Patents

Literature

255results about How to "Sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Block outputting method and implementation system thereof

ActiveCN108717630AReduce duplication of workReduce computing power consumptionSpecial service provision for substationUser identity/authority verificationBlockchainOperating system

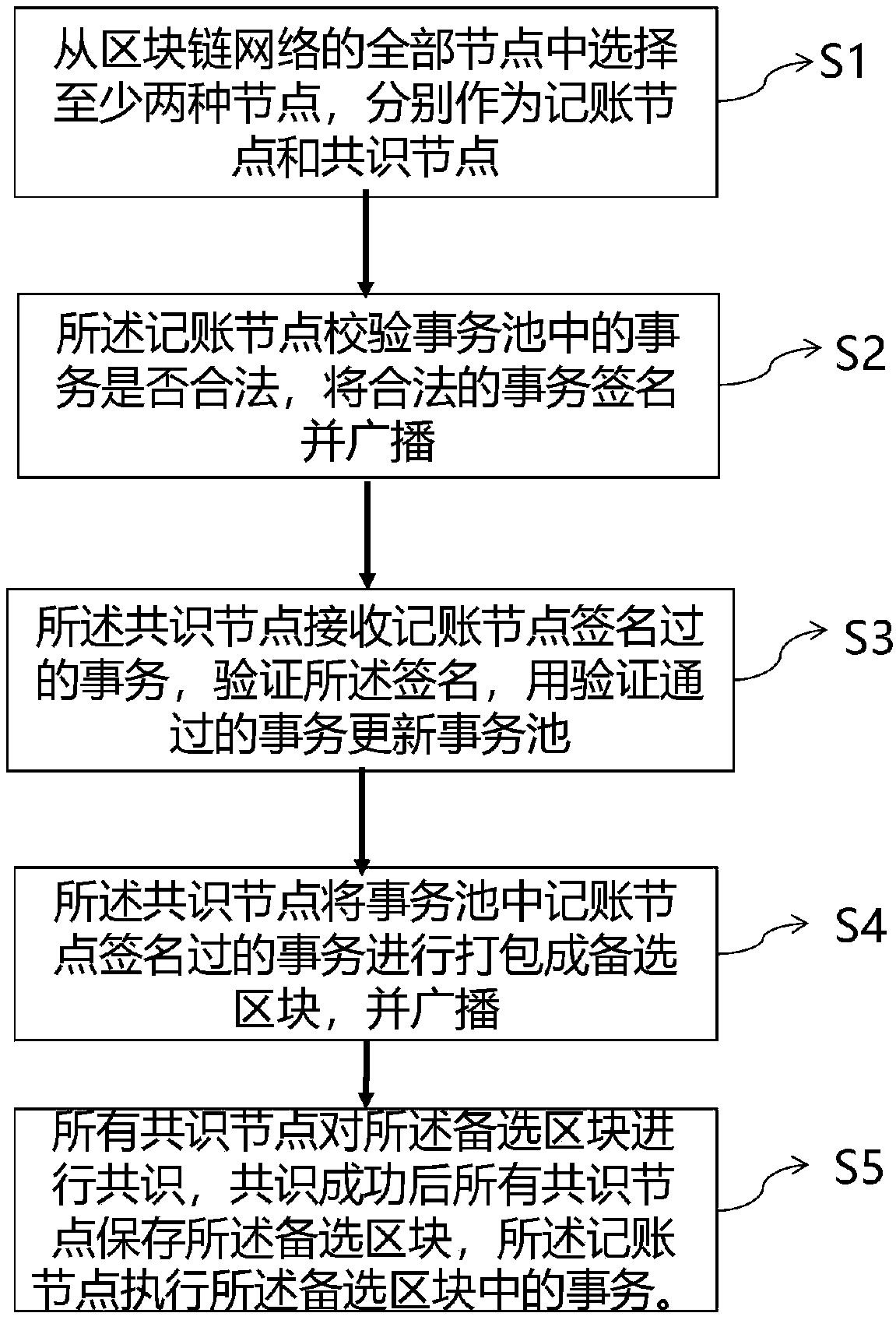

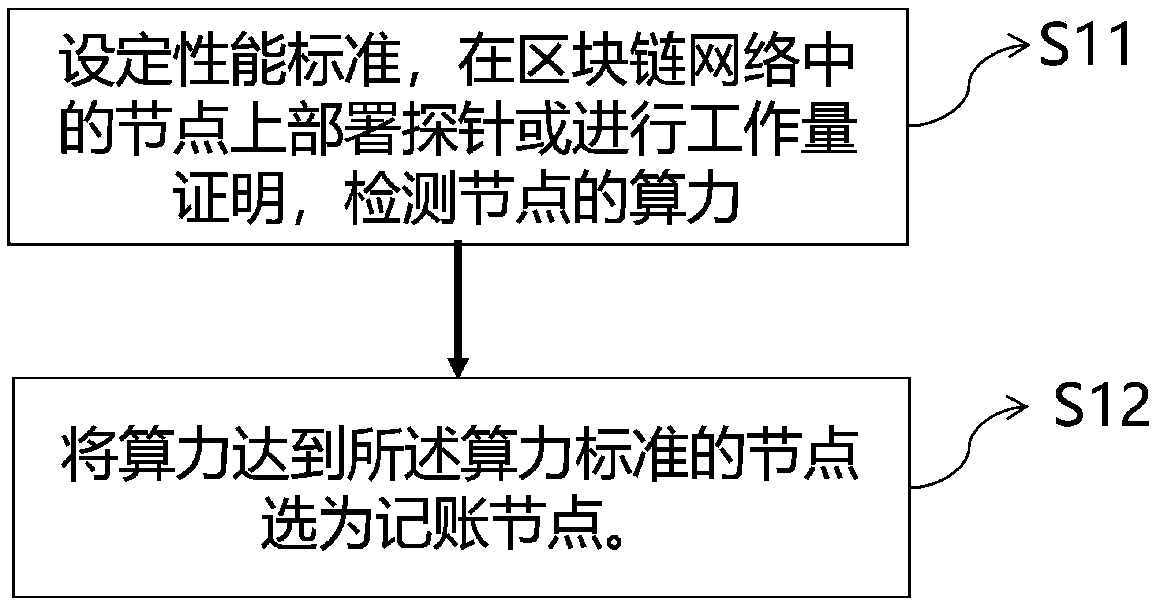

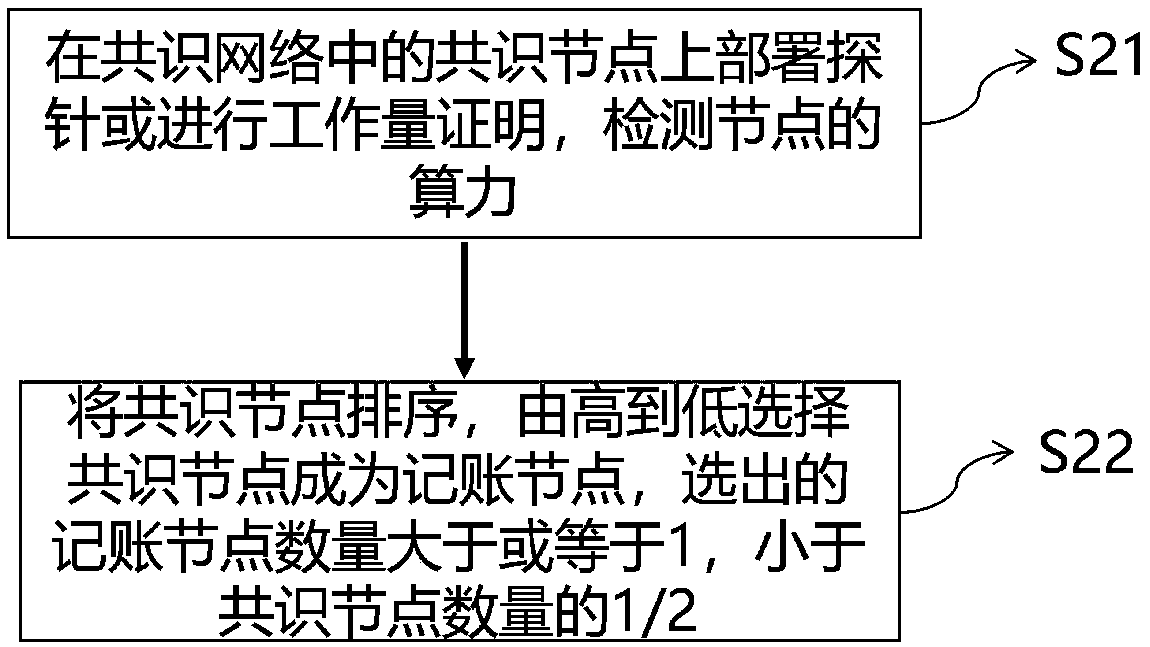

The invention discloses a block outputting method. The method comprises the following steps: a node selection step: selecting at least two nodes from all nodes of a blockchain network, respectively serving as an accounting node and a consensus node; a verification step: verifying whether transactions in a transaction pool are legal or not by the accounting node, and signing and broadcasting the legal transactions; a synchronization step: receiving the transactions signed by the accounting node by the consensus node, verifying the signature, and updating the transaction pool with the transactions that pass the verification; a block outputting step: packaging the transactions signed by the accounting node in the transaction pool by the consensus node into alternative blocks, and broadcastingthe alternative blocks; and a block saving step: carrying out consensus on the alternative blocks by all consensus nodes, saving the alternative blocks by all consensus nodes after the consensus is successful, and executing the transactions in the alternative blocks by the accounting node. The invention further discloses an implementation system of the block outputting method. The block outputting method provided by the invention greatly reduces the repetitive work of the consensus nodes, and reduces the hash rate consumption in the blockchain network.

Owner:上海分布信息科技有限公司

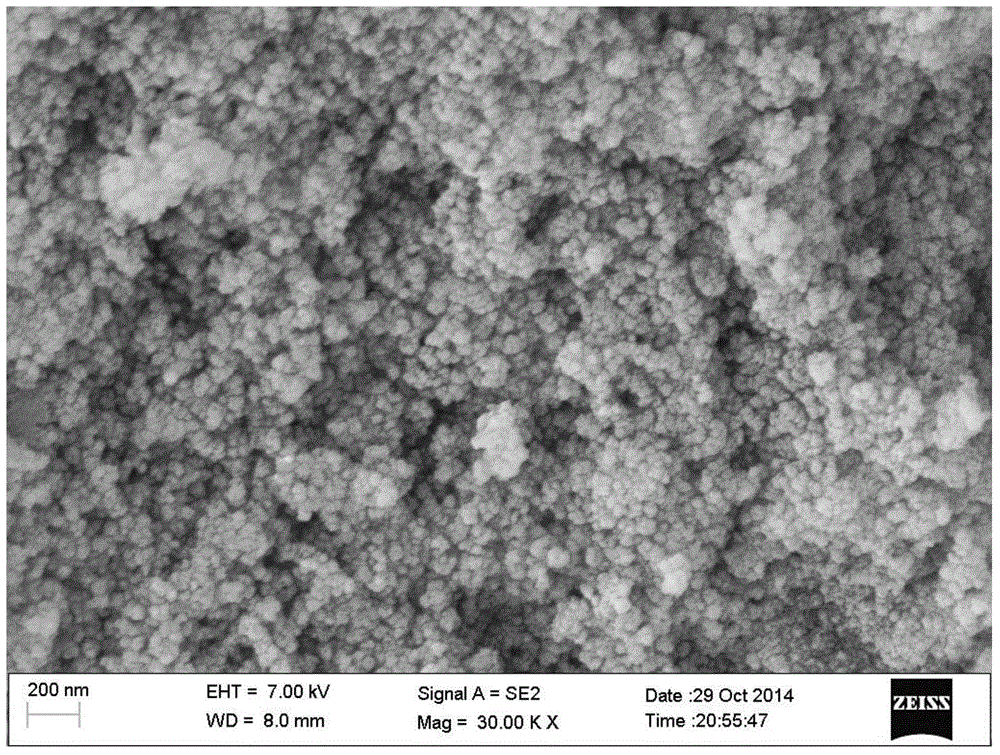

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

Production method of 3003-brand cathode aluminum foil

InactiveCN101519760AEvenly distributedImprove plasticityElectrolytic capacitorsCapacitanceMetallurgy

The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mm to 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into the blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil with the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 microfarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and makes a contribution for the trade progress.

Owner:登电集团铝加工有限公司

Bitumen recycling agent for improving high temperature stability of waste and old bitumen mixture

InactiveCN101177535AImprove high temperature stabilityLow costBuilding insulationsAntioxidantBituminous materials

The invention discloses an asphalt regenerator for improving the high temperature stability for mixing material of waste asphalt. According to the parts by weight, the components are as below: 70 to 95 of refinery waste rich in aromatic fraction and colloid; 5 to 25 of resin; 0.1 to 1 of antioxidant; 0.1 to 1 of anti-ultraviolet addition agent; 2 to 5 of stabilizing agent for high temperature. The invention also discloses the preparation method for the asphalt regenerator. Aiming at aged asphalt property in waste asphalt mixing material, the invention adds the resin, the antioxidant and the anti-ultraviolet addition agent in refinery waste rich in aromatic fraction and colloid and makes rational selection and matching for material of each material. The invention has the advantages of easy availability for raw material, low requirement for equipments, simple preparing art and convenient use. The invention obviously improves stability of high temperature for regenerated asphalt mixing material and other active results, lowers construction cost and is suitable for green ecological and sustainable development.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

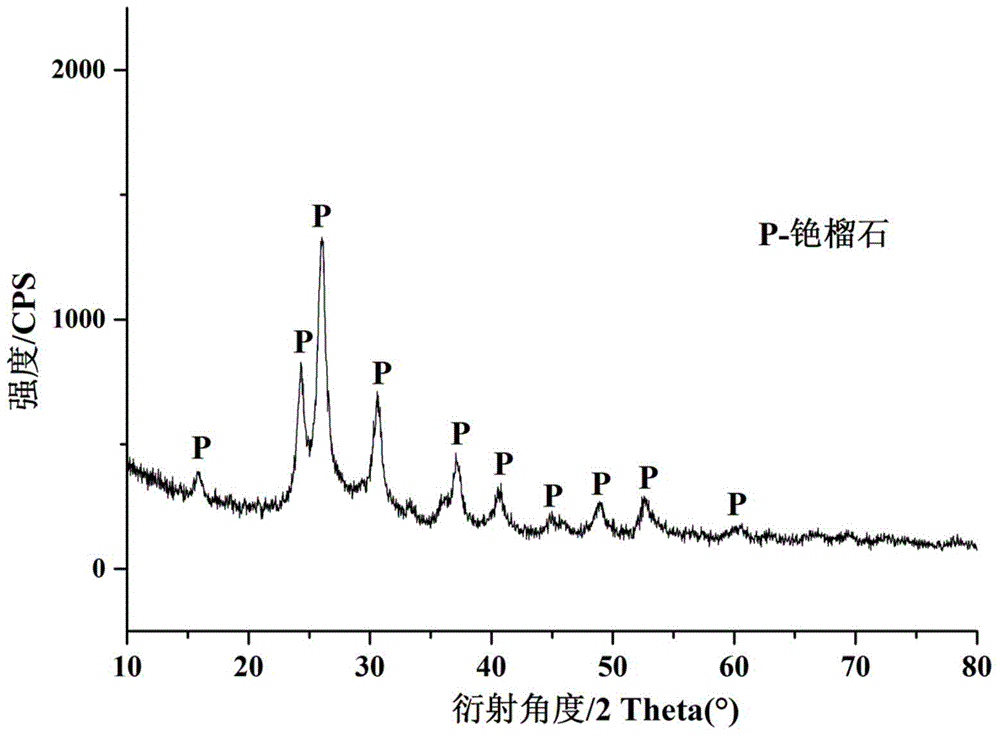

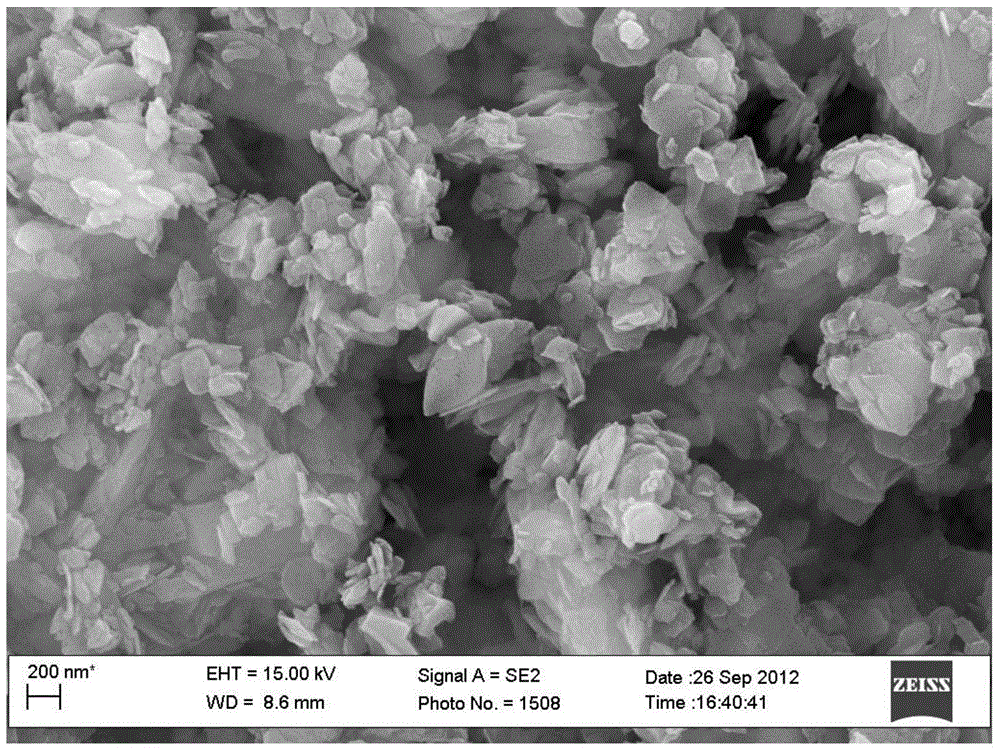

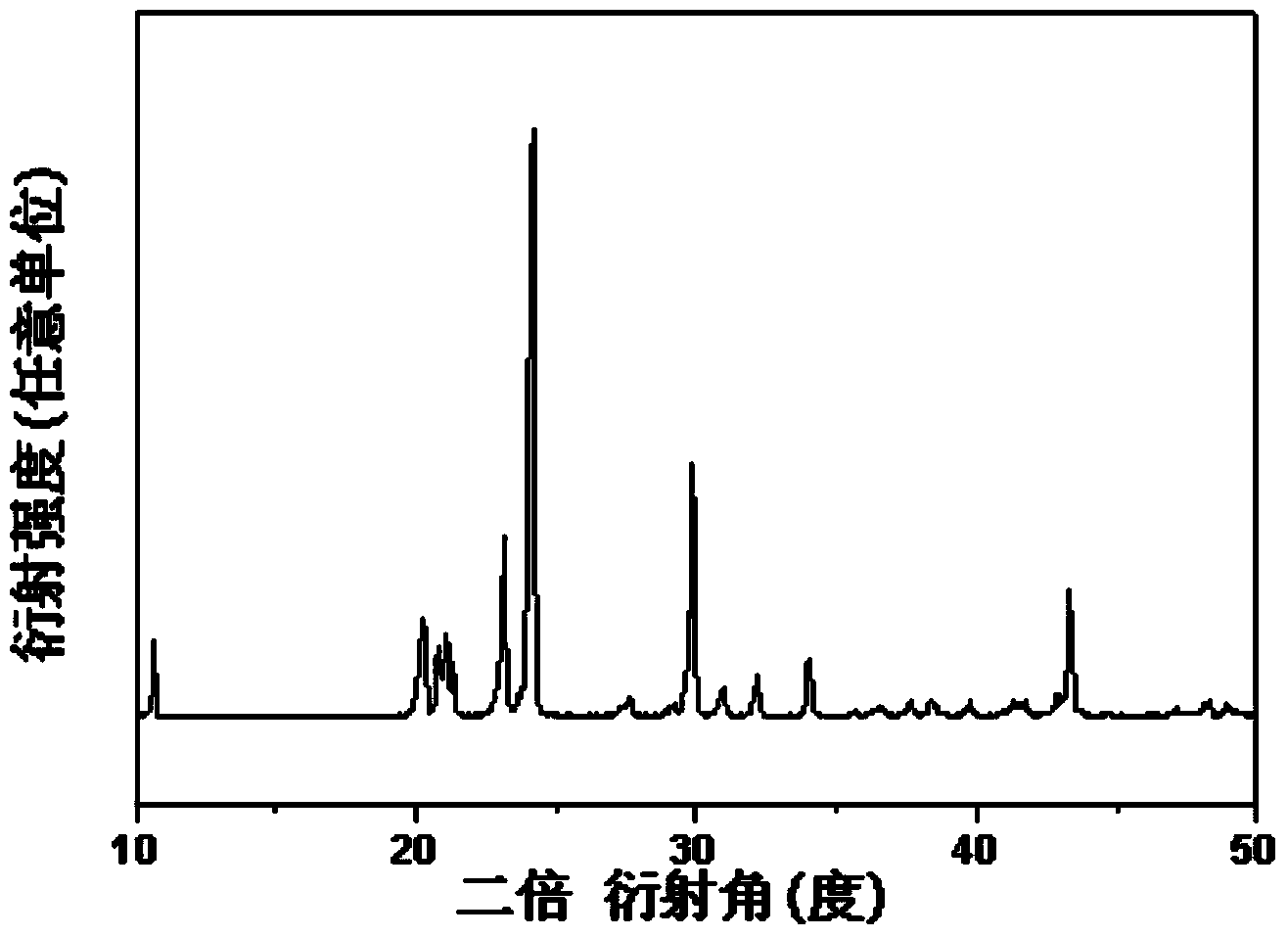

Preparation method of microcrystalline pollucite

ActiveCN104528746AImprove protectionAvoid high temperature volatilizationAluminium silicatesPotassium silicatePollucite

The invention discloses a preparation method of microcrystalline pollucite. The method comprises the following steps: dissolving cesium hydroxide in a potassium silicate solution, and cooling to room temperature to obtain a cesium potassium silicate solution; adding metakaolin to the cesium potassium silicate solution, and uniformly stirring to obtain a slurry; injecting the slurry to a steel die, carrying out closed standing at room temperature for 3-5h, and demolding to obtain a solid block; and placing the solid block in a steam autoclave, crystallizing in water steam environment with the temperature of 180DEG C and the pressure of 0.8MPa, and cooling to prepare the microcrystalline pollucite. The method realizes the low temperature synthesis of naturally scarce pollucite pollucite under mild conditions, and avoids harms of high temperature volatilization of Cs and environment pollution; and the prepared microcrystalline pollucite can be used in solidified cesium-containing radioactive wastes, can be used as a radiation source core material, can also be used in high temperature resistant materials in the aviation and aerospace field, and can be widely used in the fields of national defense and military industry.

Owner:SOUTHWEAT UNIV OF SCI & TECH

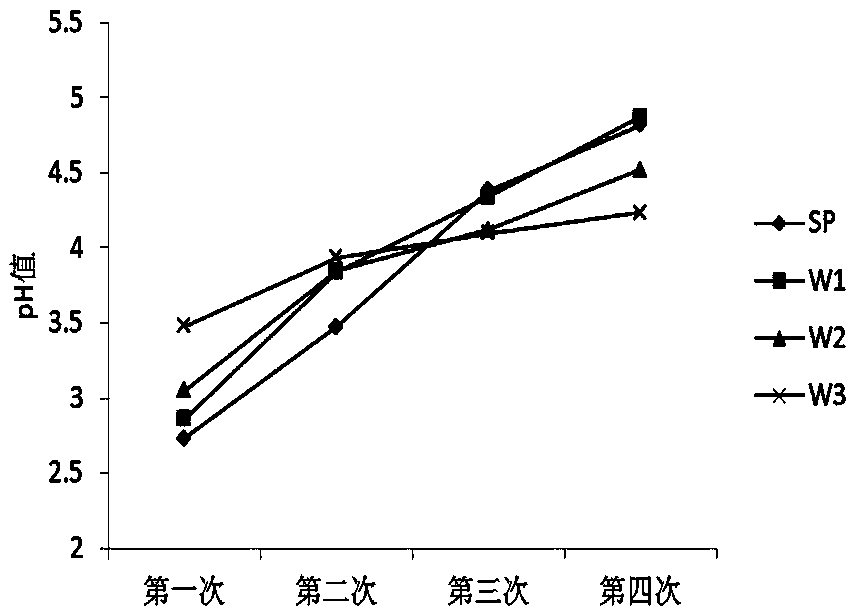

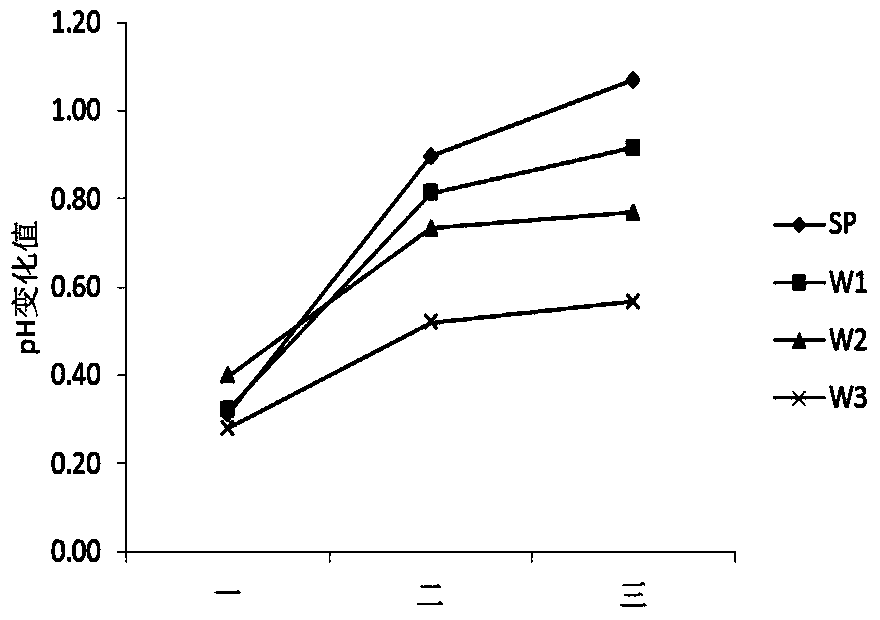

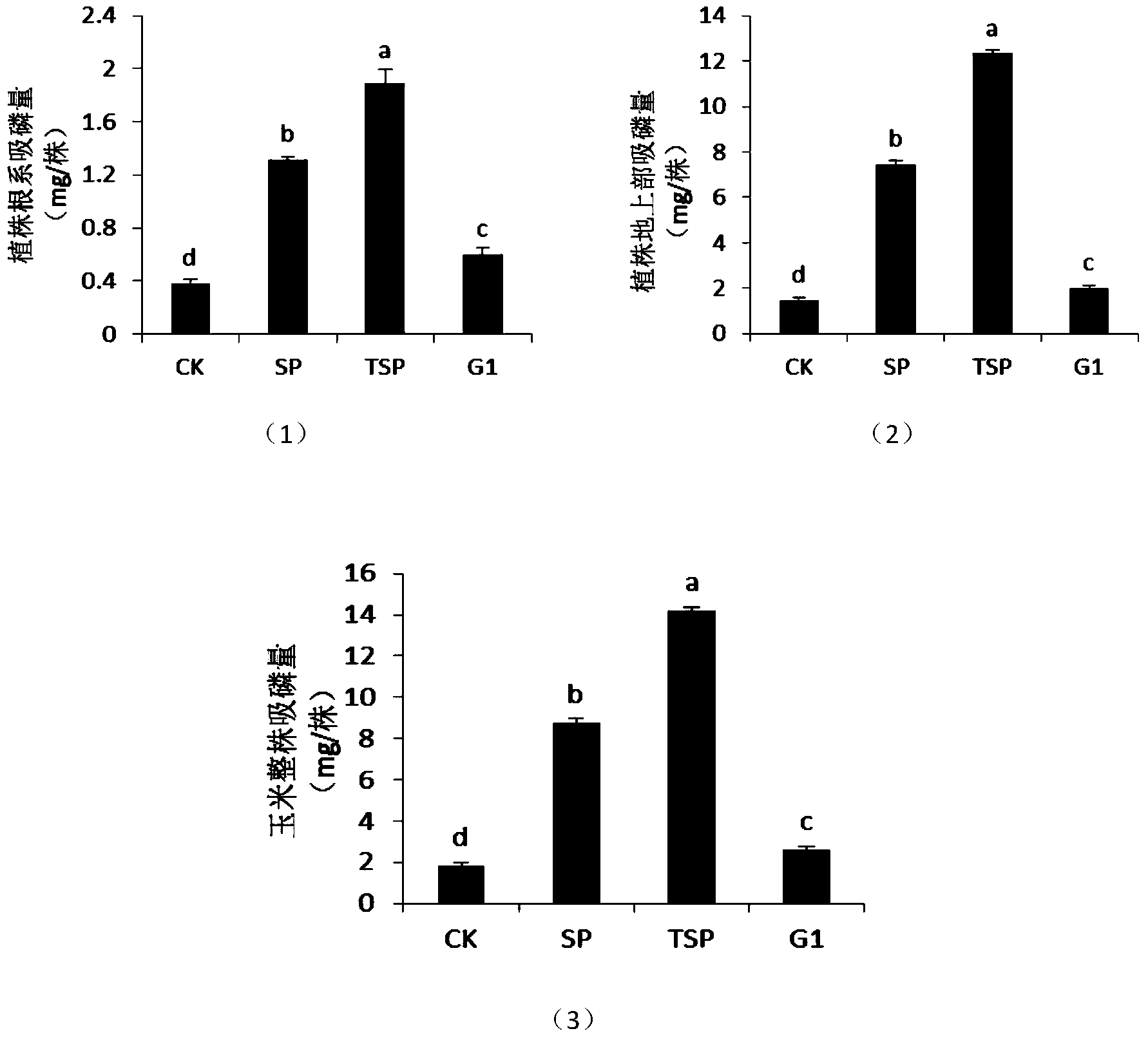

Synergistic calcium superphosphate and preparation method and application thereof

InactiveCN103951516ARelieve pressureSustainable developmentFertilizer mixturesSuspending AgentsAmino acid

The invention belongs to the field of fertilizer industry and discloses synergistic calcium superphosphate and a preparation method and application thereof. The preparation method comprises the steps of preparing organic acid, amino acid or other small-molecular organic matters containing a large number of low molecular weights by utilizing acid hydrolysis of agricultural wastes and secondary hydrolysis of wastes from a food processing plant, then taking the substance as a synergist I, then adding calcium superphosphate into the synergist I, and uniformly drying and crushing to obtain powdery sustained-release synergistic calcium superphosphate; or uniformly mixing the synergist I, a suspending agent and an emulsification coating agent to prepare a synergist II, then adding calcium superphosphate into the synergist II, and performing high-speed shearing and uniform mixing by a colloid mill to obtain liquid sustained-release synergistic calcium superphosphate. The synergistic calcium superphosphate obviously reduces the opportunity of adsorbing phosphorus by soil colloid or fixing phosphorus by iron ions and the like, increases the effectiveness of phosphorus and improves the utilization rate of fertilizer. The method has the advantages of simplicity, convenience, easiness in operation, capability of saving energy and raw materials and effect of reducing production cost. The synergistic calcium superphosphate disclosed by the invention can be applied to the field of agricultural production of vegetables, fruit trees and the like.

Owner:SOUTH CHINA AGRI UNIV

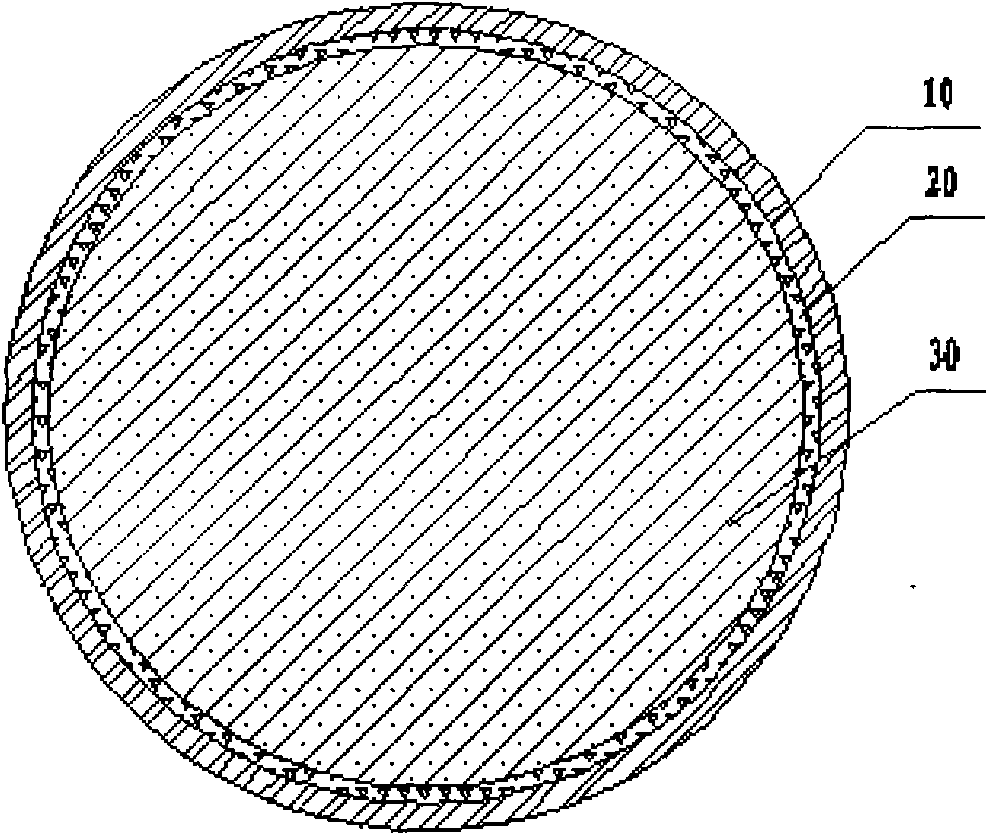

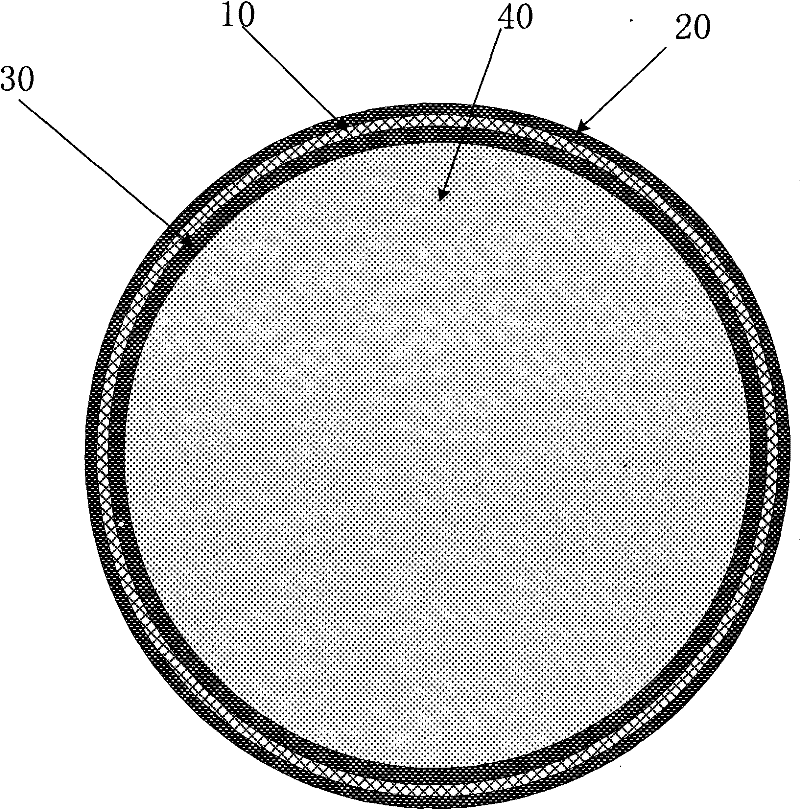

Sea-sand concrete member and manufacturing method thereof

InactiveCN101793055AEfficient use ofSolve the problem of general scarcity of resourcesStrutsPillarsEcological environmentPlastic materials

The invention relates to a sea-sand concrete member comprising a base body (10) made of a hollow steel pipe. The sea sand concrete member is characterized in that the inner wall of the base body (10) is provided with a protective layer (20); sea-sand concrete (30) made of non-desalted sea sands is poured into the protective layer (20); and the protective layer (20) is made of fiber reinforced composite plastic materials and is used for preventing the sea-sand concrete (30) made of the non-desalted sea sands from corroding the base body (10). The sea-sand concrete member can directly utilizes the sea sands without desalting the sea sands. The invention has convenient construction, can effectively utilize the sea sands, not only solves the problem that standard sandstone resources is generally deficient in coastal areas, but also prevents the extraction replenishment of long-distance sandstone materials, and is beneficial to saving the energy and protecting the ecological environment.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

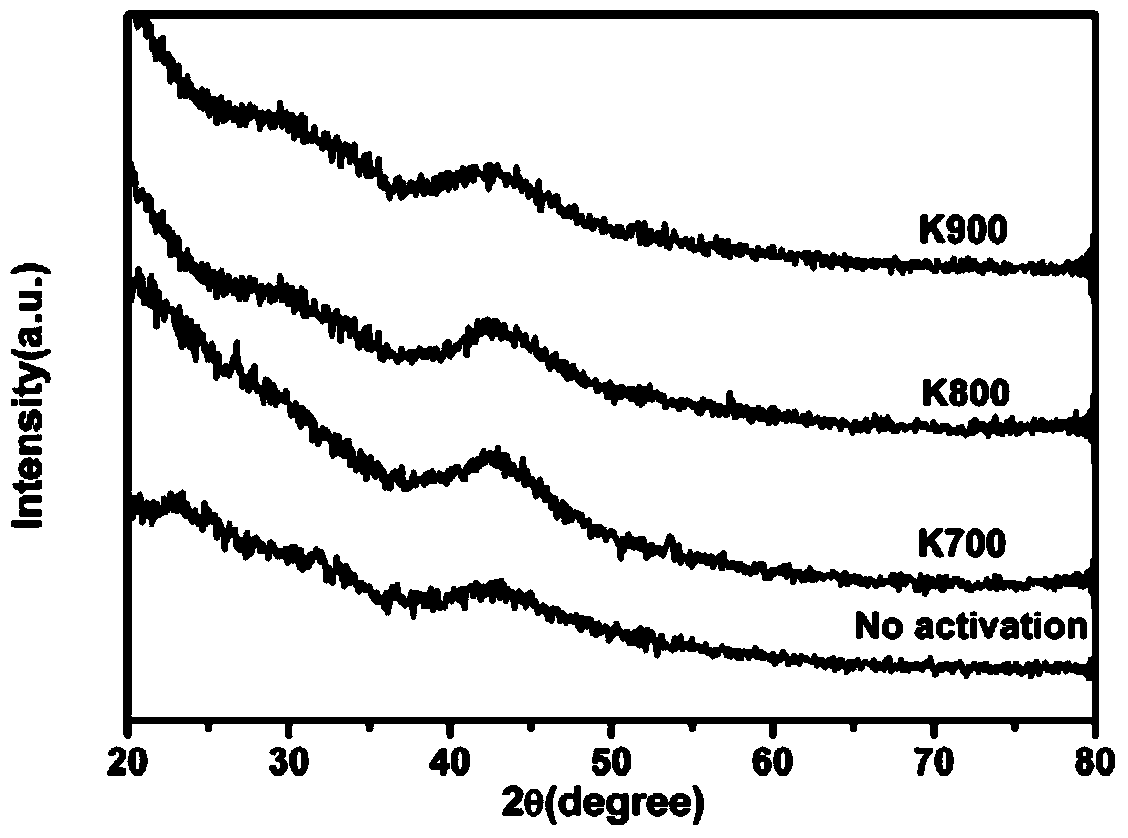

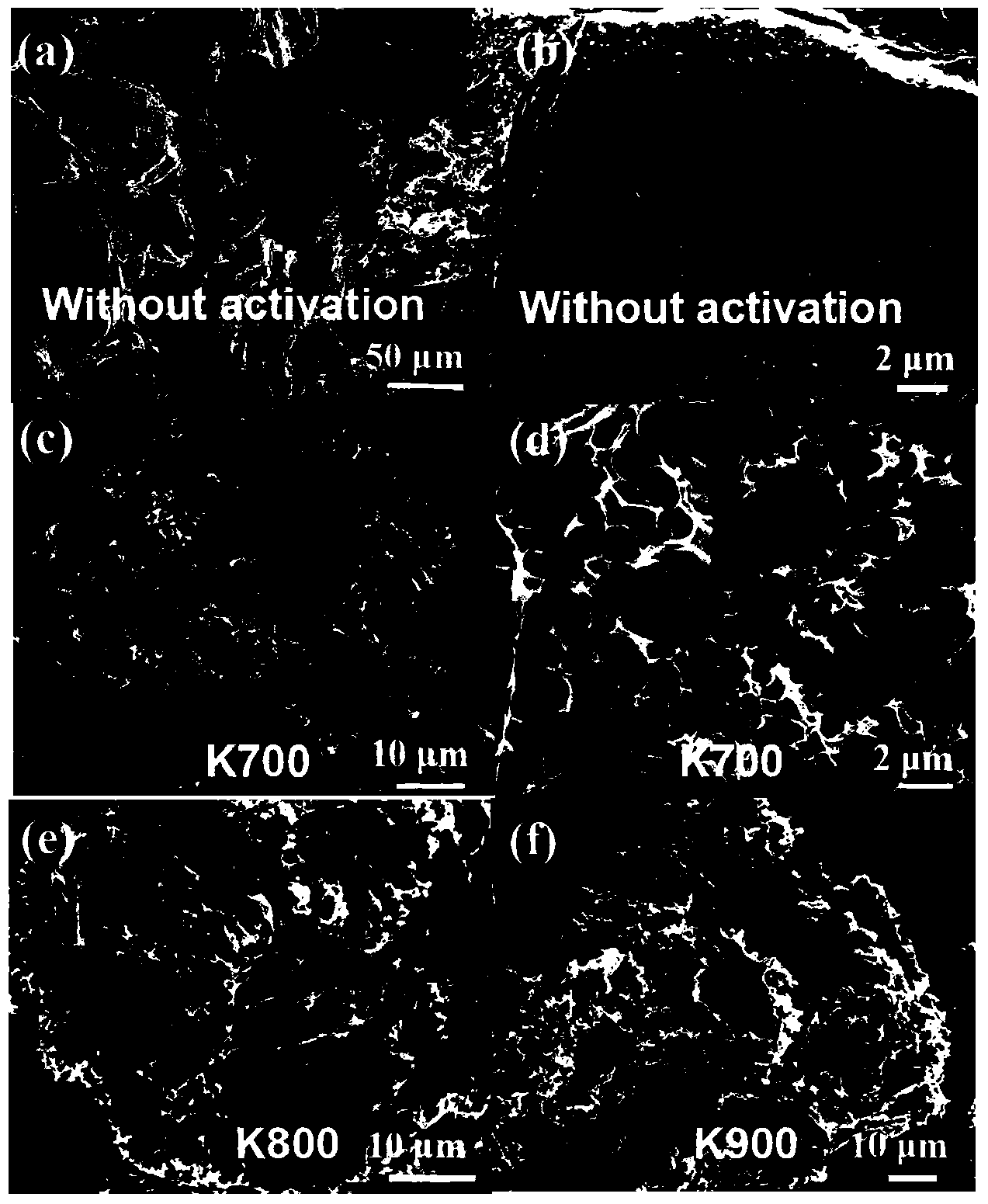

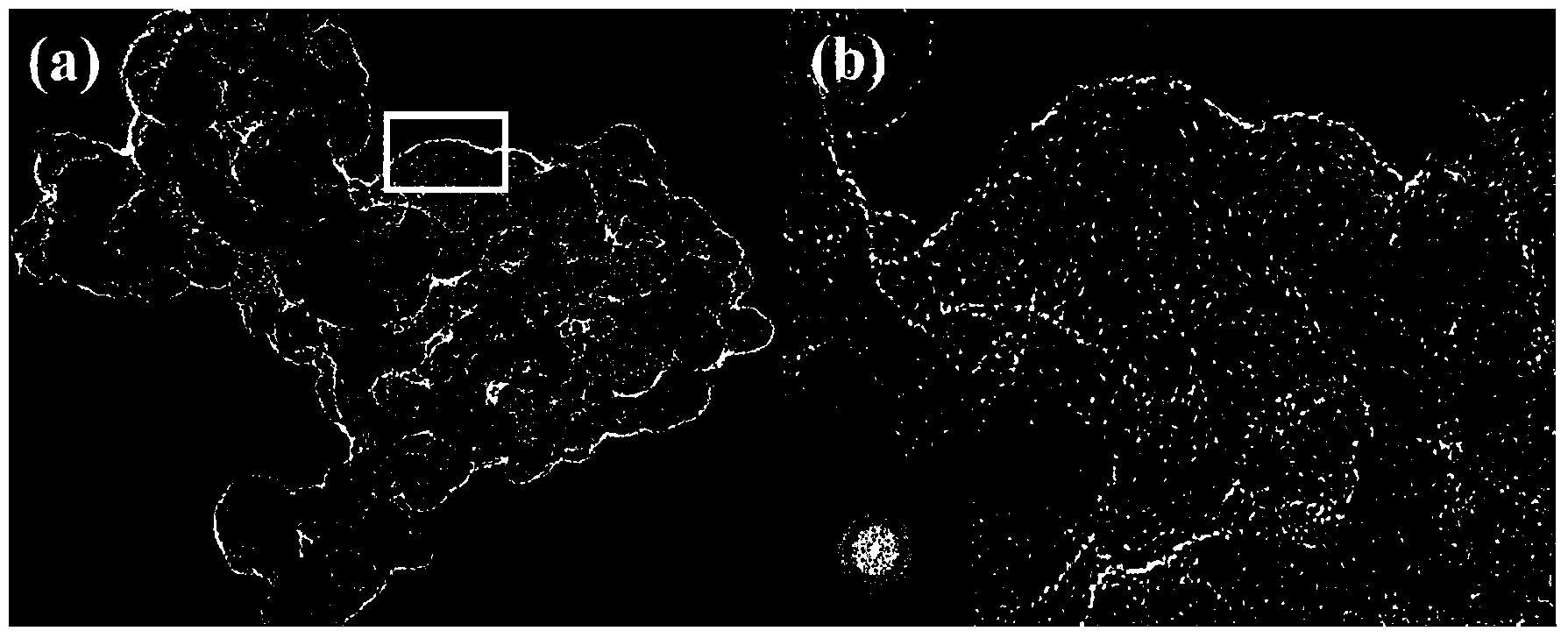

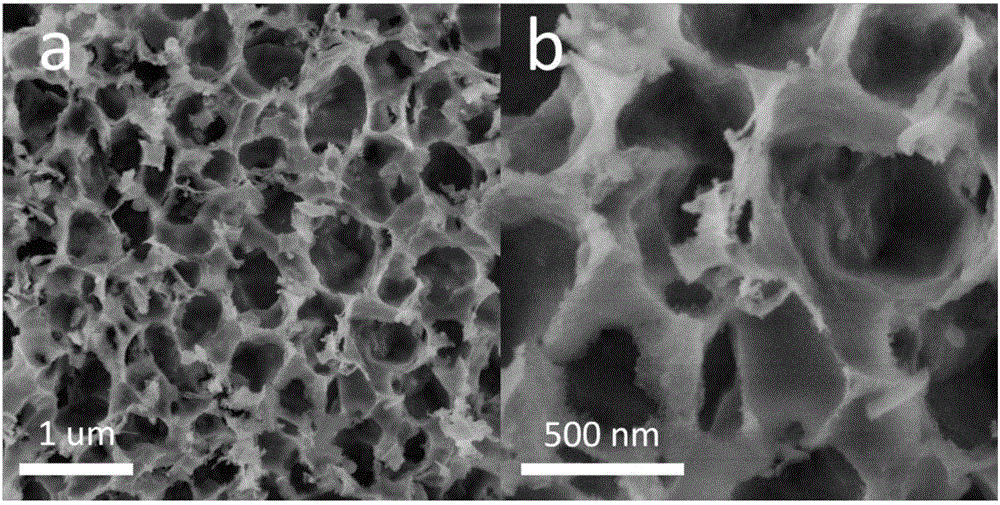

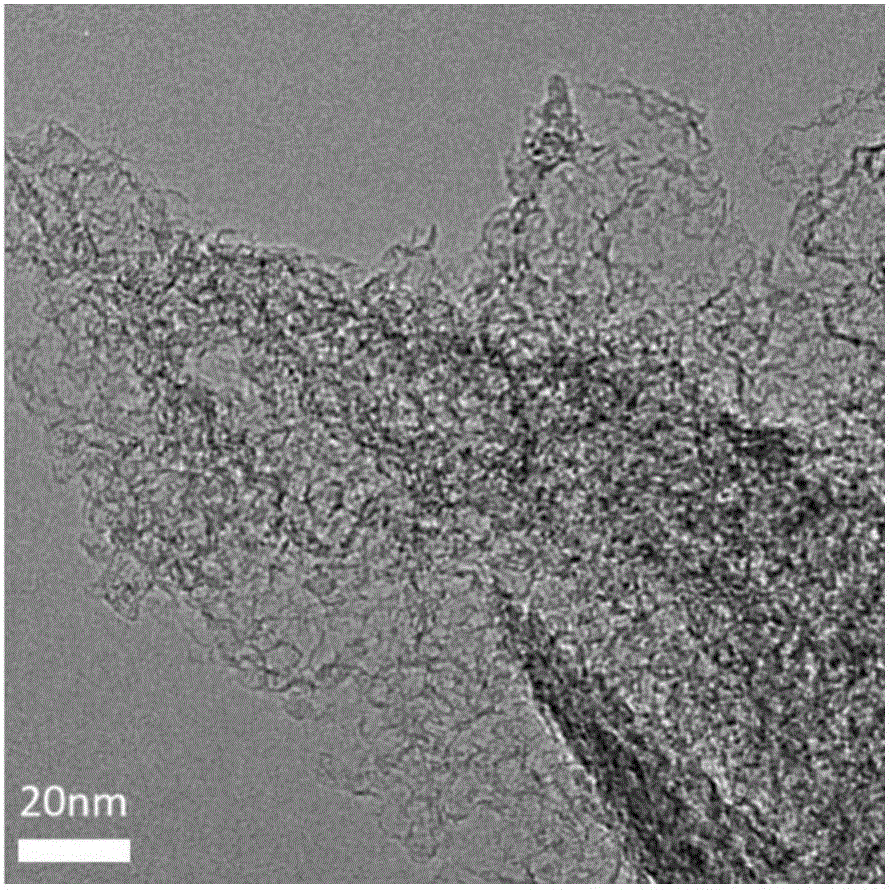

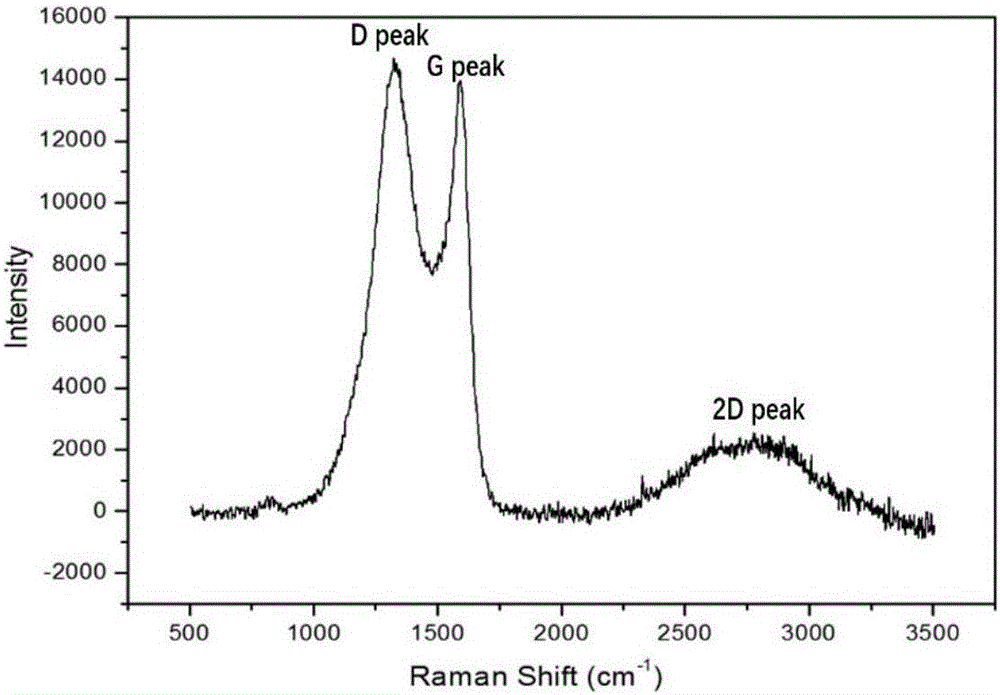

Method for preparing nitrogen self-doped three-dimensional graphene from peels

The invention relates to a method for preparing nitrogen self-doped three-dimensional graphene from peels. With peels as a carbon source and a nitrogen source, the method comprises the following steps: performing hydrothermal carbonization; performing activation treatment using an activator; and performing acid washing and drying to obtain the nitrogen self-doped three-dimensional graphene. In the invention, since the peels are selected as a raw material for preparing the nitrogen self-doped three-dimensional graphene, the needs for sustainable development and environmental protection can be met, and the raw material cost is effectively reduced. The specific surface area of the prepared product exceeds 1700m<2>g<-1>; the relatively large specific surface area and three-dimensional graphene porous structure are beneficial to the transfer and transport of ions in the electrolyte; and the electrical conductivity is very good. Due to the doping of nitrogen element, active sites for catalysis and lithium storage reactions can be formed, and the nitrogen self-doped three-dimensional graphene can be widely applied to the fields of energy storage and transformation such as fuel cells and lithium ion batteries. Moreover, the graphene material has excellent electrical conductivity, and the carbon material has relatively high activity due to the doping of nitrogen element.

Owner:WUHAN UNIV OF TECH

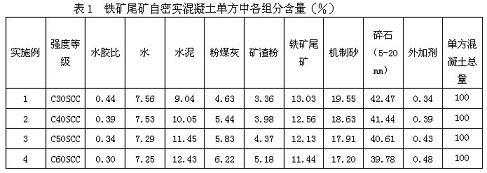

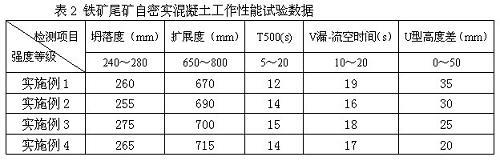

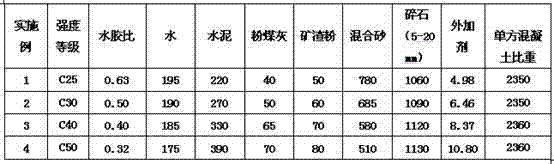

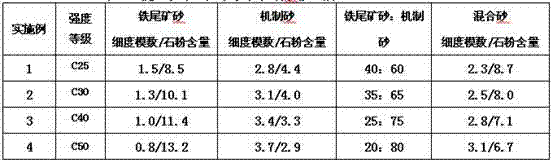

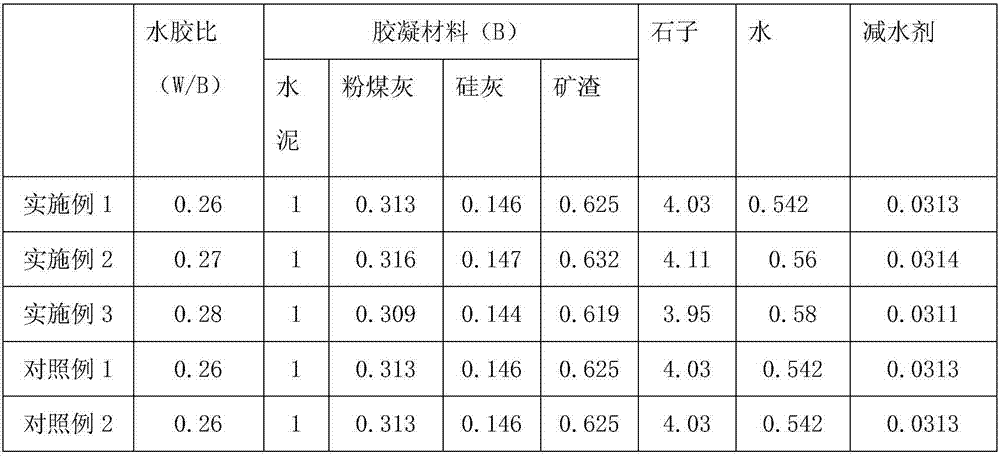

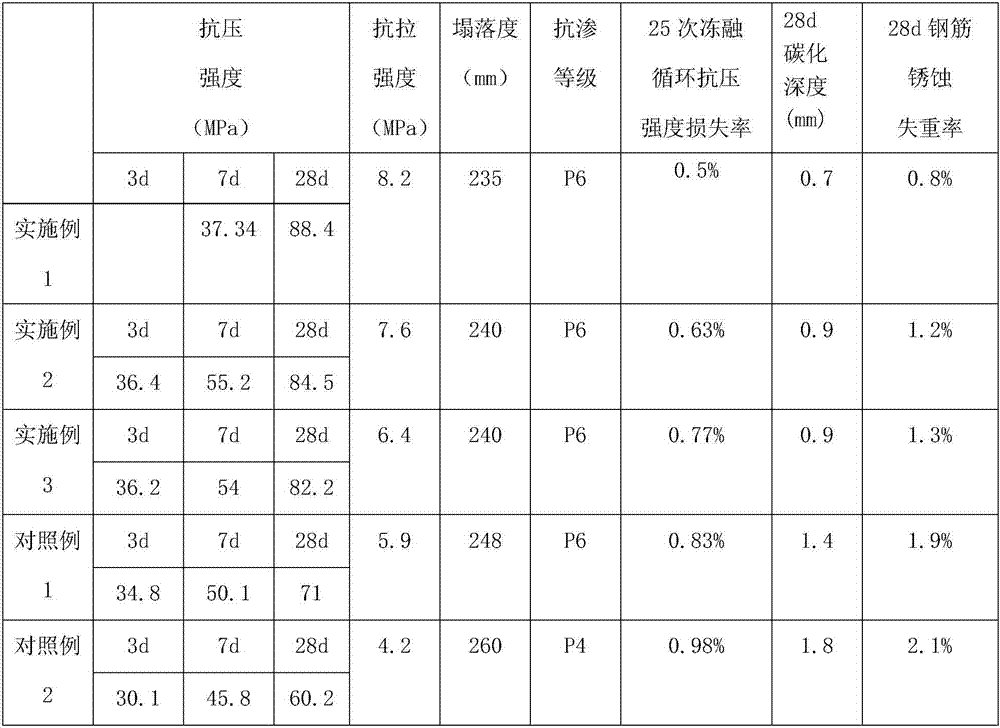

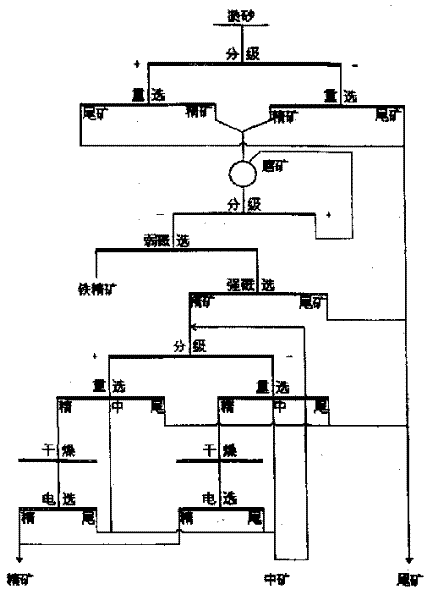

Self-compacting concrete prepared from iron ore tailings, and preparation method thereof

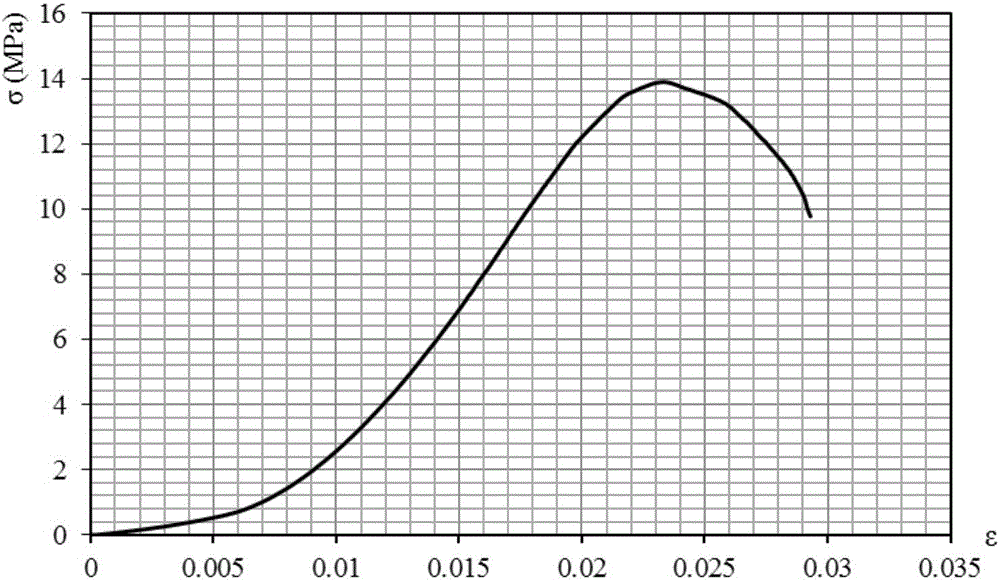

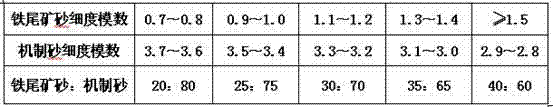

The present invention discloses a self-compacting concrete prepared from iron ore tailings, and a preparation method thereof. The self-compacting concrete is prepared through adding 38.00-46.00% of a coarse aggregate, 23.00-37.00% of a fine aggregate, cement, 15-24% of a cementing material and 0.30-0.48% of an additive to water. The coarse aggregate is prepared through mixing crushed stones with particle sizes of 5-20 mm. The fine aggregate is the mixed sands prepared from iron ore tailings and machine-made sands or natural sands, wherein the mixed sands meet the technical requirements of thesands in the region II, preferably that a mass ratio of the iron ore tailings to the machine-made sands or the natural sands is 3:7-7:3. The cementing material is a mixture, wherein the mixture comprises cement, fly ash and ground slag powder. A mass ratio of the water to the cementing material is 0.30-0.50. The additive is a mixture, wherein the mixture comprises a water reducing agent and a tackifier, the water reducing agent is a polycarboxylic superplasticizer, the tackifier comprises a cellulose polymer or an amide polymer. With the present invention, the damage to the ecology environment due to the natural sand mining is reduced; the damage to the environment due to the iron ore tailings is reduced; the waste can be utilized; a purpose of reutilization of the resource is achieved; with adopting the iron ore tailings, the concrete cost can be substantially reduced, and significant social benefits and economic benefits are provided.

Owner:CHINA MCC17 GRP

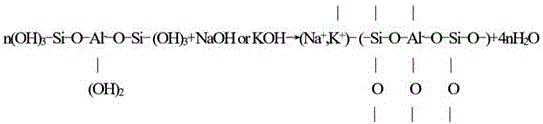

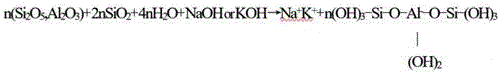

Refuse-soil geopolymer solidifying material and preparation method thereof

InactiveCN106810090AImprove stabilityHigh strengthCement productionWork performanceDecomposed granite

The invention belongs to the field of building materials, and particularly relates to a refuse-soil geopolymer solidifying material and a preparation method thereof. The refuse-soil geopolymer solidifying material comprises raw materials and alkali activators, the feeding ratio of the alkali activators to the raw materials is 1: (2.6-4.2), the raw materials comprise, by weight, 361-460 parts of refuse soil, and the refuse soil comprises one or several compositions in completely-decomposed granite backfilled soil, sludge, surplus mud, sea mud and sewage mud. The acquired refuse-soil geopolymer solidifying material products are high in practicability and good in working performance and can be widely applied to practical engineering, the products can be used for in-situ solidification of the refuse soil, the overall stability and the strength of the refuse soil are improved, the material products can be prepared into building materials for building engineering and is used for preparing neat paste, mortar, concrete, blocks and the like, the material products can serve as with pressed and bending building components, the building components comprise columns, beams, plates and the like, and the refuse-soil geopolymer solidifying material can solve the problem that the preparation cost of coal ash geopolymers rises as coal ash price is high.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Special low-viscosity easy-dispersion regenerant for modified asphalt and preparation method thereof

InactiveCN102140253AImprove high temperature stabilityImprove low temperature crack resistanceBuilding insulationsProcess engineeringAnoxomer

The invention provides a special low-viscosity easy-dispersion regenerant for modified asphalt and a preparation method thereof. The regenerant comprises the following components in parts by weight: 80-100 parts of regeneration composition, 1.0-10 parts of vulcanizer, 0.5-10 parts of accelerator, 1-10 parts of activating agent, 0-5 parts of anti-reducing agent, 0.1-2 parts of scorch retarder and 0.1-3 parts of antioxidant. The invention also discloses the preparation method of the asphalt regenerant. The processing steps comprises: a, pre-heating a reaction kettle, slowly adding the regeneration composition weighed in proportion into the reaction kettle, gradually heating to 40-100 DEG C and continuously stirring; b, putting the vulcanizer weighed in proportion into the reaction kettle, continuing to heat until the temperature is 50-130 DEG C, accelerating the stirring speed until the vulcanizer is evenly dispersed; c, continuing to rapidly stir and gradually cooling, as well as adding the scorch retarder and the antioxidant which are weighed in proportion in the process of stirring and cooling; and d, while cooling to 20-60 DEG C, adding the activating agent, the anti-reducing agent and the accelerator which are weighed in proportion, evenly stirring, and cooling to room temperature so as to obtain the special low-viscosity easy-dispersion regenerant product for the modified asphalt. The low-viscosity easy-dispersion regenerant has the characteristics of available raw material, simple preparation process and sustainable development, and meets green ecology.

Owner:SOUTHEAST UNIV

Iron tailing super-fine sand concrete

InactiveCN104743975AAvoid damageRealize the secondary utilization of resourcesSolid waste managementMining engineeringNatural sand

The invention relates to iron tailing super-fine sand concrete and discloses concrete prepared by taking mixed sands consisting of iron tailing super-fine sand and machine-made sands as a fine aggregate, and belongs to the technical field of iron tailing sand building materials. The concrete is prepared from the following components in percentage by mass: 8-15% of cement, 21-34% of iron tailing mixed sands, 44-49% of gravels, 5-7% of an admixture, 7.2-8.3% of water and 1.6-2.2% of an efficient pumping agent for concrete based on the sum of mass of the cement and the admixture. The water-binder ratio of the prepared concrete is 0.75-0.36 and the strength grade is C20-C50. The iron tailing super-fine sand concrete provided by the invention can reduce the environmental pollution caused by iron tailings, reduce the exploitation quantity and exploitation energy consumption of natural sands and lower the production cost of the concrete, and has obvious economic and social benefits.

Owner:CHINA MCC17 GRP

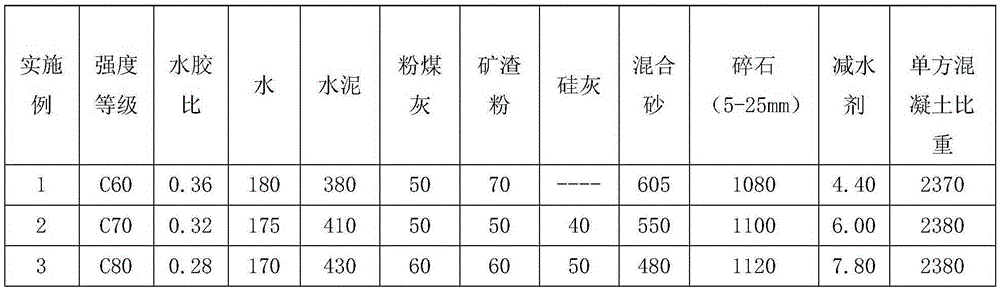

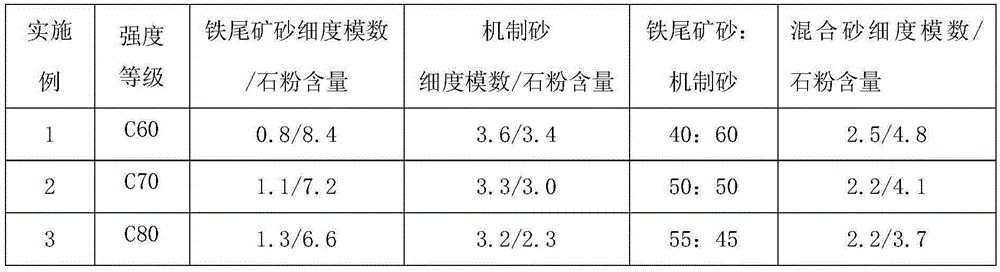

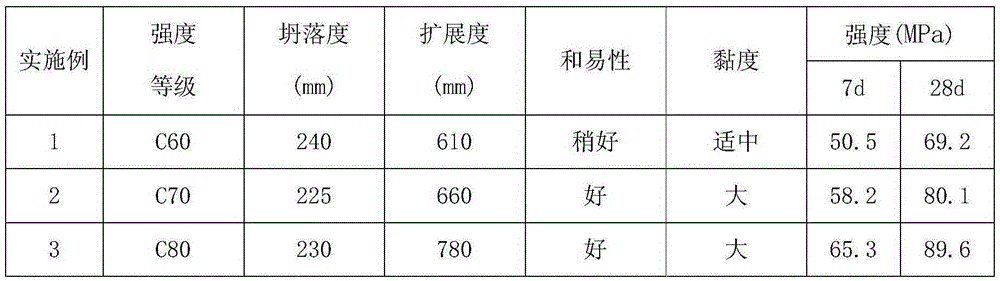

Iron tailing sand doped high-strength concrete, and preparation and applications thereof

The invention discloses an iron tailing sand doped high-strength concrete, and preparation and applications thereof. The iron tailing sand doped high-strength concrete comprises 285 to 291kg of cement, 89 to 91kg of fly ash, 178 to 182kg of mineral slag, 41.5 to 42.4kg of silicon ash, 1149 to 1173kg of cobblestone, 403 to 412kg of iron tailing sand, 154 to 169kg of water, and 8.9 to 9.1kg of a water reducer. The preparation method is simple; iron tailing sand is a mining site discharged waste, and is recycled directly after sieving; waste is changed into valuables via adjusting concrete self structure; requirements on green construction by the states are satisfied; problems such as large iron tailing sand accumulation amount and low utilization rate are solved; the municipal environment and the surrounding environment are improved at the same time; the iron tailing sand doped high-strength concrete can be applied in infrastructure construction, urbanization, and shantytowns transformation.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

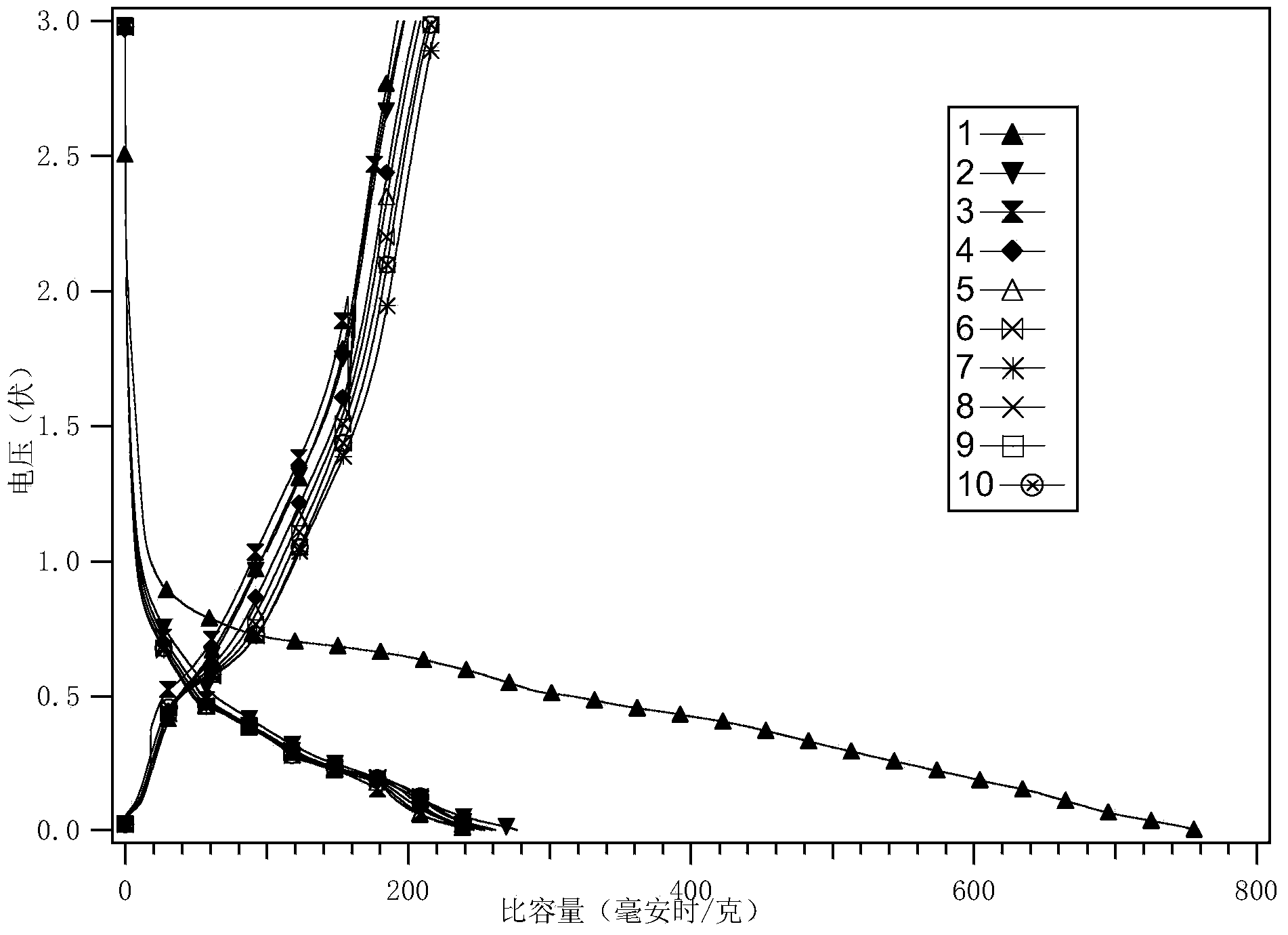

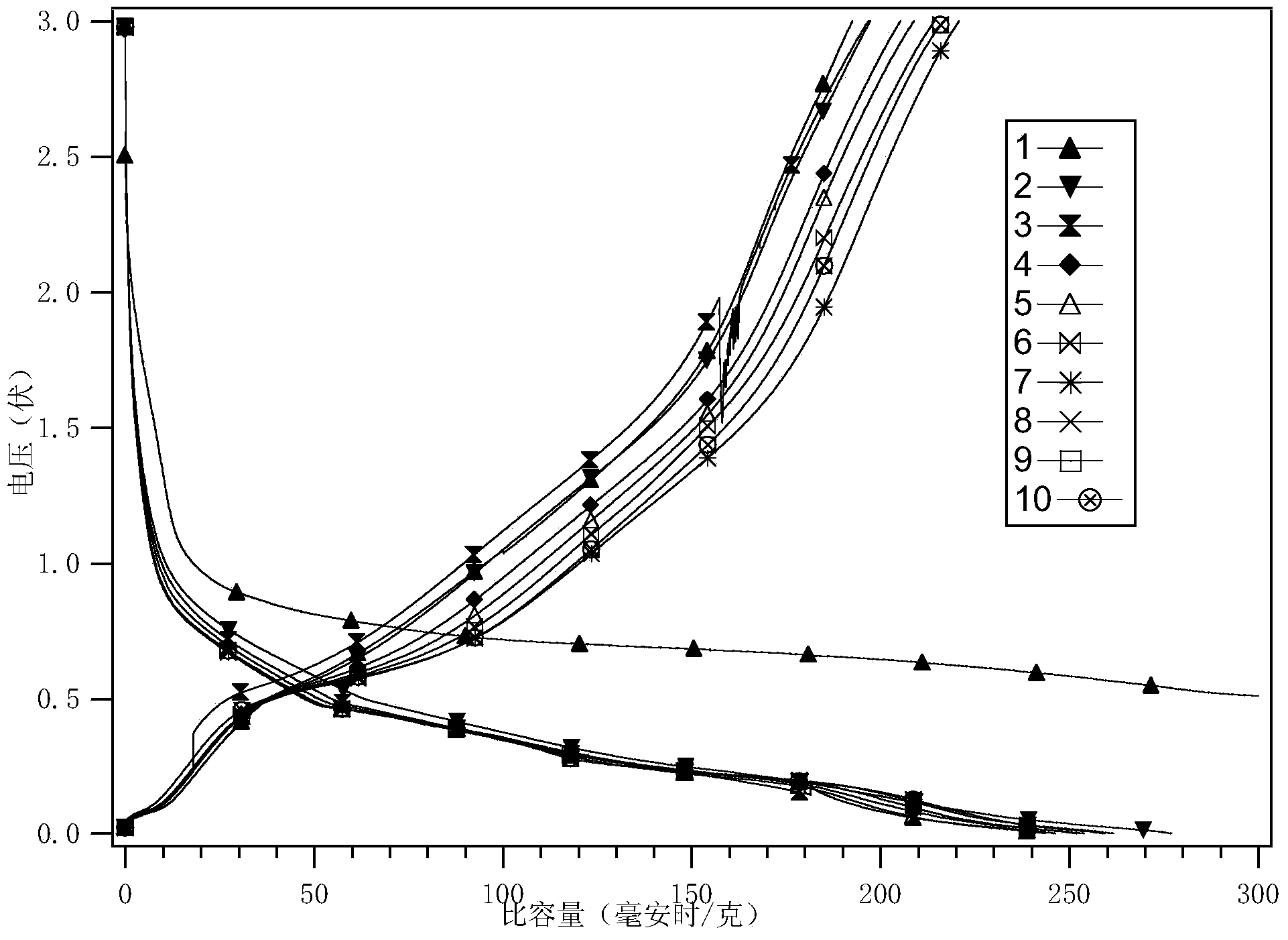

Organic cathode material for sodium ion battery

InactiveCN103456961AThe synthesis method is simpleReduce manufacturing costCell electrodesIonCharge and discharge

The invention discloses an organic cathode material for a sodium ion battery capable of being repeatedly charged and discharged, and belongs to the field of batteries. According to the organic cathode material for the sodium ion battery disclosed by the invention, an active substance of the organic cathode material is para-phthalate or a mixture of different para-phthalates; the chemical composition of the para-phthalate is C8H4O4.Rx, wherein R is Li, K, Rb, Cs, Mg, Ca, Sr, Ba, Ni, Cu, Sn, Fe, Zn, Cr, Al or Mn, and x is equal to 2 / 7, 1 / 3, 2 / 5, 1 / 2, 2 / 3, 1 or 2. The organic cathode material disclosed by the invention has low reaction potential, high quality specific capacity and excellent electrochemical cycle stability, and is simple in synthetic method and good in repeatability; the production cost is reduced, the requirement of sustainable development is met, and the organic cathode material has a wide application prospect in the field of sodium ion batteries.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

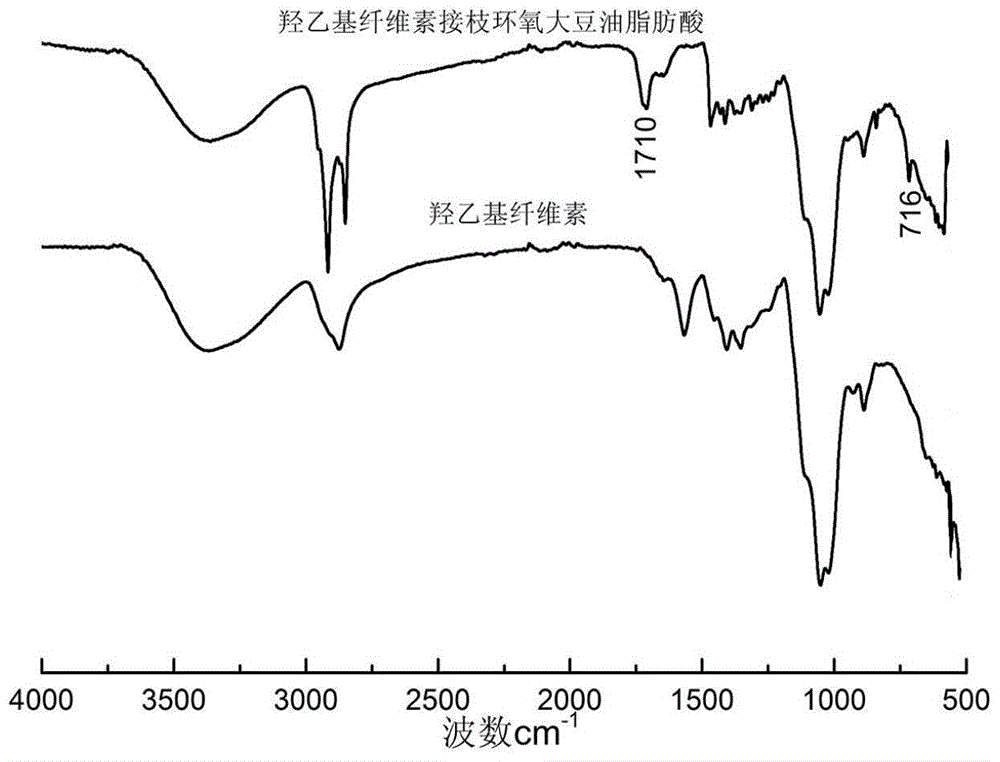

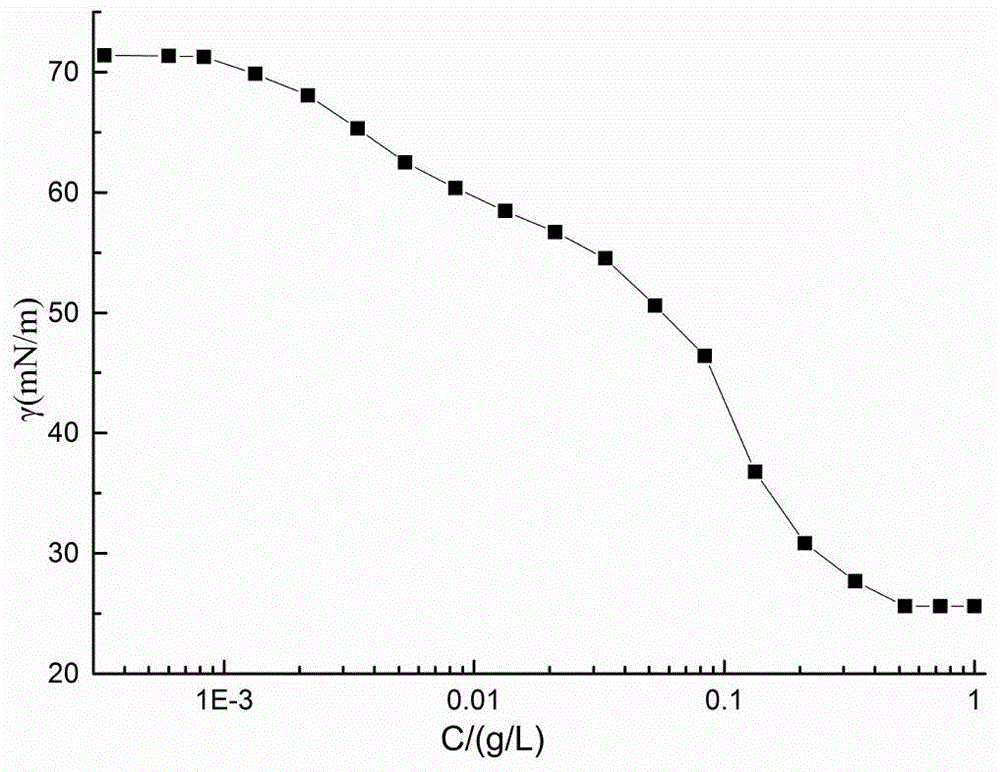

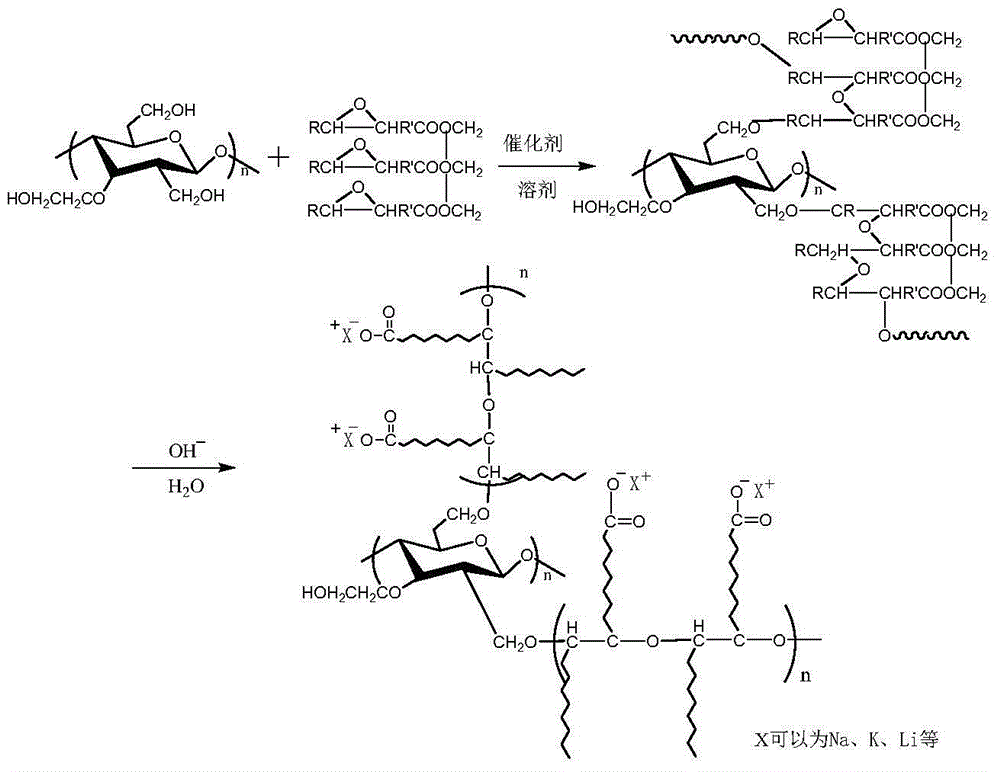

Cellulose grafted epoxy vegetable fat anionic polymeric surfactant and preparation method thereof

The invention discloses a preparation method of a cellulose grafted epoxy vegetable fat anionic polymeric surfactant. The preparation method comprises the following sequentially-connected steps: fully dissolving a cellulose material in a solvent, stirring, heating to 30-70 DEG C, adding epoxy vegetable fat, dropwise adding an initiator solution, reacting for 1-2 h under the condition of heat preservation, and removing the solvent, so that a cellulose grafted epoxy vegetable fat product is obtained; hydrolyzing the cellulose grafted epoxy vegetable fat product under the action of a catalyst, and purifying the obtained object, so that a cellulose grafted epoxy vegetable fatty acid is obtained; and dispersing the cellulose grafted epoxy vegetable fatty acid in water, adjusting the pH value to 7-11, and carrying out distillated dehydration on the obtained product, so that the cellulose grafted epoxy vegetable fat anionic polymeric surfactant is obtained. The preparation method is wide in raw material sources and low in price, the prepared surfactant is biodegradable, mild in synthetic conditions and simple in preparation process, has less pollution to the environment, and accords with the concept of sustainable development.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

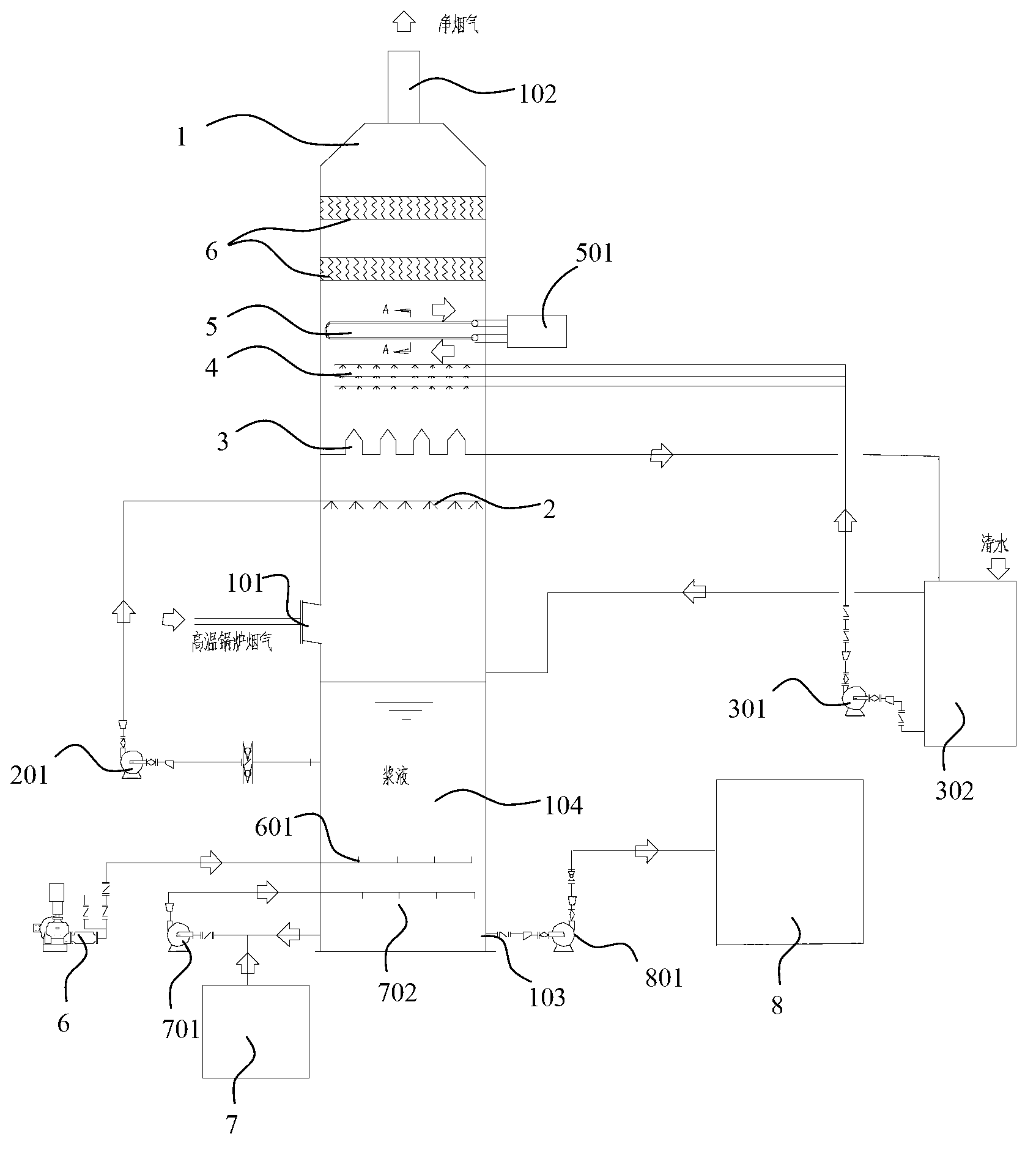

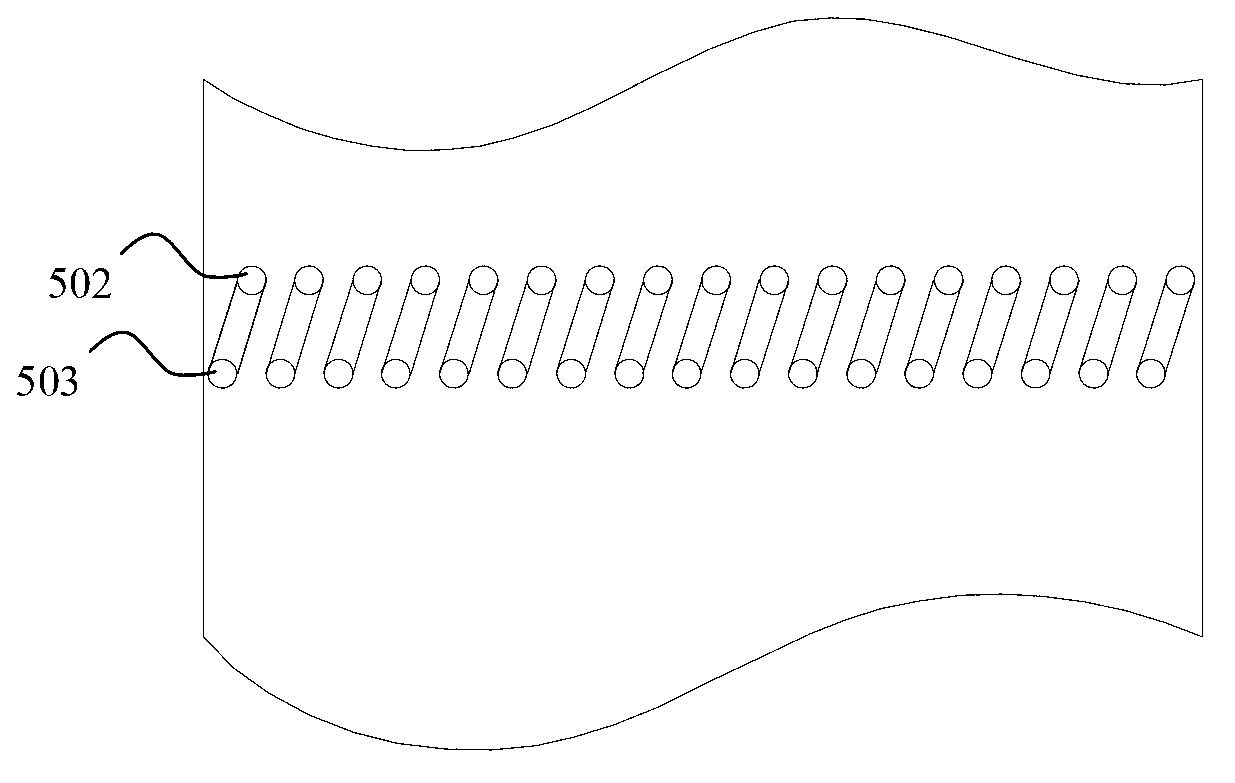

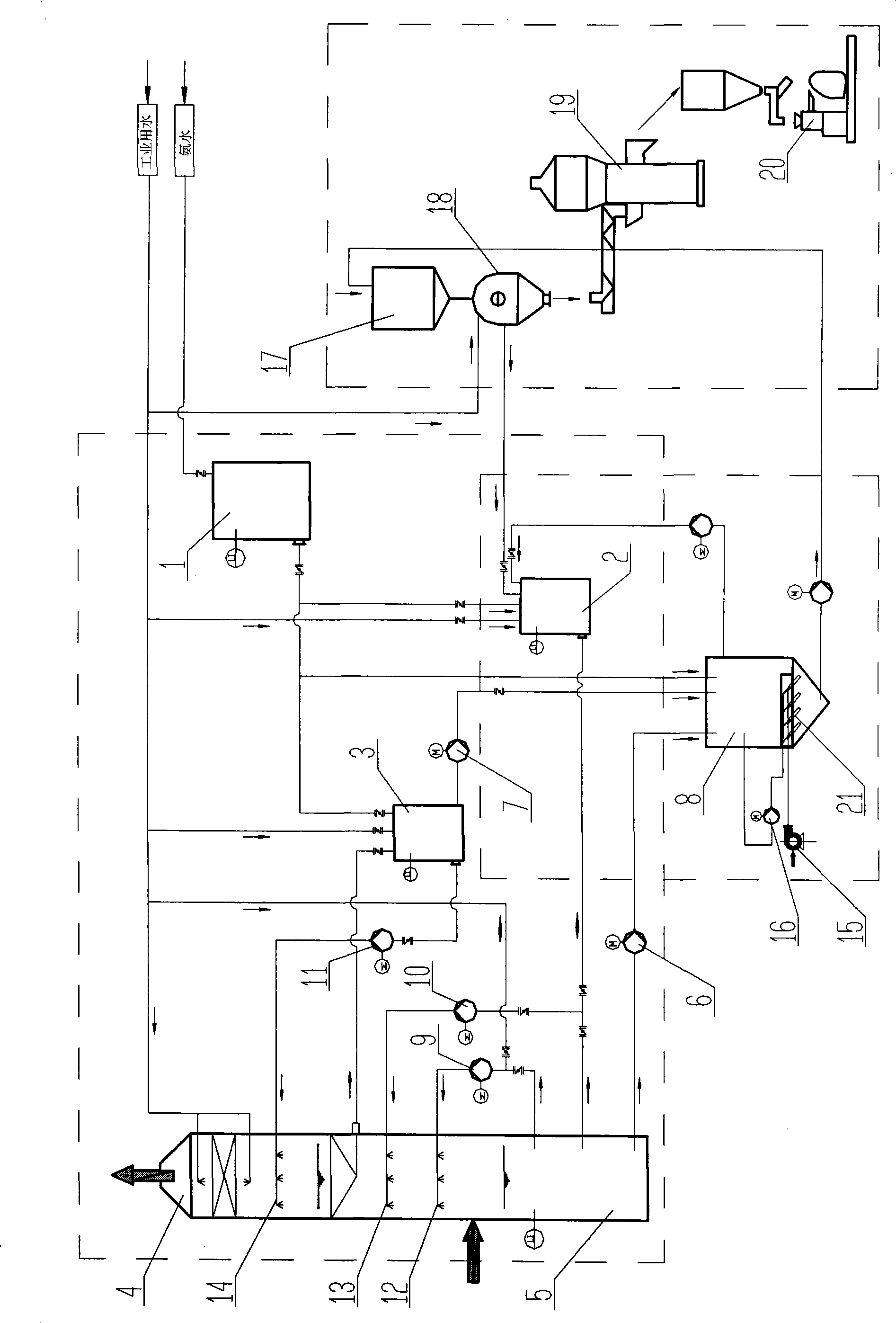

Desulfurization system and desulfurization process thereof

InactiveCN103252158AReduce consumptionUniform flow rateDispersed particle separationEscape rateSaturated water vapor

The invention discloses a desulfurization system comprising a tower body, wherein a smoke inlet is arranged in the middle of the tower body; a pure smoke outlet is arranged at the top of the tower body; a slurry pool for containing slurry is formed on the lower part of the tower body; the slurry pool is provided with a mixed liquid outlet; a slurry spraying layer, a rising air gap and a clean water spraying layer are sequentially arranged from the smoke inlet to the pure smoke outlet from bottom to top; the bottom of the slurry pool is respectively connected with an oxidization mechanism and an ammonia supplying mechanism; and the desulfurization system further comprises a slurry circulating mechanism and a clean water circulating mechanism. The invention further provides a desulfurization process; and the process is low in water consumption amount so that the amount of saturated steam in pure smoke is reduced by 30-40% and consumption of external clean water is reduced. According to the desulfurization system and the desulfurization process disclosed by the invention, the operation cost is low; and the consumption of the steam is 20% of that of an ammonia-fertilizer method process and the consumption of power is 40% of that of the ammonia-fertilizer method process. The escaping rate of ammonia is low; the content of the ammonia in the pure smoke is less than 8mg / Nm<3>; no three wastes are discharged; and secondary pollution to an environment is not caused.

Owner:九美科技有限公司

Iron tailings mixing sand concrete

InactiveCN105236860AFill the voidImprove distributionSolid waste managementCrushed stoneWater reducer

The present invention discloses an iron tailings mixing sand concrete, which comprises, by mass, 16-20% of 52.5-grade cement, 22-27% of iron tailings mixing sand, 45-48% of crushed stone, 5.5-6.5% of an admixture, 7.3-8.1% of water, and 0.2-0.3% of a polycarboxylic acid efficient water reducer. The iron tailings mixing sand concrete of the present invention has characteristics of good water retention property, easy vibration molding, and good workability.

Owner:CHINA MCC17 GRP

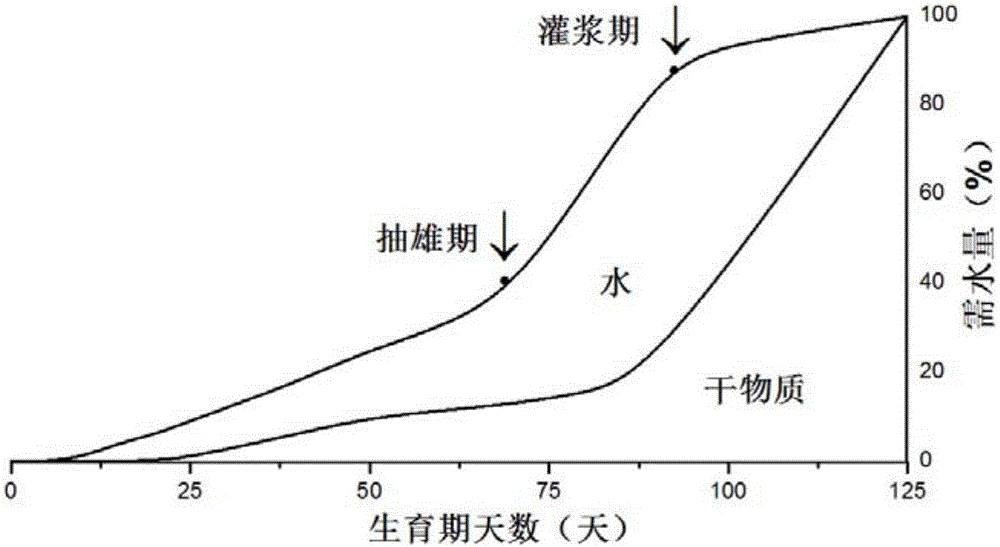

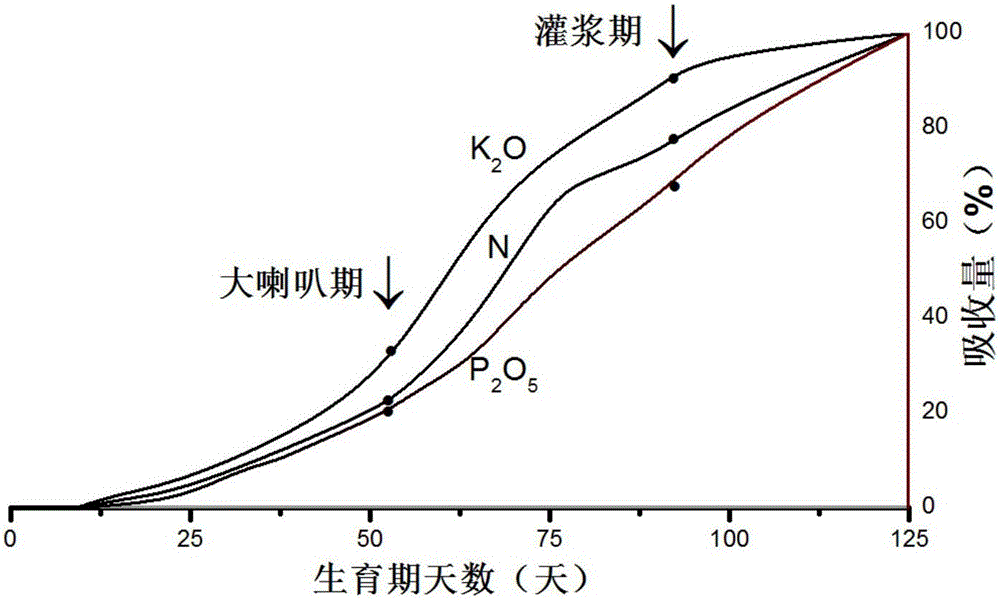

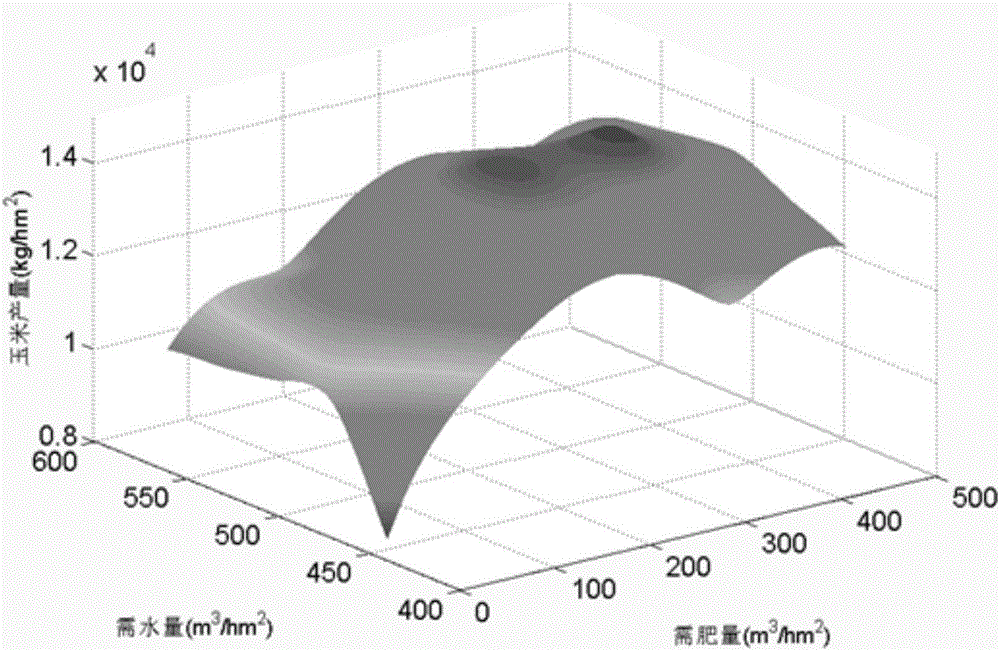

Water and fertilizer integrated drip irrigation and fertilization method for corn in semiarid regions

InactiveCN106818163AMeet reproductive needsSustainable developmentWatering devicesFertilising methodsWater savingAgricultural science

The invention provides a water-saving, fertilizer-saving, high-yield and efficient planting method for corn in semiarid regions. The water-saving, fertilizer-saving, high-yield and efficient planting method has the advantages that water and nutrients can be simultaneously supplied by the aid of drip irrigation systems according to water and nutrient requirement laws of t various growth and development stages of the corn in the semiarid regions, accordingly, water and nutrients which are required by the corn can be timely and accurately supplied, water and nutrient requirements of the corn in different periods can be met, and water and fertilizers can be cooperatively managed and efficiently utilized.

Owner:JILIN ACAD OF AGRI SCI

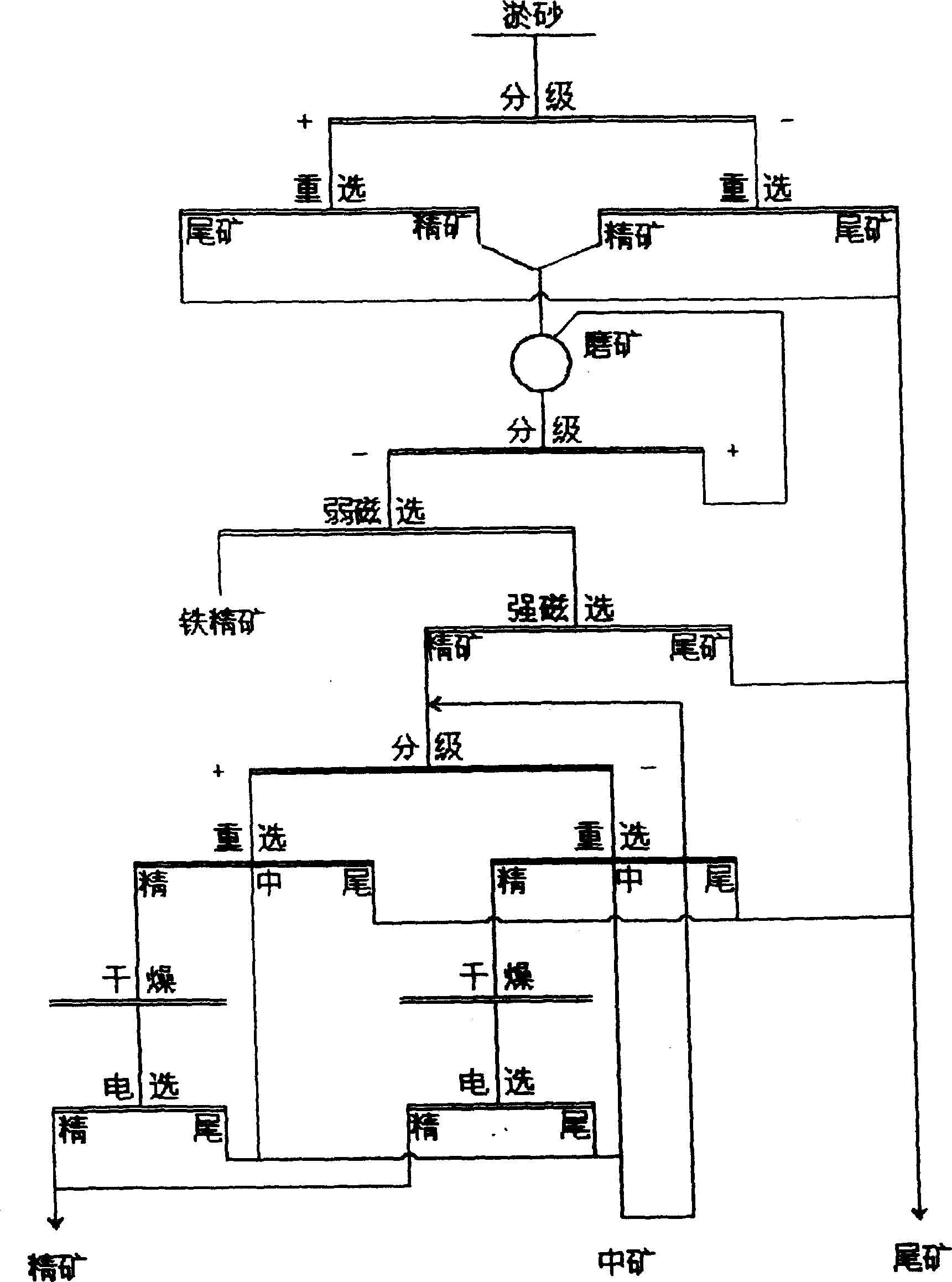

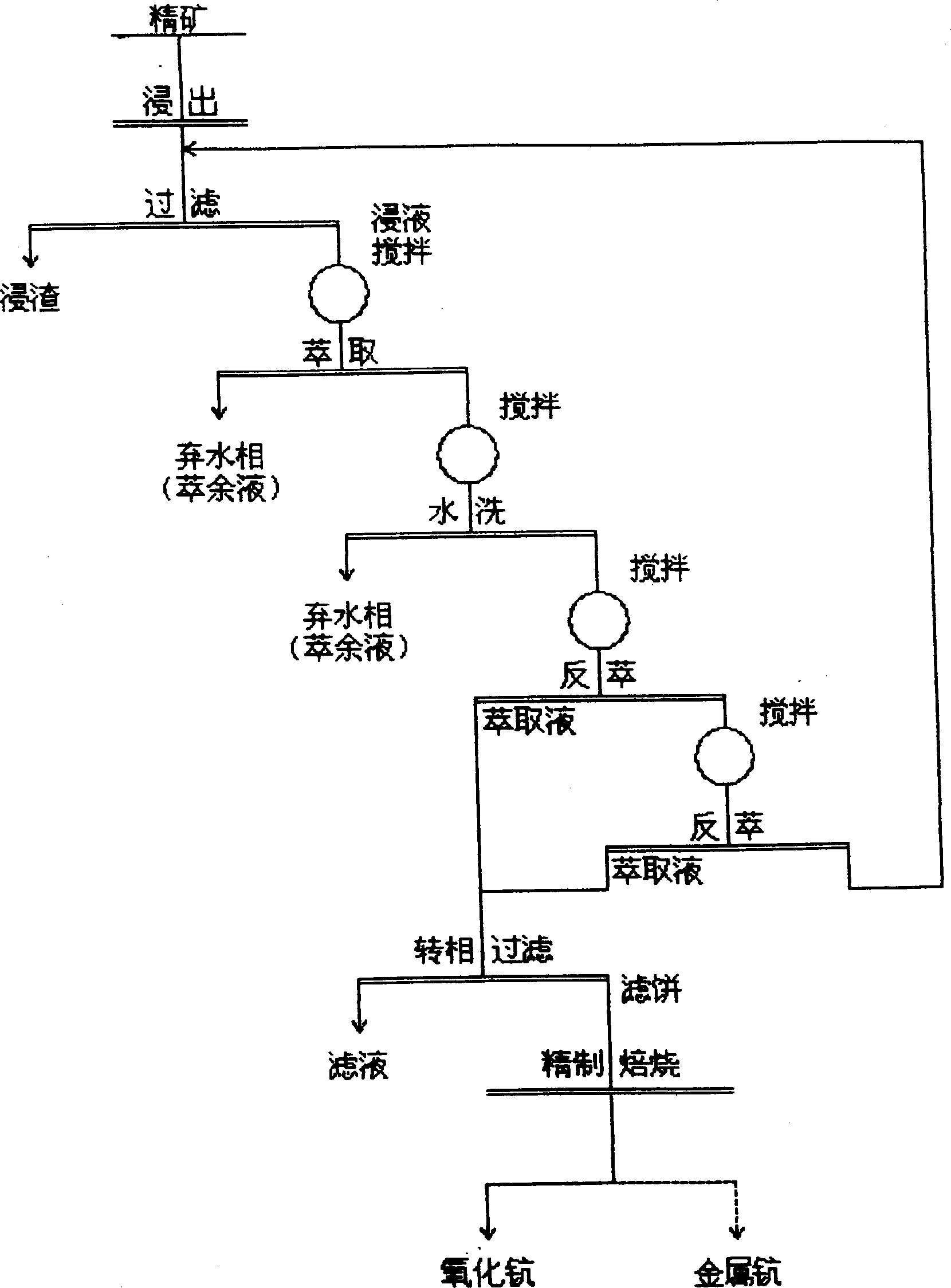

Scandium extraction method of river channel sedimentation

InactiveCN1478600AHigh puritySave mineral resourcesLiquid solutions solvent extractionWet separationElectricityMineral Sources

Owner:汪友华

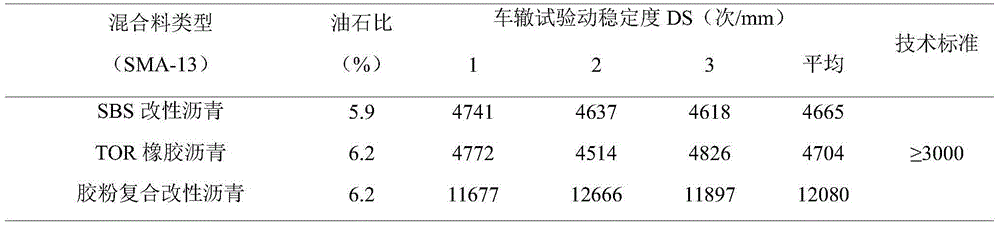

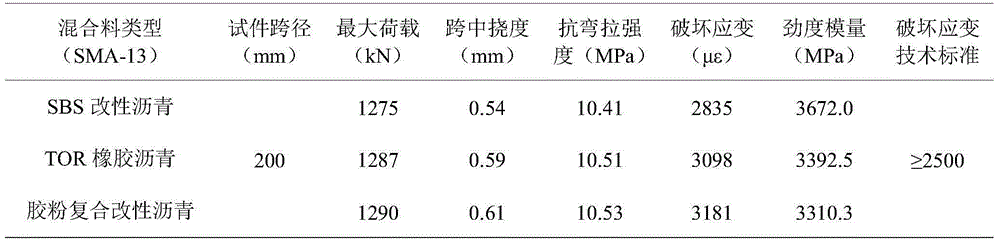

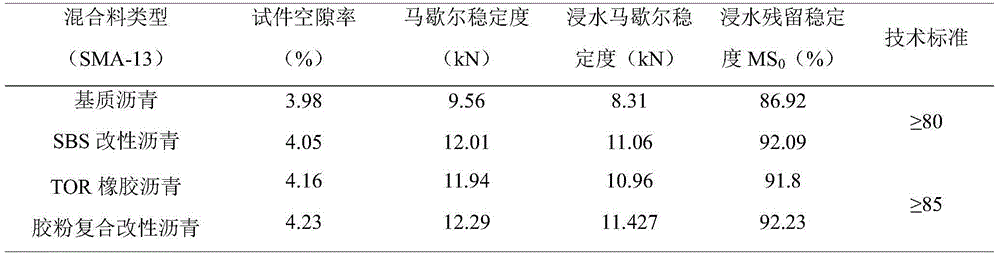

Composite modified asphalt mixture of rubber powder with high anti-rutting performance and preparation method thereof

ActiveCN104446157AImproves rutting resistanceSimple processSolid waste managementPolymer scienceMass ratio

The invention relates to a composite modified asphalt mixture of rubber powder with a high anti-rutting performance and a preparation method thereof. The mixture is mainly characterized in that in a dry process moulding preparation method, the mass ratio of tans-polyethylene rubber (TOR), rubber powder, asphalt, mineral aggregate to a complexing agent is (0.038-0.041): (0.841-0.919): (4.671-5.106): (93.337-94.052): (0.399-0.596); in a wet process moulding preparation method, the mass ratio of tans-polyethylene rubber (TOR), rubber powder, asphalt, mineral aggregate to a complexing agent is (0.016-0.035): (0.780-0.855): (4.335-4.918): (93.671-94.652): (0.217-0.492). According to the mixture provided by the invention, the anti-rutting performance of an asphalt rubber pavement is improved to a great extent, the dynamic stability is obviously increased compared with an SBS modified asphalt mixture, and the low temperature anti-cracking performance and the water stability are slightly improved. The composite modified asphalt mixture provided by the invention is simple in process, has huge social and economic benefits, and meets the characteristics of green ecology and sustainable development.

Owner:YANGZHOU UNIV

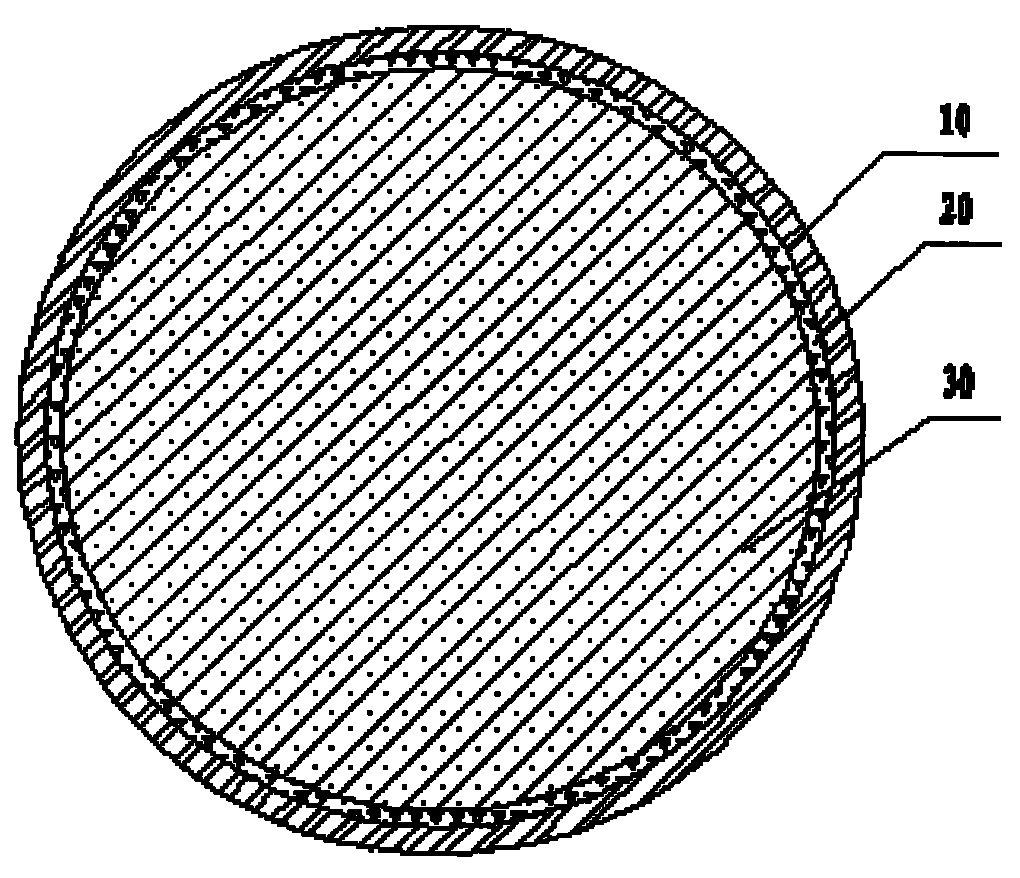

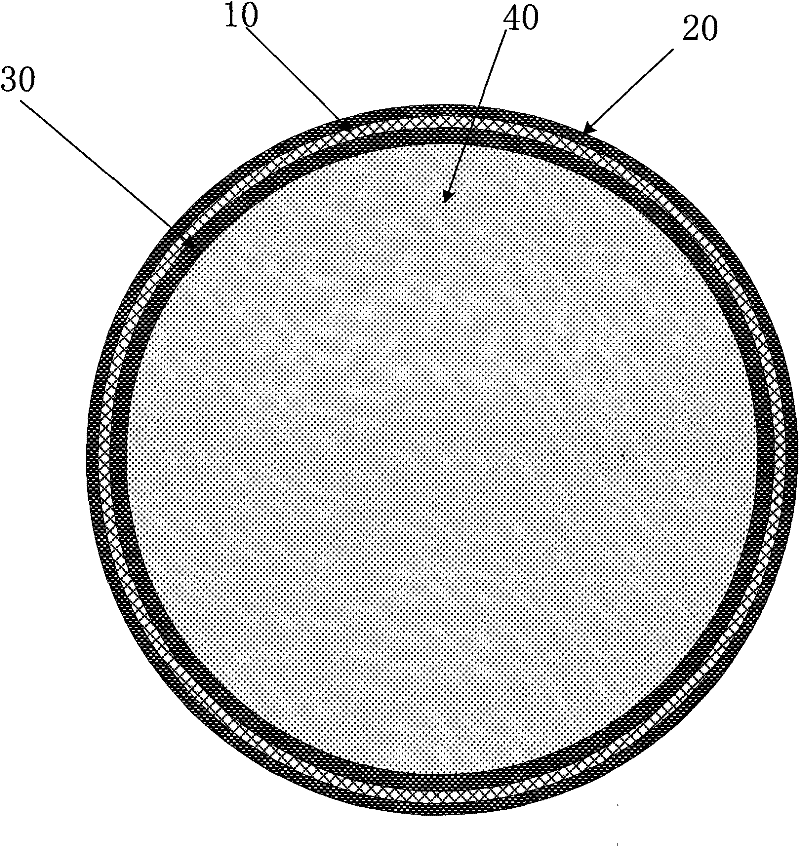

Hollow steel pipe and concrete column filled with sea sand concrete and making method thereof

ActiveCN101748862AEfficient use ofAvoid Mining for SuppliesStrutsBulkheads/pilesEcological environmentDesalination

A hollow steel pipe and concrete column filled with sea sand concrete comprises a base body (10) made by steel pipes. One outer protective layer (20) of river sand concrete is poured on the outer wall of the base body (10). An inner layer (30) of river sand concrete is poured on the inner wall of the base body (10) by a centrifugation method, and sea sand concrete (40) made by sea sand not desalted is poured into the hollow area circled by the inner layer (30) on site. Sea sand can be directly used for the hollow steel pipe and concrete column without desalination. The concrete column is conveniently built. Sea sand can be effectively utilized, so the problem that coastal areas are lacking in standard sand and stone resources in general is solved, and the exploitation and replenishment of sand and stone materials from remote places are saved. The present invention is favorable for energy saving and ecological environment protection.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Wet-type ammonia process three-circulation desulphurization technique suitable for sintered flue gas

ActiveCN101474530AGuaranteed concentrationIncrease concentrationDispersed particle separationMaterials scienceAmmonium sulfate

The invention provides a wet ammonia process ternary cycle desulfurization process applicable to sintering flue gas. In the process, the desulphurization of the sintering flue gas in the steel industry is realized by the methods of three-stage circulation absorption, outside tower oxidation, saturation and crystallization. The invention provides the desulfurization process for the sintering desulfurization reserved currently in the nation; the desulfurization process has low investment, low running cost and can realize resource recovery. Home grown coking waste ammonia or other ammonia of the steel industry are used for treating SO2 in the waste gas in a sintering machine so as to treat wastes with processes of wastes against one another; the absorptivity of the SO2 is high; the loss of the outlet ammonia of the system is low; in the running process, a great amount of steam is not needed and solid ammonium sulphate with fine quality is generated and sold as fertilizer. The invention belongs to the desulfurization process which changes waste into valuable, not only reduces the emission of sulfur dioxide, but also brings tremendous environmental benefits and definite economic benefit.

Owner:无锡高达环境科技有限公司 +1

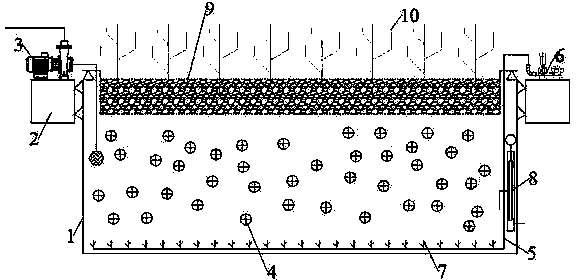

In-situ repair device and method for polluted water

InactiveCN104003527AMaterials are readily availableLow costEnergy based wastewater treatmentSustainable biological treatmentPollutantNitrogen

The invention discloses an in-situ repair device and method for polluted water. The in-situ repair device is characterized by comprising a microbial treatment system and a plant repair system arranged above the microbial treatment system, wherein the microbial treatment system mainly consists of a microbial reaction tank, a floating box, a drainage pump, suspended filler, an air hose, a fan, an aerating head and an automatic water inlet valve. The plant repair system comprises a plant fixing layer and a functional plant fixed on the plant fixing layer. The invention further discloses a method for purifying a water body by using the in-situ repair device for polluted water. According to the invneiton, the purpose of in-situ repair of the polluted water by means of microorganisms which degrade pollutants in water and plants which absorb element such as nitrogen and phosphorus in water is realized.

Owner:HENAN NORMAL UNIV

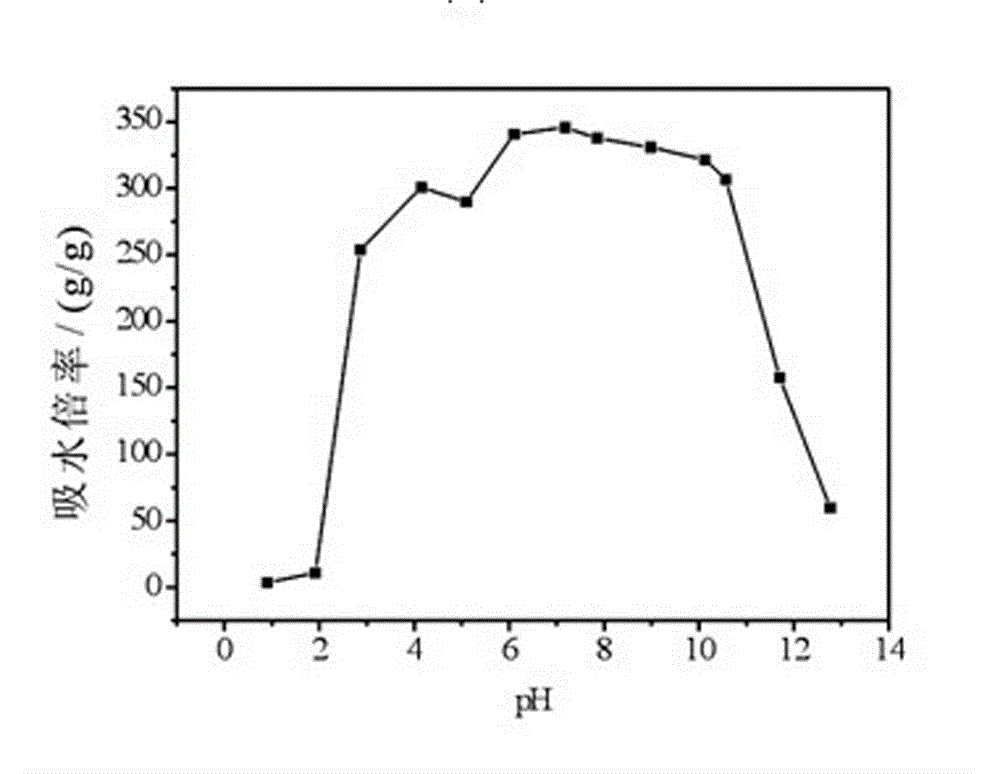

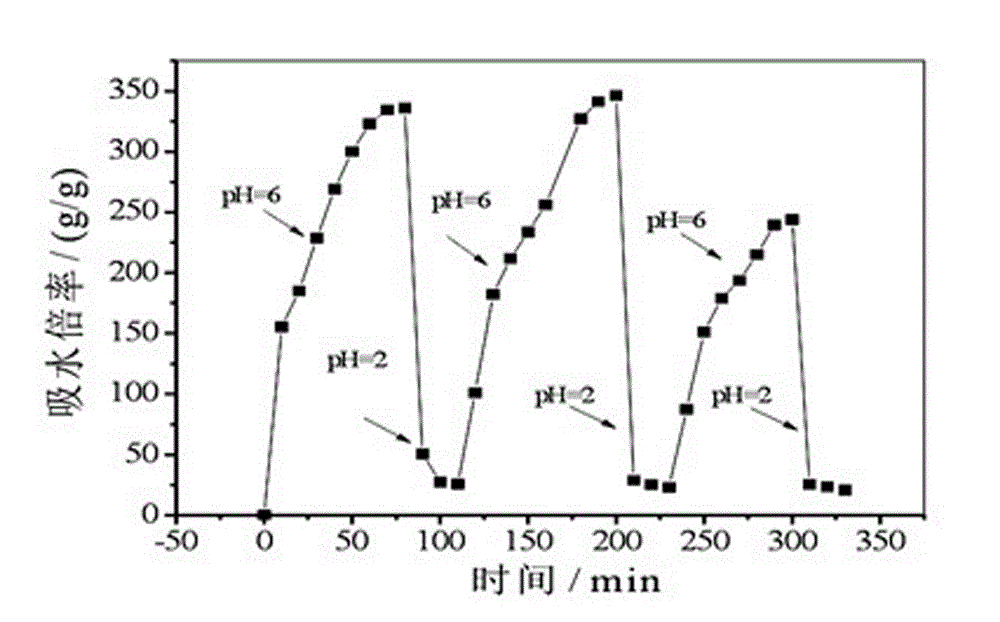

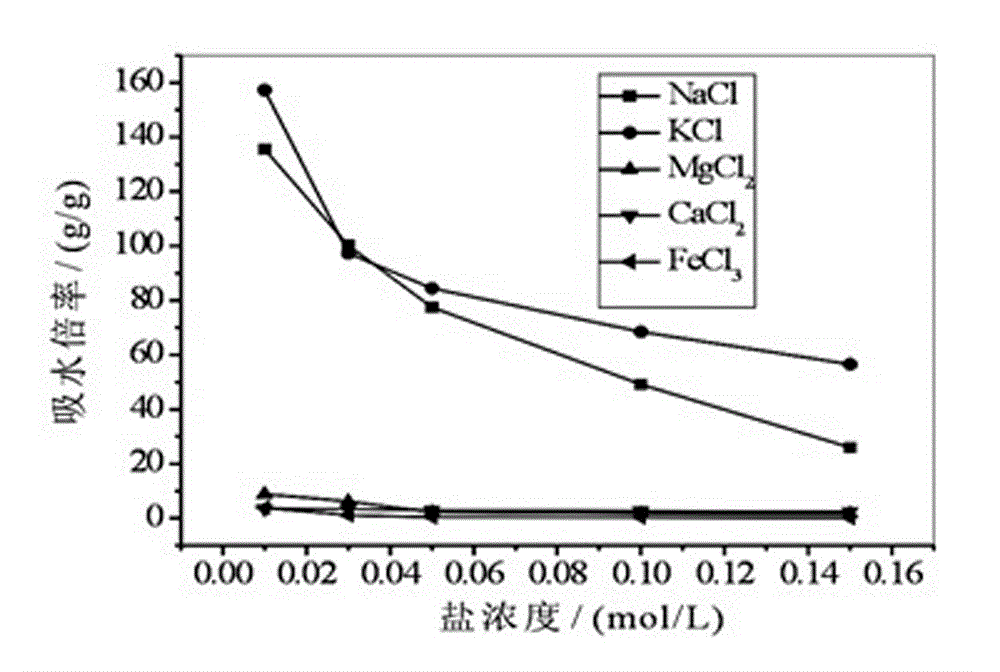

Method for preparing chitosan/crylic acid composite through initiating polymerization by using glow discharge electrolysis plasma

InactiveCN102977271ARaw materials are easy to getSimple preparation processDye absorptionElectrolysis

The invention provides a method for preparing a chitosan / crylic acid composite which is prepared by using chitosan and crylic acid as raw materials and N,N'-methylene bisacrylamide as a crosslinking agent through initiating polymerization by using glow discharge electrolysis plasma in an acetic acid water solution in a one-step manner. The chitosan / crylic acid composite has the advantages of high water absorption rate, high salt tolerance, good recycling property and large dye absorption quantity so as to be a composite water absorbing material with excellent property, and can be used in fields such as agriculture and forestry, gardening, purification of sewage and medicine slow release. In addition, the preparation method has the advantages of easily available raw materials, simple preparation process and low synthesis cost; and an initiating agent is not needed, thus the preparation method avoids the secondary pollution caused by the initiating agent, is a green synthesis technology according with the sustainable development, and has a potential application prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for reduction and decomposition of phosphogypsum with yellow phosphorus tail gas

InactiveCN101492177AEmission reductionRealize comprehensive utilizationCarbon compoundsSulfur compoundsReductive decompositionFurnace temperature

The invention relates to a method for reducing and decomposing ardealite by tail gas of phosphor. The method comprises that: the naturally dried ardealite is put into a reductive decomposition furnace and filled with the tail gas of phosphor for reaction, and the furnace temperature is controlled to be between 700 and 1,000 DEG C, and the reaction time is between 10 and 50 minutes. The obtained furnace gas in which the content of the sulfur dioxide in percentage by volume is more than or equal to 15 percent is used as a material gas for the double-rotation double-suction acid preparation process; and the content of CaO, namely a solid product is more than or equal to 70 weight percent and is used as a cement material.

Owner:KUNMING UNIV OF SCI & TECH

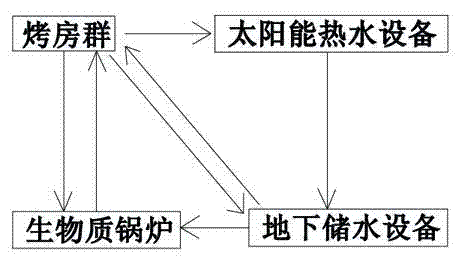

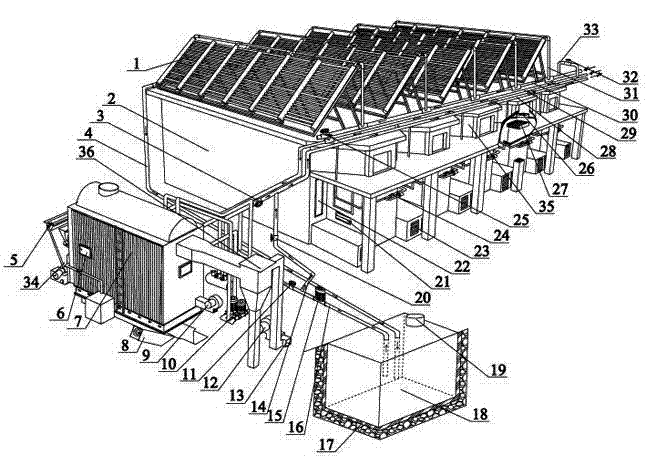

Hot-water centralized heating tobacco flue-curing device adopting combination of solar energy and biomass fuels

InactiveCN102160681ATo achieve the purpose of curing tobacco leavesSave energyTobacco preparationThermodynamicsSolar water

Owner:HENAN AGRICULTURAL UNIVERSITY

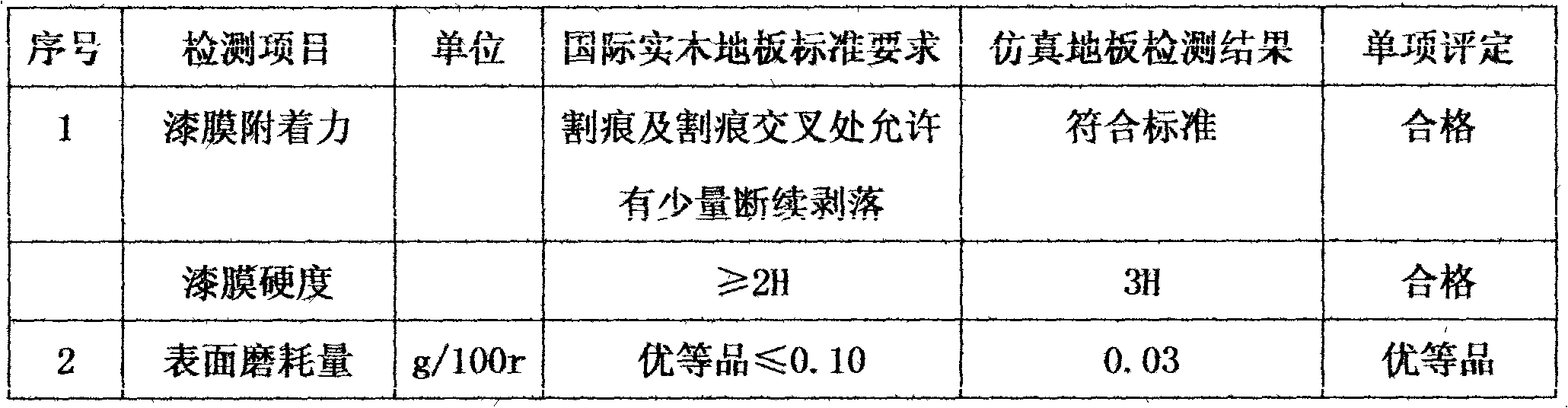

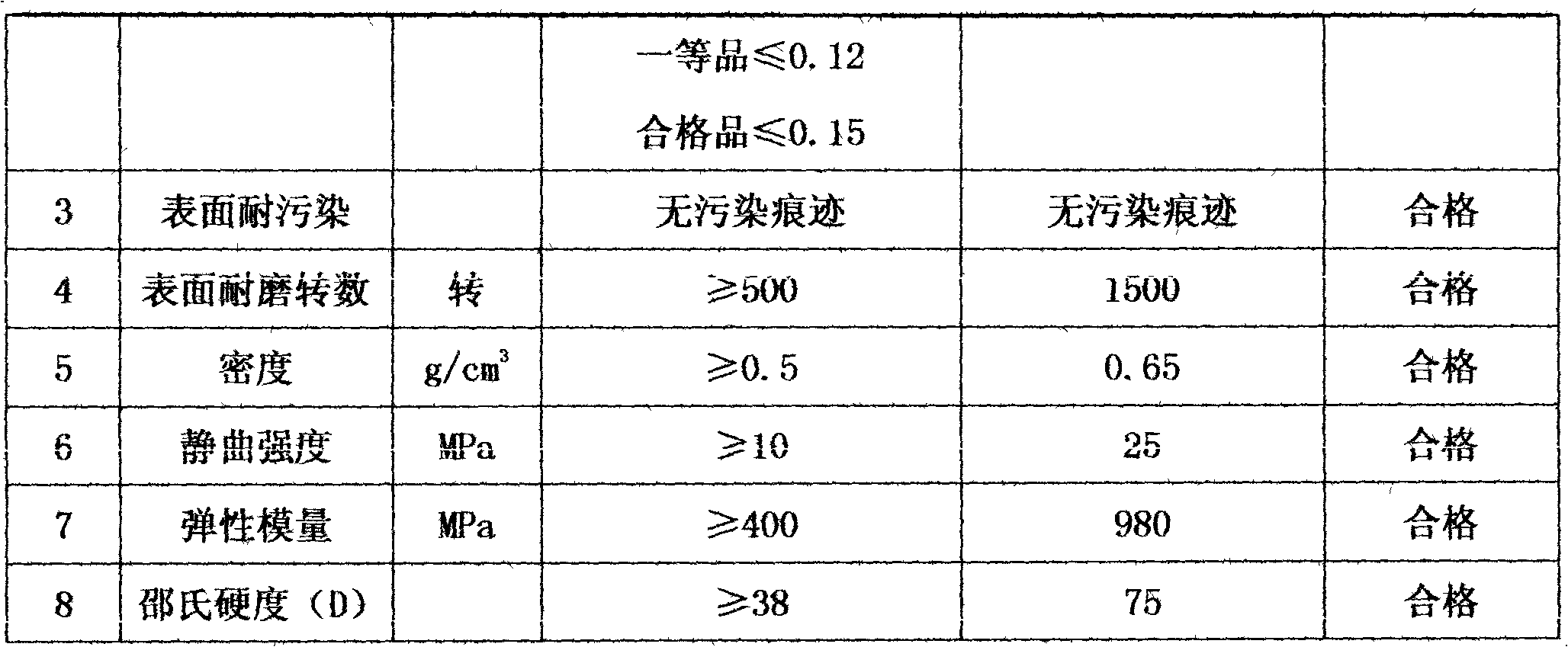

Simulated wood board and production method thereof

InactiveCN102535813AStable materialNo pollution in the processCovering/liningsDecorative surface effectsPublic placeEngineering

The invention relates to a wood board, in particular to an artificial simulated wood board and a production method thereof. The simulated wood board aims to overcome shortcomings of natural wood, is waterproof, moisture-proof, insect-proof, mothproof, anti-crack, harmless and pollution-free, does not deform, and can replace the natural wood. The simulated wood board comprises a base material layer, and a primer layer, a pattern layer made of marble and a finish layer are successively arranged at the front of the base material layer from bottom to top. The invention further provides the production method of the simulated wood board. The production method comprises following steps: selecting a base material; cutting the selected base material into a base material with the required dimension; arranging tenon fasteners on the cut base material; coating primer on the front of the base material; printing textures of natural wood on the surface of the base material coated with the primer; and coating finish on the surface of the base material printed with the textures of the natural wood. The simulated wood board can be paved on floors of various humid environments and public places, and completely overcomes shortcomings that various wood floors are expanded when wetted and are contracted when dried.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

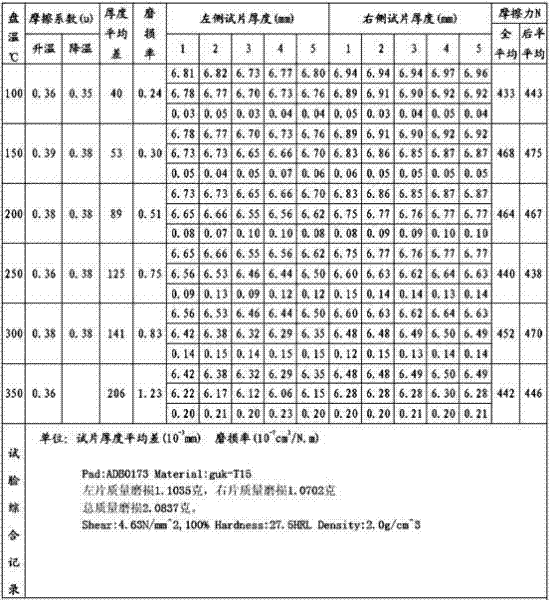

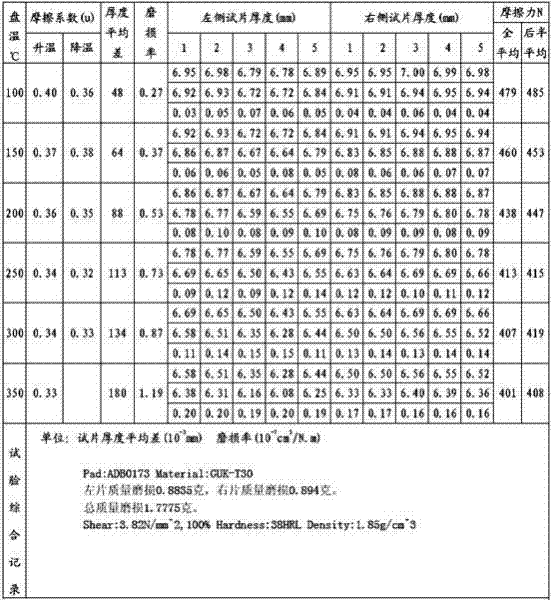

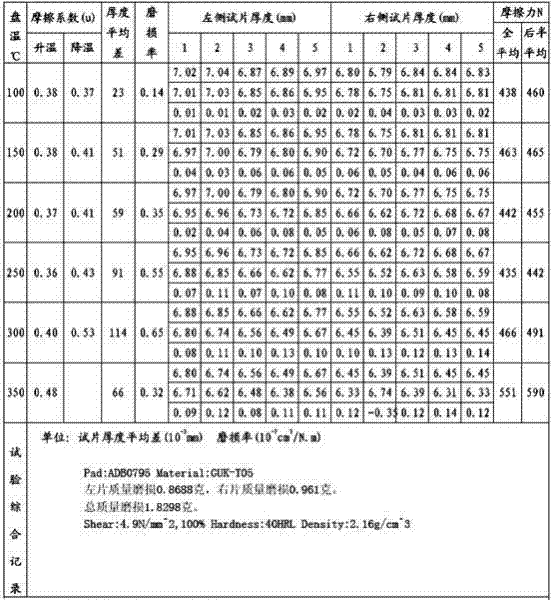

Application of rice hull carbon to preparation of brake pad and friction material of brake pad

The invention discloses application of rice hull carbon to the preparation of a brake pad and also provides a friction material for preparing the brake pad. The friction material is characterized by being prepared from the following materials in part by weight according to a conventional brake pad pressing method: 10 to 15 percent of mineral fibers, 5 to 10 percent of graphite, 15 to 25 percent of barium sulfate, 15 to 20 percent of steel wool, 1 to 3 percent of friction increasing agent, 5 to 15 percent of coke dust, 1 to 4 percent of tire powder, 7 to 11 percent of resin, 1 to 3 percent of butyronitrile powder, 1 to 2 percent of calcium oxide, 2 to 5 percent of friction powder and 5 to 30 percent of rice hull carbon. The brake pad is prepared from the friction material disclosed by the invention and other raw materials by using the rice hull carbon as a friction filler according to the conventional brake pad pressing method. By being tested in four types in a constant speed test according to the GB5763-2008 standard, the brake pad has stable friction coefficient and low wear rate and totally reaches the national standard. By being massively used on taxis of Santana, Sonata and Jetta, the brake pad is stable to brake, has no noise complaint and has service life of over 35,000km.

Owner:HANGZHOU UNITED FRICTION MATERIAL

High-stability environment-friendly carbon nanotube water dispersing liquid and preparation method thereof

The invention discloses a high-stability environment-friendly carbon nanotube water dispersing liquid and a preparation method thereof. The method comprises the steps: according to the mass parts, mixing 1-5 parts of carbon nanotubes, 0.5-20 parts of lignosulfonate and 0.1-5 parts of deionized water; and carrying out grinding treatment, adding water to dilute, adjusting the pH to 6-8, adding a stabilizer, and carrying out ultrasonic dispersion to obtain the stably dispersed carbon nanotube water dispersing liquid. The stabilizer is one or more of triton X-100, sodium dodecyl sulfate, sodium dodecyl benzene sulfonate, dodecyl sulfobetain and sodium methyl palmitate sulfonate. The high-stability environment-friendly carbon nanotube water dispersing liquid has the advantages of good dispersion effect of carbon nanotubes, high stability, high concentration, short technological process and preparation period, environmental friendliness and good compatibility with water-based resin.

Owner:SOUTH CHINA UNIV OF TECH

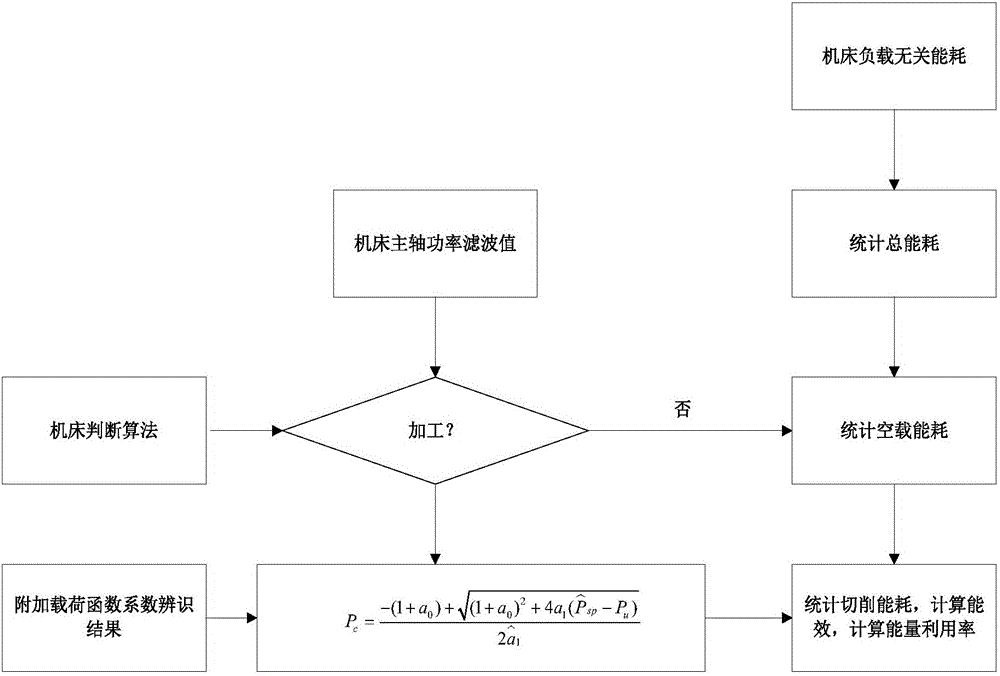

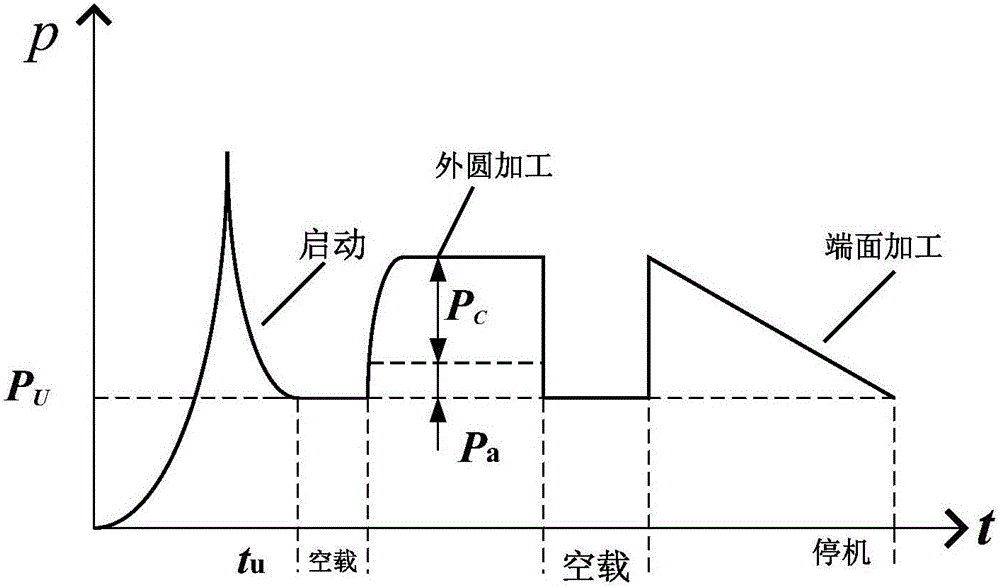

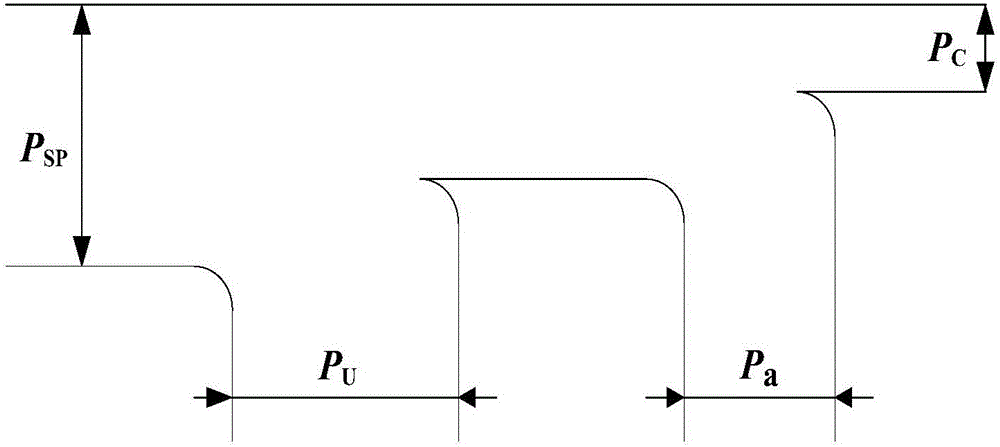

Machine tool working step energy consumption monitoring method based on least square iterative algorithm

ActiveCN105955198AImprove energy efficiencyThe method is scientific and reasonableProgramme controlComputer controlPower parameterPower Balance

The invention discloses a machine tool working step energy consumption monitoring method based on a least square iterative algorithm, and the method comprises the following steps: step1, main driving system input power is collected, and filtering processing is performed on a input power signal; step2, a machine tool on-line running state is judged through an analysis of machine tool main driving system input power data; step3, according to the measurement of machine tool spindle real-time power, a power balance equation and additional load loss characteristics of the machine tool main driving system are combined to estimate cutting power, a reasonable cutting energy consumption model is established, and on-line estimation of the machine tool cutting power is reached; and step4, an off-line identification algorithm based on machine tool additional loss function coefficients of the least square iterative algorithm is adopted to calculate machine tool cutting power parameters. According to the invention, high cost and low efficiency in cutting energy consumption measurement in a direct measuring method can be avoided, a problem of high error rate in a indirect measuring method can be processed, and the method can provide relatively precise energy consumption data for machine tool working process energy consumption monitoring.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com