A freshwater chlorella sorokiniana GS03 and its application

A technology of chlorella, CCTCCM2013607, applied in the field of biomass energy, can solve the problem of high production cost of microalgae biodiesel, achieve high carbon dioxide fixation efficiency, biomass yield and oil yield, and high carbon dioxide tolerance , the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

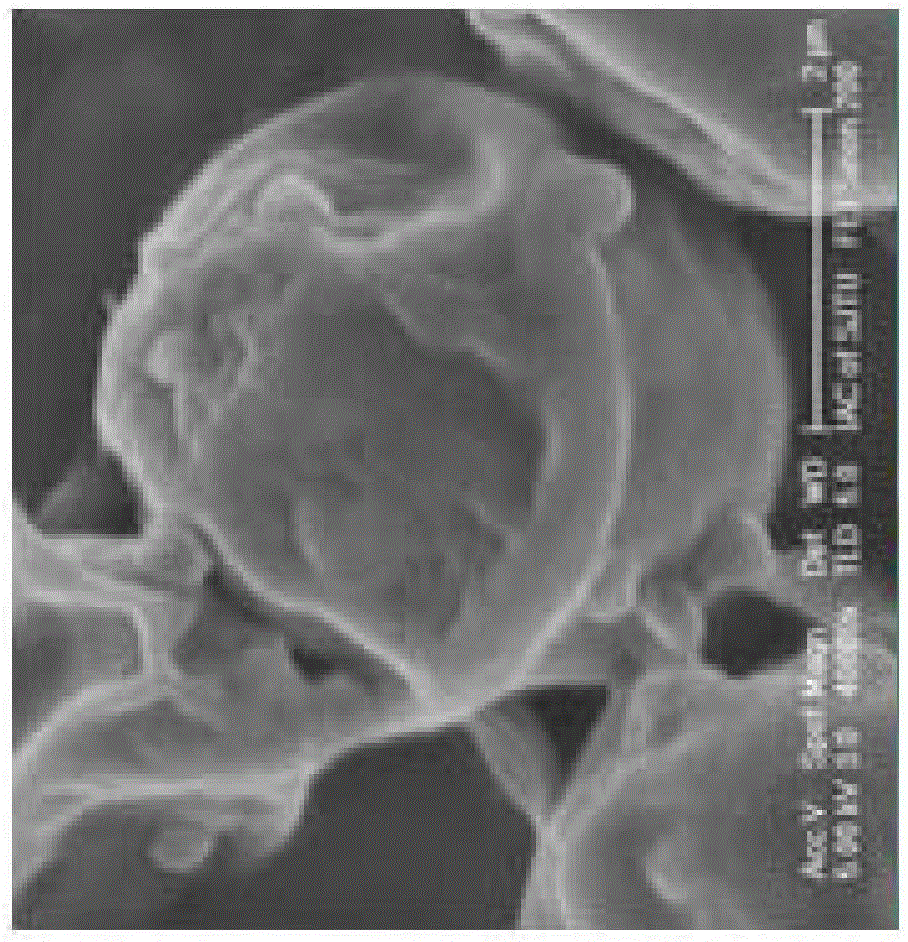

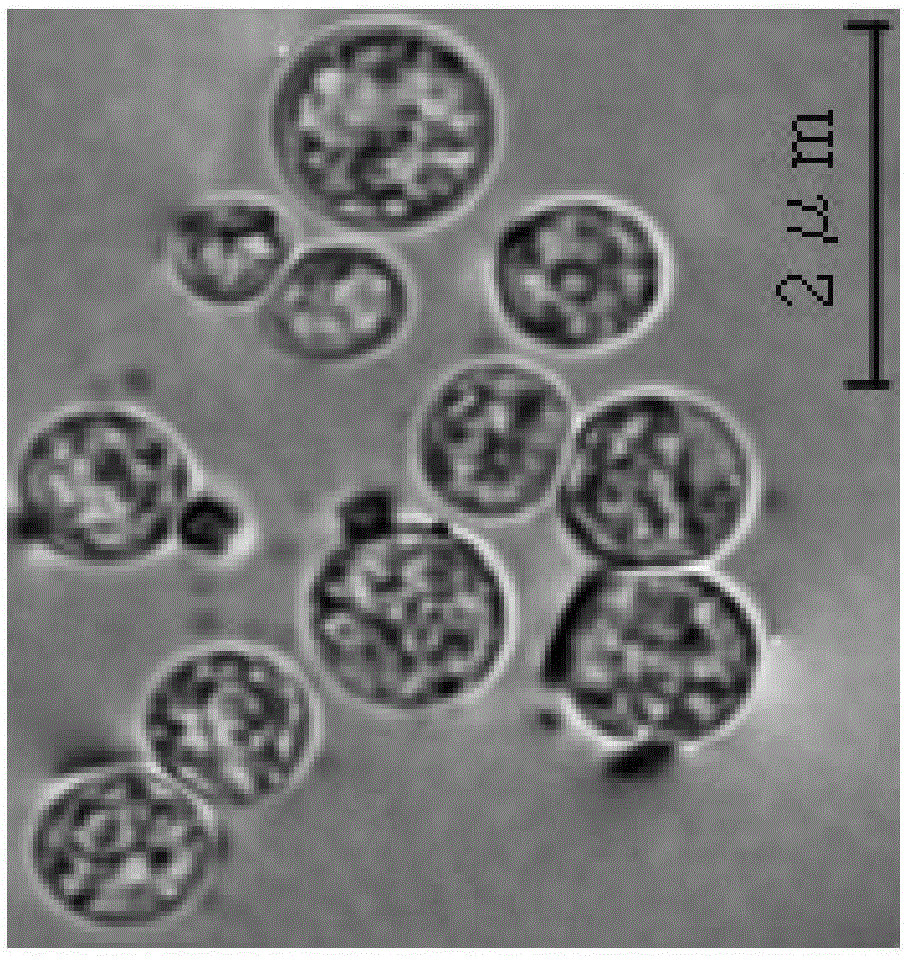

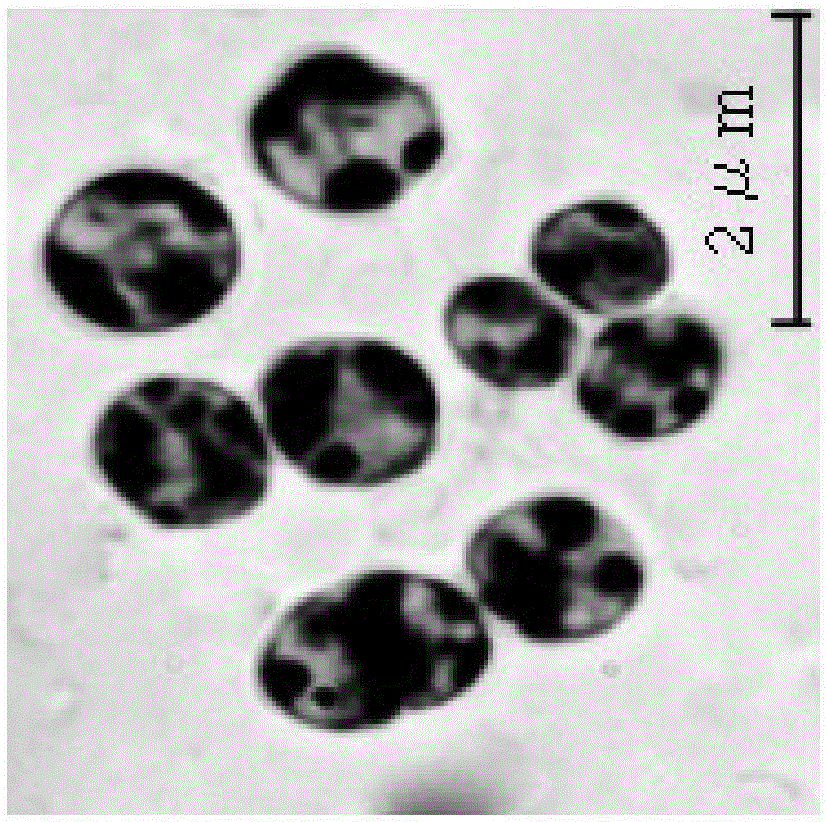

Image

Examples

Embodiment 1

[0049] Under sterile conditions, single algae were picked from a solid plate and dropped into a 100ml Erlenmeyer flask containing 30ml sterilized BG-11 culture solution, and cultured statically in a light culture rack at a temperature of 28°C and a light intensity of 7500lux for 12 days. Grow to the end of the index and expand the culture with an inoculation ratio of 1:10.

[0050] Prepare 2.4L of BG-11 medium, insert the expanded cultured cells, and inoculate the cells with optical density OD 680 = 1.2. Initial pH 4.0, temperature 15°C, light-to-dark ratio 8:16, 0.5vvm air (CO 2 The content is 0.03% (v / v)), cultured for 14 days.

[0051] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the algal powder was weighed and the dry weight was calculated. The biomass concentration of algal powder is 680mg / L, the biomass production rate is 70mg / L / d, CO 2 The fixation efficiency is 110mg / L / d, and the oil content measured by the chloroform-metha...

Embodiment 2

[0053] Pick a single algae on a solid plate under sterile conditions and drop it into a 100ml Erlenmeyer flask containing 30ml of sterilized culture solution, and place it in a light culture rack for static culture. The temperature is 28°C, and the light intensity is 7500lux. Cultivate for 12 days and grow to an index. At the end of the period, expand the culture with a 5% inoculation ratio.

[0054] Prepare 3.1L of BG-11 medium and insert it into the expanded cultured cells. The initial pH is 7.0, the temperature is 45°C, the light-to-dark ratio is 24:0, under the light intensity of 2500lux, 1vvm of 30% CO is introduced 2 (v / v), cultured for 10 days.

[0055] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the dry weight of the algal powder was weighed and calculated. The biomass concentration of algae powder is 2400mg / L, the biomass production rate is 360mg / L / d, CO 2 The fixation efficiency is 660mg / L / d, the oil content determined by ...

Embodiment 3

[0057] Pick a single algae on a solid plate under sterile conditions and drop it into a 100ml Erlenmeyer flask containing 30ml of sterilized culture solution, and place it in a light culture rack for static culture. The temperature is 28°C, and the light intensity is 7500lux. Cultivate for 12 days and grow to an index. In the final stage, the inoculation ratio was 1:10 to expand the culture.

[0058] Prepare 3.1L of BG-11 medium and insert it into the expanded cultured cells. Initial pH 11.0, temperature 10°C, light-to-dark ratio 12:12, 45% CO at 0.2vvm under light intensity of 9500lux 2 (v / v), cultured for 14 days.

[0059] The algal cells were collected by centrifugation, dried in a vacuum freeze dryer, and the dry weight of the algal powder was weighed and calculated. The biomass concentration of algae powder is 2500mg / L, the biomass production rate is 260mg / L / d, CO 2 The fixation efficiency is 480mg / L / d, and the oil content determined by the chloroform-methanol method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com