Asphalt microcosmic dynamic rheological property test method

A testing method and rheological technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of limited test frequency range, long test time, and inability to reflect the microscopic mechanical properties of asphalt, and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: if Figure 1-3 As shown, a kind of asphalt microscopic dynamic rheology test method involved in this embodiment, the specific steps are:

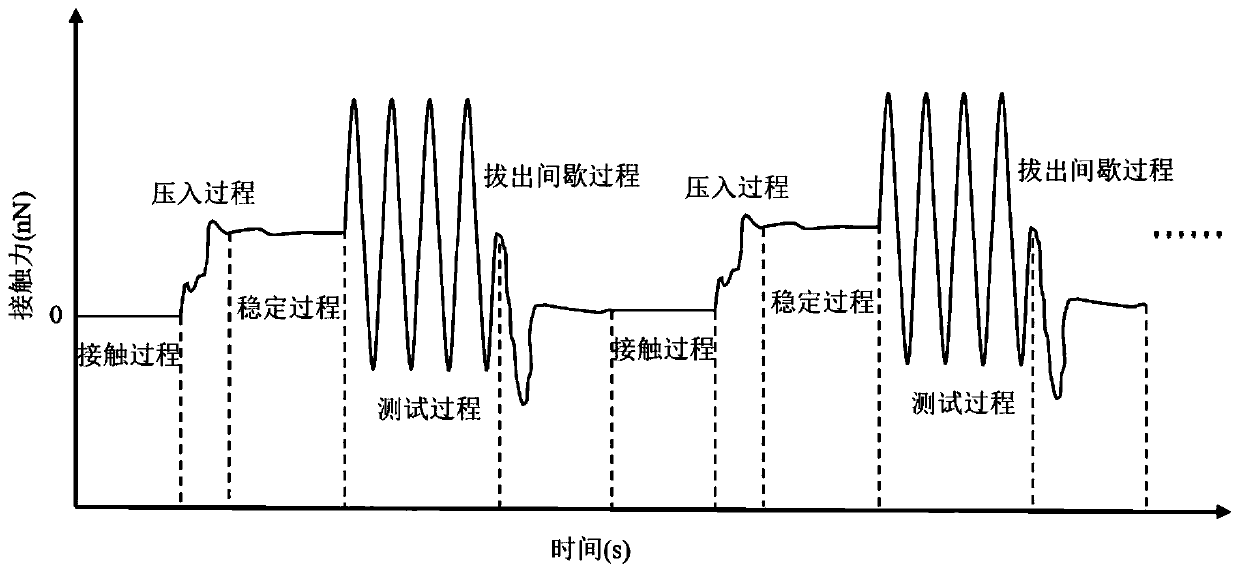

[0016] Step 1: Keep the temperature of the test environment constant, use the atomic force microscope to test the asphalt sample, get the force curve, and use the Hertz model to fit the force curve to get the corresponding elastic modulus, repeat the test three times to get the average value of the modulus As the modulus of the asphalt sample; according to the corresponding relationship between the measured modulus of the asphalt sample and the scope of application of the probe, determine the stiffness coefficient of the probe required for the microscopic dynamic rheological performance test and the type of probe used;

[0017] Step 2: Scan the asphalt microscopic topography and select a specific range as the test area, establish a rectangular test lattice in the test area, use the points in the lattice as test points...

Embodiment 2

[0020] Embodiment two: if Figure 1-3 As shown, a kind of asphalt microscopic dynamic rheology test method involved in this embodiment, the specific operation process is:

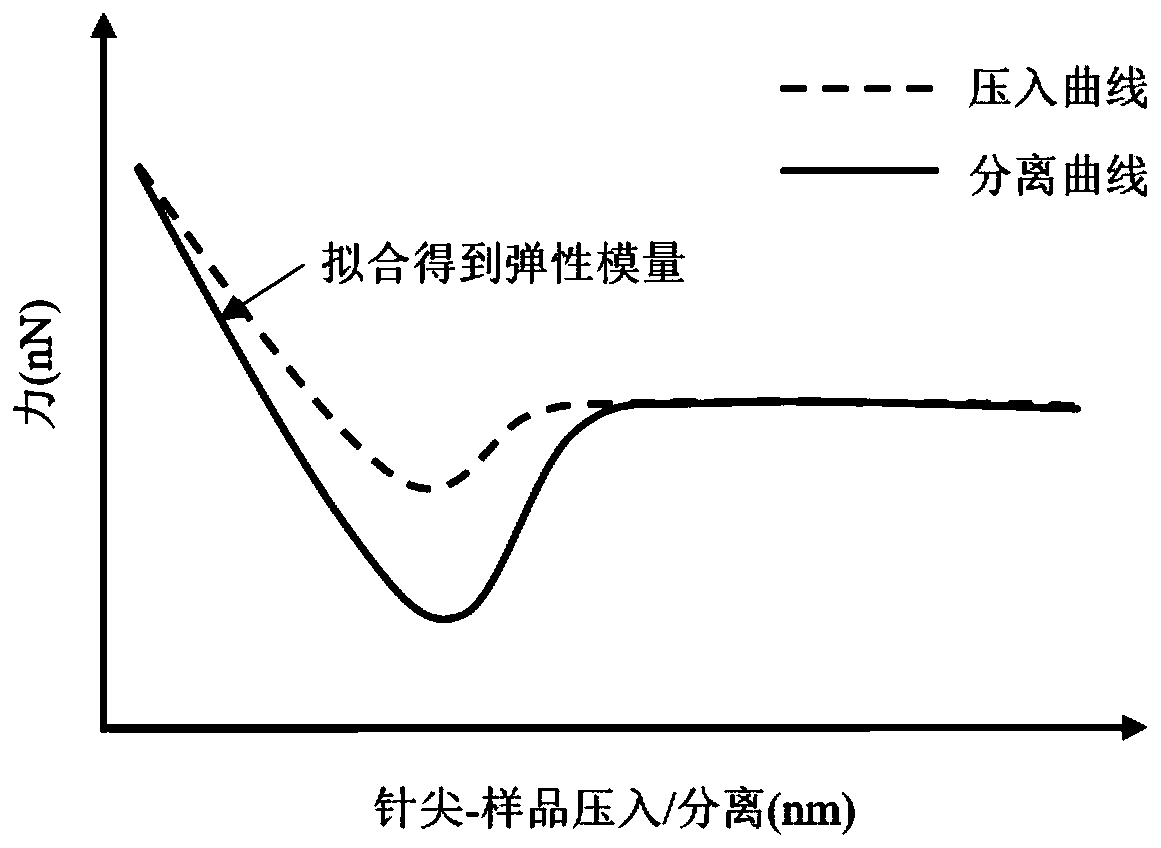

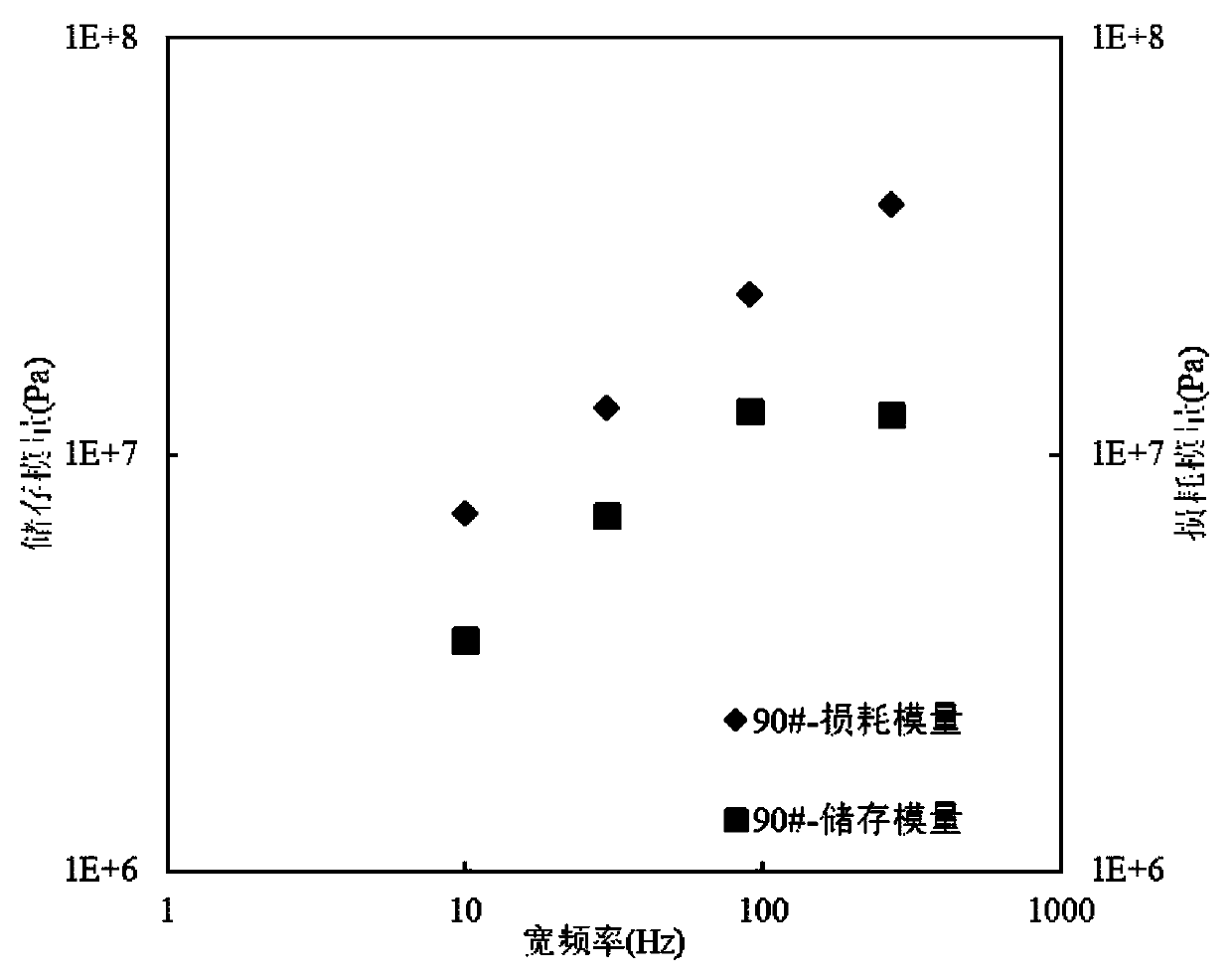

[0021] Step 1: Under the test conditions of 23°C at room temperature (the test temperature range is relatively large, and the temperature can be controlled and can be carried out at room temperature), use an atomic force microscope (AFM) to test a No. 90 matrix asphalt sample, and obtain its force curve ( Such as figure 1 Shown), using the Hertz model to fit the corresponding elastic modulus through software, repeat the test three times and get the average value of 730MPa. According to the corresponding relationship between this value and the scope of application of the probe, it is determined that the probe stiffness coefficient required for this microscopic dynamic rheological test is 2.8N / m;

[0022] Step 2: Scan the asphalt microscopic topography and select a range of 25μm×25μm as the test area, estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com