A waste gas circulation denitrification method for iron ore pellets

A technology of waste gas circulation and iron ore pellets, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of incompatible NOx concentration in desulfurization and denitrification, reduce flue gas treatment capacity, etc., reduce emissions and solve large investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

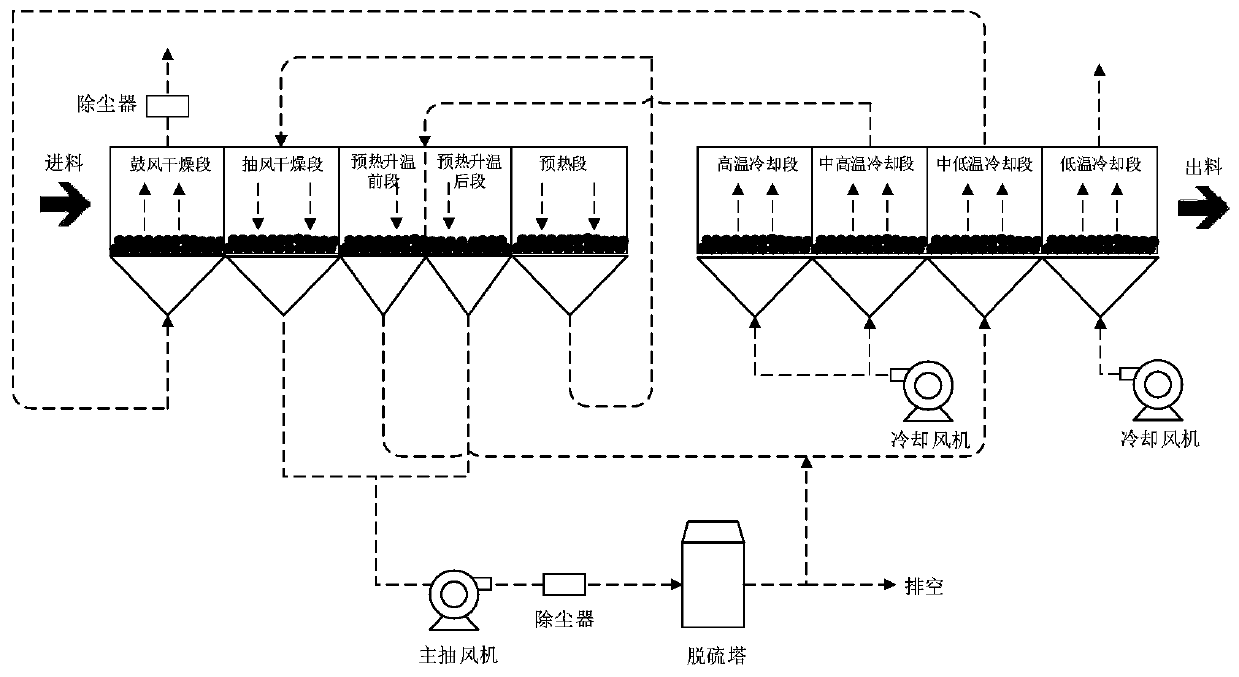

Embodiment 1

[0026] For the magnetite raw material, the SO in the preheating section 2 Concentration higher than 300mg / m 3 The high-sulfur flue gas is combined with the exhaust gas from the exhaust drying section, and the dust is removed by the dust removal device, and the exhaust gas is desulfurized to 50mg / m 3 , intercept the NOx-containing flue gas after desulfurization, and combine it with SO in the preheating and heating section 2 Concentration below 300mg / m 3 The exhaust gas is confluent, the volume ratio of the exhaust gas after desulfurization and purification treatment to the exhaust gas in the front section of the preheating and heating section is 60%:40%, and after the confluence, it is circulated to the medium and low temperature cooling section as the cooling medium, and the temperature of the circulating exhaust gas is controlled at 110 ℃, water vapor Content 10%, spray NH before the circulating exhaust gas enters the material layer of the cooling section 3 , to control NH...

Embodiment 2

[0028] For the hematite raw material, the SO in the preheating section 2 Concentration higher than 300mg / m 3 The high-sulfur flue gas is combined with the exhaust gas from the exhaust drying section, and the dust is removed by the dust removal device, and the exhaust gas is desulfurized to 30mg / m 3 , intercept the NOx-containing flue gas after desulfurization, and combine it with SO in the preheating and heating section 2 Concentration below 300mg / m 3 The waste gas is confluent, and the volume ratio of the exhaust gas after desulfurization and purification treatment to the exhaust gas in the front section of the preheating and heating section is 40%: 60%. The steam content is 5%, and NH is injected before the circulating exhaust gas enters the material layer of the cooling section 3 , to control NH 3 The / NO molar ratio is 0.4, and then it is introduced into the middle and low temperature cooling section, and its position is the area where the average temperature of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com