Comprehensive test stand for water-lubricated bearings for pumps

A technology of water-lubricated bearing and comprehensive test bench, applied in the direction of mechanical bearing testing, etc., can solve the problem that the function cannot fully meet the requirements of the water-lubricated bearing system, achieve long time dimension, simplify the system structure, and widen the adjustable speed range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

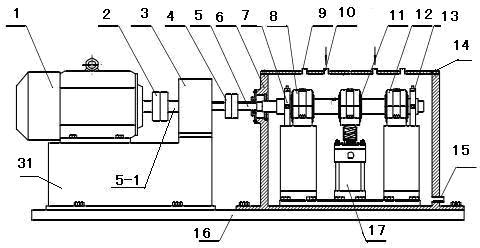

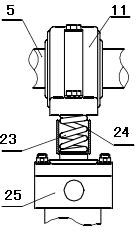

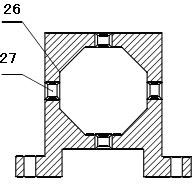

[0025] attached figure 1It is a specific embodiment of the present invention, and the present invention will be described in detail below in conjunction with this specific embodiment. The water-lubricated bearing comprehensive test bench of the present invention includes a drive transmission system, a main machine box, a bearing and its lubrication system, a loading system, a measurement system, a signal processing and analysis system, and the like. The drive transmission system includes frequency conversion motor 1, elastic coupling A2, speed-up box 3 and elastic coupling B4, etc. The main function is to provide uniform and adjustable torque for the test bench. After the variable frequency motor of the test bench is started, the speed can be stably run at a fixed speed value through the frequency converter, or a speed increase gradient (or a starting time period) can be given to study the transient characteristics of the test bench.

[0026] The torque of the driving transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com