Patents

Literature

38results about How to "Efficient emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

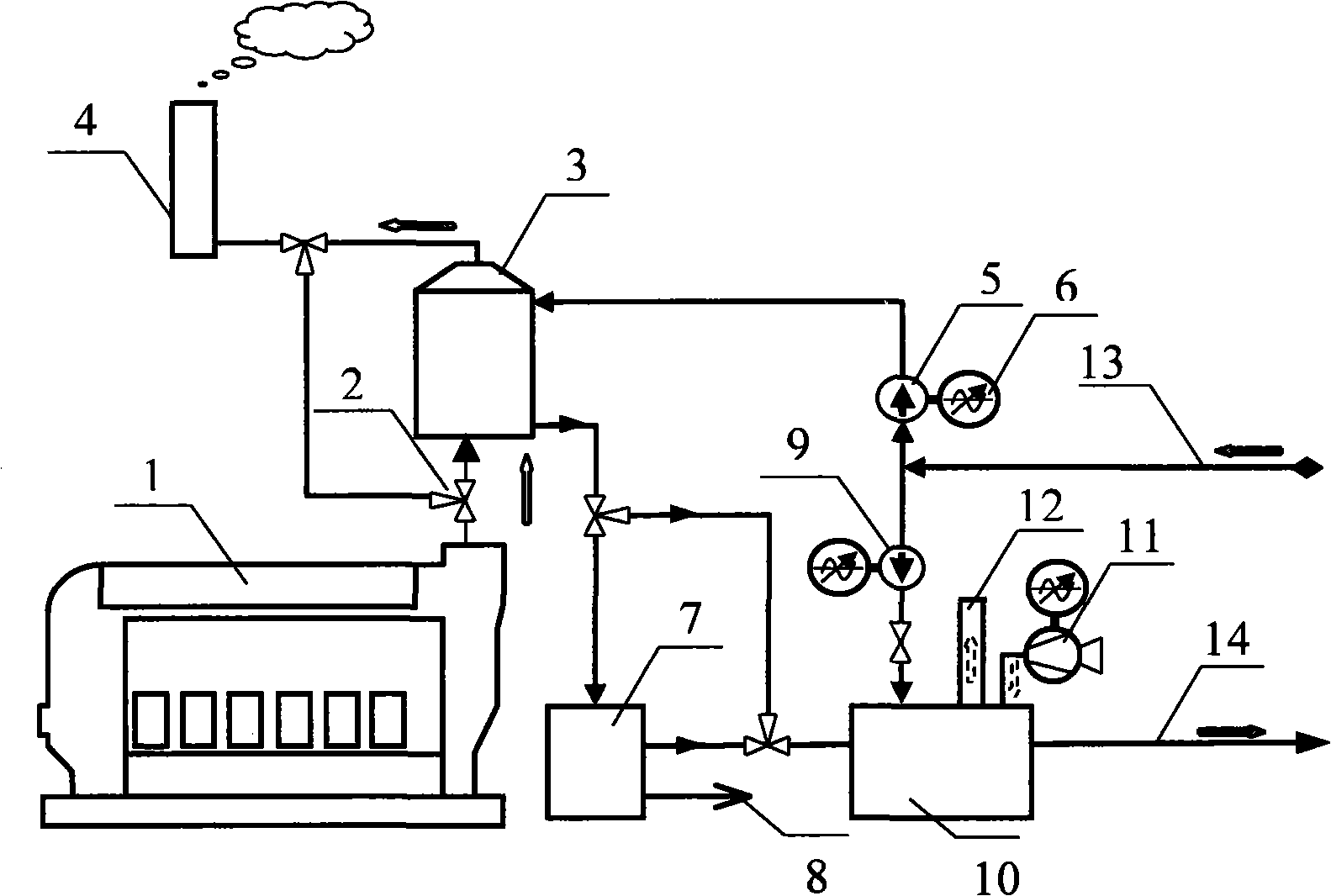

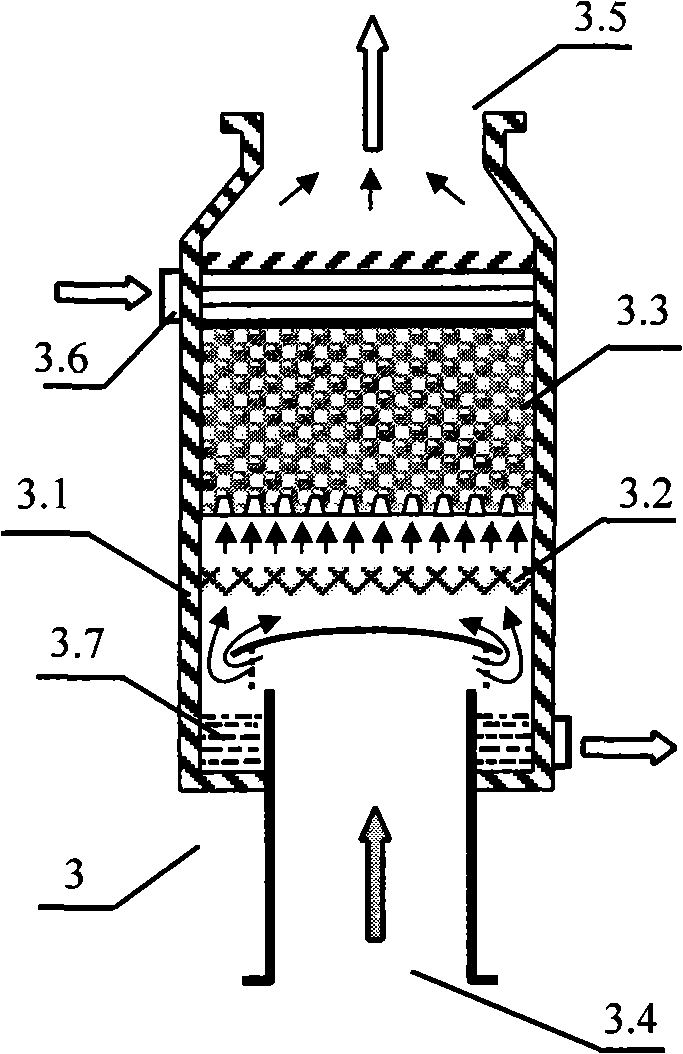

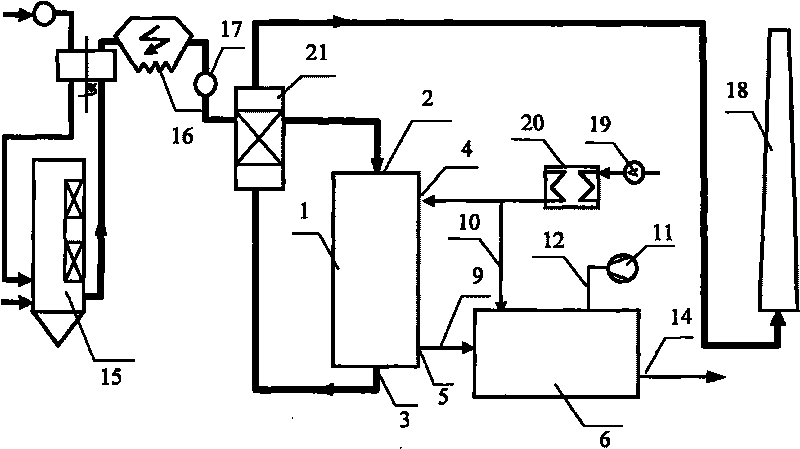

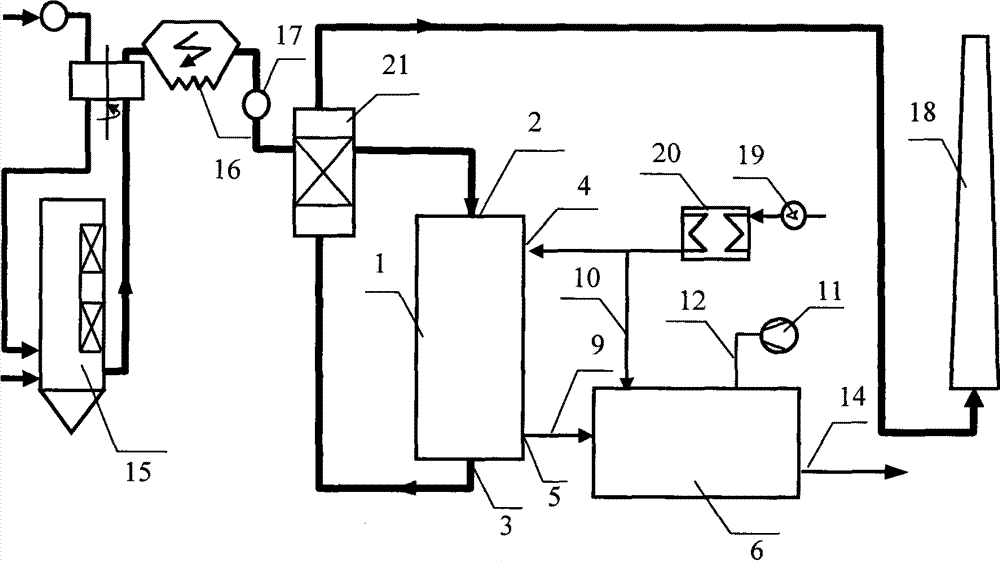

Method and apparatus for desulfurizing exhaust gas of seagoing vessel

InactiveCN101314106AGood technical effectImprove emission reduction efficiencyDispersed particle separationWater savingWater discharge

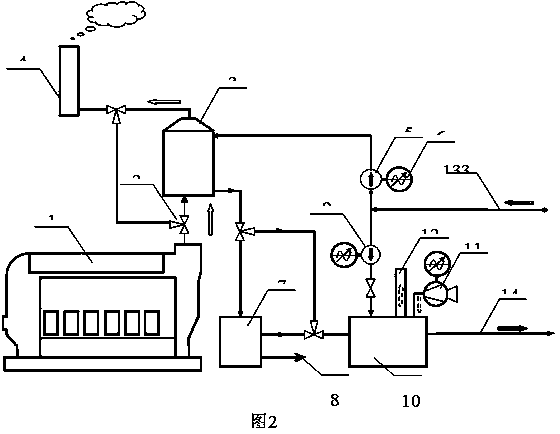

The invention relates to a method and a device for desulfurizing exhaust smoke of a sea-going ship, which uses sea water to reduce discharge of sulfur dioxide and other pollutants of the sea-going ship. The method comprises the following steps of: sea water scrubbing, acidic sea water transferring, acid separating treatment, water discharge and so on. The device comprises a scrubber and a water-saving acid separator, wherein, the upper part of the scrubber is provided with a scrubbing layer, and is communicated with a scrubbing sea water pump through a pipeline; the lower part of the scrubber is provided with a cooling layer; one end of the scrubber is communicated with a smoke exhaust pipe of a ship engine through a scrubbing inlet pipe, while the other end of the scrubber is connected with a scrubbing exhaust pipe; the lower part of the scrubber is communicated with the water-saving acid separator; and the water-saving acid separator is connected with a mixed sea water pump, a draught fan and a main discharge pipe for suitably discharging sea water which is subject to the acid separating treatment. The method and the device have the advantages of high desulfurizing efficiency, small sea water consumption, low equipment manufacturing cost and low running cost.

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

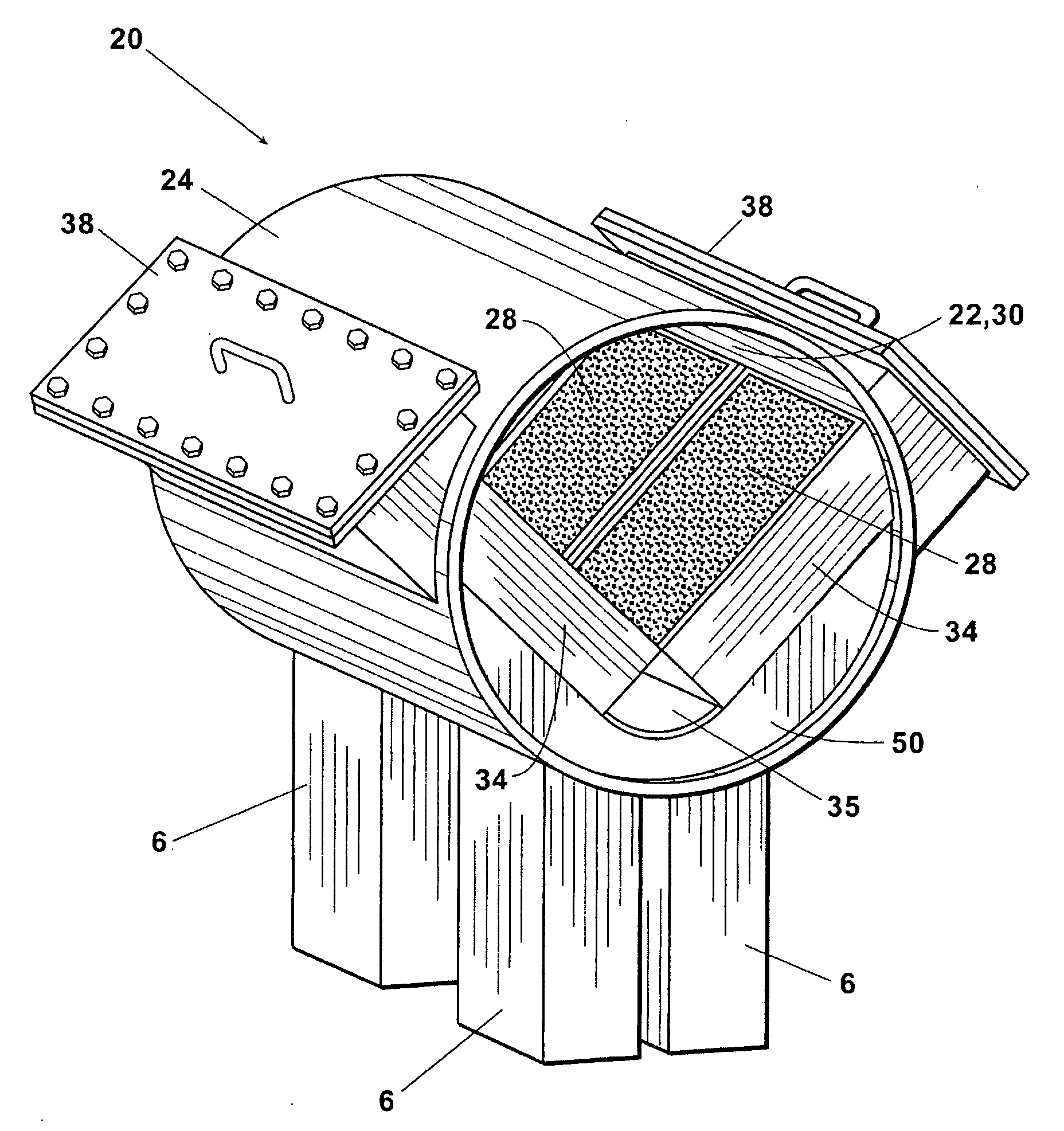

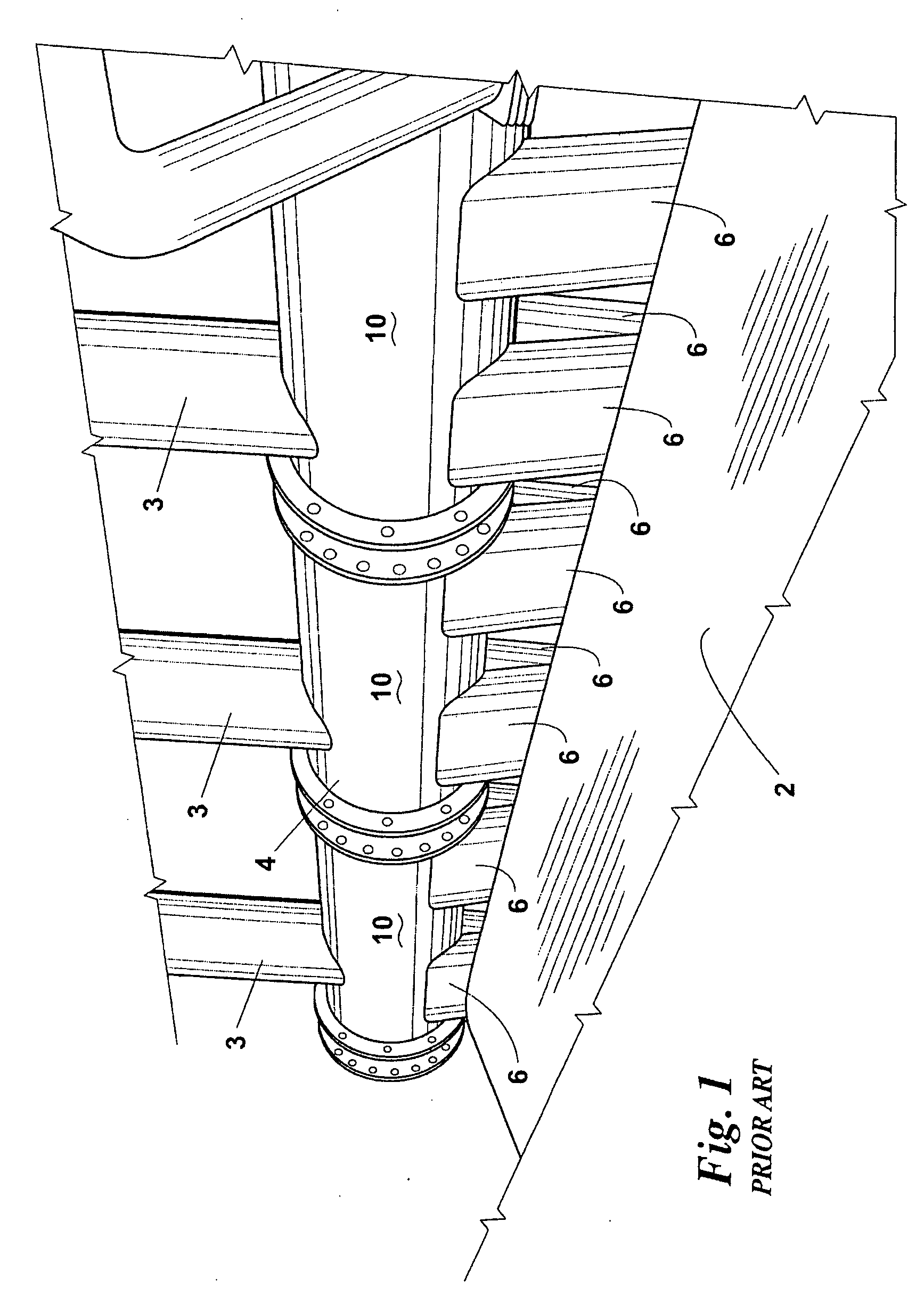

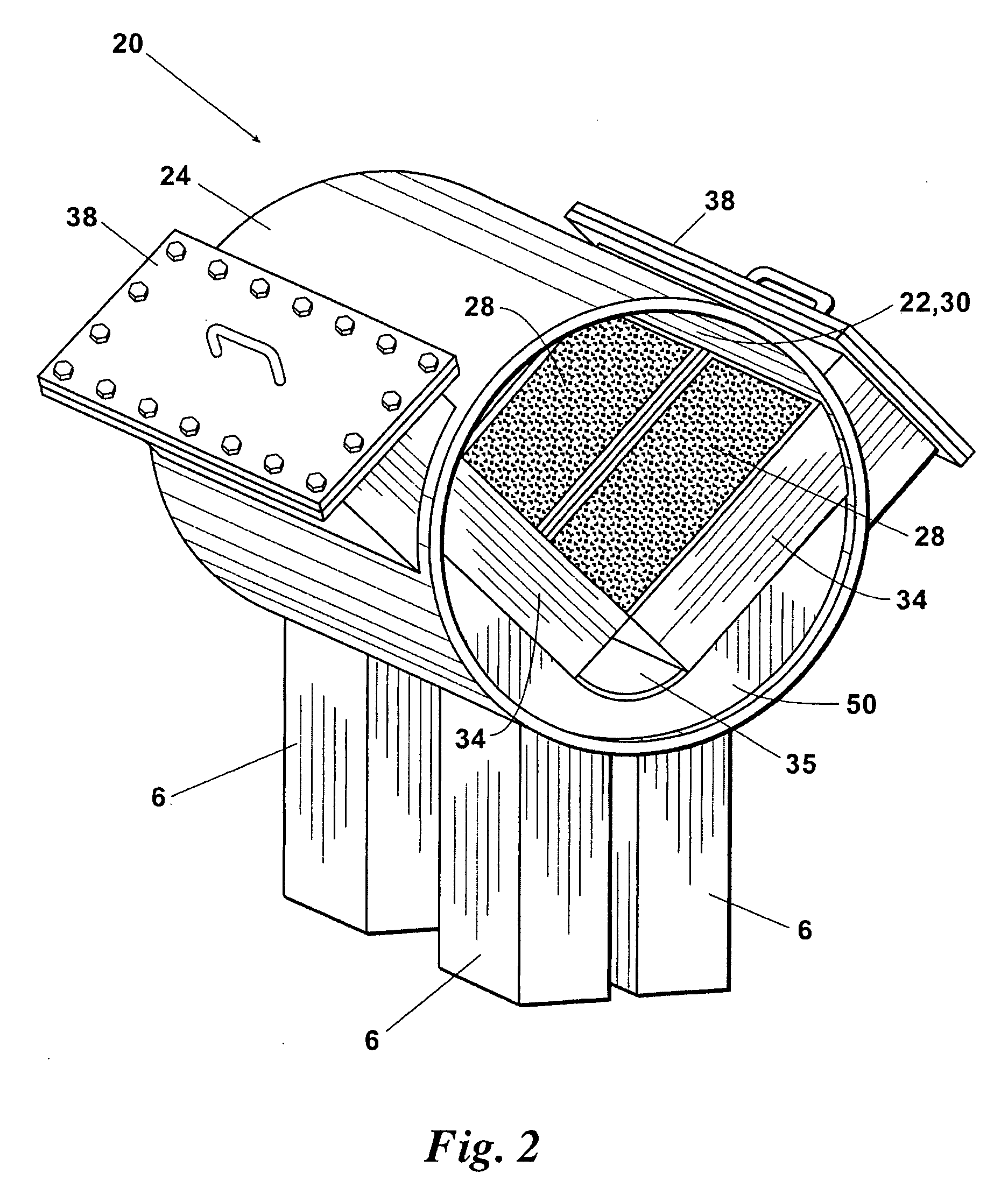

Catalytic converter system and element for diesel engines

InactiveUS20080229733A1Efficient emission reductionEasy to disassembleCombination devicesExhaust apparatusCouplingEngineering

An improved exhaust system and catalytic converter element for a diesel engine wherein the improvement comprises: holding means for restricting the movement of catalytic converter elements in an overhead exhaust manifold; an improved catalytic converter element having at least one retaining rod extending through the catalyst substrate and / or having at least one retaining lip projecting into the substrate; a stabilizer projecting from the cover for the element insertion slot for receiving an end portion of the catalytic converter element to restrict the movement of the converter element in the exhaust manifold; perforated flow distribution elements provided upstream of the catalytic converter elements; and / or vertical coupling manifolds which each receive exhaust from a pair of engine cylinders and then deliver the combined exhaust stream to a separate one of the inlet openings in the bottom of the overhead exhaust manifold.

Owner:MIRATECH GRP LLC

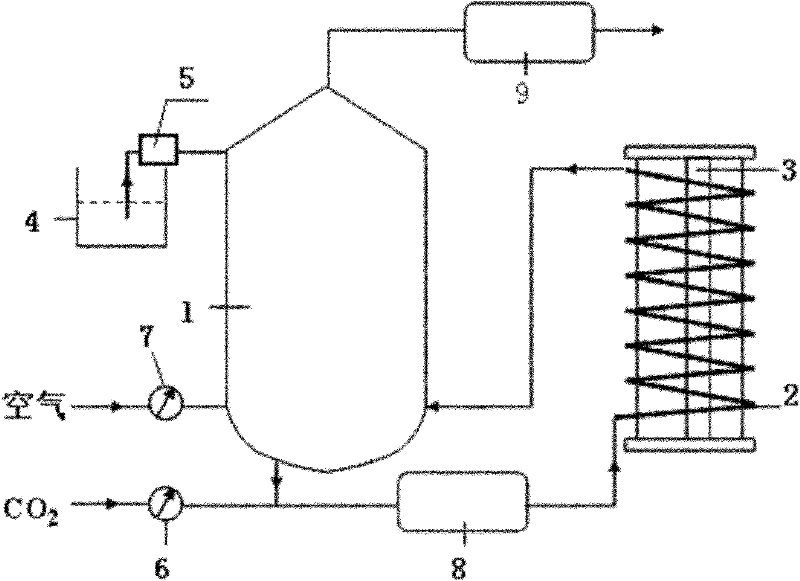

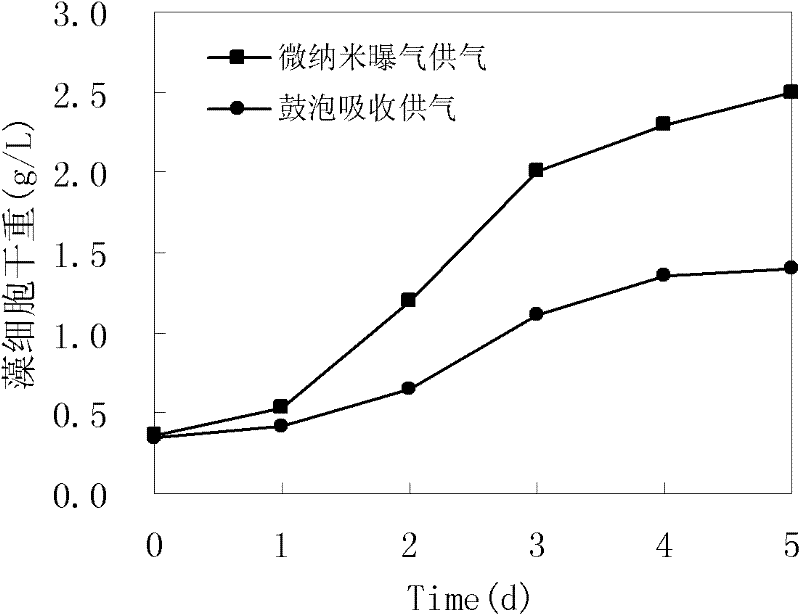

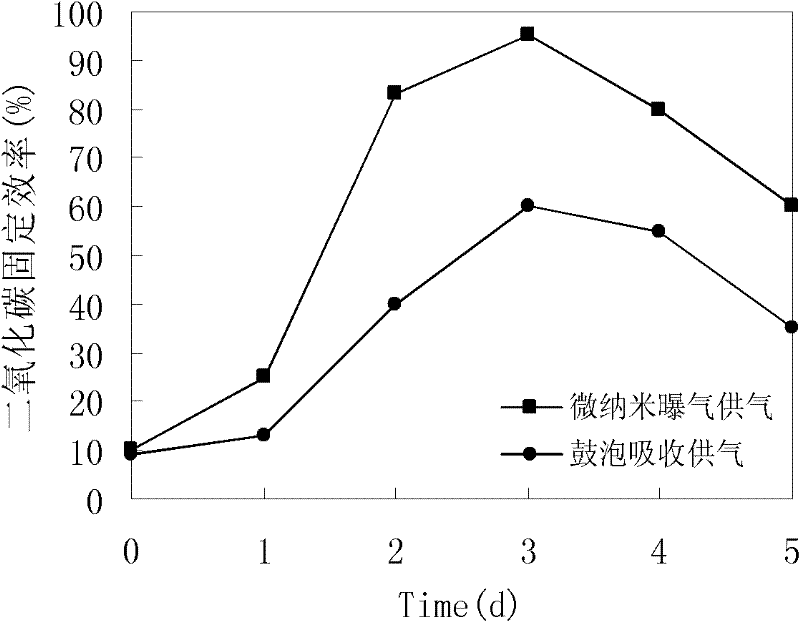

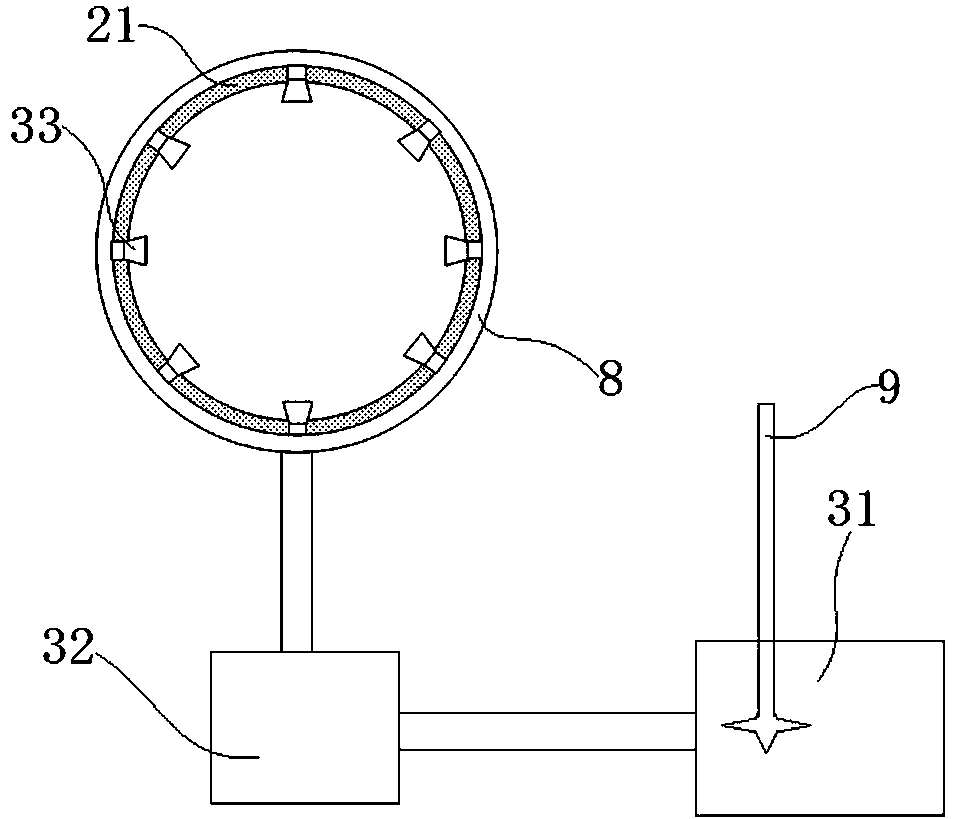

A method for cultivating microalgae and a combined photobioreactor

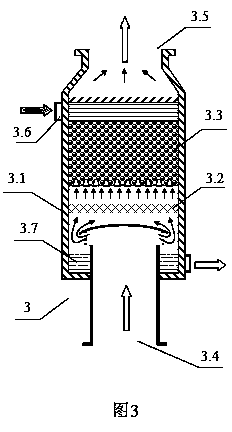

InactiveCN102268374AFast growthEffectively fixedBioreactor/fermenter combinationsBiological substance pretreatmentsMicro nanoPhotobioreactor

The invention relates to a method for using a micro-nano aerator to form micro-nano bubbles from carbon dioxide passed into a microalgae cultivation pool so as to achieve efficient fixation of carbon dioxide and efficient cultivation of microalgae, which belongs to the field of biotechnology. In the microalgae cultivation process, the present invention uses a micro-nano aerator to fully mix the culture outflow from the fermenter with the carbon dioxide introduced into it to form carbon dioxide bubbles with a diameter of 30 to 50 microns, which then flow into the culture pipeline for sufficient photosynthesis Then return to the fermenter, so that the microalgae culture can circulate in the fermenter, the micro-nano aerator and the cultivation pipeline, so as to achieve the technology and method of efficiently fixing carbon dioxide and cultivating microalgae. The invention also discloses a combined photobioreactor applied to the above method. It is characterized in that the micro-nano aerator can form tiny carbon dioxide bubbles, which not only facilitates the dissolution of carbon dioxide in the water body, but also greatly increases the residence time of carbon dioxide in the water.

Owner:UNIV OF SCI & TECH BEIJING

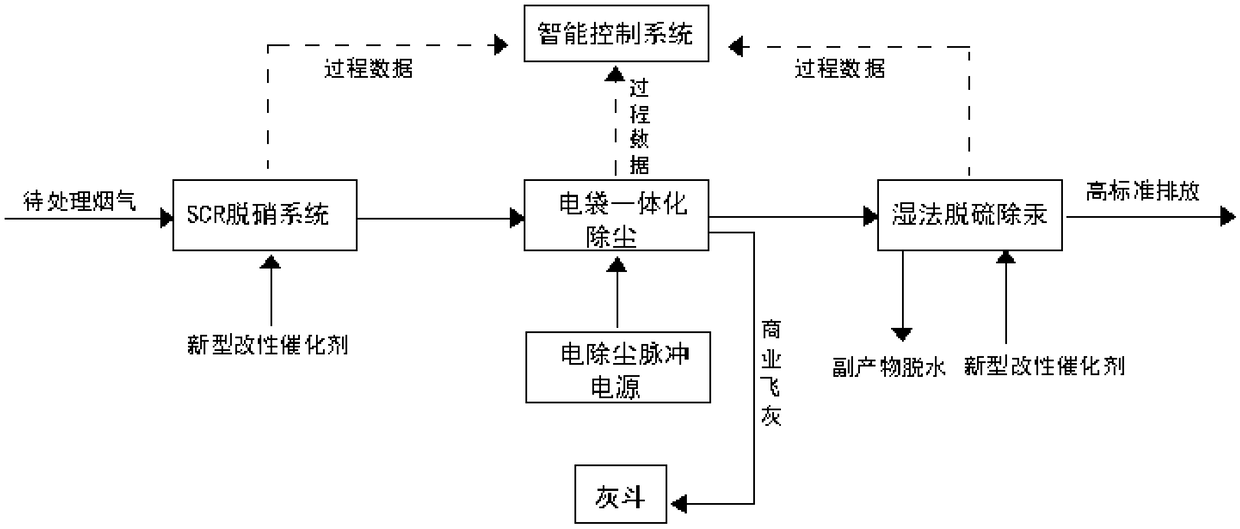

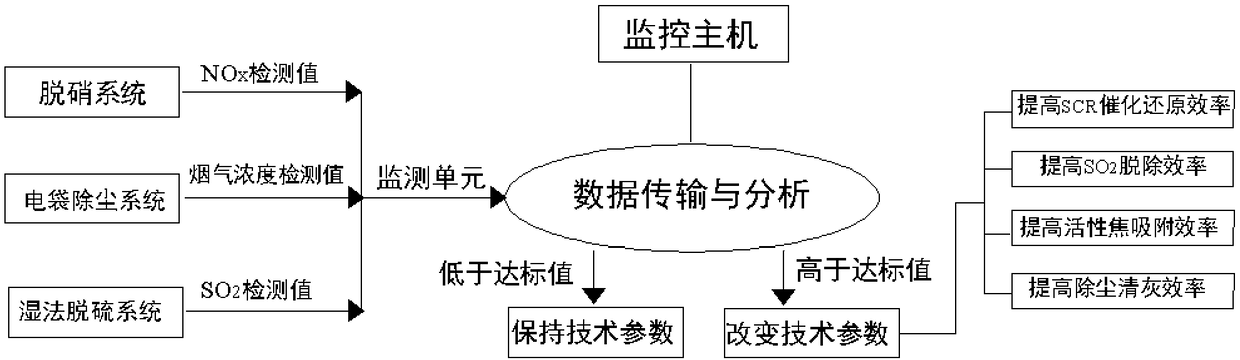

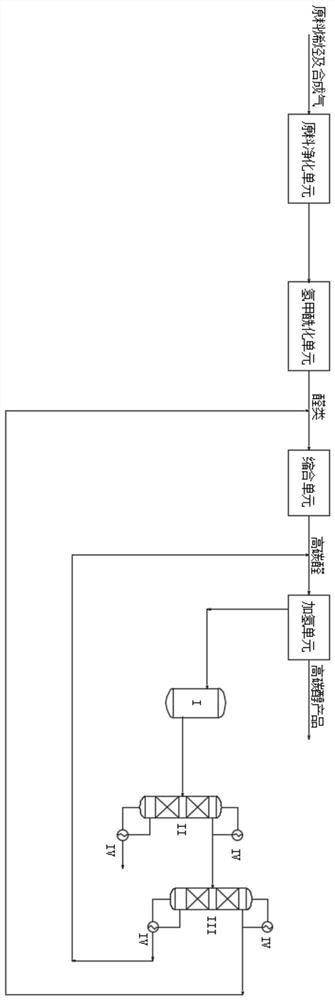

Intelligent cooperative control method of multiple contaminants in coal-fired industrial source flue gas

ActiveCN108211780AImprove removal efficiencyEfficient\" controlCombination devicesGas treatmentSorbentReducing agent

The invention discloses an intelligent cooperative control method of multiple contaminants in coal-fired industrial source flue gas. The intelligent cooperative control method comprises the followingsteps: (1) enabling to-be-processed flue gas to enter into an SCR (Selective Catalytic Reduction) denitration system to remove NOx, wherein the denitration system adopts a honeycomb type catalyst, anda denitration reducing agent is fully mixed with the flue gas by adopting a spraying form; (2) enabling the gas processed in the step (1) to enter into an electric-bag integrated dust removal system,and improving charged quantity of particles by adopting a critical pulse power technology to purify smoke dust in the gas; (3) enabling the flue gas processed in the step (2) to enter into a wet process desulfurization system, performing desulfurization by adopting an improved lime / limestone-gypsum process desulfurization absorbent; mixing the desulfurized absorbent sprayed and atomized by a flue gas ejector with the flue gas to carry out adsorption removal of heavy metal mercury. According to the intelligent cooperative control method of the multiple contaminants in the coal-fired industrial source flue gas disclosed by the invention, the removal efficiency of the multiple contaminants can be effectively improved, operation energy consumption is reduced, and a system error ratio is reduced; moreover, remote centralized operation, maintenance and fault diagnosis on the system can be achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

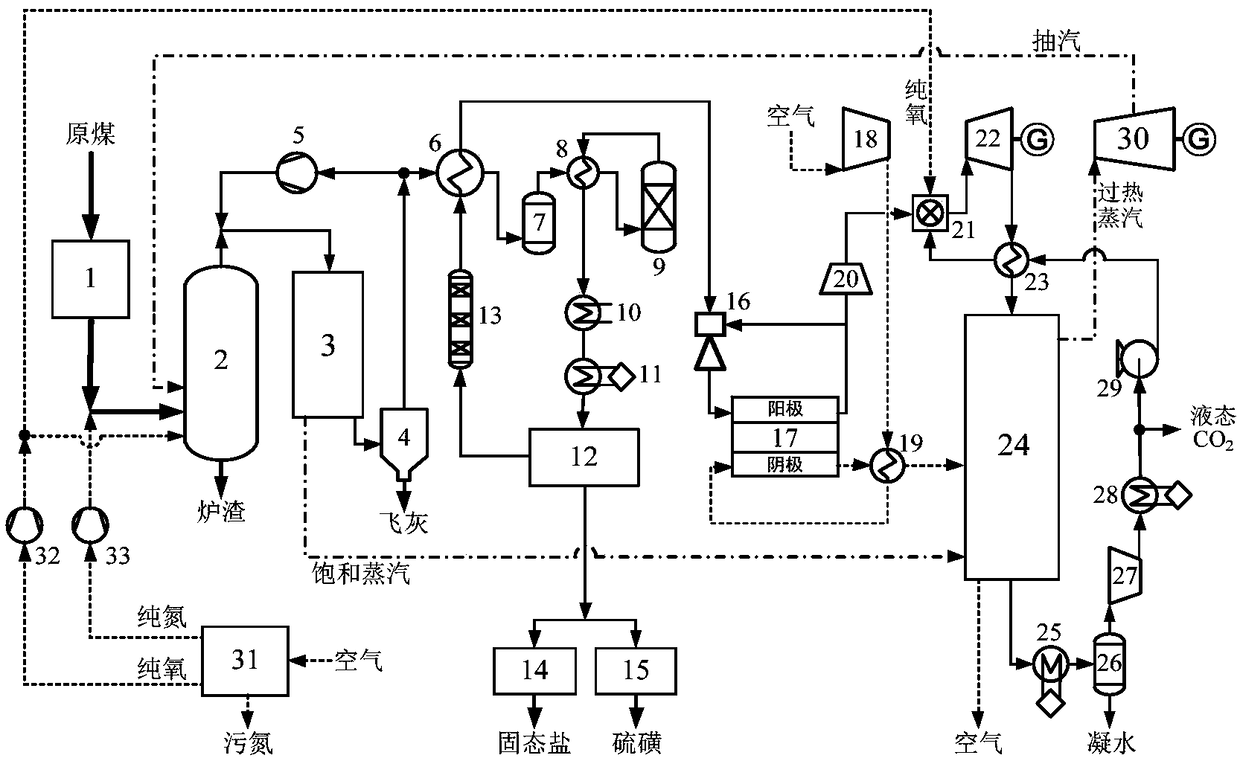

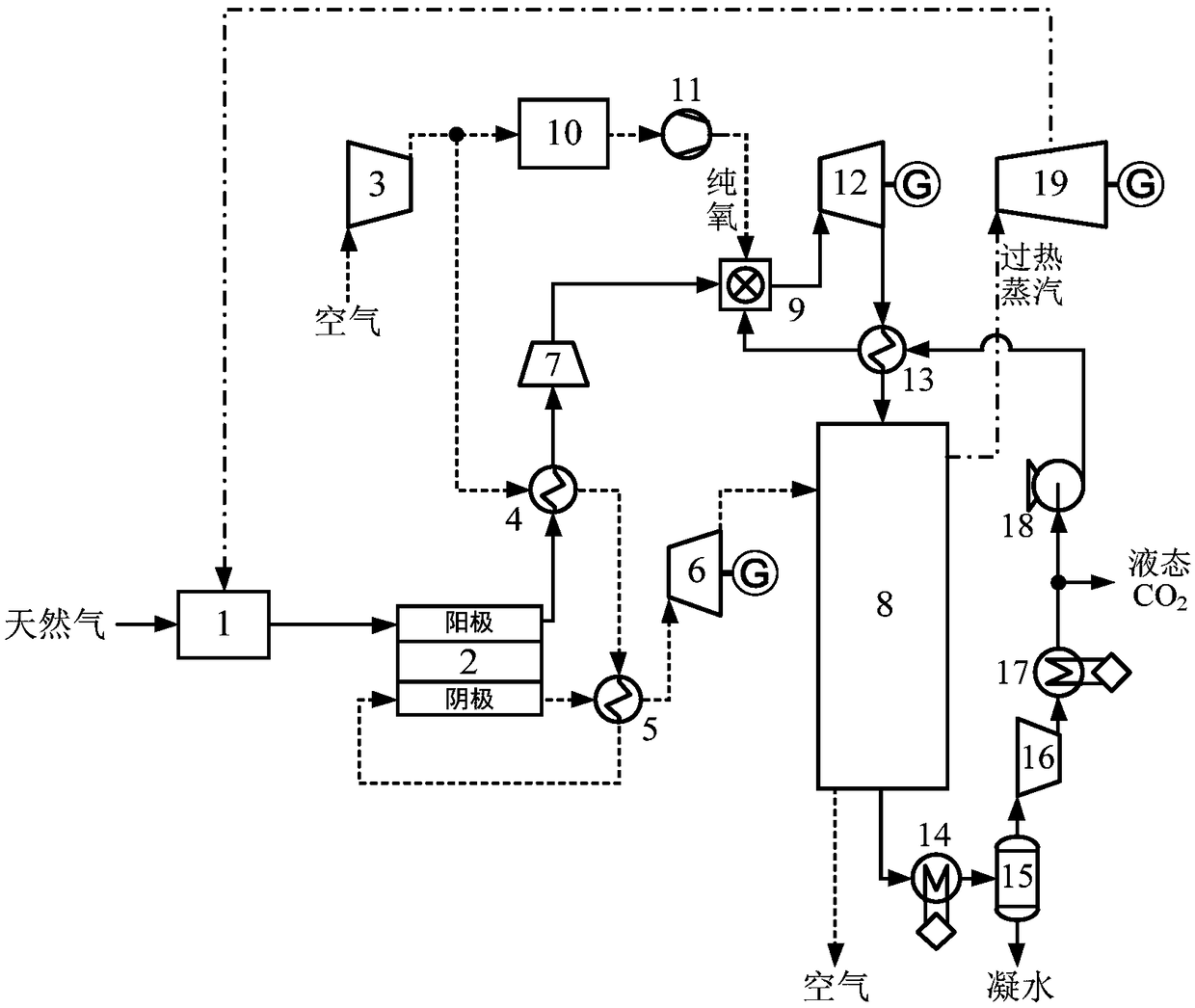

Overall gasification fuel cell power generation system and method adopting supercritical CO2 bottom circulation

PendingCN109266396AImprove power generation efficiencyReduce volumeEnergy inputGasification processes detailsGas compressorGas cooler

The invention provides an overall gasification fuel cell power generation system and method adopting supercritical CO2 bottom circulation. The system comprises a coal preparation unit, a gasifier, a gas cooler, a circulation gas compressor, an ejector, a fuel cell, a cathode air compressor, a cathode backheating device, a compressor, a pure oxygen burner, a CO2 gas turbine, a backheating device, awaste heat boiler and a turbine; on the basis of the overall gasification fuel cell power generation system, CO2 gathering is added, a CO2 cooling pressurizing device is utilized for converting CO2 gas into supercritical state CO2, supercritical state CO2 is adopted as bottom circulation to react with pure oxygen and tail gas at a fuel cell anode outlet inside the pure oxygen burner, generated high temperature and high pressure gas acts and generates electricity in the CO2 gas turbine; according to the structure, on the basis of efficient electricity generation of fuel cell electricity generation, the electricity generation efficiency is further improved; meanwhile, the system has the CO2 gathering function, and coal power generation CO2 emission reduction can be achieved efficiently withlow cost.

Owner:HUANENG CLEAN ENERGY RES INST

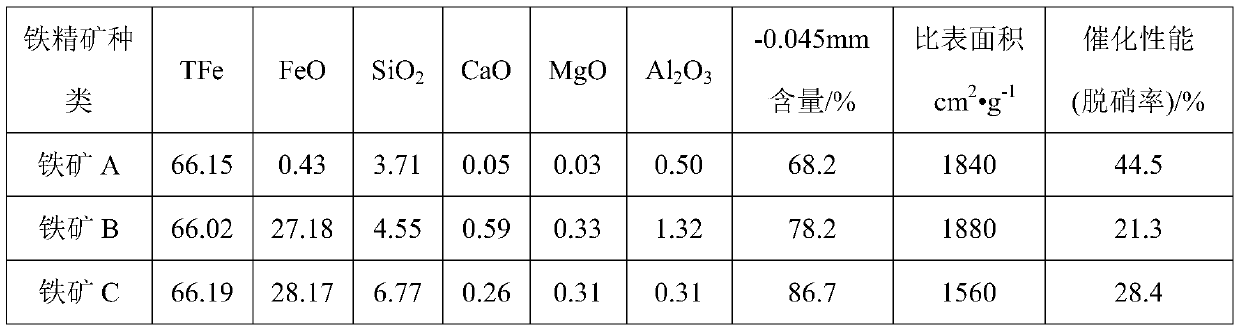

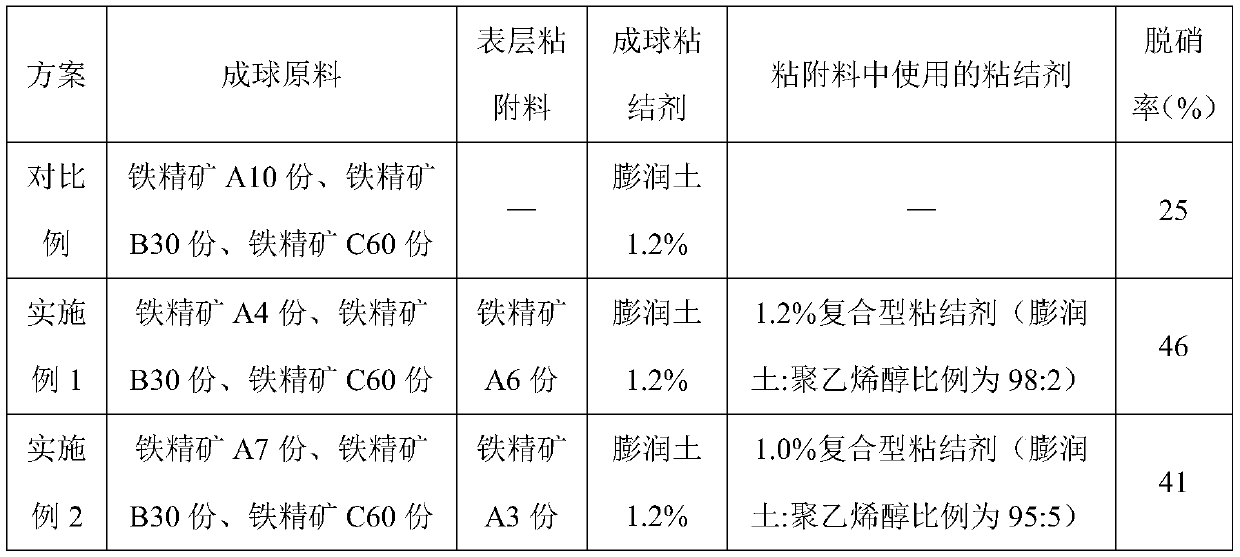

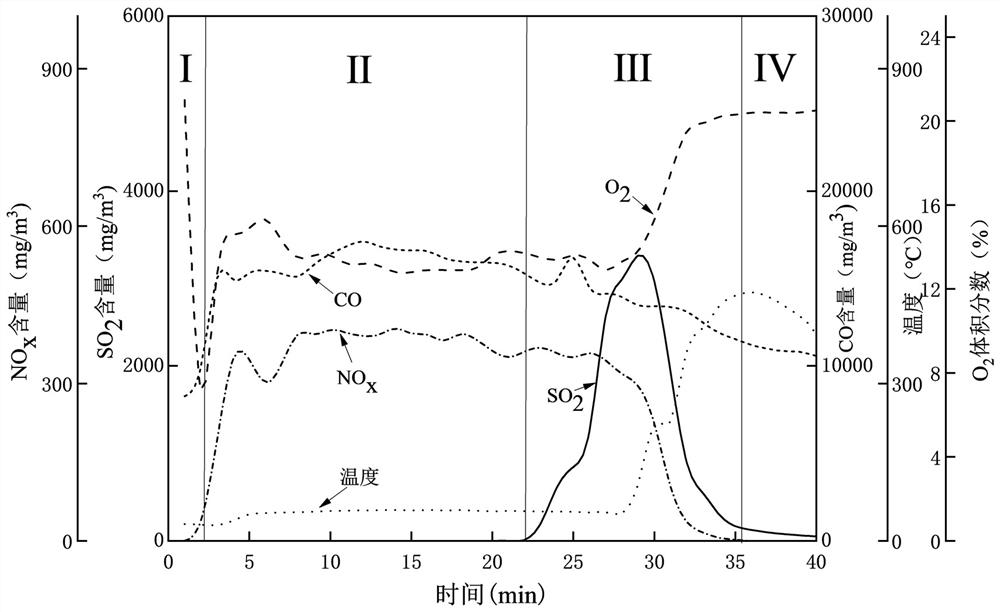

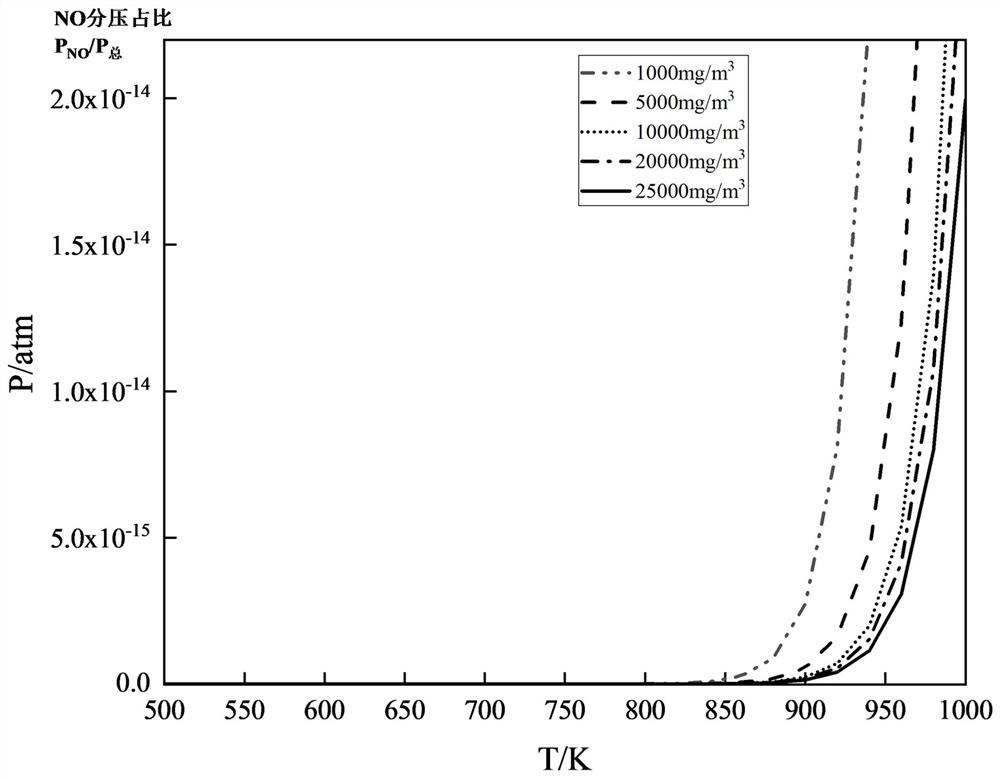

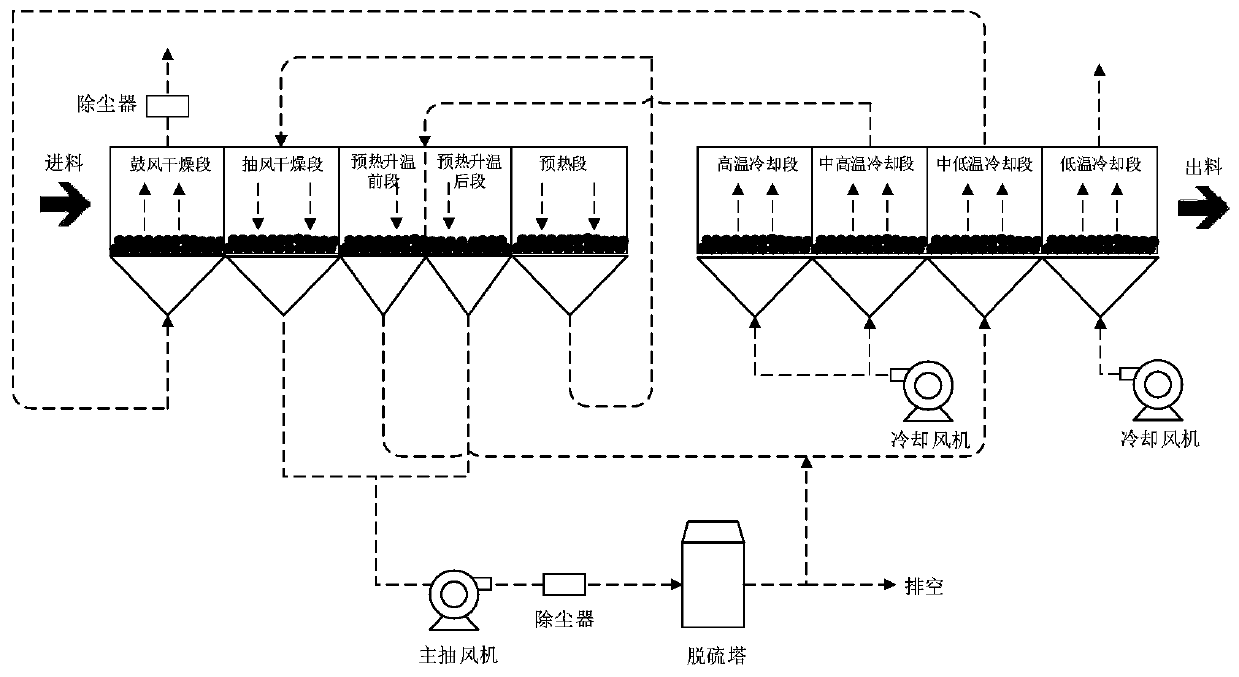

Strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets

ActiveCN110904332AImprove denitrification effectRapid responseRotary drum furnacesPhysical chemistryRaw material

The invention relates to a strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets. The method comprises the following steps of preparing green pellets by ingredients, drying and preheating a chain grate machine, and configuring ammonia injection denitration operation at an air draft drying section of the chain grate machine. The method is characterized by 1) determining pellet raw materials and a basic binder; 2) preparing a composite binder; 3) preparing green pellets with strong catalytic surfaces containing the composite binder; and 4) strengthening ammonia injection denitration on a pellet surface layer, decomposing and volatilizing the composite binder in a drying process to form rich pores in the pellet surface layer, increasing adsorption of NH3 and NOx on the pellet surface layer, accelerating a denitration reaction speed of the strong catalytic surface layer, and realizing strengthened ammonia injection denitration of thepellet surface layer. The method has advantages that a denitration rate is improved by more than 15 percent points compared with that of an existing ammonia spraying denitration technology; a pelletizing process does not need to be greatly changed, and only some improvements need to be made in the process of preparing the green pellets from the ingredients; and implementation and popularization are easy.

Owner:ANSTEEL GRP MINING CO LTD

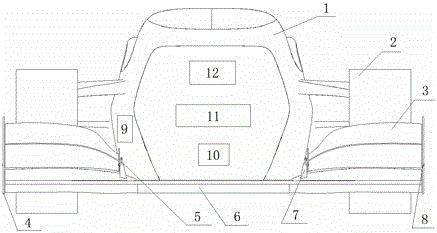

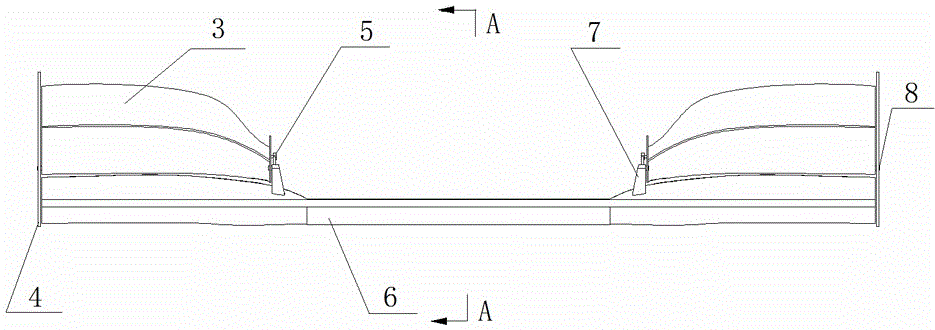

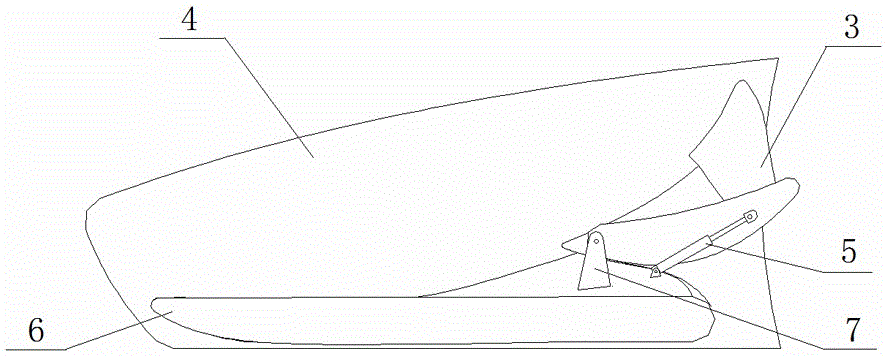

Active variable front wing of formula car

InactiveCN106428257AIncrease air intakeImprove combustion efficiencyAerodynamics improvementVehicle body streamliningFixed wingCar controls

The invention discloses an active variable front wing of formula car which compromises a fixed wing piece arranged on the inner side of a front wing end plate, a connection device for forming a rotation between the fixed wing and the end plate, a driving mechanism for driving the fixed wind piece to rotate a certain angle, a speed detector and an acceleration detector which are arranged on a car and used for detecting the car running state, a water temperature detector arranged at a cooling system. The water temperature detector and the driving mechanism are respectively connected with a car control unit. The active variable front wing of formula car can adjust the angle of the front fixed wing piece according to the car running state and the temperature of the engine, thus, the air resistance is reduced in acceleration, the amount of air input in the side box of the formula car is increased, the efficiency of the engine is improved,and the dynamic performance of the car is improved.

Owner:JILIN UNIV

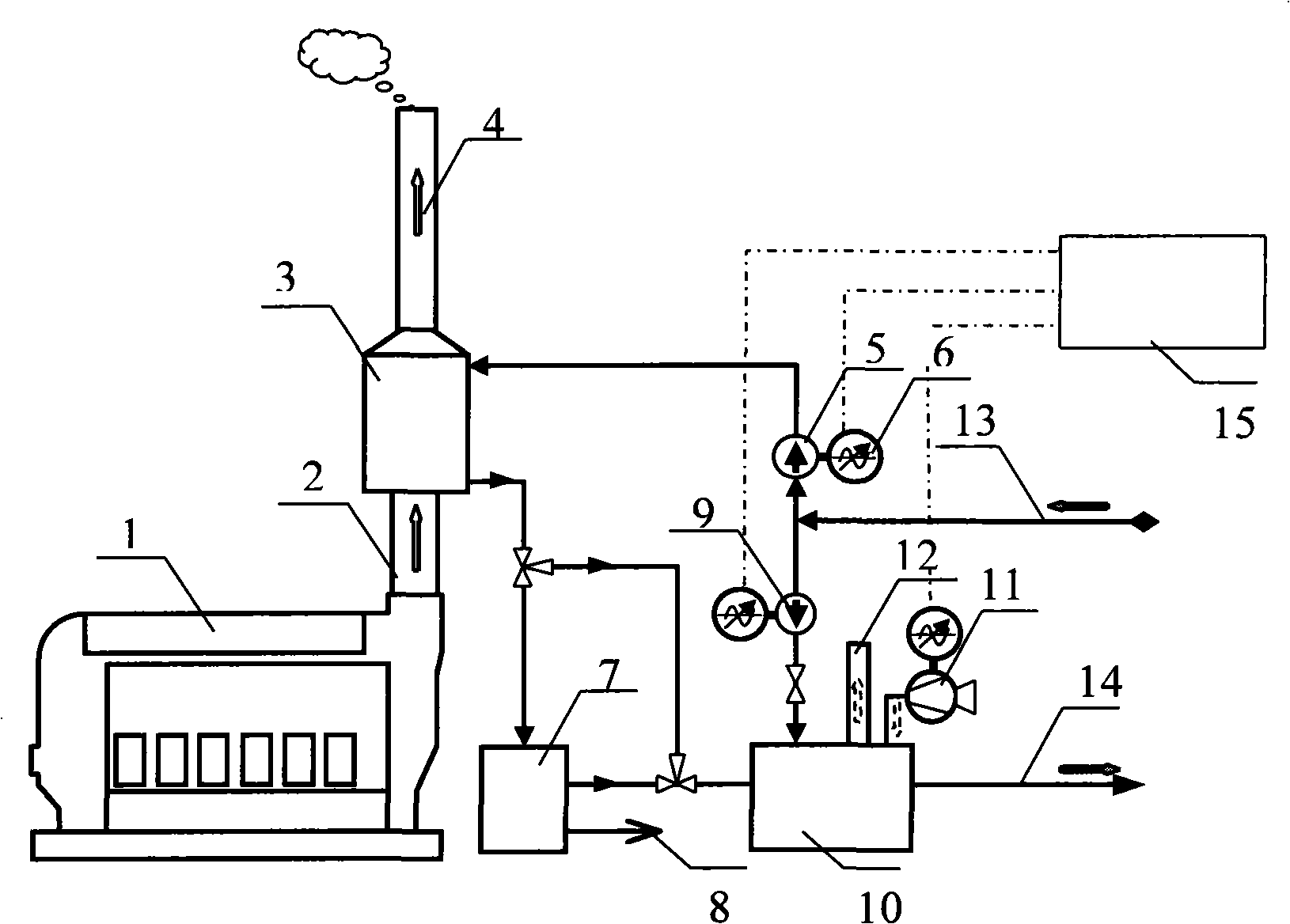

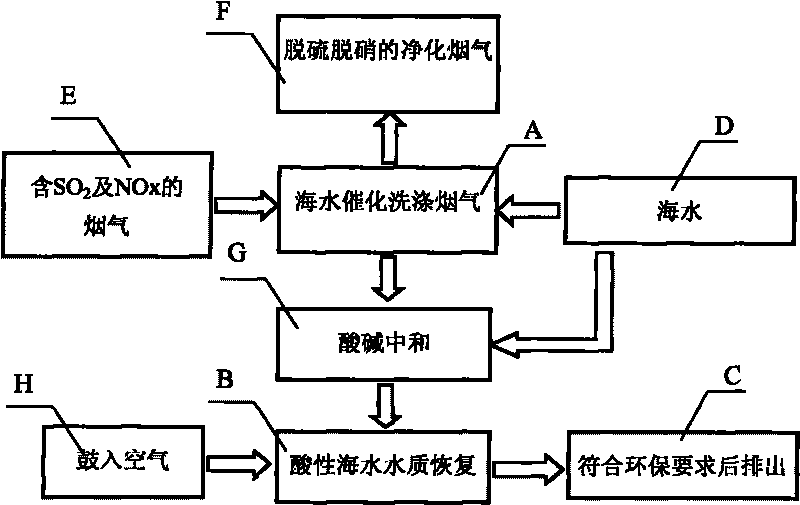

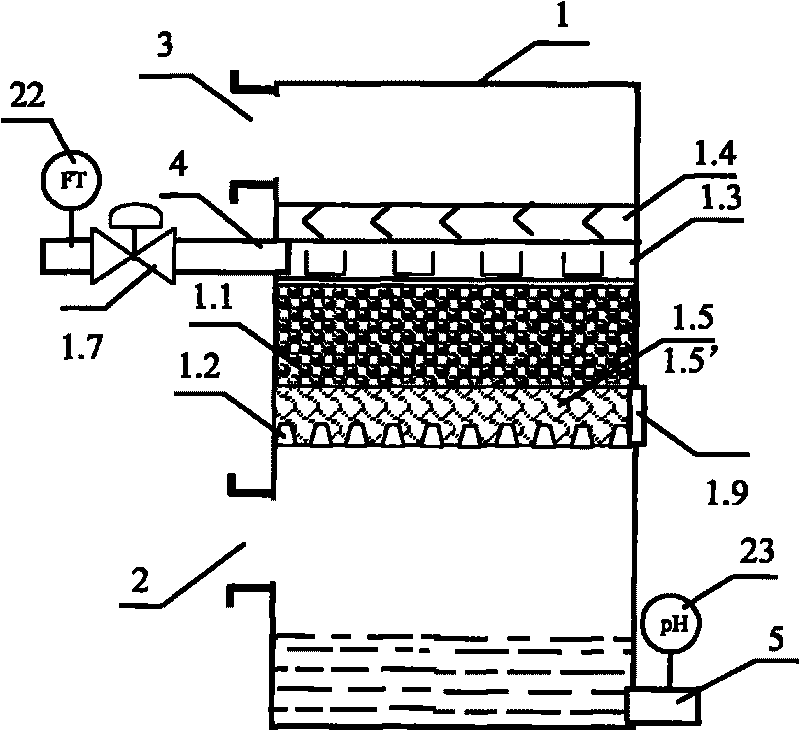

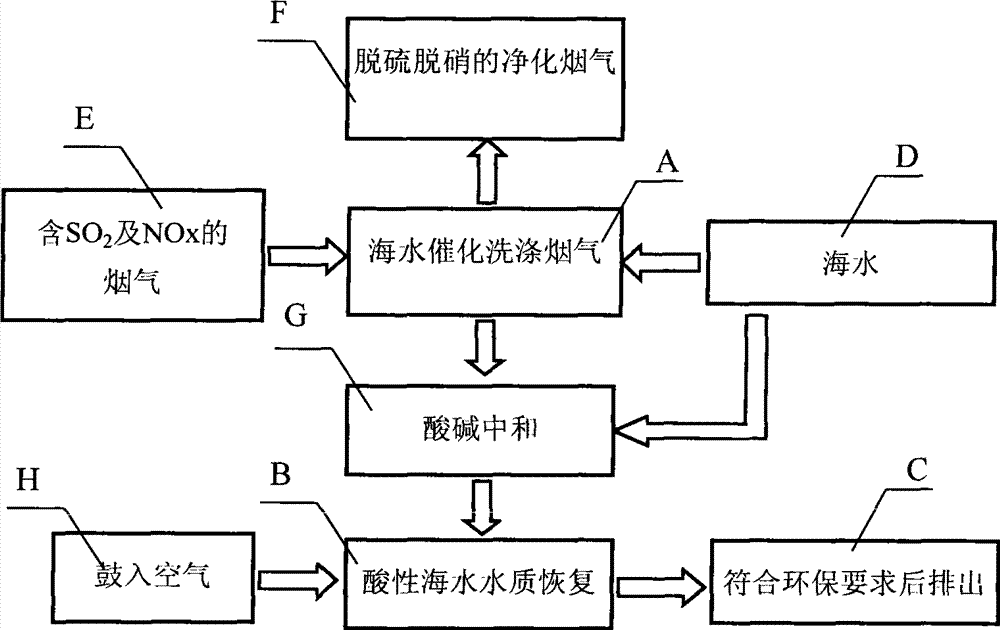

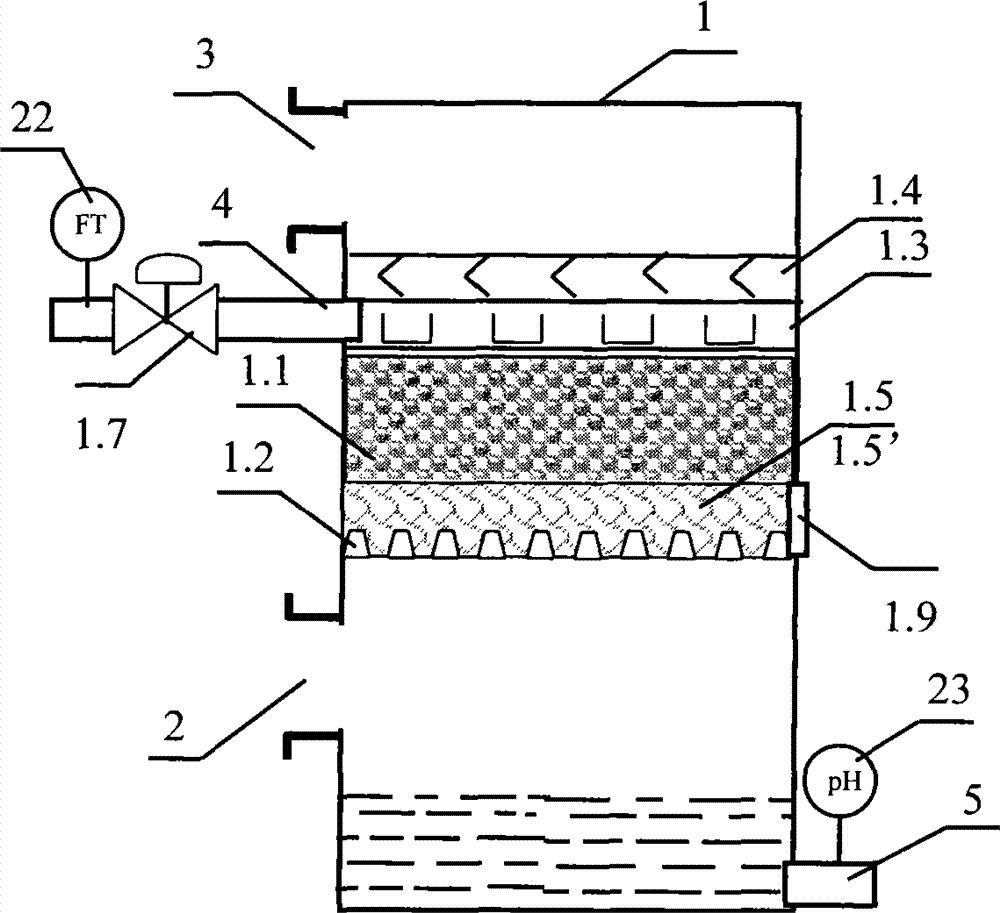

Method and device for simultaneous desulphurization and denitration by flue gas-seawater method

InactiveCN101721898ACatalyticImprove solubilityNitrous oxide captureDispersed particle separationFlue gasWater quality

The invention relates to a method and a device for simultaneous desulphurization and denitration by a flue gas-seawater method. The method comprises the following steps: A) catalyzing and washing the flue gas containing SO2 and NOx by seawater to remove the SO2 and the NOx in the flue gas, and then discharging the purified flue gas subjected to the desulphurization and the denitration and discharging acid seawater formed during washing; and B) recovering the quality of the seawater, namely adding the seawater into the acid seawater and blowing the air into the acid seawater, and discharging the seawater when the quality of the acid seawater is recovered to accord with the environment-friendly requirement. The method and the device for simultaneous desulphurization and denitration have the advantages that chemical raw materials are not needed, the emission reduction efficiency and reliability are high, the occupied area is small, the construction and running costs are low, and the method and the device are particularly suitable for simultaneous desulphurization and denitration for boiler flue gases of large and medium-sized heat power plants.

Owner:彭斯干

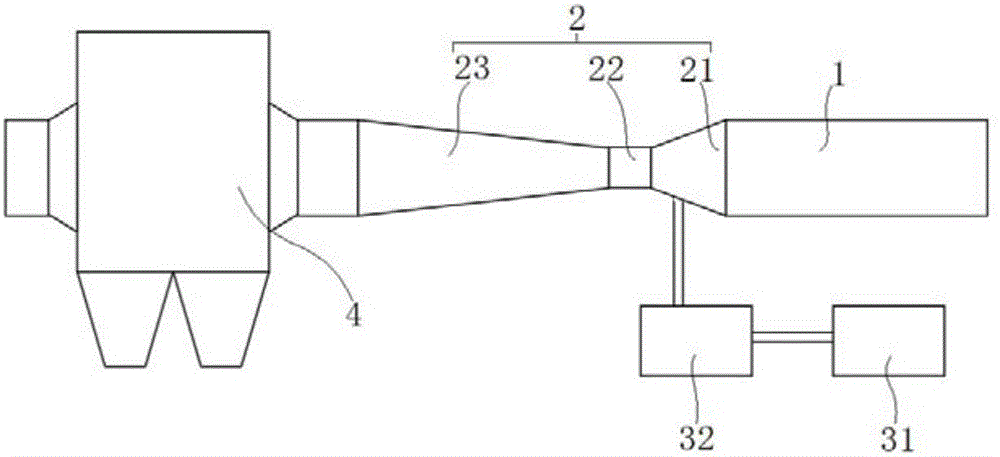

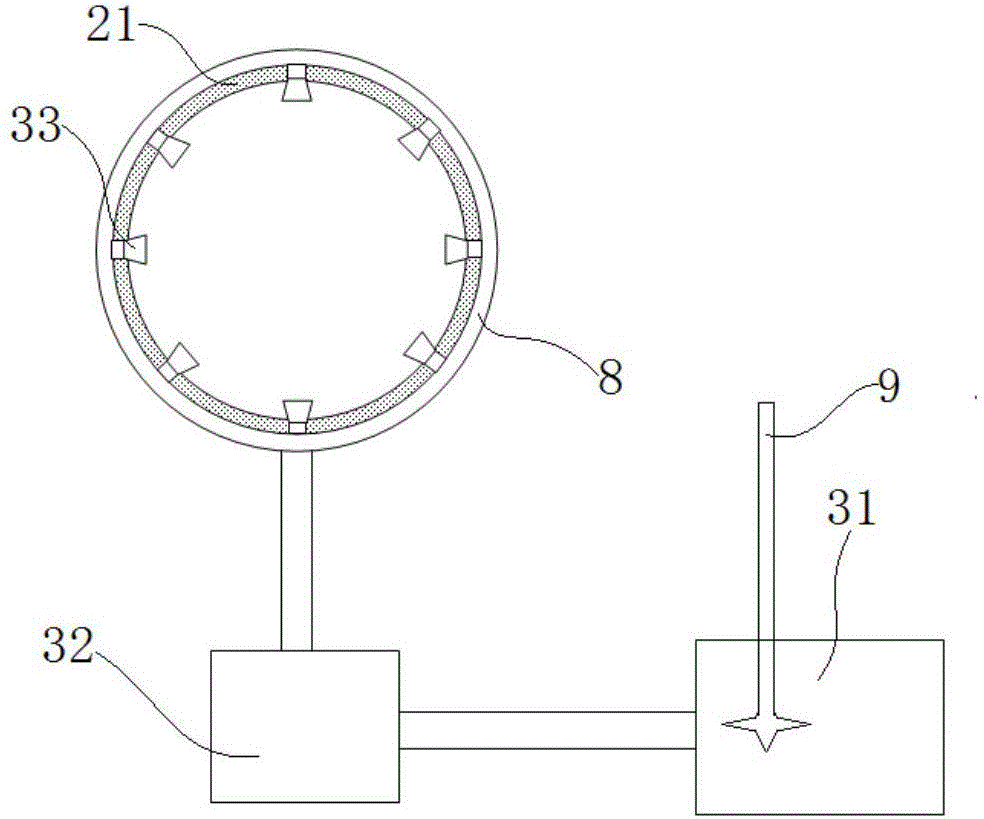

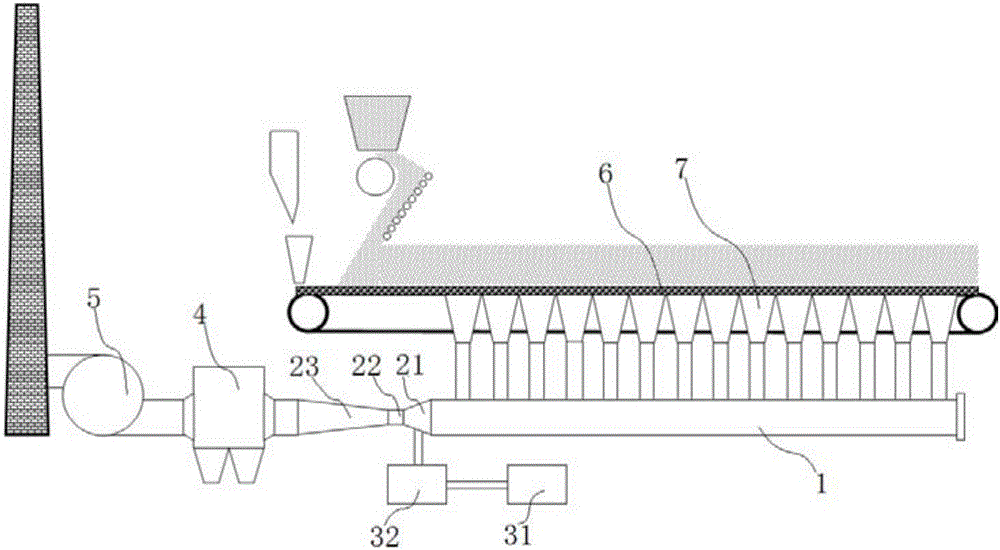

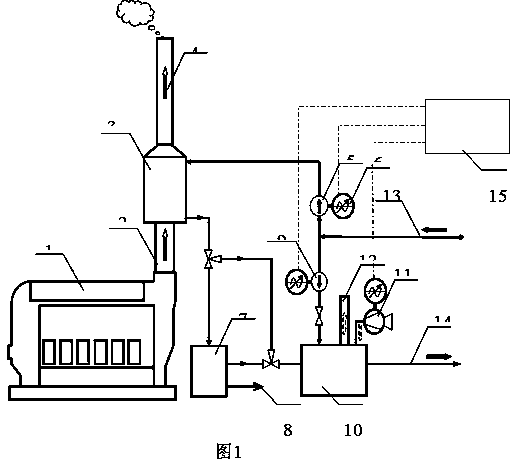

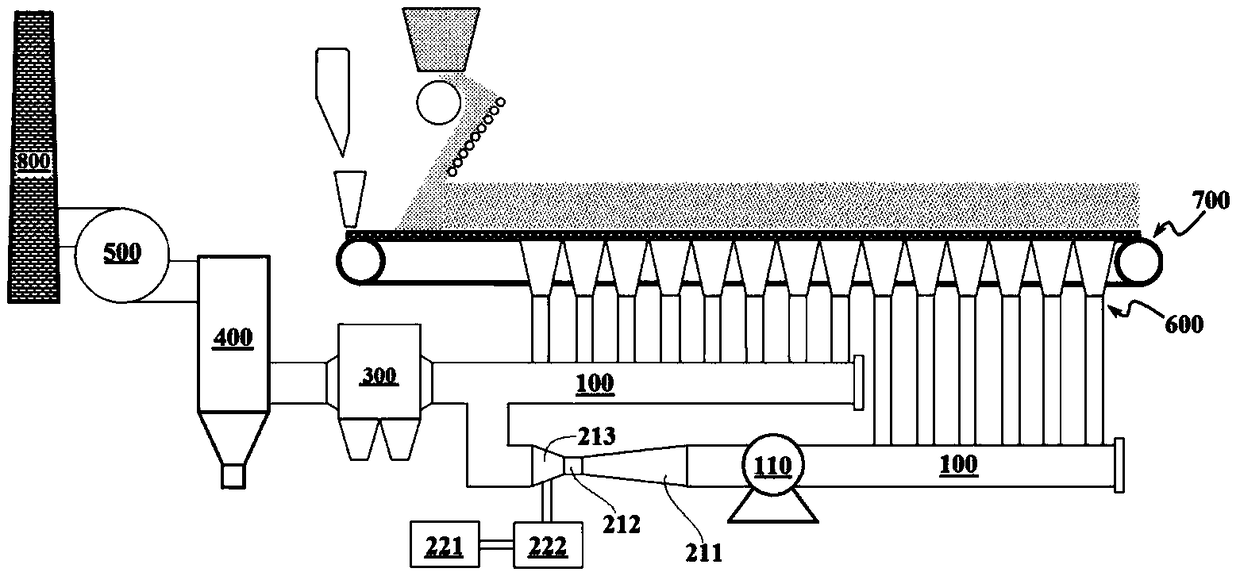

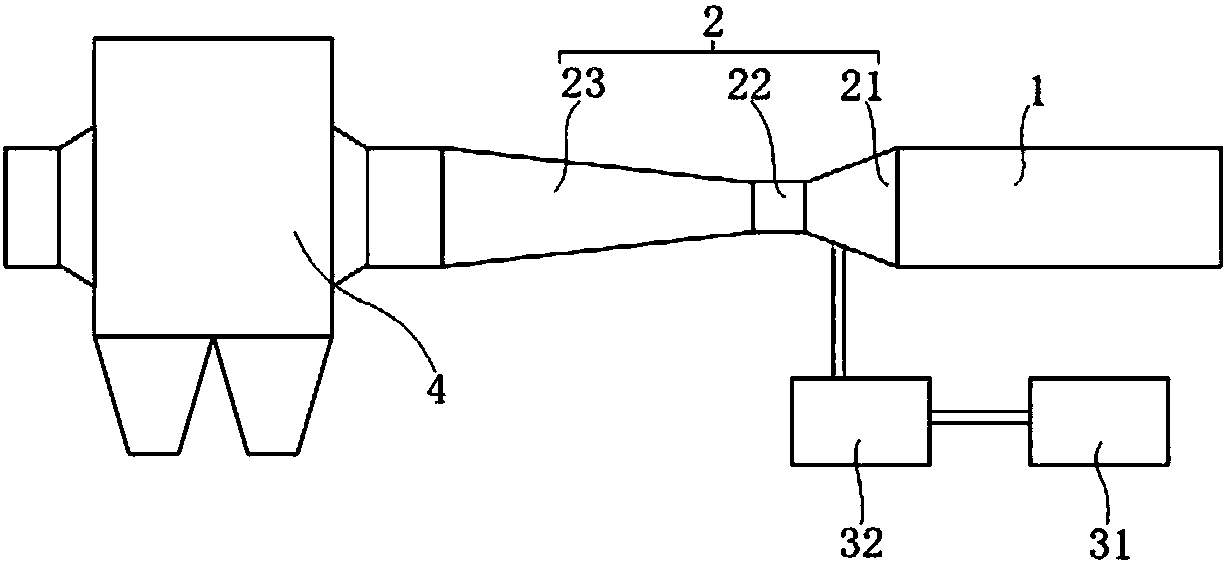

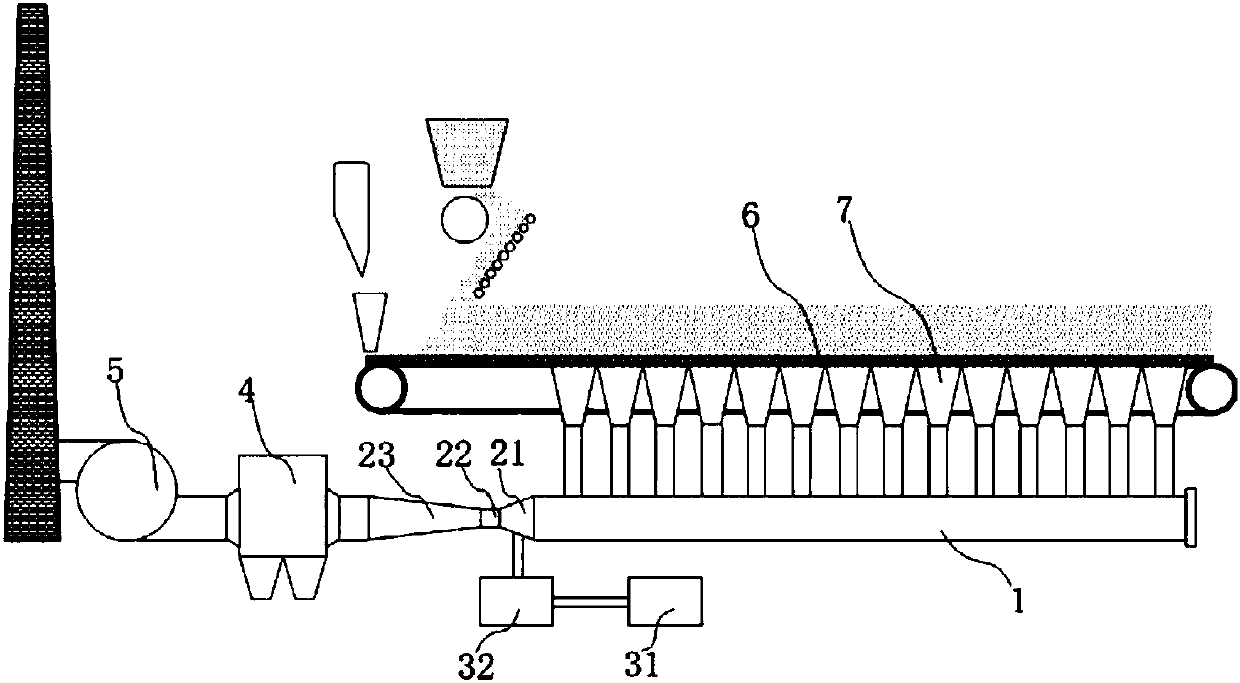

Emission reduction system for fine particles in sintering process of iron ore

ActiveCN105854501AIncrease flow rateEfficient emission reductionGas treatmentAuxillary pretreatmentFluePollutant

The invention discloses an emission reduction system for fine particles in the sintering process of iron ore, and belongs to the technical field of emission reduction of pollutants in the sintering process of iron ore. The emission reduction system for fine particles in the sintering process of iron ore comprises a fine particle atomizing and agglomerating device, an agglomerating liquid adding device and a dust removing device. The bottom of a sintering pallet is connected with a main flue through air bellows, air draft smoke is combined in the main flue through the bottom of the sintering pallet via the air bellows, the atomizing and agglomerating device, the agglomerating liquid adding device and the dust removing device are arranged on the main flue, and the smoke flows into the atomizing and agglomerating device from the main flue, and is subjected to dust removal by the dust removing device and then discharged into a chimney by a draught fan. By means of the emission reduction system, agglomerating liquid fog drops with fine particles adsorbed nucleate, collide and grow under the low-pressure condition, and form large particle agglomerated mater, the fine particles growing through agglomeration are removed with the dust removing device, and thus a bran-new emission reduction approach is provided for emission reduction of the fine particles in the sintering process of iron ore.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Natural gas fuel cell power generation system and method adopting supercritical CO2 bottom cycle

ActiveCN109346744ASolve the problem of low bottoming cycle efficiencyImprove power generation efficiencyFuel cell auxillariesGas turbine plantsAir compressorCoal

The invention provides a natural gas fuel cell power generation system and method adopting a supercritical CO2 bottom cycle. The system comprises a fuel reformer, a fuel cell, a cathode air compressor, an anode heat regenerator, a cathode heat feeding regenerator, an air turbine, a compressor, a waste heat boiler, a pure oxygen burner, a regenerator, a CO2 cooling and pressurizing device and a steam turbine; by adopting the structure, the power generation efficiency is further improved on the basis of high-efficiency power generation of a fuel cell; meanwhile, the bottom cycle adopts a supercritical carbon dioxide cycle power generation system, so that the system is simple and the equipment volume is greatly reduced; and the system also takes into account a CO2 capture function, and can realize the CO2 emission reduction of coal power generation efficiently at low cost.

Owner:HUANENG CLEAN ENERGY RES INST

Compound microorganism live bacteria preparation for enhancing activated sludge, preparation method and applications thereof

InactiveCN103421692BEasy to manufactureLow costBacteriaMicroorganism based processesActivated sludgeLiquid medium

The invention discloses a compound microorganism live bacteria preparation for enhancing activated sludge, a preparation method and applications thereof. The preparation contains Bacillus fusiformis, Comamonas sp. and Ochrobactrum sp.. The preparation method comprises the following steps: first, Bacillus fusiformis, Comamonas sp. and Ochrobactrum sp. after inclined plane activation are inoculated in liquid mediums respectively, and cultured at the temperature of 30 DEG C-37 DEG C for 40-54 h to obtain a microorganism bacteria liquid; second, the microorganism bacteria liquids obtained from the first step are mixed uniformly, dried at the temperature of 40 DEG C-60 DEG C, and the processes of crushing to 15-50 meshes and sieving are performed. The preparation can enhance activated sludge performances effectively and rapidly in applications as an activated sludge COD-degrading enhancer in the papermaking wastewater treatment process. The preparation can degrade papermaking wastewater COD efficiently and improve wastewater chromaticity and water quality.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

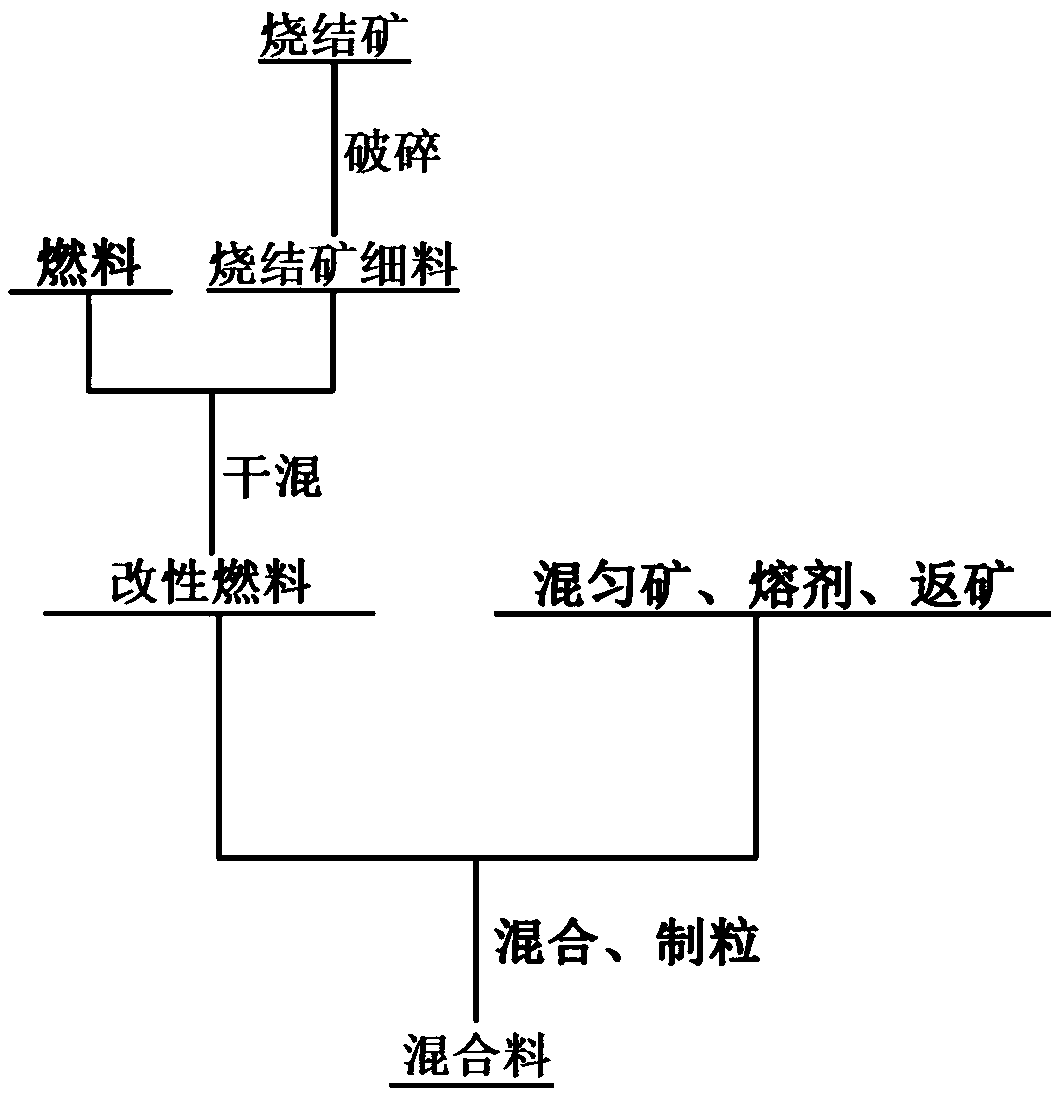

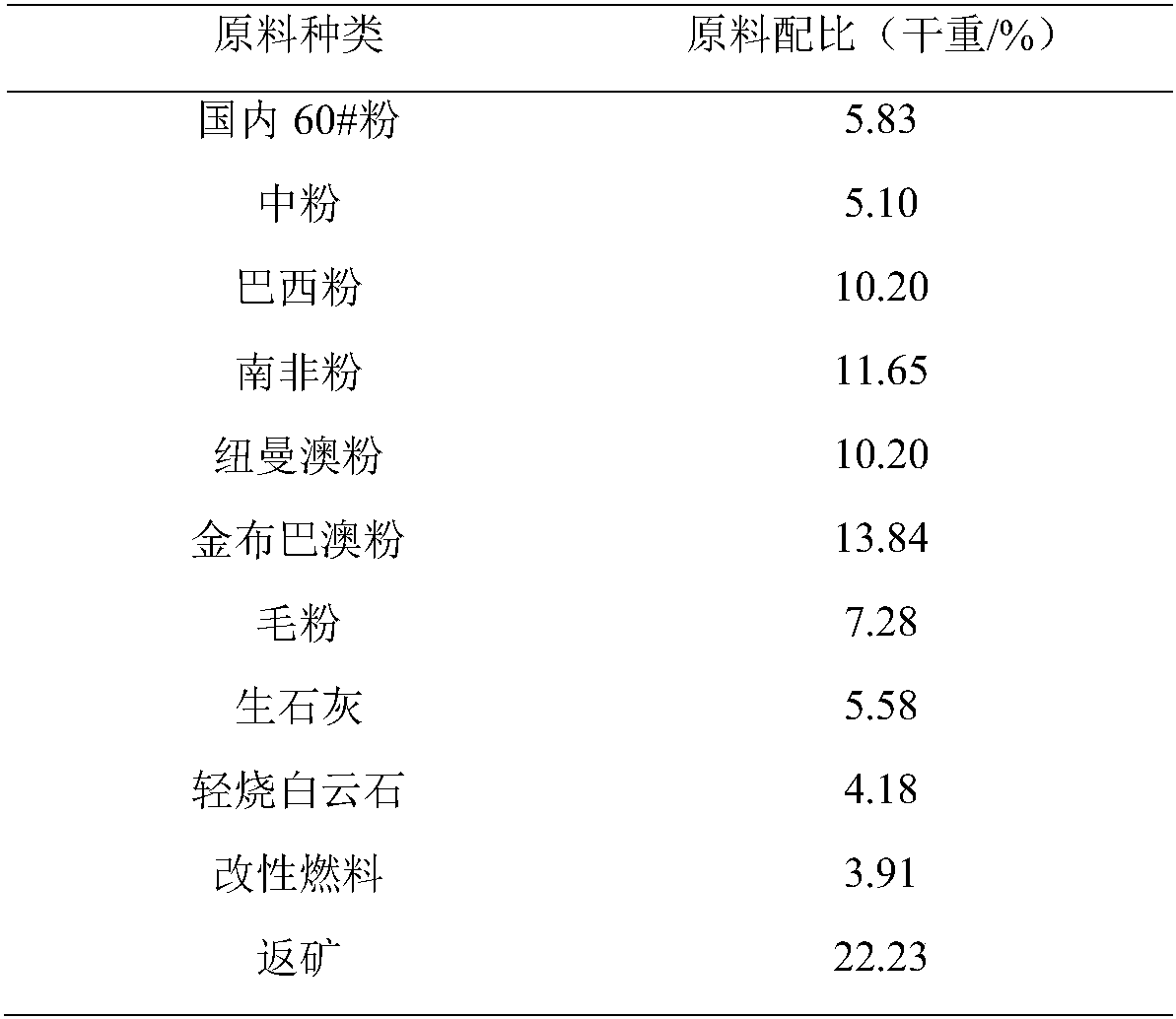

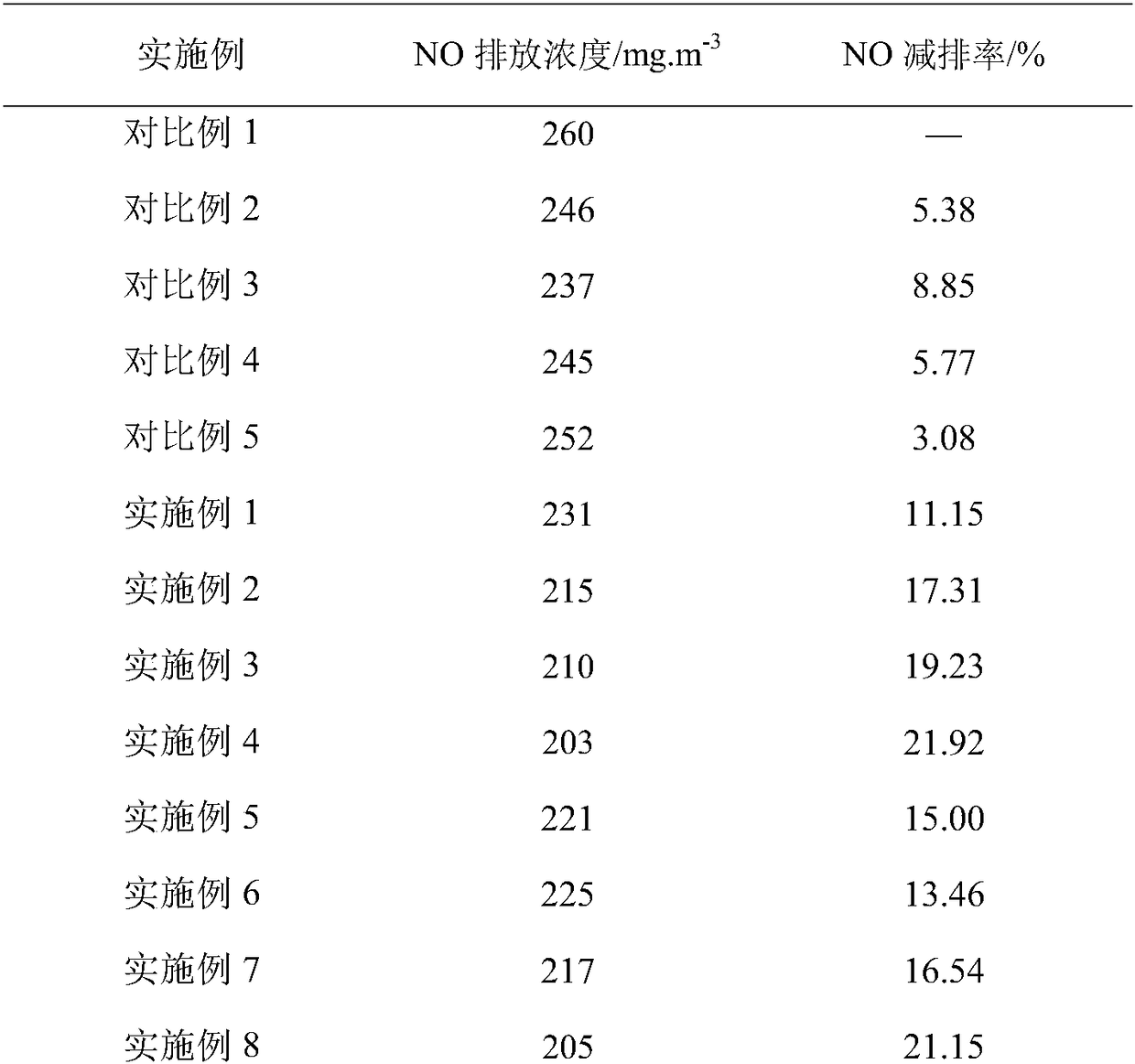

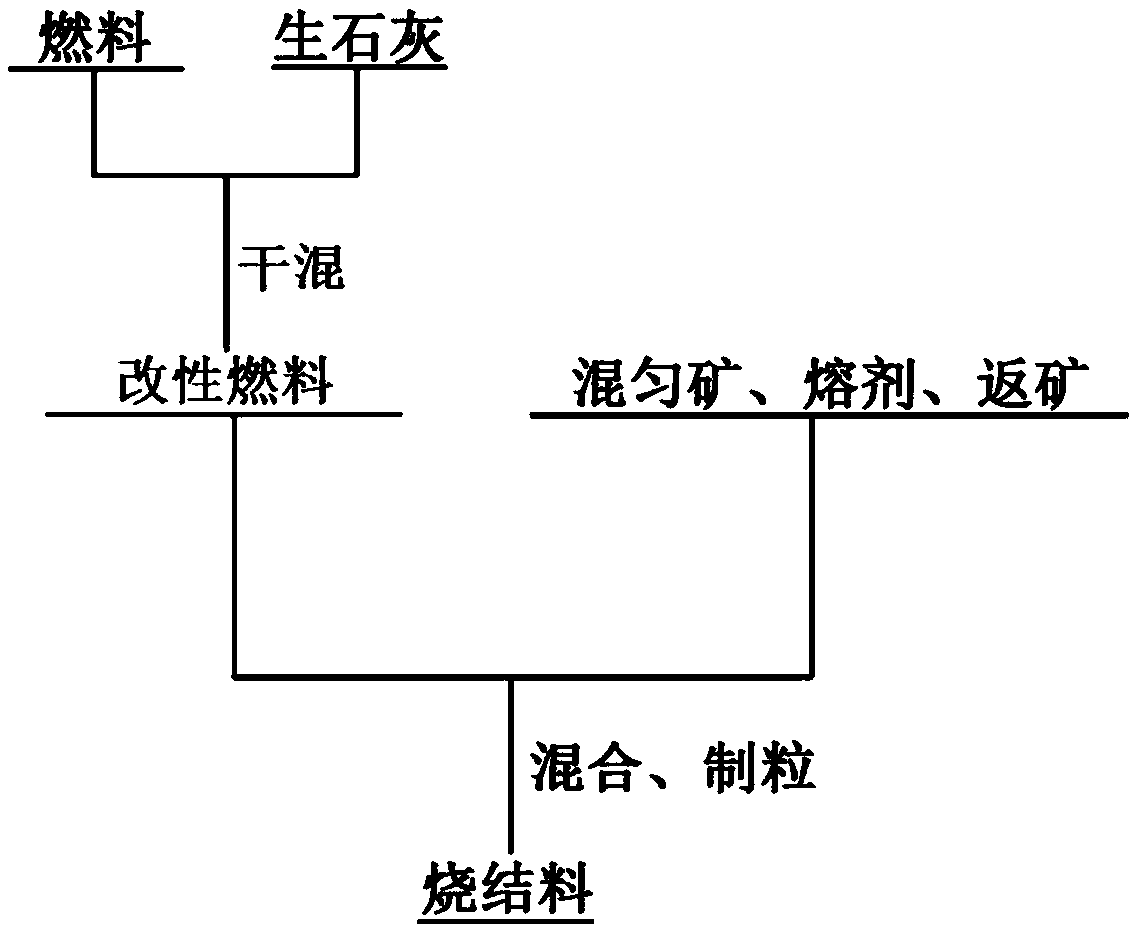

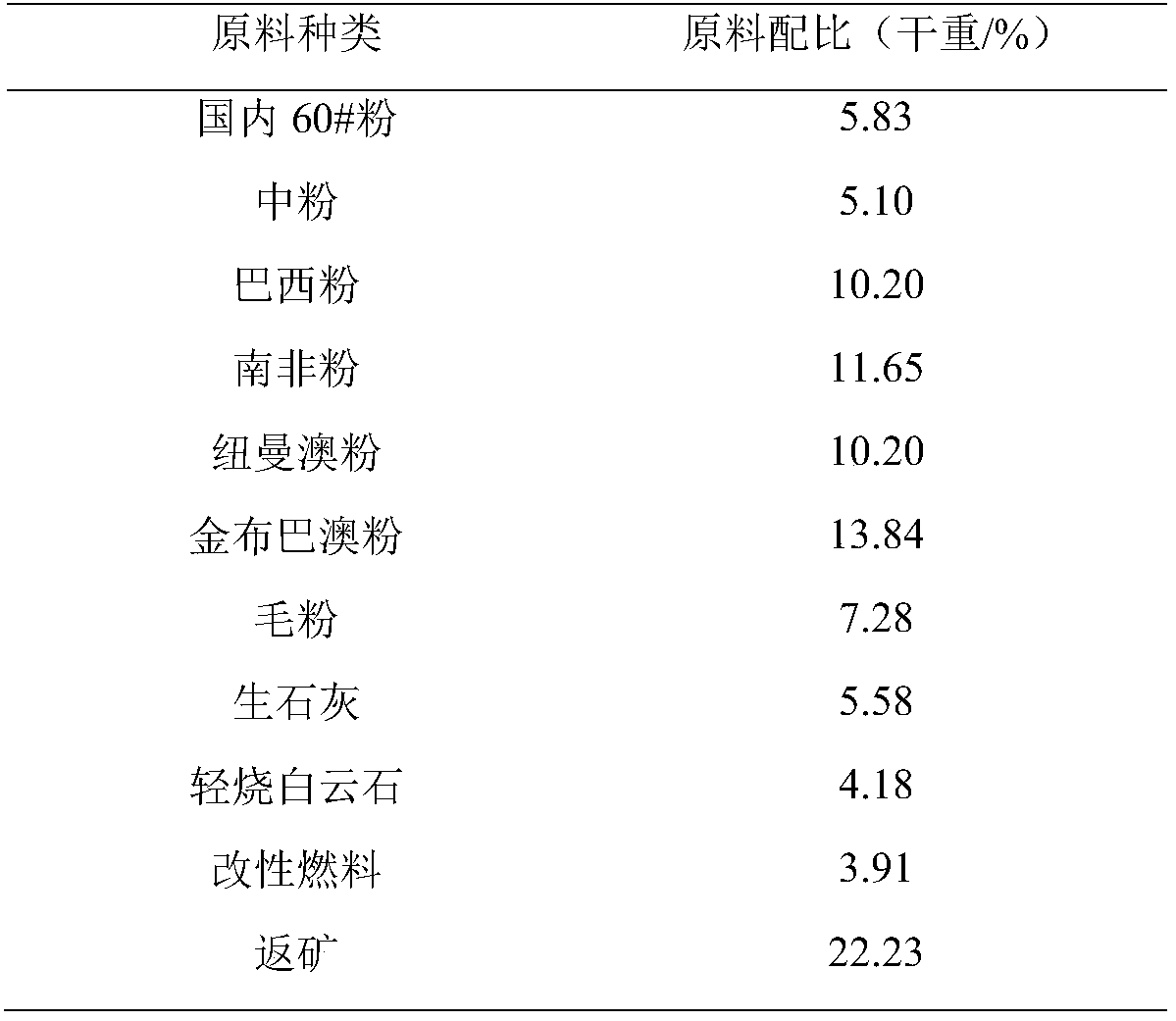

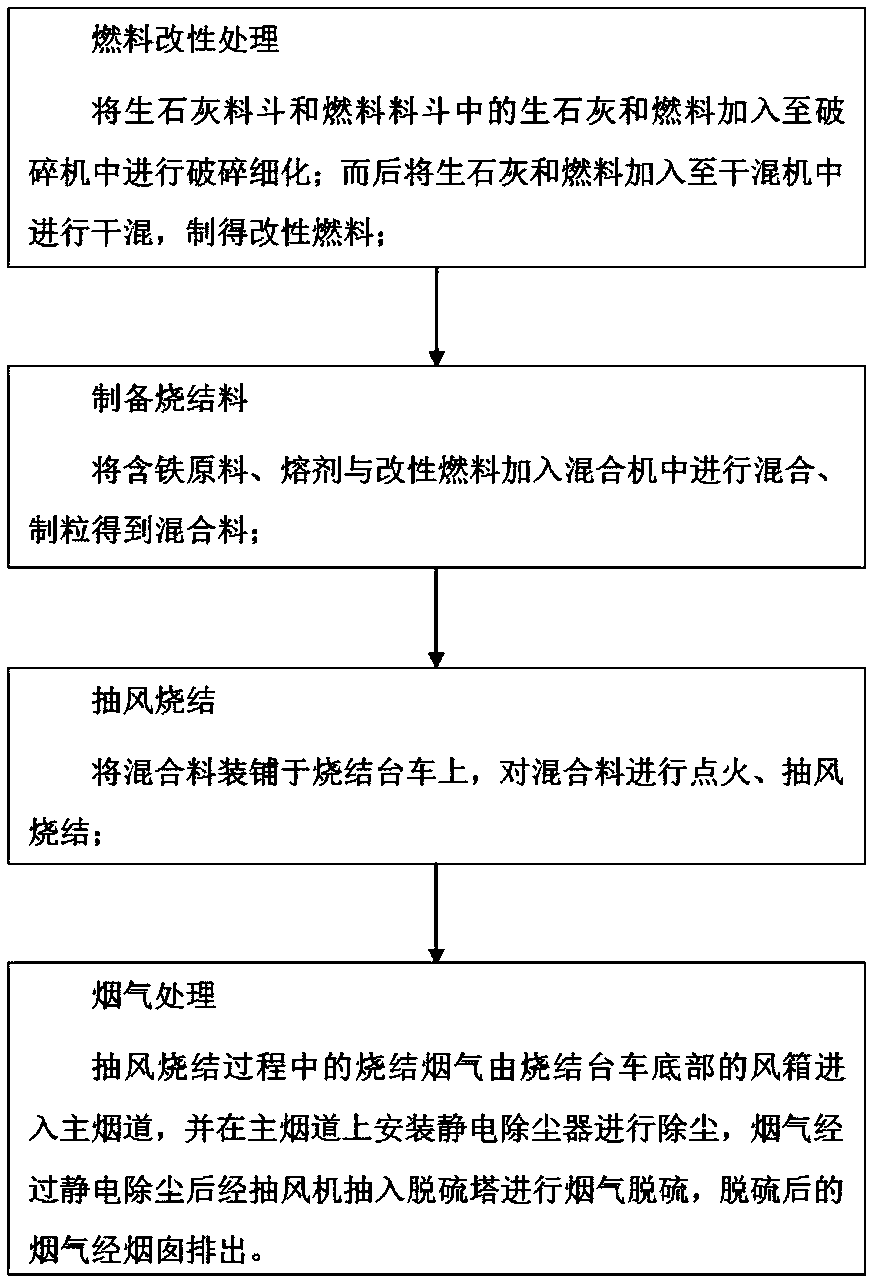

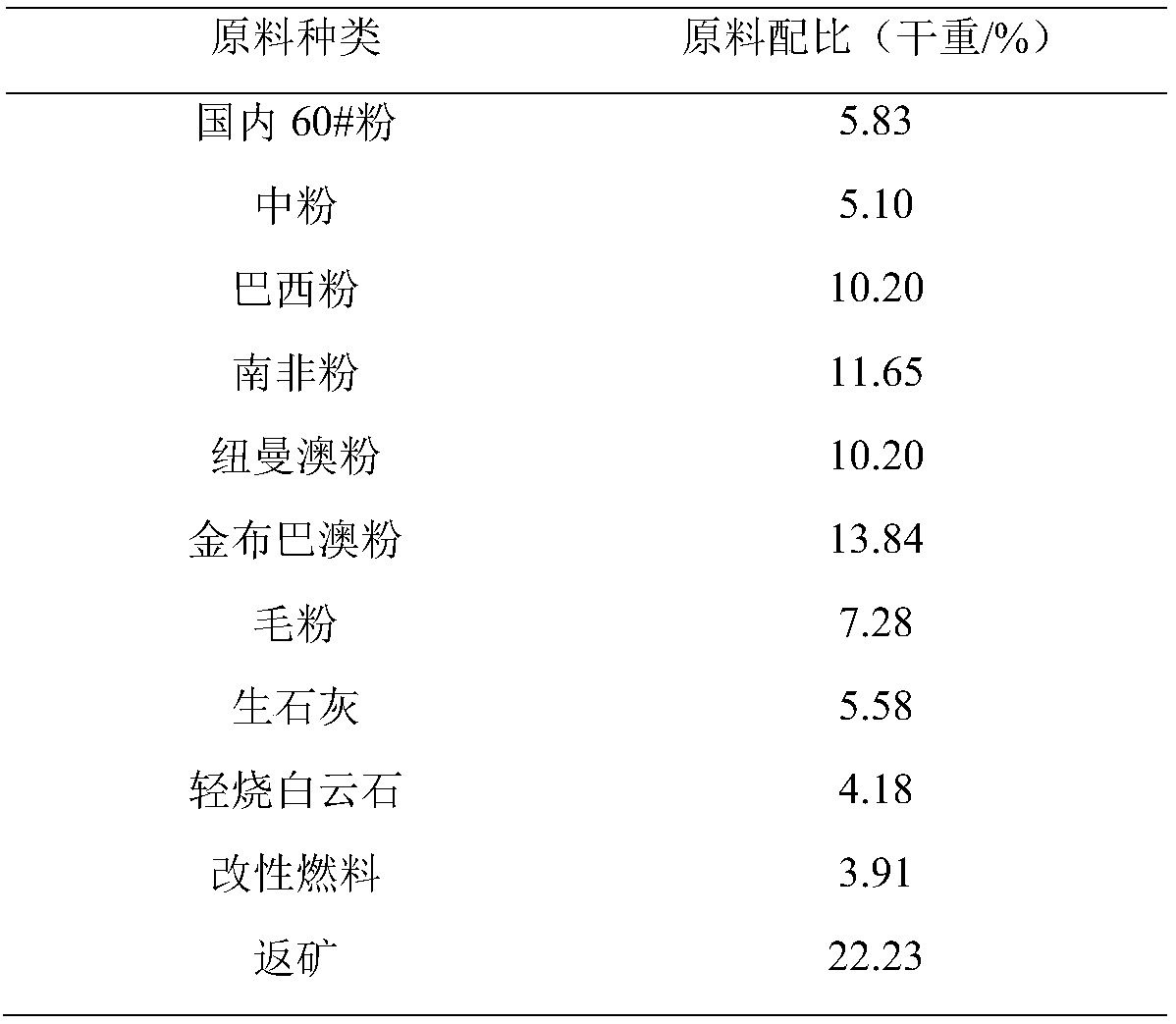

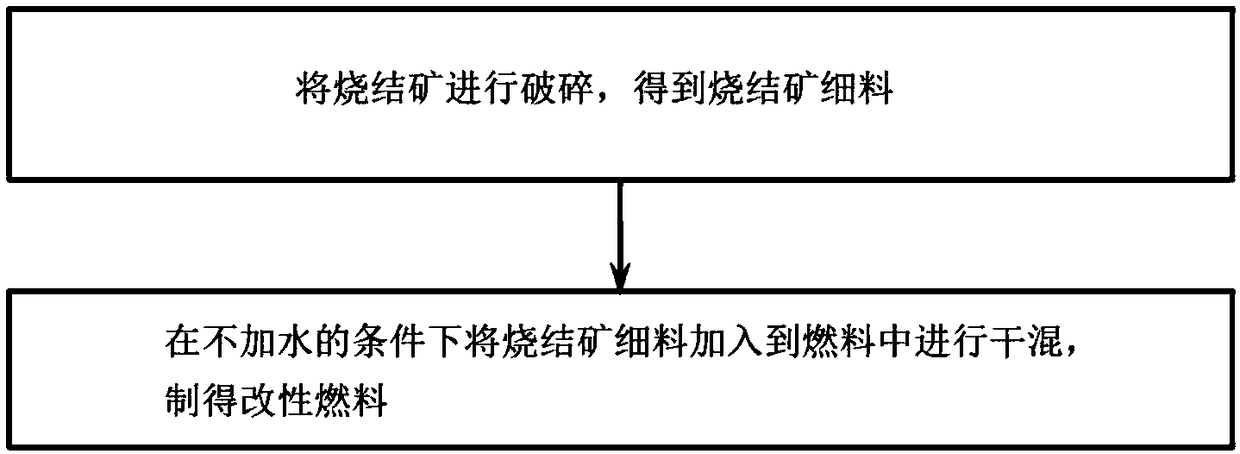

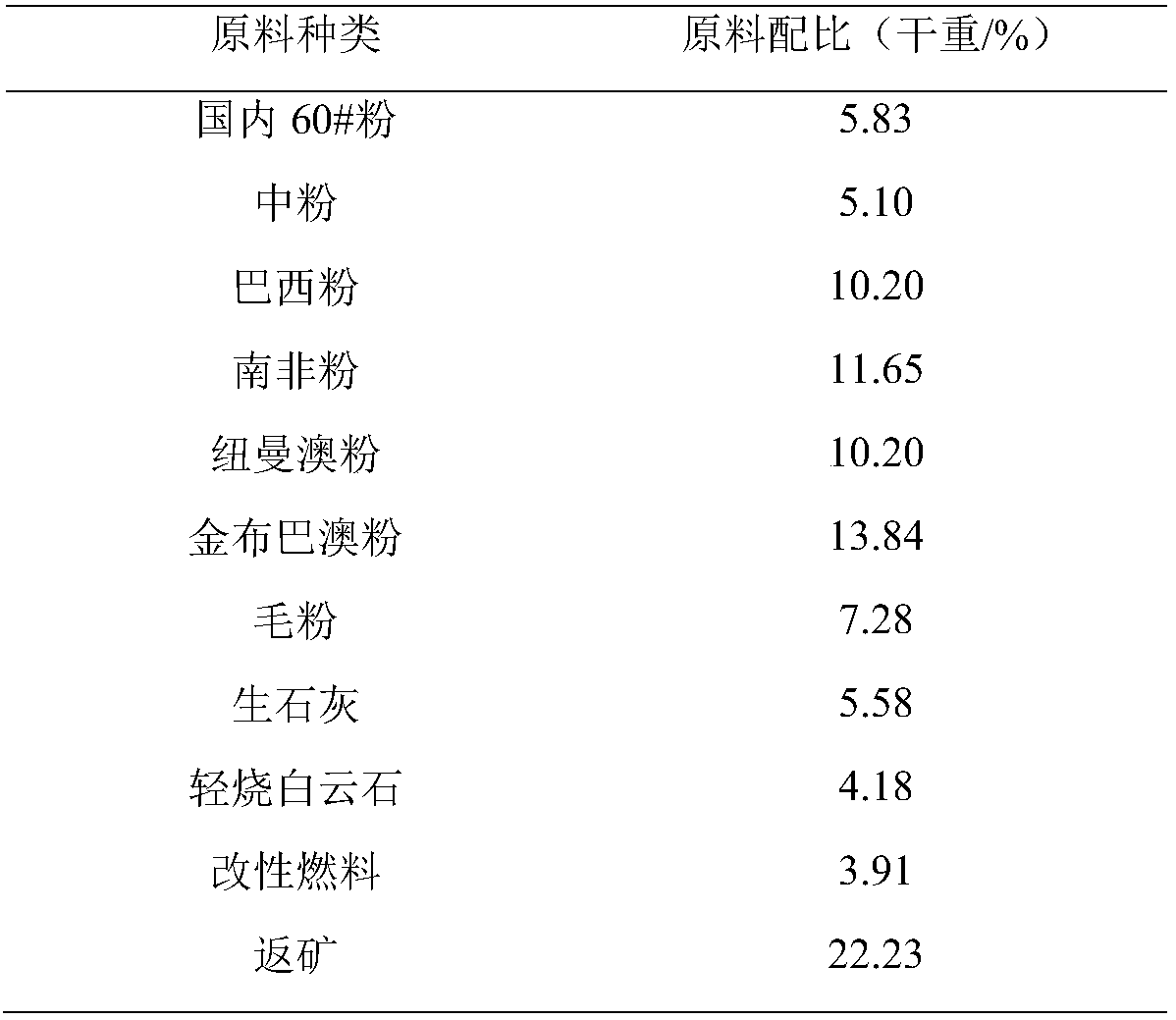

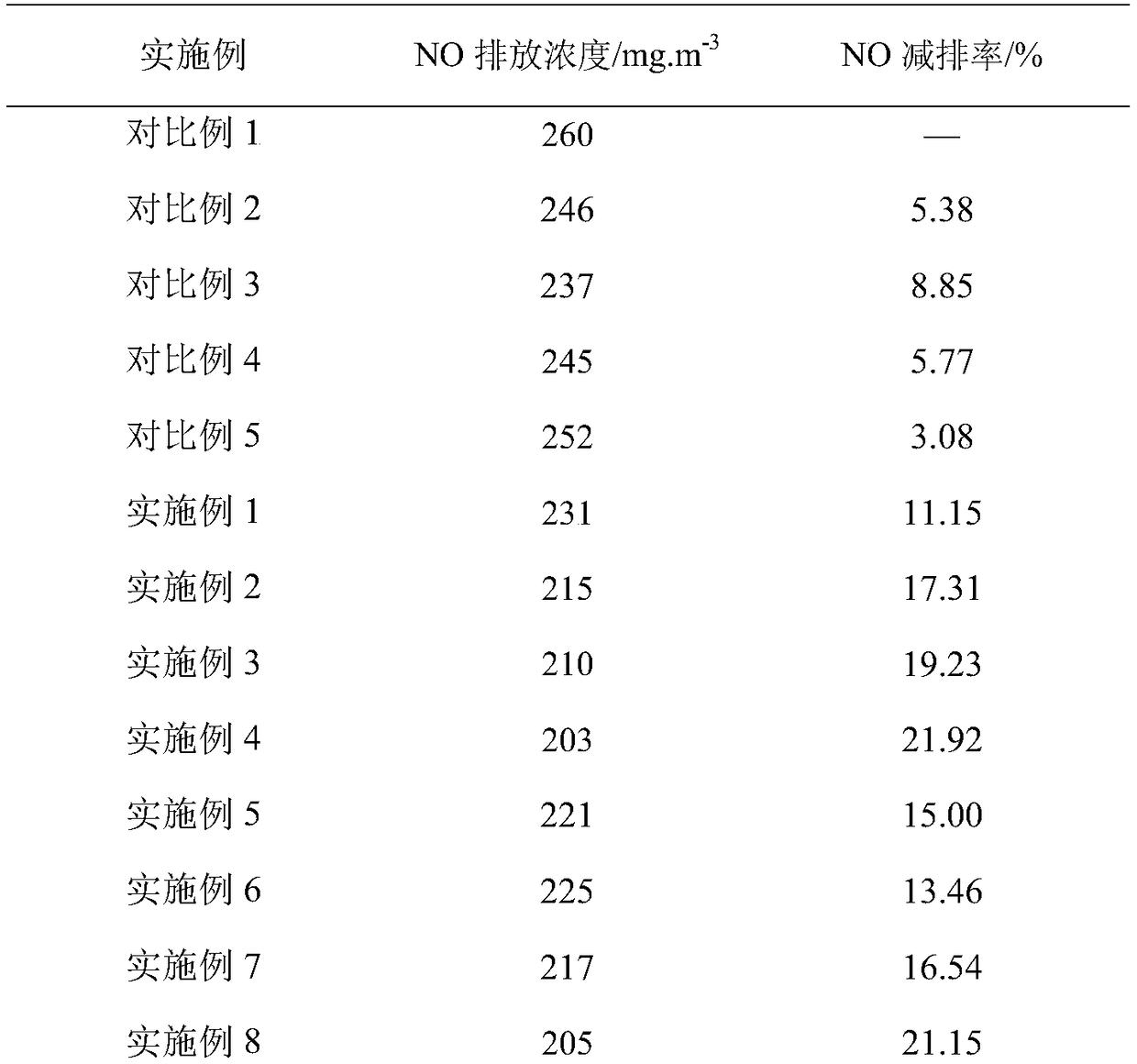

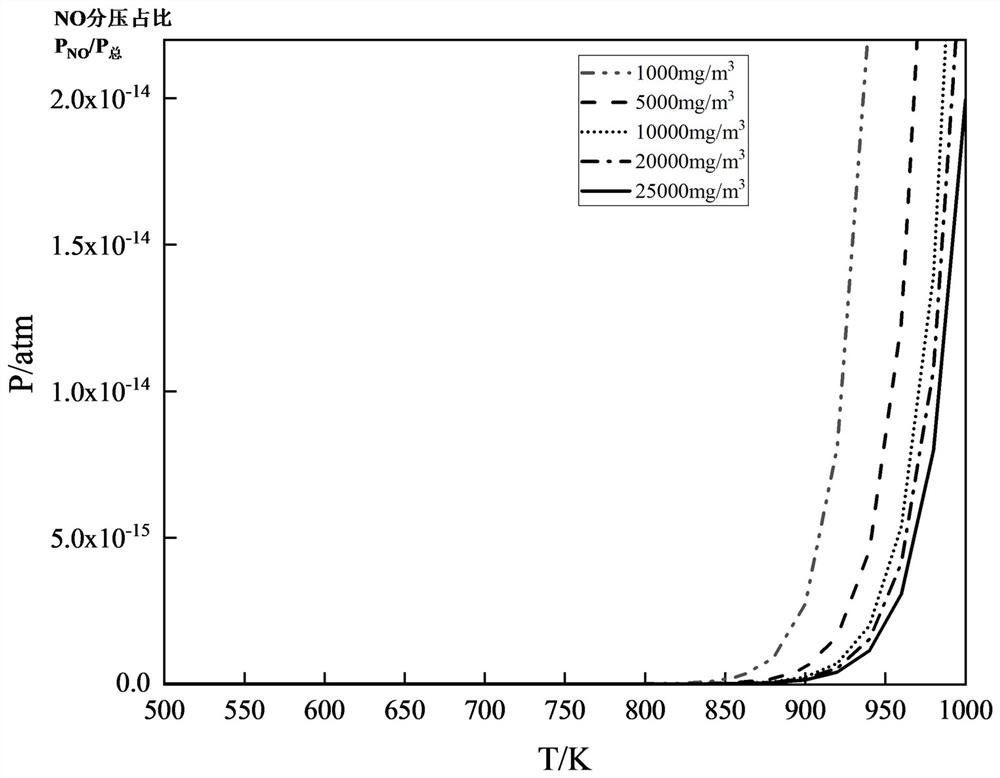

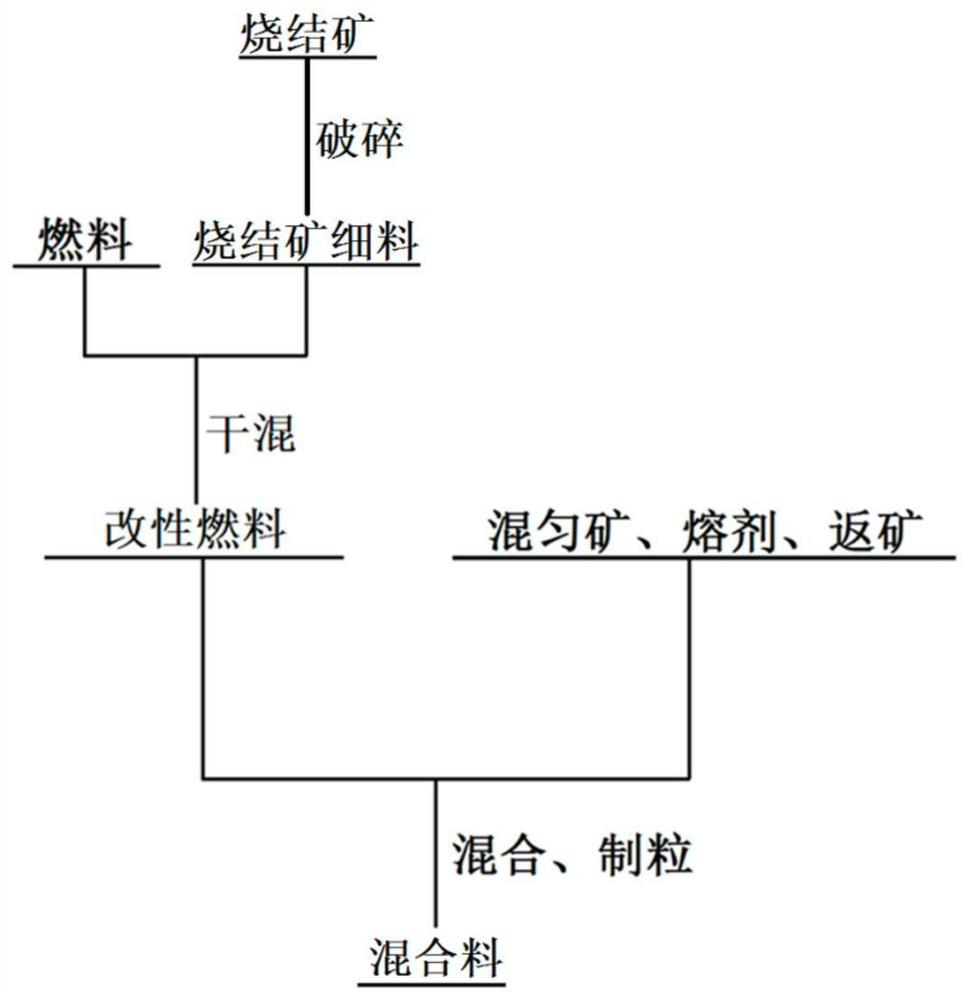

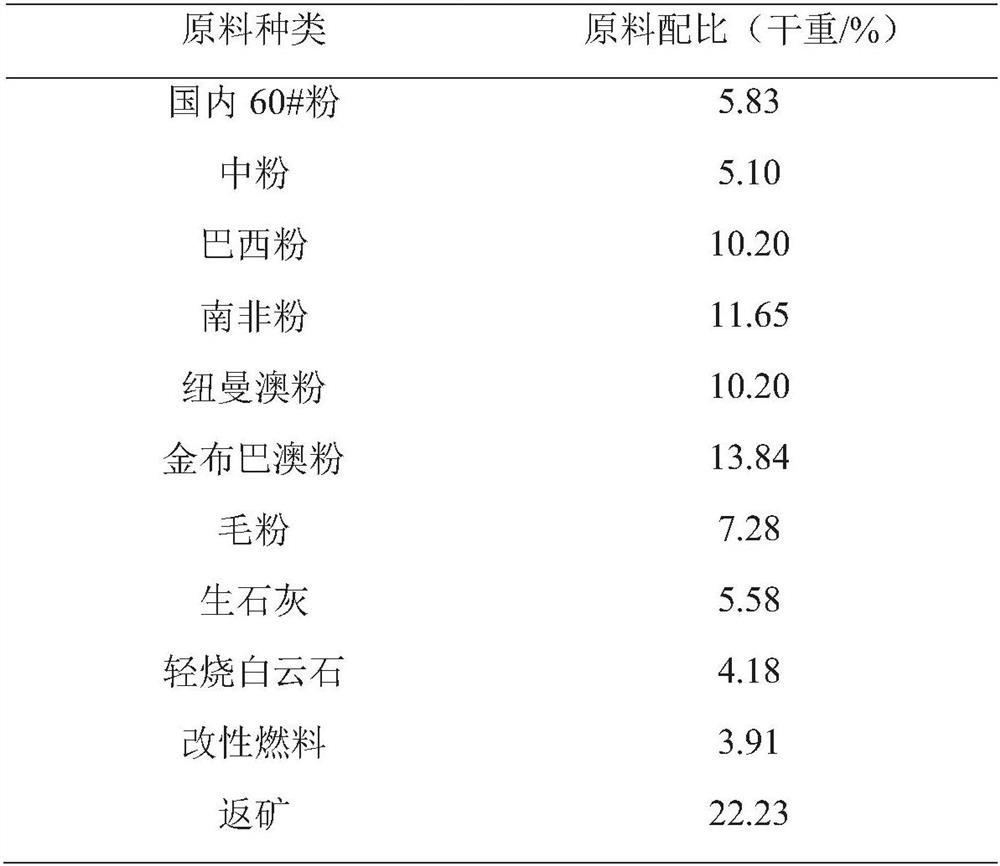

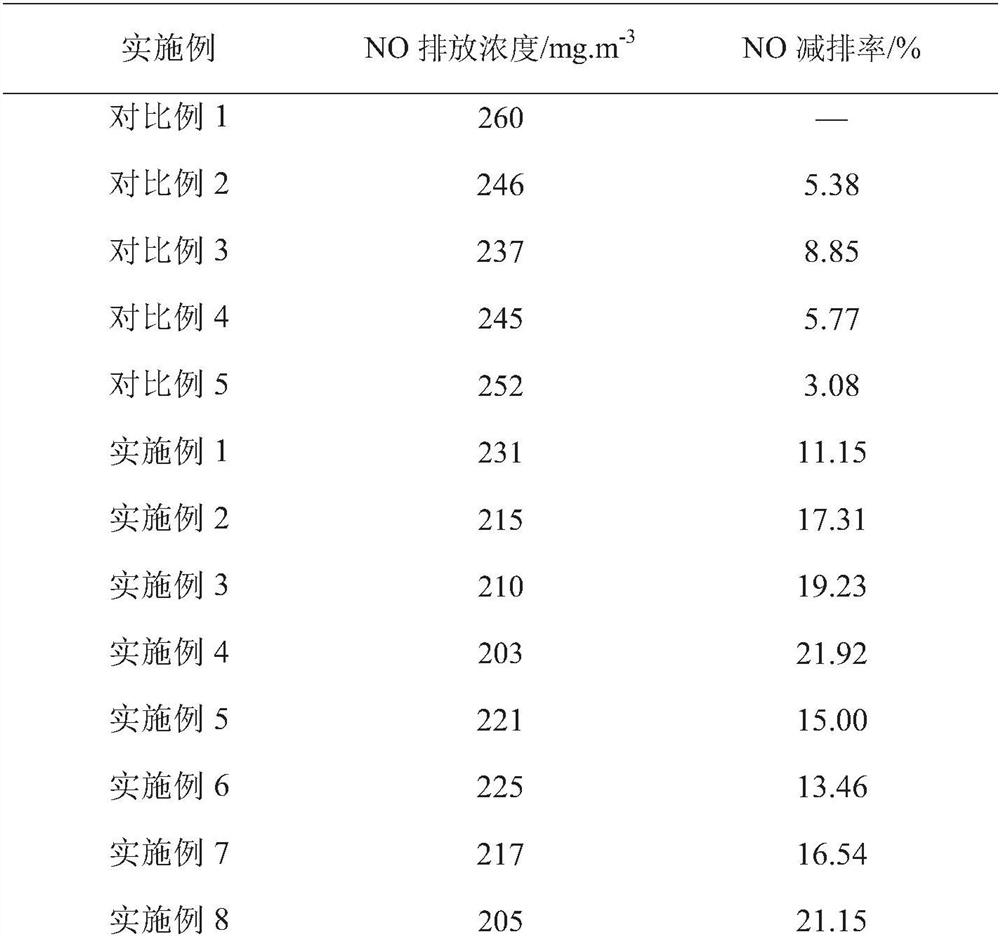

Method for reducing NOx emission in iron ore sintering process based on modified fuel

ActiveCN109251779AEfficient emission reductionAvoid obstructionSolid fuelsFuel additivesDry mixingIron ore sintering

The invention discloses a method for reducing NOx emission in an iron ore sintering process based on a modified fuel, and relates to the technical field of emission reduction of sintering pollutants.The method comprises the steps: firstly, finely grinding a sintered ore to a fine sintered ore material, then adding the fine sintered ore material to a fuel without addition of water, and carrying out dry mixing to produce the modified fuel; then mixing the modified fuel with an iron-containing raw material and a flux, and granulating to obtain a mixture; and laying the mixture on a trolley, andcarrying out ignition and air extraction sintering of the mixture. Through full dry mixing of the fine sintered ore material and the fuel, the fine sintered ore material is loosely distributed aroundthe fuel; NOx can be produced in the process of fuel combustion, the loosely distributed fine sintered ore material can highly efficiently catalyze the reduction process of NOx, and the highly efficient emission reduction of NOx in the iron ore sintering process is achieved.

Owner:LIUZHOU IRON & STEEL +1

Method and device for desulfurization of smoke discharged from ship

InactiveCN102112210BStrong solubility and absorption capacitySmall sizeGas treatmentInternal combustion piston enginesEnvironmental engineeringExhaust pipe

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

Method for reducing discharge of flue gas pollutants in iron ore sintering process

ActiveCN109136542AAchieving Joint Emission ReductionEfficient emission reductionElectrostatic separationDispersed particle separationMulti pollutantIron ore sintering

The invention discloses a method for reducing discharge of flue gas pollutants in the iron ore sintering process, and relates to the technical field of discharge reduction of sintering pollutants. Themethod comprises the following steps: adding quick lime into fuel under the condition of not adding water and performing dry mixing to obtain modified fuel, mixing and pelletizing the modified fuel,an iron-containing raw material and a fluxing agent to obtain a mixed material, paving the mixed material on a trolley, and performing ignition and air draft sintering on the mixed material; and setting an electrostatic dust remover and a desulfurization tower on a sintering flue gas pipeline. The modified fuel is mixed in the sintering mixed material, so that the discharge quantity of NOx can bereduced effectively; in addition, sintering flue gas subparticles are subjected to effective discharge reduction by an electric dust-removing mode; and the desulfurization tower is provided, so that effective discharge reduction of SO2 in the sintering process is realized and combined discharge reduction of various pollutants in the sintering process is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

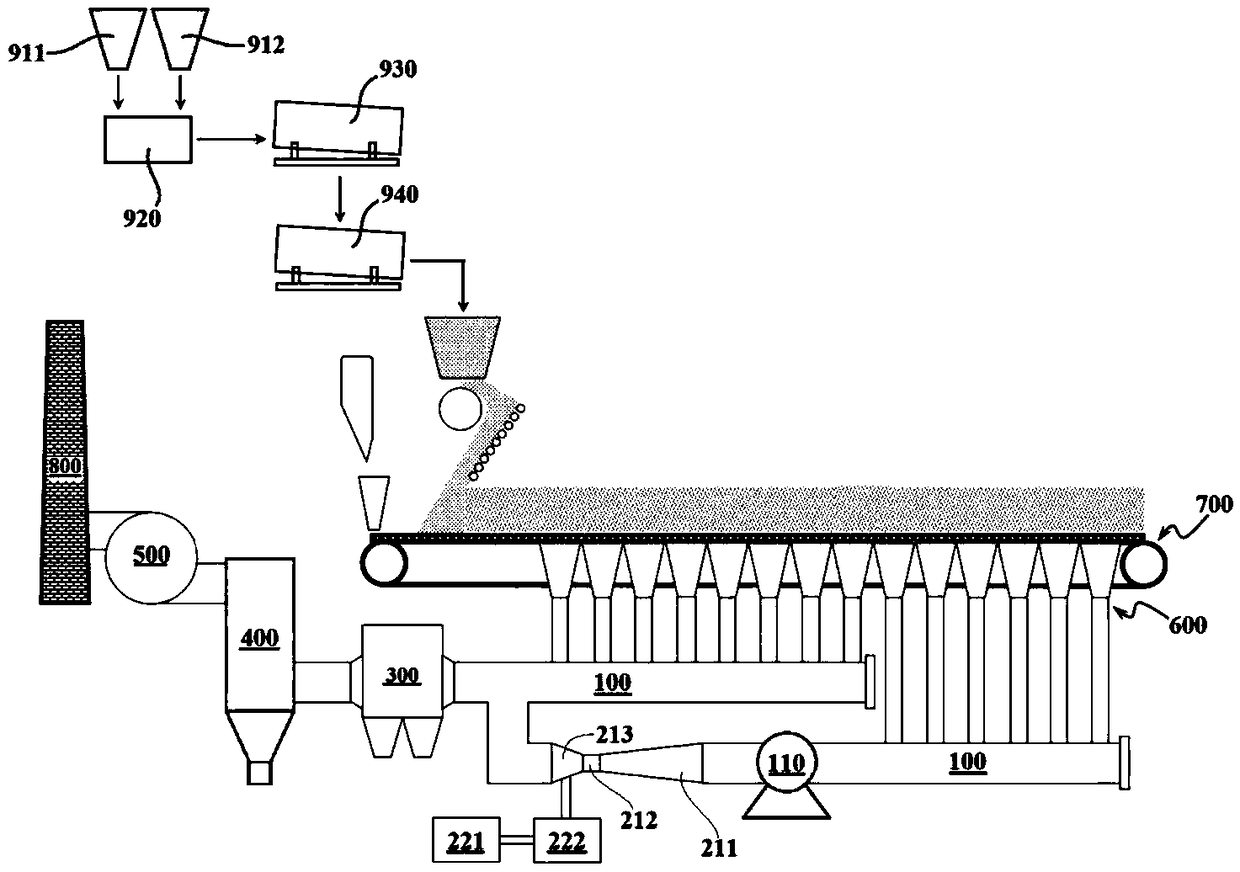

Combined emission-reducing device for multiple pollutants in flue gas caused by iron-ore sintering and use method thereof

InactiveCN109233935AJoint emission reduction achievedDry mix wellGas treatmentAuxillary pretreatmentBogieDry mixing

The invention discloses a combined emission-reducing device for multiple pollutants in flue gas caused by iron-ore sintering and a use method thereof and relates to the technical field of emission reduction of pollutants from sintering. The combined emission-reducing device comprises a fuel modifying unit, a sintering bogie and a flue-gas treating unit, wherein the fuel modifying unit comprises ahopper, a crusher, a dry mixing machine and a mixer; the hopper is arranged above the crusher, and the dry mixing machine and the mixer are arranged behind the crusher; an electrostatic dust remover and a desulfurizing tower are arranged in a main flue of the sintering bogie. The combined emission-reducing device disclosed by the invention has the beneficial effects that quick lime is adopted formodifying the fuel by the fuel modifying unit to obtain modified fuel, and after the modified fuel is added into mixture, effective emissin reduction of NOx from sintering can be realized; in addition, by arrangement of the electrostatic dust remover and the desulfurizing tower in the main flue, effective emission reduction of fine particles and SO2 of the flue gas caused by sintering can be realized and further combined emission reduction of multiple pollutants in the sintering process can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Modified fuel for reducing NOx emission in iron ore sintering process based on reduction and catalysis, and preparation method thereof

PendingCN109181809AEffective recoveryImprove emission reduction rateDispersed particle separationSolid fuelsDry mixingNitrogen oxide

The invention discloses a modified fuel for reducing NOx emission in an iron ore sintering process based on reduction and catalysis, and a preparation method thereof, and relates to the technical field of emission reduction of sintering pollutants. The modified fuel comprises agglomerate and a fuel, the addition of the agglomerate is 0.5-5% of the total mass of the fuel, and ground agglomerate andthe fuel undergo dry mixing to prepare the modified fuel. Fine agglomerate formed after crushing the agglomerate in the modified fuel is loosely distributed surrounding the fuel and mixed in a sintering mixture after being fully drily mixed with the fuel in order to promote the effective reduction of NOx generated in combustion, and the fine agglomerate can efficiently catalyze the reduction process of the NOx generated by the fuel in order to achieve the efficient emission reduction of the NOx in the agglomerate sintering process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

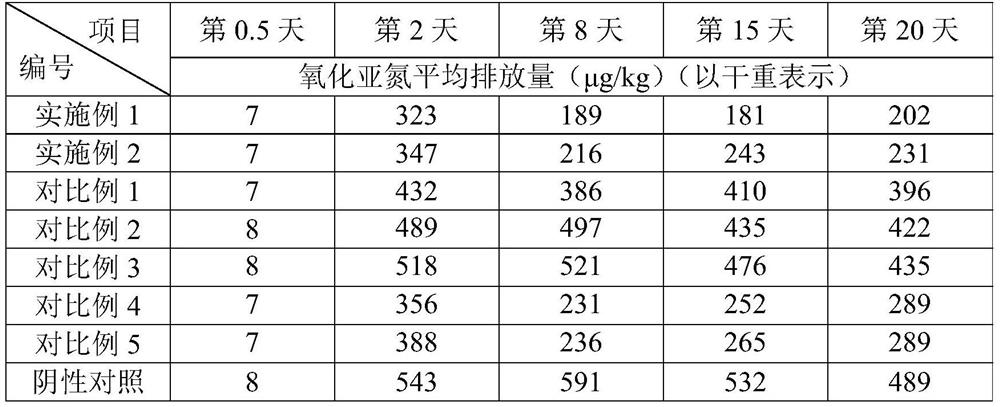

Complex microbial inoculant capable of reducing nitrous oxide emission and application of complex microbial inoculant

ActiveCN112725229AEfficient reductionEfficient emission reductionBio-organic fraction processingBacteriaBiotechnologyEcological environment

The invention discloses a complex microbial inoculant capable of reducing nitrous oxide emission in a composting process and an application of the complex microbial inoculant. The complex microbial inoculant comprises marivirga tractuosa, prevotella denticola and desulfotomaculum ruminis. Through the synergistic effect of the three strains, greenhouse gas nitrous oxide can be reduced into harmless nitrogen more efficiently. The maximum emission reduction of oxygen and nitrogen oxide reaches 402 [mu]g / kg. By adding the microbial inoculant, the emission of nitrous oxide in the composting process is effectively controlled, and the ecological environment is protected.

Owner:FUJIAN AGRI & FORESTRY UNIV

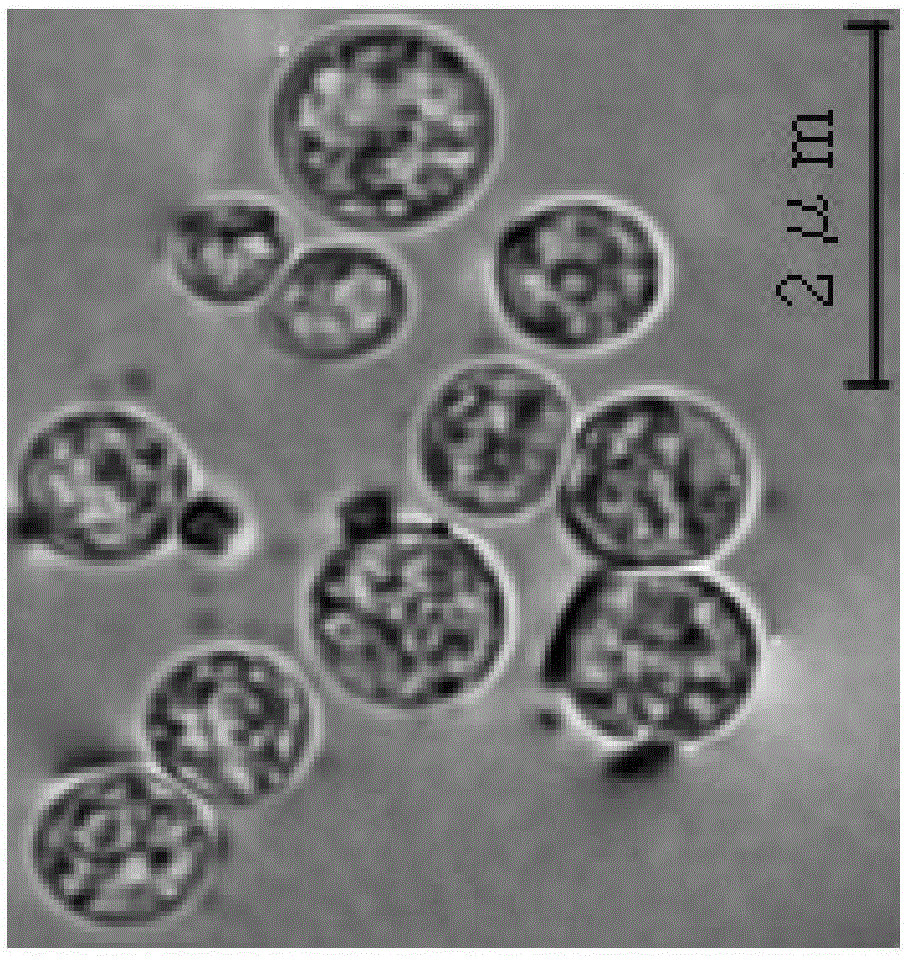

A freshwater chlorella sorokiniana GS03 and its application

InactiveCN103952312BSuitable for productionEffectively fixedUnicellular algaeBiofuelsHigh concentrationBiodiesel

The invention relates to the technical field of biomass energy, and in particular to a freshwater chlorella strain (i) Chlorella sorokiniana ( / i) GS03 and application thereof to industrial flue gas CO2 fixation and production of microalgae biodiesel. The chlorella strain (i) C.sorokiniana ( / i) GS03 provided by the invention has a preservation number of CCTCC M2013607, and higher CO2 tolerance, higher fixation efficiency of high-concentration carbon dioxide and higher biomass yield and oil yield compared with the reported microalgae strains. Therefore, the invention can greatly reduce microalgal oil production cost, and provides a good production strain for algae for efficient fixation of CO2 in typical industrial flue gas environment and biodiesel production from microalgae oil, and shows great application prospect in the field of biomass energy.

Owner:SHANGHAI JIAOTONG UNIV

An emission reduction system for fine particulate matter in iron ore sintering process

ActiveCN105854501BIncrease flow rateEfficient emission reductionGas treatmentAuxillary pretreatmentIron ore sinteringFine particulate

The invention discloses an emission reduction system for fine particles in the sintering process of iron ore, and belongs to the technical field of emission reduction of pollutants in the sintering process of iron ore. The emission reduction system for fine particles in the sintering process of iron ore comprises a fine particle atomizing and agglomerating device, an agglomerating liquid adding device and a dust removing device. The bottom of a sintering pallet is connected with a main flue through air bellows, air draft smoke is combined in the main flue through the bottom of the sintering pallet via the air bellows, the atomizing and agglomerating device, the agglomerating liquid adding device and the dust removing device are arranged on the main flue, and the smoke flows into the atomizing and agglomerating device from the main flue, and is subjected to dust removal by the dust removing device and then discharged into a chimney by a draught fan. By means of the emission reduction system, agglomerating liquid fog drops with fine particles adsorbed nucleate, collide and grow under the low-pressure condition, and form large particle agglomerated mater, the fine particles growing through agglomeration are removed with the dust removing device, and thus a bran-new emission reduction approach is provided for emission reduction of the fine particles in the sintering process of iron ore.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

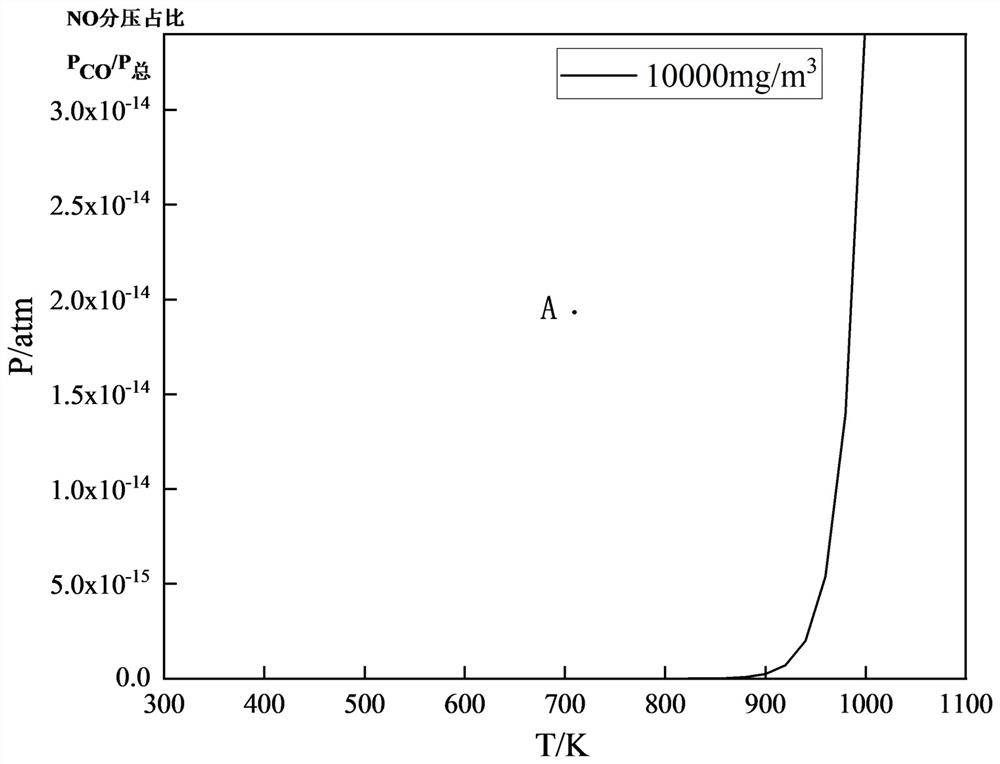

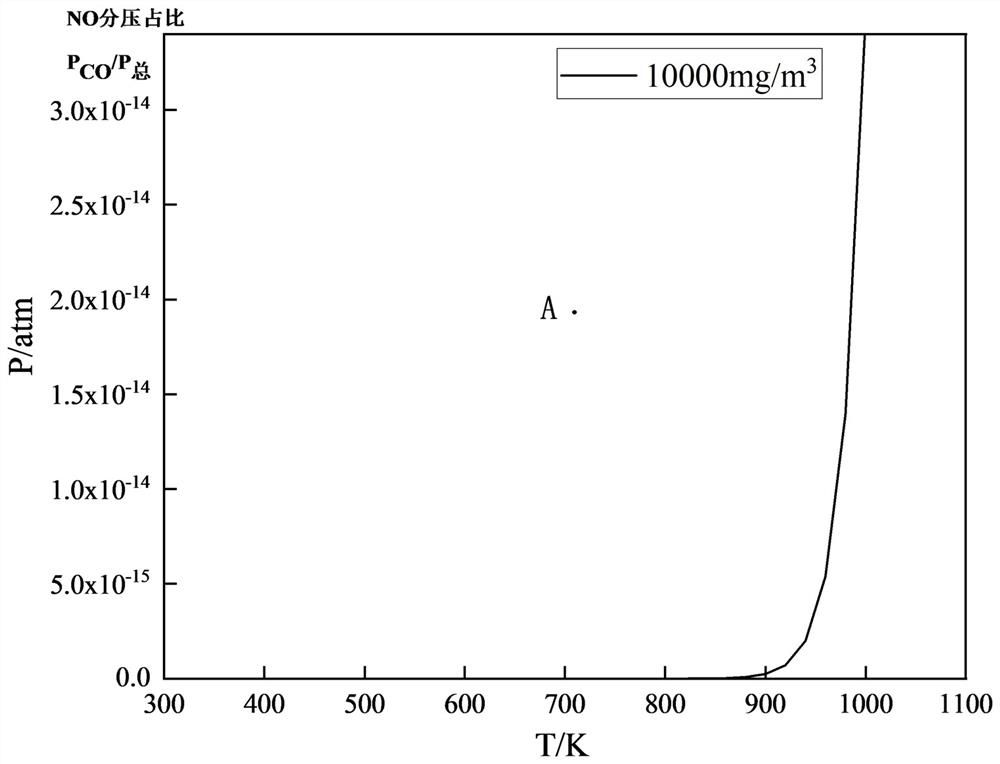

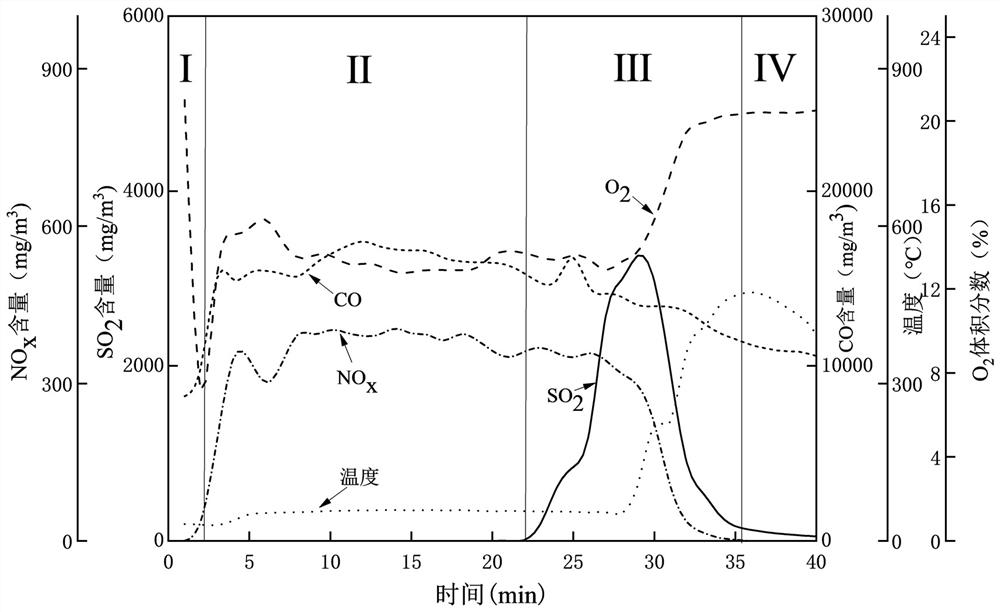

Method for denitration in sintering process by using multiple flue gases

ActiveCN114485196AImprove denitrification efficiencyEfficient emission reductionWaste heat treatmentThermodynamicsFlue gas

The invention discloses a method for denitration in a sintering process by using various flue gases. The method comprises the following steps: carrying out component analysis on flue gases of different furnaces and kilns; assembling and mixing the flue gas in a gas holder, monitoring the components and the temperature of the flue gas at an outlet of the gas holder in real time, adjusting a flue gas assembling scheme, determining that the components CO and the temperature of the assembled flue gas meet the requirements, and enabling the assembled flue gas to pass through a sintering pallet in production; after flue gas in the first middle stage of sintering production comes out of an ore deposit, the flue gas is led to a sinter circular cooler for NO removal, and the flue gas with NO removed is subjected to waste heat recovery to form external circulation; and flue gas in the later stage of sintering production is used as sintering circulating flue gas to return to the gas holder and is subjected to flue gas assembly together with industrial flue gas to form internal circulation. The effect of treating waste with waste is obvious, and a new thought is provided for efficient emission reduction of NOx in the sintering process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

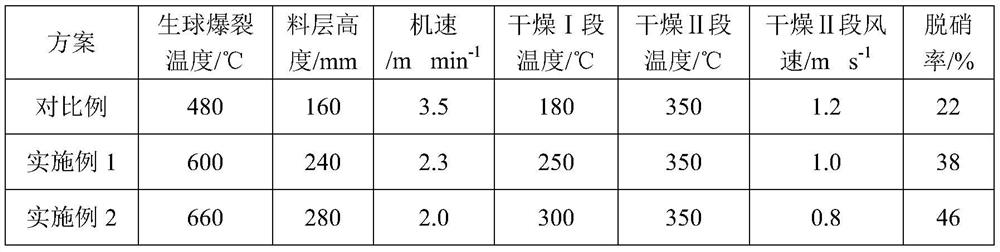

An intensified method for denitrification by ammonia spraying in the production process of iron ore pellets

ActiveCN111004914BProlong the action timeReduce difficultyGas treatmentDispersed particle separationPtru catalystAir velocity

The invention discloses an intensified method for denitrification by ammonia injection in the production process of iron ore pellets. The method is to prepare pellets with high bursting temperature and good thermal stability by adding anti-burst additives to the pellet binder bentonite. In this way, the thickness of the material layer in the heat treatment process of the pellets is increased by 1.5 to 1.75 times, the machine speed is reduced to 4 / 7 to 2 / 3, and the exhaust wind speed in the second drying section is reduced to 0.8 to 1.0m / s. Ammonia water is evenly sprayed into the air stream for denitrification. The advantages of the present invention are: due to the operation of the thick material layer and the reduction of the airflow velocity, the time for the airflow to pass through the pellet material layer is prolonged, and the concentration of iron-containing minerals and NOx, NH in the denitrification catalyst is improved. 3 The action time is longer, thereby enhancing the efficiency of ammonia spray denitrification in the drying section, and the NOx removal rate is increased by 15% to 30%.

Owner:ANSTEEL GRP MINING CO LTD

Device system and process for cracking and recycling high-carbon alcohol waste liquid

PendingCN114315524AThe device system is simple and easy to operateIncrease productionOrganic compound preparationHydroxy compound preparationSide productProcess engineering

The invention relates to a device system and process for cracking and recycling high-alcohol waste liquid, the device system comprises a hydrogenation unit, a cracking unit and a rectification unit which are connected in sequence, a waste alcohol outlet of the hydrogenation unit is connected with an inlet of the cracking unit, and a heavy component outlet of the rectification unit is connected with an inlet of the hydrogenation unit; the process comprises the following steps: introducing waste alcohol discharged after high-carbon alcohol passes through a hydrogenation unit into a cracking unit, introducing a product after cracking reaction into a rectification unit for rectification separation, and recycling obtained heavy components to the hydrogenation unit. The device system provided by the invention is simple and easy to operate, the cracking unit and the rectification unit are directly added in the original high alcohol production process, the process realizes the recycling of more than 80% of target products and byproducts in the discharged waste alcohol liquid, the high alcohol yield is obviously increased, and the device system is easy to popularize and apply.

Owner:CHINA NAT OFFSHORE OIL CORP +2

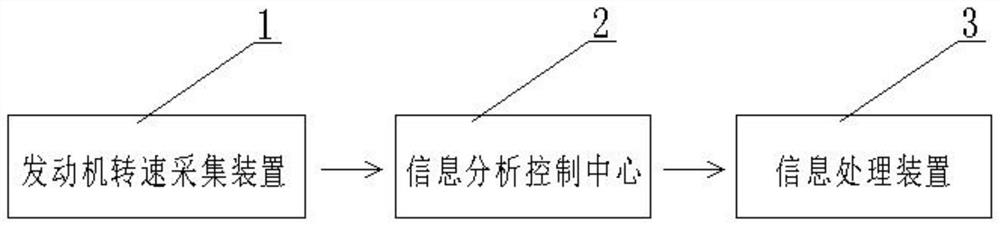

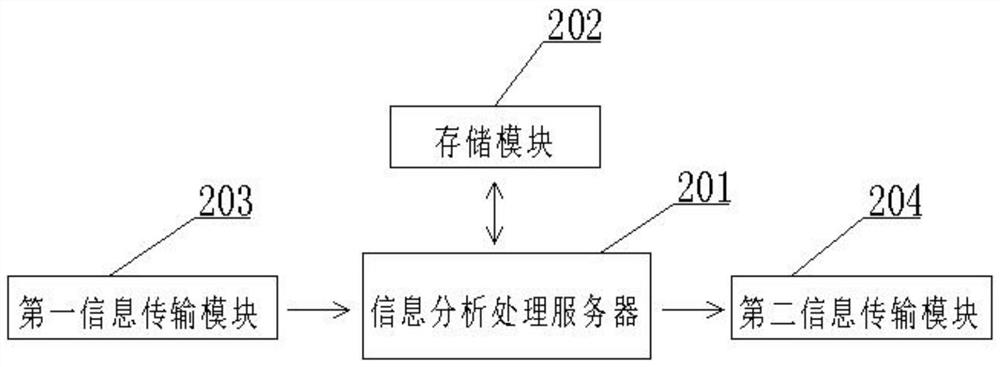

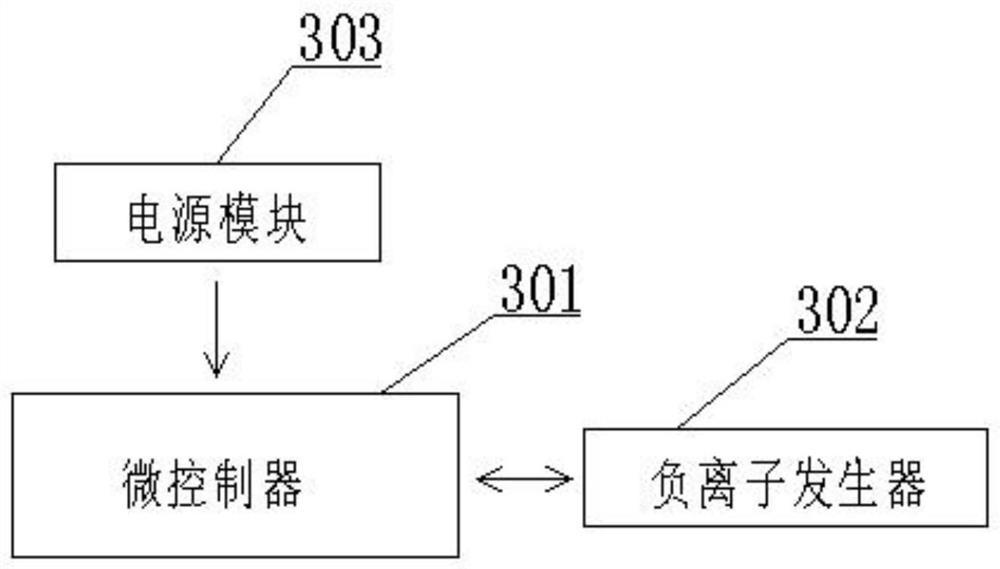

Anion intelligent oil saving and emission reduction system for automobile fuel oil engine and running method of system

PendingCN111852696AIncrease the number of openingsImprove combustion efficiencyElectrical controlCombustion-air/fuel-air treatmentFuel oilControl theory

The invention relates to an anion intelligent oil saving and emission reduction system for an automobile fuel oil engine and a running method of the system, and belongs to the field of anion and engine fuel oil. The system comprises anion generators, an engine rotating speed collection device, an information analysis control center, an information processing device and a grounded guide chain. According to the system, the air anion concentration of the end of an engine gas inlet can be adjusted according to the output power of the automobile fuel oil engine, combustion efficiency is further increased, and the effects of oil saving and emission reduction are achieved; the air anion concentration of the end of an engine exhaust port can be adjusted according to the output power of the automobile fuel oil engine, and tail gas is further purified; and in addition, when it is detected that the automobile engine is in an idling state for a long time, the number of the started anion generatorsof the end of the engine gas inlet can be improved, carbon deposition is further eliminated, the defect that current anion oil saving systems cannot achieve intelligent adjusting according to engineoutput power is finally effectively overcome, and the high efficiency, energy saving and emission reduction comprehensive effects are achieved.

Owner:秦皇岛零叁邀柒科技开发有限公司

A NOx emission reduction method based on modified fuel iron ore sintering process

ActiveCN109251779BEfficient emission reductionAvoid obstructionSolid fuelsFuel additivesIron ore sinteringCombustion process

The invention discloses a method for reducing NOx emission in the iron ore sintering process based on modified fuel, and relates to the technical field of emission reduction of sintering pollutants. In the present invention, the sintered ore is first finely ground to obtain the sintered ore fine material, and then the sintered ore fine material is added to the fuel for dry mixing without adding water to obtain a modified fuel, and then the modified fuel is mixed with iron-containing The raw materials and flux are mixed and granulated to obtain the mixture, which is loaded on the trolley, and the mixture is ignited and ventilated for sintering; the invention fully dry-mixes the fine sintered ore and fuel to make it loose It is distributed around the fuel; NOx will be generated during the fuel combustion process, and the loosely distributed sinter fines can efficiently catalyze the reduction process of NOx, thereby realizing the efficient reduction of NOx emission during the iron ore sintering process.

Owner:LIUZHOU IRON & STEEL +1

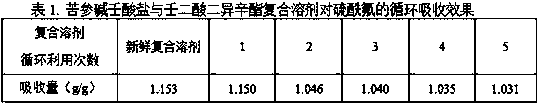

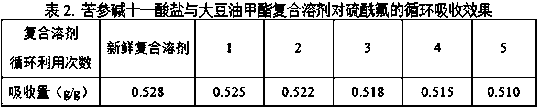

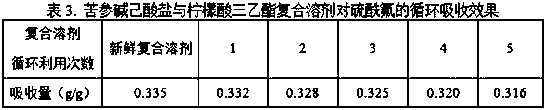

Method for absorbing residual fumigant sulfuryl fluoride by using ionic liquid composite bio-based solvent

ActiveCN110935286ALow viscosityLarge absorption capacityGas treatmentDispersed particle separationSophocarpidinePhysical chemistry

The invention discloses a method for absorbing residual fumigant sulfuryl fluoride by using an ionic liquid composite bio-based solvent. According to the method, sulfuryl fluoride gas is physically absorbed by using an ionic liquid composite bio-based solvent as an absorbent, and the rich solution after sulfuryl fluoride absorbing is desorbed, so that the regeneration of the absorbent can be achieved, wherein the ionic liquid composite bio-based solvent is formed by uniformly mixing a bio-based ionic liquid and a bio-based solvent containing carbonyl groups, and the bio-based ionic liquid is sophocarpidine hexanoate, sophocarpidine heptanoate, sophocarpidine caprylate, sophocarpidine nonanoate, sophocarpidine decanoate, sophocarpidine undecanoate or sophocarpidine tridecanoate. According to the invention, through the organic compounding of the bio-based ionic liquid and the bio-based solvent, the absorption process of sulfuryl fluoride is accelerated from mass transfer driving force and mass transfer coefficient so as to achieve the efficient and environmentally-friendly emission reduction of the residual fumigant sulfuryl fluoride.

Owner:ZHEJIANG UNIV OF TECH

A method for denitrification in sintering process using various flue gases

ActiveCN114485196BImprove denitrification efficiencyEfficient emission reductionWaste heat treatmentFlue gasProcess engineering

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A waste gas circulation denitrification method for iron ore pellets

ActiveCN108355488BReduce constructionEmission reductionGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention discloses a waste gas cyclic denitration method for iron ore pellets. According to the method, NOx-containing flue gas generated by the iron ore pellets in the production process of theiron ore pellets is cycled to a medium and low temperature cooling zone, and at the medium and low temperature cooling zone, ammonia spraying denitration is carried out. The specific method comprises:converging waste gas at a down-draft drying zone with high-sulfur flue gas at a preheating warming zone, of which SO2 concentration is greater than 300mg / m<3>; and sequentially carrying out dust removal and desulfuration purification, desulfurizing to SO2 concentration of 50mg / m<3> or below; then converging the obtained gas with front-zone waste gas at the preheating warming zone, of which SO2 concentration is lower than 300mg / m<3>; cycling the obtained gas into the medium and low temperature cooling zone to use as a cooling medium; before cycled waste gas enters a cooling-zone material layer, spraying NH3; then filling the cycled waste gas into the material layer to carry out SCR denitration; controlling a molar ratio of NH3 to NO within a range of 0.3 to 0.5, so as to realize NOx emission reduction by 15% to 25%.

Owner:CENT SOUTH UNIV

Sensing type piano recording technical scheme

InactiveCN109903741ASimple structureReasonable designElectrophonic musical instrumentsPianoSoftware system

The invention relates to a sensing type piano recording technical scheme. The sensing type piano recording technical scheme is characterized in that a recording device comprises a main control box anda sensor guide rail, the main control box is provided with a sensor interface and a USB interface, and the sensor guide rail is connected with the sensor interface on the main control box through a strip-shaped cable; four PCBs are mounted on the sensor guide rail, and each PCB is provided with 22 photoelectric sensors; the PCBs are connected with telescopic flexible flat cables; the main controlbox is connected with a computer installed with a recording software system through the USB interface and outputs data to the computer; the upward face of each photoelectric sensor is provided with alight-emitting diode and a phototransistor. The sensing type piano recording technical scheme has the advantages that the technical scheme is convenient in operation and simple in principle, the system can precisely capture a playing process by the aid of the high-sensitivity photoelectric sensors, and each moment of the playing can be precisely recorded and flexibly saved.

Owner:孔晓芳

A kind of composite bacteria agent for reducing nitrous oxide emission and its application

ActiveCN112725229BEfficient reductionEfficient emission reductionBio-organic fraction processingBacteriaBiotechnologyEcological environment

The invention discloses a composite bacterial agent for reducing nitrous oxide discharge in the composting process and an application thereof. The compound microbial agent comprises Marivirga tractuosa, Prevotella denticola and Desulfotomaculum ruminis. The three strains of the present invention act synergistically and can more efficiently reduce the greenhouse gas nitrous oxide into harmless nitrogen. The emission reduction of oxygen and nitrogen oxides reached up to 402μg / kg. The addition of these bacterial agents can effectively control the emission of nitrous oxide during the composting process and protect the ecological environment.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com