Ball bearing reliability design method

A design method, ball bearing technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as lack of principled solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A reliability design method for ball bearings,

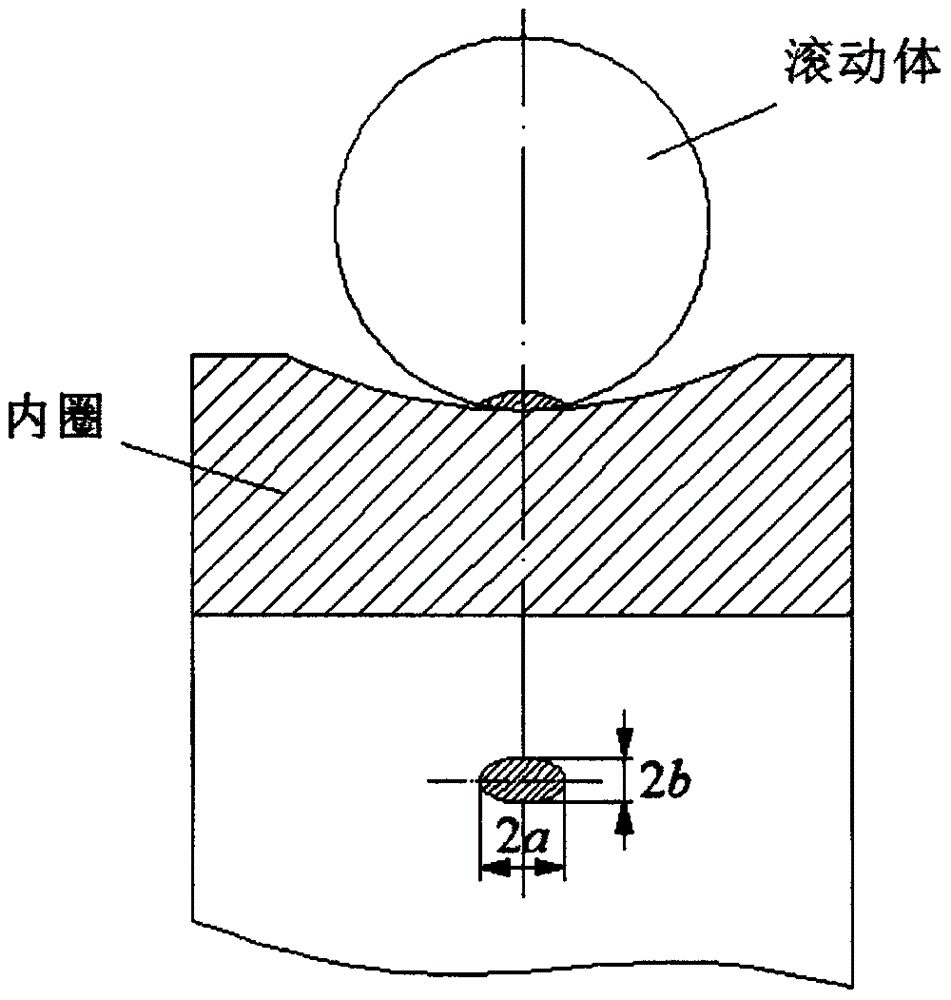

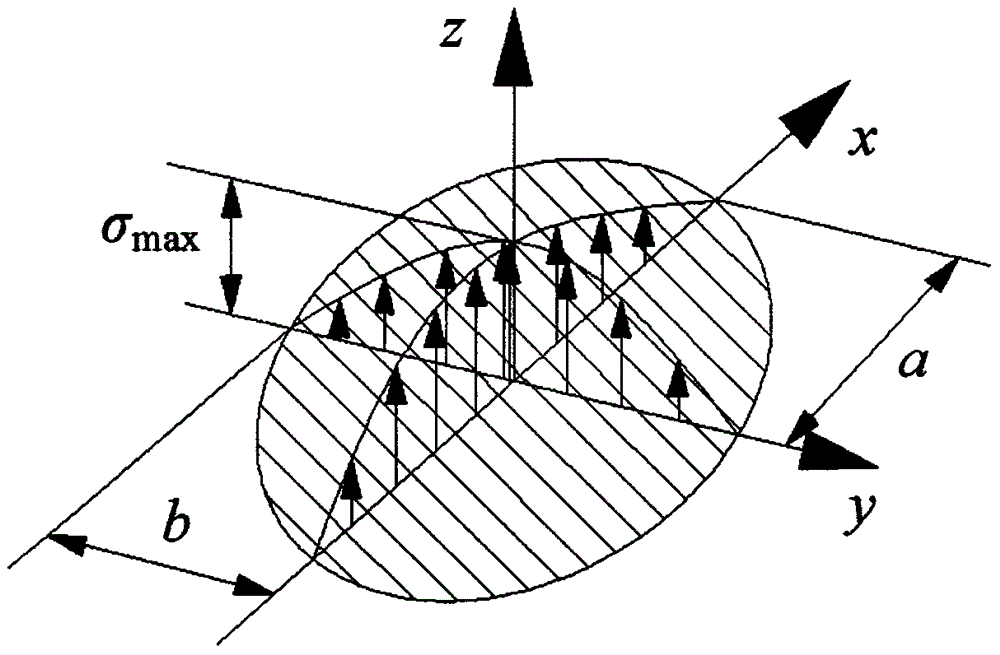

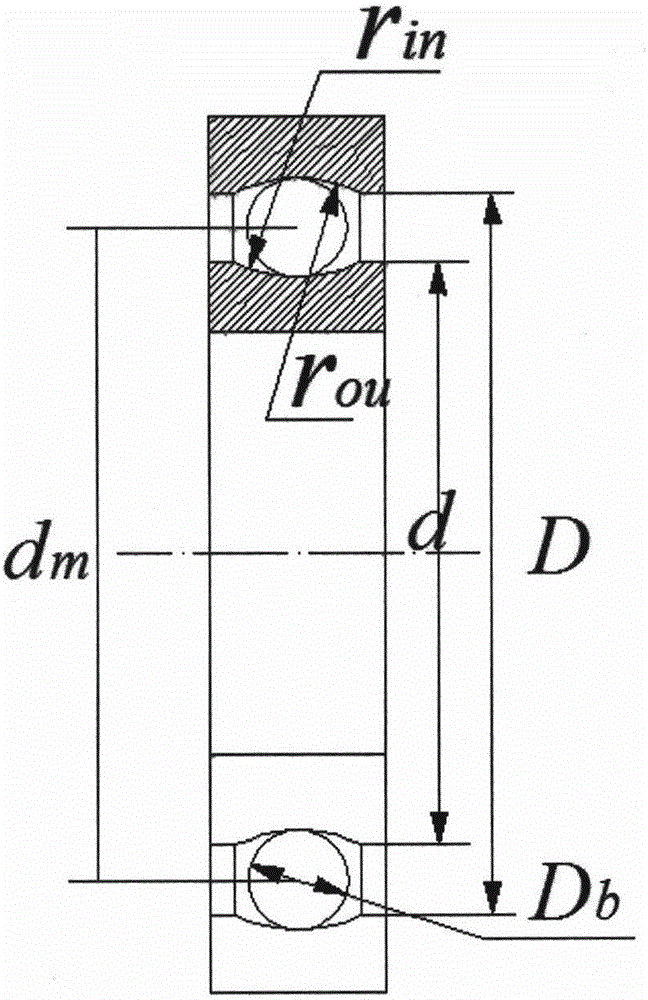

[0077] (1) The reliability design method of the ball bearing is based on the following premise: it is considered that the contact between the rolling elements of the rolling bearing and the raceways of the inner and outer rings satisfies the Hertz (Hertz) contact theory, and the contact type between the rolling elements and the raceways of the inner and outer rings of the bearing is point contact or / and line contact, in which the ball bearing rolling element and the inner and outer rings belong to point contact, and the contact between cylindrical and tapered roller bearings belongs to line contact; the relevant specific requirements of Hertz (Hertz) contact theory are as follows:

[0078] ①In ball bearings, the contact between the rolling elements and the raceways of the inner and outer rings is a point contact. Under the action of load Q, the contact point gradually expands into an elliptical contact surface. At the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com