Patents

Literature

1494results about How to "Suitable for production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

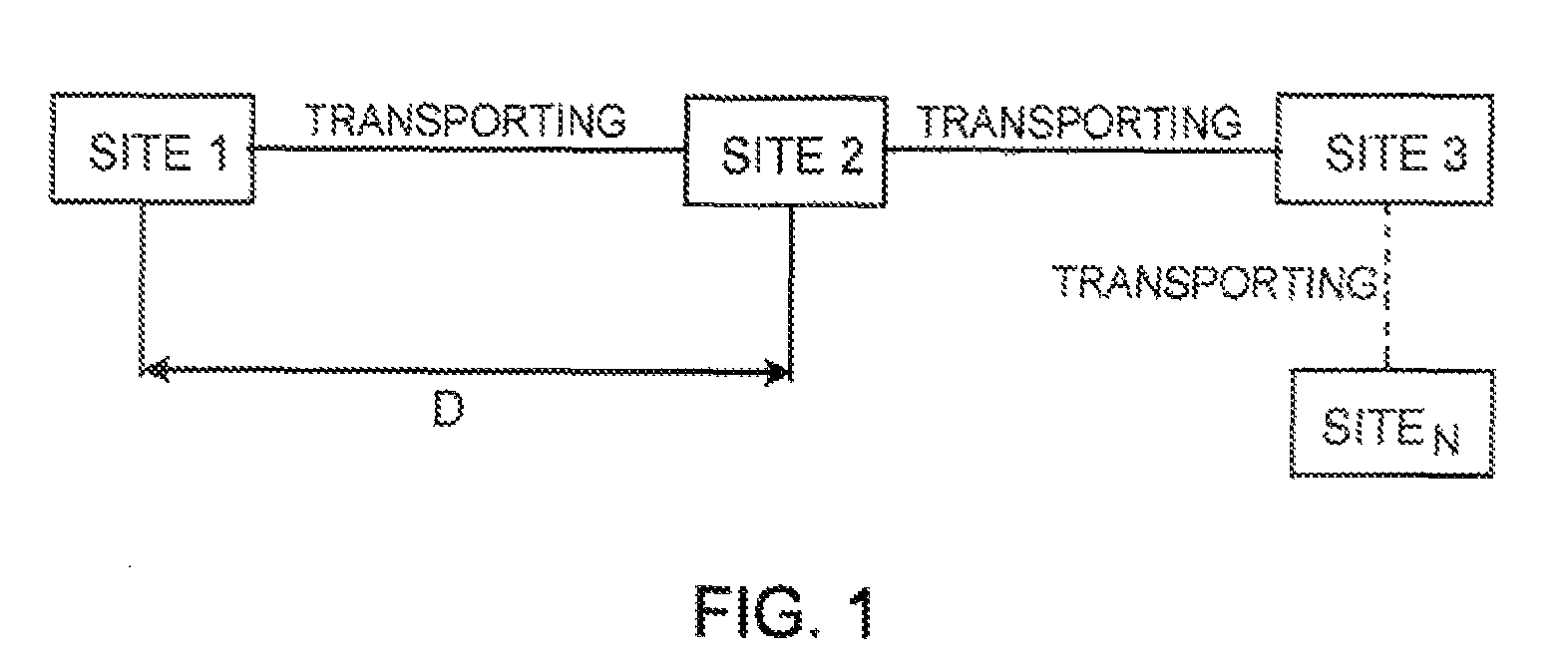

Conversion systems for biomass

ActiveUS20100064746A1Efficient and economical and convenient to moveEasy to transportBio-organic fraction processingBiofuelsBiomass transportationPetroleum

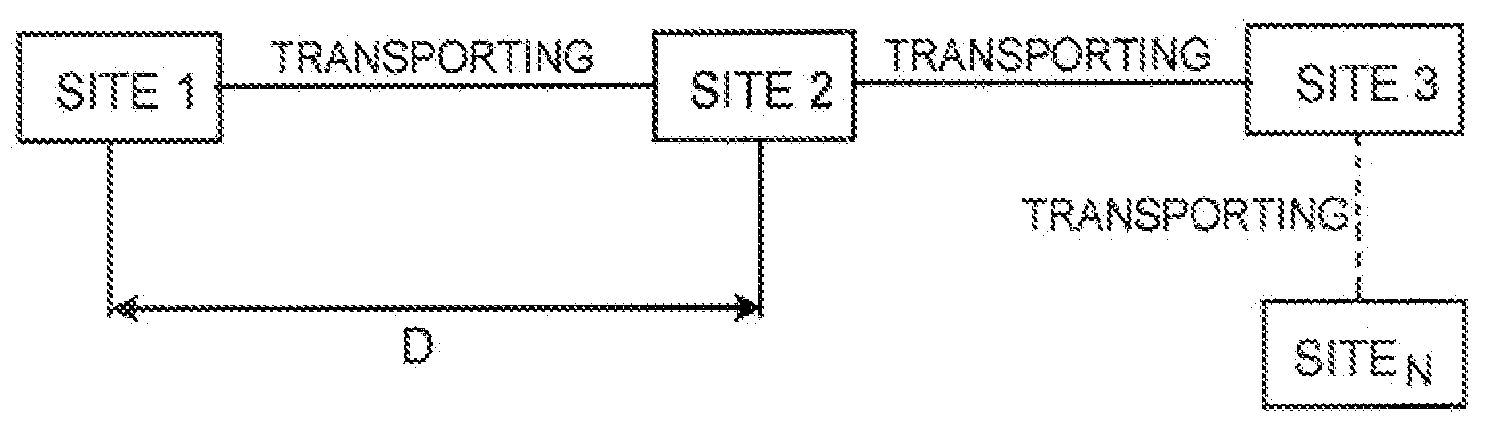

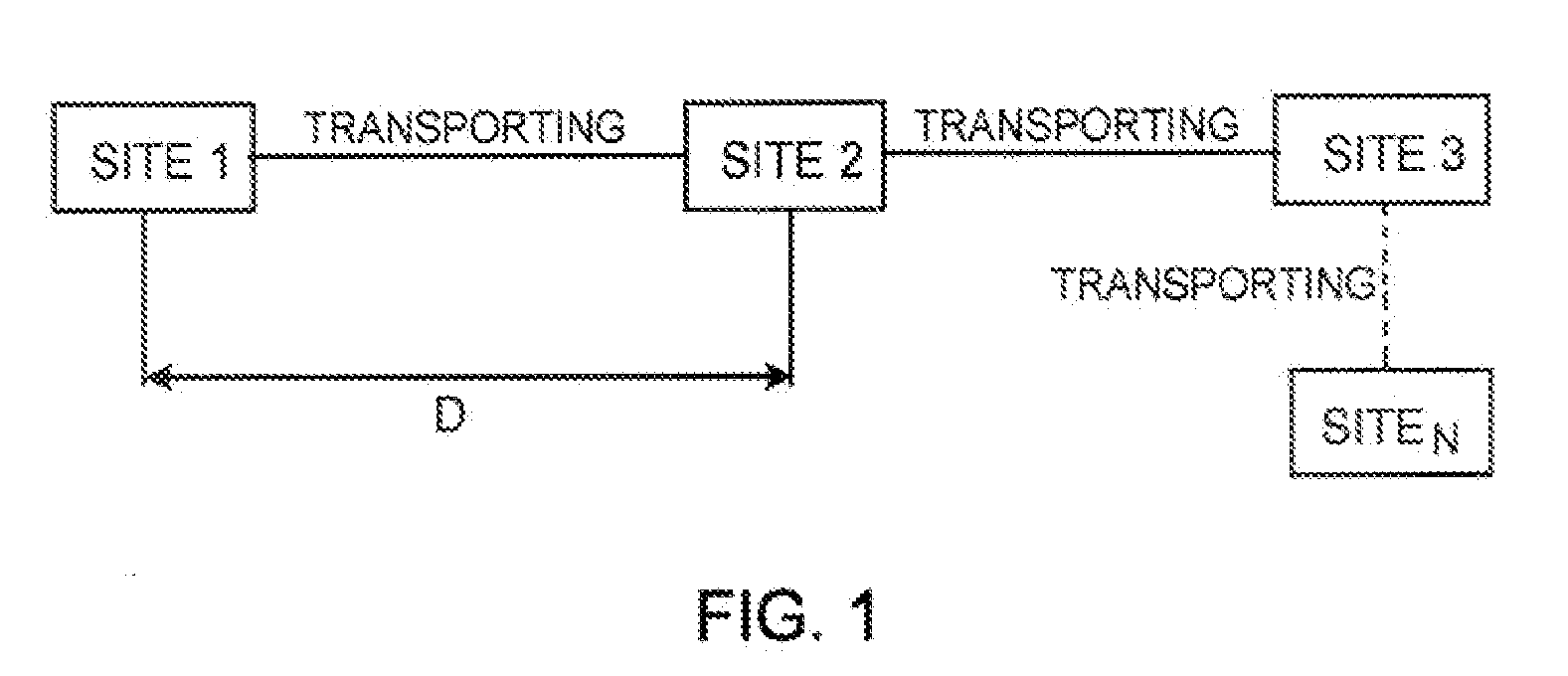

The efficient production of ethanol from low-cost biomass (e.g., corn, sugar beets, sugar cane, switchgrass and / or paper) has become increasingly important in making ethanol competitive with gasoline and decreasing the United States' dependence on foreign oil. For example, to reduce the cost of transporting biomass to ethanol production facilities, mobile systems for producing ethanol from biomass are provided. Also provided are small-scale ethanol production facilities. For example, instead of transporting biomass to the production facility, the facility is transported to the biomass or is located nearby the source of the biomass. The ethanol production facilities or components thereof may be transported via land, water, or air. Production of other products, such as hydrocarbons, natural gas, hydrogen gas, plastics, polymers, and proteins, can also be made by the methods and facilities. Any product described herein can be made in finished form or un-finished form and moved, e.g., to a fixed facility, e.g., fixed production facility.

Owner:XYLECO INC

Taggant fibers

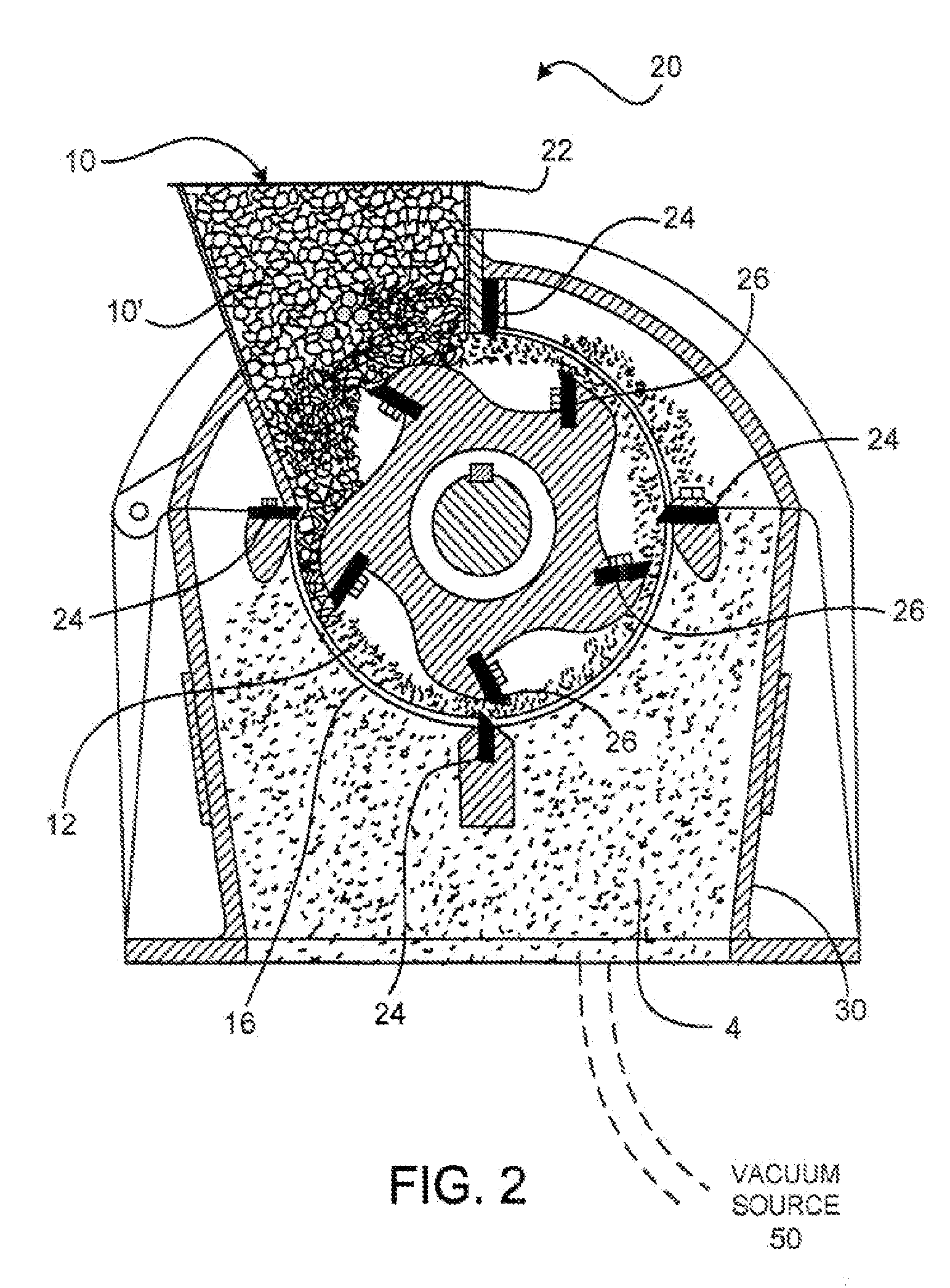

InactiveUS20050227068A1Less noticeable in useLikely to degradeMarking textilesFilament/thread formingMaterials sciencePolymer

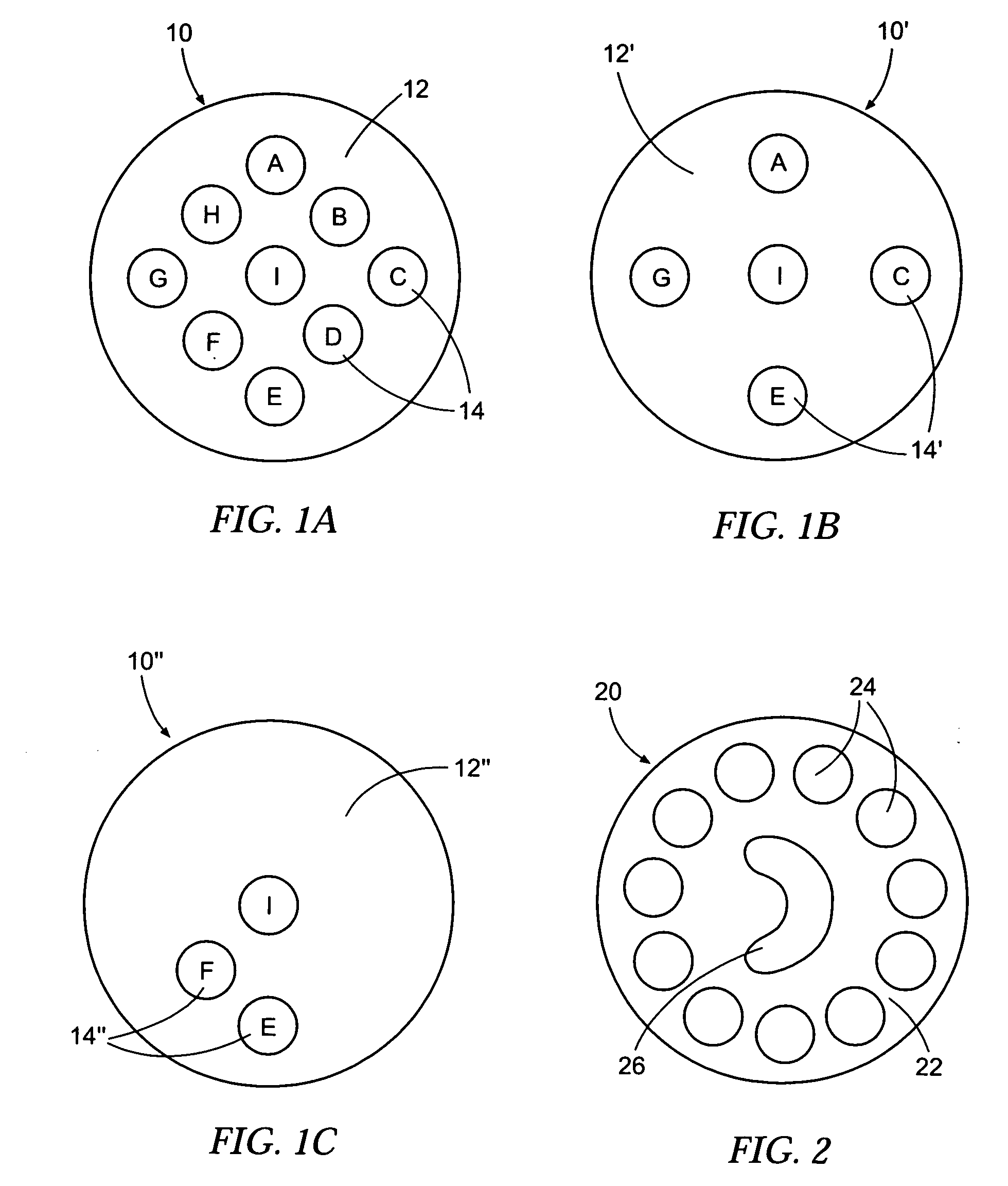

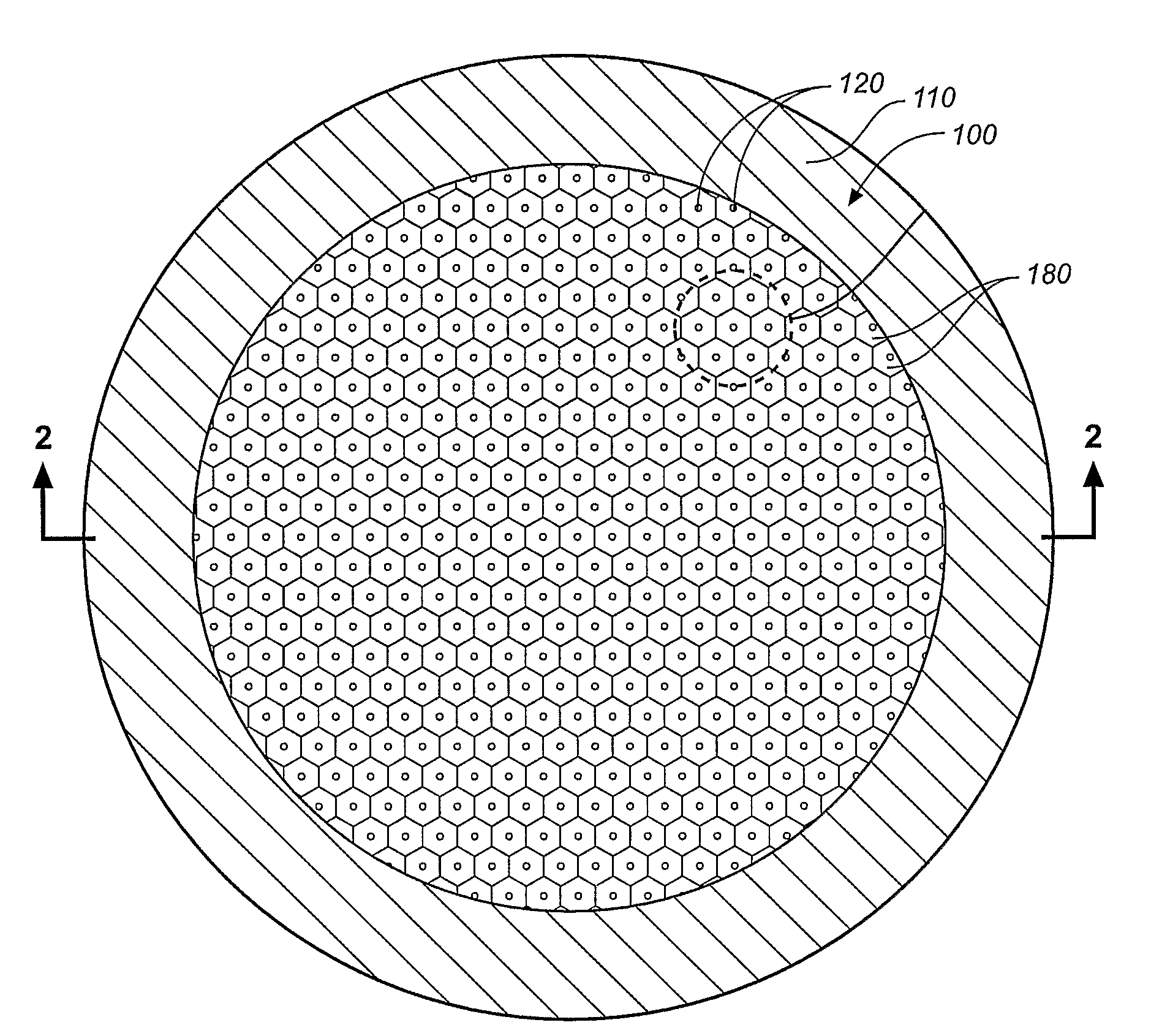

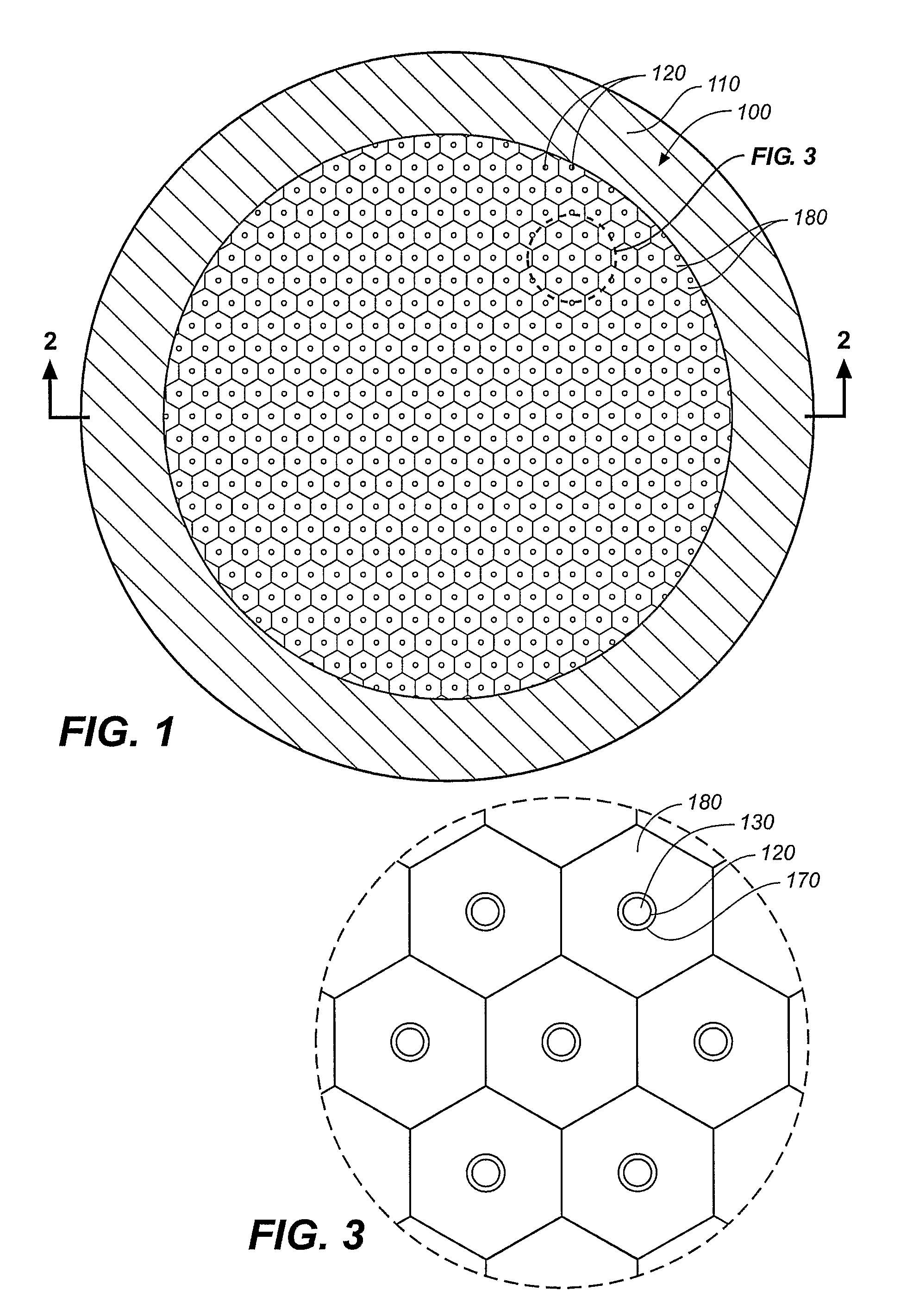

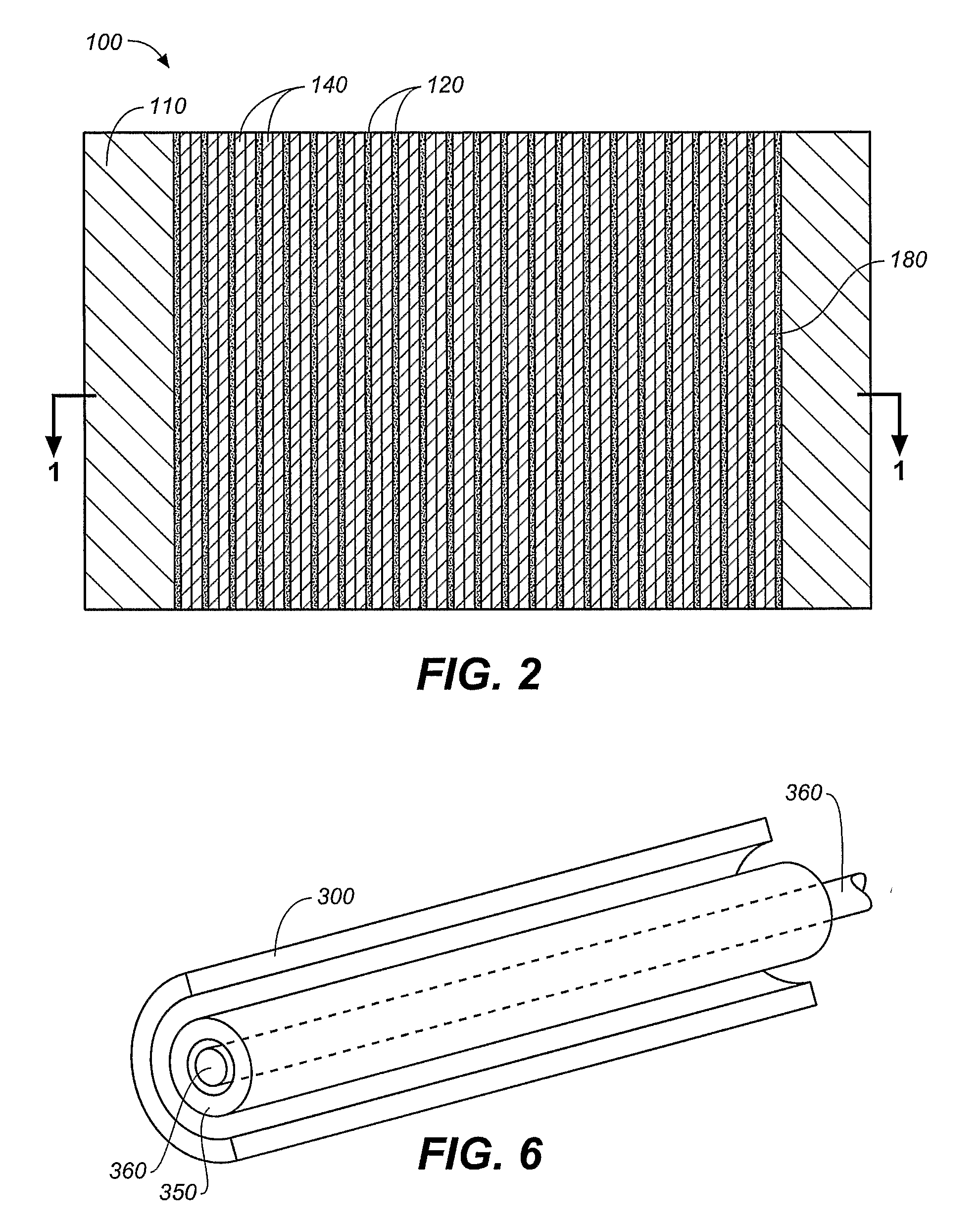

Multicomponent fibers are provided that include a plurality of coextruded polymeric components arranged in discrete structured domains. The polymer domains have one or more identifying characteristics that can be varied to form a plurality of different identifying patterns. A plurality of islands in the sea fibers can be provided, the plurality of fibers including two or more subsets of fibers, each subset comprising a uniquely identifiable cross sectional pattern of island domains, each pattern being formed from an array comprising a predetermined number of island domains in predetermined locations within the array, wherein each pattern is determined by classifying individual island domains within the array as present or absent from the pattern. The plurality of fibers can be meltspun simultaneously to form a filament yarn or tow.

Owner:FIBER INNOVATION TECH

Non Proliferating Thorium Nuclear Fuel Inert Metal Matrix Alloys for Fast Spectrum and Thermal Spectrum Thorium Converter Reactors

InactiveUS20080144762A1Improve heat transfer performanceRobust assemblyOptical rangefindersNuclear energy generationHigh energyEpithermal neutron

A set of alloy formulations is disclosed to use with thorium based nuclear fuels in a fast spectrum reactor; with thorium based nuclear fuels in existing thermal spectrum power reactors; for medical isotope production in the epithermal, the fast, the fission spectrum and the thermal spectra; and to use as fuel in test and experimental reactors that are non proliferative. The alloys form inert metal matrixes to hold fine particles of dispersed thorium containing fuel. The formulations also are useful for the production of medical and commercial isotopes in the high energy, fast and epithermal neutron spectra.

Owner:RGT UNIV OF CALIFORNIA

Drug delivery materials made by sol/gel technology

InactiveUS20060171990A1Easy to produceLow costPowder deliveryOrganic active ingredientsActive agentMedicine

The present invention relates to a method of producing a drug delivery material by encapsulating a biologically or therapeutically active agent in a shell, combining the encapsulated agent with a sol, and converting the combination into a solid or semi-solid drug delivery material. The present invention further relates to drug delivery materials produced by this exemplary method, and to implants formed at least in part from these materials.

Owner:CINVENTION AG

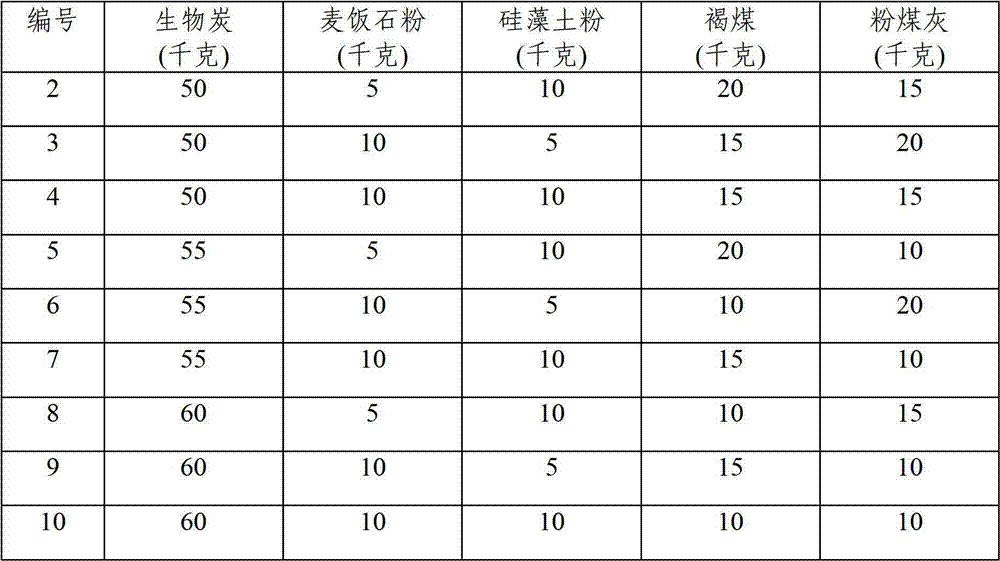

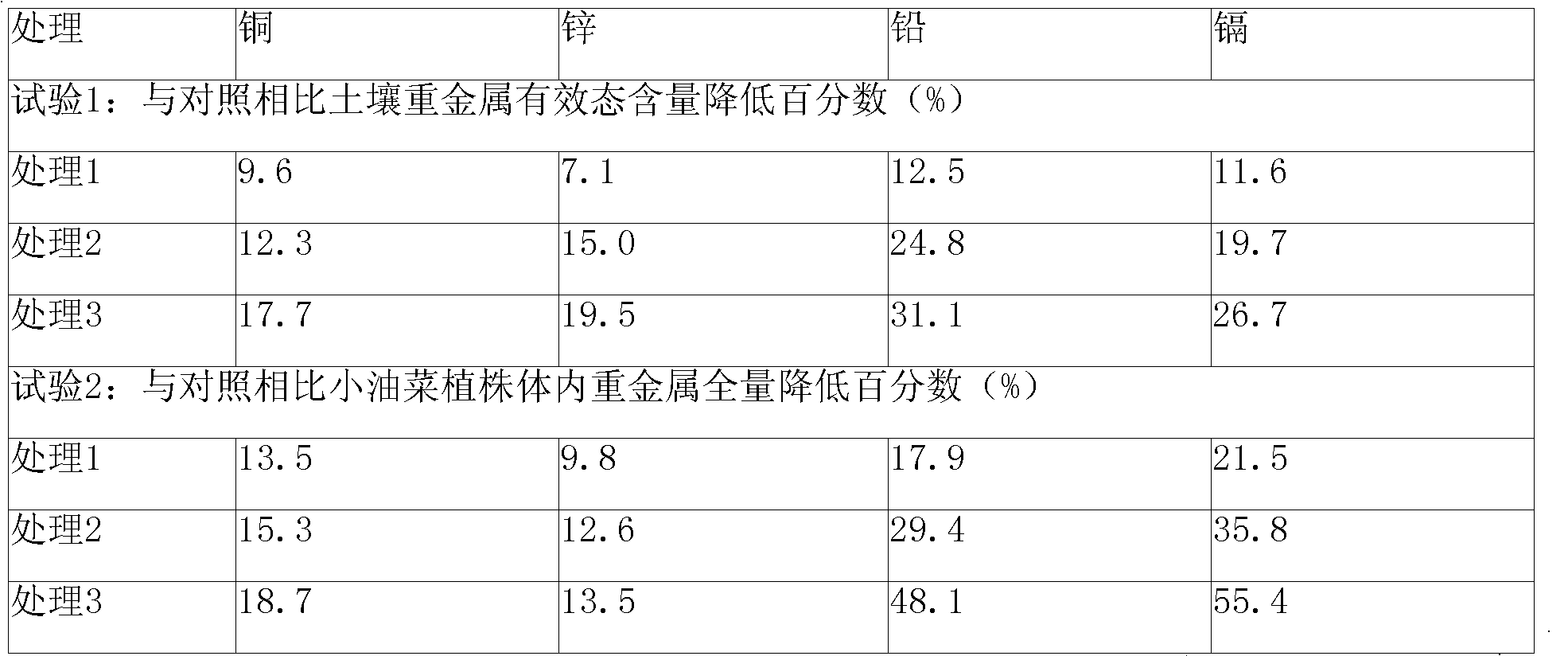

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872ASimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsBiochar

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

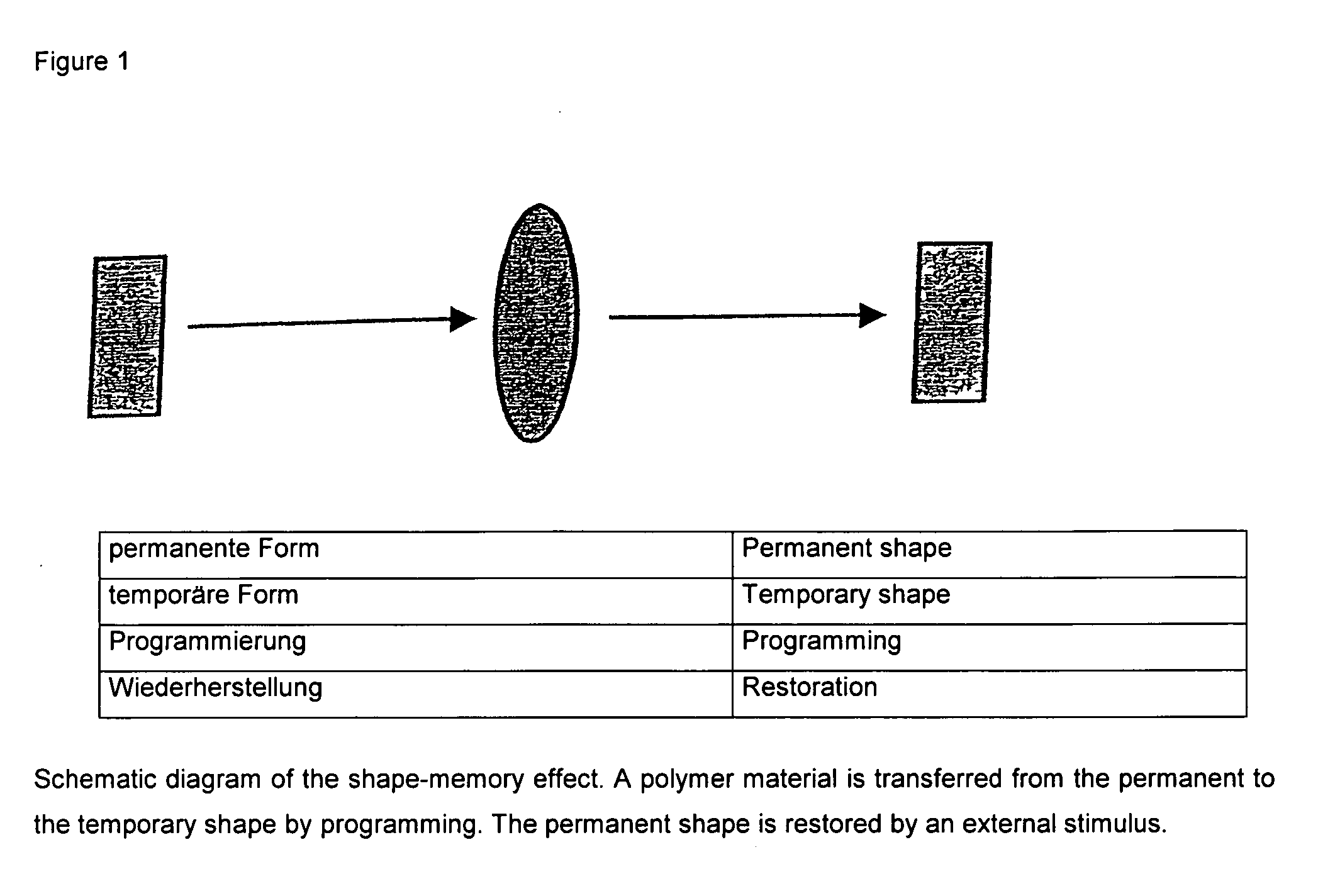

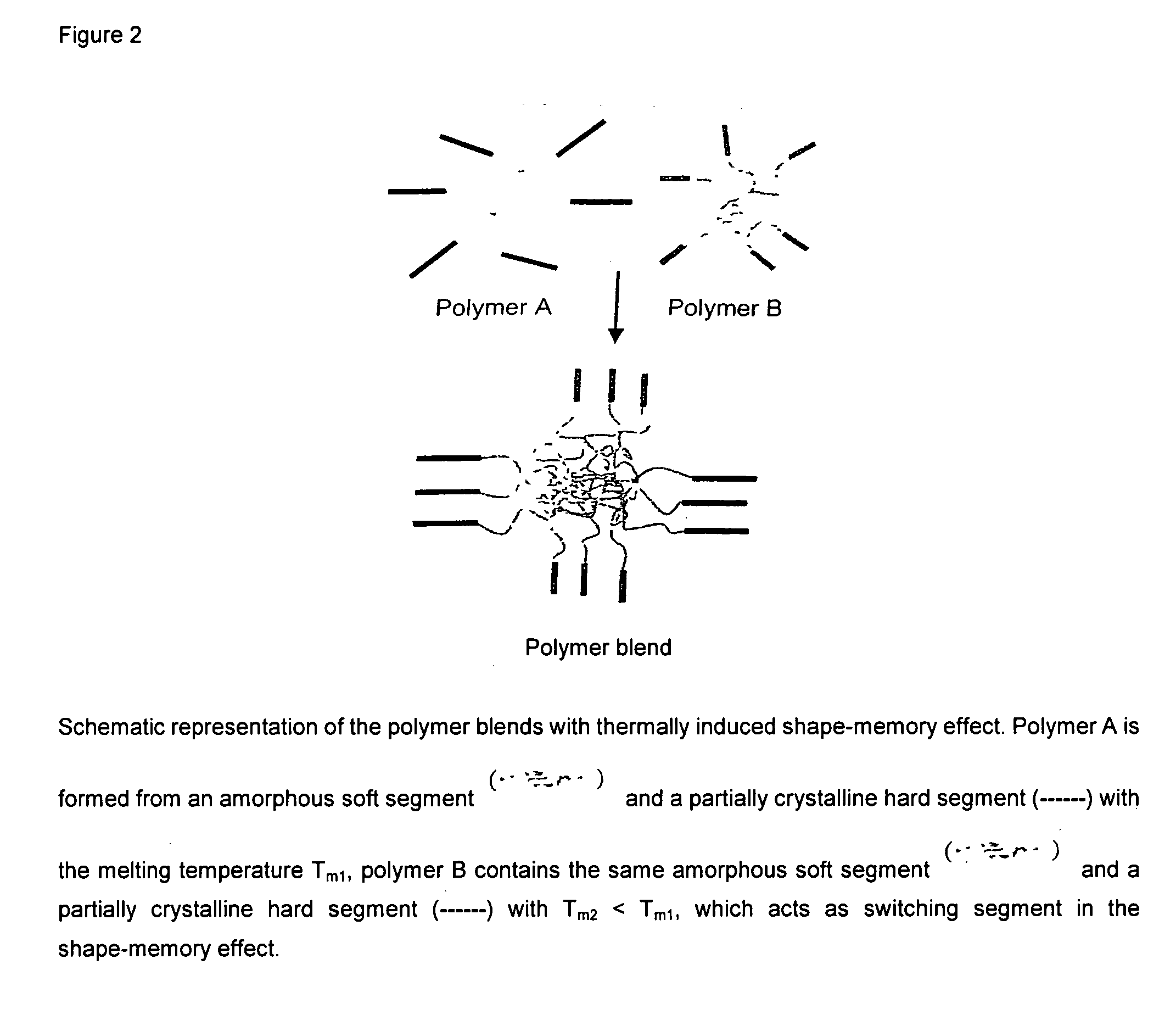

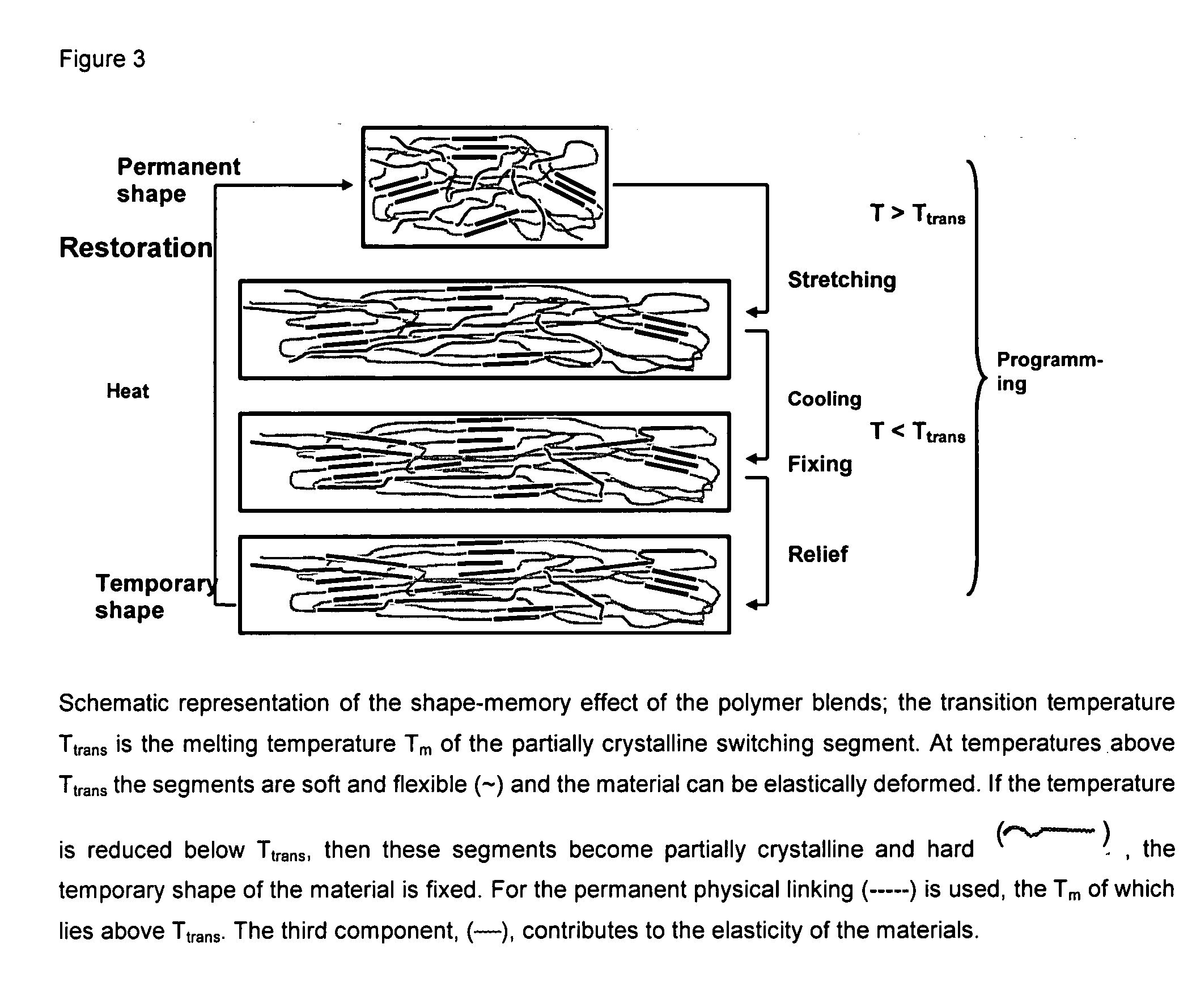

Blends with shape memory characteristics

The invention relates to a polymer blend with shape-memory characteristic comprising two different block copolymers each containing at least one hard segment and at least one soft segment, whereby the two different block copolymers comprise the same soft segment and only differ with regard to the hard segment.

Owner:MINEMOSCIENCE GMBH

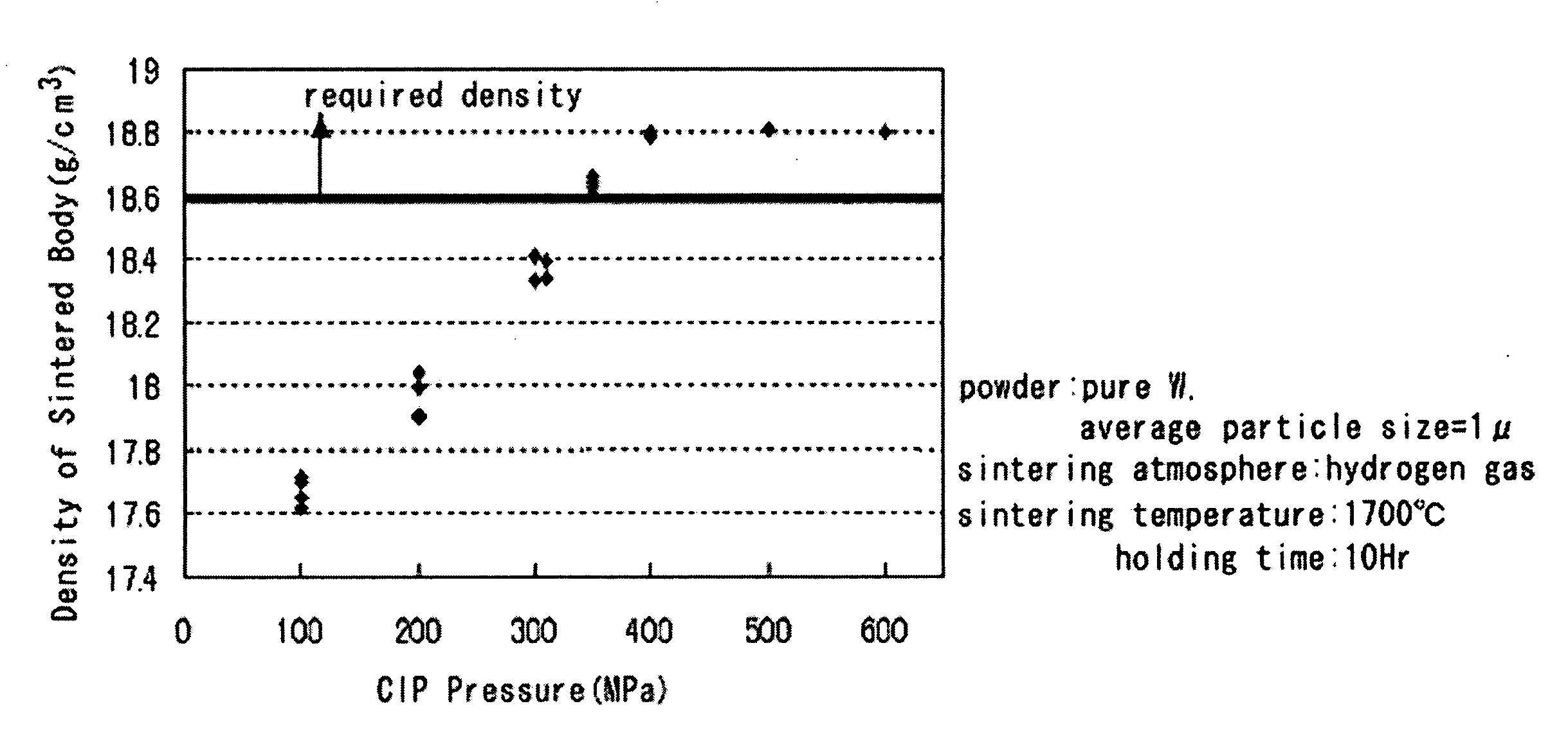

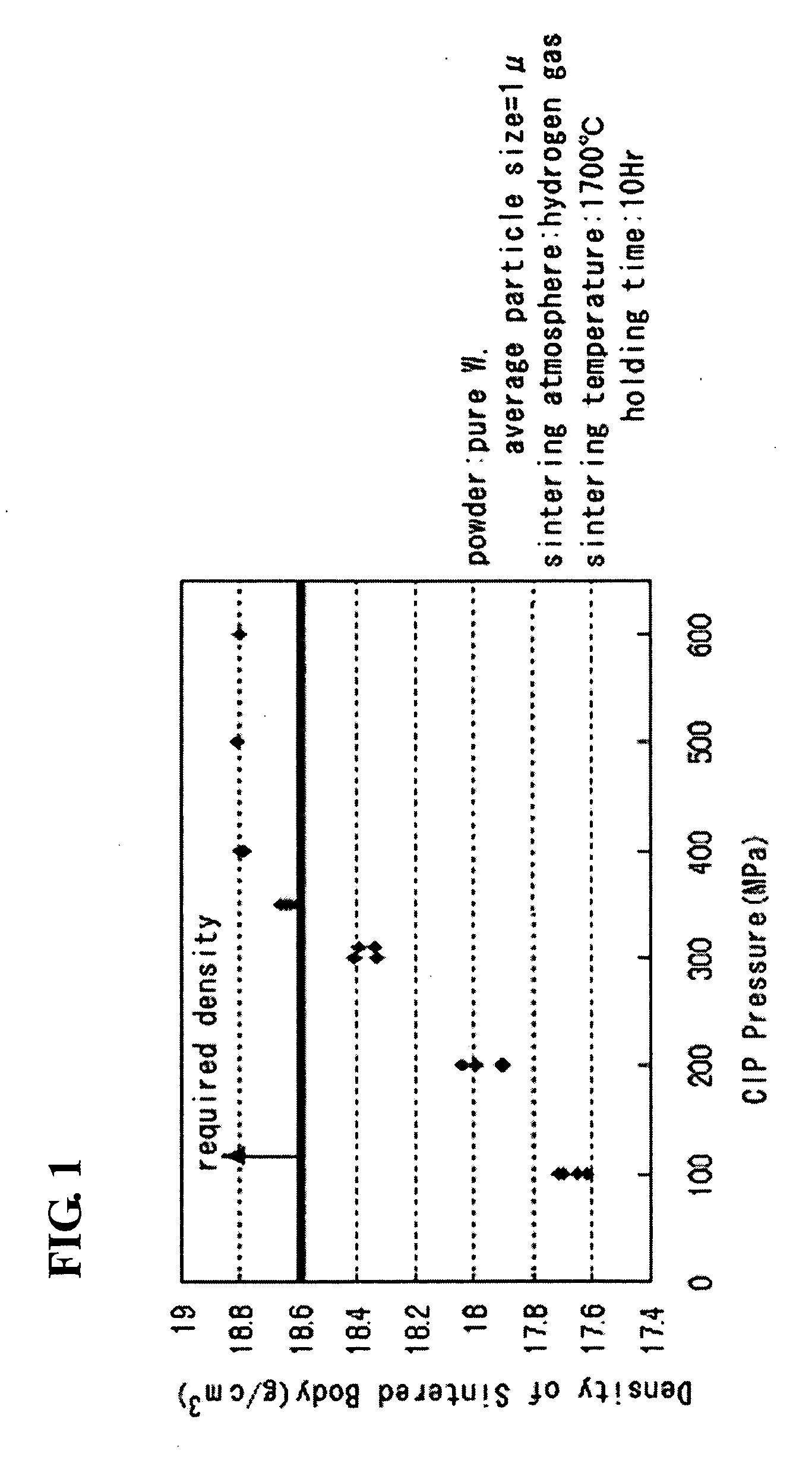

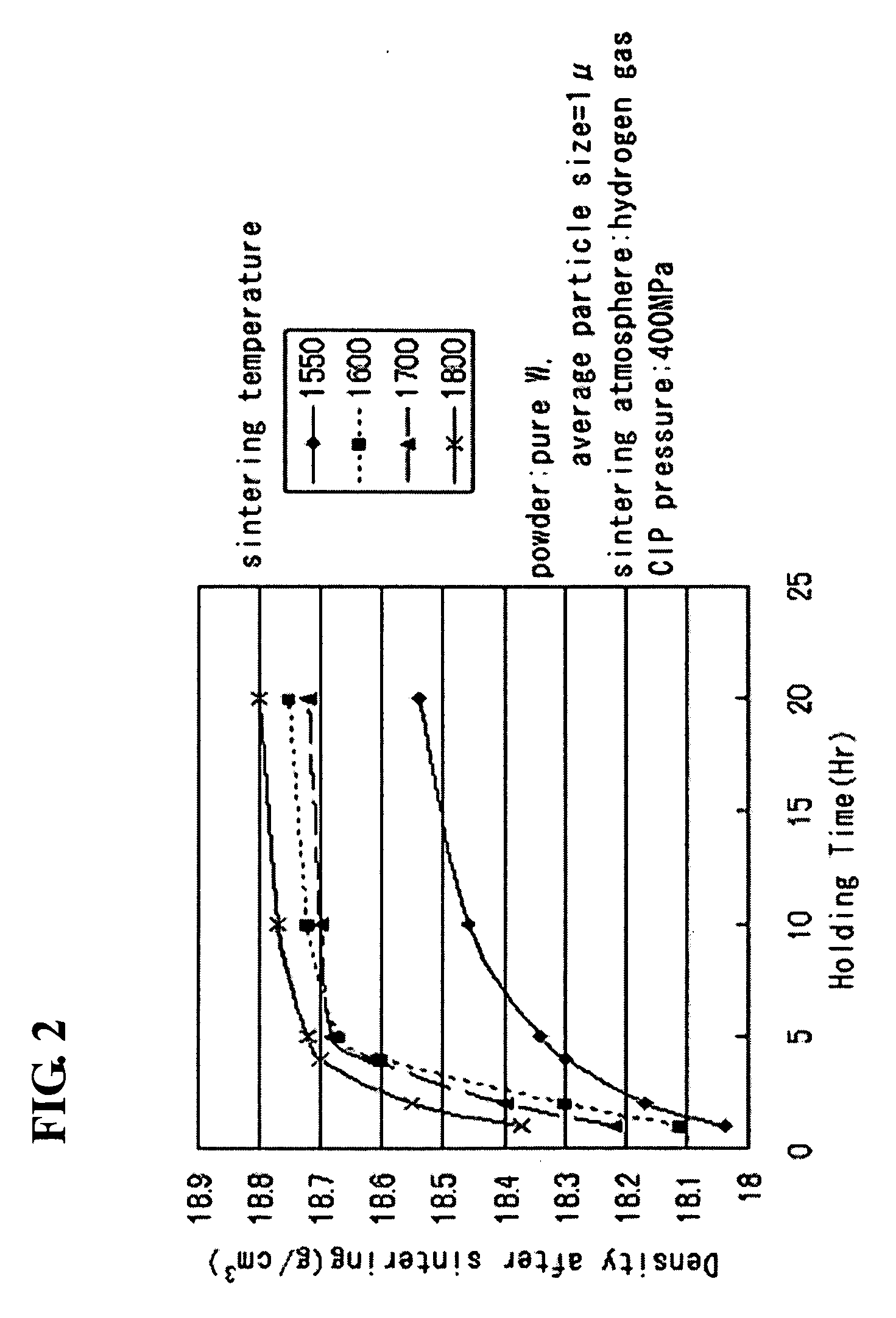

Tungsten based sintered compact and method for production thereof

InactiveUS20070172378A1Reduce the numberSmall volumeGas discharge lampsTungstenSemiconductor components

The present invention is directed to provide a tungsten-based sintered body having a relative density of 99.5% or more (a porosity of 0.5 volume % or less) and a uniform and isotropic structure, which has not been able to be achieved by conventional techniques. In particular, the tungsten-based sintered body is intended for use as a discharge lamp electrode, a sputtering target, a crucible, a radiation shielding member or a resistance welding electrode. The intended tungsten-based sintered body is produced by subjecting a tungsten-based powder to a CIP process at a pressure of 350 MPa or more to form a powder compact, sintering the powder compact in a hydrogen gas atmosphere at a sintering temperature of 1600° C. or more for a holding time of 5 hours or more to form a sintered compact, and subjecting the sintered compact to a HIP process in an argon gas atmosphere under conditions of 150 MPa or more and 1900° C. or more. The tungsten-based sintered body of the present invention is suitably used, for example, as a discharge lamp electrode, a sputtering target, a crucible, a radiation shielding member, an electric discharge machining electrode, a semiconductor element mounting substrate and a structural member.

Owner:NIPPON TUNGSTEN CORP

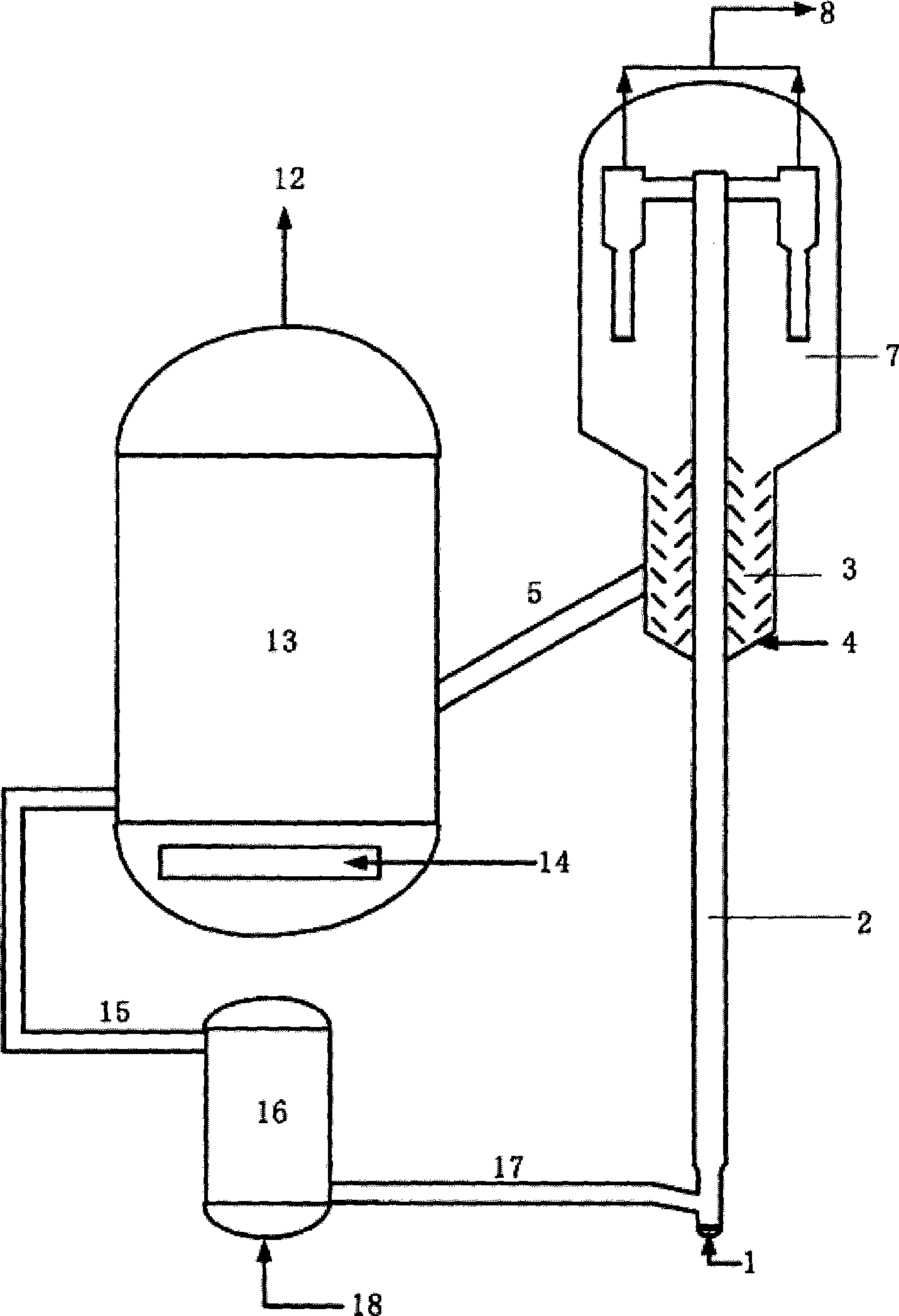

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

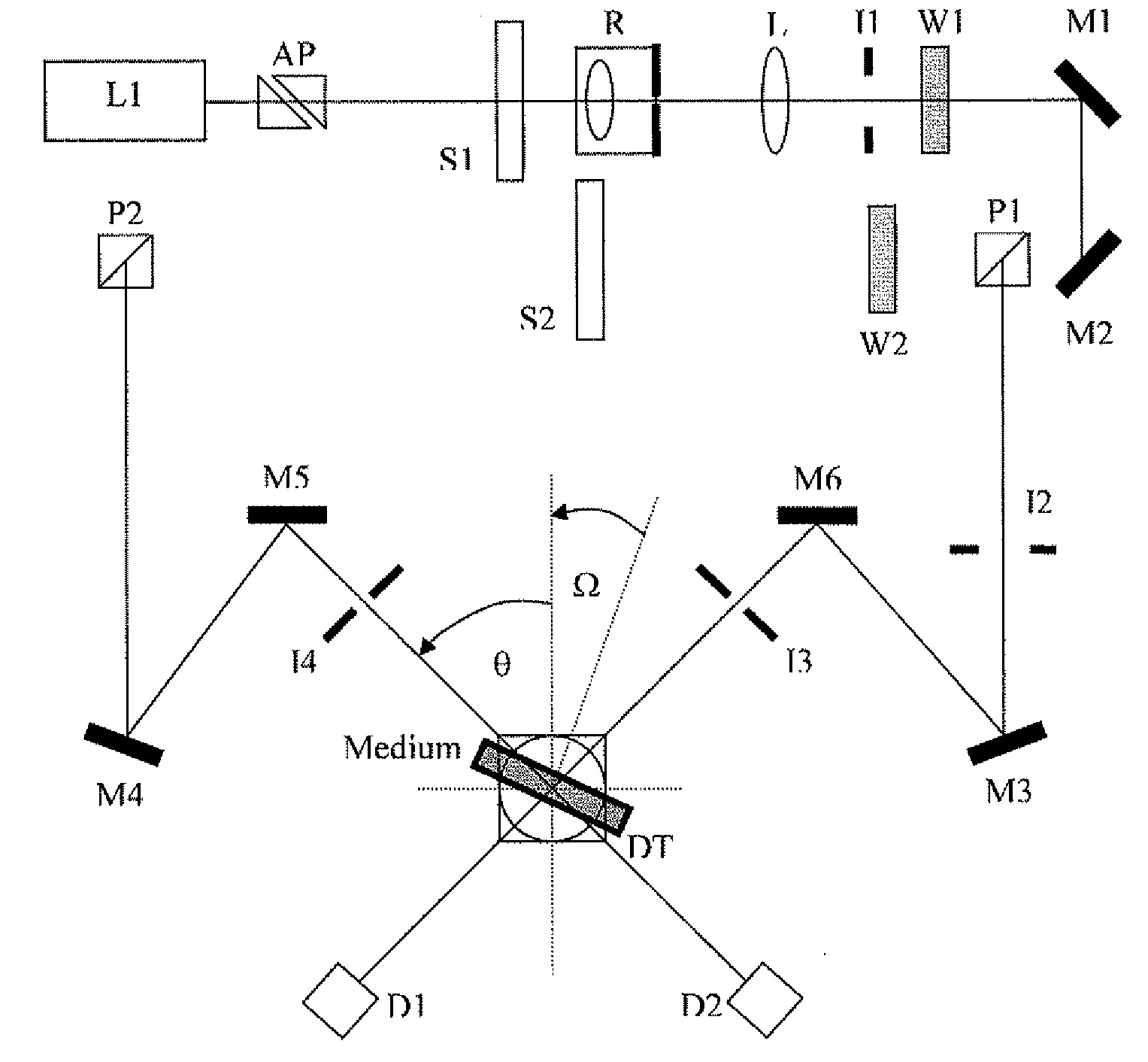

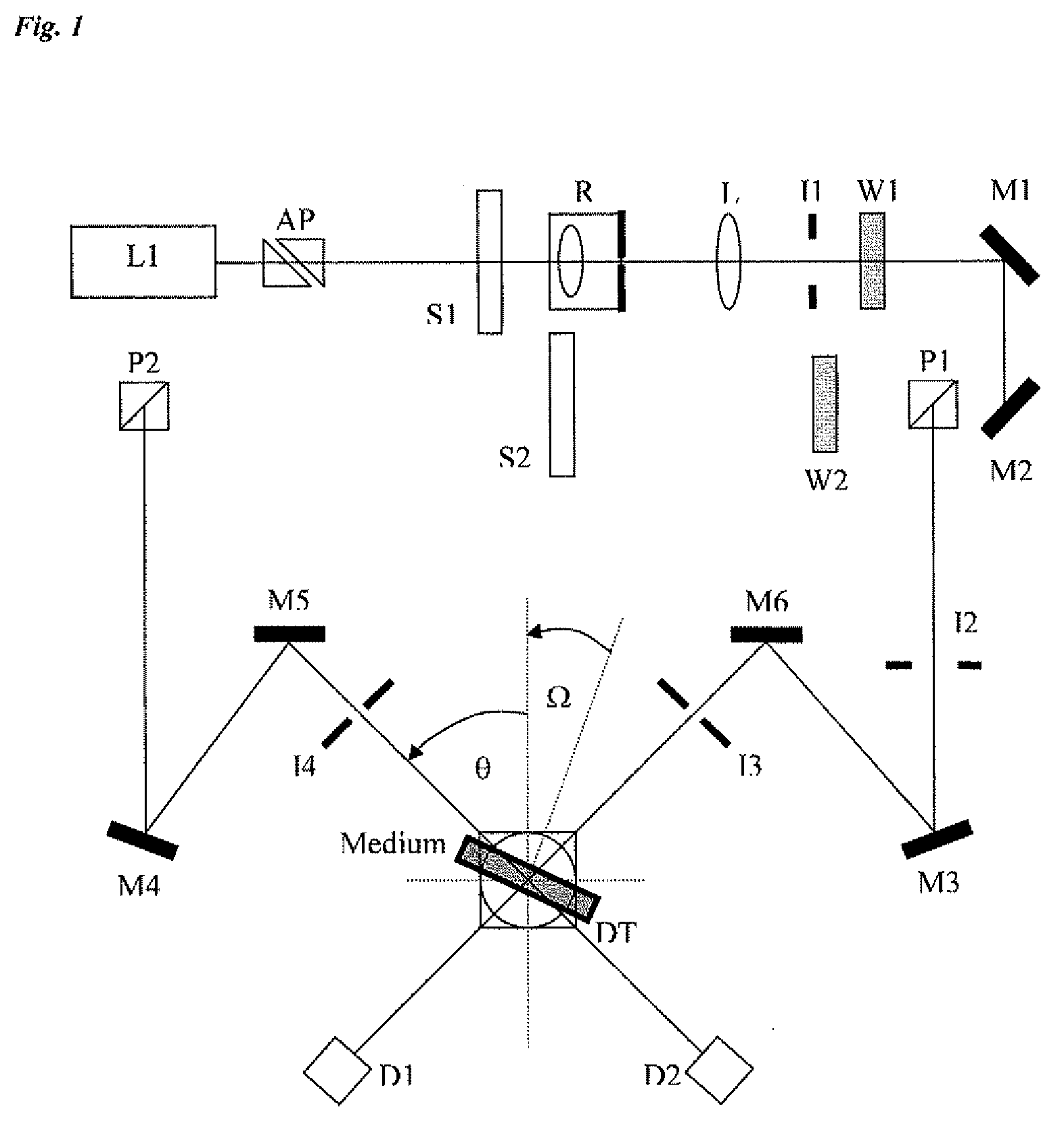

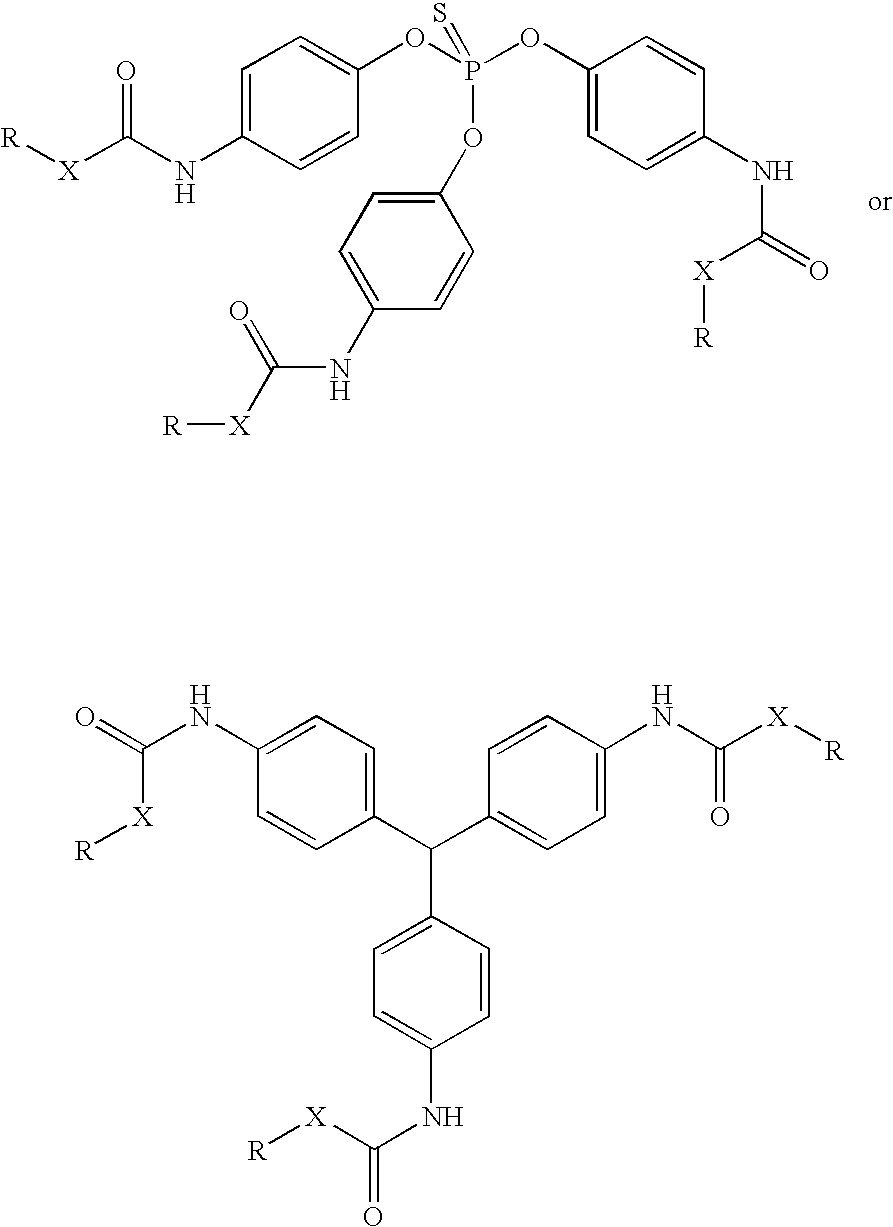

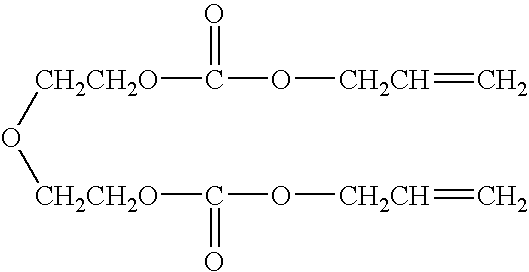

Aromatic urethane acrylates having a high refractive index

ActiveUS20080312403A1Simple as possible to prepareSuitable for productionMaterial nanotechnologyCarbamic acid derivatives preparationRefractive indexUrethane acrylate

The invention relates to novel aromatic urethane (meth)acrylates having a high refractive index, a process for the preparation thereof and a process for the production of holographic media.

Owner:COVESTRO DEUTSCHLAND AG

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

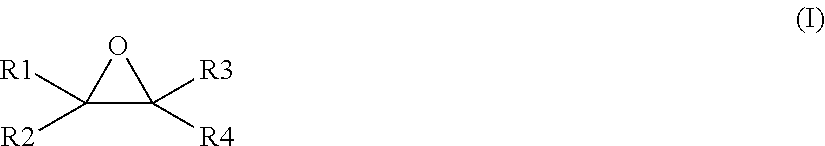

Process for the production of polyether polyols with a high ethylene oxide content

InactiveUS20110230581A1Simplify preparationSuitable for productionOrganic chemistryOxideEthylene oxide

Polyether polyols with an OH number of from 15 to 120 mg of KOH / g are produced by (i) introducing a mixture of DMC catalyst and a poly(oxyalkylene)polyol or a mixture of DMC catalyst and a polyether polyol (“heel”) obtainable by the process according to the invention is initially into a reactor and (ii) continuously introducing one (or more) low molecular weight starter compound(s) with a (mixed) hydroxyl functionality of from 2.2 to 6.0 and a mixture composed of a) 73 to 80 parts by weight (per 100 parts by weight of a) plus b)) of ethylene oxide and b) 27 to 20 parts by weight (per 100 parts by weight of a) plus b)) of at least one substituted alkylene oxide corresponding to a specified formula into the mixture from step (i). These polyether polyols are particularly useful for the production of flexible polyurethane foams.

Owner:COVESTRO LLC +1

Soil heavy metal passivant for facilities vegetable field and preparation method thereof

InactiveCN101805617AReduce the content of available heavy metalsSimple processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsStone dust

The invention relates to the soil improvement technology and the environment protection technology, in particular to a soil heavy metal passivant for the facilities vegetable field and a preparation method thereof for solving the problem that due to solid heavy metal pollution, the sustainable utilization of the facilities vegetable field is influenced. The soil heavy metal passivant for the facilities vegetable field comprises the following components in percentage by weight: 10 to 30 percent of medical stone powder, 10 to 30 percent of diatomite in powder, 10 to 20 percent of zeolite powder, 20 to 30 percent of lignite and 25 to 35 percent of fly ash. The preparation method for the soil heavy metal passivant comprises the following steps: mixing the medical stone powder passing through a 80-mesh screen, the diatomite in powder passing through a 80-mesh screen and the zeolite powder passing through a 80-mesh screen with lignite and uniformly stirring the mixture; and mixing the mixture with the fly ash passing through a 80-mesh screen, sufficiently stirring the mixture and after mixing uniformly, preparing the soil heavy metal passivant. The invention has simple preparation method and achieves the effects of passivating the soil heavy metals in the facilities vegetable filed and reducing the content of heavy metals in the soil which can be utilized by the crops by synergistic effect of the components.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

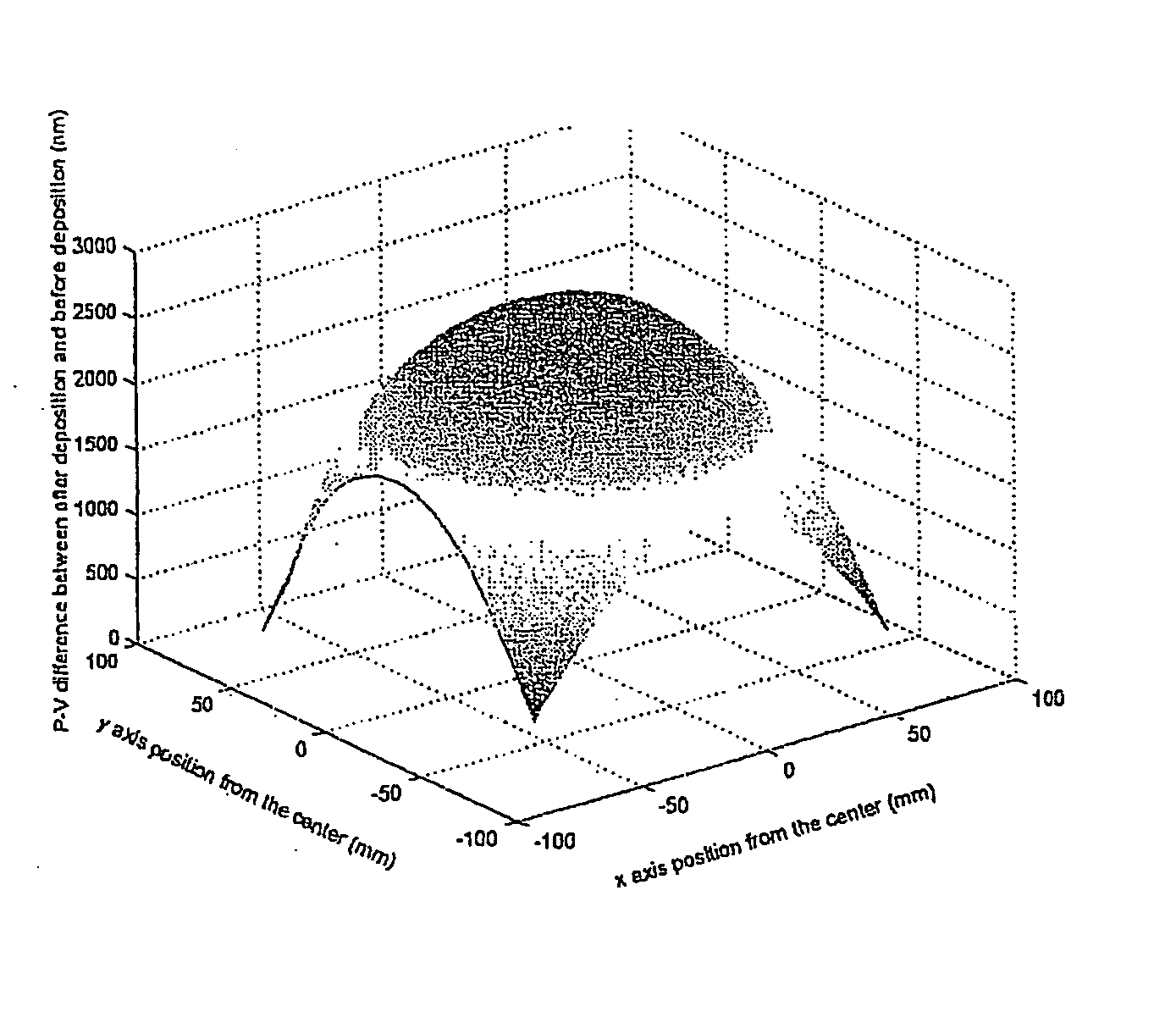

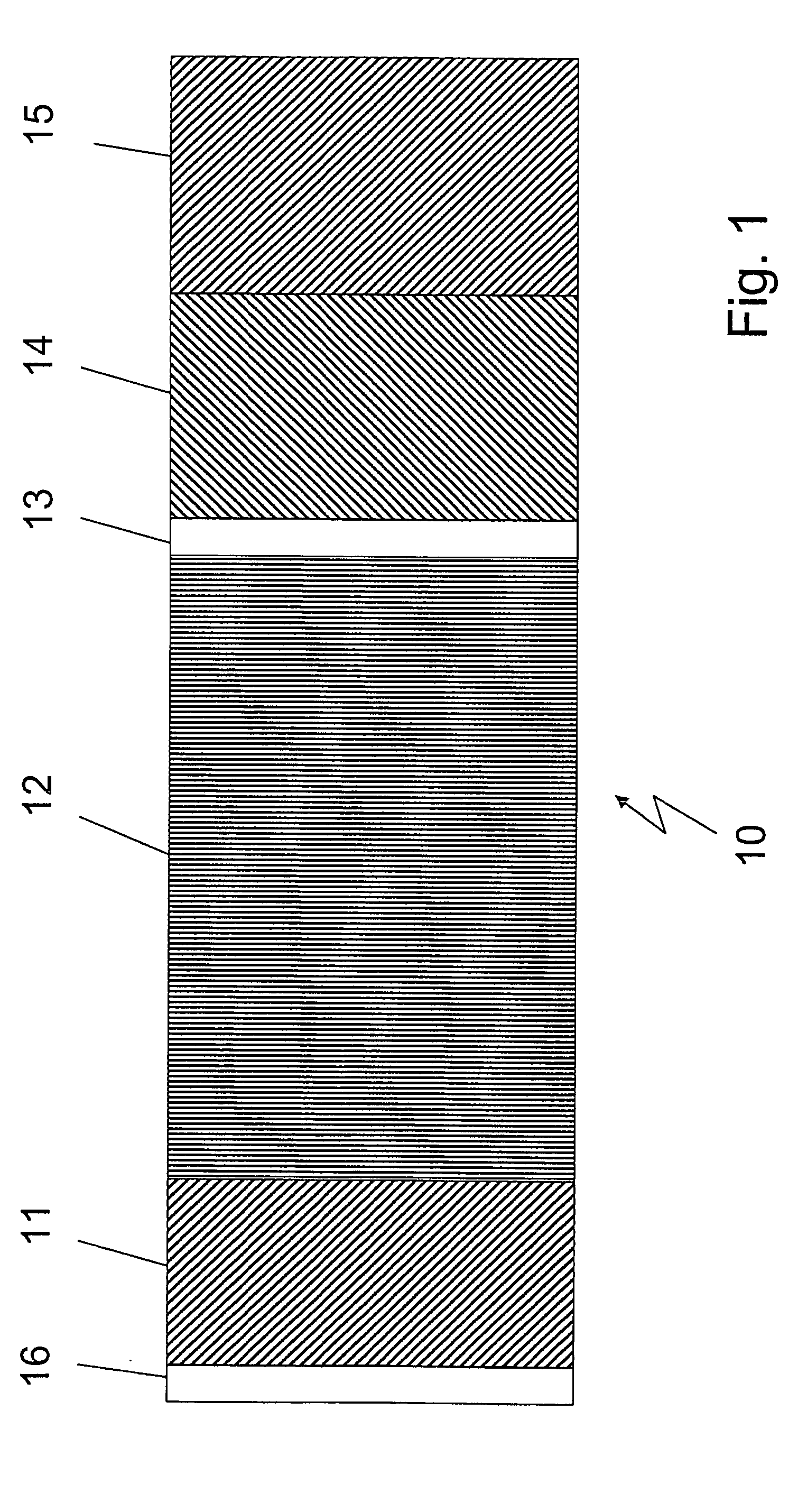

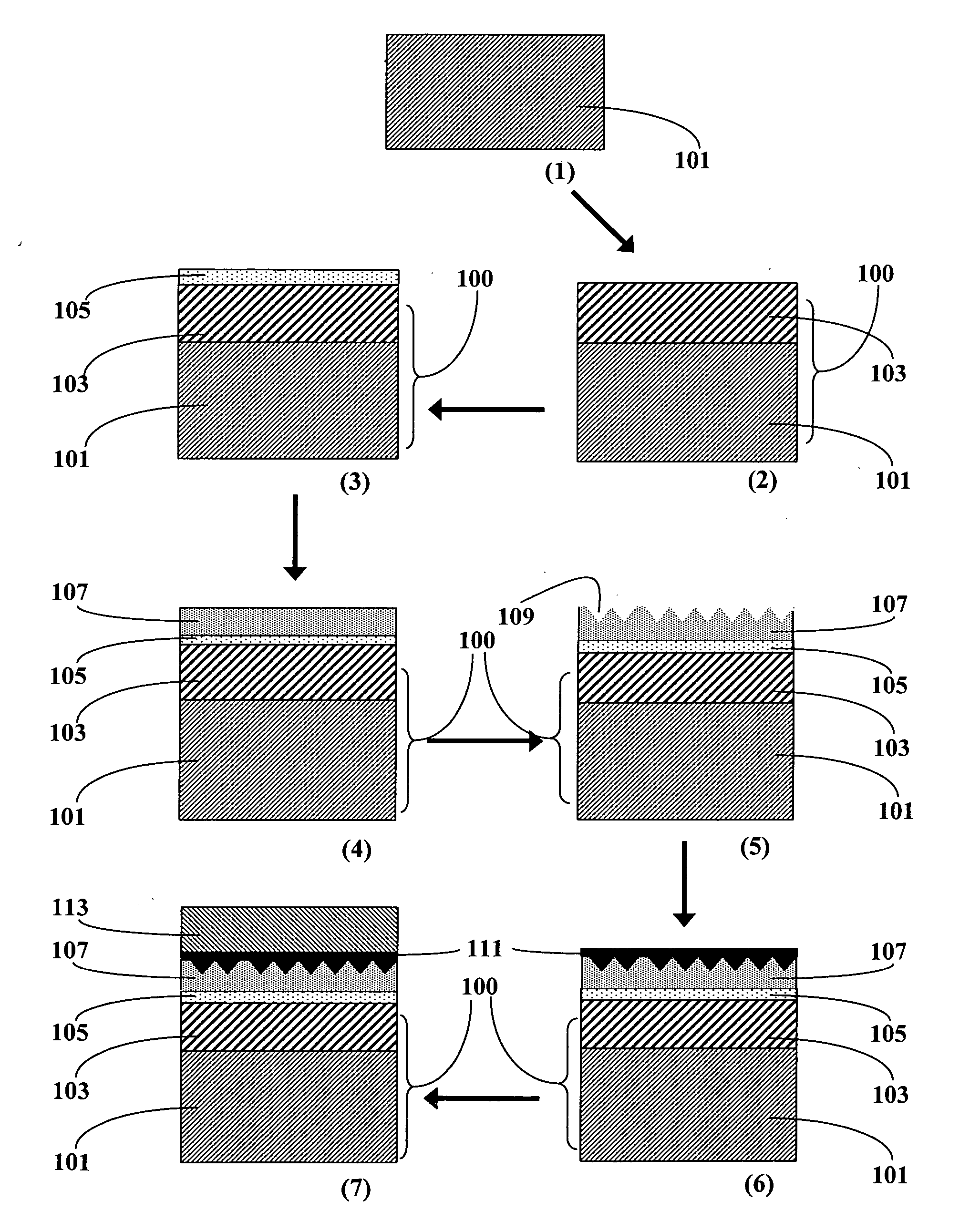

Method for manufacturing of a mask blank for EUV photolithography and mask blank

InactiveUS20060008749A1Difficult and costly to produceGenerate and manipulate easilyNanoinformaticsVacuum evaporation coatingExtreme ultravioletConductive coating

The invention relates to a method for manufacturing of a mask blank for extreme ultraviolet (EUV) photolithography, comprising the steps of: providing a substrate having a front surface and a back surface; depositing a film comprising tantalum nitride (TaN) on said front surface of said substrate for absorbing EUV light used during a photolithographic process; and depositing a conductive coating on said back surface of said substrate. Preferably, ion beam sputtering is used for depositing the film comprising tantalum nitride (TaN) and / or the conductive coating on the back surface of the substrate. Preferably, Xenon is used as a sputter gas for ion beam sputtering. Another aspect of the present invention relates to a mask blank for extreme ultraviolet (EUV) photolithography.

Owner:SCHOTT AG

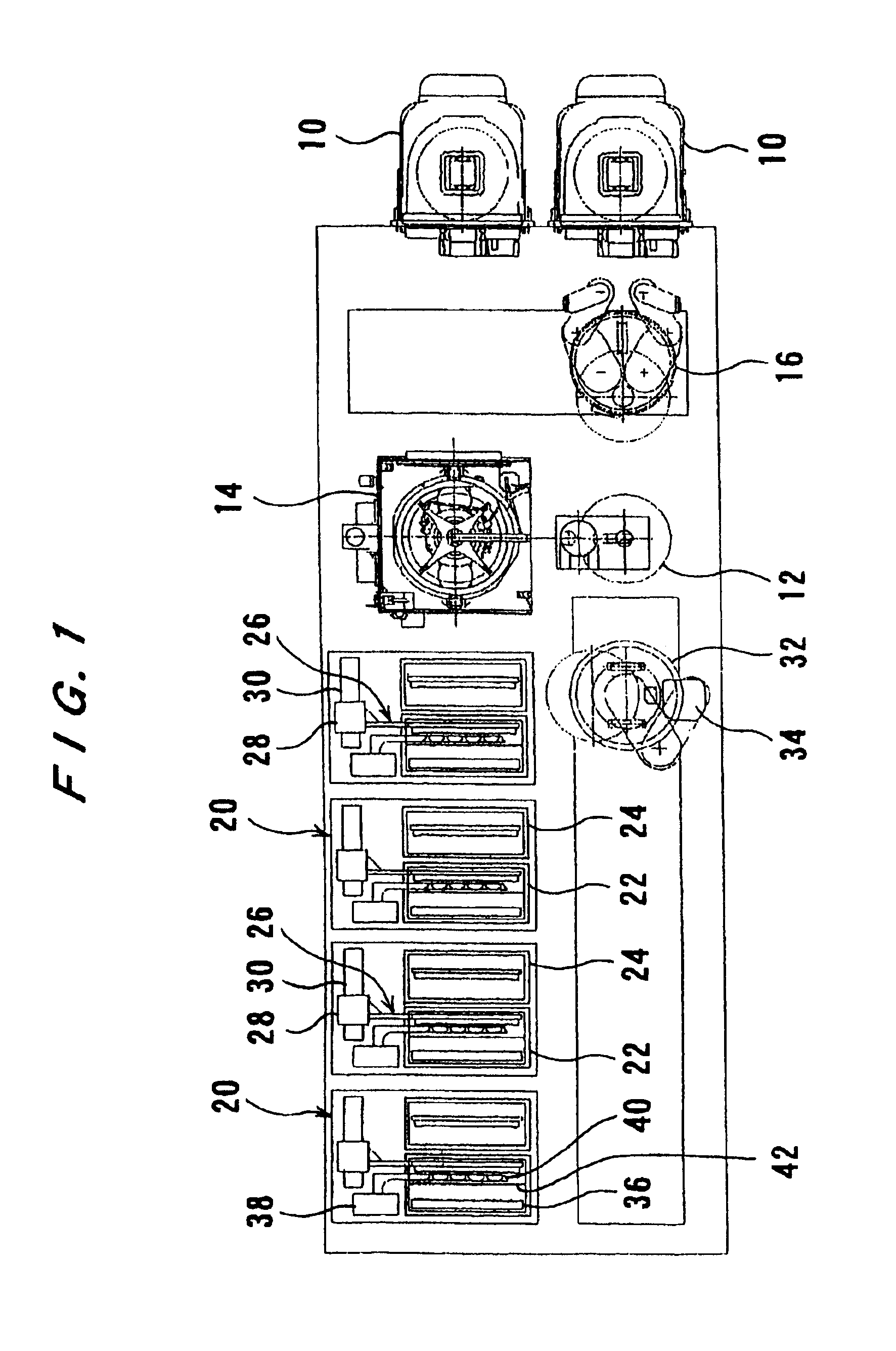

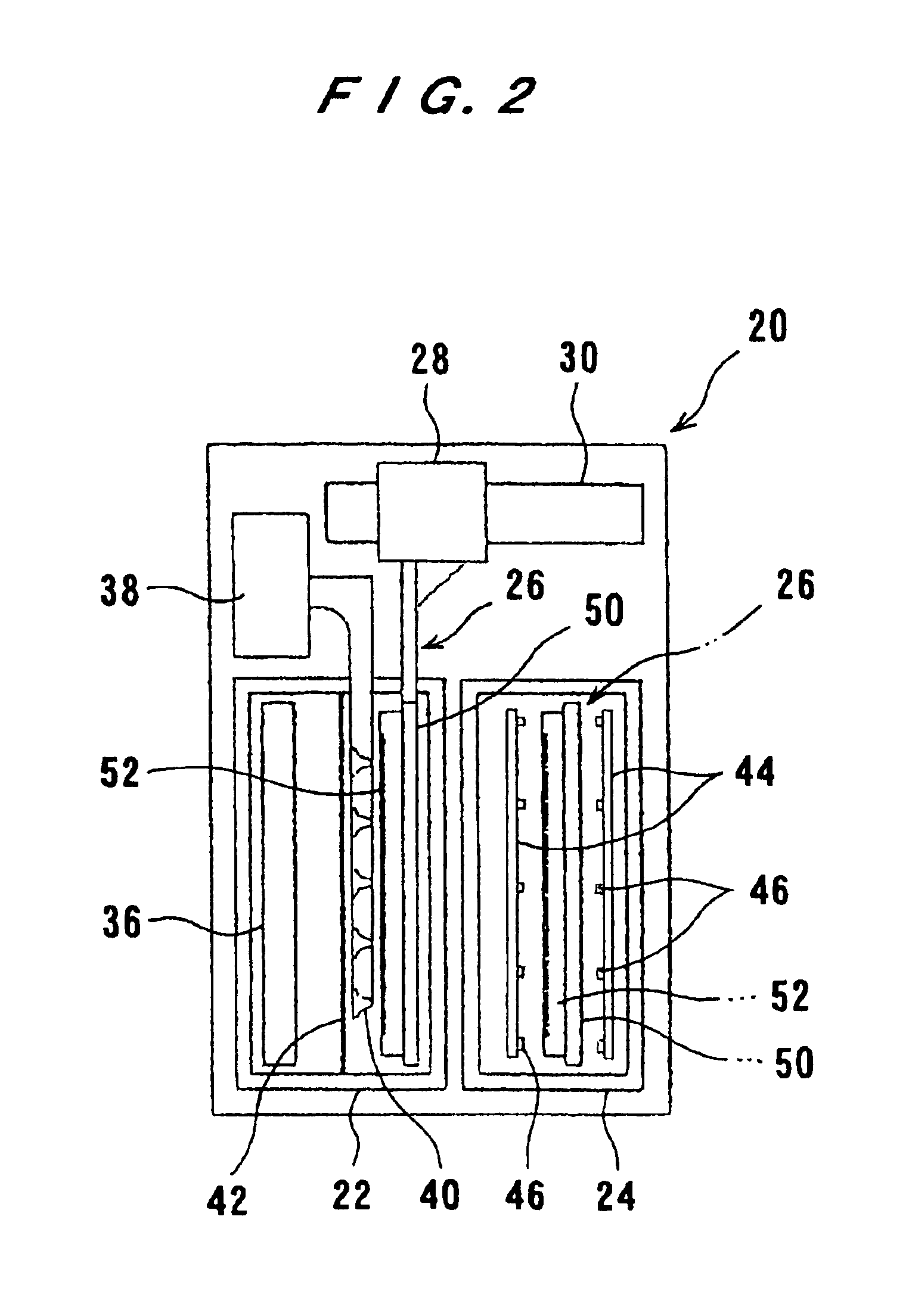

Conversion systems for biomass

ActiveUS8318453B2Efficient and economical and convenient to moveEasy to transportBio-organic fraction processingBiofuelsHydrocotyle bowlesioidesBiomass transportation

The efficient production of ethanol from low-cost biomass (e.g., corn, sugar beets, sugar cane, switchgrass and / or paper) has become increasingly important in making ethanol competitive with gasoline and decreasing the United States' dependence on foreign oil. For example, to reduce the cost of transporting biomass to ethanol production facilities, mobile systems for producing ethanol from biomass are provided. Also provided are small-scale ethanol production facilities. For example, instead of transporting biomass to the production facility, the facility is transported to the biomass or is located nearby the source of the biomass. The ethanol production facilities or components thereof may be transported via land, water, or air. Production of other products, such as hydrocarbons, natural gas, hydrogen gas, plastics, polymers, and proteins, can also be made by the methods and facilities. Any product described herein can be made in finished form or un-finished form and moved, e.g., to a fixed facility, e.g., fixed production facility.

Owner:XYLECO INC

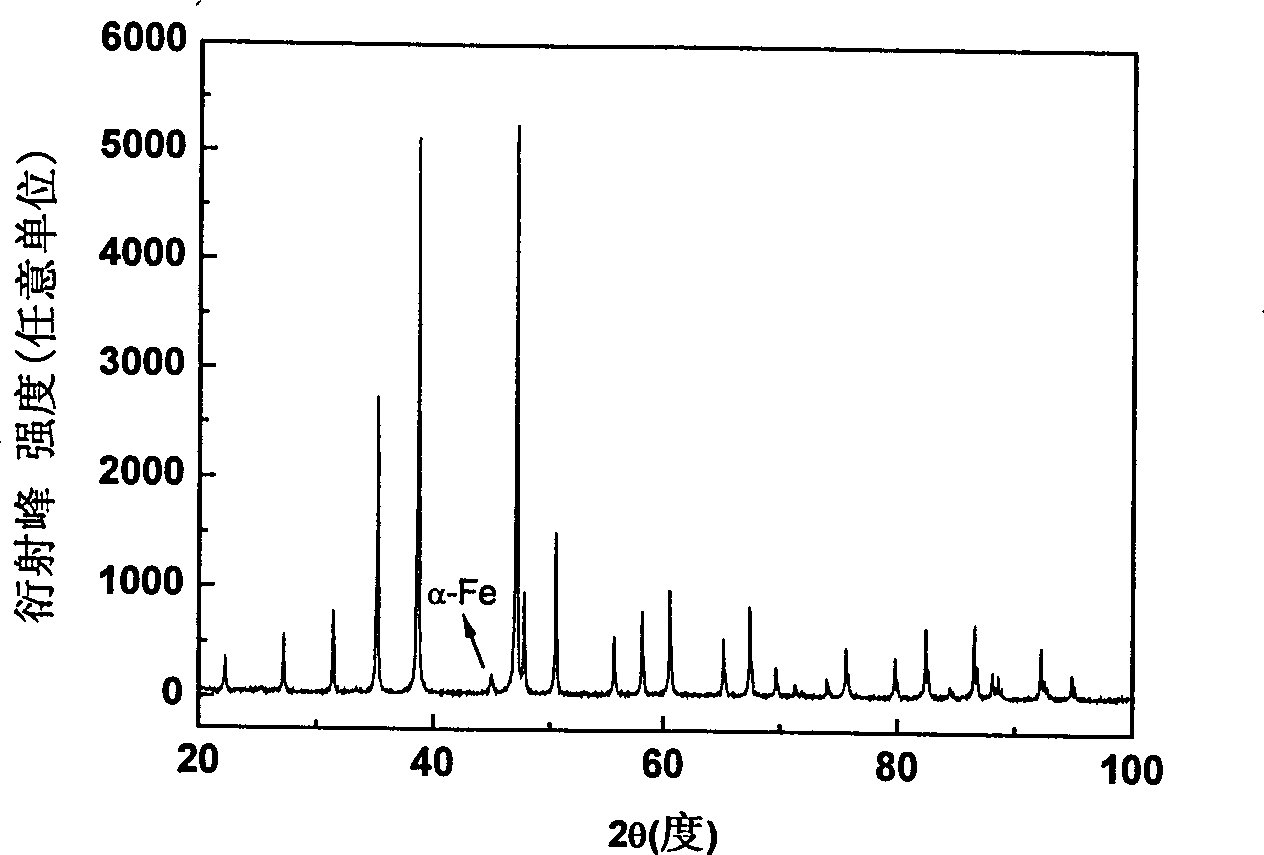

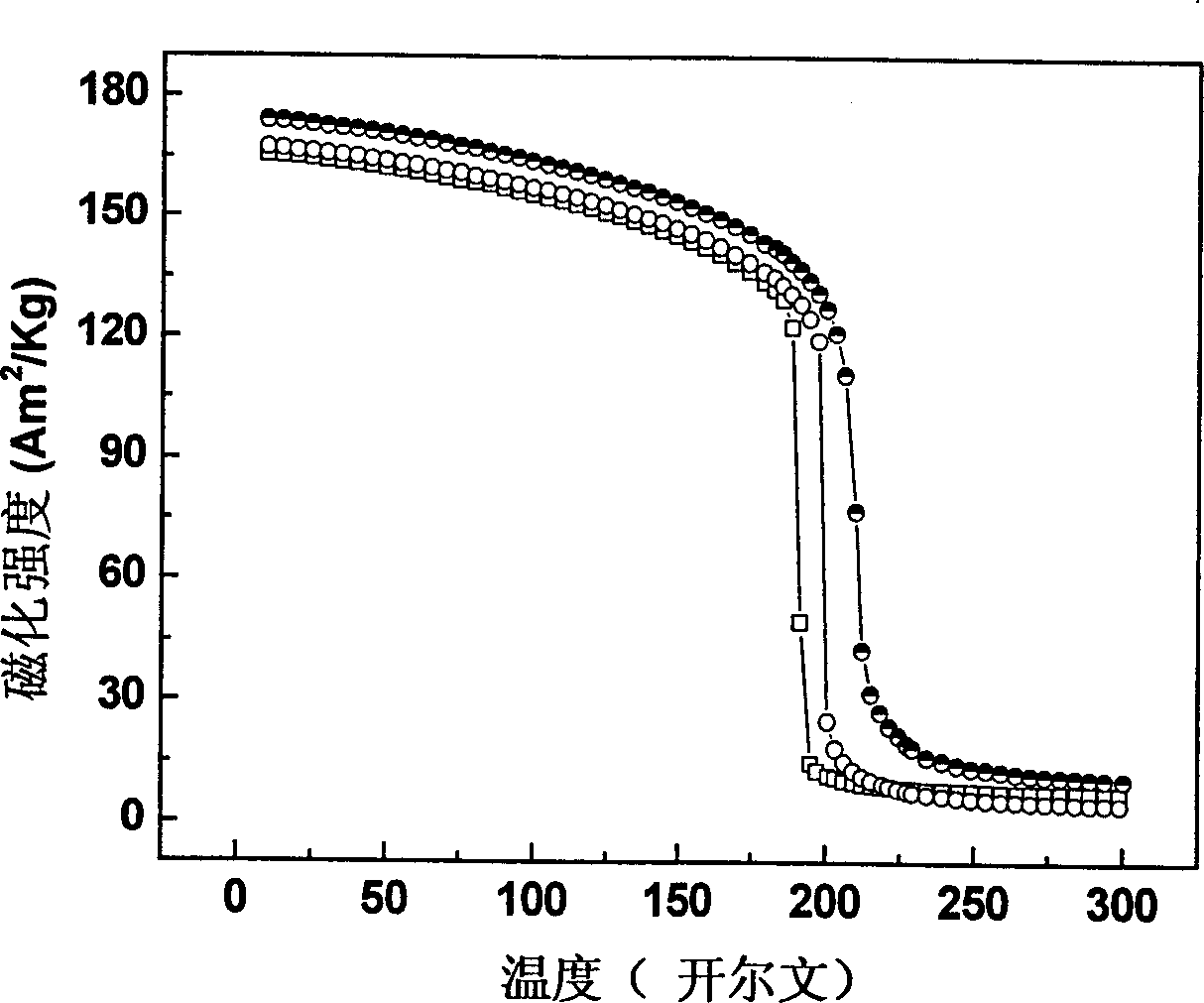

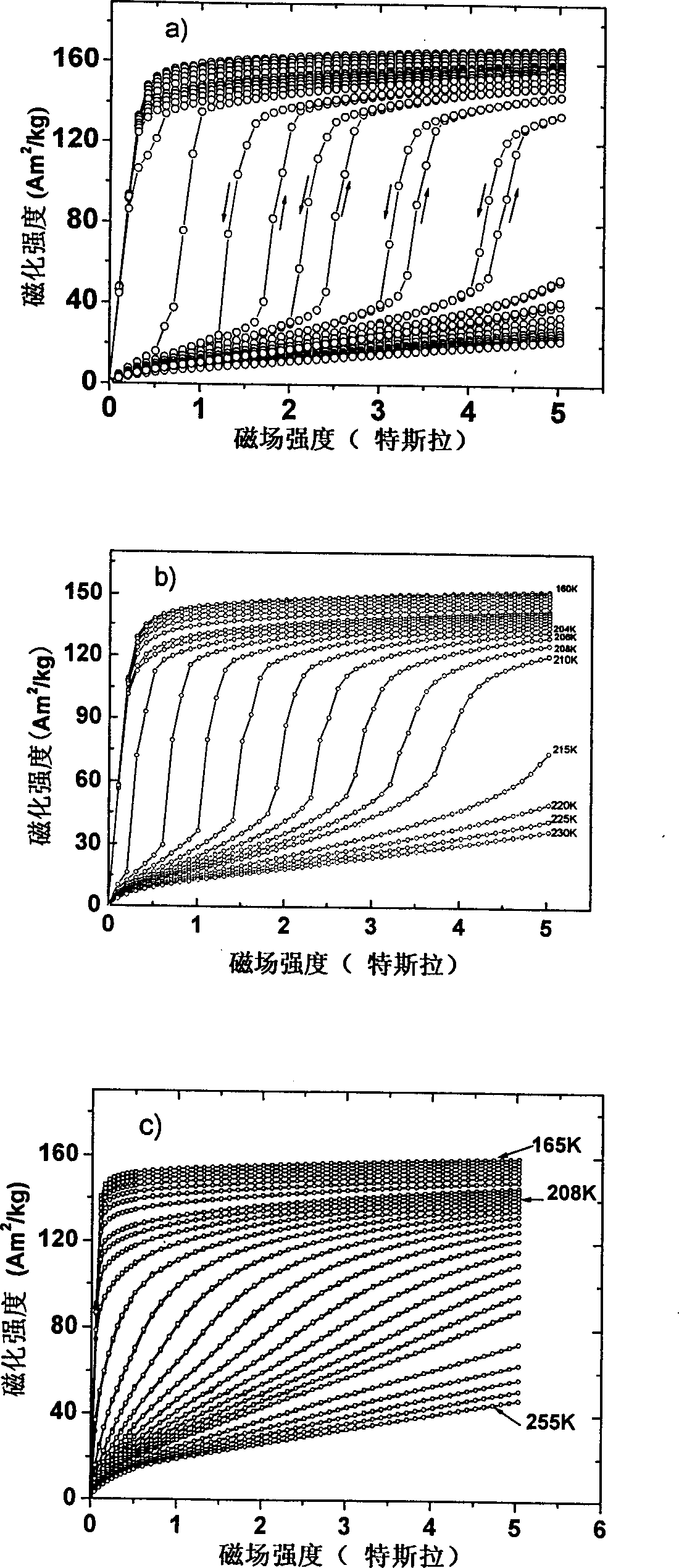

Rereearth-iron base compound magnetic refrigeration material with large magnetic entropy change and preparation process thereof

InactiveCN1450190ALarge magnetic entropy becomes highSuitable for productionEnergy efficient heating/coolingMachines using electric/magnetic effectsRare-earth elementInterstitial compound

The present invention relates to a rare earth-iron base compound magnetic refrigeration material with large magnetic entropy change and its preparation method. Its chemical general formula is La1-xRx(Fe1-yMy)13-zSizX alpha, in which R is more than one rare earth elements and its combination, M is more than one kind of Al, Co and Ga, etc. and its combination, X ix more than one kind of C, H, N andcombination of them, x is 0-0.4, y is 0-0.3, z is 0-3.0 and alpha is 0.3.0. Its preparation method includes the following steps: utilizing direct smelting and annealing treatment to can prepare La1-xRx(Fe1-yMy)13-zSiz and low C-content La1-xRx(Fe1-yMy)13-zSiz alpha gap compound, and utilizing smelting, quickly-quenching and annealing treatment to prepare high C-content La1-xRx(Re1-yMy)13-zSizC alpha gas compound.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

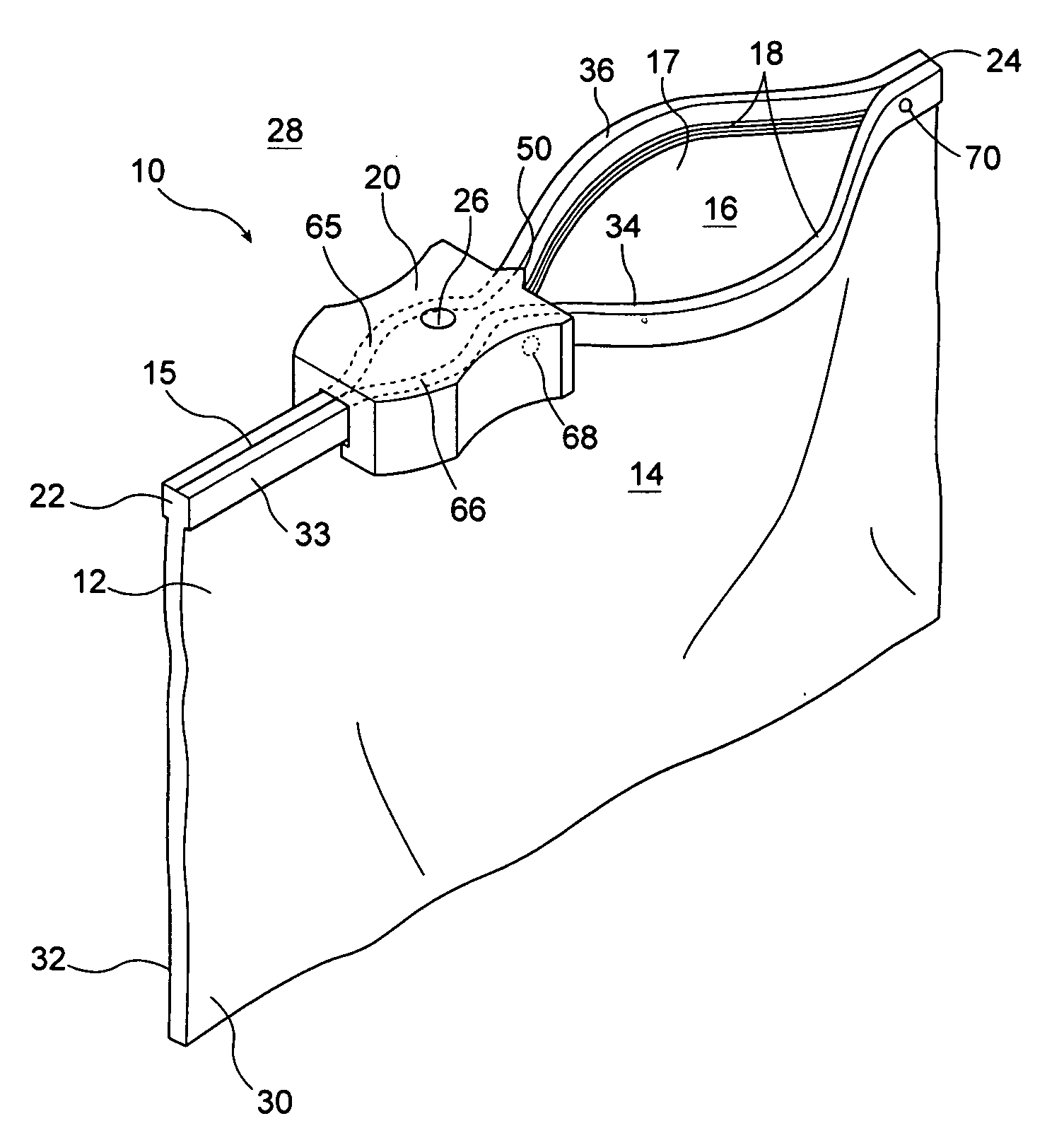

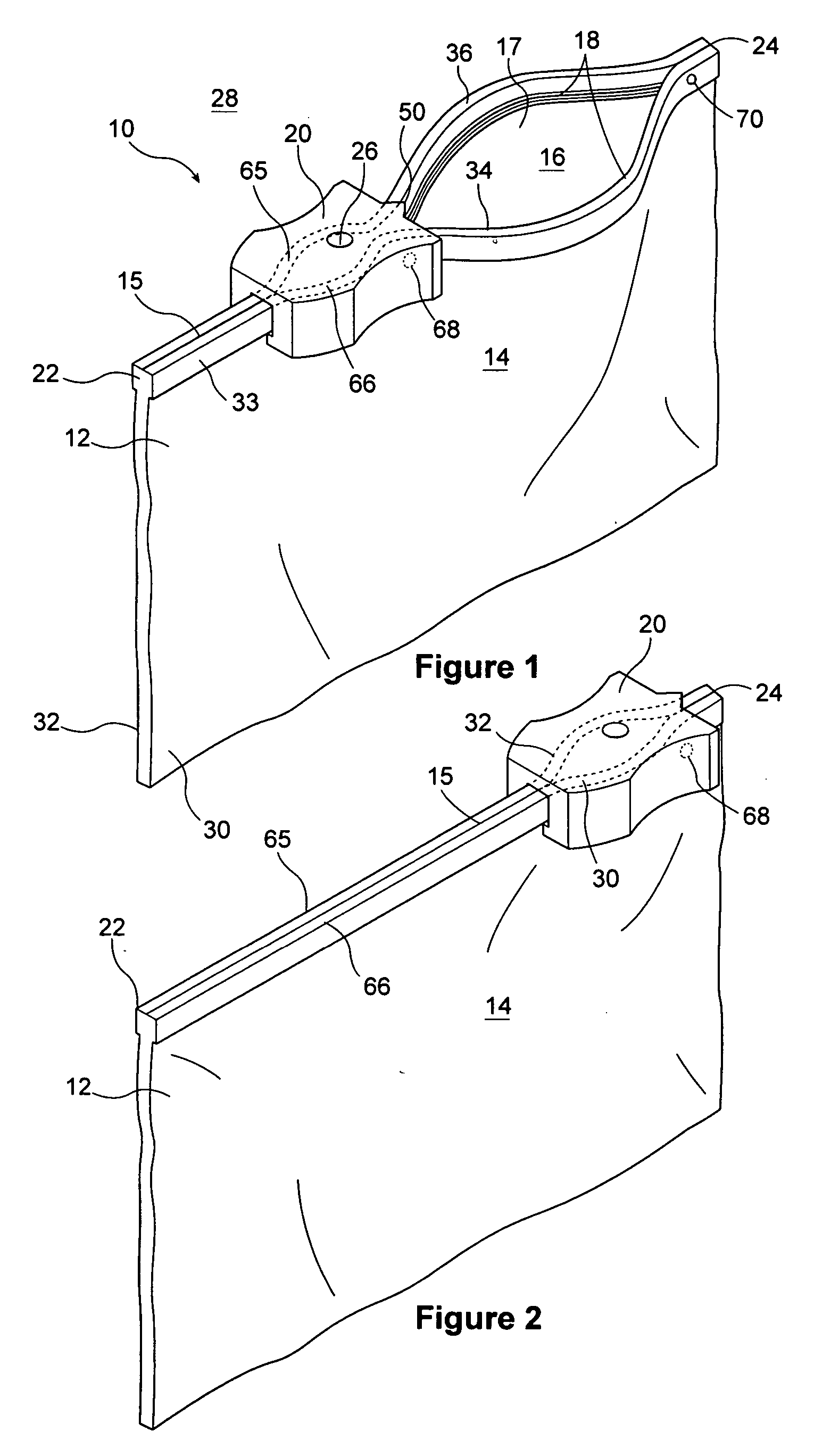

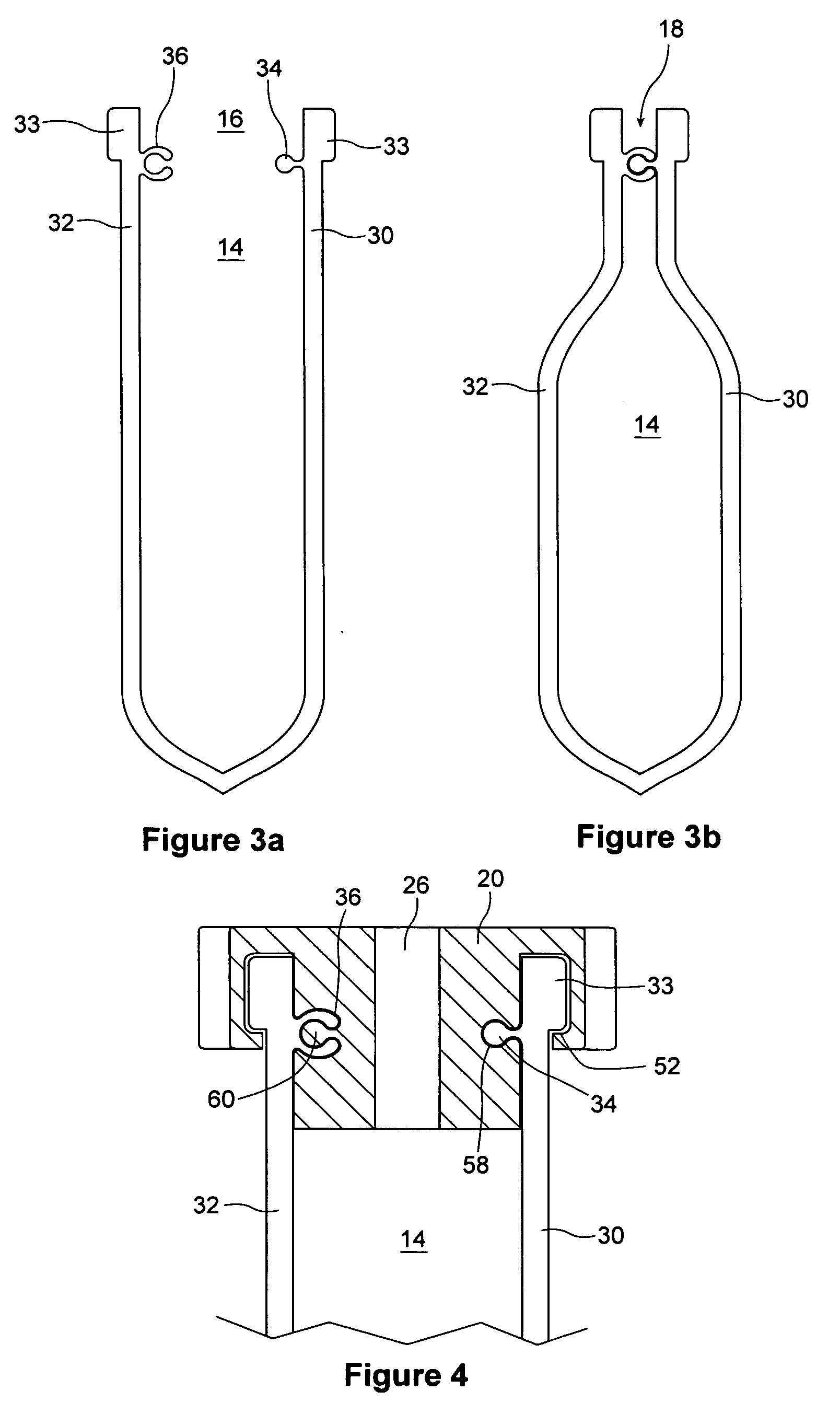

Reclosable bag

InactiveUS20060008187A1The process is simple and convenientImprove sealingSlide fastenersBagsEngineeringVALVE PORT

Owner:MO PROD

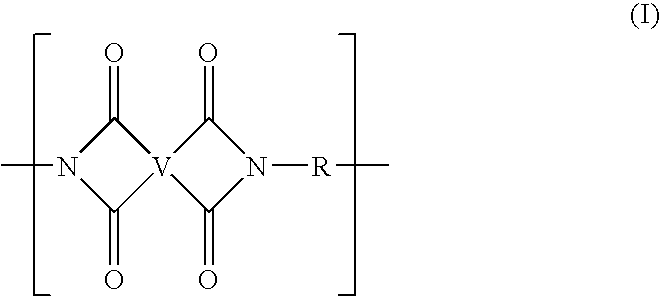

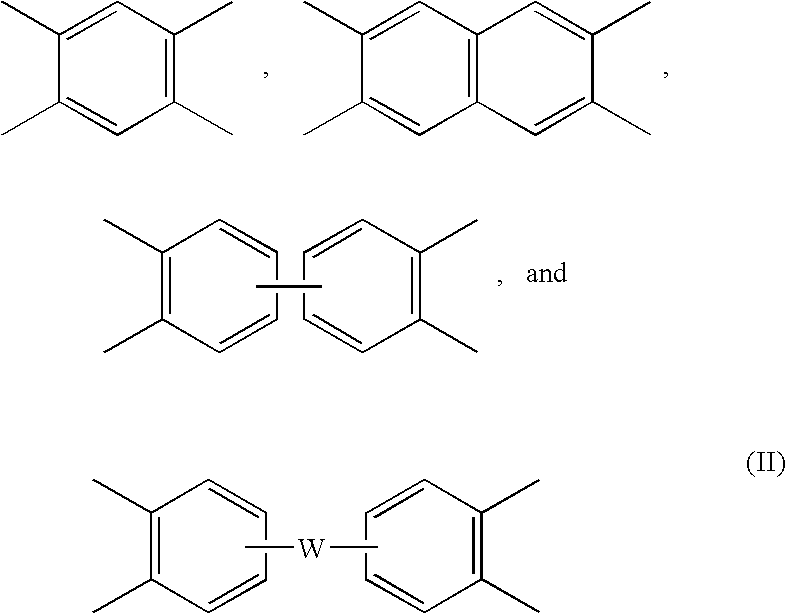

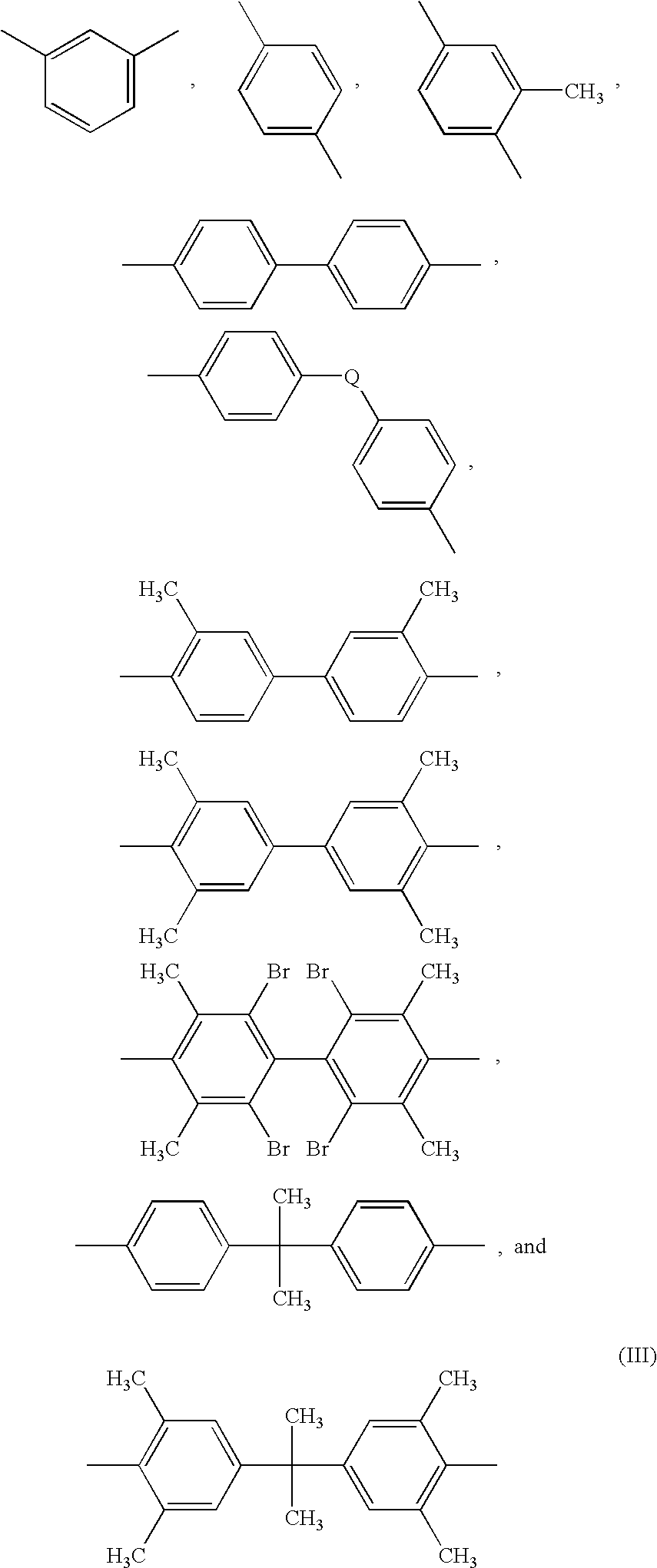

Preparation of polyimide polymers

InactiveUS20030181626A1Reduce amountIncrease coveragePretreated surfacesRecord information storageDiamineBoiling point

A process for the preparation of a reactive friable polyimide powder comprises dissolving an aromatic dianhydride and an organic diamine in a high-boiling, aprotic organic solvent to form a reaction solution; heating the reaction solution under imidization conditions to form an insoluble reactive polyimide and to effect substantially complete distillation of the water of reaction out of the reaction solution; and separating the insoluble reactive polyimide from the reaction solution to form a reactive friable polyimide powder.

Owner:SHPP GLOBAL TECH BV

Foam metal hydrogenating catalyst and its preparing method and use

ActiveCN1781595ALow densityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPorosityChemical plating

The present invention discloses hydrogenating catalyst of foam metal and its preparation process and application. The hydrogenating catalyst includes foamed metal carrier and active noble metal component in effective amount supported onto the carrier, the carrier is prepared through powder metallurgical process, and the active component is supported via chemical plating process and distributed homogeneously on the port surfaces of the foamed carrier. The catalyst has the advantages of high catalytic activity, firm combination between the active component and the carrier, high stability, simple preparation process, high porosity of the carrier, great specific surface area, etc. in addition, the catalyst provides sufficient gas-liquid contact area, is favorable to mass transfer between gas phase and liquid phase, may be used in catalytic rectification and possesses both reaction and separation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

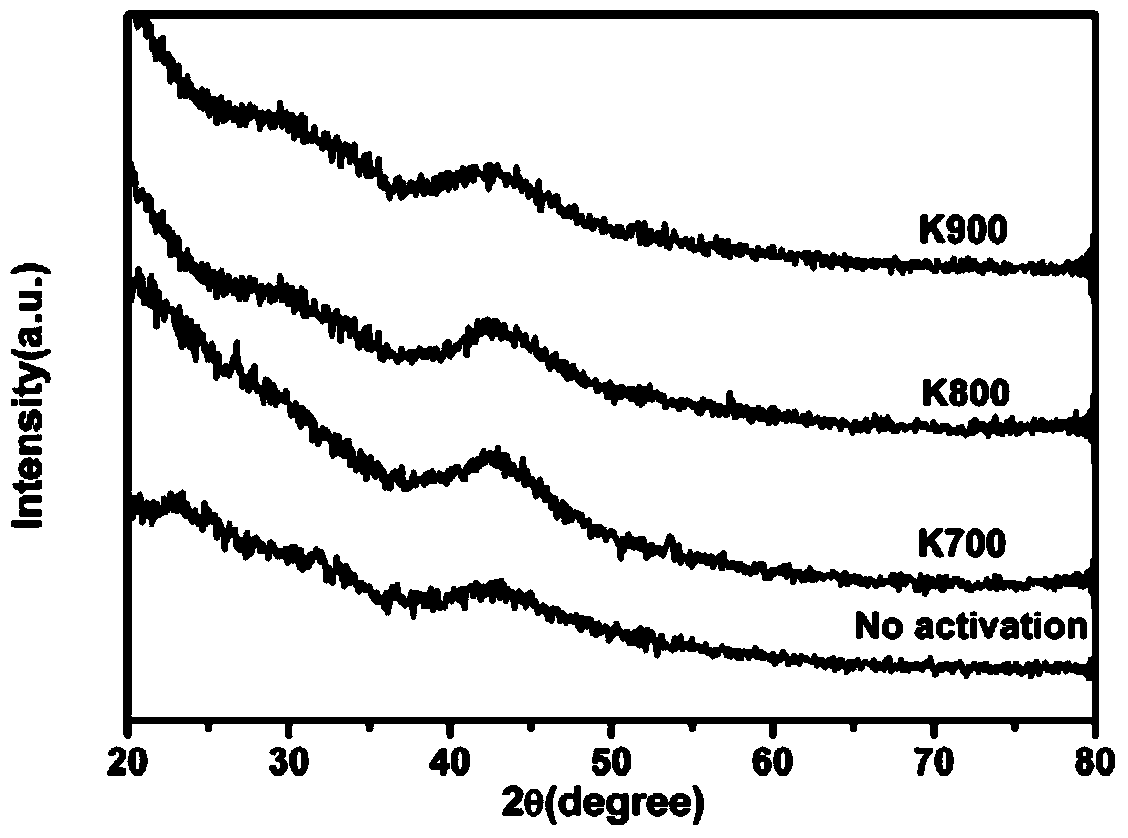

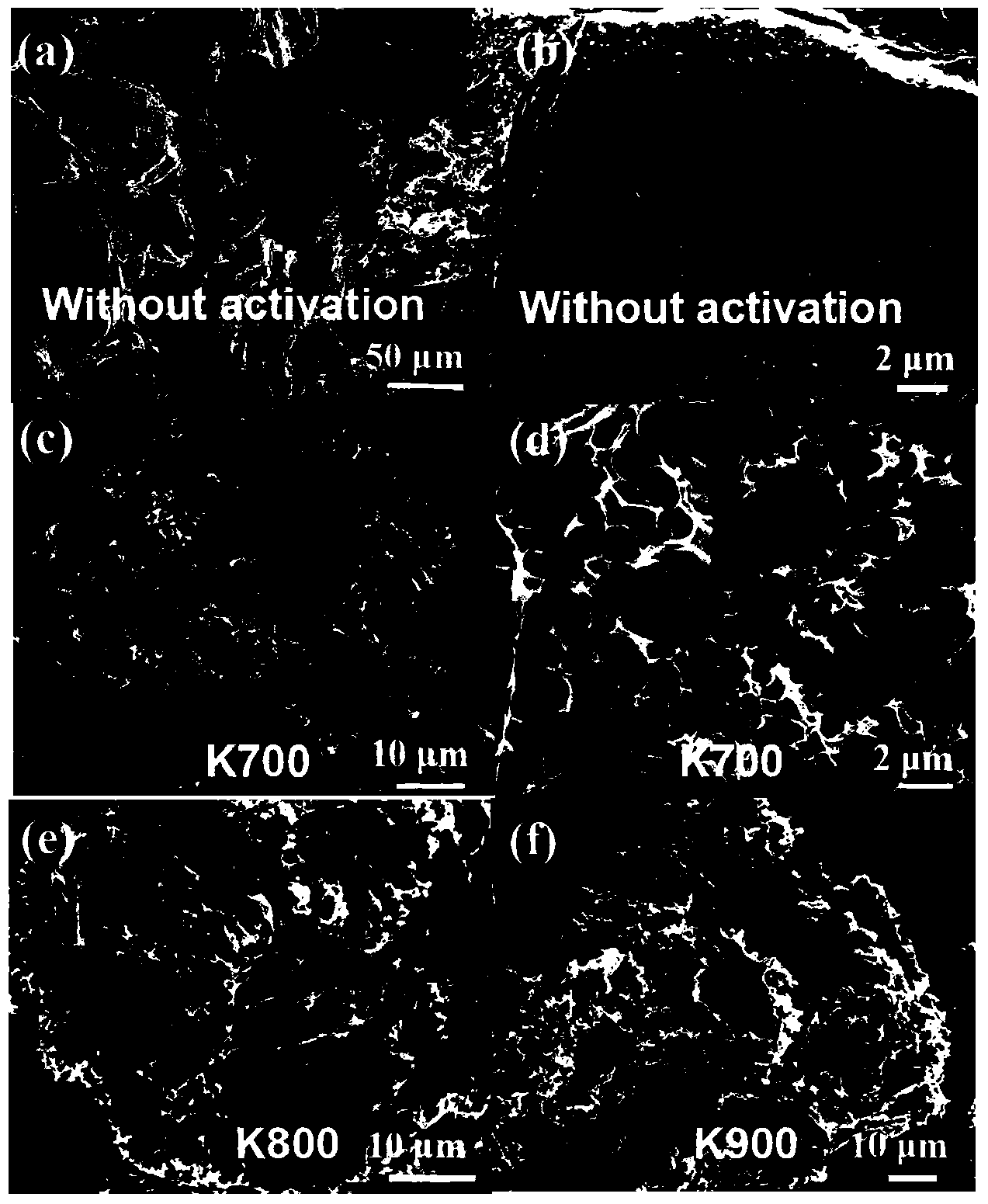

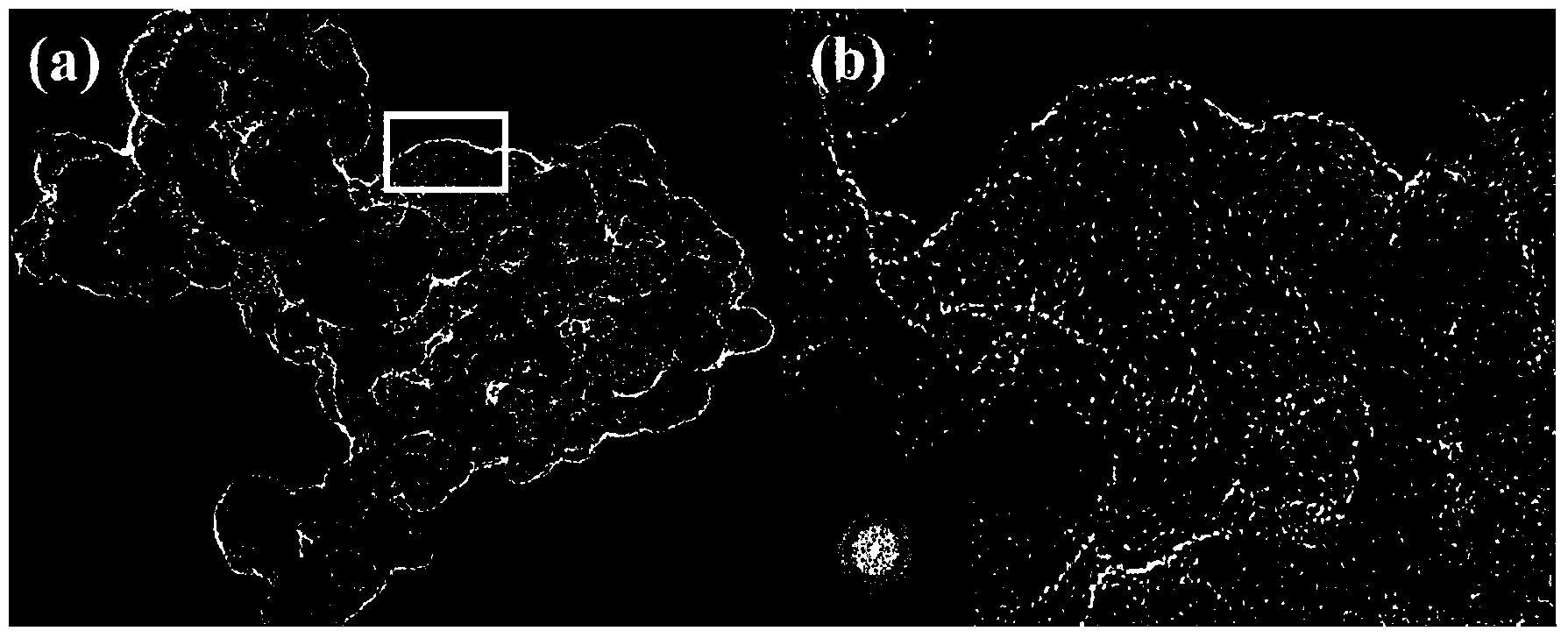

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

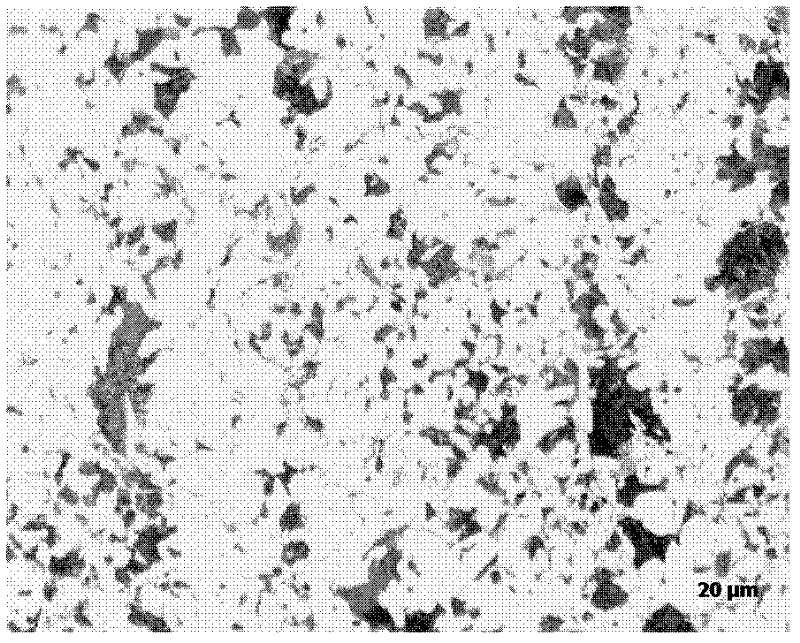

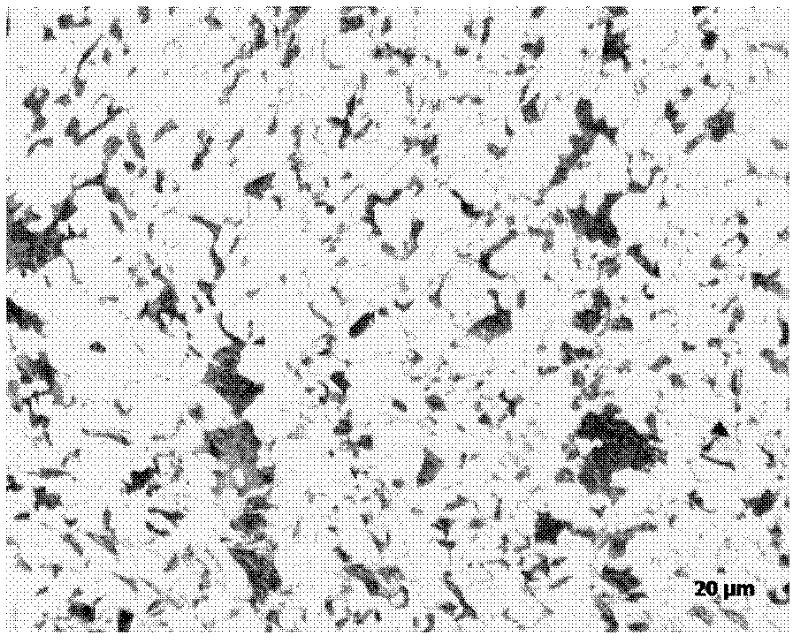

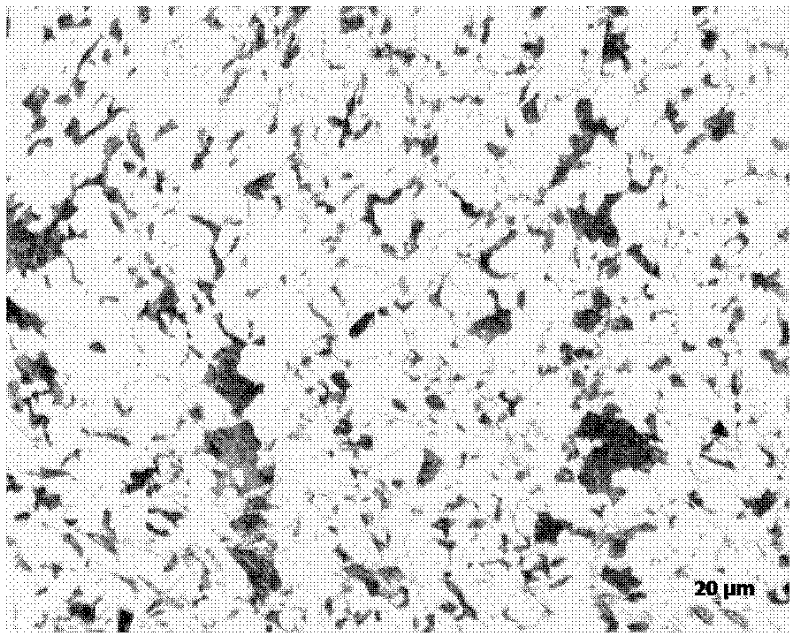

Steel plate with thickness of 80mm and low compression ratio for ocean engineering and manufacturing method thereof

ActiveCN102392192ASuitable for productionWide applicabilityTemperature control deviceFurnace typesLaminar coolingCooling temperature

The invention relates to steel for ocean engineering and a manufacturing method thereof, in particular to a steel plate with a thickness of 80mm and a low compression ratio for ocean engineering and a manufacturing method thereof. The steel plate comprises the chemical components with the weight percentages as follows: 0.12 to 0.16 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.60 percent ofMn, smaller than or equal to 0.010 percent of P, smaller than or equal to 0.003 percent of S, 0.025 to 0.050 percent of Nb, 0.030 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than or equal to 0.20 percent of Cr, 0.10 to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, smaller than or equal to 0.08 percent of Mo, 0.0250 to 0.050 percent of Al, smaller than or equal to 20ppm of O, smaller than or equal to 40ppm of N, smaller than or equal to 3ppm of H, and the remaining amount of Fe and inevitable impurities. A controlled rolling and cooling technology is adopted, the heating temperature before rolling is 1180 DEG C to 1250 DEG C, the rough rolling temperature is 1000 to 1100 DEG C, and the finish rolling starting temperature is 850 to 880 DEG C; laminar cooling is conducted after the rolling, the final cooling temperature is 640 to 680 DEG C, and the cooling rate is 5 to 15 DEG C / s; and normalizing treatment is conducted, the normalizing temperature is 890 to 910 DEG C, the heating rate is 1.4min / mm, and the heat preservation time is 50 to 90min. The obtained steel has the characteristics of high strength, good Z-direction lamellar tearing resistant performance, high plasticity, and the like.

Owner:NANJING IRON & STEEL CO LTD

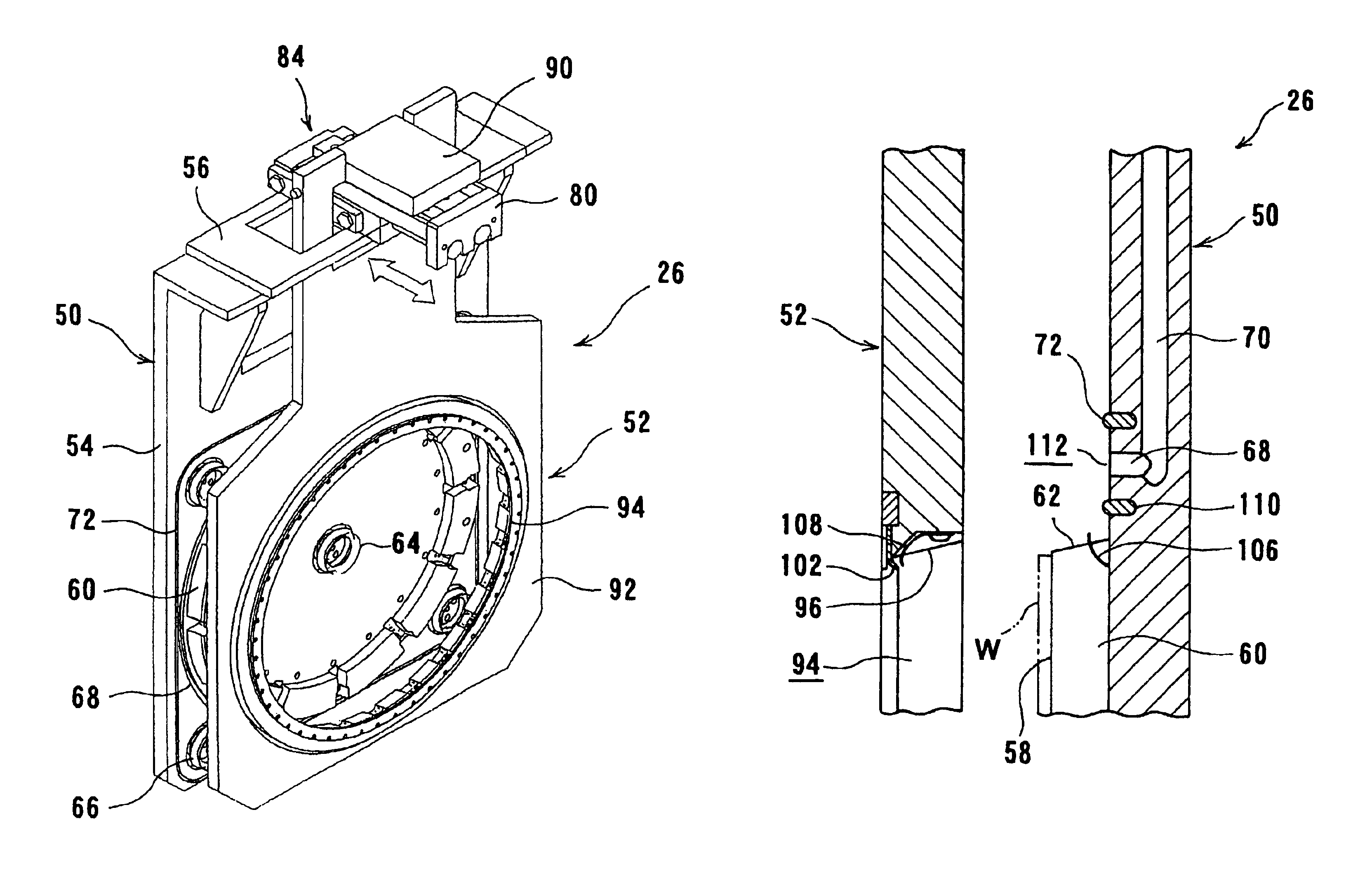

Substrate holder, plating apparatus, and plating method

InactiveUS6844274B2Small sizeSuitable for productionCellsSemiconductor/solid-state device manufacturingHermetic sealEngineering

Owner:EBARA CORP

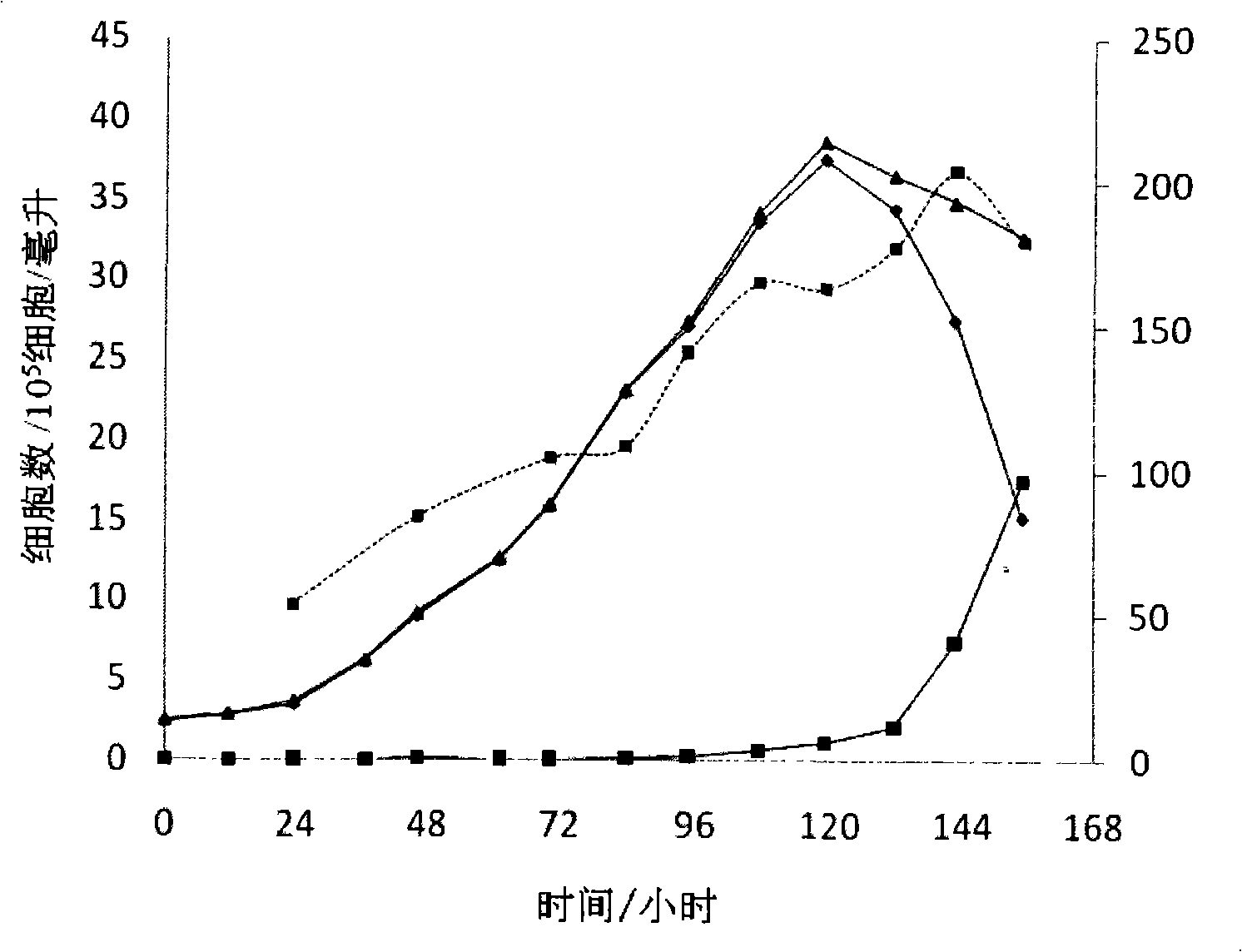

Animal origin-free low-protein culture medium suitable for animal cell product production

ActiveCN101603026AEasy to separate and purifySuitable for productionTissue cultureFermentationLipid formationAntioxidant

The invention relates to an animal origin-free low-protein culture medium suitable for animal cell product production, comprising 24 basic metabolism nutrients, 11 vitamins, 3 transferrin substitute compounds, 5 lipid compounds, 2 nucleic acid compounds, 4 hormones and growth factors, 3 antioxidants, 1 shear-resistant protective agent, 1 pH indicator, 2 pH buffers, 9 other inorganic salts, soy hydrolysates adopted to substitute animal origin component, and composition of ferrous sulfate, ferric nitrate and EDTA-2Na adopted to substitute transferrin. The culture medium can be made by dissolving the aforementioned components in triply distilled water. The positive effects of the culture medium are as follows: the culture medium contains no animal origin component, the total protein content is lower than 10mg / L, which helps separate and purify products and is suitable for production of recombinant protein medicaments; the culture medium supports normal growth and long-term subculturing of animal cells; the culture medium can be used without adaptation, is easily prepared and is suitable for massive production of animal cell products.

Owner:EAST CHINA UNIV OF SCI & TECH

Flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, preparation method thereof and applications thereof

InactiveCN103861628AStrong acidAvoid poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberActive component

The invention discloses a flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, a preparation method thereof and applications thereof. The catalyst comprises following components by weight: 70-85% of nanometer titanium dioxide, 1-3% of V2O5, 5-15% of heteropoly acid, 3-15% of glass fiber and 4-10% of an inorganic binder. In the preparation method, active components and the heteropoly acid are loaded step by step. The catalyst has high denitration performance and high performance of resistance to deactivation by the basic metallic oxides, and is particularly suitable for flue gas denitration of a power plant, an industrial boiler, an incinerator, a cement kiln, and the like, wherein the power plant, the industrial boiler, the incinerator, the cement kiln, and the like adopt biomass as fuel and contain a large amount of basic metallic oxides in flue gas.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

Light polarizing products and method of making same

ActiveUS20060146234A1Conveniently implementedSuitable for productionLaminationOptical articlesInter layerHeat resistance

Disclosed are novel light polarizing articles comprising a substrate, a light polarizing layer, an inorganic intermediate layer between the polarizing layer and the substrate, an optional inorganic sub-layer between the substrate and the inorganic intermediate layer, and a protective layer over the light polarizing layer, and method of making the same. Due to the presence of the inorganic intermediate layer and the optional sub-layer, adhesion of the polarizing layer is improved substantially. The light polarizing article has improved chemical, mechanical and thermal resistance. The light polarizing article can be used, for example, as ophthalmic products and in display devices.

Owner:CORNING INC

Partially crosslinked adhesive-supported porous film for battery separator and its use

InactiveUS20040101757A1Suitable for productionBonded firmlyLayered productsFilm/foil adhesivesEngineeringAdhesive

A partially crosslinked adhesive-supported porous film for battery separator, which in producing a battery, can effectively produce a battery as an electrode / separator laminate in which an electrode and a separator are temporarily bonded to each other without causing mutual slip movement between the electrode and the separator and which after producing a battery, functions itself as a separator having a small heat shrinkage factor even at high temperatures, and a process of producing a battery using such a partially crosslinked adhesive-supported porous film. The partially crosslinked adhesive-supported porous film for battery separator, includes a porous film substrate having supported thereon a partially crosslinked adhesive that is partially crosslinked by preparing a reactive polymer having a functional group in the molecule and capable of being crosslinked upon reaction with a polyfunctional compound having reactivity with the functional group and then reacting the reactive polymer with a polyfunctional compound.

Owner:NITTO DENKO CORP

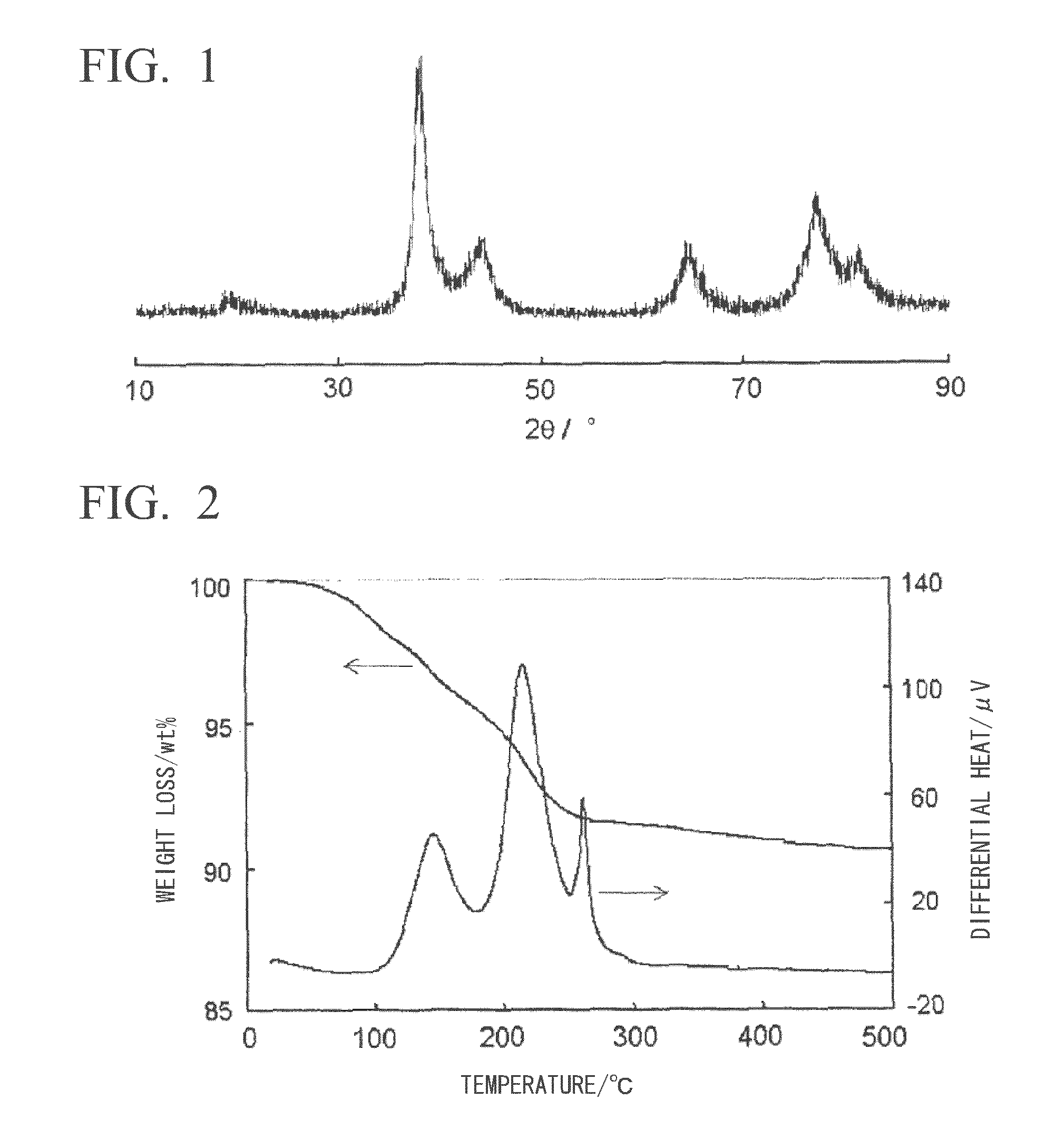

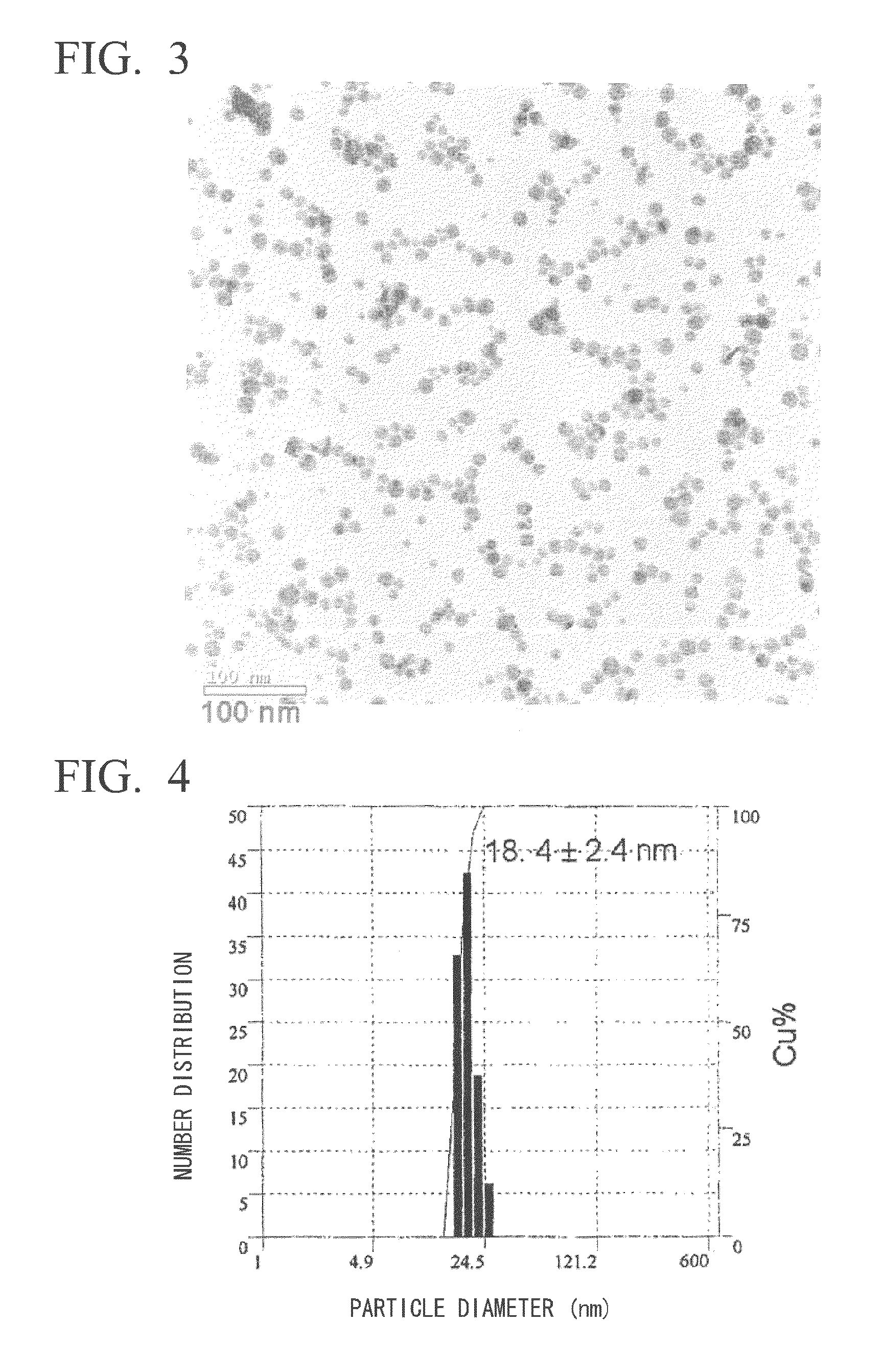

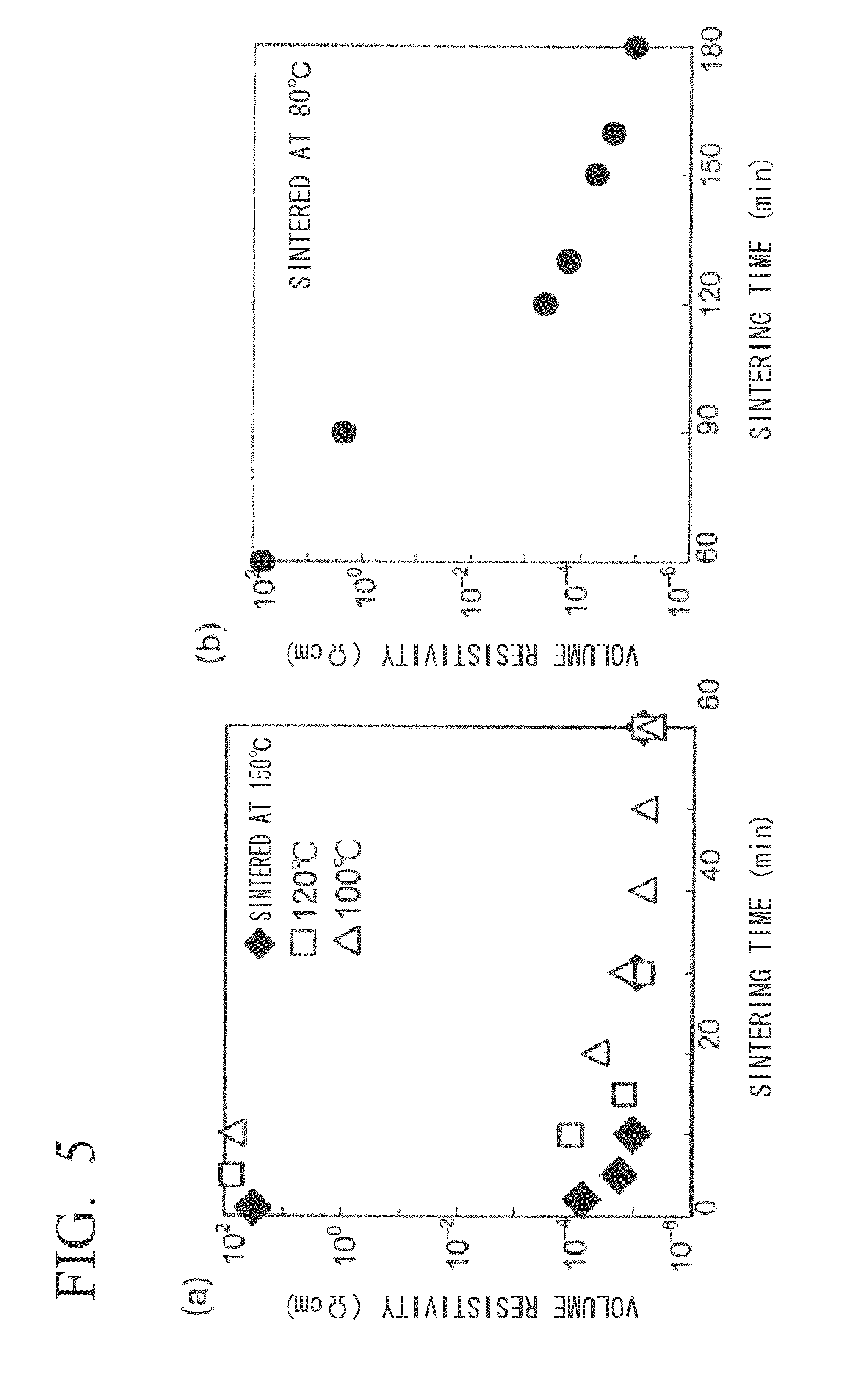

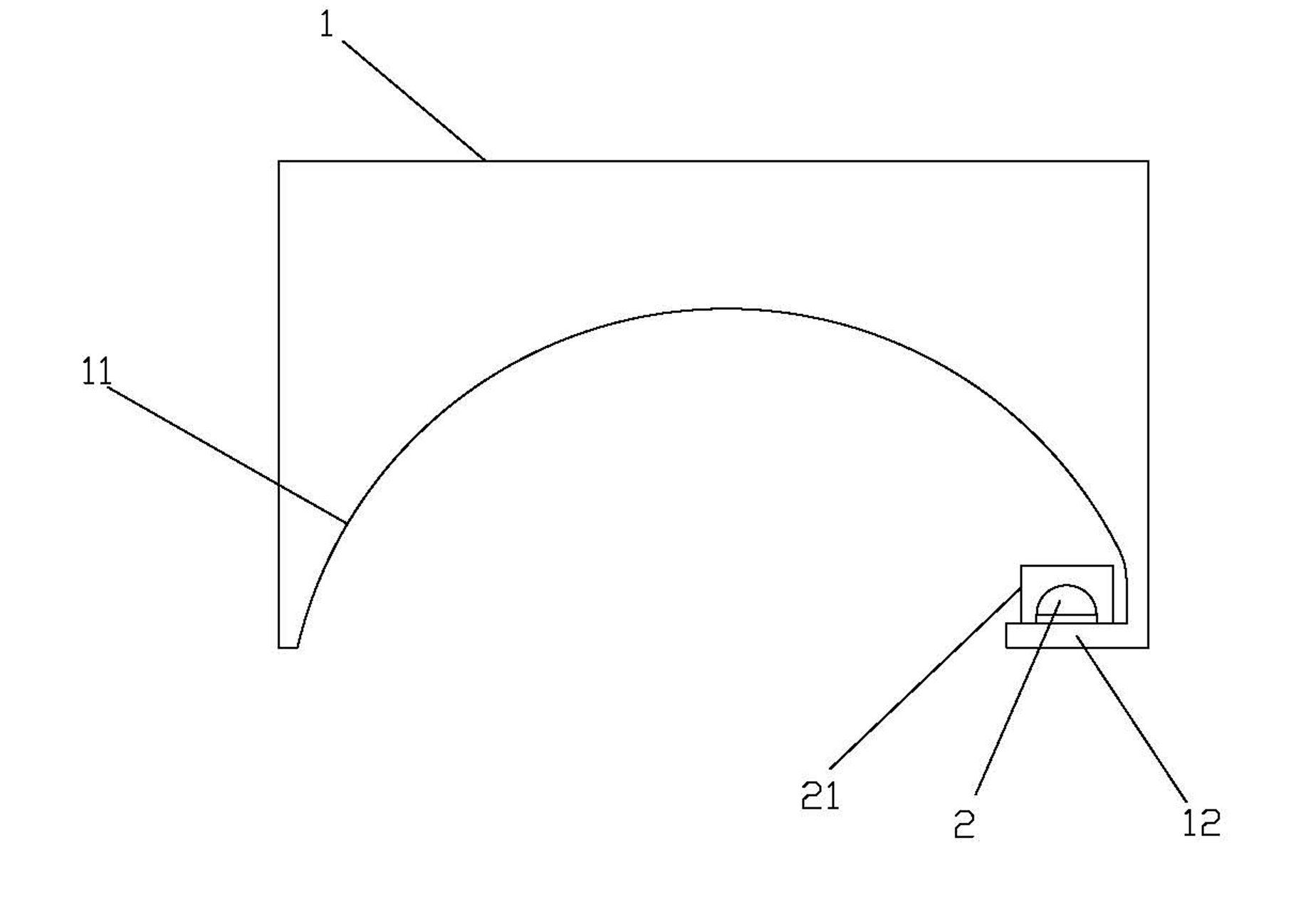

Coated silver nanoparticles and manufacturing method therefor

ActiveUS20120043510A1Enable formationReduce energy consumptionMaterial nanotechnologyNanostructure manufactureHeat resistanceConductive materials

The present invention provides coated silver nanoparticles for use as an electrically conductive material capable of sintering at lower temperatures that is able to be used even with flexible printed substrates having low heat resistance, and a manufacturing method therefor. The coated silver nanoparticles of the present invention have a mean particle diameter of 30 nm or less and are coated with protective molecules amine, and are characterized in that the weight loss rate when heated to 160° C. in thermogravimetric measurement is 30% or more. The coated silver nanoparticles of the present invention are also characterized in that a silver-colored sintered film can be formed by sintering at a temperature of 100° C. or lower for 1 hour or less. These coated silver nanoparticles are manufactured by mixing a silver compound that forms metallic silver when decomposed by heating, an alkylamine and an alkyldiamine to prepare a complex compound, and by thermally decomposing the silver compound by heating the complex compound.

Owner:YAMAGATA UNIVERSITY

Indoor light emitting diode (LED) illuminating lamp

InactiveCN102072443ANovel way of lightingNo glarePoint-like light sourceElectric circuit arrangementsDirect observationLed illumination

The invention discloses an indoor light emitting diode (LED) illuminating lamp, which comprises a support body with a reflective curved surface. A bent part is formed on the edge of the reflective curved surface, and is extended substantially towards the edge of the opposite side of the reflective curved surface. A light emitting diode module is fixed on the bent part, and cannot be directly observed at any angle, relative to the reflective curved surface, of the support body. In addition, an electric connection device is also arranged on the support body. The arrangement of a non-light tight sealing cover on the support body is avoided. The indoor LED illuminating lamp has a light weight, a portable structure and a good illumination effect, does not produce glare, and is convenient to arrange and maintain and particularly suitable for indoor illumination.

Owner:ZHONGSHAN WEIQIANG TECH

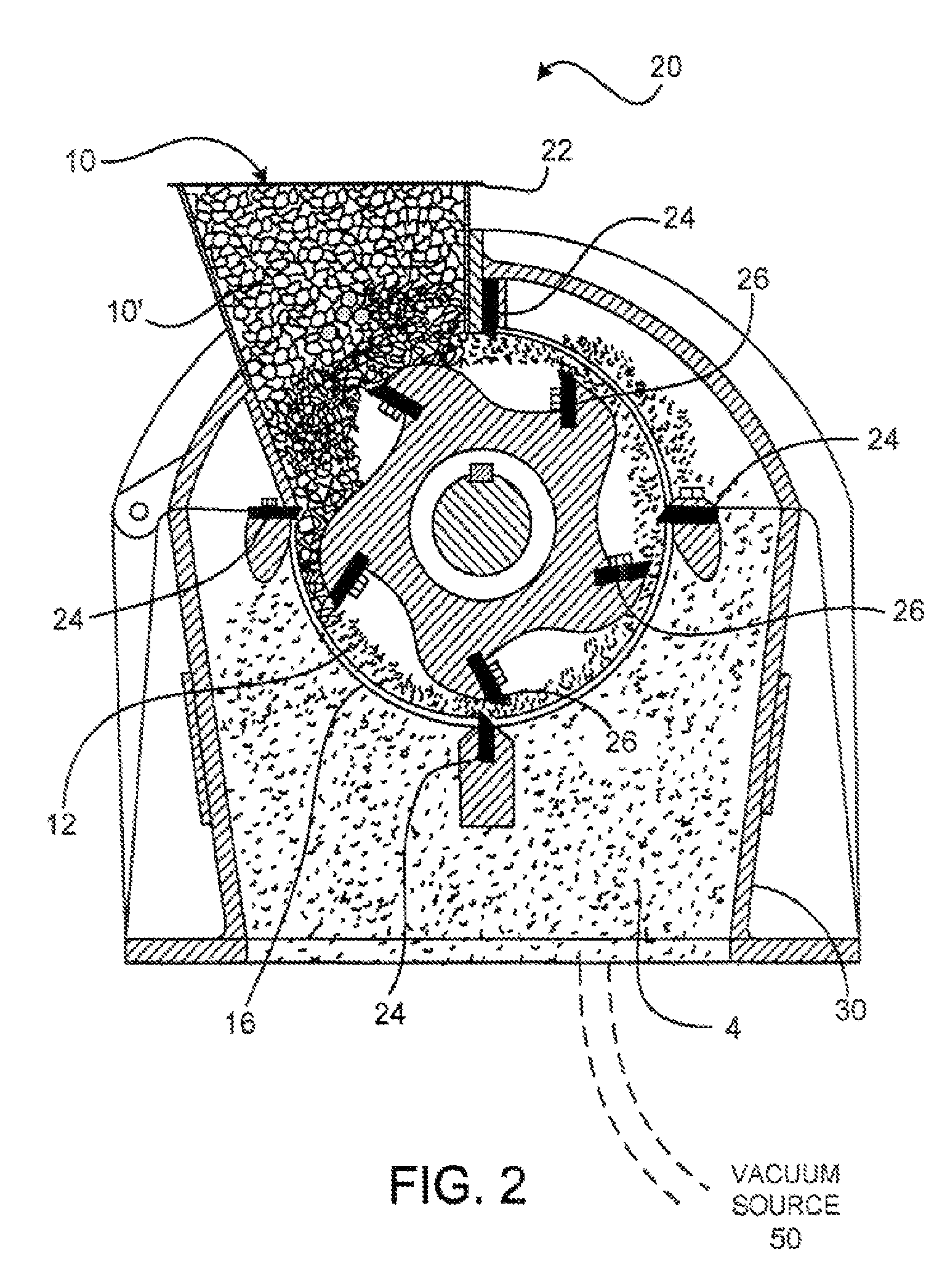

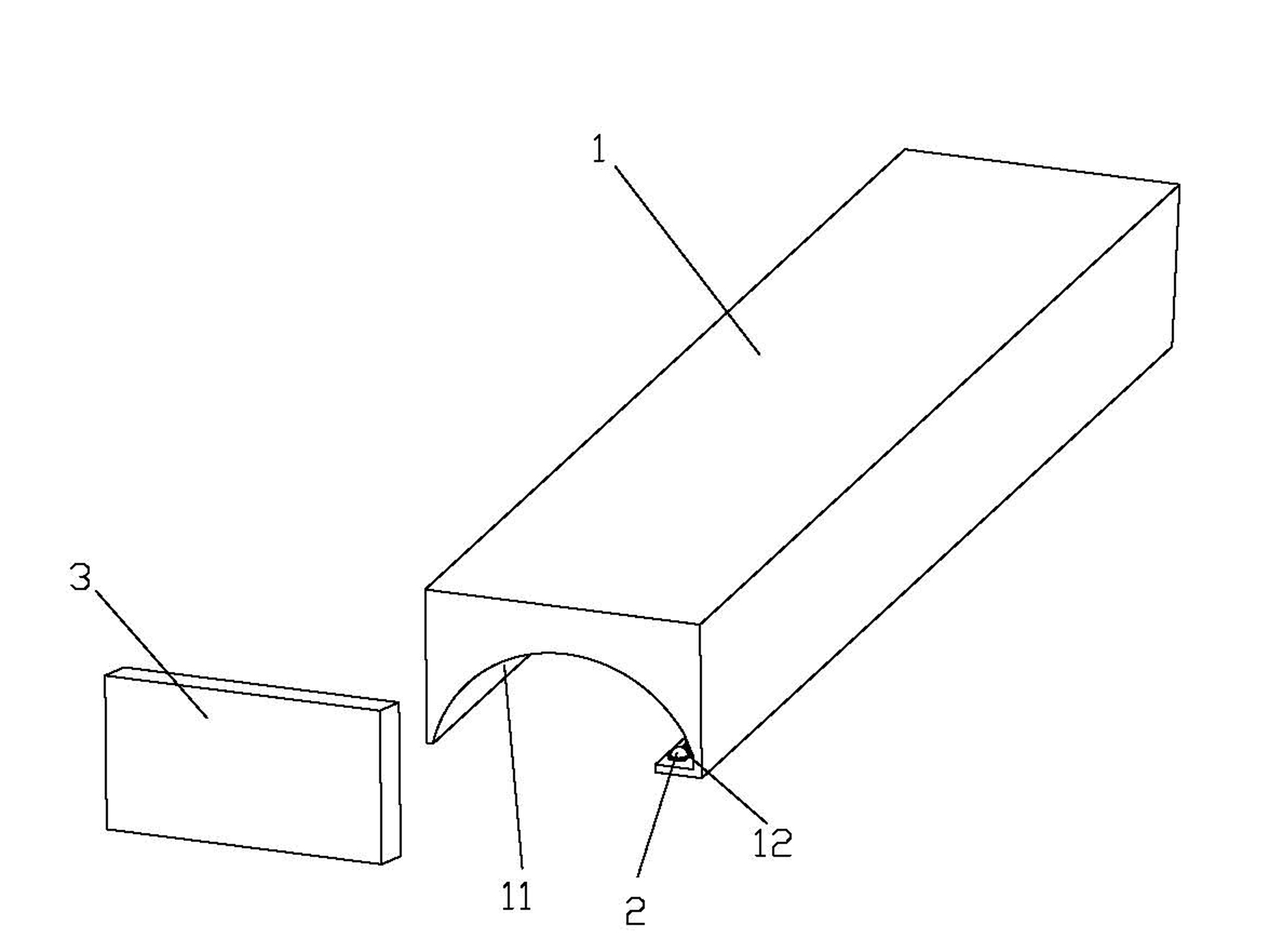

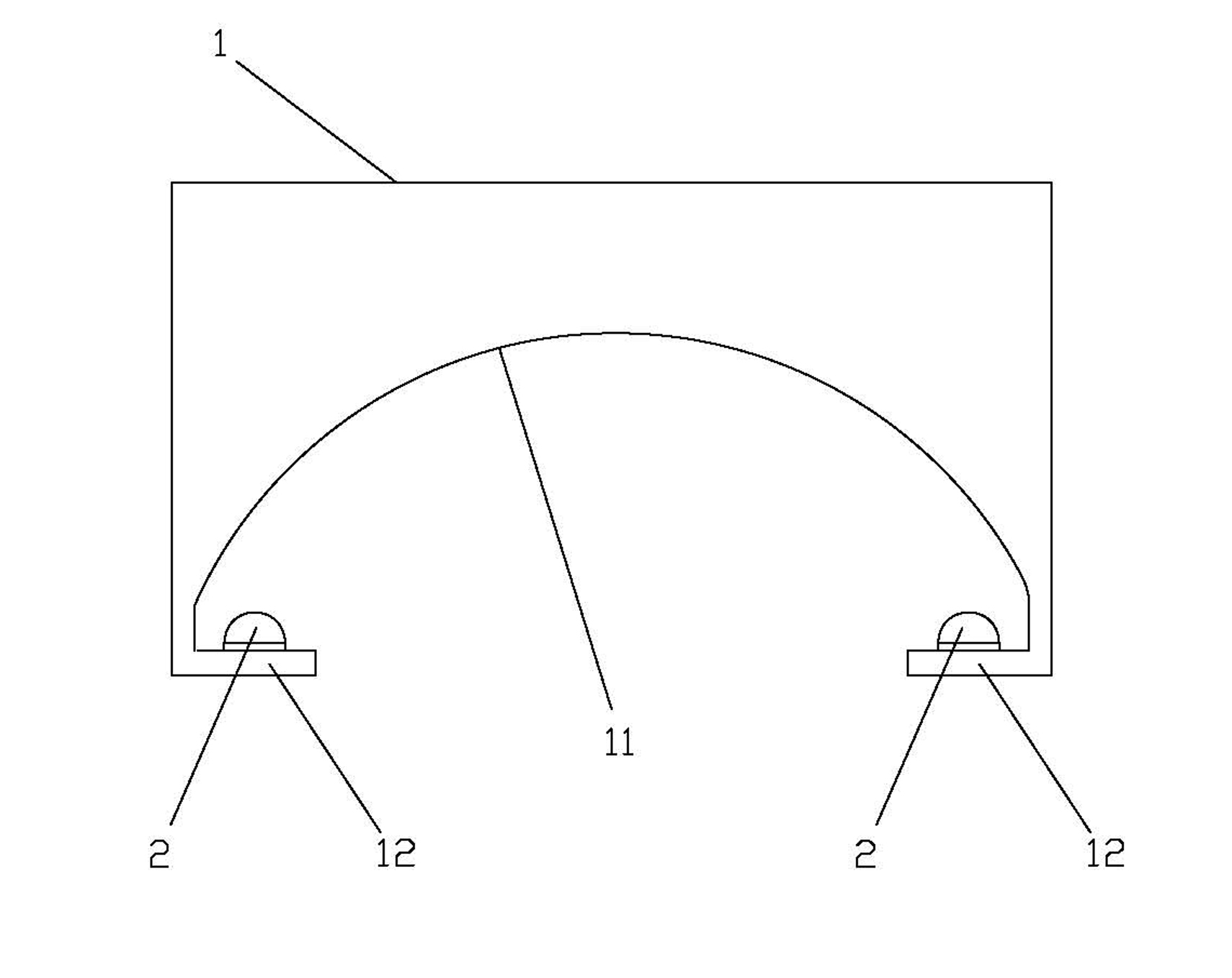

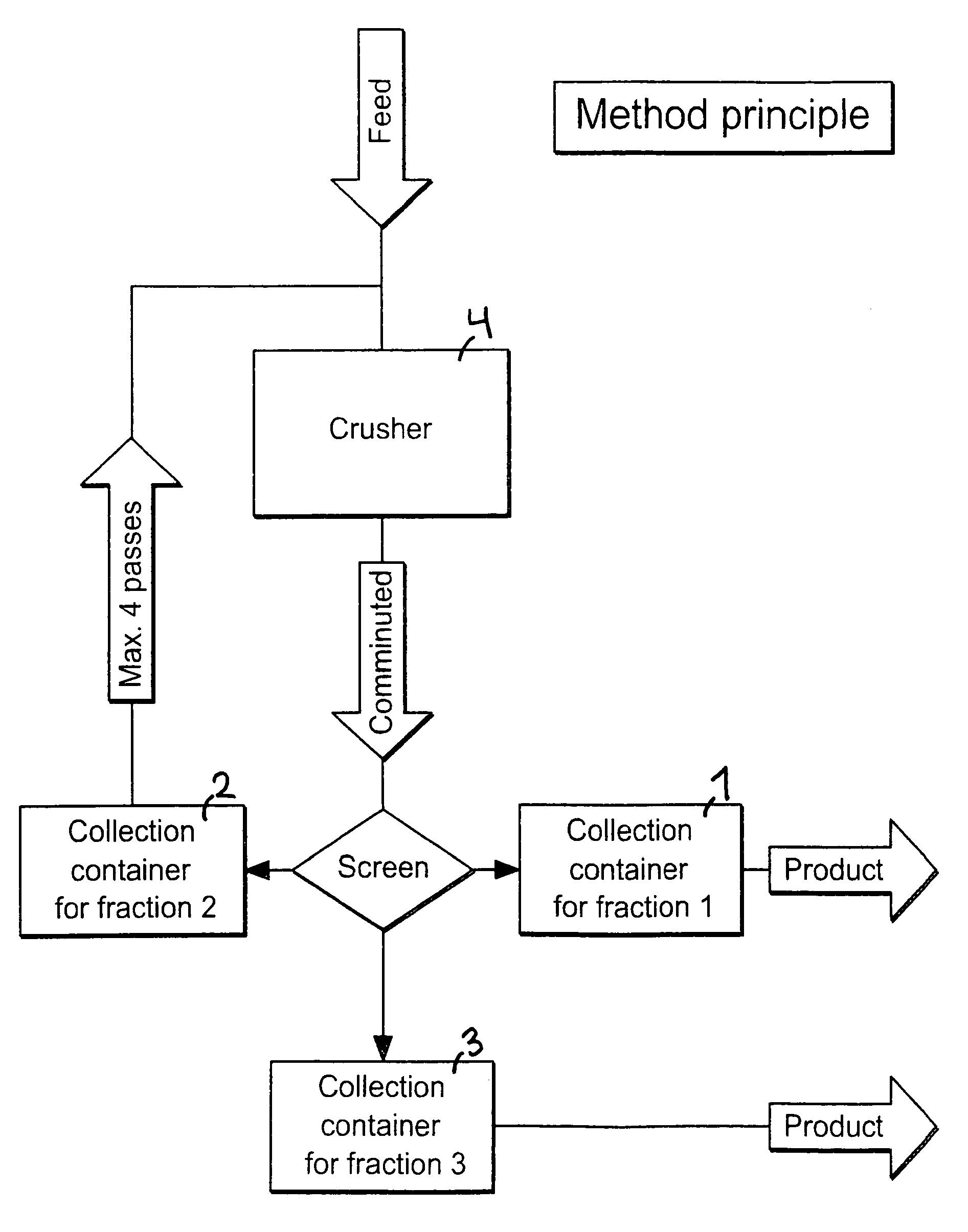

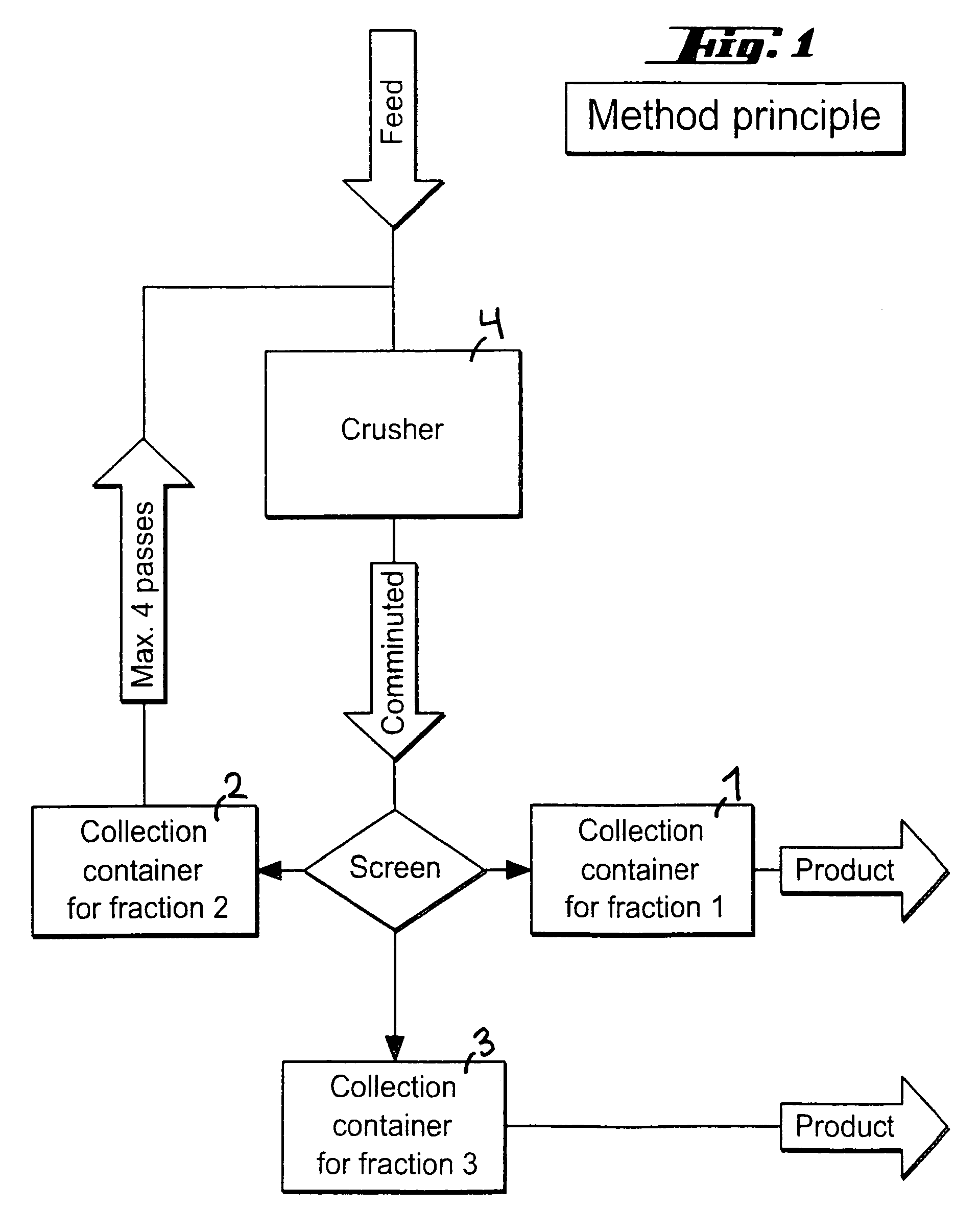

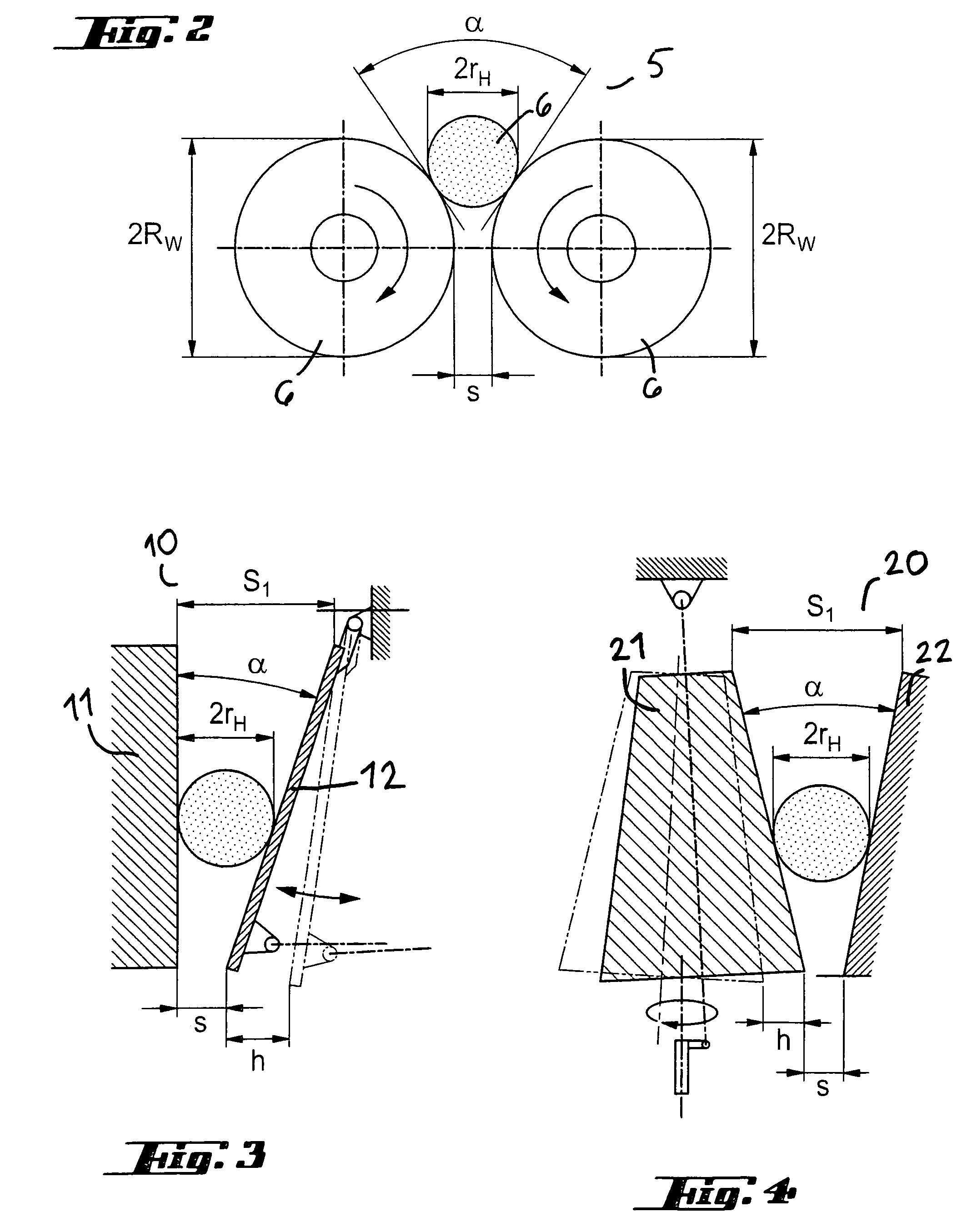

Apparatus and method for the low-contamination, automatic crushing of silicon fragments

ActiveUS7549600B2Suitable for productionImprove productivitySiliconFine working devicesWear resistantComminution

Owner:WACKER CHEM GMBH

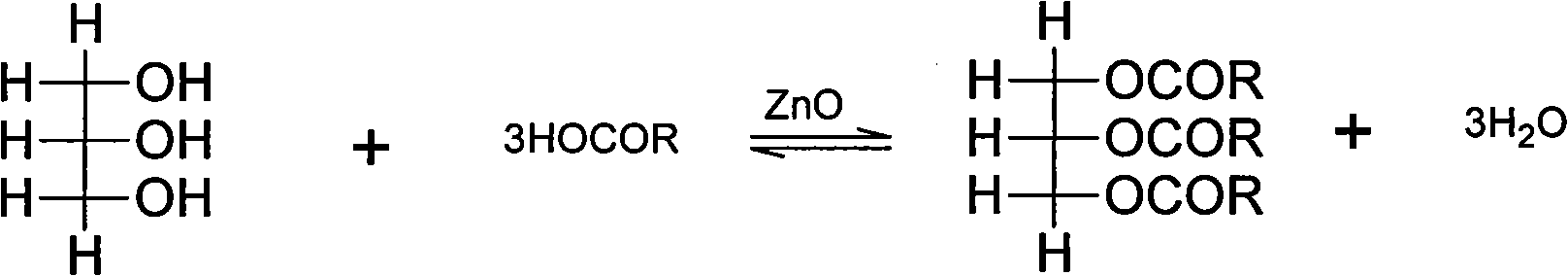

High-acid value rice bran oil esterification depickling process

InactiveCN101319167APromote esterification reactionLow acid valueFatty acid esterificationFatty-oils/fats refiningPre treatmentRice Bran Extract

The invention relates to an esterification deacidification process for high acid number rice bran oil, and the process can well solve the problem of a low refining rate. The esterification deacidification process for high acid number rice bran oil comprises grease pretreatment, namely two steps of degumming and decolorizing. A decolorized substance is obtained after the decolorizing, and then esterification deacidification is carried out. The concrete operating method comprises the following steps of: adding glycerin after the decolorized substance is stirred and heated at a vacuum degree of 0.09 MPa; adding a catalyst of zinc oxide or zinc to carry out a catalytic reaction to generate low acid number rice bran oil with an acid number of 5-7mgKOH / g. The zinc oxide or zinc which is taken as the catalyst of the esterification deacidification of the high acid number bran oil can effectively boost the esterification reaction and rapidly reduce the acid number; simultaneously the process overcomes the problems of the low refining rate lying in a traditional refining method and a great deal of sewage produced by a chemical alkali refining method; the zinc oxide or zinc has a low price, thereby reducing production cost; compared with other chemical esterification catalysts, the zinc oxide or zinc has a very low toxity, thereby being very suitable for the production of edible grease.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com