Rotor slippage complementary exciting permanent-magnetic brushless variable speed motor

A permanent magnet brushless, variable speed motor technology, applied in the fields of magnetic field/electric field shielding, electrical components, electromechanical devices, etc., can solve the problems of adding excitation windings and circuits, complex motor structure, and easy failure, to ensure continuous change, Guaranteed speed/torque characteristics, easy moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

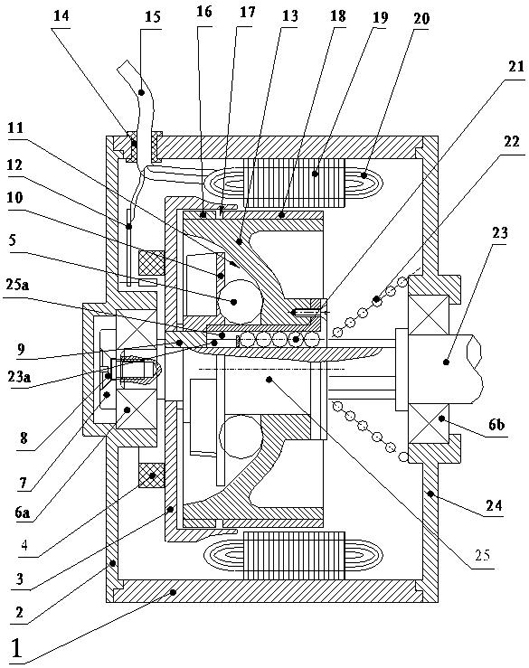

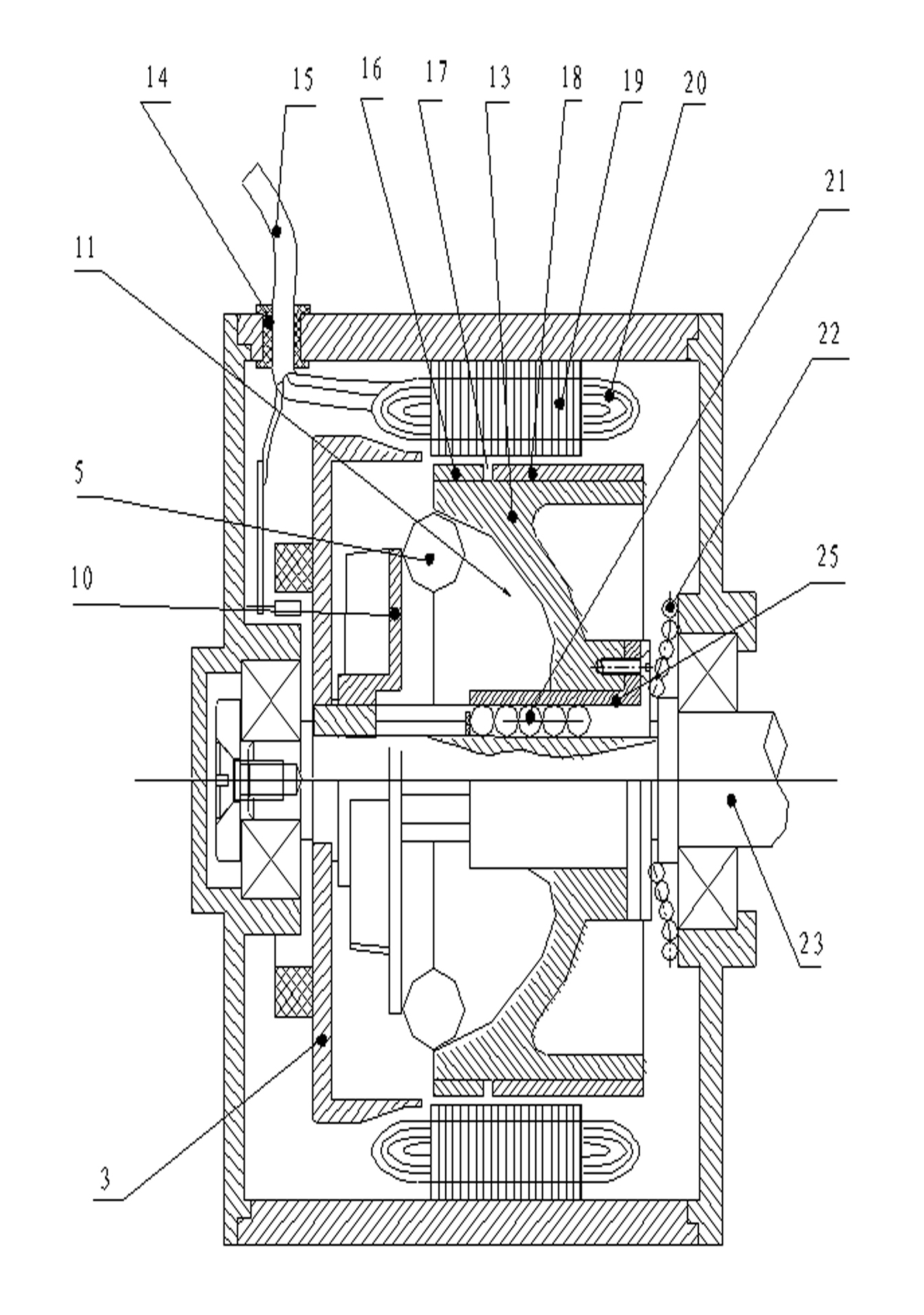

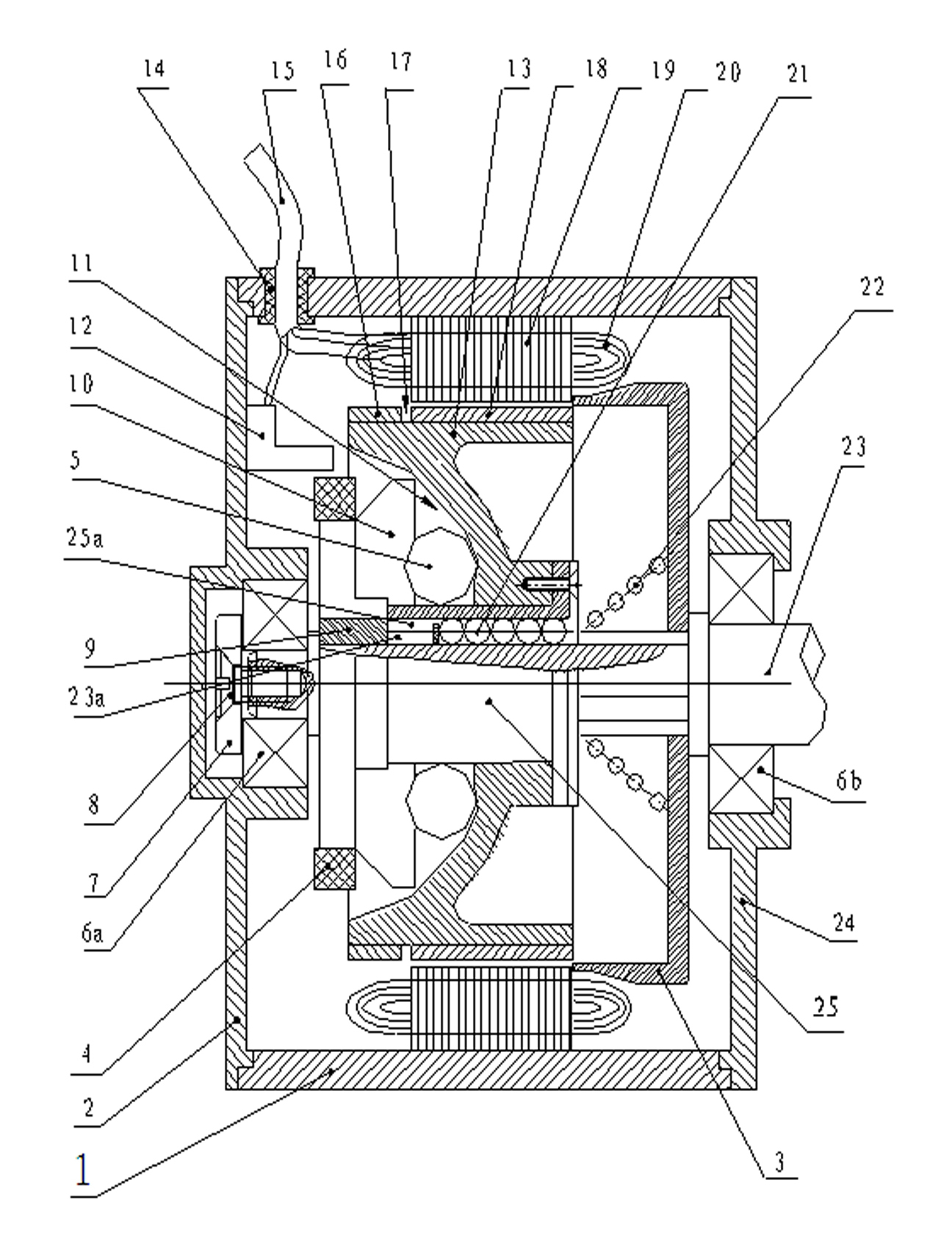

[0037] see figure 1 , figure 2 The casing 1 of the rotor slipping complementary excitation permanent magnet brushless variable speed motor of the present invention is connected with the front end cover 2 and the rear end cover 24 to form a frame, and the front end cover 2 and the rear end cover 24 are connected and fixed with the casing 1 by screws. The stator composed of windings 20 and iron core 19 is arranged on the inner cavity circumference of the casing 1, and the outgoing cable 15 of the winding 20 passes through the ferrule 14 provided on the casing 1 to support the rotor 13 and output the rotor. The motor rotating shaft 23 of torque is supported on the front end cover 2 by the bearing 6a, is supported on the rear end cover 24 by the bearing 6b, and one end of the motor rotating shaft 23 stretches out the rear end cover 24 for outputting power to the transmission mechanism. The bearing 6a is positioned by the baffle 7 and the shoulder of the motor shaft 23, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com