Method for preparing supercapacitor carbon aerogel by utilization of bagasse

A technology of supercapacitors and carbon aerogels, which is applied in the fields of hybrid capacitor electrodes and hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of difficulty in preparing high-performance carbon-based electrode materials, too large differences in structure and composition, and limited resources. and other problems, to achieve the effect of low price, abundant sources and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

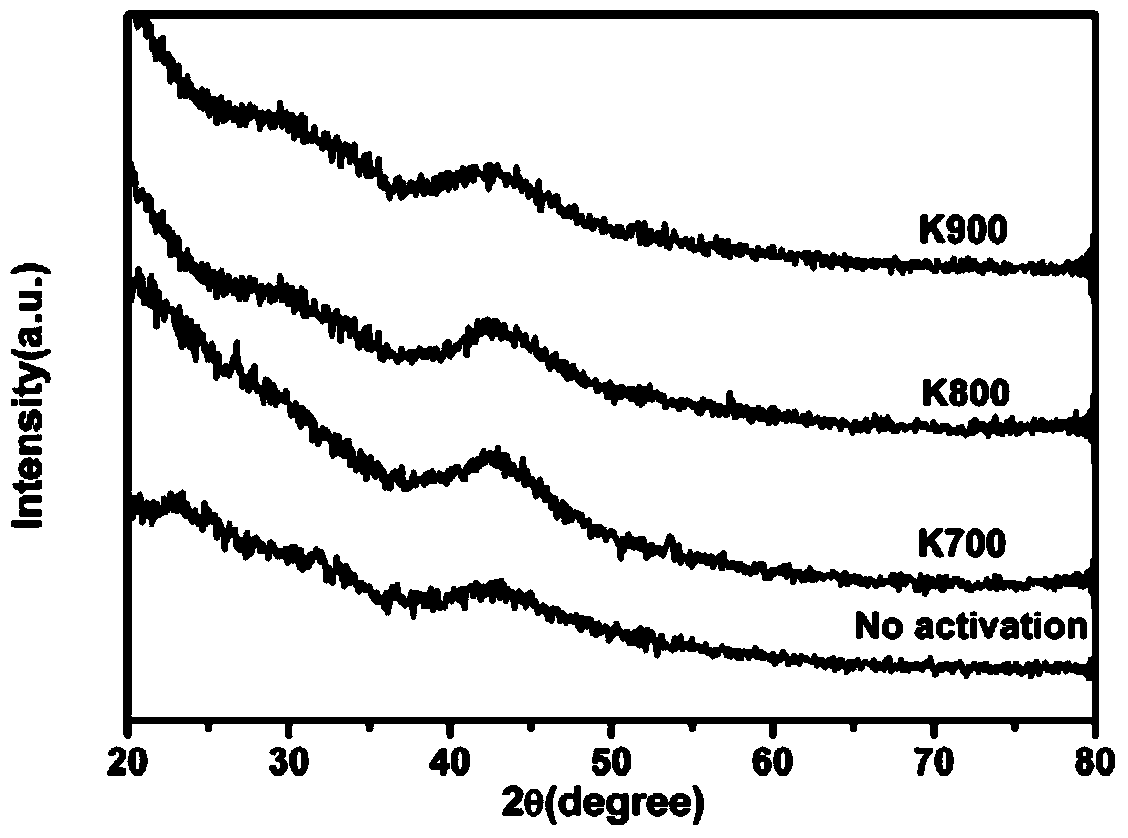

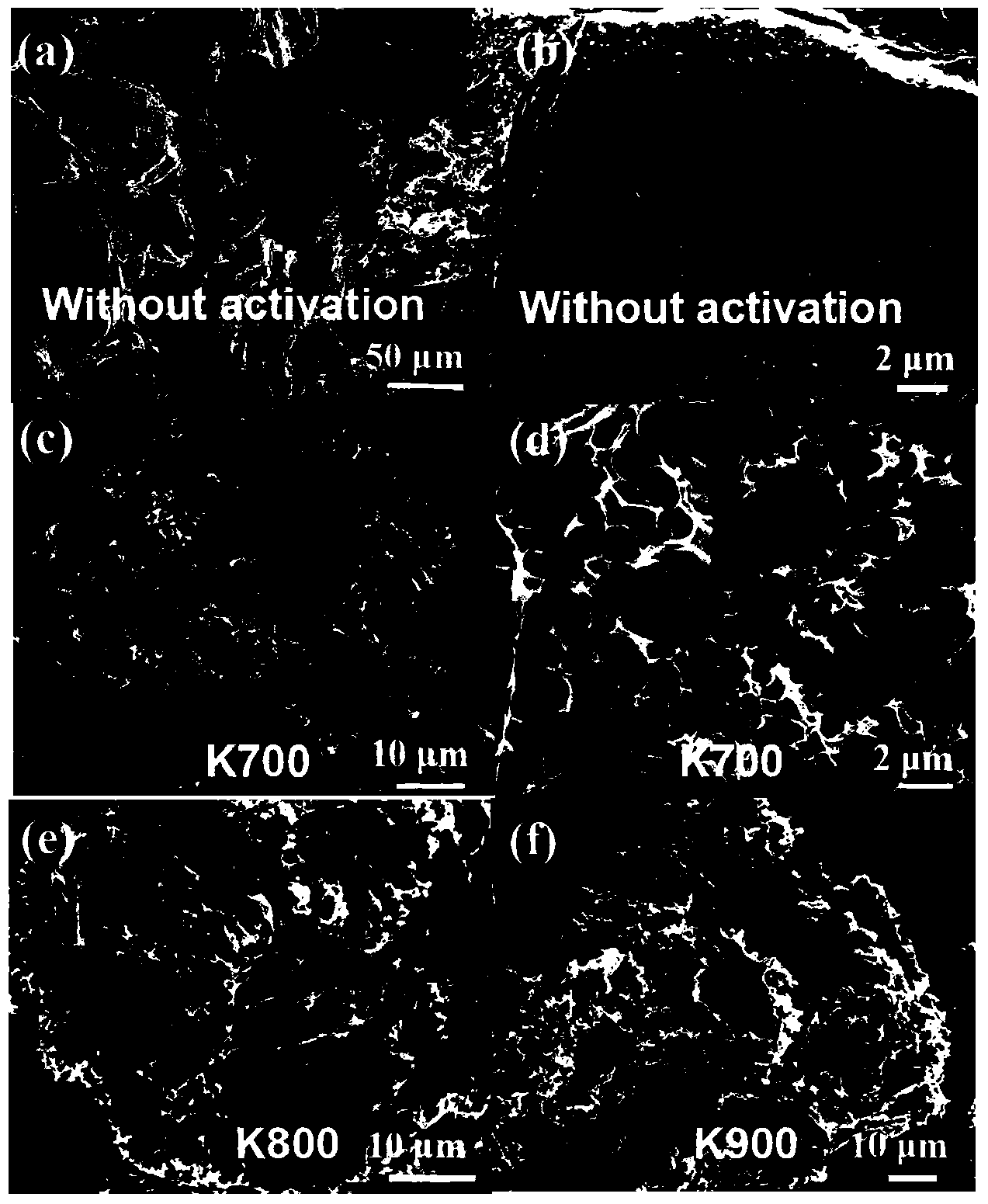

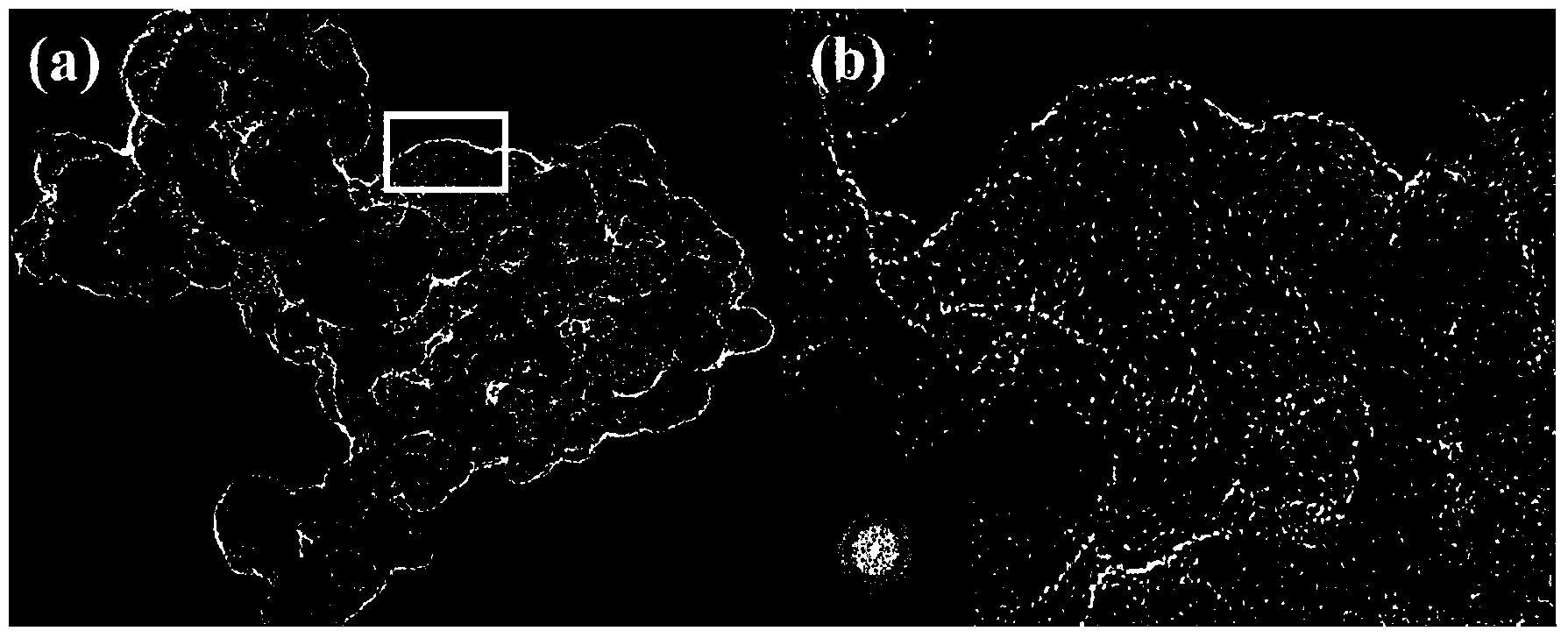

Method used

Image

Examples

Embodiment 1

[0030] ①Wash the bagasse, dry it at 50°C, grind it, put it into a NaOH solution with a concentration of 4wt%, and stir it at 80°C for 4 hours, then filter it with deionized water until it is neutral, and put it into a volume Stir in a mixture of sodium chlorite / glacial acetic acid with a ratio of 1:1 for 10 hours, then filter and wash it with deionized water to neutrality, and dry it at 80°C to obtain fibers that remove lignin and hemicellulose plain powder;

[0031] ②The cellulose powder obtained in step ① is added to the NaOH / urea aqueous solution whose mass ratio of NaOH to urea and water is 3.75:5.75:40.5 with a mass fraction of 3wt%, stirred for 2h, and then placed in- Freeze at 20°C for 10 hours, thaw at room temperature and stir until transparent to obtain a sol; place the prepared sol at room temperature for 24 hours to obtain a gel; put the obtained gel into deionized water and regenerate it at 25°C for 4 hours, and regenerate The gel was frozen at -80°C for 10 hours...

Embodiment 2

[0035] ①Wash the bagasse, dry it at 50°C, grind it, put it into a NaOH solution with a concentration of 5wt%, and stir it at 80°C for 5 hours, then filter it with deionized water until it is neutral, and put it into a volume Stir in a mixture of sodium chlorite / glacial acetic acid with a ratio of 1:1 for 11 hours, then filter and wash it with deionized water to neutrality, and dry it at 80°C to obtain fibers that remove lignin and hemicellulose plain powder;

[0036] ②The cellulose powder obtained in step ① is added to the NaOH / urea aqueous solution whose mass ratio of NaOH to urea and water is 3.75:5.75:40.5 with a mass fraction of 5wt%, stirred for 2h, and then placed in- Freeze at 20°C for 11 hours, thaw at room temperature and stir until transparent to obtain a sol; place the prepared sol at room temperature for 24 hours to obtain a gel; put the obtained gel into deionized water and regenerate at 30°C for 3 hours, and regenerate The gel was frozen at -80°C for 11 hours, a...

Embodiment 3

[0040] ①Wash the bagasse, dry it at 50°C, grind it, put it into a NaOH solution with a concentration of 6wt%, and stir it at 80°C for 6 hours, then filter it with deionized water until it is neutral, and put it into the volume Stir in a mixture of sodium chlorite / glacial acetic acid with a ratio of 1:1 for 12 hours, then filter and wash it with deionized water to neutrality, and dry it at 80°C to obtain fibers with lignin and hemicellulose removed plain powder;

[0041] ②The cellulose powder obtained in step ① is added to the NaOH / urea aqueous solution whose mass ratio of NaOH to urea and water is 3.75:5.75:40.5 with a mass fraction of 7wt%, stirred for 3h, and then placed in- Freeze at 20°C for 12 hours, thaw at room temperature and stir until transparent to obtain a sol; place the prepared sol at room temperature for 24 hours to obtain a gel; put the obtained gel into deionized water and regenerate it at 50°C for 2 hours, and regenerate The gel was frozen at -80°C for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com