Patents

Literature

128results about How to "Accurate speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

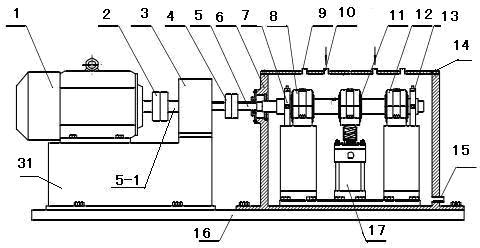

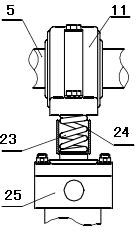

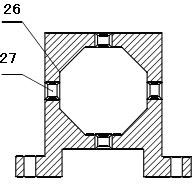

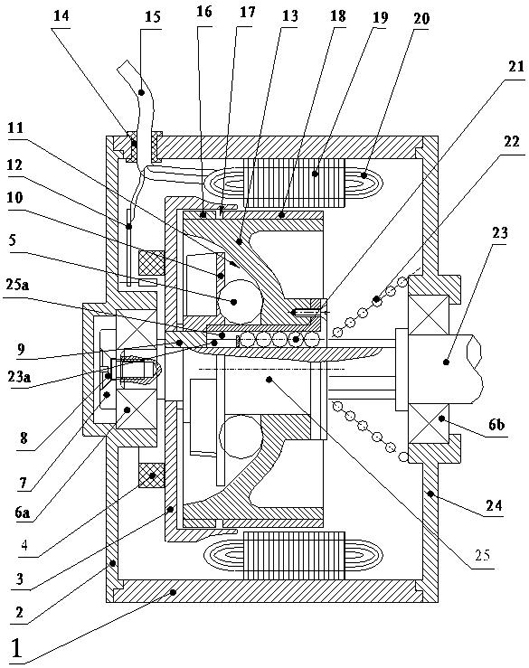

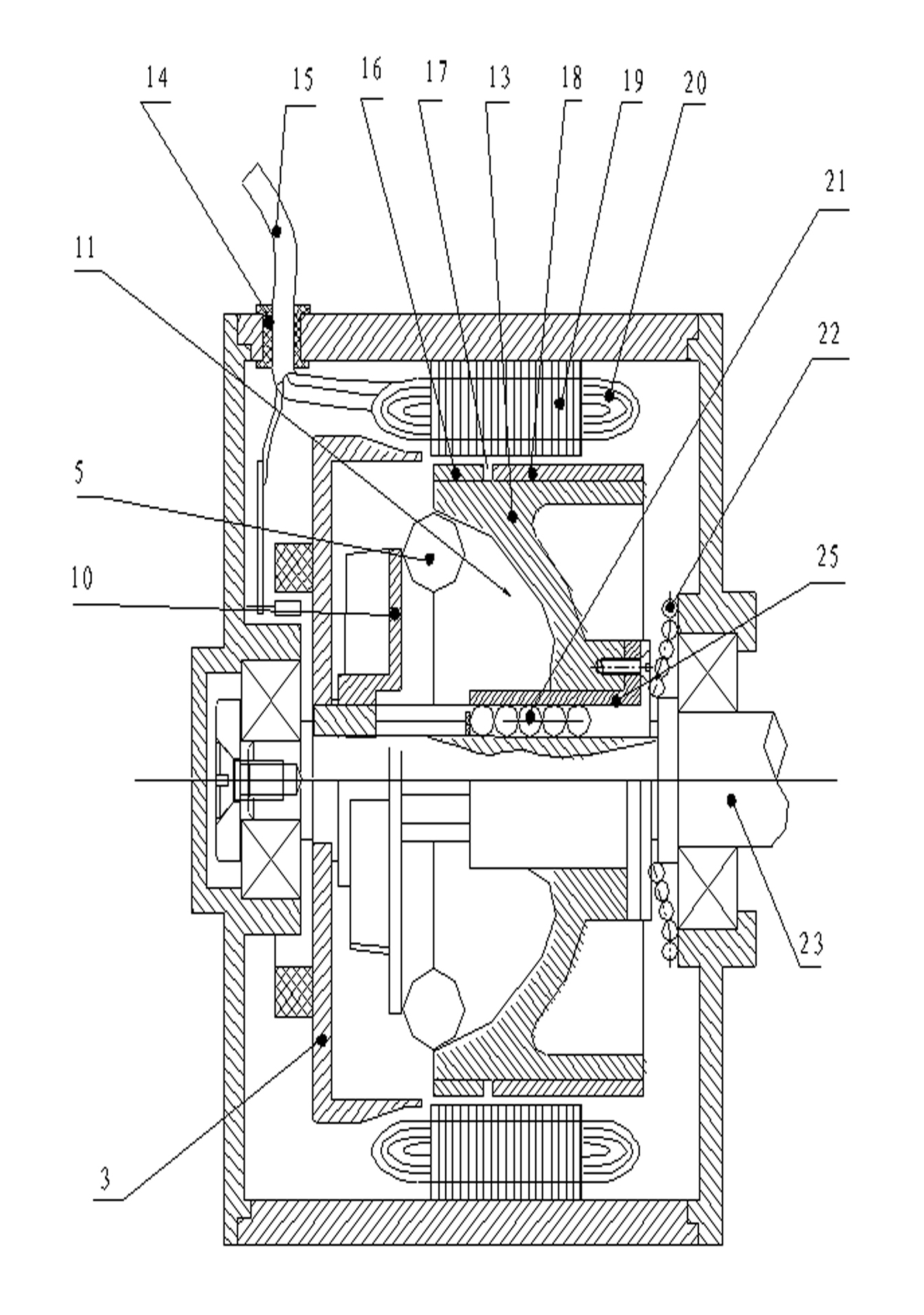

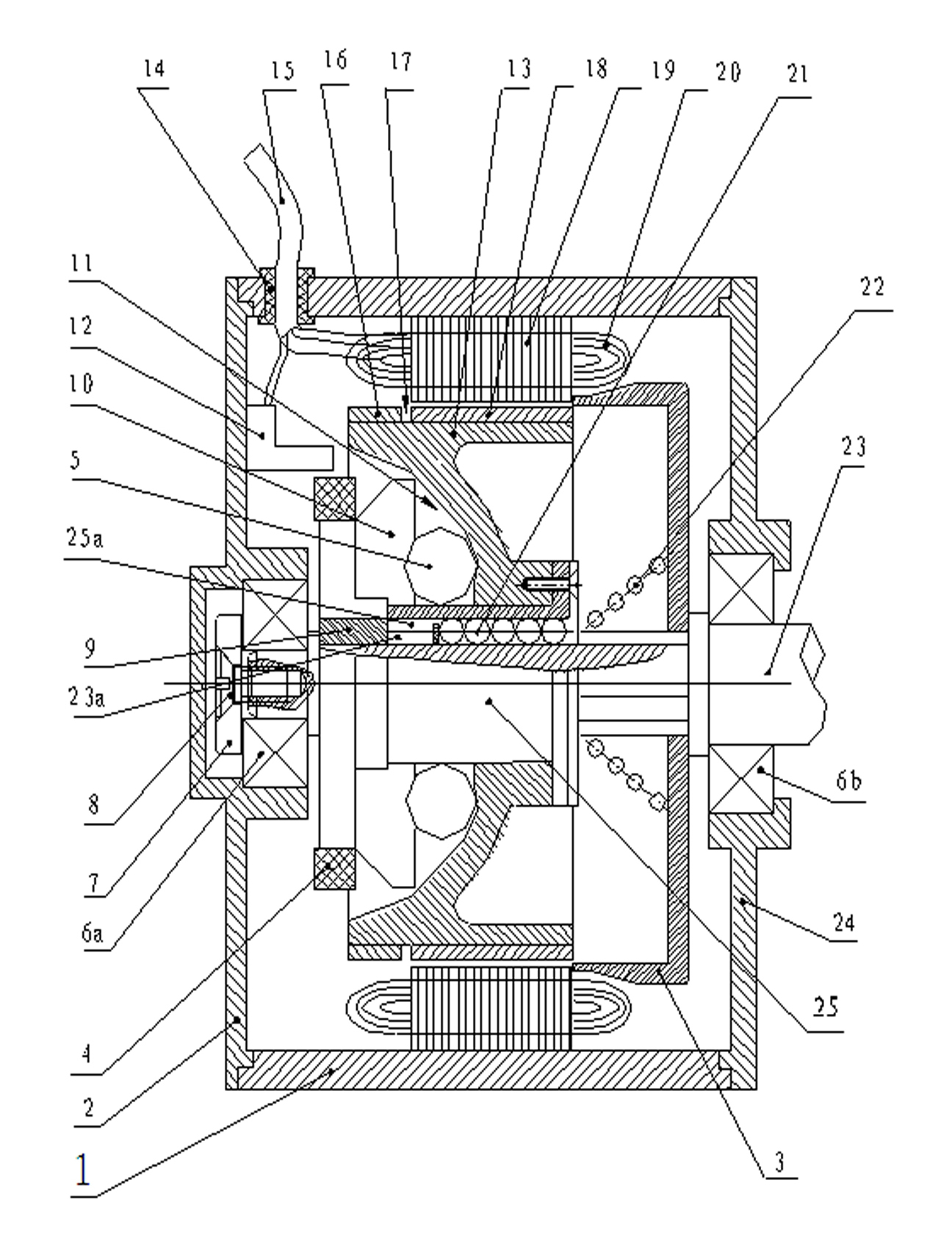

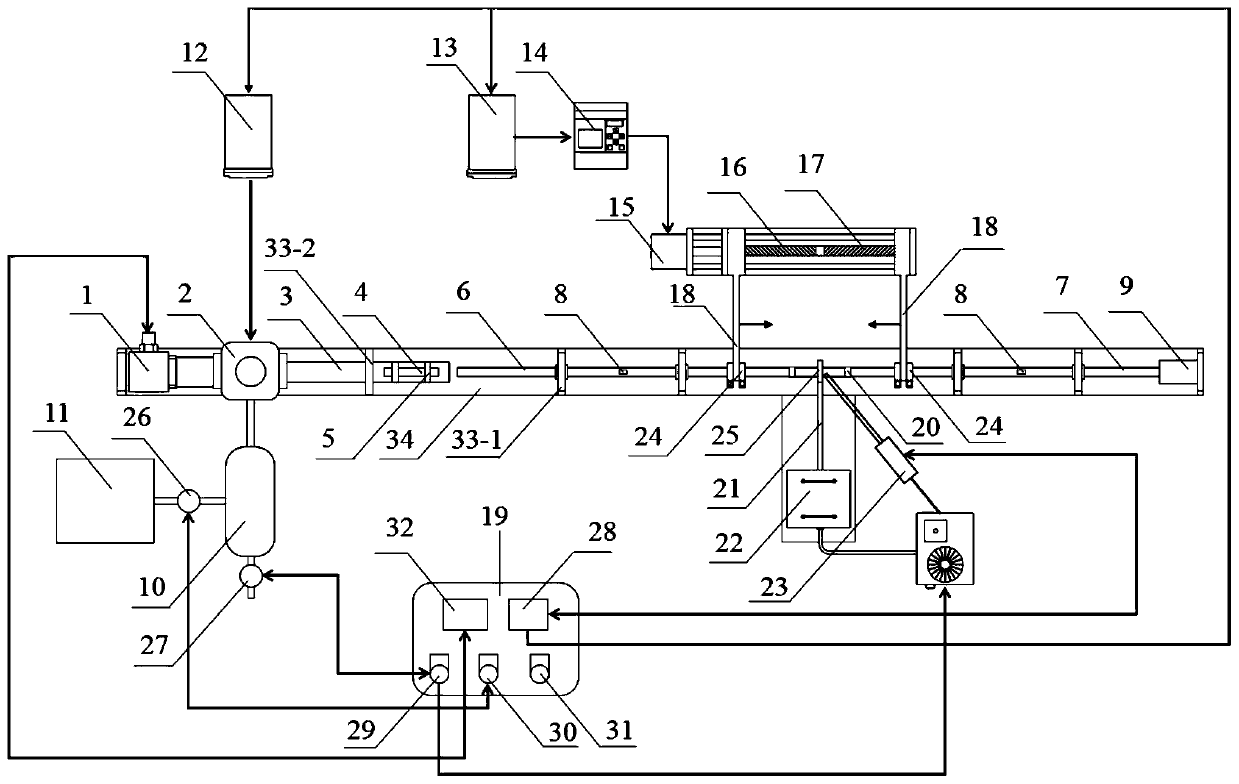

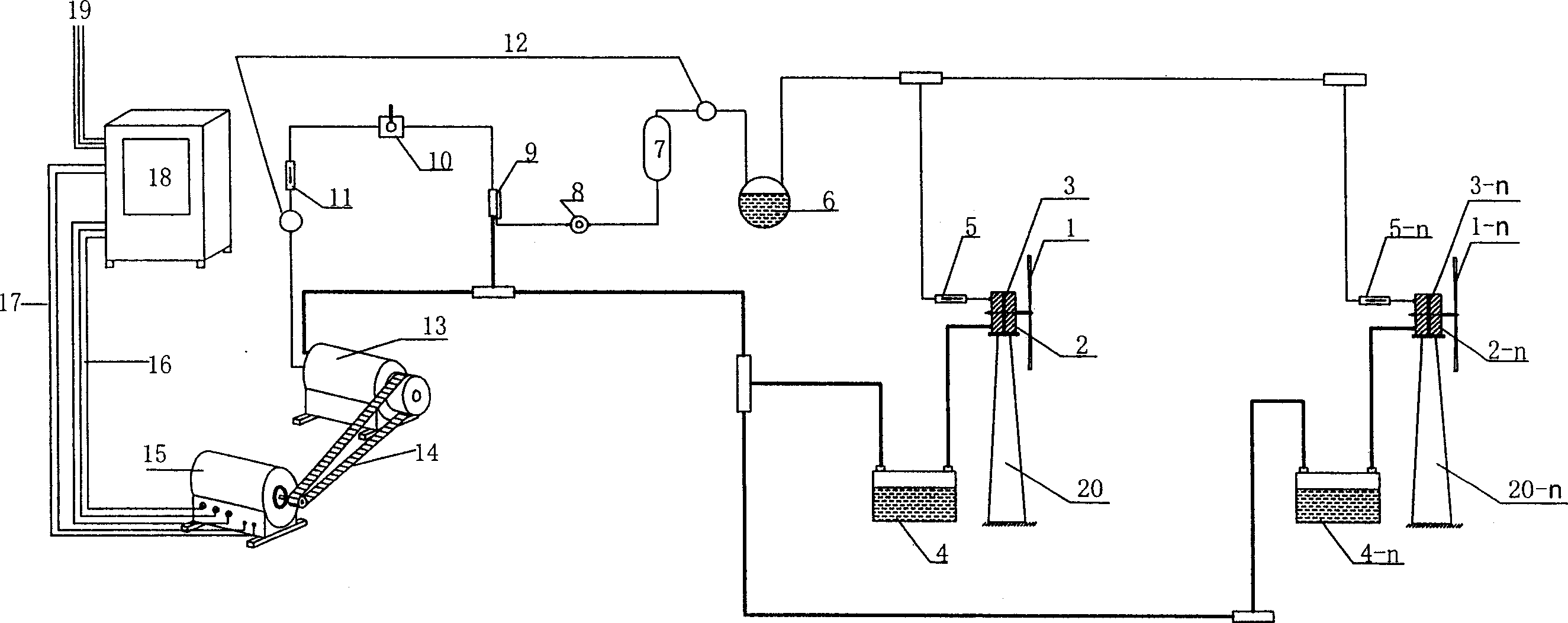

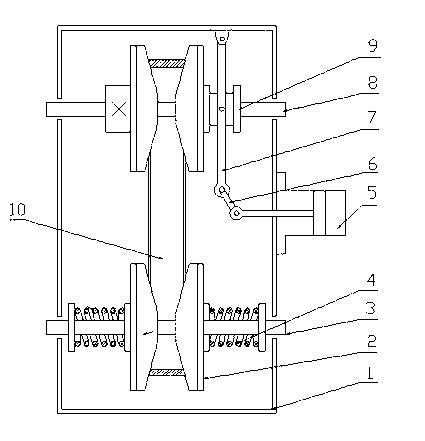

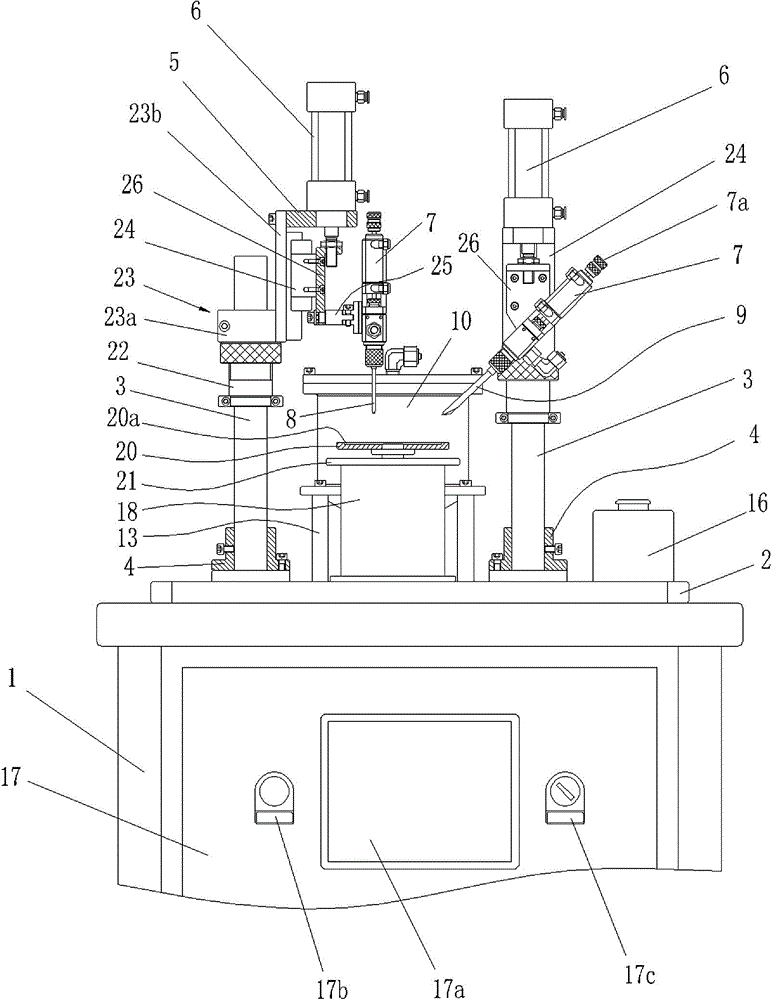

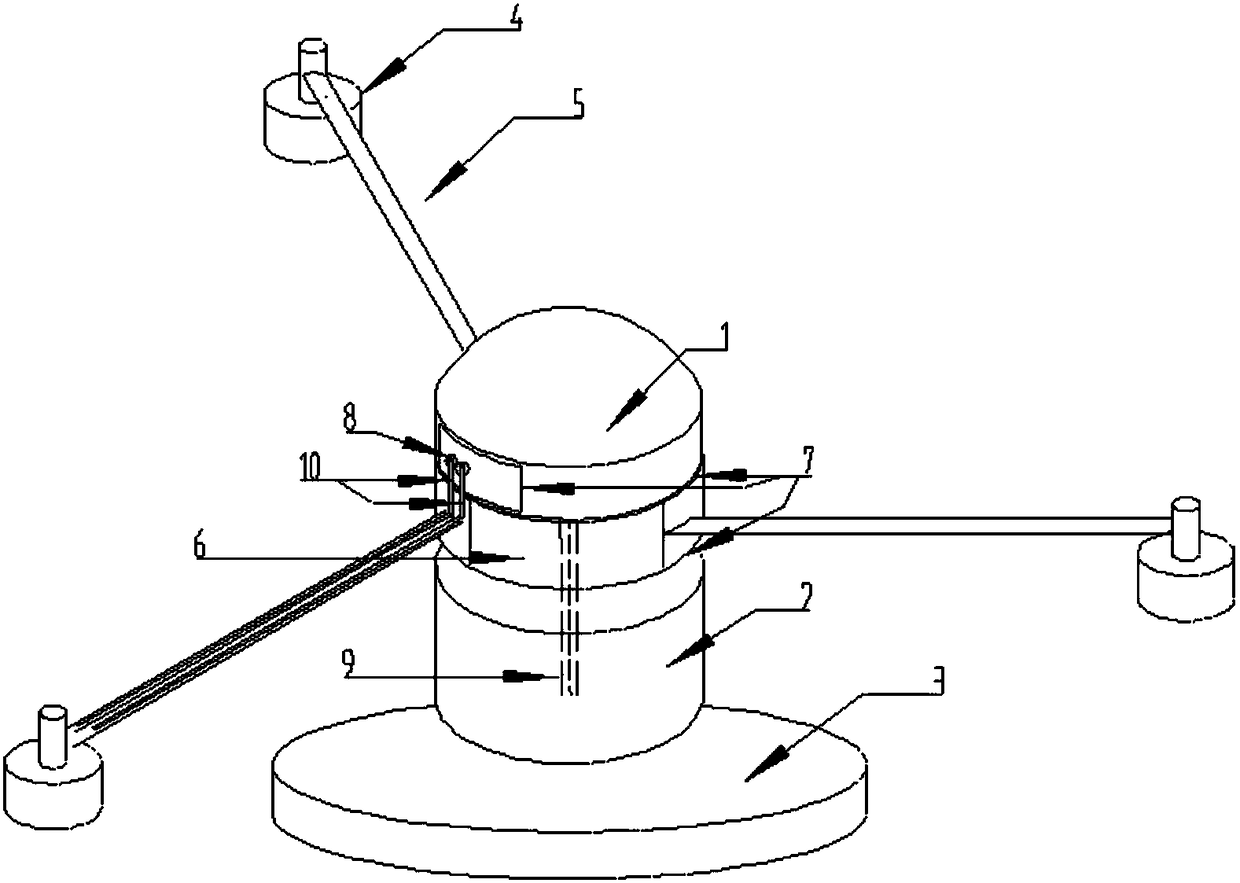

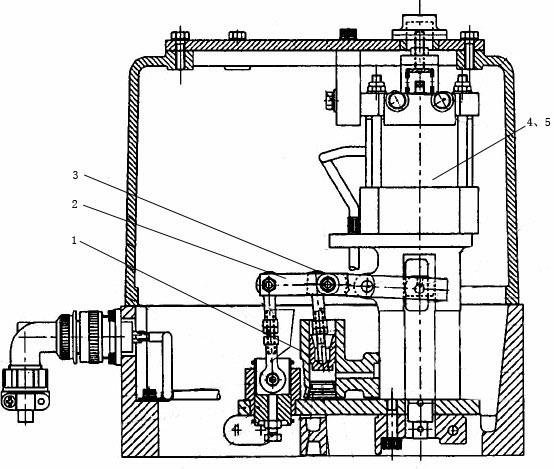

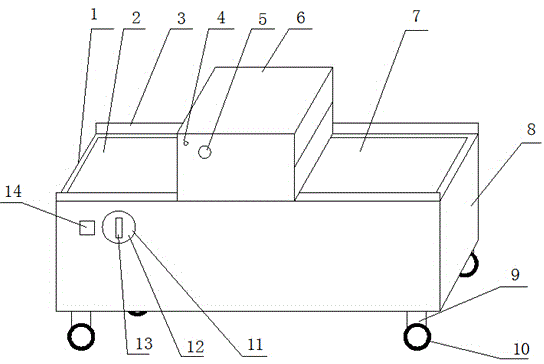

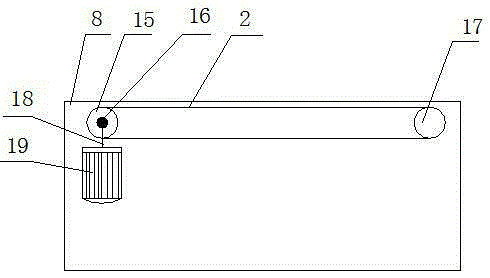

Comprehensive test stand for water-lubricated bearings for pumps

InactiveCN102607846AIncrease the maximum speedAccurate speed regulationMachine bearings testingVibration accelerationTransmission system

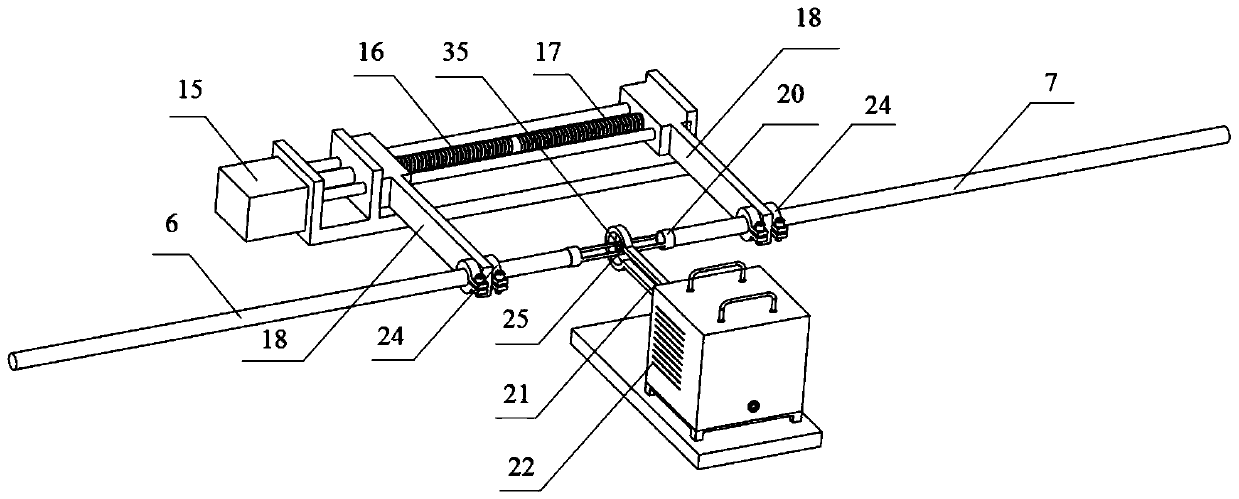

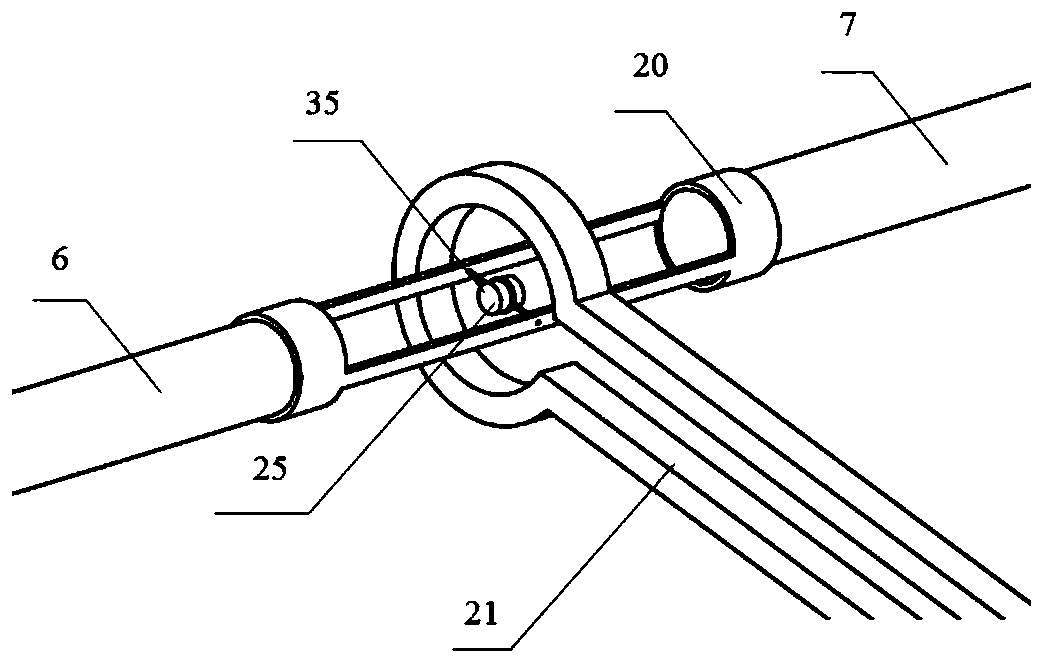

The invention discloses a comprehensive test stand for water-lubricated bearings for pumps. The comprehensive test stand comprises a driving transmission system, a main box, a bearing, a lubricating system, a loading system, a measuring system, a signal analyzing and processing system and the like, the driving transmission system consists of a variable-frequency motor, an elastic coupler, a step-up box and the like, the main box is a cube with a transparent top cover plate, and a spindle horizontally enters the box from a side wall, which is close to the end of the elastic coupler, of the main box. A pressure sensor, an eddy current sensor, a vibration acceleration sensor, a temperature sensor and the like are sequentially arranged and mounted on the spindle or around the spindle and used for acquiring displacement signals, rotation speed signals, phase signals, temperature signals, pressure signals, vibration signals and the like, and the sensed signals which are acquired by the various sensors in an online manner are transmitted to an upper computer to be processed, displayed and stored. The comprehensive test stand has the unique advantages of fine performance, high precision, low cost, environmental protection, zero pollution, friction reduction, energy conservation, noise and vibration reduction, fine fire resistance, easiness in maintenance and the like.

Owner:JIANGSU UNIV

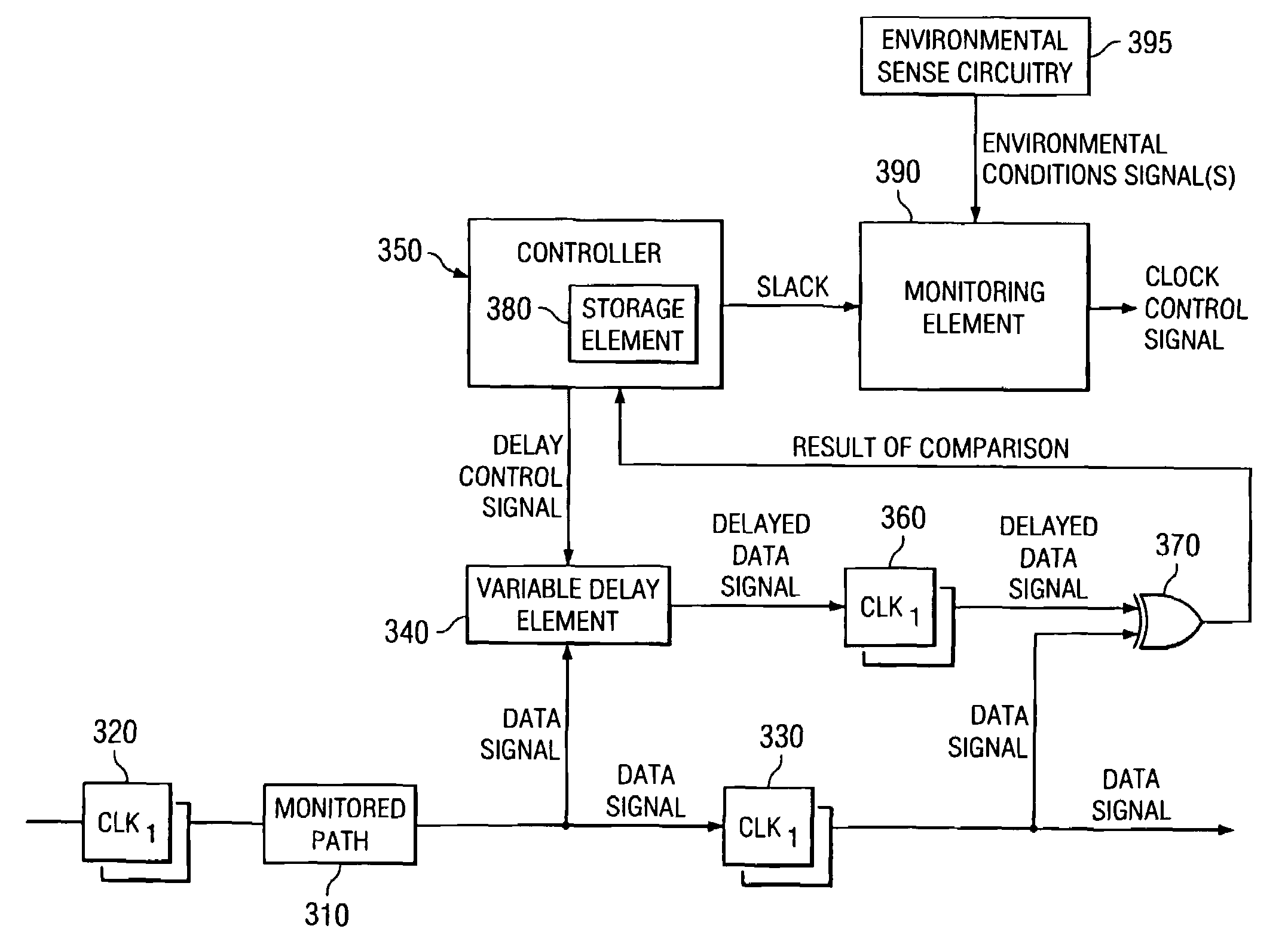

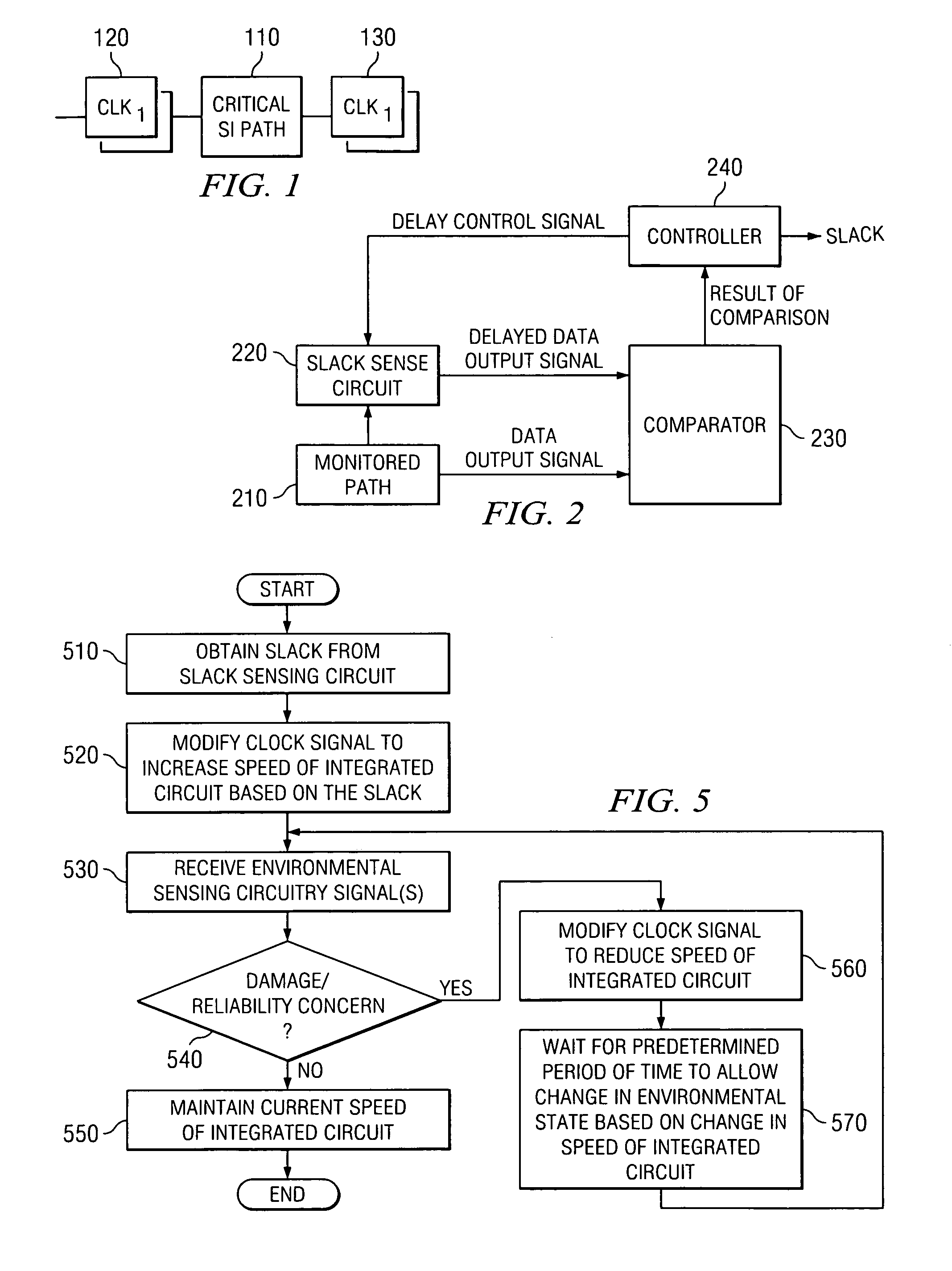

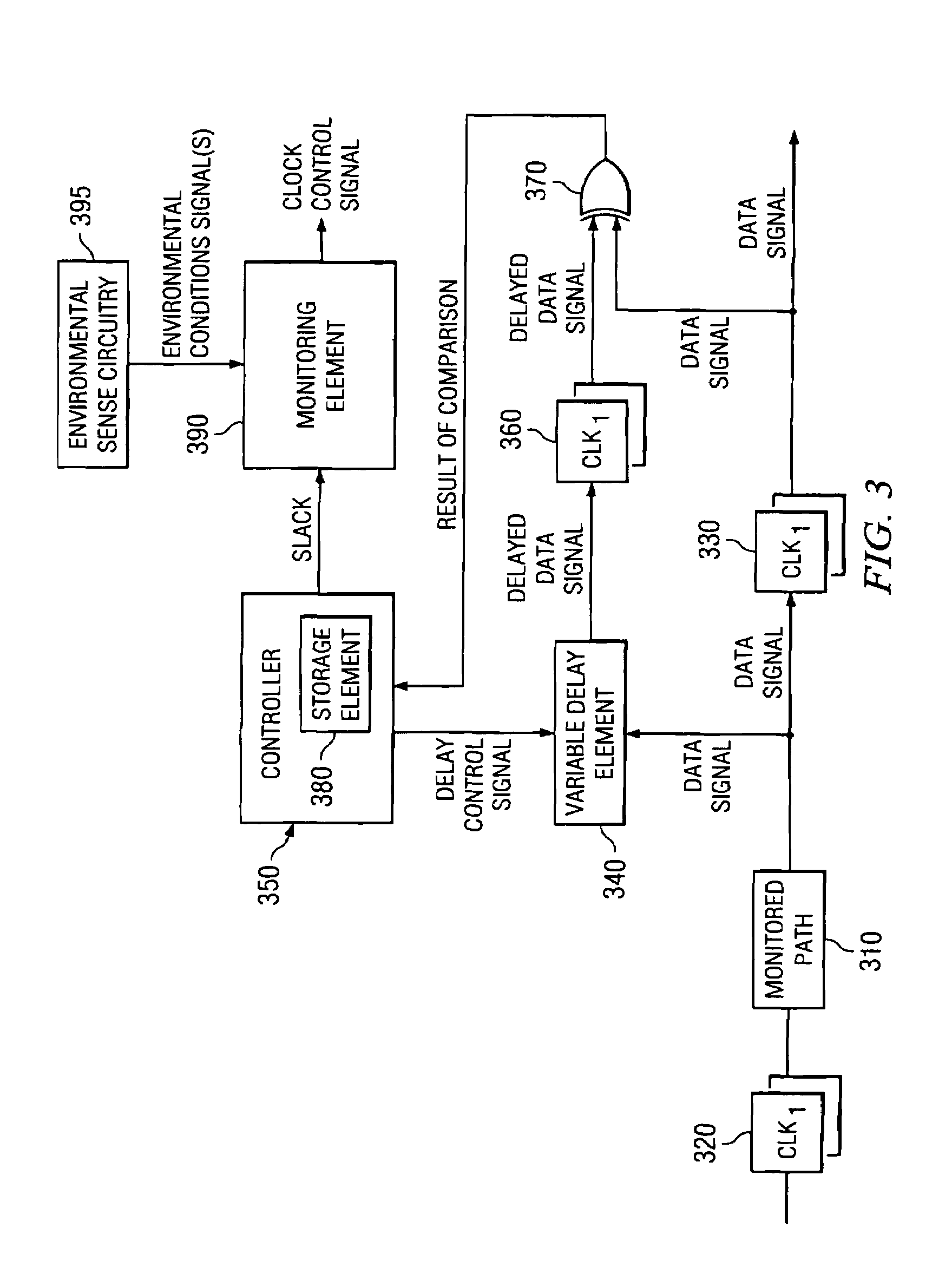

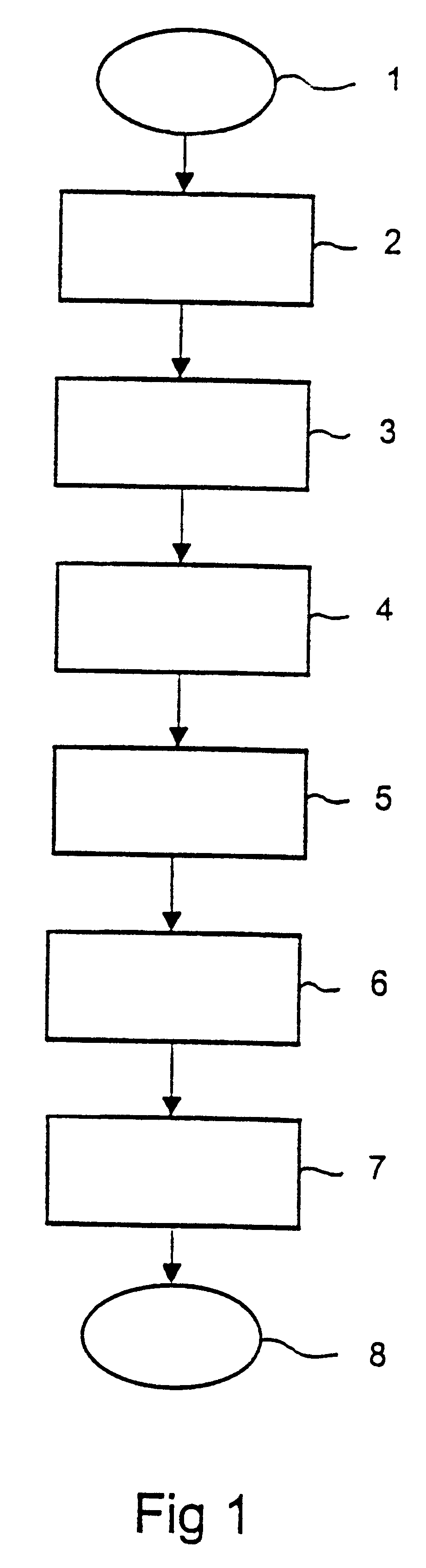

Apparatus and method for accurately tuning the speed of an integrated circuit

ActiveUS7116142B2Accurate speed regulationPulse automatic controlElectrical testingOriginal dataData signal

An apparatus and method for accurately tuning the speed of an integrated circuit, i.e. a computer chip, using a built-in sense circuit and controller are provided. The sense circuit is provided in association with a monitored path. The sense circuit includes a variable delay element coupled to a controller. A data signal from the monitored path is provided to the sense circuit which adds an amount of delay as determined by the controller to the data signal. The delayed data signal and the original data signal are compared to determine if their values match. If they match, then the amount of delay added by the variable delay element is increased. If they do not match, then a previous amount of delay, prior to the mismatch, is output as the slack of the monitored path. The slack may then be used to tune the speed of the integrated circuit.

Owner:IBM CORP

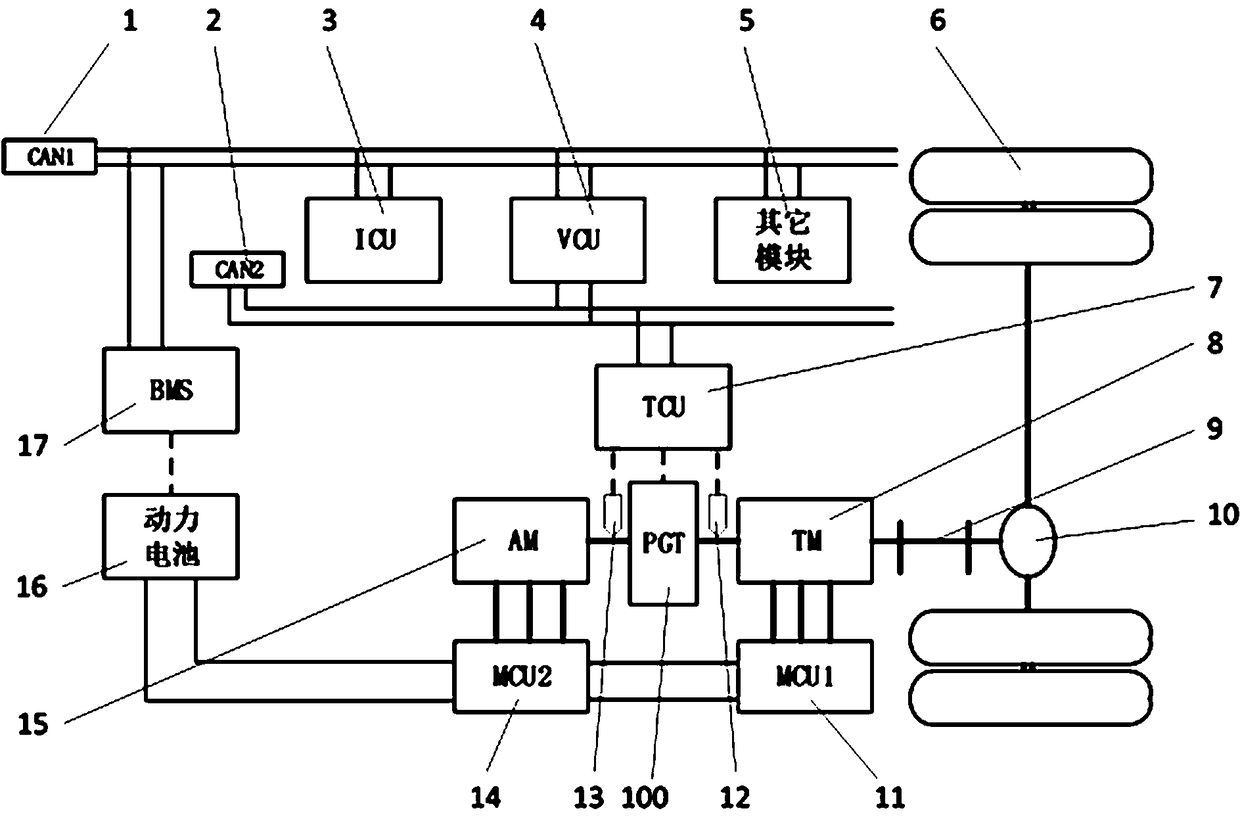

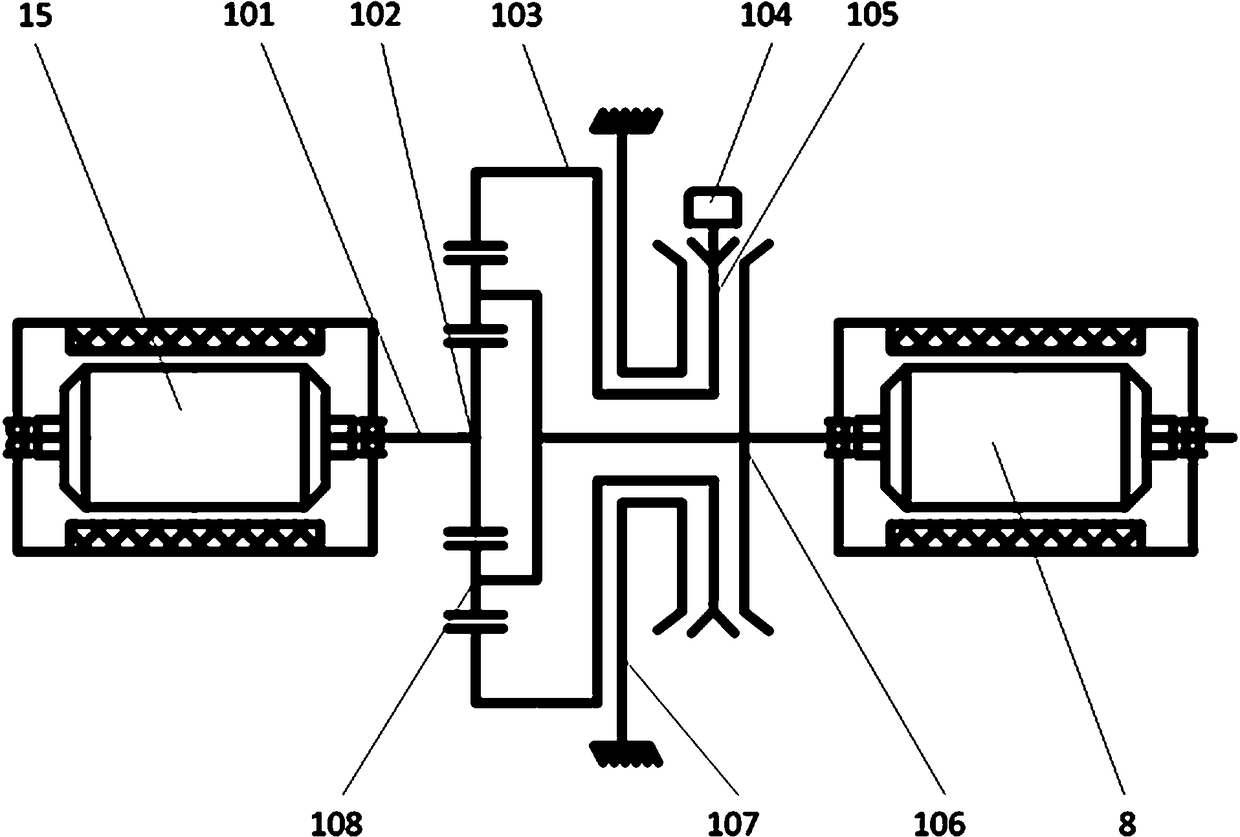

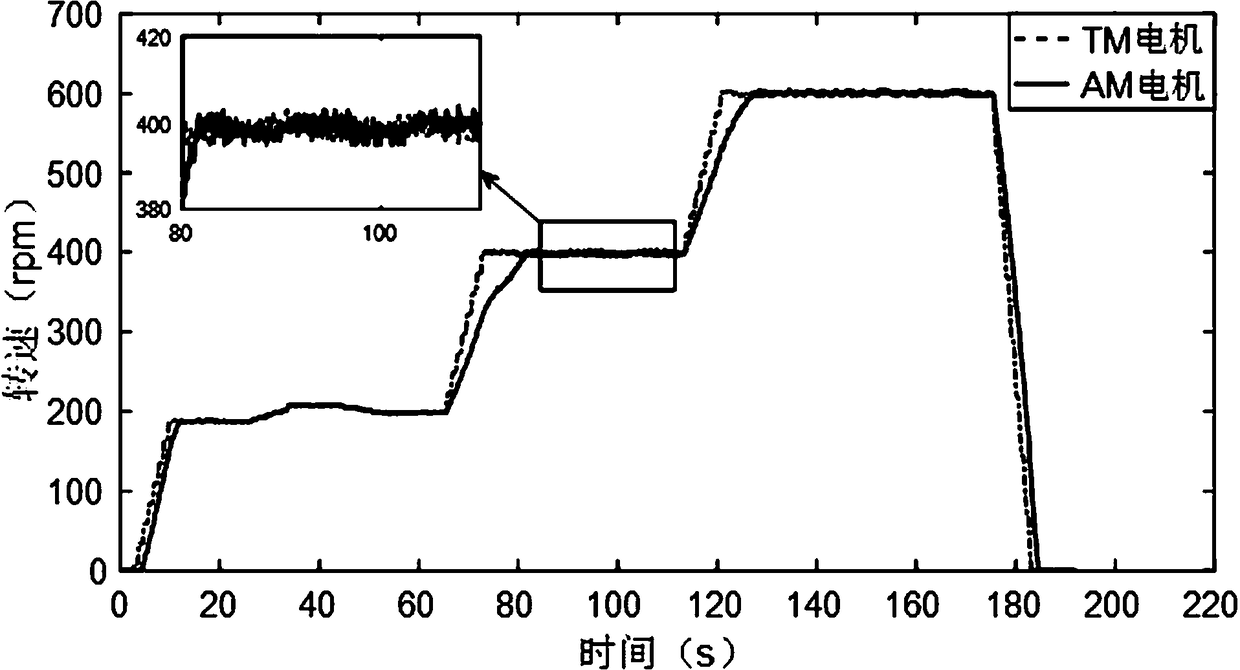

Double-motor self-adaptive speed pre-regulating multi-gear power coupling device and control method thereof

PendingCN108312896ASimplify the shifting processThere will be no phenomenon such as cyclic shiftingSpeed controllerControl devicesPower couplingDrive shaft

The invention relates to a double-motor self-adaptive speed pre-regulating multi-gear power coupling device and a control method thereof. The double-motor self-adaptive speed pre-regulating multi-gearpower coupling device comprises a main driving motor (8), a planetary line speed change device (100), an auxiliary motor (15), a vehicle transmission shaft (9) and a vehicle driving axle (10); the planetary line speed change device (100) comprises a planet gear mechanism and a double-way combining device (105); the planet gear mechanism comprises a planetary line sun gear (102), a planetary linegear ring (103), a planetary line planet carrier (108) and a planetary line shell (107); and the planetary line gear ring (103) is jointed with the planetary line shell (107) or a planet carrier output shaft (106) through the double-way combining device (105). Compared with the prior art, the double-motor self-adaptive speed pre-regulating multi-gear power coupling device has the advantages that running requirements of a pure electric bus can be satisfied, the rotation speed of the motor can be pre-regulated before the gear shifting process, self-adaptive speed regulation is realized to a certain degree, and the rotation speed relation is automatically regulated and matched according to gear shifting needs in any running state.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

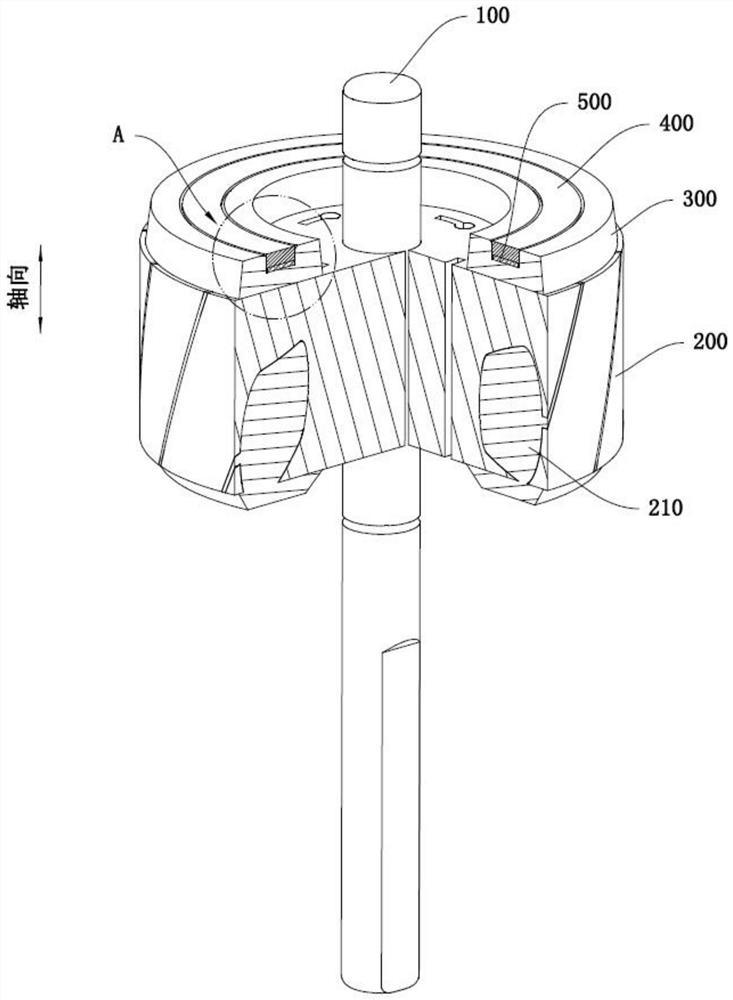

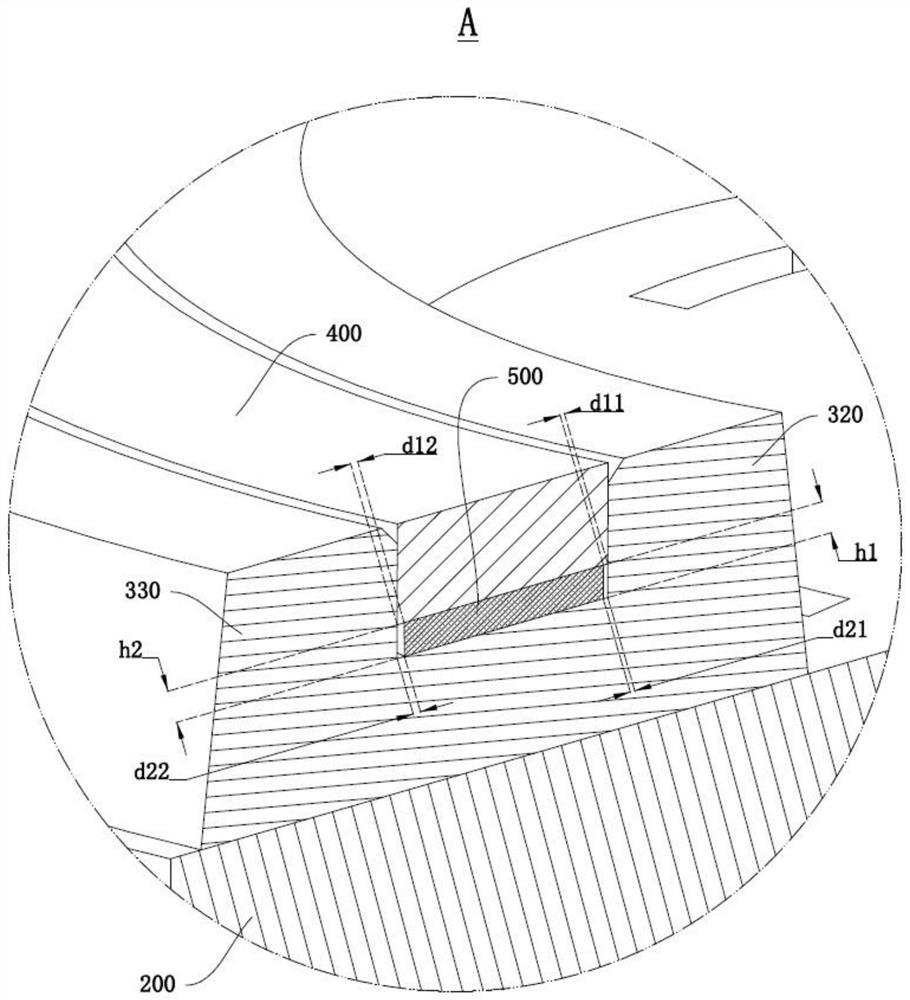

Rotor slippage complementary exciting permanent-magnetic brushless variable speed motor

InactiveCN102064656AIncrease speedRealize field weakening speed regulationMagnetic circuit rotating partsMagnetic/electric field screeningMagnetic sourceElectric machine

The invention discloses a rotor slippage complementary exciting permanent-magnetic brushless variable speed motor. A rotor of the motor is connected with a motor rotating shaft through a spline and can move along the axial direction; two groups of polarity-complementation exciting magnetic sources are arranged on the periphery of the rotor side by side, wherein one group is main flux source exciting bodies, and the other group is secondary flux source exciting bodies; the main and the secondary flux source exciting bodies are arranged with alternated polarities by permanent magnets with the same number respectively to form rings; the polarity distribution on the circumference of the secondary flux source exciting bodies is spaced by one polar distance from the polarity distribution on the circumference of the main flux source exciting bodies; a roller path disc is fixedly connected on the motor rotating shaft, and the roller path disc and a conical cavity at one end of the rotor form a wedge-shaped space; and a plurality of rollers for pushing the rotor to move along the axial direction by eccentric motion are arranged in the wedge-shaped space. In the invention, the rotor moves along the axial direction to reduce the flux so as to change the torque / rotational speed property of the motor and realize speed variation, which improves the mechanical property of the permanent-magnetic brushless variable speed motor per se, enlarges the full-power speed adjusting range of the motor, keeps the volume of the motor and saves the production cost.

Owner:杨荷

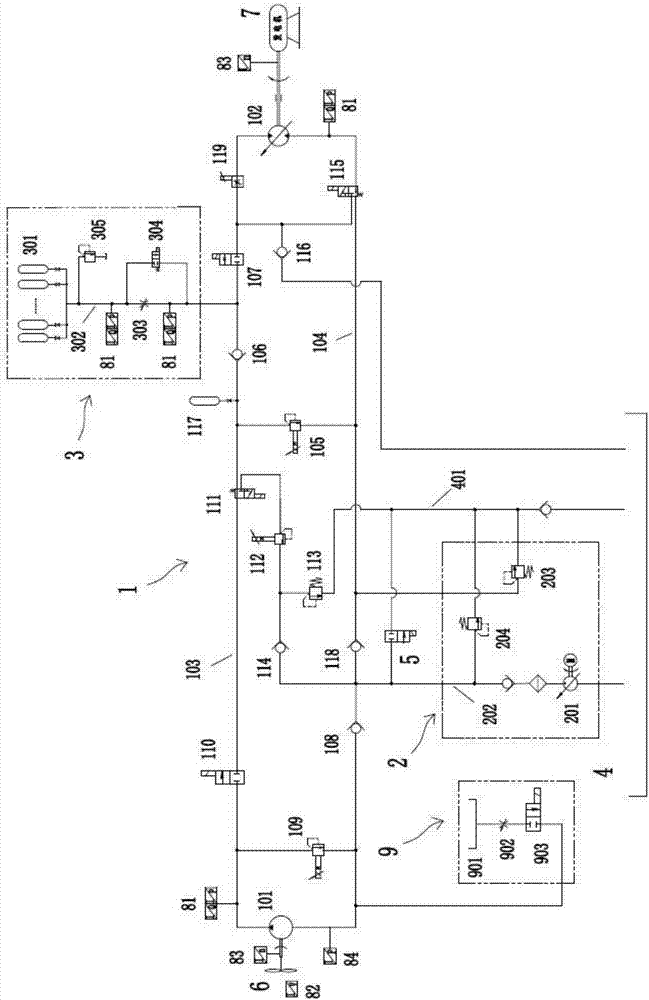

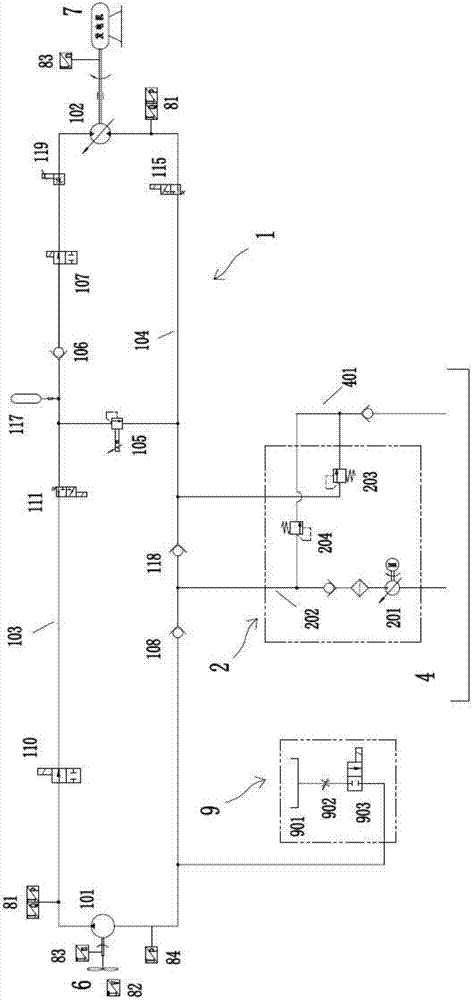

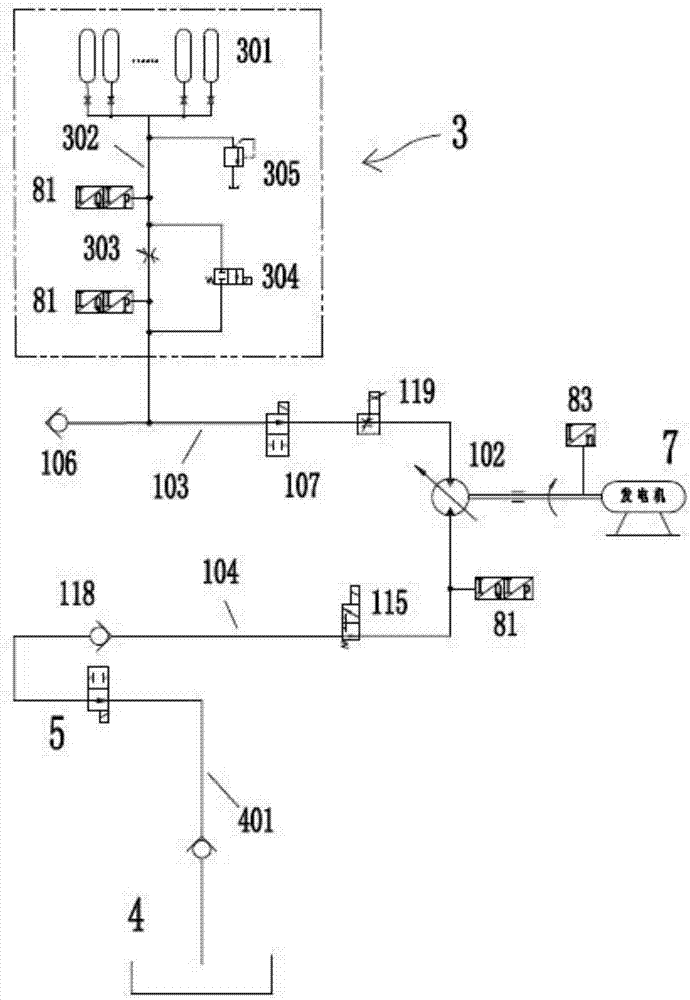

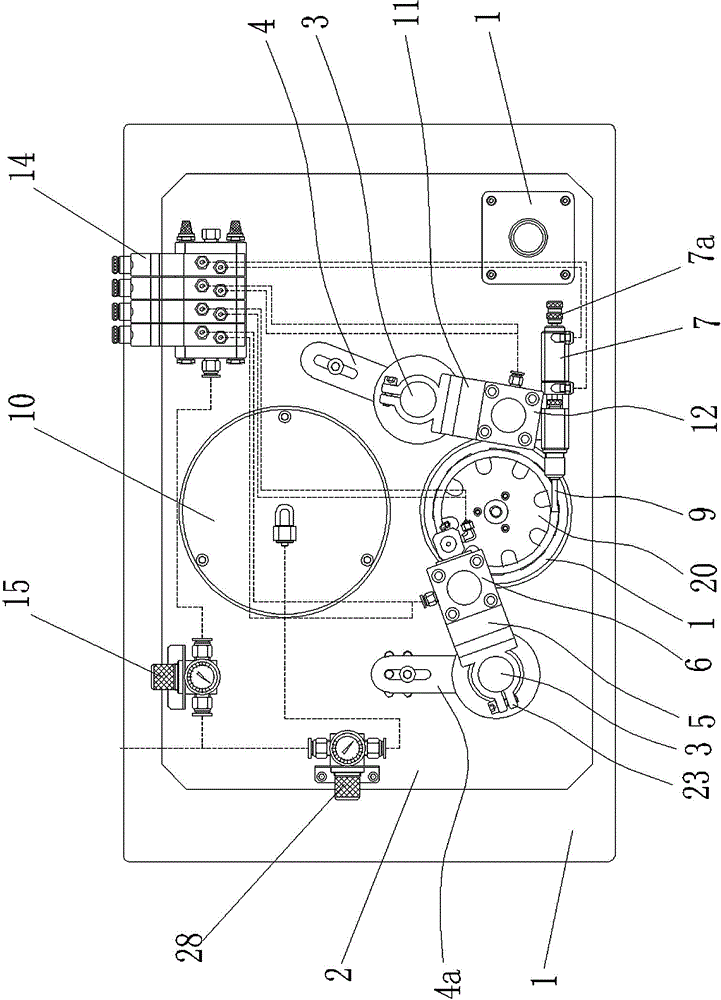

Static liquid energy storage hydraulic transmission type wind power generation set and control method

ActiveCN106870289AEasy to installEasy maintenanceWind motor controlEngine fuctionsFuel tankHydraulic pump

The invention belongs to the technical field of wind power generation control and discloses a static liquid energy storage hydraulic transmission type wind power generation set in order to solve the problems that in the actual operation process, existing wind power generation sets are unstable in power generation power due to unstable wind speed and are complicated in equipment structure during speed changing through a gear box structure. The wind power generation set comprises a main circulating system, a ground oil supplementing system, an energy storage system, a main oil tank, a first stop valve, a wind wheel and a generator, wherein the main circulating system comprises a hydraulic pump connected with the wind wheel, and a variable motor connected with the generator. According to the static liquid energy storage hydraulic transmission type wind power generation set, power fluctuation caused by wind speed change can be restrained; and in addition, the swing angle of the variable motor is adjusted according to the rotating speed of the wind wheel, thus, the output rotating speed of the variable motor is controlled, the rotating speed of the generator is stabilized, tends to the power frequency rotating speed and reaches the deviation range required by the grid-connected frequency, and grid-connected power generation is achieved more easily.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

High-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method

ActiveCN110196199APrecise dynamic compression mechanical propertiesPrecise control of hot and cold contact timeMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesPilot systemDirect test

The invention relates to a high-temperature Hopkinson tensile bar test system by using two-way electromagnetically-driven synchronous assembly and method. A high-temperature Hopkinson tensile bar system and a high-temperature compression test method which use an accurate electromagnetically-driven two-way synchronous sliding assembly system and a high-frequency electromagnetic induction rapid heating method are built. According to the device in the invention, a set of electromagnetic control device, a set of electromagnetically-driven two-way synchronous assembly device and two high-precisiondelay devices are additionally arranged on the conventional Hopkinson tensile bar, the starting and ending time of each process including an impact process, a heating process and a loading rod synchronous assembly process during the high-temperature dynamic compression test can be accurately controlled, and the cold and hot contact time during the whole test process can be further accurately controlled. A control component is designed in an integrated module mode, the test accuracy is improved, and the dynamic compression mechanical properties of the material at a high temperature can be accurately and directly tested.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

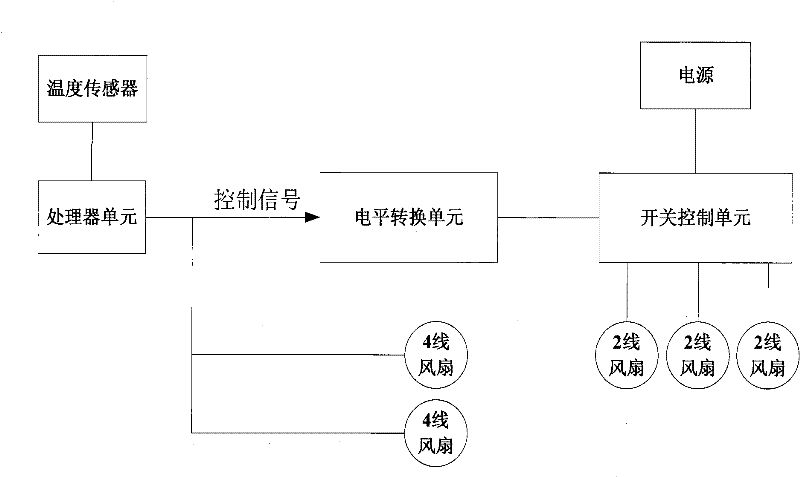

A device and method for adjusting the speed of a fan

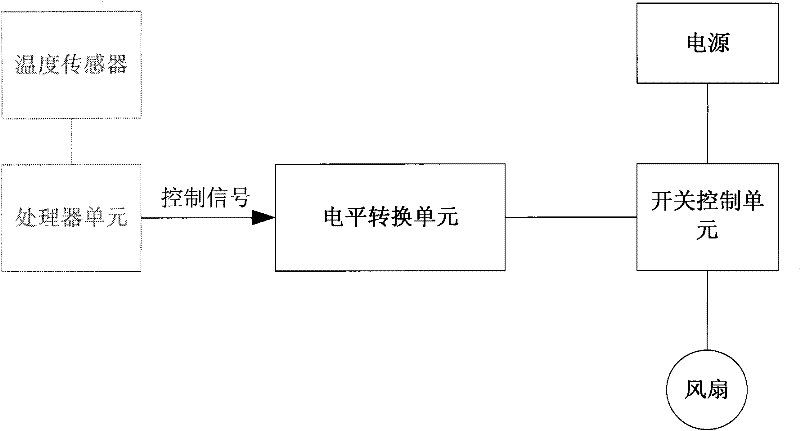

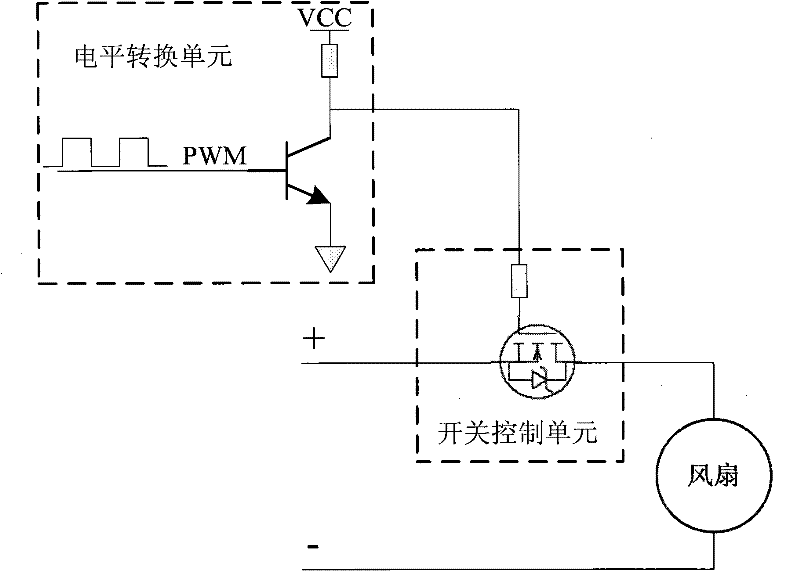

InactiveCN102261343AEasy to implementReduce power consumptionField or armature current controlEfficient regulation technologiesControl signalInput control

A device and a method of fan speed regulation comprise: an electrical level conversion unit used for carrying out electrical level conversion on an input control signal, and a switch control unit used for controlling the power of the fan to switch-on or break according to the signal outputted by the electrical level conversion unit. The device and method are easy to realize, with low power consumption and low cost, and can achieve multiple rotating speed gears which can accurately regulate the speed and obtain good effect according to need.

Owner:ZTE CORP

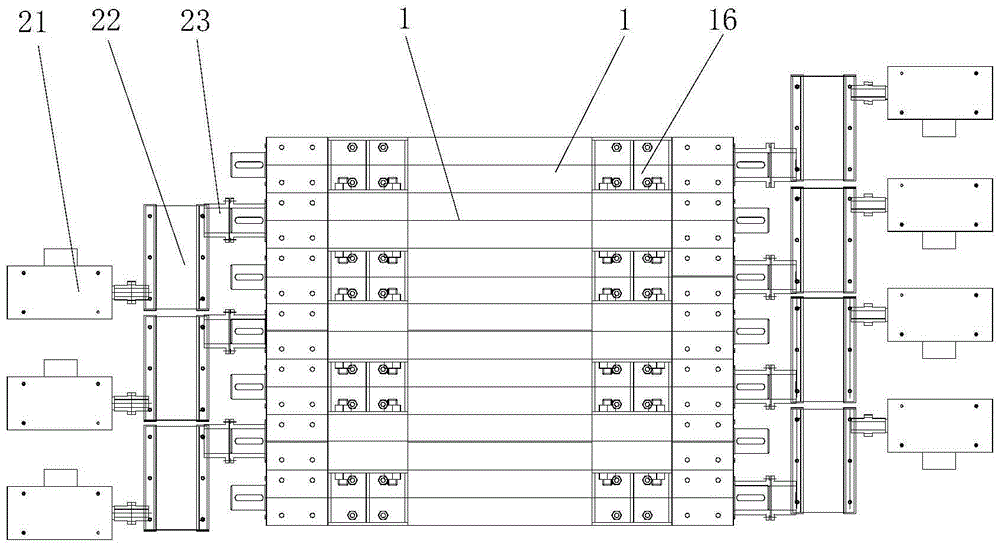

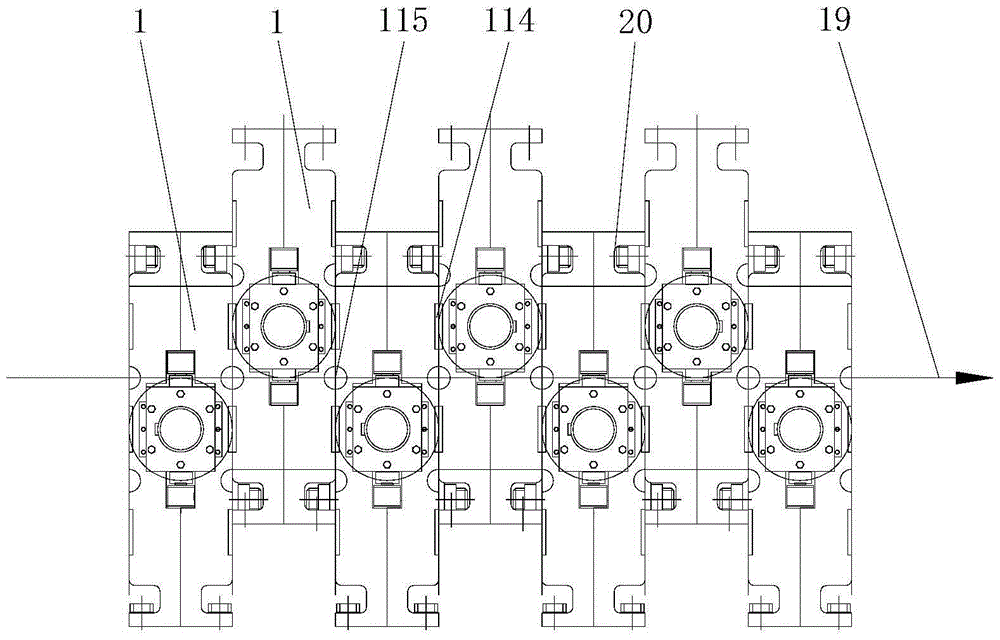

Combined type straightening machine

The invention discloses a combined type straightening machine. The combined type straightening machine comprises at least three detachable straightening roll devices. Each straightening roll device is connected with a drive device. Every two adjacent straightening roll devices are movably connected and arranged in an up-down staggered mode. Plates or profiles are straightened by the straightening roll devices by penetrating through the straightening roll devices which are arranged in the up-down staggered mode. According to the combined type straightening machine, the straightening roll devices are movably connected and arranged in the up-down staggered mode, and compared with an existing straightening machine of a fixed structure, the roll number and the roll distance of the straightening machine can be changed by increasing or decreasing the number of the straightening roll devices according to needs without replacing the whole straightening machine. The weight of a machine frame of the straightening machine can be lowered, the size can be decreased, the rigidity can be improved, and the straightening technological requirement of the plates or profiles of different thicknesses can be met. Moreover, each straightening roll device is connected with the corresponding drive device, and the roll speed of each straightening roll device can be automatically adjusted, so that the plates or the profiles are better straightened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

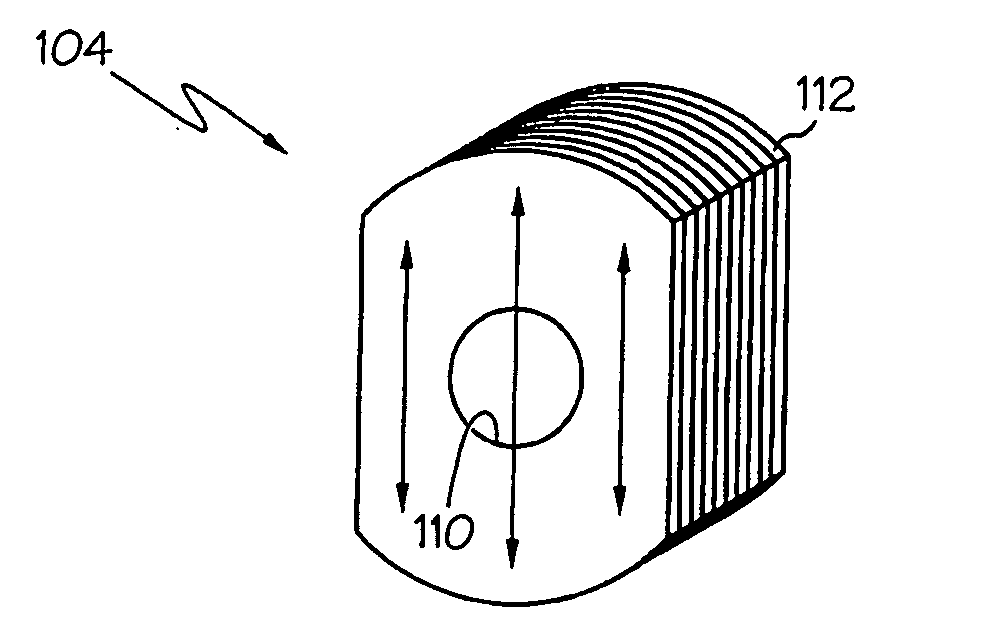

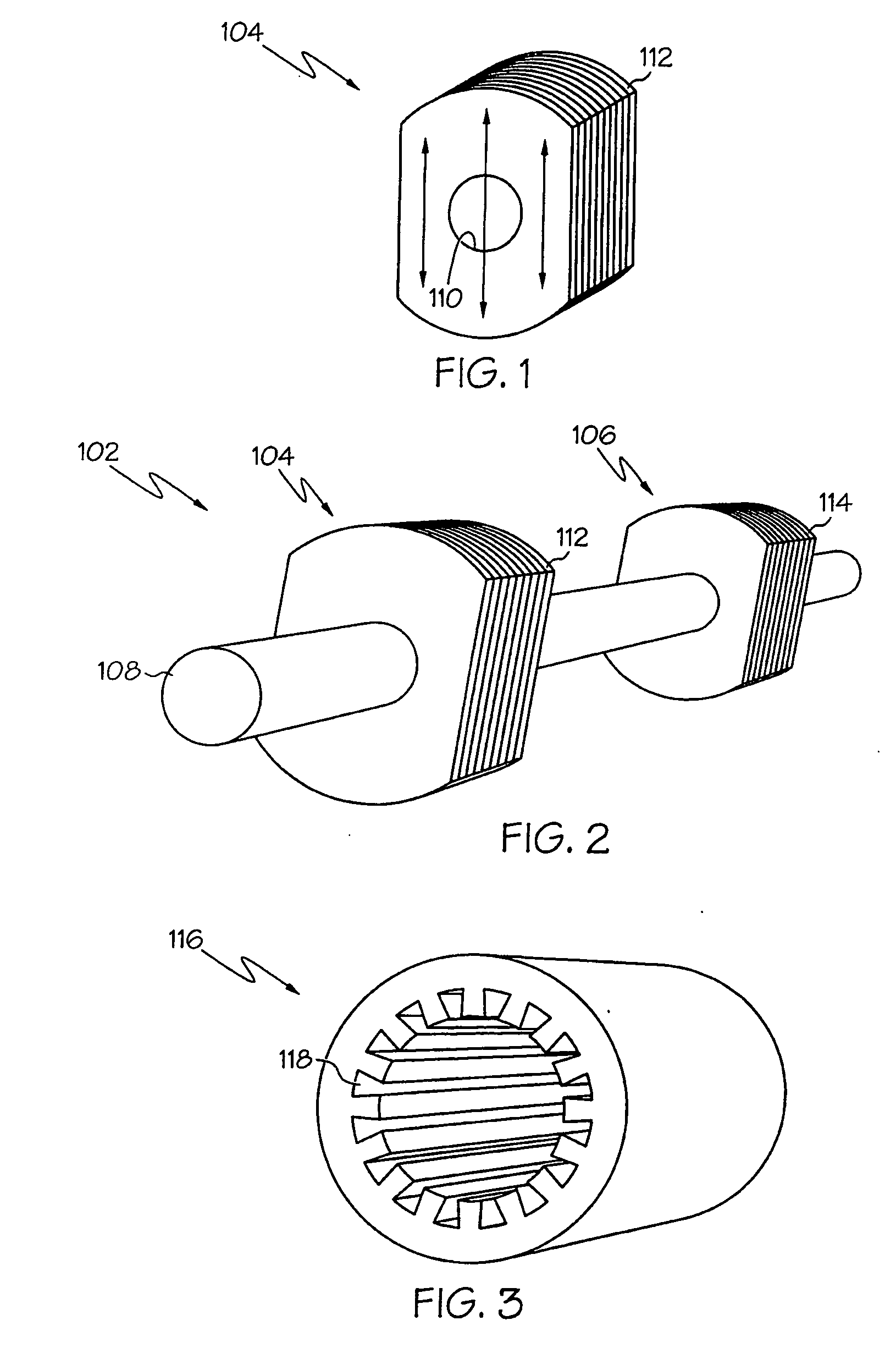

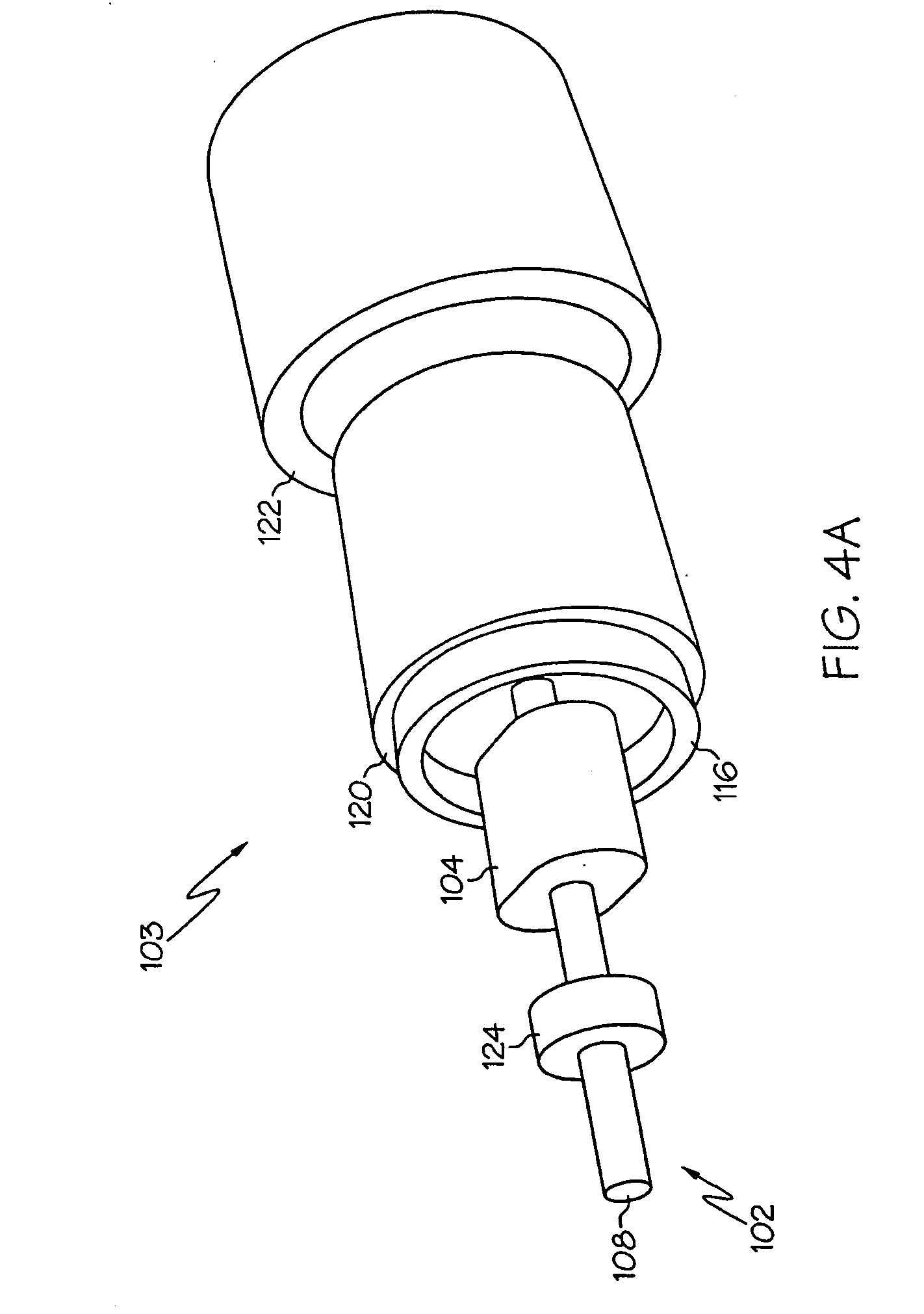

Differential flux permanent magnet machine

InactiveUS20050275303A1Easy to operateAccurate speed regulationMagnetic circuitSynchronous motorsPhysicsMagnet

A differential flux motor includes a rotor and a stator assembly. The rotor has a shaft and rotor section(s) attached to the shaft. The stator assembly has first and second stator cores, first and second magnets, and a shell. The first stator core includes a first winding and concentrically surrounds at least a portion of the rotor. The second stator core has a second winding and concentrically surrounds at least a different portion of the rotor. The first magnet concentrically surrounds at least part of the first stator core, and the second magnet concentrically surrounds at least part of the second stator core. The first and second magnets are formed from permanent magnet material and have opposite polarities. The shell concentrically surrounds at least part of each of the first magnet and the second magnet. A method of manufacturing a differential flux motor is also provided.

Owner:TETMEYER MICHAEL EDWARD

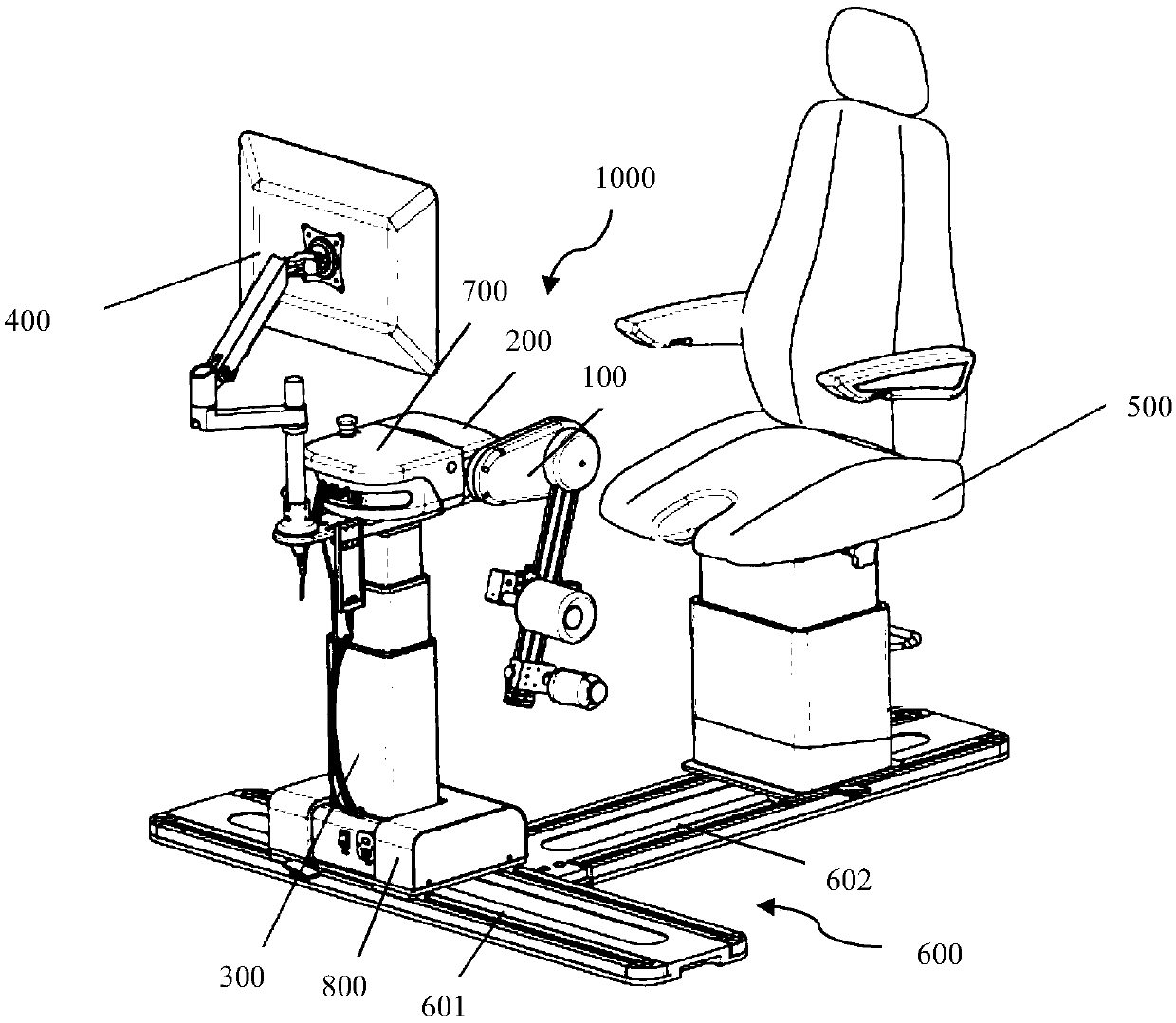

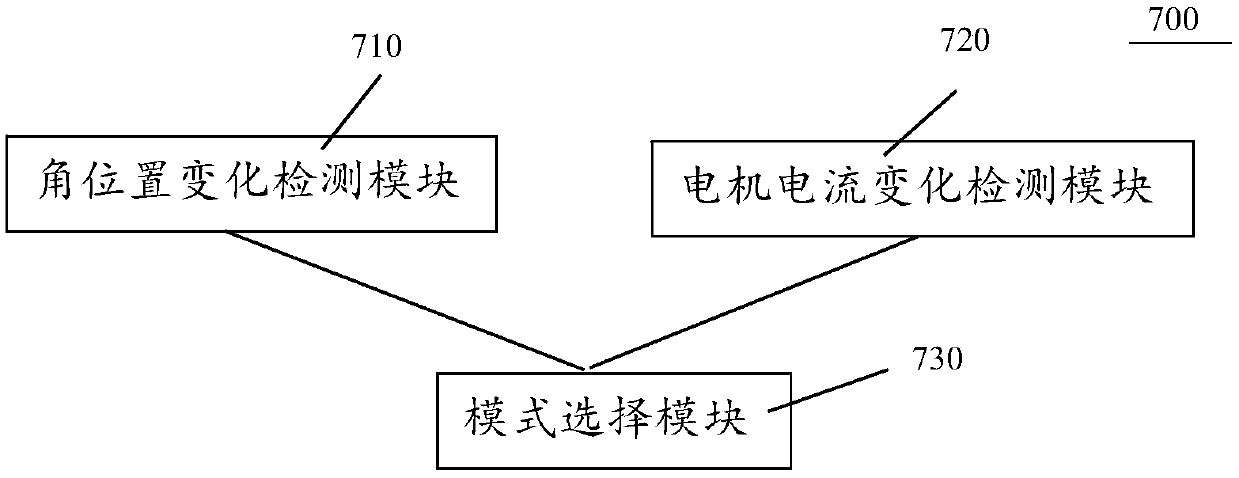

Knee joint training adapter, rehabilitation training equipment and training control method

PendingCN110393895AIncrease joint mobilityEnsure safetyChiropractic devicesMuscle exercising devicesMuscle strengthKnee Joint

The invention discloses a knee joint training adapter, rehabilitation training equipment and a training control method thereof. The knee joint training adapter comprises a knee joint adapter and a motion control host. The knee joint adapter comprises an adjuster, a position adjustment mechanism, a shank fixing piece and an ankle fixing piece; and the shank fixing piece and the ankle fixing piece are connected with the adjuster via the position adjustment mechanism. The motion control host comprises a driving motor and a control module; the adjustor is connected with the driving motor via a transmission mechanism; the control module is connected with the driving motor; and the control module comprises an angle position change detection module, a motor current change detection module and a mode selection module. According to the knee joint training adapter, the rehabilitation training equipment and the training control method thereof, the joint exercise of the patient can be assisted, the muscle strength can be enhanced, the joint activity can be improved, and the stiff joints can be drawn to loosen.

Owner:BEIJING LTK REHAB TECH LTD +1

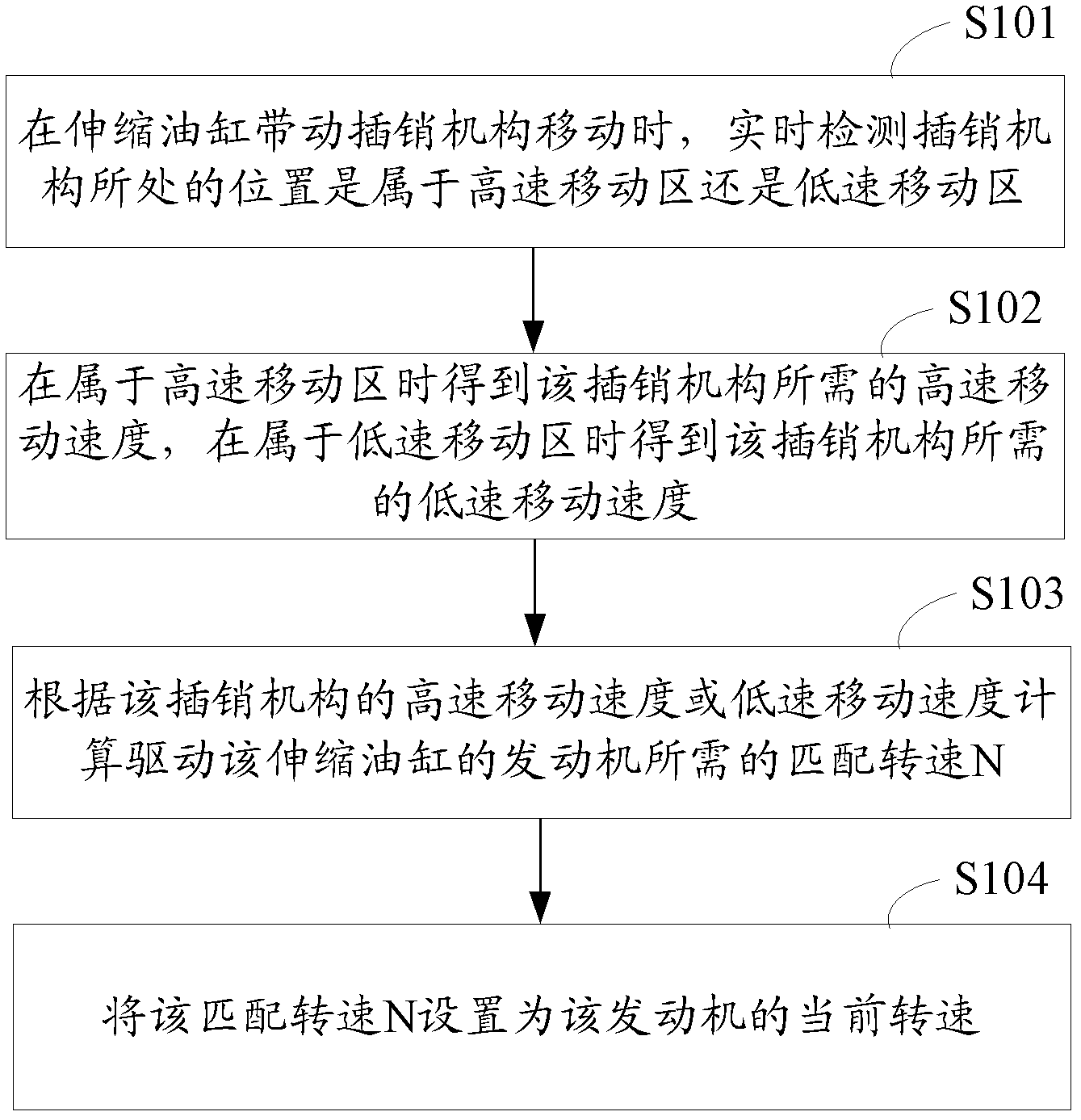

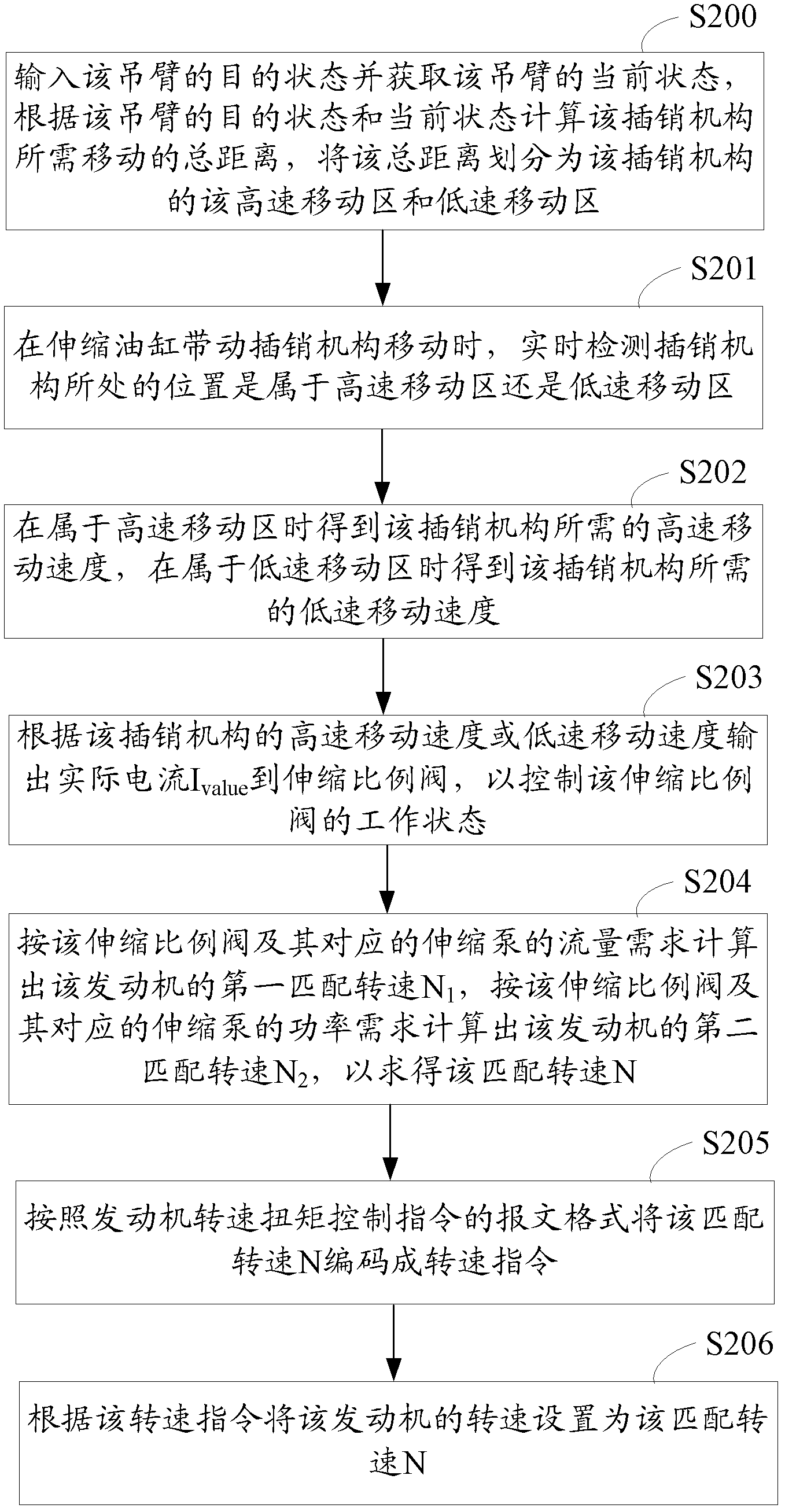

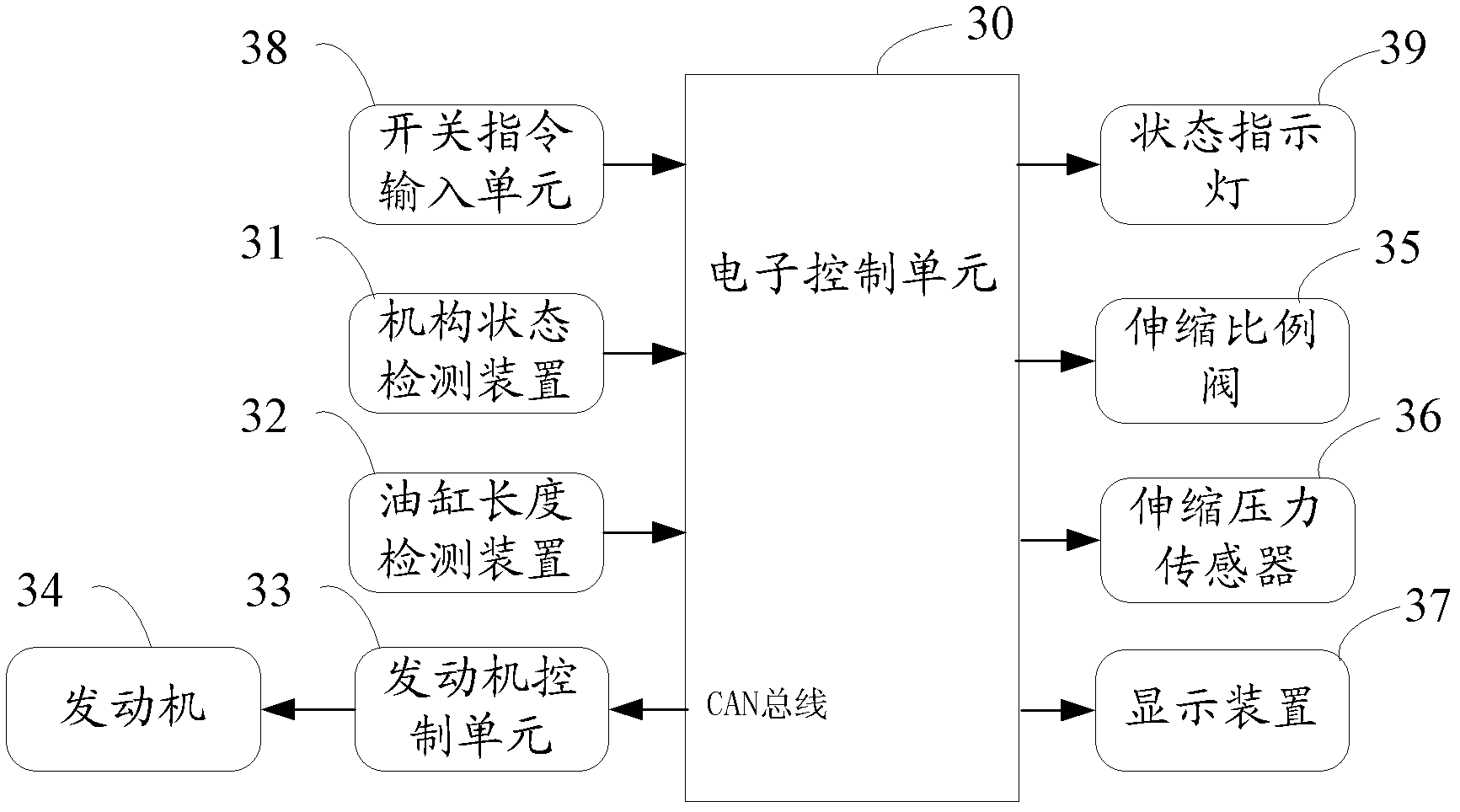

Telescopic follow-up control method and system of suspension arm

ActiveCN102637047AAccurate speed regulationHigh precisionLoad-engaging elementsSpeed/accelaration control without auxillary powerRisk factorMoving speed

The invention discloses a telescopic follow-up control method and a system of a suspension arm. The method comprises the steps of: detecting whether the position of a latch pin mechanism is located in a high speed moving region or a low speed moving region when a telescopic oil cylinder drives the latch pin mechanism to move; obtaining the high speed moving speed required by the latch pin mechanism in the high speed moving region, and obtaining the low speed moving speed required by the latch pin mechanism in the low speed moving region; calculating a matched rotating speed N required for driving the engine of the telescopic oil cylinder according to the high speed moving speed or the low speed moving speed of the latch pin mechanism; and setting the matched rotating speed N as the current rotating speed of the engine. According to the embodiment of the invention, the matched rotating speed N required for driving the engine is calculated according to the moving speed of the latch pin mechanism and the rotating speed of the engine is intelligently and accurately adjusted to be the matched rotating speed N, so that the rotating speed of the engine is matched with the expansion speed of the latch pin mechanism, thereby avoiding the risk factors caused by manual operation errors and improving the working efficiency.

Owner:ZOOMLION HEAVY IND CO LTD

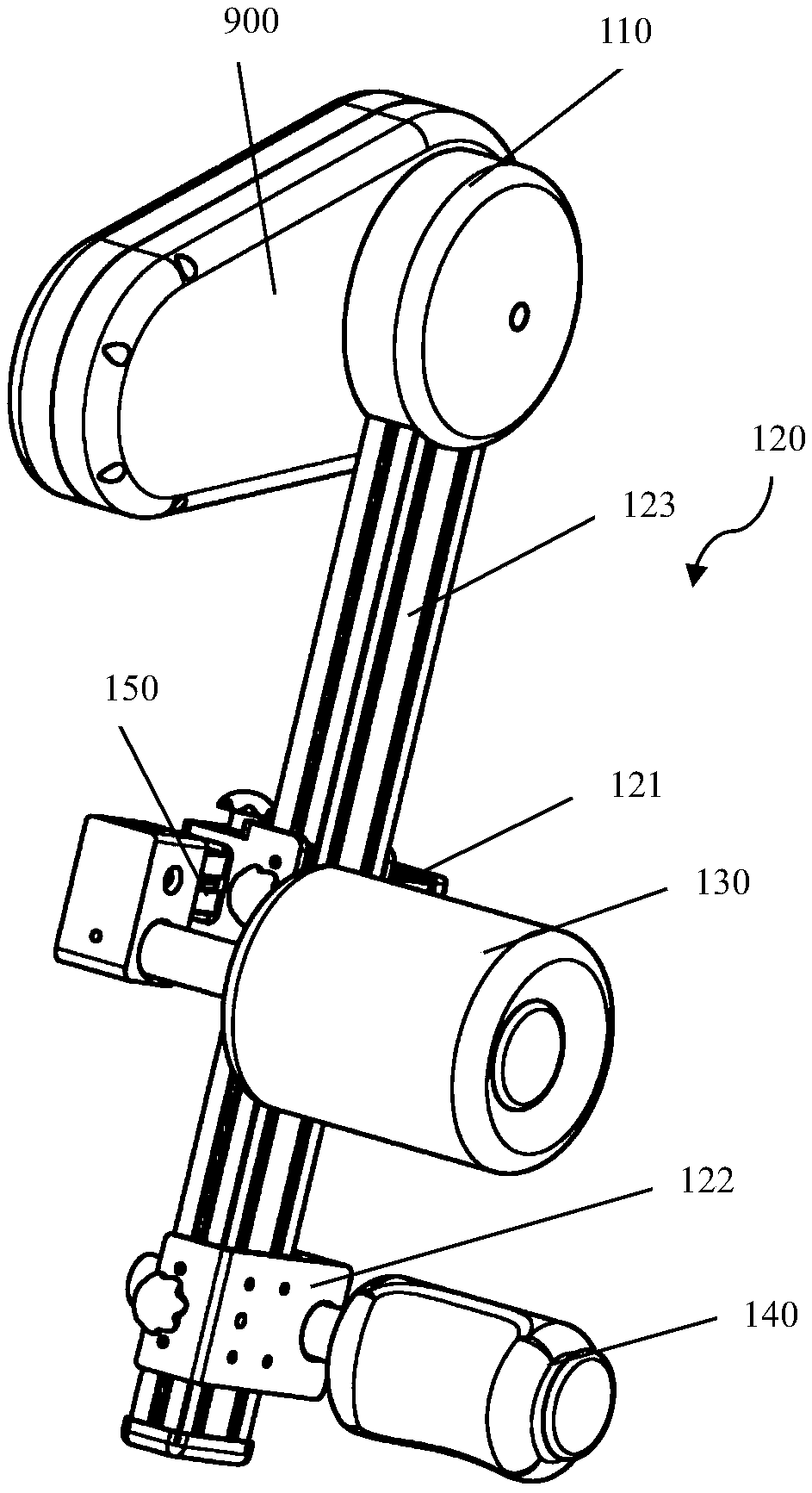

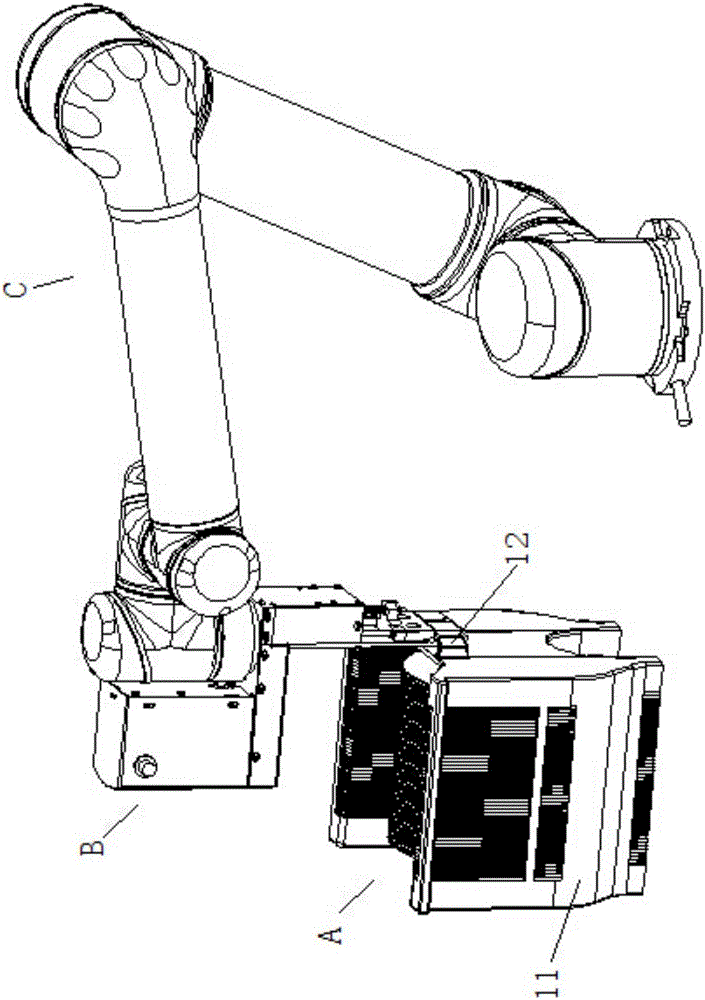

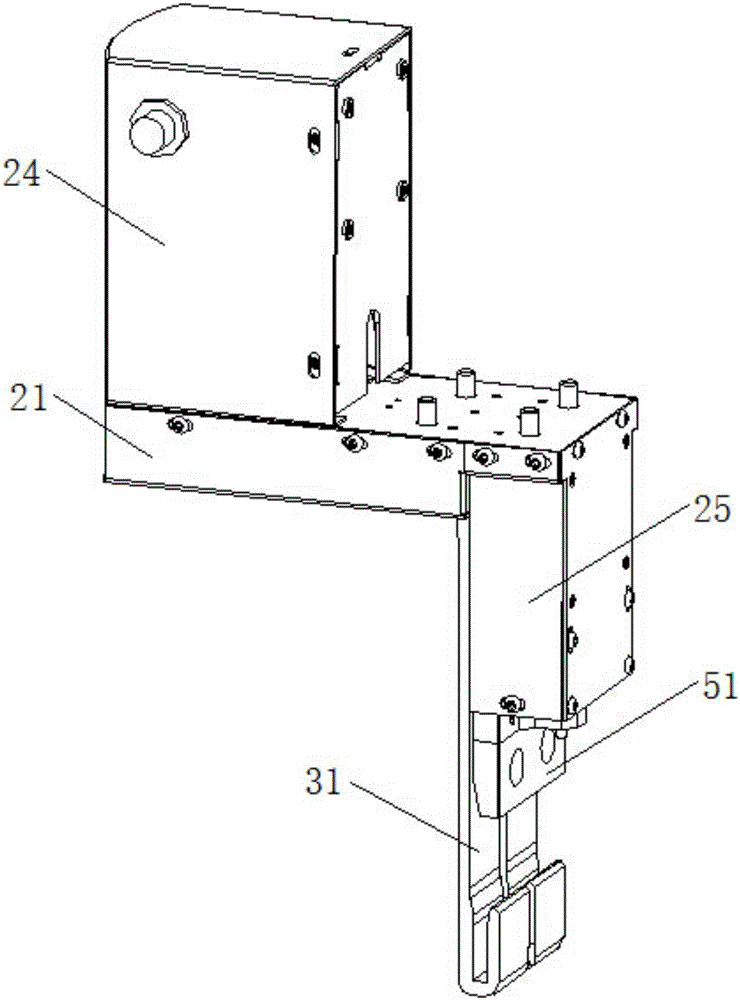

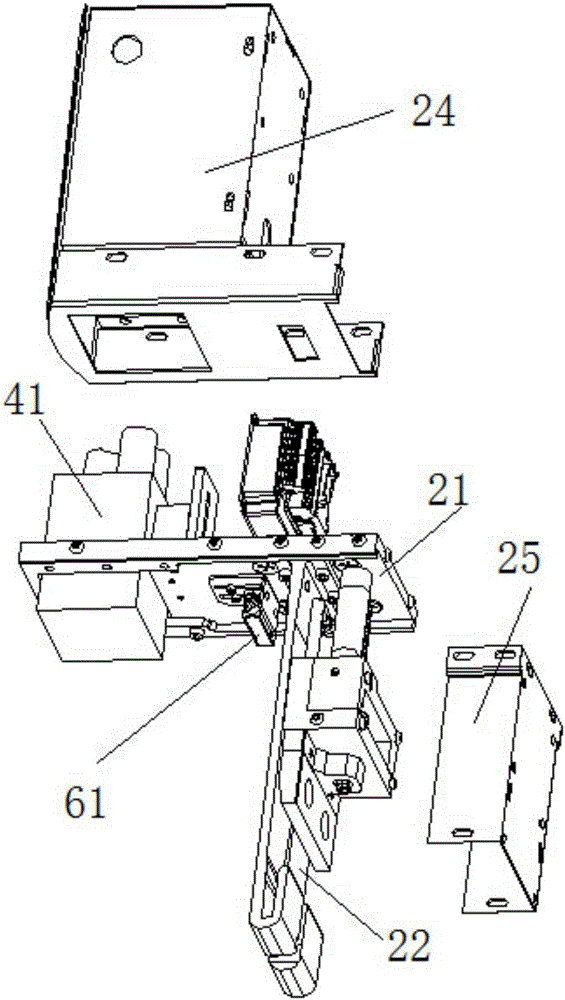

Reliable and efficient carrying mechanical arm used for wafer cassette

ActiveCN106393105AEliminate the effects of positional deviationEnsure safetyProgramme-controlled manipulatorGripping headsUnit/actuationManipulator

The invention discloses a reliable and efficient carrying mechanical arm used for a wafer cassette. The wafer cassette comprises a cassette body and a handle, the handle is roughly in a U shape in an overlooked manner, the mechanical arm comprises a paw, a positioning sensor and a locking mechanism, the paw is roughly in a J shape in a side-looking manner, the positioning sensor is arranged on the side of a non-bending hook of the paw and is communicated with a carrying controller, the locking mechanism comprises a locking block, a locking drive unit and a locking controller, the locking block is arranged on one side of a bending hook of the paw, the locking drive unit drives the locking block to vertically move, and the locking block ascends to enable the lower end of the locking block to be away from the bending hook free end of the paw or descends to enable the lower end of the locking block to abut against the bending hook free end of the paw. The mechanical arm is small in size and compact in structure and has the vision identifying and sensing detection function, and a material locking mechanism is arranged on a mechanical structure. It is ensured that the mechanical arm can accurately and reliably grab the wafer cassette, in the carrying process, the wafer cassette can be prevented from sliding off, and efficient and reliable work is achieved.

Owner:SUZHOU XINYOUHUA INVESTMENT ADVISOR CO LTD

Combined wind energy and hydraulic power varying generator

InactiveCN1740559AAccurate speed regulationReduce manufacturing difficultyWind motor controlFinal product manufactureWind forceElectricity price

The wind energy hydraulic power varying generator is one wind force power generator to convert wind energy into hydraulic energy to drive great power generator to produce electric power. The structural principle of the present invention is that the kinetic energy of several wind wheels are combined and converted into hydraulic energy mechanically, and the hydraulic energy is integrated into one powerful hydraulic transmission mechanism and used in driving one great power generator. The present invention has computer control to regulate hydraulic transmission and to stabilize rotation speed, and generator with varying power to output voltage. The present invention has simple structure, easy manufacture, low cost and great electrical power.

Owner:柳海源

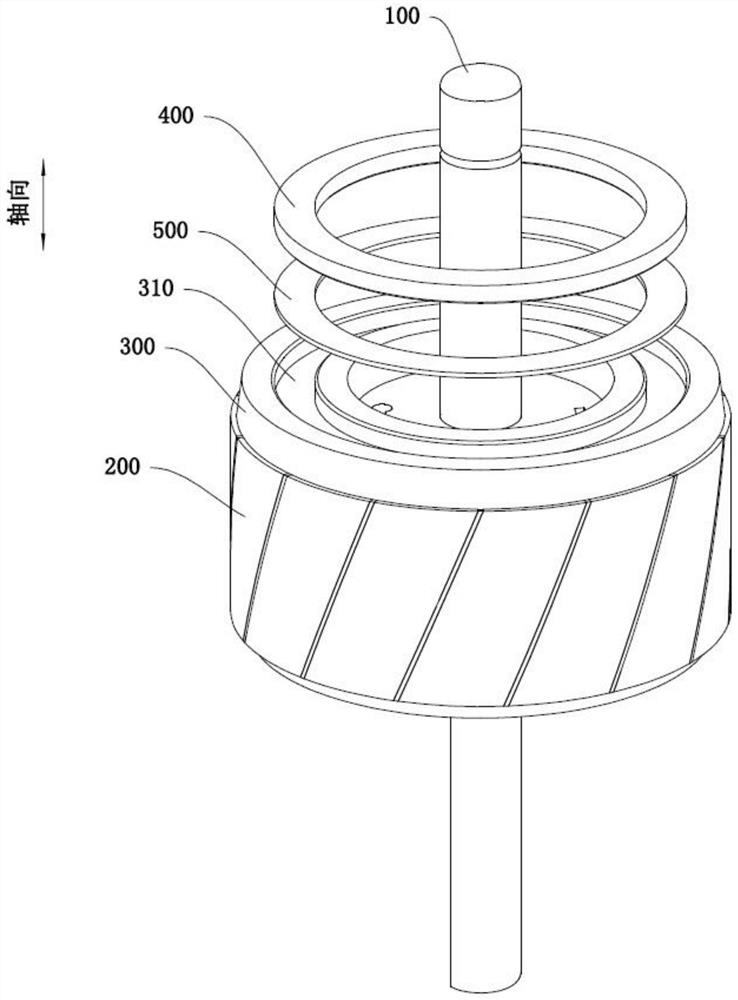

Rotor, motor and household appliance

ActiveCN113300542AImprove reliabilityAccurate speed regulationAsynchronous induction motorsStructural associationElectric machineEngineering

The invention discloses a rotor, a motor and a household appliance. The rotor comprises a rotating shaft, an iron core, an end ring, a magnet and a shielding part. The iron core is wound on the peripheral wall of the rotating shaft, the end ring is located at one end of the iron core in the axial direction of the rotating shaft, and a groove is formed in the end, away from the iron core, of the end ring. The magnet is mounted in the groove; the shielding part is made of a magnetic conductive material, the shielding part is installed in the groove and located on the side, facing the iron core, of the magnet, and due to the fact that the magnetic conductivity of the shielding part is far larger than that of air, more magnetic lines, penetrating through the groove, of a rotor magnetic field can pass through the shielding part to form a closed loop. Therefore, the influence of the rotor magnetic field on the magnetic field of the magnet is reduced, the interference of harmonic waves on the magnetic field induction device is reduced, the detection precision of the magnetic field induction device on the magnetic field of the magnet is improved, and the speed regulation precision of the motor is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Method for compensating inertia of sensor in rolling and unrolling system of coating machine

ActiveCN103287897AAutomatically adjust real-time speedKeep the tension constantWebs handlingProgrammable logic controllerData signal

The invention discloses a method for compensating inertia of a sensor in a rolling and unrolling system of a coating machine. According to the compensation method, the sensor is adopted for measuring a rolling diameter; a rolling diameter value is transmitted to an AD (analog-digital) conversion module, and the AD conversion module transmits a rolling diameter data signal to a PLC (programmable logic controller); and in the PLC, a corresponding rolling diameter value is taken as a control variable, a rotating speed is corrected, a set value of the corrected rotating speed is transmitted to an executing mechanism, and the executing mechanism automatically adjusts the rotating speed. According to the method for compensating the inertia of the sensor in the rolling and unrolling system of the coating machine, rolling and unrolling inertia and friction force can be accurately compensated, so that constant tension of a strip material is kept.

Owner:SNTO TECH GRP

Explosive loading equipment and explosive loading method of emulsion explosive

InactiveCN101823925AAccurate speed regulationImprove charging capacityExplosive working-up apparatusEmulsion explosiveEngineering

The invention discloses explosive loading equipment and an explosive loading method of emulsion explosive. The explosive loading equipment of the emulsion explosive is a multi-branch emulsion explosive film explosive loading machine which comprises a conveying pump, the downstream of the conveying pump is connected with a multi-path conveying pipeline, each path conveying pipeline is respectively connected with an explosive loading mechanism branch, a switching valve is respectively arranged on each branch, coil making machines, opening sealing machines and coil conveying mechanisms are arranged at the downstream of the switching valve, the emulsion explosive is conveyed by a pump through a plurality of branches, the branches are respectively provided with the coil making machines, the coil making machines continuously make coils and are matched with the conveying pump for sending a plurality of explosive coils in one step, the opening sealing machines are used for sealing openings and cutting off the explosive coils, and finally, the coil conveying mechanisms are used for conveying a plurality of explosive coils to a subsequent work procedure. The invention adopts a multi-branch and multi-station continuous conveying method for realizing large-production-capacity explosive loading.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

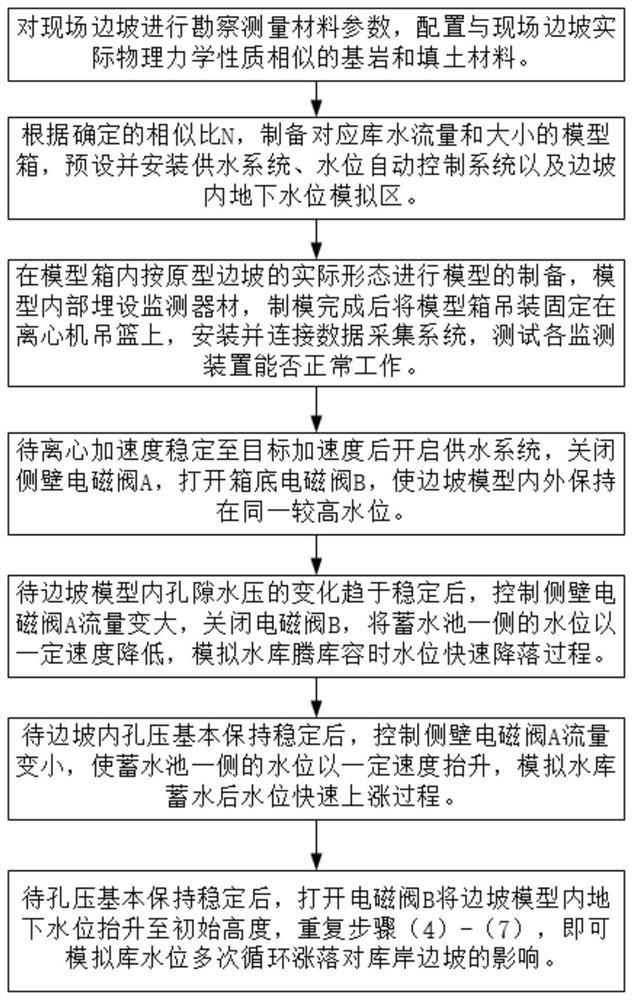

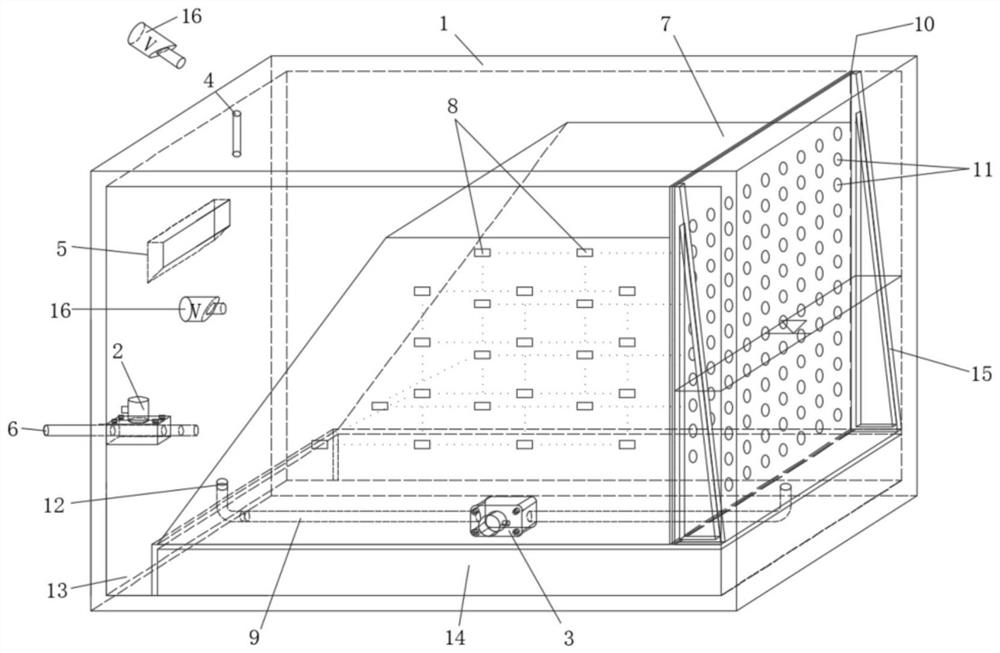

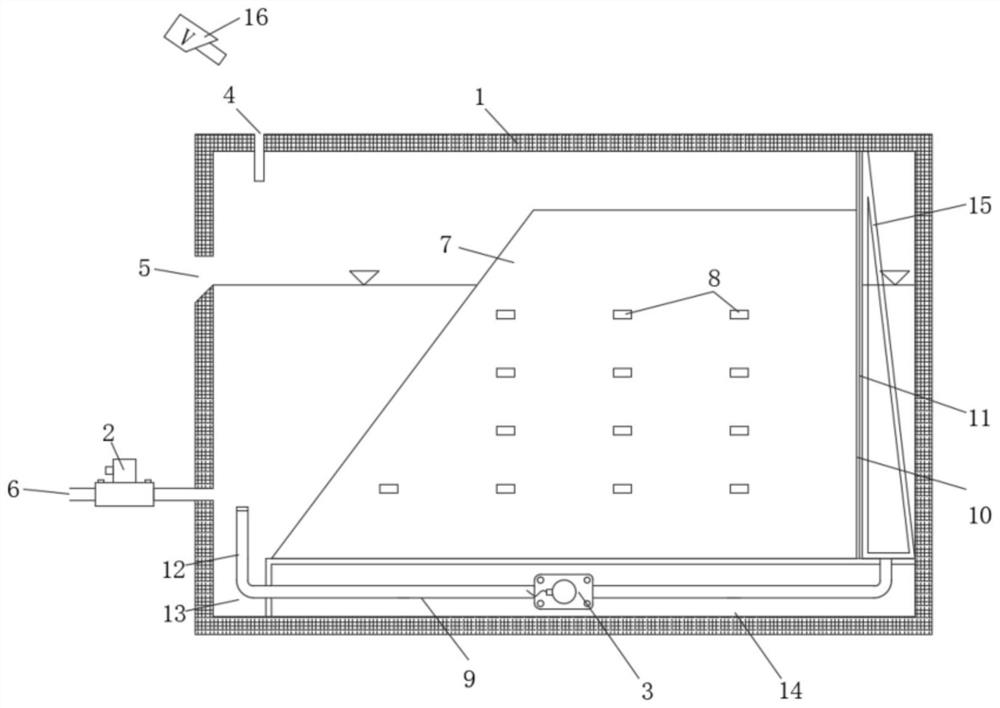

Centrifugal model test device and method for simulating reservoir bank slope instability induced by water level fluctuations

ActiveCN112255390AReflect the actual situationAccurate speed regulationEarth material testingOutfallWater level fluctuation

The invention discloses a centrifugal model test device and method for simulating reservoir bank slope instability induced by water level fluctuations. A reservoir water level simulation area is formed between the near-water side of a slope and the inner wall of a model box, a water inlet is formed in the top wall of the model box of the reservoir water level simulation area, an overflow port anda water outlet are sequentially formed in the side wall of the model box of the reservoir water level simulation area from top to bottom, and an electromagnetic valve A is arranged at the water outlet; and a triangular support is arranged between the downstream side of the slope and the inner wall of the model box, the bottom edge of the triangular support is supported on a support, an undergroundwater level simulation area is formed between the downstream side of the slope and the inner wall of the model box, a communicating pipe is fixedly connected to the support and communicates with thereservoir water level simulation area and the underground water level simulation area, and a micro pressure type water level sensor is arranged in the slope. The centrifugal model test device and themethod can simulate reservoir water level elevation, fluctuation speeds and stable repose angles, can guarantee that the test result can truly reflect the deformation and stability conditions of the actual reservoir bank slope, and have good reference significance for the slope maintenance and reinforcement technology.

Owner:NANJING HYDRAULIC RES INST

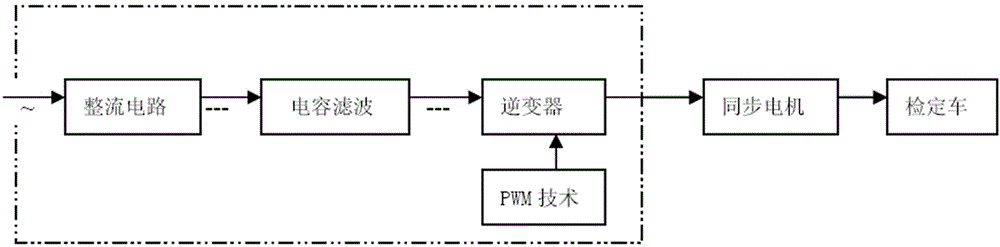

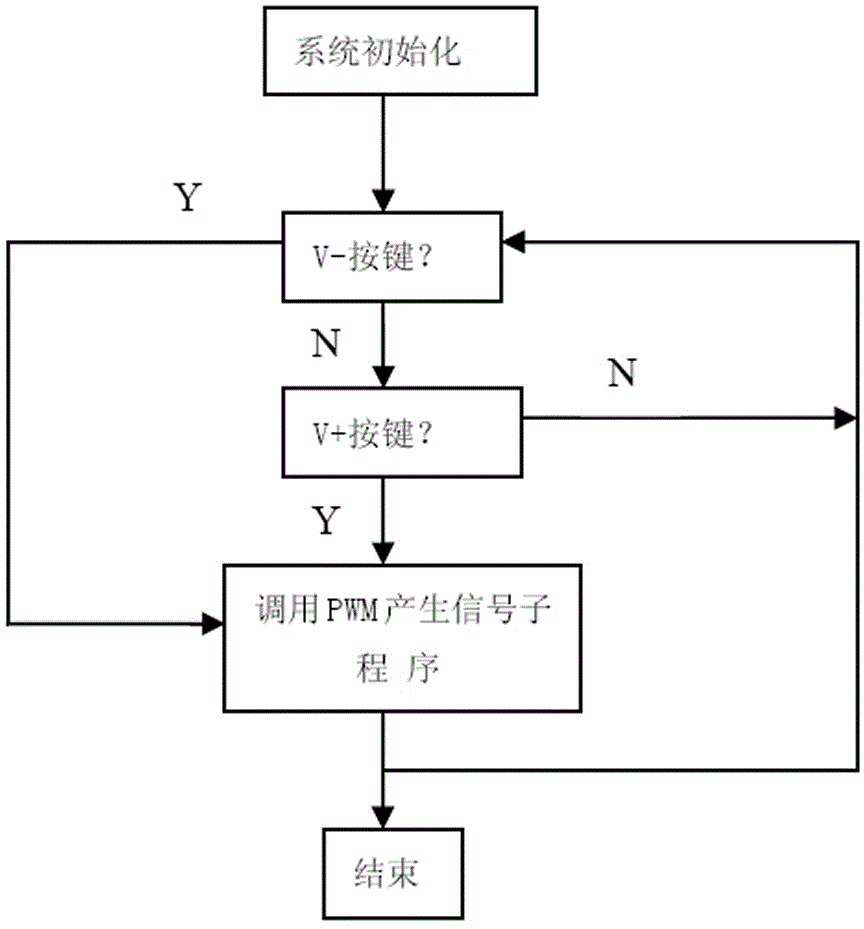

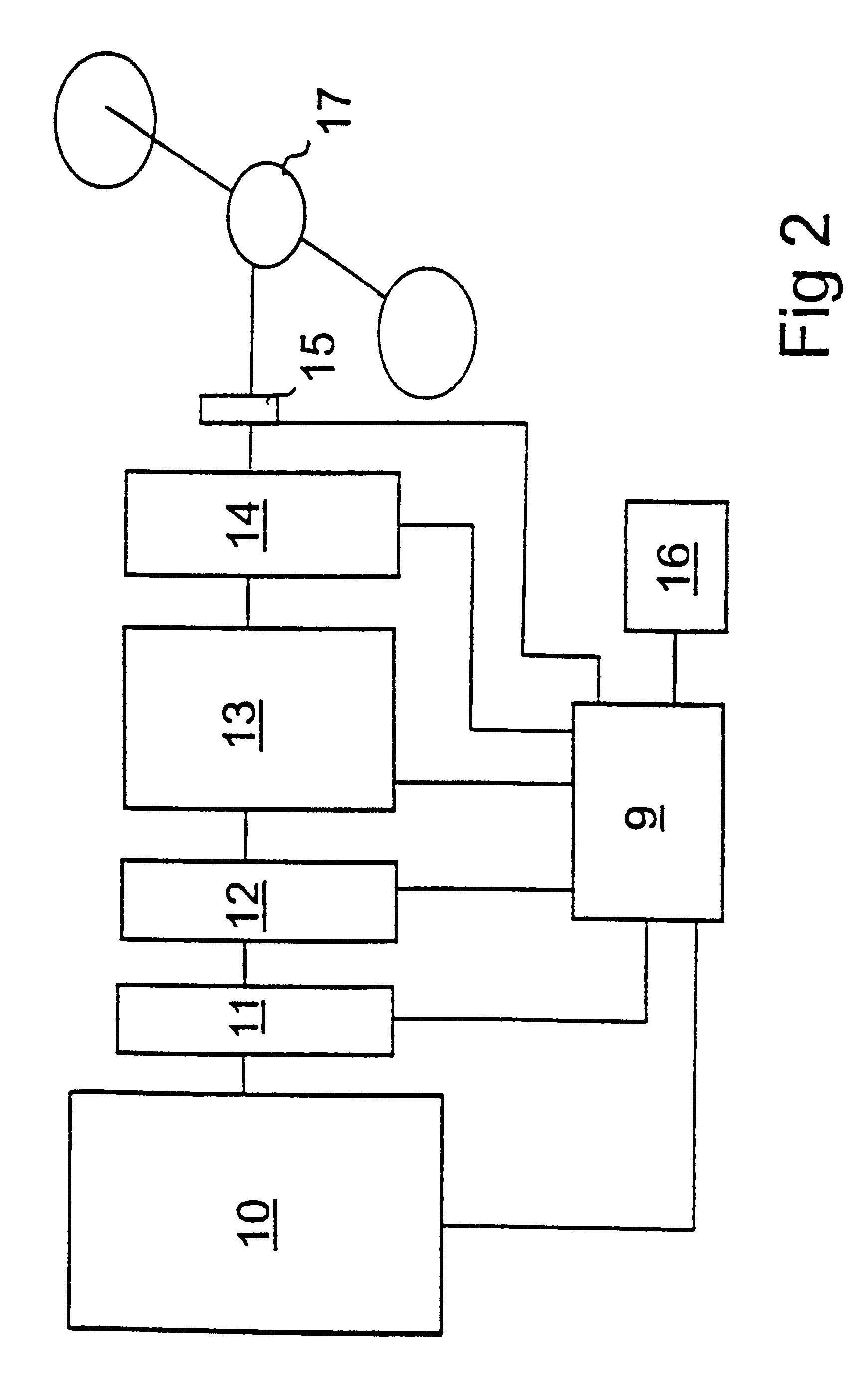

Velocity meter verification system

InactiveCN104655878AAccurate speed regulationImprove operational efficiencyTesting/calibration of speed/acceleration/shock measurement devicesSynchronous motorVerification system

A velocity meter verification system belongs to the technical field of data acquisition. The invention especially relates to a velocity meter verification system. The invention provides a velocity meter verification system which has the advantages of high running efficiency and fast dynamic response. The velocity meter verification system comprises a rectifier circuit, a capacitor filter part, an inverter, a PWM control part, a synchronous motor, a verification vehicle, and a weighing part. The velocity meter verification system is structurally characterized in that the rectifier circuit, the capacitor filter part, the inverter, the PWM control part, the synchronous motor and the verification vehicle are connected in sequence; the PWM control part is connected with the inverter, and the weighing part is connected with the verification vehicle; and an inverting circuit converts constant-frequency and constant-voltage alternating-current power into three-phase bridge voltage-regulated alternating-current power, the synchronous motor is driven by the output of the inverting circuit to rotate at different speeds, a running flow circuit of the verification vehicle in velocity meter equipment converts the alternating-current power into direct-current power under control, and after capacitor filtering, the inverter inverts the direct-current power into different frequencies.

Owner:姜韫英

Stepless speed regulating mechanism

The invention discloses a stepless speed regulating mechanism. The stepless speed regulating mechanism is provided with a rectangular driving box body, wherein a driving shaft and a driven shaft which are mutually parallel are arranged in the driving box body up and down; a pair of friction wheels of which the conical corners are opposite is respectively arranged on the driving shaft and the driven shaft; the friction wheel moveably arranged on the driven shaft slides along the axial line; a cylinder is fixedly arranged on the outer side surface of the driving box body; one end of a lever is hinged with the interior of the driving box body; the middle part of the lever is hinged with a slide sleeve; and the other end of the lever is hinged with the end part of a piston rod of the cylinder. V-shaped opening degree between the friction wheels is controlled by the cylinder to regulate speed, so that the speed regulating mechanism has the advantages of simple structure, accurate speed regulating precision and particularly capability of automatically regulating speed. The performance and the automation level of equipment can be obviously improved.

Owner:JIANGSU BADA HEAVY IND MACHINERY

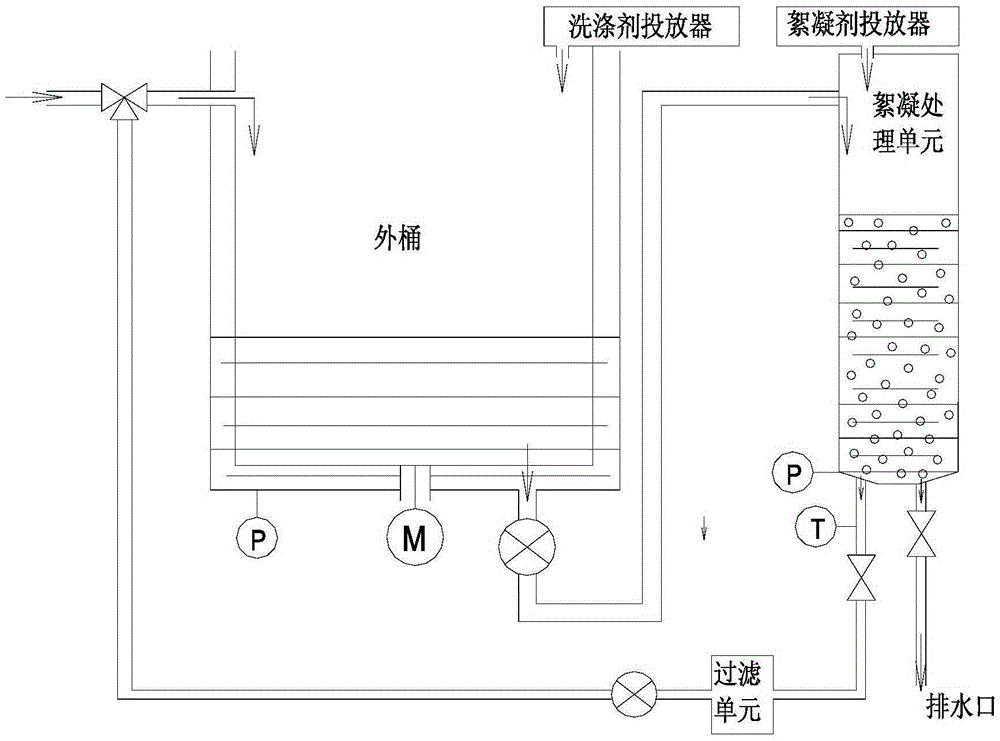

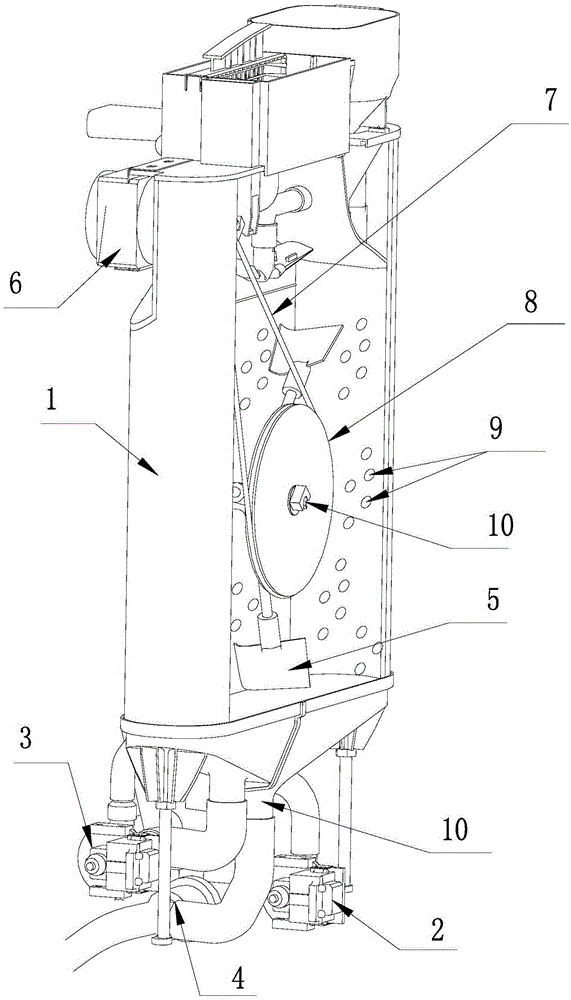

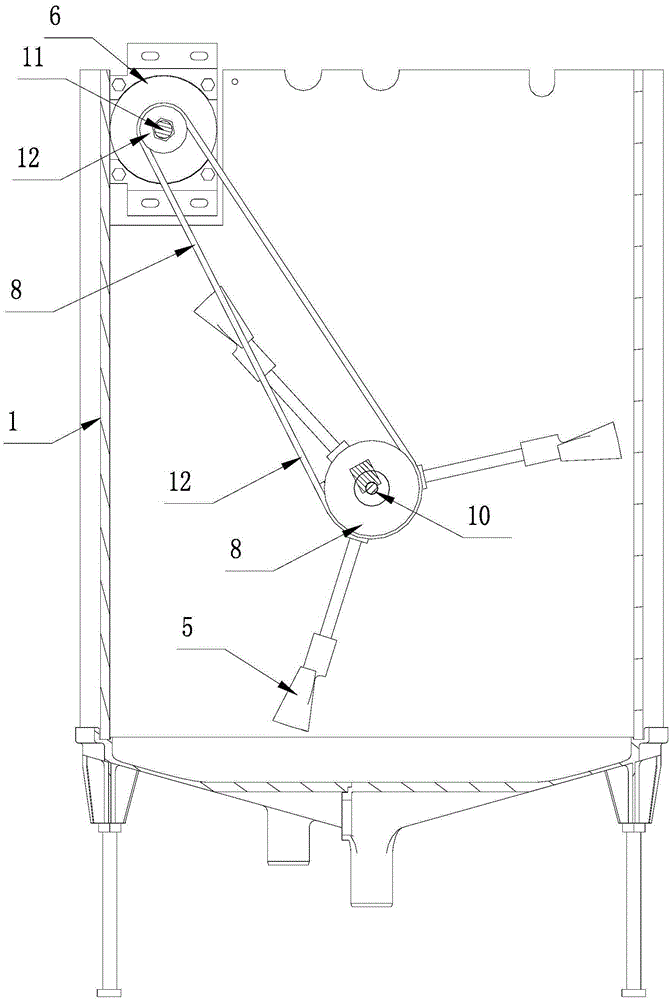

Driving method of stirring motor in the flocculation treatment process and washing machine

InactiveCN106637804ARealize automatic repairRealize remote monitoringControl devices for washing apparatusTextiles and paperFlocculationMotor drive

The invention relates to a drying method of a stirring motor in the flocculation treatment process. When the washing machine executes a flocculation program, the motor drives the stirring mechanism to work, and a stirring mechanism rotating speed V is detected; when a detection value V is smaller than a set value Vi, the motor is adjusted to increase the stirring mechanism rotating speed; when the detection value V is smaller than the set value Vi, the motor is adjusted to reduce the stirring mechanism rotating speed. Through the control method, input power and the like of the motor can be subjected to controllable adjustment so as to achieve precise control over the stirring mechanism rotating speed and the purpose of improving flocculation reaction efficiency. The invention further relates to a flocculation washing machine applied to stirring motor driving method. The flocculation washing machine achieves precise control over the flocculation process and precise judgment of the flocculation washing machine fault so as to avoid backflow conditions of sub-standard flocculation water from generating. Meanwhile, the flocculation washing machine is simple in structure, the method is brief, the effect is remarkable, and the flocculation washing machine is suitable for application and popularization.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

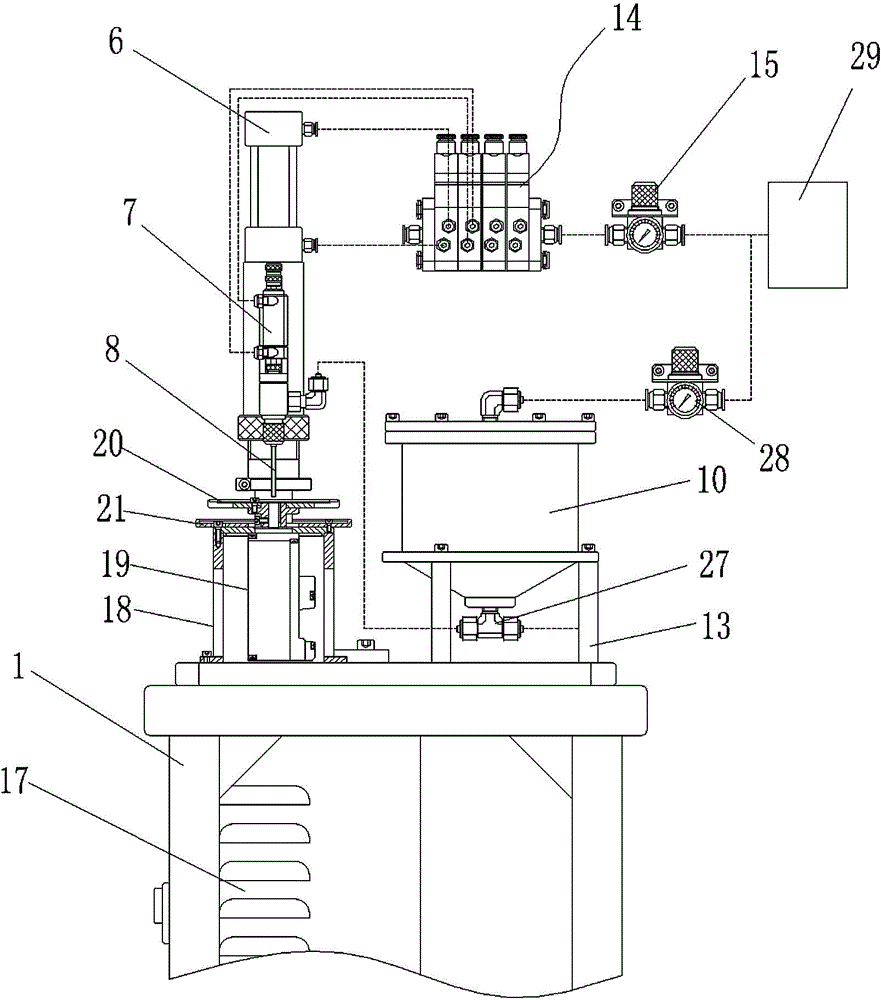

Gumming machine for belt pulley scrubbing ring

ActiveCN104353583AAccurate angle adjustmentAccurate speed regulationLiquid surface applicatorsCoatingsEngineeringSingle line

The invention relates to a gumming machine for a belt pulley scrubbing ring. The gumming machine is characterized by comprising a rack (1), wherein a control cabinet (17), two uprights (3), a motor (19), a gum material barrel (10) and a starting switch (16) are respectively connected onto the rack; linear sliding rails (24) and fixed plates (5) are connected onto the uprights by means of horizontal regulating bases, connecting plates (26) and air cylinders (6) which are mutually connected are arranged on the linear sliding rails and the fixed plates, the connecting plates are connected with dispensing valves (7), a single-line gum discharging pipe (8) and a dual-line gum discharging pipe (9) are respectively connected onto the two dispensing valves; an output shaft of the motor is connected with a rotary tray (20) where the single-line gum discharging pipe and the dual-line gum discharging pipe are correspondingly matched. The gumming machine has the advantages that gum application is controlled by virtue of the air cylinder and the motor, so that the automation, one-touch operation and uniformity and consistency of coated gum layers of the gum application are realized, the convenience is brought for the operation, the gum applying speed is high and the efficiency is high.

Owner:ANHUI HAOFANG ELECTROMECHANICS

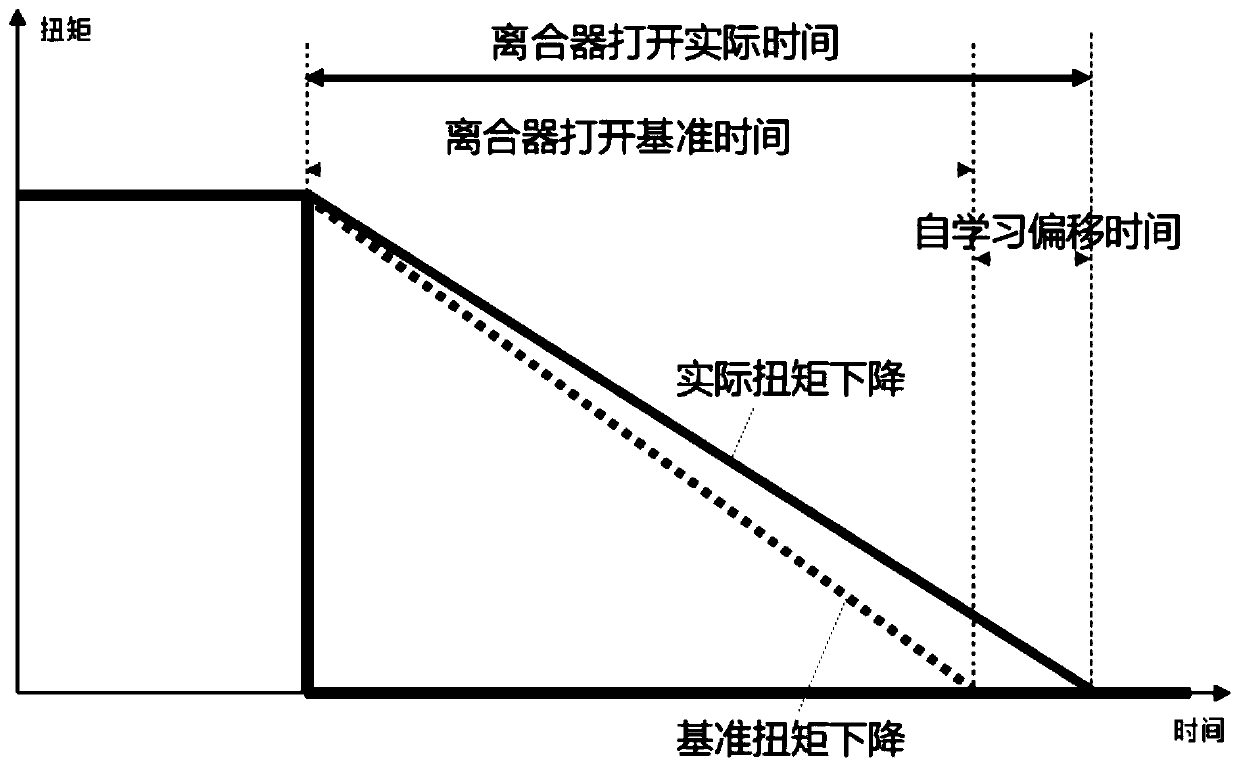

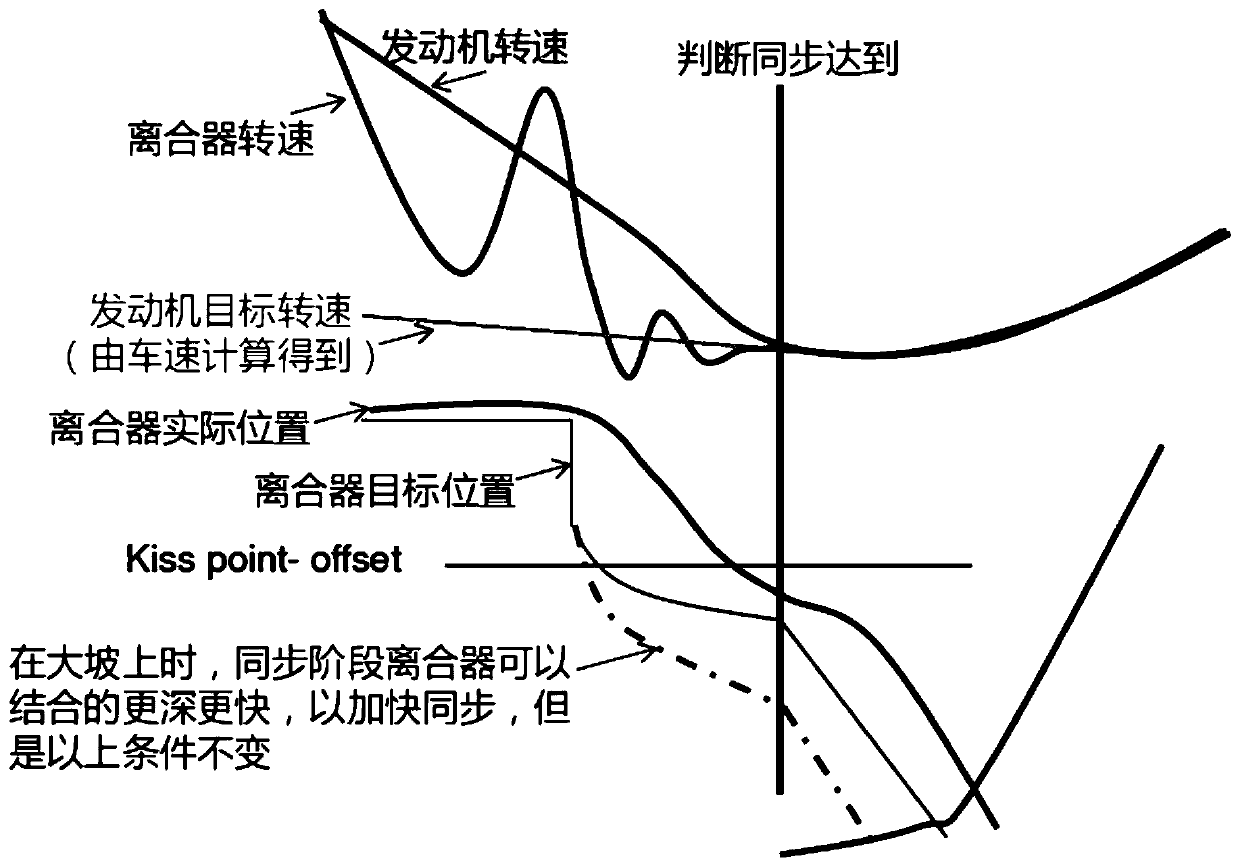

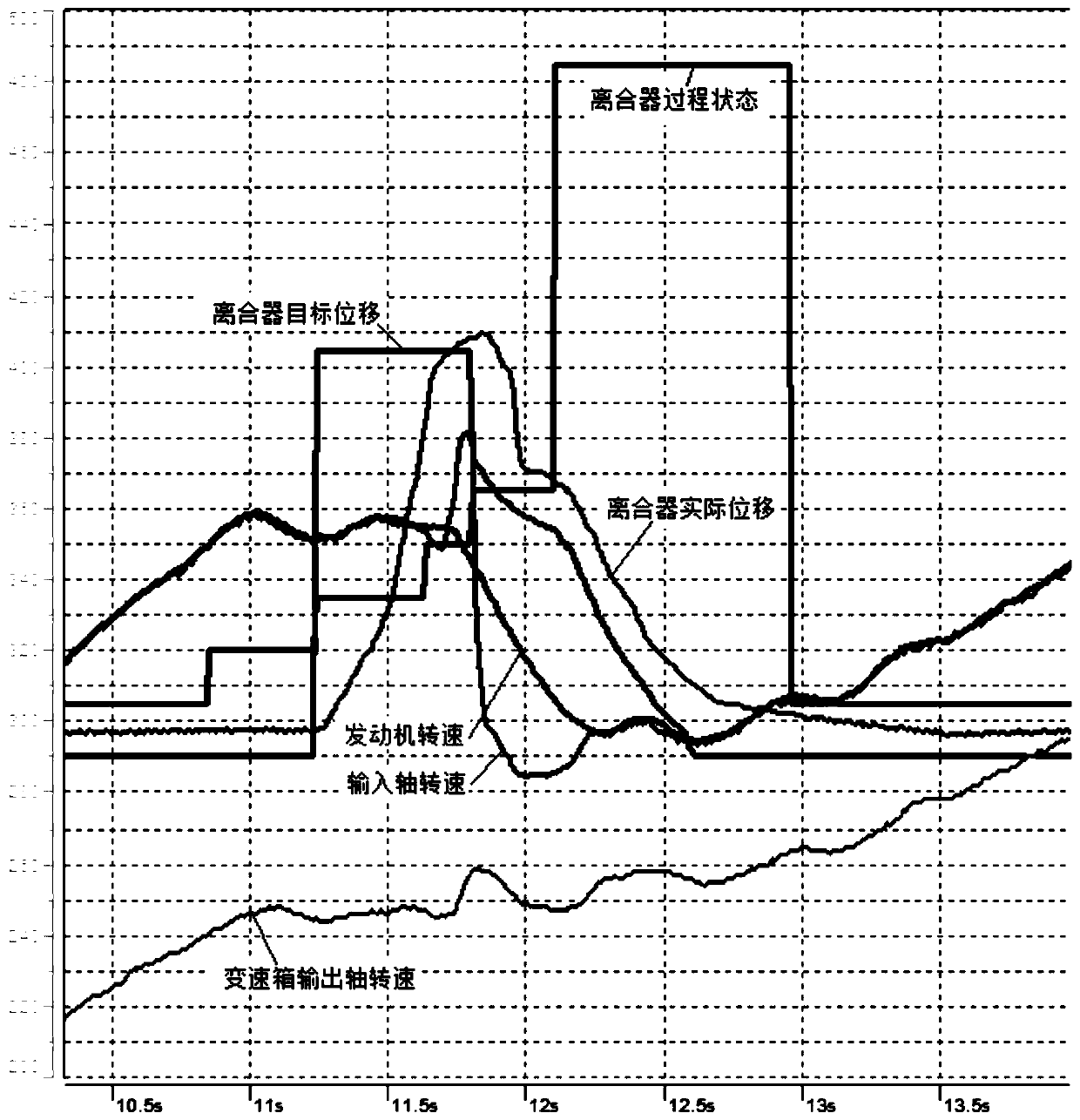

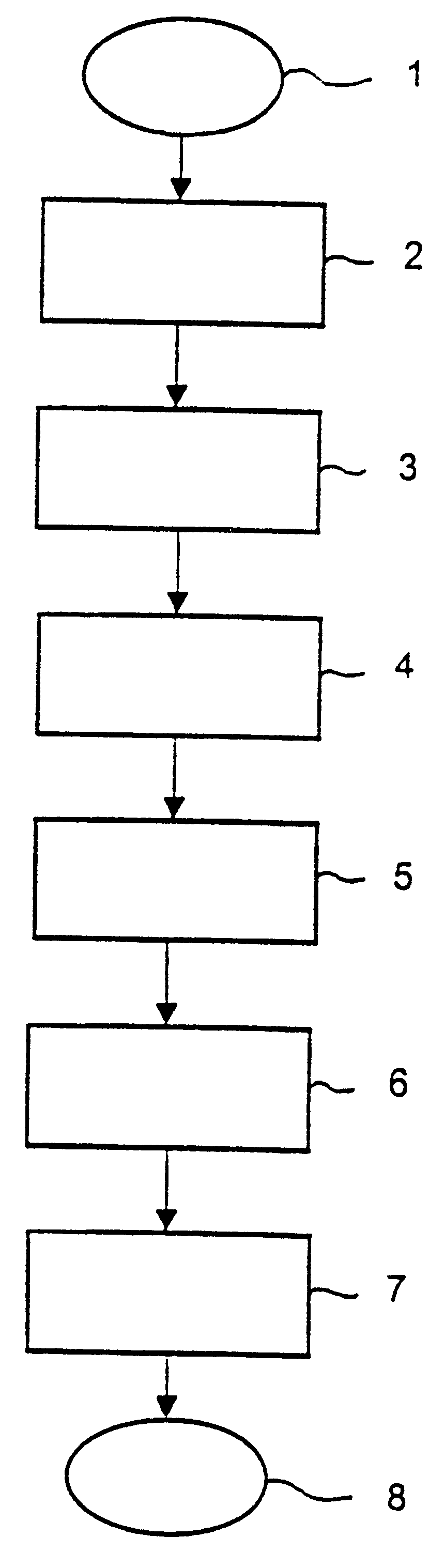

Heavy duty vehicle AMT engine and clutch self-adaption coordination control method

ActiveCN110159743AOptimal separation pointEasy to separateMechanical actuated clutchesGearing controlEngineeringControl theory

The invention relates to a heavy duty vehicle AMT engine and clutch self-adaption coordination control method. The heavy duty vehicle AMT engine and clutch self-adaption coordination control method comprises the following steps of firstly, the Roll off stage, wherein an engine is subjected to torque decreasing before a gear is disengaged, and then a clutch is controlled to be opened; secondly, theSpeed Contral stage, wherein the engine is subjected to speed regulation to the target rotating speed; and thirdly, the Roll On stage, wherein the clutch is engaged, after the rotating speed of the engine and the rotating speed of the clutch are synchronized, the torque of the engine is restored. The design can adaptively learn the clutch separation time and ensure the vehicle smoothness and thedynamic property.

Owner:DONGFENG COMML VEHICLE CO LTD

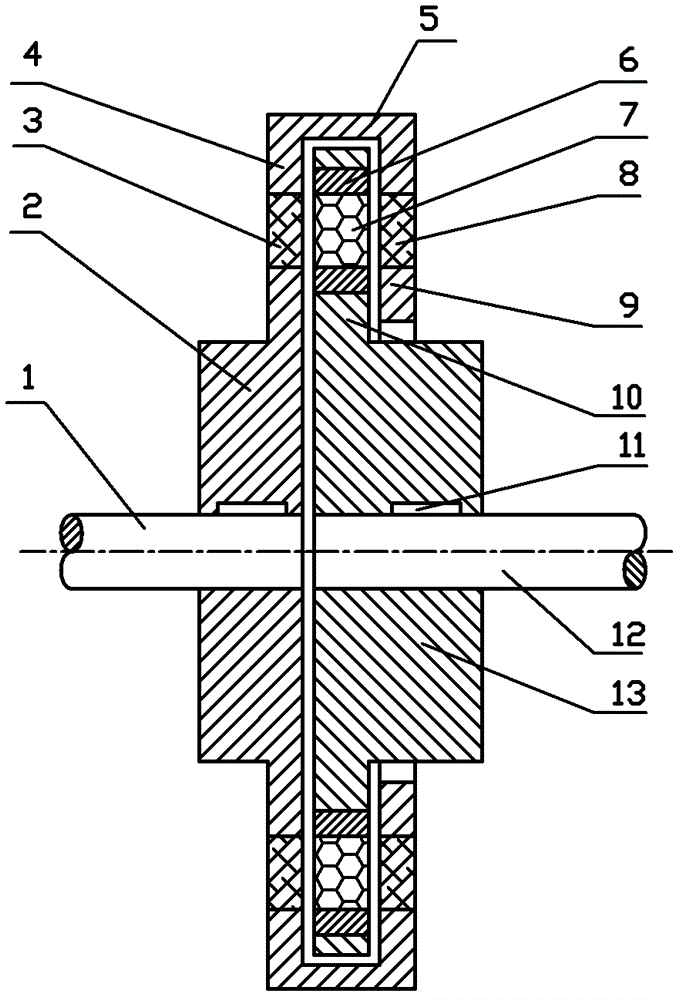

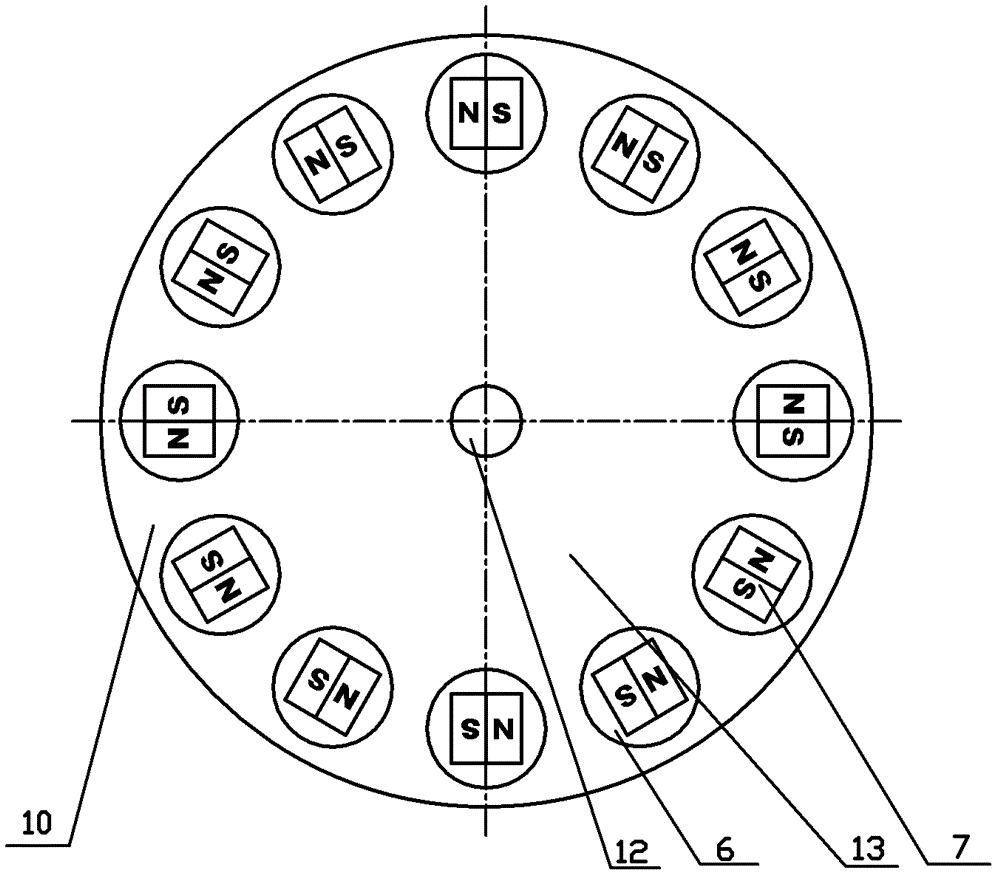

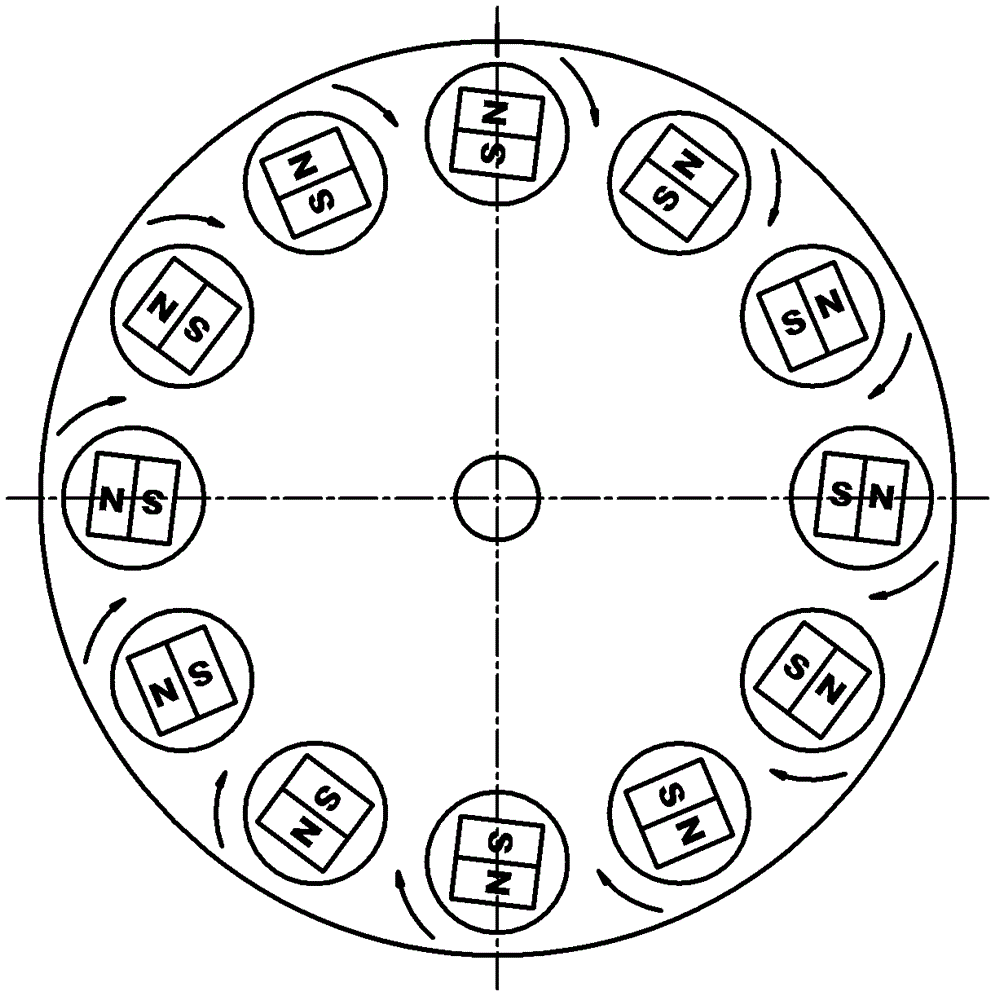

Magnetic force coupling adjustable transmission gear box

InactiveCN102299611BNo impactSimple structureDynamo-electric gearsMagnetic tension forceElectrical conductor

The invention relates to a speed changer structure and provides a magnetic force coupling adjustable transmission gear box. The transmission gear box is characterized in that: an input shaft (1) is fixedly connected with a 1# conductor disc (4) which is embedded with or attached with a 1# conductor ring (3). An air gap range extension pad (5) connects with a 2# conductor disc (9) and a 2# conductor ring (8). An output shaft (12) is fixedly connected with a magnetic force disc (10). On same circumference of the magnetic force disc (10), a plurality of rotatable rotation round blocks (6) are embedded, and two close permanent magnets (7) with different polarities are placed into each rotation round block (6). S / N polarities of all permanent magnets (7) are in central symmetry with a center of circle of the magnetic force disc (10). The magnetic force disc (10) of the output shaft (12) is positioned between the 1# conductor disc (4) and the 2# conductor disc (9) of the input shaft (1), and axial clearance is existed between the two conductor discs. The rotation round blocks (6) can be in synchronization rotation manually or automatically on the magnetic force disc (10). The conductor ring and the permanent magnet are in corresponding arrangement, torsional force of eddy-current coupling realizes power transmission, angles of the rotatable rotation round blocks are changed, transmission torque is changed, and a purpose of changing load rotating speed is realized.

Owner:SHANGHAI POTEVIO

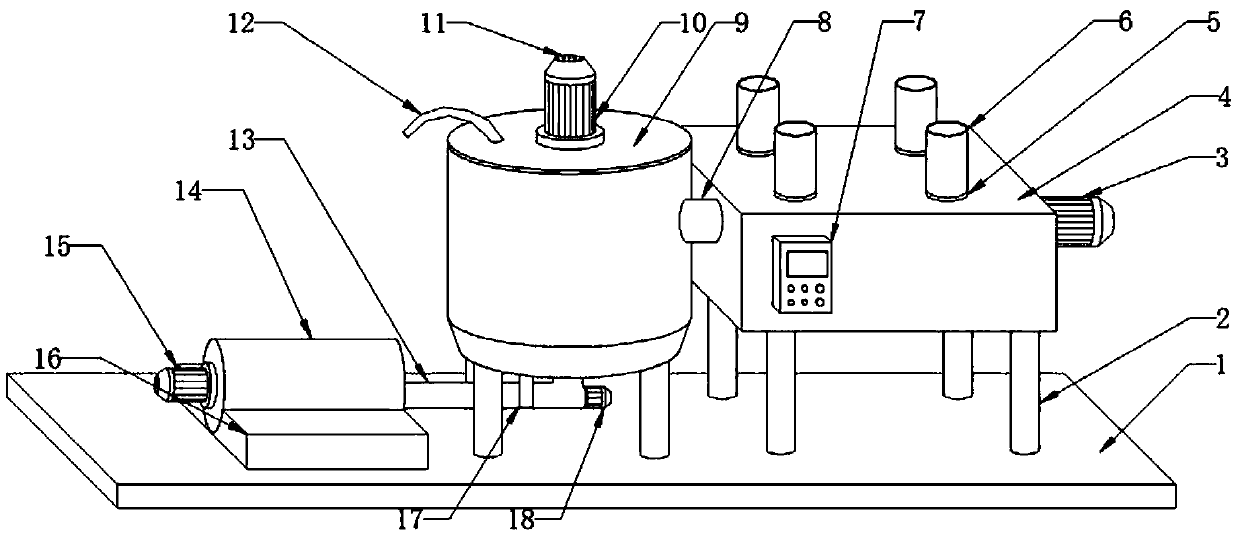

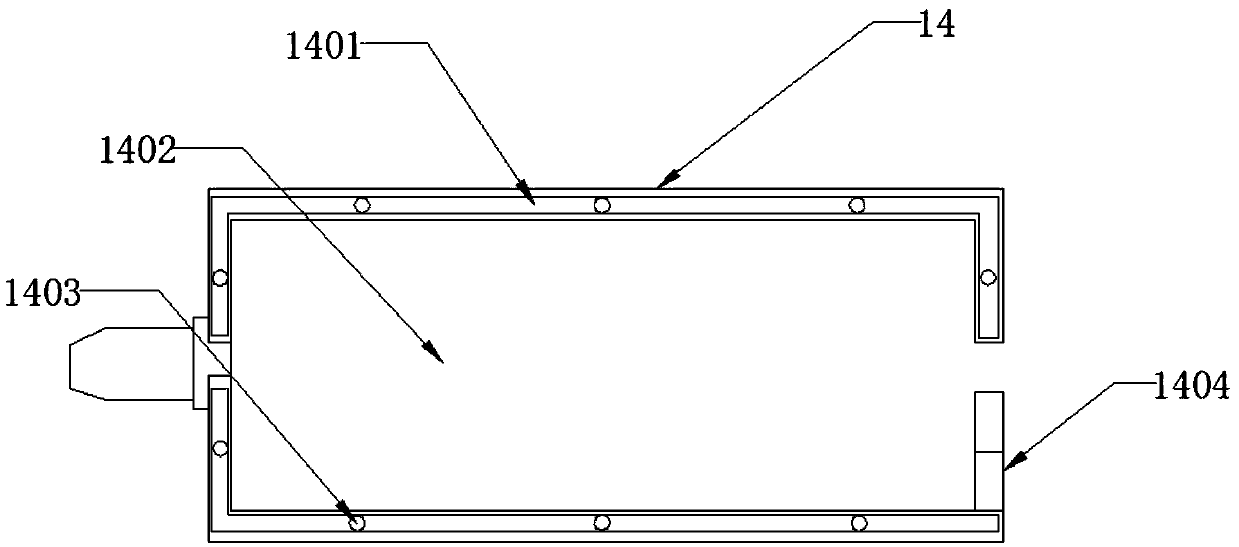

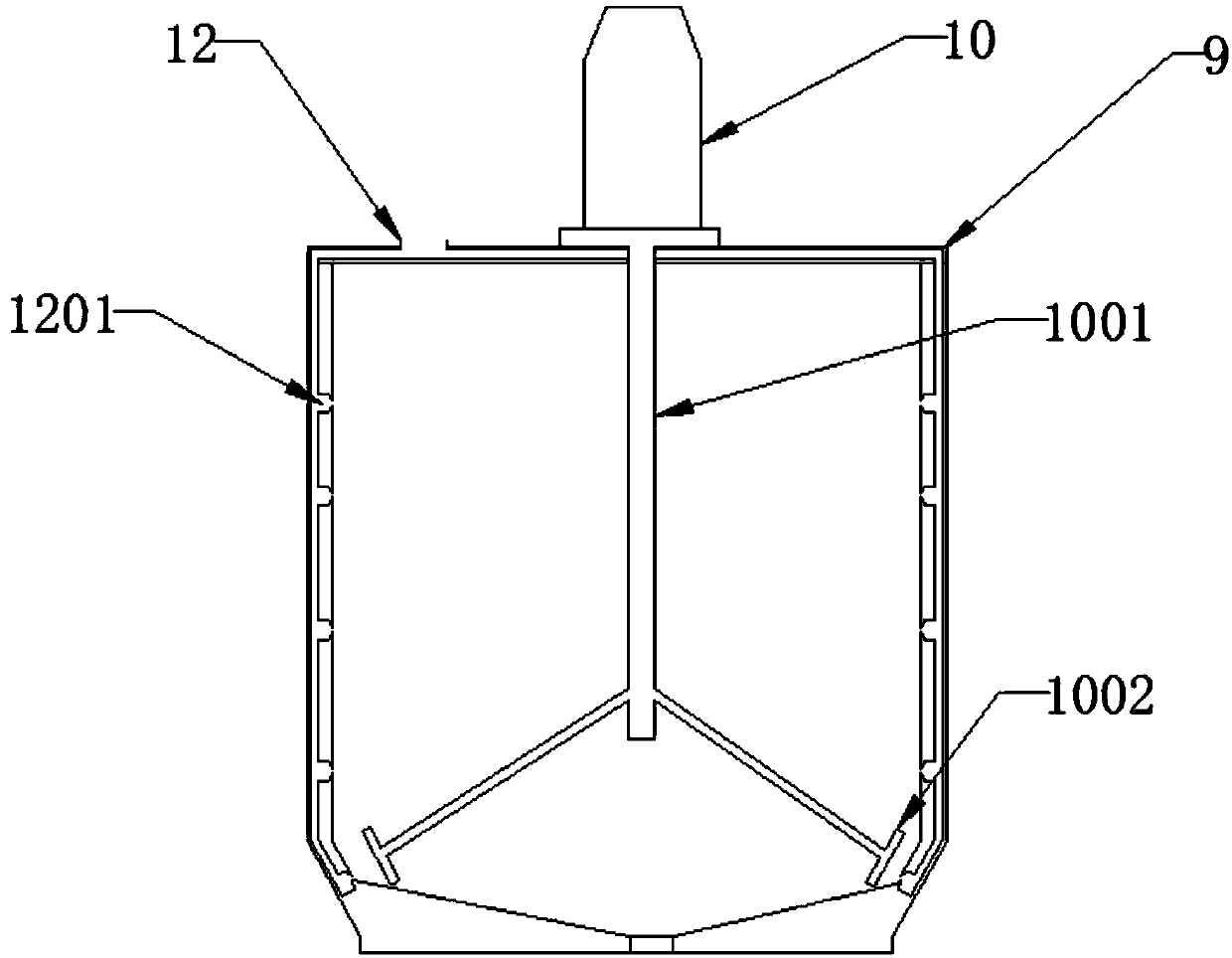

Novel material color master batch washing, weighing and drying machine

InactiveCN108679959ASpeed adjustmentAccurate speed regulationGranular material dryingDrying machines with non-progressive movementsMotor shaftEngineering

The invention discloses a novel material color master batch washing, weighing and drying machine. The novel material color master batch washing, weighing and drying machine comprises a fixing bottom board; a drying barrel body is arranged on the top of a drying barrel fixing board; a heating board and a discharging outlet are formed inside the drying barrel body; a conveying motor is arranged at one end of a conveying pipe; a washing barrel body is arranged on the top of the conveying pipe; a pressure water inlet pipe and a washing motor are arranged on the top of the washing barrel body; a pressure water outlet is formed inside the washing barrel body; a washing motor shaft is arranged at the bottom of the washing motor; a water pulling piece is arranged at one end of the washing motor shaft; a weighing barrel base is arranged at one end of a pushing pipe; a weighing board is arranged on the top of the weighing barrel base; a weighing barrel is arranged on the top of the weighing board; and a weighing rotary shaft and a weighing rotary board are arranged inside the weighing barrel base. Therefore, the novel material color master batch washing, weighing and drying machine achievesthe purposes of full-automatic integration, accurate weighing, thorough washing and short drying time through the powerful weighing barrel, the washing barrel body and the drying barrel body.

Owner:林晓凤

Method and device for controlling an internal combustion engine

InactiveUS6558292B1Increase speedLow costElectrical controlConjoint controlExternal combustion engineEngineering

In a vehicle's driveline, the clutch between drive engine and gearbox has the task of ensuring a final speed adjustment between the engine and the gearbox at the time when the clutch pedal is allowed to rise on completion of a gear change. The invention has the object of reducing the stress on the clutch and the disadvantages which arise from a lengthy sliding-in process with large speed differences. This is achieved by adjusting the engine speed to the gear being engaged, so that only a small speed difference has to be absorbed in the clutch.

Owner:SCANIA CV AB

Impeller-type aerator for aquaculture

InactiveCN108207764AControl speedAccurate speed regulationPisciculture and aquariaImpellerPower flow

The invention provides an impeller-type aerator for aquaculture. The impeller-type aerator includes a motor controller protection hood, a support rod device, a brushless direct-current motor, supportrods, buoys and an impeller; the support rod device is mounted at the upper end of the brushless direct-current motor, the motor controller protection hood is mounted at the upper end of the support rod device, the support rods are assembled on the support rod device, the buoys are arranged at the outer ends of the support rods, and the impeller is assembled under the brushless direct-current motor. According to the impeller-type aerator for the aquaculture, the motor controller protection hood is used for waterproof protection, the support rod device is subjected to waterproof protection, andthe design improves the overall stability of the impeller-type aerator; the impeller-type aerator is easy to operate, convenient to mount and good in stability, the function of overload protection isachieved, the magnitude of currents is convenient to detect.

Owner:山东优万电子科技有限公司

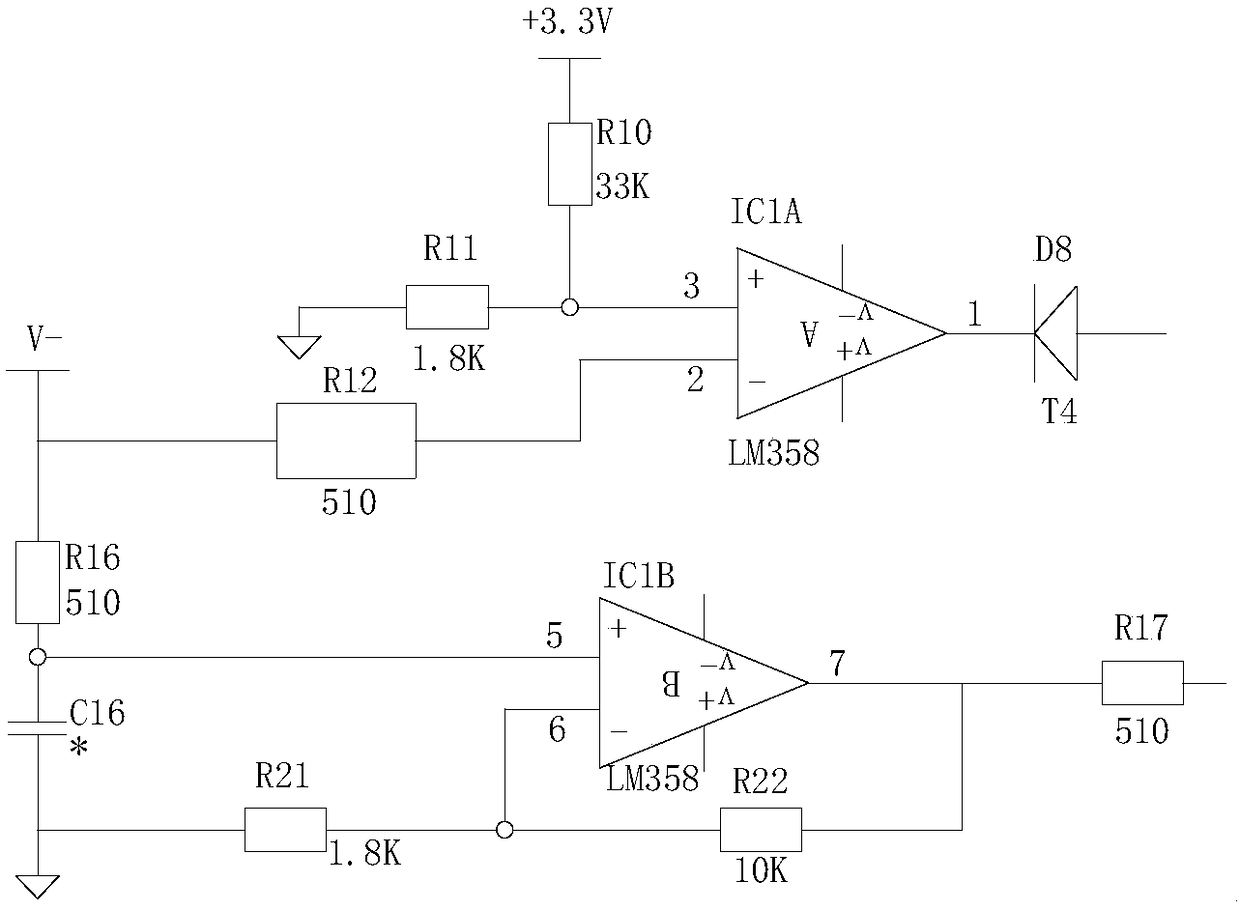

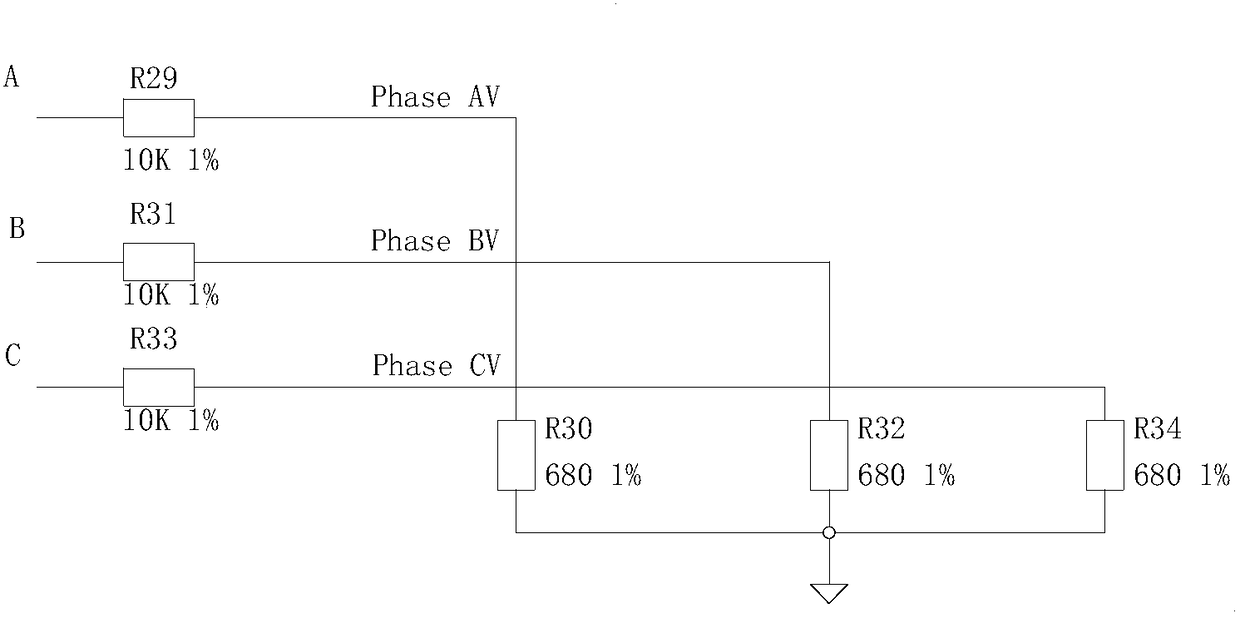

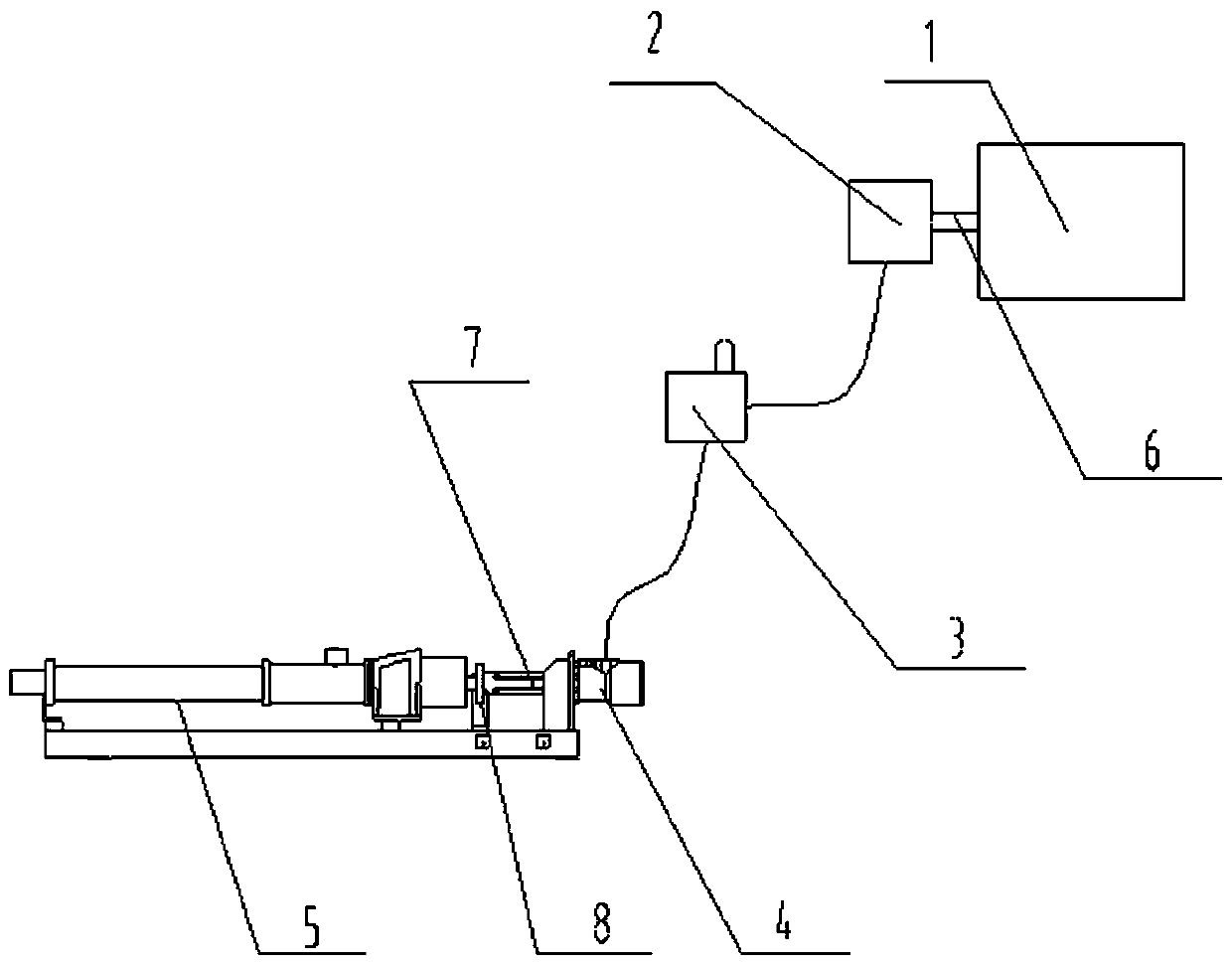

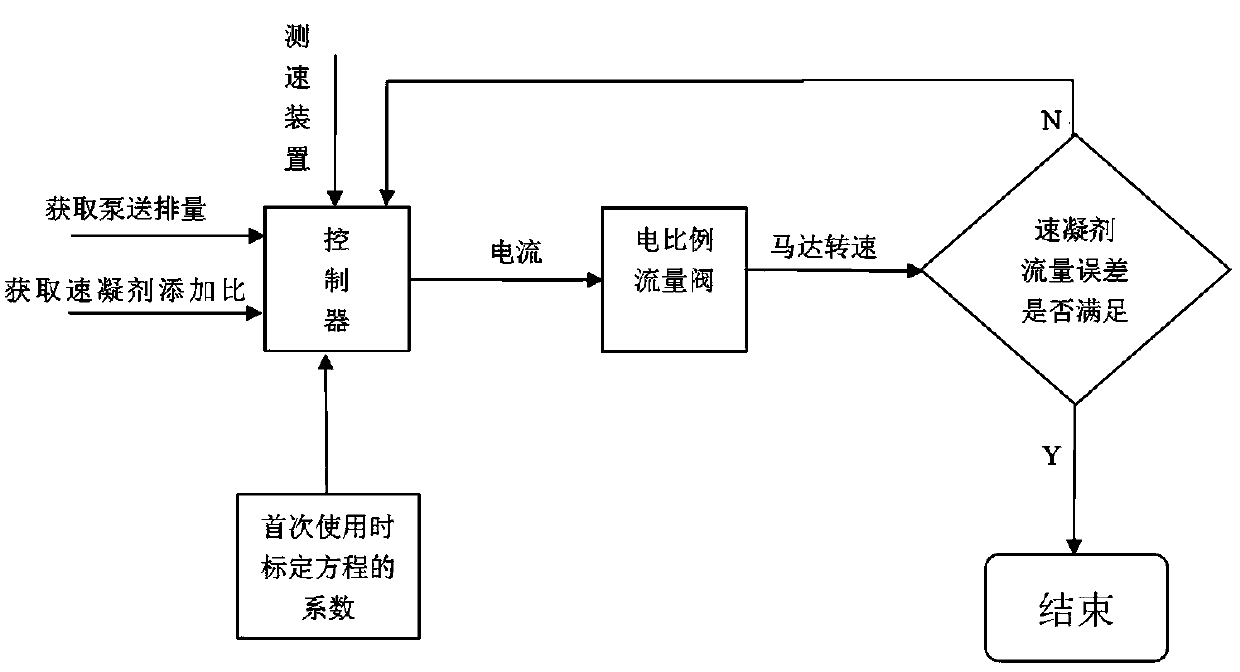

Accelerator conveying and speed regulating control system and calibration method

InactiveCN110142876AAccurate speed regulationThe method is simple and fastPipeline systemsPump controlElectricityControl system

The invention discloses an accelerator conveying and speed regulating control system. The system comprises an electrical machine, an oil pump, an electric proportional flow regulating valve, a motor and an accelerator pump which are connected in sequence, wherein the oil pump is connected with the electrical machine through a coupler I, the accelerator pump is connected with the motor through a coupler II, a speed measuring device is arranged on the coupler II, the electrical machine drives oil in the oil pump to flow into the motor through the electric proportional flow regulating valve, themotor is used for driving the accelerator pump, and the oil supply amount of the motor is changed by adjusting the electric proportional flow regulating valve so as to change the rotating speed of theaccelerator pump. According to the control system, data are collected through testing, curve fitting is carried out, the difference between the different accelerator pumps and adjusting flow proportional valves is considered, and the rapid and accurate speed regulation of an accelerator system is realized through data calibration during debugging. The method is simple, rapid, free of oscillation,rapid and stable, and high in precision.

Owner:HUNAN PENGXIANG XINGTONG AUTOMOBILE CO LTD

Electromechanical switching control mechanism of double-pulse speed governor

ActiveCN102352795AFast auto switchImprove reliabilityFuel-injection pumpsMachines/enginesControl valvesHigh pressure

The invention discloses an electromechanical switching control mechanism of a double-pulse speed governor. The mechanism is used for automatically switching the electronic control of the speed governor to mechanical control when the electronic control part breaks down. Under the normal circumstance, the control current of electromagnet in an actuating mechanism is increased when an diesel engine load is increased and speed is lowered; a control valve moves downwards to cause high-pressure oil to flow below a servo piston; the left end of a switching lever is connected with a reset piston by ahinge pin to move downwards to cause the main control valve to move downwards; and therefore, a power piston moves downwards and fuel is added so as to drive an output shaft to rotate towards fuel adding direction to improve regulation speed. When the electronic control part of the speed governor loses effect after failing and the revolving speed of the diesel engine is lowered to be lower than 5% of the normal speed set by the speed governor, the switching lever and a slide valve are completely separated without contacting; at the time, a high-response electromagnetism servo mechanism does not take effect; and the revolving speed of the diesel engine is controlled by the mechanical part of the speed governor.

Owner:CHONGQING HONGJIANG MACHINERY

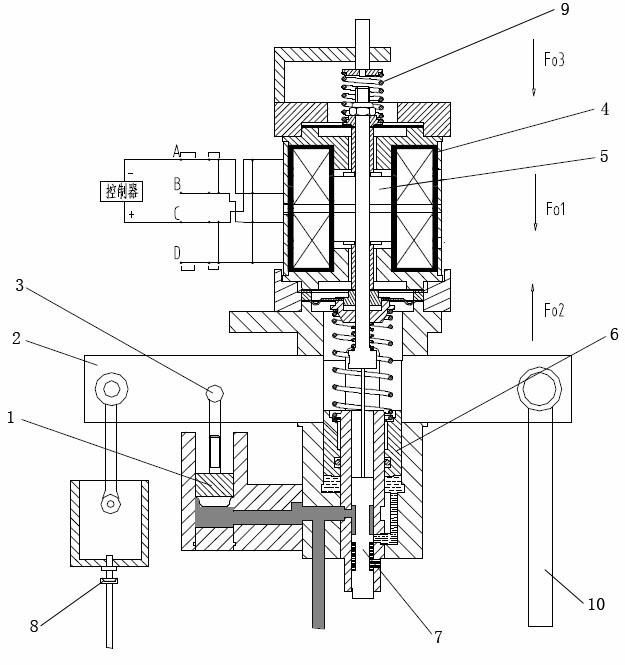

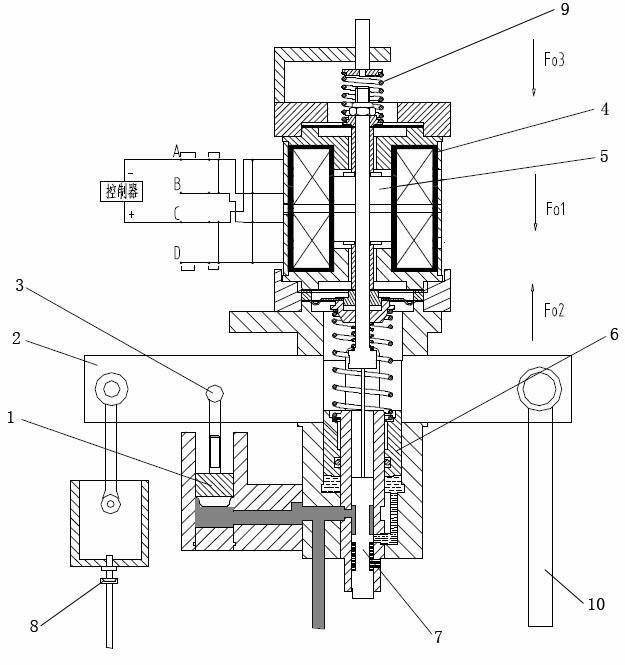

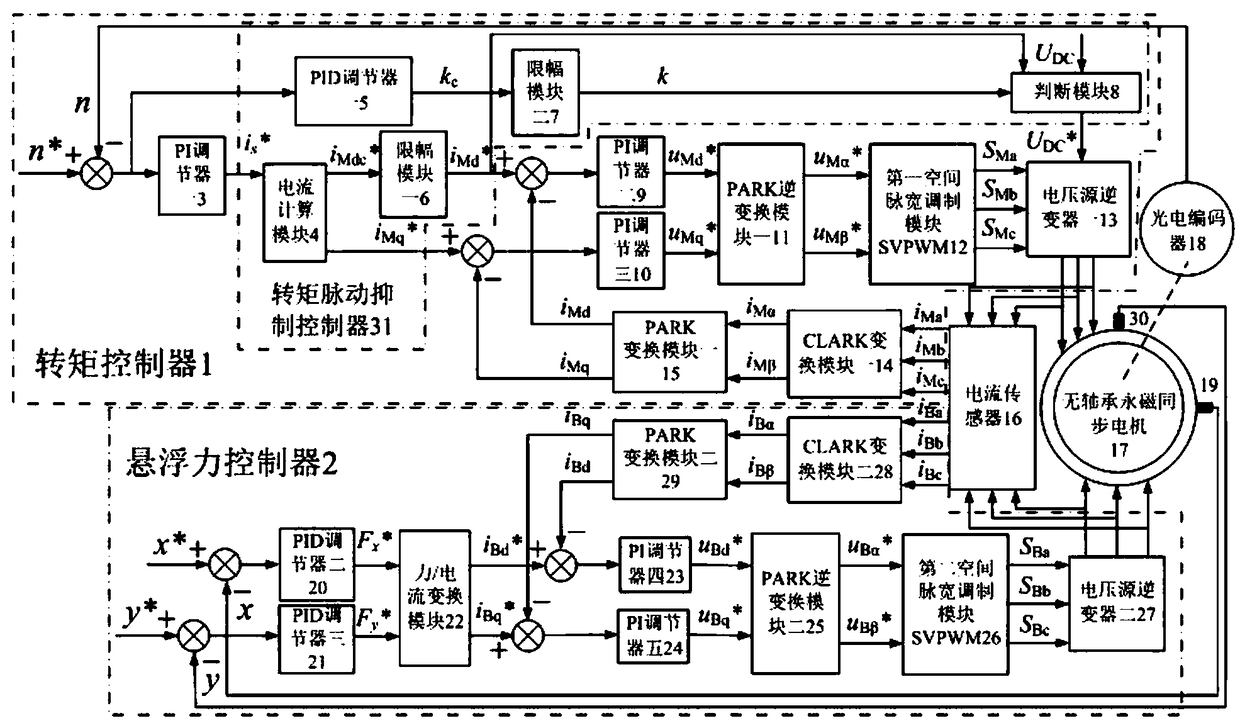

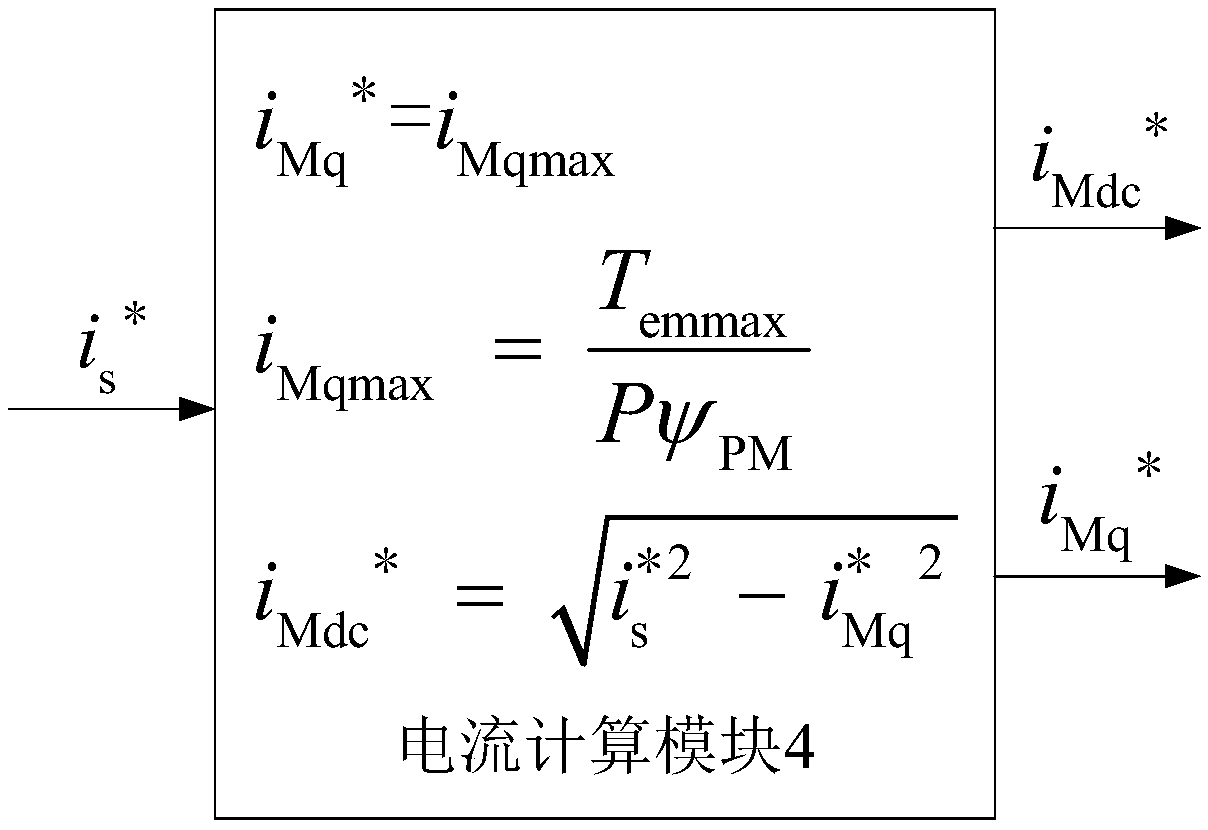

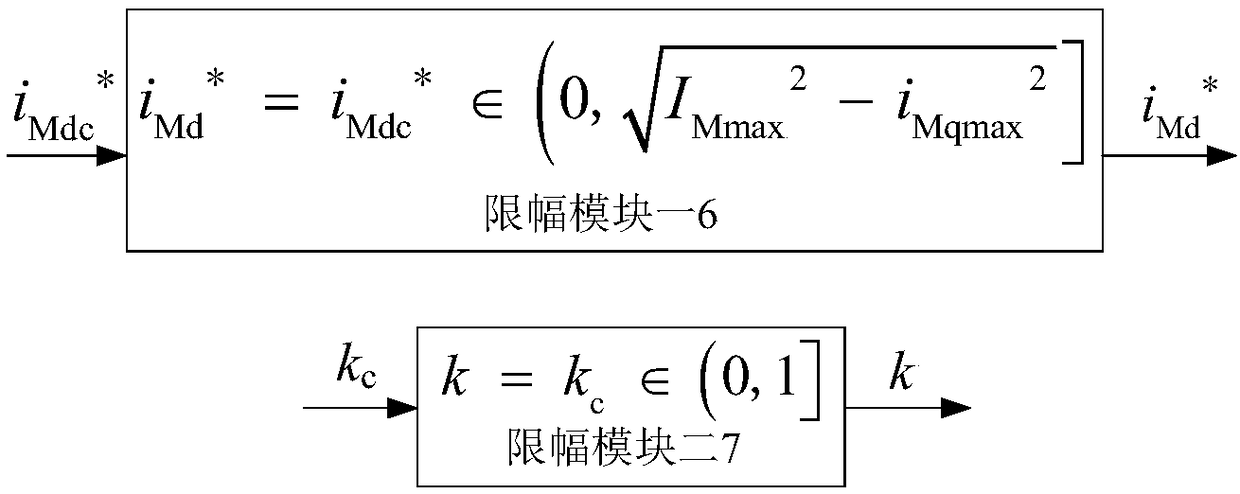

Torque ripple rejection controller of bearingless permanent magnet synchronous motor and construction method of torque ripple rejection controller

PendingCN109361332AAccurate speed regulationImprove work performanceTorque ripple controlAC motor controlStatorPower flow

The invention discloses a torque ripple rejection controller of a bearingless permanent magnet synchronous motor and a construction method of the torque ripple rejection controller. Through a torque controller, a suspension force controller, a current sensor, an optical-electricity encoder and eddy current displacement sensors, the torque ripple rejection controller in the torque controller is modulated by a first PID (proportion integration differentiation) regulator to obtain an initial proportion value kc, is processed by a second amplitude limiting module to obtain a proportion value k andis modulated by a first PI (proportional integral) regulator to obtain a rotor resultant current instruction value is*, the rotor resultant current instruction value is* is input into a current calculation module to obtain an initial direct-axis current instruction value iMdc* and an initial quadrature-axis current instruction value iMq*, the initial direct-axis current instruction value iMdc* isprocessed by a first amplitude limiting module to obtain a direct-axis current instruction value iMd*, and the proportion value k and the direct-axis current instruction value iMd* are input into a judging module to realize controlling of magnetism increasing and voltage regulation. The torque ripple rejection controller has the advantages that torque ripples of the motor can be rejected, precisespeed regulation of the bearingless permanent magnet synchronous motor can be realized, the influence of motor load effect on suspension stability is weakened, and working performances of the bearingless permanent magnet synchronous motor in high-speed and superhigh-speed operation states are improved.

Owner:JIANGSU UNIV

Full-automatic indenting machine for packaging box machining

InactiveCN106696348ASpeed regulation and controlRPM regulation regulation and controlBox making operationsPaper-makingDrive wheelMachining

The invention provides a full-automatic indenting machine for packaging box machining and relates to the technical field of packaging box machining equipment. The full-automatic indenting machine comprises an operation table and an indenting device. The indenting device is arranged on one side of the operation table which is fixedly connected with the indenting device. A feeding table is arranged on one side of the operation table, and a discharging table is arranged on the other side of the operation table. A motor is arranged in the operation table. A rotating shaft is arranged on one side of the motor, a drive wheel is arranged on one side of the rotating shaft, and a rotator is arranged between the rotating shaft and the drive wheel. A driven wheel is arranged on one side of the drive wheel, and a conveying belt is arranged between the drive wheel and the driven wheel. The operation table is provided with a conveying switch, and a power switch and a power indicating lamp arranged on one side of the power switch are arranged on the indenting device. According to the full-automatic indenting machine for packaging box machining, the automatic indenting effect of the device can be achieved through the motor and a conveying device in the operation table, the indenting effect is greatly improved, and the workload is relieved.

Owner:HENGYANG MINGZHU PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com