Patents

Literature

68 results about "Contact dynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact dynamics deals with the motion of multibody systems subjected to unilateral contacts and friction. Such systems are omnipresent in many multibody dynamics applications. In the following it is discussed how such mechanical systems with unilateral contacts and friction can be modeled and how the time evolution of such systems can be obtained by numerical integration. In addition, some examples are given.

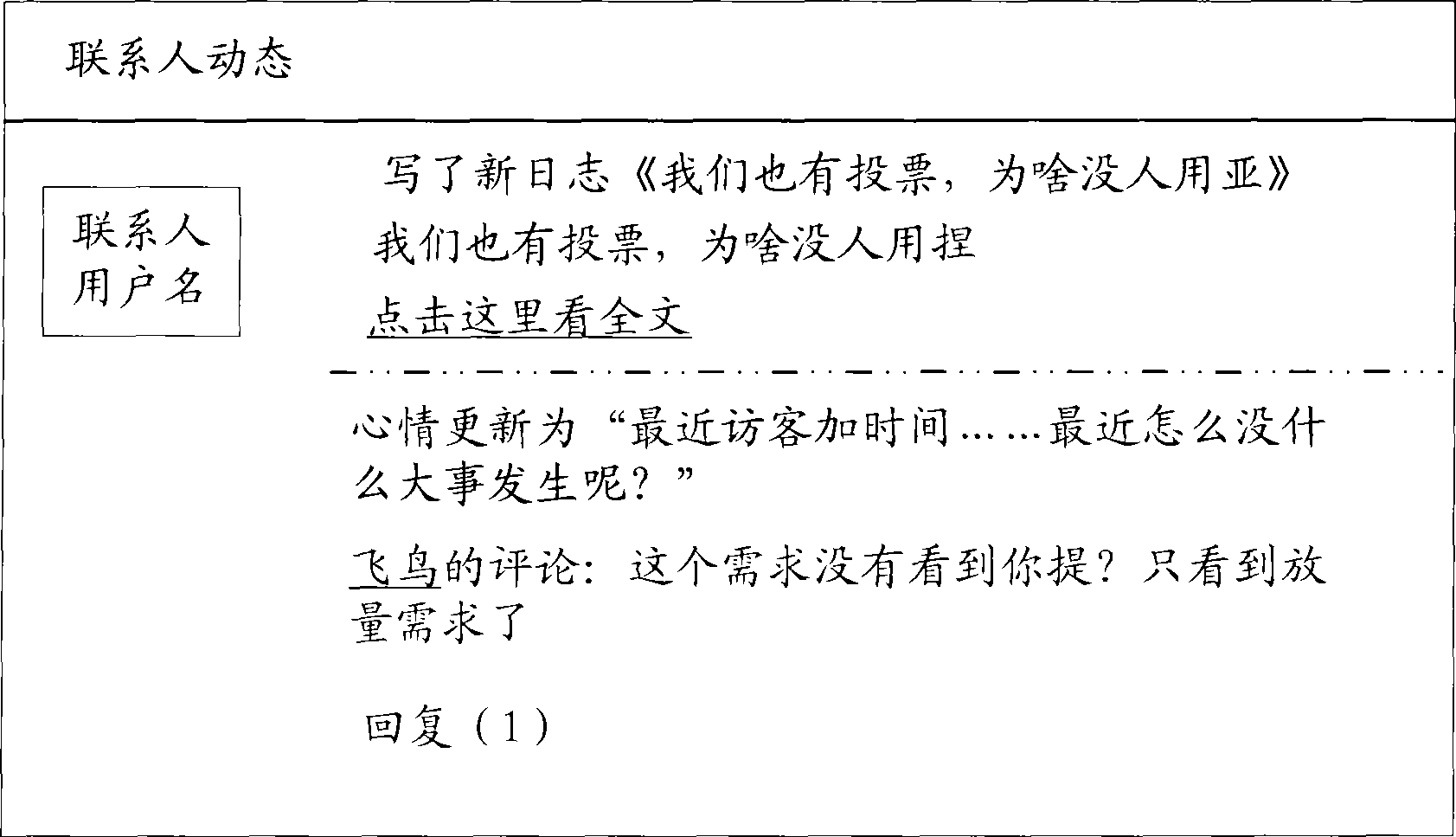

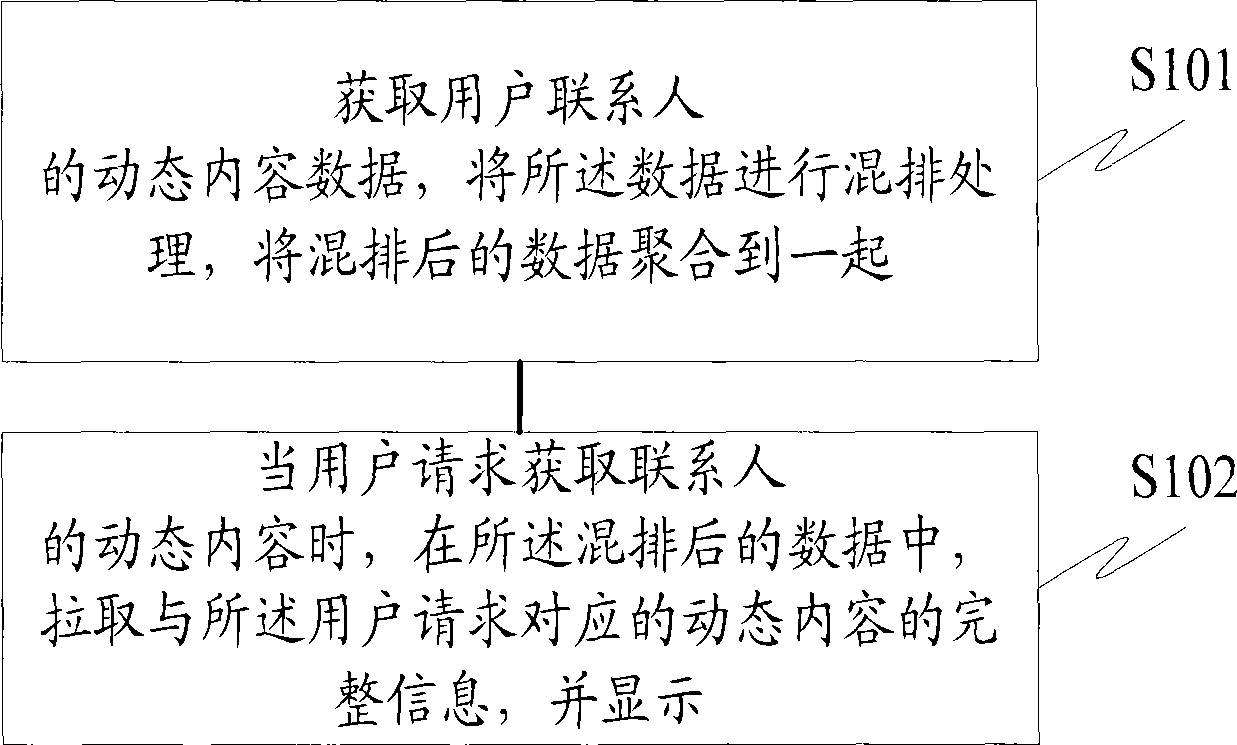

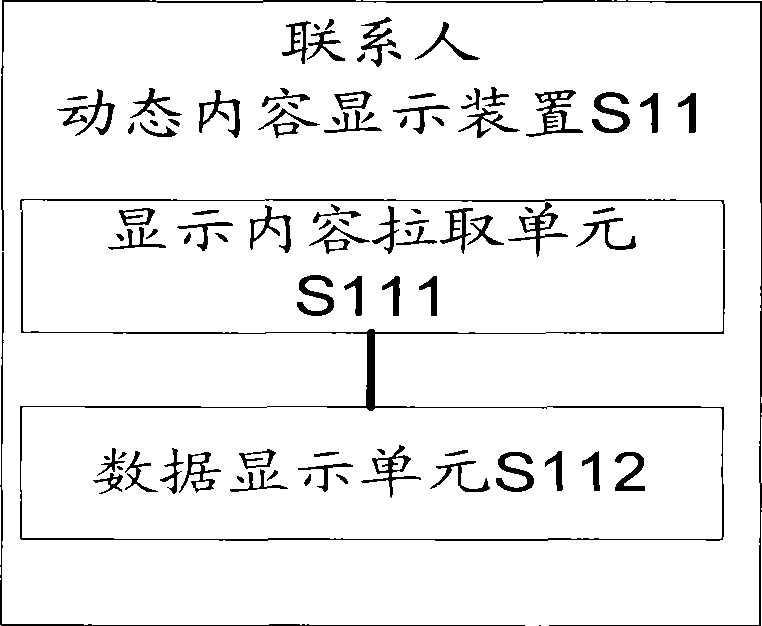

Contact dynamic content polymerization process and system based on social network relationship chain

The invention relates to a method and a system for aggregating dynamic contents of the contacts based on a social network relationship chain. The technical proposal comprises the following steps: acquiring the dynamic content data of user contacts, aggregating the integrated data together after integrating the data, and when the user requests to acquire the dynamic contents of the contacts, pulling the complete information of the dynamic contents corresponding to the user request in the integrated data and displaying the complete information. The invention further relates to a system for aggregating dynamic contents of the contacts based on a social network relationship chain. With the technical proposal, the complete contents of the dynamic information updated by the user contacts can be showed to users or clients.

Owner:TENCENT TECH (SHENZHEN) CO LTD

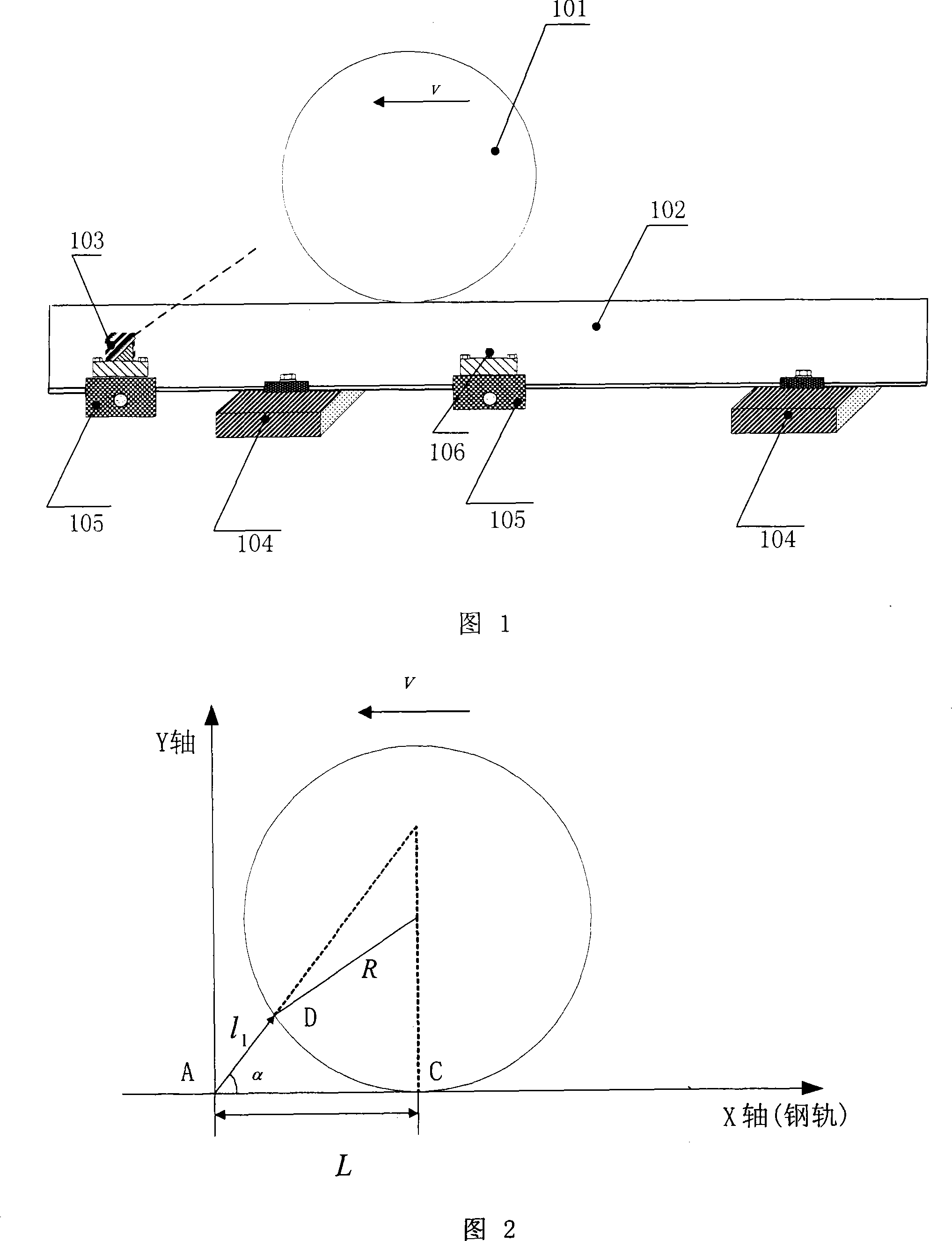

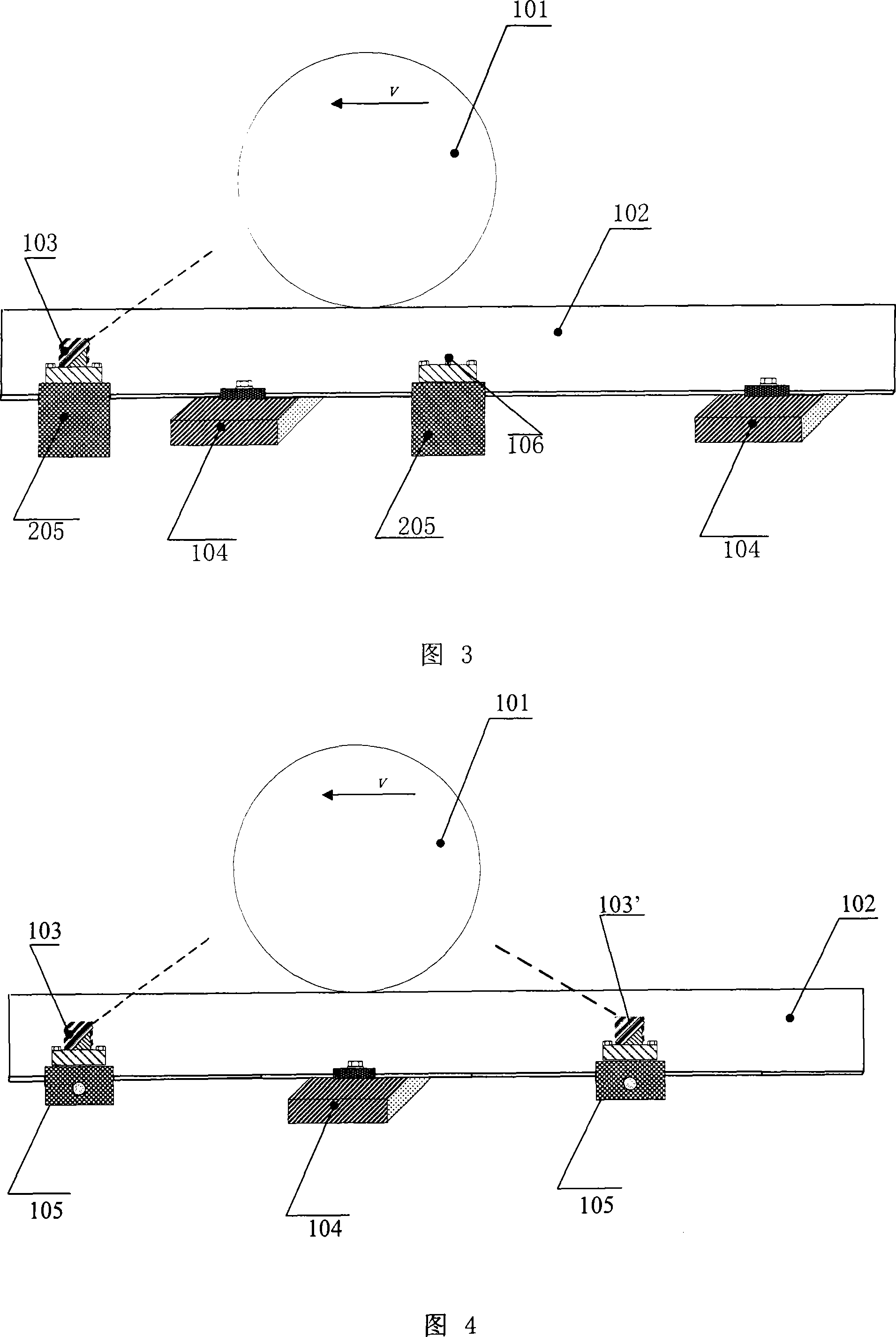

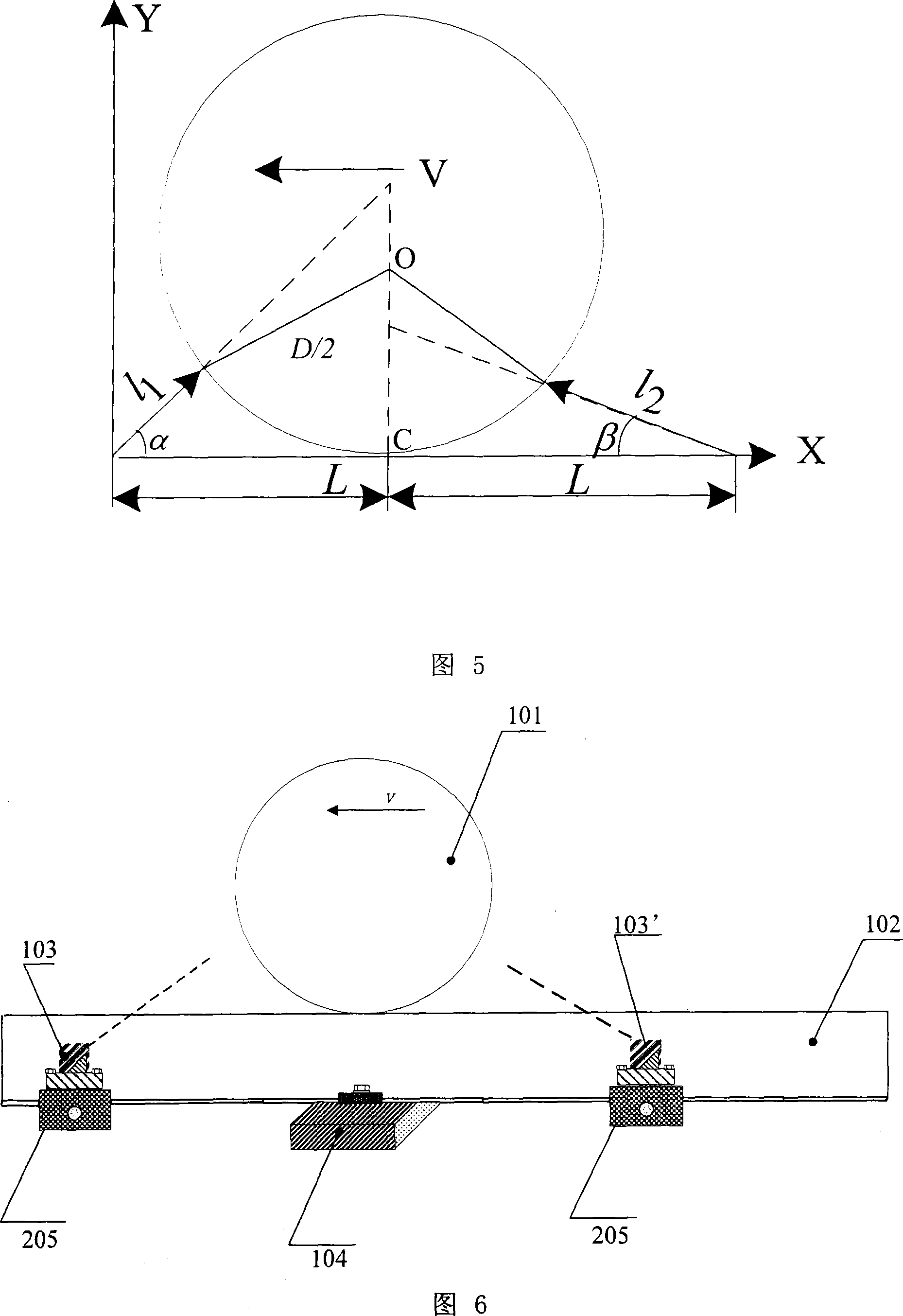

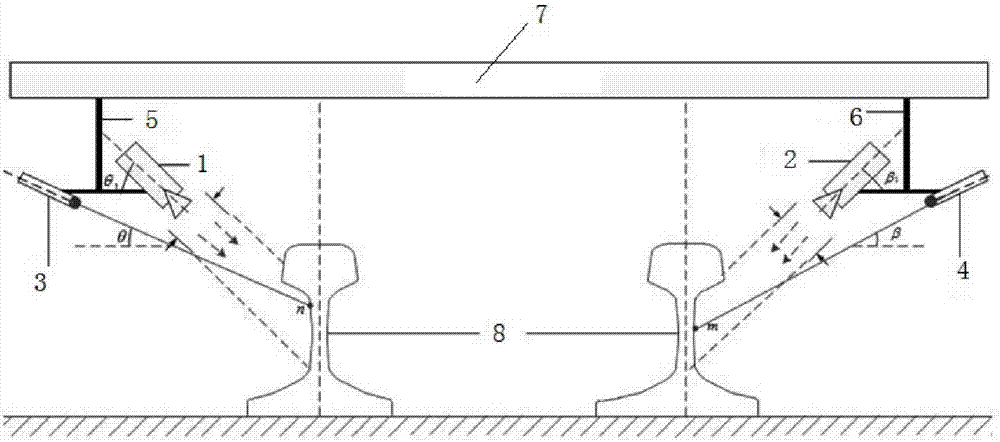

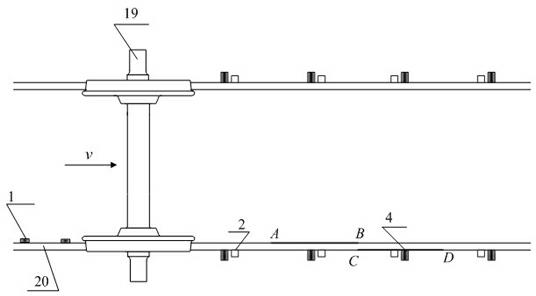

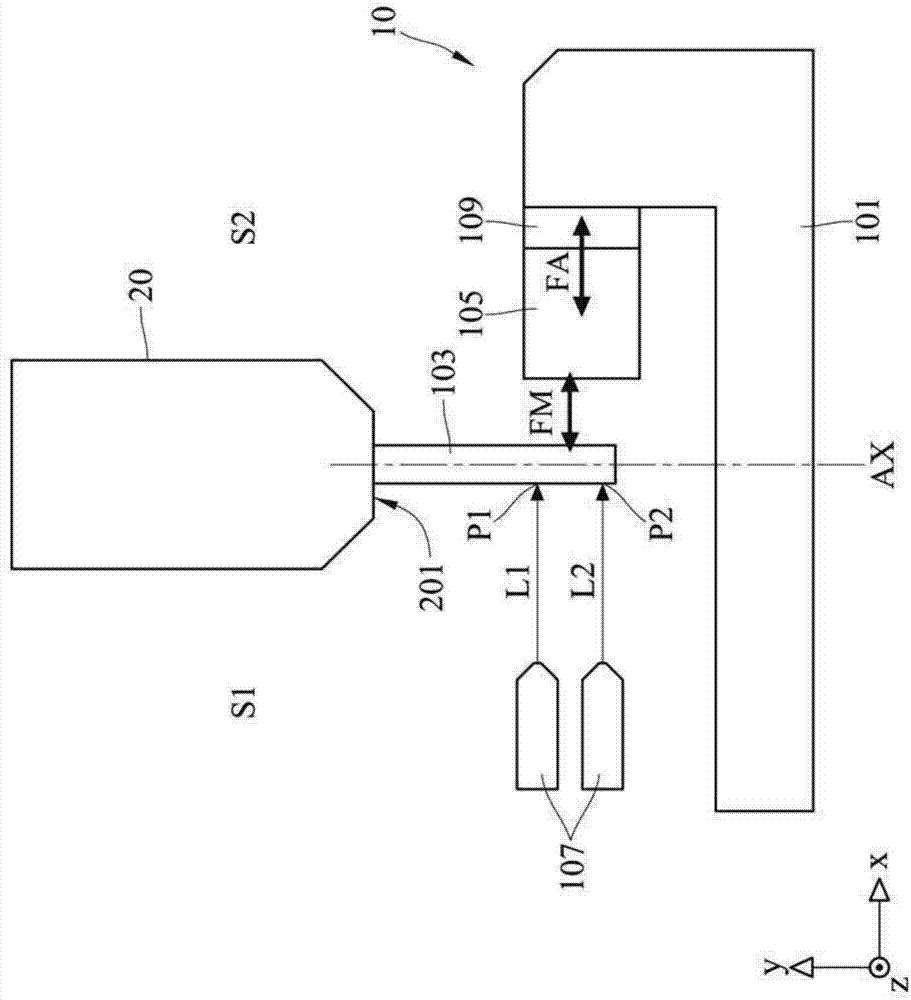

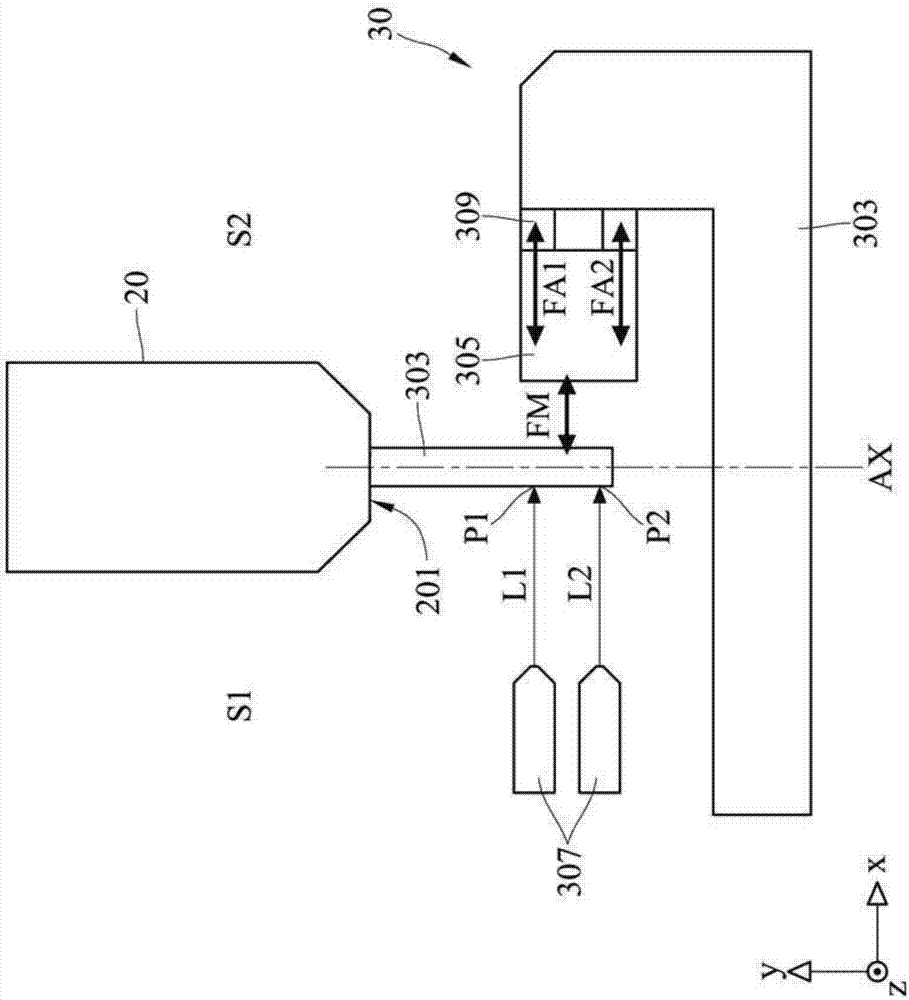

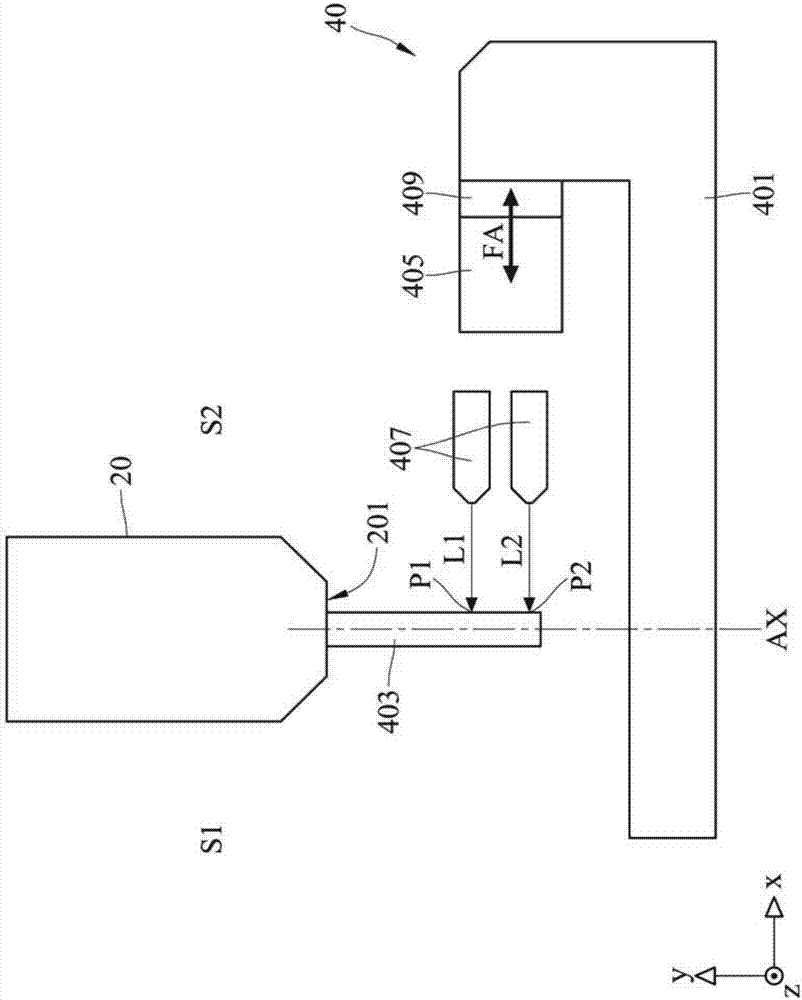

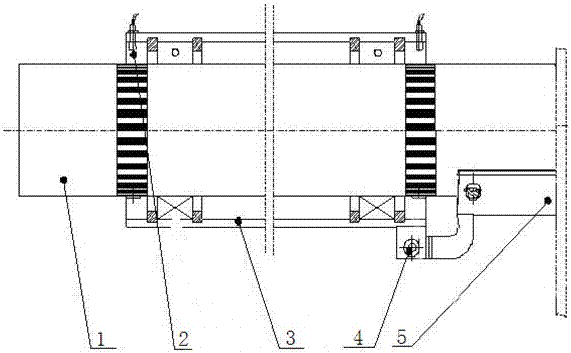

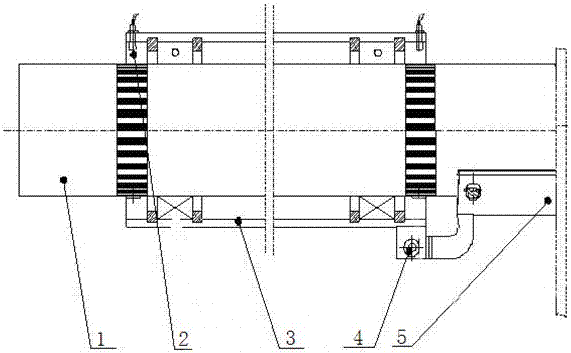

Non-contact type dynamic measuring device and method for wheel diameter based on laser and method thereof

ActiveCN101219672ASimple measuring principlePractical measurement principleWheel-rims surveying/measuringMeasurement deviceOptoelectronics

The invention discloses a non-contact dynamic measuring device for a wheel diameter based on laser and a method thereof. The measuring device consists of a laser displacement sensor, a wheel positioning sensor or two laser displacement sensors; the two sensors are arranged along the direction of a steel rail. When the two laser displacement sensors are applied, light spots of irradiation laser can directly irradiate onto two opposite surfaces of the measured wheel; the two laser displacement sensors respectively and continuously measure the distance between each sensor and corresponding point on a tread of the wheel; the reading data of distance in each laser displacement sensor is recorded when the sum of the distance measured by the two laser displacement sensors is basically unchanged, to calculate the diameter of the train wheel. The invention requires two sensors at most, and measurement principle is simple and practical.

Owner:BEIJING JIAOTONG UNIV

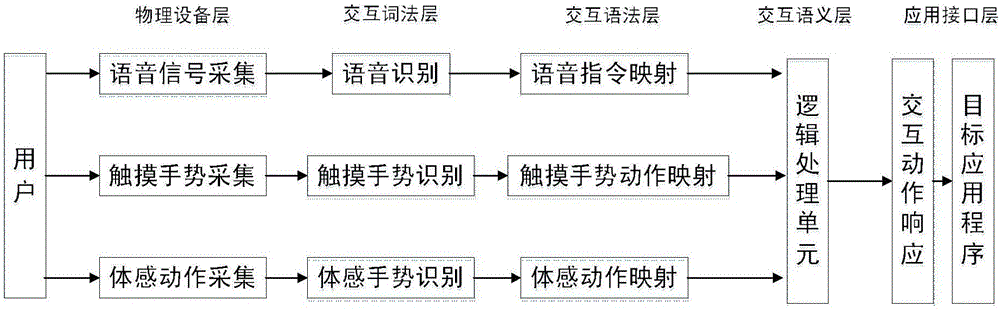

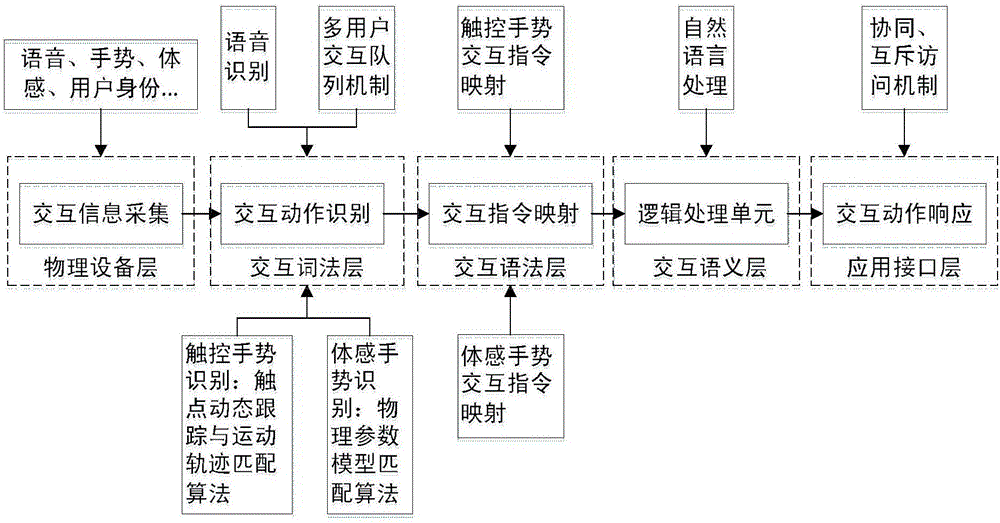

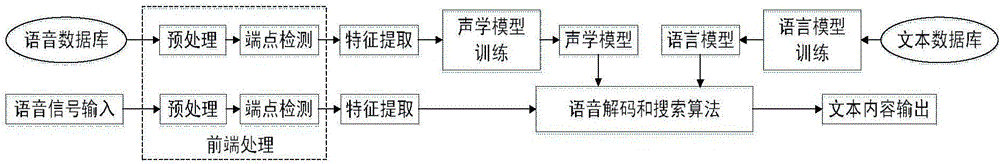

Multi-modal man-machine interaction system and control method thereof

InactiveCN106569613AAchieve consistencyImplement responseInput/output for user-computer interactionSound input/outputCouplingHuman–computer interaction

The invention discloses a multi-modal man-machine interaction system and a control method thereof. The main interaction process comprises: interaction information collection, interaction motion identification, interaction instruction mapping, logic processing unit, and interaction motion response. The interactive identification algorithm of voice, touch gesture and body feeling and gesture is broken through. The method comprises contact dynamic tracking and movement track coupling algorithm, physical parameter model coupling method, multi-user interaction queue mechanism. Touch control / body feeling gesture interaction mapping instruction and logic processing, cooperation / mutual exclusion access mechanism are set; the user control instruction is converted into service instruction of application system scheduling execution; multi-user interaction is supported; the system has strong anti-interference capability and identification efficiency.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

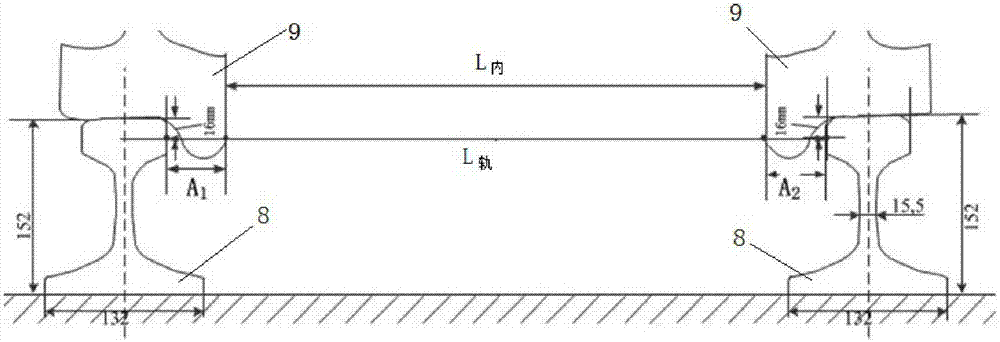

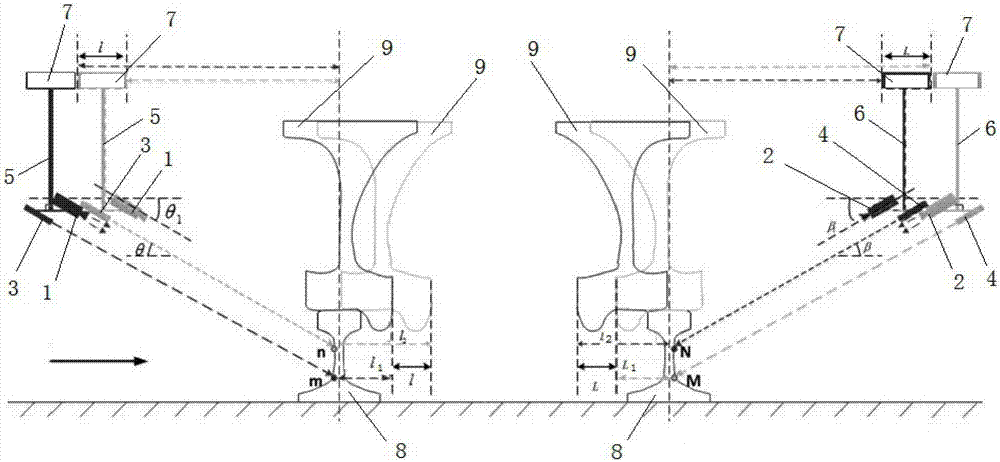

Vehicle-mounted rail gauge measurement system and measurement method

ActiveCN106871805AReduce distractionsHigh-resolutionUsing optical meansHardware structureEngineering

The present invention discloses a vehicle-mounted rail gauge measurement system and measurement method and belongs to the technical field of metering equipment characterized by using optical methods. According to the method, two sets of laser sources and cameras are combined together to obtain the lateral displacement change quantities of a locomotive relative to a left rail and a right rail respectively; the difference value of the lateral displacement change quantities of the locomotive relative to the left rail and the right rail is utilized to reflect the change of the lateral movement quantity between wheel tracks; and therefore, indirect measurement of the rail gauge of the rails can be realized. The rail gauge measurement method has the advantages of simple hardware structure, small data computation amount and high precision measurement, and can realize the non-contact dynamic measurement of rail gauge parameters.

Owner:SHIJIAZHUANG TIEDAO UNIV

Method for reducing power consumption of embedded system by contact dynamic sampling technique

ActiveCN102902349AImprove experienceTimely responsePower supply for data processingInput/output processes for data processingTouchscreenEmbedded system

A method for reducing power consumption of an embedded system by a contact dynamic sampling technique belongs to the technical field of the touch screen of the embedded system. The method is suitable for the Android platform and comprises the following steps of: scanning the screen by the system to capture a touch event, performing the dynamic sampling technique, mapping the scene to a sample space, classifying the sample space and dynamically adjusting the sampling frequency, thereby reducing the system power consumption. The touch sampling technique provided by the invention is simple and also capable of effectively utilizing the system resources to reduce the system power consumption.

Owner:SHANDONG UNIV

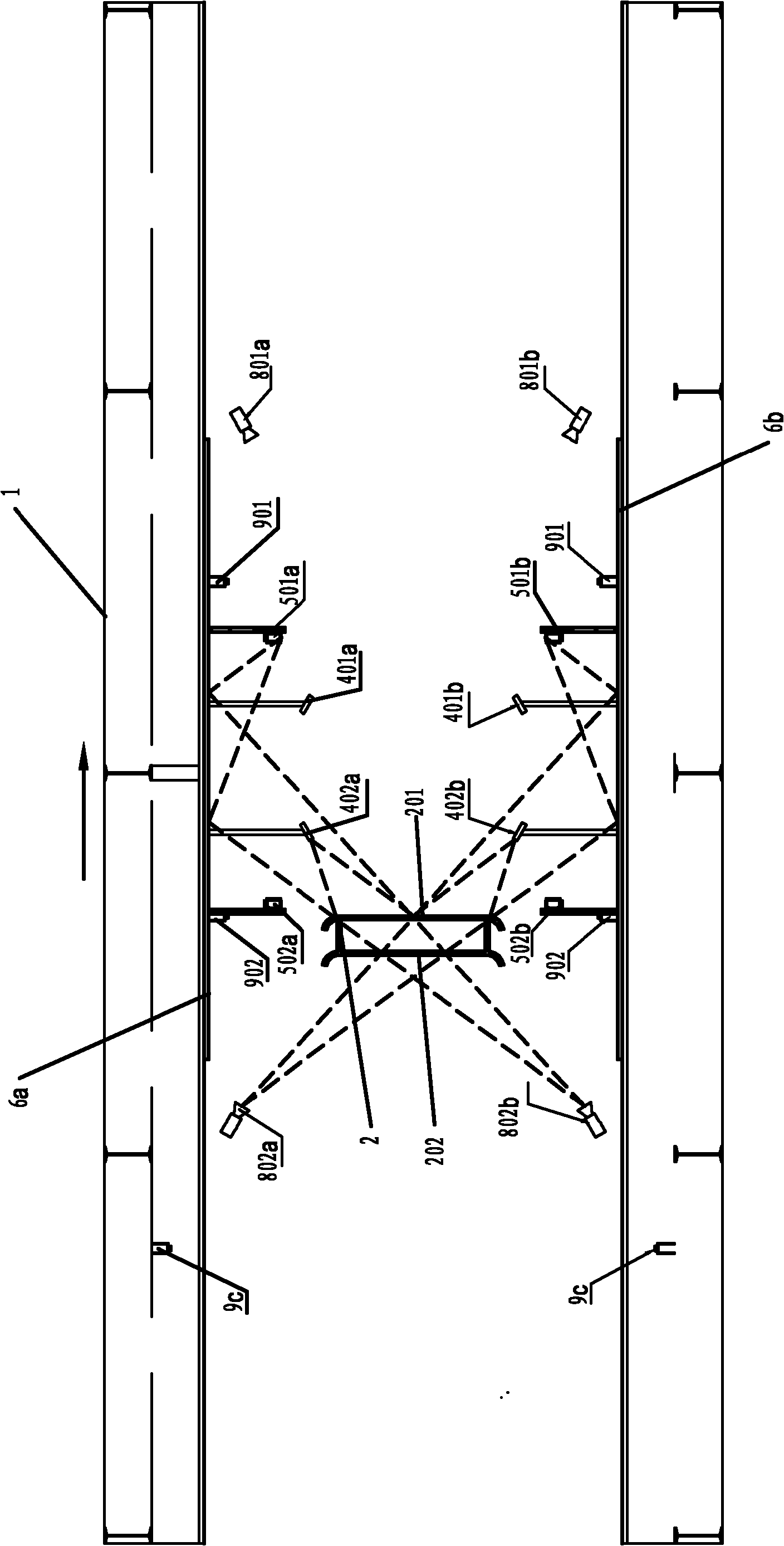

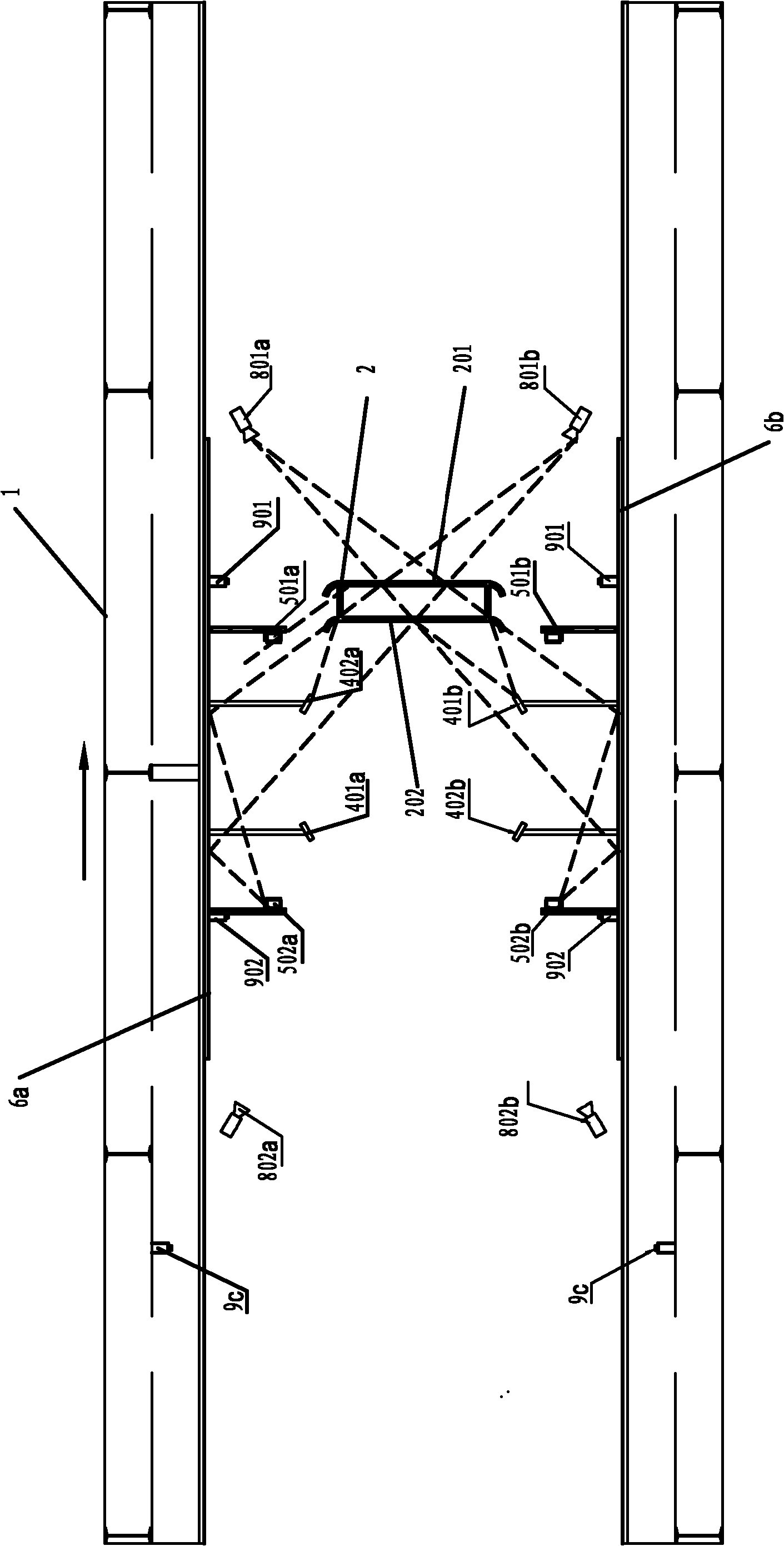

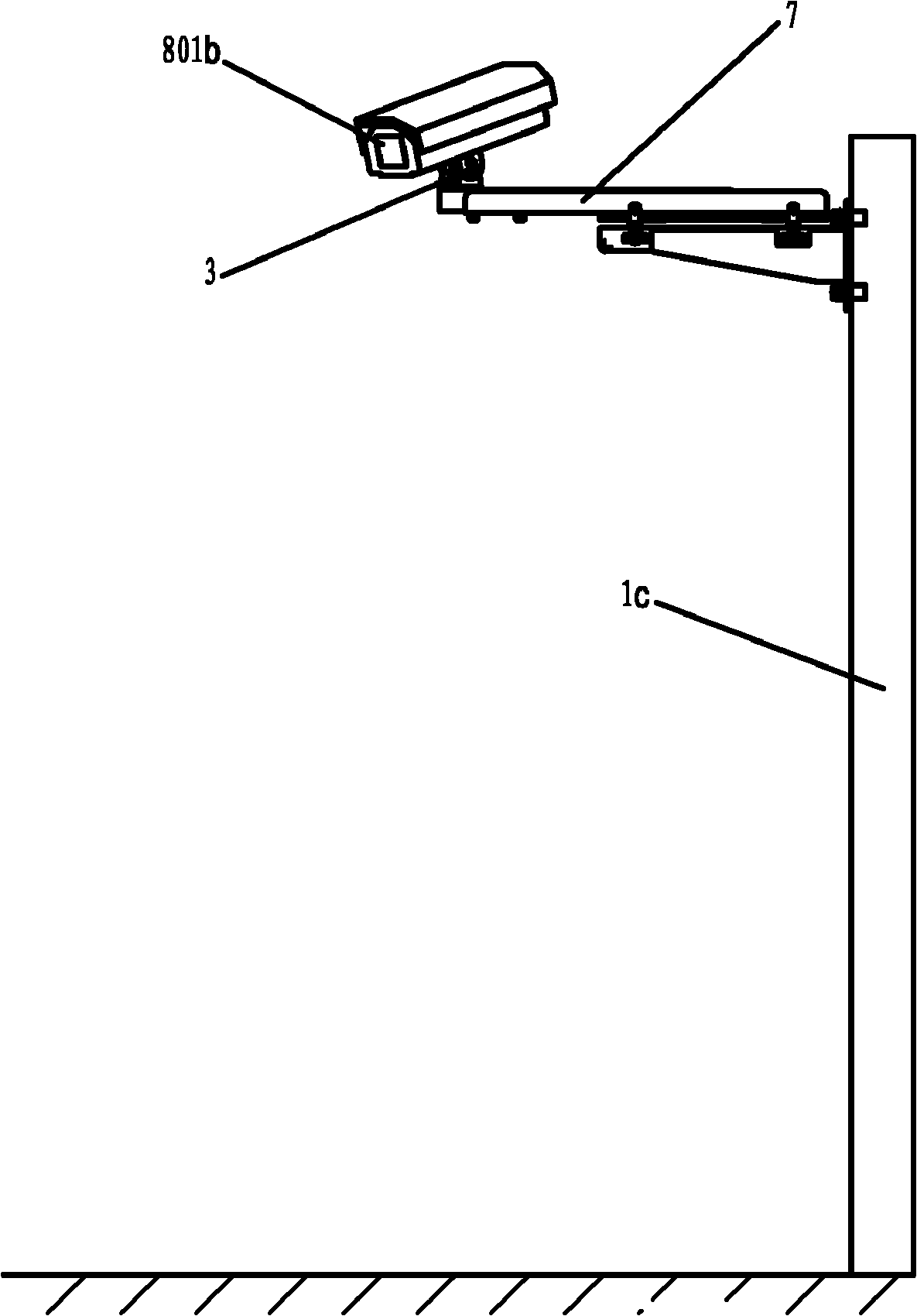

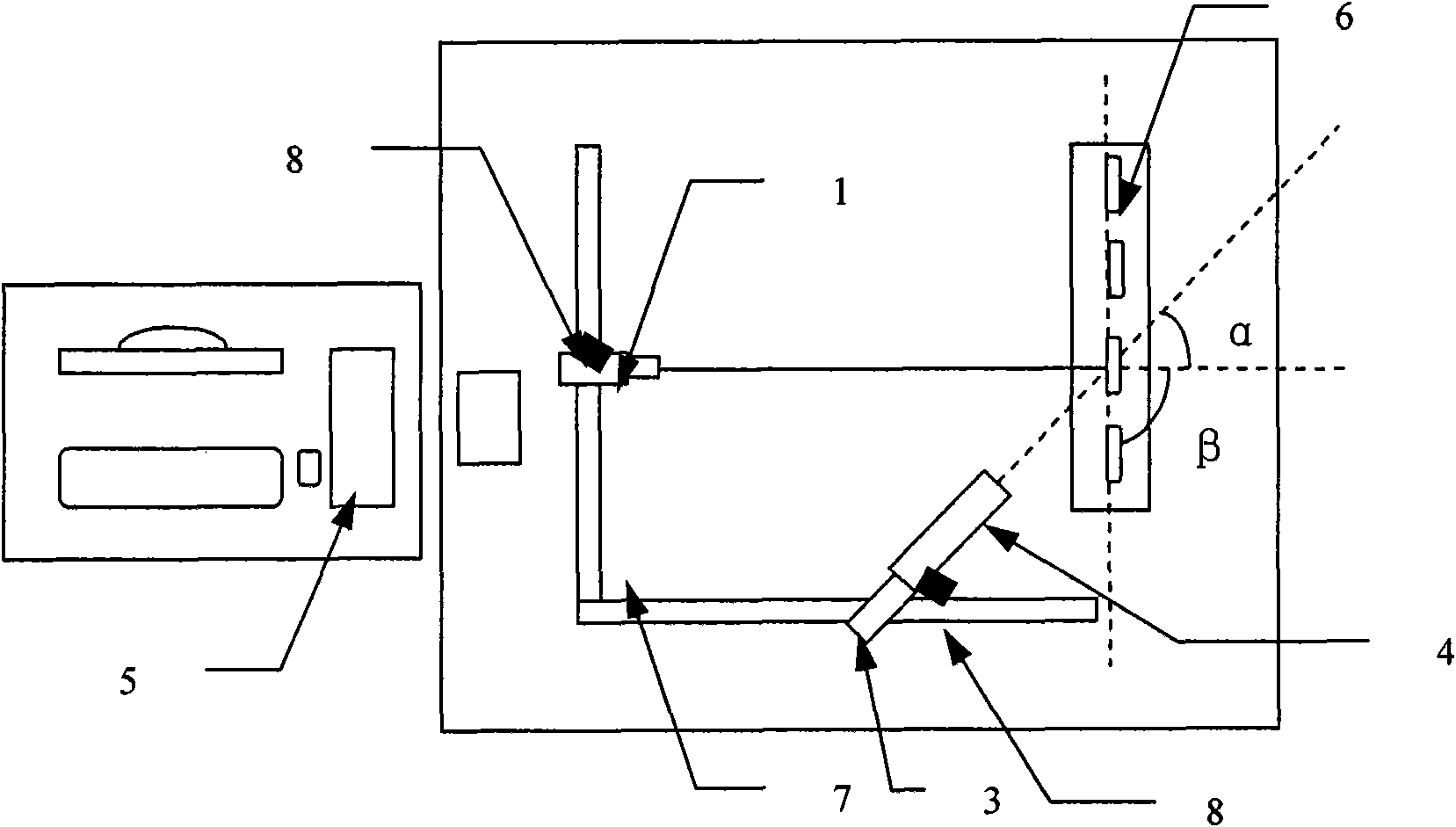

Device for automatically detecting abrasion of pantograph pan of locomotive online

The invention provides a device for automatically detecting the abrasion of the pantograph pan of a locomotive online. A front trigger switch and a rear trigger switch connected with a data processing and controlling device are fixed to the lateral surface of a detection shed at the height thereof being the same as the pantograph pan; a left background plate and a right background plate are respectively mounted on the left and right lateral surfaces of the detection shed; four image sensors are mounted on the detection shed; wherein a rear left image sensor and a rear right image sensor with the forward and downward viewing angle are respectively aimed at the front parts of the right background plate and the left background plate, and the rear left image sensor and the rear right image sensor are respectively aimed at the right half part and the left half part of a front plate of the pantograph pan of the locomotive when the rear trigger switch is triggered; and a front left image sensor and a front right image sensor with the backward and downward viewing angle are respectively aimed at the rear parts of the right background plate and the left background plate, and the front left image sensor and the front right image sensor are respectively aimed at the right half part and the left half part of the pantograph pan of the locomotive when the front trigger switch is triggered. Accordingly, the device capable of carrying out the automatic non-contact dynamic detection on the locomotive online has the advantages of high detection accuracy, safe and convenient application, high stability and reliability and long service life.

Owner:CHENGDU TIEAN SCI & TECH

Non-contact dynamic profile measuring method and measuring device

The invention relates to a non-contact dynamic profile measuring method and a measuring device. A monochromatic laser with a sheet laser is arranged in front of a measured object, and the plane of the sheet laser is vertical to the plane of the measured object. A digital camera with a narrow bandpass filter is arranged in side front of the measured object, and strongest laser energy is irradiated to a measuring area of the measured object. The camera shoots concave and convex changed images of the measured object, and the shot images are input into a computer through an image acquisition card and are compared with a target image with a known depth gradient so as to calculate the dynamic data of appearance profile changes of the measured object. Only a low-price semiconductor laser can filter intense light background noise without an expensive high-energy pulse laser, and the semiconductor laser has strong capacity of resisting disturbance, can measure dynamic profile change data of an object under high-temperature flame environment in a non-contact mode and has accurate measurement and calculation result. Required equipment is simple and easy to use, operate and maintain.

Owner:魏润杰

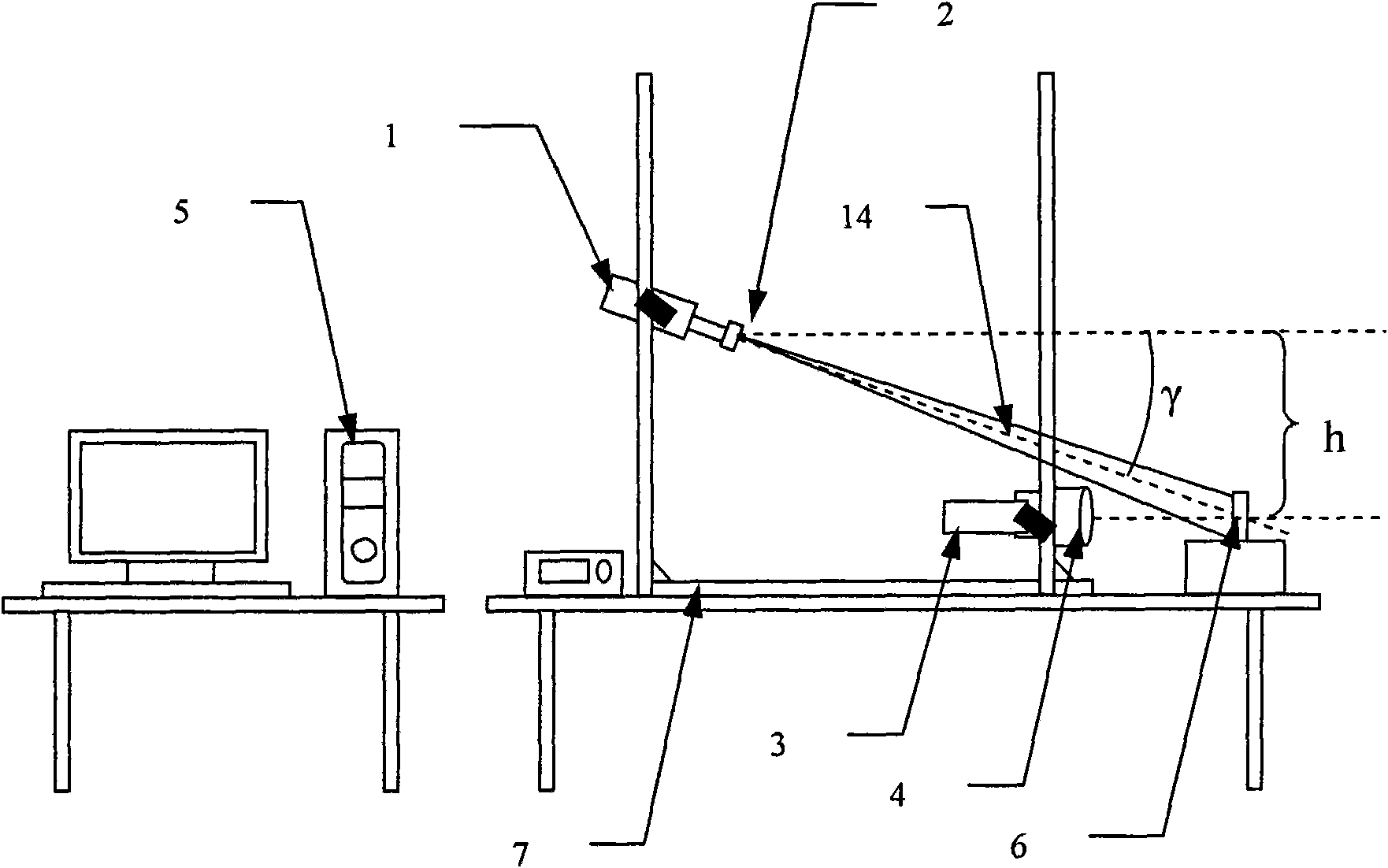

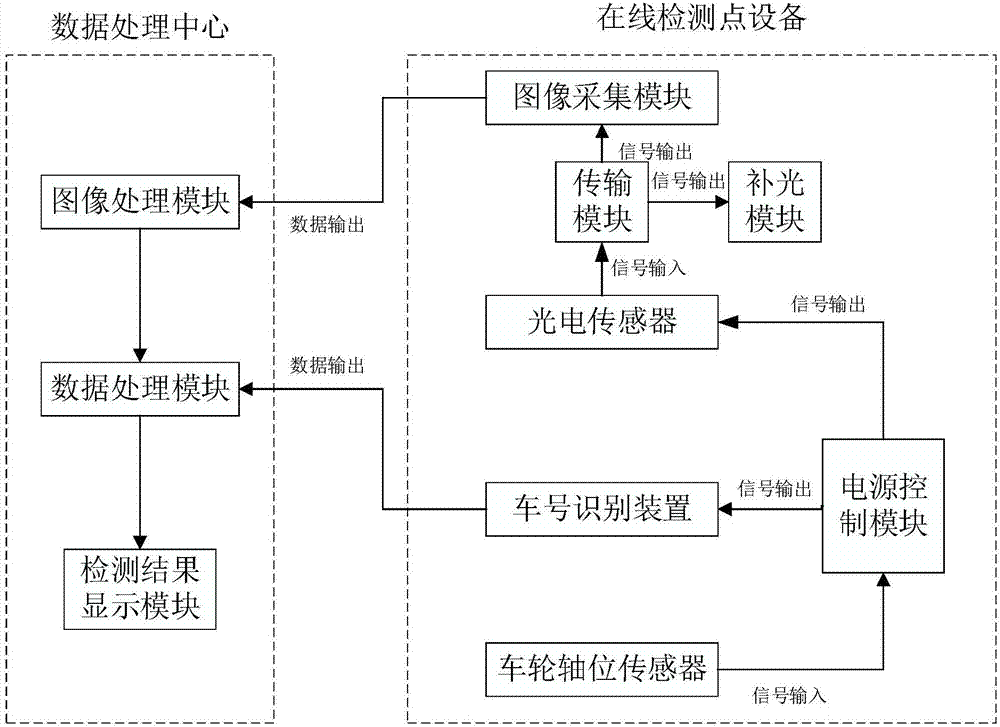

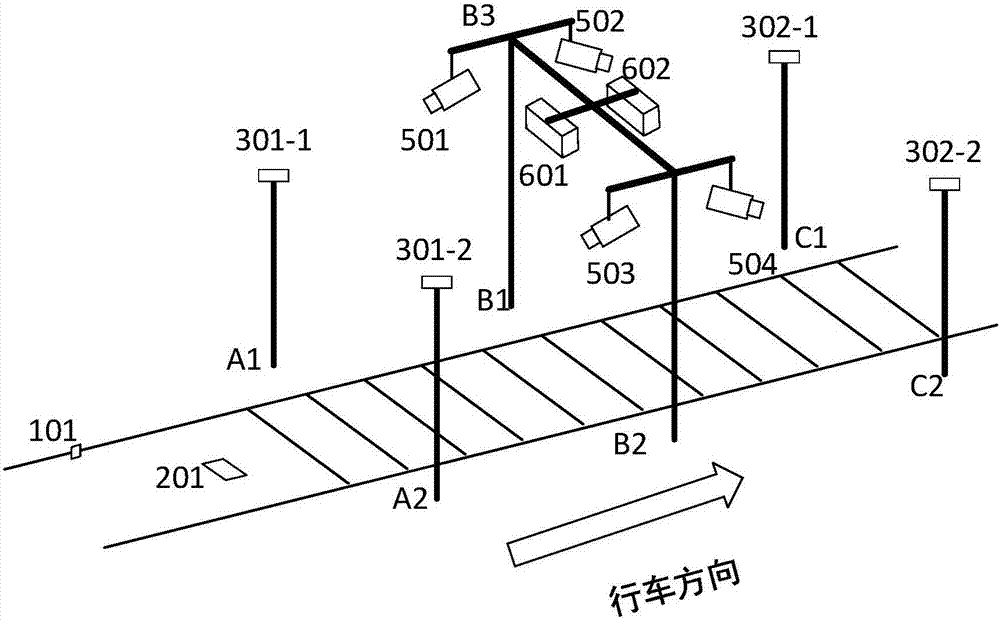

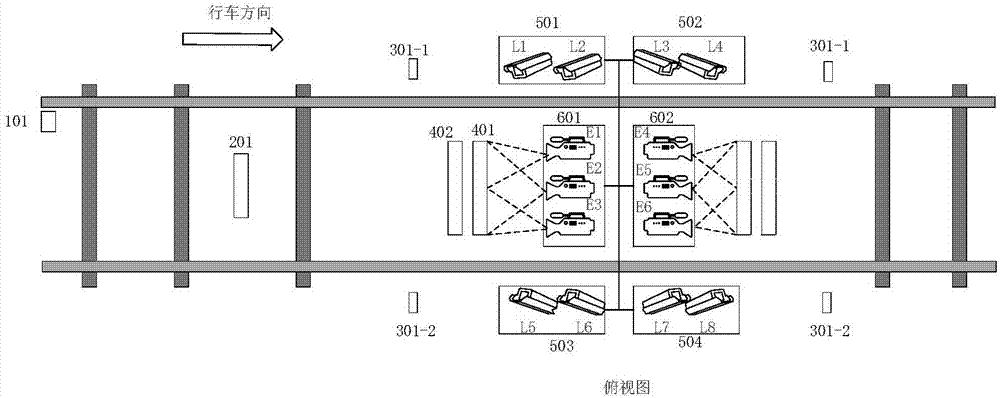

Urban rail train pantograph on-line detection device and method

InactiveCN107167098AEffective fill lightRealize online detectionUsing optical meansElectricityImaging processing

Owner:NANJING UNIV OF SCI & TECH

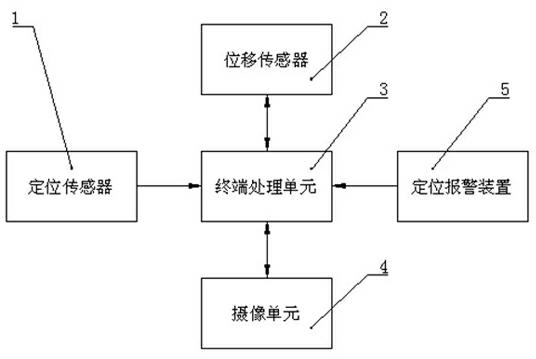

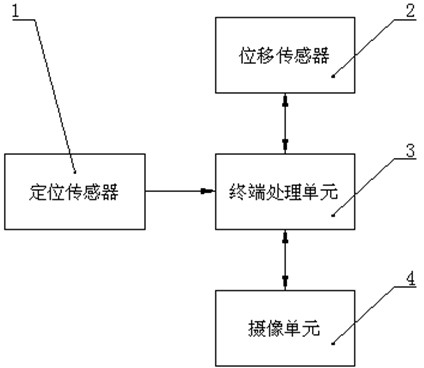

Non-contact dynamic detection device and detection method for tire tread defects

InactiveCN102501887AAvoid wear and tearRealize online dynamic detectionWheel-rims surveying/measuringOptically investigating flaws/contaminationEngineeringTread

The invention discloses a non-contact dynamic detection device and a detection method for tire tread defects, wherein, the non-contact dynamic detection device comprises a terminal processing unit and a positioning sensor; the positioning sensor is arranged on one side of a steel rail; the positioning sensor is connected with the terminal processing unit; and the terminal processing unit is connected with a displacement sensor and a camera unit which are arranged on both sides of the steel rail. The invention has the outstanding advantages as follows: firstly, a non-contact dynamic measuring method is adopted, and on-line dynamic detection can be achieved; secondly, the circumference of a tire tread can be detected roundly; thirdly, the type of the tire tread defects can be distinguished according to texture characteristics, and corresponding defect parameters can be calculated according to the type, wherein, the type of the tire tread defects is divided into scraping and stripping; and fourthly, small personal error can be caused.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

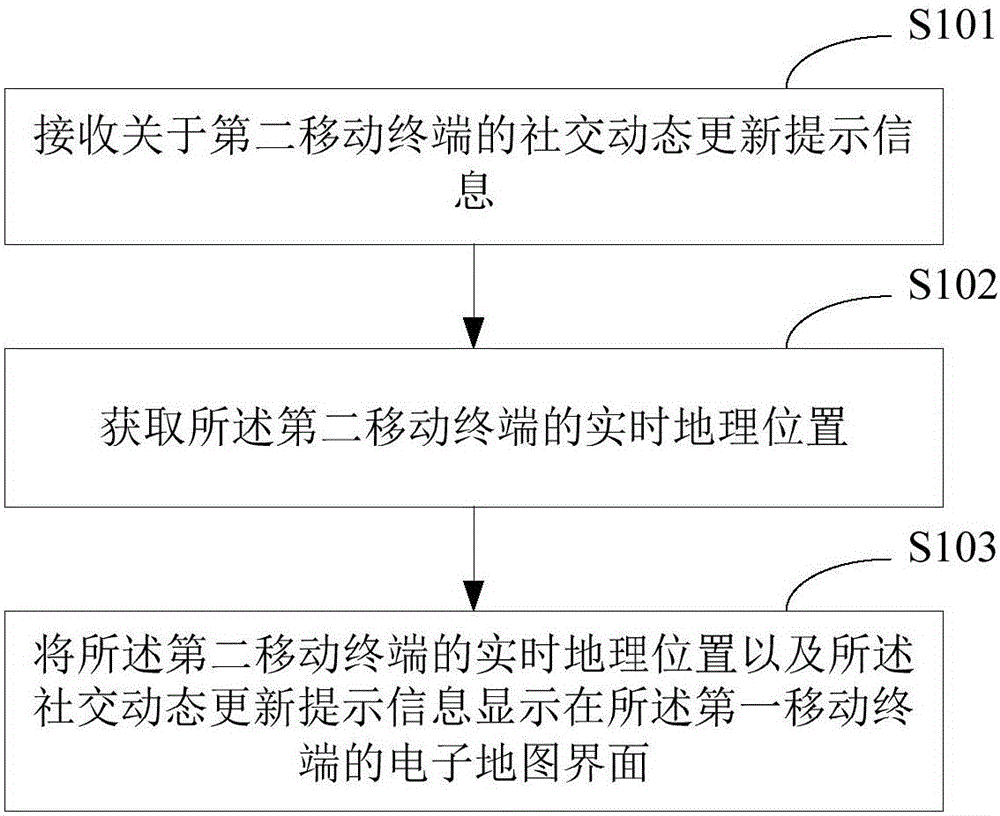

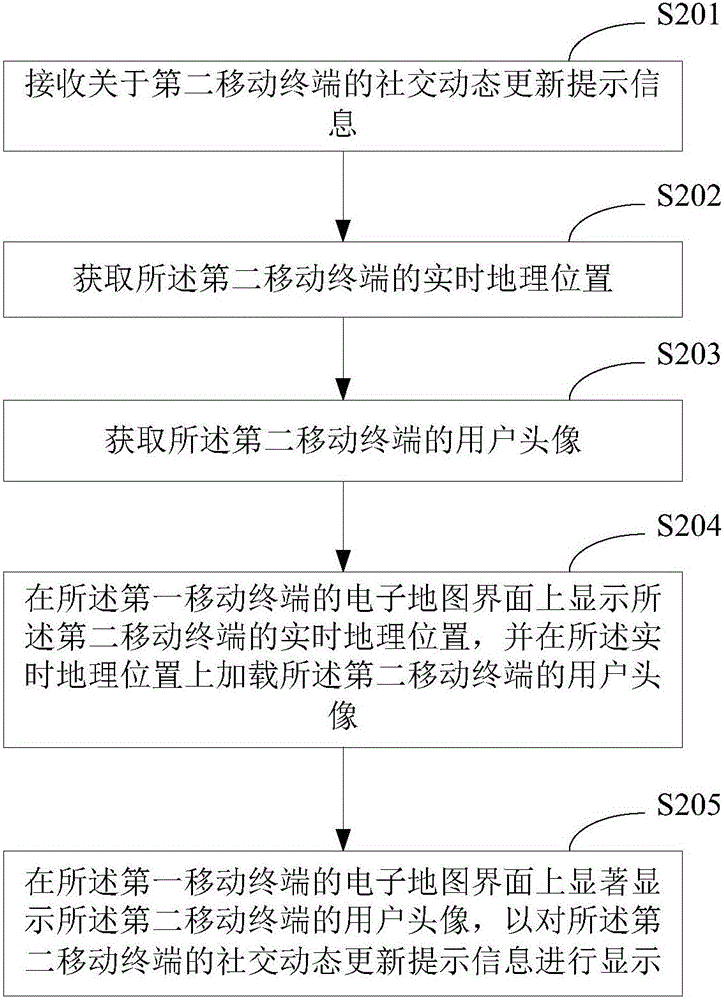

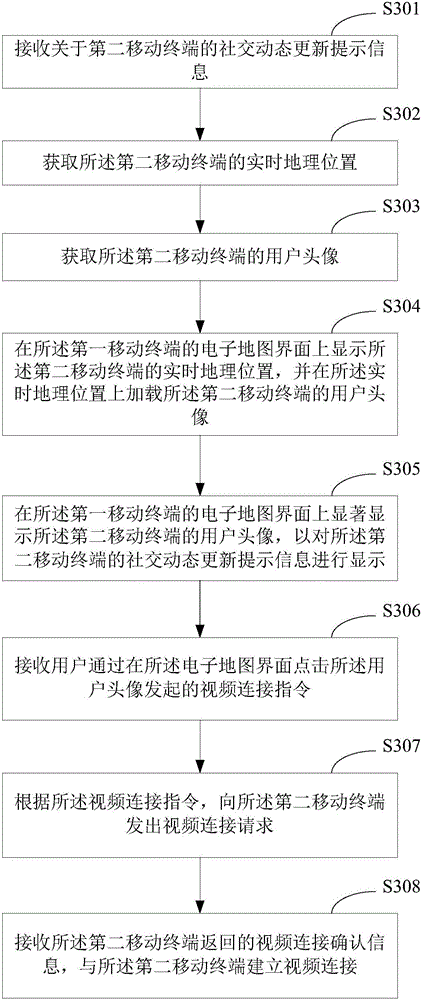

Display method of real-time data and mobile terminal

ActiveCN106815345AMeet social needsExpand social functionsData processing applicationsGeographical information databasesGeographic siteReal-time data

The invention is applicable to the field of network technologies and provides a display method of real-time data and a mobile terminal. The method comprises the steps that social contact dynamic update prompt information about a second mobile terminal is received; a real-time geographic position of the second mobile terminal is acquired; and the real-time geographic position of the second mobile terminal and the social contact dynamic update prompt information are displayed on an electronic map interface of a first mobile terminal. By the display method of the real-time data provided by the embodiment of the invention, a user can check real-time state information of the second mobile terminal in a map, so social contact dynamic information could be updated and prompted in real time, and the real-time position data could be shared. By the display method of the real-time data provided by the embodiment of the invention, the map can be used to associate a social contact network, and increasingly growing demands of the user for social contact could be satisfied; and the embodiment is achieved based by map type software, so that social contact functions of the map type software are extended.

Owner:VIVO MOBILE COMM CO LTD

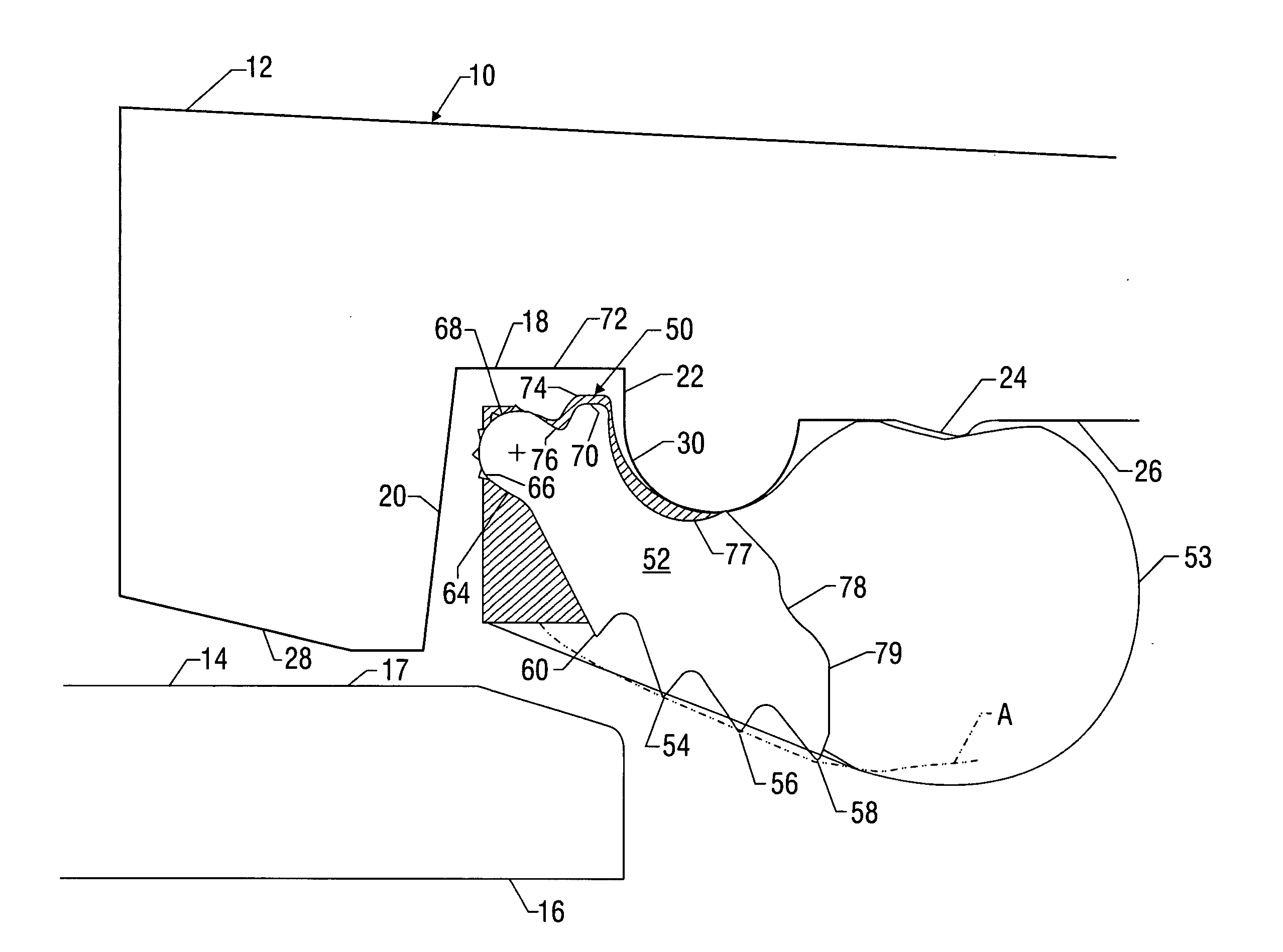

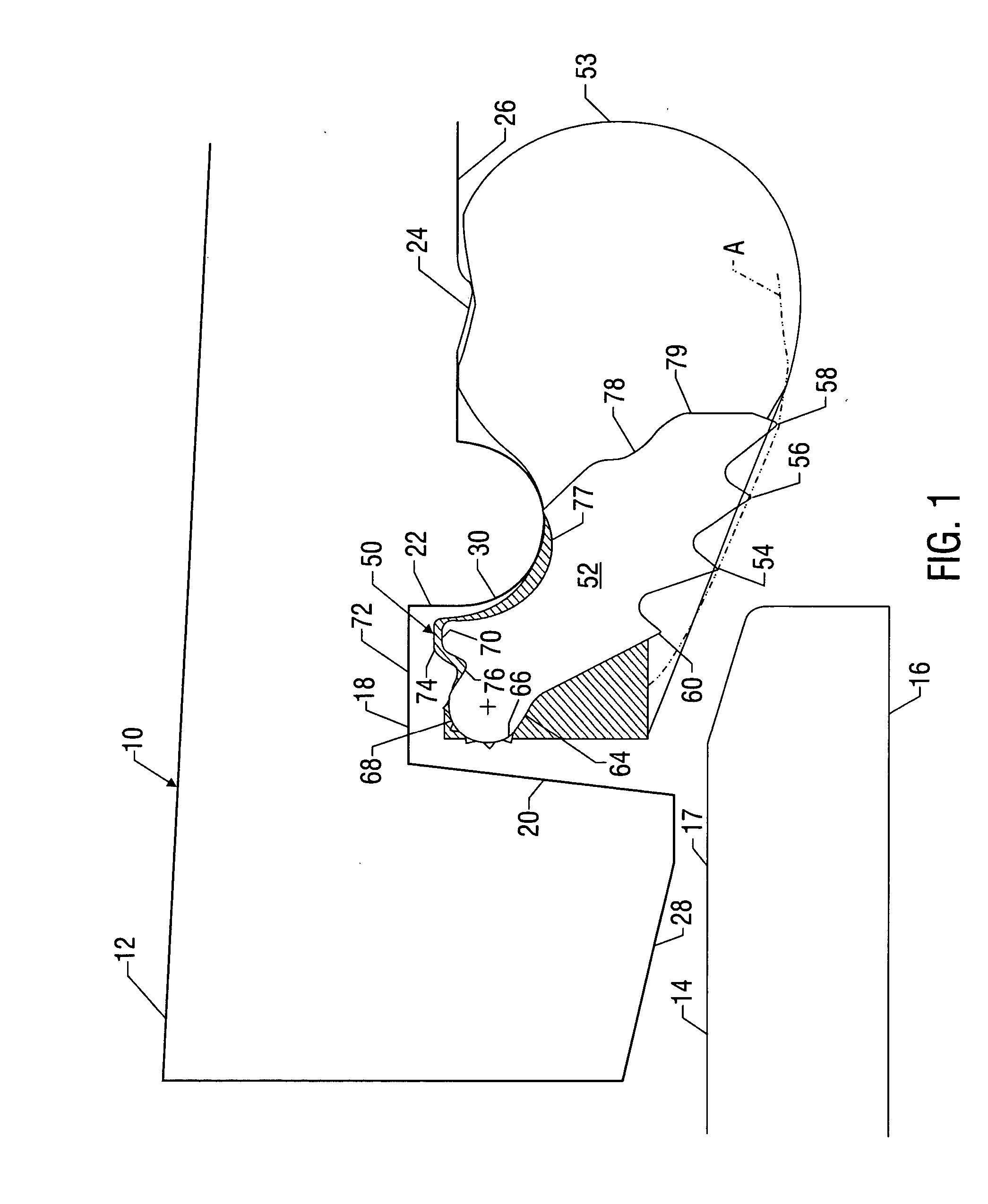

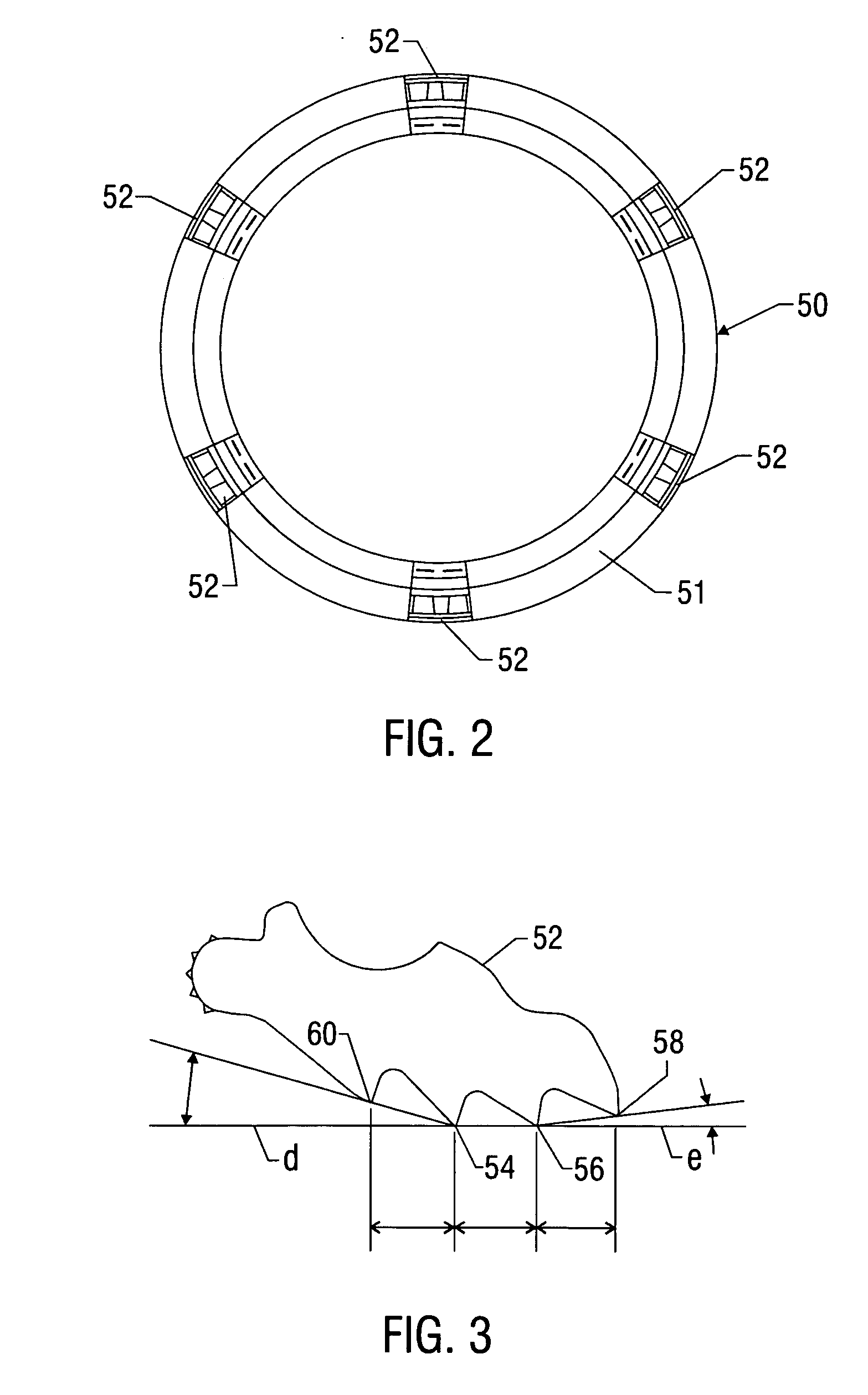

Mechanical joint gripping gasket

InactiveUS20050275217A1Add locking functionEasy to assembleSleeve/socket jointsFluid pressure sealed jointsTransverse grooveEngineering

A novel gasket includes at least one gripping element embedded in an annular member for forming a seal between two tubulars. For tubulars having socket and spigot ends, the gripping element includes teeth for gripping an outer surface of the spigot end and a blunt nose for contacting a front wall of a gland that compresses the gasket against surfaces of the socket and spigot ends. The blunt nose rolls along the front wall of the gland during relative movement between the tubulars and can include a contacting face of a specialized geometry to adjust contact dynamics and / or roughened surfaces to increase the frictional contact between the blunt nose and the front wall. The gripping elements can also include at least four teeth arranged such that no more than two teeth normally grip the outer surface of the spigot end. One or more teeth can also include a transverse groove to enhance penetration into the outer surface of the spigot end.

Owner:STAR PIPE PRODS

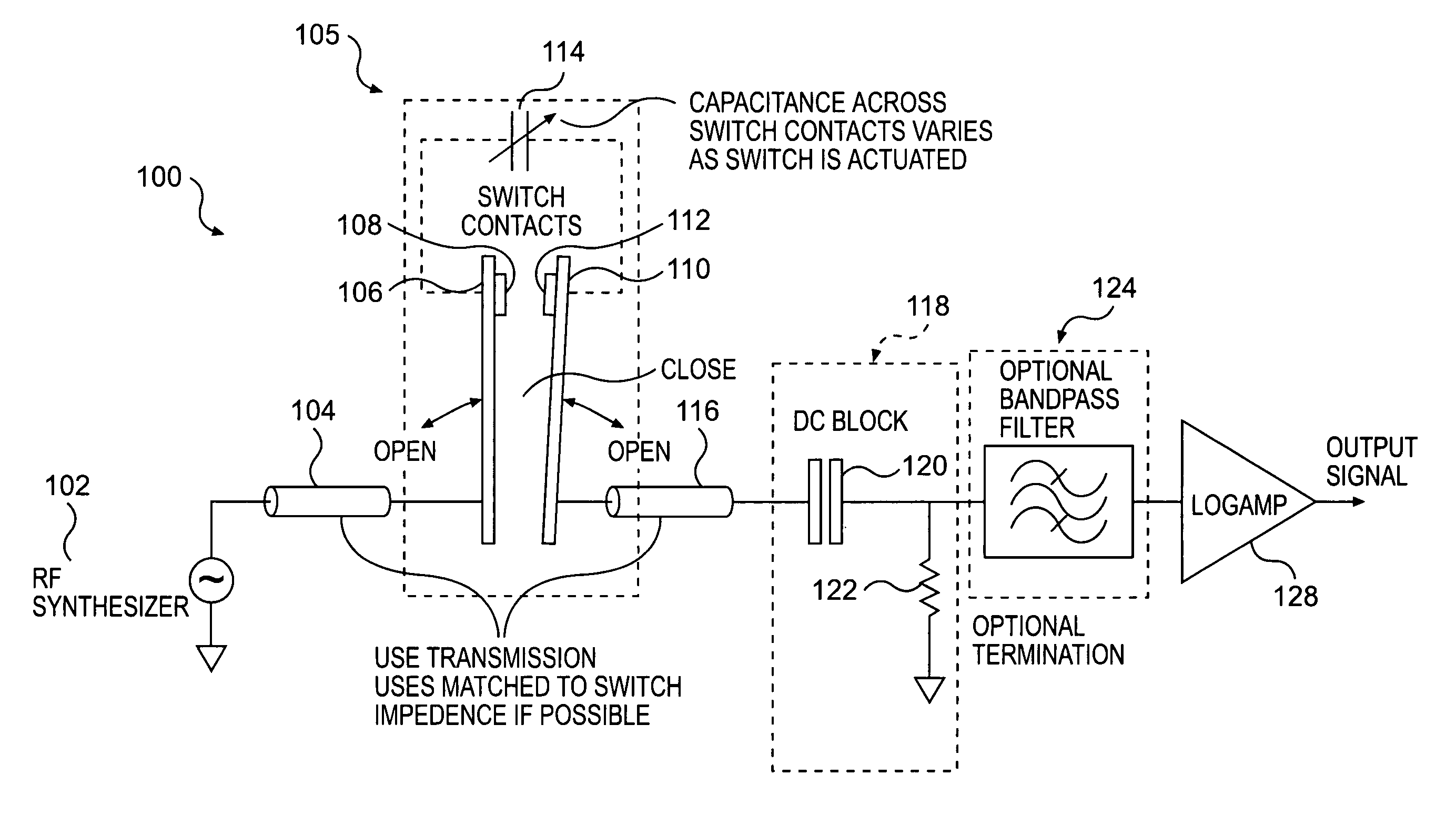

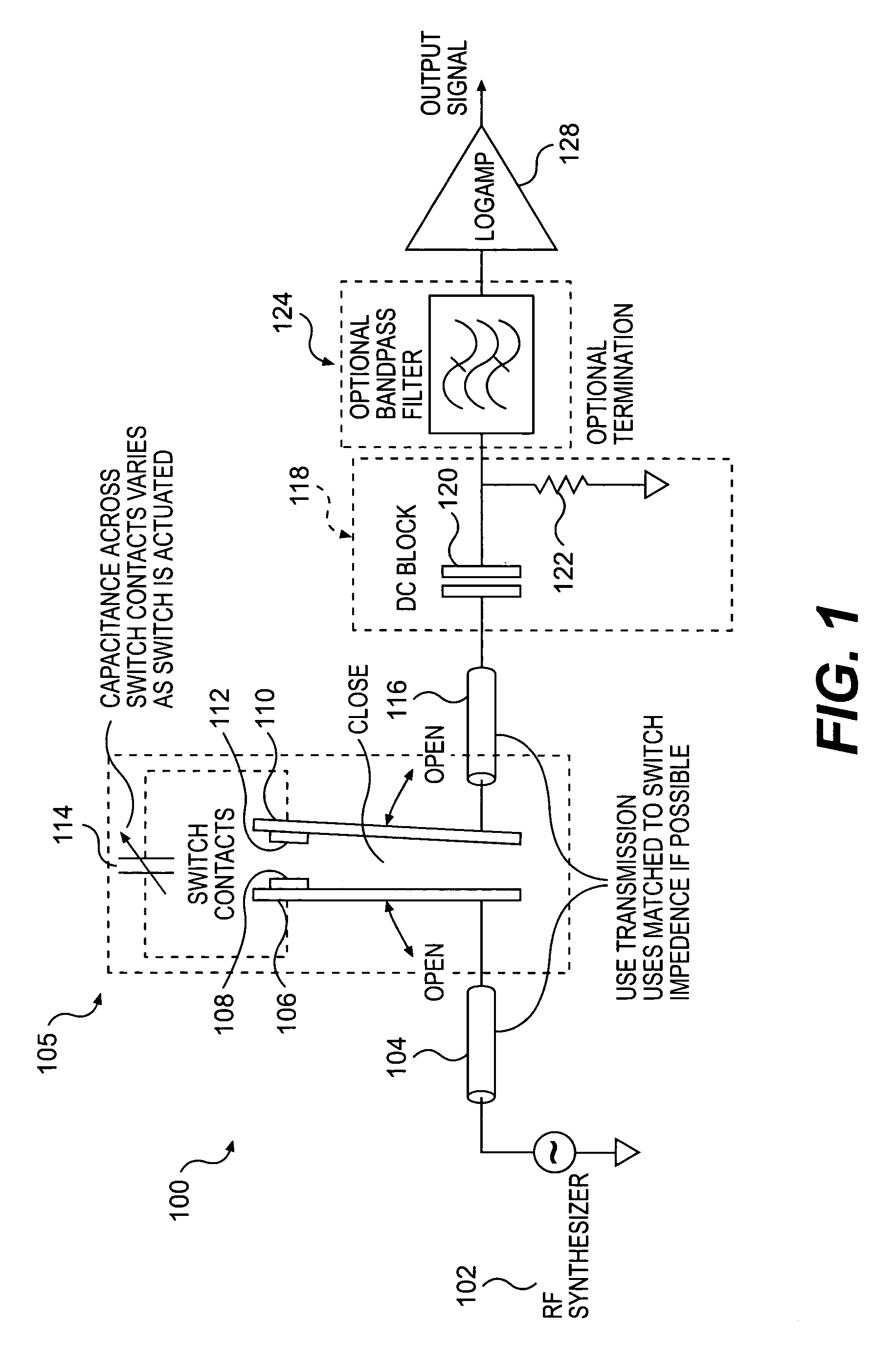

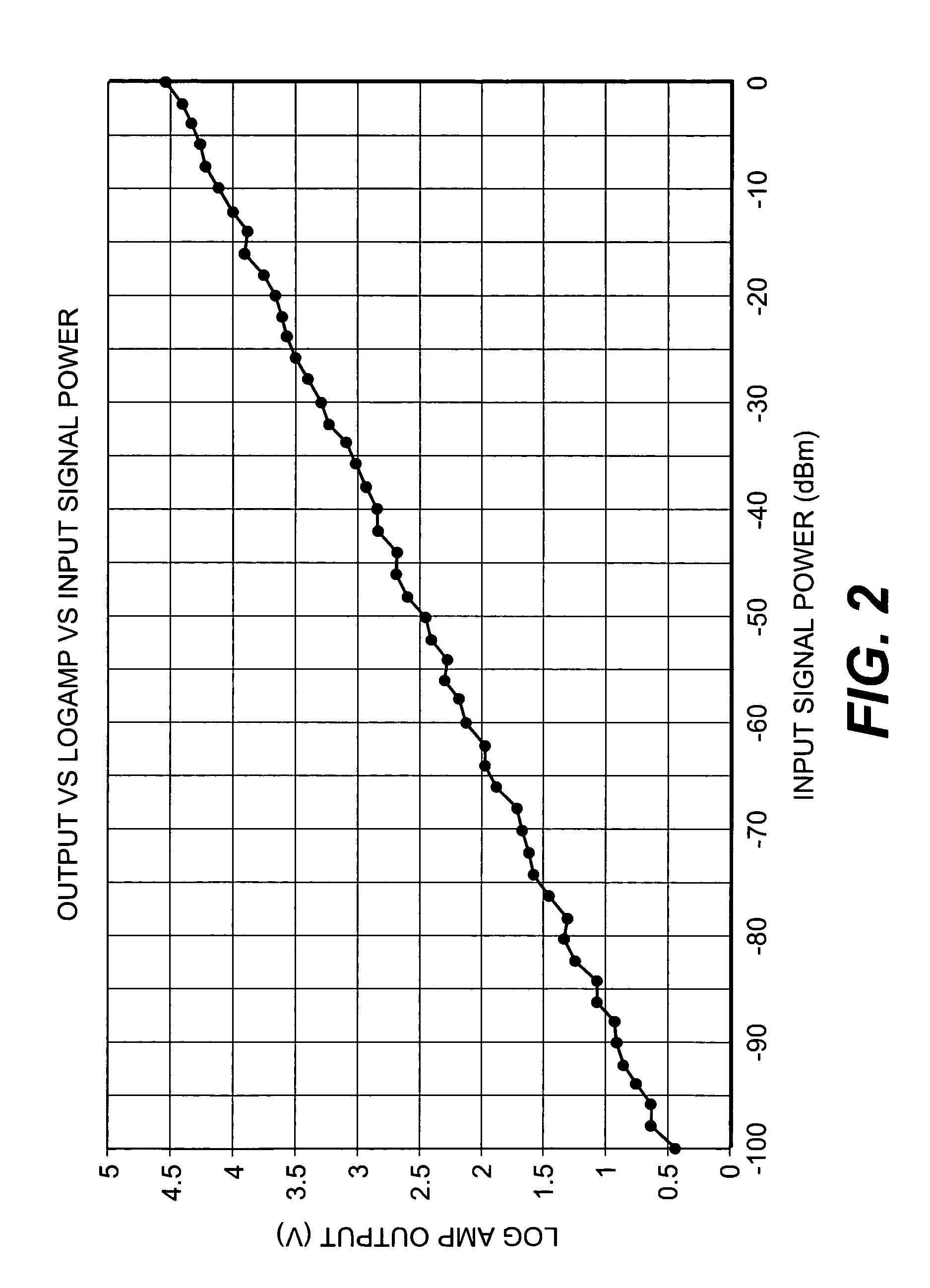

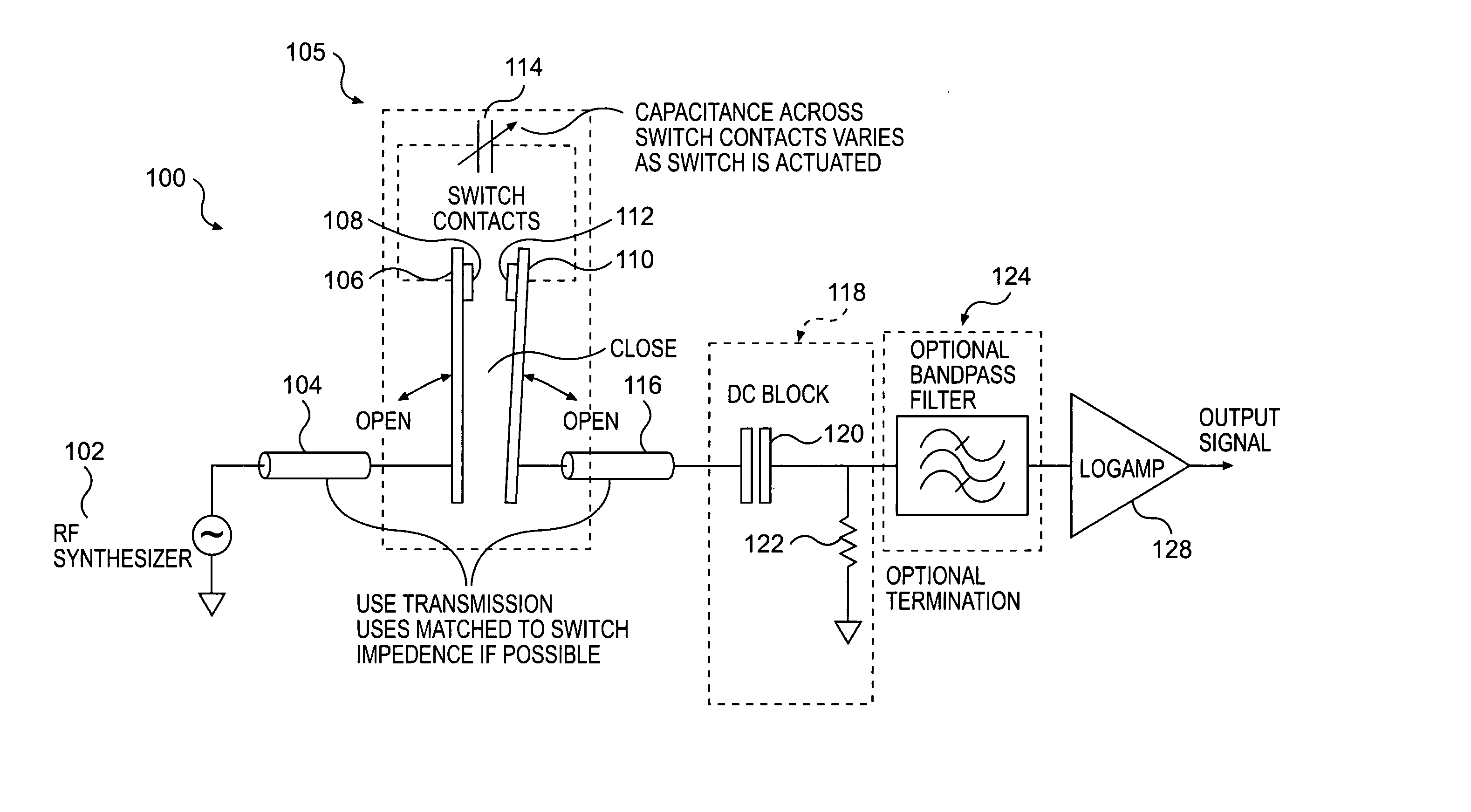

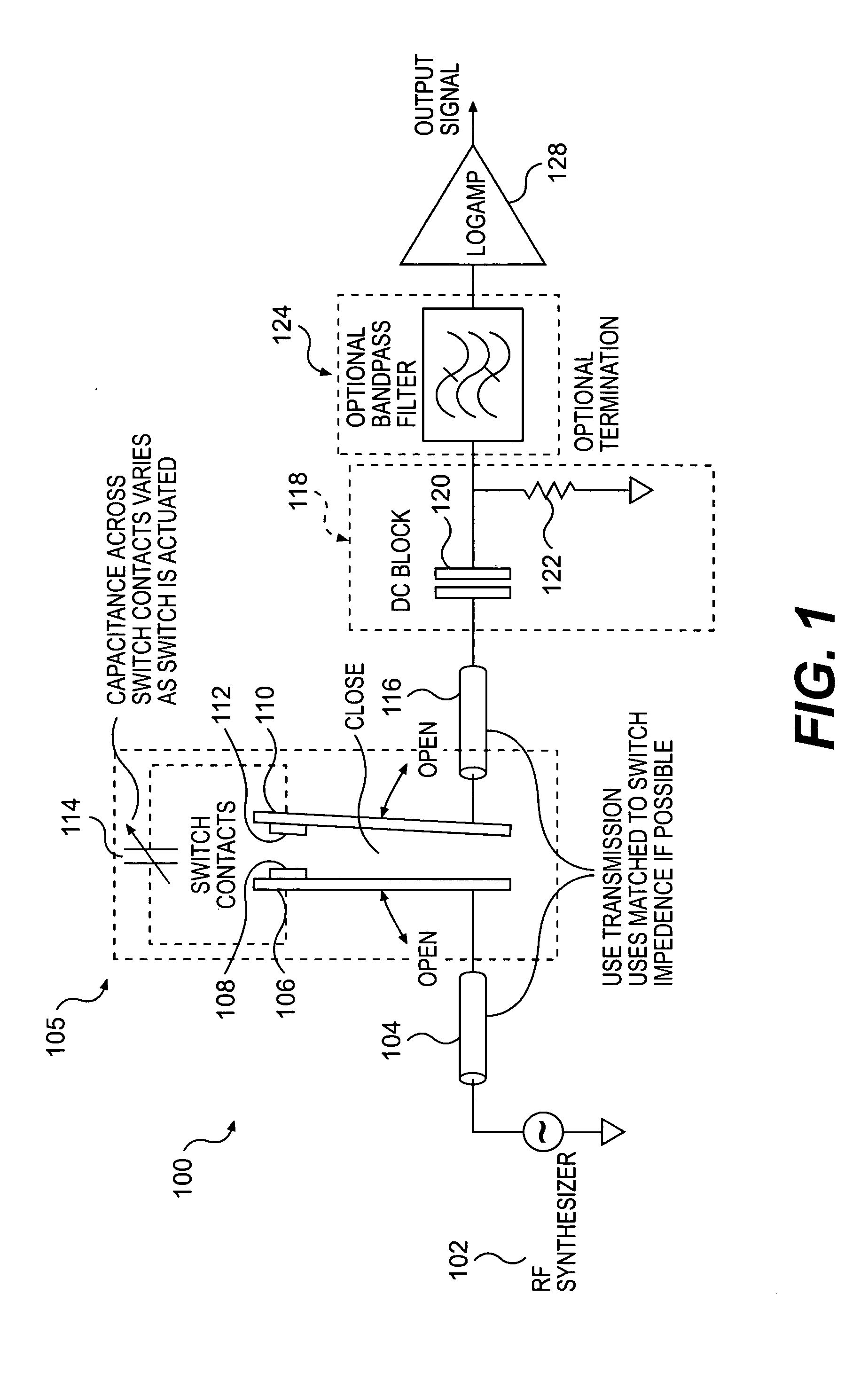

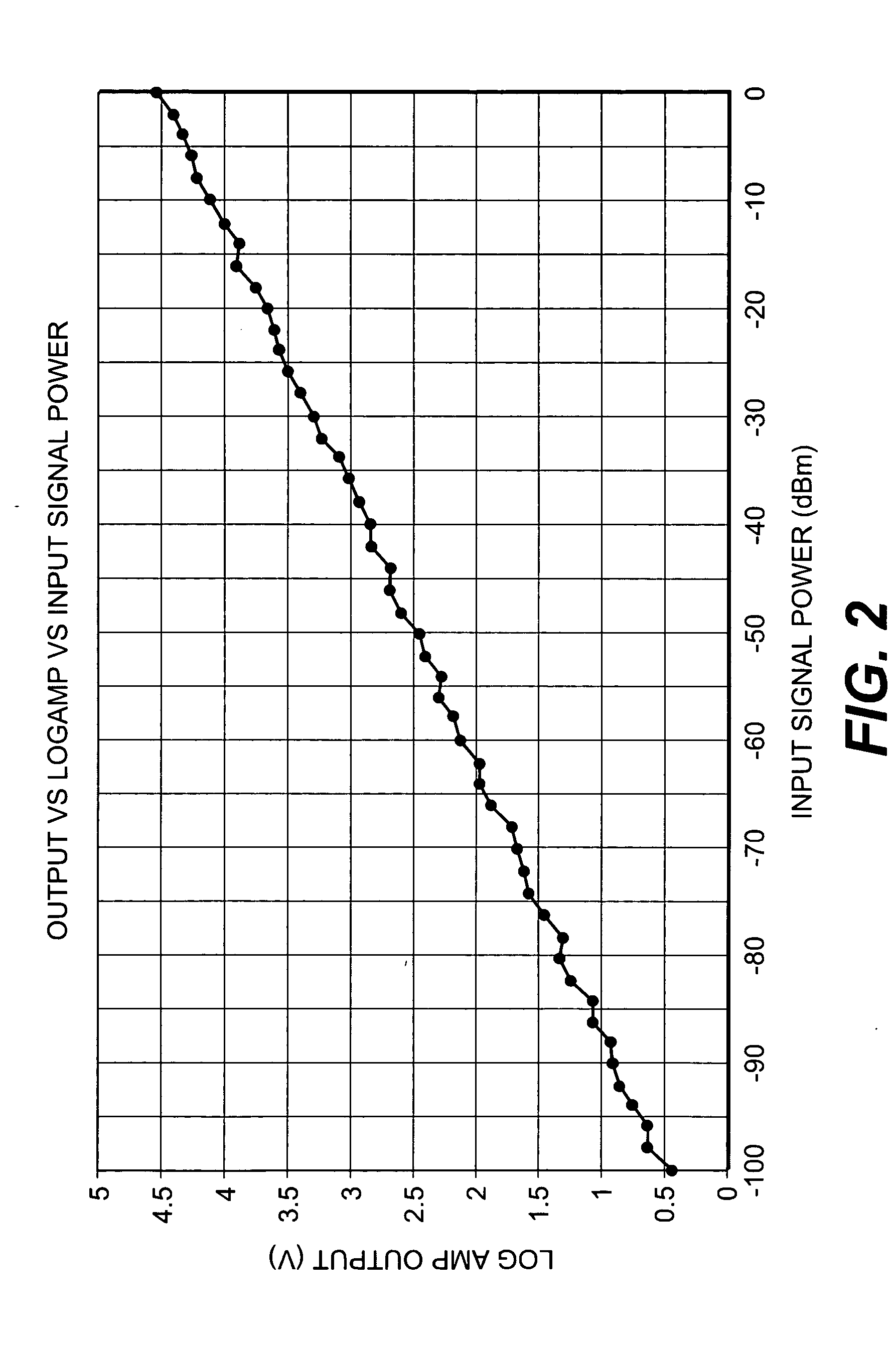

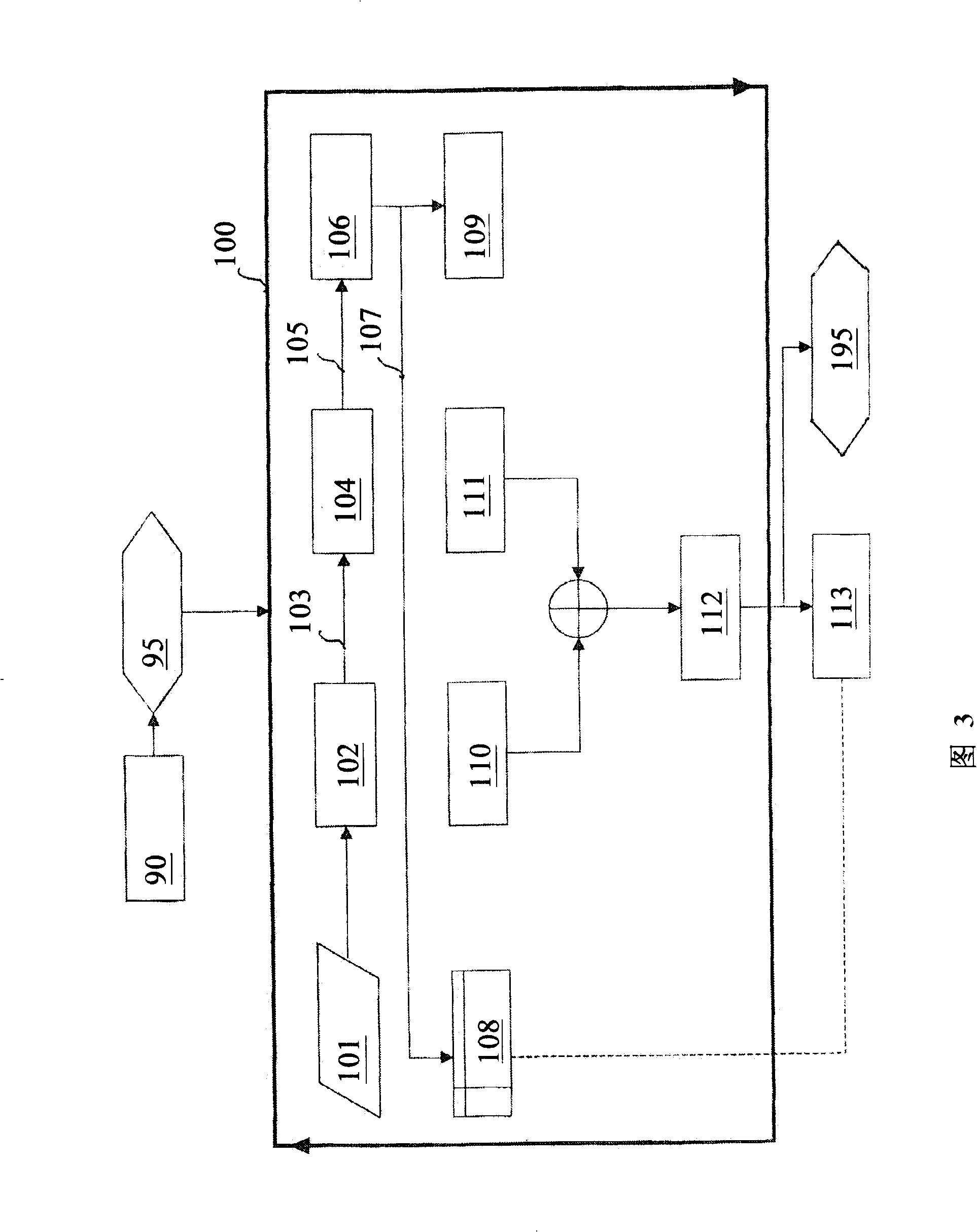

Apparatus and method for determining contact dynamics

The invention relates to an apparatus and method to determine contact dynamics between conductive surfaces, and more particularly to determine the dynamics of contact closure in mechanical switches and analysis of the dynamics of other mechanical systems, in general. A log amp is in electrical communication with the RF synthesizer via a transmission line. The log amp outputs a voltage converted from an envelope of an RF waveform to determine a capacitance between at least two conductive surfaces.

Owner:INT BUSINESS MASCH CORP

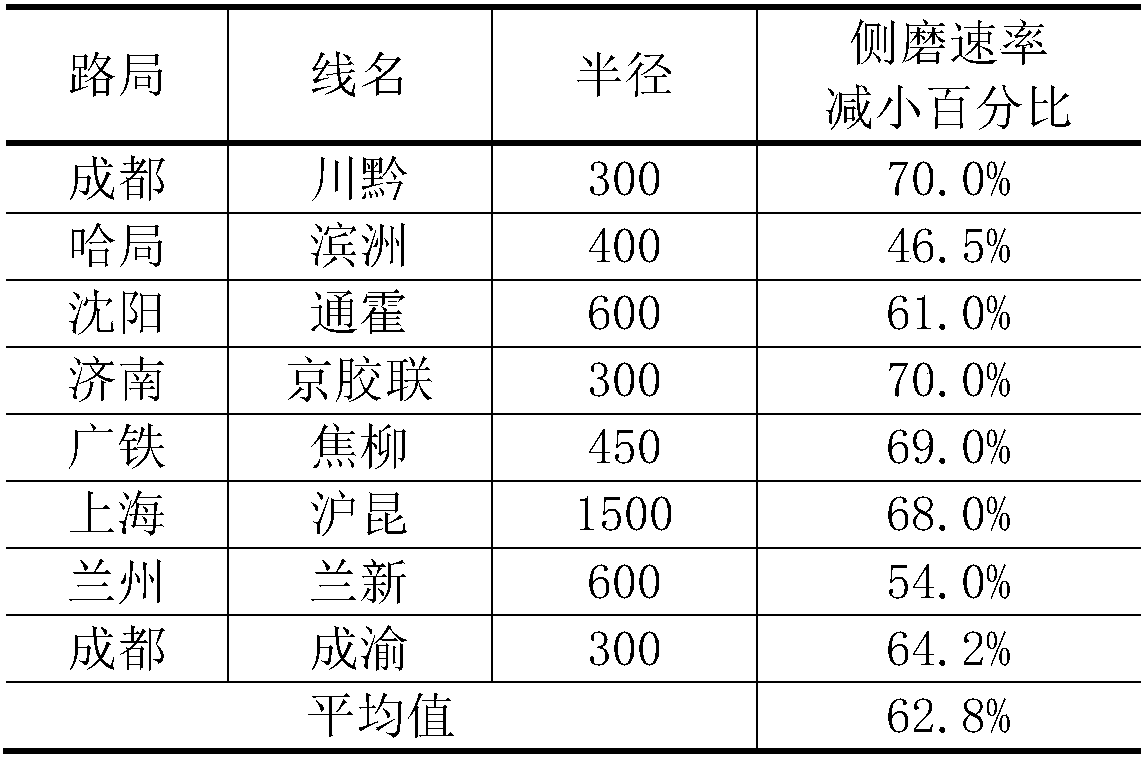

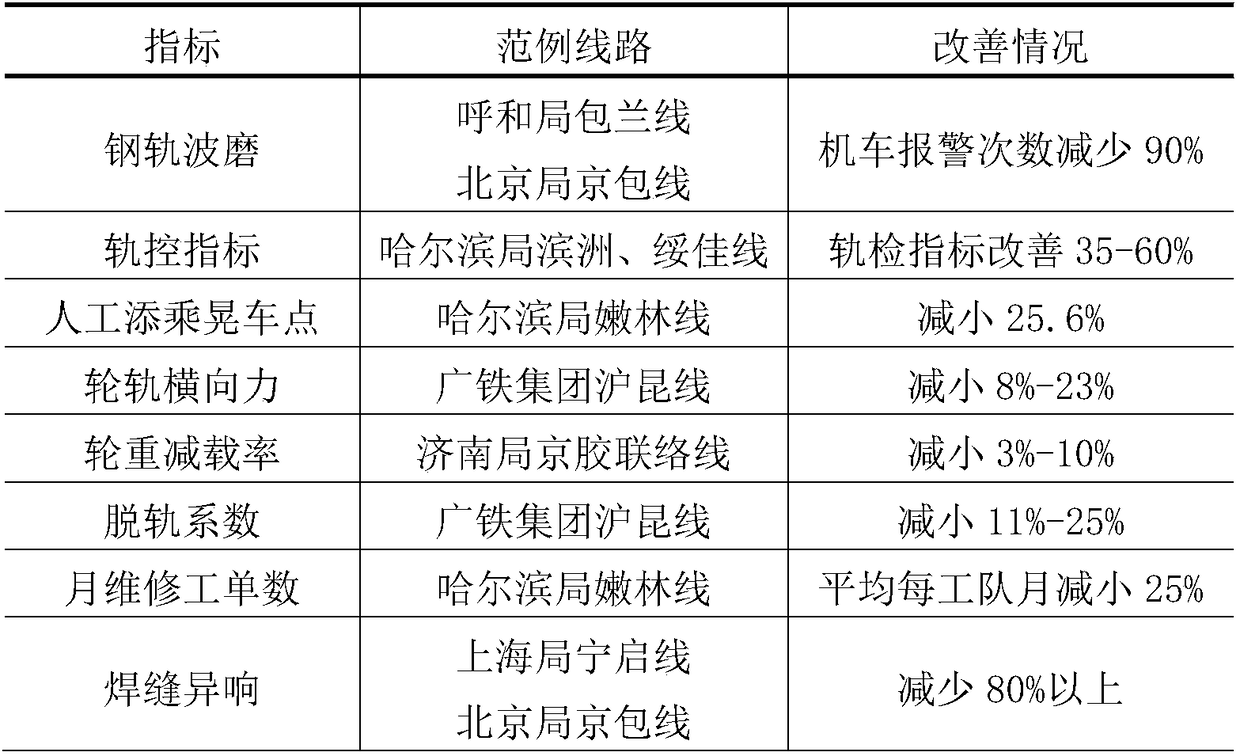

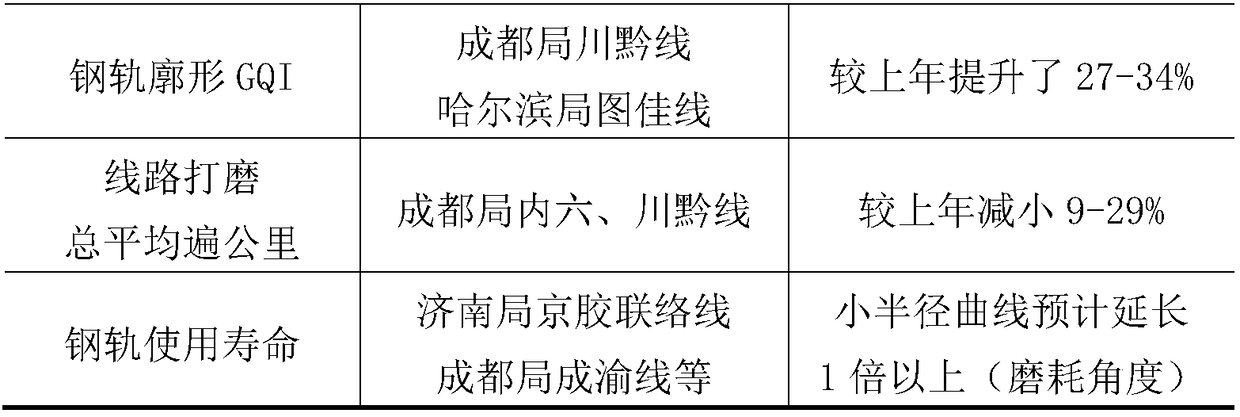

Individualized railway steel rail grinding target profile design method

ActiveCN108589449AAchieve personalized goal controlTargeted optimizationRailway track constructionPersonalizationRail profile

The invention provides an individualized railway steel rail grinding target profile design method. The method includes the steps that 1, steel rail profiles with different gradient radius curves and lines are measured; 2, wheel profiles corresponding to different types of vehicles are acquired; 3, a steel rail grinding target profile bank is established; 4, a real parameter wheel and track coupling model is established; 5, non-dynamic wheel and track contact relationships between actually-measured wheel profiles in different vehicle models and steel rail profiles in the target profile bank arecalculated, and the steel rail profiles with the high parameter limit exceeding rates are abandoned when the steel rail profiles are matched with the different actually-measured wheel profiles; 6, analysis and simulation are conducted on the vehicle-track coupling dynamic performance of the obtained steel rail profiles and the different wheel profiles in the set radius passing process, a wheel and track contact dynamic index serves as a criterion, and scanning is conducted; and 7, target profile comparison and selection based on the minimum grinding amount are conducted. By the adoption of the method, the conditions of an actual line, steel rails, vehicles and wheels are considered, an obtained result is good in pertinence, and individualized target control of steel rail grinding can be achieved.

Owner:中铁物总运维科技有限公司

Apparatus and method for determining contact dynamics

The invention relates to an apparatus and method to determine contact dynamics between conductive surfaces, and more particularly to determine the dynamics of contact closure in mechanical switches and analysis of the dynamics of other mechanical systems, in general. A log amp is in electrical communication with the RF synthesizer via a transmission line. The log amp outputs a voltage converted from an envelope of an RF waveform to determine a capacitance between at least two conductive surfaces.

Owner:IBM CORP

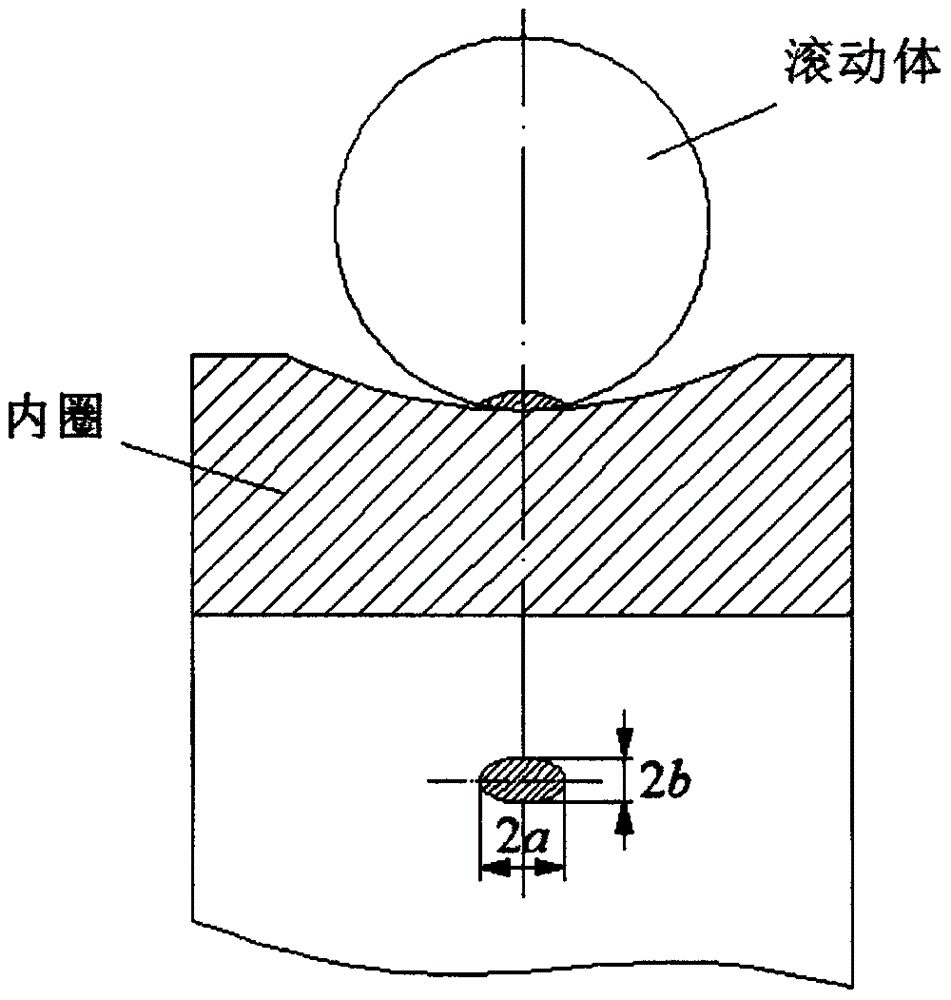

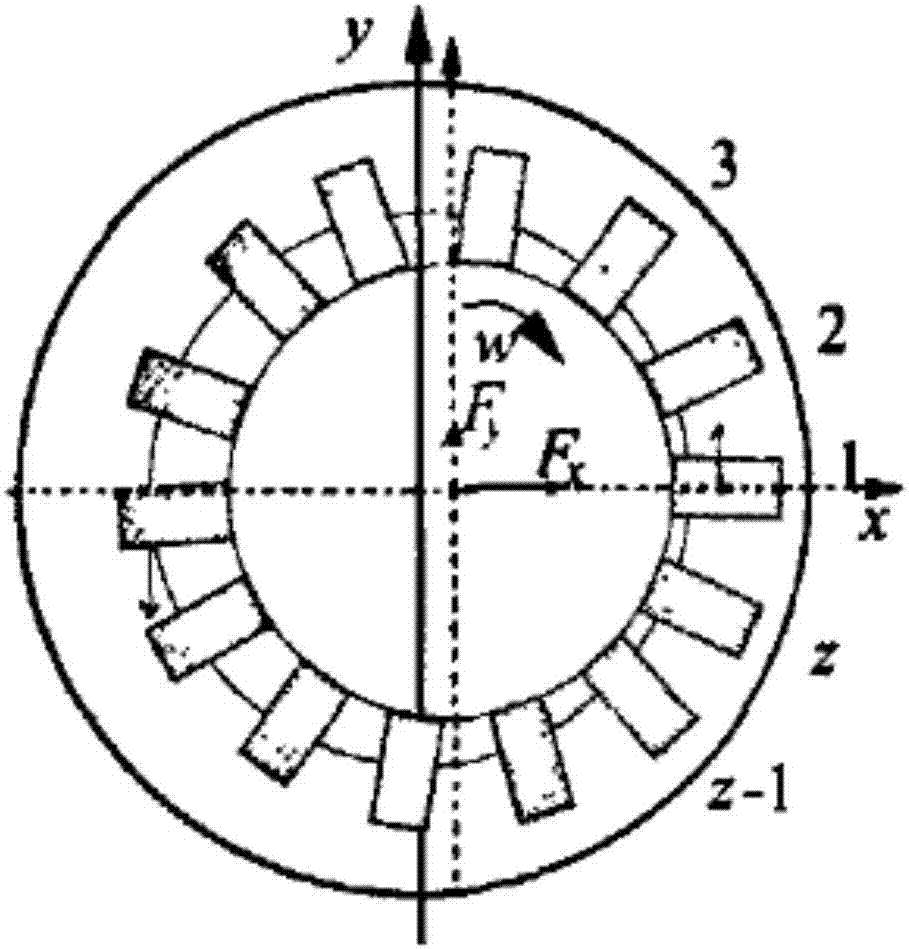

Ball bearing reliability design method

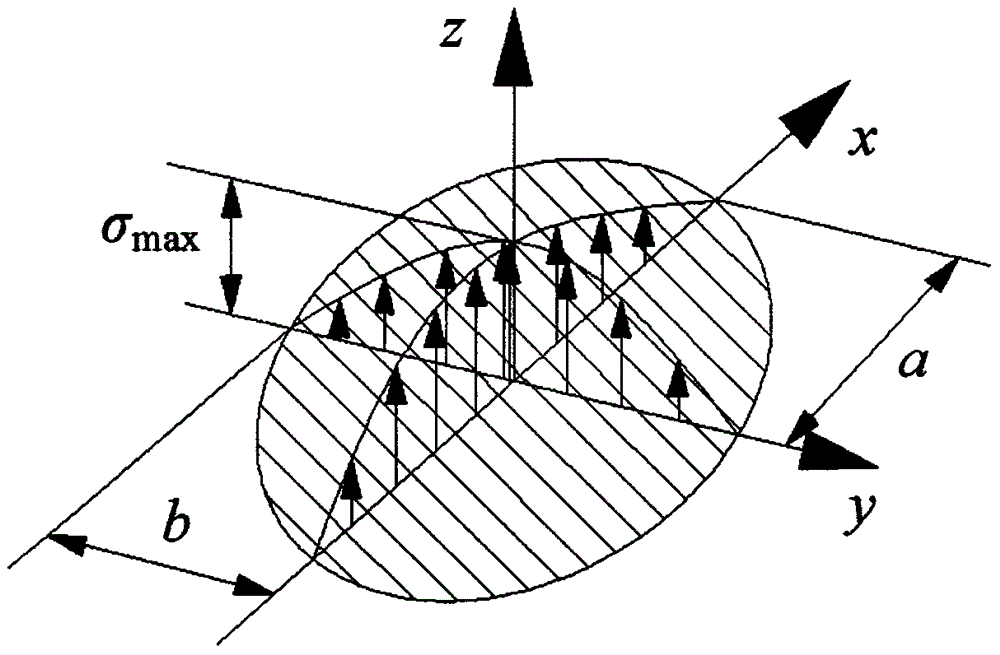

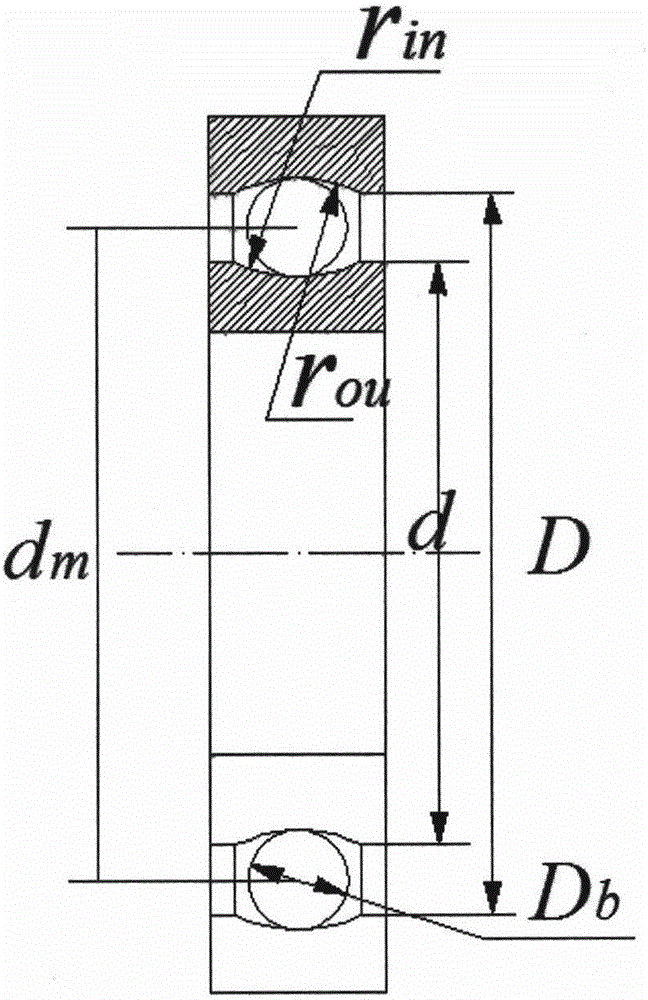

A ball bearing reliability design method is based on the following prerequisites: 1, the contact between an antifriction bearing rolling body and internal / external raceway satisfies the Hertz contact theory, and the contact type between the rolling body and the bearing internal / external raceway is point contact or / and line contact; 2, the ball bearing reliability design method satisfies the following requirements: firstly building a deep groove ball bearing flexible multi-body contact dynamics model, simulating and parsing a deep groove ball bearing rotation process so as to obtain each part angular velocity and dynamic contact impact stress changing rules, and using obtained data to finish the ball bearing reliability design. The invention provides the reference method for ball bearing reliability design and fatigue life research; related principles can be promoted to all transplantable related technical fields; the ball bearing reliability design method has large latent economy value and social value.

Owner:梁明轩

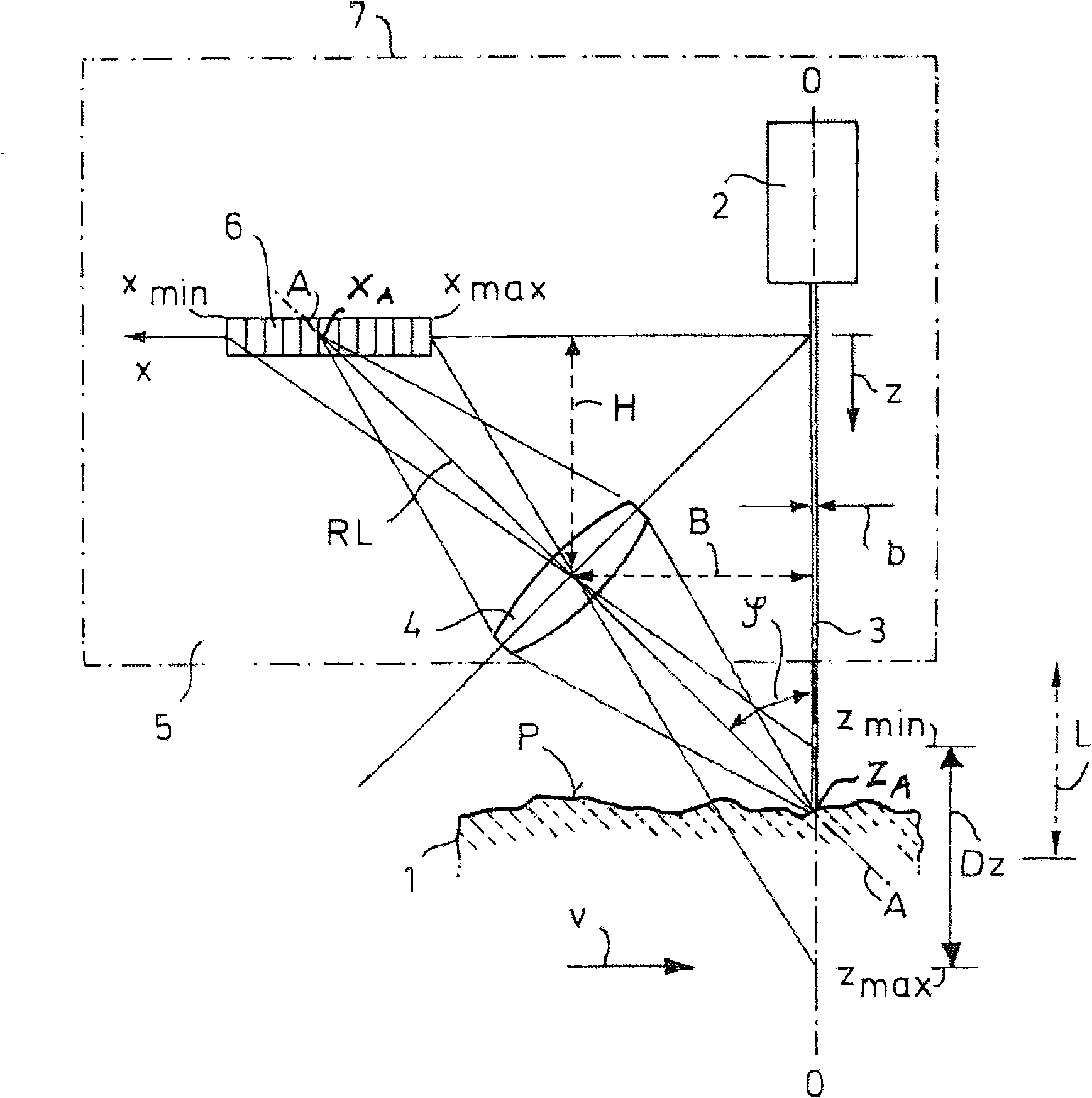

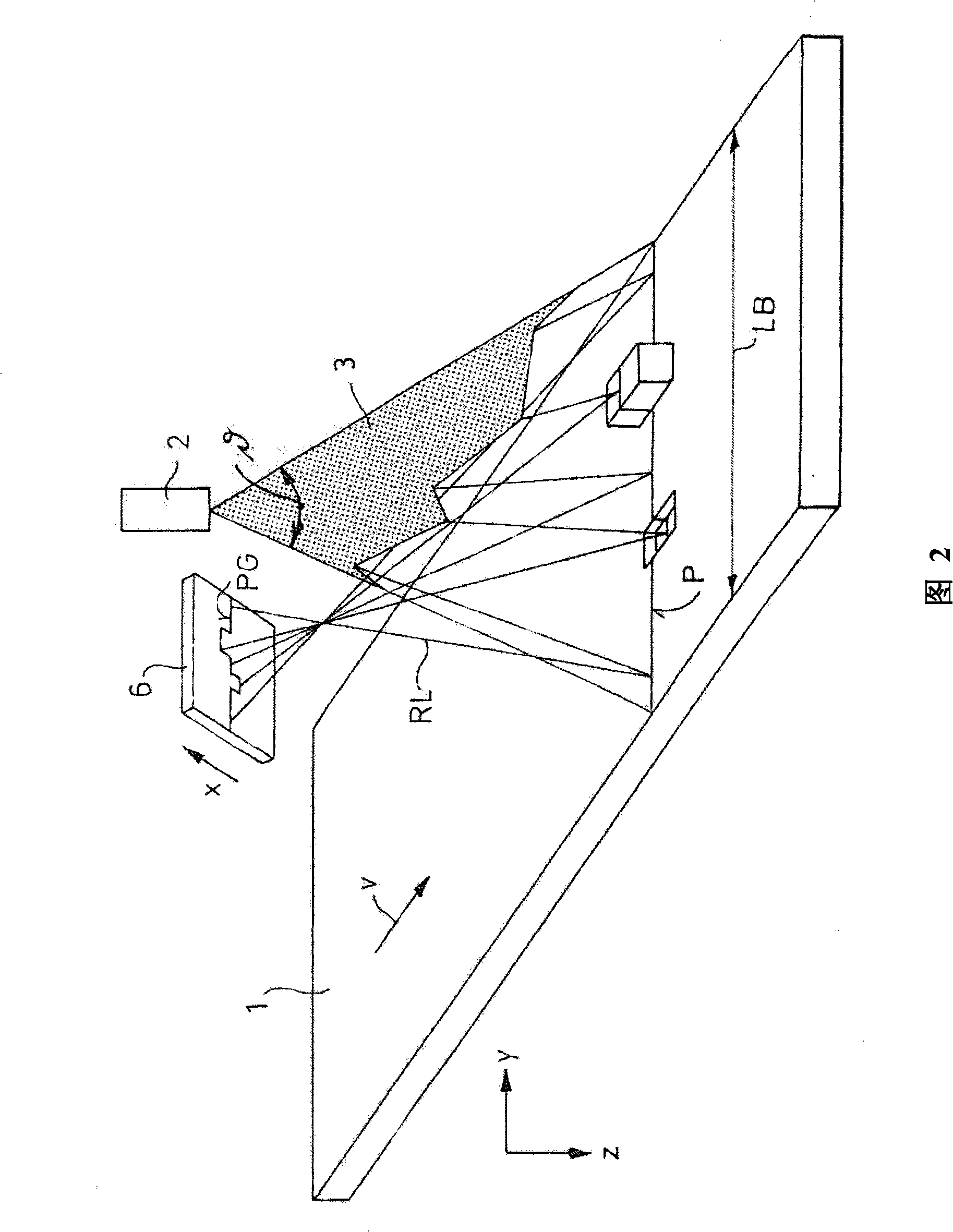

Method for non-contact dynamic detection of solid contour

InactiveCN101283234AEnables accelerated assaysReduce spendingUsing optical meansOptical axisTriangulation

The invention relates to a method for contactless dynamic detection of the profile of a solid body (1), wherein at least one light beam which is generated by a laser device (2) and is expanded to form at least one linear light band (3) is projected onto the moving surface of the solid body (1) and the light reflected from the surface of the solid body (1) is focused in an imaging device (5), the optical axis of which is at a fixed triangulation angle with respect to the projection direction of the laser device (2) and which is arranged at a fixed basic distance from the laser device (2), and is detected by means of an areal light recording element (6), after which, from signals emitted by the light recording element (6), in a manner dependent on the triangulation angle and the basic distance, in a data processing device,; by means of trigonometrical relationships and with combination with correction values determined according to the speed of movement of the solid body (1), the measured values of the profile are obtained and stored as a profilogram. It is proposed to perform a determination of initial conditions of the solid body (1) at an initial instant and then to determine a detection instant from the initial conditions.

Owner:GUTEHOFFNUNGSHUTTE RADSATZ

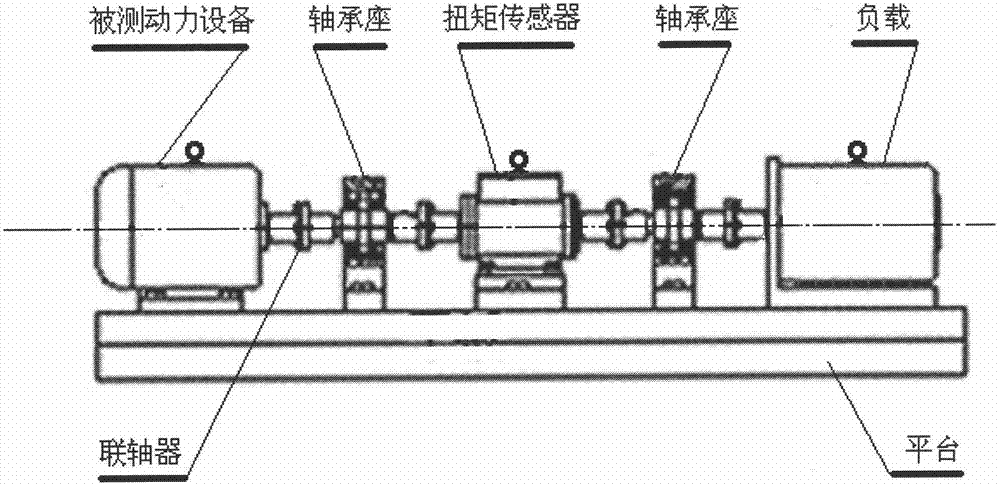

Non-contact dynamic torque, rotating speed and shaft power signal transducer

InactiveCN102788654AEasy to measureImprove intelligenceWork measurementLinear/angular speed measurementSignal processing circuitsCoupling

The invention relates to measurement of rotation motive power of mechanical transmission as well as application of data thereof. According to the invention, an existing flexible coupler is utilized, and signal testing points are arranged on a driving half and a driven half of the flexible coupler respectively; through signal receivers arranged at the signal testing points on the two opposite coupling halves, relative positions of the driving half and the driven half during the rotation, as well as motion (rotating speed and rotating direction) signals thereof, can be obtained in a non-contact manner; and meanwhile, torque and rotating speed data can be obtained through a signal processing circuit, and the real-time shaft power of the mechanical transmission can be derived from the relation between the shaft power and the torque / the rotating speed. By the non-contact dynamic torque, rotating speed and shaft power signal transducer, the torque, the rotating speed and the shaft power in the mechanical transmission can be measured more simply and conveniently; the relevant equipment is simpler in structure, smaller in size, lighter in weight and lower in manufacture cost; the improvement of intelligentizing and lightening of the mechanical equipment is facilitated; the popularization of the intelligent mechanical equipment is facilitated; the optimization of the fit degree among the mechanical equipment is facilitated; the improvement of the mechanical transmission efficiency is facilitated; and the energy conservation and the emission reduction are facilitated.

Owner:王建钧

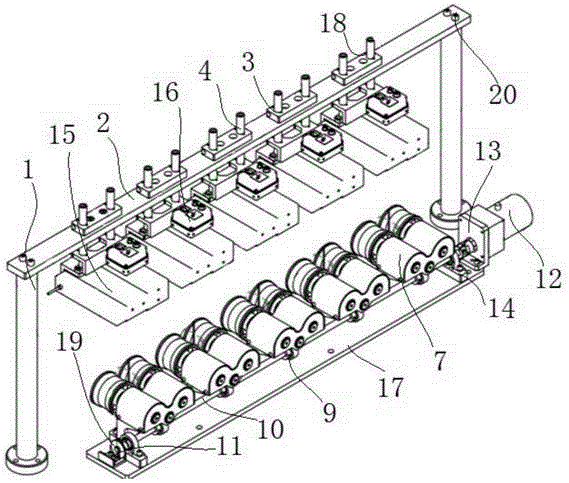

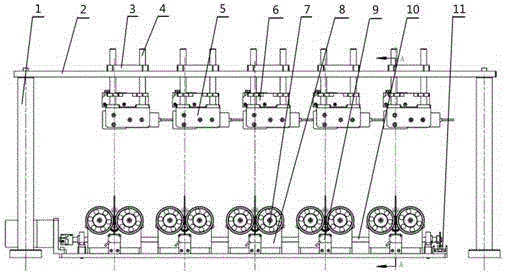

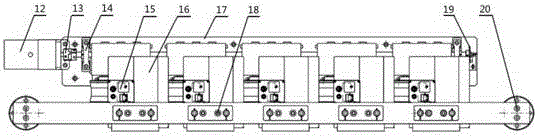

Detection device for piston pin outer circle defects

InactiveCN106290397ARealize quality managementSolve the detection speed is slowMaterial analysis by optical meansVisual recognitionEngineering

The invention provides a detection device for piston pin outer circle defects. The detection device is structurally characterized in that supporting columns and an installing beam are fixed through bolts, fixing plates are arranged on the installing beam, adjusting columns are fixed to the installing beam through the fixing plates, a camera fixing plate and a light source fixing plate are fixed to the corresponding adjusting column, a light source is installed on each light source fixing plate through bolts, a line scanning camera is installed on each camera fixing plate through bolts, and the light sources and the line scanning cameras are located over rolling wheel V-type bases; the rolling wheel V-type bases are installed on a bottom plate, in-place sensors are located below the rolling wheel V-type bases and installed on the bottom plate, and the rolling wheel V-type bases are connected through rolling wheel driving shafts; rolling wheels are arranged on the rolling wheel V-type bases, a rolling rotation driving device is arranged at one side of each rolling wheel, and a shading piece is arranged at the other side of each rolling wheel. The detection device can detect the piston pin outer circle defects, visual recognition is adopted, non-contact dynamic detection is achieved, and the working efficiency is greatly improved while measurement accuracy is ensured.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD

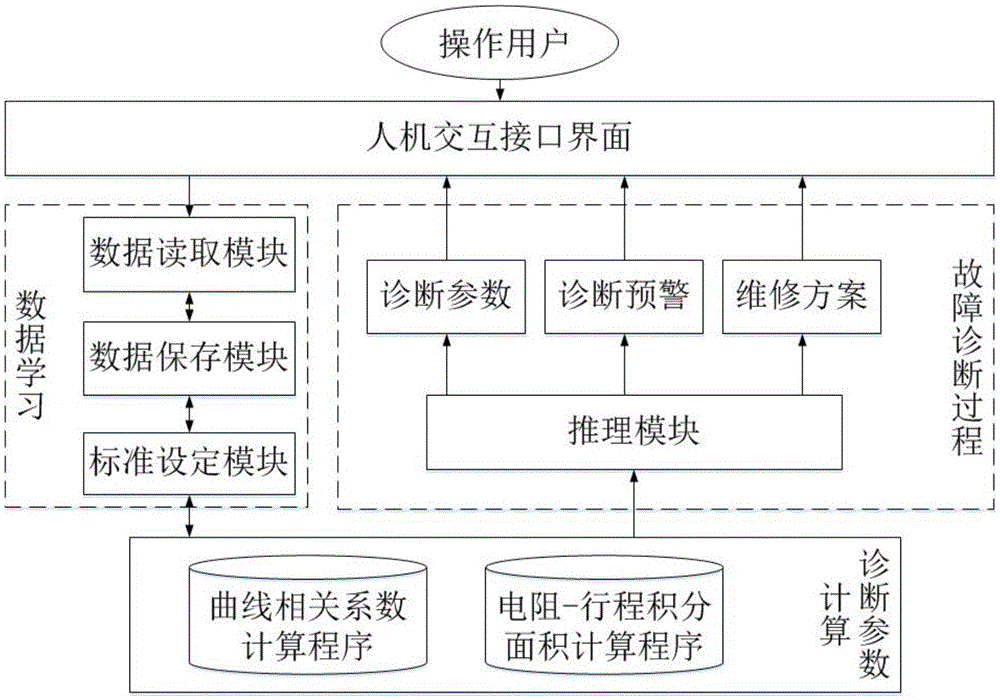

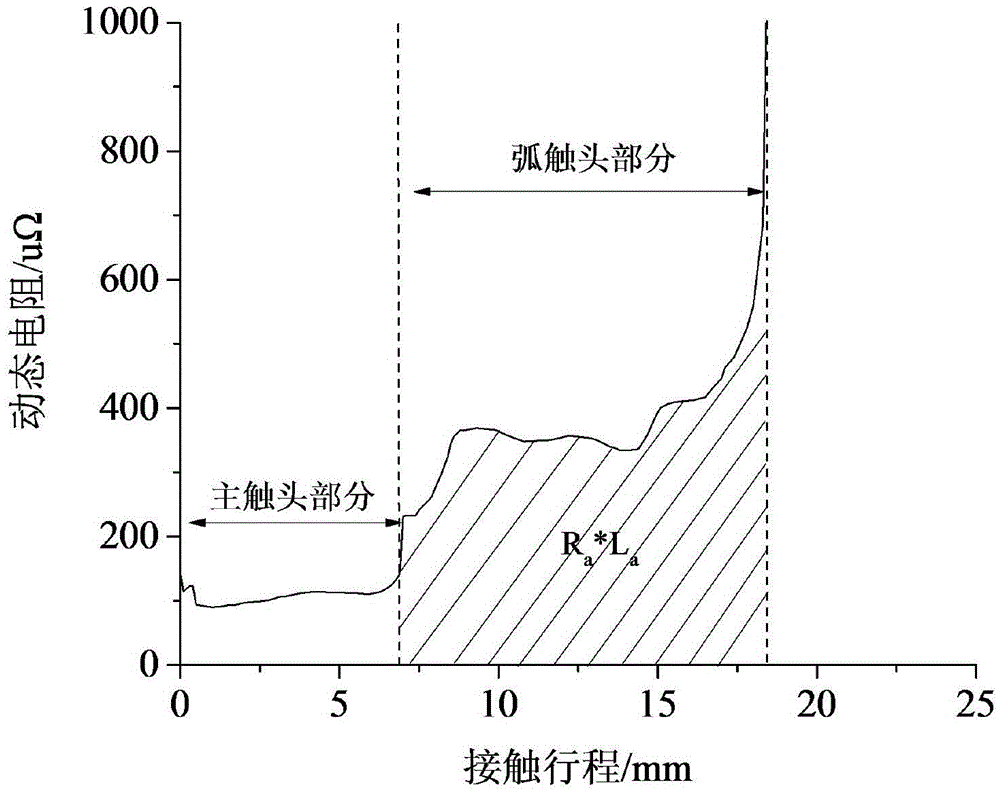

Diagnostic system and diagnostic method of contact state of high-voltage circuit breaker

InactiveCN105548867AEasy diagnosisNo need to disassembleCircuit interrupters testingCorrelation coefficientElectrical resistance and conductance

The present invention relates to a diagnostic system and diagnostic method of a contact state of a high-voltage circuit breaker. The diagnostic system is formed by connecting a contact dynamic resistance measurement device and a contact state diagnostic device. The method comprises: the contact dynamic resistance measurement device is configured to obtain a dynamic resistance-stroke curve of the opening process of the breaker contact; the contact state diagnostic device is configured to calculate the correlation coefficient of the dynamic resistance-stroke curve of the opening process and an initial curve; and the contact state diagnostic device is configured to compare the correlation coefficient of the curves and the area of the contact portion of the arc contact with a standard value to obtain the diagnosis result of the contact state. According to the invention, the correlation coefficient of a dynamic resistance curve and the area of the contact portion of an arc contact are taken as characteristic quantities and are used for comparing with a standard value to obtain a contact state so as to facilitate effective diagnosis of the inner condition of an arc extinguish chamber, and therefore the diagnostic system and diagnostic method of a contact state of a high-voltage circuit breaker diagnose are high in accuracy, fast in detection speed, convenient and rapid, and do not need to disassemble the arc extinguish chamber, etc.

Owner:TIANJIN ELECTRIC POWER TECH DEV CO LTD

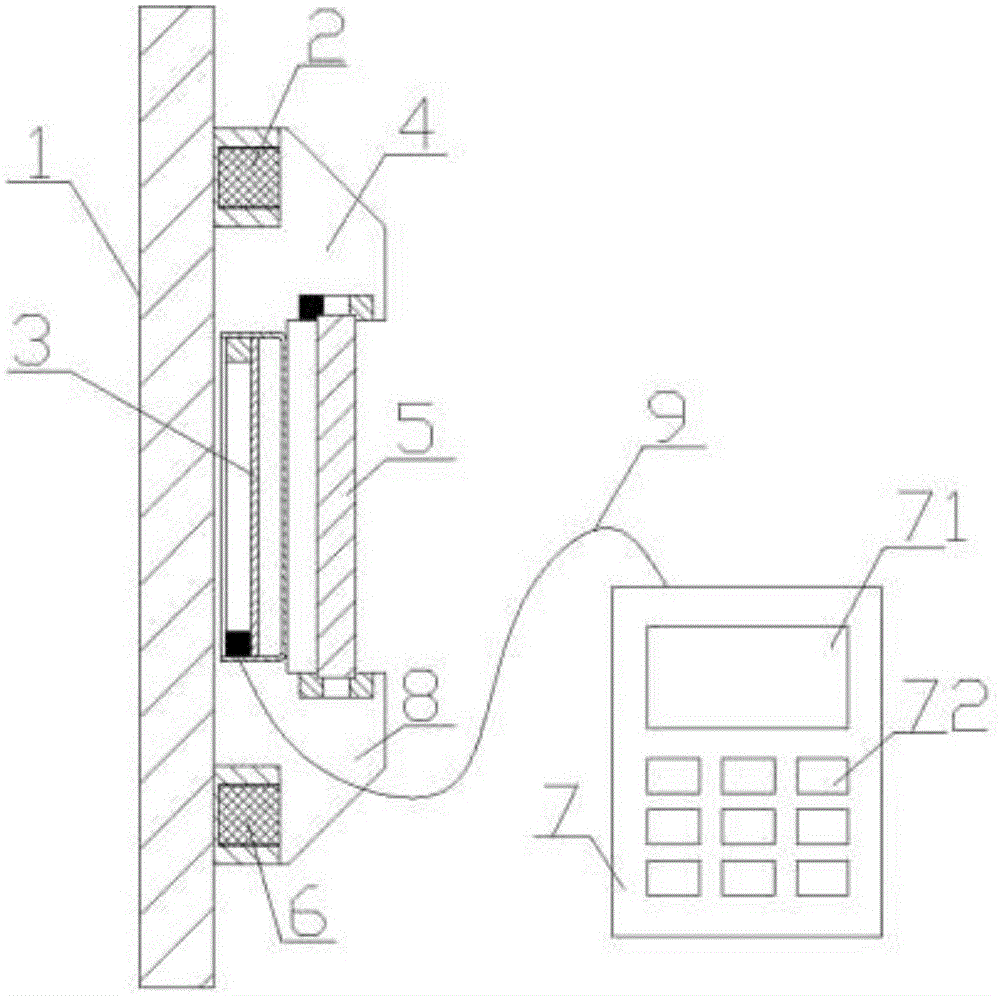

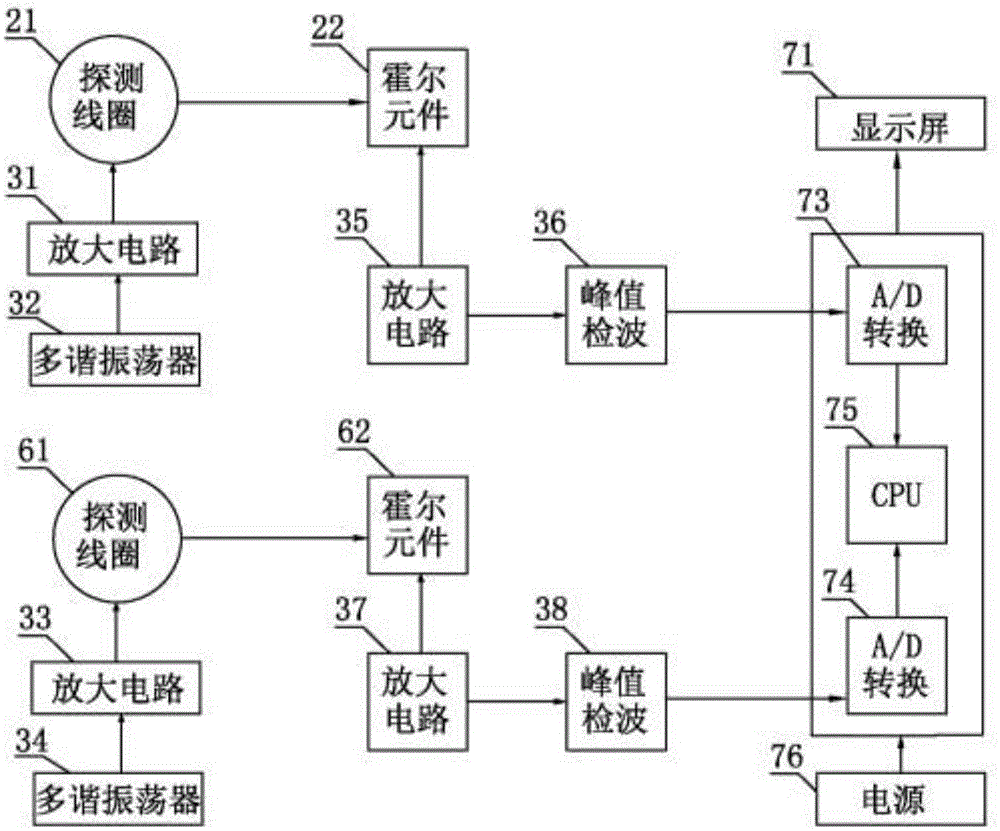

Wire rope lay pitch on-line detection device and method

ActiveCN105066868ARealize non-contact measurementRealize dynamic measurementUsing electrical meansSignal conditioning circuitsData acquisition

The invention relates to a wire rope lay pitch on-line detection device and method. The wire rope lay pitch on-line detection device comprises a wire rope lay pitch detection sensor and a data collector. The wire rope lay pitch detection sensor comprises eddy current displacement sensors, a signal conditioning circuit board, a housing and a handle, wherein the number of the eddy current displacement sensors is two, and the two eddy current displacement sensors are arranged on two ends in the housing; the signal conditioning circuit board is arranged on the middle part in the housing; and the handle is arranged on the housing. The data collector is connected with the wire rope lay pitch detection sensor through a data cable. The front surface of the data collector is provided with a display screen and buttons. The display screen is arranged above the buttons. The data collector is internally provided with a CPU microprocessor, a power supply and an A / D conversion circuit. The CPU microprocessor is connected with the A / D conversion circuit. The wire rope lay pitch on-line detection device and method realize non-contact dynamic on-line measurement of a wire rope lay pitch, the detection requirements are met, and the wire rope lay pitch on-line detection device can be conveniently carried to a site for usage.

Owner:洛阳百克特科技发展股份有限公司

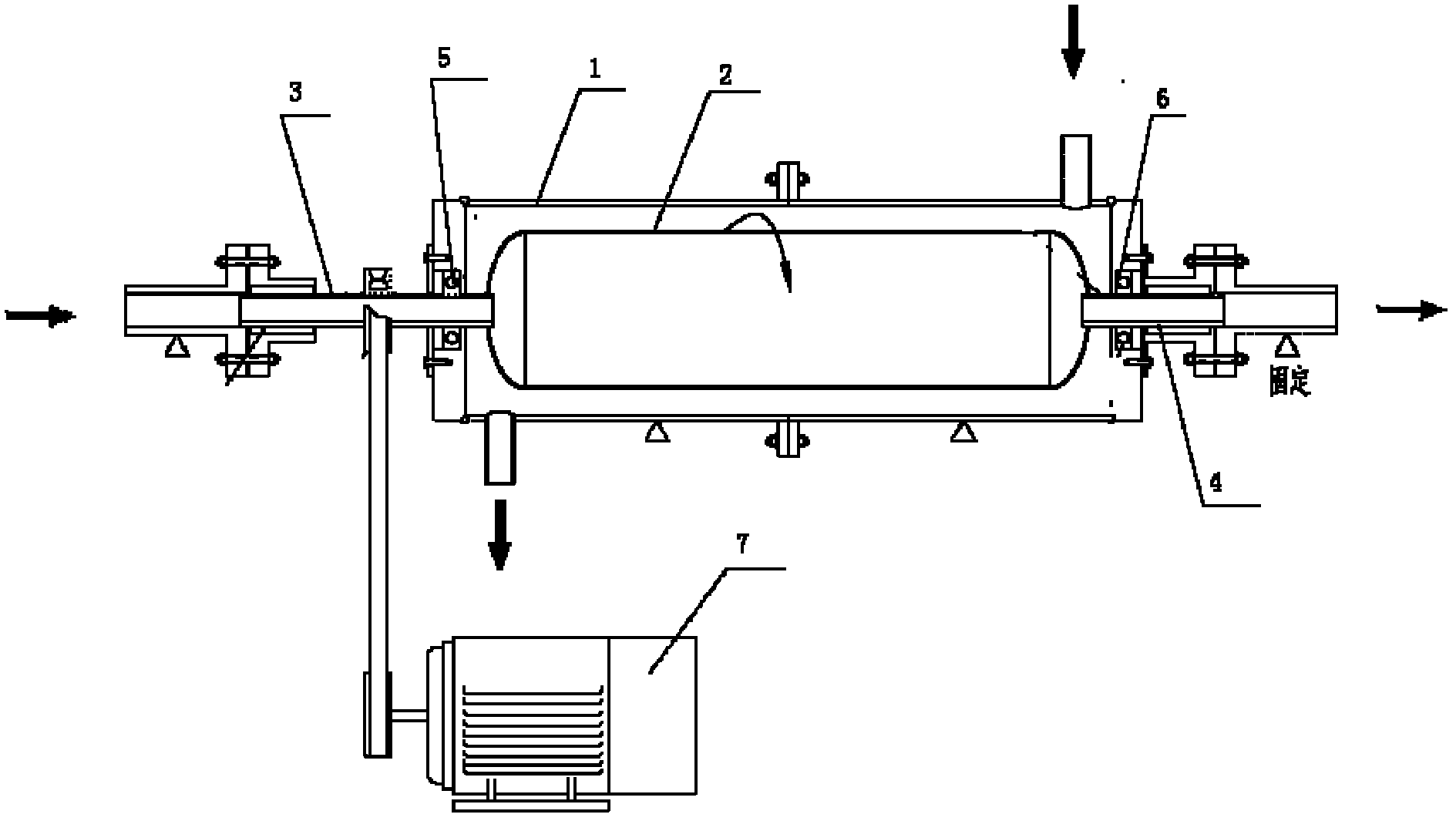

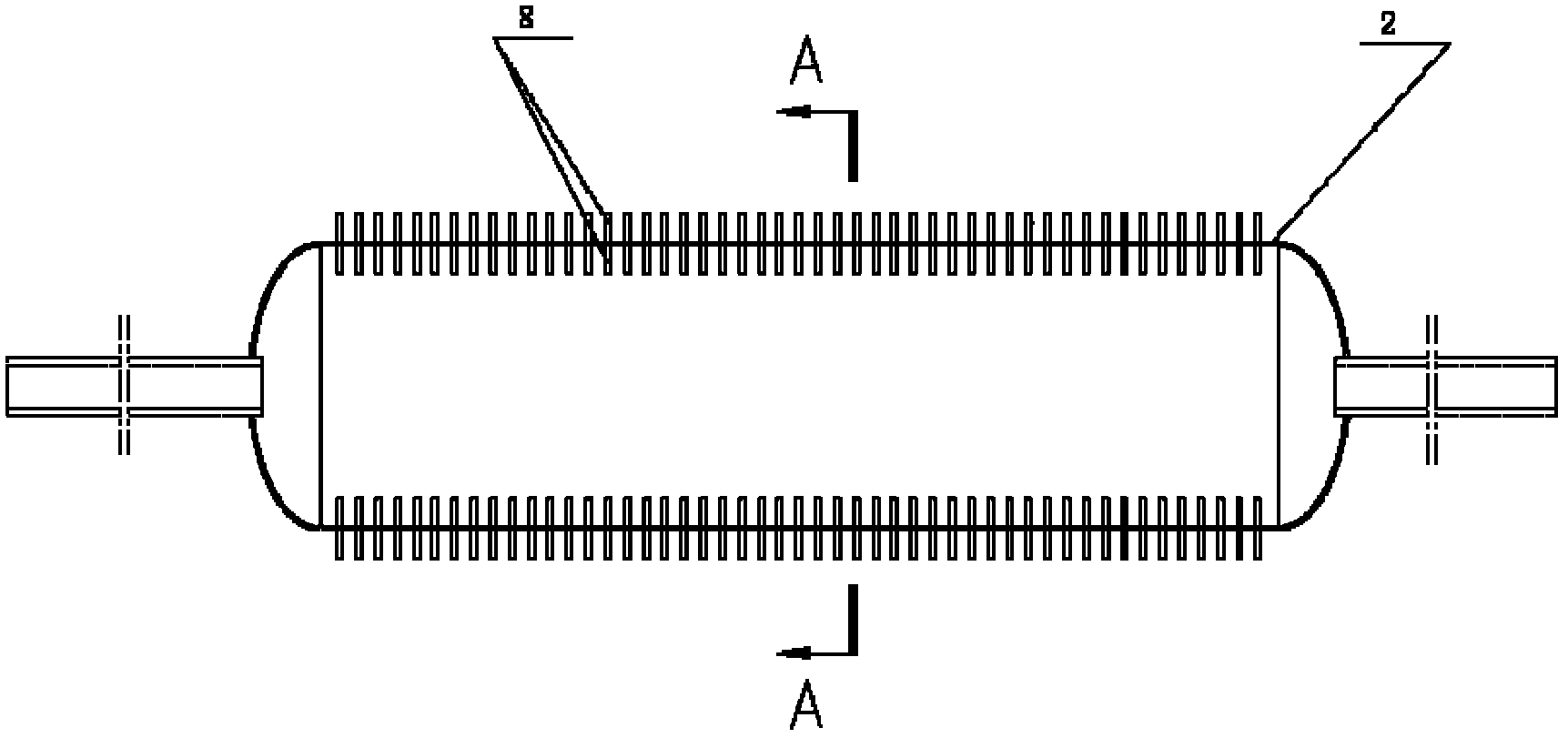

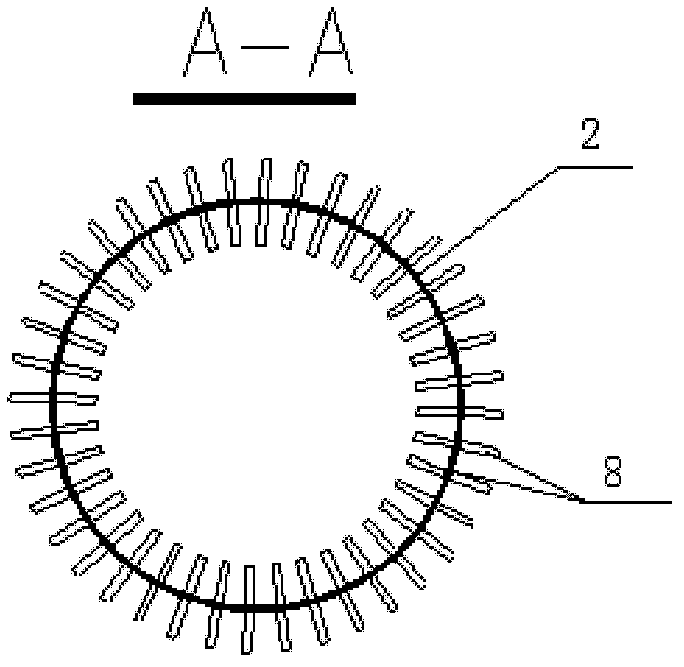

Heat exchanger with heat exchange surface capable of rotating so as to strengthen heat exchange

InactiveCN102519282AAvoid mutual leakageIncrease the heat exchange areaMoving conduit heat exchangersNeck structurePlate heat exchanger

The invention relates to a heat exchanger, in particular to a heat exchanger for viscous fluid with poor liquidity. The heat exchanger can be used for the fields of chemical engineering, petrochemical industry, food, medicine, papermaking, ships and the like and comprises a shell, an inner barrel, a motor, a heat exchange medium a, a heat exchange medium b, a bearing a and a bearing b; a fluid inlet and an outlet are arranged at the upper end and the lower end of the shell and are located at two ends of the shell; through holes are arranged at the left end and the right end of the shell, and annular grooves are arranged on the through holes; two ends of the inner barrel are necking structures; the heat exchange surface is capable of rotating, so that heat exchange area is increased, disturbance is improved so as to strengthen heat exchange, and the heat exchange medium a and the heat exchange medium b do not permeate to each other; and as hermetic connection between a rotating pipeline and an outer barrel is in non-elastic contact dynamic sealing, mutual permeation of the two heat exchange media can be prevented.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

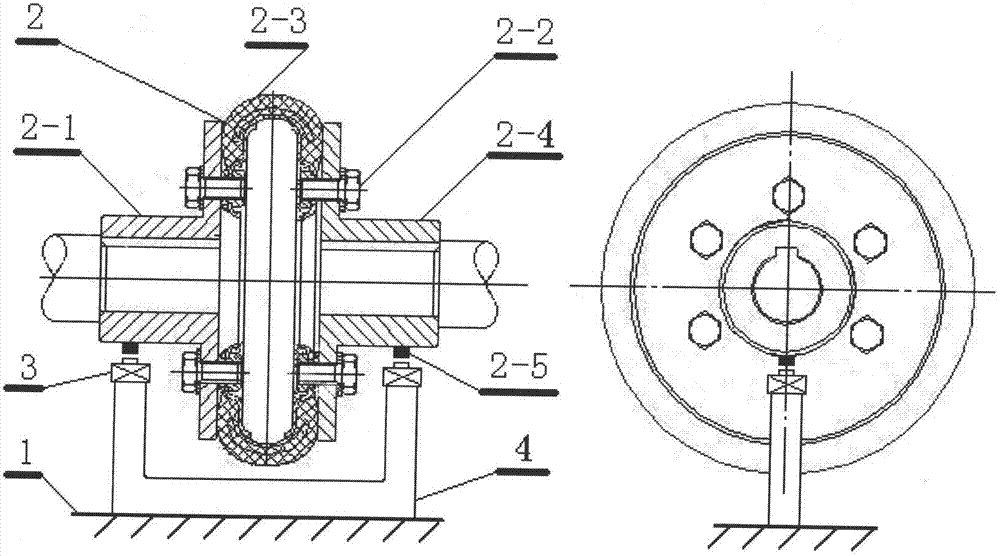

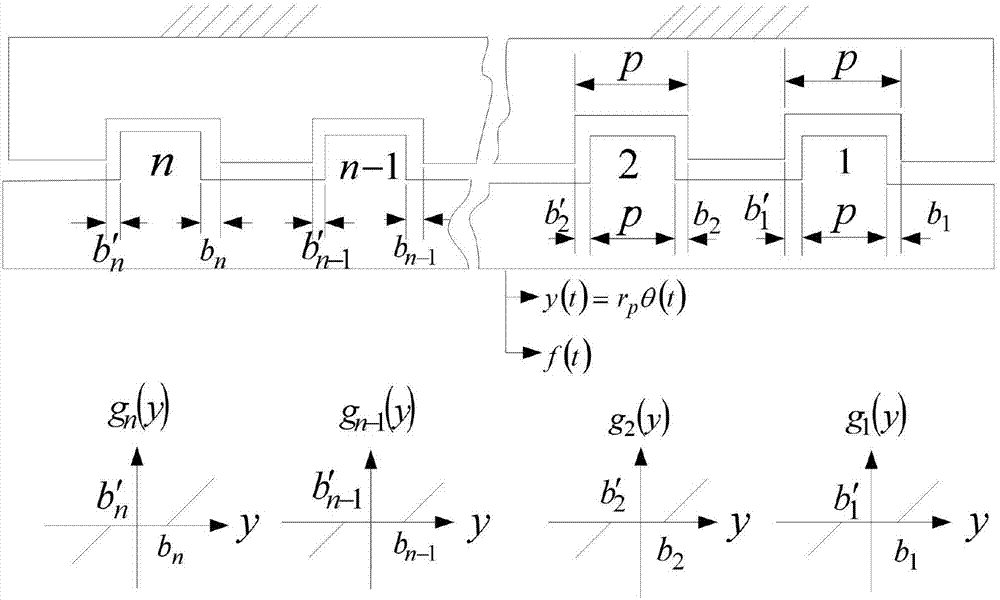

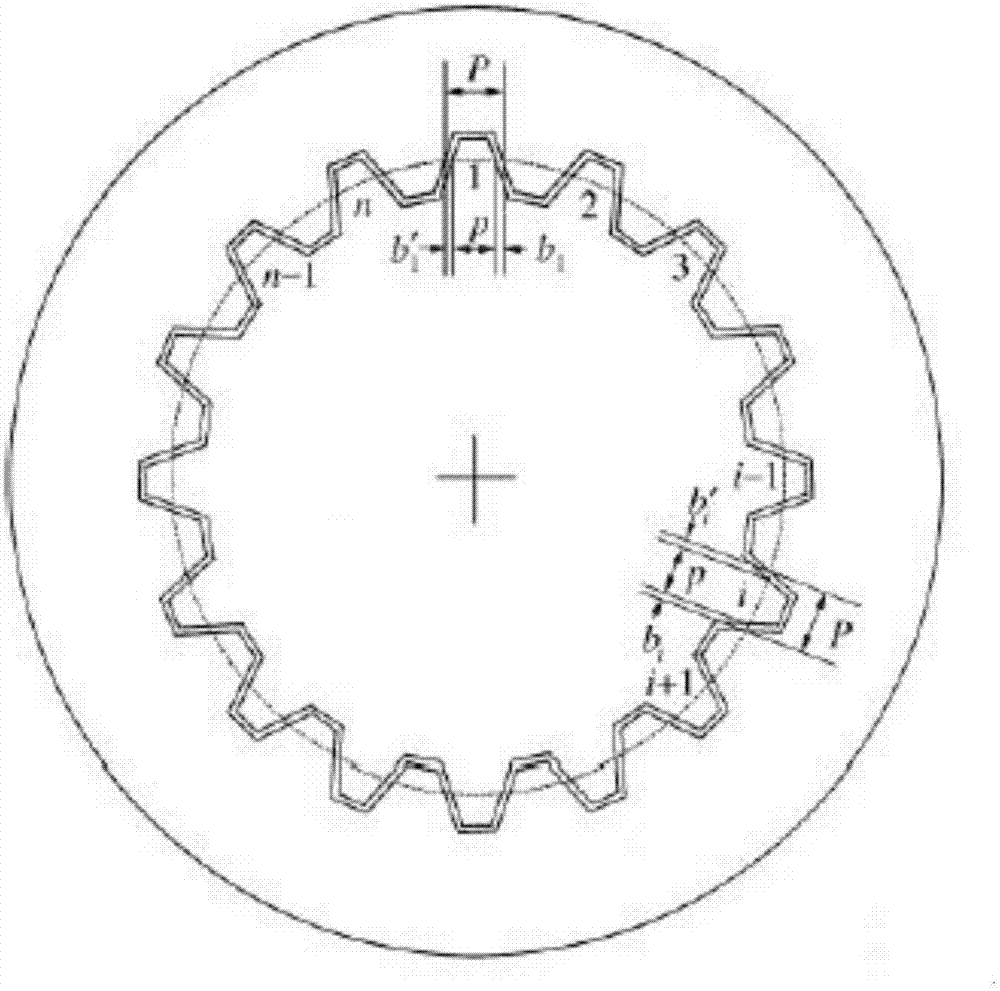

Rectangular spline contact kinetics simulating method based on assembly feature information

InactiveCN107247841AMatch the real resultsDesign results close to realityGeometric CADDesign optimisation/simulationSimulationContact force

The invention relates to the technical field of simulation, in particular to a rectangular spline contact kinetics simulating method based on assembly feature information. The method comprises the following steps: first step, analyzing spline assembly feature information; second step, establishing a perfect spline geometrical model; third step, adding the assembly feature information; fourth step, establishing a contact kinetics model; and fifth step, solving a simulating result. The rectangular spline contact kinetics simulating method based on the assembly feature information has the beneficial effects that spline assembly feature information including fit tolerance and tooth profile tolerance is considered, the working state of a spline is simulated by contact kinetics, according to a simulating result, influences of the fit tolerance of the spline and the tooth profile tolerance of the spline to the dynamic characteristics of the spline can be obtained, influence of different tolerance selection to spline tooth contact forces is obtained, the simulating result conforms to a real result, the service life of the spline can be analysis under the effect of impact load, simulation calculation can be carried out by the algorithm, and the design result can be close to reality.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

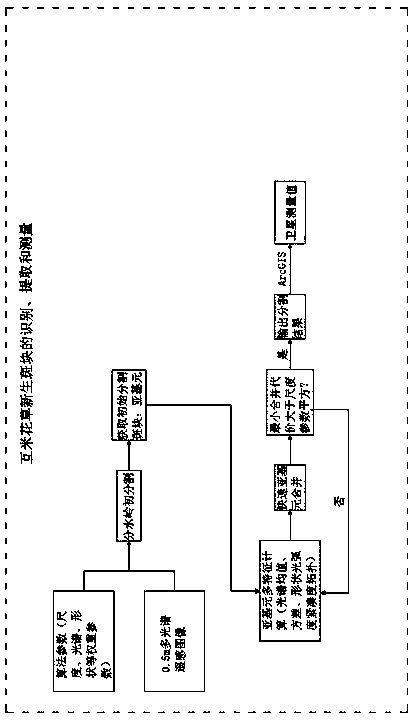

Dynamic monitoring method for new plaques of spartina alterniflora

ActiveCN110032963AReal-time dynamic monitoringThere is no way of knowing the initial spreadImage enhancementImage analysisRiver mouthMulti platform

The invention discloses a dynamic monitoring method for the new plaques of spartina alterniflora, and belongs to the technical field of environment monitoring. The method mainly aims to solve the problems that the estuary wetland environment is complex, the field monitoring and measurement work of the new plaques of spartina alterniflora is difficult to carry out, and more medium-spatial resolution satellites can only meet the monitoring requirement of a landscape scale and cannot identify the new small plaques due to the limitation of the spatial resolution of the medium-spatial resolution satellites; by uasing a single-platform high-resolution satellite, due to a revisit period and weather restrictions of cloudy and rainy estuary, the dynamic change monitoring of new plaques is not facilitated, while the multi-platform high-resolution satellite has different spatial resolutions, the accurate new plaque identification and measurement cannot be obtained when the multi-platform high-resolution satellite is directly and respectively used, so that the large-range and non-contact dynamic monitoring method for the new plaque of the spartina alterniflora based on the multi-platform high-resolution satellite data fusion technology is provided.

Owner:CAPITAL NORMAL UNIVERSITY

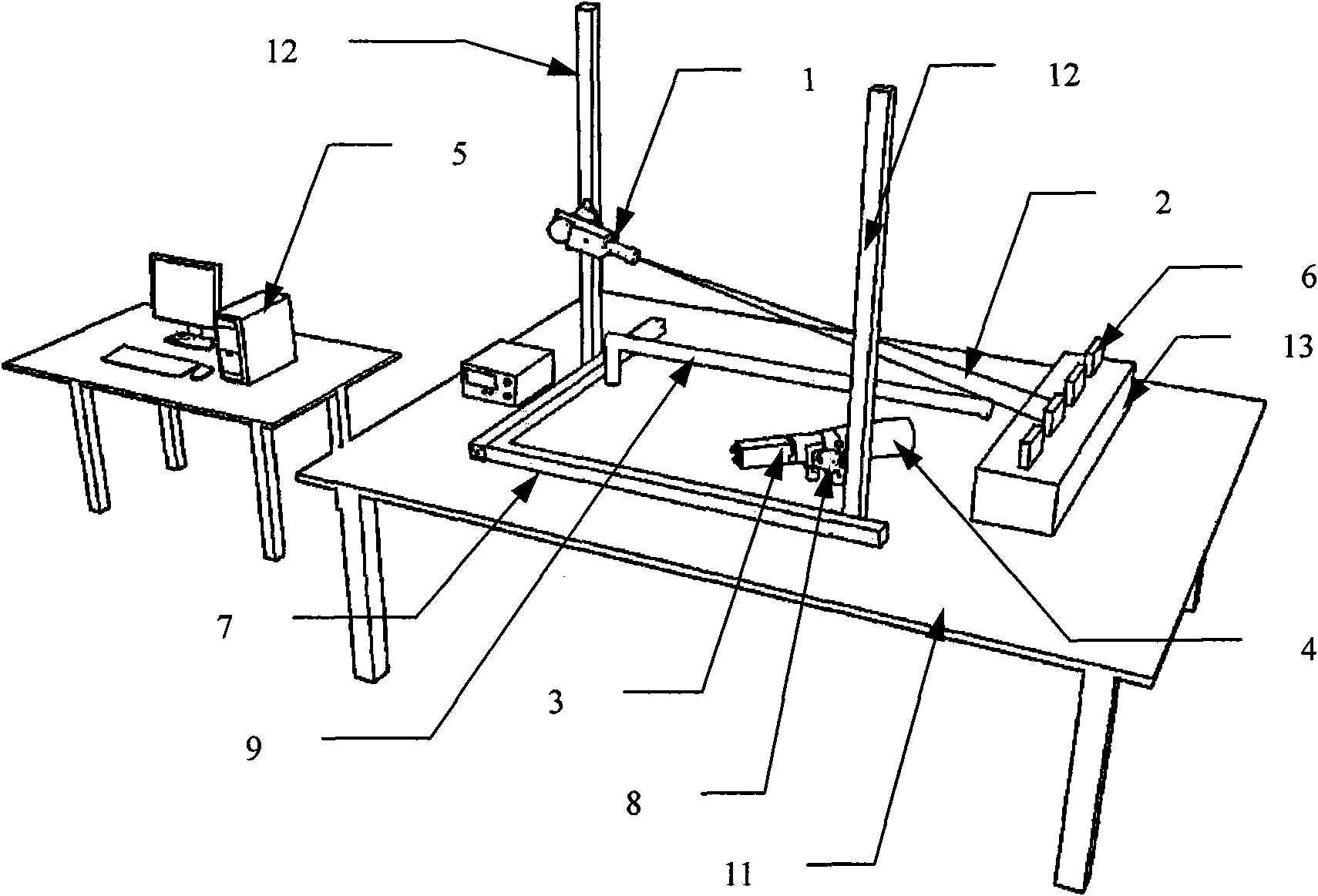

Non-contact dynamic stiffness measurment system and method thereof

InactiveCN108007657AAnalysing solids using sonic/ultrasonic/infrasonic wavesElasticity measurementLaser doppler velocimeterEngineering

The invention discloses a non-contact dynamic stiffness measurement system and a method thereof. The non-contact dynamic stiffness measurement system includes a base, a test bar, an exciter, a force sensor, a laser Doppler velocimeter, and a controller. The force sensor is connected to the exciter and the base. The exciter is located between the test bar and the force sensor. The controller is electrically connected to the force sensor and the laser Doppler velocimeter. The test bar is detachably set in a holder of the main shaft under test. The exciter provides an electromagnetic force to thetest bar. The force sensor measures the acting force of the exciter. The laser Doppler velocimeter provides a first laser beam and a second laser beam. The laser Doppler velocimeter measures a vibration response with reflected laser beams. The controller determines an equivalent main shaft stiffness value of the main shaft under test according to the acting force and the vibration response.

Owner:IND TECH RES INST

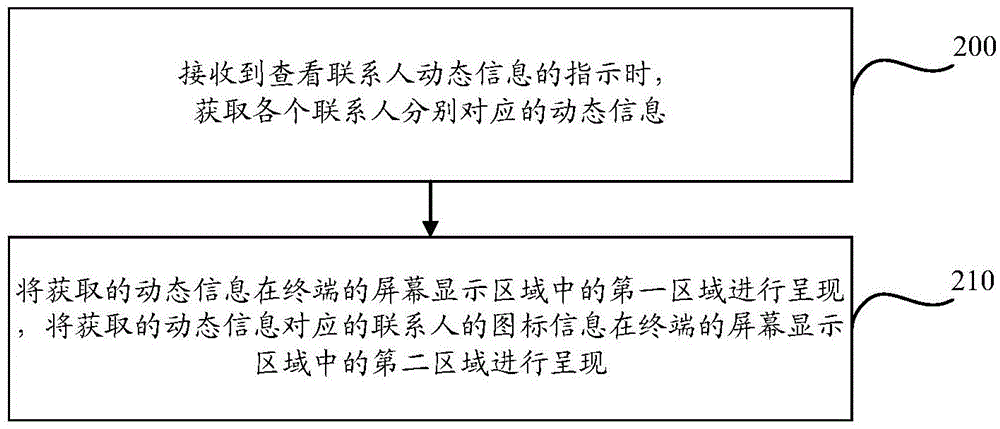

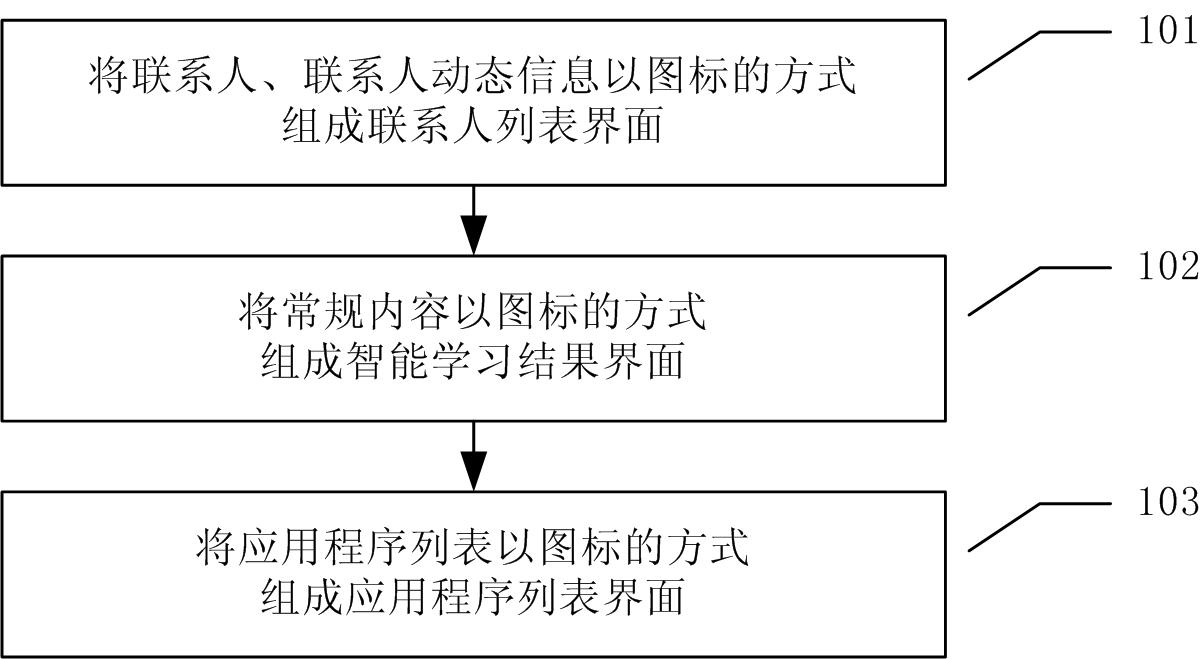

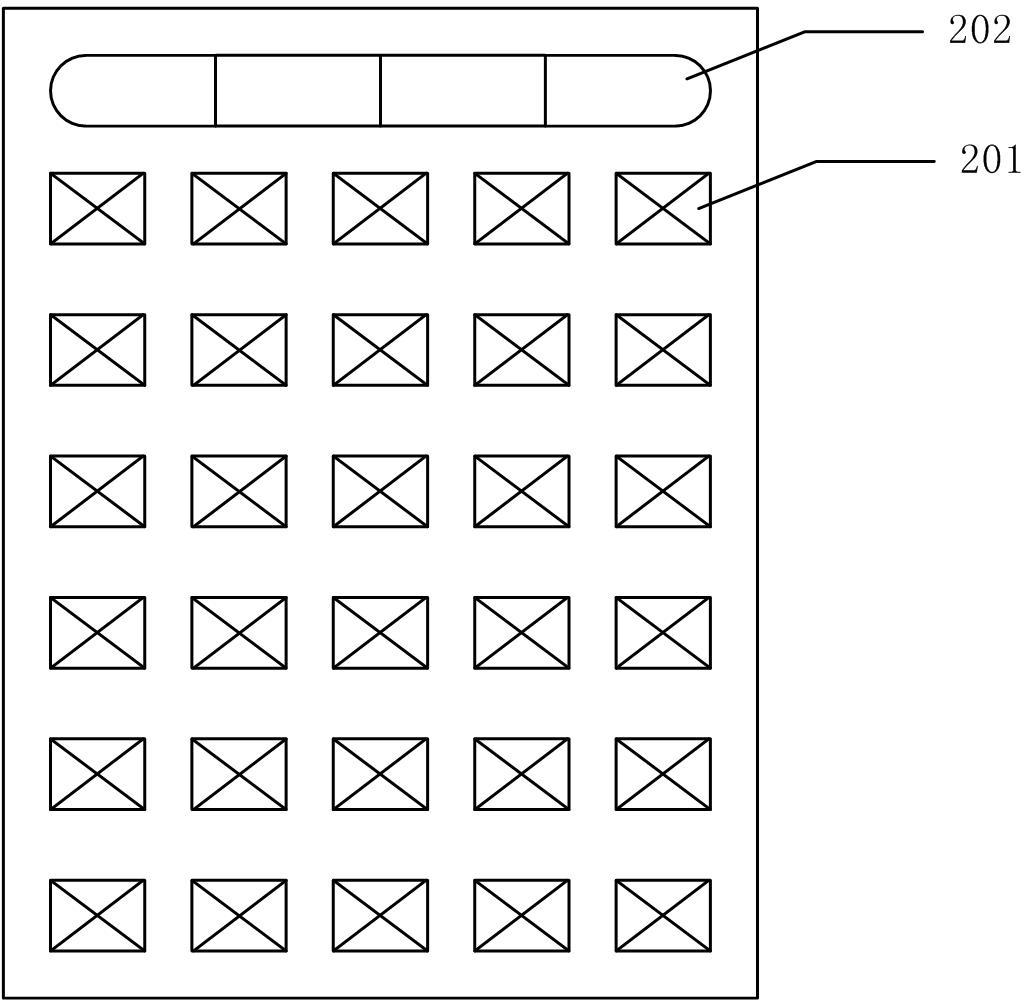

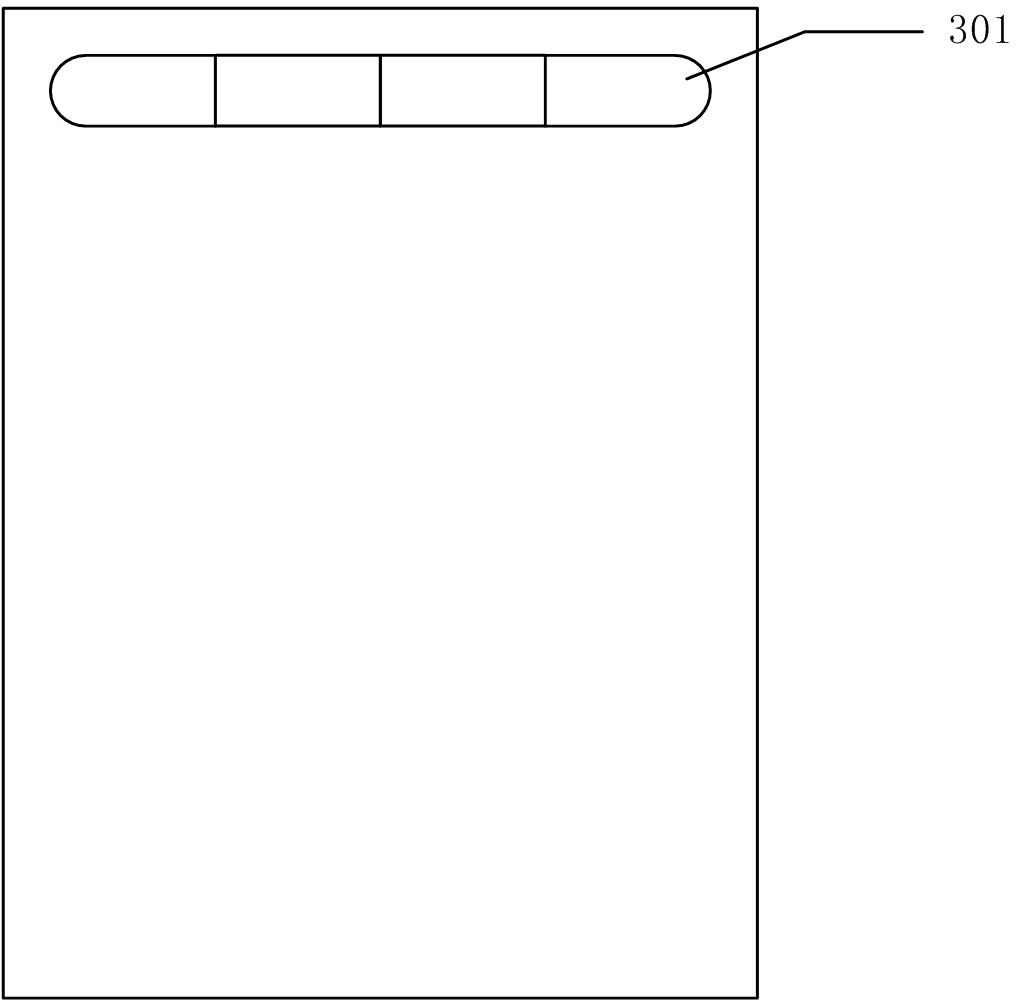

Display method and device of dynamic information of contacts

InactiveCN104636055ASolve complexityTime-consuming to solveInput/output processes for data processingComputer terminalNetwork communication

The invention relates to the technical field of network communication, and discloses a display method and device of dynamic information of contacts. The method comprises the steps that when an instruction of viewing the dynamic information of the contacts is received, updated dynamic information corresponding to the contacts is acquired, the acquired dynamic information is displayed in a first area of a screen display area of a terminal, and icon information of the contacts corresponding to the acquired dynamic information is displayed in a second area of the screen display area of the terminal. Because interaction with the contacts can be achieved after the icon information in the second area is clicked on, and it is unnecessary to enter homepages of the contacts and click many times, the problems that in the prior art, in interaction with multiple contacts in a contact dynamic information display interface, complexity is high and time consumption is large are solved.

Owner:HUAWEI TECH CO LTD

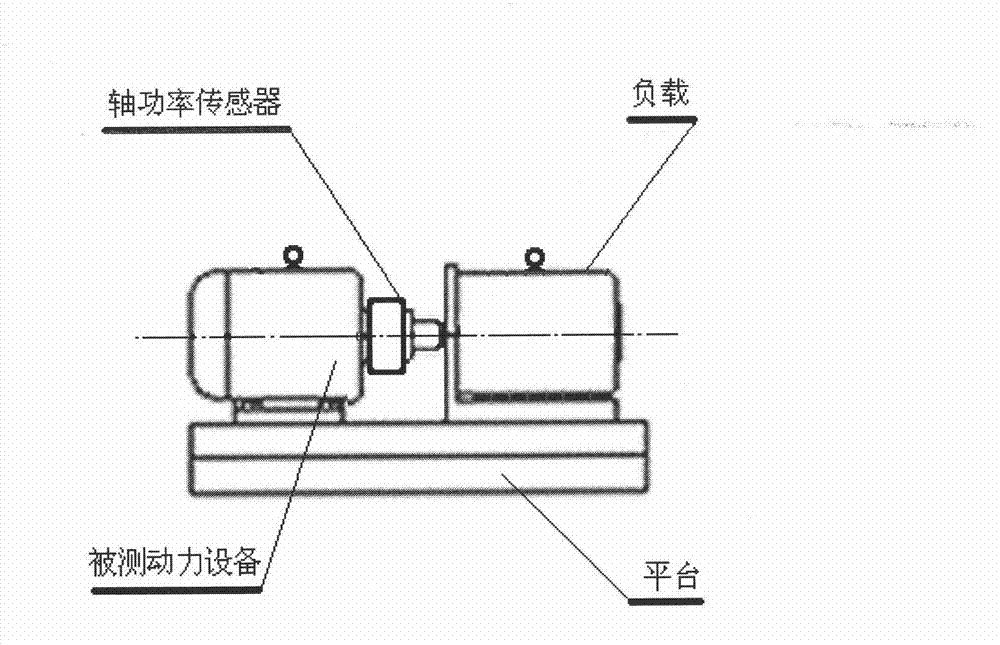

Non-contact dynamic measurement system for torque of rotating shaft based on optical fibers

InactiveCN102494817AMeet the test environment requirementsSimple structureWork measurementTorque measurementPhase differenceEngineering

The invention relates to a non-contact dynamic measurement system for the torque of a rotating shaft based on optical fibers. Stripe color codes are arranged on a measured shaft at intervals, and fiber probes are additionally mounted above the stripe color codes and firmly fixed onto a connecting component. When the measured shaft rotates, the spline rotating shaft correspondingly has angular deformation under different loads along with rotation of the measured shaft under different working conditions, the stripe color codes on the spline rotating shaft have phase difference by means of angular deformation, the phase difference measured by each group of optical fibers corresponds to the measured torque of the measured spline rotating shaft, and the phase difference is measured by the optical fibers so that accurate torque variation data of the spline rotating shaft can be obtained. The torque of the rotating shaft is measured in a non-contact dynamic online manner, the rotating shaft is not provided with an accessory mechanical part, the geometric dimensions of the laser fiber probes can meet the requirements of testing environments, and the non-contact dynamic measurement system has the advantages of simple structure, ingenious design and fine stability.

Owner:SHANGHAI MARINE EQUIP RES INST

Method for processing display of main screen of mobile terminal

InactiveCN102223450AImprove the efficiency of using mobile terminalsImprove efficiencySubstation equipmentThird partyComputer terminal

The invention relates to a method for processing the display of a main screen of a mobile terminal. The method comprises the following steps of: forming a contact list interface by contact and contact dynamic information in an icon mode; forming an intelligent learning outcome interface by content of phone call, short message and operation prediction in an icon mode; listing all application program lists in an icon mode to form an application program list interface; changing the content of a corresponding contact icon in the contact list interface by a third-party program for informing a user that some states related to the contact are changed or some information is updated; and allowing the third-party program to define corresponding operation after a main screen program clicks the contact icon in a plug-in mode so as to expand interactive operation related to the contact.

Owner:BEIJING BORQS SOFTWARE TECH CO LTD

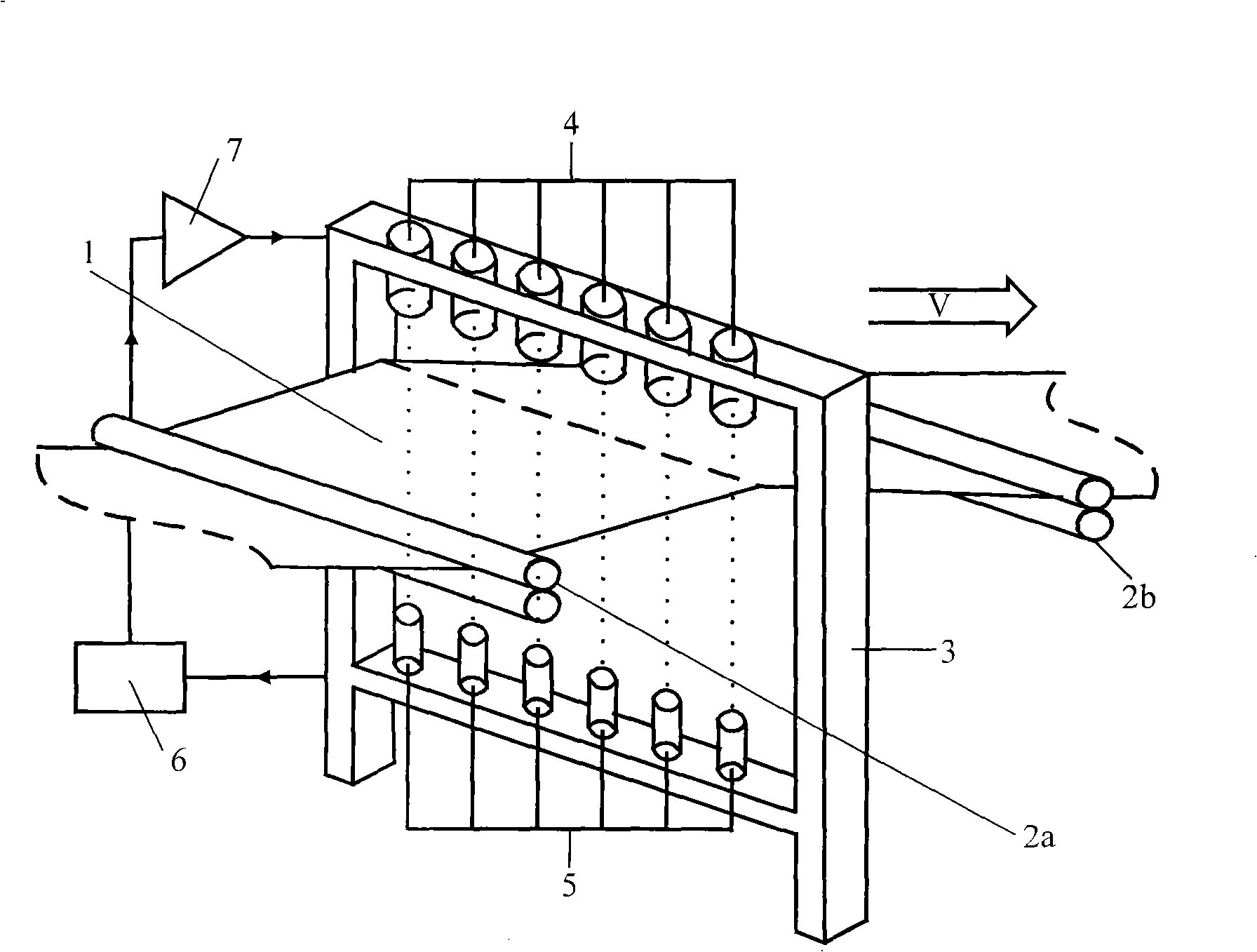

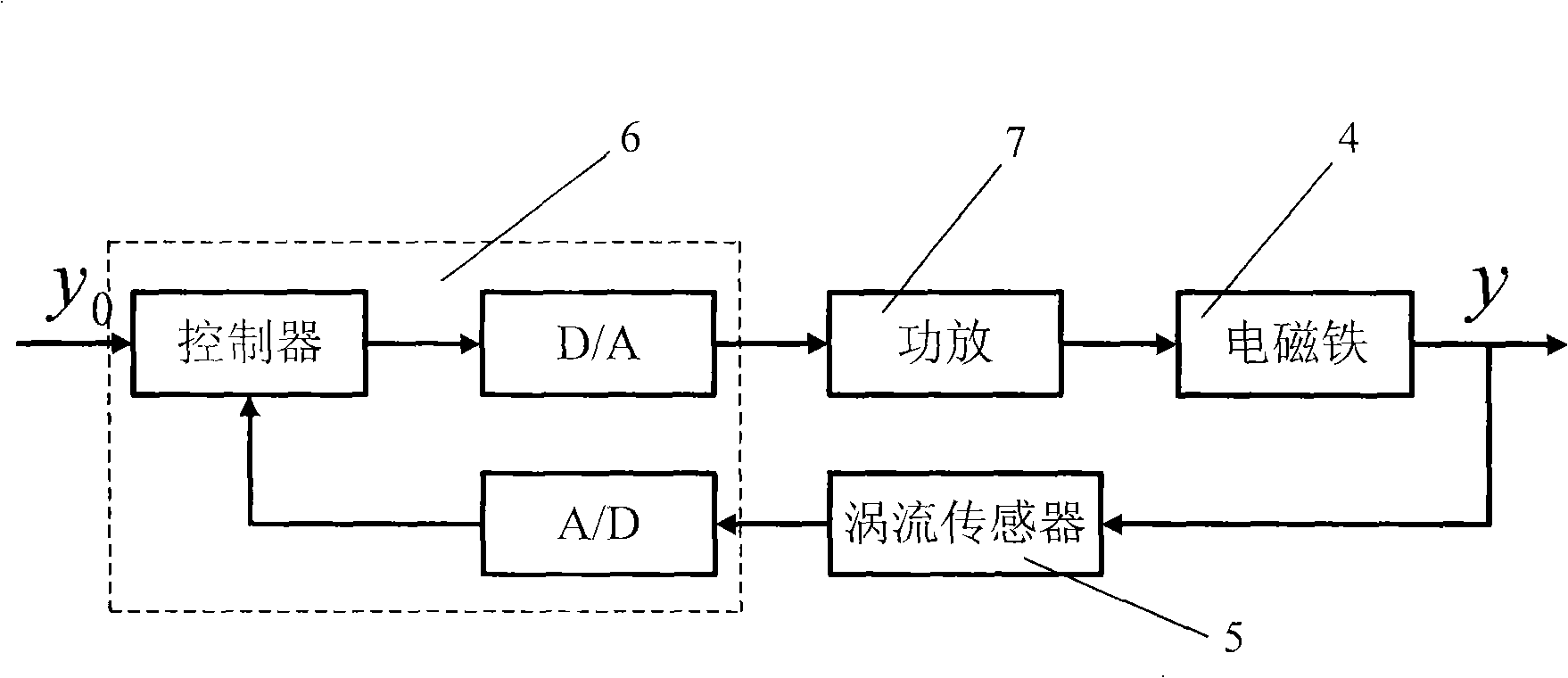

Magnetic suspension type dynamic sheet shape testing method

InactiveCN101264485AWon't hurtEasy to detectMeasuring devicesElectric/magnetic roughness/irregularity measurementsControl systemEngineering

The invention relates to a detection method for profile measurement in the process of strip rolling, in particular to a magnetic levitation type dynamic detection method for profile measurement, which is suitable for non-contact dynamic detection method for profile measurement in the process of metal sheet rolling. The invention is characterized in that (1) the detecting band steel is tensed by the front convey roller and the back convey roller, (2) the band steel in the process of convey is raised a certain height upwards vertical to the convey direction through the magnetic levitation control system, and (3) the control current data of the magnetic levitation control system is acquired and operated, the output signal drives the electromagnet of the control system raise the band steel to the predetermined altitude, and the profile information is acquired. The detection method for profile measurement in the process of strip rolling has the advantages of adopting non-contact detection method, dynamic detection of corresponding electromagnet winding coil amperage size of each parts of the band steel in the production process, dynamic detection of band steel profile information, free of damage of band steel surface caused by friction, free of abrasion of detecting equipment, convenient detecting, long service life of equipment, and easy maintenance.

Owner:BAOSHAN IRON & STEEL CO LTD

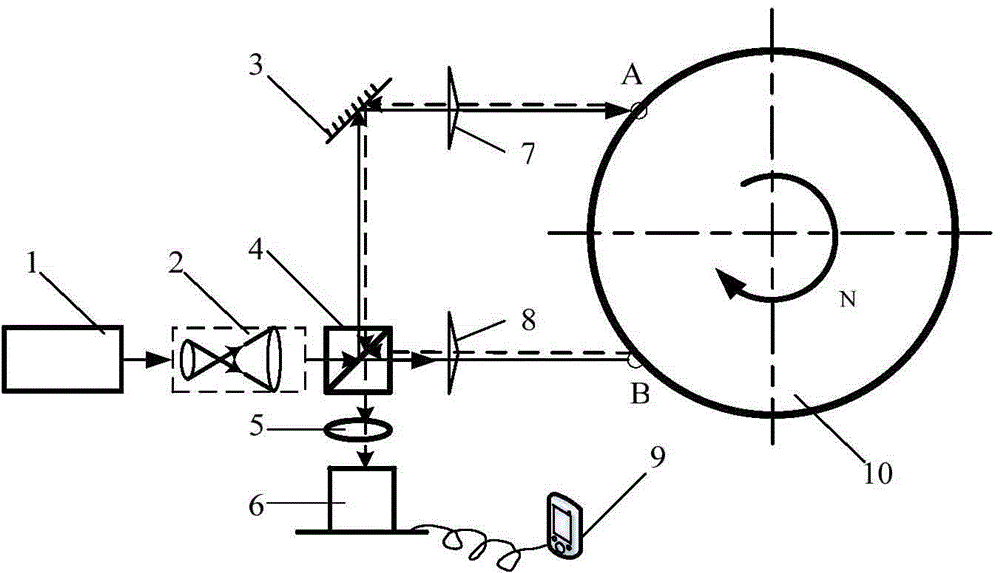

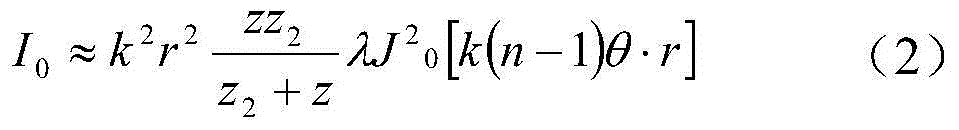

Instantaneous rotational speed measuring method, device and system based on no-diffraction light beams

InactiveCN104360095AAvoid measurement errorsGuaranteed measurement accuracyDevices using optical meansHeterodyne interferometerMeasuring instrument

The invention provides an instantaneous rotational speed measuring method, device and system based on no-diffraction light beams, relates to the technical field of rotation speed measurement and solves the problem that an optical path system of an existing laser rotational speed measuring instrument is complicated, defocusing has great effects on measuring accuracy and assembly and adjustment are complicated. The technical scheme includes that the no-diffraction light beam irradiates on the surface of rotating members, laser beams are scattered on the irradiated surface to generate the Doppler effect under the action of the rotational speed, and heterodyne interferometer of instantaneous rotational speed of rotary parts is performed. By the instantaneous rotational speed measuring method, device and system, non-contact dynamic high-precision measurement of the instantaneous rotational speed of the rotary parts can be realized, and assembly and adjustment are facilitated. In addition, the instantaneous rotational speed measuring method, device and system is applicable to research and real-time monitoring of dynamic rotation characteristics of the rotary parts.

Owner:SOUTHWEAT UNIV OF SCI & TECH

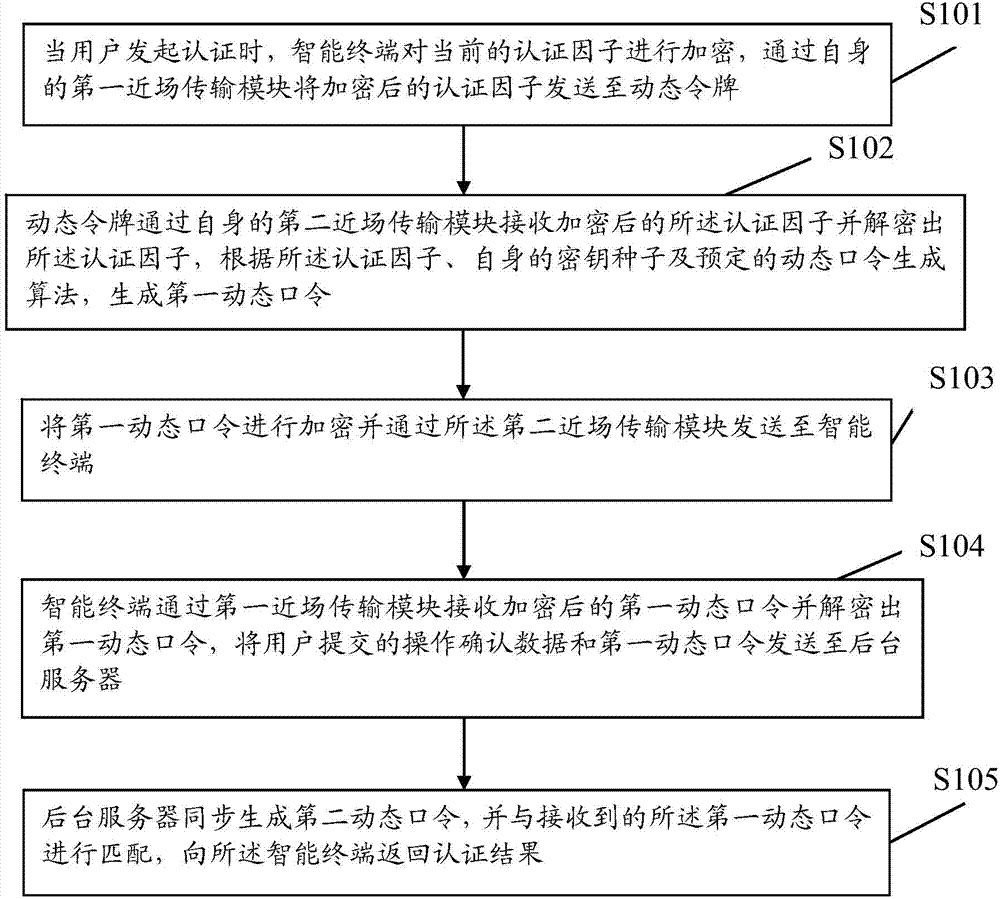

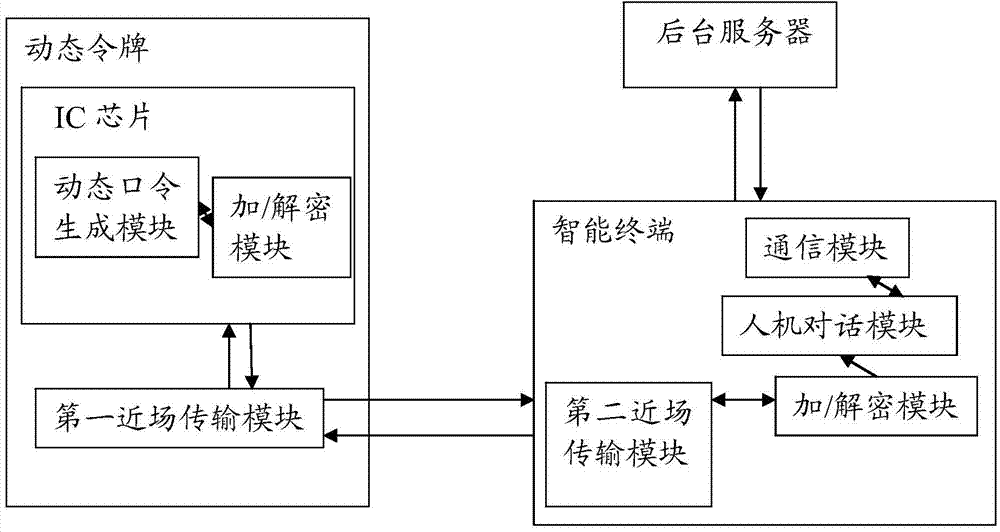

Method and system for non-contact dynamic password authentication

InactiveCN104125072AImprove securityAvoid typosUser identity/authority verificationPasswordData needs

The invention provides a method and a system for non-contact dynamic password authentication and aims at solving the problems of inconvenient operation and low safety of the existing dynamic password authentication. The method comprises the following steps: when the user initiates authentication, an intelligent terminal encrypts the current authentication factor and sends the authentication factor to a dynamic token by use of own first near-field transmission module; the dynamic token receives and decrypts the authentication factor, generates a first dynamic password according to the authentication factor, own key seed and a predetermined dynamic password generation algorithm and sends the first dynamic password to the intelligent terminal; the intelligent terminal receives the encrypted first dynamic password and descripts the first dynamic password, and then sends the first dynamic password to a background server; the background server synchronously generates a second dynamic password, carries out authentication and returns an authentication result to the intelligent terminal. The method for non-contact dynamic password authentication does not require manual operation in the authentication process; in addition, the data need to be encrypted before near-field transmission so that the security of the data can be greatly improved.

Owner:SHANGHAI PEOPLENET SECURITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com