Patents

Literature

114 results about "Force curves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

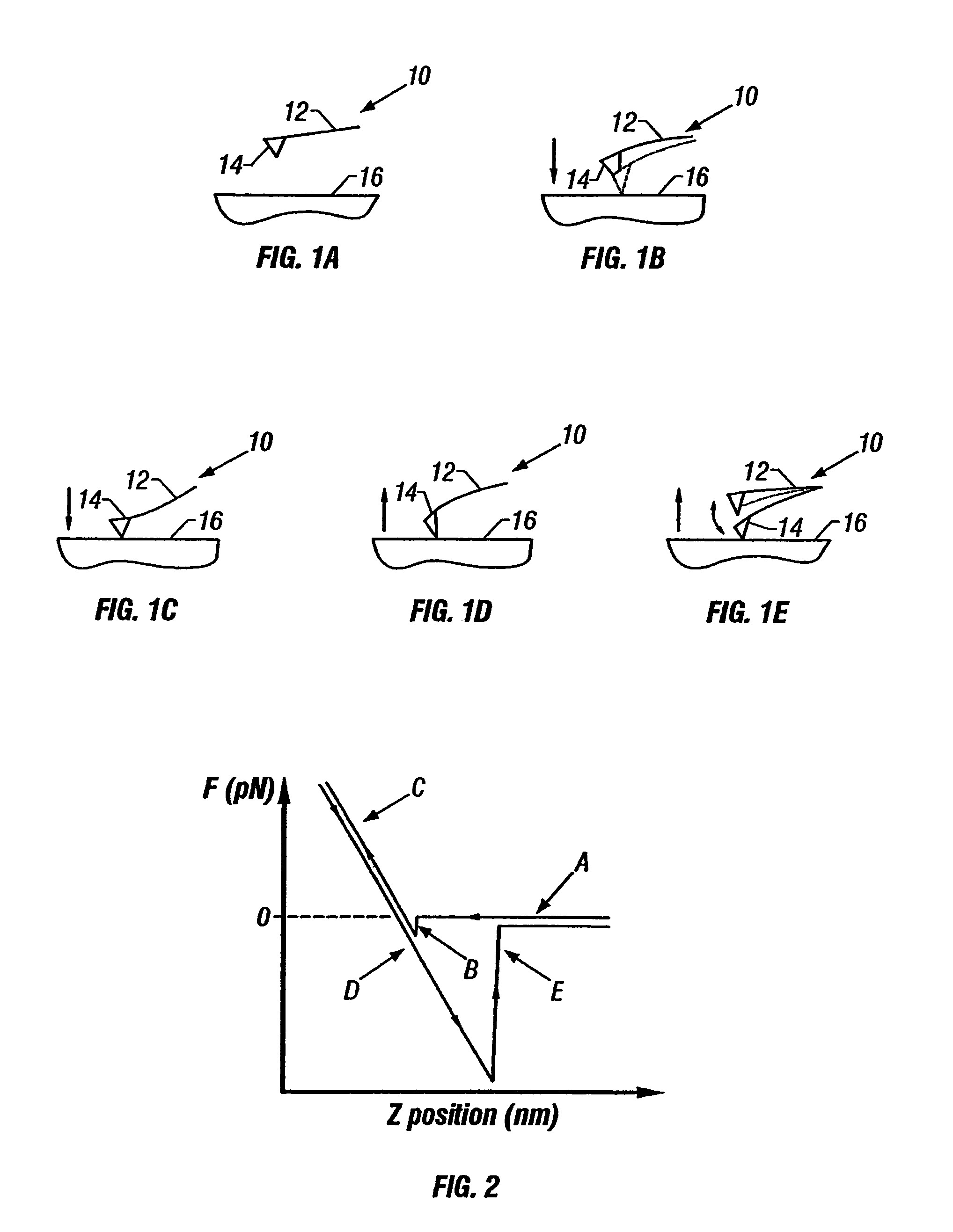

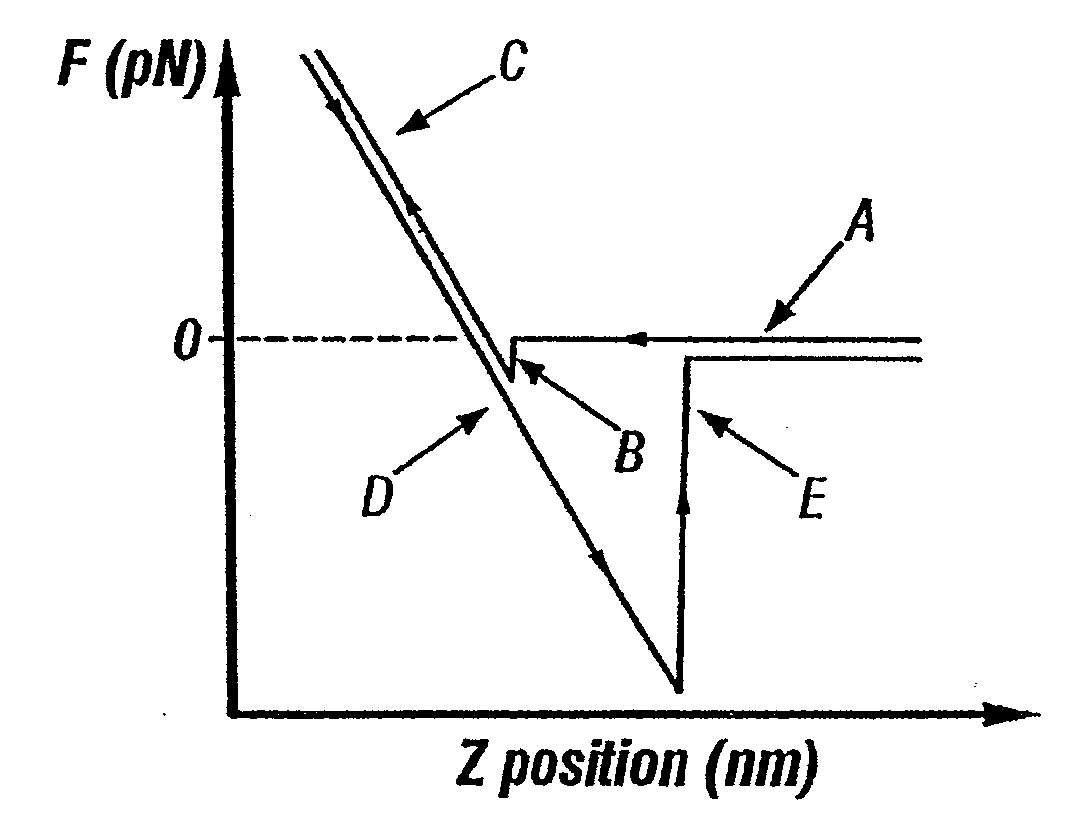

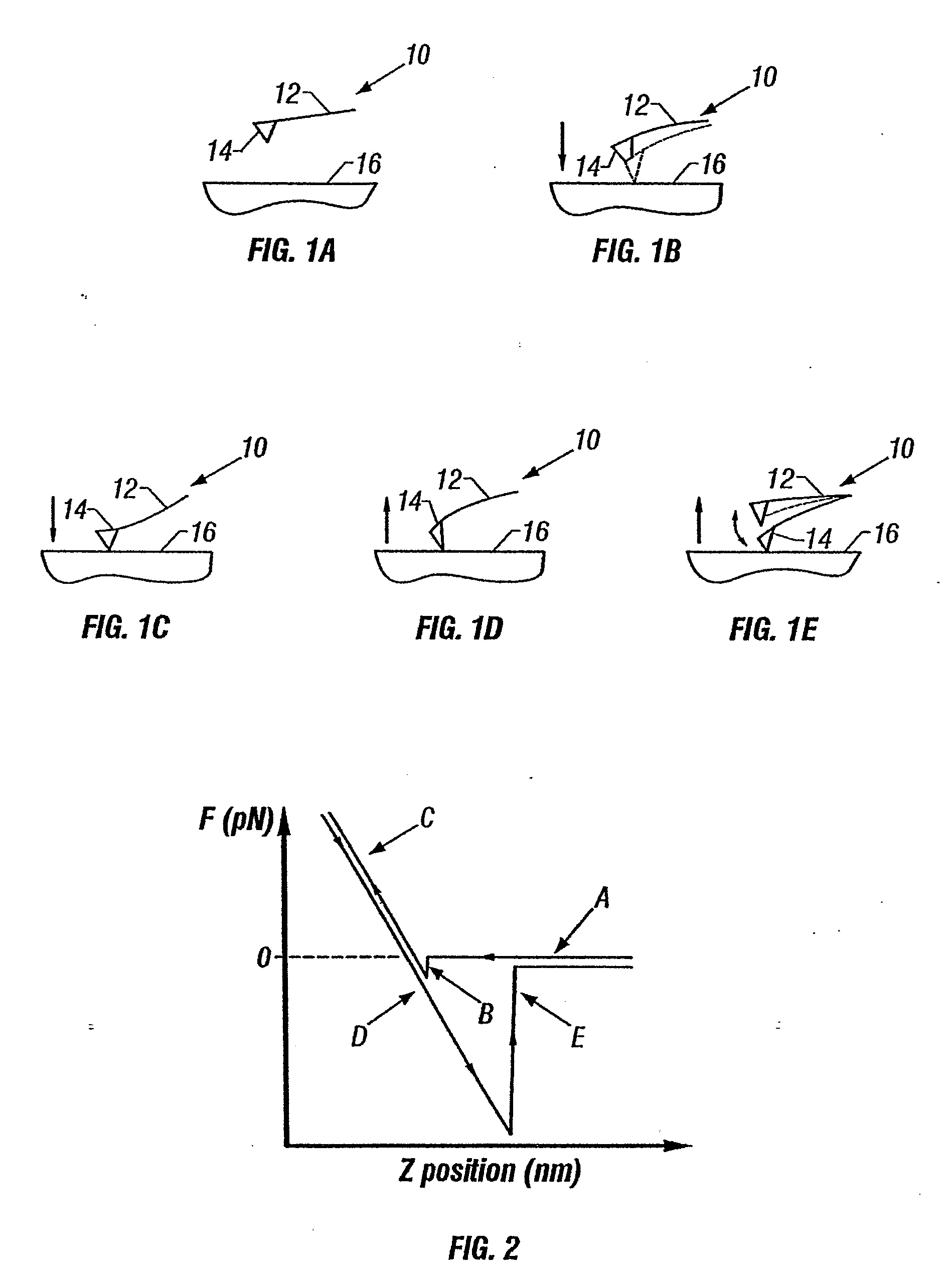

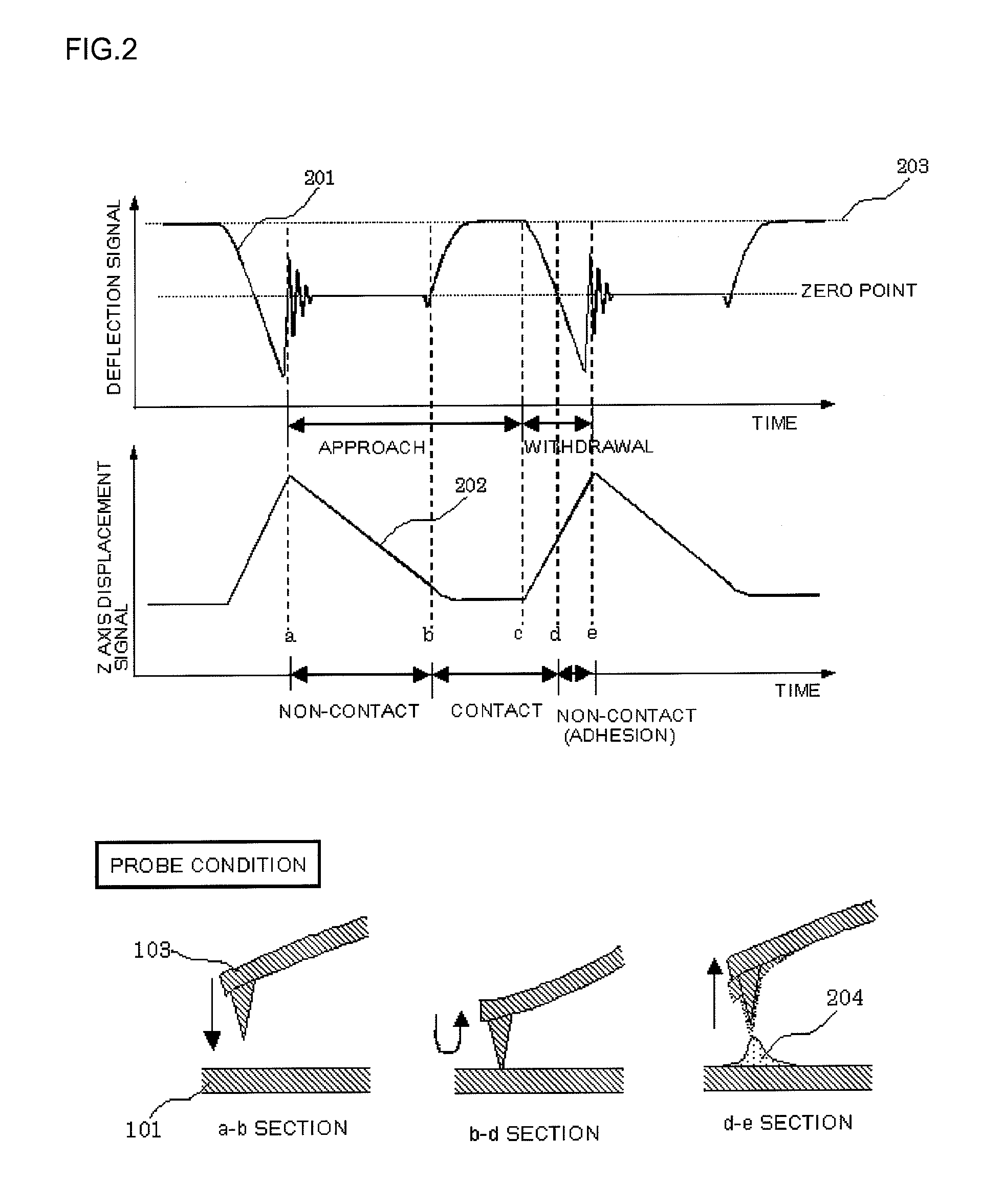

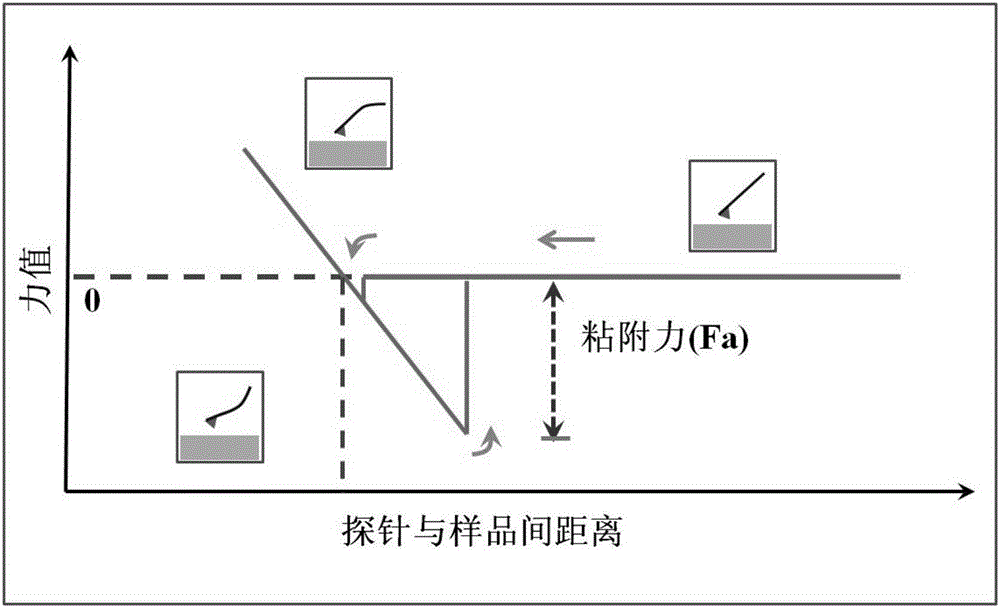

Force curves( force-versus-distance curve) typically show the deflection of the free end of the AFM cantilever as the fixed end of the cantilever is brought vertically towards and then away from the sample surface.

Force scanning probe microscope

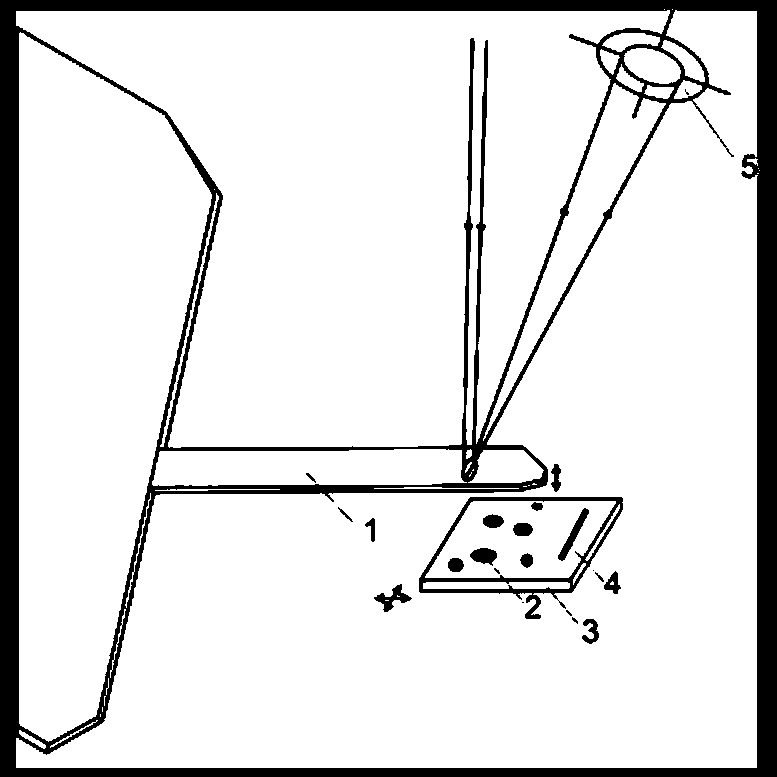

InactiveUS7044007B2Maximizing integrityEasy to measureNanotechPiezoelectric/electrostriction/magnetostriction machinesElectricityClosed loop

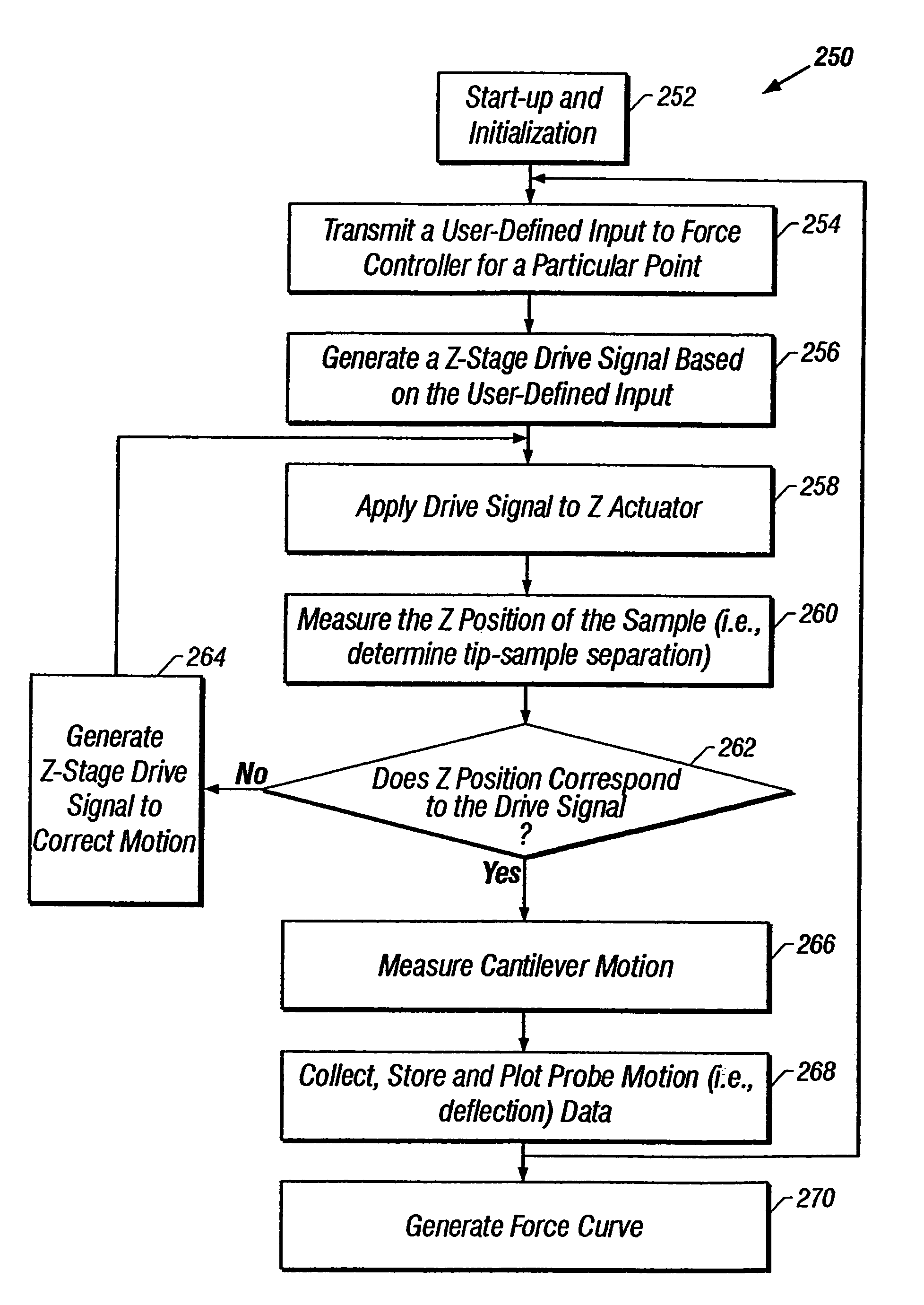

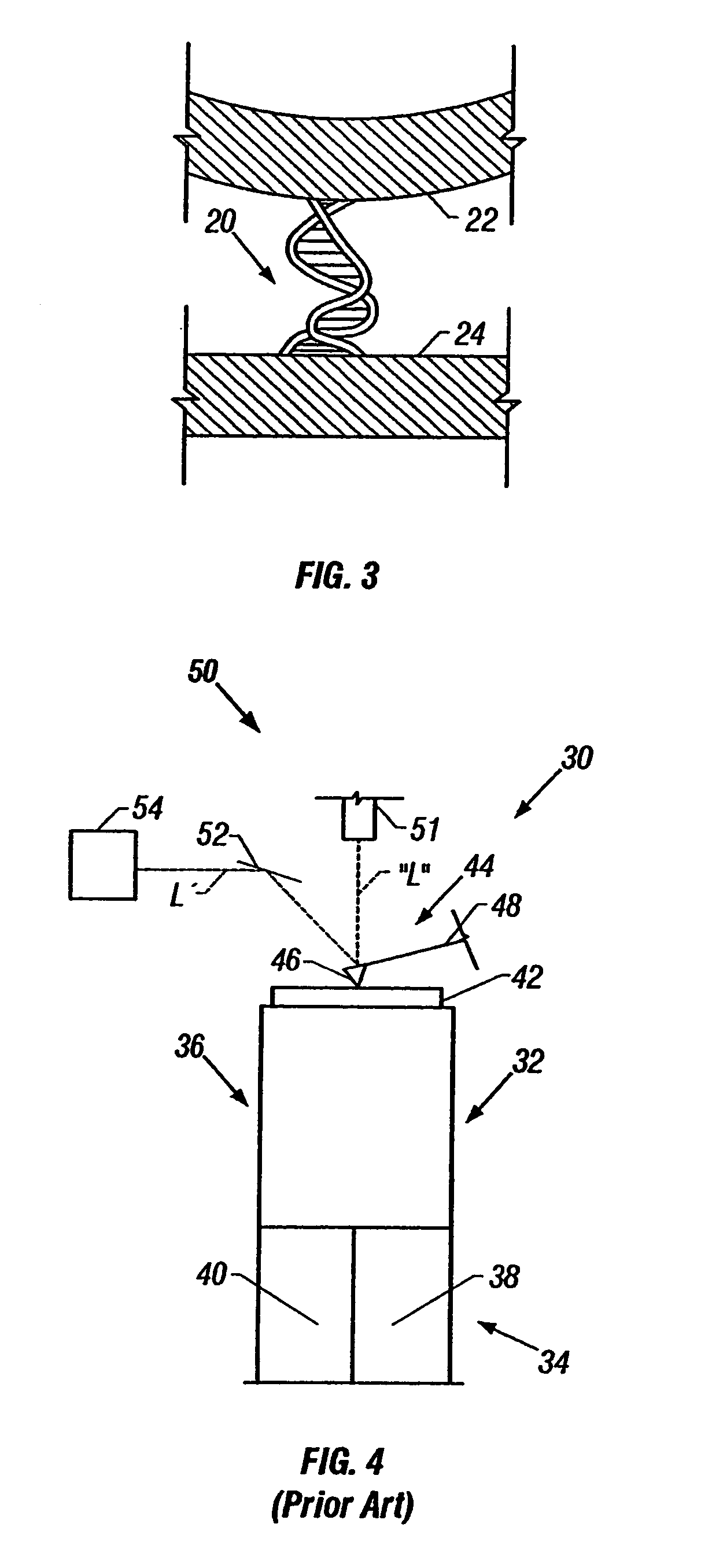

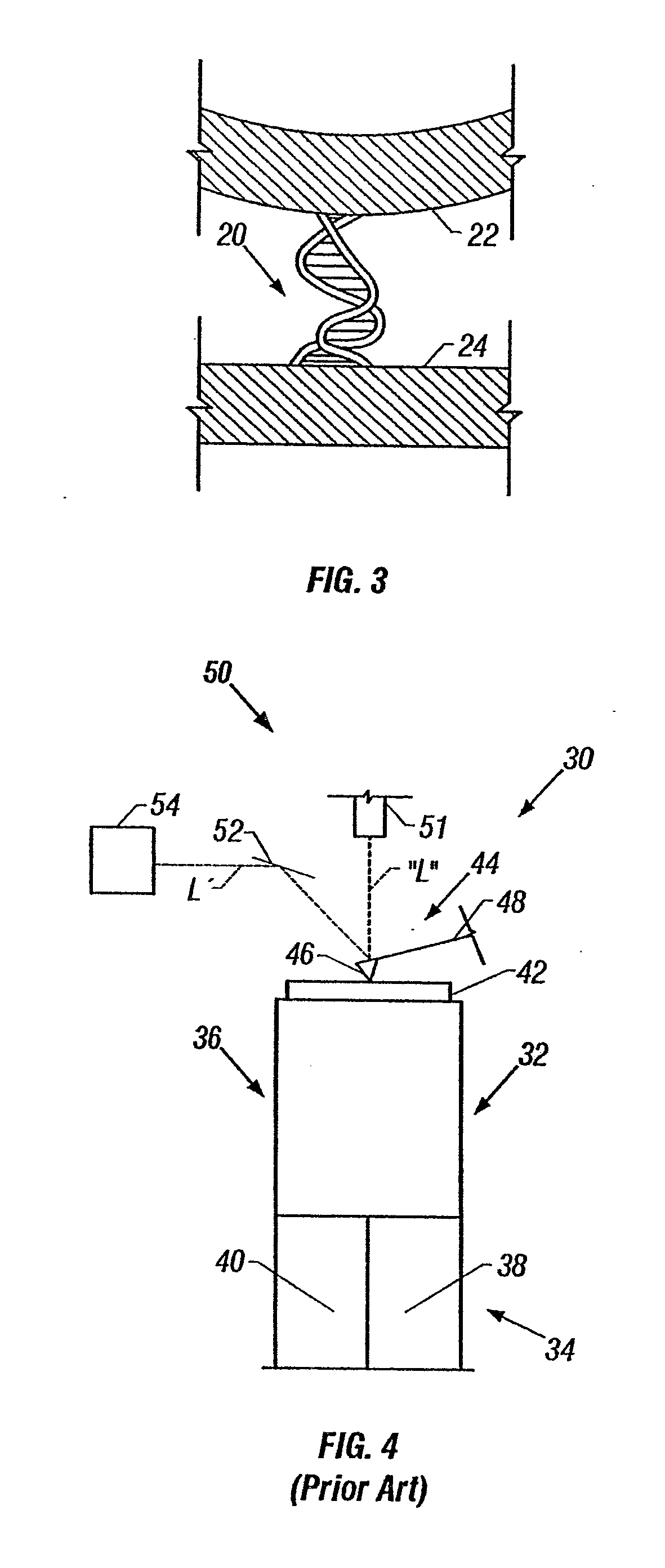

A force scanning probe microscope (FSPM) and associated method of making force measurements on a sample includes a piezoelectric scanner having a surface that supports the sample so as to move the sample in three orthogonal directions. The FSPM also includes a displacement sensor that measures movement of the sample in a direction orthogonal to the surface and generates a corresponding position signal so as to provide closed loop position feedback. In addition, a probe is fixed relative to the piezoelectric scanner, while a deflection detection apparatus is employed to sense a deflection of the probe. The FSPM also includes a controller that generates a scanner drive signal based on the position signal, and is adapted to operate according to a user-defined input that can change a force curve measurement parameter during data acquisition.

Owner:BRUKER NANO INC

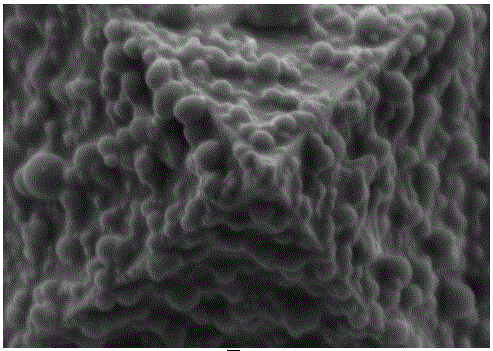

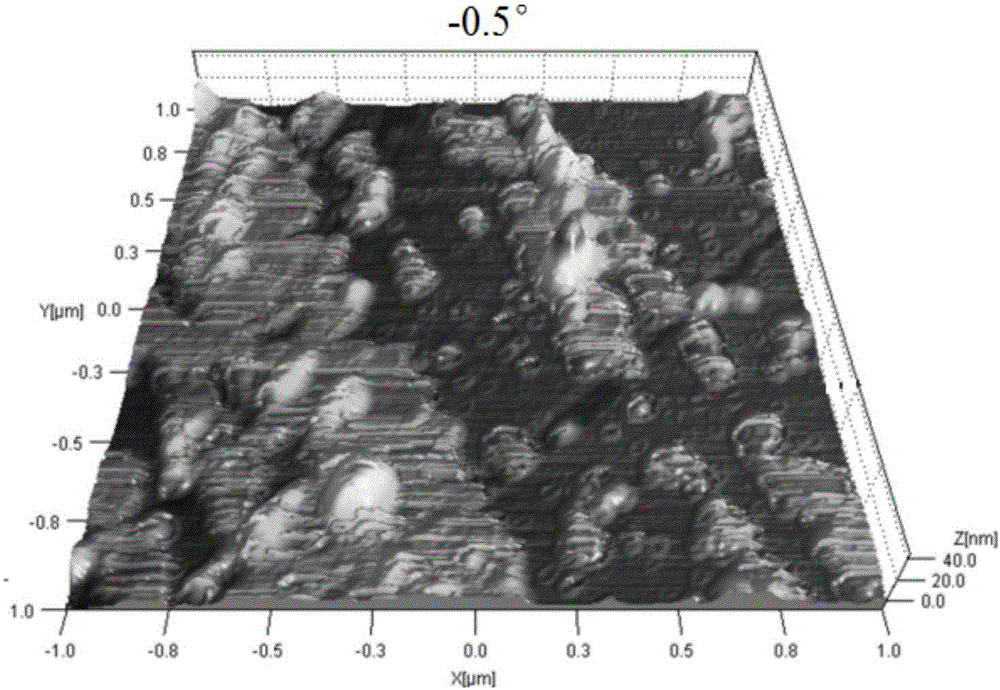

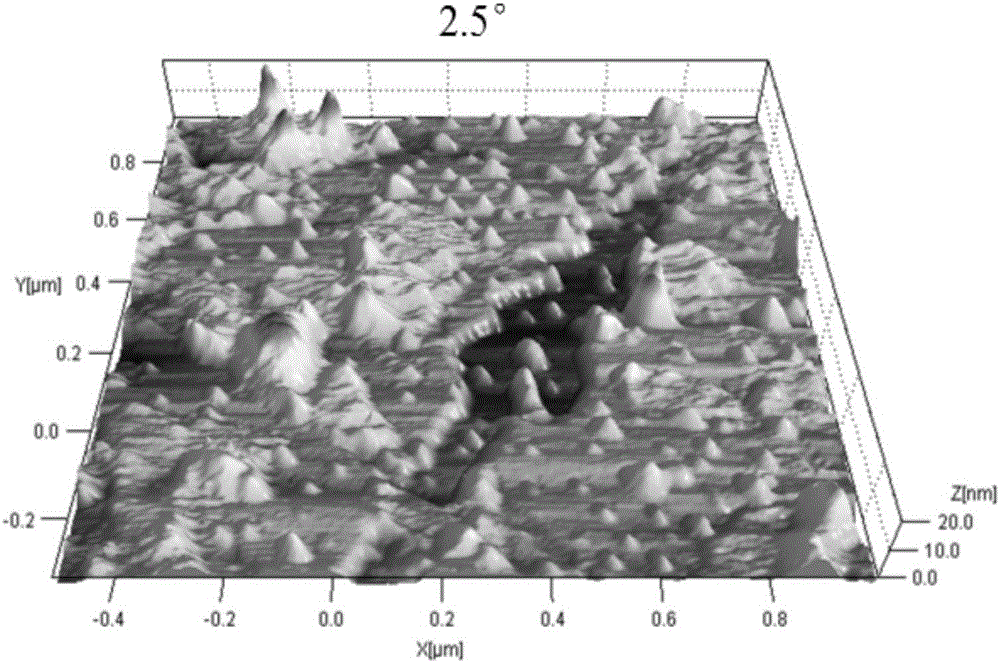

Method based on atomic force microscope for researching microscopic characteristics of asphalt

InactiveCN103529244AImprove spatial resolutionHigh material microstructure analysis functionScanning probe microscopySelf-healingForce curves

The invention provides a method based on an atomic force microscope for researching microscopic characteristics of asphalt. The method comprises the following steps: preparing an asphalt sample for atomic force microscope observation, imaging surface morphology, performing high-precision and quantitative analysis on roughness and analyzing adhesion; (1) preparing the asphalt sample so as to enable the asphalt sample to meet observation requirements of the atomic force microscope; (2) imaging the surface morphology: observing the size and density of a honeycomb structure in a selected area on the surface of the asphalt sample from a two-dimensional angle and with a high resolution by using the atomic force microscope; (3) performing high-precision and quantitative analysis on the roughness: acquiring a roughness parameter in the image area of the atomic force microscope by using proper data analysis software; (4) analyzing the adhesion: acquiring a force curve by using the atomic force microscope, and acquiring an adhesion value through the force curve; (5) quantitatively evaluating the adhesiveness and self-healing performance of the asphalt according to the roughness and adhesion. The method provides an effective way for recognizing and analyzing material properties from a microscopic view for researchers.

Owner:SOUTHEAST UNIV

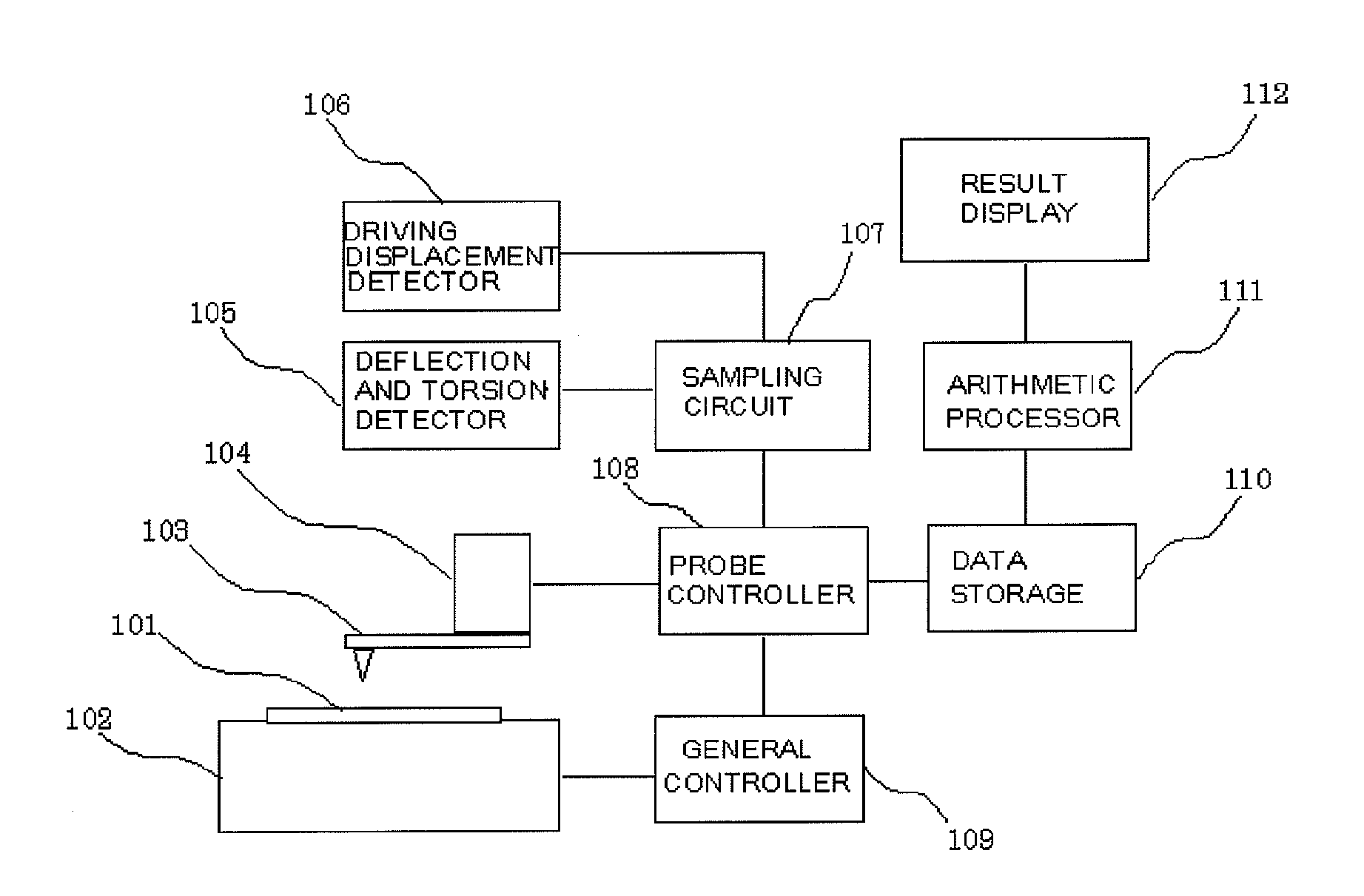

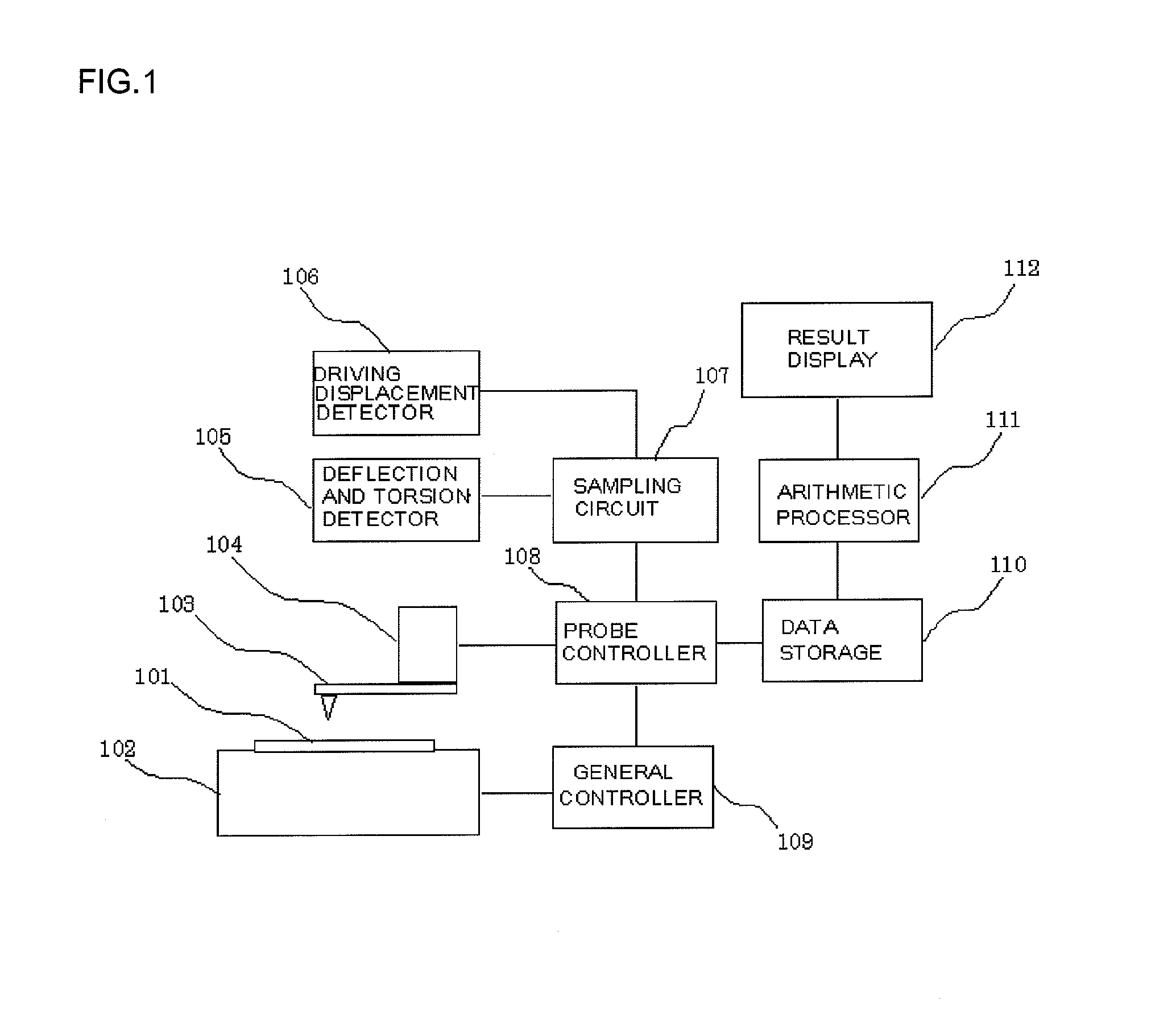

Scanning Probe Microscope

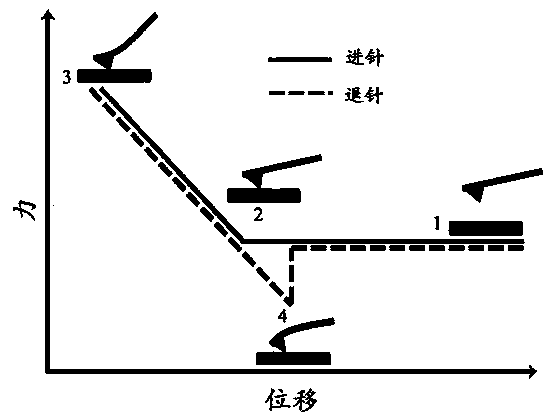

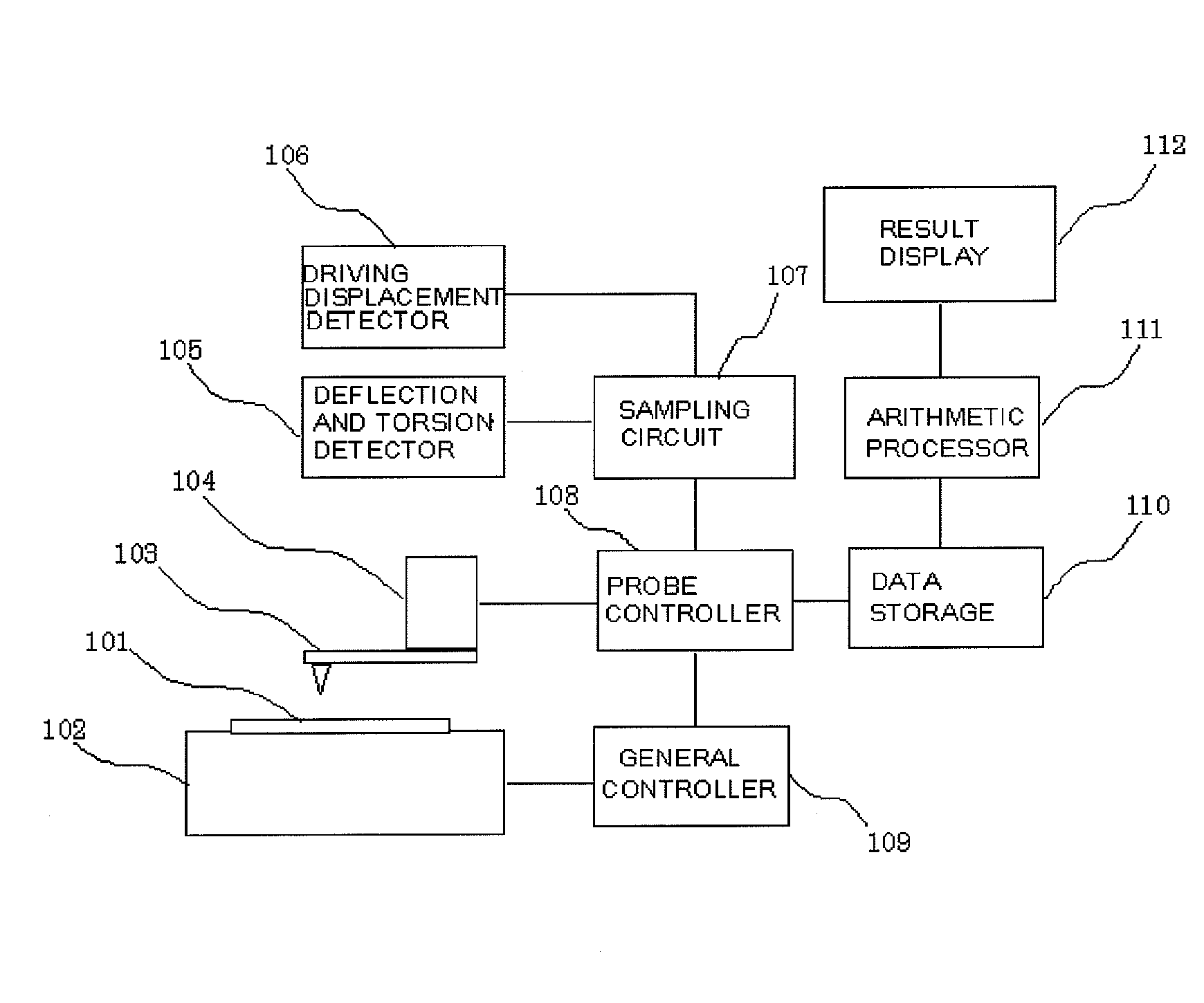

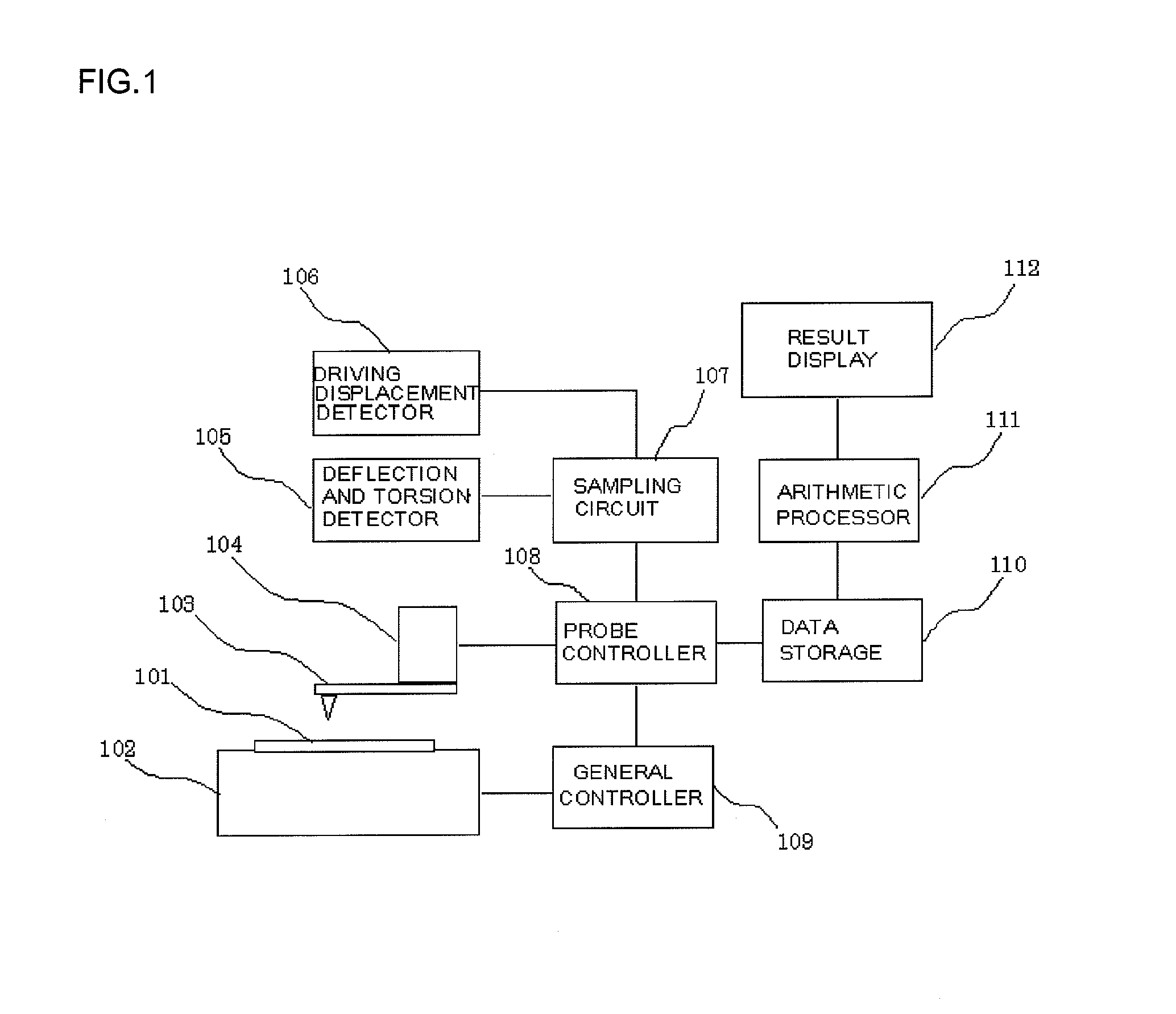

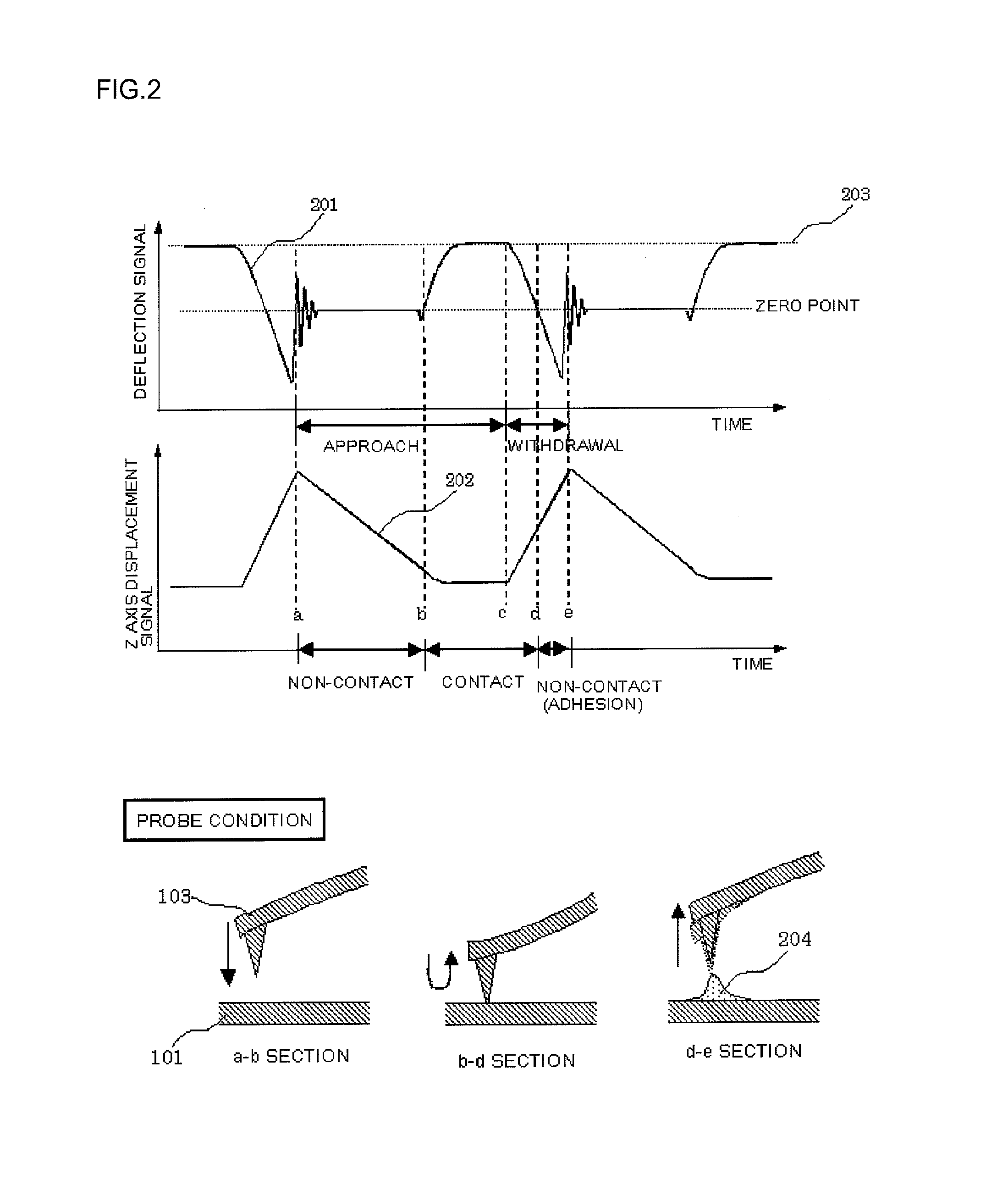

InactiveUS20070266780A1Eliminate human influenceRapid and reliable detectionSemiconductor/solid-state device testing/measurementSurface/boundary effectProperty valueForce curves

With a scanning probe microscope, if a plurality of sample properties are measured using a scanning scheme of allowing a probe to approach and withdraw from a sample, the sample properties need to be accurately and reliably detected in the minimum required measurement time. Further, the acting force between the probe and the sample varies depending on the type of the probe and the wear condition of a probe tip. Thus, disadvantageously, property values acquired using different probes cannot be compared with one another unless the artifactual effect of the measuring probes are eliminated. In accordance with the present invention, with a scanning probe microscope, the probe is brought into intermittent contact with the sample, while driving means repeatedly allows the probe to approach and withdraw from the sample with a variable amplitude. The sample property is thus acquired at a high speed. Further, a calibration sample is used in a given environment (given temperature and humidity) to acquire a force curve for at least one point. Information obtained from the force curve is used to correct measurements to display the distribution of the sample property.

Owner:HITACHI LTD

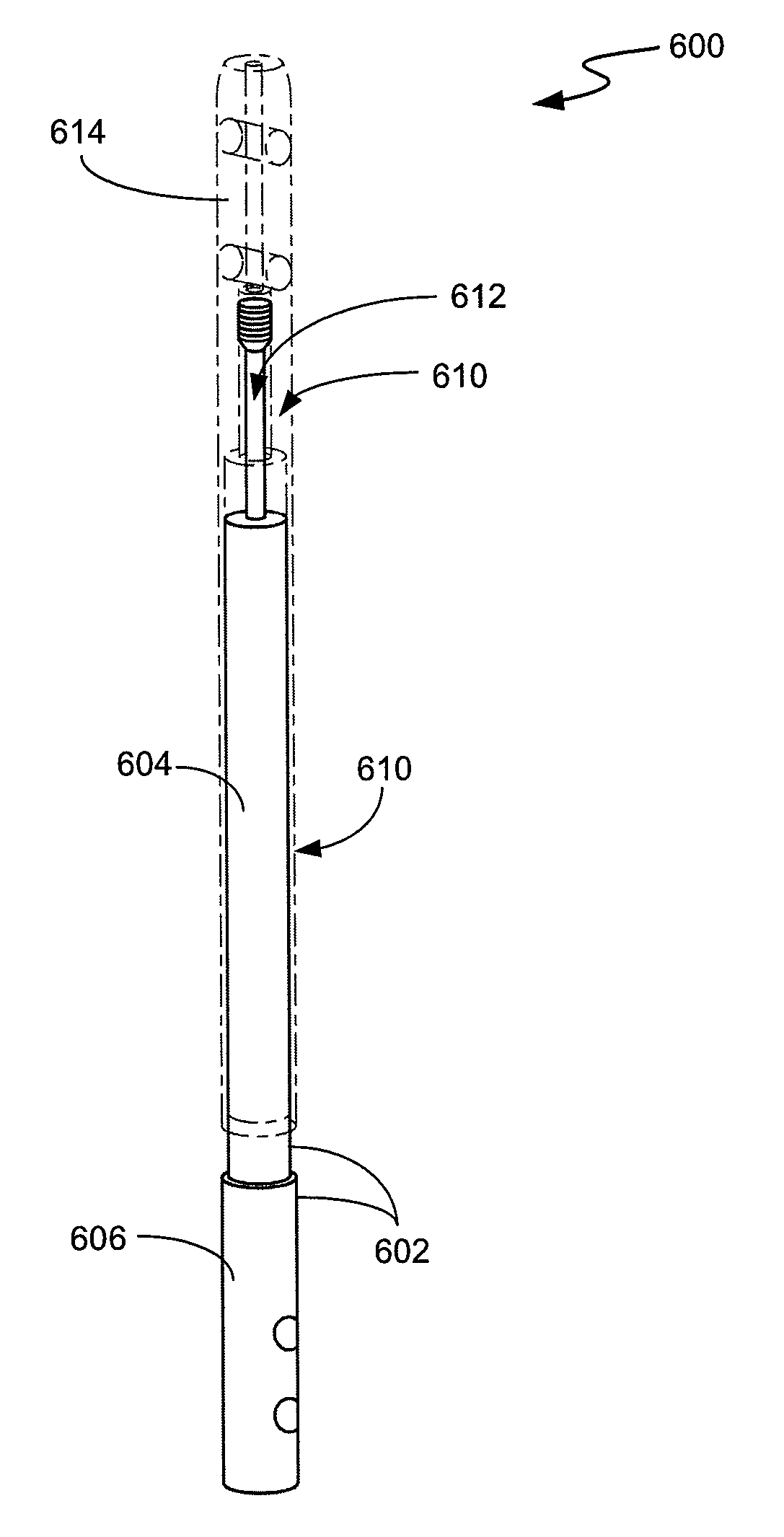

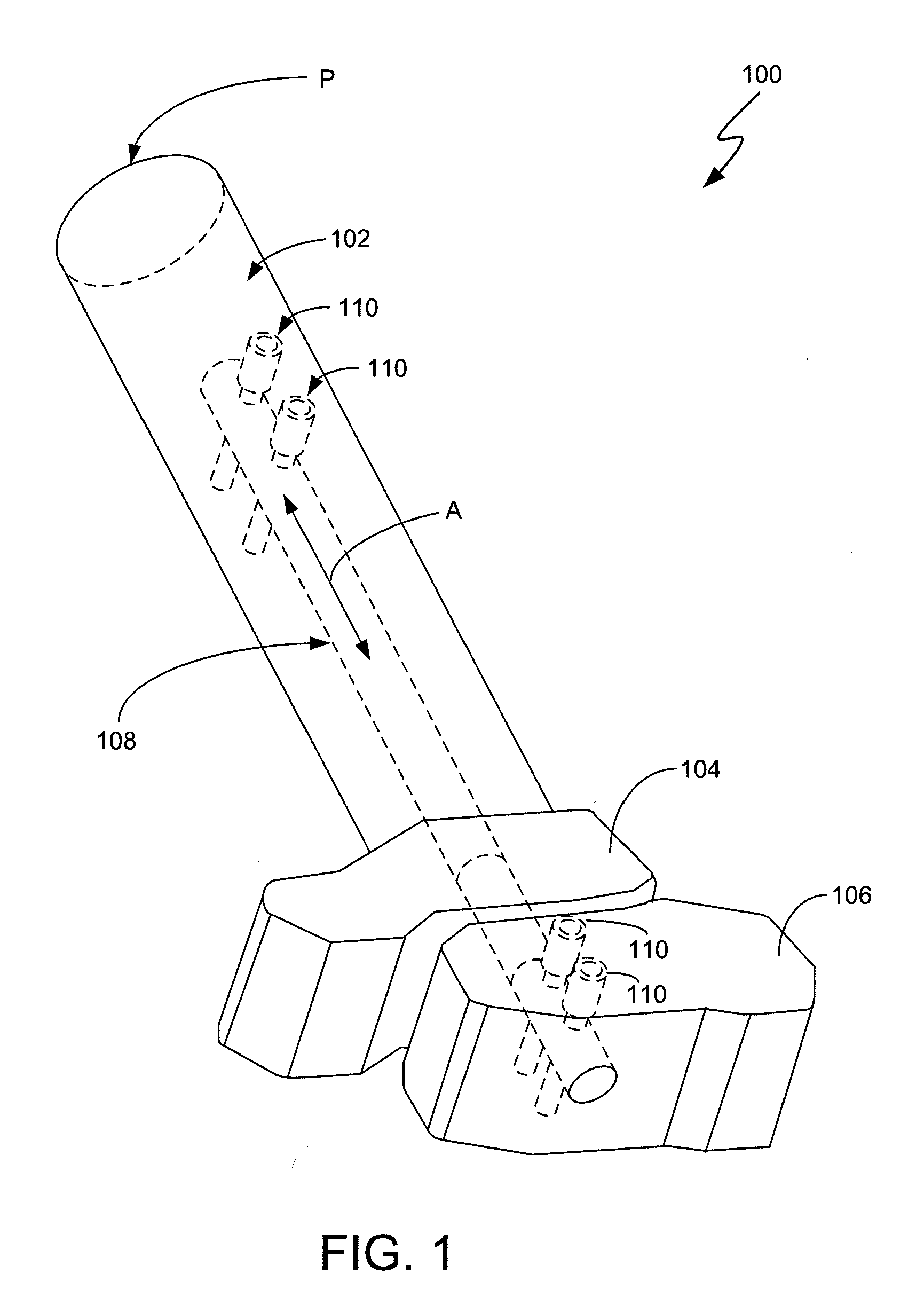

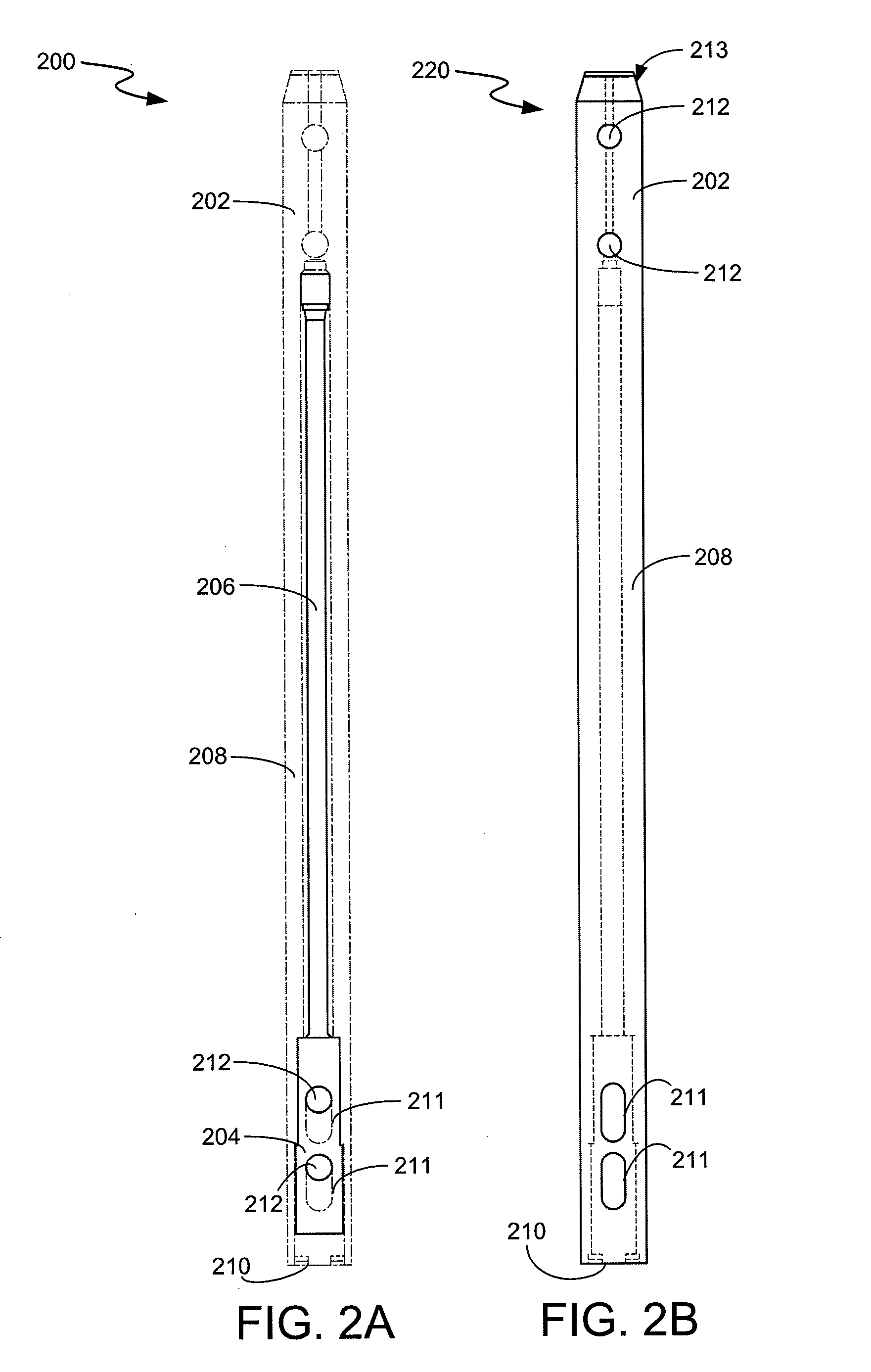

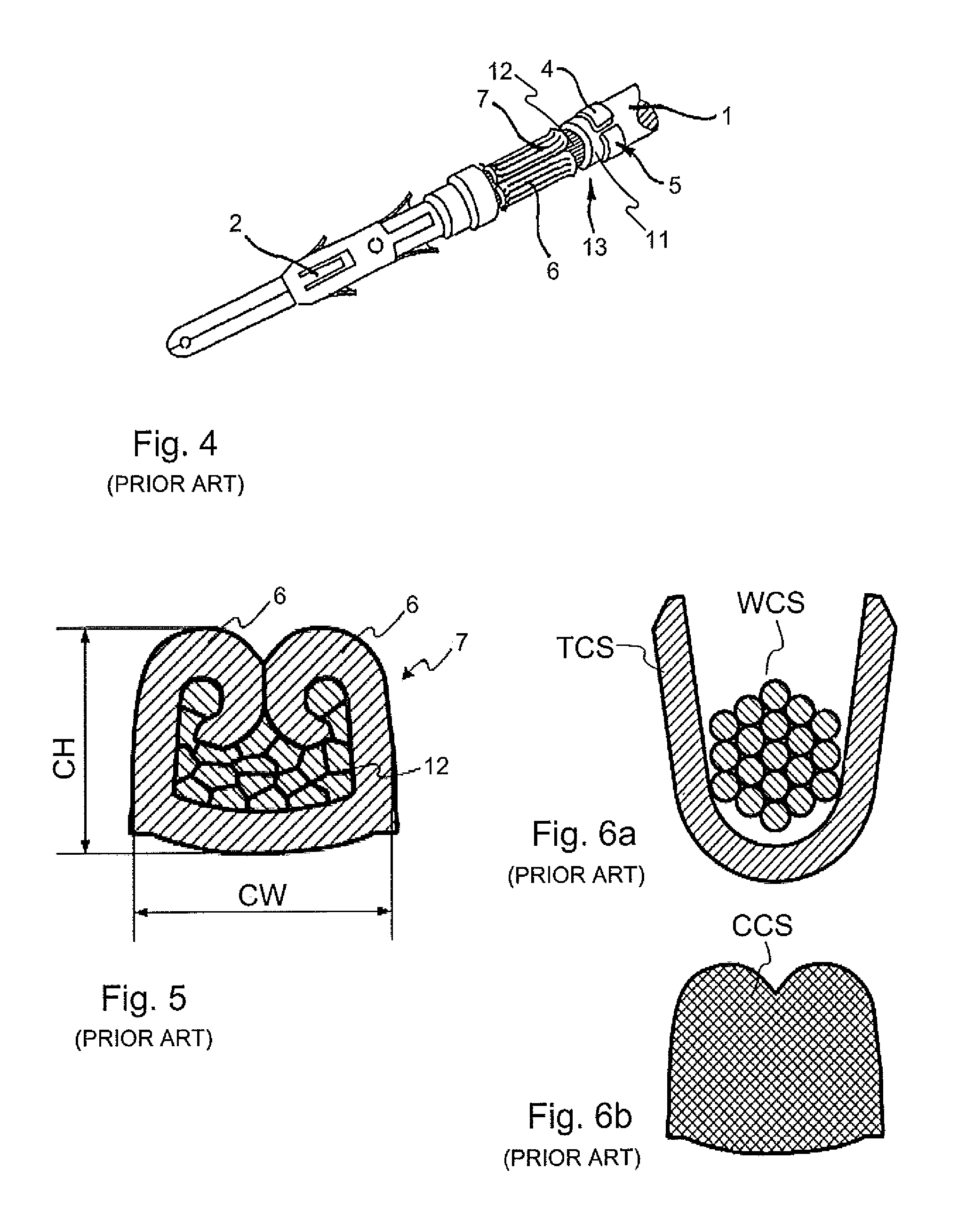

Intramedullary medical device and methods of use and manufacture

Intramedullary medical devices (e.g., intramedullary nails) and methods for their use and manufacture are described herein. The intramedullary medical devices described herein may provide sustained compressive forces across a bone fusion site despite bone resorption processes. Through various embodiments, the intramedullary medical devices described herein may provide non-linear force curves relative to displacement. Intramedullary medical devices are described with multiple elements made of different materials. Examples of intramedullary medical devices are described with shape memory alloys.

Owner:MEDSHAPE

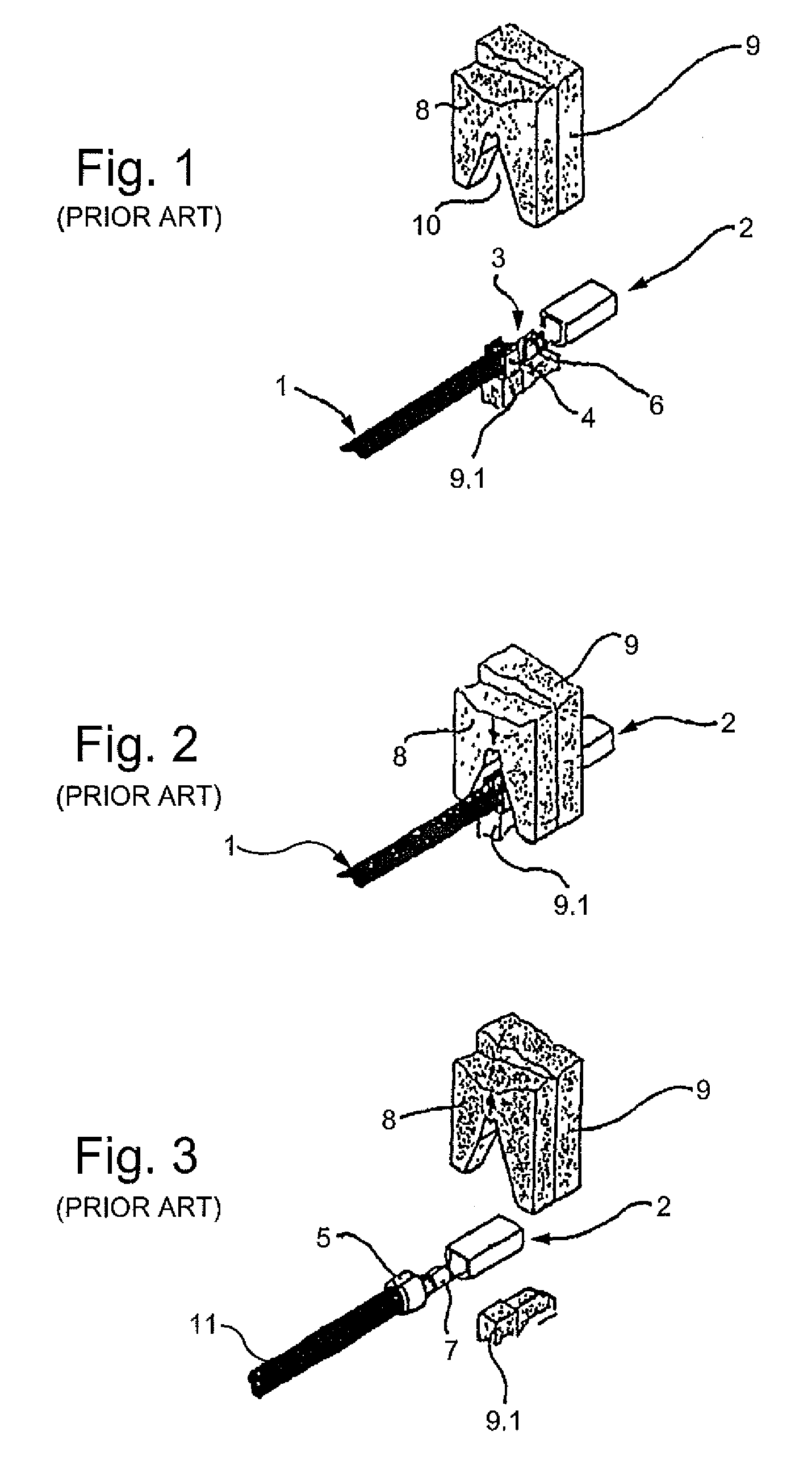

Method for determining the quality of a crimped connection between a conductor and a contact

ActiveUS20100139351A1Improve quality assuranceAvoid disadvantagesLine/current collector detailsAutomatic control devicesElectrical conductorEngineering

A method for determining the quality of a crimped connection between a conductor and a contact includes operating a crimping device to exert a crimping force on the conductor and the contact. From the crimping force curve that occurs during the crimping, a normalized force-distance crimping force curve is derived and a compression area is determined which lies under a reference crimping force curve. The crimping force curve and the reference crimping force curve are subdivided into several zones, the subdivision taking place under consideration of the size of the compression area. A further area that lies under the crimping force curve is determined and used to infer the quality of the crimped connection. A device for performing the method is provided.

Owner:KOMAX HOLDING

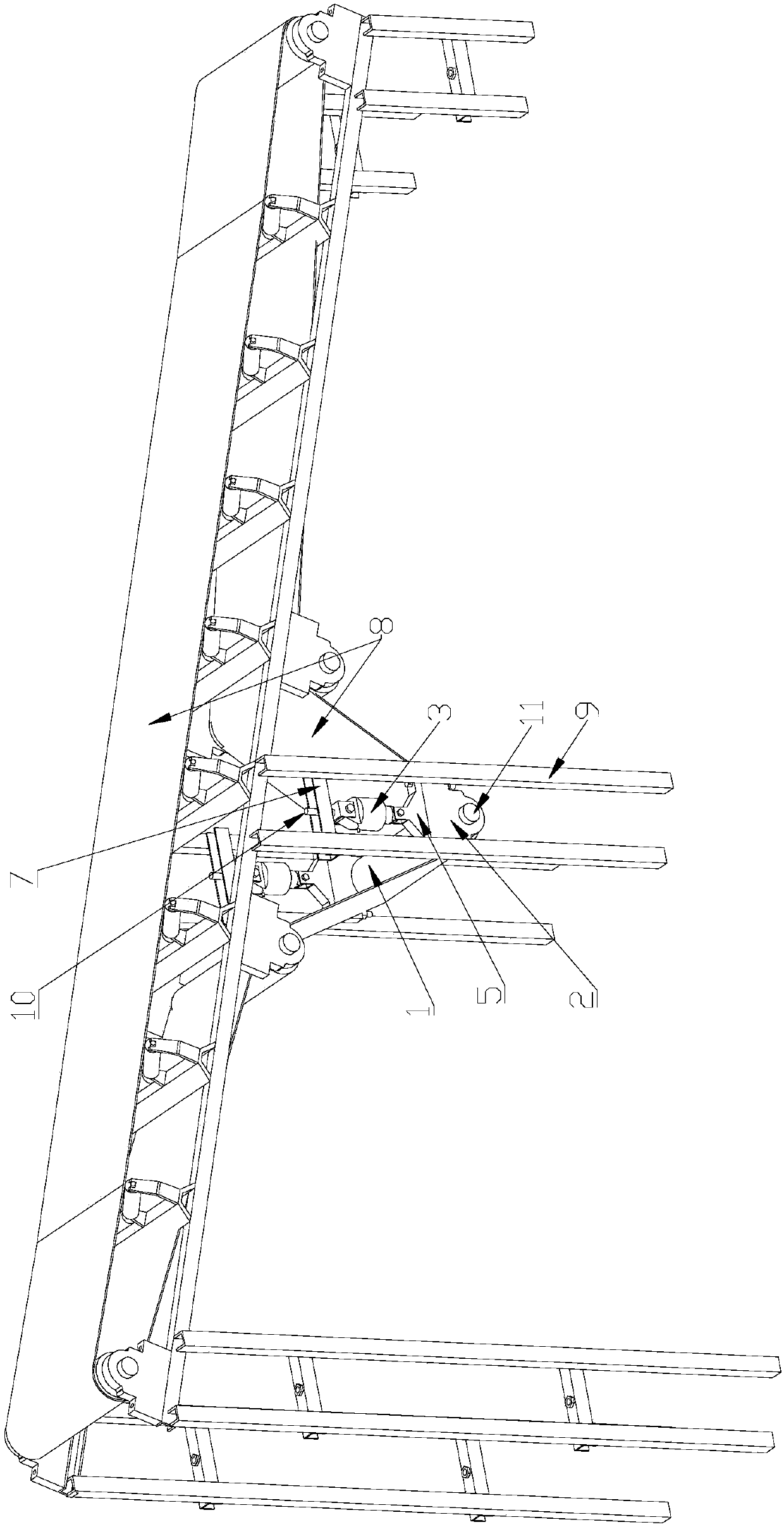

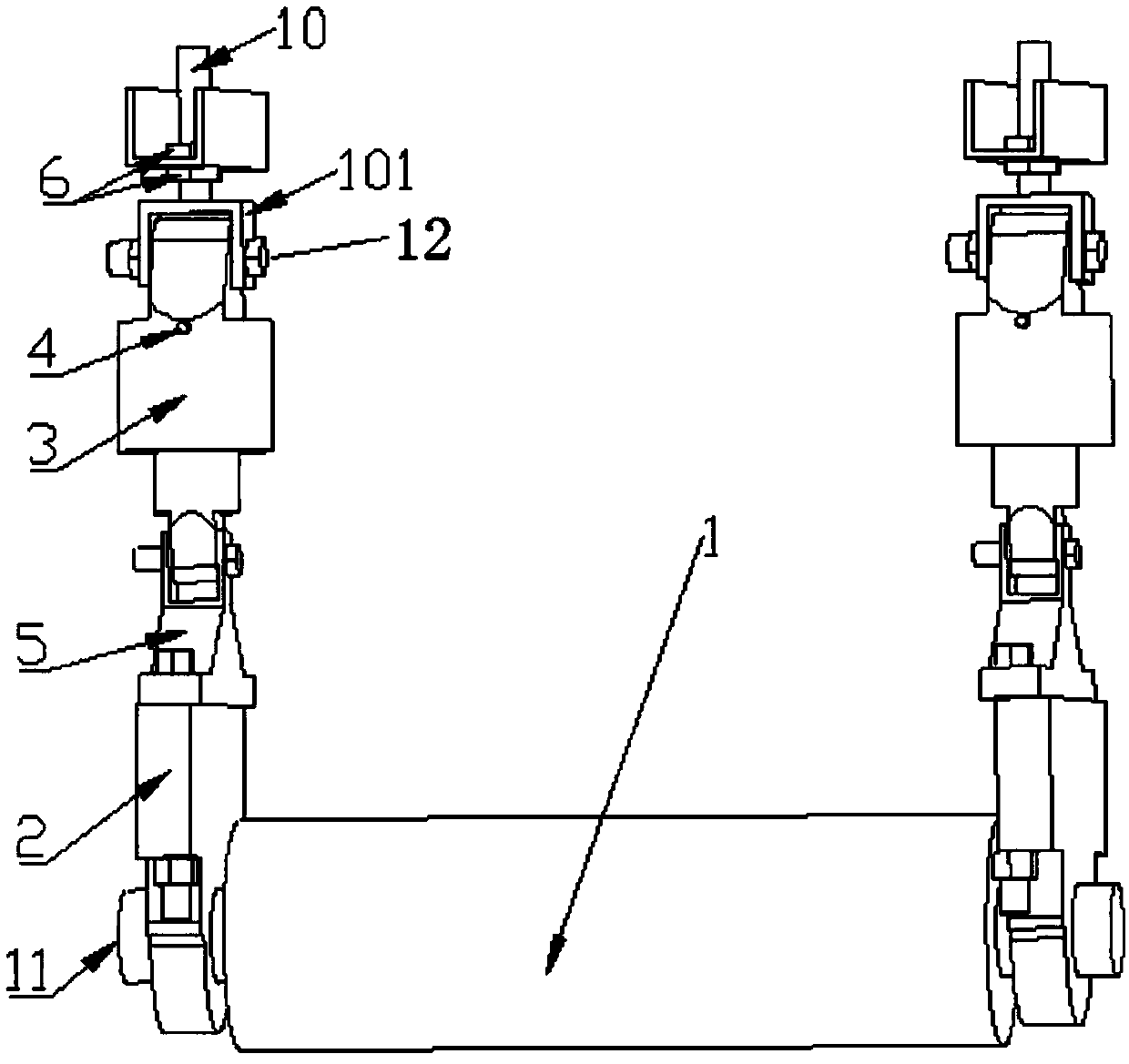

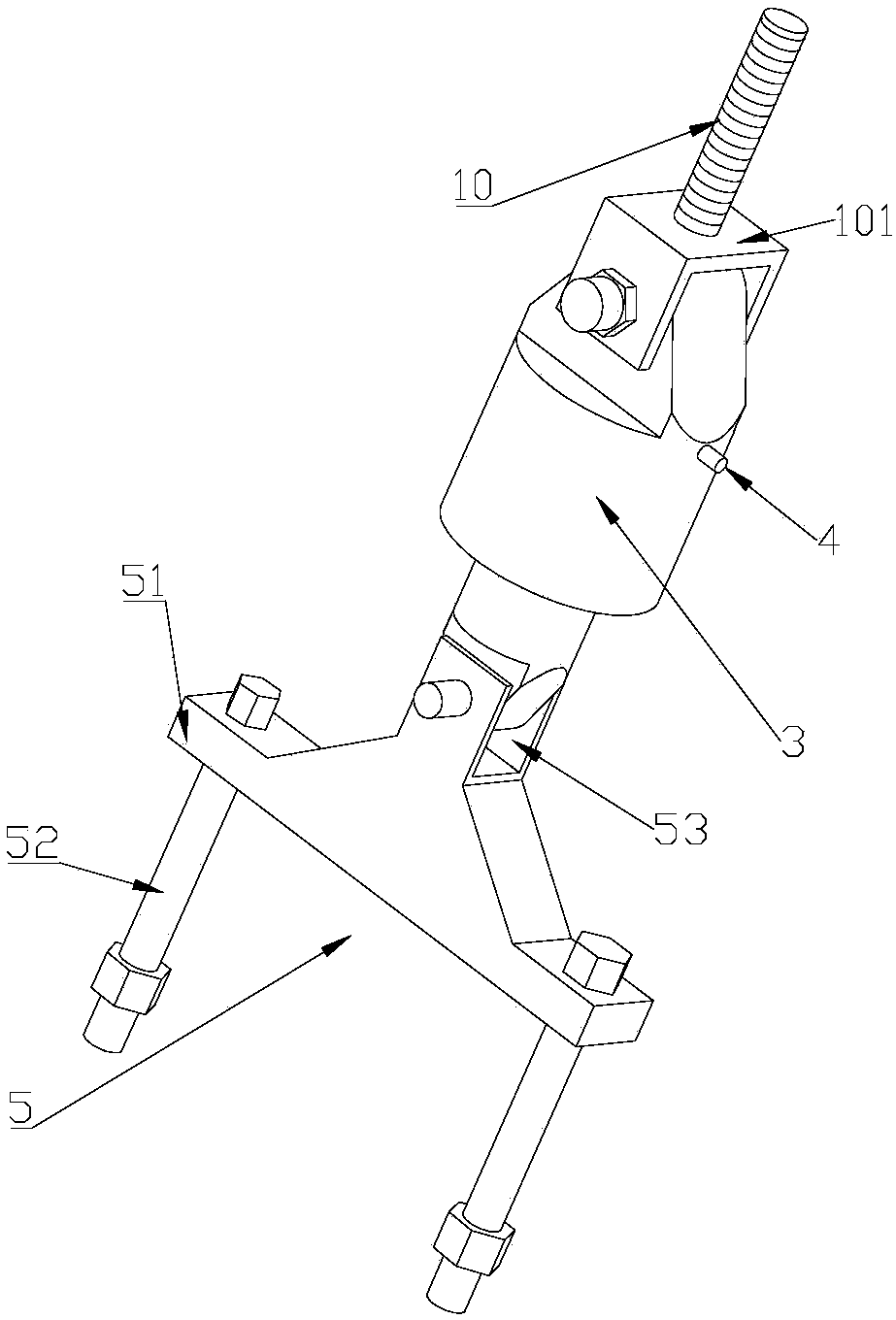

Belt conveyor automatically detecting and adjusting tension

InactiveCN107555093AReal-time tension detectionStable tensionConveyorsControl devices for conveyorsControl systemForce curves

The invention relates to the technical field of belt tensioning wheels, in particular to a belt conveyor automatically detecting and adjusting tension. The belt conveyor comprises a rack, a belt, a tensioning wheel and shaft lugs connected to the rack. A shaft hole is formed in the position, close to one end, of each shaft lug. Shaft parts at the two ends of the tensioning wheel are rotationally connected into the shaft holes of the shaft lugs on the two sides correspondingly. The belt conveyor is characterized by further comprising a tension detecting and adjusting device, and the signal endsof hydraulic pressure sensors of the tension detecting and adjusting device are in both-way connection with the signal input end of a control system. Compared with the prior art, the structure characteristics of the belt conveyor are sufficiently combined; commonly, the conveyor only needs the two hydraulic pressure sensors, the design of the control system is relatively simple, a real-time tensioning force curve and abnormal alarms can be provided for production and management personnel in combination with a man-machine interaction system, the tension of the belt conveyor can be detected inreal time and finely adjusted, the tension of the belt conveyor is kept to be constantly stabilized near the set value, and stability of production technology parameters is ensured.

Owner:SHANGHAI YUNTONG INFORMATION SCI & TECH CO LTD

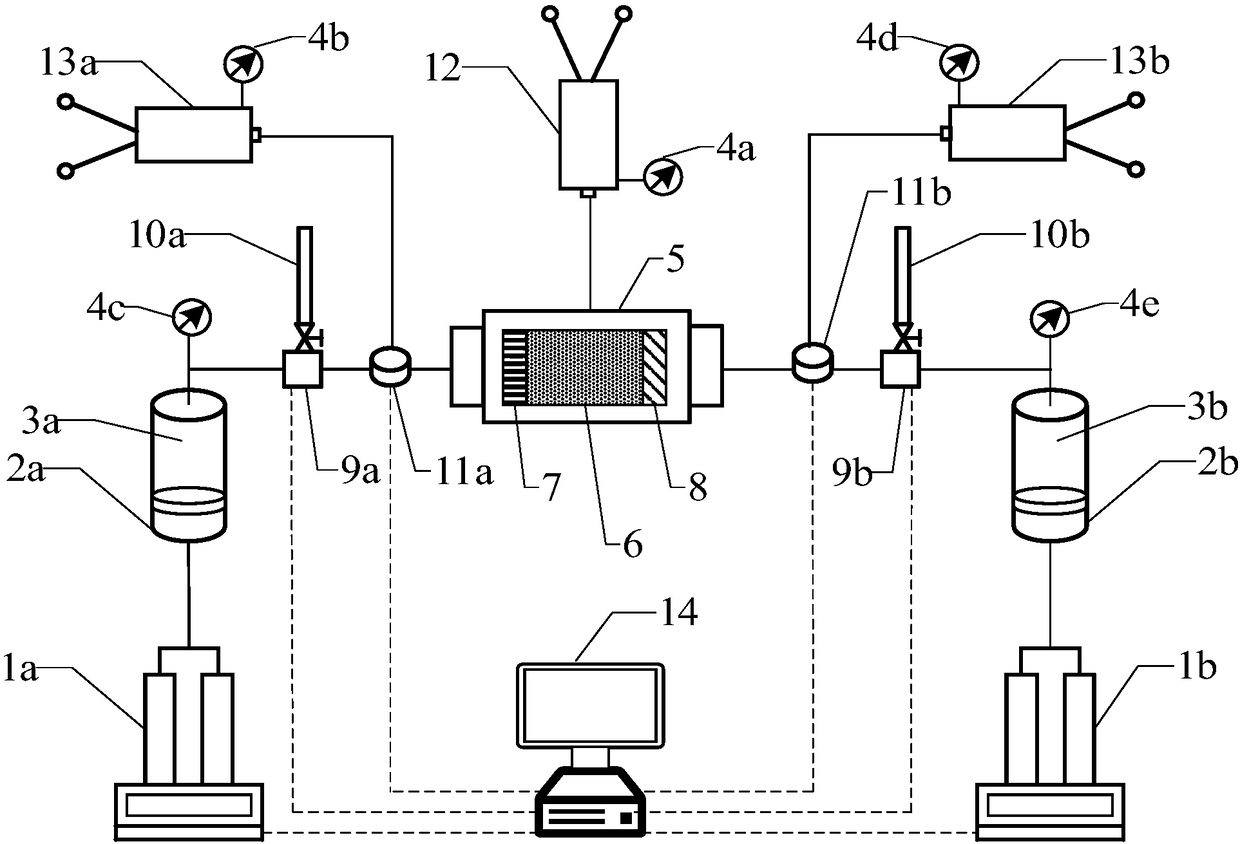

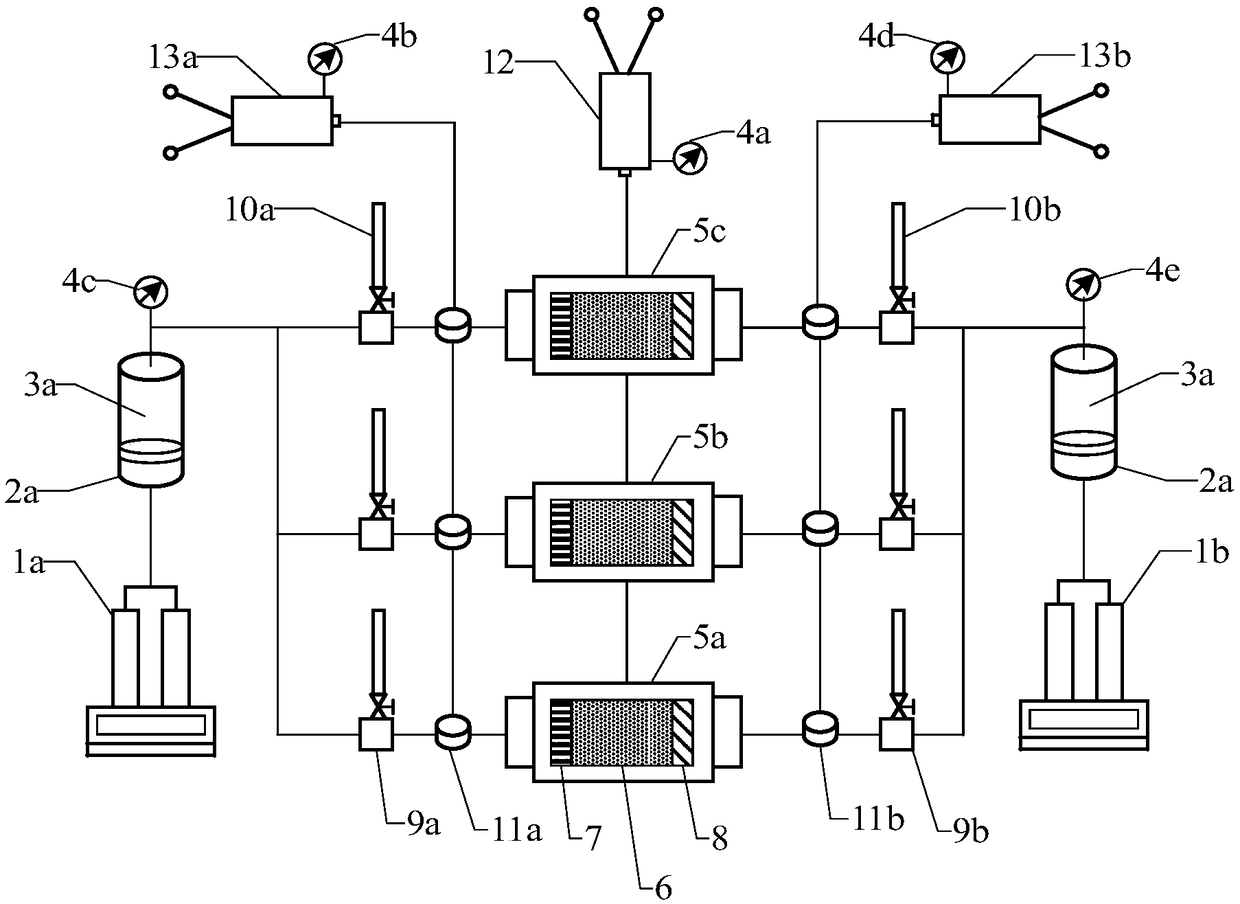

Device and method for simultaneous detection of displacement and sucking capillary force curves under oil reservoir conditions

PendingCN108181224ASolve the disadvantages of only measuring displacement capillary force curveSolve the problem of continuous accurate measurementPermeability/surface area analysisEngineeringThermostat

The invention relates to a device and a method for simultaneous detection of displacement and sucking capillary force curves under oil reservoir conditions. The device comprises a triaxial stress rockcore holder, wherein a wet phase semi-permeable separator and a non-wetting phase semi-permeable separator are respectively placed at both ends of a rock core, an annular pressure and axial pressuremechanical pump and a back pressure mechanical pump are used to pressurize and simulate formation pressure, a thermostat simulates formation temperature, a non-wetting phase fluid piston container, awet phase fluid piston container and a constant speed constant pressure micro pump control a displacement and suction process, a pressure flow rate sensor group, a pressure gauge, a metering tube anda computer collect pressure and liquid volume data and process and calculate the displacement and sucking capillary force curves; the method continuously measures the displacement and sucking capillary force curves of different wettable rocks in one time and scans the displacement and sucking capillary force curves by simulating true oil reservoir temperature pressure and fluid conditions, makes up for the shortcomings of conventional methods, solves the defect that a common instrument can only measure displacement capillary force curves, and solves the problem of continuous accurate measurement of underground real displacement and sucking capillary force curves.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Force scanning probe microscope

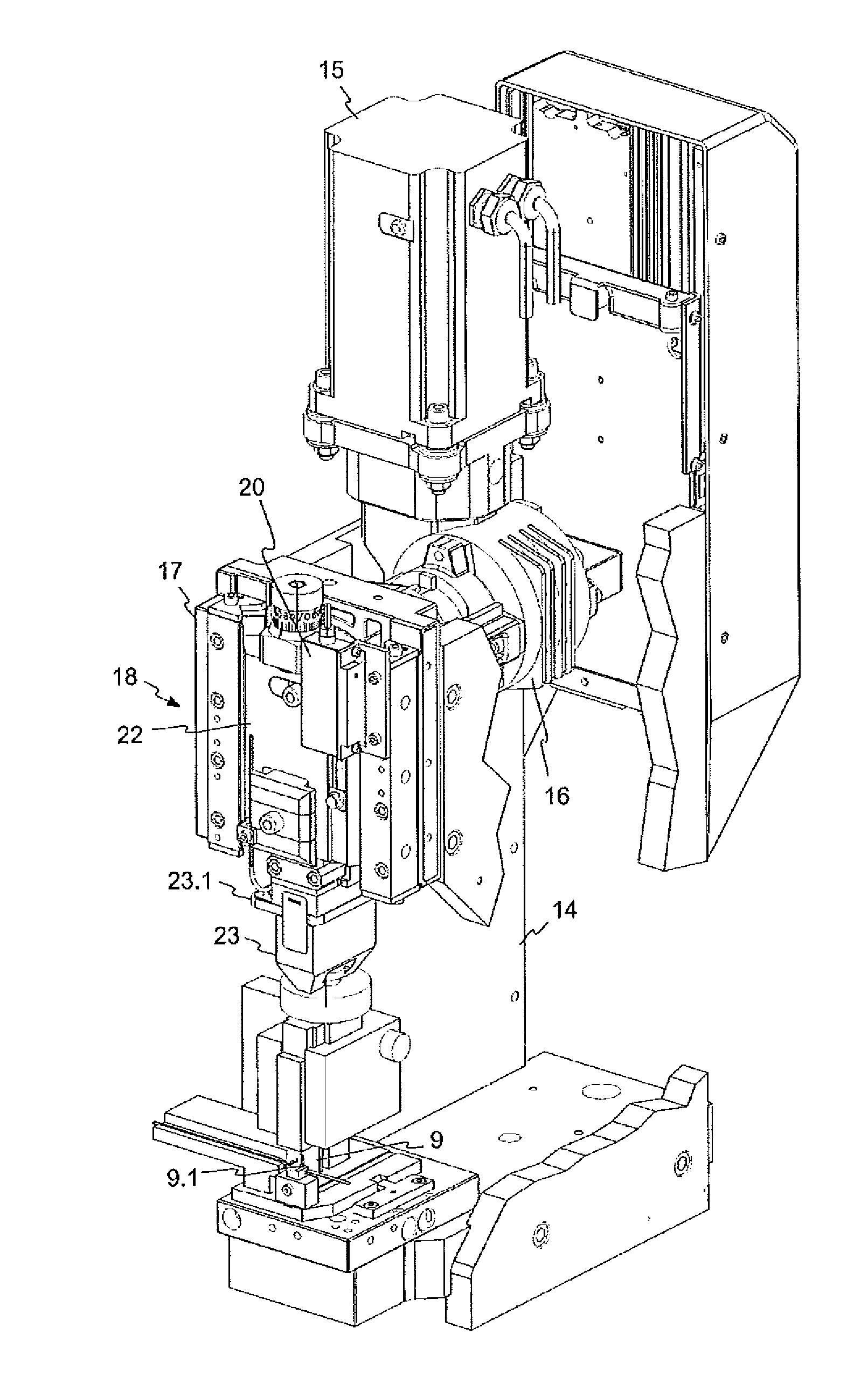

InactiveUS20060283240A1Maximizing integrityEasy to measureNanotechPiezoelectric/electrostriction/magnetostriction machinesElectricityData acquisition

A force scanning probe microscope (FSPM) and associated method of making force measurements on a sample includes a piezoelectric scanner having a surface that supports the sample so as to move the sample in three orthogonal directions. The FSPM also includes a displacement sensor that measures movement of the sample in a direction orthogonal to the surface and generates a corresponding position signal so as to provide closed loop position feedback. In addition, a probe is fixed relative to the piezoelectric scanner, while a deflection detection apparatus is employed to sense a deflection of the probe. The FSPM also includes a controller that generates a scanner drive signal based on the position signal, and is adapted to operate according to a user-defined input that can change a force curve measurement parameter during data acquisition.

Owner:BRUKER NANO INC

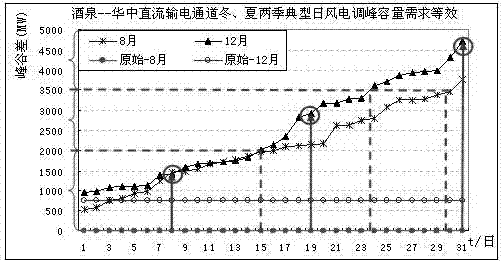

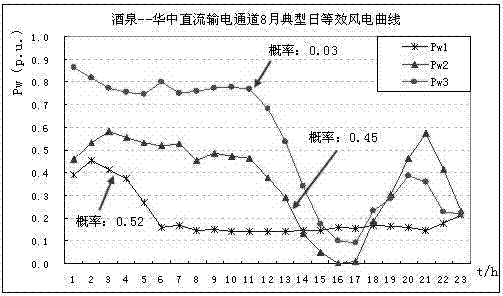

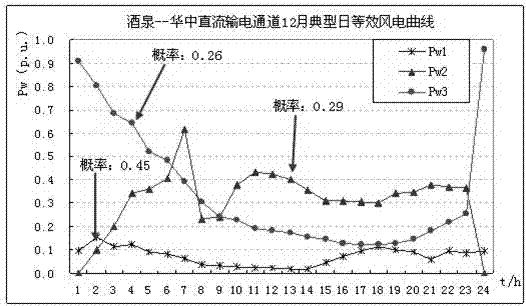

Method for determining typical sunrise force curves of wind power station

InactiveCN102968747AAdd depthData processing applicationsSystems intergating technologiesElectric power systemForce curves

The invention discloses a method for determining typical sunrise force curves of a wind power station, and relates to electric power deployment and wind power planning. The method comprises the following steps of: firstly, respectively clustering wind power sunrise force curves according to system peak regulation requirements, counting the probability of different types of curves, and selecting representative curves; and then, placing each representative curve into a system to perform production run simulation, performing probability weighted sum on results to obtain expected values of each technical and economic index of the system, such as wind power generating capacity, thermal power generating capacity, thermal power peak regulation depth, abandoned wind power quantity, thermal power fuel consumption, expected values of pollutant discharge and the like, and then evaluating the peak regulation economical efficiency of a given wind power grid system. The method has the advantages that the randomness of wind power output is considered, and the method is adopted to the conventional electric power and electric quantity balance computation; the conventional electric power system planning research method is enriched, and the depth of wind power system planning researches is improved; and power enterprises can develop electric power system operation simulation software products comprising wind power systems according to the method.

Owner:WUHAN CENT CHINA POWER GRID +1

Ground monitoring method for dangerous condition in heavy-load train operation

InactiveCN102350996AMany test pointsRich relevant informationRailway signalling and safetyRailway auxillary equipmentFiltrationInstability

The invention discloses a ground monitoring method for a dangerous condition in heavy-load train operation. The method comprises the following steps of: testing the vertical wheeltrack force and horizontal wheeltrack force on a track test point as well as corresponding time when the train passes by a strain test module; after the modification and filtration of a regulator, converting the verticalwheeltrack force and horizontal wheeltrack force into a digital signal of the track test point by a data acquisition card; converting the digital signal into continuous vertical and horizontal wheeltrack force curves of each point of a wheel set by a data processing system; comparing the vertical wheeltrack force curve with a wheel scratch curve in a database, and judging whether the wheel is scratched as well as the scratched wheel position; performing frequency-domain and time-domain analysis on the horizontal wheeltrack force curve, and judging whether the wheel experiences snakelike instability as well as the instable wheel position; and sending a corresponding warning signal and a corresponding position signal. Through the invention, the dangerous operation conditions of snakelike instability and wheel scratch of the heavy-load train can be reliably identified and monitored in real time, and the wheel set position information in snakelike instability and wheel scratch can be displayed in real time so as to guarantee the safety in train operation.

Owner:SOUTHWEST JIAOTONG UNIV

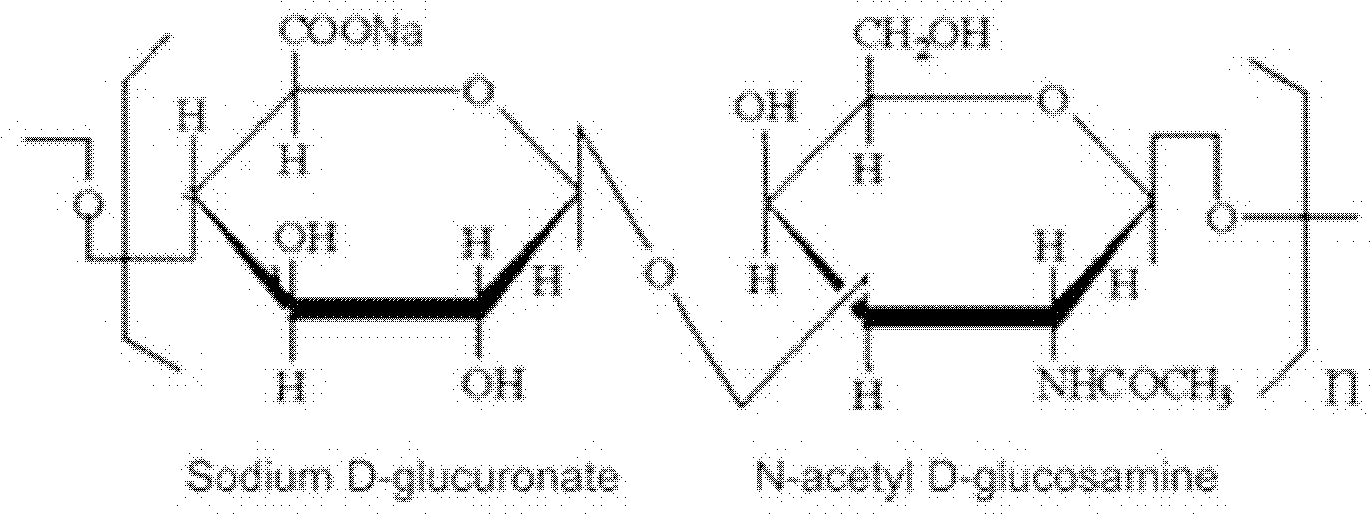

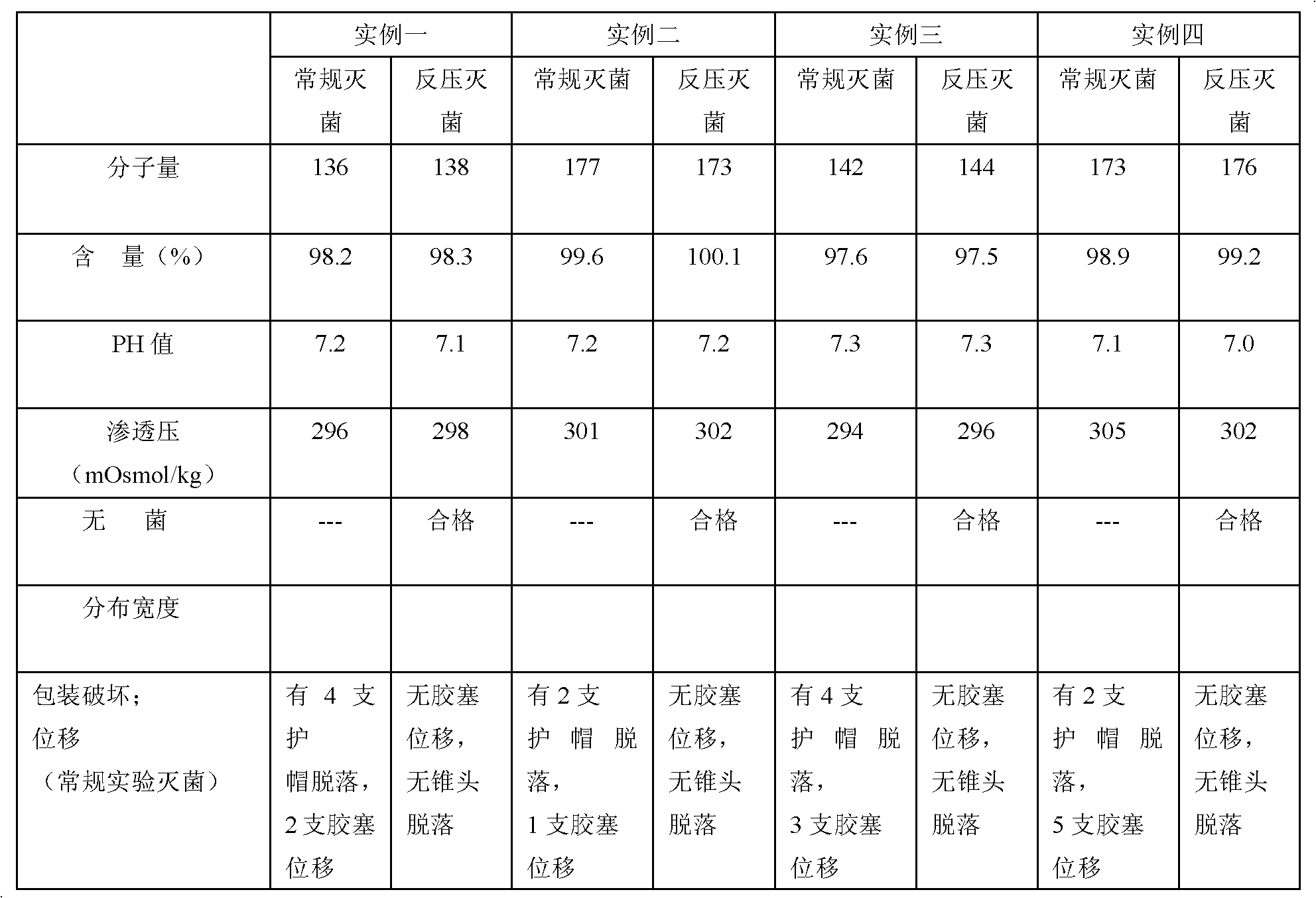

Sodium hyaluronate injection sterilization method for guaranteeing aseptic packaging

InactiveCN102488911AReduce degradationTo achieve the purpose of sterilizationHeatForce curvesBiology

The invention relates to a sodium hyaluronate injection sterilization method for guaranteeing aseptic packaging, and the method comprises the following steps: firstly, determining sterilization parameters for the fewest degradation of sodium hyaluronates in different concentrations and specifications, and determining the temperature and the time when a certain sterilization effect is achieved; then, under the condition of the temperature and the acting time, obtaining expansive acting force curves of sodium hyaluronate injections (in different concentrations and specifications) in an aseptic packaging type prefillable syringe; setting the acting force value of each expansive acting force curve into a control program of sterilization equipment, thereby obtaining automatic back-pressing control programs for product sterilization in different concentrations and specifications; and in the process of sterilization, introducing a certain proportion of compressed air to carry out back pressing, so that the pressure of a sterilizing chamber is controlled so as to prevent aseptic packaging from being damaged due to the displacement of a rubber plug.

Owner:SHANGHAI JINGFENG PHARMA

Scanning probe microscope

InactiveUS7631548B2Rapid and reliable detectionSemiconductor/solid-state device testing/measurementNanotechnologyProperty valueScanning Hall probe microscope

Owner:HITACHI LTD

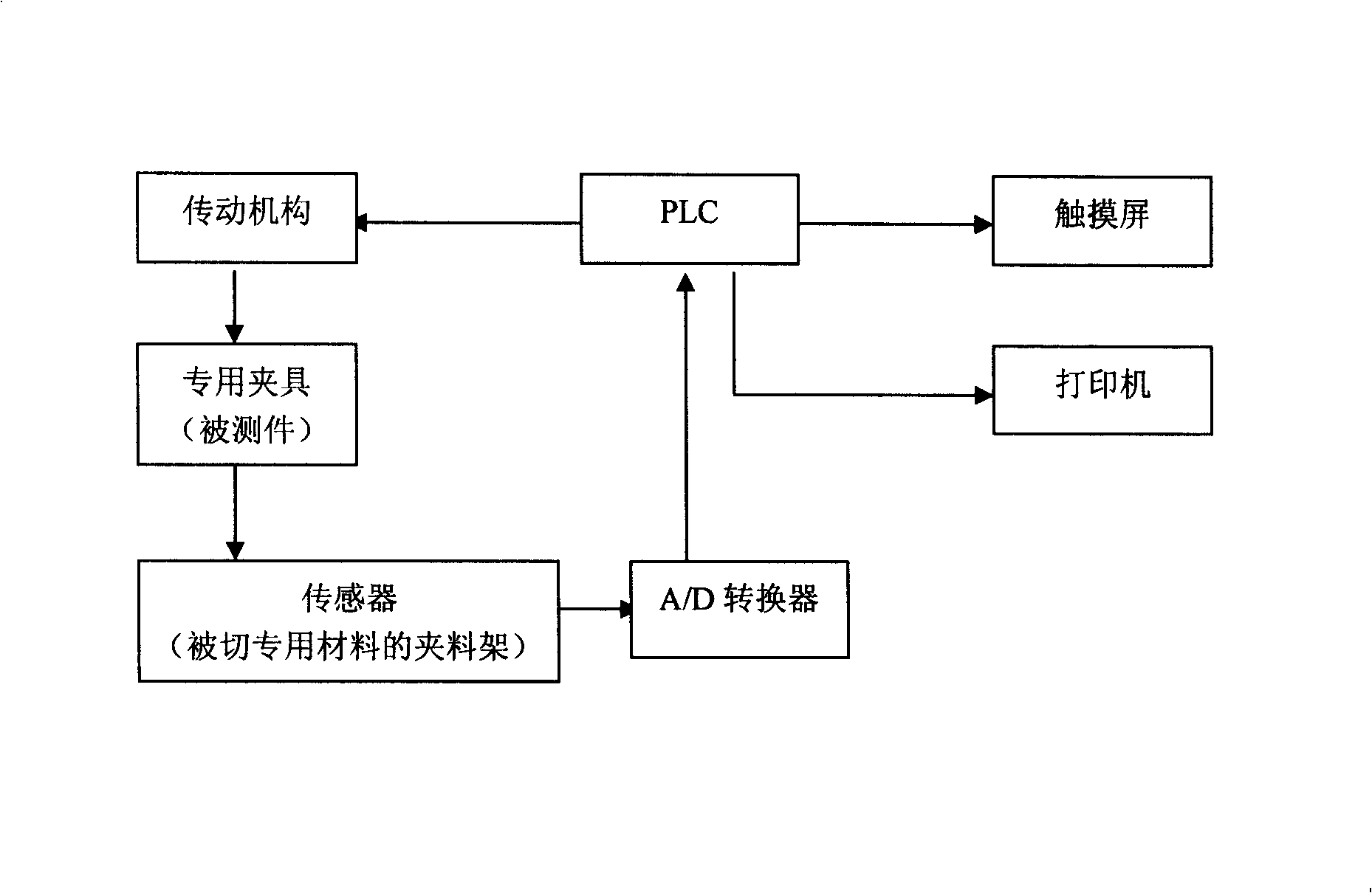

Tester for tartness degree of tool cutting edge

InactiveCN101256129AEasy to useImprove reliabilityInvestigating machinabilityMeasuring instrumentTester device

The invention relates to a knife quality detection device, particularly relates to a knife edge sharpness tester. It includes a PLC, an input device, an output device, a transmission mechanism, a special fixture, a kind ofspecial-purpose material equipped with a sensor for being cut, an A / D converter, wherein: the PLC is the kernel component, which is used for receiving command inputted from the input device to control the transmission mechanism and the special fixture for carrying out the cutting movement, then for receiving the signal converted by the A / D from the sensor, then outputs the tested value from the output device. The device can display the needed value and the cutting-off force curve when the knife cuts off special-purpose material, the measure equipment is a reliable, has accurate data, can make magnitude evaluation of the knife edge sharpness, and is convenient to use. The special fixture is mounted for testing and evaluating the shearing force of scissor. Compared with original artificial subjective test and judgment, the obtained test result is more objective and accurate.

Owner:SHANGHAI HENGYI PHARMA EQUIP

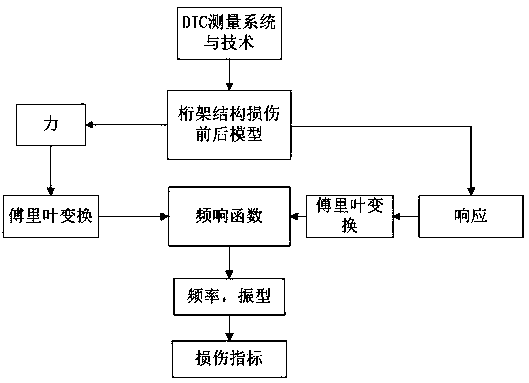

DIC-(Digital Image Correlation)-technique-based curvature modal damage recognition method

ActiveCN109115877ASolve usabilitySolve problems in engineering practiceAnalysing solids using sonic/ultrasonic/infrasonic wavesForce curvesCorrelation analysis

The invention discloses a DIC-(Digital Image Correlation)-technique-based curvature modal damage recognition method. The method comprises the following steps of S1, applying a dynamic hammer excitation to a model of a truss structure, shooting an initial truss structure and the truss structure, to which the hammer excitation is applied, respectively by utilizing a DIC technique, so as to obtain time-sequence images of the deformation of the truss structure, meanwhile, measuring time-interval signals of the hammer excitation by utilizing a dynamic and static acquisition instrument, so as to obtain an exciting force curve, and carrying out correlation analysis treatment on the time-sequence images, so as to obtain a displacement curve; S2, enabling the obtained displacement curve and exciting force curve to correspond in accordance with a time order, importing into a dynamic signal test and analysis system, so as to obtain a frequency response function, and deriving the inherent frequency and the vibration modal of the truss structure according to the frequency response function; and S3, after the inherent frequency and the vibration modal are obtained, acquiring a difference value by using curvature modals to obtain a difference-value index of the curvature modals, and determining a difference between the curvature modals, before and after the deformation, of the truss structure, so as to judge whether the damage is generated to the truss structure, to position the damage and to judge the extent of the damage.

Owner:GUANGDONG UNIV OF TECH

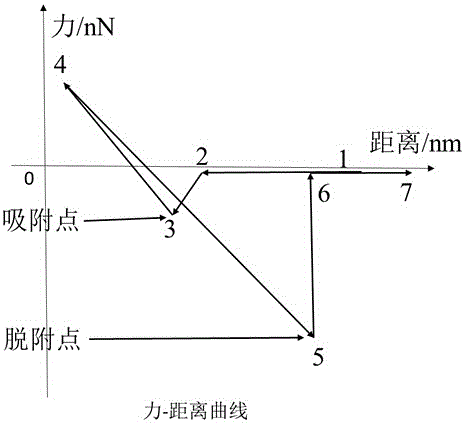

Method for detecting carbon material surface activity based on AFM tip force curve

InactiveCN106324290AStrong theoretical significanceStrong practical valueScanning probe microscopyDesorptionEngineering

The invention discloses a method for detecting carbon material surface activity based on an AFM tip force curve. The method comprises the steps that S1 a specific macromolecular modified AFM tip is adopted; S2 a detection sample is prepared; S3 a force curve is measured; and S4 the values of absorption force and desorption force are obtained according to the force curve obtained in the step S3. The specific macromolecular modified AFM tip is utilized so that quantitative measurement of surface absorption and desorption force of carbon black, graphene, nano-diamond, crystalline flake graphite and other carbon materials can be realized, and thus the foundation is laid for establishing an evaluation system for the reinforcing property of the carbon materials and macromolecular materials.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

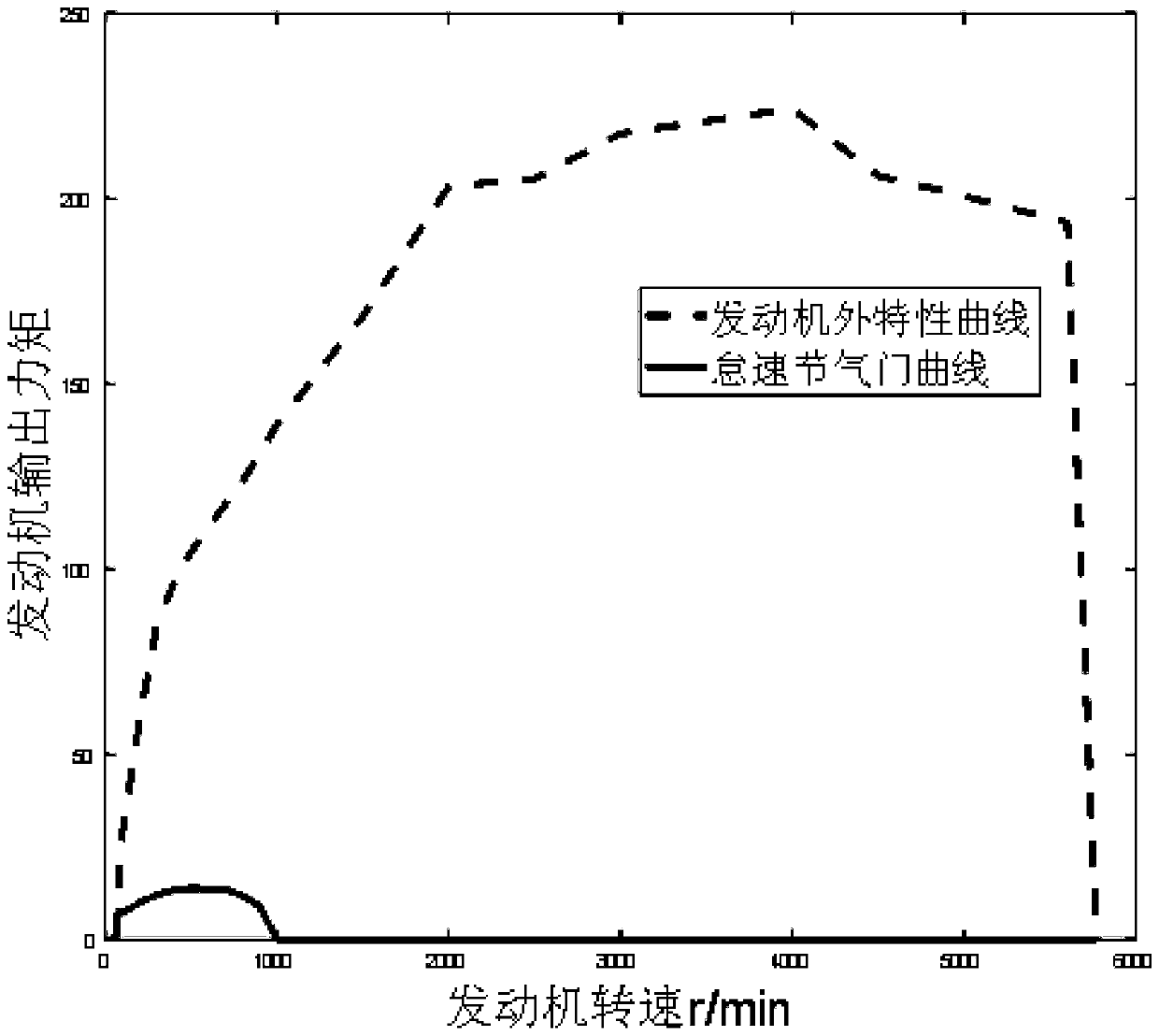

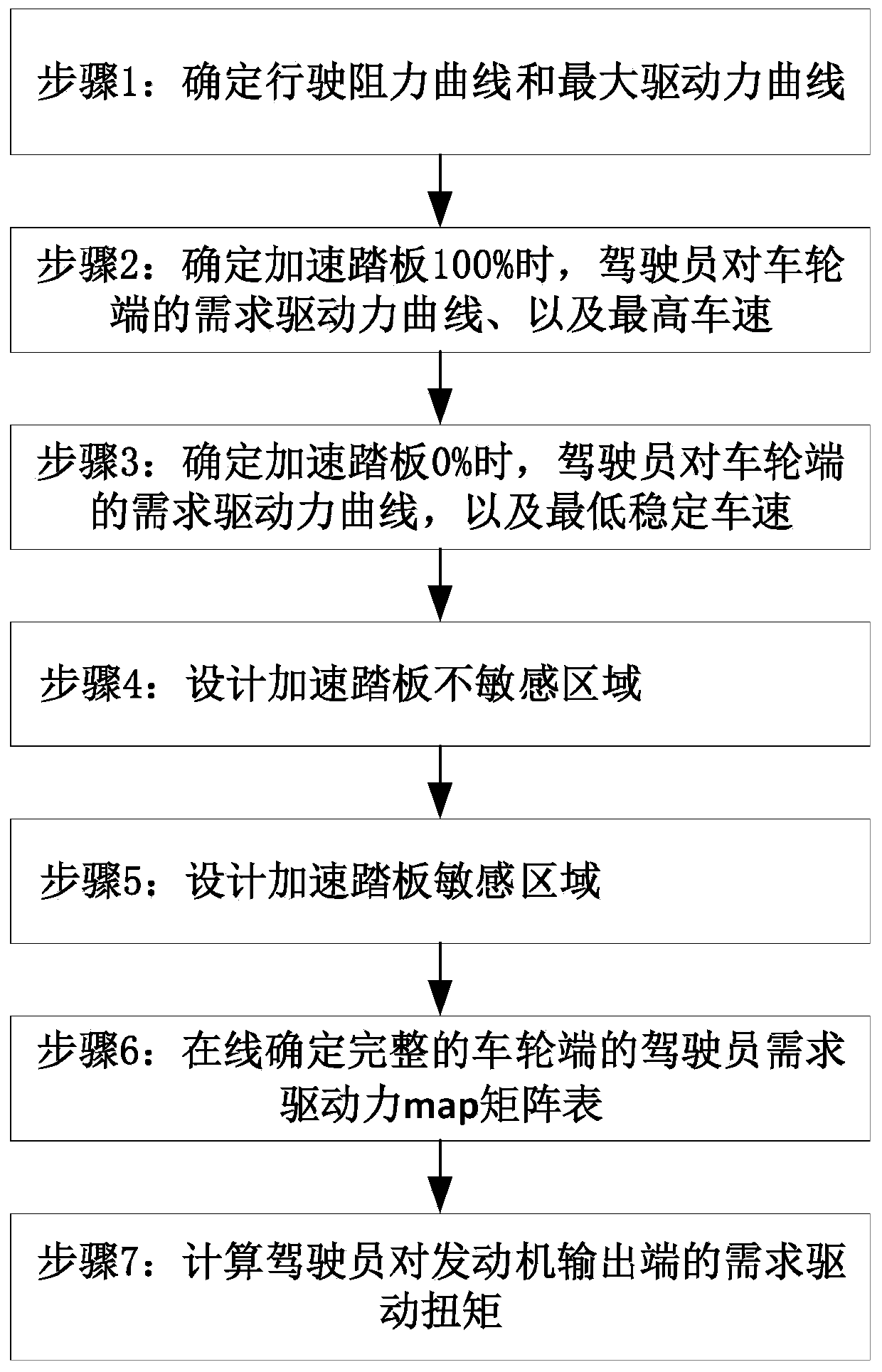

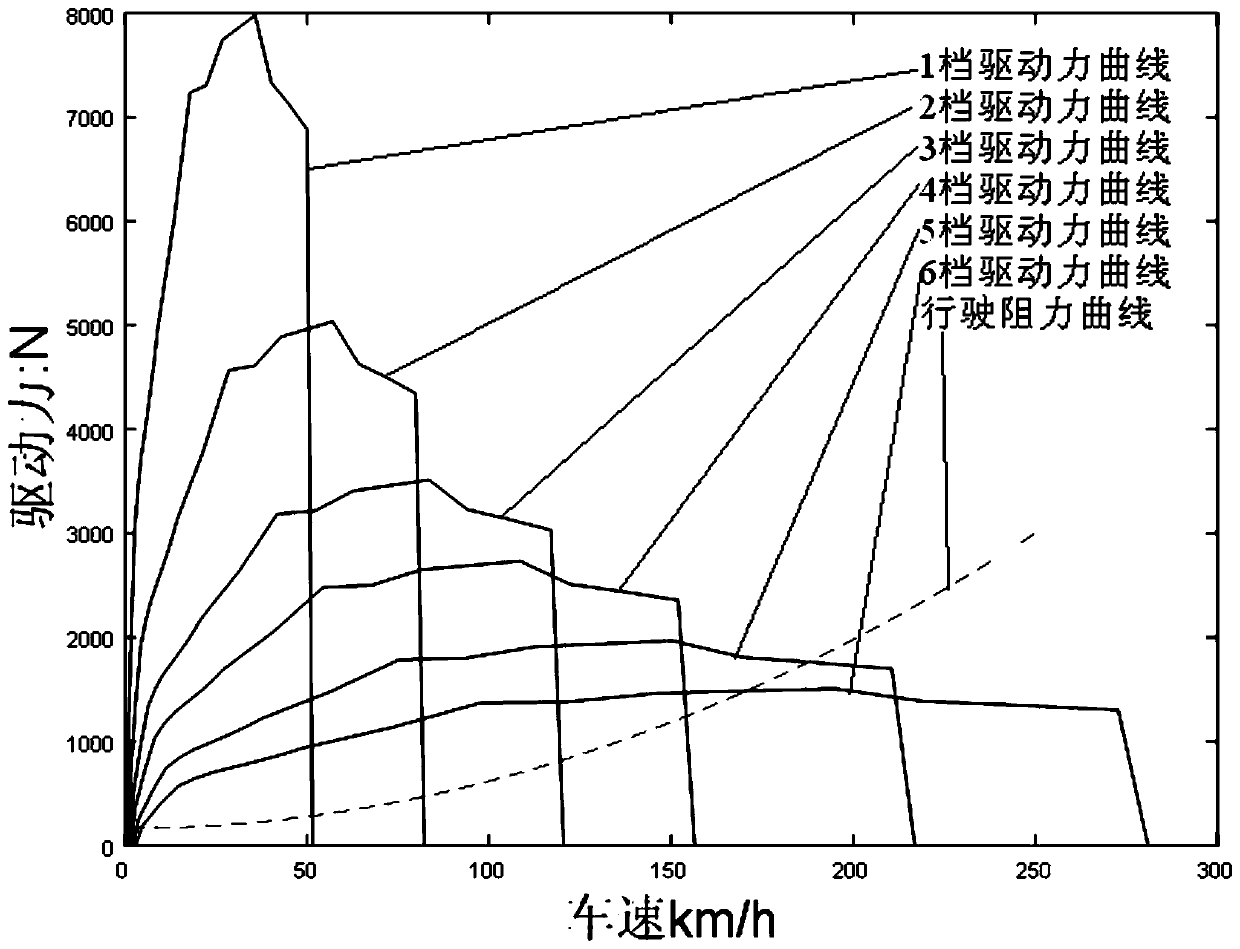

Online determination method for drive torque required by driver

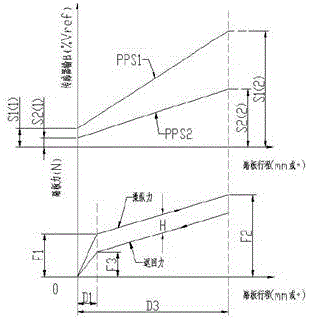

ActiveCN110154784ASolve the problem of poor speed controllabilityAvoid time costSpeed controllerDriver interactionsEngineeringForce curves

The invention relates to an online determination method for drive torque required by a driver and belongs to the technical field of calibration of the drive torque required by a whole vehicle. The method comprises the steps of determining a traveling resistance curve and the largest drive force curve, determining the request curve of drive force required by the wheel end and the highest vehicle speed when an acceleration pedal is 100%, designing an insensitive area and a sensitive area of the acceleration pedal, determining the complete map matrix table of drive force required by the driver ofthe wheel end online, and calculating the required drive torque of the driver to the output end of an engine. The described online determination method for the drive torque required by the driver issimple and practical, calibration of an off-line driver required drive toque map table is not needed, and the development time and cost of the whole vehicle are shortened and reduced. According to themethod, by planning the sensitive area and the insensitive area of the pedal online, acceleration / reduction and vehicle speed easy control performance of a car in various traveling environments is ensured, and the driving quality of the car is effectively improved.

Owner:JILIN UNIV

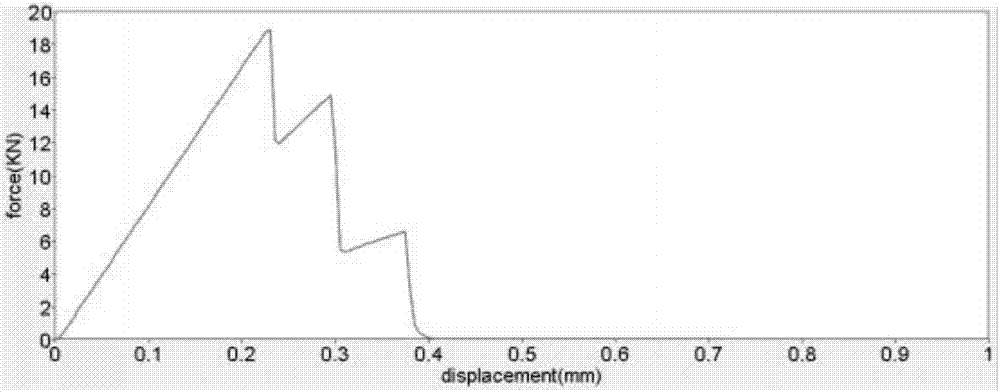

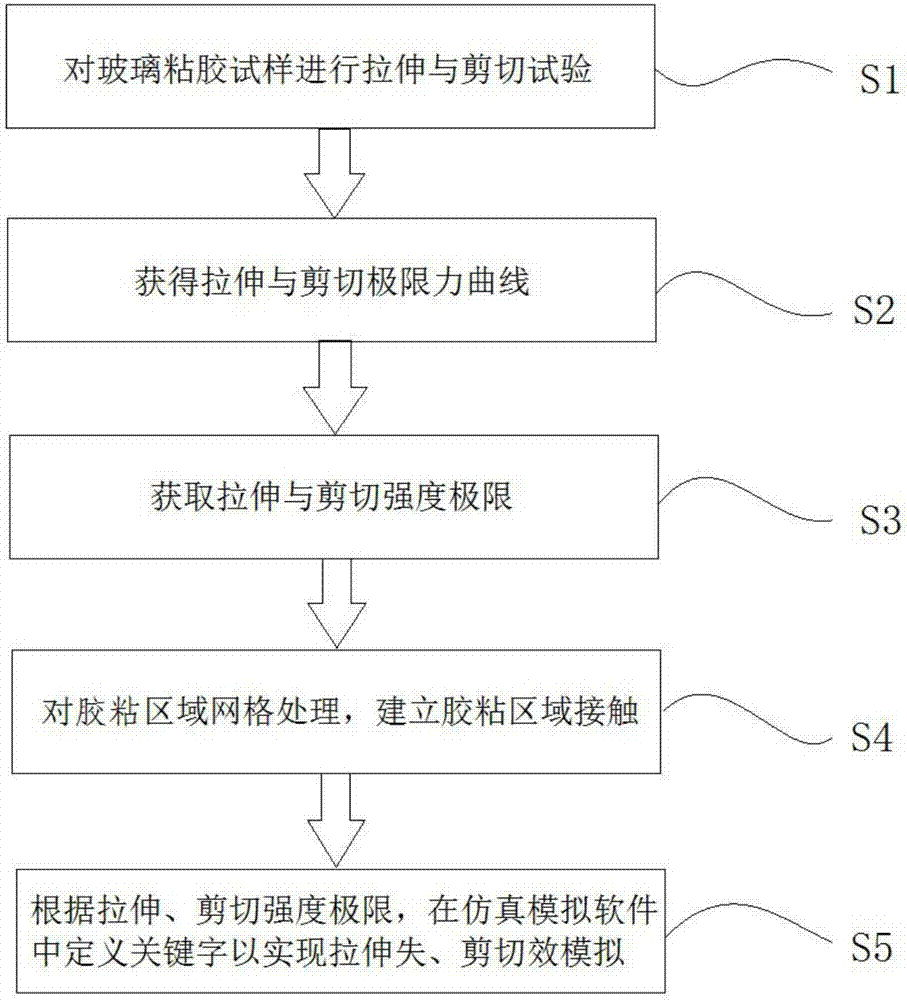

Method for performing simulated analysis on glass glue failure

InactiveCN107202756AFit closelyDeformation mode is smallUsing mechanical meansMaterial analysisTest sampleSimulation

The invention relates to the technical field of simulated analysis, in particular to a method for performing simulated analysis on glass glue failure. The method is characterized by comprising the following steps: S1, performing tensile and shear test on a glass glue test sample; S2, obtaining a tensile and shear limiting force curve through the test; S3, obtaining tensile and shear strength limit through the above limiting force curve; S4, according to the tensile and shear strength limit, defining keywords in simulated software to realize tensile and shear failure simulation. According to the method for performing simulated analysis on glass glue failure, provided by the invention, the glass glue failure condition is subjected to simulated analysis, so that the failure of the glass glue connection in the whole vehicle collision simulation can be identical to the failure of the glass glue connection in the actual vehicle collision well, the difference between the local deformation mode of the whole vehicle and the test is small, and the simulation accuracy degree is increased.

Owner:JASMIN INT AUTO RES ANDDEV BEIJING CO LTD

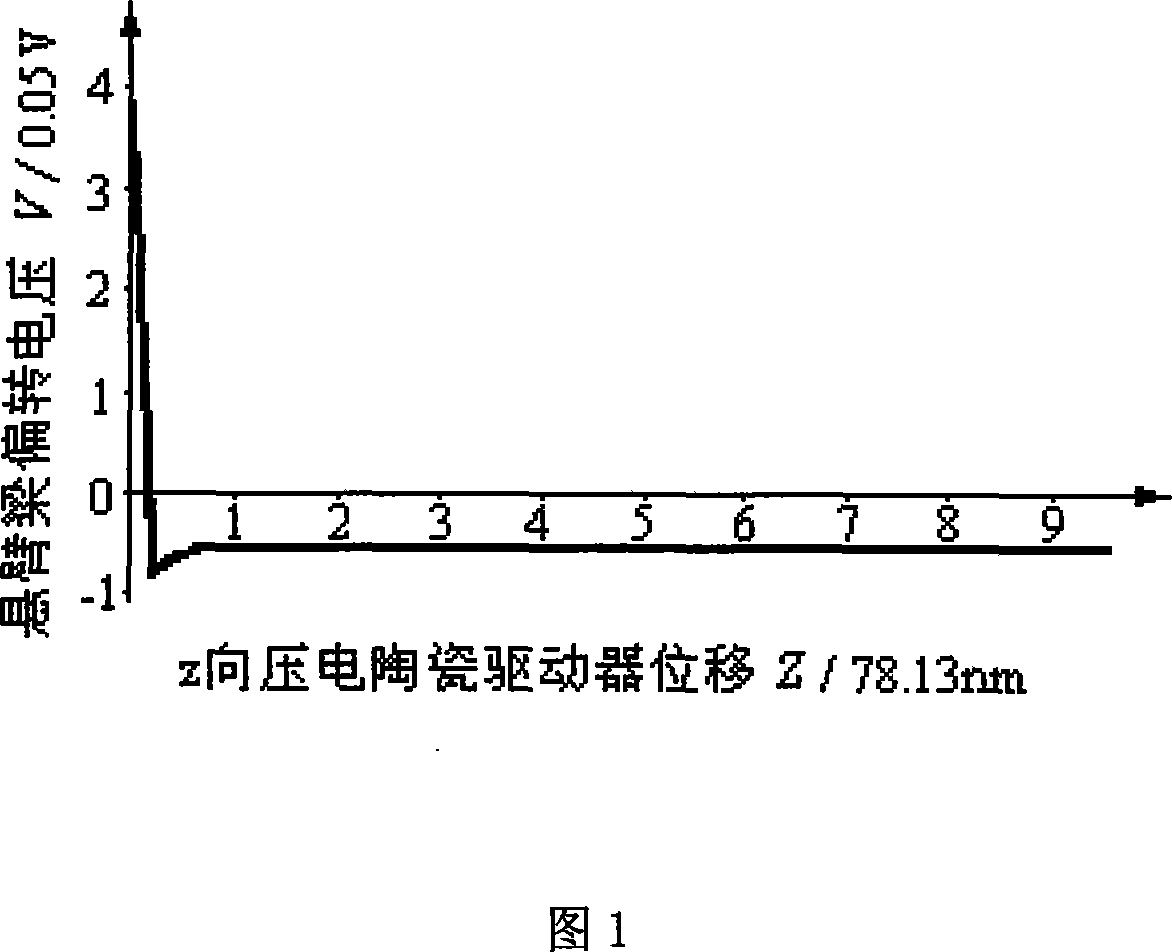

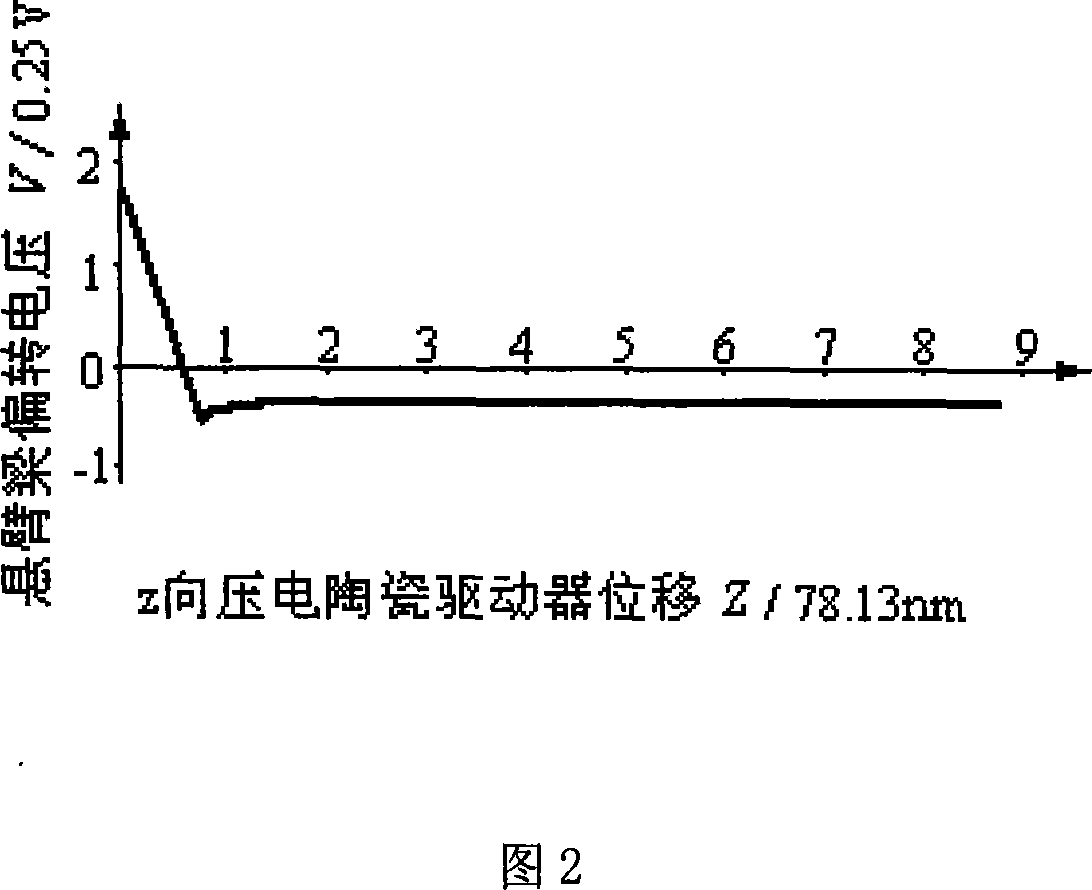

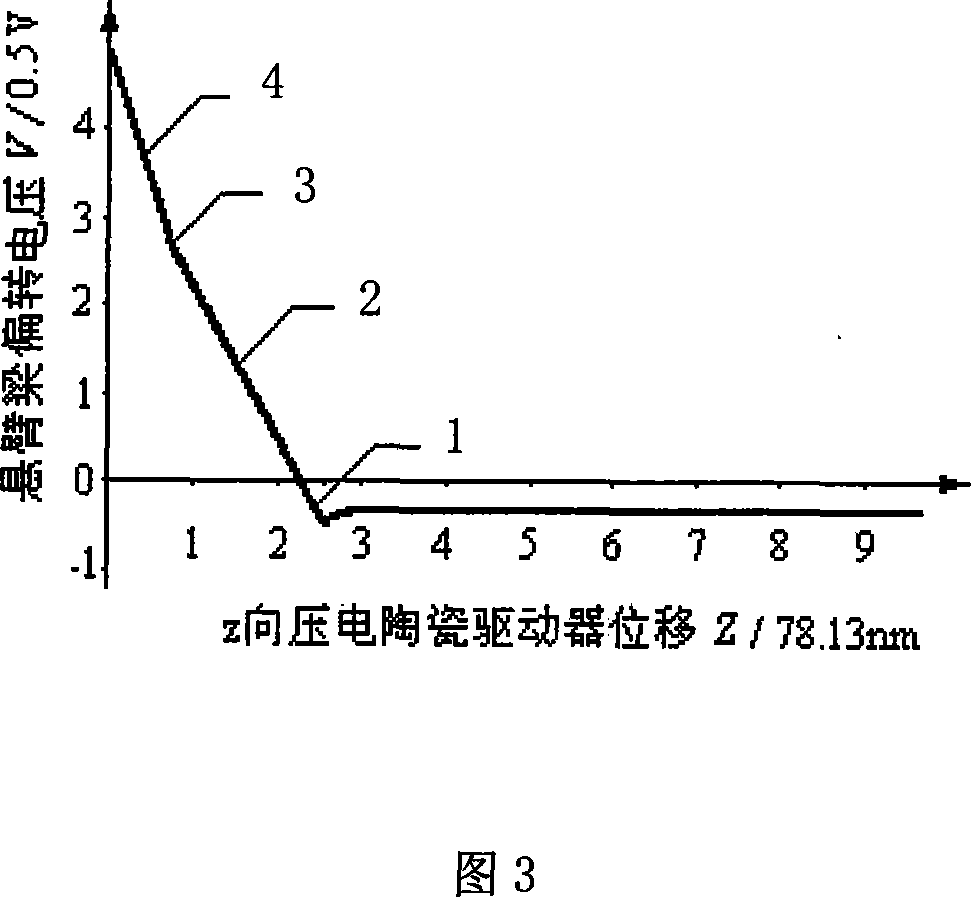

Intraocular tension testing device

InactiveCN101822528ALong range measurement requirementsNon-invasive measurement requirementsTonometersPhysical medicine and rehabilitationIntraocular pressure

The invention discloses an intraocular tension testing method and an intraocular tension testing device based on a magnetic interaction. The method comprises the following steps: (1) wearing a corneal contact lens embedded with an inner magnetic disk to make the inner magnetic disk closely contact with the corneas; (2) placing another outer magnetic disk in front of the eyes perpendicular to the inner magnetic disk to make the two magnetic disks form a mutually repulsion force field; and (3) with the movement of the outer magnetic disk, picking up a repulsive force curve by a pressure sensor, and calculating the intraocular tension value through the inflexion point or the slope change of the curve. In the technical scheme of the invention, the outer magnetic disk is driven to move forward or backward by a built-in straight-line motion mechanism to adjust the repulsive force between the outer magnetic disk and the inner magnetic disk so as to realizing pressure application without contacting, and the measuring head can not directly contact with the eyeballs, thereby causing no pain; the invention does not require the testing of a doctor, the patient can operate individually, and the device can automatically calculate and store the measured intraocular tension value. When the invention is used, the intraocular tension can be tested by the method of calculating and obtaining the intraocular tension value through the curve of the repulsive force between the inner magnetic disk in the corneal contact lens and the moving outer magnetic disk, and the testing result can be accurate and reliable by performing the intraocular tension testing for five times and taking the average value.

Owner:HUAZHONG UNIV OF SCI & TECH

Non-destructive measurement method of nanometer cantilever thickness based on force curve of atomic force microscope

InactiveCN101046374ARealize precise measurementAccurate measurementSemi-permeable membranesMeasurement devicesNon destructiveForce curves

The non-destructive measurement method of nanometer cantilever thickness based on force curve of atomic force microscope includes the first scanning measurement to obtain the 3D topographic information of the nanometer cantilever area and the distance between the upper surface and the base of the nanometer cantilever; the subsequent reducing the scanning range to locate the probe of the atomic force microscope precisely and to load and unload vertically with the probe until the lower surface of the nanometer cantilever contacts with the base and the force curve exhibits turnover, and recording the real-time force curve of the atomic force microscope during loading and unloading to obtain the distance between the lower surface and the substrate of the nanometer cantilever; and finally subtracting the data obtained in the foregoing steps to calculate the nanometer cantilever thickness. The said method may be also used in measuring other dimensions of nanometer structure.

Owner:TIANJIN UNIV

Simulating method for flying process of aircraft

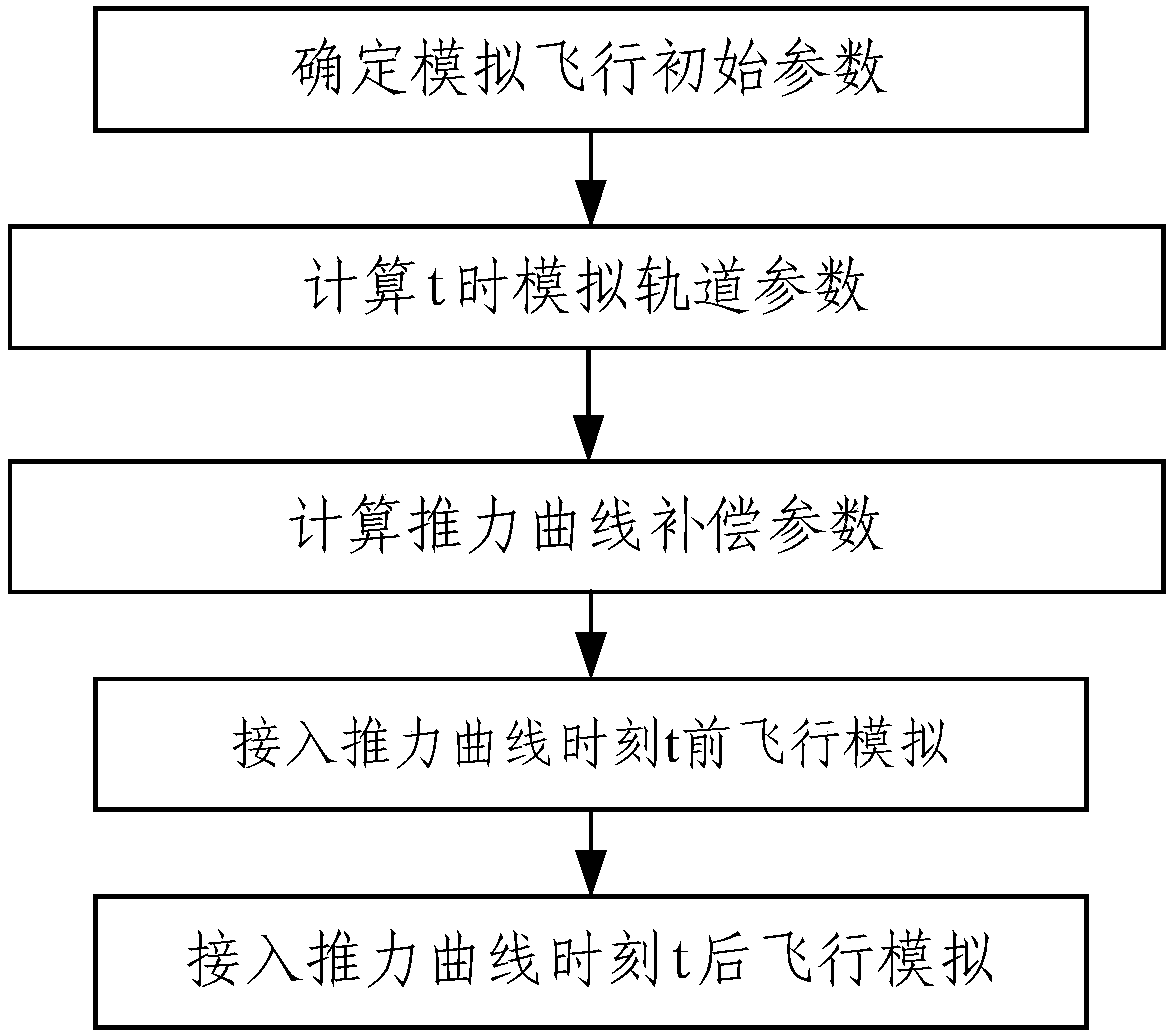

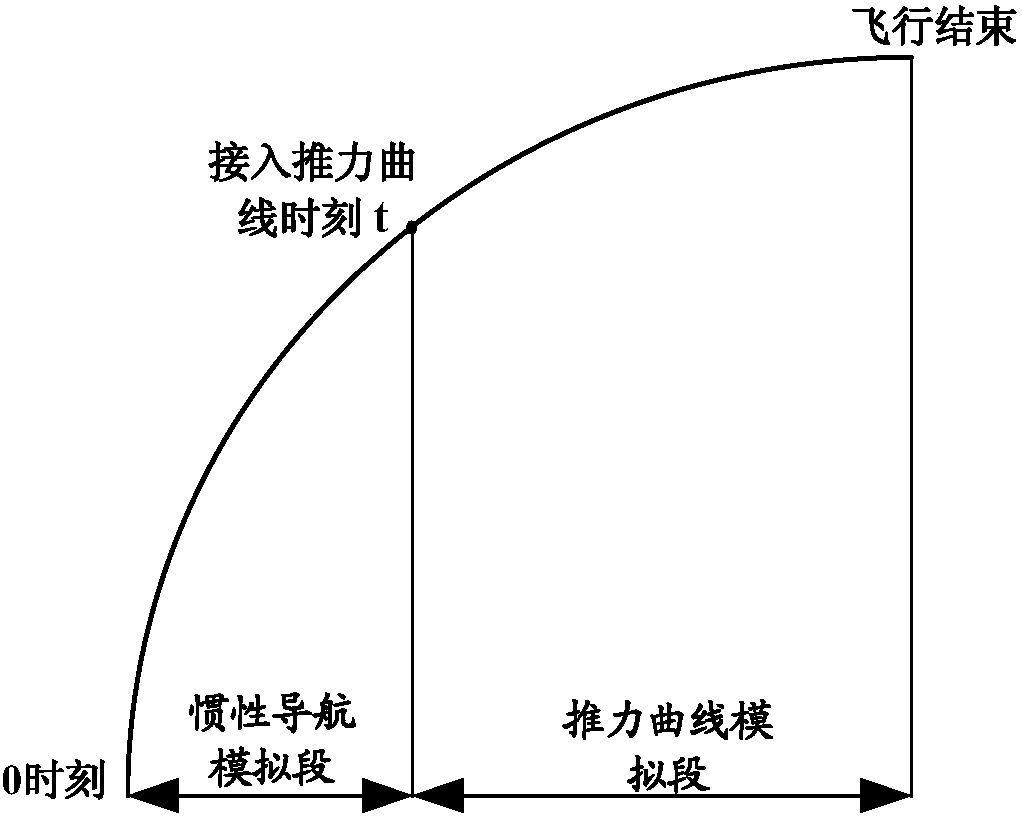

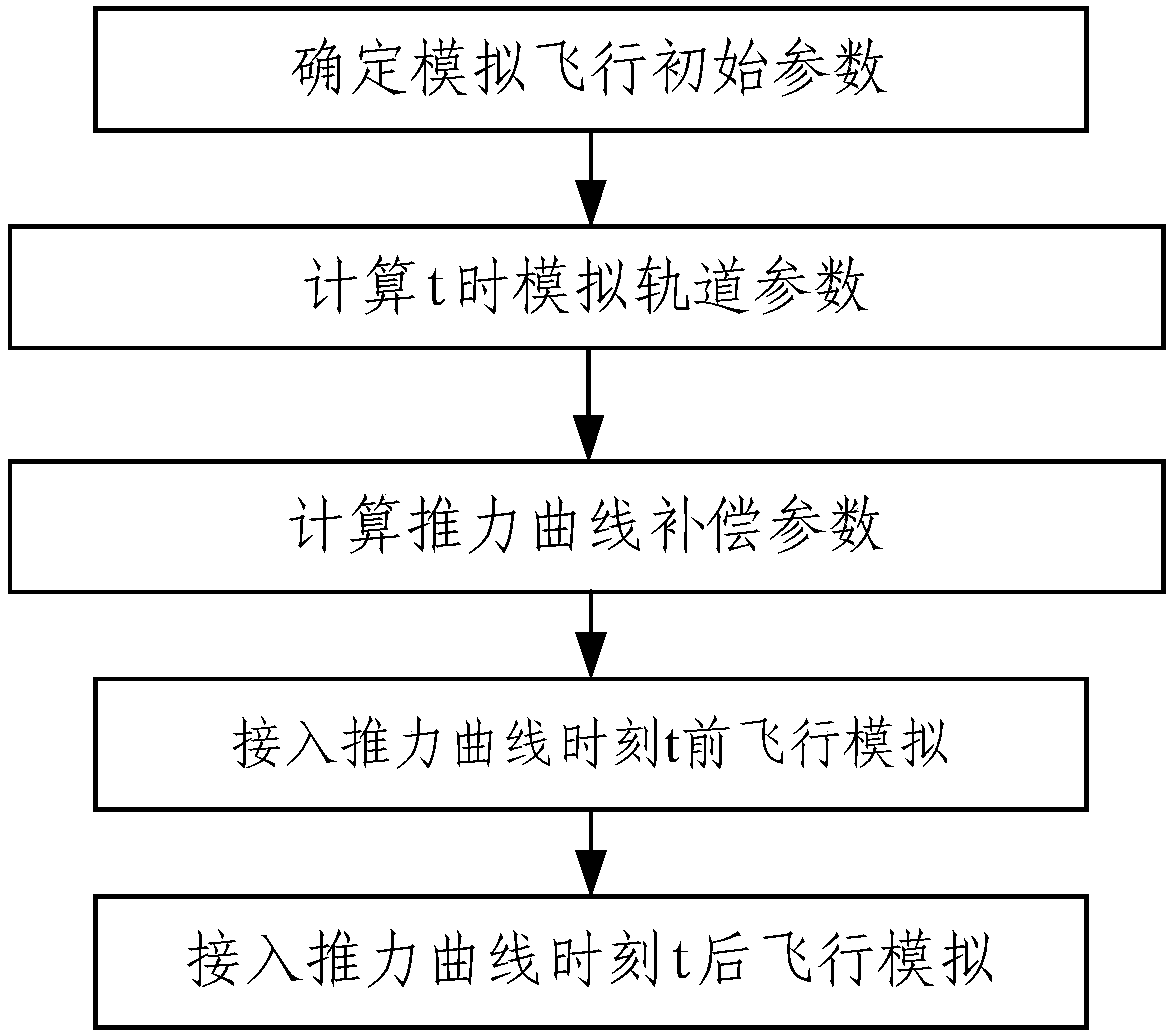

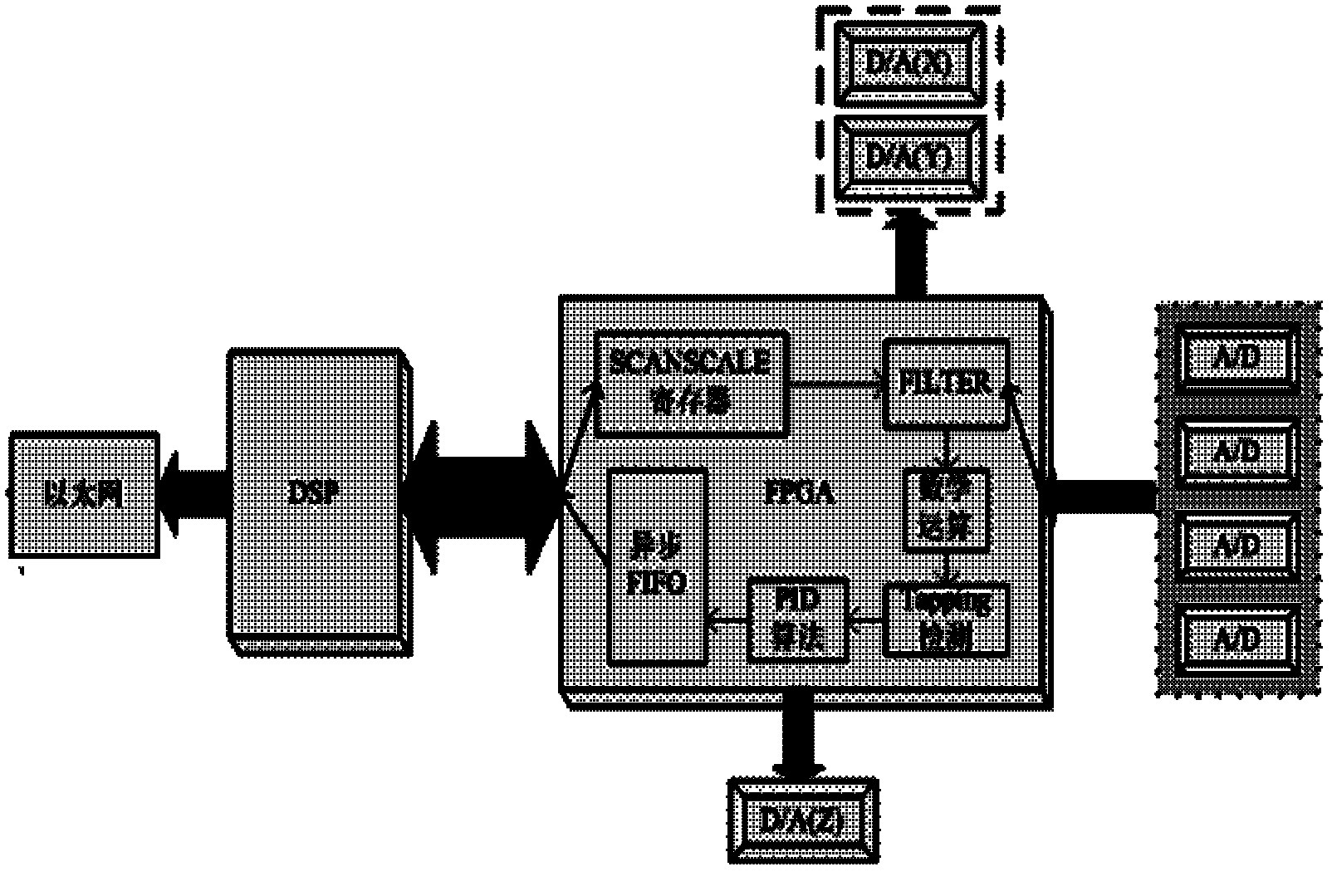

ActiveCN107063244AThe ground test is true and reliableSimple calculationNavigation by speed/acceleration measurementsGyroscopeAccelerometer

The invention relates to a simulating method for a flying process of an air craft. The simulating method comprises the following steps: obtaining initial parameters of a secondary starting moment t of a standard orbiting aircraft; performing navigation computation to obtain inertial navigation parameters of the moment t; calculating propelling force curve compensation parameters of the moment t; performing inertial navigation computation by utilizing gyroscope data of the inertial navigation equipment and data output by an accelerometer in real time, and simulating orbital data from 0 to moment t; obtaining the parameters of the moment t, performing compensation and taking the parameters as initial parameters of a propelling force curve section, performing inertial navigation computation until flying is ended, and obtaining the orbital data from the moment t to the flying ending section, thereby completing flying simulation after a propelling force curve is accessed. According to the simulating method, true inertial group data is adopted to perform inertial navigation simulation before the secondary starting moment, and propelling force curve stimulation is adopted after the secondary starting moment, so that the true rail can be stimulated, true inertial unit characteristics are reflected, error conditions in practical flying is closer, and therefore, ground test is more true and reliable.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

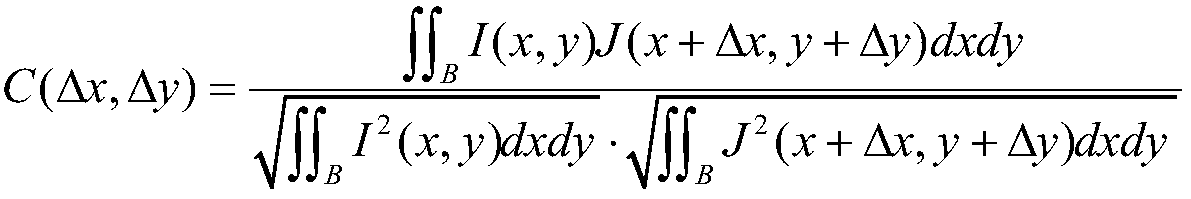

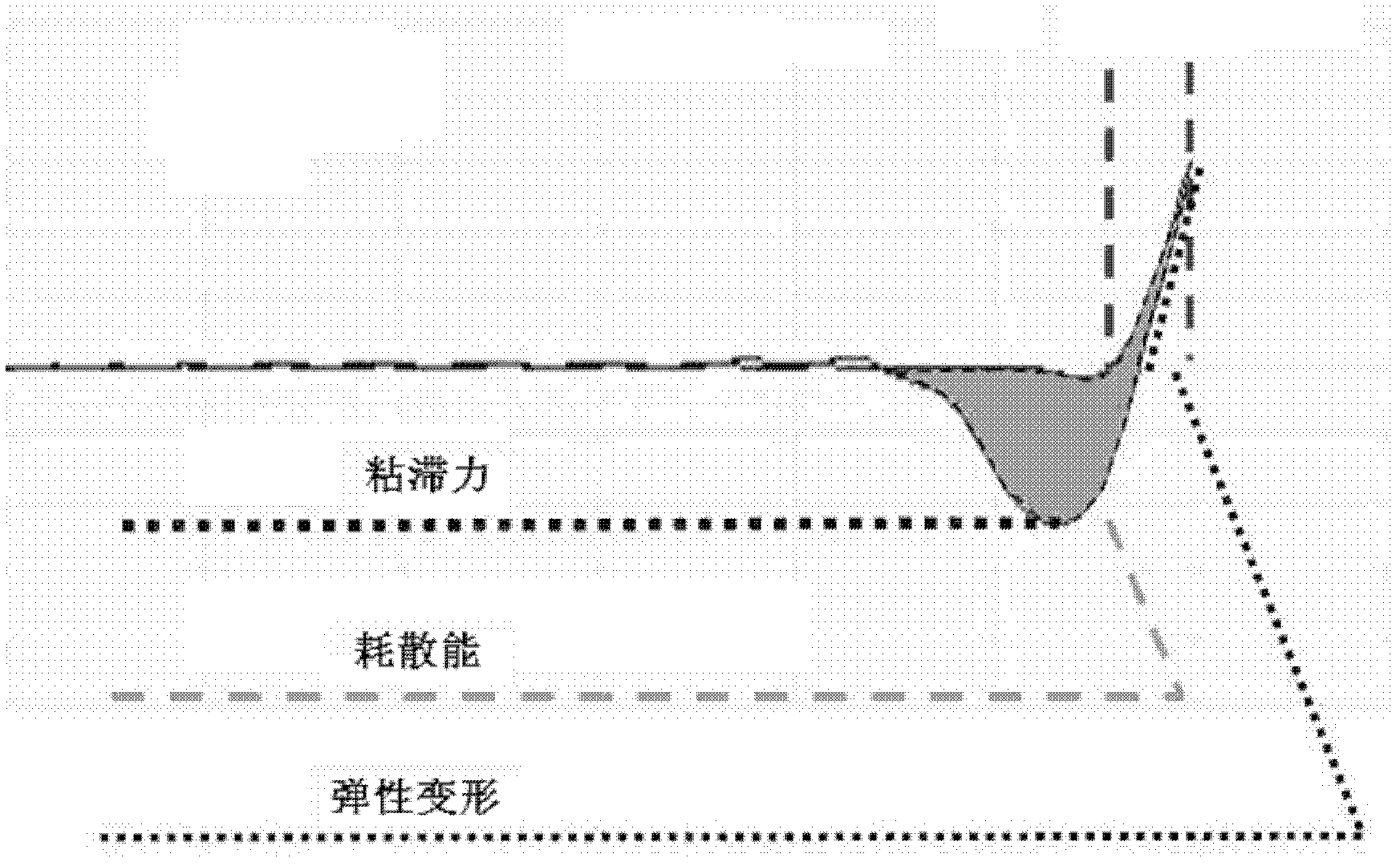

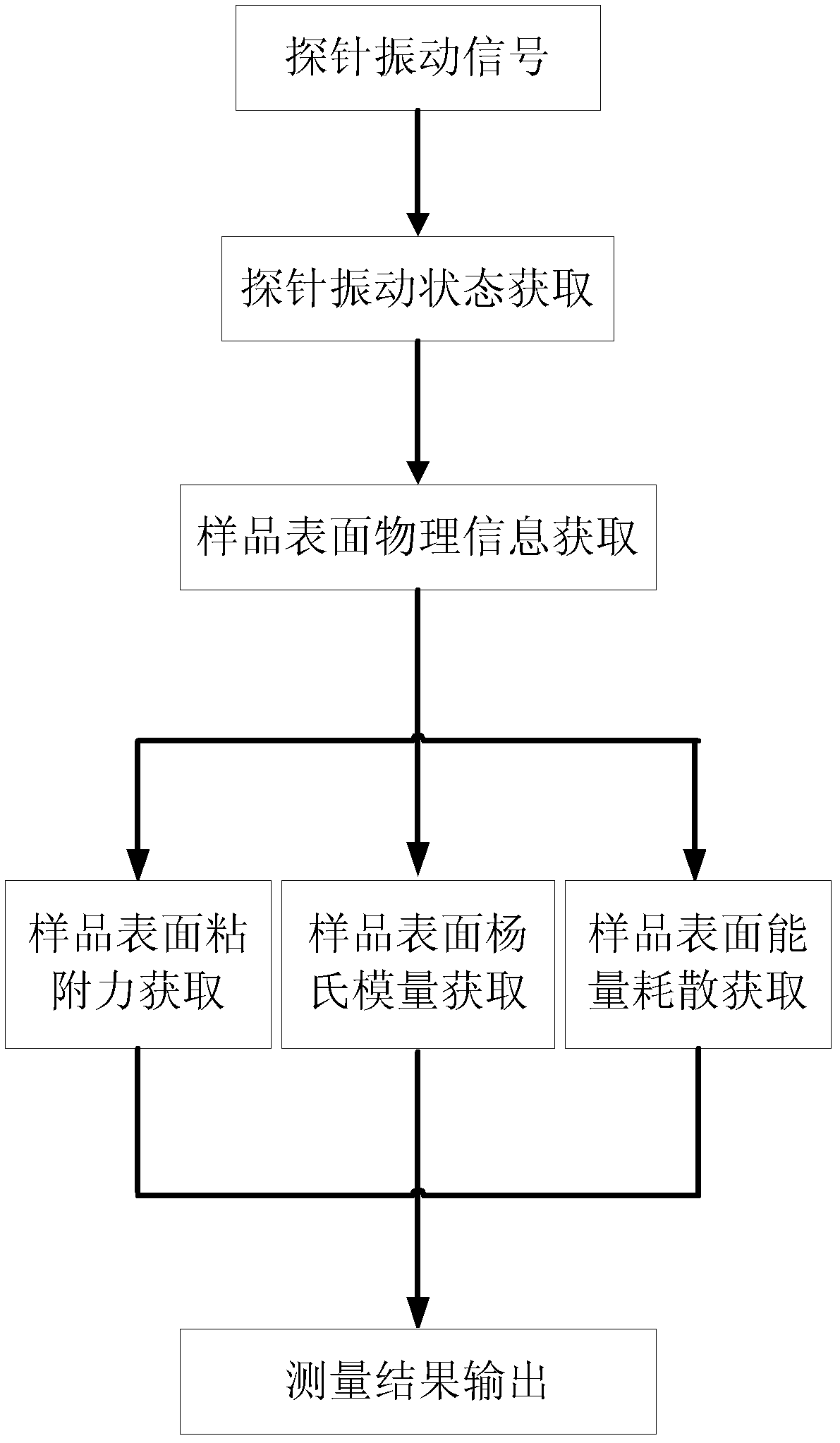

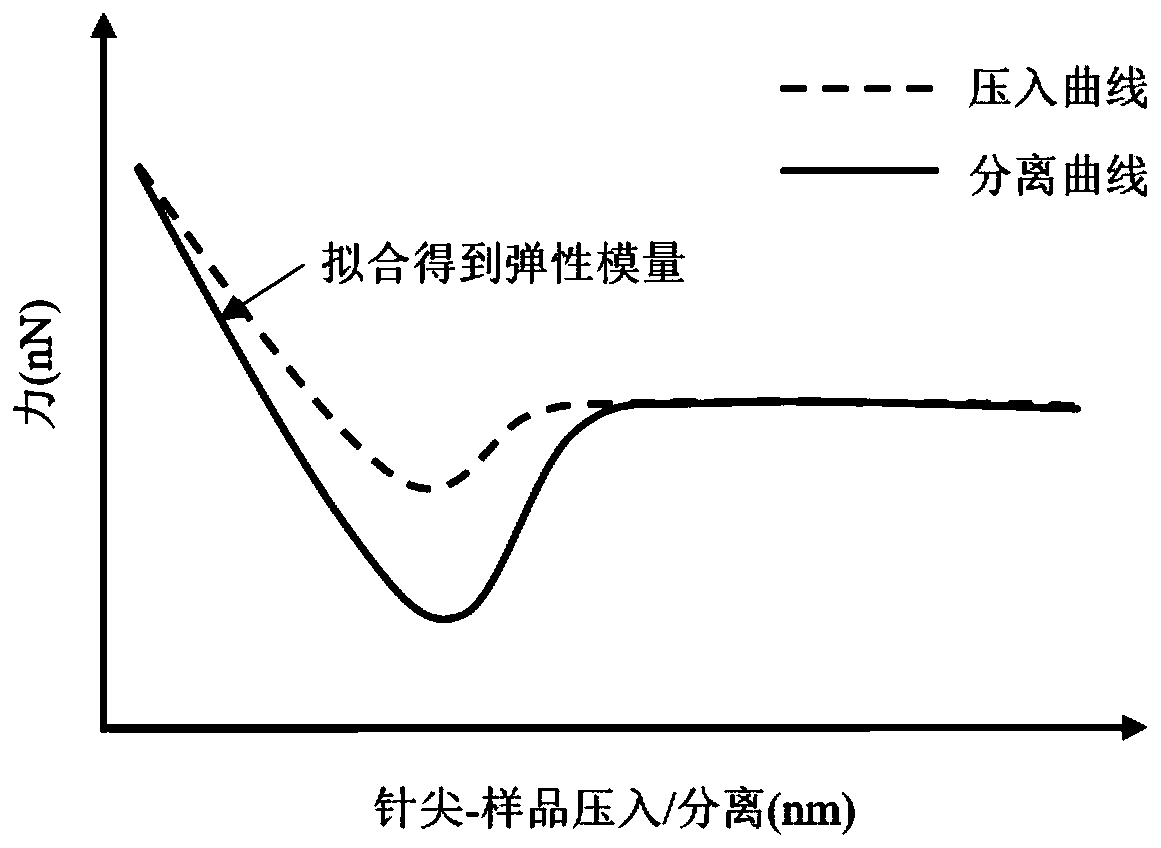

Physical property measurement system and method for material based on probe force curve

The invention discloses a physical property measurement system and a method for a material based on an AFM (atomic force microscope) probe force curve. According to the method, a high-speed and high-precision digital acquisition card and a digital controller are adopted to realize broad-band and high-resolution measurement during a probe force curve testing process. Therefore, a peak force in the probe force curve can be controlled and measured precisely. On the basis of acquiring the force curve, a Hertz contact model and a Derjaguin-Muller-Toporov (DMT) model are used for acquiring appearance information of the surface of a sample, and a power dissipation and force curve area integral method is used for acquiring a viscous force and dissipated energy information of the sample. According to the system and the method, a large amount of information reflecting physical properties of the surface of the sample is included. The application scope of an AFM is expanded greatly, the development of correlational study fields is promoted, and the system and the method have very important scientific values and good application prospects.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

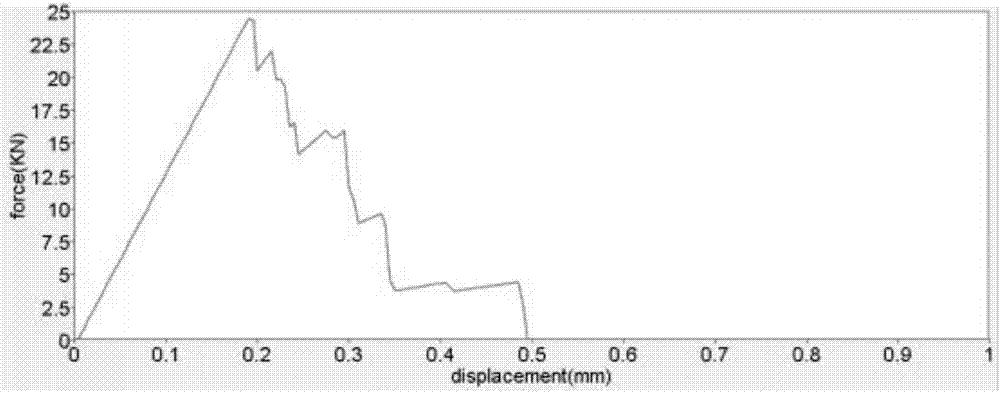

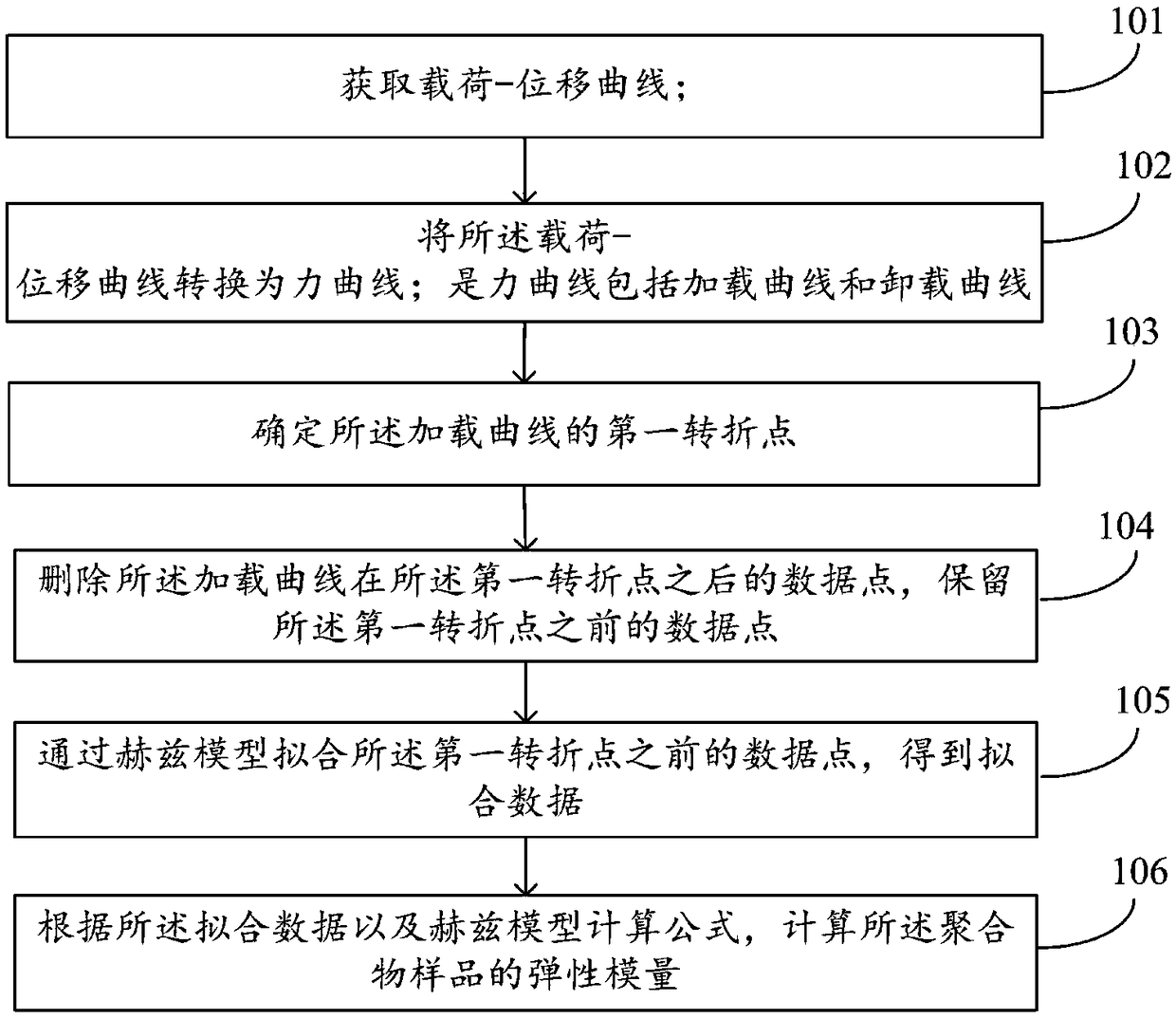

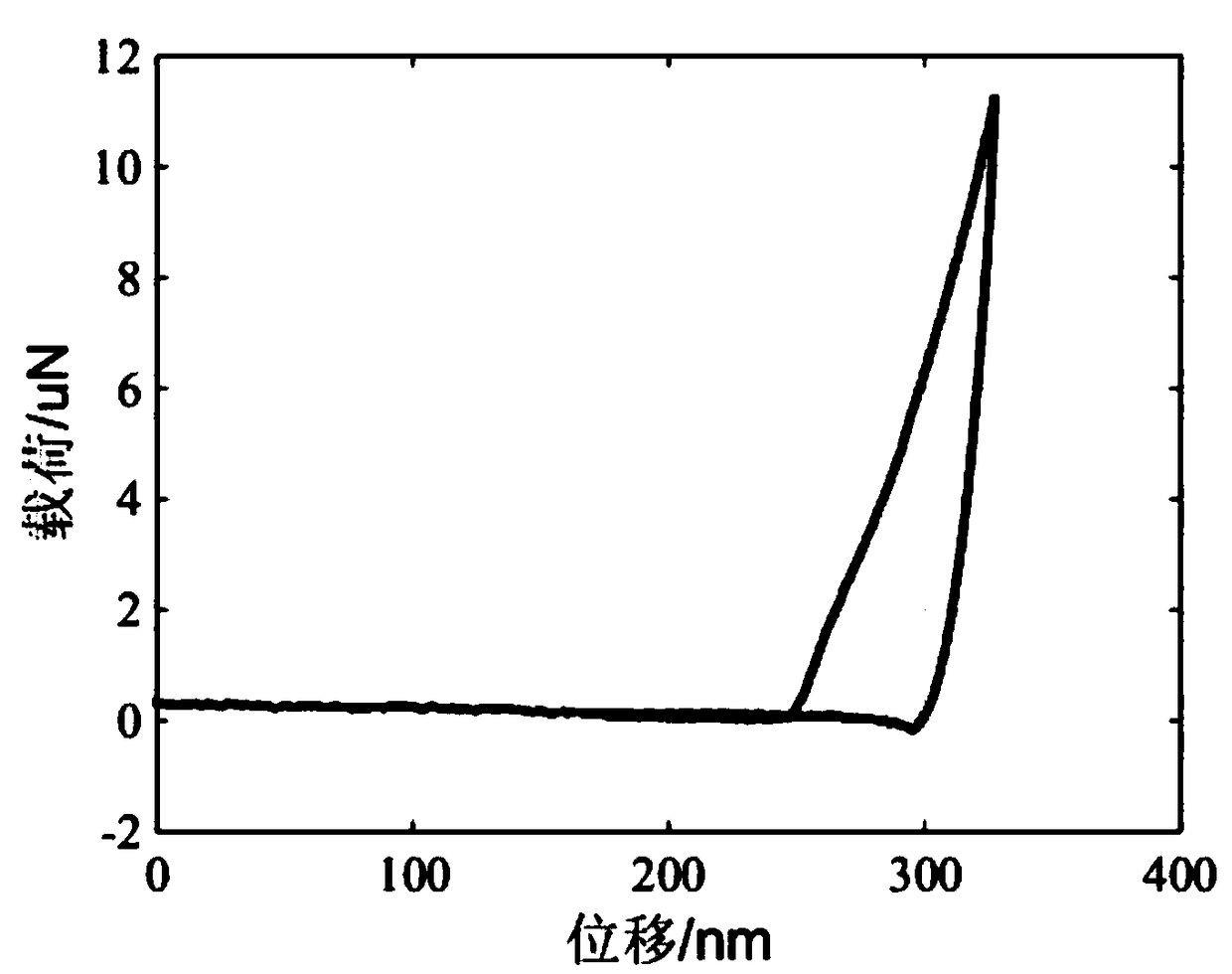

Measuring method and system for elasticity modulus of polymer

ActiveCN109269892AImprove processing efficiencyImprove accuracyMaterial strength using tensile/compressive forcesElectricityComputational physics

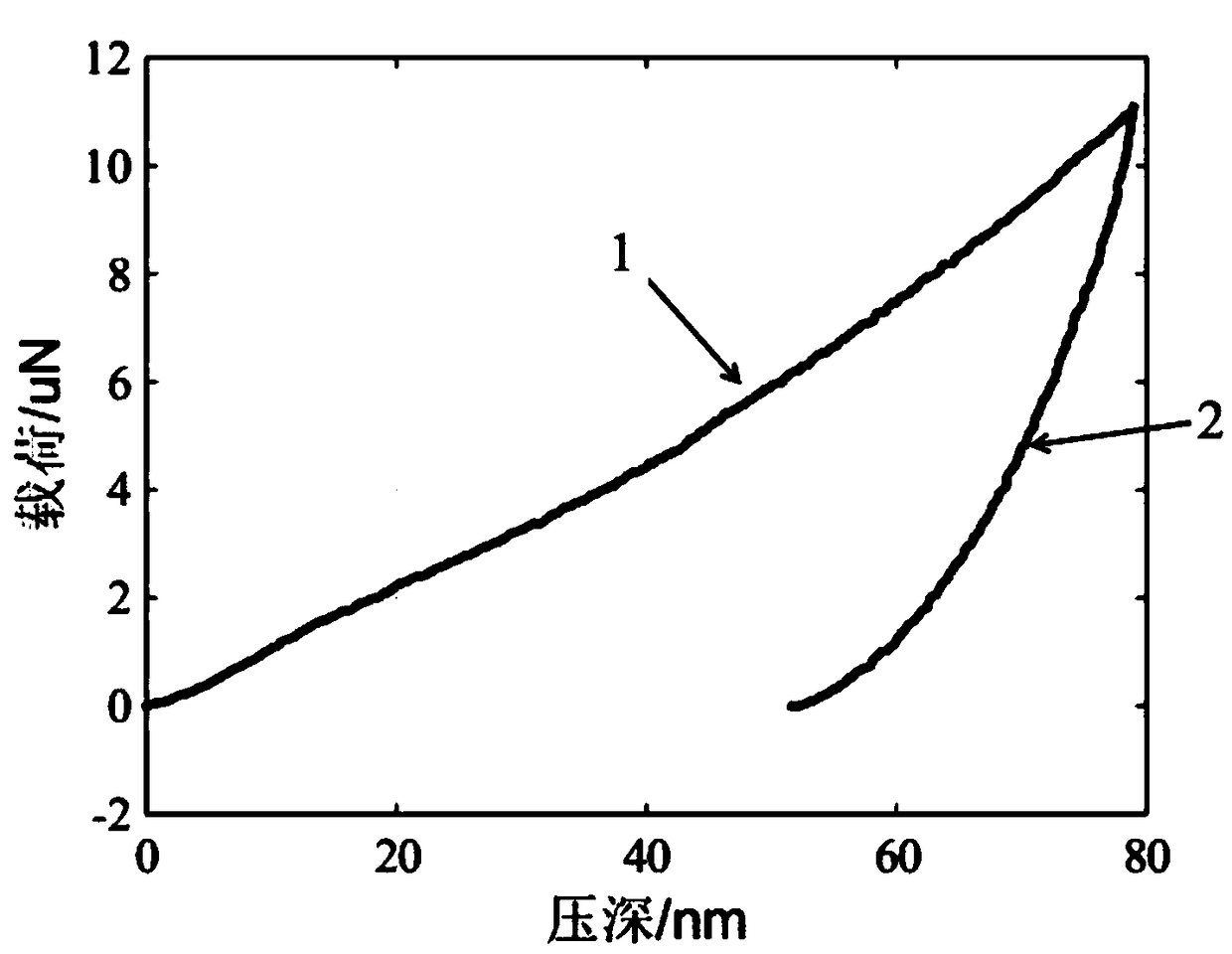

The invention discloses a measuring method and system for elasticity modulus of a polymer. The method comprises the steps that a load-displacement curve is acquired; the load-displacement curve is a change curve of load applied to a probe of an atomic force microscope with displacement of a piezoelectric ceramics scanning pipe when the atomic force microscope is used for conducting a nanoindentation experiment on a polymer sample; the load-displacement curve is converted into a force curve; the force curve comprises a loading curve and an unloading curve; a first turning point of the loading curve is determined; data points behind the first turning point of the loading curve are deleted, and data points before the first turning point of the loading curve are reserved; the data points before the first turning point are subjected to fitting through a hertz model to obtain fitting data; according to the fitting data and a hertz model calculating formula, the elasticity modulus of the polymer sample is calculated. According to the method, the fitting range can be definitely selected, therefore the Hertz model can be conveniently and accurately utilized for conducting fitting on the loading curve, and the obtained elasticity modulus of the polymer can be more accurate after calculation.

Owner:YANSHAN UNIV

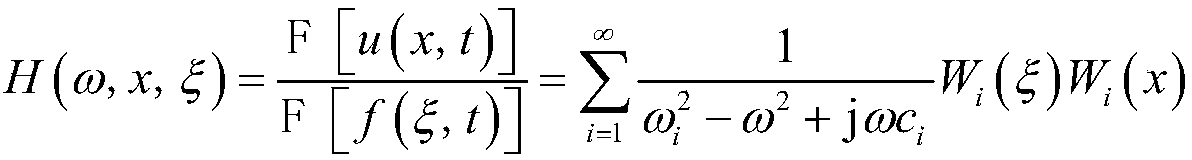

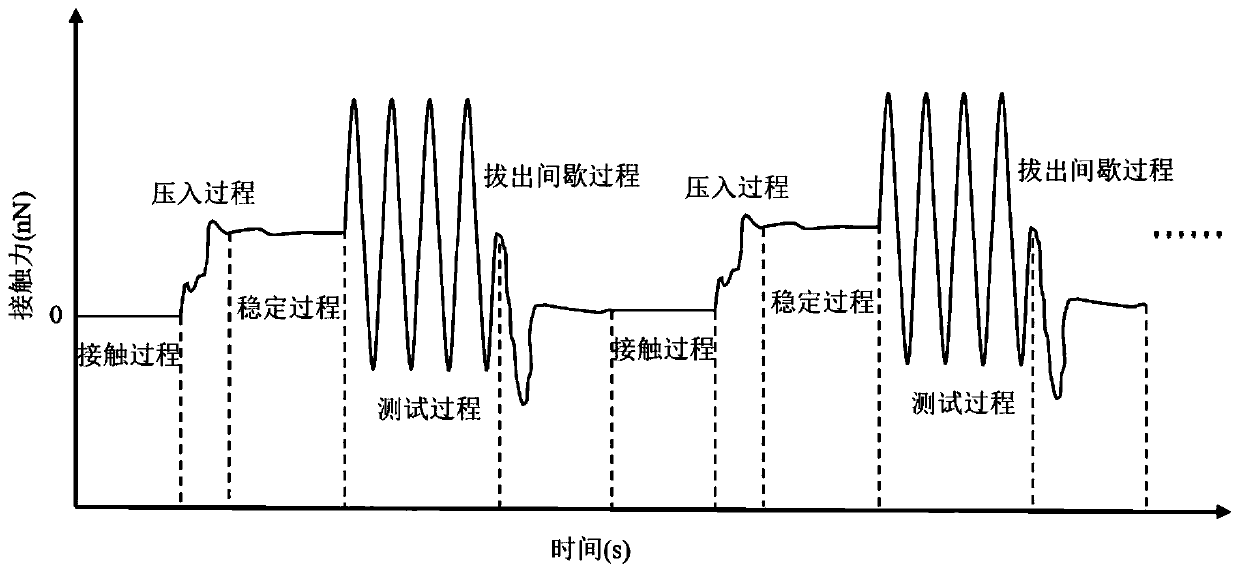

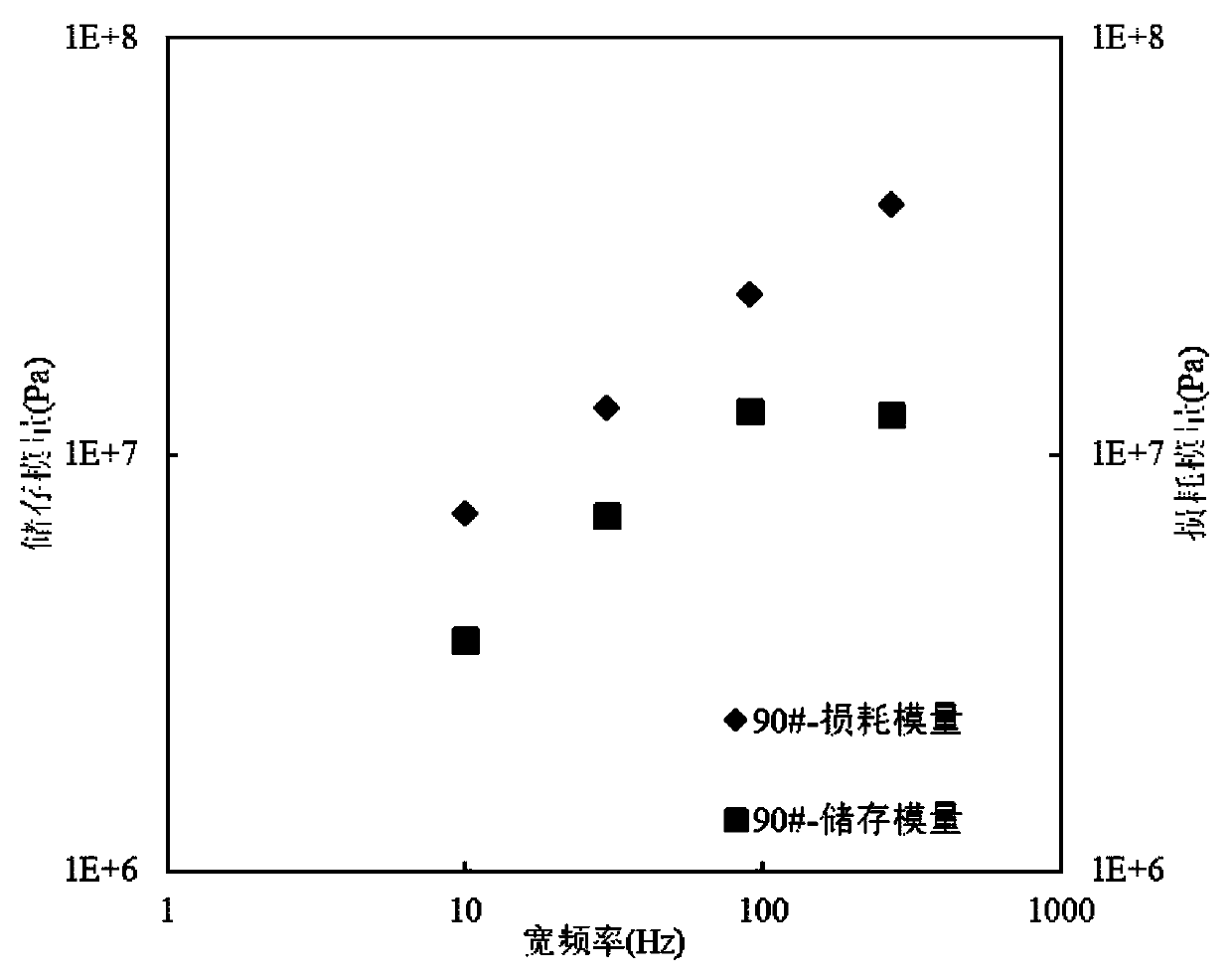

Asphalt microcosmic dynamic rheological property test method

The invention provides an asphalt microcosmic dynamic rheological property test method, and belongs to the field of a asphalt dynamic rheological property test. The asphalt microcosmic dynamic rheological property test method comprises the steps of: firstly, carrying out a common force curve test on an asphalt sample by utilizing an atomic force microscope so as to determine a type of a probe required for the test; then scanning an asphalt microcosmic topography and selecting a test point; controlling the atomic force microscope probe to be pressed into the surface of an asphalt material; whenan acting force between a tip of the probe and the asphalt sample reaches a certain value, keeping the position of the probe unchanged, vibrating inside asphalt under a certain frequency and amplitude and recording a force curve in the vibrating process; and after vibration is finished, lifting up the probe for a certain time until the surface of asphalt is stable, and repeating the steps above under the same amplitude and different frequencies. According to the invention, the microcosmic dynamic rheological property of the asphalt is tested, a microcosmic dynamic viscoelastic parameter of the asphalt can be obtained, and the asphalt microcosmic dynamic rheological property test method is helpful for knowing the microcosmic rheological property of the asphalt and has very important significance for establishing an asphalt microcosmic structure and macroscopic performance relationship and improving asphalt performance test efficiency.

Owner:HARBIN INST OF TECH

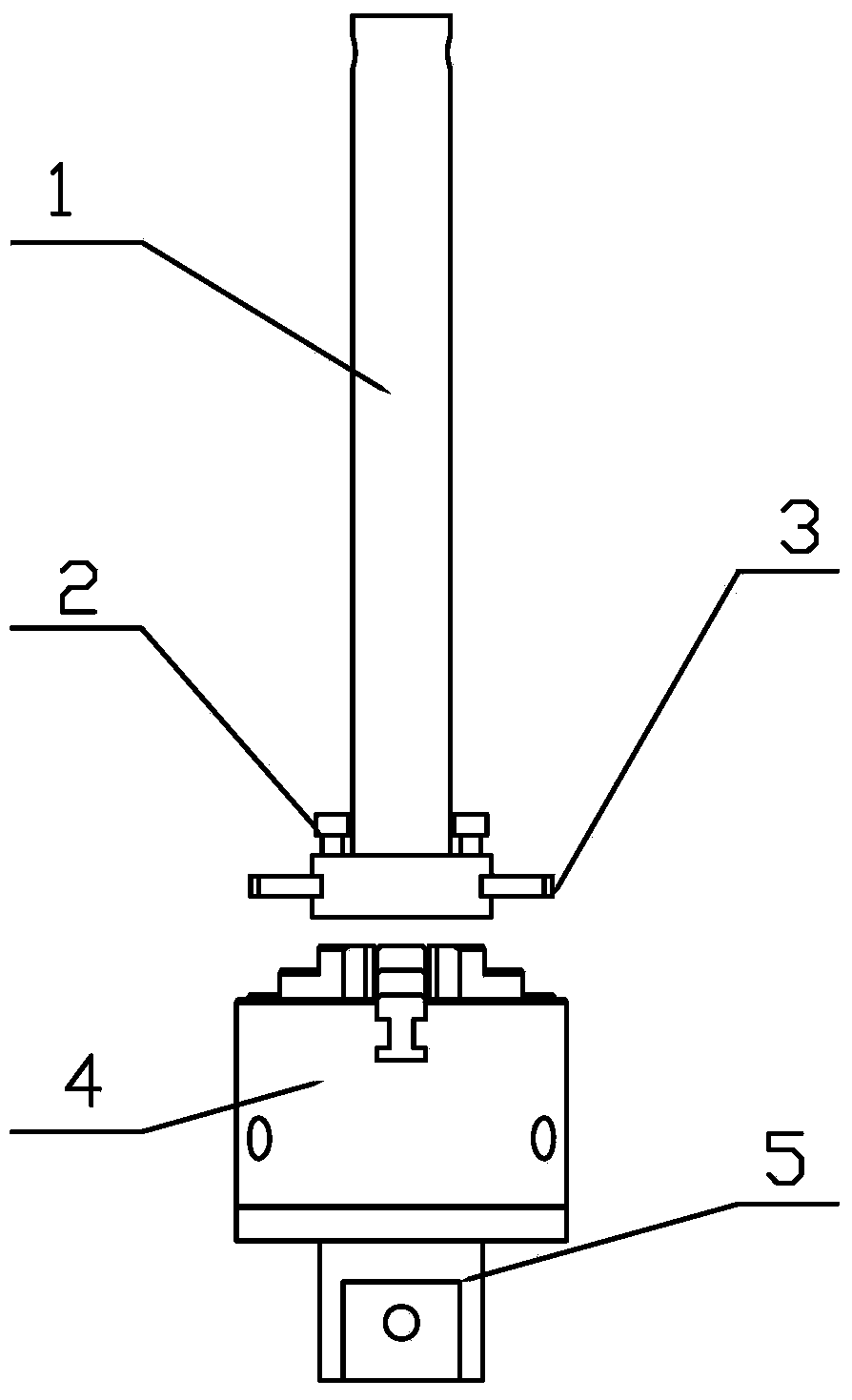

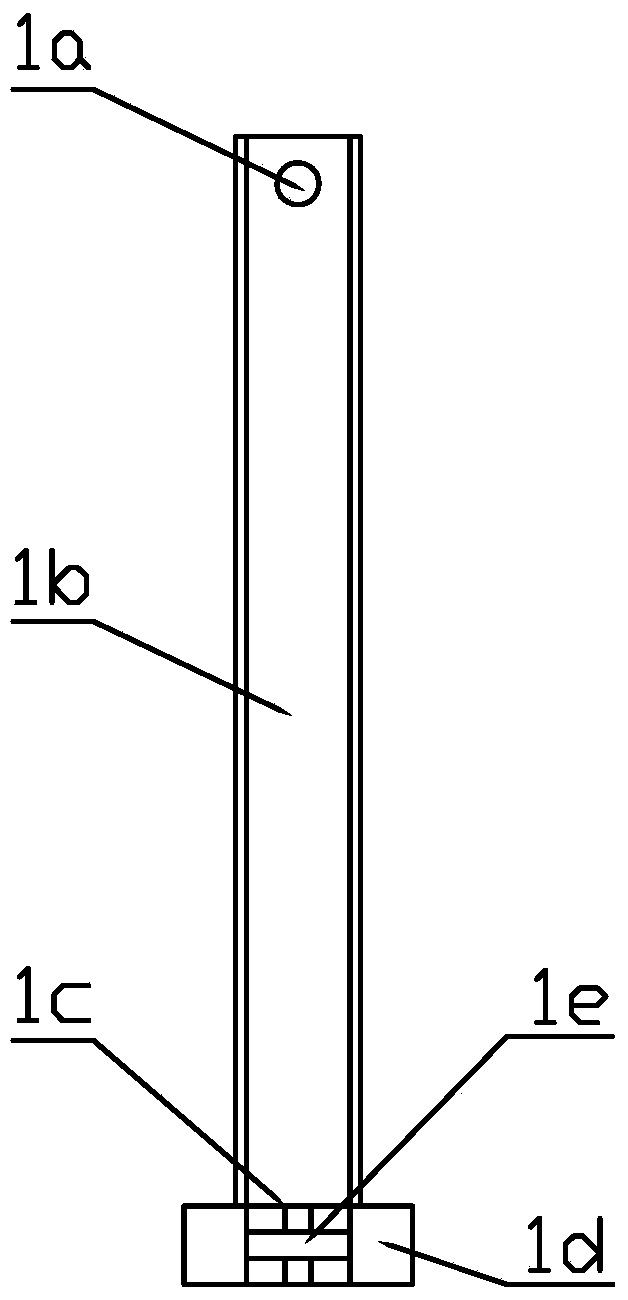

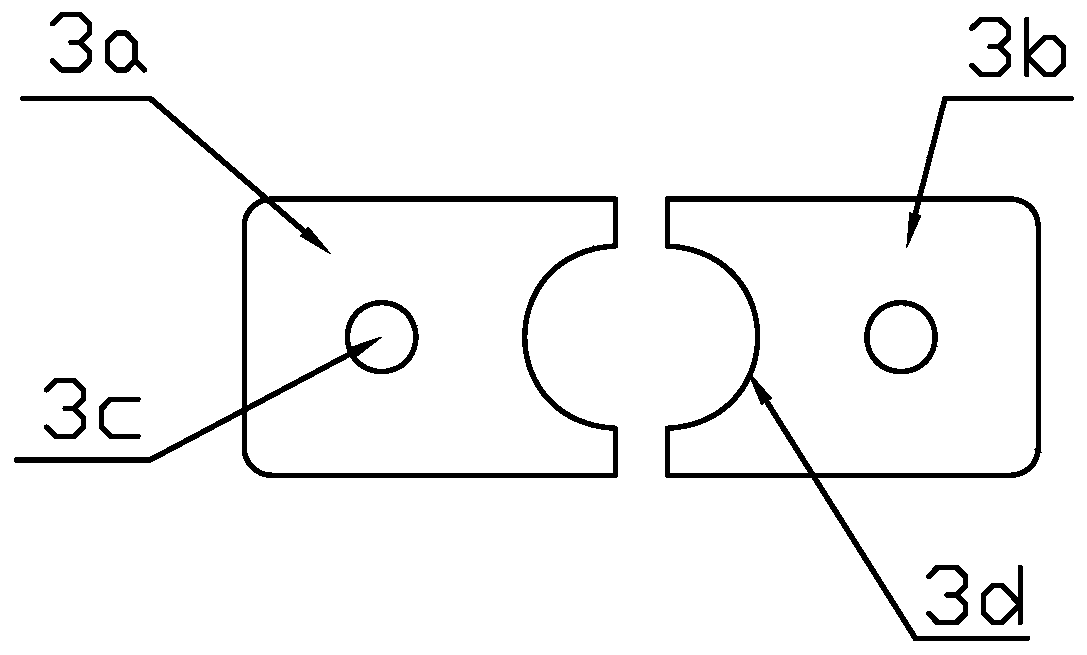

Optical cable and electric cable outer jacket coating force measurement device and measurement method

ActiveCN103439039AAccurate measurementMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementMeasurement deviceForce curves

The invention discloses an optical cable and electric cable outer jacket coating force measurement device and measurement method, and relates to the field of electric cable and optical cable performance testing. The optical cable and electric cable outer jacket coating force measurement device comprises an outer jacket pulling rod, an outer jacket clamping sheet and a clamping mechanism. The outer jacket pulling rod is fixedly connected with an up stroke hook of a tension tester through a pin and used for receiving and fixing a sample to be tested. The outer jacket clamping sheet is inserted in the lower end of the outer jacket pulling rod in an embedded mode. The clamping mechanism is located below the outer jacket clamping sheet. The 15-30cm distance is kept between the clamping mechanism and the outer jacket clamping sheet. The clamping mechanism is fixedly connected with a down stroke hook of the tension tester through a pin. According to the optical cable and electric cable outer jacket coating force measurement device and measurement method, the locating function of the outer jacket clamping sheet and the clamping function of the clamping mechanism are used, the tension function of the tension tester is cooperated, the coating force of an electric cable and optical cable outer jacket and the outer jacket coating force curve can be accurately measured, and theoretical bases are provided for studying the electric cable and optical cable tensile performance and the PE jacket material heat retraction performance.

Owner:FENGHUO COMM SCI & TECH CO LTD

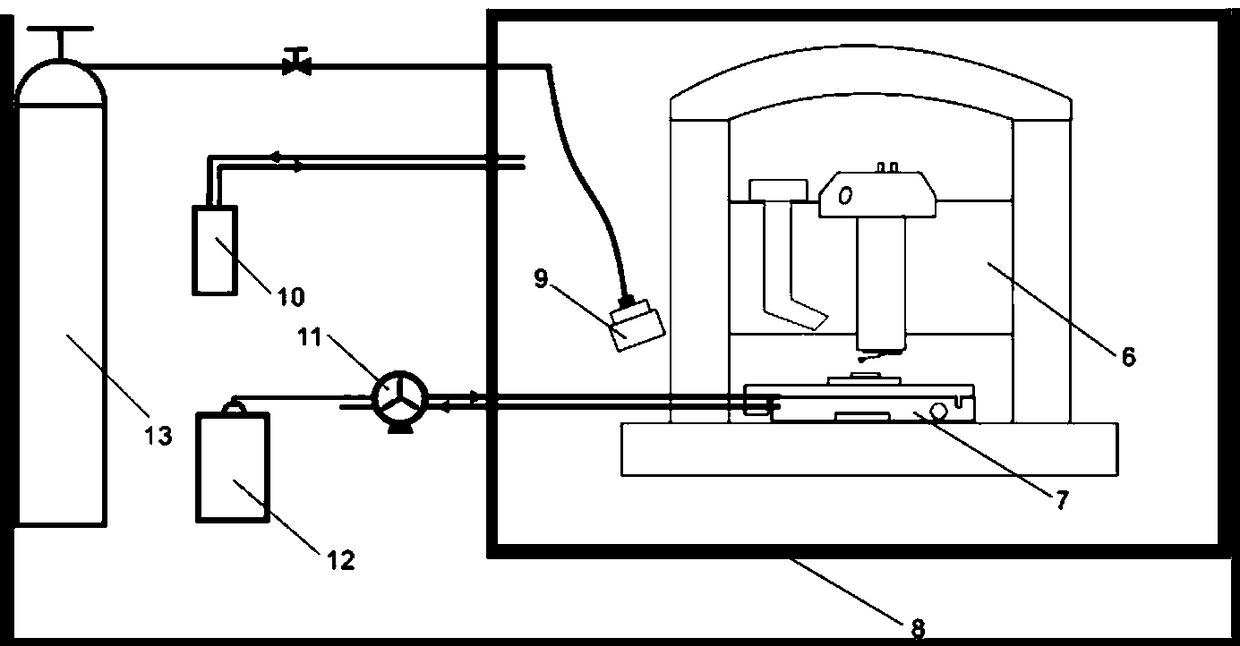

Testing device and method for adhesive force between gas hydrate and mineral particles

ActiveCN109323986AAchieve adhesionGood practical valueConstructionsUsing mechanical meansThermal insulationMineral particles

The invention provides a testing device and method for adhesive force between gas hydrate and mineral particles. The device comprises an atomic power microscope, a thermal insulation glove box, a low-temperature sample table, a circulating cooling fan, a high-pressure air source, a pump and a liquid nitrogen tank, wherein the atomic power microscope, a high-pressure cavity and refrigeration equipment are combined to realize the in-situ synthesis of a gas hydrate sample on the low-temperature sample table and keep the gas hydrate stable, and external force required when the gas hydrate and themineral particles are separated under a constant-pressure low-temperature condition is obtained through the single-point force curve technology of the atomic power microscope, wherein external force is adhesive force between the hydrate and the mineral particles. By use of the device, the adhesive force between the hydrate and the mineral particles can be conveniently and accurately measured, andthe device has an obvious practical value for evaluating the mechanical property of a hydrate reservoir and guiding sea area hydrate development.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

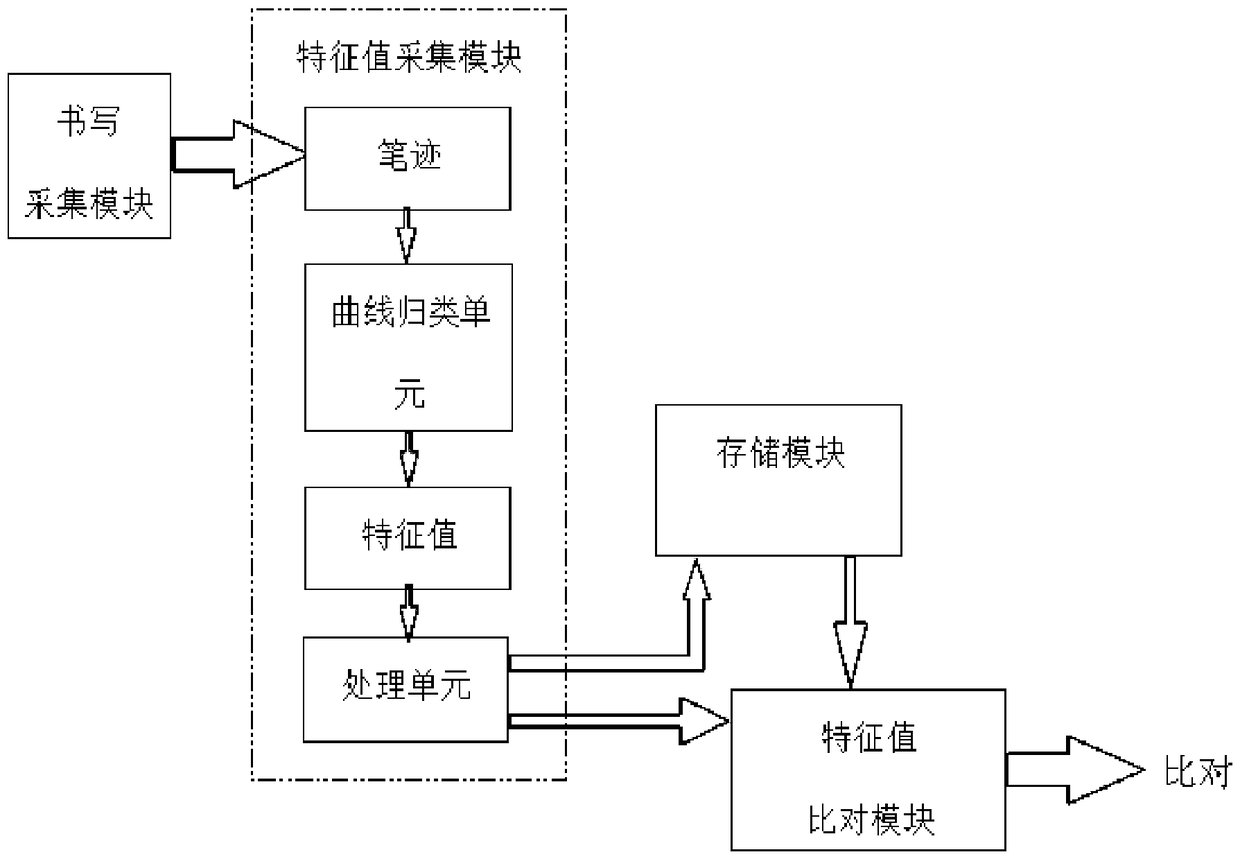

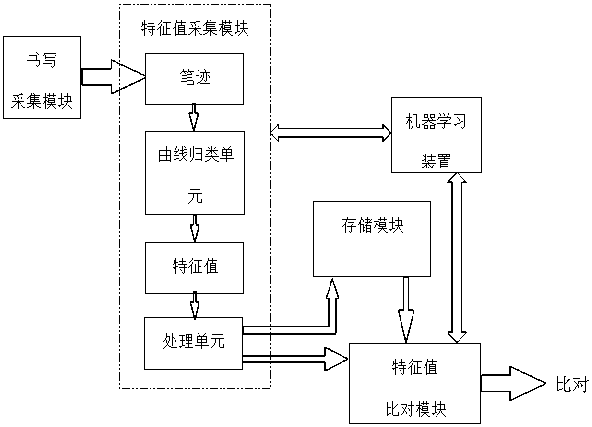

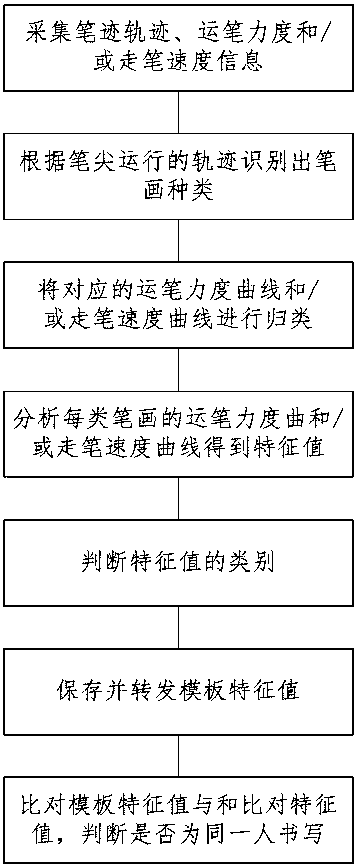

Writing handwriting identification system and method

InactiveCN108416249APrevent imitationHigh identification accuracyCharacter and pattern recognitionHandwritingComputer graphics (images)

The present invention discloses a writing handwriting identification method. The method comprises the steps of: collecting brushstroke force, writing speed and a handwriting track to generate a brushstroke force curve and / or writing speed curve when a writer is writing, a handwriting identification unit is configured to distinguish the types of strokes through identification of a nib moving trackto classify the obtained brushstroke force curve and / or writing speed curve according to the types of strokes and extract feature values which can best differ from other persons, wherein the obtainedfeature values can be taken as a feature value template stored in a storage module, or can be taken a comparison feature value sent to a feature value comparison module for comparison with the featurevalue template. In the handwriting identification method, the brushstroke force and / or writing speed can be collected, and / or the brushstroke force curve and / or writing speed curve are generated in the handwriting identification method to perform analysis, because the brushstroke force and the writing speed are both writing features invisible to human eyes, and other persons cannot perform imitation, it can be prevented from imitation by other persons in any one way or both ways, and therefore, the discrimination accuracy can be improved.

Owner:肖奇

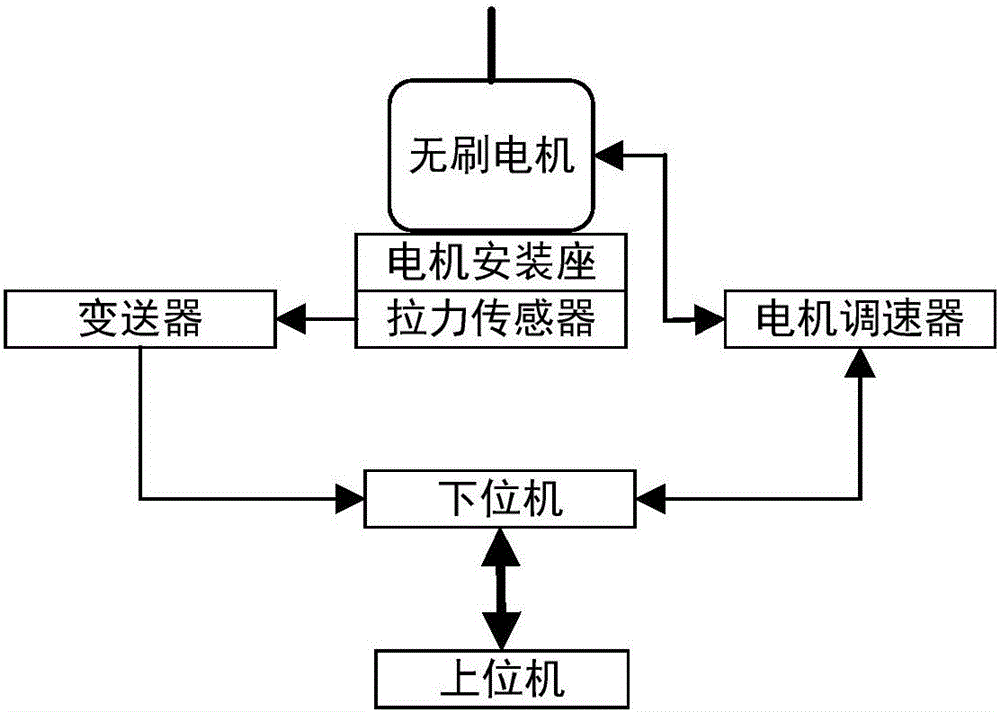

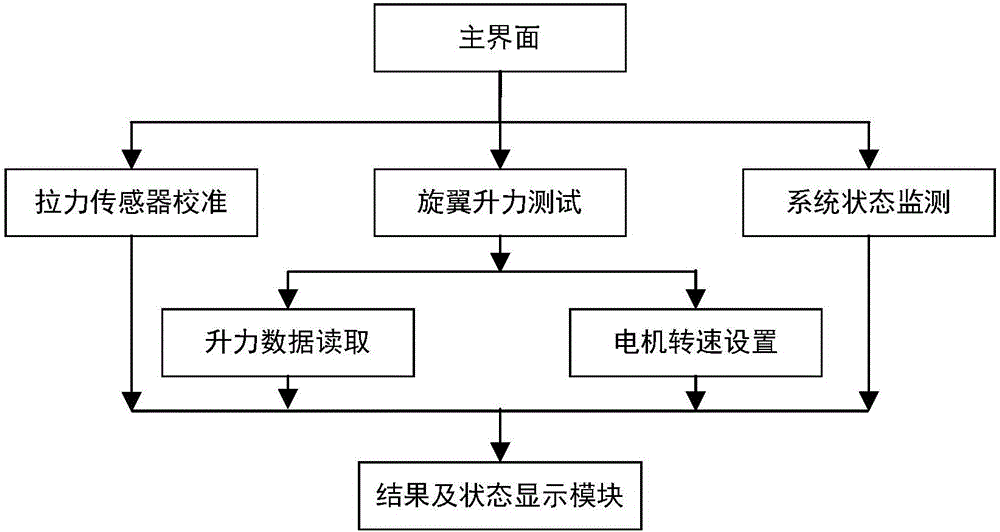

Rotor lift force testing system for unmanned aerial vehicle

The invention discloses a rotor lift force testing system for an unmanned aerial vehicle. The testing system is applied to lift force testing of a rotor of an unmanned aerial vehicle, and can be used for giving out a motor rotating speed-rotor lift force curve and fit empirical equation. The system comprises a brushless motor, a motor governor, a motor mounting base, a tension sensor, a transmitter, a lower computer and an upper computer. The lower computer has the following main functions: (1) collecting a rotor lift force signal; (2) controlling the rotating speed of the brushless motor; (3) communicating with the upper computer to transmit data; and (4) feeding back the running state of the system to the upper computer. The upper computer comprises a tension sensor correction module (1), an unmanned aerial vehicle rotor lift force testing module (2), a brushless motor rotating speed setting module (3), a system state monitoring module (4) and a testing result and system state display module (5).

Owner:ANHUI UNIV OF SCI & TECH

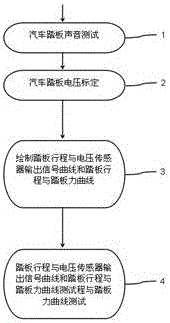

Automobile pedal test method

InactiveCN106404421APros and consReduce false positive rateVehicle testingForce curvesVoltage transducers

The invention belongs to the technical field of automobile pedal testing and specifically relates to an automobile pedal test method which comprises the following steps: a step of automobile pedal sound testing, a step of automobile pedal voltage calibration, a step of drawing pedal travel and voltage transducer output signal curves, a step of drawing pedal travel and pedal force curves, a step of testing the pedal travel and voltage transducer output signal curves and a step of testing the pedal travel and pedal force curves; the automobile pedal test method helps solve a problem that each kind of products cannot be measured through tool changeovers via technologies of the prior art; beneficial technical effects of the automobile pedal test method are that whether an automobile pedal is good or poor in quality can be determined, a misjudgement rate caused by human intervention can be lowered, authenticity of traceability can be improved, and calibration accuracy can be increased.

Owner:TIANJIN RUIYITAIKE AUTO ELECTRONICS

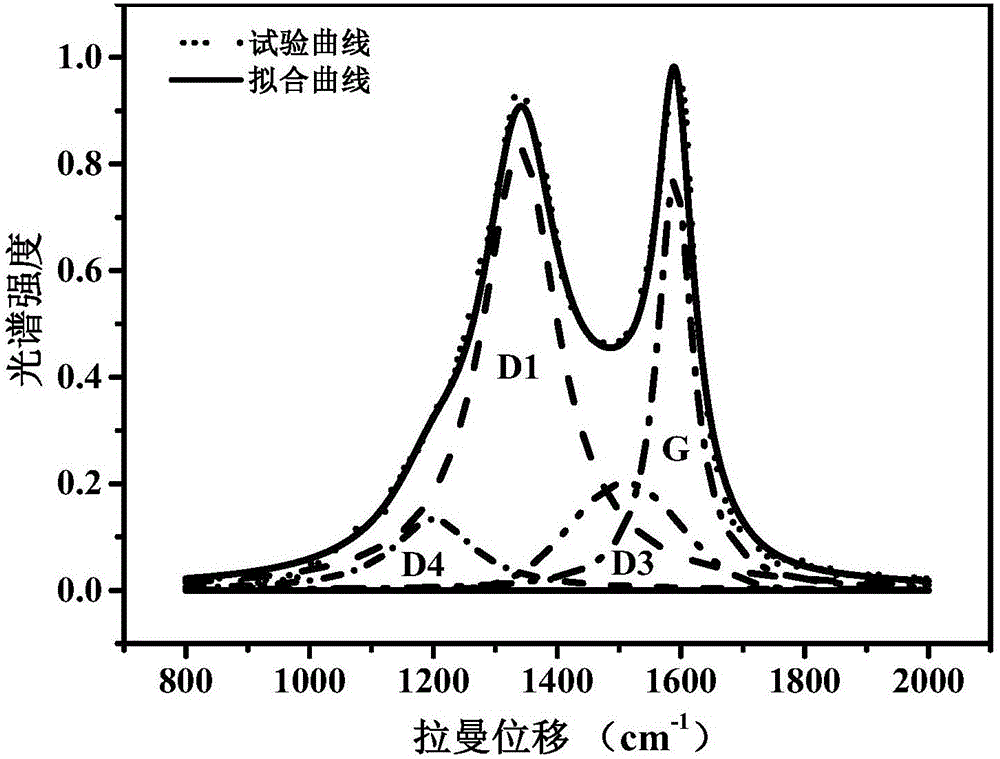

Method for detecting physical characteristics of nano-scale soot microparticles and application of method

The invention discloses a method for detecting physical characteristics of nano-scale soot microparticles. The method is used for simultaneously detecting the three-dimensional morphology, mechanical characteristics and degree of graphitization of the same position of each nano-scale soot microparticle by using an atomic force microscope and Raman spectrometer combination system and comprises the following steps: acquiring the three-dimensional morphology, force curve and Raman spectrogram of a nano-scale soot microparticle sample, and carrying out peak-differentiating-imitating on the Raman spectrogram by using software origin so as to evaluate the degree of graphitization of the nano-scale soot microparticle sample; finally obtaining the mechanical characteristics of the nano-scale soot microparticle sample, wherein the mechanical characteristics comprise an adsorption force, a van der Waals force and an adhesion force. According to the method and the application thereof, the rule of evolution of the three-dimensional morphology, mechanical characteristics and degree of graphitization of soot microparticles generated from different source combustion processes can be researched, and research results contribute to the deep understanding of generation and evolution mechanisms of the soot microparticles, so that a theoretical instruction is provided for the reduction of emission of the soot microparticles and the control on atmospheric environment pollution.

Owner:TIANJIN UNIV

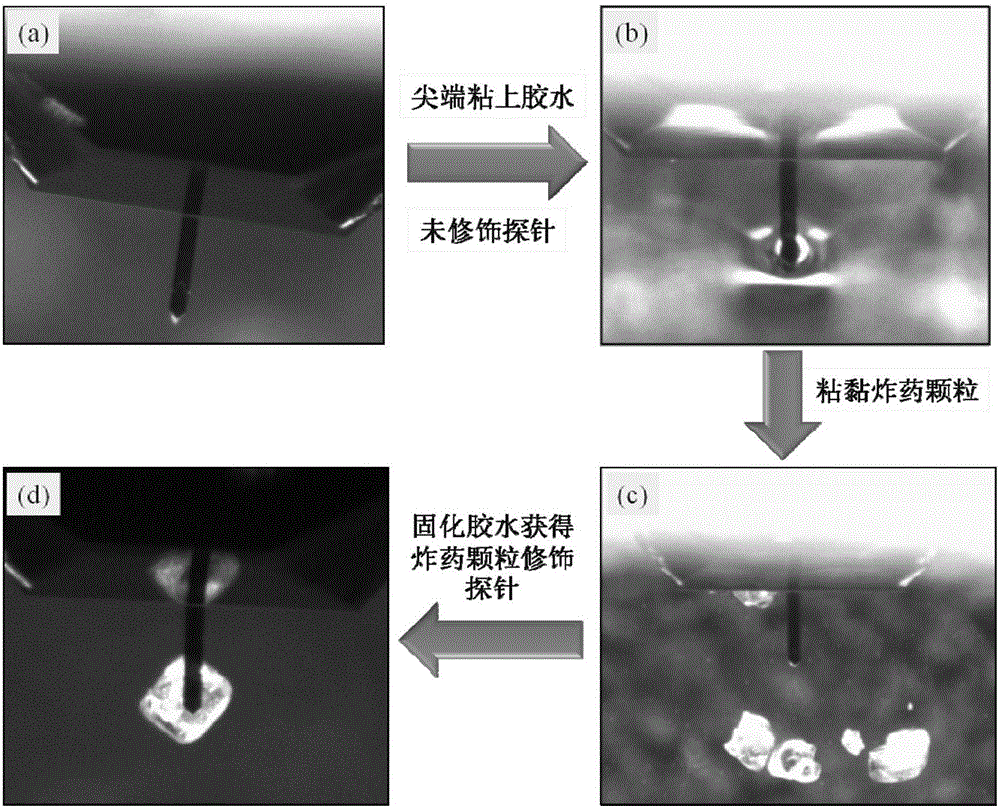

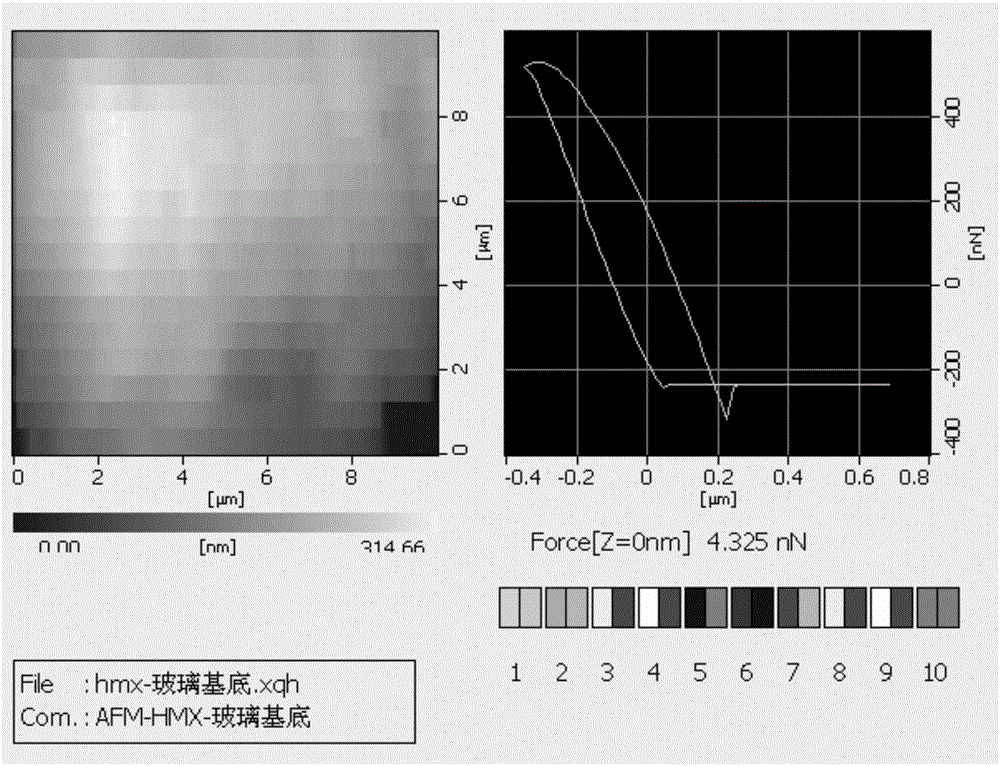

Method for representing interfacial force between explosive and bonding agent

InactiveCN106841686ASimple processSimple and fast operationScanning probe microscopyAdhesiveEngineering

The invention discloses a method for representing an interfacial force between explosive and bonding agent. The method comprises the following steps of modifying the tip end of an AFM probe micro-cantilever by explosive particles through a binding medium, or directly modifying the tip end of the AFM probe micro-cantilever by adhesive, thereby obtaining a modified probe; applying the adhesive on a flat substrate, or fixing the explosive particles on the flat substrate; by means of a force spectrum scanning mode of an atomic force microscope, performing force curve representation by means of the modified probe on the surface of the bonding agent or explosive particles; and extracting a corresponding bonding force parameter according to a force curve, thereby obtaining the interfacial force between the explosive and the bonding agent. The method realizes direct and quantitative representation of the interfacial force between explosive and components of the bonding agent, thereby realizing a new facility for mechanical characteristic research of a crystal / adhesive interface in PBX explosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com