Patents

Literature

125results about How to "Increase surface contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

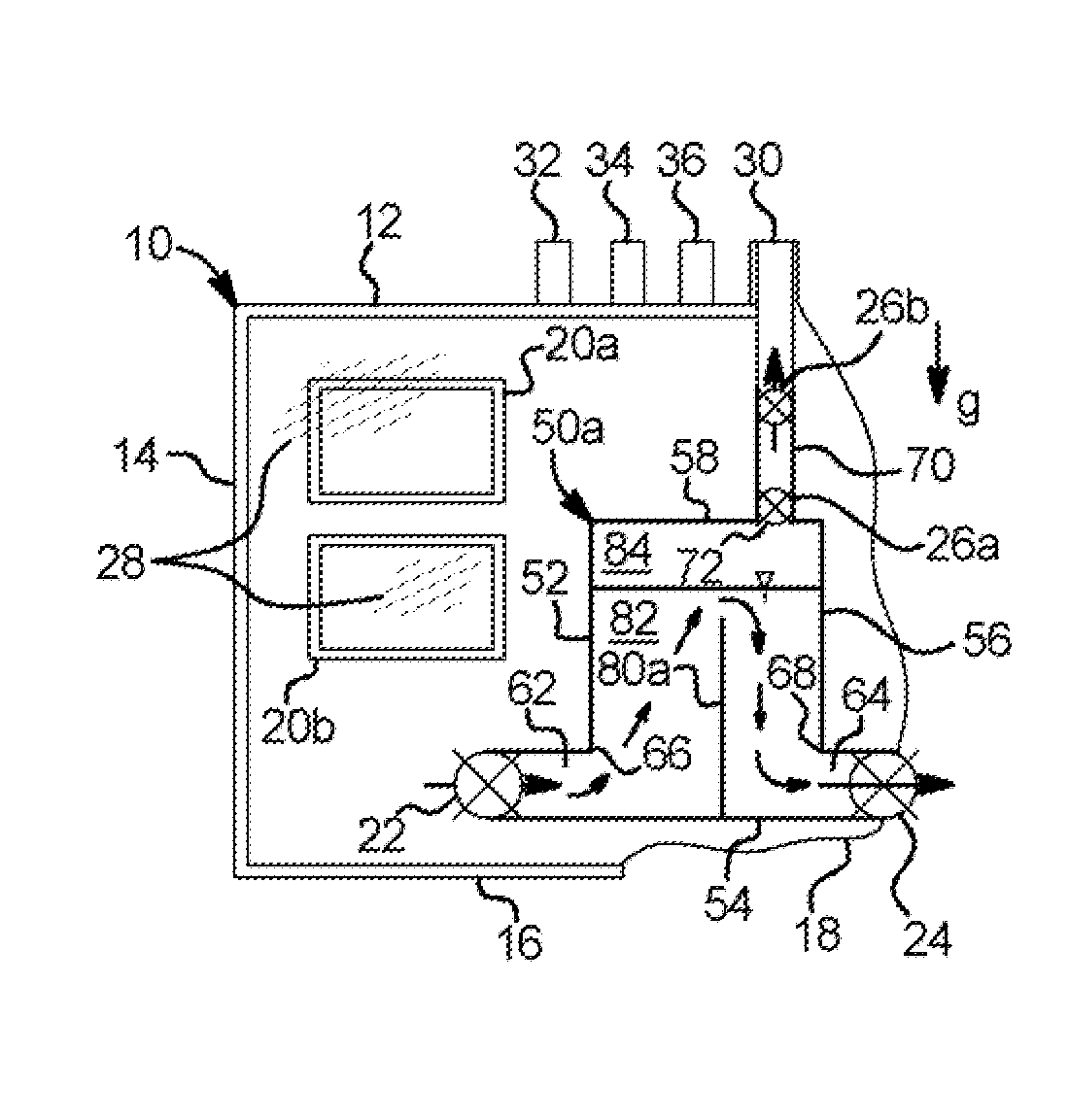

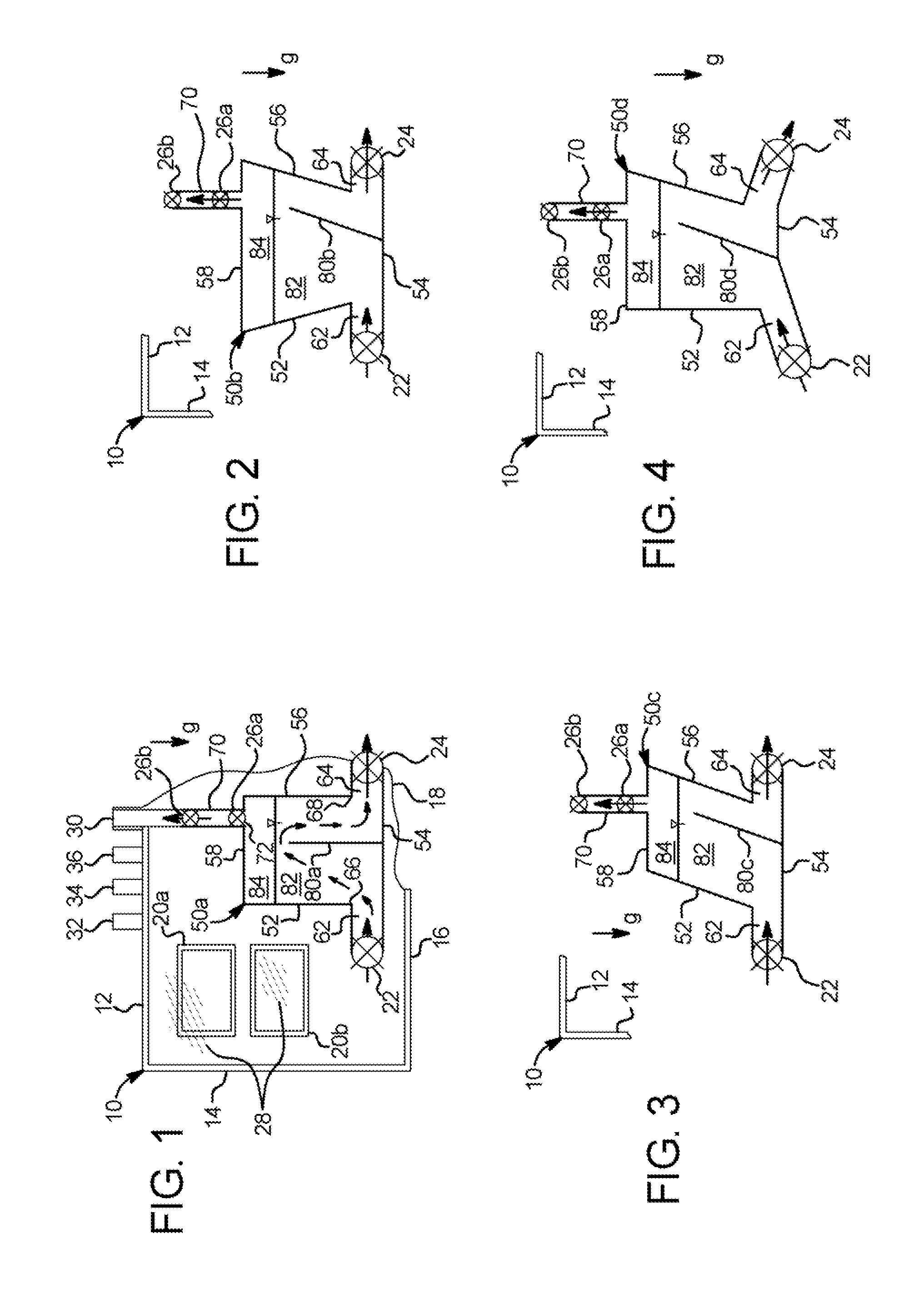

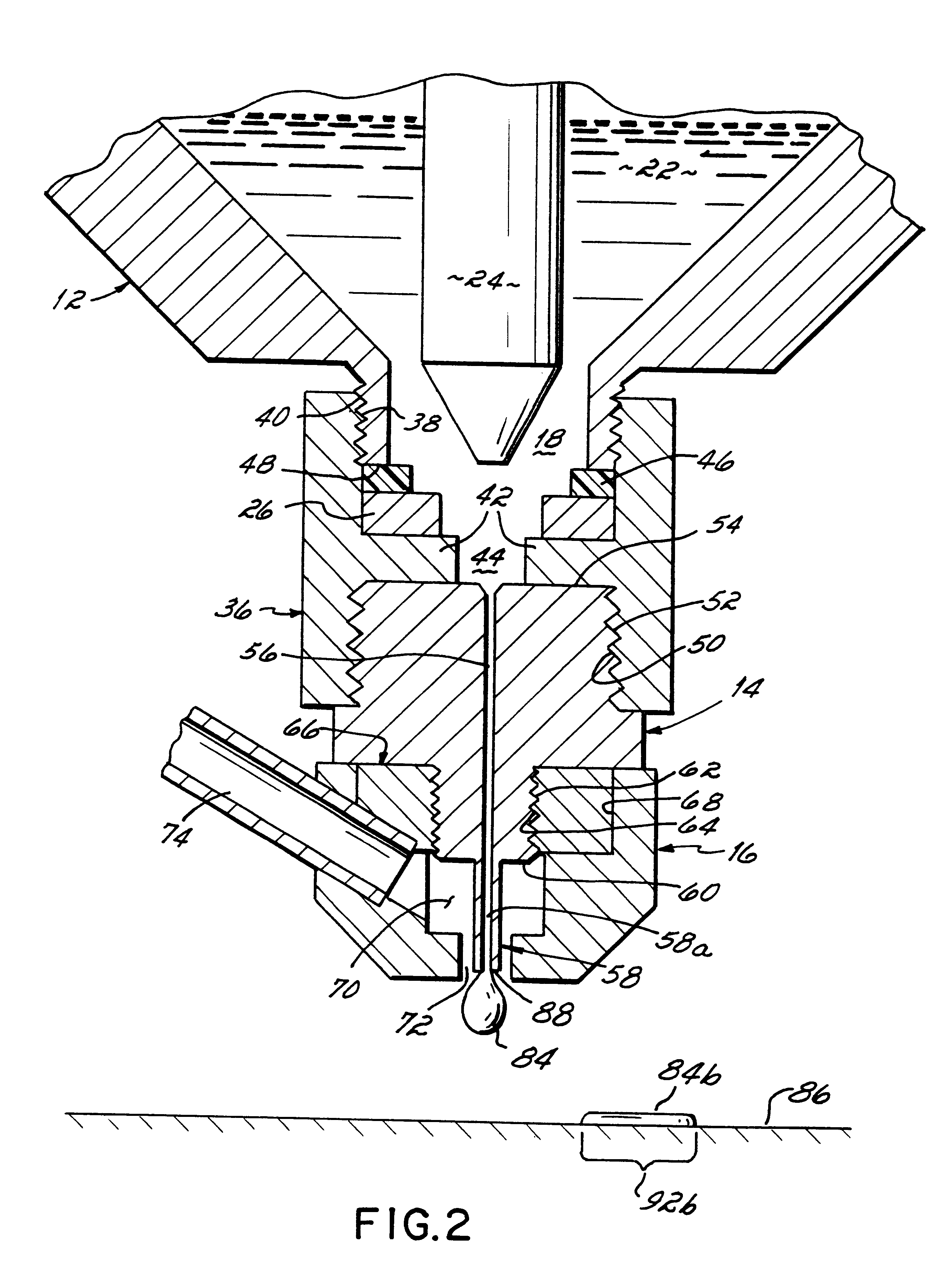

Dialysis systems and methods having vibration-aided air removal

ActiveUS20110137237A1Increase surface contact areaGood removal effectLiquid degasificationSolvent extractionAir separationIntensive care medicine

Owner:BAXTER INT INC +1

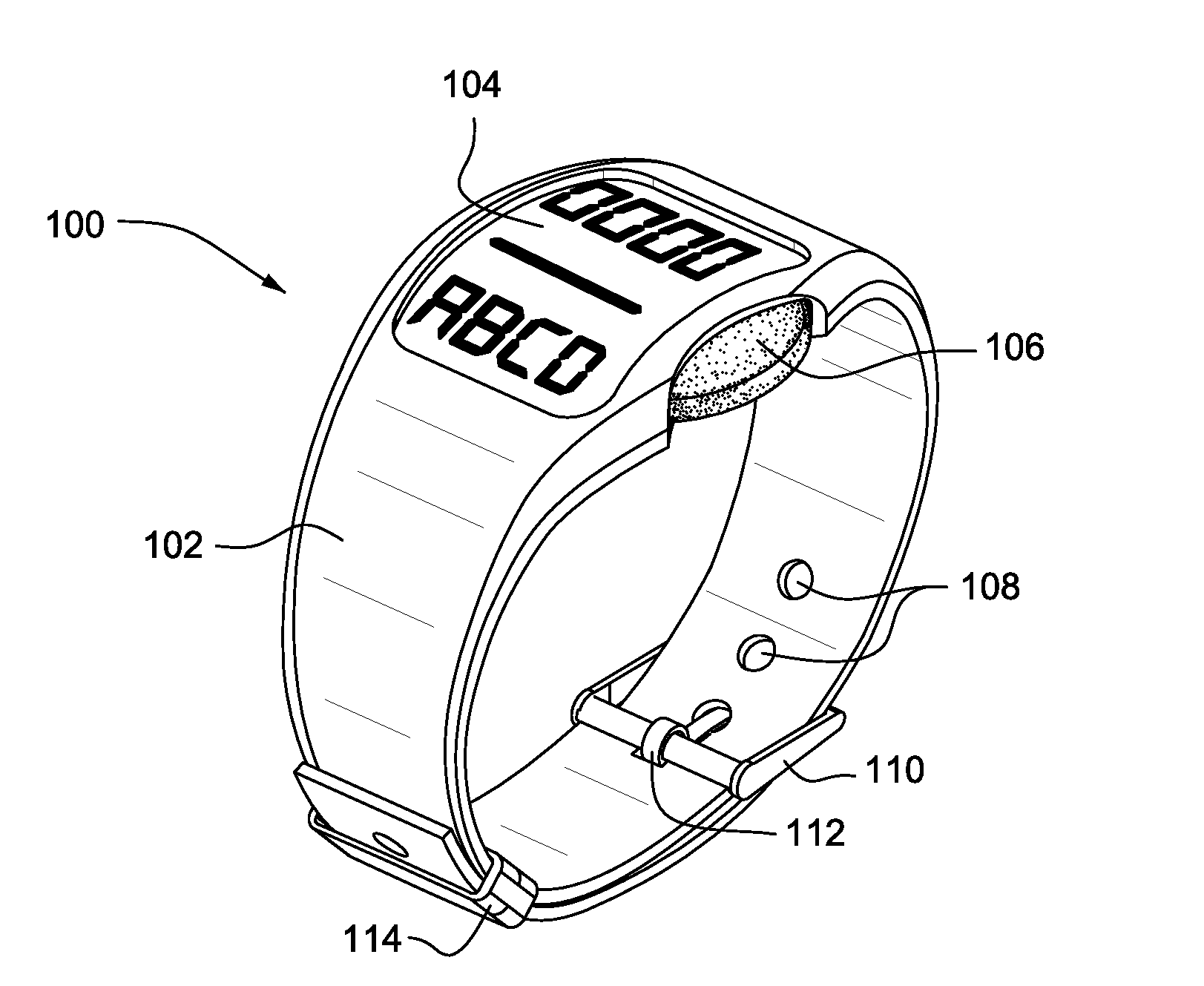

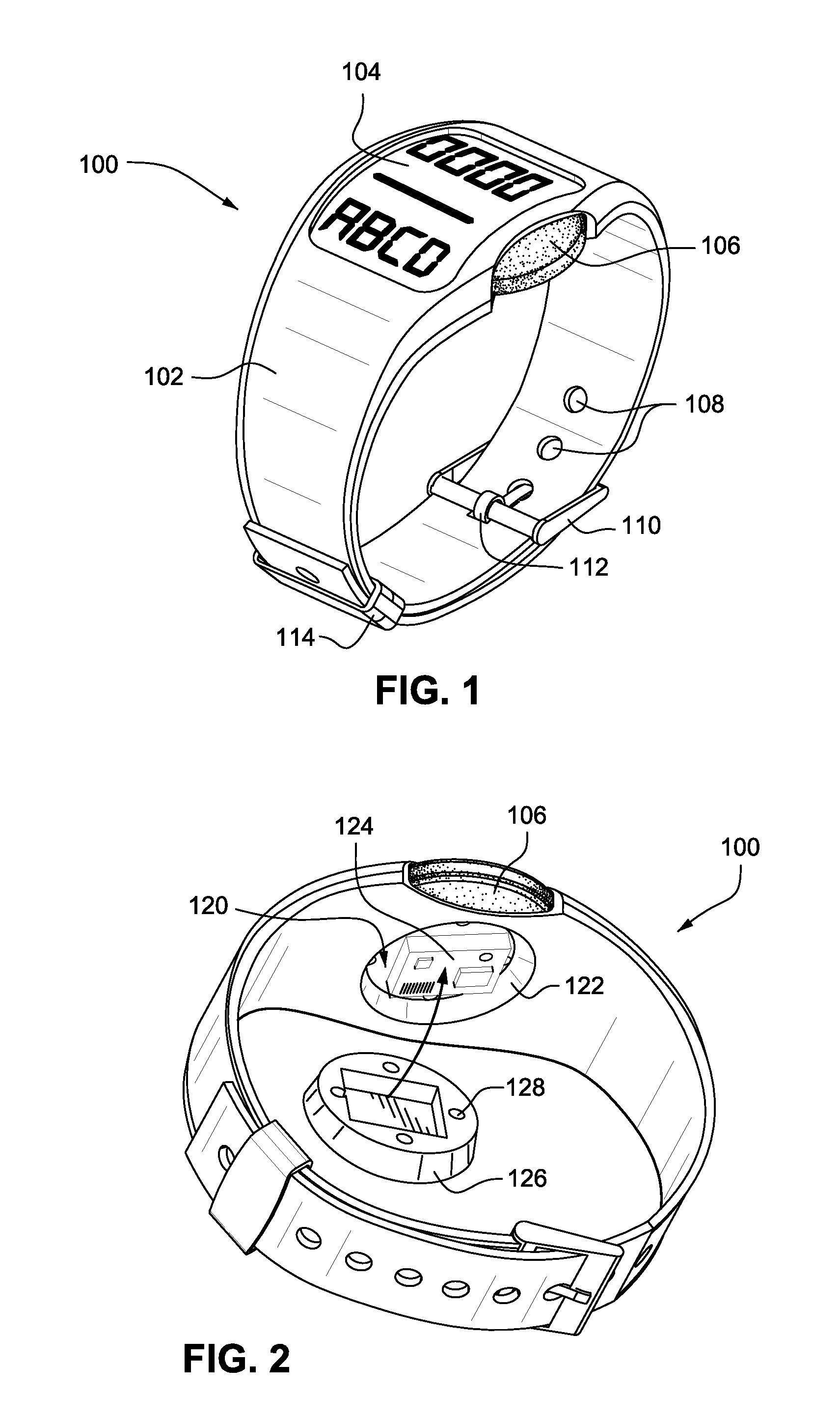

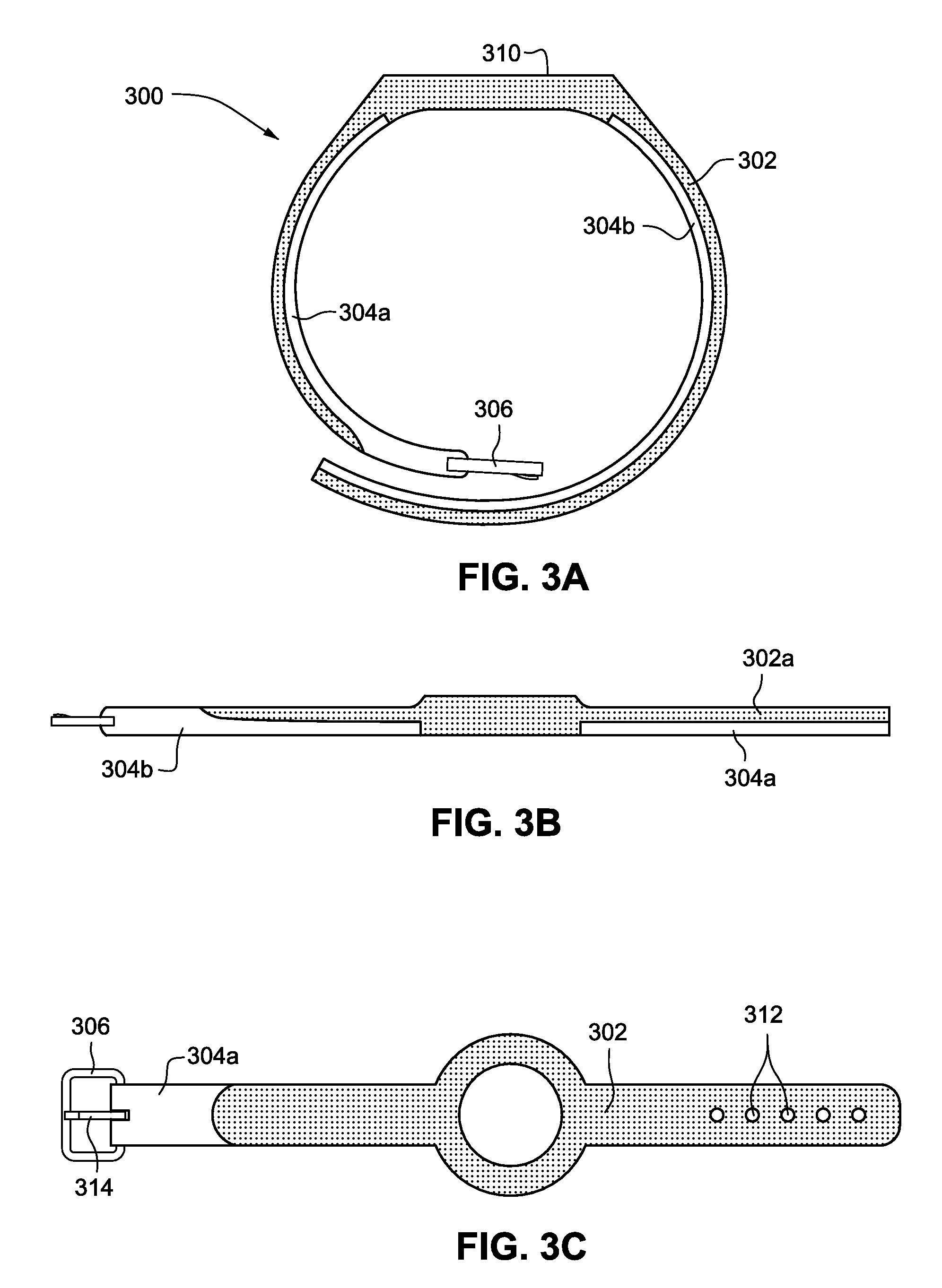

Tamper-alert resistant bands for human limbs and associated monitoring systems and methods

ActiveUS9064391B2Increase surface contact areaReduce the prevalenceDigital data processing detailsIndividual entry/exit registersMonitoring systemEngineering

A tamper alert band is provided that includes a strap with conductive and non-conductive elements or layers. The tamper alert band includes an electronic or RFID device that is configured to communicate with RFID readers and / or exciters. The strap may be a single unitary body that has a conductive layer and a non-conductive layer.

Owner:EHRMAN DOV MR

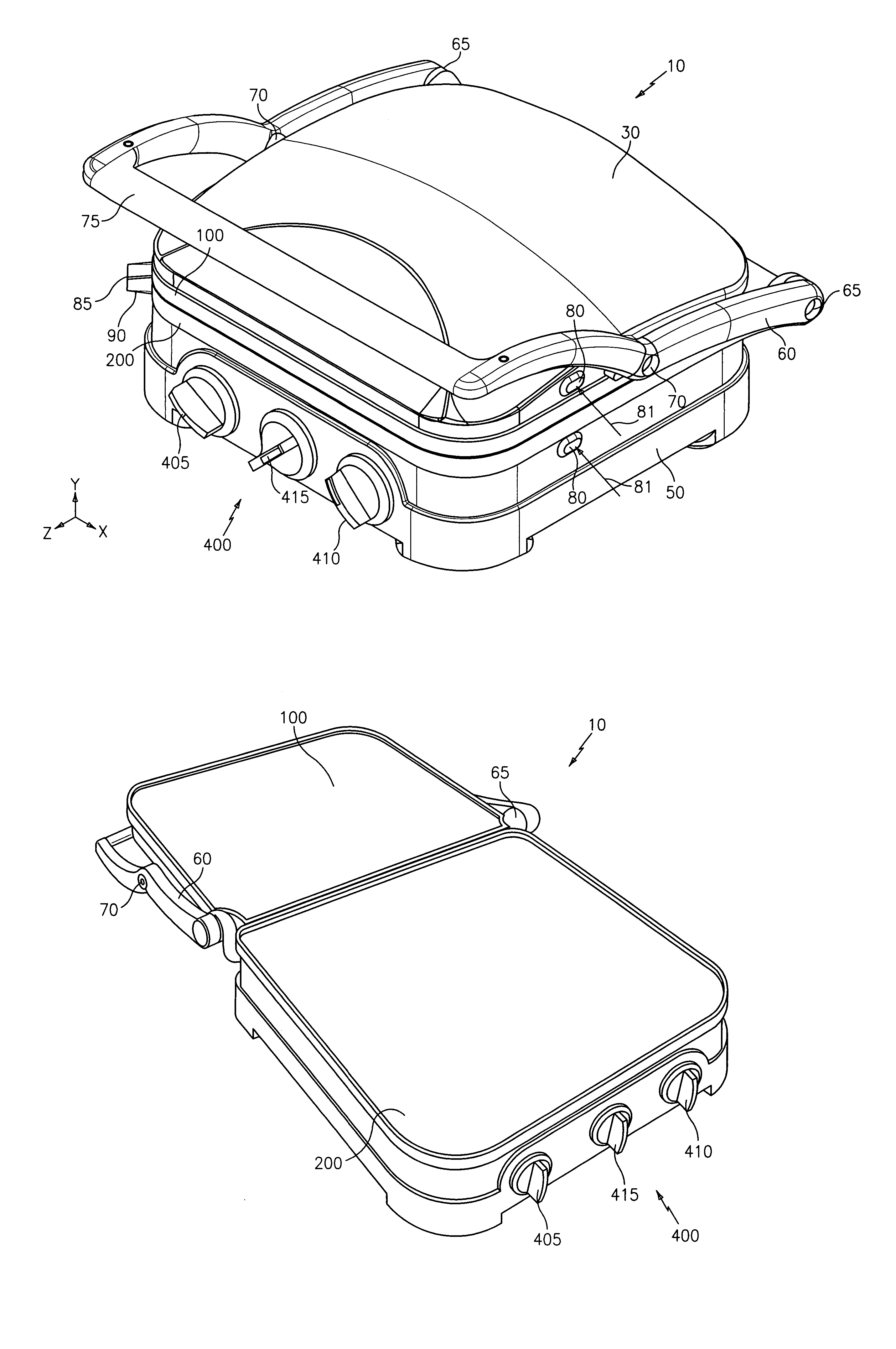

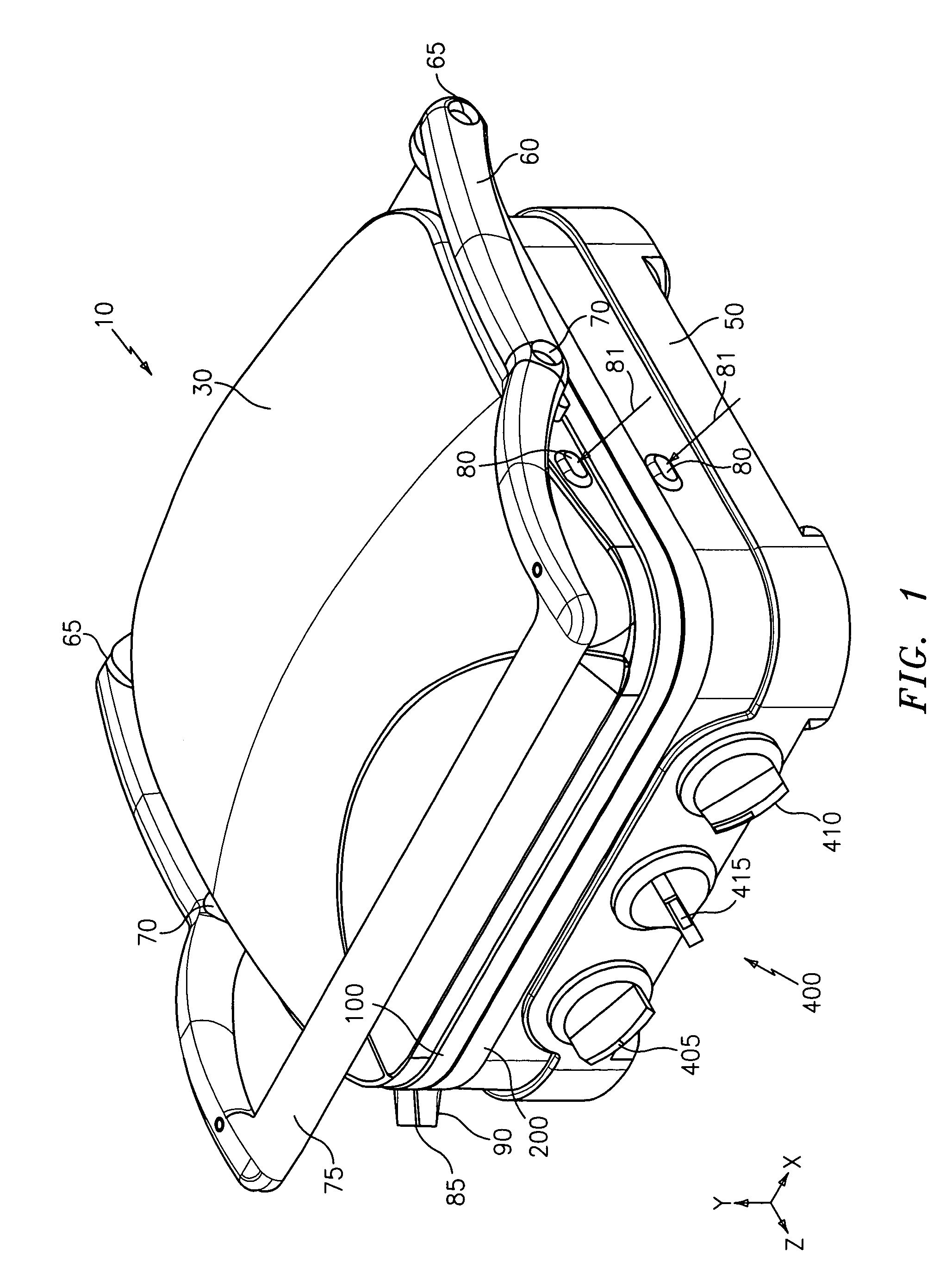

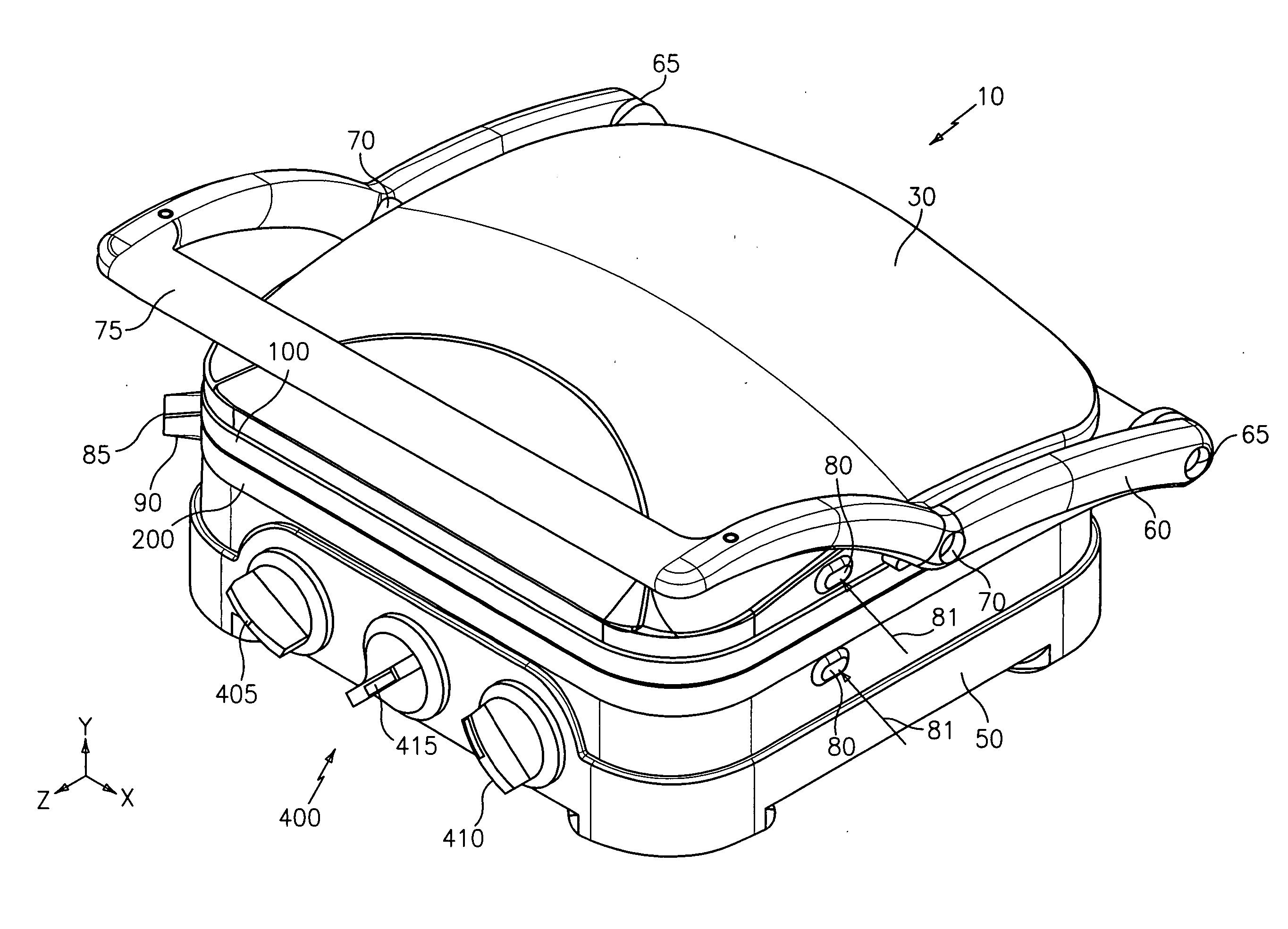

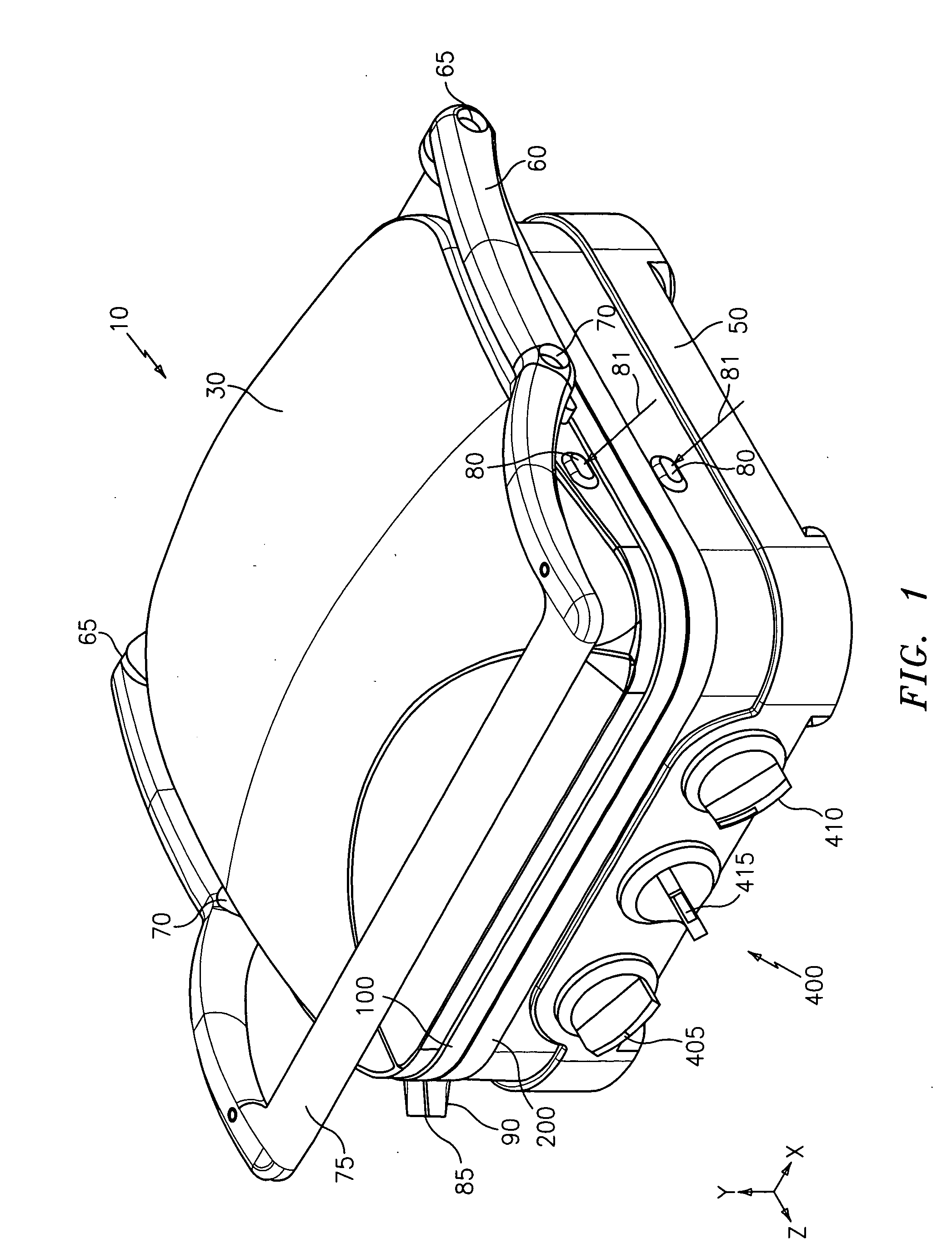

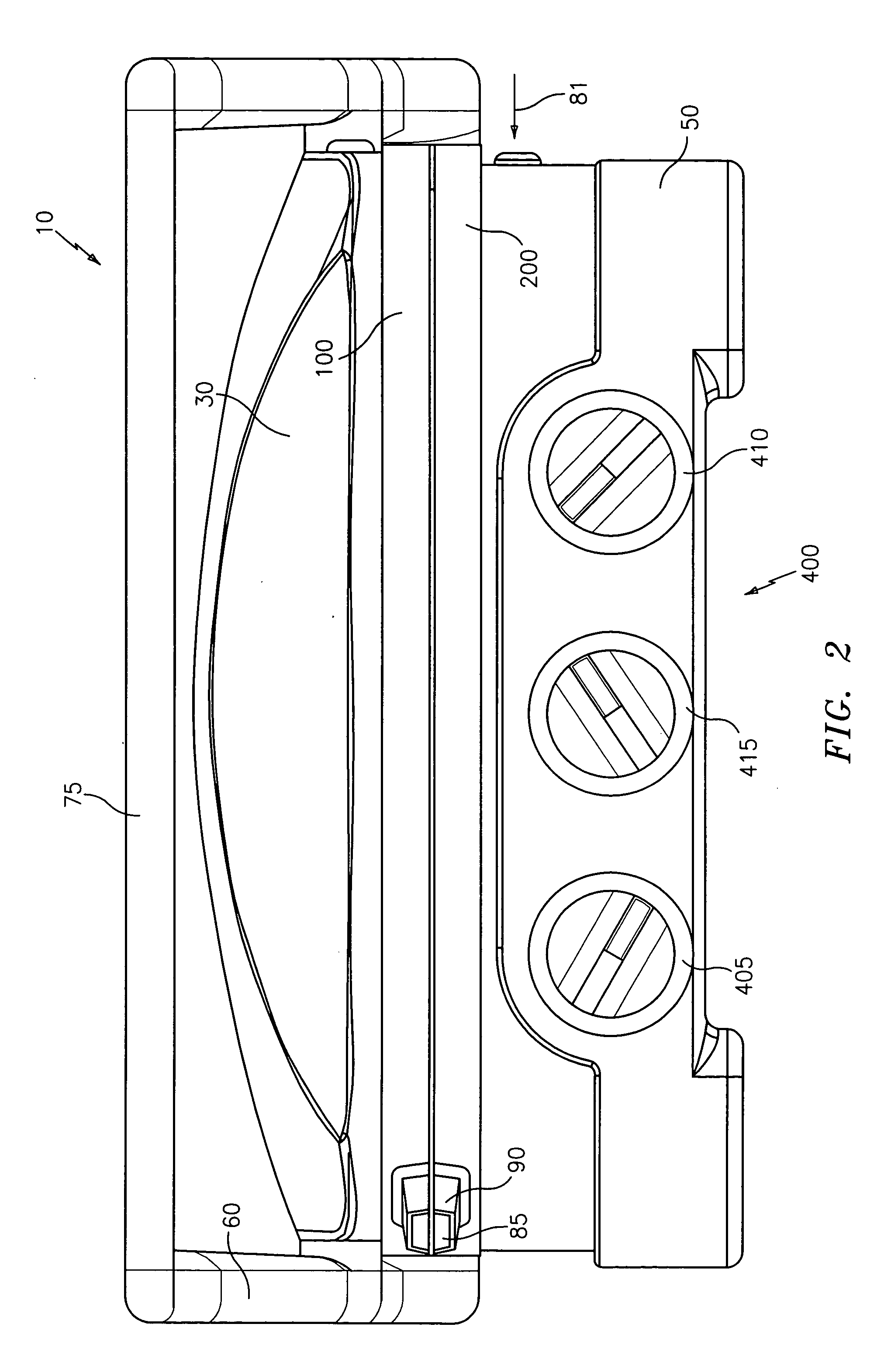

Grill

ActiveUS7109442B2Improve thermal efficiencyEven heat distributionDomestic stoves or rangesElectrical heating fuelEngineeringMechanical engineering

Owner:CONAIR CORP

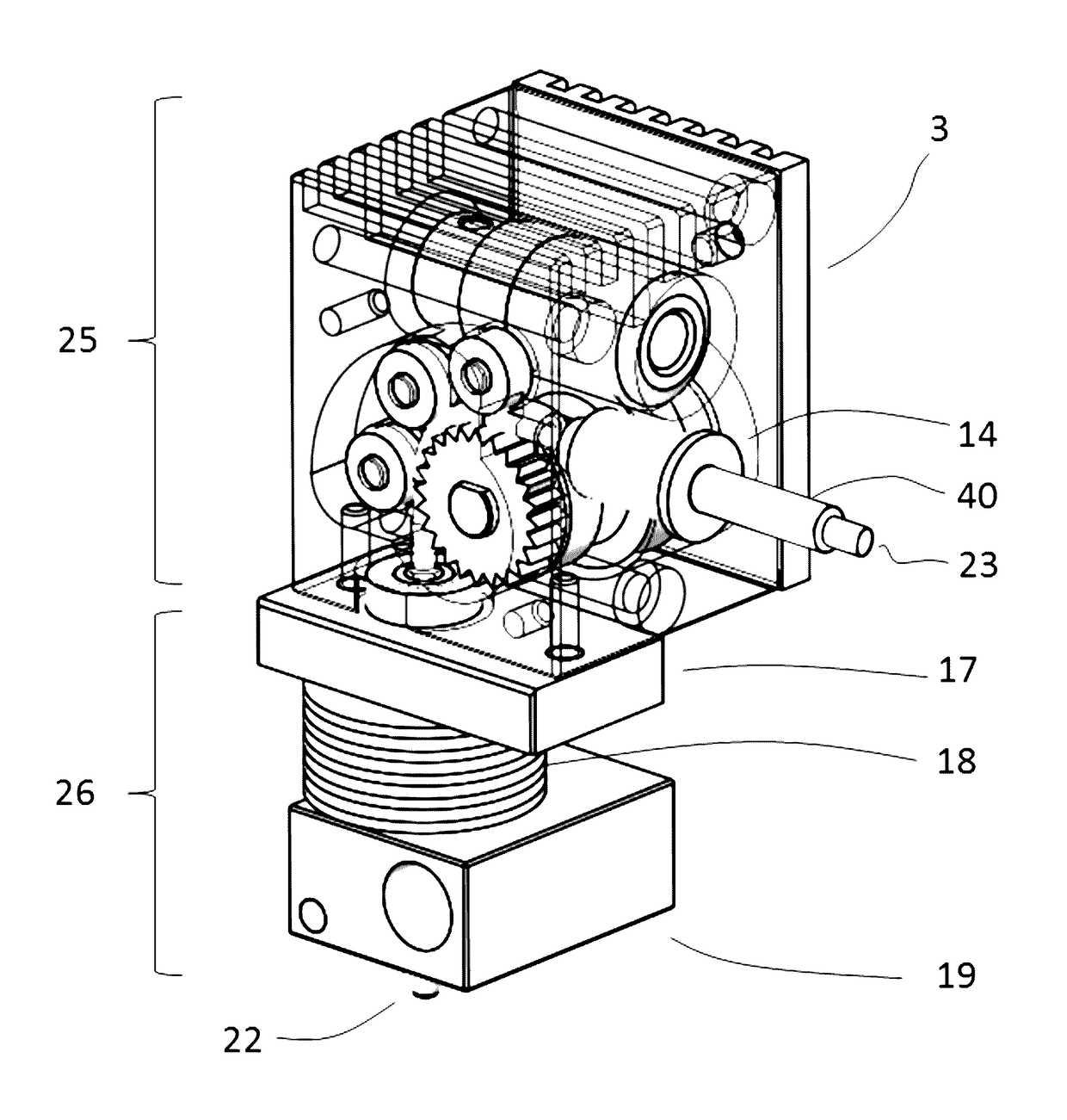

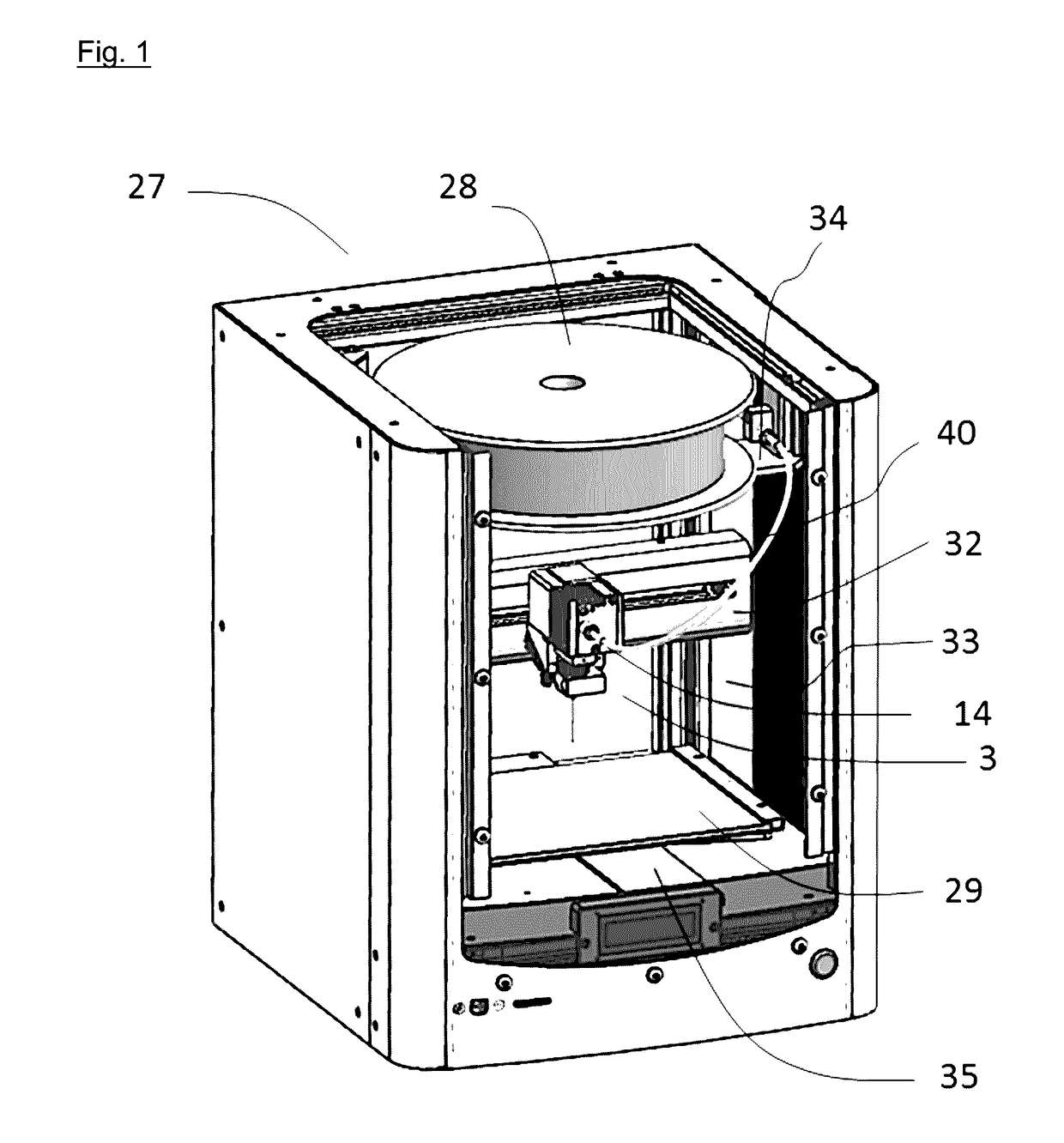

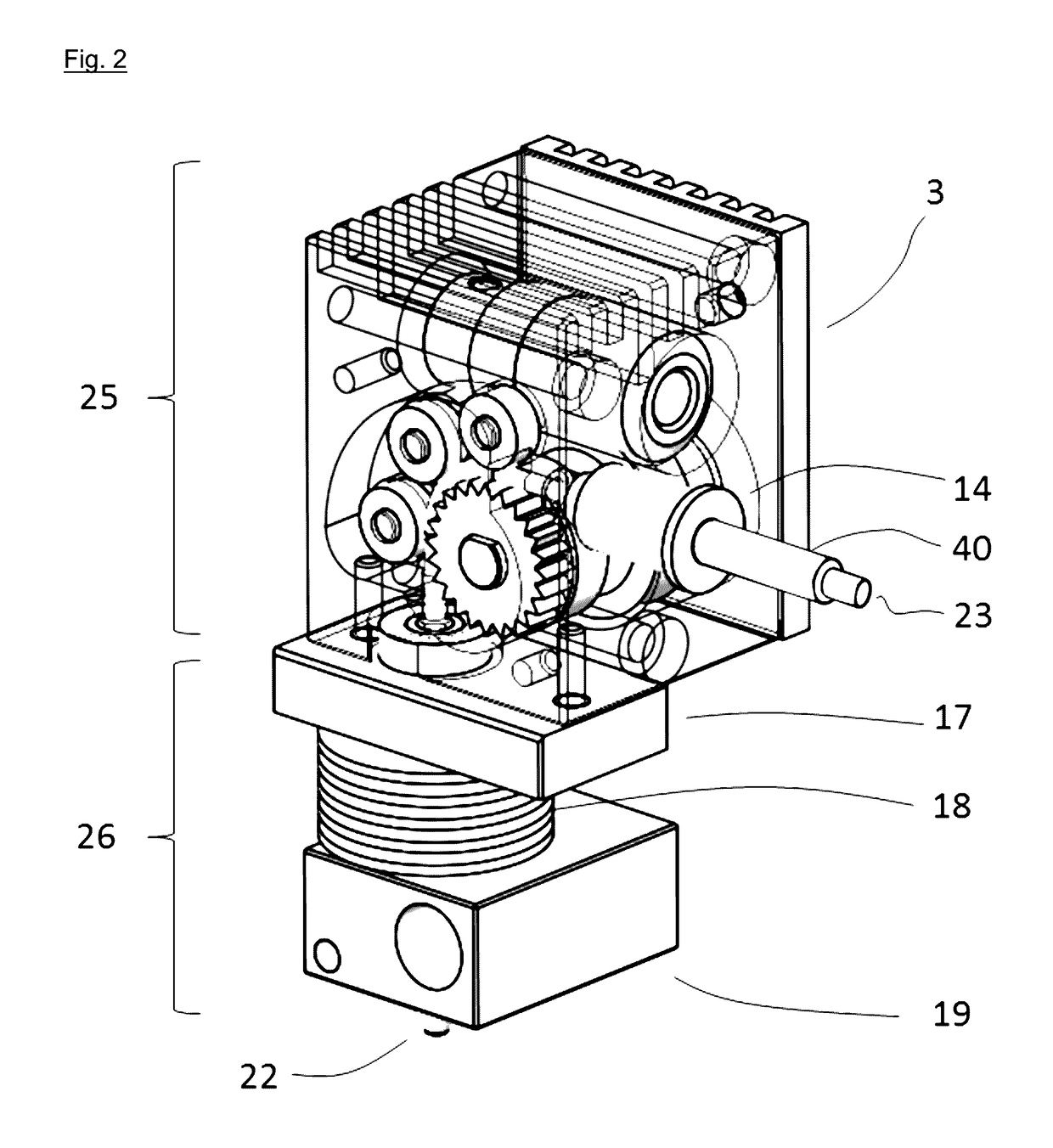

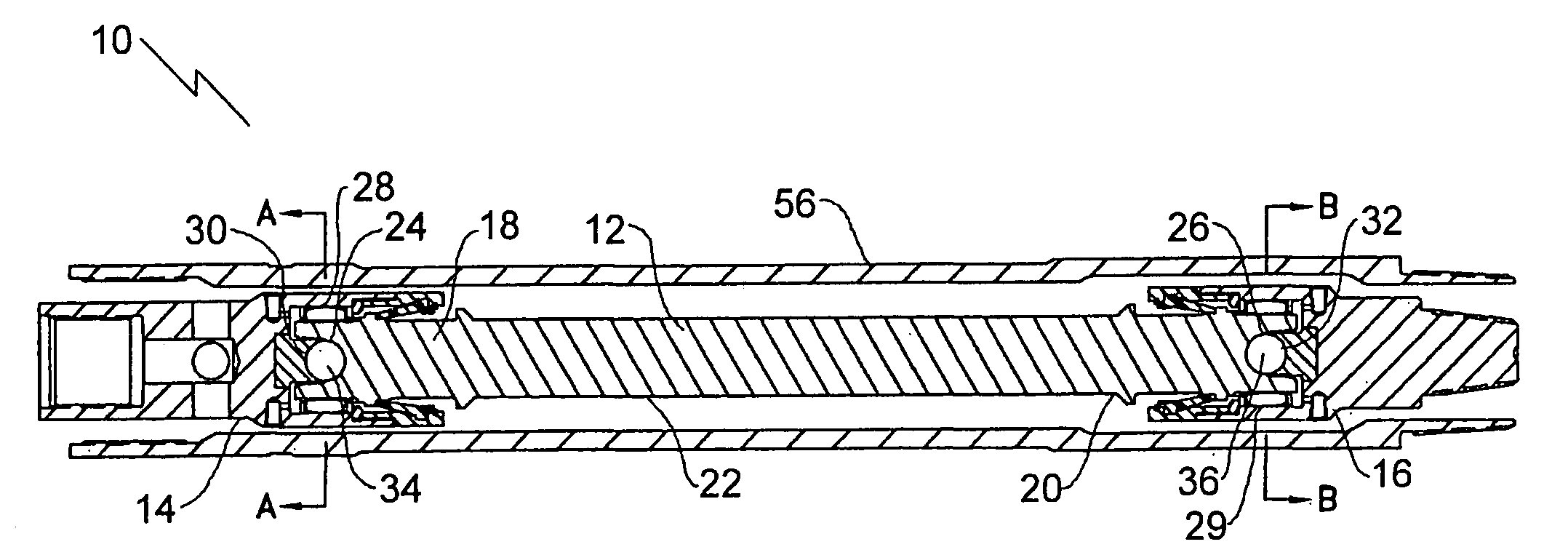

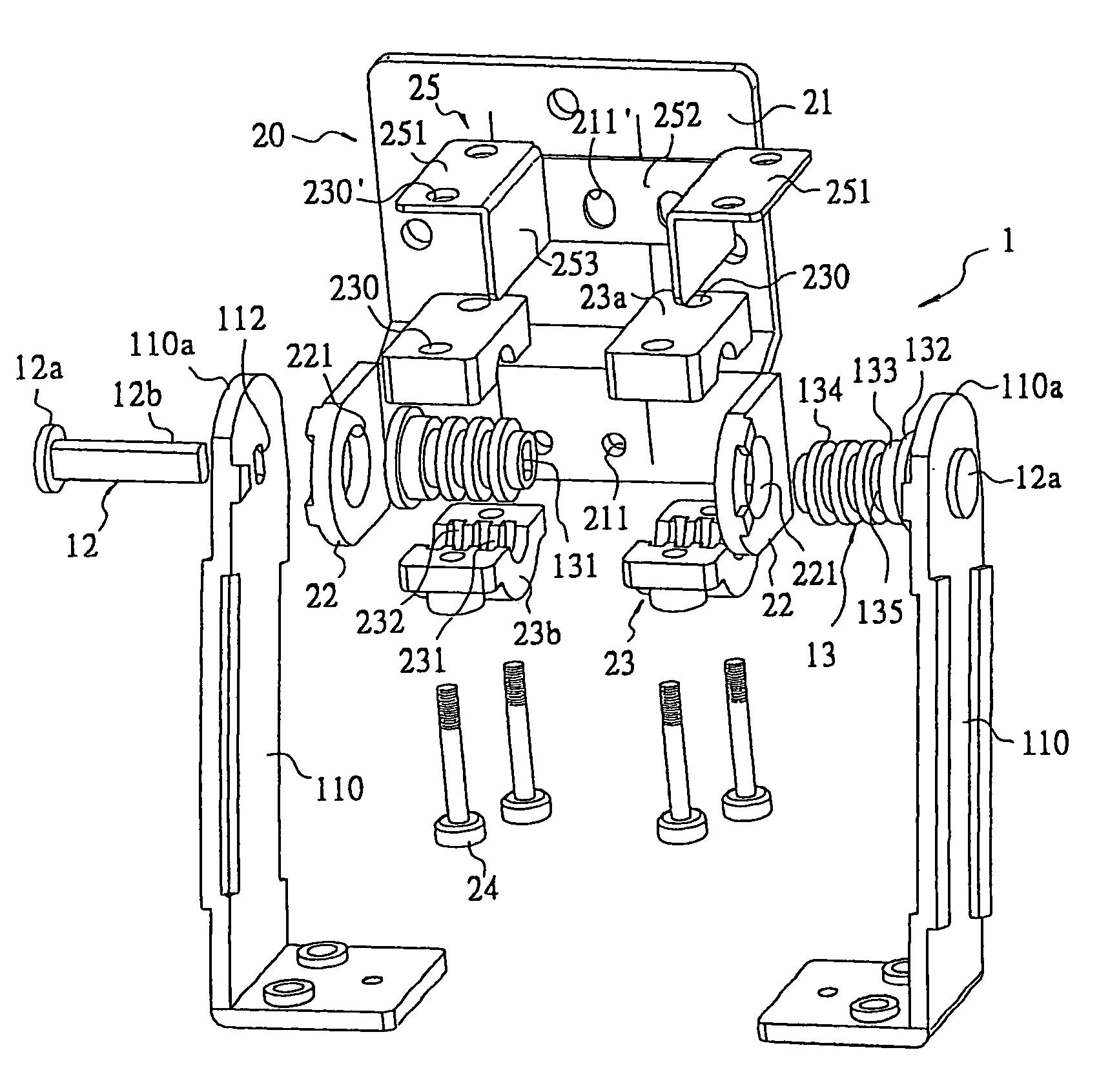

Extruder for fused filament fabrication 3D printer

InactiveUS20170157826A1Increase extrusion speedIncrease feed rateAdditive manufacturing with liquids3D object support structuresFused filament fabricationHigh acceleration

Disclosed is an improved extruder head for a fused filament fabrication 3D printer. It would be beneficial with a thinner nozzle diameter and higher extrusion speed without slippage in the feeding mechanism. The proposed improved extruder head enables extrusion of thinner extruded material at a higher extrusion speed without any slippage in filament feeding mechanism, thereby allowing higher overall building speed of the 3D printer with high quality build. Higher feed-rate of the filament material is achieved by increased usable friction between pinch wheel and filament by increasing the grippable area of the filament. This is done by feeding the filament into the feeding mechanism at an angle different to the outlet angle and routing it around the pinch wheel, back supported by a plurality of support rollers, so that the filament is in frictional contact with the pinch wheel along a greater part of its circumference, thereby increasing the surface contact area between the pinch wheel and the filament. Owing to non-slippage of the filament feeder, nominal volume of extruded material is exactly the same as desired volume with high filament feeding rate. Due to compact feeding mechanism, total mass of extruder kept small enough to enable higher acceleration of the printing nozzle resulting higher printing speed. Owing to horizontal loading of the filament material, feed roll can be mounted just above the extruder for smooth filament supply and compact size of 3D printer.

Owner:RHOMBUS INT TECH

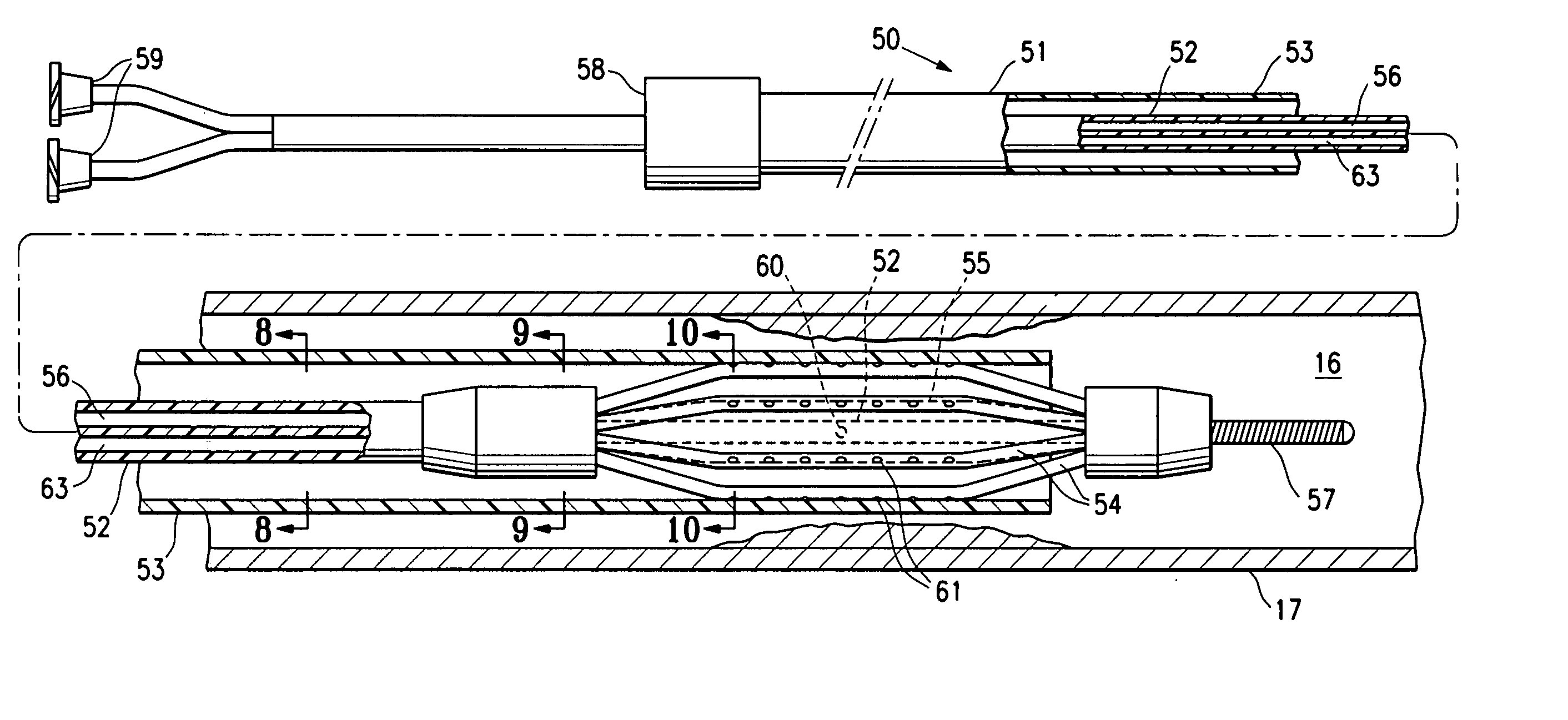

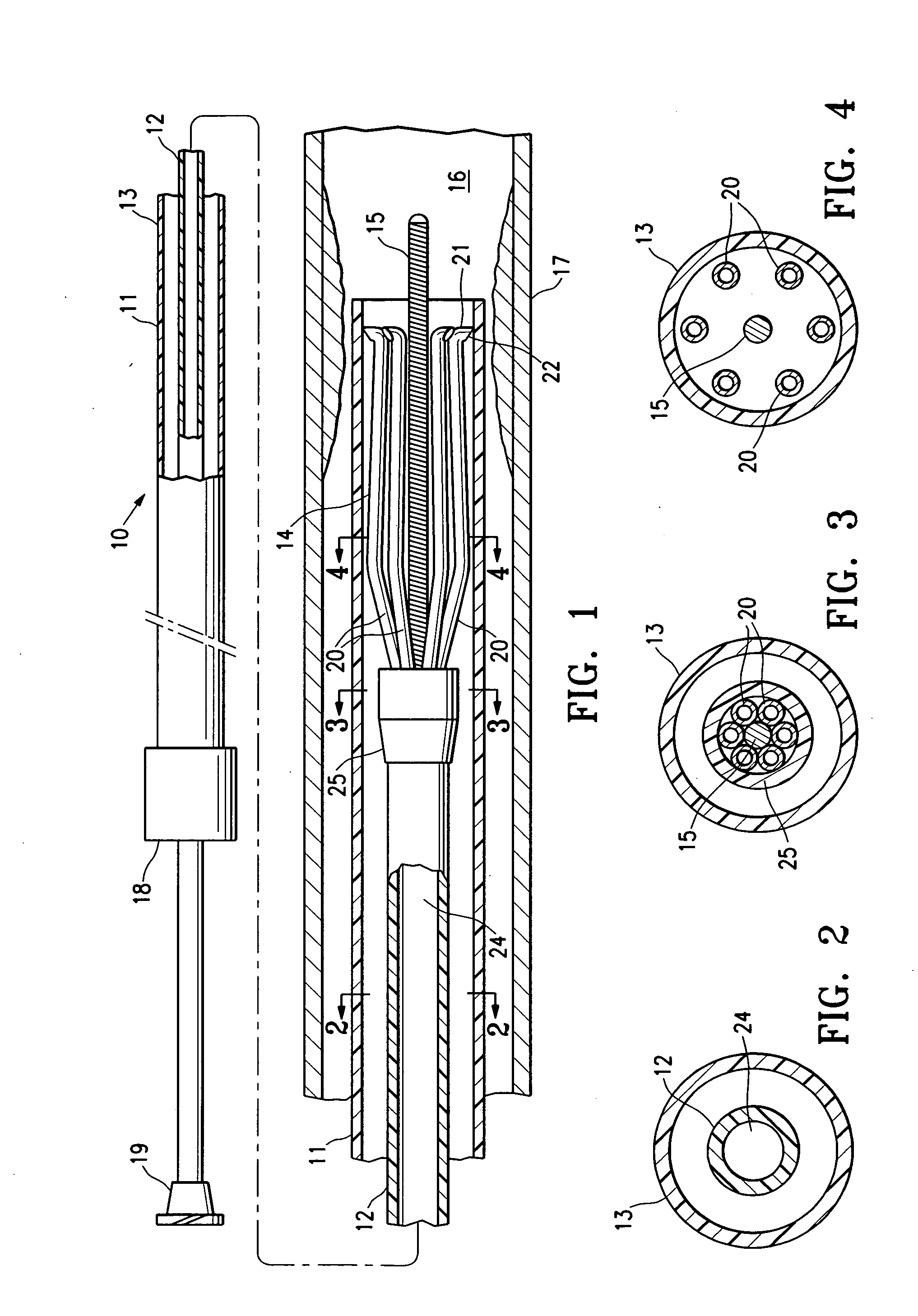

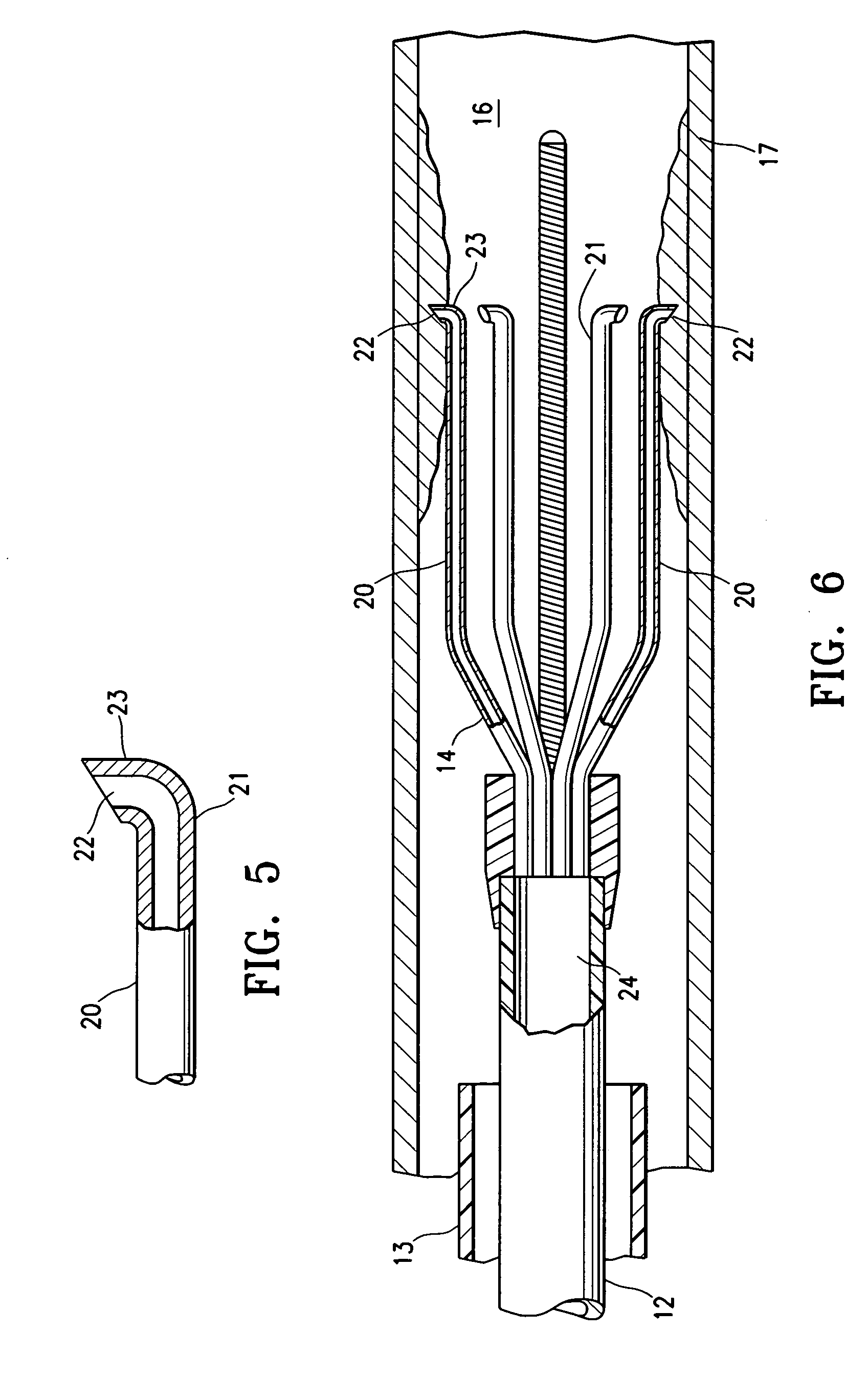

Devices and methods for intravascular drug delivery

InactiveUS20070250035A1Optimize agent deliveryIncrease surface contact areaGuide needlesBalloon catheterBlood vesselBlood vessel walls

A catheter configured for delivering an agent to a patient's vessel wall, having self-expanding frame, and a method of delivering an agent to a patient's vessel wall. A first catheter has an elongated shaft with an agent delivery lumen and self-expanding frame on a distal shaft section formed of plurality of hollow tubes having joined first ends and free second ends, the free end of each hollow tube having an agent delivery port in fluid communication with the shaft agent delivery lumen and having a hooked tip configured for penetrating the vessel wall in the expanded configuration. Another catheter has a frame around the outer surface of a lining member such as a balloon or a tubular sleeve, such that the frame expanded against the vessel wall and the lining member together define a plurality of pockets between the vessel wall and the outer surface of the lining member.

Owner:ABBOTT CARDIOVASCULAR

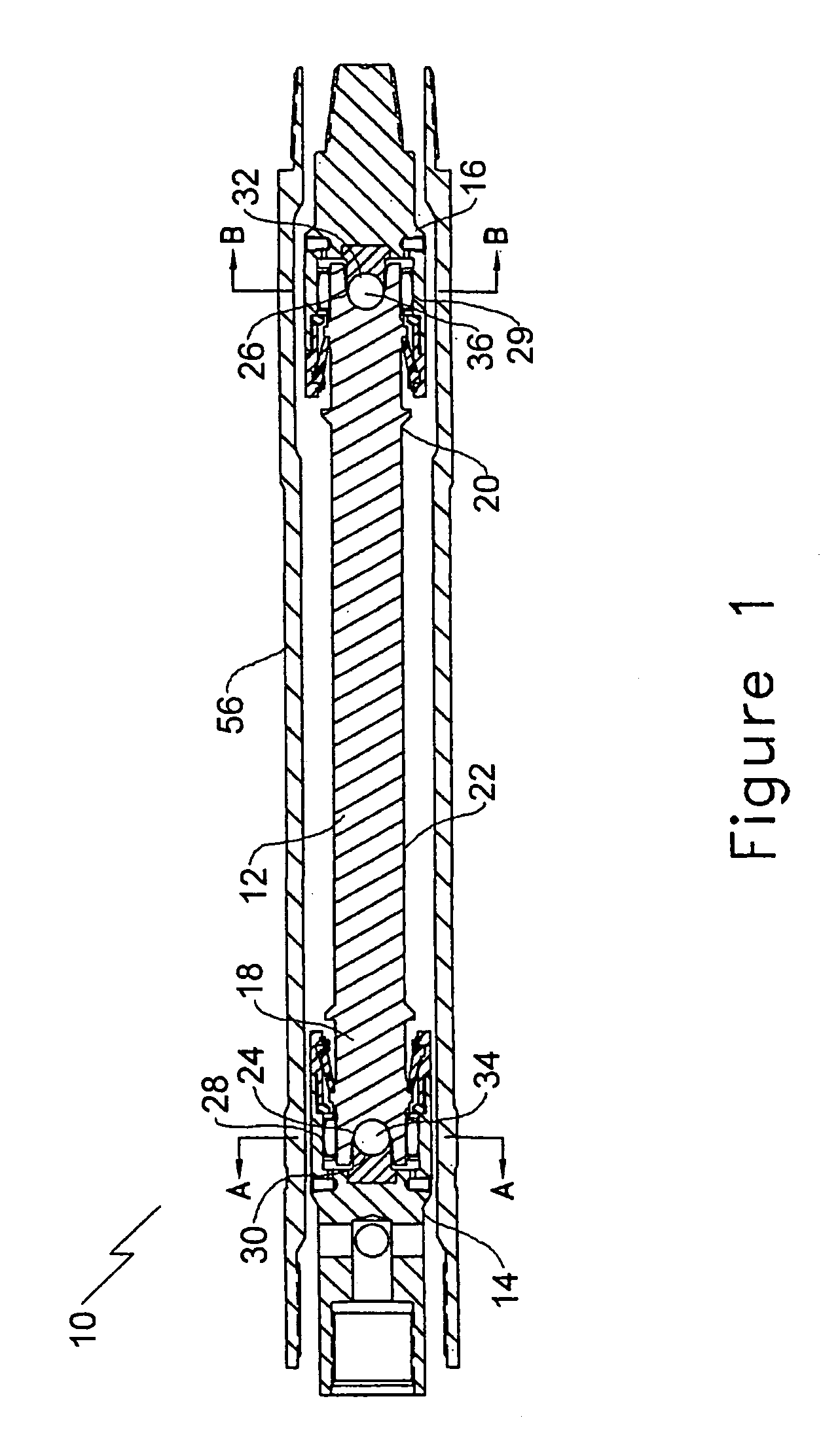

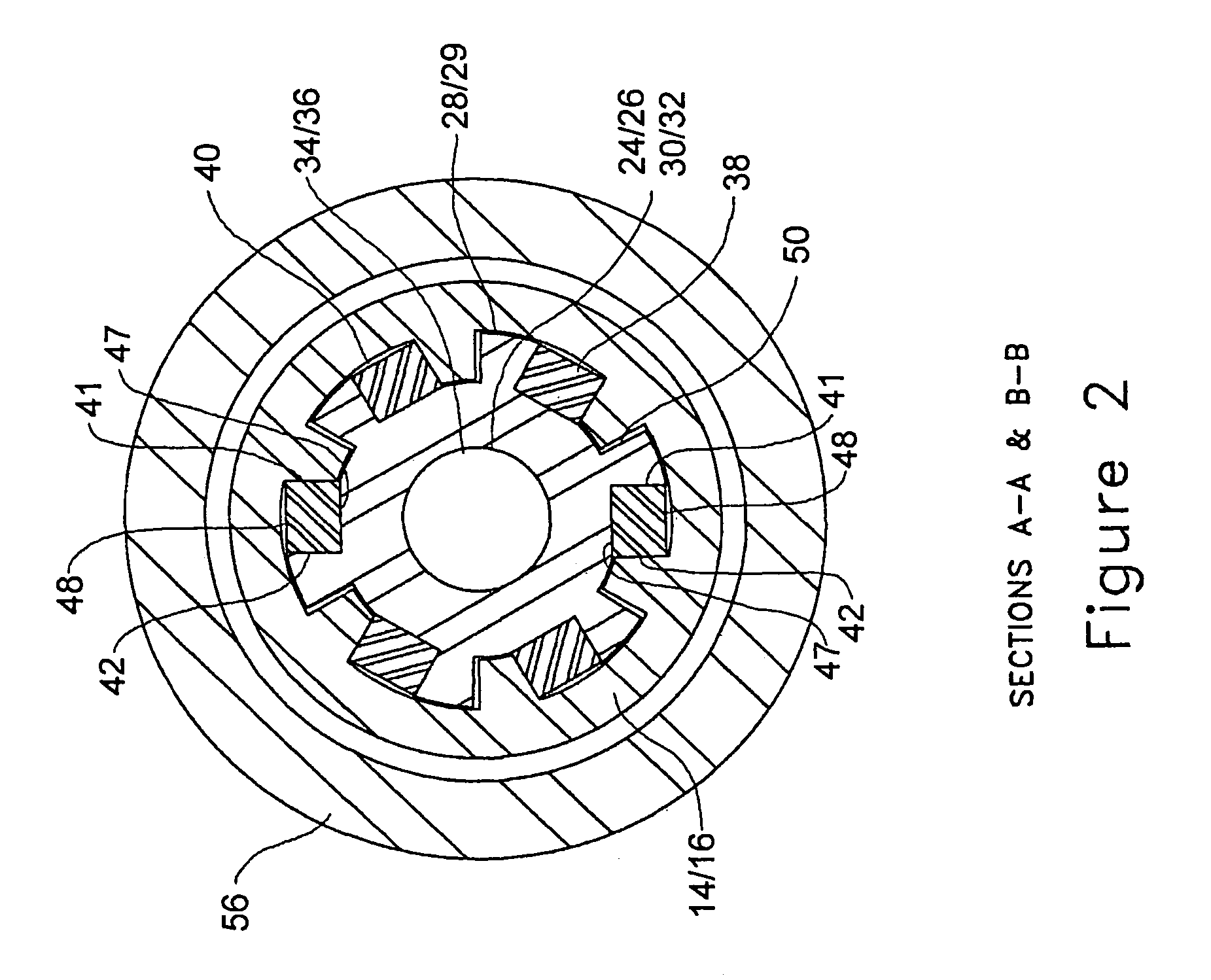

Drive line for down hole mud motor

ActiveUS7186182B2Facilitating omni-directional pivotal movementIncrease surface contact areaYielding couplingDrilling rodsTorque transmissionMud motor

A drive line for a down hole mud motor has a plurality of elongate keys extending radially from an exterior surface of a central shaft for the purpose of transmitting torque. A plurality of circumferentially spaced axial keyways are provided in an interior surface of each end housing, which are adapted to receive the keys. Each of the keys has opposed sides, opposed ends and a front face. The front face is radiused both in a first direction between the opposed ends and in a second direction between the opposed sides, thereby accommodating the omni-directional pivotal movement of the shaft relative to the housing. The use of keys for torque transmission increases available contact area, with a corresponding increase in torque load capacity.

Owner:WENZEL DOWNHOLE TOOLS

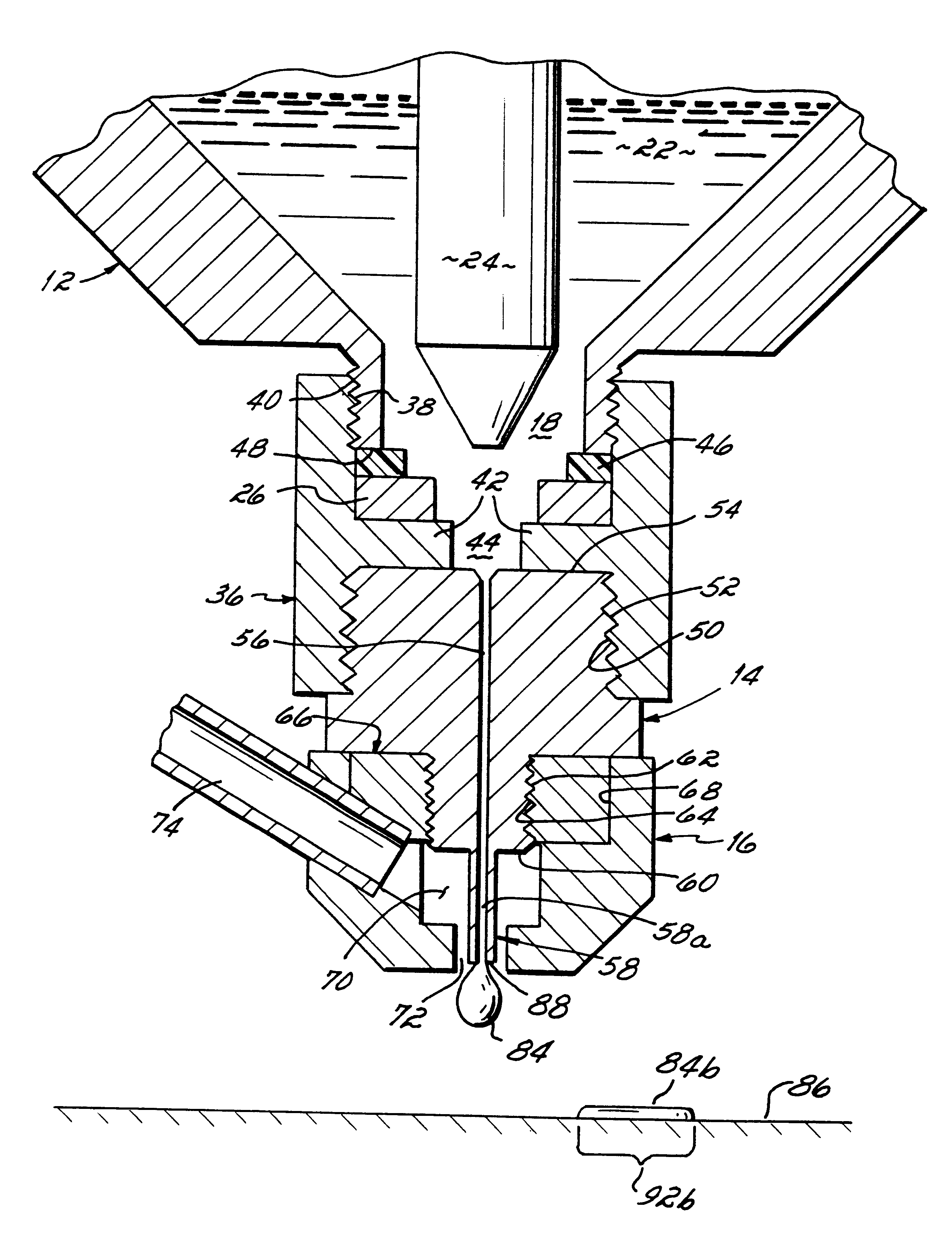

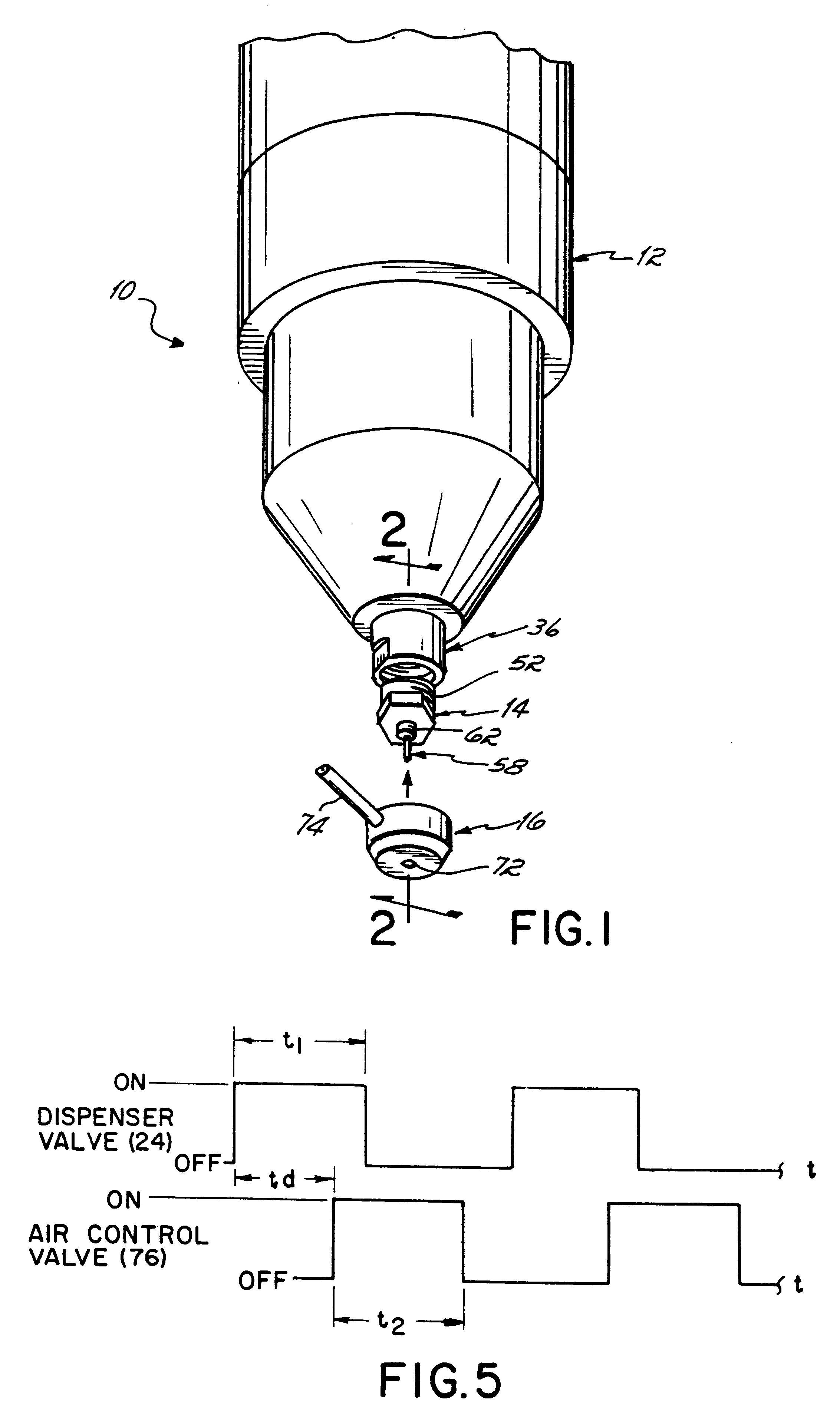

Method for increasing contact area between a viscous liquid and a substrate

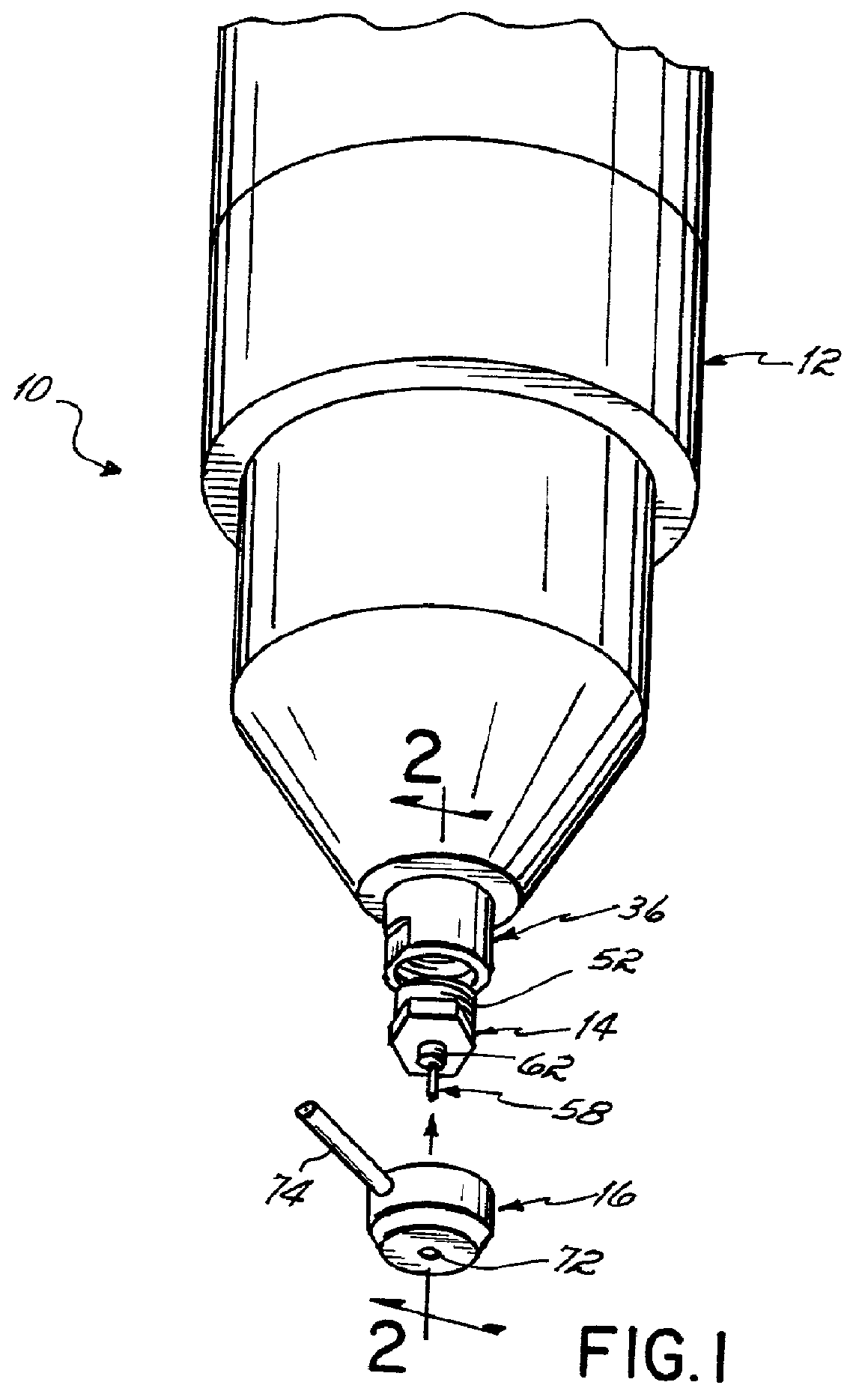

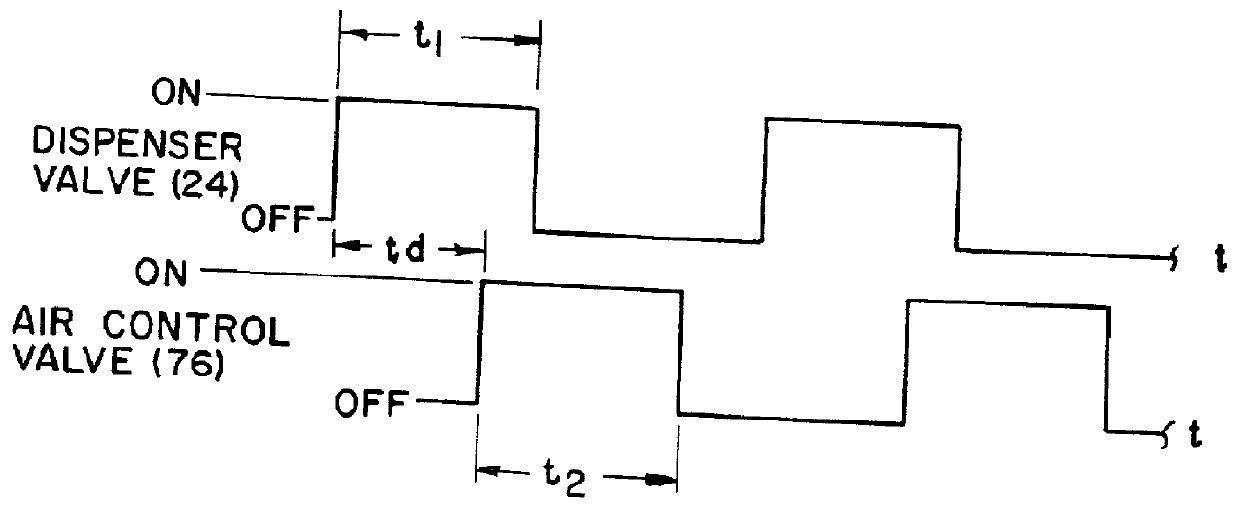

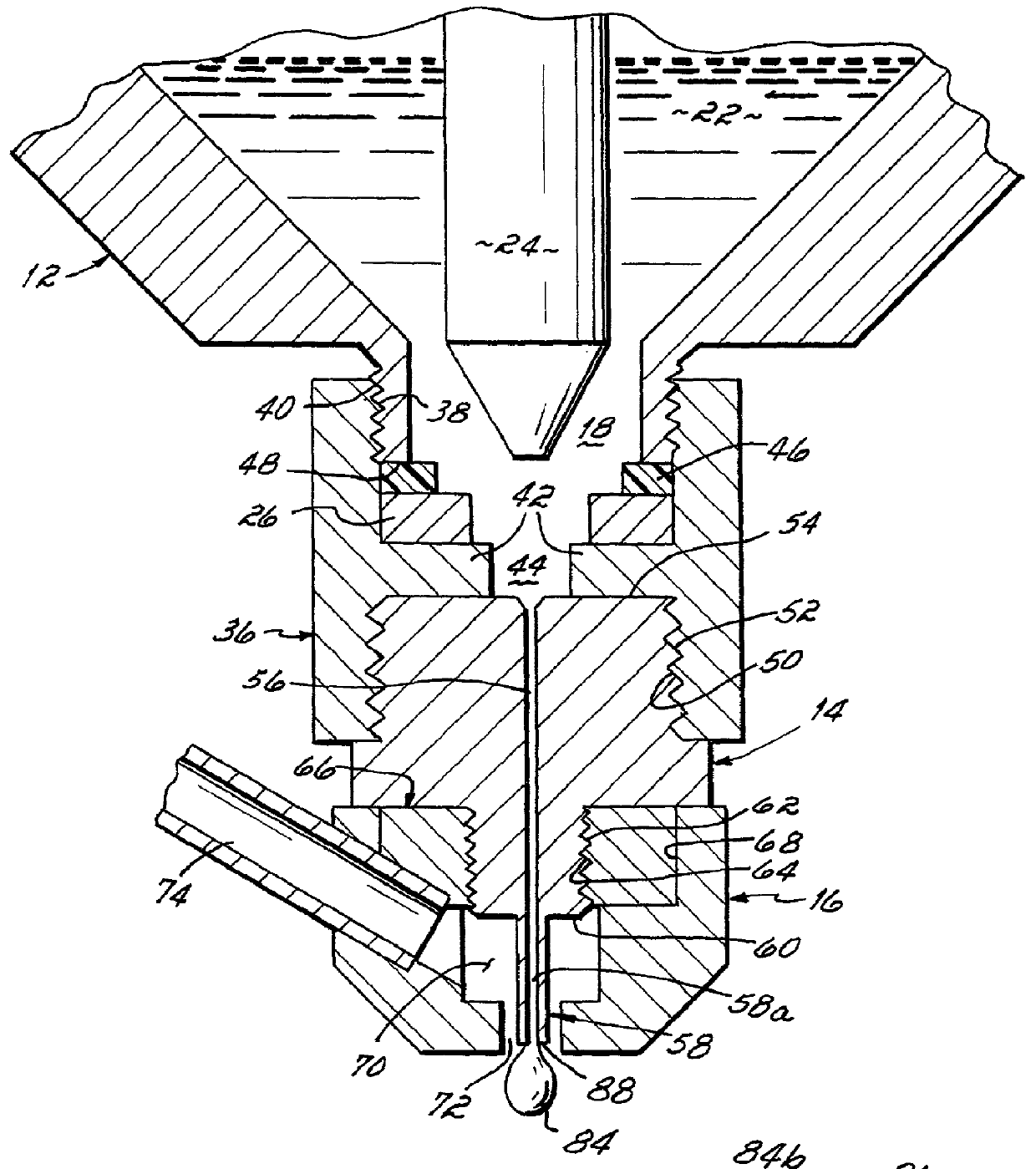

InactiveUS6291016B1Increase surface contact areaFirmly connectedPrinted circuit assemblingSpray nozzlesViscous liquidHigh surface

A method of assembling electronic components using a dispenser having a nozzle in fluid communication with a source of viscous liquid having a high surface tension and having an air discharge passage in fluid communication with a source of pressurized air. A droplet of the viscous liquid is dispensed from the nozzle onto a printed circuit board to form an initial contact area between the droplet and the printed circuit board and the high surface tension of the droplet causes the initial contact area to remain substantially constant. A burst of air is then discharged from the air discharge passage for impinging the droplet after the droplet contacts the printed circuit board, which increases the initial contact area between the droplet and the printed circuit board.

Owner:NORDSON CORP

Grill

ActiveUS20050005777A1Improve thermal efficiencyEven heat distributionDomestic stoves or rangesElectrical heating fuelMechanical engineering

Owner:CONAIR CORP

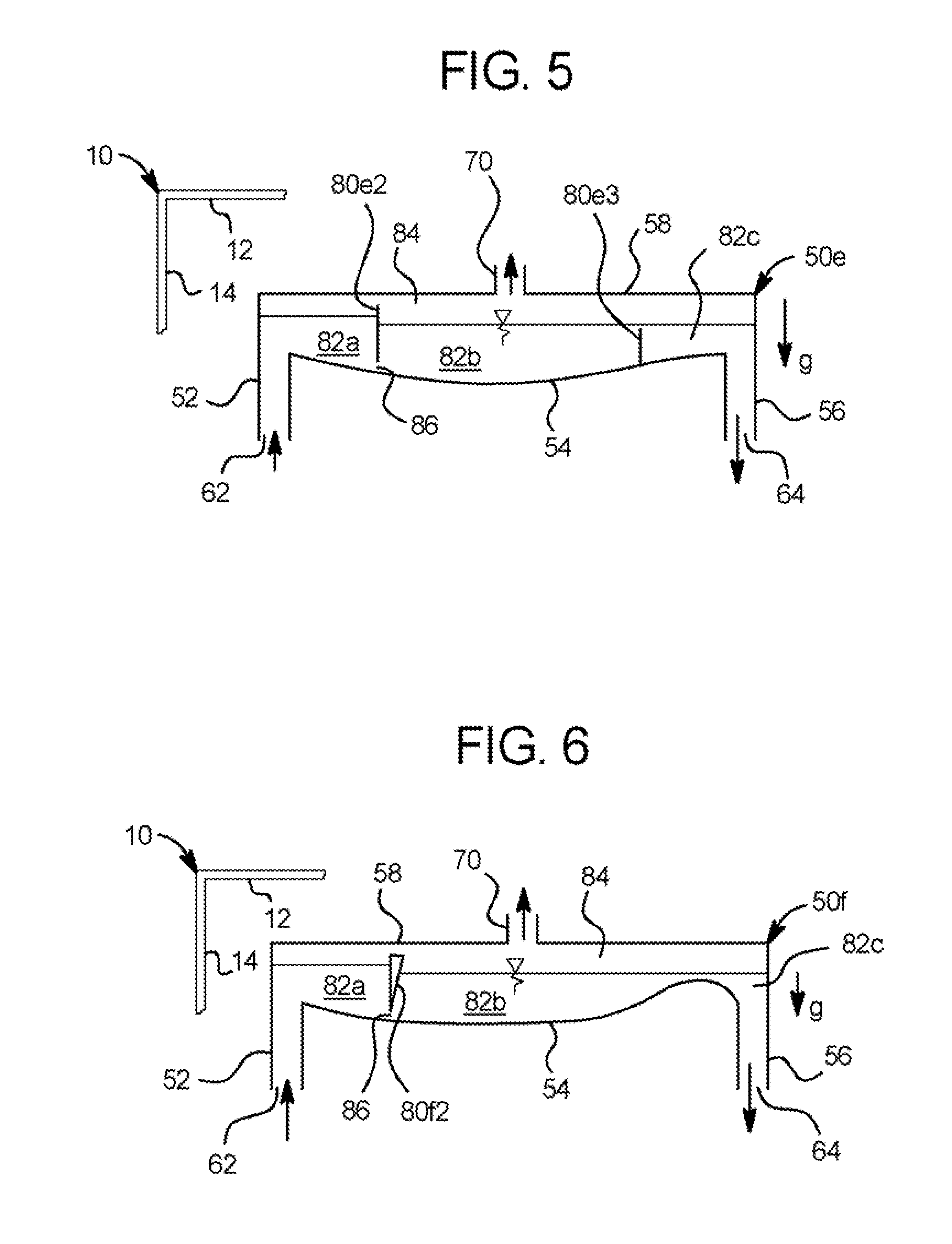

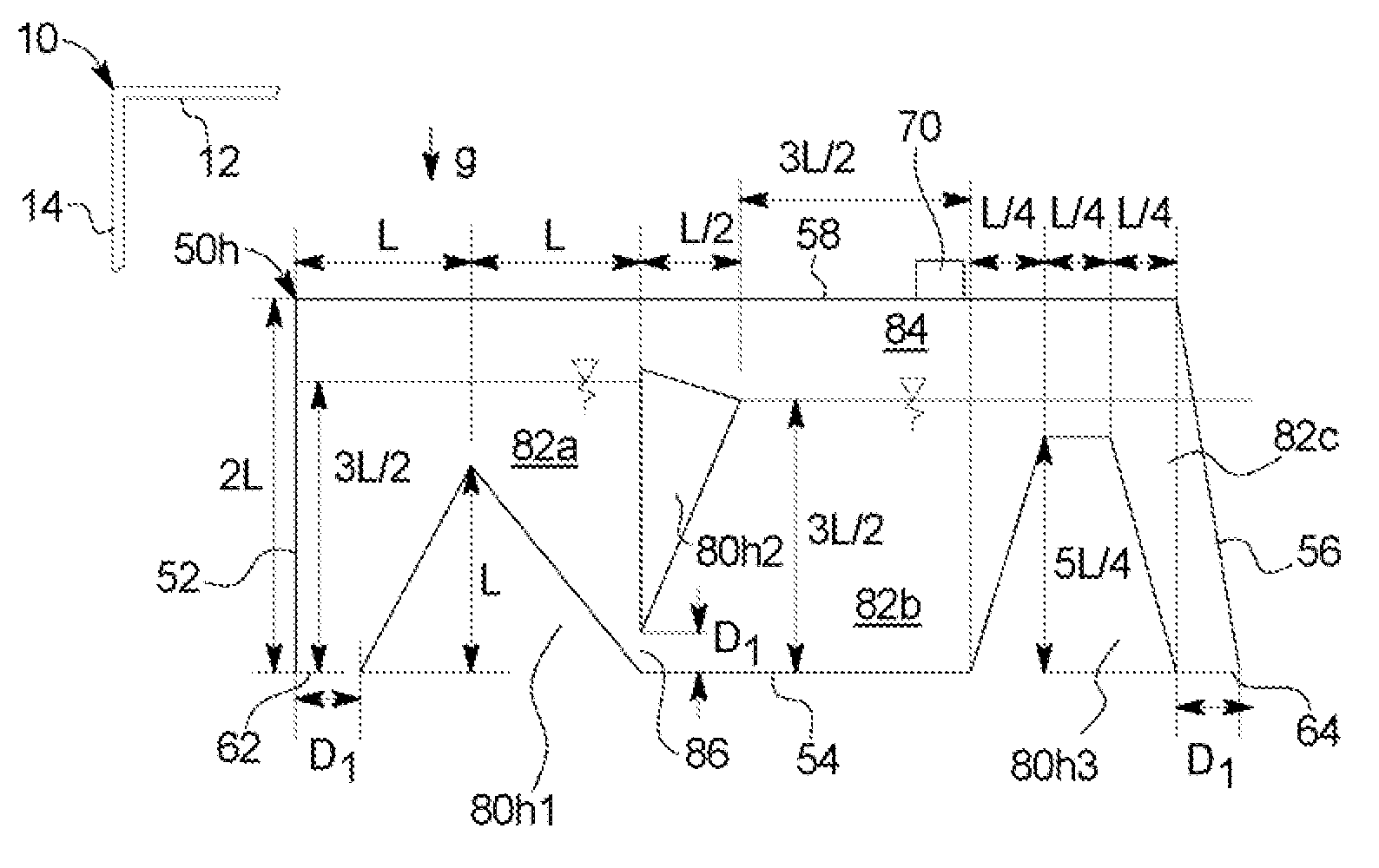

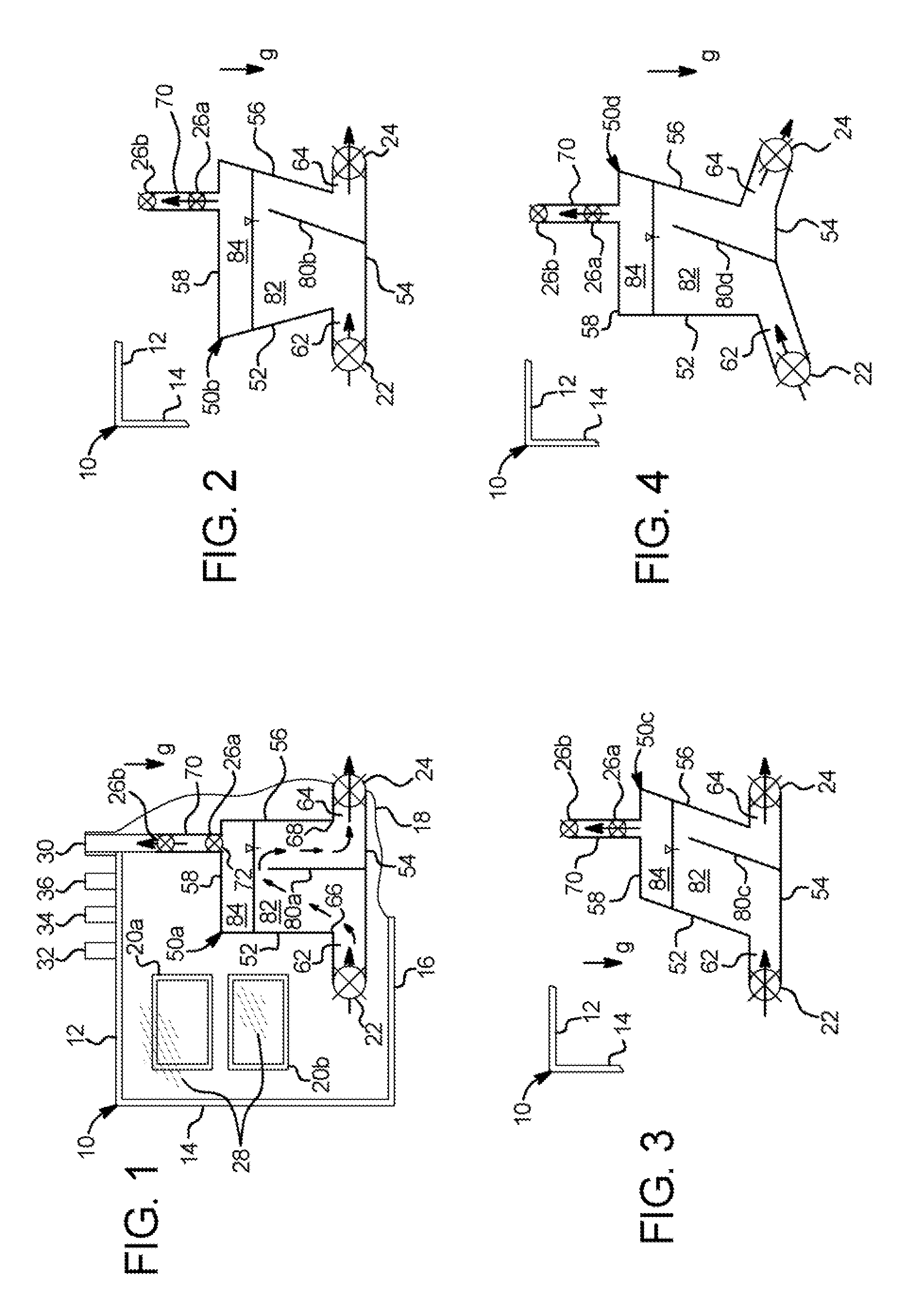

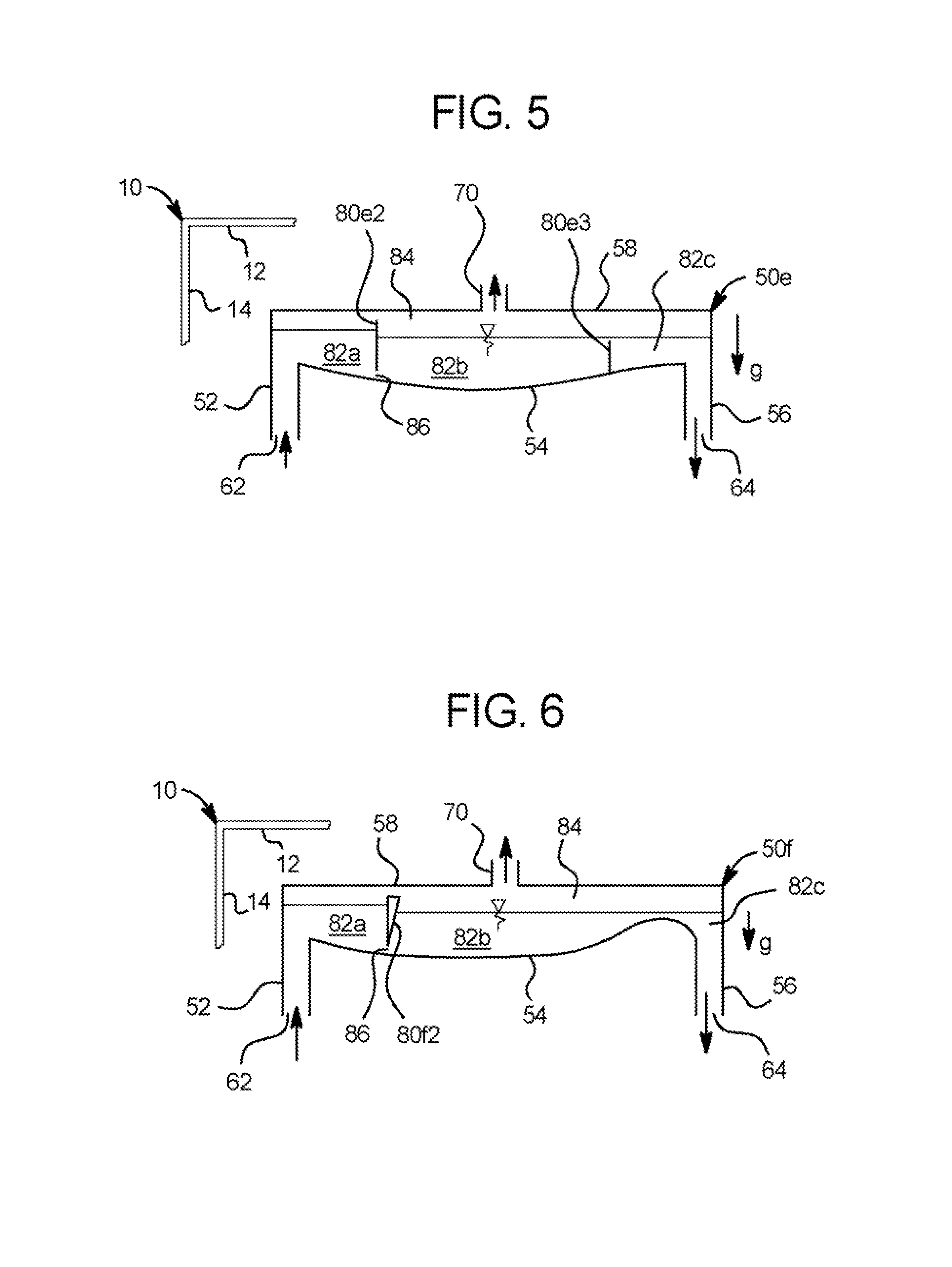

Dialysis systems having air traps with internal structures to enhance air removal

ActiveUS7892332B2Increased surface contact areaGood removalLiquid degasificationMedical devicesDialysis fluidAir separation

A dialysis fluid cassette includes a rigid portion defining first and second valve chambers, the rigid portion further defining an air separation chamber in fluid communication with the first and second valve chambers, the air separation chamber including a baffle and structured such that when the cassette is placed in a dialysis instrument, (i) the baffle extends upwardly from a bottom of the air separation chamber and (ii) first and second openings to the air separation chamber, communicating fluidly and respectively with the first and second valve chambers, are located near the bottom of the air separation chamber, such that the dialysis fluid is forced up one side of the baffle and down the other side of the baffle when flowing through the air separation chamber.

Owner:BAXTER HEALTHCARE SA +1

Bentonite composition modified asphalt and its preparing method

InactiveCN1587320AImprove high and low temperature performanceImprove road performanceBuilding insulationsWaxButadiene-styrene rubber

The bentonite composition modified asphalt consists of asphalt in 94-98 portions, bentonite in 1-3 portions and powdered styrene-butadiene rubber in 1-3 portions. The bentonite is at least one of calcium base bentonite, sodium bentonite and organic bentonite. The preparation process of the bentonite composition modified asphalt includes the following steps: eliminating sand in bentonite, drying, grinding and 325-mesh sieving bentonite; adding bentonite into the asphalt matrix; and adding powdered styrene-butadiene rubber while slowly stirring to mix homogeneously. The modified asphalt has the features of high temperature stability, low temperature cracking resistance, excellent anti-ageing performance, low cost, etc.

Owner:NORTHWEST NORMAL UNIVERSITY

Air assisted liquid dispensing apparatus and method for increasing contact area between the liquid and a substrate

InactiveUS20010053420A1Increase surface contact areaFirmly connectedPrinted circuit assemblingSpray nozzlesSpray nozzleEngineering

An apparatus to dispense a droplet of liquid, such as solder flux, onto the surface of a substrate, such as a printed circuit board, and thereafter flatten the droplet with a burst of pressurized air directed onto the droplet. A dispenser has a dispenser body, which has a liquid supply passageway adapted to connect to a source of liquid. A nozzle body connects to the dispenser body and includes a liquid discharge passageway in fluid communication with the liquid supply passageway. The nozzle body also has an air discharge orifice which is adapted to connect to a source of pressurized air for selectively discharging bursts of pressurized air. The air discharge orifice is configured and aligned with the liquid discharge passageway so that the discharged bursts of pressurized air impinge upon one of the droplets of liquid dispensed from the liquid discharge passageway so as to flatten that droplet and thereby increase the contact area between the droplet and the substrate.

Owner:NORDSON CORP

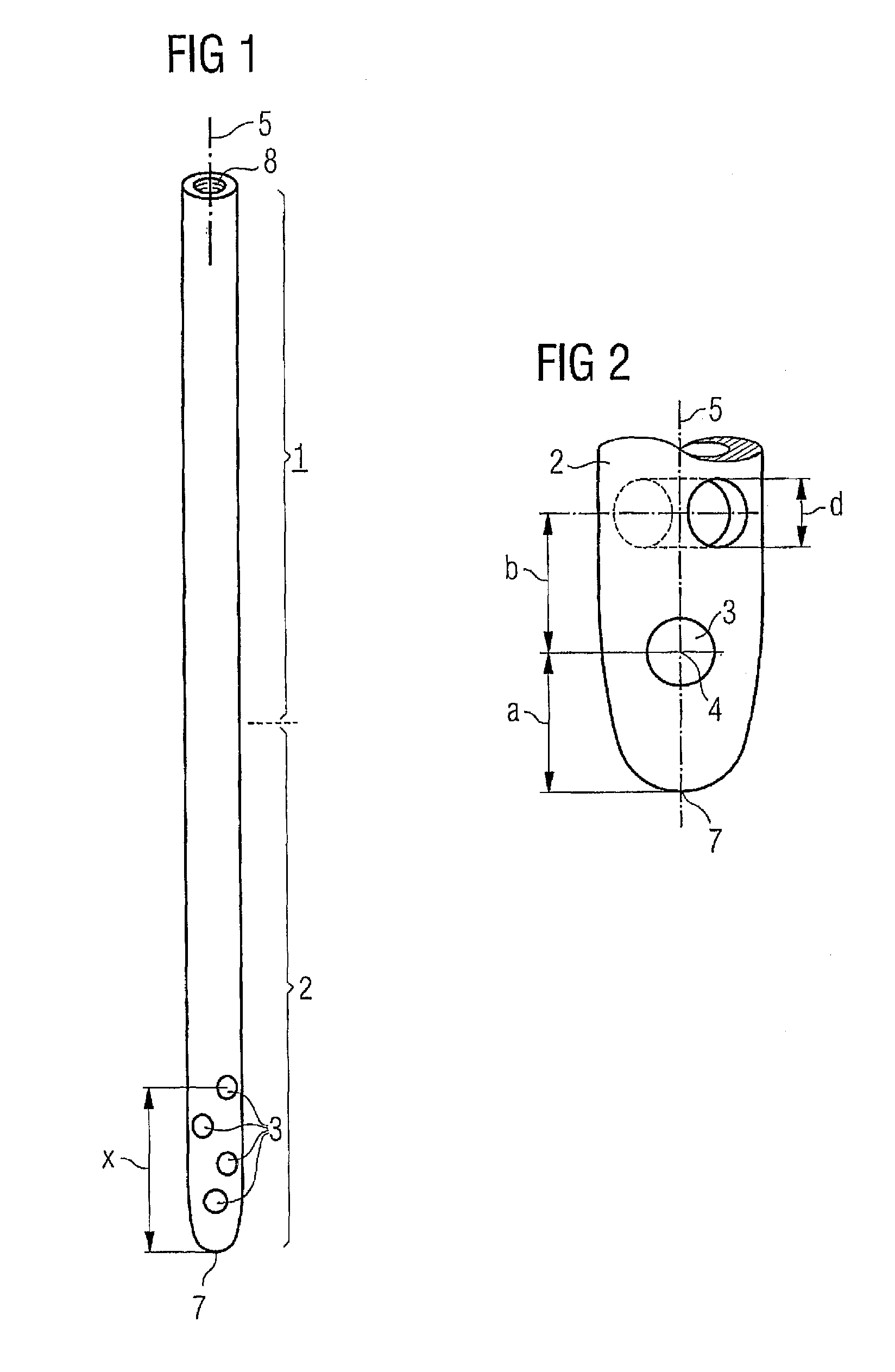

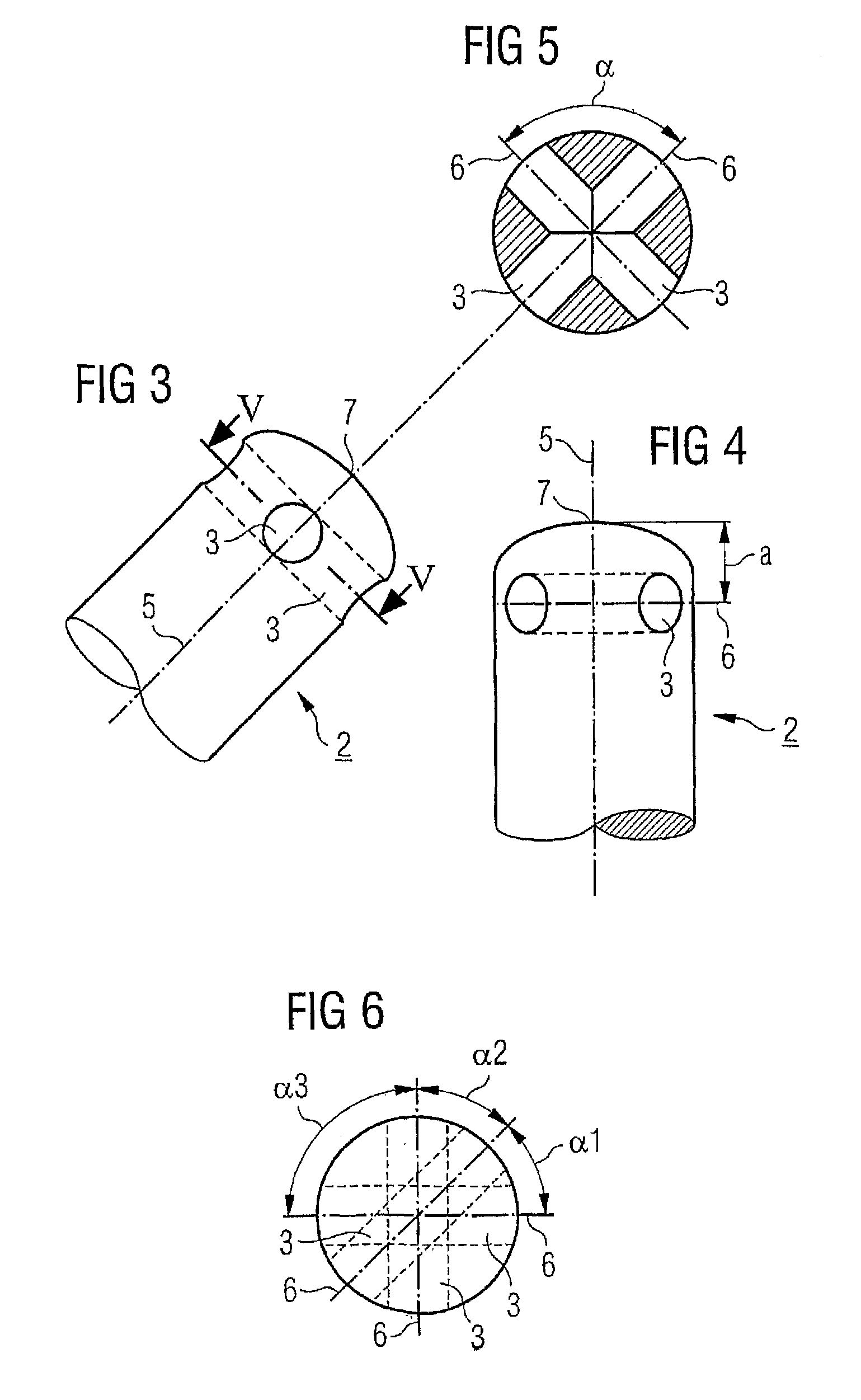

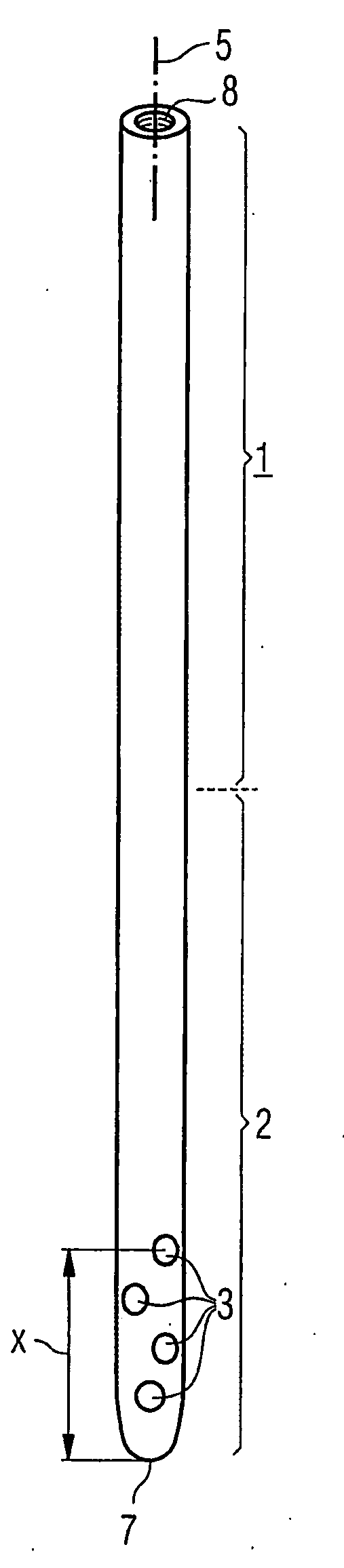

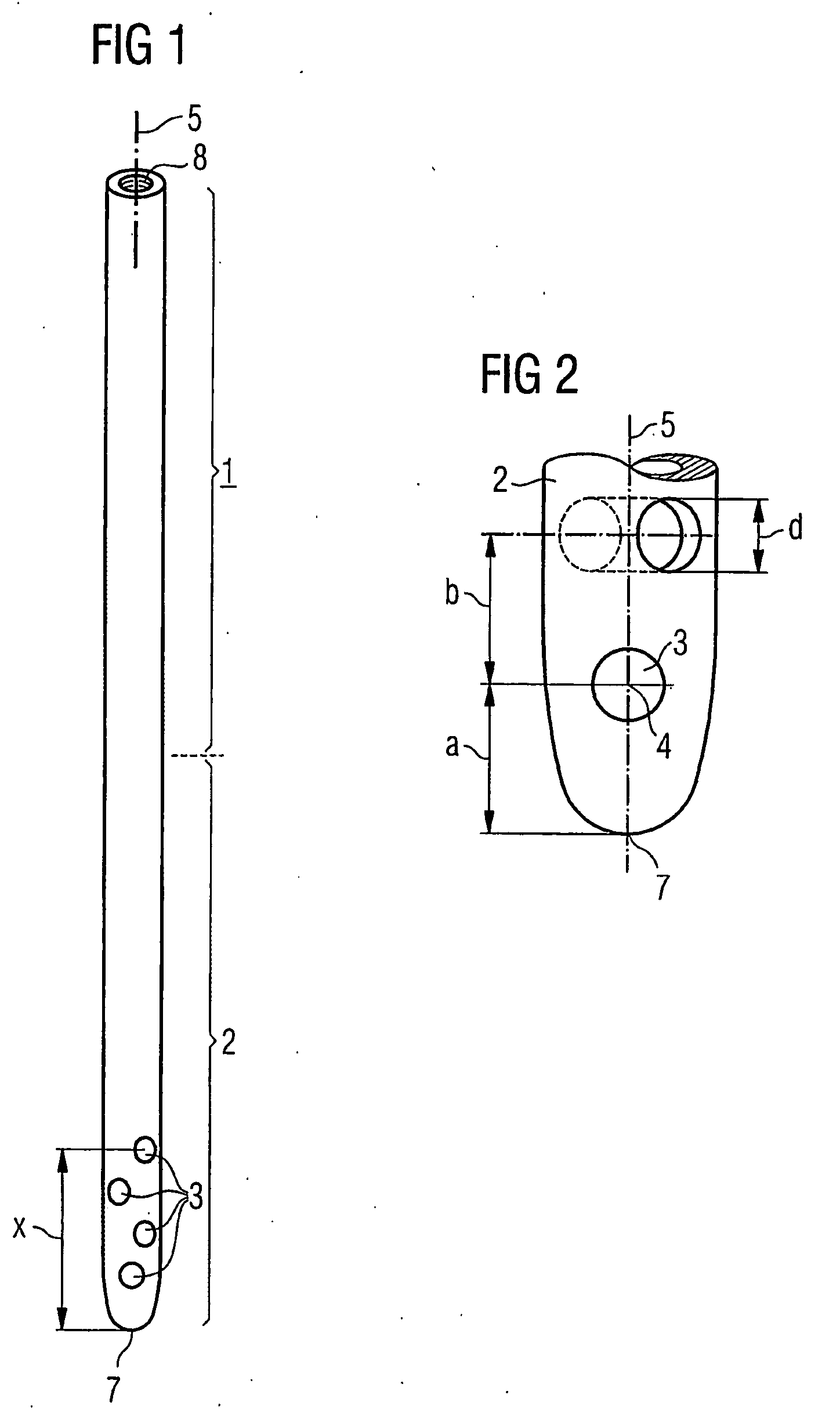

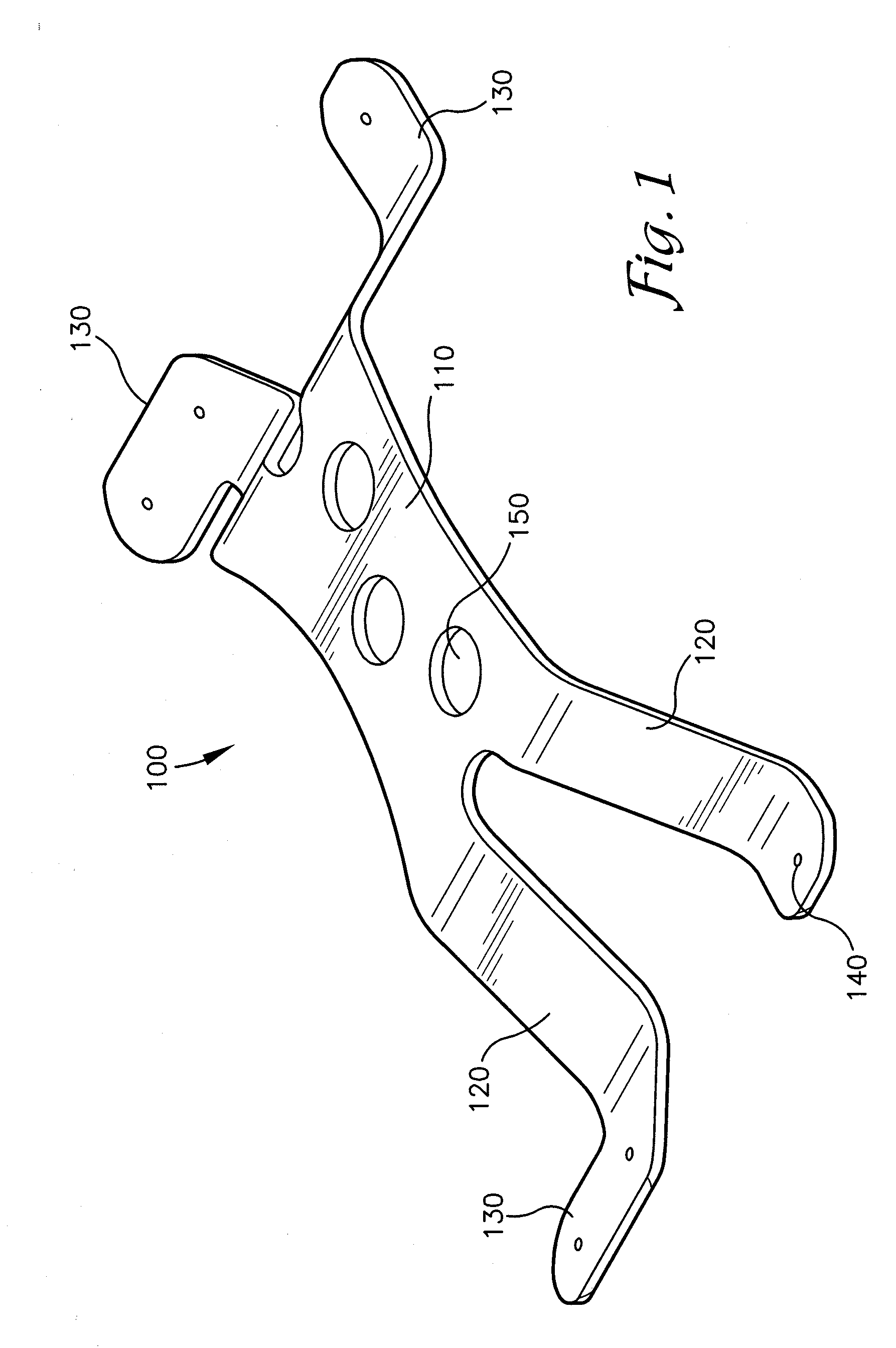

Intramedullary nail

ActiveUS8083742B2Increase surface contact areaStorage much simpler and less costlyInternal osteosythesisJoint implantsBiomedical engineeringInsertion device

Owner:AO TECH AG

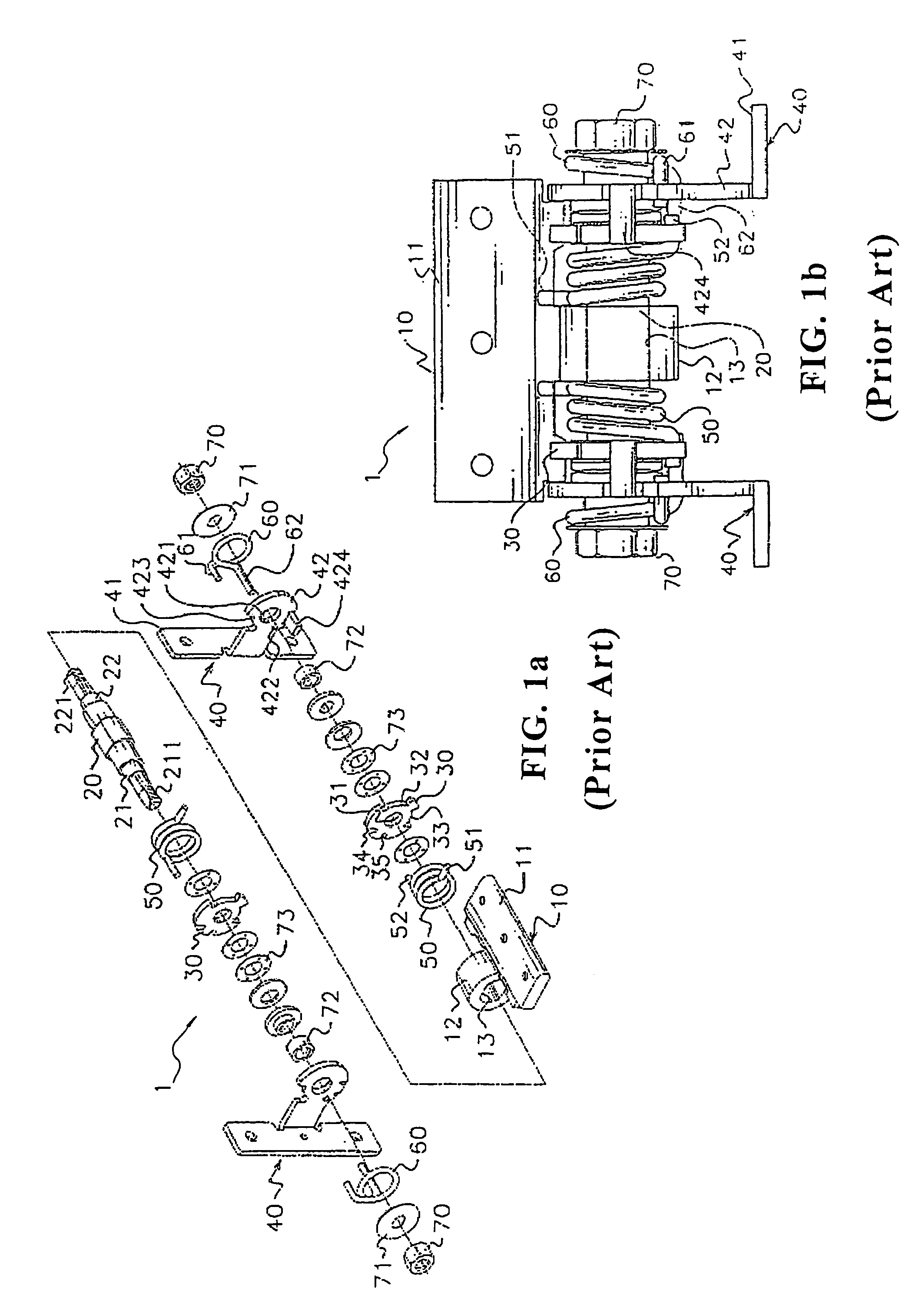

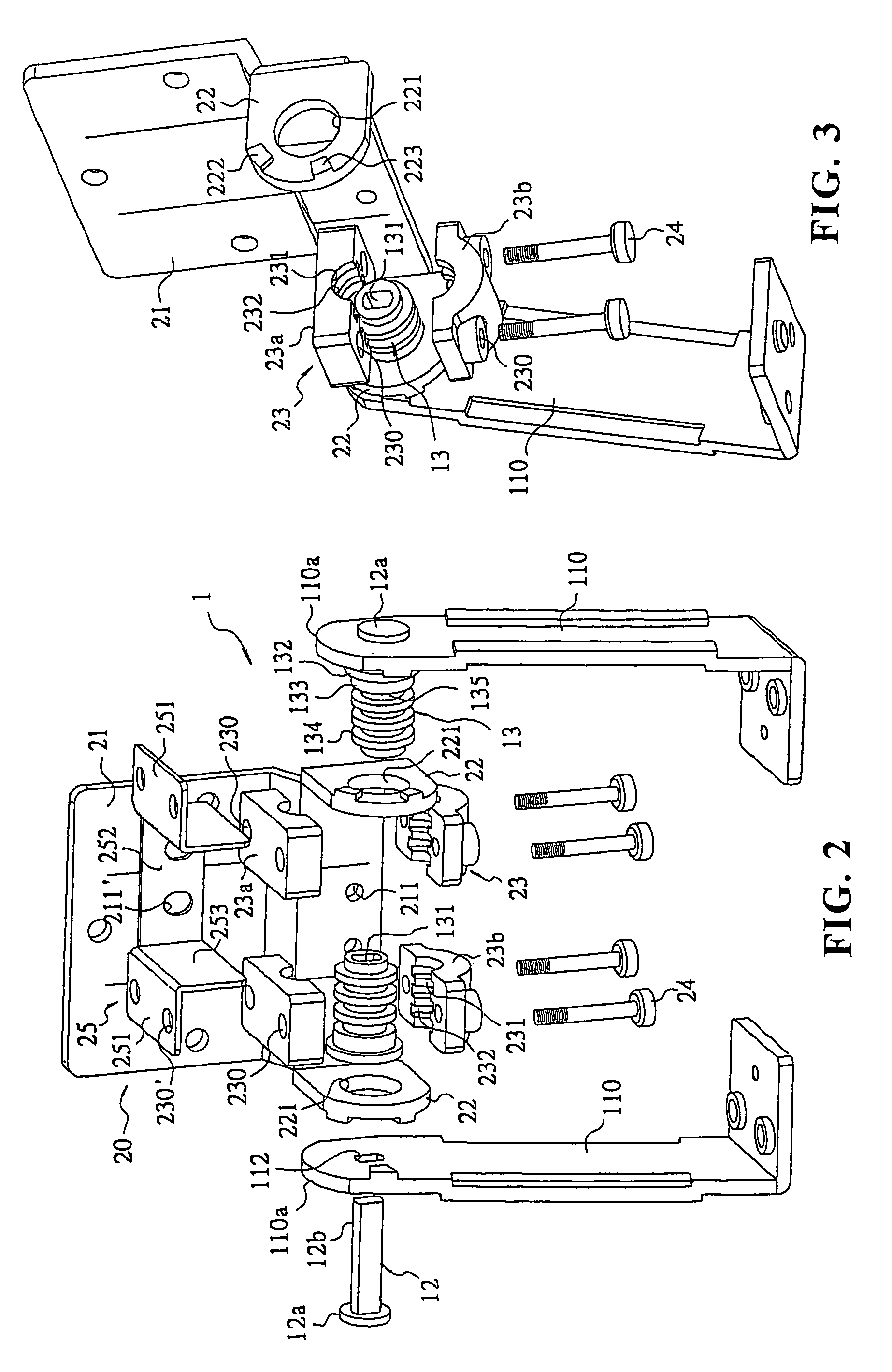

Hinge device for a flat panel display

InactiveUS7114218B1FrictionSimple structureWing fastenersDetails for portable computersDisplay deviceEngineering

A hinge device for a flat panel display which is able to be adjusted and retained at any desired angle, comprises a fixed unit and a pivotal unit, wherein the fixed unit has a base, a pair of supports, a pair spindles and a pair of bushings mounted around the spindle, the pivotal unit includes a mounting part integrated with two pivotal bearing parts, two pair of bearing blocks respectively mounted around the bushings and a connecting member, a plurality of annular grooves being defined around an aperture defined in a center of the bearing blocks corresponding to the plurality of the annular ribs formed around the external surface of the bushing, thereby the pivotal unit is able to be retained at any desired angle by the friction between the contacting surfaces of the bearing blocks and the bushing.

Owner:JIIN MING IND

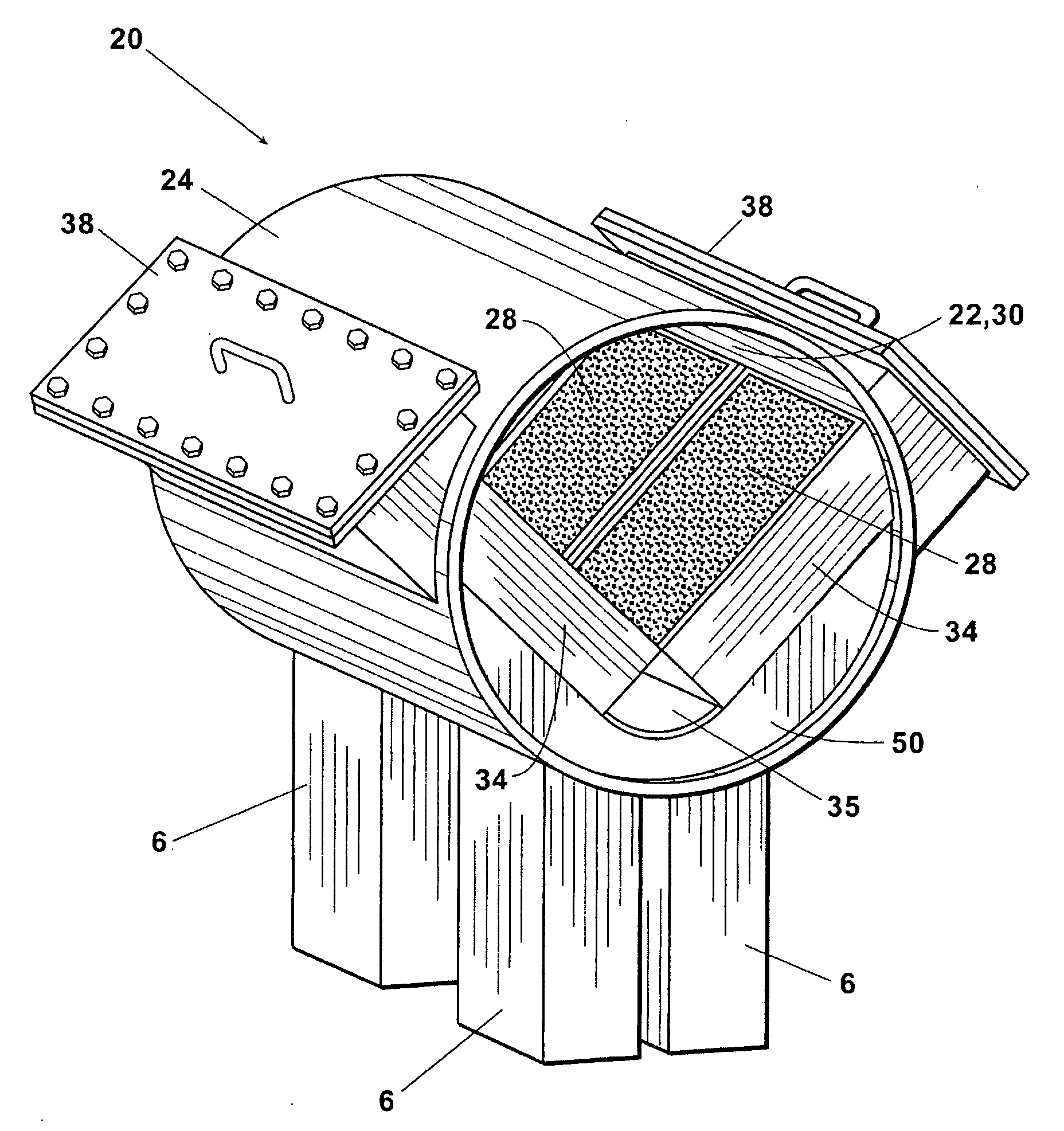

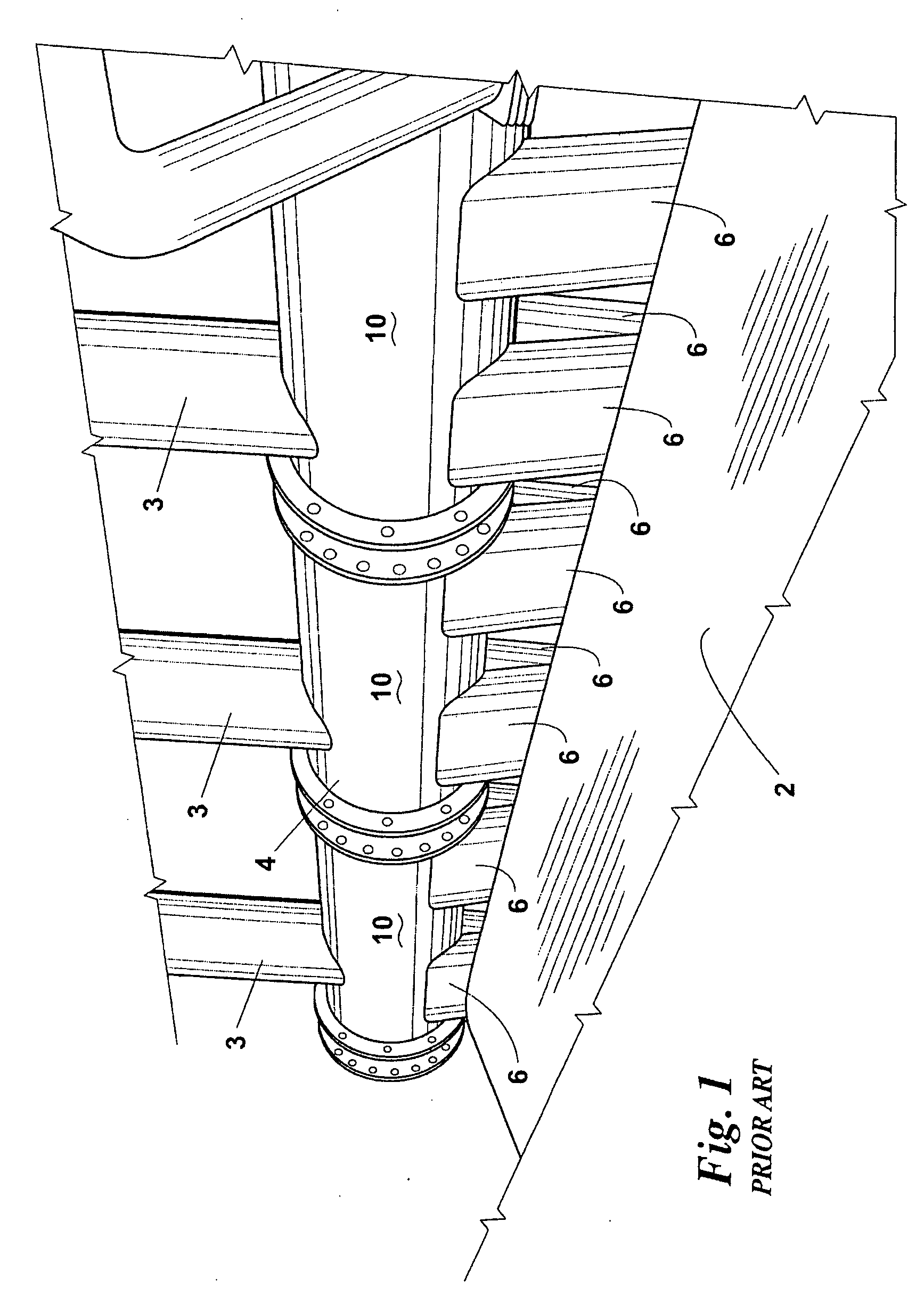

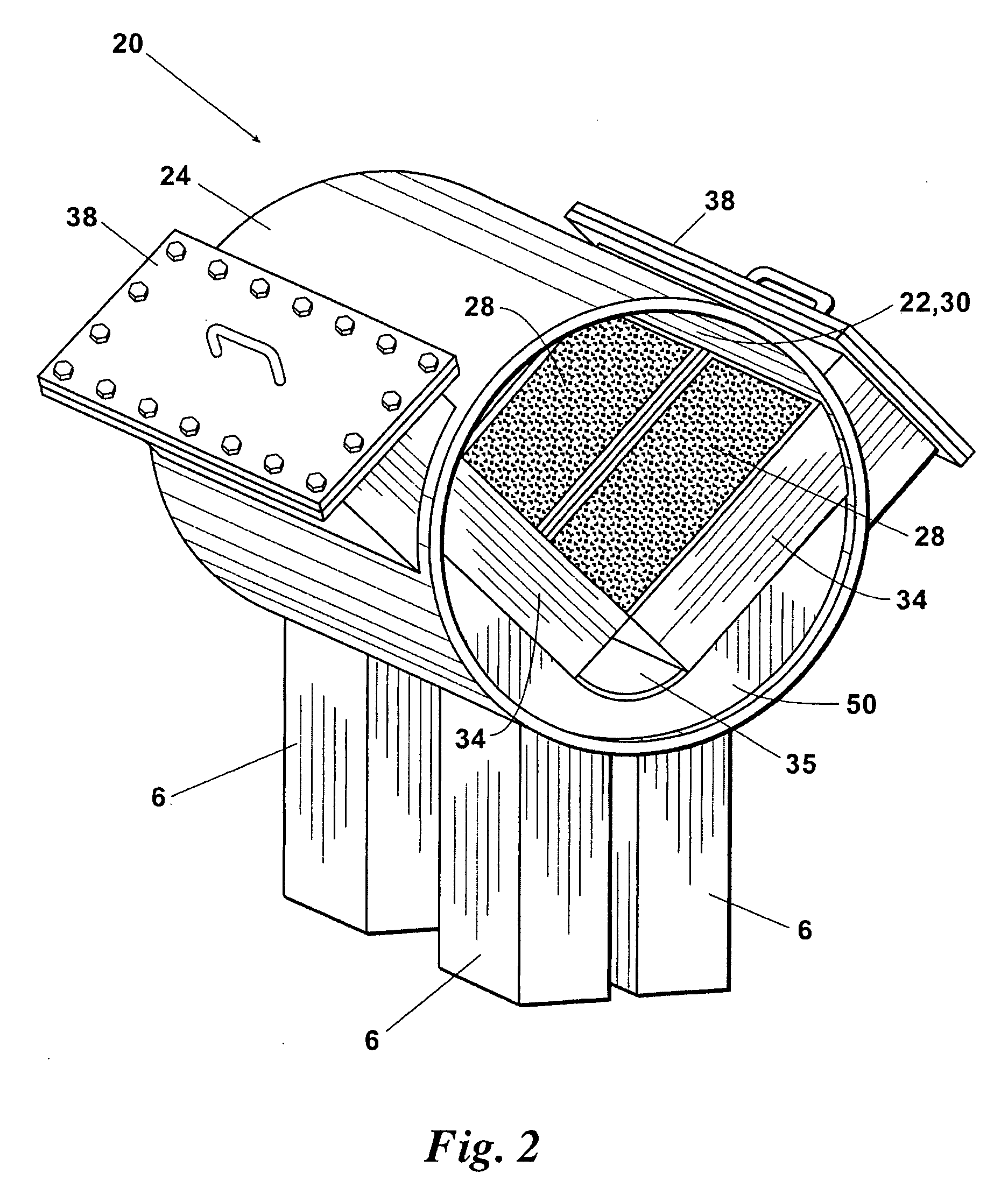

Catalytic converter system and element for diesel engines

InactiveUS20080229733A1Efficient emission reductionEasy to disassembleCombination devicesExhaust apparatusCouplingEngineering

An improved exhaust system and catalytic converter element for a diesel engine wherein the improvement comprises: holding means for restricting the movement of catalytic converter elements in an overhead exhaust manifold; an improved catalytic converter element having at least one retaining rod extending through the catalyst substrate and / or having at least one retaining lip projecting into the substrate; a stabilizer projecting from the cover for the element insertion slot for receiving an end portion of the catalytic converter element to restrict the movement of the converter element in the exhaust manifold; perforated flow distribution elements provided upstream of the catalytic converter elements; and / or vertical coupling manifolds which each receive exhaust from a pair of engine cylinders and then deliver the combined exhaust stream to a separate one of the inlet openings in the bottom of the overhead exhaust manifold.

Owner:MIRATECH GRP LLC

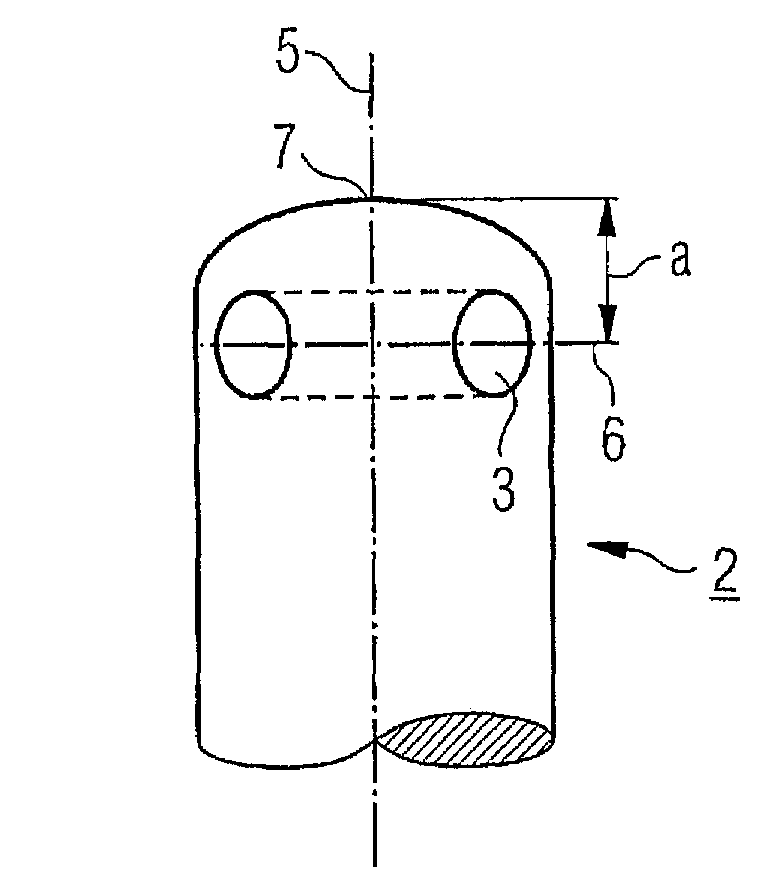

Intramedullary nail

ActiveUS20060235394A1Reduce crack propagationFixed securityInternal osteosythesisJoint implantsIntramedullary rodBiomedical engineering

The intramedullary nail has a longitudinal axis (5), a near end (1) with means (8) for coupling to an insertion device and a far end (2) with a tip (7) for insertion into the intramedullary canal of a long bone. The far end (2) is provided with at least two traversing through holes (3) with axes (6), all of said through holes (3) being grouped in said far end (2) within a distance x measured from said tip (7) to the axis (6) of the most distant hole (3). The nail is provided with at least a third through hole (3) with axis (6) in said far end (2) which contains the first and second holes (3) and the projection of the hole axis (6) of said through holes (3) in a plane orthogonal to said longitudinal axis (5) is such that at least two of said projected hole axis (6) are at an angle α greater than zero and less than 90° with respect to each other.

Owner:AO TECH AG

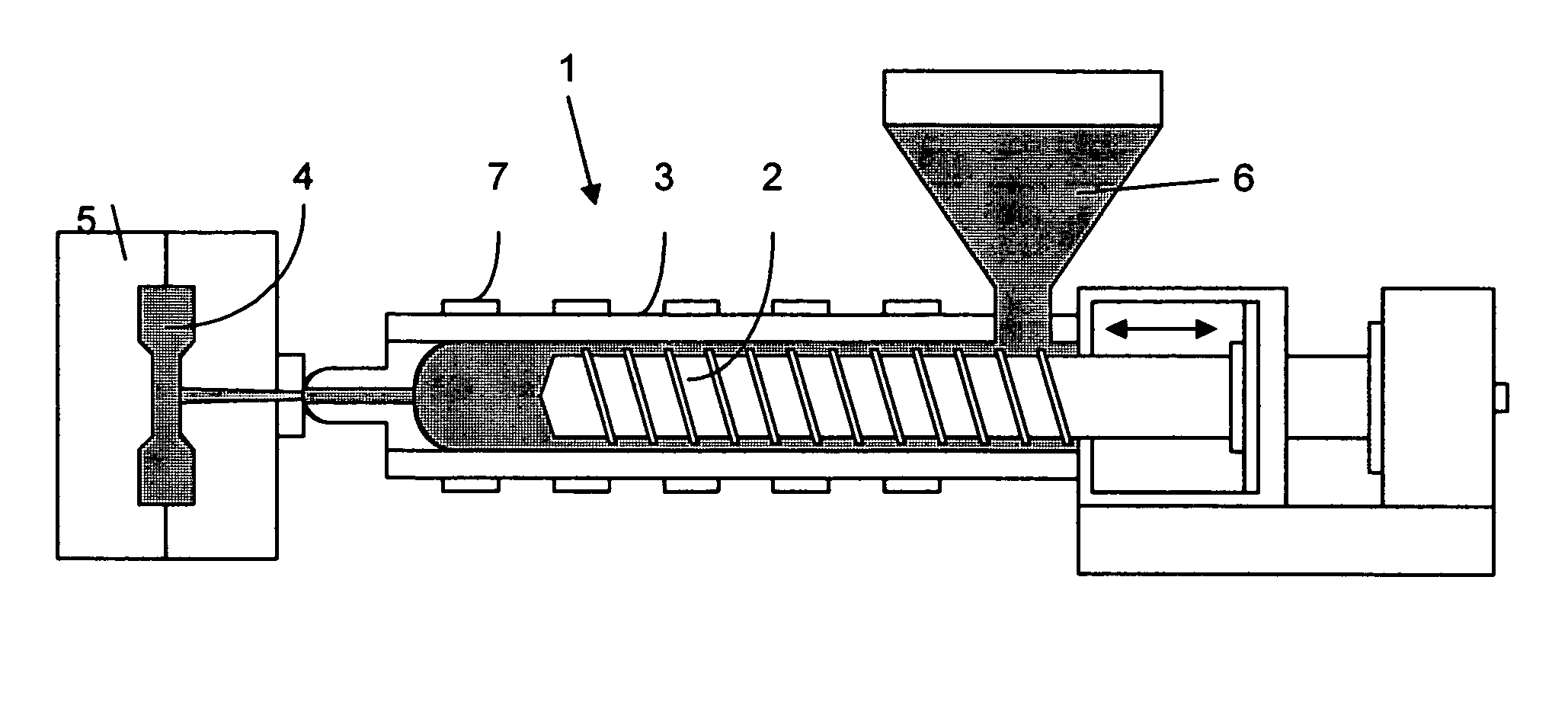

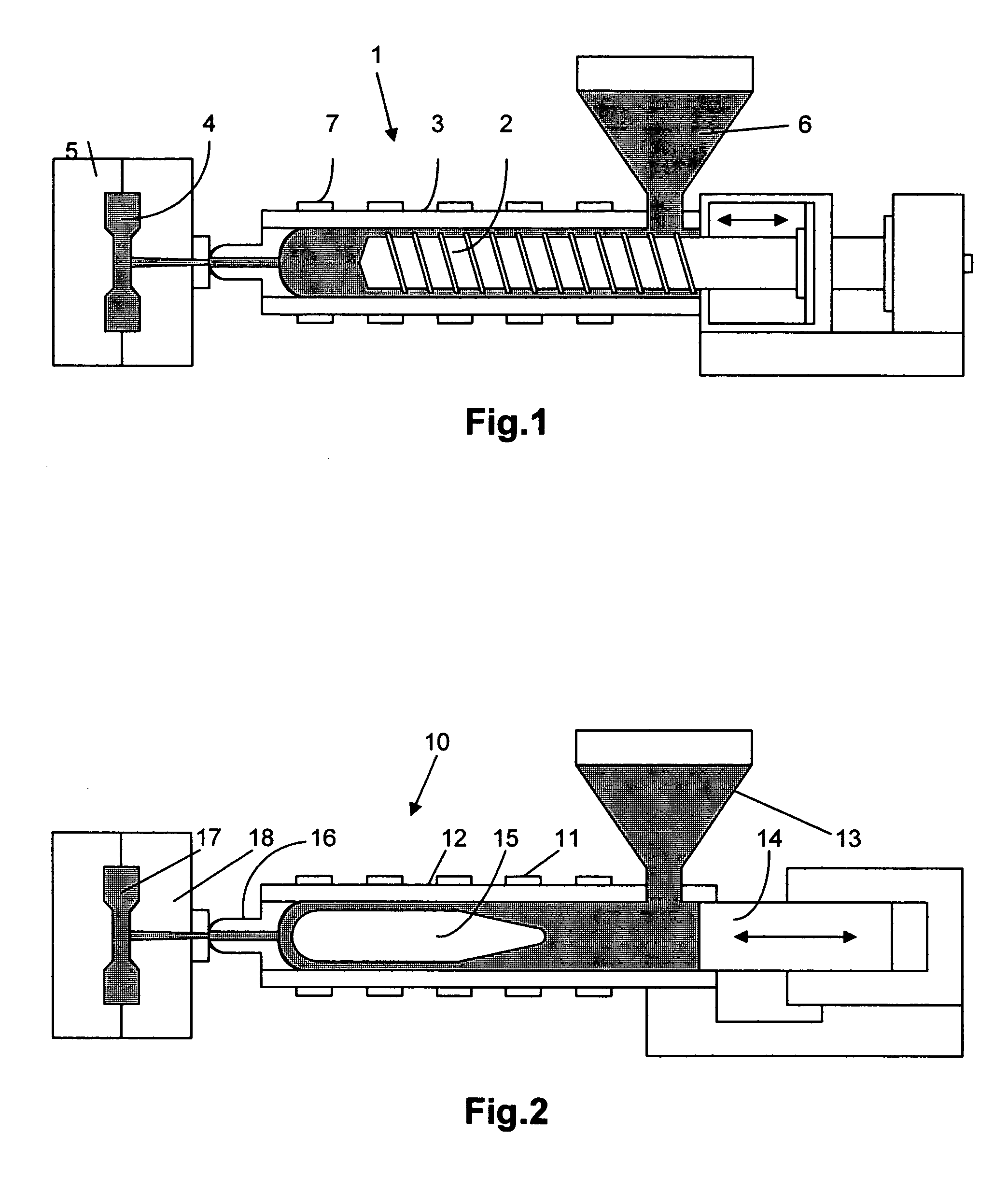

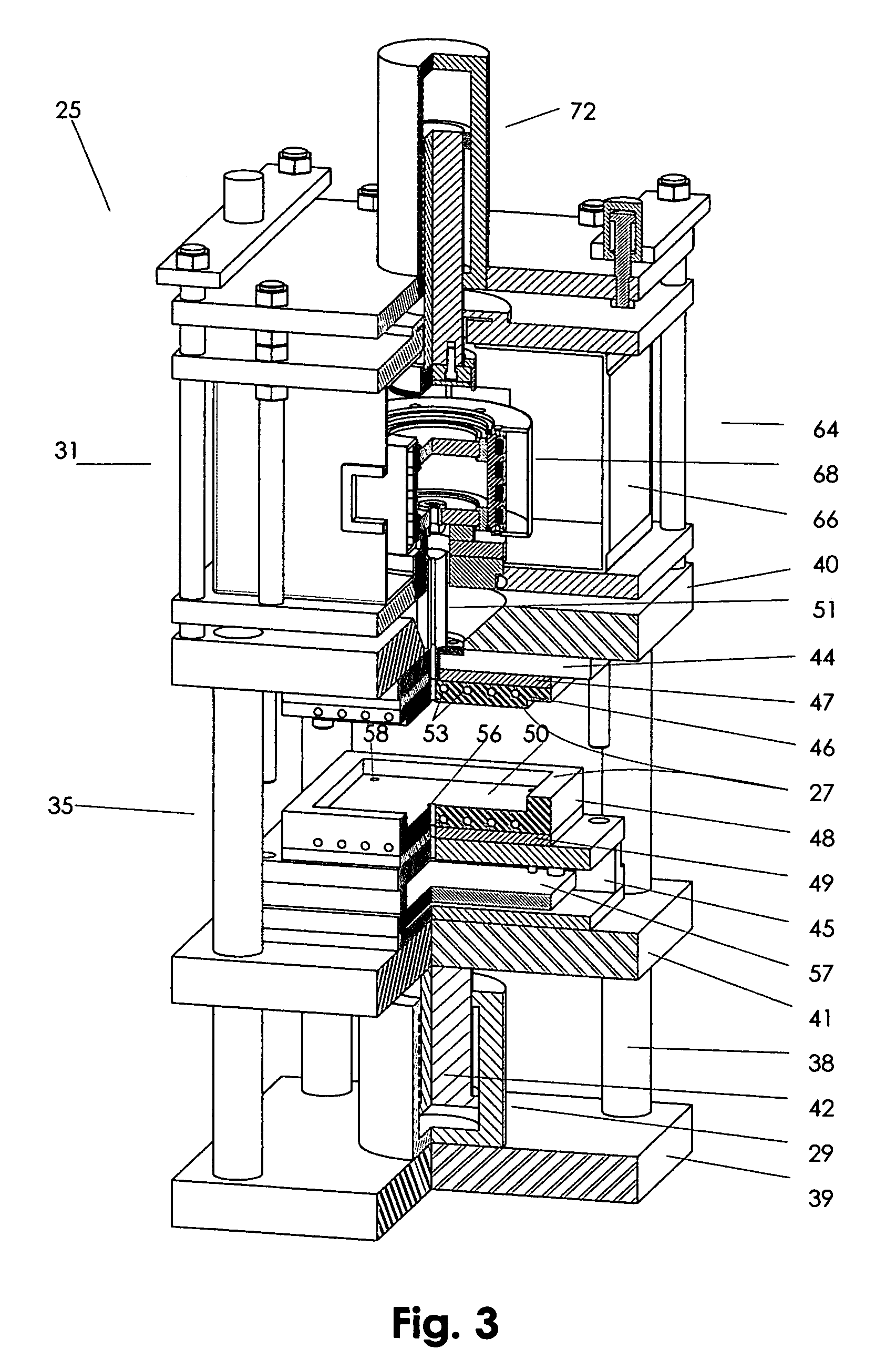

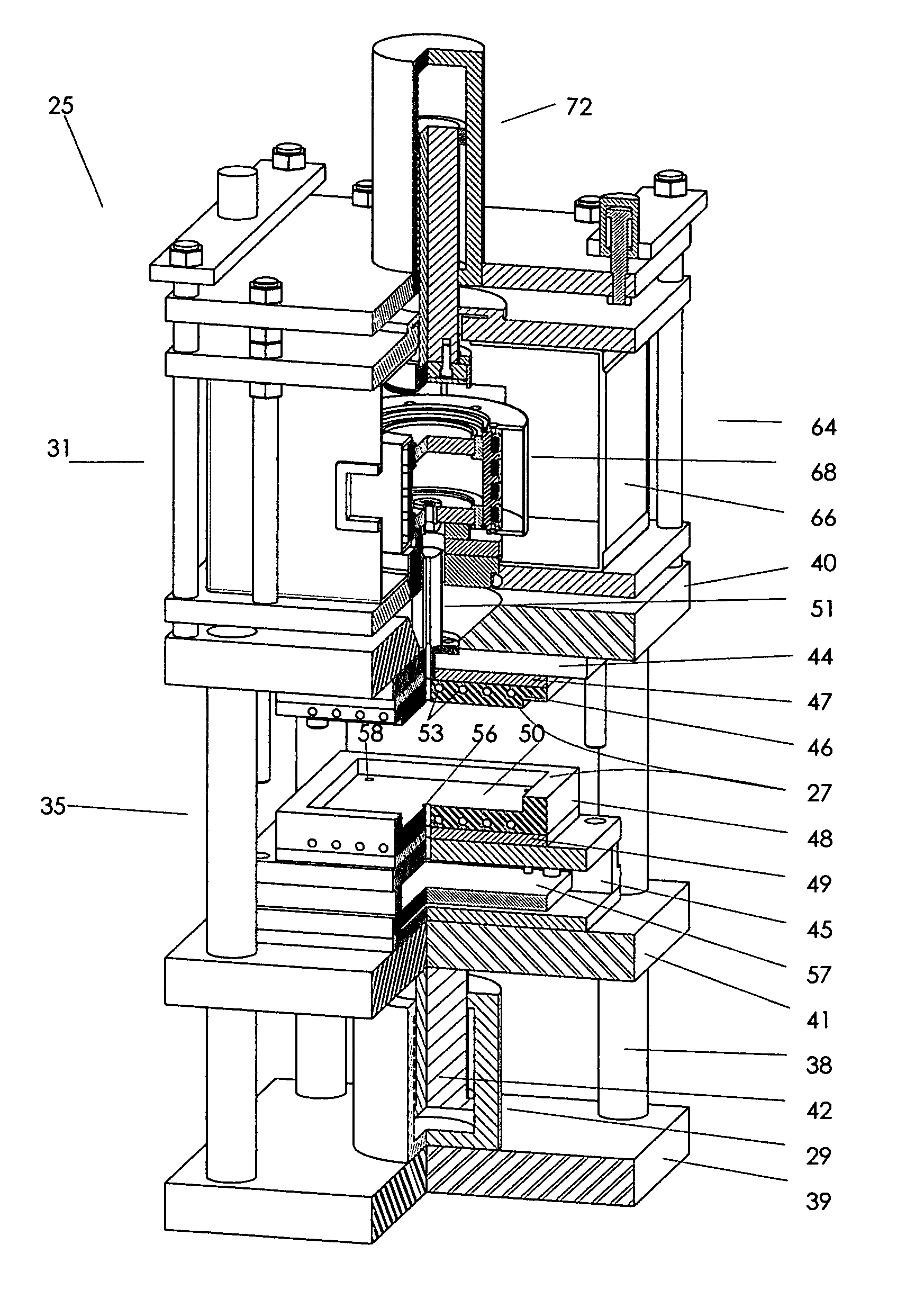

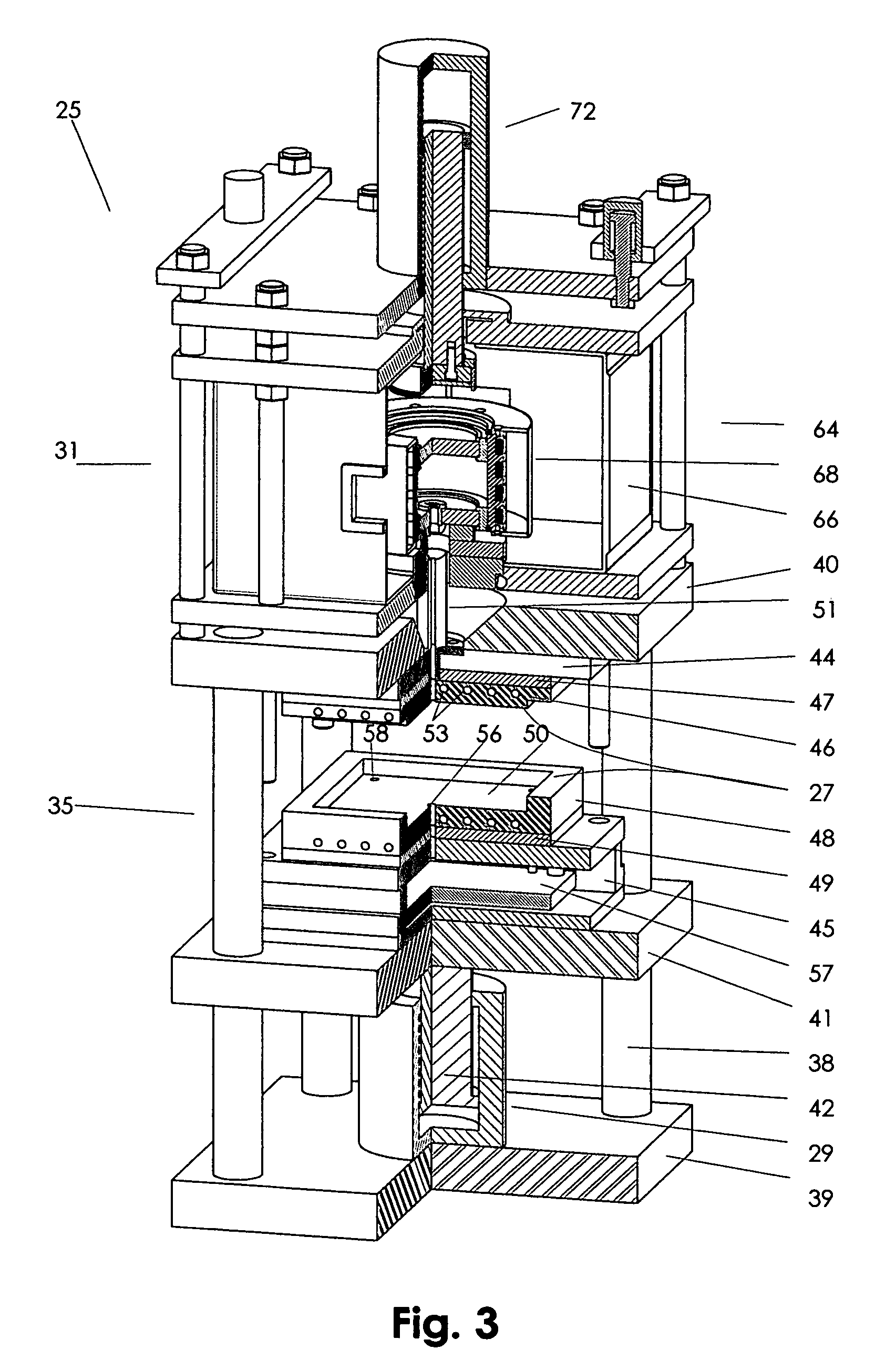

Injection molding of polymers by microwave heating

InactiveUS20050184434A1Little orientationReduce injection pressureDielectric heatingFood shapingMicrowave ovenActuator

Injection molding machine utilizes microwave heating. A microwave oven adapted to receive a microwave absorbent plasticizing vessel is utilized with or incorporated into an injection molding system to form a plasticizing unit for heating polymer granules to an injection temperature and injection of the melt into the cavity of the injection mold. The polymer granules may be preheated by conventional heating systems to a temperature at which the granules become microwave absorbent before heating to the injection temperature in the microwave oven. The injection molding machine also contains a hydraulic actuator for injection of the melt. The ceramic materials forming the plasticizing vessel are selected to provide equal heating rates of mold members and relatively uniform heating of polymer to desired injection temperature.

Owner:AKOPYAN RAZMIK L

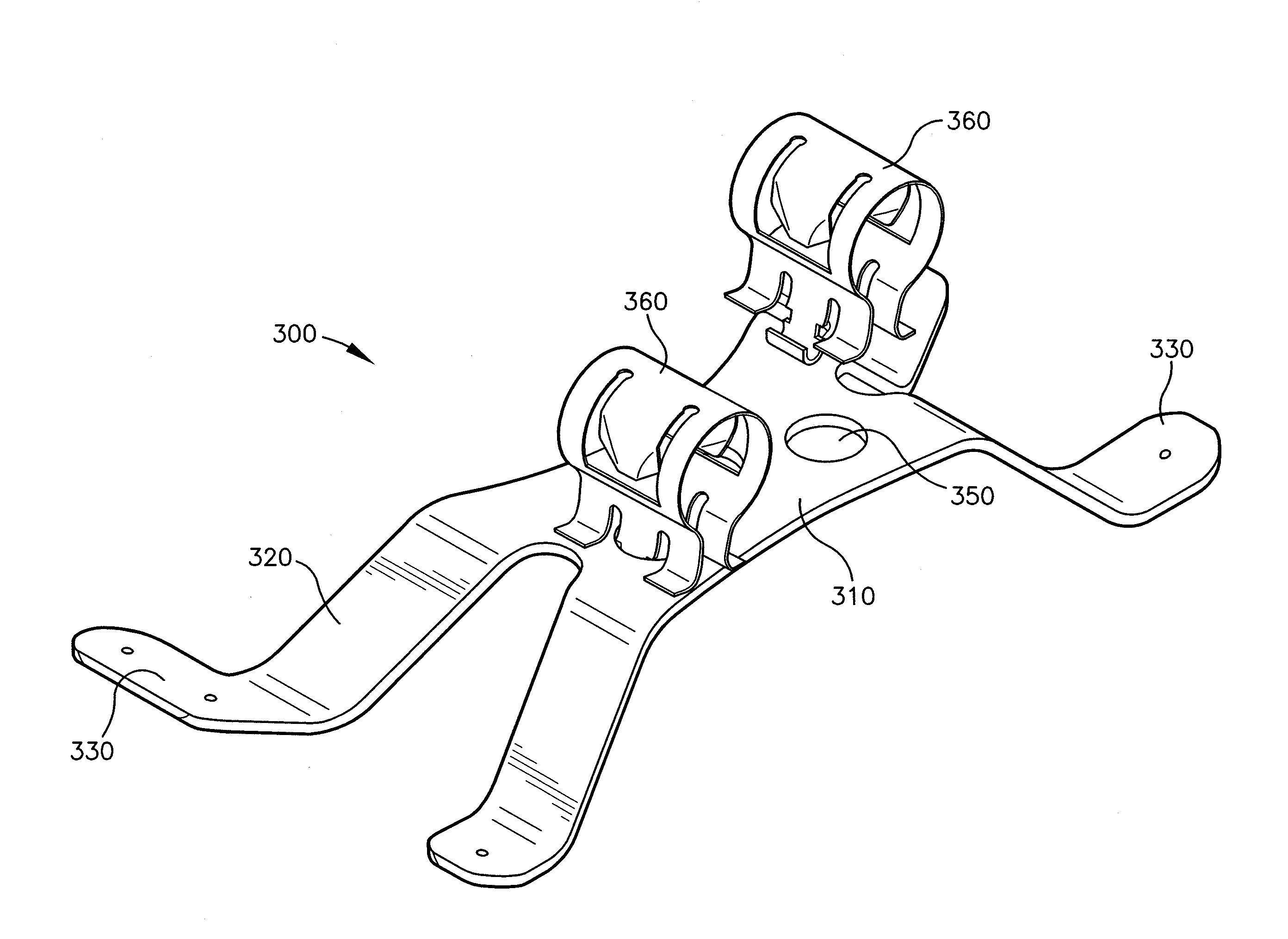

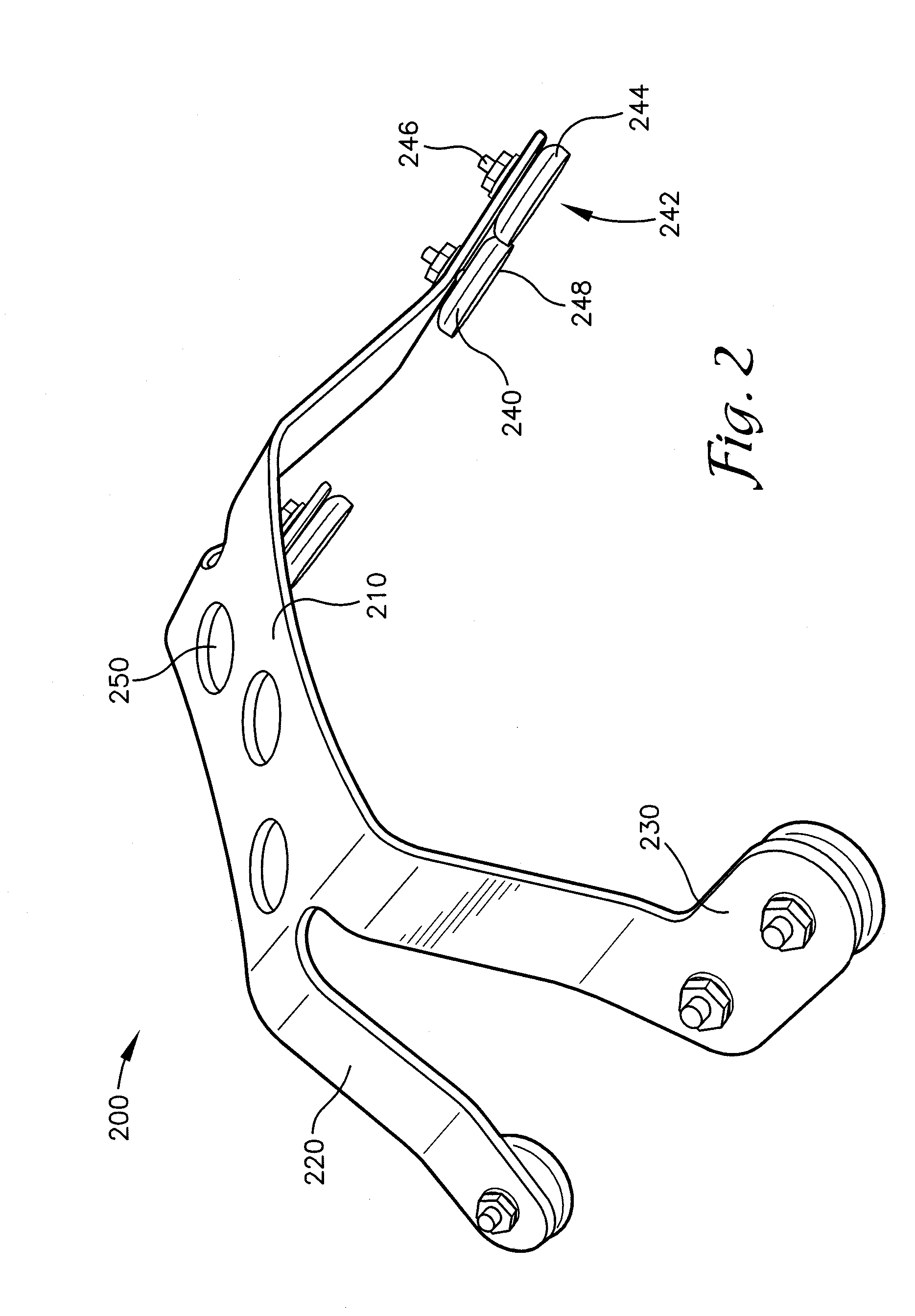

Cable Mounting Bracket System

ActiveUS20140306071A1Reduce aspect ratioStand steadyPipe supportsElectrical apparatusMechanical engineeringEngineering

A bracket and a cable mounting system which includes a bracket with at least two legs, which is angled to match the radius of a structure to which the bracket is to be applied. The bracket has at least one hole in the center panel for securing a component to the bracket. The bracket can have magnetic pads located on the distal end of the legs so that the bracket may be attached to a structure by magnetic force. The cable mounting system may also consist of two brackets a distance apart and a support rail placed in between the brackets and coupled to the brackets.

Owner:STECHMANN ERIC

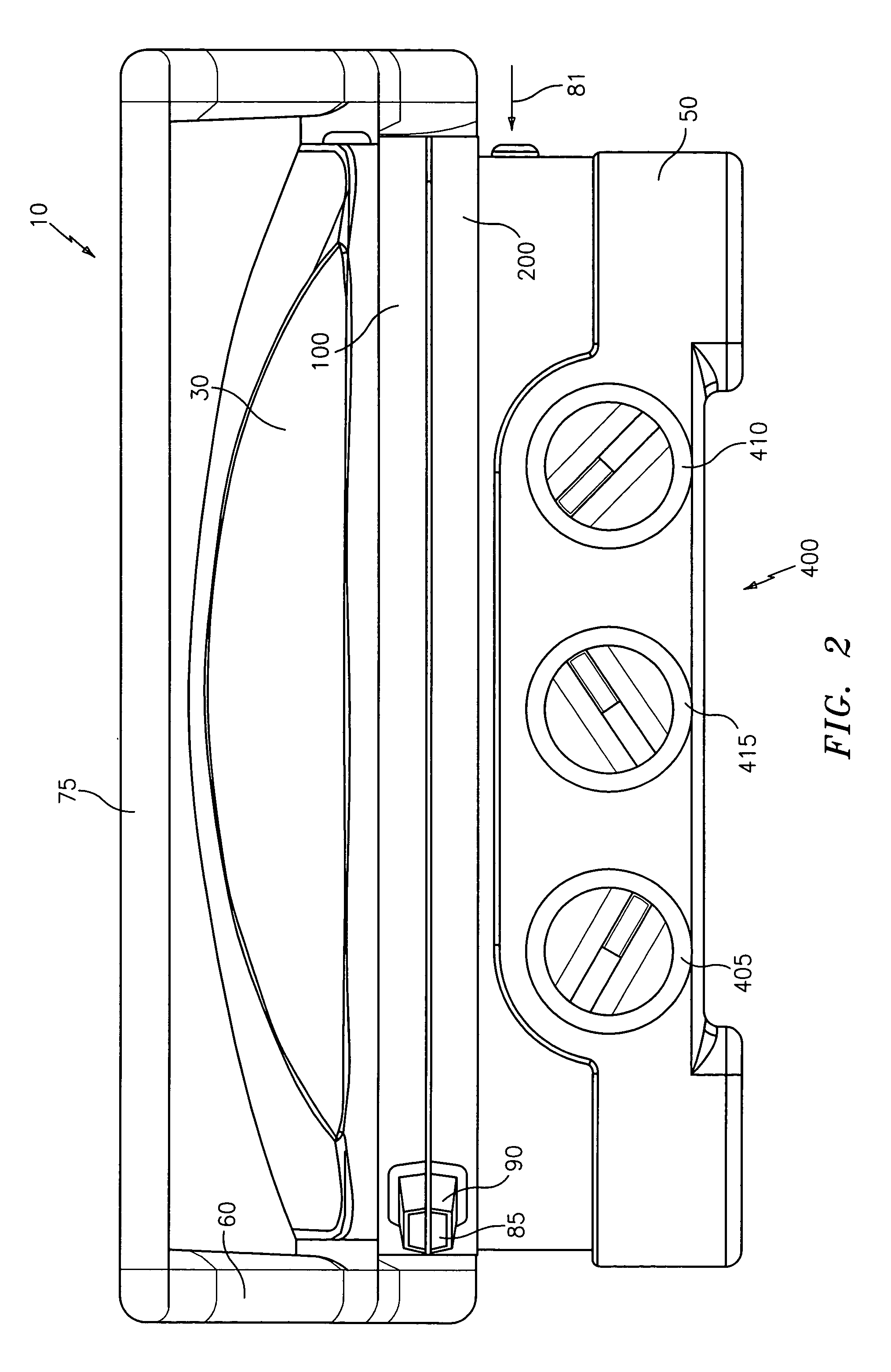

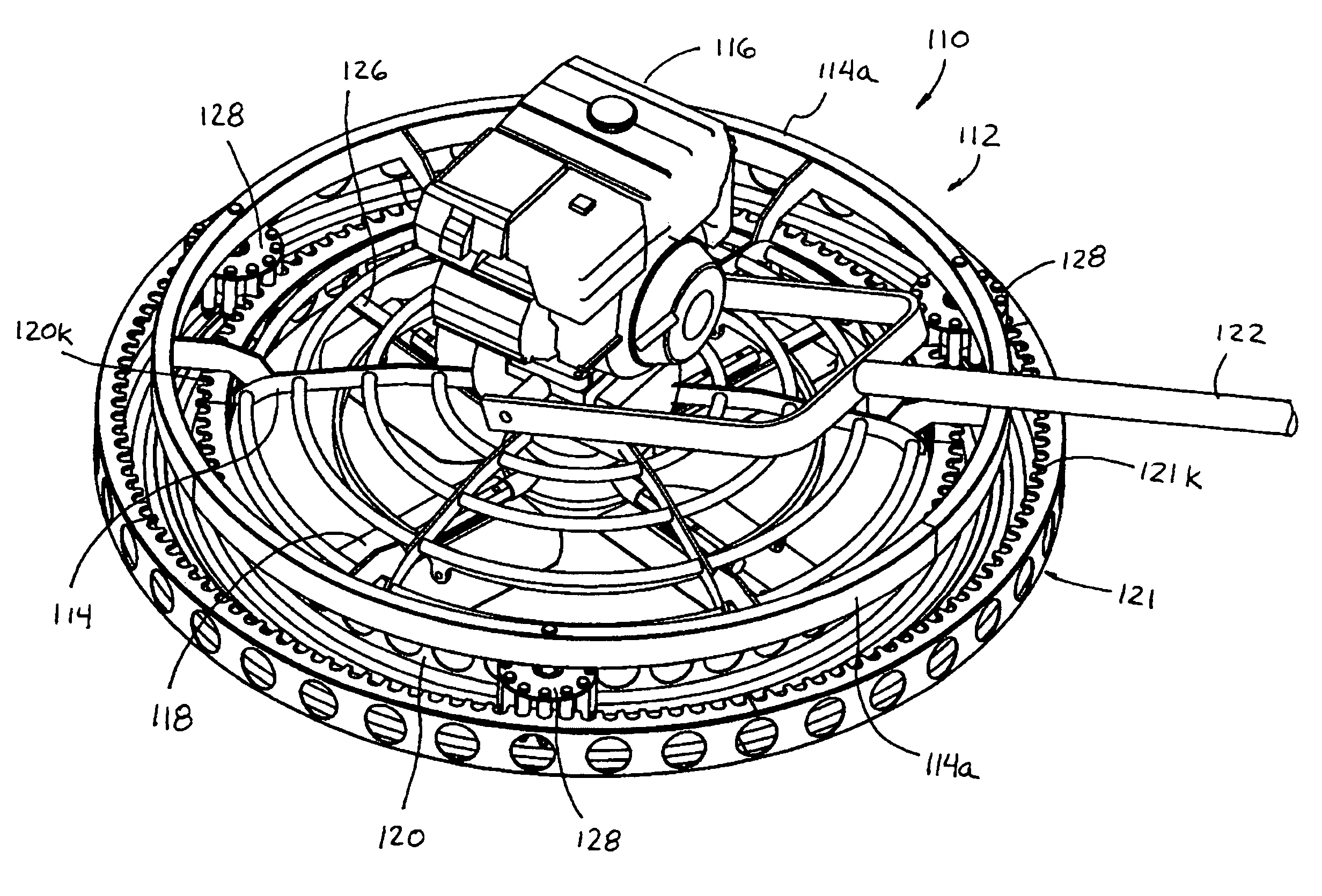

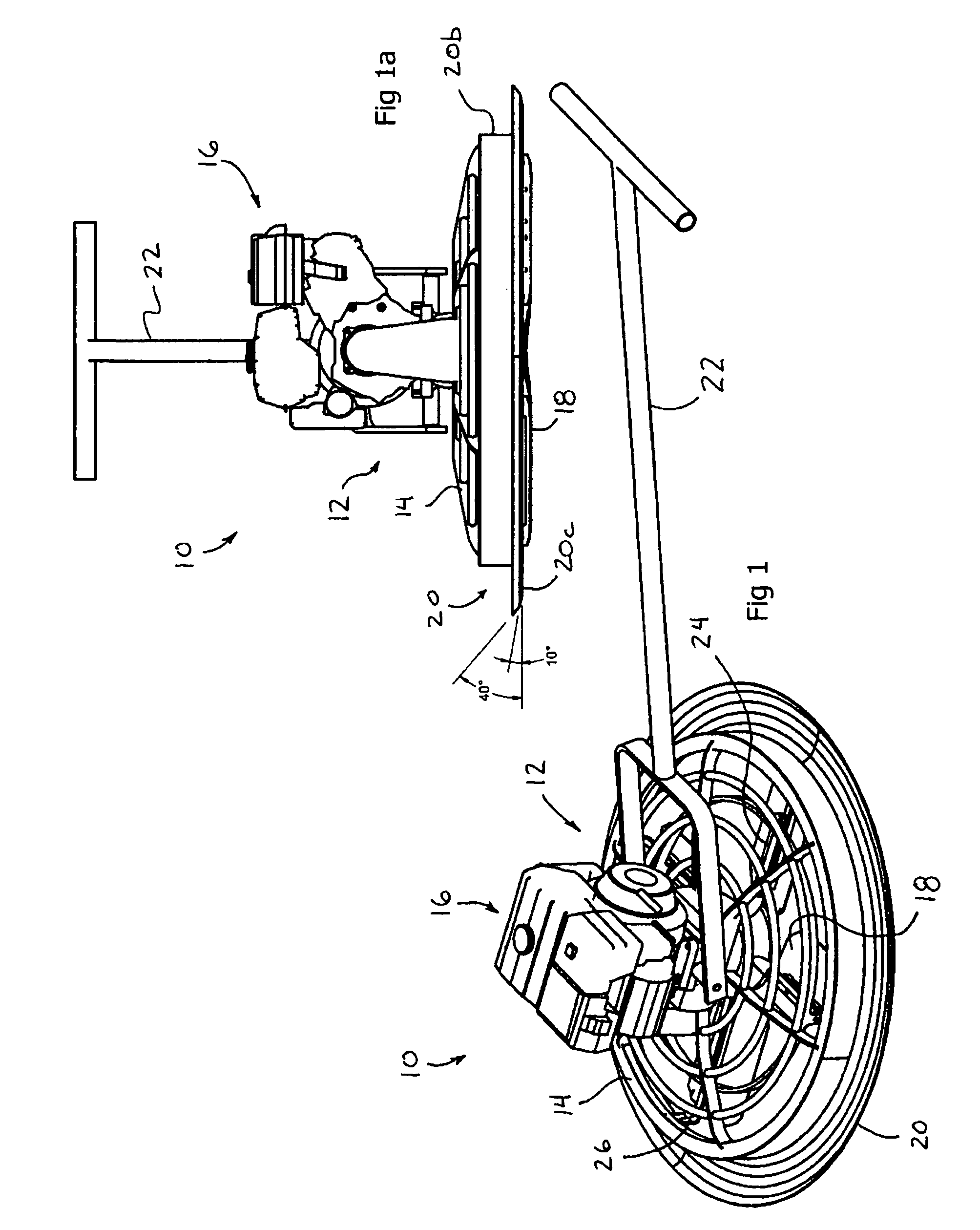

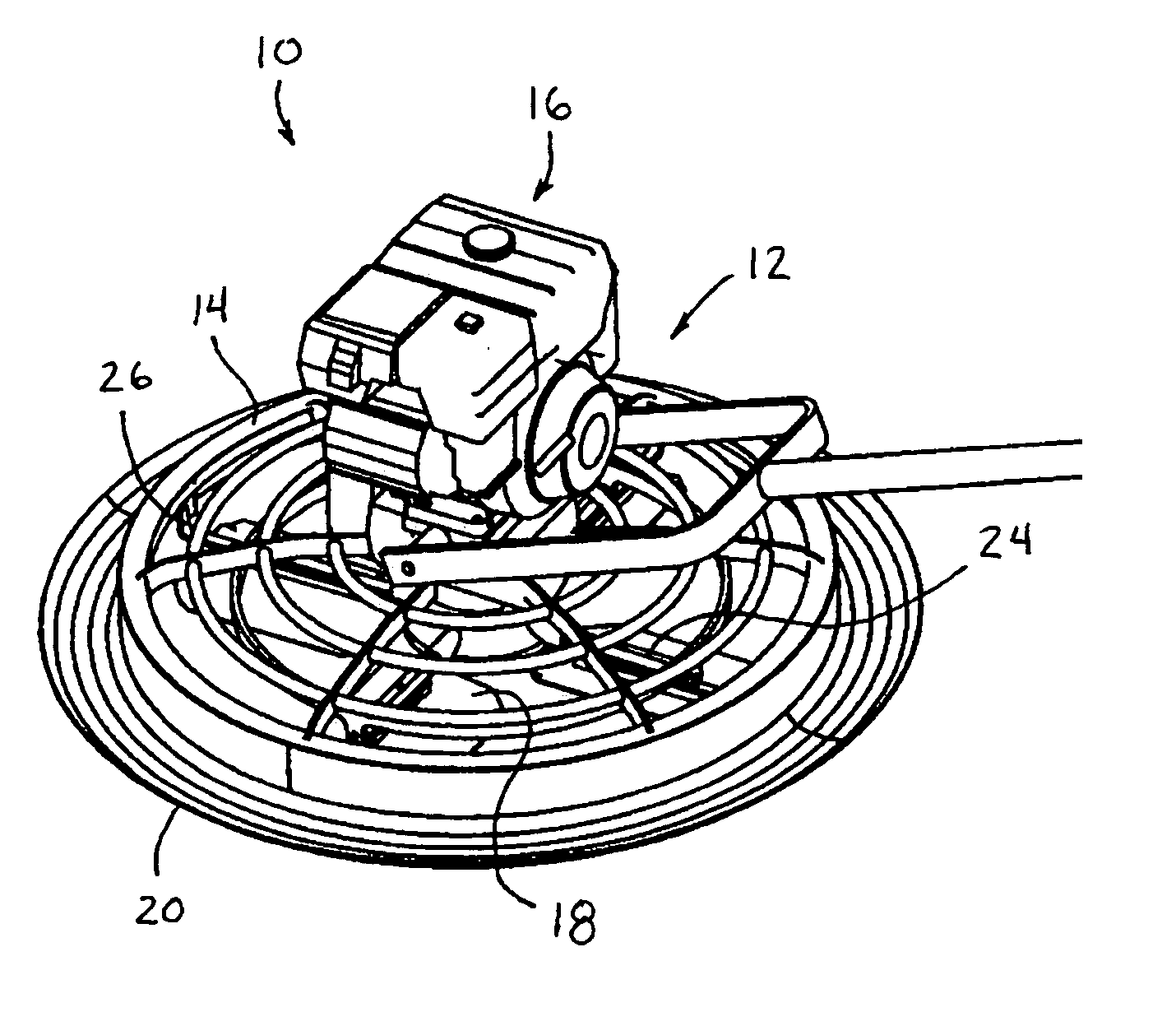

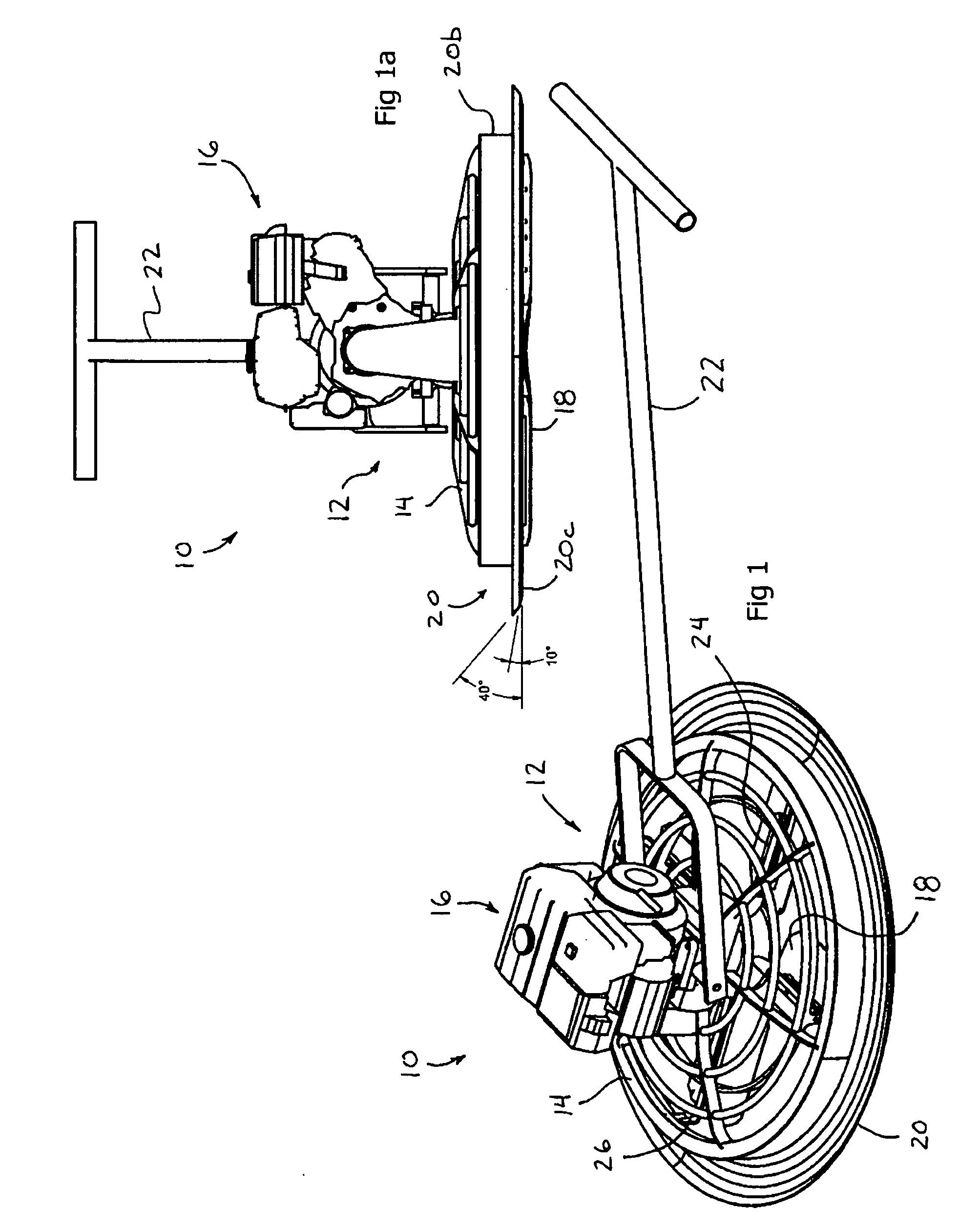

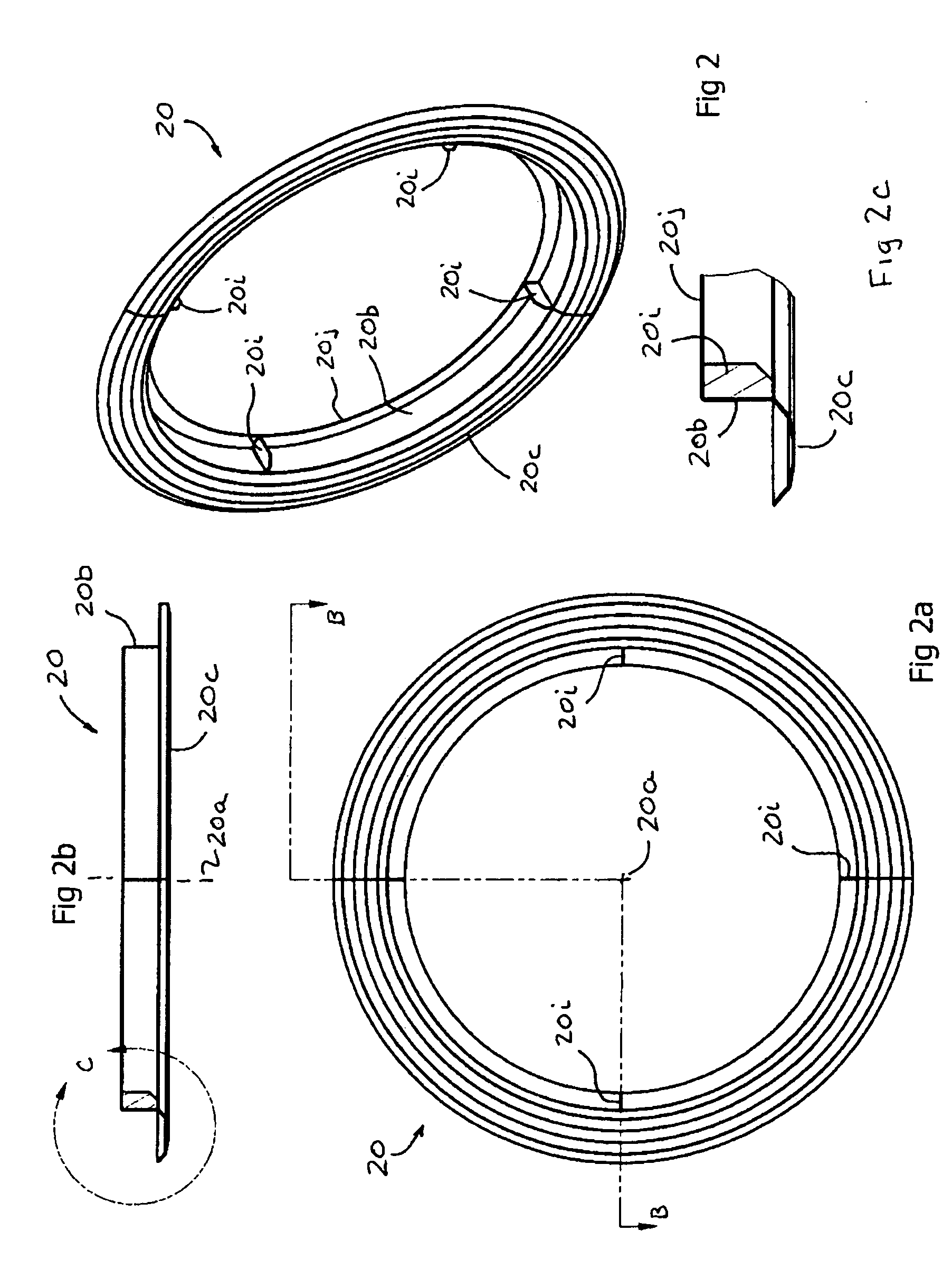

Concrete finishing apparatus

ActiveUS7891906B2High degree-flatness and smoothnessQuality improvementIn situ pavingsBuilding constructionsCement pasteConstruction aggregate

A concrete finishing apparatus and method for smoothing and flattening partially set-up concrete to a close-tolerance surface includes a movable unit that is movable and supported at a partially set-up concrete surface and at least one rotatable ring finishing member mounted to the movable unit. The rotatable ring finishing member is positioned at the concrete surface and rotatable to engage and finish the surface of the partially set-up concrete to a higher quality, closer-tolerance flat and level concrete floor surface. The apparatus may include a pair of rotatable ring finishing members that may be rotatable in opposite directions to enhance the floating and finishing processes and to transport any cement paste, sand, small aggregate, or concrete mix residue forward with the rotatable ring finishing members working surfaces to cut high areas and fill in any low areas as the concrete finishing apparatus moves over the partially set-up concrete.

Owner:SOMERO ENTERPRISES INC

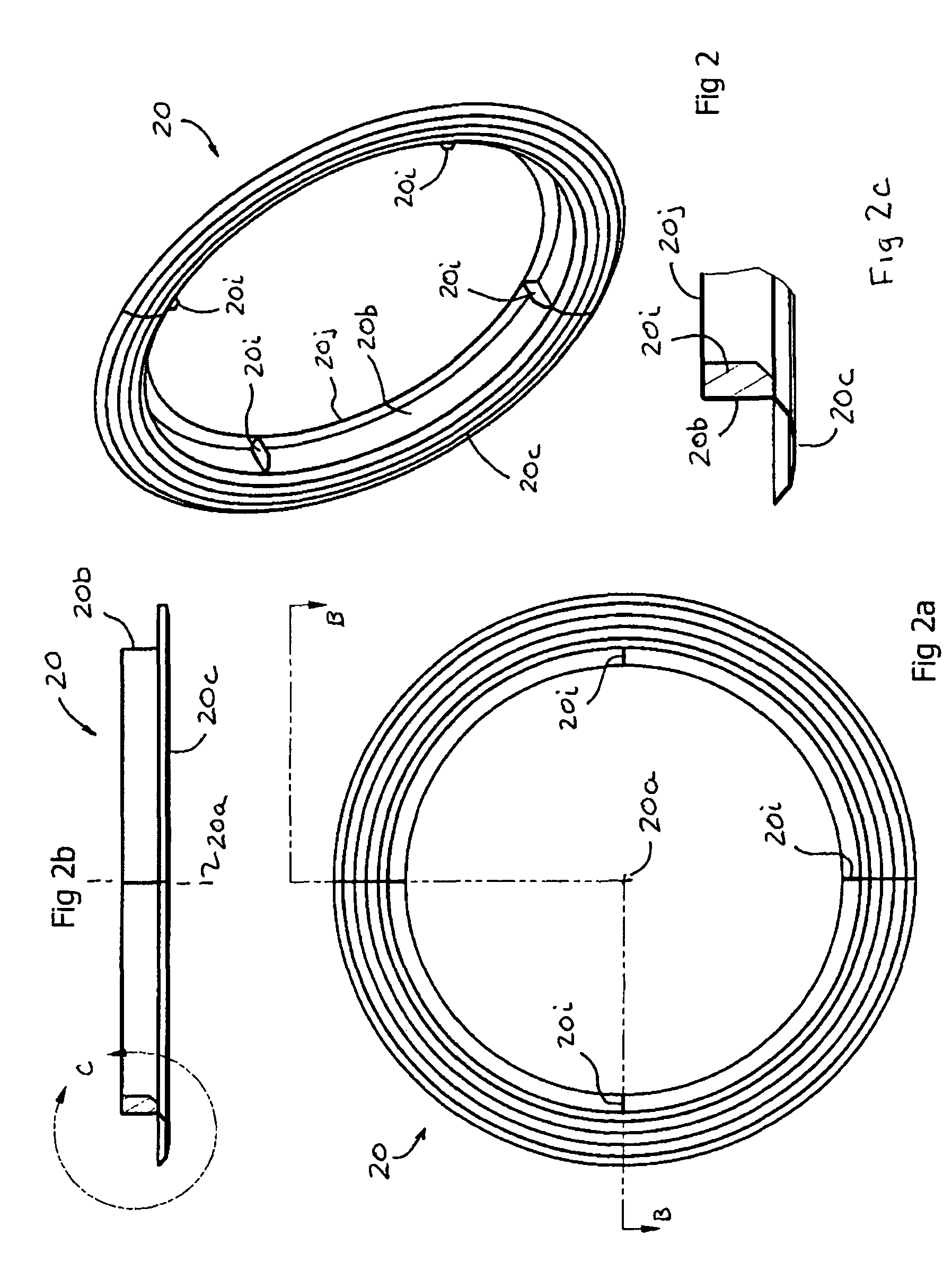

Preparation method of porous implant filled with O-intersecting lines units

InactiveCN105559947AThe preparation method is reliable and feasibleGreat potentialJoint implantsFemoral headsSand blastingPorous implant

The invention provides a preparation method of a porous implant filled with O-intersecting lines units. The preparation method comprises the following steps: drawing a three-dimensional model of the O-intersecting lines units, controlling the bore diameter, wall thickness and porosity of the three-dimensional model according to the given specific dimension so as to generate a unit structure cell body, carrying out array copying operation on the unit structure cell body, thus obtaining a space porous network body, introducing in a femoral three-dimensional surface model, scaling the model to reach the proportion actually needed, carrying out cutting and Boolean operation on the porous network body and the femoral three-dimensional surface, thus obtaining a porous main body part, drawing the femoral steam end and a bolt positioning hole part by utilizing three-dimensional modeling, combing the porous main body part to enable the porous main body part to form a single-output porous implant body, saving the single-output porous implant body into an output format file and transmitting the file to layering software, adding with a bottom surface support, printing the porous implant body by adopting a 3D printer, clearing a substrate plate, taking out the porous implant, carrying out sand blasting treatment on the porous implant, and packaging the porous implant. With the adoption of the preparation method, units which are regular and uniform and having no closure can be generated, and the stressing uniformity is guaranteed.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Concrete finishing apparatus

ActiveUS20090214294A1Little extra relative effort and costHigh smoothnessIn situ pavingsBuilding constructionsSmall aggregateConstruction aggregate

A concrete finishing apparatus and method for smoothing and flattening partially set-up concrete to a close-tolerance surface includes a movable unit that is movable and supported at a partially set-up concrete surface and at least one rotatable ring finishing member mounted to the movable unit. The rotatable ring finishing member is positioned at the concrete surface and rotatable to engage and finish the surface of the partially set-up concrete to a higher quality, closer-tolerance flat and level concrete floor surface. The apparatus may include a pair of rotatable ring finishing members that may be rotatable in opposite directions to enhance the floating and finishing processes and to transport any cement paste, sand, small aggregate, or concrete mix residue forward with the rotatable ring finishing members working surfaces to cut high areas and fill in any low areas as the concrete finishing apparatus moves over the partially set-up concrete.

Owner:SOMERO ENTERPRISES INC

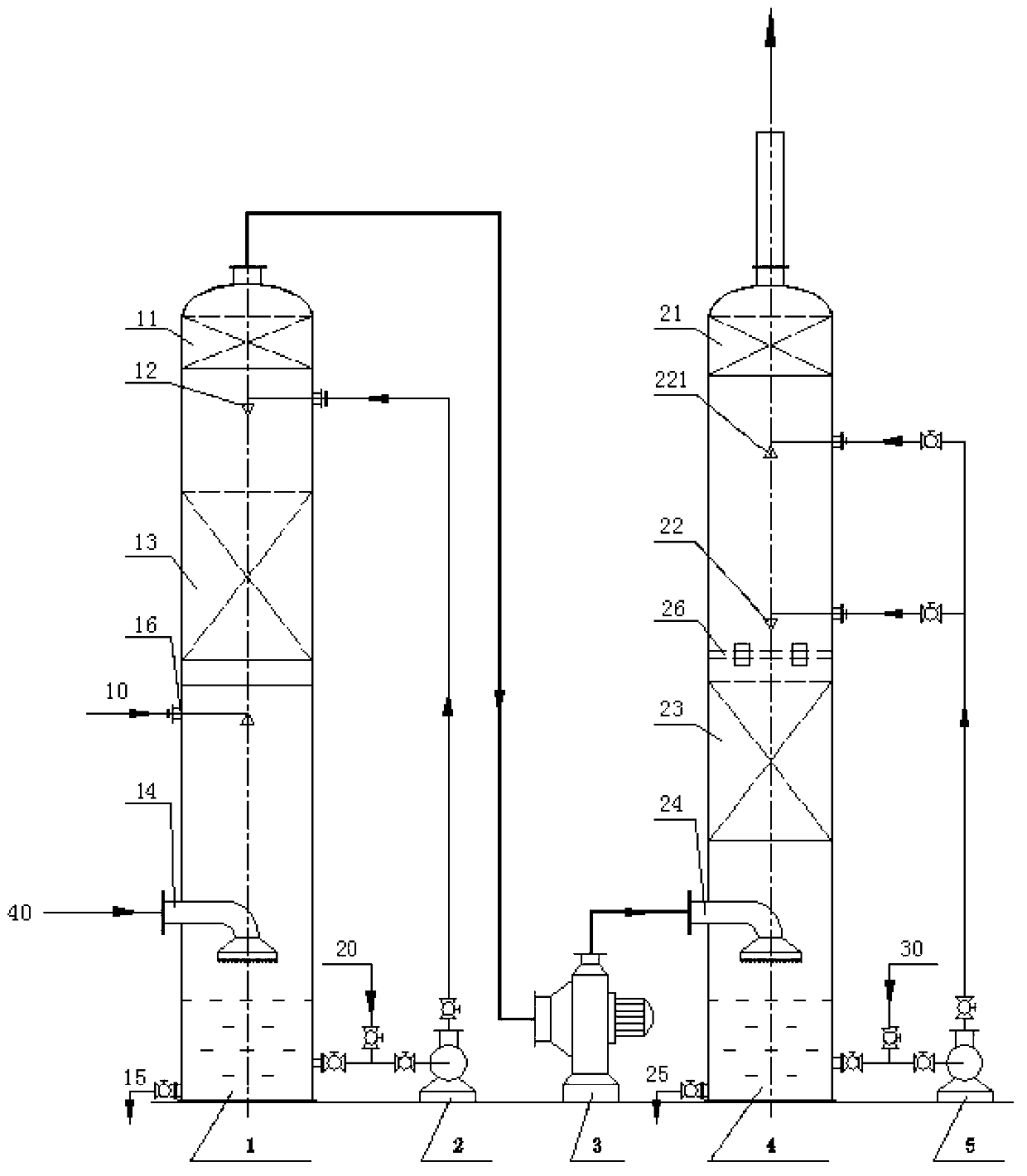

Process for treating malodorous gases in sludge

The invention relates to a process for treating malodorous gases in sludge. The process comprises the following steps that: due to adoption of two-stage absorption manners in two absorption towers, gas passes through a first-stage absorption tower at first so as to enable alkaline waste gas, reductive waste gas and solid impurities in gas to be eliminated by using acid absorption liquid; then, gas passes through a second-stage absorption tower so as to enable residual little chlorine and acidic substances in gas to be absorbed by alkali absorption liquid; and finally, absorbed and purified gas is discharged through an exhaust pipe on the top of the second-stage absorption tower in a standard reaching manner. The process for treating malodorous gases in sludge disclosed by the invention is capable of effectively treating malodorous gases emitted from sludge, therefore, secondary pollution of waste gas to air is reduced; the living environment of people is greatly improved; and health of people gets a certain guarantee.

Owner:杭州国泰环保科技股份有限公司

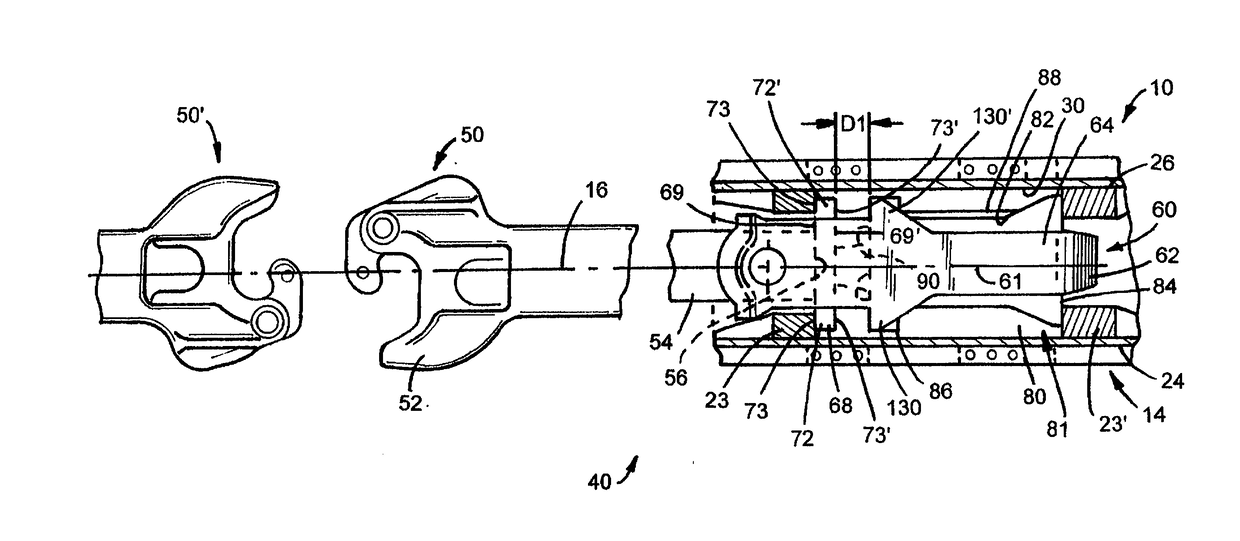

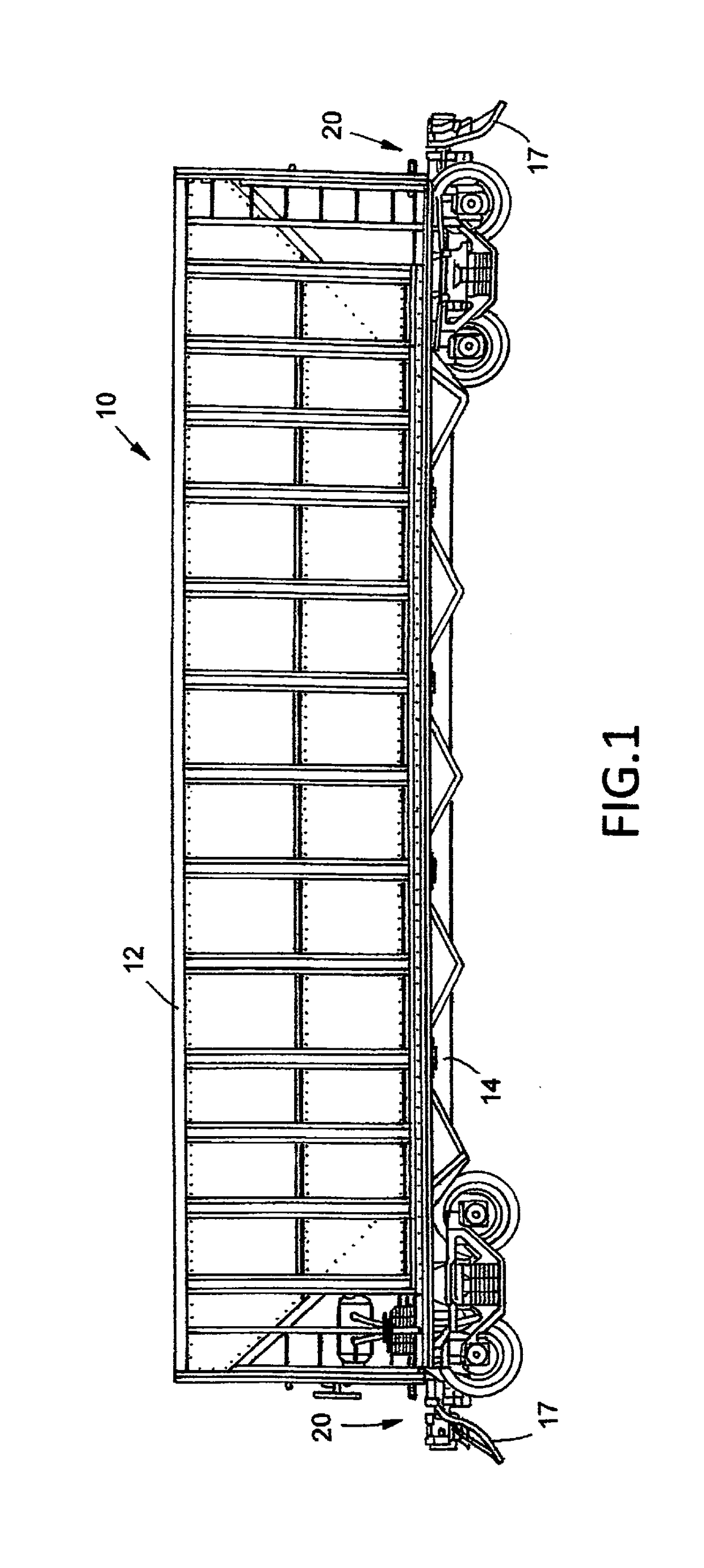

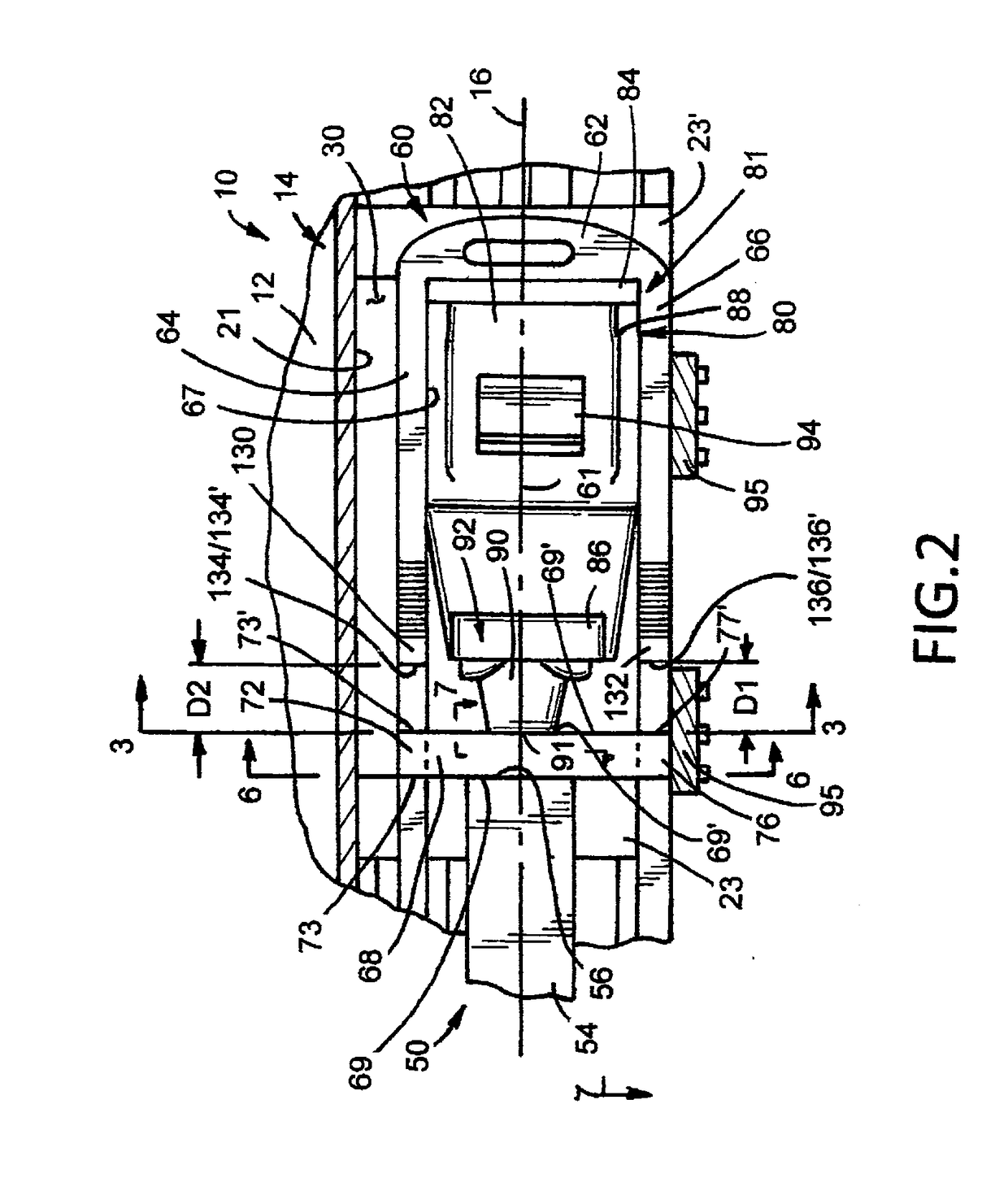

Railroad car coupling system

ActiveUS20170166225A1Avoid separationOptimize allocationBufferDraw-gearCoupling systemMechanical engineering

A railroad car coupling system including a draft sill with front and rear stops, a coupler along with an energy management assembly for receiving and dissipating external forces experienced by the coupler. A yoke also forms part of the coupling system and is operably coupled to the coupler. The yoke includes top and bottom walls which each include two forward facing stops. A follower is mounted substantially between the top and bottom walls of the yoke for receiving forces experienced by the coupler. The follower is configured with two laterally spaced vertical extensions disposed toward opposed upper corners of the follower and two laterally spaced vertical extensions disposed toward opposed lower corners of the follower. Forward facing surfaces on the follower extensions arc arranged in generally coplanar relationship relative to each other. Rearward facing surfaces on the follower extensions are arranged in generally coplanar relationship with each other and operably engage with the forward facing stops on the yoke to enhance the distribution of forces when the follower engages the front stops on the center sill when the coupling system is in a full draft condition.

Owner:MINER ENTERPRISES INC

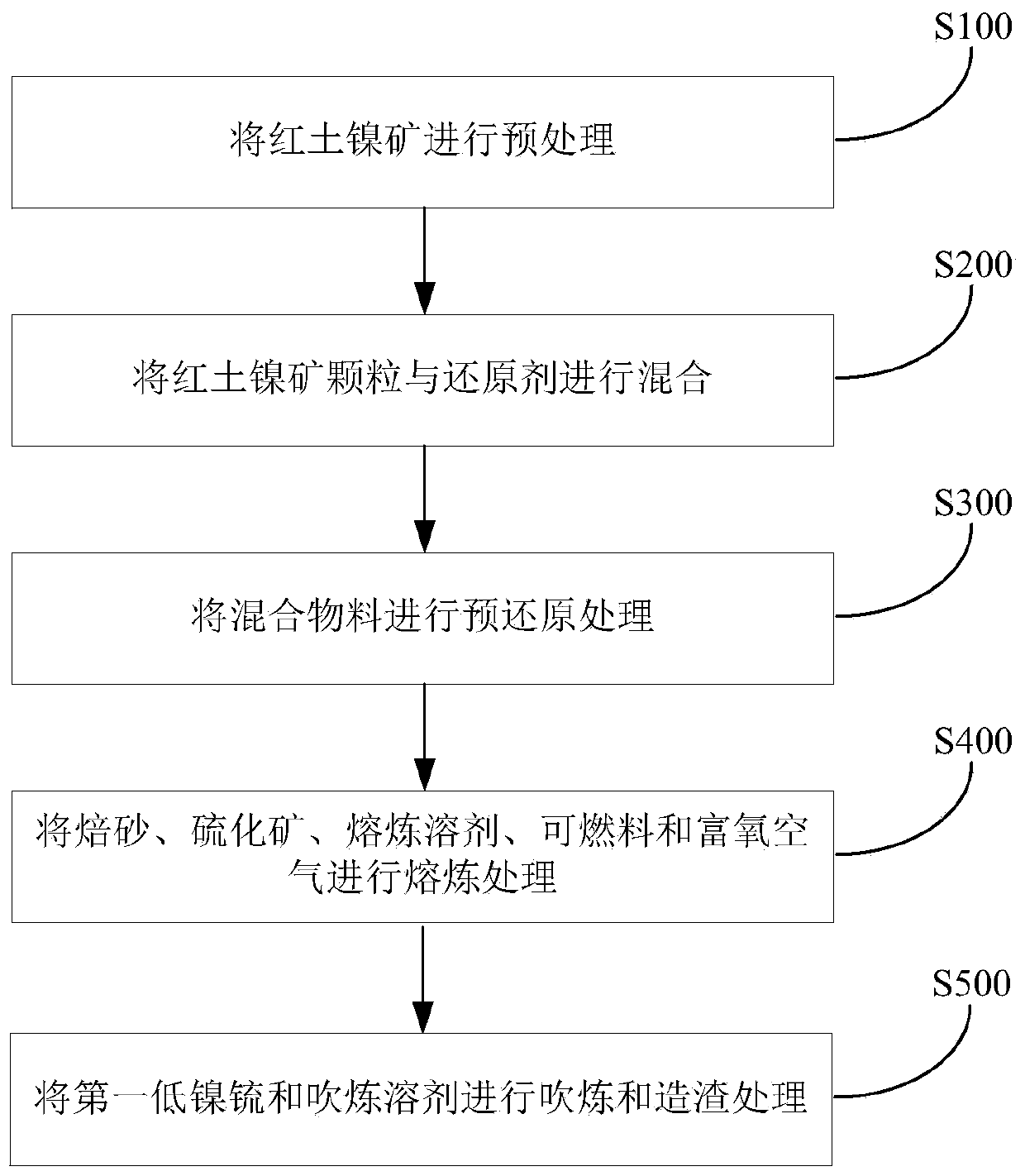

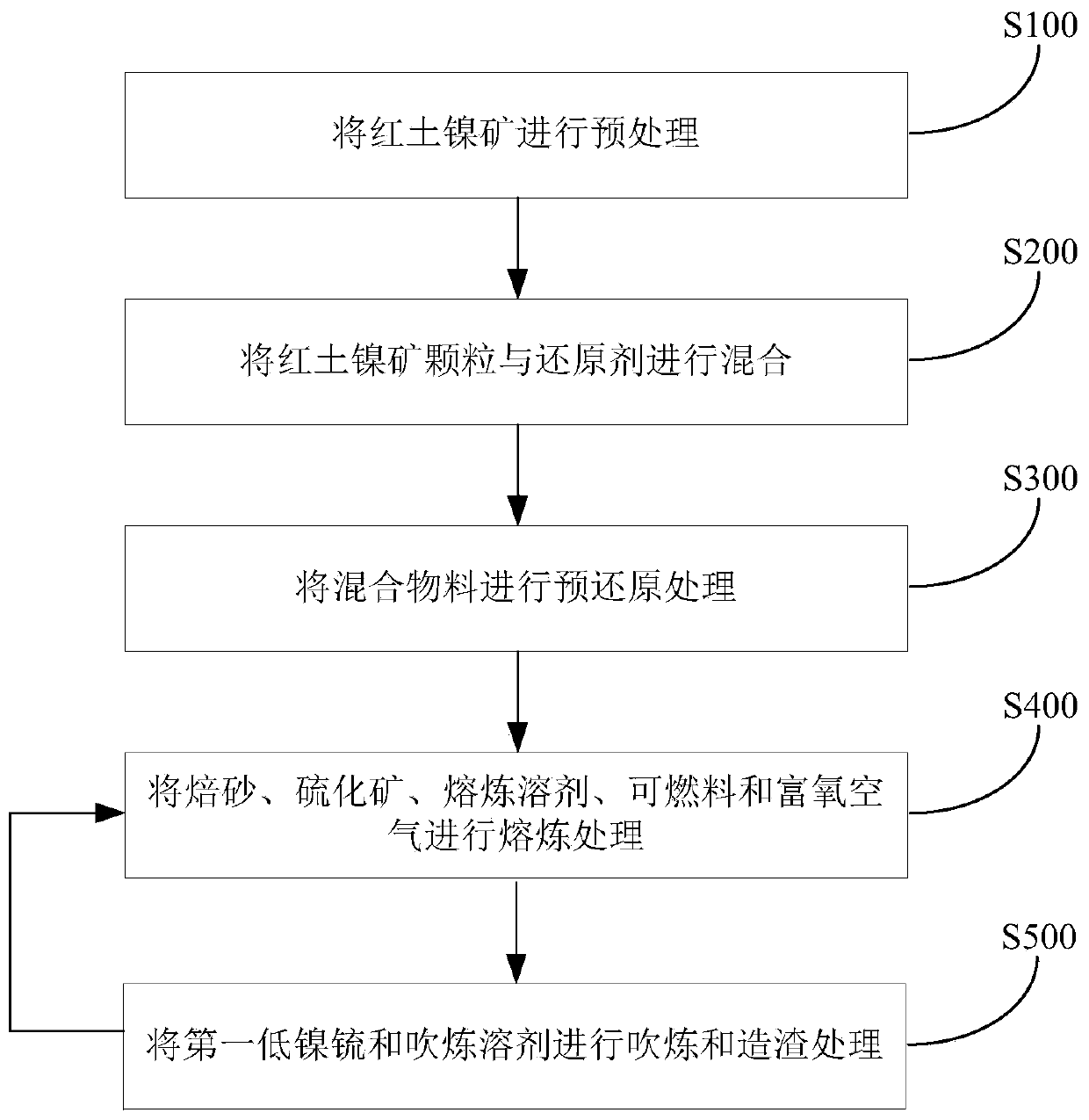

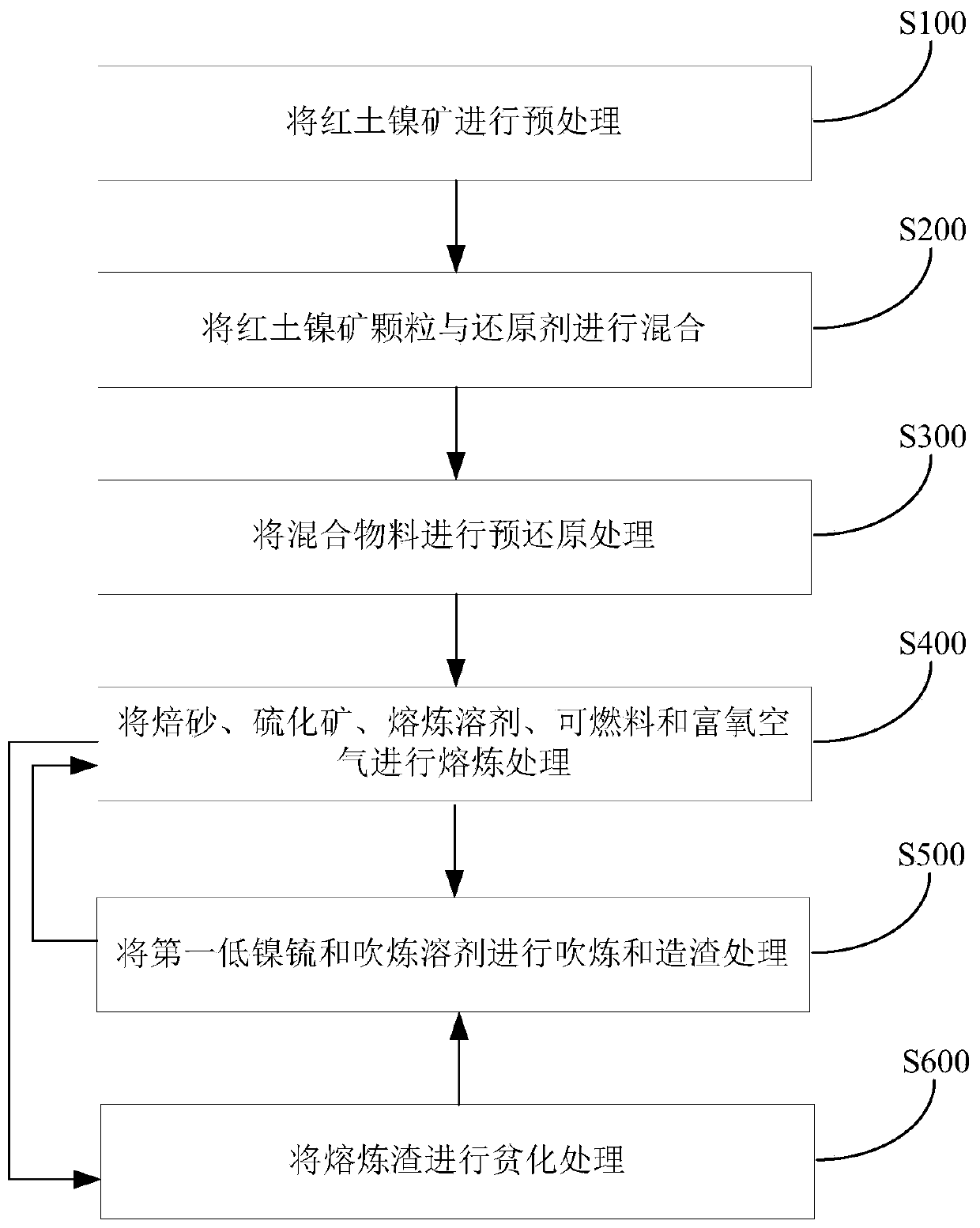

Method for treating laterite-nickel ore

The invention discloses a method for treating laterite-nickel ore. The method comprises the following steps of: (1) pretreating the laterite-nickel ore to obtain laterite-nickel ore particles; (2) mixing the laterite-nickel ore particles with a reducing agent to obtain a mixed material; (3) pre-reducing the mixed material to obtain roasted ore; (4) smelting the roasted ore, sulfide ore, a smeltingsolvent, combustible and oxygen-enriched air to obtain first low-nickel matte and smelting slag; and (5) blowing and slagging the first low-nickel matte and a blowing solvent to obtain high-nickel matte and blowing slag. The method is high in efficiency, low in energy consumption and high in metal recovery rate when used for treating the laterite-nickel ore.

Owner:CHINA ENFI ENGINEERING CORPORATION

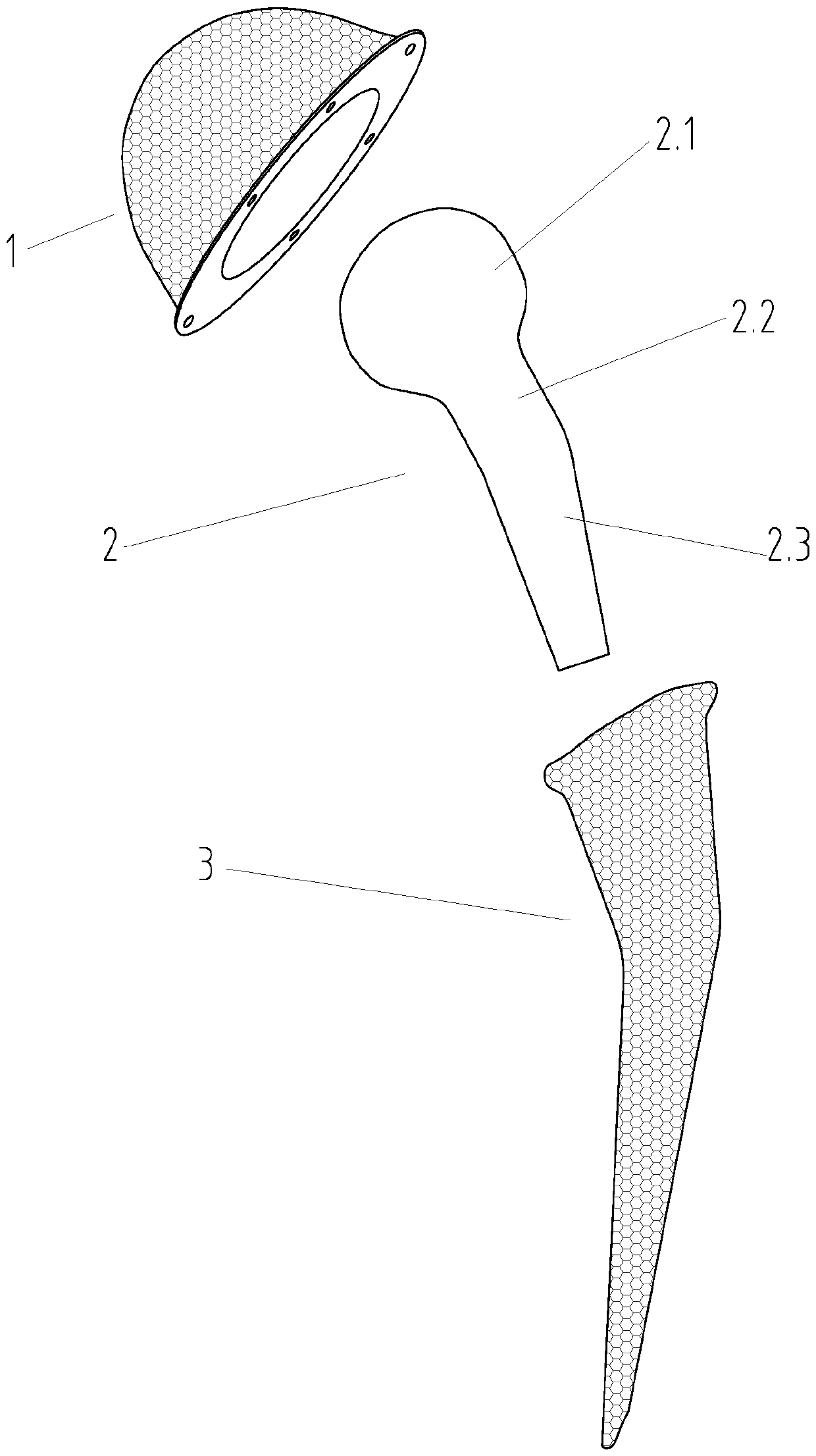

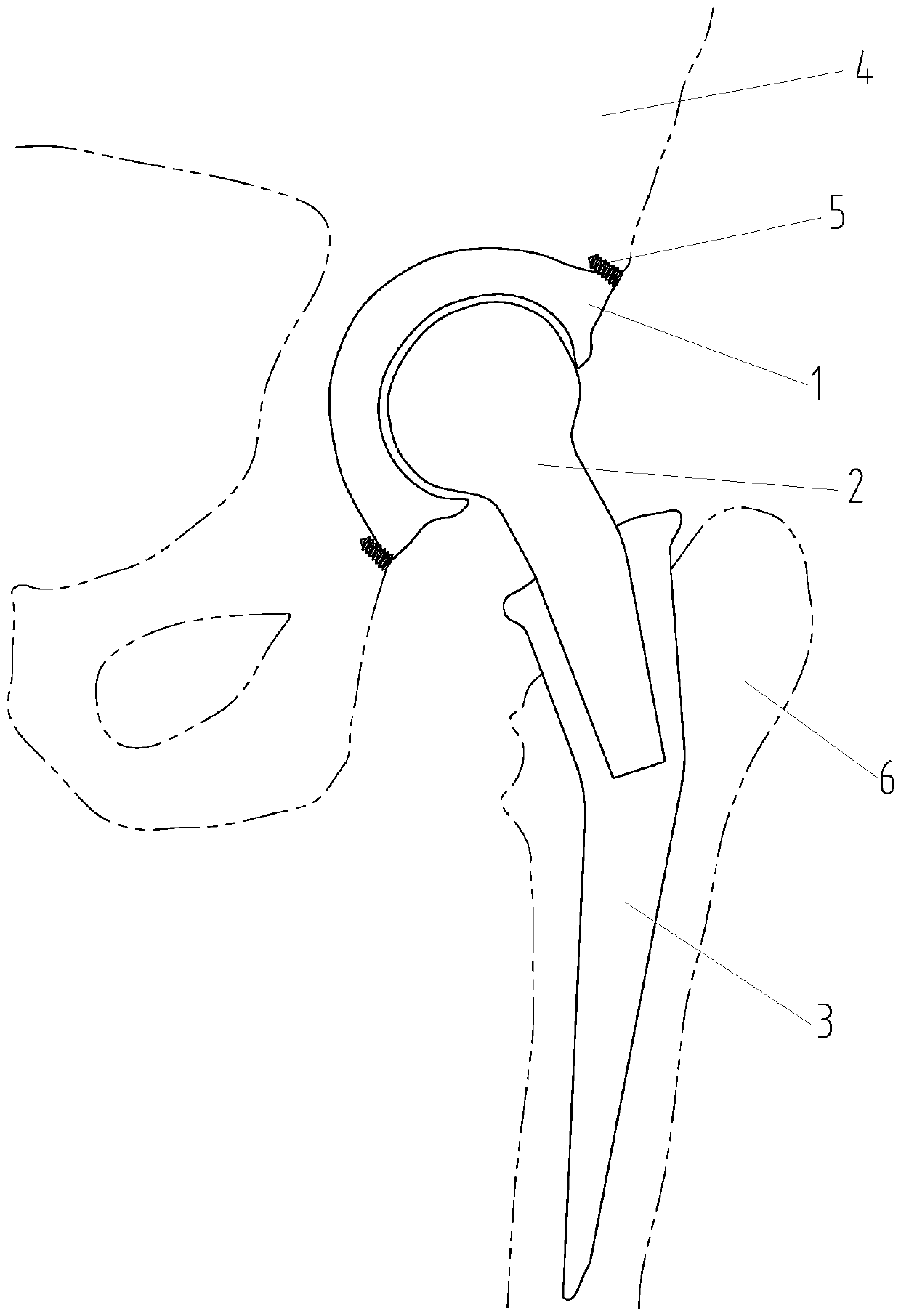

Preparation method of super-wear-resistant and high-toughness artificial hip joint with biological activity

ActiveCN107899083ABiologically activePromote migrationJoint implantsTissue regenerationSelf-healingWear resistant

The invention provides a preparation method of super-wear-resistant and high-toughness artificial hip joint with biological activity. The preparation method comprises six steps of preparation of a steel mold, preparation of an artificial hip joint germule, formation of a pore, filling of the pore with a PLLA / nHA compound, spraying of a PGA / nHA composite coating layer and surface degradation treatment. A composite material of polyether-ether-ketone and hydroxyapatite whiskers is used as a stent material; the pore is formed in a position corresponding to the stent material, and is filled with the degradable PLLA / nHA active composite material; then the PGA / nHA composite coating layer is sprayed; after the surface degradation treatment is performed, the super-wear-resistant and high-toughnessartificial hip joint with biological activity is obtained. The artificial hip joint prepared through the preparation method is combined with bones via the self-healing effect of bone induced cells onthe bones, and is higher in mechanical property, biological compatibility and bone combination strength than a conventional product.

Owner:NANNING YUEYANG TECH

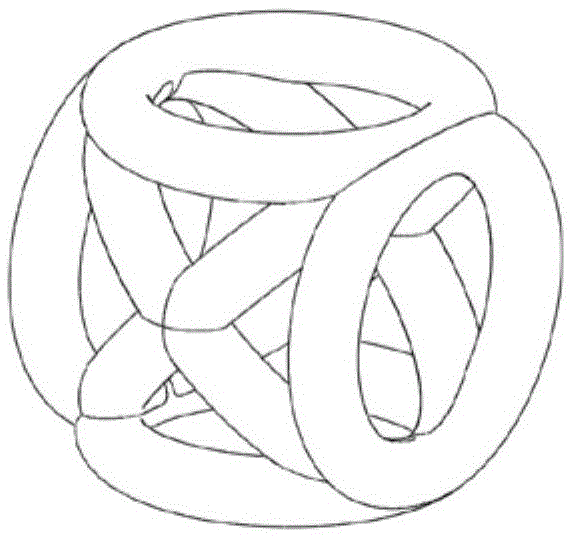

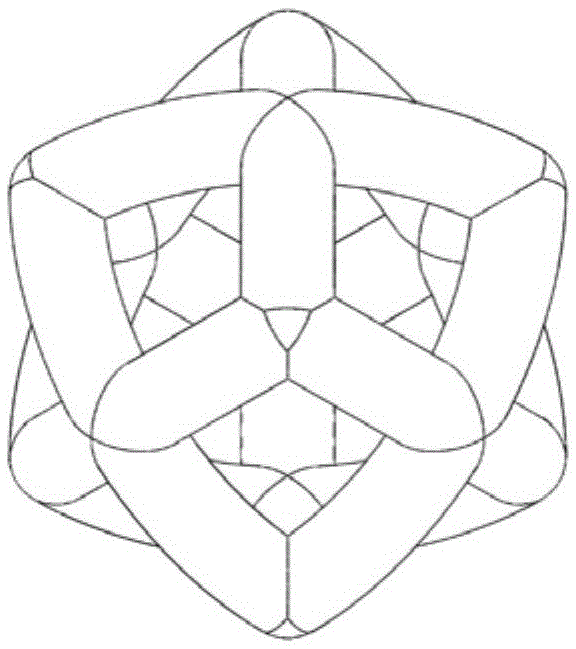

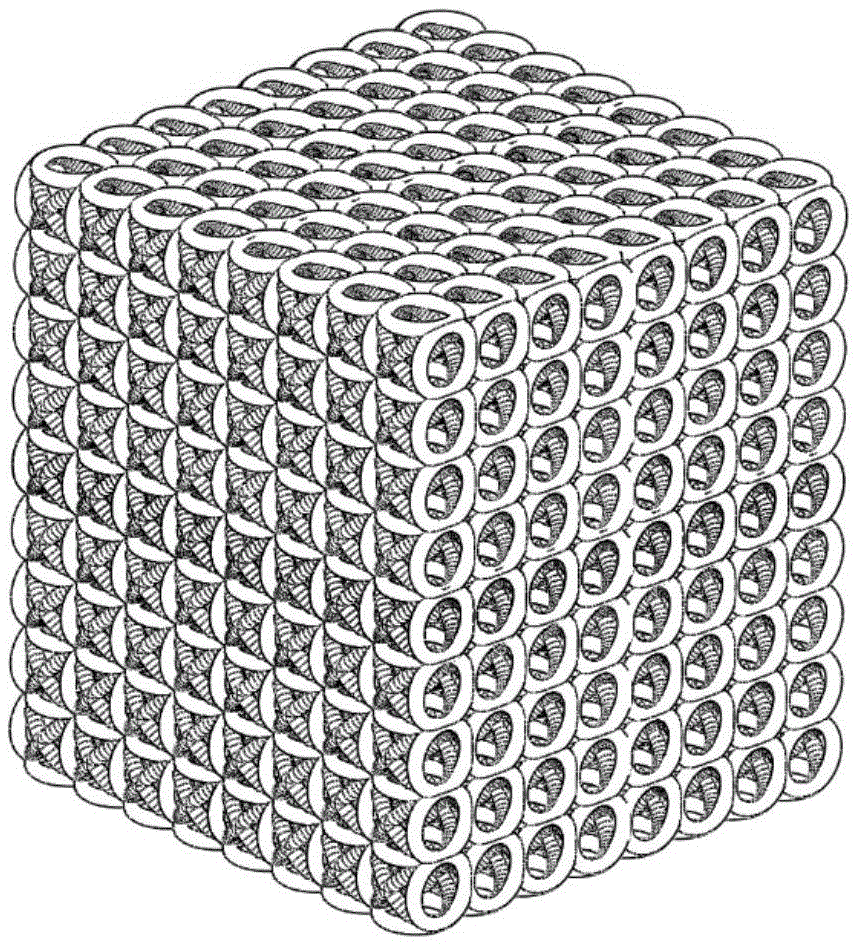

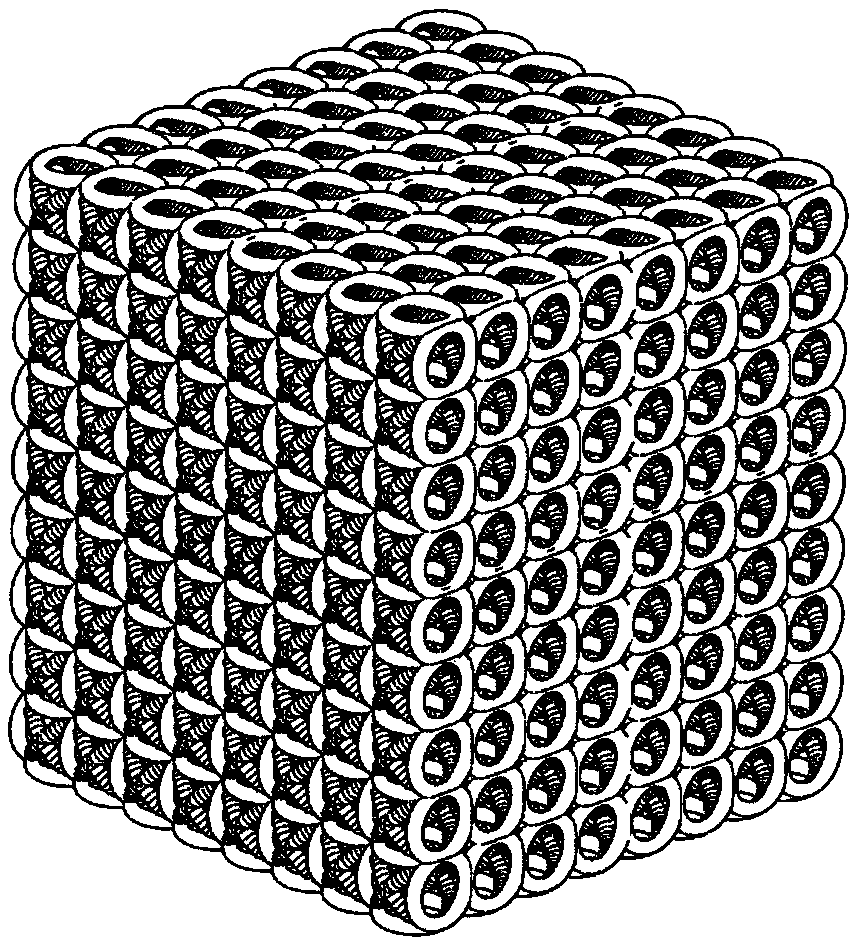

Porous implant filled with O-intersecting lines units

InactiveCN105496611AThe preparation method is reliable and feasibleGreat potentialJoint implantsTissue regenerationBone structureTissue fluid

A porous implant filled with O-intersecting lines units is mainly oriented to femoral stems and comprises a femoral stem end, a porous main body part and a screw positioning hole part, wherein the femoral stem end is used for positioning the porous implant, the screw positioning hole part is used for fixing the implant and a host, the porous main body part is a three-dimensional through porous network entity mainly formed by being filled with the O-intersecting lines units, the porous network entity comprises hollowed-out entities formed by scanning of O-intersecting lines unit cylinders penetrating through and crossing with one another in space, the hollowed-out entities are formed by pairwise perpendicular and linearly stacked O-intersecting lines unit cylinder surfaces, and the porous network entity has the pore diameter ranging from 400 mu m to 1,000 mu m, the unit wall thickness ranging from 80 mu m to 120 mu m and the porosity ranging from 55% to 85%. Thus, a porous network structure formed by stacking of the hollowed-out entities is close to a bone structure, has the high porosity, the high communication ratio and the larger surface contact area, is suitable for new bone ingrowth and circulation of nutrition tissue liquids and has the considerable clinical medical prospect.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

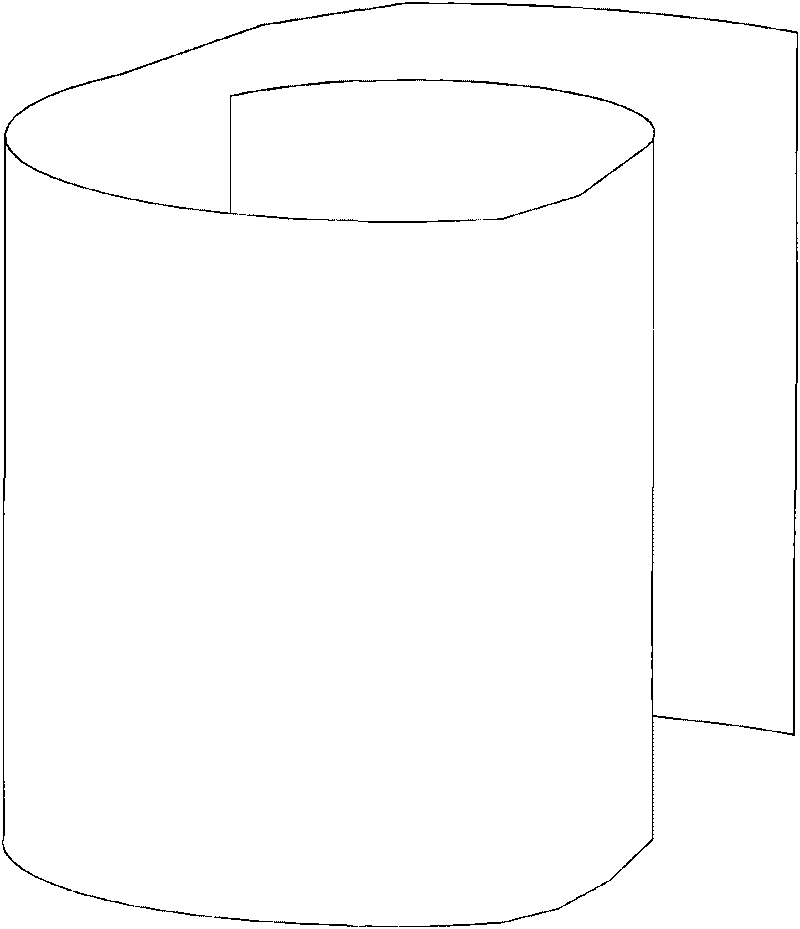

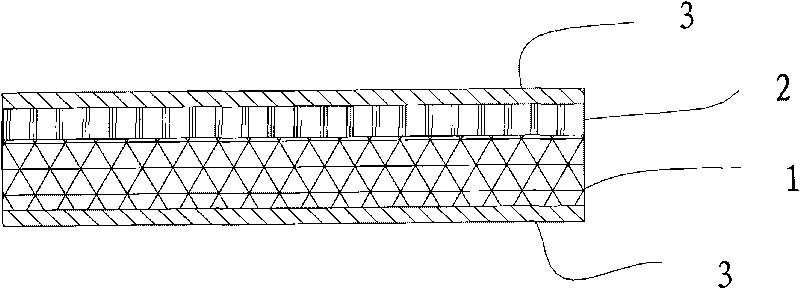

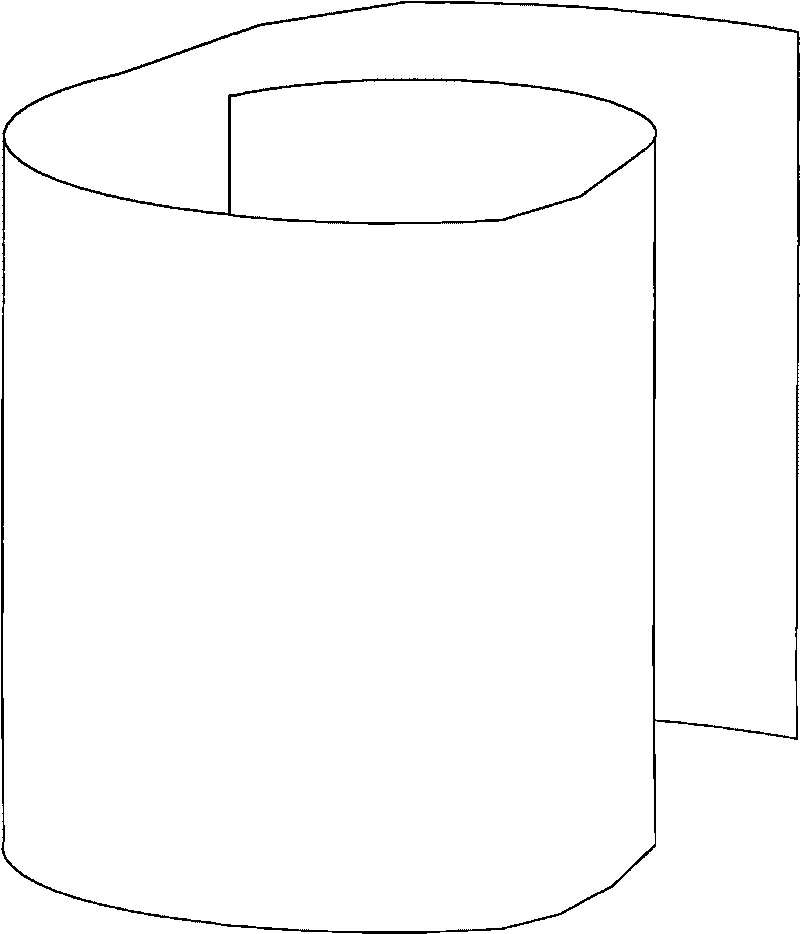

Microorganism immobilized carrier and preparation method thereof

ActiveCN101724620AIncrease surface contact areaEasy to operateOn/in organic carrierMicroorganismPolyvinyl alcohol

The invention discloses a microorganism immobilized carrier and a preparation method thereof. The immobilized carrier is a helical tube, which is formed by superposing a stainless steel mesh and a nylon mesh and then winding same. A magnetic polyvinylalcohol thin-film layer is covered outside the stainless steel mesh and the nylon mesh. The preparation method for the microorganism immobilized carrier comprises the following steps: preparing the magnetic polyvinylalcohol thin-film layer; modifying and activating the magnetic polyvinylalcohol thin-film layer; preparing the helical tube structure; and immobilizing a microorganism. The microorganism immobilized carrier has the advantages of large surface contact area, multiple absorbed microorganisms, magnetism, simple operation, reduction of production and operation steps, reduction of cost, strong adsorbability, and strong activity and reliability of the carrier, thereby achieving the recycling aim. The occupancy space is reduced; the product yield is improved; and the mass transfer effect cannot be influenced simultaneously.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

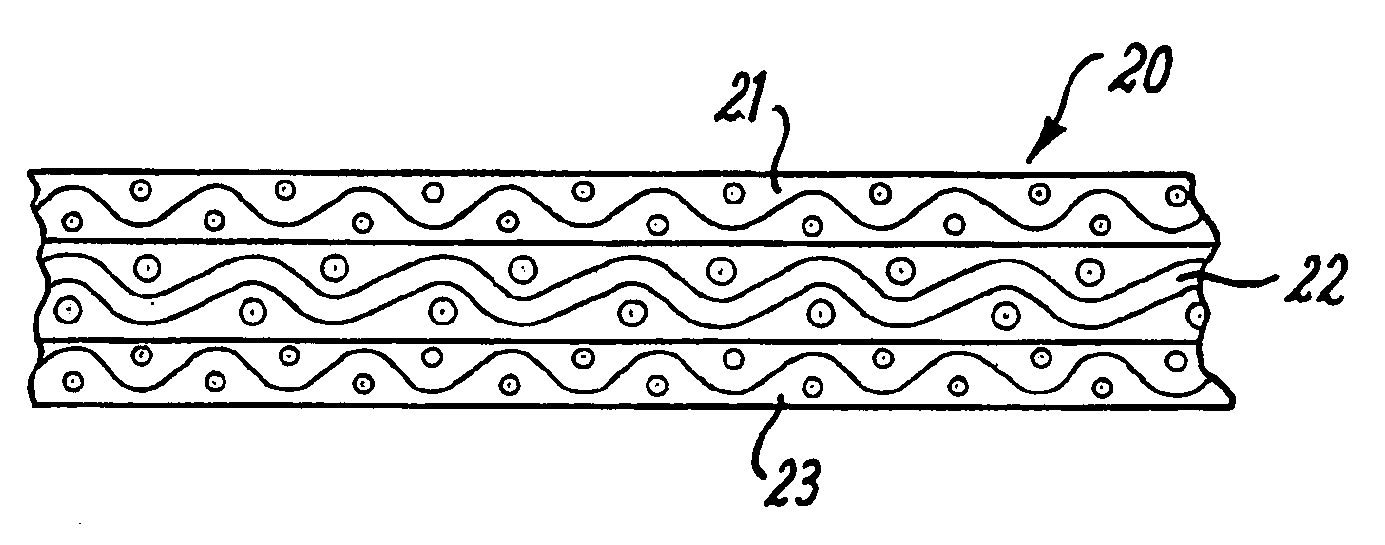

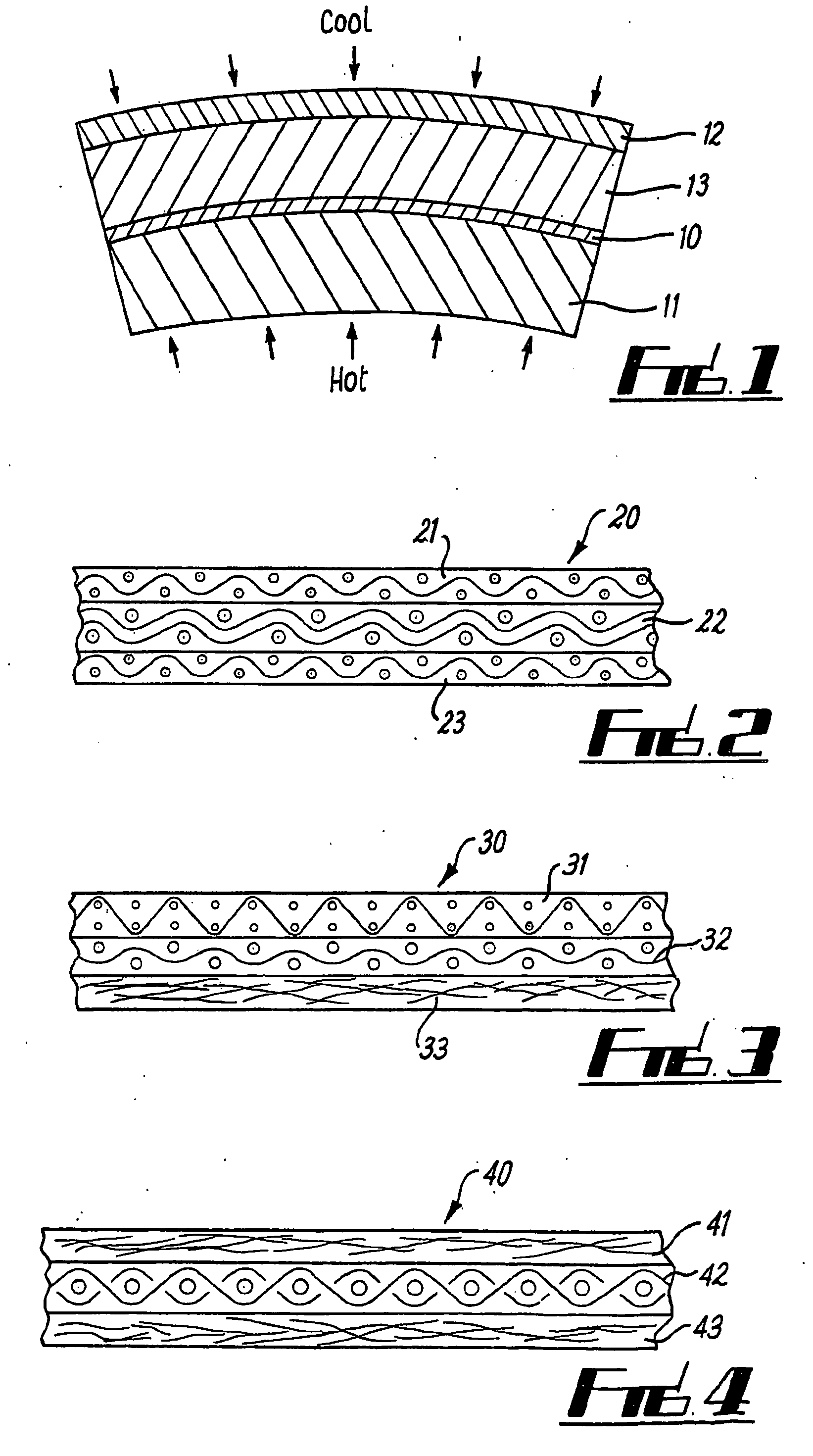

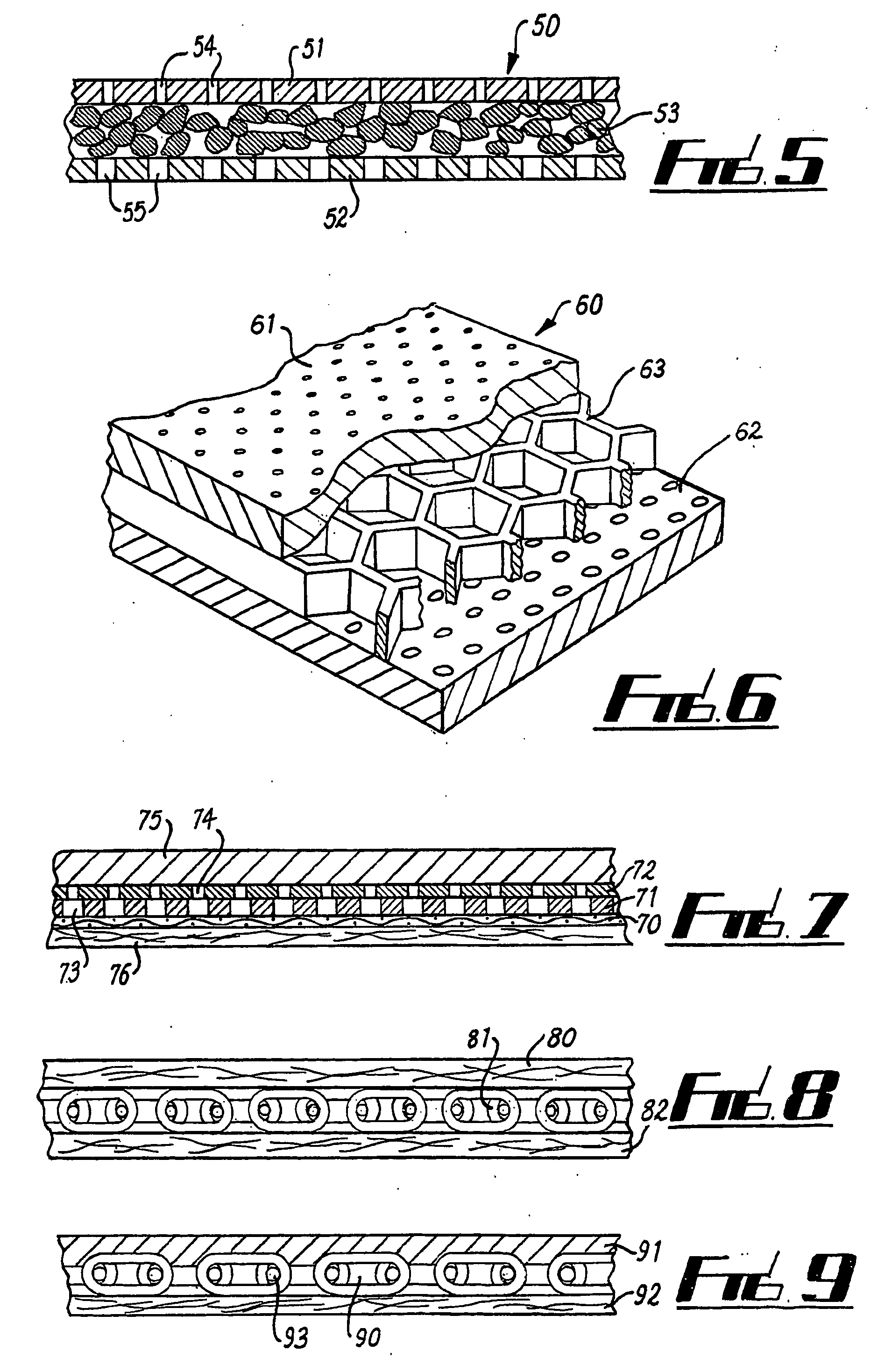

Condensation dryer fabric

InactiveUS20070111625A1Large poresLow capillary forceLayered productsMachine wet endFine structureHoneycomb

A fabric for use in dynamic condensation drying apparatus comprises a single fabric comprising at least a core layer (22) of relatively large structure and large void size, and a paper support layer (21) of relatively fine structure and pore size, and optionally a cylinder side layer (23) of intermediate structure and pore size. A range of alternatives are shown, including the use of fibrous batts, woven fabrics, perforated membranes, sintered layers, chain-link fabrics, and honeycomb layers, as well as unitary woven or sintered fabrics incorporating the layers in a single structure.

Owner:VOTH FABRICS PATENT GMBH

Injection molding of polymers by microwave heating

InactiveUS7122146B2Improve efficiencyIncrease surface contact areaDielectric heatingAuxillary shaping apparatusMicrowave ovenInjection molding machine

Injection molding machine utilizes microwave heating. A microwave oven adapted to receive a microwave absorbent plasticizing vessel is utilized with or incorporated into an injection molding system to form a plasticizing unit for heating polymer granules to an injection temperature and injection of the melt into the cavity of the injection mold. The polymer granules may be preheated by conventional heating systems to a temperature at which the granules become microwave absorbent before heating to the injection temperature in the microwave oven. The injection molding machine also contains a hydraulic actuator for injection of the melt. The ceramic materials forming the plasticizing vessel are selected to provide equal heating rates of mold members and relatively uniform heating of polymer to desired injection temperature.

Owner:AKOPYAN RAZMIK L

Arthrodial cartilage proto micro-carrier

InactiveCN1868424AImprove adhesionIncrease surface contact areaJoint implantsFreeze-dryingDistilled water

A proto-microcarrier for arthrodial cartilage is prepared from fresh joint cartilage through freeze drying, pulverizing, sieving adding trypsin to the particles, oscillating at 37 deg.C for 24-48 hr, washing with distilled water three times, adding TritonX-100, oscillating at 4 deg.C for 48-72 hr, flushing with distilled water for 48 hr, centrifugal separation of deposit, mixing with distilled water, freeze drying, UV irradiating, Co60 irradiation, digestion by trypsin, stirring, pulverizing and washing with distilled water three times.

Owner:GENERAL HOSPITAL OF PLA

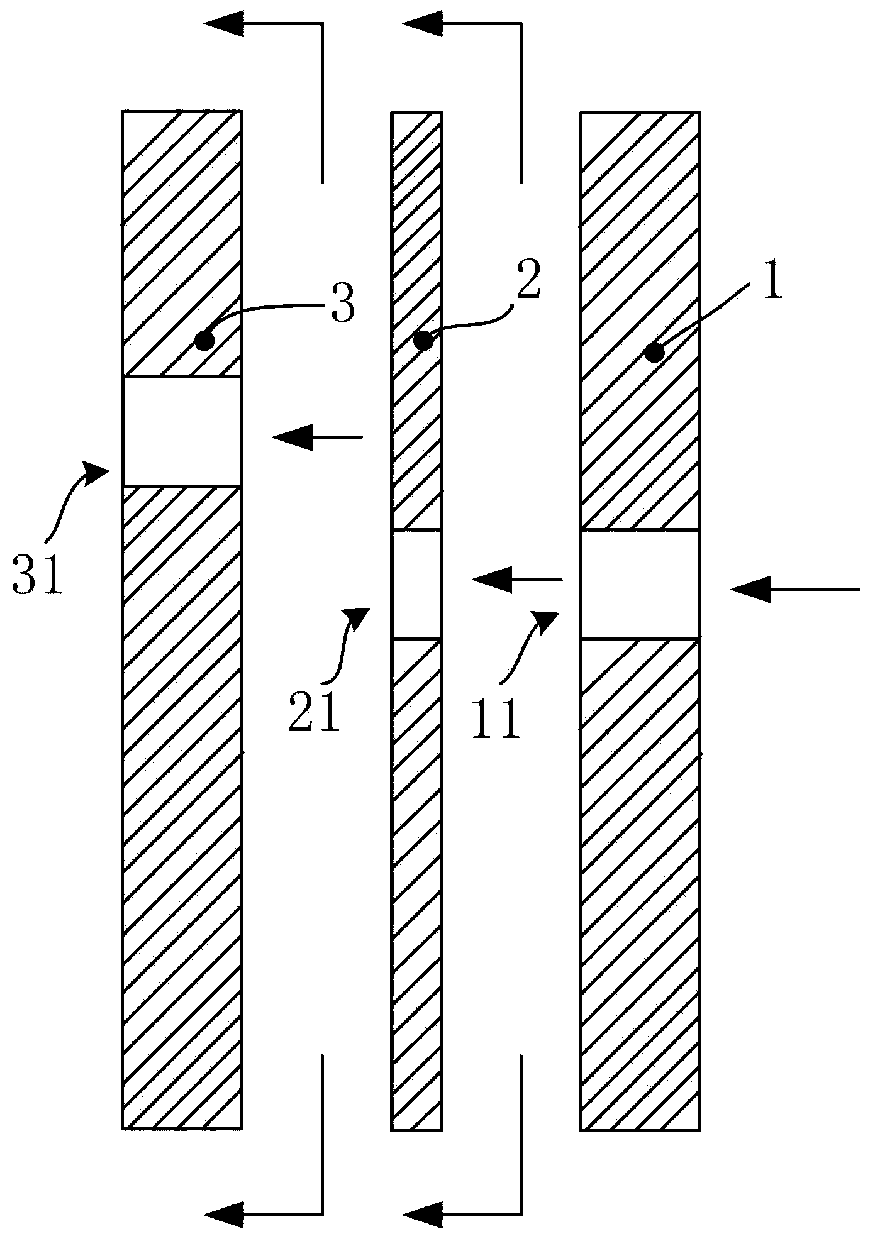

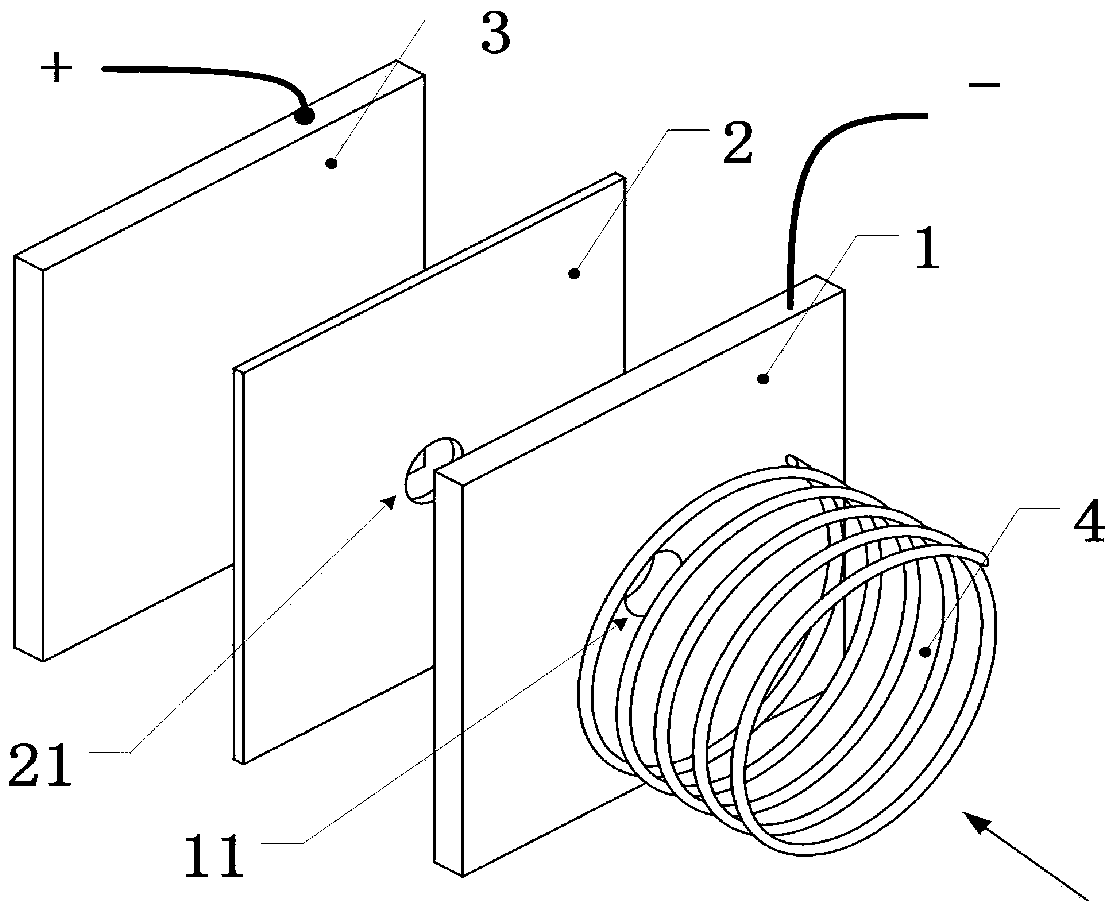

Ozone electrolysis chamber electrolysis structure

PendingCN109487293AIncrease surface contact areaImprove electrolysis efficiencyCellsWater contaminantsElectrolysisWater flow

The invention discloses an ozone electrolysis chamber electrolysis structure. The ozone electrolysis chamber electrolysis structure comprises a cathode sheet, an anode sheet and a membrane arranged between the cathode sheet and the anode sheet. One side face of the membrane is parallel and opposite to the side face of the cathode sheet, the other side face of the membrane is parallel and oppositeto the side face of the anode sheet, and the surfaces / the surface of the cathode sheet and / or the anode sheet are / is provided with through holes. The through holes formed in the cathode sheet and theanode sheet are staggered, and axial projections are not overlapped. Through holes formed in the surface of the membrane are axially opposite to the through holes formed in the surface of cathode sheet or the anode sheet. The cathode sheet and the anode sheet are electrically connected through water flowing through the cathode sheet and the anode sheet. Compared with the prior art, the technical scheme has the advantages that the structure is simple, and disinfection is efficient; and the purposes that the ozone water electrolytic tank manufacturing cost is reduced, and the ozone water generation efficiency and sterilization purification capability are improved can be effectively achieved.

Owner:GUANGZHOU DEPOSON ELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com