Patents

Literature

984 results about "Conical cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

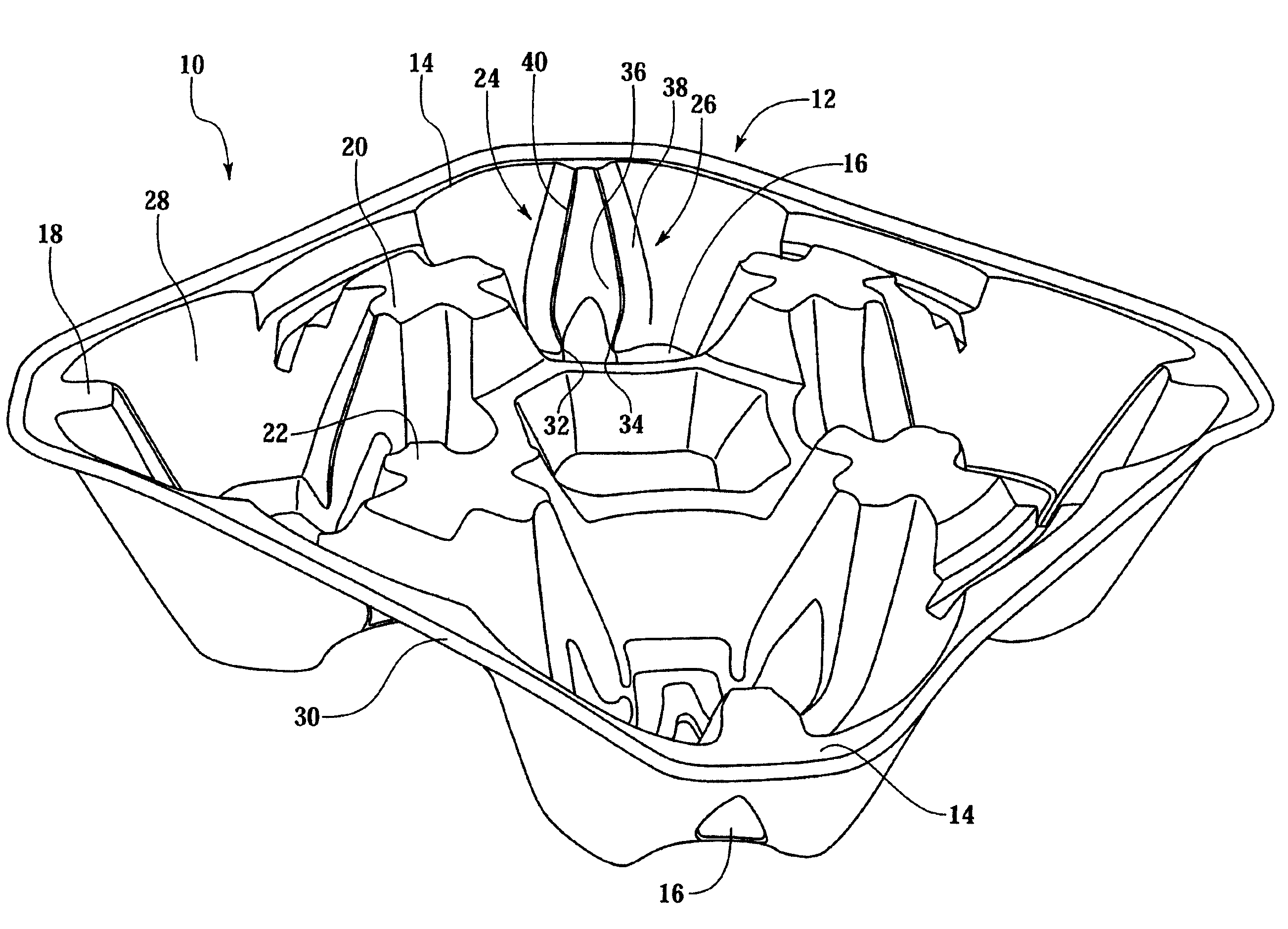

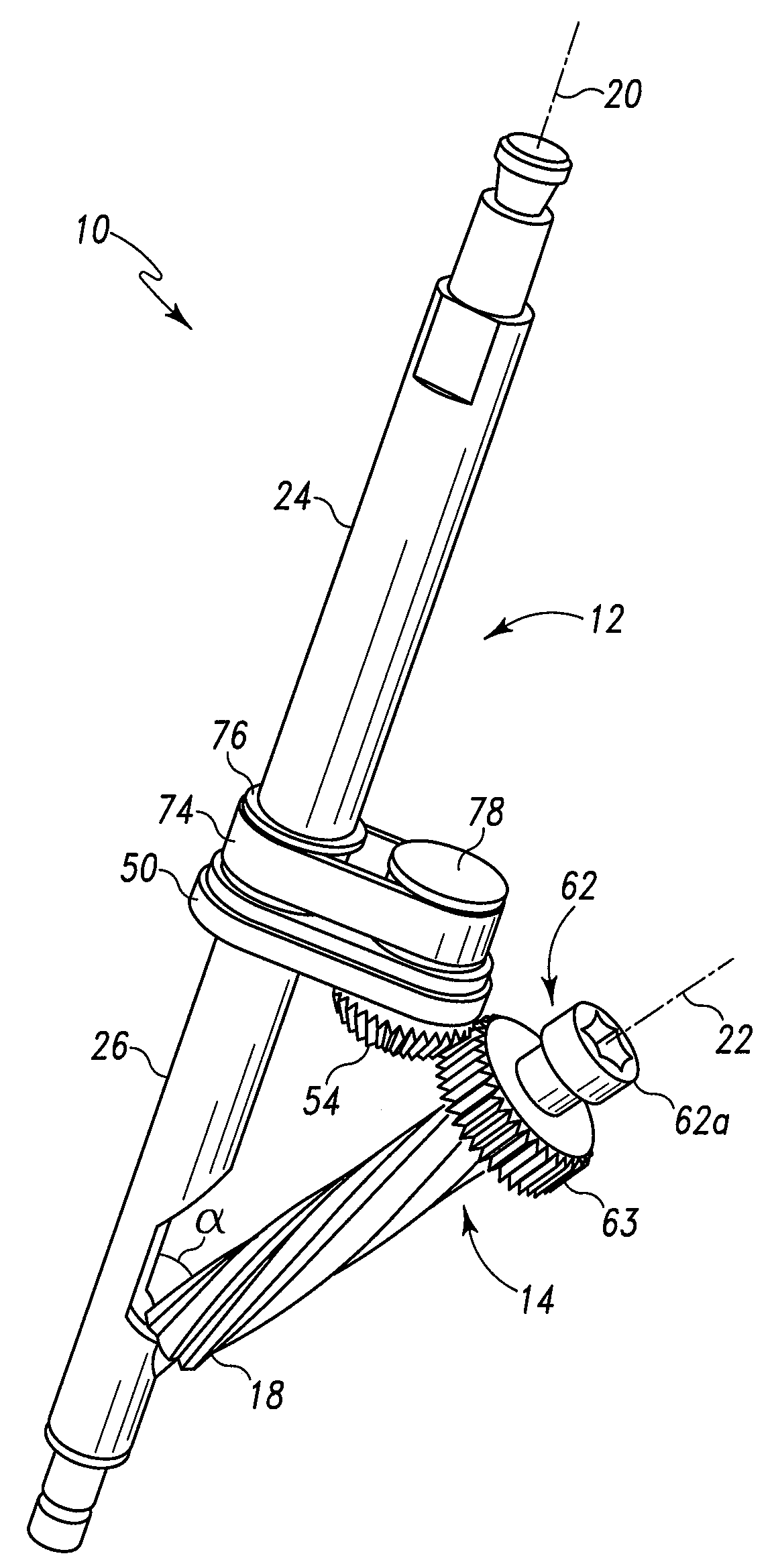

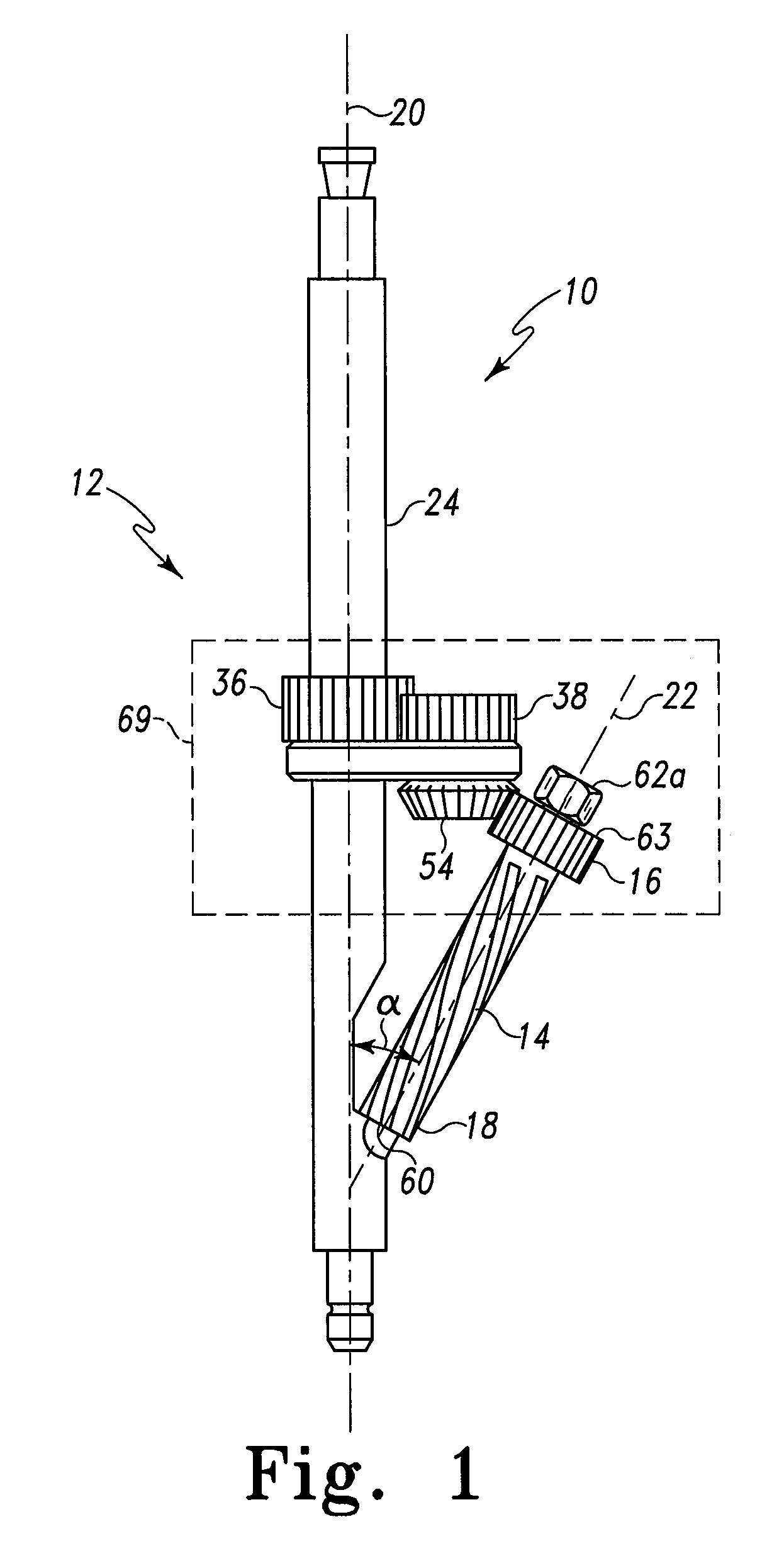

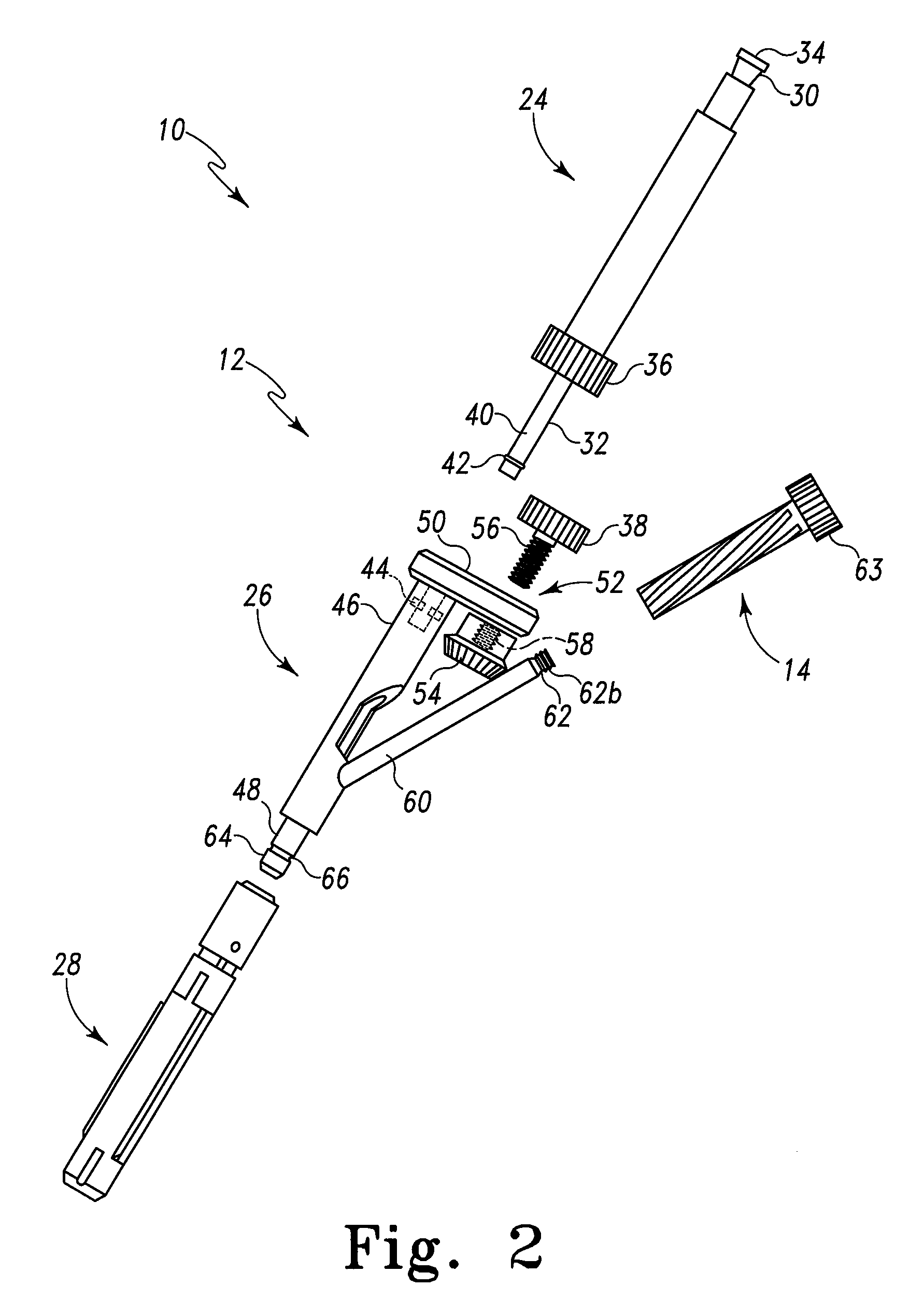

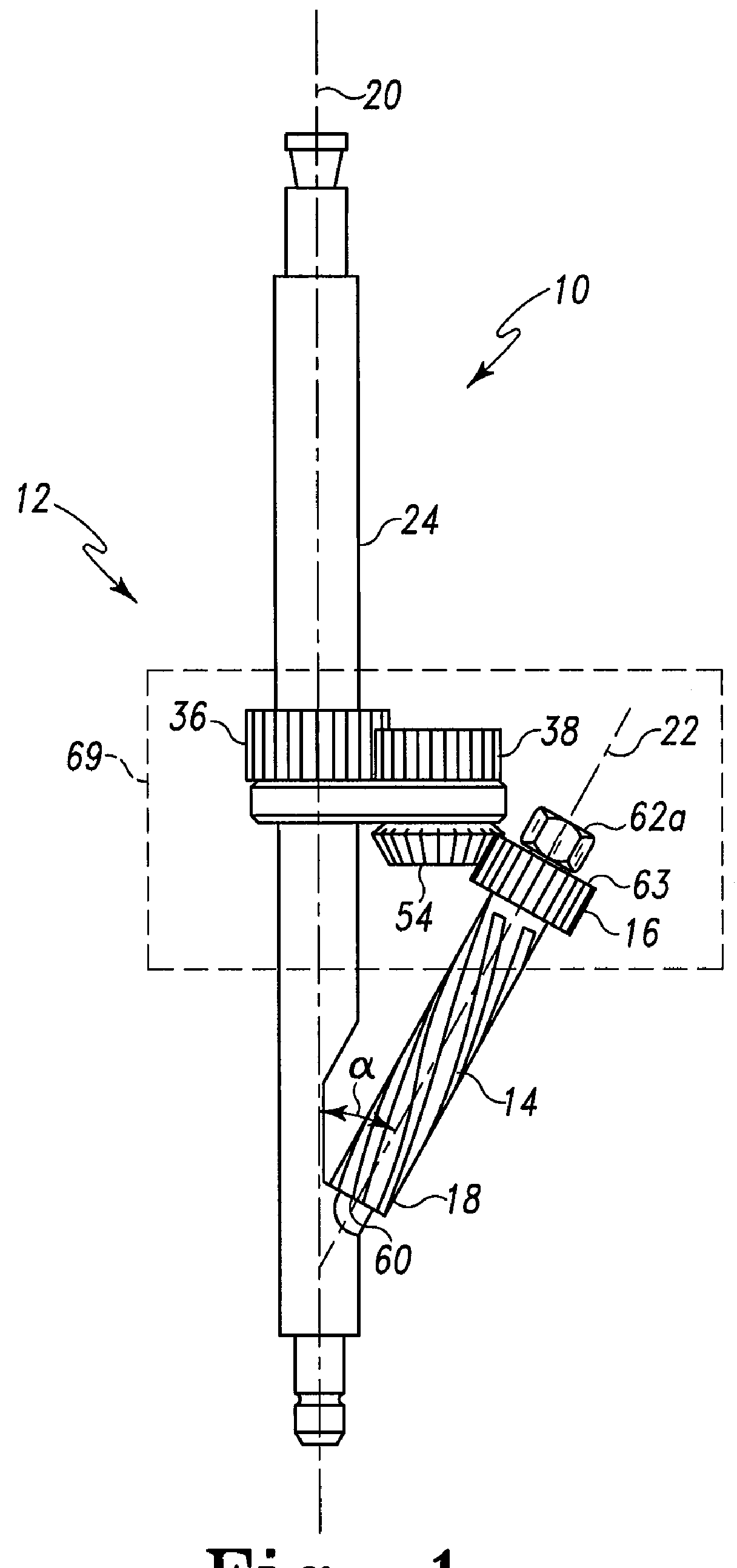

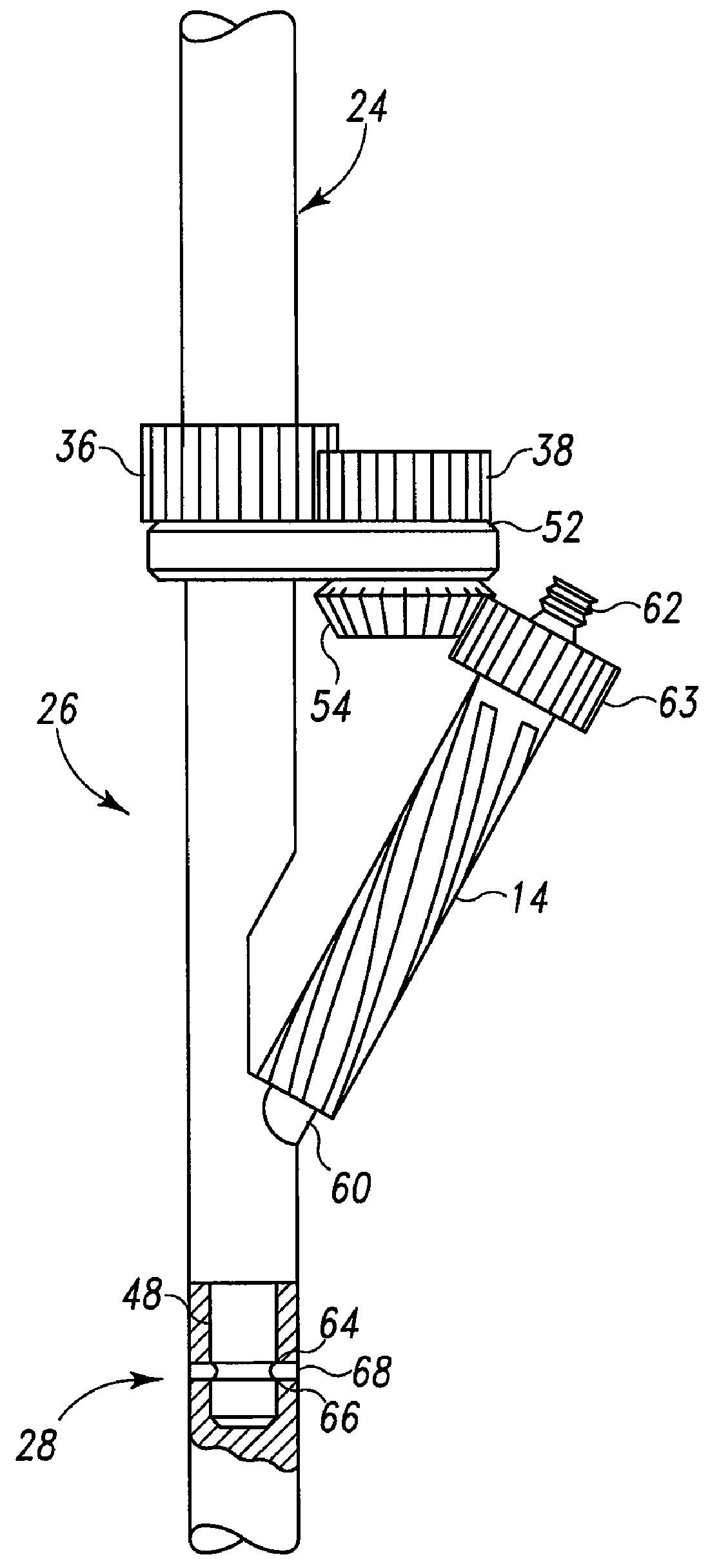

Minimally invasive bone broach

ActiveUS20050288676A1Reduce gapImproving the initial and long-term bone ingrowth/fixationJoint implantsBone drill guidesAcute angleAnatomy

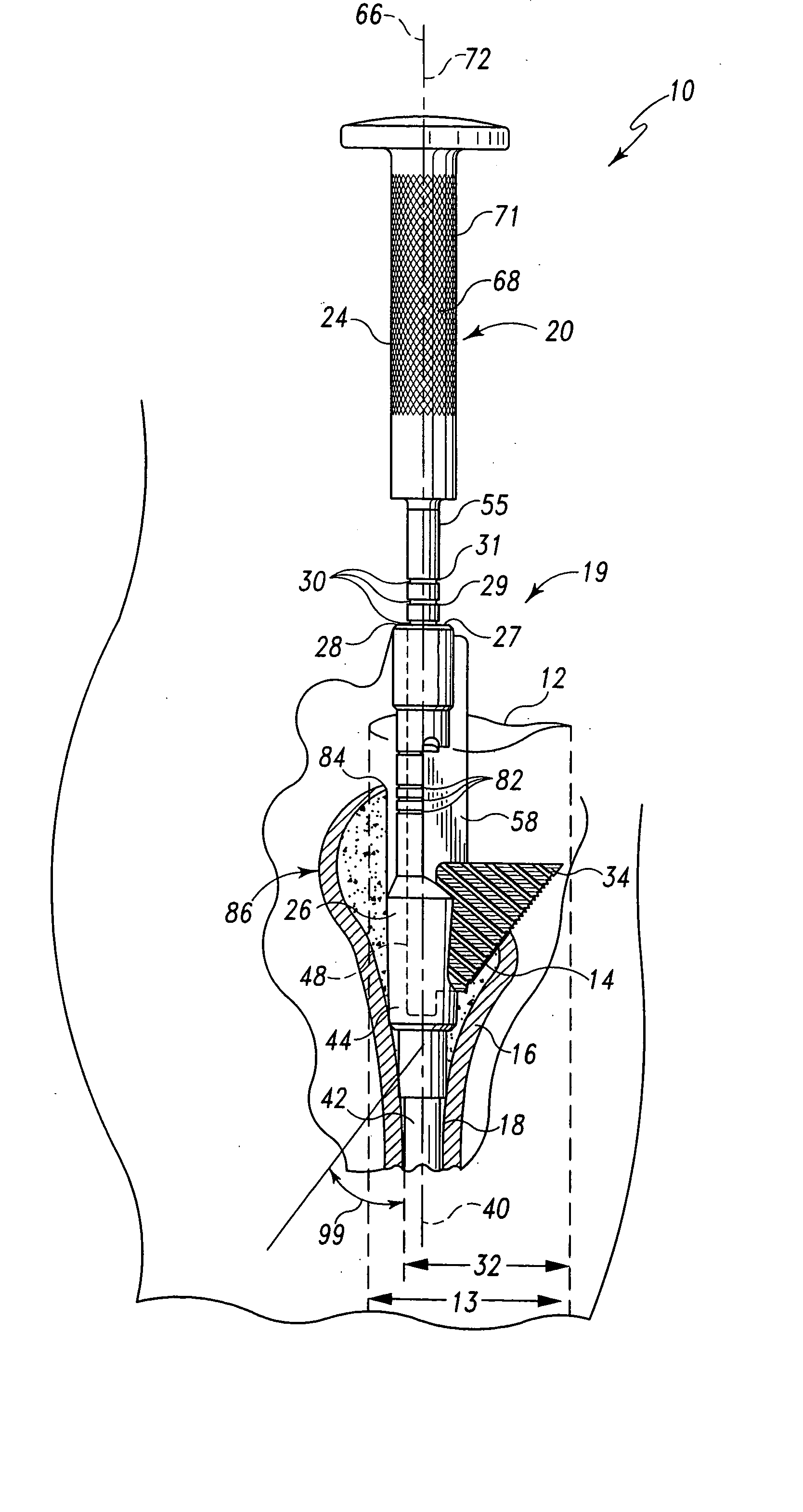

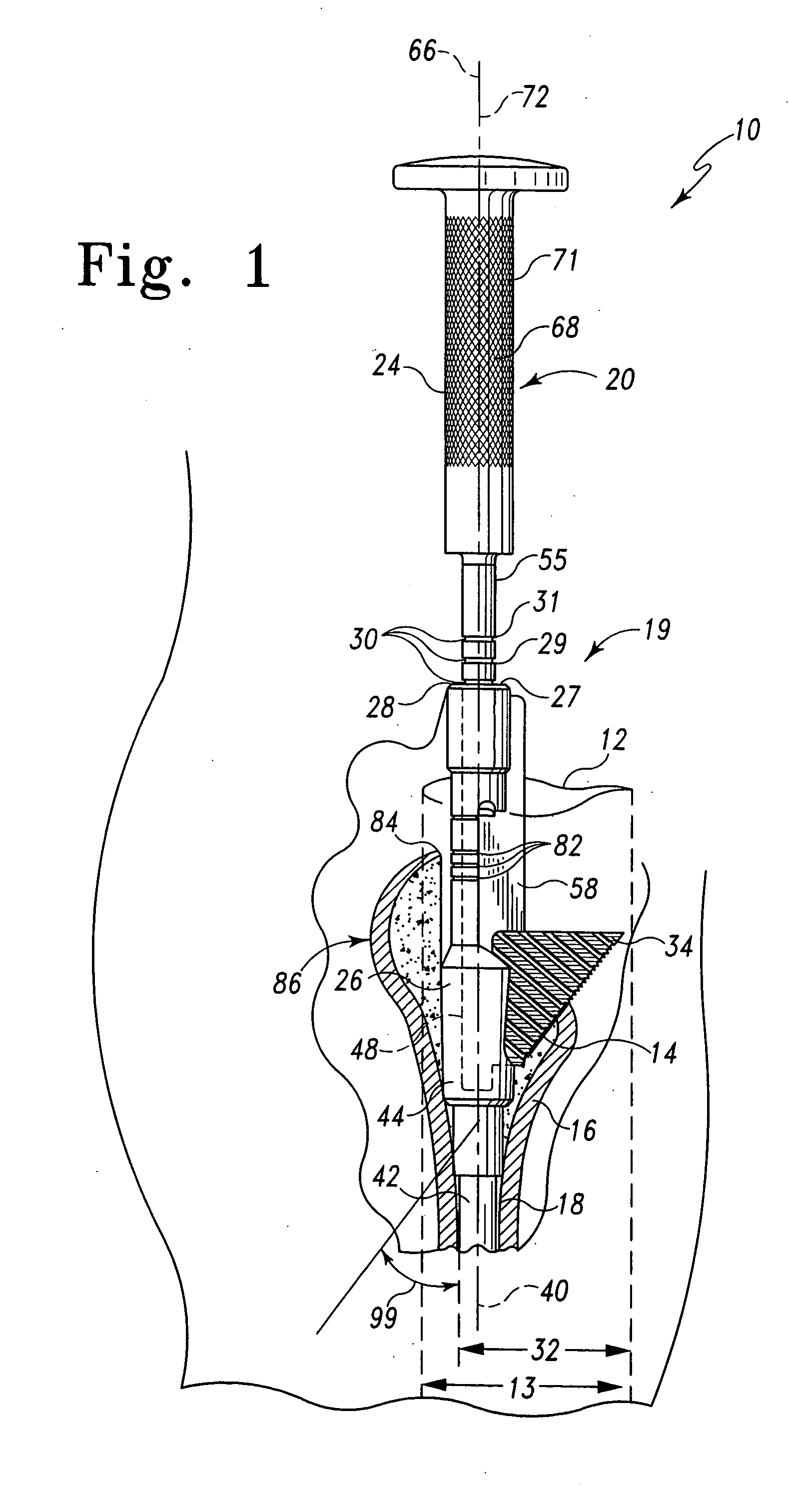

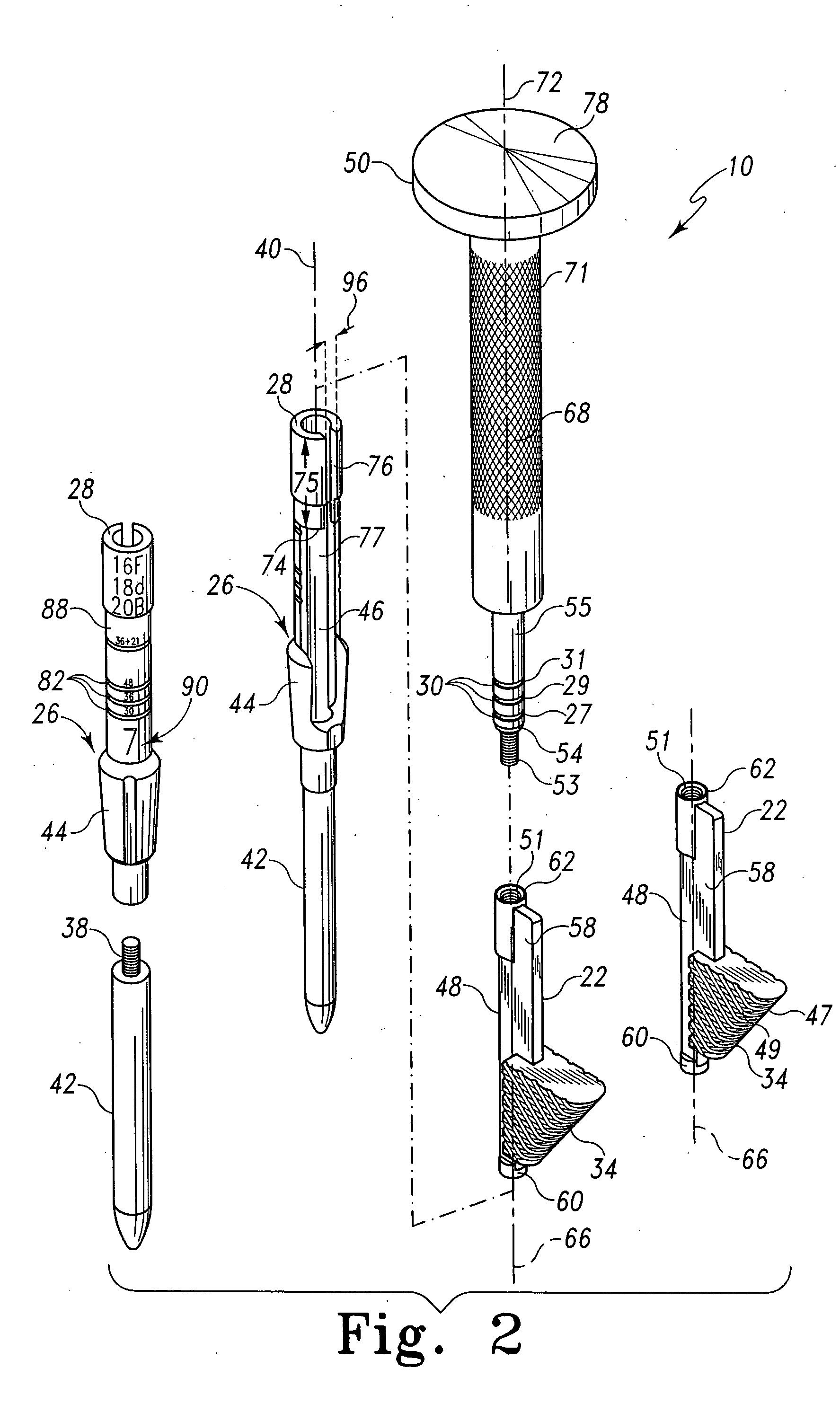

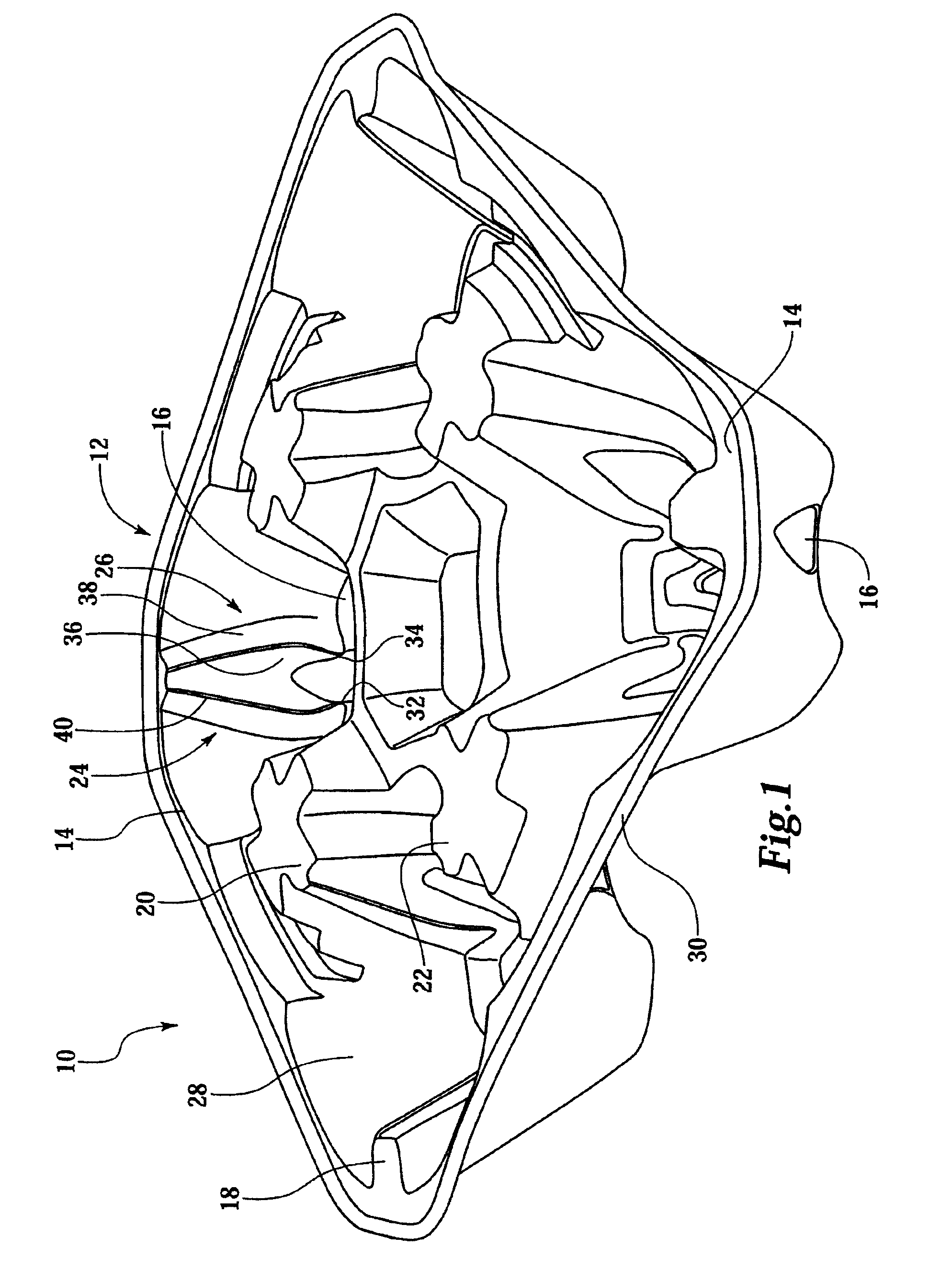

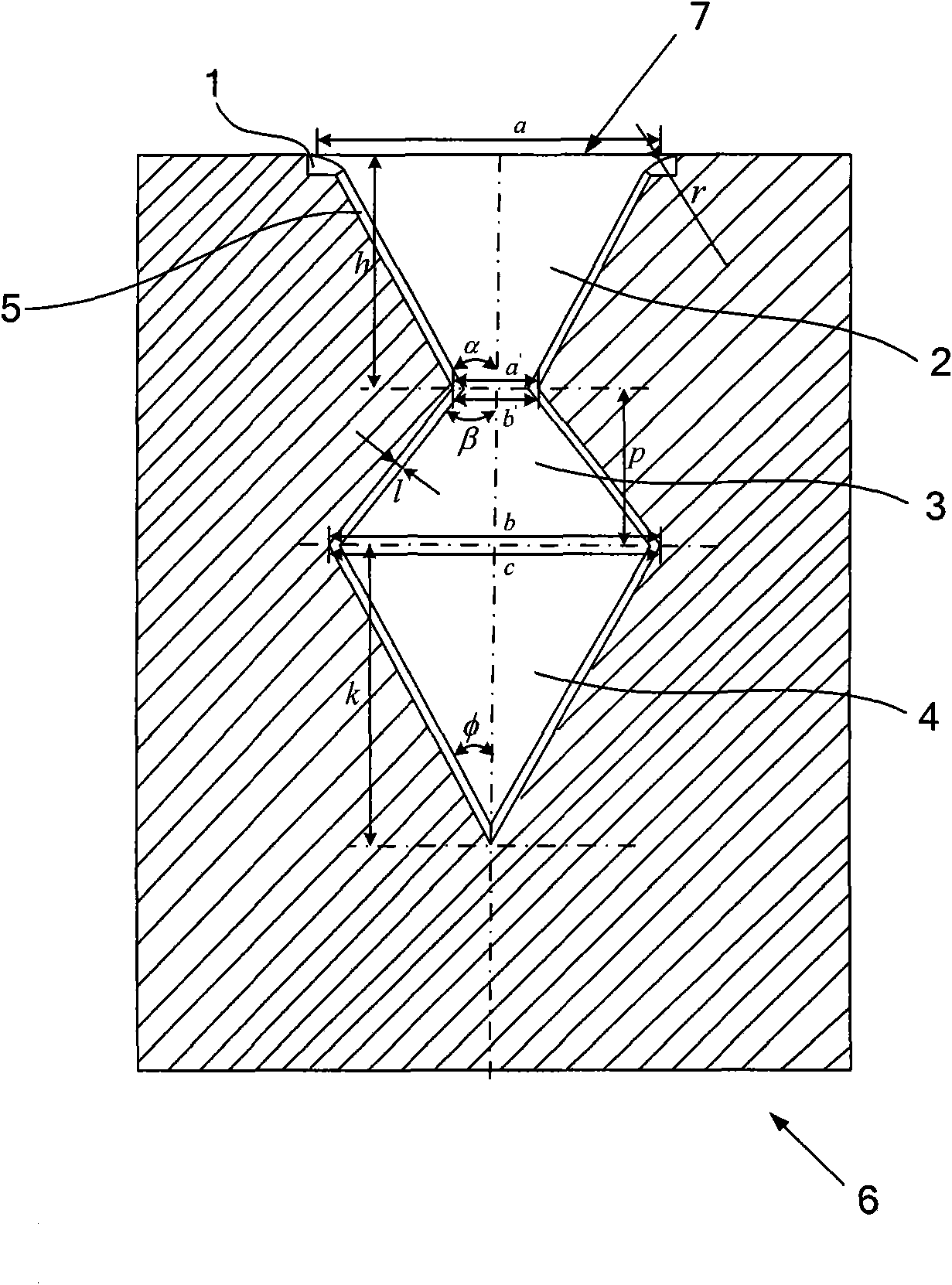

A broaching system is disclosed for creating a cavity in a bone. The cavity has a cross section which has a generally triangular profile having a first side generally parallel with an axis of the bone and a second side forming an acute angle with the first side. The cavity is contiguous with a pre-existing conical cavity in the bone. The apparatus comprises as shaft and a broach. The shaft has a longitudinal axis. The broach is mounted to the shaft and has a first cutting side mounted at the acute angle relative to the longitudinal axis of the shaft. The first cutting side is formed to include teeth. The shaft and broach are configured so that when the longitudinal axis of the shaft is advanced into the bone along the axis of the bone, the teeth of the broach form the triangular cavity. A method for cutting a triangular cavity in bone is also described. The method comprises a providing a shaft step, an incising step and a cutting step. The provided shaft is configured to be movable relative to the bone to be prepared and includes a broach coupled thereto to dispose a cutting surface of the broach at an acute angle relative to the shaft. The shaft and broach have a width defined by the distance between the shaft and the outer most portion of the cutting surface. The incising step includes incising the patient adjacent the bone to be prepared to form an incision having a length approximating the width of shaft and broach. The cutting step includes cutting the cavity by driving the broach by moving the shaft relative to the bone.

Owner:DEPUY PROD INC

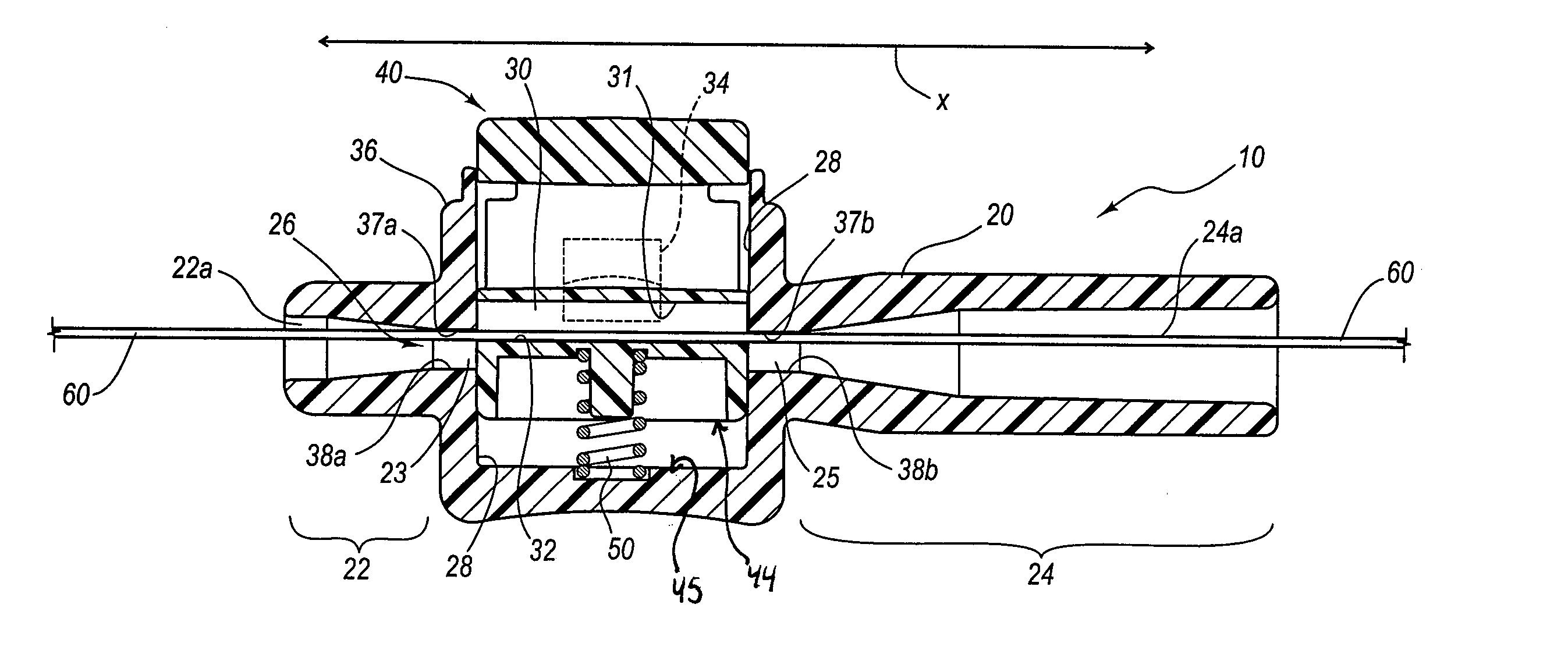

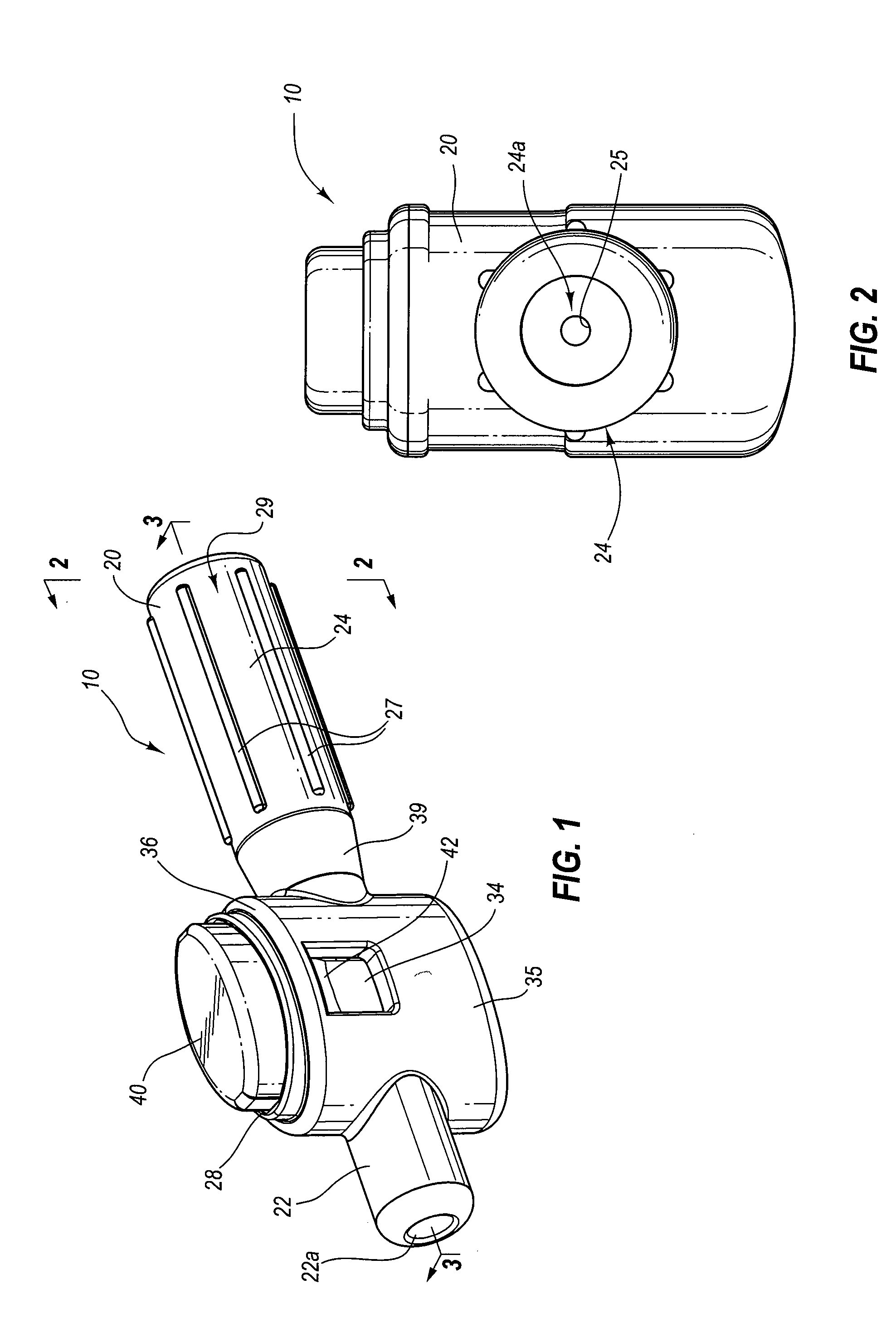

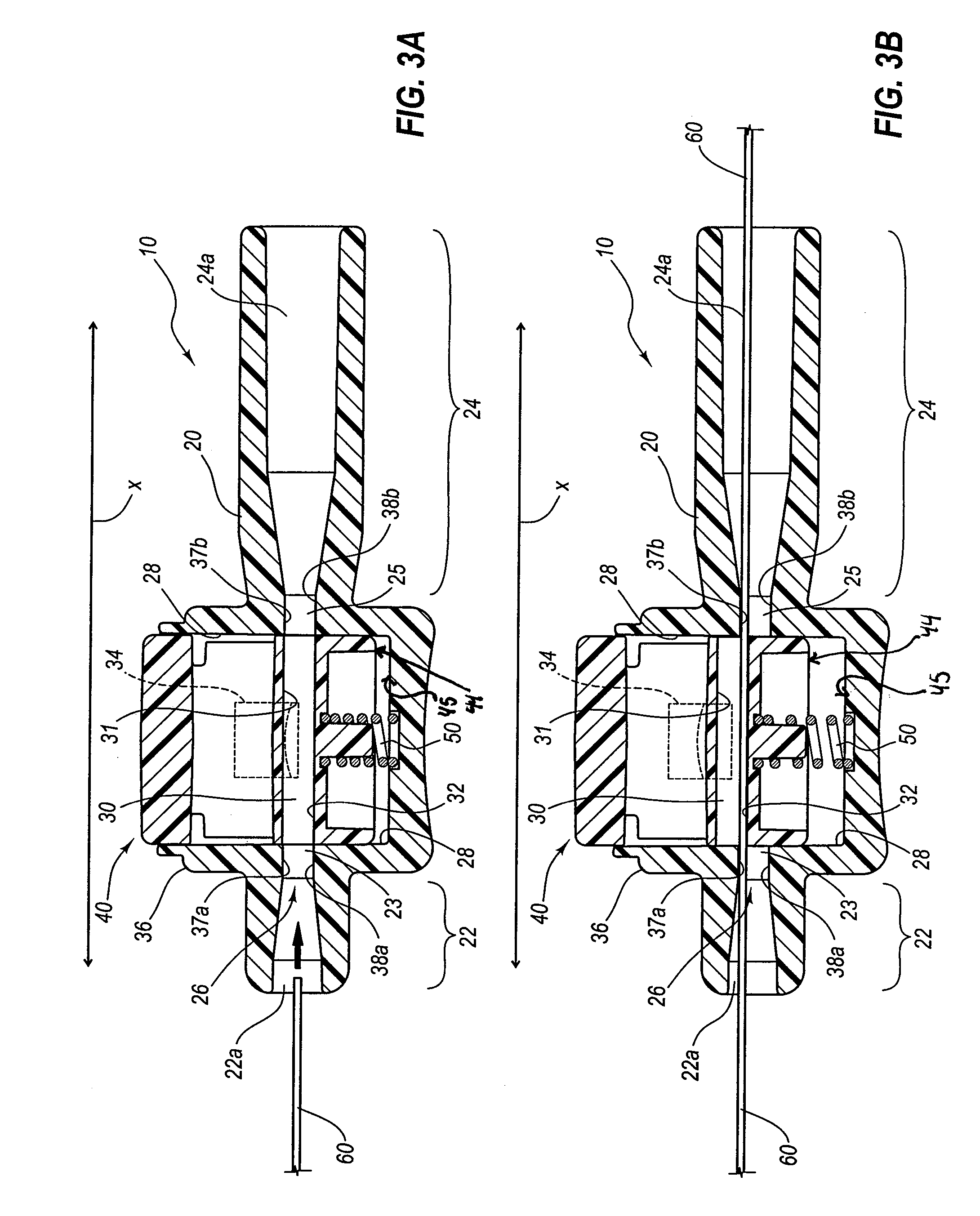

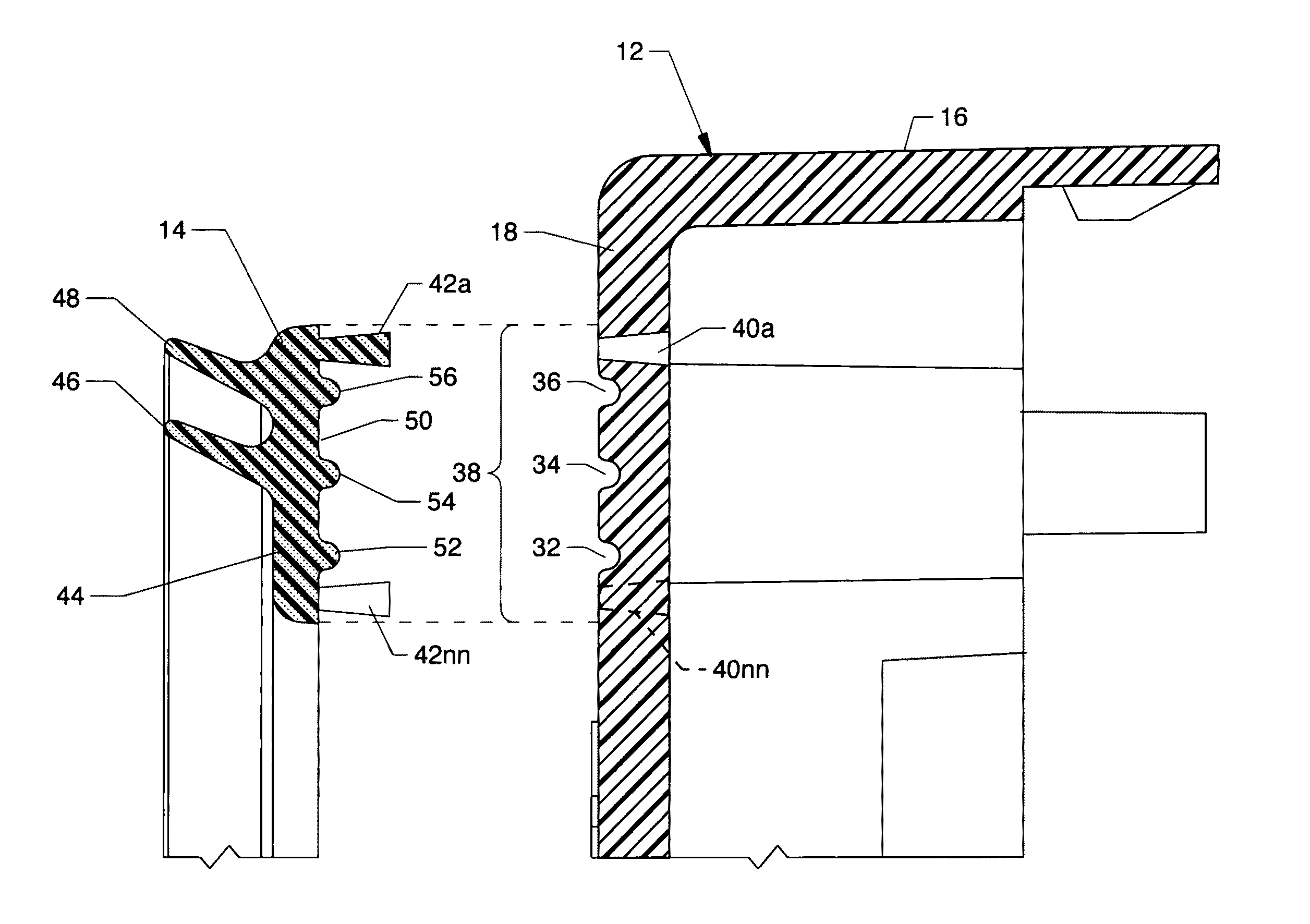

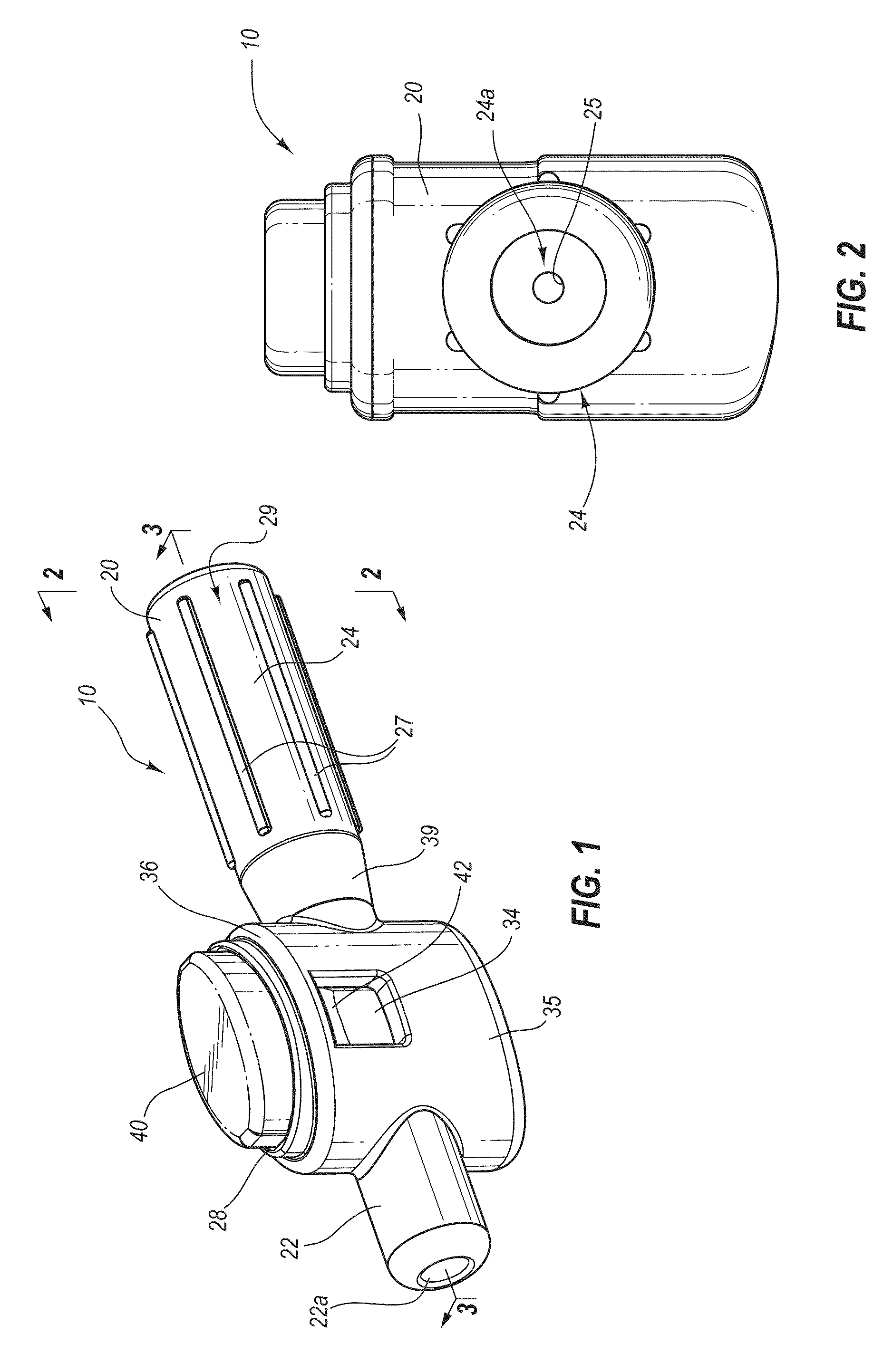

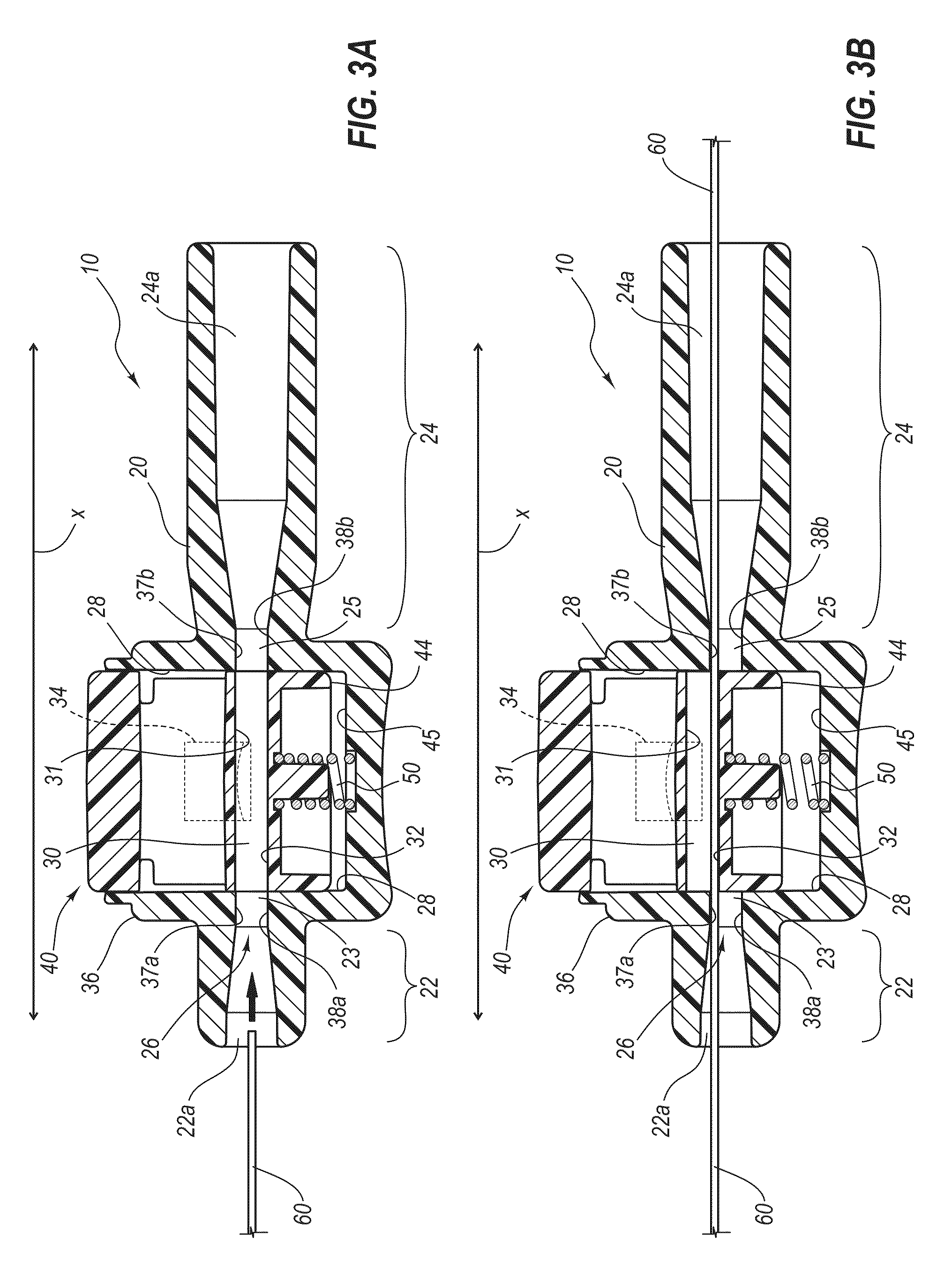

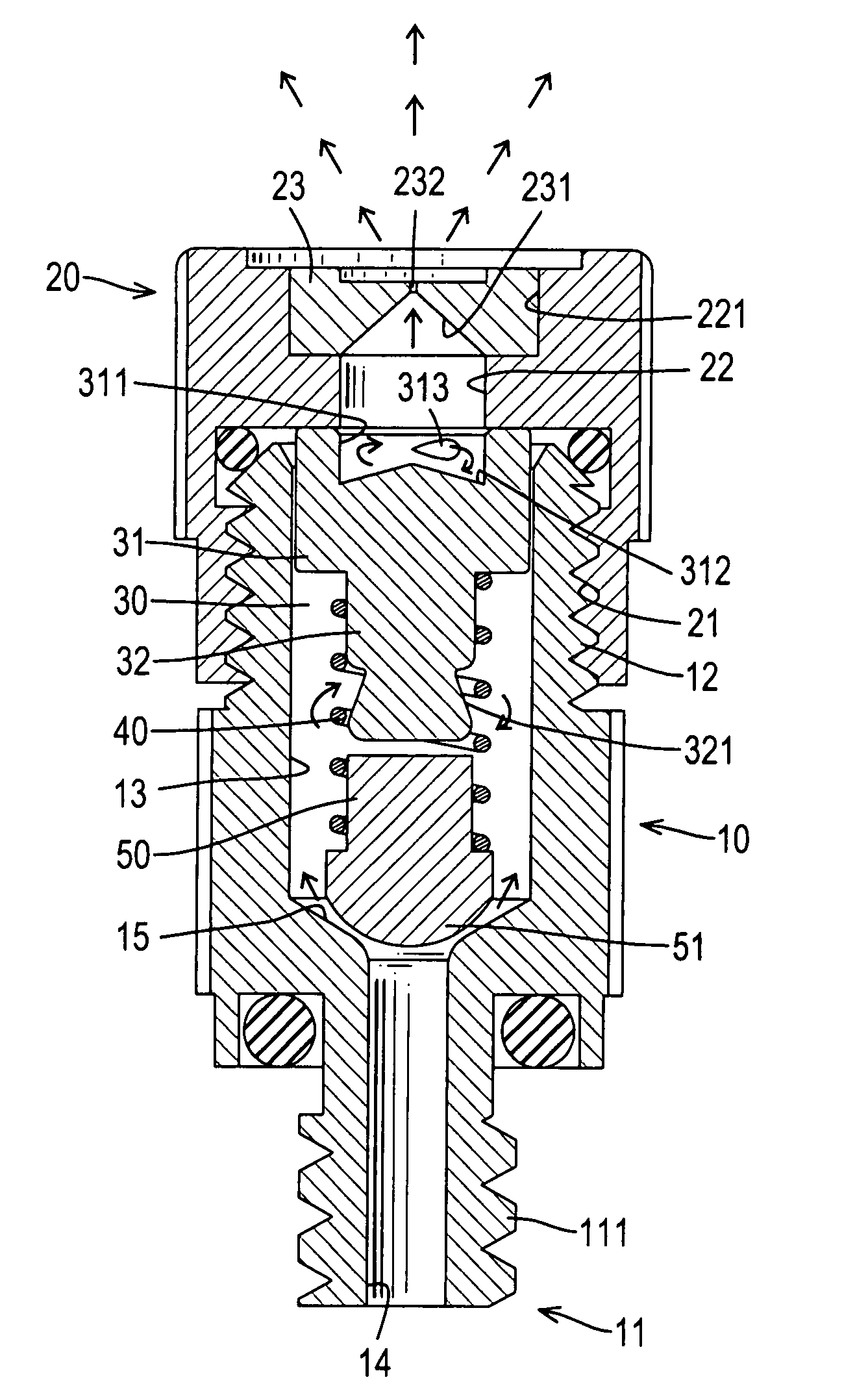

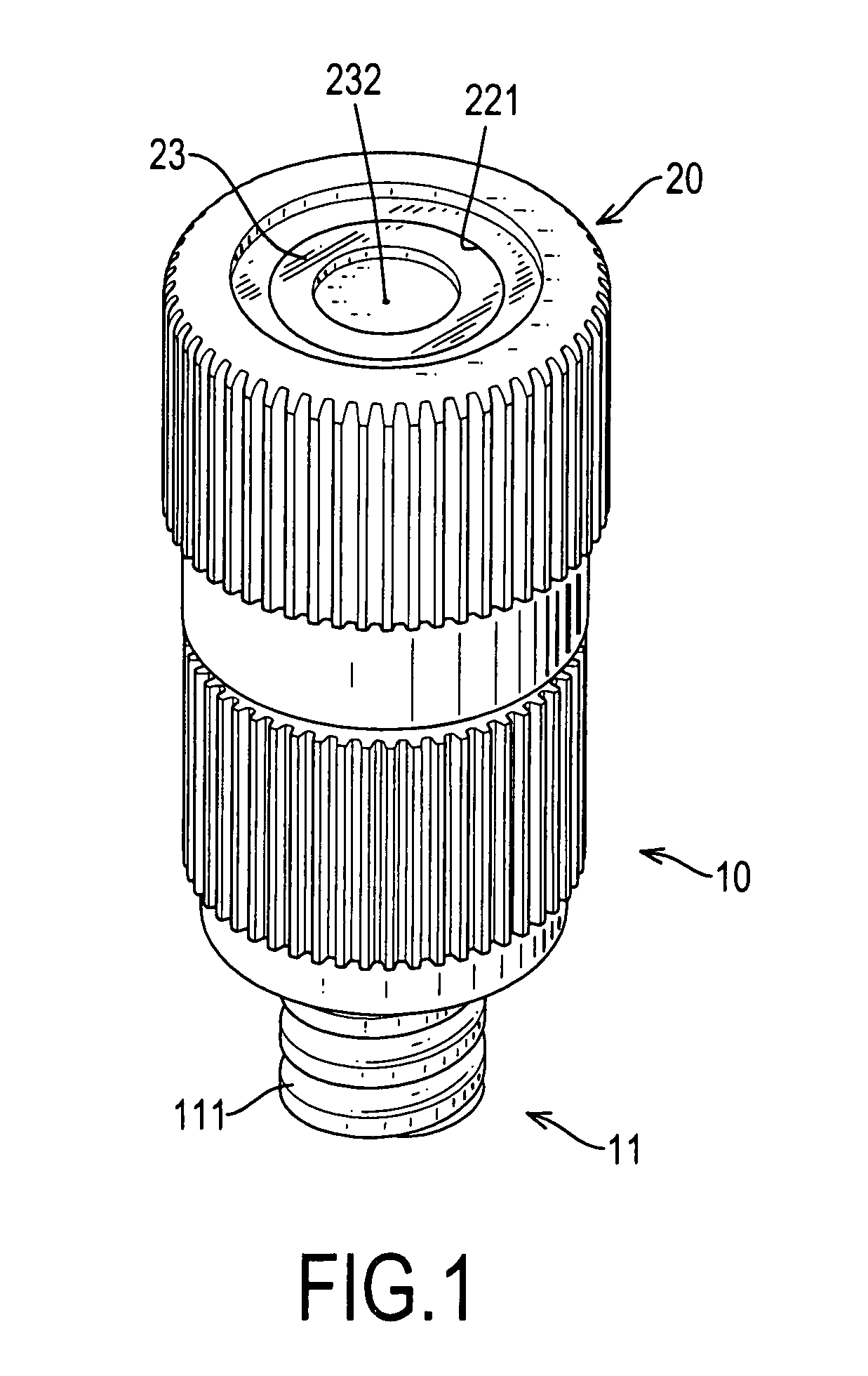

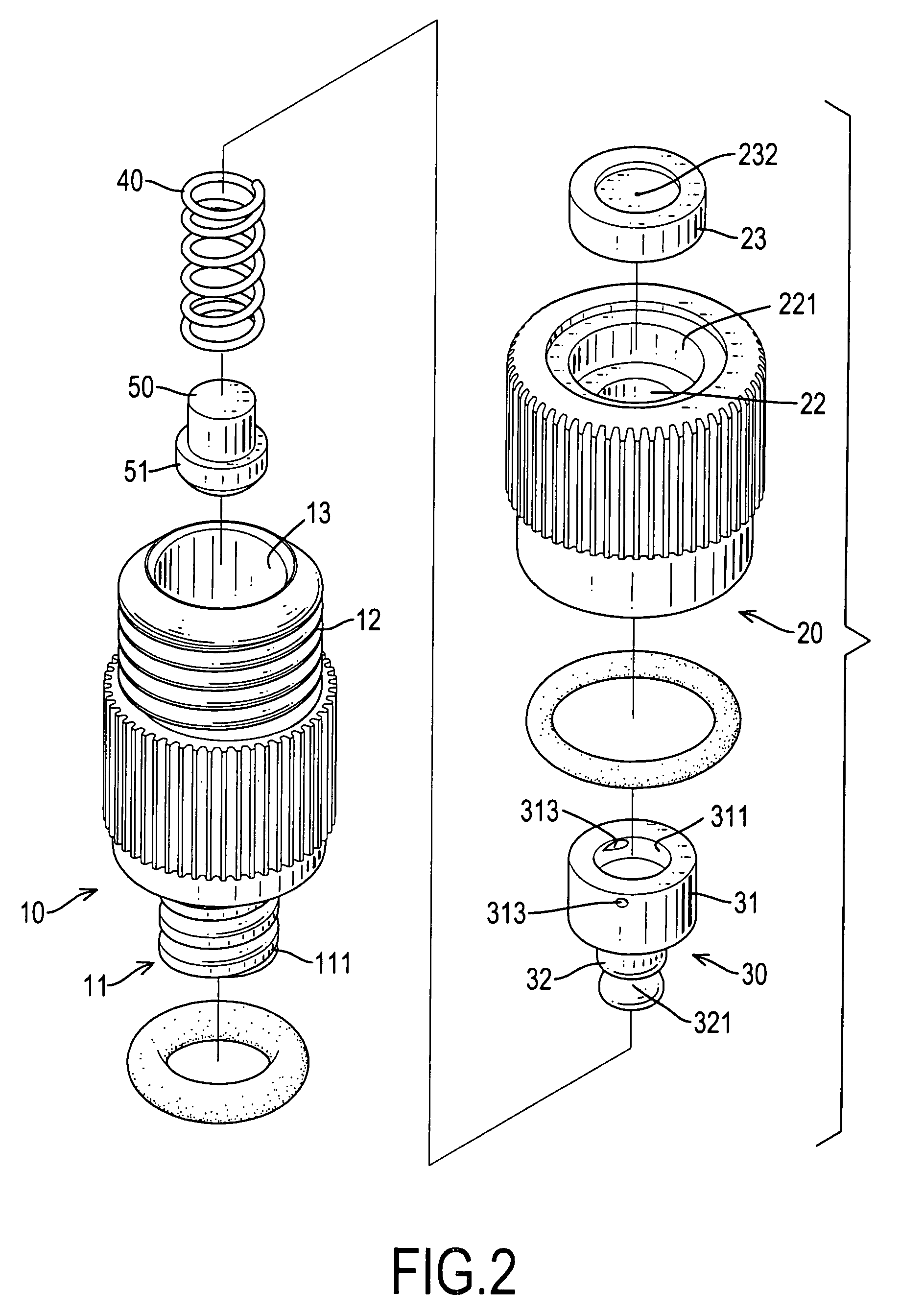

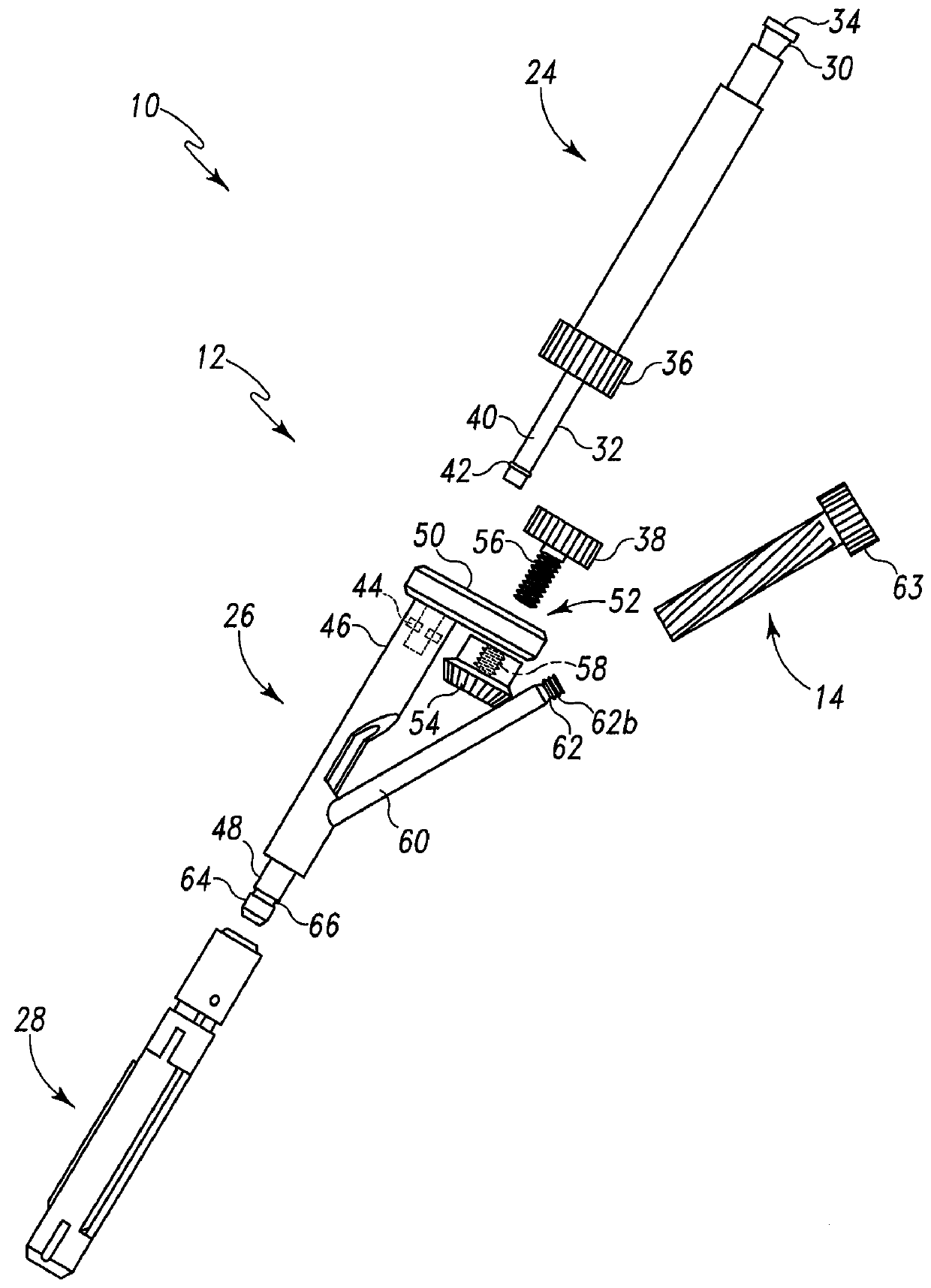

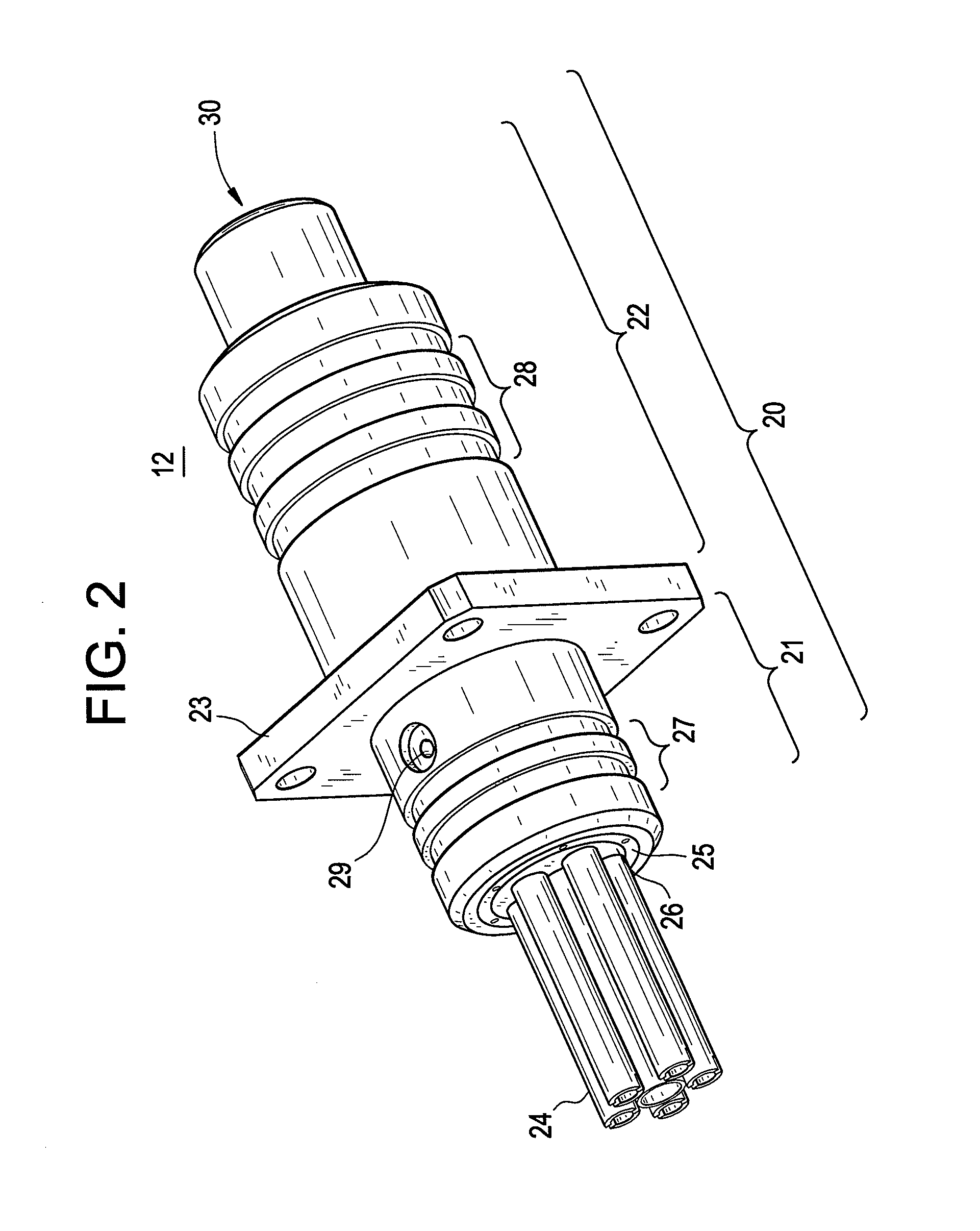

Torque device for a medical guidewire

ActiveUS20070219467A1Improve gripAvoid misuseGuide wiresDiagnostic recording/measuringConical cavityEngineering

A torque device for selectively gripping a medical guidewire. The device includes a housing, an actuator slidably mounted on the housing, and a resilient member biasing the actuator. A lumen dimensioned to receive the guidewire extends through the housing and actuator. The resilient member biases the actuator from a first position in which the lumen portions are aligned, toward a second position in which the lumen portions are misaligned. The actuator may include a catch that interferes with a stop of the housing to retain the actuator within the housing. The actuator may be oblong or otherwise shaped to maintain the lumen portions in substantial alignment in a longitudinal direction. Preferably, at least a portion of the lumen is teardrop-shaped in cross-section. The housing may include circumferentially or longitudinally extending ribs defining an outer grasping surface. Frusto-conical cavities may be defined at entry and exit ends of the lumen.

Owner:MERIT MEDICAL SYST INC

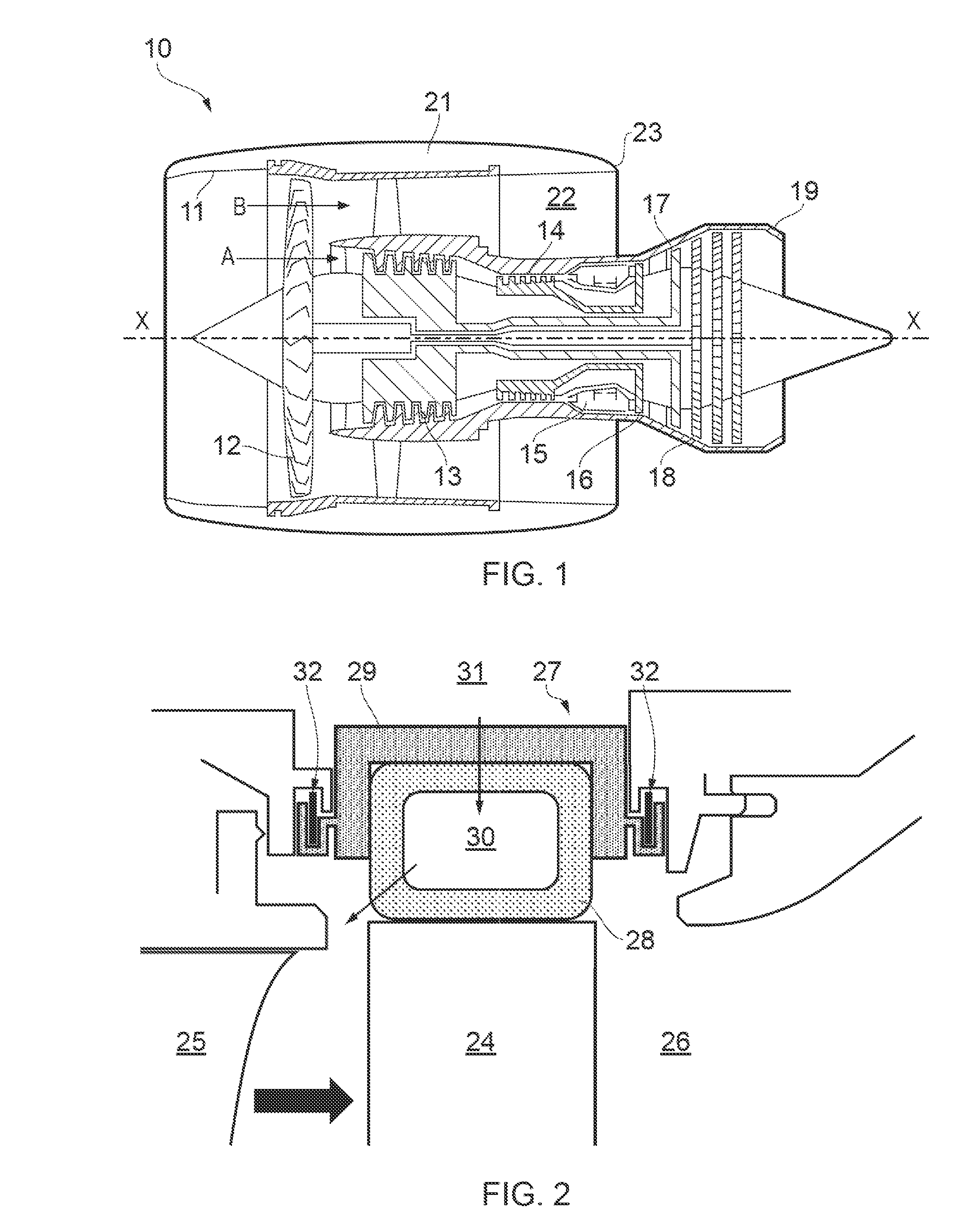

Fastener

InactiveUS20140023490A1Simple structureFunction increaseEngine sealsEngine manufactureEngineeringConical cavity

A fastener is provided for connecting two or more structural elements having matching apertures which, when aligned, form a frusto-conical cavity. The fastener includes a body portion having a frusto-conical outer surface which is receivable in the aligned apertures of the structural elements such that the outer surface of the body portion is in mating engagement with the cavity formed by the aligned apertures. The fastener further includes an elongate member which extends from the body portion at the narrow end of the frusto-conical outer surface. The fastener further includes a fixing element carried by the elongate member. The fixing element is operable to exert a clamping force between the frusto-conical outer surface and the fixing element to retain the structural elements in connection therebetween. The fastener further includes a through-hole which extends along the elongate member and which allows fluid communication between opposing sides of the connected structural elements.

Owner:ROLLS ROYCE PLC

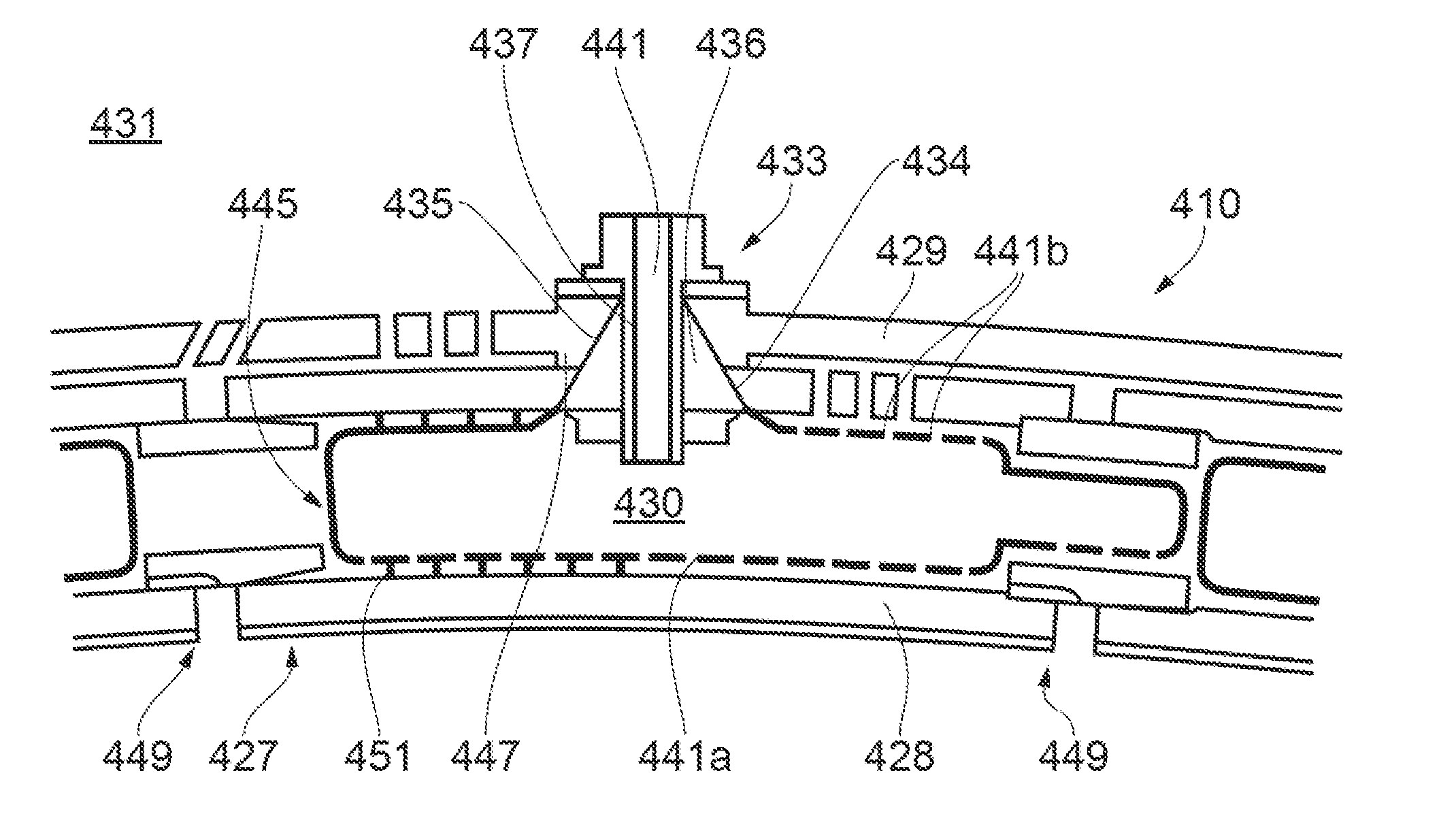

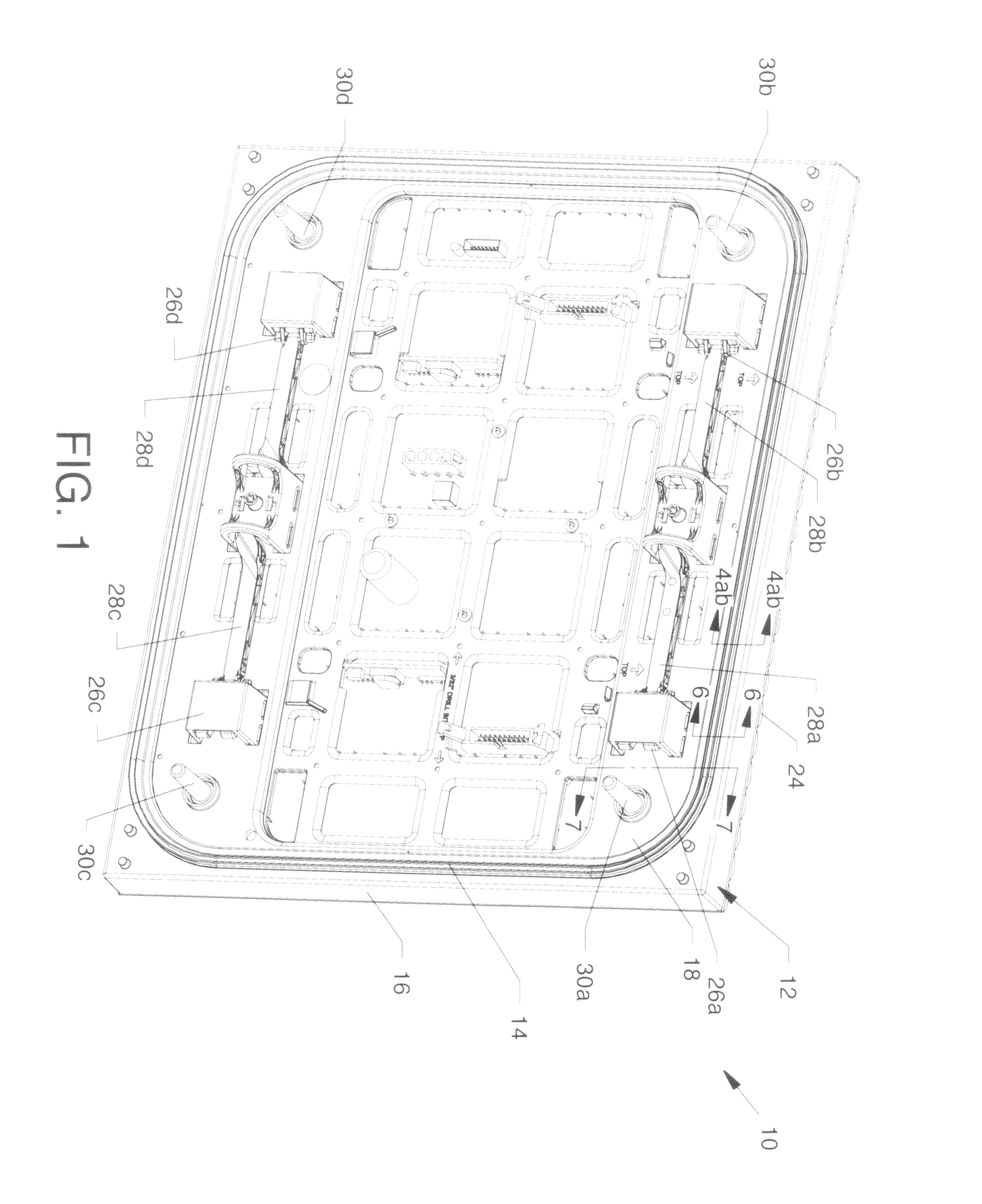

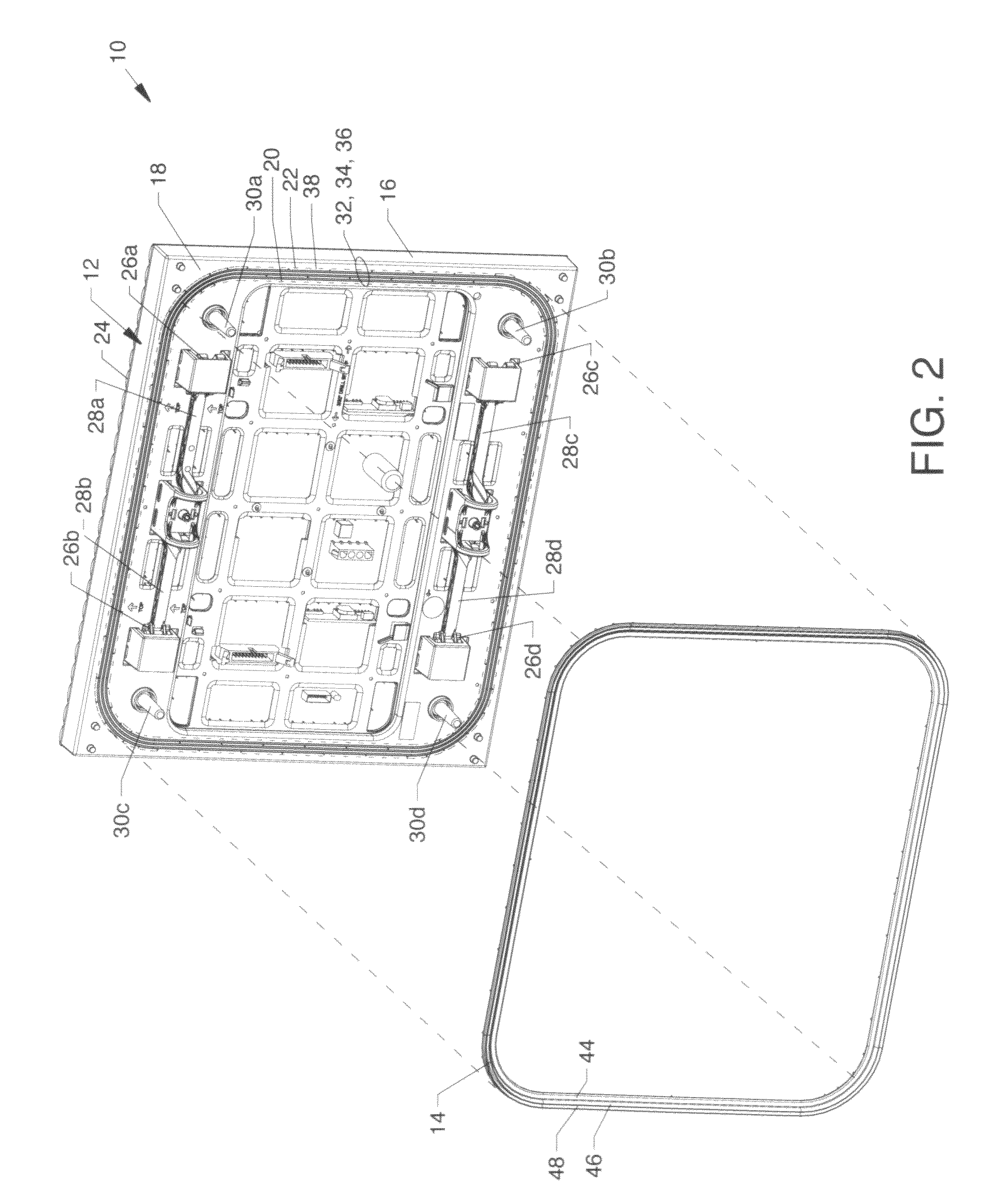

Electronic sign module housing having an overmolded gasket seal

ActiveUS8136279B1Eliminate errorsSolution to short lifeSleeve/socket jointsEngine sealsElastomerCompound (substance)

An electronic sign module housing having an overmolded gasket seal including an elastomer overmolded gasket seal with an inner and an outer lip and a base overmolded to a rearwardly located contact surface of an electronic sign module housing. Grooves on the contact surface of the electronic sign module housing provide additional bonding surfaces with a greater surface area to enhance the chemically-bonded overmolding of the overmolded gasket seal. Truncated conical projections extending forwardly from the elastomer base extend into correspondingly shaped truncated conical cavities in the electronic sign module housing in order to provide additional chemical bonding and to provide a geometrically based frictional engagement arrangement.

Owner:DAKTRONICS

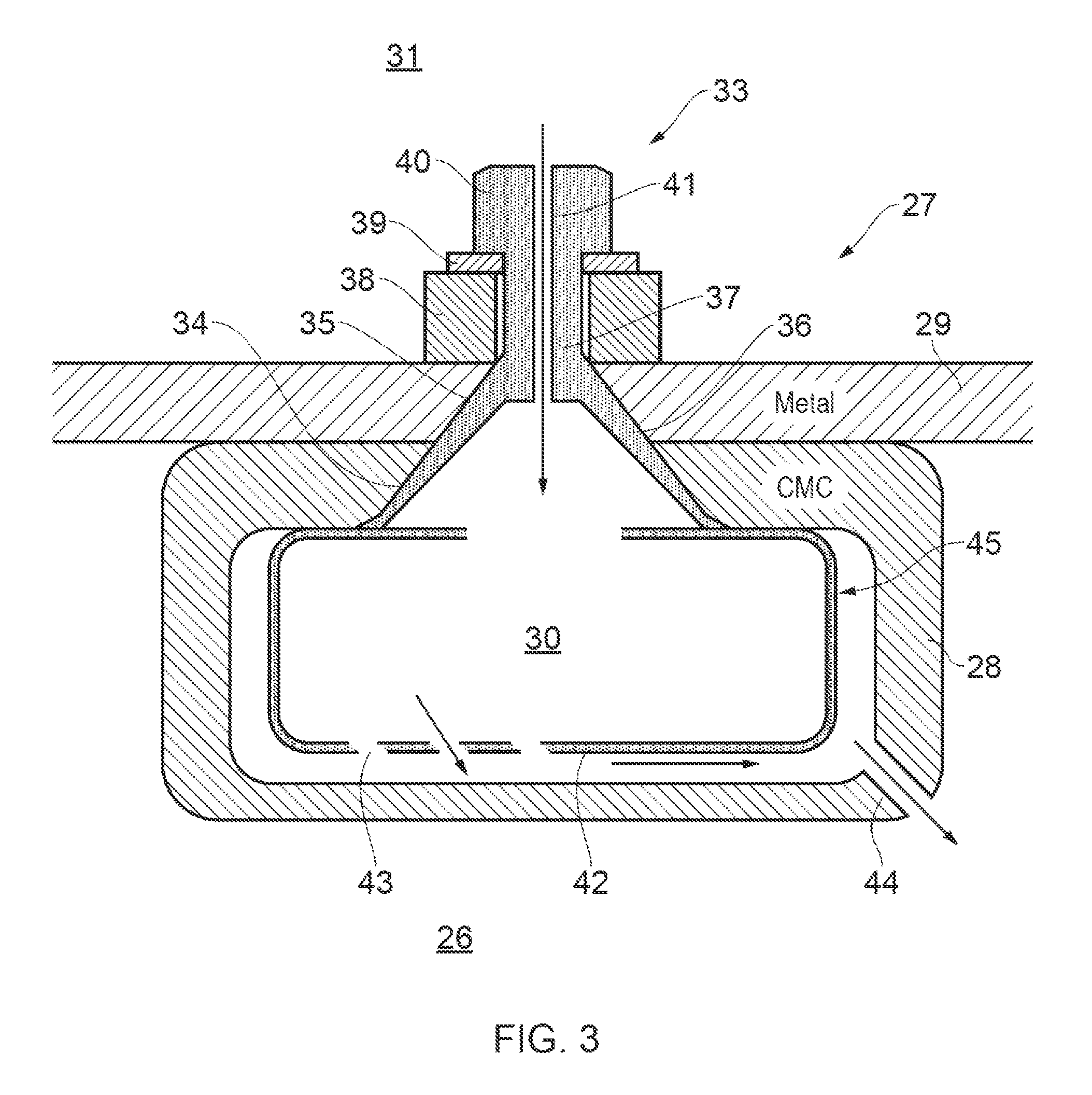

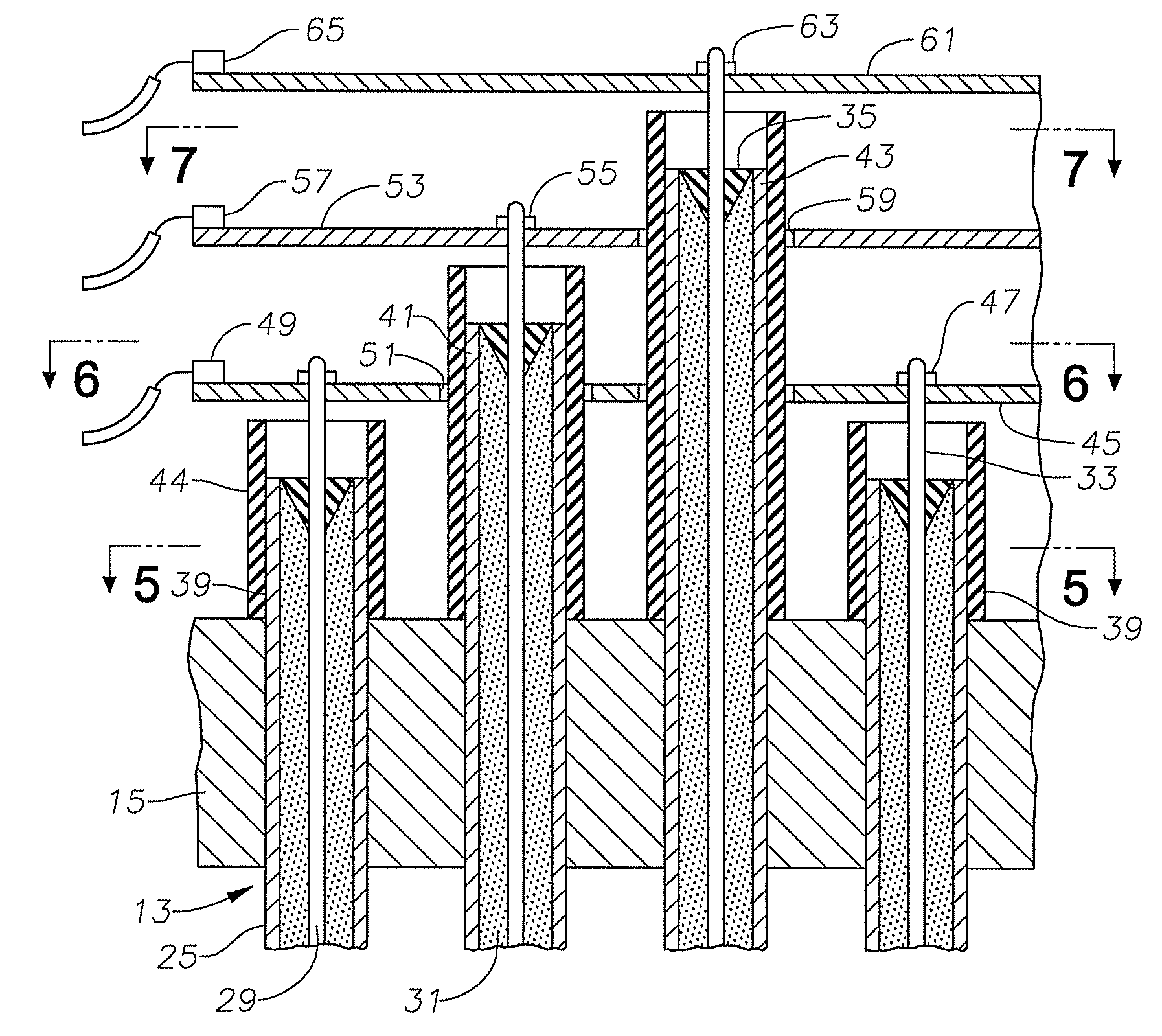

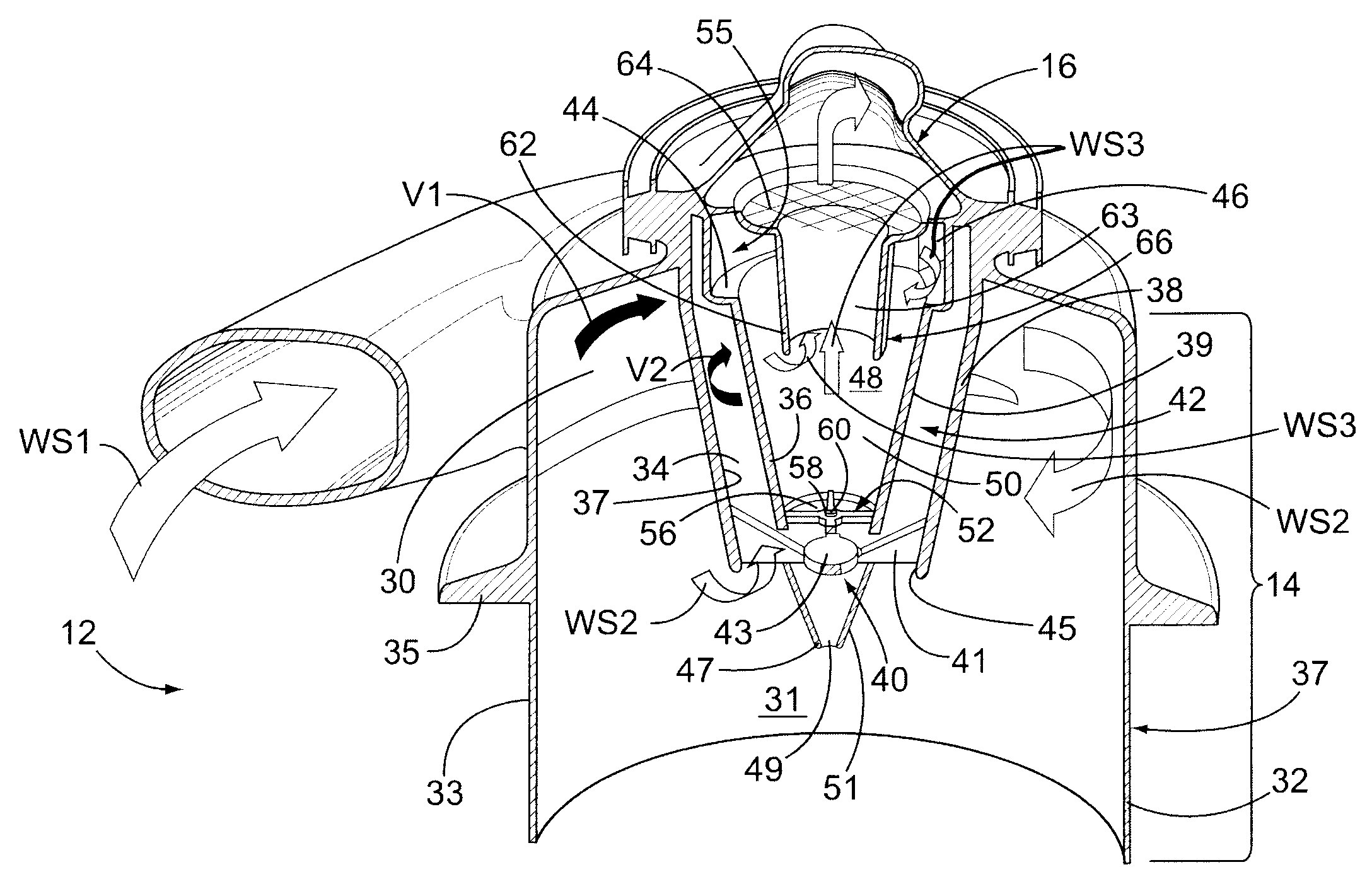

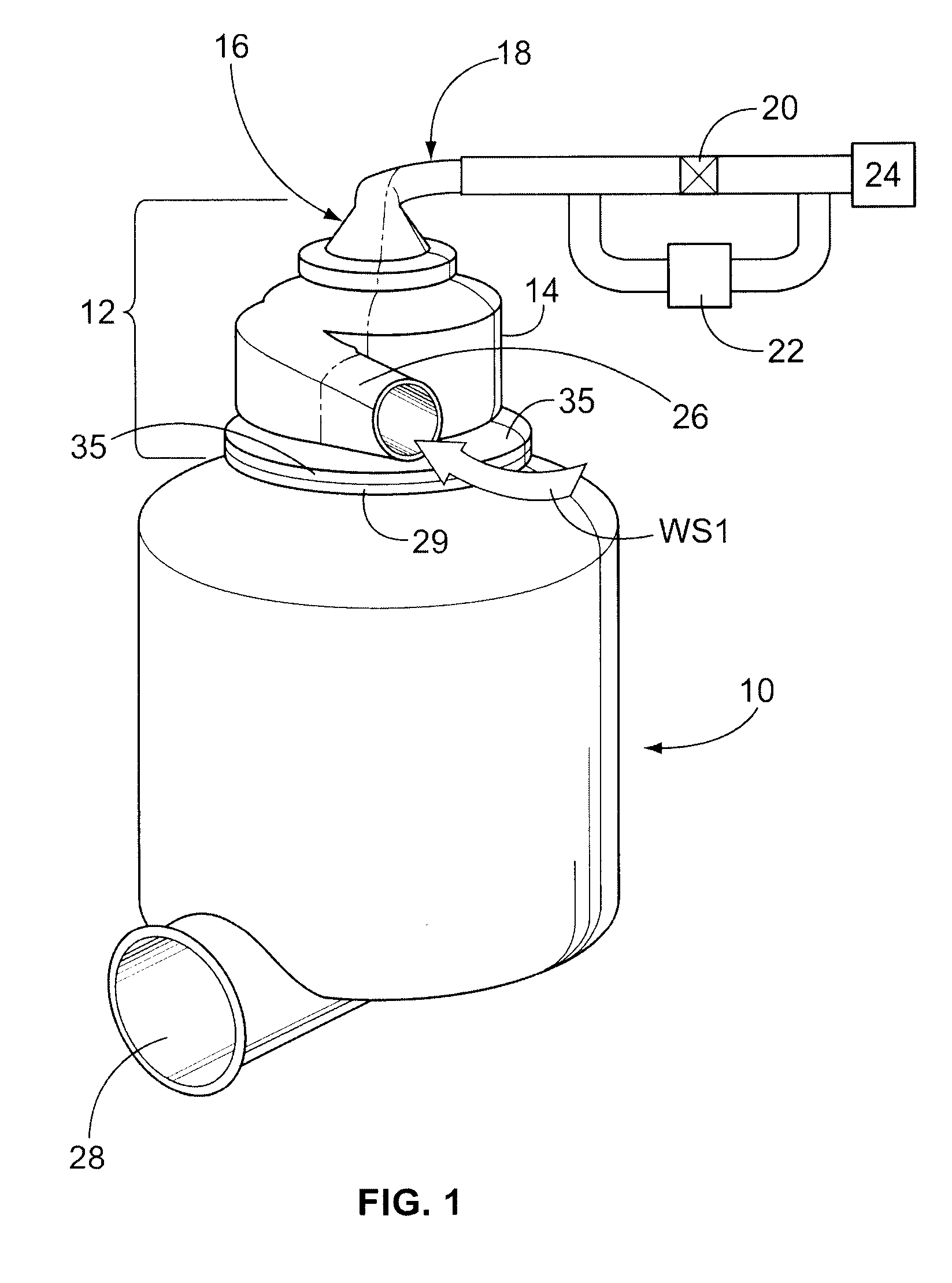

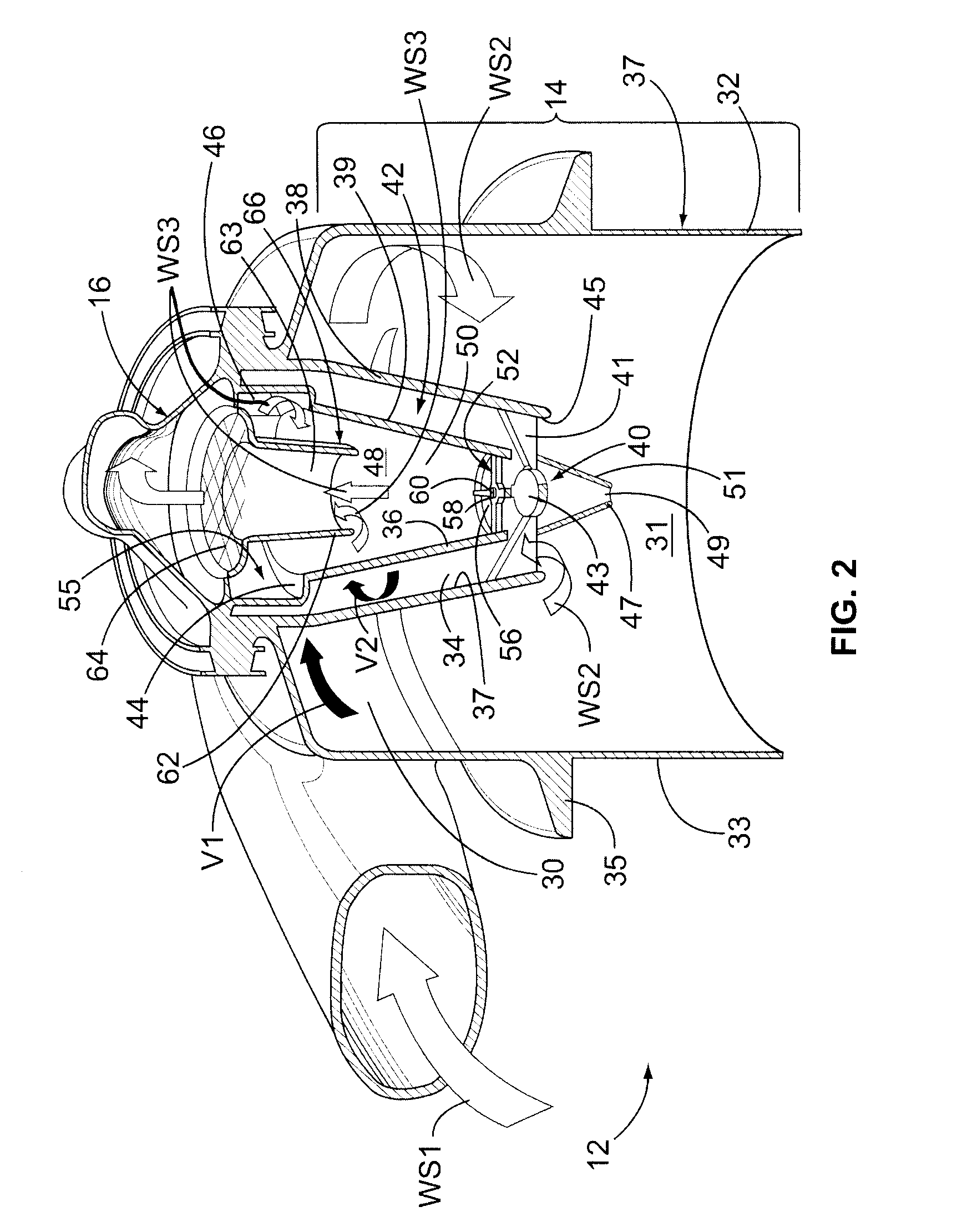

Vortex waste separator apparatus

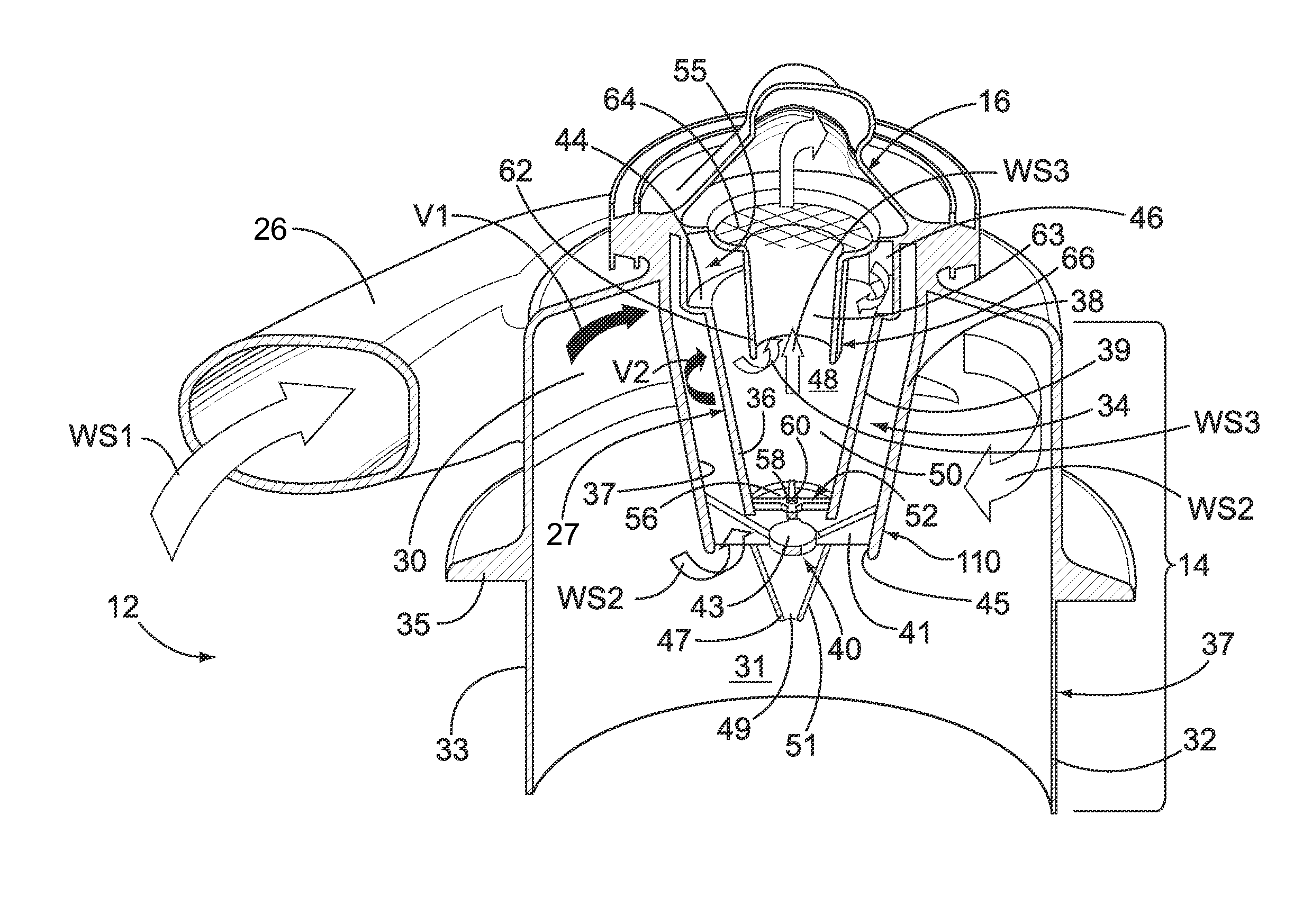

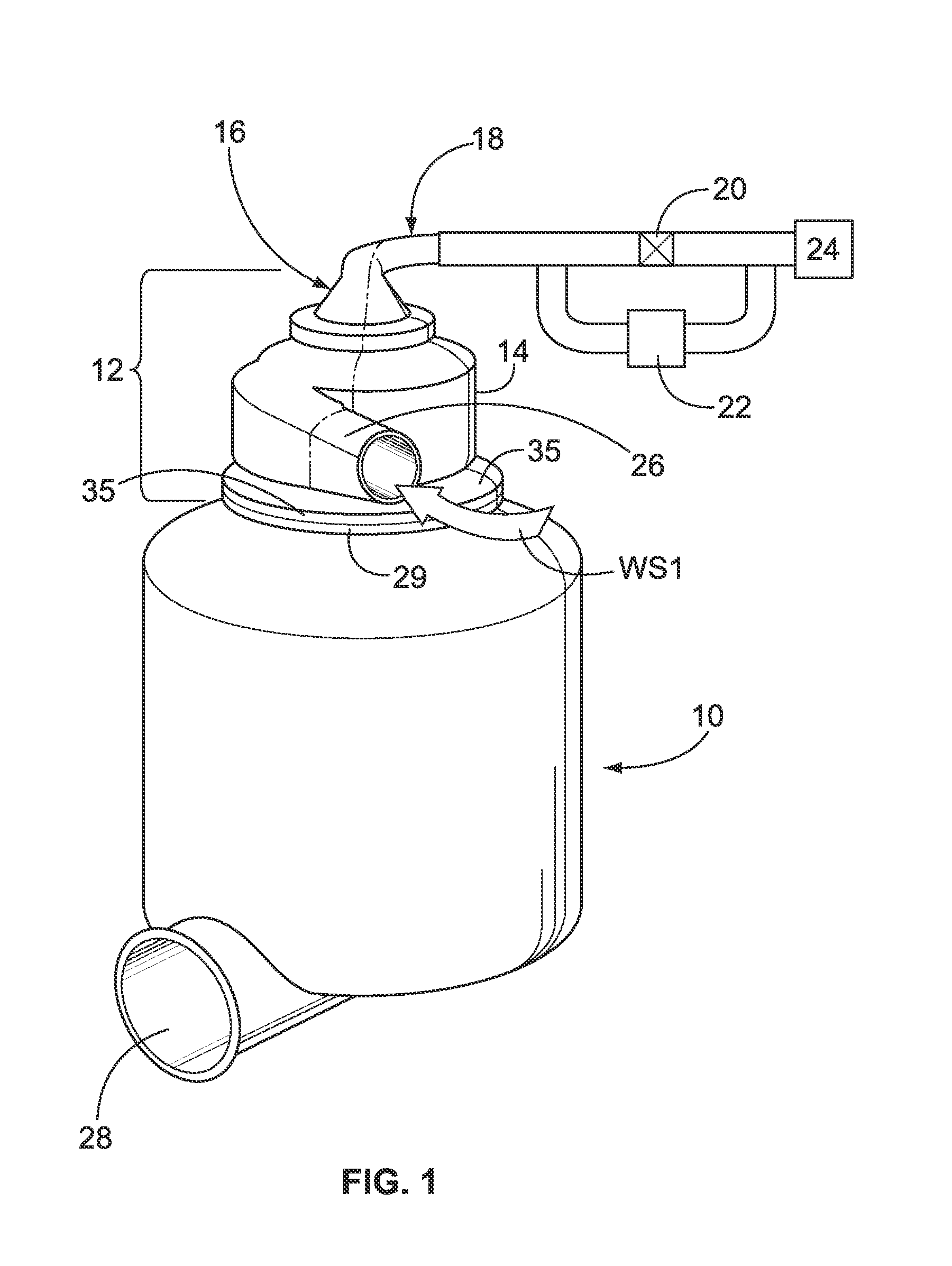

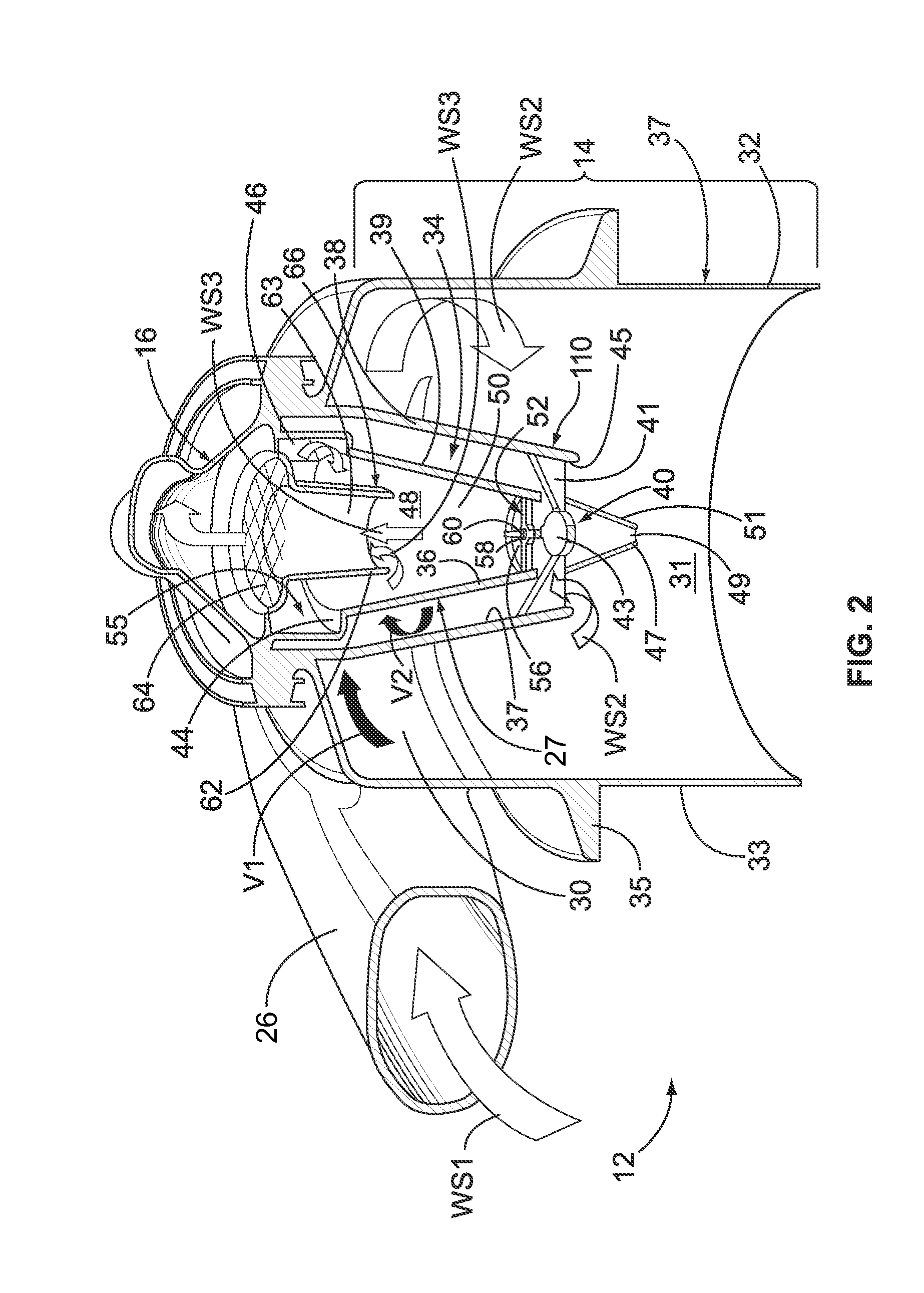

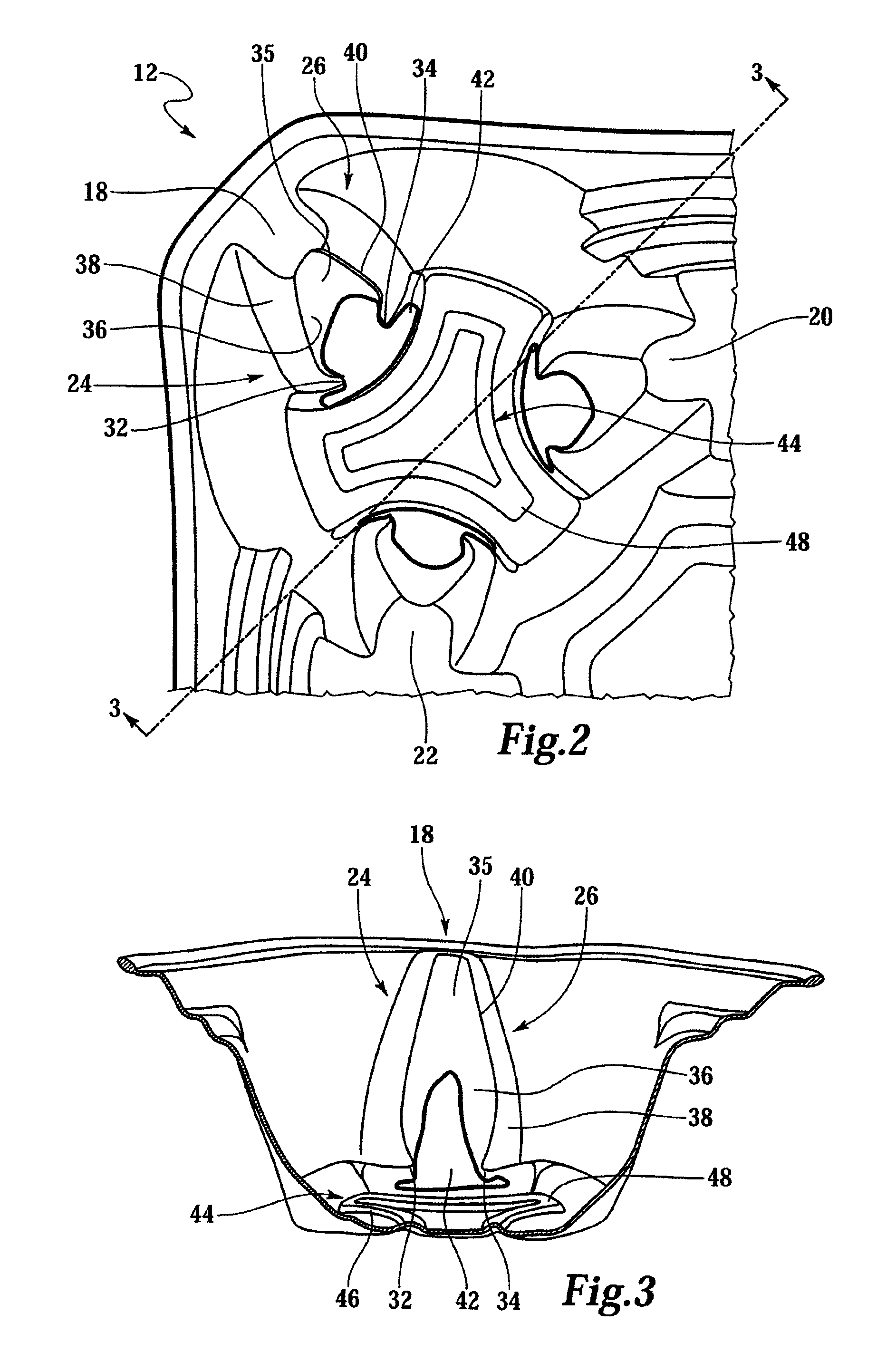

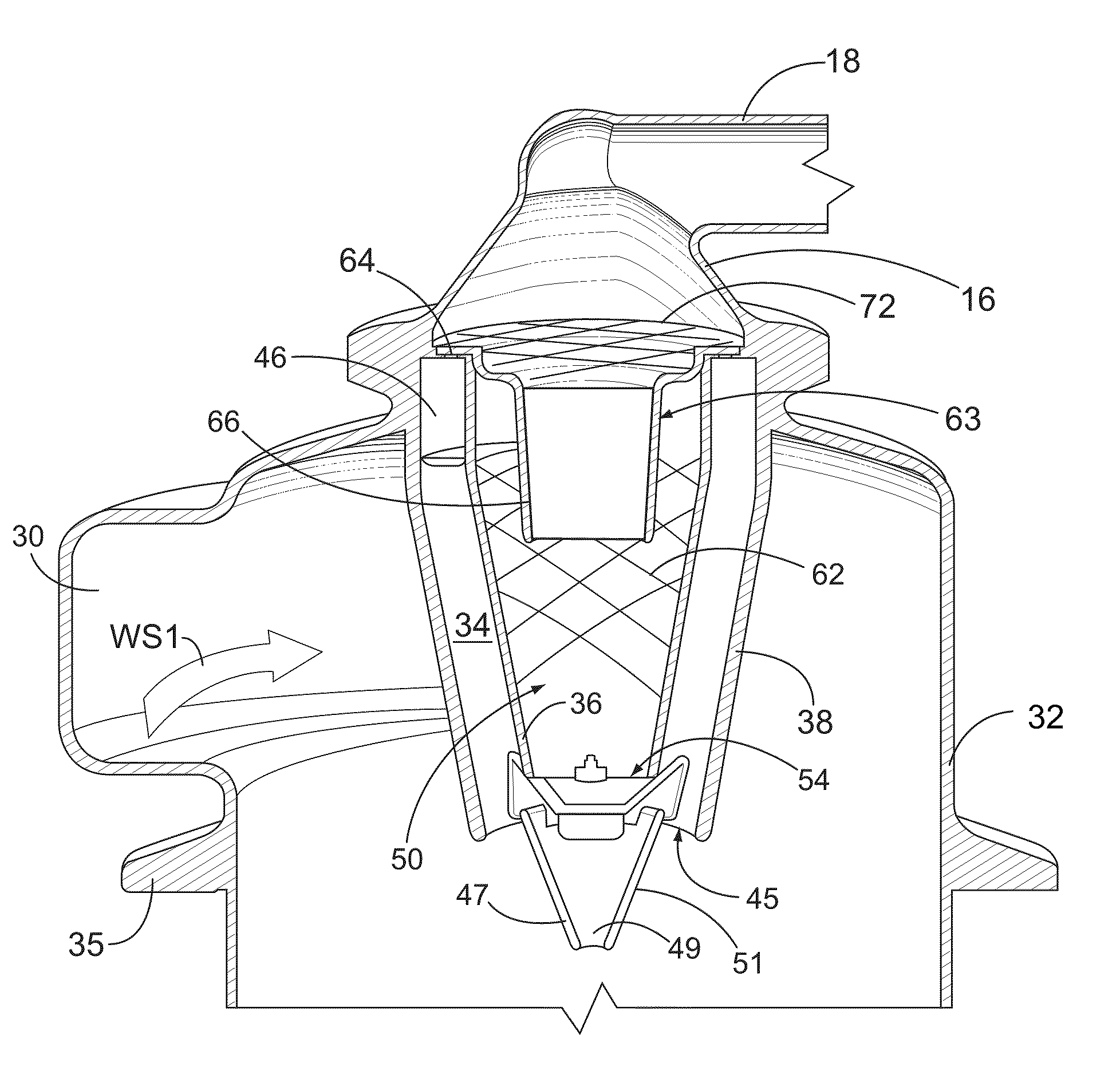

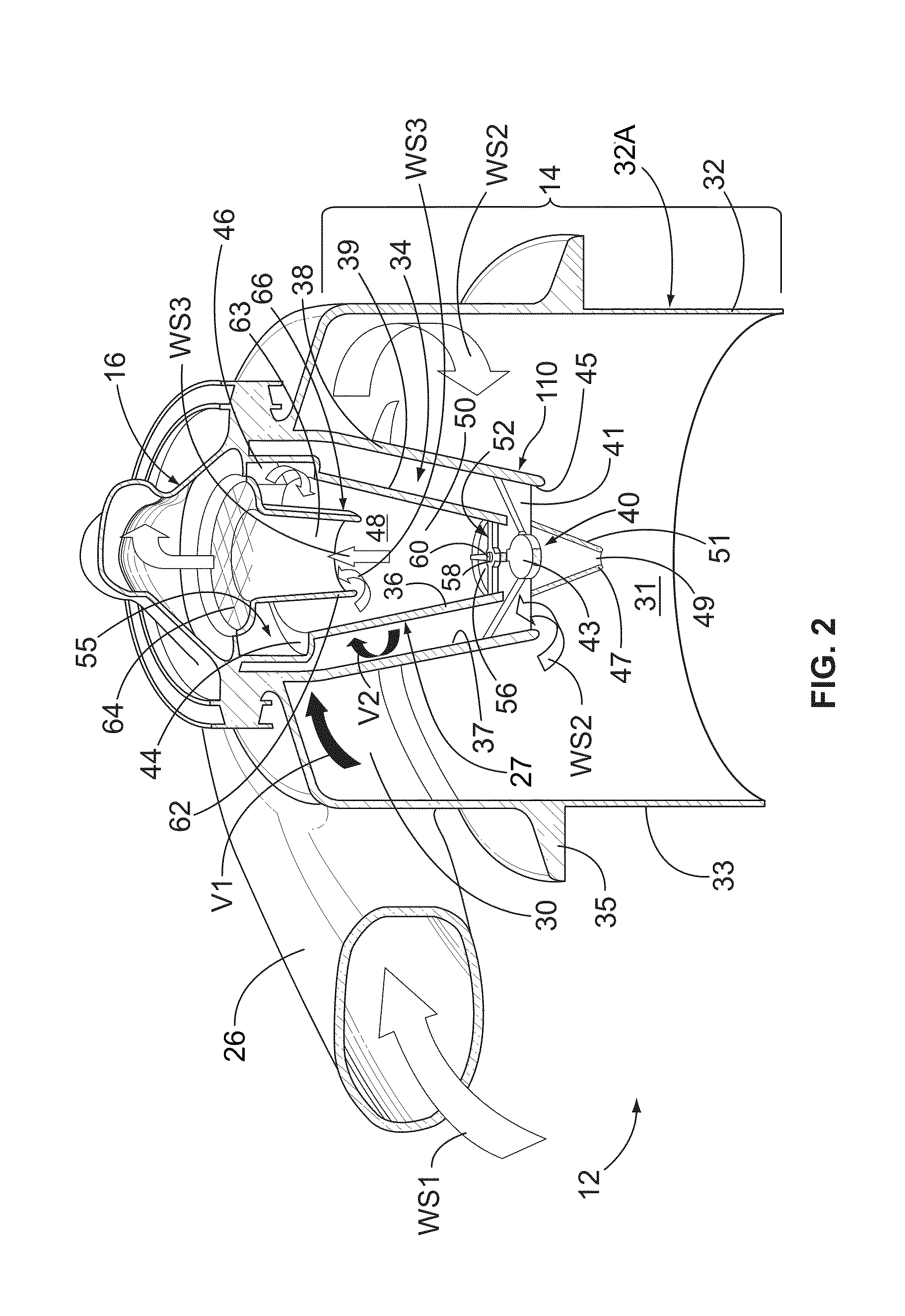

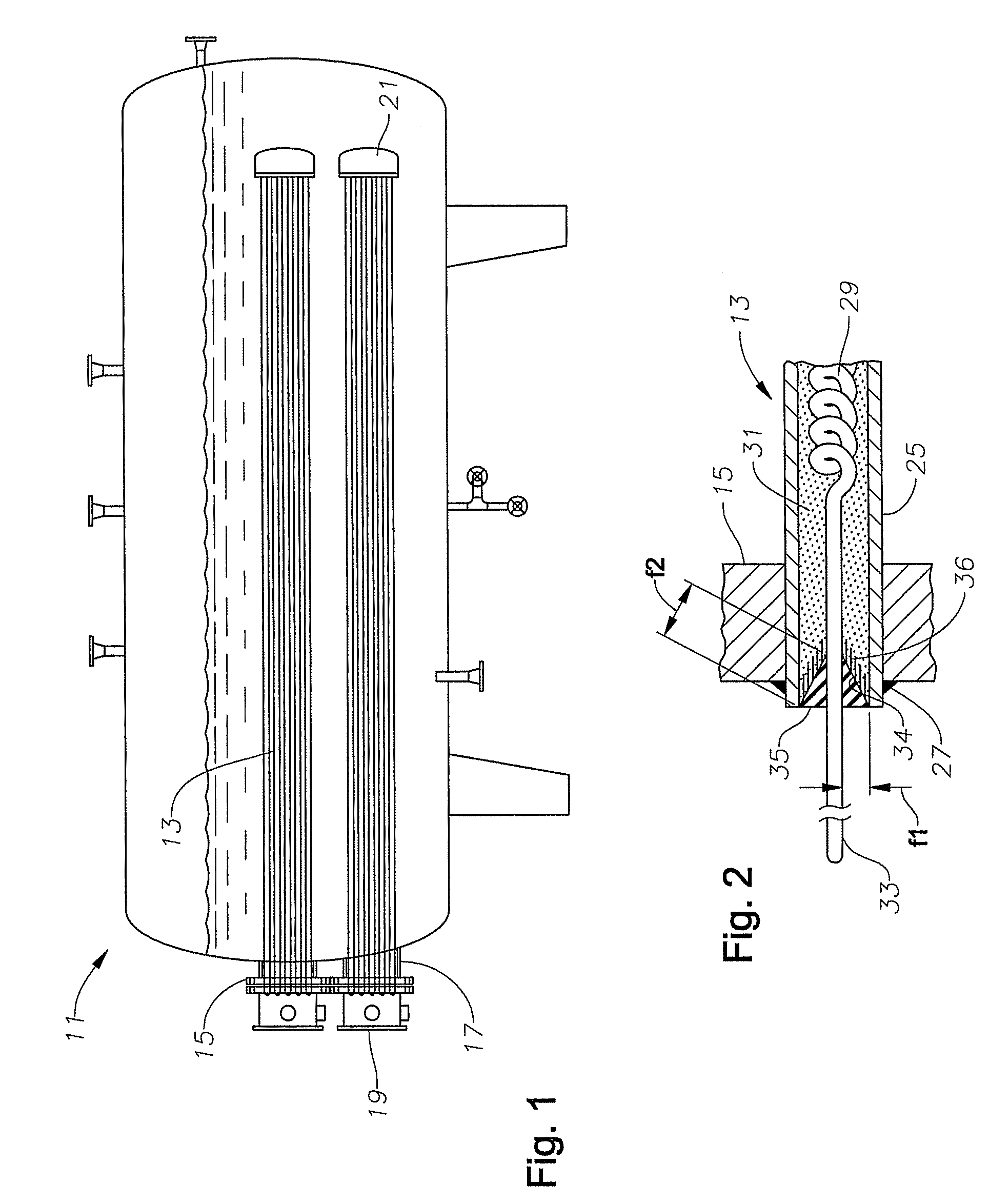

ActiveUS20100083832A1Avoid cross contaminationWater/sewage treatment by centrifugal separationLiquid degasificationEddy current separatorWaste stream

A vortex separator for drawing a substantially moisture-free airstream from a waste stream having an annular channel defining a first vortex flow path for separating liquid and solid waste from this waste stream and preferably a filter unit with an inverted conical cavity between nested inverted cones defining a second vortex flow path that is isolated from the first vortex flow path for separating additional liquid and solid waste from the waste stream before it exits the vortex separator. In preferred embodiments, the separator includes a removable filter unit cartridge positioned within the outer cone and a helix isolator to respectively make use of the separator more convenient to use and more efficient.

Owner:BE AEROSPACE INCORPORATED

Cup holder having frusto-conical cavities

InactiveUS7225927B2Improve stabilityImprove retentionWash-standsTable equipmentsGrip forceConical cavity

Owner:PACTIV CORP

Vortex waste separator apparatus

ActiveUS7998251B2Avoid cross contaminationWater/sewage treatment by centrifugal separationLiquid degasificationEddy current separatorWaste stream

Owner:BE AEROSPACE INCORPORATED

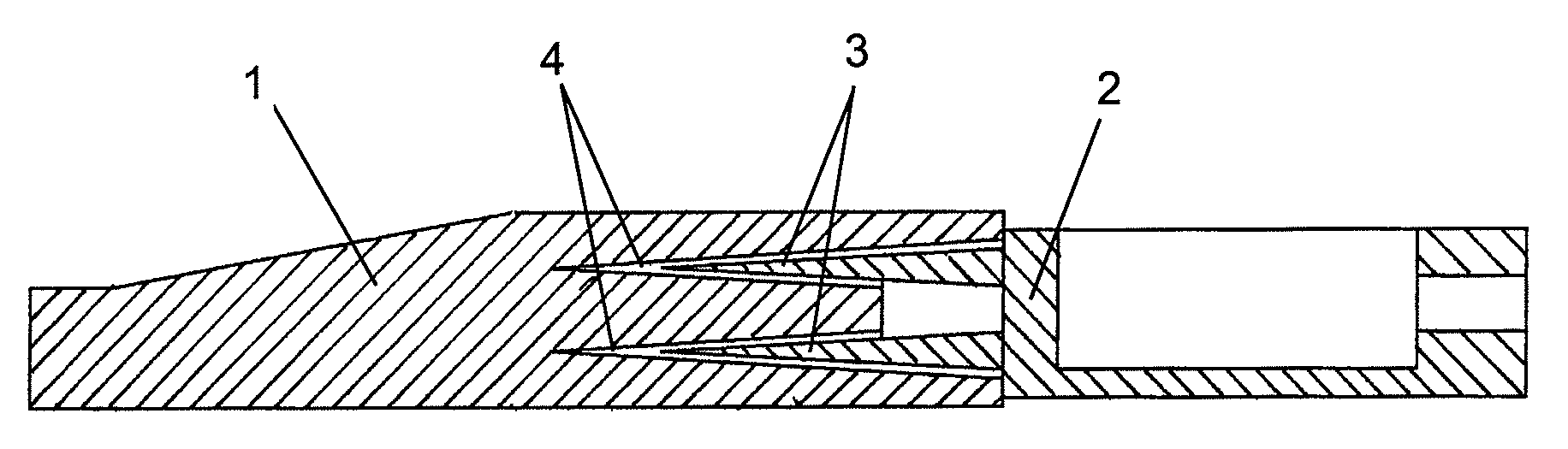

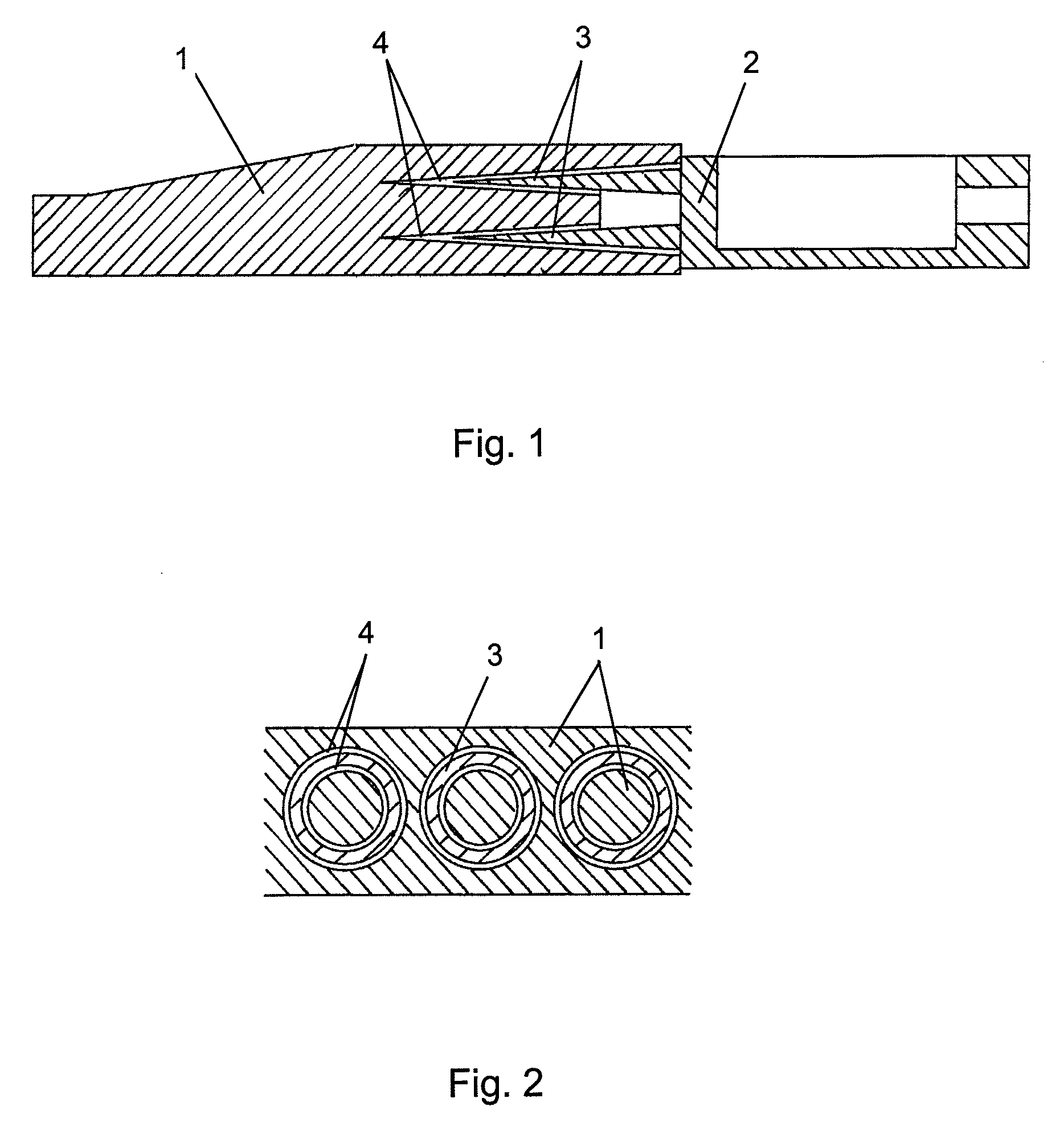

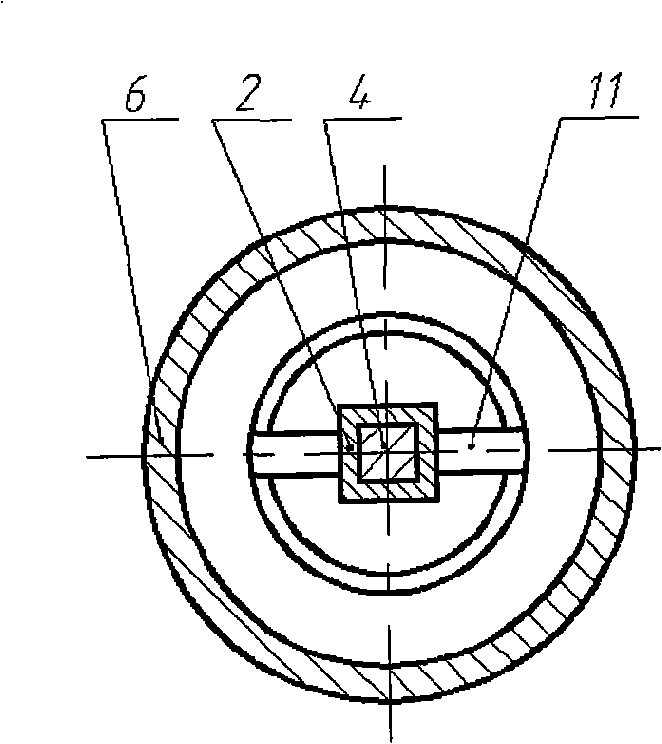

Blade insert

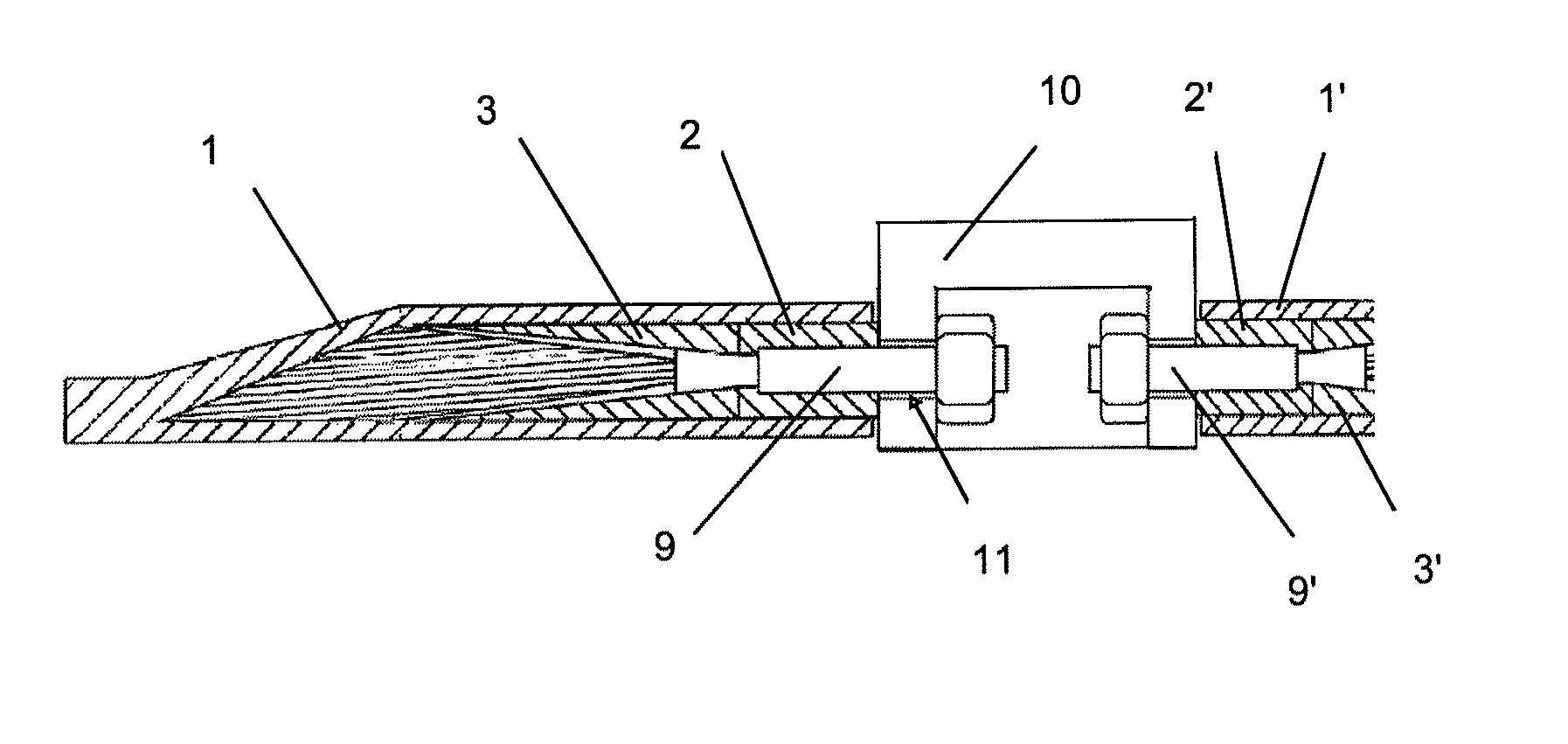

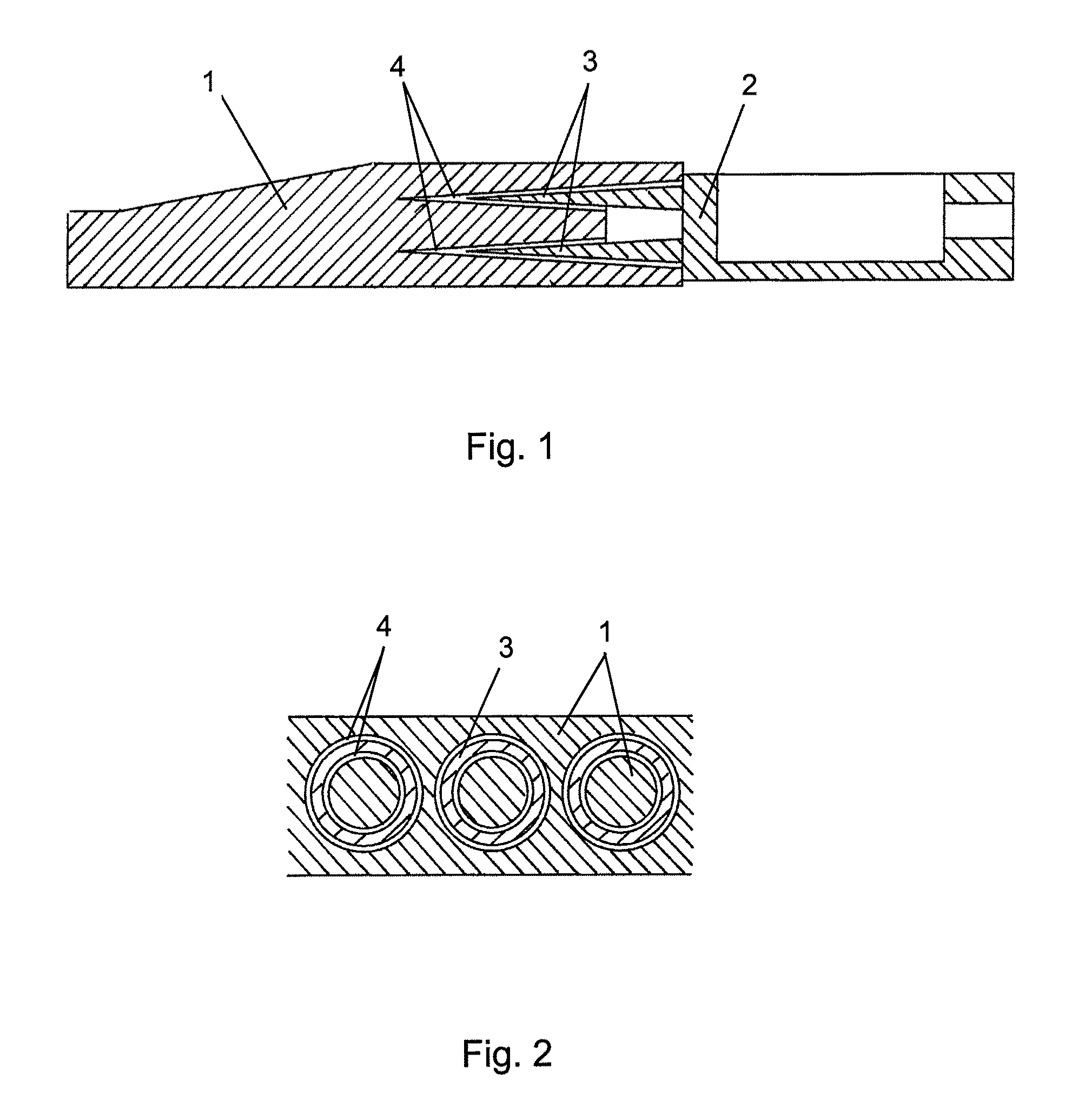

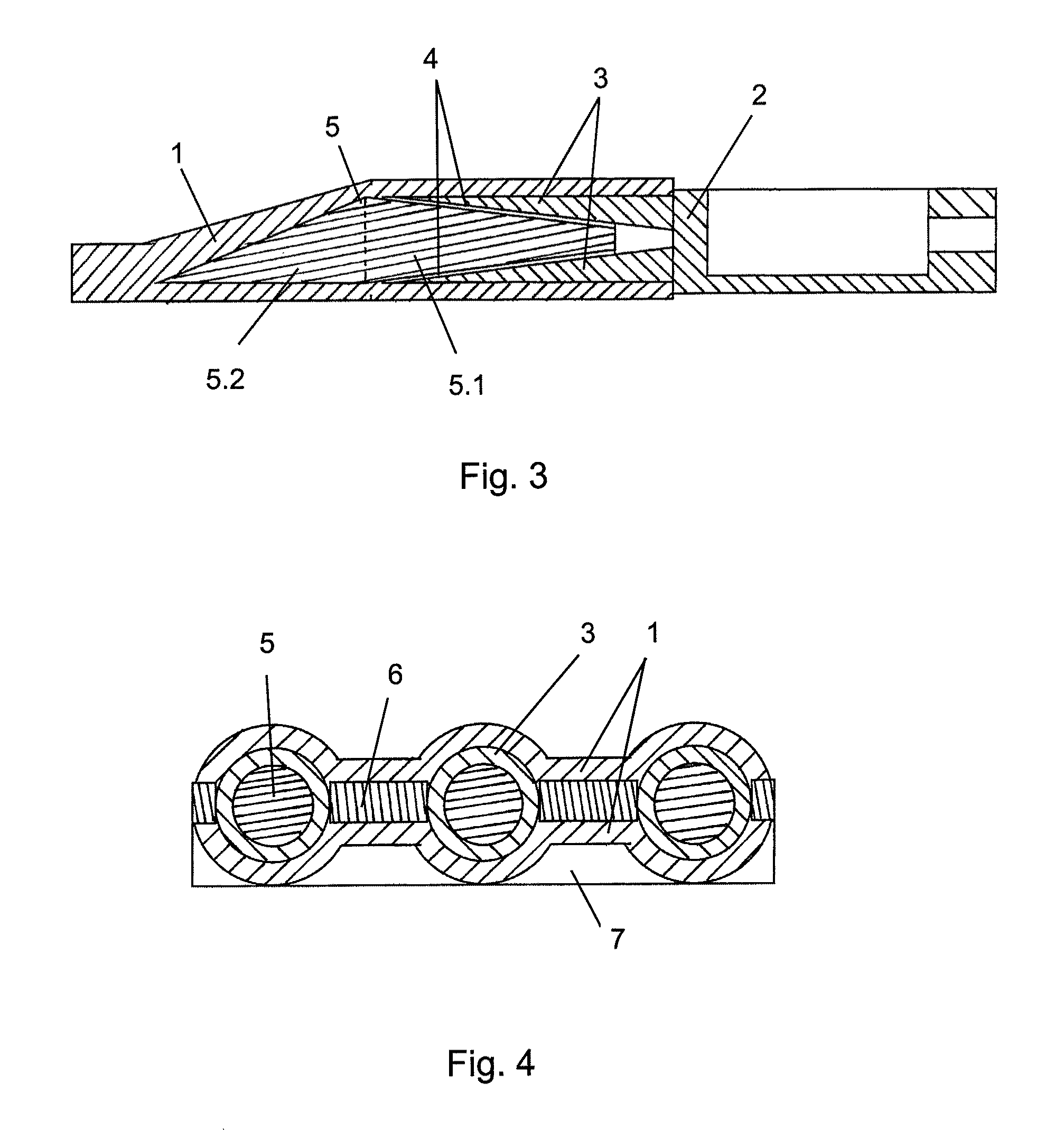

Blade insert connected in the lamination of a blade determining a double shear joint between insert and lamination. The insert is made up of two defined parts, head (2), designed to screw the insert to another structure (2′), and the body (3) that determines a cylindrical or conical shape with an internal conical cavity. In an embodiment, the insert is designed to be joined to the lamination (1) of the blade with adhesive means (4). In another embodiment, the insert is embedded in the blade lamination with an inner part (5) stuck to the body (3) of the insert.

Owner:GAMESA INNOVATION & TECH SA

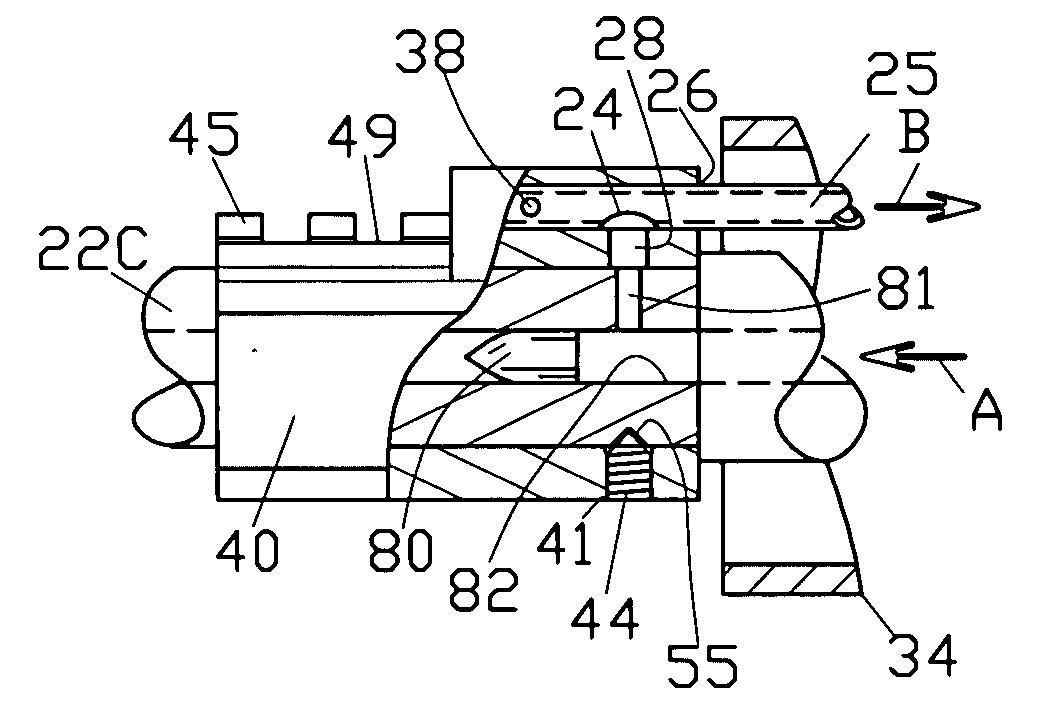

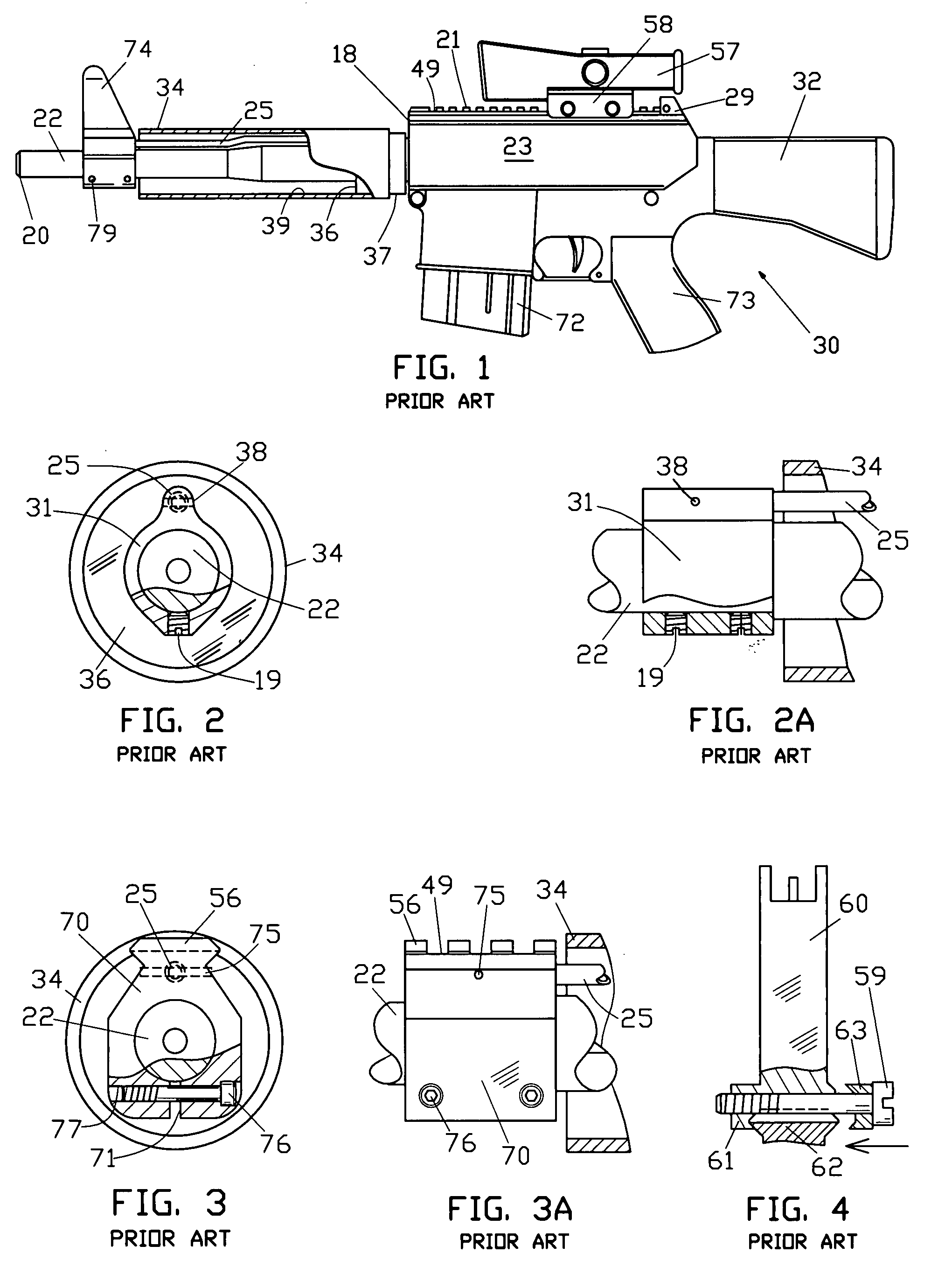

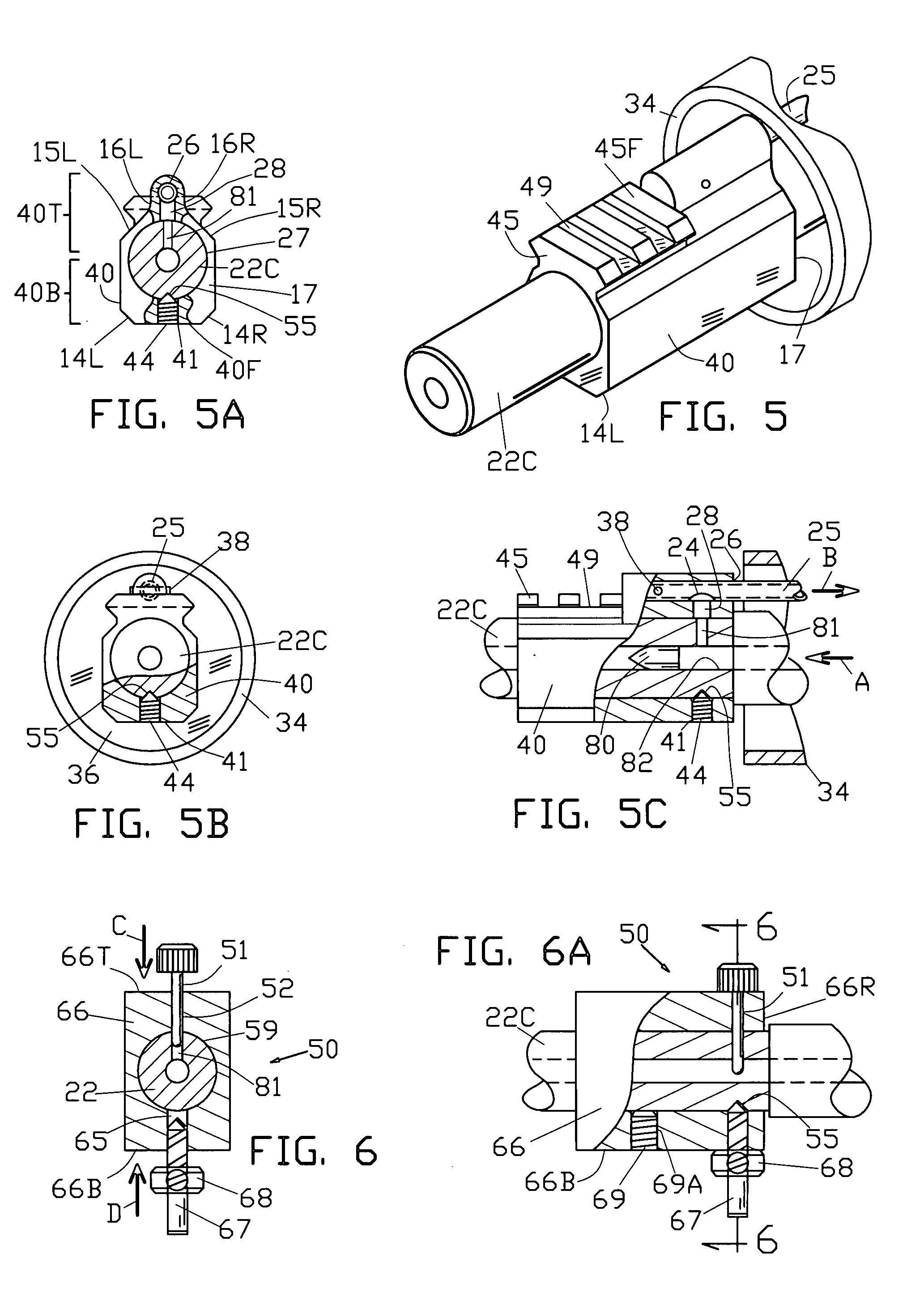

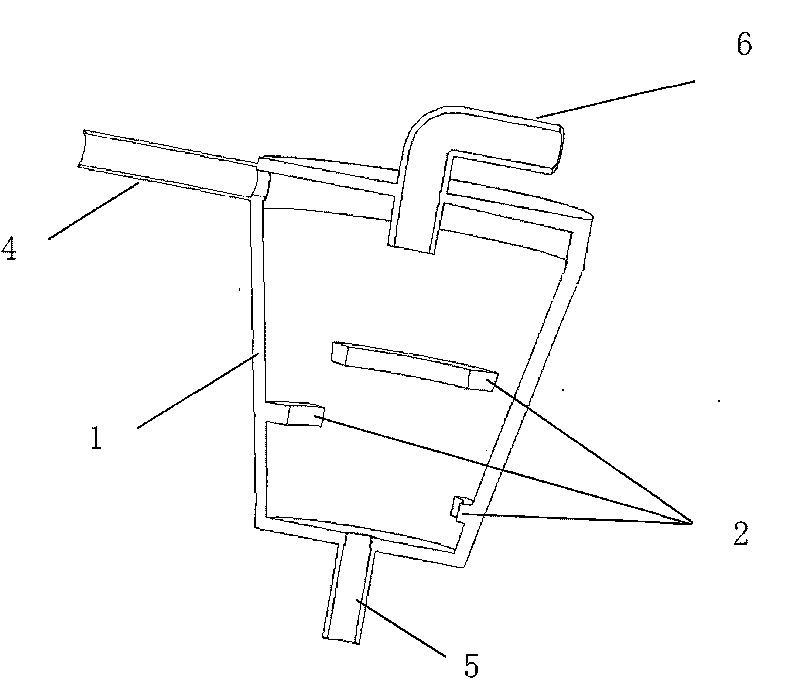

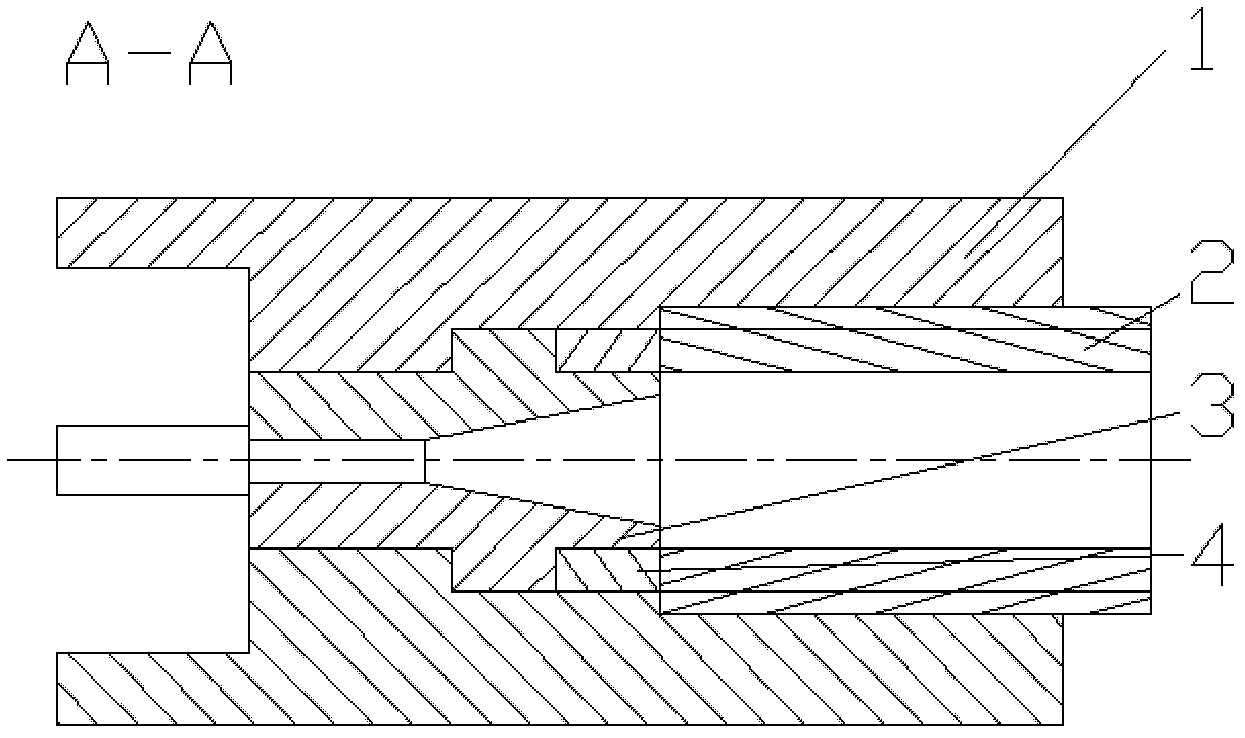

Gas block and installation device

InactiveUS20100282066A1Good handling qualityImprove handling qualitySighting devicesButtsProduct gasConical cavity

An improved gas block for a firearm has a first longitudinal bore for receiving a firearm barrel, the barrel having a gas port, the gas block having a second longitudinal bore for receiving a gas tube or operating element. The block includes a vertical bore aligned with the barrel gas port and connecting the first and second block bores and permitting passage of cartridge gas from the barrel gas port to the gas tube. The improved gas block may include a military rail, forward of the gas tube, the forward location permitting the rail and accessories to lie close to the barrel, improving handling and reducing bulk. The barrel may include a conical cavity generally opposite the gas port. The block may include a conical point set screw adapted to mate with the barrel conical cavity, the screw when tightened forcing alignment of the block vertical bore with the barrel gas port and simultaneously clamping the block to the barrel. An installation device provides a means for forming a conical cavity in the barrel surface.

Owner:TANKERSLEY JEROME BENEDICT

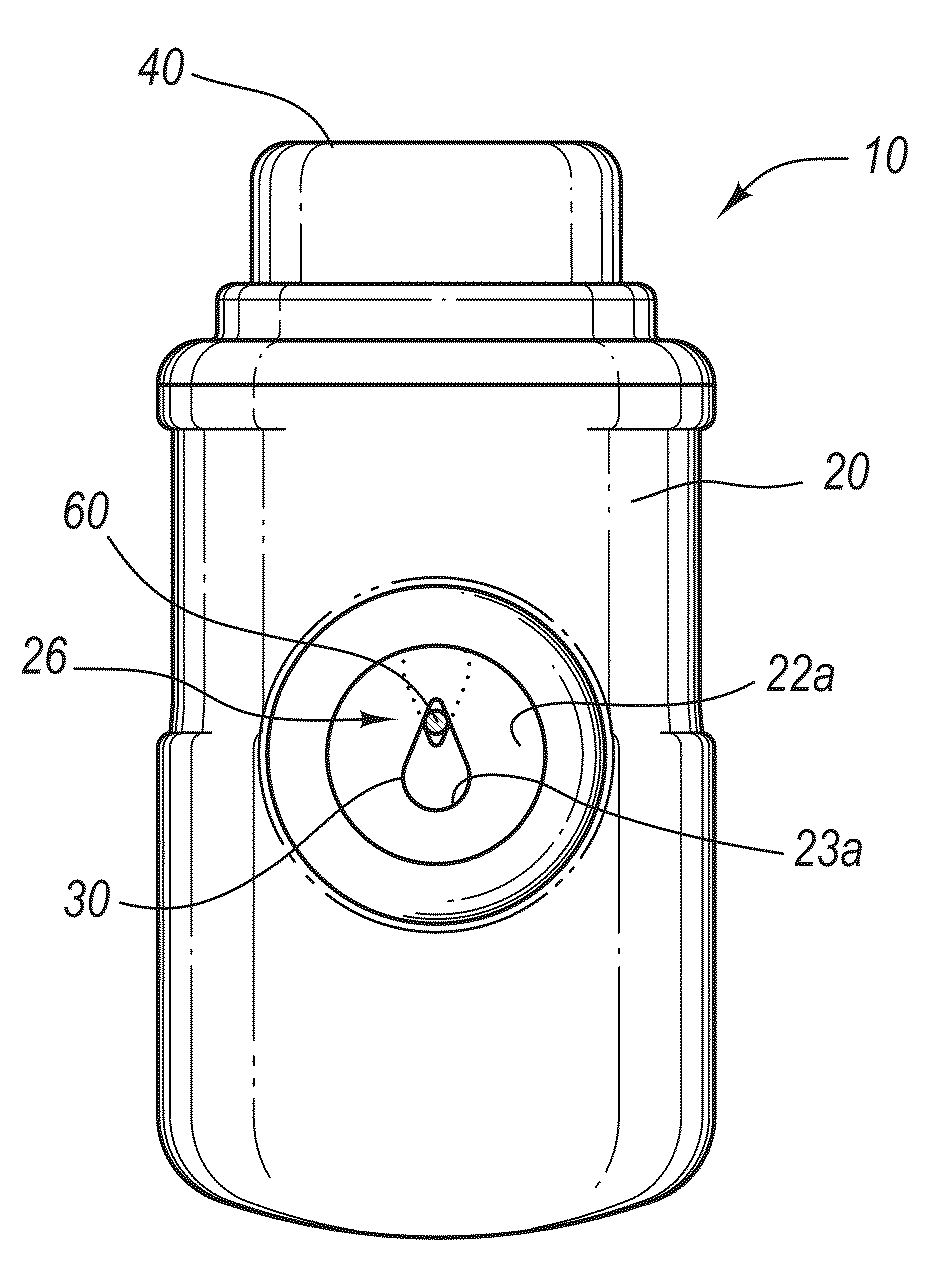

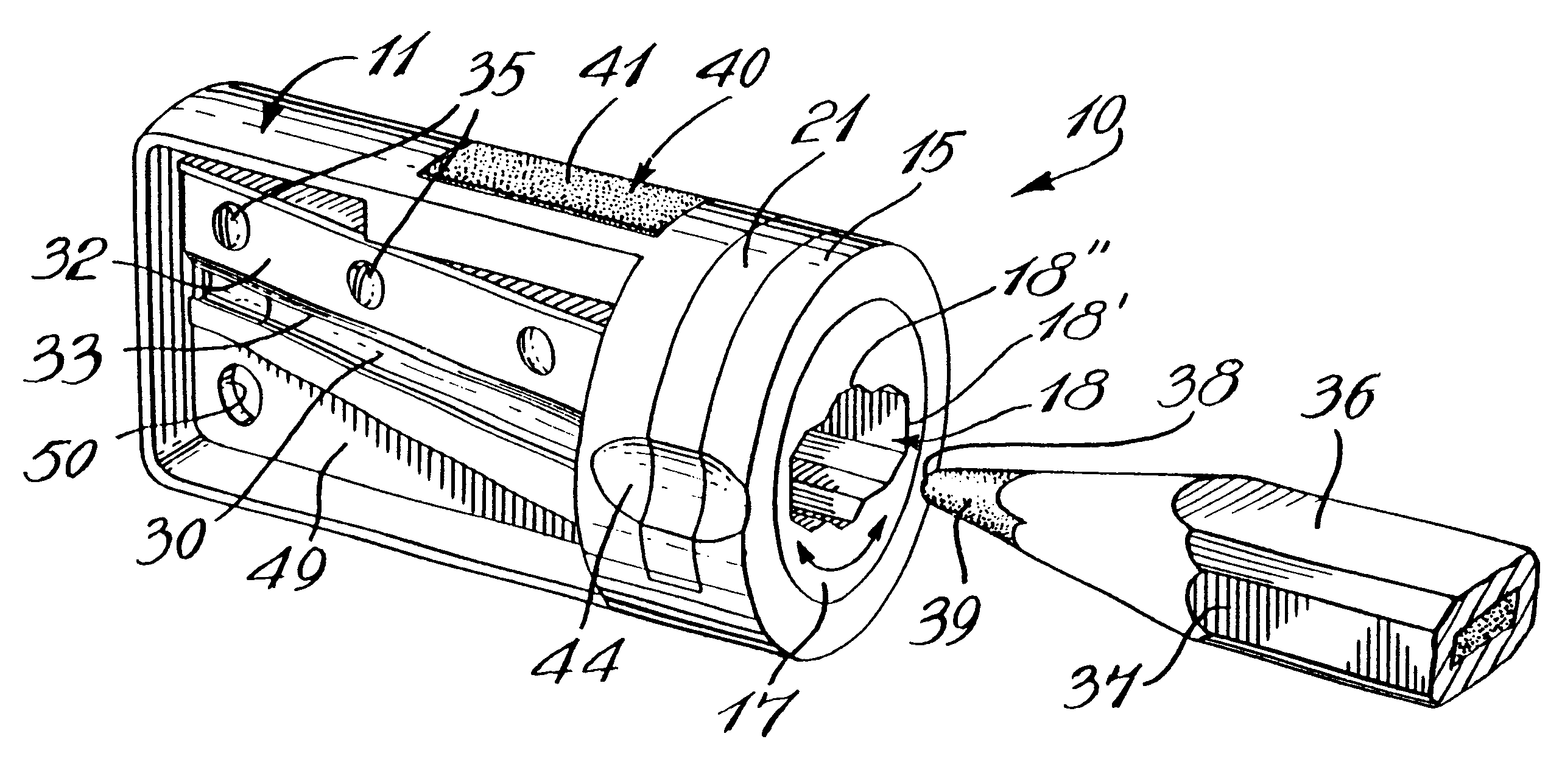

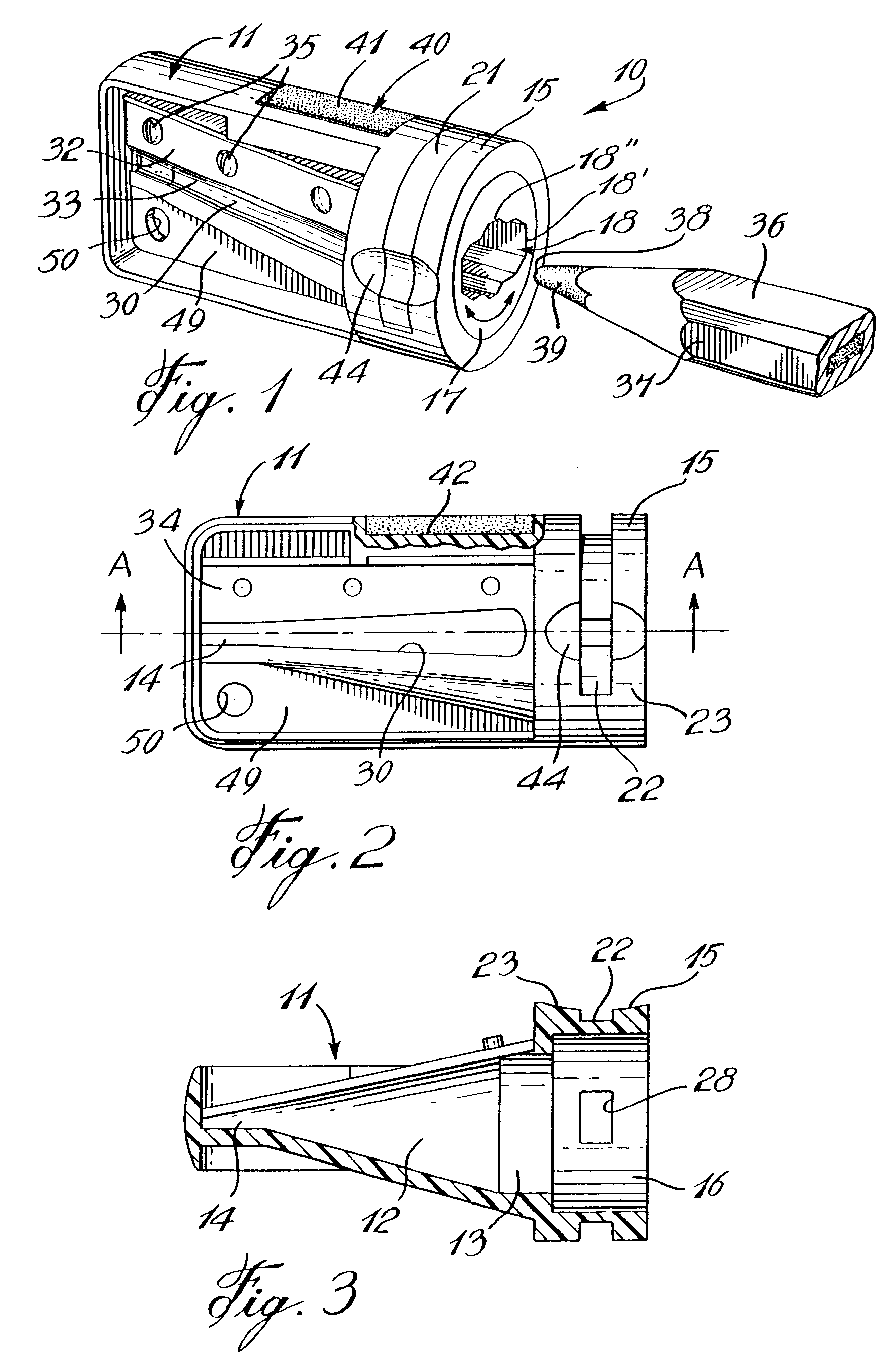

Torque device for a medical guidewire

ActiveUS7972282B2Improve gripAvoid misuseGuide wiresDiagnostic recording/measuringEngineeringConical cavity

A torque device for selectively gripping a medical guidewire. The device includes a housing, an actuator slidably mounted on the housing, and a resilient member biasing the actuator. A lumen dimensioned to receive the guidewire extends through the housing and actuator. The resilient member biases the actuator from a first position in which the lumen portions are aligned, toward a second position in which the lumen portions are misaligned. The actuator may include a catch that interferes with a stop of the housing to retain the actuator within the housing. The actuator may be oblong or otherwise shaped to maintain the lumen portions in substantial alignment in a longitudinal direction. Preferably, at least a portion of the lumen is teardrop-shaped in cross-section. The housing may include circumferentially or longitudinally extending ribs defining an outer grasping surface. Frusto-conical cavities may be defined at entry and exit ends of the lumen.

Owner:MERIT MEDICAL SYST INC

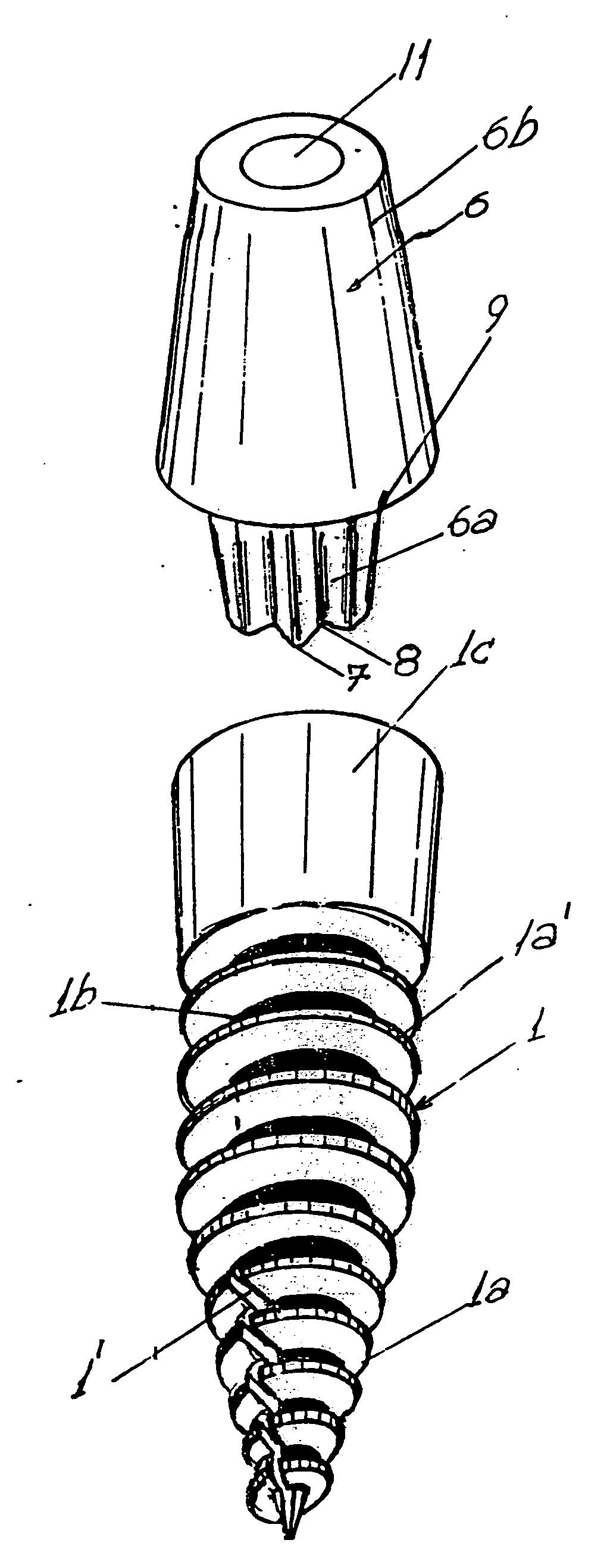

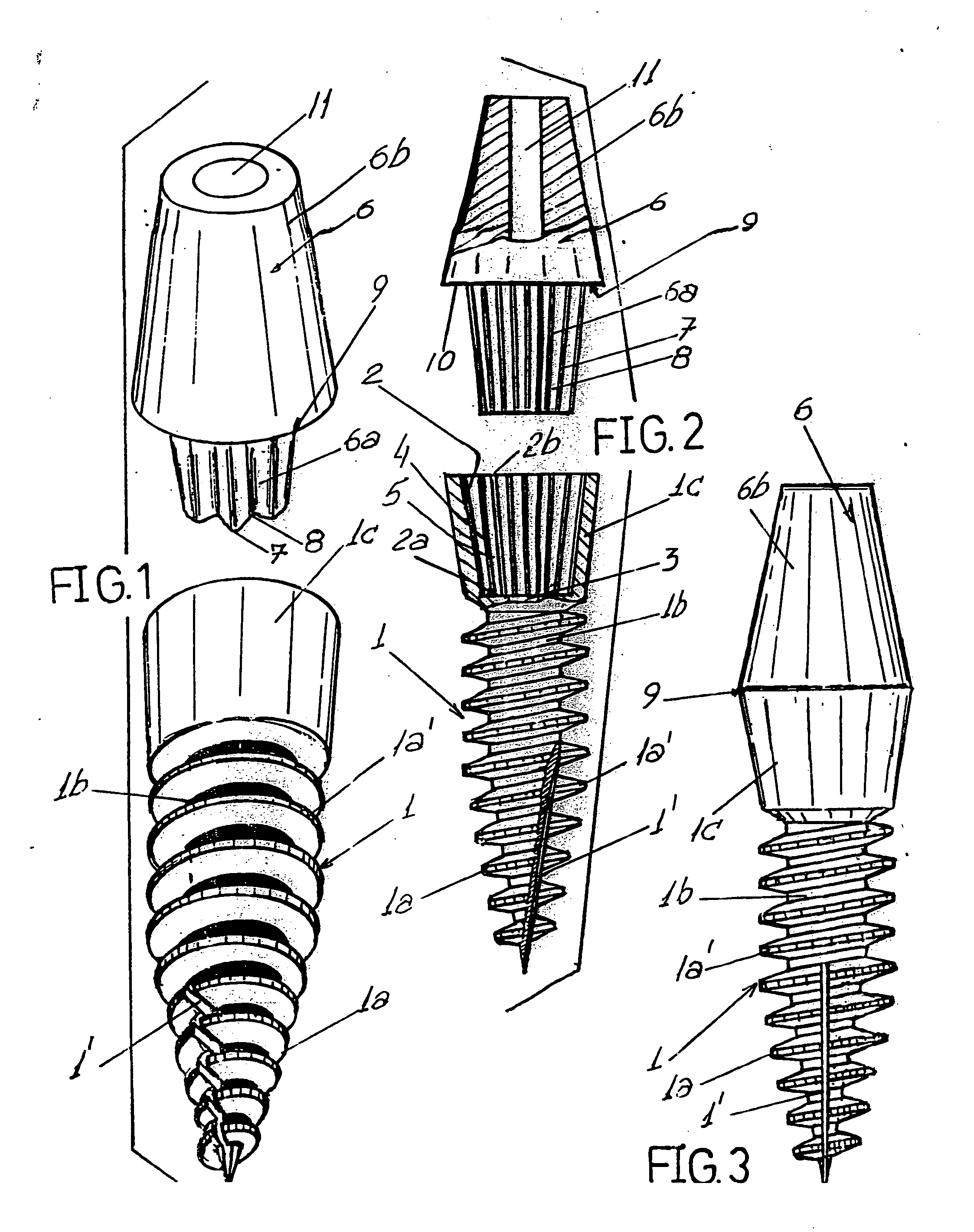

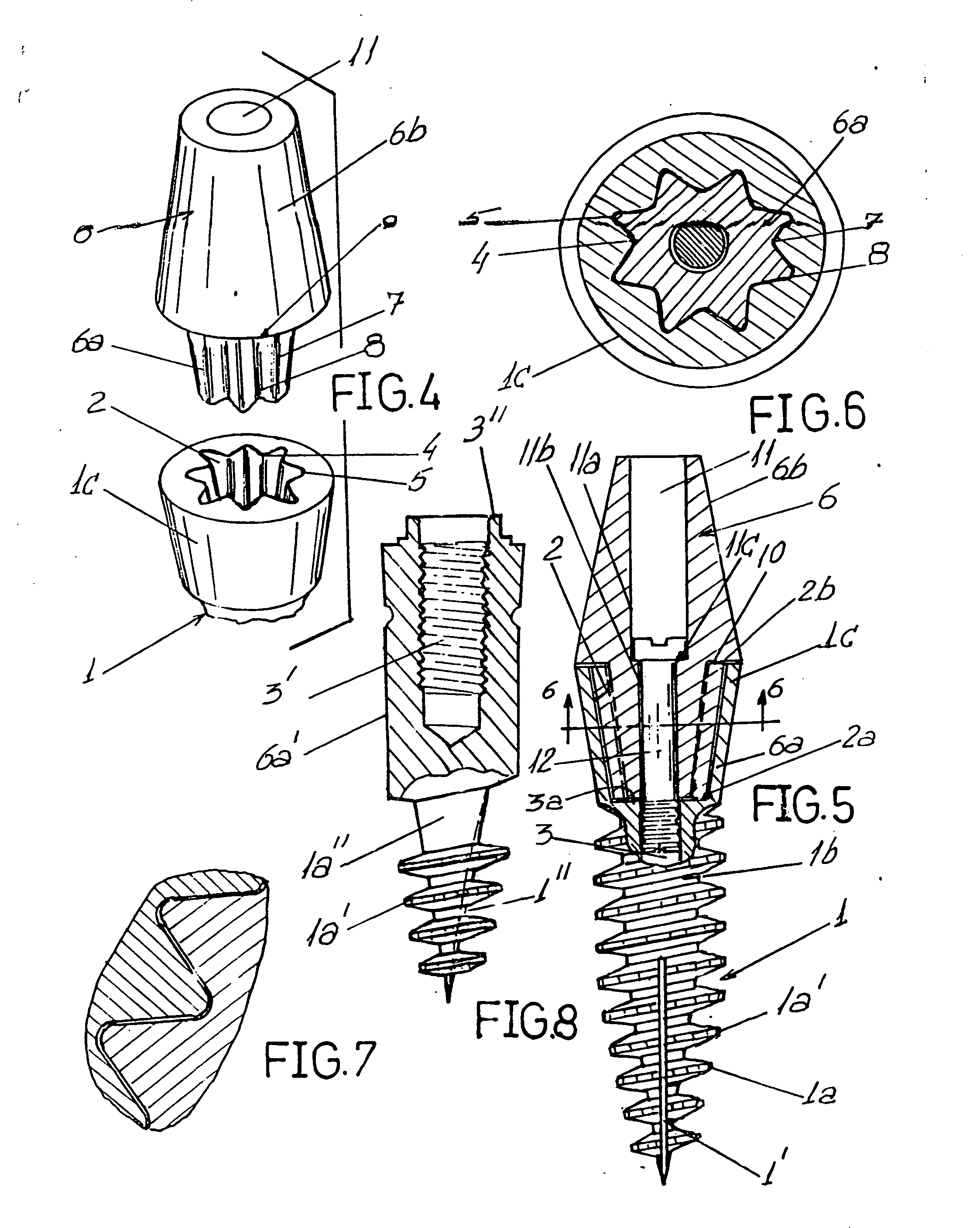

Dental implants intergrated into the bone to sustain a dental prosthesis

InactiveUS20050186537A1Increase surface contact areaImprove permeabilityDental implantsProsthesisCircular cone

An implant system comprising a body that defines a highly sharp conical end portion provided with a longitudinal milled section that continues as a cylindrical central portion, both portions having a trapezoidal-sectional thread and ending at the top in a truncated conical head that has a truncated conical cavity from whose bottom a threaded blind hole projects, the inner wall of the truncated conical cavity being thus provided with a plurality of projections lying in divergent planes that match its large diameter matching the coronal end and its small diameter matching the apical end, said projections having a triangular cross-section whose free edges are parallel to the annular surface of the cavity and have a rounded profile, said projections forming a star-shaped figure, and a prosthetic support structure being obtained in said cavity, having a truncated conical portion whose side wall has cross-sectional projections homologous to the projections of said cavity, said projections delimiting rounded-bottom cuttings, which form, with the projections of the cavity, a joint between both pieces, a longitudinally drilled truncated conical portion projecting from the prosthetic structure.

Owner:ODONTIT

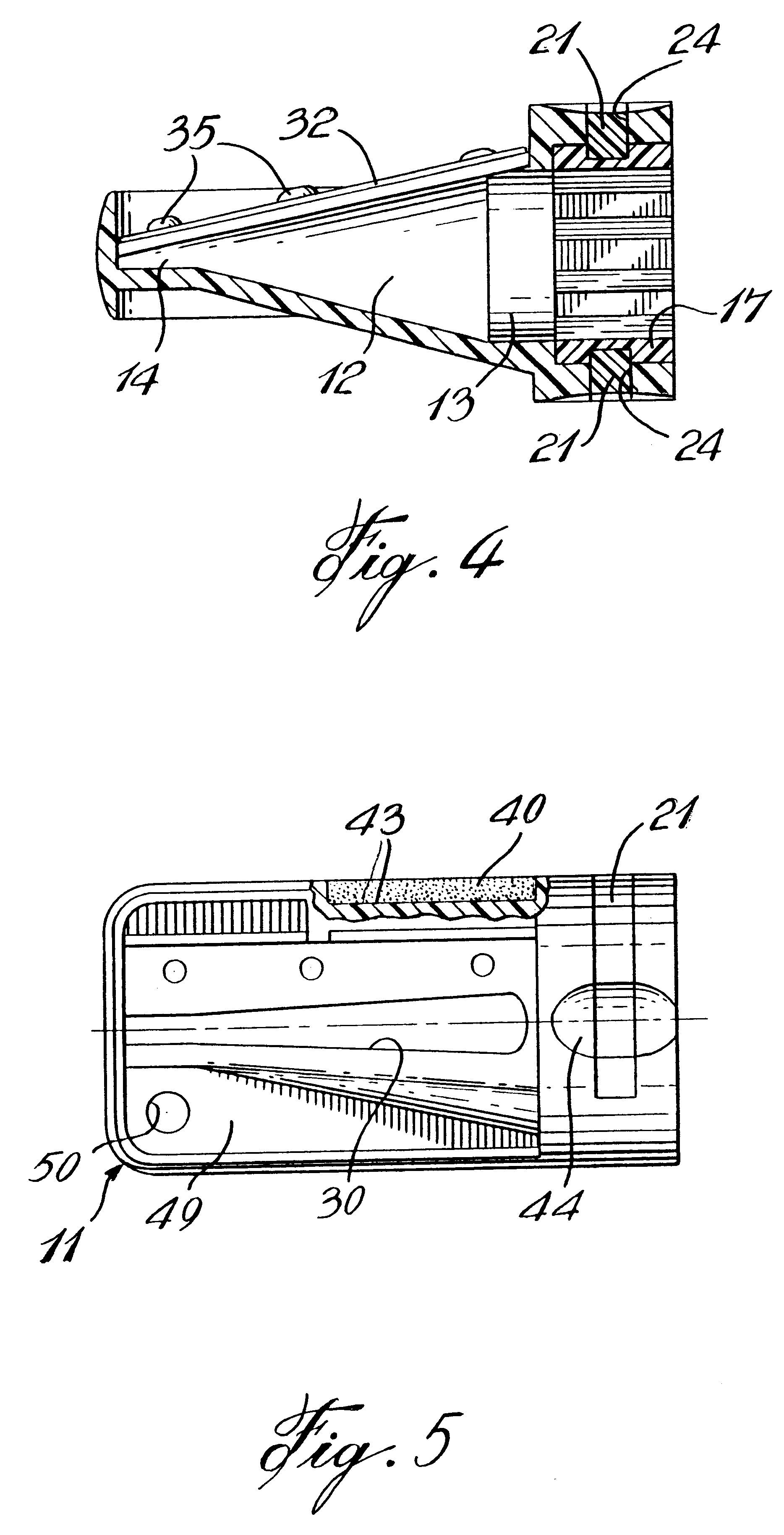

Pencil sharpener for carpenter's pencil

A hand-operable and portable pencil sharpener which is comprised of a housing having a conical cavity therein. The cavity is of circular cross-section and defines an open inlet end tapering to a narrow inner end. A collar is provided about the open inlet end and formed integral with the housing. A pencil centering insert is rotatably secured in the collar by a flexible and removable snap ring. A slot is provided along the side wall of the conical cavity and a blade having a,sharp edge is secured adjacent to the slot with the sharp edge projecting slightly into the cavity whereby to shave a portion of the wood and lead on the extremity of a carpenter's pencil rotated in the conical cavity and centered by a centering slot in the pencil centering insert. An abrading element is secured to the housing to permit the abrading of a sharp point on the end of the lead.

Owner:3551466 CANADA

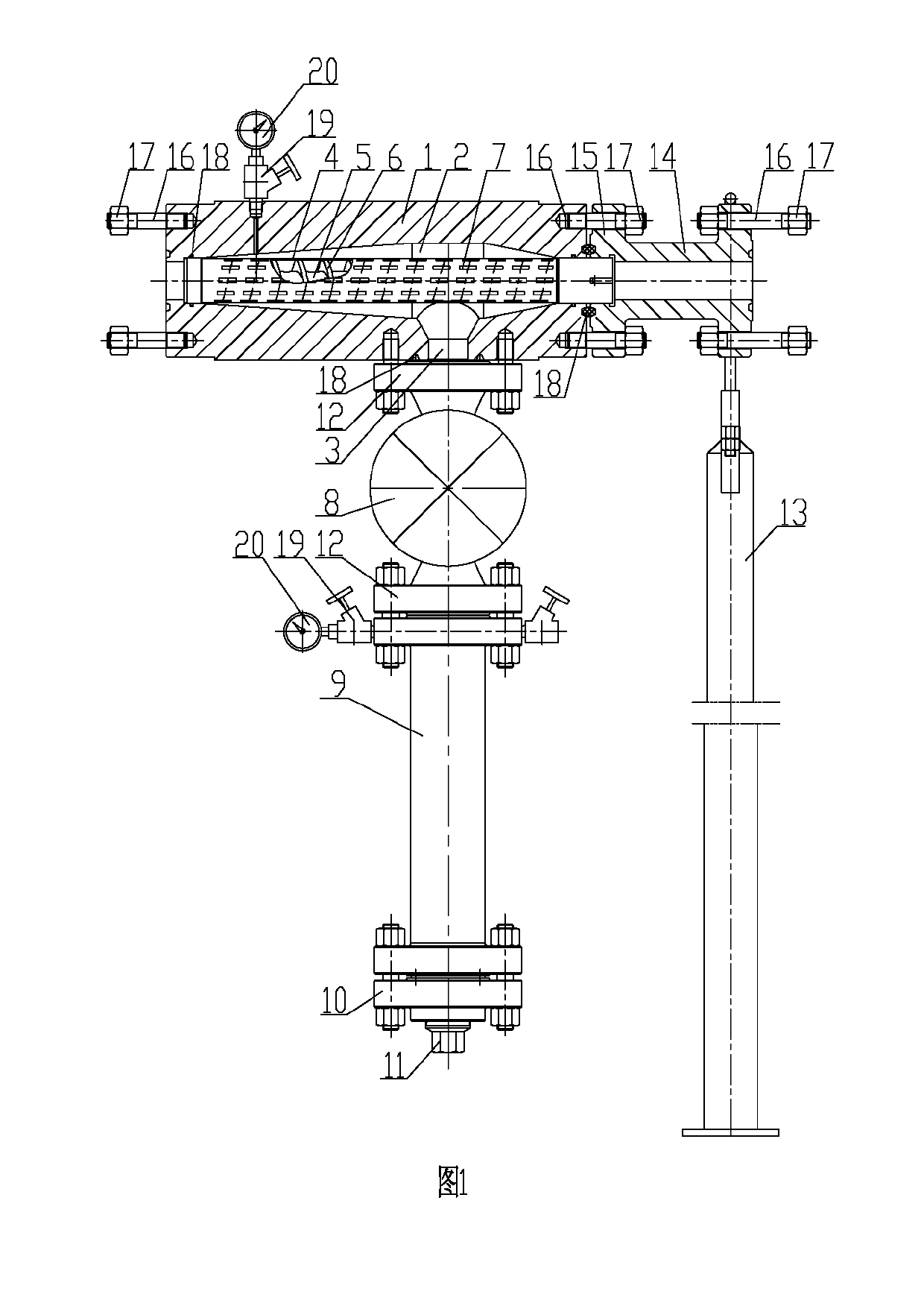

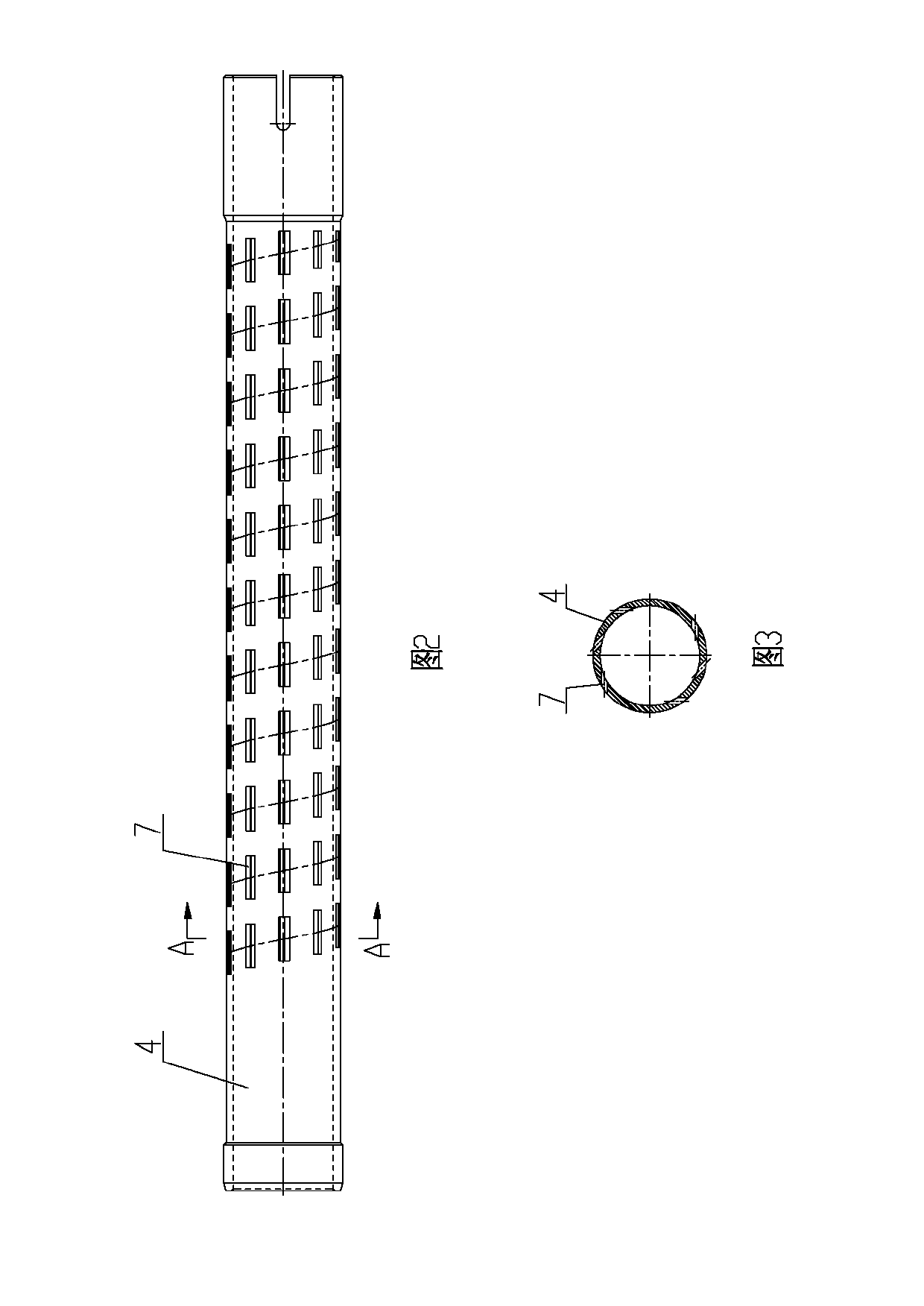

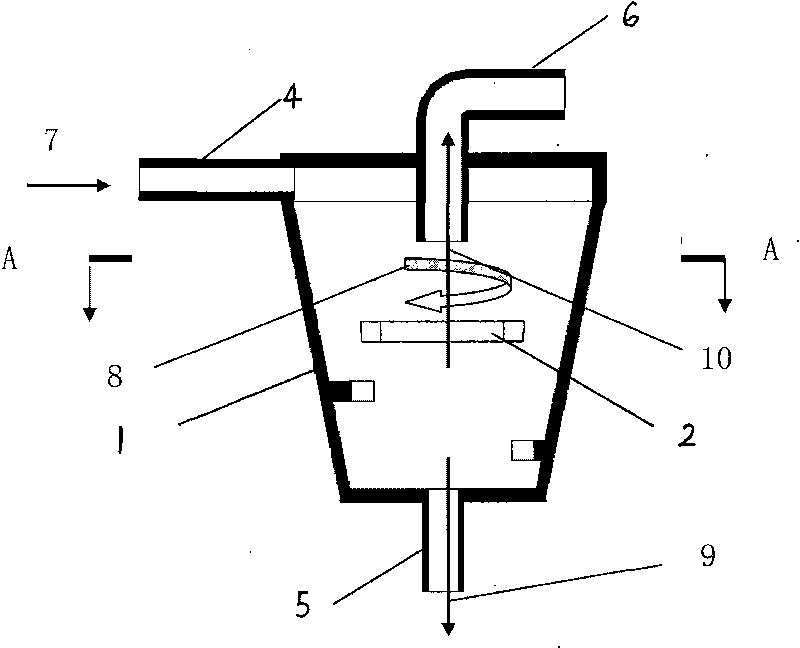

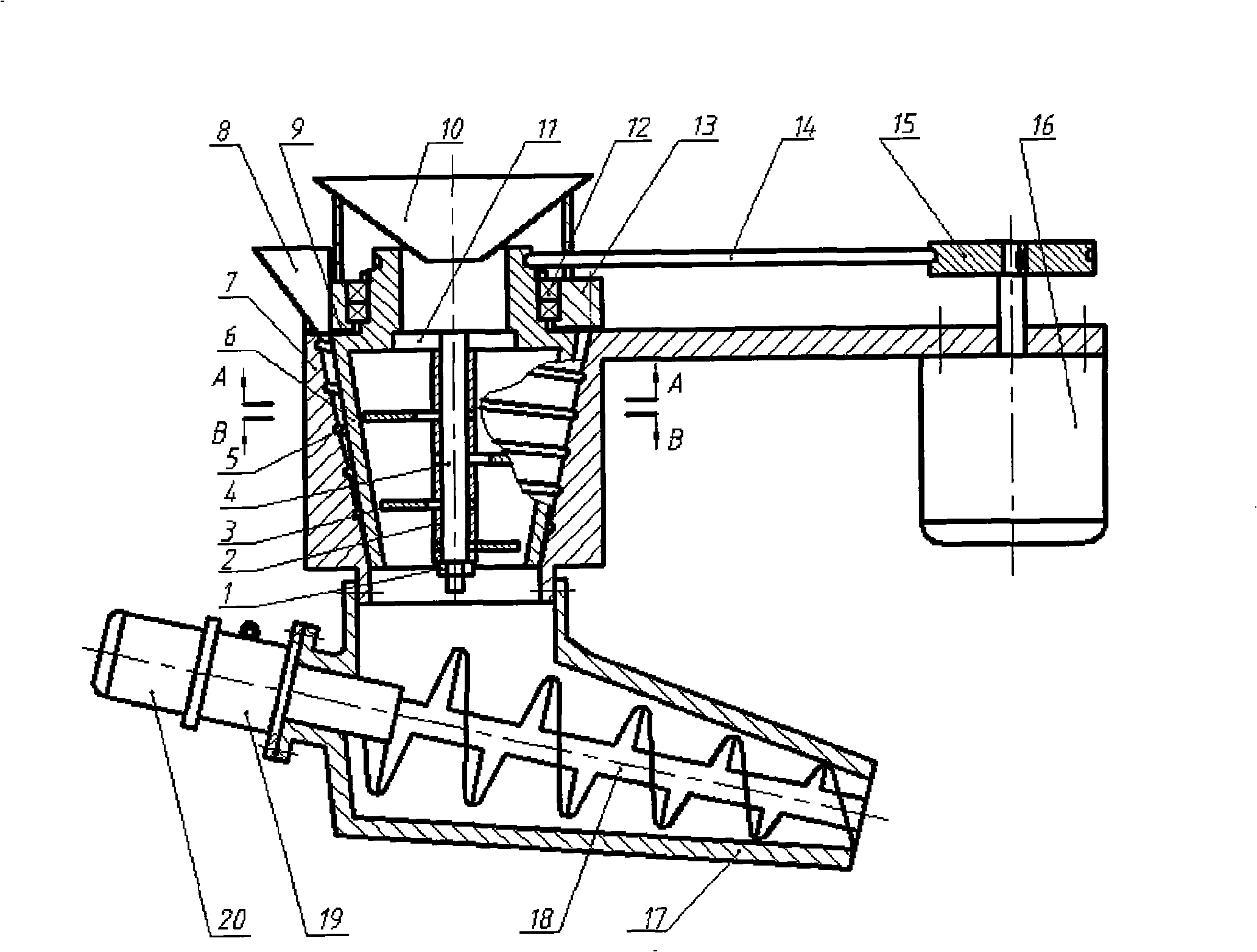

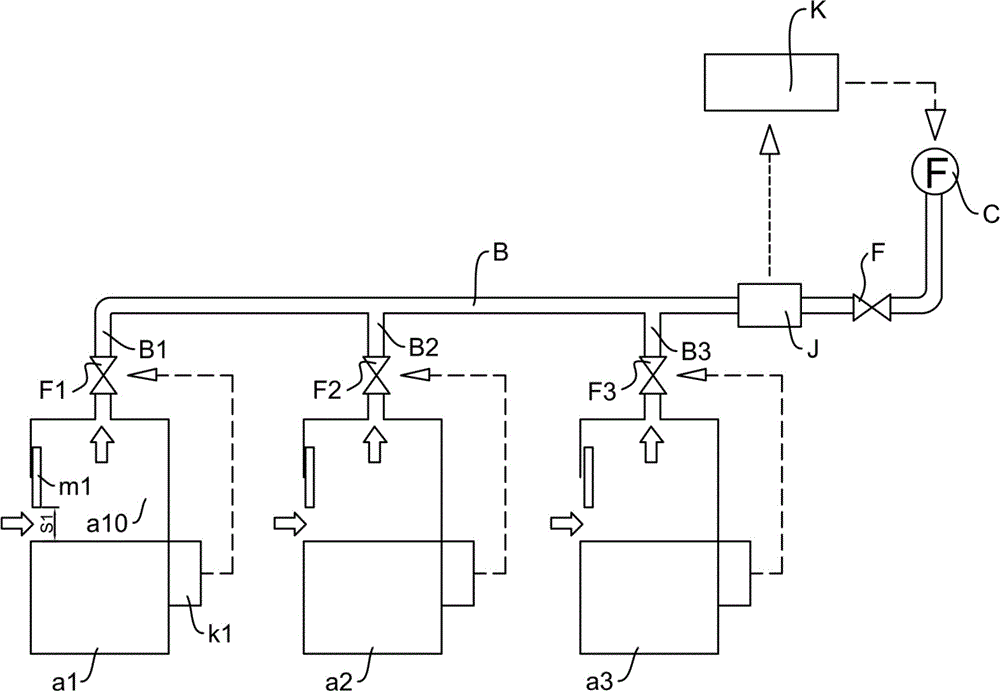

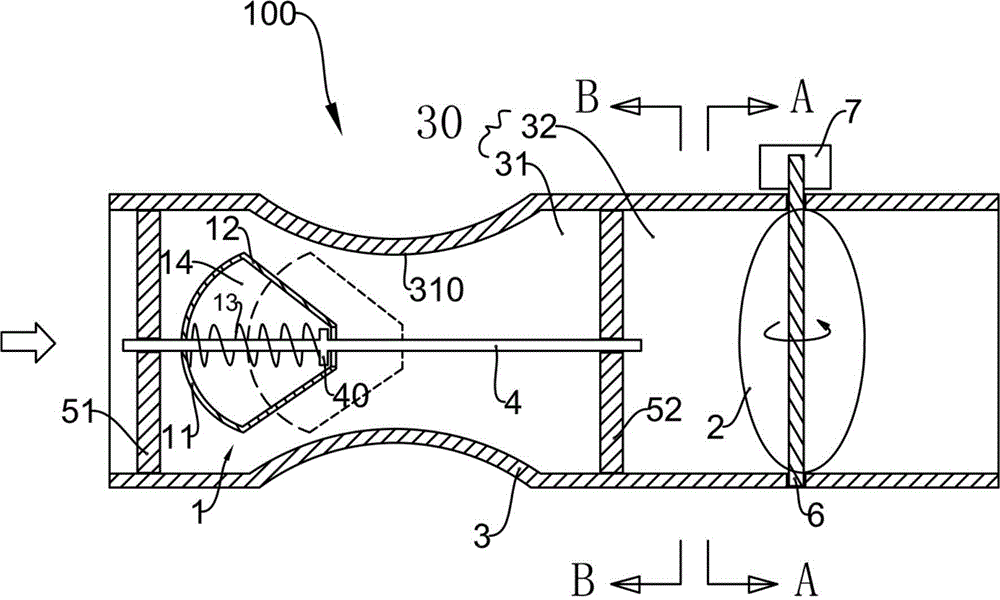

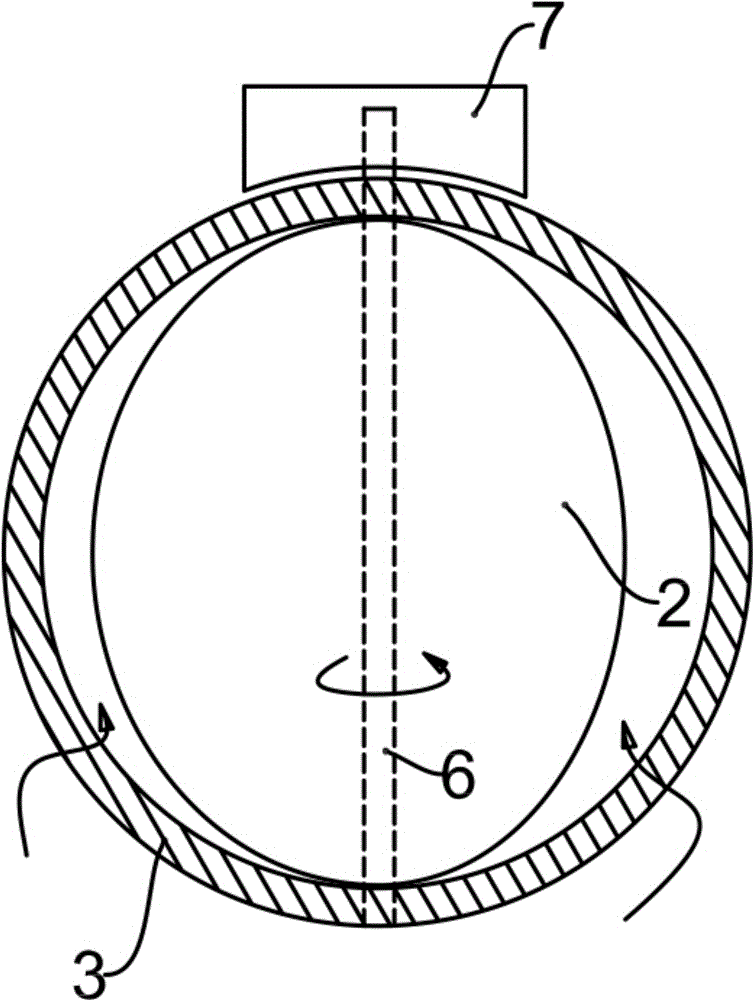

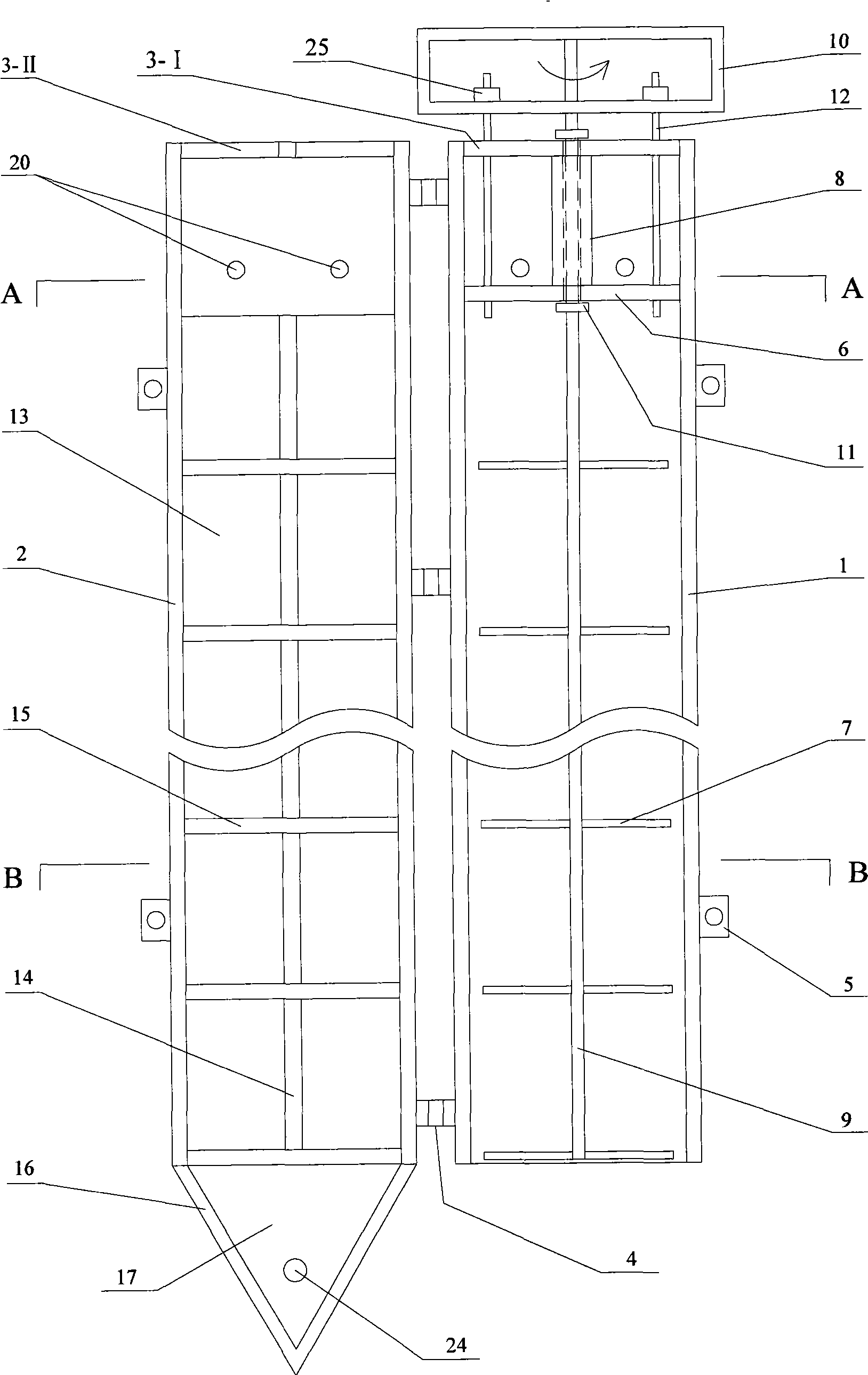

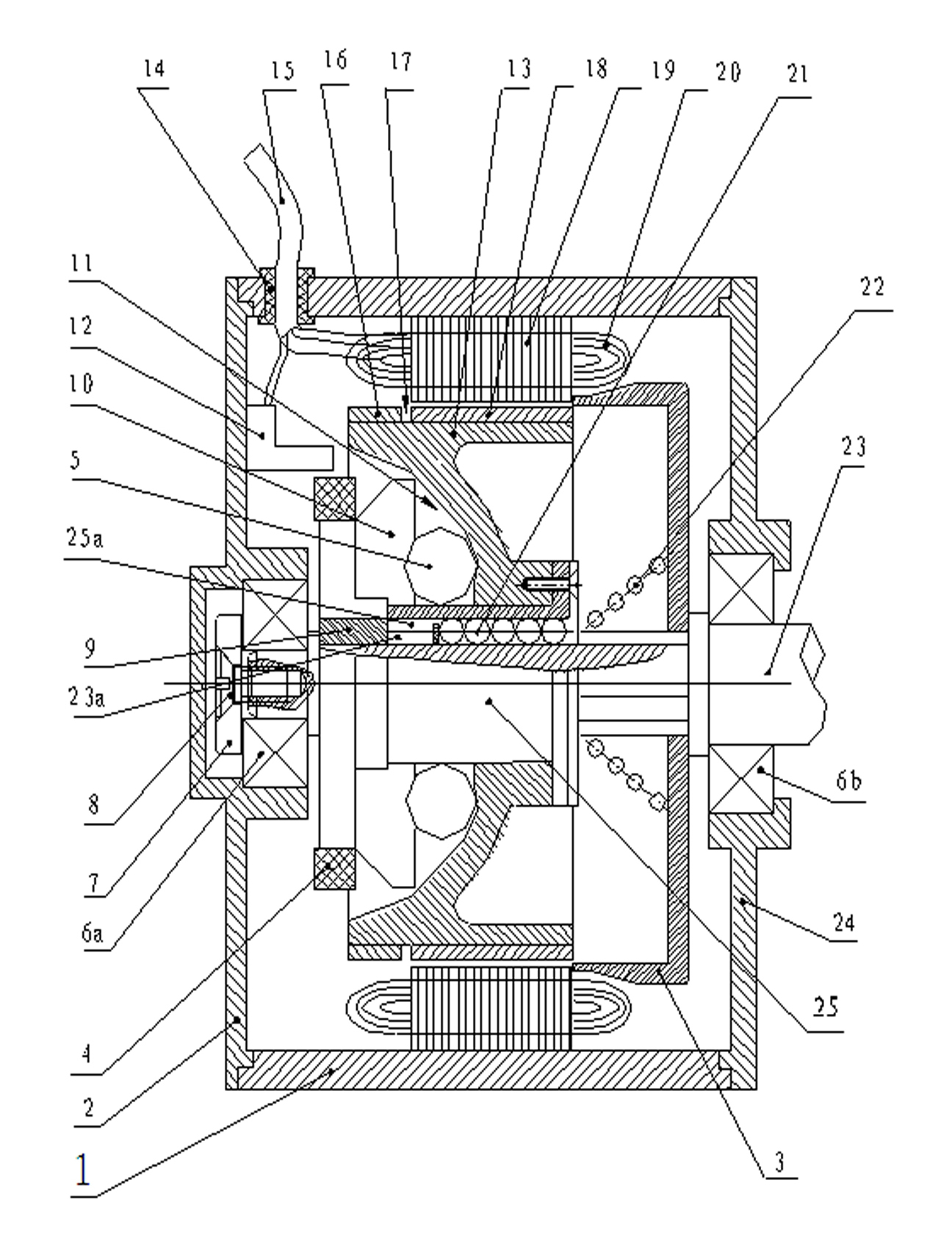

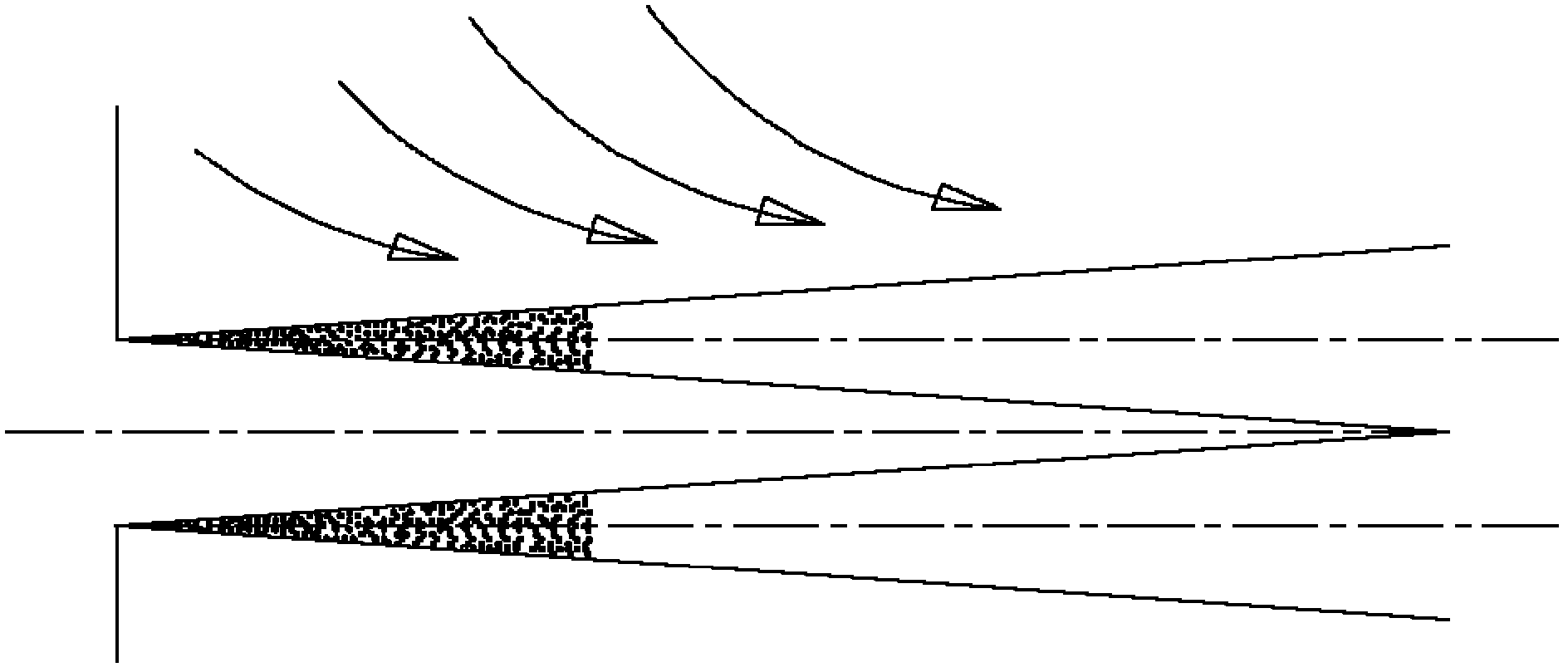

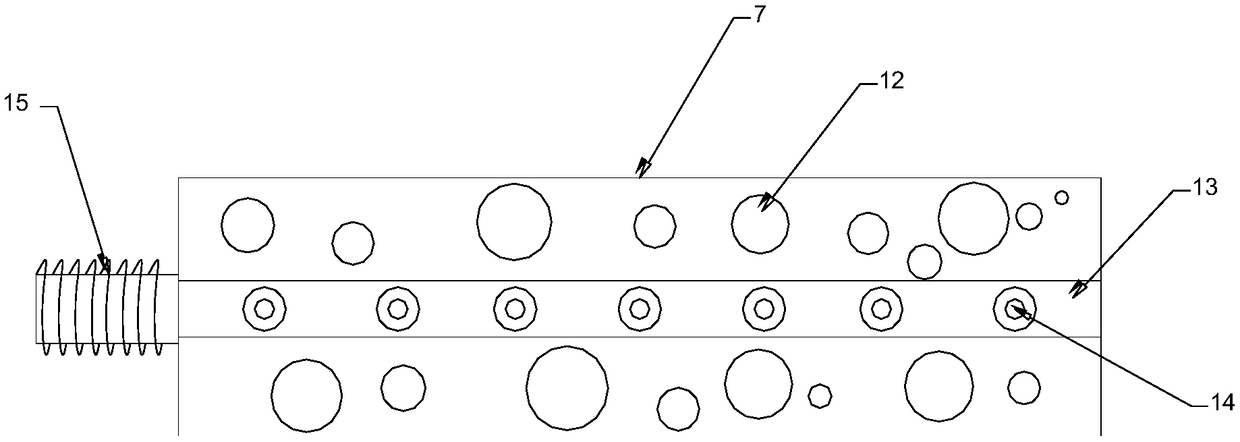

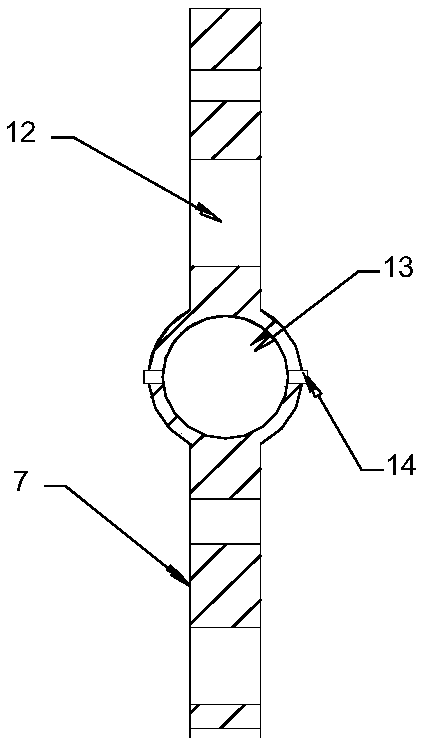

High-efficiency spiral-flow type sand remover for oil field wellhead

ActiveCN102716604AEfficient ConcentrationCompact and reasonable structureCentrifugal force sediment separationFluid removalSpiral bladeEngineering

The invention relates to the technical field of sand removers, in particular to a high-efficiency spiral-flow type sand remover for an oil field wellhead. The high-efficiency spiral-flow type sand remover comprises a barrel body, a sand unloading device, a sand discharging separation barrel and a flow guide rod, wherein a liquid inlet and a liquid outlet are respectively formed at the left end and the right end of the barrel body; the sand discharging separation barrel is fixedly arranged in the barrel body; the flow guide rod is arranged in the sand discharging separation barrel; spiral blades are fixed on the flow guide rod; and a liquid conveying channel is formed between the spiral blades and the sand discharging separation barrel. The high-efficiency spiral-flow type sand remover is rational and compact in structure and convenient to use; a sand discharging cavity is a conical cavity in which a communicating hole is used as a center and two sides are provided with narrow outer parts and wide inner parts; furthermore, the sand discharging elongated holes are distributed along the circumference in a rightward spiral manner, and the axial direction of the sand discharging elongated holes is tangent with the inner wall of the barrel body; therefore, impurity particles can be effectively concentrated at the communicating hole, and the sand discharging effect is relatively good; impurities can be prevented from being retained in the sand discharging cavity; and moreover, the sand discharging elongated holes are elongated, so that the sand discharging amount is increased, and the working efficiency is improved.

Owner:库尔勒金沙石油机械制造有限责任公司

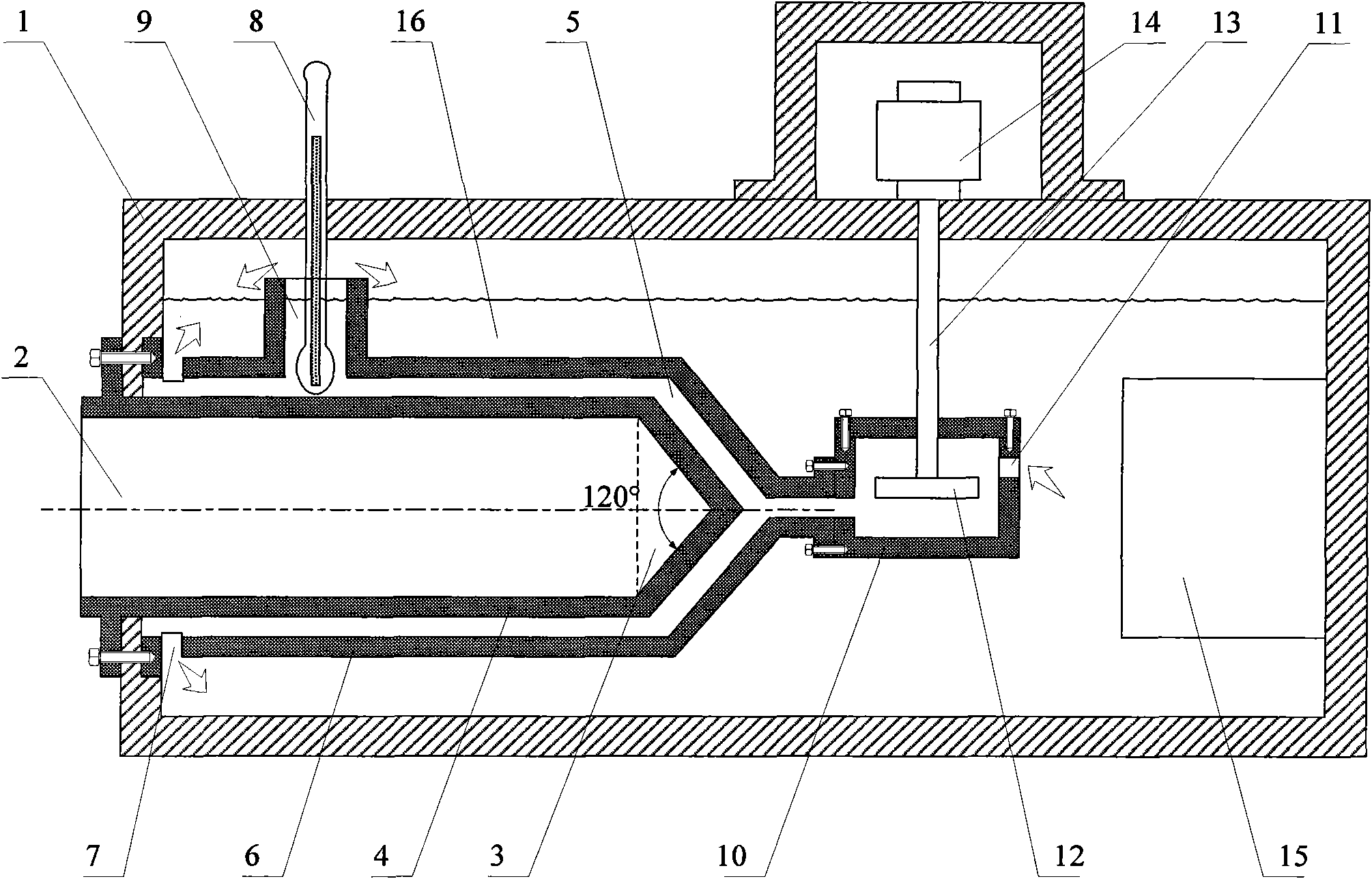

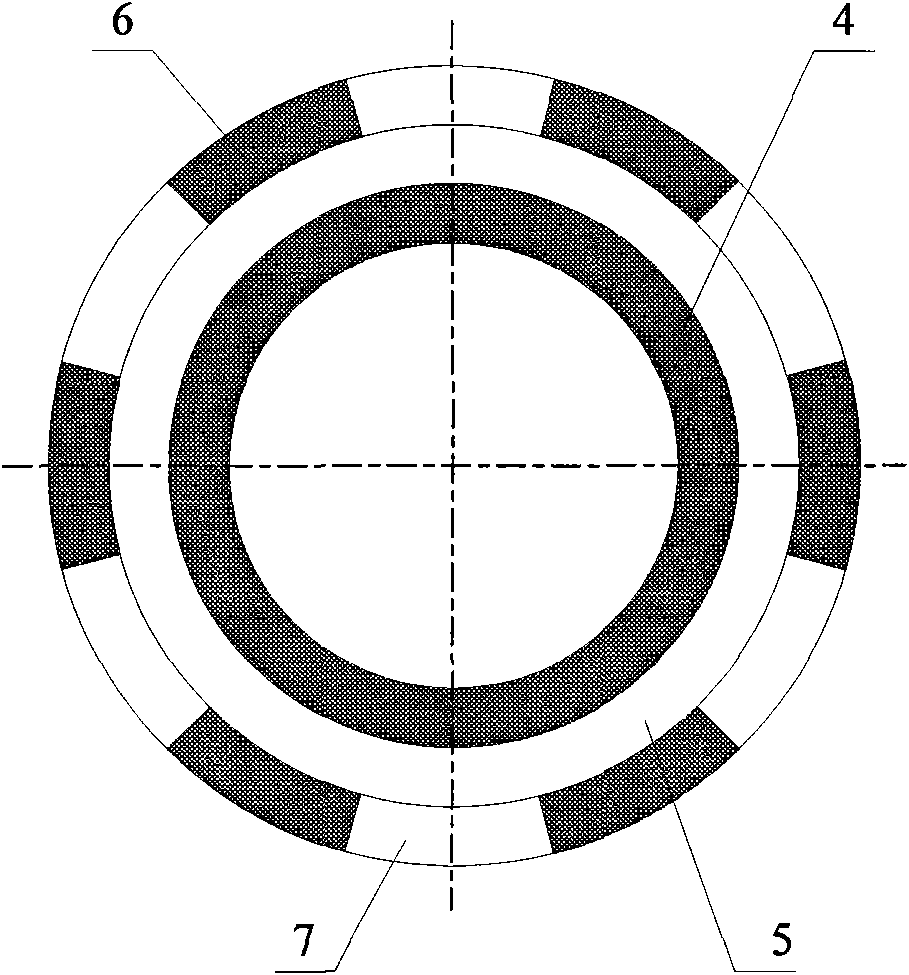

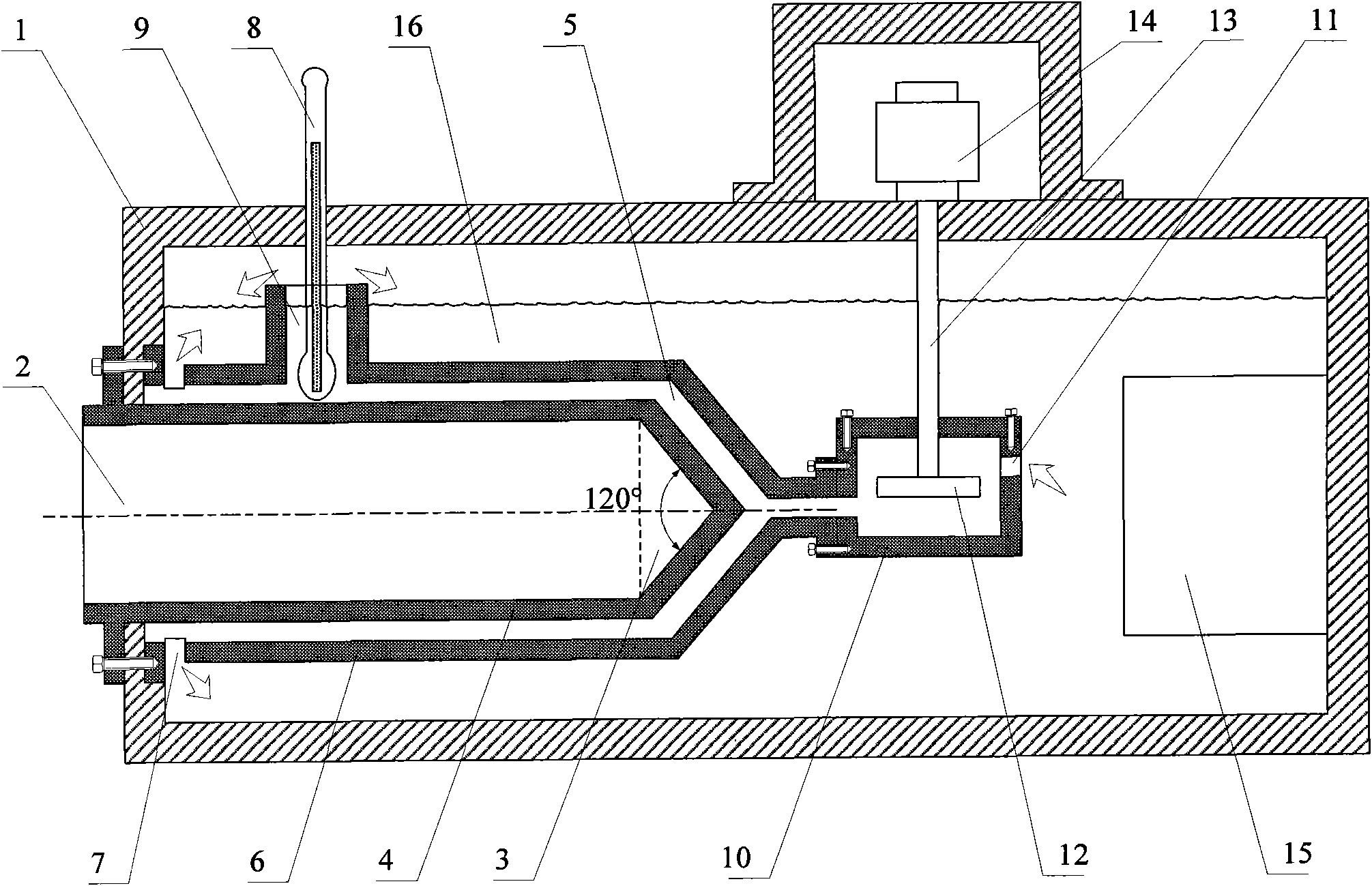

Black body cavity radiation source

InactiveCN101873728AImprove temperature distributionHigh emissivityRadiation pyrometryOhmic-resistance heating detailsImpellerLiquid medium

The invention discloses a black body cavity radiation source which comprises a liquid thermostat, a black body cavity, a temperature controller, a pump and a standard thermometer. The black body cavity and the temperature controller are installed in the liquid thermostat, the black body cavity comprises a cavity inner shell and a cavity outer shell, and the inner wall of the cavity inner shell and the inner wall of the cavity outer shell are coated with black diffuse reflection coatings. The cavity inner shell with the front end being a conical cavity and the rear end being a columniform cavity is coaxially installed in the liquid thermostat, and the cavity outer shell with the same shape as that of the cavity inner shell is installed outside the cavity inner shell to form an equally spaced hollow interlayer. The end surface of the cavity inner shell is connected with the outer wall of the liquid thermostat, a conical cavity opening of the cavity outer shell is communicated with a pump shell, the pump shell is communicated with the liquid thermostat through the opening, an impeller in the pump shell is connected with a motor through a pump shaft, the standard thermometer is arranged in the hollow interlayer, and openings are equally distributed on the cavity outer shell. In the invention, the cavity outer shell and the pump are additionally arranged to enable liquid medium in the thermostat to flow in a circulating way in the hollow interlayer, thereby improving the temperature distribution of a black body cavity, enabling the black body cavity to have the characteristic of isothermy and further enhancing the emissivity of the black body cavity.

Owner:CHINA JILIANG UNIV

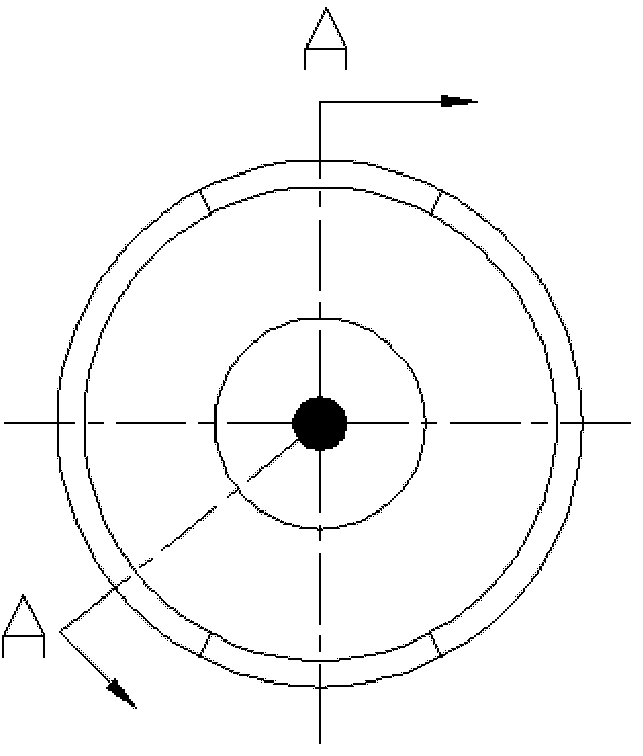

Minimally invasive bone miller apparatus

A miller assembly for creating a cavity in a bone. The cavity has a cross section which has a generally triangular profile having a first side generally parallel with an axis of the bone and a second side forming an acute angle with the first side, and is contiguous with a pre-existing conical cavity in the bone. The miller assembly includes a cutter and a frame for carrying the cutter. The frame includes a connection portion having a longitudinal axis and a cutter mount for mounting the cutter at a first angle approximating the acute angle with respect to the longitudinal axis of the connection portion. The cutter mount extends at the first angle from the longitudinal axis of the connection portion and is configured to receive a portion of the cutter and maintain the received cutter oriented at the first angle during rotation. The frame further includes a handle configured to form a portion of a drive joint for coupling the frame to a drill, the handle having a longitudinal axis. The longitudinal axis of the handle is coincident with the longitudinal axis of the frame.

Owner:DEPUY PROD INC

Millimeter wave blackbody radiation calibration source with biconical cavity serial structure

InactiveCN101666684AReduce return rateImprove temperature consistencyRadiation pyrometryAbsorption ratioBlack-body radiation

The invention discloses a millimeter wave blackbody radiation calibration source with a biconical cavity serial structure, which is cylindrical as a whole and has a cylindrical structure made of metalmaterial. An integrated cavity structure connected in series by a lip, a circular cavity, a transition section and a conical cavity which are all in rounding off from top to bottom is arranged in thecenter of a cylinder, and the opening surface of the cavity is arranged in the center of the top of the cylinder. A cavity inner wall wave-absorbing material coating is made of wave-absorbing material coated on the inner wall of the cavity according to the required thickness. The invention lowers the probability that radiation energy incident from the opening surface is reflected and returned from the opening surface during transmission in the cavity so that the radiation energy is reflected many times in the cavity and absorbed. Through controlling the coating depth, the invention solves theproblem that the consistency of temperatures of blackbody calibration sources is influenced due to overlarge coating depth and poor thermal conductivity while improving the absorptivity of the cavityinner wall of the blackbody radiation calibration source to the radiation energy.

Owner:BEIHANG UNIV

Spraying head assembly

InactiveUS7464885B1Reduce particlesIncrease distanceSpray nozzlesConical cavityMechanical engineering

A spraying head assembly has a tubular body, a cap, an upper plug, a lower plug and a spring. The cap is attached to the body and has a spraying channel, a conical cavity and a spraying hole. The conical cavity is defined inside the cap and communicates with the spraying channel and the spraying hole. The upper plug is held in the body and comprises a spraying end, a connecting end, a head and shaft. The head has a recess communicating with the spraying channel having a conical bottom. Multiple passages are defined in the head and communicate with the recess. The lower plug is mounted movably in the chamber in the body and is connected to the upper plug using the spring. In this arrangement, a liquid supplied to the connecting end forms vortexes in the body to reduce particles of liquid nebulization and raise ejection speed and therefore distance.

Owner:TANONG PRECISION TECH CO LTD

Blade insert

Blade insert connected in the lamination of a blade determining a double shear joint between insert and lamination. The insert is made up of two defined parts, head (2), designed to screw the insert to another structure (2′), and the body (3) that determines a cylindrical or conical shape with an internal conical cavity. In an embodiment, the insert is designed to be joined to the lamination (1) of the blade with adhesive means (4). In another embodiment, the insert is embedded in the blade lamination with an inner part (5) stuck to the body (3) of the insert.

Owner:GAMESA INNOVATION & TECH SA

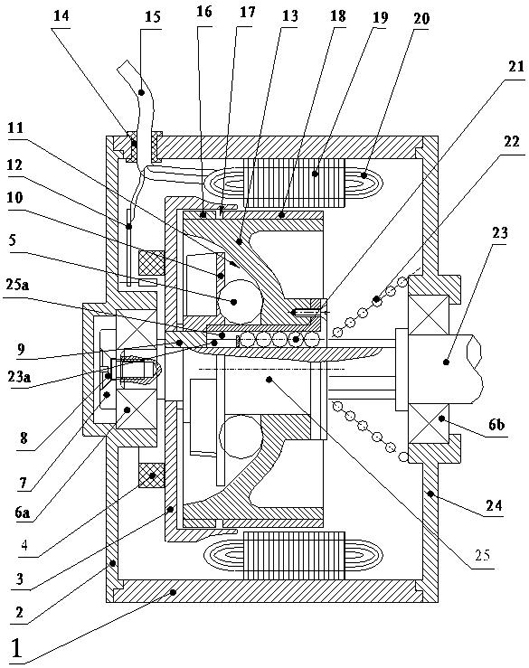

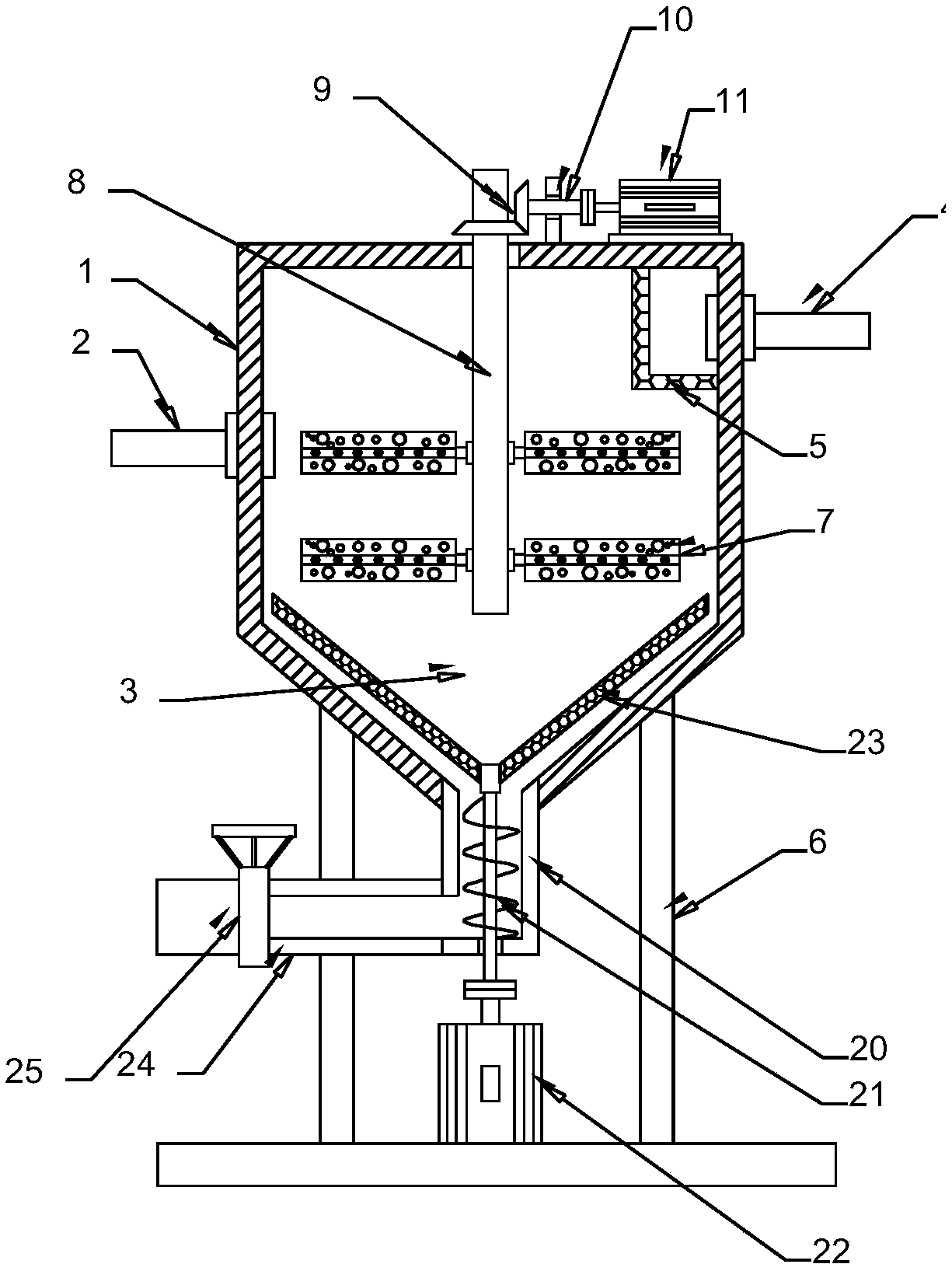

Cyclone type oil-gas separator of engine

InactiveCN101749081AImprove the bumping effectImprove adhesionMachines/enginesCrankcase ventillationCycloneCombustion chamber

The invention provides a cyclone type oil-gas separator of an engine. The separator comprises a conical cavity body, wherein the side wall of the upper part of the conical cavity body is provided with a mixed oil-gas inlet tube, the top part of the conical cavity body is provided with a gas discharge opening, and the bottom part of the conical cavity body is provided with an oil return opening; and the inner wall of the conical cavity body is provided with a spiral type maze separation path from the top to the bottom, the spiral type maze separation path is a protruding strip forming the surface of the inner wall of the conical cavity body and spirally goes down on the inner wall of the conical cavity body, and the spiral type maze separation path is of a discontinuous type. The separator adopts a structure of the combination of the conical cavity body and the spiral type maze, so that under the same manufacturing process conditions, the separator has the advantages of improving the wall collision effect when the oil and the gas centrifugally rotate, improving the adhesive capability of the oil and the gas, reducing the amount of the mixed gas entering a combustion chamber of the engine, lowering emission, and reducing the consumption of engine oil.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

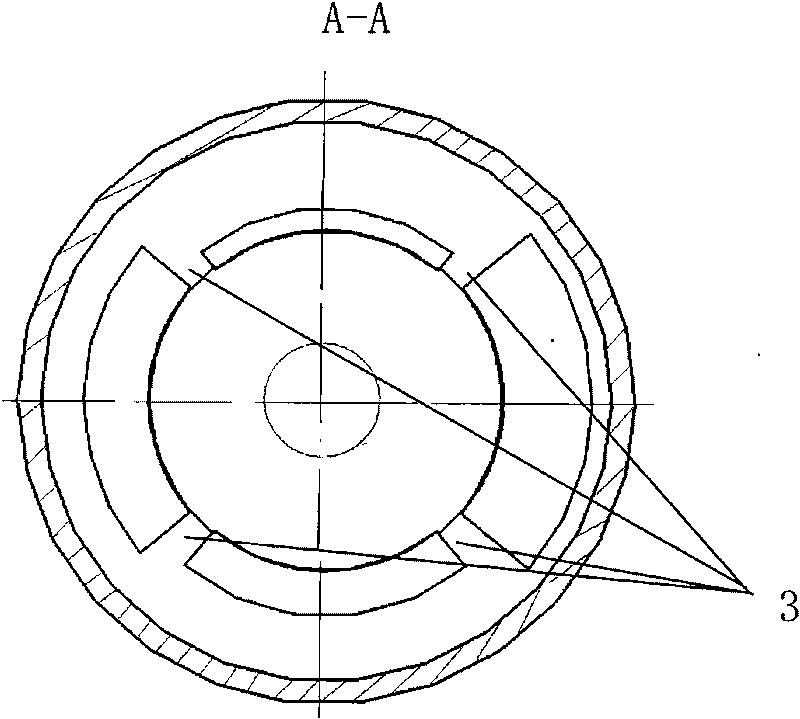

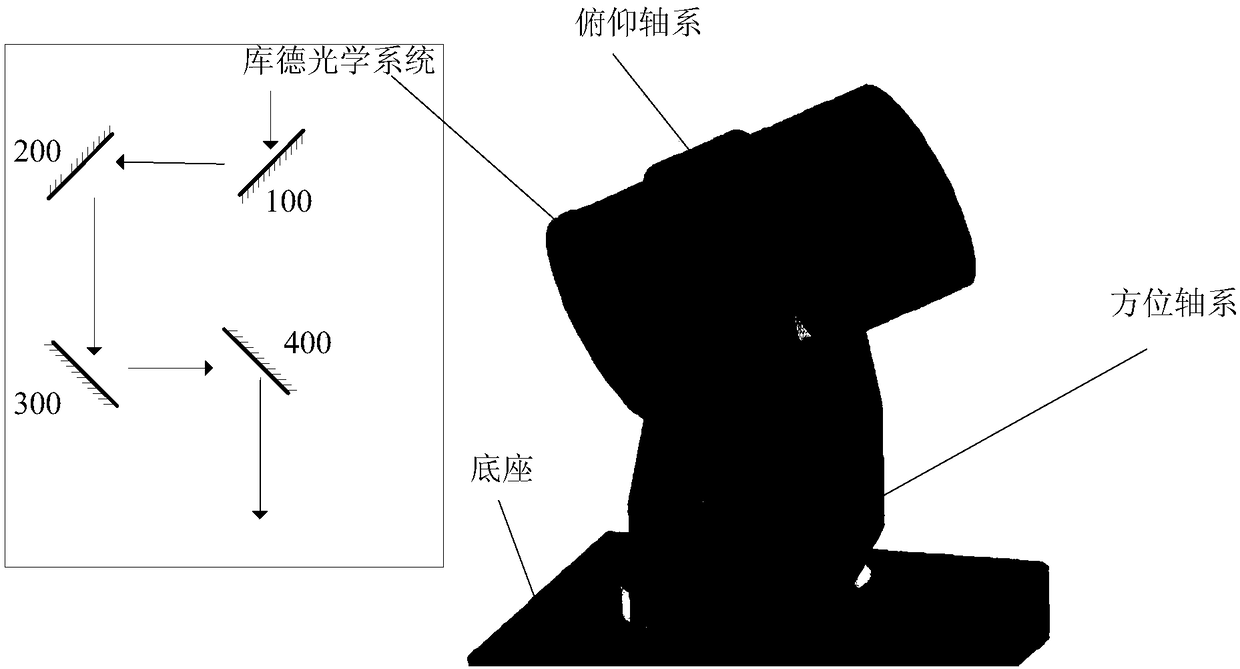

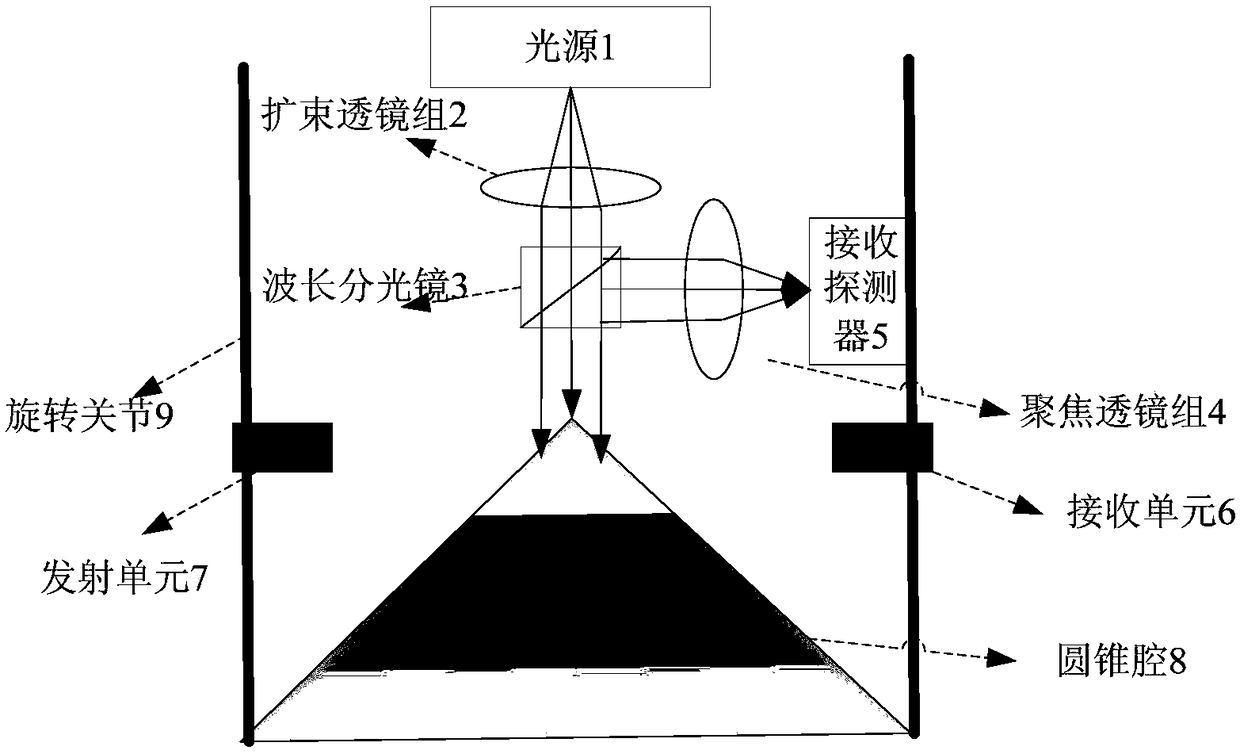

Novel optical communication system and method suitable for rotary joint

ActiveCN108270486AReduce in quantitySimple designClose-range type systemsOptical elementsCommunications systemLight beam

The invention discloses a novel optical communication system and method suitable for a rotary joint. The system comprises a light source, an optical beam expanding lens battery, a wavelength spectroscope, a focusing lens battery, a receiving detector, a reception unit, an emission unit and a conical cavity; a light beam emitted by the light source is collimated by the optical beam expanding lens battery, the collimated light beam is transmitted by the wavelength spectroscope in which reception is separated from transmission; the transmitted light beam is reflected by the surface of the conicalsurface into a circular ring light beam, and the reception unit receives the circular ring light beam; collimated light emitted by the emission unit irradiates the surface of the conical cavity, reflected by the surface of the conical cavity to the wavelength spectroscope, and reflected by the wavelength spectroscope to the focusing lens battery, and the light beam gathered by the focusing lens battery is transmitted to the receiving detector. Bidirectional communication of an emission light ring and optical reception are realized without being influenced by a rotation mechanism, and information interaction can be realized for two servo mechanisms including the internal and external stators or the rotary joint.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Electric grinding and pulverizing method

ActiveCN101347759APlay smashPlay the role of grindingGrain treatmentsElectric machineryConical cavity

The invention relates to an electric grinding and crushing device. The technical proposal of the device is as follows: a rotary cylindriconical ball mill (6) is arranged in a conical cavity which is fixed with a spiral mill (7) through a rolling bearing (12), a spiral groove (5) is processed on the inner wall of the conical cavity which is fixed with the spiral mill (7), and the taper of the conical cavity which is fixed with the spiral mill (7) is larger than the taper of a conical surface of the rotary cylindriconical ball mill (6). A first feed hopper (8) is arranged at the gap between the upper end of the conical surface of the rotary cylindriconical ball mill (6) and the upper end of the conical cavity which is fixed with the spiral mill (7), and a second feed hopper (10) is arranged over the center of the inner cavity of the rotary cylindriconical ball mill (6). A central square shaft (4) is fixed at the upper part of the center of the inner cavity of the rotary cylindriconical ball mill (6), and 3 to 30 blades (3) are arranged on the central square shaft (4). A first motor (16) is linked with the rotary cylindriconical ball mill (6) by a belt wheel (15) and a belt (14), and a second motor (20) of a conveying extrusion mechanism directly drives a conical screw rod (17) by a speed reducer (19). The electric grinding and crushing device is characterized by convenient use, low cost and small using space.

Owner:扬州力德工程技术有限公司

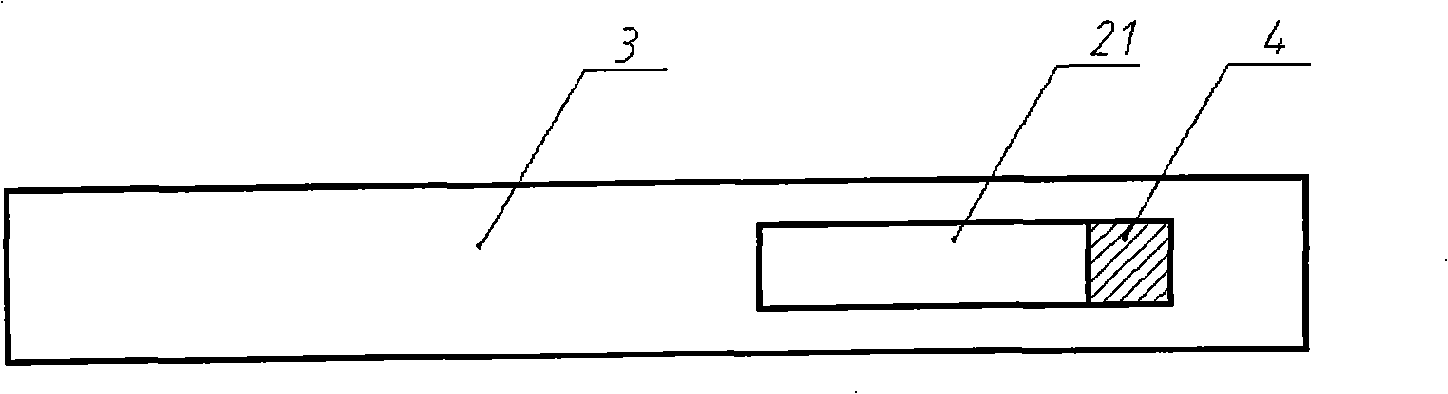

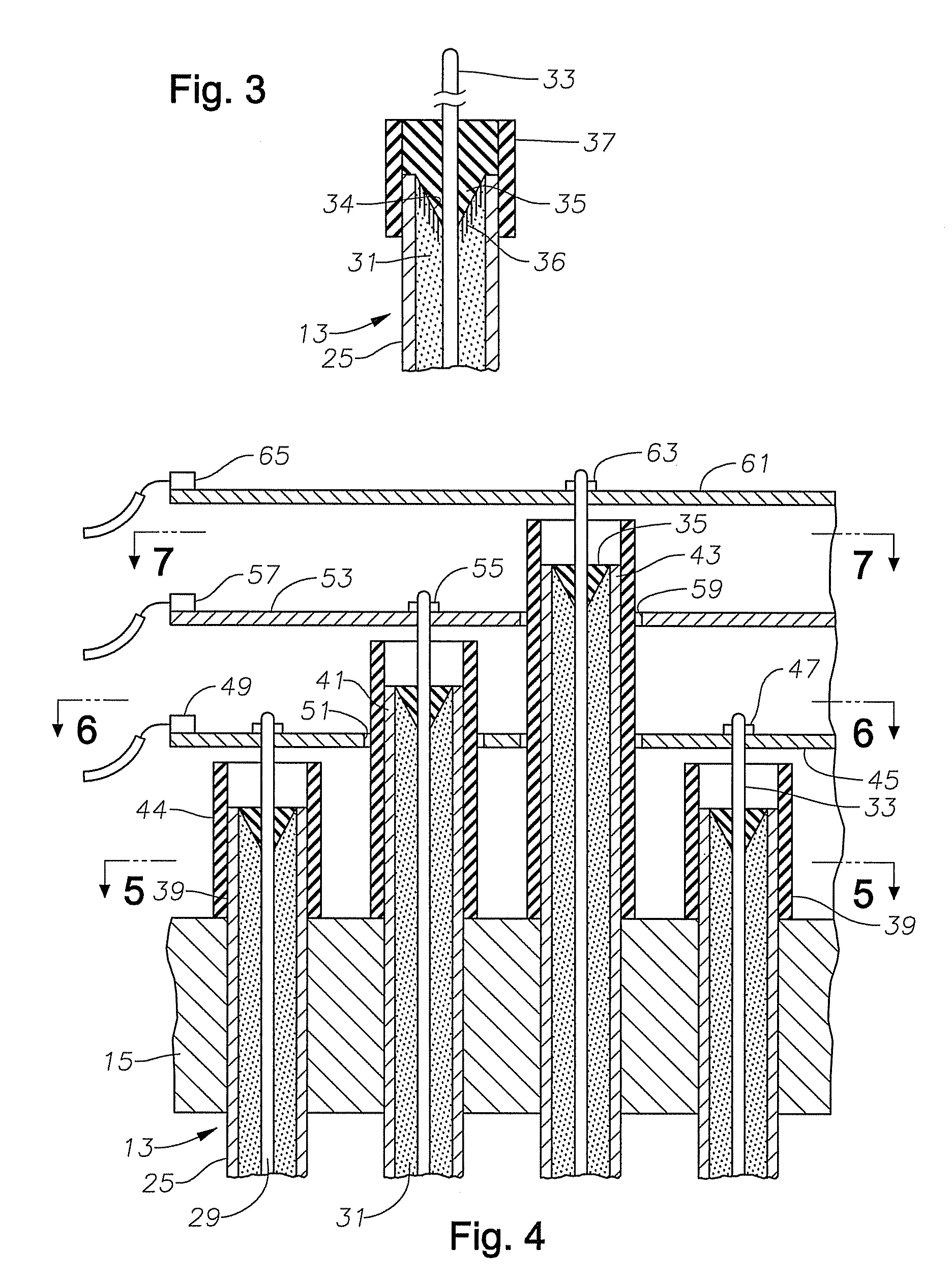

Medium voltage heater element

An electrical heater bundle has heater elements, each including a metal tube, an electrical resistance coil within the tube, a conductor pin connected to the coil and protruding from an end of the tube, and an electrical insulation powder surrounding the coil within the tube. A conical cavity is located in the insulation powder at the end of the tube, the cavity extending from an inner diameter of the tube to the conductor pin. The cavity is filled with an epoxy that is cured in place. The insulation powder may have an infiltrated layer at the cavity that is an uncured liquid silicone. The heater elements are mounted to a header plate, and the elements associated with the three different phases of electrical power may protrude past the header plate at different distances.

Owner:GAUMER

Minimally invasive bone miller apparatus

A miller assembly for creating a cavity in a bone. The cavity has a cross section which has a generally triangular profile having a first side generally parallel with an axis of the bone and a second side forming an acute angle with the first side, and is contiguous with a pre-existing conical cavity in the bone. The miller assembly includes a cutter and a frame for carrying the cutter. The frame includes a connection portion having a longitudinal axis and a cutter mount for mounting the cutter at a first angle approximating the acute angle with respect to the longitudinal axis of the connection portion. The cutter mount extends at the first angle from the longitudinal axis of the connection portion and is configured to receive a portion of the cutter and maintain the received cutter oriented at the first angle during rotation. The frame further includes a handle configured to form a portion of a drive joint for coupling the frame to a drill, the handle having a longitudinal axis. The longitudinal axis of the handle is coincident with the longitudinal axis of the frame.

Owner:DEPUY PROD INC

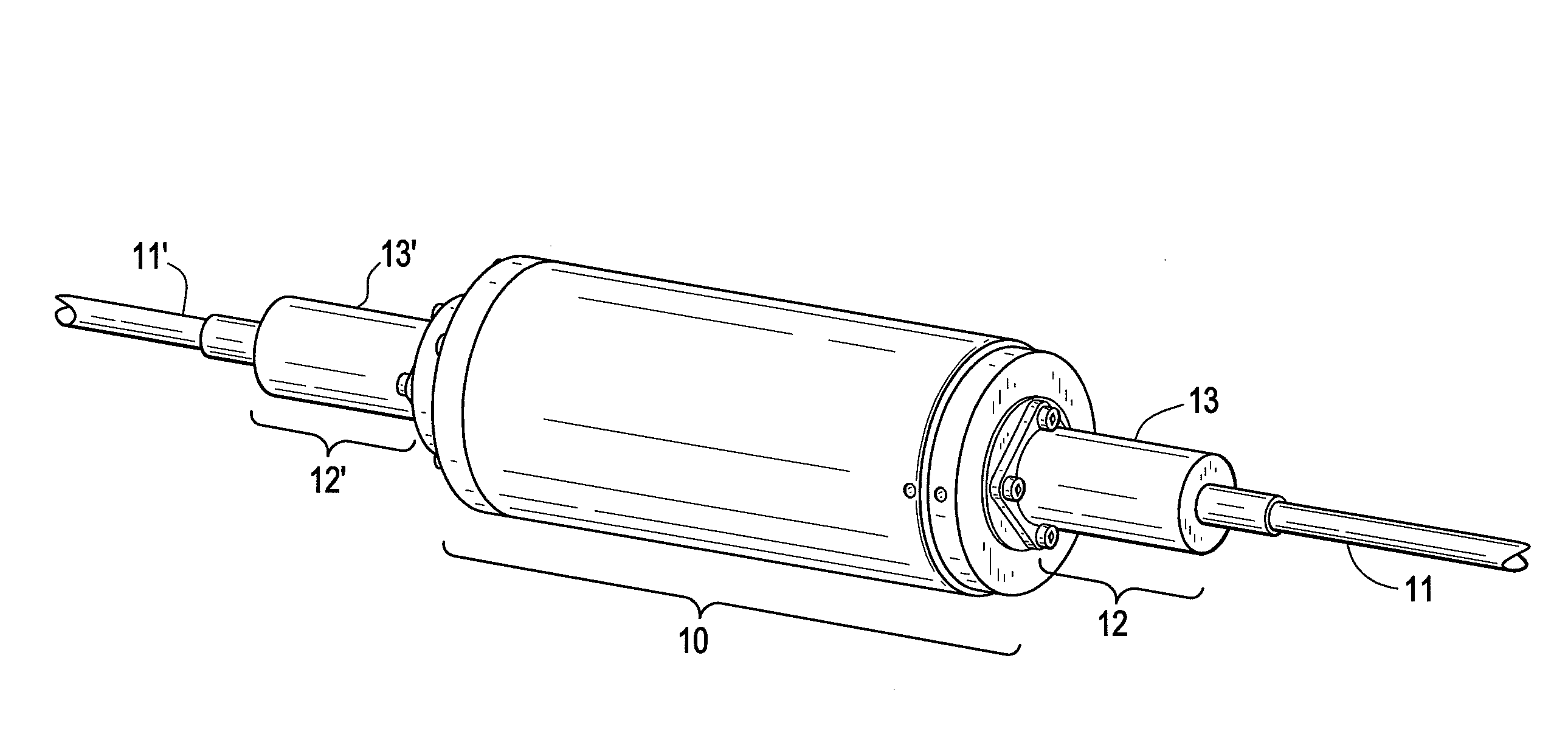

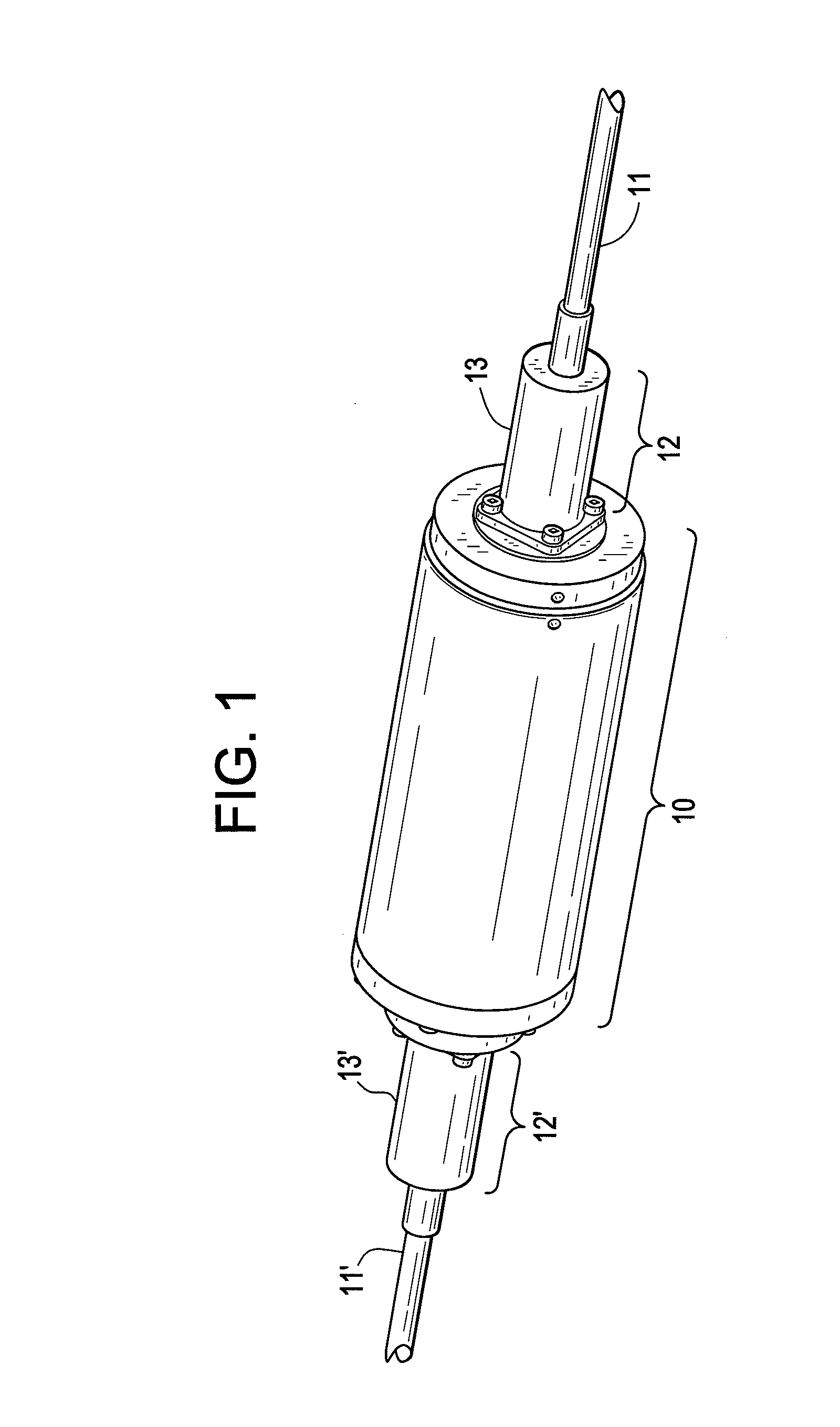

High reliability armored termination/epoxy gland

An armored cable termination / fiber-optic seal which connects a fiber optic cable—the fiber optic cable including one or more armor wires and one or more cable tubes—to a pressure housing, the armored cable termination / fiber-optic seal including: an armored termination which locks the one or more armor wires in a conical cavity; sealing paths which block water from traveling in the interstitial space between the one or more armor wires and the one or more cable tubes into the pressure housing; and fiber feed-through tubes which block water from traveling in the interior of the one or more cable tubes into the pressure housing.

Owner:AFL COMM LLC

Air volume adjusting valve with novel structure

ActiveCN105257830AAchieve stabilityReduce manufacturing costEqualizing valvesDirt cleaningAir volumeDrive shaft

The invention discloses an air volume adjusting valve with a novel structure. The air volume adjusting valve comprises a valve body with valve cavities, a first valve element and a second valve element, wherein the first valve element and the second valve element are contained in the valve cavities. The valve cavities comprise the front valve cavity and the rear valve cavity which are arranged in a front-and-back through manner. The first valve element is arranged in the front valve cavity, and the second valve element is arranged in the rear valve cavity. The first valve element is roughly in a conical shape so as to be provided with a conical side face and a conical bottom face. The front valve cavity is provided with a conical cavity face roughly matched with the conical side face of the first valve element. The conical bottom face faces an air inlet end. A positioning shaft is fixedly arranged in the front valve cavity. A cone hole is formed in the first valve element. The first valve element is arranged on the positioning shaft through the cone hole in a sleeving manner and is combined with a reset spring. The reset spring is arranged on the positioning shaft in a sleeving manner, and the axial position of the positioning end of the reset spring can be adjusted. The second valve element is in a disc shape and can be arranged in the rear valve cavity in a radial rotation manner. The driving shaft is rotated to penetrate the cavity wall of the rear valve cavity to be connected to the second valve element. Thus, the air volume adjusting valve can deal with laboratory environments changing continuously, and therefore the face velocity of a ventilation cabinet can be stably controlled.

Owner:广东科艺普实验室设备研制有限公司

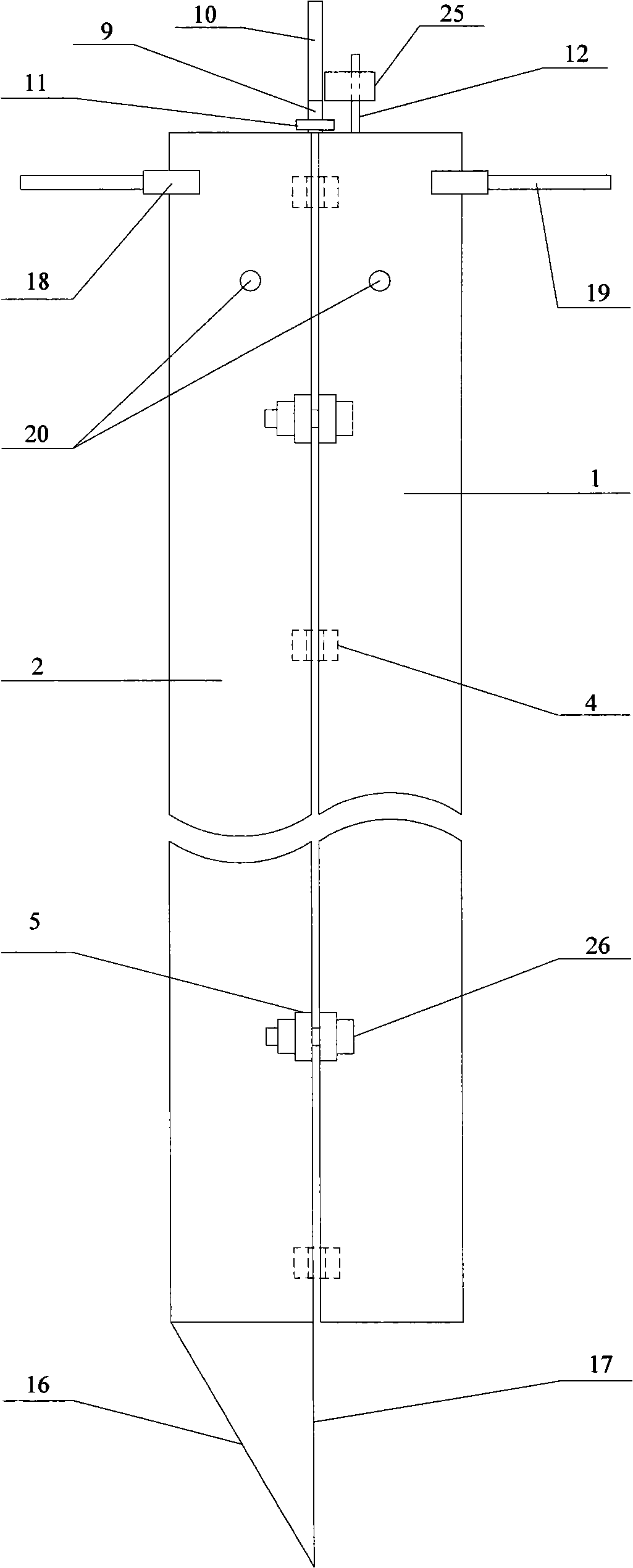

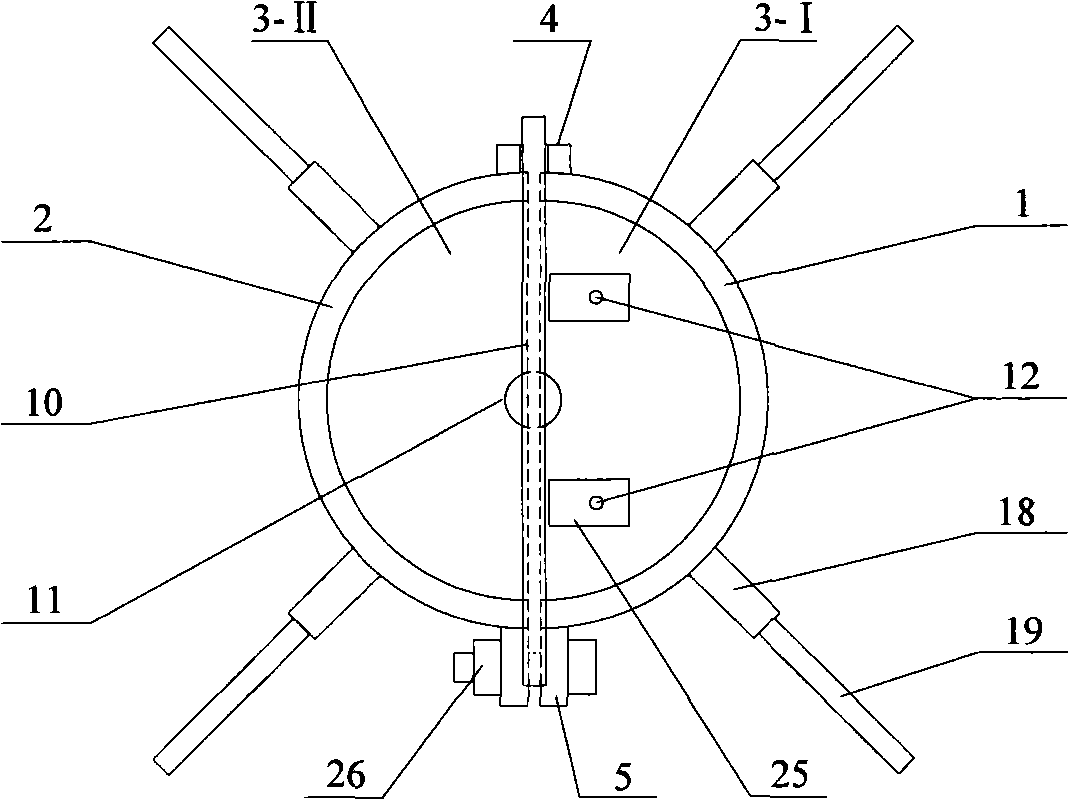

Rotary-cutting column type deposit sampler

The invention discloses a rotary columnar deposit sampler, comprising a sampling tube, a rotary cutting system and a supporting board. The sampling tube comprises a positive half-tube, a matching half-tube, a top cover, a mouth piece and a manual rod; the sampling tube comprises a positive half-tube and a matching half-tube, and can be switched on or off with a hinge by the bolt and nut arranged on both axial sides; the mouth piece comprises a half right-circular conical cavity and a triangular plate, the bottom side thereof is fixedly connected with the bottom side of the matching half-tube, and the flank is blocked by a triangular plate; the rotary cutting system comprises a rotary cutting blade, a bushing, a rotary rod, a rotary-cutting handle and a stop clipping-hook, the rotary cutting blade is in semicircle shape and vertically fixed on the rotary rod by equal distances, the rotary rod is fixed on the axial line of the positive half-tube and can make horizontal circumrotation; the supporting board comprises a plurality of rectangular clapboards fixed on the matching half-tube by equal intervals, and the gap between two neighboring flat-plates can ensure free rotary cutting movements of the rotary cutting blade. The sampler adopts a rotary cutting manner to stratify the deposit, the structure is simple, the cost is low, the operation is convenient, and the disassembly and maintenance are easy, and is light to carry.

Owner:NANKAI UNIV

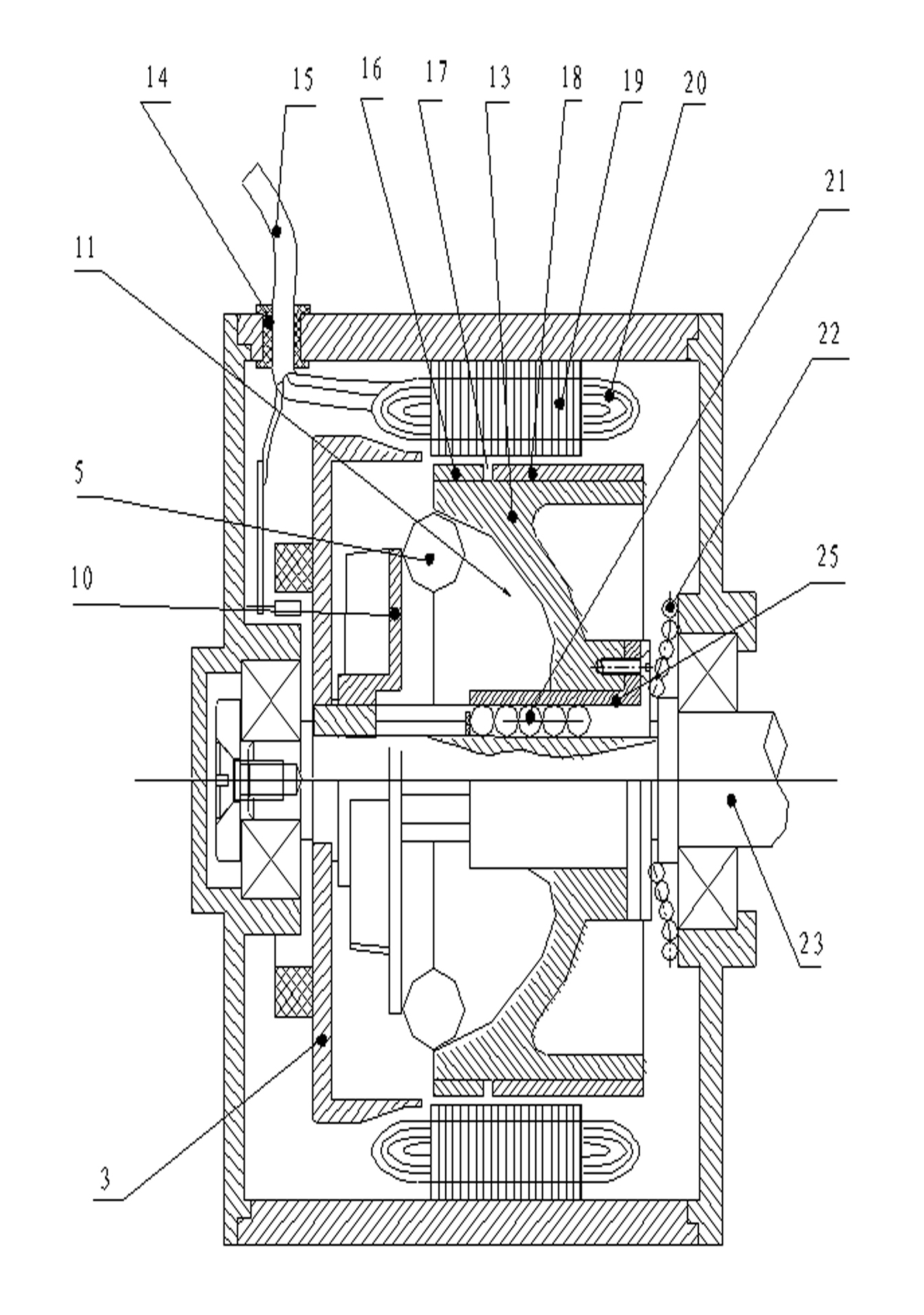

Rotor slippage complementary exciting permanent-magnetic brushless variable speed motor

InactiveCN102064656AIncrease speedRealize field weakening speed regulationMagnetic circuit rotating partsMagnetic/electric field screeningMagnetic sourceElectric machine

The invention discloses a rotor slippage complementary exciting permanent-magnetic brushless variable speed motor. A rotor of the motor is connected with a motor rotating shaft through a spline and can move along the axial direction; two groups of polarity-complementation exciting magnetic sources are arranged on the periphery of the rotor side by side, wherein one group is main flux source exciting bodies, and the other group is secondary flux source exciting bodies; the main and the secondary flux source exciting bodies are arranged with alternated polarities by permanent magnets with the same number respectively to form rings; the polarity distribution on the circumference of the secondary flux source exciting bodies is spaced by one polar distance from the polarity distribution on the circumference of the main flux source exciting bodies; a roller path disc is fixedly connected on the motor rotating shaft, and the roller path disc and a conical cavity at one end of the rotor form a wedge-shaped space; and a plurality of rollers for pushing the rotor to move along the axial direction by eccentric motion are arranged in the wedge-shaped space. In the invention, the rotor moves along the axial direction to reduce the flux so as to change the torque / rotational speed property of the motor and realize speed variation, which improves the mechanical property of the permanent-magnetic brushless variable speed motor per se, enlarges the full-power speed adjusting range of the motor, keeps the volume of the motor and saves the production cost.

Owner:杨荷

Multiple vortex waste separator apparatus

ActiveUS20100084352A1Combination devicesWater/sewage treatment by centrifugal separationEddy current separatorWaste stream

A multiple vortex separator for drawing a substantially moisture-free airstream from a waste stream having an annular channel defining a first vortex flow path for separating liquid and solid waste from this waste stream and an inverted conical cavity between nested inverted cones defining a second vortex flow path that is isolated from the first vortex flow path for separating additional liquid and solid waste from the waste stream before it exits the vortex separator.

Owner:BE AEROSPACE INCORPORATED

Cavitation type ultrahigh pressure water hammer type water gun sprayer

The invention discloses a cavitation type ultrahigh pressure water hammer type water gun sprayer. Under the high pressure, a nozzle of the sprayer sprays out water hammer jet flow with cavitation proficiency. The sprayer comprises a sprayer cavity comprising an accordion cavity, a Helmholtz cavity and a conical nozzle outlet control section, wherein the accordion cavity and the Helmholtz cavity are axially through along the sprayer. A conical cavity transition section is formed between the accordion cavity and the Helmholtz cavity, high-speed fluid flows from the accordion cavity to a nozzle outlet to form water hammer flow with self-oscillation, and the water hammer flow produces vertex adhering wall effect at the nozzle outlet control section so that a cavitation phenomenon is induced at the nozzle outlet control section. The water jet flow sprayed out by the sprayer belongs to discontinuous cavitation water hammer flow, water attacking strength is in alternate tension with relaxation, alternating stress can be exerted on the surface of an attacked object, and the surface of the attacked object can be easily damaged or surrendered due to fatigue strength by means of the alternating stress and the cavitation effect. The cavitation type ultrahigh pressure water hammer type water gun sprayer is applied to occasions requiring rust removal, cleaning, scrabbing on the surface of concrete and the like.

Owner:天津开发区博新工贸有限公司

Sewage sedimentation device convenient for sludge discharge

InactiveCN108939628AEfficient collectionEfficient effluxSettling tanks feed/dischargeSedimentation settling tanksSludgeSewage

The invention discloses a sewage sedimentation device convenient for sludge discharge. The device comprises a tank, a water inlet pipe, a stirring plate and a mixer shaft. the bottom of the tank is provided with a conical cavity shaped as an inverted cone structure. The inner wall of the conical cavity is abutted against symmetrically-arranged scraper plates. The bottom of the tank is communicatedwith a vertical pipe, inside which a spiral blanking roller is arranged. the top of the spiral blanking roller is fixedly connected with the scraper plates. Through the tank provided with the conicalcavity, the scraper plates which are abutted against and slidingly connected with the inner wall of the conical cavity and the spiral blanking roller arranged inside the vertical pipe, the settled sludge is efficiently collected and discharged, and it is convenient to clean sludge while obstruction of a sludge discharge pipe is avoided. Through the stirring plate provided with a central pipelineand an overflow orifice, a gear pump and a hollow mixer shaft, efficient and uniform diffusion of a flocculating agent is realized, mixing uniformity and efficiency of the flocculating agent are raised, and sediment generation is accelerated.

Owner:袁慧初

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com