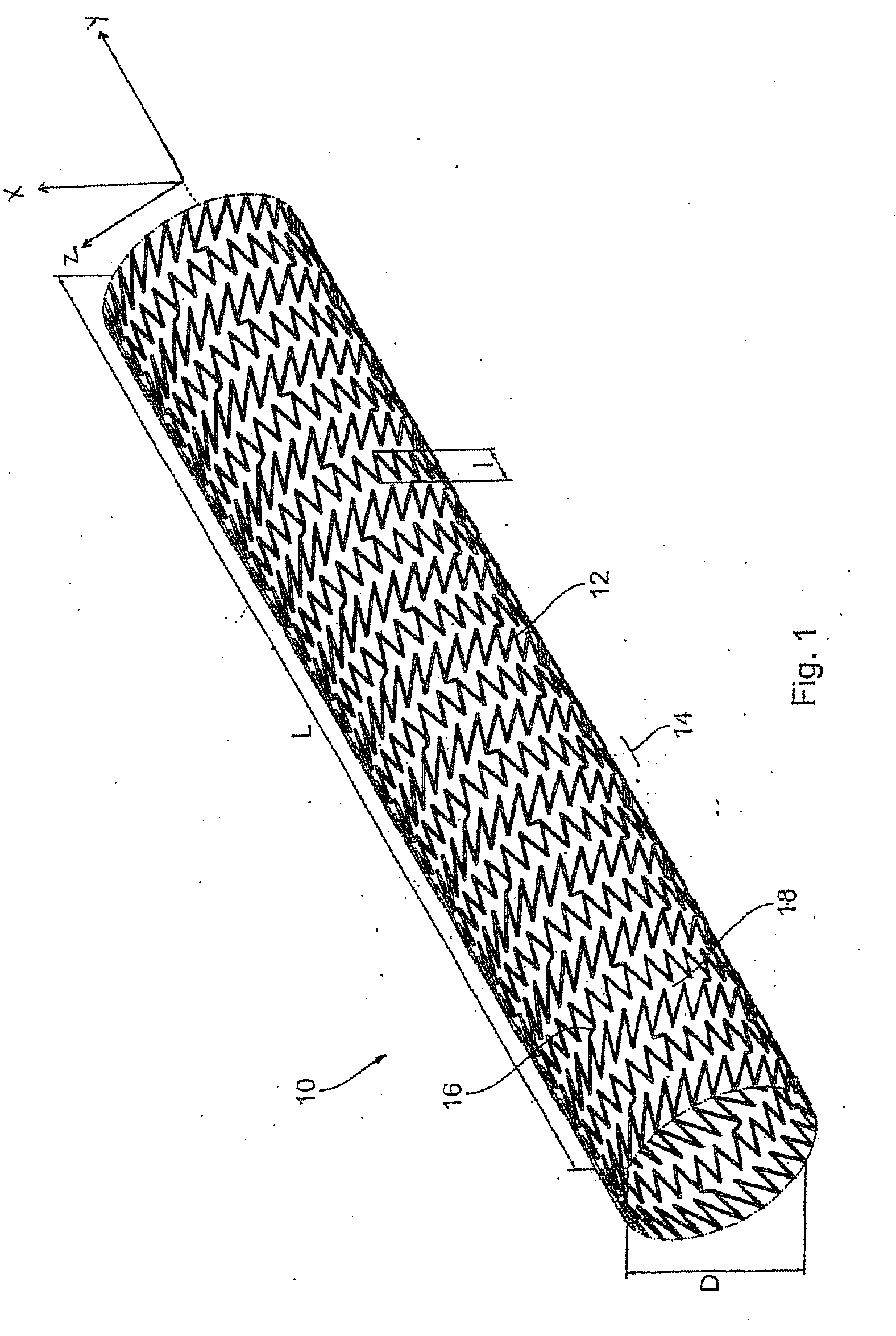

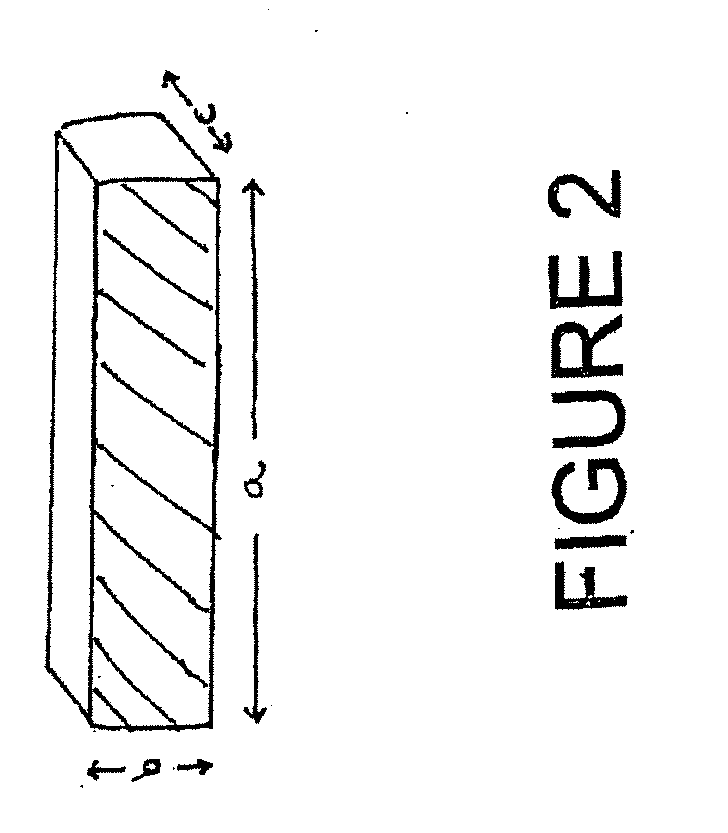

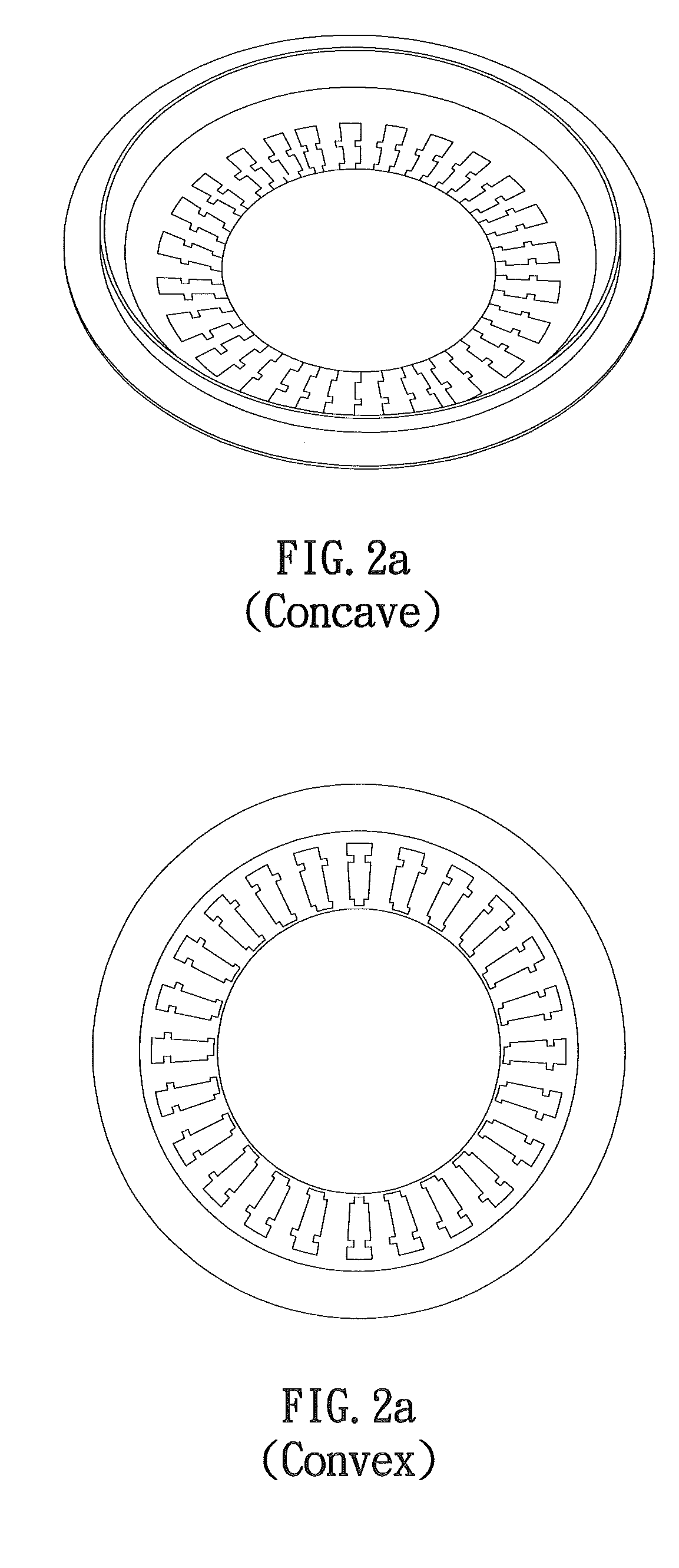

Fluid dynamic bearing having pressure-generating surface patterns

InactiveUS7699529B2Easy to shapeReduce negative impactBearing componentsSliding contact bearingsSurface patternEngineering

A fluid dynamic bearing system having pressure-generating asymmetric surface patterns, having at least two bearing parts that are rotatable with respect to each other and form a bearing gap filled with a bearing fluid between associated bearing surfaces. The surface patterns are disposed on at least one bearing surface so that hydrodynamic pressure is generated within the bearing gap when the bearing parts rotate with respect to each other. Each surface pattern comprises at least three sections, each section generating a pumping action in a defined direction, and the pumping actions of adjacent sections being substantially aligned in opposite directions. Due to the special geometry of the surface patterns, tolerances in the geometry of the bearing gap have a less significant effect on the pre-defined pumping direction.

Owner:MINEBEA CO LTD

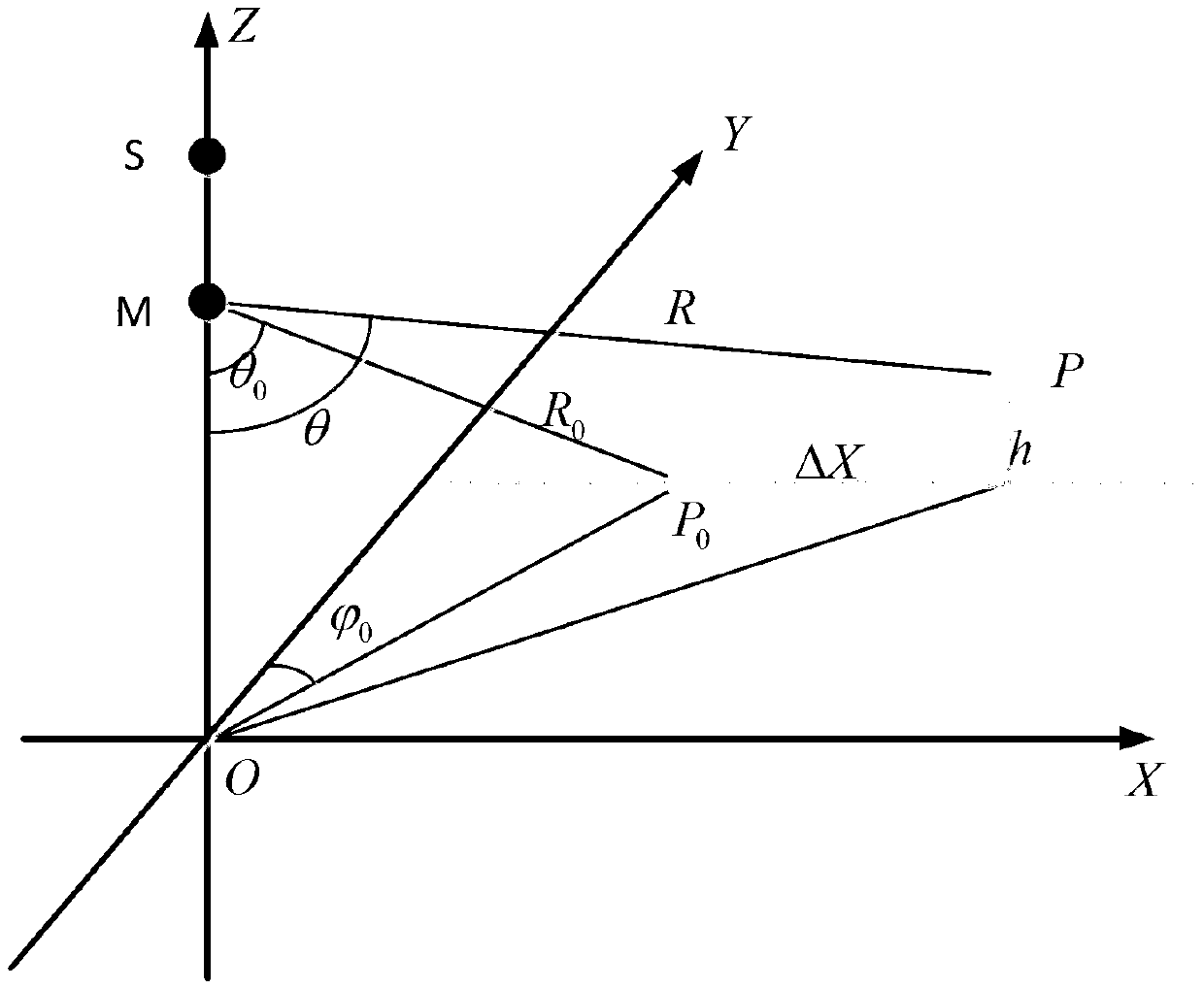

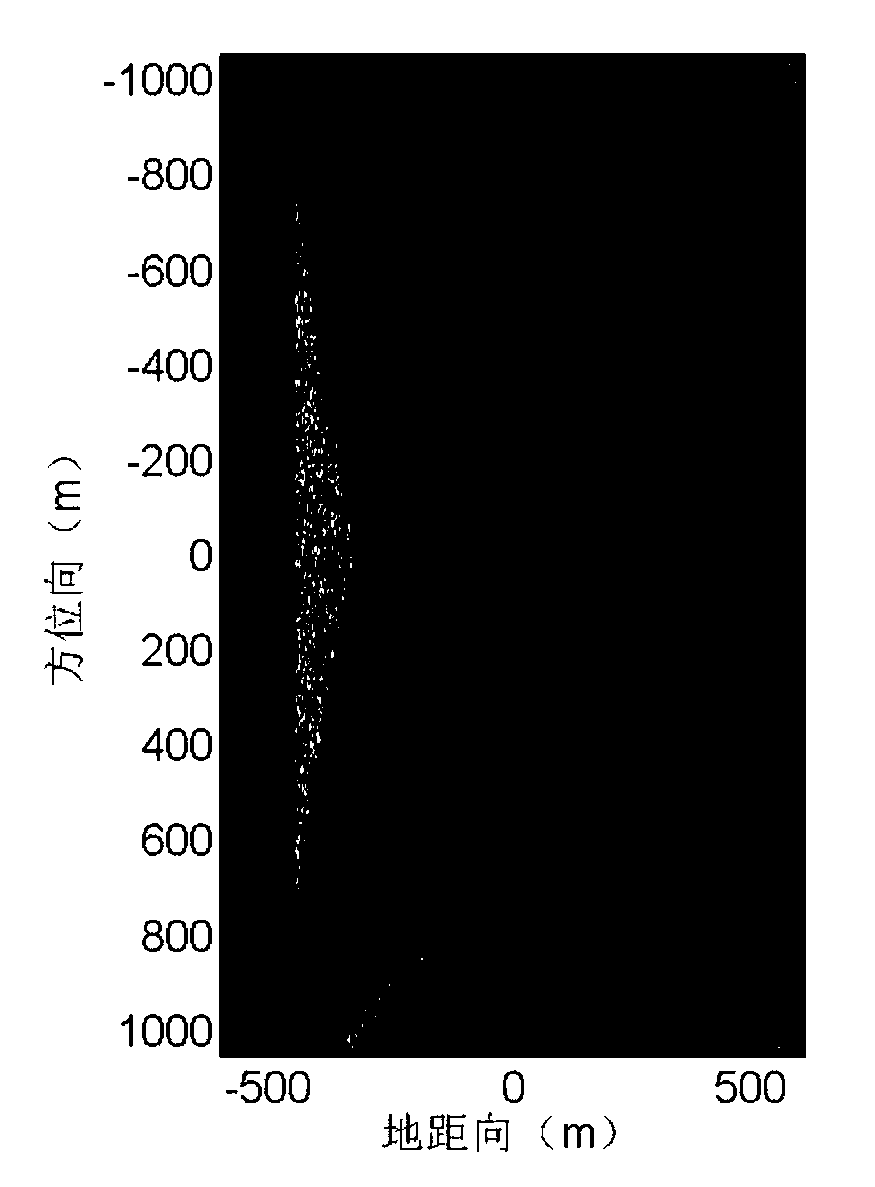

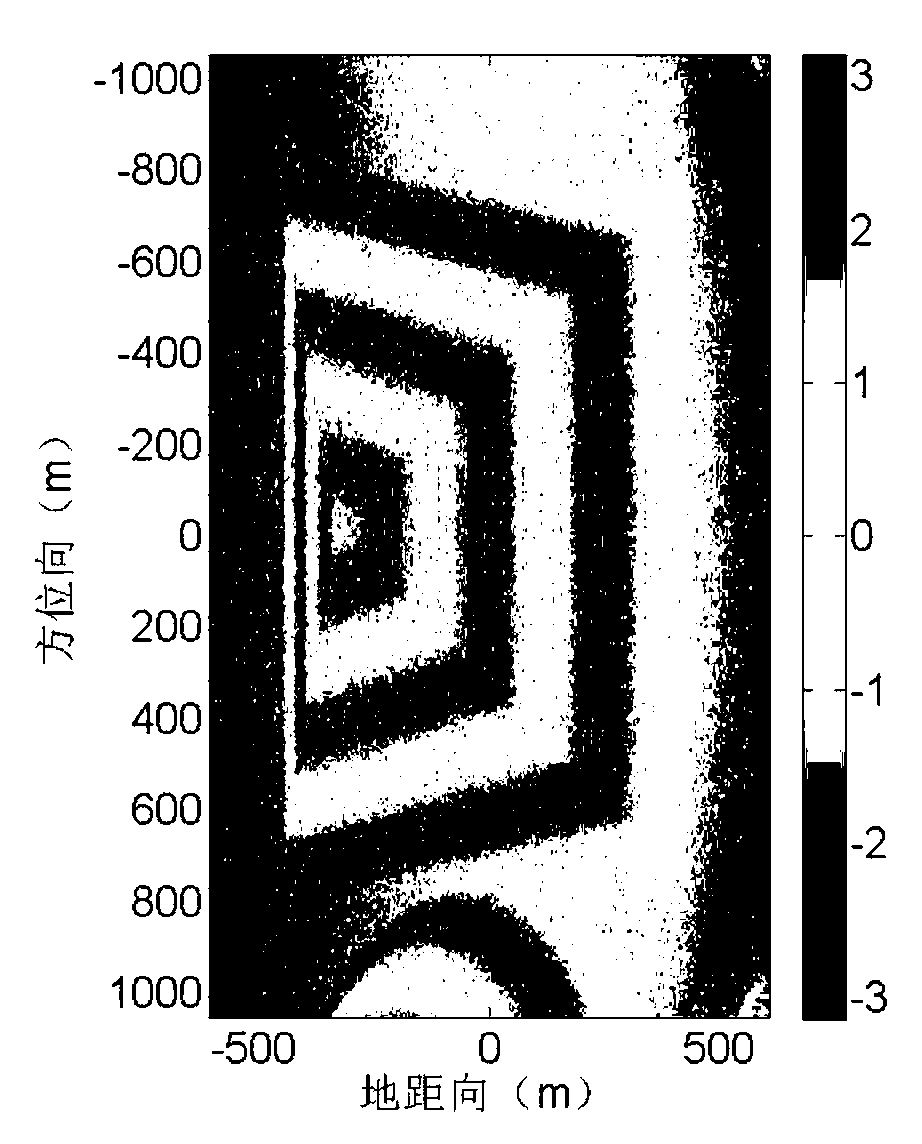

One-station fixed bistatic interference synthetic aperture radar (SAR) processing method

InactiveCN103308914AApplicable treatmentHigh precisionRadio wave reradiation/reflectionInterferometric synthetic aperture radarSpecial geometry

The invention discloses a one-station fixed bistatic interference synthetic aperture radar (SAR) processing method, and belongs to the technical field of SARs. According to the one-station fixed bistatic interference SAR processing method, a data processing method special for one-station fixed bistatic interference is provided for a special bistatic geometric model, an elevation inversion method is improved to be applied to the processing of interference data in a one-station fixed bistatic mode on the basis of the conventional monostatic model, a more accurate result is obtained, and the elevation information of a scene can be inversed by data processing. The method is applied to a bistatic interference processing technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

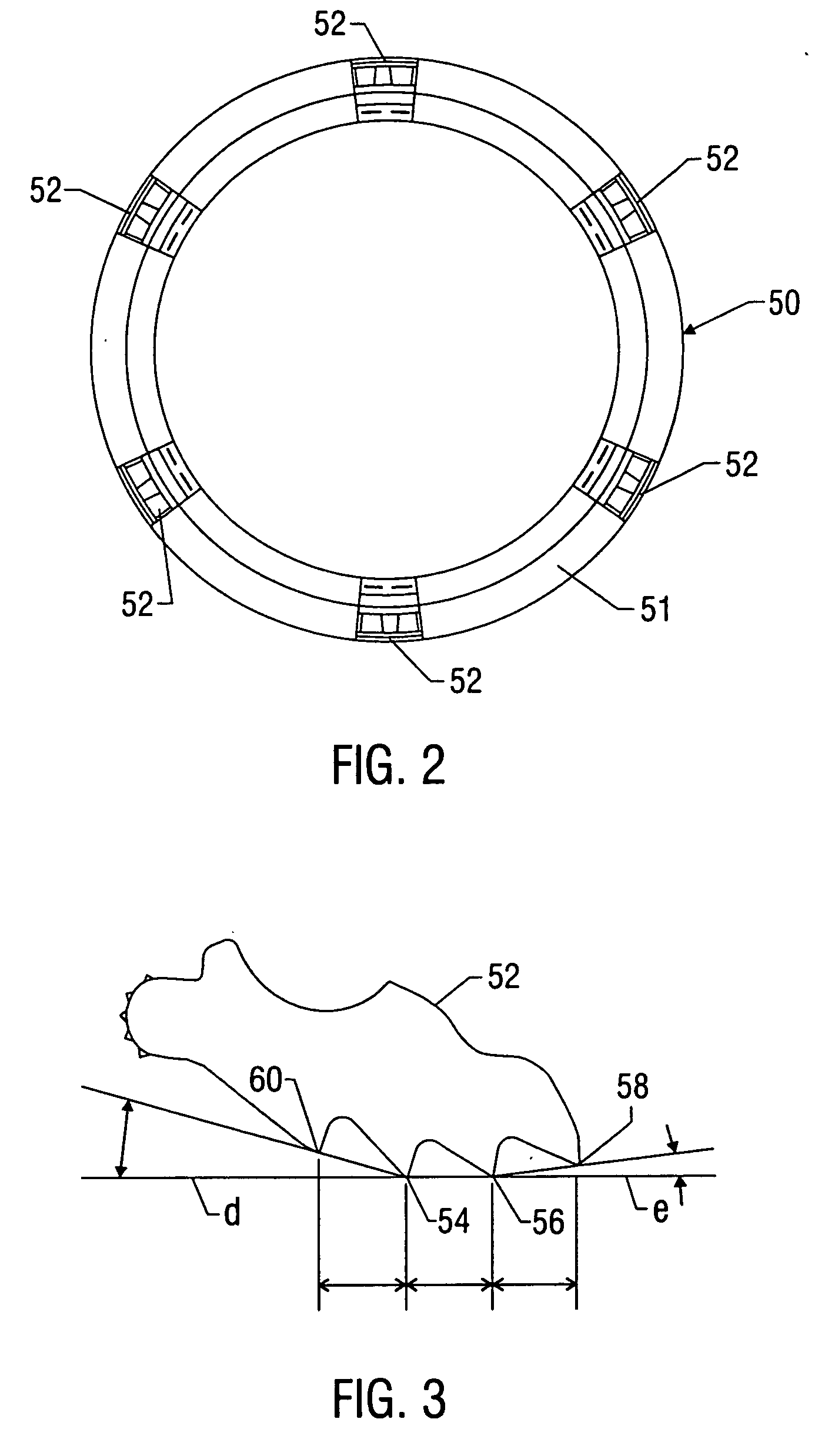

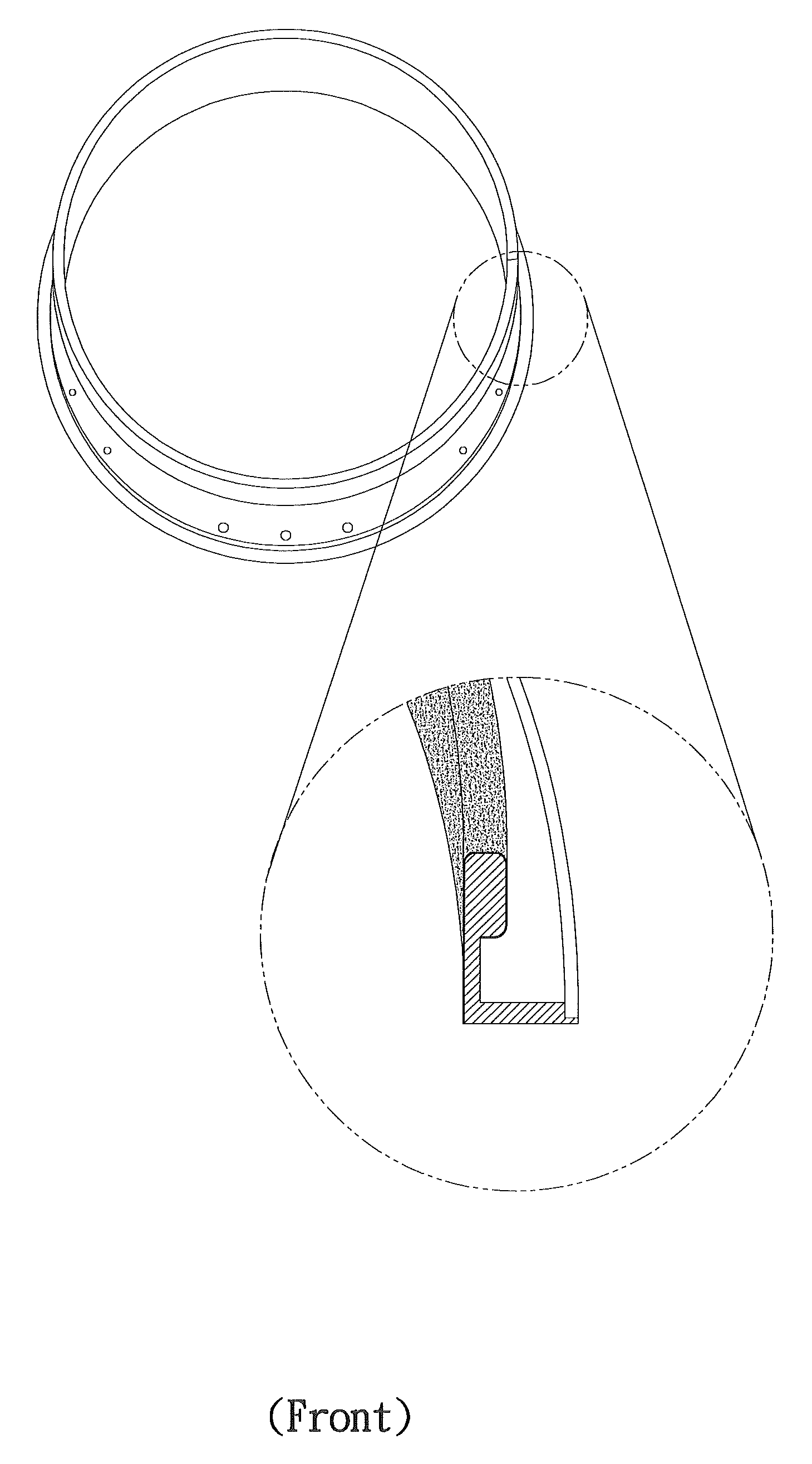

Gripping gasket

ActiveUS20050218605A1Enhancing rolling contactIncreased frictional contactSleeve/socket jointsFluid pressure sealed jointsRough surfacePipe fitting

A novel gasket includes at least one gripping element embedded in an annular member for forming a seal between two tubulars. For tubulars having socket and spigot ends, the gripping element includes teeth for gripping an outer surface of the spigot end and a blunt tooth for contacting a front wall of the socket end. The blunt tooth rolls along the front wall during relative movement between the tubulars and can include a contacting face of a specialized geometry to adjust contact dynamics and / or roughened surfaces to increase the frictional contact between the blunt tooth and the front wall. The embedded element can also include at least four teeth arranged such that no more than two teeth normally grip the outer surface of the spigot end. One or more teeth can also include a transverse groove to enhance penetration into the outer surface of the spigot end.

Owner:STAR PIPE PRODS

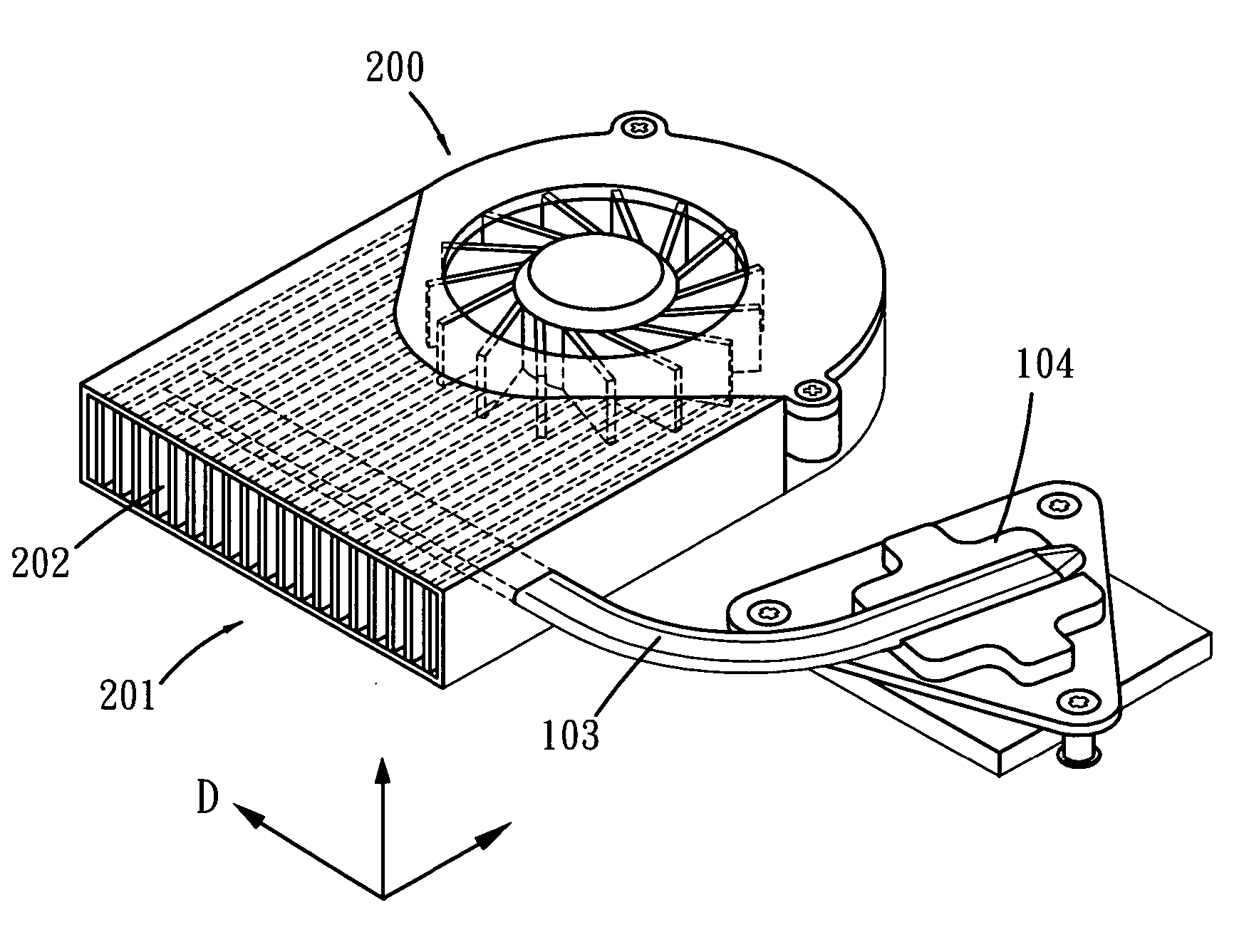

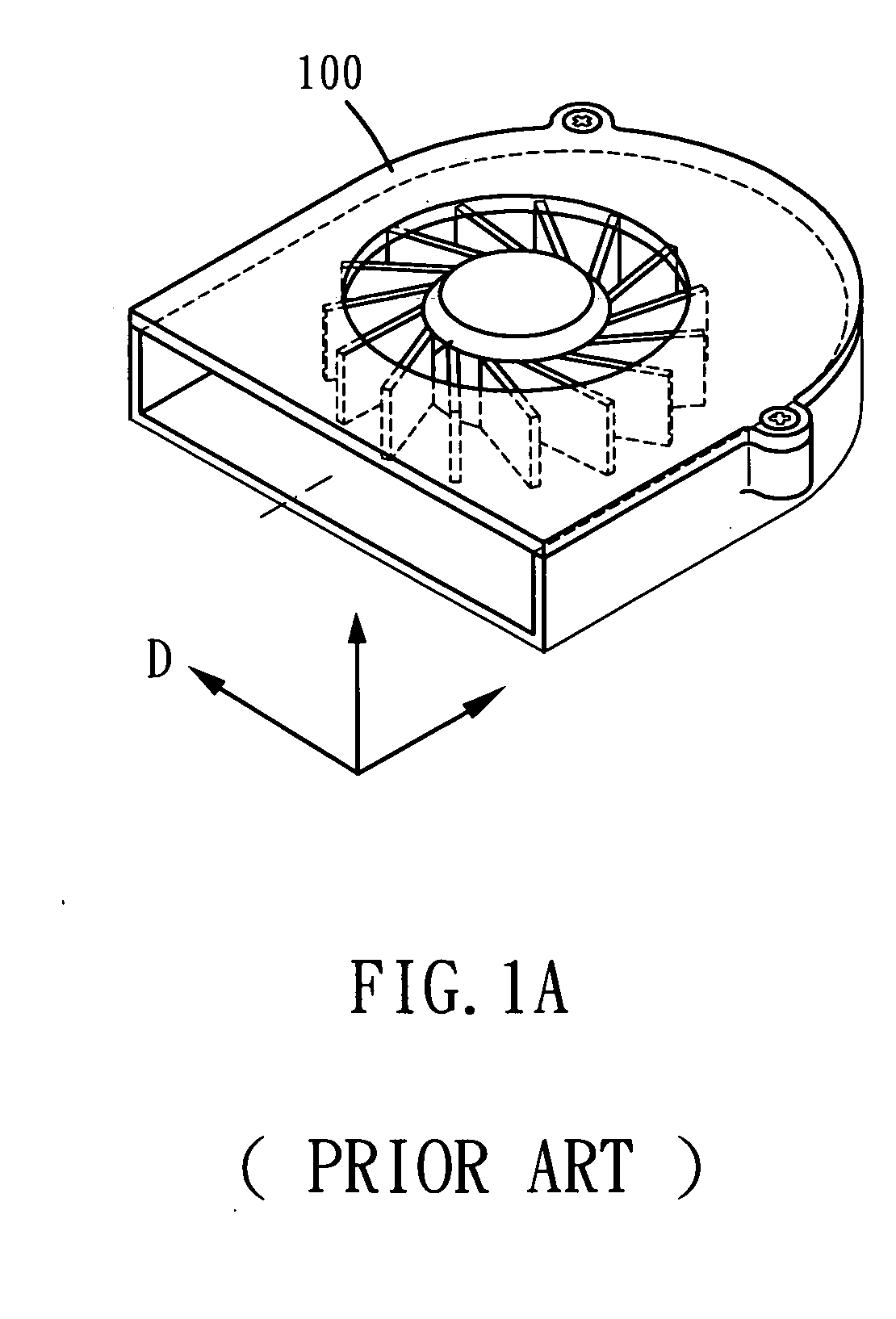

Heatsink thermal module with noise improvement

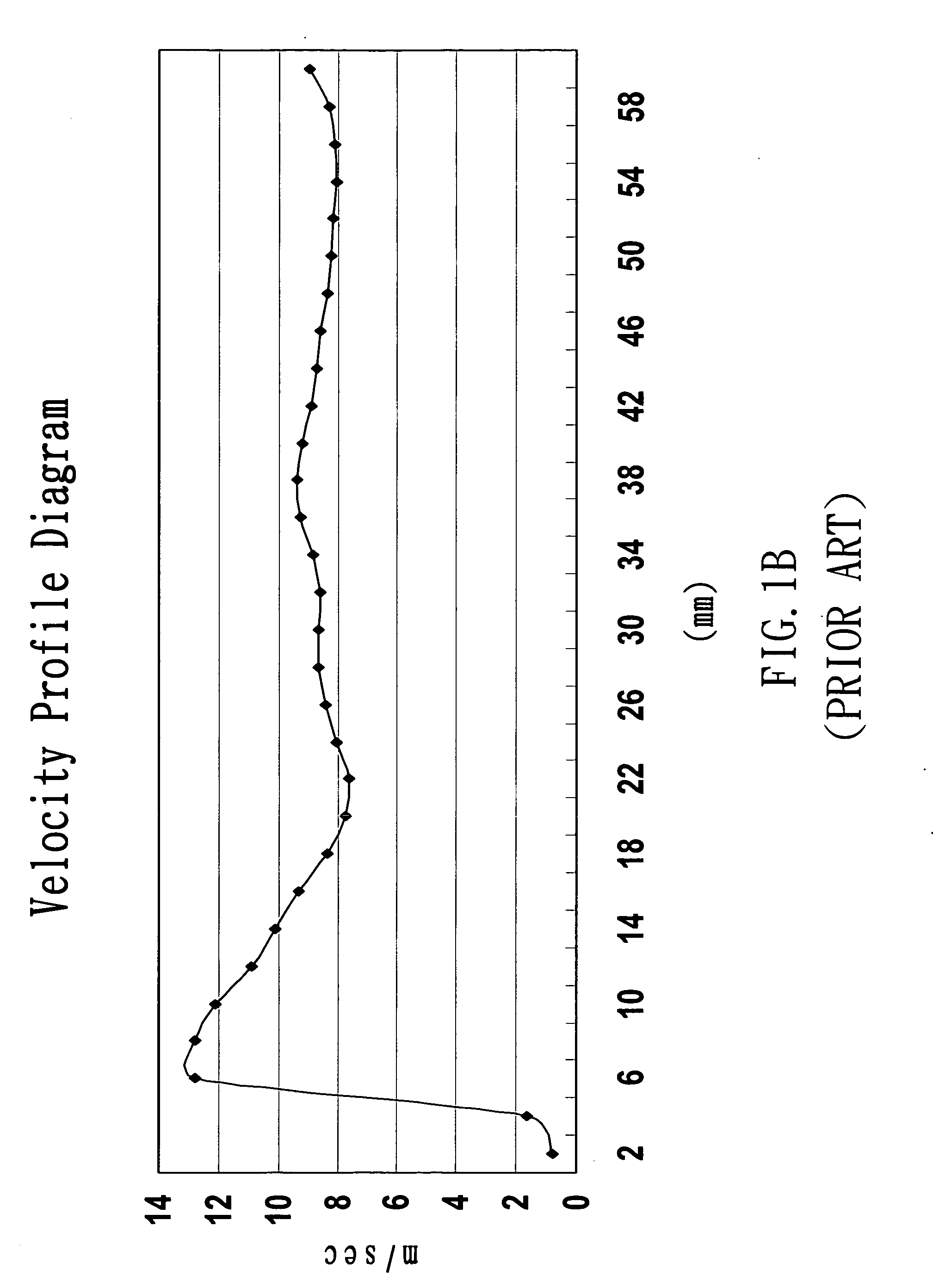

ActiveUS20060181849A1Reduce wind resistanceImprove noiseSemiconductor/solid-state device detailsSolid-state devicesEngineeringSpecial geometry

The invention provided a heatsink thermal module with noise improvement, which has a heatsink thermal module additionally consisting of a heat pipe, a heatsink fins set and a fan module; the fan module is combined with the heatsink fins set which consists of multiple heatsink fins with different lengths and is combined to the fan module with its end with a special geometric shape having the function of lowering the wind drag; by lowering the wind drag, not only the heat dissipation efficiency can be increased, but the noise caused by the heatsink thermal module can also be improved.

Owner:INVENTEC CORP

Gripping gasket

InactiveUS20080018104A1Increase contactIncreased frictional contactSleeve/socket jointsFluid pressure sealed jointsRough surfaceTransverse groove

A novel gasket includes at least one gripping element embedded in an annular member for forming a seal between two tubulars. For tubulars having socket and spigot ends, the gripping element includes teeth for gripping an outer surface of the spigot end and a blunt tooth for contacting a front wall of the socket end. The blunt tooth rolls along the front wall during relative movement between the tubulars and can include a contacting face of a specialized geometry to adjust contact dynamics and / or roughened surfaces to increase the frictional contact between the blunt tooth and the front wall. The embedded element can also include at least four teeth arranged such that no more than two teeth normally grip the outer surface of the spigot end. One or more teeth can also include a transverse groove to enhance penetration into the outer surface of the spigot end.

Owner:STAR PIPE PRODS

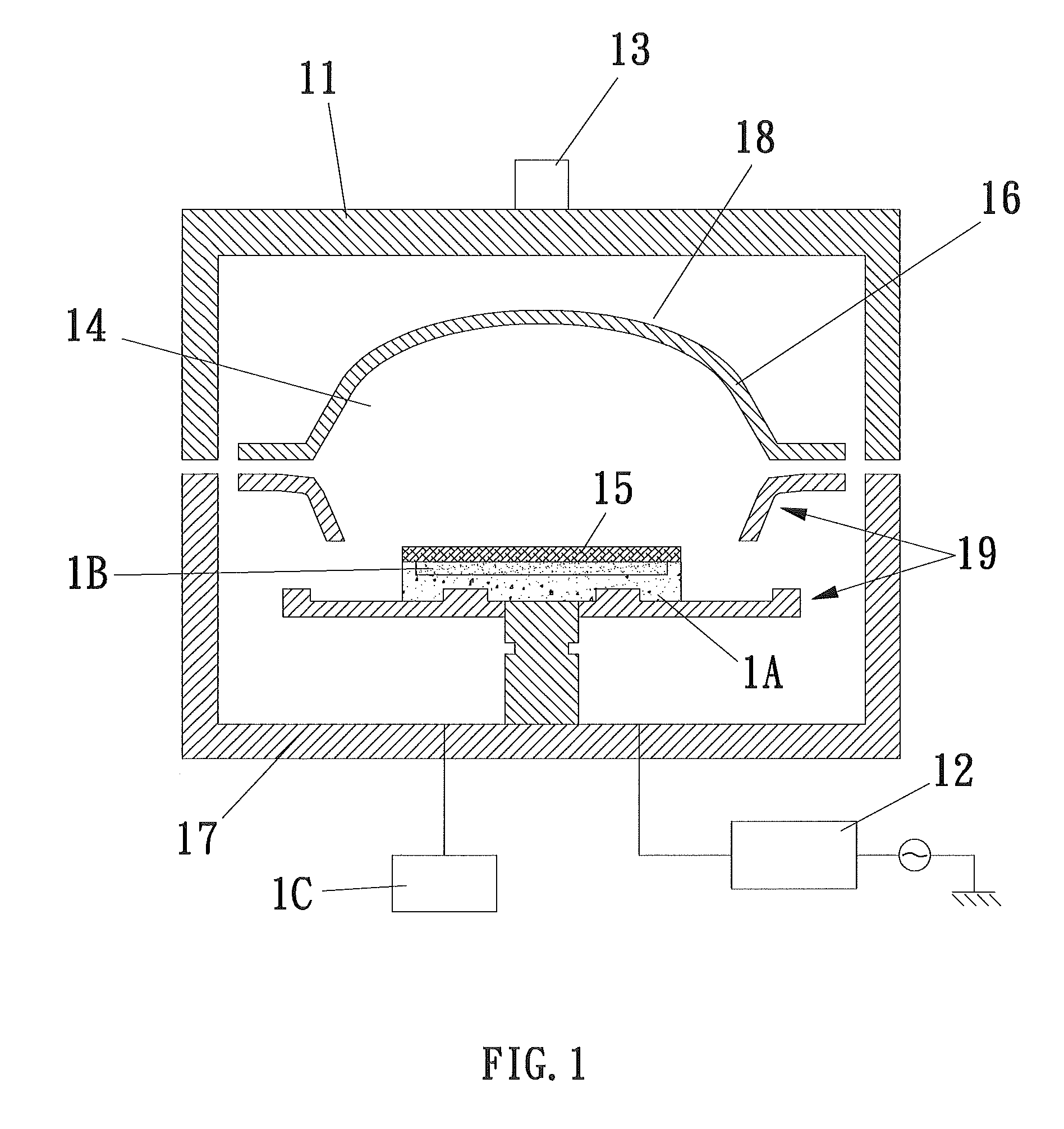

Reaction chamber structural parts with thermal spray ceramic coating and method for forming the ceramic coating thereof

InactiveUS20090311145A1Effectively minimizing uneven distribution of plasmaExtended service lifeGaseous chemical processesLiquid surface applicatorsThermal sprayingMetallurgy

In a reaction chamber for manufacturing semiconductor devices, flat displays, solar panels, a thermal spray ceramic coating with special geometric patterns is provided on structural parts in the reaction chamber. The geometric patterns of the ceramic coating are designed according to operating conditions in the reaction chamber, such as the energy source and the plasma producing gases being used, the intended plasma distribution and subsequent reactions in the reaction chamber, and compositions of the ceramic coating. To form the ceramic coating with special geometric patterns, a special masking process is adopted, and, after the forming of the ceramic coating with desired geometric patterns, a post grit blasting treatment is conducted to obtain a desired surface coarseness for the ceramic coating.

Owner:SHIH HER TECH

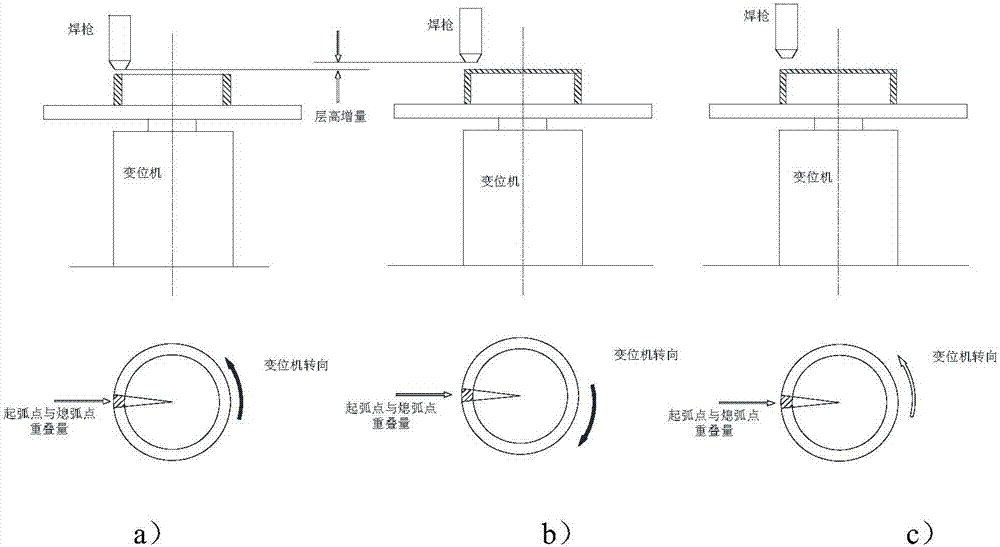

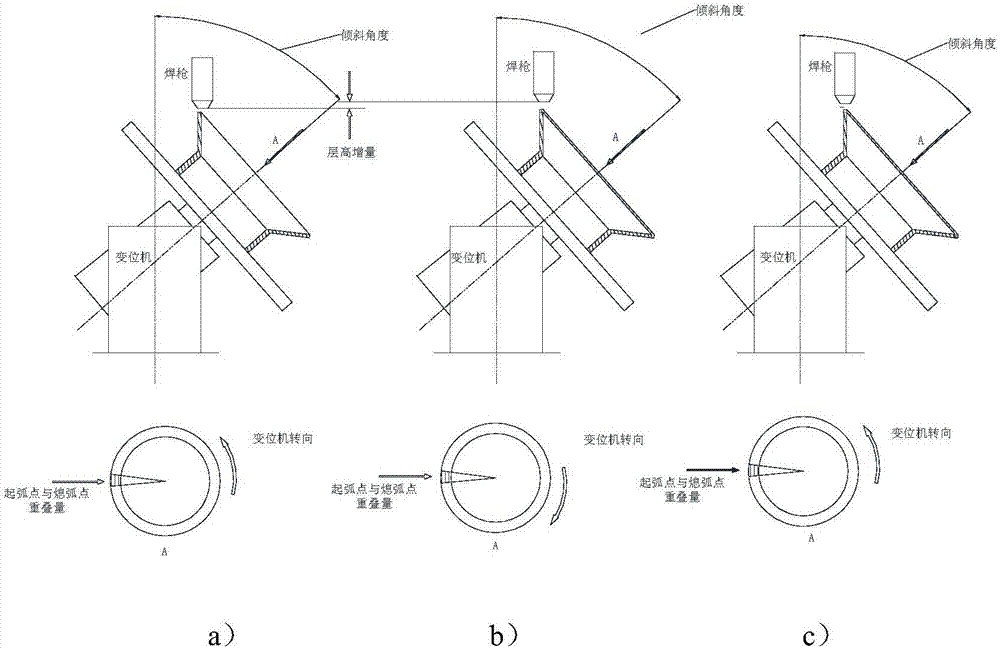

Carbon steel structural component self-compression electric arc additive manufacturing method

ActiveCN107457469AImprove mechanical propertiesAvoid overall overheatingArc welding apparatusVolumetric Mass DensityMechanical property

Owner:NANJING UNIV OF SCI & TECH

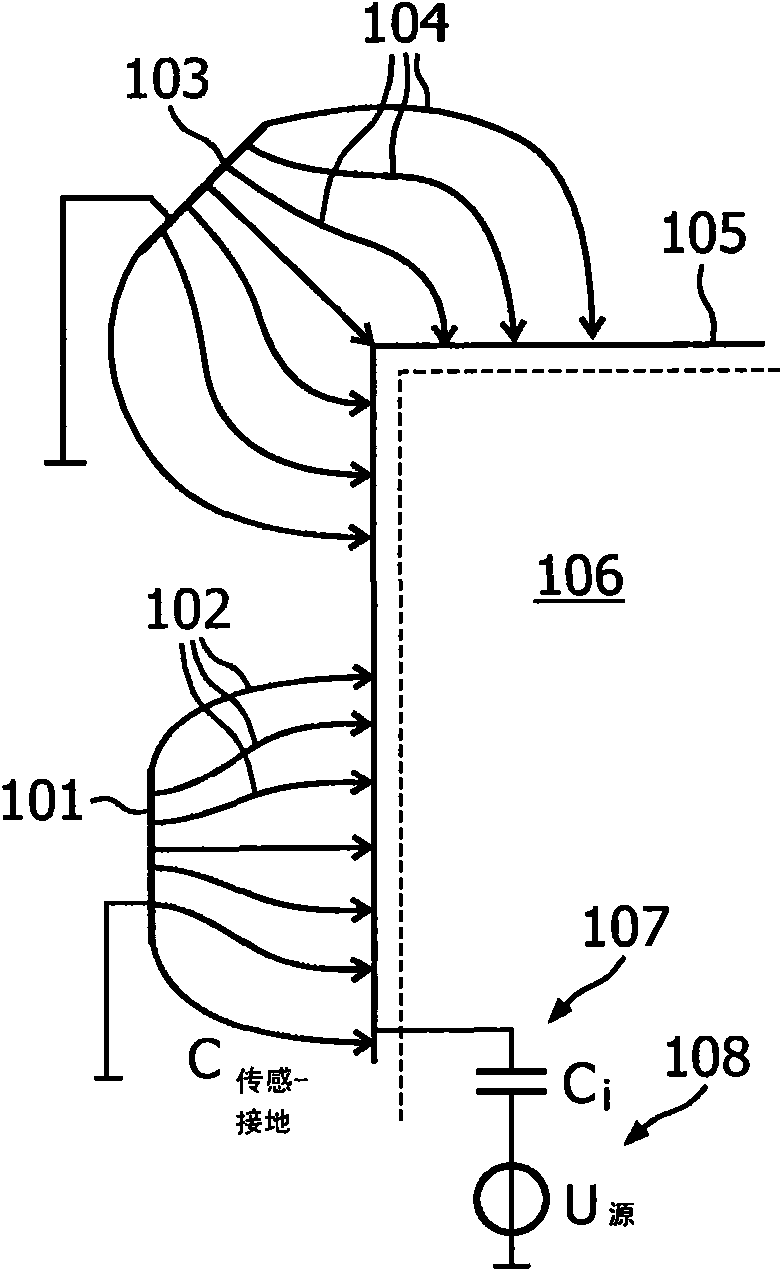

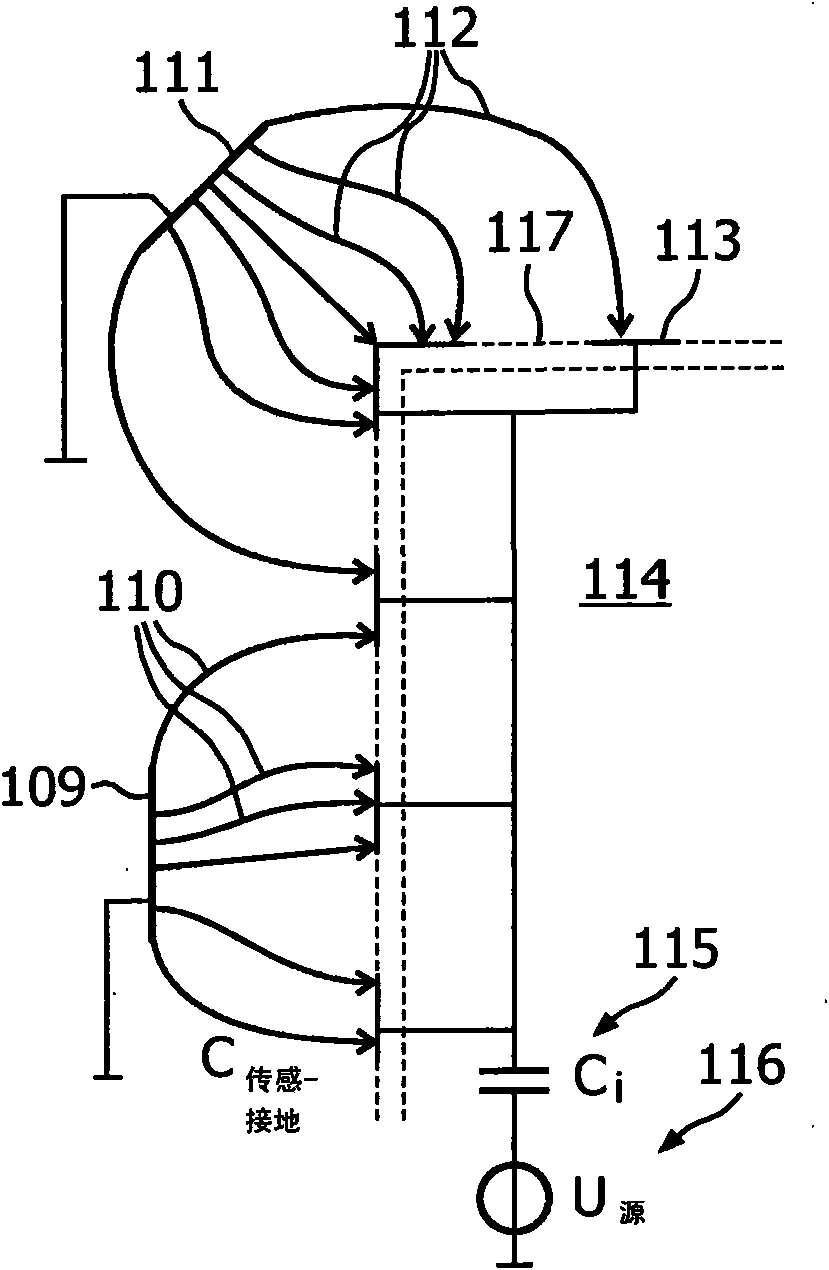

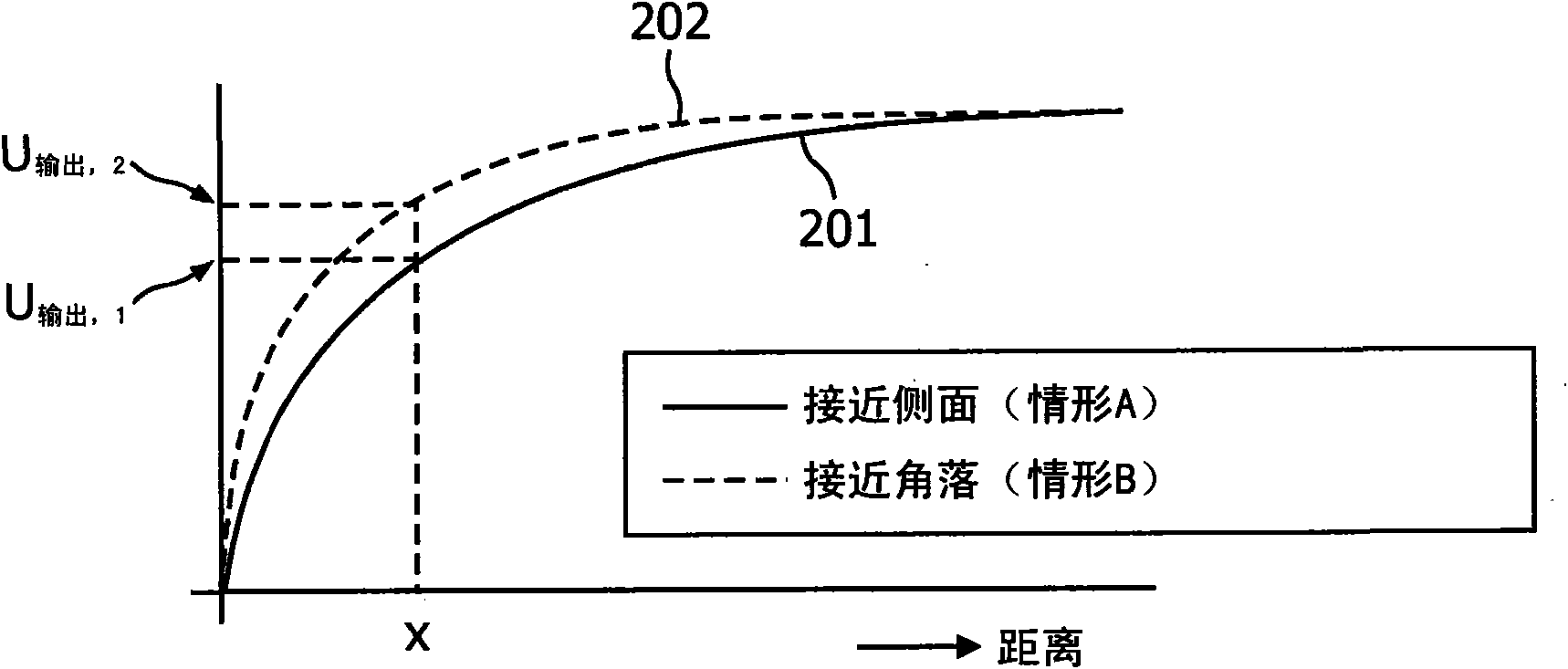

Capacitive type proximity sensor

ActiveCN101896794AOptimal UniformitySensitivity optimizationElectronic switchingConverting sensor output electrically/magneticallySoft x rayCapacitance

It is provided a capacitive type proximity sensor, comprising a sensing electrode, whereas the sensing electrode has a surface with electroconductive areas 113 and not-electroconductive areas 117, whereas the sensor is adapted for measuring an electrical field 110, 112 between the sensing electrode and an object 109, 111. Further it is described an apparatus for medical x-ray diagnosis and / or x-ray therapy and / or nuclear diagnosis / therapy, e.g. SPECT, a system for medical x-ray diagnosis and / or x- ray therapy and / or nuclear diagnosis / therapy, e.g. SPECT, a method for avoiding collision between an apparatus for medical x-ray diagnosis and / or x-ray therapy and / or nuclear diagnosis / therapy, e.g. SPECT, and an object, a programme element and a computer readable medium. It is disclosed a capacitance type proximity sensor whose sensitivity of approaching objects has an improved independence from the special geometry of the sensor itself.

Owner:KONINK PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com