Patents

Literature

191 results about "Contact model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact predication based large-scale mobile delay tolerant network cluster-based routing method and system thereof

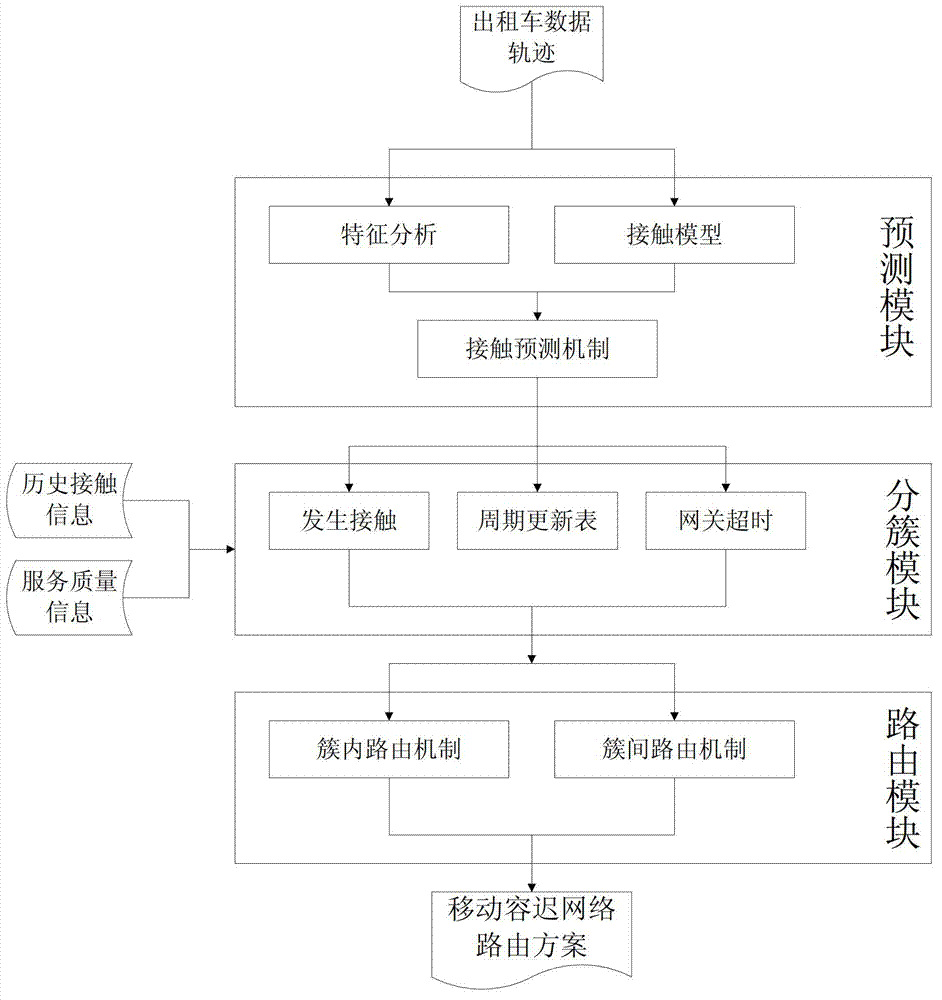

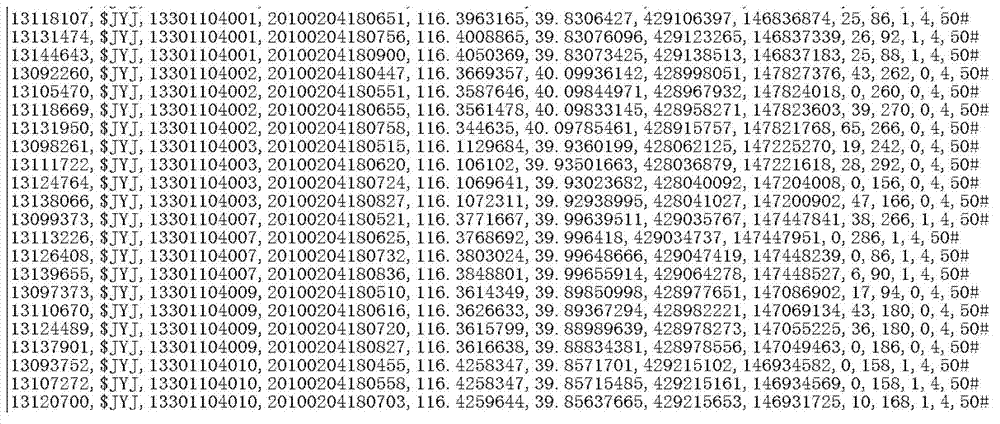

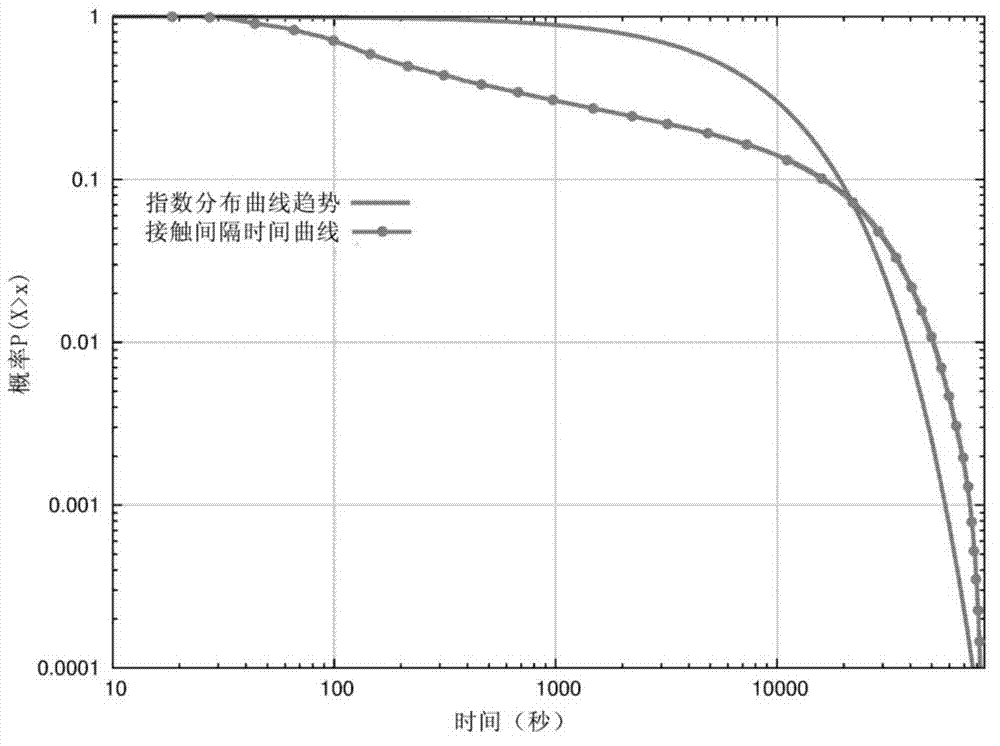

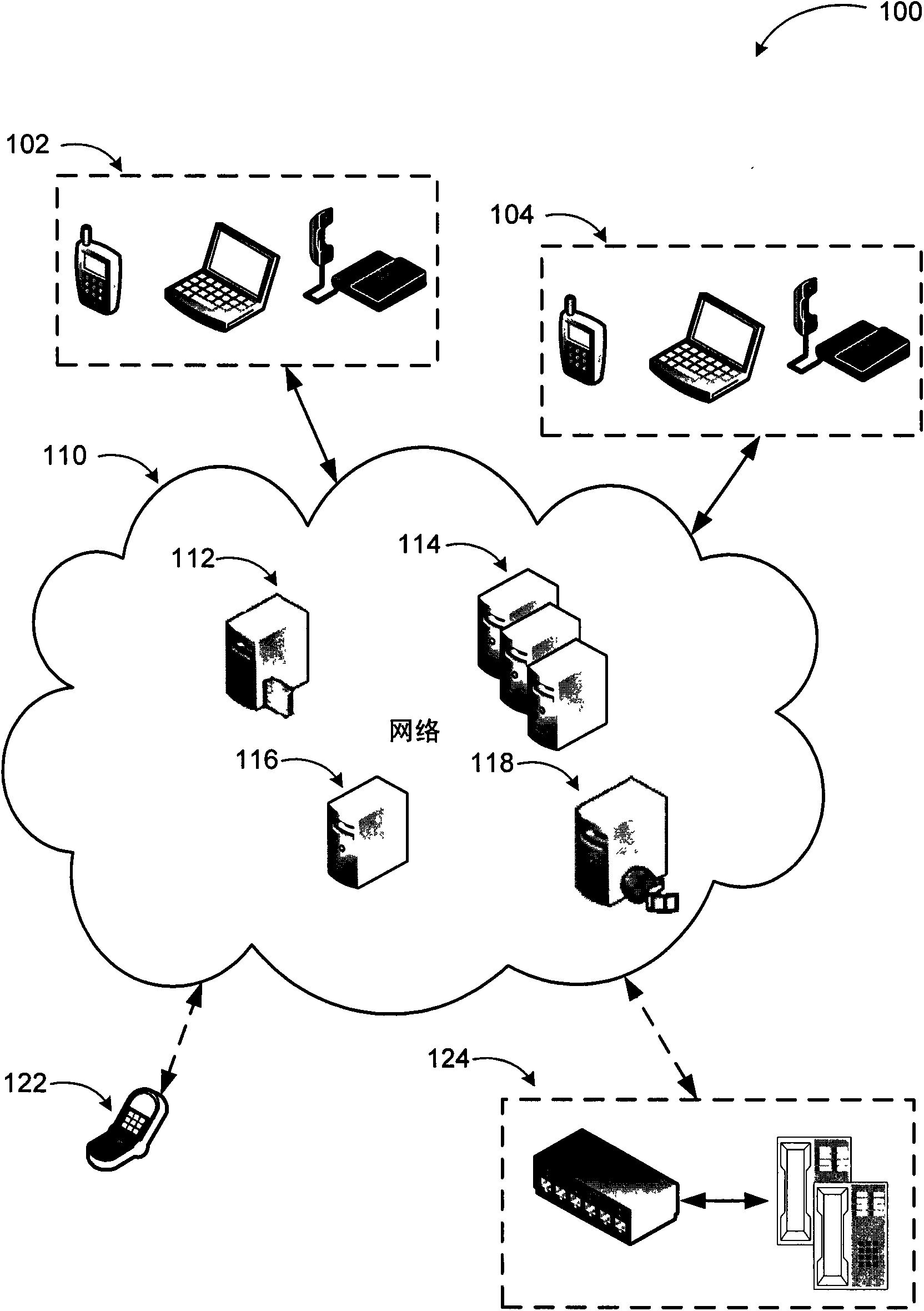

The invention relates to a contact predication based large-scale mobile delay tolerant network cluster-based routing method and a system thereof. The method includes: analyzing a truthful data set of a large-scale urban taxi network to disclose the intrinsic contact and clustering characteristics; designing a contact model among nodes and determining a probability distribution expressing form of contact time interval among the nodes; designing and implementing a contact predication based distributed cluster-based routing algorithm, and dividing nodes with high mutual contact probability into a same cluster under the large-scale dynamic environment; and designing and implementing a direct delivery based in-cluster routing algorithm and a flooding based inter-cluster routing algorithm to guarantee effectiveness and expandability in routing transmission on the basis of clustering. The contact predication based large-scale mobile delay tolerant network cluster-based routing method and the system thereof can be widely applied to message communication of large-scale urban transportation networks such as dynamic navigation systems, automatic vehicle driving systems and vehicular entertainment systems.

Owner:BEIHANG UNIV

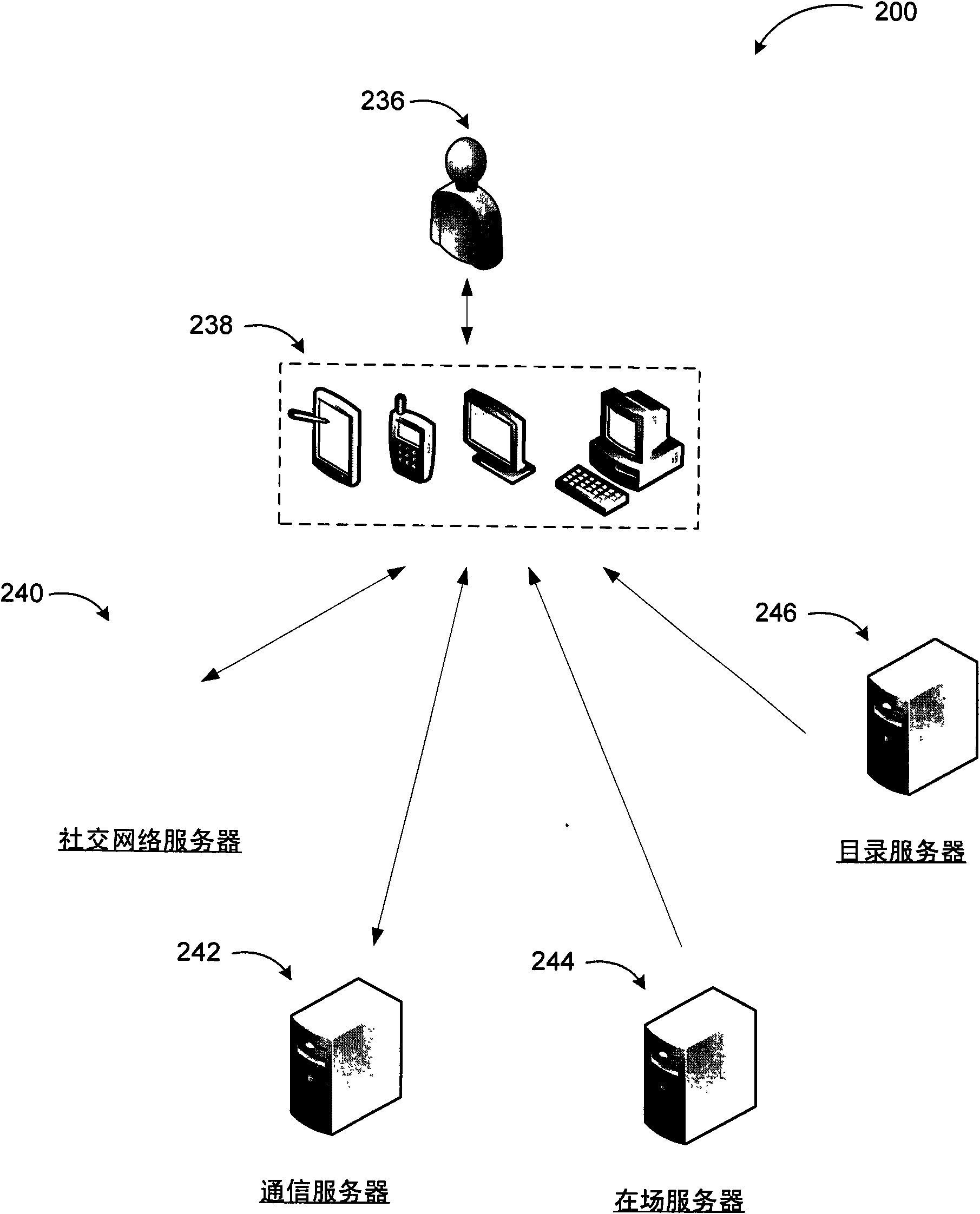

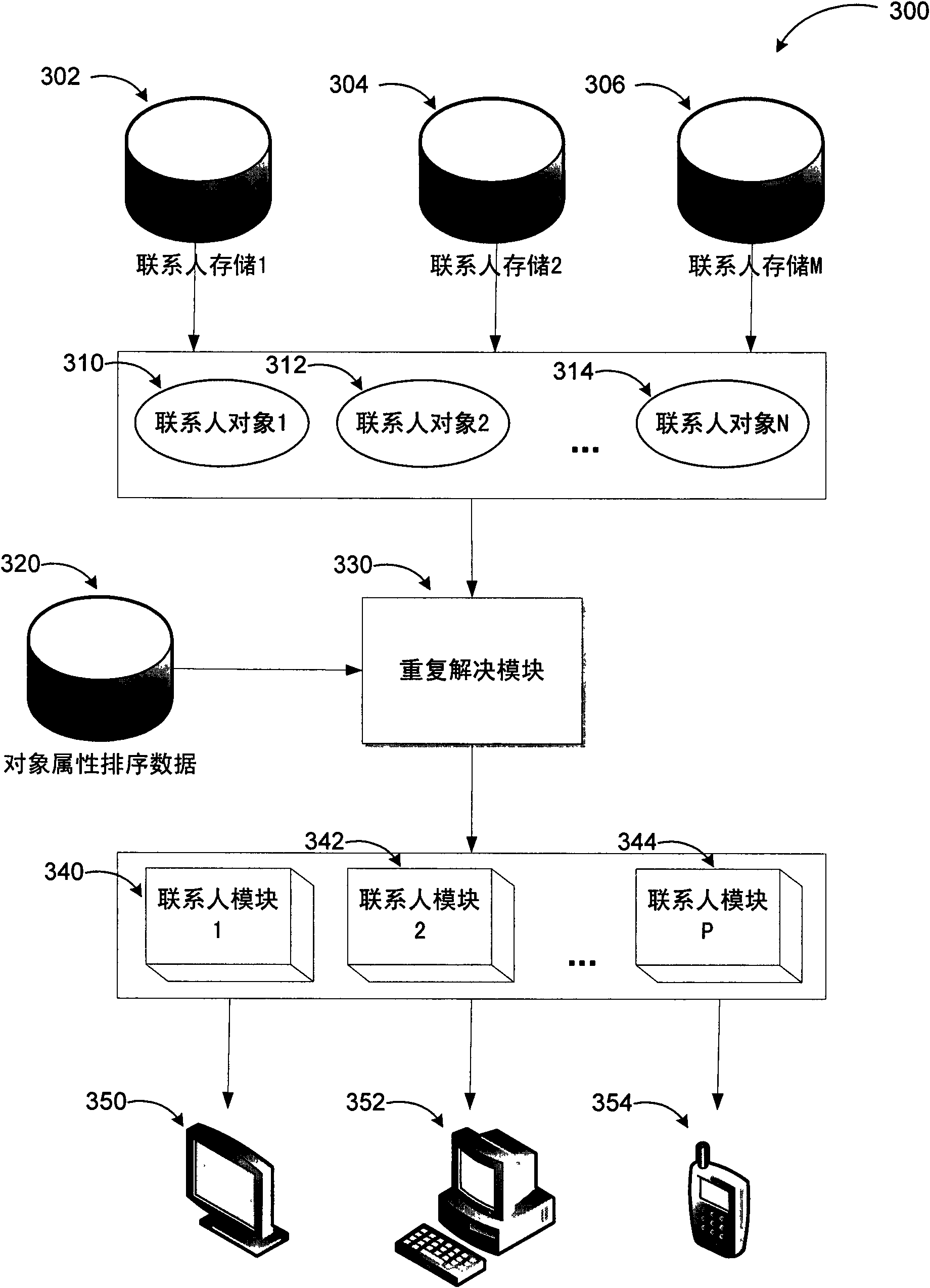

Consolidation and duplicate resolution of contact information

The invention discloses the merging and duplication solution of contact information. By using contact objects and aggregating contact objects into contact models, cross-platform contact information merging and duplication can be solved. Contact data can be obtained from internal and / or external data stores and a contact object can be created for each contact from each contact store. A contact model is created for each contact entity by aggregating contact data from contact objects across multiple contact stores. Aggregation may include iterative resolution through weighting of communication system types, ranking of contact information types, and similar methods. The contact model can be dynamically updated based on changes to the contact object.

Owner:MICROSOFT TECH LICENSING LLC

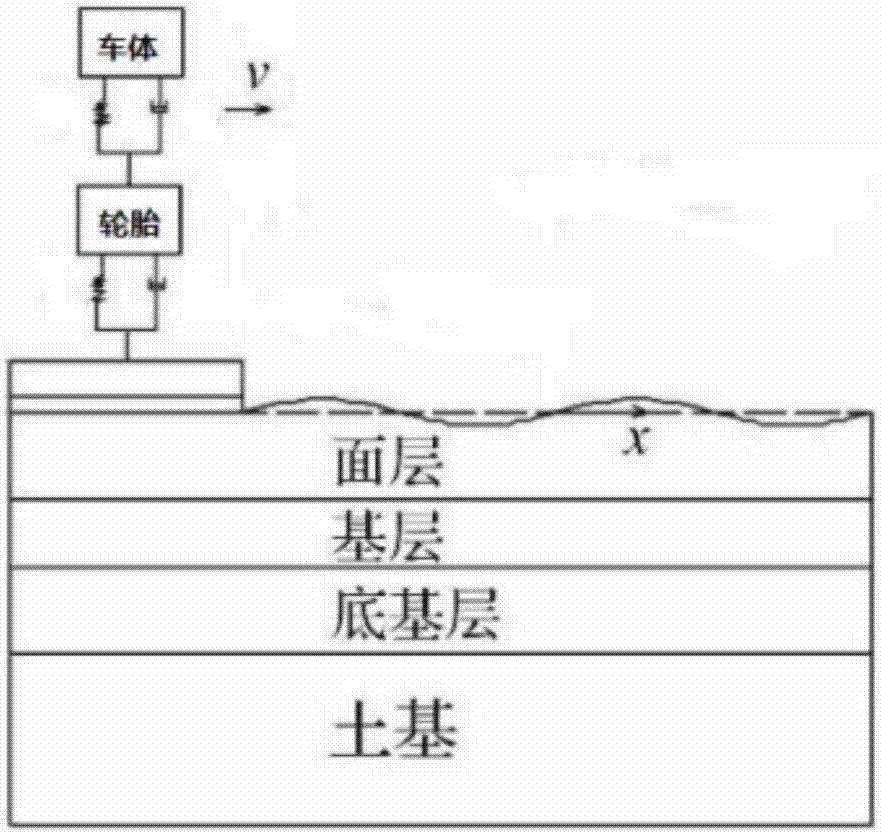

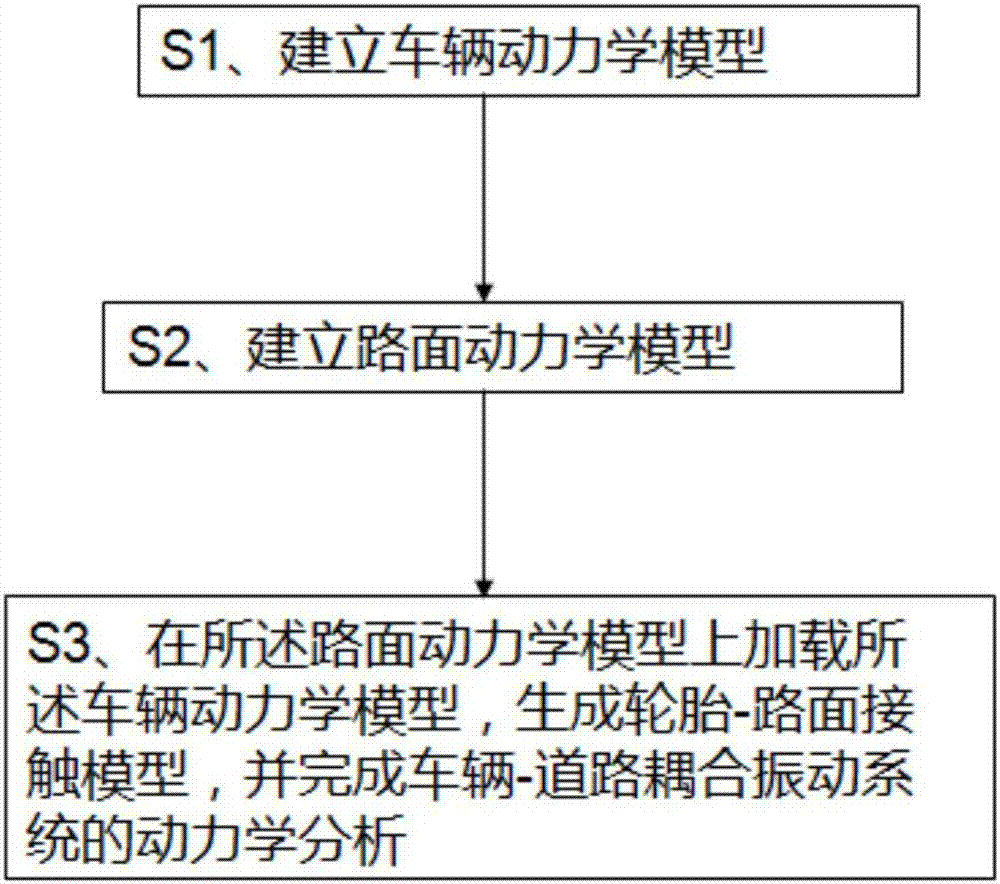

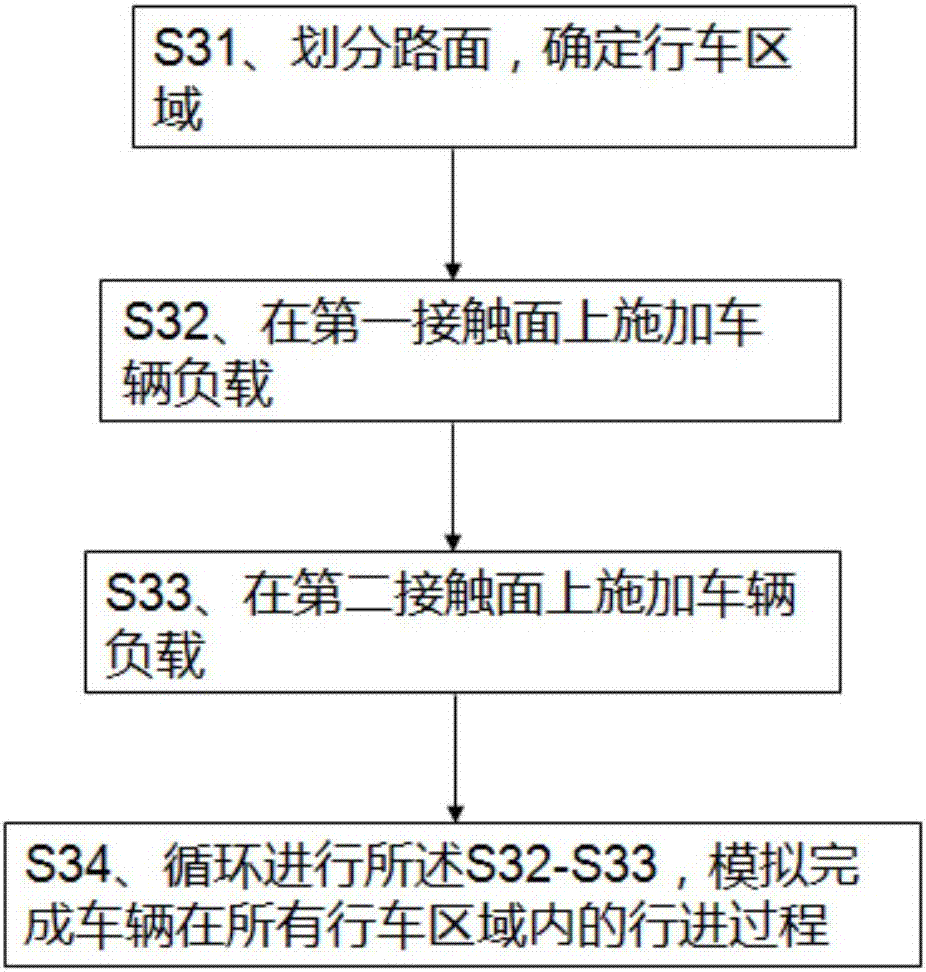

Joint simulation method for vehicle-road coupled vibration system

InactiveCN106897518AImprove accuracyEasy to operateGeometric CADSustainable transportationVehicle dynamicsDynamic models

The invention relates to a joint simulation method for a vehicle-road coupled vibration system. The method comprises the following steps of S1, building a vehicle dynamics model according to a dynamics equation; S2, building a pavement dynamics model according to a structural mechanics finite element equation; and S3, loading the vehicle dynamics model in the pavement dynamics model to generate a tire-pavement contact model, and finishing dynamics analysis of the vehicle-road coupled vibration system. According to the method, joint modeling of the vehicle-road coupled vibration system is realized by adopting efficient engineering software Matlab and Ansys; and by taking Matlab as control software and performing secondary development on Ansys, joint simulation of Matlab and Ansys is realized, and dynamics analysis of the vehicle-road coupled vibration system under complex road and vehicle conditions is finished.

Owner:WUHAN UNIV OF SCI & TECH

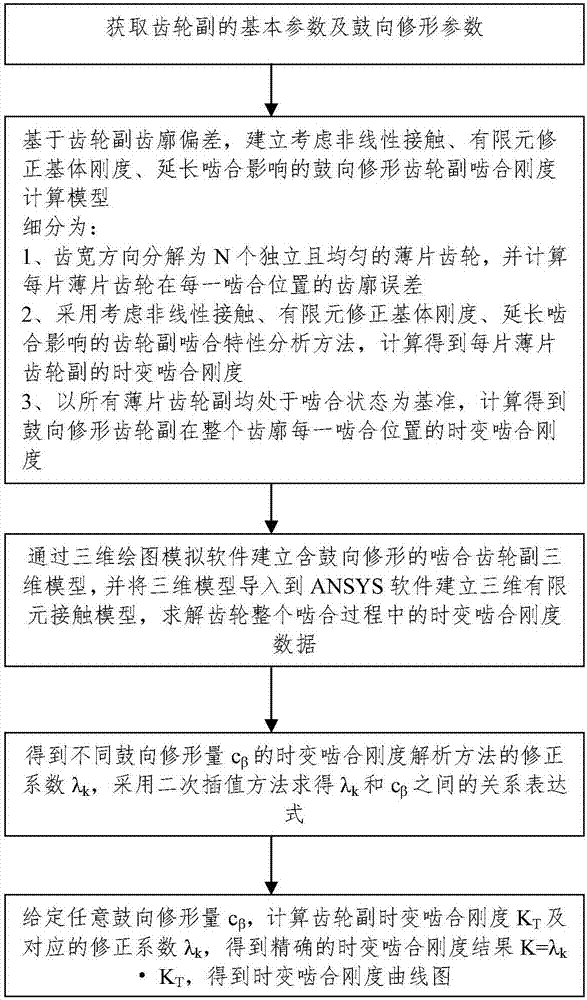

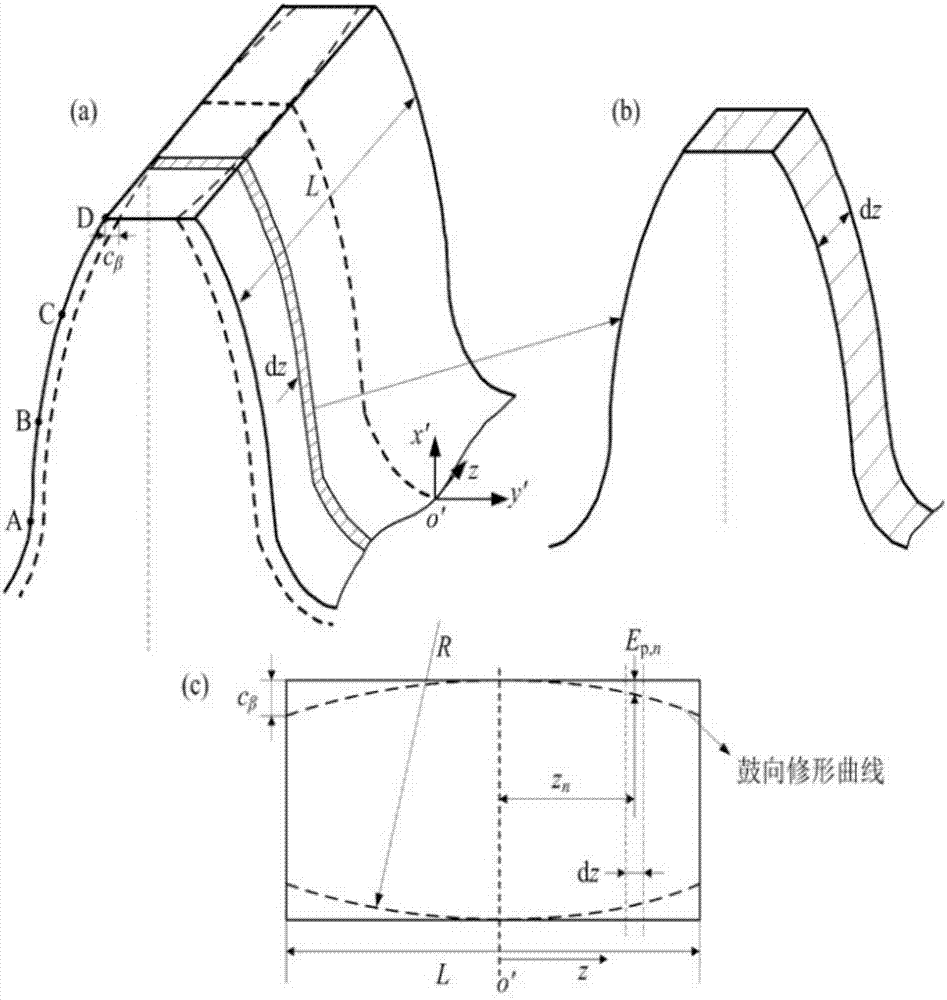

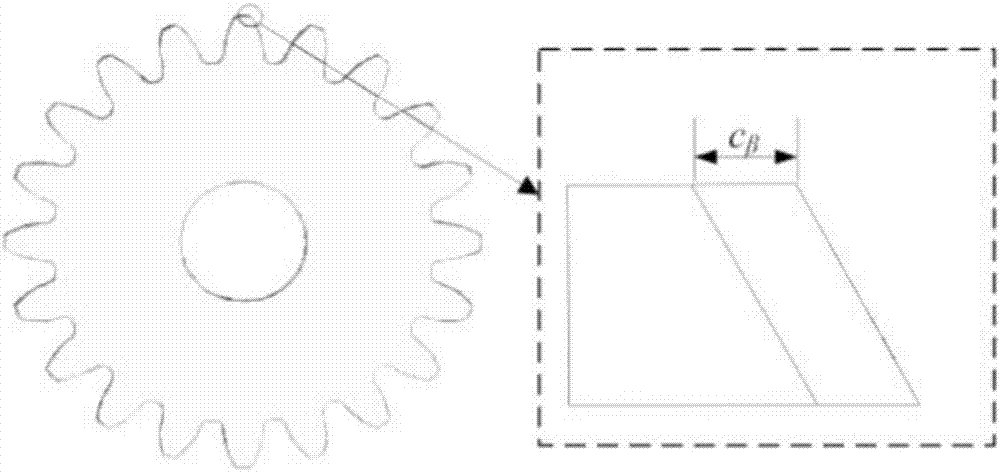

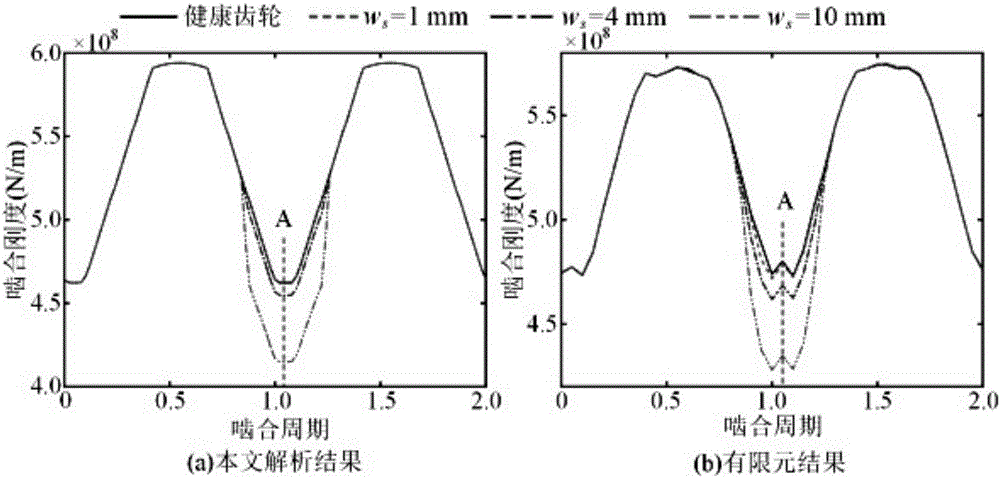

Amended gear pair meshing characteristic analysis method taking drum modification into consideration

ActiveCN107153736AThe meshing characteristics truly reflectLower performance requirementsGeometric CADDesign optimisation/simulationContact modelAnsys software

The invention relates to an amended gear pair meshing characteristic analysis method taking drum modification into consideration. In order to acquire basic parameters of a gear pair and drum modification parameters, gear teeth of the gear pair are divided into N independent even web gears in the direction of tooth width; the time-variant meshing stiffness of each web gear pair is calculated by adopting the gear pair meshing characteristic analysis method taking prolonging the meshing influence into consideration on the basis of the error of a gear profile of a drum modification gear pair; a meshing gear pair three-dimensional model comprising drum modification is established through three-dimensional drawing simulation software, the three-dimensional model is guided into an ANSYS software to create a three-dimensional finite element contact model, and time-variant meshing stiffness data in the whole meshing process of the gear are solved. The analysis method is simple in modelling process and low in calculated quantity, the requirement on a computer is low, and the calculation result is accurate and true.

Owner:NORTHEASTERN UNIV

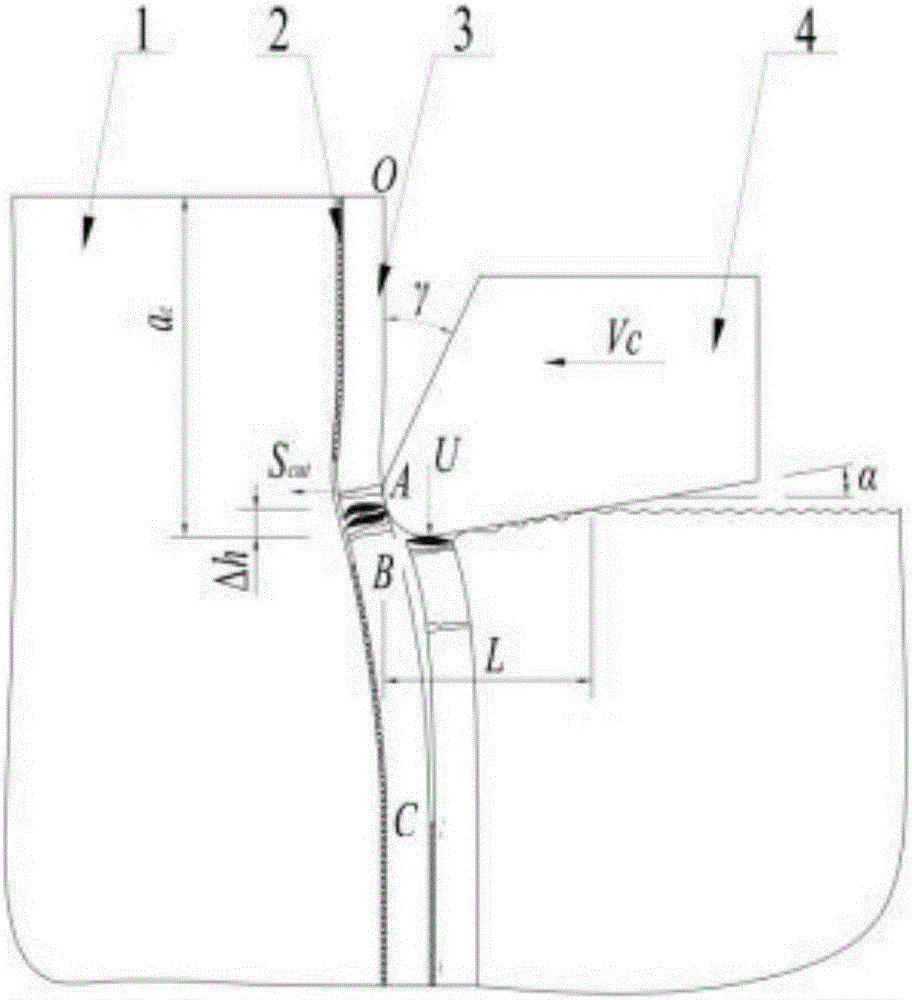

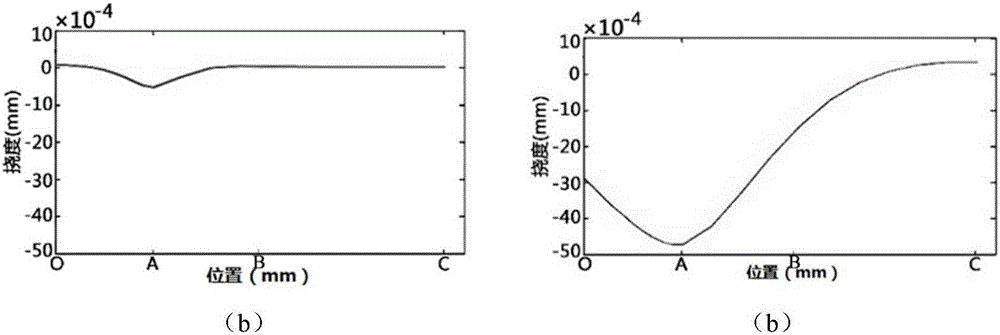

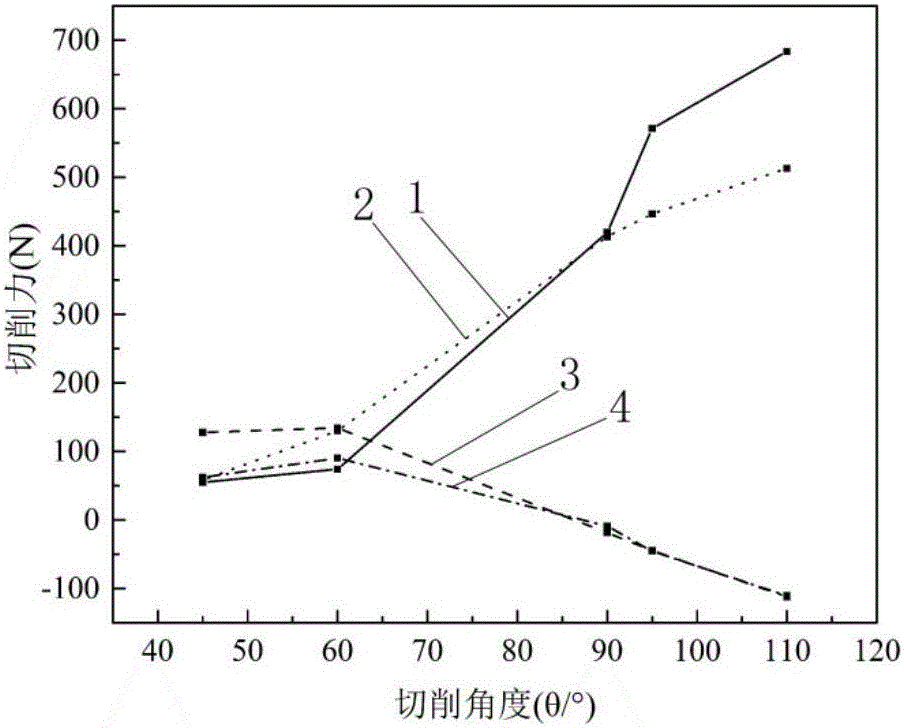

Building method of carbon fiber composite material cutting model

The invention belongs to the field of carbon fiber composite material cutting and processing researching, and relates to a building method of a carbon fiber composite material cutting model. The building method comprises the steps that firstly, a bidirectionally matrix-constrained single-fiber cut-off model is built, wherein the fiber deformation characteristics are described in three segments through the boundary condition difference in the fiber length direction according to the differences of the fiber stress and the borne matrix constraining action of the model in the fiber direction, the first segment starts from the top end to a cutting edge contact point, the second segment starts from the cutting edge contact point to a cutting plane, and the third segment starts from the cutting plane to a certain point far away from a processing surface; secondly, a contact model and a single-fiber compression-shearing model for a cutting edge and fibers are built; lastly, a composite material cutting force model is built. According to the method, fiber breakage, resin interface crack and the extruding action of a rear cutter surface on the fibers can be represented, a quantitative relation between the cutting force and processing parameters in composite material cutting and processing can be obtained, and an experimental basis is provided for actual cutter design and technological parameter establishment.

Owner:DALIAN UNIV OF TECH

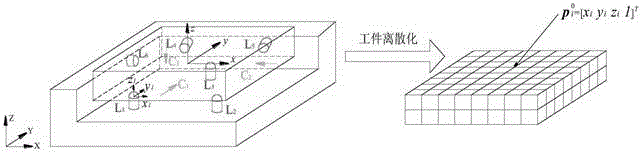

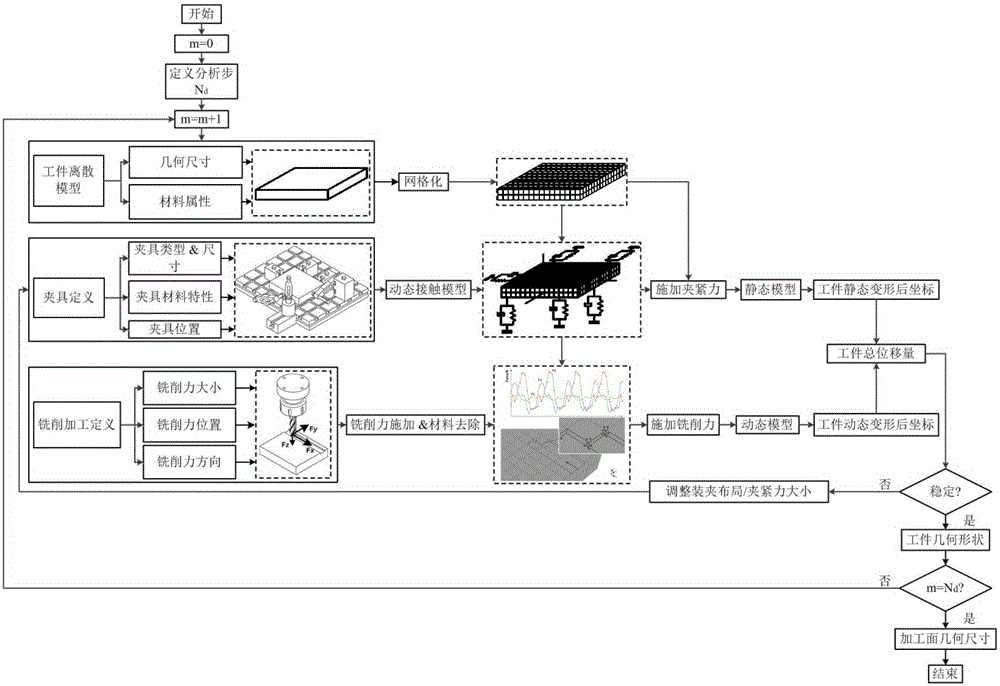

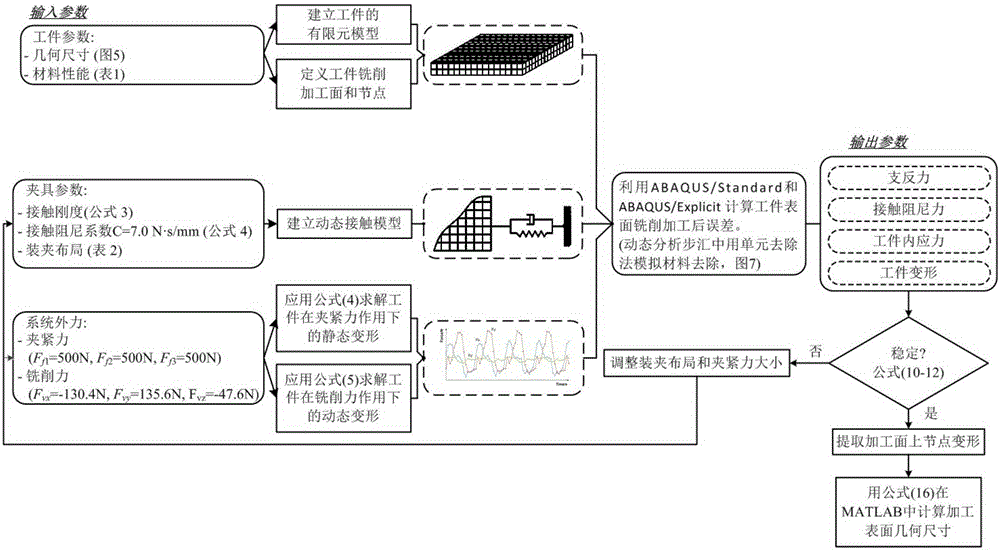

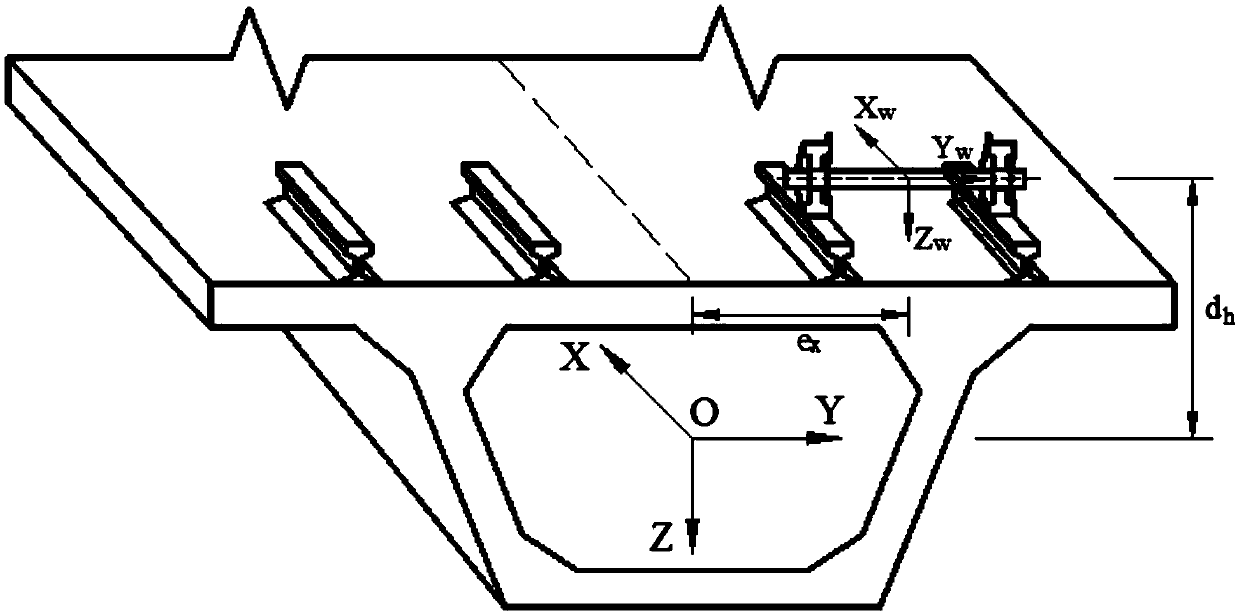

Method for predicting milling surface errors based on dynamic workpiece clamping system

ActiveCN105184007AMachining Error PredictionSpecial data processing applicationsContact modelEngineering

The invention provides a method for predicting milling surface errors based on a dynamic workpiece clamping system. The technical problem that a weak-rigidity part is difficult to machine is solved. The method includes the following steps of firstly, establishing a coordinate system of a workpiece and positioning element system; secondly, establishing a workpiece and positioning element contact model according to the coordinate system of the workpiece and positioning element system, wherein when a positioning element is a round head element, the contact rigidity between the positioning element and a workpiece nonlinearly changes while the normal contact force changes; thirdly, establishing a workpiece and positioning element system model through the combination of the workpiece and positioning element contact model; fourthly, judging the stability of the workpiece and positioning element system according to the workpiece and positioning element system model; fifthly, predicting and calculating machining errors on the premise that the workpiece and positioning element system is stable.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

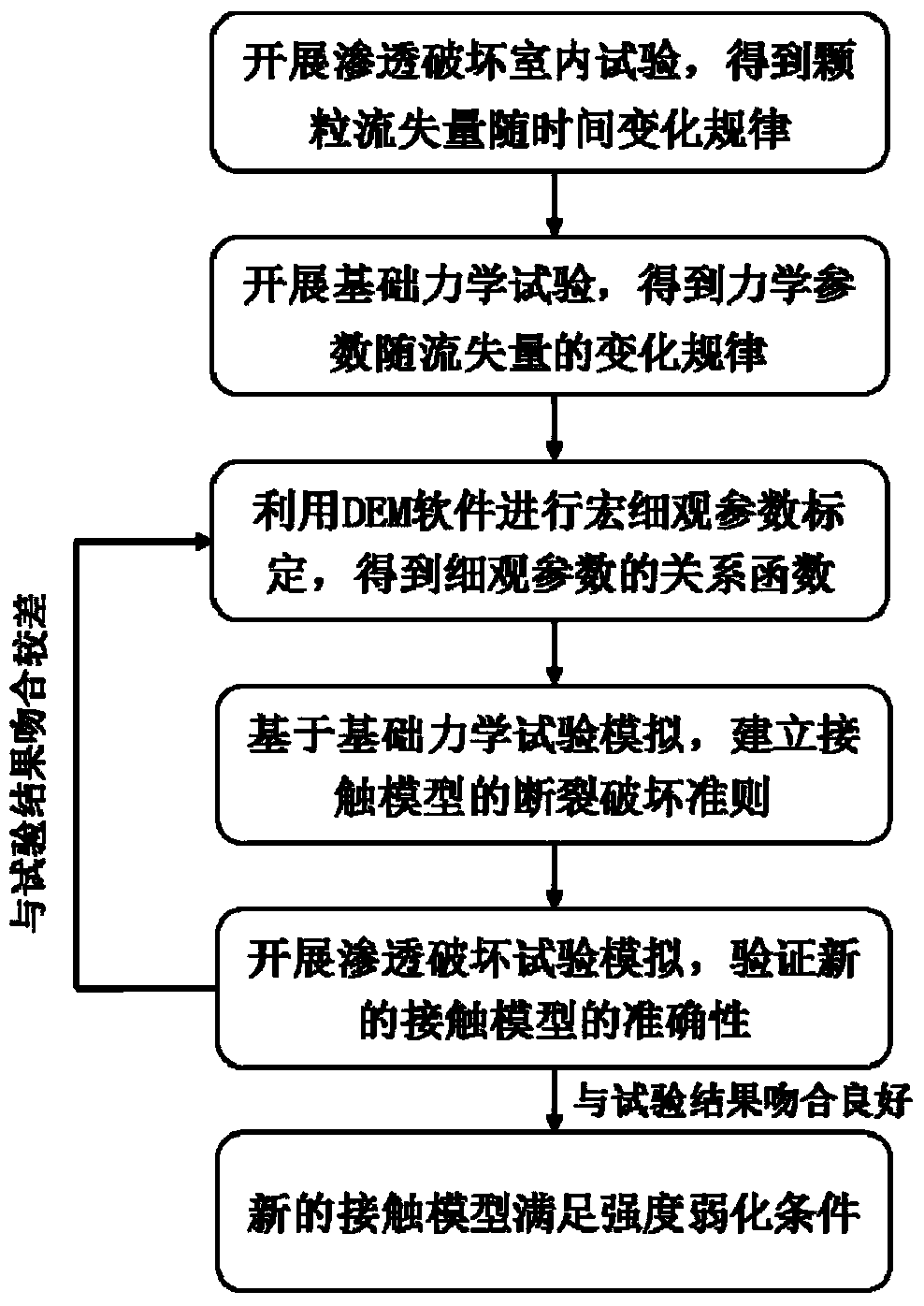

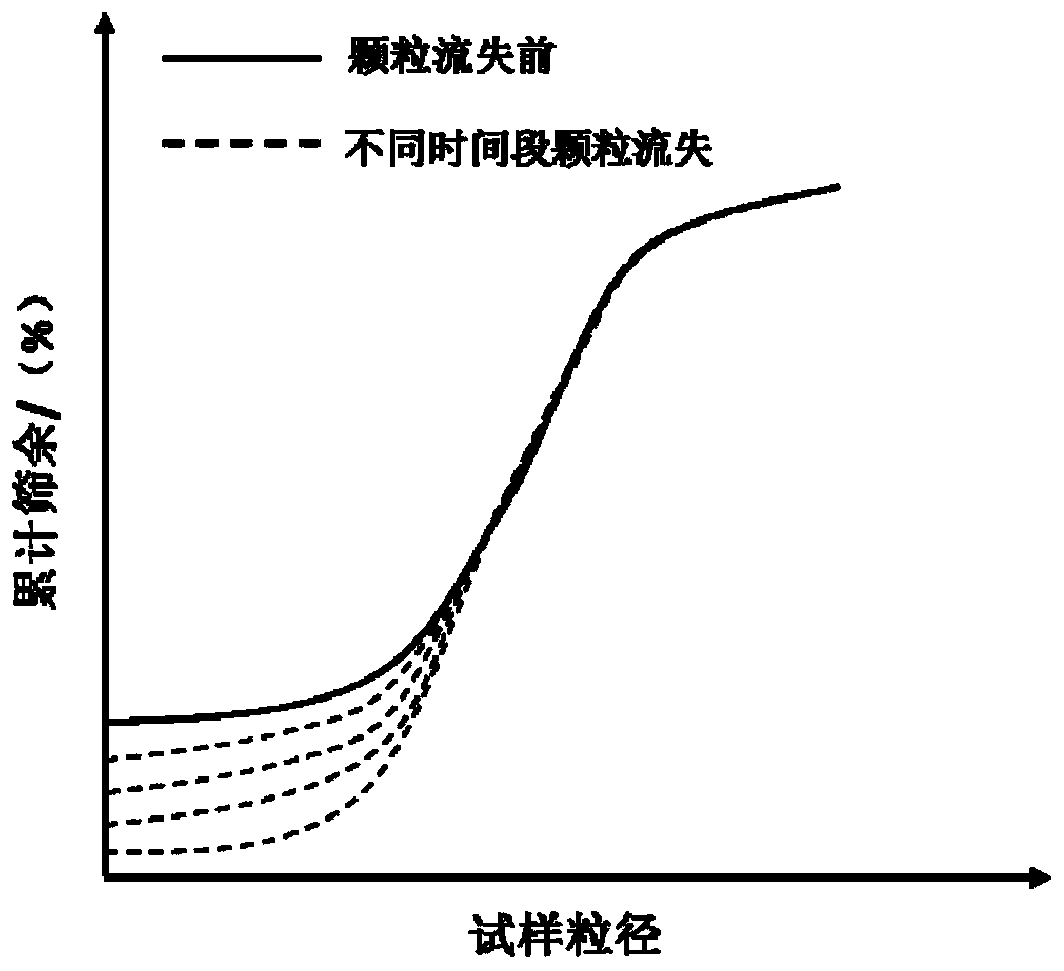

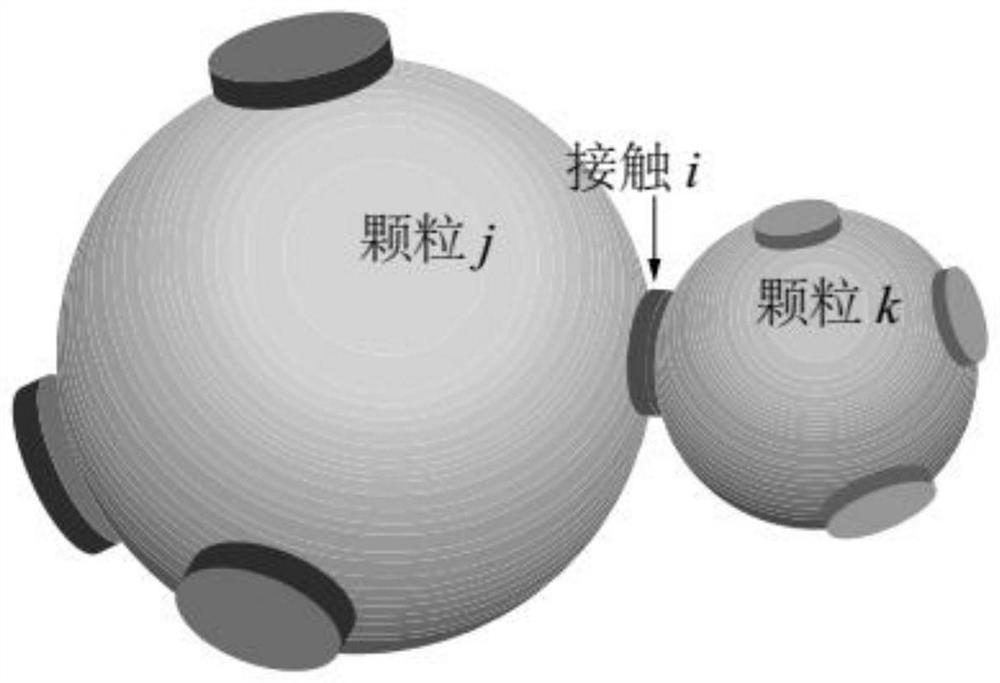

DEM contact model construction method capable of reflecting weakening of seepage to rock-soil mass strength

ActiveCN111024588AMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSoil scienceSoil mass

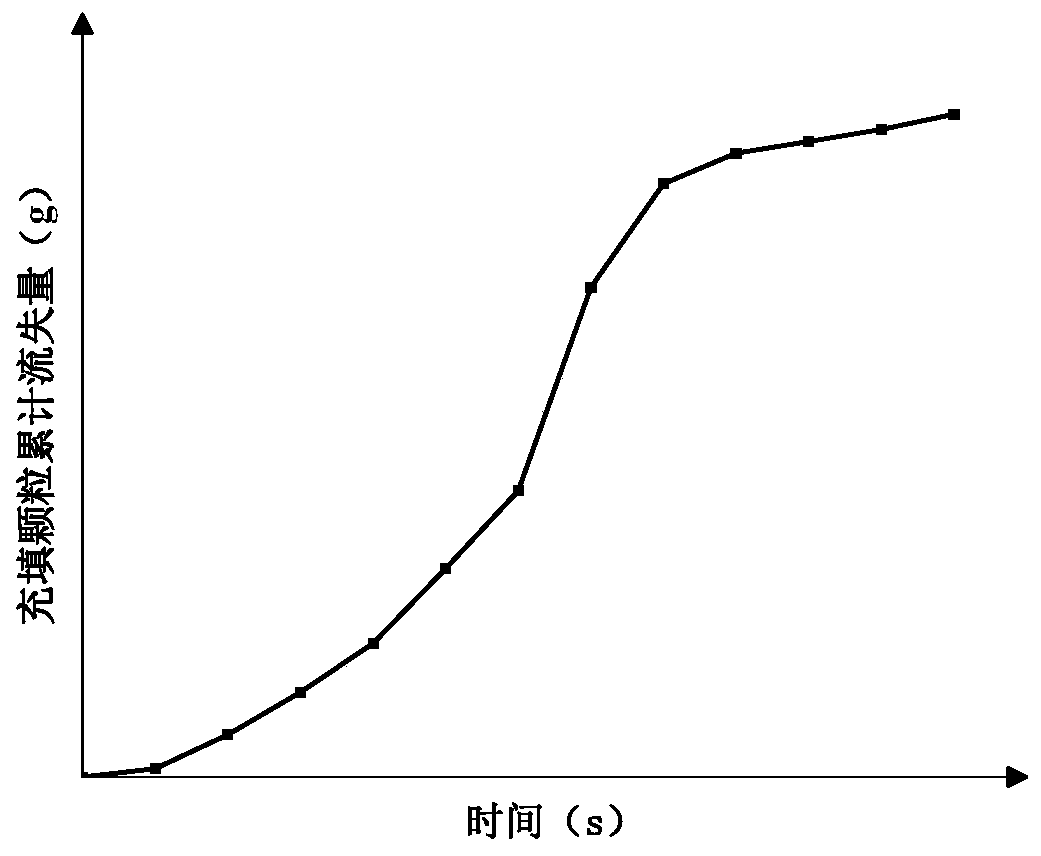

The invention provides a DEM (Digital Elevation Model) contact model construction method for reflecting weakening of seepage to rock-soil mass strength, which comprises the following steps: selectinga filling body in a disaster-causing structure to obtain a change rule of accumulated loss amount of the filling body along with time under the action of seepage and a change rule of mechanical parameters of the filling body along with the loss amount of the filling body; carrying out test simulation, and determining a relation function of each group of corresponding mesomechanics parameters in each time period and DEM contact model mesomechanics parameters capable of representing the change rule of the macromechanics parameters of the filling body; embedding each mesoscopic parameter relationfunction into an existing particle contact model, carrying out test simulation, and updating the fracture failure criterion of the contact model according to the corresponding relation of macro-mesoscopic strength when the model is damaged, so as to realize the simulation of the continuous weakening process of the filling body strength; and based on an indoor seepage failure test, establishing aseepage failure discrete element calculation model, and simulating the seepage failure process of the rock-soil body by adopting the obtained particle contact model and the fracture criterion thereof.

Owner:SHANDONG UNIV

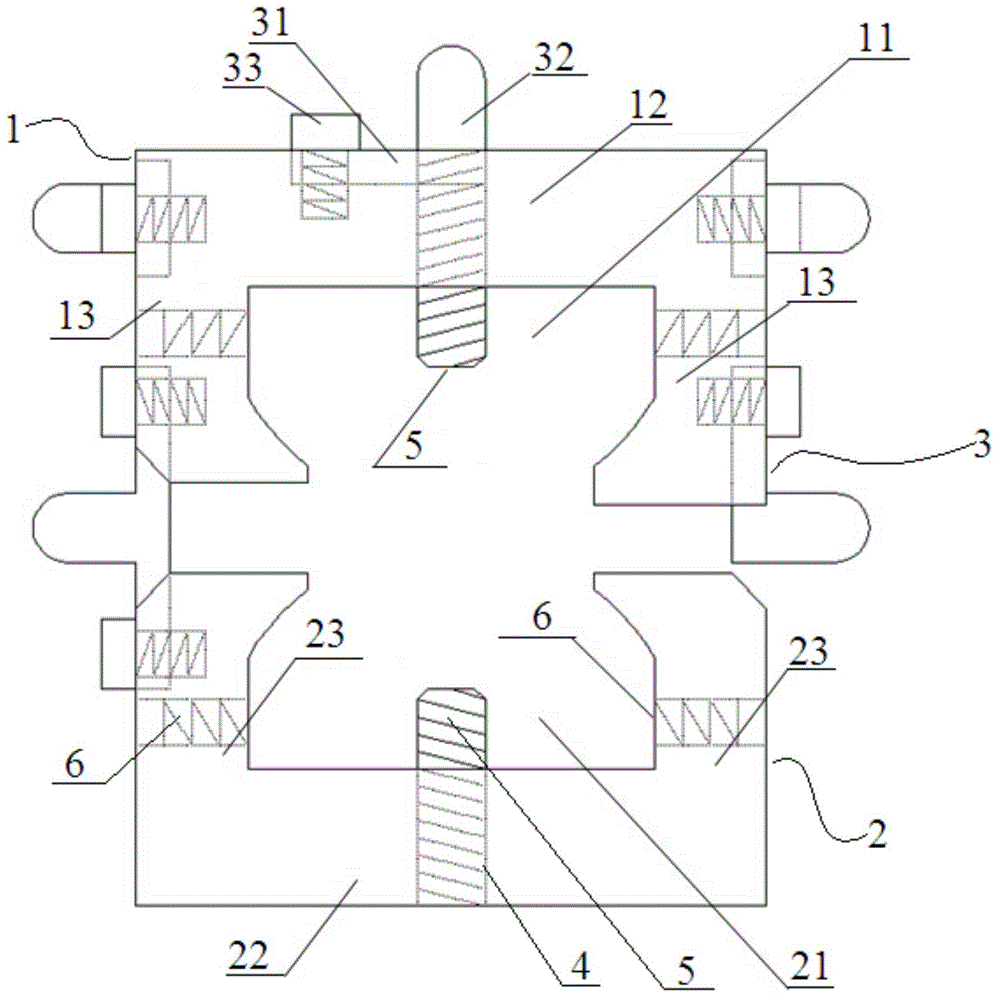

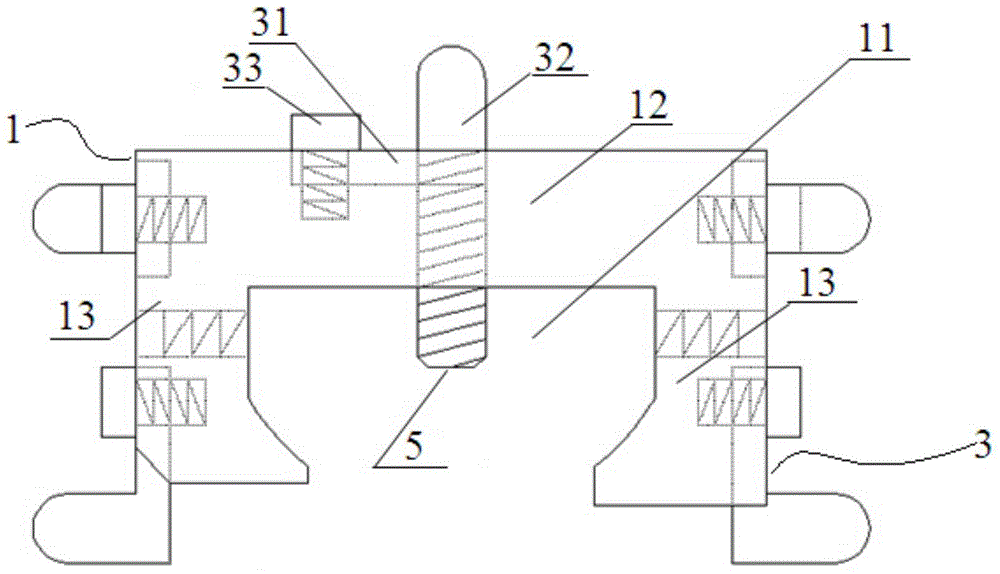

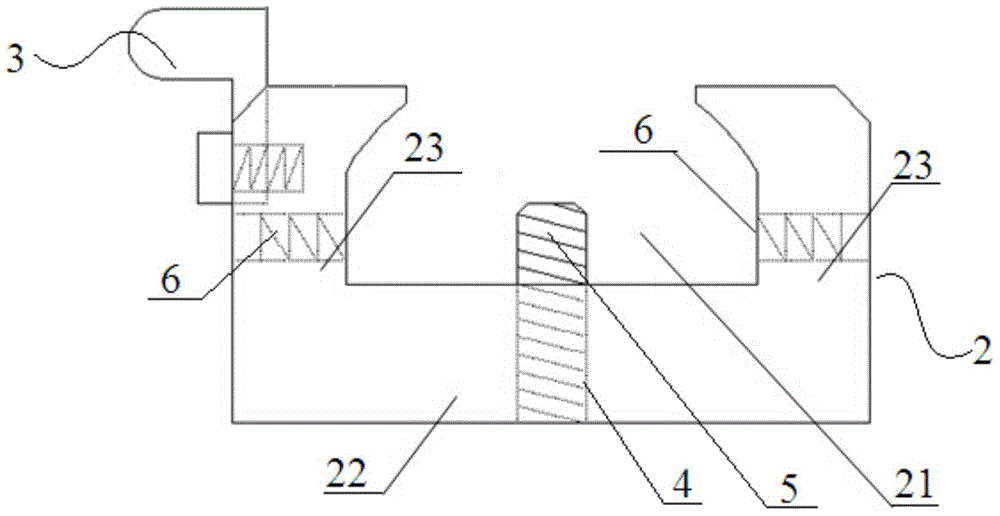

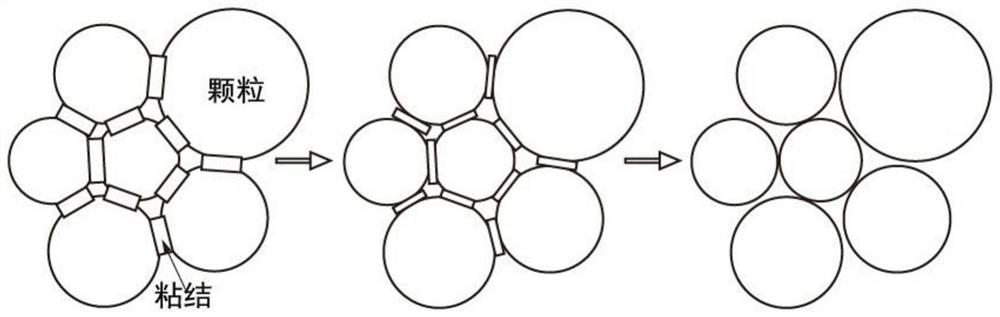

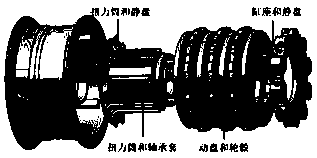

Testing device for contact shear resistance, bending resistance and torsion resistance of hemispherical ideal cementation particles

InactiveCN104614258ARealize test verificationMaterial strength using steady bending forcesMaterial strength using steady torsional forcesContact modelContact resistance

The invention relates to a testing device for contact shear resistance, bending resistance and torsion resistance of hemispherical ideal cementation particles. The testing device comprises an upper clamping piece and a lower clamping piece which are aligned up and down; an upper bath opening is formed in the lower side of the upper clamping piece; a lower bath opening is formed in the upper side of the lower clamping piece; the upper bath opening and the lower bath opening are communicated, and form clamping space clamping the hemispherical ideal cementation particles; force applying pieces used for force application are arranged on the outer sides of the upper clamping piece and the lower clamping piece respectively; the upper clamping piece comprises an upper top plate and two upper side surface plates connected with the two sides of the upper top plate; the upper bath opening is defined by the two upper side surface plates and the upper top plate; the lower clamping piece comprises a lower top plate and two lower side surface plates connected with the two sides of the lower top plate; the lower bath opening is defined by the two lower side surface plates and the lower top plate. Compared with the prior art, the testing device can realize test verification of a discrete element microcosmic contact model under a three-dimensional condition, particularly torsion resisting and bending resisting torque characteristic test of cementation particles, and provides abundant test foundation for three-dimensional model verification.

Owner:TONGJI UNIV

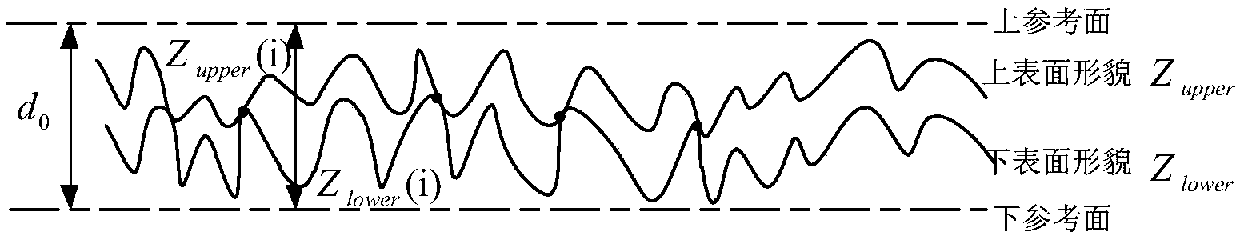

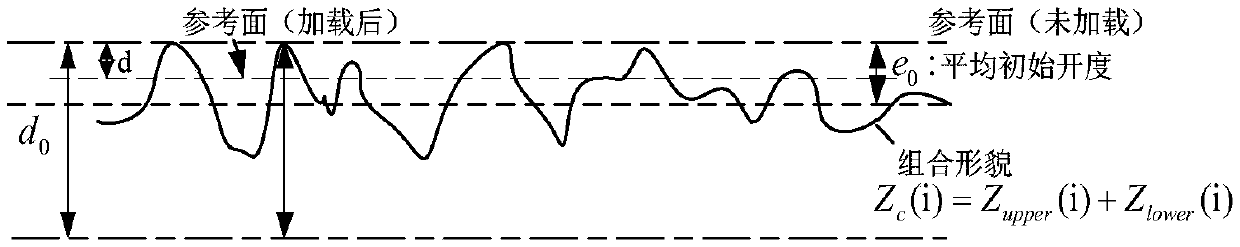

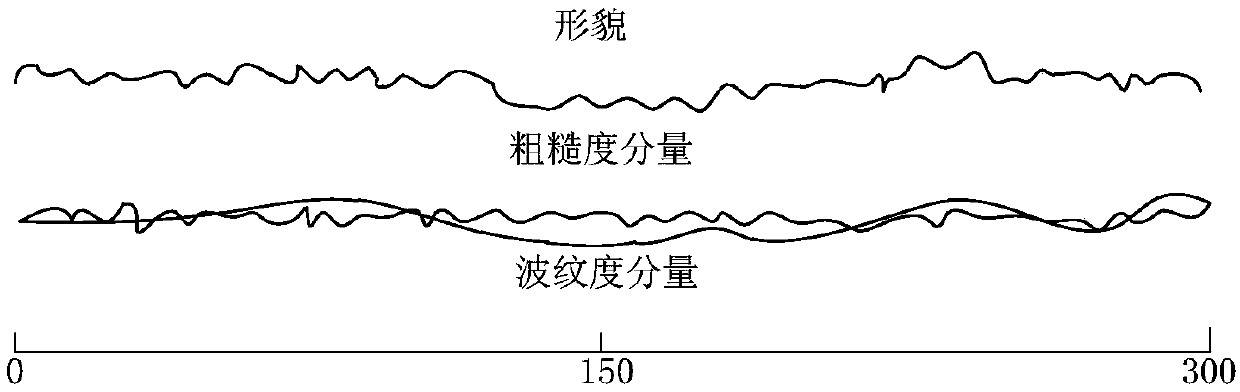

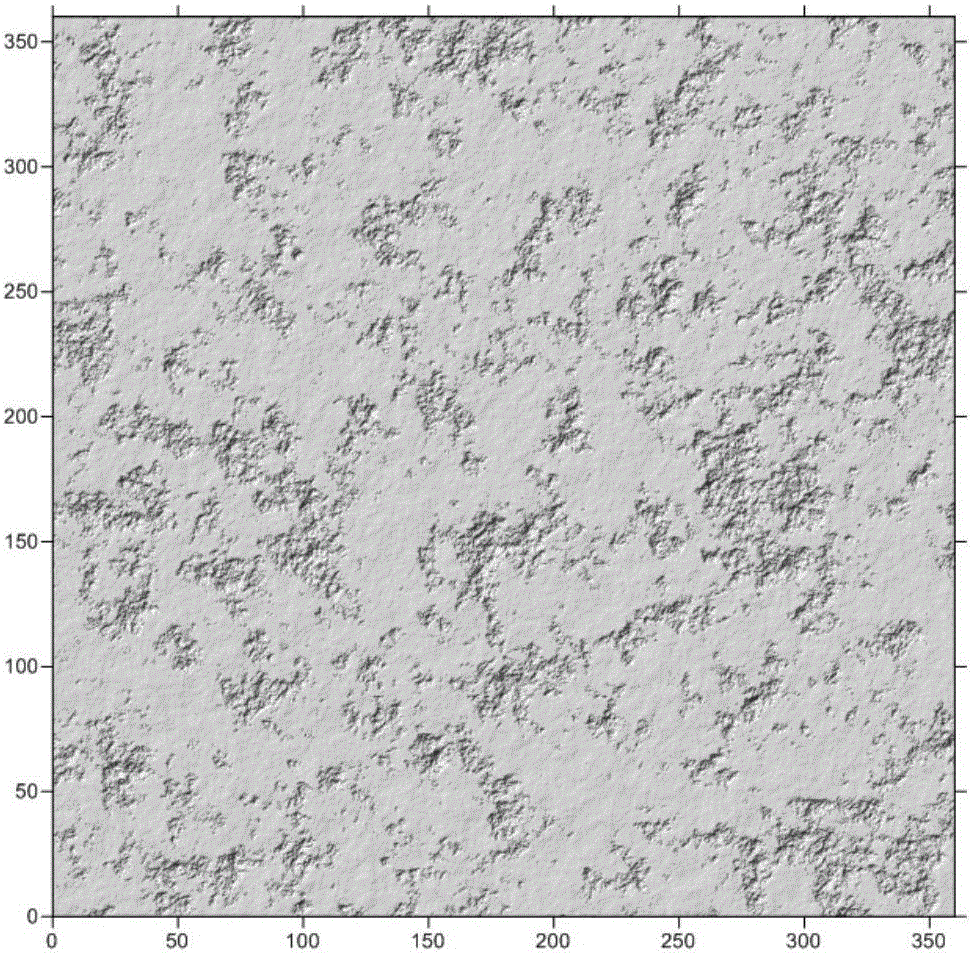

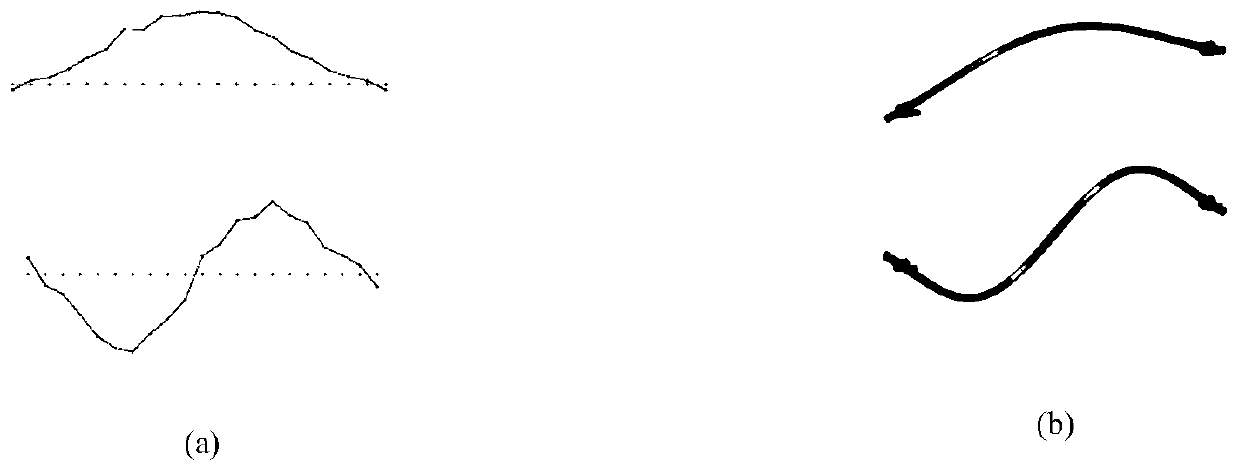

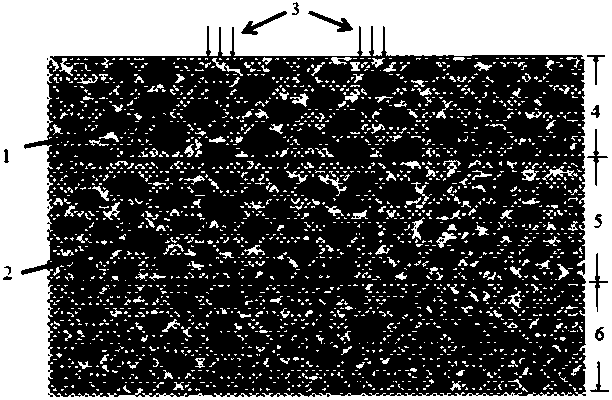

Combined surface modeling method considering rough surface waviness and micro-bulge interaction

InactiveCN108829909AVerify correctnessConvenient researchGeometric CADDesign optimisation/simulationRough surfaceThree dimensional morphology

The invention discloses a combined surface modeling method considering rough surface waviness and micro-bulge interaction. The method comprises the steps of obtaining microscopic outline data of a tested surface through a three-dimensional morphology measuring instrument, and superposing morphology data of corresponding points of an upper surface and a lower surface by utilizing a superposition principle of random components to obtain a combined morphology of a combined surface; and separating a waviness component and a roughness component of the combined morphology by adopting Fourier series,wherein the combined morphology of the combined surface contains the waviness and the roughness. A new combined surface contact model is provided; the influence of a contact state of the combined surface, the waviness and the roughness in the morphology and micro-bulge deformation interaction on a contact characteristic of the combined surface is considered; and the obtained data is compared withtest data to verify the correctness of the built model. The model solves the problem of an existing contact model and provides a new idea and method for researching a contact mechanism of the combined surface.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

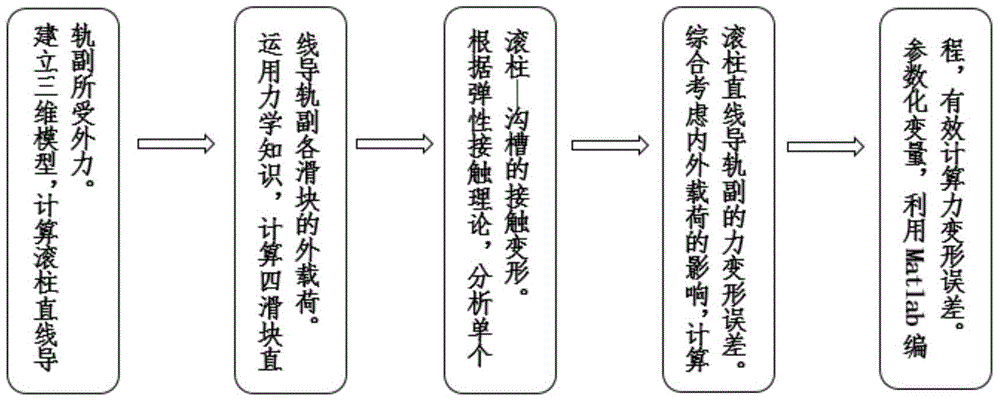

Force deformation error calculation method for pin roller linear guide rail pair under vertical loads

InactiveCN104915468AAccurate calculationImprove computing efficiencySpecial data processing applicationsStress conditionsEngineering

The invention provides a force deformation error calculation method for a pin roller linear guide rail pair under vertical loads, and belongs to the precision design field of linear guide rail pairs. The method aims at obtaining deformation of the linear guide rail pair under the load action and improving calculation efficiency. A force deformation error of the pin roller linear guide rail pair is calculated in consideration of the action of the outer loads. Three-dimensional CAD software is used for parametric modeling, the stress condition of the pin roller linear guide rail pair is analyzed, and a mechanical analysis model of the guide rail pair is established under the action of the outer loads. A linear guide rail pair contact model is then researched, and an improved Palmgren formula is applied to analyzing the relation between elastic deformation and the corresponding load when a single pin roller makes contact with a groove. Loads borne by rolling bodies are solved according to the outer loads, elastic deformation quantities of the rolling bodies are worked out, and the displacement quantity of a sliding block is deduced and serves as the force deformation error of the whole linear guide rail pair. Finally, Matlab programming parametric modeling is applied, and the conclusion provides a theoretical basis for movement precision and service life calculation of rolling linear guide rails.

Owner:BEIJING UNIV OF TECH

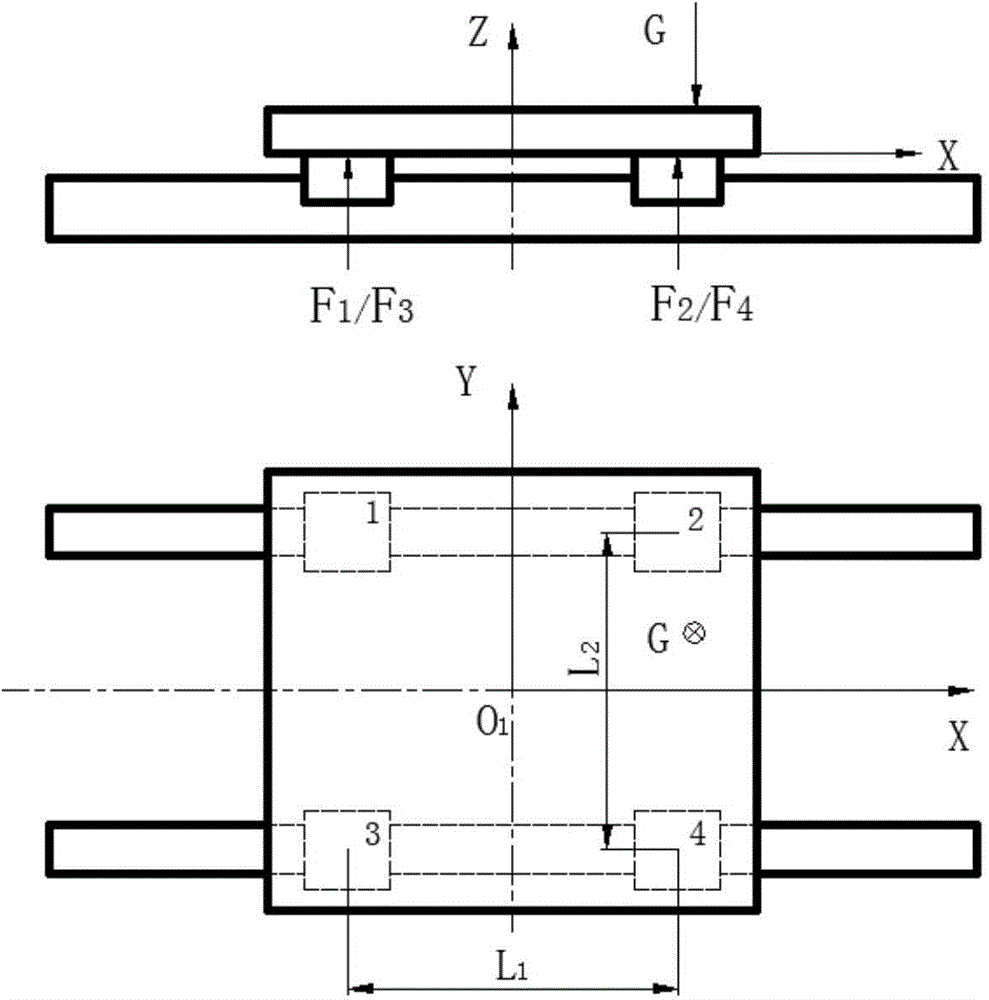

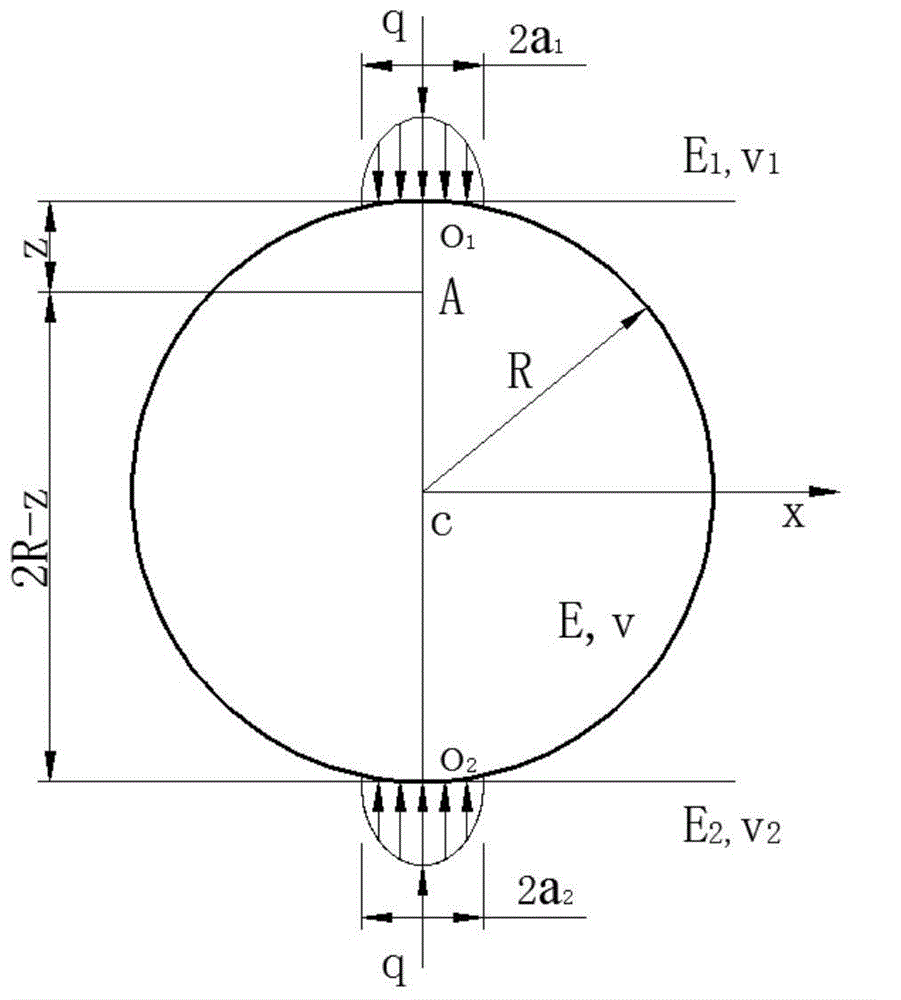

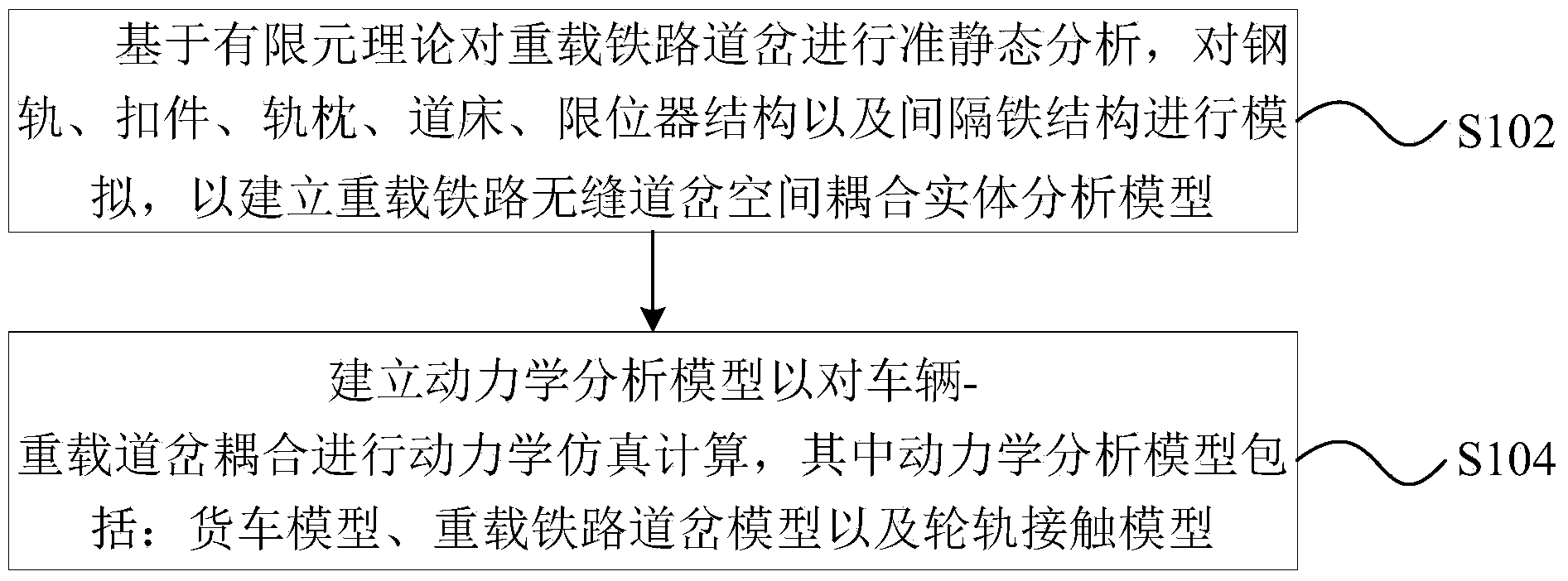

Heavy haul railway turnout static and dynamic design model construction method

InactiveCN103853876AMeet the use requirementsHigh degree of simulationSpecial data processing applicationsFreight trainsBallast

The invention discloses a heavy haul railway turnout static and dynamic design model construction method. The heavy haul railway turnout static and dynamic design model construction method is characterized in that the method comprises the steps of performing quasi-static analysis on a heavy haul railway turnout based on a finite-element theory, and simulating rail, rail fastening, sleeper, ballast and limiter structures and filler structures to construct a heavy haul railway seamless space coupling entity analysis model; constructing a dynamic analysis model to perform dynamic simulation calculation on car-heavy haul turnout coupling, wherein the dynamic analysis model comprises a freight train model, a heavy haul railway turnout model and a wheel-rail contact model. By adopting the technical scheme, the constructed heavy haul railway seamless space coupling entity analysis model and the constructed dynamic analysis model can provide higher-simulation-degree models for heavy haul railway turnout design and analysis; by using the models constructed by adopting the scheme provided by the invention, heavy haul railway turnouts which can fully meet use requirements can be designed.

Owner:CHINA SHENHUA ENERGY CO LTD +1

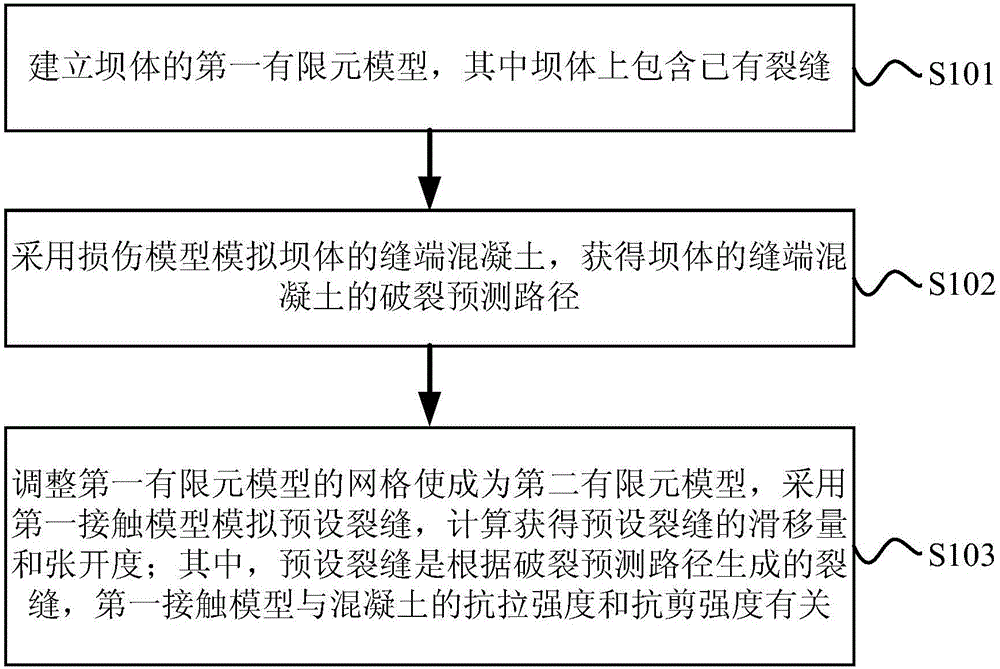

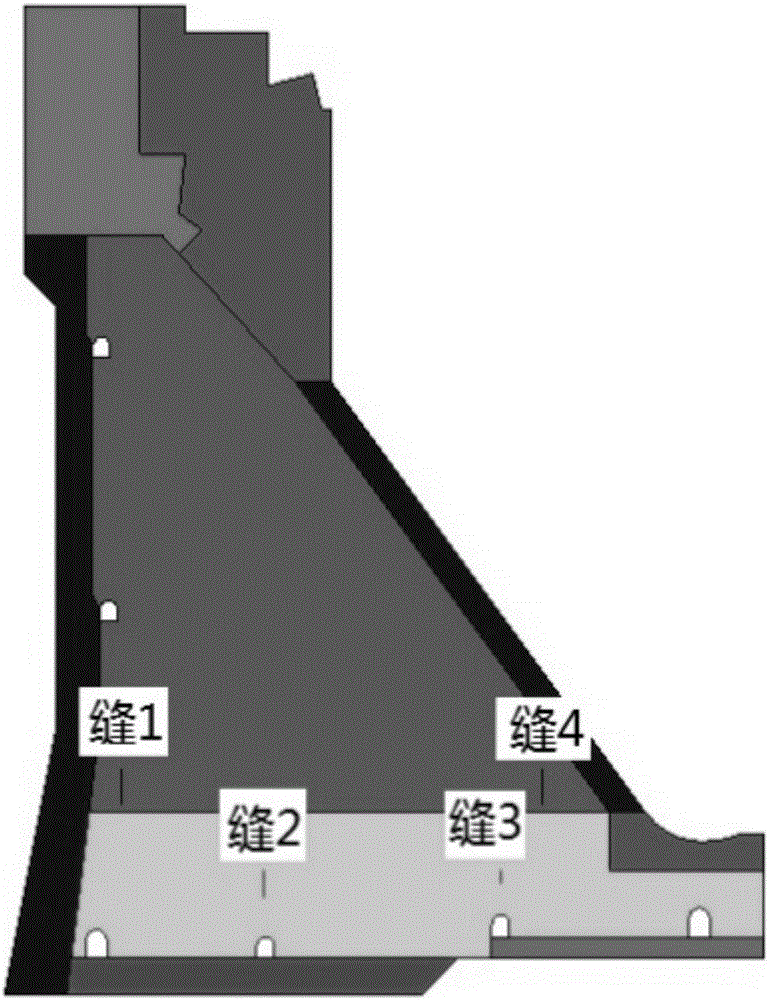

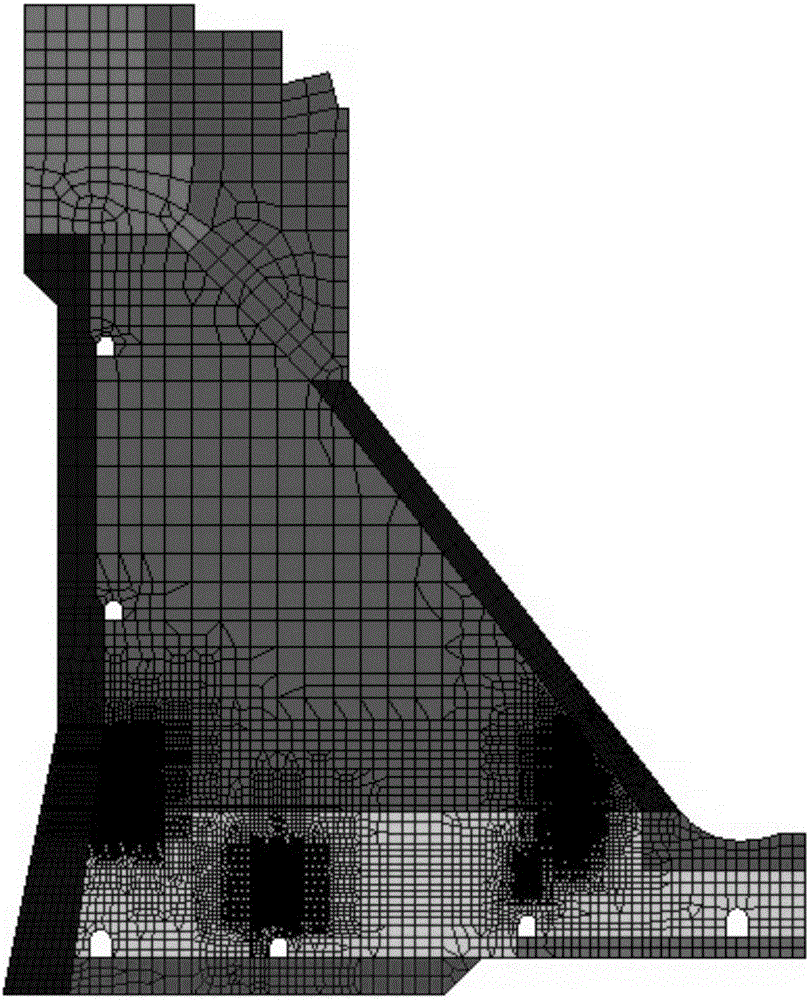

Analysis method for predicting crack propagation of dam body of concrete dam

InactiveCN107180125AHigh simulationOvercome limitationsDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

The invention provides an analysis method for predicting crack propagation of a dam body of a concrete dam. The method comprises the following steps of building a first finite element model of the dam body, wherein the dam body contains an existing crack; simulating crack end concrete of the dam body by adopting a damage model to obtain a fracture prediction path of the crack end concrete of the dam body; adjusting a grid of the first finite element model to form a second finite element model, simulating a preset crack by adopting a first contact model, and performing calculation to obtain a slip quantity and an opening degree of the preset crack, wherein the preset crack is a crack generated according to the fracture prediction path, and the first contact model relates to the tensile strength and the shear strength of the concrete. According to the method, the advantages of the damage model and the contact model are coupled; the finite element analysis method for predicting the crack propagation by two stages is proposed; the limitation of a numerical analysis method in the present stage is overcome; and the method can be applied to the prediction of the crack propagation of the dam body of the concrete dam.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

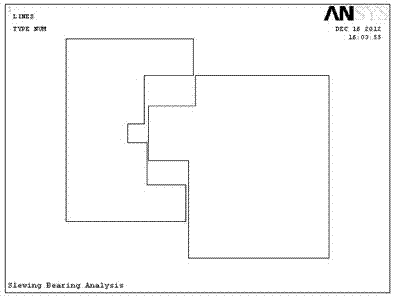

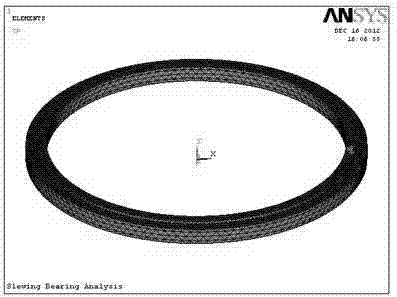

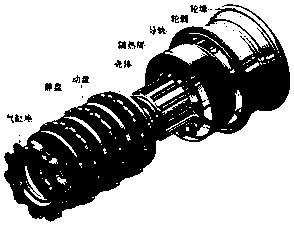

Method of utilizing finite element modeling to judge whether turntable bearing meets requirements

InactiveCN103116672ASuperiorLower requirementSpecial data processing applicationsComputer resourcesElement model

Provided is a method of utilizing finite element modeling to judge whether a turntable bearing meets requirements. A turntable bearing model is established in ANSYS according to a structure parameter of the turntable bearing. Total freedom constraints are imposed on a lower end face of an outer ring of the turntable bearing model, and a radial load, an axial load and an overturning moment load are imposed on an inner ring. Load data of a rolling body is solved and obtained. The security coefficient of the bearing is calculated by utilizing the maximum rolling body load data, and whether the security coefficient meets the requirements. According to the method of utilizing the finite element modeling to judge whether the turntable bearing meets the requirements, the ANSYS is utilized to establish a 'rod-entity' hybrid finite element model of the turntable bearing, and a contact model between an entity rolling body and an entity rolling path is dispensed. The finite element model obviously lowers requirements to computer resources, and the calculation time is greatly shortened.

Owner:HENAN UNIV OF SCI & TECH

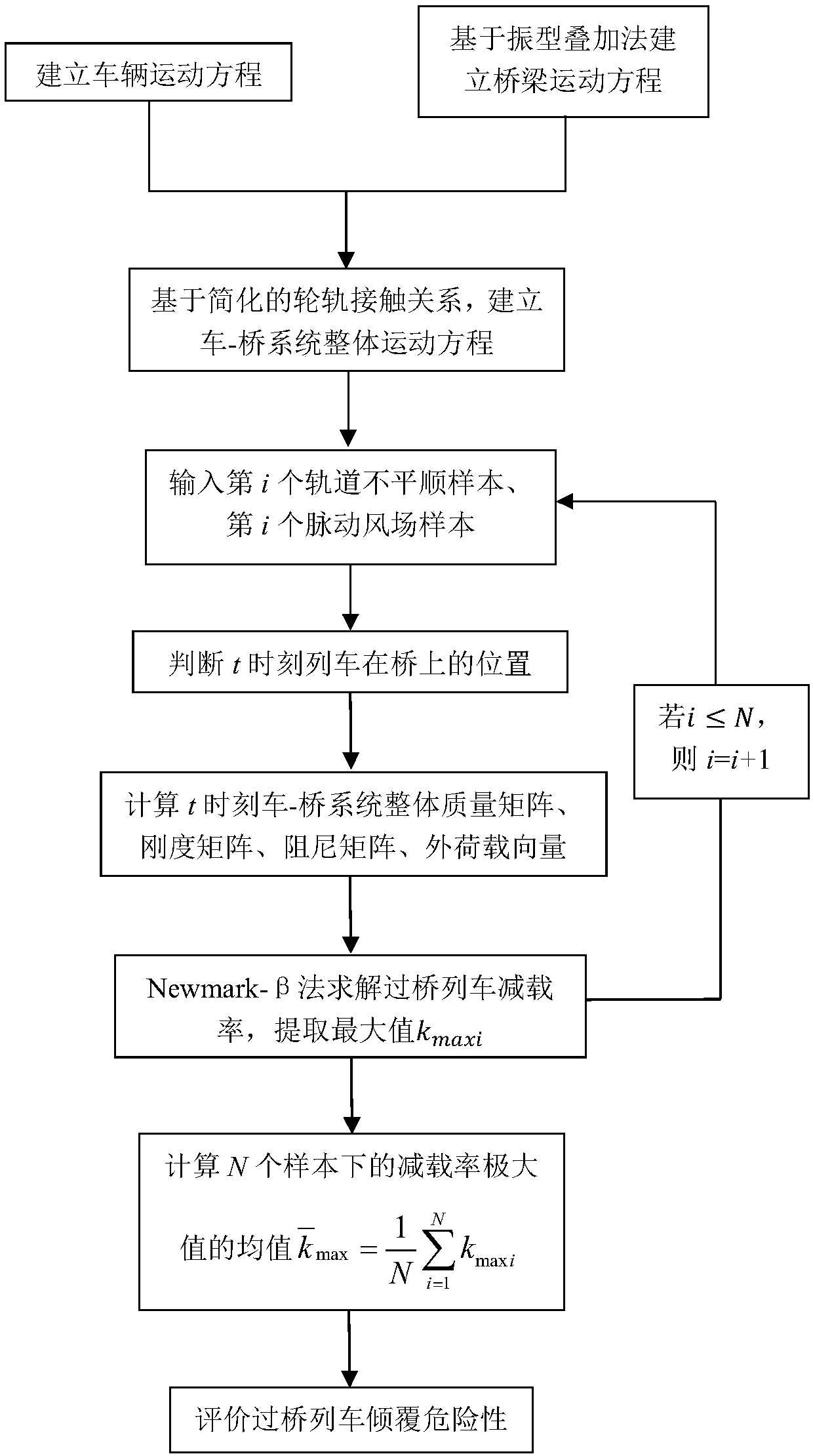

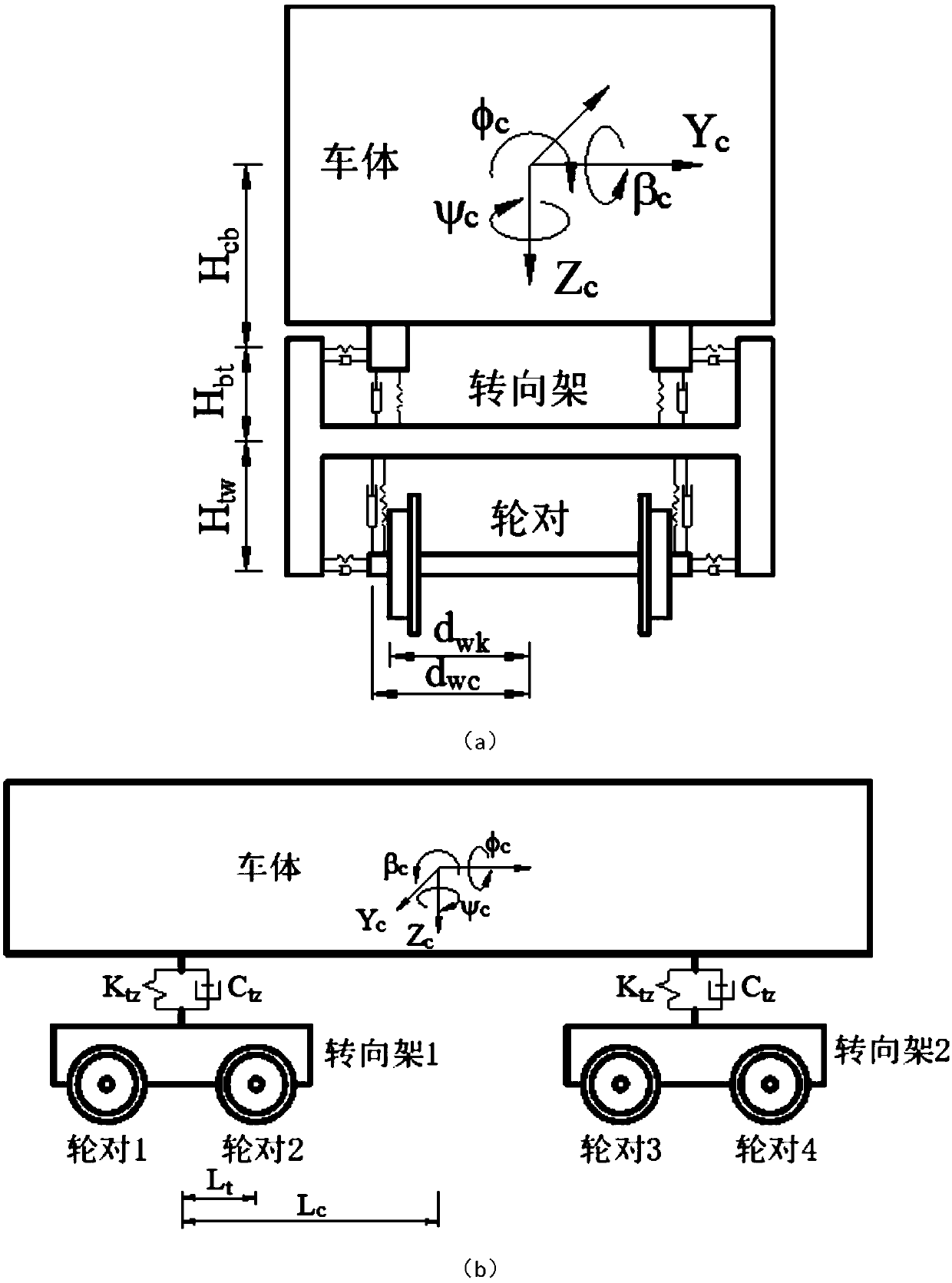

Bridge crossing train overturning risk assessment method based on mode superposition method

InactiveCN108763716ALess freedomSmall amount of calculationDesign optimisation/simulationResourcesContact modelEngineering

Owner:SOUTHWEST JIAOTONG UNIV +1

Contact characteristic analysis method based on three-dimensional microscopic surface morphology

InactiveCN108168492AImprove accuracyMeasurement devicesSpecial data processing applicationsMultiscale decompositionThree dimensional morphology

The invention discloses a contact characteristic analysis method based on three-dimensional microscopic surface morphology, and is suitable for researching the contact rigidity and the contact dampingof the combined surface based on the multi-scale theory. According to the method, the surface morphology of the combined surface is obtained through a three-dimensional morphology measuring instrument, and multi-scale decomposition reconstruction is carried out through wavelet transformation, and a three-dimensional entity model for the data of separated different frequency bands. Due to the factthat the established contact model is based on real surface data and influences of different scales are considered, the accuracy of the contact model is improved to a great extent, and the research of the contact characteristic of the combined surface is closer to the actual situation. The real surface morphology height matrix is subjected to multi-scale separation by wavelet transformation, andthe three-dimensional entity model for the data of the separated different frequency bands. Due to the fact that the established contact model is based on real surface data and influences of differentscales are considered, the accuracy of the contact model is improved to a great extent.

Owner:BEIJING UNIV OF TECH

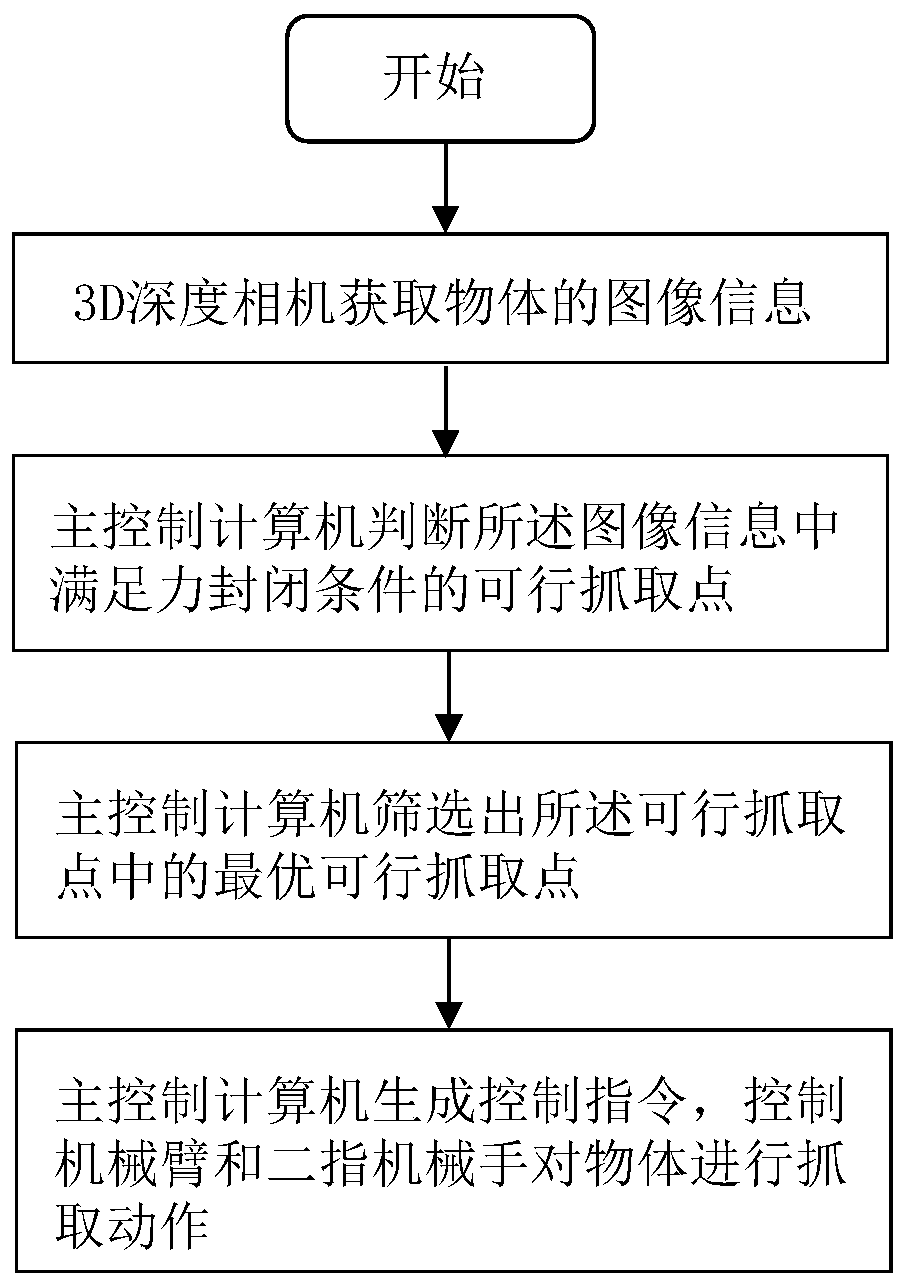

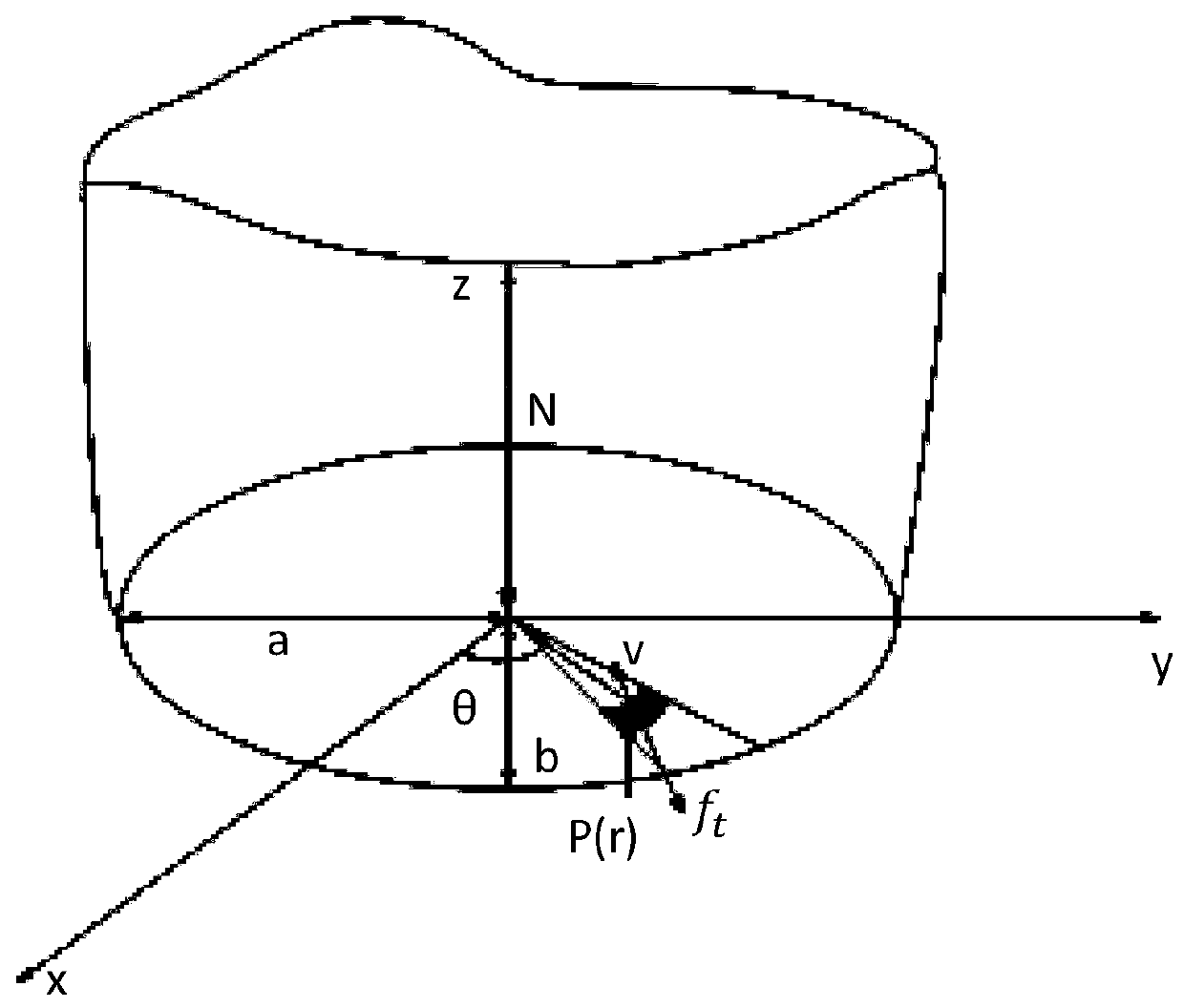

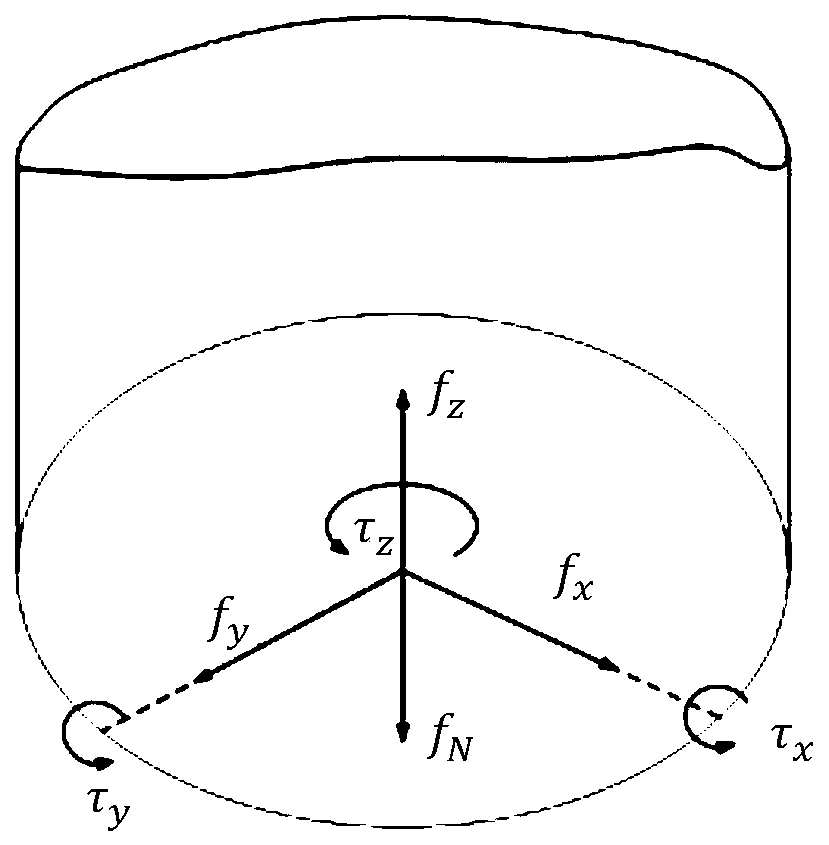

Object grabbing method based on oval surface contact

ActiveCN110271000AImprove gripHigh first-time crawl success rateProgramme-controlled manipulatorSimulationContact model

The invention discloses an object grabbing method based on oval surface contact. The object grabbing method comprises the following steps that firstly, a 3D depth camera obtains the image information of an object; secondly, a master control computer judges the feasible grabbing area, meeting the force closure condition, in the image information; thirdly, the master control computer screens out the optimal feasible grabbing area in the feasible grabbing area; and fourthly, the master control computer generates a control instruction, and a mechanical arm and a two-finger mechanical hand are controlled to conduct the grabbing action on the object. Through modeling of the mechanical hand and target object contact shape in the real scene, the force closure condition in an oval surface contact model is obtained, and the mechanical hand and target object contact real situation can be further restored; through the convolutional neural network, the optimal feasible grabbing area with the grabbing probability is screened out, the mechanical arm is controlled to achieve stable grabbing, the high one-time grabbing success rate can be achieved in the actual operation process, and the repeated operating and grabbing time cost and energy cost are reduced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

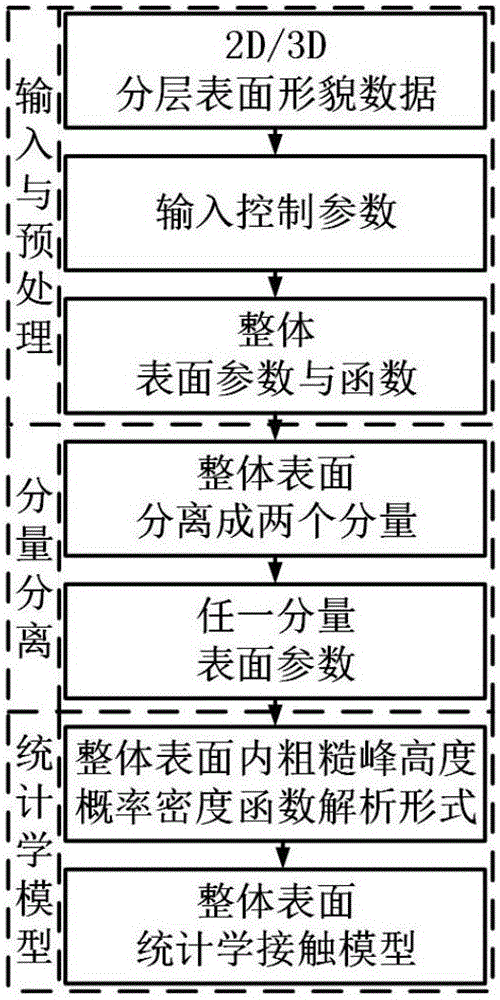

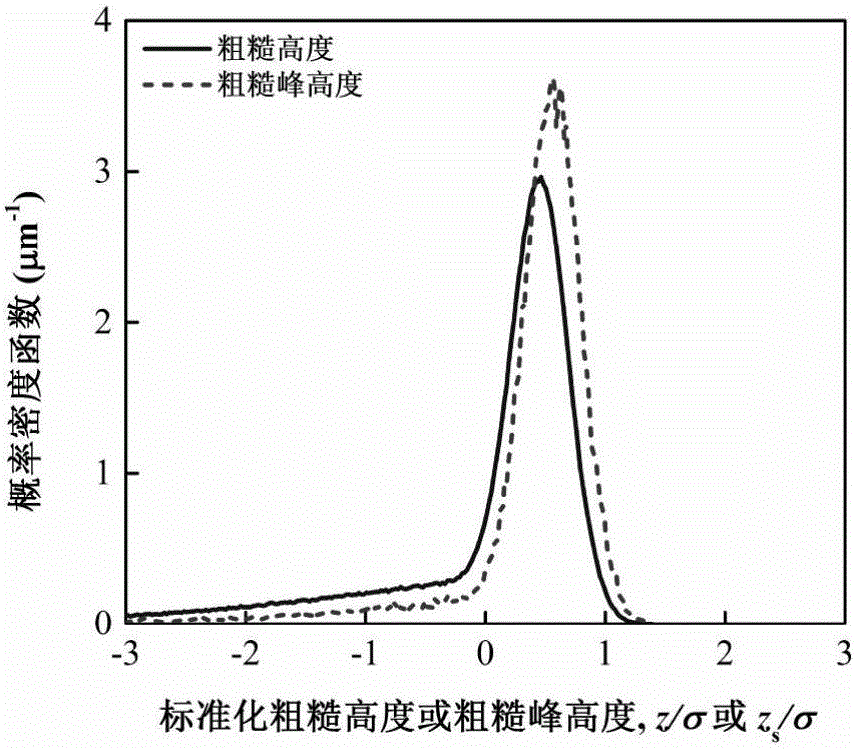

Method for analyzing contact property of layered rough surface

ActiveCN105956299ADesign optimisation/simulationSpecial data processing applicationsRough surfaceNormal density

The invention discloses a method for analyzing the contact property of a layered rough surface. The precision and the efficiency for prediction of the contact property of the layered rough surface are increased; control parameters required by morphology data and surface analysis of a 2D / 3D layered rough surface are input; an overall surface parameter and a surface function are calculated; the overall rough surface is separated into two component surfaces by adoption of layering thought; therefore, a surface parameter of any component surface is obtained; the surface parameter of the component surface is utilized for constructing an analytical expression of a rough peak height probability density function in the layered rough surface; therefore, a statistical contact model of the layered rough surface is established, such that the contact property of the layered rough surface is researched; and the method disclosed by the invention is applied to analyzing the contact property of the layered rough surface, and particularly suitable for a multi-process surface (such as the surface of an inner cylinder processed in a fat top honing manner in an automobile engine) and a worn surface.

Owner:TSINGHUA UNIV

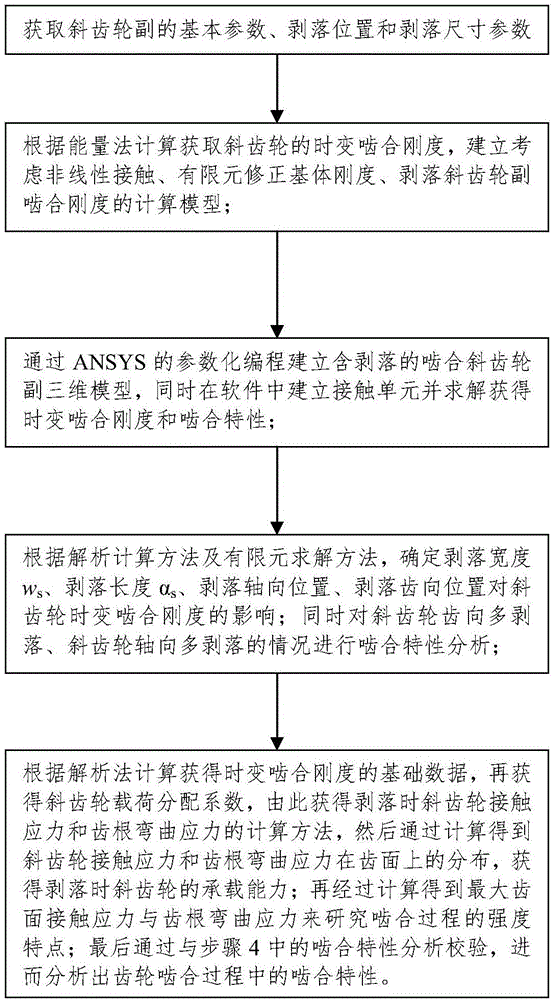

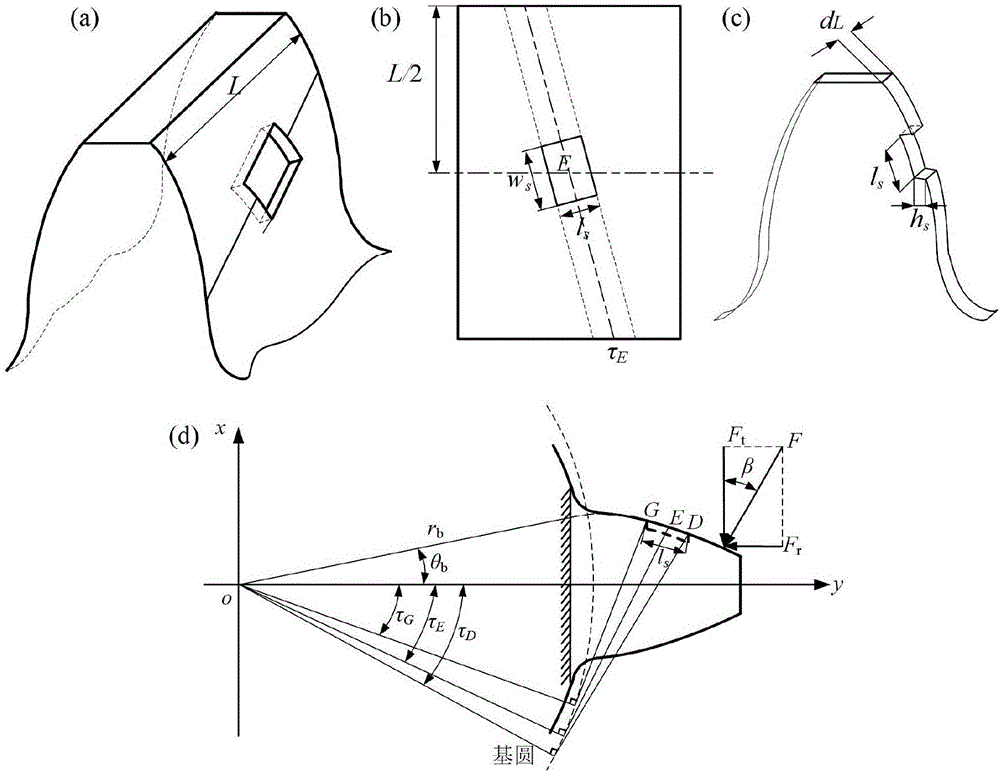

Meshing characteristic analysis method of stripping bevel gear pair which is corrected by considering substrate rigidity

ActiveCN107436982AExplicit effect of time-varying mesh stiffnessImprove computing efficiencyGeometric CADDesign optimisation/simulationContact modelEngineering

The invention belongs to the technical field of mechanical dynamics, and particularly relates to a meshing characteristic analysis method of stripping bevel gear pair which is corrected by considering substrate rigidity. According to the method, firstly the gear tooth of a bevel gear pair is divided into N independent and uniform thin-sheet straight gears in the tooth width direction, and based on the known stripping size and position parameters, the stripping condition of each straight gear is determined; through a potential energy method, a finite element substrate rigidity correction coefficient is introduced to calculate the time-varying meshing rigidity of each single stripping straight bevel gear; based on ANSYS software parameterized programming, a three-dimensional finite element stripping bevel gear contact model is established, the time-varying meshing rigidity is solved and obtained, and analysis and comparison with an analysis method result are conveniently achieved. Based on an analysis and finite element solution method, the influence of the stripping width ws, the stripping length as, the stripping axial position and the stripping tooth-direction position on the bevel gear time-varying meshing rigidity is analyzed, and the influence of axial multi-stripping and tooth-direction multi-stripping on the bevel gear meshing rigidity is considered at the same time.

Owner:NORTHEASTERN UNIV

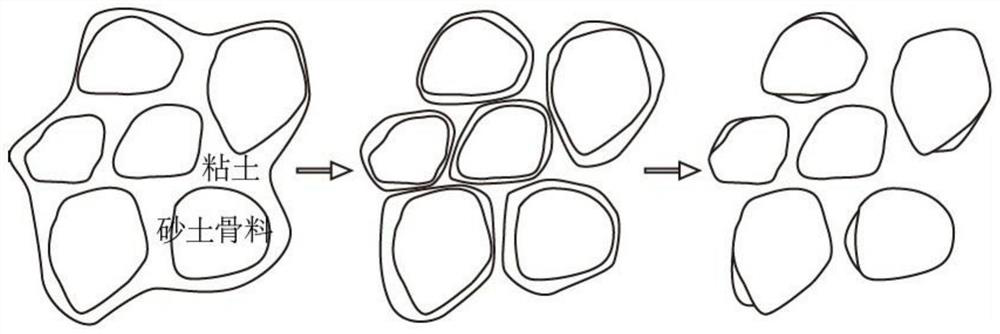

Discrete element numerical simulation method for viscous sandy soil hydraulic erosion damage

ActiveCN111709148AObserve and record movementSimple thinkingDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationSoil science

The invention discloses a discrete element numerical simulation method for viscous sandy soil hydraulic erosion damage. The method comprises the steps of:establishing an initial calculation space areaand a viscous sandy soil numerical model; initializing a numerical model and balancing stress; compiling a strength degradation criterion linear bonding contact model based on a time effect to simulate a clay phase between aggregate particles in the viscous sandy soil; selecting a contact model as a mesomechanics model of contact between aggregate particles, and valuing mesoscopic parameters of the contact model; calibrating the numerical model through a direct shear strength test; establishing a flow field to simulate the hydraulic erosion damage process of the viscous sandy soil; and obtaining a numerical simulation result of the hydraulic erosion damage test. According to the method, the viscous sand hydraulic erosion damage is simulated through the discrete elements, the thought is simplified, the viscous sand hydraulic erosion damage process can be truly simulated on the mesoscopic level under the conditions that the calculated amount is reduced as much as possible and the calculation efficiency is improved, the migration situation of soil particles is observed and recorded, and the result is accurate.

Owner:HEBEI UNIV OF TECH

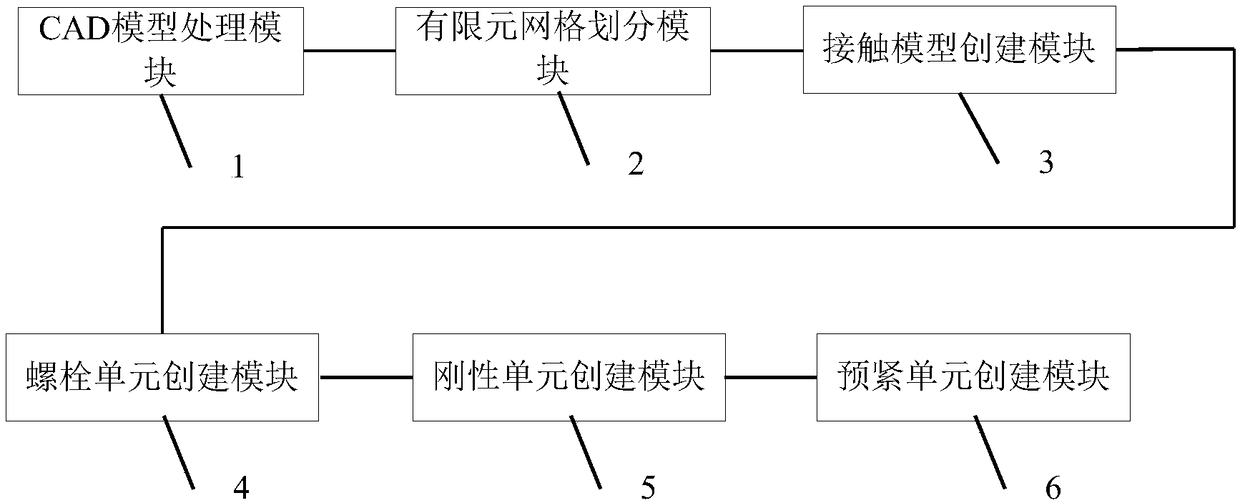

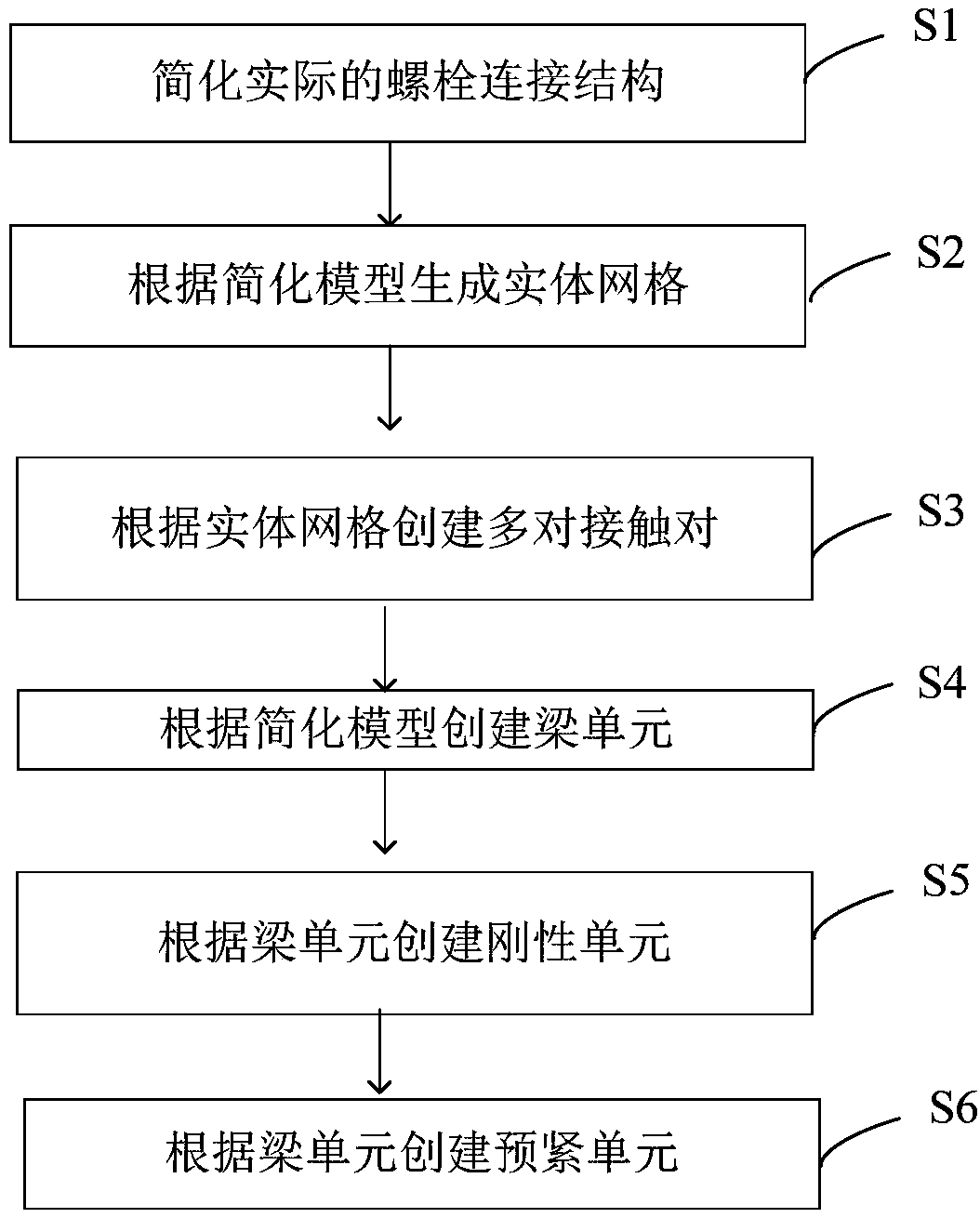

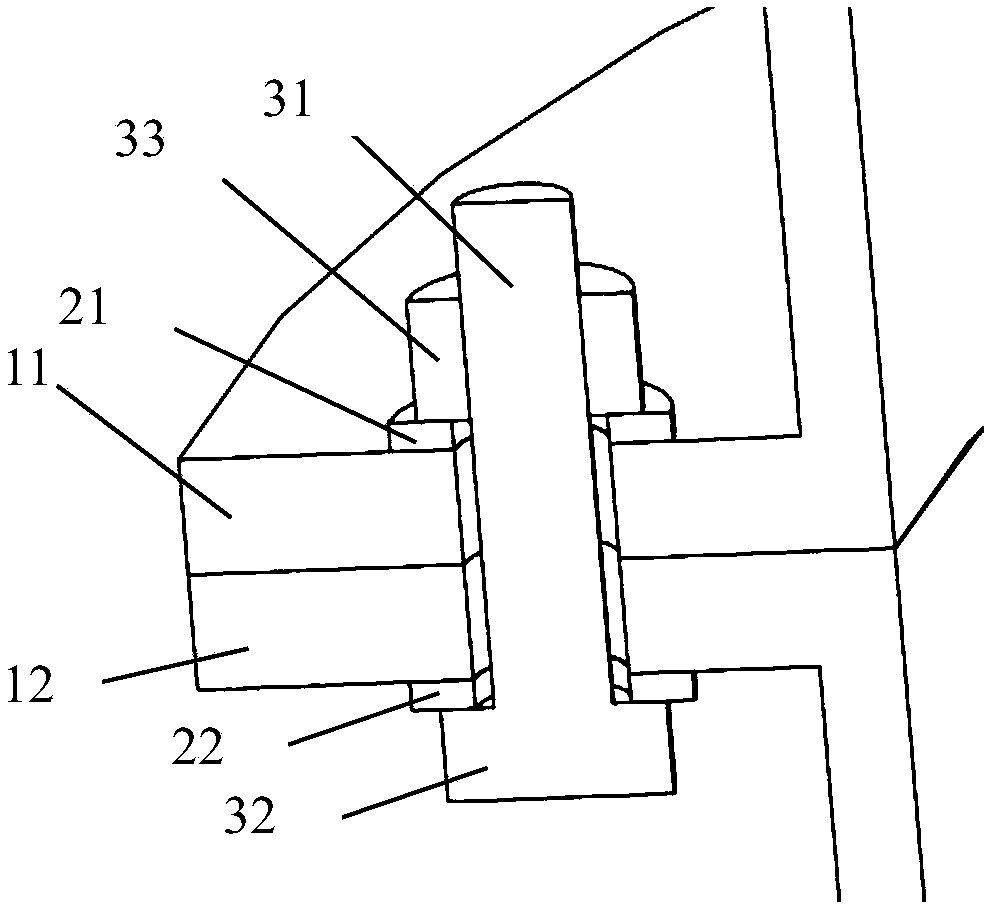

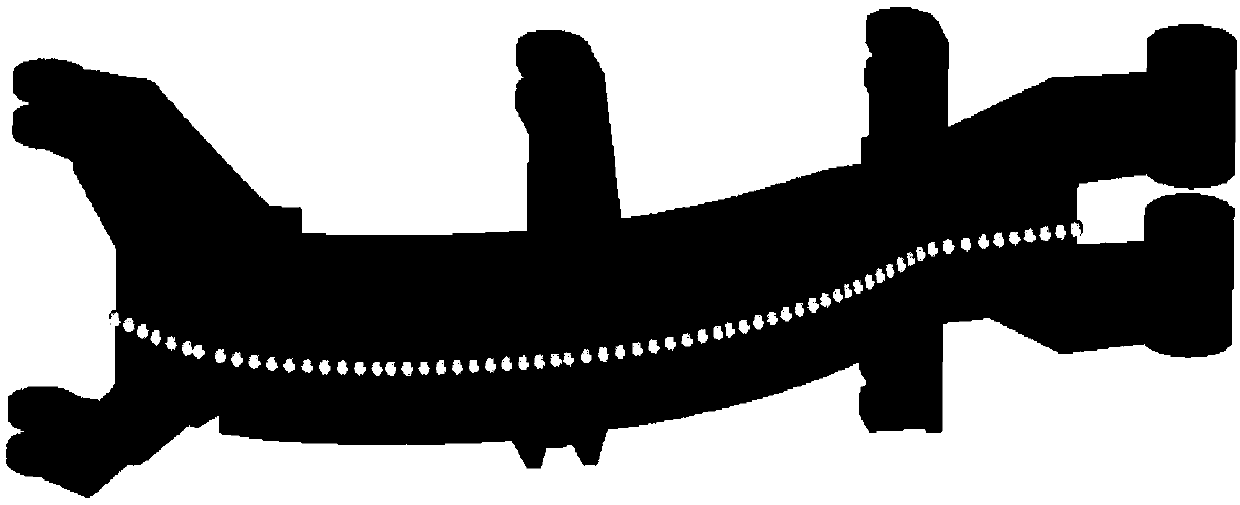

Finite element modeling system and method for bolt connection structure

InactiveCN108170942AWide applicabilityImprove modeling efficiencyDesign optimisation/simulationSpecial data processing applicationsSimulationContact model

The invention discloses a finite element modeling system and method for a bolt connection structure. The finite element modeling system comprises a CAD model processing module, a finite element meshing module, a contact model creation module, a bolt element creation module, a rigid element creation module and a pretension element creation module. Compared to the prior art, the system and method provided by the invention have wide application; when key details are reserved, modeling and calculation efficiency is improved; and problems of fussy process and large calculation amount of detailed modeling and a problem of large error of simplified modeling are solved.

Owner:BEIJING INST OF RADIO MEASUREMENT

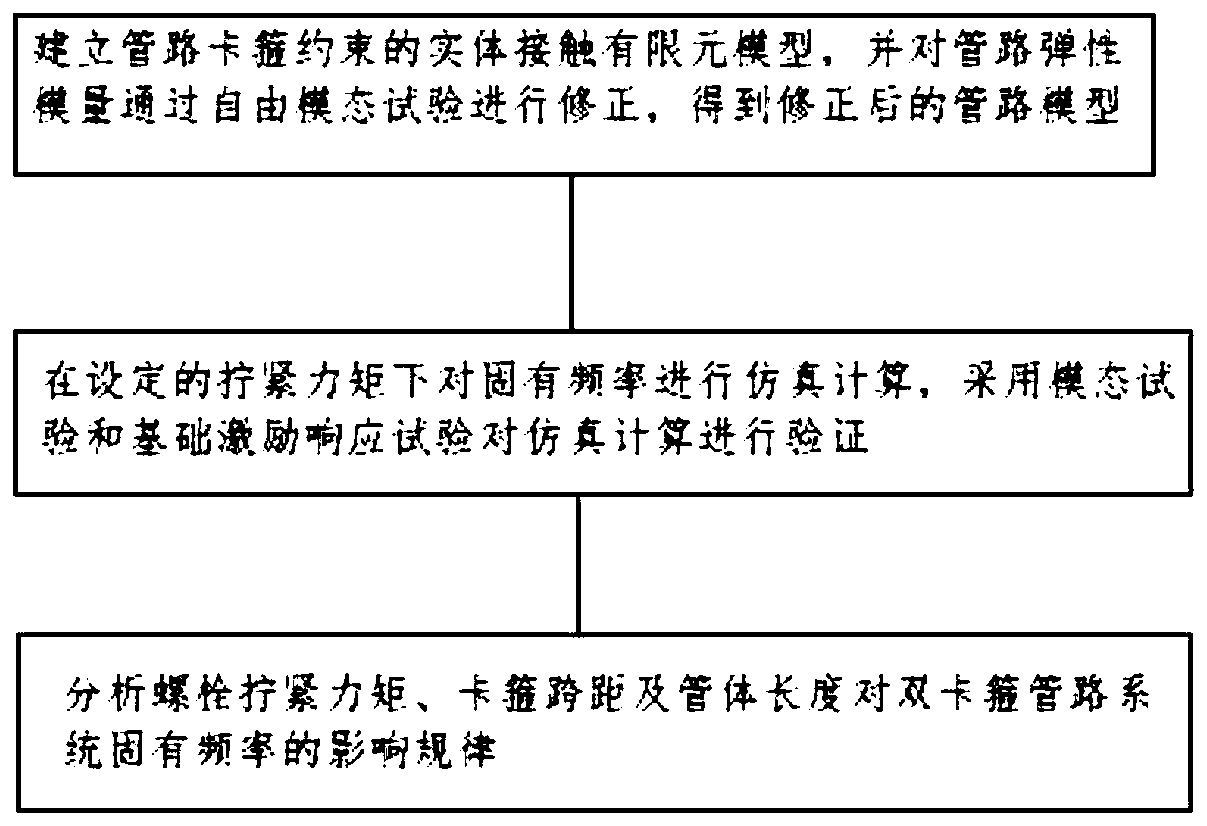

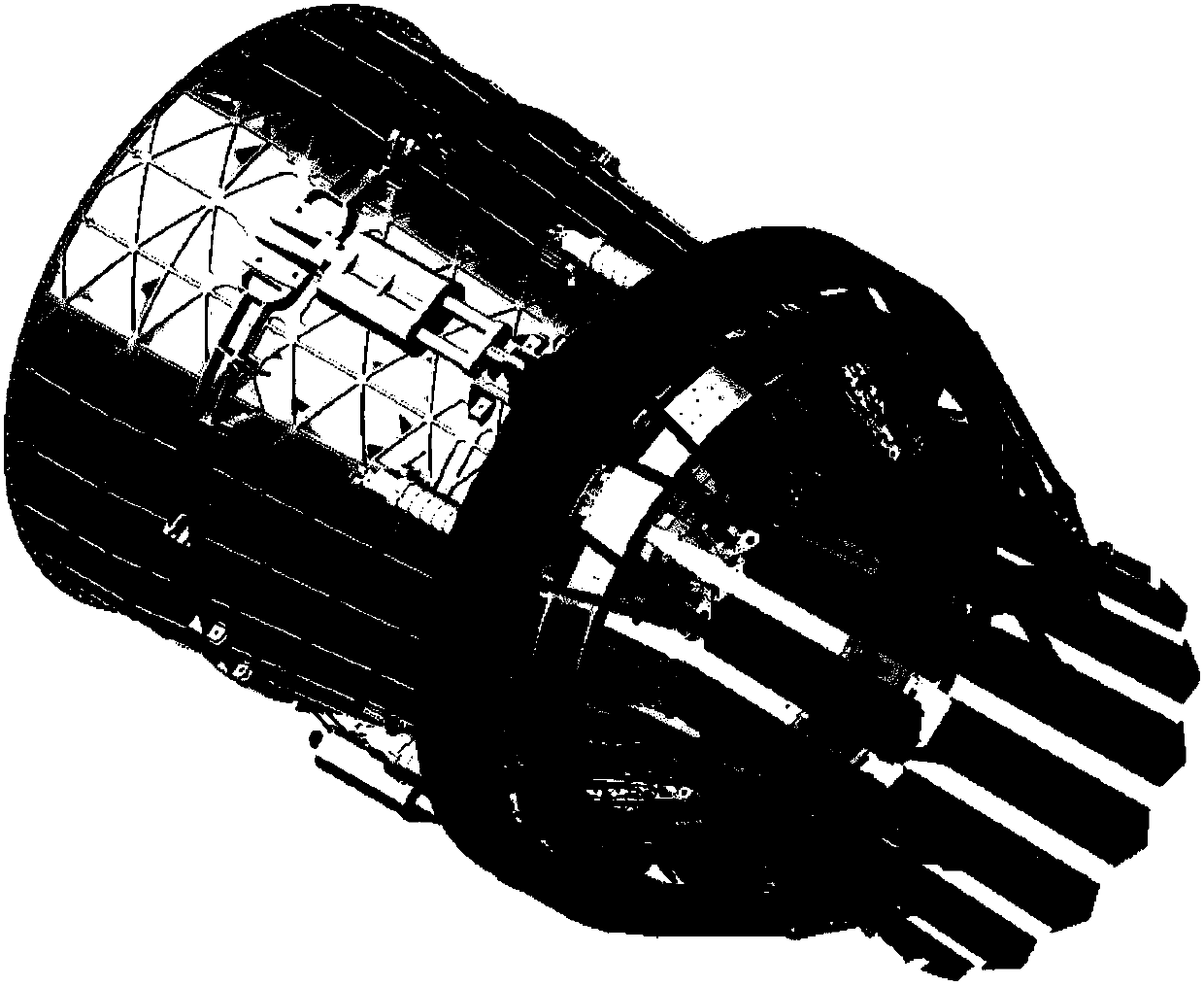

A modeling and vibration characteristic analysis method of an aerial pipeline considering bolt connection

ActiveCN109902439AThe calculation result is accurateSustainable transportationSpecial data processing applicationsAviationElement model

The invention belongs to the technical field of mechanical dynamics, and particularly relates to an aviation pipeline modeling and vibration characteristic analysis method considering bolt connection.The method comprises the following steps: establishing an entity contact finite element model constrained by a pipeline clamp, and correcting the elasticity modulus of a pipeline through a free modaltest to obtain a corrected pipeline model; Carrying out simulation calculation on the inherent frequency under the set tightening torque, and verifying the simulation calculation by adopting a modaltest and a basic excitation response test; And analyzing the rule of the influence of the bolt tightening torque, the clamp span and the pipe body length on the inherent frequency of the double-clamppipeline system. According to the method, a finite element contact model is adopted and is combined with a test to carry out comparative study, and the modeling method is accurate in calculation result and conforms to the actual structure.

Owner:NORTHEASTERN UNIV

Implementation method applied to flexible line higher pair constraint simplification model

InactiveCN107688684AImprove stabilityReliable deflection efficiencyGeometric CADDesign optimisation/simulationContact modelDynamic simulation model

The invention discloses an implementation method applied to a flexible line higher pair constraint simplification model. The method includes: defining a workpiece with at least one arc face being a contact face as a flexible component A; subjecting a flexible component A and roller mutual contact model to constraint simplification to obtain a flexible line higher pair constraint model; defining aface, acting on a roller, of the flexible component A as an operating face of the flexible component A to construct a dynamic flexible line, and subjecting to further constraint processing; subjectingthe roller and flexible component A simplified model to loading processing; finally calculating a roller driving angle. By adoption of the method, defects of high mechanism contact quantity, poor calculation stability, difficulty in convergence, high simulation result burr quantity, low calculation efficiency and the like in axisymmetric vectoring exhaust nozzle many-body dynamics simulation canbe overcome.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

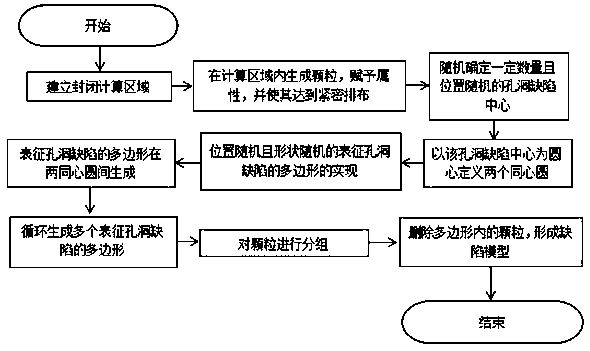

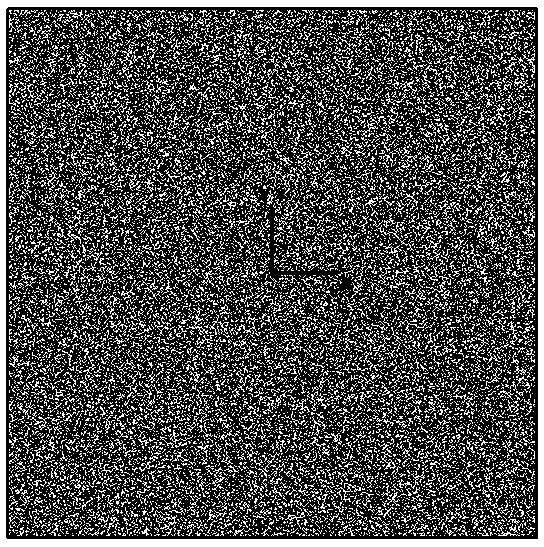

Brittle material discrete element modeling method considering shape of hole defect and distribution randomness thereof

ActiveCN108846186ADesign optimisation/simulationSpecial data processing applicationsMaterial defectDiscrete element simulation

The invention discloses a brittle material discrete element modeling method for considering a shape of a hole defect and the distribution randomness thereof, which is mainly used for the discrete element simulation research of brittle materials such as engineering ceramics. The method includes: creating a closed area, and adding a certain number of particles with uniformly or normally distributedradiuses into the closed area to achieve tight arrangement of the particles; selecting an appropriate contact model to give the particles a certain strength of connection keys; determining a certain number of randomly located hole defect centers through a position random function, and constructing each hole defect polygon with shape randomness; and finally deleting a closed area wall, and deletingthe particles in the polygon to form a hole defect. The method is easy to program, is simple to debug, conforms to the existence state of the actual brittle material defects, can make the simulationexperiment result more accurate, more in line with the actual situation, and can improve the effectiveness of the simulation experiment.

Owner:XIANGTAN UNIV

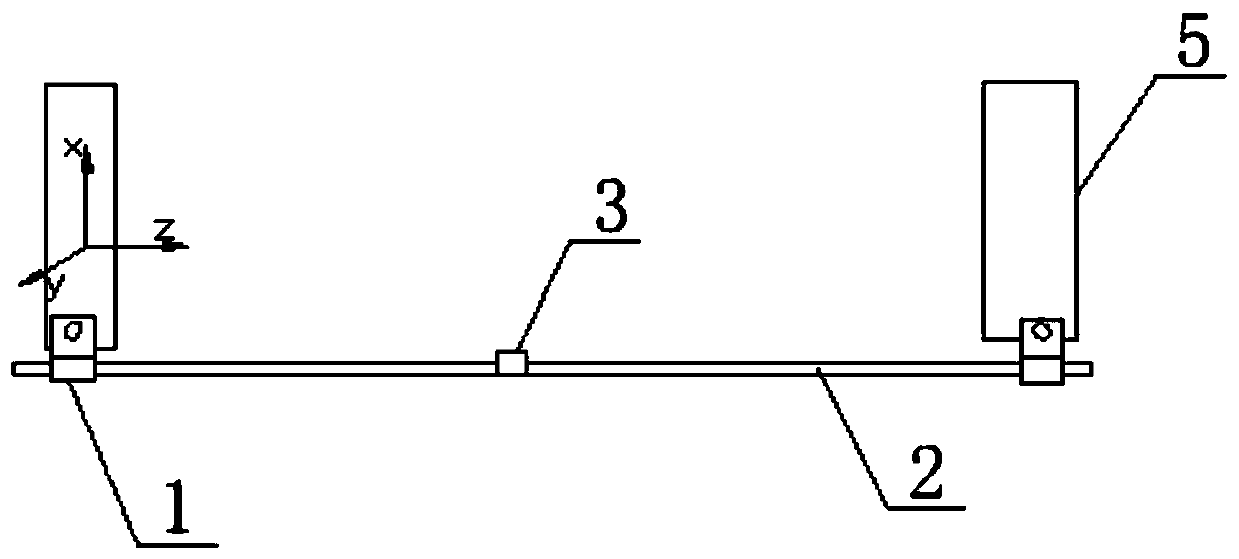

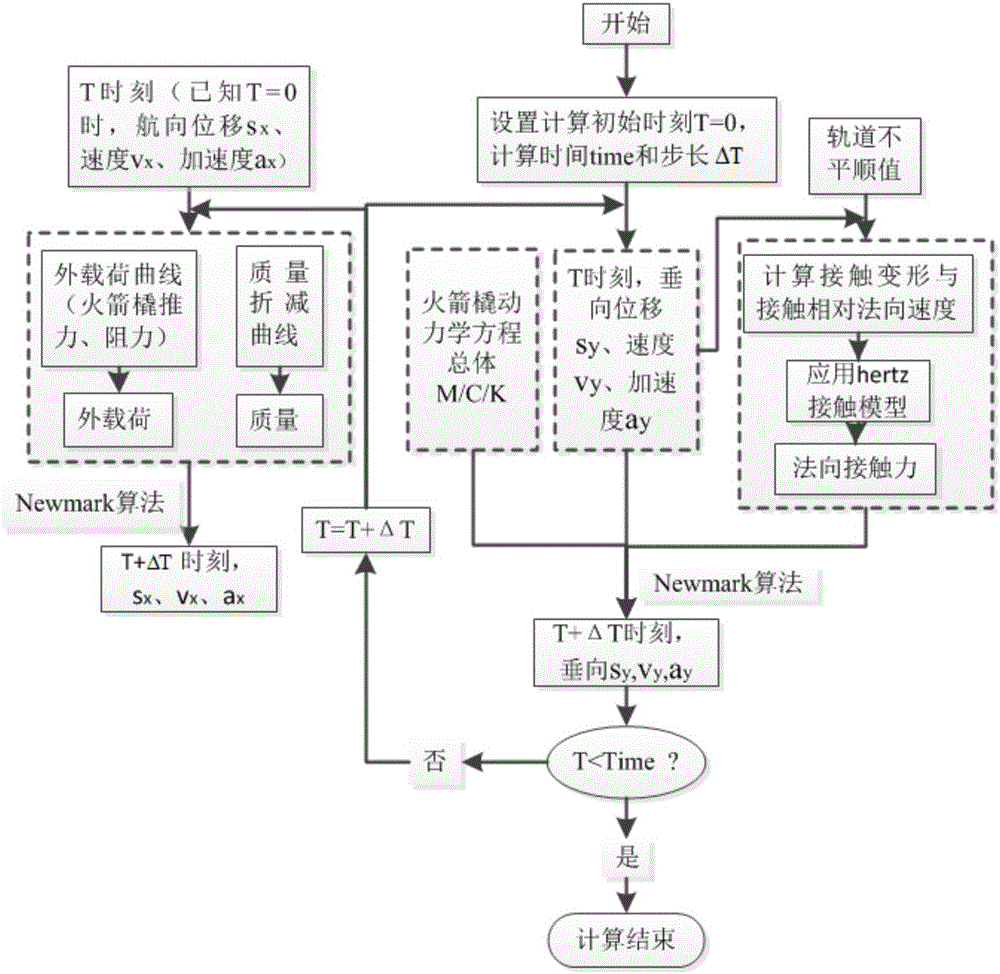

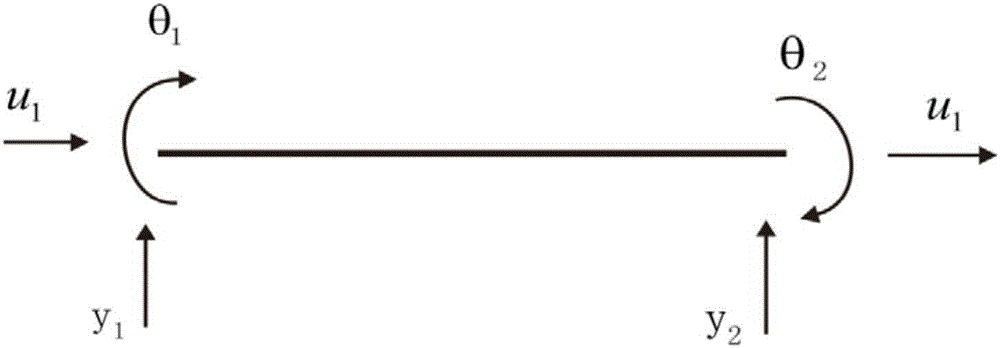

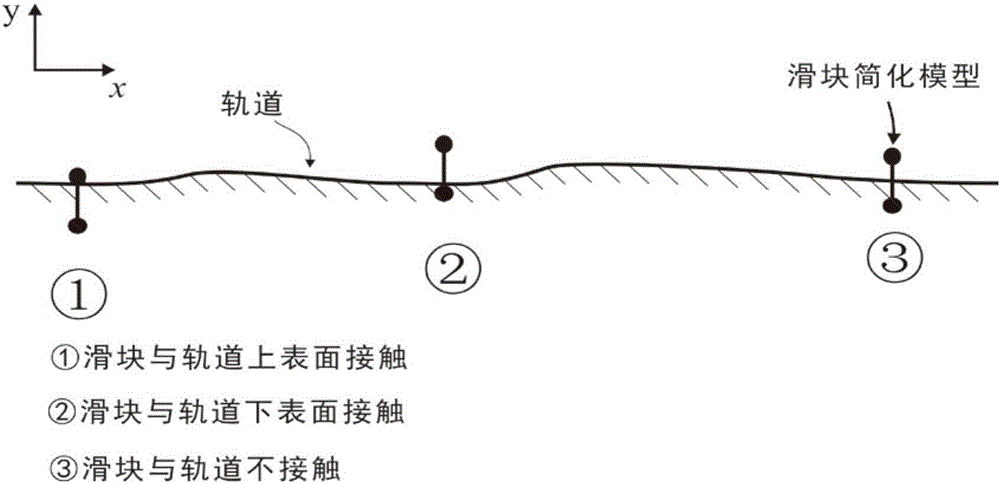

Vertical response calculating method of three-slide-block monorail flexible rocket sled

InactiveCN106066922AFast solutionImprove engineering applicabilityDesign optimisation/simulationSpecial data processing applicationsContact forceContact model

The invention discloses a vertical response calculating method of a three-slide-block monorail flexible rocket sled. Bearings of the rocket sled are analyzed, and a rocket body is dispersed into finite element beam models; structural vibration, caused by unsmoothness of a rail, of the rocket sled and the rail is taken into consideration and a Hertz nonlinear contact model is used to calculate collision contact forces born by the rocket body in different time; and the whole-course vertical dynamic response of a three-slide-block monorail rocket sled system within given time is calculated by utilizing a central difference value method. In the calculation process, flexible deformation characteristic of a rocket sled body and a quality reduction effect, caused by fuel ejection, of the rocket sled system are taken into consideration, the nonlinear contact problem caused by that the rail is unsmooth is also considered, and thus, a more reliably dynamic response result can be obtained.

Owner:BEIHANG UNIV

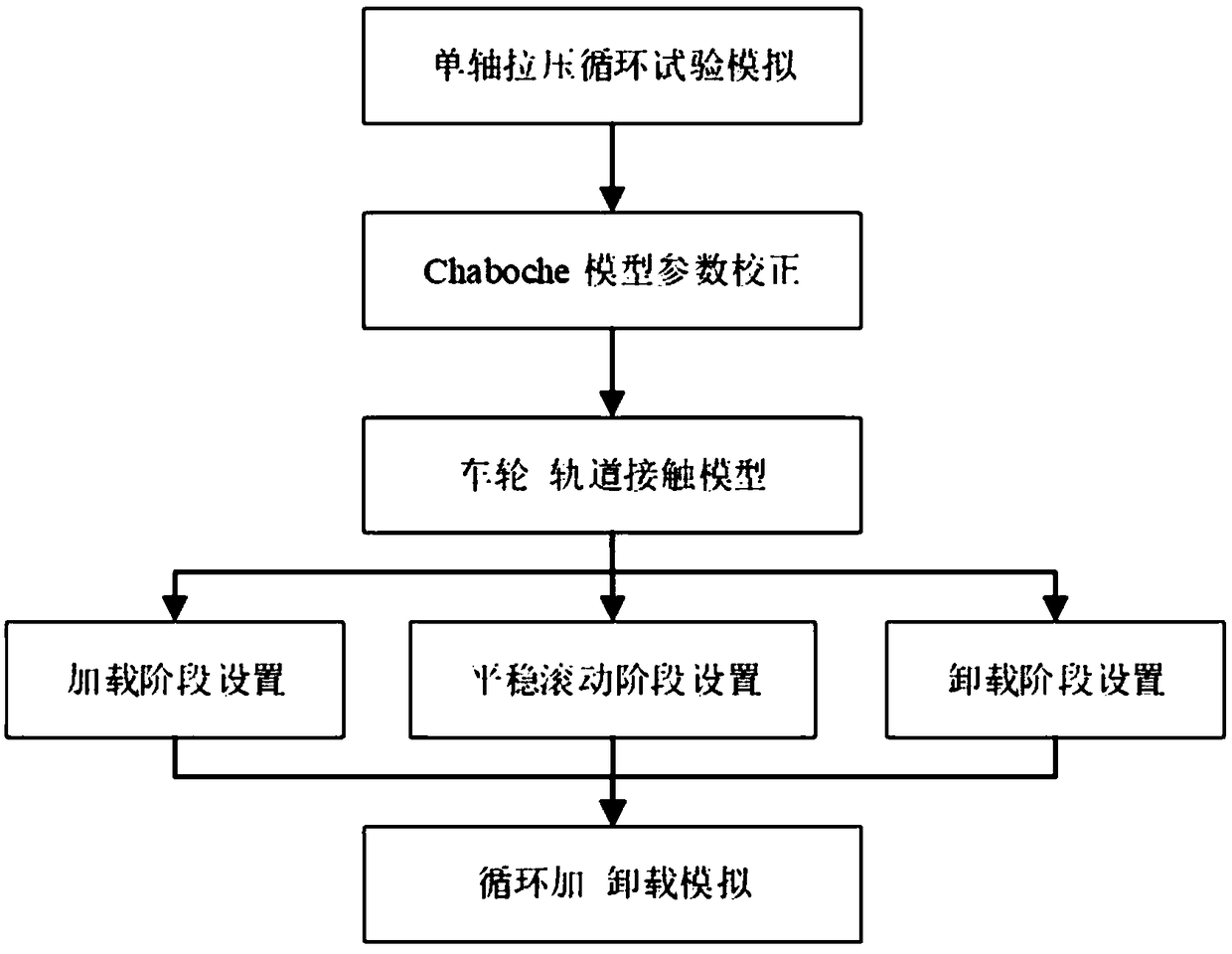

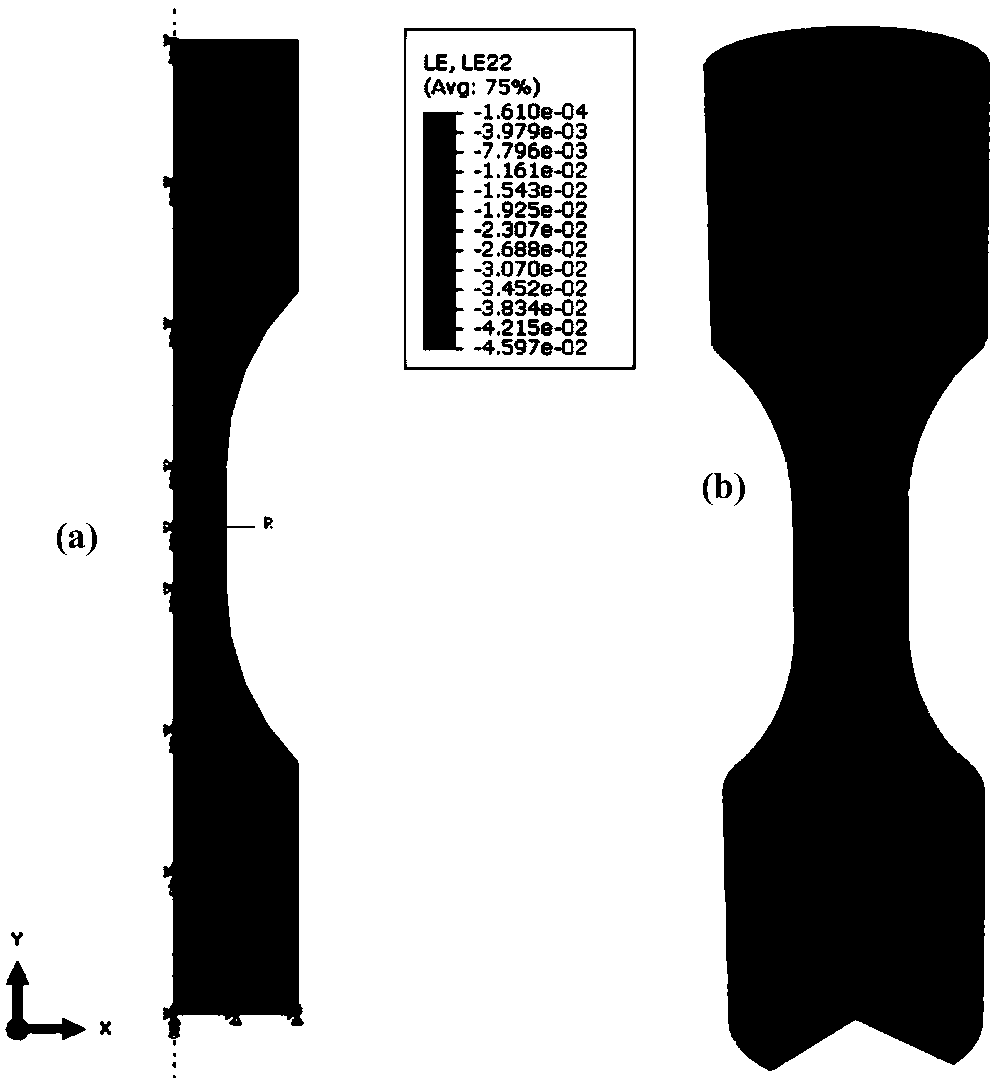

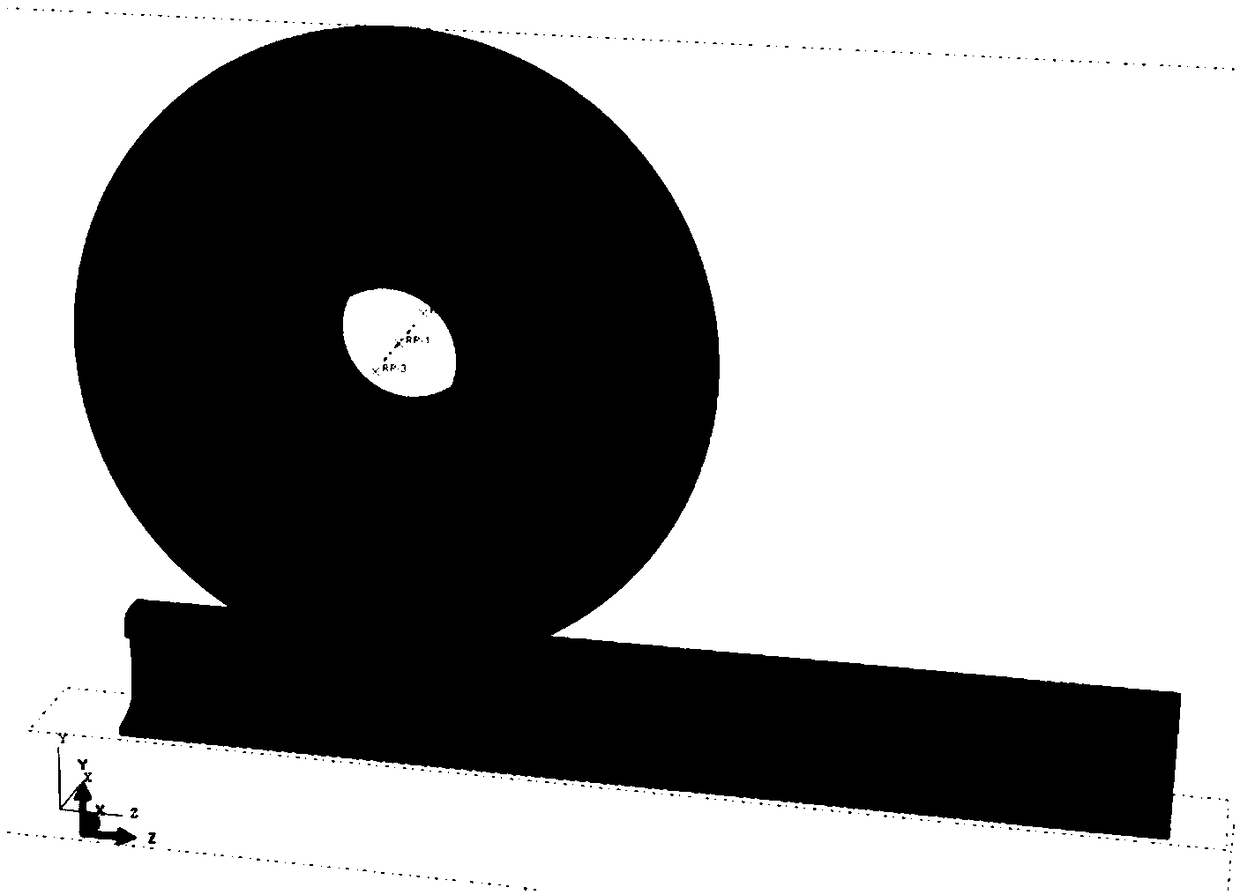

Finite element simulation-based wheel-track contact cyclic loading-unloading simulation analysis method

InactiveCN108664707ASolve the defects of cyclic load descriptionDesign optimisation/simulationSpecial data processing applicationsTime cyclesSymmetric model

The invention discloses a finite element simulation-based wheel-track contact cyclic loading-unloading simulation analysis method. The method comprises the following main steps of (a) building a uniaxial tension and compression axial symmetric model by utilizing finite element software ABAQUS; (b) performing uniaxial tension and compression cyclic test simulation, and according to an indoor test result and a Chaboche model, performing correction on a nonlinear hardening parameter of a material; (c) building a wheel-track contact model, and setting material parameters and contact parameters; (d) decomposing a single-time cycle into three stages including a loading stage, a stable rolling stage and an unloading stage, and setting a loading condition, a constraint condition, a contact condition and a boundary condition; and (e) by utilizing a restart mechanism, importing a previous calculation result, performing wheel track contact loading-unloading simulation based on this, and storing an unloading stage result to serve as an initial condition of the next cycle. Based on a nonlinear finite element simulation method and a contact mechanic theory, cyclic loading and unloading behaviorsof wheel track fatigue, damage and the like can be subjected to simulation analysis.

Owner:SOUTHWEST JIAOTONG UNIV

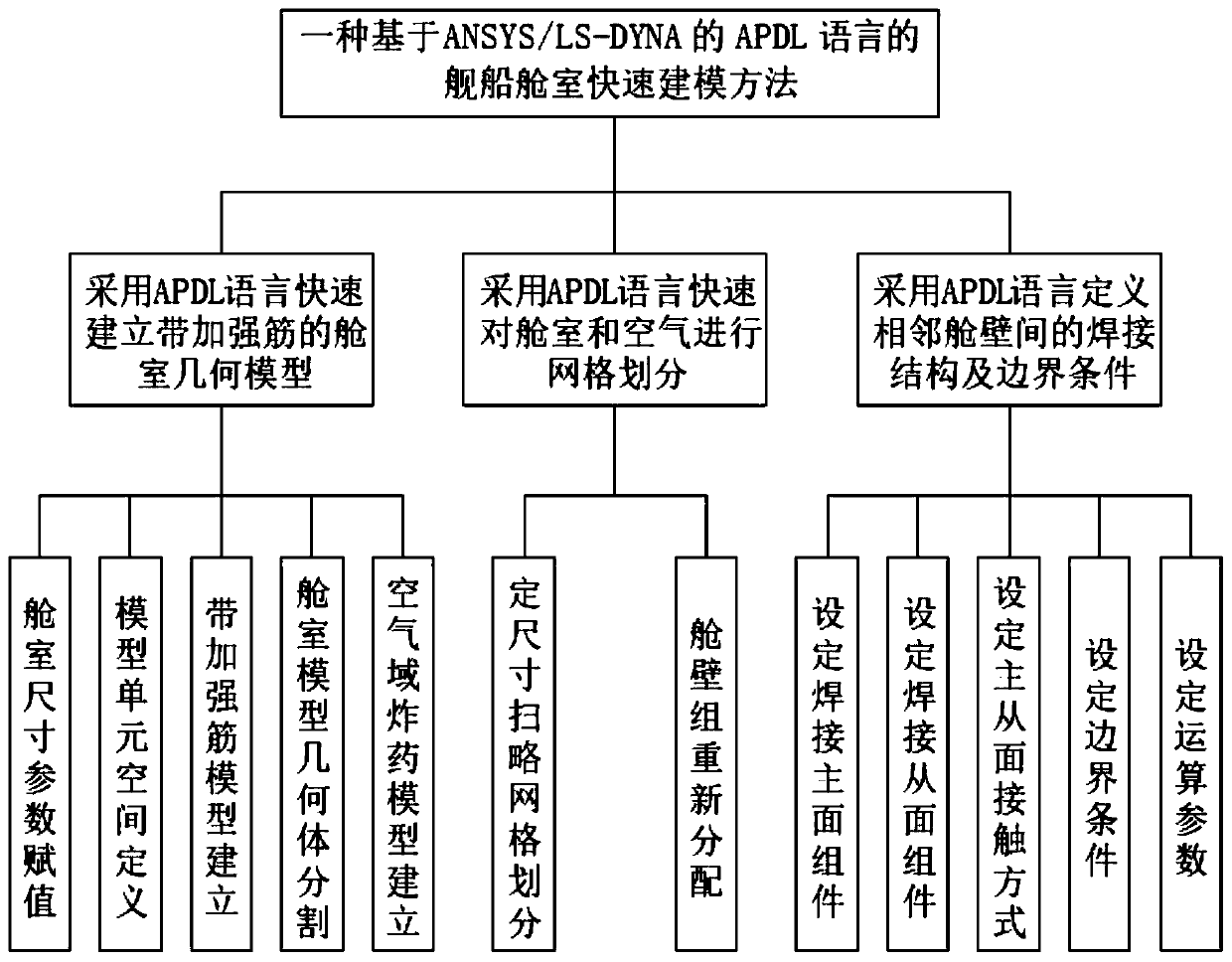

Ship cabin rapid modeling method based on APDL language of ANSYS/LS-DYNA

InactiveCN110427645AAccurate Response ResultsImprove efficiencySpecial data processing applicationsElement analysisLS-DYNA

The invention relates to a ship cabin rapid modeling method based on an APDL language of ANSYS / LS-DYNA. The method comprises the following steps: firstly, parameterizing each panel of a cabin and eachkey size of a reinforcing rib structure of the panel, then carrying out common node setting on an overlapping region of a cabin wall and a reinforcing rib by utilizing an APDL language, establishinga solid model of each panel and the reinforcing rib of the cabin, and quickly cutting the model by adopting a cyclic instruction, controlling a distance and changing the position and direction of a working surface; secondly, performing grid rapid division on the cabin model and the air domain by utilizing a hexahedron entity unit with a specific size, defining a welding structure between cabin walls by adopting a fixedly connected fracture contact model (TSTS), and establishing a ship cabin finite element analysis model. According to the method, a common node method and a fixed connection fracture failure method are adopted to define a single cabin wall inner welding structure, and the reliability of ship cabin indoor explosion test damage effect research is improved.

Owner:NAVAL UNIV OF ENG PLA

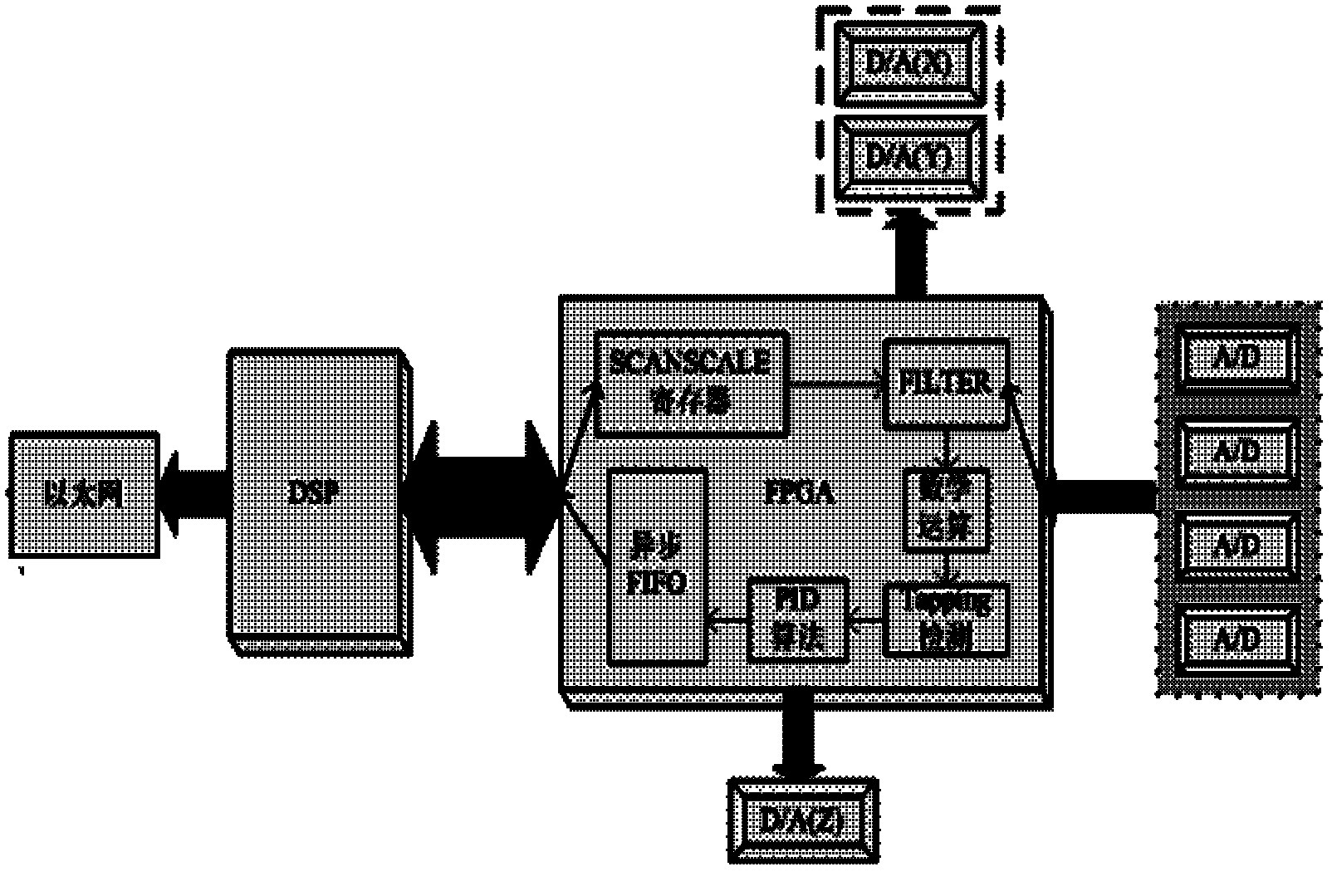

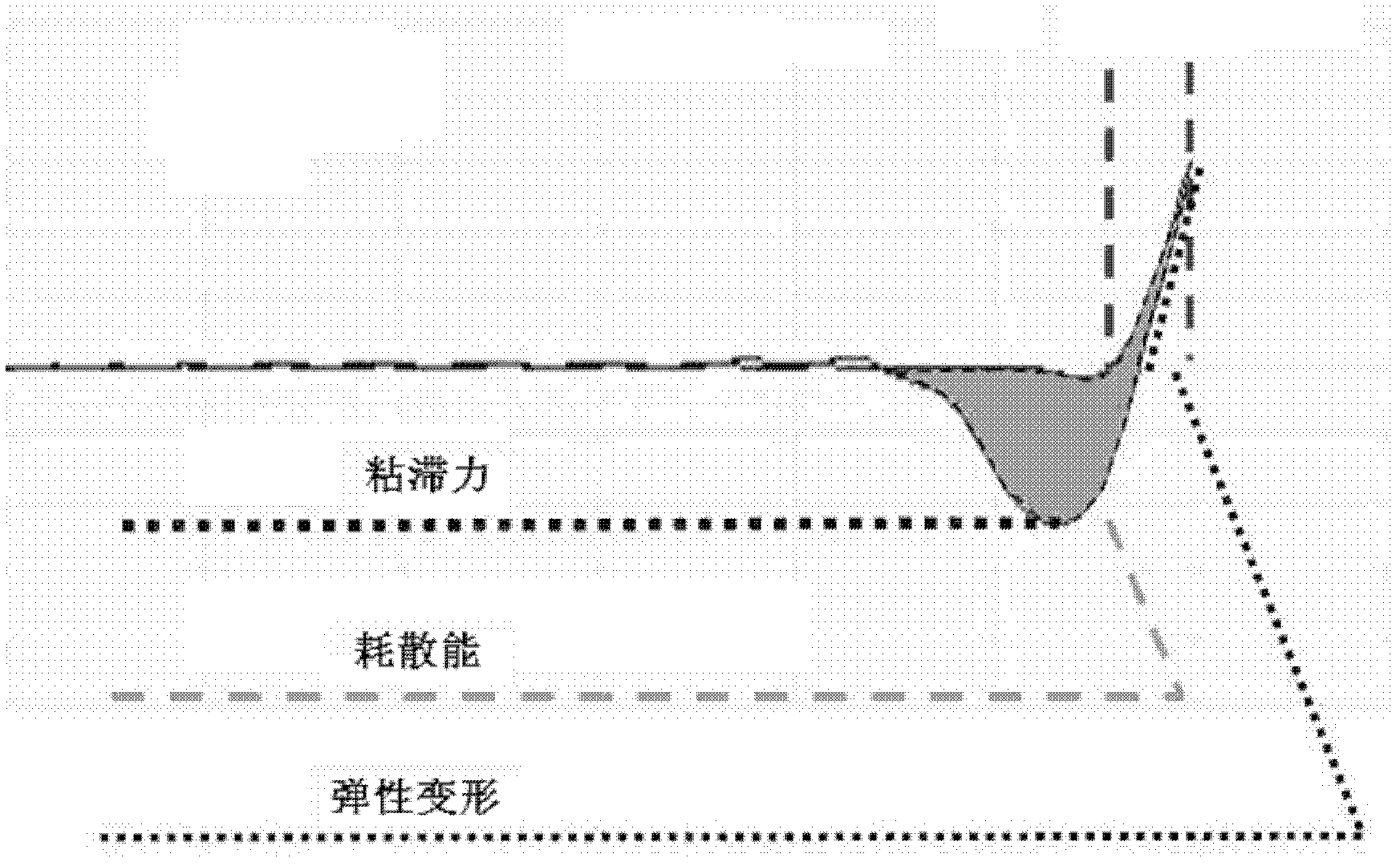

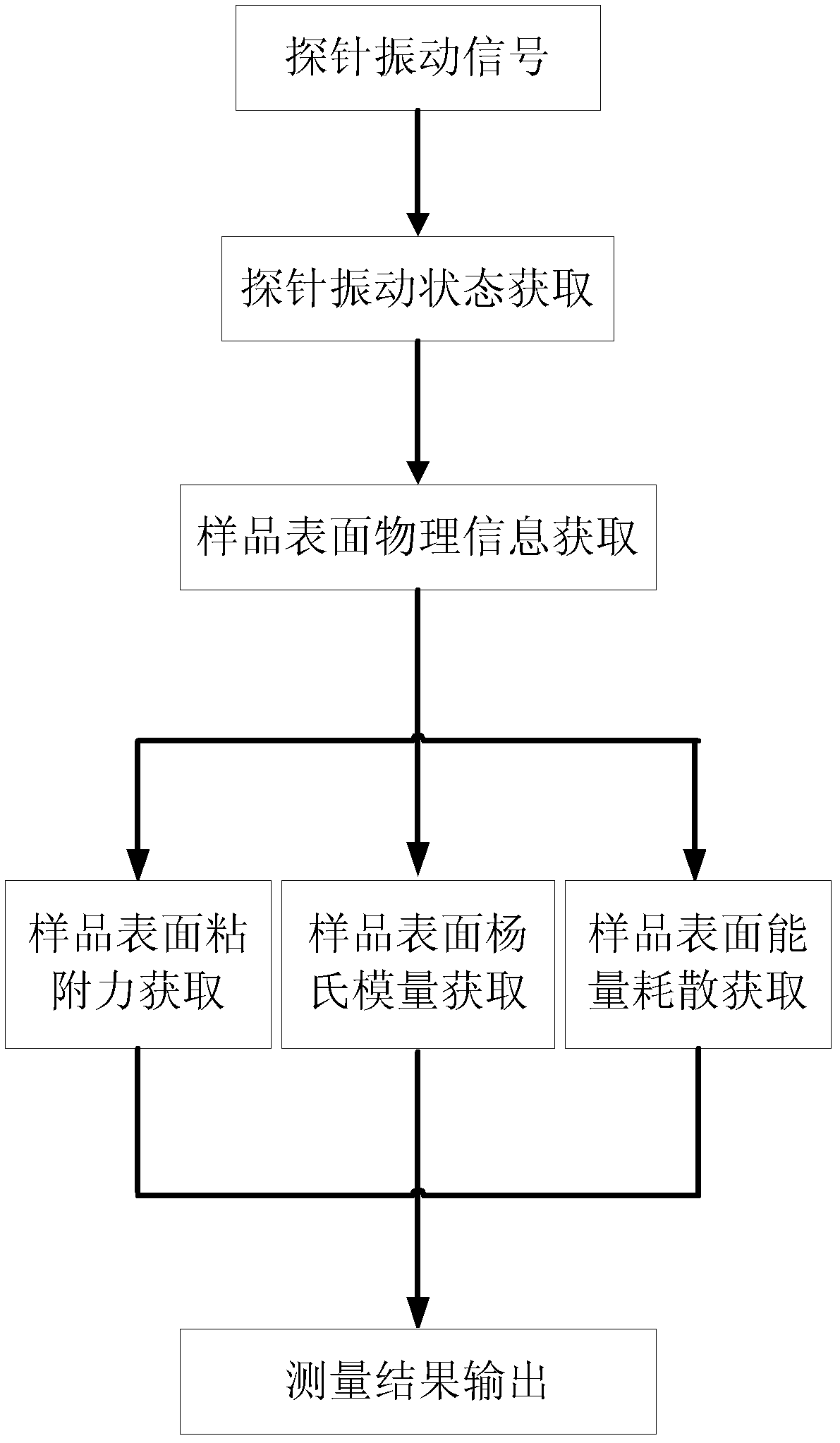

Physical property measurement system and method for material based on probe force curve

The invention discloses a physical property measurement system and a method for a material based on an AFM (atomic force microscope) probe force curve. According to the method, a high-speed and high-precision digital acquisition card and a digital controller are adopted to realize broad-band and high-resolution measurement during a probe force curve testing process. Therefore, a peak force in the probe force curve can be controlled and measured precisely. On the basis of acquiring the force curve, a Hertz contact model and a Derjaguin-Muller-Toporov (DMT) model are used for acquiring appearance information of the surface of a sample, and a power dissipation and force curve area integral method is used for acquiring a viscous force and dissipated energy information of the sample. According to the system and the method, a large amount of information reflecting physical properties of the surface of the sample is included. The application scope of an AFM is expanded greatly, the development of correlational study fields is promoted, and the system and the method have very important scientific values and good application prospects.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Aircraft wheel vibration analysis method based on finite elements

The invention provides an aircraft wheel vibration analysis method based on finite elements. The method is used for analyzing vibration characteristics of an aircraft wheel. The method comprises the following steps: 1, establishing an airplane wheel geometric model, and importing airplane wheel geometric model to software to establish a finite element model; 2, establishing a contact model of each assembly part of the airplane wheel; 3, setting material parameters of each part of the airplane wheel; 4, calculating a wheel static lateral load, an inflation load, a bearing supporting force and a piston applied pressure; 5, carrying out modal analysis on the airplane wheel under prestress; 6, importing the modal analysis result into a harmonic response analysis module; carrying out harmonic response analysis to obtain displacement frequency domain curves, speed frequency domain curves and acceleration frequency domain curves of the airplane wheel and components thereof, analyzing vibration types through the frequency curves, and judging frequencies of three main vibration modes of flutter, howling and vortex motion to obtain vibration characteristics of the airplane wheel, so that anti-vibration design and optimization can be conveniently carried out in the later period.

Owner:CENT SOUTH UNIV

Method for analyzing stress of an asphalt pavement structure in different interlayer bonding states

PendingCN110472337AMonitoring force dataSolve mechanical responseSpecial data processing applicationsTensile strainStress conditions

The invention provides a method for analyzing stress of an asphalt pavement structure in different interlayer bonding states, and belongs to the technical field of asphalt pavements. The problems thatat present, modeling of pavement structures in different interlayer bonding states is inaccurate, and results have errors are solved. The method comprises the following steps: generating an asphalt pavement structure initial model with determined gradation of each layer by adopting discrete element software; secondly, setting corresponding boundary conditions, physical parameters of a material ina pavement structure layer and a contact model among unit particles, and establishing a discrete element mechanical analysis model; and finally, using a servo mechanism for simulating vehicle loads to load the asphalt pavement in different combination states, monitoring tensile stress, shear stress, tensile strain and pavement surface deflection value data at the load positions of all structurallayers of the pavement, drawing a stress data comparison graph, and analyzing the stress conditions of the asphalt pavement structure in different interlayer combination states. The method provided bythe invention is visual, simple and convenient, accurate in calculation data, and suitable for simulating various asphalt pavements in different interlayer states.

Owner:NANJING FORESTRY UNIV

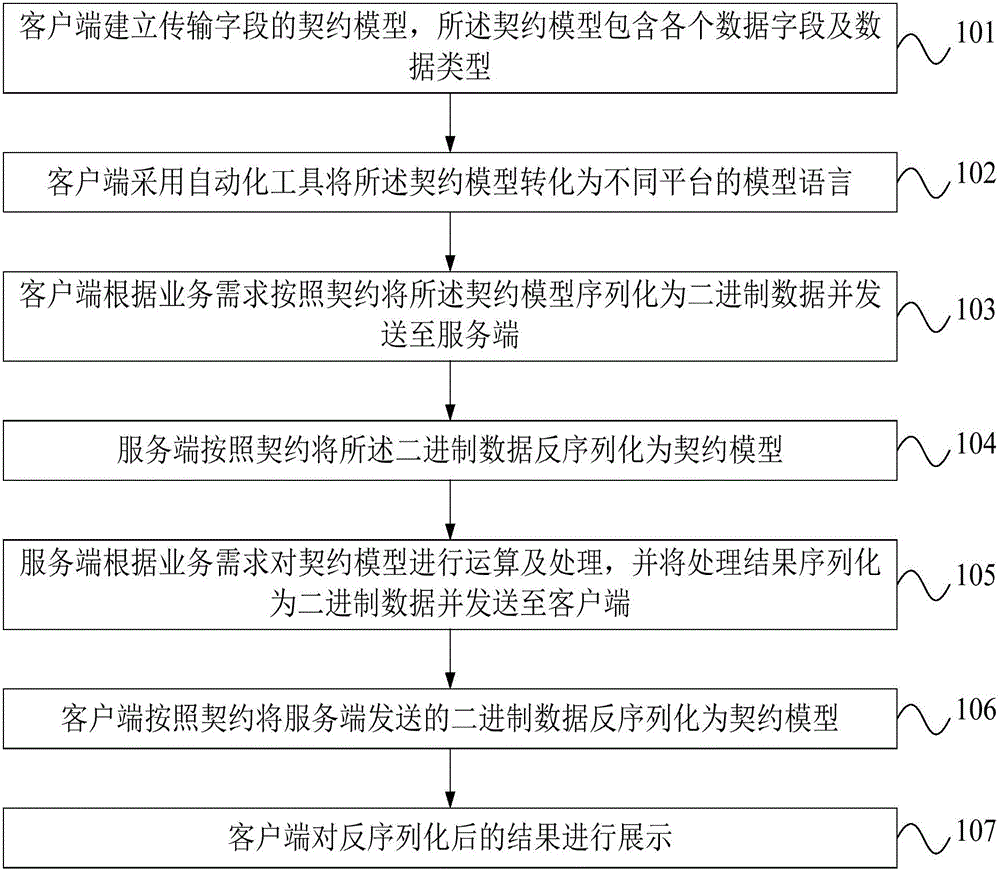

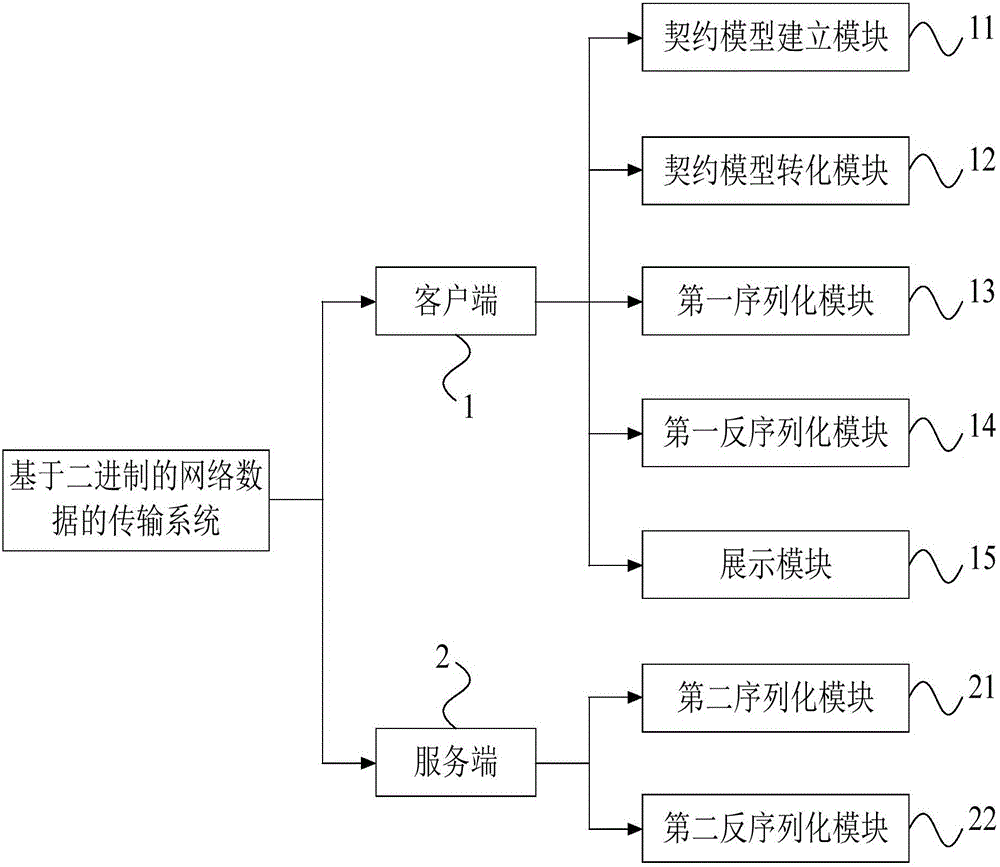

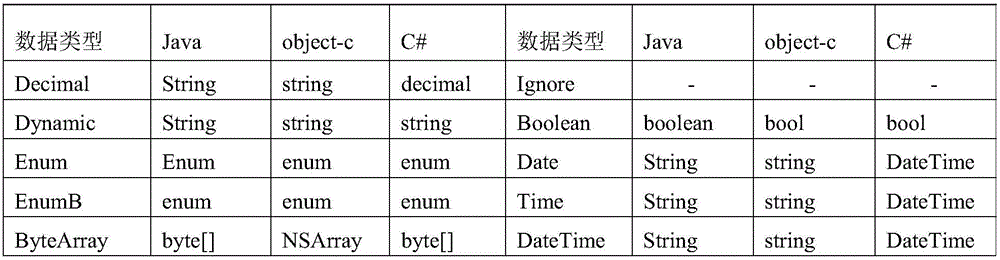

Binary-system-based network data transmission method and system

InactiveCN105681333AIncrease supportabilityImprove scalabilityTransmissionExtensibilityTransmission protocol

The invention discloses a binary-system-based network data transmission method and system. The method comprises: S1, a client establishes a contract model of a transmission field, wherein the contact model includes a plurality of data fields and data types; S2, a client uses an automatic tool to convert the contact model into model languages of different platforms; S3, the client carries out serialization on the contact model to obtain binary data and then the data are sent to a server side; S4, the server side carries out deserialization on the binary data to obtain a contact model; S5, the server side carries out operation and processing on the contract model and carries out serialization on the processing result to obtain binary data, and then the binary data are sent to the client; and S6, the client carries out deserialization on the binary data sent by the server side to obtain a contract model. According to the invention, network data transmission is carried out based on an extensible binary data transmission protocol with good data type support and the data format can be defined by the user. Therefore, the transmission data volume is reduced; and the data extensibility and supportability are enhanced.

Owner:CTRIP COMP TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com