Method for representing interfacial force between explosive and bonding agent

A technology of adhesive and force, which is applied in the field of interface mechanical properties of explosive components, can solve the problems of difficult particle probe technology and few applications, and achieve the effects of strong practicability, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

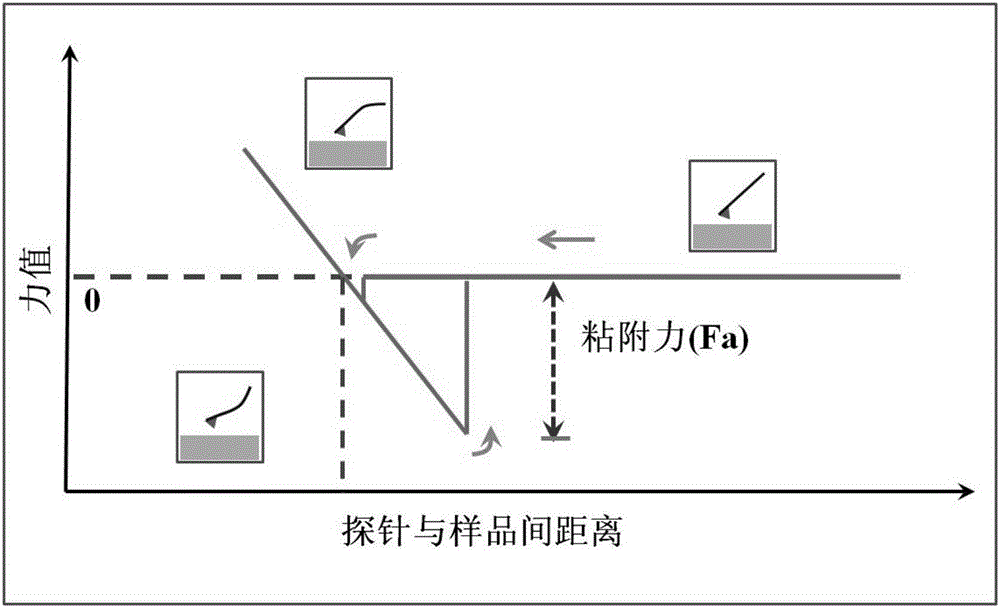

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

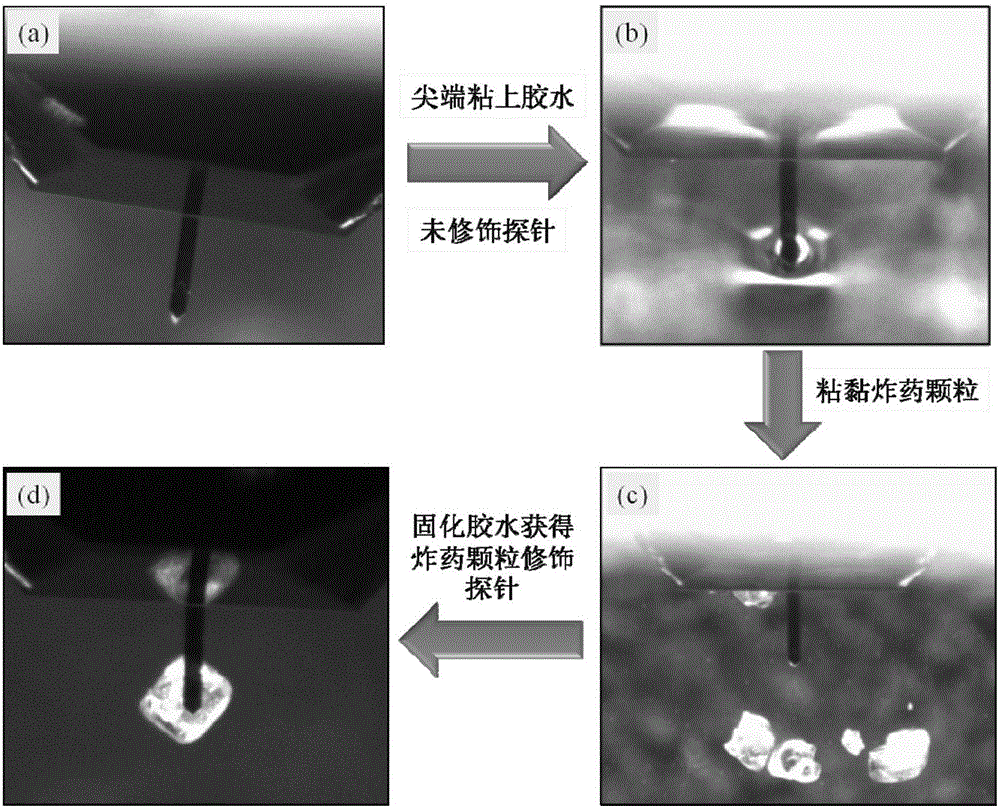

[0041] (1) Drop the UV curable glue on the glass slide A and place it in the field of view of the optical microscope; install the unmodified needle-free AFM probe in the probe groove on the probe holder, and fix it with a spring piece, The position of the probe is controlled by a four-axis displacement controller and moved to the top of the cured glue, and then gradually approached, so that a small amount of UV cured glue is dipped on the tip of the AFM probe microcantilever.

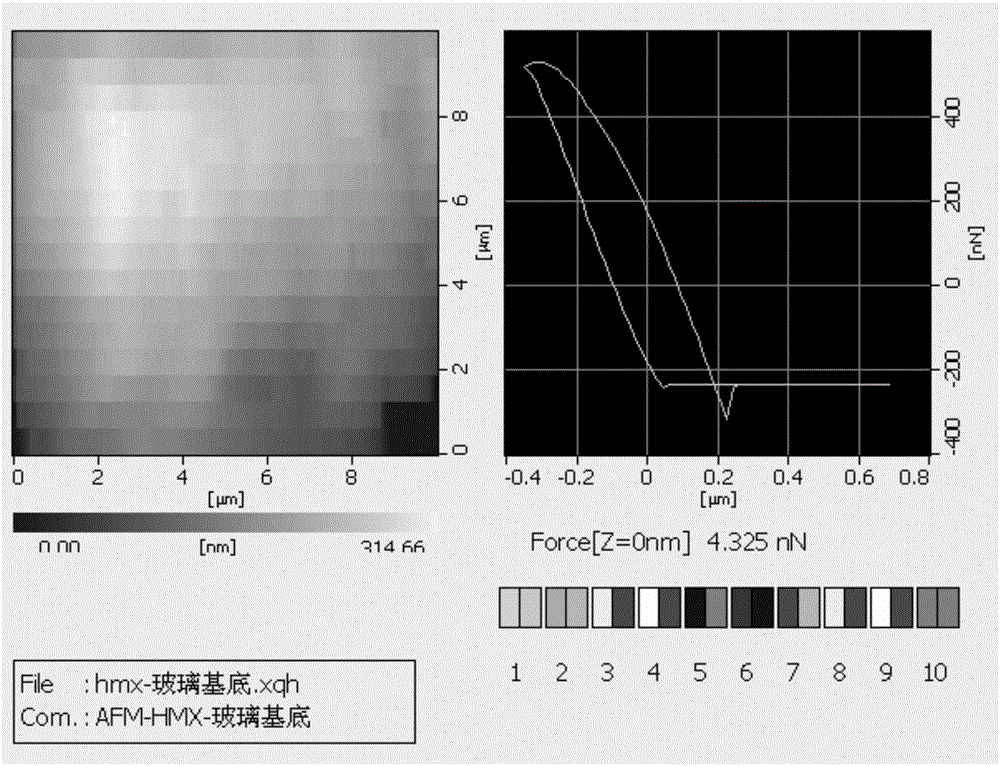

[0042] (2) Disperse the HMX explosive crystal particles with an average particle size of about 20 μm on the glass slide B and place them in the field of view of the optical microscope; move the probe dipped in cured glue to the top of the explosive particles through a four-axis displacement controller , and then gradually approach the explosive particles, stick the explosive particles on the tip of the AFM probe microcantilever through the curing glue, and then irradiate with ultraviolet light for 15 min...

Embodiment 2

[0046] The method is the same as in Example 1, except that the binder used in step 3 is polyurethane.

Embodiment 3

[0048] The method is the same as in Example 1, except that the binder used in step 3 is paraffin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com