Patents

Literature

73 results about "Contact theory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact Theory. A theory devised to explain electrification, the charging of bodies by friction, or rubbing, and the production of current by the voltaic battery. It holds that two bodies, by mere contact become oppositely electrified.

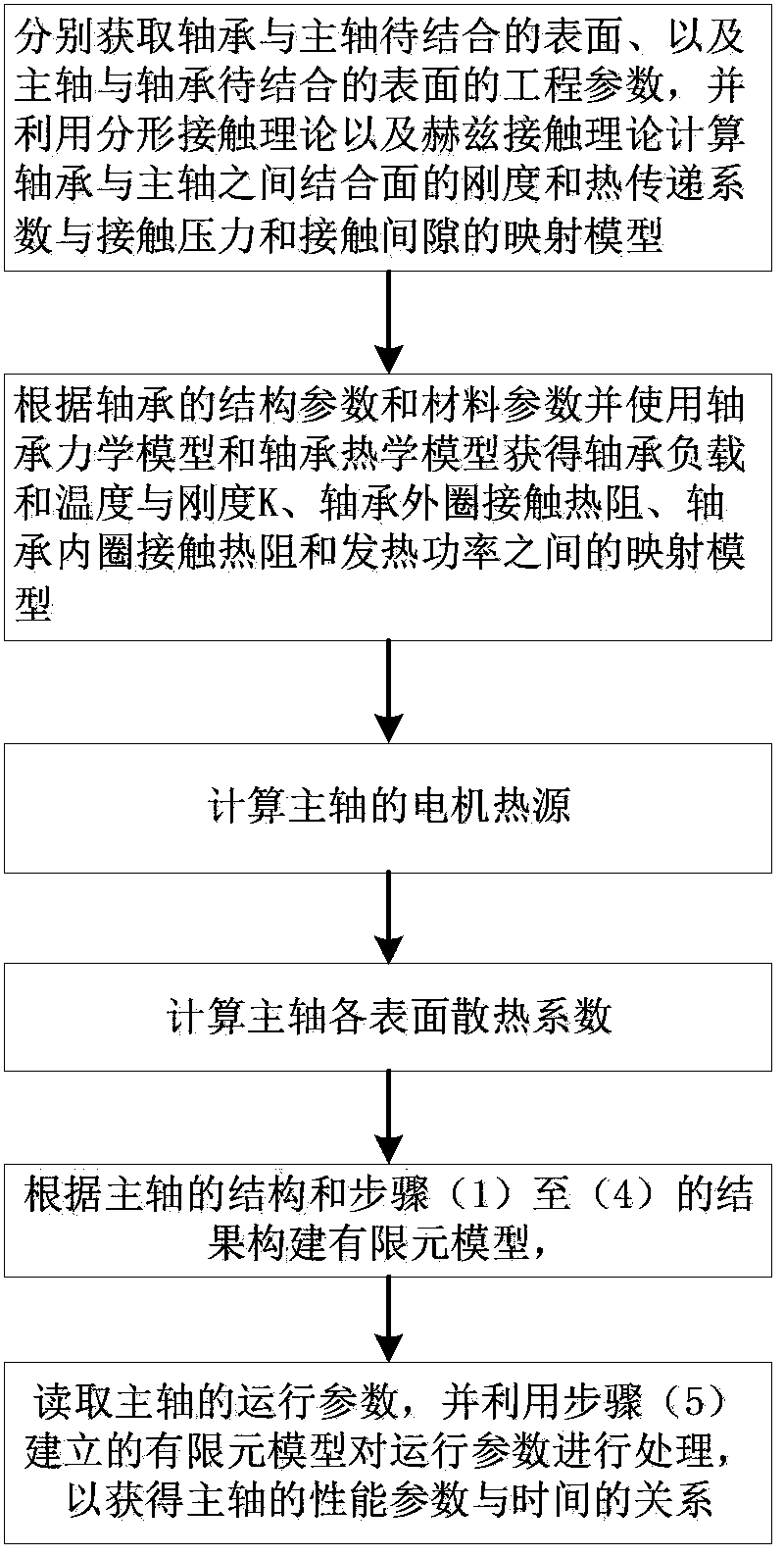

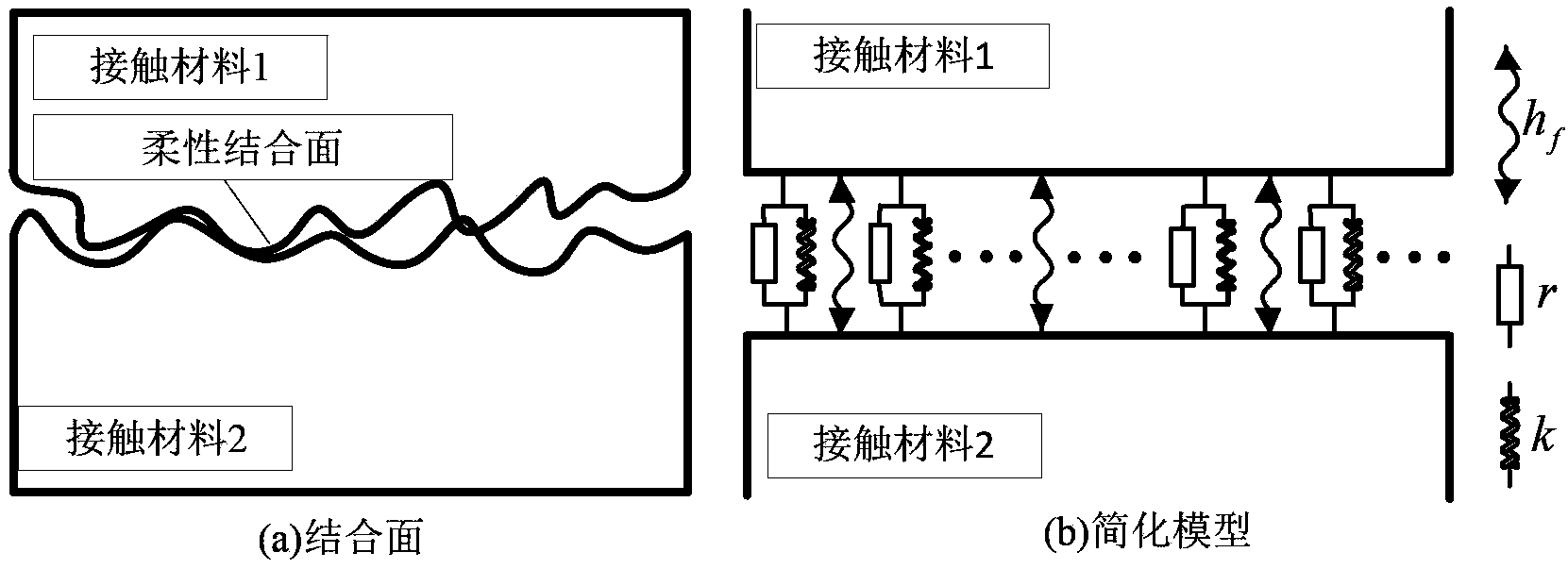

High-speed electric spindle power-heat coupling modeling method

InactiveCN103366050AReduce mistakesSpecial data processing applicationsElement modelContact pressure

The invention discloses a high-speed electric spindle power-heat coupling modeling method. The method comprises the steps as follows: respectively acquiring the engineering parameters of the to-be-combined surfaces of a bearing and a spindle; by utilizing the fractal contact theory and the hertz contact theory, calculating a mapping model between the rigidity and the heat transfer coefficient of the joint surface of the bearing and the spindle and contact pressure and contact gap; according to the structure and material parameters of the bearing, acquiring a mapping model between the load and temperature of the bearing and rigidity, outer ring thermal contact resistance of the bearing, the inner ring thermal contact resistance of the bearing and heating power by using a bearing mechanical model and a bearing thermal model; calculating the motor heat source of the spindle; calculating the heat radiation coefficient of each surface of the spindle; establishing a finite element model of the structure of the spindle and the result; reading the running parameters of the spindle; processing the running parameters by utilizing the finite element. The method disclosed by the invention can reduce errors caused by the joint surface of the conventional method and errors caused by the non-update of the model joint surface and the bearing mechanical and thermal parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

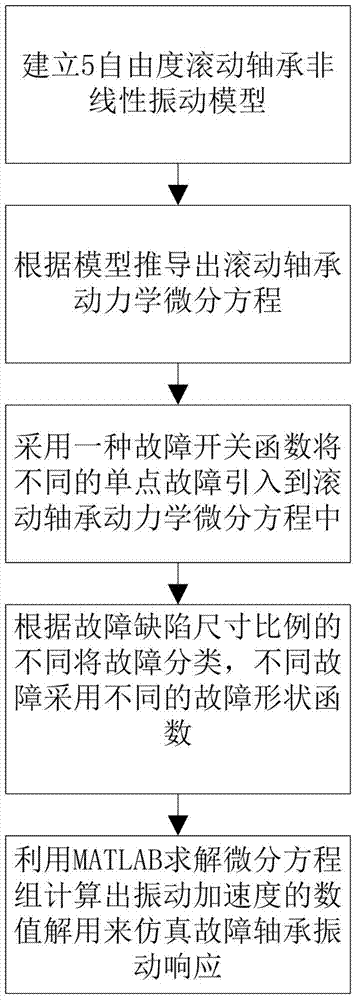

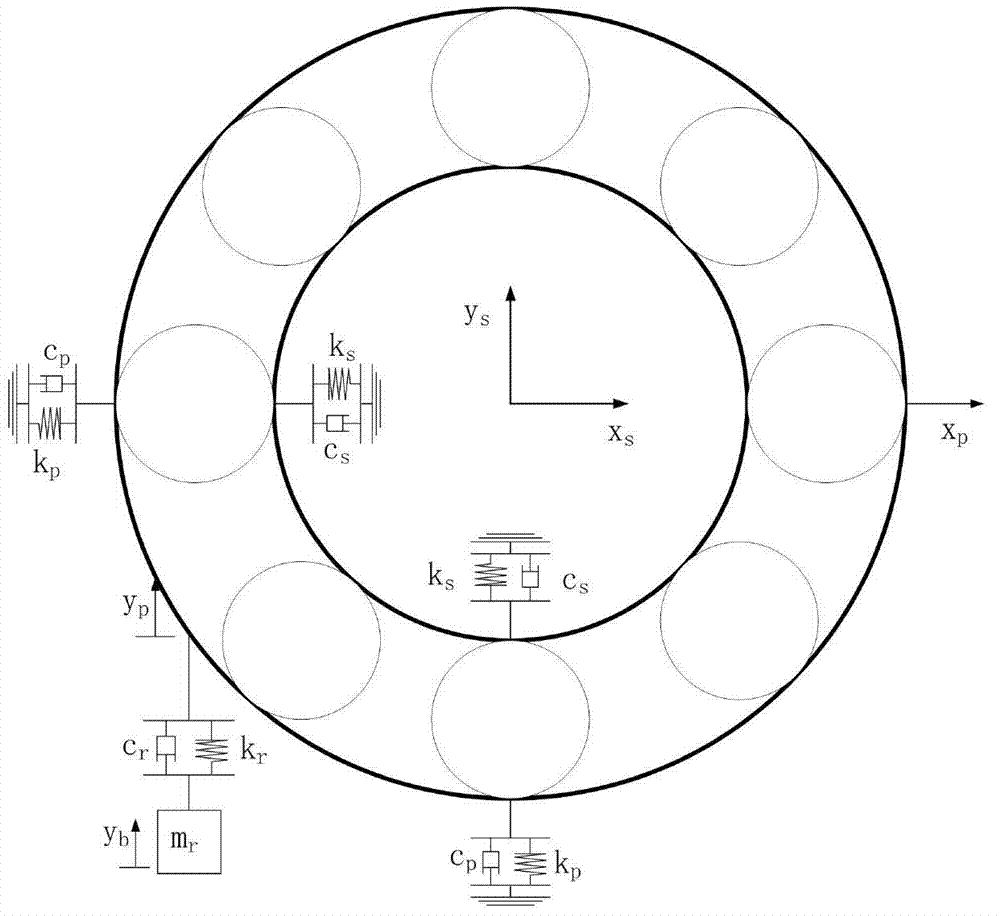

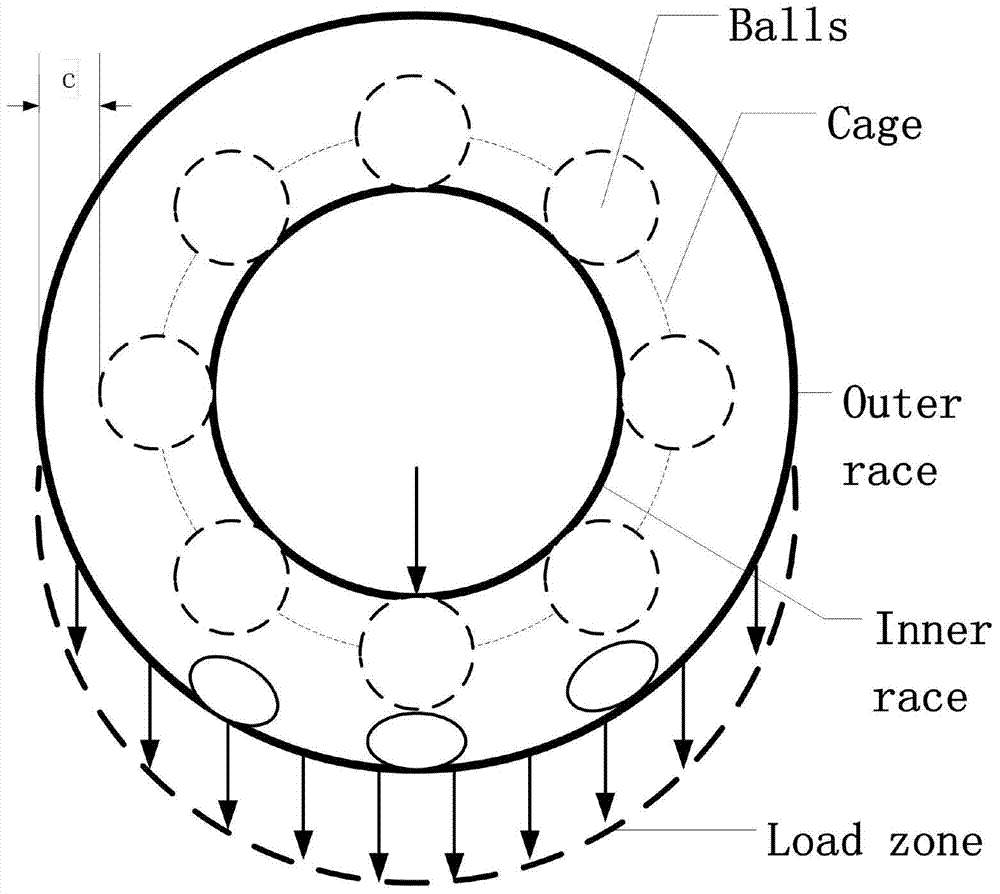

Vibration response simulation analyzing method for rolling bearing with single-point failures

ActiveCN103927414ASolve the problem of long cycle and high costSpecial data processing applicationsEngineeringMATLAB

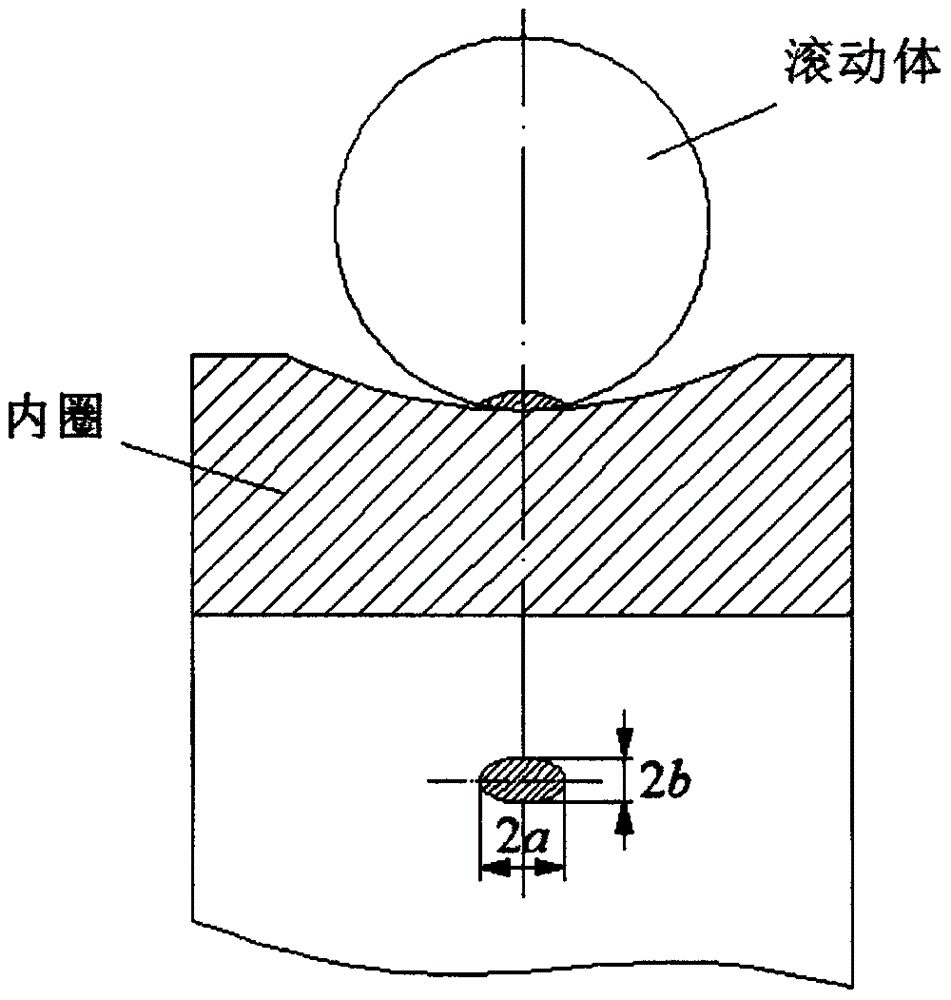

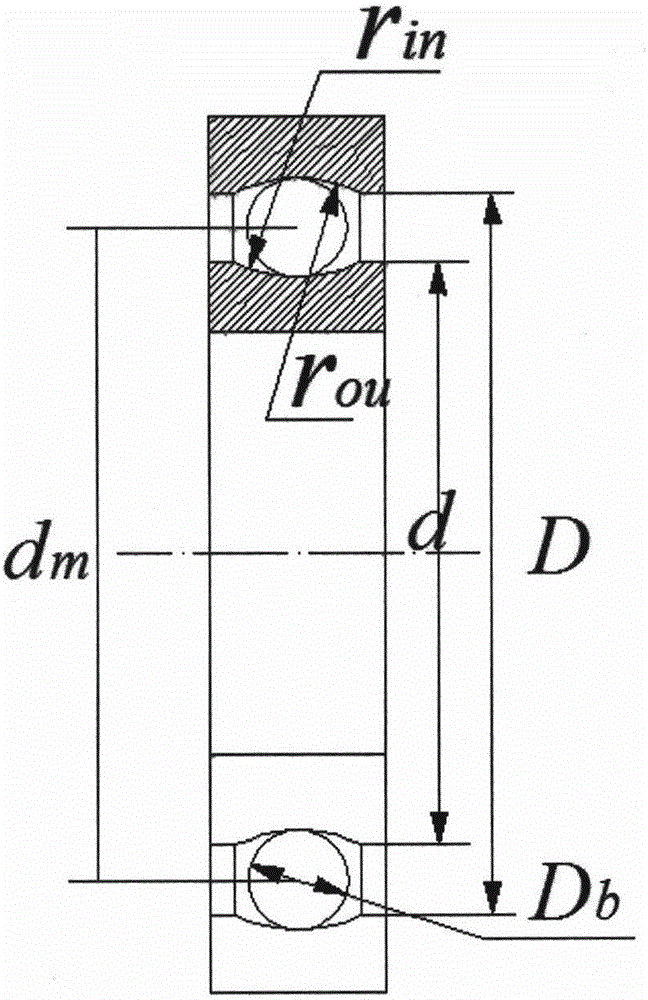

The invention relates to a vibration response simulation analyzing method for a rolling bearing with single-point failures. On the basis of a Hertz contact theory, related knowledge about kinematics and kinetics are utilized to establish a five-degree-of-freedom nonlinear vibration mode of a rolling bearing and kinetic differential equations of the rolling bearing while influencing factors like slipping of rolling balls, oil slick rigidity and the like are taken into consideration, according to that the rolling balls change due to contact deformation is caused when the rolling balls roll through partial failures, a partial failure model of the rolling bearing is introduced into the kinetic differential equations of the rolling bearing, and the single-point failures of the rolling bearing are classified according to length-width ratios of the failures and size ratios between the failures and the rolling balls so as to establish different failure shape functions; the differential equations are solved by an ode solver in MATLAB (matrix laboratory) software, and vibration responses of the rolling bearing are simulated when an inner ring, an outer ring and the rolling balls of the rolling bearing are suffered from the single-point failures. By the aid of the vibration response simulation analyzing method, vibration responses of the bearings with failures in different sizes can be simulated. Compared with traditional methods for acquiring vibration responses of failed bearings, the vibration response simulation analyzing method has the advantages that an experimental period is short and experimental cost is saved. The computation for the vibration responses for the failed rolling bearings can lay the foundation of late failure diagnosis for the rolling bearings.

Owner:BEIJING UNIV OF TECH

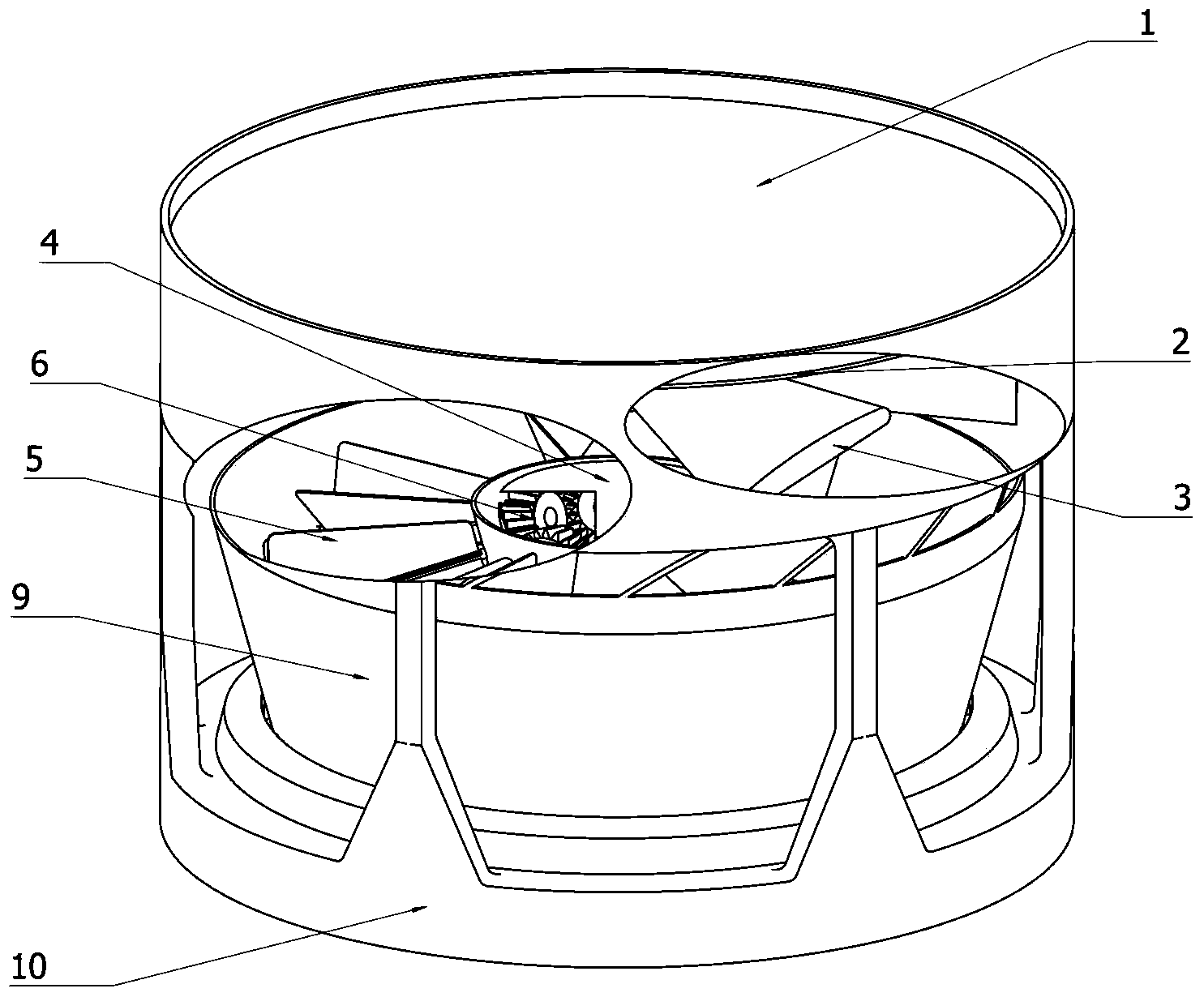

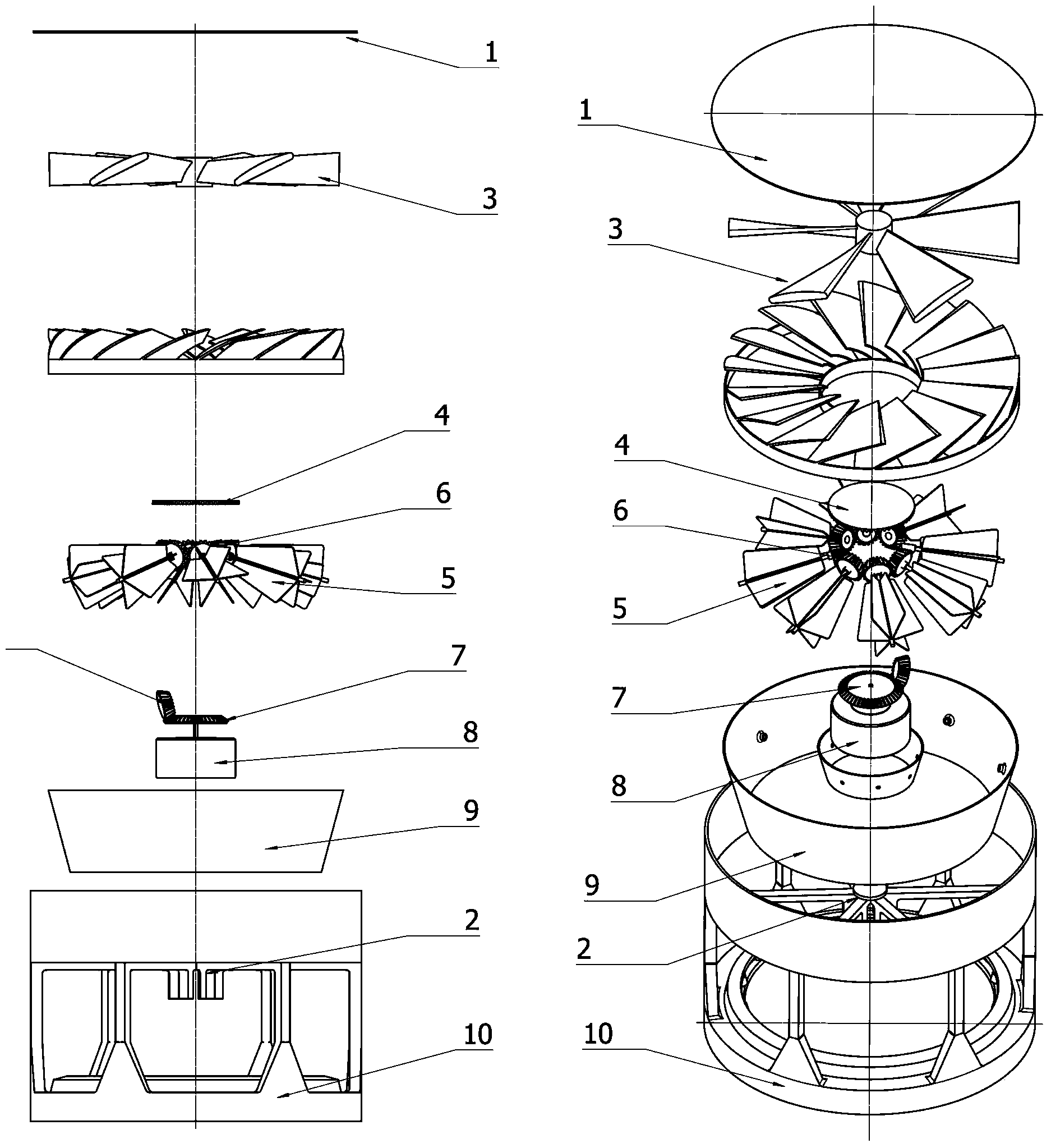

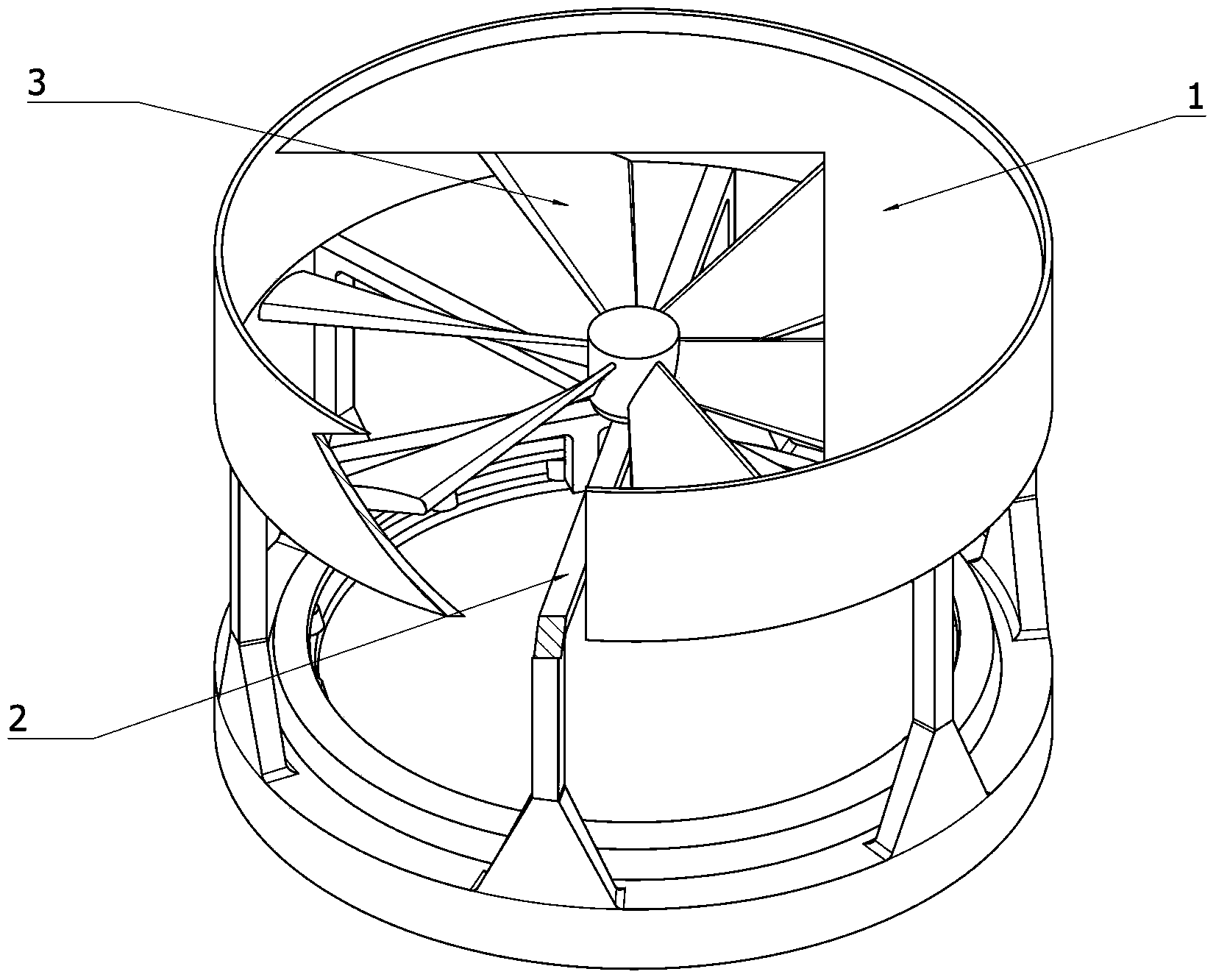

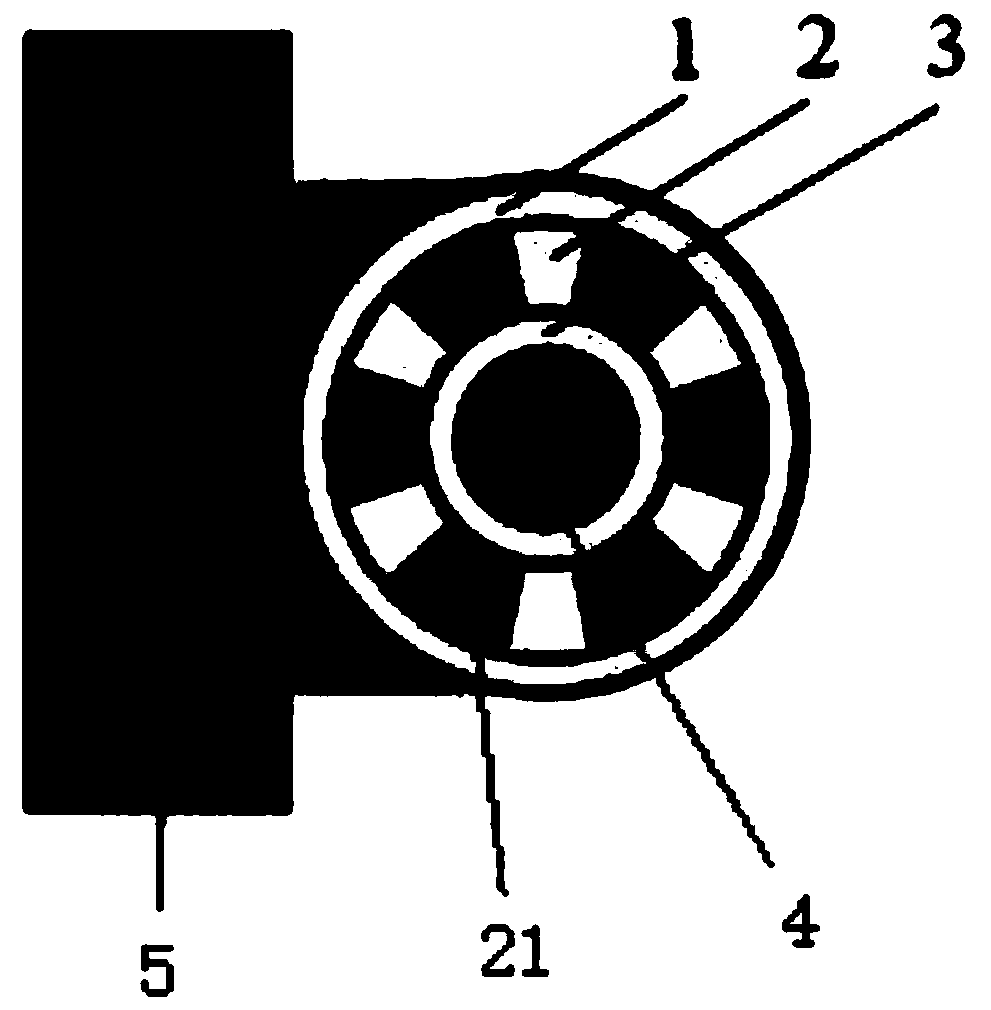

Annular air purifying-humidifying device

ActiveCN103933816AImprove interaction qualityAvoid regular replacementCombination devicesLighting and heating apparatusGear driveMotor drive

The invention relates to an annular air purifying-humidifying device. By utilizing a blade-stirring gas-liquid contact theory, the device can be used for removing various dust particles, formaldehyde pollutants in air and simultaneously sterilizing, disinfecting and humidifying air. The device comprises a motor driving mechanism, a blade stirring mechanism, a gear driving mechanism and a stander. The annular air purifying-humidifying device has the beneficial effects that by smartly utilizing a gas-liquid contact stirring theory, the dust removal, disinfection and humidification processes are simultaneously carried out; as a stirring blade can carry out rotation and revolution, the interaction quality of air purifying-humidifying liquid and air is improved; the device is simple in structure, and transmission mechanisms are all made of plastic, so that the cost is low; meanwhile, the troubles that a filter net of a traditional purifying device needs to be periodically exchanged and cleaned are avoided.

Owner:北京中科敏智科技有限公司

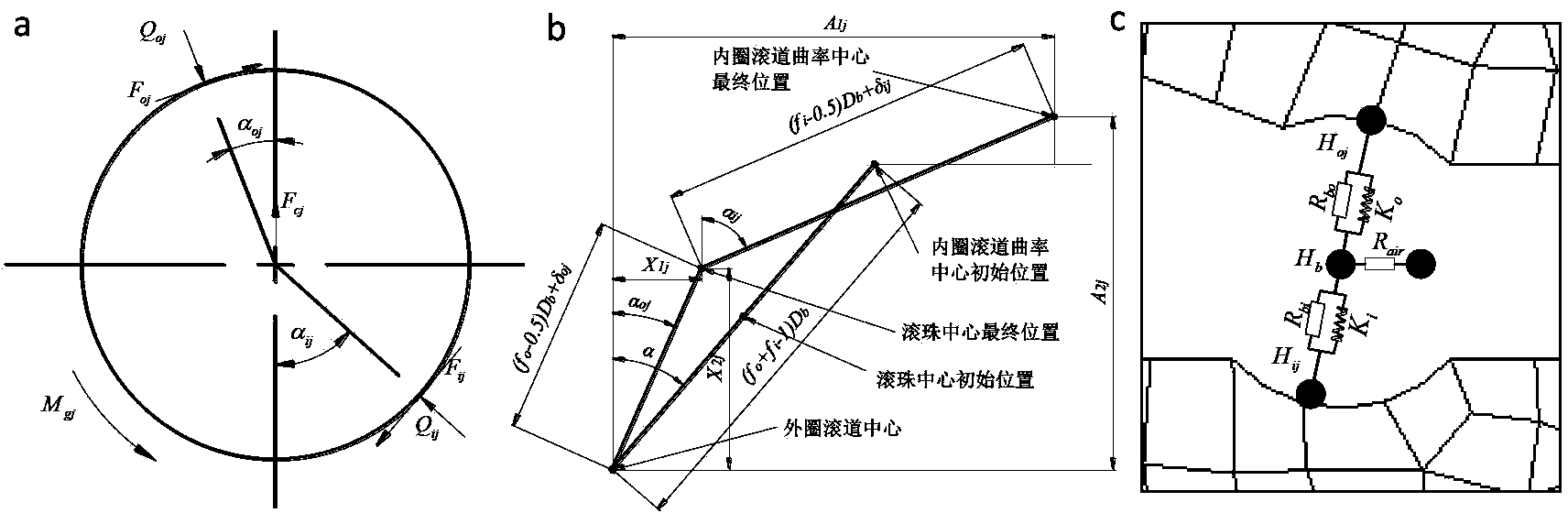

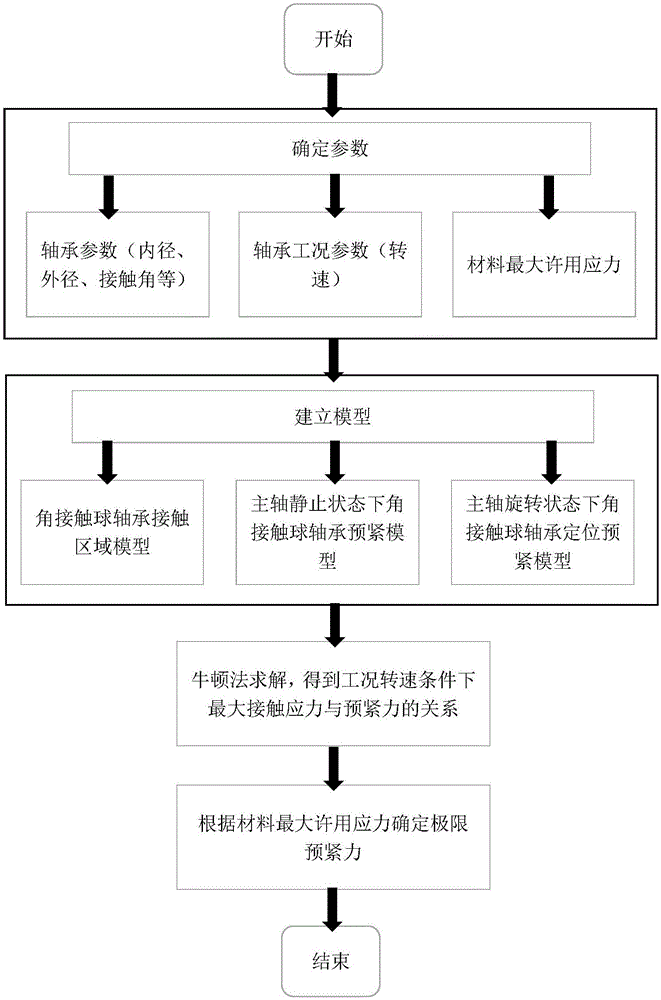

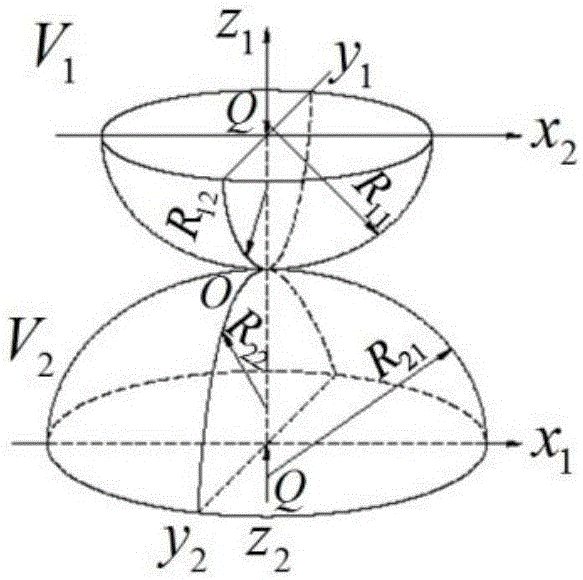

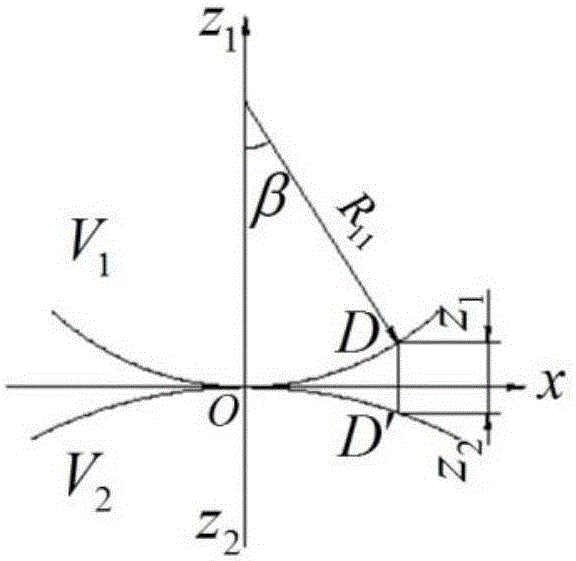

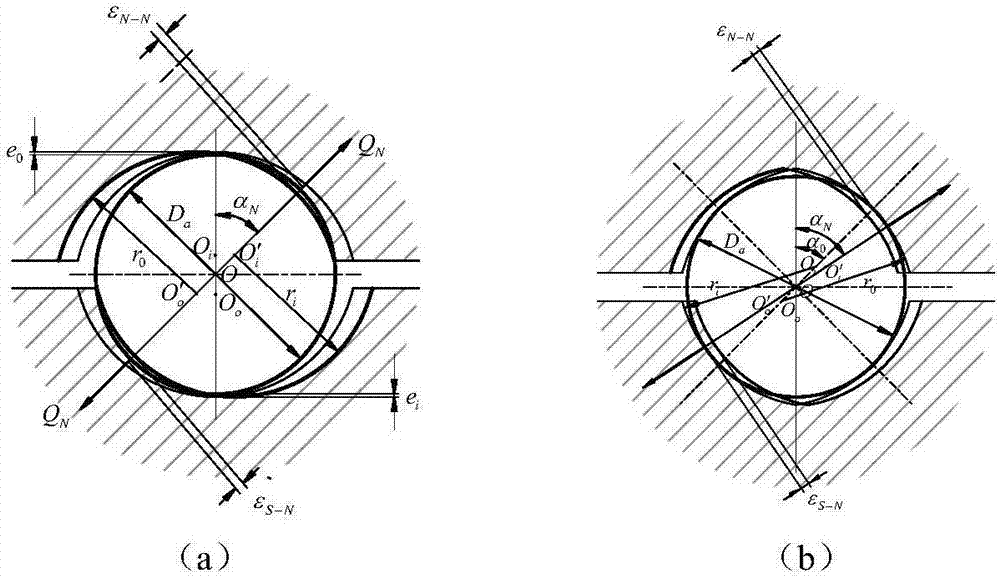

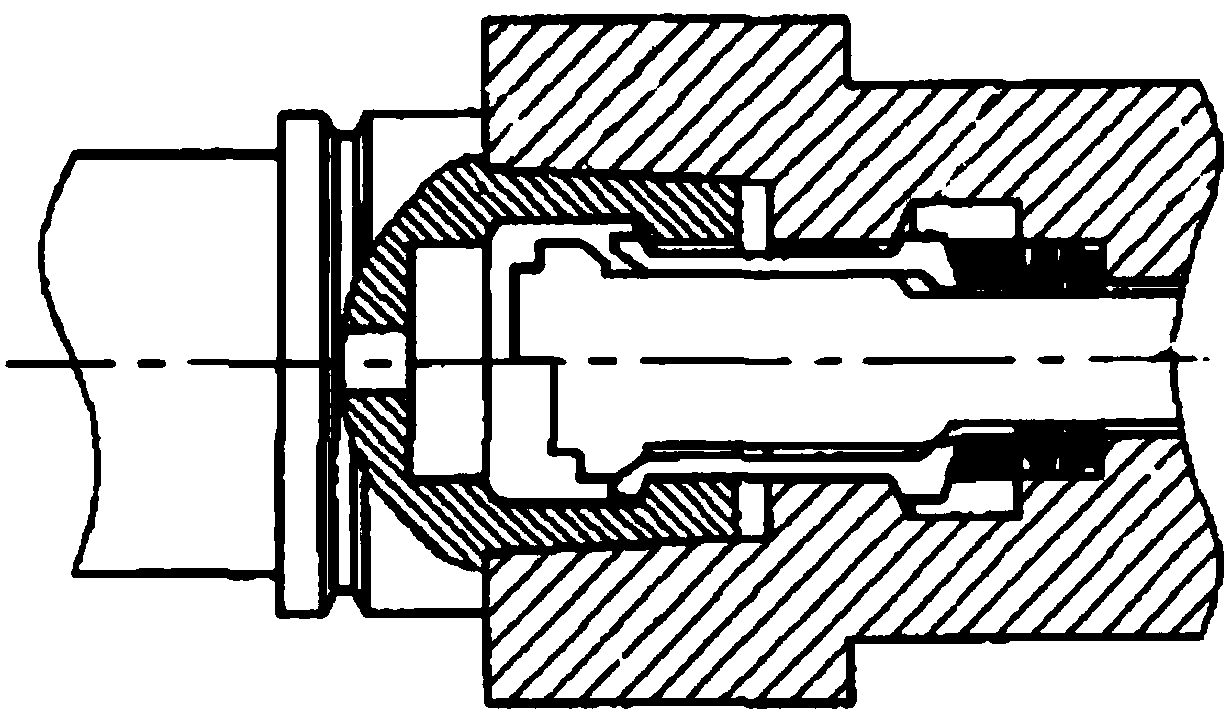

Method for analyzing limit pretension force of angular contact ball bearing under fixed-position pretension of high-speed electric spindle

InactiveCN105138814AImprove accuracyGood repeatabilityBall bearingsSpecial data processing applicationsBall bearingEngineering

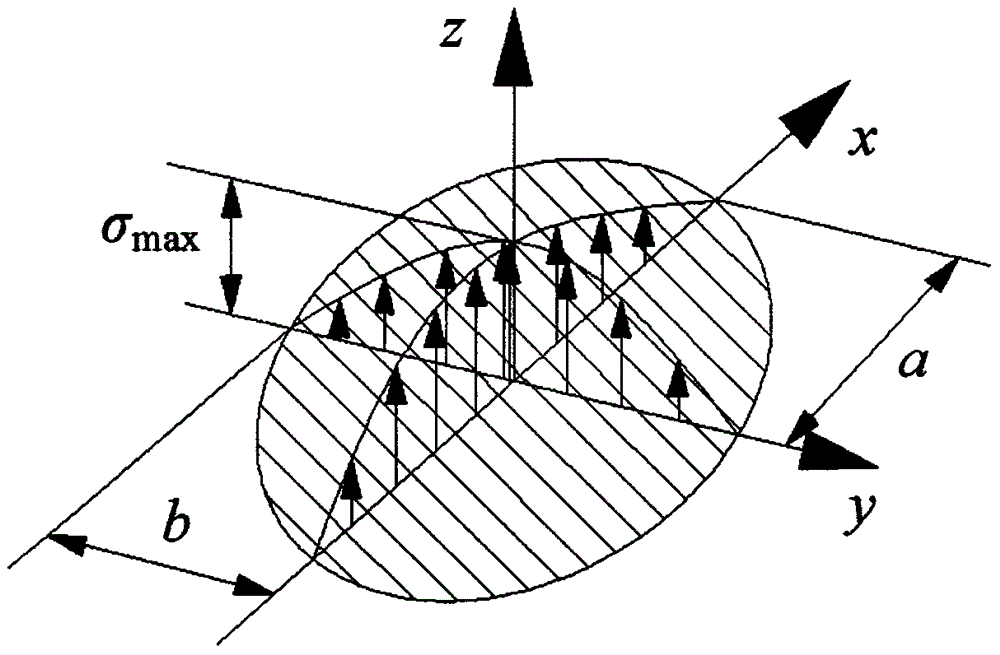

A method for analyzing limit pretension force of an angular contact ball bearing under fixed-position pretension of a high-speed electric spindle belongs to the technical field of bearing pretension. According to the method, firstly, parameters including a bearing type, a working condition, maximum permissible stress of a material and the like are determined; secondly, based on a Hertz contact theory, the influences of pretension force, centrifugal force and gyroscopic torque of the bearing are considered, and a kinetic model of the angular contact ball bearing under the fixed-position pretension is established, wherein the kinetic model includes a contact region model of the angular contact ball bearing, a pretension model of the angular contact ball bearing in a static state of the spindle, and a pretension model of the angular contact ball bearing in a rotating state of the spindle; thirdly, a relation between the pretension force and maximum contact stress of a bearing rolling body and bearing inner and outer rings under the condition of rated speed is solved with a Newton method; and finally, the pretension force, i.e., the limit pretension force, of the bearing under the permissible stress of the material is analyzed out.

Owner:BEIJING UNIV OF TECH

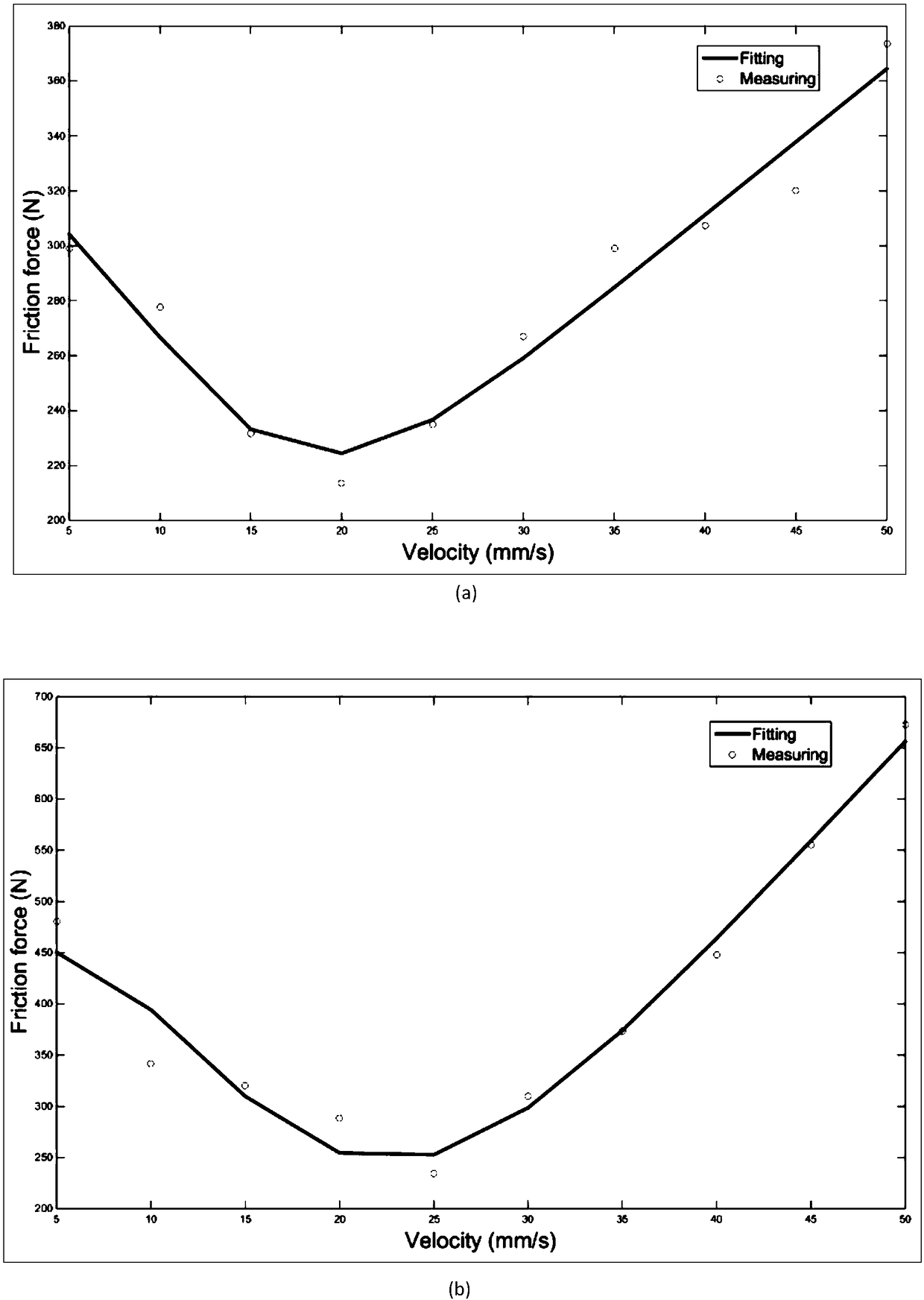

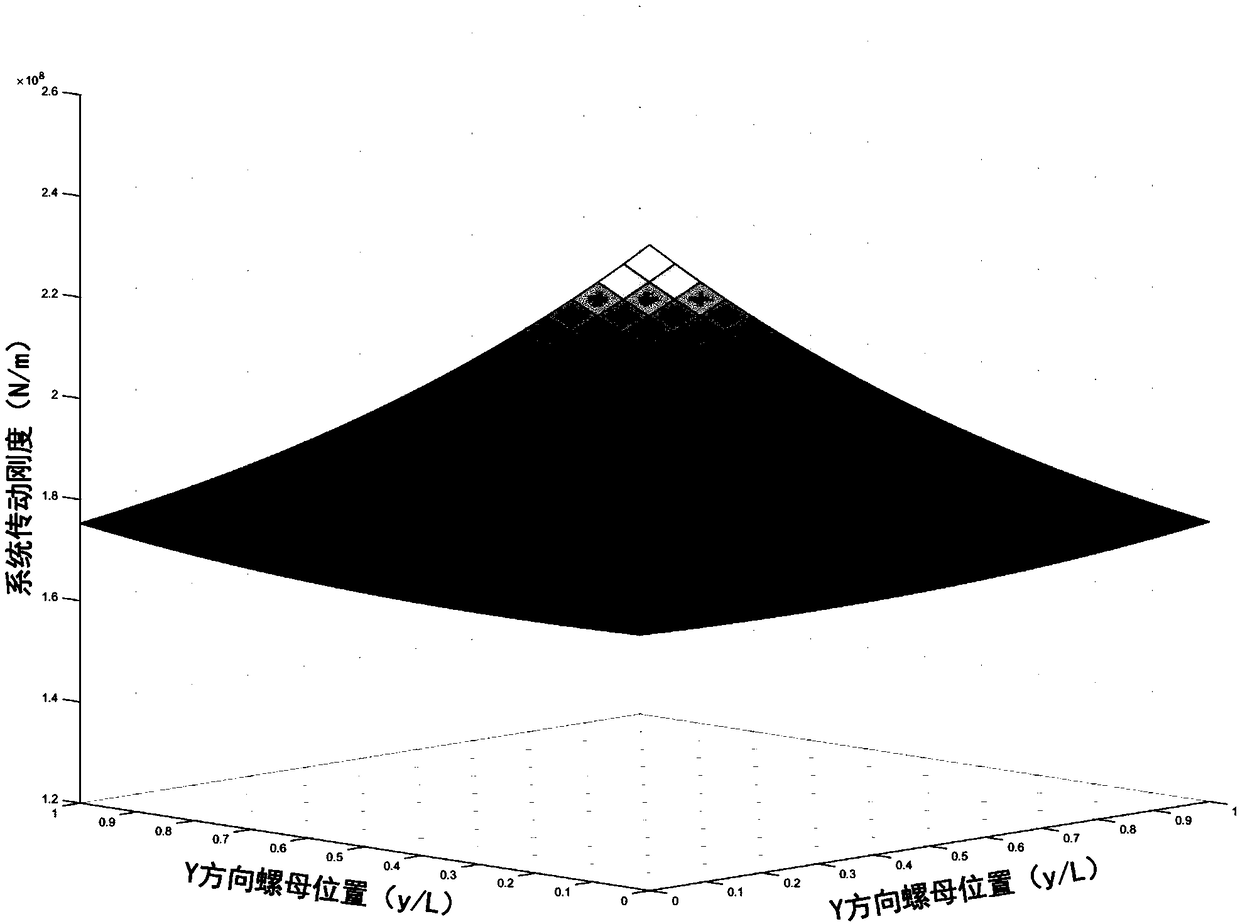

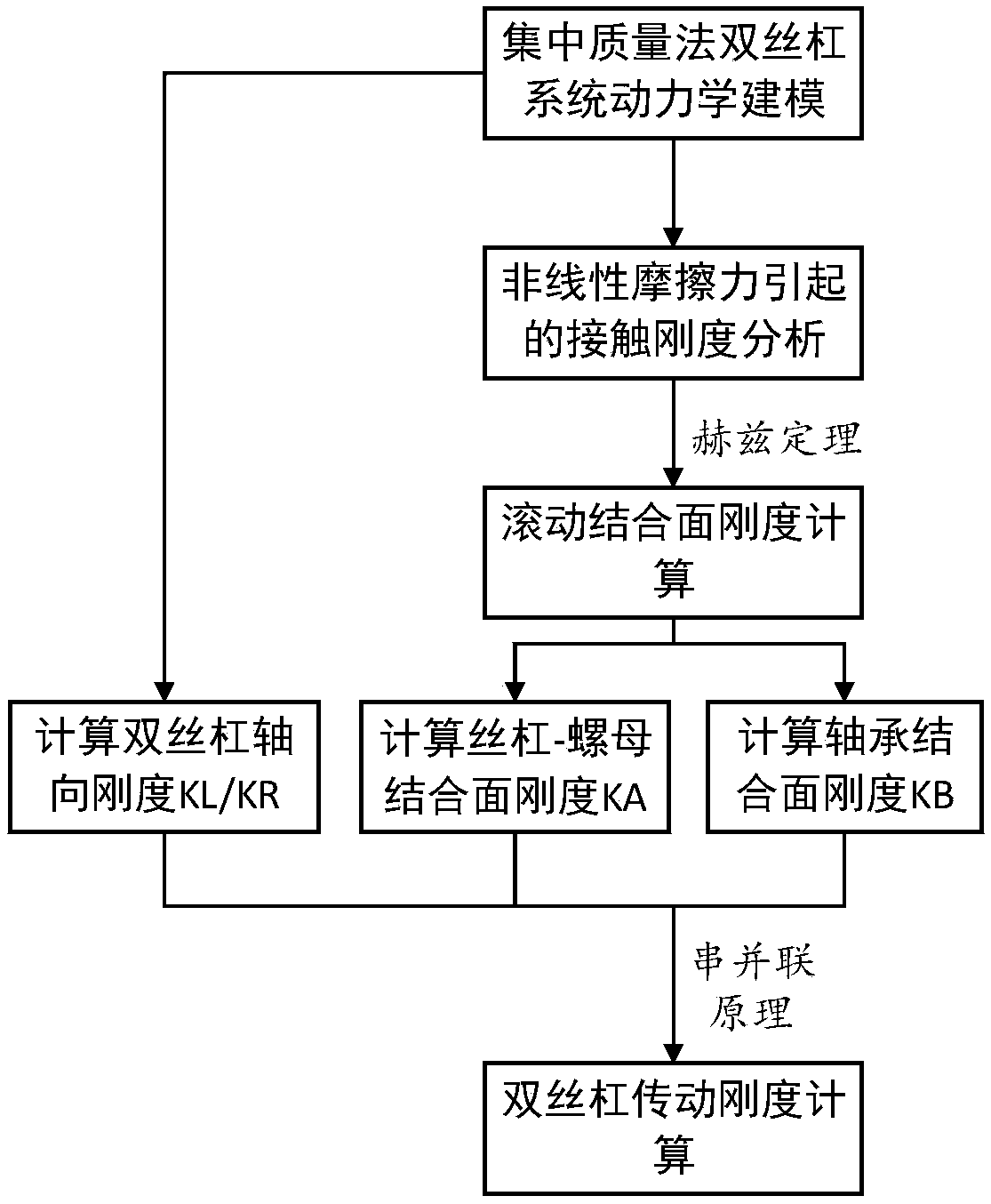

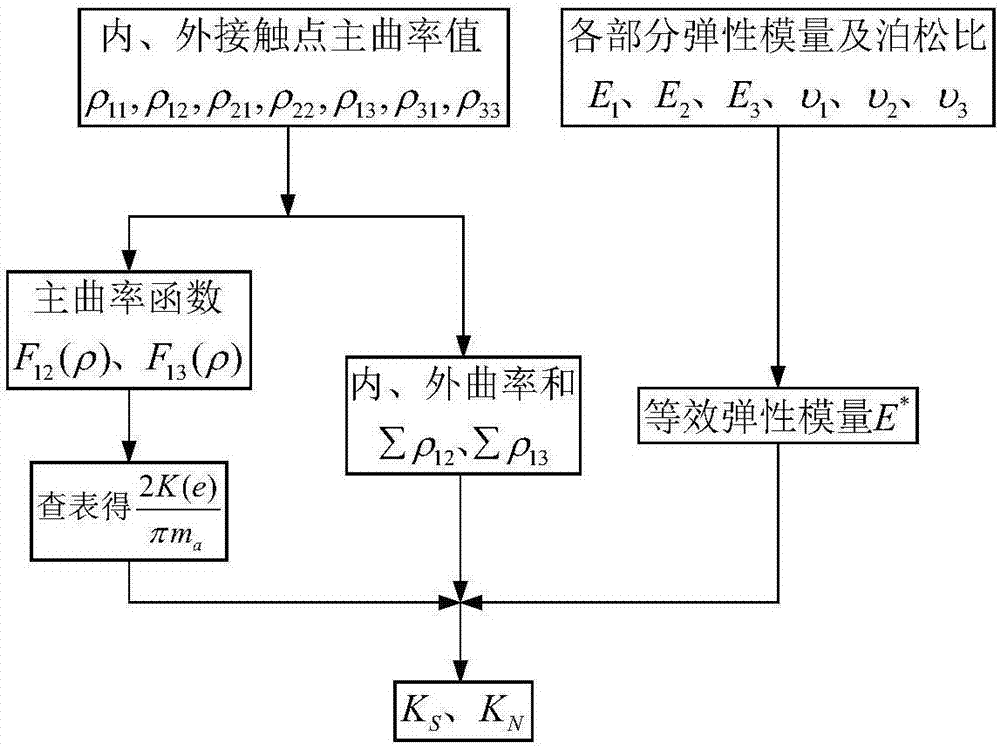

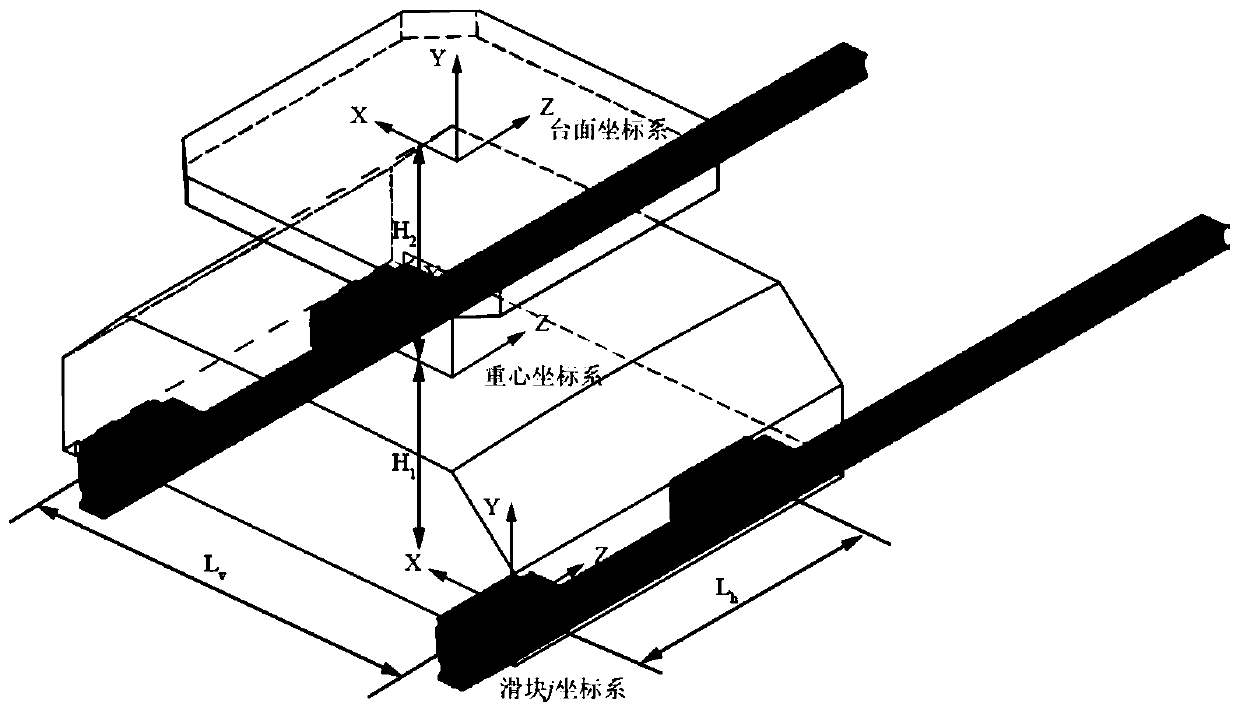

A method for modeling rigidity of a transmission chain of a double-screw drive system

ActiveCN108984831AAccurately Calculated Stiffness ValuesImprove modeling accuracyGeometric CADMachine gearing/transmission testingEngineeringHertz

A method for modeling rigidity of a transmission chain of a double lead screw drive system includes as the steps of calculating the rigidity of a rolling joint surface, analyzing the contact rigiditycause by friction force of lead screw, calculating the rigidity of fixed joint surface, modeling the dynamics of double lead screw, and calculating the rigidity of drive chain of double lead screw, etc, wherein the rolling joint surface comprises a lead screw-nut joint surface and a bearing joint surface, the fixed bonding surface includes a workbench-slide block joint surface, and the contact stiffness of the rolling joint is calculated by using the Hertz contact theory; establishing a friction model and taking into account the stiffness change of the joint surface caused by the friction force of the lead screw; considering the coupling effect of the worktable, establishing an accurate rigidity chain model of the double screw drive system by using the centralized mass method, thereby improving the dynamic modeling accuracy of the double screw drive system and the asynchronous error of the double-drive feed and improving the positioning accuracy of the double-drive machine tool. The method solves the problem that the rigidity of the joint surface is ignored in the dynamics modeling of a conventional double-screw drive system, and the model accuracy is low.

Owner:WUHAN UNIV OF TECH

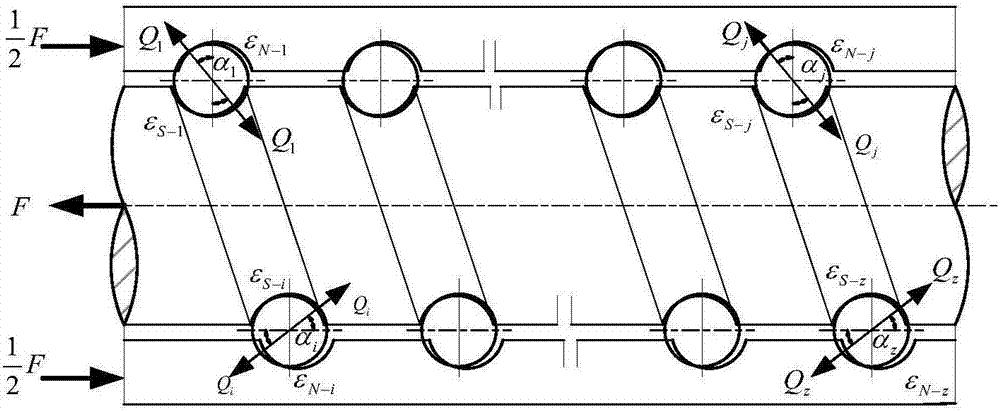

Extraction method of load spectrum of ball screw pair

ActiveCN107357967AAccurately determineDesign optimisation/simulationProbabilistic CADPower flowNonlinear systems of equations

The invention belongs to the field of contact mechanics and relates to an extraction method of a load spectrum of a ball screw pair. The method comprises the following steps: setting up a load distribution model of a single-nut ball screw pair; setting up a nonlinear system of equations for load distribution of the single-nut ball screw pair based on a hertz contact theory according to the principle of deformation compatibility; solving the nonlinear system of equations for contact load of a single-ball model; setting up a solving model for dynamic contact characters of high-speed motion state of the ball screw pair and solving value of the nonlinear system of equations; calculating the change rule between contact load of the screw nut pair and positions based on relations of working positions and torque current of a servo motor with time; and working out the load spectrum of the ball screw pair. The extraction method of the load spectrum of the ball screw pair utilizes precisely-determined load spectrums of all components of the screw nut pair to provide reference for reliability design of a feeding system.

Owner:NORTHEASTERN UNIV

Method for realizing precision straightening of thin-wall seamless steel tubes by adopting six-roller straightener

InactiveCN101927278AReduce the number of squashesIncrease the number of squashesMechanical engineeringSteel tube

The invention discloses a method for realizing the precision straightening of thin-wall seamless steel tubes by adopting a six-roller straightener, aiming at providing a method for obtaining optimum technological parameters and producing thin-wall seamless steel tubes with high surface quality by calculating straightening press-down quantity and correcting press-down quantity, comparing the resultant force of straightening applied force and correcting applied force with and hertz contact force, and checking straightness accuracy and the diameter difference of long shafts and short shafts of an ellipse. The method comprises the following steps: confirming the press-down bending and straightening frequency and press-flat bending and correcting frequency; confirming the straightening press-down quantity, the straightening applied force, the correcting press-down quantity and the correcting applied force; working out the hertz contact force resulting in the sag deformation of the seamless steel tubes according to a hertz contact theory; comparing the hertz contact force with the resultant force of the straightening applied force and the correcting applied force; calculating straightness error according to the actual straightening press-down quantity from 1 to the last straightening; and calculating the corrected diameter difference of the long shafts of the ellipse and the diameter difference of the short shafts of the ellipse from 1 to the last correcting and comparing with a standard value.

Owner:TIANJIN UNIV OF COMMERCE

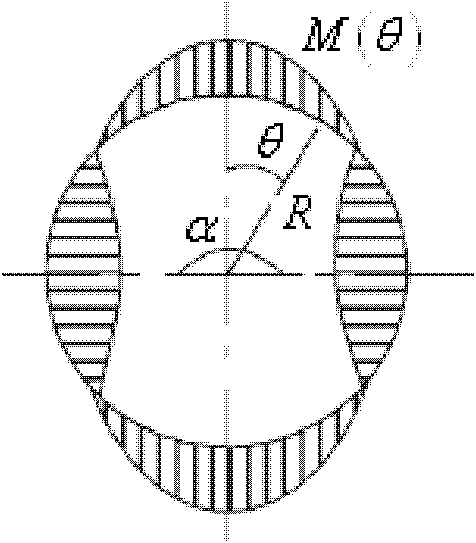

HSK100 main shaft handle's combined surface rigidity calculation method based on the condition of its high speed rotation

ActiveCN107063601ASpecial data processing applicationsElasticity measurementEngineeringHandling system

The invention provides an HSK100 main shaft handle's combined surface rigidity calculation method based on the condition of its high speed rotation, which belongs to the mechanical design and manufacturing field. The method considers the bearing changes of the HSK main shaft handle in different high-speed rotations because the connection performance of the handle is affected by a plurality of reasons. The contact of the handle's main shaft belongs to the non-linear research theory and if research is to be carried out on the connection performance of the connection parameters of the main shaft handle system, one should start from the non-linear consideration. However, the fractal geometry and optimized Hertz contact theory start to do research on the contact problem from the micro perspective to the macro perspective, and when fractal method is utilized to calculate the overall contact rigidity of the HSK100 main shaft handle's combined surface when the main shaft handle rigidity reaches the balanced state. The method raises the calculation of the rigidity of the HSK100 main shaft handle's combined part in high speed rotations through the use of the fractal theory and the Hertz contact theory for the first time. The method can provide a theoretical basis for the contact rigidity of the HSK100 main shaft handle and can better increase the HSK100 main shaft handle's precision and service lifetime.

Owner:BEIJING UNIV OF TECH

Ball bearing reliability design method

A ball bearing reliability design method is based on the following prerequisites: 1, the contact between an antifriction bearing rolling body and internal / external raceway satisfies the Hertz contact theory, and the contact type between the rolling body and the bearing internal / external raceway is point contact or / and line contact; 2, the ball bearing reliability design method satisfies the following requirements: firstly building a deep groove ball bearing flexible multi-body contact dynamics model, simulating and parsing a deep groove ball bearing rotation process so as to obtain each part angular velocity and dynamic contact impact stress changing rules, and using obtained data to finish the ball bearing reliability design. The invention provides the reference method for ball bearing reliability design and fatigue life research; related principles can be promoted to all transplantable related technical fields; the ball bearing reliability design method has large latent economy value and social value.

Owner:梁明轩

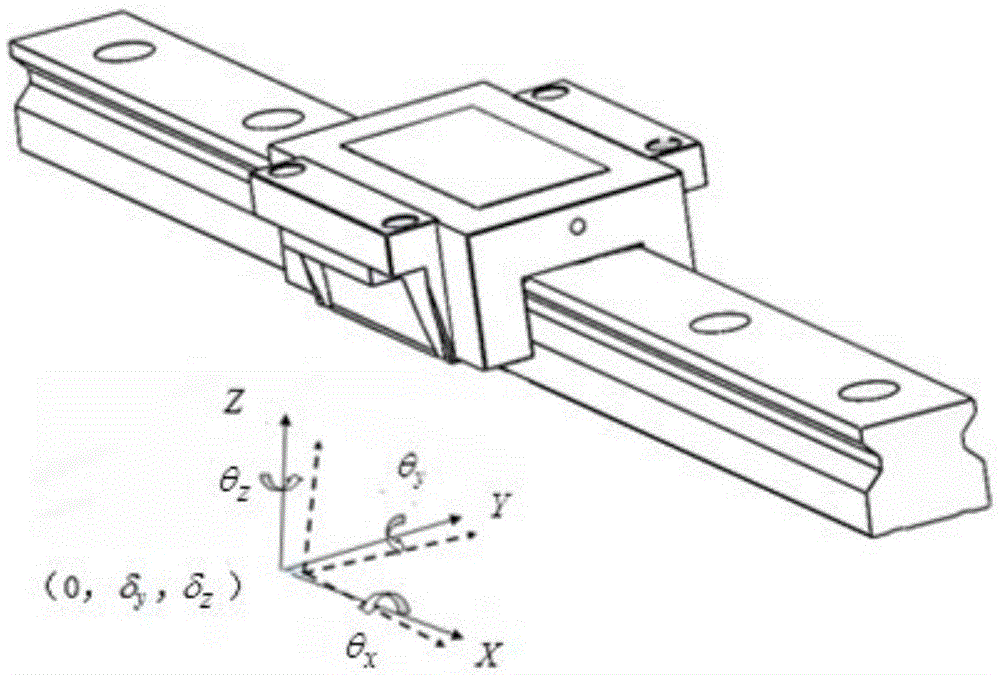

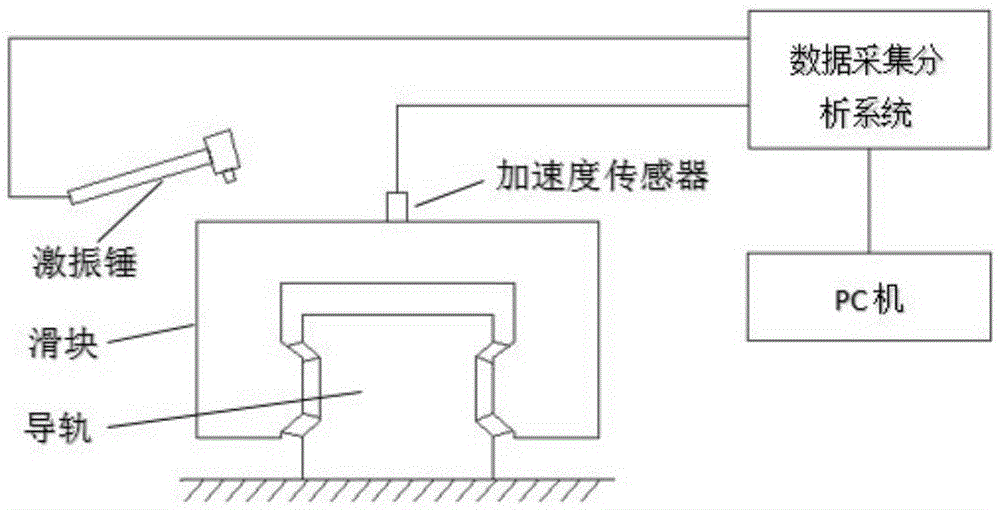

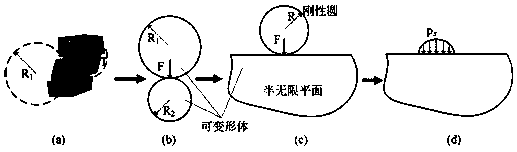

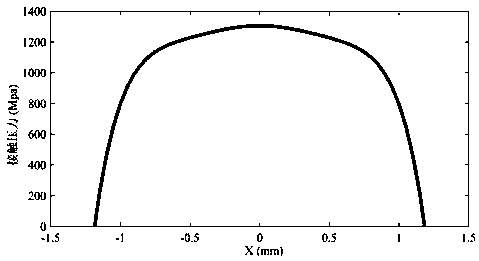

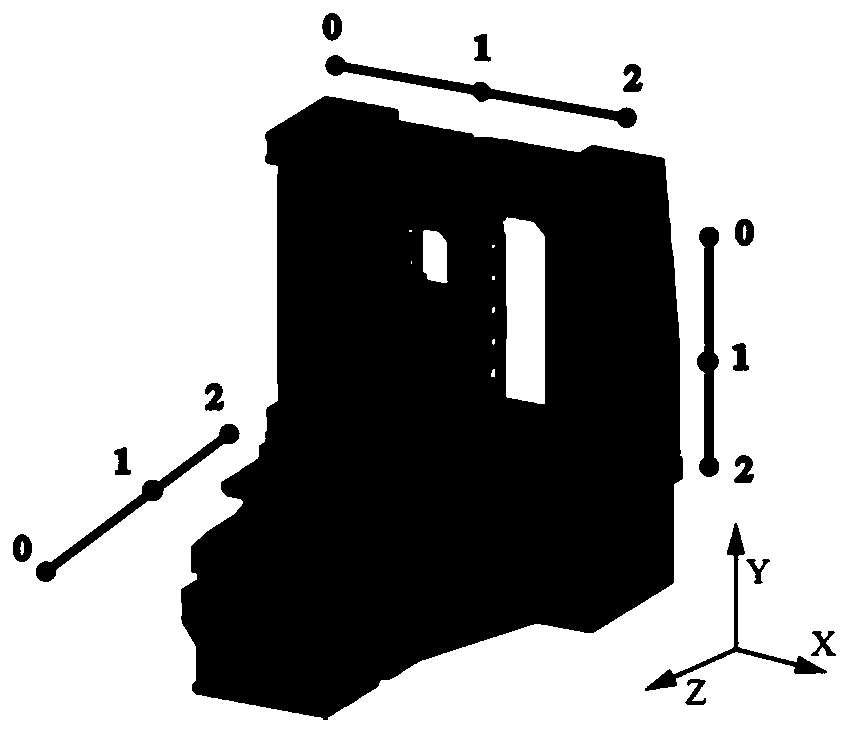

Guideway joint feature-considered vibration response analysis method for upright post-spindle system

InactiveCN105571847ATrue expressivenessSolving for Response CurvesMachine part testingSystem dynamics modelHarmonic balance

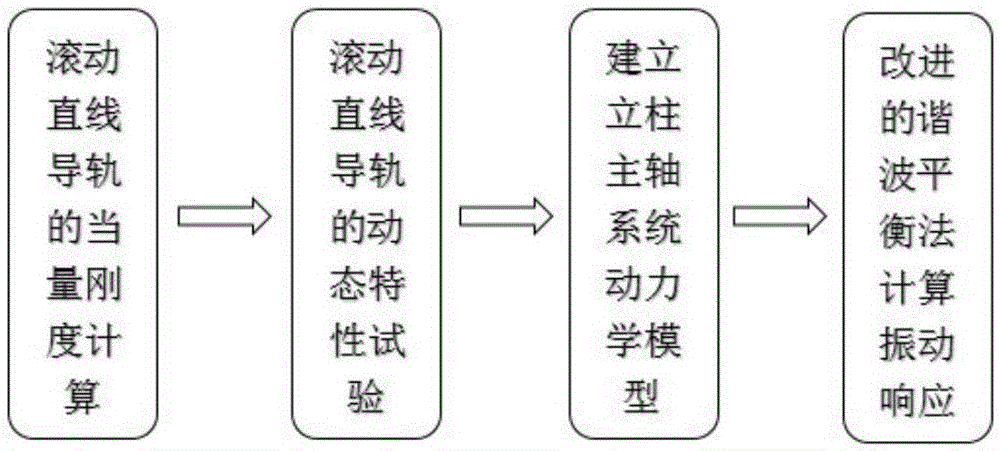

The invention provides a guideway joint feature-considered vibration response analysis method for an upright post-spindle system. Firstly, the relationship between a single roller and the bearing capacity is represented based on the Hertz contact theory, and a relational expression between the load and the deformation is established. After that, in the multiple-support excitation and multiple-support response manner, the inherent frequency and the inherent damping of a guideway joint at each order are identified. Then, a kinetic model for the upright post-spindle system is established. Finally, according to the improved harmonic balance method, the vibration response of the upright post-spindle system under the effect of sinusoidal excitation is calculated. According to the technical scheme of the invention, on one hand, the equivalent stiffness of a roller linear guide rail under an arbitrary load is calculated, and the guideway joint is simplified as a system capable of providing the non-linear restoring force. On the other hand, the nonlinear vibration theory-based calculation method is adopted to provide a vibration model for the upright post-spindle system, and the harmonic balance method is improved. Moreover, a response curve is obtained more quickly based on the principle of least square method. The above method provides a solving means for conducting the accuracy research and the optimized design of linear guide rails.

Owner:BEIJING UNIV OF TECH

Prediction method for crack initiation of secondary surface of heavy-load gear

InactiveCN108256241ASolve long-standing technical problemsPredicted positionGeometric CADDesign optimisation/simulationContact pressurePredictive methods

The invention discloses a prediction method for crack initiation of a secondary surface of a heavy-load gear. The method comprises the following steps that 1, based on a hertz contact theory, the contact of a gear pair is simplified, a meshed position parameter is calculated according to geometric kinematics, and a contact analysis model is established; 2, based on the contact analysis model of the gear pair, by using a value calculation method, the surface contact pressure of the analysis model under the heavy-load condition is obtained; 3, a material constant related to the service life of crack initiation is solved; 4, based on a continuous damage mechanics theory, by using critical damage amount, whether or not a crack occurs on the secondary surface is judged, and a gear contact elastic-plastic constitutive equation of coupling damage is established; 5, the service life of crack initiation is calculated, and the position of crack initiation is obtained. According to the predictionmethod, the technical difficult problem which exists for a long time in the machinery industry is solved, the position and service life of crack initiation of the secondary surface of the heavy-loadgear can be effectively predicted, and the basis is provided for design, manufacturing and use of the gear.

Owner:CHONGQING UNIV

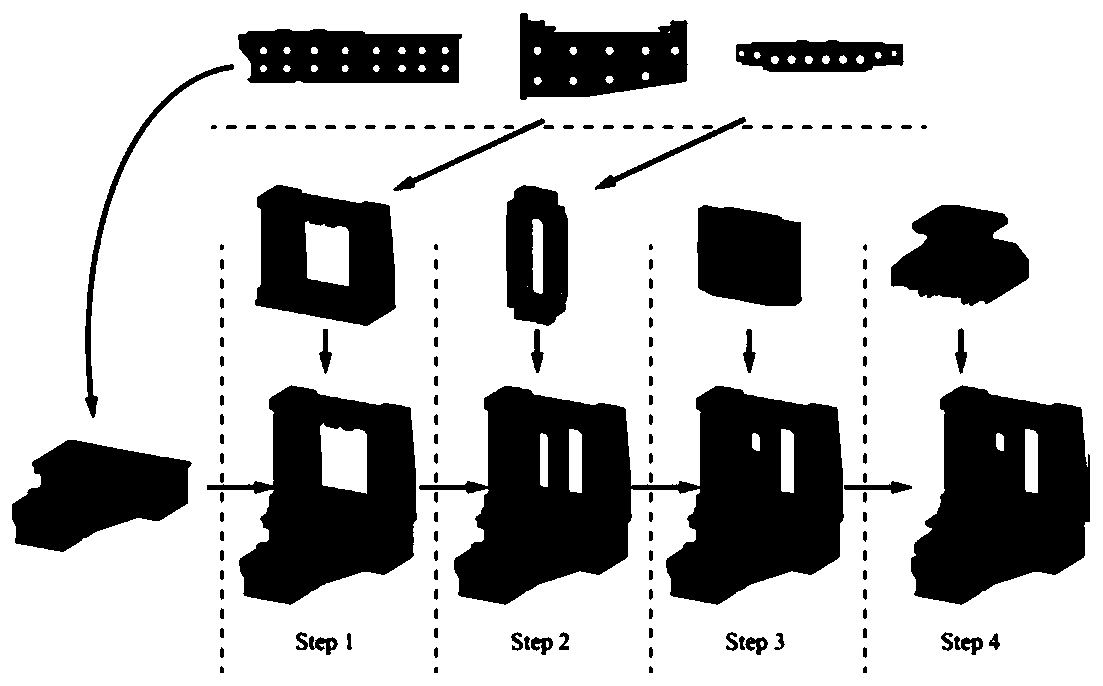

Machine tool assembly error prediction and control method

ActiveCN110096762AAccurate and efficient guidanceComply with the objective assembly situationDesign optimisation/simulationTotal factory controlGeometric errorTransfer model

The invention discloses a machine tool assembly error prediction and control method which comprises the following steps: (1) based on a Hertz contact theory, establishing and linearing a rolling guiderail error-workbench error transfer model based on deformation coordination; (2) for a precise horizontal machining center, establishing a finite element model by means of ABAQUS simulation software,and extracting a gravity deformation result of each assembly step; (3) on the basis of an assembly error transfer model based on a differential vector method, establishing a complete machine error model considering assembly deformation and guide rail errors; and (4) for the established complete machine error model, providing a corresponding assembly error adjustment and control strategy. The influence of the rolling guide rail geometric error on error transmission is comprehensively considered, and the method better conforms to the objective installation condition; the variability of gravitydeformation is considered, the deformation result is analyzed step by step, and step-by-step prediction and tail end error control are achieved more accurately.

Owner:TIANJIN UNIV

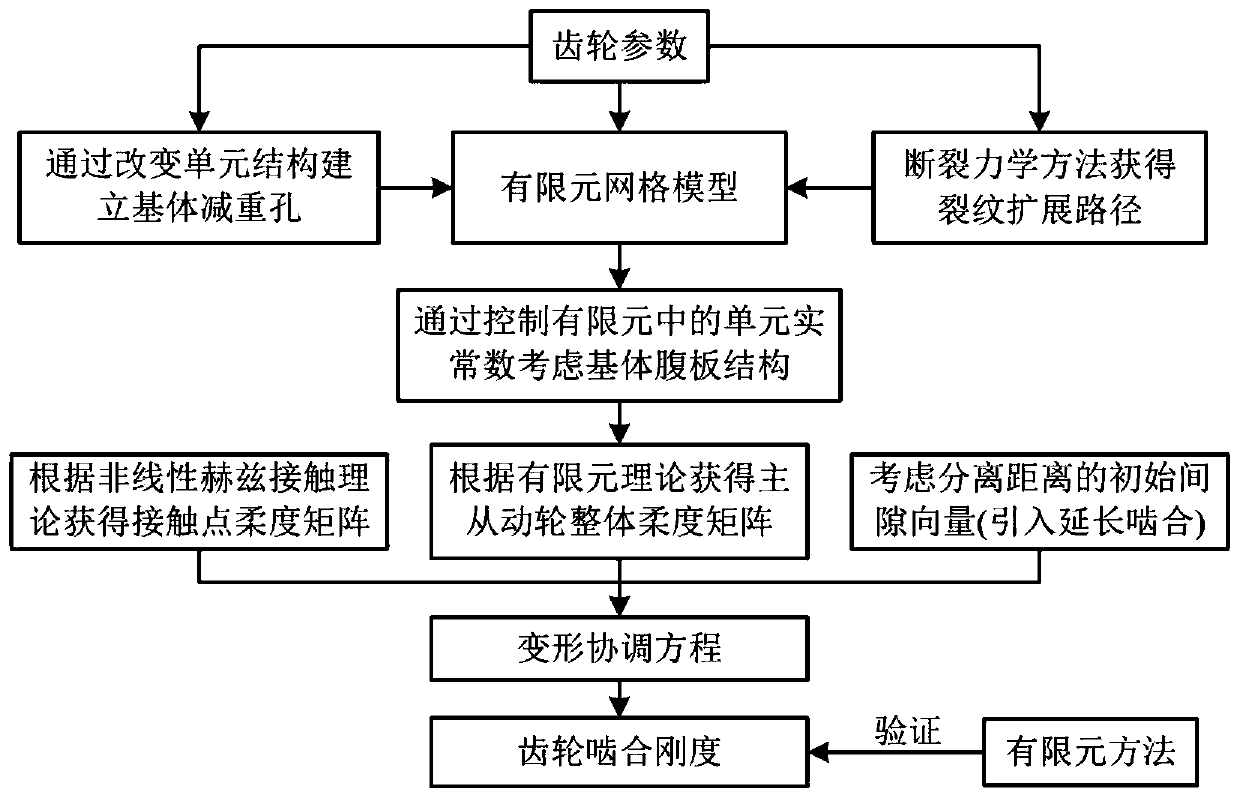

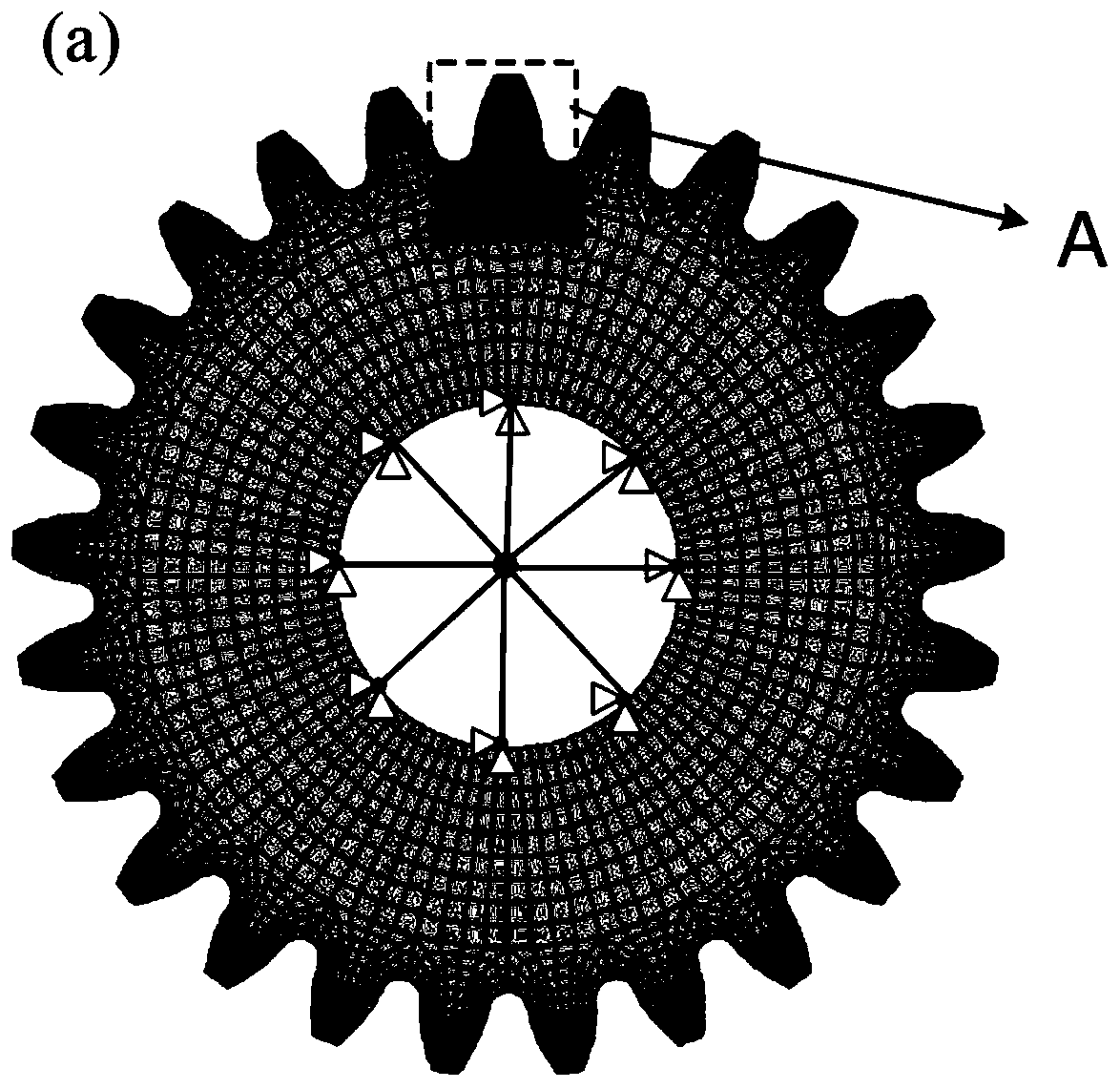

A straight gear meshing stiffness calculation method considering a complex matrix and a crack propagation path

ActiveCN109726520AHigh meshing stiffnessHigh precisionSpecial data processing applicationsDrive wheelWeb structure

The invention relates to a straight gear meshing stiffness calculation method considering complex matrix and crack propagation, and the method comprises the steps: obtaining an overall flexibility matrix of a driving wheel and a driven wheel of a meshing gear based on a finite element theory, and determining an overall flexibility matrix of a possible contact point at each meshing position; Introducing a nonlinear Hertz contact theory, and calculating a contact flexibility matrix of possible contact points at each meshing position; And introducing the overall flexibility matrix, the contact flexibility matrix and the initial gap vector of the possible contact point into a deformation coordination equation, and calculating the meshing stiffness of the meshing position. According to the method, crack propagation paths obtained through fracture mechanics can be considered at the same time, and the influence of a complex matrix structure (including a web structure and a lightening hole structure) on the meshing rigidity of the straight gear can be considered at the same time. According to the method, the straight gear meshing stiffness considering the gear web structure, the lighteninghole structure and the crack propagation path can be calculated at the same time. The result of the method is verified by adopting a three-dimensional contact finite element method, and the result shows that the method disclosed by the invention has higher precision for calculating the meshing stiffness of the crack-containing complex matrix gear.

Owner:NORTHEASTERN UNIV

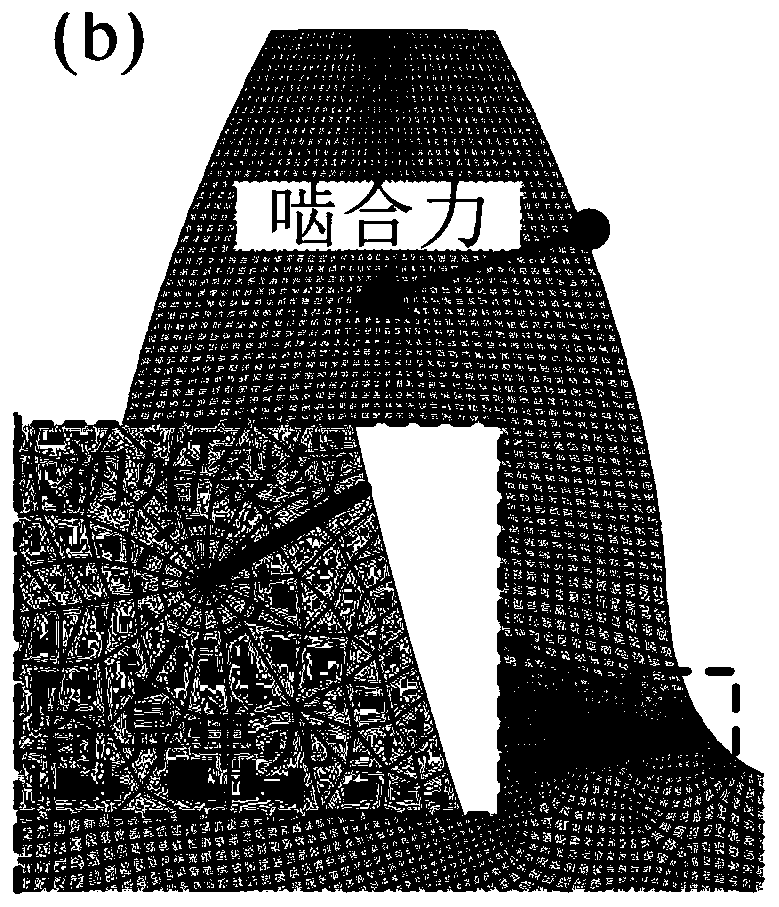

Force-position mixing control method for grinding and polishing of force-controlled robot

InactiveCN109927028AControl pressureFeed speed controlProgramme-controlled manipulatorPositive pressureRobot position

The invention provides a force-position mixing control method for grinding and polishing of a force-controlled robot. According to the method, on the basis of a workpiece three-dimensional model, a grinding and polishing tool machining track and / or a five-axis NC program matched with a workpiece is generated according to different machining surfaces, and then a robot position control program is generated; based on a Hertz contact theory, suppose the pressure intensity of each position grinding and polishing contact point is the same, the grinding and polishing positive pressure of the contactarea is obtained according to the contact surface pressure stress distribution rule; the feeding speed is obtained through a feeding speed self-adaptive model; and in the grinding and polishing process, the position of the robot is controlled, the grinding and polishing pressure and the feeding speed of the grinding and polishing tool are controlled at the same time, so that the grinding and polishing precision and the surface uniformity of a complex curved surface workpiece can be effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

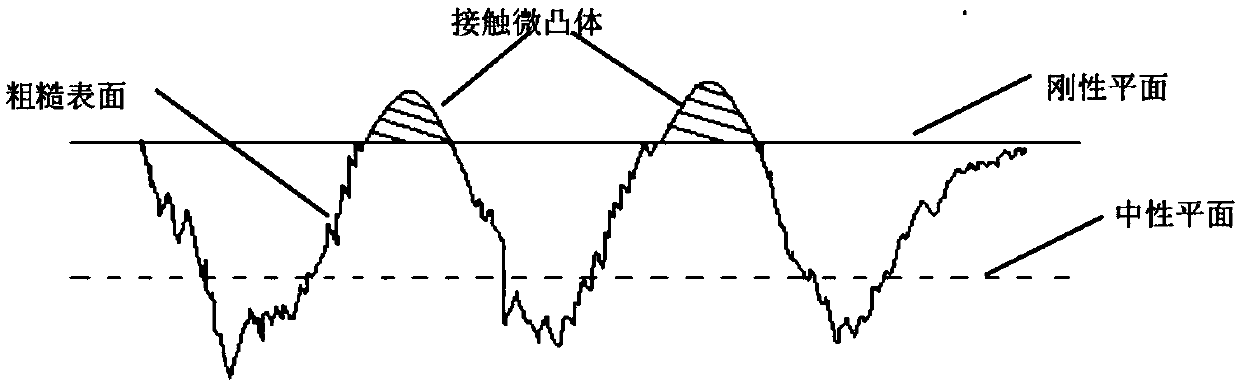

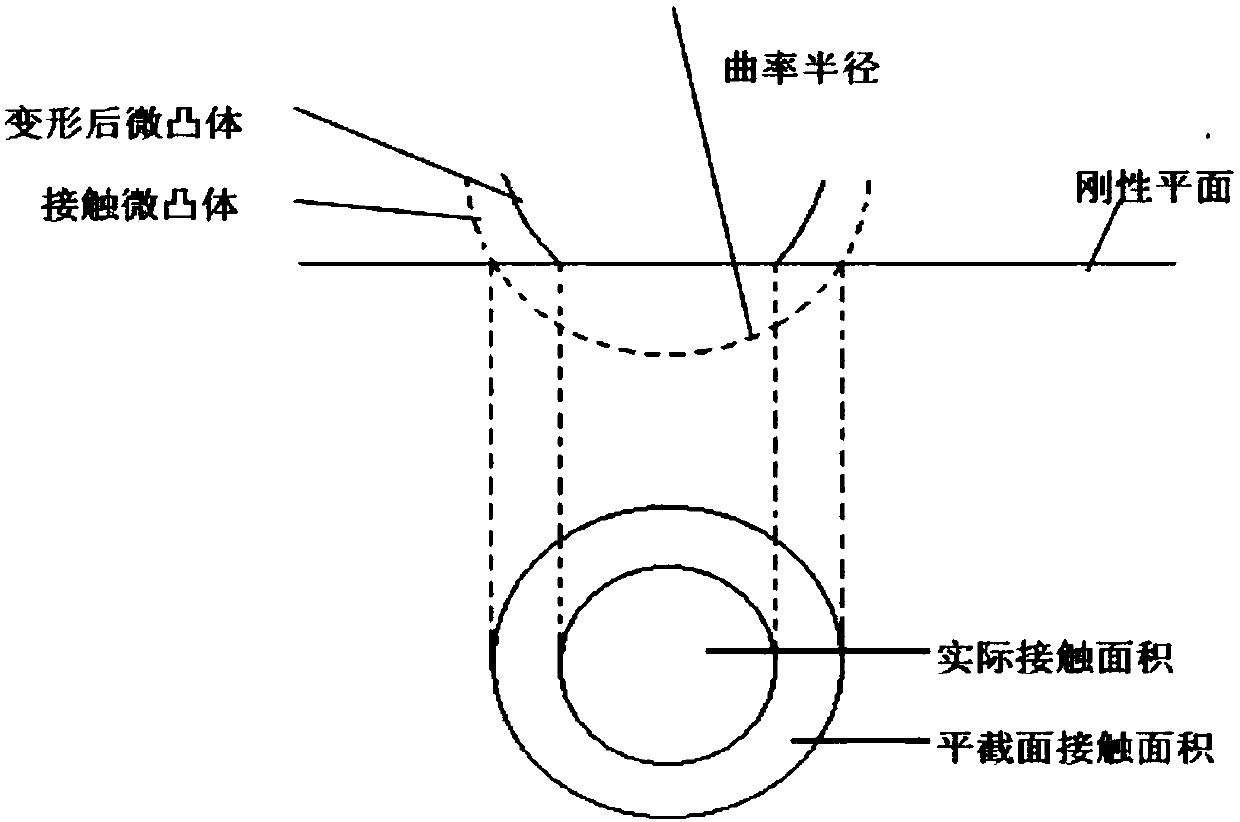

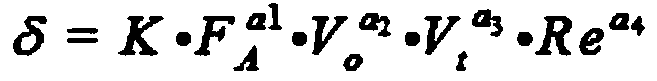

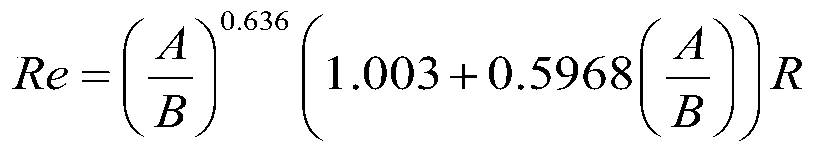

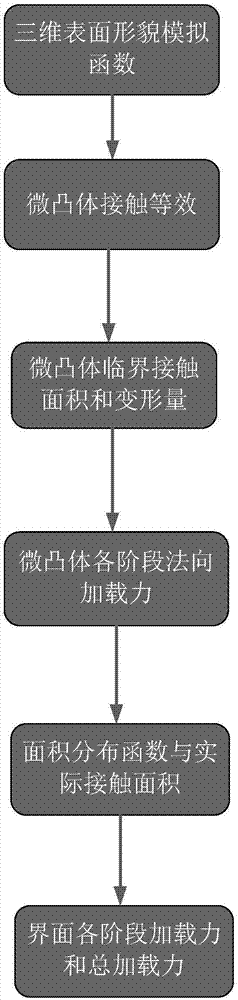

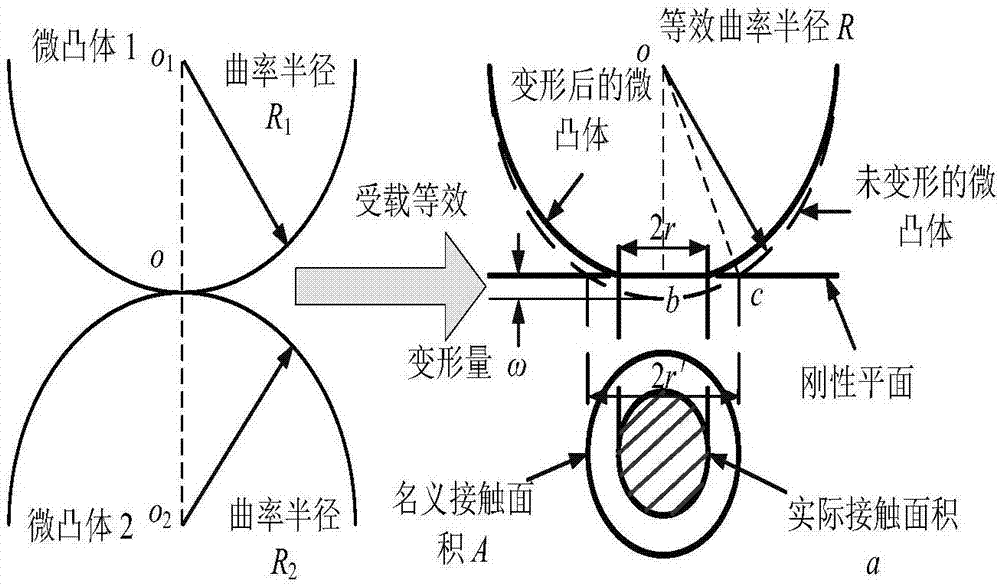

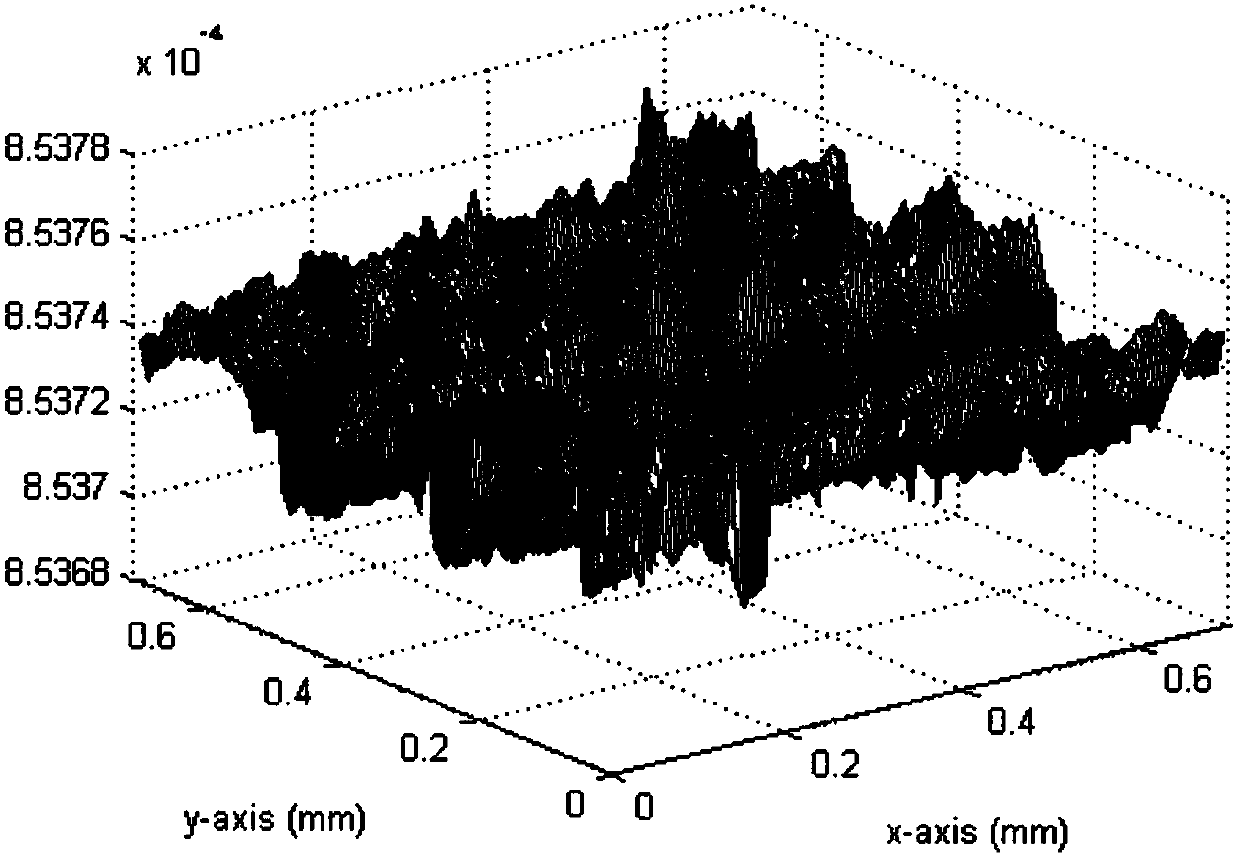

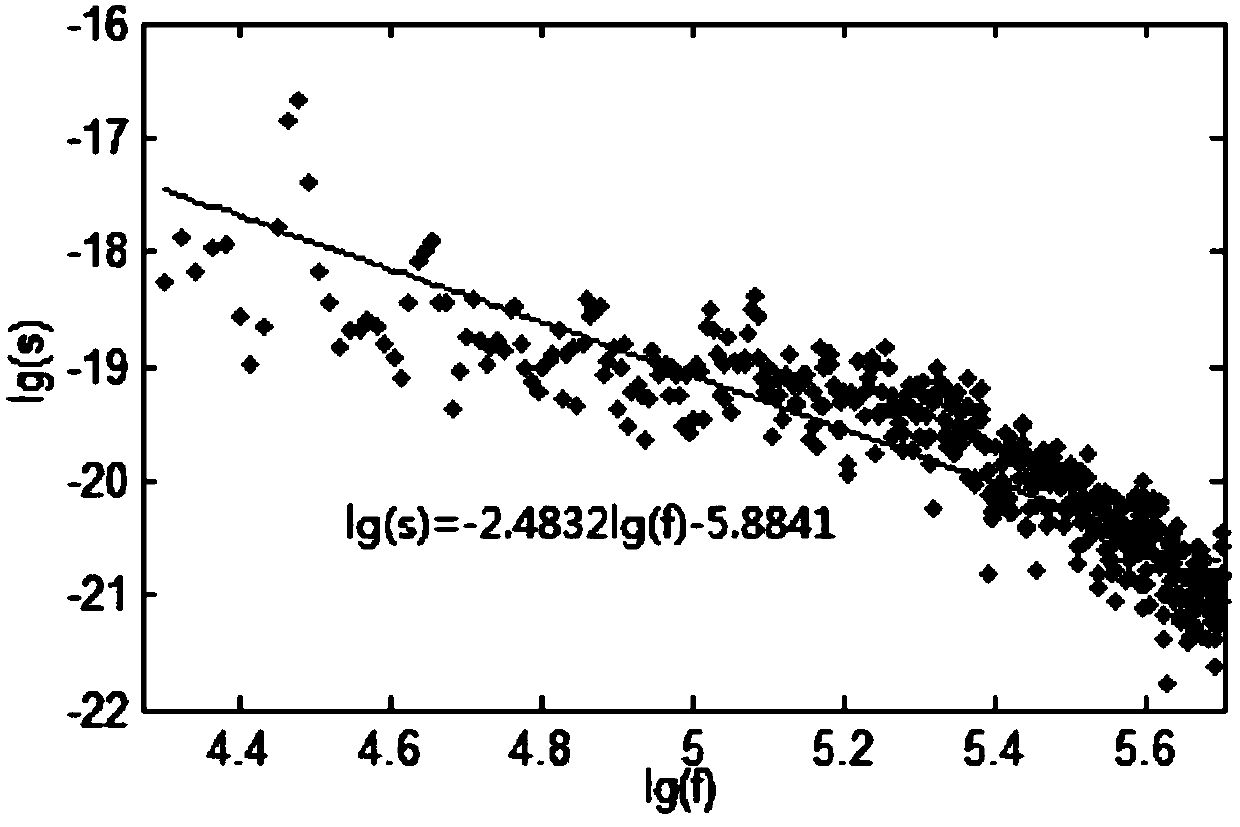

Prediction method of interface loading force in consideration of three-dimensional fractal

The invention discloses a prediction method of interface loading force in consideration of three-dimensional fractal. When two metal surfaces are contacted with each other, the formed interface contact is the contact among micro-bulges in fact from micro perspective. The loaded micro-bulges experience three stages of deformations of elasticity, elasticity-plasticity and plasticity in succession. In consideration of the three-dimensional fractal distribution characteristic of the micro-bulges in the interface, a prediction method of metal interface loading force under dry friction is provided based on fractal geometry theory and Hertz contact theory. The method considers three-dimensional fractal surface topography, friction coefficient and elastic-plastic deformation on the contact interface on the basis of the conventional contact analysis. The method makes the interface loading force which is hard to detect easy to obtain with simple calculation and easy operation, capable of being applied to interfacial dynamic characteristics analysis of precision machinery in projects.

Owner:NORTHEASTERN UNIV

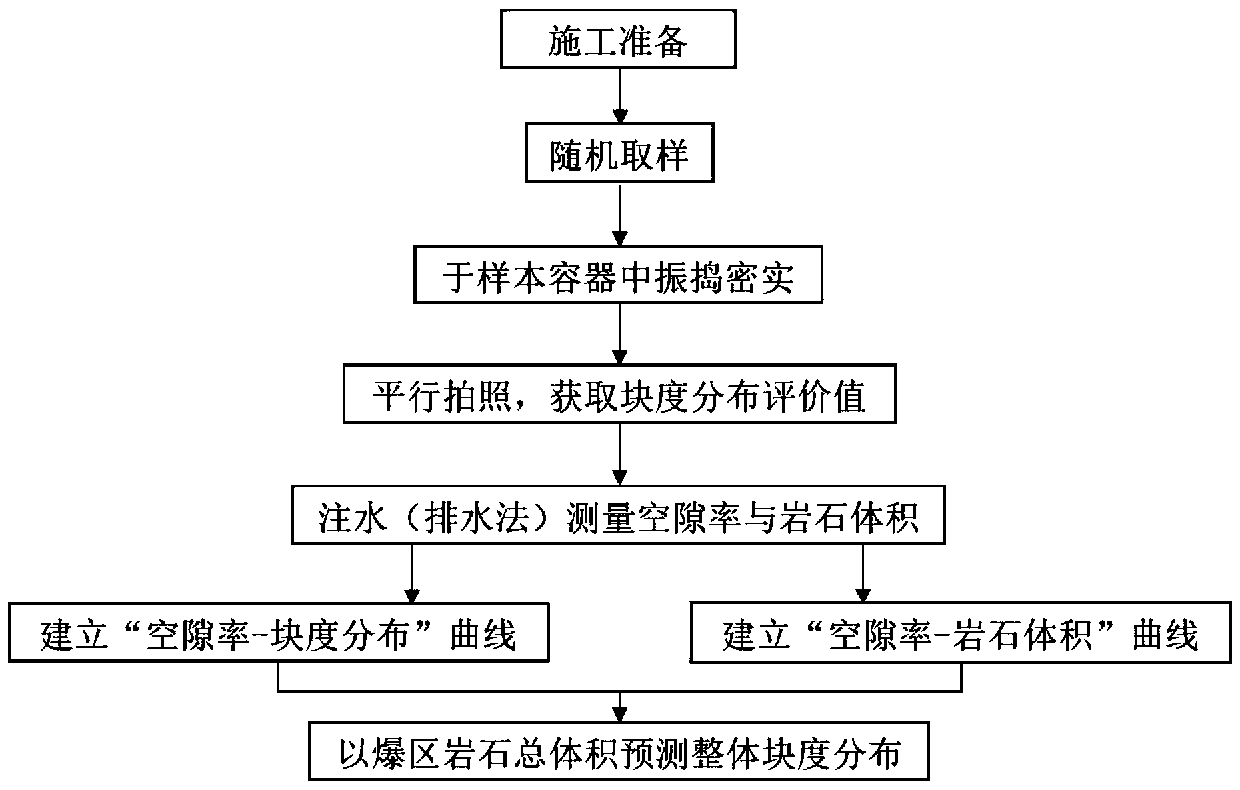

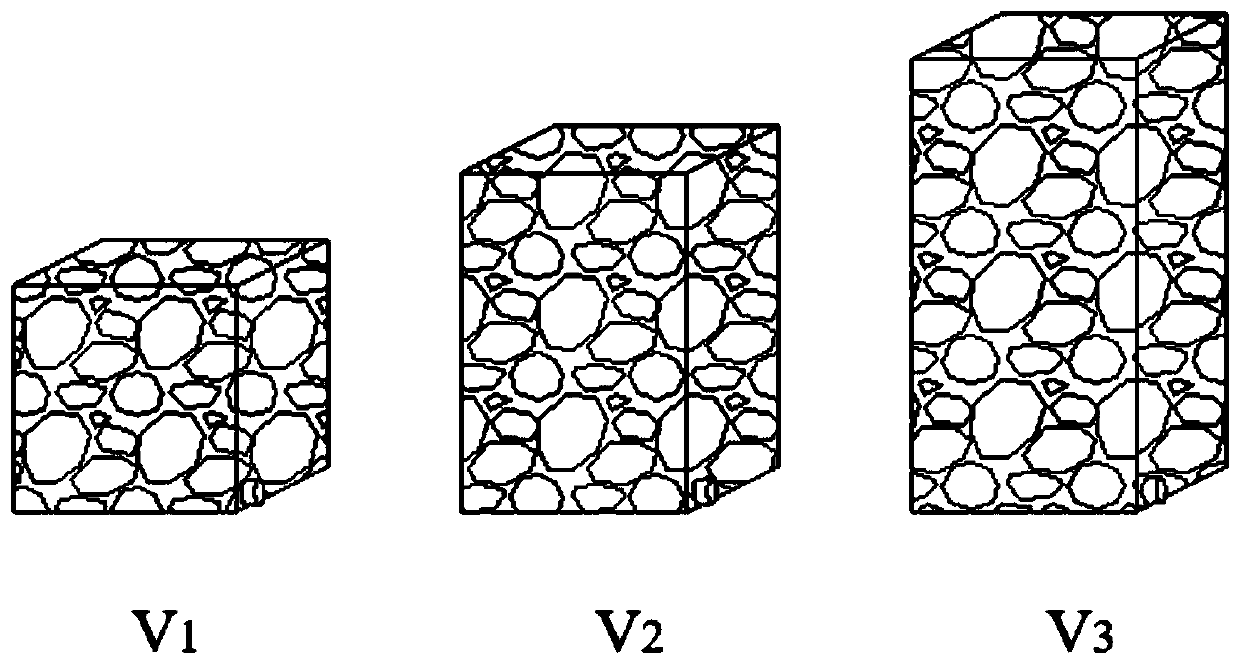

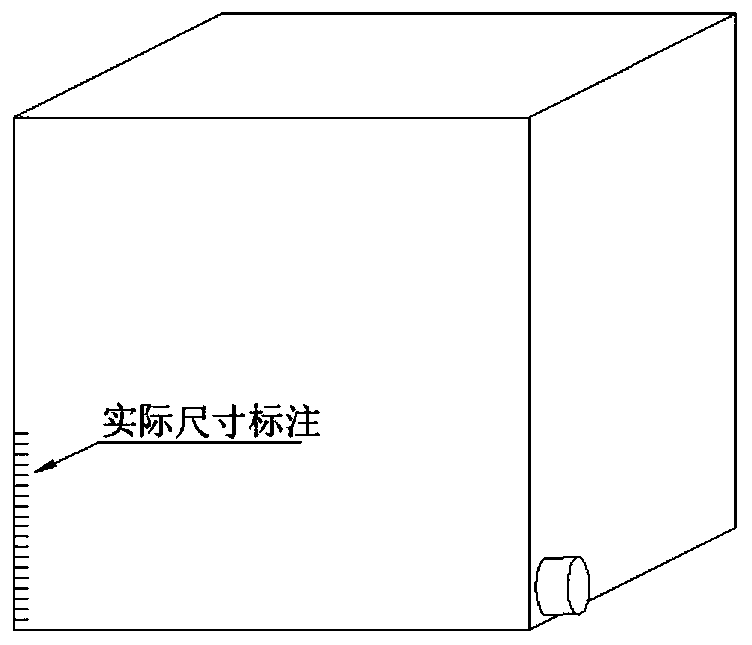

Blasting lumpiness measuring method based on photogrammetry and particle contact theory

ActiveCN110068573AQuick and easy measurementReduce workloadMaterial analysis by optical meansRock sampleSurface projection

The invention provides a blasting lumpiness measuring method based on photogrammetry and a particle contact theory, which comprises the following steps: Step 1, randomly selecting a rock sample from the blasted pile rock, and filling at least three containers; Step 2, vibrating and compacting the rock samples to form a test piece container; Step 3, respectively photographing the side surface of each test piece container to obtain a side surface projection image of the rock sample, and selecting a geometric characteristic parameter for measuring the rock lumpiness; carrying out lumpiness statistics on the particle size range to be solved to obtain the rock lumpiness condition; Step 4, measuring the void volume of the rock in each test piece container, and calculating the corresponding voidratio and the volume of the rock; Step 5, establishing a relation curve N1 between the void ratio and the rock lumpiness; and Step 6, establishing a relation curve N2 between the rock volume and the void ratio, then predicting the void ratio of the blasted pile rock under the same vibration compaction condition after blasting according to the total volume of the rock before blasting based on the curve N2, and estimating the rock lumpiness of the blasted pile rock according to the curve N1.

Owner:WUHAN UNIV

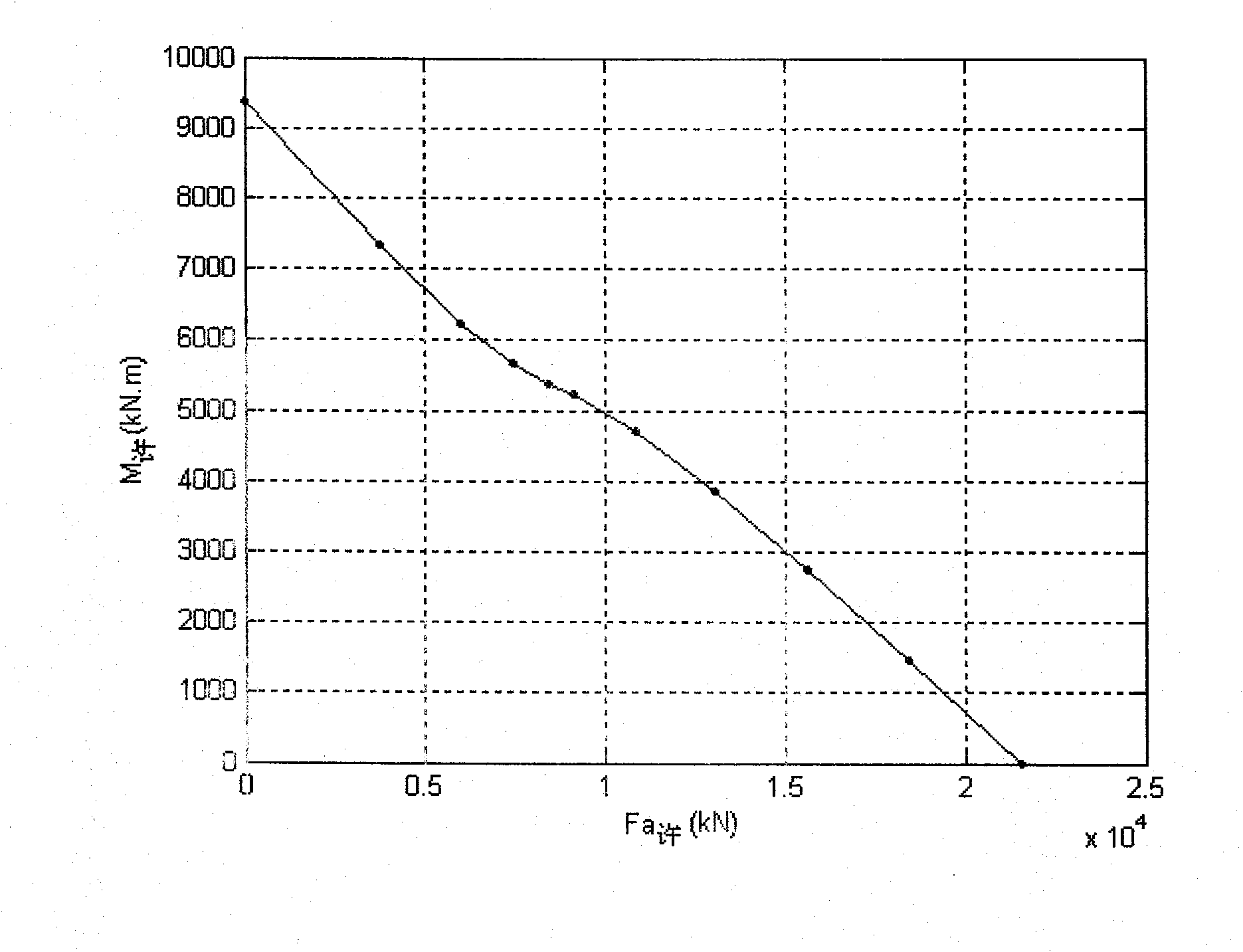

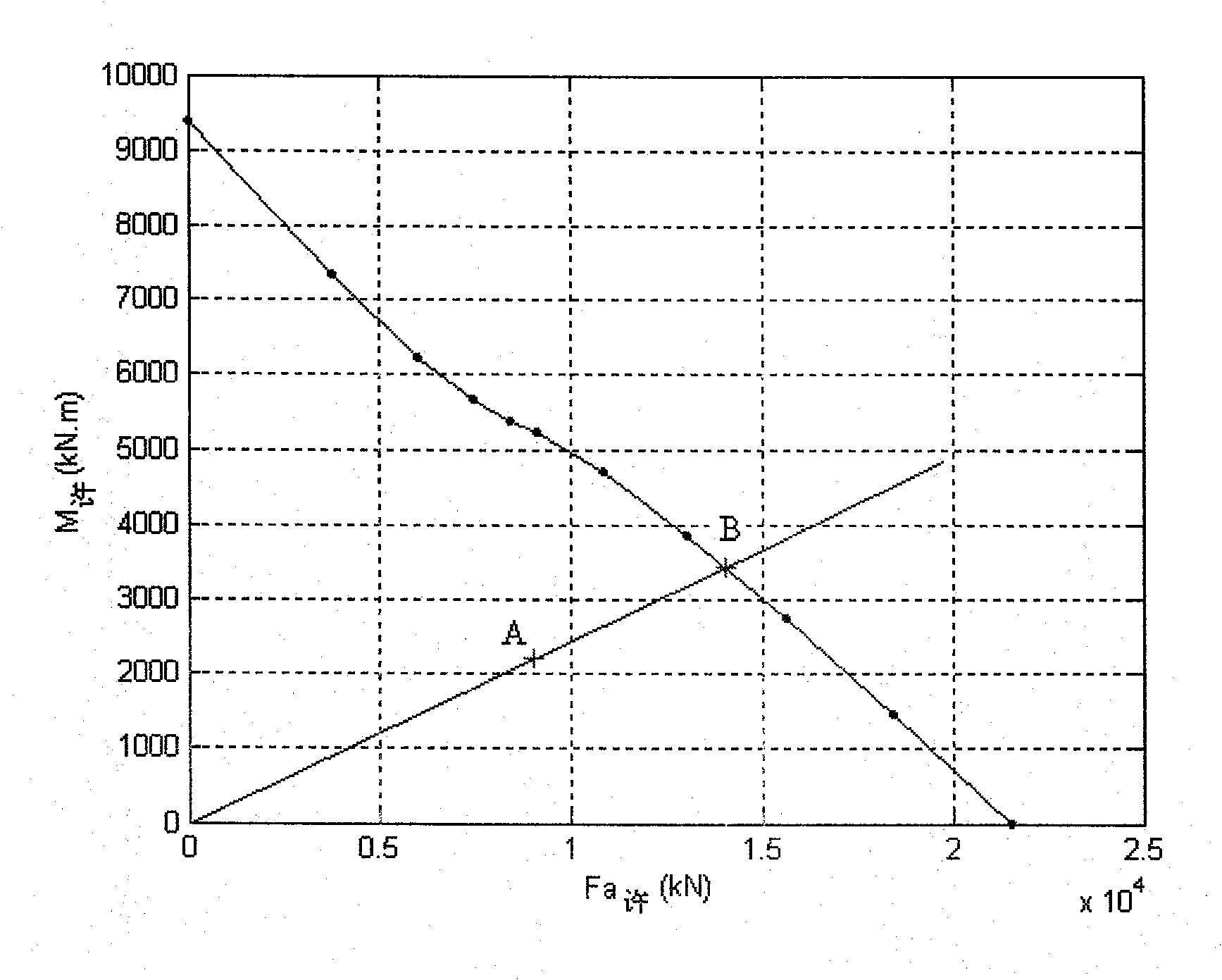

Method for allowing for using maximum load of rolling body to set static load bearing curve of blade bearing

InactiveCN101782105AMeet design needsSmall amount of calculationRolling contact bearingsEngineeringGreek letter epsilon

The invention provides a method for allowing for using the maximum load of a rolling body to set a static load bearing curve of a blade bearing. The method comprises the following steps of: according to a hertz contact theory, obtaining an allowable maximum load [Qmax] of the rolling body, substituting the [Qmax] to obtain the axial load Fa allowed of the blade bearing and the static load computing formula M allowed of the capsizing moment; under a principle of selecting minimum values, determining the value of the epsilon 1 or the epsilon 2, and making the value meet two parallel conditions: 1, when the epsilon 1 is less than 1, the summation of the epsilon 1 and the epsilon 2 is equal to 1, and the epsilon 1 is more than or equal to the epsilon 2; and 2, when the epsilon 1 is more than or equal to 1, the epsilon 2 is equal to 0; calculating the Fa allowed value and the M allowed value according to the values of the epsilon 1 and the epsilon 2; and setting the static load bearing curve of the blade bearing by taking the axial dynamic load Fa allowed as the horizontal coordinate and the capsizing moment dynamic load M allowed as the vertical coordinate. By the use method for setting the static load bearing curve of the blade bearing according to the allowed maximum load of the rolling body, whether the lectotype of the blade bearing meets the use requirement can be validated, and the method can also be used as a reference for optimizing the design parameters of the blade bearing.

Owner:LUOYANG BEARING RES INST CO LTD

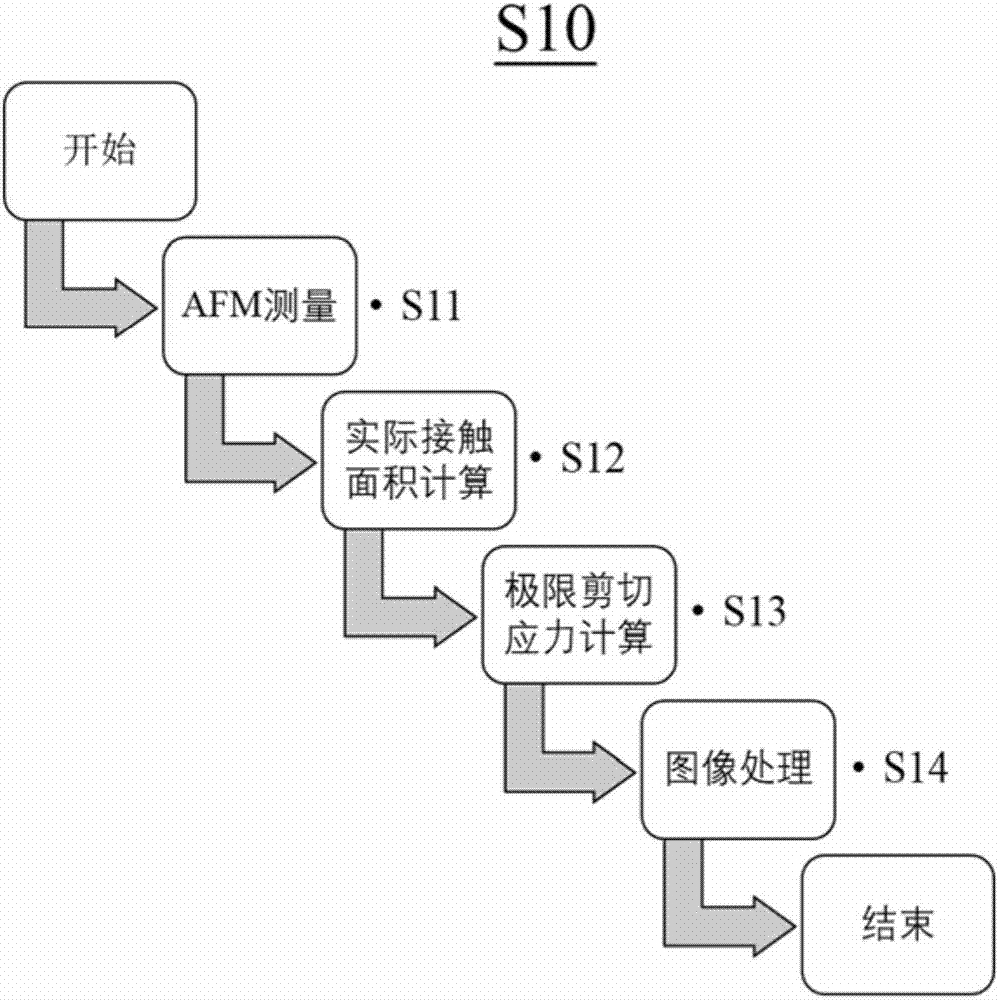

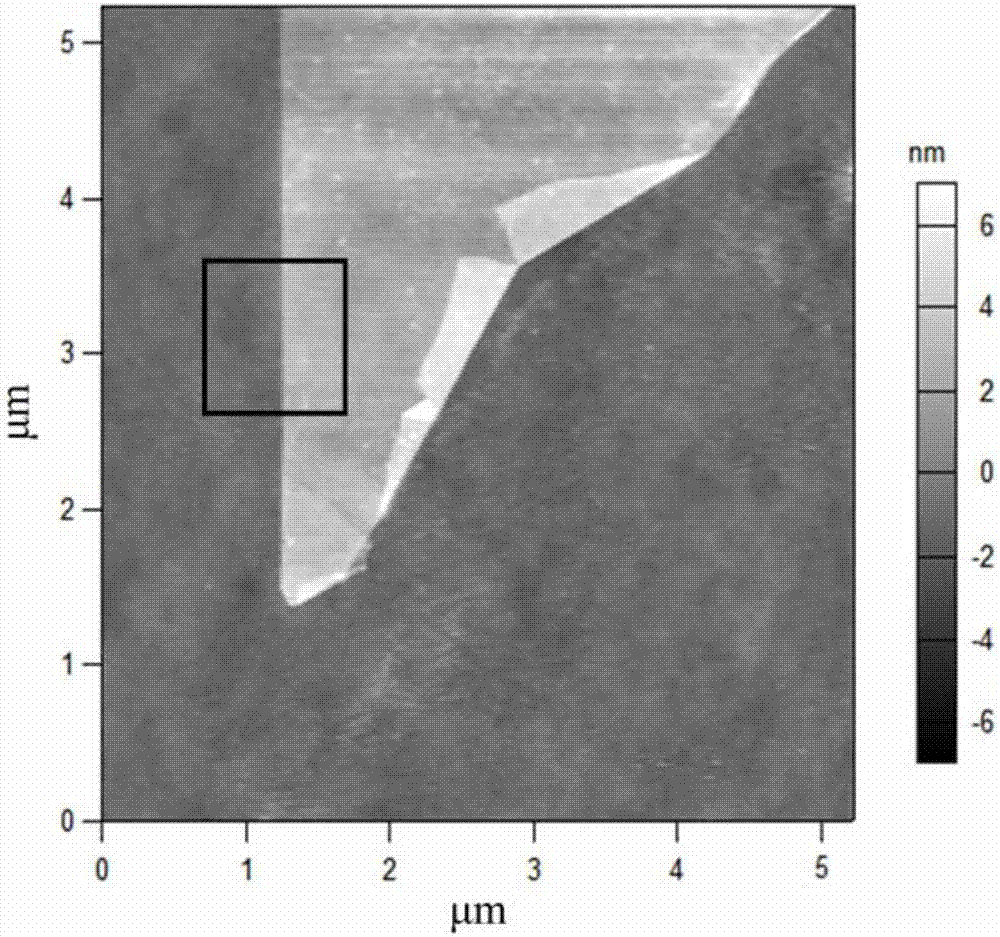

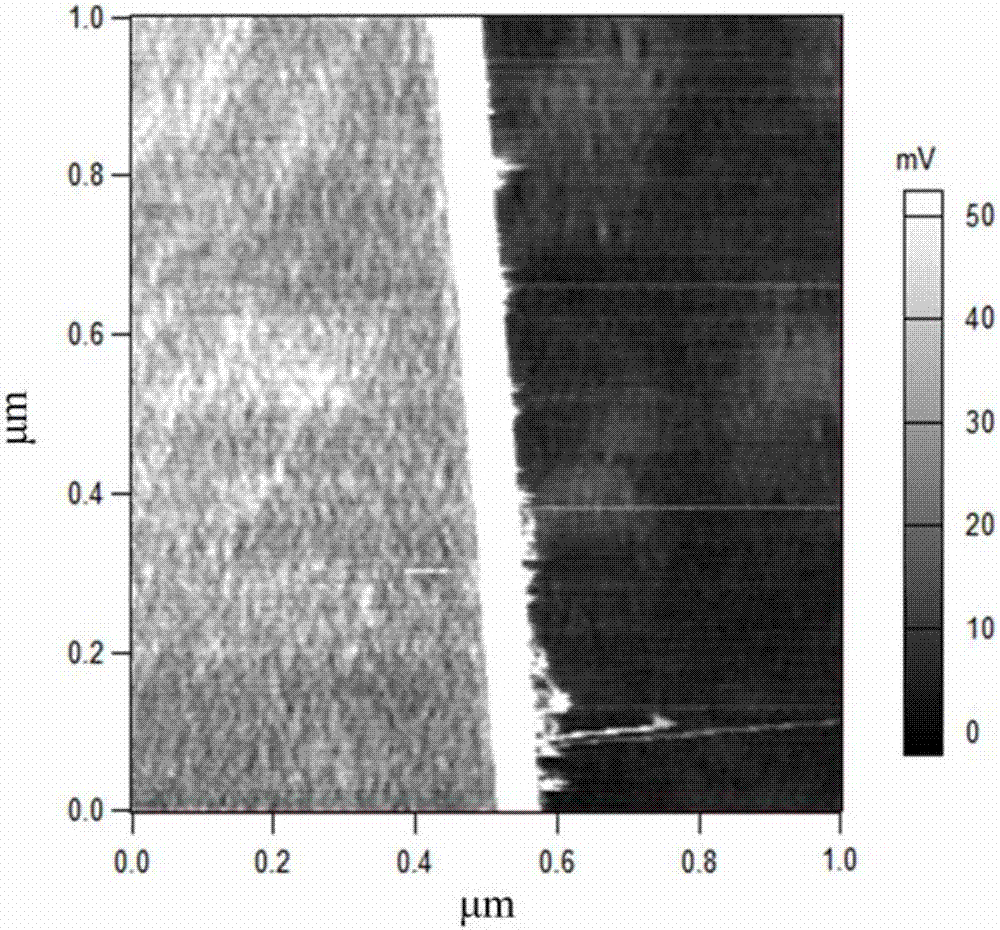

Measuring method for limiting shearing stress of nanometer material

InactiveCN106979897AEasy to operateLow surface topography requirementsMaterial strength using steady shearing forcesNormal loadStress measures

The invention relates to a measuring method for a limiting shearing stress of a nanometer material. The method comprises the following steps: by using an atomic force microscope (AFM), applying a normal load Fn and measuring a friction force Ff and an average adhesive force Fad of each point in a selected area on the surface of a sample; calculating the limiting shearing stress of the material according to a formula based on an elastic contact theory and an interface friction theory; processing the limiting shearing stress at each point on the surface of the nanometer material into a distributed image. According to the invention, an atomic force microscope technique based on high mechanical sensitivity, compared with the traditional measuring technique for the limiting shearing stress, has the advantages of higher quantitative measurement precision, low demand on surface appearance of the sample and suitability for various nanometer materials. The widely accepted JKR elastic contact theory and interface friction theory are considered as the theories on which the method provided by the invention is based, the theories are widely applied to the research on the mechanical performances of the nanometer material and the reliability of the measuring method is guaranteed by the theories.

Owner:XIANGTAN UNIV

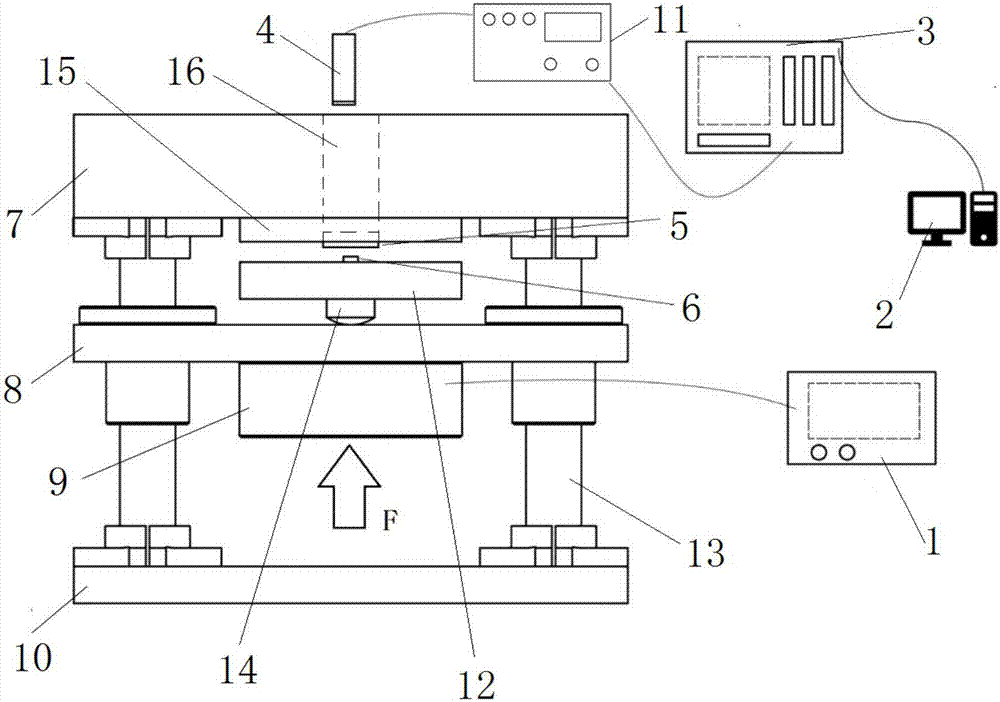

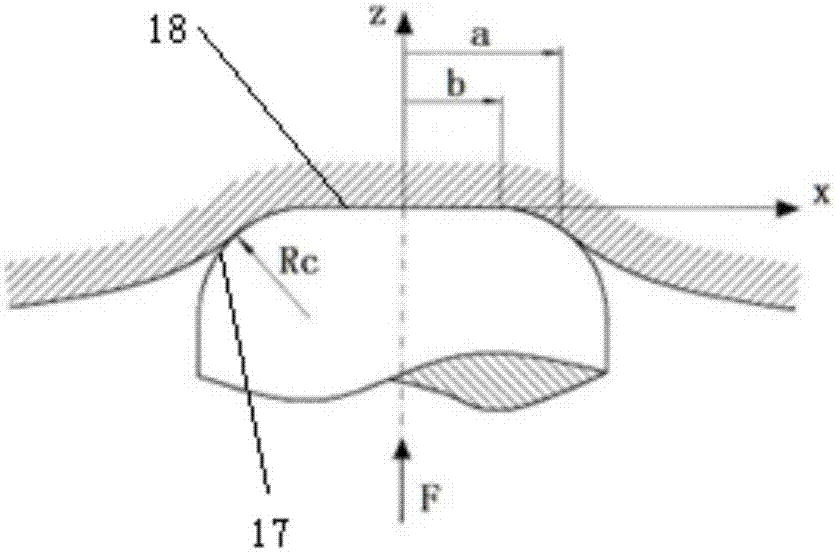

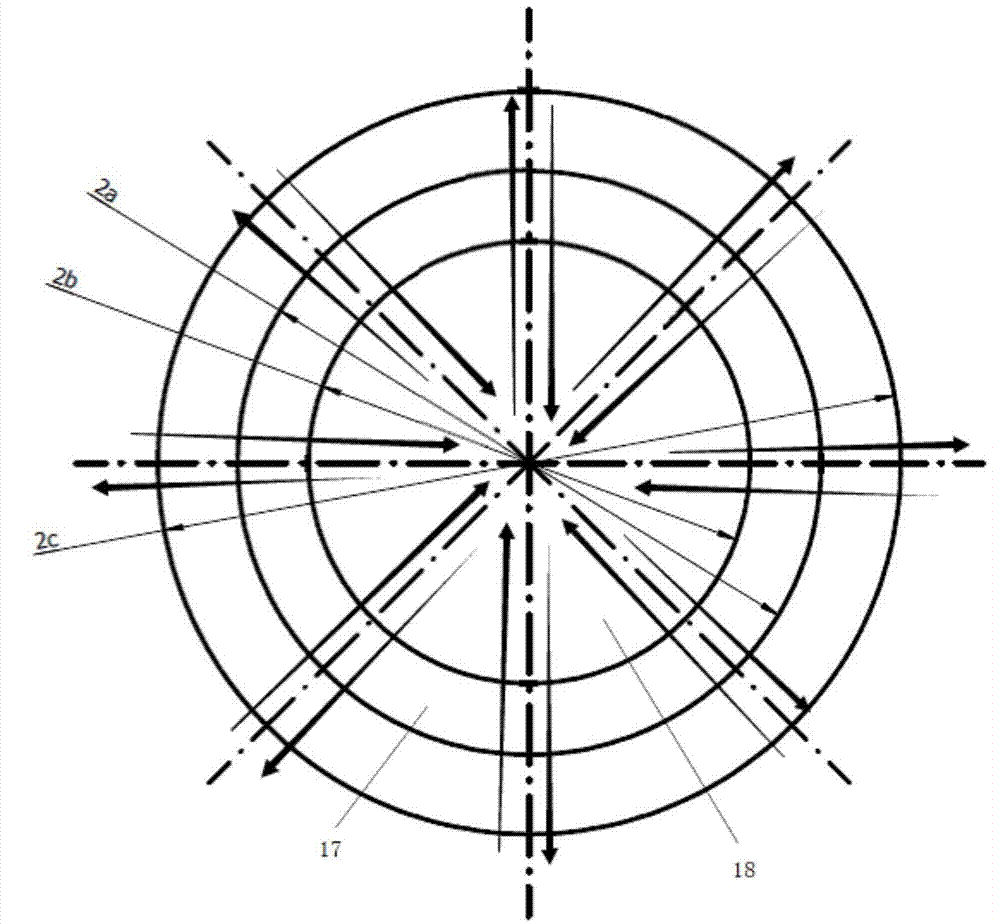

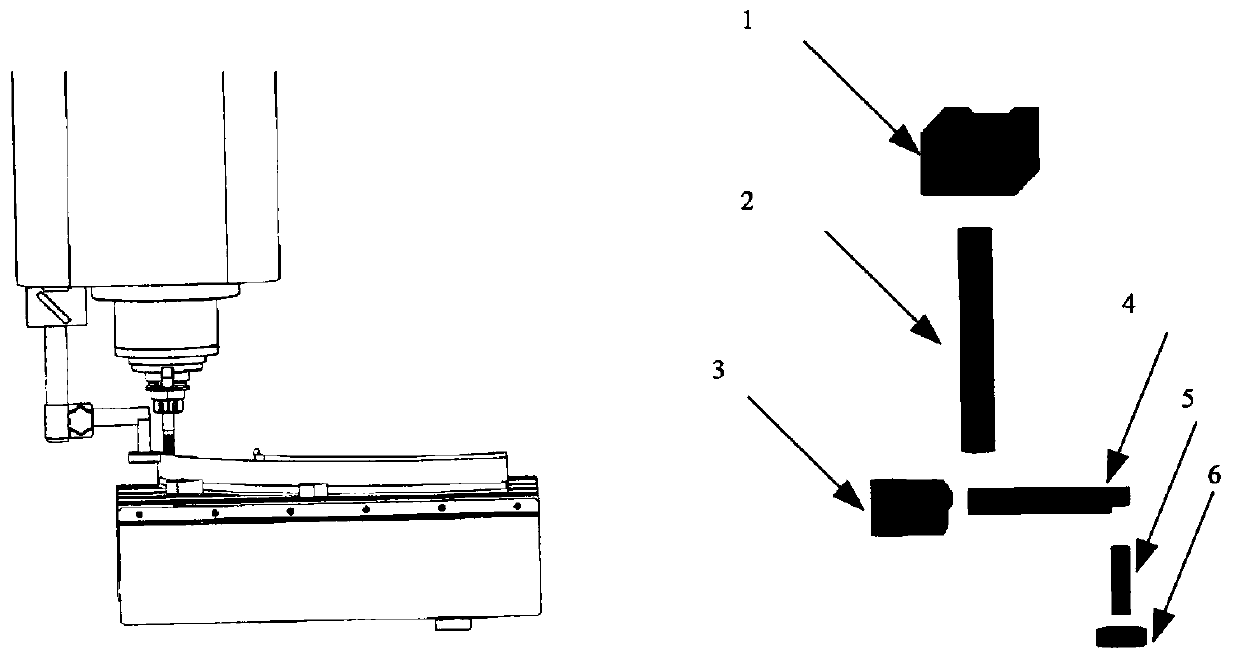

Interface ultrasonic reflectivity-pressure relation curve establishment method based on fillet plane contact theory and loading test stand

ActiveCN106932277AImprove detection accuracyForce measurementMaterial strength using tensile/compressive forcesUltrasonic sensorTransceiver

The invention discloses an interface ultrasonic reflectivity-pressure relation curve establishment method based on fillet plane contact theory and a loading test stand. The loading test stand includes a pressure display, a control terminal, an oscilloscope, a water logging ultrasonic transducer, a large cylinder, a small cylinder, an upper panel, a movable plate, a pressure sensor, a lower panel, an ultrasonic transceiver and a small cylinder connecting plate. Compared with the existing schemes, the interface ultrasonic reflectivity-pressure relation curve establishment method based on fillet plane contact theory and the loading test stand provided by the invention can construct a more accurate ultrasonic reflectivity-pressure relation curve, and the detection precision is high.

Owner:DALIAN UNIV OF TECH

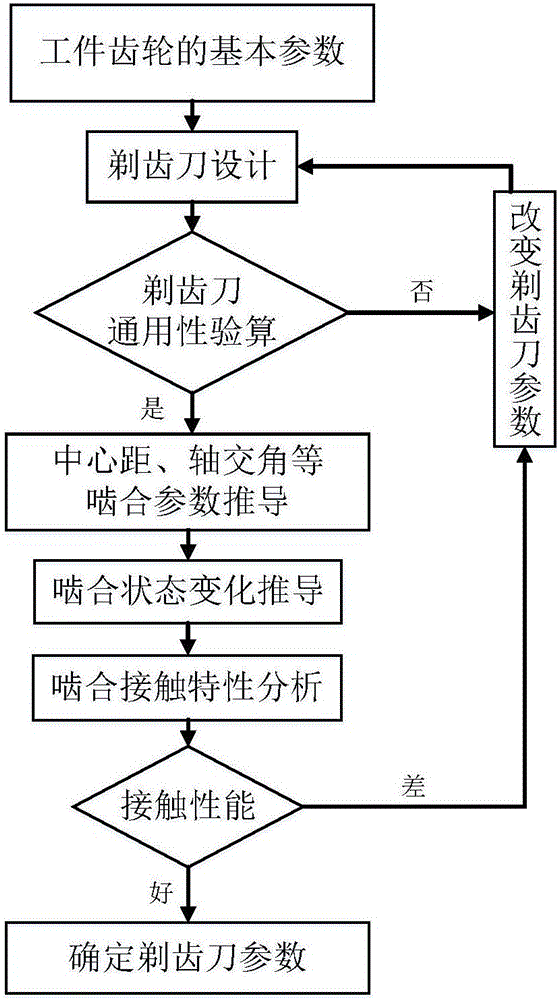

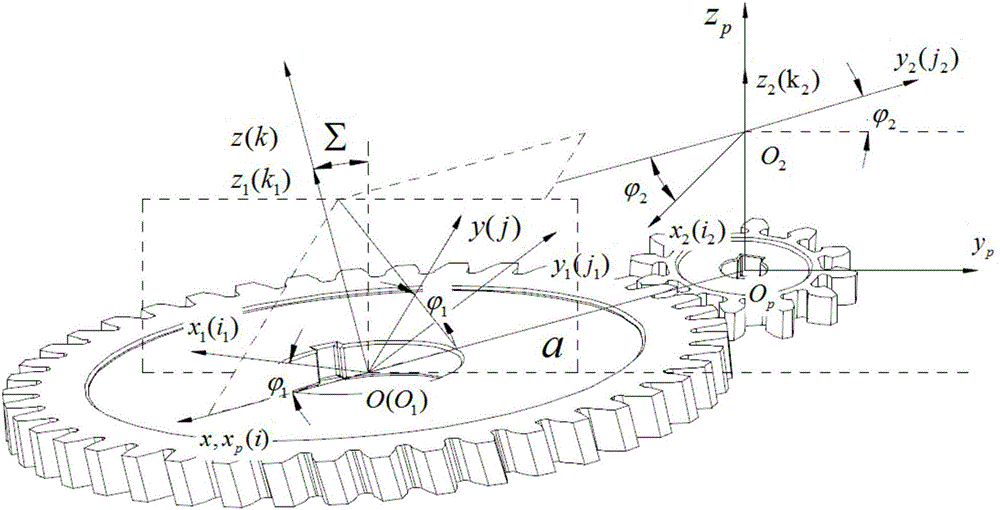

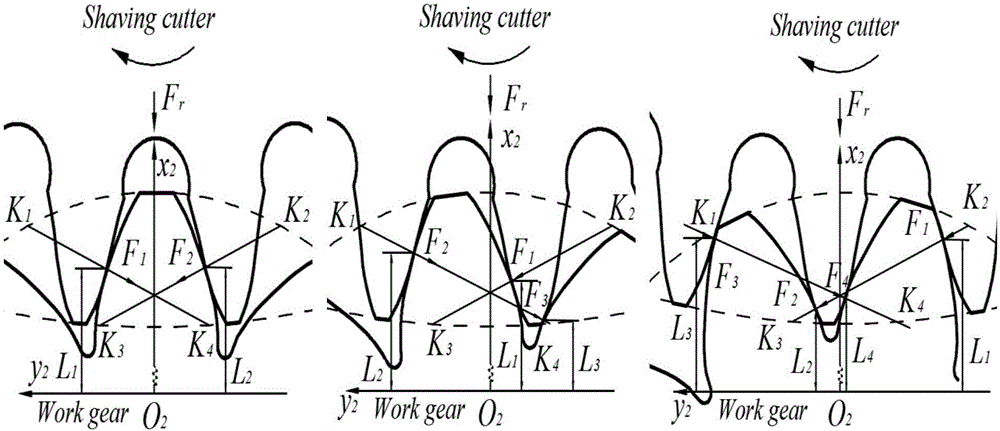

Shaving cutter design method based on analysis on meshing contact property of shaving gears

InactiveCN106611080ASatisfied with contactAvoid trial shavesGeometric CADGear teeth manufacturing toolsMechanical modelsMathematical model

The invention relates to a shaving cutter design method based on analysis on a meshing contact property of shaving gears, belongs to the field of non-linear contact theories and gear surface machining. The shaving cutter meeting a shaving condition and with excellent meshing performance is designed according to workpiece gear parameters based on a meshing theory and a contact theory; the shaving gear meshing contact property (including a normal acting force, a contact stress and deformation of arbitrary curvature radius on an effective tooth profile) is derived by building a mathematical model and a mechanical model about meshing of the shaving gears; the parameter of the shaving cutter is modified according to the contact property and the shaving condition; the modified meshing contact property is acquired after checking computation on universality of the shaving cutter is met; and finally the shaving cutter design parameter is determined. According to the method of the invention, the shaving cutter with excellent contact performance can be accurately designed, a link of trying to use the shaving cutter is effectively avoided, a contact property curve when the shaving gears are meshing is intuitively derived by using a mathematical method, and an important guiding significance is provided for improving shaving efficiency and reducing meshing impacts and tooth errors of the shaving gears.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

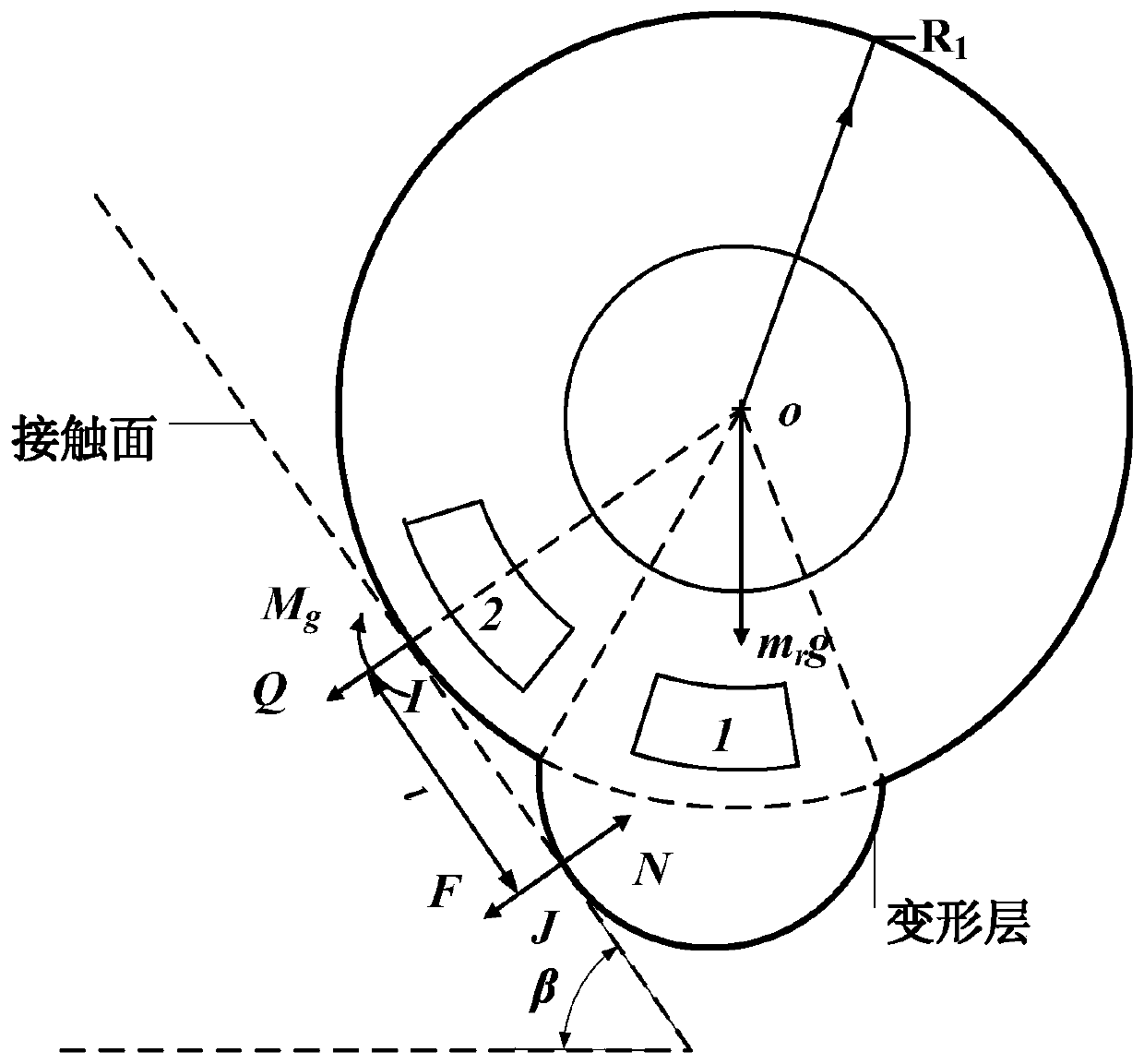

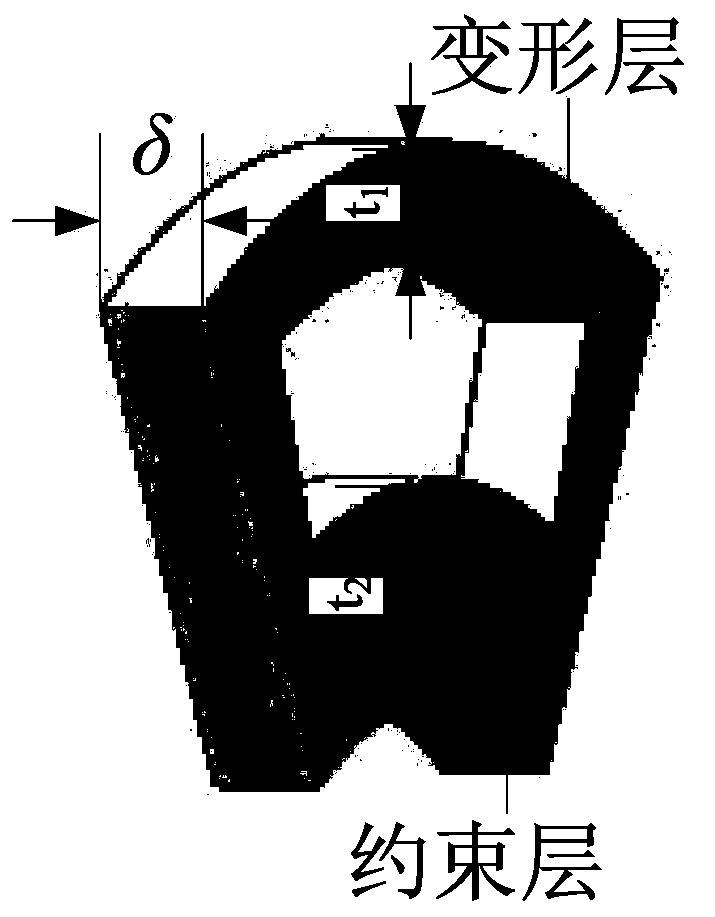

Modeling method for soft climbing robot

ActiveCN110142760AExcellent on-target performanceProgramme-controlled manipulatorModel methodEngineering

The invention discloses a modeling method for a soft climbing robot. The soft climbing robot comprises a deformation layer (1), a supporting layer (2), a restraining layer (3) and a central accommodating cavity (4) which are sequentially arranged from outside to inside. By using the minimum potential energy principle in elastic mechanics, the relation between deformation of points on a deformationlayer of a cavity and pressure intensity inside the cavity is analyzed so as to obtain the deformation needed by the contact theory formed by the deformation layer and a cable surface, and thereforethe optimal soft climbing robot conforming to the target performance can be easily obtained.

Owner:NANJING UNIV OF POSTS & TELECOMM

Thin-wall piece milling vibration restraining method based on movable support

ActiveCN109968099AHigh removal rateSuppress chatterGeometric CADDesign optimisation/simulationMaterial removalEquivalent stiffness

The invention relates to a thin-wall piece milling vibration restraining method based on a movable support. The mass, rigidity and a damping matrix of a workpiece are obtained through the finite element; equivalent stiffness and damping provided through the movable support are calculated through the contact theory and assembled to rigidity and a damping matrix of an initial workpiece; and finally,dynamics parameters of the workpiece at different tool position points are rapidly obtained through a numerical calculation method, and stability prediction is conducted. The functions of efficient restraining of vibration and rapid prediction of vibration stability in the whole machining process are achieved, and the material removal rate in the milling process is improved by 67% to the maximumin the embodiment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

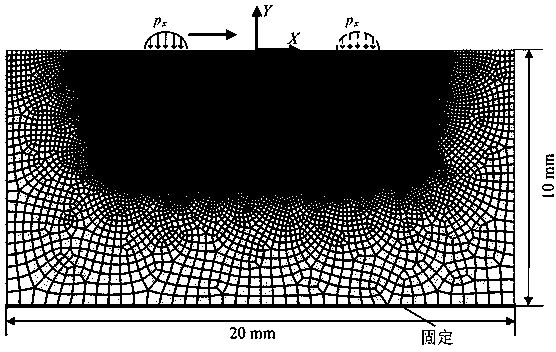

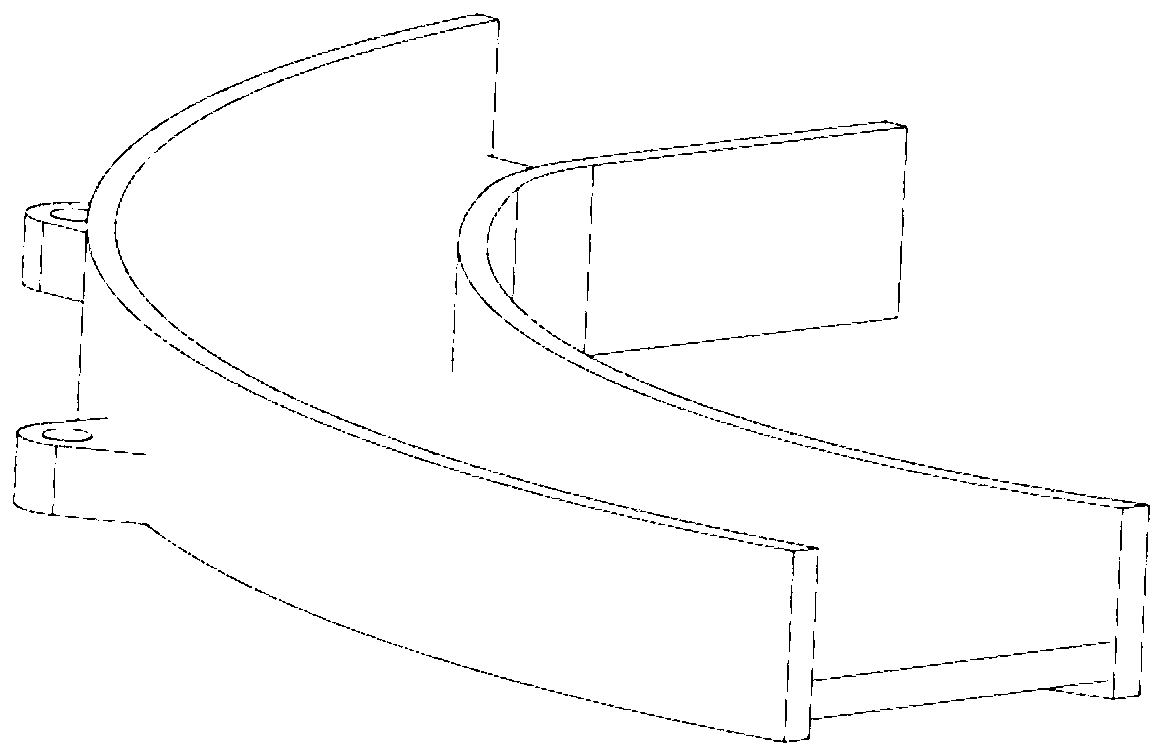

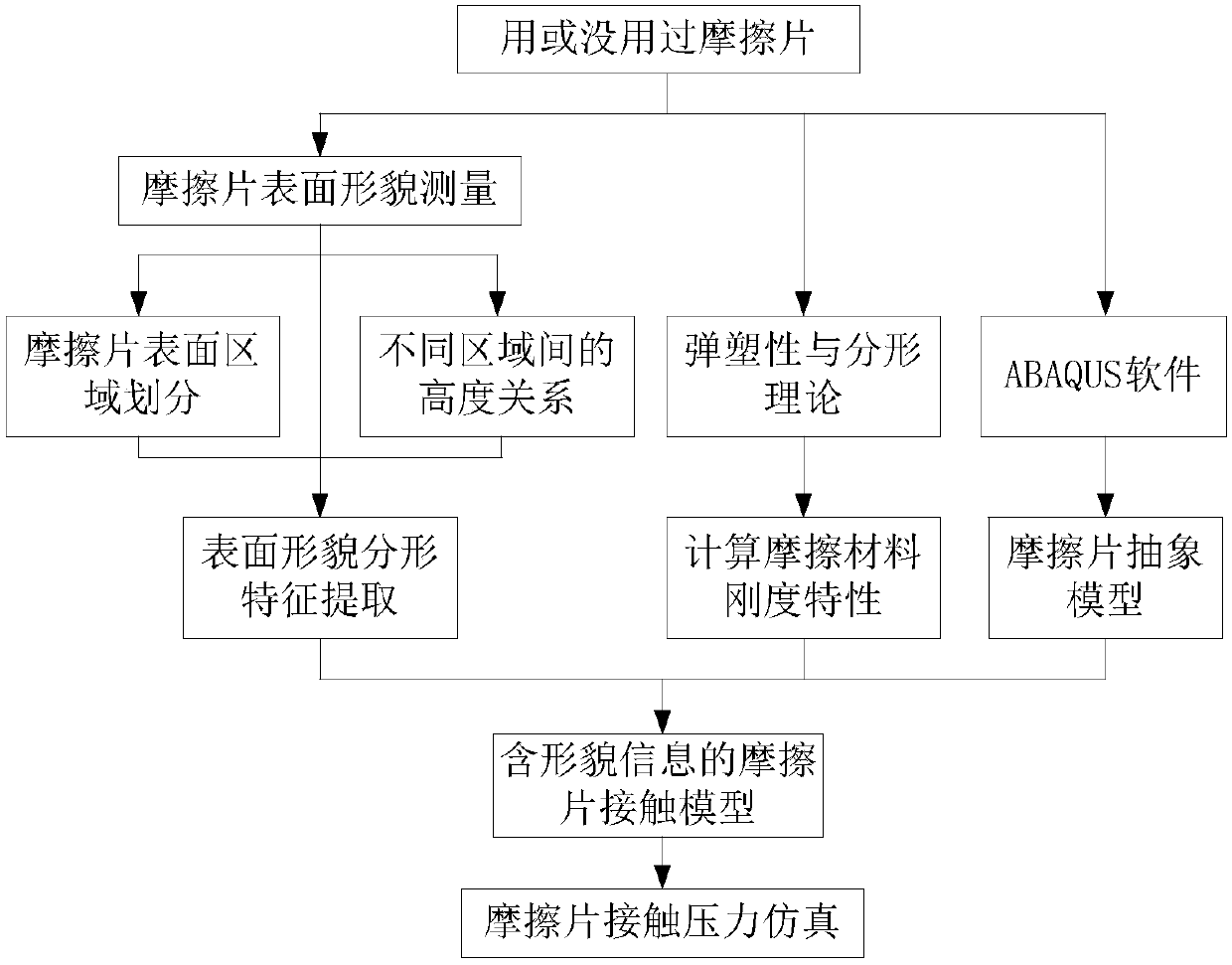

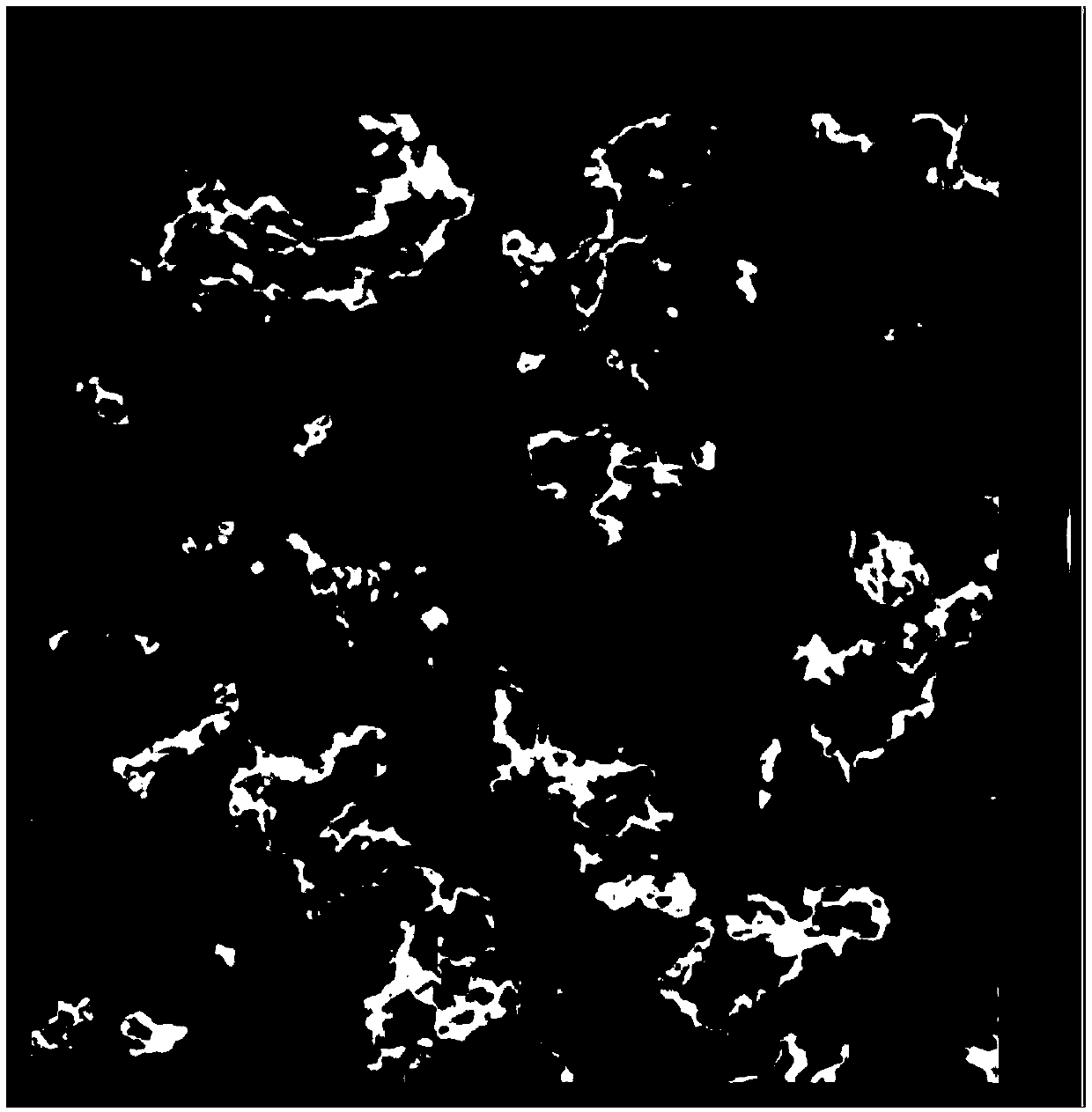

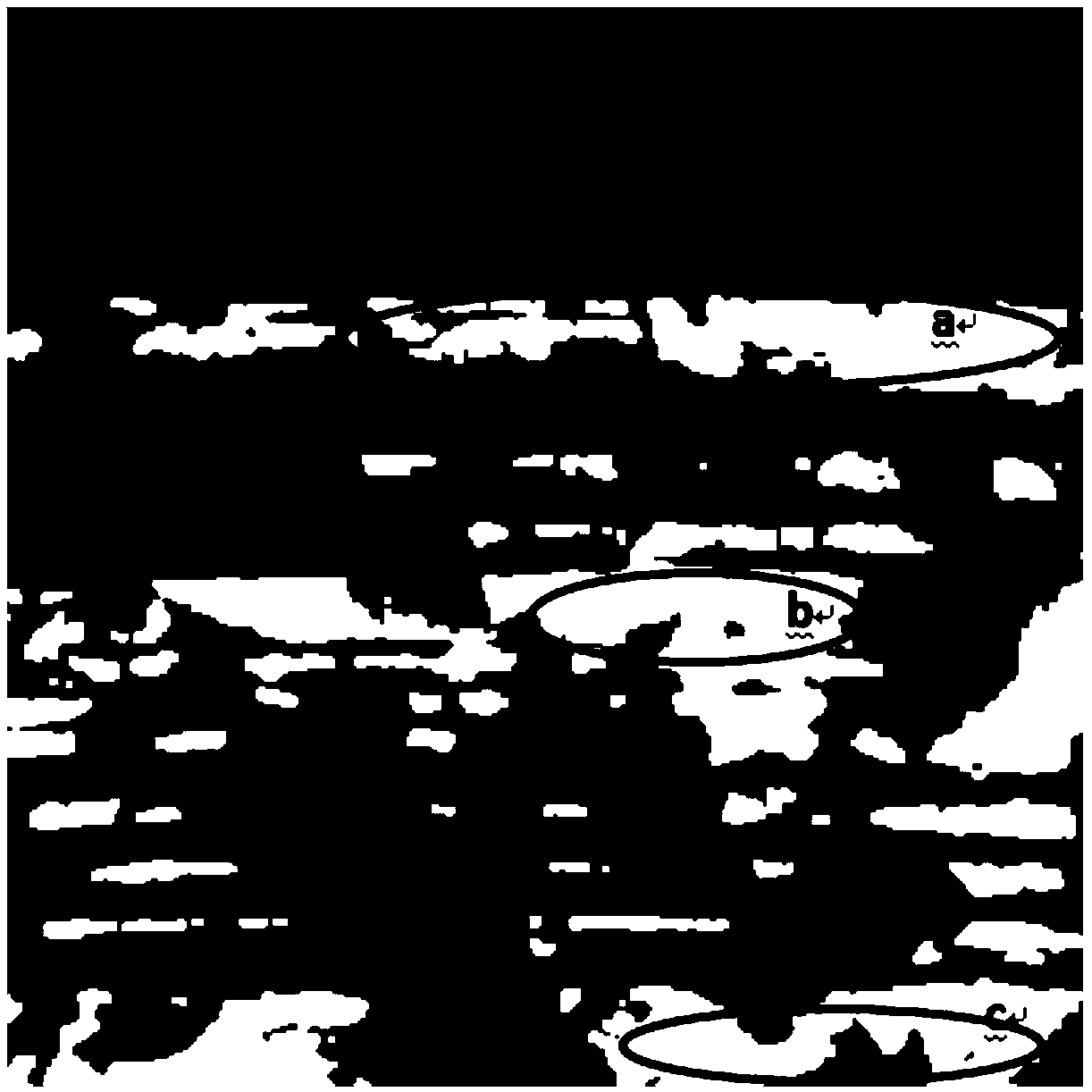

Method for simulating contact pressure of friction plates with surface morphological information

ActiveCN108287967AImprove practicalityReduce Pressure Simulation CostsDesign optimisation/simulationSpecial data processing applicationsContact theoryEngineering

The invention discloses a method for simulating contact pressure of friction plates with surface morphological information. According to the method, measure concepts of image processing and contact analysis are utilized to superpose surface morphological information into model grids so as to realize simulation of contact detail information of friction plates. According to the method, contact pressure of friction plates with surface morphological information can be simulated, and micro surface information is added onto a macro friction plate contact model, so that contact pressure simulation distribution of the friction plates is closer to the practical condition. Through combining a micro contact theory and macro practical engineering, the contact pressure simulation of the friction plateshas theoretical support and using meaning.

Owner:BEIHANG UNIV

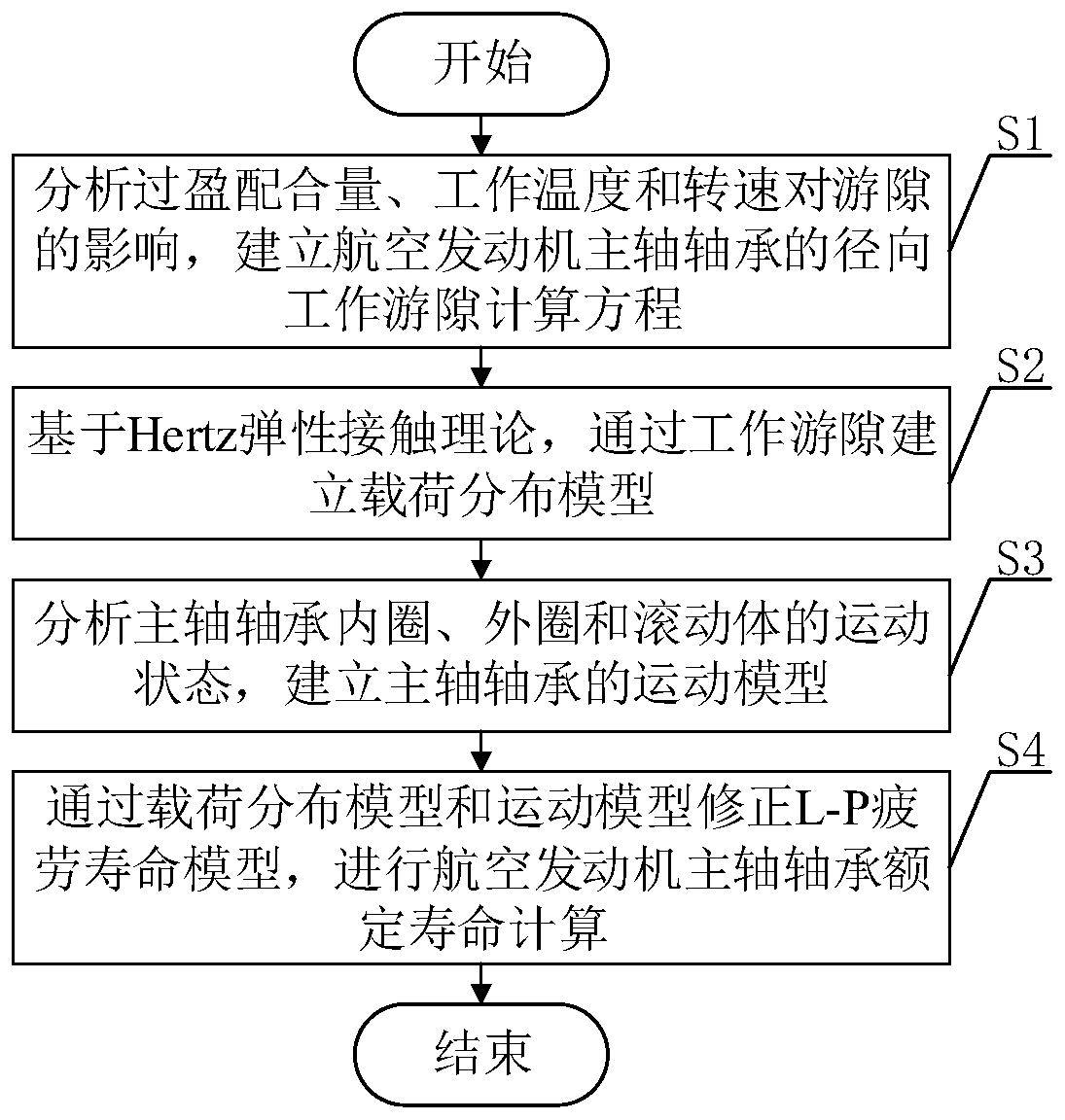

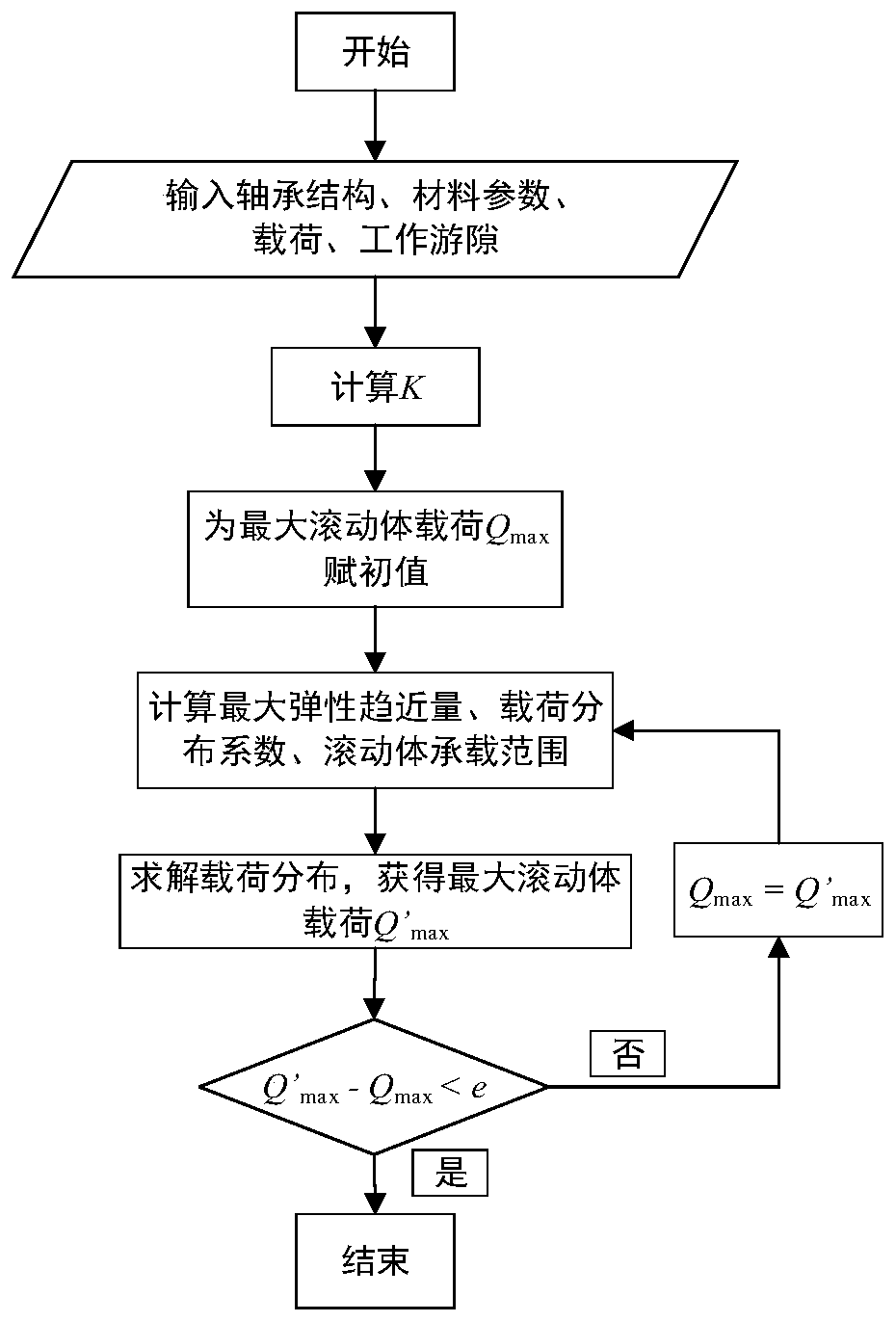

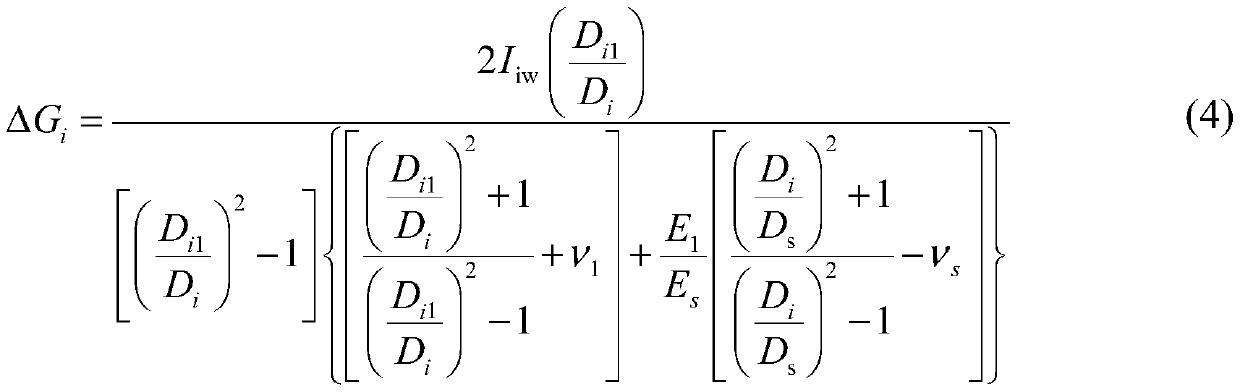

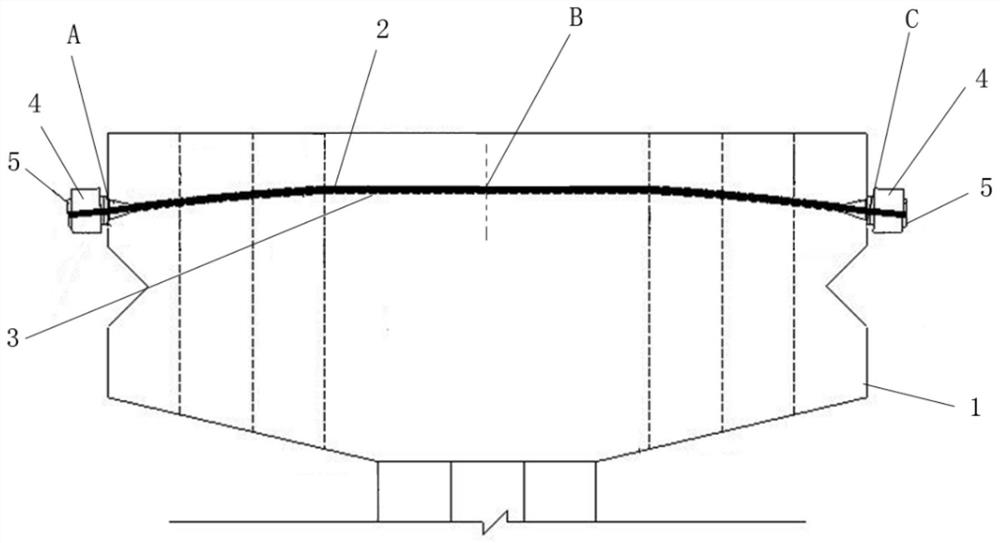

Aero-engine main spindle bearing rated life calculation method considering backlash change

InactiveCN110348168AIn line with the actual working lifeBest working clearance intervalGeometric CADSpecial data processing applicationsAviationInterference fit

The invention discloses an aero-engine spindle bearing rated life calculation method considering backlash change, which comprises the following steps: analyzing the influence of interference fit, working temperature and rotating speed on a working backlash, and obtaining the working backlash by establishing a radial working backlash calculation equation of an aero-engine spindle bearing; based ona Hertz elastic contact theory, carrying out load distribution analysis of the main shaft bearing through a working clearance, and establishing a load distribution model; analyzing the motion states of the spindle bearing inner ring, the main shaft bearing outer ring and the rolling body to obtain a motion model of the main shaft bearing; and correcting the L-P fatigue life model through the loaddistribution model and the motion model, and calculating the rated life of the aero-engine main shaft bearing.. The method enables the prediction of the rated life of the aero-engine main shaft bearing to be more accurate.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Prestressed pipeline friction loss test and calculation method

InactiveCN112014310AEasy to testImprove efficiencyUsing mechanical meansMaterial analysisPre stressFriction loss

The invention provides a prestressed pipeline friction loss test and calculation method. The test and calculation method comprises the following steps: (1) carrying out multiple times of asymmetric tensioning and symmetric tensioning operations on a prestressed steel bundle, and recording related data; (2) deducing a calculation formula of a friction influence coefficient of the prestressed pipeline based on a stress uniform distribution principle in a Hertz contact theory; and (3) according to the deduced calculation formula, calculating a friction influence coefficient of the prestressed pipeline by utilizing the elongation difference of the prestressed steel beams which are tensioned twice, and evaluating the prestressed friction loss. The method is based on the stress uniform distribution principle of the Hertz contact theory and skillfully utilizes the Hooke law; the test method is convenient and economical, can effectively and reasonably calculate the friction influence coefficient and the prestress friction loss value of the prestress pipeline, and is suitable for prestress concrete bridges with symmetrically arranged prestress steel beams; and the prestressed pipeline friction loss test and calculation method is convenient and fast in test, high in efficiency, low in cost, good in economy and high in accuracy.

Owner:GUANGXI UNIV

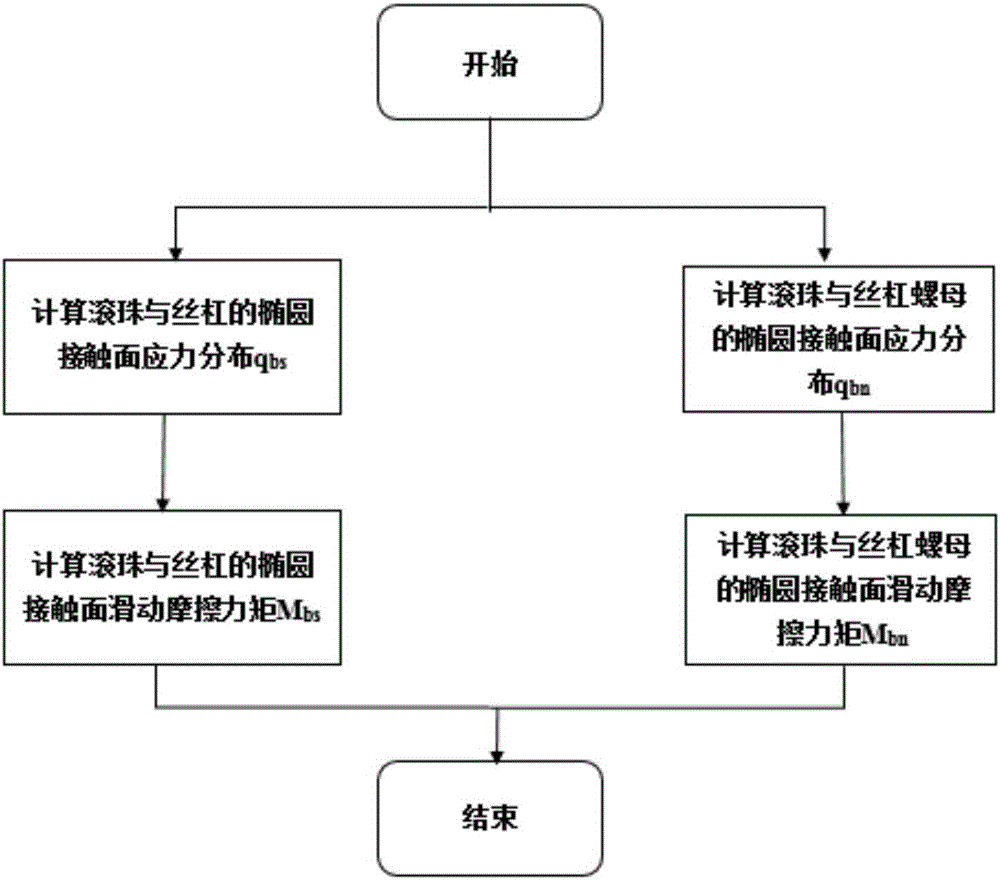

A nonlinear correction method for an ideal linear coefficient of inertia of a ball screw type inertial container

ActiveCN106844920AThe correction method is simpleInertia coefficient trueGeometric CADSpecial data processing applicationsRolling resistanceBall screw

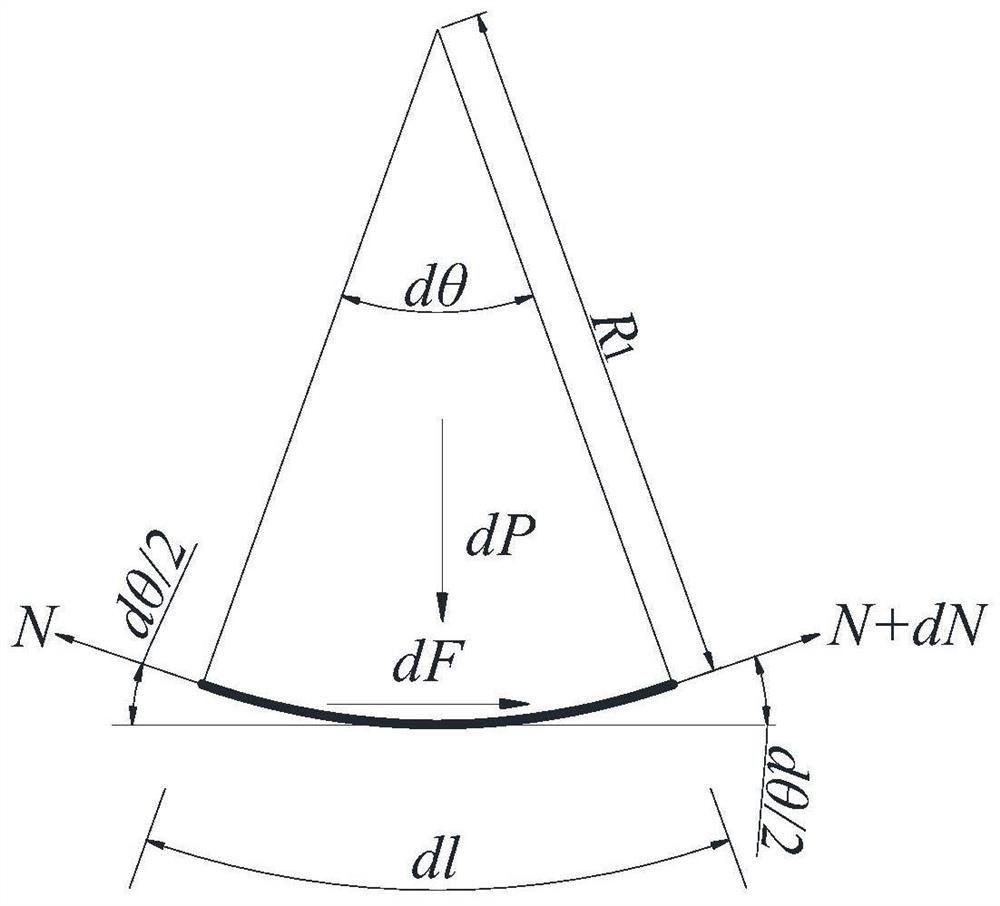

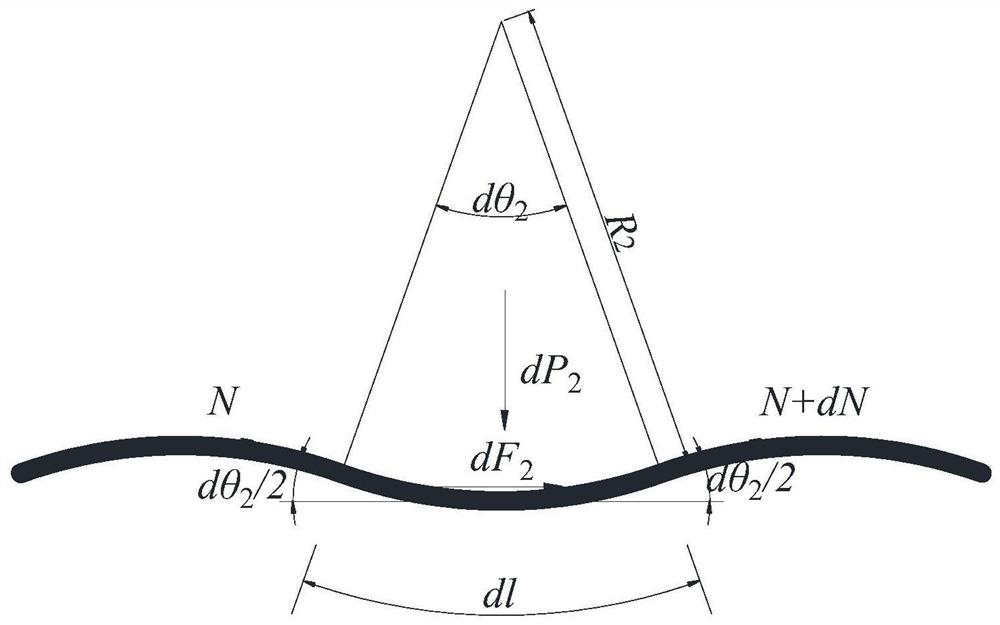

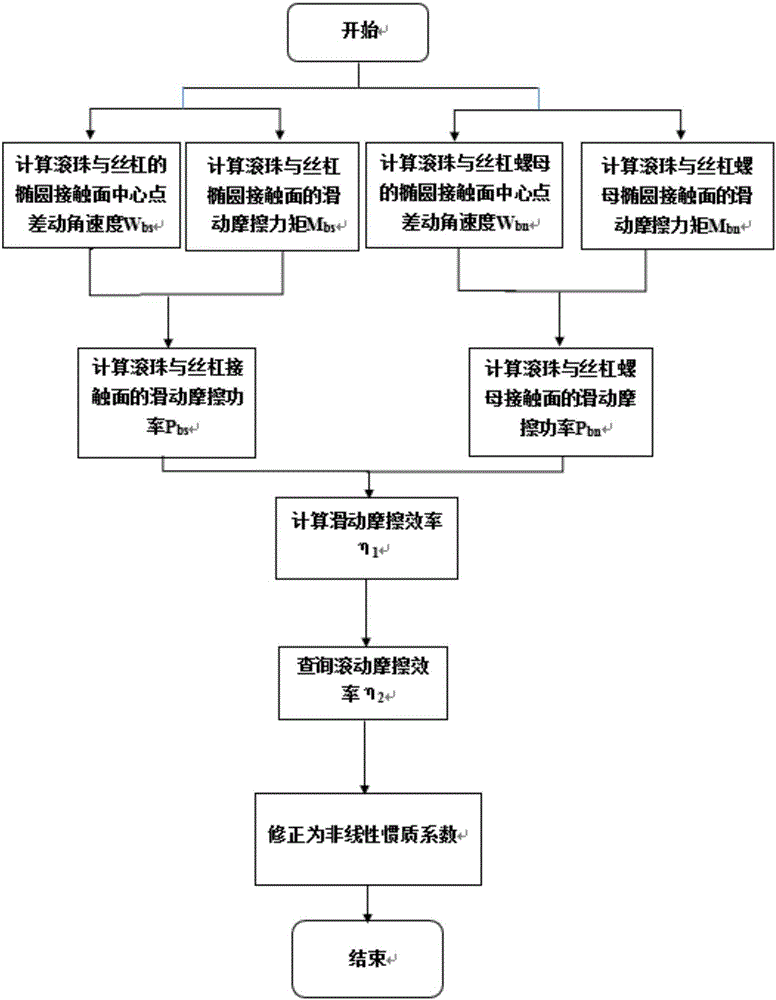

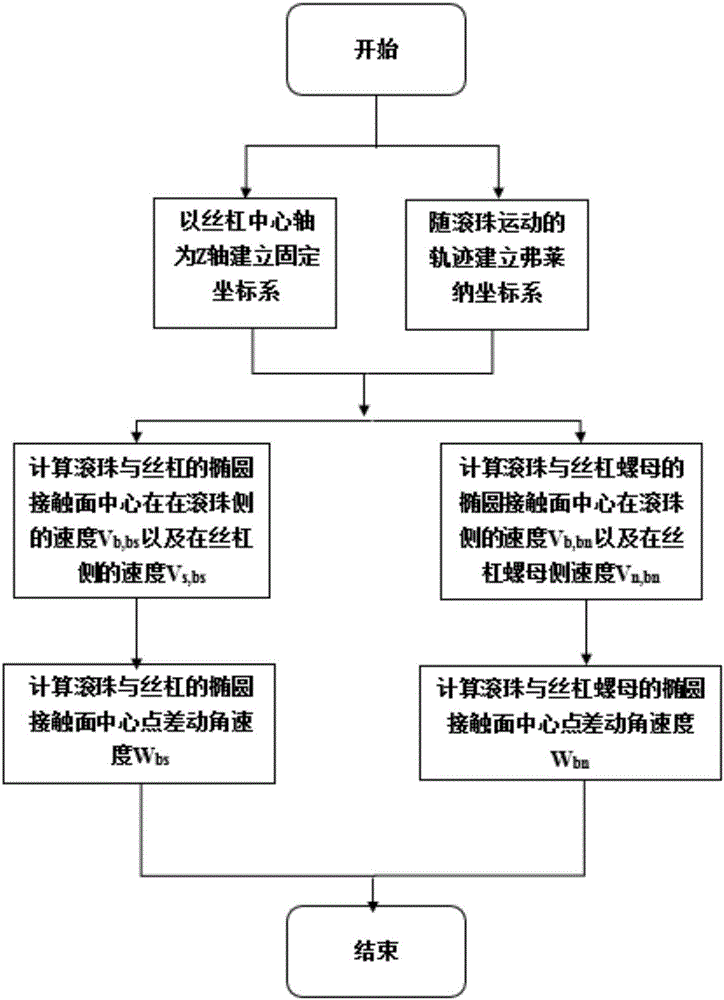

The invention discloses a nonlinear correction method for an ideal linear coefficient of inertia of a ball screw type inertial container. First, based on Frenet frame theory and Hertz contact theory, relative sliding velocity and sliding friction moment between a ball of a ball screw pair and a raceway are deducted to obtain friction power of the sliding of the ball, the ratio between the friction power and exciting power is the efficiency of sliding friction of the ball; the efficiency of rolling friction of the ball is introduced, and finally the ideal linear coefficient of inertia of the ball screw type inertial container is corrected as the nonlinear coefficient of inertia. According to the nonlinear correction method, the nonlinear friction between the ball and the raceway in the ball screw type inertial container is considered, which is more in line with the actual situation. Compared with the correction method of the coefficient of inertia obtained by numerical simulation, the correction method is simple and reliable, can provide more accurate coefficient of inertia for the design of the ball screw type inertial container and the application in engineering vibration damping system, promotes and develops the theory and method of the inertial container, and has practical engineering significance.

Owner:JIANGSU UNIV OF SCI & TECH

Blocked analysis method for large-size machine tool structural member

InactiveCN107589670AImprove dynamic performanceGuide designSpecial data processing applicationsAdaptive controlEngineeringThree dimensional model

The invention discloses a blocked analysis method for a large-size machine tool structural member. The method comprises the steps of establishing a combining surface rigid model based on a three-dimensional fractal contact theory, and identifying a normal stiffness and lateral stiffness; performing parameter modeling of the large-size structural member (crossbeam) based on a definite element method, and integrating the identified normal stiffness and the lateral stiffness into a large-size structural member three-dimensional model; and utilizing a parameter blocked designing method and a particle swarm optimization method, optimizing the dynamic performance of the large-size structural member (crossbeam), and designing the optimized large-size structural member (crossbeam) three-dimensional model by means of an optimization result. A re-manufacturing factor is taken into a designing period so that the structural member not only can satisfy function and performance requirement of a product and furthermore facilitates manufacturing, transportation, assembling and re-manufacturing. The blocked analysis method for the large-size machine tool structural member is deeply understood, thereby better guiding designing and application of the large-size machine tool structural member.

Owner:BEIJING UNIV OF TECH

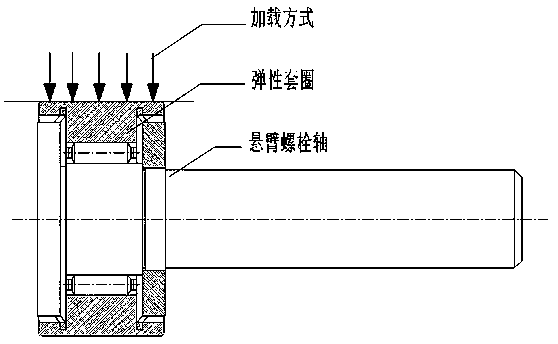

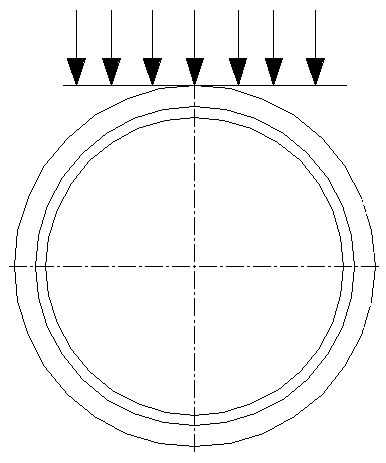

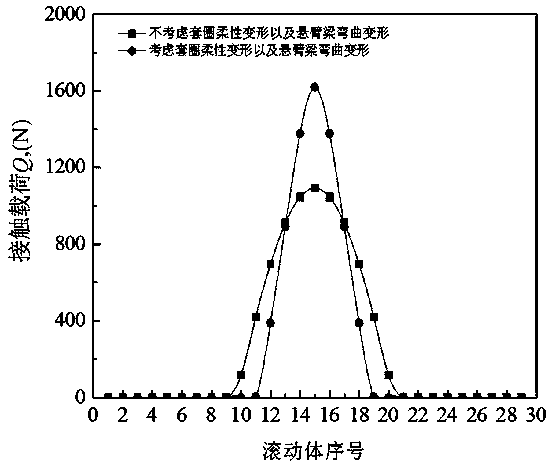

A rated dynamic load determination method for a roller needle bearing mounted on a bolt shaft cantilever

ActiveCN109902429ASustainable transportationMachine bearings testingNeedle roller bearingRolling-element bearing

The invention discloses a rated dynamic load determination method for a roller needle bearing mounted on a bolt shaft cantilever. On the basis of the Hertz contact theory, the influence of the flexible deformation of the ferrule and the modification of the roller pin on the load distribution is considered, meanwhile, the influence of the inclination of the roller pin on the load distribution caused by the flexural deformation of the bolt shaft is considered, and a local flexible supporting roller pin bearing mathematical model installed on the cantilever bolt shaft is established. And accurateiterative solution is performed on the force balance equation by adopting a numerical analysis method to obtain load distribution of the roller needle roller bearing under the action of external dynamic load, and further the service life of the bearing is obtained according to a rolling bearing fatigue life calculation theory. And on the basis, a relation curve graph of the fatigue life and the external dynamic load is drawn, and then the rated dynamic load of the roller needle bearing is quickly obtained through the curve graph according to the definition of the rated dynamic load of the rolling bearing.

Owner:HENAN UNIV OF SCI & TECH

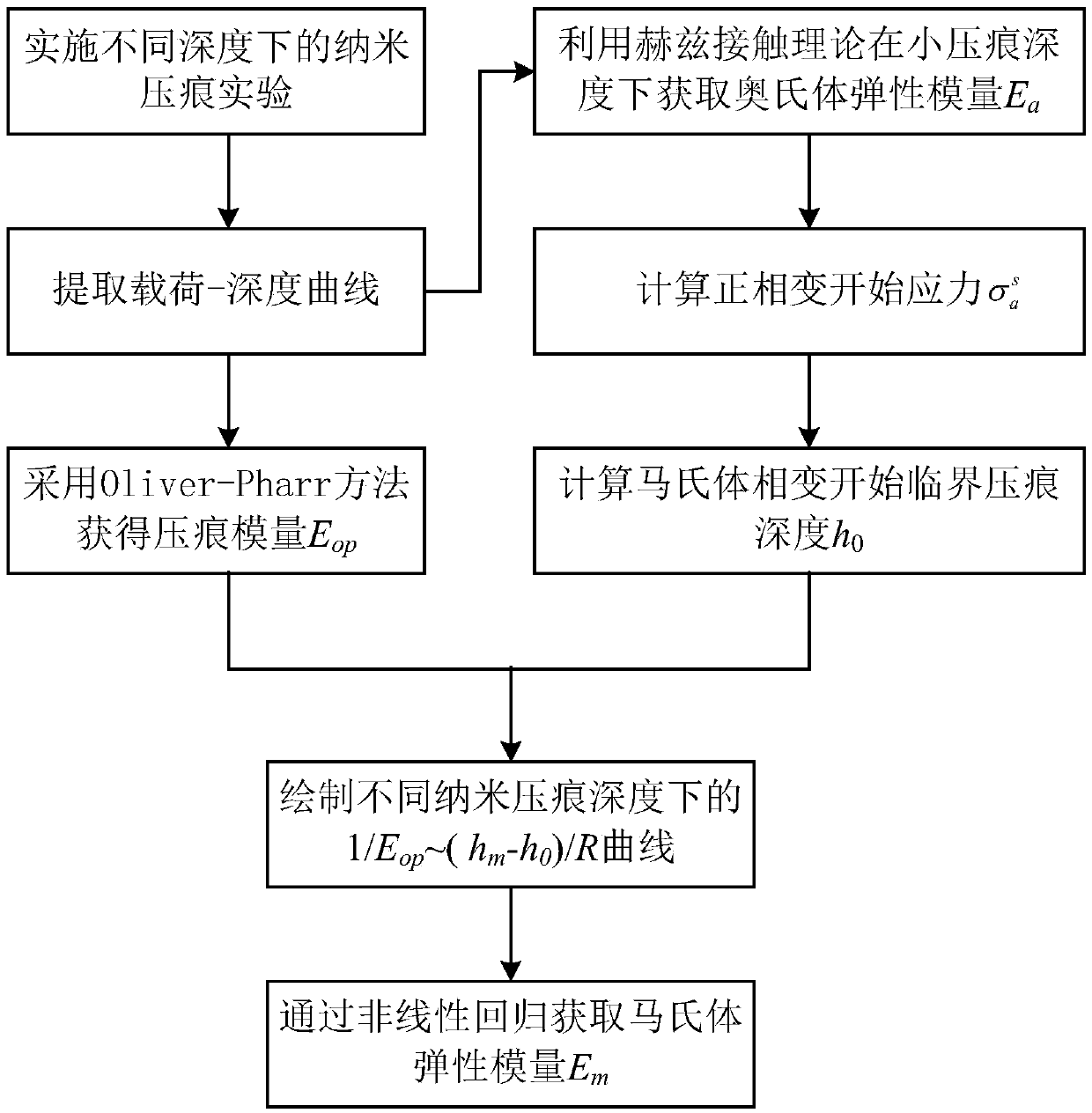

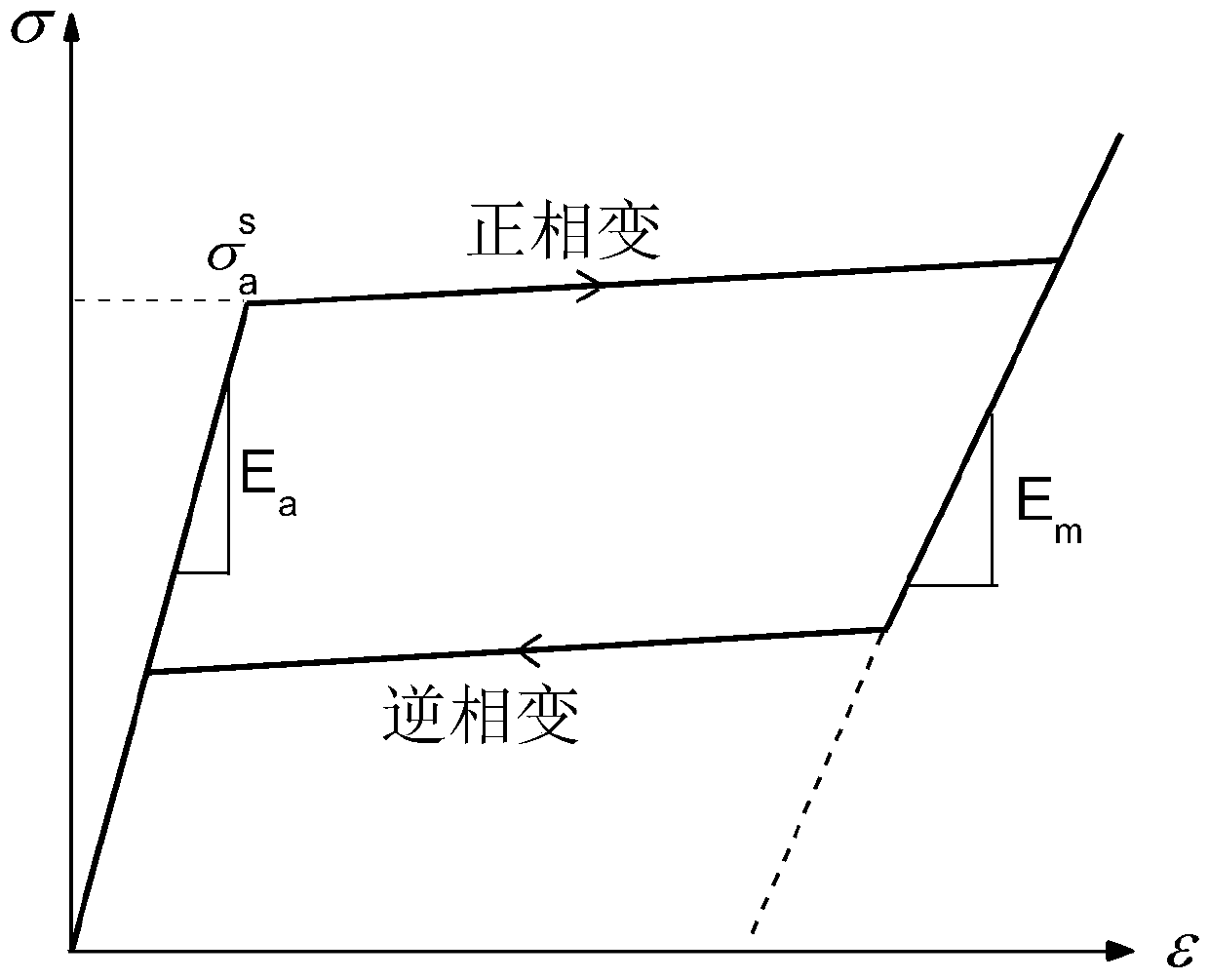

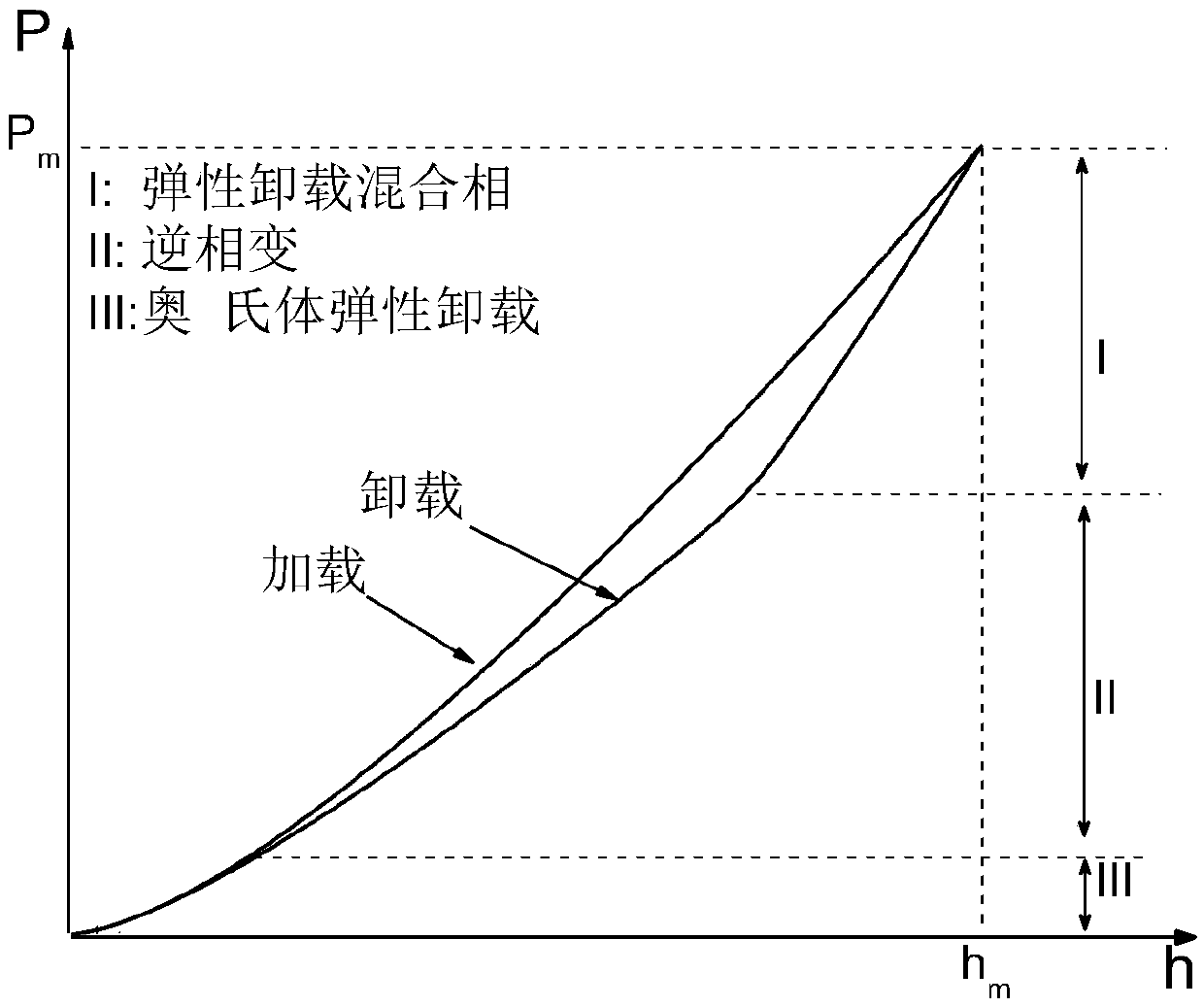

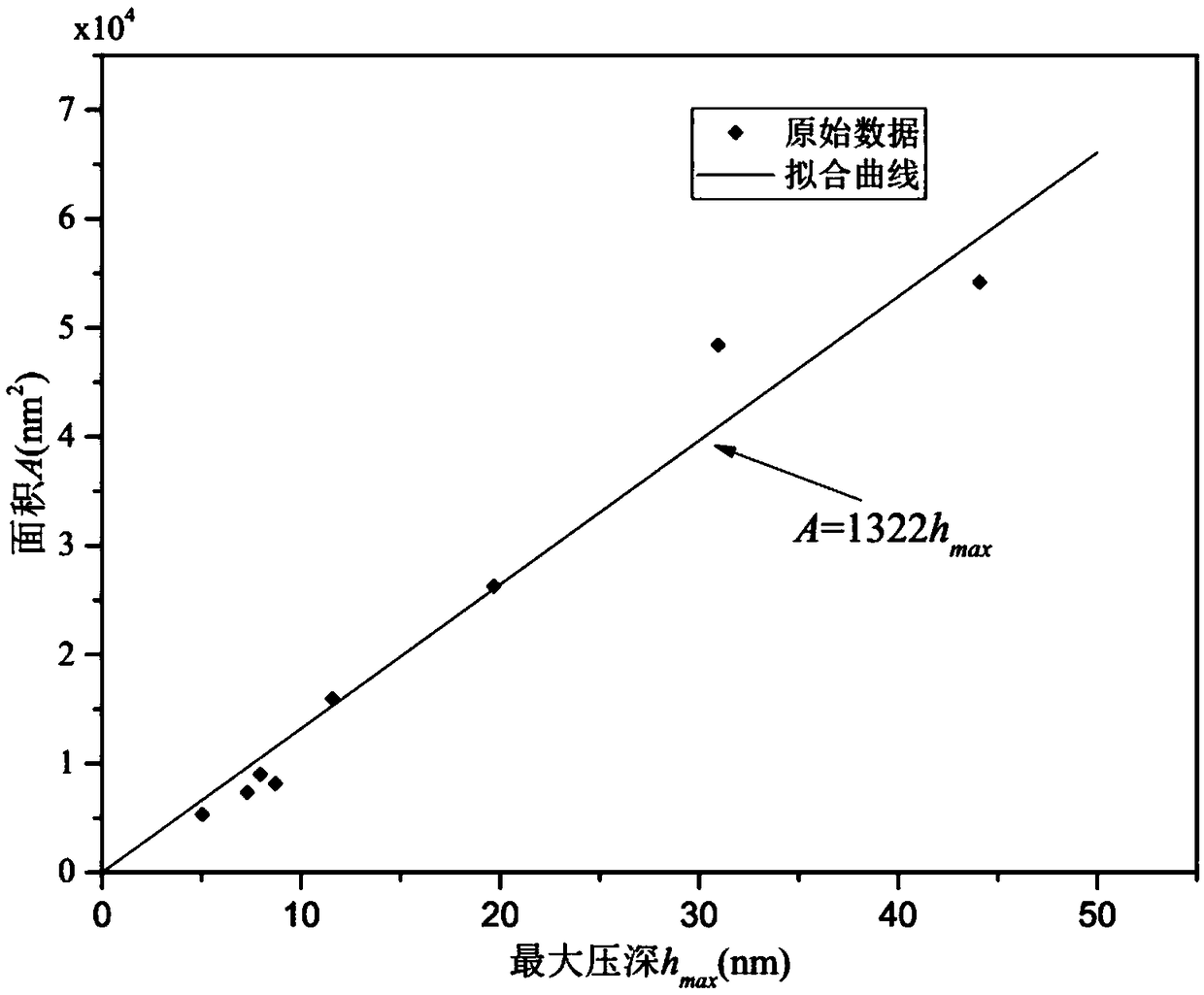

Nanoindentation testing method for elastic moduli of austenite phase and martensite phase of shape memory alloy

InactiveCN105510162AImprove accuracyIncrease credibilityInvestigating material hardnessRegression analysisShape-memory alloy

The invention provides a nanoindentation testing method for the elastic moduli of an austenite phase and a martensite phase of a shape memory alloy. The method comprises the following steps: multiple nanoindentation experiments at different depths; data processing by using the Oliver-Pharr method on the basis of experimental results; and regression analysis via empirical formulas obtained by using the Hertz contact theory and parameter analysis so as to obtain the elastic moduli of the austenite phase and the martensite phase. The testing method is simple in principles and easy in steps and can rapidly obtain the elastic moduli of the austenite phase and the martensite phase by implementing the nanoindentation experiments at different depths and using the calculation formulas put forward; and formulas used in the process of calculation are based on theories, experimental results are highly reliable, the process of a data processing algorithm is intelligible, and the data processing algorithm can be easily programmed.

Owner:SOUTHWEST JIAOTONG UNIV

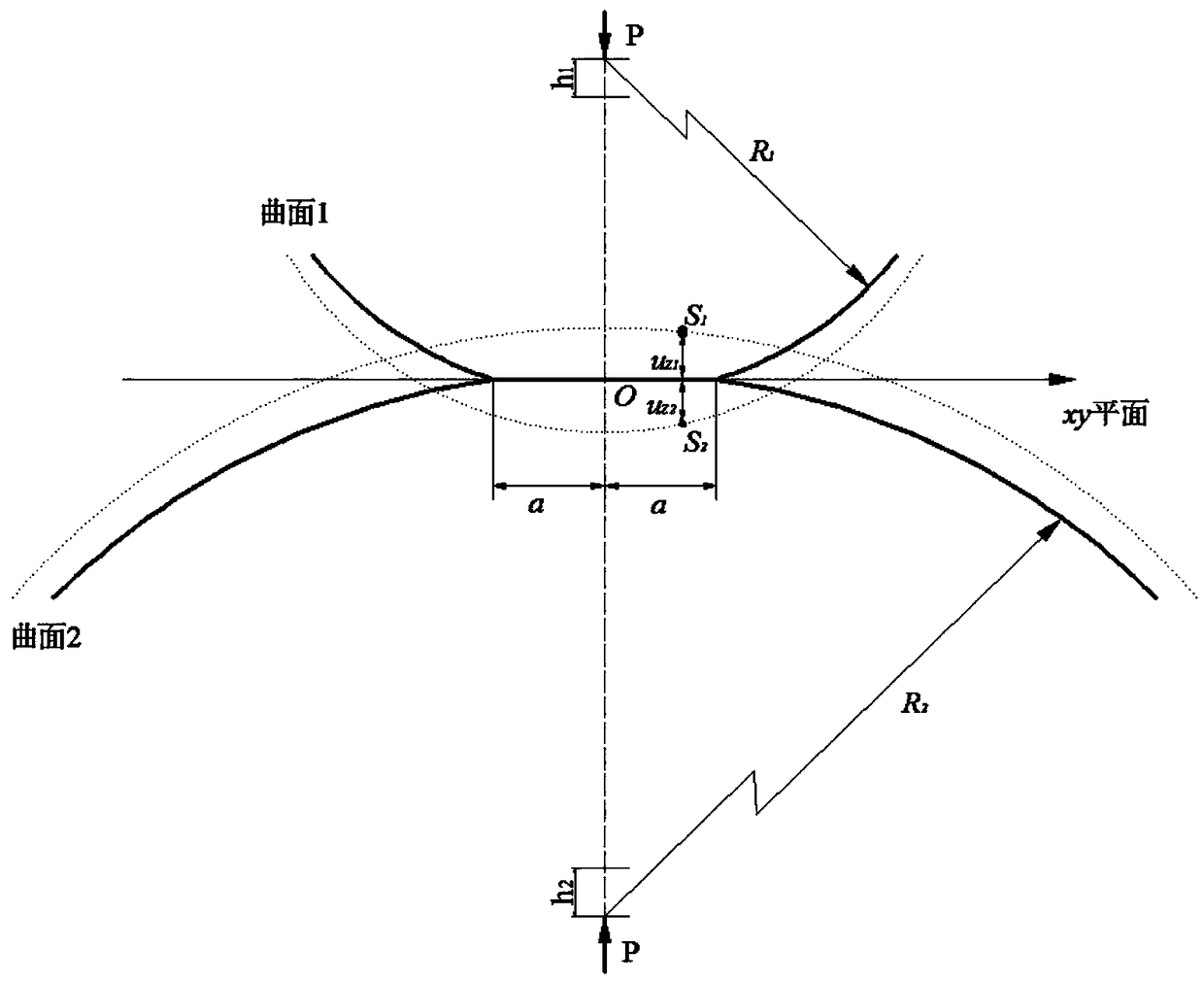

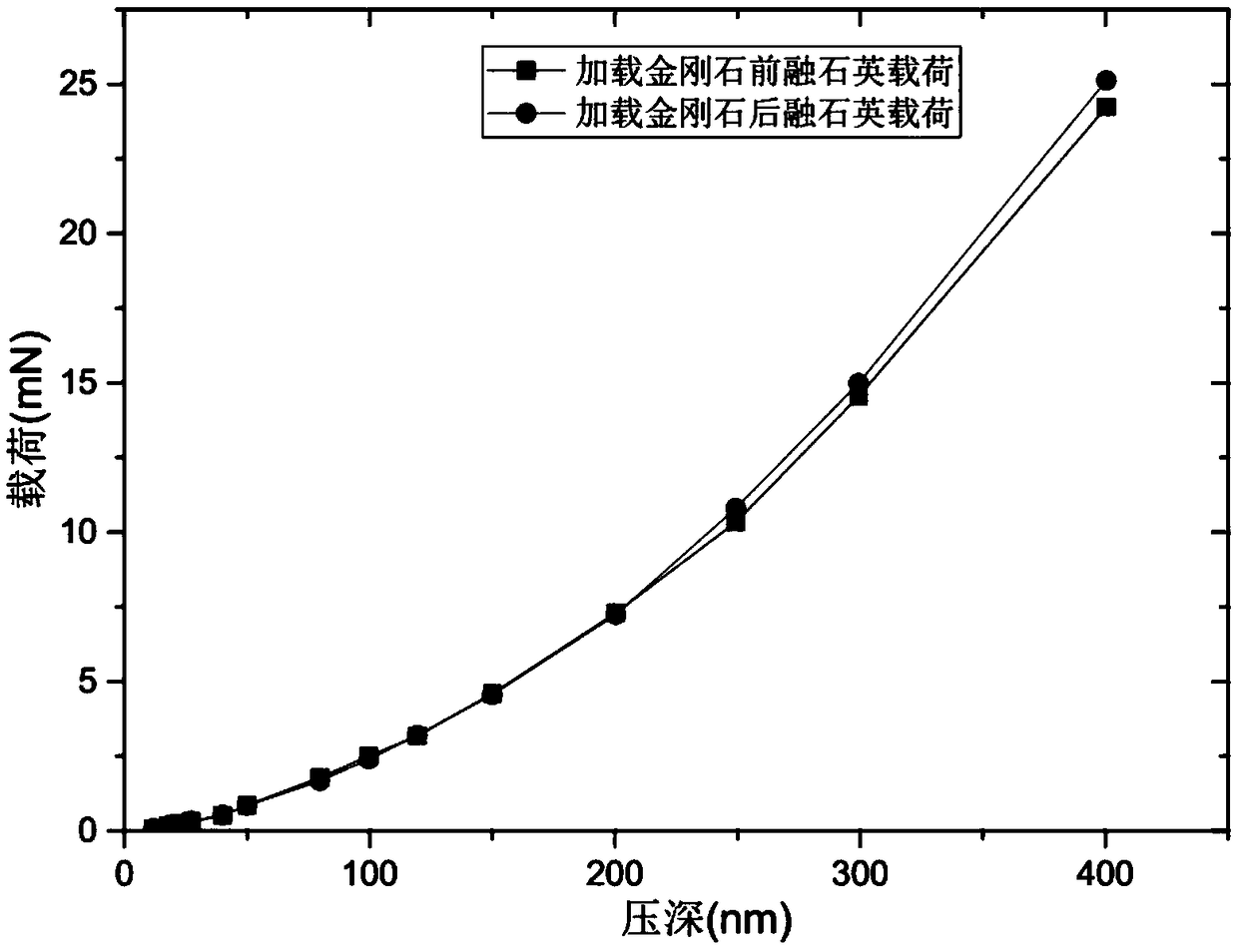

Super hard material nanometer hardness measuring method considering press head elastic deformation

InactiveCN109115639AHardness evaluationData processing is simpleInvestigating material hardnessSuperhard materialLinear relationship

The invention relates to a super hard material nanometer hardness measuring method considering press head elastic deformation, and belongs to the technical field of nanometer hardness measurement. Themethod comprises the following steps of 1, building two object elastic contact models on the basis of a Hertz elastic contact theory; deducing a hardness calculation formula according to the model; 2, loading a standard molten quartz sample by a press head at different press depths; correcting the area function of the press head according to loading and unloading data of the molten quartz samples; 3, calculating the data of tested samples obtained through nanometer press mark experiments by using the area function obtained in the step 2; obtaining the hardness of the sample to be tested. Thebuilt super hard material nanometer hardness measuring method considering press head elastic deformation has the advantages that the elastic deformation of the press head is considered by the built hardness calculation formula; the hardness of the tested material can be more accurately evaluated. The area function is the linear relationship between the contact area and the maximum press depth; thedata processing is simpler.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com