Method and device for desulfurization of smoke discharged from ship

A desulfurization device, sea-going ship technology, applied in the direction of exhaust device, noise reduction device, separation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

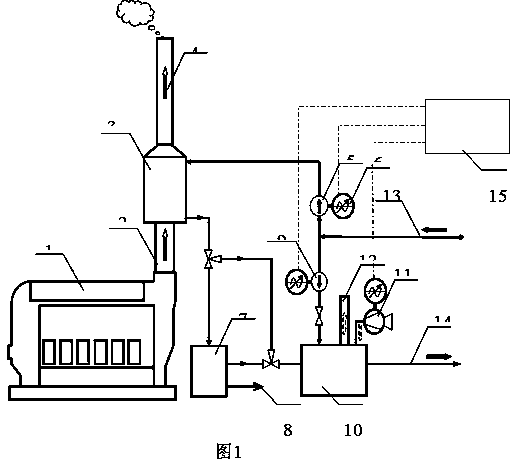

[0063] Example 1: Such as figure 1 As shown, there is a desulfurization controller. The steps of the sea-going ship's flue gas desulfurization method in this embodiment are as follows:

[0064] a. Washing: containing SO discharged from ship engines 2 The high-temperature flue gas is cooled and then washed, and then the cleaned flue gas is discharged; the washing is washed with seawater in the scrubber; b. Transferring acidic seawater: the washing process absorbs SO 2 The acidic seawater formed is transferred from the scrubber to the water-saving deacidification device; c. Deacidification treatment: the acidic seawater entering the water-saving deacidification device is mixed with alkaline seawater to make it mixed seawater, and the mixed seawater Blowing in air; d. Drainage: Discharging the suitable drainable seawater that has been deacidified to the sea; washing with seawater in the scrubber in the washing step is carried out in a scrubber with a filler washing layer;

[0065] In...

Embodiment 2

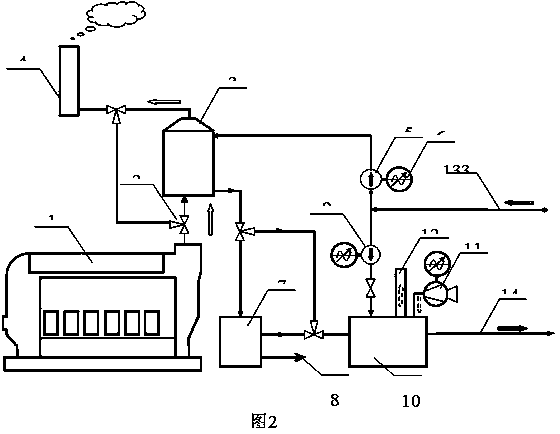

[0069] Example 2: Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the scrubber 3 has a parallel bypass exhaust pipe, that is, the marine engine 1 and the scrubber exhaust pipe 4 have a direct communication exhaust pipe, which is convenient for switching the scrubber 3. Desulfurization control is manual control.

[0070] The ship used in this embodiment has a large tonnage, is equipped with a 60MW diesel engine, emits smoke at a temperature of 200 to 430 ℃, and emits smoke about 310,100Nm 3 / h; Implementing the desulfurization method of the present invention, under the condition of 3% fuel sulfur content, the sulfur dioxide emission reduction to the desulfurization equivalent fuel sulfur content meets 1.5% of the SECA control standard (2005), and the pH of the drainage is ≥6.5. The sea water consumption in the sea area is:

[0071] Baltic Sea Washing water volume 980m 3 / h Blended seawater volume 3600m 3 / h

[0072] Pacific Ocean Washing ...

Embodiment 3

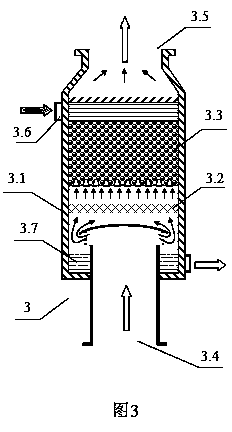

[0075] Such as figure 1 , image 3 Shown is a sea-going ship flue gas desulfurization device used in the method of the present invention. The intake pipe 3.1 of the scrubber 3 introduces high-temperature flue gas 3.2 from the lower part of the scrubber 3, which is suitable for the implementation of the flue gas entering the scrubber vertically upwards occasion. A sea-going ship's flue gas desulfurization device, which has a scrubber 3, a water-saving deacidifier 10; the scrubber 3 has a scrubbing layer 3.3 on the upper part, which is connected with the scrubbing sea water pump 5 through a pipeline; the lower part is a cooling layer 3.2; One end of the scrubber 3 is connected with the exhaust pipe of the ship engine 1 through the scrubbing intake pipe 2, and the other end is connected with the scrubbing exhaust pipe 4; the lower part of the scrubber 3 is connected with the water-saving deacidifier 10; the water-saving deacidifier 10 is connected with the blended sea water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com